Automated packaging robot

A technology of automatic packaging and robots, applied in packaging and other directions, can solve the problems of high time cost, high economic cost and low work efficiency, and achieve the effect of high work efficiency, reduced total economic cost and less time cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

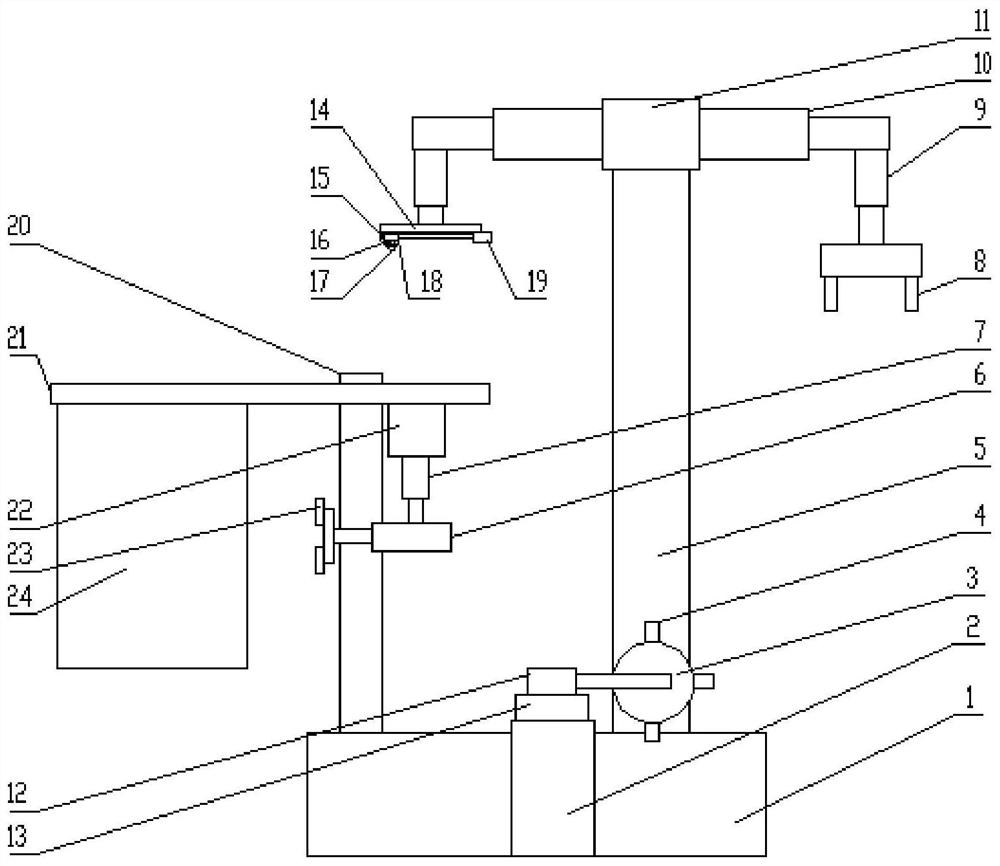

[0051] Such as figure 1 As shown, a kind of automatic packaging robot provided by the present invention includes:

[0052] The seat body 1 provides support for the whole body, and the side of the seat body 1 is fixedly connected with a multifunctional arm. ,

[0053] Among them, the structure of the multifunctional arm includes:

[0054] A column one 5 vertically fixed to the seat body 1, one end of the column one 5 away from the seat body 1 is fixedly connected to the turntable one 11, and the turntable one 11 is evenly arranged with support arm one and support arm two, support arm one and support arm two have the same structure.

[0055] Among them, the turntable one 11 can realize indexing at any position in the circumferential direction, and in this structure, it is used to realize the transposition work of the support arm one and the support arm two on the turntable one 11 .

[0056] Wherein, the support arm one includes a turntable two 10 fixed to the circumference o...

Embodiment 2

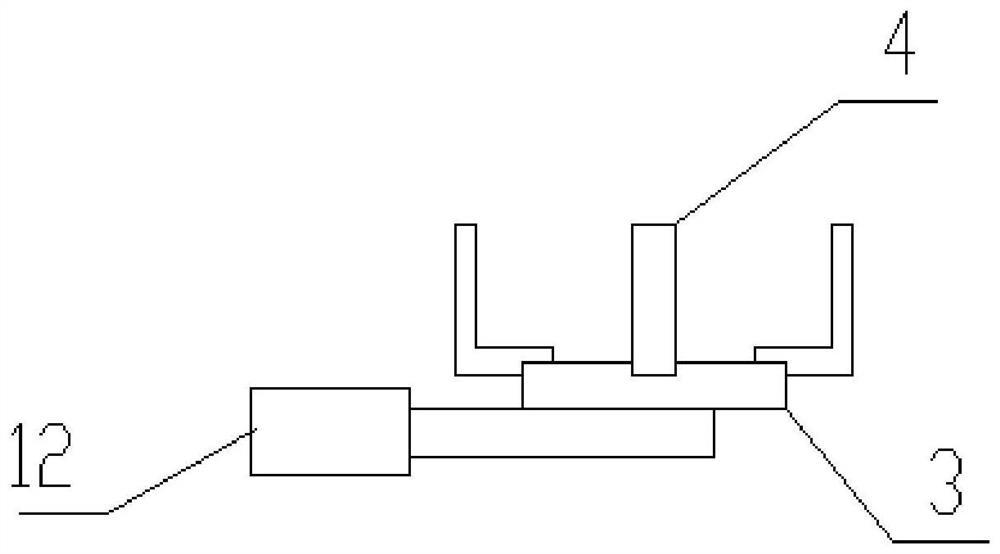

[0078] As a further improvement on the basis of Embodiment 1, in order to realize the packaging of multiple sides of the box body, an overturning device is also provided.

[0079] The structure of the turning device includes:

[0080] The hydraulic cylinder four 2 fixed on the side of the seat body 1, the hydraulic cylinder four 2 is arranged on the opposite side of the column one 5.

[0081] The end of the hydraulic cylinder four 2 away from the seat body 1 is fixedly connected with the turntable three 13 .

[0082] A steering gear 12 is fixed above the turntable three 13, and the steering gear 12 is used for angle adjustment within a certain angle range, and is specifically used to realize turning over of the box body.

[0083] Such as figure 2 As shown, the index plate 3 is fixed on the circumference of the output shaft of the steering gear 12, and the central axis of the index plate 3 is perpendicular to the central axis of the index plate 3;

[0084] The supporting cl...

Embodiment 3

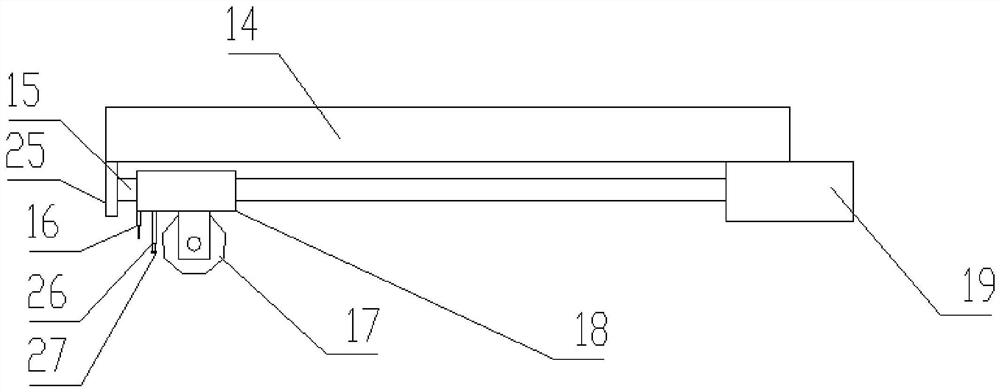

[0089] As a further adjustment on the basis of Embodiment 2, in order to improve the automation level of the whole device and reduce the degree of manpower participation, a supply device is added.

[0090] Wherein, the structure of the supply device includes:

[0091] The second column 20 is vertically fixed to the seat body 1 and is arranged on the side of the first column 5;

[0092] The beam 21 is arranged on the upper end of the second column 20 and is perpendicular to the second column 20;

[0093] The storage box 24 is used for accommodating the packing box, and is arranged on the side of the beam 21 away from the column-5;

[0094] The turntable 4 22 is arranged on the side of the beam 21 away from the storage box 24, its center line is horizontal to the column 2 20, and is arranged close to the seat body 1;

[0095] The fifth hydraulic cylinder 7 is arranged on the side of the fourth turntable 22 away from the turntable four 22;

[0096] Hydraulic cylinder six 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com