Packaging robot for food production

A robot and packaging technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of dust falling, difficult to clean, occupying space and work efficiency, and achieve easy installation and disassembly, reduce floor space, and clean effect. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

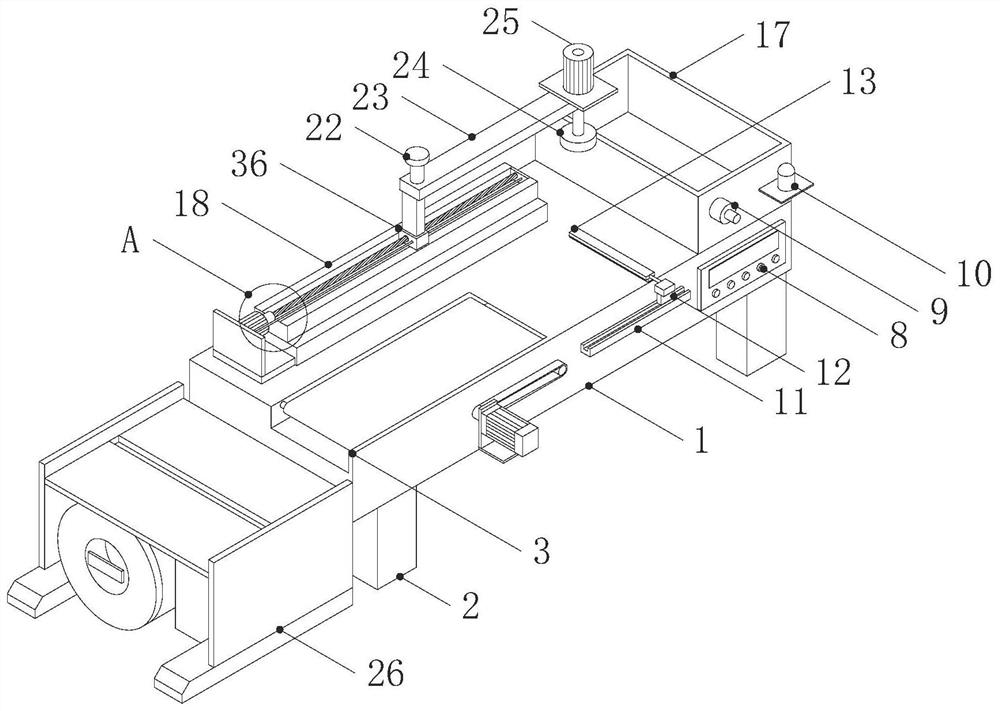

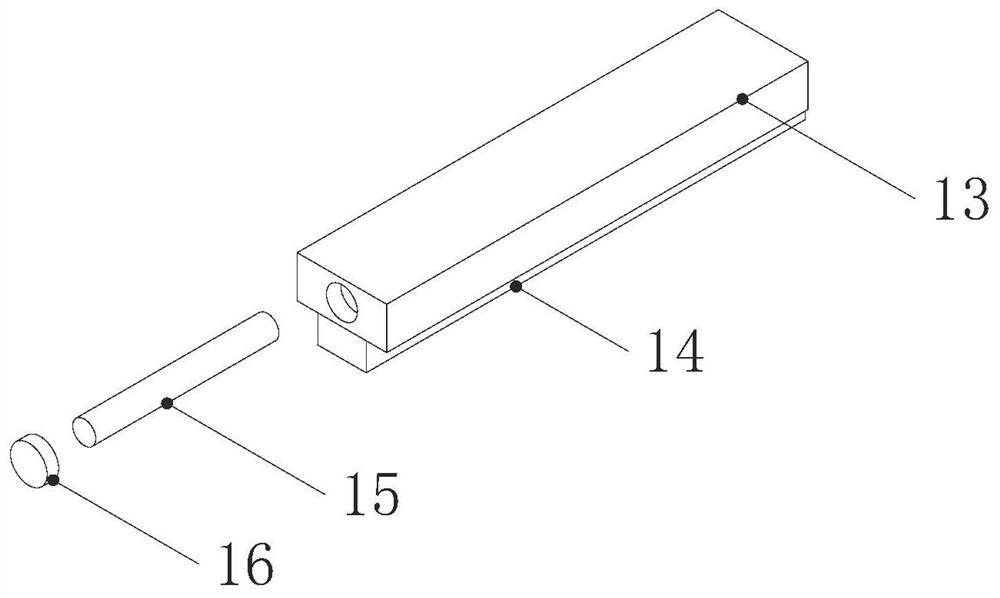

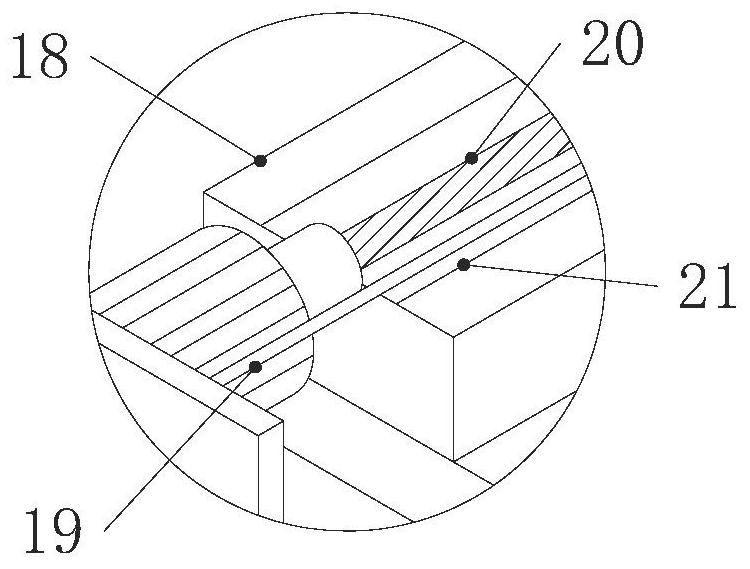

[0028] Example: such as figure 1 , image 3 As shown, a packaging robot for food production of the present invention includes a workbench 1, a storage tank 17, a suction head 24 and a hydraulic cylinder 25, and the top side of the workbench 1 is fixedly provided with a storage tank 17, and the workbench 1 A connecting plate 18 is fixedly installed at one end of the top of the connecting plate, and the connecting plate 18 is in a “concave” shape, and a steel plate is fixedly installed on one side of the top of the connecting plate 18, and a first motor 19 is fixedly installed on one side of the steel plate, and the first motor 19 The output end of the output end is fixedly connected with a threaded rod 20, and the side of the threaded rod 20 away from the steel plate is fixedly installed with a limit rod 21, which effectively moves the moving block 36 laterally.

[0029] Wherein, the surface of the threaded rod 20 is movably installed with a moving block 36, the top of the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com