Winding packaging robot

A robot and packaging technology, applied in packaging, transportation packaging, winding strips, etc., can solve problems such as uneven packaging, affecting product quality, and film tension changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

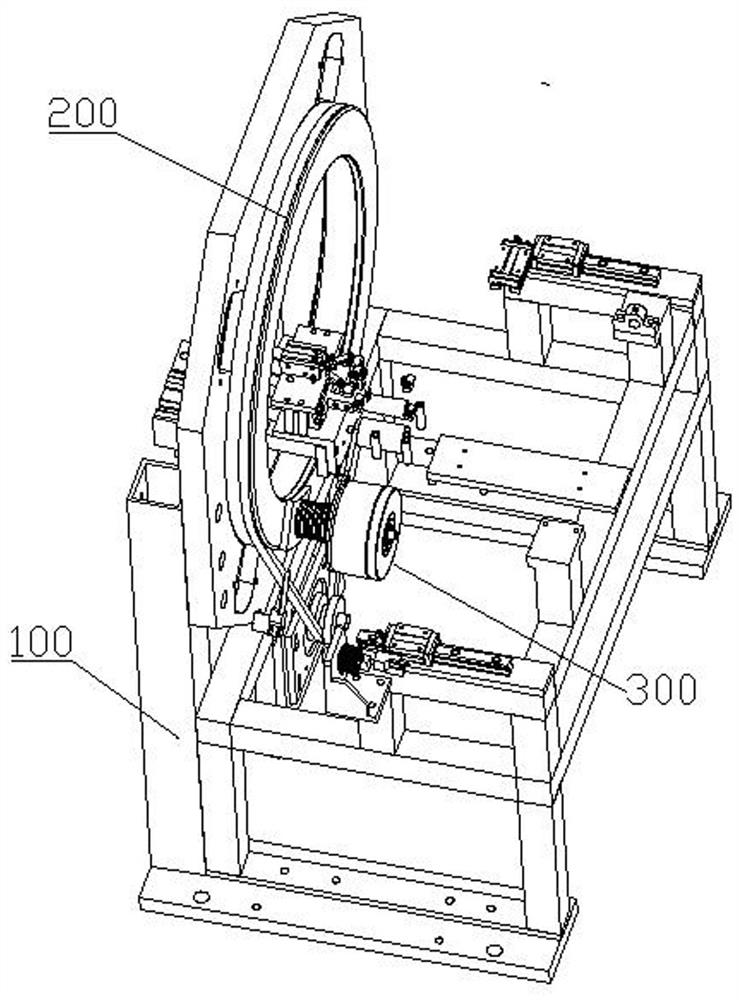

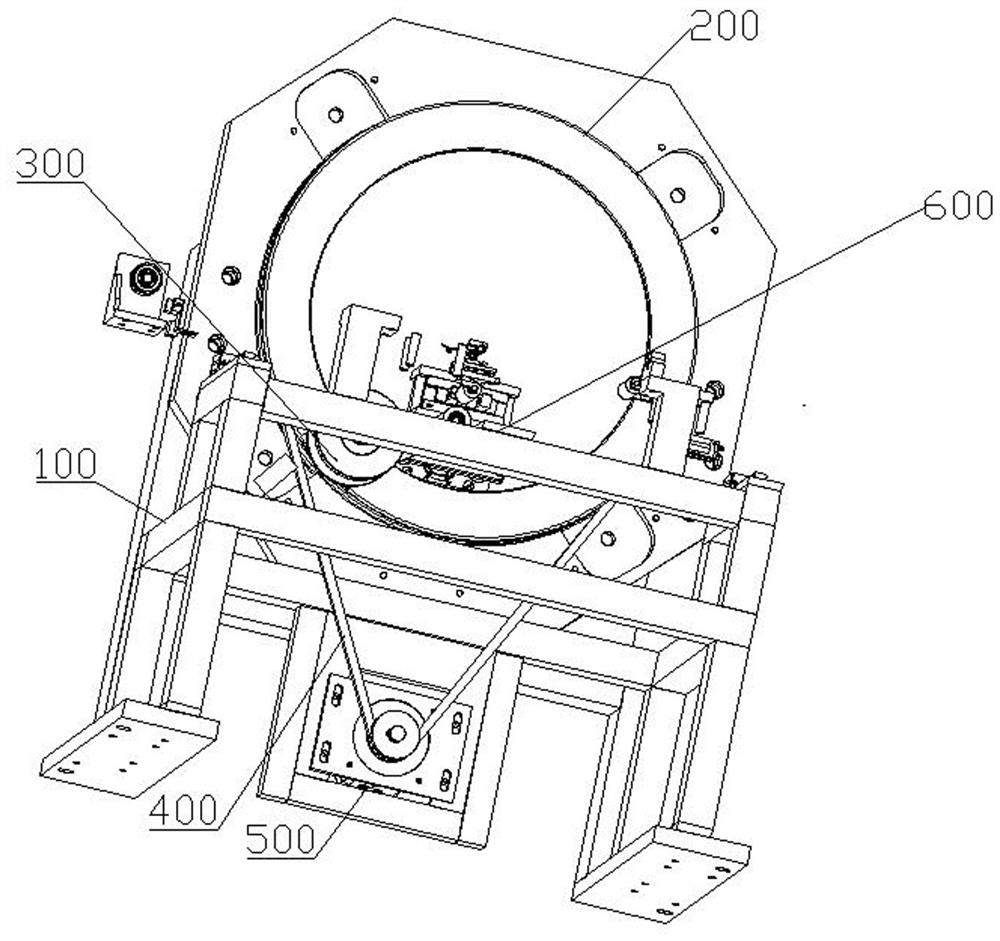

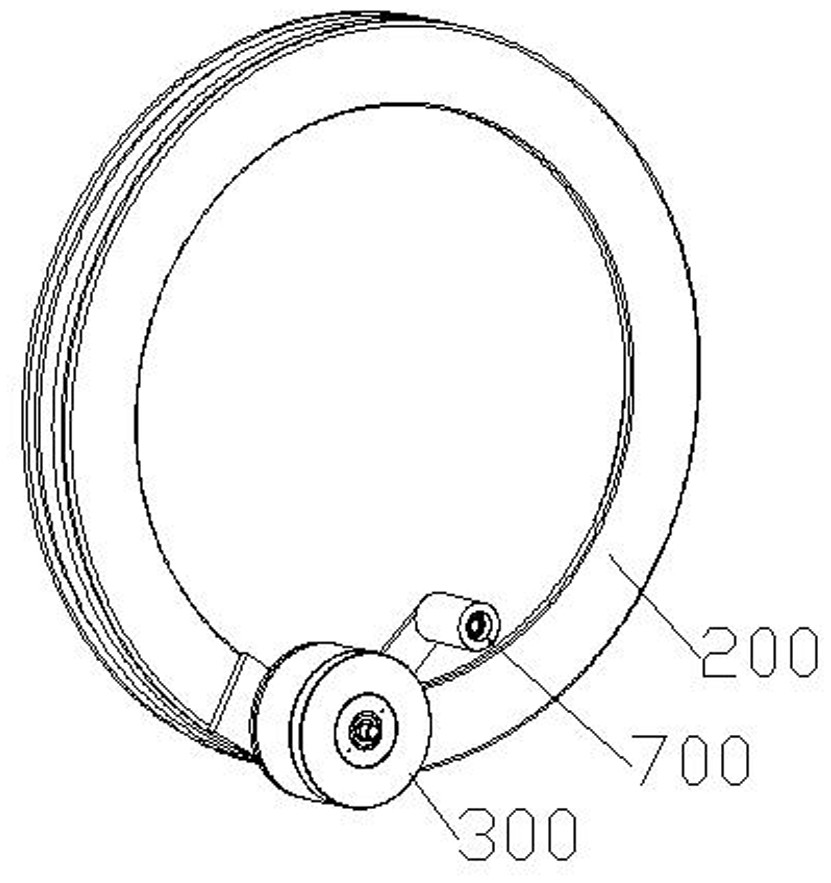

[0019] Such as figure 1 and figure 2 As shown, the present embodiment provides a winding packaging robot, including a body 100, a runner 200 positioned on the body, a mounting wheel 300, a transmission belt 400, a driving machine 500, and a fixing unit 600. For other conventional components, see Fig. not shown in . The fixing unit described in this embodiment fixes the product to be packaged at the center of the runner 200. The runner 200 is connected to the driving machine 500 through the transmission belt 400, and the driving machine drives the runner to rotate through the transmission belt. The edge of the wheel is equipped with a mounting wheel 300, and the mounting wheel is provided with a packaging film. The rotation of the runner makes the mounting wheel rotate and then the film is packaged on the product on the fixed unit. When packaging, the fixed unit can also be driven to move (such as figure 1 left and right directions in the middle), and then carry out film-coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com