Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Manufacturing process management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing process management (MPM) is a collection of technologies and methods used to define how products are to be manufactured. MPM differs from ERP/MRP which is used to plan the ordering of materials and other resources, set manufacturing schedules, and compile cost data.

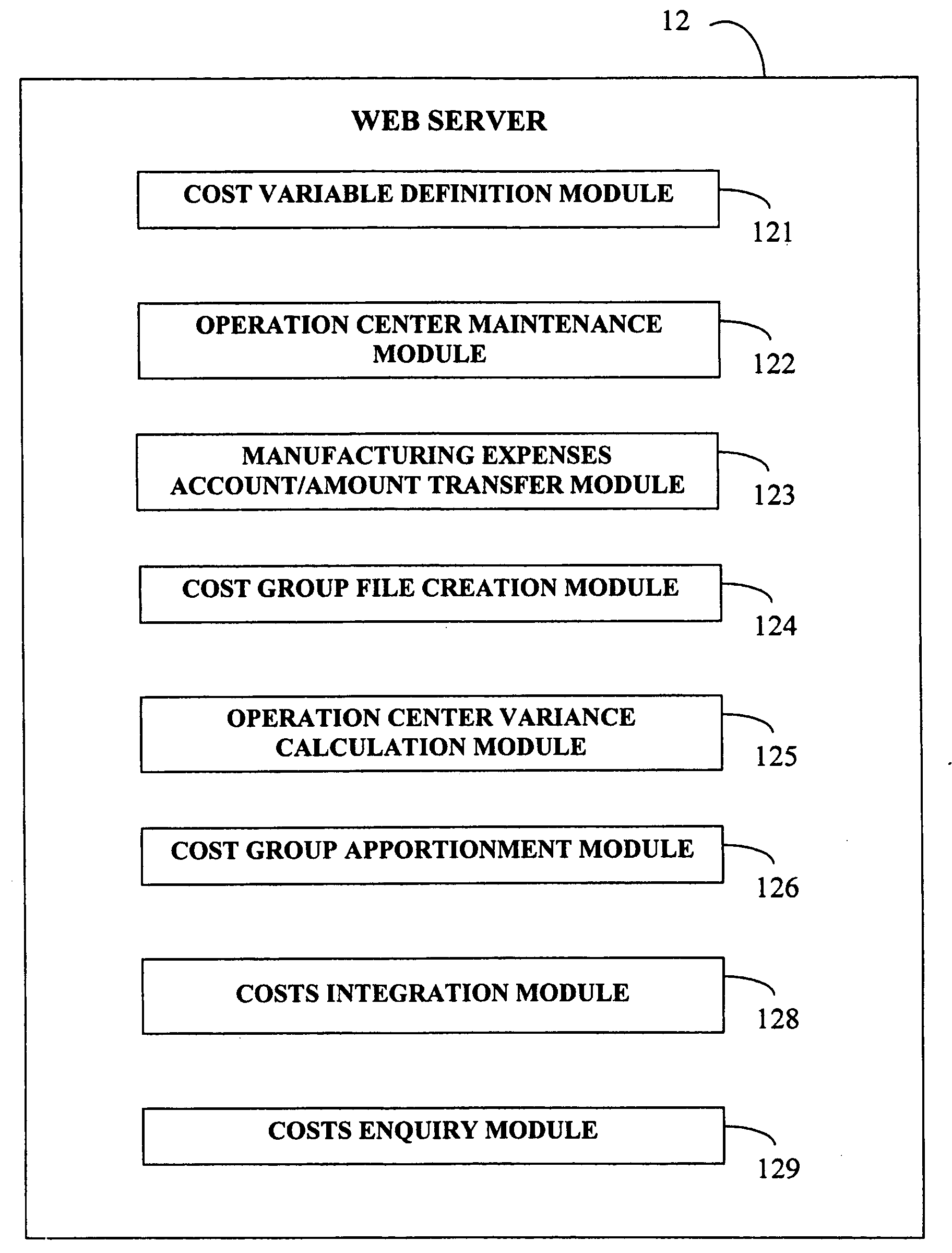

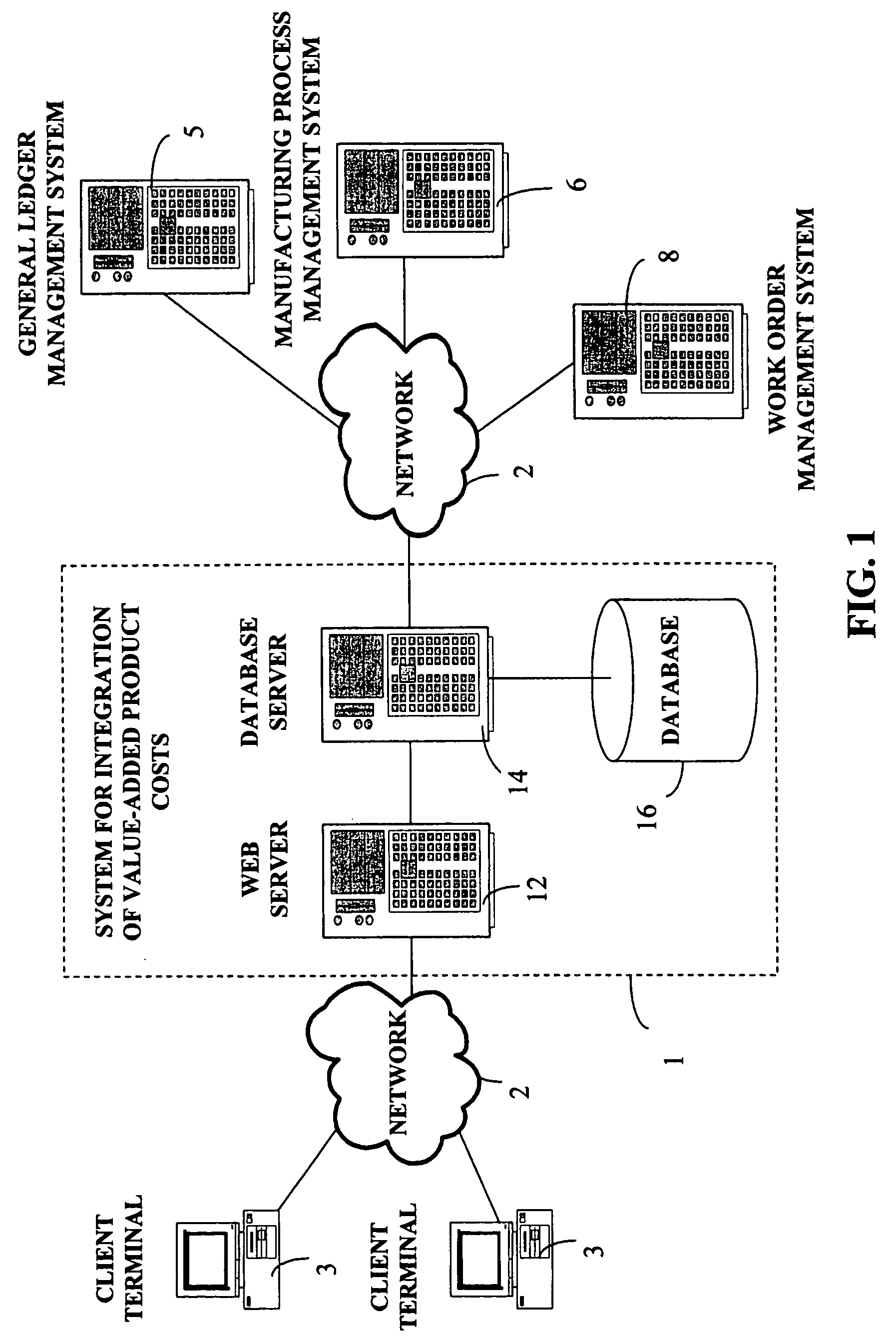

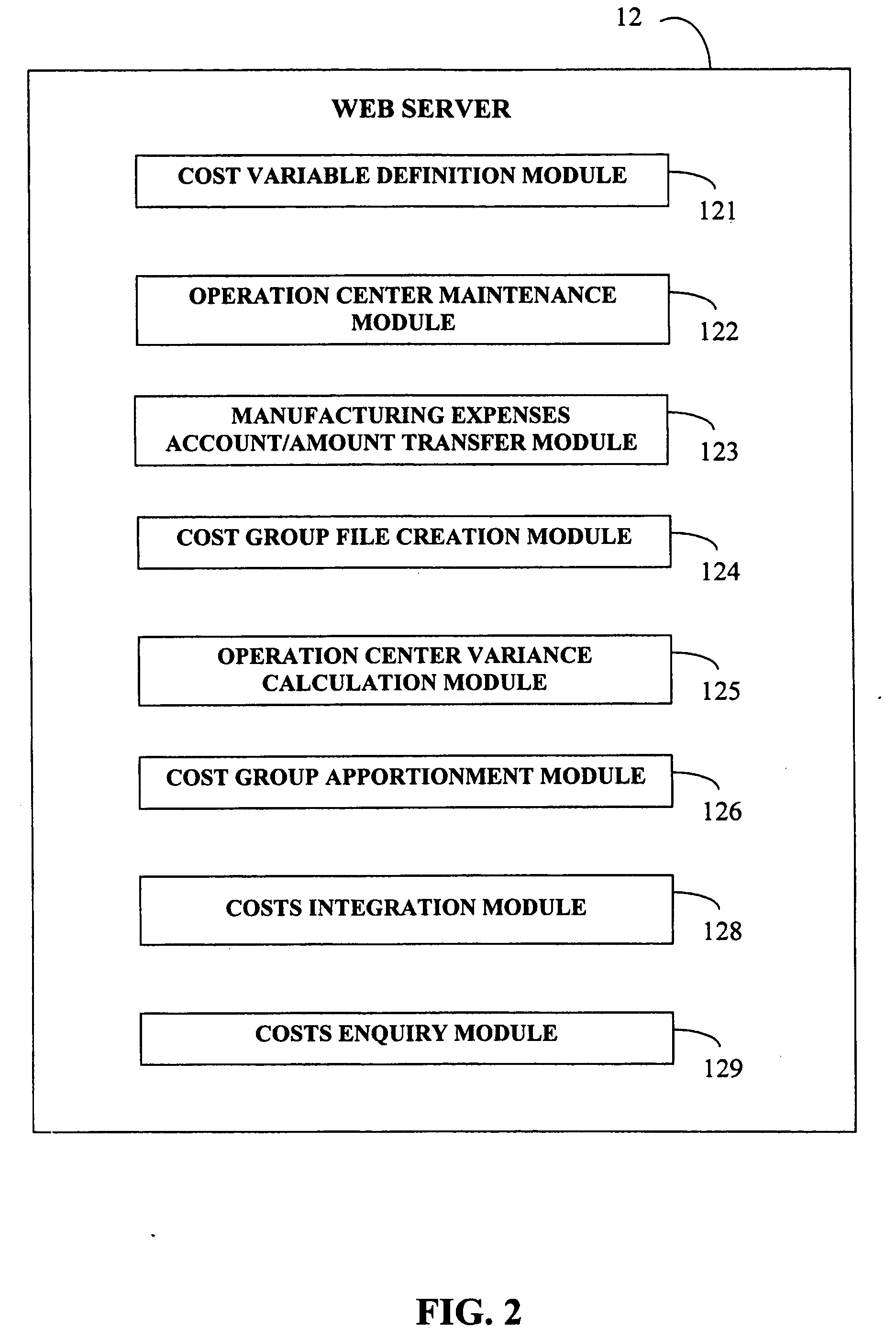

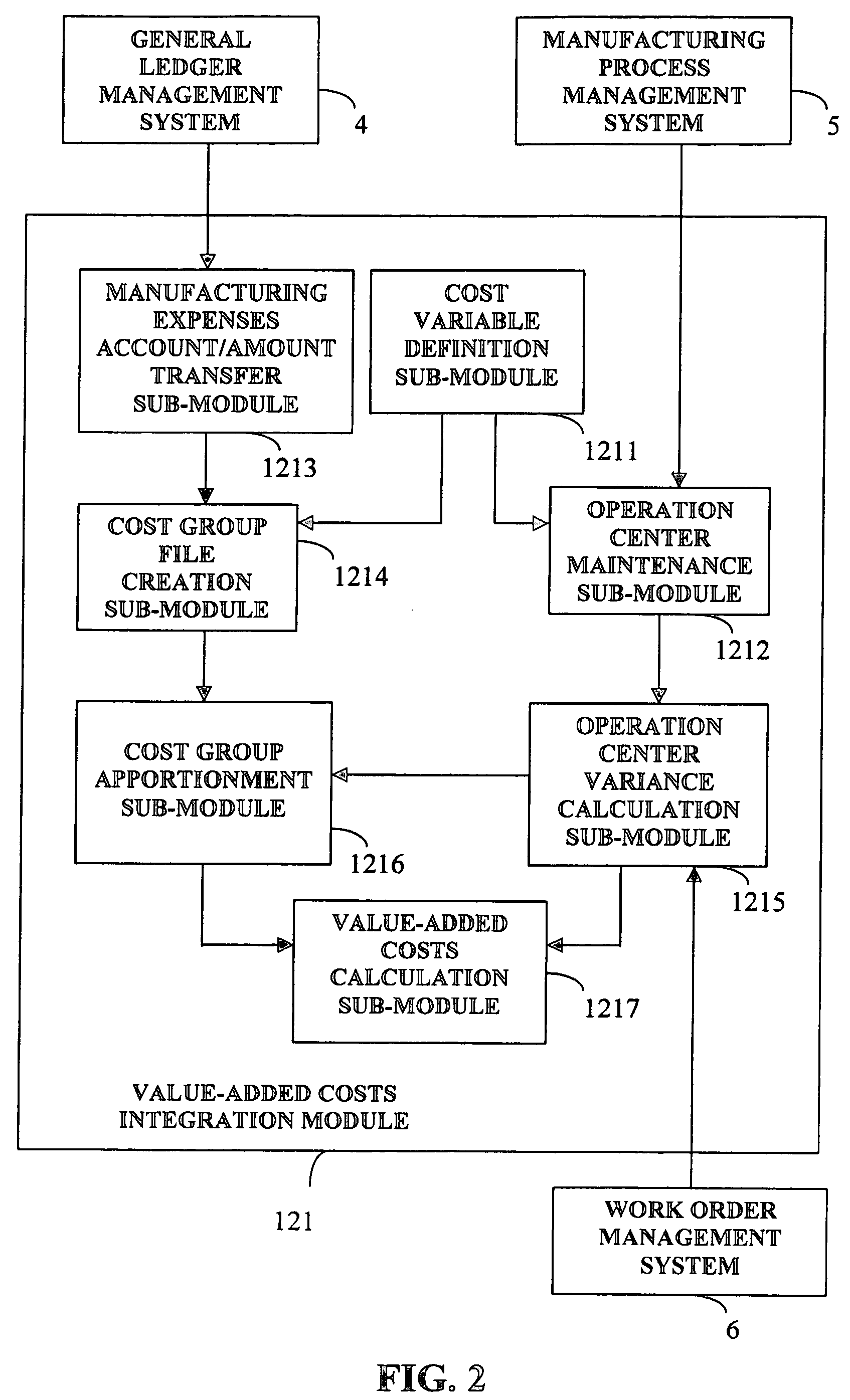

System and method for integration of value-added product costs

A system for integration of value-added product costs (1) can calculate a product's value-added costs according to manufacturing expenses and work time data on work orders. The system for integration of value-added product costs is connected to a number of client terminals (3), a general ledger management system (5), a manufacturing process management system (6) and a work order management system (8) via a network (2). The system for integration of value-added product costs includes a web server (12), a database server (14), and a database (16). The web server is connected to the database server, which contains the database. The web server stores a series of software function modules for receiving and processing data from the client terminals, and for returning results to the client terminals after processing. A related method is also provided.

Owner:HON HAI PRECISION IND CO LTD

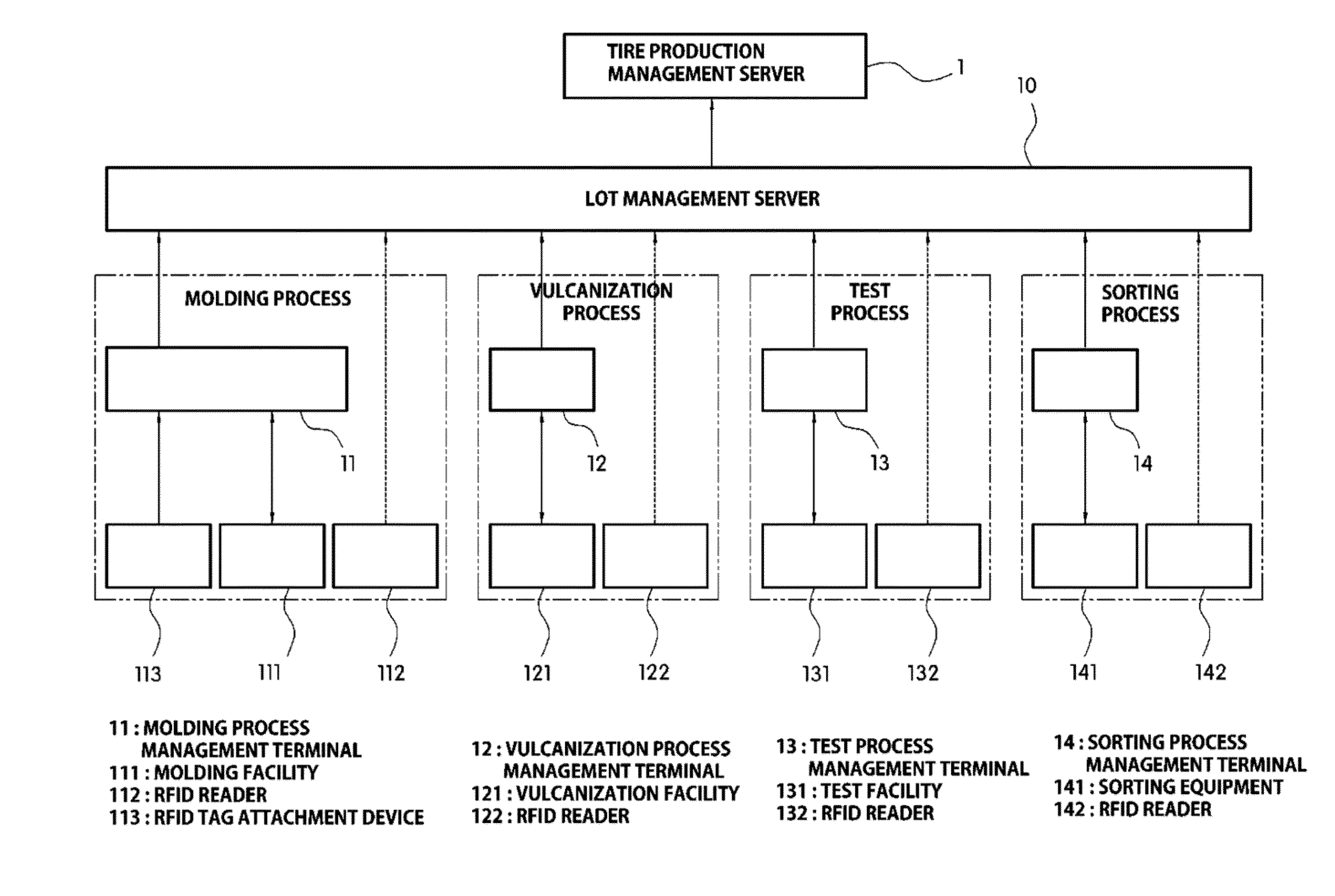

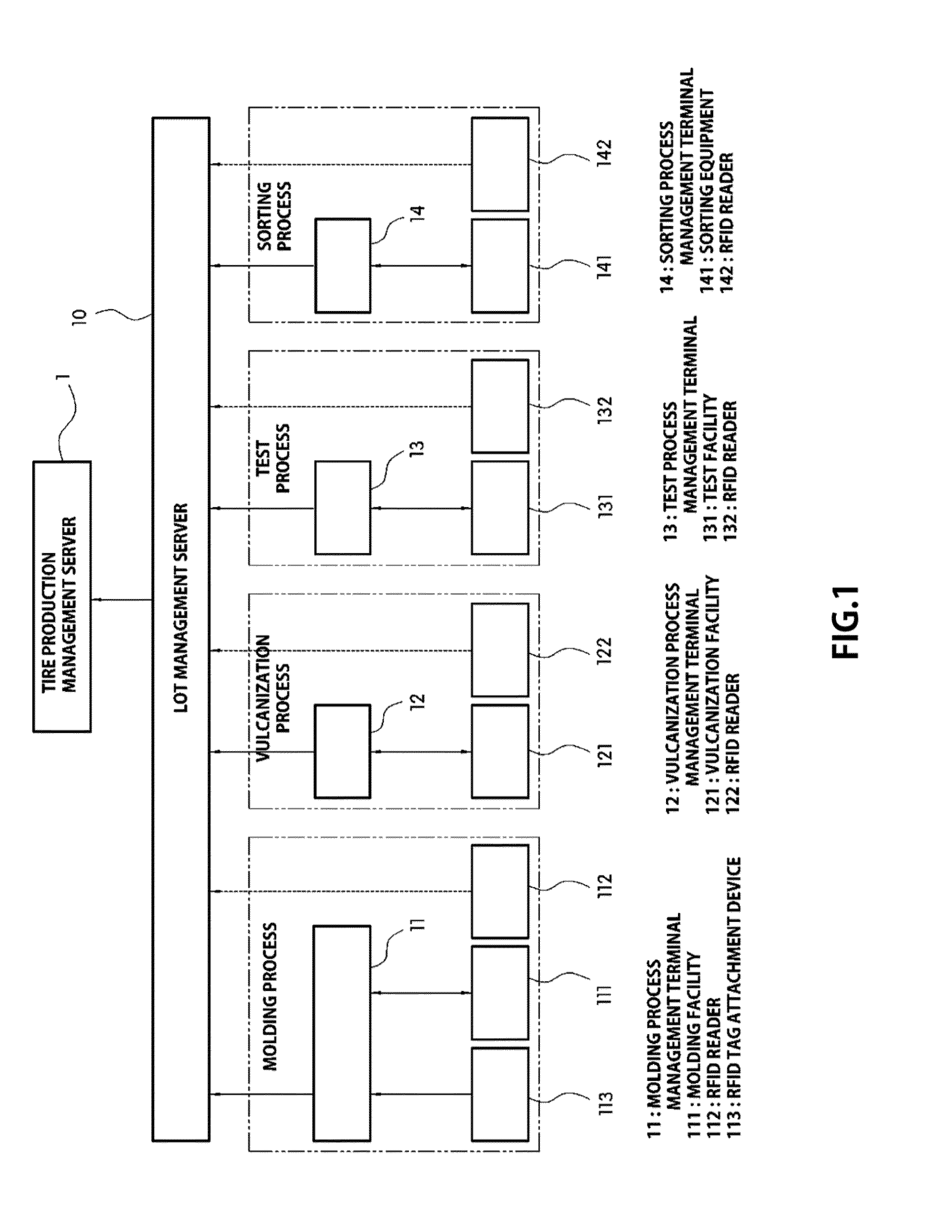

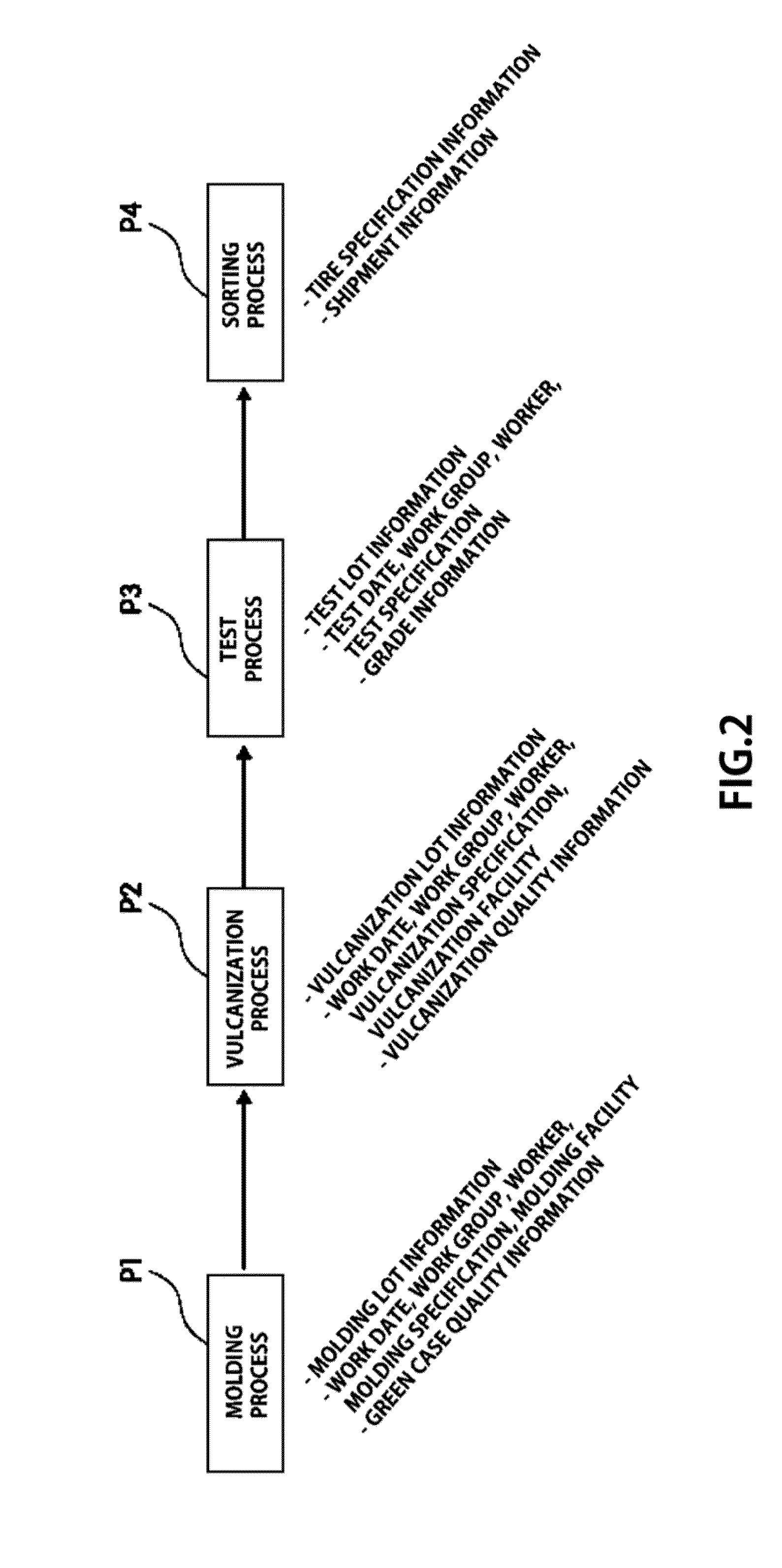

Tire production management system using RFID tag

Disclosed is a tire production management system, and more particularly to, a tire production management system using a radio frequency identification (RFID) tag, which may attach an RFID tag to a tire before producing a finished tire in tire manufacturing processes, recognize the tire tag attached to the tire in each of manufacturing processes, and thus manage information according to a manufacturing process on an individual tire. The tire production management system using an RFID tag comprises: an RFID tag attachment part; a plurality of RFID readers; a plurality of management terminals for respective processes; a lot management server; and a tire production management server.

Owner:ASIANA IDT

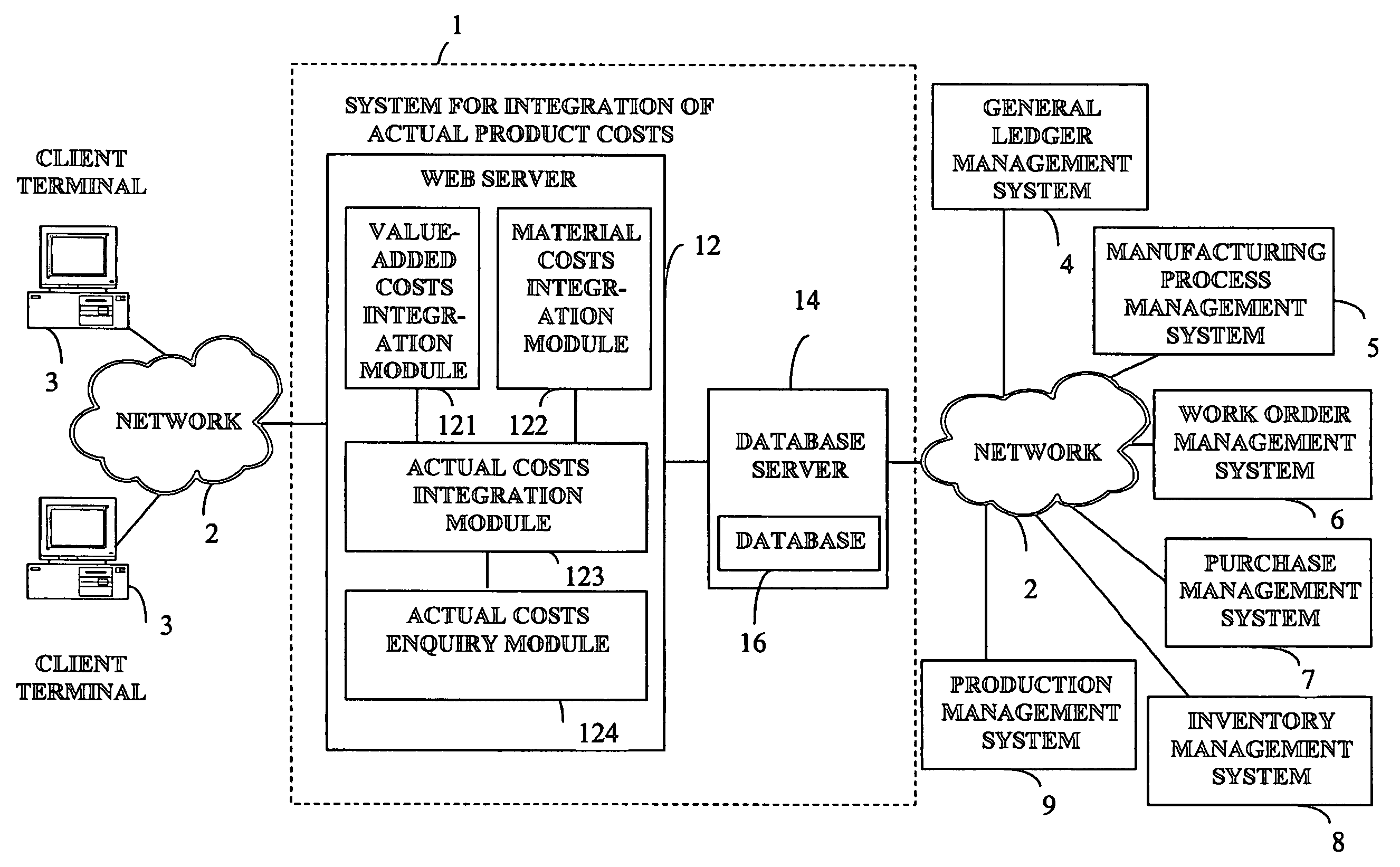

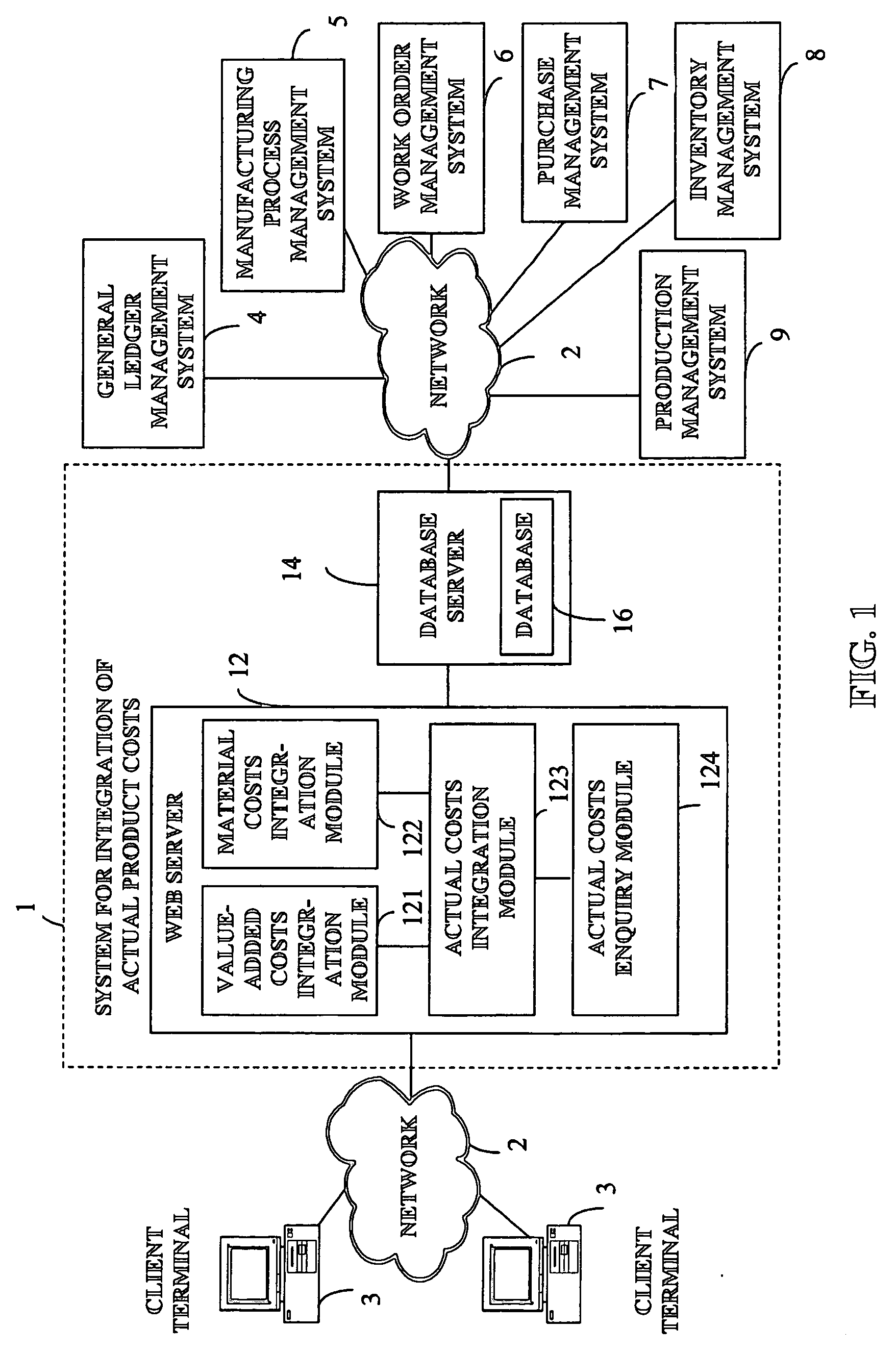

System and method for integration of actual product costs

A system for integration of actual product costs (1) can calculate a product's actual costs by adding the product's value-added costs and the product's material costs. The system for integration of actual product costs is connected to a number of client terminals (3), a general ledger management system (4), a manufacturing process management system (5), a work order management system (6), a purchase management system (7), an inventory management system (8), and a production management system (9). The system for integration of actual product costs includes a web server (12), a database server (14), and a database (16). The web server includes a value-added costs integration module (121), a material costs integration module (122), an actual costs integration module (123), and an actual costs enquiry module (124). A related method is also provided.

Owner:HON HAI PRECISION IND CO LTD

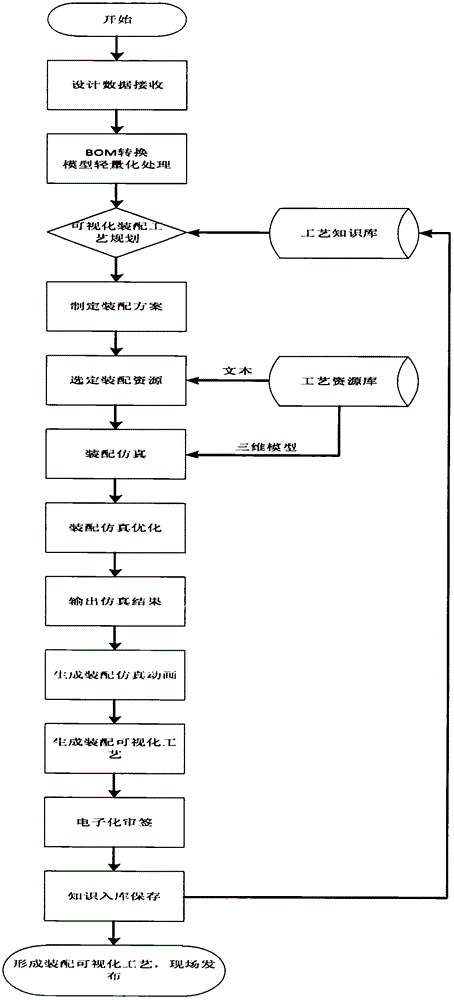

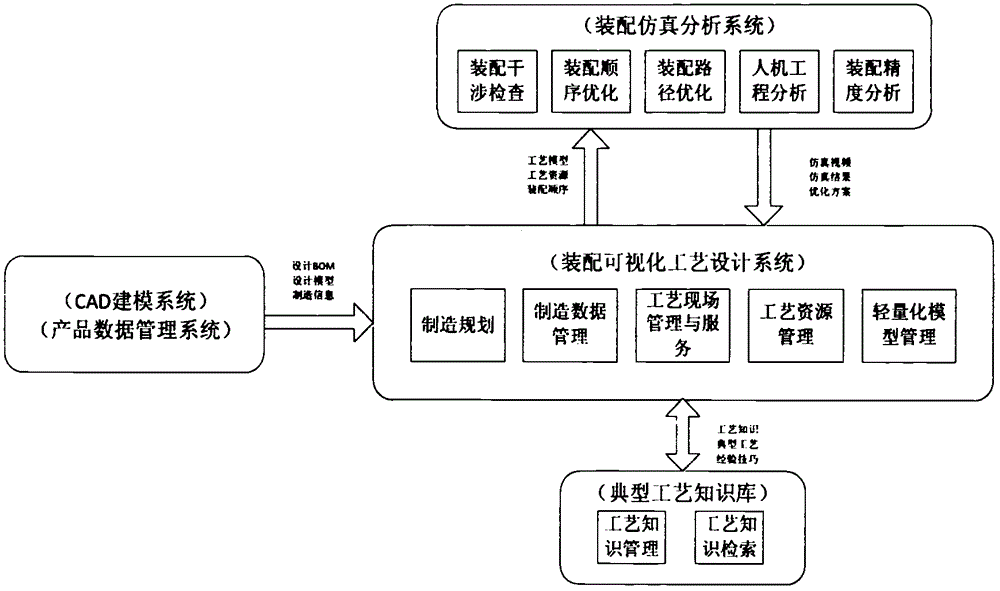

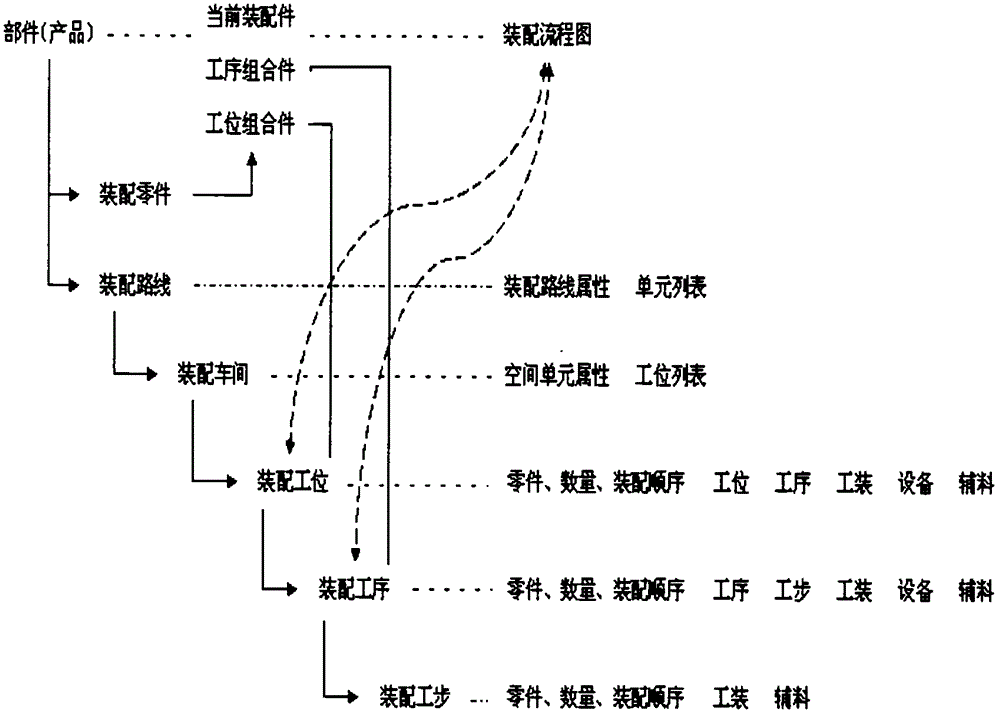

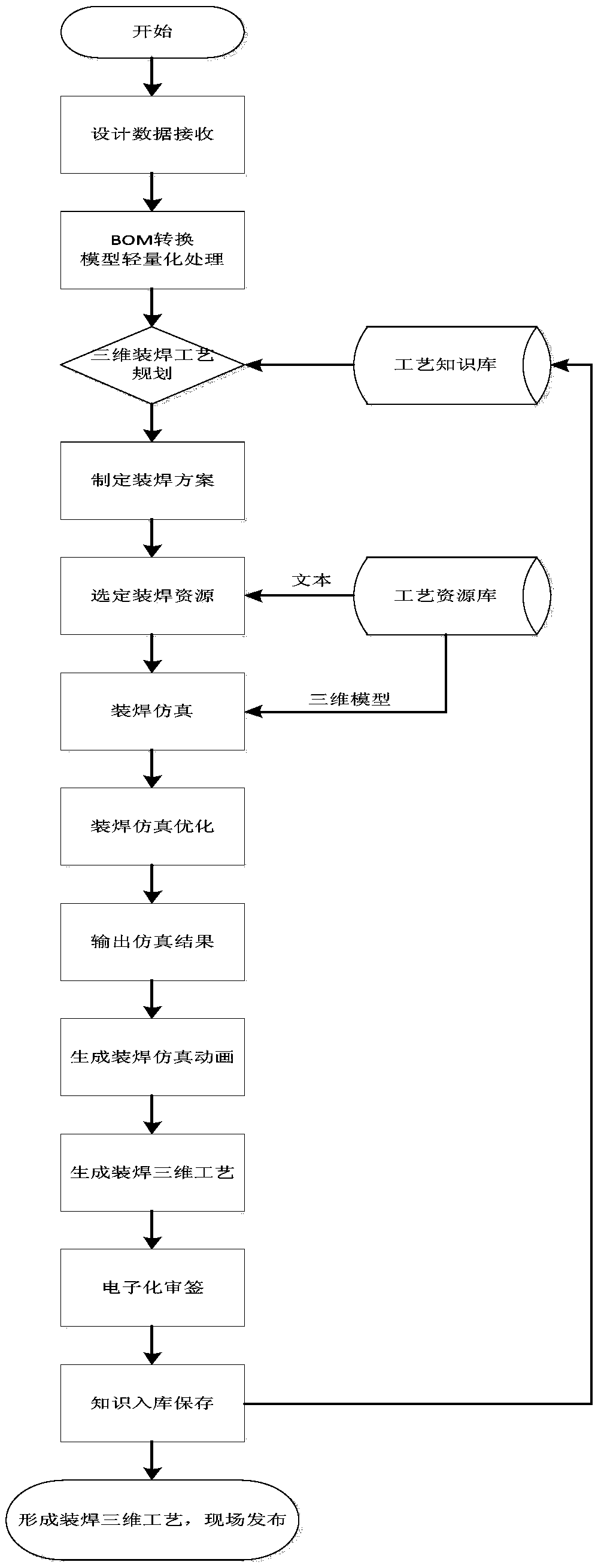

Assembly visualization process design method

InactiveCN106446319AImprove assembly efficiencyReduce dependenceDesign optimisation/simulationSpecial data processing applicationsComputer-aidedComputer aid

The invention relates to an assembly visualization process design method, and solves problems existing in a traditional computer aided assembly process design technology. On the basis of a MPMS (Manufacture Process Management System), a unique assembly visualization process design system is developed; on the basis of the system, through an open interface, the system is integrated with a CAD (Computer Aided Design) modeling system, an assembly simulation analysis system, a product data management system and a typical knowledge base through a multi-system integration way. The integrated system has the following main functions of planning and designing the assembly process, carrying out weight reduction and storage on a three-dimensional process model, carrying out simulation verification and optimization on an assembly course, integrating a process resource base, a three-dimensional model base and a typical process resource base, and carrying out electronic countersigning and visual holographic releasing. Through assembly visualization process teaching, the design intention of the assembly process can be visually and clearly embodied, so that the assembly efficiency of assembly workers can be improved, phenomena including assembly missing and wrong assembly can be inhibited, and product assembly quality can be greatly improved.

Owner:INNER MONGOLIA FIRST MACHINERY GRP

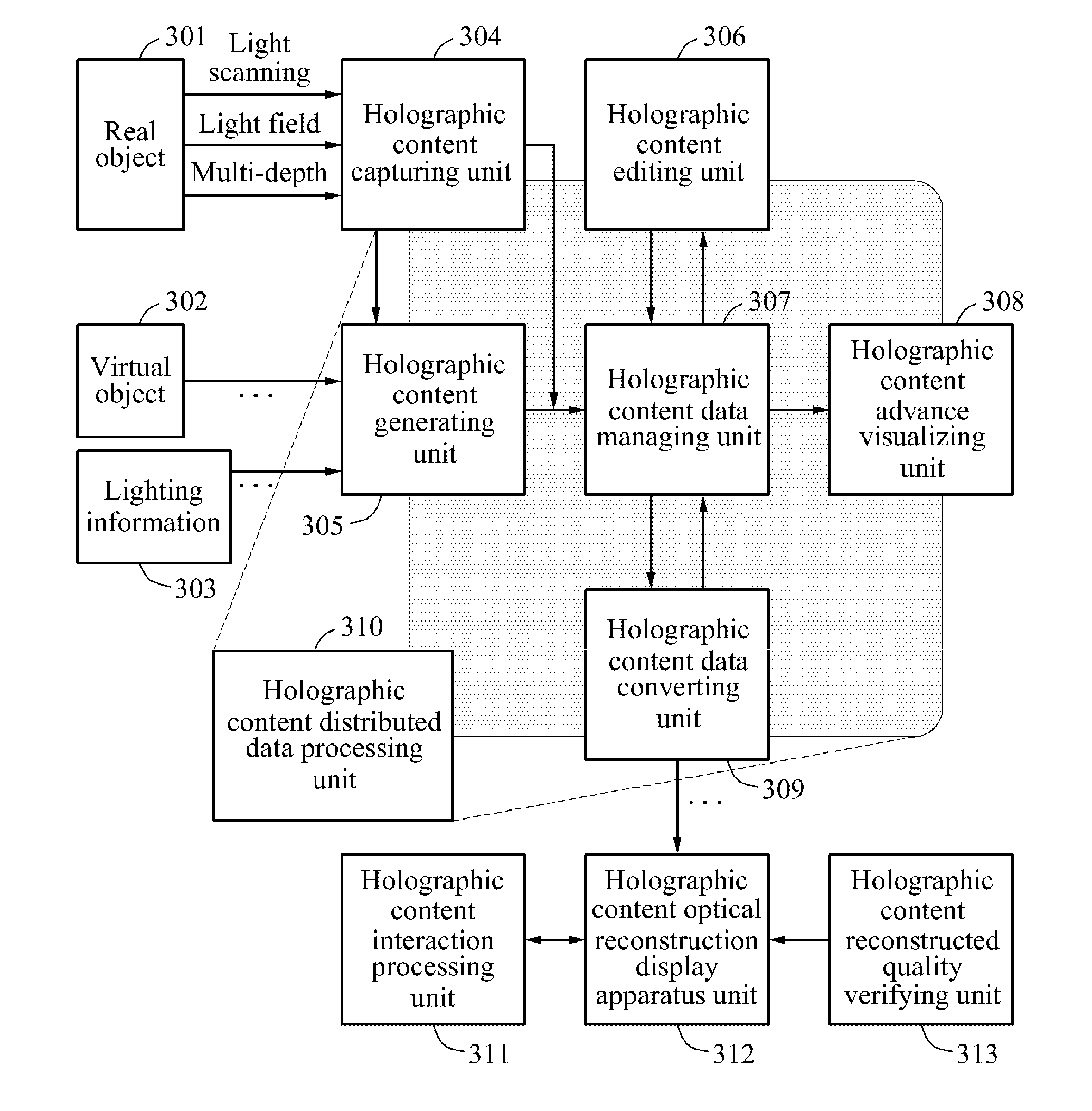

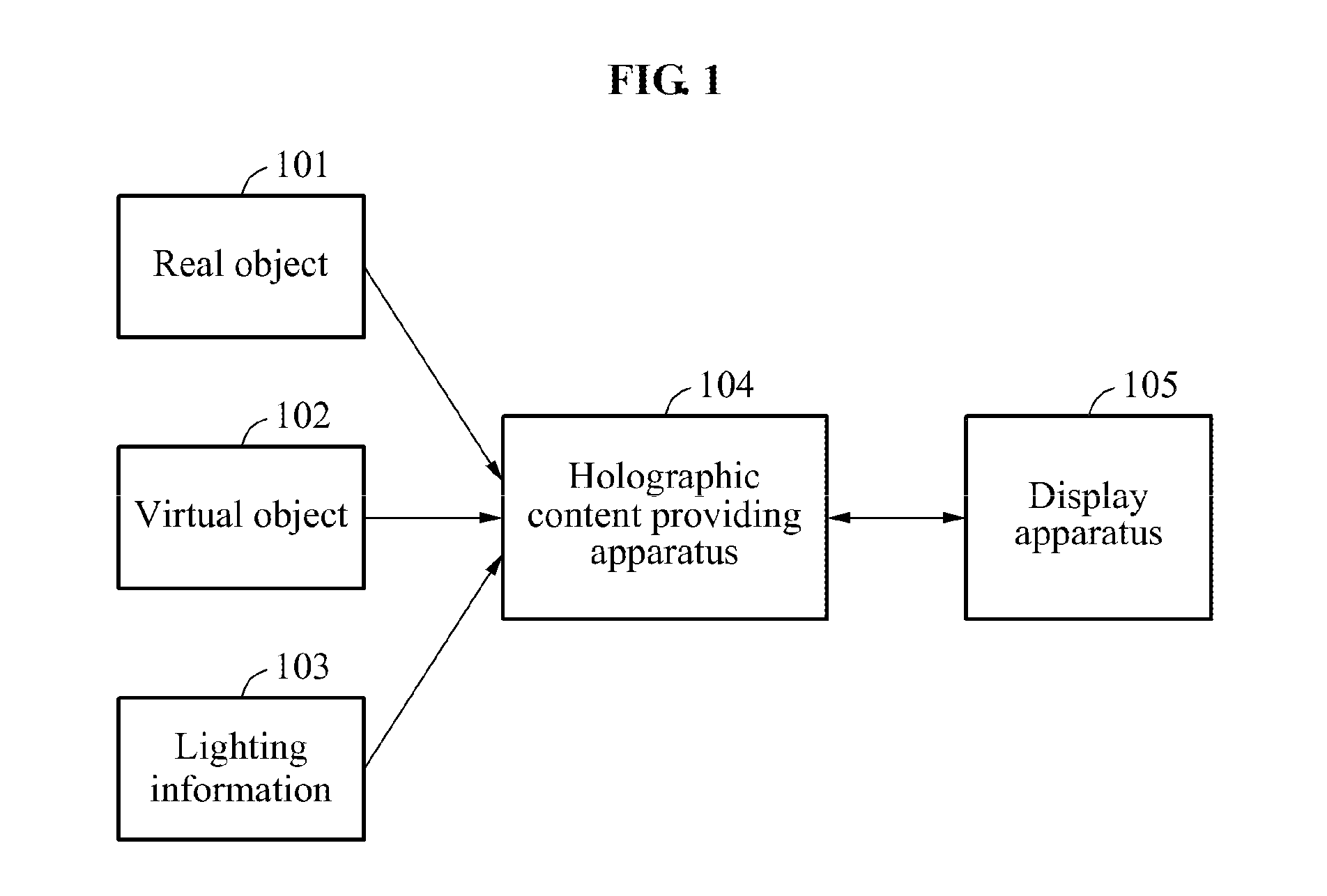

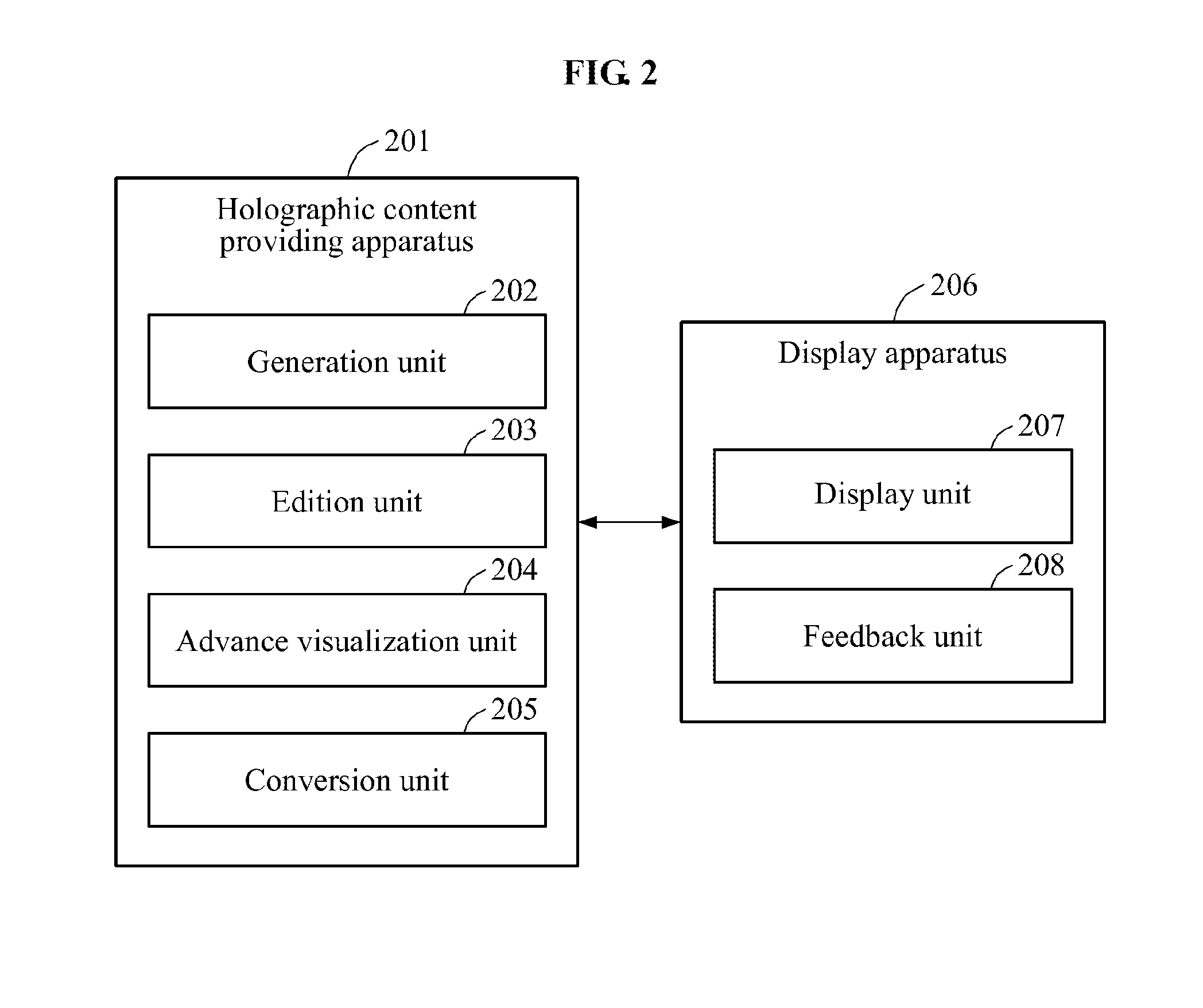

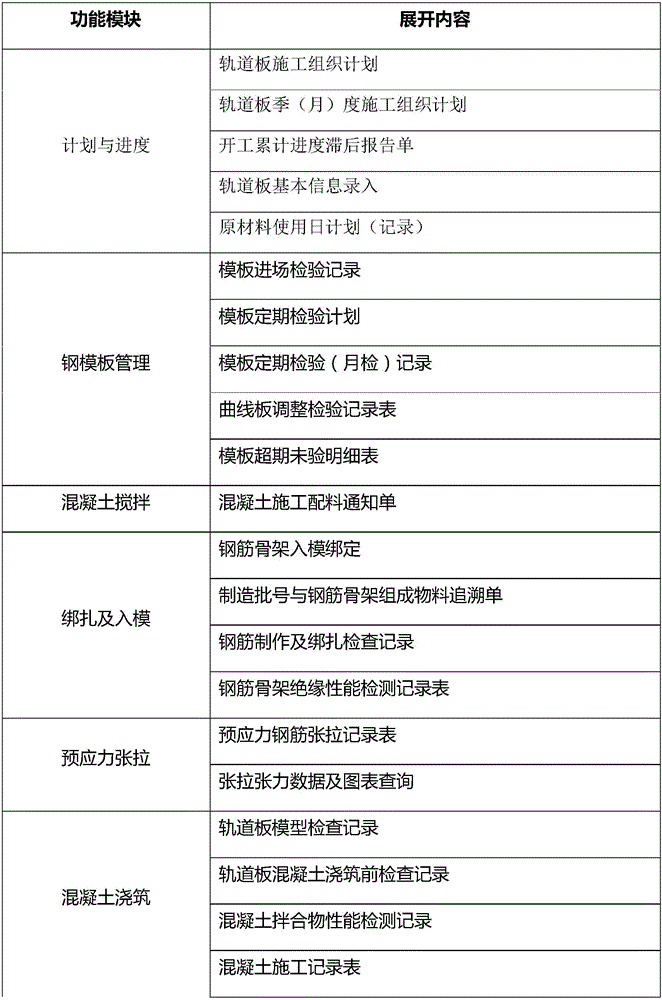

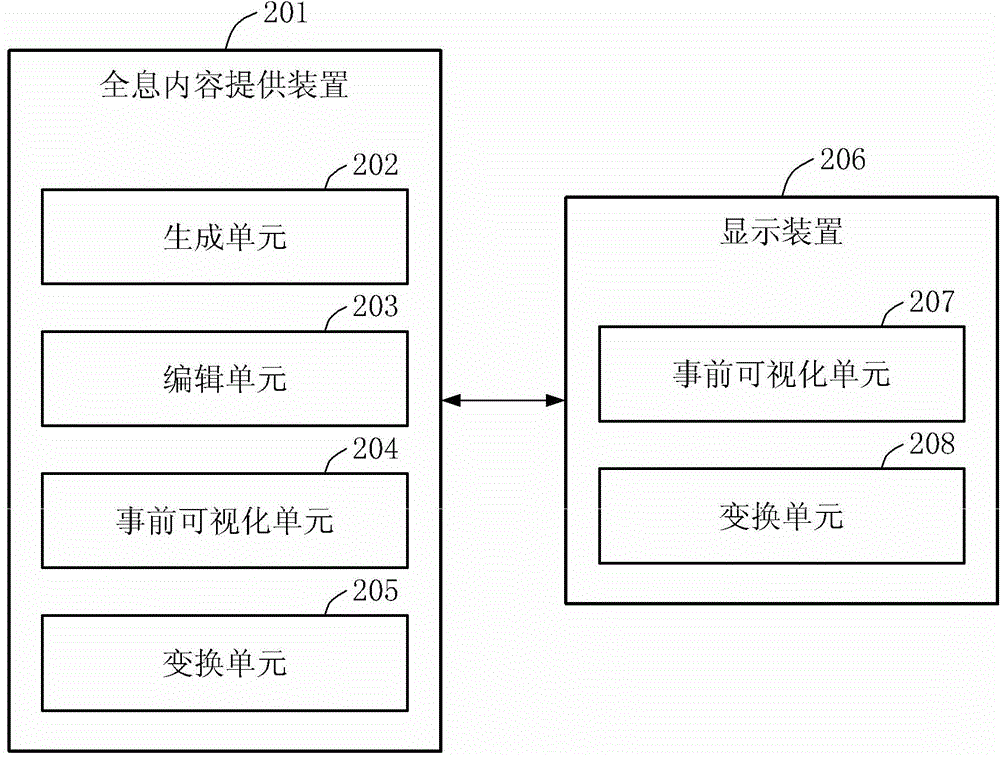

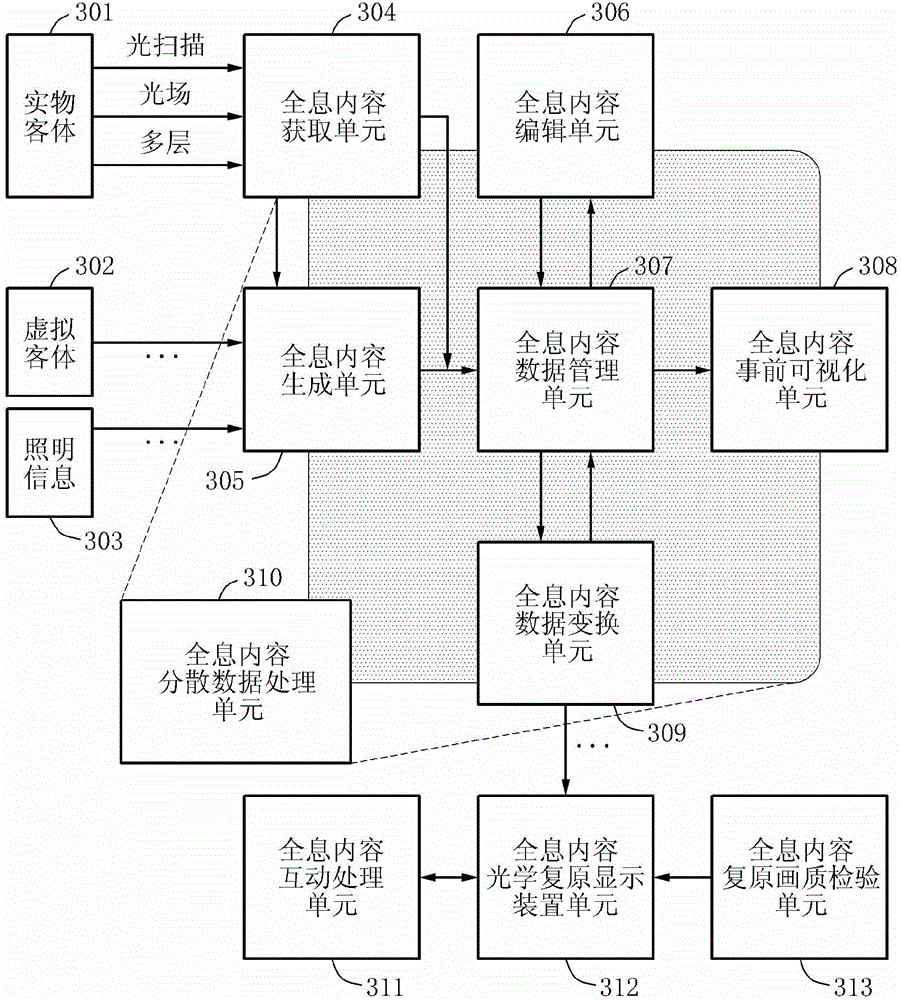

Holographic content providing method, and holographic content providing apparatus and display apparatus using the method

InactiveUS20150146269A1Produce significantHolographic object characteristicsAs DirectedOptical reconstruction

A holographic content providing method, and a holographic content providing apparatus and a display apparatus using the method may capture and generate holographic content using a real object, a virtual object and lighting information, and may conduct integrated processing on the generated holographic content, such as direct edition, advance visualization, data format conversion, element technologies for optical reconstruction and manufacture process management techniques of holographic content, thereby producing ultrahigh-quality interactive holographic content.

Owner:ELECTRONICS & TELECOMM RES INST

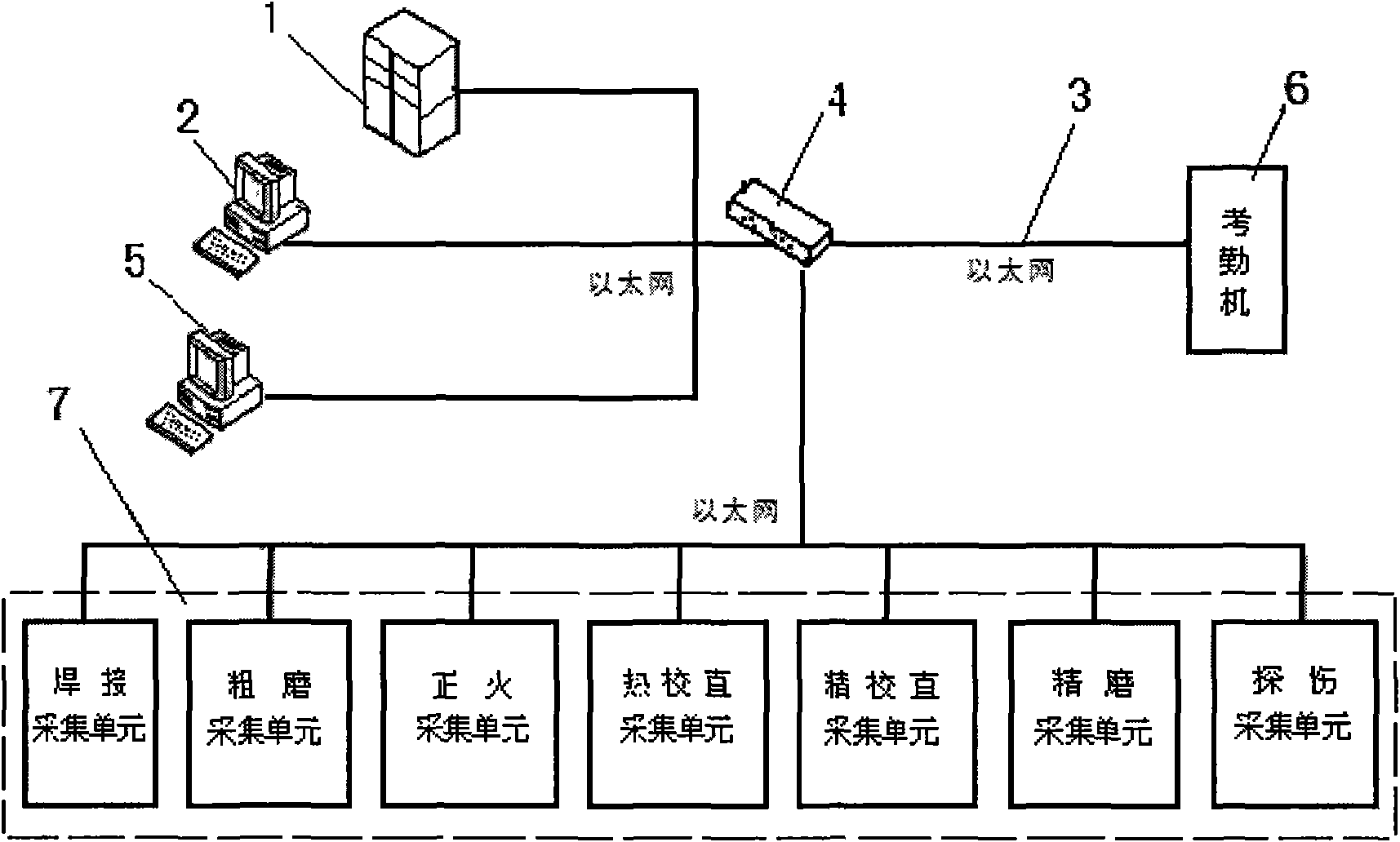

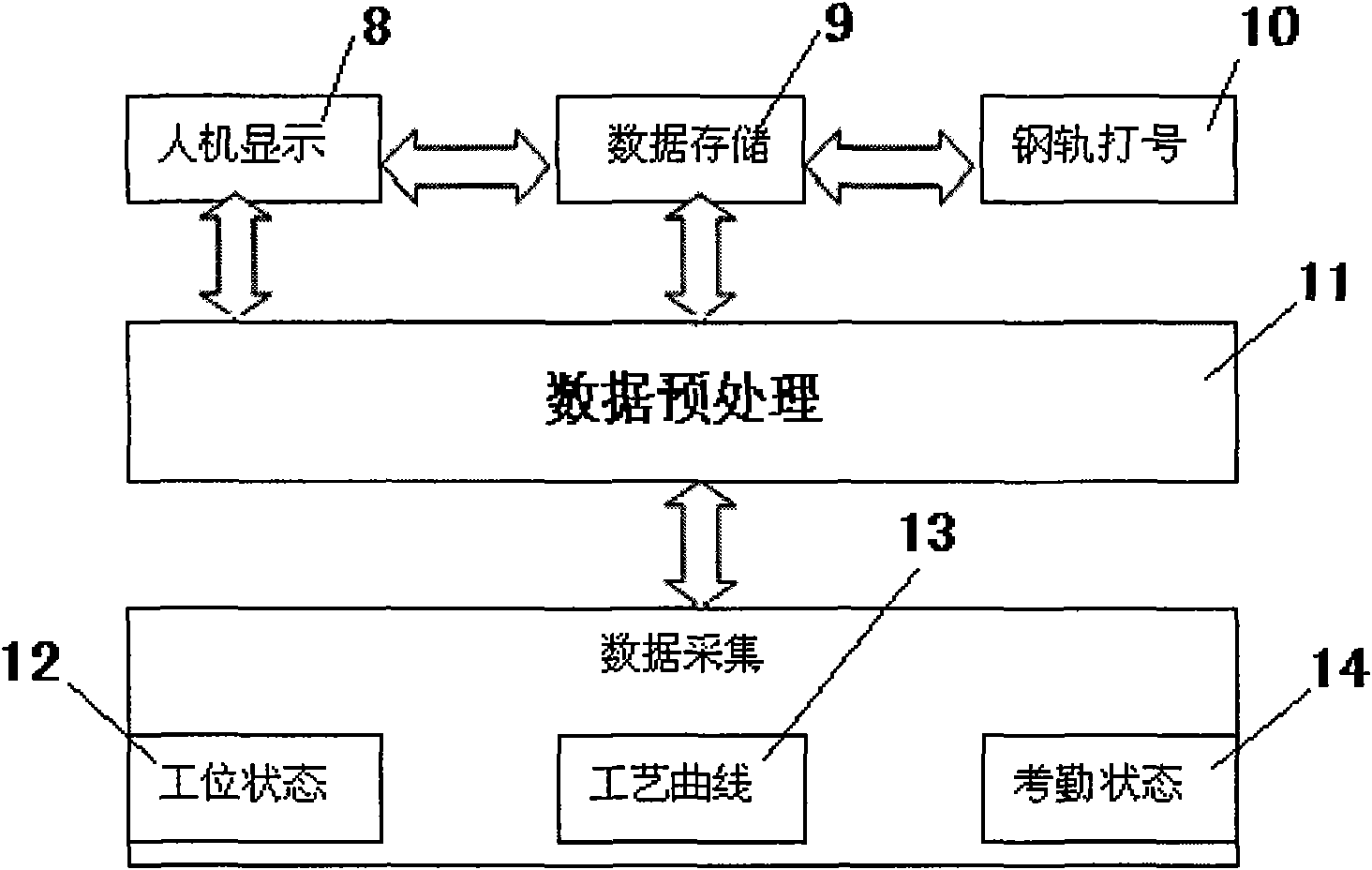

Comprehensive monitoring management system and method of long-rail welding process

InactiveCN101653853ARealize the display effectAchieve securityArc welding apparatusData acquisitionEngineering

The invention relates to the manufacturing process management of railway transportation equipment, in particular to comprehensive monitoring management system and method of a long-rail welding process. A server, a data acquisition host, a switch, a stamping machine, an attendance machine and a station data acquisition unit are connected by adopting an Ethernet field bus and interactively communicated so that working equipment on a rail-welding base is assembled into a data acquisition monitoring management network. The method comprises the following steps: data preprocessing is as follows: data storage, station states, process curves, attendance states and human-computer display are carried out the data processing in a real-time roundrobin mode, and the data preprocessing is interlocked with a rail line for control. The invention realizes the state display and the safety interlocking of various stations, improves the production efficiency and the working environment, ensures the safe production and lays the foundation for the life-cycle quality management of steel rails.

Owner:南昌路通高新技术有限责任公司

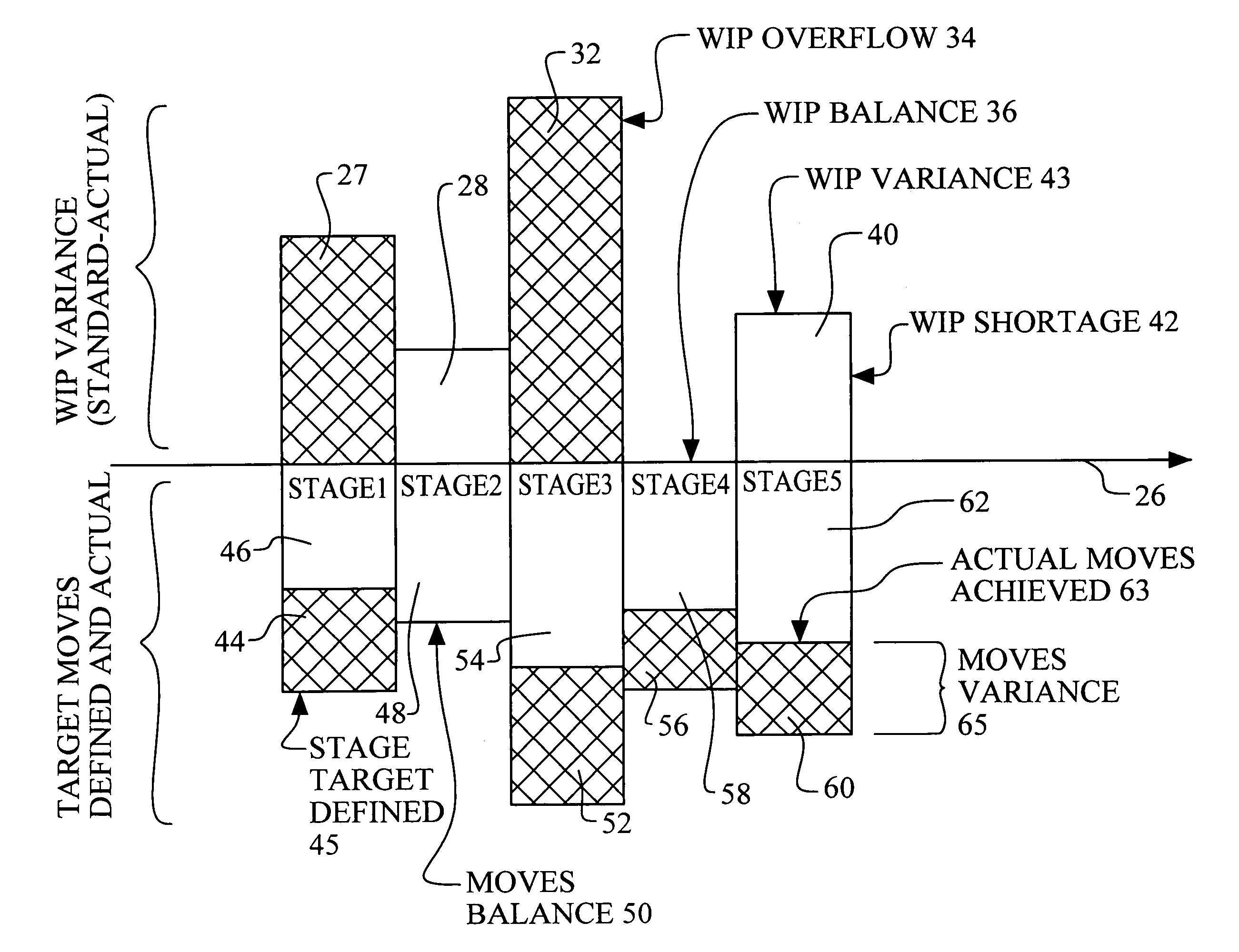

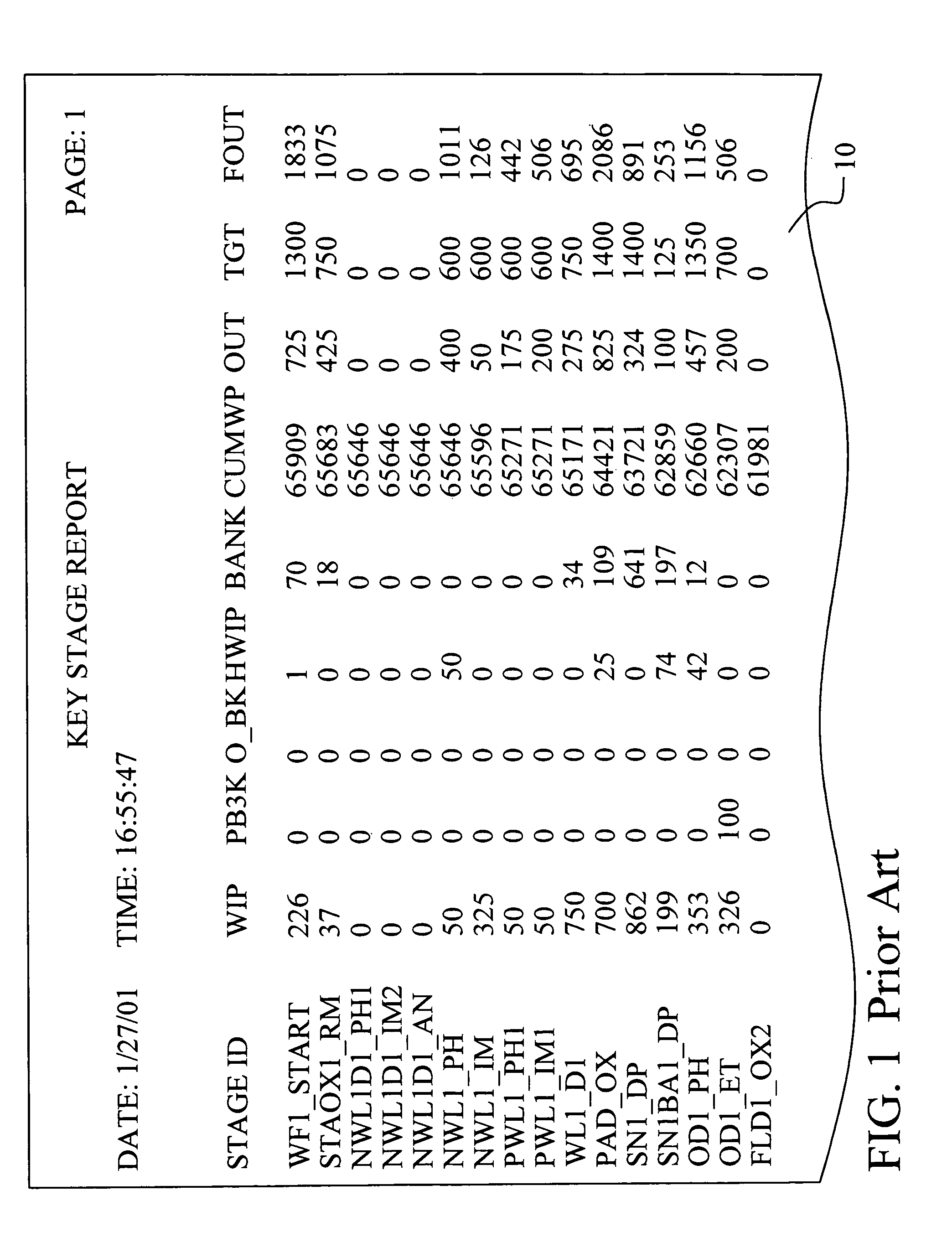

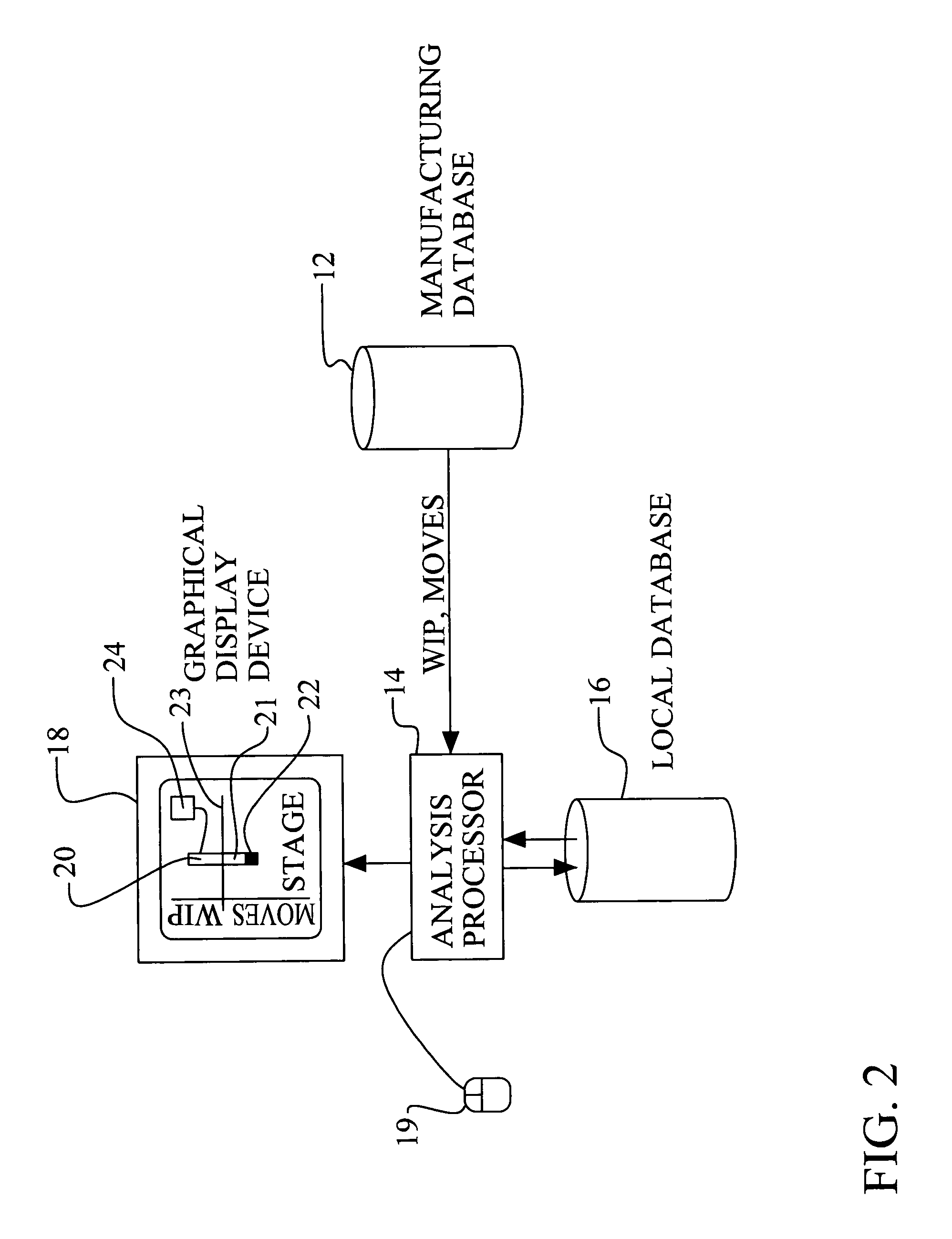

Method and apparatus for displaying production data for improved manufacturing decision making

InactiveUS6999081B1Easy to explainEffective displayData processing applicationsDrawing from basic elementsGraphicsComputer science

A new data processing and display method for use in interactive manufacturing process management is achieved. A first variable value, such as WIP, for a manufacturing stage is uploaded from a database and is subtracted from a first target value to obtain a first variable variance. A first variable variance bar is displayed above a stage axis on a graphical display device and is non-filled if the first variable variance is positive and is filled if the first variable variance is negative. A second variable value, such as production moves, is uploaded and is subtracted from a second target value to obtain a second variable variance. A second variable value bar is displayed below the stage axis on the graphical display device and is non-filled. A second variable variance bar is displayed below the second variable value bar on the graphical display device if the second variable variance is positive.

Owner:TAIWAN SEMICON MFG CO LTD

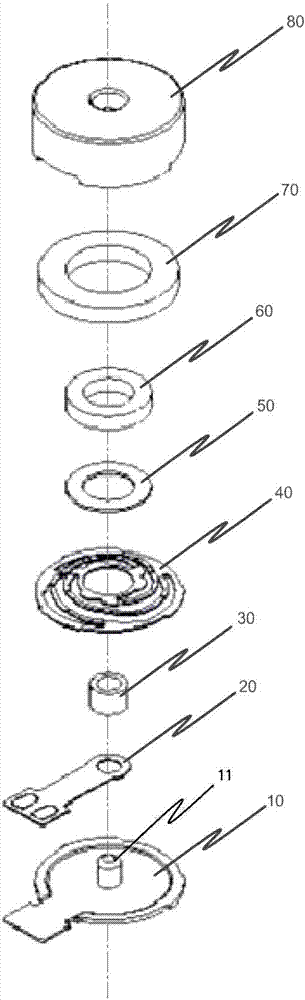

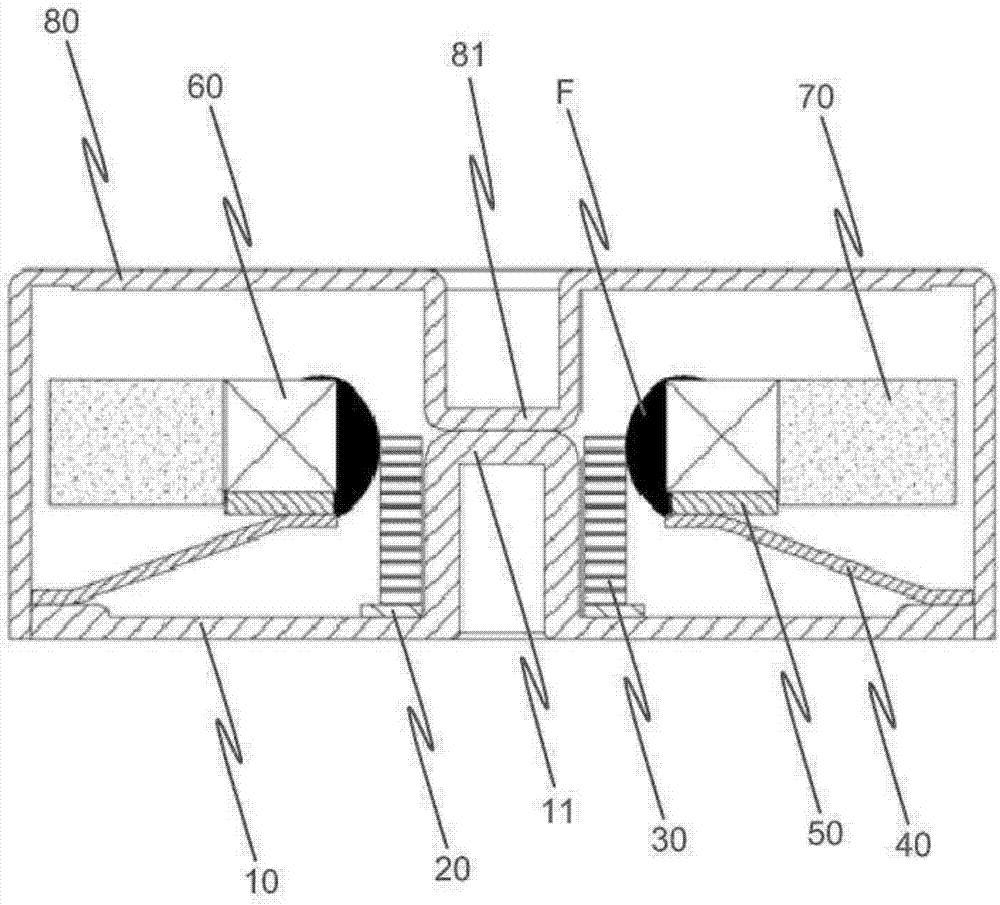

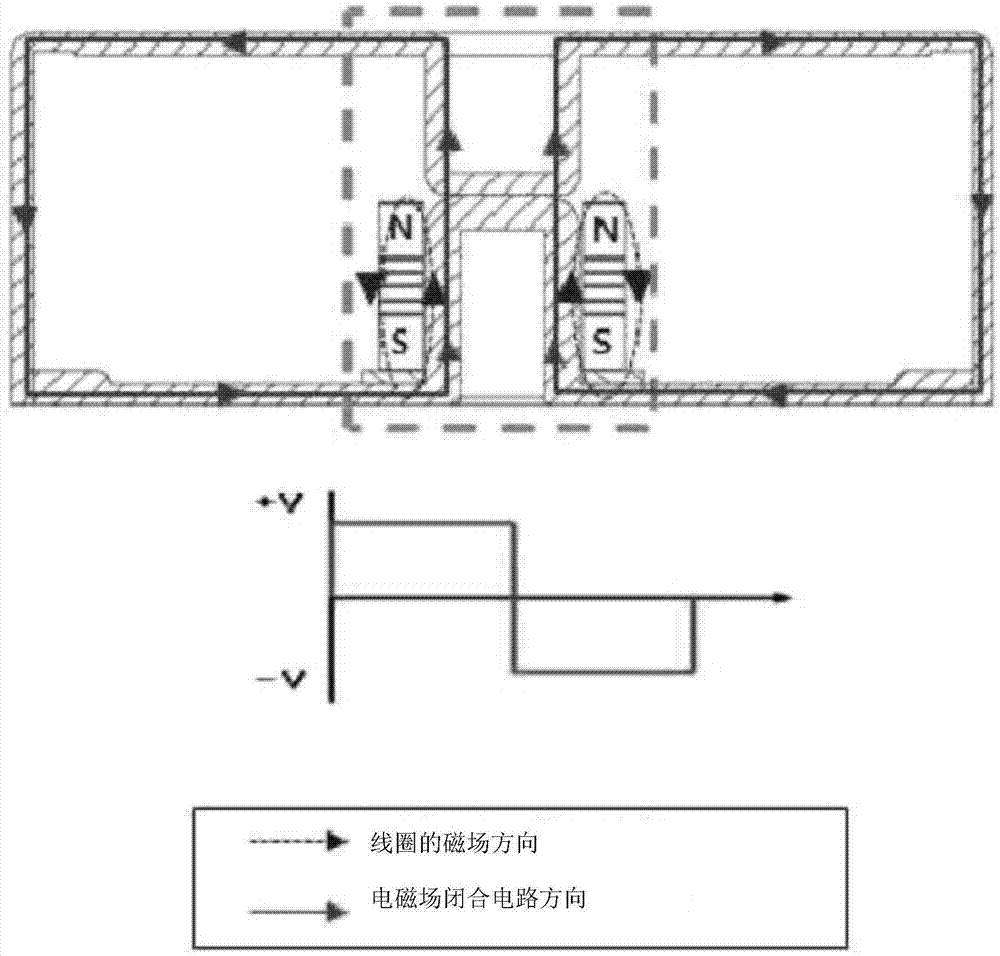

Linear up-down vibration motor comprising shell formed by magnetic field closed circuit

ActiveCN107294339AImprove vibrationEnhanced magnetic forceMechanical energy handlingSupports/enclosures/casingsVertical vibrationEngineering

The invention relates to a linear up-down vibration motor comprising a shell formed by a magnetic field closed circuit, the motor comprises a magnetic yoke support and a coil, the magnetic yoke support is bonded with an F-PCB, the coil and a spring and also comprises an upward protrude portion of which plane center portion protrudes upwards, the upward protrude portion is bonded with the magnetic yoke support, the coil is arranged in a central cut-through mode and is vertically bonded with the plane of the above F-PCB, and vertical vibration of a vibrating body are generated through action with a magnet. The magnetic force can be improved, the improved magnetic is gathered, so that the vibration force of the vibration motor can be further improved. According to the invention, the manufacturing process management is simple and convenient, and the poor bond of the production can be minimized. In addition, the motor can reduce tremble and noise caused by tremblling during vibration.

Owner:天津富禄通信技术有限公司

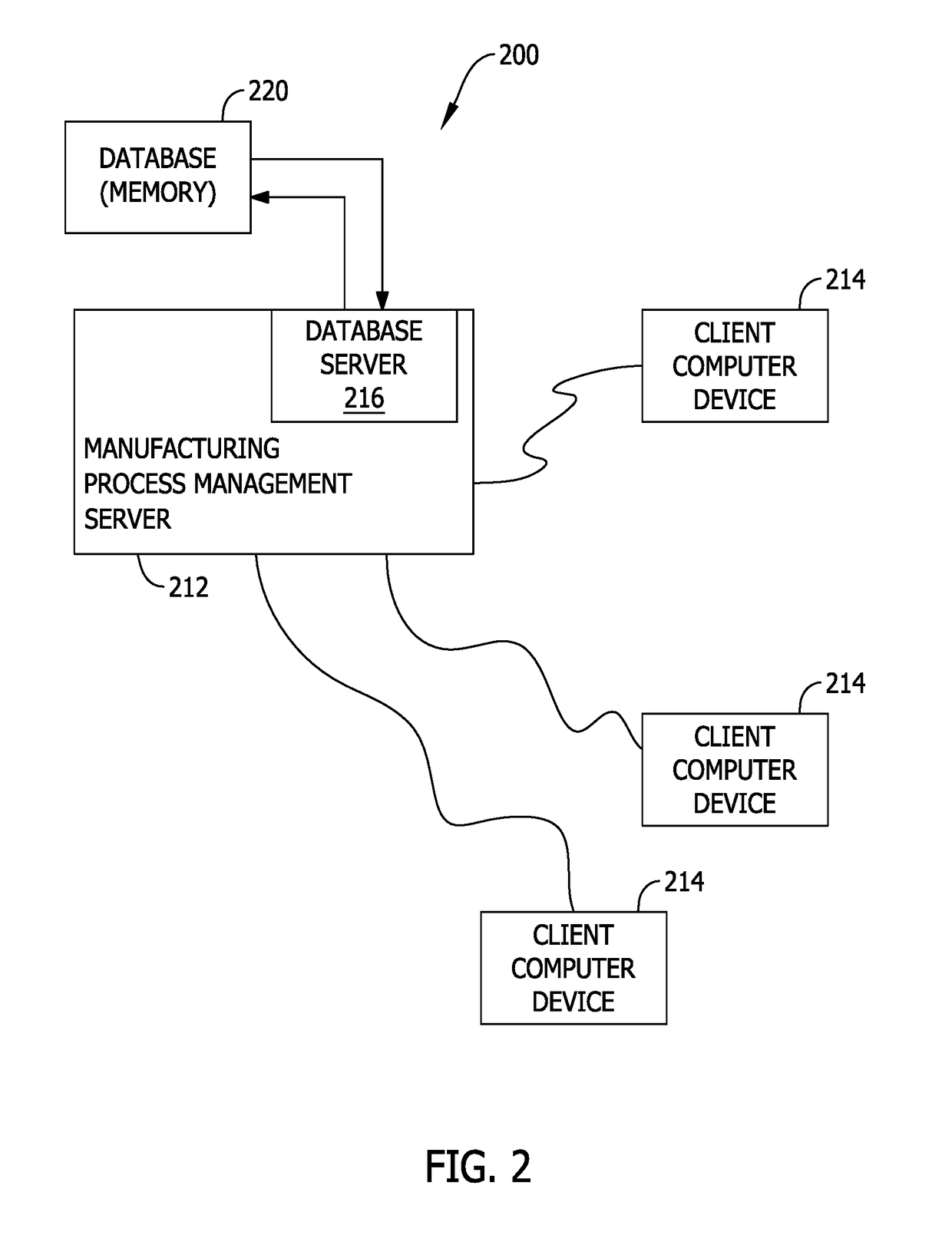

System and methods for managing changes to a product in a manufacturing environment including a minor model relational design

A manufacturing process management (MPM) computer device is provided. The MPM computer device is configured to store a first version of a product and a second version of the product. The second version includes the first plurality of parts, the second plurality of parts, and a third plurality of parts associated with the plug. The first location is between the first plurality of locations and the second plurality of locations. The MPM computer device is also configured to calculate a first numbering system, calculate a second numbering system for a third plurality of locations associated with the third plurality of parts, determine a first grid overlay for the first version of the product based on the first numbering system, determine a second grid overlay for the second version of the product based on the first numbering system and the second numbering system.

Owner:THE BOEING CO

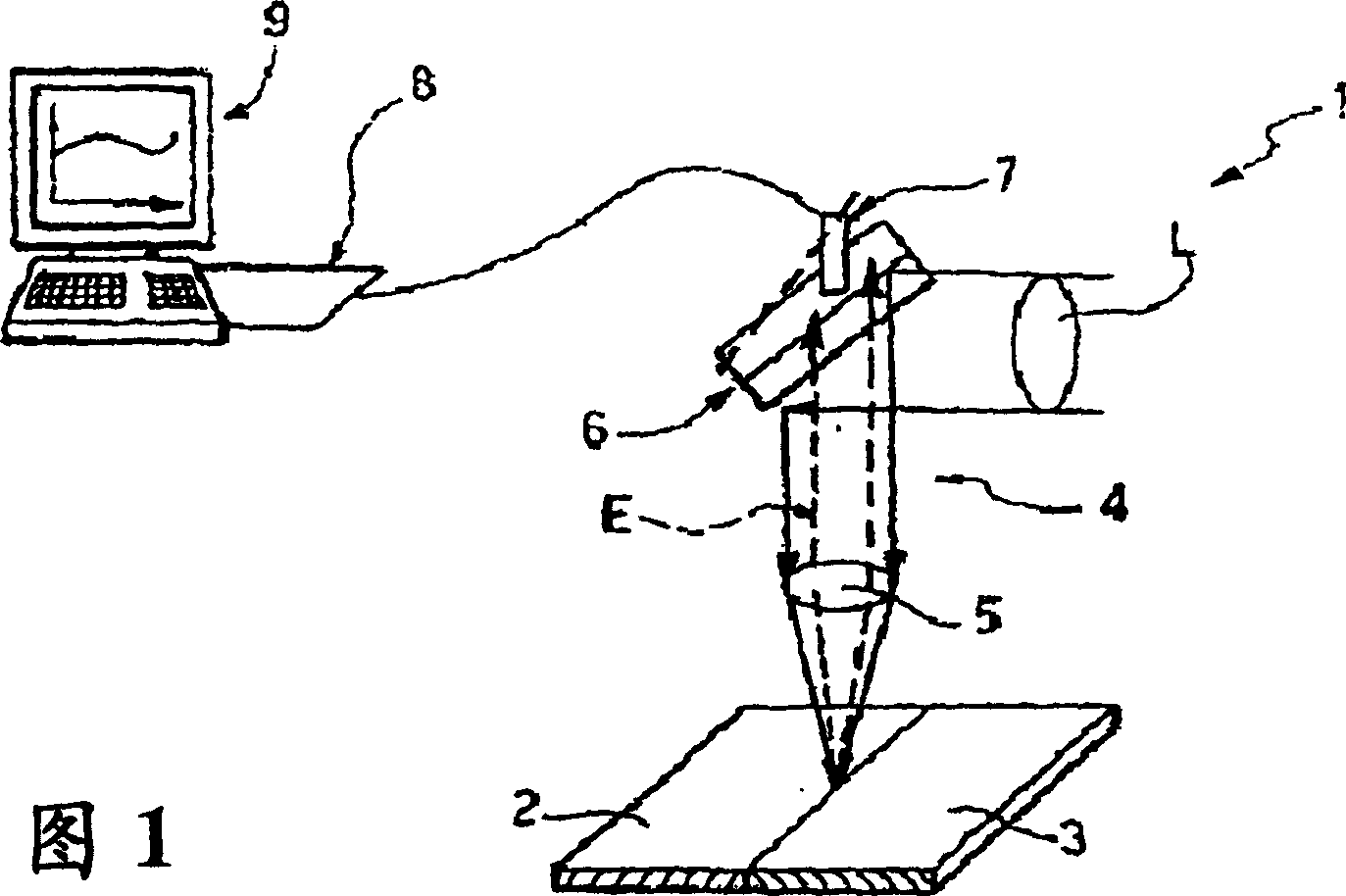

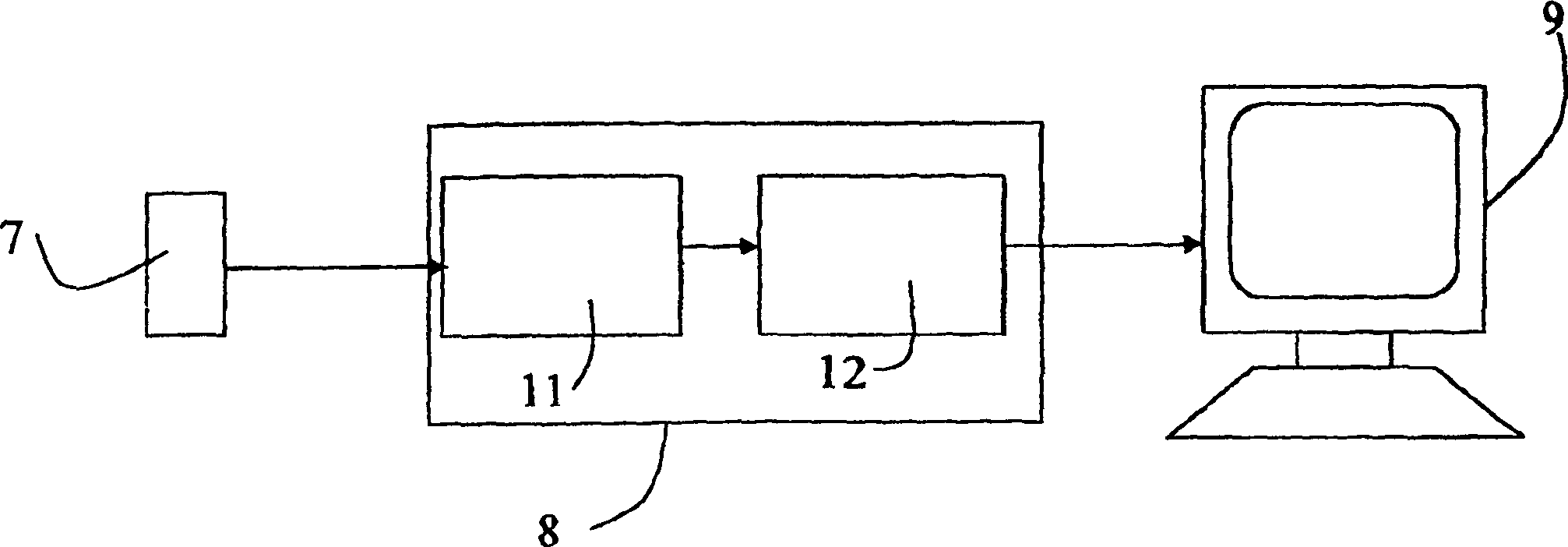

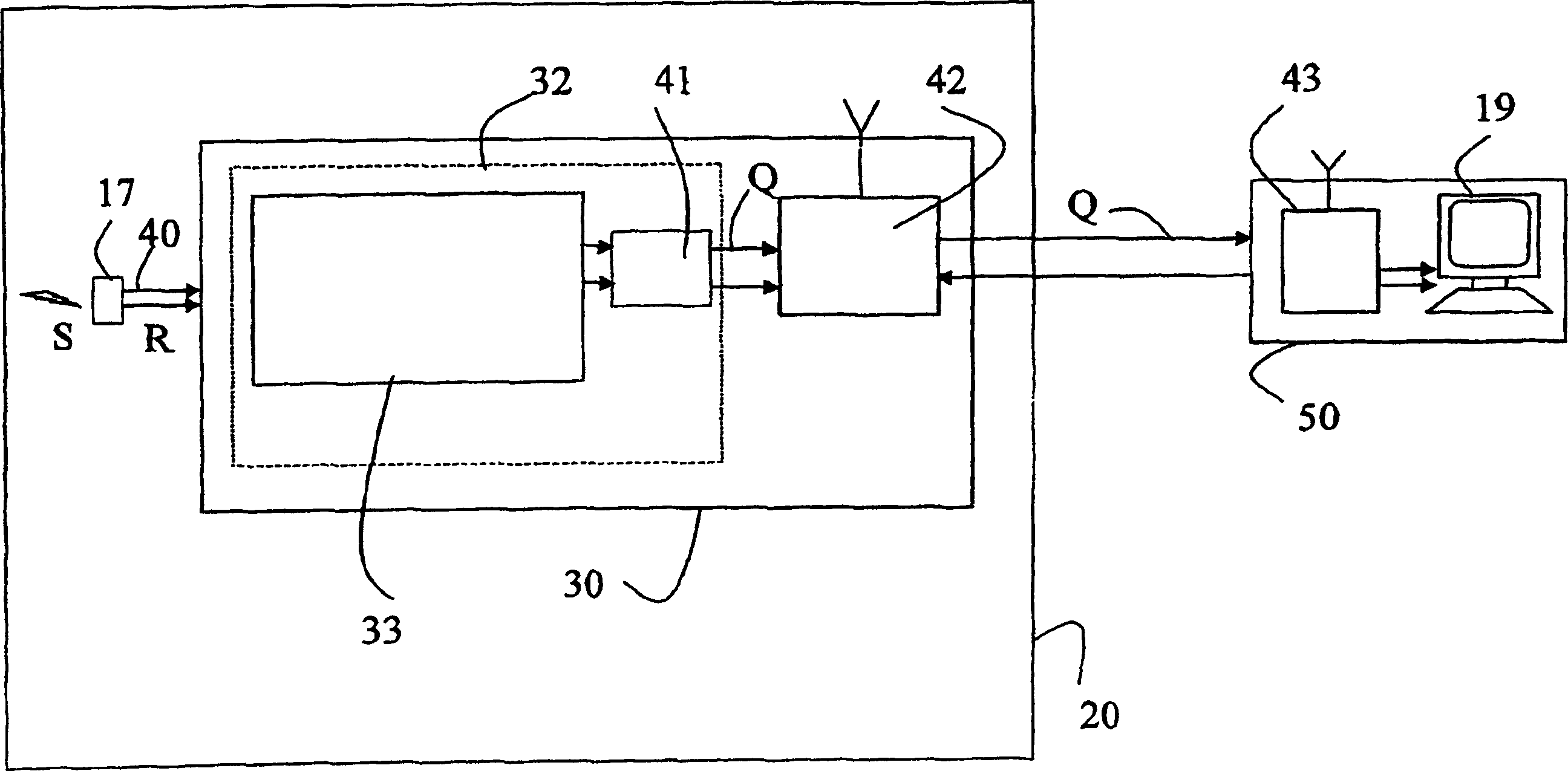

System for monitoring the quality of industrial processes and method therefrom

InactiveCN1763673ASampled-variable control systemsData processing applicationsWireless transceiverProcess quality

The invention relates to a system for monitoring an industrial process, comprising: sensor means (7; 17) for detecting one or more process parameters in at least one processing station (20); capture and processing means (8, 9; 32), which acts on the signal (R) generated by the sensor device (7; 17) in order to obtain process quality information (Q); and a manufacturing process management device (9; 19), which operates based on the process quality information (Q) Q) Do the work. The capture and processing device (32) is disposed locally in the at least one processing station (20), and the manufacturing process management device (19) is disposed at a remote location relative to the capture and processing device (32), Wireless transceiver means (42, 43) are also provided for exchanging said process quality information (Q) between said capture and processing means (32) and said manufacturing process management means (19).

Owner:CENT RICERCHE FIAT SCPA

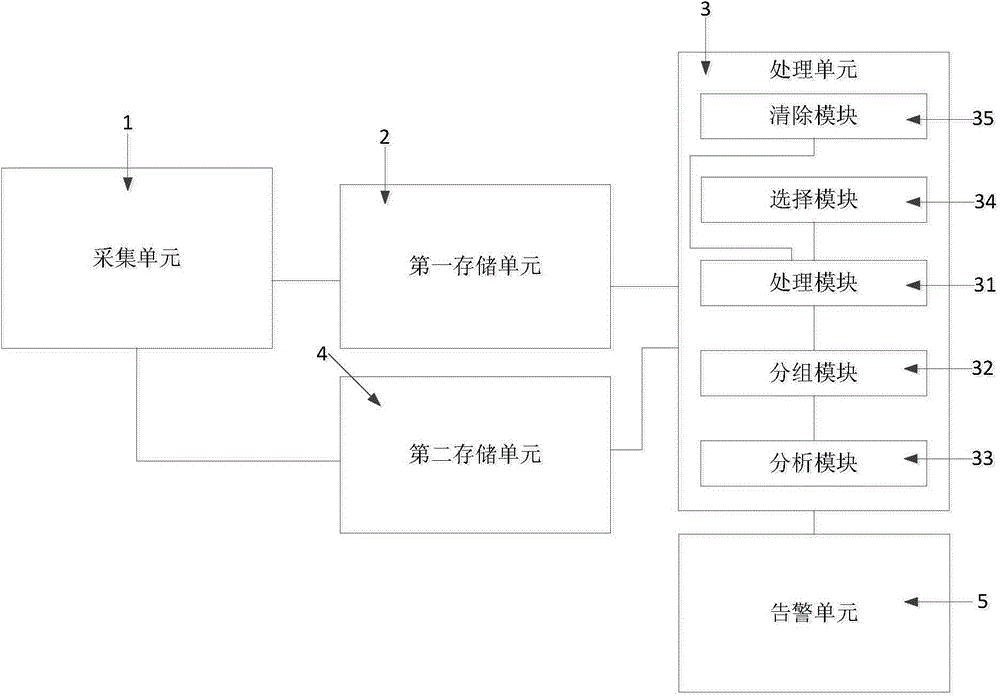

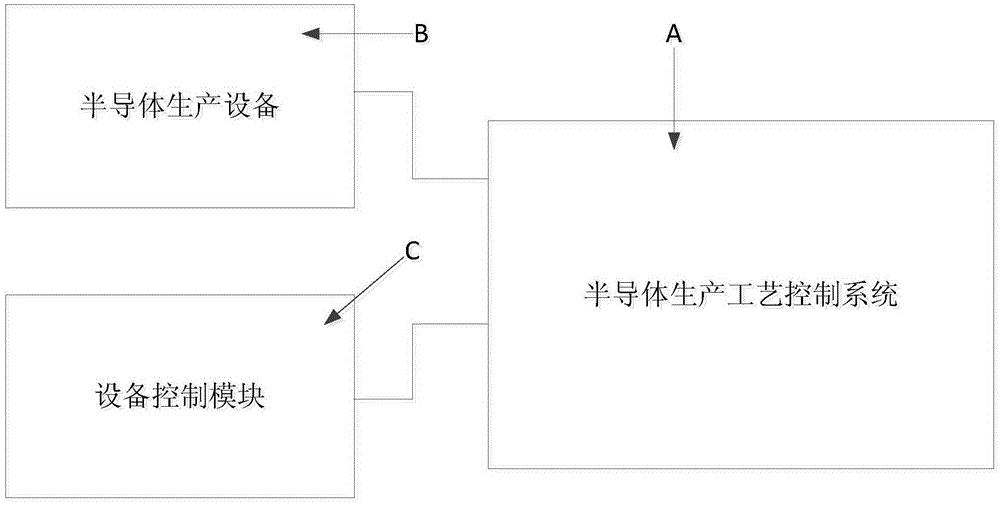

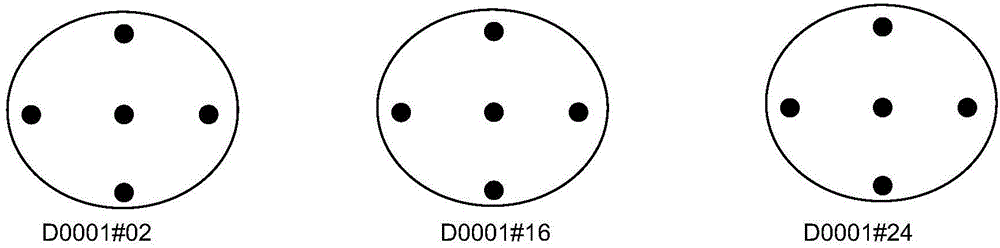

Semiconductor manufacturing process control system and analysis method

InactiveCN105470163AAvoid Fragmentation RiskGuaranteed yieldSemiconductor/solid-state device manufacturingControl systemOriginal data

The invention discloses a manufacturing process control system and an analysis method, which belong to the technical field of semiconductor manufacturing process management and control. The semiconductor manufacturing process control system comprises an acquisition unit, a first storage unit, a processing unit and an alarm unit, wherein the acquisition unit acquires wafer original data; the first storage unit stores the wafer original data; the processing unit extracts the wafer original data and processes the wafer original data to obtain multiple groups of grouped data, and analyzes and outputs a variation trend of the grouped data; and the alarm unit receives an analysis result and outputs an alarm signal. The analysis method comprises the steps of: acquiring the wafer original data and storing the wafer original data in the first storage unit; extracting the wafer original data from the first storage unit, and processing the wafer original data to obtain the corresponding grouped data and dividing the grouped data into groups; and analyzing the variation trend of the grouped data, and outputting the analysis result to the alarm unit for alarm. The semiconductor manufacturing process control system and the analysis method have the beneficial effects of reducing alarm time delay and omission, avoiding fragment risk of products, and ensuring product yield.

Owner:SEMICON MFG INT (SHANGHAI) CORP

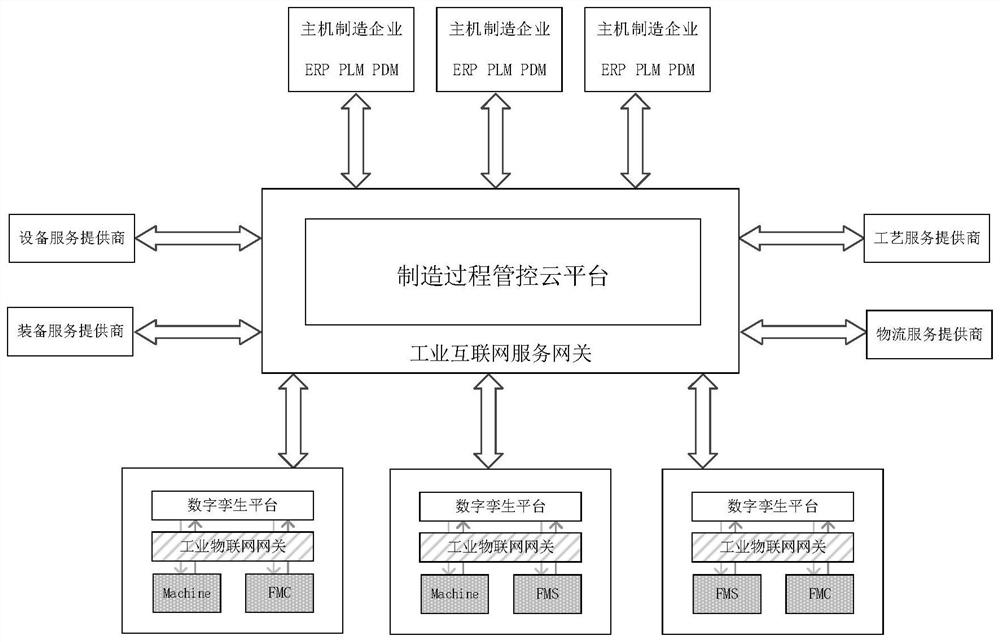

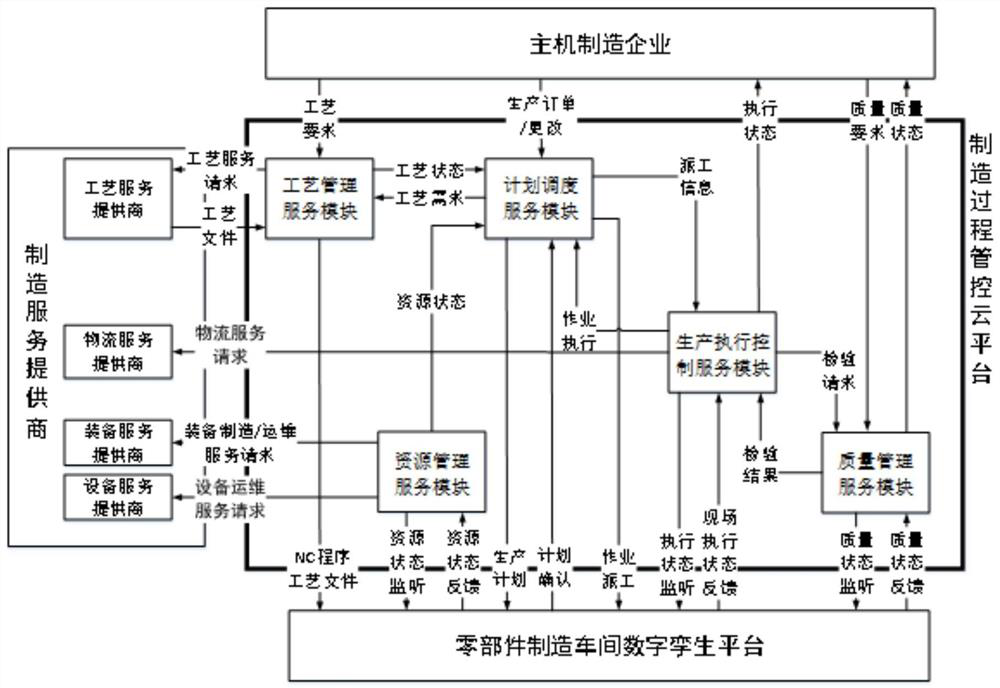

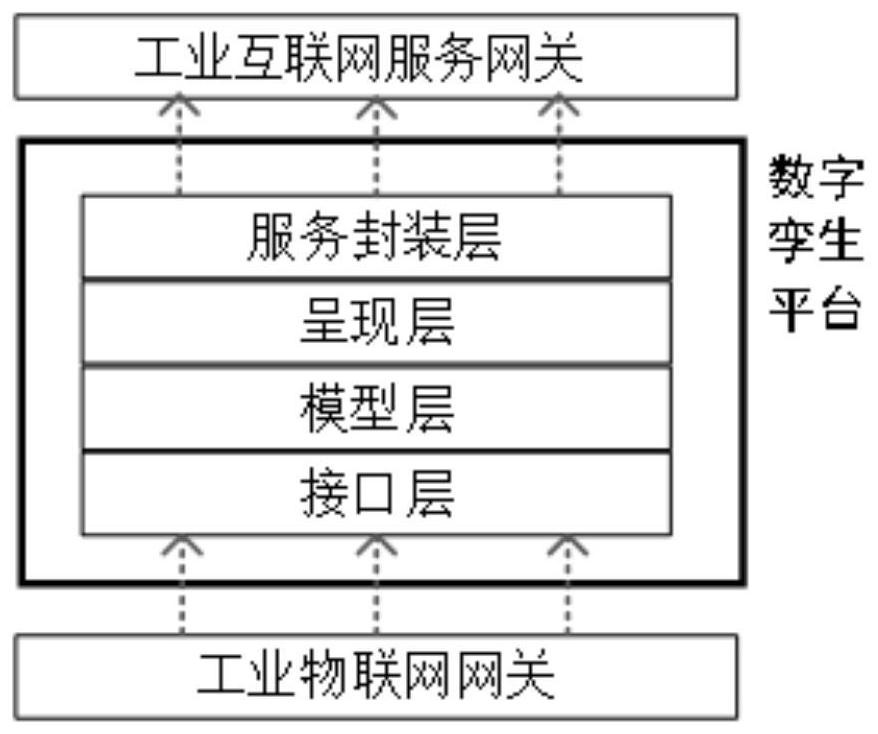

Manufacturing process management and control system architecture for aviation industry cluster

ActiveCN113433909AGuarantee product qualityGuarantee efficiencyTotal factory controlProgramme total factory controlAviationThe Internet

The invention discloses an aviation industry cluster-oriented manufacturing process management and control system architecture and relates to the technical field of intelligent manufacturing. The architecture comprises a manufacturing process management and control cloud platform, a digital twin platform, an industrial internet service gateway and an industrial Internet of Things gateway, the manufacturing process management and control cloud platform can complete collaboration of the production and manufacturing processes of the aeronautical manufacturing cluster enterprises; the digital twin platform can effectively virtualize a manufacturing workshop; the industrial internet service gateway can realize service packaging and information interaction of the manufacturing process management and control cloud platform, various service providers, a host manufacturing enterprise information system and various part manufacturing enterprise digital twin platforms; the industrial Internet of Things gateway can obtain various state data of a workshop manufacturing site, and completes business collaboration among an upstream host manufacturing enterprise, a downstream part manufacturing enterprise and various midstream service providers through data and information interaction among the four components so as to meet the requirement of space-time collaboration manufacturing of an aeronautical manufacturing industry cluster.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

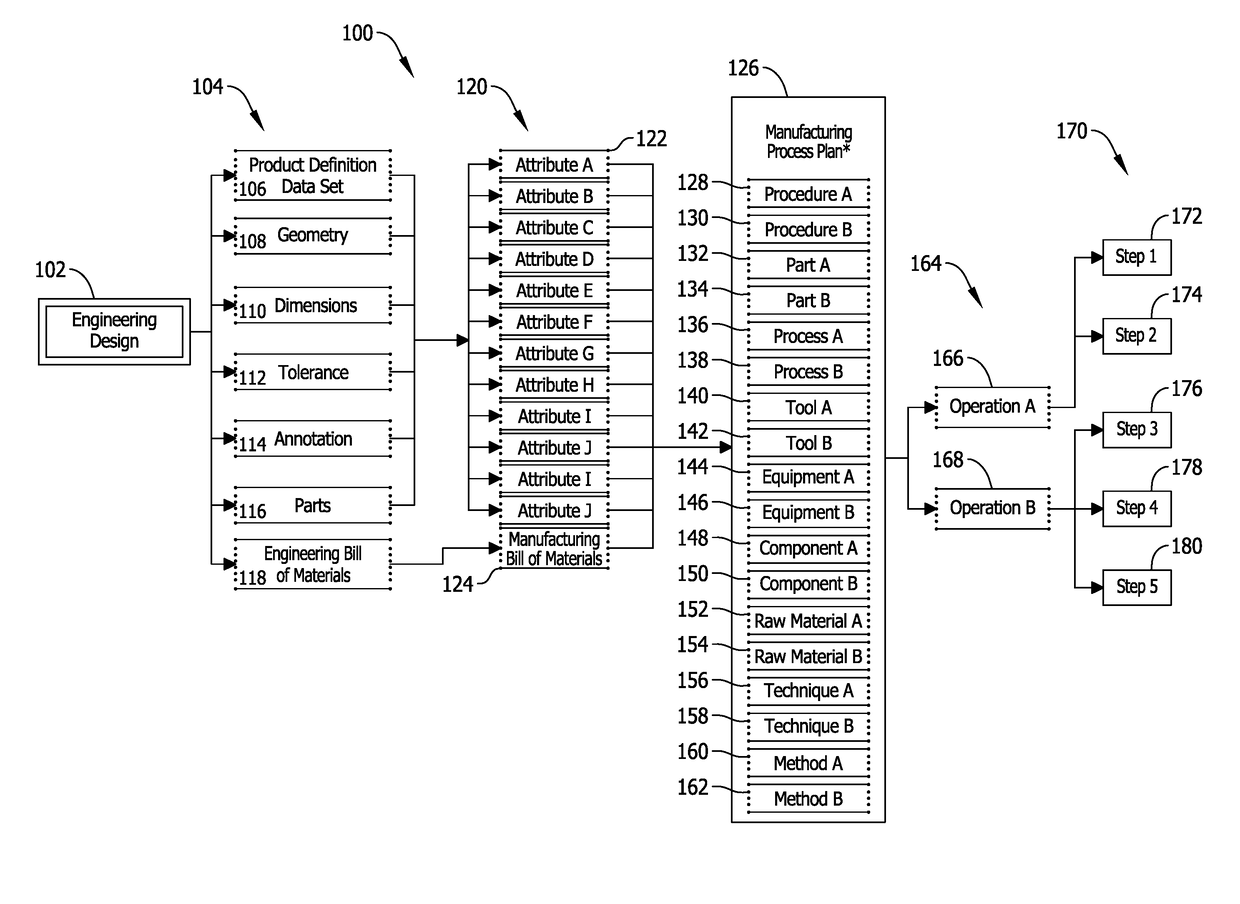

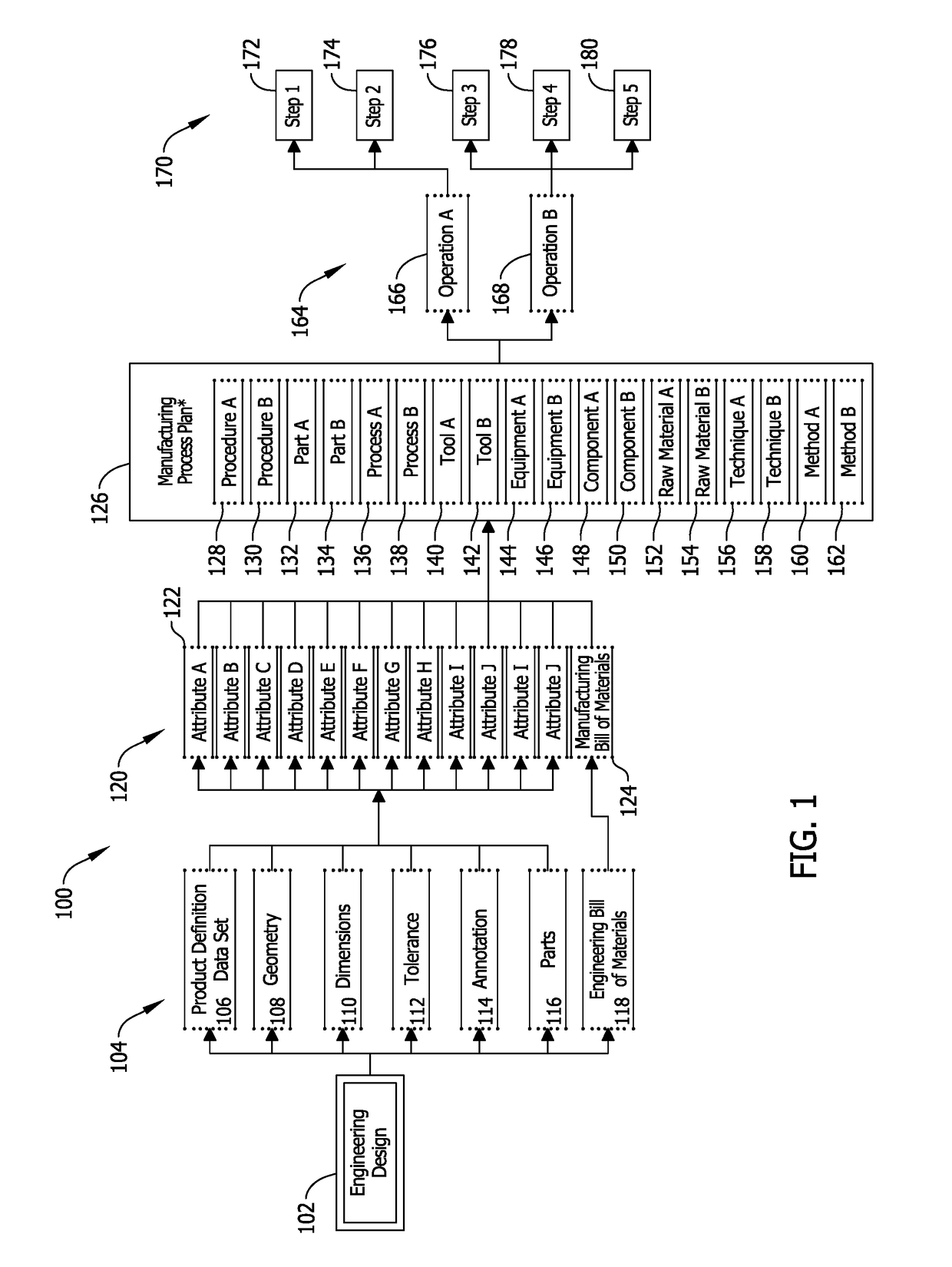

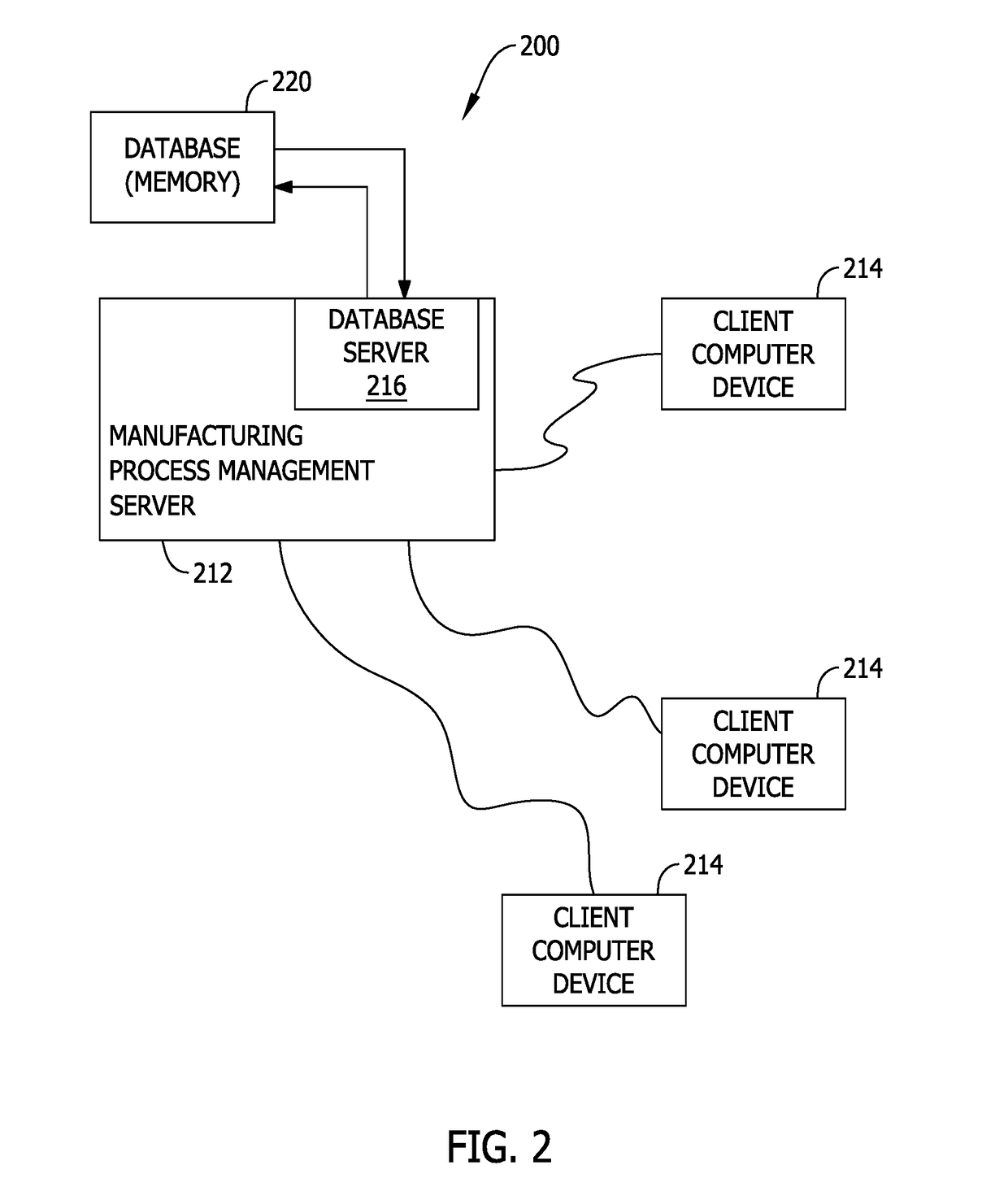

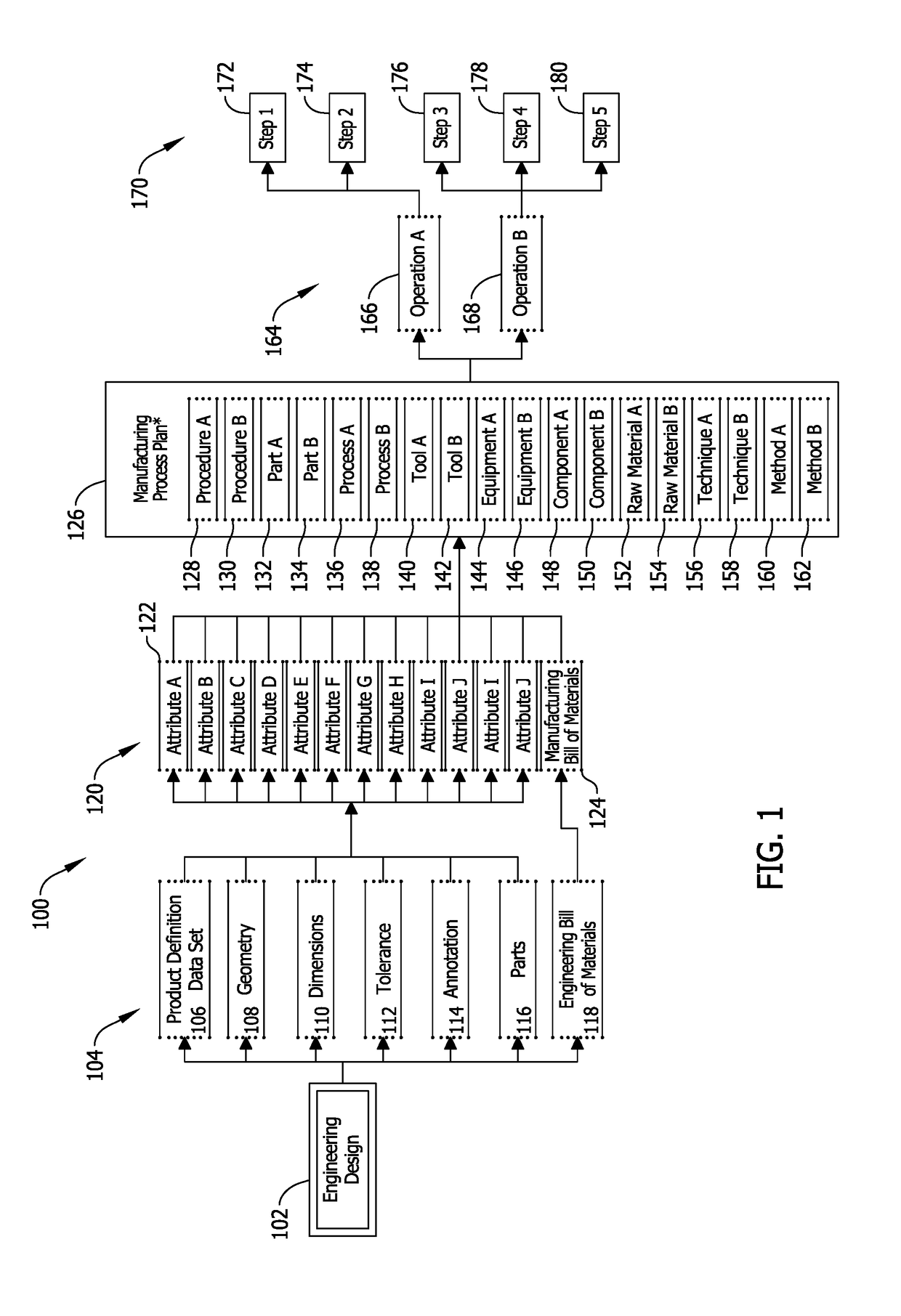

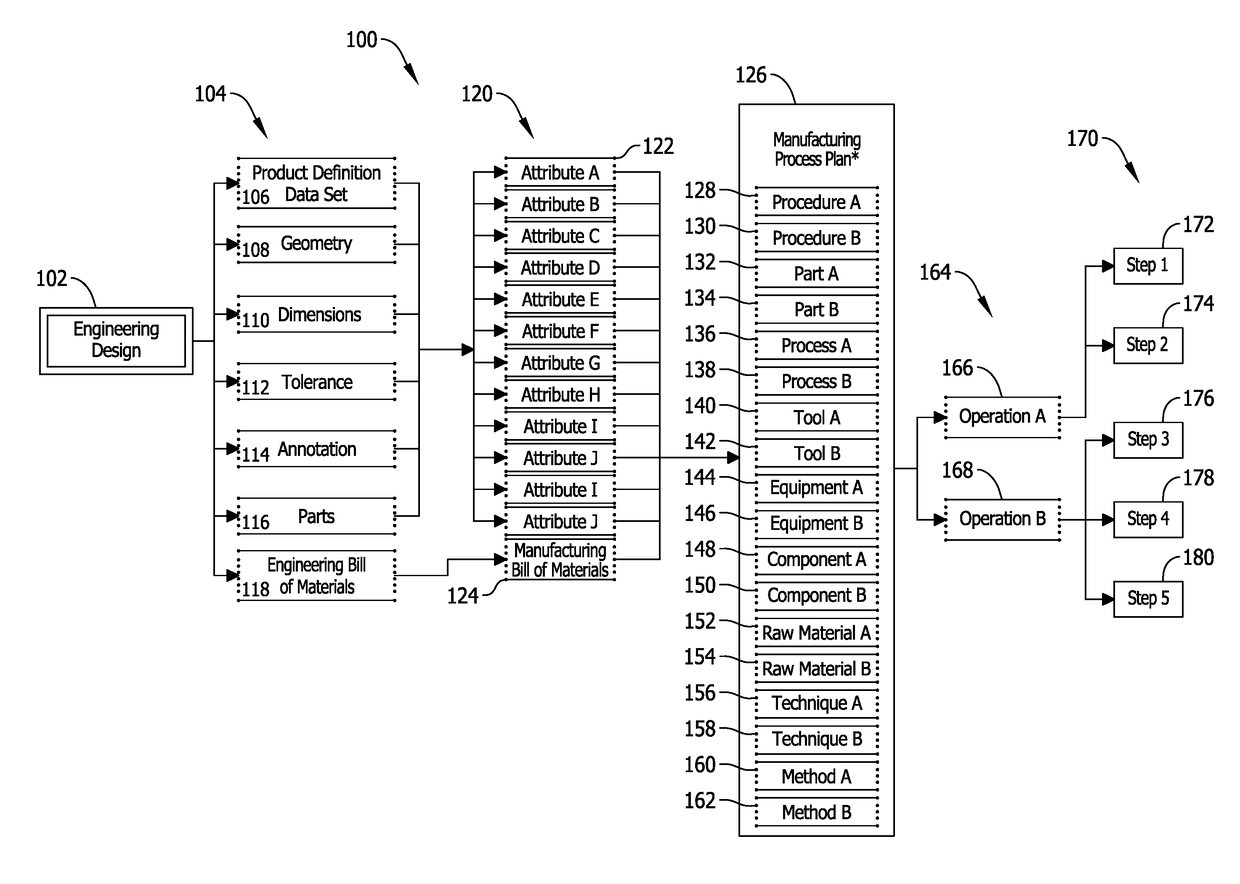

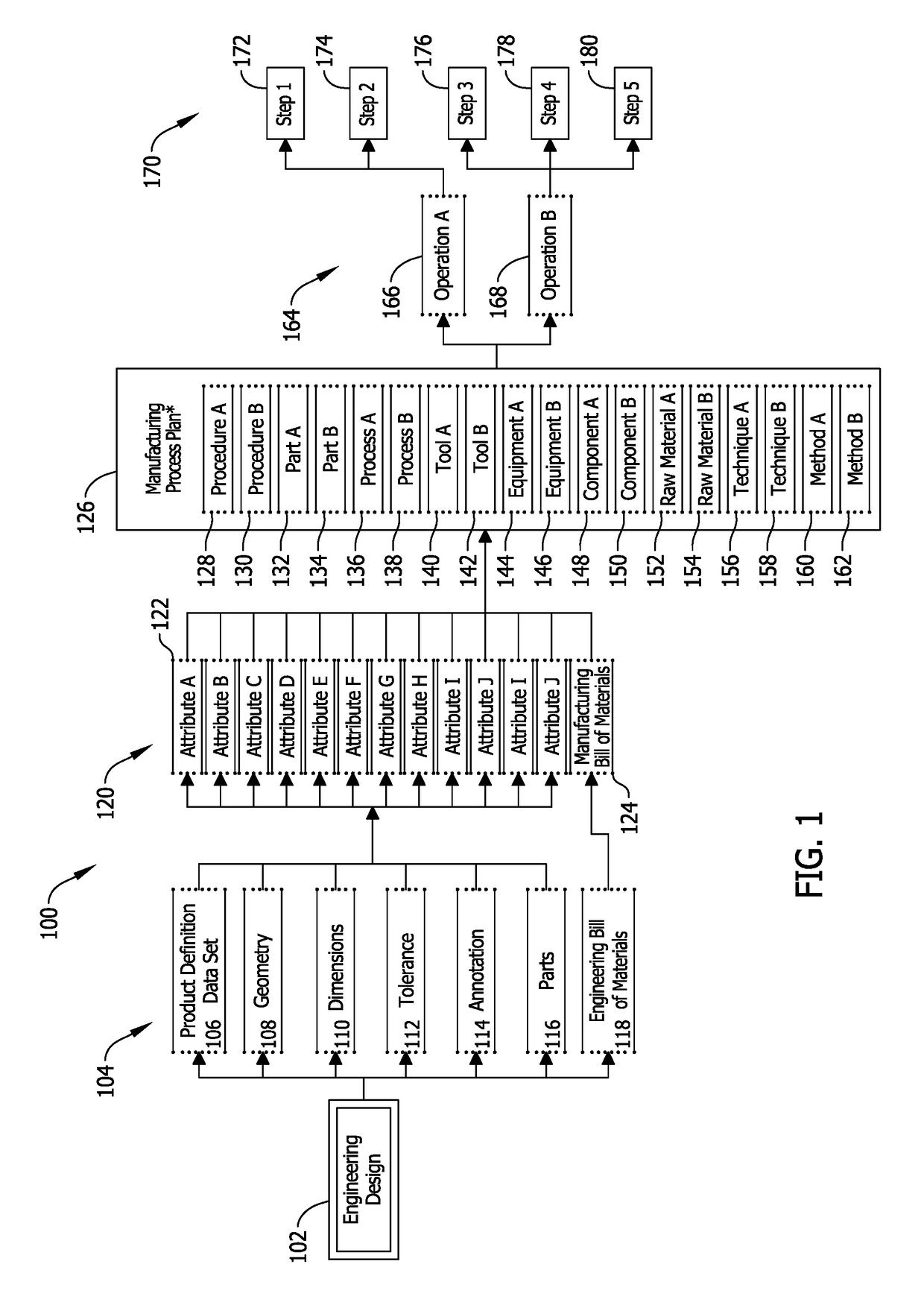

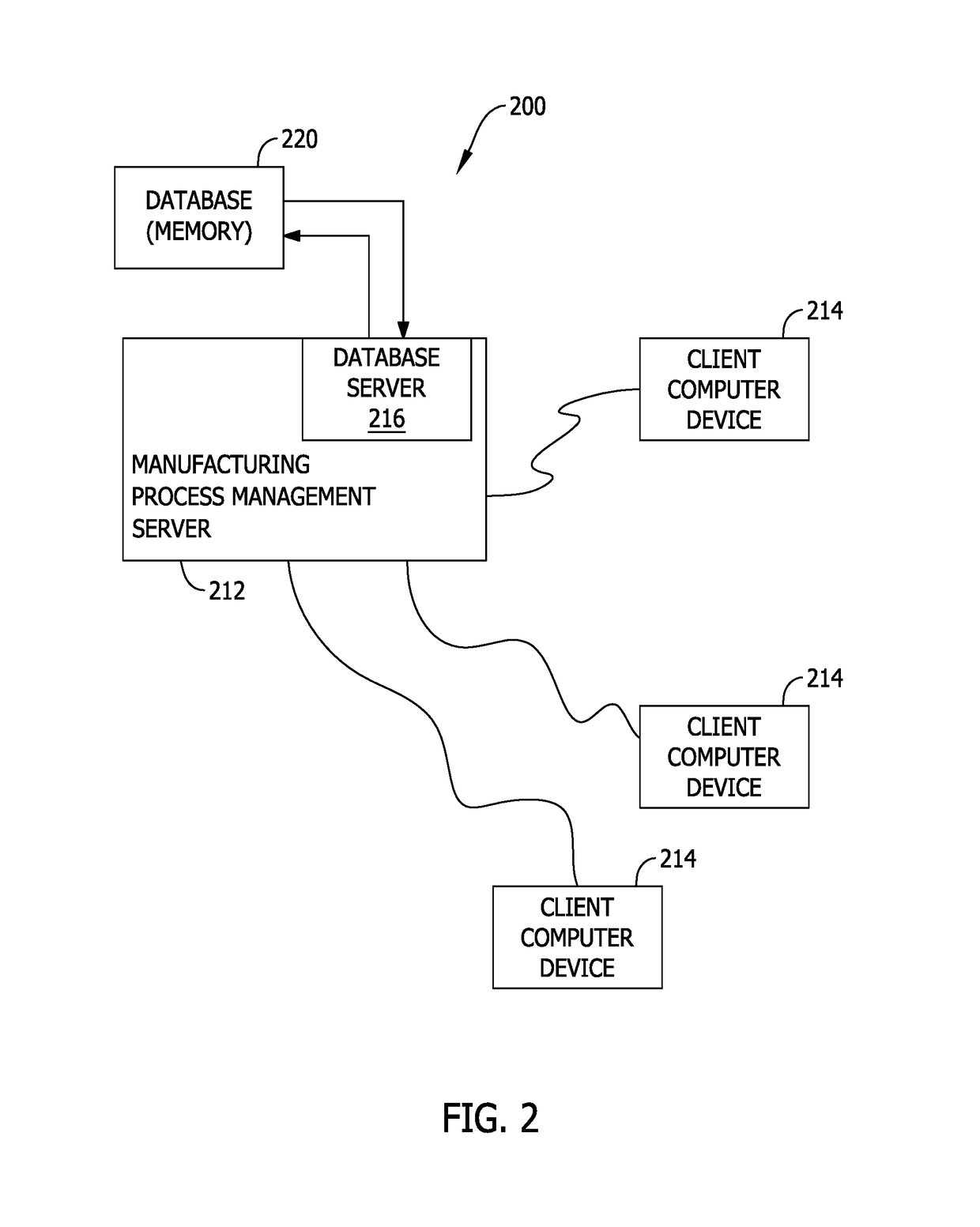

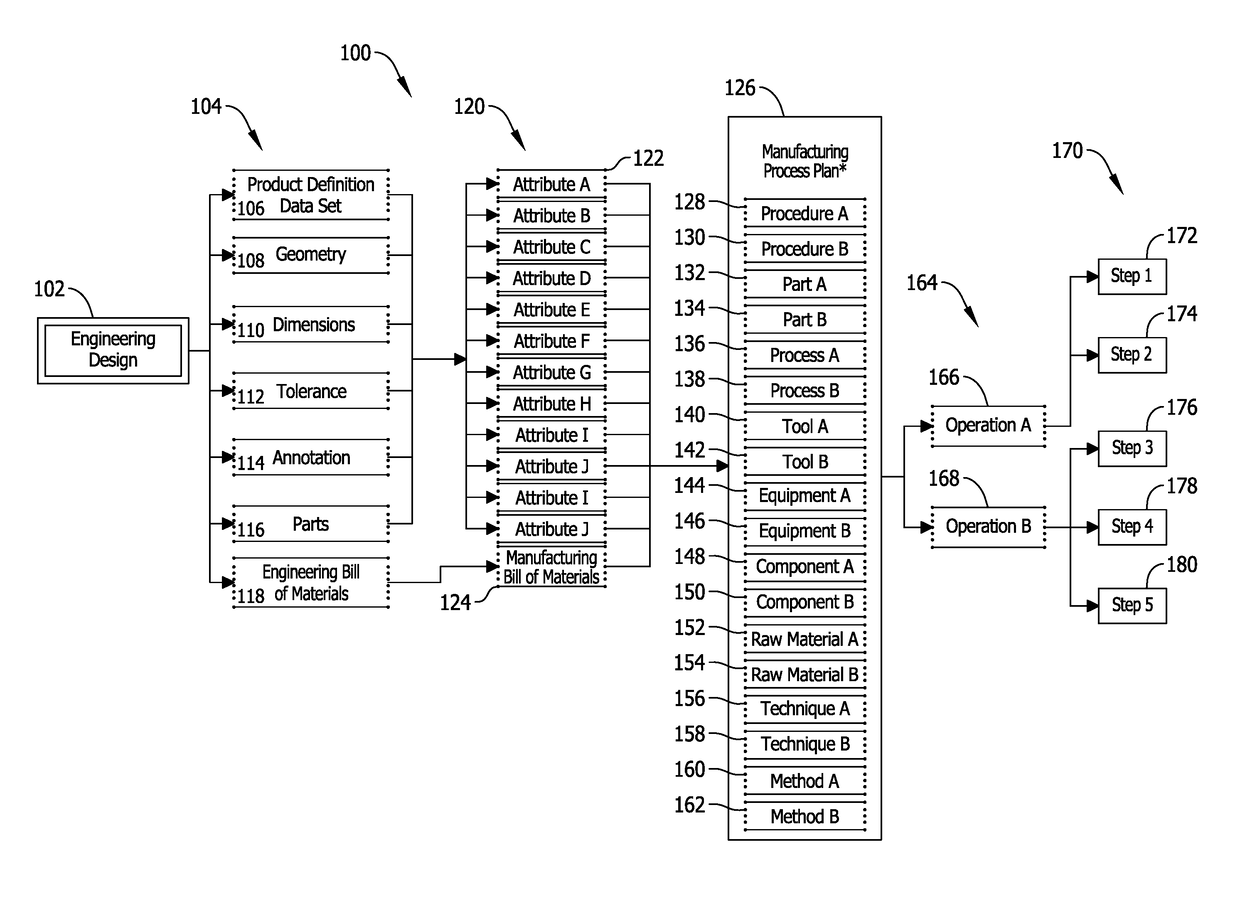

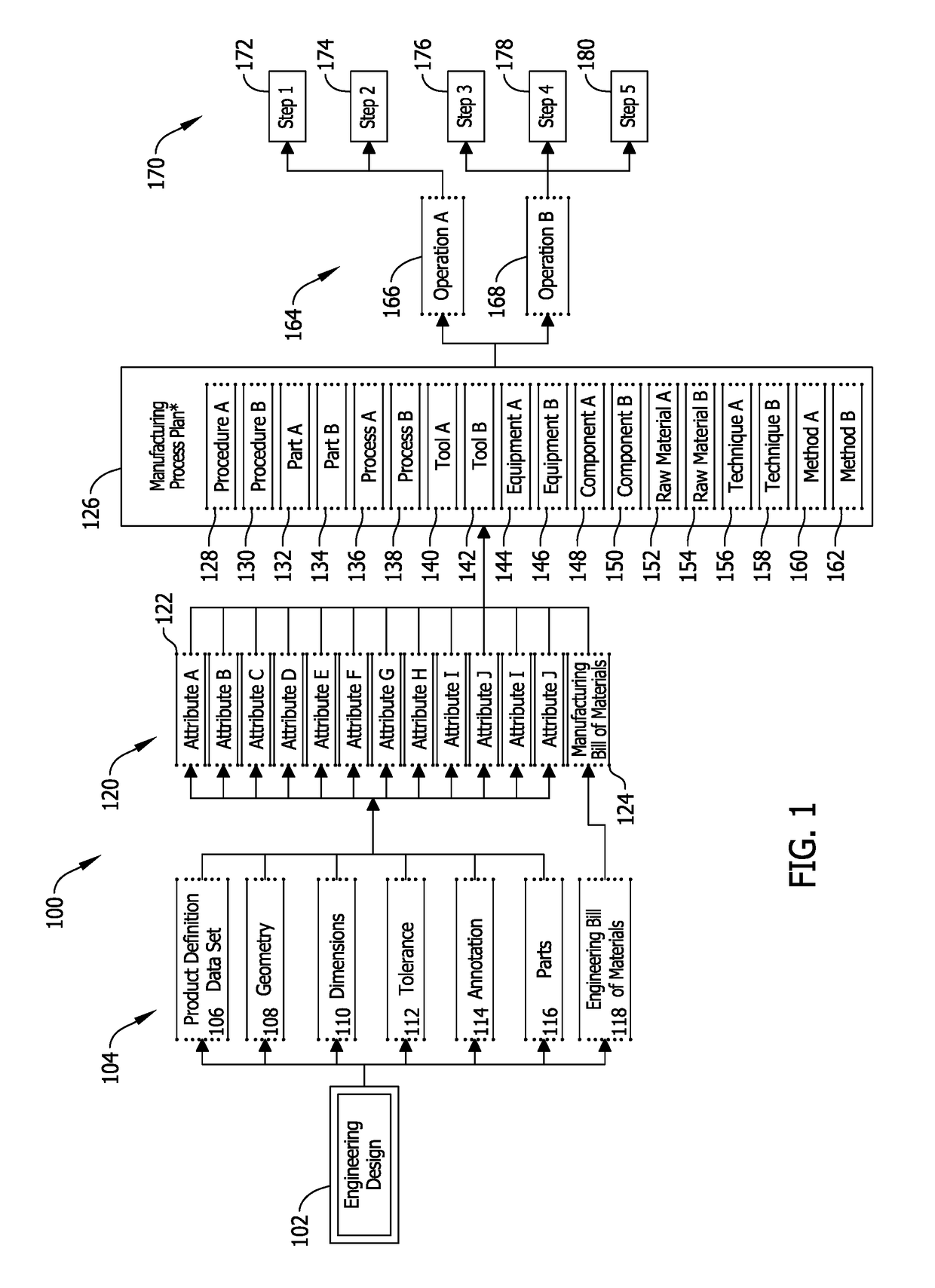

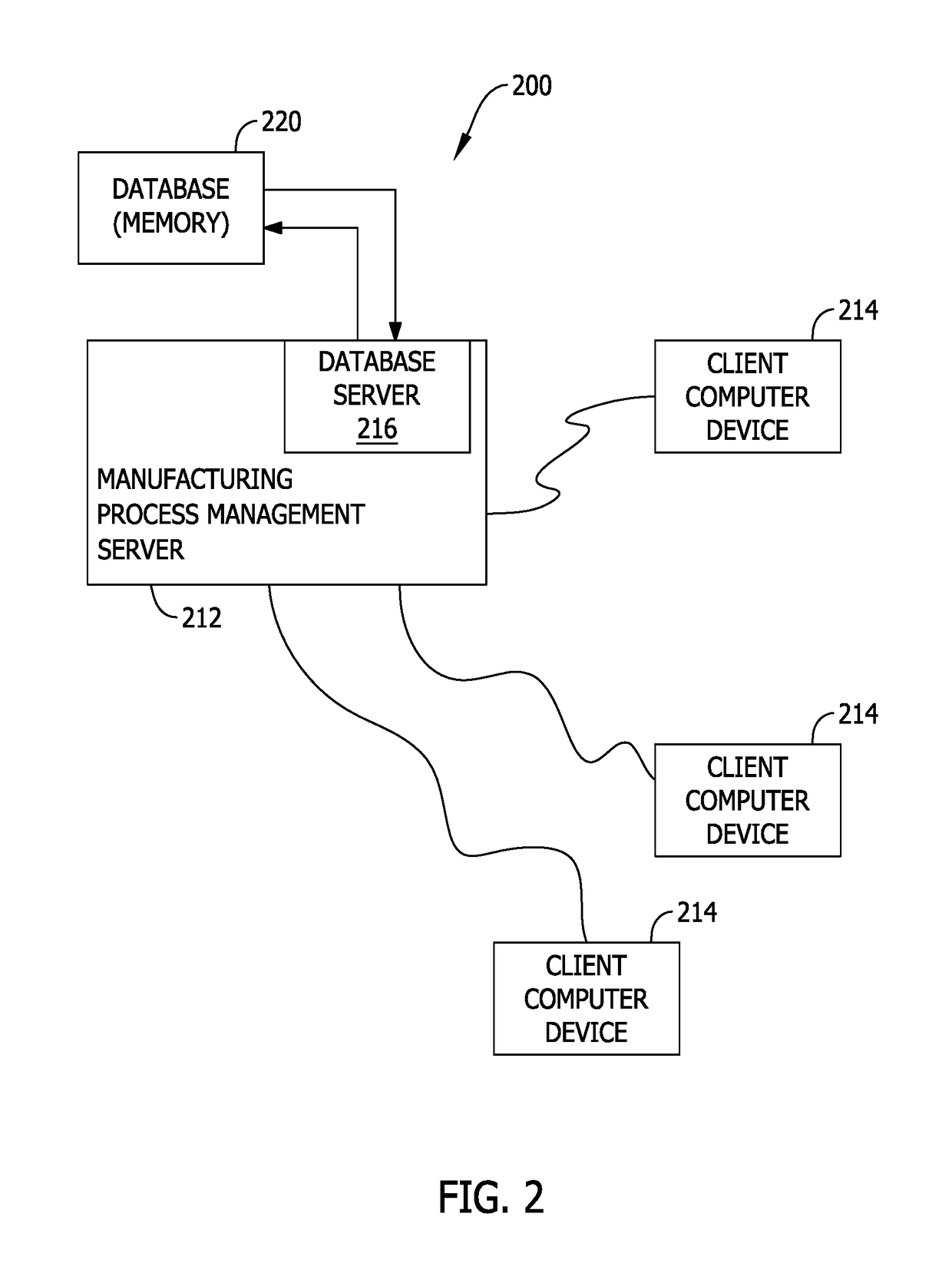

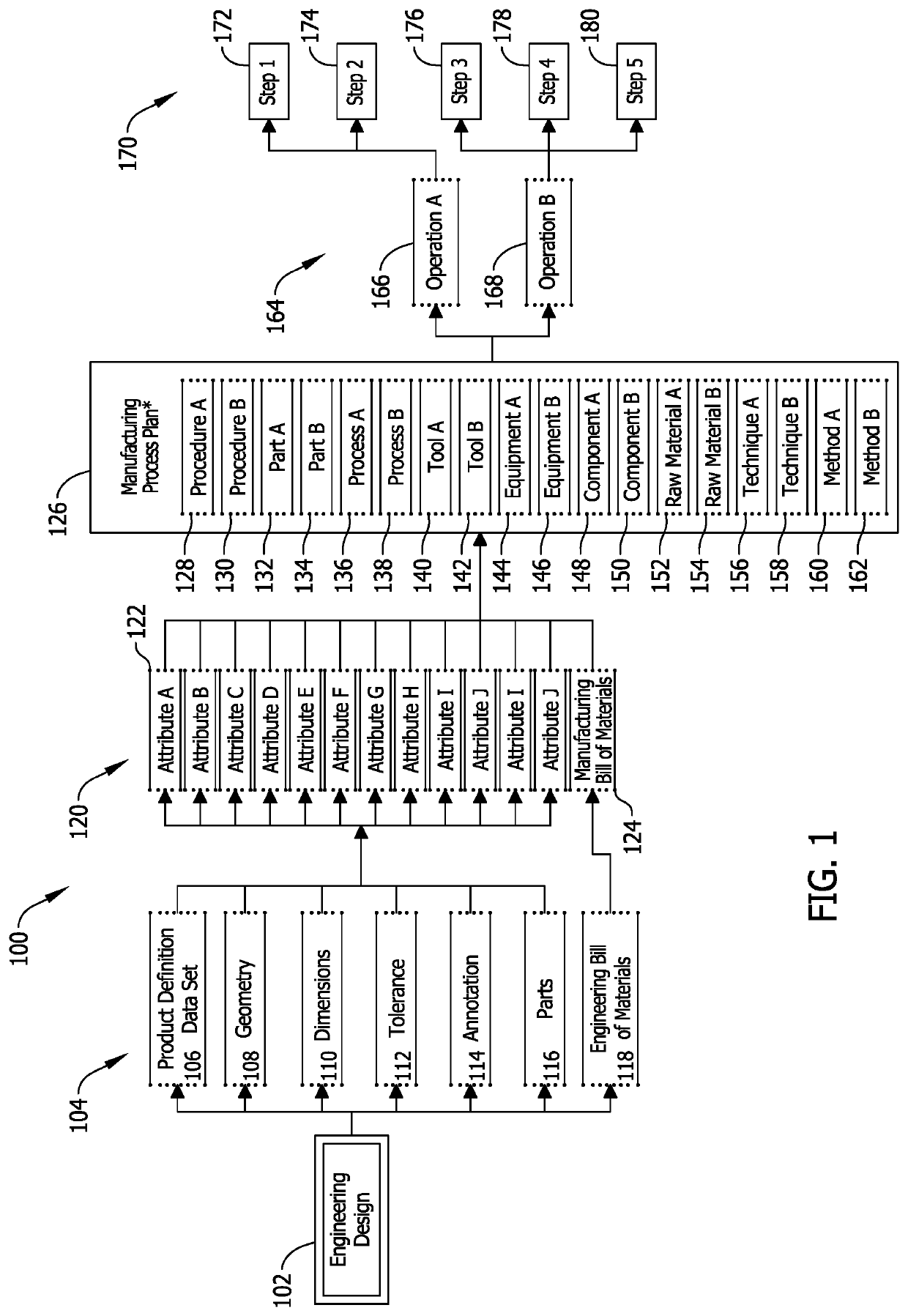

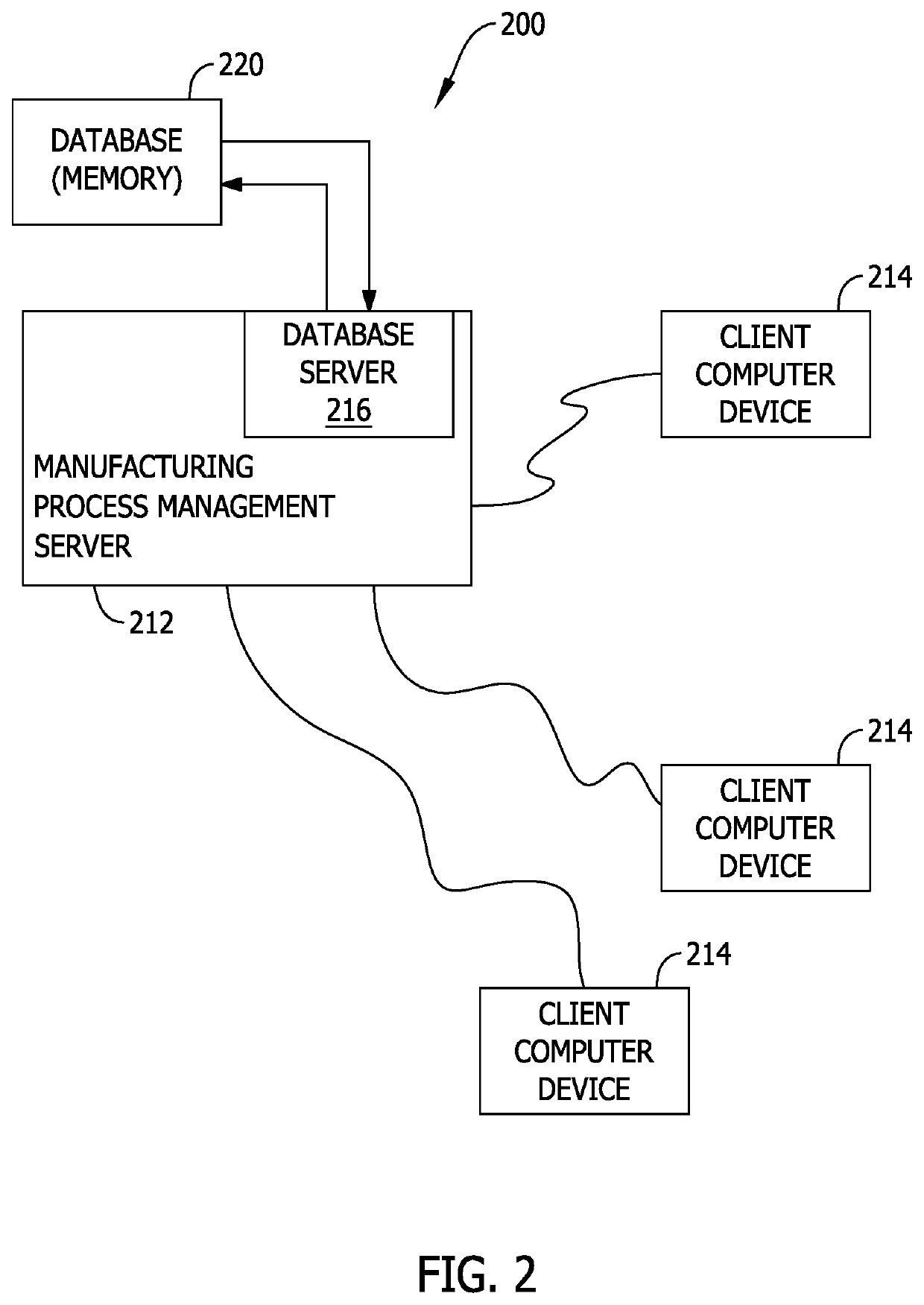

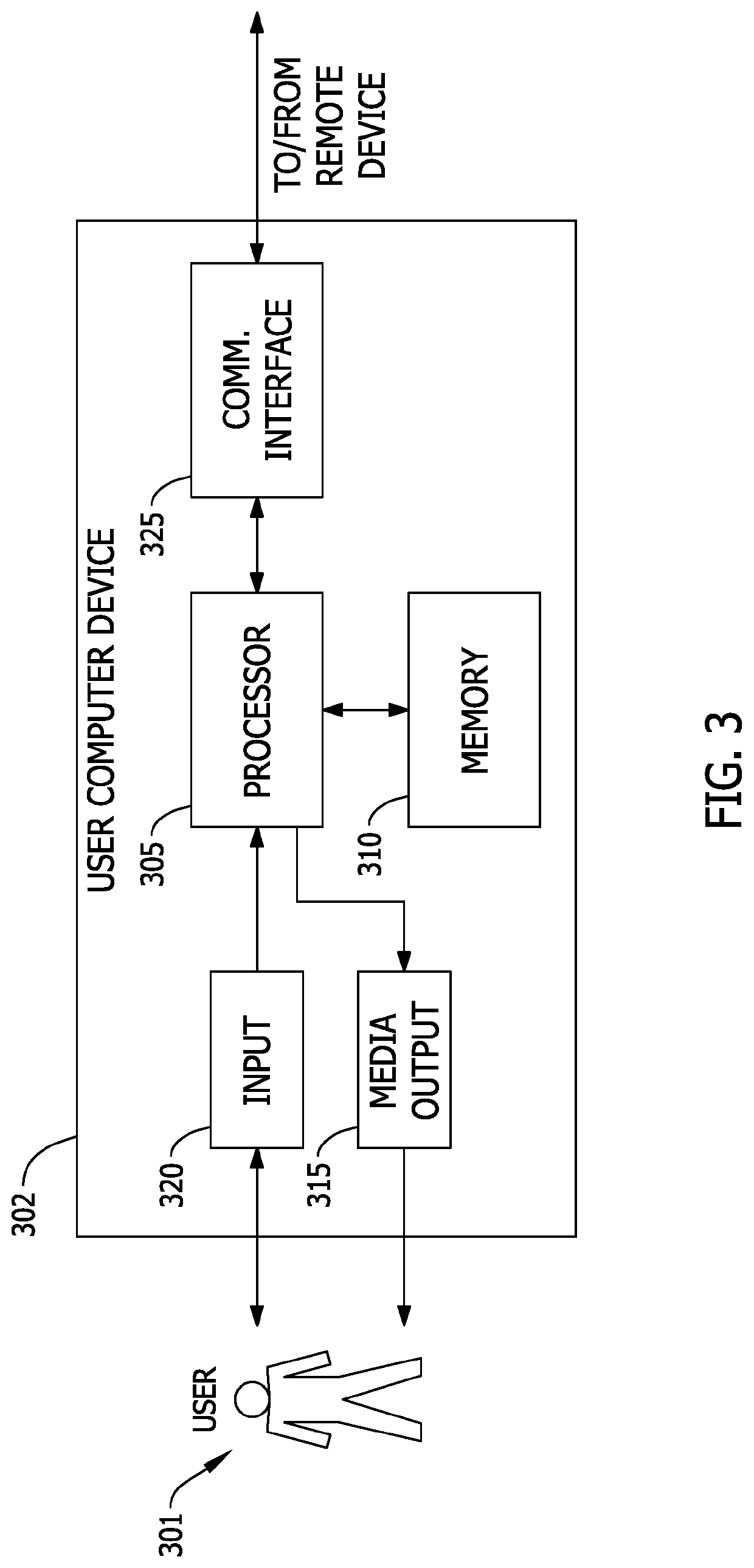

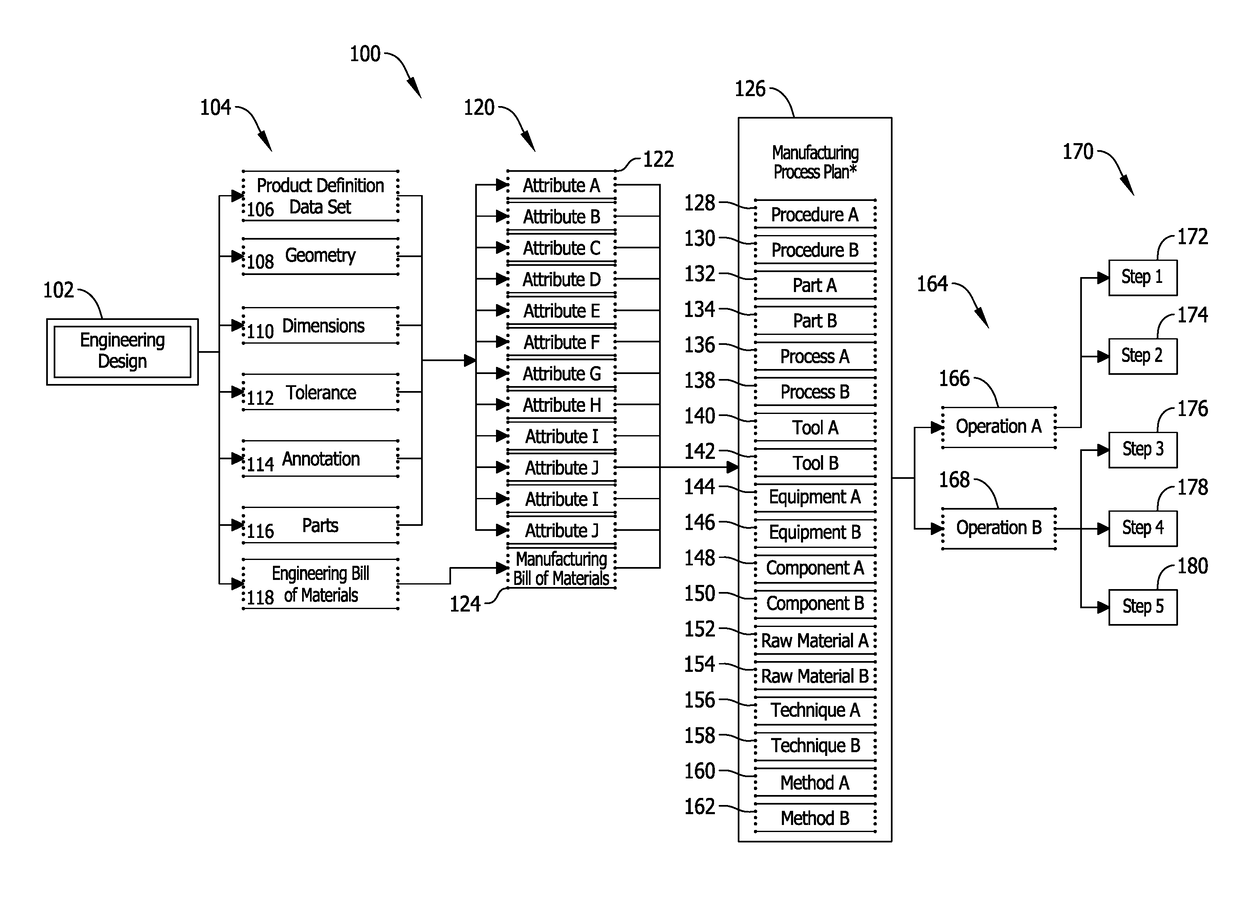

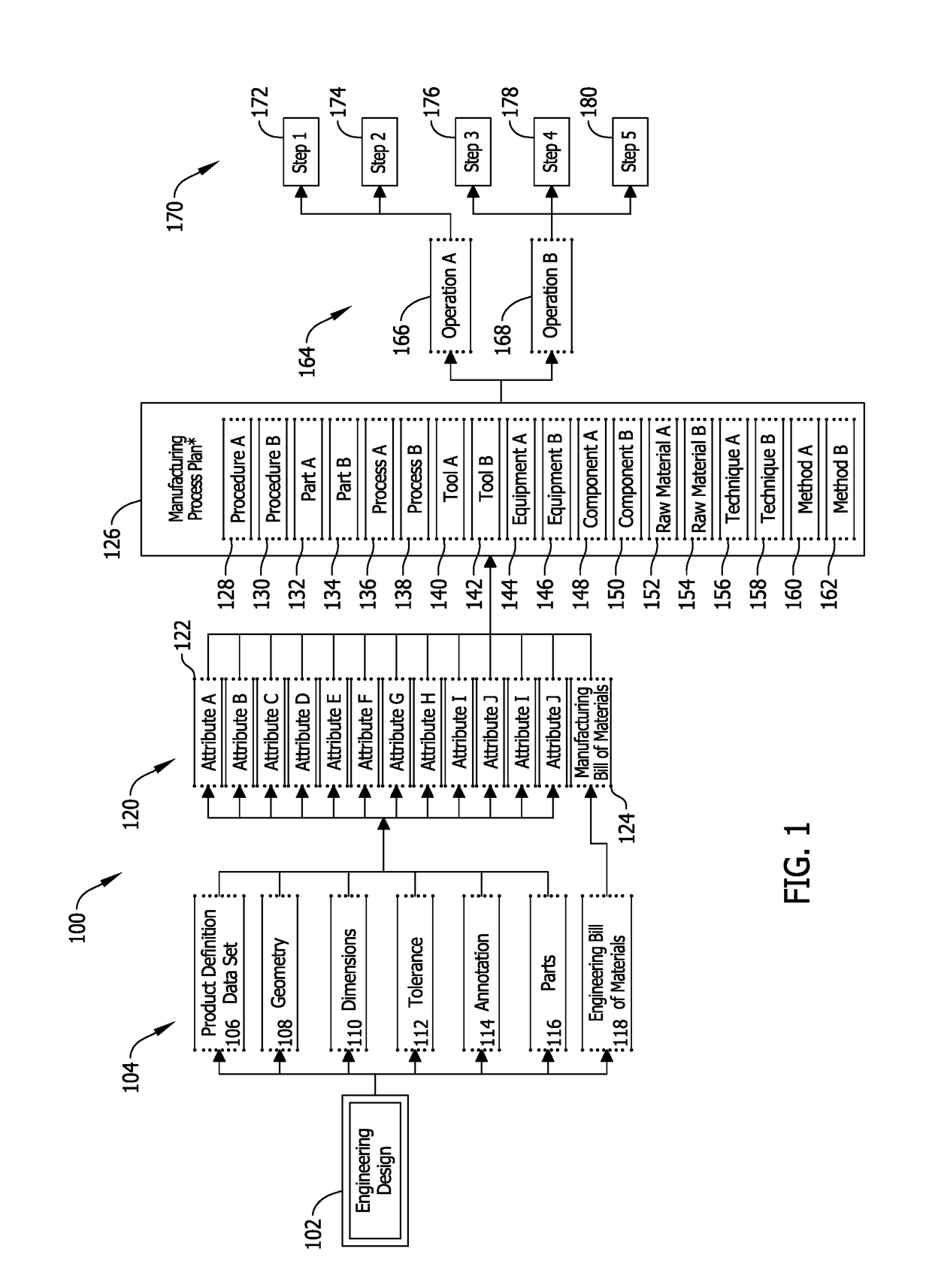

System and methods for managing changes to a product in a manufacturing environment including conversion of an engineering bill of material to a manufacturing bill of material

A manufacturing process management (MPM) computer device is provided. The MPM computer device is configured to store an engineering bill of materials for a product to be assembled including a first plurality of parts, store a manufacturing bill of materials for the product to be assembled including a second plurality of parts and a status, receive a request from a user to change the status of the manufacturing bill of materials, compare the first plurality of parts with the second plurality of parts, determine whether the first plurality of parts matches the second plurality of parts based on the comparison, if the comparison matches, change the status of the manufacturing bill of materials, and if the comparison does not match, prevent the status of the manufacturing bill of materials from changing.

Owner:THE BOEING CO

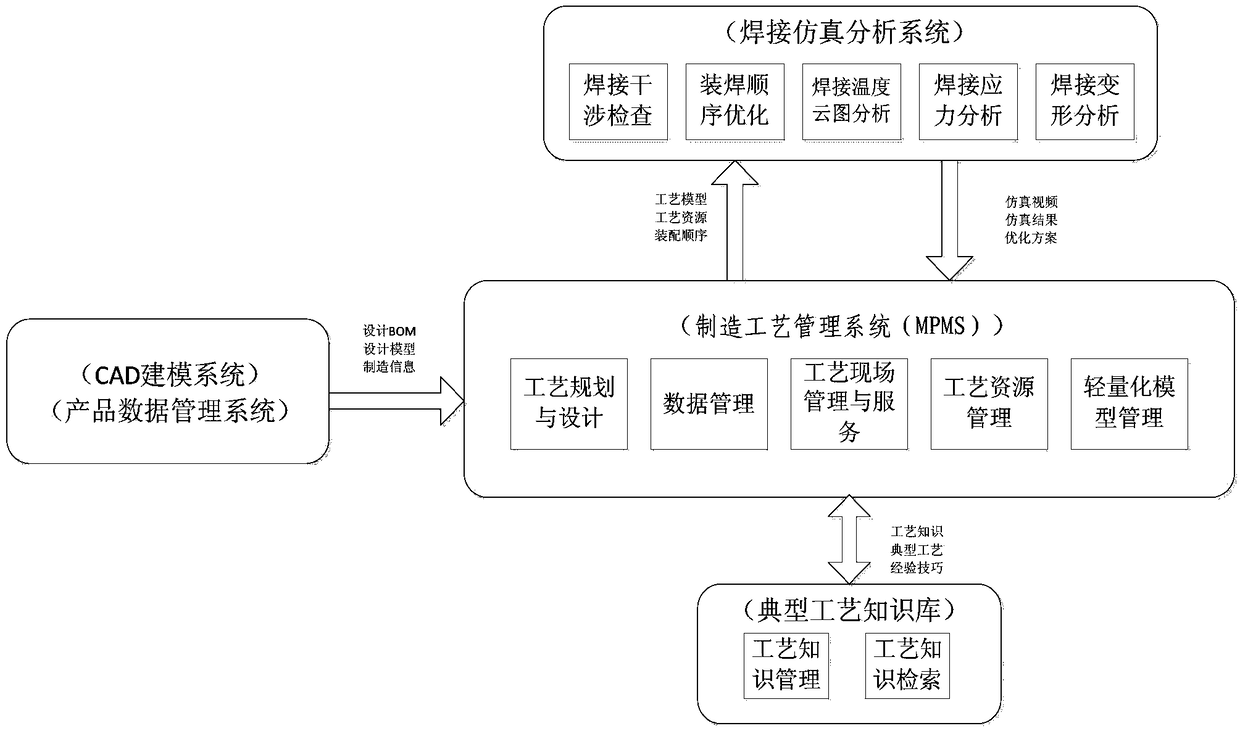

A system for assemble and welding three-dimensional process planning

InactiveCN109145384AFast and low-cost designImprove welding efficiencyGeometric CADDesign optimisation/simulationKnowledge baseWelding process

The invention discloses an assembly and welding three-dimensional process planning system, which is integrated by a manufacturing process management system, a CAD modeling system, a welding simulationanalysis system, a product data management system and a typical process knowledge base. The invention realizes the rapid and low-cost design of the assembly welding process, and not only shortens thedesign period of assembly welding process, but also improves the quality of assembly welding process. Through the teaching of three-dimensional assembly welding process, the intent of assembly welding process design can be directly and clearly reflected, the assembly welding efficiency of welding workers can be improved, the miswelding can be restrained, the phenomenon of out-of-order assembly welding can occurr, and the assembly welding quality of products can be greatly improved. At the same time, conditions for the accumulation of process knowledge are provided and the competitiveness of enterprises is enhanced.

Owner:内蒙古第一机械集团股份有限公司

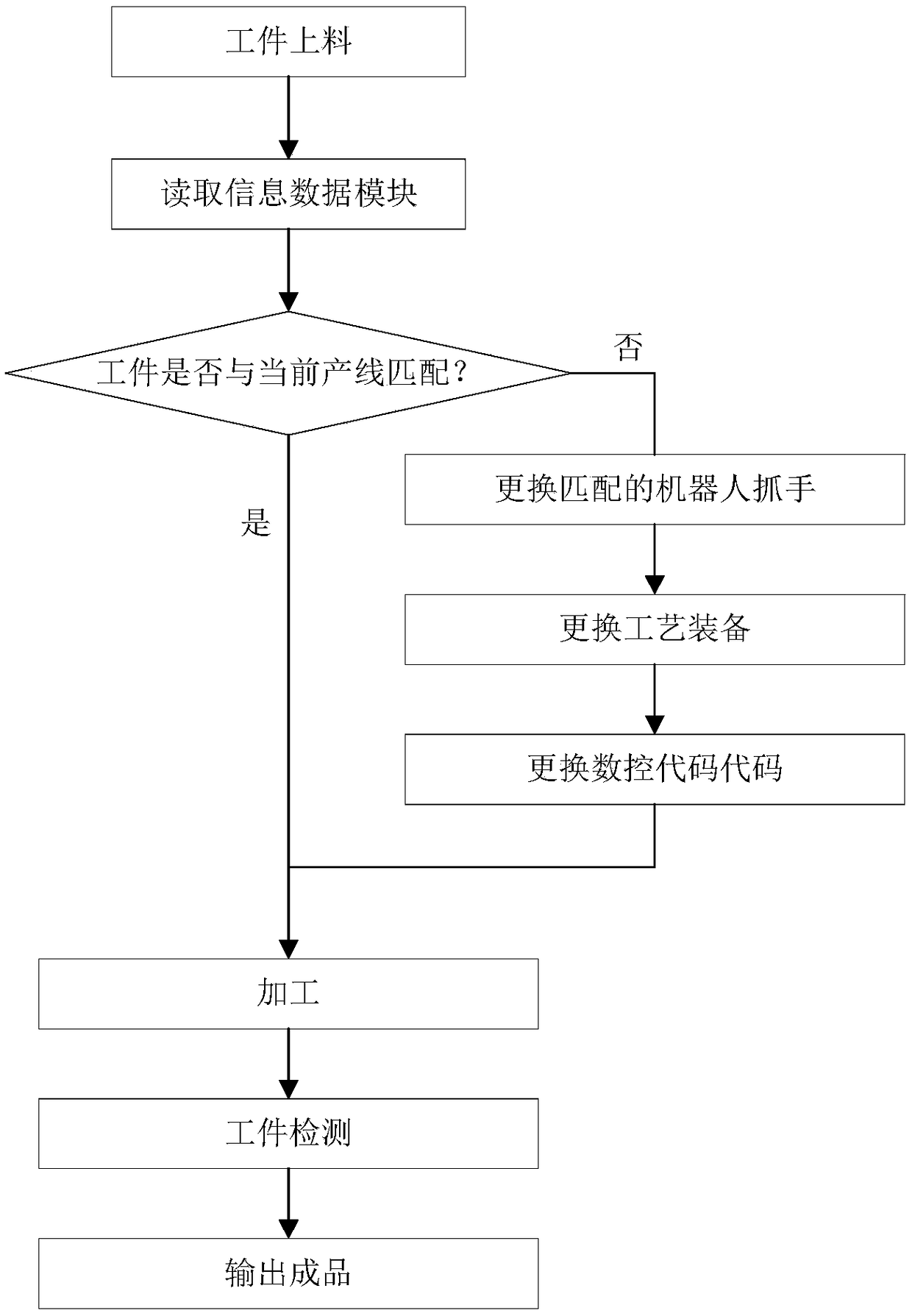

Automatic production change type flexible manufacturing system and method

ActiveCN109164777AStrong control abilityFully automatedTotal factory controlProgramme total factory controlEffective solutionInformation repository

The invention provides an automatic production change type flexible manufacturing system and method. The system comprises an information data module, a manufacturing module, a storage module, a tool carrying and transporting module, a workpiece carrying and transporting module and a manufacturing process management module. The automatic production change type flexible manufacturing system is suitable for machining and manufacturing. Identification portions are arranged on a tool and a workpiece; the identification portion comprises an RFID data chip and / or a category information two-dimensional code; the information data module comprises a workpiece category information library, a tool category information library and an information data reading device; and the manufacturing process management module can determine a production change step through the category information identified by the information data module, and fully automatically complete the production change. Compared with thetraditional production mode, the automatic production change type flexible manufacturing system provided by the invention has the advantages of high production efficiency, high adaptability, short production change period, low consumption of human resources and the like, and provides an effective solution for improving the production efficiency of a machining production line and reducing the production cost.

Owner:SHANGHAI SMARTSTATE TECH CO LTD

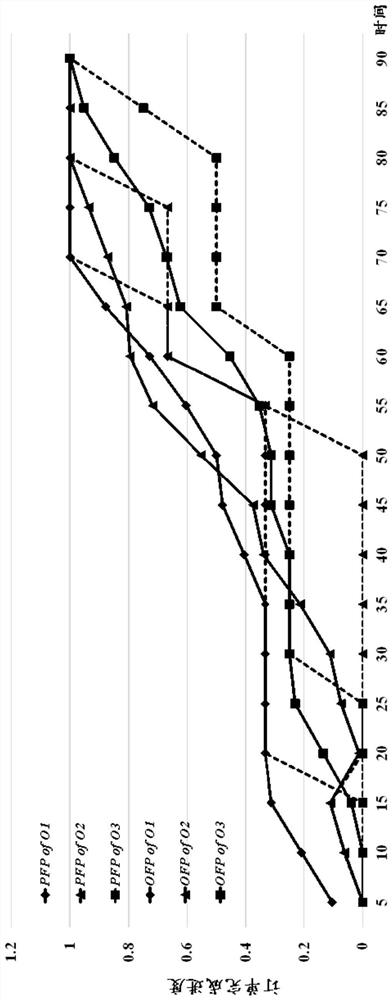

Method and system for evaluating completion progress of manufactured product

The invention relates to a method and a system for evaluating the completion progress of a manufactured product, and belongs to the technical field of product manufacturing process management and collaborative manufacturing. The evaluation method comprises the following steps: (1) receiving order product information and a production scheduling scheme matched with an order product; (2) if the abnormal event influencing the production scheduling scheme does not occur, calculating the completion progress of the order at the moment T according to a calculation model (shown in the description), wherein the processed time t<ed>p of the operation Jp under the original production scheduling scheme and the minimum production period t<mc>p of the operation Jp under the original production schedulingscheme according to the starting and ending time of each production operation determined by the production scheduling scheme. The method can reflect the actual completion progress of the manufacturedproduct more accurately, has higher universality on a product manufacturing progress evaluation object, and can be widely applied to process management and collaborative manufacturing in the manufacturing field.

Owner:ZHEJIANG UNIV

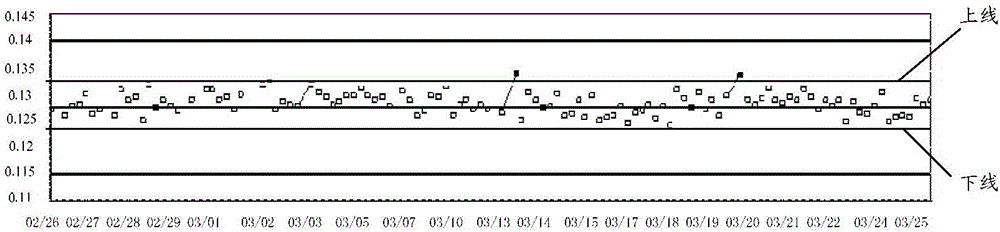

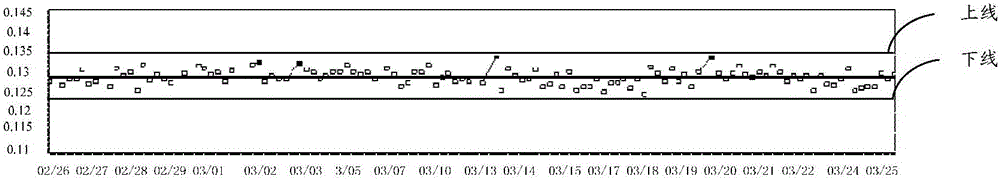

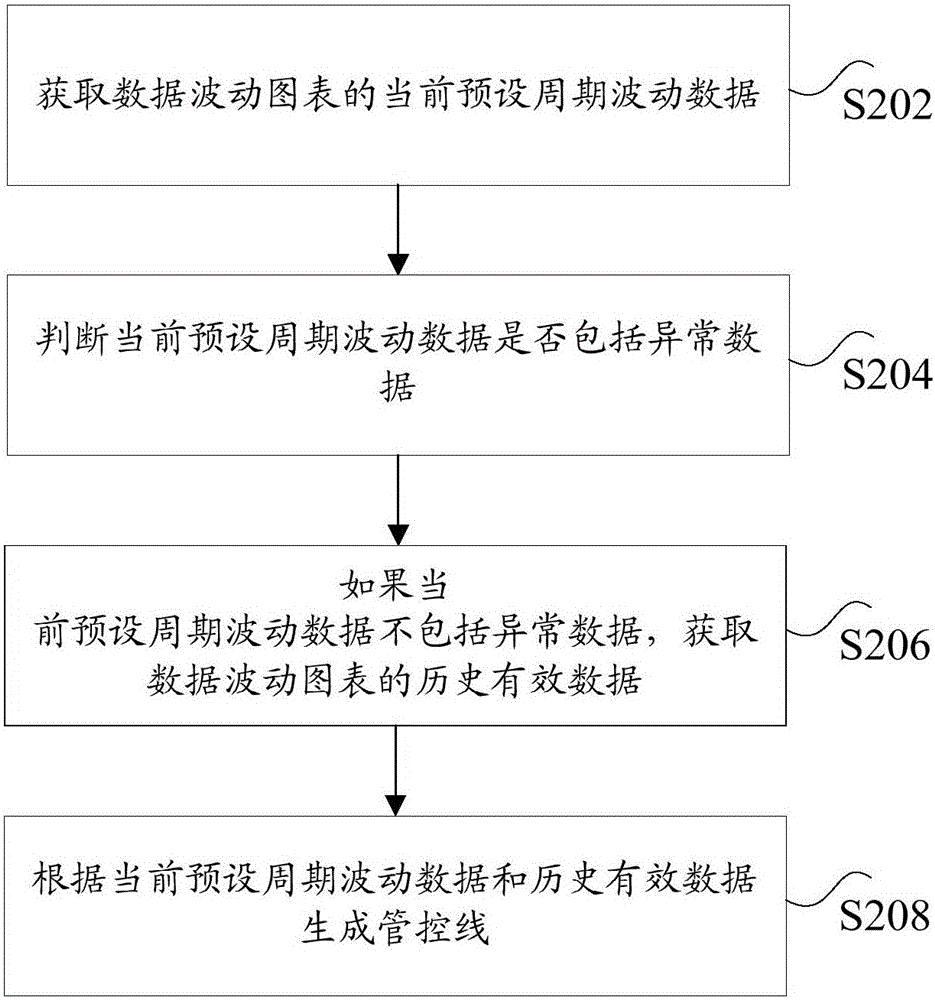

Manufacturing process management and control line generating method and device, and manufacturing process management and control system

ActiveCN106325227AAvoid false positivesTroubleshooting technical issues with false positivesTotal factory controlProgramme total factory controlControl systemControl line

The invention discloses a manufacturing process management and control line generating method, a manufacturing process management and control line generating device, and a manufacturing process management and control system. The manufacturing process management and control line generating method comprises the steps of: acquiring current preset cycle fluctuation data of a data fluctuation chart; determining whether the current preset cycle fluctuation data includes abnormal data; if not, acquiring historical valid data of the data fluctuation chart, wherein the historical valid data is historical data in which abnormal data is filtered out; and generating a management and control line according to the current preset cycle fluctuation data and the historical valid data. The manufacturing process management and control line generating method, the manufacturing process management and control line generating device and the manufacturing process management and control system solve the technical problem of false alarm caused by an overstrict management and control line since the existing automatic management and control system can only tighten the management and control line.

Owner:SEMICON MFG INT (SHANGHAI) CORP

System and methods for managing changes to a product in a manufacturing environment including a bill of material pre-processor

A manufacturing process management (MPM) computer device is provided. The MPM computer device includes a processor and at least one memory device. The processor is in communication with the at least one memory device. The MPM computer device is configured to receive a first engineering design for a first configuration of a product to be assembled including a plurality of features, determine a plurality of parts associated with the plurality of features based on the received engineering design, and prior to completion of a manufacturing process plan, generate a manufacturing bill of materials based on the determined plurality of parts.

Owner:THE BOEING CO

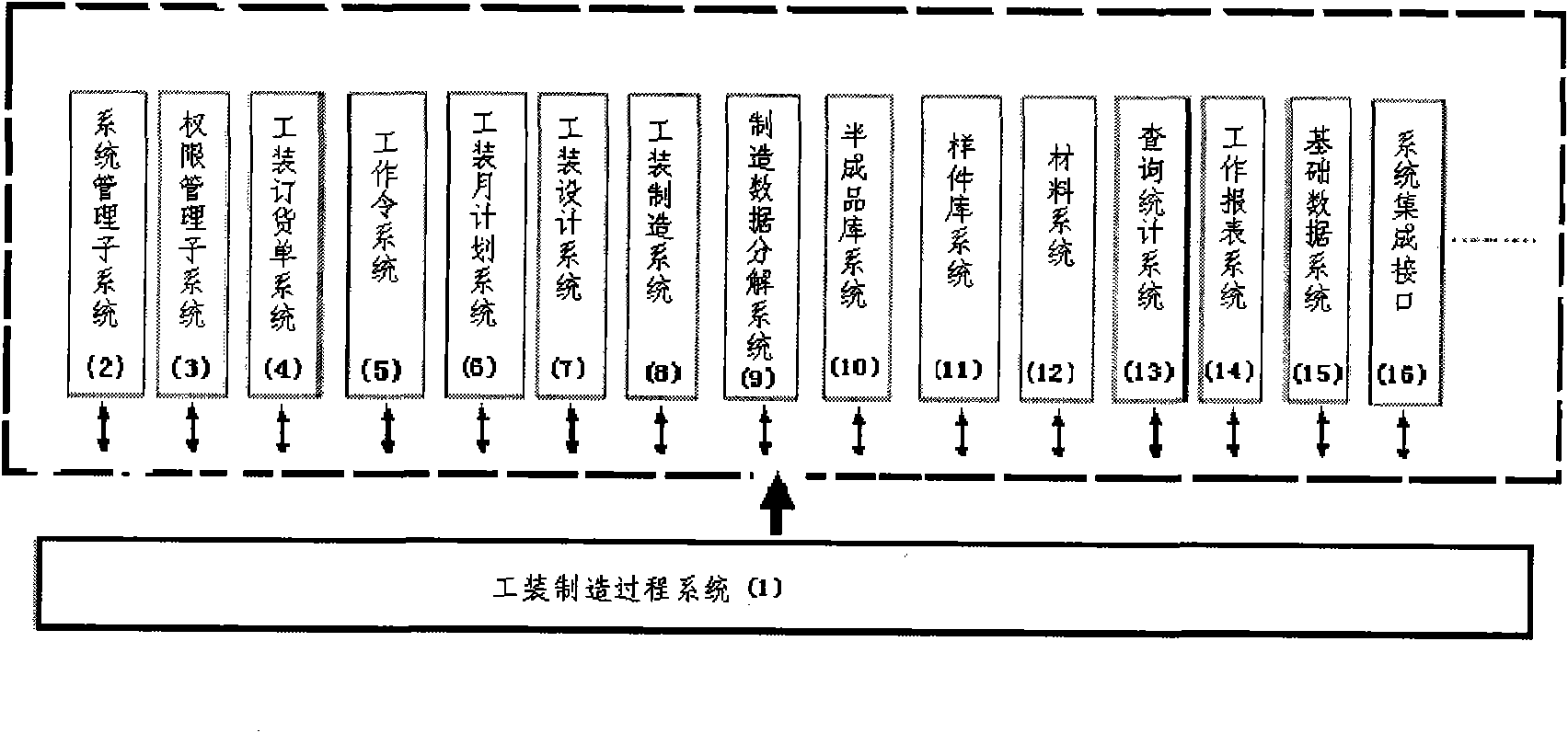

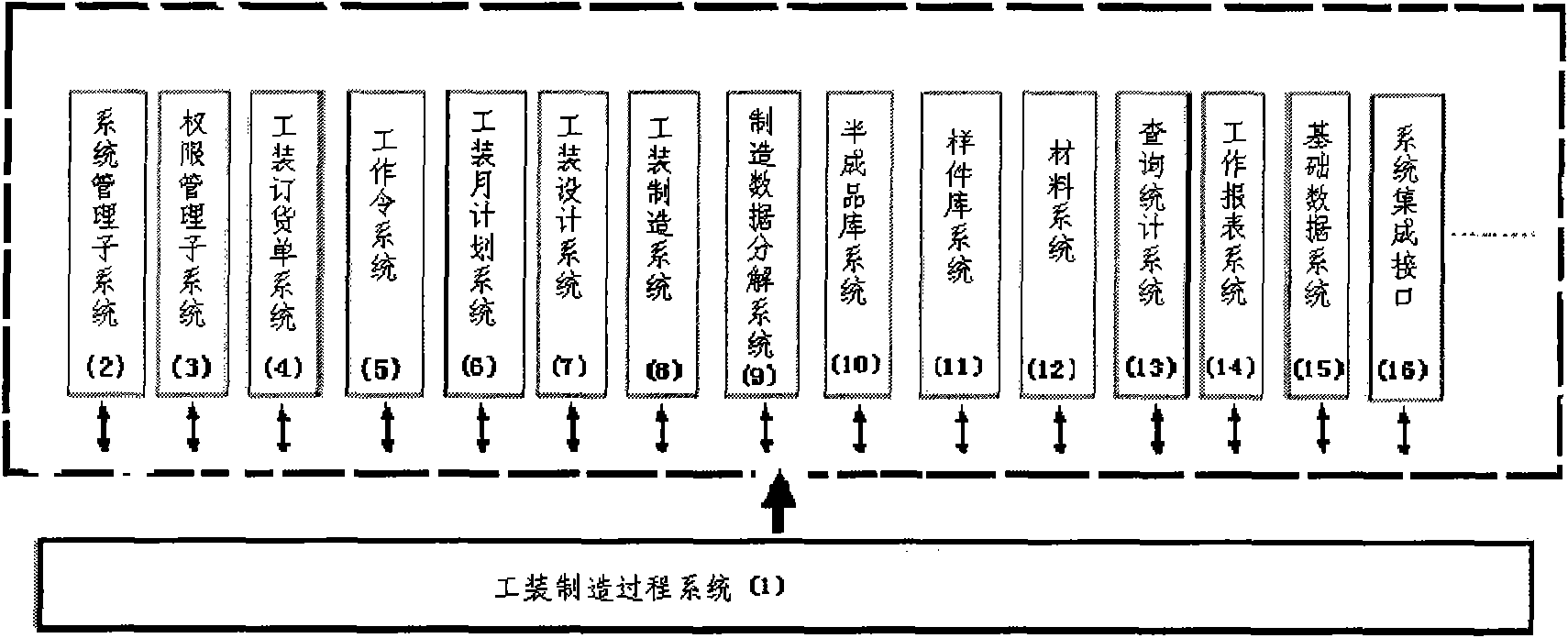

Aircraft tooling digital design and manufacture implementation system

InactiveCN102117438AIncrease productivityImplement trackingResourcesSpecial data processing applicationsData streamNumbering system

The invention belongs to the aircraft tooling digitization technology, and relates to an aircraft tooling digital design and manufacture implementation system. Through developing, implementing and applying a tooling manufacturing process management system, the implementation system realizes the digital standard management on whole tooling business process from design to manufacture, improves the production efficiency of tooling manufacture, realizes tracking and controlling on the tooling design and manufacture progress, realizes the integration of a computer-aided technological design system, an aircraft tooling manufacturing process management system and a numbering system, breaks through data streams among all systems related to tooling, and realizes the digital transmission and sharing of data information. The system realizes the control and management functions on all links in the manufacture and implementation process of a tooling digital production line, and provides a complete implementation scheme and a complete implementation method for realizing constructing the tooling manufacturing process management system.

Owner:HARBIN

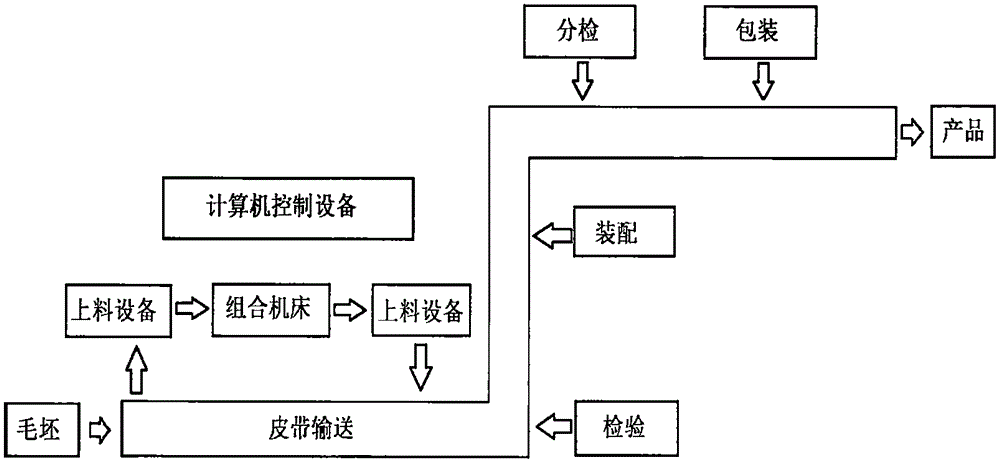

Machinery manufacturing technical process practice teaching experiment system and method

The invention discloses a machinery manufacturing technical process practice teaching experiment system and method. The system comprises a blank, a feeding device, a combination machine tool, a computer control device, examination, assembling, sorting, packaging and a product. The machinery manufacturing technical process practice teaching experiment system and method can be applied to improvement of a conventional machinery manufacturing technical process practice teaching experiment system and method. The system can be used for visual teaching in a classroom, the teaching experiment system and teaching method are especially applied to development of teaching experiments of such professional knowledge and skills as student-oriented mechanical machining, a machining technical process, mechanical machining equipment, an automatic feeding and discharging apparatus, a robot technology, a tool clamp, tolerance measurement, a mechanical assembling process, manufacturing process management, an automatic control technology and the like, and the system and method belong to an innovative technology of a teaching experiment.

Owner:SHANDONG TRANSPORT VOCATIONAL COLLEGE

System and methods for managing changes to a product in a manufacturing environment including a minor model relational design

A manufacturing process management (MPM) computer device is provided. The MPM computer device is configured to store a first version of a product and a second version of the product. The second version includes the first plurality of parts, the second plurality of parts, and a third plurality of parts associated with the plug. The first location is between the first plurality of locations and the second plurality of locations. The MPM computer device is also configured to calculate a first numbering system, calculate a second numbering system for a third plurality of locations associated with the third plurality of parts, determine a first grid overlay for the first version of the product based on the first numbering system, determine a second grid overlay for the second version of the product based on the first numbering system and the second numbering system.

Owner:THE BOEING CO

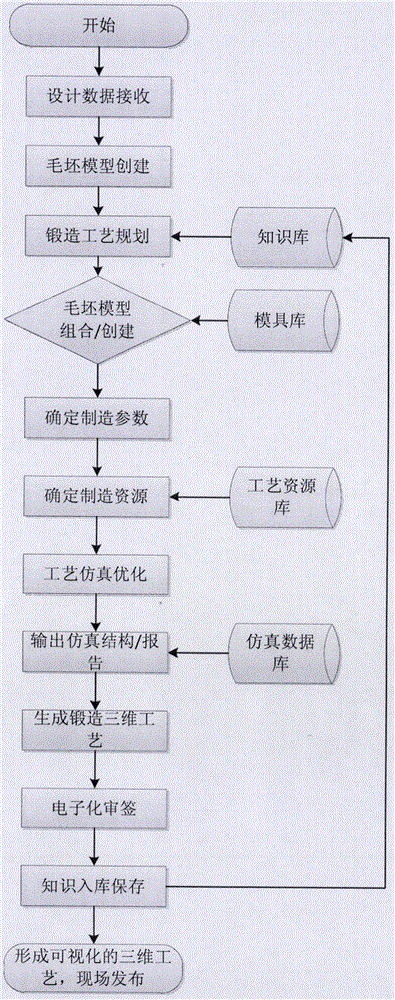

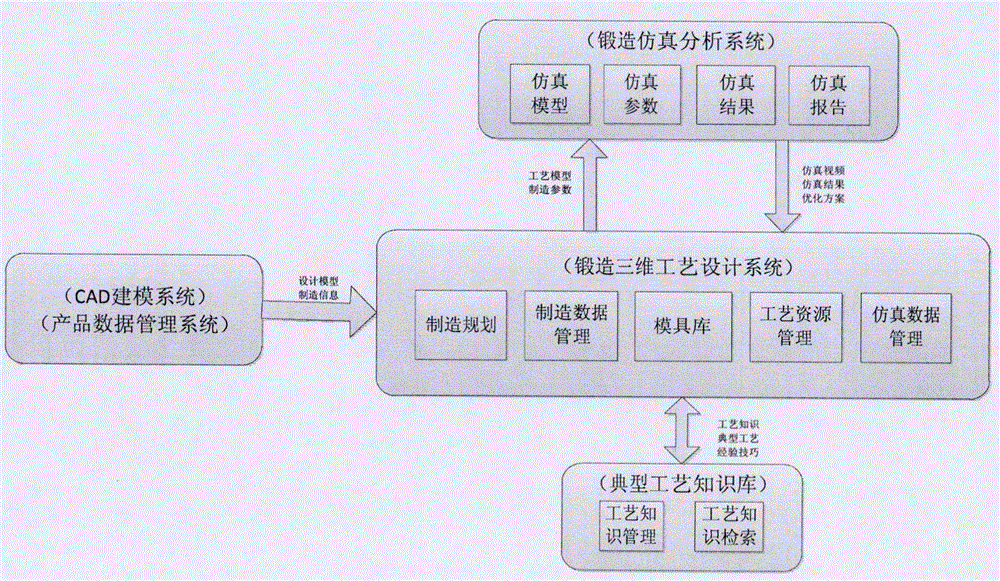

Design method of forging three-dimensional technique

InactiveCN106844930AImprove pass rateHigh yieldDesign optimisation/simulationImage data processingEngineeringData management

The invention relates to a design method of forging three-dimensional technique, and solves the problem existed in the forging technique design applying a two-dimensional model at present. The method includes steps of developing a unique forging three-dimensional technique design system on the basis of a manufacturing process management system (MPMS), and then integrating the system with a CAN modeling system, a technical process simulation analysis system, a product data management system, and a typical knowledge base; the main function of the system after integration includes 1) design of manufacturing parameter; 2) storage of three-dimensional technical model; 3) technical database; 4) forging of mould base; 5) typical technical knowledge base; 6) simulative data management base; 7) electronic auditing and signature, and visible holographic publish. The design method improves the technical design efficiency, guarantees the technical quality, shortens the technical development cycle, and greatly improves the yield and the manufacturing rate of the forging piece; meanwhile, the method further provides a condition for the technical knowledge accumulation of the enterprise.

Owner:INNER MONGOLIA FIRST MACHINERY GRP

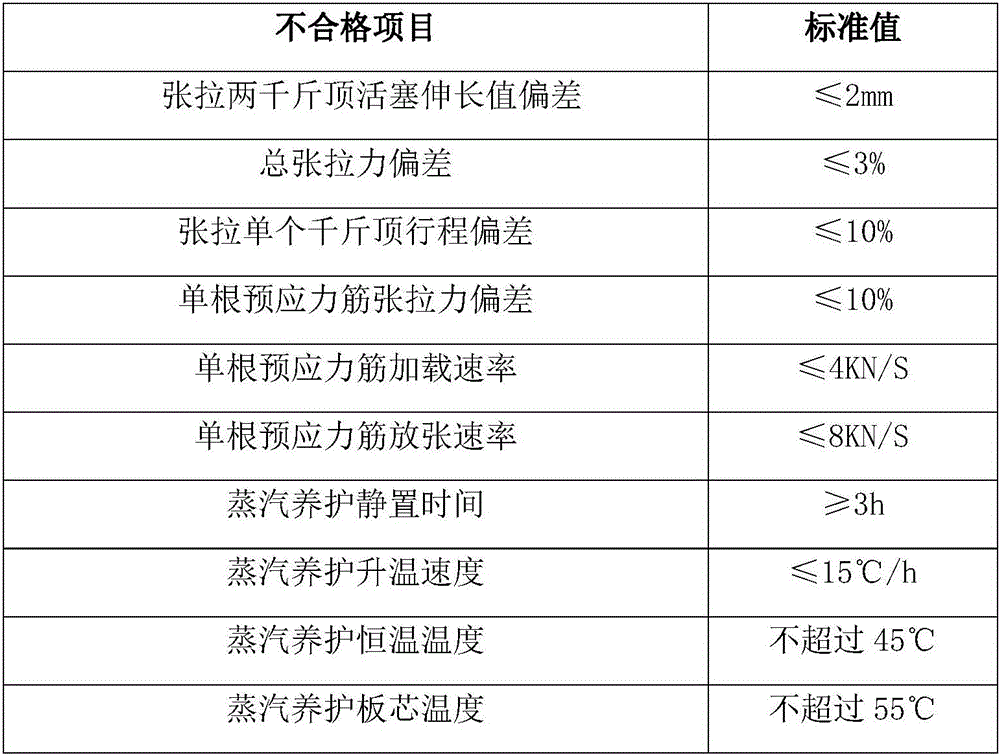

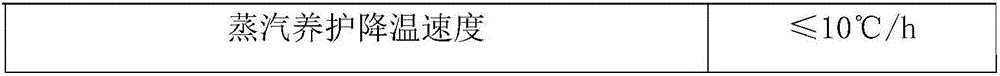

Bi-directional pre-tensioned pre-stressed concrete track board manufacture informationized management system

ActiveCN105930956AEasy to controlImprove standardization management levelResourcesManufacturing computing systemsPre stressingData interface

The invention provides a bi-directional pre-tensioned pre-stressed concrete track board manufacture informationized management system. The system includes a plan progress management module, a manufacture process management module, a track board tracing module and a data interface module; the plan progress management module carries out classification plan management according to the specifications and types of track boards; the manufacture process management module is used for carrying out standardized management on the whole manufacture process of the track boards; the track board tracing module is used for tracing the production and manufacture information of the track boards through RFID electronic tags; and the data interface module is used for managing data interfaces which communicate with production and manufacturing equipment of the bi-directional pre-tensioned pre-stressed concrete track boards. With the system of the invention adopted, business process optimization, communication and coordination of various levels, various departments and various links, internal and external information integration, and the consistency, archiving, query and tracing of data can be promoted, and the work efficiency of each link can be improved.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

Holographic content providing method, and holographic content providing apparatus and display apparatus

InactiveCN104679235ARealize large-scale calculationDigital holographic content timelyInput/output for user-computer interactionHolographic object characteristicsAs DirectedOptical reconstruction

A holographic content providing method, and a holographic content providing apparatus and a display apparatus using the method may capture and generate holographic content using a real object, a virtual object and lighting information, and may conduct integrated processing on the generated holographic content, such as direct edition, advance visualization, data format conversion, element technologies for optical reconstruction and manufacture process management techniques of holographic content, thereby producing ultrahigh-quality interactive holographic content.

Owner:ELECTRONICS & TELECOMM RES INST

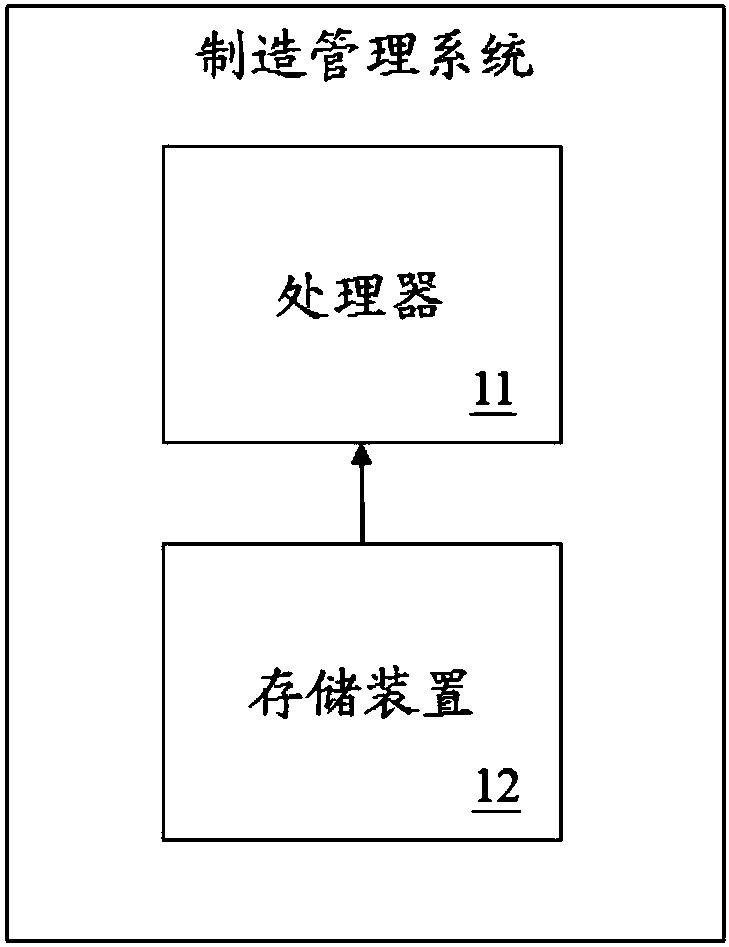

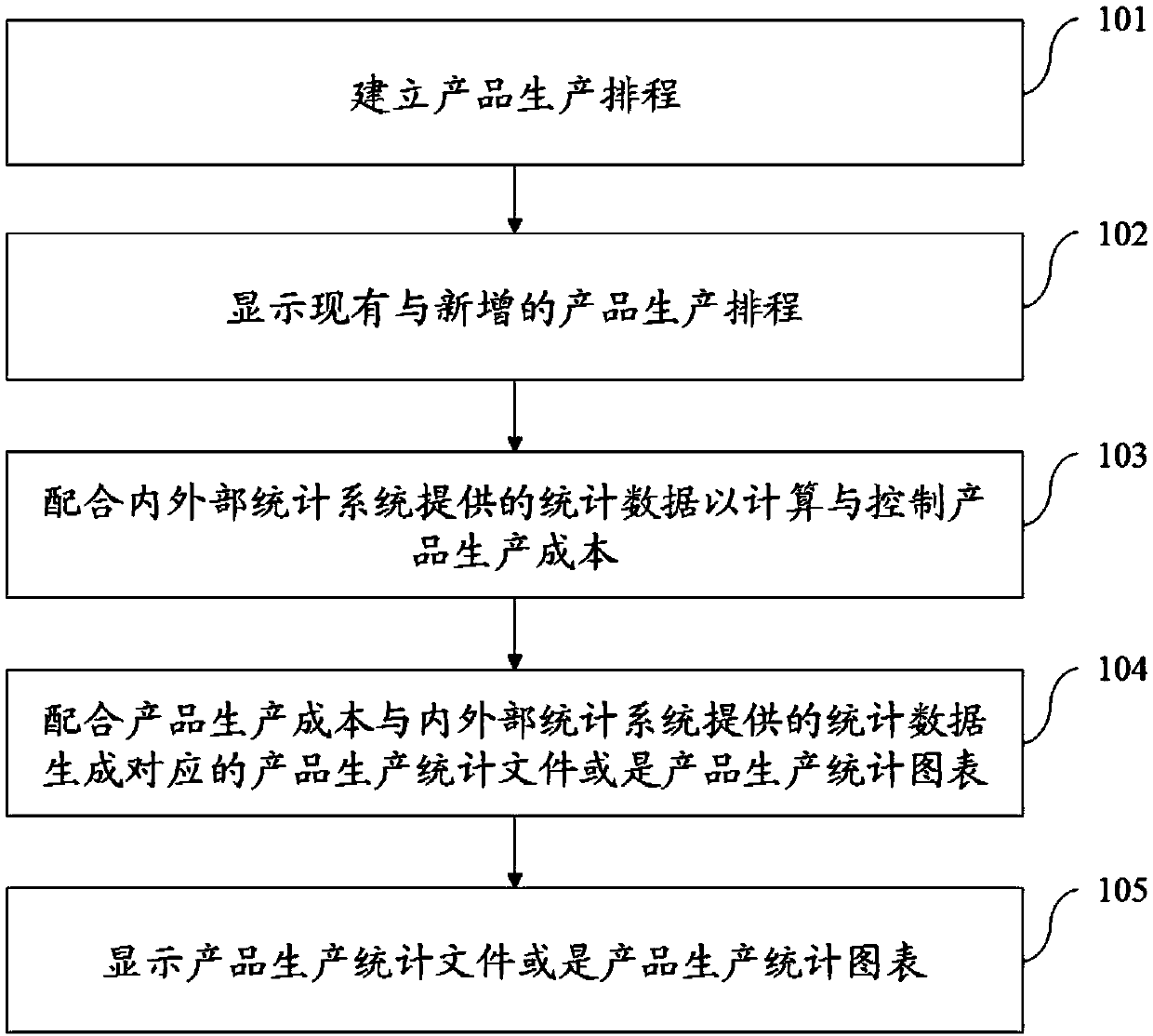

A manufacturing process management system and method for product production

InactiveCN109902906AFacilitate production and manufacturing managementResourcesManufacturing computing systemsProduction scheduleManufacturing management

The invention discloses a manufacturing process management system and method for product production. A product production schedule is established; the production cost of the product is calculated andcontrolled in cooperation with statistical data provided by an internal and external statistical system; and a corresponding product production statistical file or a product production statistical chart is generated by matching the product production cost with statistical data provided by an internal and external statistical system, so that the technical effect of facilitating product production and manufacturing management can be achieved.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

System and methods for managing changes to a product in a manufacturing environment including conversion of an engineering bill of material to a manufacturing bill of material

A manufacturing process management (MPM) computer device is provided. The MPM computer device is configured to store an engineering bill of materials for a product to be assembled including a first plurality of parts, store a manufacturing bill of materials for the product to be assembled including a second plurality of parts and a status, receive a request from a user to change the status of the manufacturing bill of materials, compare the first plurality of parts with the second plurality of parts, determine whether the first plurality of parts matches the second plurality of parts based on the comparison, if the comparison matches, change the status of the manufacturing bill of materials, and if the comparison does not match, prevent the status of the manufacturing bill of materials from changing.

Owner:THE BOEING CO

System and methods for managing changes to a product in a manufacturing environment including a bill of material pre-processor

A manufacturing process management (MPM) computer device is provided. The MPM computer device includes a processor and at least one memory device. The processor is in communication with the at least one memory device. The MPM computer device is configured to receive a first engineering design for a first configuration of a product to be assembled including a plurality of features, determine a plurality of parts associated with the plurality of features based on the received engineering design, and prior to completion of a manufacturing process plan, generate a manufacturing bill of materials based on the determined plurality of parts.

Owner:THE BOEING CO

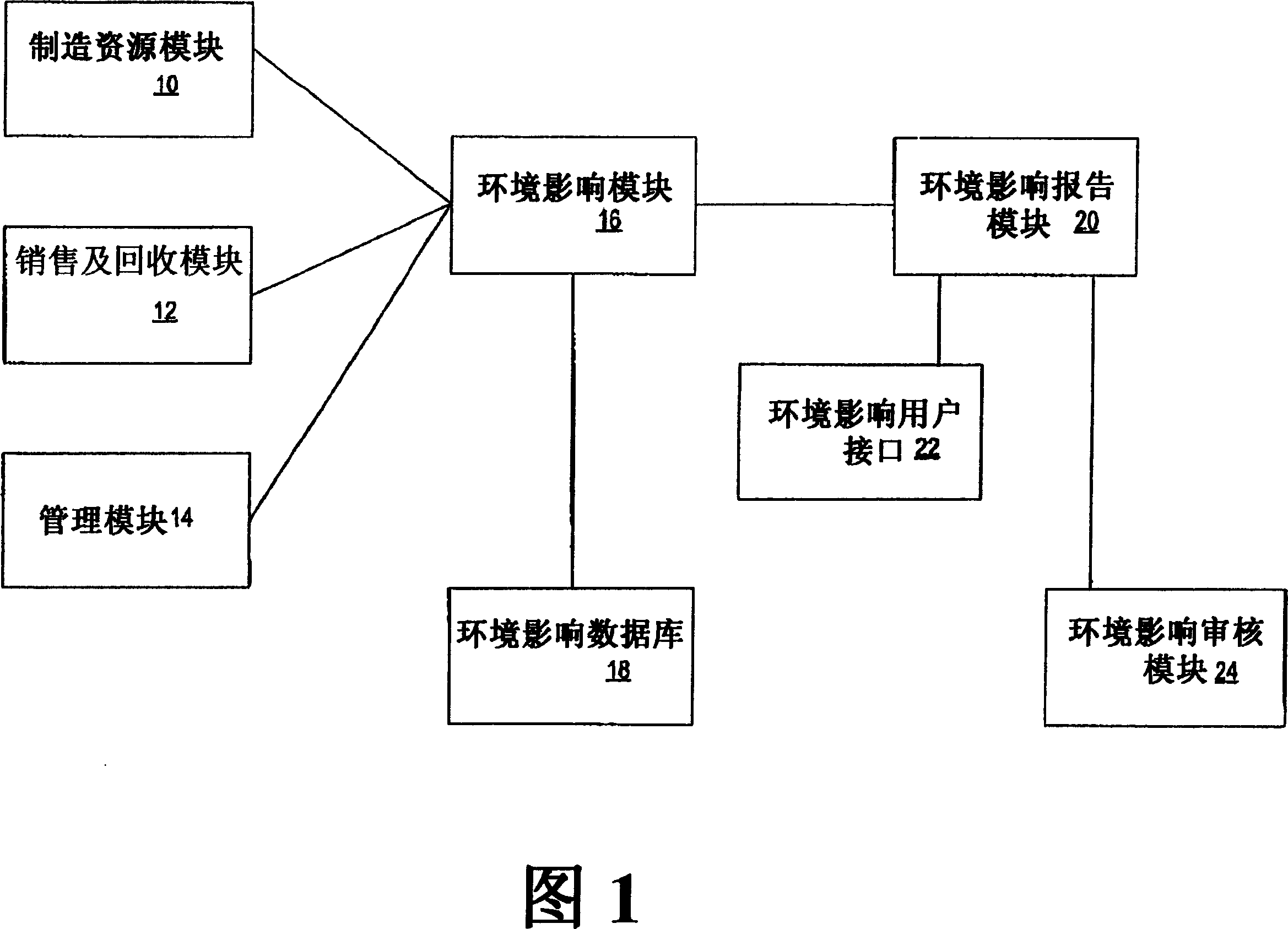

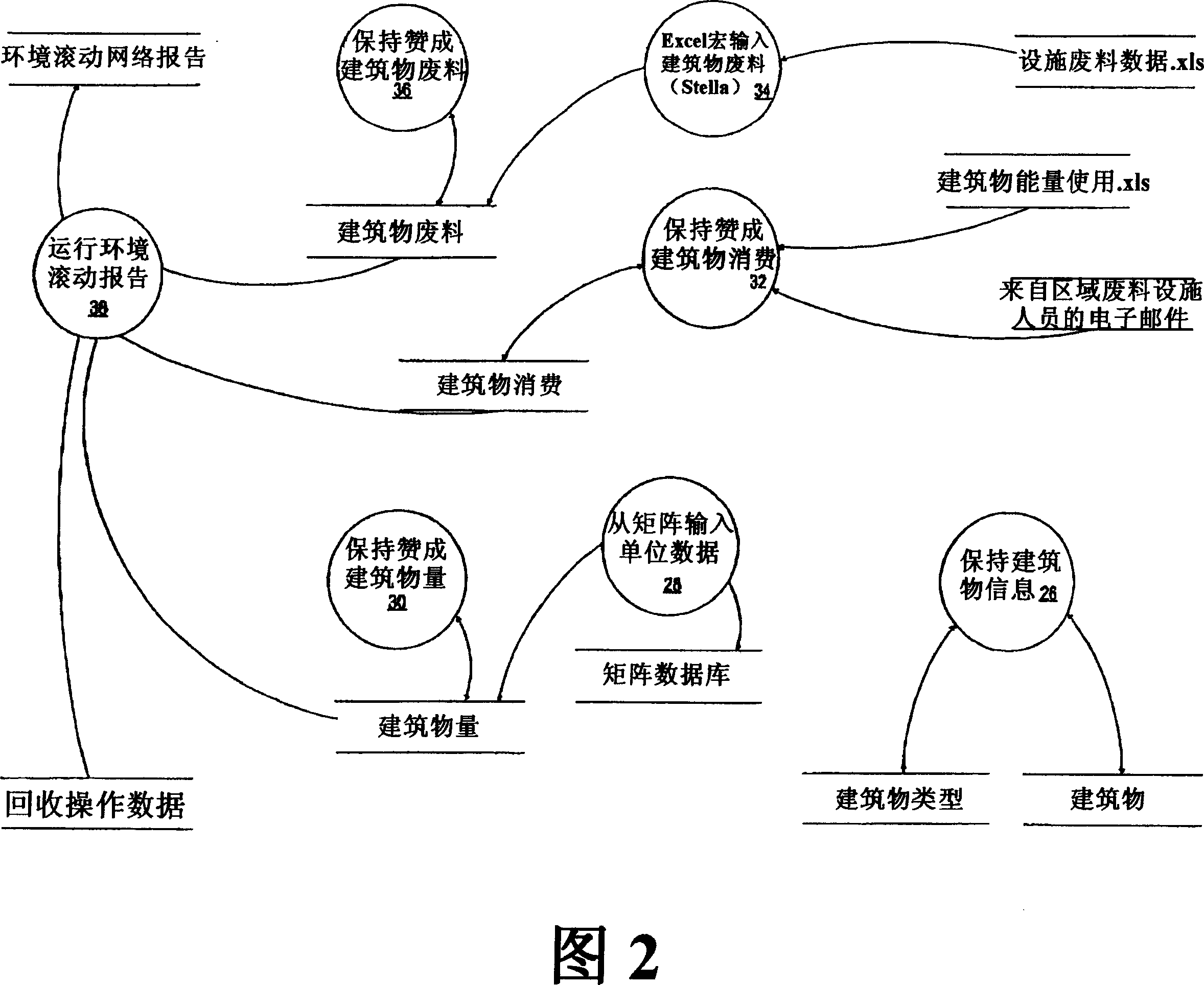

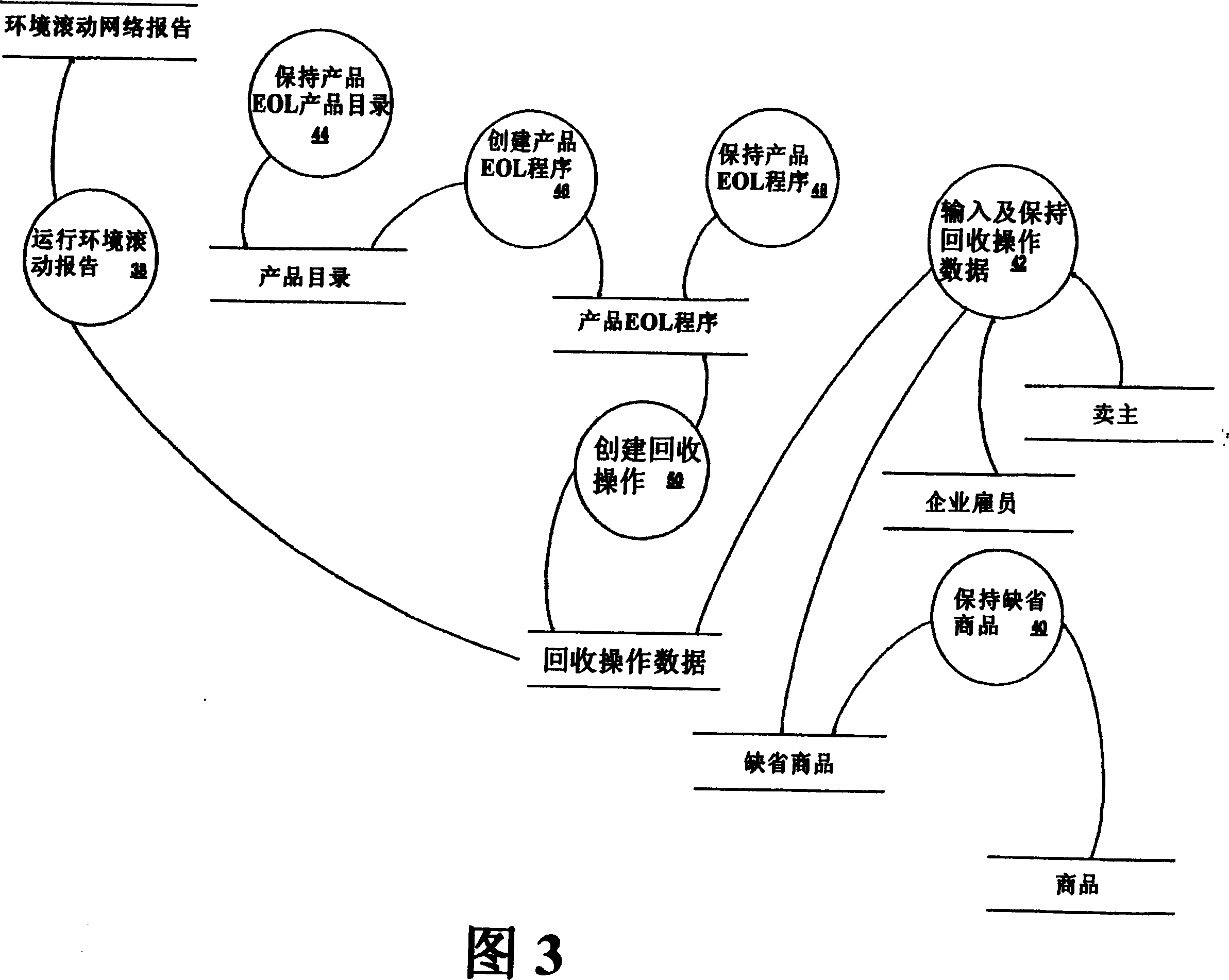

System and method for managing enterprise environmental impacts

InactiveCN101059852AEasy to operateEasy to manageBuying/selling/leasing transactionsEnvironment effectEngineering

Environmental impacts from enterprise operations are efficiently and accurately tracked and reported. Manufacturing resource activities and sales and recovery activities are automatically aggregated for selection of environmental information by an environmental impact engine and storage at an environmental impact database. The environmental information is coordinated for presentation as environmental impact reports that are verified with an audit module by reference to the environmental impact database. Accurate and verifiable environmental impact information enables planning of manufacture processes that efficiently use environmental resources and tracking of manufacturing to verify that manufacturing processes manage resources in a socially responsible manner.

Owner:DELL PROD LP

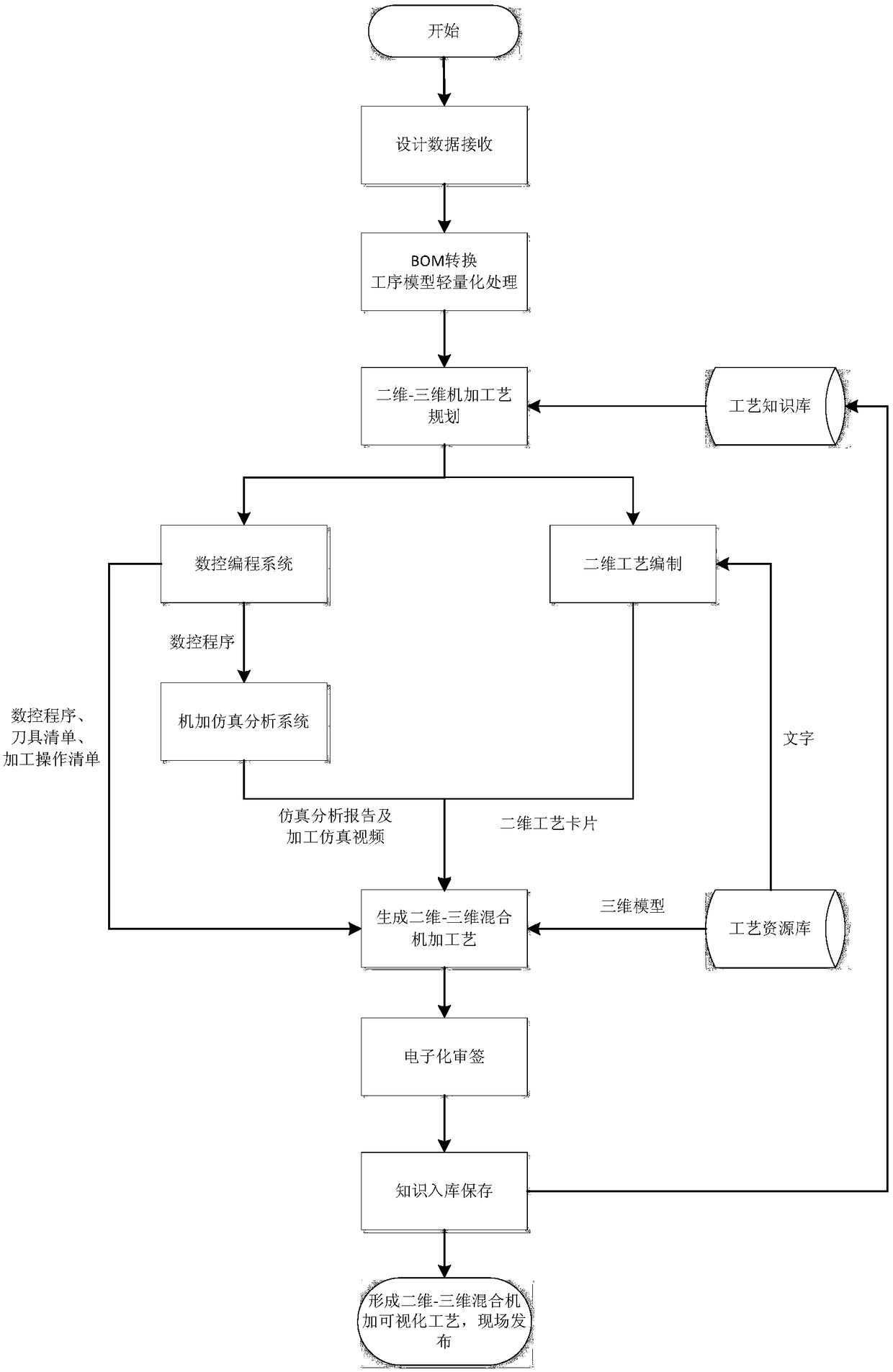

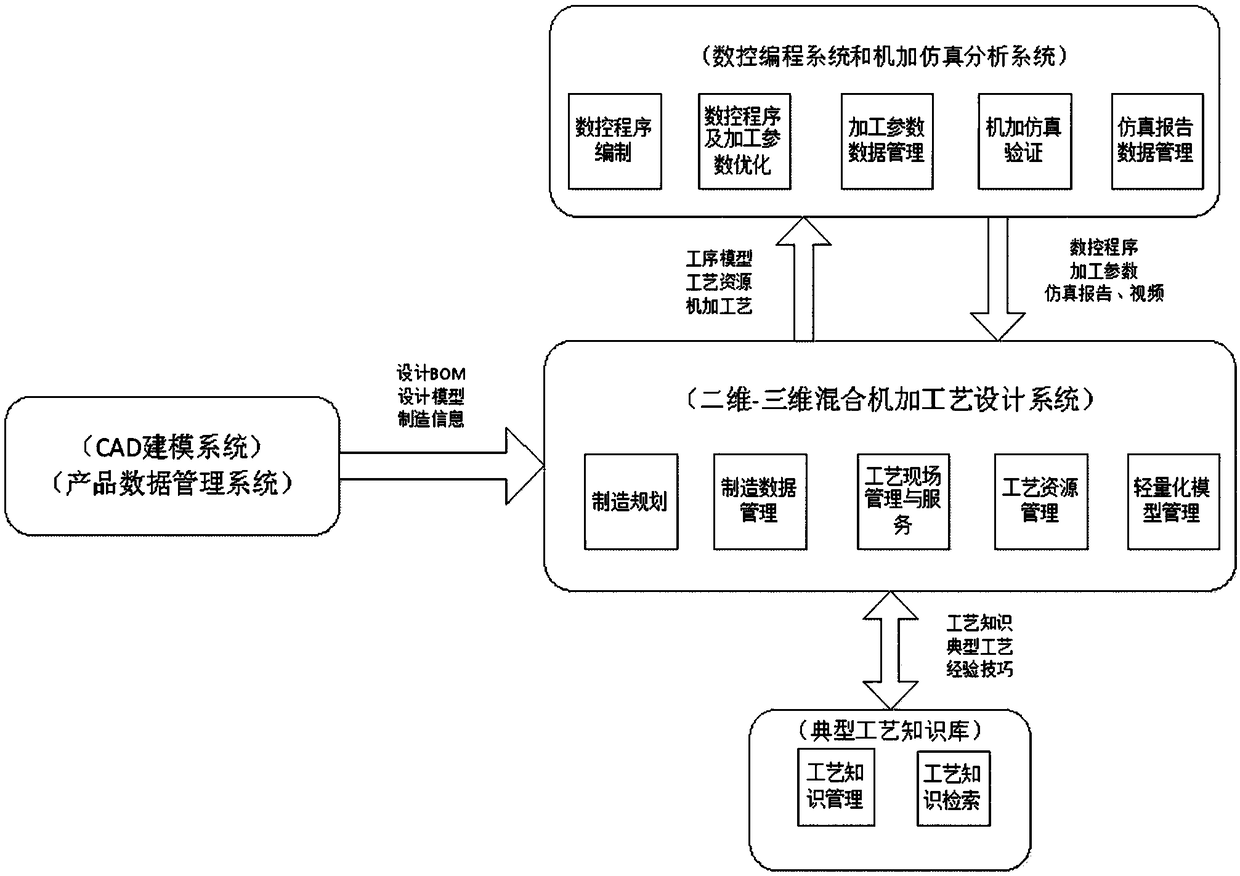

A mixing machining process design system

PendingCN109271710AShorten the design cycleQuality improvementGeometric CADDesign optimisation/simulationNumerical controlManufacturing data

The invention discloses a mixing machining process design system, which comprises a manufacturing process management system, a CAD modeling system, a numerical control programming system, a machiningsimulation analysis system, a product data management system and a typical knowledge base. The invention utilizes accurate process planning, programming and simulation, greatly reduces the loss and cost caused by design errors, simulates the machining state before on-site machining, verifies the process, reduces the problem occurrence rate during actual machining, reduces the reworking rate of theoperator, and greatly improves the product quality and the machining efficiency. The efficiency of process design is greatly improved and the information island mode of each department is changed. The information is smooth and the data consistency is high. Diversification of process information, visualization of manufacturing data and three dimension of on-site data are realized, shortening the understanding digestion time of the process by the operator, improving the efficiency and accuracy of on-site machining, and greatly improving the quality.

Owner:内蒙古第一机械集团股份有限公司

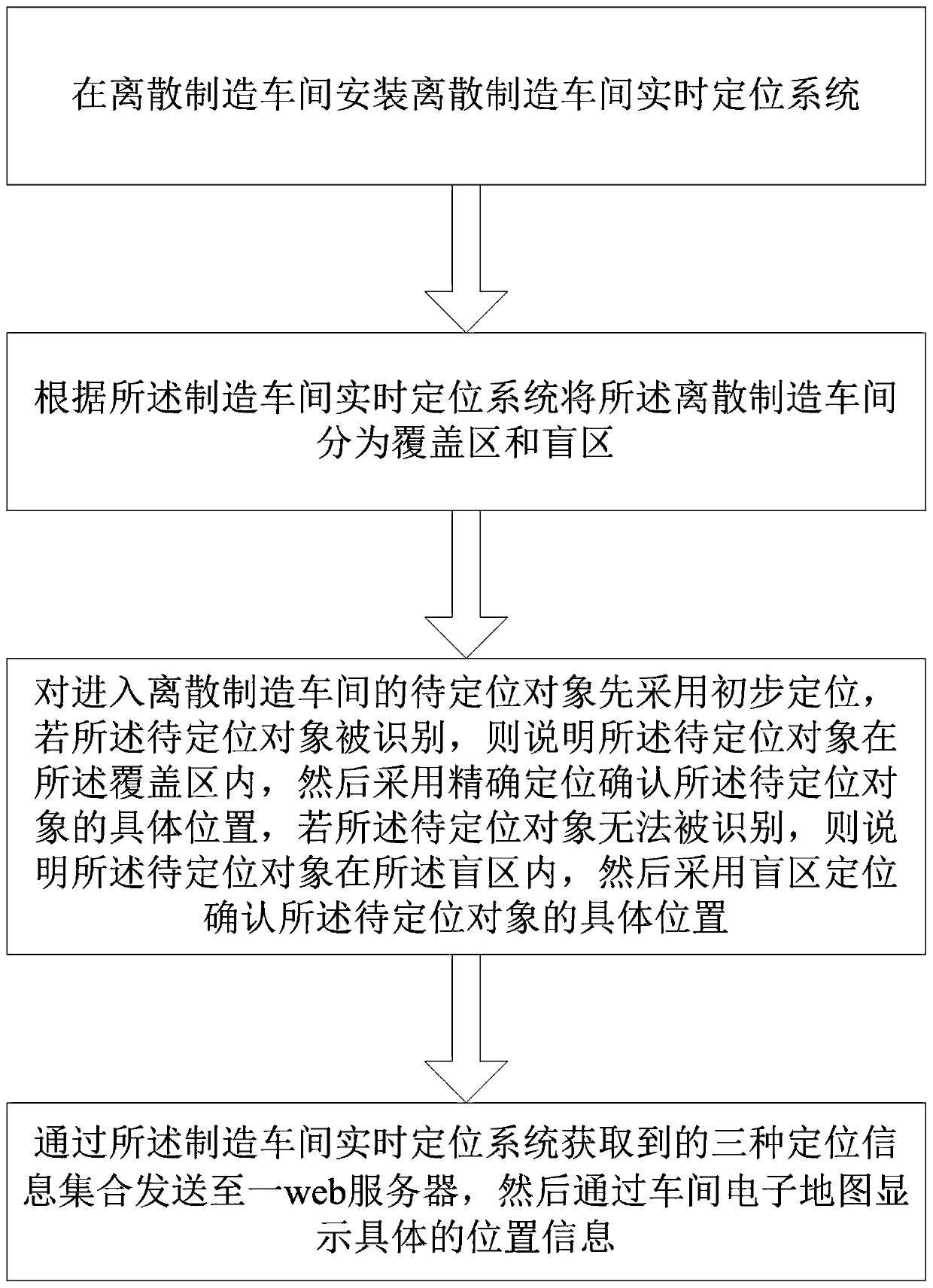

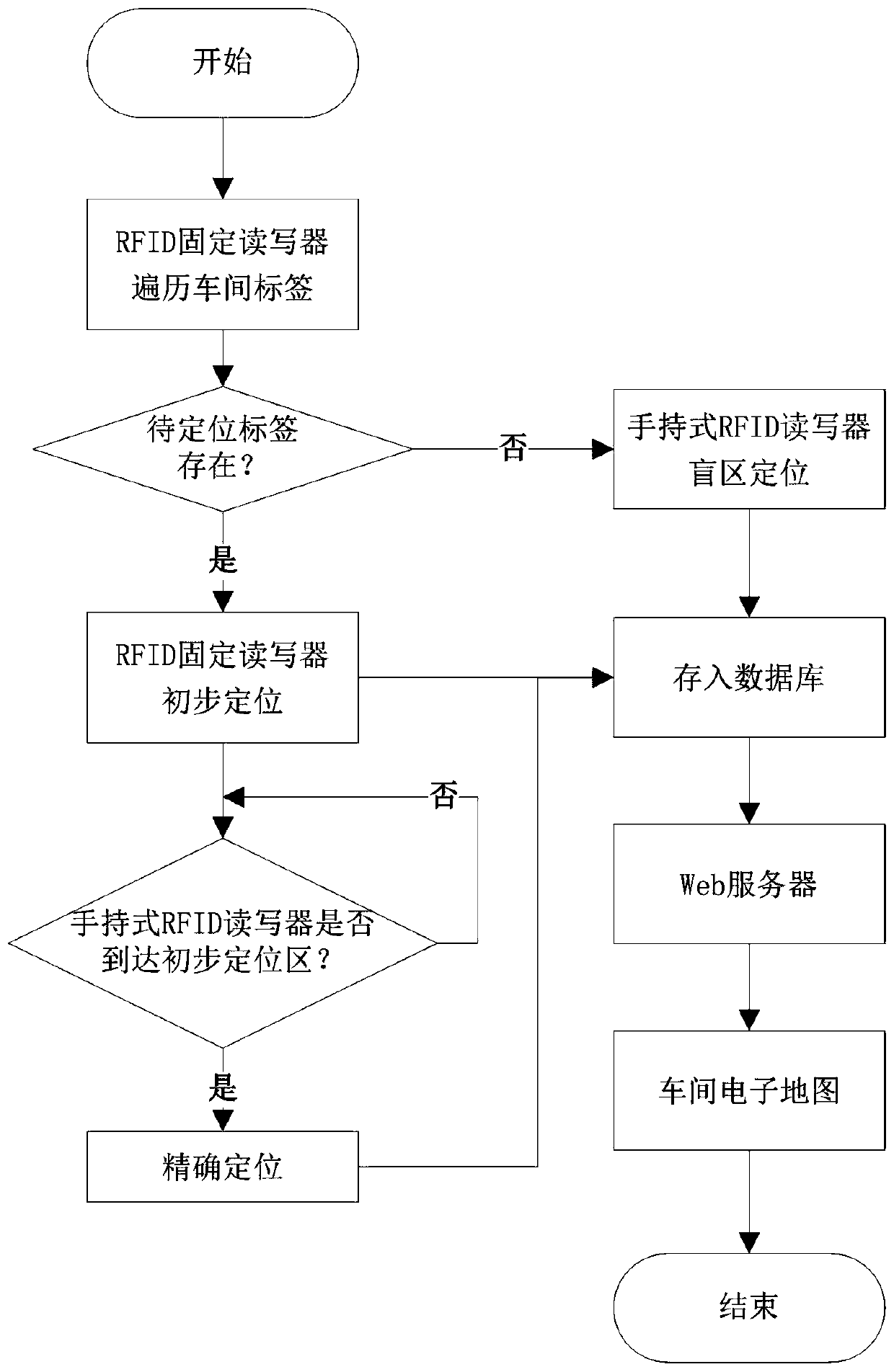

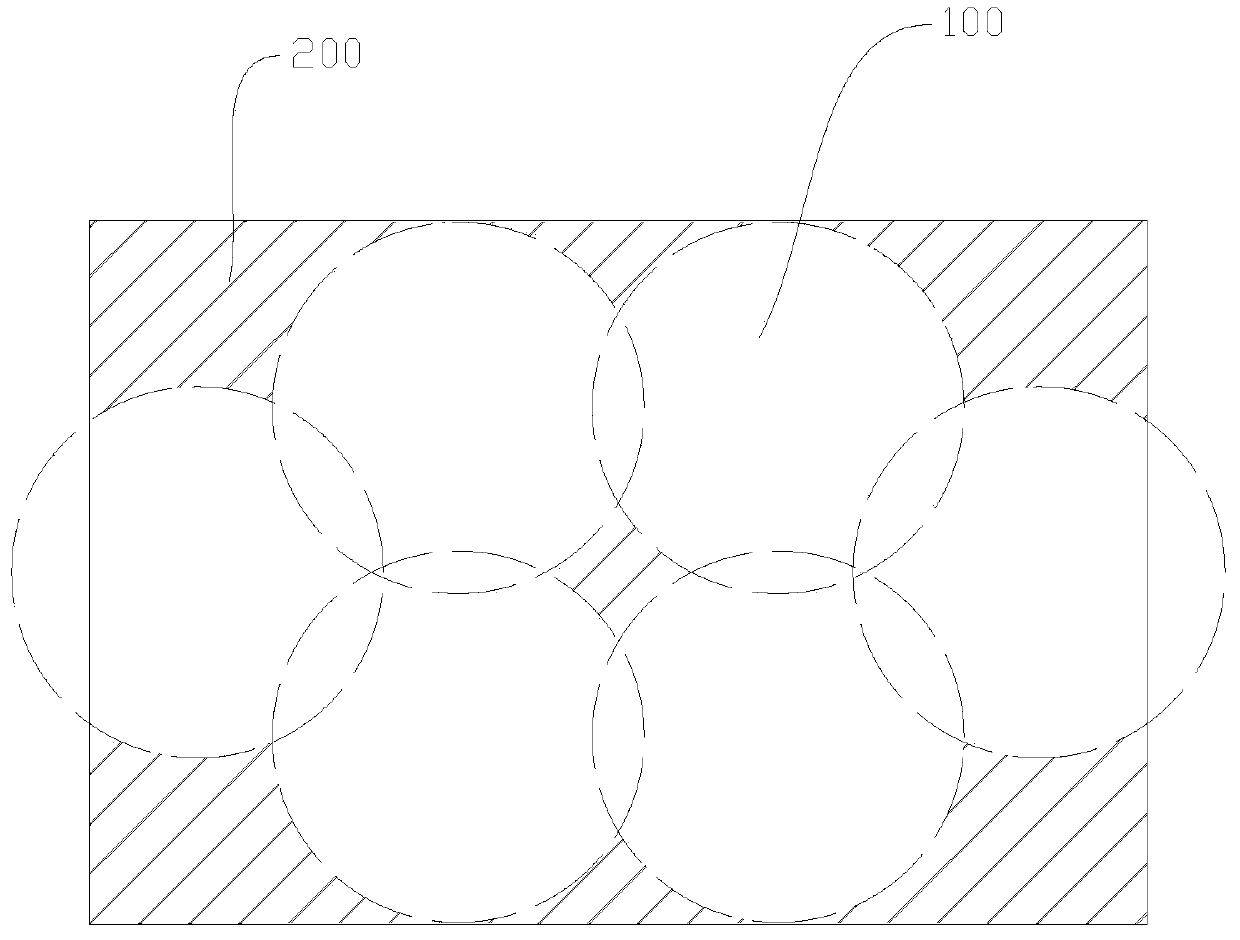

Discrete manufacturing three-dimensional positioning method based on RFID

InactiveCN111586562ASpeed up the processImprove real-time performanceParticular environment based servicesCo-operative working arrangementsBlind zoneDiscrete manufacturing

The invention provides a discrete manufacturing three-dimensional positioning method based on RFID. The method comprises the following specific steps, installing a discrete manufacturing workshop real-time positioning system in a discrete manufacturing workshop; dividing the discrete manufacturing workshop into a coverage area and a blind area according to the manufacturing workshop real-time positioning system; preliminarily positioning a to-be-positioned object entering the discrete manufacturing workshop; if the to-be-positioned object is identified, indicating that the to-be-positioned object is in the coverage area, and then, determining the specific position of the to-be-positioned object by adopting accurate positioning; if the to-be-positioned object cannot be identified, indicating that the to-be-positioned object is in the blind area, then, using blind area positioning to determine the specific position of the to-be-positioned object, Three positioning information sets obtained through the manufacturing workshop real-time positioning system are sent to a web server, then specific position information is displayed through a workshop electronic map, the real-time performance and accuracy of workshop production information collection are improved, and transparency and automation of manufacturing process management are achieved.

Owner:HUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com