Assembly visualization process design method

A technology of process design and assembly process, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve the problem of low design efficiency, lack of knowledge accumulation and reuse means, poor product assembly design and process planning support capabilities, etc. problems, to achieve rapid and low-cost design, improve the quality of assembly process, reduce the effect of prototype trial assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

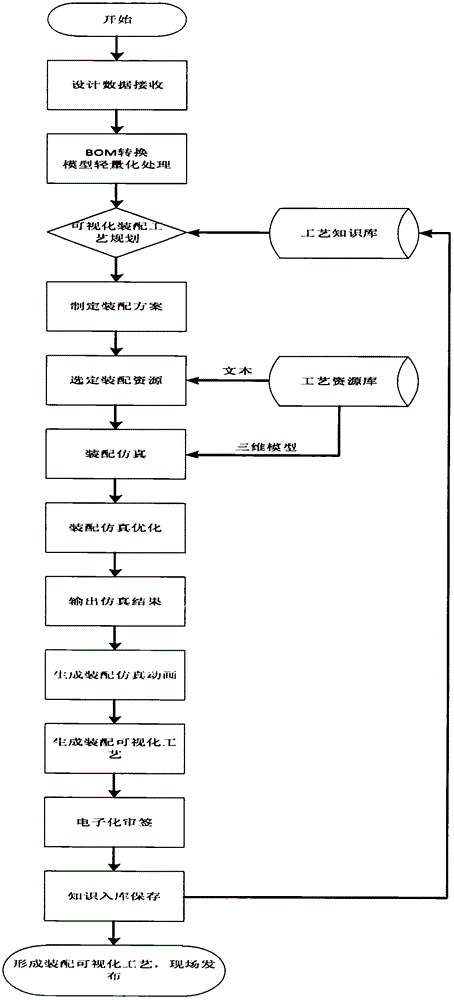

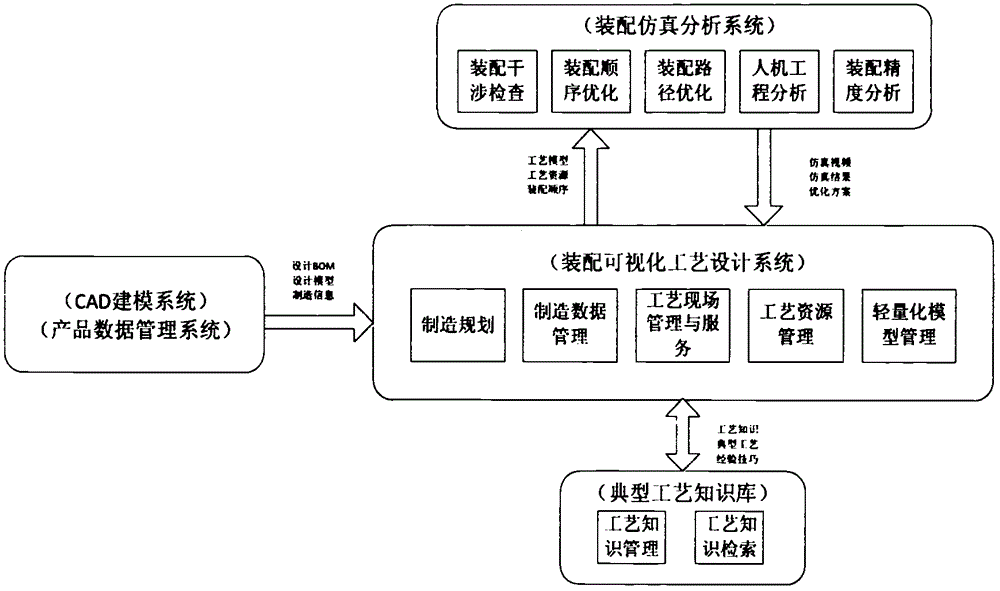

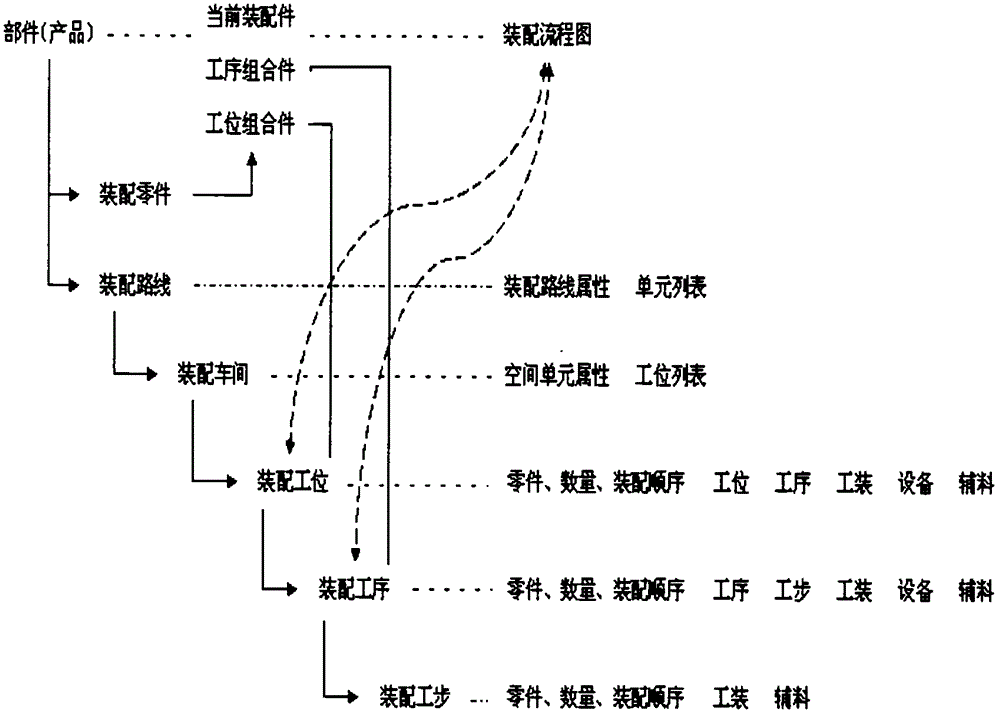

[0030] The invention provides an assembly visualization process design method. Through the development of a unique assembly visualization process design system based on the manufacturing process management system (MPMS), relying on the system, through the open interface, the system is integrated with the CAD modeling system and assembly simulation analysis in a multi-system integration manner System, product data management system, and typical knowledge base are integrated. The main functions of the integrated system are: 1) assembly process planning and design; 2) 3D process model lightweight and storage; 3) assembly process simulation verification and optimization; 4) Process resource library; 5) 3D model library; 6) Typical process knowledge base; 7) Electronic verification and visual holographic release.

[0031] Such as Figure 1-3 As shown, the present invention is based on the following ideas: on the basis of the manufacturing process management system (MPMS), design a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com