Comprehensive monitoring management system and method of long-rail welding process

A welding process and comprehensive monitoring technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., to achieve the effects of ensuring safe production, improving production efficiency, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

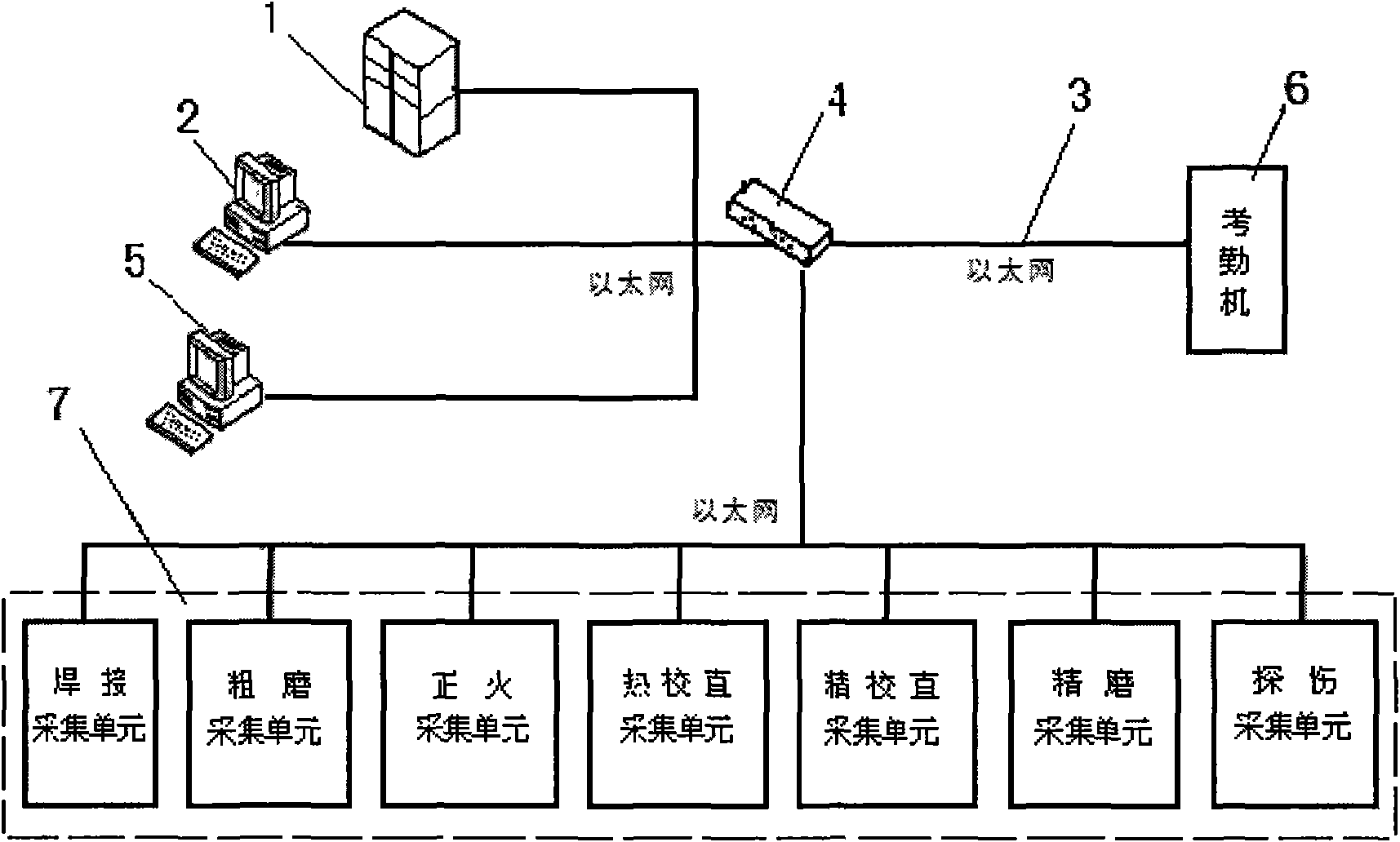

[0062] The comprehensive monitoring and management system for long rail welding process of the present invention is responsible for monitoring the working status of the production line and partially controlling the running of the roller table of the production line, wherein the production line includes a welding line (or hot line) and a finishing line (or cold line).

[0063] The starting station of welding line and finishing line (welding line: welding station, finishing line: fine straightening station) is used as the control station of this production line, so these two stations each have a work permit button . In addition, all stations include stop, work buttons and stop, allow work, work indicator lights, and a human-machine interface to display the working status and roller table running status of all stations in the production line where the station is located.

[0064] When the system is started, the following system information should be confirmed: weld identification...

Embodiment 2

[0075] The comprehensive monitoring and management system for long rail welding process of the present invention is responsible for monitoring the working status of the production line and partially controlling the running of the rollers of the production line, and controls and manages the welding line or the finishing line through the comprehensive monitoring and management system of the welding rail base production line.

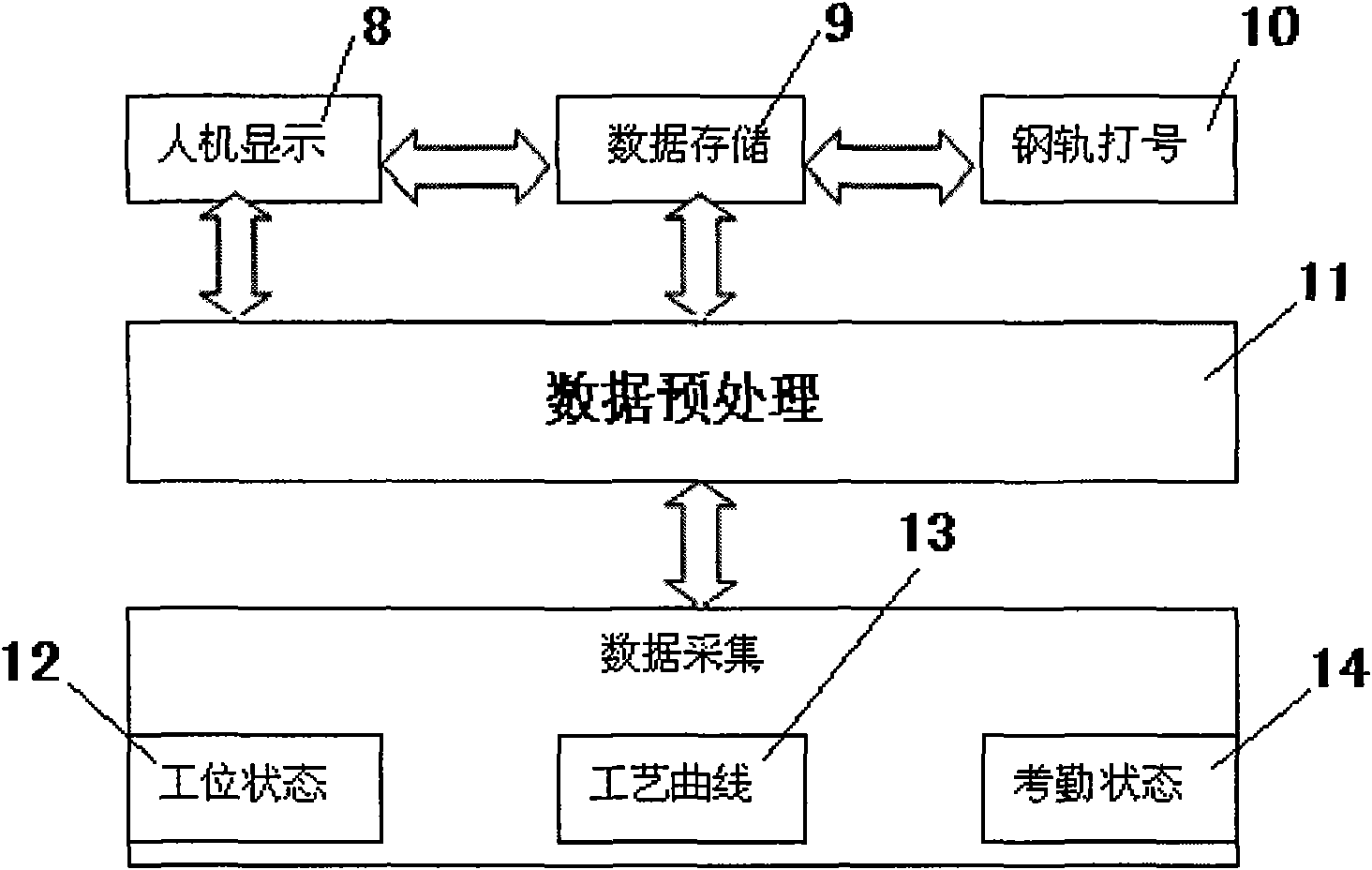

[0076] The interface of the system acquisition host fully displays the working status of the welding line and finishing line and the running status of the roller table. Classification of unit numbers, when the working state of the welding line is collected, the data preprocessing is completed according to the same steps as in Example 1, and further refined to collection, display, and storage; when the working state of the finishing line is collected, it is implemented according to the The same steps as Example 1 complete the data preprocessing, and further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com