Method and system for evaluating completion progress of manufactured product

A progress and product technology, applied in the field of evaluation of the completion progress of in-process products, which can solve problems such as damage to sensors such as radio frequency tags, difficulty in obtaining the completion progress of in-process products in real time, and delay in order production progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

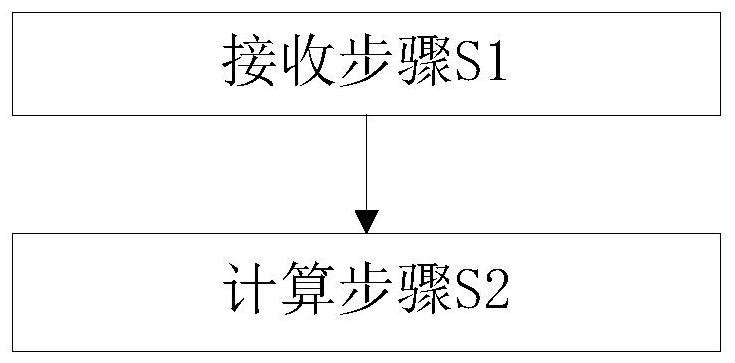

[0062] see figure 1 , the method for assessing the completion progress of the product in process in the present invention specifically includes a receiving step S1 and an evaluating step S2, and the specific process is as follows:

[0063] The receiving step S1 is to receive the order product information and the production scheduling plan matching the order product.

[0064] Case 2 includes 10 jobs and 4 devices. Abnormal events are randomly set and can be obtained through RFID. The basic information of the test cases is shown in Table 1.

[0065] Table 1: Order product information table

[0066]

[0067] According to the existing assignment rules, a feasible scheduling scheme is as follows:

[0068]

[0069] After the scheduling plan is generated, the Gantt chart of each production job can be generated, as shown in Figure 4 As shown, the production start time and completion time of each task can be determined according to the generated Gantt chart.

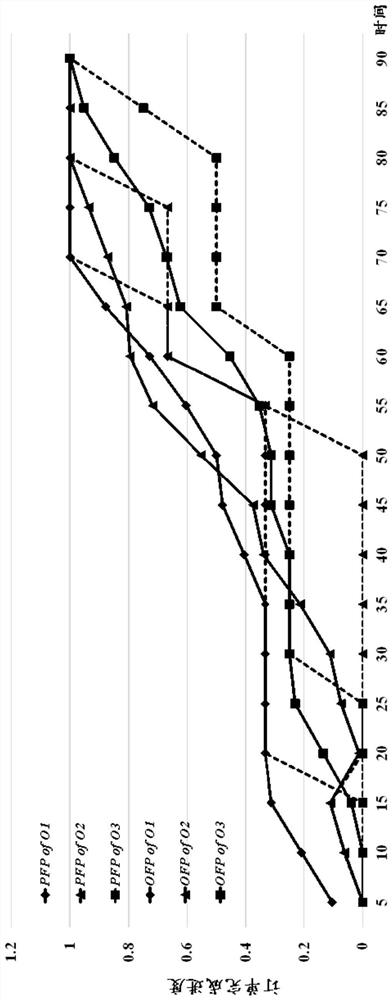

[0070] Calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com