Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Chloroprene Polymers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

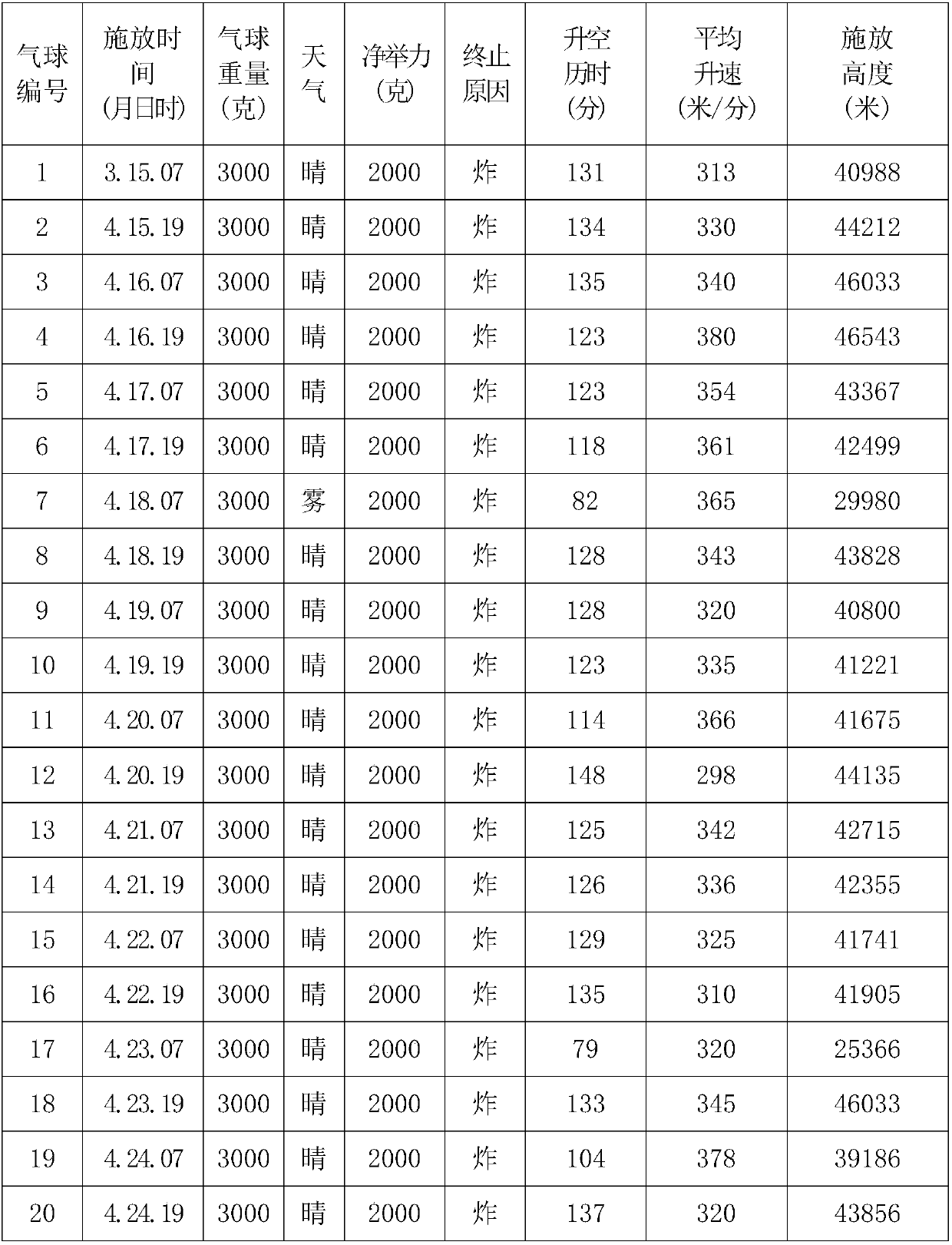

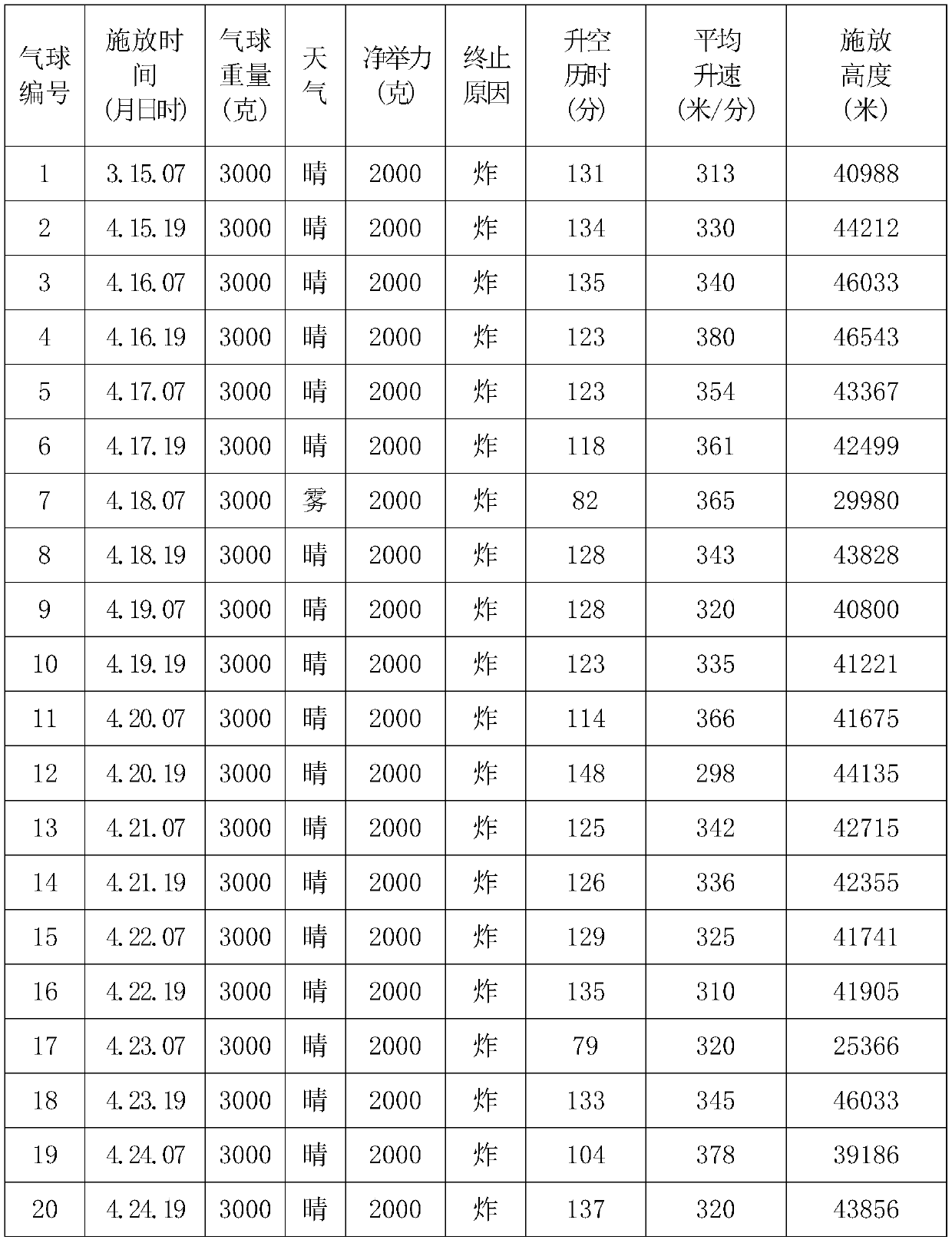

Meteorologic balloon and production method thereof

ActiveCN101592742AThere will be no problem of uneven distributionAgainst destructive powerInstrumentsPotassium hydroxideDioctyl sebacate

The invention discloses a meteorologic balloon and a production method thereof. The raw materials consist of a solid raw material, an oily raw material and a gluey raw material; the solid raw material comprises the following components by weight: 0 to 0.30 portion of potassium hydroxide, 0 to 0.15 portion of casein, 0 to 0.10 portion of peregal O, 1.00 to 3 portions of sulfur, 1.00 to 2 portions of N-phenyl-2-naphthylamine, 1.00 to 2 portions of N-phenyl-N'-isopropyl-ursol, 1.50 to 3 portions of ethyl-phenyl-zinc dithiocarbamate, 0.20 to 5 portions of zinc oxide, and 5 to 30 portions of chloroprene polymer; the oily raw material is dioctyl sebacate, and the weight rate of the dioctyl sebacate is 5.00 to 10.0 portions; and the gluey raw material is centrifugally-concentrated natural latex, and the adding amount of the centrifugal concentrated natural latex is 100 portions. The weight of the meteorologic balloon is 1,600 to 1,700 grams, the length of the balloon body is 3.05 to 3.55 meters, the width of the ball handle is 10 to 11 centimeters, and the length of the ball handle is 12 to 16 centimeters. The meteorologic balloon can adapt to the requirement of probing high-altitude meteorological elements of more than 35,000 meters, has the advantages of good aging resistance, high blastoff height, long balloon service time and the like, and can effectively overcome the morning-evening difference.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

Chloroprene block copolymer and soapless polychloroprene latex, and processes for production of copolymer and latex

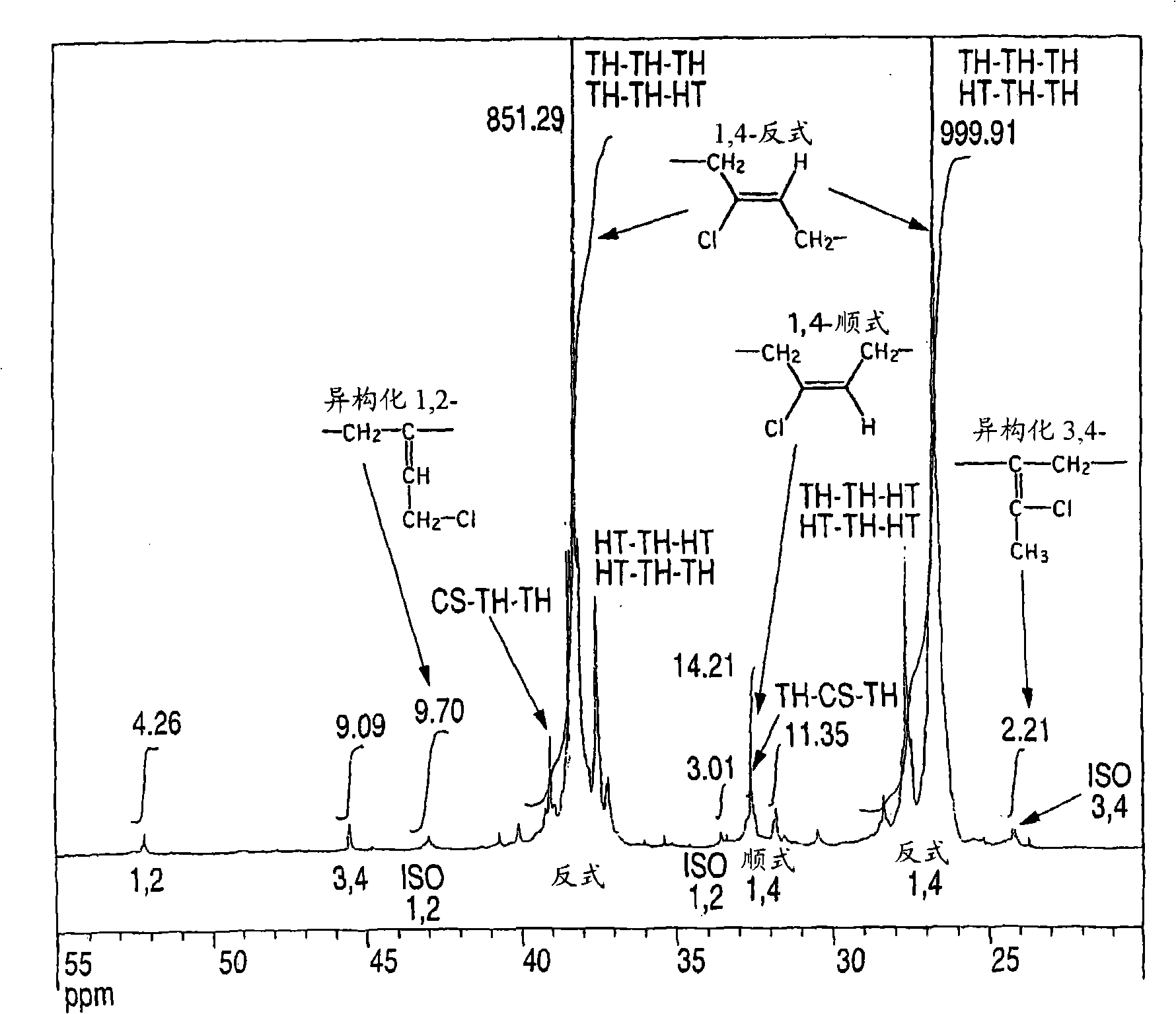

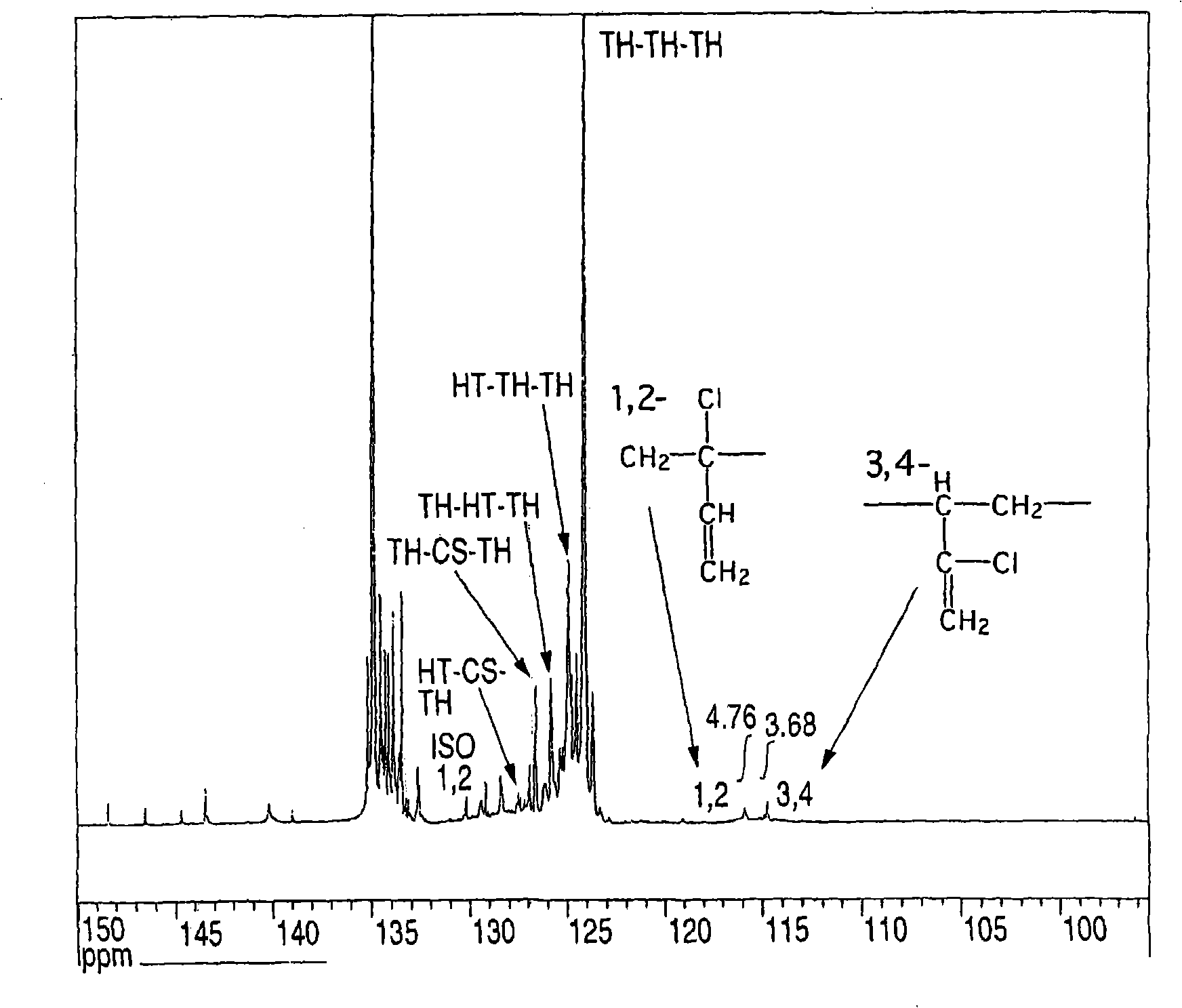

Disclosed are a novel polychloroprene copolymer, a soapless polychloroprene latex, and a process for producing the copolymer or latex in a simple manner, which are intended to be used for the improvement in adhesion property and water resistance of a conventional polychloroprene adhesive or the improvement in oil resistance and adhesion property of a conventional styrene-butadiene block copolymer. A chloroprene block copolymer comprising a polymer (A) having the composition represented by the general formula (1) in the description and a chloroprene polymer (B), the polymer (A) being linked to one terminal or both termini of the chloroprene polymer (B), and the total amount of the 1,2-bond and the isomerized 1,2-bond in the chloroprene polymer (B) as measured by carbon-13 nuclear magnetic resonance spectrometry being 2.0 mol% or less; a soapless polychloroprene latex comprising an amphiphilic chloroprene copolymer having a hydrophobic chloroprene polymer and a hydrophilic oligomer or polymer having an acidic functional group attached to the hydrophobic chloroprene polymer and 2 wt% or less of an emulsifying agent; and a process for producing the chloroprene block copolymer or soapless polychloroprene latex.

Owner:TOSOH CORP

Weather monitoring device and application thereof

ActiveCN102718994AGood dispersionSame plasticizing effectBalloon aircraftsInstrumentsDibutyl sebacateDIETHYL SEBACATE

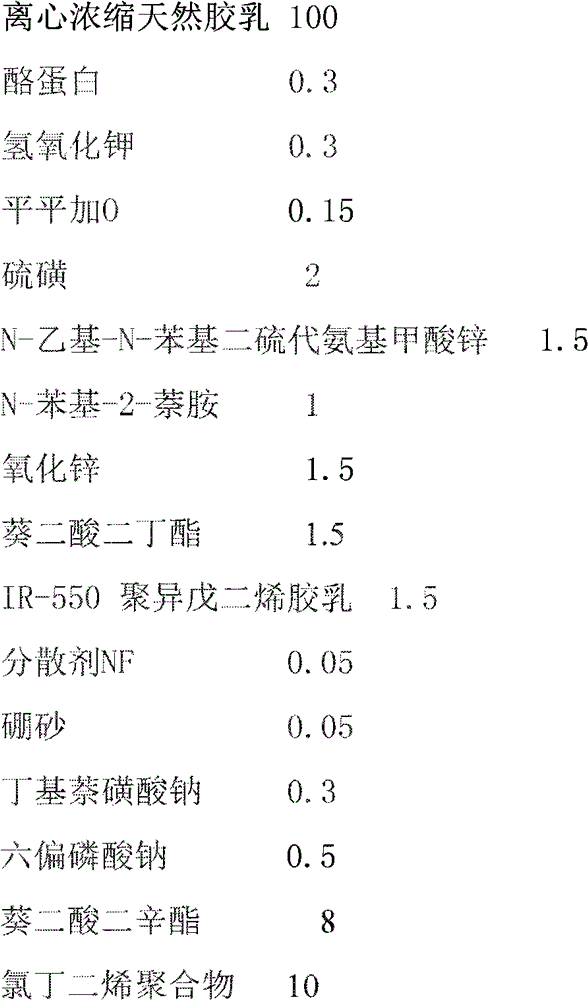

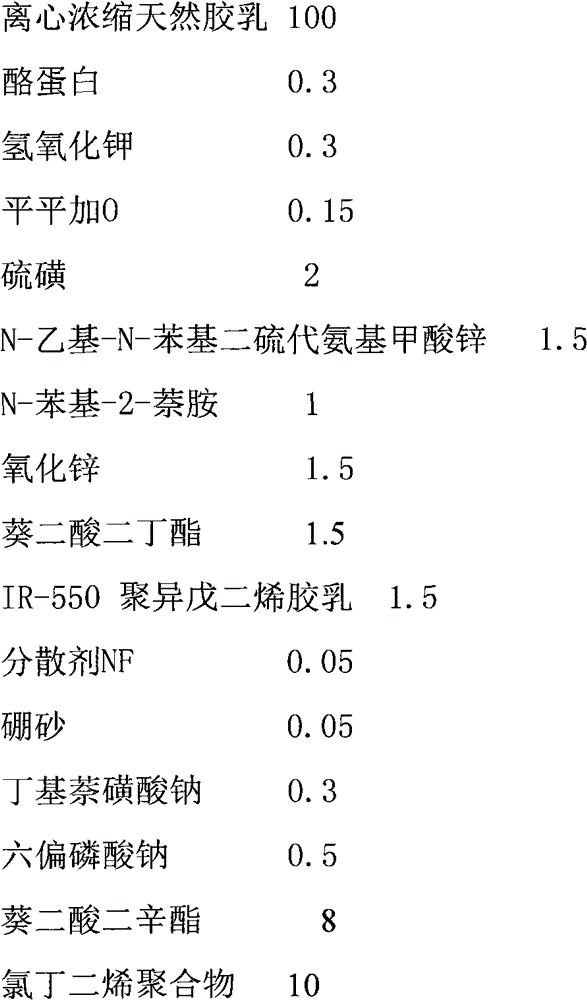

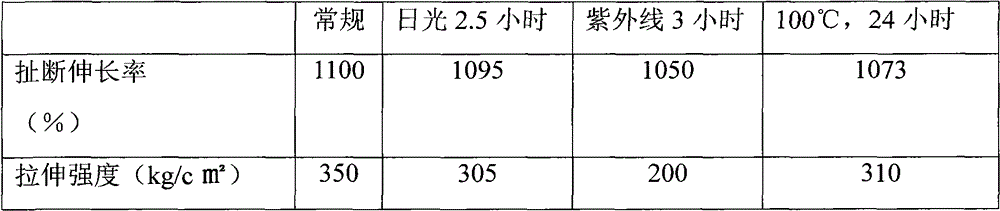

The invention relates to a weather monitoring device, in particular to a new weather balloon, which comprises the following components by weight percent: 100 of centrifugal concentrated natural latex, 0.3 of casein, 0.3 of potassium hydroxide, 0.15 of peregal 0, 2 of sulphur, 1.5 of N-ethyl-N-phenyl dithiocarbamate zinc, 1 of N-phenyl-2-naphthylamine, 1.5 of zinc oxide, 1.5 of dibutyl sebacate, 1.5 of IR-550 polyisoprene latex, 0.05 of dispersing agent NF, 0.05 of borax, 0.3 of sodium butylnaphthalenesulfonate, 0.5 of sodium hexametaphosphate, 8 of dioctyl sebacate and 10 of chloroprene polymer. The new weather balloon provided by the invention has the advantages of high sounding altitude, long sounding time and wide application prospect.

Owner:南通市通州区新志浩实业有限公司

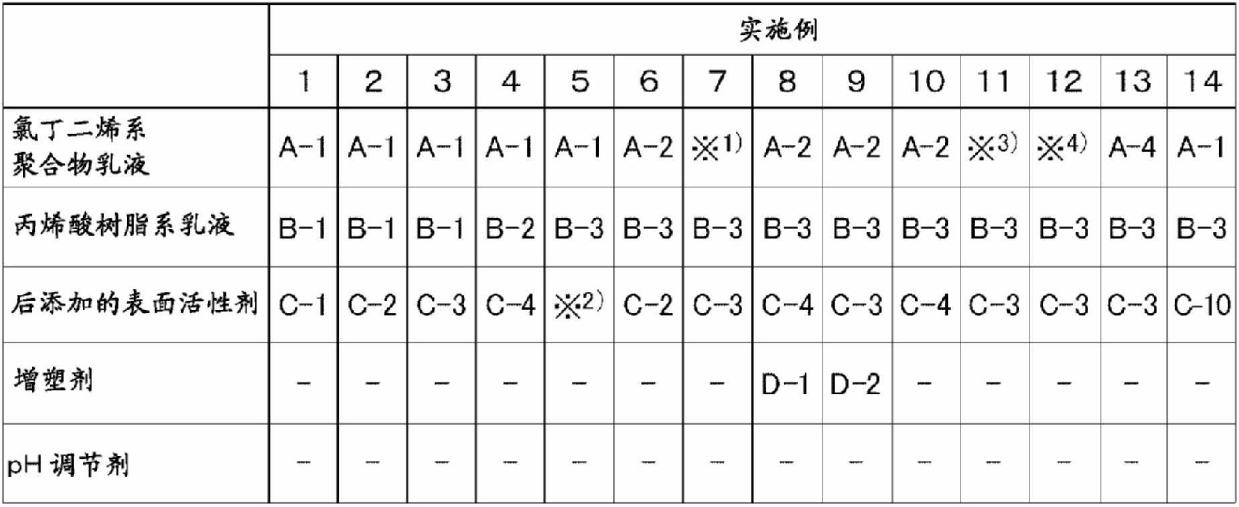

Chloroprene polymer latex composition and use thereof

InactiveUS20120238678A1Fast crystallizationLowering storage stability and spray coating propertyChloroprene adhesivesPolymer scienceAcrylic resin

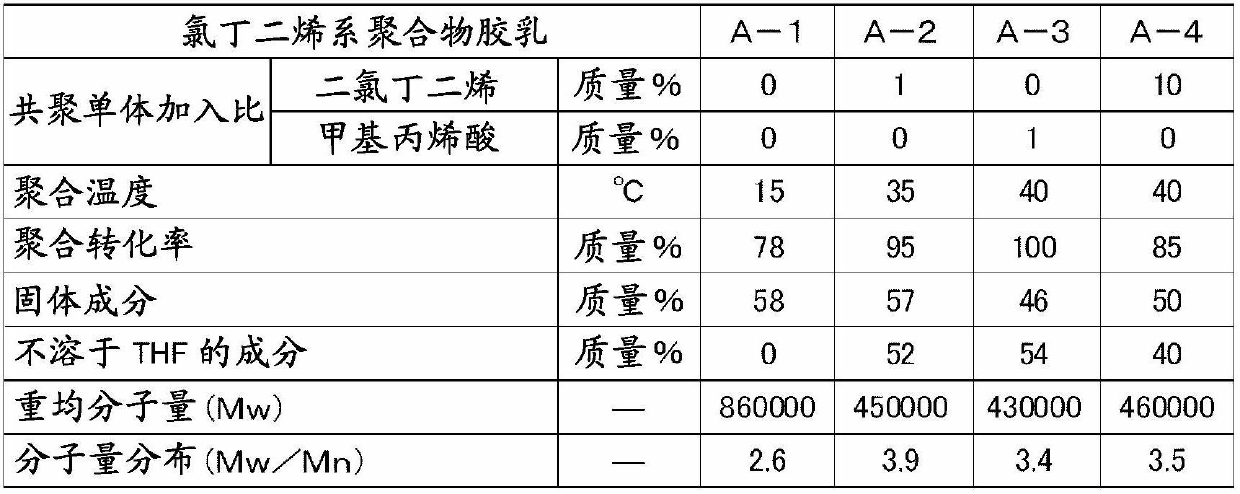

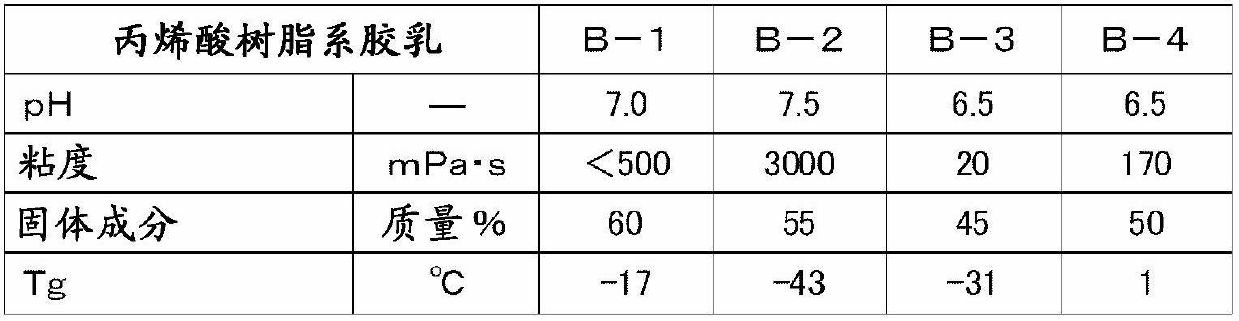

Disclosed is a chloroprene polymer latex composition for water-based one-liquid type adhesives having well-balanced initial adhesive force, contact properties, storage stability and spray coating properties, characterized by comprising 60-95 mass % (in terms of solid content) of the chloroprene polymer latex (A), 5-40 mass % (in terms of solid content) of an acrylic resin latex (B) containing an acrylic polymer having a glass transition temperature of −50 to 0° C., and 0.02-5 parts by mass (in terms of solid content), per 100 parts by mass (containing water) of the sum of said chloroprene polymer latex (A) and said acrylic resin latex (B), of a surfactant (C) represented by general formula (1): RO—(CH2CH2O)n—SO3M(1) wherein R represents an aliphatic alkyl group having 5 to 20 carbon atoms on average; M represents sodium or ammonium; and n (average) is from 2 to 60.

Owner:SHOWA DENKO KK

Ccoal-winning machine low-smoke low-halogen screening rubber cover flexible cable

InactiveCN101168604AImprove flame retardant performanceFlexible cablesFlexible conductorsEngineeringChlorinated paraffins

The invention relates to a low-smoke and low-halogen shielded rubber-sheathed flexible cable for a coal mining machine. A low-smoke and low-halogen shielded rubber-sheathed flexible cable for coal mining machines, including a rubber sheath made of chloroprene polymer as the main material; zinc oxide or magnesium oxide, 2246 parts of anti-aging agent, protective agent, hard Fatty acid, paraffin wax, chlorinated paraffin wax, HZR-2 flame retardant, white carbon black, sunfast yellow, silane. The cable of the present invention is greatly reduced by burning rate (only about 20% of the original mining cable), and the amount of smoke and the amount of HCL gas released by the burning of the outer sheath rubber of itself are very low (about 10 %), which is only about 20% of the amount of smoke released by the combustion of the original flame-retardant mine cable. Release 10% of the volume of HCL gas. The concentration of smog HCL gas in the entire environmental space of the fire is even lower. From this point of view, it is a reliable guarantee to improve the safety and reliability of cables used in underground coal mines, reduce the degree of fire hazards, and prevent accidents caused by cables.

Owner:上海胜华电缆厂有限公司

Chloroprene polymer latex composition and use thereof

ActiveCN102666708AFast crystallizationDoes not reduce storage stabilityEster polymer adhesivesChloroprene adhesivesWater basedAdhesive

Owner:RESONAC CORPORATION

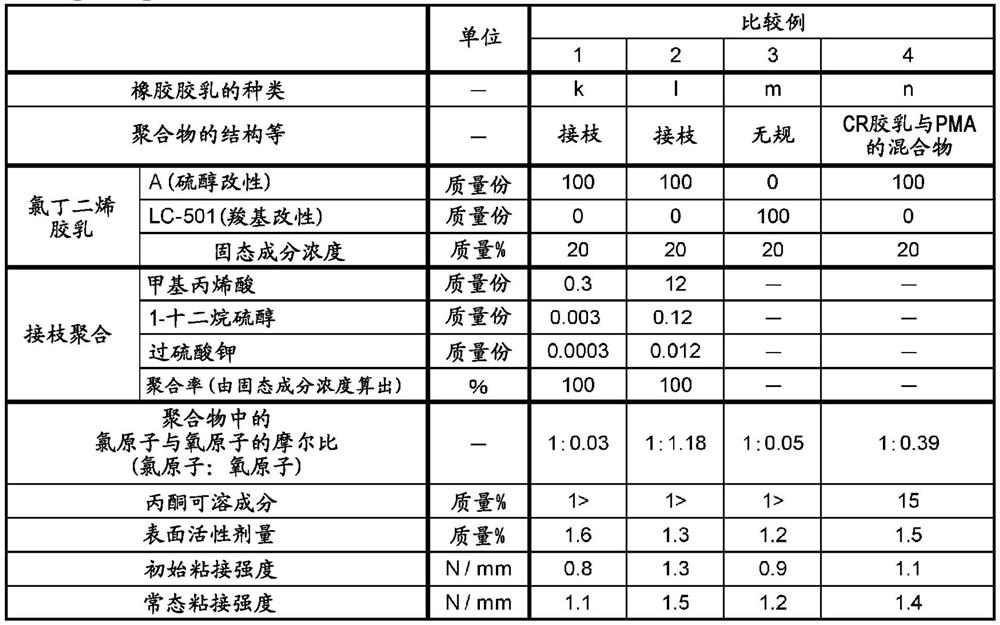

Chloroprene graft copolymer latex, method for producing same, bonding agent and adhesive

ActiveUS20190169344A1High bonding strengthGraft polymer adhesivesChloroprene adhesivesMethacrylateMeth-

Provided is a method for producing a chloroprene graft copolymer latex containing no organic solvent and exhibiting high adhesive strength even for soft polyvinyl chloride. A method for producing a chloroprene graft copolymer latex includes a chloroprene polymerization step of giving a chloroprene polymer latex and a graft copolymerization step of giving a chloroprene graft copolymer latex. The chloroprene polymerization step is a step of subjecting at least chloroprene (A-1) of chloroprene (A-1) and a monomer (A-2) copolymerizable with chloroprene (A-1) to emulsion radical polymerization. The graft copolymerization step is a step of adding, to the chloroprene polymer latex, a (meth)acrylate (B) and an organic peroxide (C) having an octanol / water partition coefficient of −2.0 or more and 3.0 or less to subject the chloroprene polymer to graft copolymerization with the (meth)acrylate (B) at a temperature of 10° C. or more and 40° C. or less.

Owner:RESONAC CORP

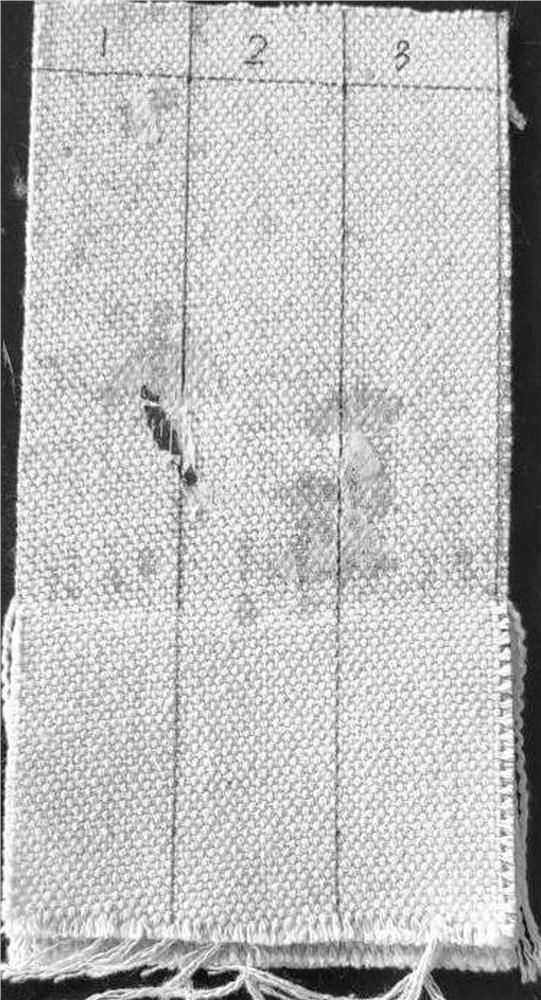

Chloroprene rubber composition and adhesive composition using said chloroprene rubber composition

ActiveUS20160017130A1Excellent discoloration resistanceSimple methodGraft polymer adhesivesChloroprene adhesivesPolymer scienceButadiene Dioxide

An object of the invention is to provide a chloroprene polymer composition resistant to discoloration under heat or light. Provided is a chloroprene rubber composition, prepared by carrying out emulsion polymerization in the presence of 0.5 to 7.0 parts by mass of a rosin acid salt as emulsifier and terminating the emulsion polymerization by addition of a polymerization inhibitor and a phosphorus- or phenol-based compound as antioxidant. It is possible according to the invention to obtain a chloroprene polymer composition superior in discoloration resistance under heat or light. The chloroprene polymer composition according to the present invention can be used favorably for adhesion of cloths, leathers, foamed sheets, papers, woods, shoe parts, and others.

Owner:DENKA CO LTD

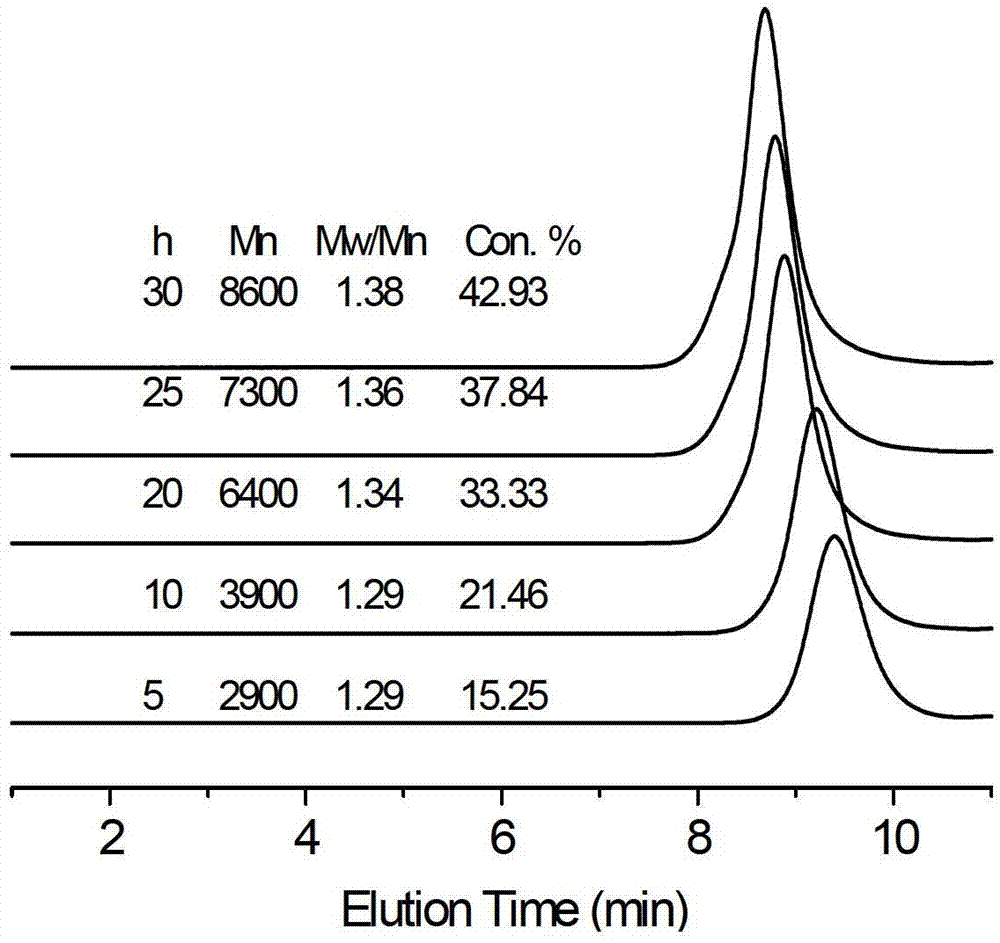

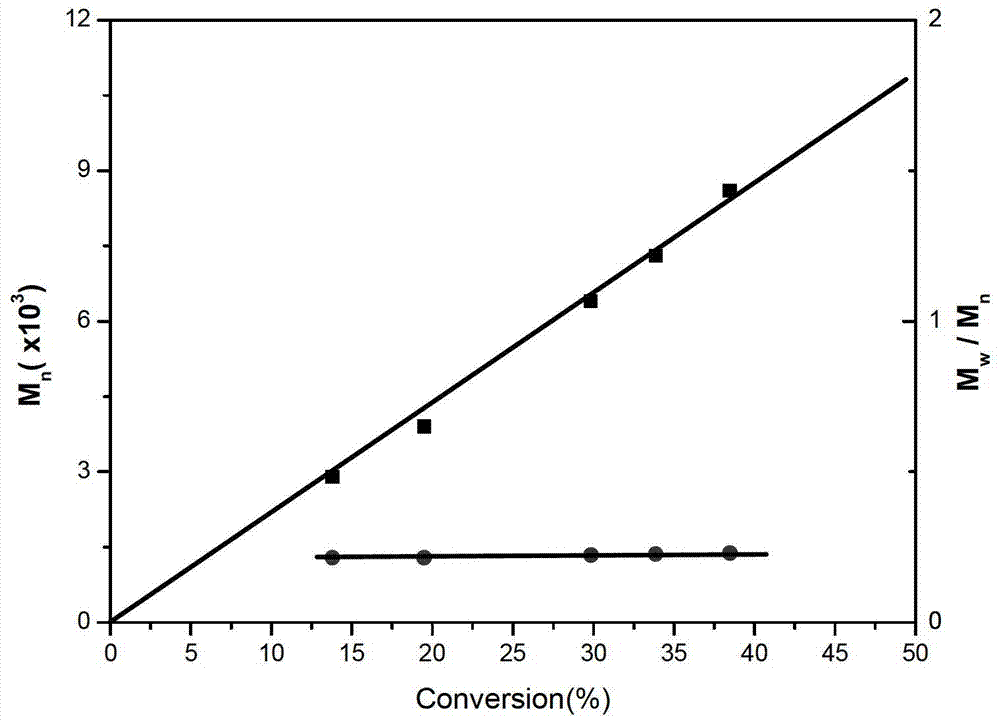

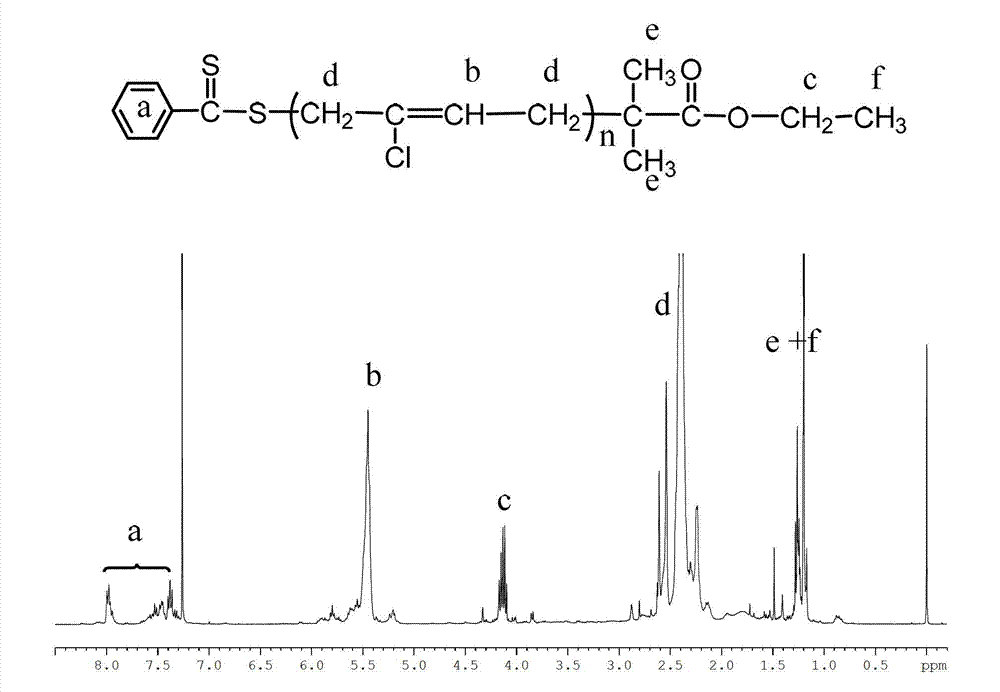

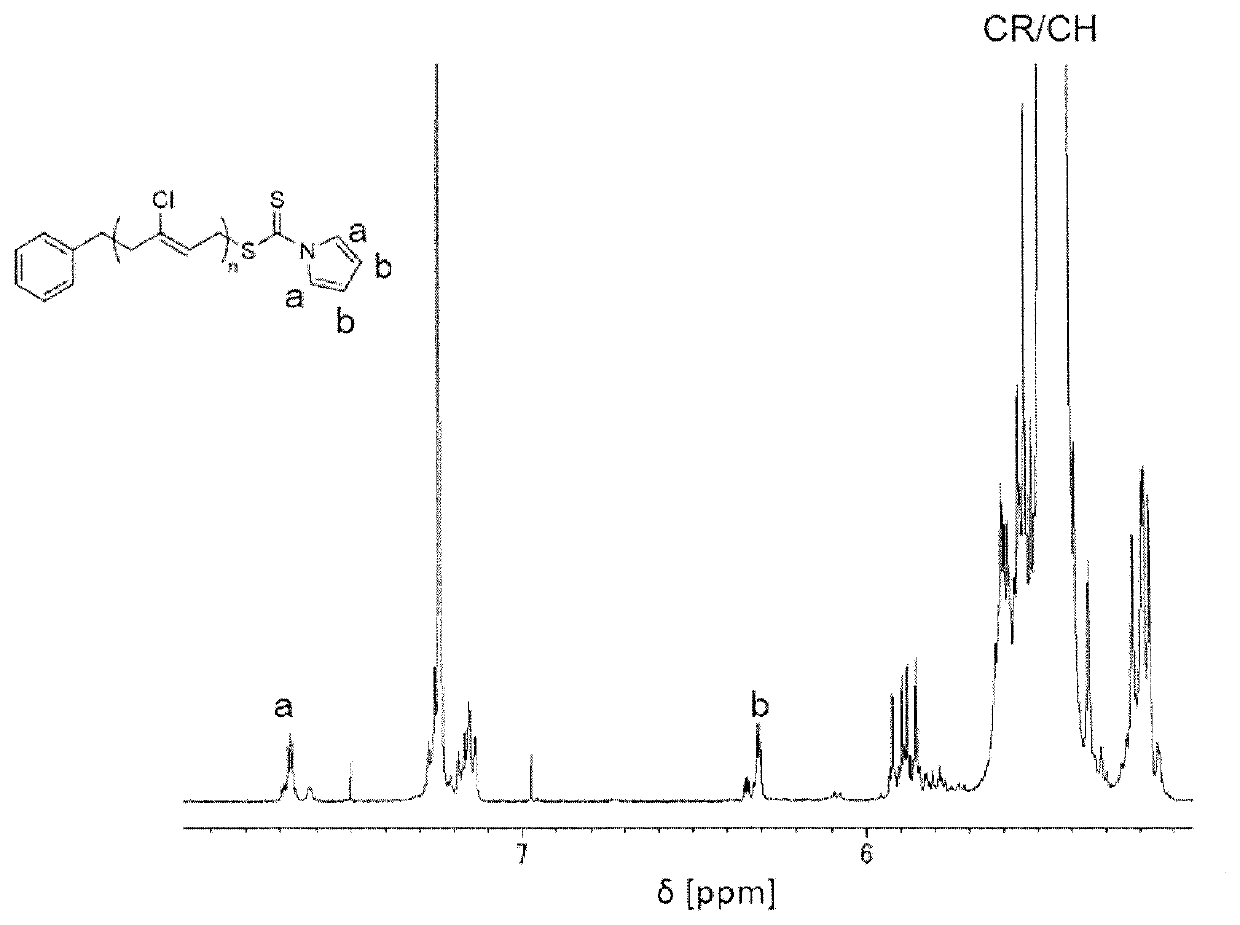

Chloroprene 'activity'/controllable radical polymerization method

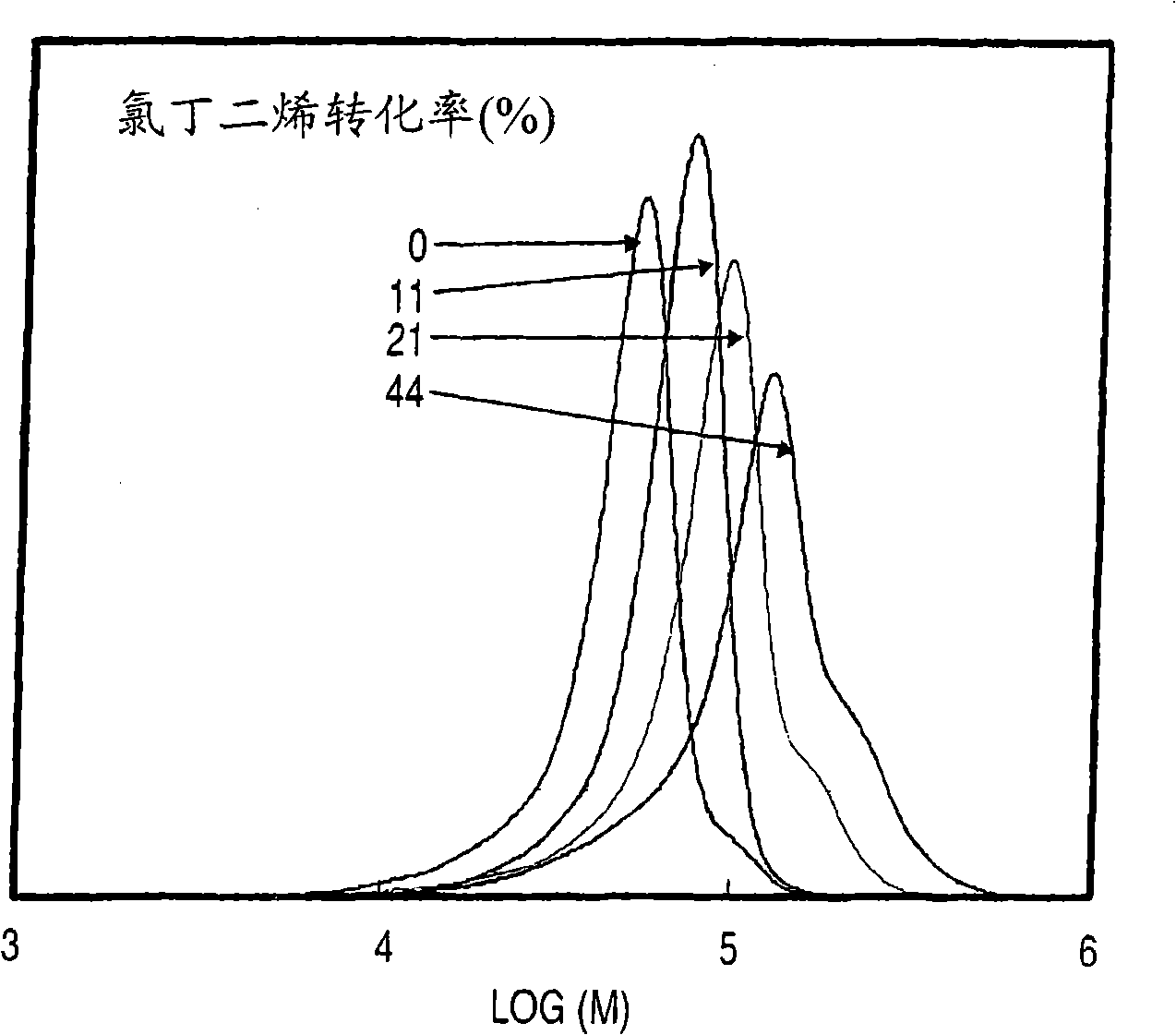

A chloroprene 'activity' / controllable radical polymerization method is used for preparing polychloroprene controllable in molecular weight and narrow in molecular weight distribution. RAFT (reversible addition-fragmentation chain transfer) reagents serve as chain transfer agents to be used for chloroprene polymerization at the temperature of 30-70 DEG C, so that living polymerization of the chloroprene is realized. The molecular size of a polymerization product is adjusted by changing feed ratio of raw materials or controlling polymerization time, so that the chloroprene polymer molecular weight is accurately controlled, polymer is narrow in molecular weight distribution (PDI 1.4), and the actual molecular weight of the polymer is consistent with the theoretical polymer. A molecular chain of the chloroprene polymer generated in polymerization has an active end of an RAFT capped structure, and accordingly, the chloroprene polymer can continue to serve as macromolecular chain transfer agents and continue to transfer and initiate polymerization of a second monomer to prepare a block polymer.

Owner:BEIJING UNIV OF CHEM TECH

Chloroprene polymer latex and process for producing the same

ActiveUS20100010136A1Improve initial viscosityNarrow molecular weight distributionSpecial tyresInksPolymer adhesiveHeat resistance

A latex of a chloroprene polymer formed from one or more monomers comprising 2-chloro-1,3-butadiene as the main monomer ingredient, characterized in that the solid matter in the polymer latex has a gel content less than 3 mass %, the solid matter in the polymer latex includes a tetrahydrofuran-soluble component having a weight-average molecular weight of from 550,000 to 1,100,000 and a molecular-weight distribution (Mw / Mn) of from 2.0 to 3.1, and the dried solid matter in the polymer latex has a crystallization rate (R) represented by hardness increase at −10° C. (R is the time required for initial hardness (time=0) to increase by 30 points at −10° C. as measured according to JIS-K6301) less than 60 minutes. The chloroprene polymer latex has an excellent balance among initial bond strength, contact adhesion, and water resistance. This latex is useful as an adhesive and can be used in applications where heat resistance of 60° C. or higher, initial bond strength, and contact adhesion are required.

Owner:RESONAC CORP

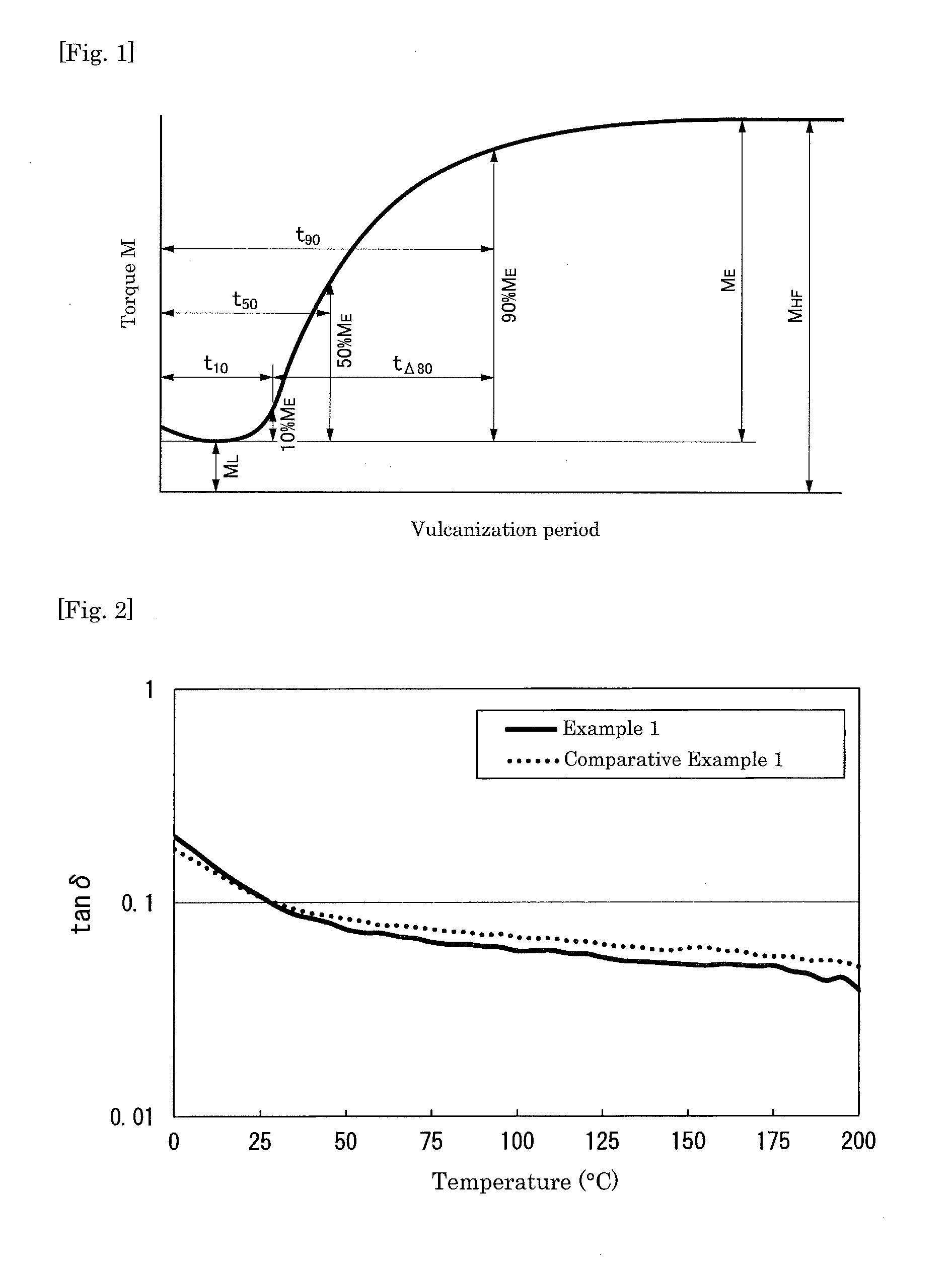

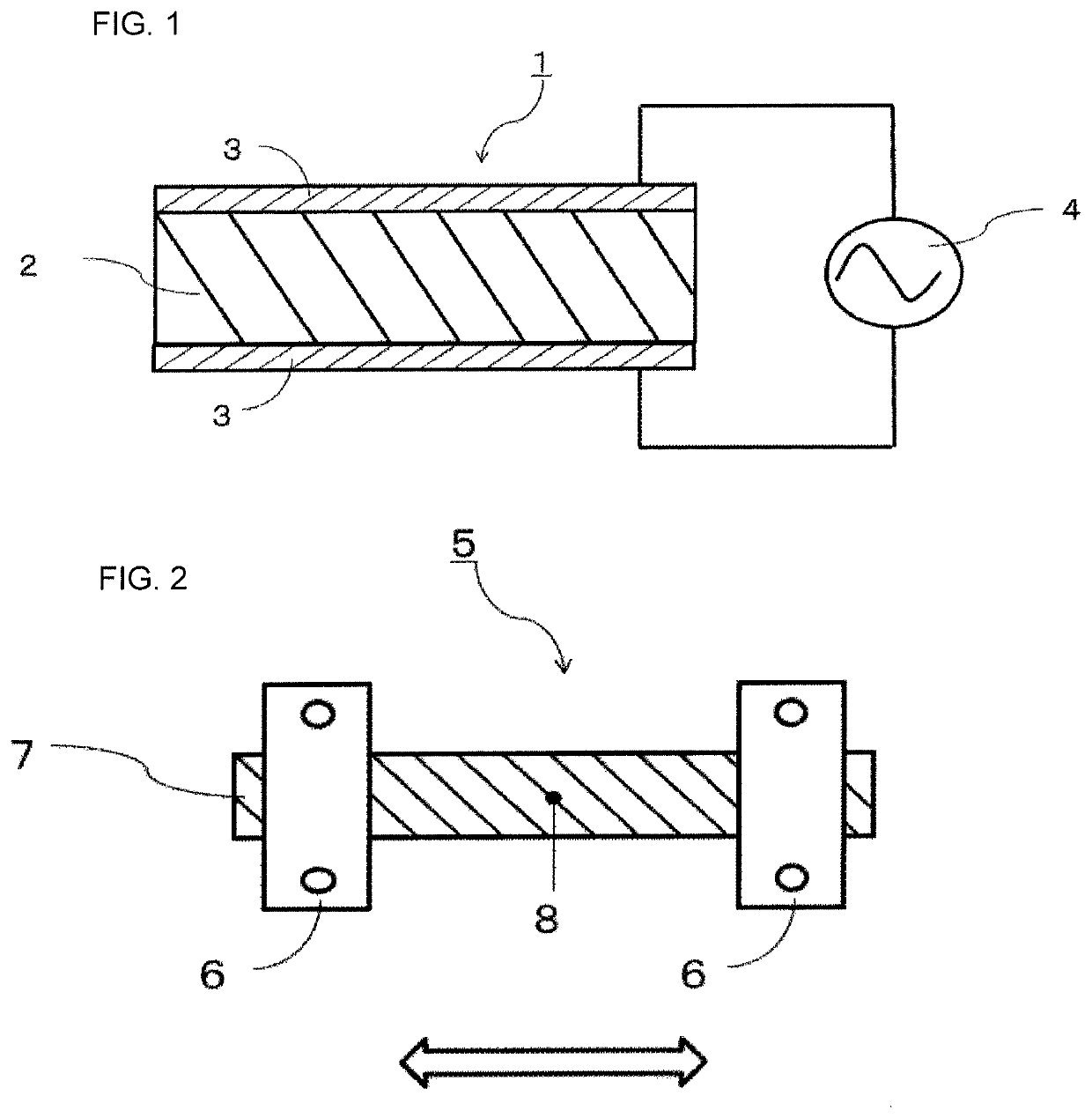

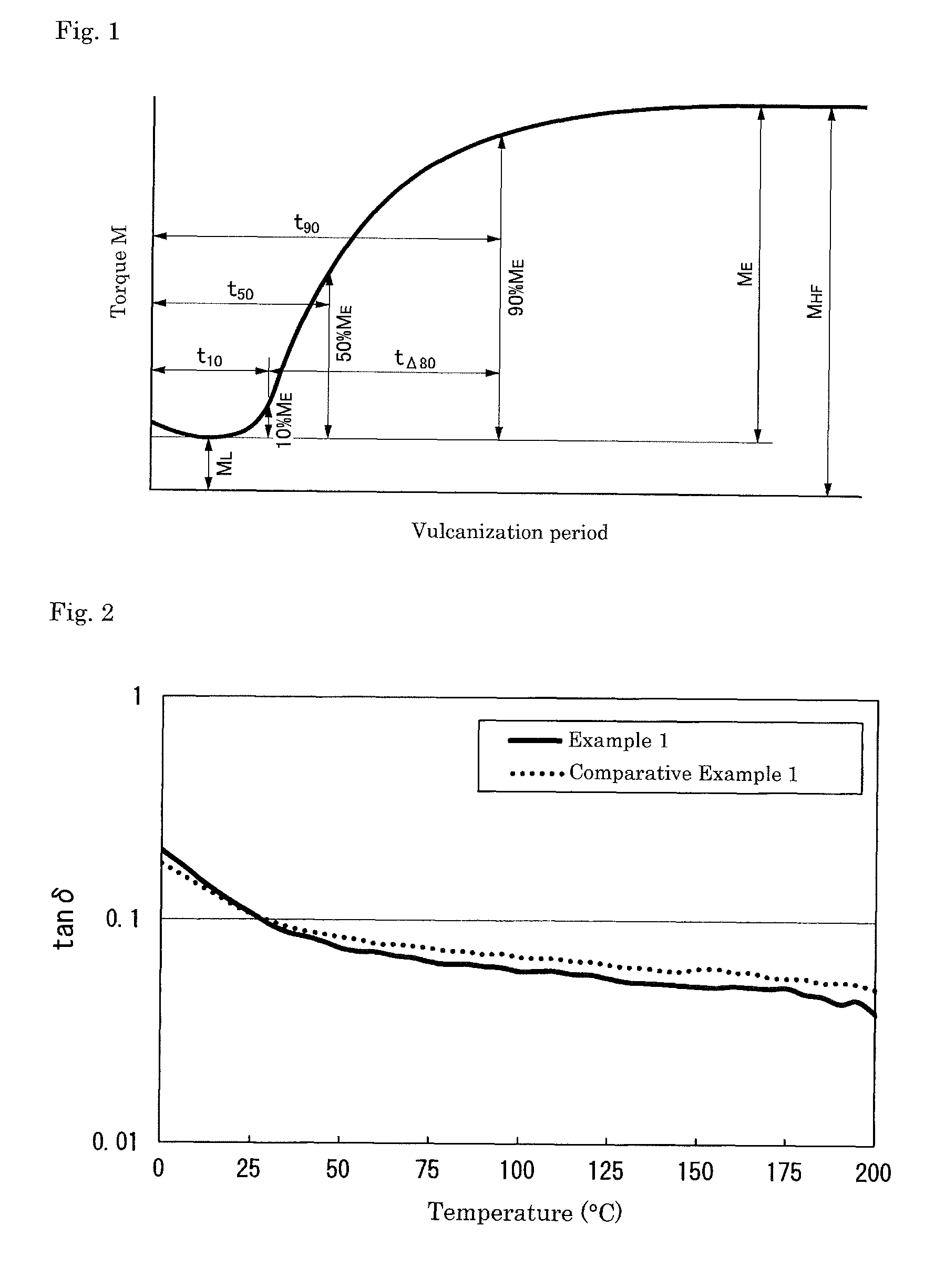

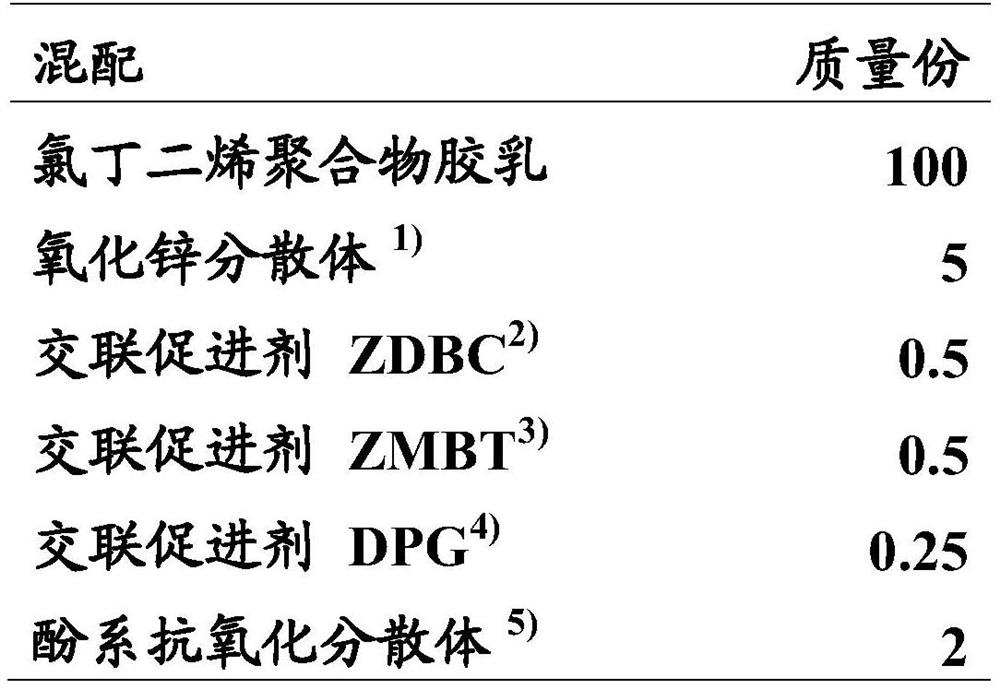

Vulcanizate and process for producing same

Provided are a vulcanizate of a chloroprene rubber composition containing carbon black that generates a smaller amount of heat when used and a method for producing the same by a simpler and more convenient method. First, an unvulcanized rubber composition at least containing a chloroprene polymer and carbon black is vulcanization-molded, to give a semivulcanized molded article having a cure characteristic value, as determined by the method specified in JIS K6300-2: 2001, in the range of t10 to t80. Then, the semivulcanized molded article obtained by semivulcanized film-forming step is additionally vulcanized in the state as it is deformed entirely and the deformation is removed, to give vulcanizate in a desired shape.

Owner:NAT UNIV CORP NAGAOKA UNIV TECH +1

Chloroprene rubber composition and adhesive composition using said chloroprene rubber composition

ActiveUS9328228B2Excellent discoloration resistanceSimple methodGraft polymer adhesivesChloroprene adhesivesPolymer scienceAntioxidant

An object of the invention is to provide a chloroprene polymer composition resistant to discoloration under heat or light. Provided is a chloroprene rubber composition, prepared by carrying out emulsion polymerization in the presence of 0.5 to 7.0 parts by mass of a rosin acid salt as emulsifier and terminating the emulsion polymerization by addition of a polymerization inhibitor and a phosphorus- or phenol-based compound as antioxidant. It is possible according to the invention to obtain a chloroprene polymer composition superior in discoloration resistance under heat or light. The chloroprene polymer composition according to the present invention can be used favorably for adhesion of cloths, leathers, foamed sheets, papers, woods, shoe parts, and others.

Owner:DENKA CO LTD

Slurry for flexible electrodes, and flexible electrode using same

ActiveUS20200165469A1Electric resistance value can be suppressedChloropene polymer coatingsNon-conductive material with dispersed conductive materialPolymer scienceCarbamate

According to one of various aspects of the present invention, a slurry for a flexible electrode contains a component (a) dispersed in an aqueous emulsion. The emulsion includes one or more polymer components selected from the group consisting of acrylic polymers, urethane polymers, fluorine polymers, urea polymers, chloroprene polymers, and butadiene polymers. The emulsion has a pH of 6.5 to 8.0. In the slurry, the total of the polymer component(s) and the component (a) is 20 to 30% by mass. Of the total of the polymer component(s) and the component (a) in the slurry, the polymer component(s) is 60 to 85% by mass, and the component (a) is 15 to 40% by mass. Component (a) is carbon black having a DBP absorption amount under uncompressed conditions of 150 to 300 mL / 100 g and a BET specific surface area of 35 to 140 m2 / g.

Owner:DENKA CO LTD

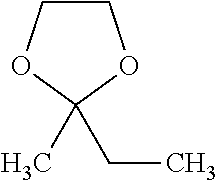

Use of a ketal as a solvent in adhesives and ketal-containing adhesive composition

InactiveUS20150152296A1High solvencyAppropriate drying timeNon-macromolecular adhesive additivesChloroprene adhesivesPolymer scienceAdhesive

The present invention relates to the use of a cyclic ketal, 2-methyl-2-ethyl-1,3-dioxolane as a solvent in adhesives, as well as an adhesive composition comprising said ketal. 2-Methyl-2-ethyl-1,3-dioxolane has high solubilization power of the polychloroprene polymer, forming solutions having high viscosity and having suitable drying time after application of a film onto a surface. Due to the good technical performance, the adhesive composition made according to the present invention is well accepted in the market, finding use to substitute compositions containing toluene or other aromatic and oxygenated solvents.

Owner:OXITENO S A IND E COMERCIO

Chloroprene latex composition, and method for its production and adhesive composition employing it

InactiveUS7030186B2Good initial adhesionBalance of heat resistance and water resistanceChloroprene adhesivesPolymer scienceHeat resistance

A chloroprene latex composition wherein the gel content of the chloroprene polymer is from 3 to 40 wt %, and the weight average molecular weight of the sol content is at least 400,000, and a chloroprene latex is presented which is excellent in the initial adhesive performance and normal adhesive performance and which has a good balance of heat resistance, water resistance, etc. with the adhesive properties.

Owner:DENKA CO LTD

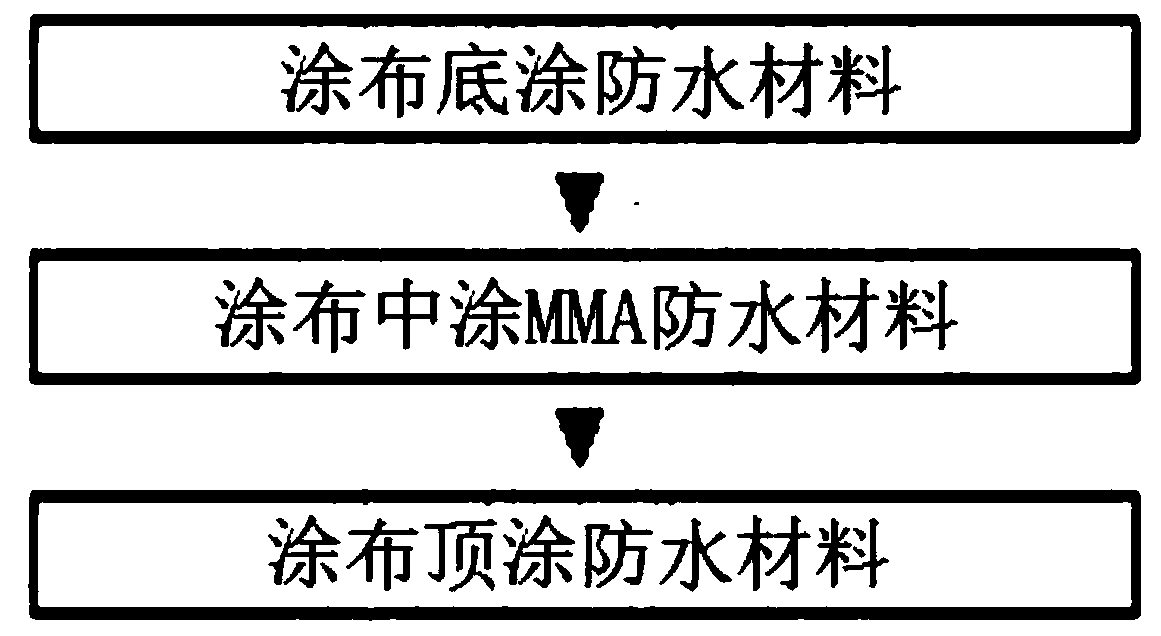

Waterproof agent for surface of bridges and process for waterproofing surface of bridges using that

ActiveCN107337992AIncreased durabilityWith waterproof functionChloropene polymer coatingsAnti-corrosive paintsBridge deckEngineering

The present invention relates to a bridge deck waterproof material and a bridge deck waterproofing method using the same. More specifically, the present invention relates to a bridge deck waterproof material and a bridge deck waterproofing method using the same, for forming a coating layer, which cures in a short time after the application of the bridge deck waterproof material, effectively bonds with the ground surface, and provides excellent durability and water resistance to the bridge deck, on concrete and steel plate bridge decks, thereby preventing deterioration of the bridge deck. The present invention comprises: a lower waterproof material, mixed with 91-95 wt% of 2-ethyl-2-(hydroxymethyl)-1,3-propanediol polymer and 5-9 wt% of admixture, and coated on the bridge deck; a middle waterproof material, mixed with 15-35 wt% of MMA resin, 32.5-42.5 wt% of calcium carbonate, 7.5-17.5 wt% of silica sand No. 3, and 20-30 wt% of silica sand No. 5, and coated on the lower waterproof material; and an upper waterproof material, mixed with 45-55 wt% of 2-chlorobutadiene polymer, 25-35 wt% of toluene or xylene, and 15-25 wt% of sprayed asphalt, and coated on the middle waterproof material.

Owner:SAM JOONG C M TECH

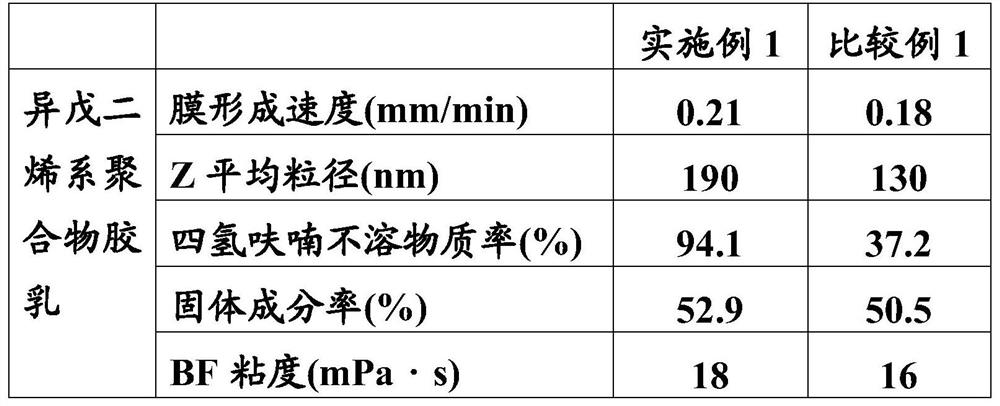

Isoprene-based polymer latex composition

PendingUS20220073657A1Improve performanceMaintains the quality of the compositionDomestic articlesCoatingsPolymer sciencePolymer adhesive

An isoprene-based polymer latex composition includes a chloroprene polymer latex (A) and an isoprene polymer latex (B), in which the chloroprene polymer has a z-average particle size of 180 nm or greater and smaller than 300 nm, and a tetrahydrofuran-insoluble fraction of 80 to 99% by mass; the chloroprene polymer latex (A) is (1) a copolymer latex of chloroprene (A-1) and 2,3-dichloro-1,3-butadiene (A-2-1), or (2) a copolymer latex of the above (A-1) and (A-2-1), and another monomer (A-2-2); and the copolymer is obtained by copolymerization in which the ratio of 2,3-dichloro-1,3-butadiene (A-2-1) is 5.0 to 30.0% by mass relative to the total amount of the monomer components chloroprene (A-1) and 2,3-dichloro-1,3-butadiene (A-2-1) of 100% by mass. The isoprene-based polymer latex composition's quality is maintained, and the properties after cross-linking of a molded product obtained by dipping a dipping former into the composition multiple times do not deteriorate.

Owner:RESONAC CORP

Use of a ketal as a solvent in adhesives and ketal-containing adhesive composition

InactiveUS9464215B2High solvencyHigh viscosityNon-macromolecular adhesive additivesChloroprene adhesivesPolymer scienceAdhesive

The present invention relates to the use of a cyclic ketal, 2-methyl-2-ethyl-1,3-dioxolane as a solvent in adhesives, as well as an adhesive composition comprising said ketal. 2-Methyl-2-ethyl-1,3-dioxolane has high solubilization power of the polychloroprene polymer, forming solutions having high viscosity and having suitable drying time after application of a film onto a surface. Due to the good technical performance, the adhesive composition made according to the present invention is well accepted in the market, finding use to substitute compositions containing toluene or other aromatic and oxygenated solvents.

Owner:OXITENO S A IND E COMERCIO

Vulcanizate and process for producing same

Provided are a vulcanizate of a chloroprene rubber composition containing carbon black that generates a smaller amount of heat when used and a method for producing the same by a simpler and more convenient method. First, an unvulcanized rubber composition at least containing a chloroprene polymer and carbon black is vulcanization-molded, to give a semivulcanized molded article having a cure characteristic value, as determined by the method specified in JIS K6300-2: 2001, in the range of t10 to t80. Then, the semivulcanized molded article obtained by semivulcanized film-forming step is additionally vulcanized in the state as it is deformed entirely and the deformation is removed, to give vulcanizate in a desired shape.

Owner:NAT UNIV CORP NAGAOKA UNIV TECH +1

Isoprene polymer latex composition

ActiveCN113260666AGuaranteed qualityImprove performanceDomestic articlesCoatingsPolymer sciencePolymer adhesive

The present invention relates to an isoprene polymer latex composition that contains a chloroprene polymer latex (A) and an isoprene polymer latex (B); the chloroprene polymer has a Z average particle size of 180 to less than 300 nm and a tetrahydrofuran-insoluble fraction of 80-99 mass%; the chloroprene polymer latex (A) is a copolymer latex of (1) chloroprene (A-1) and 2,3-dichloro-1,3-butadiene (A-2-1) or a copolymer latex of (2) the above (A-1) and (A-2-1) and another monomer (A-2-2), and the copolymer is one obtained by copolymerizing 5.0-30.0 mass% of 2,3-dichloro-1,3-butadiene (A-2-1) per a total of 100 mass% of the monomer components chloroprene (A-1) and 2,3-dichloro-1,3-butadiene (A-2-1). The present invention maintains the quality of the isoprene polymer latex composition, and the properties after crosslinking of a molded product obtained by dipping a dipping former into the composition multiple times do not decline.

Owner:RESONAC CORPORATION

Chloroprene polymer latex and process for producing the same

ActiveUS8586670B2Improve initial viscosityNarrow molecular weight distributionSpecial tyresChloroprene adhesivesPolymer adhesiveSolid matter

A latex of a chloroprene polymer formed from one or more monomers comprising 2-chloro-1,3-butadiene as the main monomer ingredient, characterized in that the solid matter in the polymer latex has a gel content less than 3 mass %, the solid matter in the polymer latex includes a tetrahydrofuran-soluble component having a weight-average molecular weight of from 550,000 to 1,100,000 and a molecular-weight distribution (Mw / Mn) of from 2.0 to 3.1, and the dried solid matter in the polymer latex has a crystallization rate (R) represented by hardness increase at −10° C. (R is the time required for initial hardness (time=0) to increase by 30 points at −10° C. as measured according to JIS-K6301) less than 60 minutes. The chloroprene polymer latex has an excellent balance among initial bond strength, contact adhesion, and water resistance. This latex is useful as an adhesive and can be used in applications where heat resistance of 60° C. or higher, initial bond strength, and contact adhesion are required.

Owner:RESONAC CORPORATION

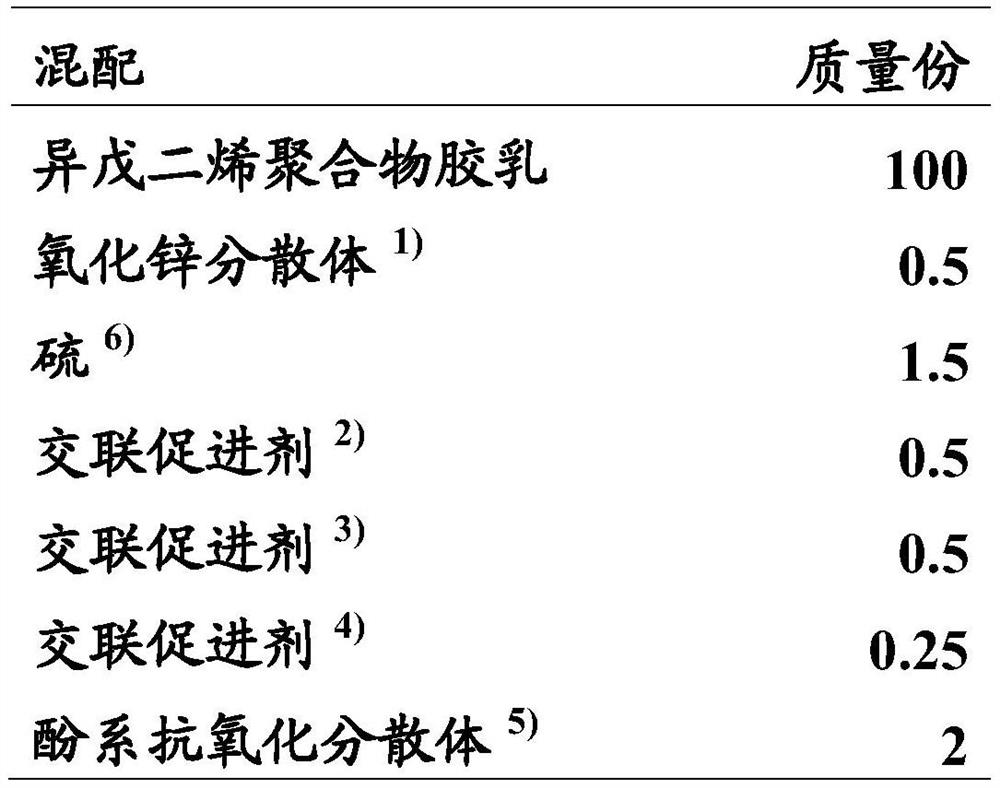

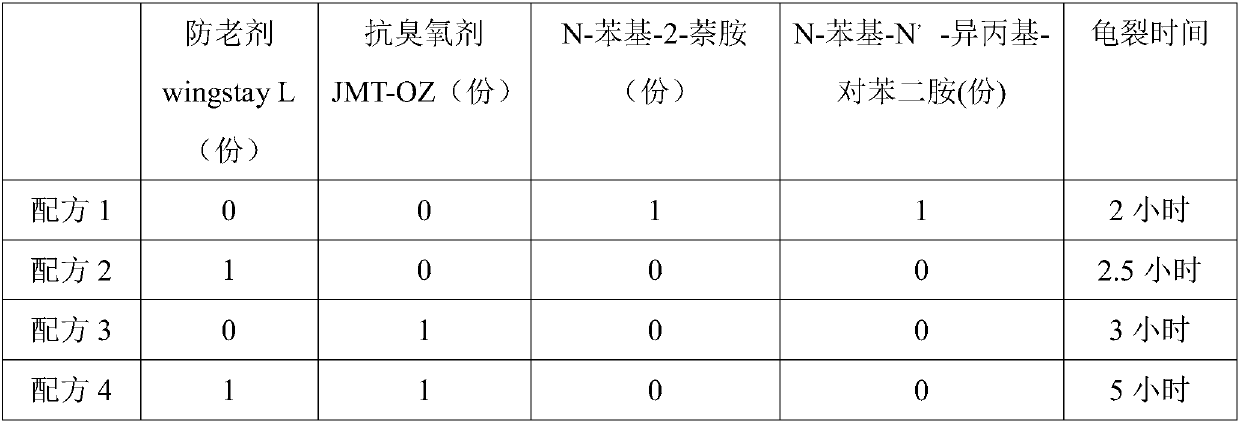

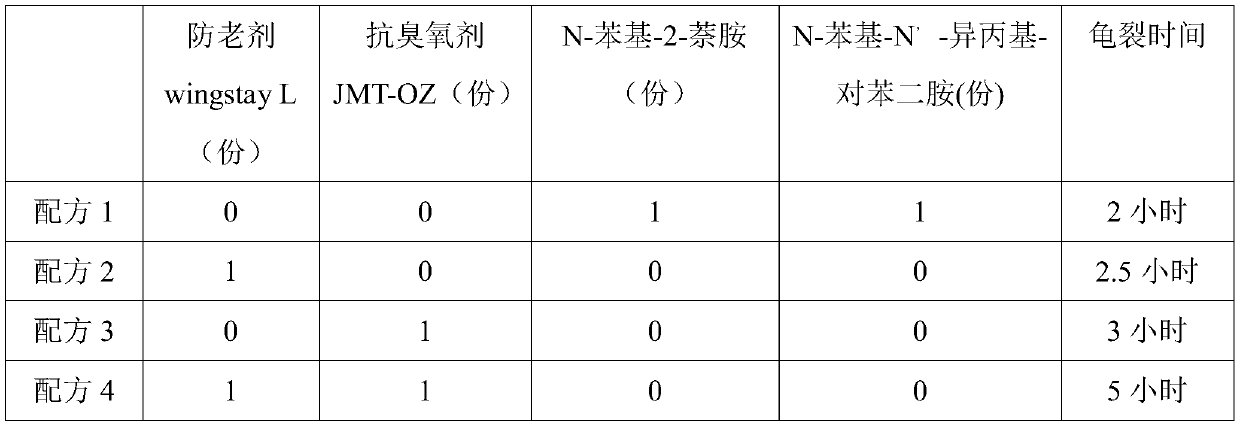

Anti-aging meteorological balloon and production method thereof

The invention relates to an anti-aging meteorological balloon and a production method thereof. Raw materials of the meteorological balloon include a solid raw material, an oily raw material and an adhesive raw material. The adhesive raw material includes 100 parts by weight of centrifugation-concentrated natural latex. The solid raw material comprises 0.05-0.6 part by weight of an aqueous solutioningredient, 4.5-15 parts by weight of an aqueous dispersion ingredient, and 5-30 parts by weight of chloroprene polymer, wherein the aqueous dispersion ingredient includes 1-2 parts of an antioxidantwingstay L and 1-2 parts of an antiozonant JMT-OZ. The meteorological balloon weighs 2900-3300 g, the length of the balloon body is 4.2-5 m, the width of the handle is 16-19 cm, and the length of thehandle is 12-16 cm. The meteorological balloon can detect meteorological factors of the upper air which is no lower than 40000 m, is excellent in aging resistance, high in lift-off height, and long in service time, and has ozone aging resistance.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

A kind of anti-aging weather balloon and production method thereof

The invention relates to an anti-aging meteorological balloon and a production method thereof. Raw materials of the meteorological balloon include a solid raw material, an oily raw material and an adhesive raw material. The adhesive raw material includes 100 parts by weight of centrifugation-concentrated natural latex. The solid raw material comprises 0.05-0.6 part by weight of an aqueous solutioningredient, 4.5-15 parts by weight of an aqueous dispersion ingredient, and 5-30 parts by weight of chloroprene polymer, wherein the aqueous dispersion ingredient includes 1-2 parts of an antioxidantwingstay L and 1-2 parts of an antiozonant JMT-OZ. The meteorological balloon weighs 2900-3300 g, the length of the balloon body is 4.2-5 m, the width of the handle is 16-19 cm, and the length of thehandle is 12-16 cm. The meteorological balloon can detect meteorological factors of the upper air which is no lower than 40000 m, is excellent in aging resistance, high in lift-off height, and long in service time, and has ozone aging resistance.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

Rubber latex and water-based adhesive composition

InactiveCN113474376AHigh initial bond strengthNon-macromolecular adhesive additivesGraft polymer adhesivesPolymer scienceActive agent

A rubber latex containing a graft copolymer and a surfactant, the rubber latex being such: that the graft copolymer has a chloroprene polymer chain, and a graft chain including structural units derived from an ethylenic unsaturated carboxylic acid, the graft chain being bonded to the chloroprene polymer chain; and the molar ratio of the oxygen atom content to the chlorine atom content in the graft copolymer is 0.04-1.

Owner:DENKA CO LTD

Bridge deck waterproof material and bridge deck waterproof construction method using it

ActiveCN107337992BIncreased durabilityWith waterproof functionChloropene polymer coatingsAnti-corrosive paintsXylyleneBridge deck

The present invention relates to a bridge deck waterproof material and a bridge deck waterproofing method using the same. More specifically, the present invention relates to a bridge deck waterproof material and a bridge deck waterproofing method using the same, for forming a coating layer, which cures in a short time after the application of the bridge deck waterproof material, effectively bonds with the ground surface, and provides excellent durability and water resistance to the bridge deck, on concrete and steel plate bridge decks, thereby preventing deterioration of the bridge deck. The present invention comprises: a lower waterproof material, mixed with 91-95 wt% of 2-ethyl-2-(hydroxymethyl)-1,3-propanediol polymer and 5-9 wt% of admixture, and coated on the bridge deck; a middle waterproof material, mixed with 15-35 wt% of MMA resin, 32.5-42.5 wt% of calcium carbonate, 7.5-17.5 wt% of silica sand No. 3, and 20-30 wt% of silica sand No. 5, and coated on the lower waterproof material; and an upper waterproof material, mixed with 45-55 wt% of 2-chlorobutadiene polymer, 25-35 wt% of toluene or xylene, and 15-25 wt% of sprayed asphalt, and coated on the middle waterproof material.

Owner:SAM JOONG C M TECH

Sulfur-modified chloroprene rubber composition, vulcanized product, molded article using said vulcanized product and method for producing sulfur-modified chloroprene rubber composition

Provided is a technology for producing a sulfur-modified chloroprene rubber which has excellent compression set and excellent wear resistance, while being reduced in heat generation. Provided is a sulfur-modified chloroprene rubber composition that is obtained by having a sulfur-modified chloroprene rubber, which contains at least a sulfur-modified chloroprene polymer and an emulsifying agent, contain a sulfenamide which may have an arbitrary substituent in an amount of 0.0005-0.01 part by mass per 100 parts by mass of the sulfur-modified chloroprene rubber.

Owner:DENKA CO LTD

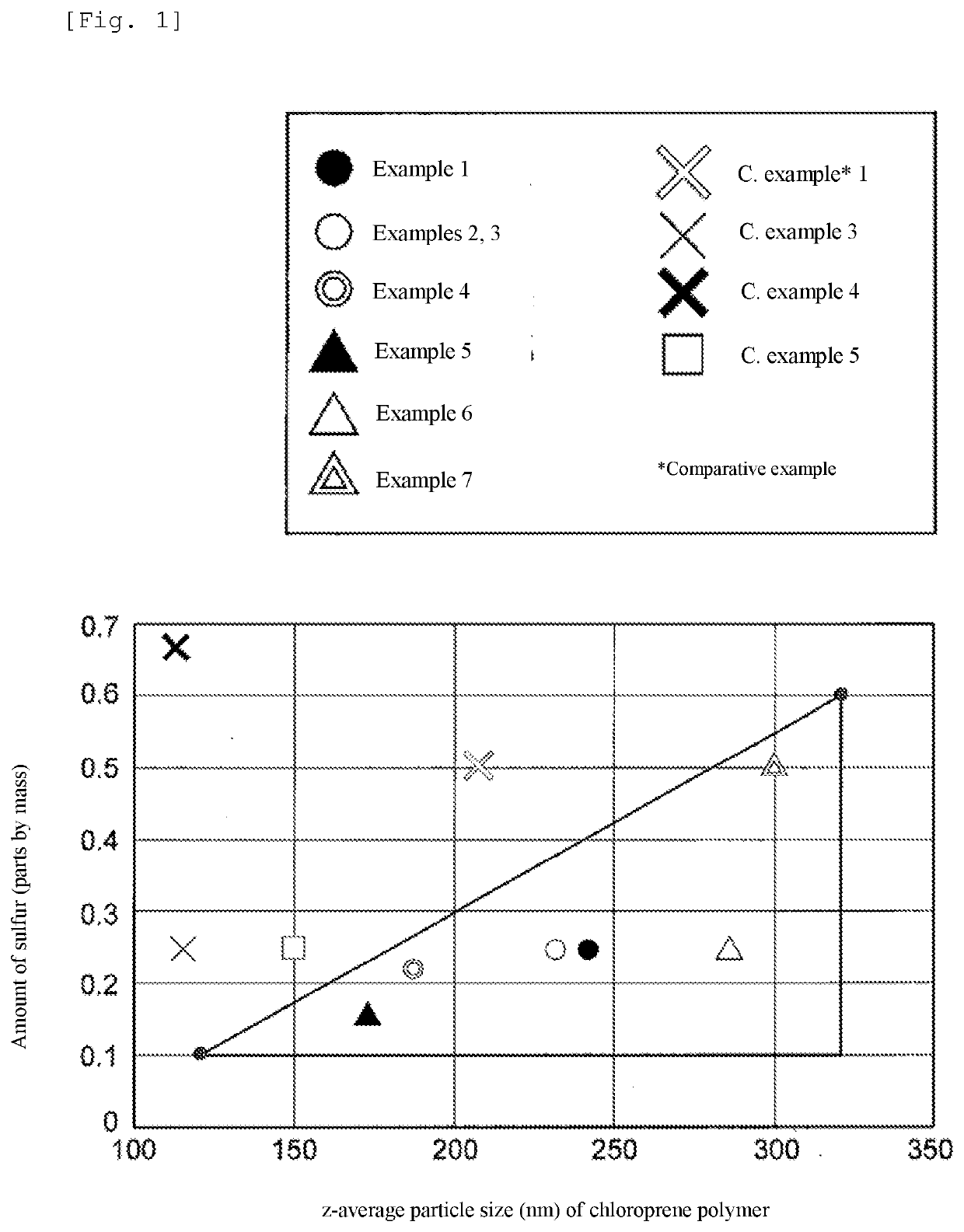

Chloroprene polymer latex and method for producing same

PendingUS20220162427A1Polymer degradation is suppressedMaintain physical propertiesGlovesPolymer sciencePolymer chemistry

A sulfur-modified chloroprene polymer latex includes an emulsifier and a sulfur-modified chloroprene polymer obtained by modifying a chloroprene polymer (A) with sulfur (B), wherein the sulfur amount Y in the sulfur-modified chloroprene polymer and the z-average particle size X of the sulfur-modified chloroprene polymer satisfy formulae (1) to (3) (formula (1): 0.10<Y<0.60; formula (2): 120<X<320; and formula (3): Y<0.0025X−0.20), the total amount of a chloroprene monomer (A-1) and a monomer (A-2) copolymerizable with the chloroprene monomer which constitute the chloroprene polymer is 100 parts by mass, the amount of sulfur (B) contained in the sulfur-modified chloroprene polymer is Y parts by mass, and the z-average particle size of the sulfur-modified chloroprene polymer is X nm. The sulfur-modified chloroprene polymer latex composition can also include a metal oxide (C), a cross-linking accelerator (D), and an antioxidant (E).

Owner:SHOWA DENKO KK

Method for producing chloroprene polymer latex

The present invention relates to a method for producing a chloroprene polymer latex, comprising: adding (B) a sodium. salt of a naphthalene sulfonate formaldehyde condensate and. (C) sodium dodecylbenzenesulfonate to a monomer solution that contains (A-1) 2-chloro-1,3-butadiene (chloroprene) or a monomer solution that contains (A-1) 2-chloro-1,3-butadiene (chloroprene) and (A-2-1) 2,3-dichloro-1,3-butadiene, and performing polymerization. Consequently, the present invention enables the production of a chloroprene polymer latex which is suppressed in aggregates that are generated during the production of a chloroprene polymer latex having a high solid content.

Owner:RESONAC CORP

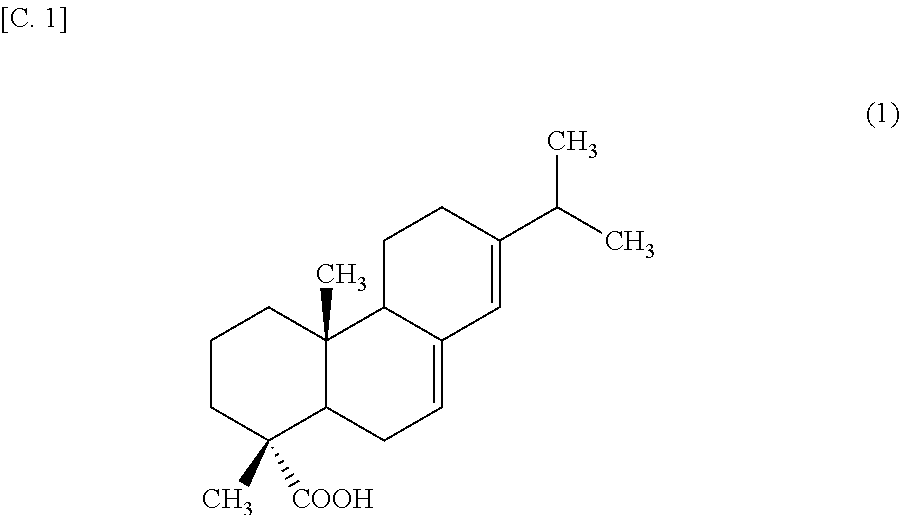

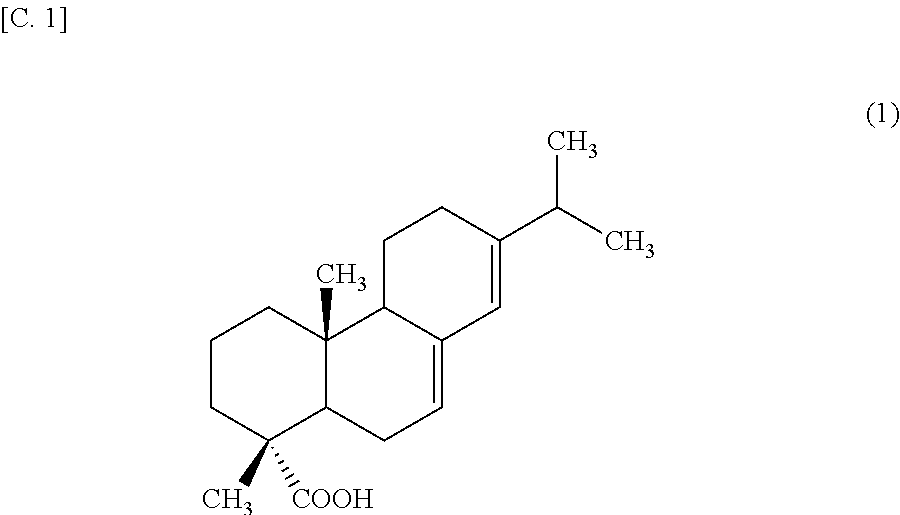

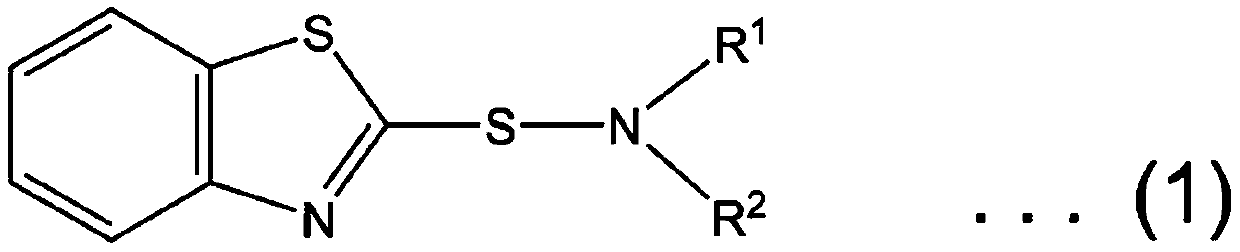

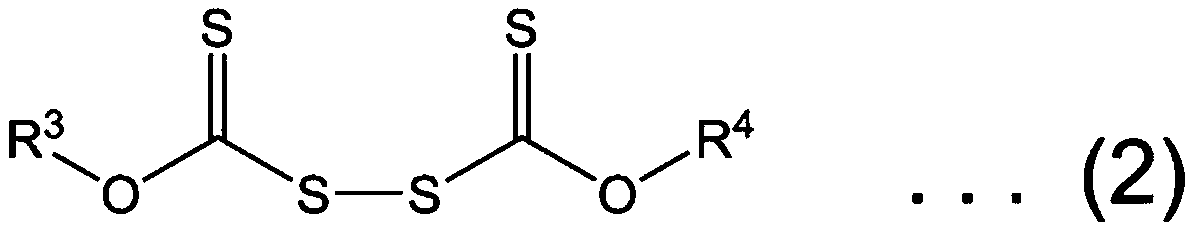

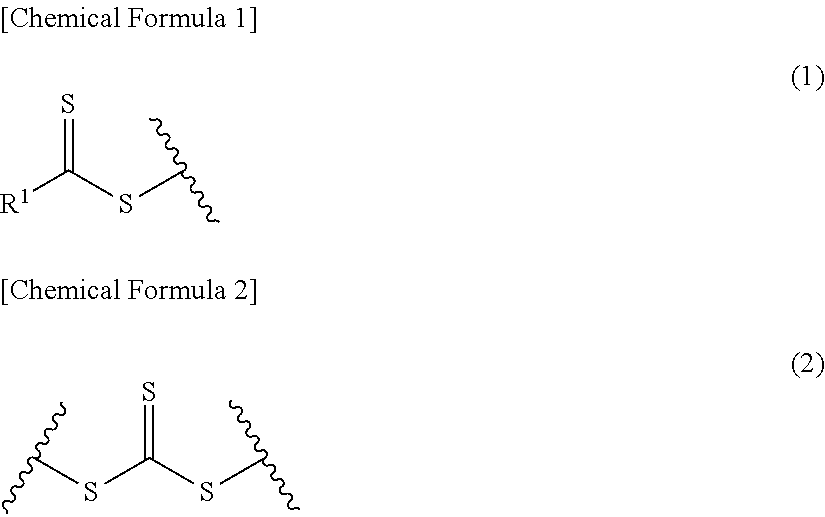

Chloroprene polymer and production method therefor

ActiveUS11254807B2Increased durabilityImprove fatigueHalogen rubber derivative adheisvesChloroprene adhesivesArylPolymer science

Provided is a chloroprene-based polymer having an industrially applicable sufficient molecular weight and capable of obtaining a vulcanized rubber excellent in durability and fatigue endurance and an adhesive excellent in layer separation resistance. A chloroprene-based polymer having a number average molecular weight Mn of 150000 to 300000 and comprising a functional group of a structure represented by the general formula (1) or (2) below:(wherein in the general formula (1), R1 shows hydrogen, chlorine, a substituted or unsubstituted alkyl group, a substituted or unsubstituted alkenyl group, a substituted or unsubstituted aryl group, or a substituted or unsubstituted heterocyclyl group.)

Owner:DENKA CO LTD

Preparation method of chloroprene and methyl methacrylate copolymer

The invention belongs to the technical field of chloroprene rubber preparation, provides a preparation method of a chloroprene and methyl methacrylate copolymer, and aims to solve the problem that two monomers of chloroprene and methyl methacrylate (MMA) are difficult to polymerize, wherein MMA is introduced into polychloroprene in a chloroprene emulsion polymerization process, so that the purpose of modification by using a second monomer is achieved. According to the method, a chloroprene monomer and MMA are copolymerized, the MMA is introduced into polychloroprene macromolecules in a polymerization reaction stage, the chloroprene monomer is partially homopolymerized at low temperature to form a structure based on polychloroprene, then the system is heated to 70-80 DEG C, and an oil-soluble initiator is added, so that the MMA is initiated to react, and finally a product modified by the MMA is obtained. According to the invention, the obtained product takes a chloroprene polymer macromolecular structure as a main body, and an MMA polymer is introduced, so that the product has higher affinity when being in contact with cotton, leather, PVC (Polyvinyl Chloride) and the like so as to obtain better adhesive property.

Owner:SHANNA SYNTHETIC RUBBER

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com