Preparation method of chloroprene and methyl methacrylate copolymer

A technology of methyl methacrylate and chloroprene, which is applied in the field of preparation of chloroprene and methyl methacrylate copolymers, and can solve problems such as difficult polymerization of monomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: A copolymer of chloroprene and methyl methacrylate, wherein the oil phase: 380g of chloroprene, 56g of MMA, 0.4g of DDM; the water phase: 587g of water, 2.2g of sodium hydroxide, 16g of H95 , 1.6g of anhydrous sodium sulfite, 15g of sodium soap.

[0021] The oil phase and the water phase are prepared according to the formula. After the oil phase and the water phase are completely dissolved, emulsify and emulsify at 25-28°C for 25-30 minutes. After emulsification, add 2.5ml of diethanolamine DEA solution, within 10-30 minutes Heat to 35-38°C, then continuously add 3.5% aqueous initiator potassium persulfate solution. After adding the initiator, at the beginning of the initiation reaction, the temperature of the jacket is lowered to control the reaction temperature at 39-41°C, and the specific gravity reaches d 4 40 After -1.035, heat up to 45-48°C and continue to react until the specific gravity is d 4 50 —1.060; then heat up to 70-80°C, add 16% Na 2 SO ...

Embodiment 2

[0026] Example 2: A copolymer of chloroprene and methyl methacrylate, wherein, the oil phase: 380g of chloroprene, 106g of MMA, 0.55g of DDM; the water phase: 587g of water, 2.2g of sodium hydroxide, 18g of H95 , 1.6g of anhydrous sodium sulfite, 15g of sodium soap.

[0027] Operation method is the same as embodiment 1. Take a certain quality of emulsion, add enough methanol, precipitate solids and air-dry them at room temperature for 24 hours; vacuum-dry them at 70°C until constant, and convert to get the total solids.

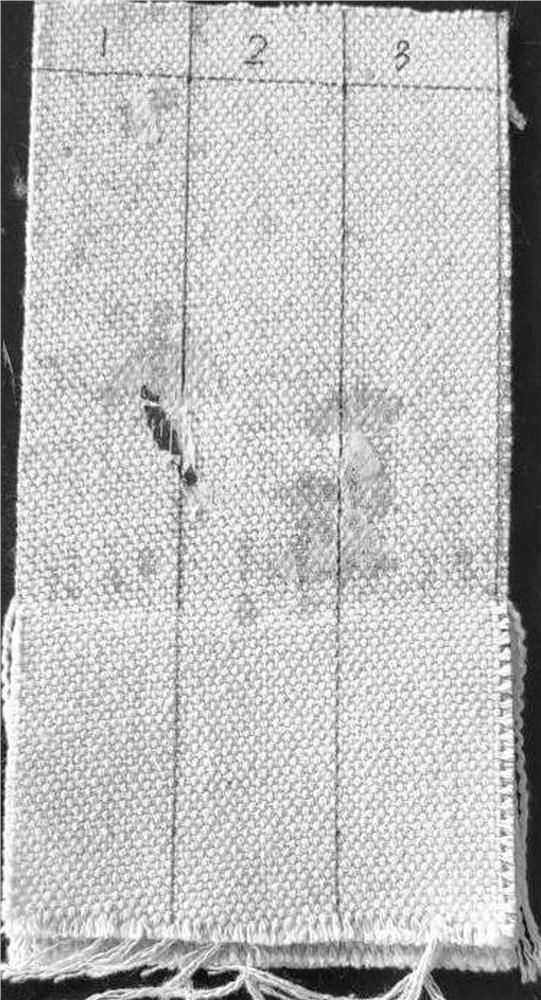

[0028] The obtained precipitate contains MMA homopolymer, non-copolymerized chloroprene rubber (CR) and a copolymer of chloroprene and MMA. Dry the precipitate and take a dry sample (W 0 ) is cut into tiny shapes and placed in the filter cloth of the Soxhlet extractor, heated to boiling with acetone, repeatedly extracting the MMA homopolymer in the sediment by reflux, continuous extraction for 72h, and taking out the separated solid in the filter cloth, Fi...

Embodiment 3

[0029]Example 3: A copolymer of chloroprene and methyl methacrylate, wherein the oil phase: 380g of chloroprene, 156g of MMA, 0.7g of DDM; the water phase: 587g of water, 2.2g of sodium hydroxide, 20g of H95 , 1.6g of anhydrous sodium sulfite, 15g of sodium soap.

[0030] Operation method is the same as embodiment 1. Take a certain quality of emulsion, add enough methanol, precipitate solids and air-dry them at room temperature for 24 hours; vacuum-dry them at 70°C until constant, and convert to get the total solids.

[0031] The obtained precipitate contains MMA homopolymer, non-copolymerized chloroprene rubber (CR) and a copolymer of chloroprene and MMA. Dry the precipitate and take a dry sample (W 0 ) is cut into tiny shapes and placed in the filter cloth of the Soxhlet extractor, heated to boiling with acetone, repeatedly extracting the MMA homopolymer in the sediment by reflux, continuous extraction for 72h, and taking out the separated solid in the filter cloth, First...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com