Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

119 results about "Ball bearing motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A ball bearing motor is an unusual electric motor that consists of two ball-bearing-type bearings, with the inner races mounted on a common conductive shaft, and the outer races connected to a high current, low voltage power supply. An alternative construction fits the outer races inside a metal tube, while the inner races are mounted on a shaft with a non-conductive section (e.g. two sleeves on an insulating rod). This method has the advantage that the tube will act as a flywheel. The direction of rotation is determined by the initial spin which is usually required to get it going.

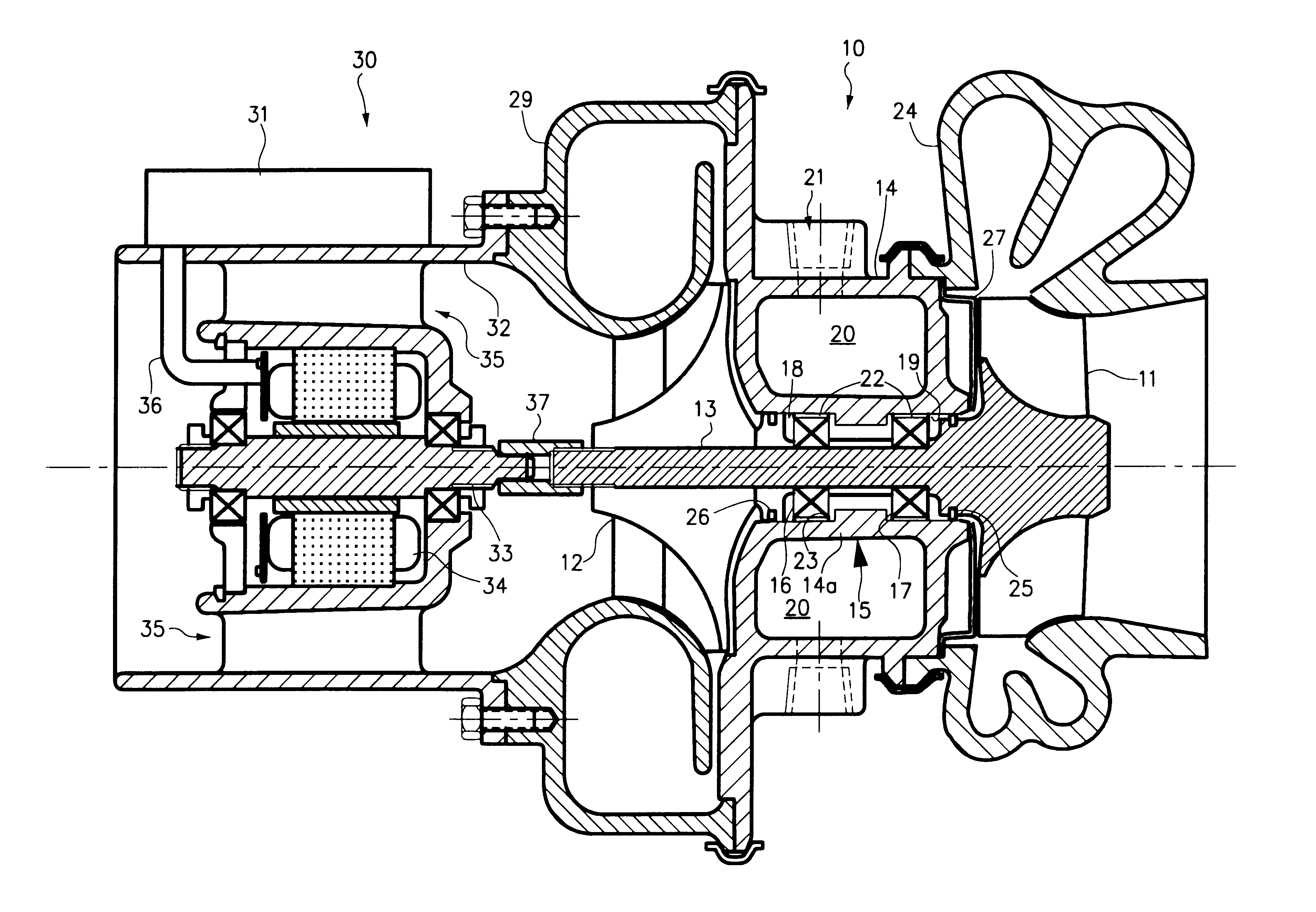

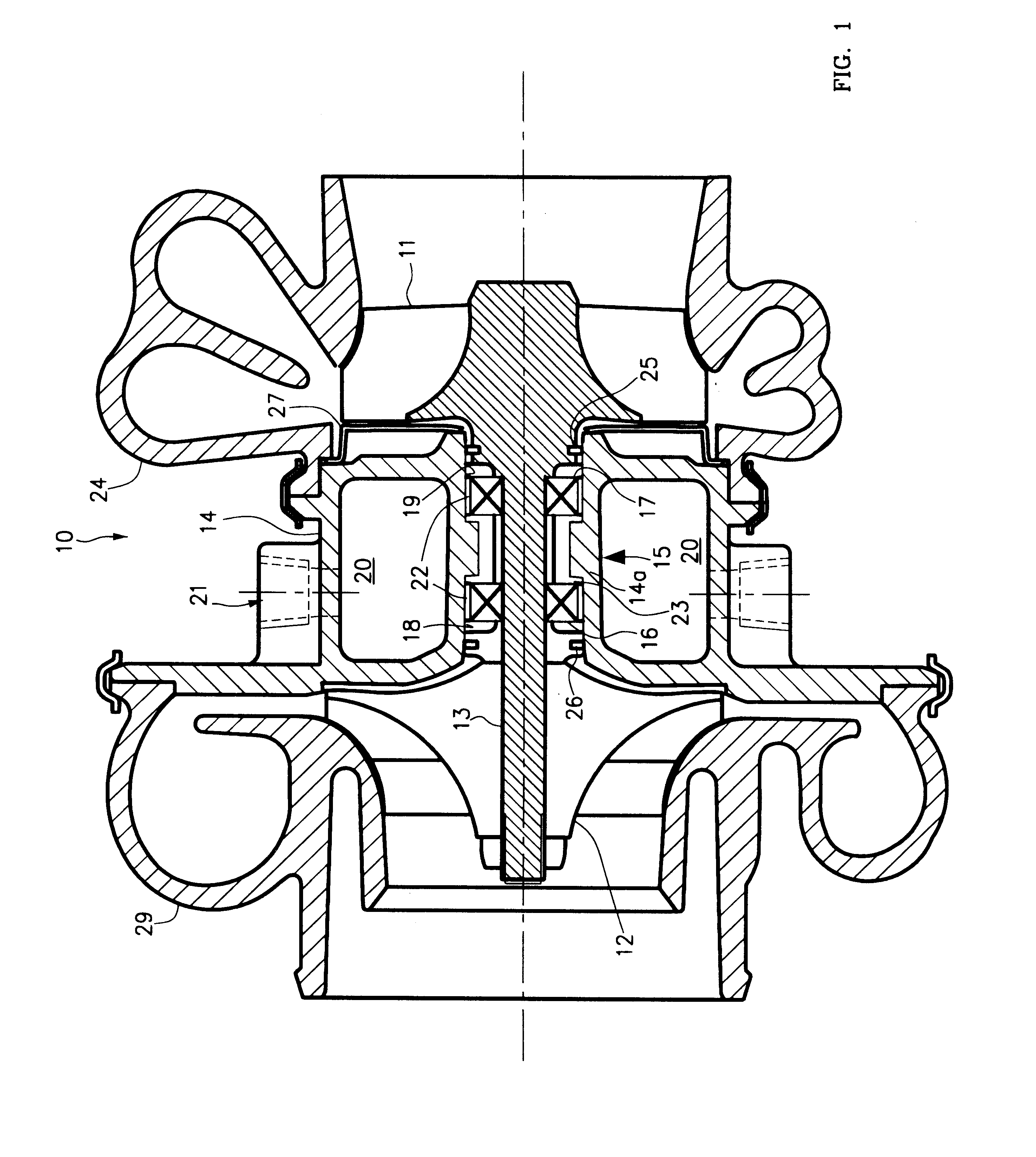

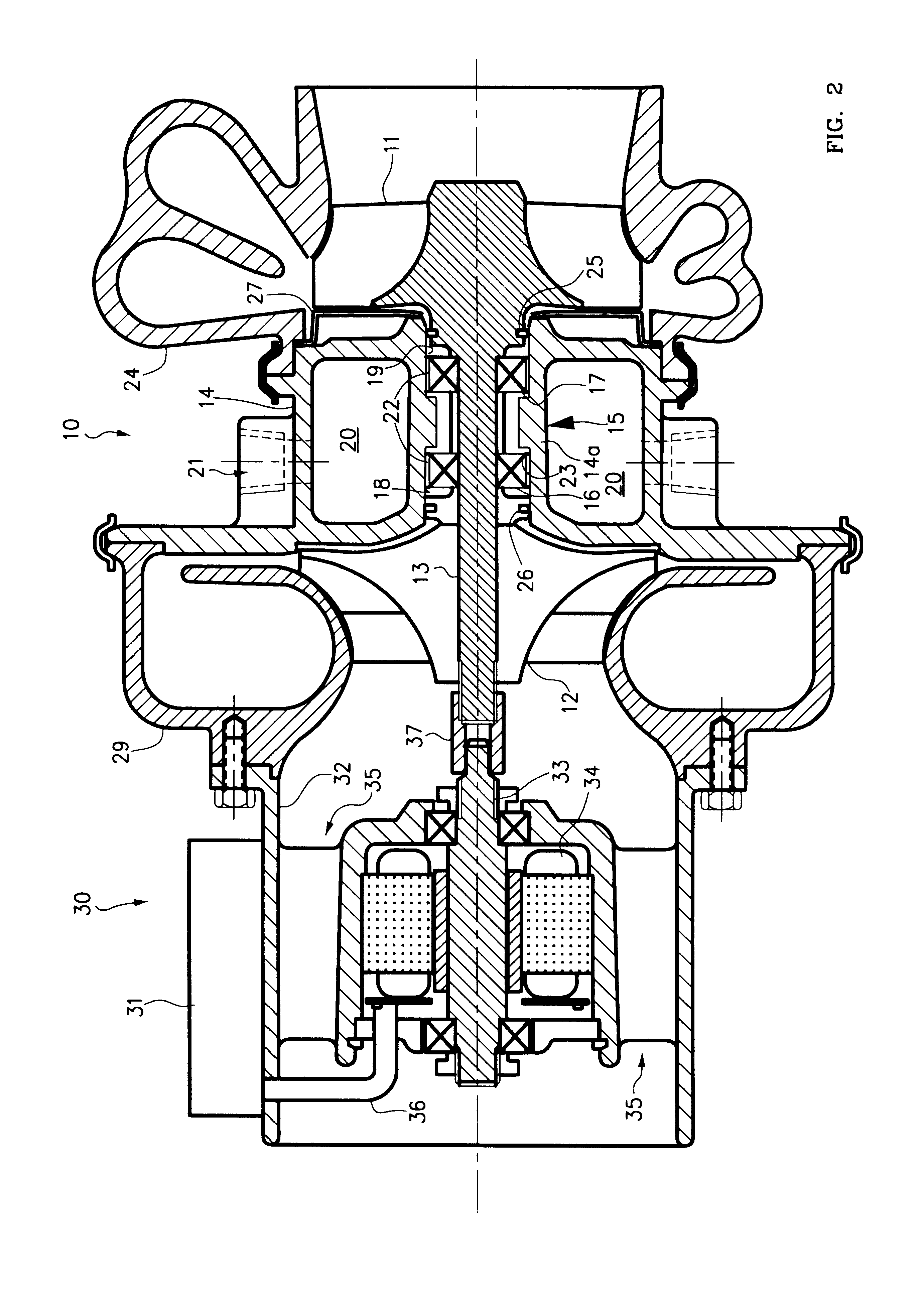

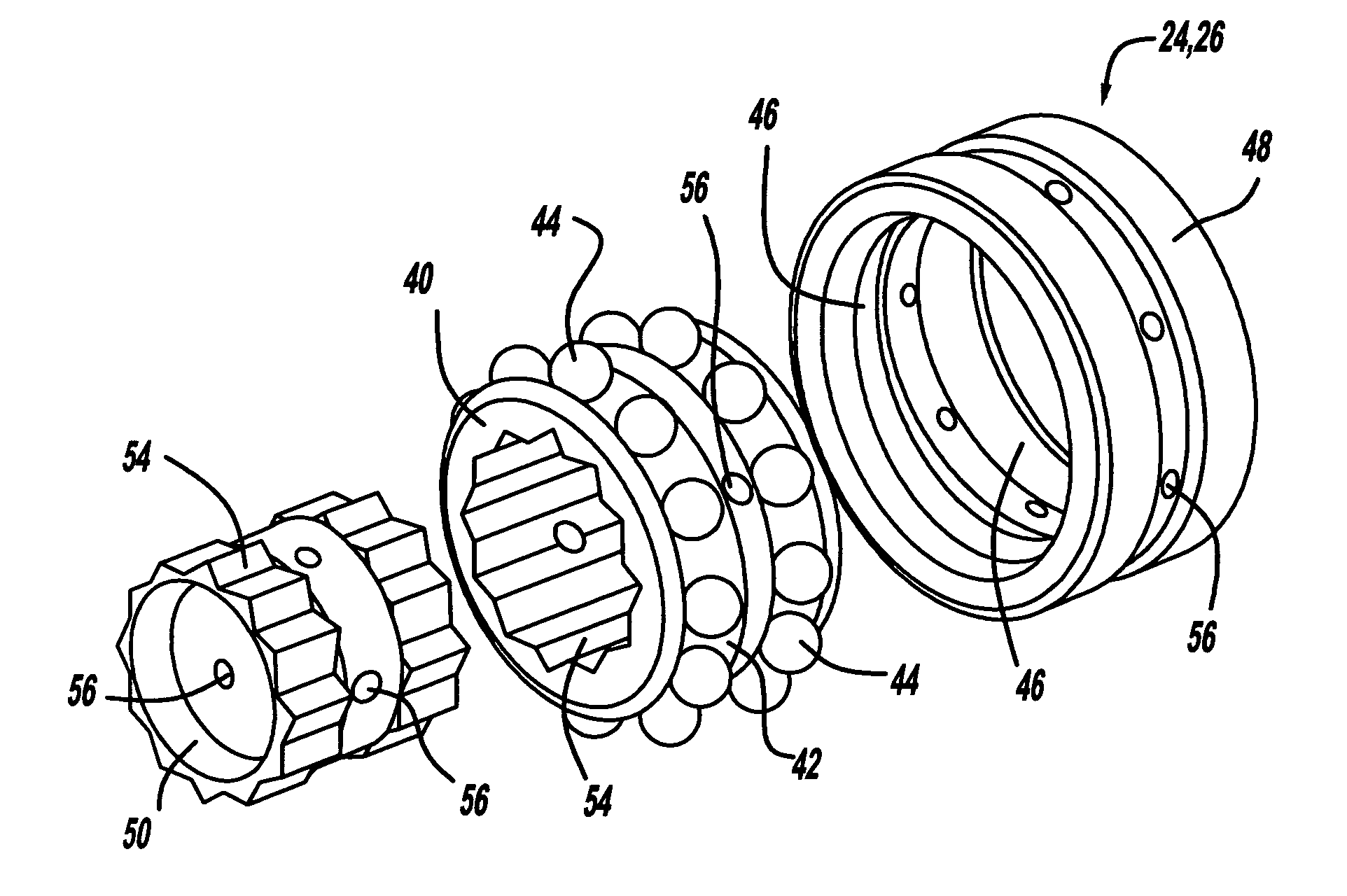

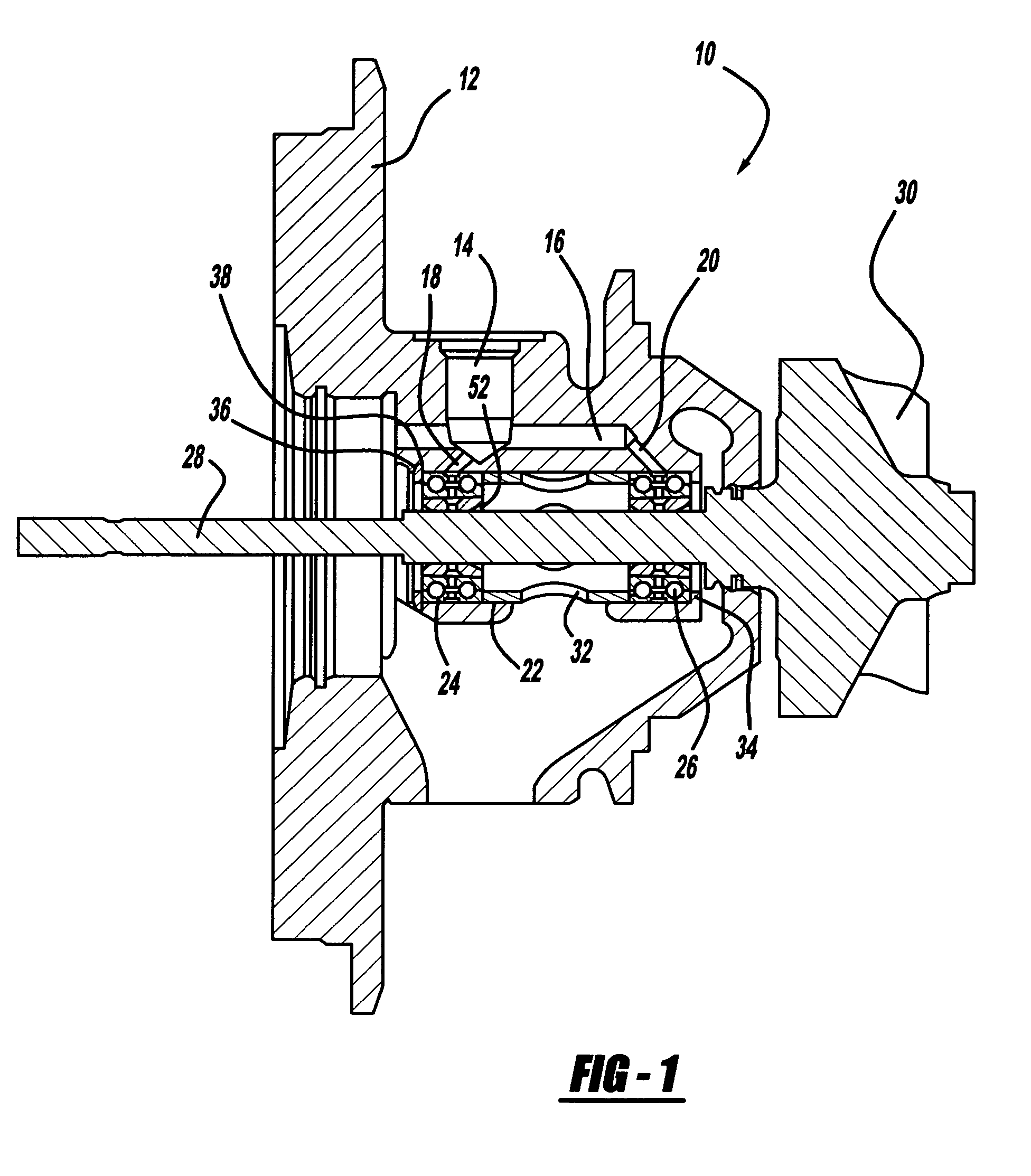

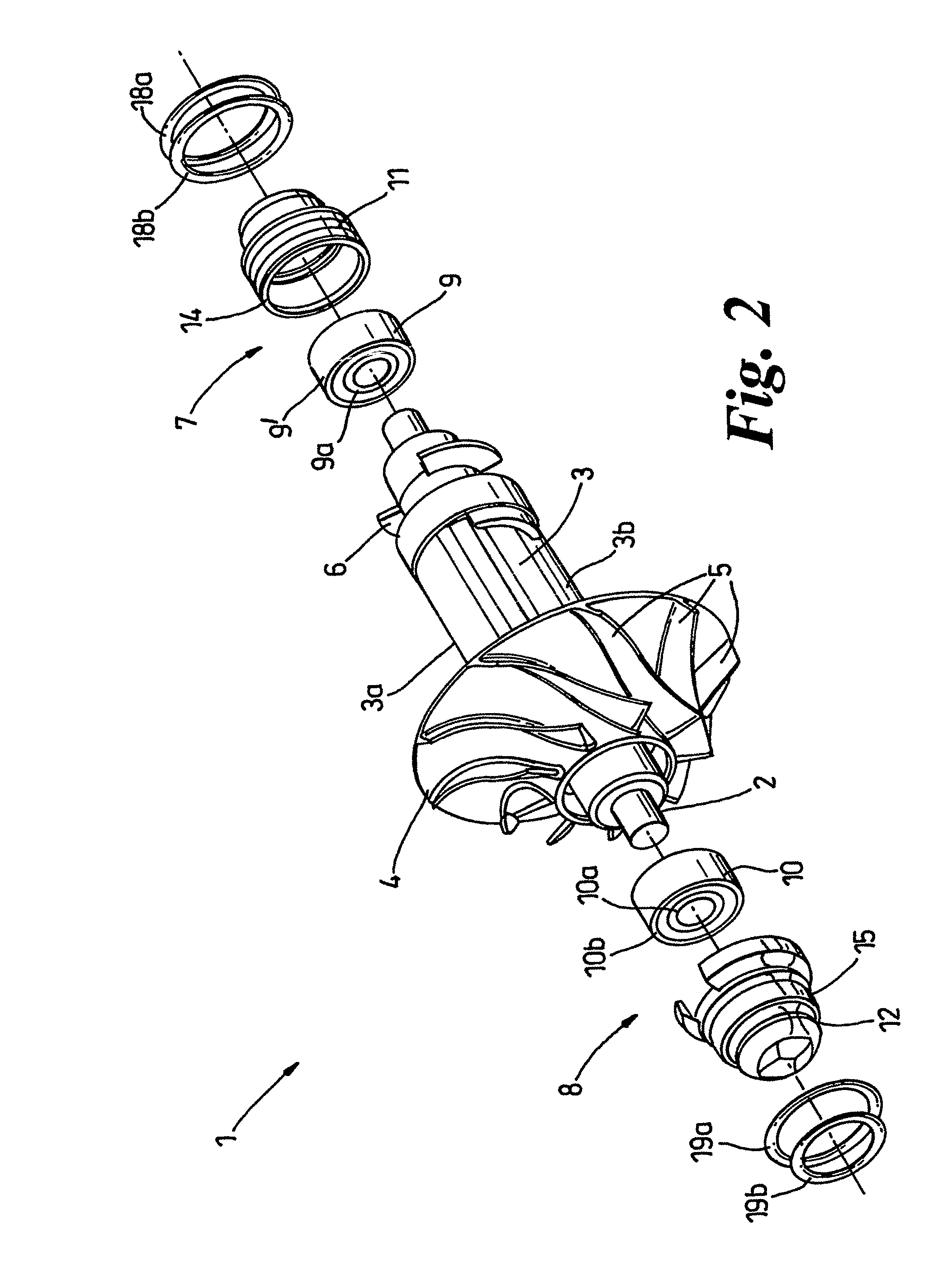

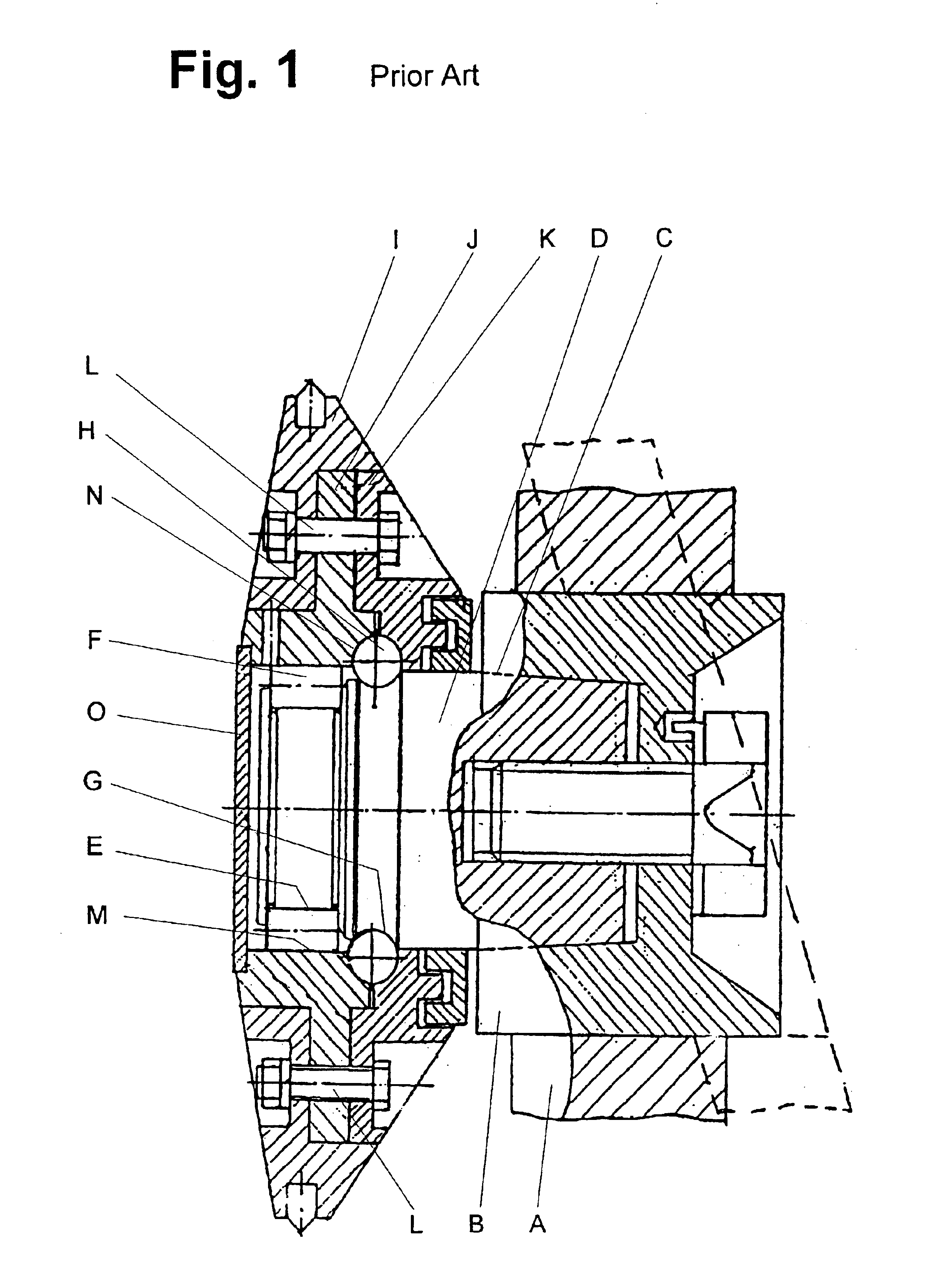

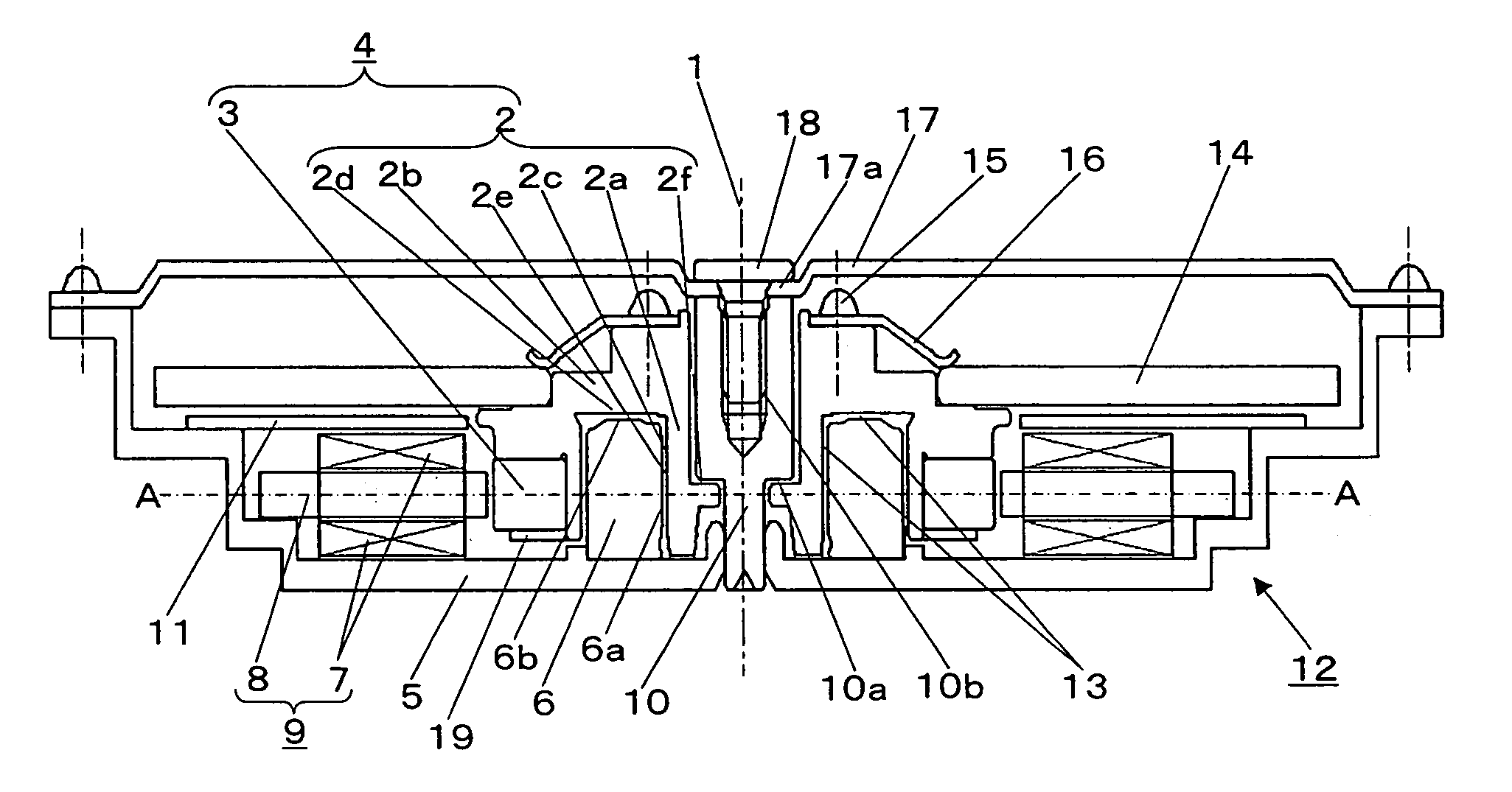

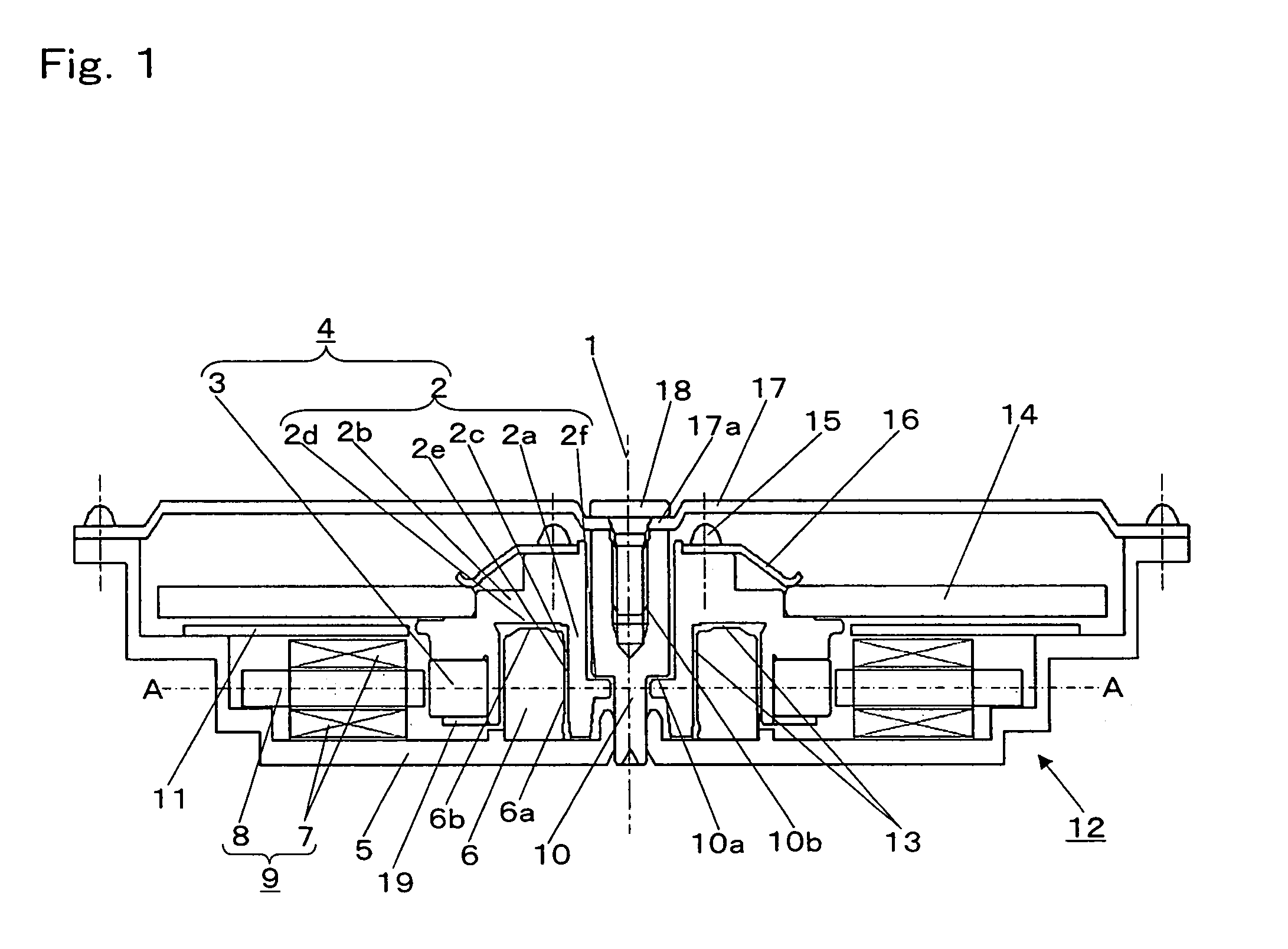

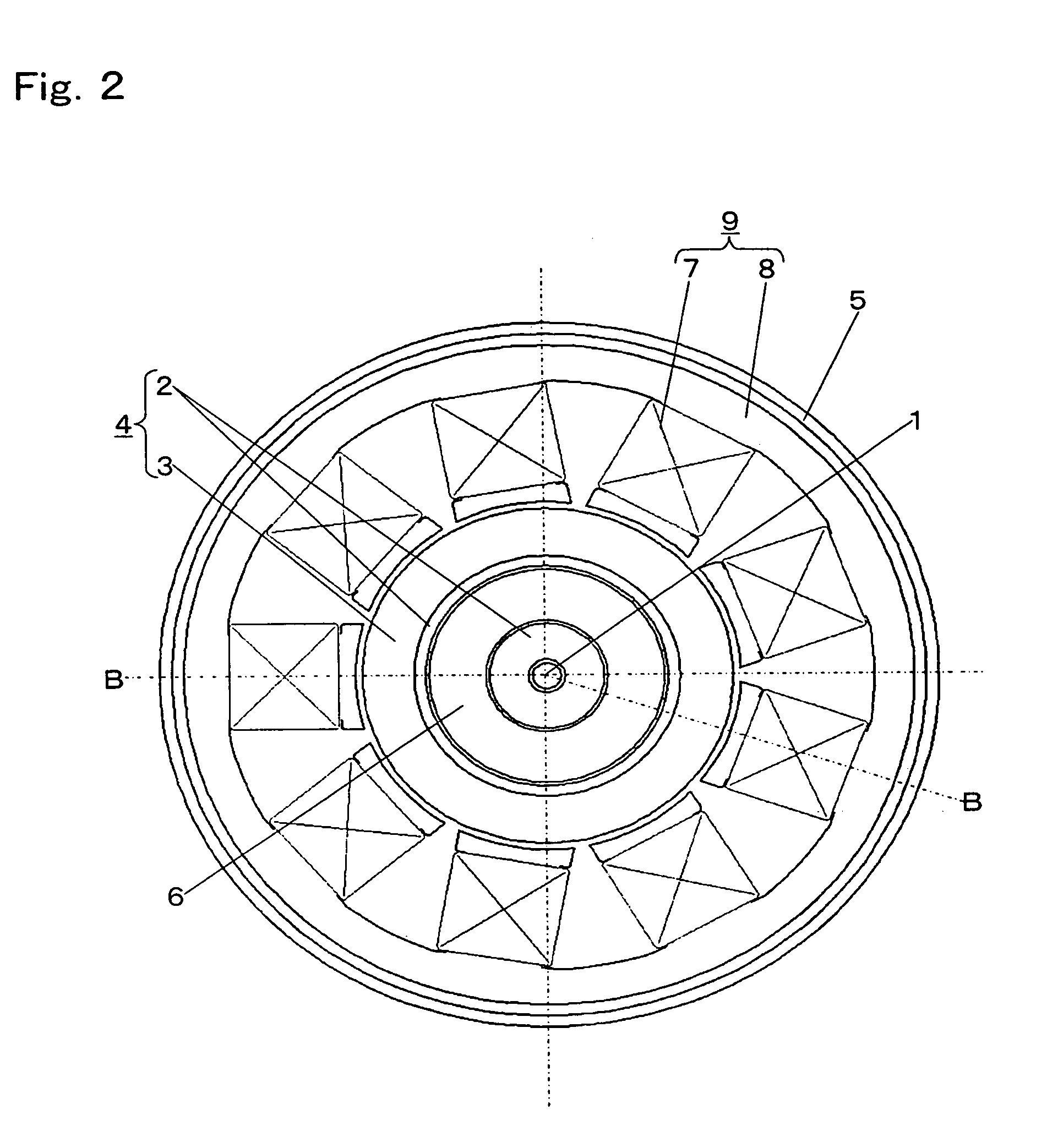

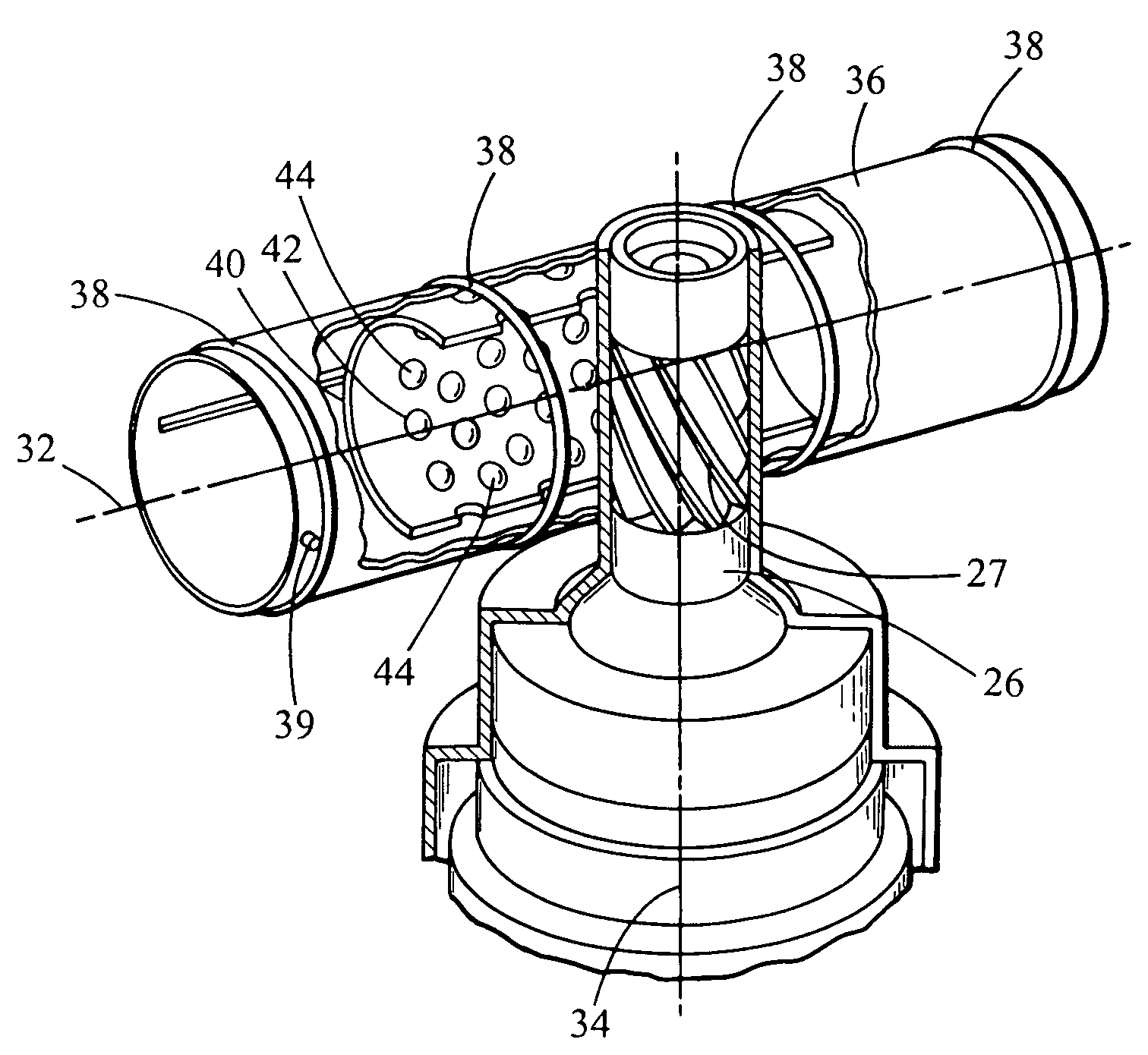

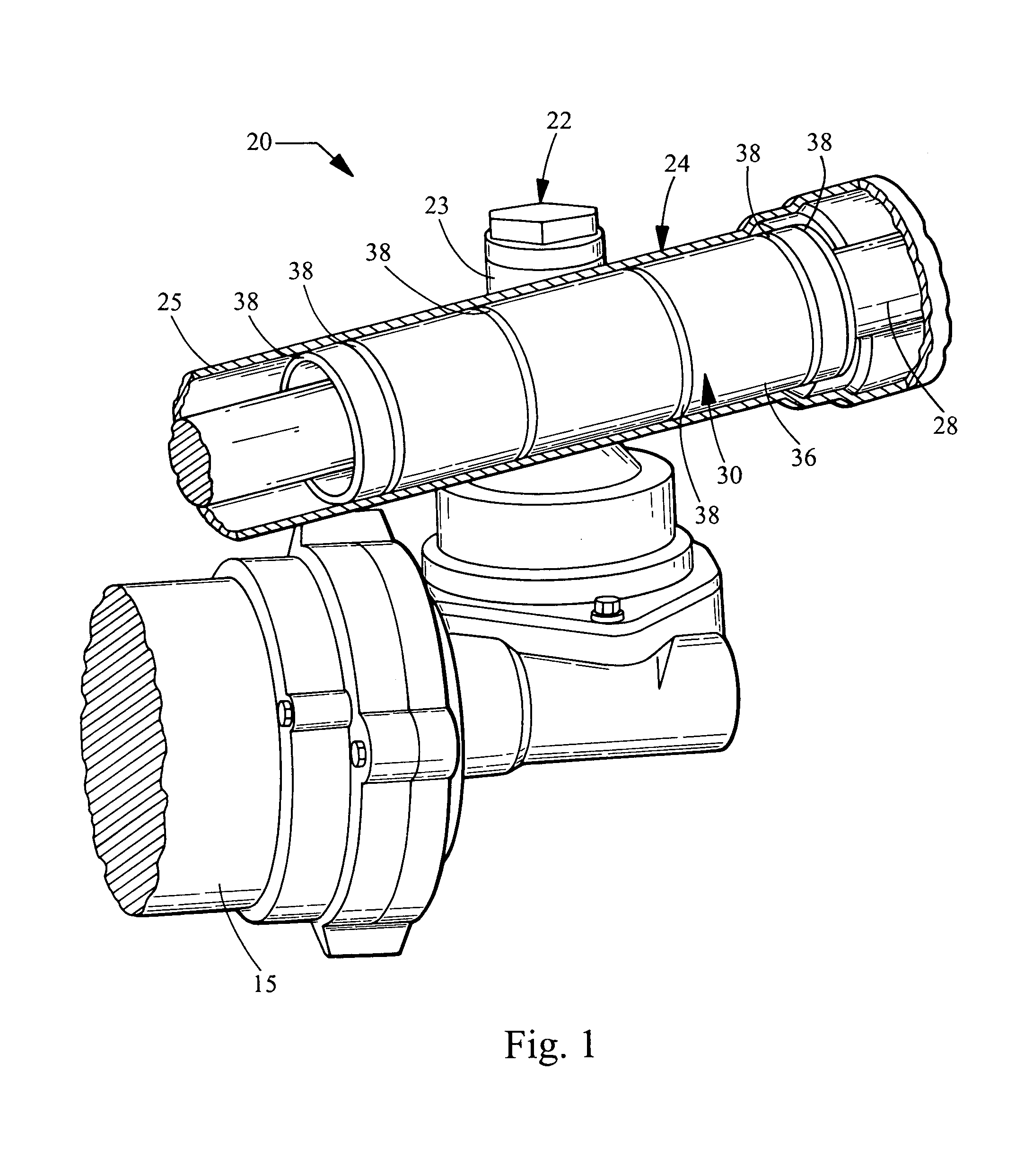

Compact turbocharger

InactiveUS6739845B2Minimal lengthLow thermal expansionInternal combustion piston enginesPump componentsTurbochargerControl theory

A turbocharger comprising two closely spaced ball bearings that does not require lubricating oil from an engine. The bearing housing forms a cooling jacket with two bearing engagement surfaces engaged with the outer races of the ball bearings through an intermediate radial spring. Closely spacing the ball bearings provides a rotor shaft of minimal length. In addition, an external motor-generator may be by mounted on the turbocharger, with the motor rotor solidly connected to the turbocharger rotor. In such an assembly, an electronic control is energizes the motor from battery power during acceleration up to approximately torque peak speed; thereafter, the control changes to a generator mode when there is excess energy in the engine exhaust gas.

Owner:WOOLLENWEBER WILLIAM E

Combination hydrodynamic and rolling bearing system

InactiveUS8016554B2Compensate for misalignmentAbsorption of heatRotary combination bearingsPump componentsRolling-element bearingTurbocharger

The present invention is directed toward a hybrid bearing which will have the advantages of ball bearings as well as hydrodynamic oil films. The present invention is a hybrid bearing assembly for a turbocharger unit, having an inner race track with a series of grooves, and one or more roller balls located in the grooves of the inner race track. There is also an outer race track having a series of grooves for receiving the one or more roller balls, where the outer race track circumscribes the inner race track. The hybrid bearing also includes a sleeve made from an established tribological material located inside the inner race track, with a shaft located inside the sleeve. A hydrodynamic oil film is located between the sleeve and the shaft, wherein the hydrodynamic oil film allows the shaft to spin at greater speeds than the inner race track.

Owner:BORGWARNER INC

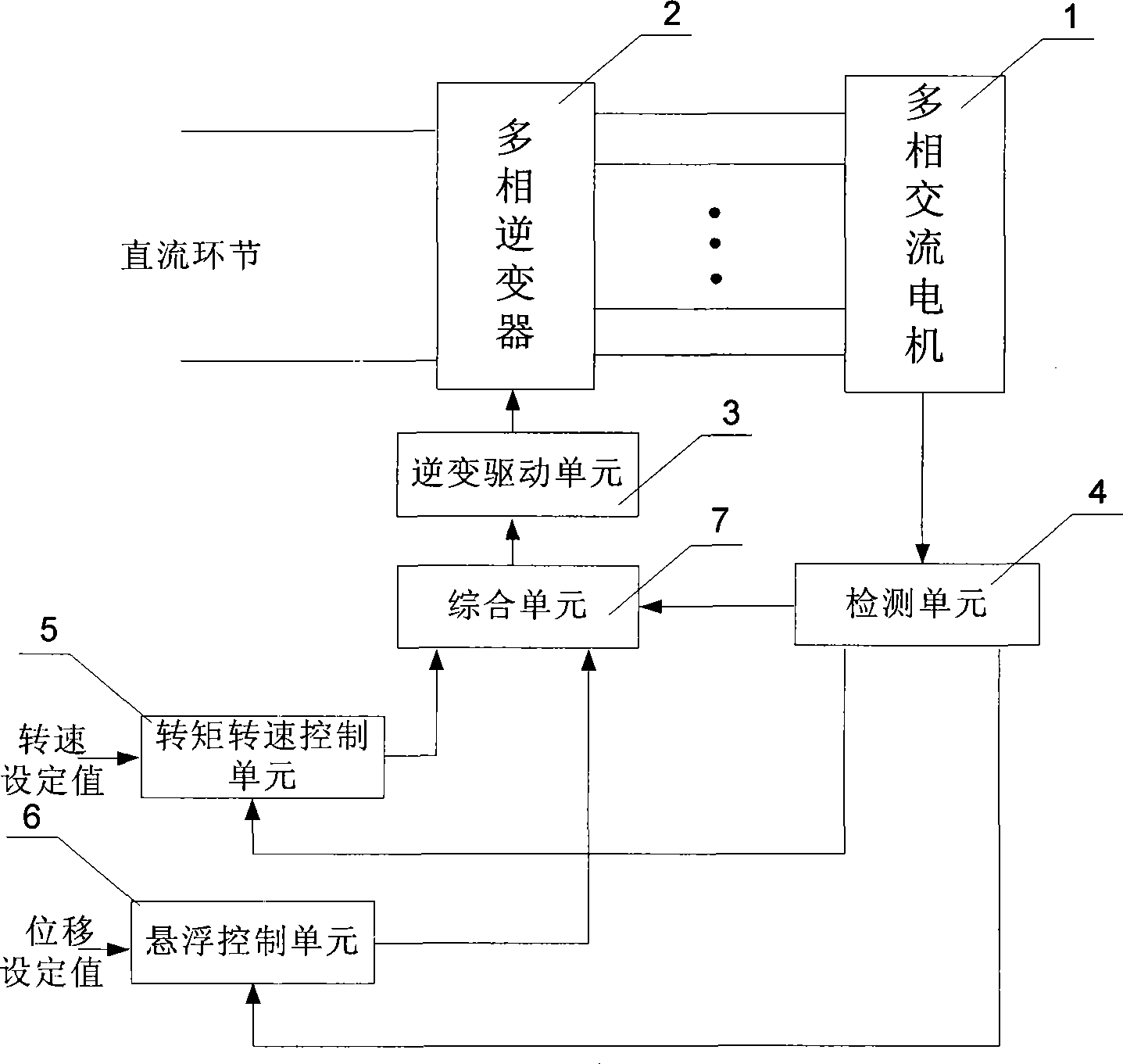

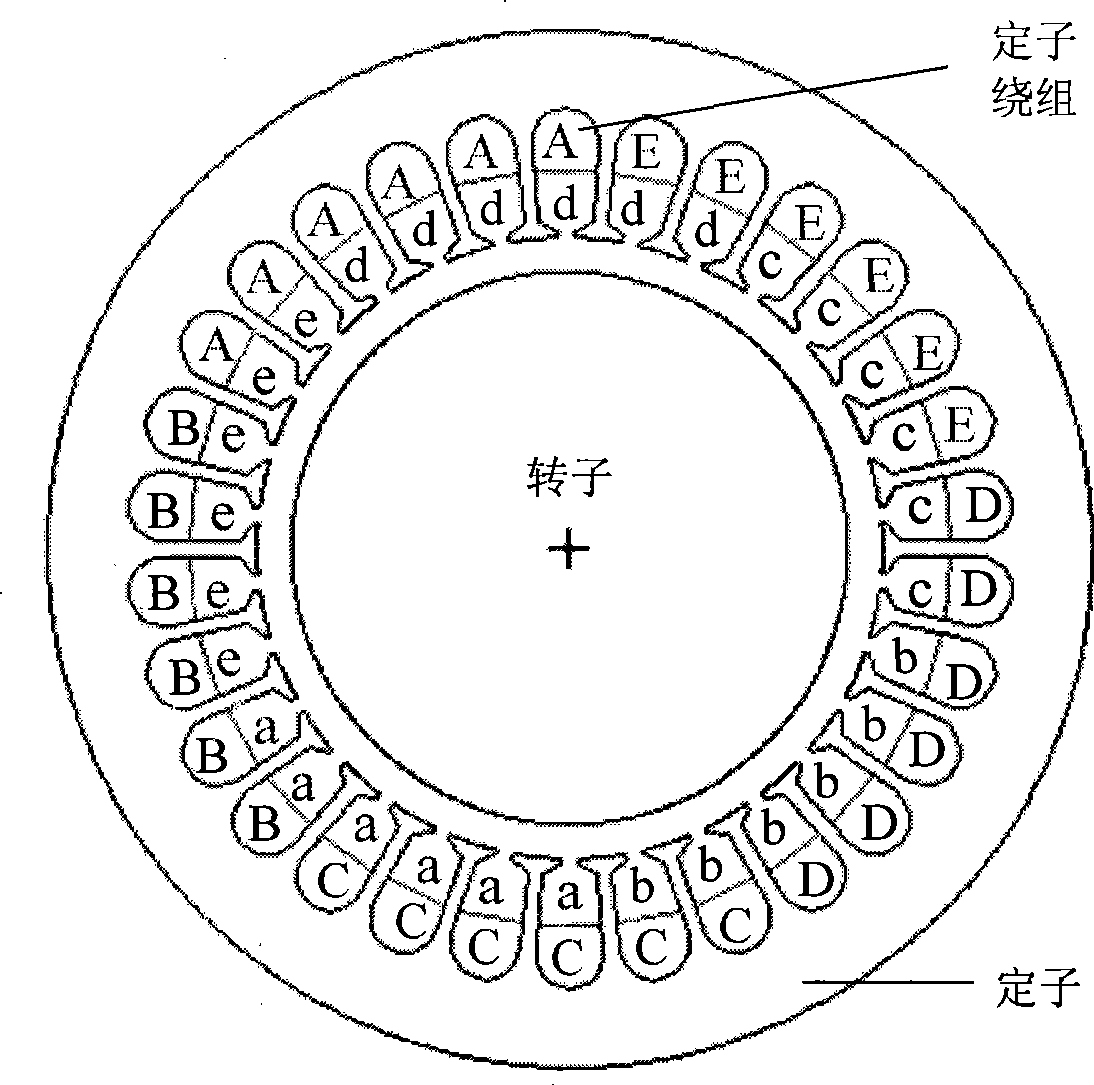

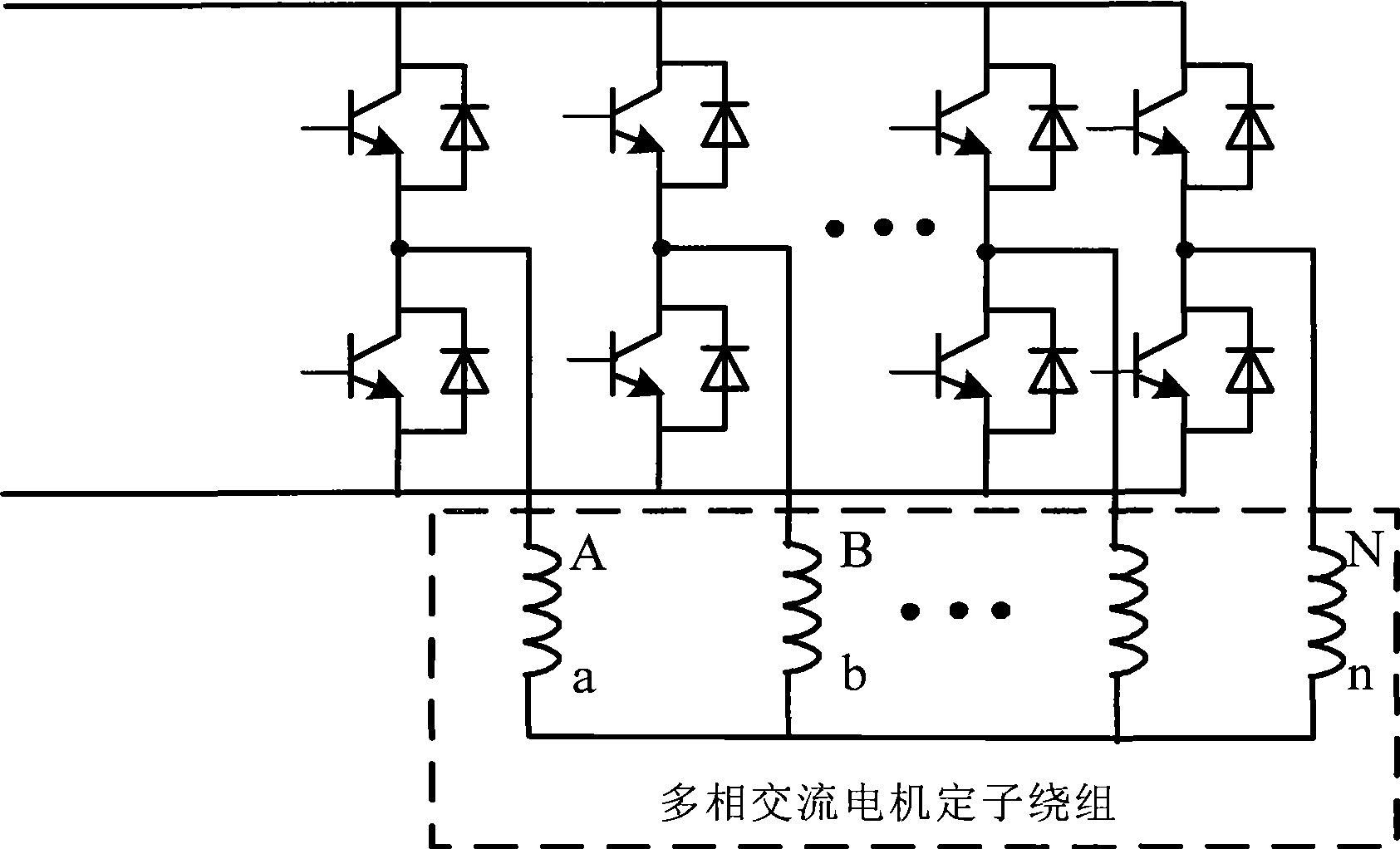

Motor transmission system without bearing for multiphase single sleeve winding

InactiveCN101459408AAvoid direct stringRuled easilyAC motor controlMagnetic holding devicesMotor drivePhase difference

The invention discloses a multi-phase single winding non-bearing motor driving system, which comprises a multi-phase alternating current motor, a multi-phase inverter, an inversion driving unit, a detection unit, a torque and rotary speed control unit, a suspended control unit and a comprehensive unit, wherein the multi-phase alternating current motor has a set of windings with phase number n>=5, a motor stator winding is formed by windings whose axial lines are separated in an angle of 2 pi / n, each phase winding simultaneously comprises odd spatial harmonics and even spatial harmonics, the torque and the suspended control of the multi-phase alternating current motor are respectively finished in different control freedom degrees, two groups of currents with different phase differences of adjacent phases are simultaneously electrified into the motor through the multi-phase inverter for respectively realizing the torque driving and the rotor suspension of the driving system. The motor driving system adopts a set of multi-phase motor windings and a set of multi-phase univertor, realizes the non-bearing operation of the driving system, and has the windings with simple structure, is much easier to embed wires than a traditional double-winding non-bearing motor, is easy to realize the large power driving, and has higher reliability.

Owner:ZHEJIANG UNIV

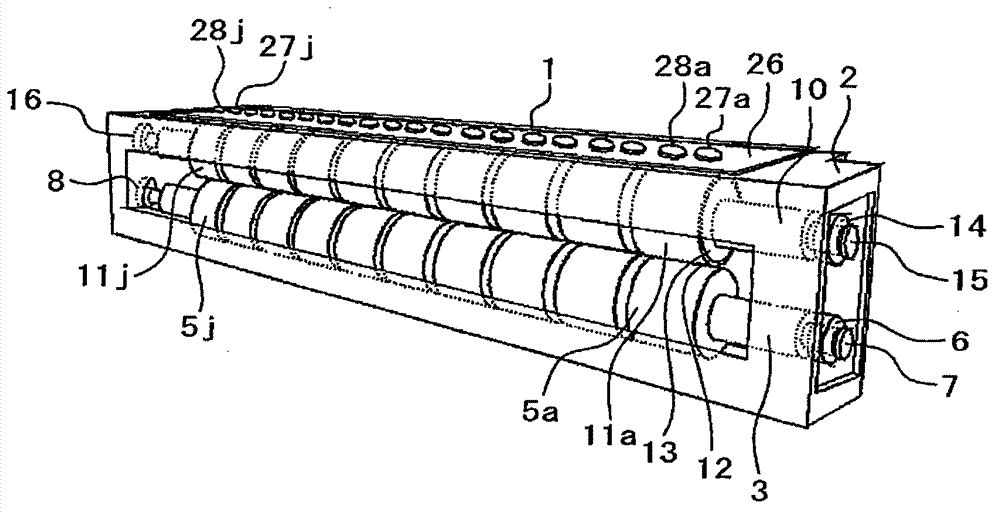

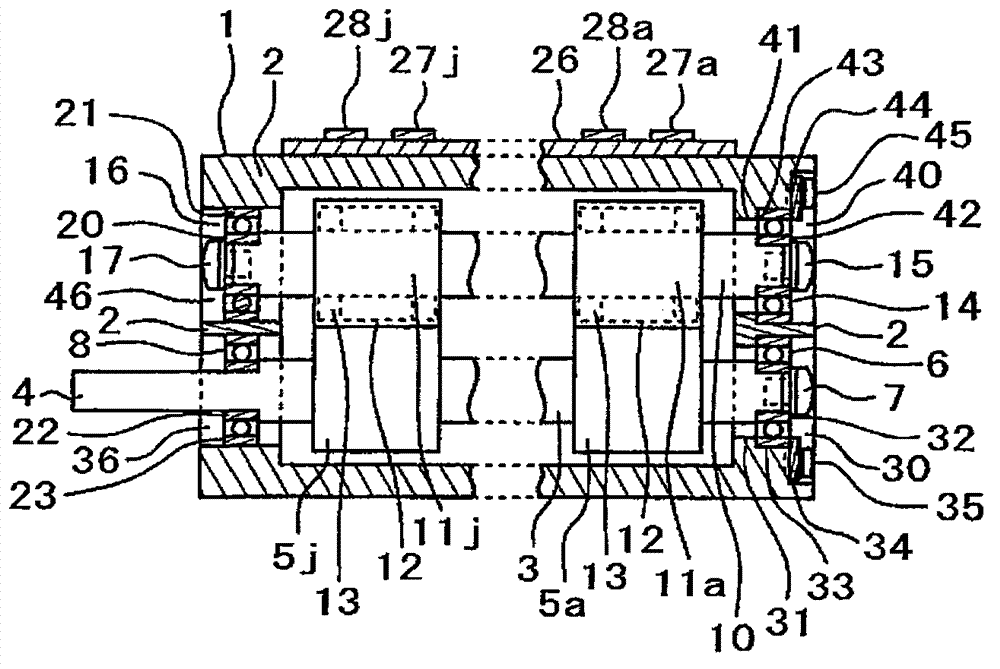

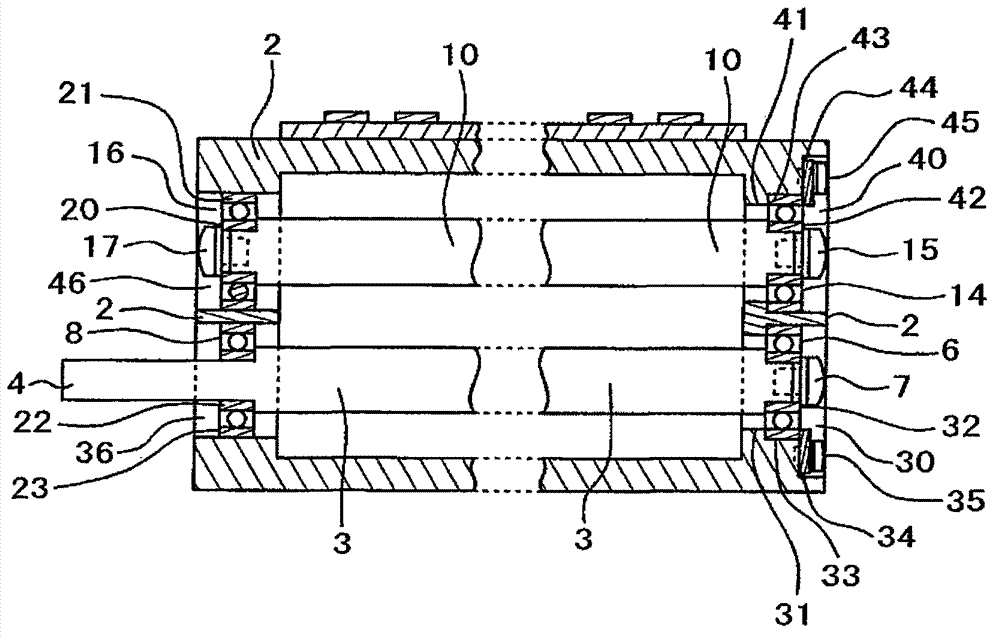

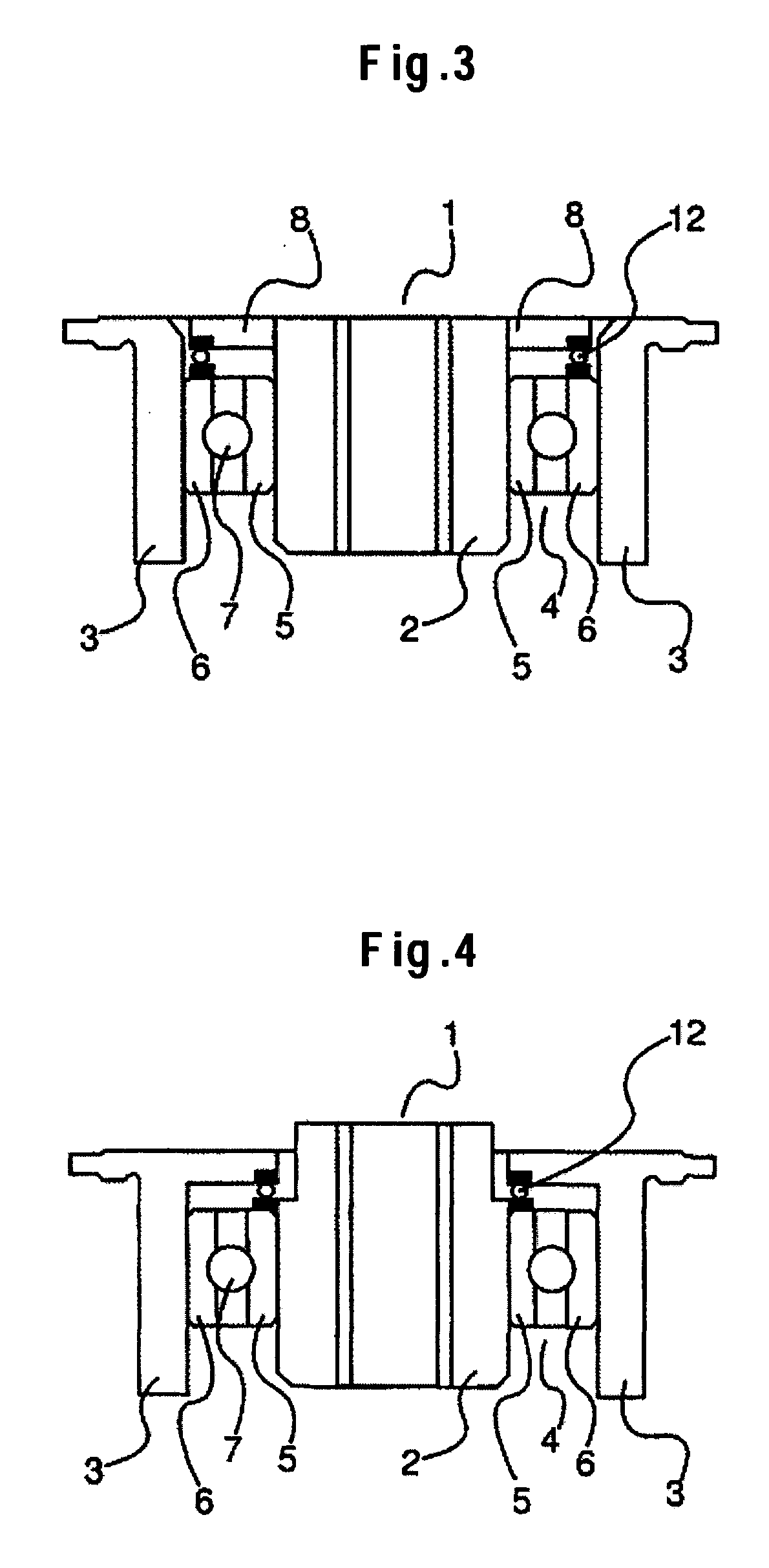

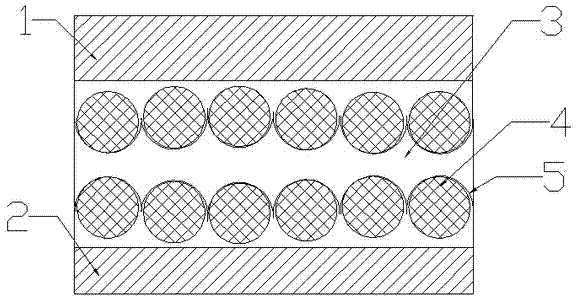

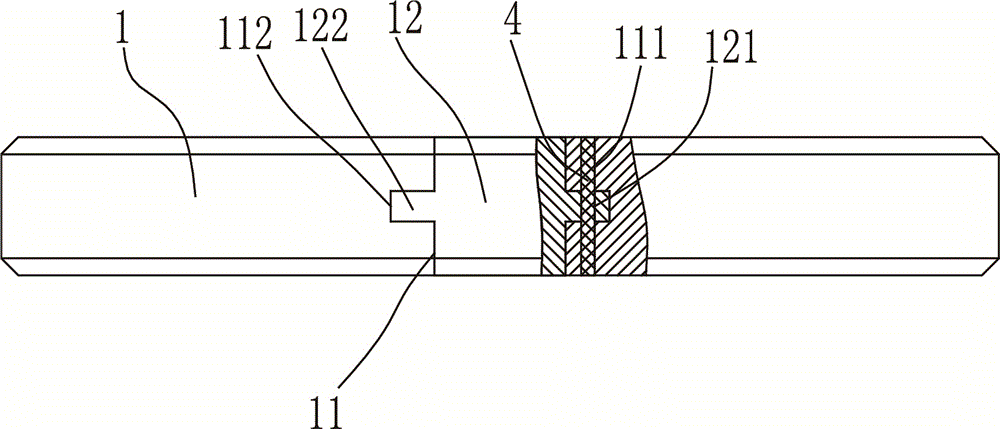

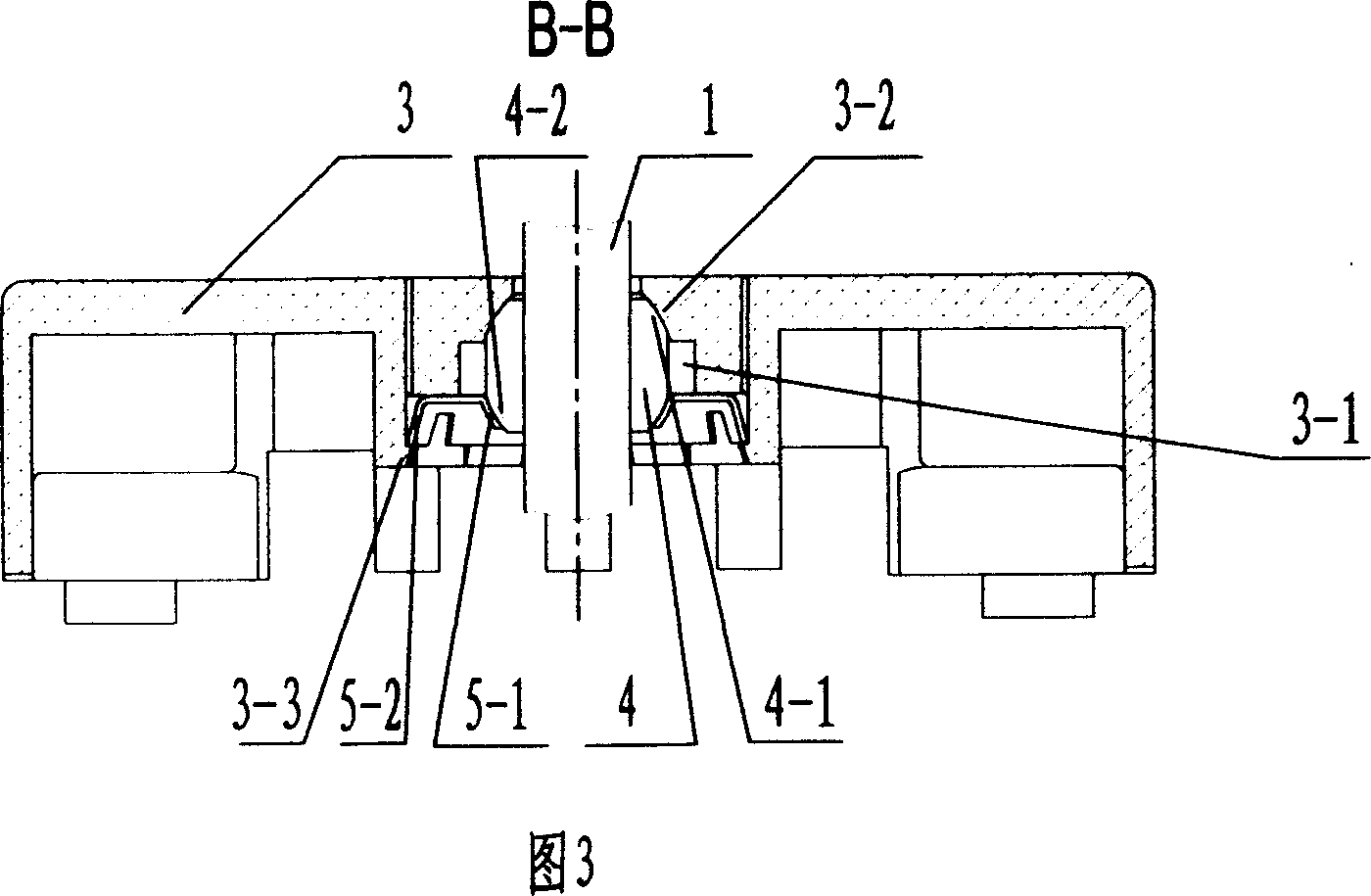

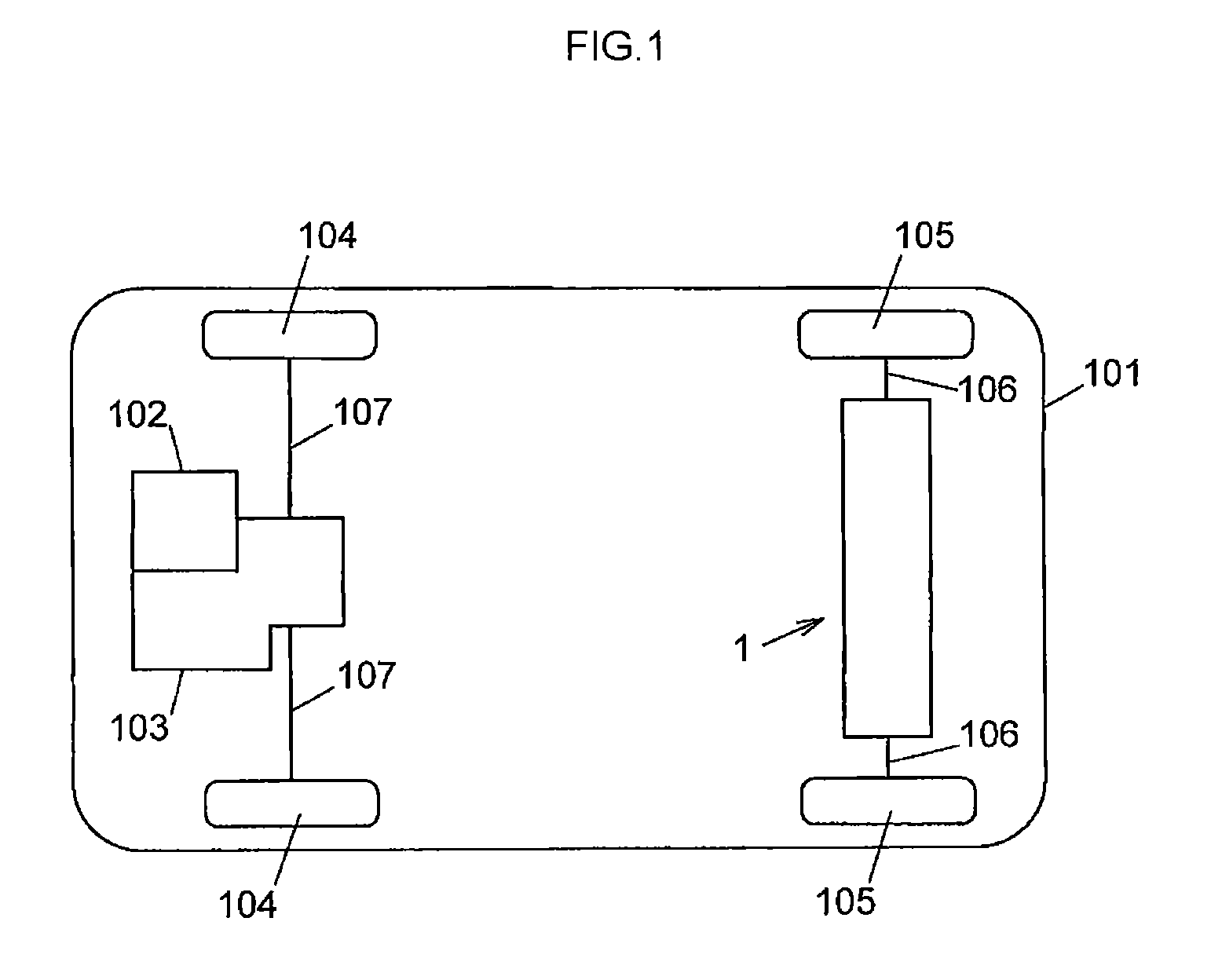

A paper sheet thickness detection device and a note processing device

ActiveCN102968847AEliminate thermal deformationAccurate detectionPaper-money testing devicesAdhesive beltPaper sheet

The invention provides a paper sheet thickness detection device which can be disposed on an automatic note processing device and accurately detect altered notes bound with tapes. The paper sheet thickness detection device comprises a housing supporting detection rollers and reference rollers in a rotary manner, and a plurality of displacement detection sensors disposed on the upper surface, which is opposite to the detection rollers, of the housing and used for detecting displacements of the detection rollers. The paper sheet thickness detection device is used for detecting the thicknesses of paper sheets conveyed through contact parts between the reference rollers and the detection rollers. Inner rings of ball bearings are fixed to the both ends of a rotating shaft of the reference rollers and a rotating shaft of the detection rollers; outer rings of the ball bearings fixed to the ends of one of the rotating shafts of the reference rollers and the detection rollers are fixed to installation holes of the housing; and the outer rings of the ball bearings installed on the ends of the other rotating shaft of the reference rollers and the detections rollers are inserted in the installation holes of the housing.

Owner:HITACHI OMRON TERMINAL SOLUTIONS CORP

Electromagnetic type rigidity-variable flexible rotating joint

The invention provides an electromagnetic type rigidity-variable flexible rotating joint of the technical field of robots. The electromagnetic type rigidity-variable flexible rotating joint comprises an electromagnetic rigidity variable unit provided with an output shaft, a joint outer shell and a base, wherein the joint outer shell, the base and the electromagnetic rigidity variable unit are coaxially arranged. A first ball bearing and a second ball bearing are fixed the two ends of the output end, the first ball bearing is arranged in the joint outer shell, and the second ball bearing is arranged in the base. The electromagnetic rigidity variable unit comprises a stator and a rotor which are coaxially arranged with the output shaft. A plurality of stator iron cores are evenly distributed in the stator in the circumferential direction and wound with stator coils, the rotor is arranged in the stator, and the rotor and the stator iron cores are oppositely arranged. The output shaft is fixedly connected with the rotor through a key groove structure, and a check ring is arranged on the upper end face of the rotor and connected with the first ball bearing. According to the electromagnetic type rigidity-variable flexible rotating joint, torsion rigidity of the rotating joint is controlled and adjusted through electric current; and the electromagnetic type rigidity-variable flexible rotating joint has the characteristics that the mechanical structure is simple, weight is light, the size is small, and rigidity adjustment is quick and convenient.

Owner:SHANGHAI JIAO TONG UNIV

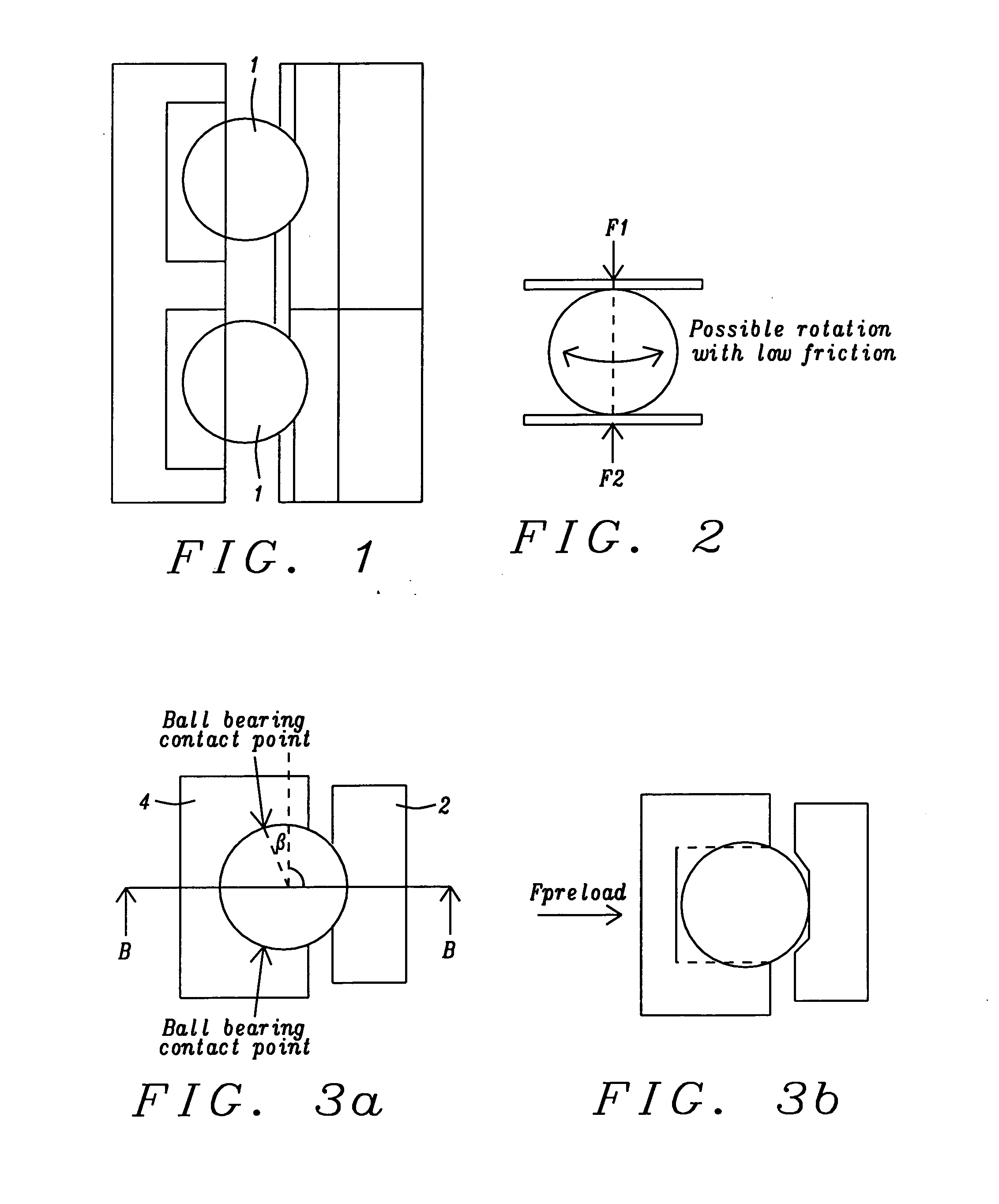

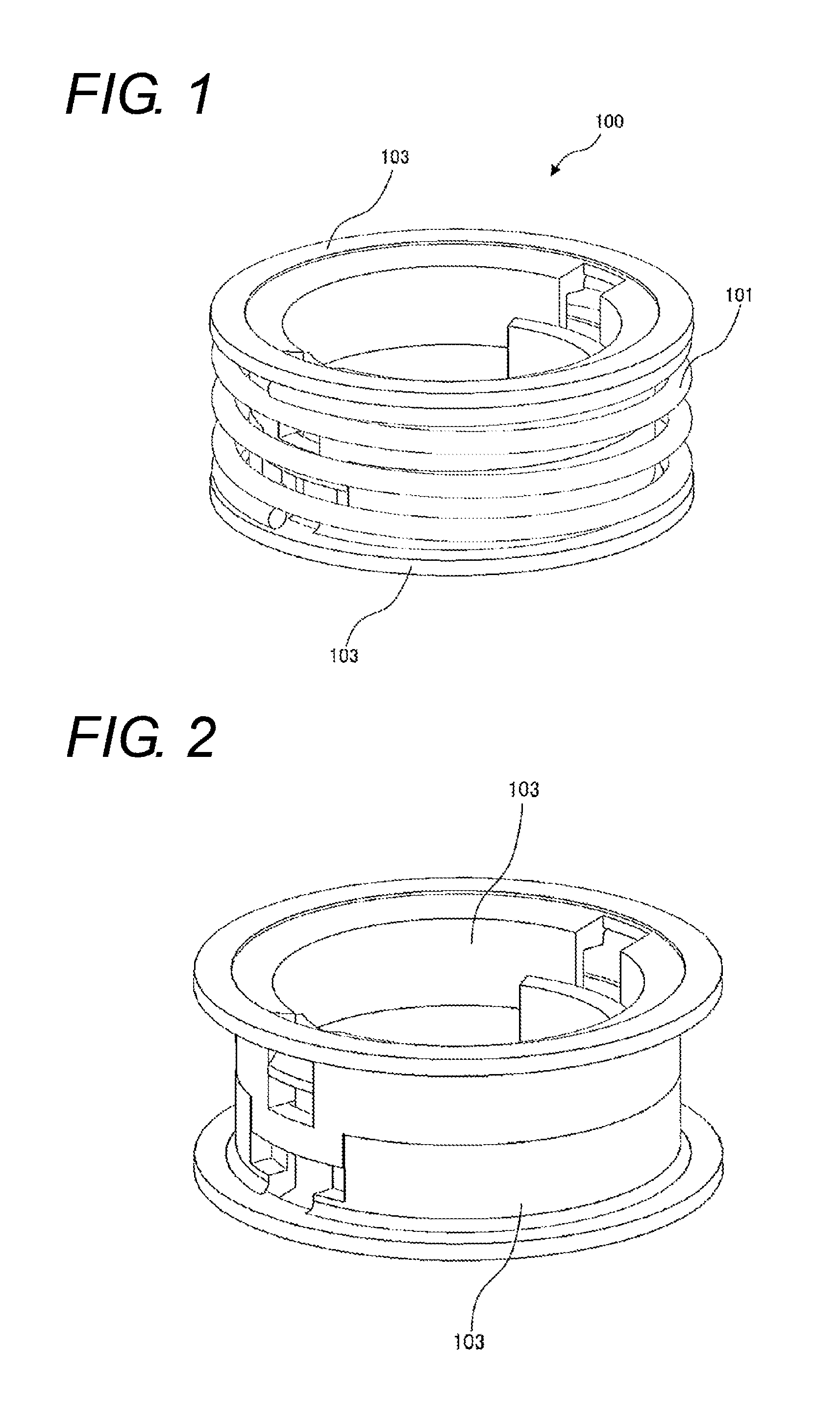

Integrated ball cage

InactiveUS20120237147A1Lower manufacturing requirementsLower assembly costsLinear bearingsProjector focusing arrangementMechanical impactCamera module

Systems and methods to reduce manufacturing and assembly costs for measures to avoid blocking or creeping ball conditions for linear ball bearings are disclosed. In preferred embodiments two linear ball bearings, a fixed ball bearing and a non-locating ball bearing, are applied to guide movements of a lens barrel of camera modules. Ball cages, which are integrated either in a moving part or in a fixed part of an actuator, are lowering manufacturing and assembly costs. A constant magnetic preload force is applied to both ball bearings to keep the bearings together in case of a mechanic shock. Ball bearing contact points of the fixed ball bearing are shifted asymmetrically by a small angle to withstand horizontal preload forces.

Owner:RPX CORP

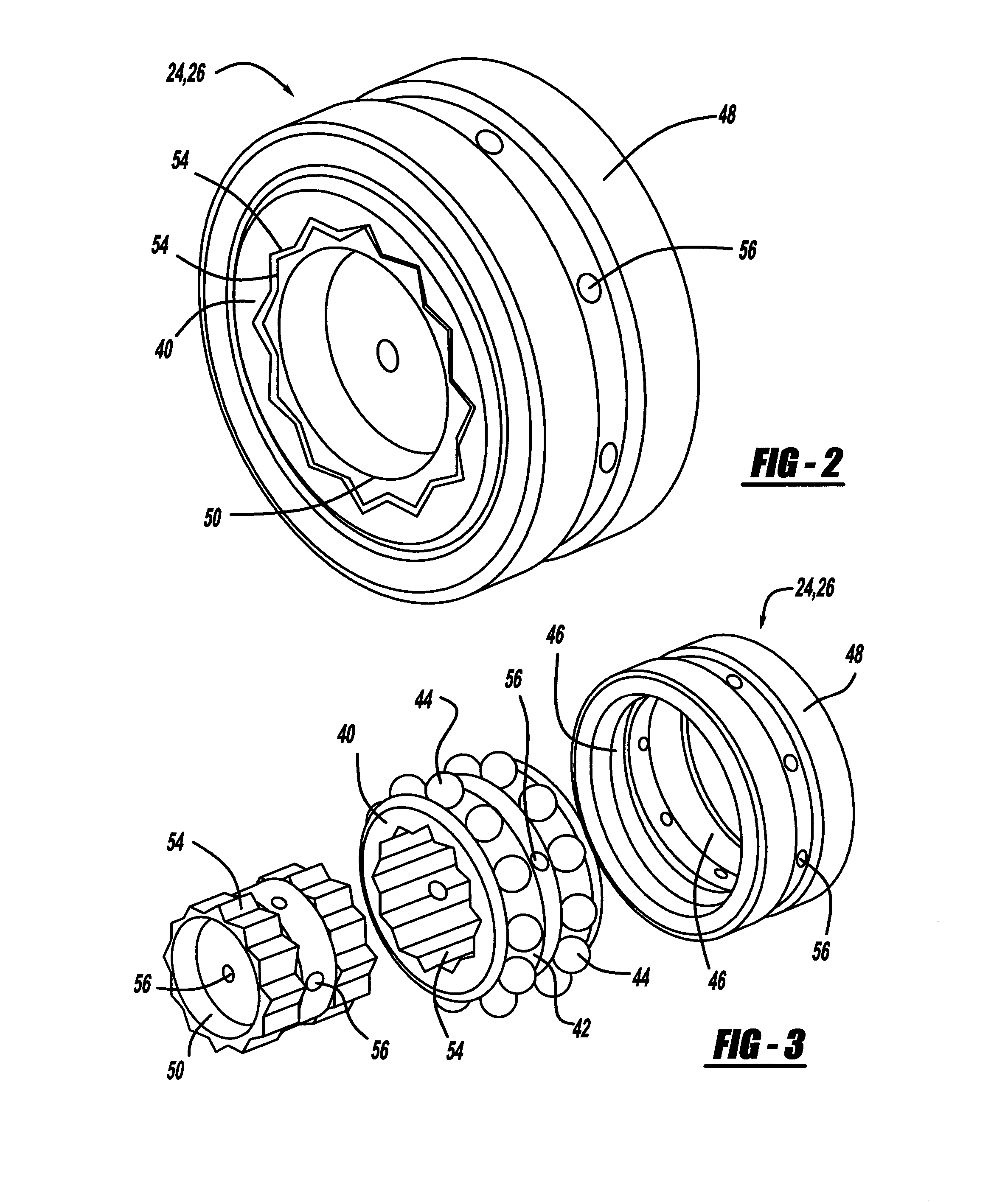

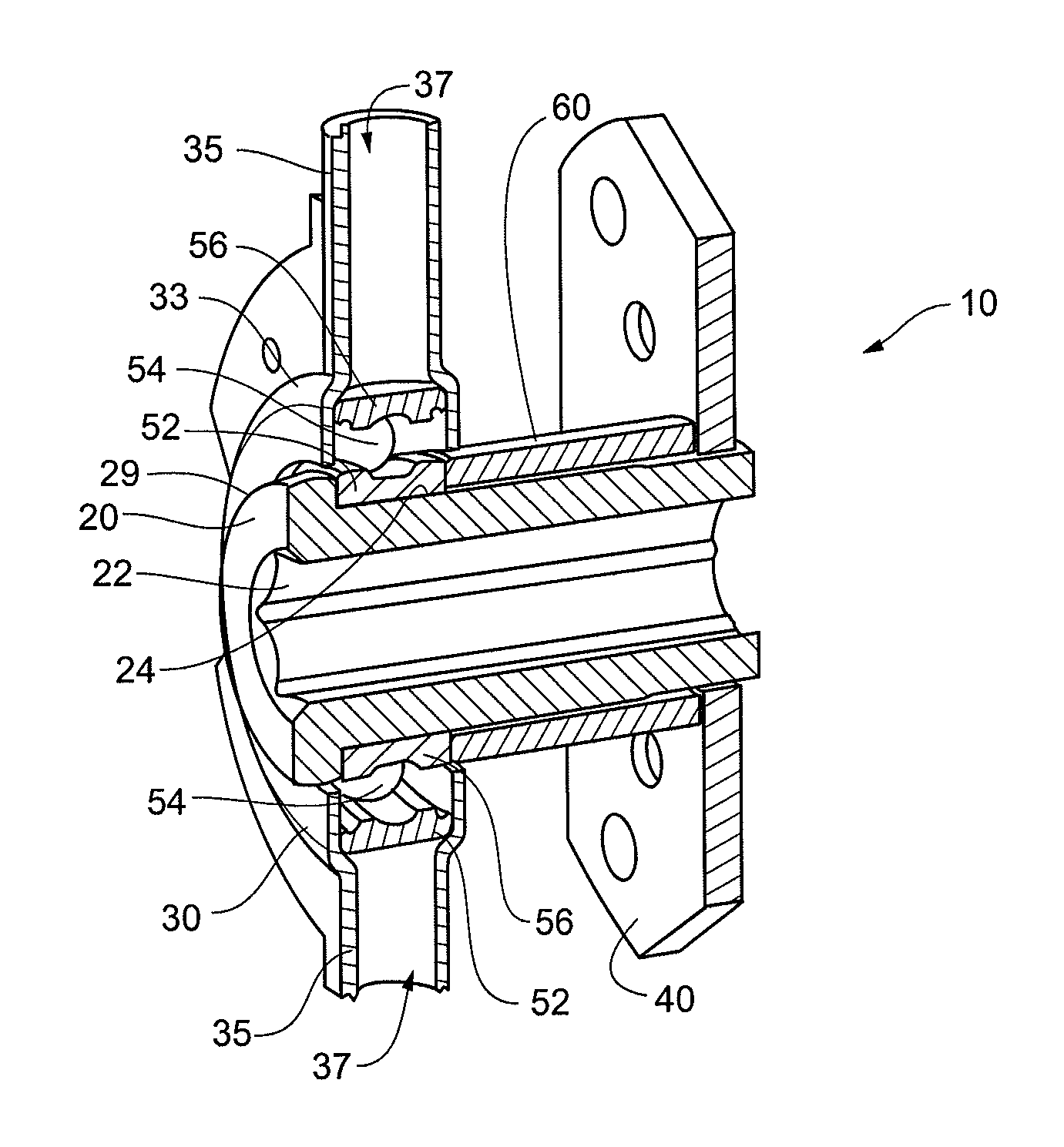

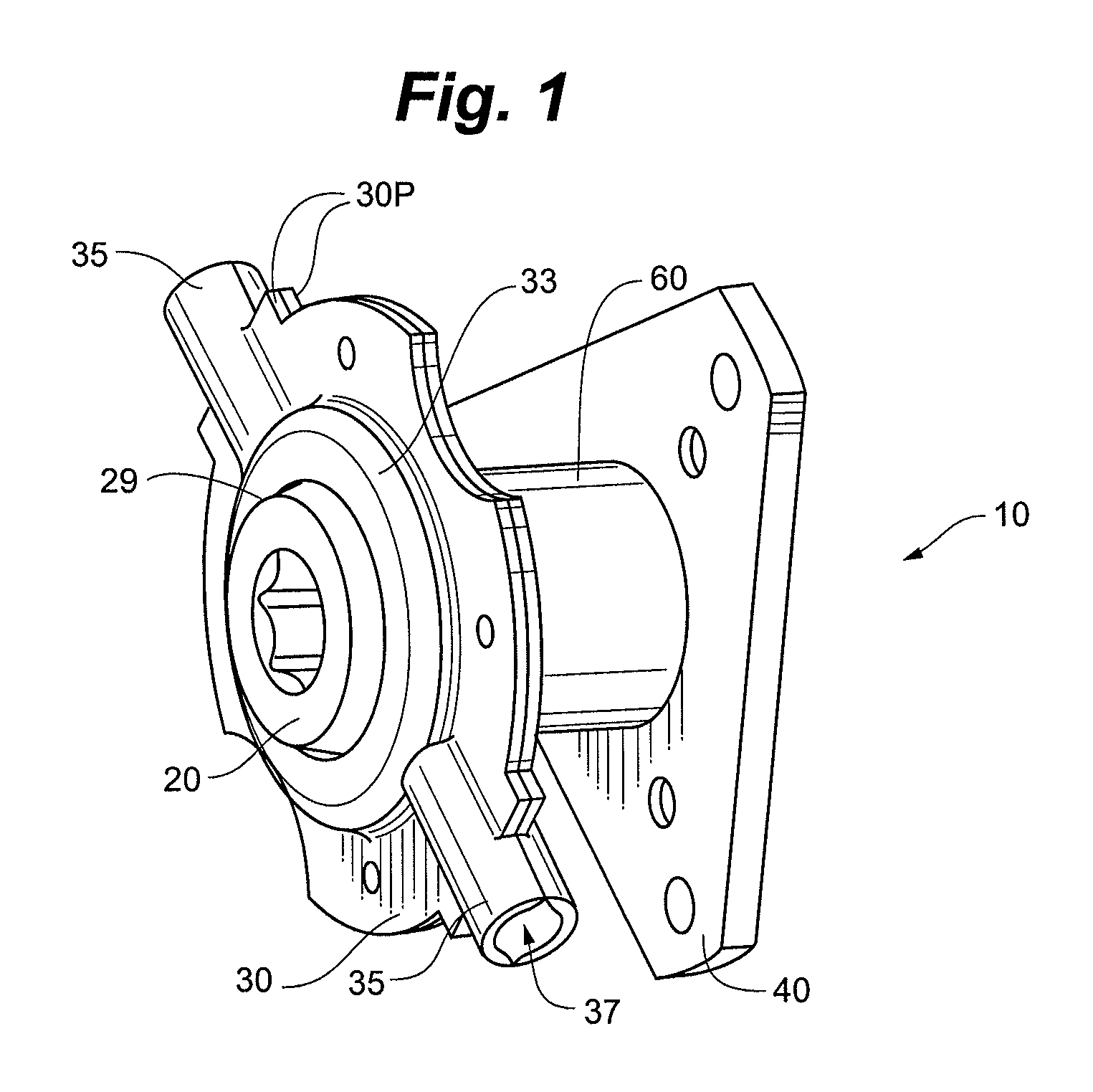

Bearing assembly

InactiveUS7834501B2Reduced life-timeGuaranteed uptimeRolling contact bearingsShaftsEngineeringBall bearing motor

A bearing assembly particularly suitable for the rotor arrangement of an electrical motor or generator includes a bearing located in a housing. The bearing has an inner race, an outer race, and a plurality of ball bearings between the inner and outer races. A portion of the housing is made up of a deformable flexible wall which permits the housing to conform to the shape of the outer race member, rather than forcing the outer race to conform to the shape of the housing, as was experienced hitherto.

Owner:DYSON TECH LTD

Device for measuring friction torque of curved groove ball bearing

PendingCN107576434AHigh measurement accuracyEliminate wobbleApparatus for force/torque/work measurementFriction torquePull force

The invention discloses a device for measuring friction torque of a curved groove ball bearing and belongs to the field of mechanical engineering. The device is composed of a motor reducer, gears, a rotor, a base, a chuck, a loading device, and a tension sensor. In order to solve the problem that measuring precision is affected since a pull rope in an existing device for measuring friction torqueof a curved groove ball bearing swings up and down during measuring, a template for processing a curved groove in the outer circle of the original curved groove ball bearing or a curved groove ball bearing of the same type is used as the rotor for use with a phase adjusting mechanism, vertical swing of the curved groove in the outer circle is counteracted by the vertical swing of a curved groove in the template during rotation, the pull rope is kept not swinging up and down during the testing of the friction torque of the curved groove ball bearing, and measuring precision is improved. The device disclosed herein has the advantages that by using the rotor having the same swing amplitude and period as a curved groove ball bearing, vertical swing of the curved groove ball bearing can be eliminated; loading is easy, and adjusting is convenient; the device is simple in structure and low in cost.

Owner:NORTHWEST A & F UNIV

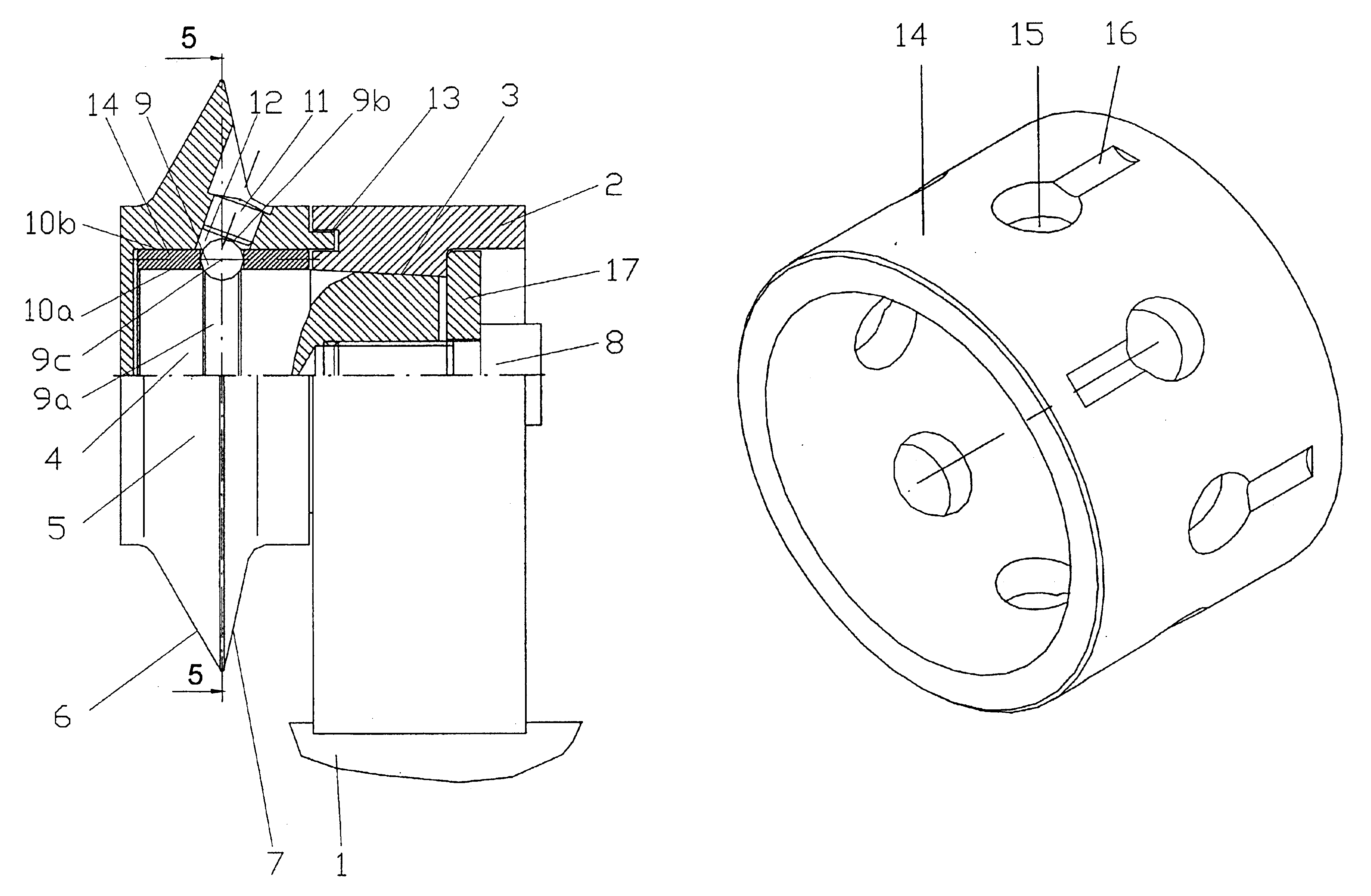

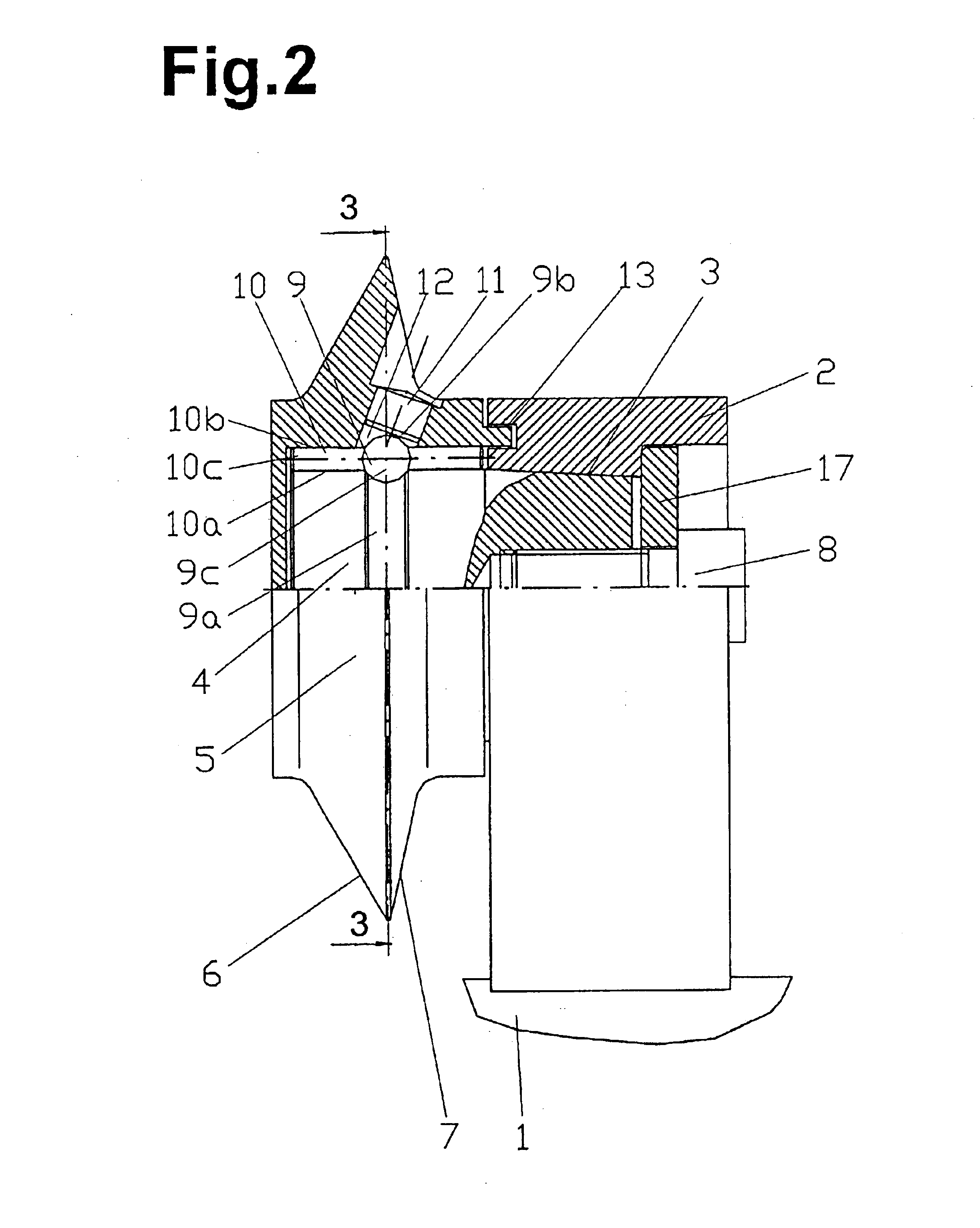

Mini disk bit

InactiveUS6935443B2Extended service lifeImprove stabilityDrill bitsRotary combination bearingsCircular discNeedle roller bearing

A small sized disk bit includes a bit holder accommodated in a bearing journal on its side (overhangingly), and a disk body with asymmetrically designed wedge flanks mounted rotatably thereon. To enable the disk body to absorb high radial and axial strong forces encountered during the engagement of the disk on a solid rock, the disk body is designed as a one-part disk body with a blind hole with its surface and the bearing journal surface being designed as components of the bearing. The bearing involves the combination of a radial and thrust bearing each, where the thrust bearing is milled into the track of the radial bearing. A ball bearing is used as the axial bearing and a needle roller bearing, a cylindrical roller bearing or a slide bearing is used as the radial bearing. The diameter of the ball bearing is larger than the diameter of the needle rollers, or the cylindrical rollers or the thickness of the sliding bush of the slide bearing.

Owner:MAN TAKRAF FORDERTECHN

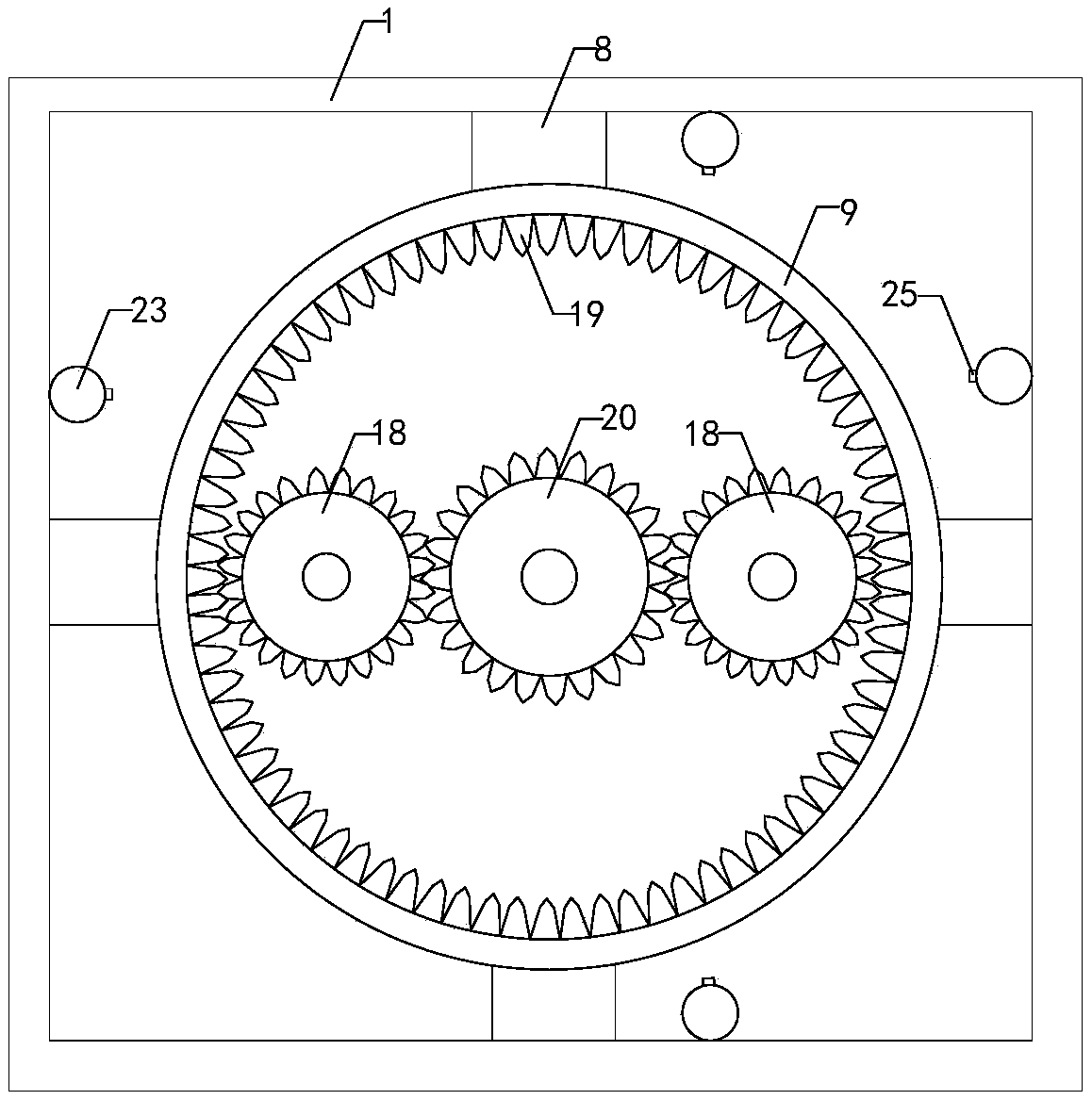

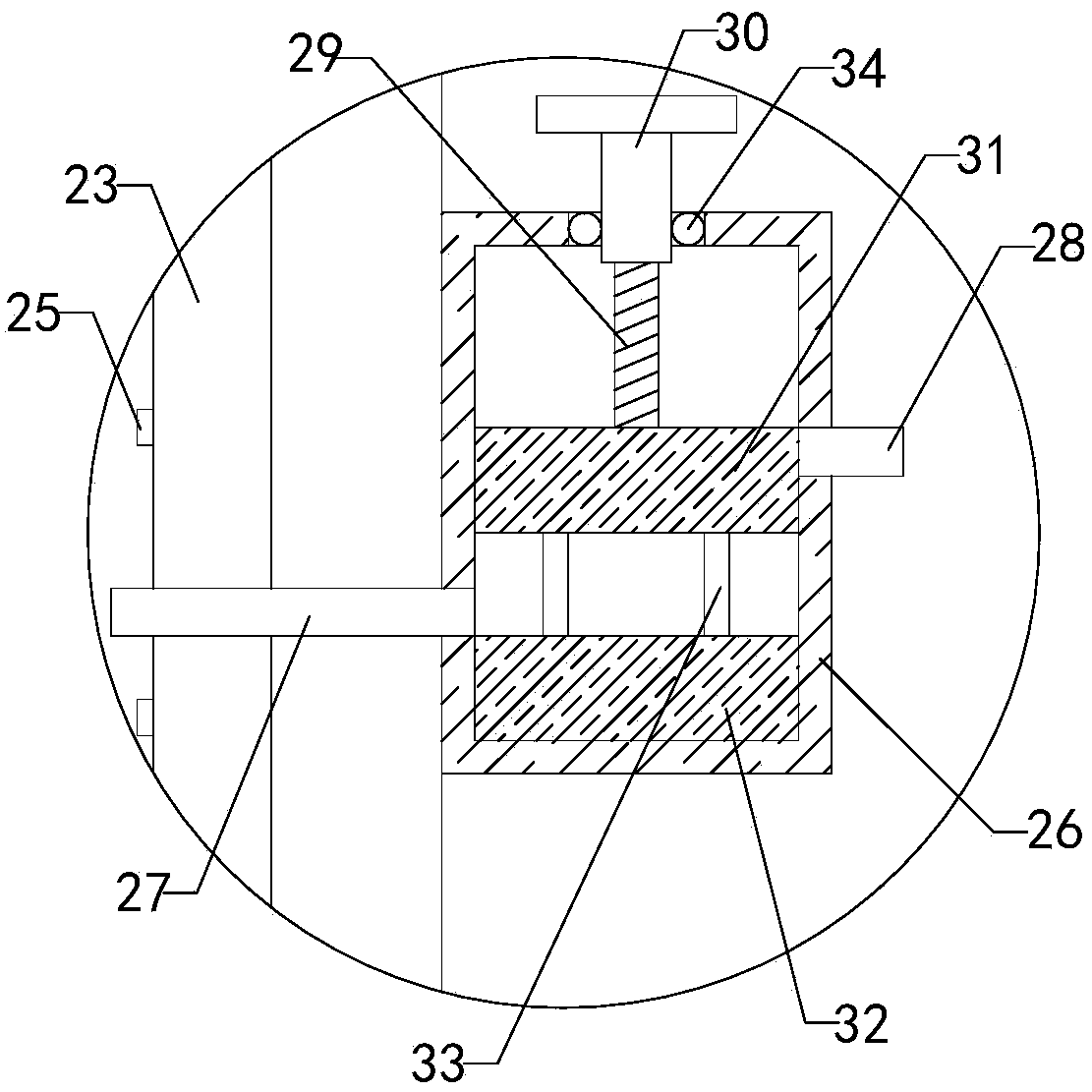

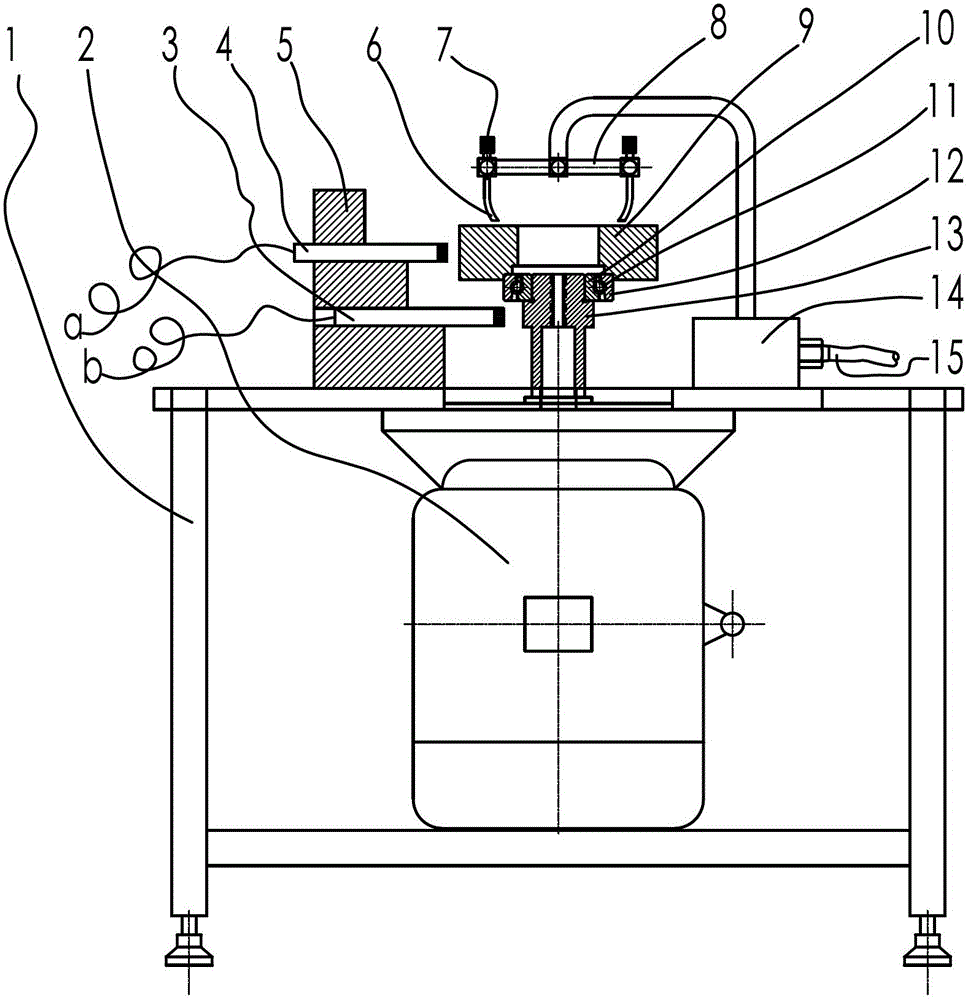

Dye preparation device for garment processing

InactiveCN109012356AStir wellEasy to cleanRotary stirring mixersTransportation and packagingDrive shaftReducer

The invention relates to the technical field of accessory devices for garment processing, in particular to a dye preparation device for garment processing. The stirring efficiency is improved and thestirring effect is enhanced, a working chamber is convenient to clean, and use reliability is raised; and the configuration in the working chamber is convenient to observe and practicality is enhanced. The device of the invention comprises a preparation box, a motor, a reducer, a feed pipe, a discharging tube, a water supply pipe, a transmission shaft, four connecting plates, a ring gear, an upperdead plate, a lower dead plate, two rotating shafts, a first ball bearing, a second ball bearing, a third ball bearing, two fourth ball bearings, two fifth ball bearings, two first gears, internal teeth, a second gear, multiple first stirring blades and multiple second stirring blades, and further comprises four nozzles, four medium pressure pumps and a sampling device. The sampling device comprises a sampling box, a connecting tube, a sampling tube, a threaded rod, a threaded tube, an upper sealing plate, a lower sealing plate and a connecting rod.

Owner:YANCHENG DIJIANI CLOTHING

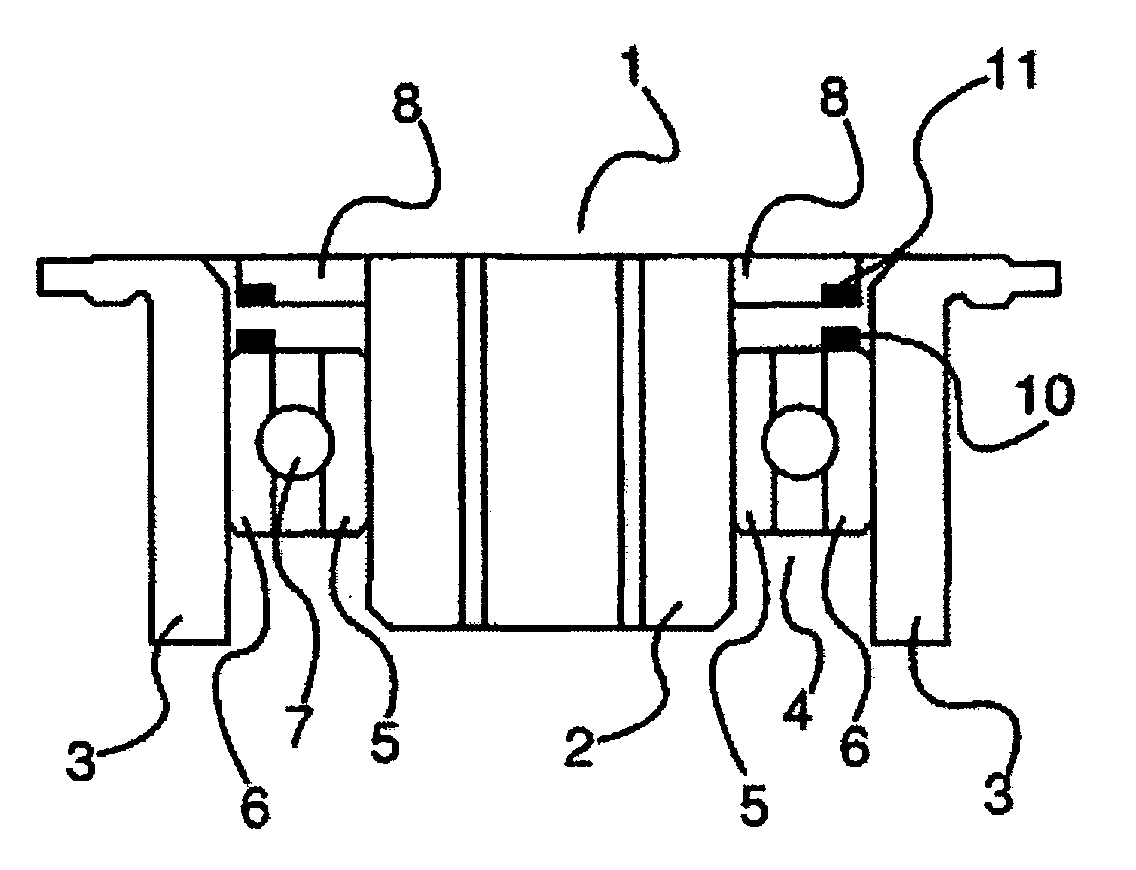

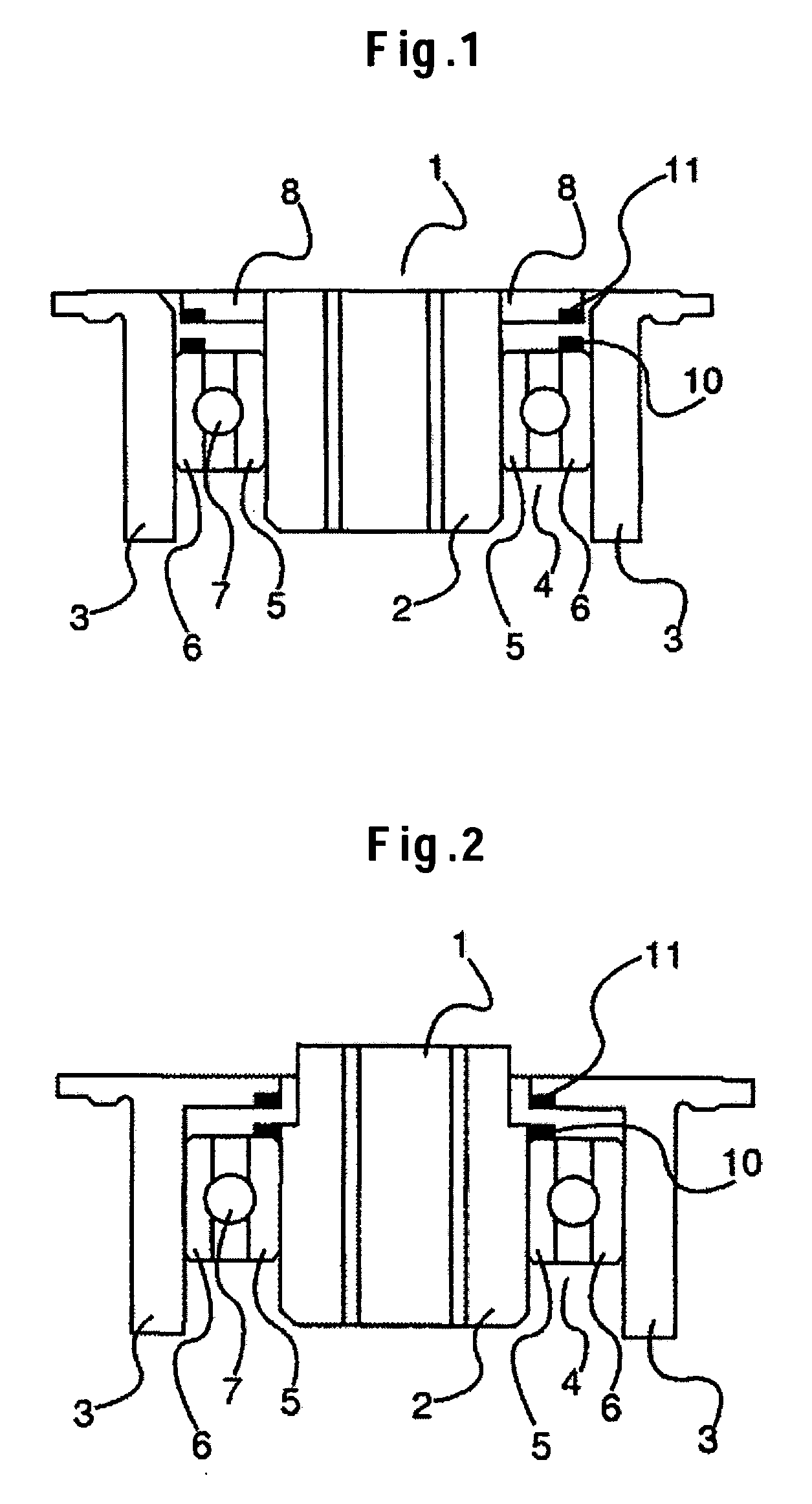

Bearing mechanism, carriage assembly, and magnetic disk drive

InactiveUS20060083453A1Reduce the overall heightThin structureRolling contact bearingsRecord information storageEngineeringMagnet

Embodiments of the invention are directed to keeping a height of a pivot bearing low in order to build a thinner magnetic disk drive. In one embodiment, a ball bearing is provided between a shaft and a sleeve. An inner race of the ball bearing is secured to the shaft through bonding or the like. An outer race of the ball bearing is secured to the sleeve through bonding or the like. A bearing ball is placed between the inner race and the outer race of the ball bearing. A magnet is fitted to the outer race of the ball bearing. A magnet is mounted on a circular plate mounted on one end of the shaft. The magnet is located at a position opposing the magnet mounted on the outer race so as to generate a repulsive force therebetween.

Owner:WESTERN DIGITAL TECH INC

Swivel ball bearing

A swivel bearing assembly consists of an outer housing, a ball and a shaft, a cover, and ball bearings, wherein a free-zone channel.A free-zone channel allows the ball bearings to roll freely in the assembly as they follow the motion of the ball and shaft. The ball bearings eliminate friction between ball and outer housing. The ball and shaft can have simultaneous rotational and angular motion. Only unidirectional load can be applied to the bearing in the direction of the mounting surface.

Owner:BRODOWSKI JOHN

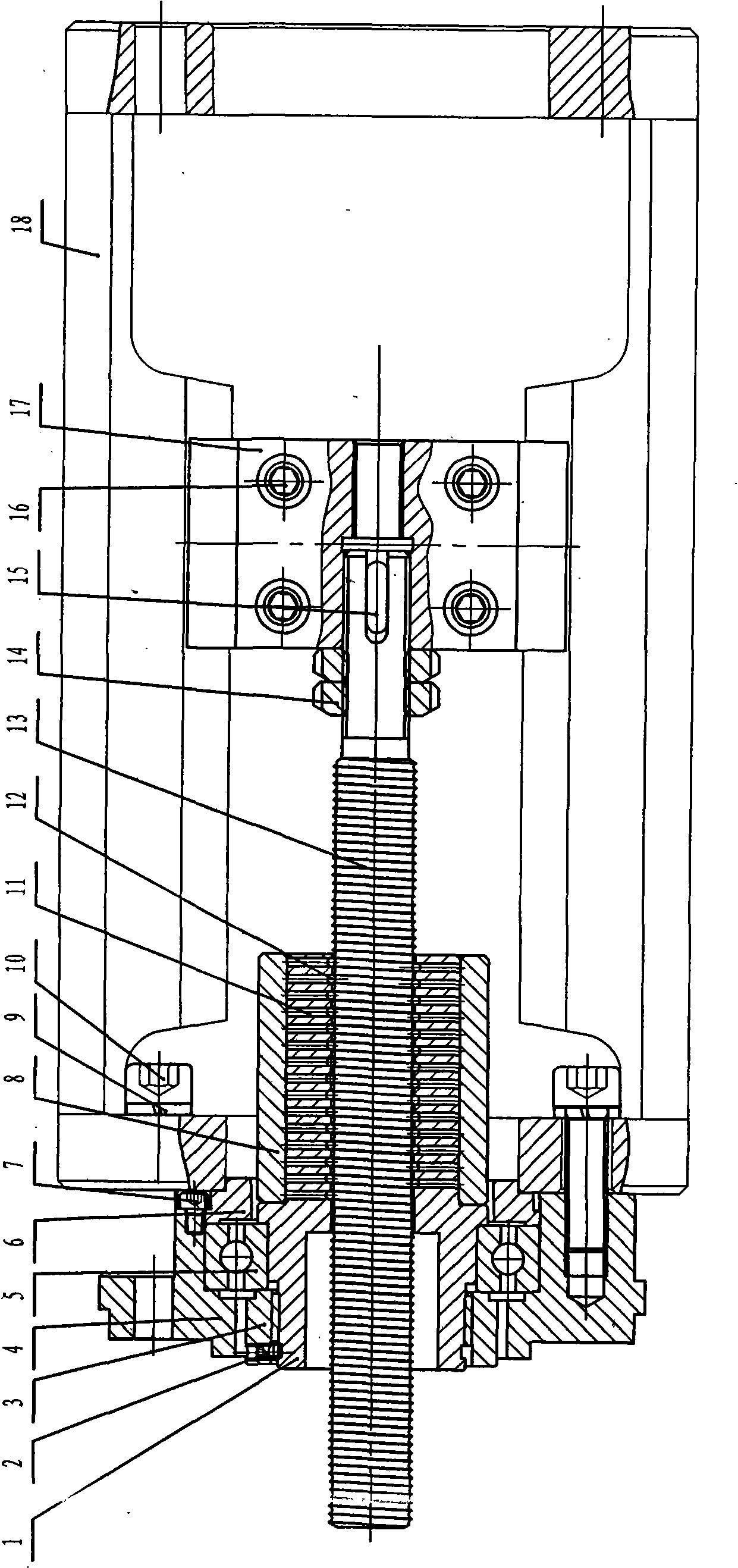

Pre-tightening device of coupled thrust ball bearings

PendingCN107830065AIncrease contact areaUniform elasticityRolling contact bearingsShaftsDrive shaftPre compression

Disclosed is a pre-tightening device of coupled thrust ball bearings. The pre-tightening device of coupled thrust ball bearings includes a nut, a circular inclined section spring, and two clamping plates. The two thrust ball bearings are arranged on a transmission shaft back to back in a sleeving mode and the outer rings are all supported on a bearing seat; the inner rings of the two thrust ball bearings are fixed through the nut and a first shaft sleeve; the outer rings of the two thrust ball bearings are fixed through a bearing end cover, and a second shaft sleeve; a first clamping plate isarranged on the shaft shoulder of the transmission shaft; a second clamping plate is arranged on an inner ring of the thrust ball bearing close to the shaft shoulder of the transmission shaft; an elastic part is arranged between the first clamping plate and the second clamping plate in a clamping mode; and the elastic part is pressed by force when the nut is tightly screwed. According to the pre-tightening device of coupled thrust ball bearings, the circular inclined section spring is adopted, the contact area is larger and elastic force is uniformed. During arranging, the spring is forced togenerate certain pre-compression by screwing the nut tightly in different degrees, and amount of clearance generated by abrasion of a rolling element and a roller path can be compensated automaticallyin virtue of a characteristic of automatic recovery of deformation of a spring.

Owner:LUOYANG INST OF SCI & TECH

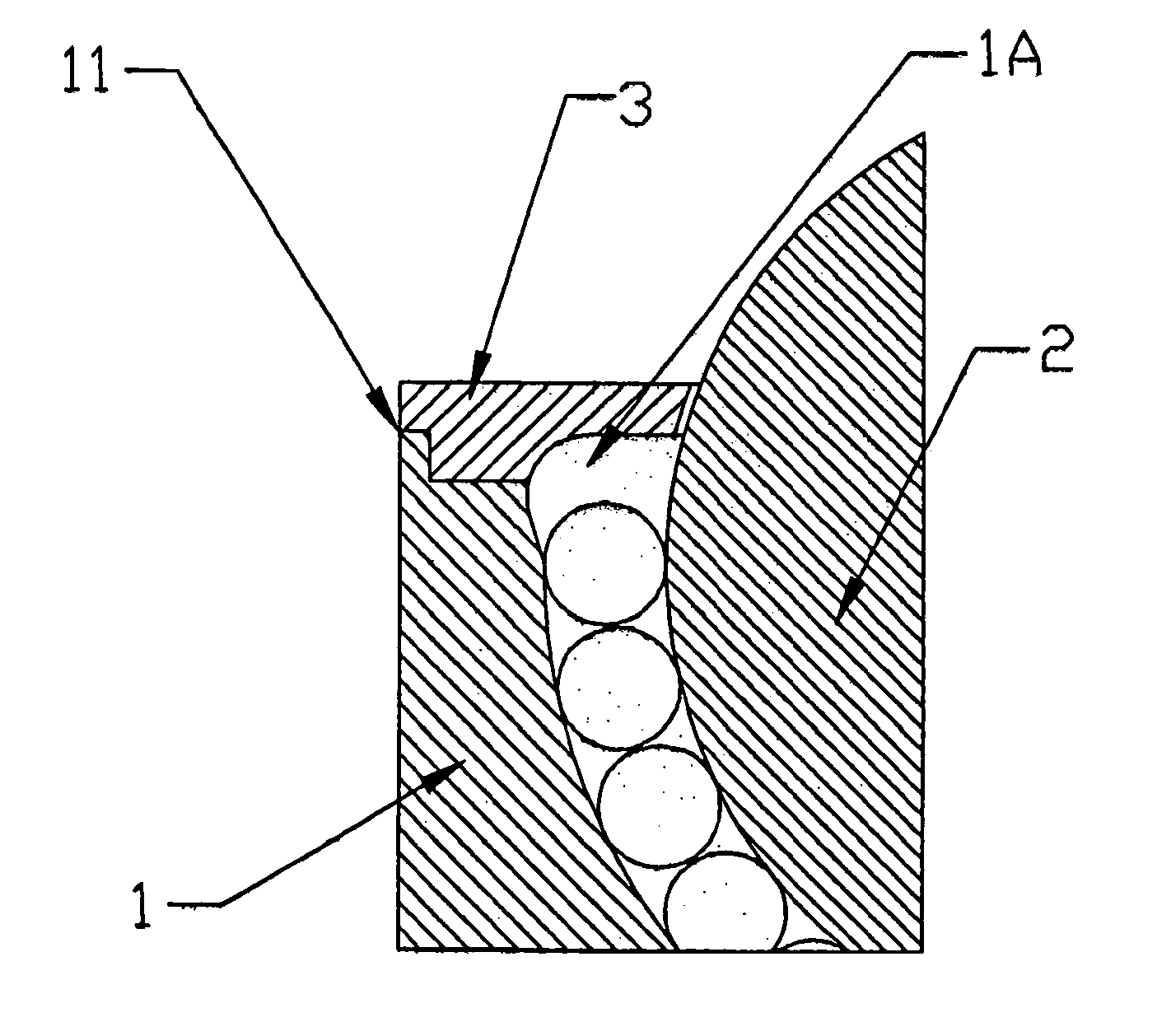

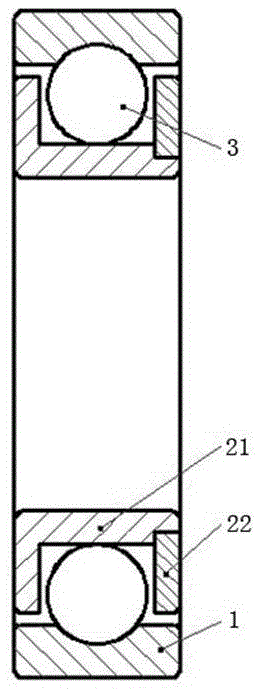

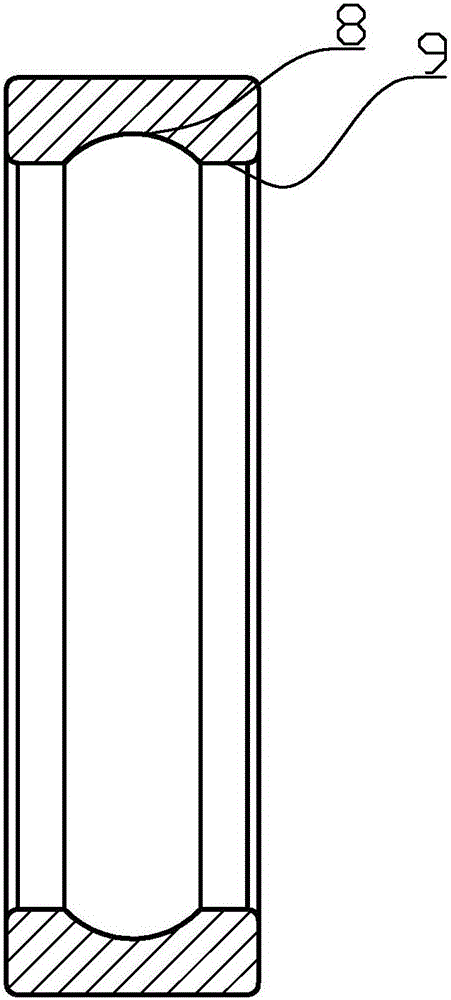

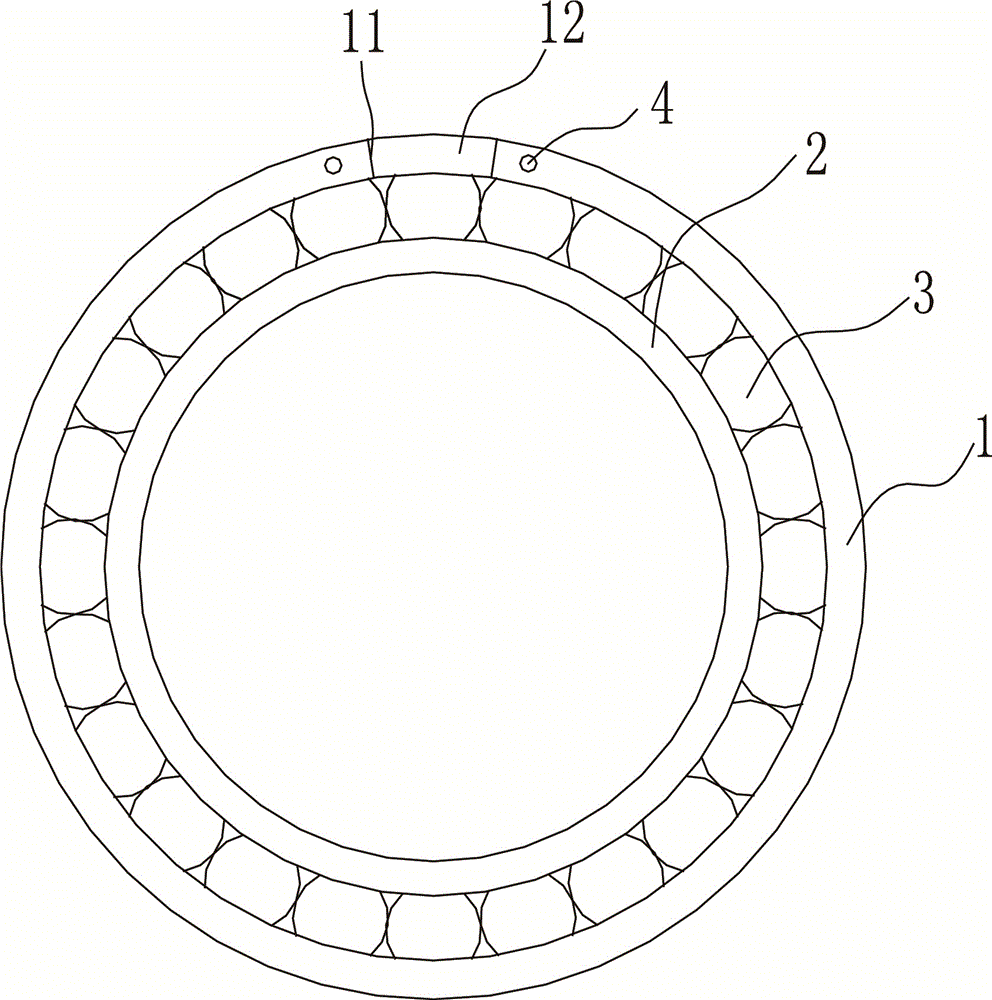

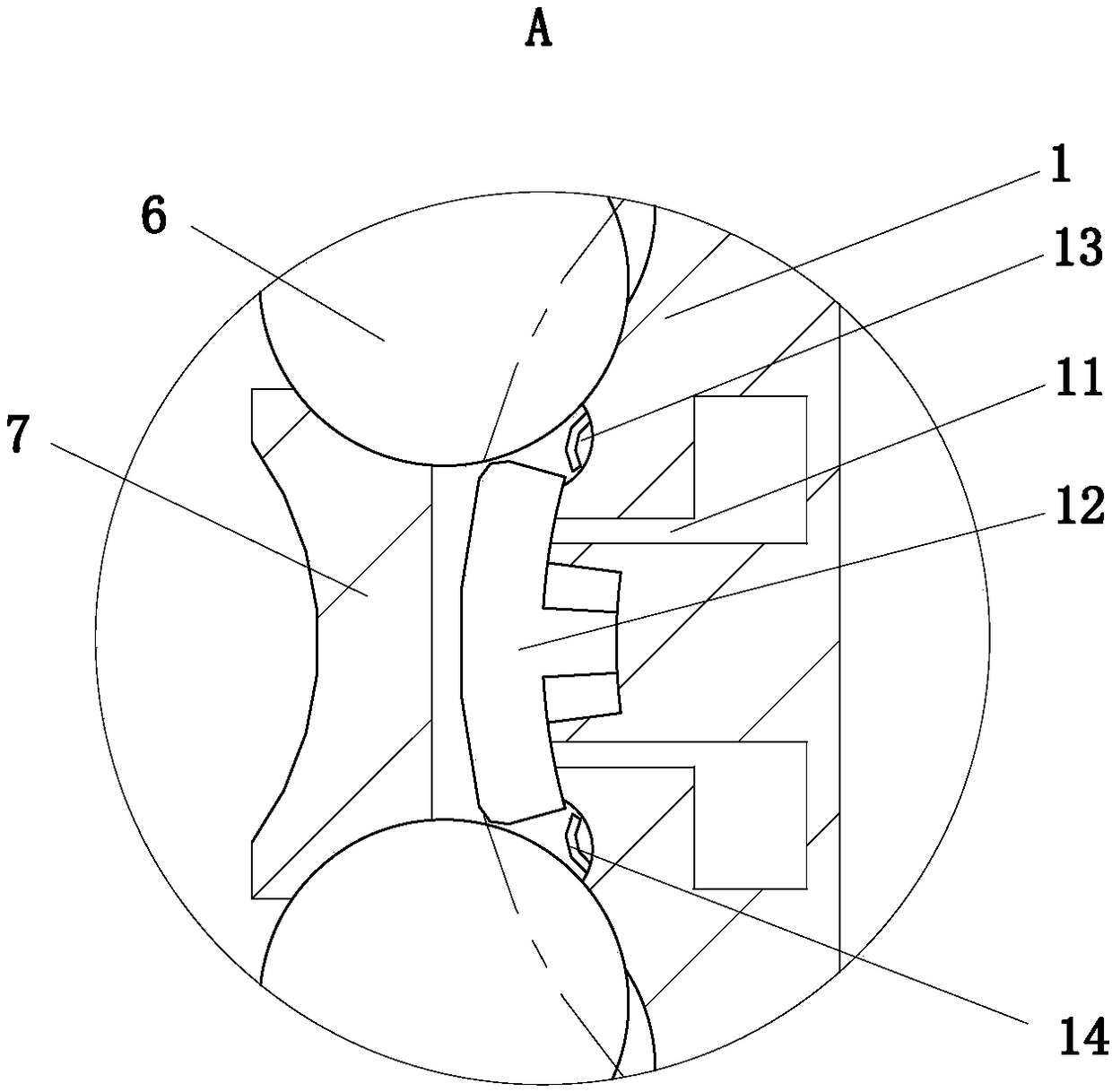

Bearing inner ring and full-ball bearing

ActiveCN105134765AReduce frictional torqueImprove stabilityBall bearingsBearing componentsEngineeringCentrifugal force

The invention provides a bearing inner ring and a full-ball bearing. The full-ball bearing comprises a ball, the bearing inner ring and a bearing outer ring, wherein the axes of the bearing inner ring and the bearing outer ring extend left and right. The bearing inner ring is provided with a flat outer circumferential face used for being in rolling fit with the ball, and the diameter of the flat outer circumferential face is unchanged in the axial direction. An inner circumferential face of the bearing outer ring is provided with an arc rolling track which is in rolling fit with the ball and protrudes outwards in the radial direction. Thus, the groove curvature of the bearing inner ring is almost infinite and far higher than that of the arc rolling track of the bearing outer ring, friction caused by differential sliding is eliminated, and frictional torque is reduced. The bearing inner ring is free of channels, so that the machining difficulty and machining cost of the bearing inner ring are effectively reduced. Meanwhile, when rotating at high speed, the ball moves outwards in the radial direction under centrifugal force and is tightly attached to the arc rolling track on the inner circumferential face of the bearing outer ring, the arc face of the arc rolling track limits the ball in the axial direction, it is ensured that the ball rotates stably, and bearing stability is improved.

Owner:LUOYANG BEARING RES INST CO LTD

Fluid bearing motor, and disk drive mounted with same

The stop ring having a surface nearly vertical to the rotational center axis, which is projected at the inner periphery of the hollow cylinder of the rotor section, and the stepped surface of the fixed shaft secured on the chassis are opposed to each other with a predetermined slight clearance provided therebetween. The clearance is filled with magnetic fluid, and further, a permanent magnet is disposed on the chassis, opposing to the other surface of the stop ring.

Owner:PANASONIC CORP

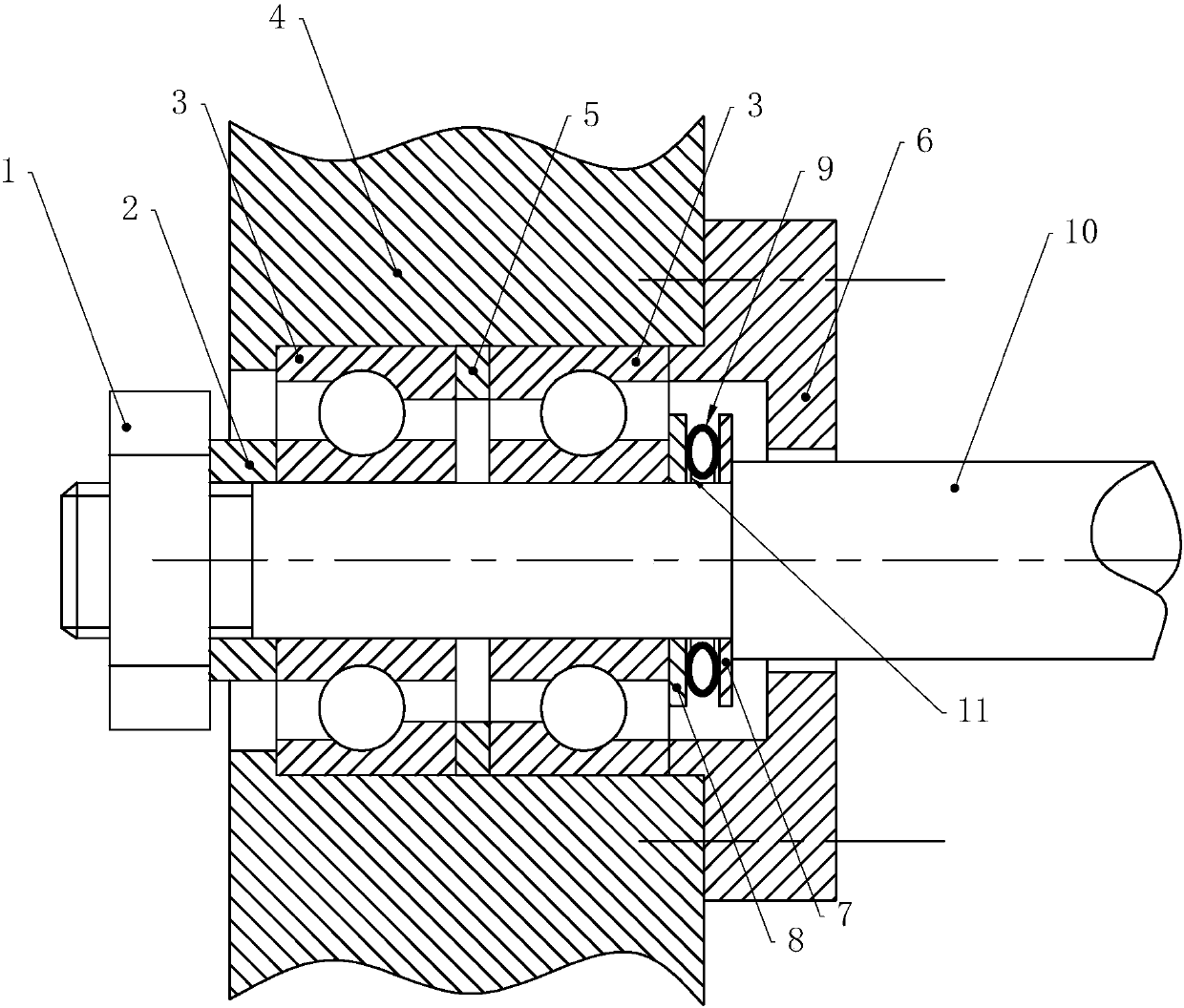

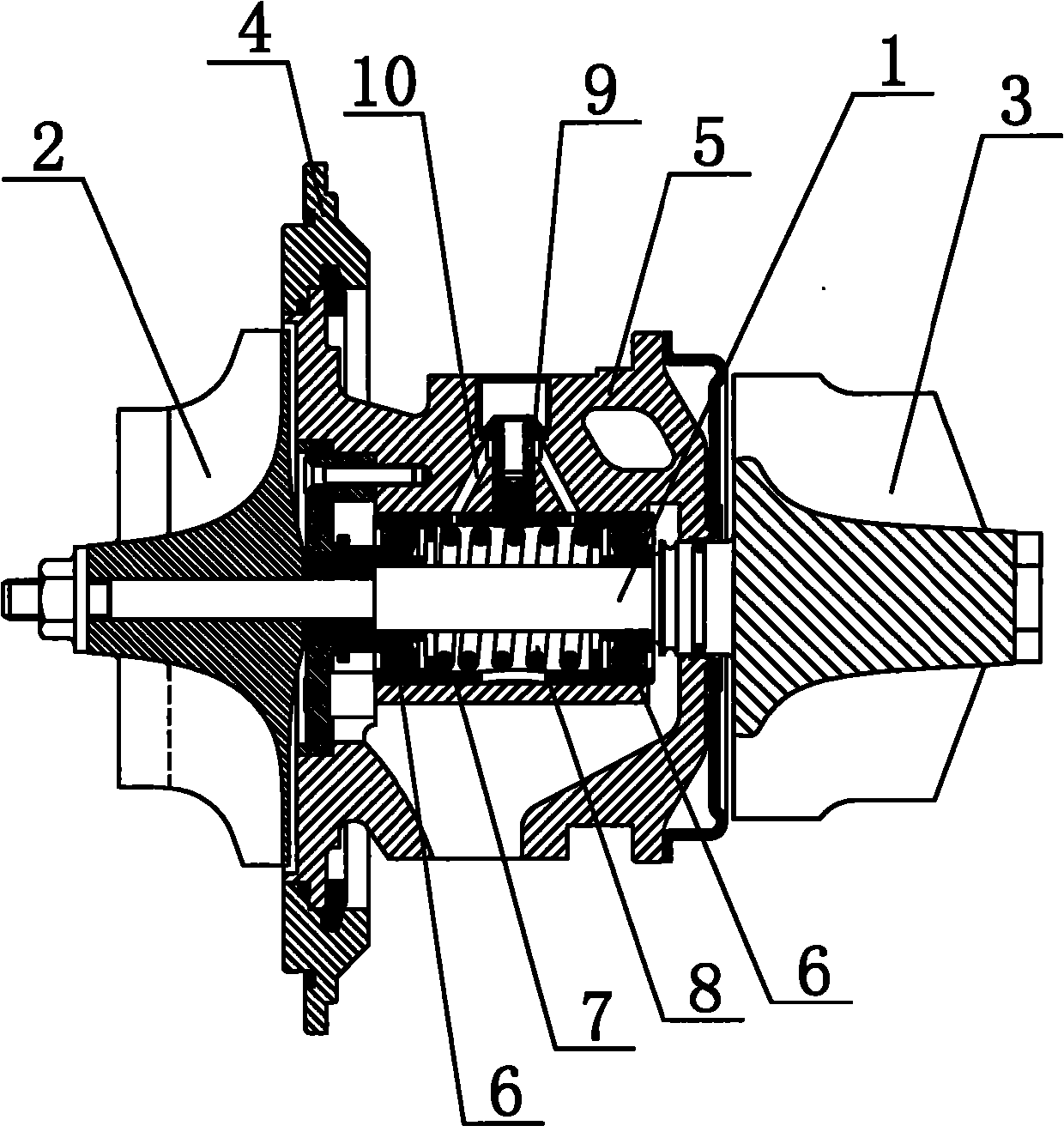

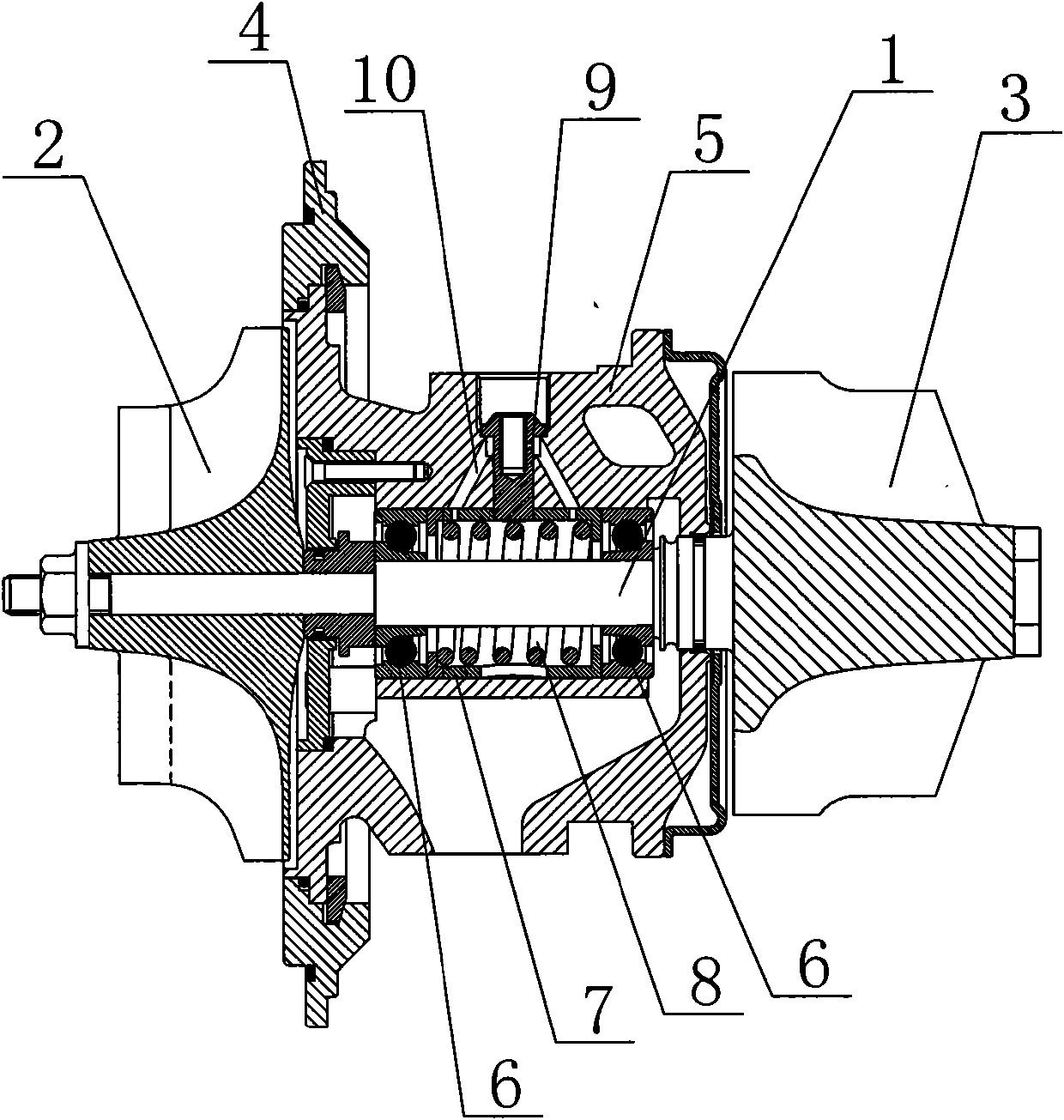

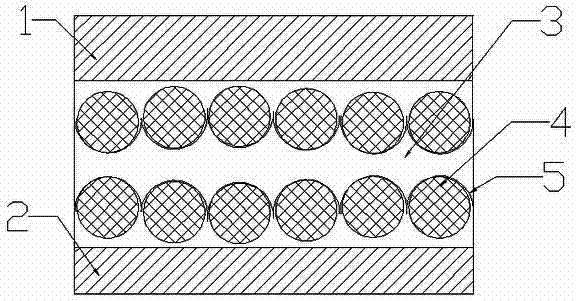

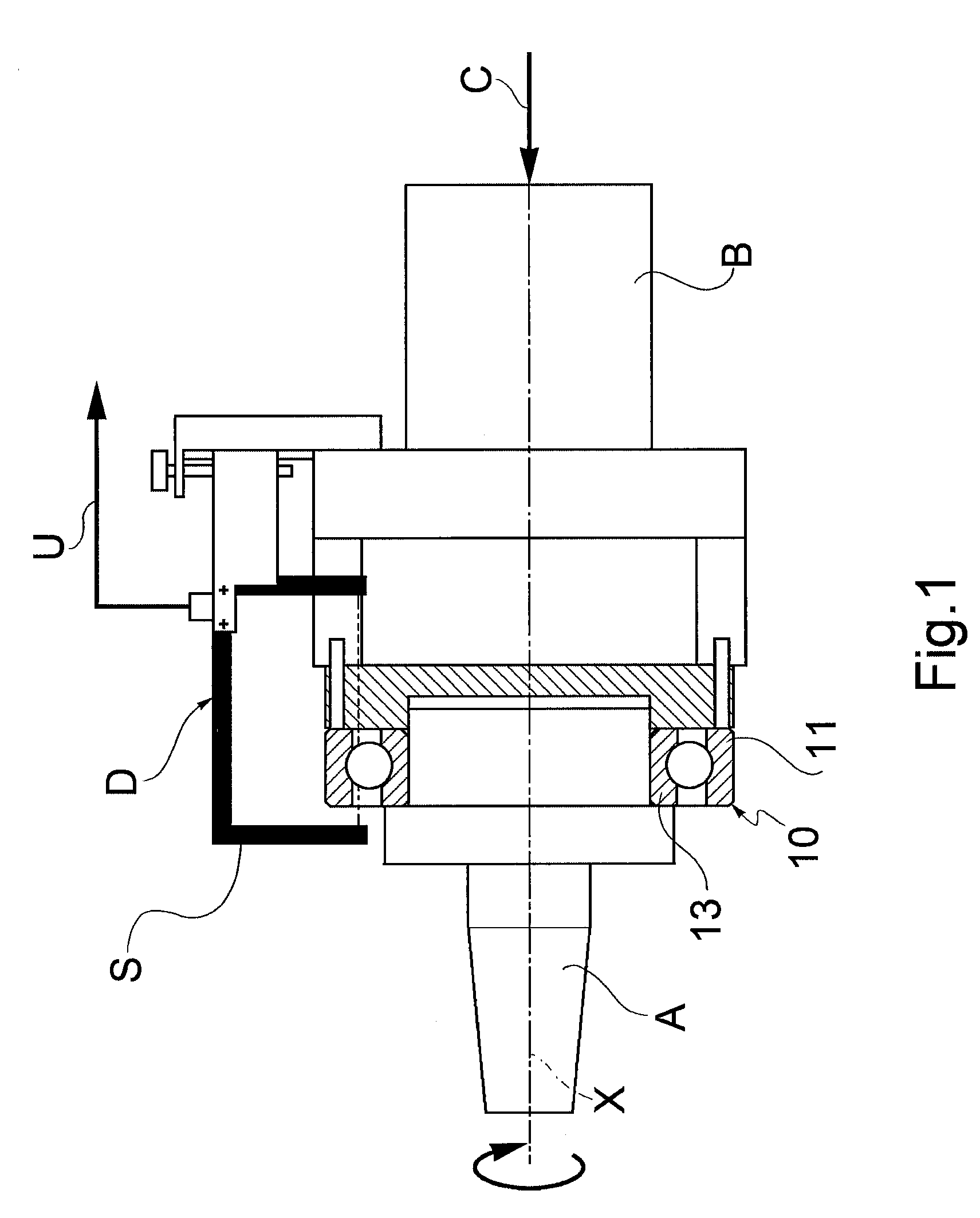

Turbocharger with double ball bearings

InactiveCN101949310AReduce frictionExtended service lifeGas turbine plantsEngine componentsImpellerTurbocharger

The invention discloses a turbocharger with double ball bearings, which comprises a rotor spindle with a turbine and an impeller, an intermediate body and a diffusion board, wherein the rotor spindle is supported by a first bearing and a second bearing to be arranged in the intermediate body; the first bearing and the second bearing are mixing angle contact ceramic ball bearings; a distance spring housing is arranged between the first bearing and the second bearing; a spring is arranged in the distance spring housing; a fuel feed hole is arranged on the intermediate body; a fuel feed locating pin is arranged on the fuel feed hole; and the fuel feed hole is connected with a lubricant passage communicated with the distance spring housing. The turbocharger with double ball bearings has the advantages that the structure is simple; the starting response speed is accelerated; the acceleration performance, the kinaesthetic and the operating feeling of vehicles can be greatly improved; and the requirements on lubricating oil are low and the actual life is enhanced because the friction of the ball bearings is less.

Owner:无锡科博增压器有限公司

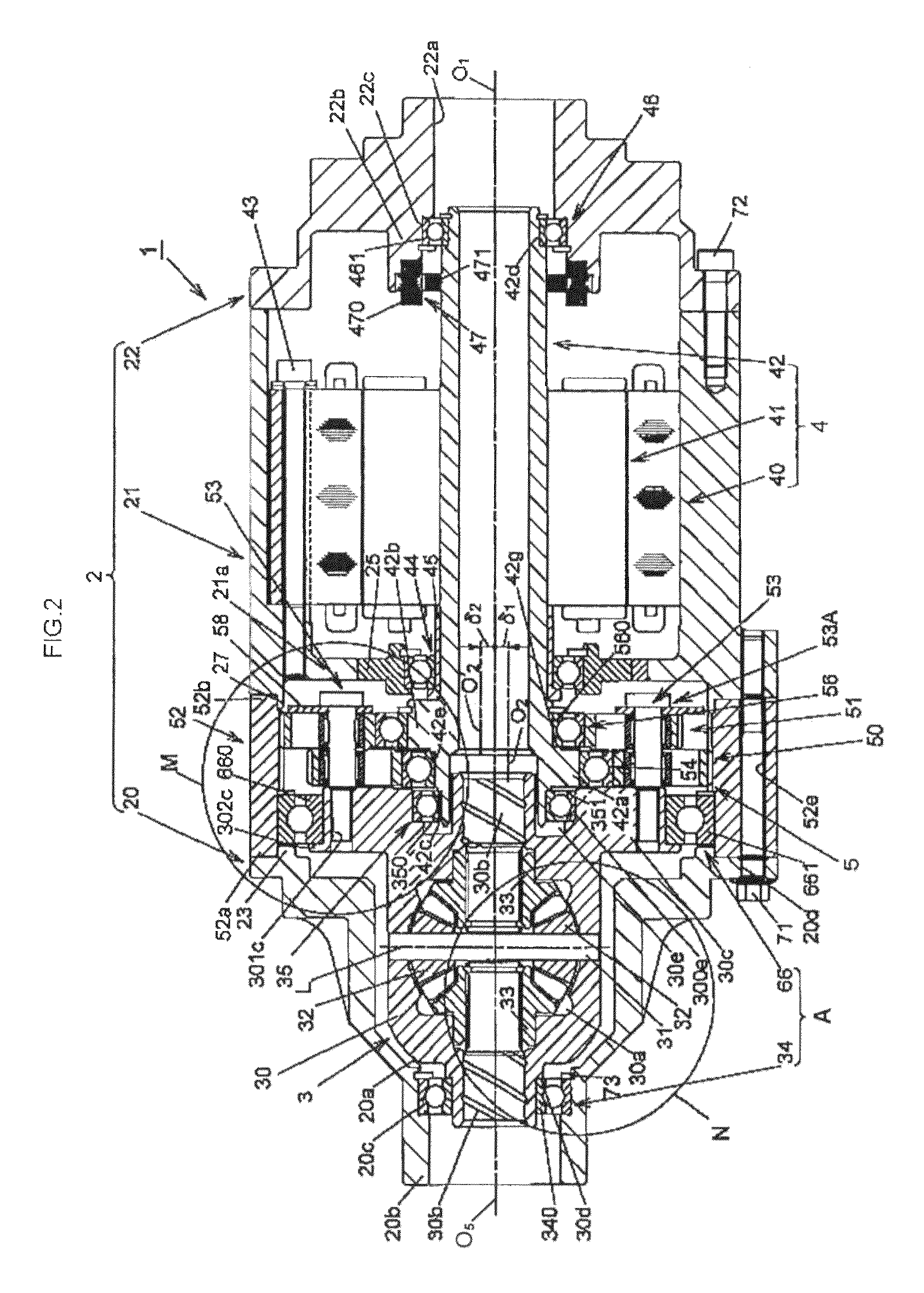

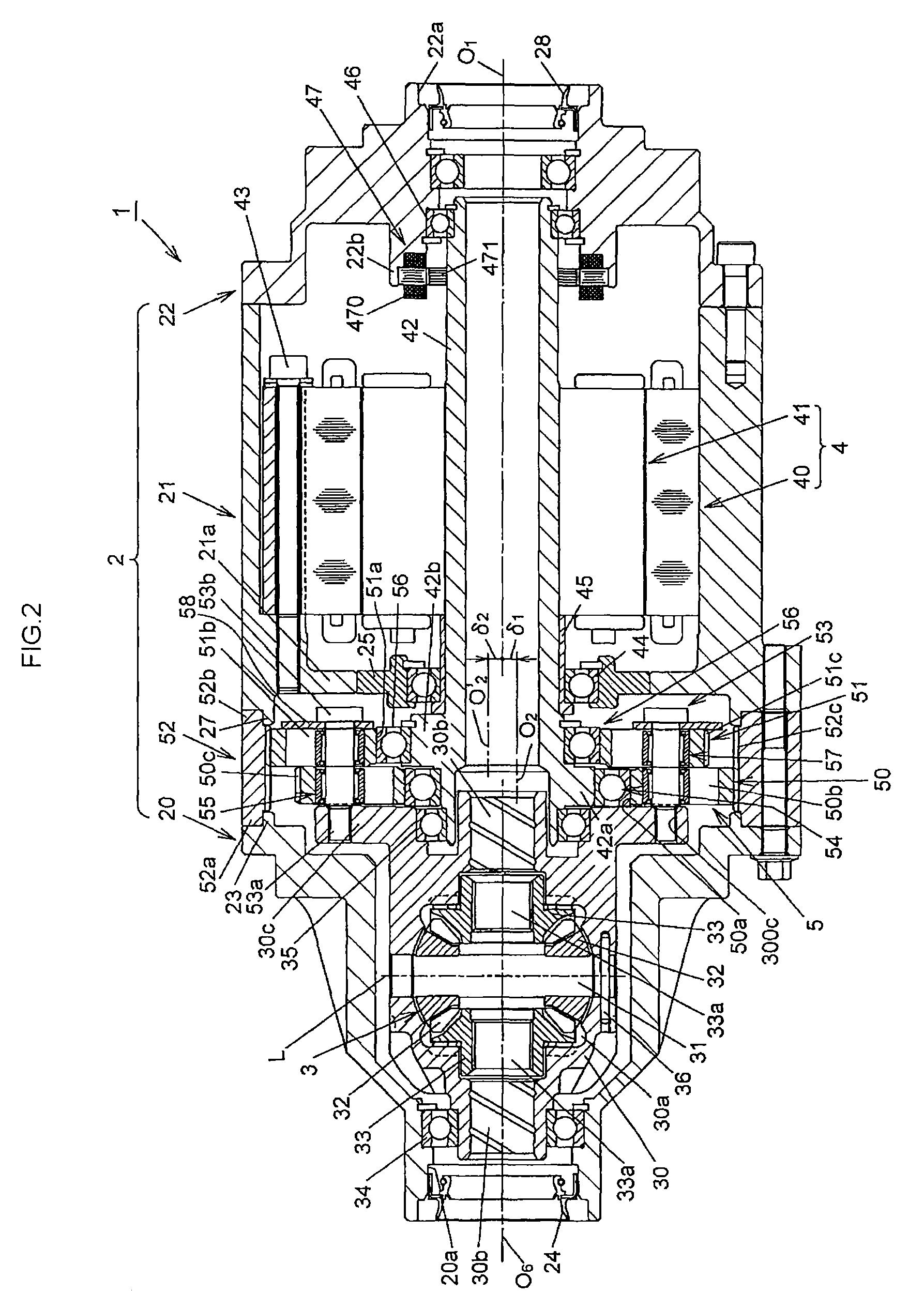

Speed reduction mechanism and motor torque transmission apparatus including the same

Owner:JTEKT CORP

Ball bearing

InactiveCN102338157AReduce frictionReduce coefficient of frictionRolling contact bearingsBearing componentsEngineeringTemperature resistance

The invention relates to a ball bearing. The ball bearing is structurally characterized in that an annular dual-row ball roller path is arranged correspondingly between a bearing outer ring and a bearing inner ring; two columns of balls are arranged on the annular dual-row ball roller path; half-moon-type concave antifriction retainers which are arrayed uniformly are placed among the balls; and I-shaped or rectangular structural lubrication holes are arranged at the middle position of the half-moon-type concave structure. The friction between the balls and the roller path can be reduced effectively by the structure; teflon materials are adopted as lubrication materials, which is good for prolonging the service life of the bearing; and the teflon materials have the advantages of extremely low friction coefficient, high self-lubrication capability, abrasion resistance, high-temperature resistance and the like.

Owner:栾清杨

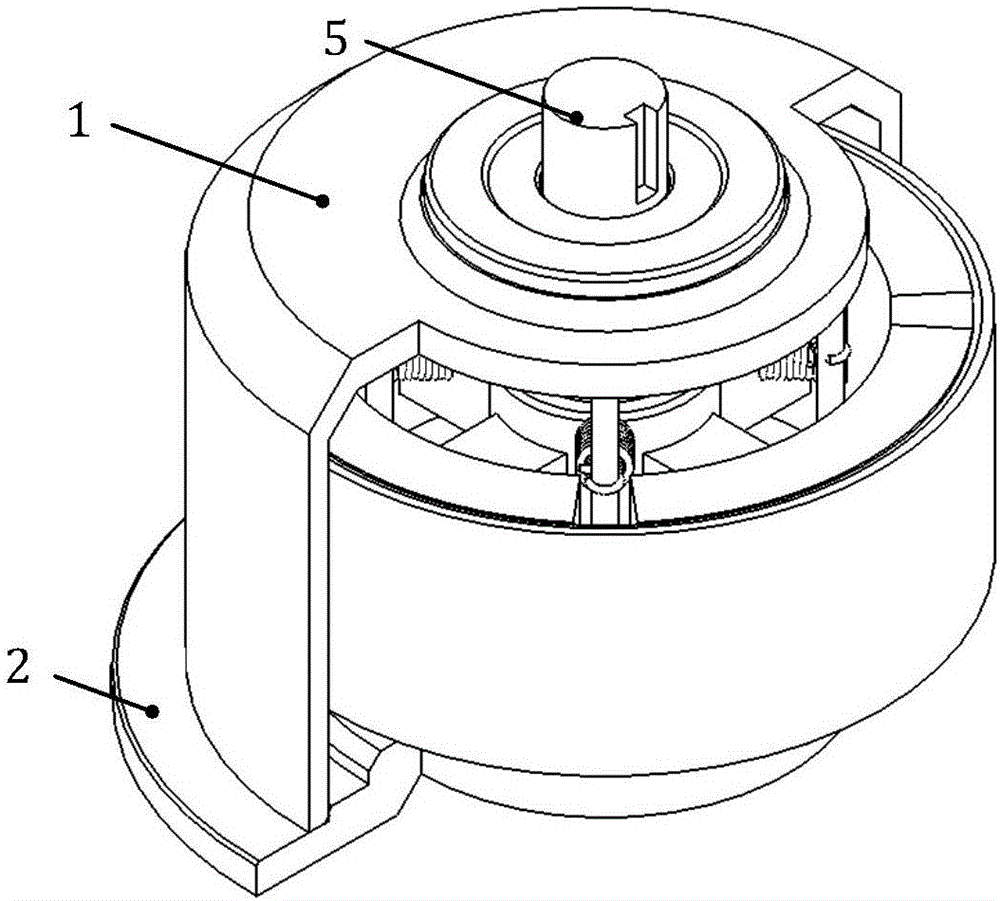

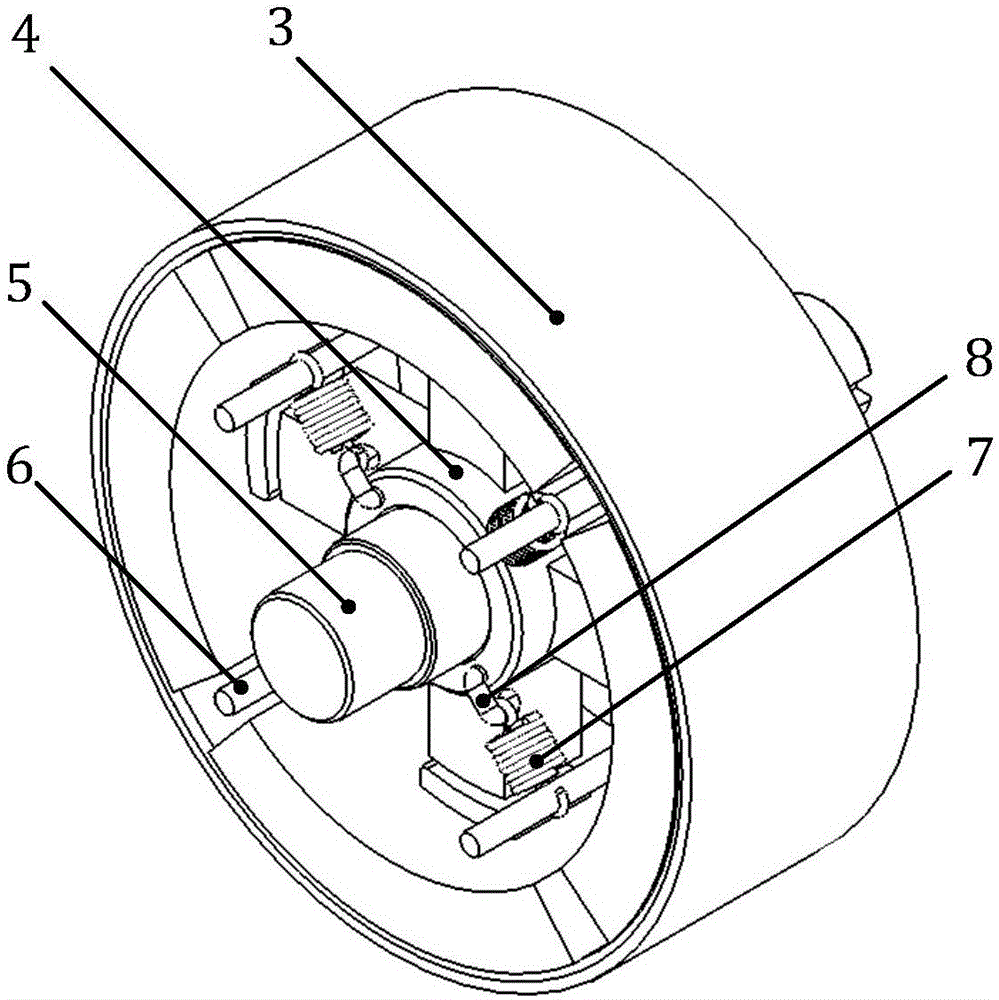

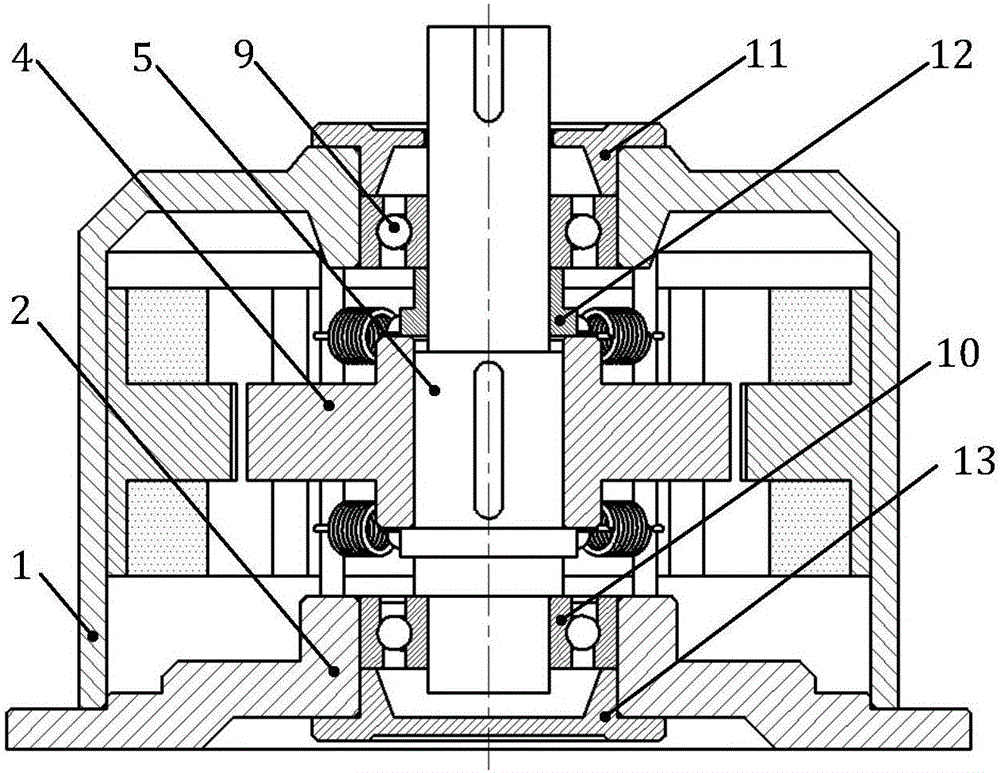

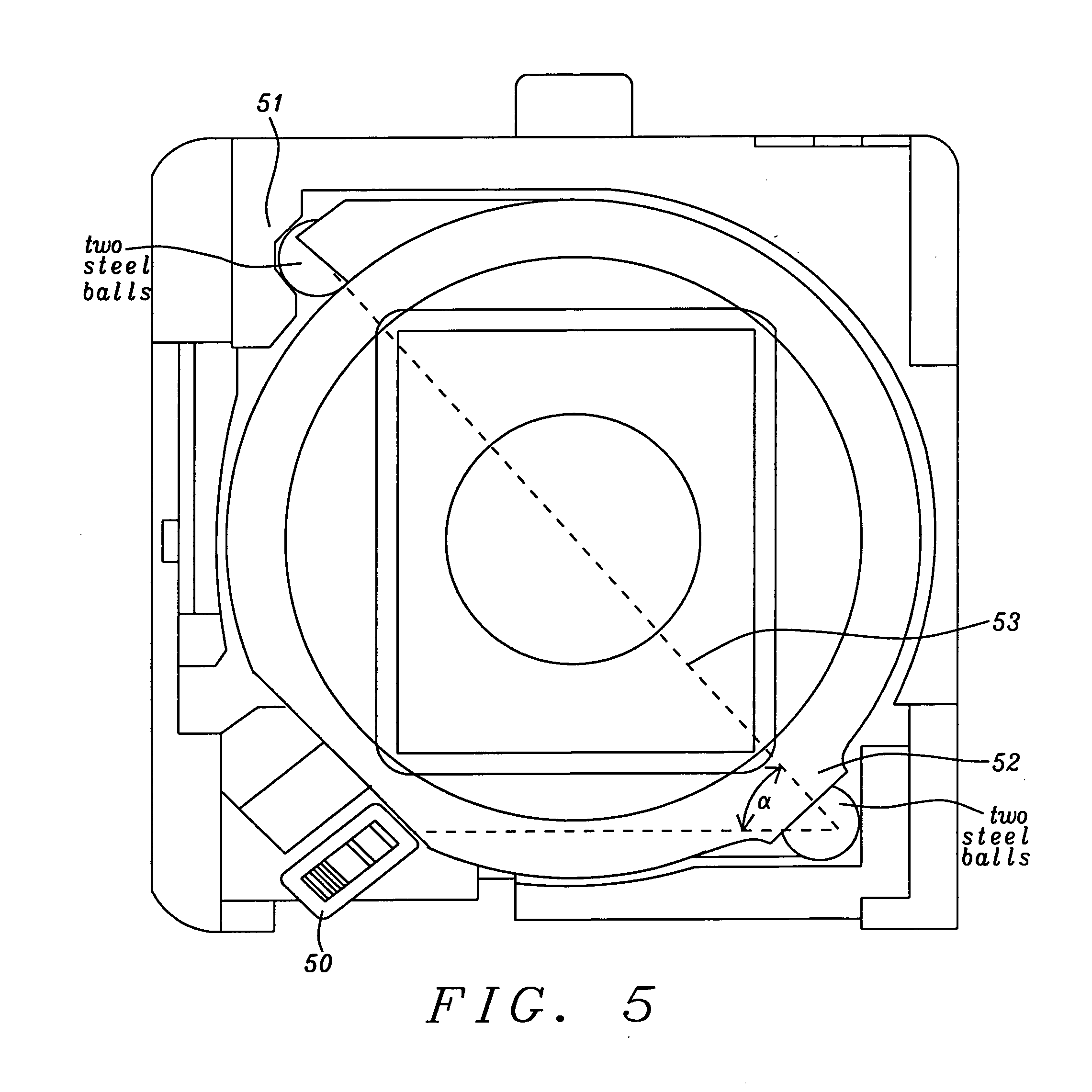

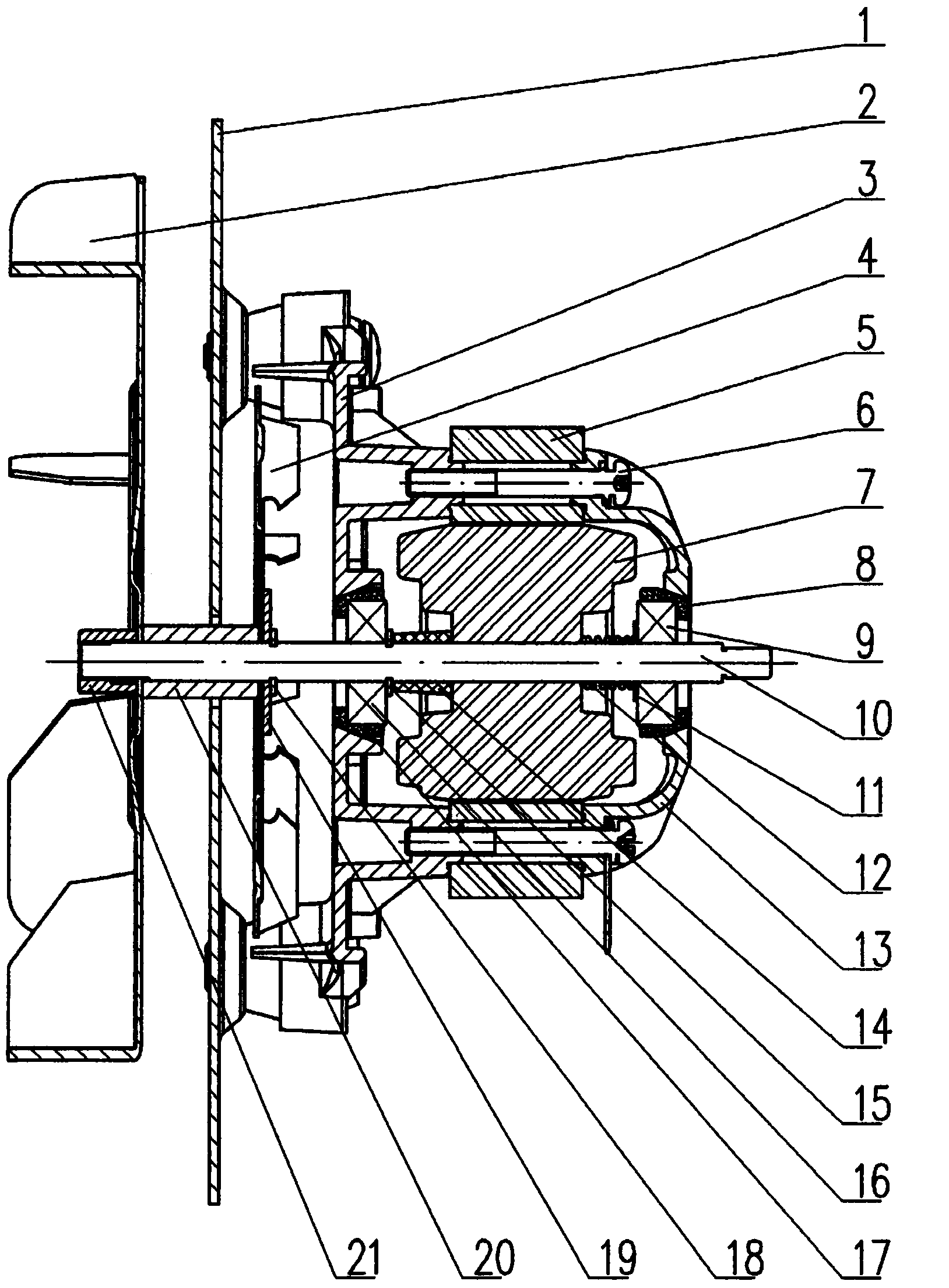

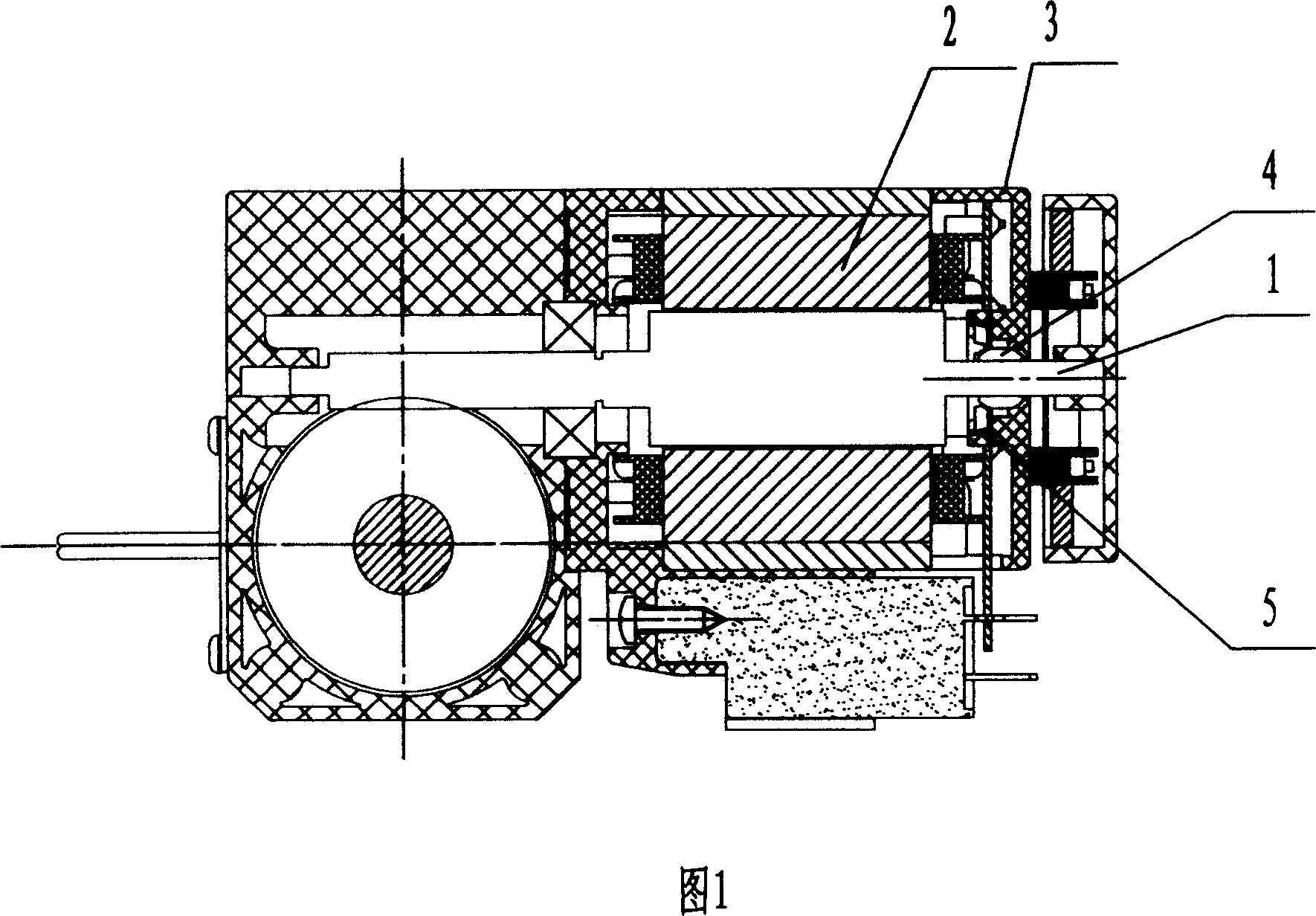

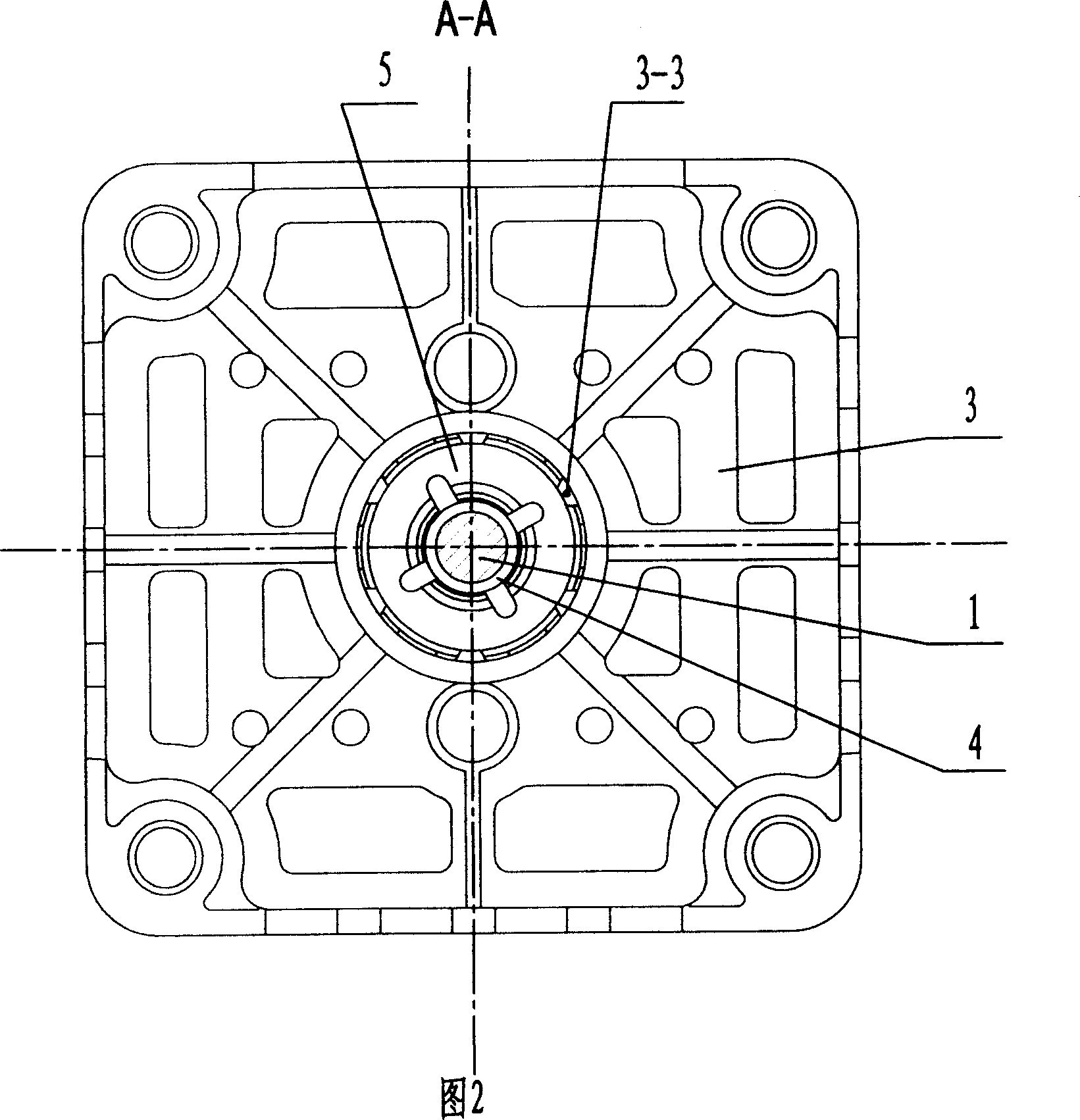

Ball bearing motor capable of adjusting center automatically

ActiveCN103532290ALow machining accuracy requirementsReduce assembly requirementsCooling/ventillation arrangementSupports/enclosures/casingsLow noiseLow voltage

The invention discloses a ball bearing motor capable of adjusting the center automatically and relates to the technical field of micro motors. The ball bearing motor comprises a main stator core component 5, a rotor component, a front-end support 3, a tail-end support 13, a front-end bearing, a tail-end bearing, a self-heat-dissipation fan blade component and a load fan blade component. The ball bearing motor has the characteristics of simple structure, convenience in machining, low noise, long service life of ball bearings, good low-voltage startability, stable rotating speed, higher efficiency, capability of automatic center adjustment and the like. As a shaded pole type micro motor, the ball bearing motor is applied to equipment with higher rotating speeds, longer service lives and lower noise.

Owner:科力尔电机集团股份有限公司

Method and device for measuring contact angle of ball bearing

ActiveCN102749063AEasy to operateAccurate and reliable measurement result dataMachine bearings testingElectric machineryEngineering

Owner:WUXI NO 2 BEARING

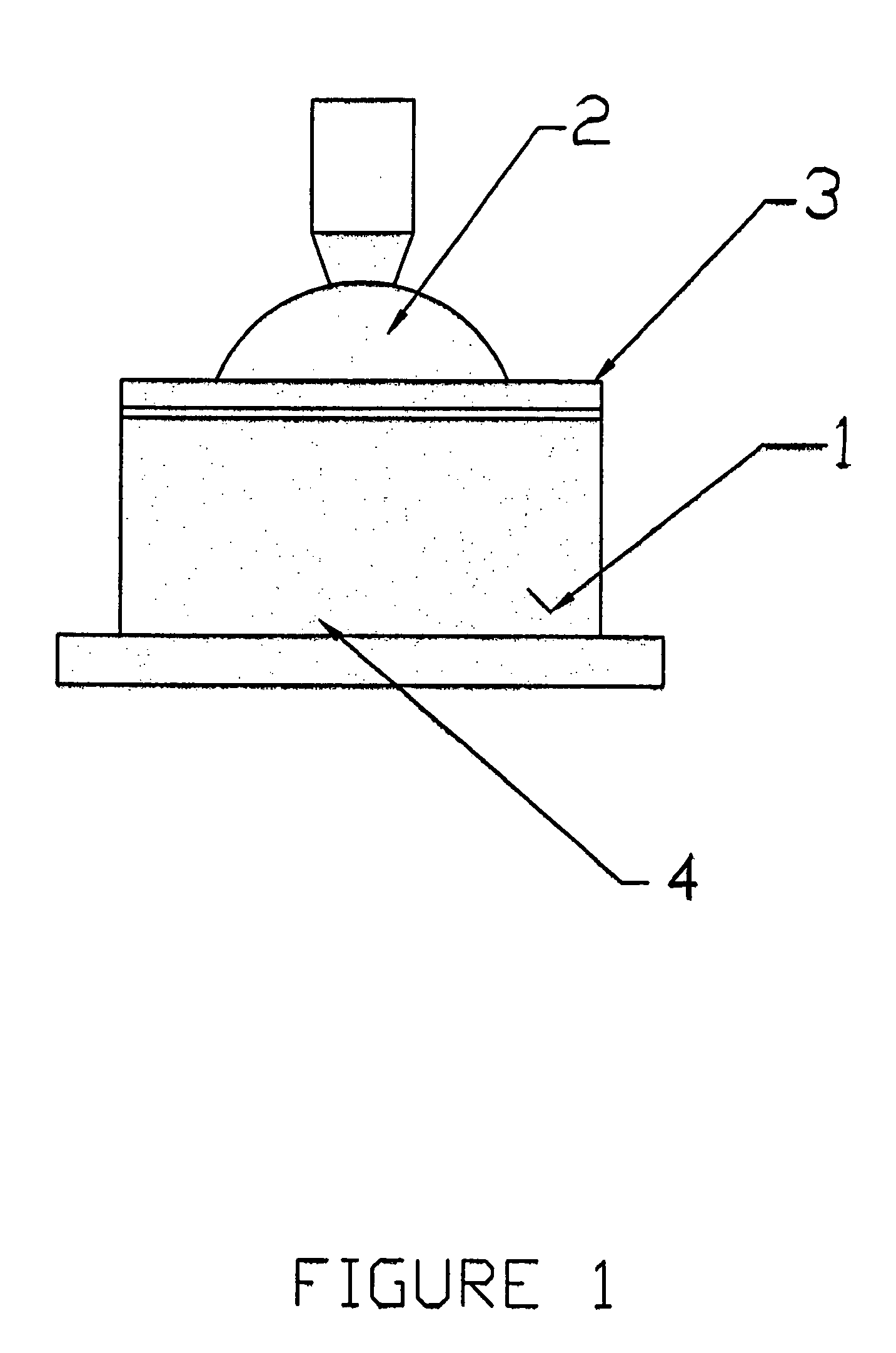

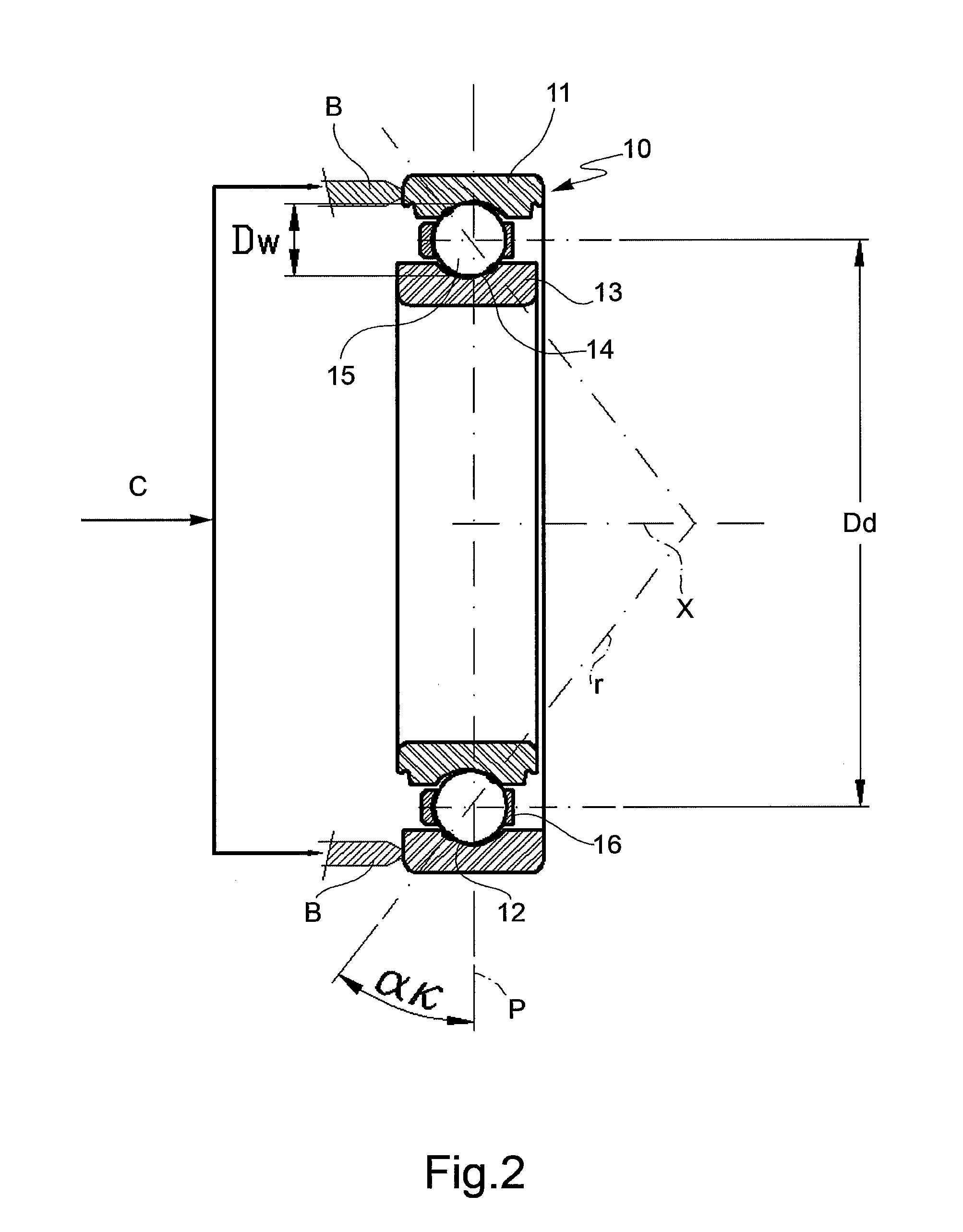

Method of Determining the Contact Angle of a Ball Bearing

ActiveUS20110228261A1Accurate measurementEasy to measureAngle measurementMachine bearings testingEngineeringBall bearing motor

To determine the contact angle of a ball bearing, one of two rings is rotated while the other ring is held stationary. The number of revolutions of the rotated ring and the number of revolutions accomplished in the same period by the balls, and therefore by the retaining cage, are detected. The revolutions of the balls are detected through an optical detecting device which projects a radiation through the bearing, in the gap between the outer and inner rings, whereby the radiation is intercepted directly by the balls and / or the cage. The contact angle is determined using the following parameters: the number of revolutions of the rotating ring, the number of revolutions of the balls or of the cage, the diameter of the balls, and the pitch diameter.

Owner:AB SKF

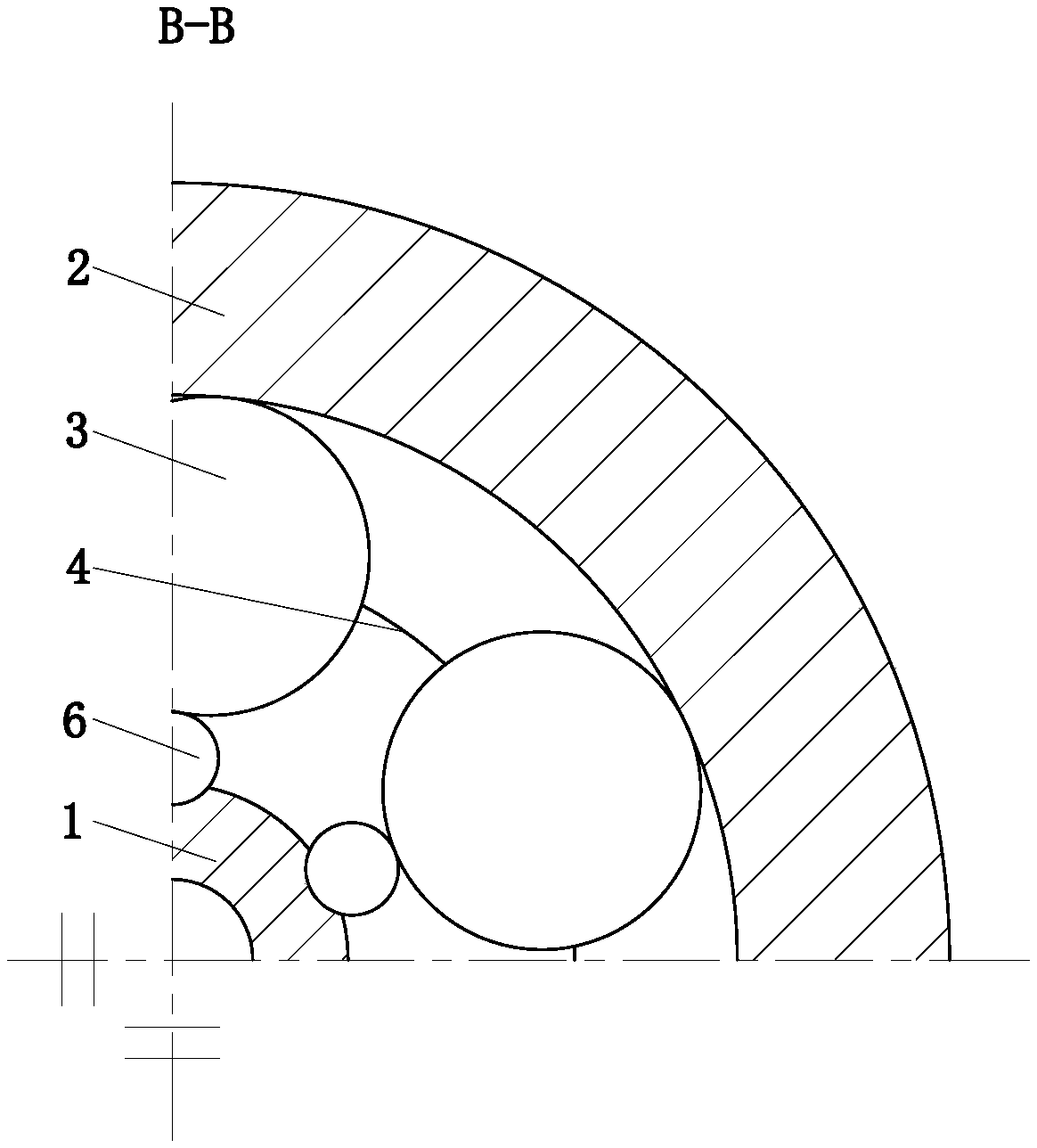

Axial and radial combined deep groove ball thrust ball bearing

InactiveCN106089994AImprove bearing capacityExtended service lifeRolling contact bearingsBearing componentsSteel ballPetroleum engineering

The invention discloses an axial and radial combined deep groove ball thrust ball bearing which comprises a radial bearing assembly and an axial bearing assembly; the radial bearing assembly comprises an outer ring, an inner ring and a radial bearing steel ball mounted between the outer ring and the inner ring in a rolling manner; the radial bearing steel ball is mounted on a radial retainer; the axial bearing assembly comprises an inner ring, a race and an axial steel ball group connected between the inner ring and the race in a rolling manner; and the axial steel ball group is mounted on an axial retainer. The axial bearing force of the axial and radial combined deep groove ball thrust ball bearing is greatly increased; the axial and radial combined deep groove ball thrust ball bearing can bear higher revolving speed, saves the mounting space, is convenient to mount, reduces the mounting spoilage, and prolongs the service life; the inner ring of the radial bearing assembly serves as a blowout patch of the axial bearing assembly, so that the space is saved, the cost is reduced, and the service life is prolonged; and the axial and radial combined deep groove ball thrust ball bearing is compact in structure and more stable in operation, improves the coaxiality, can bear higher revolving speed, and lowers the noise.

Owner:DEQING TIANMA BEARING CO LTD

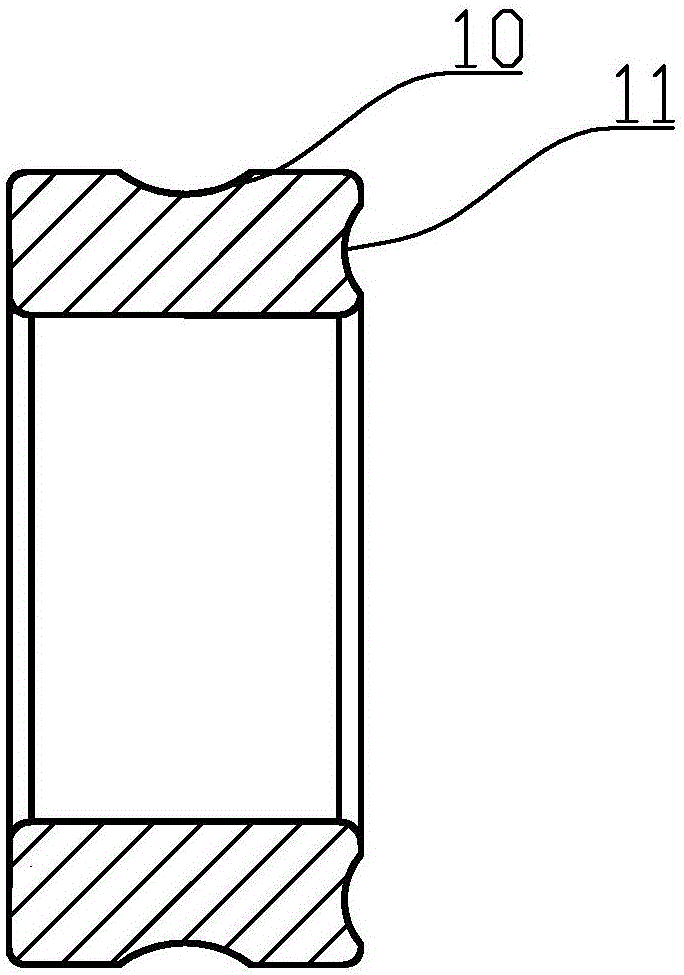

Crowded ball bearing

InactiveCN104314988AImprove bearing capacityPrevent running outBall bearingsBearing componentsMechanical engineeringBall bearing motor

The invention discloses a crowded ball bearing which comprises an outer bearing ring and an inner bearing ring, wherein balls are arranged between the outer bearing ring and the inner bearing ring; an incision is formed in the outer bearing ring; a clamping block is arranged at the incision; the balls can pass through the incision; at least two first through holes are formed in the clamping block; at least two second through holes are formed in two sides of the incision; when the clamping block is arranged in the incision, the first through holes and the second through holes are coaxial; insertion pins are arranged in the first through holes and the second through holes. By virtue of the structure, the bearing capacity of the bearing is improved, and retainers for preventing the balls from falling off are not needed, so that surface contact between the balls and the retainers is avoided, abrasion to the balls is reduced, and the service life is prolonged.

Owner:NINGBO GREAT GRP

Yoke bearing providing improved support

A steering gear assembly includes a pinion defining a pinion axis and a rack defining a rack axis. A bearing assembly includes a roller bearing biased against the rack to generate a normal force pressing the rack into engagement with the pinion. The bearing assembly engages an outer surface of the rack at two points circumferentially spanning a large angle to provide improved support. The roller bearing is preferably a plurality of ball bearings engaging an outer race. A deformable member may be utilized that is positioned between the outer race and the rack housing. The deformable member may comprise a series of O-rings which providing a force biasing the outer race towards the pinion.

Owner:TEDRIVE HLDG

Bearing assembly

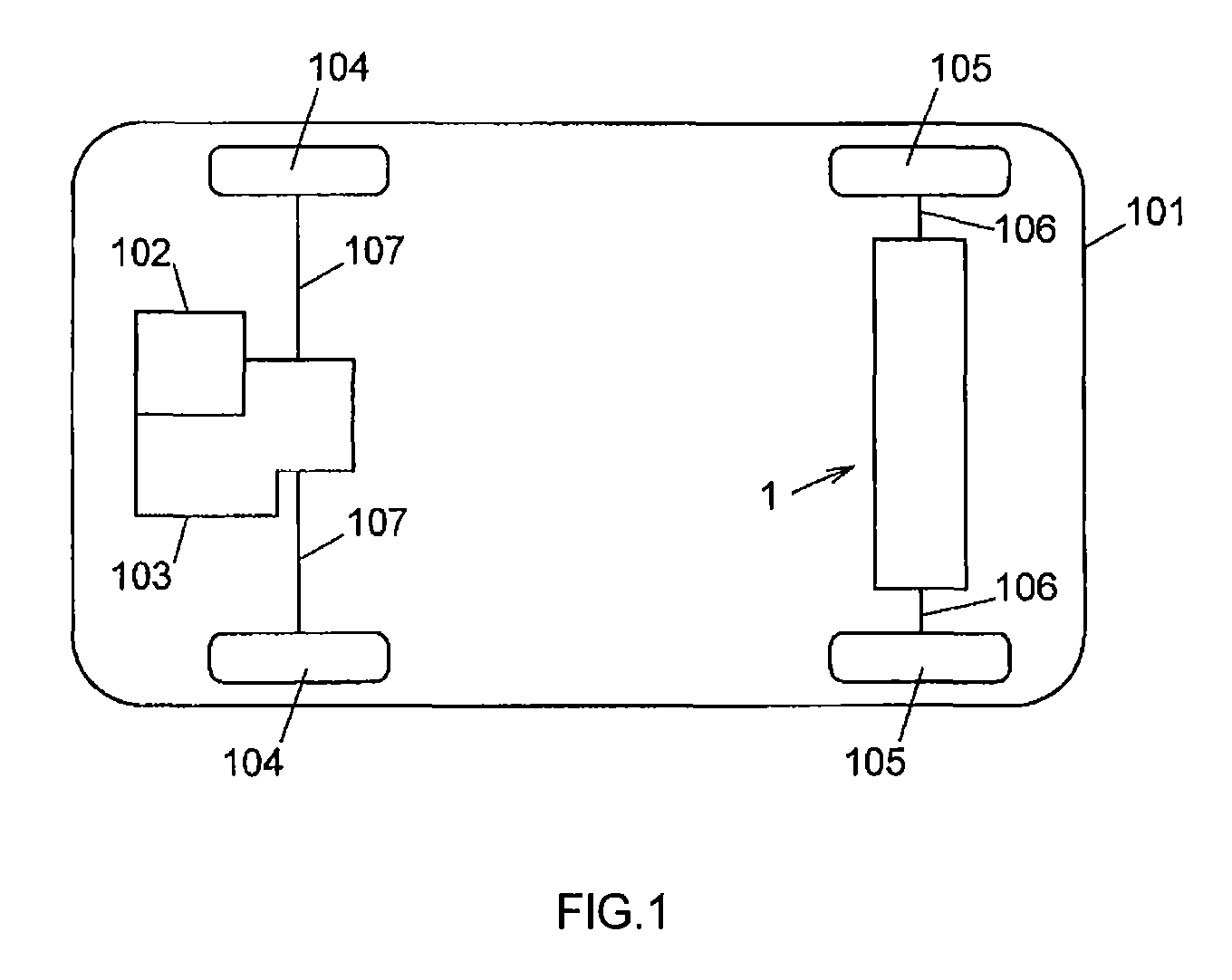

The invention provides a trunnion bearing assembly for the drive system of a snow blower, mower, tractor, or other self-propelled utility vehicle. In certain embodiments, the trunnion assembly comprises a bearing having ball bearings, roller bearings, or another type of bearing set. This can provide free relative rotation of several components of the bearing assembly relative to a trunnion housing of the bearing assembly. This rotation is imparted when a friction disk of the assembly engages a spinning motor flywheel of the drive system.

Owner:OCONOMOWOC MFG

Electric machine

InactiveCN1949631ASame strengthConsistent connection sizeSupports/enclosures/casingsElectric machineEngineering

The invention discloses a motor, comprising stator, rotor shaft and end cover, where the end cover is equipped with bearing room, a ball bearing is arranged in the bearing room, at least one end of the rotor shaft is supported in the ball bearing, the inner wall of the bearing room has an inner spherical surface contacting a side spherical surface of the ball bearing, the inlet end of the bearing room is fastened with an elastic shield ring, the elastic shield ring has an inner spherical surface contacting the other side spherical surface of the ball bearing. And it can make the pressure of the elastic shield ring to the bearing meet the design requirements, unable to cause higher or lower pressure phenomenon and convenient to manufacture and low-cost.

Owner:常州美能特机电制造有限公司

Linear stroke transmission device of electric valve actuator

ActiveCN101566251AEasy hardening processImprove wear resistanceOperating means/releasing devices for valvesValve actuatorDrive shaft

The invention relates to a linear stroke transmission device of an electric valve actuator, which comprises a thrust base, a bracket, a driving shaft housing and a thrust rod. One end of the thrust rod is provided with a screw rod, and the other end thereof is fixedly connected with a valve rod of a controlled valve by a plywood; the two sides of the plywood are embedded in the vertical groove of the bracket; as the screw rod of the thrust rod is provided with arc groove threads, the driving shaft housing is evenly provided with ball bearing holes along the spiral direction corresponding to the arc groove threads of the thrust rod, and ball bearings and needle rollers are arranged in the ball bearing holes; the ball bearings are provided with spherical circular arcs matched with the thrust rod arc groove threads; and the driving shaft housing outside the needle rollers is provided with a fixed housing. External threads of the thrust rod are matched the ball bearings in the driving shaft housing in a rolling way for transmission so as to reduce the friction and improve the fitting accuracy thereof; in addition, the transmission device has the advantages of stable and reliable accuracy control, and long product service life and the like, thus being applied to adjustment of the valve actuator.

Owner:ROTORK ACTUATOR

Ball bearing

ActiveCN108716510AReduce wearReduce vibrationRolling contact bearingsBearing componentsEngineeringMechanical engineering

The invention belongs to the technical field of bearings and particularly provides a ball bearing which comprises an inner ring, an outer ring, a rolling body and a first holder. The ball bearing further comprises rotating devices and balls. The inner ring is in a ball shape. An installing hole of an installing shaft is formed in the middle portion of the inner ring. The rotating devices are arranged on the top and the bottom of the inner ring correspondingly. Each rotating device comprises a rotating ring and cushion blocks. An outer ring of each rotating ring is provided with a set of cushion blocks. The ends of the cushion blocks are connected with the balls. The sides of the balls make contact with the rolling body, and the other sides of the balls are installed in a vertical groove inthe outer side of the inner ring. The balls form a circular ring shape. Two sets of balls in the circular ring shape are installed on the periphery of the inner ring through a second holder. The balls push an arc-shaped sliding block to slide, lubricating oil in an oil tank is splashed to the balls through a spring piece, the coverage area of the lubricating oil is increased, and thus the lubricating effect is improved.

Owner:馆陶县正磊轴承制造有限公司

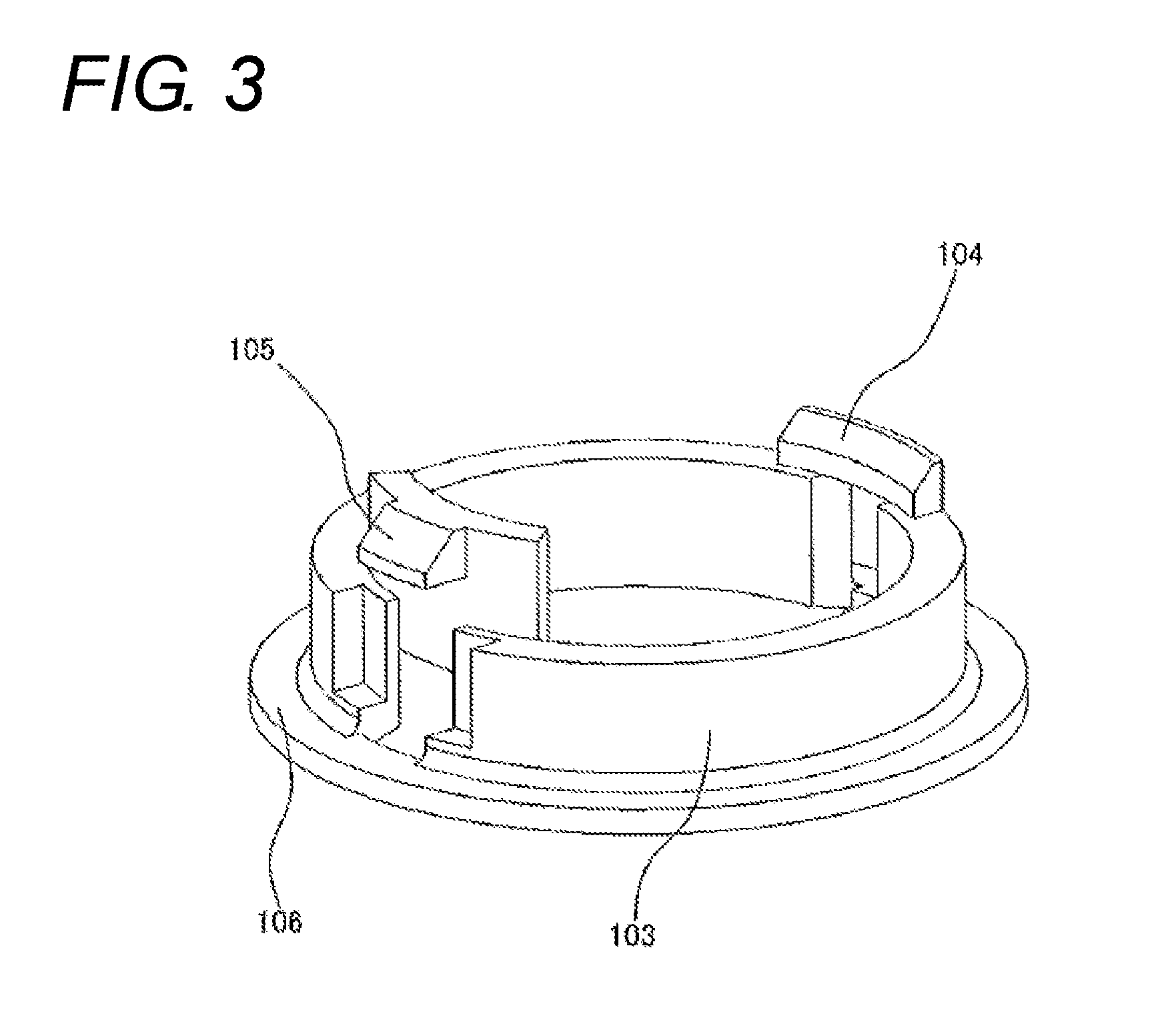

Preload device of ball bearing and motor having the preload device

A constant preload device of a ball bearing is provided. The preload device includes an elastic member having a hollow shape with openings at both sides in an elastic direction, and two holders inserted into the openings at the both sides of the elastic member, respectively. Each holder includes a flange part configured to contact an end portion of the opening, into which the holder is inserted, to regulate an extension of the elastic member in the elastic direction, and a claw part configured to engage with the other holder to regulate separation from the other holder. The holders are engaged to each other by the claw parts such that the elastic member is exposed from the holders. When the preload device applies preload to the ball bearing, the ball bearing contacts the preload device only at an outer ring of the ball bearing.

Owner:MINEBEAMITSUMI INC

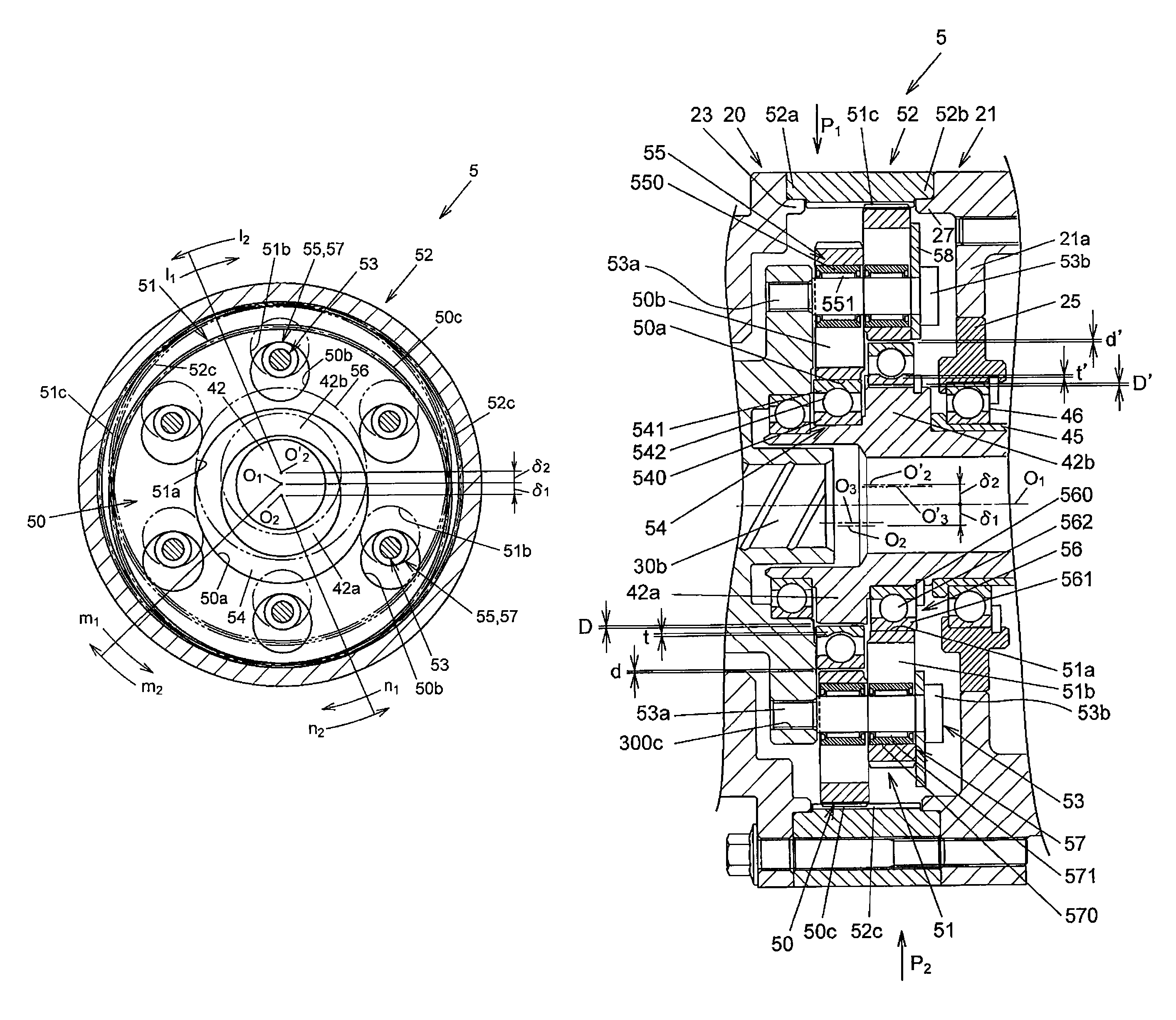

Speed reduction mechanism, and motor torque transmission device including the speed reduction mechanism

InactiveUS9397533B2Low costExtended service lifeSpeed controllerElectric propulsion mountingNeedle roller bearingEngineering

In a reduction-transmission mechanism, an input member is arranged at such a position that a size obtained by adding a fitting clearance formed between a ball bearing and an outer periphery of an eccentric portion, a fitting clearance formed between the ball bearing and an inner periphery of the input member, which defines a center hole, and a radial internal clearance of the ball bearing is smaller than a size obtained by adding a fitting clearance formed between an outer periphery of each of a plurality of output members and a corresponding one of needle roller bearings, a fitting clearance formed between each of the needle roller bearings and an inner periphery of the input member, which defines a corresponding one of a plurality of pin insertion holes, and a radial internal clearance of each of the needle roller bearings.

Owner:JTEKT CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com