Ball bearing

A ball bearing and rolling ball technology, applied in the field of bearings, can solve the problems of limitation, insufficient bearing lubrication, and inability to relieve vibration, and achieve the effects of reducing wear, improving lubrication effect, and increasing coverage area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

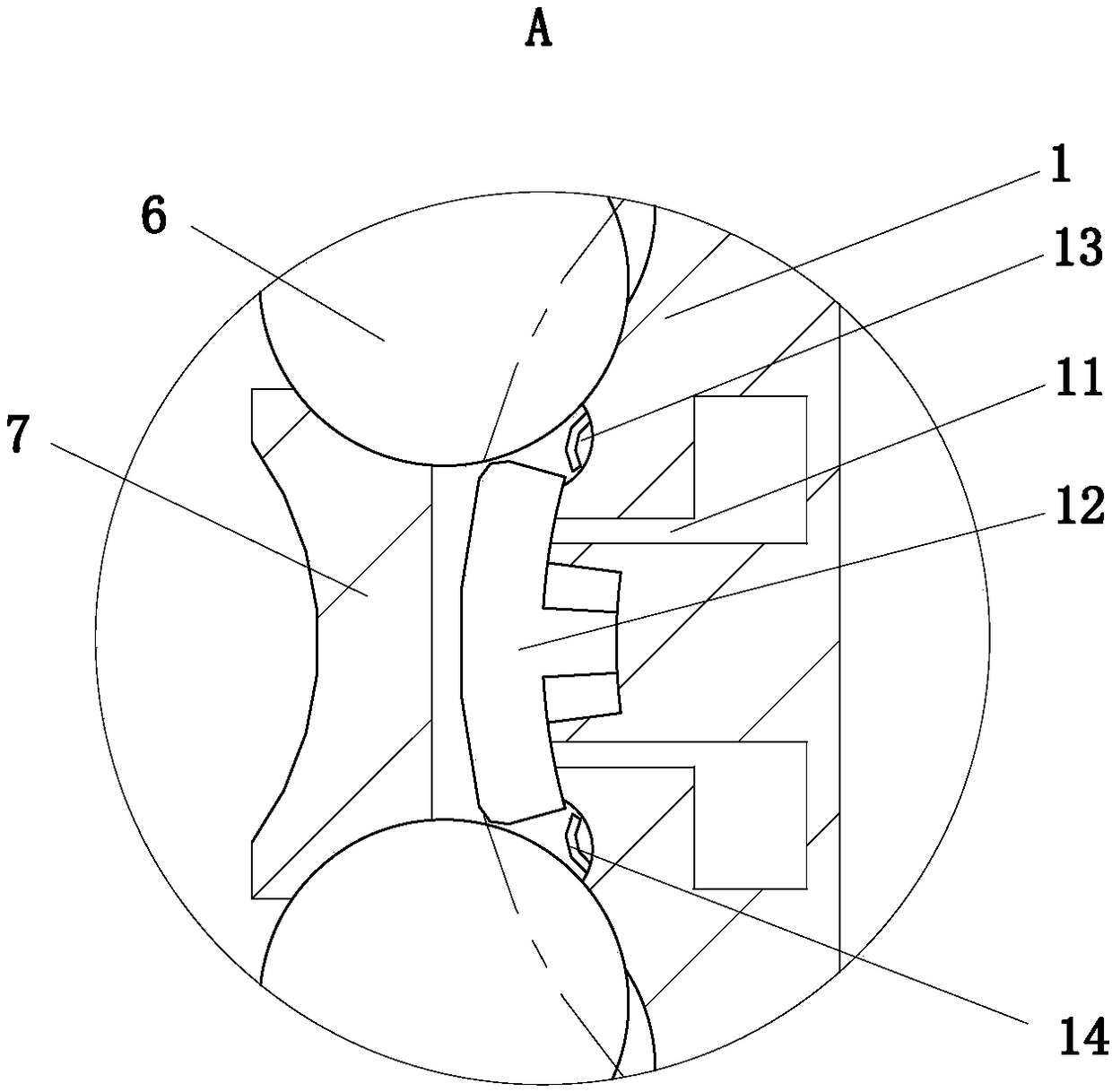

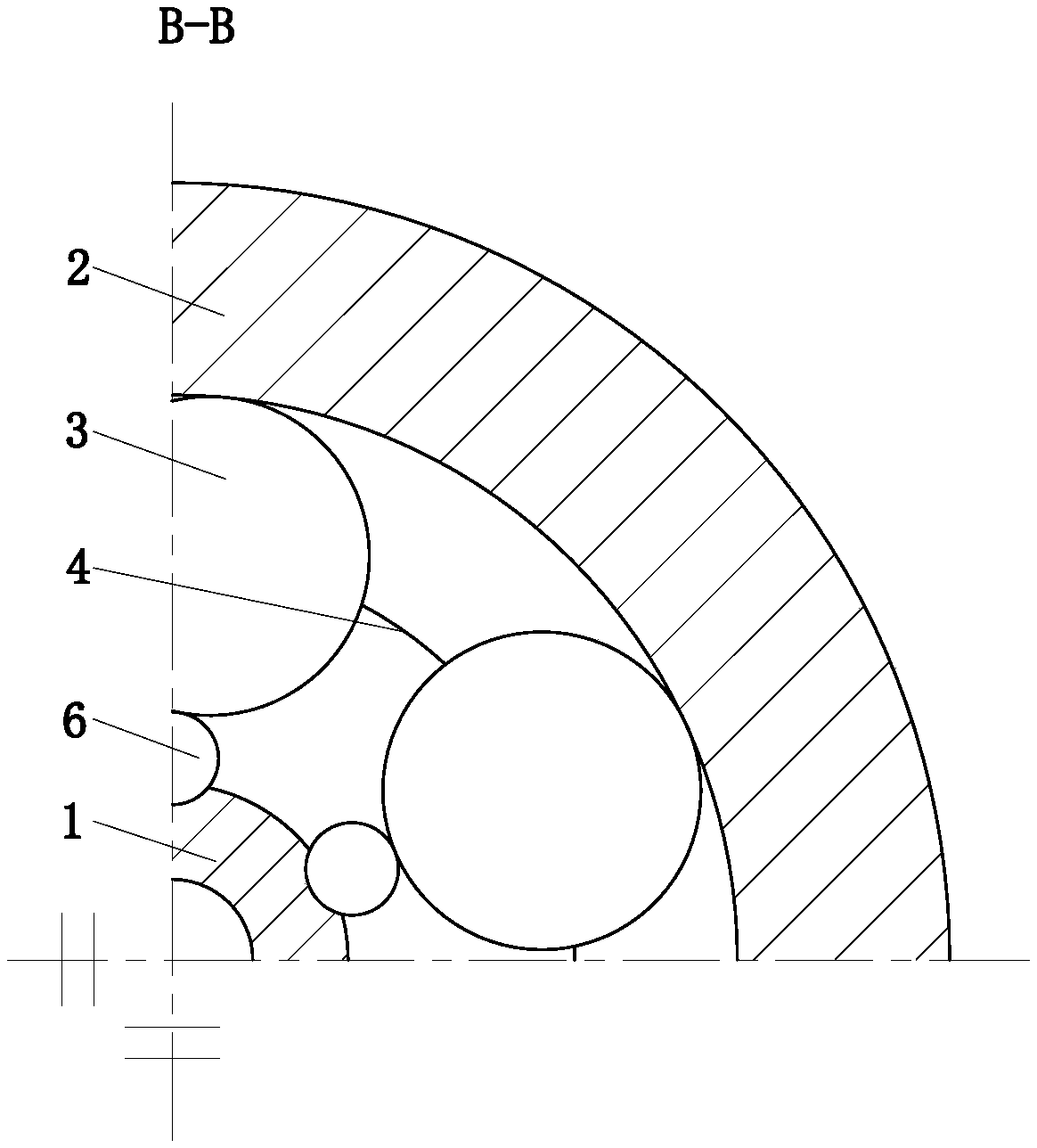

[0023] As an embodiment of the present invention, one side of the rotating plate 54 is provided with a group of circular arc grooves 55 with equal arc lengths; the rolling ball 6 is located in the circular arc grooves 55; the ends of the rotating plate 54 The bottom of the arc groove 55 is provided with a through hole; the through hole is provided with a connecting rod 56 fixedly connected to the rotating ring 51, and the connecting rod 56 is used to jack up the rolling ball 6; one side of the connecting rod 56 is provided with There is a steel wire 57 fixedly connected on the rotating ring 51, and the steel wire 57 passes through the through hole of the rotating plate 54 and is connected with the rolling ball 6. During work, the rolling ball 6 squeezes the rotating plate 54 and rotates to the side close to the rotating ring 51. During the rotation, the rolling ball 6 touches the connecting rod 56. Under the action of the connecting rod 56, the rolling ball 6 moves from the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com