Ball bearing

A ball bearing and ball technology, applied in the field of ball bearings, can solve the problems of reducing the service life of the bearing and damage to the raceway, and achieve the effects of reducing friction, strong self-lubricating ability and small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

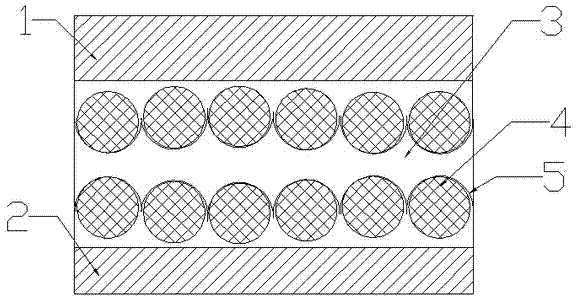

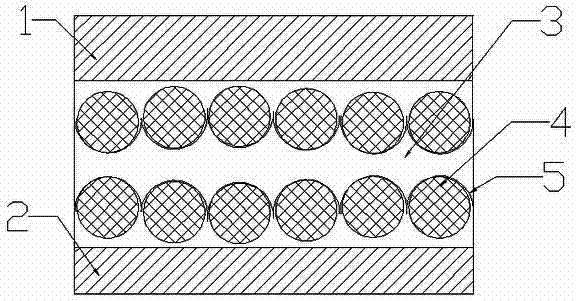

[0013] The structure of the ball bearing is as follows: a ring-shaped double-row ball raceway is arranged between the bearing outer ring 1 and the bearing inner ring 2, and two rows of balls 4 are arranged on the ring-shaped double-row ball raceway. The anti-friction cage 3 of the arranged half-moon concave position 5.

[0014] The ball 4 is a spherical structure made of silicon nitride ceramics.

[0015] The anti-friction cage 3 is a cage with evenly arranged half-moon-shaped recesses 5 structures, and the middle position of the half-moon-shaped recesses 5 structures has a lubricating hole of a specific shape, and the lubricating material is polytetrafluoroethylene.

[0016] The lubricating hole of the specific shape can be an I-shaped or rectangular structure, preferably an I-shaped structure, which can effectively reduce the friction between the ball and the raceway.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com