Ball bearing motor capable of adjusting center automatically

A ball bearing, self-aligning technology, used in electrical components, electromechanical devices, electrical components, etc., can solve problems such as increasing manufacturing costs, and achieve the effects of low noise, low friction coefficient and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment, the present invention will be further described. The following description is by way of example, but the protection scope of the present invention is not limited thereto.

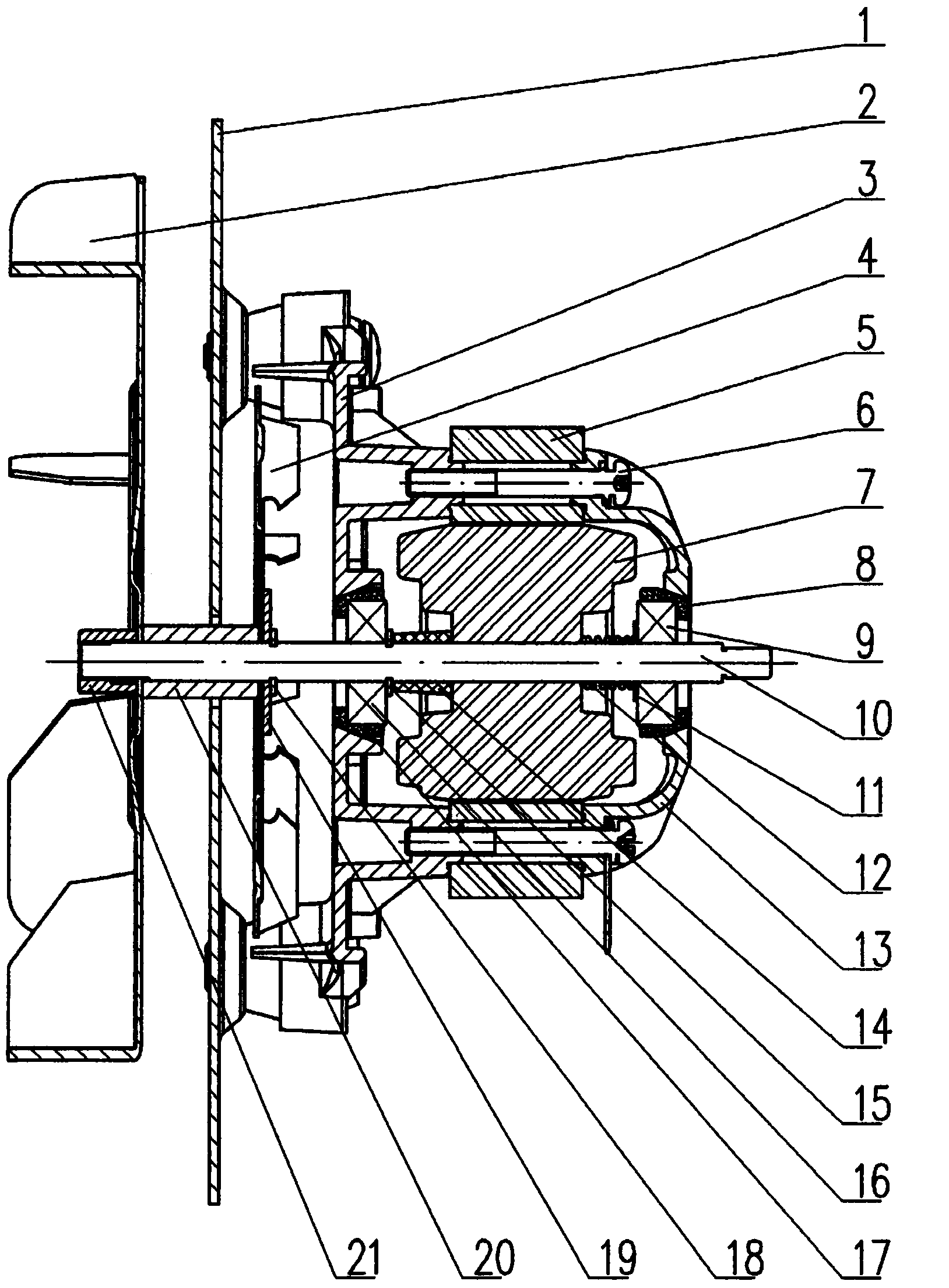

[0022] The self-aligning ball bearing motor of this embodiment is composed of a main stator core assembly 5, a rotor assembly, a front end bracket 3, a rear end bracket 13, a front end bearing, a tail end bearing, a self-radiating fan blade assembly and a load fan blade assembly constitute.

[0023] The front end bracket 3 and the tail end bracket 13 are all the same as the existing ones, and the bearing chamber is an inner conical surface, that is, one end facing the rotor 7 is larger and the other end is smaller.

[0024] The front end bearing is composed of the front end bearing sleeve 17 and the front end ball bearing 16, and the tail end bearing is composed of the tail end bearing sleeve 8 and the tail end ball bearing 9; the front end bearing sleeve 17 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com