Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103 results about "Bakery equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

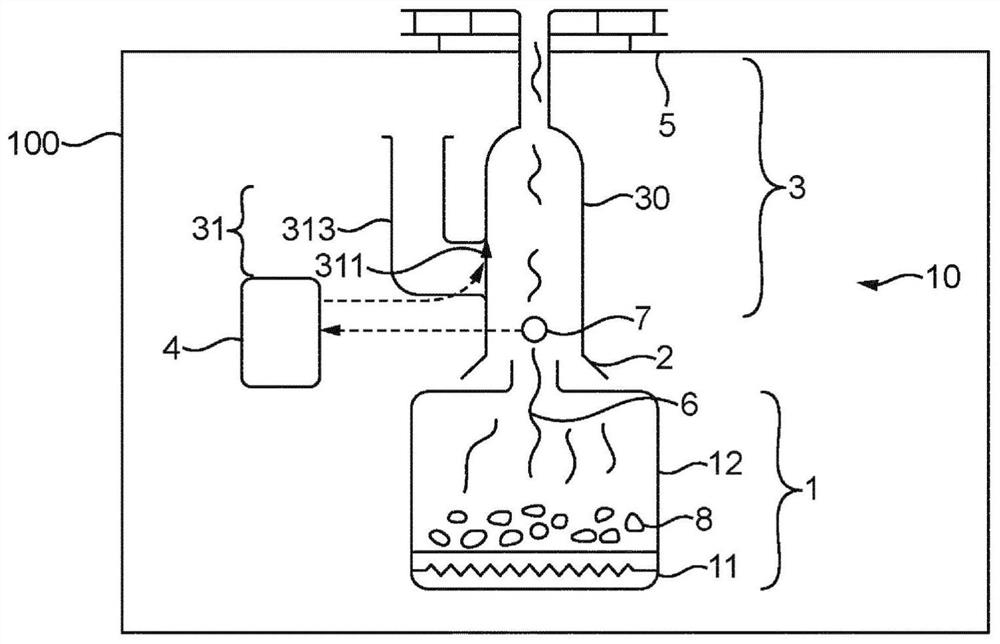

Roasting system

InactiveUS7285300B1Maintain consistencyEasy to downloadMilk preservationWort preparationParticulatesAir cycle

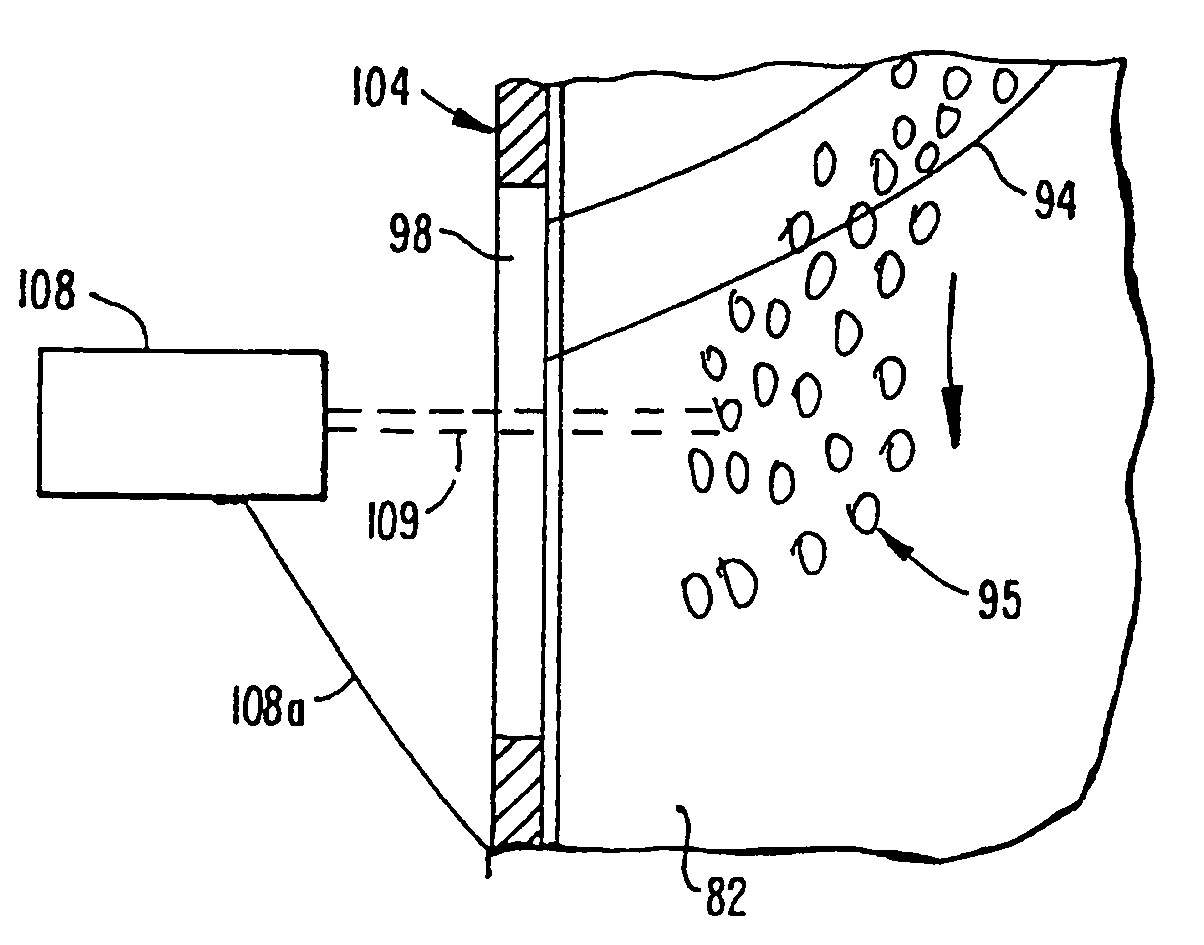

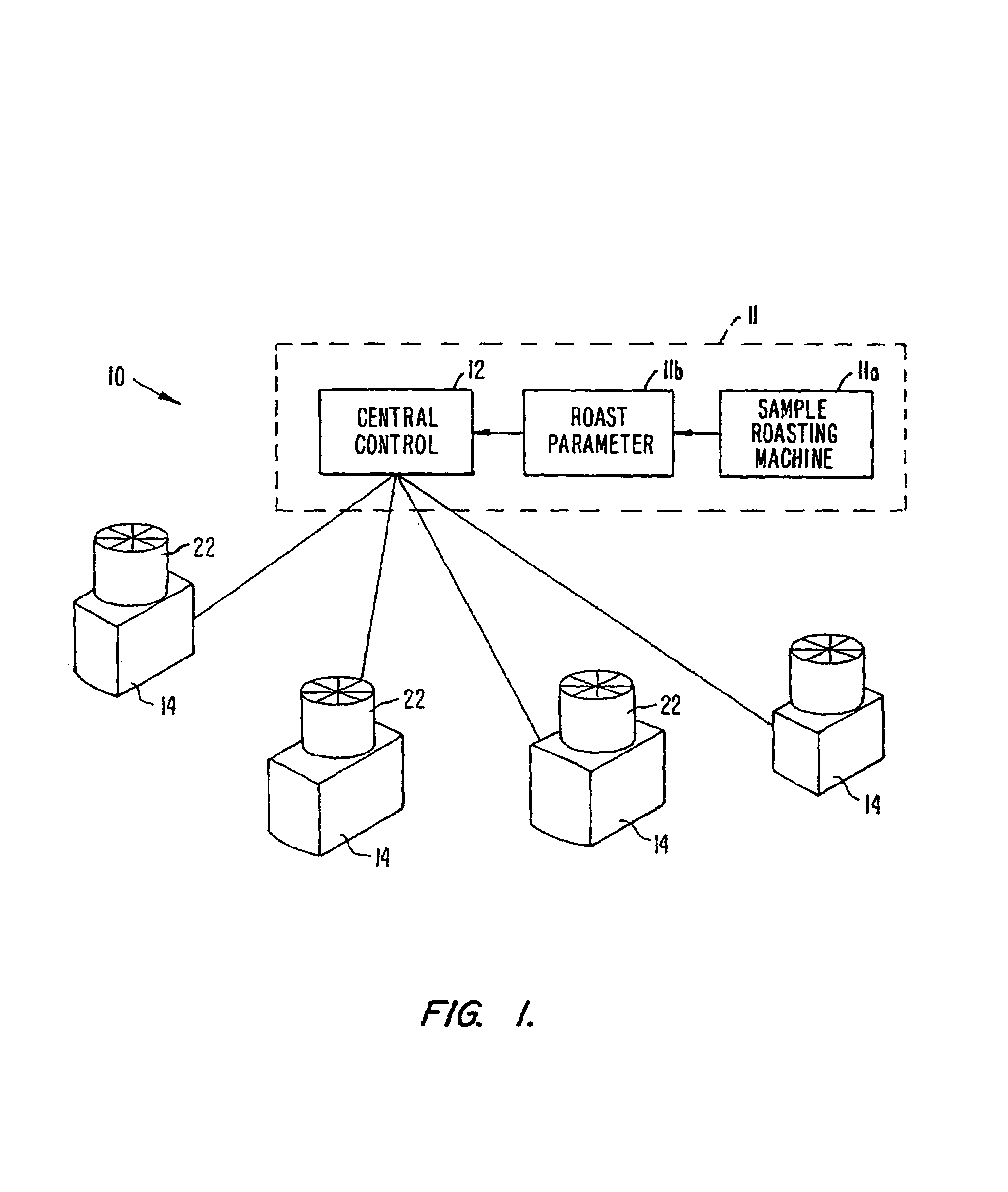

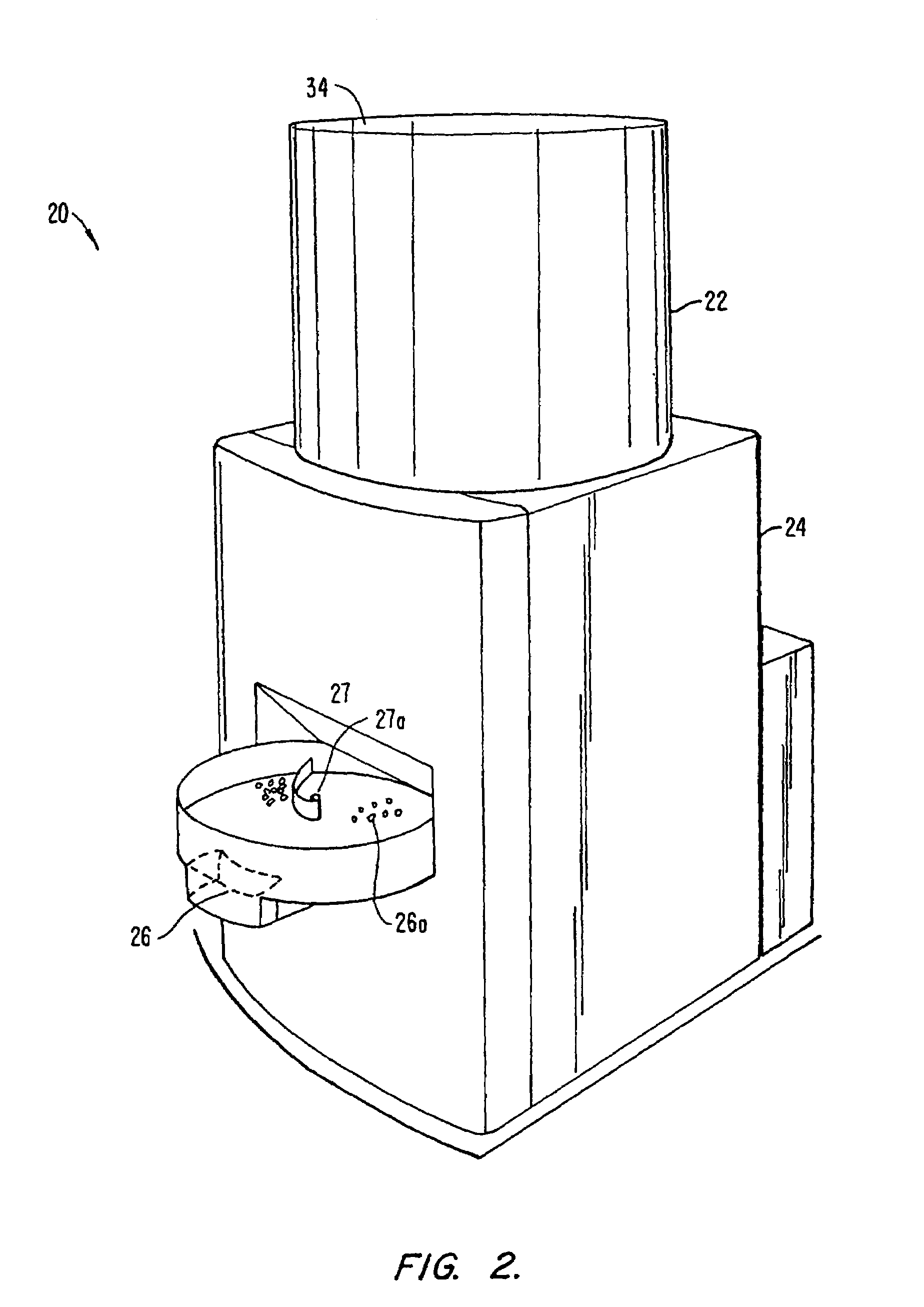

An apparatus and method of roasting foodstuff such as coffee beans employ a roasting chamber for roasting the beans. An air circulation system operatively coupled with the chamber flows heated air over the beans and thereby roasts the beans, and an air cleaning arrangement is operatively coupled with the air circulation system and located downstream of the chamber for removing substantially all particulates, smoke and volatiles entrained in the used air as it flows through the container and into the air cleaning arrangement to provide substantially pollutant-free used air. The circulation system uses atmospheric air and heats, cleans and cools it within as little as ¼ second. Sensors and a electronic controller are provided to monitor various parameters in the roasting apparatus and control the roasting characteristics. The darkness and / or color of the beans during roasting is monitored to ensure proper roasting. The roasting in roasting machines at a plurality of geographically separate locations is controlled by equipping each roasting machine with a computer with memory and providing a central control station for downloading control signals to the computer to control roasting.

Owner:GROUP 32 DEVMENT & ENG

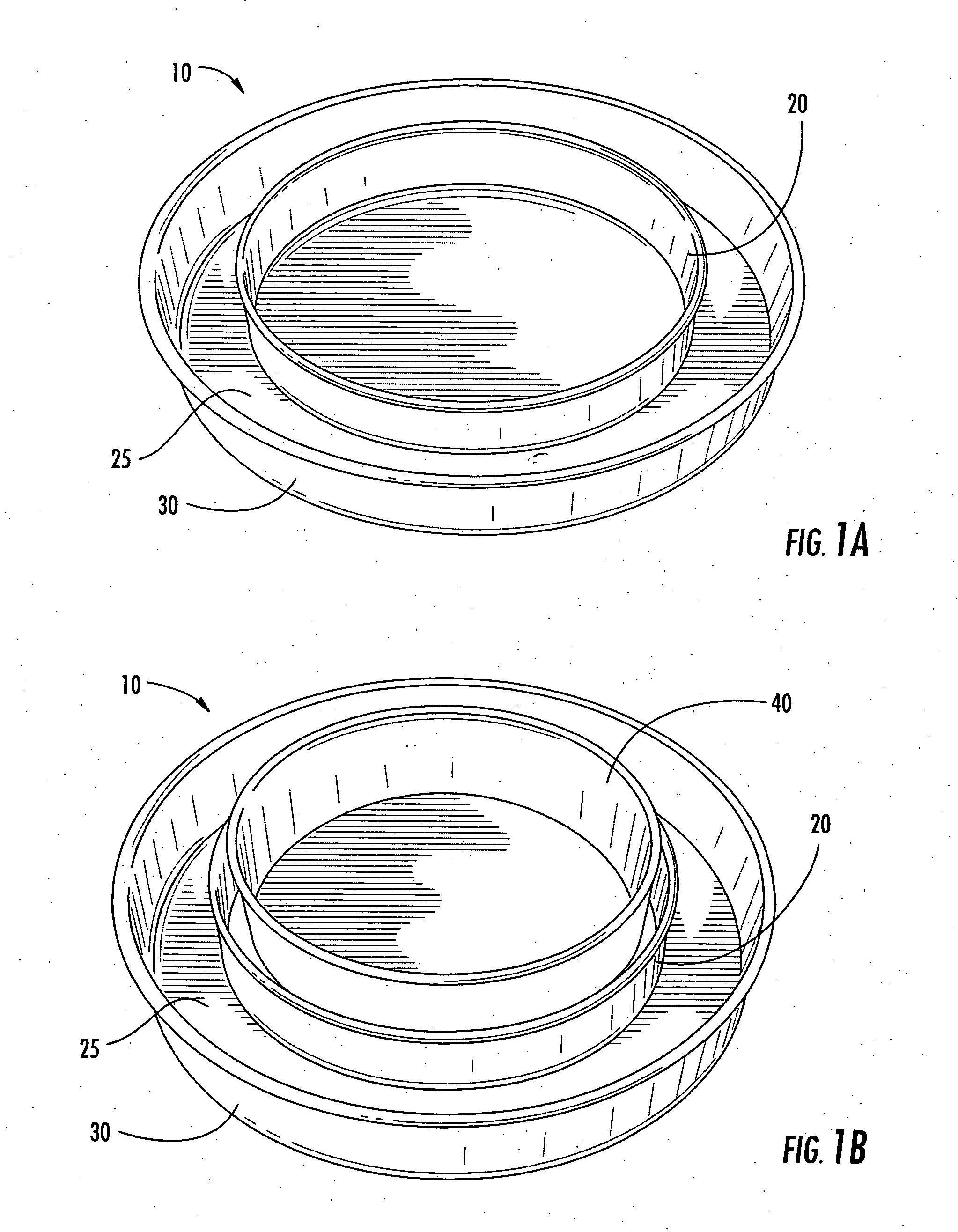

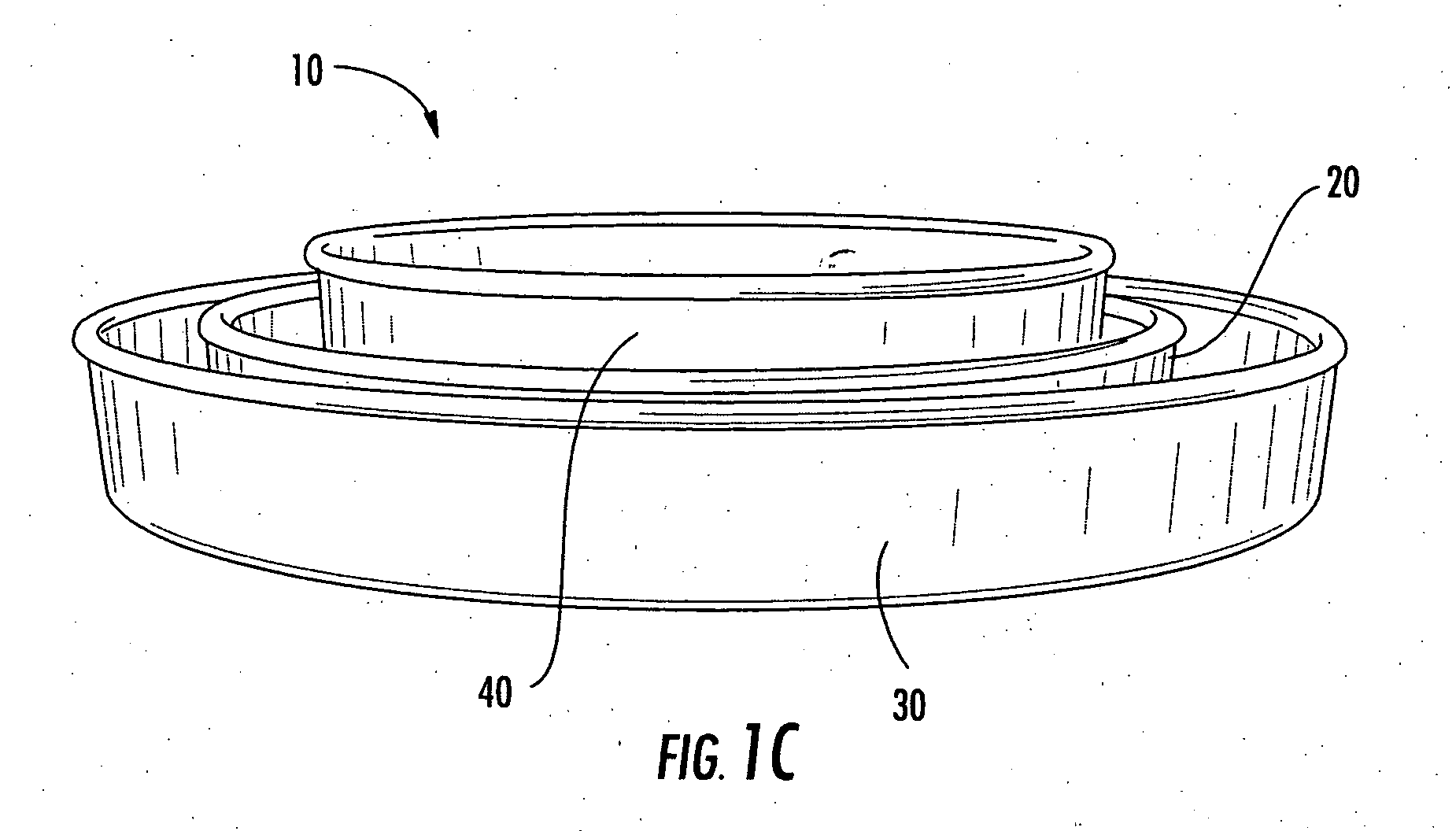

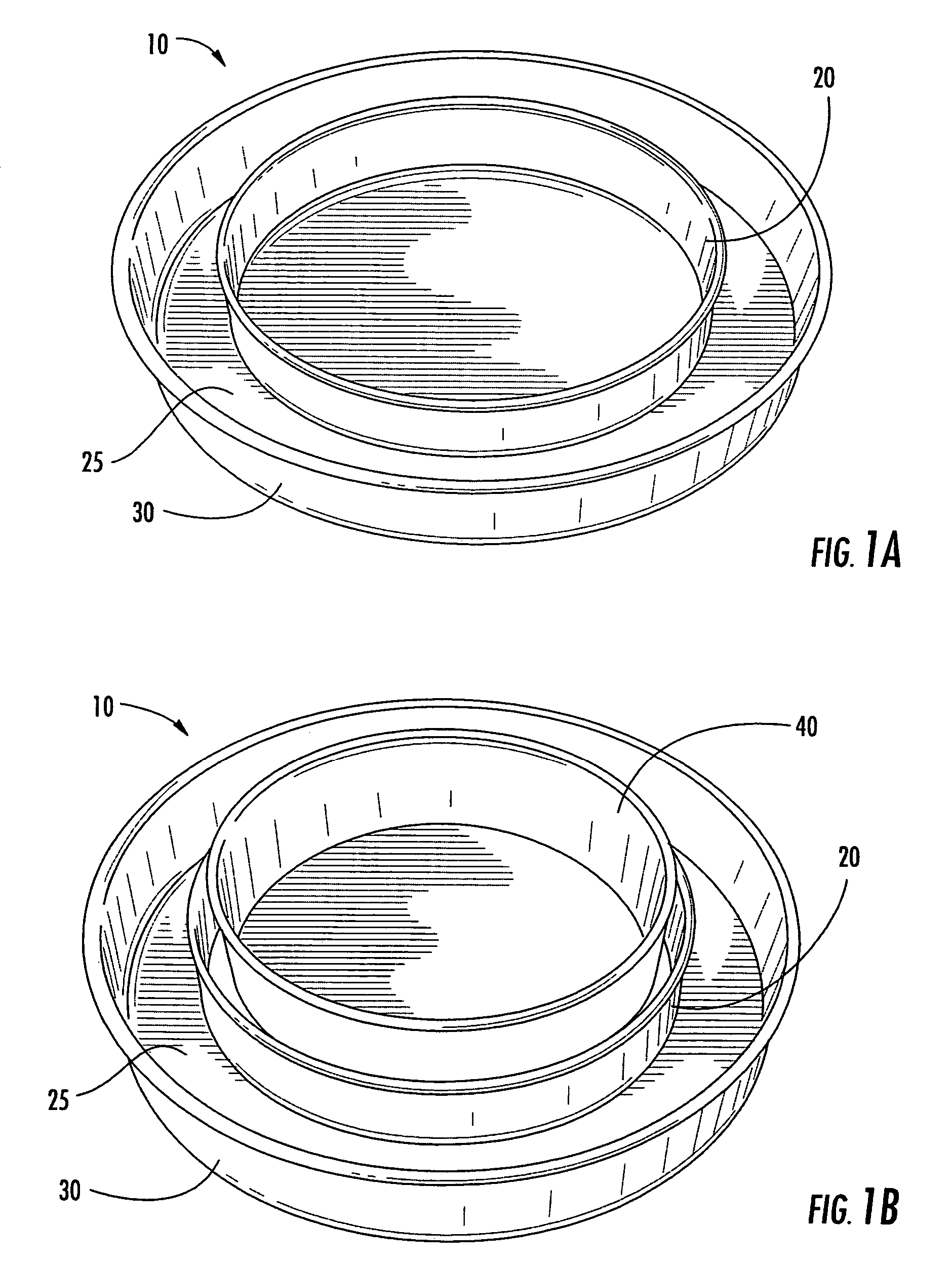

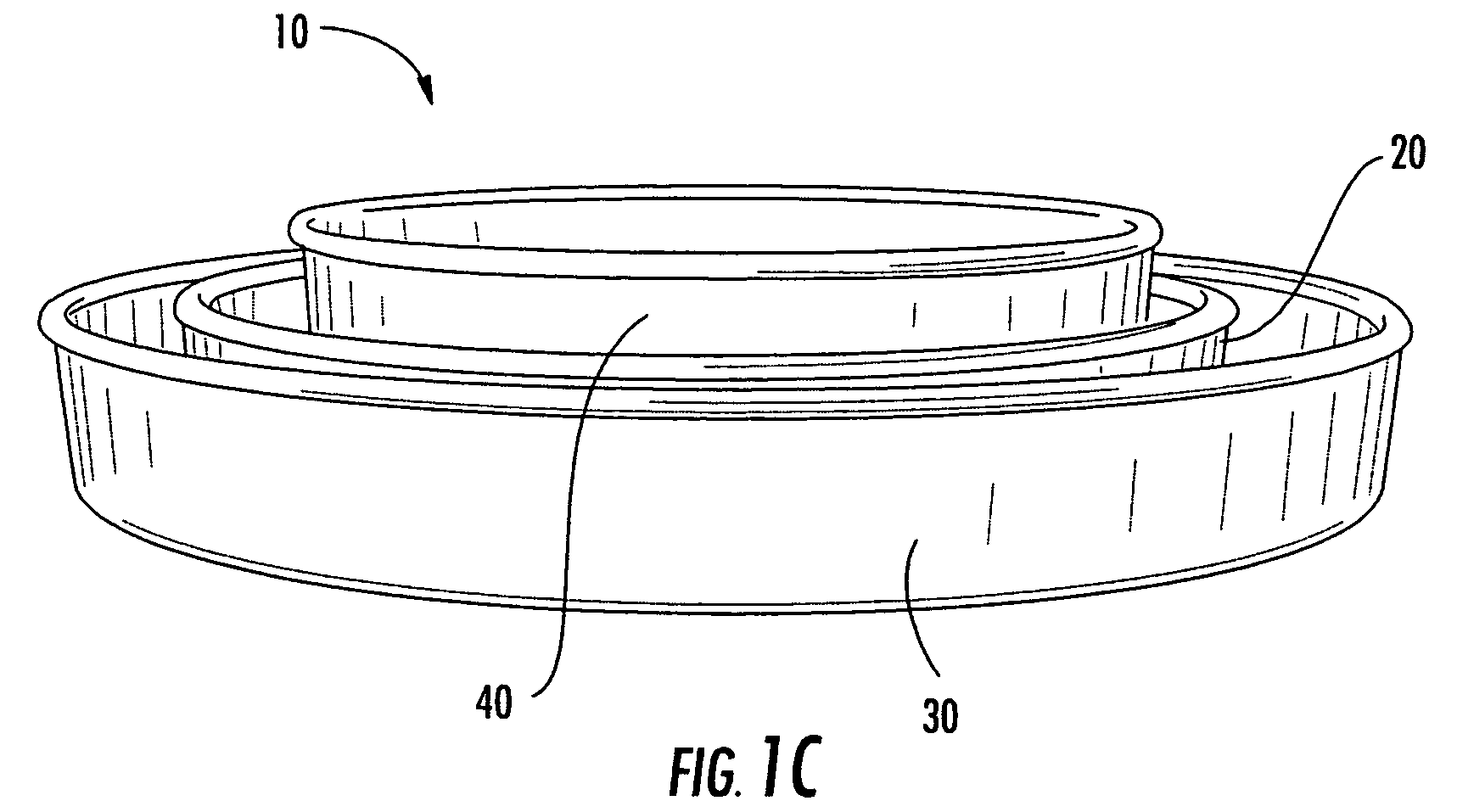

Baking apparatuses and methods of use

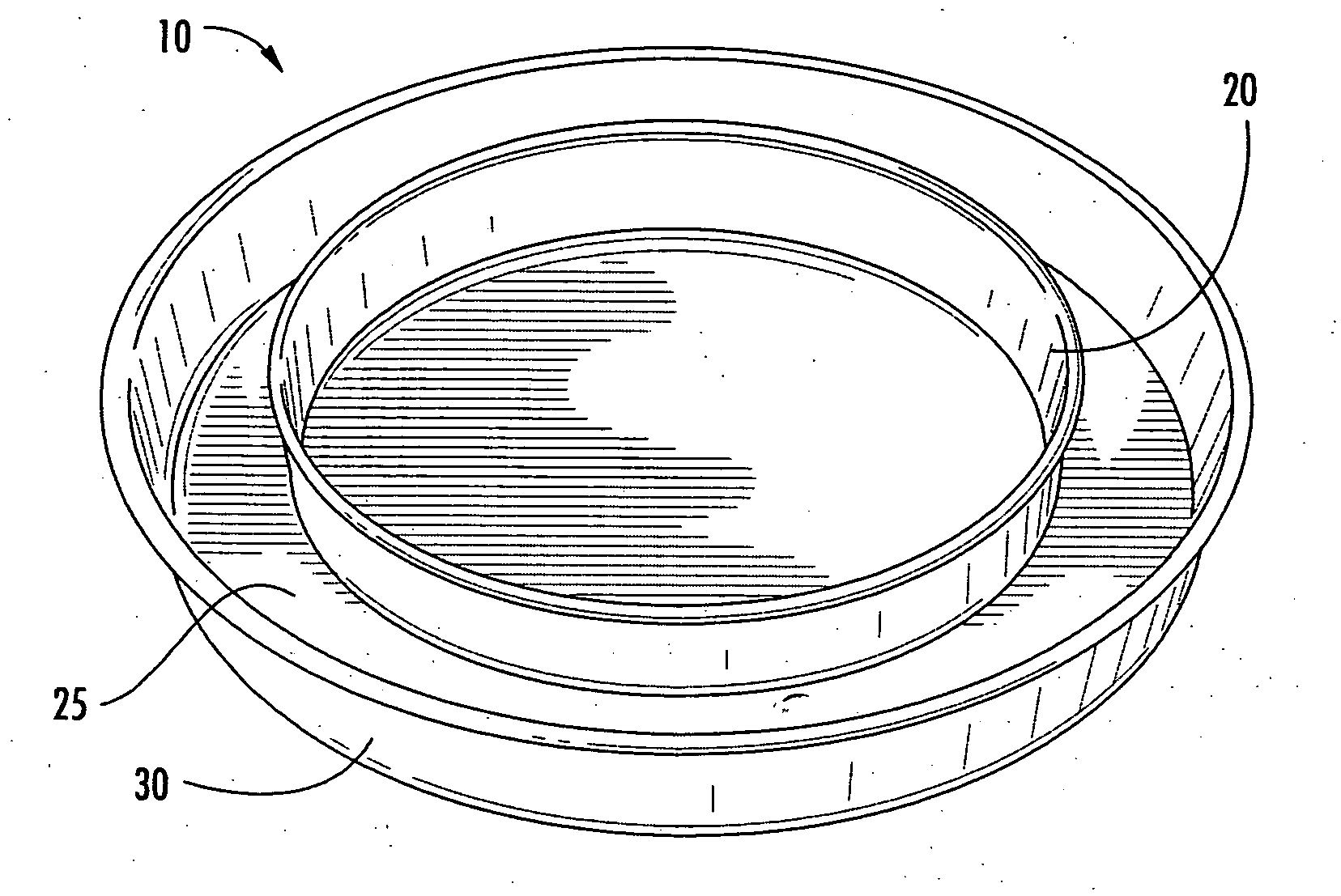

The present invention is directed to baking apparatuses that are adapted for use in baking cakes, custards and other dishes that involve the use of a water bath. In a disclosed embodiment of the invention a baking apparatus is disclosed that includes an inner and outer pan, which may be formed as an integral unit. The outer pan is preferably adapted to receive and hold water and the inner pan is adapted to receive a springform containing a cheesecake batter or other mixture. The side or sides of the inner pan are preferably watertight and prevent leakage of water into the inner pan. The present invention offers the advantage of water bath baking without the problem of water from the bath leaking into the springform that contains the cake batter.

Owner:MILLER ROBERT J +1

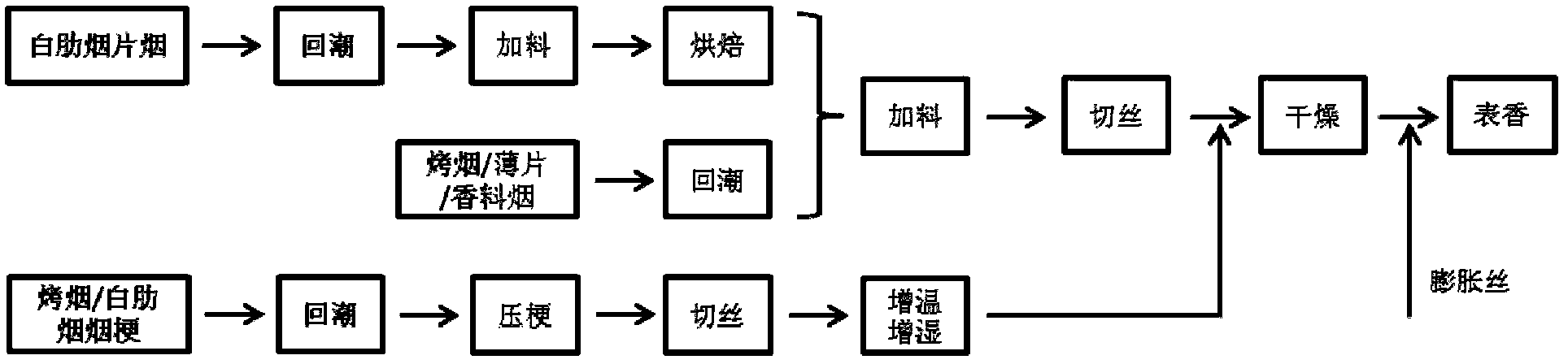

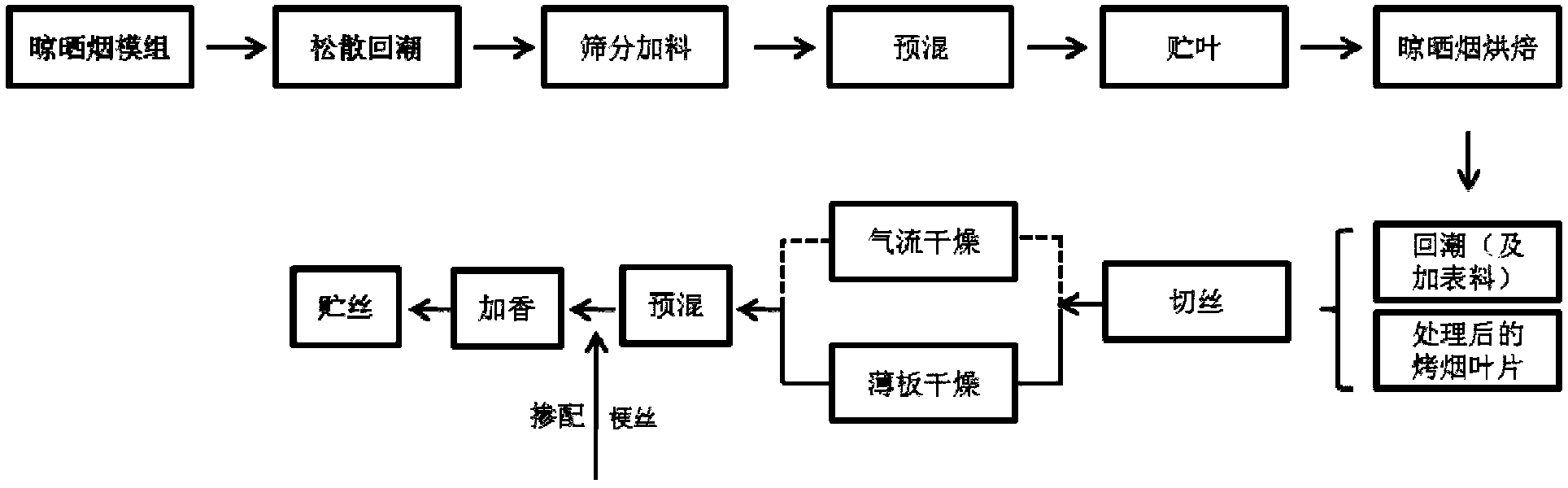

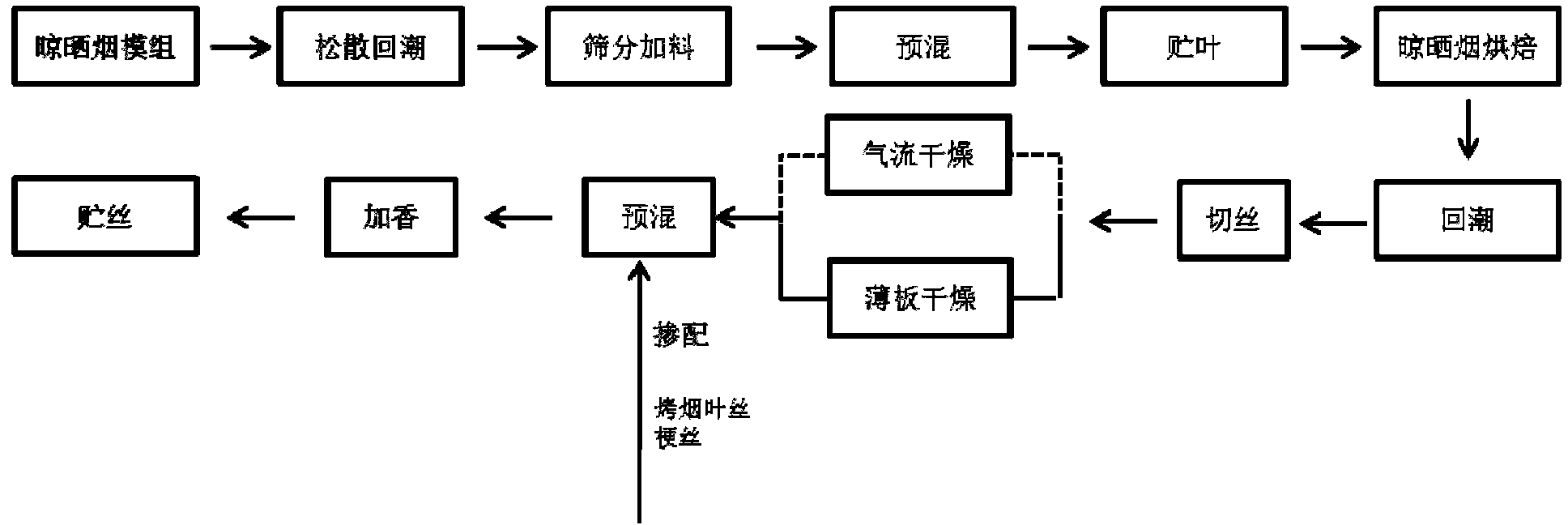

Method for improving sun-cured tobacco processing quality

The invention discloses a method for improving sun-cured tobacco processing quality. The method includes respectively taking burley tobacco, aromatic tobacco, yellow sun-cured tobacco or red sun-cured tobacco as independent formula modules for grouping and processing, selecting differentiated process parameters and baking equipment to bake the sun-cured tobacco and prepare shredded tobacco according to product style positioning and processing characteristics of the sun-cured tobacco, and blending and flavoring the processed sun-cured tobacco set by means of leaf blending or shredded tobacco blending and flue-cured tobacco, cut stems and slices. Consequently, inherent excellent quality of the sun-cured tobacco is maintained to the greatest extent, own unexpected factors of the sun-cured tobacco are effectively eliminated, biggest value of cigarette materials is realized, and bigger space is provided for process adjustment. Compared with conventional 'packaging-type' mixed production modes, the method is more exquisite and conducive to demonstration of characteristic aromas of the sun-cured tobacco and effective removal of offensive odors.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Baking apparatuses and methods of use

The present invention is directed to baking apparatuses that are adapted for use in baking cakes, custards and other dishes that involve the use of a water bath. In a disclosed embodiment of the invention a baking apparatus is disclosed that includes an inner and outer pan, which may be formed as an integral unit. The outer pan is preferably adapted to receive and hold water and the inner pan is adapted to receive a springform containing a cheesecake batter or other mixture. The side or sides of the inner pan are preferably watertight and prevent leakage of water into the inner pan. The present invention offers the advantage of water bath baking without the problem of water from the bath leaking into the springform that contains the cake batter.

Owner:MILLER ROBERT J +1

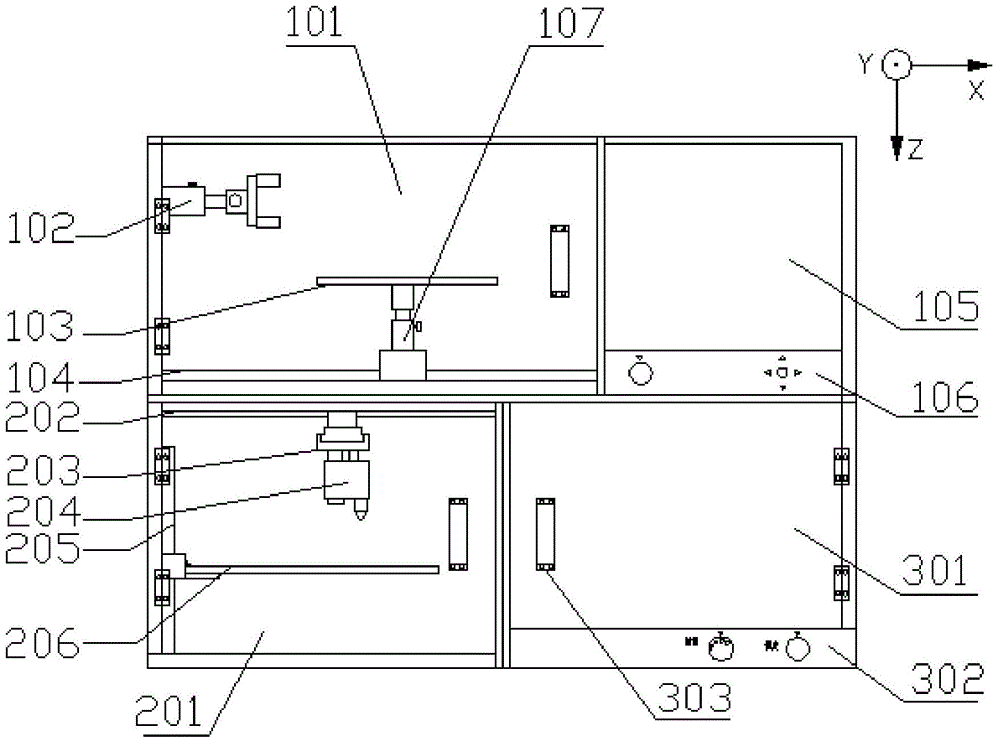

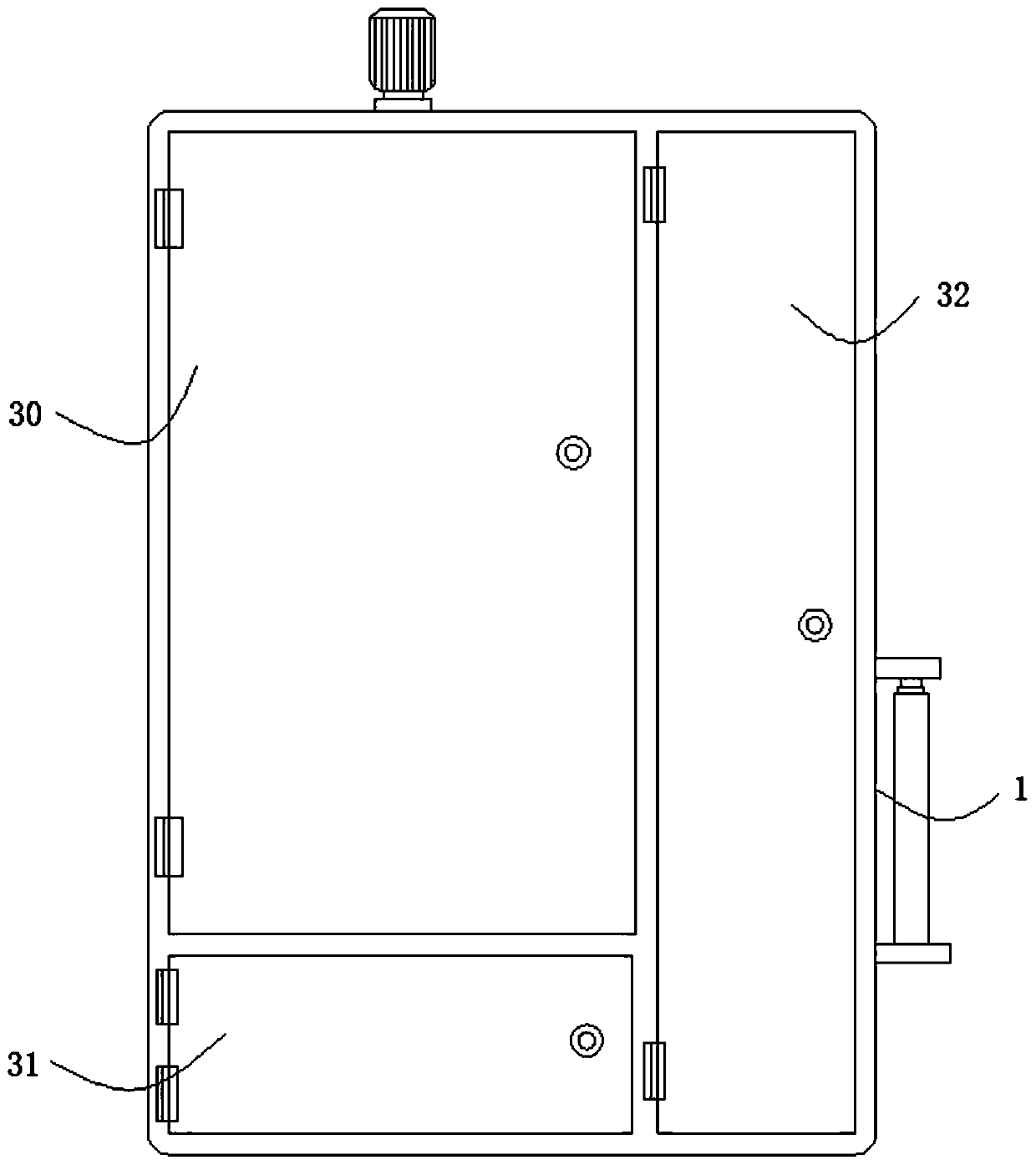

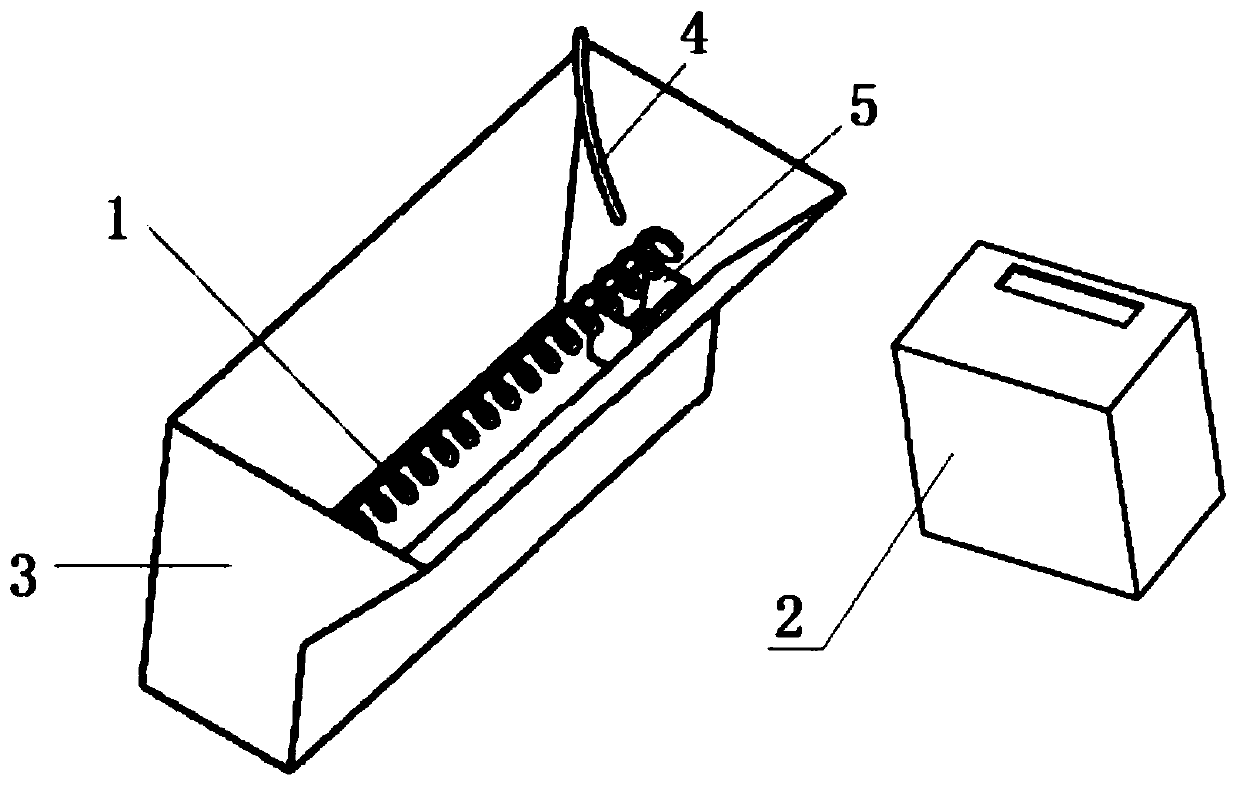

3D food printer

InactiveCN104921281AImprove efficiencyEasy and quick to makeAdditive manufacturing apparatusFood coatingCooking & bakingData transmission

The invention discloses a 3D food printer. The printer comprises a box, a 3D scanning device, a 3D printing device and a baking device, wherein the 3D scanning device is located on the first layer of the box, the 3D printing device and the baking device are located on the second layer of the box, the 3D scanning device, the 3D printing device and the baking device are provided with transparent doors respectively, the 3D scanning device is connected with the 3D printing device through data transmission, and products printed with the 3D printing device are made into food through the baking device. According to the 3D food printer, 3D modeling, 3D printing and food making are integrated, and the integrated functions of establishing a 3D printing model through 3D scanning and making the printed products into food can be realized. Furthermore, a complex 3D printing model can be established, modeling efficiency is improved, and daily food can be made easily and quickly. Meanwhile, structure is simple, occupied space is small, operation is convenient, and using effect is good.

Owner:SHANGHAI DIANJI UNIV

Baking apparatus and method for baking edible products

InactiveUS7231871B1Easy to detectReduce chanceBaking ovenBaking vesselsBakery equipmentWaste management

Baking apparatus for baking edible products located on a conveying surface and preferably travelling along a conveyor track, comprising a number of electric infrared radiators arranged above the conveyor track. The infrared radiators each comprise at least one spiral filament having a gastight, infrared radiation-transmitting, breakable casing, in particular a glass casing. The baking apparatus further comprises monitoring means for monitoring breakage of the casings of the infrared radiators. The invention also relates to a method for baking an edible product by means of an electric infrared radiator having a breakable casing.

Owner:WEGRA BEHEER

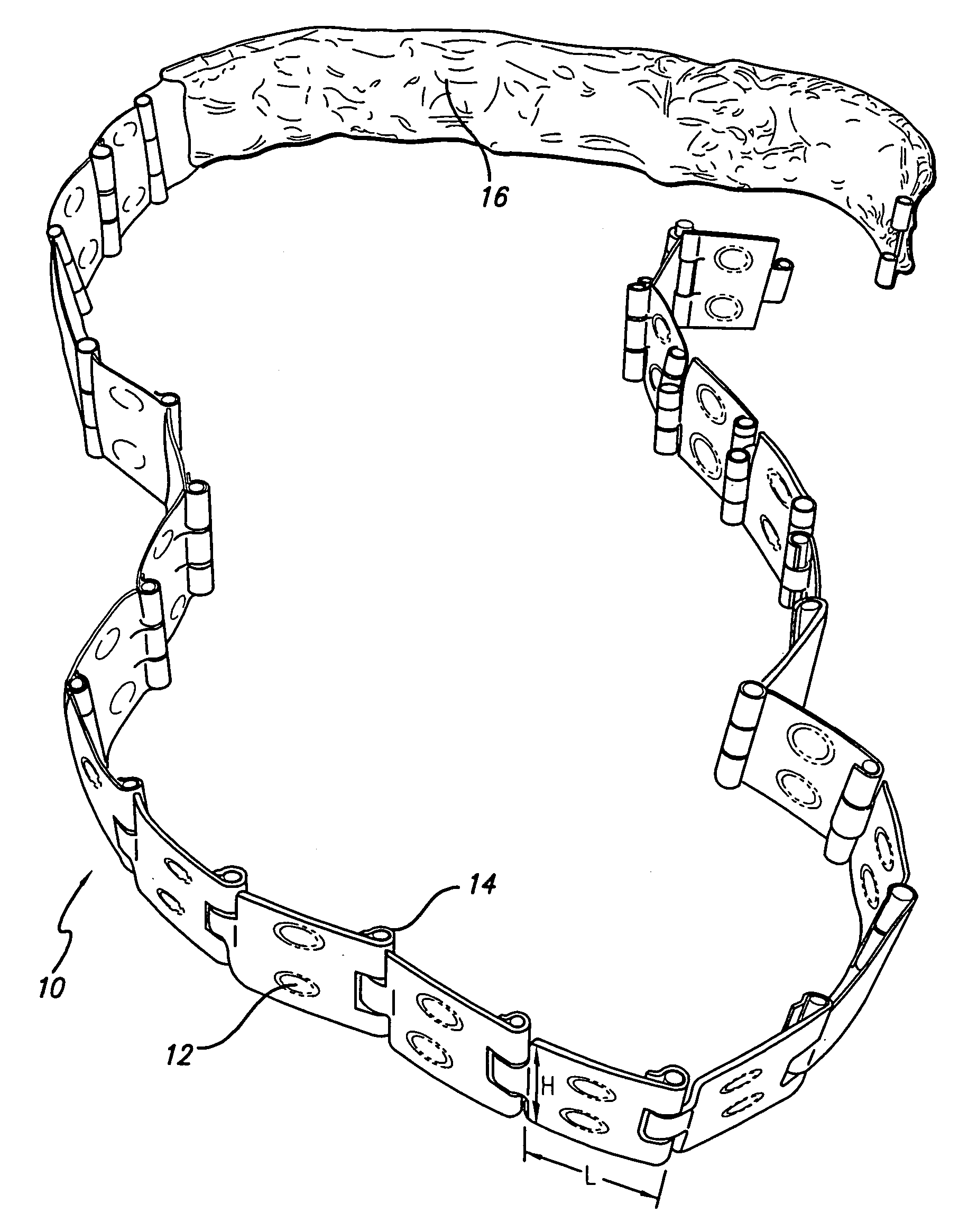

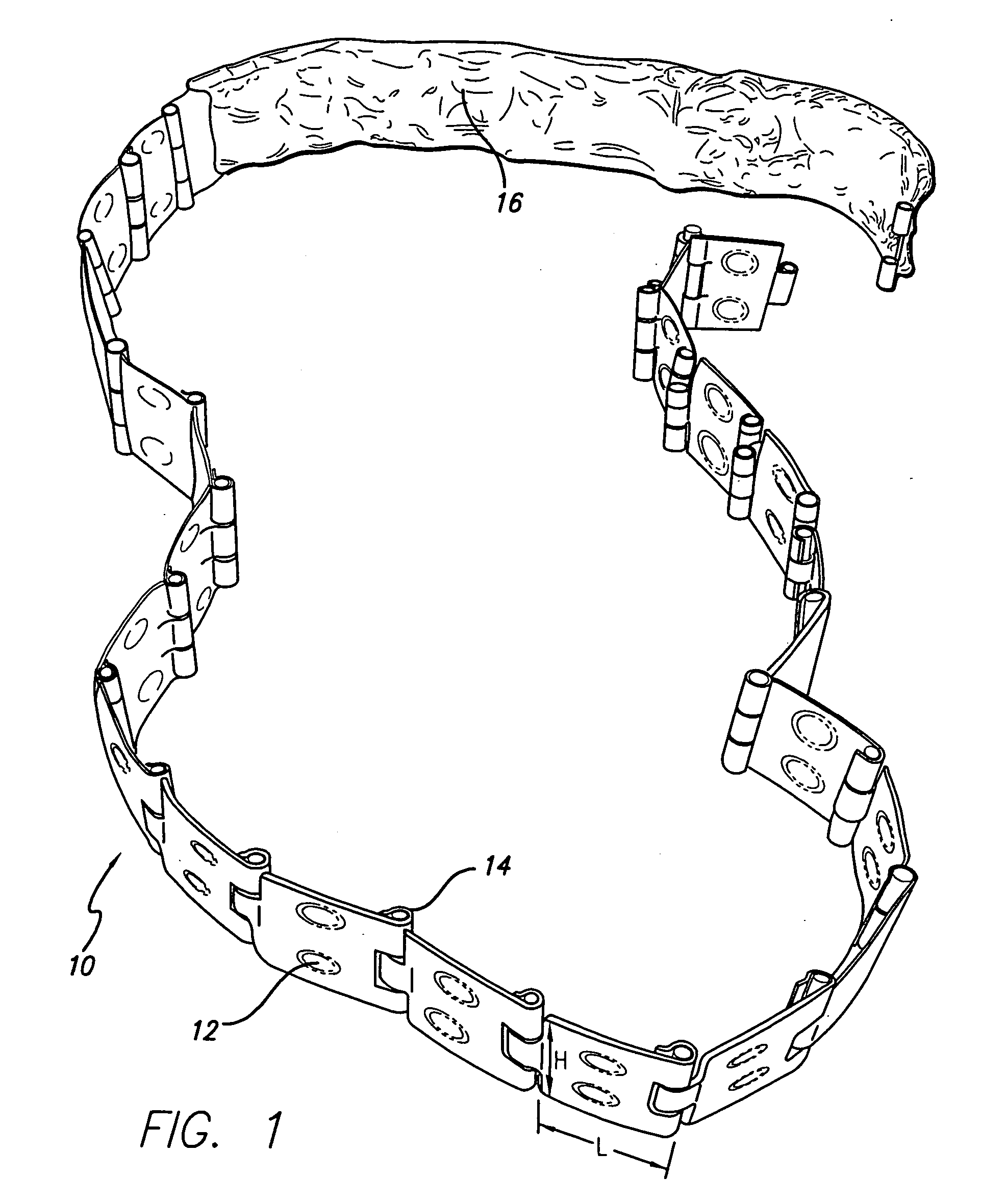

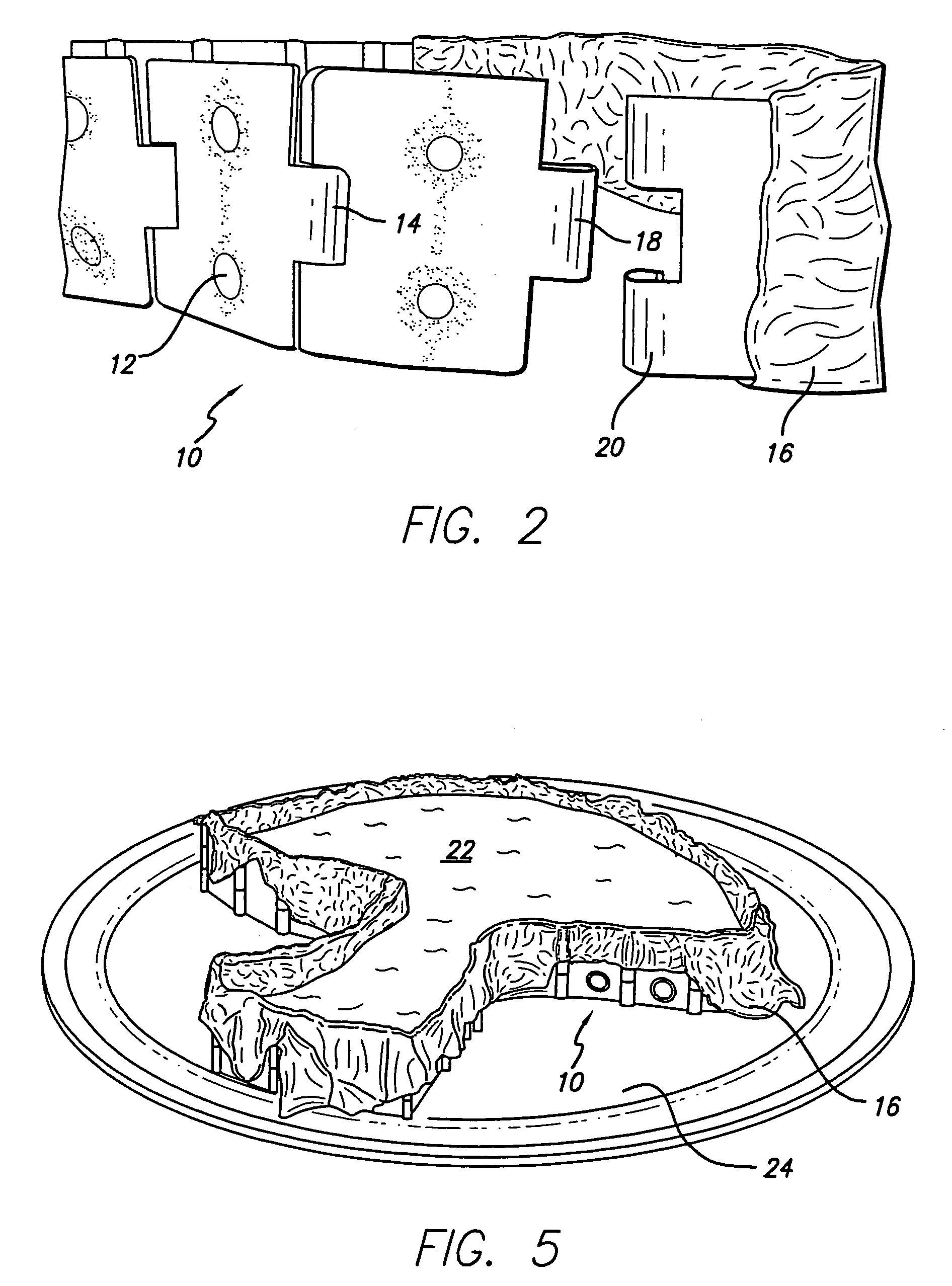

Flexible baking apparatus

InactiveUS20060027104A1Increase temperatureMeat processingKitchen equipmentThermoplasticCooking & baking

A flexible baking apparatus is disclosed having a strip of malleable material configured to be hand-manipulated into a desired shape. The malleable strip material is a thermoplastic, metal, alloy or other material capable of withstanding high temperatures. After forming the desired shape, the ends of the strip are joined together to form a baking vessel.

Owner:THE LICENSING GROUP

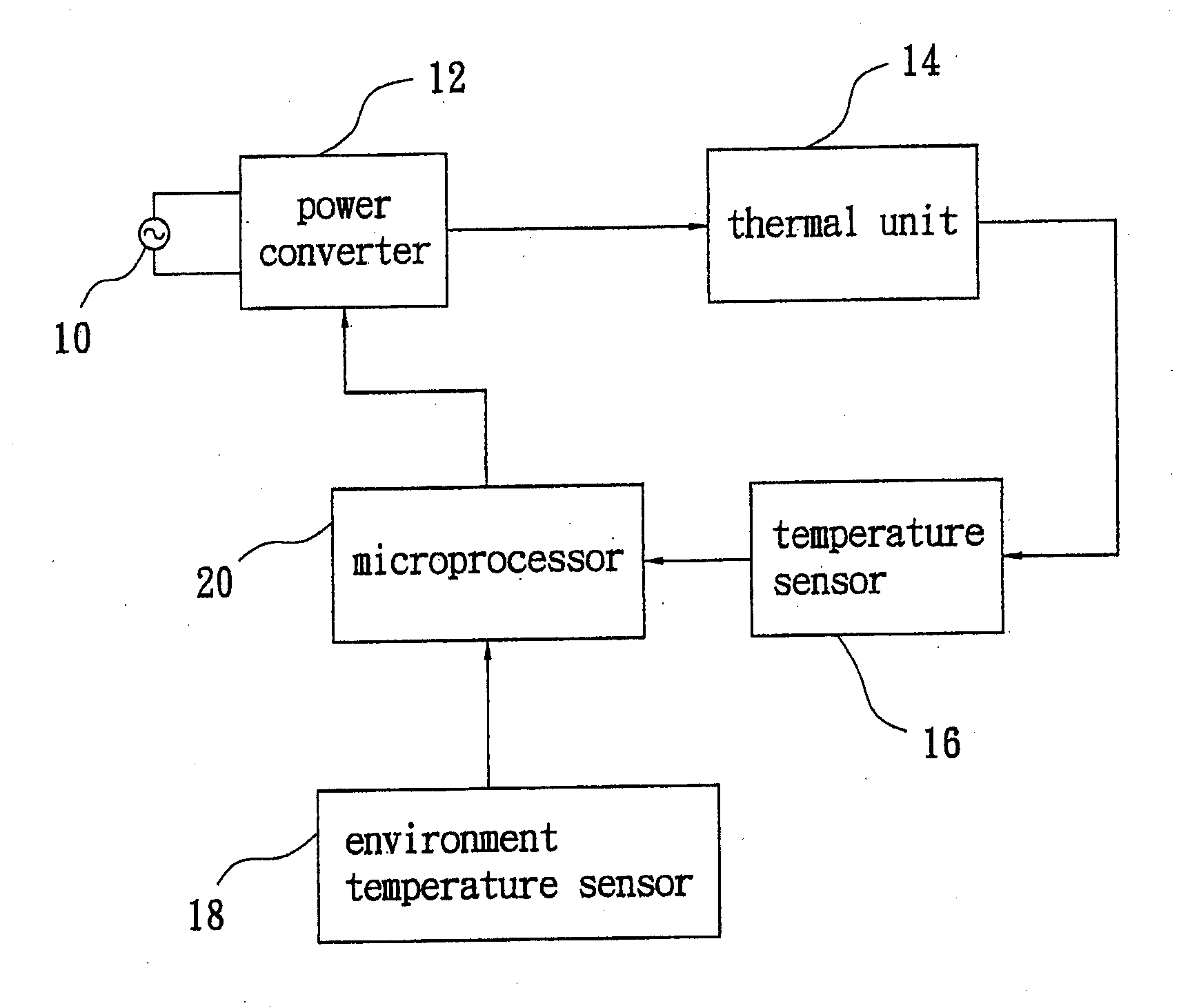

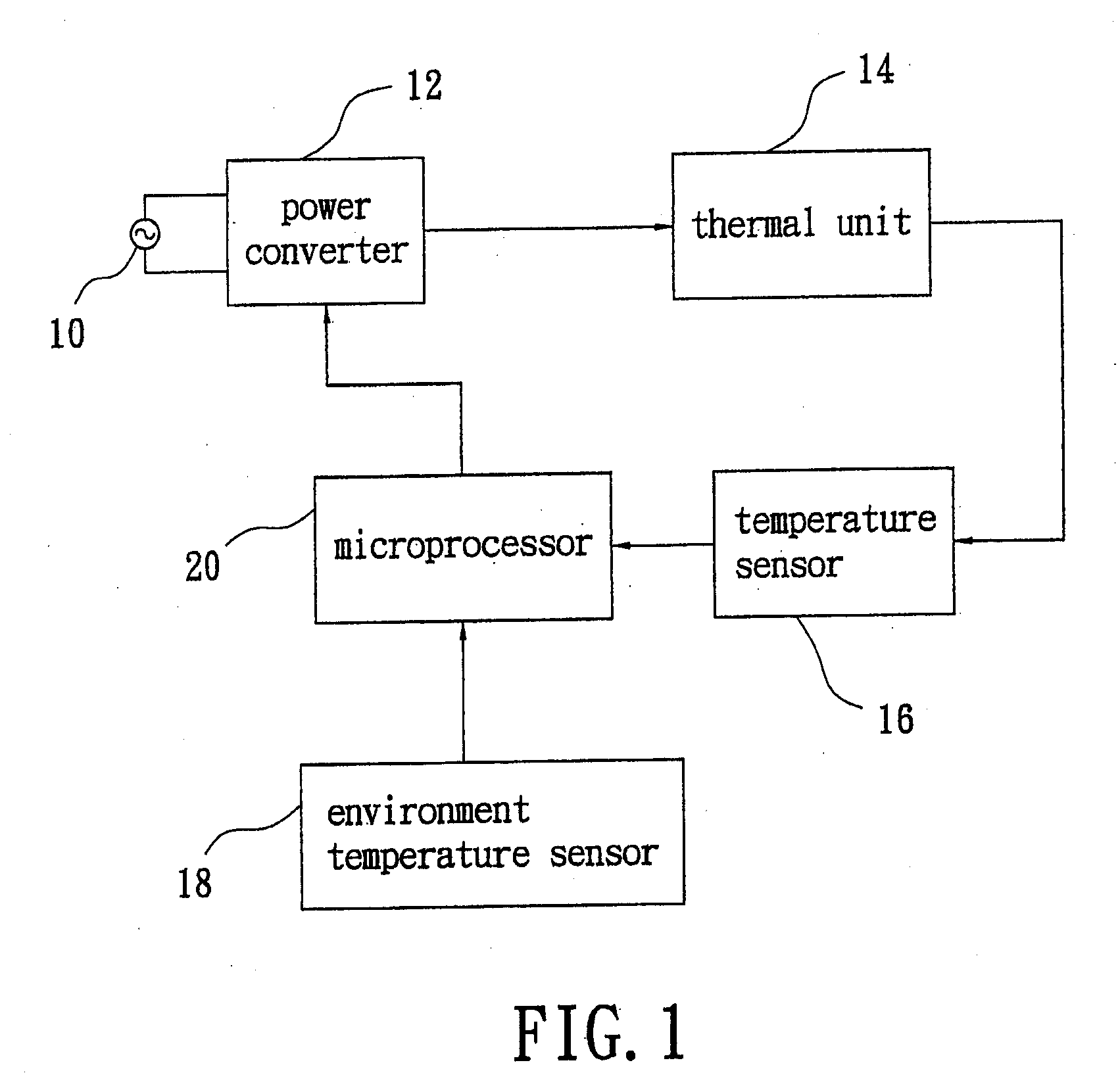

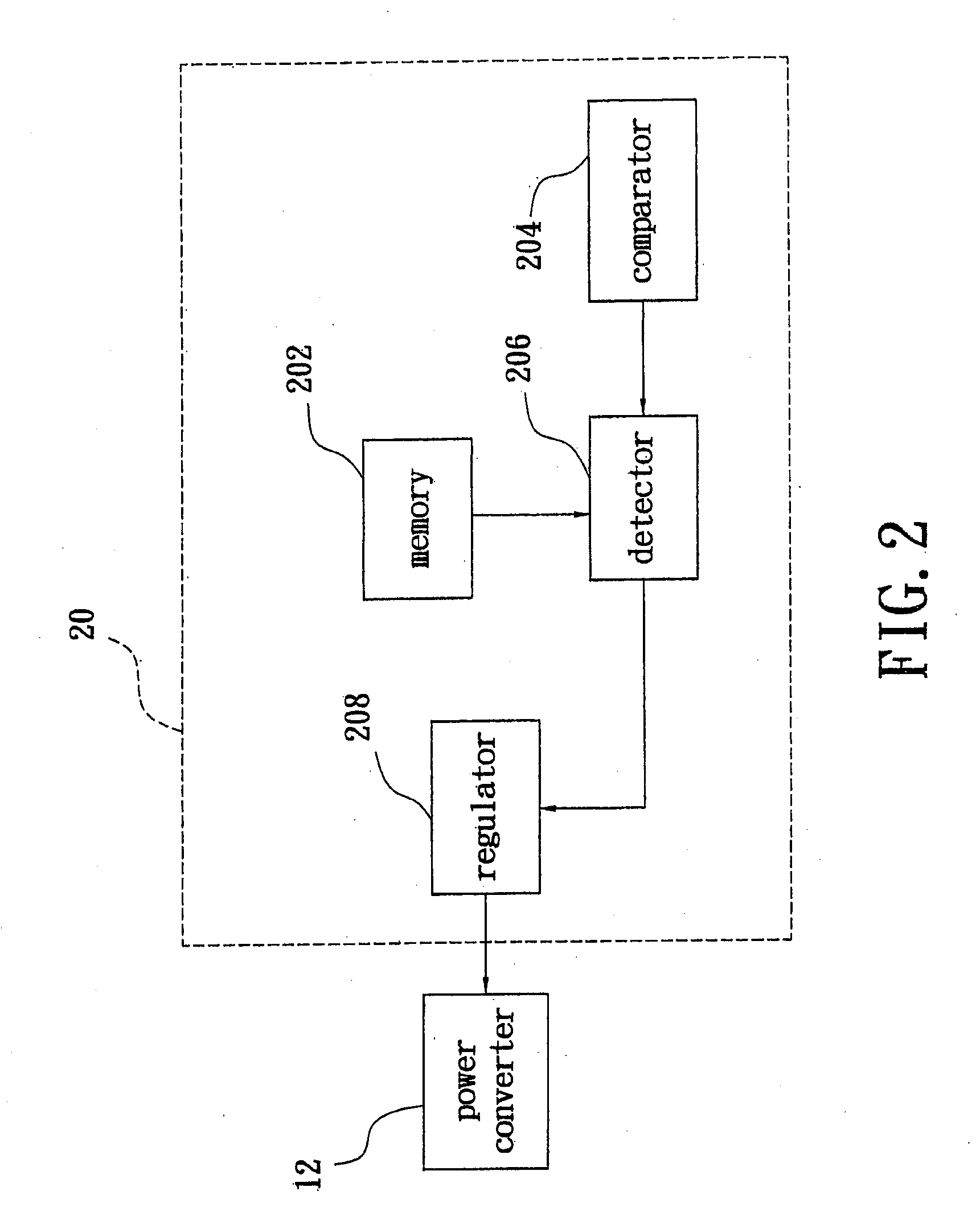

Baking device and method thereof for controlling a reliable browning level

InactiveUS20080057170A1Reliable levelingBoiling over preventionFood shapingEngineeringImpedance sensor

The present invention discloses a baking device and method thereof for controlling a reliable browning level and a baking method which controls the parameters of a browning level of a baking device in order to reach the browning level desired by a user. The baking device of the present invention includes a temperature sensor, a weight sensor or an impedance sensor to judge the current browning level of a baked food by the difference in temperature, the weight or the impedance of the baked food. It then compares the results with the reliable browning level stored in the microprocessor of the baking device. The comparing result of the current browning level and the reliable browning are used as a basis of whether to continue to heat the thermal grid or not.

Owner:FEGO PRECISION INDAL

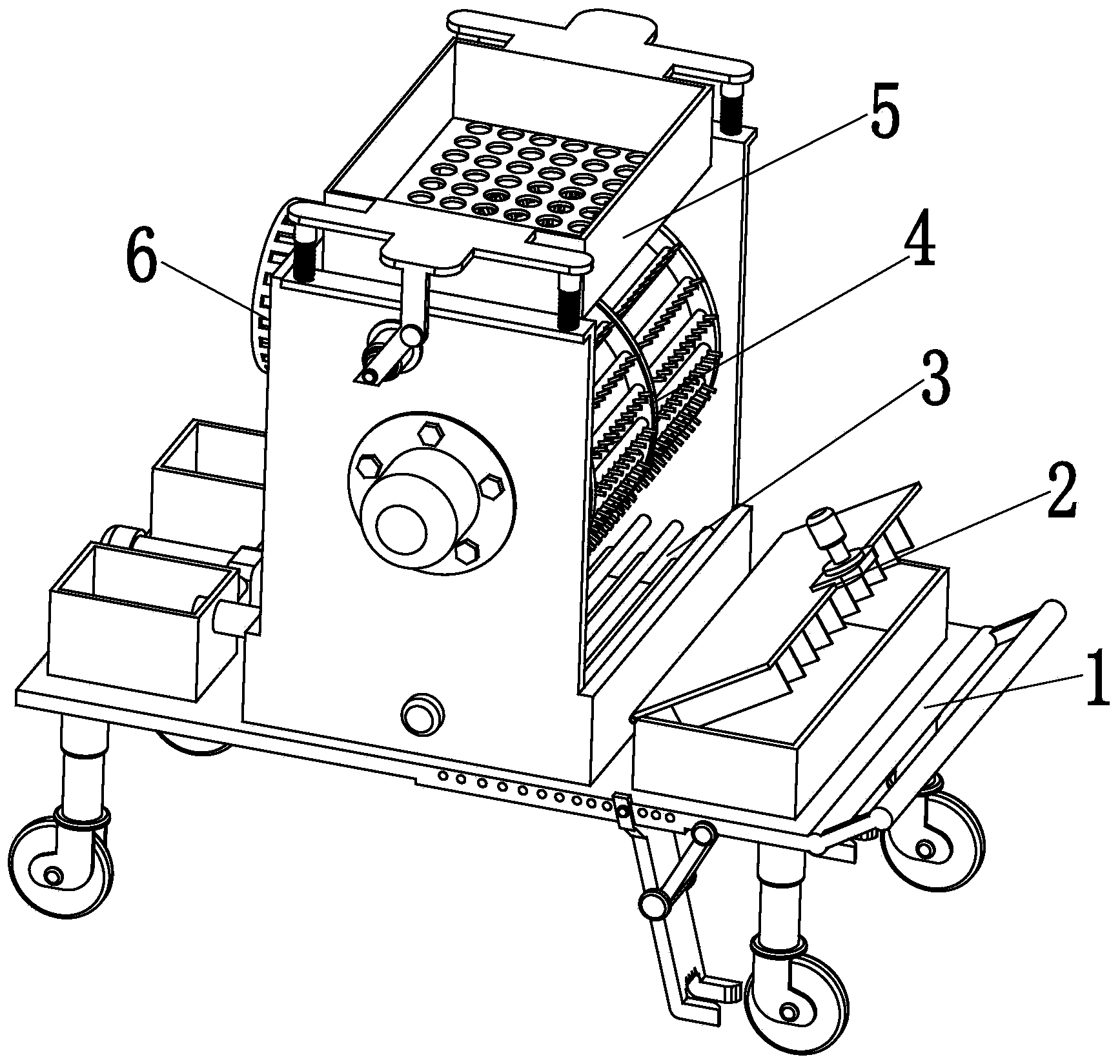

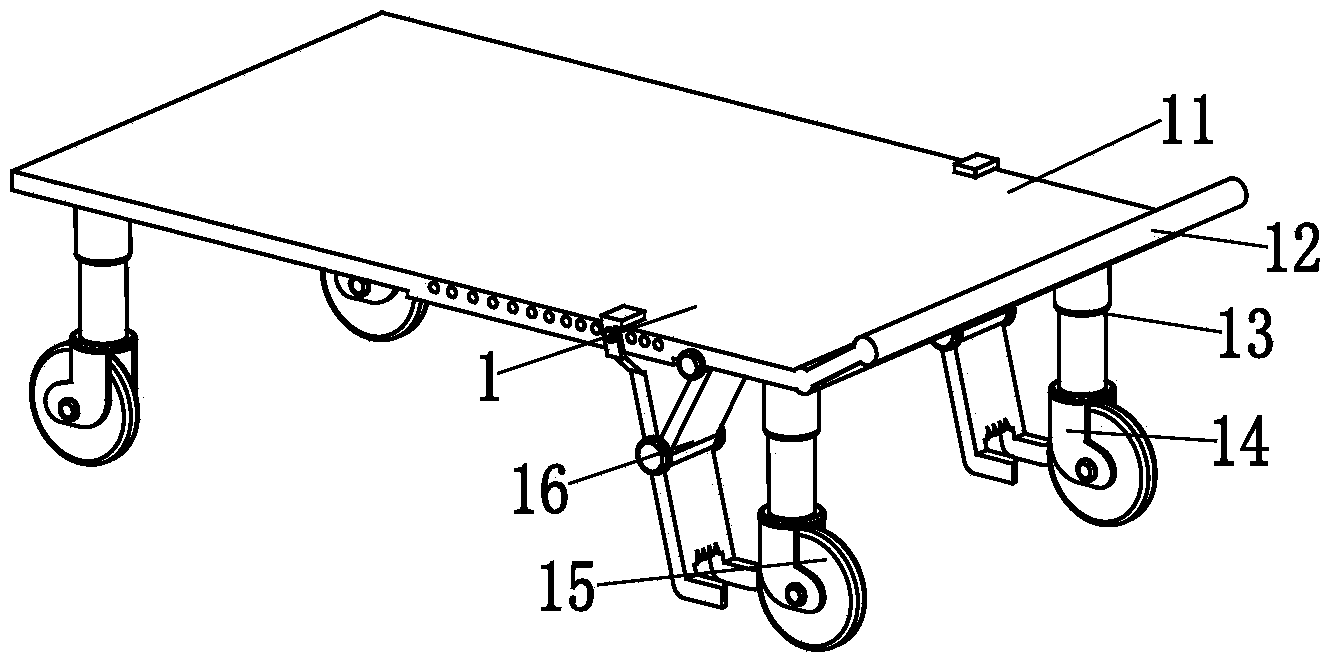

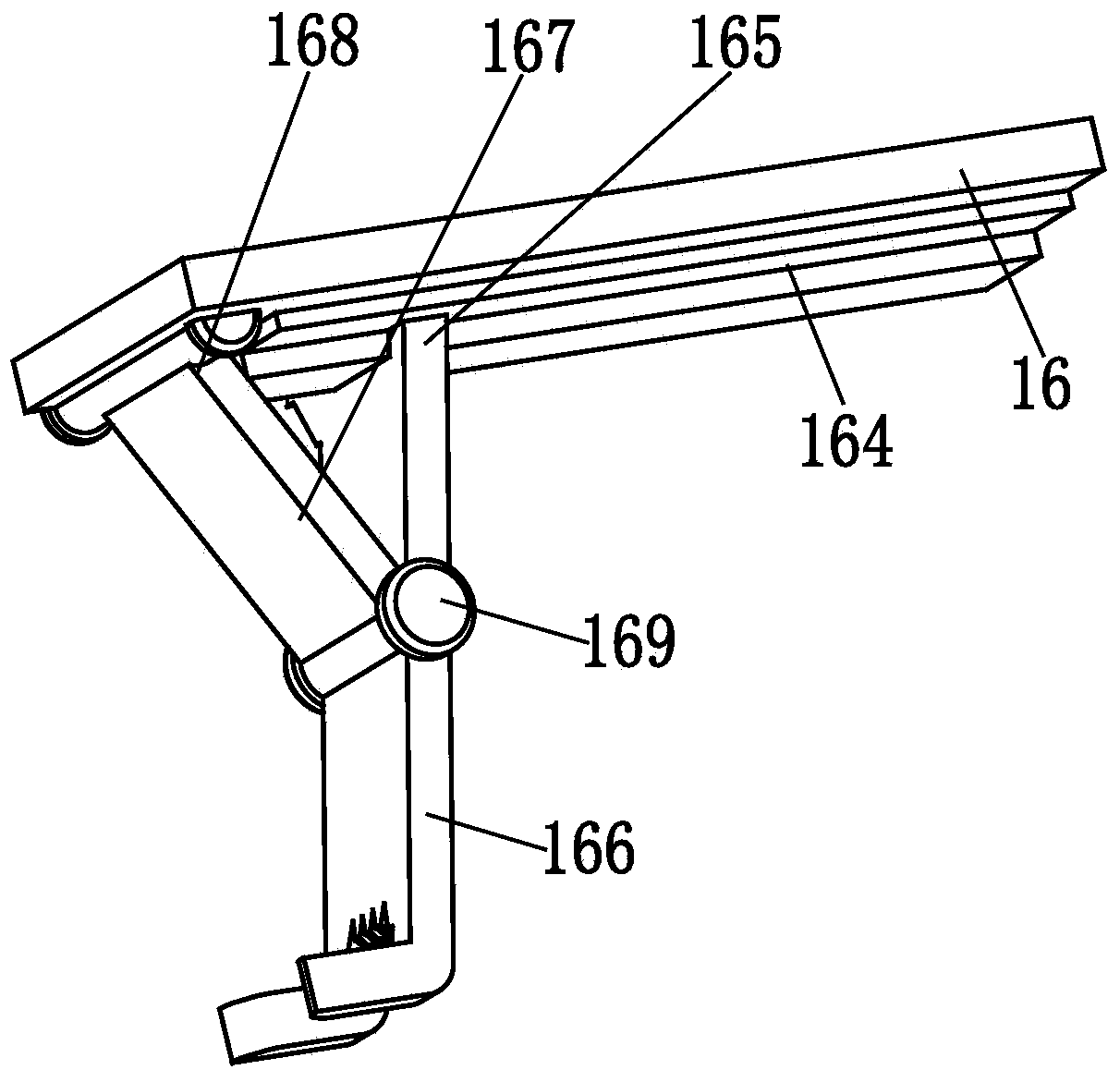

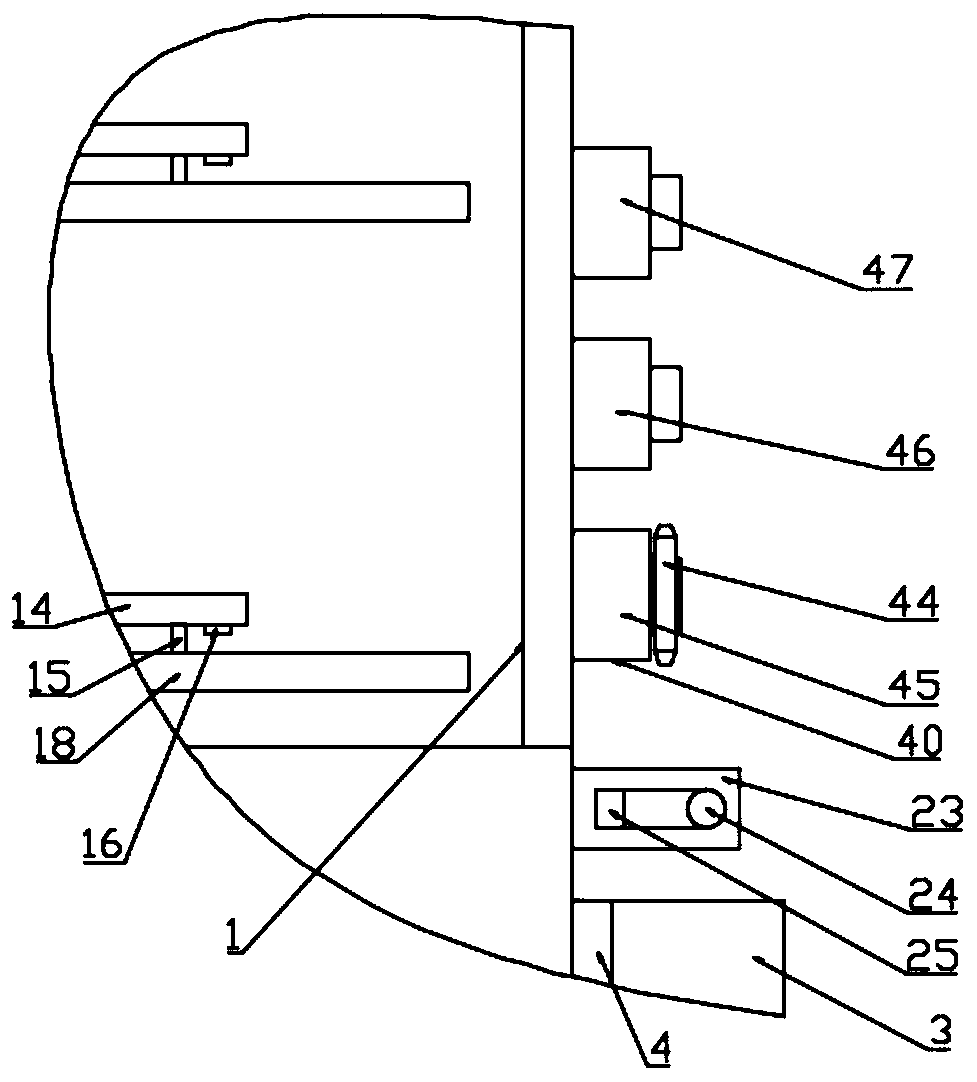

Baking equipment

ActiveCN104223967ASimple structureEasy to operateRoasters/grillsBread-toastersProcess engineeringAutomation

The invention relates to baking equipment. The baking equipment comprises a movable trolley, a slicing device, a baking oven, a grill, a material spreading device and a smoke exhaust device, wherein the slicing device is located on the rear side of the movable trolley, the baking oven is located right ahead the slicing device and the baking oven is fixedly connected with the movable trolley; the grill is installed above the baking oven and the material spreading device is located right above the grill; the smoke exhaust device is located on the front side of the baking oven and the smoke exhaust device is fixedly connected with the baking oven. The baking equipment has the advantages of simple structure, convenience in operation, low manufacturing cost and the like; the baking equipment can realize a function of rotatably baking sliced bread, the baking uniformity is good and the baking efficiency is high; the baking device can also realize a function of automatically spreading materials, and the automation level is improved; heat produced during baking is fully utilized and energy waste is reduced.

Owner:徐州市铜山区汉王镇农业服务发展有限公司

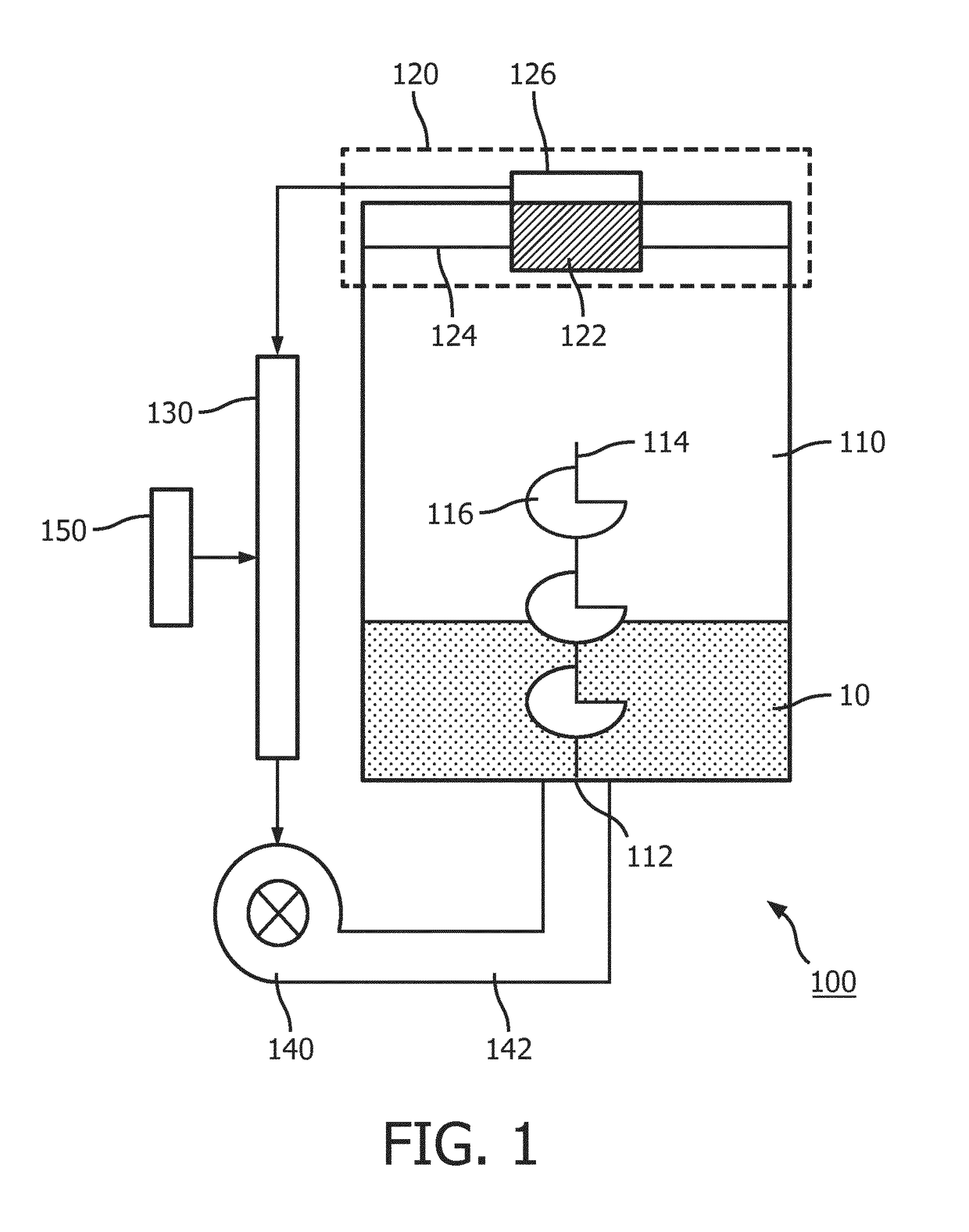

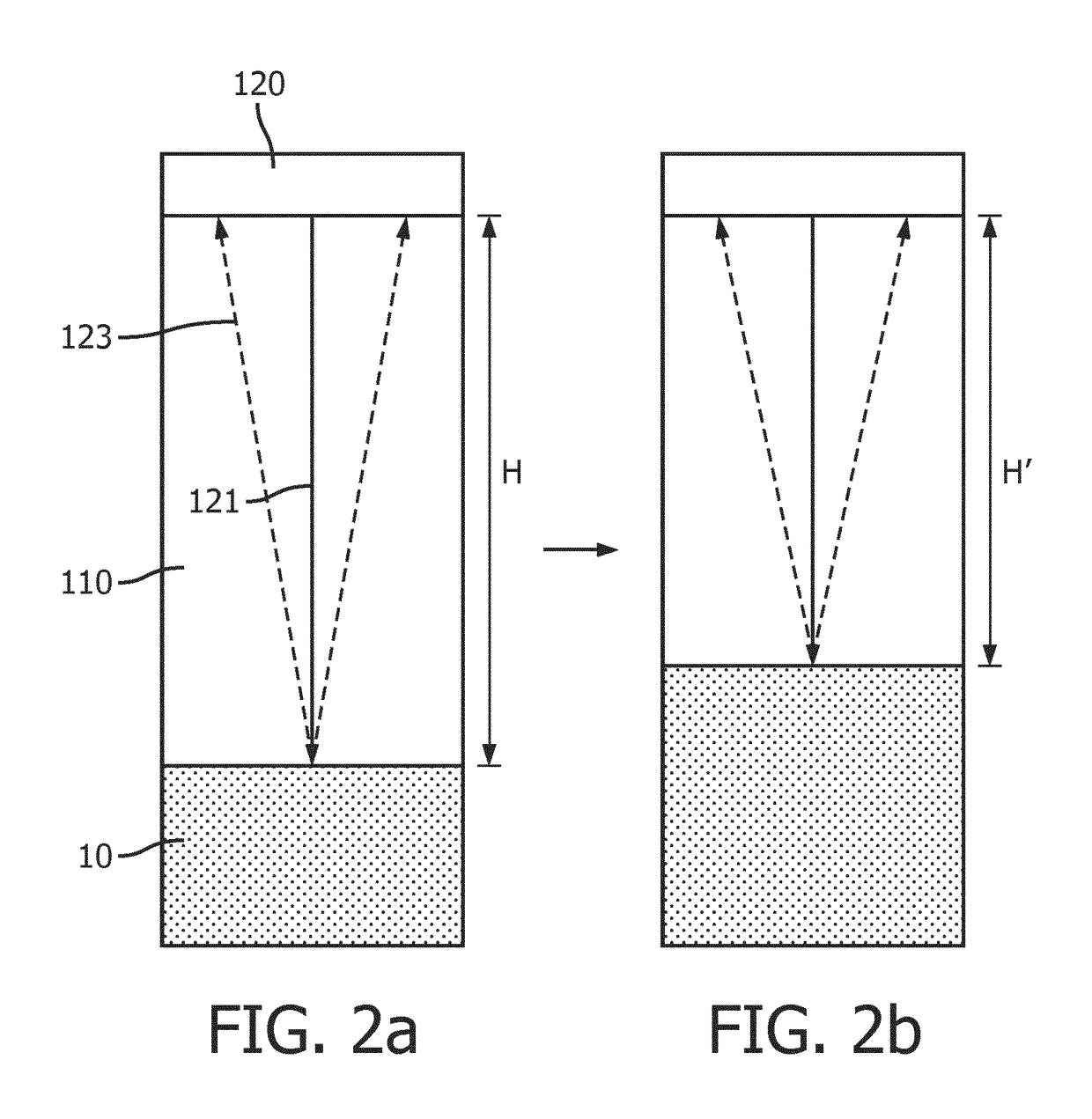

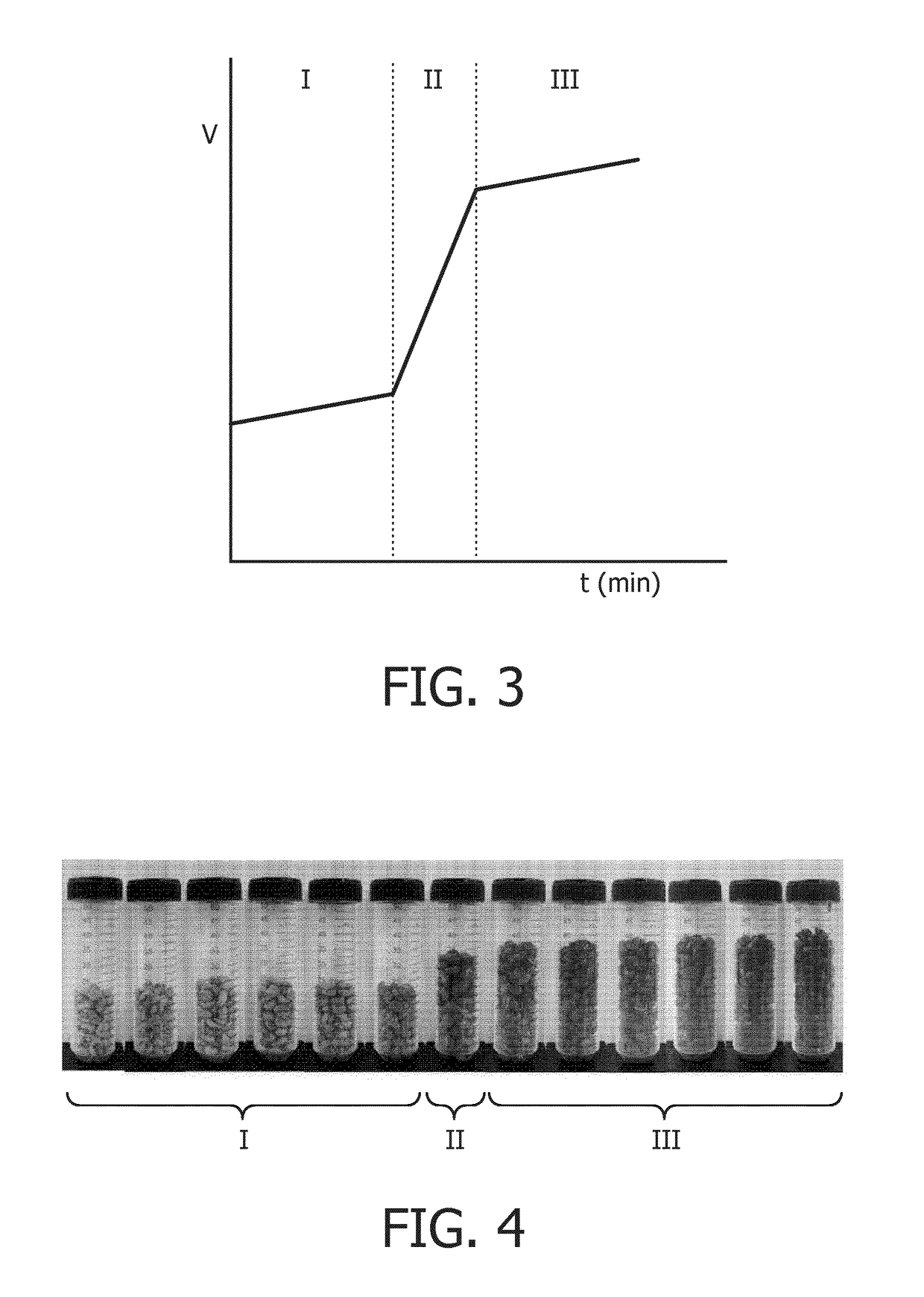

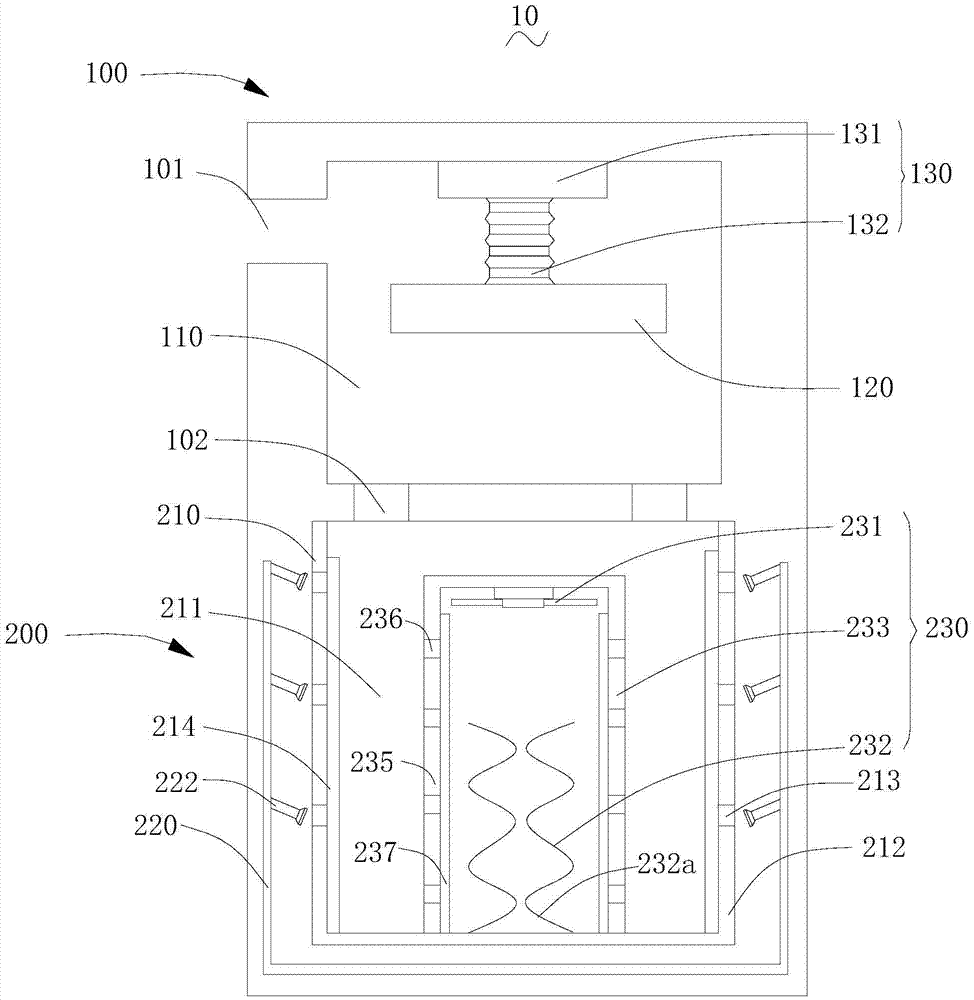

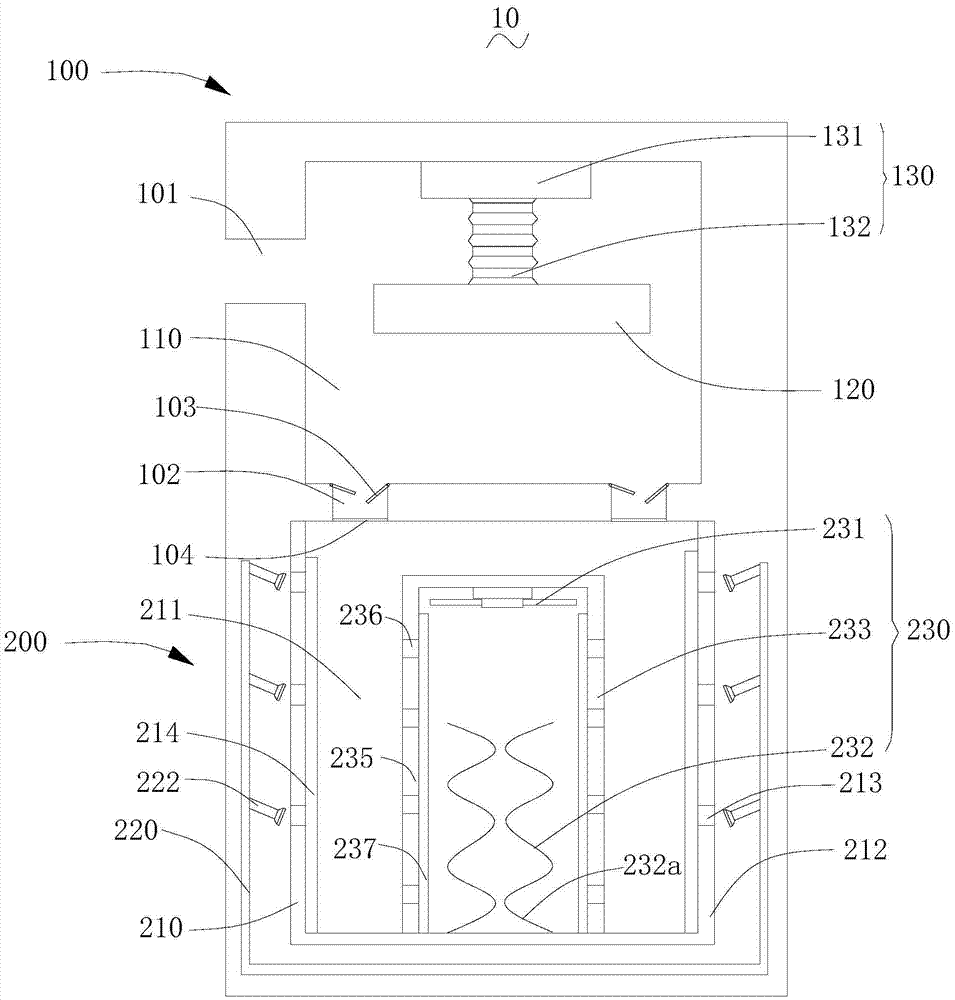

Coffee roasting apparatus, coffee brewing apparatus and coffee roasting method

ActiveUS20170215451A1Material analysis using sonic/ultrasonic/infrasonic wavesAnalysis by subjecting material to chemical reactionEngineeringBrewing

A coffee roasting apparatus (100) is disclosed comprising a compartment (110) for holding coffee beans (10); a roasting element (140) for roasting the coffee beans in said compartment; and a controller (130) for controlling the roasting element. The controller is adapted to control the roasting element as a function of a change in the volume of the coffee beans residing in the compartment. A coffee brewing apparatus including such a coffee roasting apparatus and a coffee roasting method are also disclosed.

Owner:VERSUNI HLDG BV

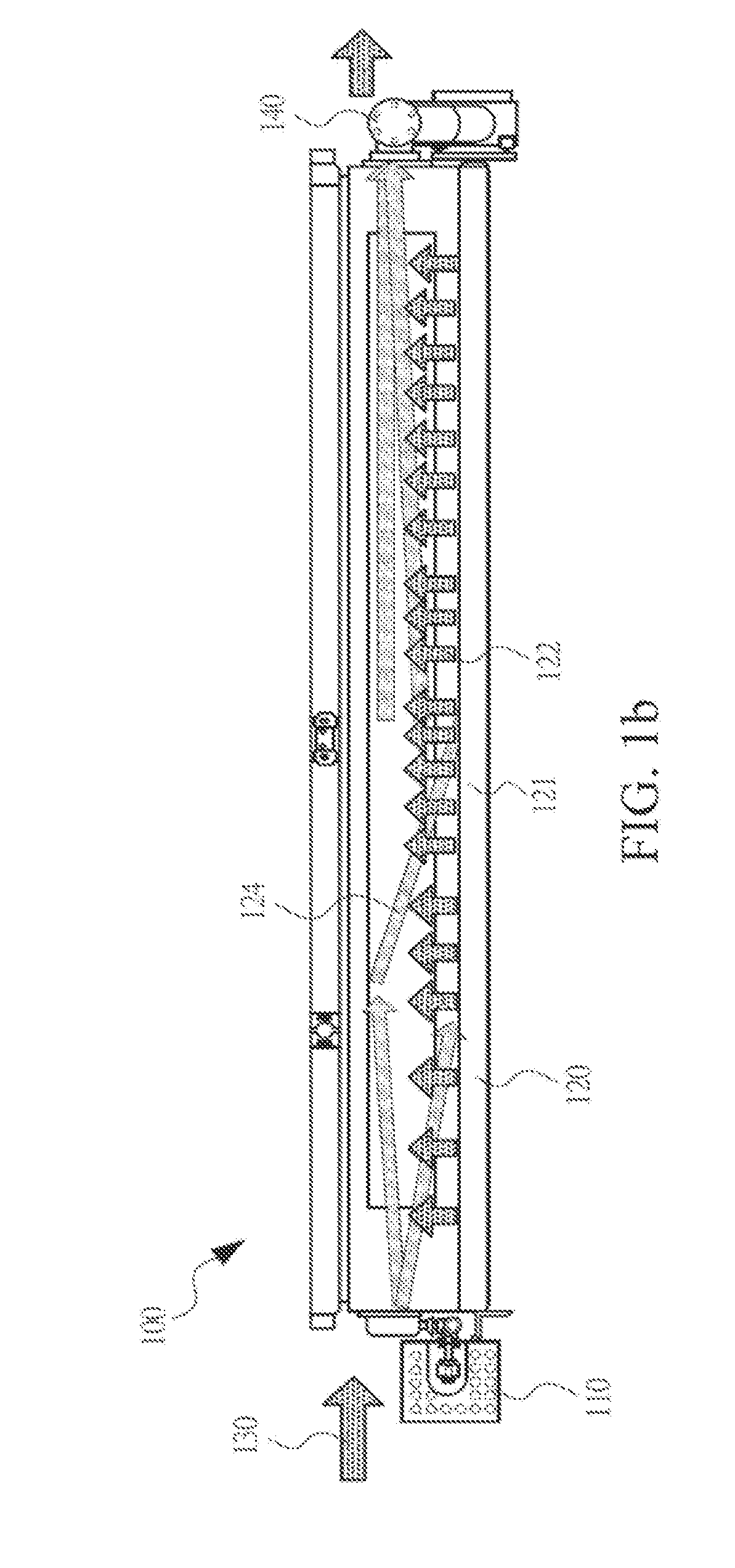

Method, continuous apparatus, and burner for producing a surface-roasted product

InactiveUS20120015084A1Satisfies needReduce decreaseDomestic stoves or rangesBaking ovenCombustorEngineering

An apparatus, a loop burner element, and a method for surface-roasting a food product wherein the roasting apparatus comprises (a) a conveyor which carries the food product and (b) at least one non-linear ribbon flame burner element or element assembly which preferably applies a ribbon flame to at least the upper and side surfaces of the food product as it is conducted through the roasting apparatus.

Owner:MARLEN INT

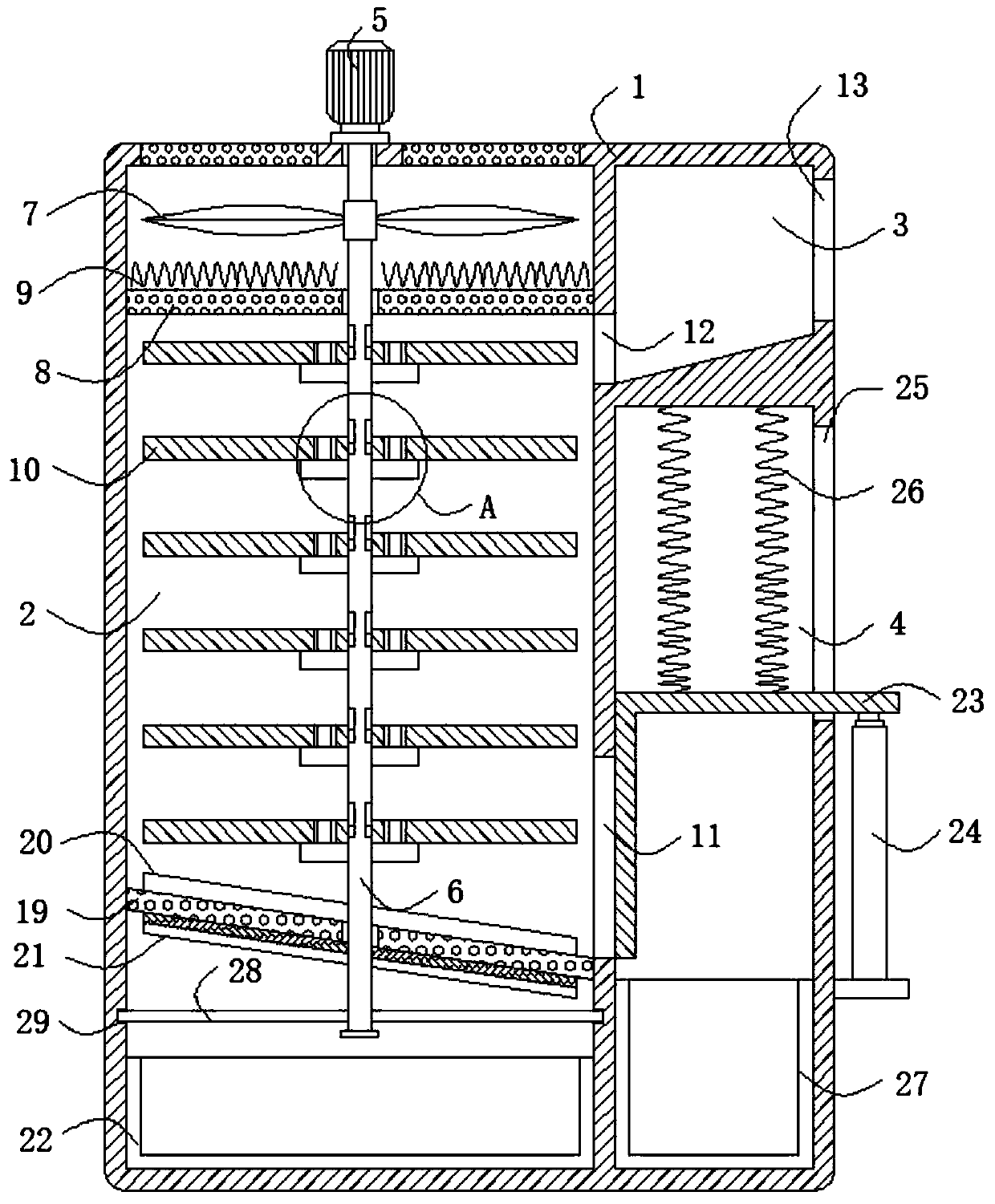

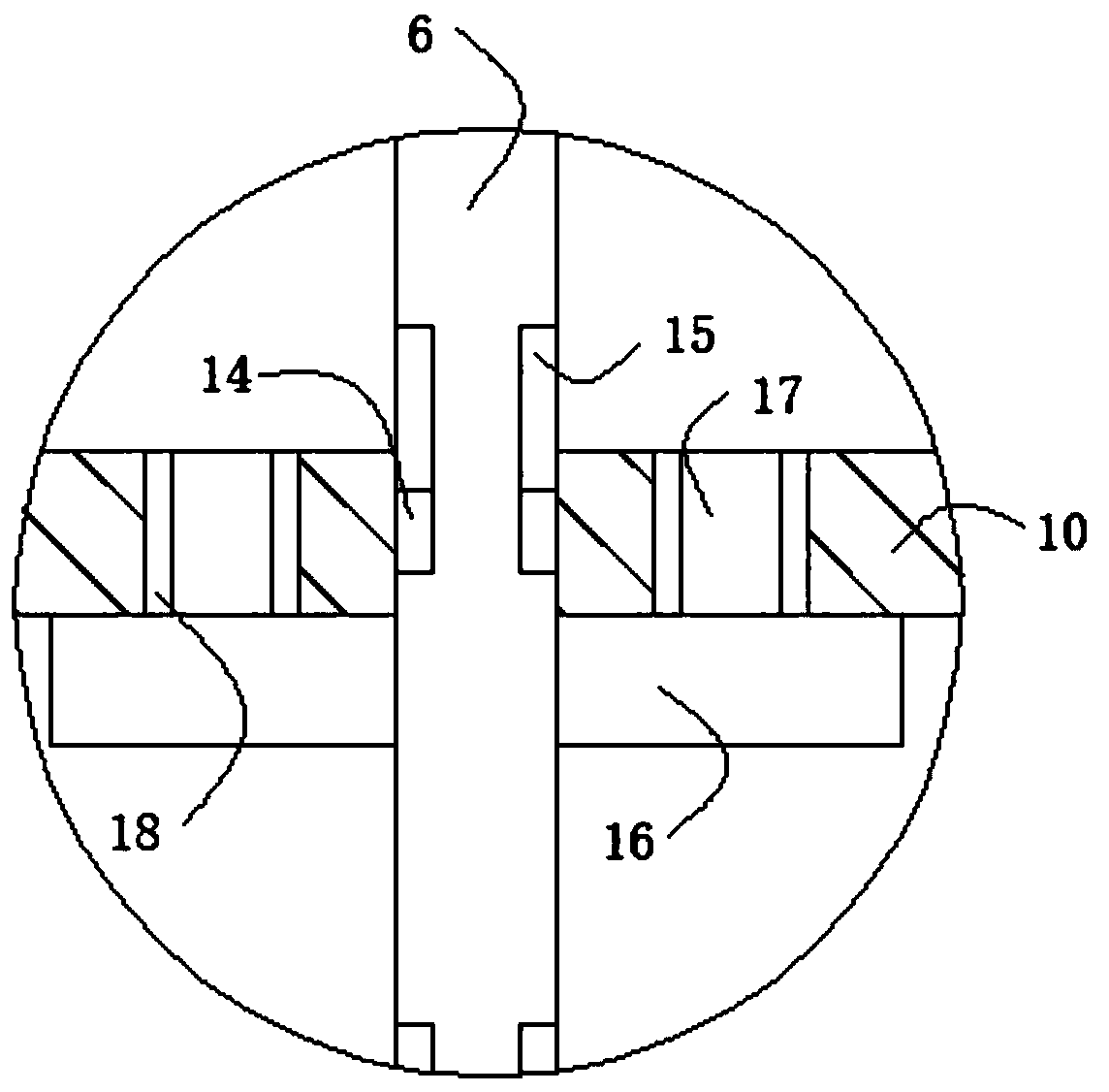

Baking equipment for food processing

ActiveCN110645782ASolve the problem that it is not easy to replace partsImprove work performanceSievingScreeningElectric machineryEngineering

The invention discloses baking equipment for food processing, and relates to the technical field of food processing equipment. To solve the problem that parts of existing baking equipment are inconvenient to replace, the baking equipment for food processing is provided and includes a processing box, and the processing box is internally provided with a braking cavity, a material conveying cavity and a receiving cavity. The material conveying cavity is a trapezoid cavity, a vertically arranged driving motor is welded to the top of the processing box, an output end of the driving motor is in transmission connection with a vertically arranged rotating shaft, the end, away from the driving motor, of the rotating shaft extends into the baking cavity, and the outer wall of the portion, in the baking cavity, of the rotating shaft is fixedly sleeved with a transversely arranged fan. The equipment can bake and process preserved fruits efficiently, stir the preserved fruits and filter away fine impurities in the preserved fruits, the processing efficiency is high, and the equipment is convenient to use.

Owner:安徽采林间食品有限公司

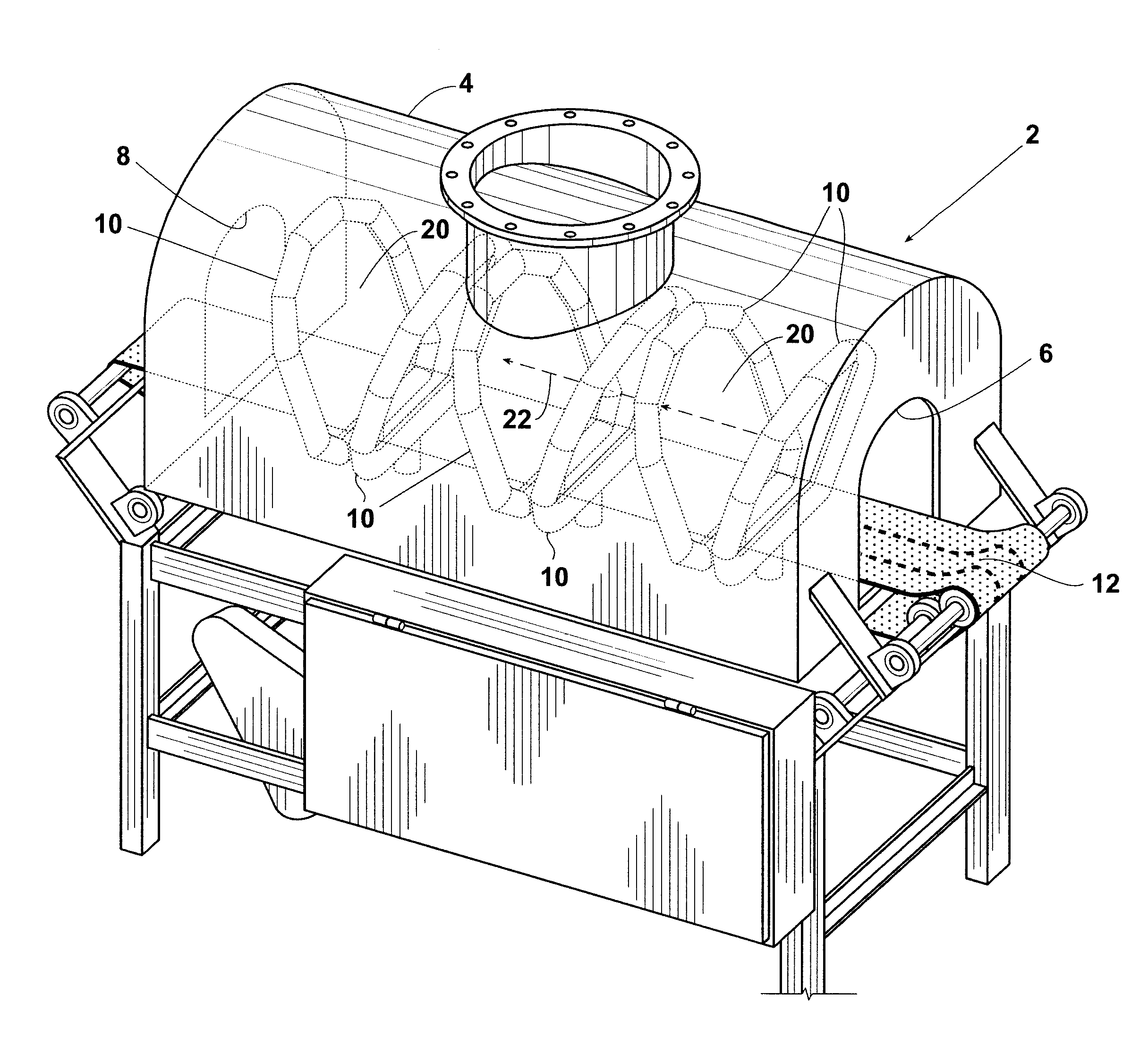

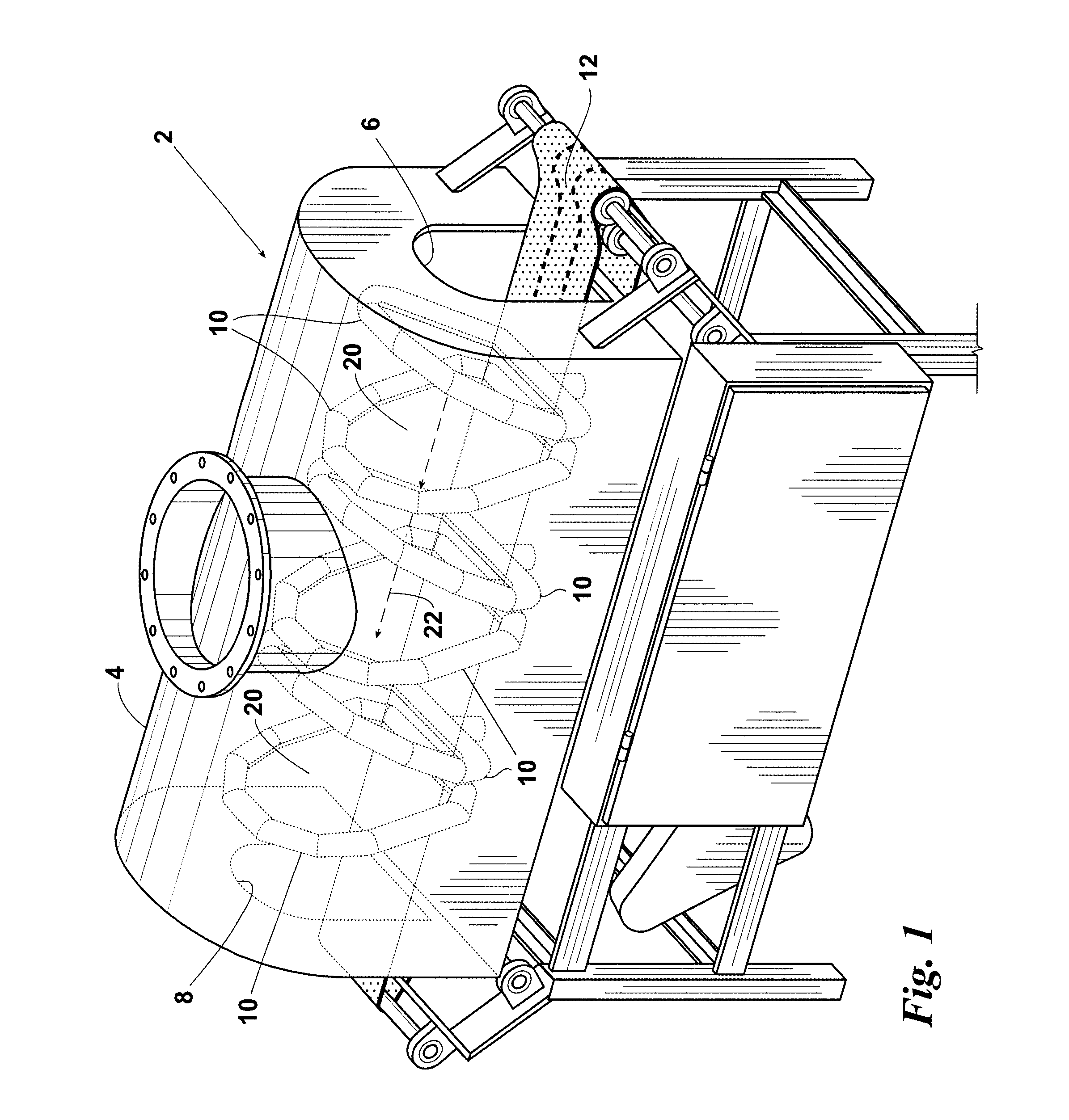

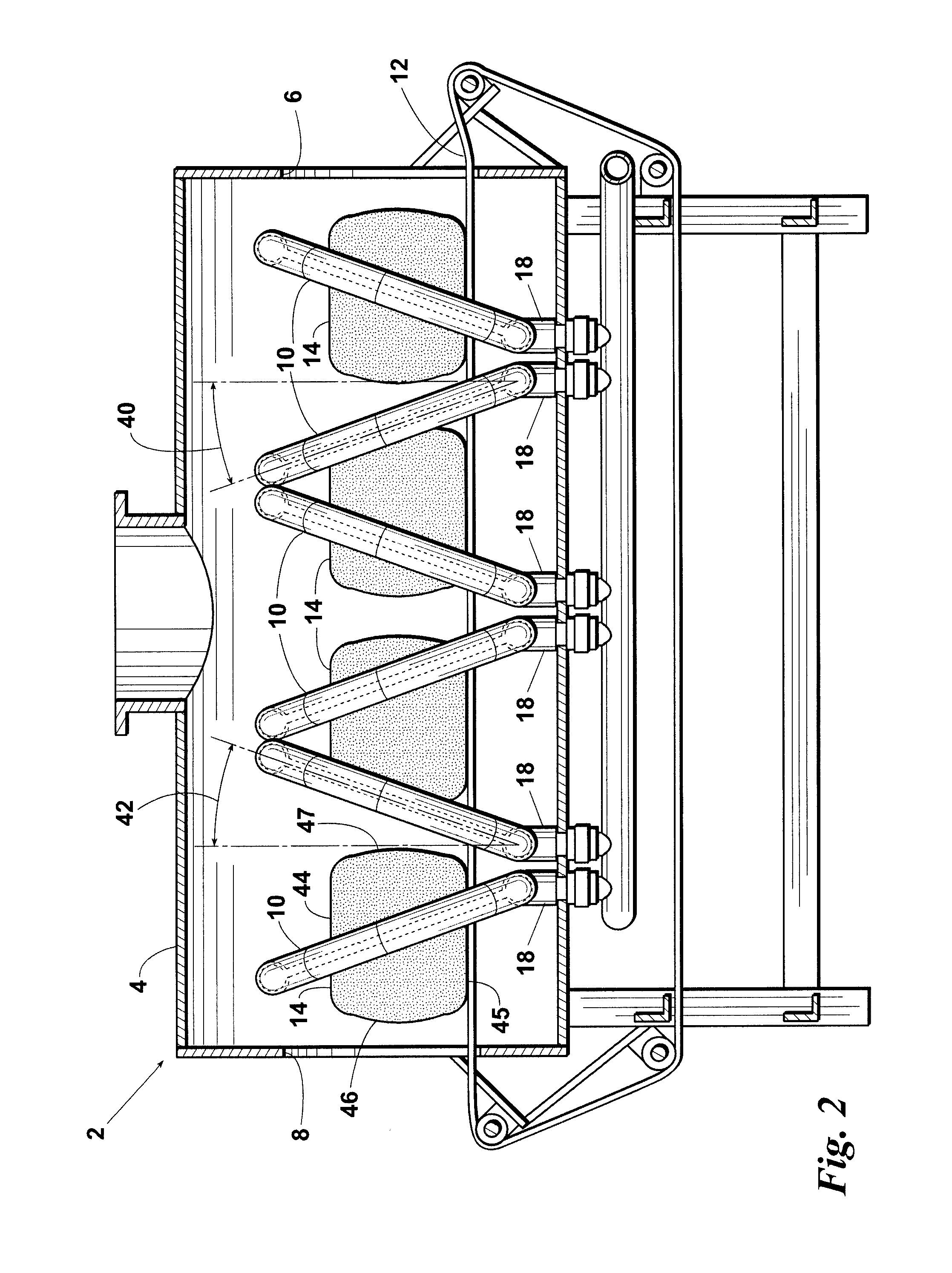

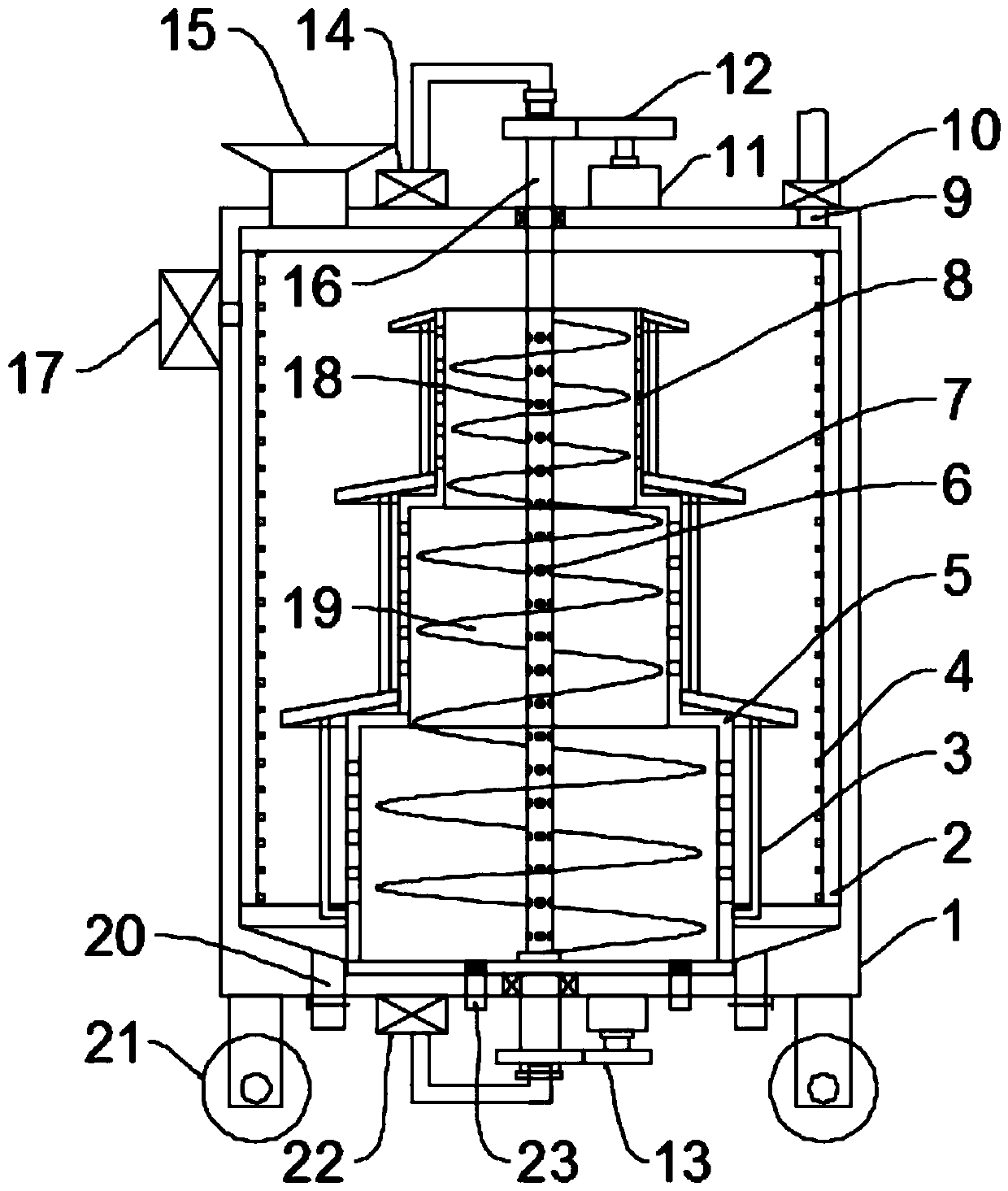

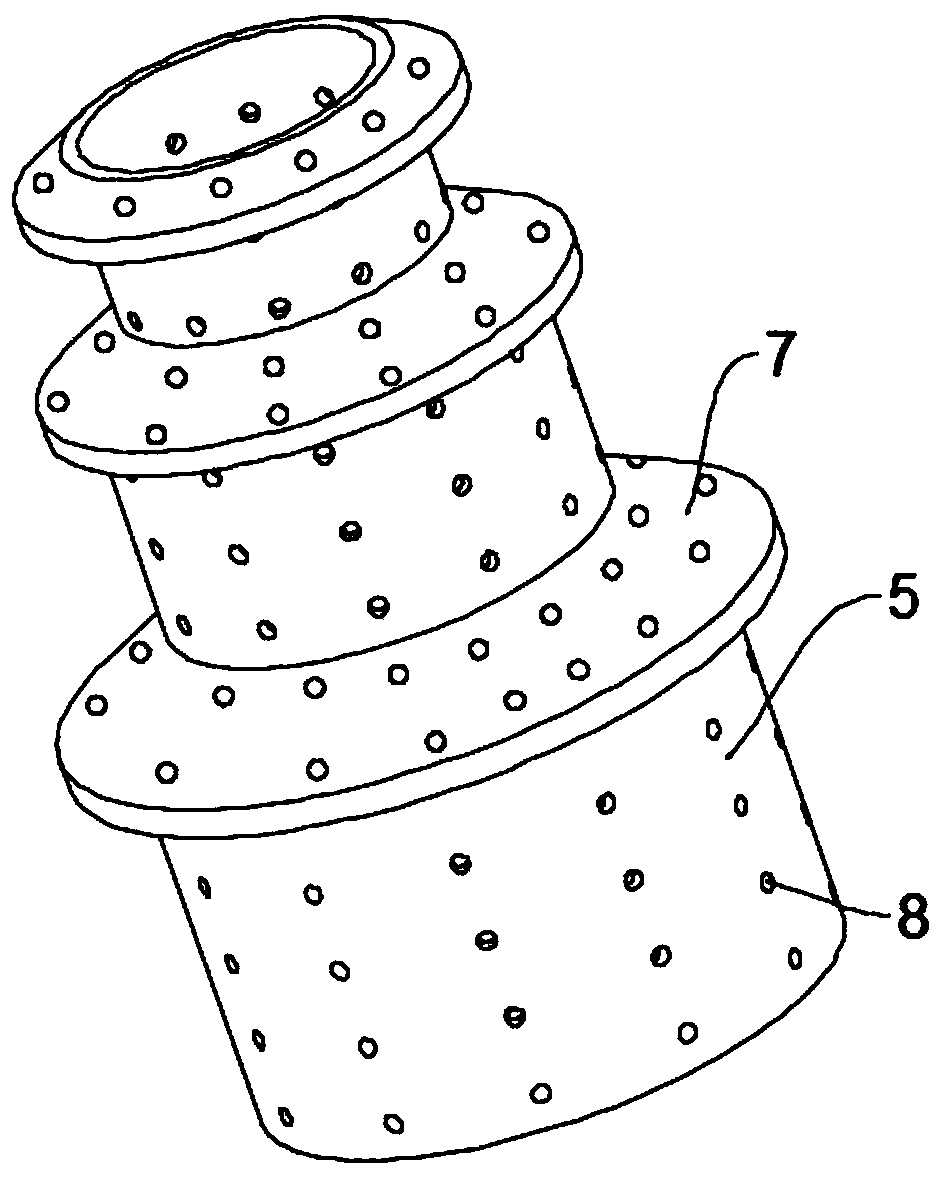

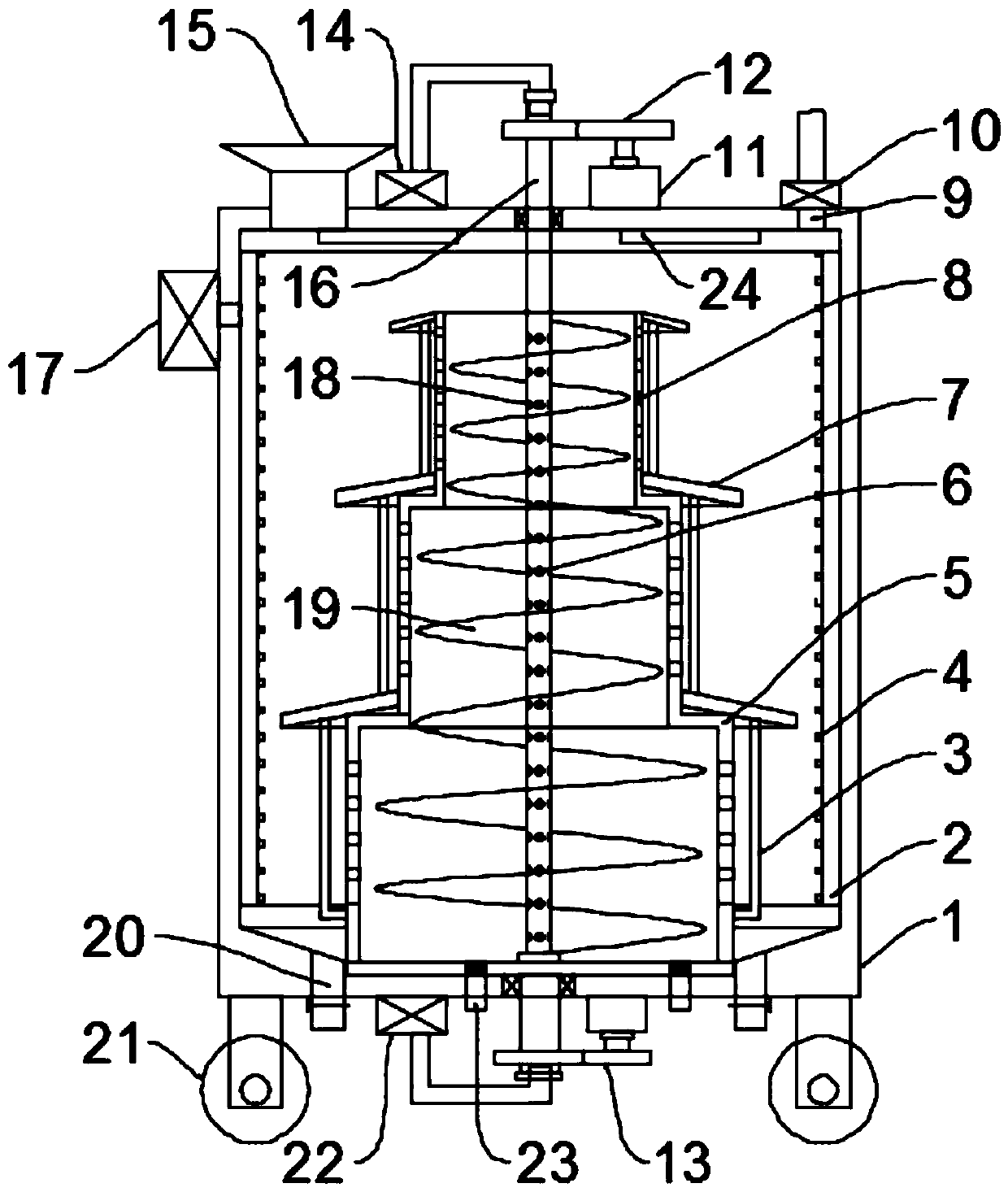

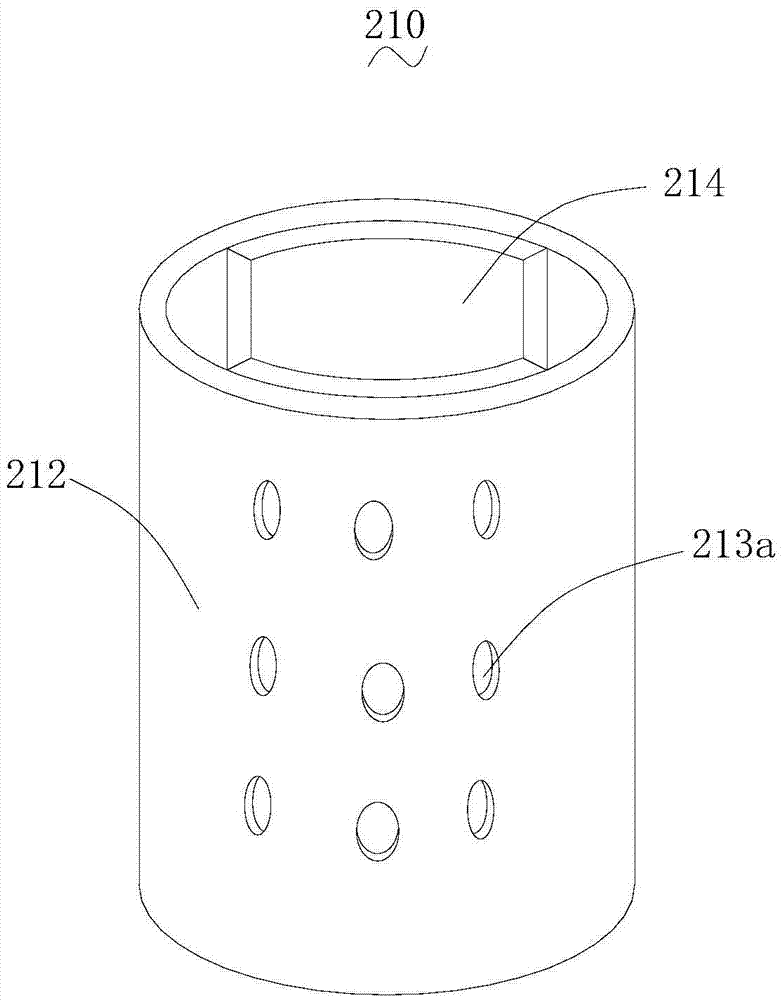

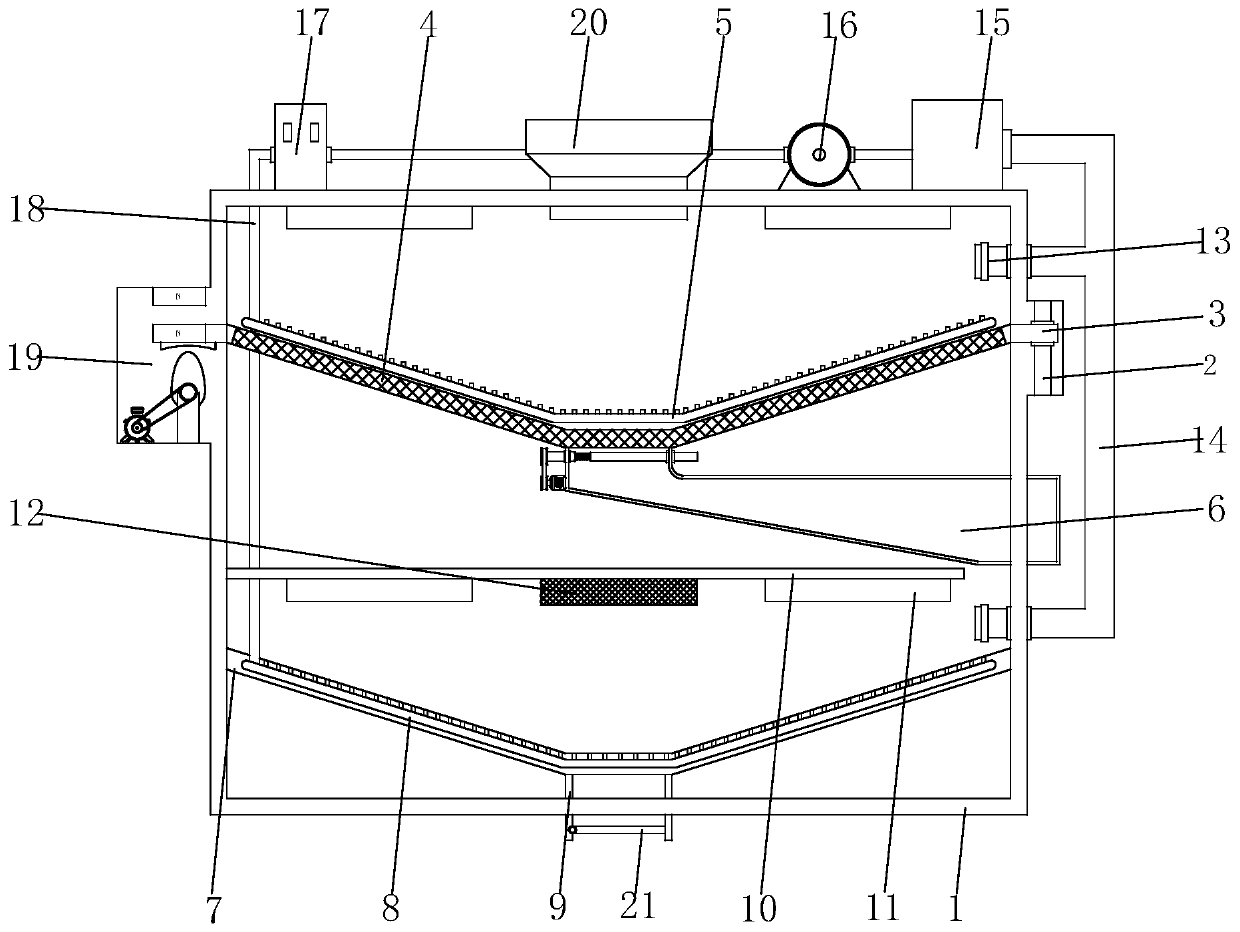

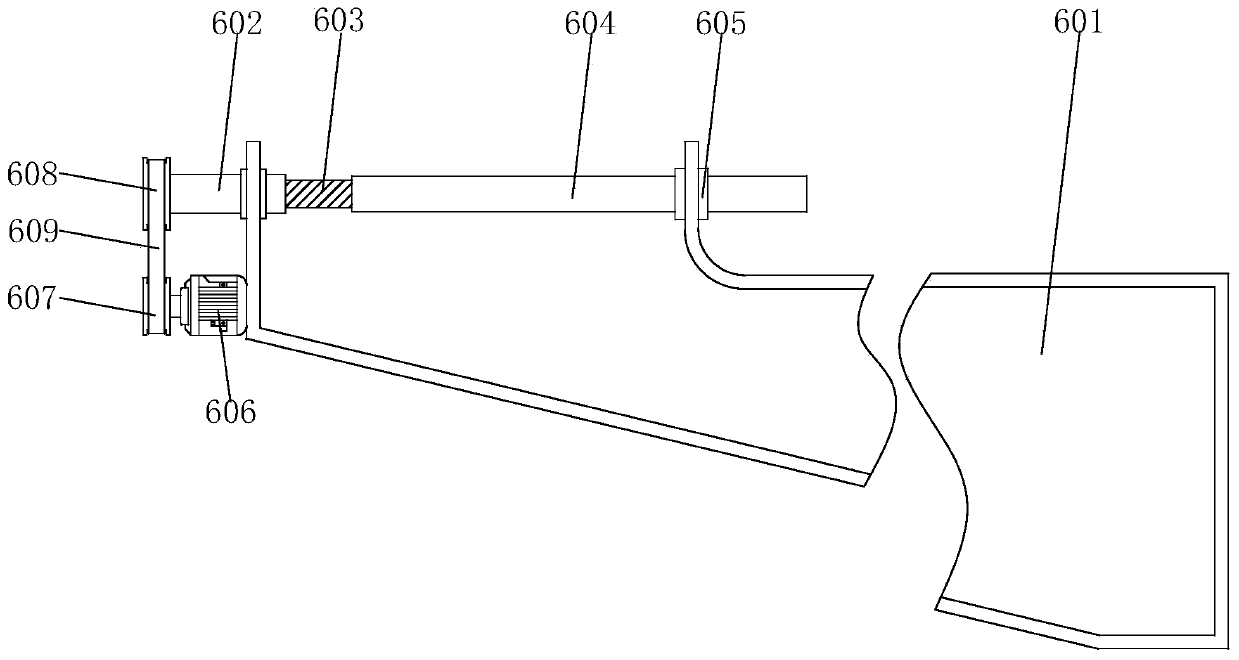

Baking equipment for biomass processing

ActiveCN111023785AFully dryFully contactedDrying gas arrangementsDrying solid materialsProcess engineeringAir blower

The invention discloses baking equipment for biomass processing. The baking equipment comprises an outer barrel body and a drying unit, wherein the drying unit comprises a stepped inner barrel, a rotating shaft, a lifting auger, a dispersing disc and a hot air drying assembly, wherein the hot air drying assembly comprises a first hot air blower, a second hot air blower, a third hot air blower, airspraying holes and a drying barrel; the drying unit comprises a stepped inner barrel, a rotating shaft, a lifting auger, dispersing discs and a hot air drying assembly; biomass enters the stepped inner barrel, and a first driving mechanism drives the rotating shaft and the lifting auger to rotate, the second driving mechanism drives the stepped inner barrel to rotate reversely; and biomass is lifted upwards, then scattered out from the top part of the stepped inner barrel, sequentially falls down from the plurality of dispersion discs in a multi-layer curtain shape, is dried sufficiently andevenly and then enters the stepped inner barrel again. Through the circulation falling and dispersing type drying, the baking equipment has the advantages of fast drying speed and high efficiency, isprovided with the hot air drying assembly and can dry the biomass from the interior and the exterior at the same time.

Owner:吉林安心良品食品有限公司

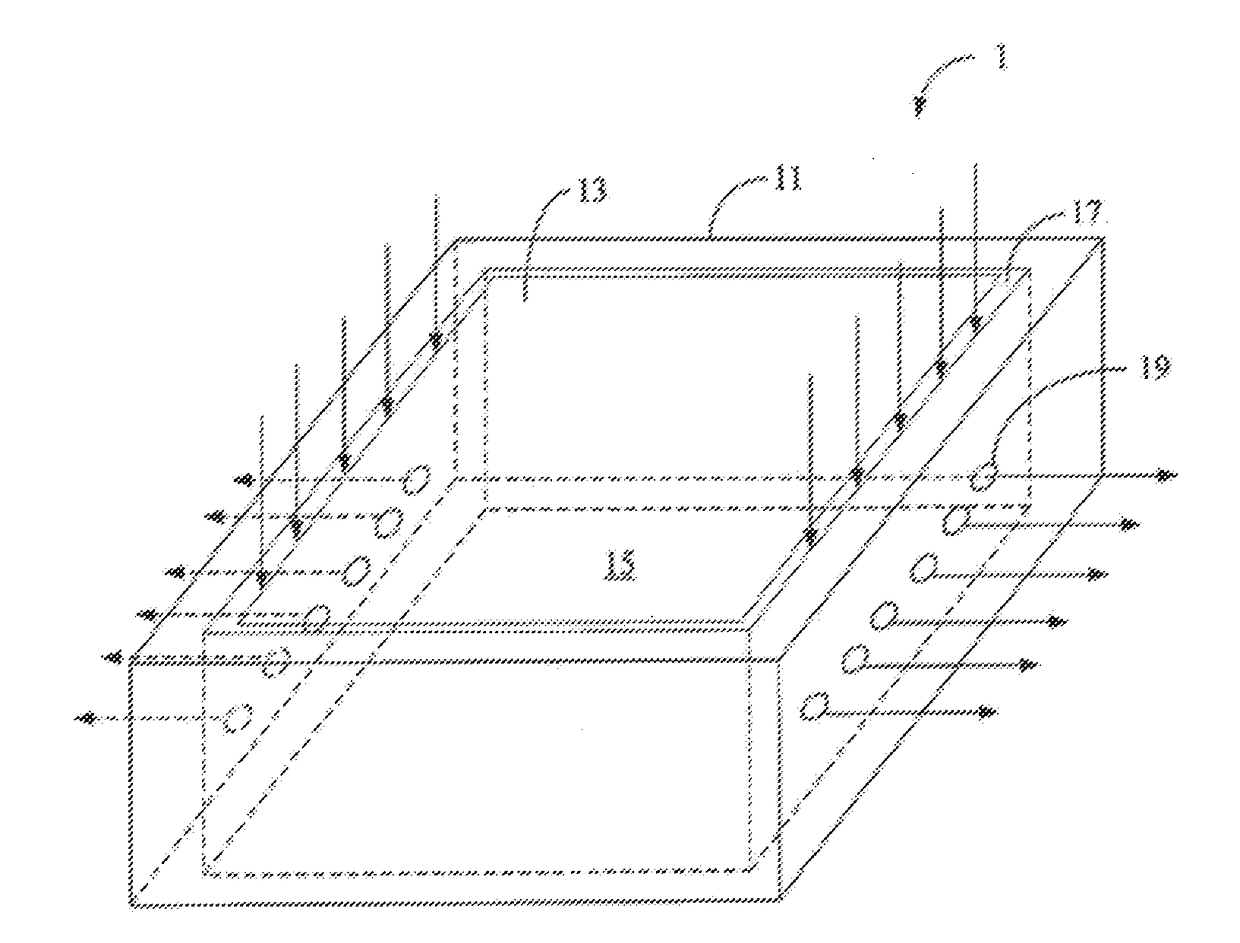

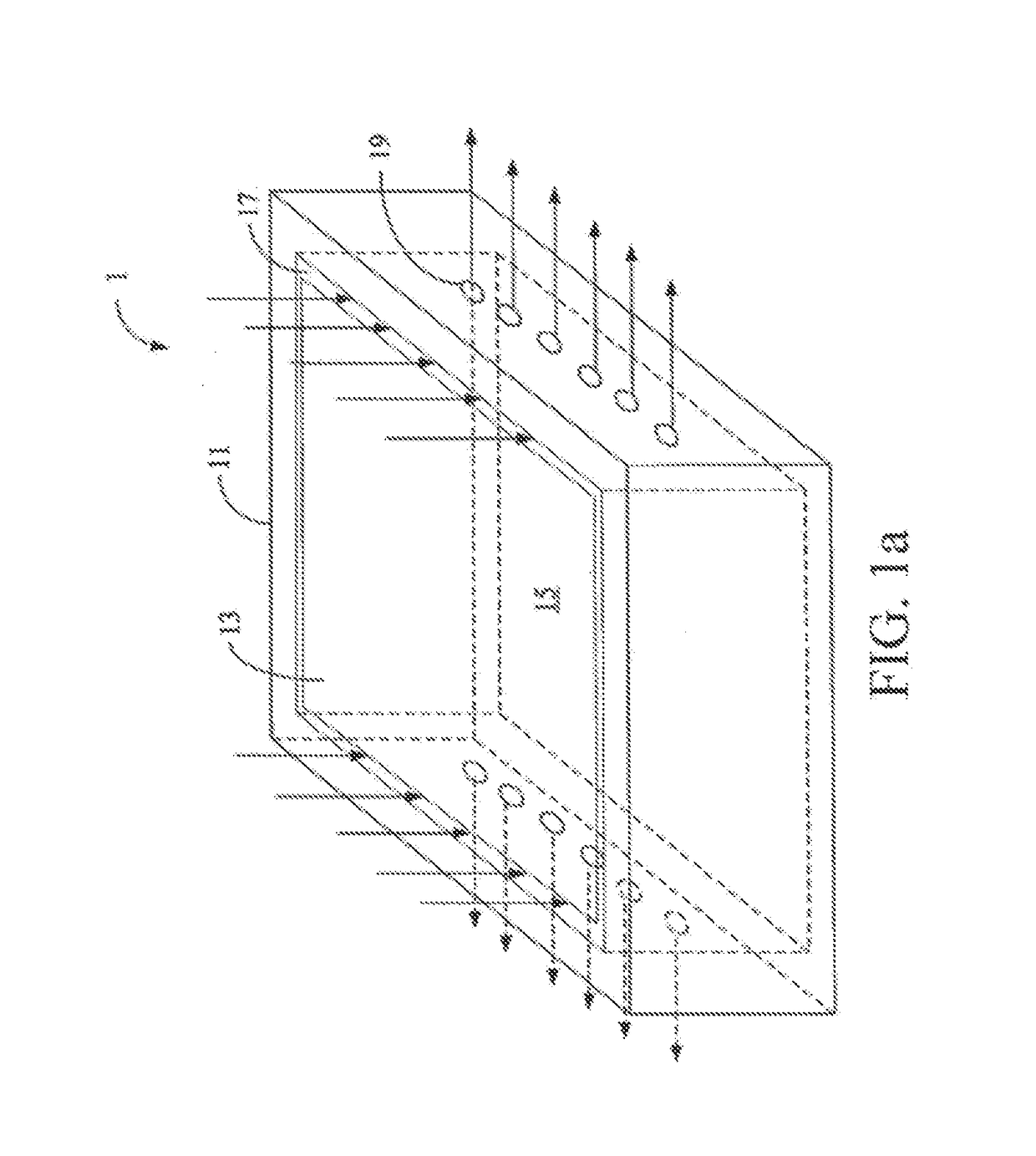

Substrate baking apparatus and baking operation mehod thereof

InactiveUS20180329304A1Speed up the flowStable flowSemiconductor/solid-state device manufacturingPhotosensitive material processingProcess engineeringMechanical engineering

This application provides a substrate baking apparatus and a baking operation method. The apparatus includes: a ring-shaped bearer body, used to cover a substrate; a cover plate, disposed on the ring-shaped bearer body, which, together with the cover plate, defines a sealed chamber, where a surface of the substrate is located inside the sealed chamber; an air intake unit and an exhaust discharge unit, respectively disposed on an intake end and a discharge end of the sealed chamber; and an exhaust regulation air-extraction system, disposed on an upper part of the cover plate, communicated with the sealed chamber, and used to regulate and discharge evaporated gases of a great number of volatiles of the substrate.

Owner:HKC CORP LTD +1

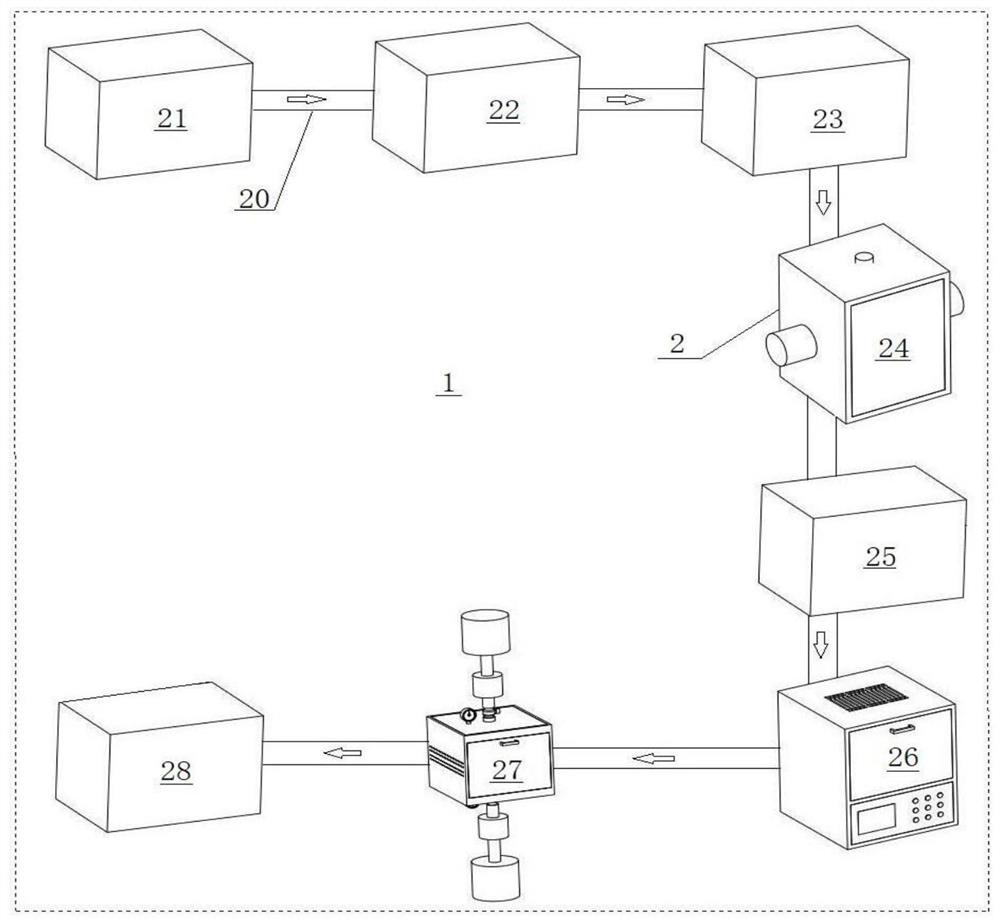

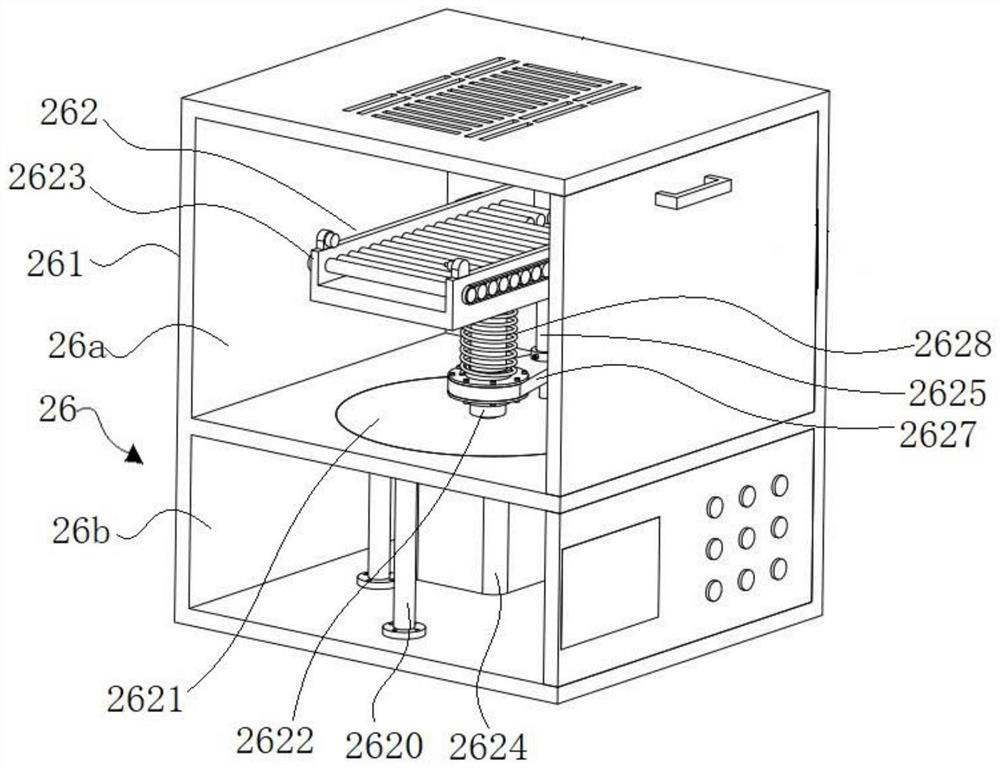

Meat product sterile processing workshop system and meat product sterile processing technology

InactiveCN111685283AFully heatedEvenly heatedMeat/fish preservation by freezing/coolingMeat processing devicesProcess engineeringBakery equipment

The invention discloses a meat product sterile processing workshop system and a meat product sterile processing technology. The meat product sterile processing workshop system comprises a sterile processing workshop and a blocky meat product processing assembly line located in the sterile processing workshop. The blocky meat product processing assembly line comprises a primary cleaning device, a disinfection and sterilization device, a secondary cleaning device, moisture reducing and air drying equipment, a seasoning and pickling device, baking equipment, rapid cooling equipment and a packaging device, and the primary cleaning device, the disinfection and sterilization device, the secondary cleaning device, the moisture reducing and air drying equipment, the seasoning and pickling device,baking equipment, the rapid cooling equipment and the packaging device are sequentially arranged on the assembly line. The moisture reducing and air-drying equipment comprises an air-drying box and anair blower mounted on the outer box wall of the air-drying box; the baking equipment comprises a baking box and a rotary conveying turnover unit arranged in the baking box; and the rapid cooling equipment comprises a cooling box, a liquid nitrogen arrangement plate and a liquid nitrogen supply source. According to the meat product sterile processing workshop system and the meat product sterile processing technology, complete and uniform heating of blocky meat products is realized through the baking equipment, the color quality and delicious taste of the processed meat products are greatly ensured, the whole set of sterile processing flow is arranged, the operation is reasonable, and the processing efficiency of the meat products is further improved.

Owner:张桂云

Novel French-fries processing factory deep-frying equipment

The invention discloses a novel frying equipment for a french fries processing plant, comprising a protective shell, a french fries placing plate, a support frame, a transmission wheel, and a controller. One side of the protective shell is provided with the french fries placing plate. One side of the french fries placing plate is provided with the support frame, the upper part of the support frame is provided with the transmission wheel, one side of the transmission wheel is provided with the controller, and one side of the controller is provided with There is a frying box, a heating pipe is arranged below the frying box, a tumbling fan is arranged above the side of the heating pipe, a connecting shaft is arranged on one side of the tumbling fan, and one side of the connecting shaft is arranged A French fries entry device is provided, and a reinforcing plate is arranged on one side of the French fries entry device. The beneficial effects are as follows: the structure is compact, the operation is convenient, the frying, discharging and feeding actions of the french fries are realized, the safety factor of the operator is improved, and the work efficiency is high.

Owner:XUZHOU BEIER ELECTRIC CO LTD

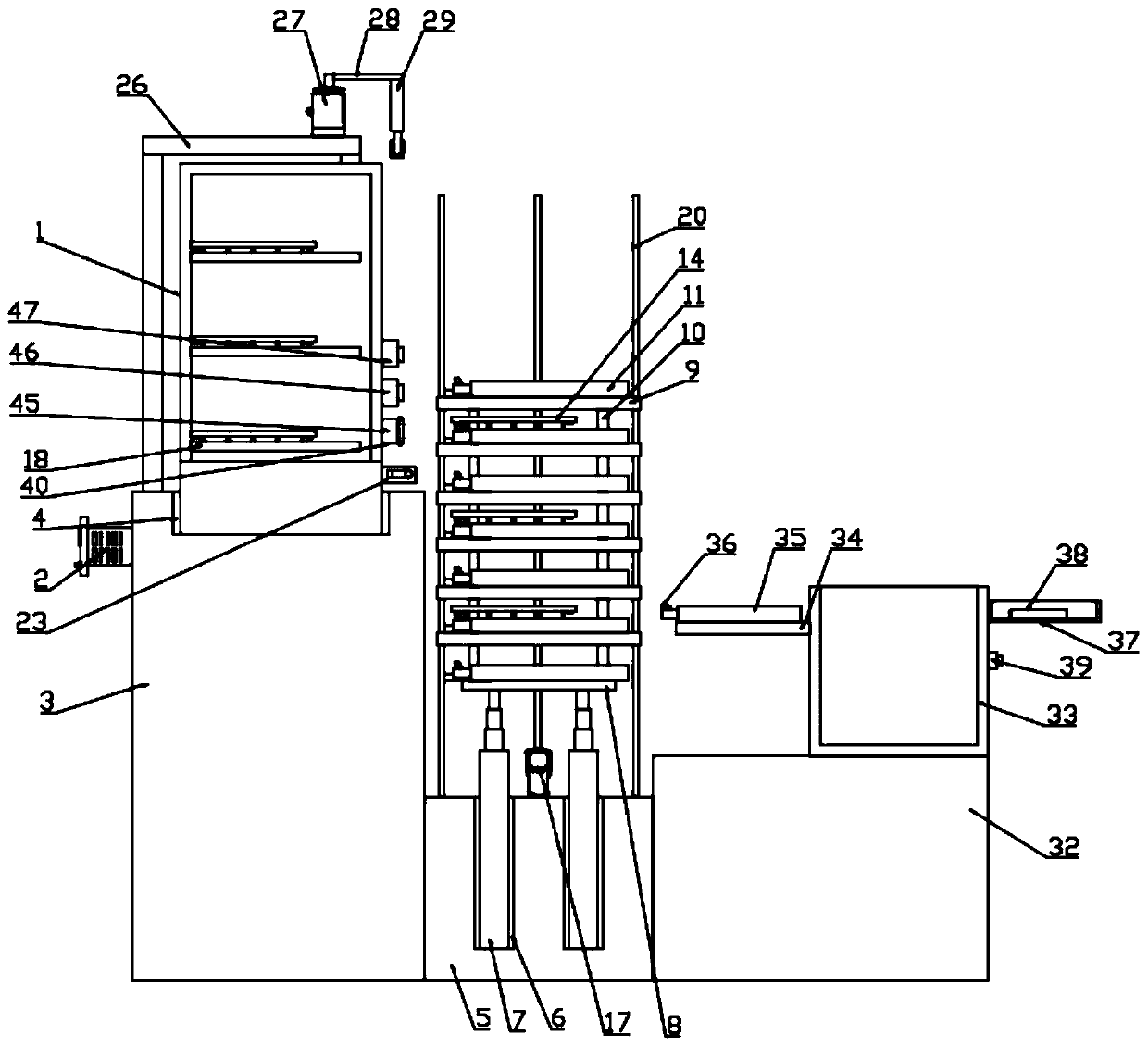

Efficient continuous biscuit automatic baking equipment

ActiveCN114451431AHeat and dry evenlyHigh synchronization rateCharging/discharging ovensBaking-tinsProcess engineeringIndustrial engineering

The invention relates to the technical field of biscuit baking, in particular to efficient continuous automatic biscuit baking equipment which comprises a baking oven, a plurality of trays and a plurality of supporting frames. Trays containing biscuits are sequentially placed on the bearing frames in the baking oven through the material moving assembly, the driving assembly drives the two conveying assemblies to operate at the same time, all the bearing frames are driven to move up and down in the baking oven through the conveying assemblies on the two sides of the baking oven, and therefore the trays placed on the bearing frames are driven; according to the cookie baking device, the tray moves up and down in the baking oven, cookies on all the trays can be evenly heated and dried in the up-and-down moving process, the baking quality of the baking oven is improved, the baking efficiency is improved, the baked cookies are taken down from the bearing frame through the material moving assembly, and the baked trays are transported away; therefore, the biscuits can be continuously baked, and the efficiency of producing the biscuits is improved.

Owner:江中食疗科技有限公司

Baking device capable of taking or placing baked foods rapidly

InactiveCN110326633AHigh speedReduce sheddingCharging/discharging ovensDough processingBaked goodsEngineering

Owner:福建一品居食品有限公司

Baking equipment

ActiveCN105433405AEvenly heatedImprove the baking effectFood treatmentBakery equipmentHeating element

The present invention relates to baking equipment which comprises a baking device. The baking device consists of a baking barrel, a fire supply mechanism, a fire supply regulating mechanism, a hot wind mechanism, and a hot wind regulating mechanism. A baking chamber is arranged in the baking barrel. The hot wind mechanism includes a wind blowing device, a heating element and a hot wind channel, the heating element is arranged in the hot wind channel, a hot wind outlet is arranged in the hot wind channel and is adjacent to the baking chamber and faces towards the interior of the baking chamber. The hot wind regulating mechanism and hot wind mechanism are collected. A second barrel wall is arranged in the baking barrel. Several burner ports are arranged in the fire supply mechanism and each burner port faces the second barrel wall. The fire supply regulating mechanism and fire supply mechanism are matched. The wind blowing device is arranged in one side of the hot wind channel far away from the hot wind outlet. The baking equipment combines the baking ways of fire supply style, hot wind style and semi-direct fire and semi-hot wind style. Coffee beans are baked by a common regulation of hot wind and fire supply. The baking equipment has common advantages of the three baking methods and enables the coffee beans to be heated more evenly and have an excellent baking effect.

Owner:温州市康尔微晶器皿有限公司

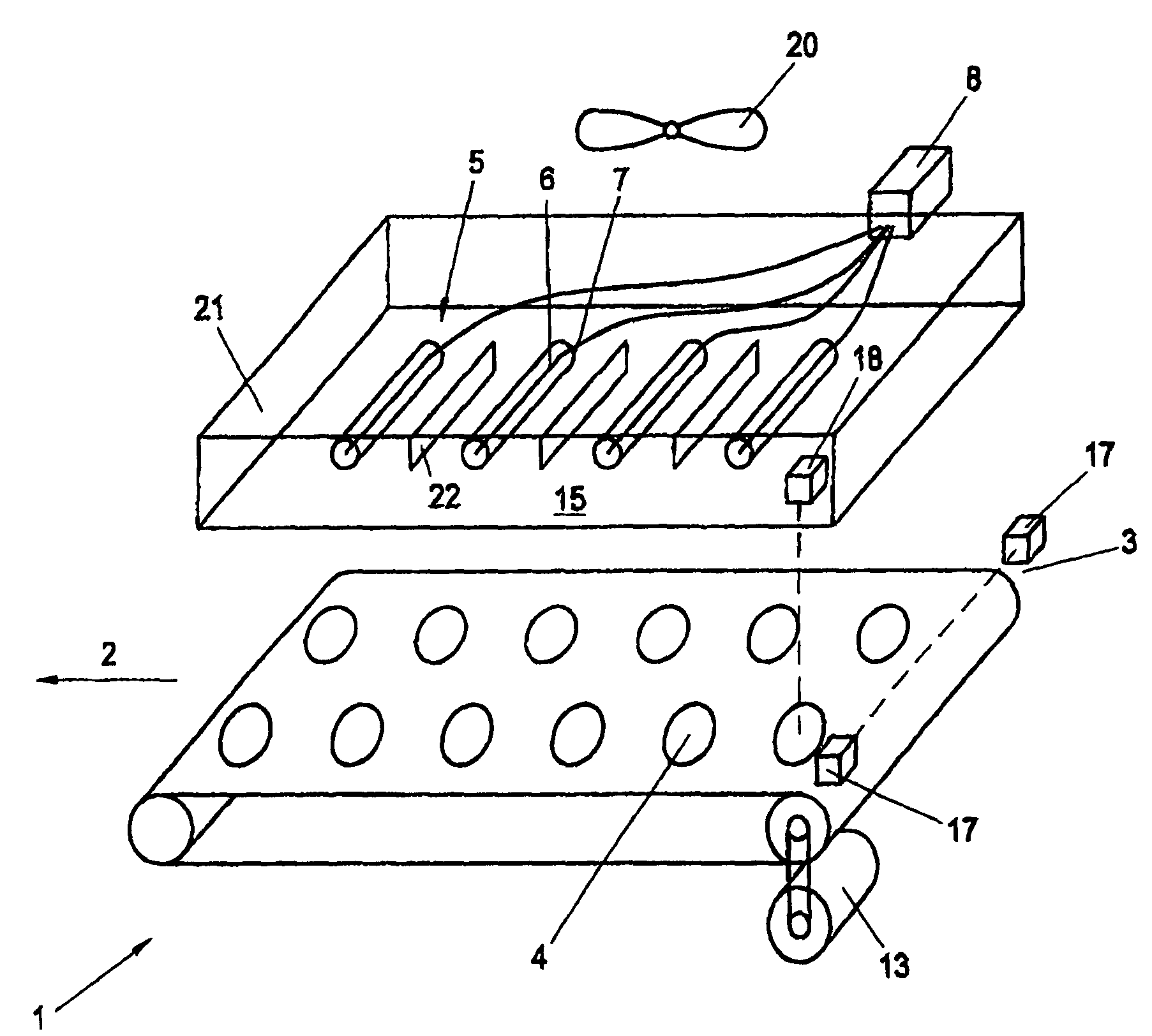

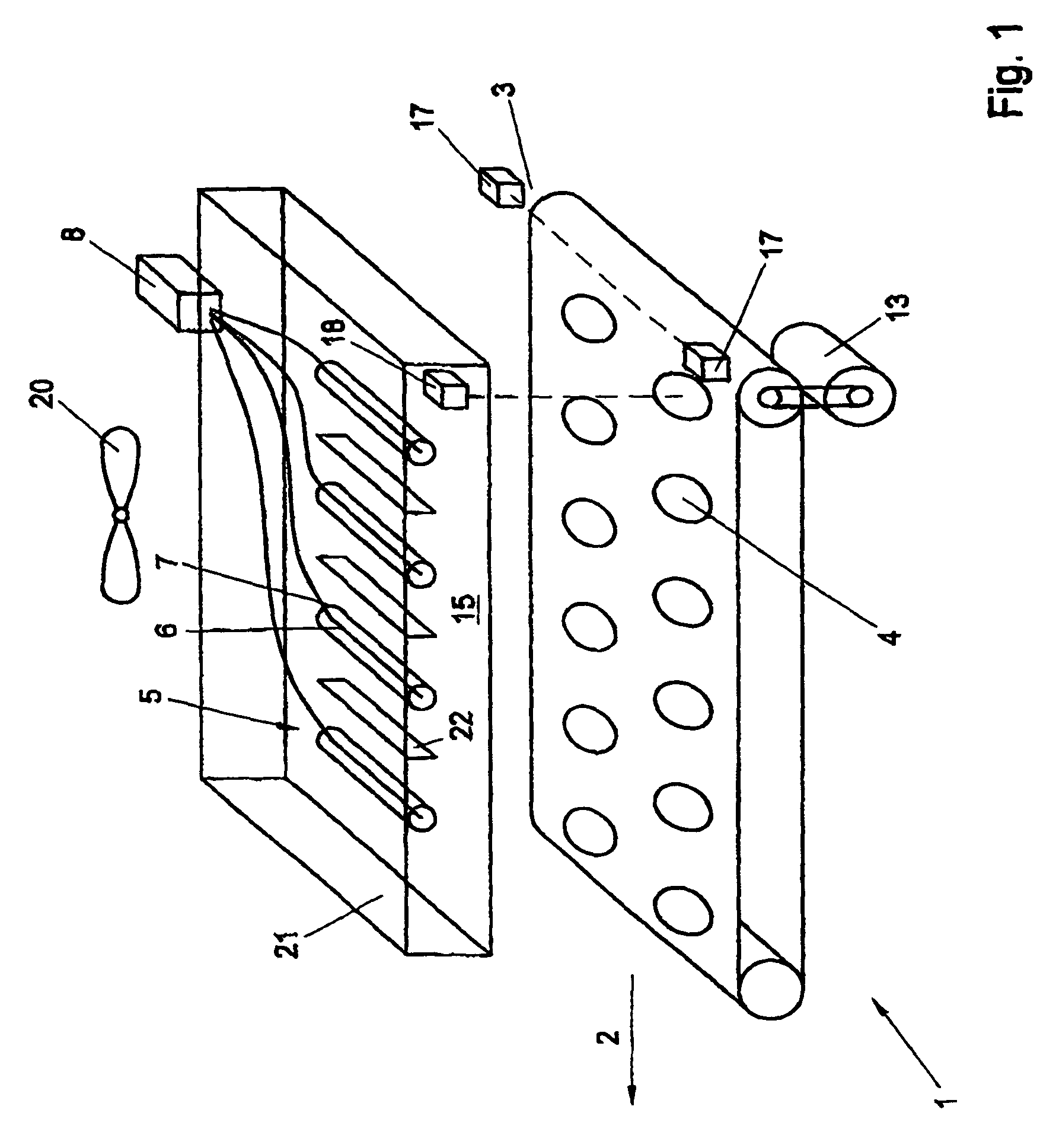

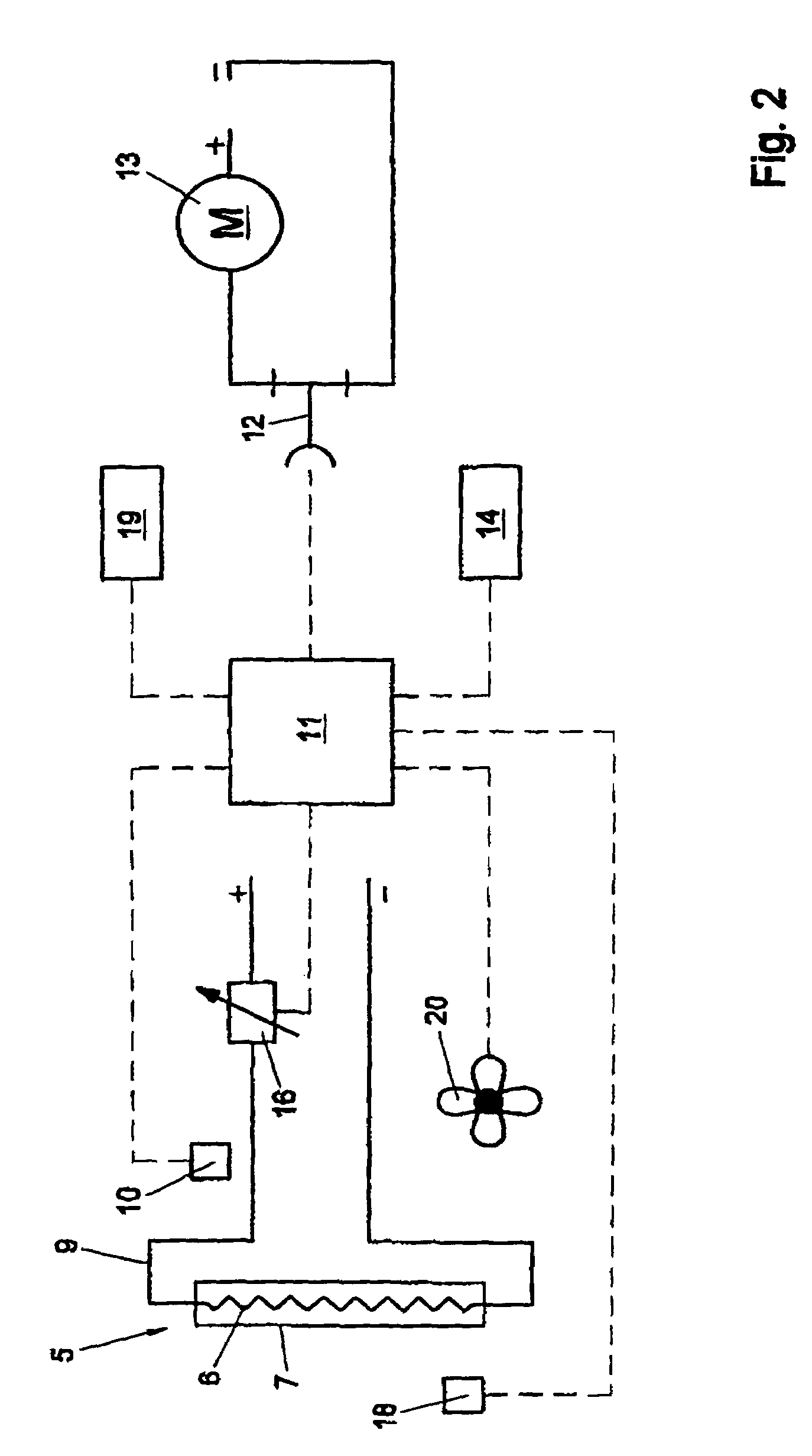

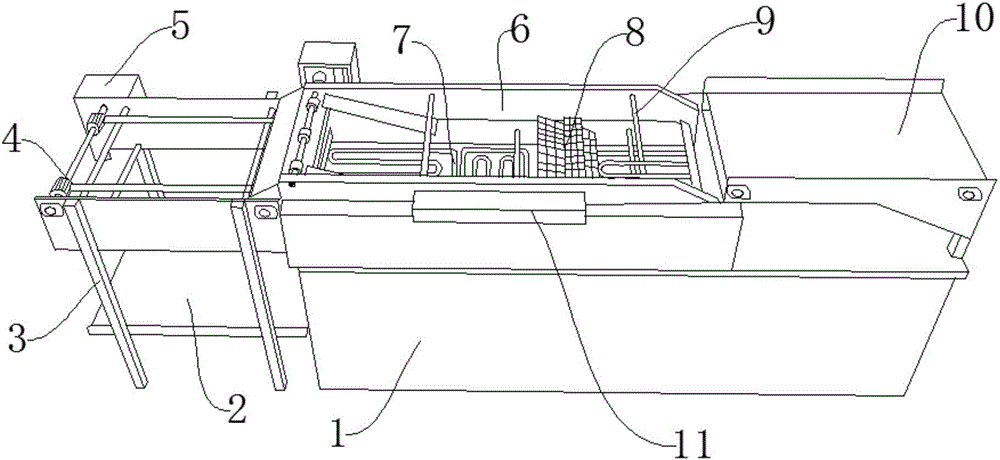

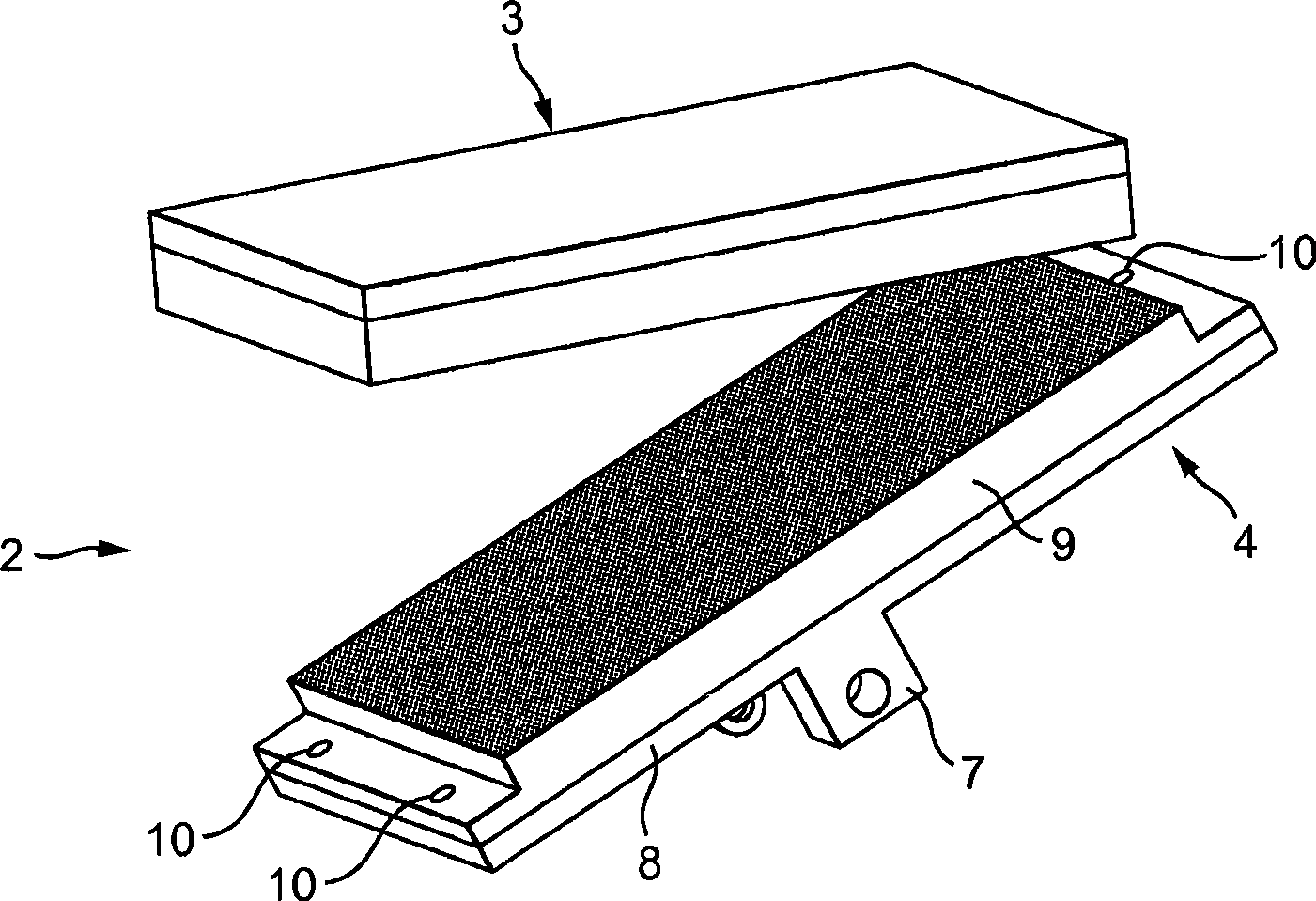

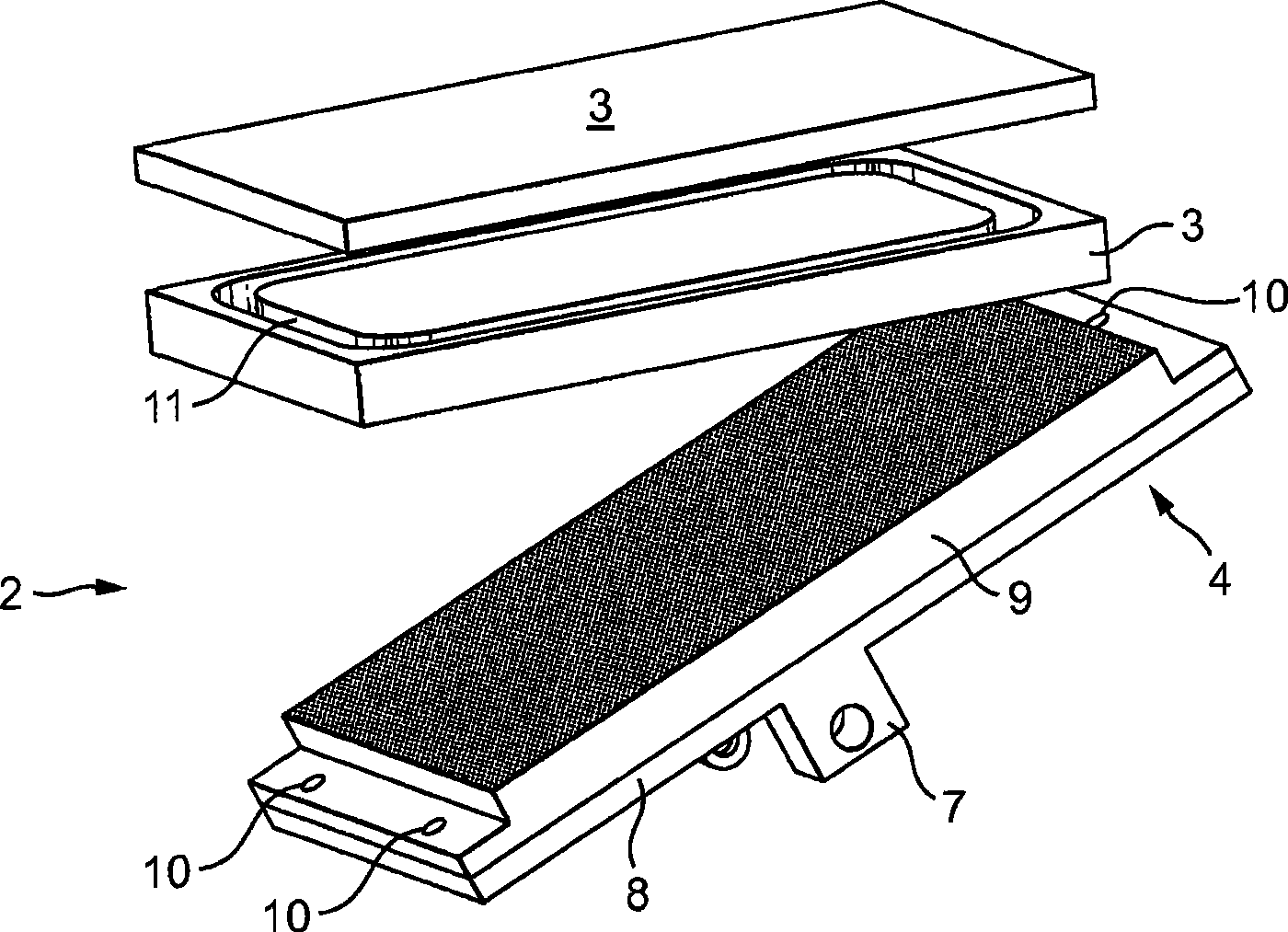

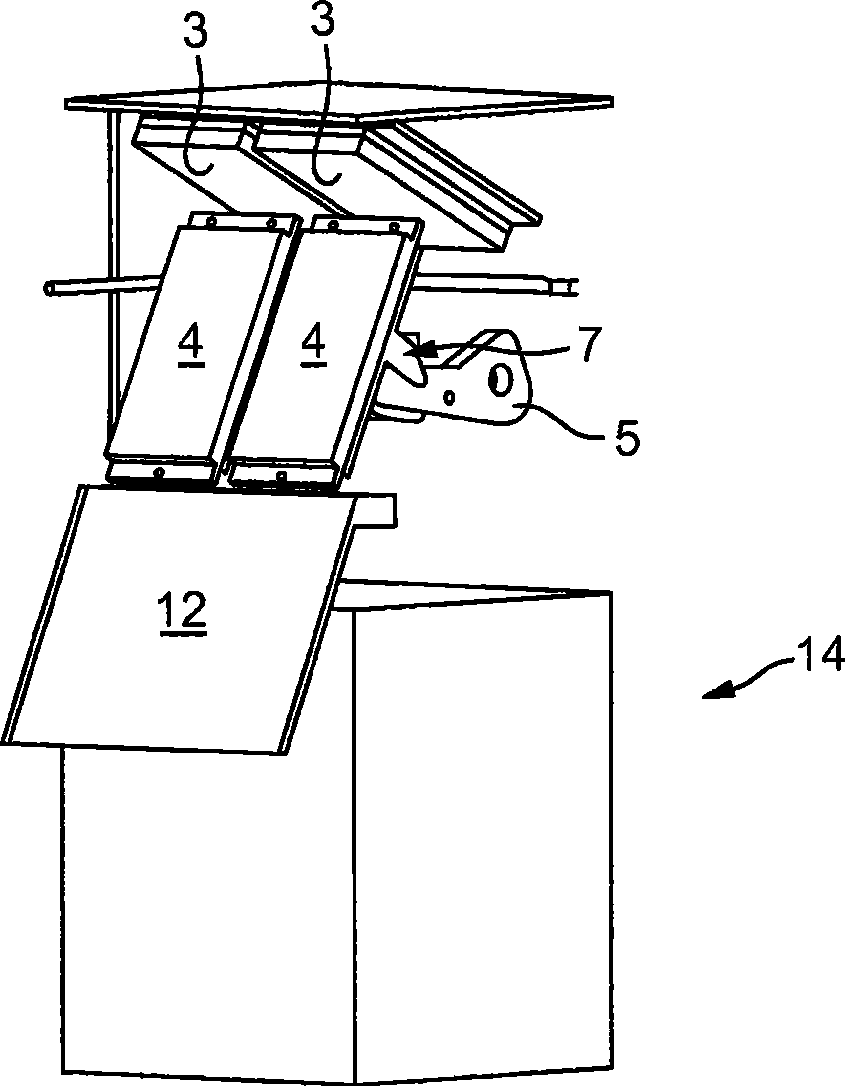

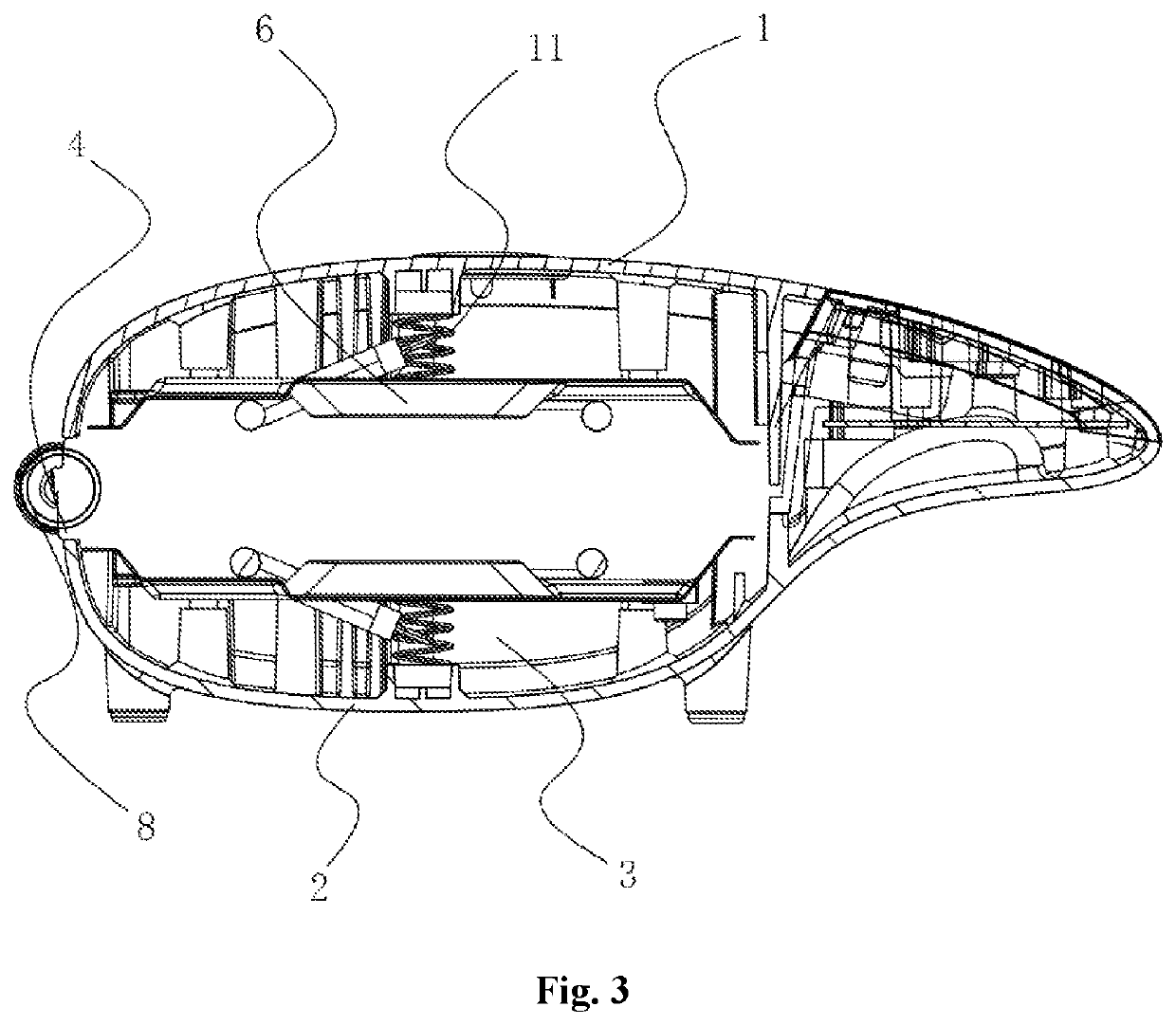

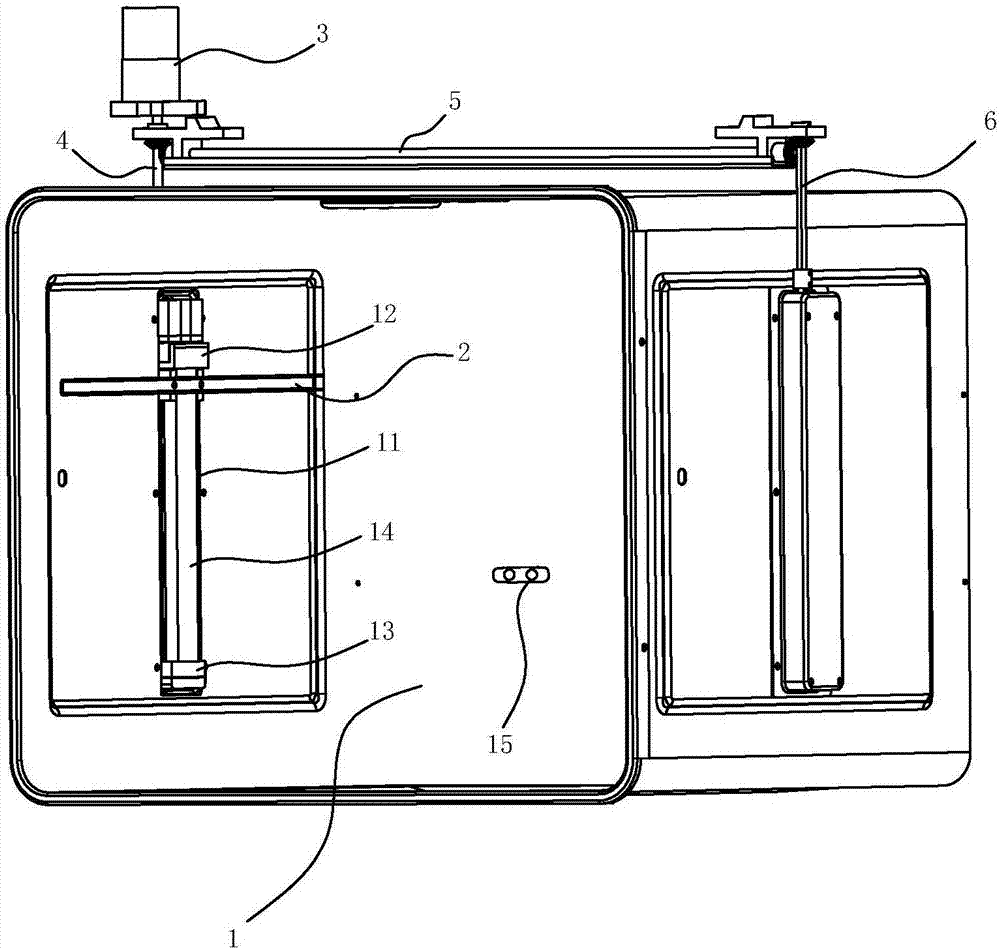

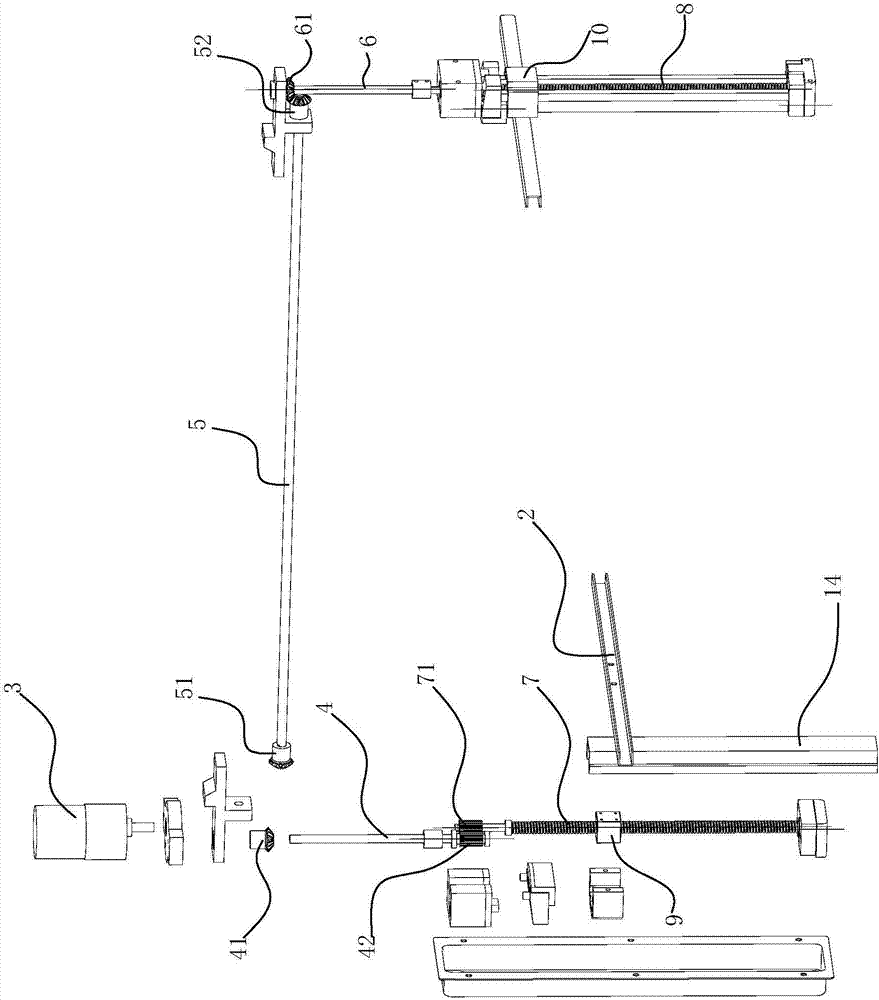

An induction wafer baking system

InactiveCN101511196ARegulated net outputAvoid wear and tearHollow article bakingProcess engineeringBakery equipment

The present invention relates to an automatic wafer baking apparatus (1) for baking wafers from a liquid or pasty dough, said apparatus (1) comprising at least two baking moulds (2), each having one pair of top (3) and lower (4) baking plates, said apparatus (1) further comprising moving means (5, 6, 7) for moving at least one plate relative to the other so that each baking mould (2) can move from a closed configuration to an open configuration, heating means for heating the plates (3, 4) to a predetermined baking temperature, means for injecting a predetermined quantity of dough between the baking plates (3, 4) of each mould (2), and means (12, 13) for removing a baked wafer from a baking mould (2), characterized in that each baking mould (2) is stationary in the apparatus (1) and is independent from the other(s).

Owner:NESTEC SA

Environment-friendly energy-saving type oolong tea processing device

ActiveCN110521794AImprove baking efficiencyAvoid OverbakingSievingPre-extraction tea treatmentAgricultural engineeringTea leaf

The present invention discloses an environment-friendly energy-saving type oolong tea processing device. The environment-friendly energy-saving type oolong tea processing device comprises a drying box, a left side of a limiting sleeve block is connected with a tea leaf screening filter screen through a universal joint, a top part of the tea leaf screening filter screen is fixedly connected with anouter spray pipe, a tea residue drying conical plate is fixedly connected in the drying box and at a position close to a lower part, an inner part of the tea residue drying conical plate is fixedly connected with an inner stirring spray pipe, an absorption inner pipe is fixedly connected at a right side in the drying box and located above the tea leaf screening filter screen and the tea residue drying conical plate, and an output end of the absorption inner pipe communicates with a heat preservation pipes. The environment-friendly energy-saving type oolong tea processing device belongs to thetechnical field of oolong tea processing and achieves purposes of accelerating tea leaf baking efficiency, avoiding partial tea leaves to be excessively baked, improving tea leaf baking quality, avoiding a large number of heat losing of baking devices, and improving environmental protection and energy saving.

Owner:安徽省屯溪实验茶场

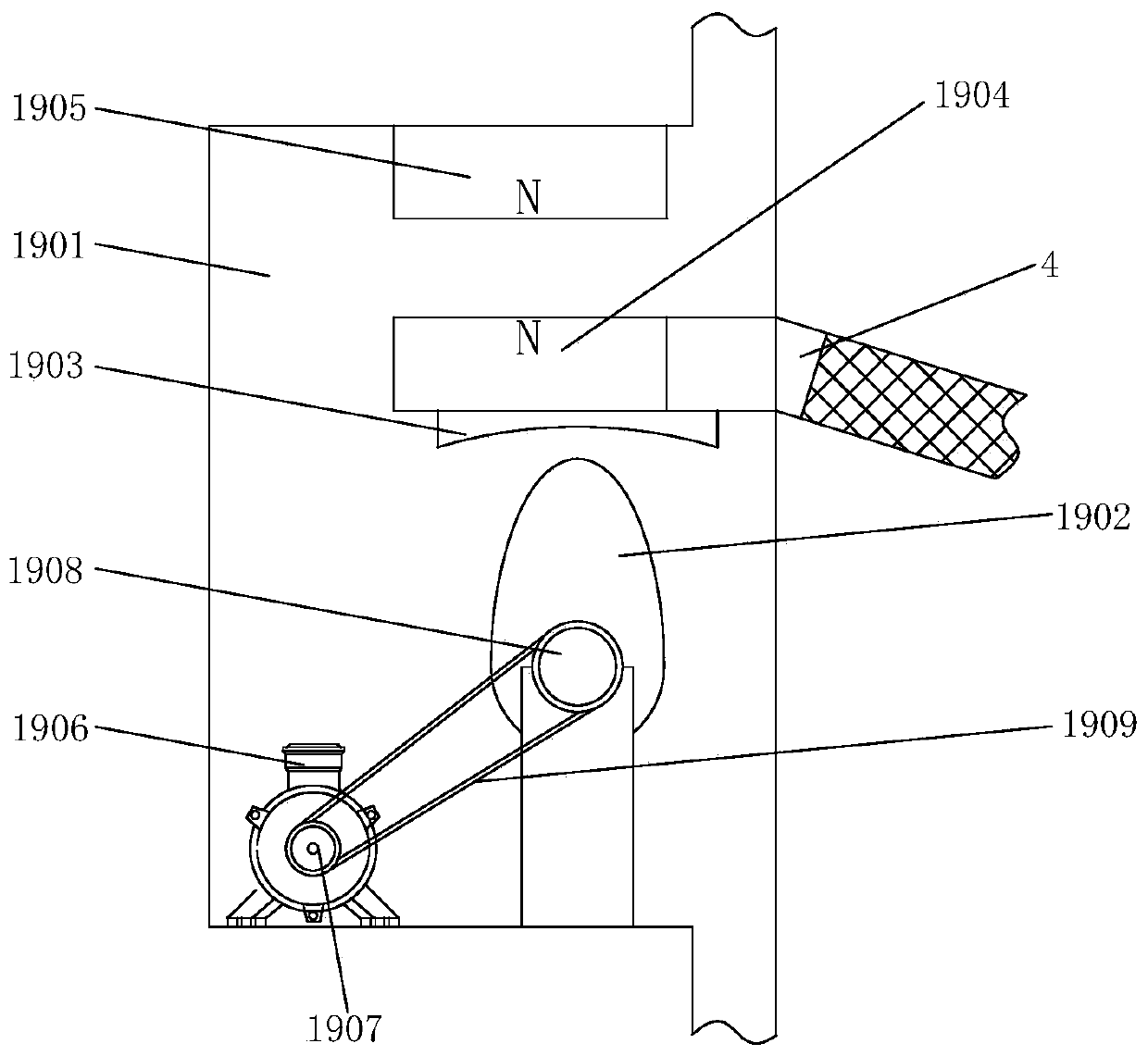

Electrostatic deslagging device for cut tobacco baking equipment

ActiveCN110893003ASeparation in timeSimple structureTobacco preparationAgricultural engineeringStructural engineering

The invention provides an electrostatic deslagging device for cut tobacco baking equipment. The device comprises a roller, an electrostatic generator and a cut tobacco recovery box. The upper end of the cut tobacco recovery box is communicated with a storage area arranged above the cut tobacco baking equipment. The lower end of the cut tobacco recycling box extends downwards in the vertical direction. Spiral hobbing teeth are arranged on the outer peripheral surface of the roller. The front end and the rear end of the hobbing are installed on the inner walls of the left side and the right sidein the cut tobacco recycling box through rolling bearings, the gap between the edge of the hobbing and the inner wall of the front side or the inner wall of the rear side in the cut tobacco recyclingbox is larger than the cut tobacco diameter and smaller than 2 mm, and the electrostatic generator is independently installed in the tobacco shred recycling box and electrically connected with the hobbing. By the adoption of the technical scheme, cut tobacco and impurities can be effectively separated and collected separately while the cut tobacco baking equipment operates. The device has the advantages of being simple in structure, convenient to use and the like, the process time is saved, the cigarette production efficiency is improved, and a foundation is laid for improving the cigarette production quality.

Owner:CHINA TOBACCO GUIZHOU IND

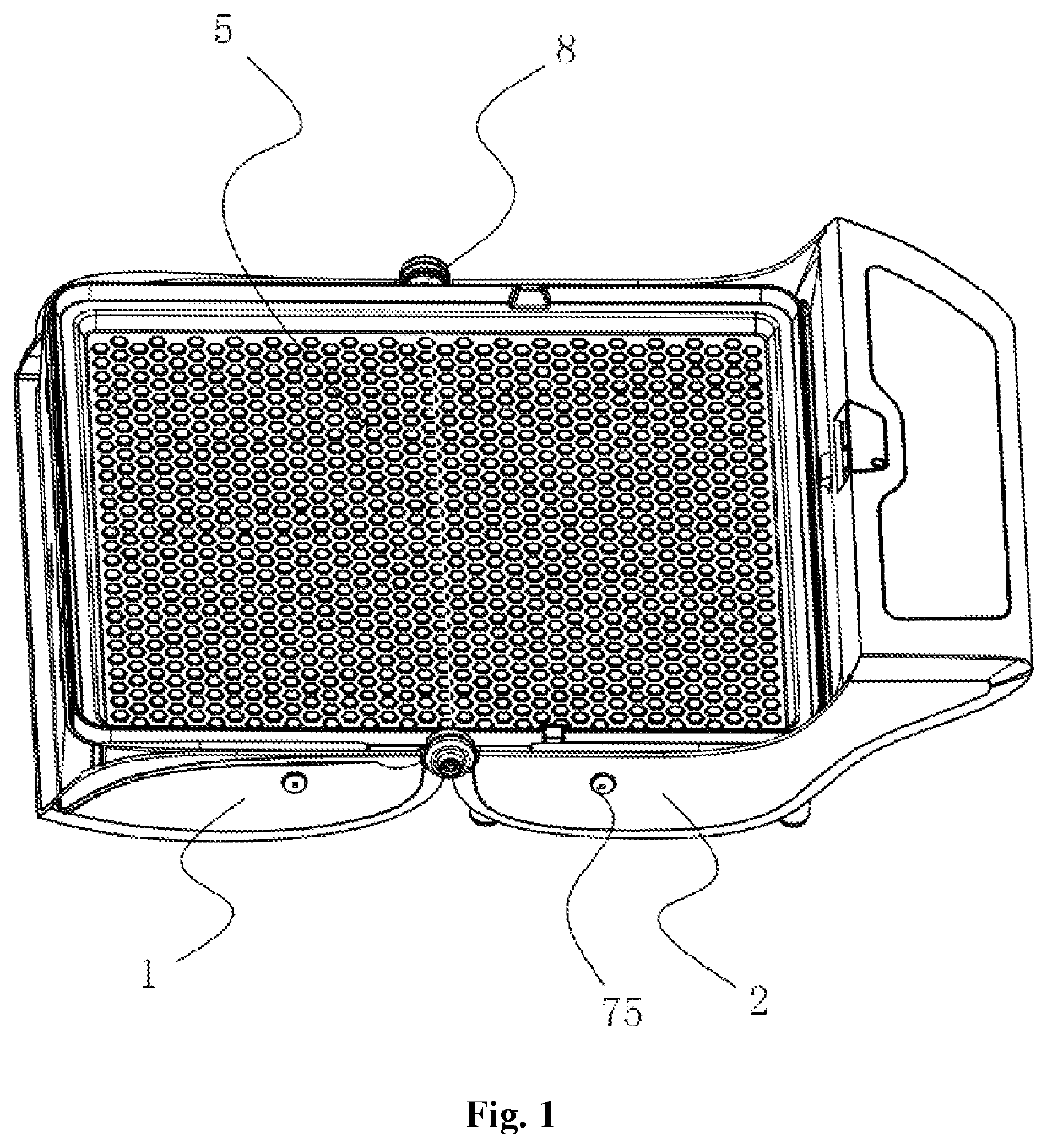

Cooking and baking device with seamlessly-jointed griddle plates

ActiveUS10835077B2Improve sealingEasy to cleanFood processingRoasters/grillsStructural engineeringFood material

Owner:JIANGMEN CITY XINHUI HENGLONG INNOVATIVE HOUSEWARES CO LTD

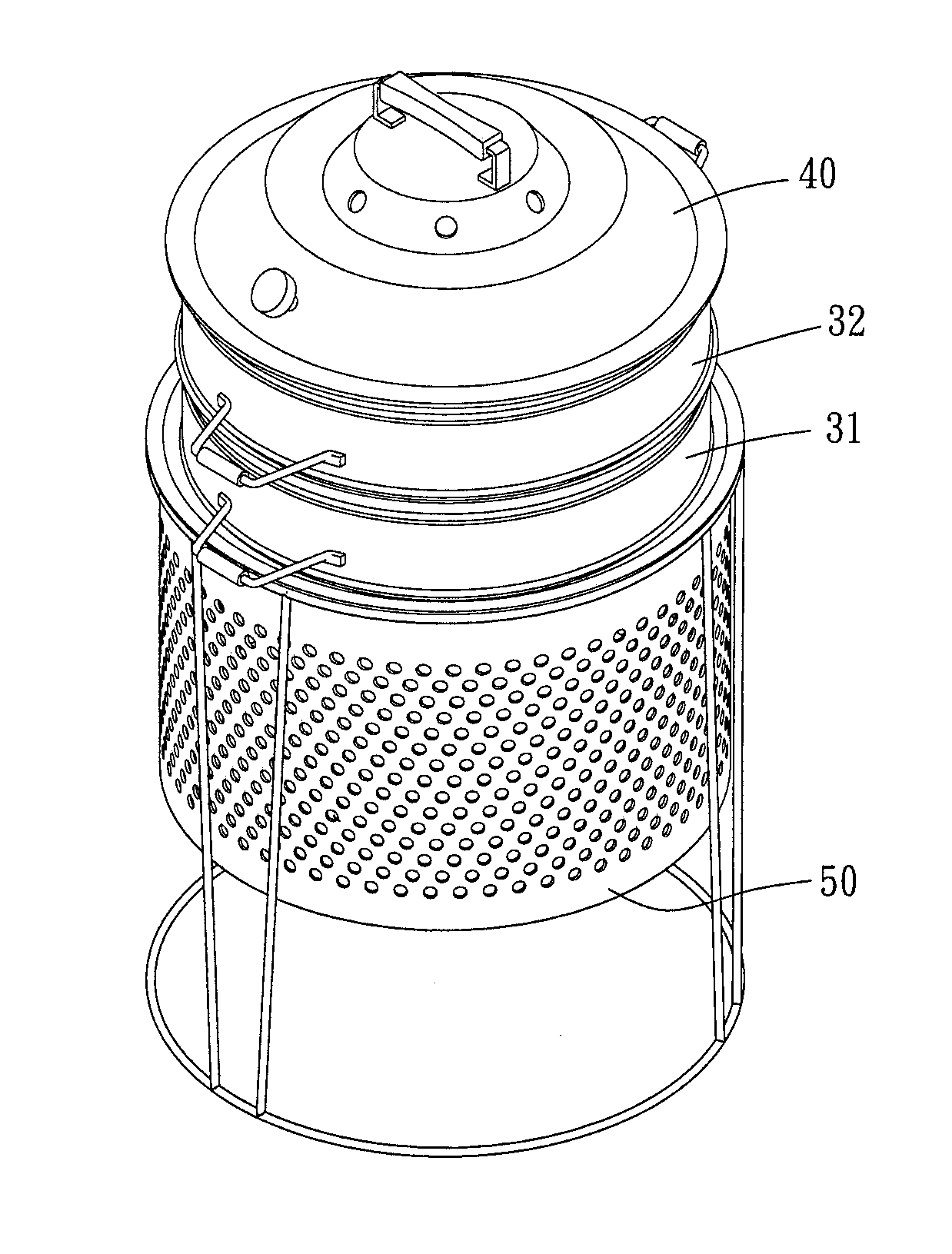

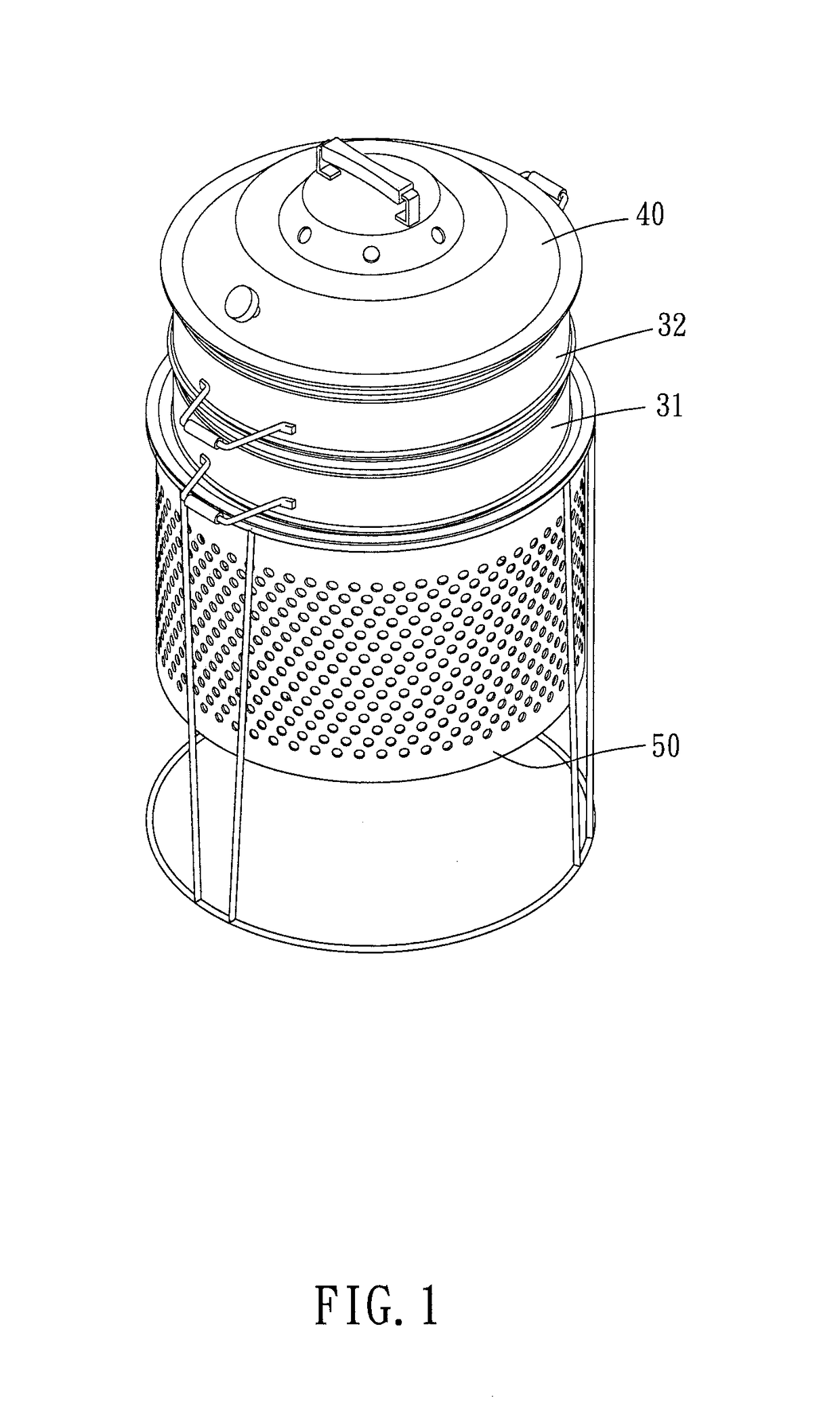

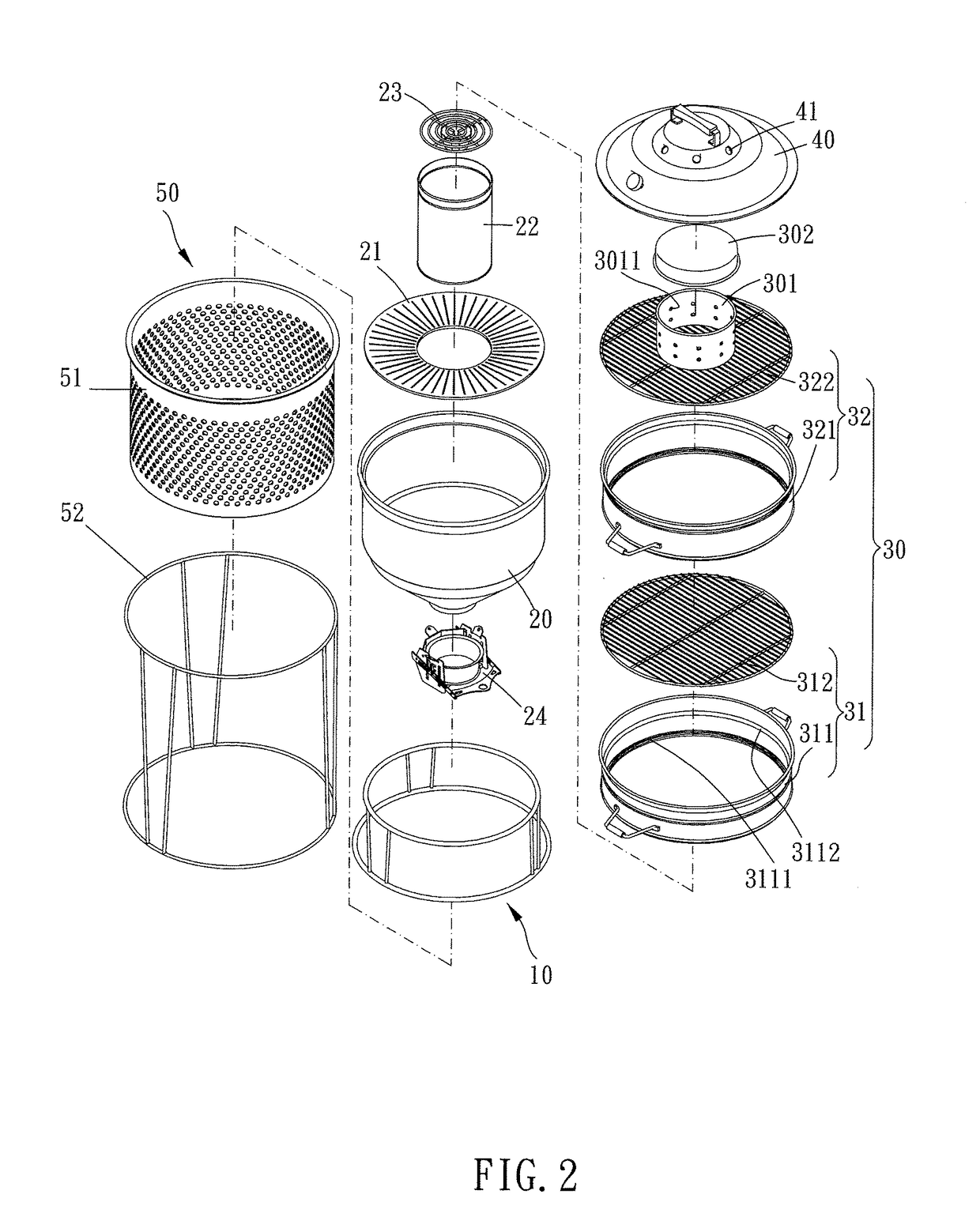

Multilayer roasting furnace

InactiveUS20170181577A1Reduce lossesAvoid burnsClimate change adaptationRoasters/grillsEngineeringMechanical engineering

A multilayer roasting furnace includes a support rack, a furnace, at least two roasting apparatuses, and a lid. The furnace is disposed on the support rack to have a predetermined distance from the ground. Air is able to enter the furnace from a bottom thereof. Each roasting apparatus includes a main body and a roasting net. The main body is hollow. The roasting net is arranged in the main body and is positioned on an inner wall of the main body. The main bodies of the roasting apparatuses are stacked to form a roasting space vertically and are placed on the furnace. A central portion of the roasting net of the roasting apparatus is disposed with a charcoal collecting cylinder. The charcoal collecting cylinder is hollow and is perforated on the side wall thereof. The lid is disposed on and covers the top roasting apparatus.

Owner:CHANG ANNIE

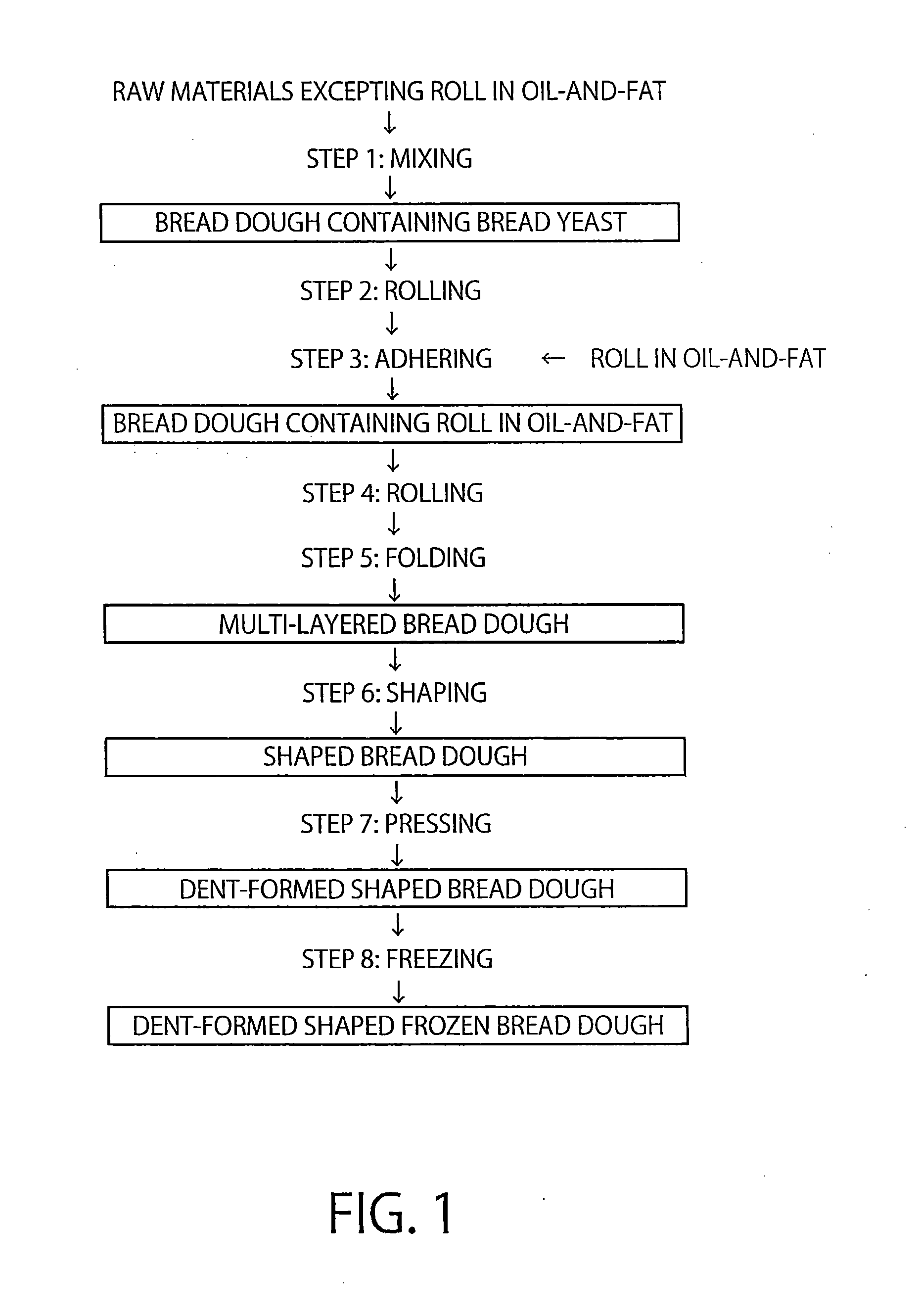

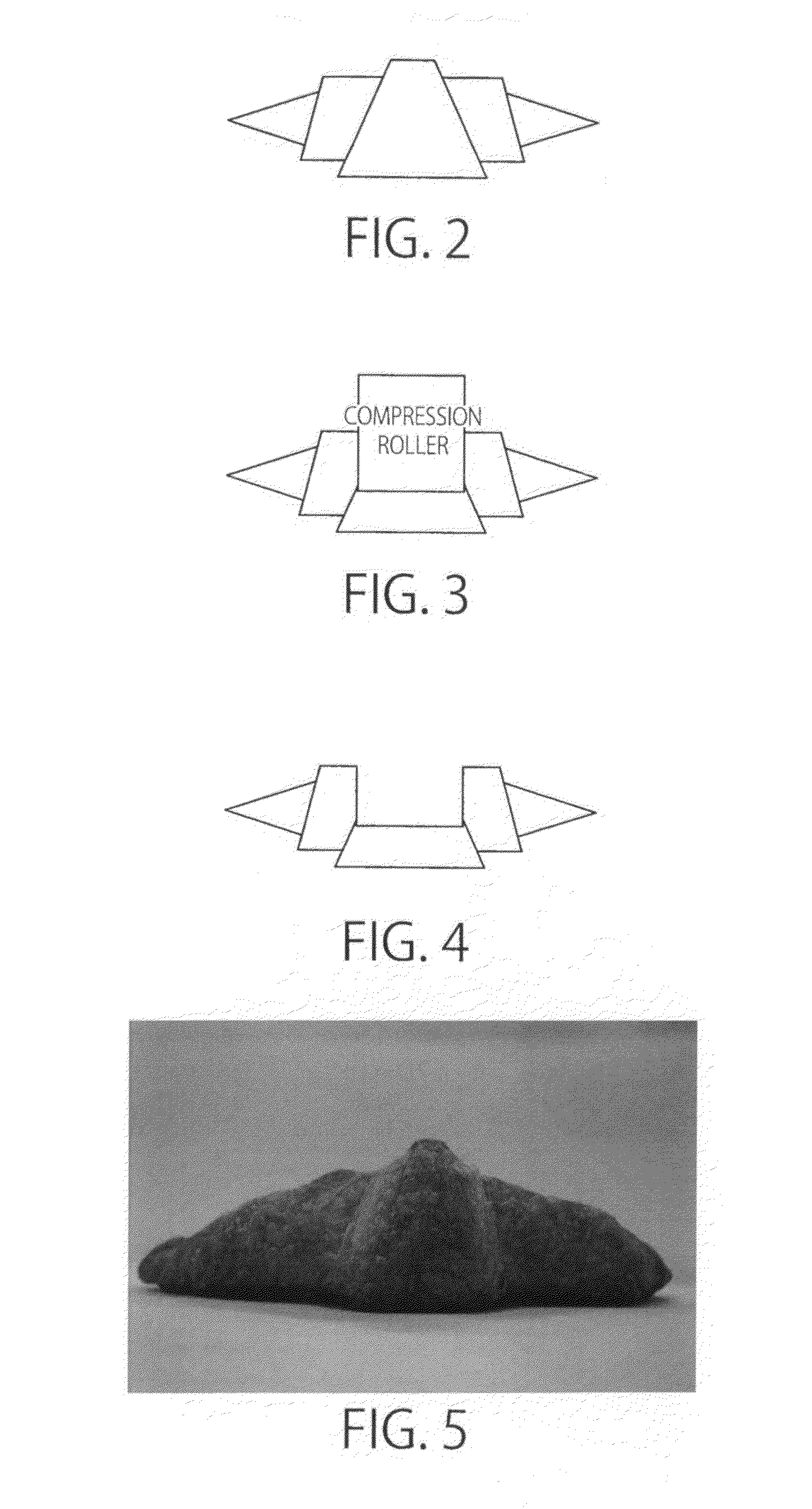

Method for producing frozen bread dough which does not require thawing or fermentation step

InactiveUS20130183406A1Short timeReduce flavorMilk preparationPre-baking dough treatmentYeastCooking & baking

Provided is shaped frozen bread dough from which a baked bread product having favorable post-baked qualities (taste, texture, flavor, appearance (voluminousness), and the like) can be prepared using a commonly employed baking facility, without requiring a special facility for thawing and fermenting. A bread dough having a continuous, multi-layered structure is prepared by using a cereal flour composition containing yeast and an oil-and-fat composition (roll in oil-and-fat), the bread dough is formed into a desired shape, and then a dent is made on the surface of the thickest portion having the length which is 13% to 70% of the longitudinal length of the shaped article.

Owner:AJINOMOTO CO INC

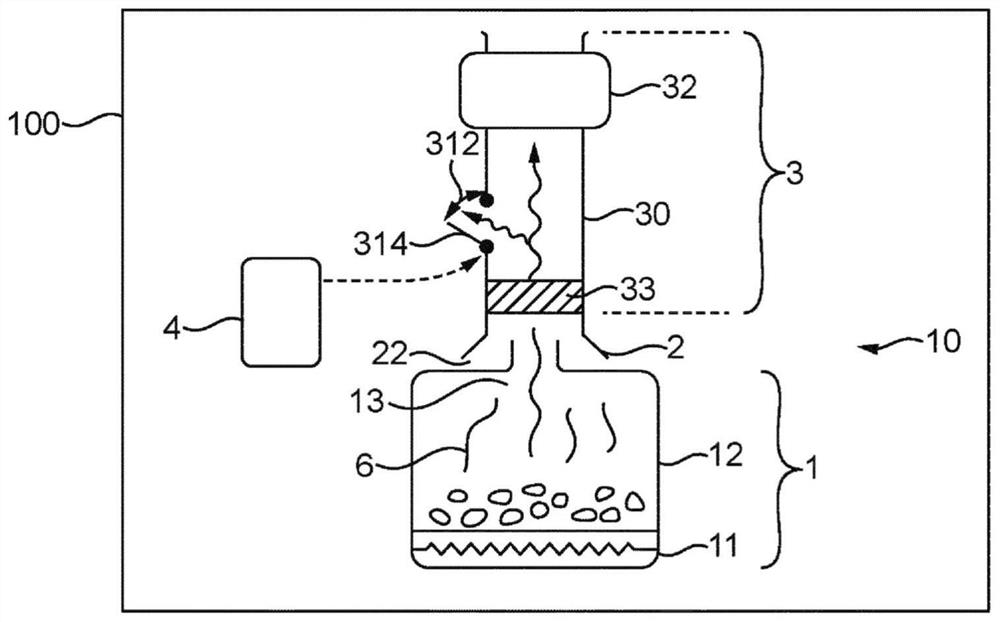

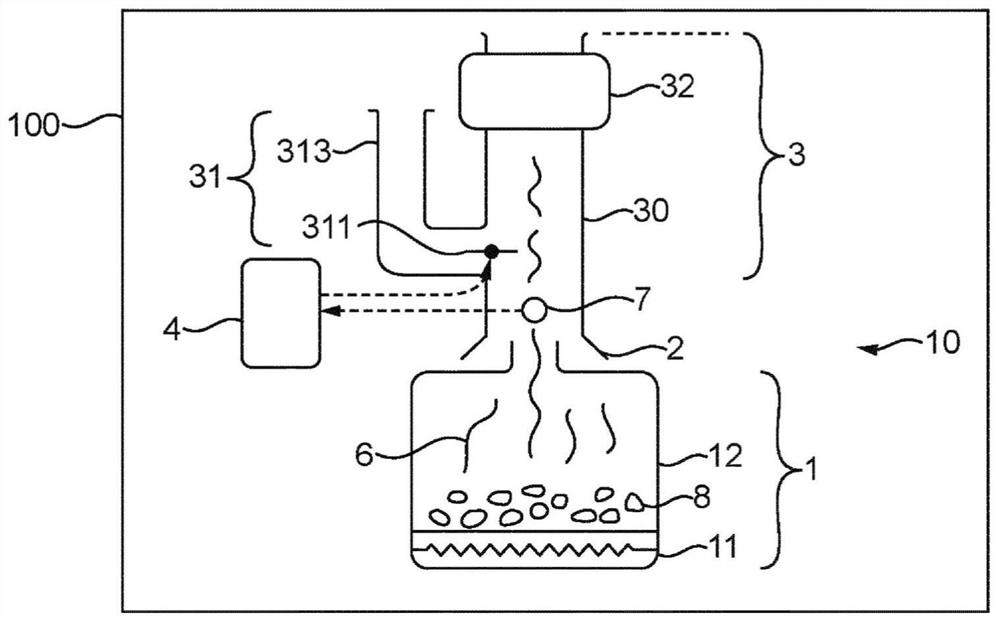

Apparatus and method for roasting coffee beans

Owner:SOC DES PROD NESTLE SA

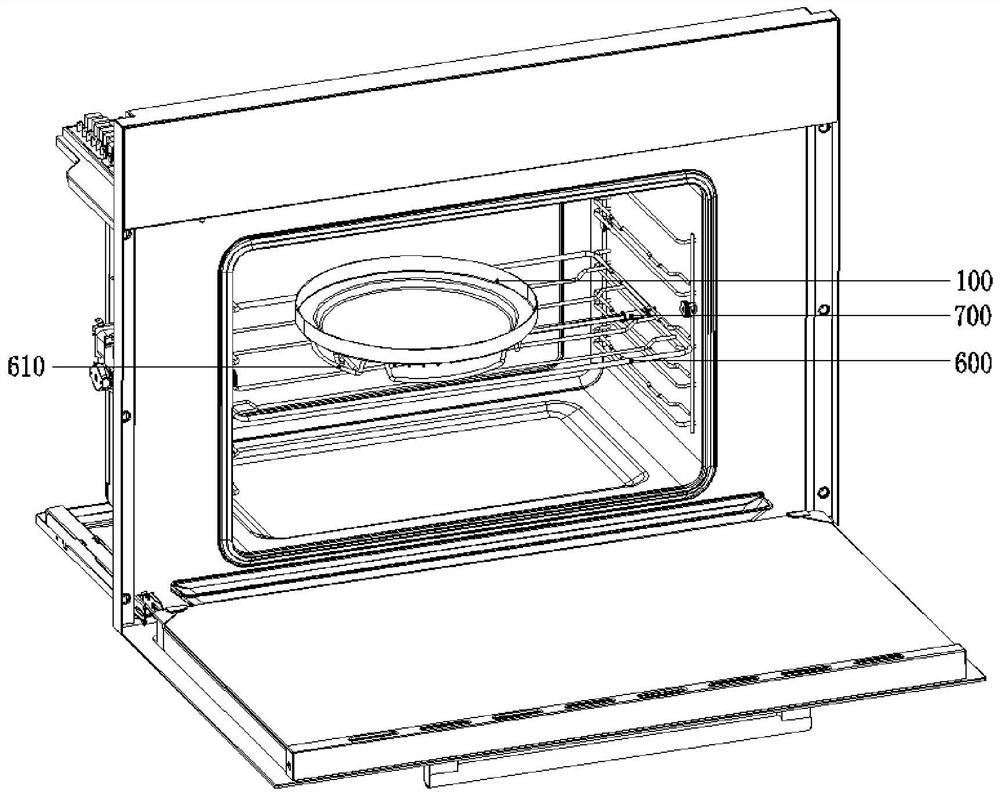

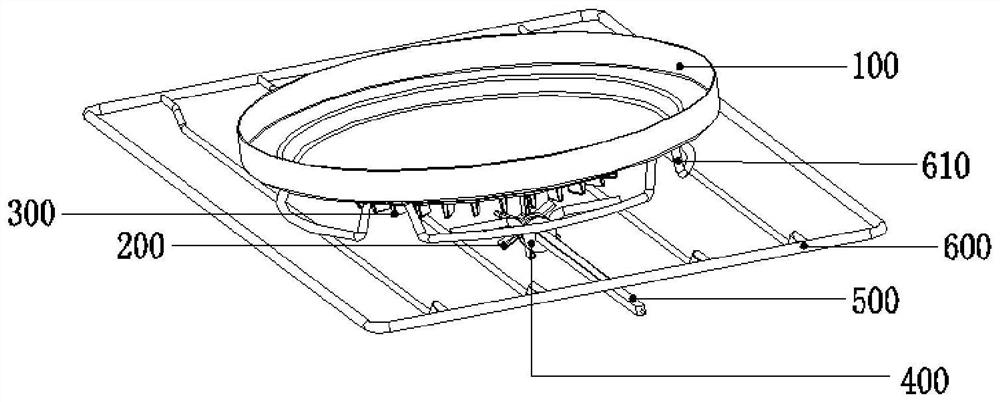

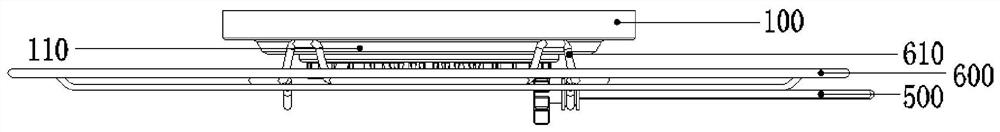

Baking tray assembly and cooking electric appliance with baking function

PendingCN113261859ASimple structureSmall footprintRoasting apparatusRoasters/grillsMechanical engineeringBakery equipment

The invention provides a baking tray assembly and a cooking electric appliance with a baking function, and relates to the technical field of food baking equipment. The baking tray assembly comprises a rotating part, a driving device and a baking tray; the rotating piece is arranged below the baking tray; the rotating piece is provided with a first tooth piece, the bottom of the baking tray is provided with a plurality of second tooth pieces, the second tooth pieces are distributed in a circular ring shape, and the first tooth piece is meshed with the second tooth pieces; and the driving device is used for driving the rotating part to rotate. By means of the baking tray assembly, the technical problems that when biscuits, pizza and other foods with flat appearances are baked, a driving structure for driving a baking tray to rotate in an existing rotatable baking tray structure can affect the flowing direction of hot air in an oven, metal chippings can fall onto the baking tray after long-time use, and the body health of a user is affected are solved; and the technical effect that the food cooking uniformity is improved on the premise that cooking is not affected is achieved.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

Baking preheating control system and method based on food making progress recognition

ActiveCN112075851AAvoid technical problems with too long a gapAvoid gatheringRoasters/grillsControl systemProcess engineering

The invention discloses a baking preheating control system and method based on food making progress recognition. The baking preheating control system comprises a pop-up camera, a pressure sensor, a processor and a temperature controller, wherein the pop-up camera is disposed on a baking mold and is used for obtaining an image of to-be-baked food in a mold cavity; the pressure sensor is used for acquiring the pressure change of a mold cavity disc; the processor is used for carrying out real-time identification on the to-be-baked food image when the pressure value of the mold cavity disc is increased, namely, obtaining the interval time T0 of the moment of filling to-be-baked food into one mold cavity and the moment of filling to-be-baked food into the next mold cavity , calculating the average interval time T1 according to the interval time T0, and predicting an interval time T2 between the moment of finishing filling of all the mold cavities in the mold cavity disc and the current moment, obtaining the optimal preheating temperature of the to-be-baked food and the heating power of baking equipment, calculating a time interval T3 required for heating the baking equipment to the optimal preheating temperature, judging whether the interval time T2 is consistent with the time interval T3 or not, and if yes, sending a preheating instruction; and the temperature controller is on thebaking equipment and is used for receiving the preheating instruction so as to control a heating device to start preheating.

Owner:湖北康康食品有限公司

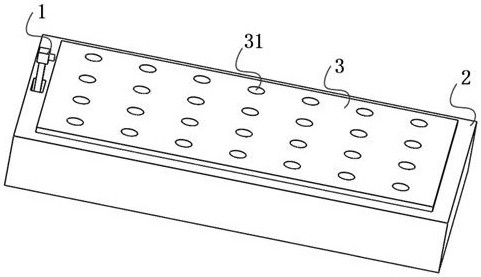

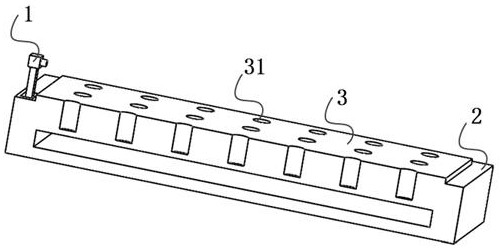

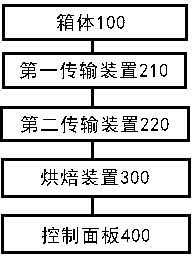

Food processing and baking equipment

The invention discloses food processing and baking equipment. The equipment is characterized by comprising a box body, wherein a feeding hole end is arranged at one end of the box body; a discharge hole end is arranged at the other end of the box body; a first transmission device is installed at the feeding hole end; a second transmission device is installed at the discharge hole end; baking devices are arranged inside the box body and are installed at the bottom end and top end of the box body; and signal input ends of the baking devices are connected with a control panel on the surface of the box body. The equipment has the beneficial effects that the equipment has a simple structure and ingenious design and can effectively bake food in the food processing course, thus overcoming the defects in the prior art and achieving the aim of the invention.

Owner:SUZHOU MAIKE FOOD MACHINERY PLASTIC CEMENT

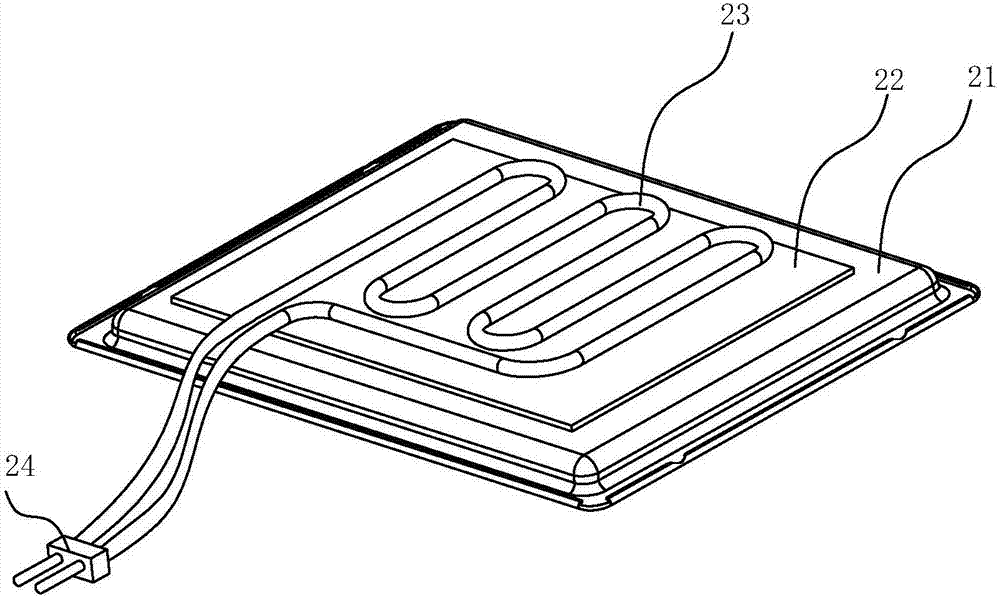

Baking tray and baking equipment adopting baking tray

PendingCN107969929ARealize the function of frying and roastingBaking ovenHigh-frequency/infra-red heating bakingProcess engineeringGraphite

The invention relates to a baking tray and baking equipment adopting the baking tray, wherein the baking tray comprises a tray body by which food can be placed; the baking tray is characterized in that a graphite sheet is attached to the bottom of the tray body, and a baking tray heating element is attached to the bottom of the graphite sheet. Compared with the prior art, the baking tray providedby the invention has the advantages that the graphite sheet and the baking tray heating element is attached to the bottom of the baking tray, most of heat energy, which is generated by the baking trayheating element, is absorbed by the graphite sheet, so that the baking tray and the food are heated, and rest heat energy is conducted downwards; and when juice thickening or baking is required, thebaking tray heating element is started, so that a baking function is achieved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com