Electrostatic deslagging device for cut tobacco baking equipment

A shredded tobacco and equipment technology, which is applied in the field of cigarette production equipment, can solve problems such as aggravating the harm of smoking, affecting the taste of smoking, and affecting the quality of cigarette production, and achieves the effects of improving cigarette production quality, simple structure, and saving process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

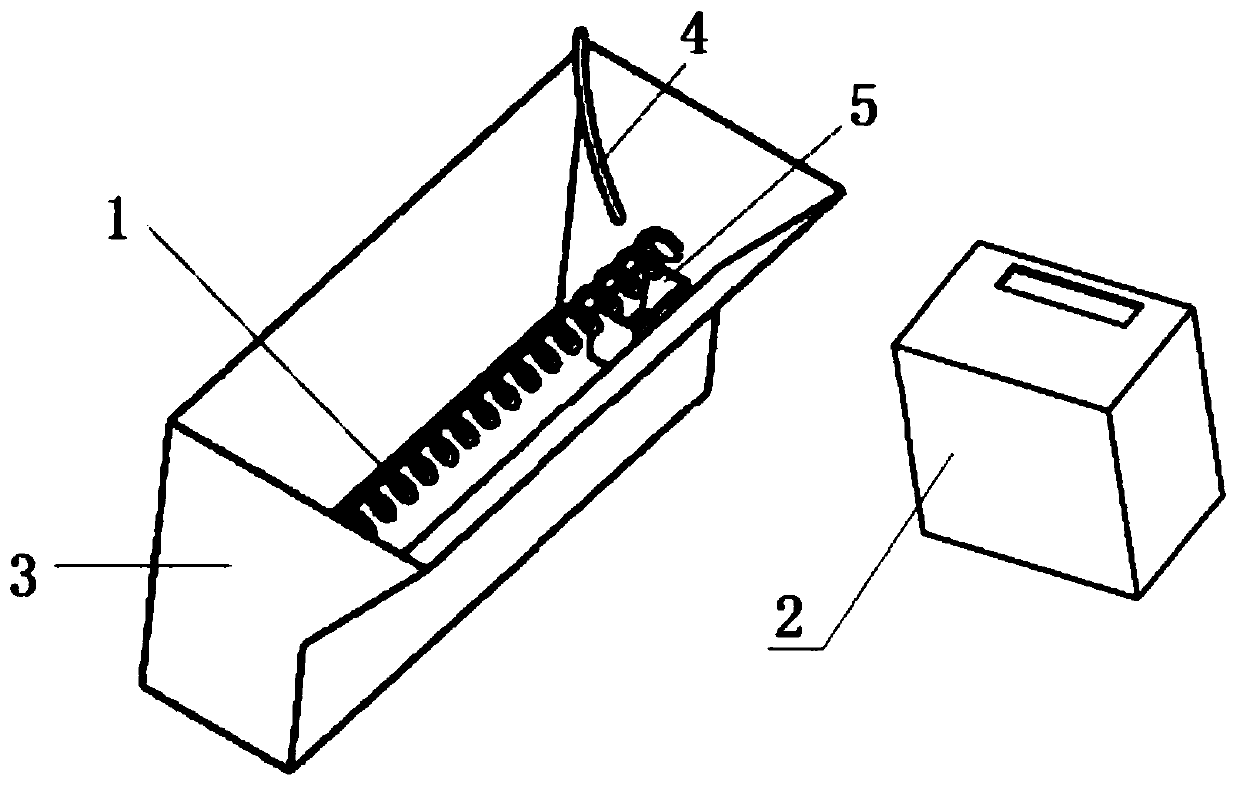

[0016] The invention provides an electrostatic slag removal device used for shredded tobacco roasting equipment, such as figure 1 As shown, it includes a drum 1, an electrostatic generator 2, and a shredded tobacco recovery box 3 that is hollow at the upper and lower ends. Extending down, the outer peripheral surface of the drum 1 is provided with a spiral hobbing gear, and its front and rear ends are installed on the inner walls of the left and right sides within the shredded tobacco recovery box 3 through rolling bearings, and the edges of the hobbing teeth are relative to the front side inner wall or the inside of the shredded tobacco recovery box 3. The gap between the rear inner walls is greater than the diameter of the shredded tobacco and less than 2mm. The electrostatic generator 2 is independently installed in the shredded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com