Baking preheating control system and method based on food making progress recognition

A technology of preheating control and control method, which is applied in the direction of roaster/barbecue grill, kitchen utensils, household utensils, etc. The effect of too long files

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] refer to Figure 1~3 as well as Figure 5 shown. This embodiment provides a baking preheating control system based on food production progress identification, the system includes:

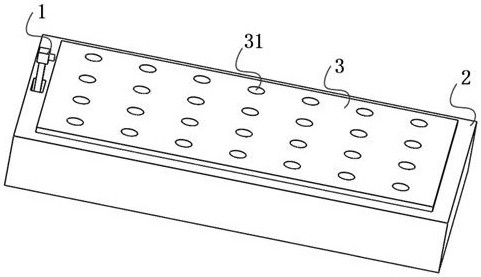

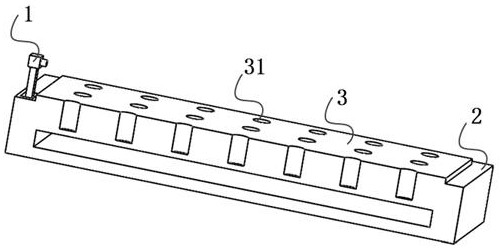

[0054] A pop-up camera 1 arranged on at least one baking mold is used to acquire images of food to be baked in the cavity; wherein the baking mold is composed of a base 2 and a cavity plate 3 provided with a plurality of the cavity, The cavity plate 3 is erected on the base 2 and has a distance from the bottom surface of the base 2 .

[0055] At least one pressure sensor 4 arranged under the edge area of the cavity plate 3 erected on the base 2 is used to obtain pressure changes of the cavity plate 3 .

[0056] The processor 5 arranged in the baking mold is electrically connected with the pop-up camera 1 and the pressure sensor 4 respectively, and is used for real-time monitoring of the image of the food to be baked when the pressure value of the cavity plate 3 increases. The specific ...

Embodiment 2

[0071] refer to Figure 1~3 as well as Figure 5 shown. The embodiment is basically the same as the first embodiment, the difference is that in this embodiment, the pop-up camera 1 is also used to acquire images of the food preparation area, and the processor 5 is also used When the pressure value of 3 increases, the image of the food production area is recognized in real time. The specific identification process is: the interval time T between the food maker in the food production area before and after making the food to be baked is obtained. 4 , according to the interval T 4 Calculate the average interval time T 5 , according to the average interval T 5 Predict the current interval time T from the end of filling of all the cavities in the cavity plate 3 2 .

[0072] The image of the food production area is the image when the baker makes the baked food. The processor 5 recognizes the image of the food production area in real time when the pressure value of the cavity pl...

Embodiment 3

[0074] refer to Figure 1~5 shown. This embodiment is basically the same as Embodiment 1, the difference is that in this embodiment, the system further includes:

[0075] The pop-up preheating block 8 arranged on the inner wall of the baking cavity of the baking equipment is used for popping into the baking cavity when the heating device 7 starts preheating, and retracting to the inner wall of the baking cavity when the preheating ends.

[0076] The preheating block is a graphite block.

[0077] Wherein, the pop-up preheating block 8 adopts a lifting type pop-up, that is, a groove is set on the inner wall of the baking cavity, and the pop-up preheating block 8 is arranged inside the groove, and when the signal of the heating device 7 to start preheating is received, the Rising from the groove, it will retract from the groove when receiving the signal that the heating device 7 ends the preheating.

[0078]The preheating block in this embodiment is located in the middle of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com