Apparatus and method for roasting coffee beans

A technology of coffee beans and coffee, applied in the method, application, food science, etc. of roasting coffee, which can solve the problem of capturing or destroying the aroma of coffee beans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

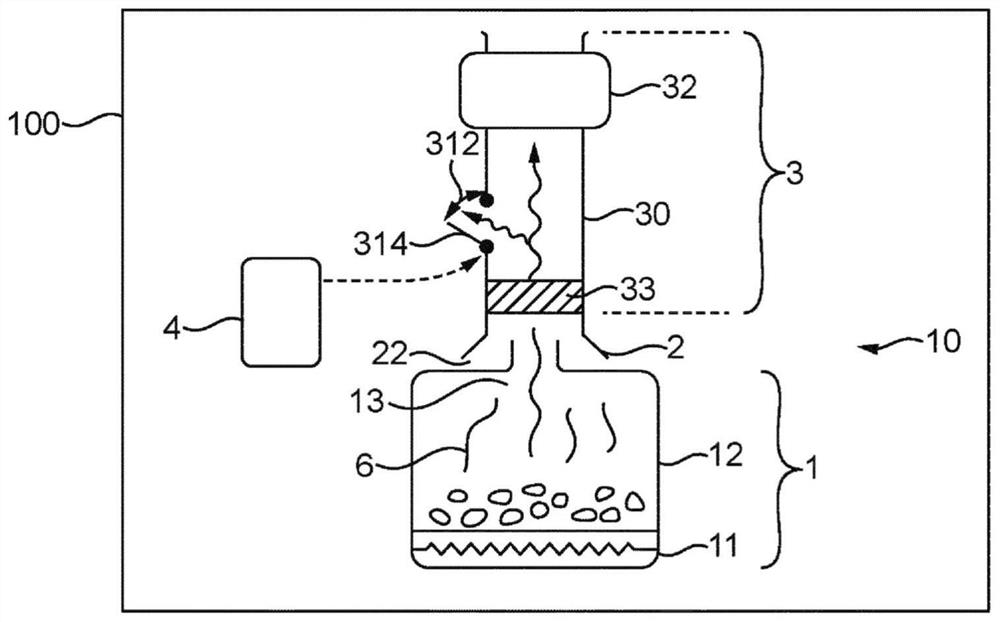

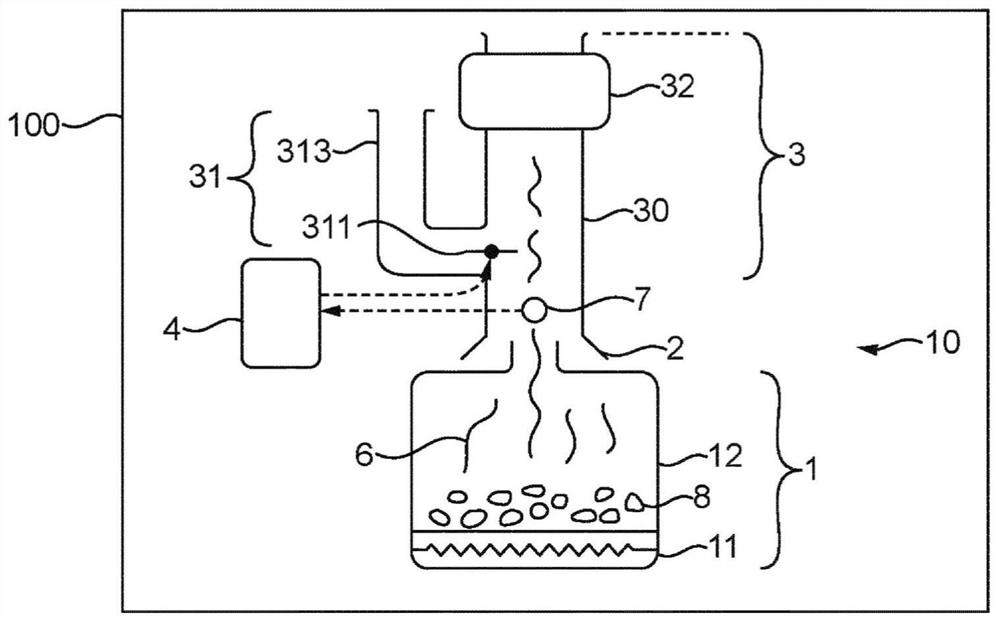

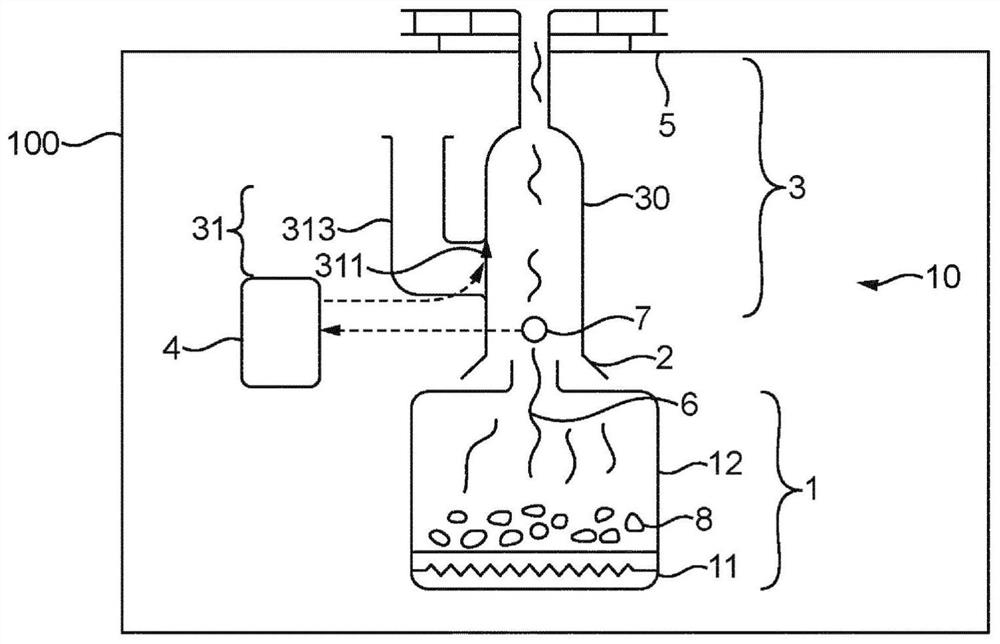

[0154] figure 1 The torrefaction device 10 is schematically shown during a torrefaction operation. The device comprises a roasting device 1 configured to roast coffee beans 8 . The roasting device comprises a roasting chamber 12 capable of introducing and heating coffee beans. A heater 11 is provided to heat the coffee beans. As mentioned above, any type of baking chamber and heating can be implemented. Preferably, however, the heater is an electric heater. During roasting, coffee beans 8 produce smoke 6 . The flue gas 6 is collected by the flue gas collection device 2 . In the embodiment shown, the collecting means 2 is a simple hood positioned above the fume outlet 13 of the torrefaction chamber in order to capture the fumes. The shroud is positioned so as to maintain a gap 22 from the outlet 13 and to provide a connection to the ambient atmosphere. Other types of fume collection devices may be used; for example, Figure 4 A collecting device 2 is shown comprising a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com