Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124 results about "Algorithm robustness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The robustness is the property that characterizes how effective your algorithm is while being tested on the new independent (but similar) dataset. In the other words, the robust algorithm is the one, the testing error of which is close to the training error.

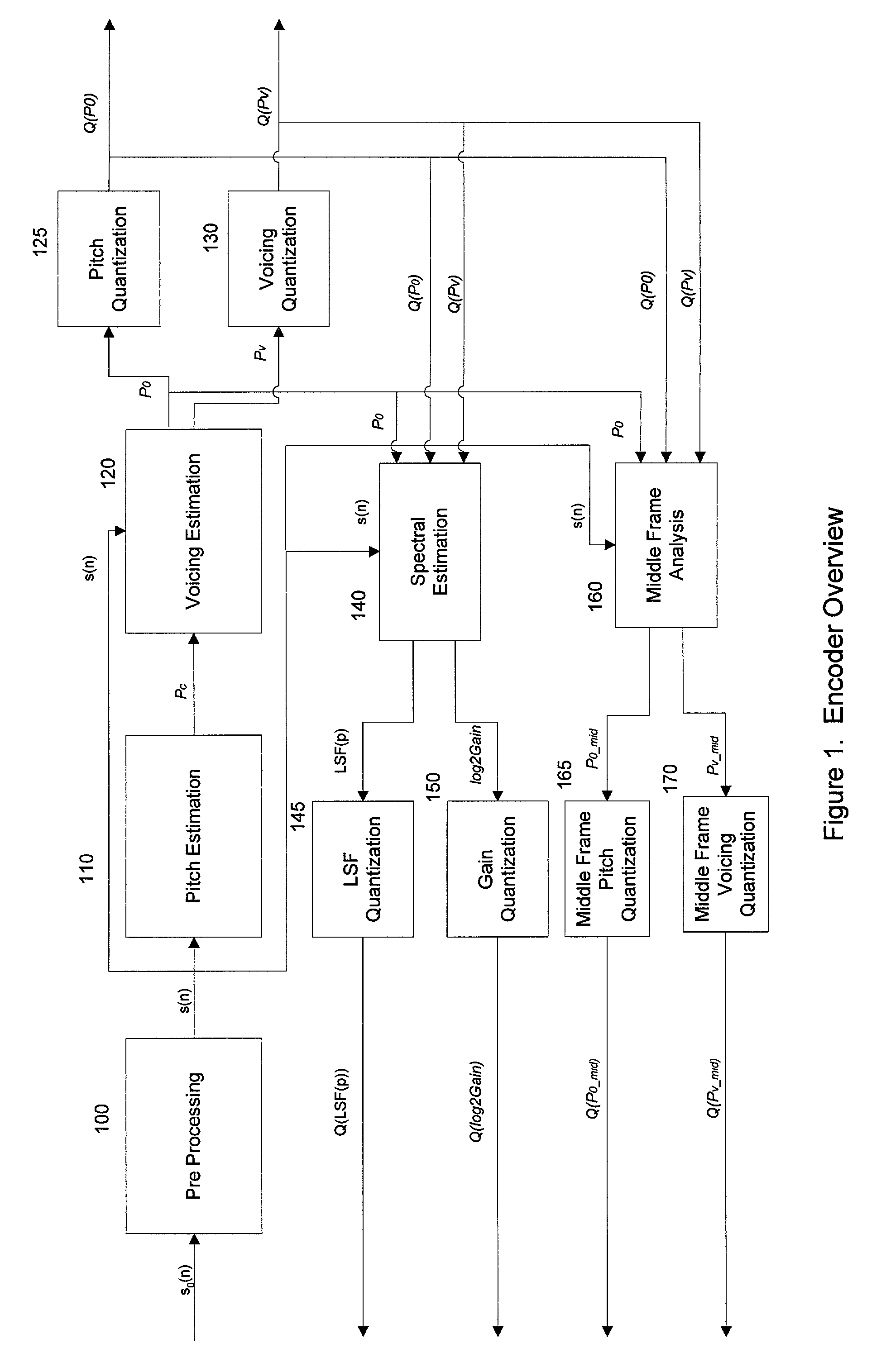

Parametric speech codec for representing synthetic speech in the presence of background noise

InactiveUS20060064301A1Accurate representationImprove perceived qualitySpeech recognitionSpeech synthesisFrequency spectrumBackground noise

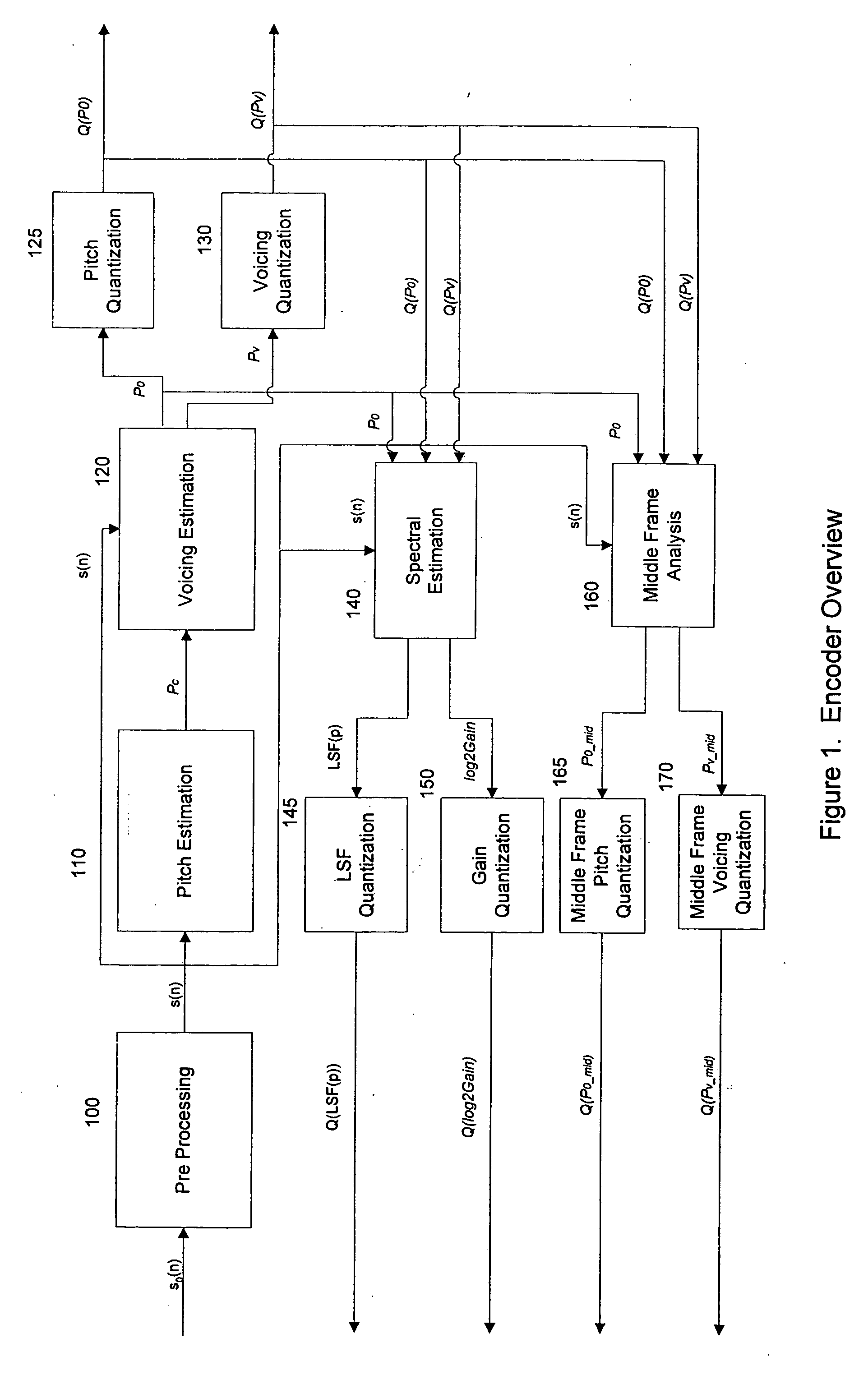

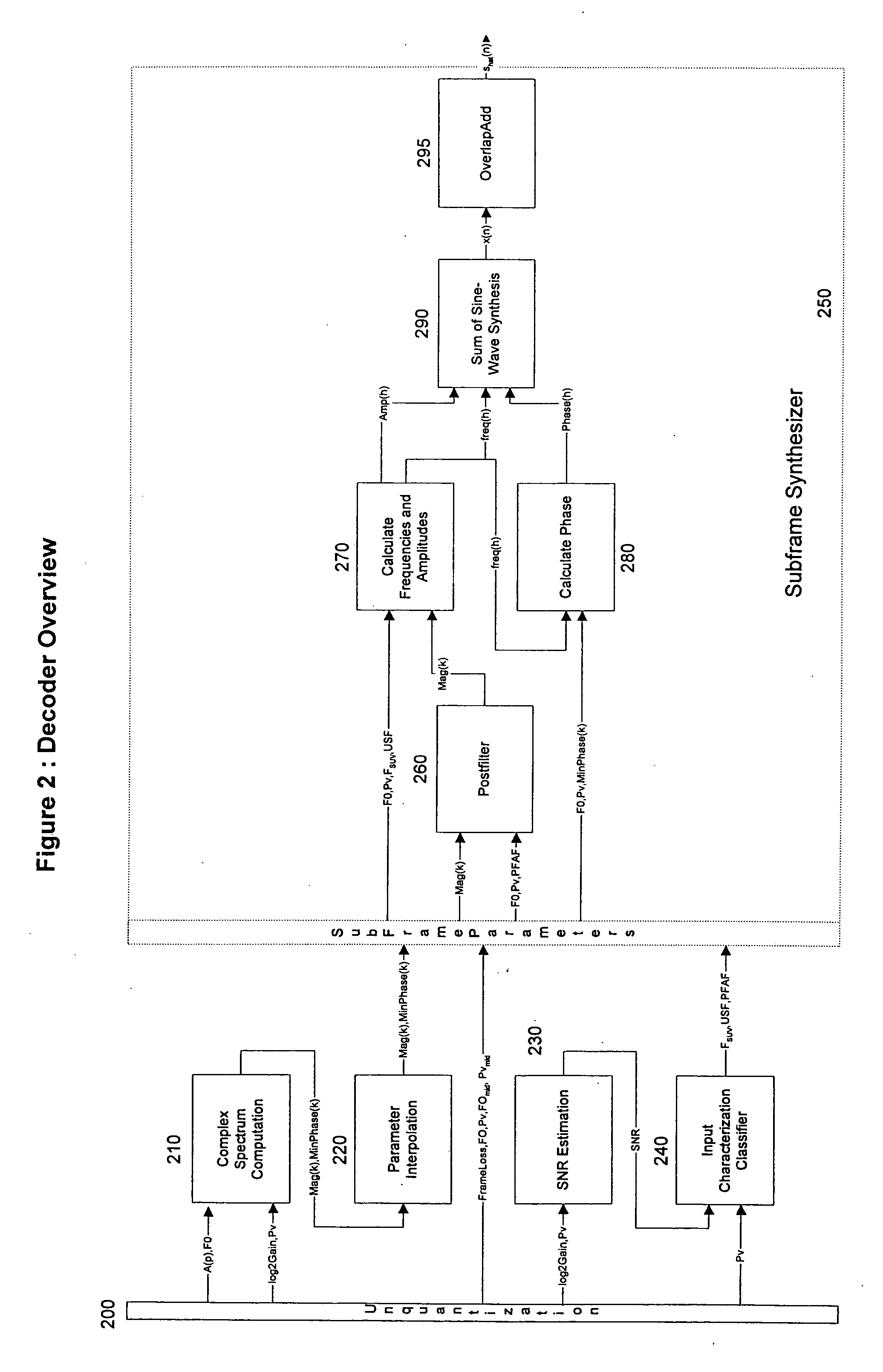

A system and method are provided for processing audio and speech signals using a pitch and voicing dependent spectral estimation algorithm (voicing algorithm) to accurately represent voiced speech, unvoiced speech, and mixed speech in the presence of background noise, and background noise with a single model. The present invention also modifies the synthesis model based on an estimate of the current input signal to improve the perceptual quality of the speech and background noise under a variety of input conditions. The present invention also improves the voicing dependent spectral estimation algorithm robustness by introducing the use of a Multi-Layer Neural Network in the estimation process. The voicing dependent spectral estimation algorithm provides an accurate and robust estimate of the voicing probability under a variety of background noise conditions. This is essential to providing high quality intelligible speech in the presence of background noise.

Owner:LUCENT TECH INC

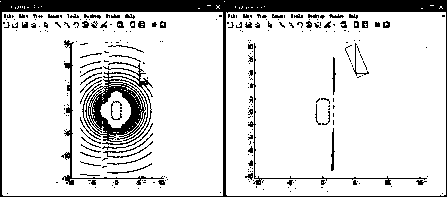

Road boundary detection method based on three-dimensional laser radar

InactiveCN104850834AEffective filteringImprove robustnessCharacter and pattern recognitionRoad surfaceTime complexity

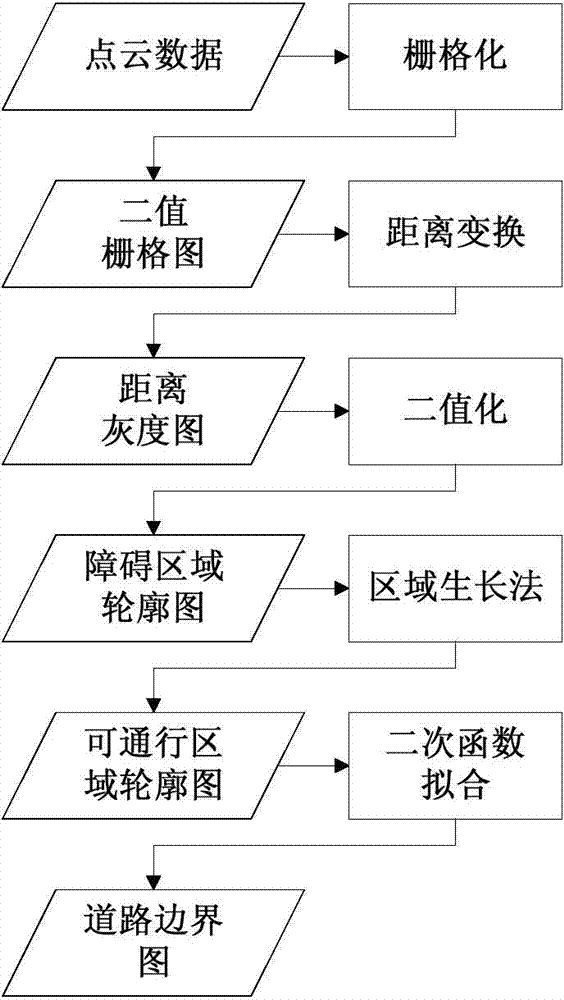

The present invention discloses a road boundary detection method based on a three-dimensional laser radar. In the process of intelligent vehicle driving, point cloud data collected by a vehicle-mounted three-dimensional laser radar is subjected to rasterizing processing to generate a binary raster graphic. The binary raster graphic is subjected to a distance conversion operation to obtain a distance grey-scale map, a filing distance is smaller than the narrow space between obstacle points of certain thresholds, the overall contour of the obstacle points is not changed, and an obstacle area contour map is obtained. A region growing method is used, with the position of an intelligent vehicle as a start point, the region growing is carried out forward, the passable area contour map of a road is obtained, and combined with the original binary raster graphic, a road area contour map is obtained. The contours of two sides of the road area contour map are extracted, the second function fitting is carried out, and a road boundary is obtained. The method is applicable to an urban road, a rural road and other roads, the influence of obstacles on a detection effect is small, the time complexity is low, the real-time processing is achieved, day and night work is achieved, and the algorithm robustness is good.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

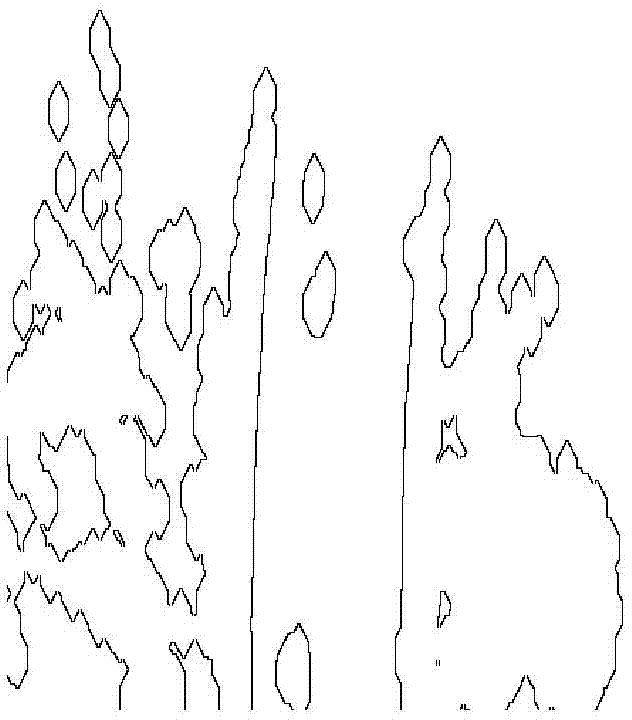

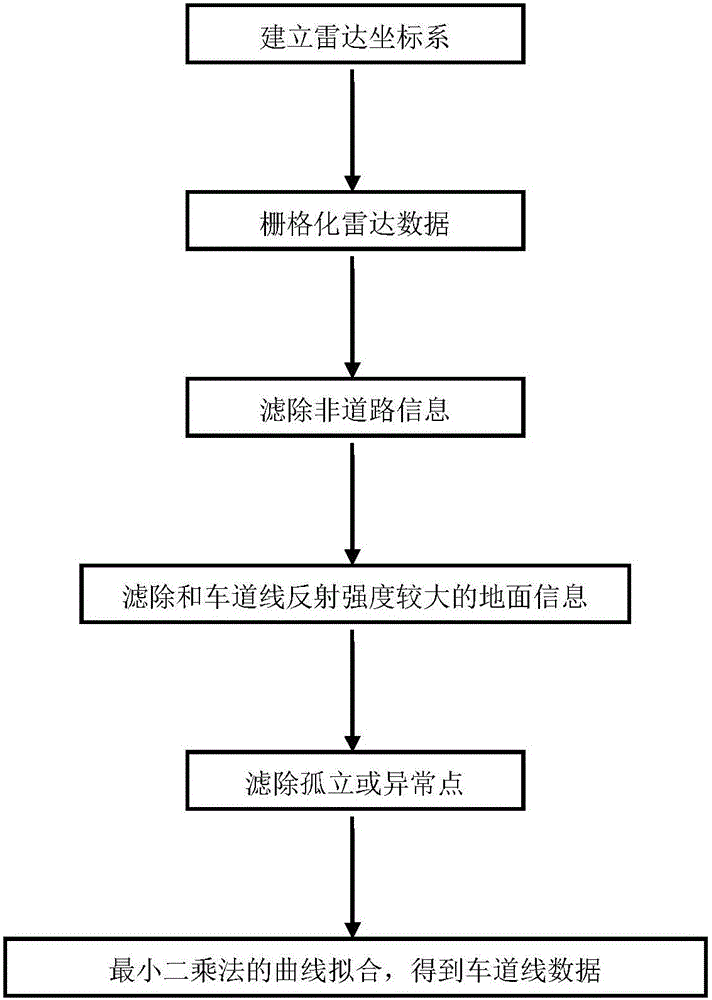

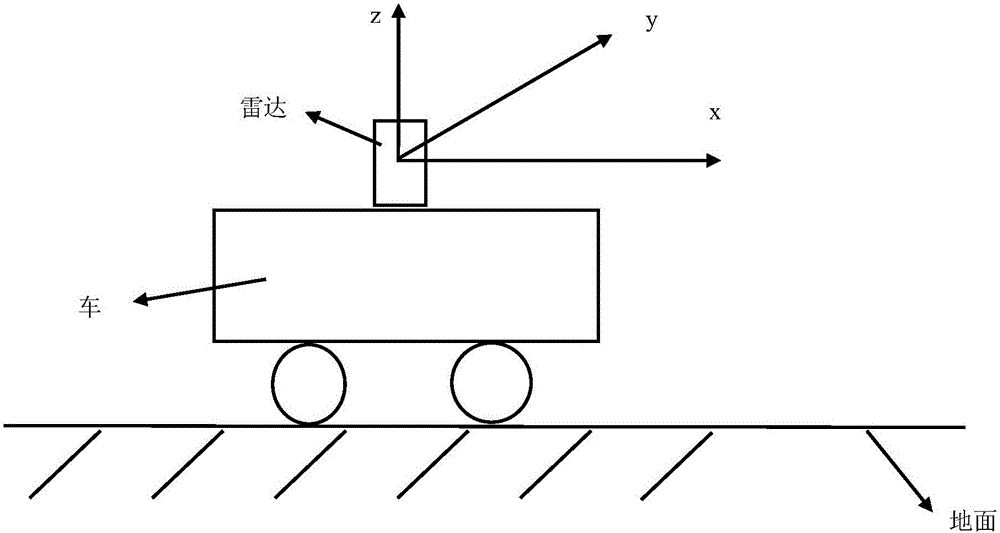

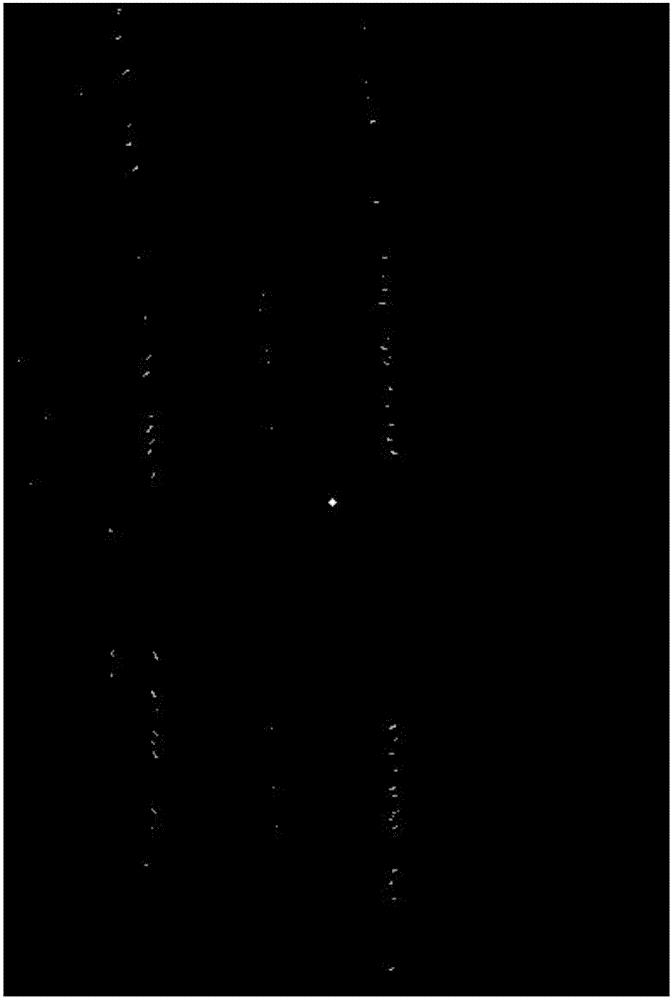

Road lane line detection method based on three-dimensional laser radar

InactiveCN106127113AReduce the difficulty of detectionImprove reliabilityCharacter and pattern recognitionGrounding gridRadar

The invention relates to a road lane line detection method based on a three-dimensional laser radar. The method comprises the following steps: 1) establishing the radar coordinate system oxyz of a detection vehicle; 2) establishing an area of interest under a radar coordinate system oxy, and carrying out rasterization processing on the data, which is collected by the laser radar, of the area of interest; 3) according to highest point data and lowest point data in a grid, filtering a non-ground grid, and utilizing the highest point data to filter a non-lane internal grid; 4) solving the average value of laser radar reflection intensity data in the grid, setting the threshold value of laser radar collection data reflection intensity, and filtering the grid which has a big difference with lane line reflection intensity; 5) filtering an isolate or exceptional grid which is close to lane line reflection intensity information; and 6) carrying out the curve fitting of a least square method on the above obtained grid to obtain a road lane line. The method can carry out real-time processing, can work day and night, and has the advantages of being high in detection effect accuracy, high in reliability and good in algorithm robustness.

Owner:BEIJING UNION UNIVERSITY

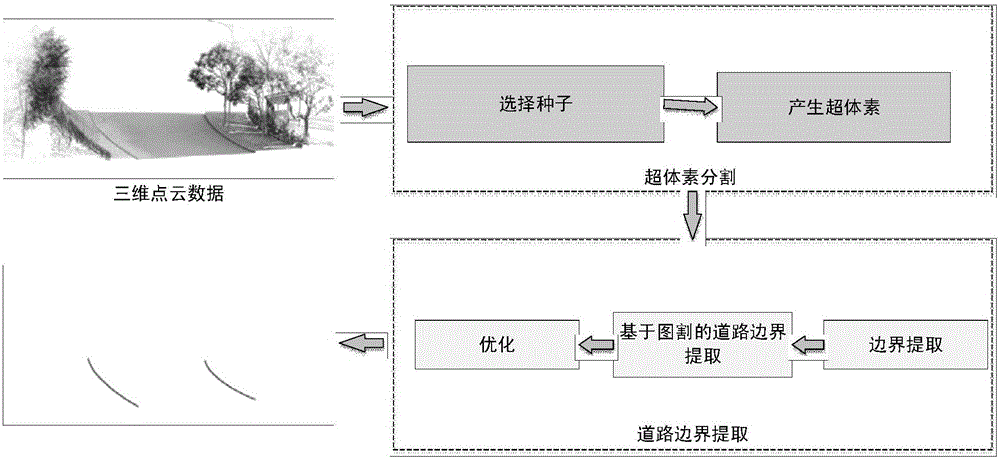

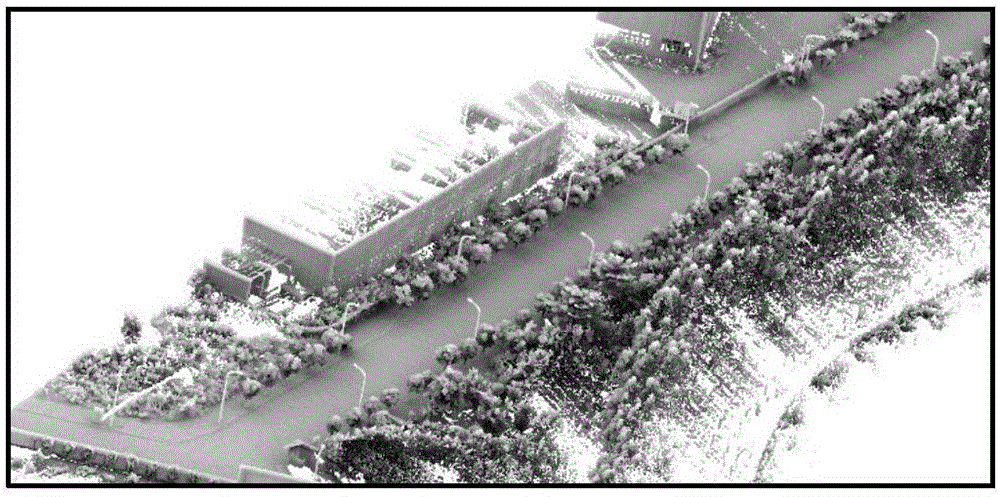

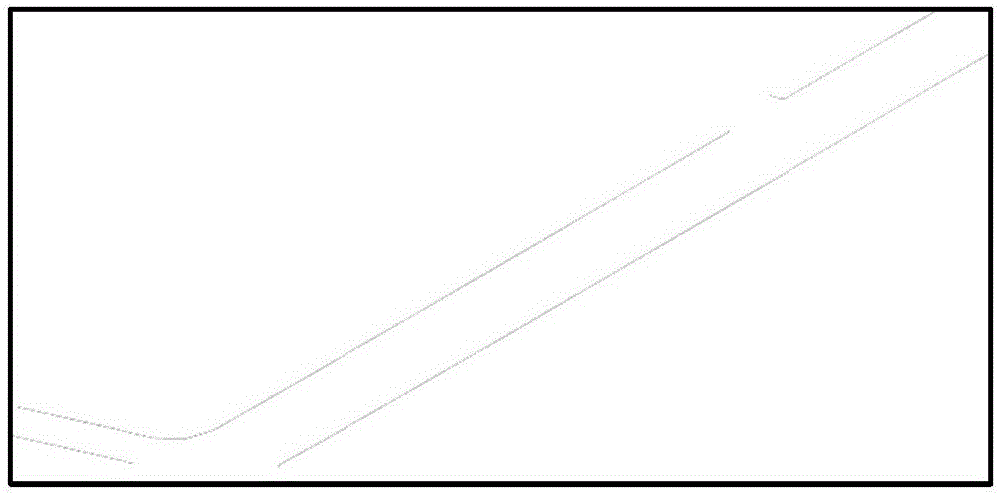

Three-dimensional point cloud road boundary automatic extraction method

ActiveCN106780524AReduce human subjective interventionThe result is stable and robustImage enhancementImage analysisCluster algorithmVoxel

The invention relates to the field of point cloud processing, and specifically discloses a three-dimensional point cloud road boundary automatic extraction method. The method comprises the steps of S1, screening seed points for the whole acquired three-dimensional point cloud data set P so as to perform super voxel classification; S2, extracting boundary points between adjacent non-coplanar super voxels by using an alpha-shape algorithm; S3, extracting road boundary points by using a graph cut based energy minimization algorithm; S4, removing outliers based on an Euclidean distance clustering algorithm; and S5, fitting the extracted road boundary points into a smooth curve. The method can directly operate on the large-scale three-dimensional point cloud, can be applied to different scenes, is high in calculation speed and good in algorithm robustness, and can extract road boundaries quickly.

Owner:XIAMEN UNIV

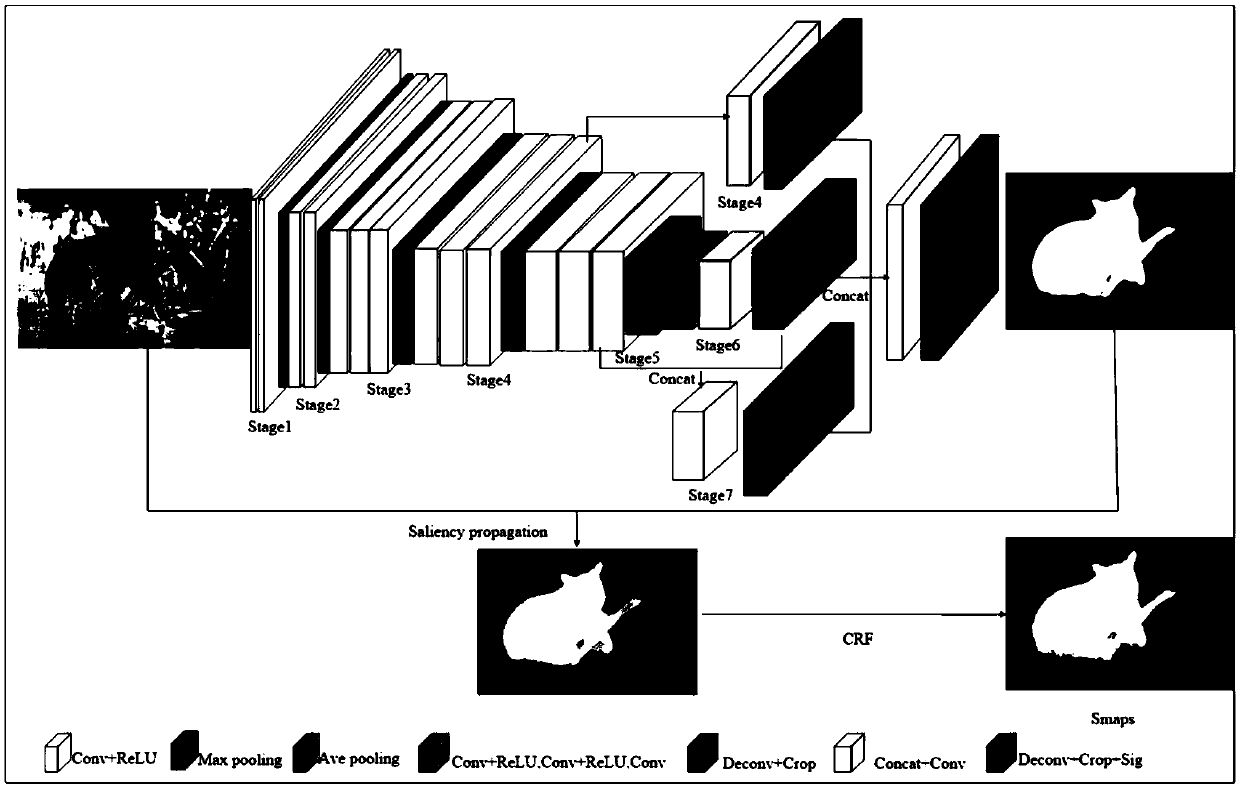

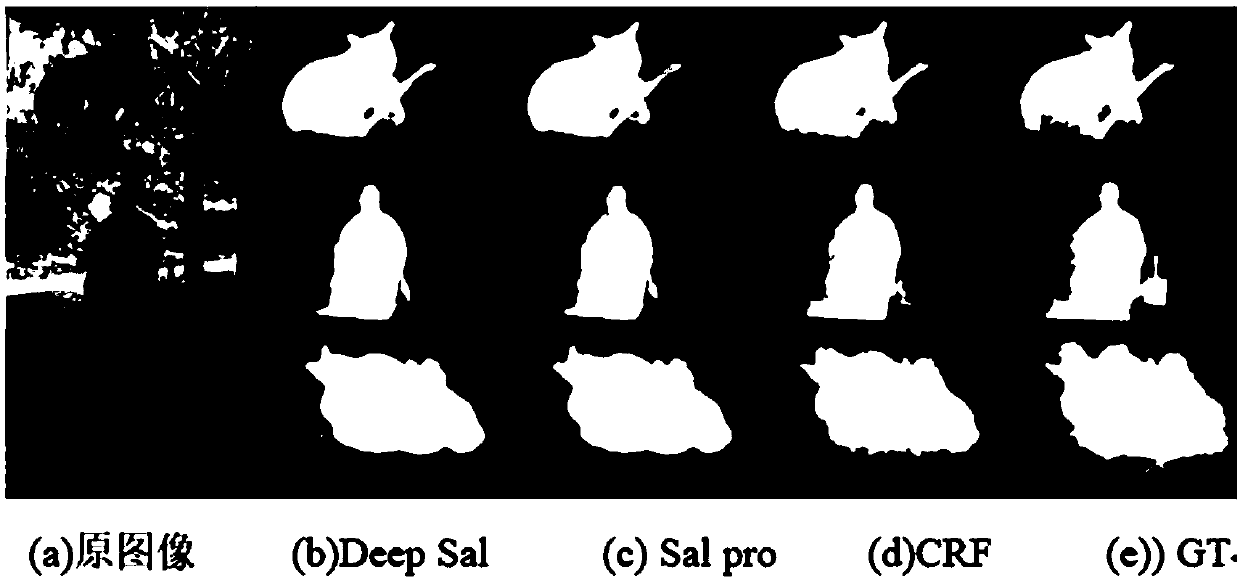

Image salient target detection method combined with deep learning

InactiveCN108898145AImprove robustnessEasy to integrateCharacter and pattern recognitionConditional random fieldSaliency map

The invention provides an image salient target detection method combined with deep learning. The method is based on an improved RFCN deep convolution neural network of cross-level feature fusion, anda network model comprises two parts of basic feature extraction and cross-level feature fusion. The method comprises: firstly, using an improved deep convolution network model to extract features of an input image, and using a cross-level fusion framework for feature fusion, to generate a high-level semantic feature preliminary saliency map; then, fusing the preliminary saliency map with image bottom-layer features to perform saliency propagation and obtain structure information; finally, using a conditional random field (CRF) to optimize a saliency propagation result to obtain a final saliency map. In a PR curve graph obtain by the method, F value and MAE effect are better than those obtained by other nine algorithms. The method can improve integrity of salient target detection, and has characteristics of less background noise and high algorithm robustness.

Owner:SOUTHWEST JIAOTONG UNIV

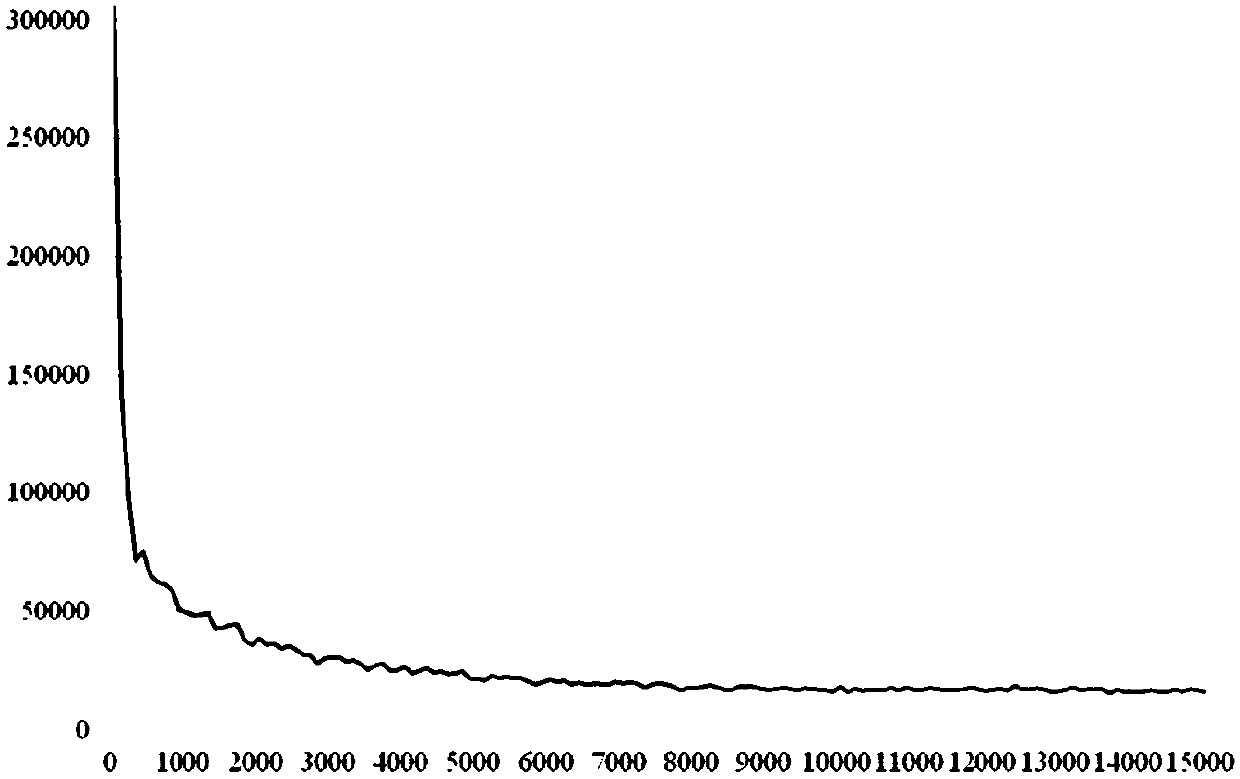

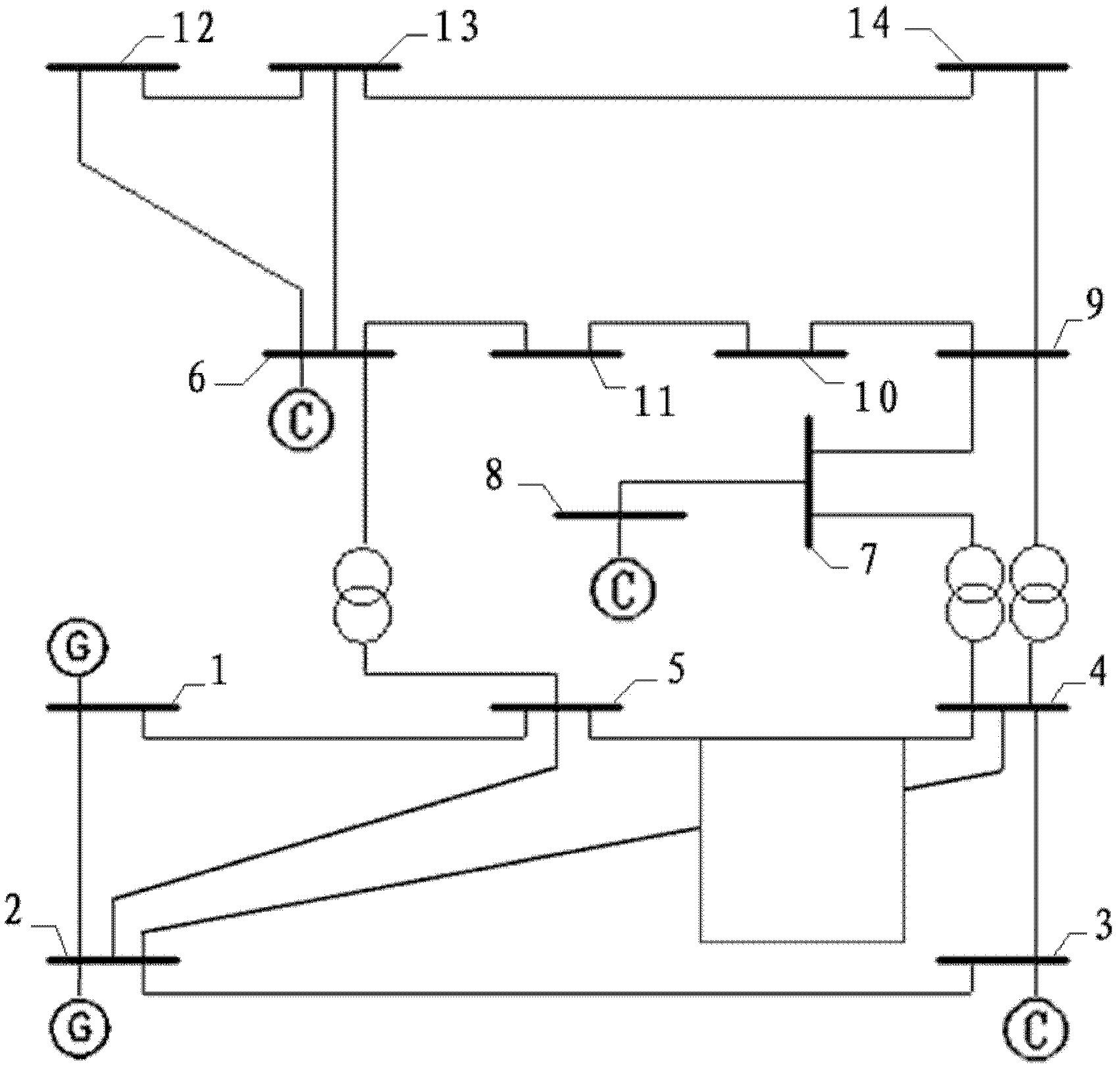

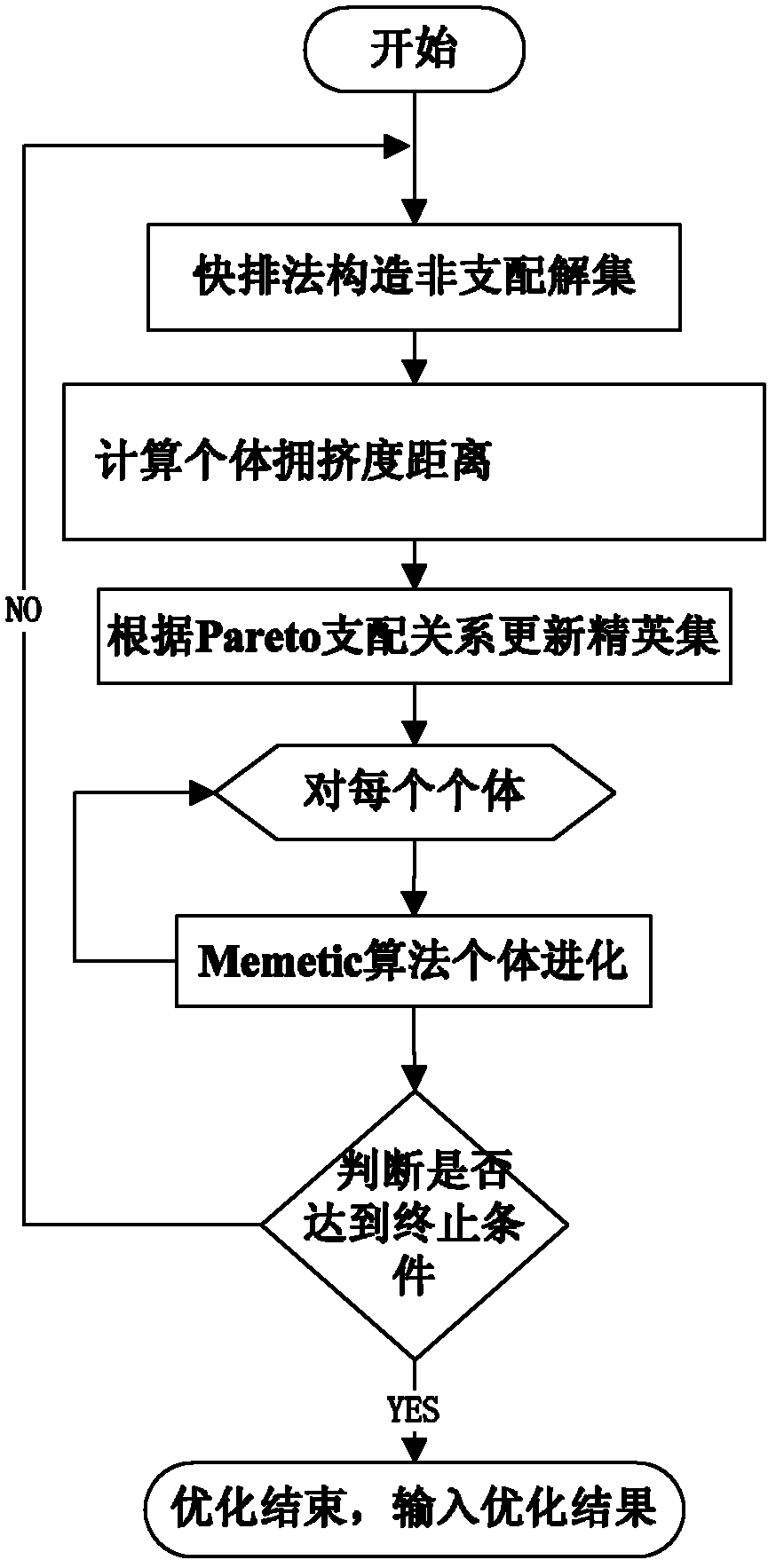

Multi-target reactive power optimization method for electric system

InactiveCN102611119AImprove robustnessEasy searchReactive power adjustment/elimination/compensationReactive power compensationMemetic algorithmElectric power system

The invention discloses a multi-target reactive power optimization method for an electric system, which belongs to the field of reactive power optimization for electric systems. The method includes: modifying the Memetic algorithm to adapt to multi-target optimization, applying the modified Memetic algorithm to the problem of multi-target reactive power optimization for the electric system, and working out a Pareto optimal solution of the multi-target problem; and judging whether algorithm convergence conditions are met or not, and if yes, completing optimization and outputting optimization results. The multi-target reactive power optimization method has the advantages that the algorithm for solving the problem of multi-target reactive power optimization is provided, the method is more suitable for solving the multi-target problem while giving play to existing advantages of the Memetic algorithm which integrates local searching and evolutionary computation and has high global search capacity and the like, and searching efficiency is improved while algorithm robustness is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Parametric speech codec for representing synthetic speech in the presence of background noise

InactiveUS7092881B1Accurate representationImprove perceived qualitySpeech recognitionFrequency spectrumAudio frequency

Owner:LUCENT TECH INC

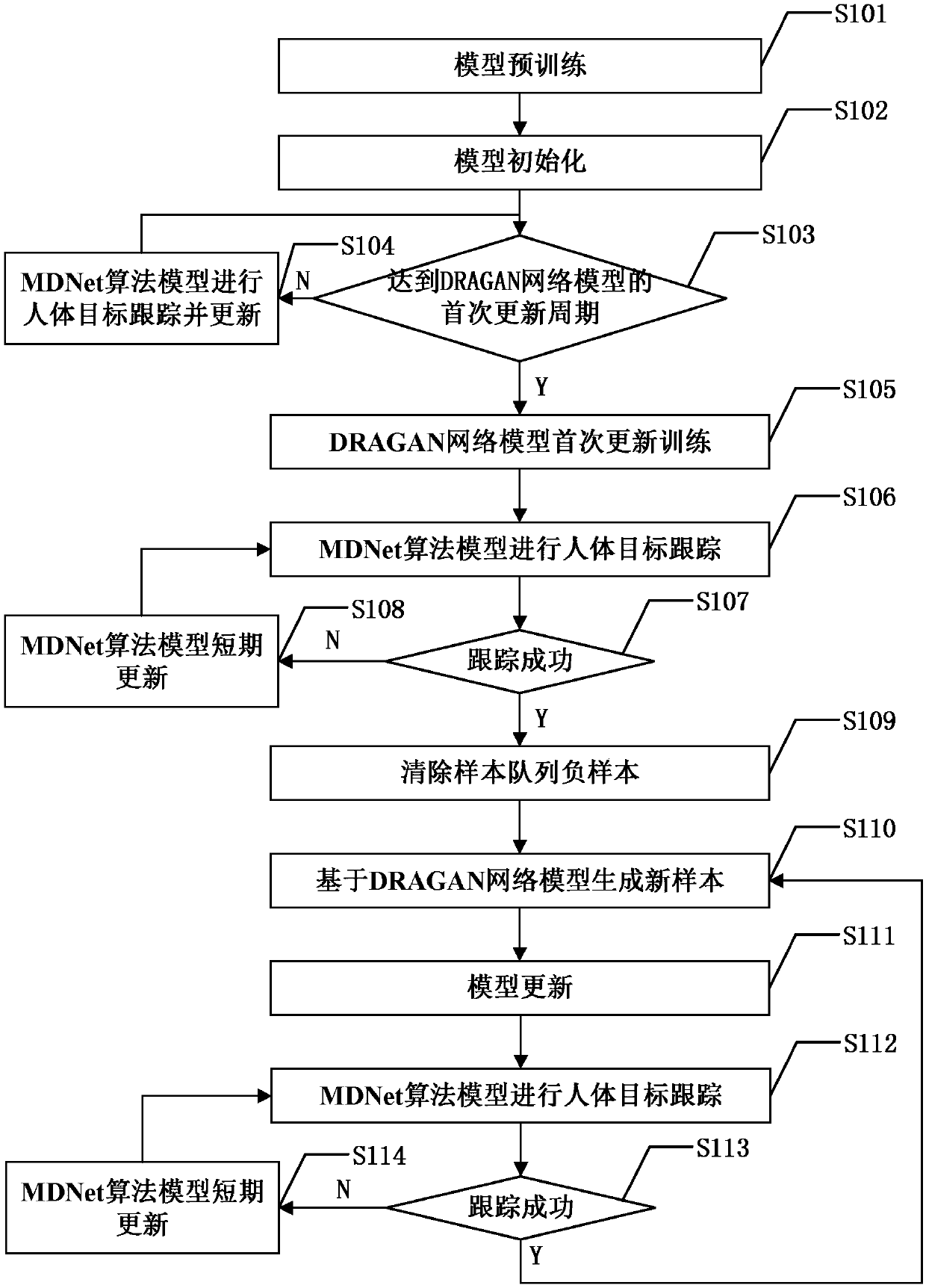

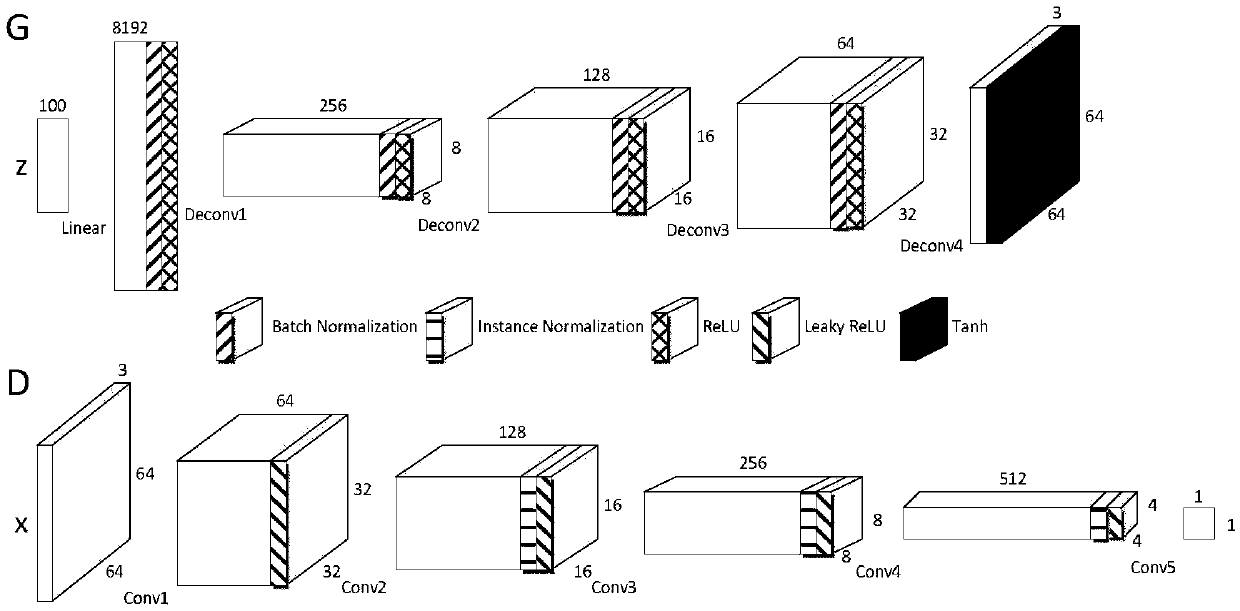

Human body target tracking method based on Generative Adversarial Net (GAN) negative sample enhancement

InactiveCN108681774AReduce redundancyIncrease richnessNeural architecturesNeural learning methodsPositive sampleHuman body

The invention discloses a human body target tracking method based on Generative Adversarial Net (GAN) negative sample enhancement, a DRAGAN network model and an MDNet algorithm model which are built are pre-trained, then a target rectangular box of a human body target calibrated by the first frame is adopted to initialize the MDNet algorithm, a sample queue of the MDNet algorithm model and a training set of the DRAGAN network model are initialized, and the MDNet algorithm model is continuously adopted to track; and when the DRAGAN network model completes update training for the first time, a generator network thereof is adopted to generate a batch of negative samples as part of negative samples adopted in update training of the MDNet algorithm model, update training is performed on the MDNet algorithm model according to the need, and positive samples obtained according to a tracking result is periodically adopted to perform update training on the DRAGAN network model. The human body target tracking method based on GAN negative sample enhancement can improve the degree of accuracy of human body target tracking of the MDNet algorithm model, suppress tracking drifting, and enhance algorithm robustness.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

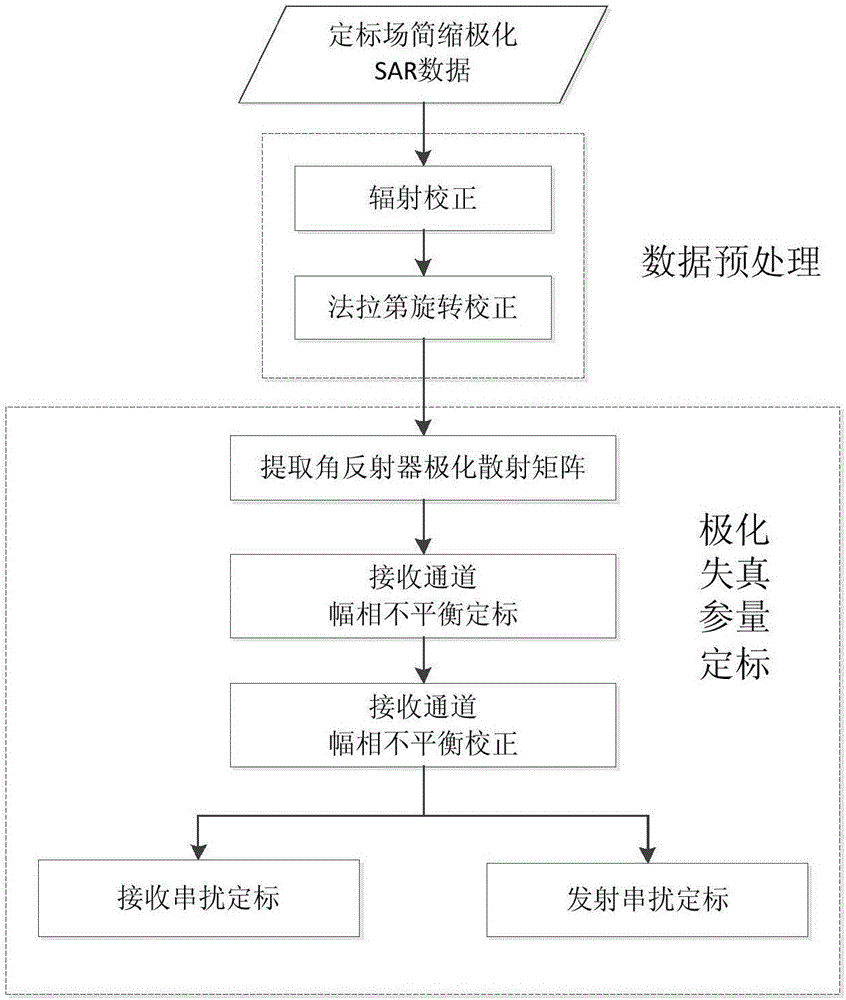

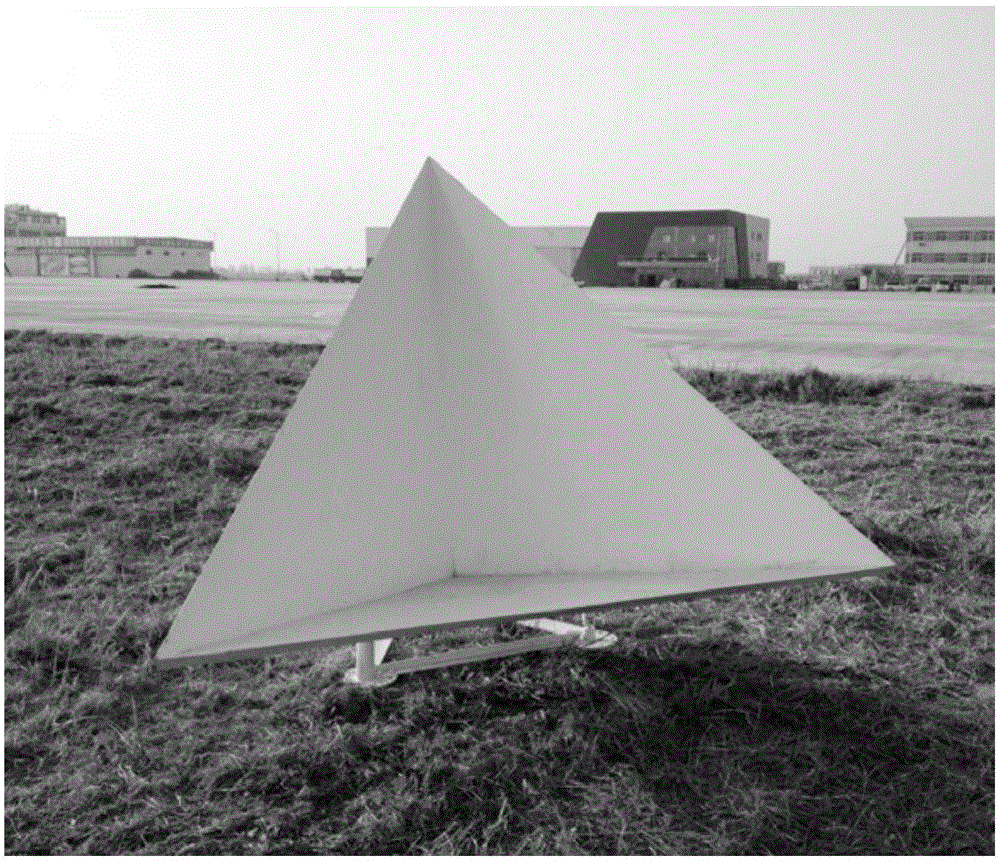

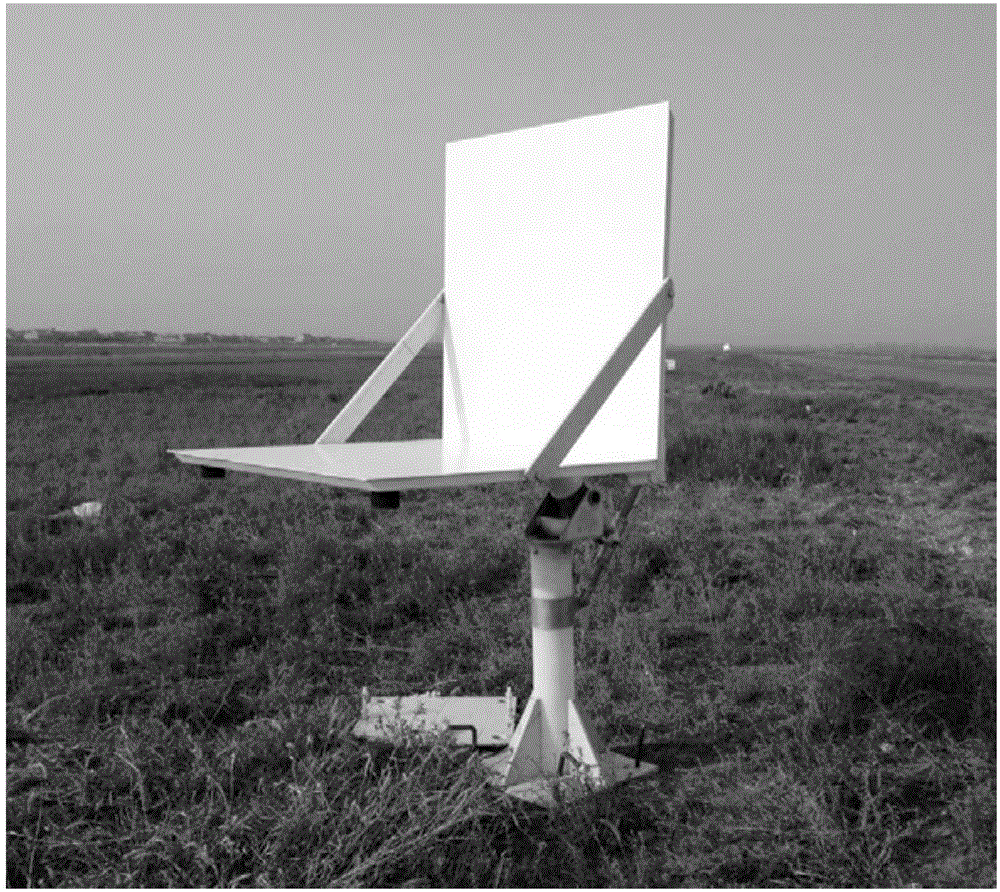

Multi-polarization SAR compact polarimetry calibration method

ActiveCN106405547AReduce weightSimplify requirementsRadio wave reradiation/reflectionPolarimetric sarCalibration algorithm

The invention provides a multi-polarization SAR compact polarimetry calibration method which comprises a calibration field compact polarimetry SAR data preprocessing process and a polarization distortion parameter calibration process. In the calibration field compact polarimetry SAR data preprocessing process, compact polarimetry SAR data radiation correction and Faraday rotation correction are mainly completed. In the polarization distortion parameter calibration process, four different types of common corner reflectors are used as reference calibrators, and a compact polarimetry calibration method (namely, a compact polarimetry polarization distortion parameter calibration method) is deduced based on a calibration model. Through the method, a polarization distortion parameter can be calibrated precisely. The calibration algorithm does not depend on the absolute RCS values of the corner reflectors, and calibration error caused by RCS inconsistency of different corner reflectors can be avoided effectively. The algorithm is of high robustness and practicability.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

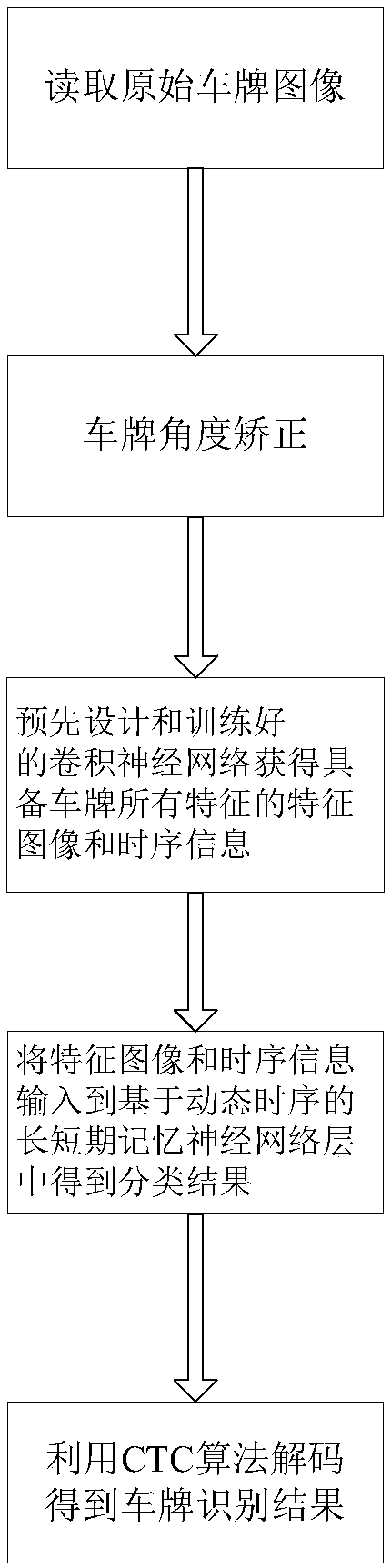

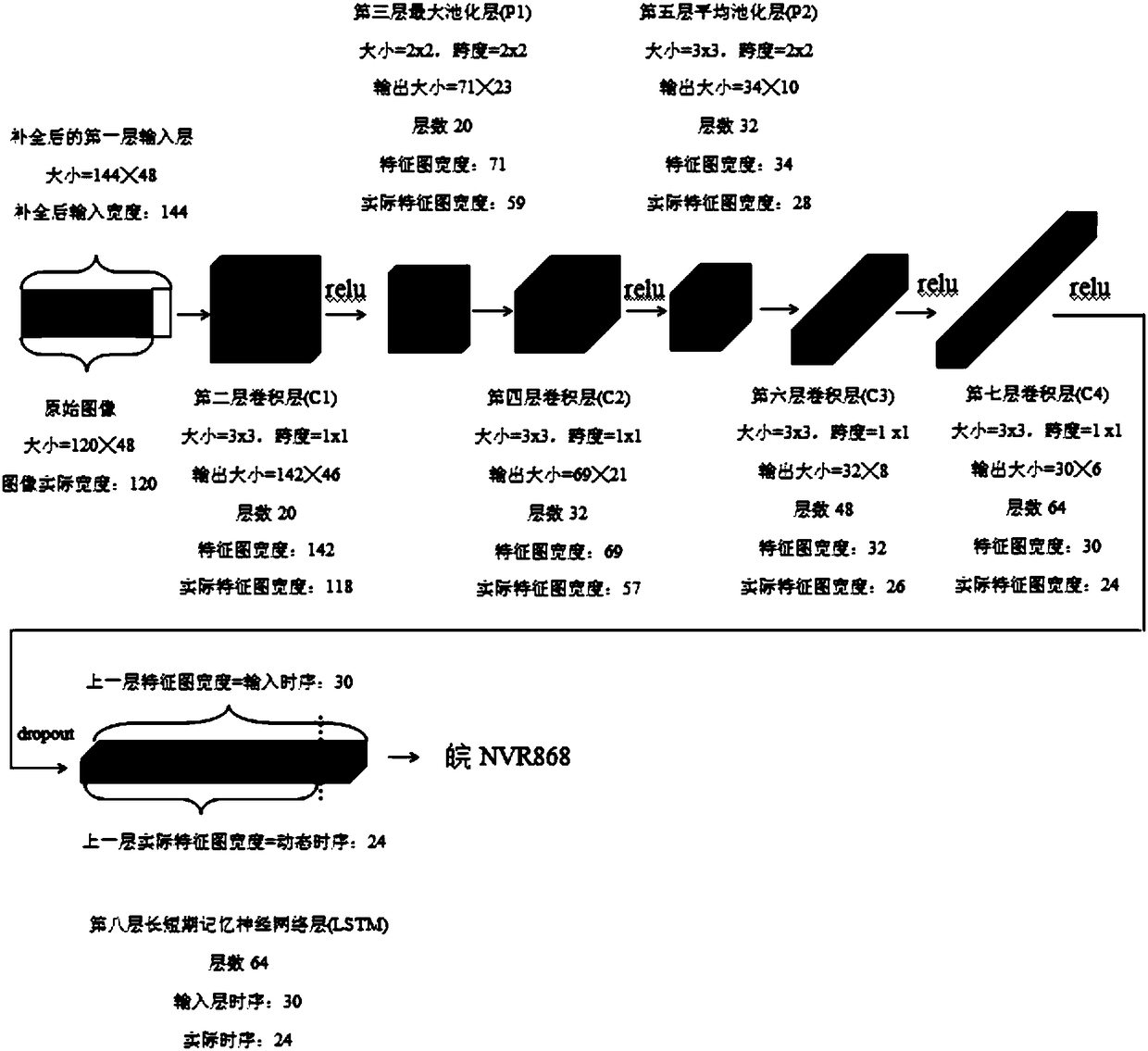

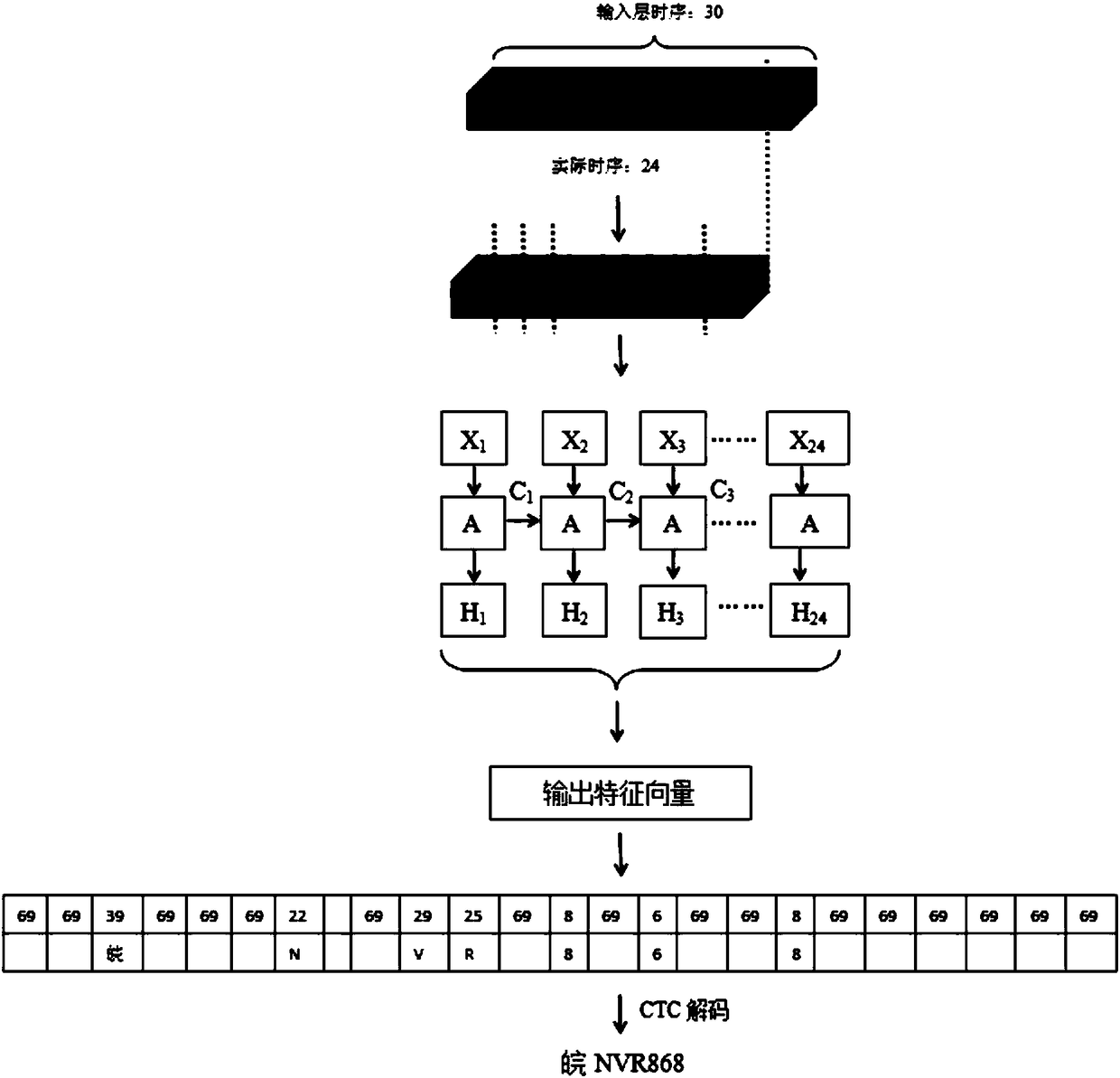

Dynamic time sequence convolutional neural network-based license plate recognition method

ActiveCN108388896AReduce training parametersSolve the problem of low accuracy rate and wrong recognition resultsCharacter and pattern recognitionNeural architecturesShort-term memoryLeak detection

The invention discloses a dynamic time sequence convolutional neural network-based license plate recognition method. The method comprises the following steps of: reading an original license plate image; carrying out license plate angle correction to obtain a to-be-recognized license plate image; inputting the to-be-recognized license plate image into a previously designed and trained convolutionalneural network so as to obtain a feature image and time sequence information, wherein the feature image comprises all the features of the license plate; and carrying out character recognition, inputting the feature image into a convolutional neural network of a long and short-term memory neural network layer on the basis of time sequence information of the last layer so as to obtain a classification result, and carrying out decoding by utilizing a CTC algorithm so as to obtain a final license plate character result. According to the method, vision modes are directly recognized from original images through using convolutional neural networks, self-learning and correction are carried out, the convolutional neural networks can be repeatedly used after being trained for one time, and the timeof single recognition is in a millisecond level, so that the method can be applied to the scenes needing to recognize license plates in real time. The dynamic time sequence-based long and short-termneural network layer is combined with CTC algorithm-based decoding, so that recognition error problems such as leak detection and repeated detection are effectively avoided, and the algorithm robustness is improved.

Owner:浙江芯劢微电子股份有限公司

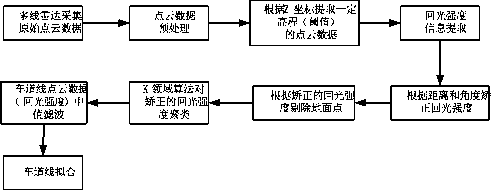

Multiline laser radar mass point cloud data rapid and effective extraction and vehicle and lane line feature recognition method

PendingCN107192994ALower requirementReduce consumptionWave based measurement systemsPoint cloudRadar

The unmanned vehicle acquires three-dimensional mass point cloud data (point cloud field) through multiline laser radar for hundreds of MB per second, and the data storage space and processing timeliness have extremely high requirement for the computing resource. The invention provides a multiline laser radar three-dimensional point cloud data rapid and effective extraction method without influencing vehicle and lane line feature recognition. The r layer point cloud data of the vehicle multilayer point cloud data in the area of interest of the unmanned vehicle acquired through multiline laser radar are extracted by adaptive distance. Besides, the invention also provides a lane line extraction method through the return light intensity based on distance and angle correction. The requirement of mass point cloud data processing for the computer hardware can be reduced, the storage space and cost can be saved, the timeliness of point cloud data processing can be accelerated and rapid and effective extraction and feature recognition of the vehicle and lane line point cloud data in the area of interest of the unmanned vehicle can be realized. The method is suitable for multiple urban roads so as to be high in anti-interference capability and great in algorithm robustness.

Owner:SHANDONG UNIV OF TECH

Analog circuit fault diagnosis method based on cascade connection integrated classifier

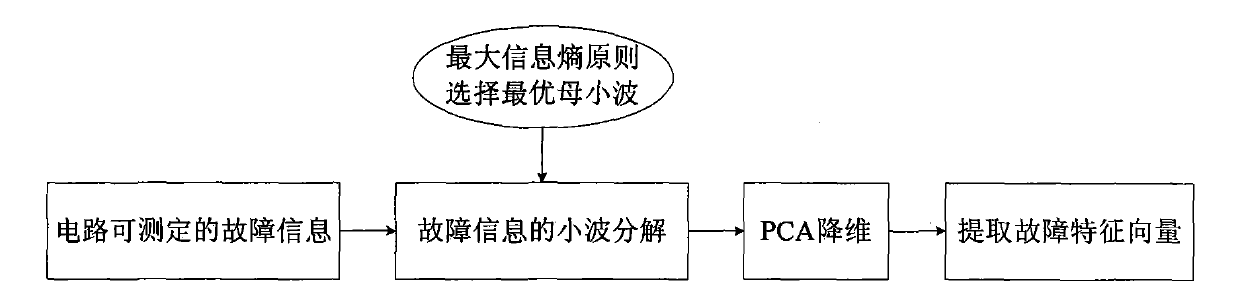

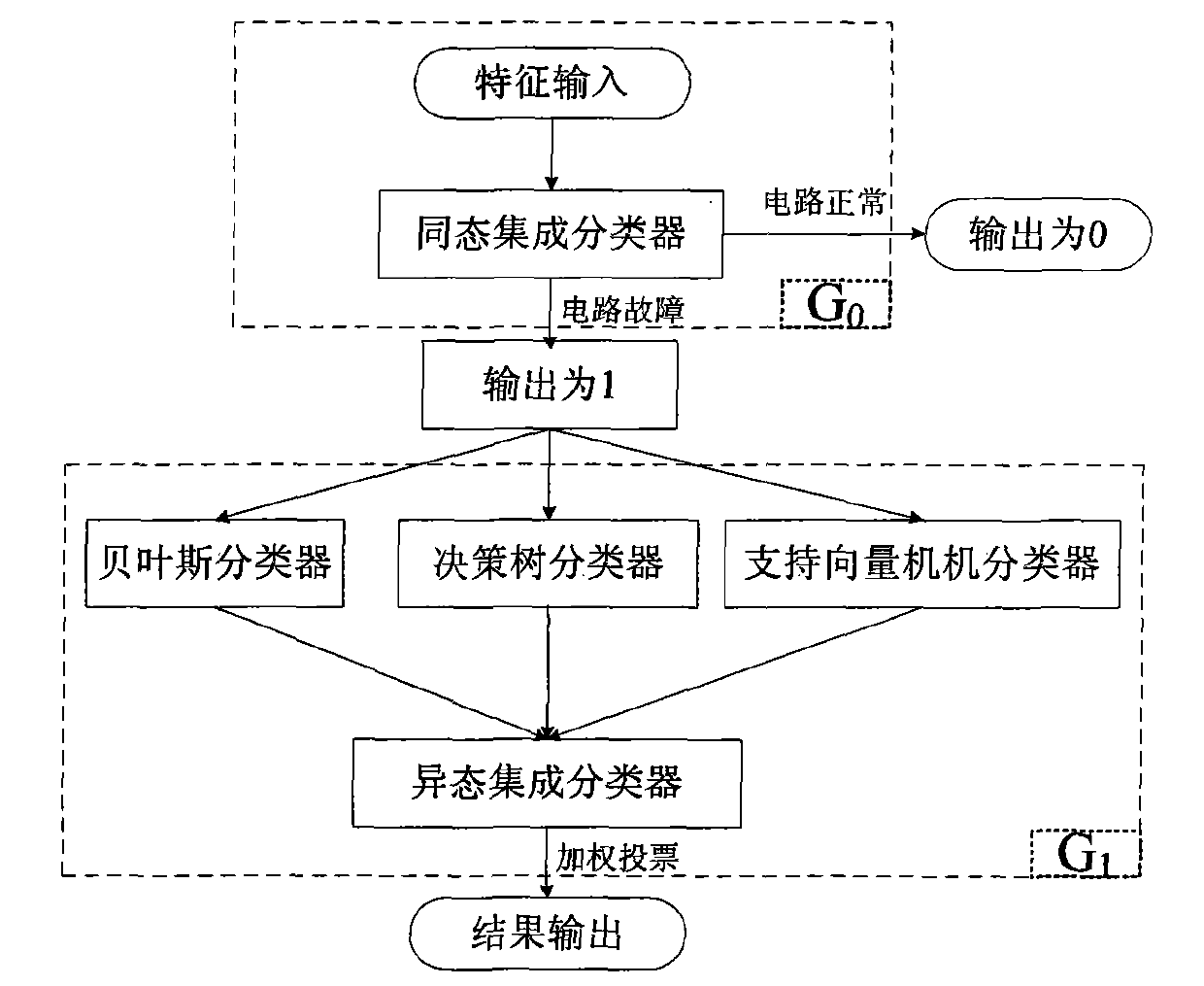

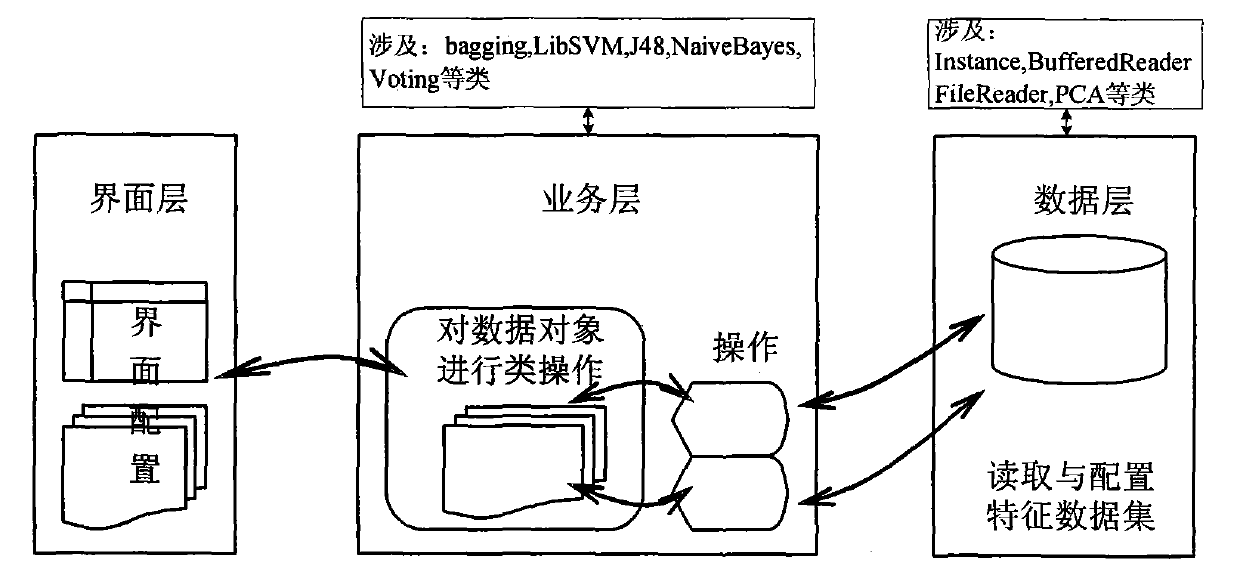

InactiveCN103728551ASolving indistinguishable problemsSolve the imbalanceElectrical testingInformation repositoryPrincipal component analysis

The invention discloses an analog circuit fault diagnosis method and an implementation method of the analog circuit fault diagnosis method. The content includes the first part of analog circuit fault feature information extraction, the second part of fault classifier construction, and the third part of implementation of algorithm software. The analog circuit fault diagnosis method includes the following steps of constructing a fault feature information base, selecting an optimal mother wavelet through an information entropy maximizing principle, conducting wavelet decomposition on response nodes of a measured circuit, extracting the optimal feature of the measured circuit, conducting dimensionality reduction on the fault features through principal component analysis, conducting fault classification and intelligent diagnosis, constructing a fault diagnosis device according to the obtained fault feature information and through a multi-classifier cascade connection model and the classifier integration technology so as to recognize existing faults and causes of the faults, and conducting specific implementation on the algorithm through a C#.NET platform and through combination with the Weka software. The diagnosis method and the implementation method have the advantages of being high in fault diagnosis performance, wider in diagnosis range, higher in algorithm robustness and higher in interpretability.

Owner:NAVAL AERONAUTICAL & ASTRONAUTICAL UNIV PLA

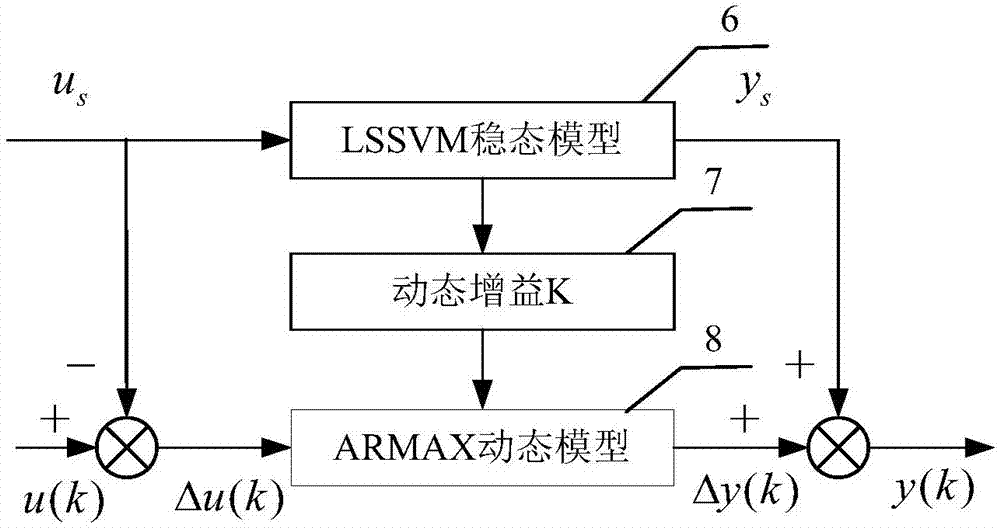

Cement decomposing furnace control method and system based on combined model predicting control technology

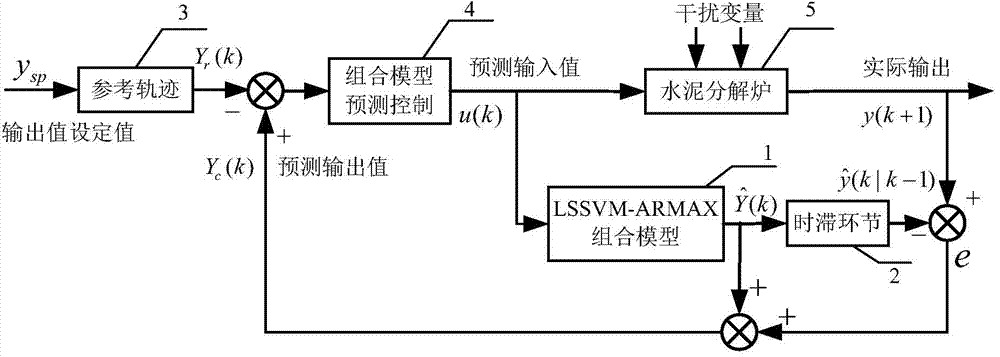

ActiveCN104765350AResponse to actual operating conditionsHigh precisionSimulator controlTotal factory controlTime lagTime delays

The invention relates to a cement decomposing furnace control method and system based on a combined model predicting control technology. The method comprises the steps that firstly, a central controlling machine utilizes a data communication interface to collect data of the raw material predecomposition process of a cement decomposing furnace; secondly, the data are classified, model identification is carried out separately, an LSSVM steady state model and an ARMAX dynamic state model are obtained, and the LSSVM steady state model and the ARMAX dynamic state model are combined into a combined model; thirdly, the combined model containing a time delay element is used for predicting a future output state of the raw material predecomposition process, and a reference trajectory of an output value is set; fourthly, a sequential quadratic programming method is adopted on a non-linear controller to carry out rolling solving on a target function, and an optimal control value of the cement decomposing furnace is obtained. The system comprises a decomposing furnace intelligent measuring meter, an actuator, the communication interface and the central controlling machine. A combined model predicting control algorithm is embedded in the central controlling machine. According to the cement decomposing furnace control method and system based on the combined model predicting control technology, the model identification accuracy is high, the algorithm robustness is high, coupling, non-linearity and time lag between multiple variables of the decomposing furnace can be adapted, and the good control effect is achieved.

Owner:YANSHAN UNIV

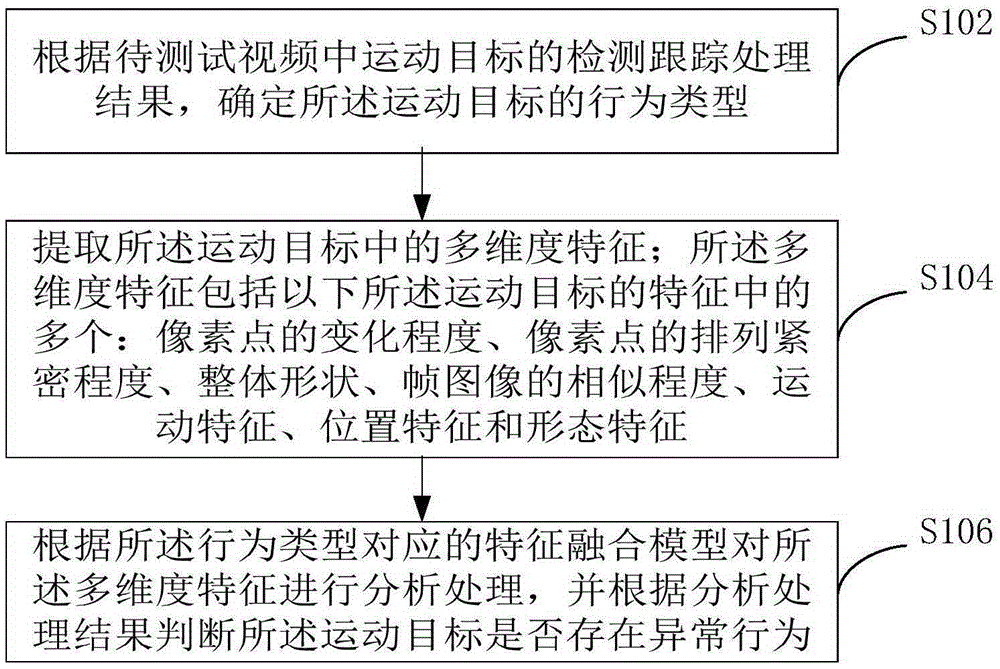

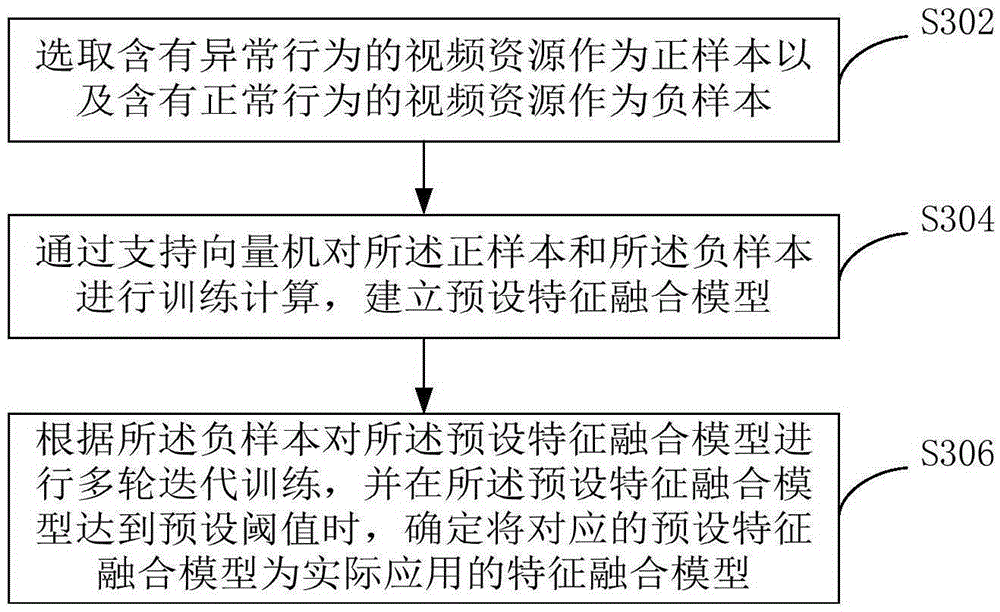

Abnormal behavior detection method and abnormal behavior detection device based fused characteristics

ActiveCN105405150AImprove robustnessImprove stabilityImage enhancementImage analysisRobustificationPattern recognition

The invention provides an abnormal behavior detection method and an abnormal behavior detection device based fused characteristics. The method comprises steps that, according to a detection tracking processing result of a motion target in a to-be-detected video, a behavior type of the motion target is determined; multi-dimensional characteristics of the motion target are extracted, including a pixel point change degree, a pixel point arrangement tightness degree, an integral shape, a frame image similarity degree, motion characteristics, position characteristics and form characteristics; the multi-dimensional characteristics are analyzed and processed according to a characteristic fusion model corresponding to the behavior type, whether the motion target has abnormal behaviors is determined according to the processing result; according to innovative characteristics of the multiple abnormal behaviors, algorithm robustness and stability can be effectively improved, according to the characteristic fusion model acquired through learning and training large-scale abnormal behaviors, the multi-dimensional characteristics are analyzed and processed, problems of algorithm overfitting and insufficient fitting can be effectively avoided, the method is suitable for multiple types of complex application scenes, time cost and manpower cost are greatly saved, and the method has high popularization values.

Owner:NETPOSA TECH

BP neural network image restoration algorithm based on self-adaption genetic algorithm

InactiveCN104820977AImprove robustnessReduce forecast errorImage enhancementGenetic modelsAlgorithmImage restoration

The invention relates to a BP neural network image restoration algorithm and especially relates to the BP neural network image restoration algorithm based on a self-adaption genetic algorithm. The algorithm comprises the following steps: S1) population initialization; S2) design of a fitness function; S3) selection design; S4) cross-over design; S5) variation design; and S6) crossing-over rate and variation rate dynamic adjustment. The algorithm has smaller prediction error and more reliable stability, and enhances algorithm robustness.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

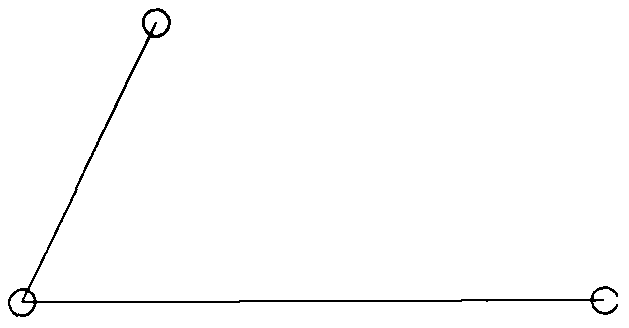

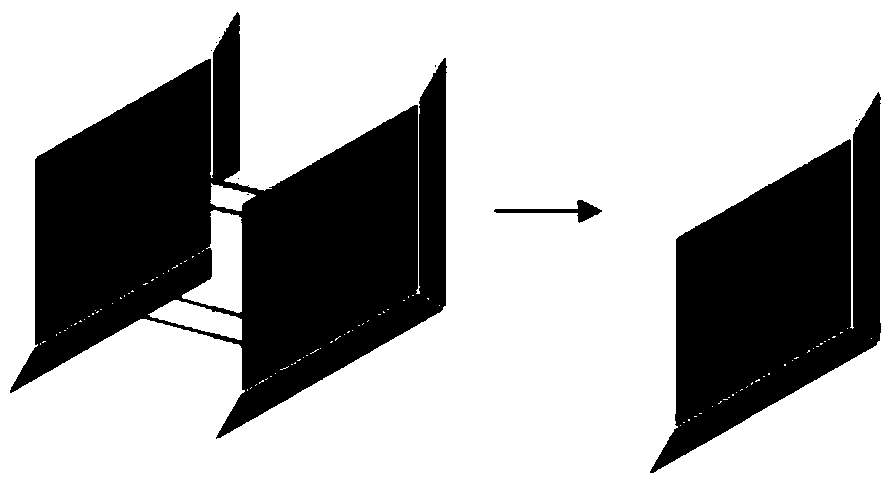

Multi-camera internal and external parameter calibration method based on three-point calibration object

The invention discloses a multi-camera internal and external parameter calibration method based on a three-point calibration object. The method comprises steps of S10, image point data acquisition; S20, every-two-camera internal and external parameter calibration; S30, multi-camera internal and external parameter calibration under a unified reference camera coordinate system; and S40, multi-camera internal and external parameter calibration under a designated world coordinate system. The method is advantaged in that a calibration tool is simple to make, limiting the calibration objects to move in a public view field of all the cameras is not needed, strong operability is realized, a multi-camera cascade path is determined through utilizing the common view field relationship, more image points participate into operation, and algorithm robustness is better.

Owner:北京轻威科技有限责任公司

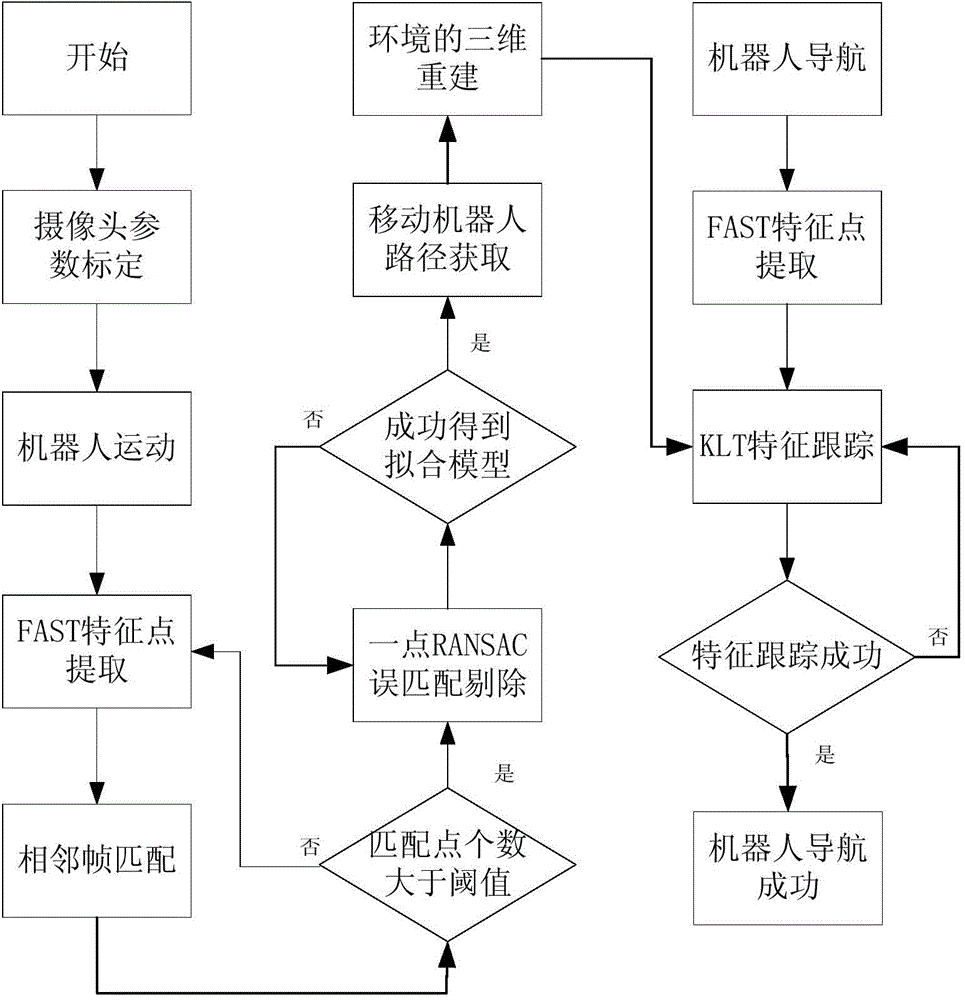

Mobile robot navigation method based on one point RANSAC and FAST algorithm

ActiveCN104881029AImprove real-time performanceReduce the number of iterationsPosition/course control in two dimensionsPrior informationFast algorithm

The invention provides a mobile robot navigation method based on one point RANSAC and FAST algorithms. The method mainly includes that a robot adopts the FAST corner extraction algorithm for collecting surround environment information through a self-equipped camera; the one point RANSAC algorithm combined with extension Kalman filtering is adopted during a matching process for error matching remove; and obtained matching points are used for three-dimensional environment reconstruction and map creation. Aiming at a problem that the number of iterations is too large in the prior art employing the RANSAC algorithm, prior information obtained in a filtering phase is utilized fully. In this way, the number of iterations of the algorithm is reduced effectively and the algorithm robustness is guaranteed at the same time, so that feature matching is implemented. Problems that a traditional mobile robot is poor in monocular vision navigation real time performance and robustness and the number of iterations of the RANSAC algorithm is too large are solved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

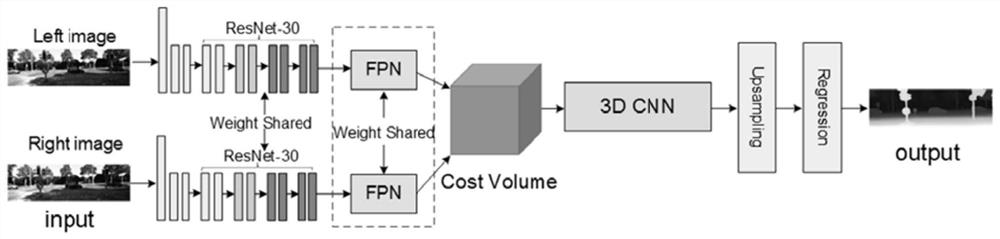

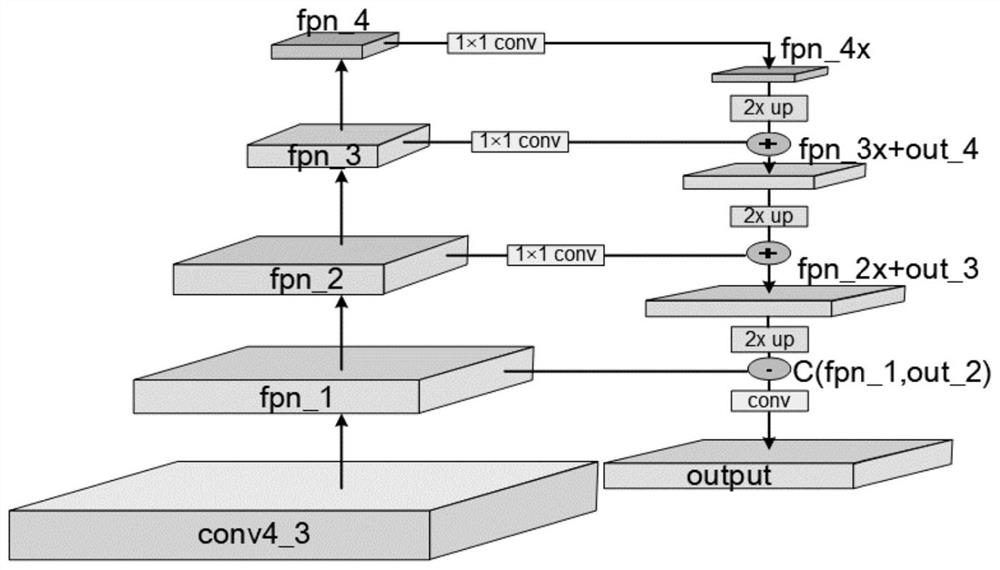

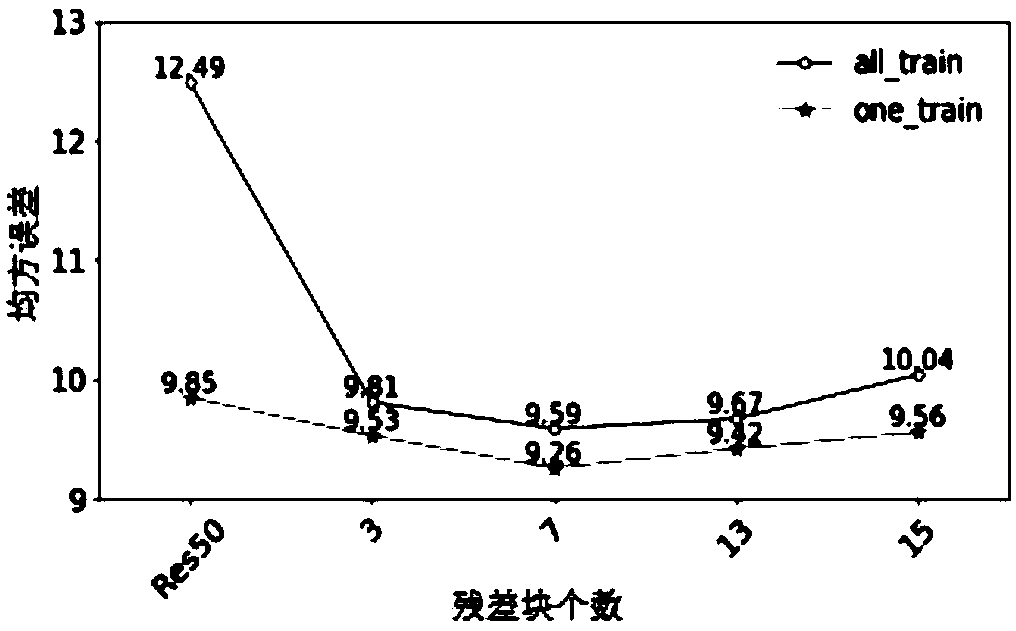

End-to-end stereo matching method based on convolutional neural network

PendingCN111696148AEasy to useTake advantage ofImage enhancementImage analysisStereo matchingComputer vision

The invention discloses an end-to-end stereo matching method based on a convolutional neural network. The end-to-end stereo matching method comprises the following steps: respectively extracting respective feature maps of left and right images through a residual convolutional neural network; respectively extracting feature information of the left and right feature maps on multiple scales by usingthe feature pyramid to obtain final feature maps of the left and right images; fusing the final feature maps of the left and right images to form a four-dimensional cost amount; using a three-dimensional convolutional neural network stacked by a multi-scale hourglass network to carry out cost normalization on a four-dimensional cost amount, and obtaining a disparity map through up-sampling and disparity regression. According to the method, global information can be fully utilized, so that a more accurate disparity map is obtained; compared with a traditional stereo matching algorithm, the problem that the matching effect in an ill-conditioned area is poor is greatly improved, the algorithm robustness is better, and the generalization ability is higher. Compared with other stereo matching algorithms based on the convolutional neural network, the matching effect of the details of the disparity map is effectively improved, and the corresponding mismatching rate is lower.

Owner:UNIV OF SCI & TECH OF CHINA

Method for constructing prototype vector and reconstructing sequence parameter based on semantic information in image comprehension

InactiveCN101373518AOvercoming rigidity of rulesImage understanding facilitatesCharacter and pattern recognitionStructural representationReduction treatment

The invention provides a semantic-based information prototype vector composition and order parameter reconstruction method in image understanding. The method comprises the following steps: 1. the prototype vector representation of scene and target semantic information; 2. the structural representation of scene and target prototype vectors; 3. the reduction treatment of the scene and target prototype vectors; and 4. the reconstruction of scene and target order parameters. The method is based on the synergetics and the synergetic pattern recognition principles, extracts and reconstructs the features of the scene and the target in an image and carries out the feature description which is added by semantic information of the scene and the target in the scene to achieve the purpose of recognizing the image, the computational complexity is low, the study ability is strong, the recognition efficiency is high and the algorithm robustness is stronger.

Owner:HEFEI UNIV OF TECH

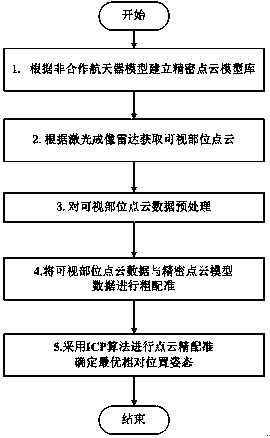

Laser imaging radar-based non-cooperative aircraft relative position posture measuring method

ActiveCN106441311AImprove anti-interference abilityImprove robustnessInstruments for comonautical navigationShortest distanceSpace operations

The invention provides a laser imaging radar-based non-cooperative aircraft relative position posture measuring method. A laser imaging radar is used as a measuring device to realize measurement of the relative posture of a non-cooperative aircraft having no obvious features. The method mainly comprises the following steps: 1, establishing a precise point cloud model library; 2, acquiring visible position cloud data by using the laser imaging radar; 3, preprocessing the visible cloud data; 4, carrying out coarse registration on the visible position cloud data and precise point cloud model data; and 5, carrying out point cloud precise registration by adopting an ICP algorithm to determine an optimal relative position posture. The method realizes measurement of the relative position posture of the non-cooperative aircraft with any configuration, and has the advantages of strong anti-interfere ability, good algorithm robustness, high relative position posture measurement precision and meeting of relative navigation task requirements of a short-distance non-cooperative target in space operation by establishing the point cloud database and reasonably selecting a point cloud to be registered.

Owner:SHANGHAI AEROSPACE SYST ENG INST

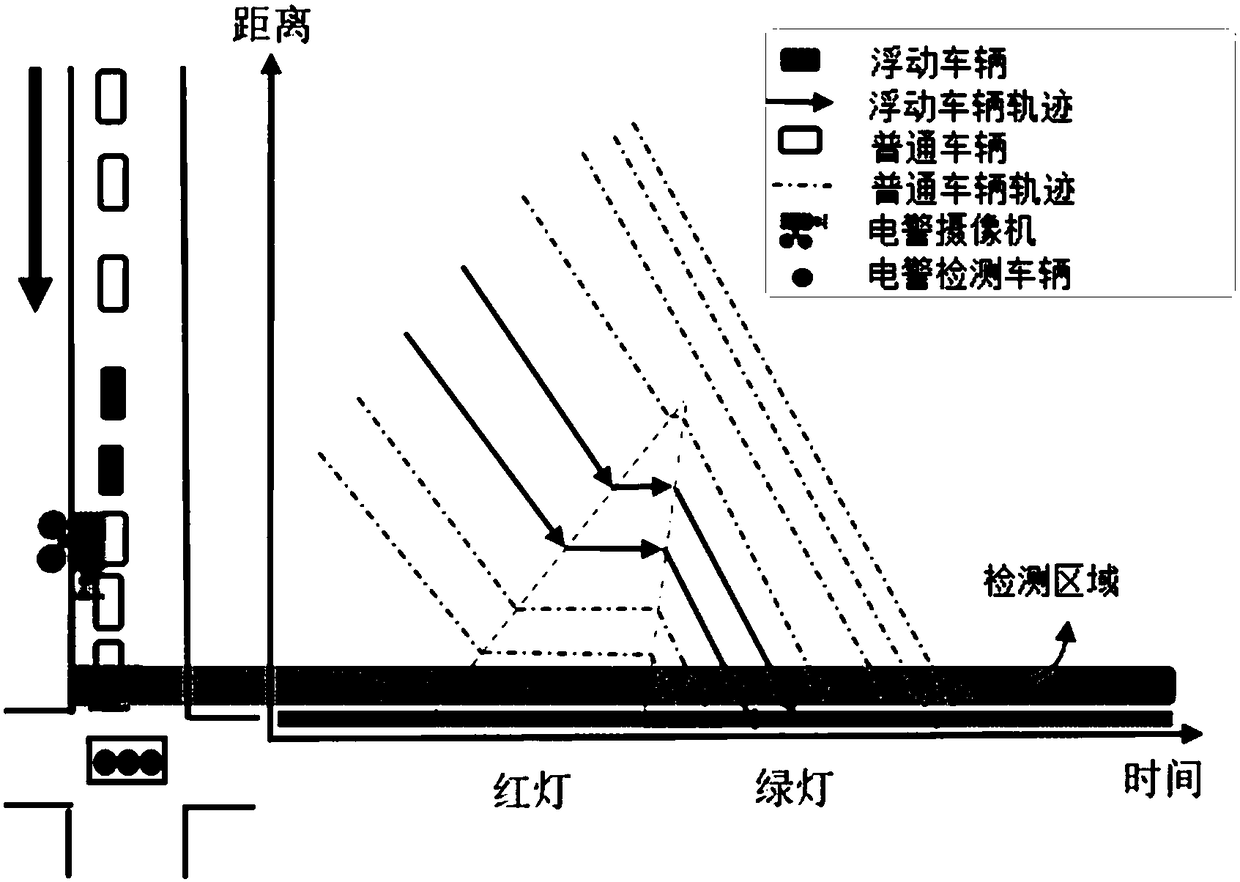

Method for estimating queuing length of signal control intersection

ActiveCN109272756AImprove robustnessHigh precisionRoad vehicles traffic controlDensity distributionData Matrix

The invention relates to a method for estimating a queuing length of a signal control intersection. The method comprises the steps of: 1) acquiring electronic police data and floating vehicle trajectory data and pre-processing the data to obtain a corresponding data matrix, and determining a queuing sequence serial number of a floating vehicle in a current lane according to moment matching of theelectronic police data and the floating vehicle trajectory data; 2) acquiring vehicle dispersion headstock time interval and parking line passing moment density distribution; 3) and estimating a lane-level queuing length of the intersection, wherein the estimation is implemented by adopting a probability statistics method to fuse the electronic police data and the floating vehicle trajectory data,and estimating and correcting the lane-level queuing length. Compared with the prior art, the method has the advantages of good algorithm robustness, high algorithm precision, wide application rangeand the like.

Owner:TONGJI UNIV

Visual inspection method for step defects of bearing rivets

ActiveCN106680287AImprove robustnessImprove stabilityImage enhancementImage analysisHough transformMachine vision

The invention provides a visual inspection method for step defects of bearing rivets. The method comprises the following steps: step 1, bearing rivet image acquisition; step 2, bearing rivet image preprocessing; step 3, inner step defect detection; step 4, outer step defect detection; step 5, result analysis for judging qualification of rivets, wherein unqualified phenomena comprise inner step defects, outer step defects, inner and outer step defects or other types of defects. The method has the following advantages: 1) rivet regions are positioned reasonably and the defects are detected with an adaptive detection method, and the algorithm robustness is good; 2) in the aspect of detection of rivet inner step defects, an region labeling method is good in stability; 3) for inner steps, the inner step judging accuracy is enhanced with a secondary region labeling algorithm; 4) during outer step detection, outer ring parameters are detected firstly through Hough Transform, then whether outer step regions are effective or not is judged according to a geometric constraint relation between outer rings and rivet regions, judgment is effective, and misjudgment is avoided.

Owner:无锡市莱科自动化科技有限公司

Real-time self-adaptive contour error estimation method

InactiveCN105388840AEstimated error works wellImprove robustnessNumerical controlAlgorithmEstimation methods

The invention discloses a real-time self-adaptive contour error estimation method, which can be used for a numerical control system or a contour controller of a robot. The contour error estimation method comprises the steps: generating extra interpolation points by properly modifying a conventional parameter curve interpolation method, wherein the generated extra interpolation points are only used for contour error estimation and do not serve as reference instructions of a motion controller; searching among original interpolation points the nearest point from an actual cutter position, preliminarily determining a search scope; and further determining foot points through a binary search method. A distance between the foot points and an actual cutter point is an estimated contour error. Compared with conventional estimation methods, the real-time self-adaptive contour error estimation method is more accurate in estimation precision. In particular, the method can still have a great effect and exhibit excellent algorithm robustness when the estimation effects of the conventional methods suddenly become bad in a condition with high speed movement and high curvature of a curve. Moreover, the method needs moderate computational complexity, fully meets the requirement of real-time applications, and is highly practical.

Owner:SHANGHAI JIAO TONG UNIV

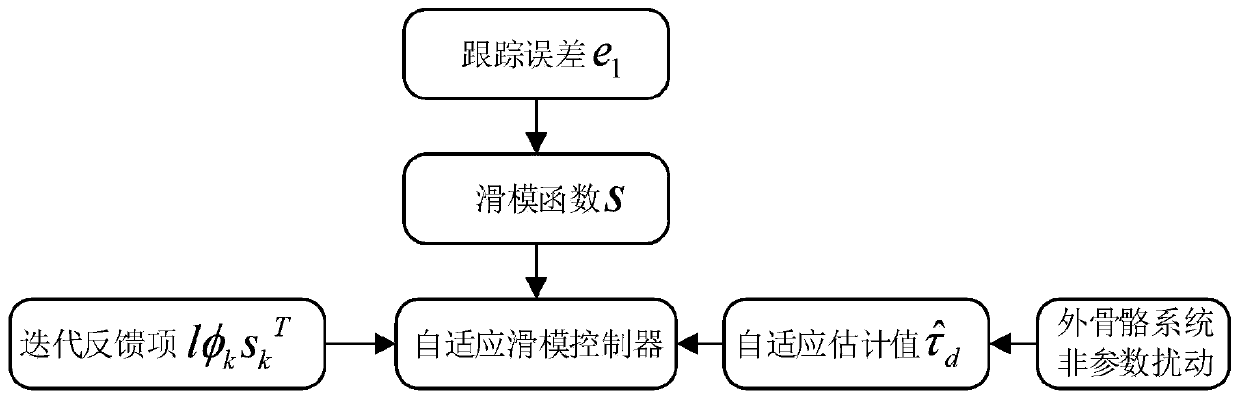

Robust iterative learning control strategy for five-degree-of-freedom upper limb exoskeleton system

The invention discloses a robust iterative learning control strategy for a five-degree-of-freedom upper limb exoskeleton system. The control strategy employs a multivariable iterative learning item toestimate time-varying parameters in an upper limb exoskeleton model, and does not need to build an accurate mathematic model; besides, in order to improve tracking precision and obtain high robustness, sliding mode control is introduced into an iterative learning scheme; and a sliding mode controller is used for processing non-periodic lumped disturbance, and a self-adaptive law is designed in the control strategy and used for compensating uncertainty in the controller, so that a buffeting phenomenon caused by a switching item is weakened, tracking errors between human and machines are reduced, and tracking errors of all joints can be converged to be close to zero within limited iteration times. According to the control strategy, the tracking control problem of the five-degree-of-freedomupper limb exoskeleton system robot under unknown model parameters and aperiodic disturbance is solved, and the control strategy is high in algorithm robustness, small in control buffeting and good intracking performance.

Owner:HEBEI UNIV OF TECH

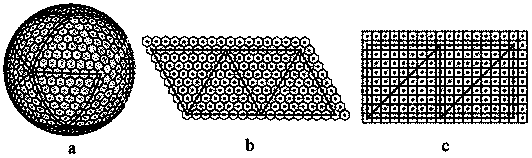

Spherical feature extraction method

ActiveCN104217459AReal-time detectabilityReal-time description3D-image renderingFeature extraction algorithmVisual perception

The invention discloses a spherical feature extraction method, and relates to the field of computer vision. The method comprises the following steps: acquiring a spherical image which is represented in a uniformly parametric manner through a geodesic grid; performing FAST (Features from Accelerated Segment Test) feature detection on the spherical image; and processing filtered feature points through a spherical image feature point description algorithm for image gray value comparison to obtain descriptors of the filtered feature points. The method is high in computing speed, and spherical features can be detected and described in real time. Compared with an existing spherical feature extraction algorithm and a method based on local planar projection, the method disclosed by the invention has high algorithm robustness. The robustness of the method is reflected in case of rotation and movement of a camera.

Owner:TIANJIN UNIV

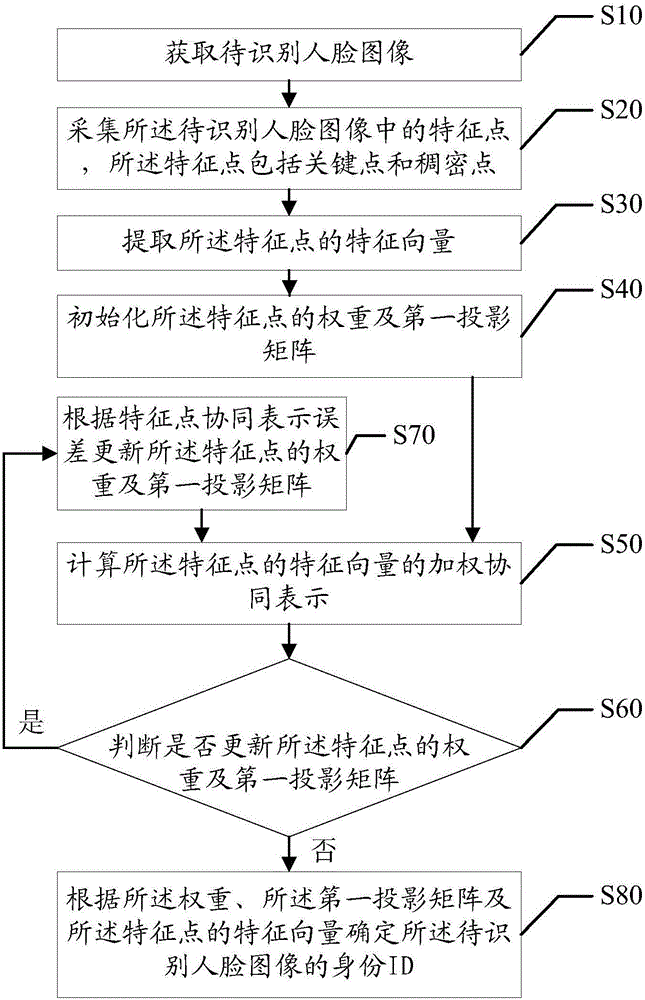

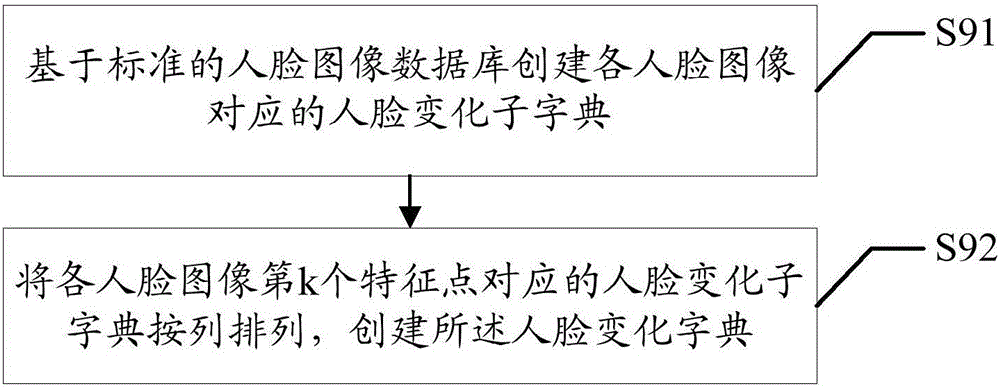

Single-sample face identification method and system based on face feature point

ActiveCN105809107AEasy to identifyIncrease weightCharacter and pattern recognitionHat matrixSingle sample

The invention discloses a single-sample face identification method and system based on a face feature point. The method comprises the following steps: obtaining a face image to be identified; acquiring a feature point in the face image to be identified, wherein the feature point comprises a key point and a dense point; extracting a feature vector of the feature point; initializing a weight of the feature point and a first projection matrix; calculating a weighting cooperation expression of the feature vector so as to obtain an expression coefficient of the feature vector; determining whether to update the weight of the feature point and the first projection matrix; if so, after a cooperation expression error of the feature vector is calculated according to the expression coefficient, according to the cooperation expression error, updating the weight of the feature point and the first projection matrix, and returning to recalculate the weighting cooperation expression of the feature vector; and if not, according to the weight, the first projection matrix and the feature vector, determining the identity of the face image to be identified. According to the invention, the algorithm robustness can be enhanced, the face identification rate is improved, and the calculation complexity during identification is reduced.

Owner:SHENZHEN UNIV

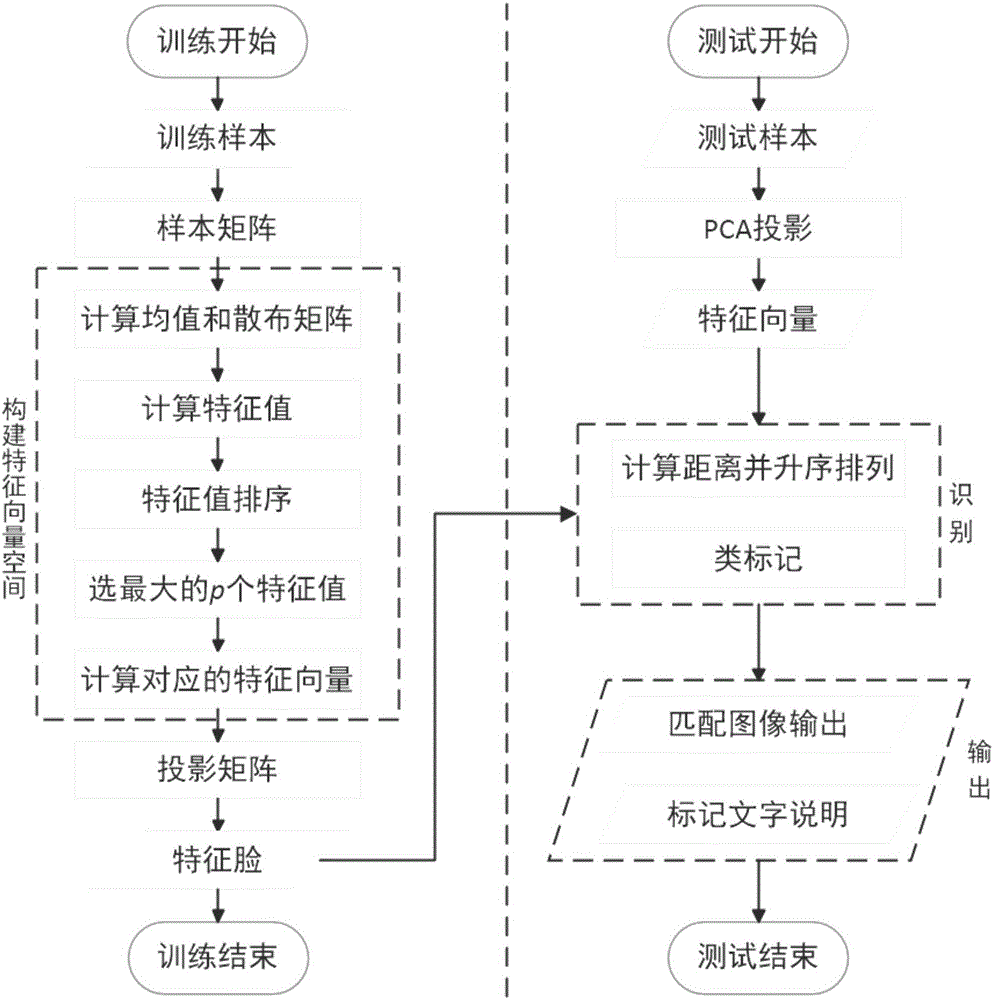

Low-rank matrix and eigenface-based human face identification method

InactiveCN106096517AEnhance expressive abilityHigh expressionCharacter and pattern recognitionShortest distanceSample image

The invention discloses a low-rank matrix and eigenface-based human face identification method, which relates to the technical fields of digital image processing, mode identification, computer vision, physiology and the like, and is used for solving the problem in human face identification based on static images or video images in various scenes. A low-rank matrix is applied to preprocessing of a human face picture based on a low-rank matrix concept, and the influence of changes of illumination, expressions and the like is reduced through low-rank processing on a training picture, so that the algorithm robustness and the identification accuracy are improved. According to the key points of the technical scheme, the method comprises the following steps of firstly acquiring a human face sample picture and establishing a sample library; secondly during a training stage, constructing an eigenvector space through operations of calculating a sample mean value, an eigenvalue, an eigenvector and the like, and projecting the eigenvector to obtain an eigenface; and finally during a test stage, performing PCA projection on a test sample to obtain an eigenvector, calculating a distance between the eigenvector and the eigenface, taking a shortest distance as an identification result, and outputting the identification result.

Owner:BEIJING UNION UNIVERSITY

A method for estimating air particulate pollution degree based on shallow convolution neural network

ActiveCN109523013AAutomatic extractionAvoid featuresCharacter and pattern recognitionNeural architecturesFeature extractionParticulate pollution

The invention discloses a method for estimating air particulate pollution degree based on shallow convolution neural network. The basic steps of the method include: 1. Constructing a shallow convolution neural network (PMIE) model with a layer enhancement function; 2. Combining the output of PMIE model with four kinds of weather eigenvalues to construct regression model; 3. Trainning PMIE model and regression model; 4. The PM2.5 index of the test set image is estimated by using the trained PMIE model and regression model. The invention provides a shallow convolution neural network model with layer enhancement function, Combining the output results with four kinds of weather features to estimate the degree of air particulate pollution in the image, the problem caused by feature extraction and feature optimization is effectively avoided, and the specific PM2.5 index value is obtained, which improves the training convergence speed and algorithm robustness, and has better performance.

Owner:NORTHWEST UNIV(CN)

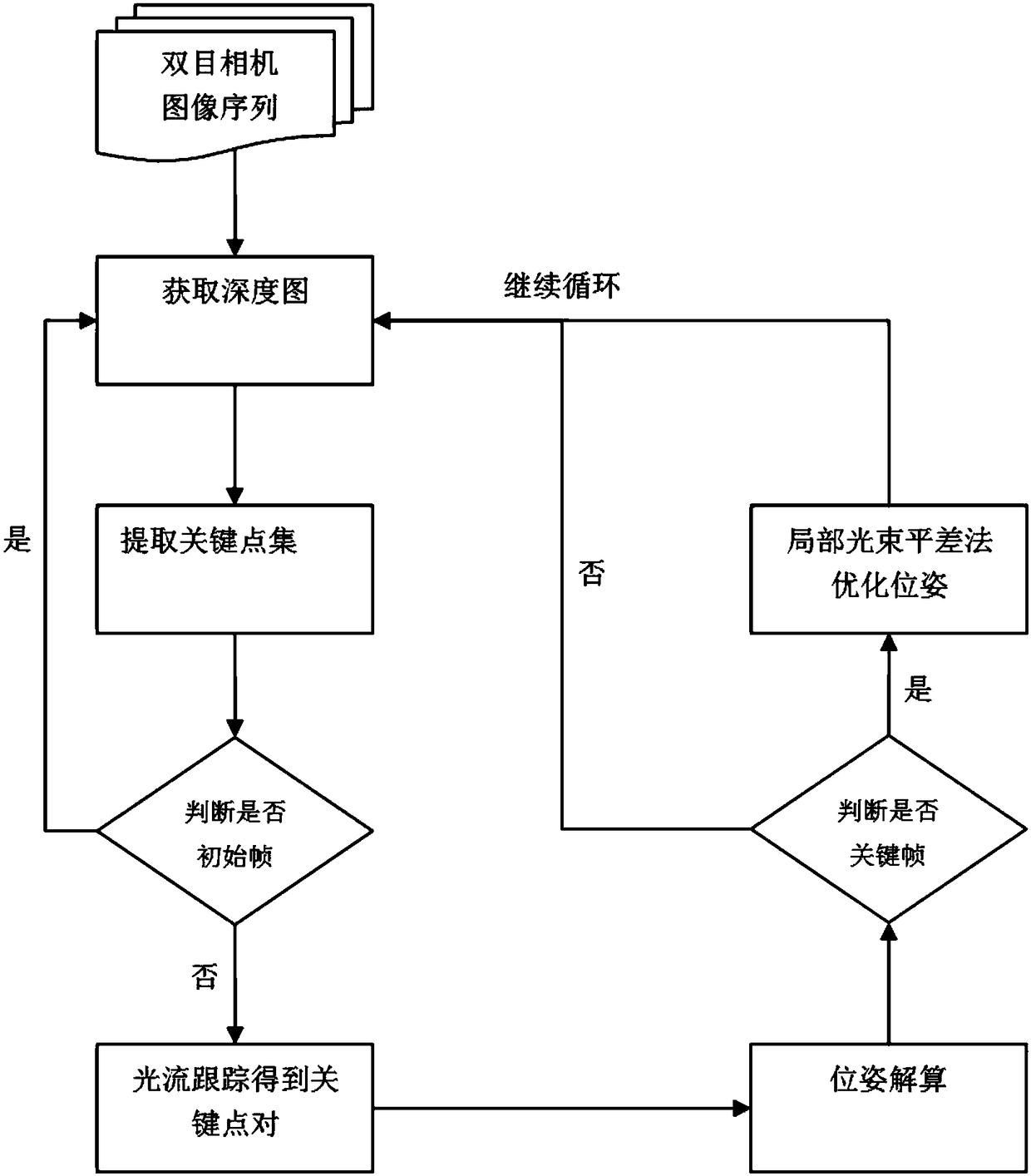

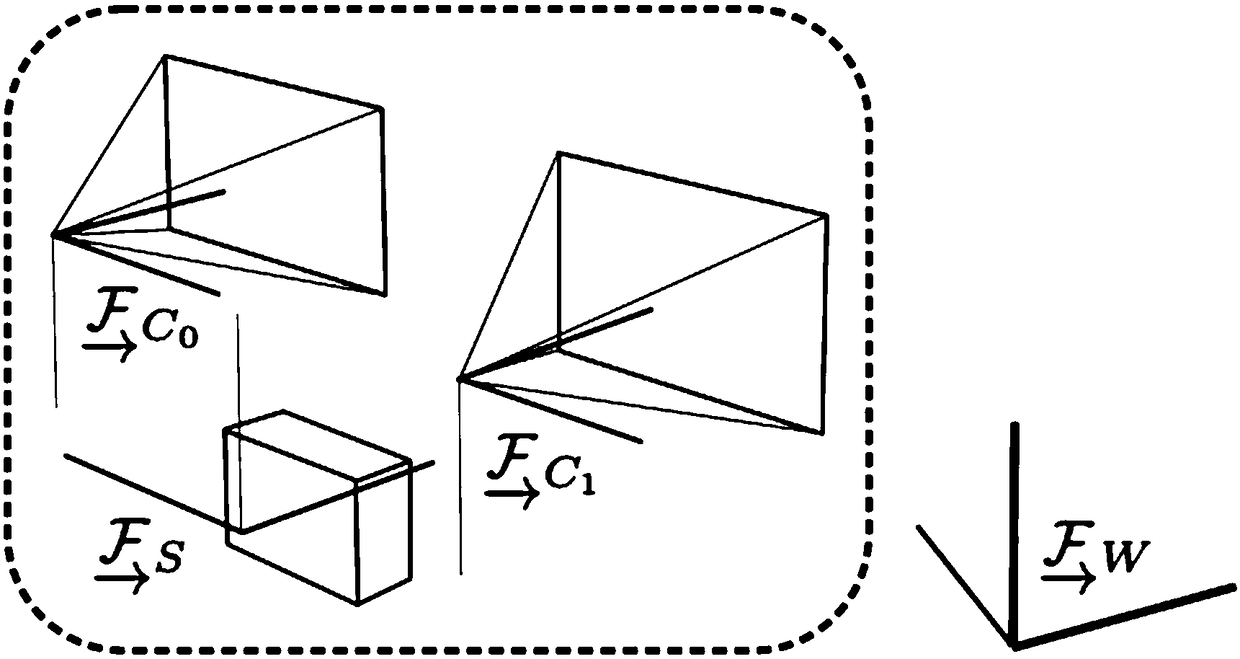

Binocular vision-based unmanned aerial vehicle positioning and navigating method

ActiveCN108520559AImprove the problem that the target depth cannot be accurately estimatedHigh precisionImage data processingControl systemUncrewed vehicle

The invention discloses a binocular vision-based unmanned aerial vehicle positioning and navigating method. The method comprises the steps that an image left-right view and a camera parameter can be obtained based on a binocular camera of an unmanned airborne control system, and obtain a corrected left-right view, and further obtain the depth information of the corresponding pixel; the key pointsof the left view are extracted to be filtered and screened; a matched key point set is found through optical flow tracking in the current frame, and a matched key point pair is obtained; a final poseresult is obtained according to the matched key point pair calculation cost function; finally, the input continuous image frames are screened to obtain a key image frame, and a combined cost functionis calculated for the key point set and the pose of the key image frame, and the cost function can be optimized and solved to obtain a updated pose. According to the method, the reliable depth data can be quickly obtained through the binocular camera; meanwhile, the matching relation is quickly calculated by utilizing the optical flow method; the real-time performance is high, the algorithm robustness is high, and the unmanned aerial vehicle positioning and navigation work can be completed under the indoor and outdoor large and medium scenes.

Owner:西安因诺航空科技有限公司

Single-point calibration object-based multi-camera calibration

The invention relates to a single-point calibration object-based multi-camera internal and external parameter calibration method and a calibration component. The calibration method comprises the following steps of: acquiring a single calibration point which moves freely and an image point of an L-shaped rigid body which is used for indicating a world coordinate system by using a plurality of infrared cameras which are fixed at different positions in a scene; and uploading the single calibration point and the image point into an upper computer so as to calibrate internal and external parametersof the plurality of cameras by utilizing image point data. According to the method, cameras with common viewpoints can be calibrated in pairs according to a pinhole and distortion camera model and anepipolar geometric constraint relationship between image point pairs. According to the method, a utilized calibration tool is simple to manufacture, and calibration objects do not need to be limitedto move in a common view field of all the cameras, so that the operability is strong; through a multi-camera cascade path determined by utilizing a common view field relationship, more image points can participate in operation, so that the algorithm robustness is better; and through multi-step optimization, calibration parameters can achieve sub pixel-level re-projection errors, so that high-precision demands can be completely satisfied.

Owner:北京轻威科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com