Environment-friendly heat-insulating and flame-retardant PBT waterproof and seepage-proof coiled material and production process thereof

A PBT resin, environmentally friendly technology, used in building thermal insulation materials, protection devices, infrastructure engineering and other directions, can solve the problems of easy to cause safety accidents, insufficient waterproof performance, large molding shrinkage rate, etc., to achieve good heat resistance, waterproof and waterproof. The effect of remarkable penetration effect and excellent performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

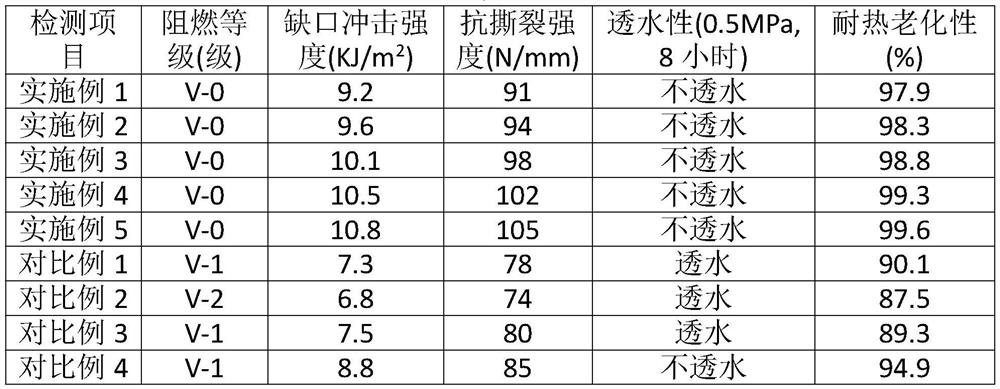

Examples

Embodiment 1

[0029] An environmentally friendly, heat-insulating, flame-retardant PBT waterproof and anti-seepage coiled material is characterized in that it is made of the following raw materials in parts by weight: 55 parts of PBT resin, 15 parts of sulfonated SBS, 2,4-diamino-6 - Diallylamino-1,3,5-triazine / 2,5-bis(1,2,4-triazol-1-yl) terephthalic acid polycondensate 10 parts, tetrakis(3-mercaptopropionic acid ) 3 parts of pentaerythritol ester, 8 parts of modified POSS, 2 parts of phosphorus pentoxide, 1 part of initiator, 1 part of antioxidant, and 0.5 part of foaming agent.

[0030] The foaming agent is azodicarbonamide; the antioxidant is di-tert-butyl-p-cresol; the initiator is methyl ethyl ketone peroxide; and the modified POSS is octavinyl POSS.

[0031]The 2,4-diamino-6-diallylamino-1,3,5-triazine / 2,5-bis(1,2,4-triazol-1-yl) terephthalic acid polycondensate The preparation method comprises the following steps: 2,4-diamino-6-diallylamino-1,3,5-triazine, 2,5-bis(1,2,4-triazole-1-...

Embodiment 2

[0035] An environmentally friendly, heat-insulating, flame-retardant PBT waterproof and anti-seepage coiled material is characterized in that it is made of the following raw materials in parts by weight: 57 parts of PBT resin, 17 parts of sulfonated SBS, 2,4-diamino-6 -diallylamino-1,3,5-triazine / 2,5-bis(1,2,4-triazol-1-yl)terephthalic acid polycondensate 11 parts, tetrakis(3-mercaptopropionic acid 3.5 parts of pentaerythritol ester, 9 parts of modified POSS, 2.5 parts of phosphorus pentoxide, 1.2 parts of initiator, 1.3 parts of antioxidant, and 0.6 parts of blowing agent.

[0036] The foaming agent is azobisisobutyronitrile; the antioxidant is butyl hydroxyanisole; the initiator is benzoyl peroxide; and the modified POSS is octa-p-aminophenyl POSS.

[0037] The 2,4-diamino-6-diallylamino-1,3,5-triazine / 2,5-bis(1,2,4-triazol-1-yl) terephthalic acid polycondensate The preparation method comprises the following steps: 2,4-diamino-6-diallylamino-1,3,5-triazine, 2,5-bis(1,2,4-tr...

Embodiment 3

[0041] An environmentally friendly, heat-insulating, flame-retardant PBT waterproof and anti-seepage coiled material is characterized in that it is made of the following raw materials in parts by weight: 60 parts of PBT resin, 20 parts of sulfonated SBS, 2,4-diamino-6 -diallylamino-1,3,5-triazine / 2,5-bis(1,2,4-triazol-1-yl)terephthalic acid polycondensate 13 parts, tetrakis(3-mercaptopropionic acid ) 4 parts of pentaerythritol ester, 11 parts of modified POSS, 3 parts of phosphorus pentoxide, 1.5 parts of initiator, 2 parts of antioxidant, and 0.65 parts of foaming agent.

[0042] The foaming agent is sodium bicarbonate; the antioxidant is dibutyl hydroxytoluene; the initiator is benzoyl tert-butyl peroxide; and the modified POSS is octavinyl POSS.

[0043] The 2,4-diamino-6-diallylamino-1,3,5-triazine / 2,5-bis(1,2,4-triazol-1-yl) terephthalic acid polycondensate The preparation method comprises the following steps: 2,4-diamino-6-diallylamino-1,3,5-triazine, 2,5-bis(1,2,4-tria...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com