Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Strong burning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

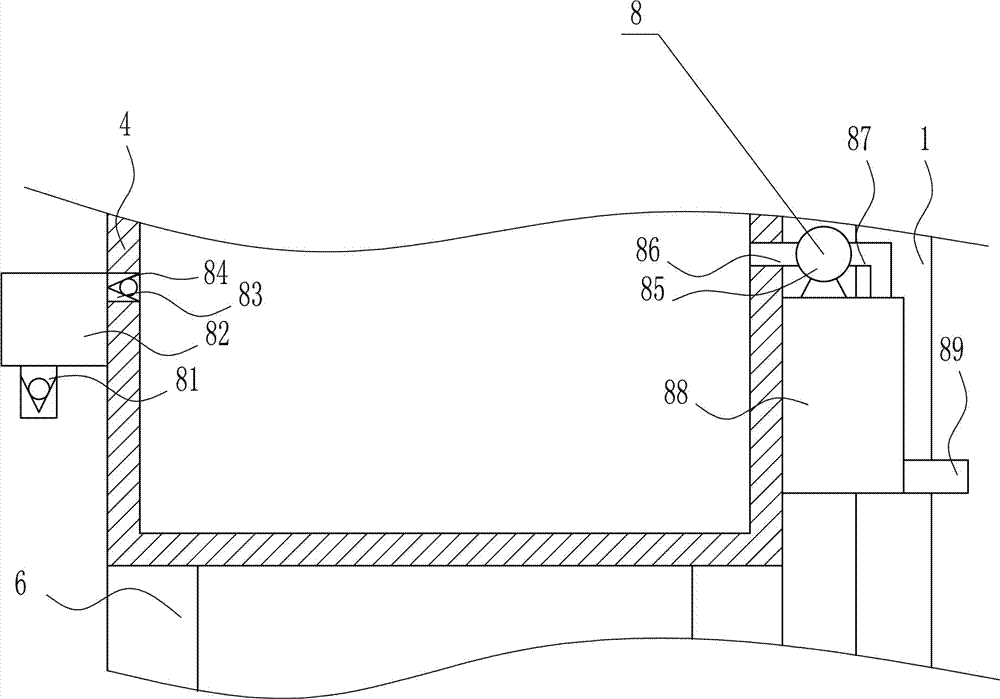

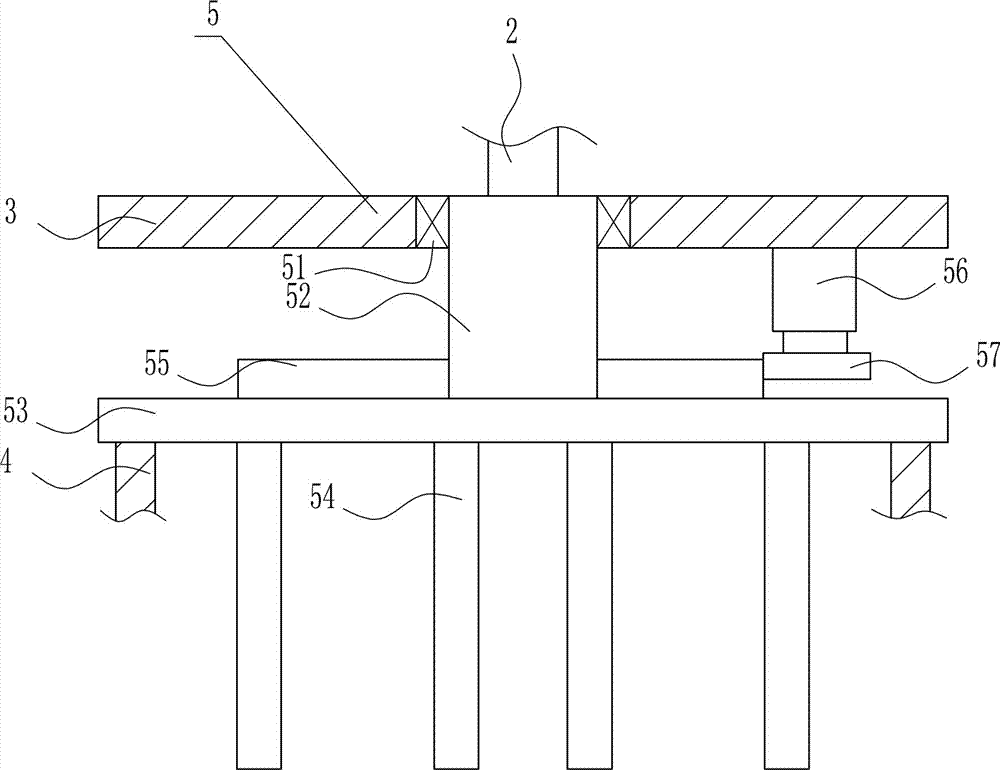

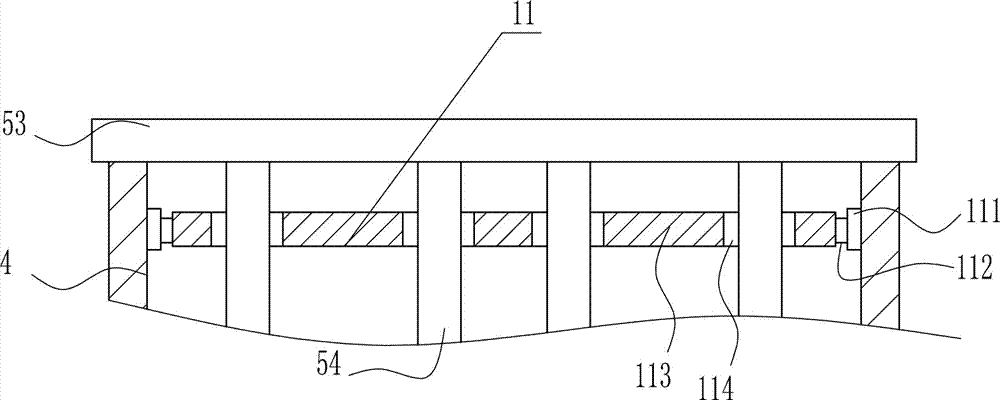

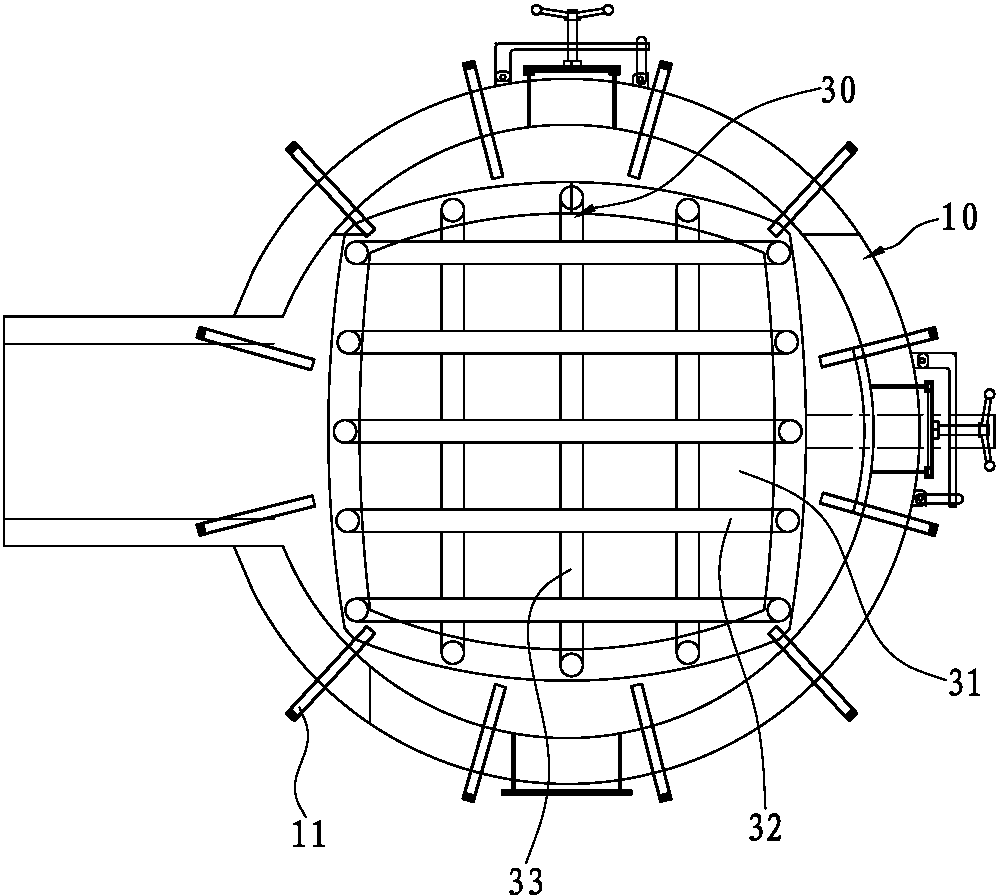

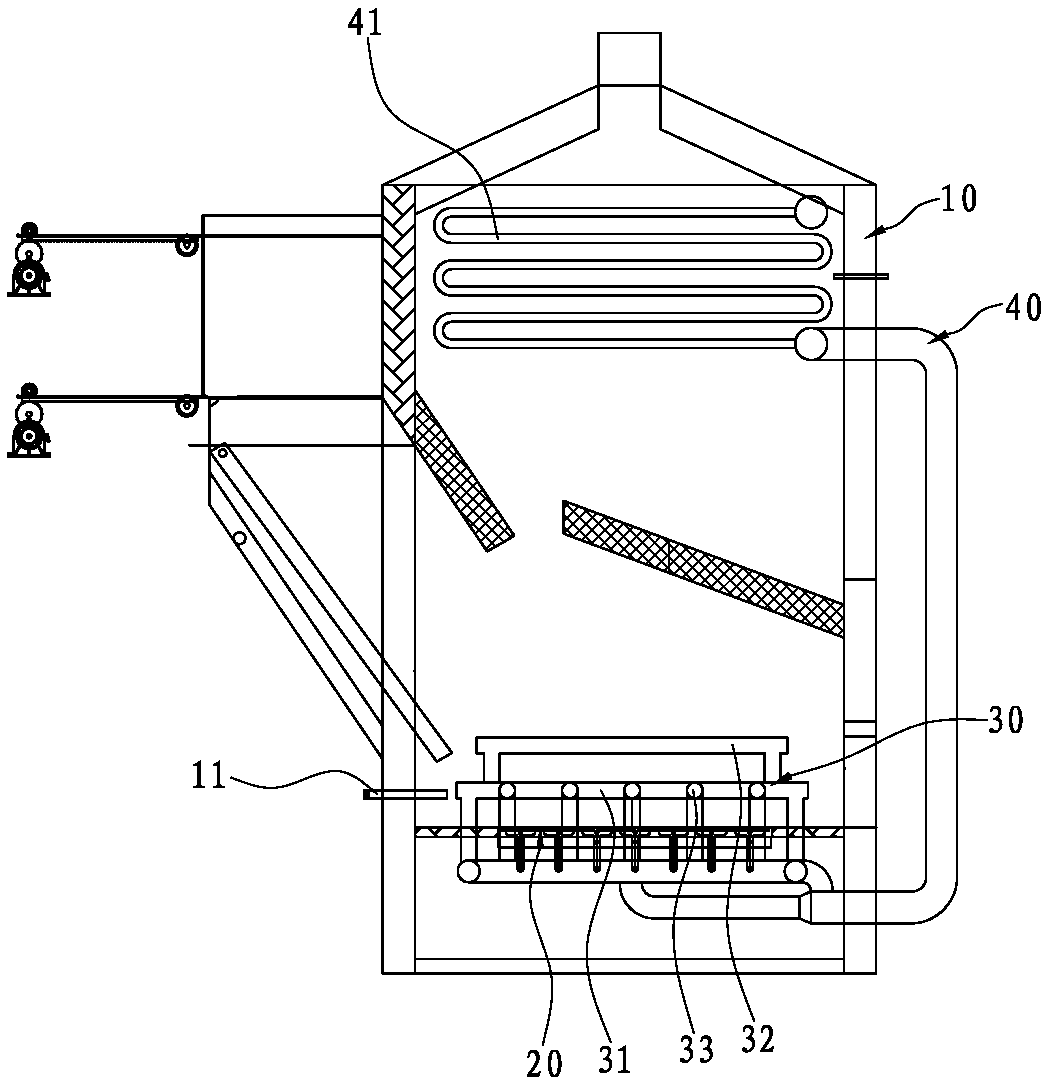

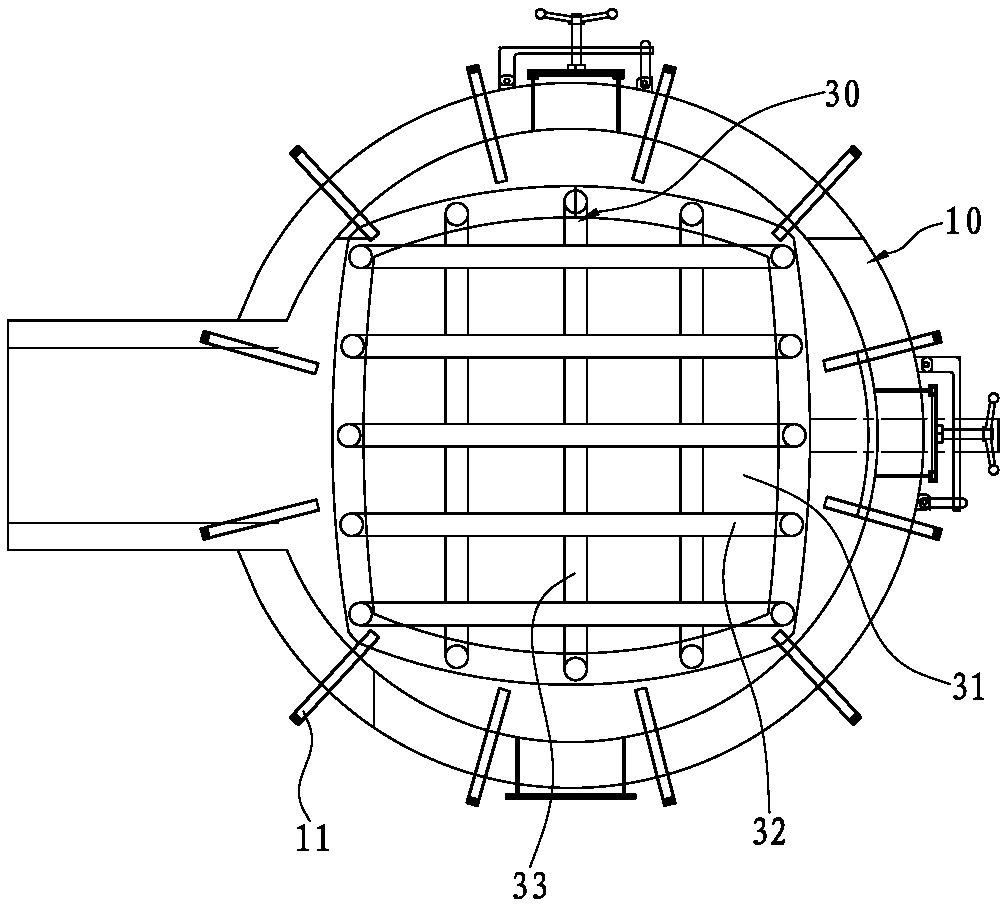

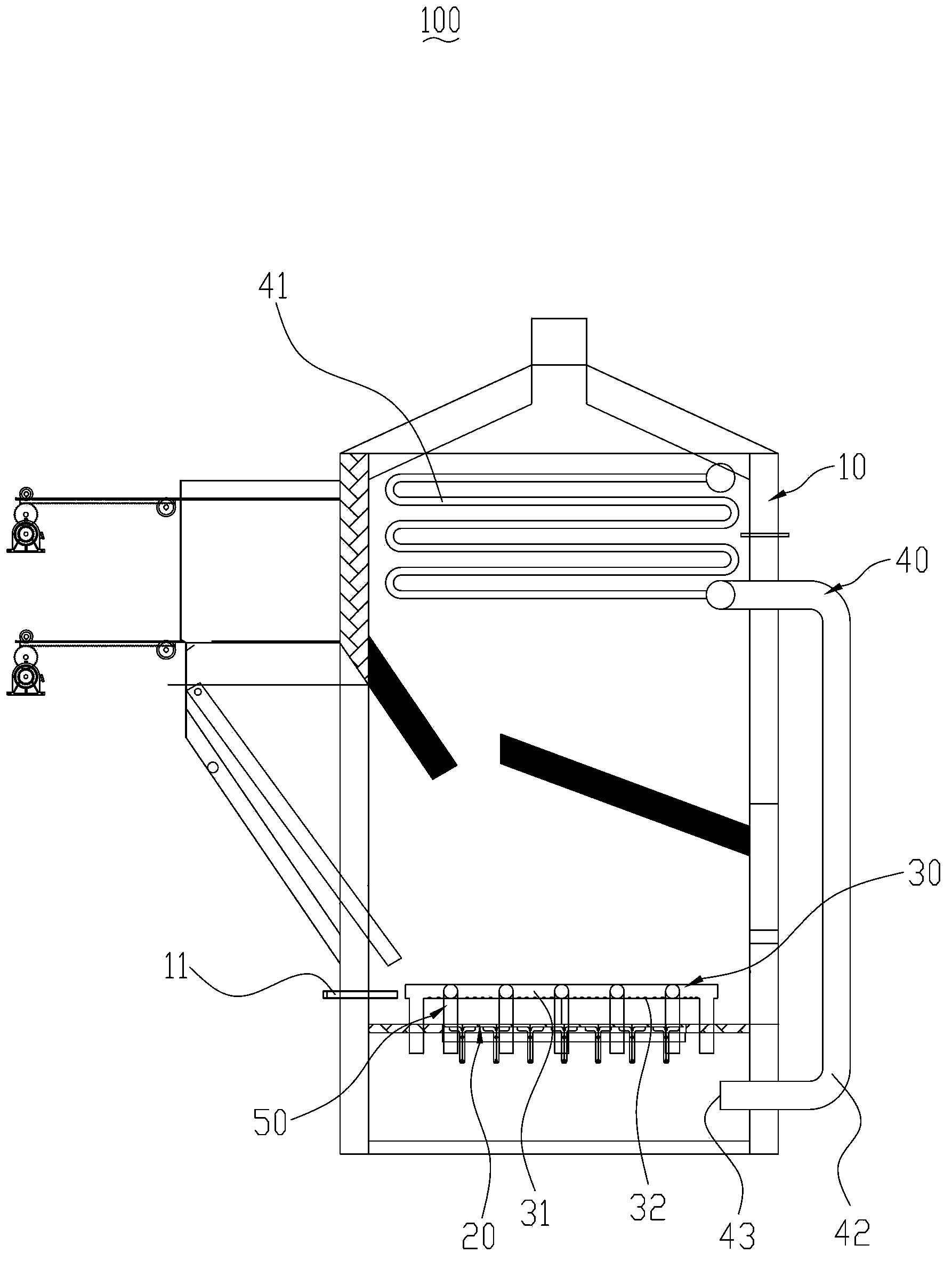

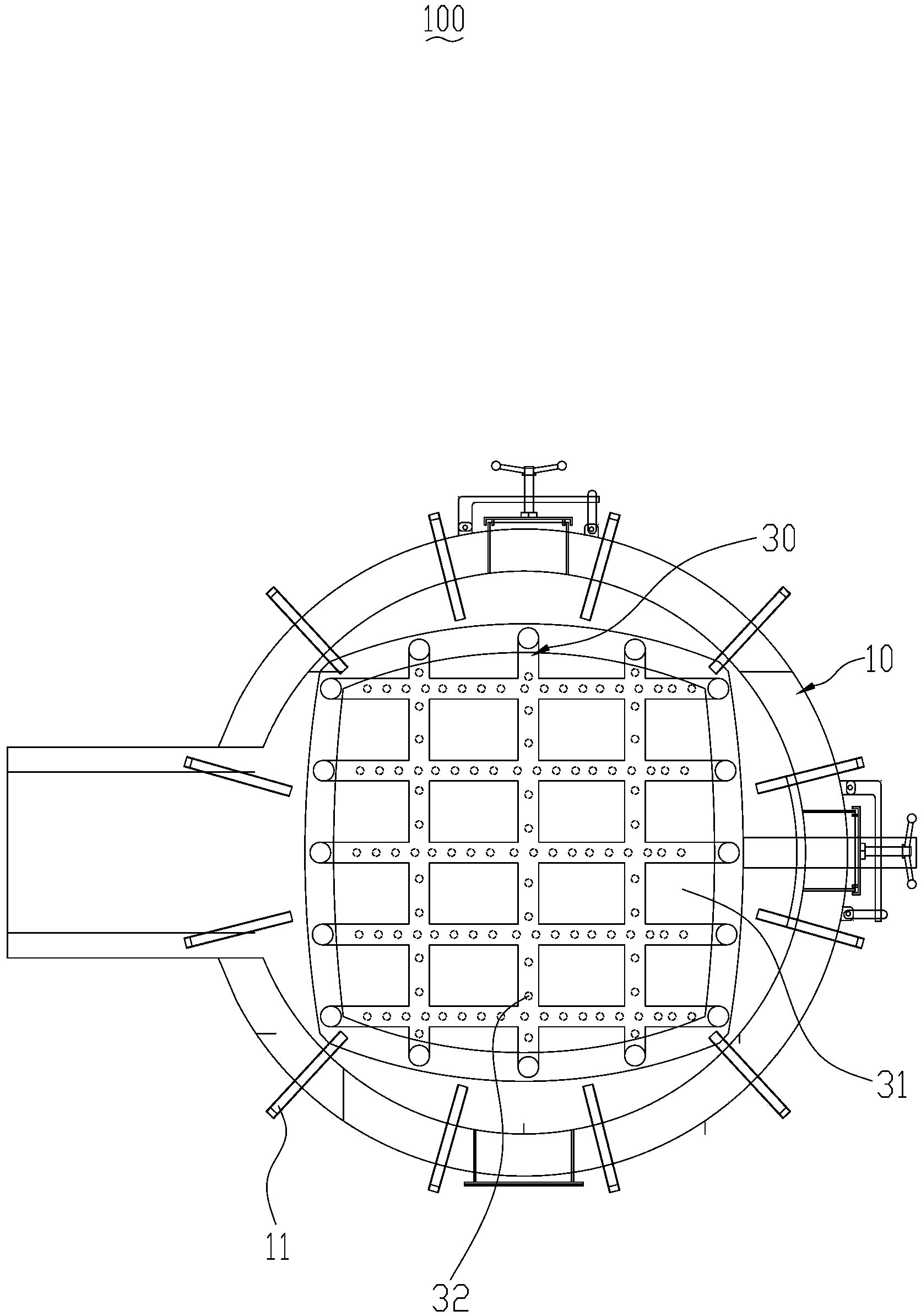

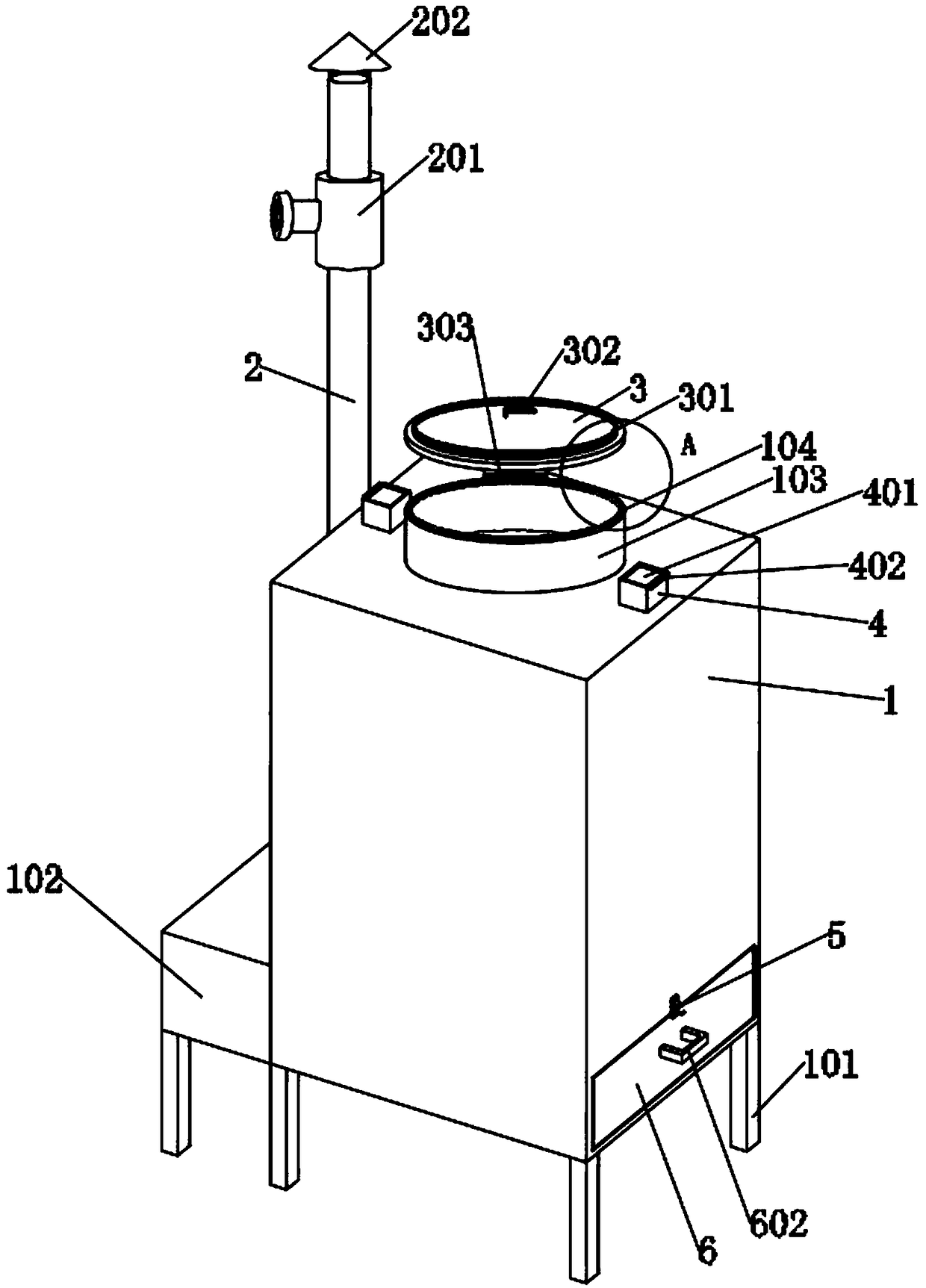

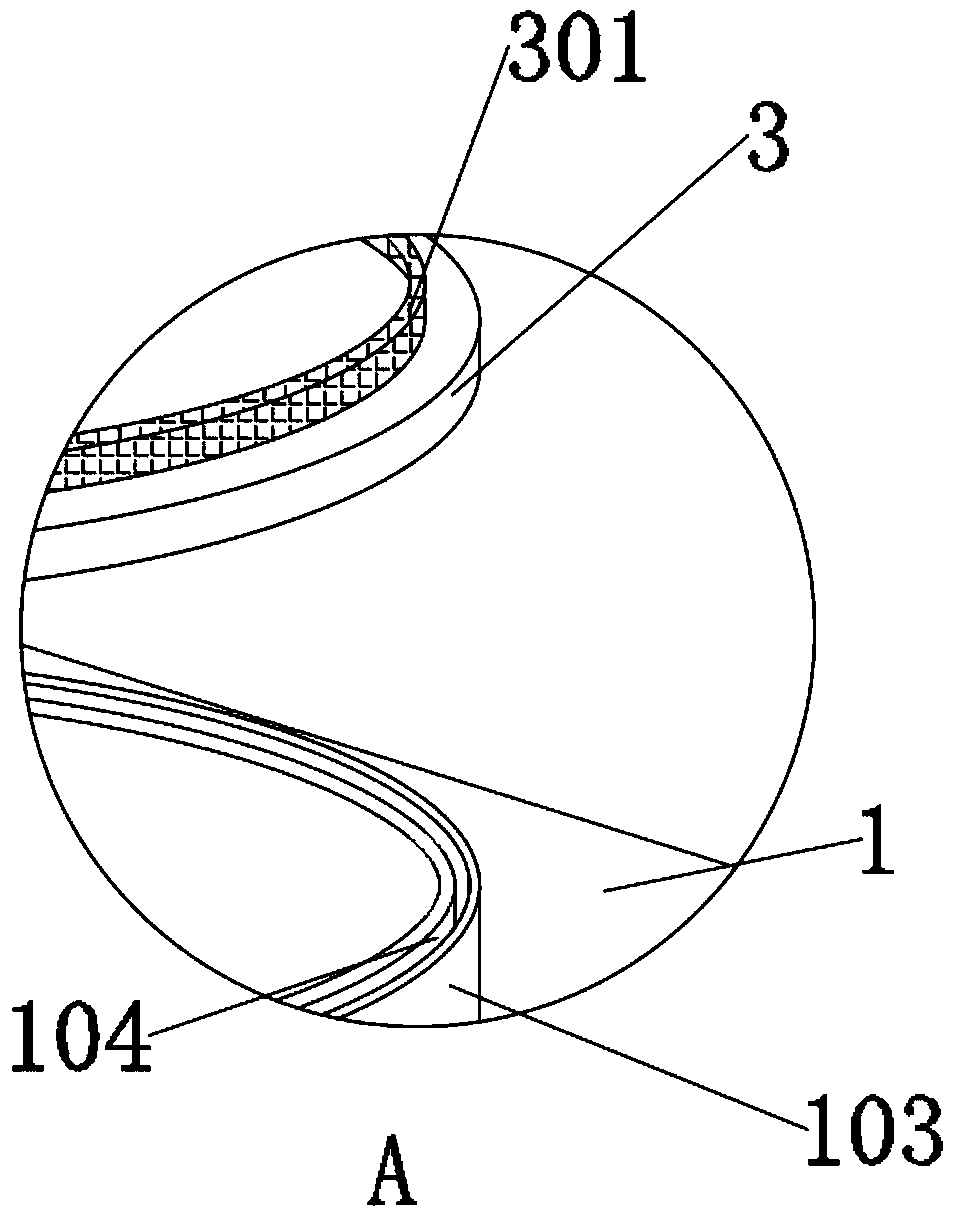

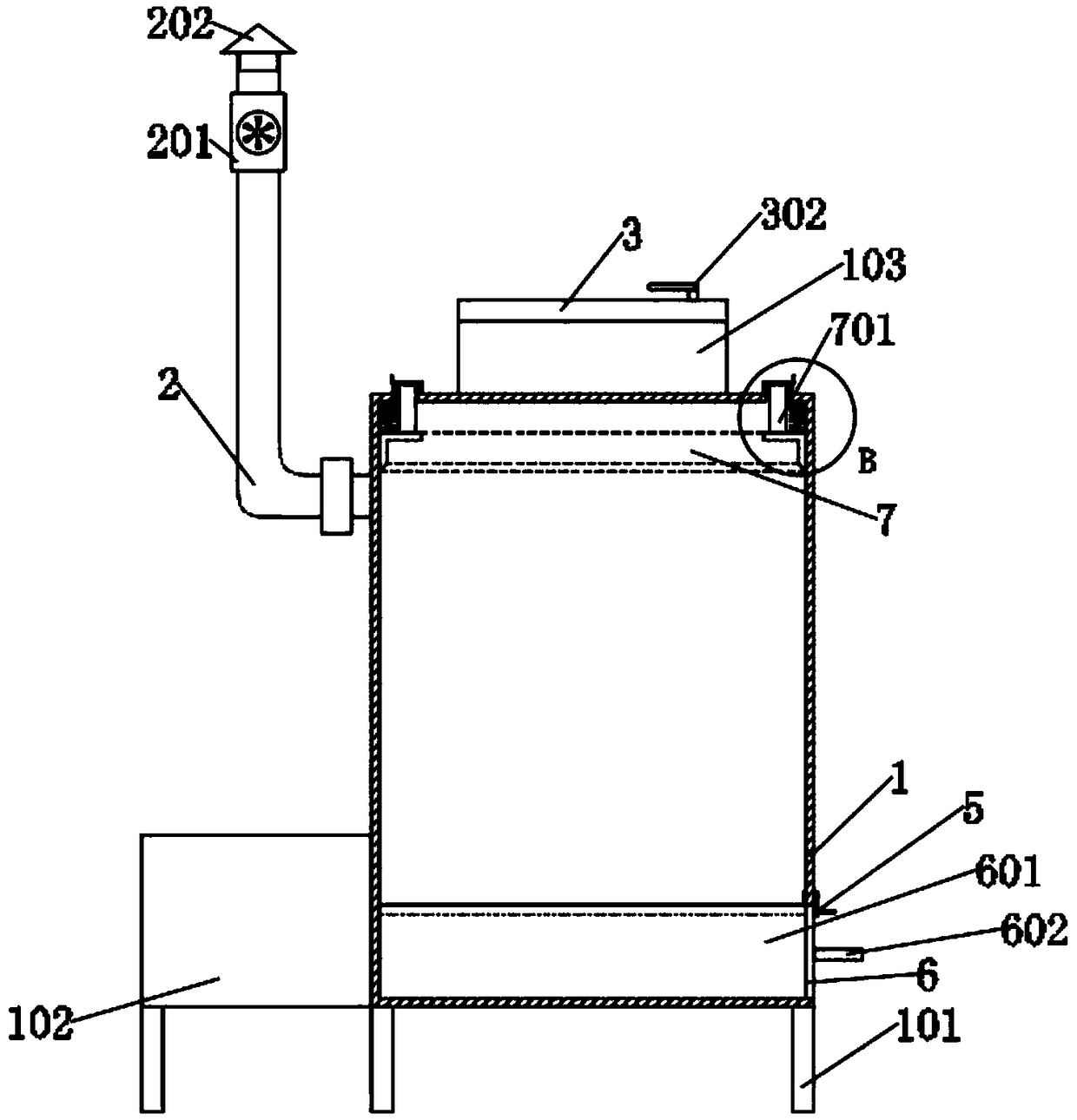

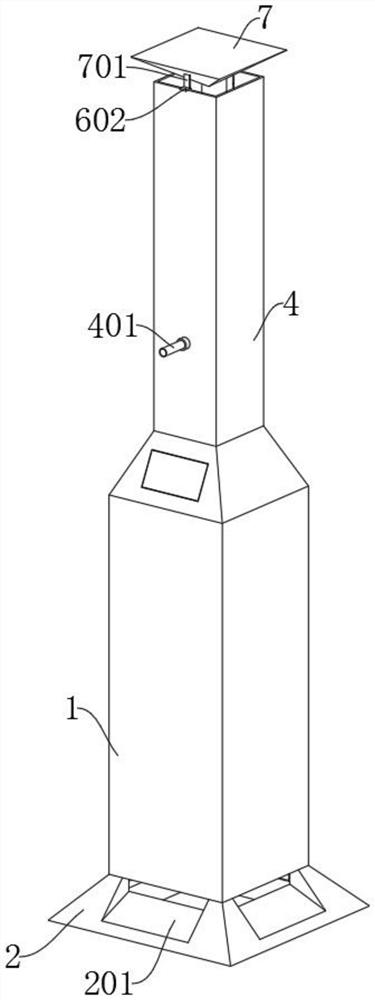

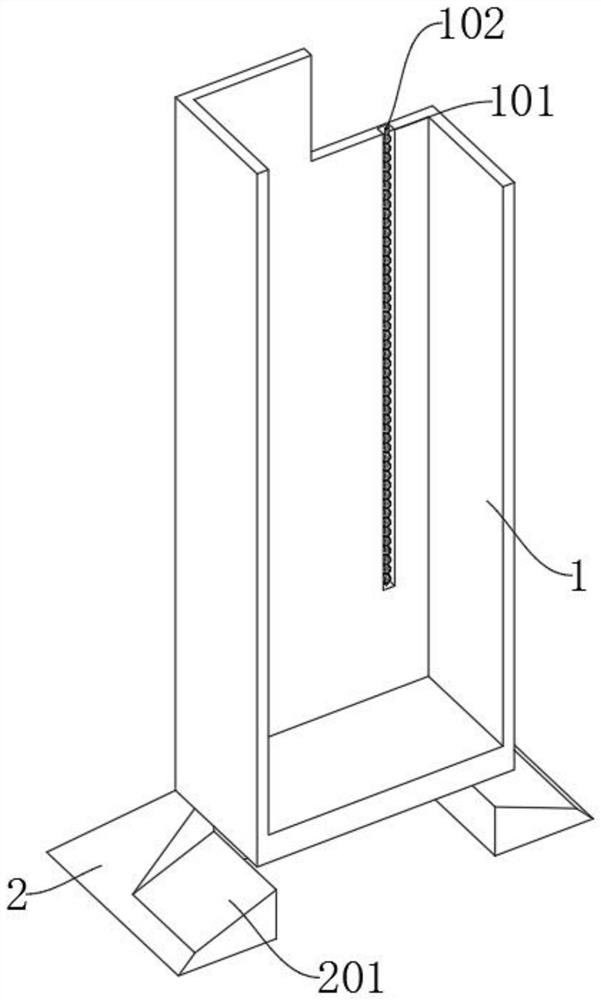

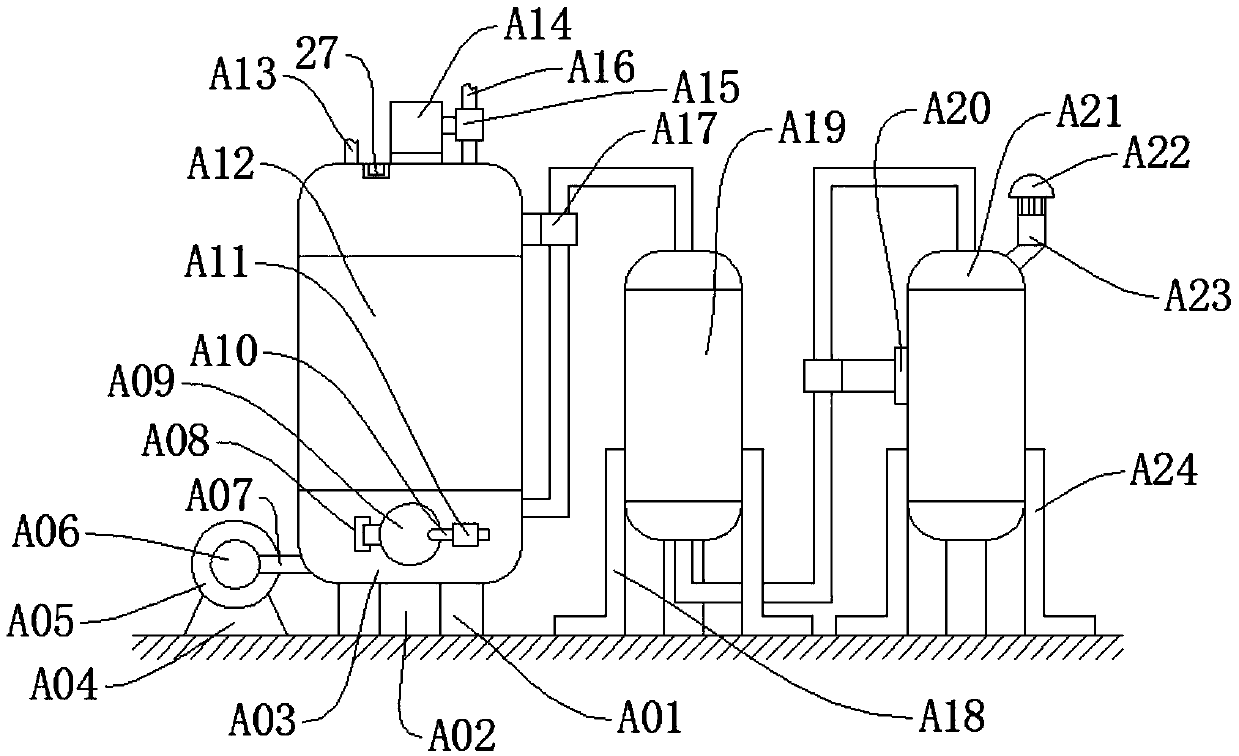

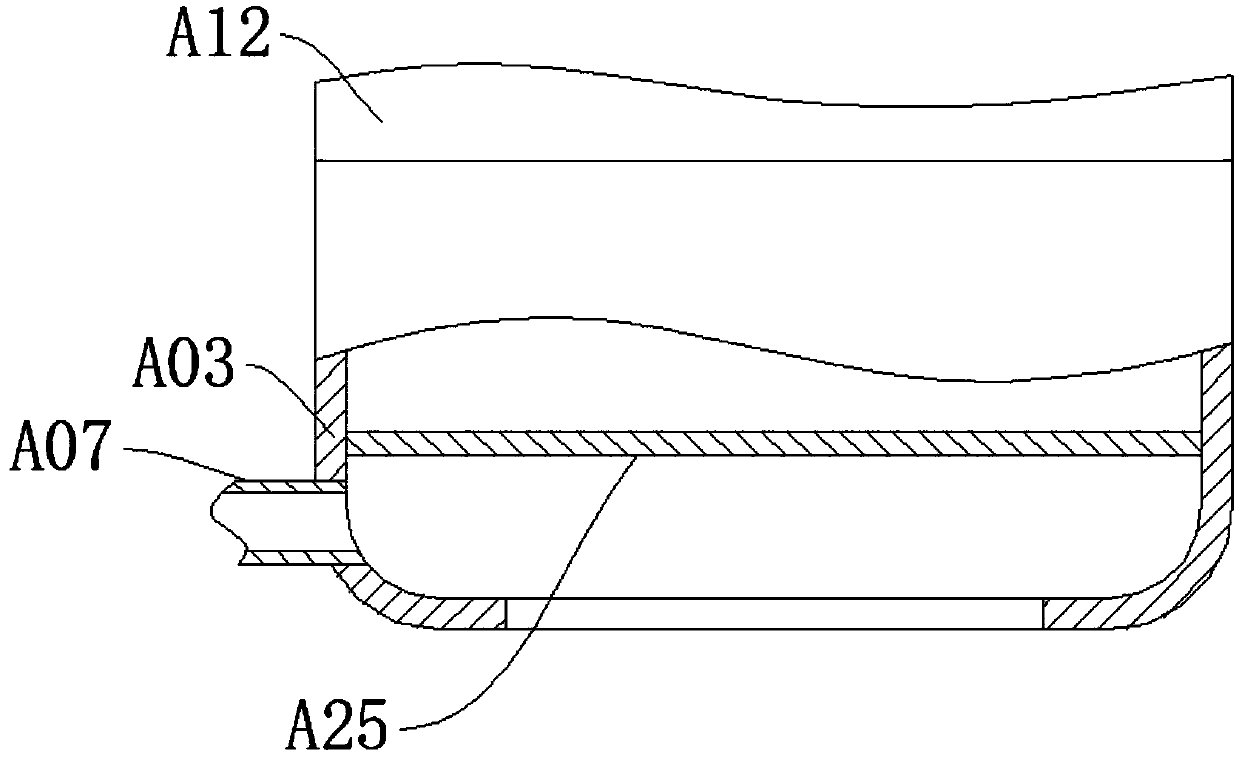

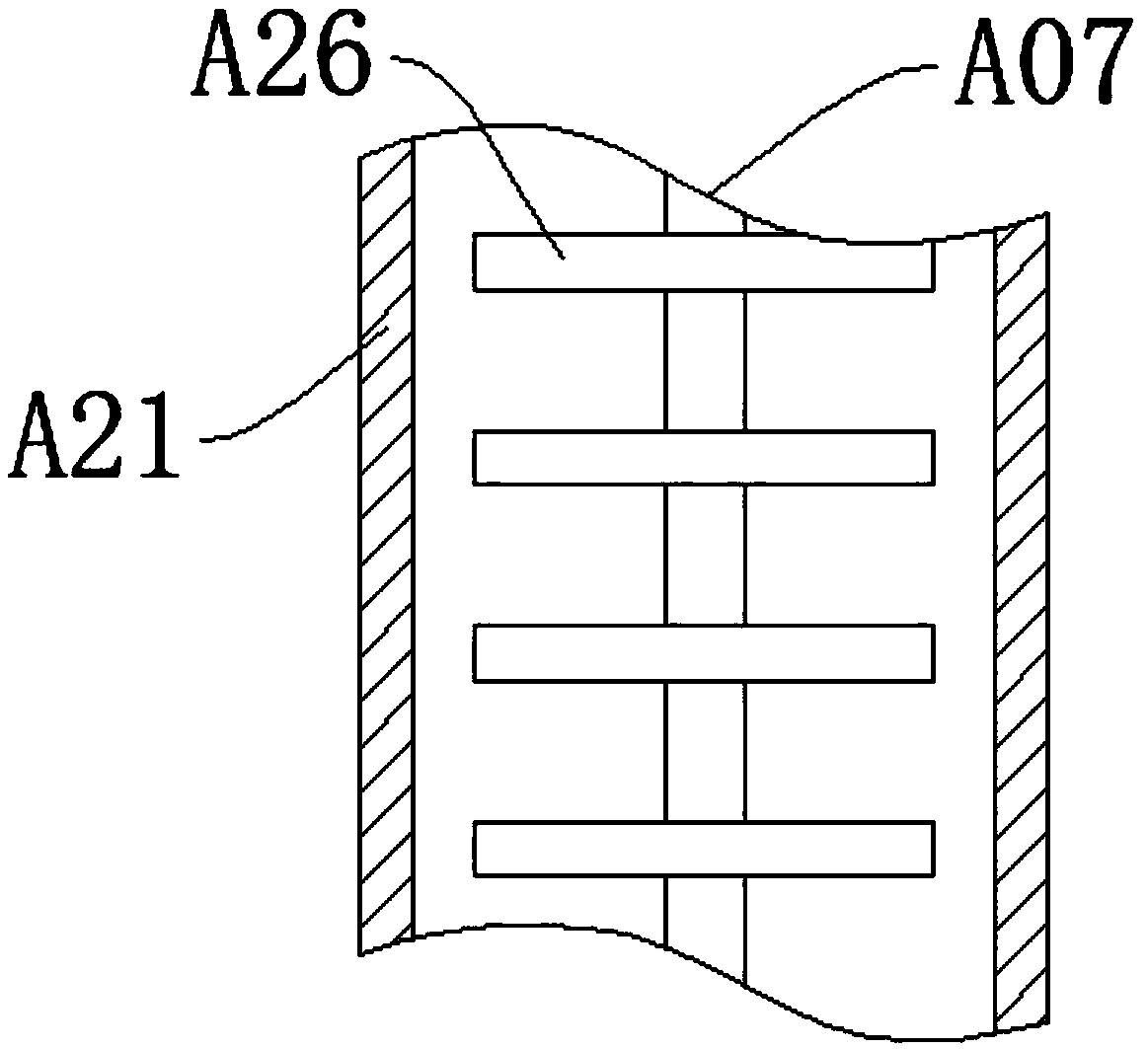

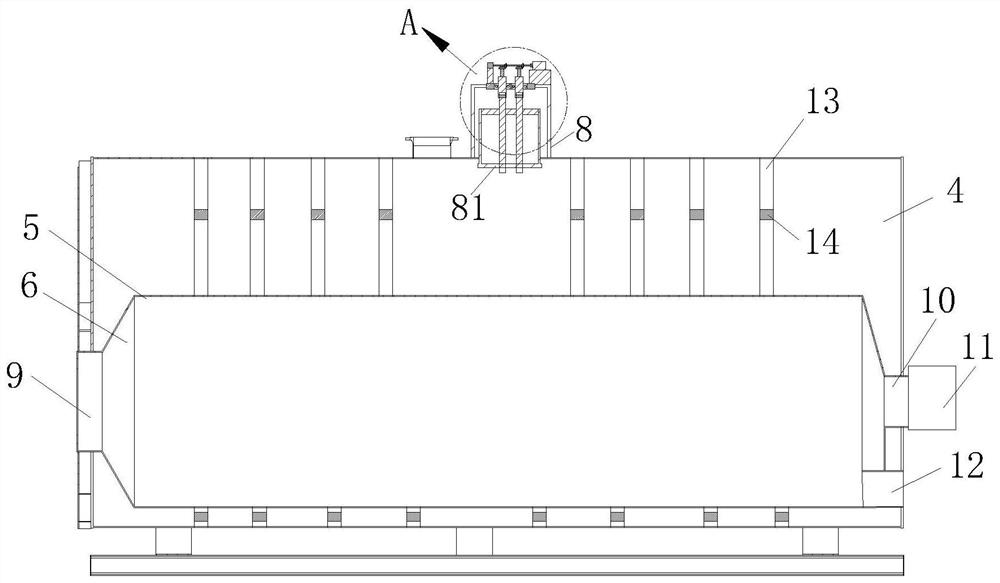

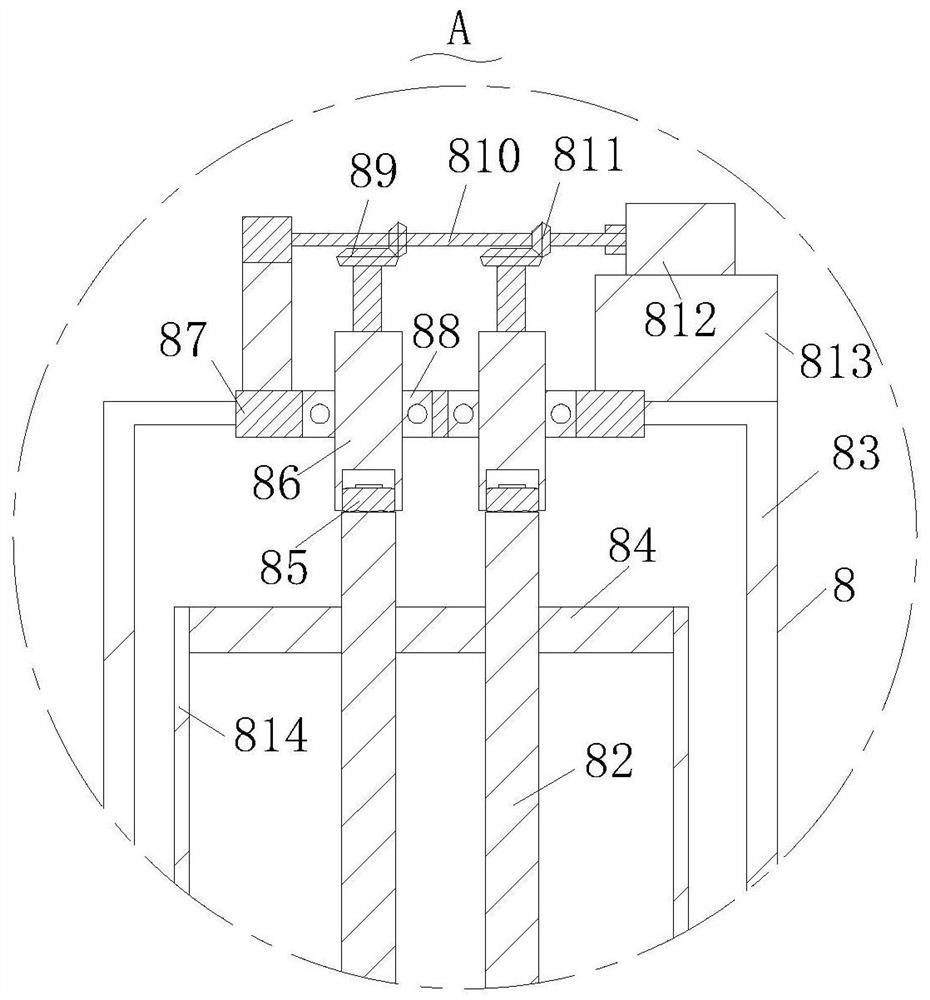

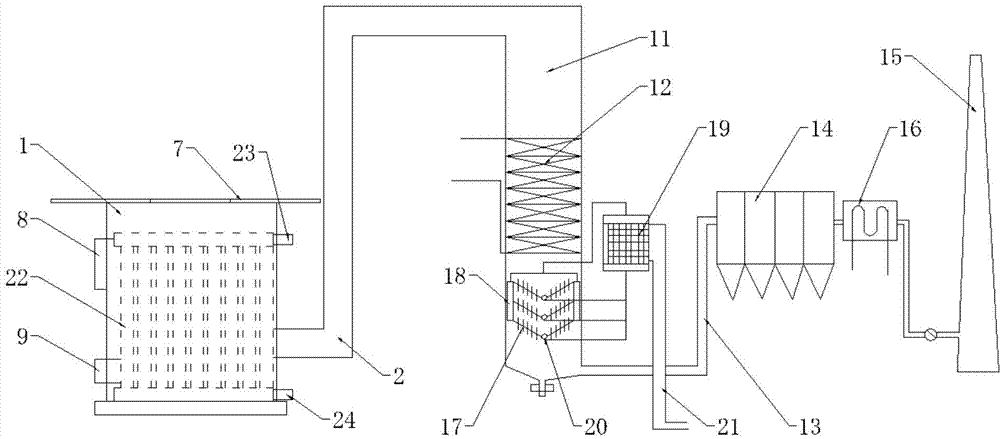

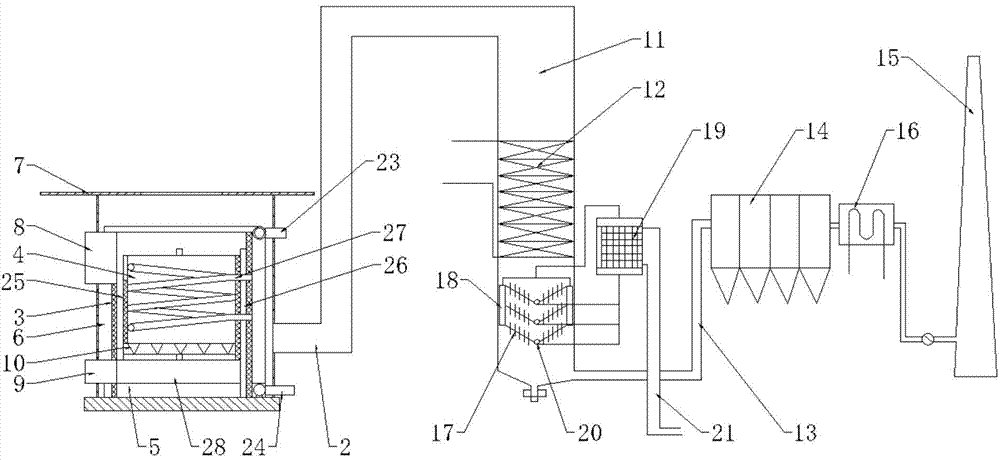

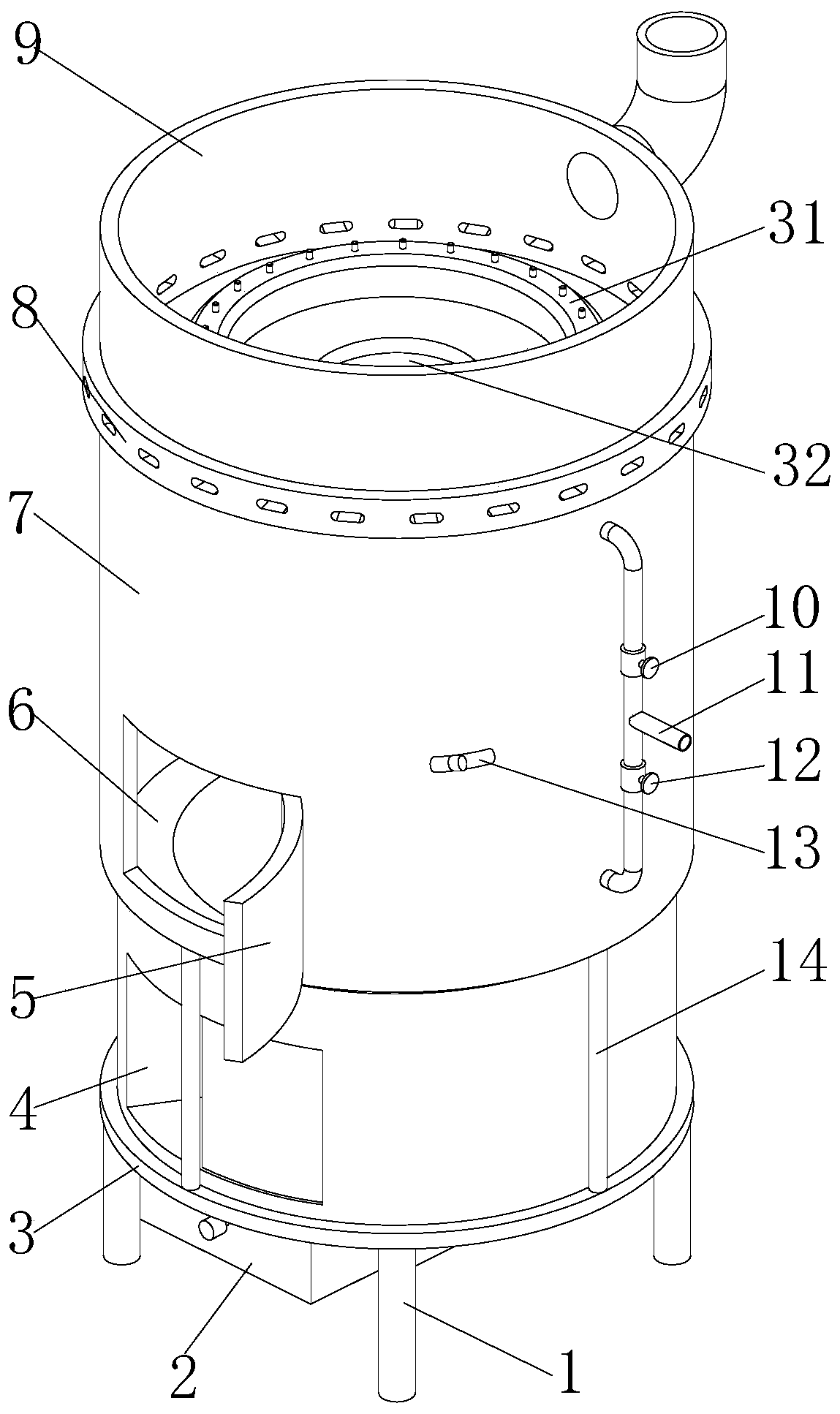

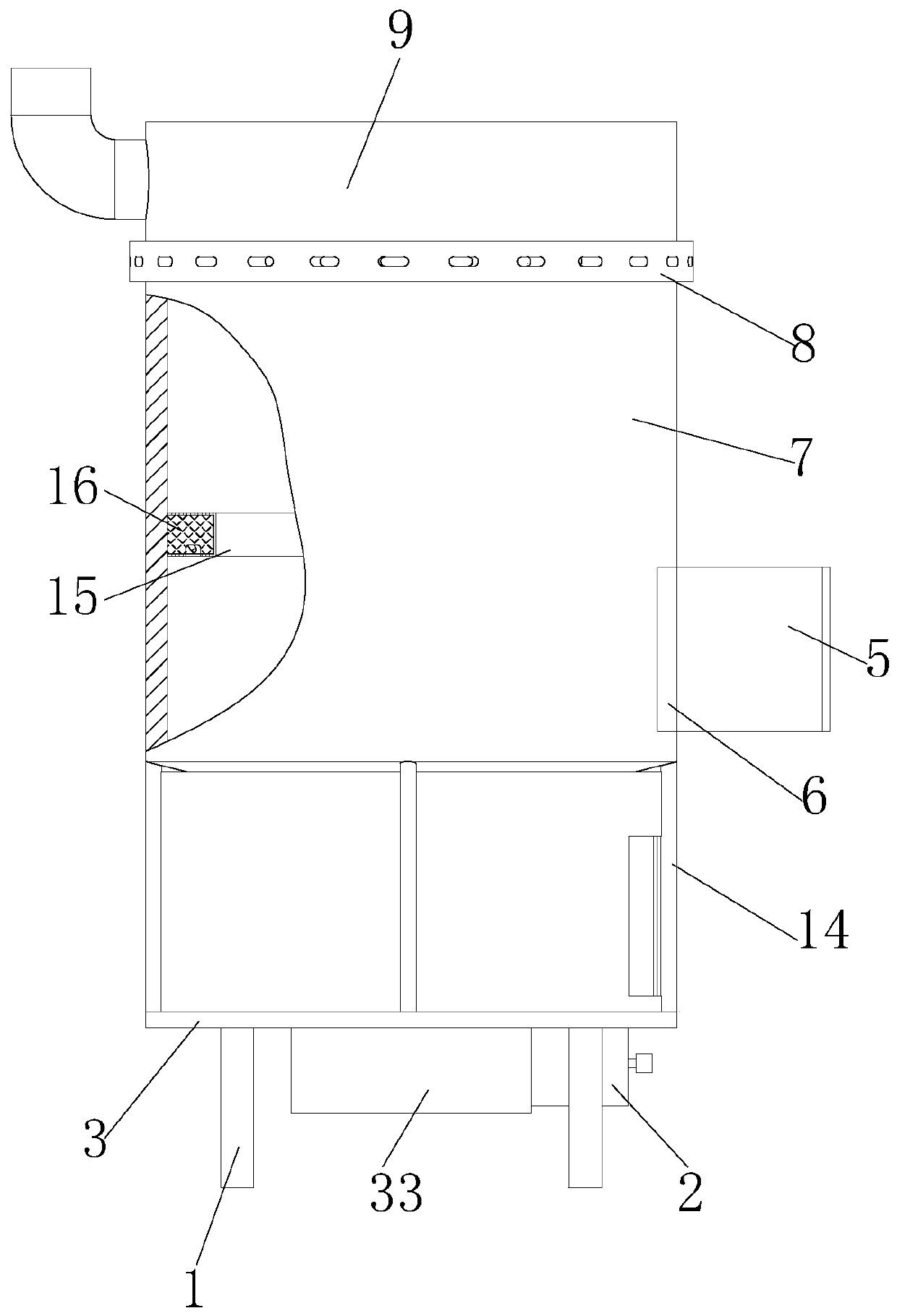

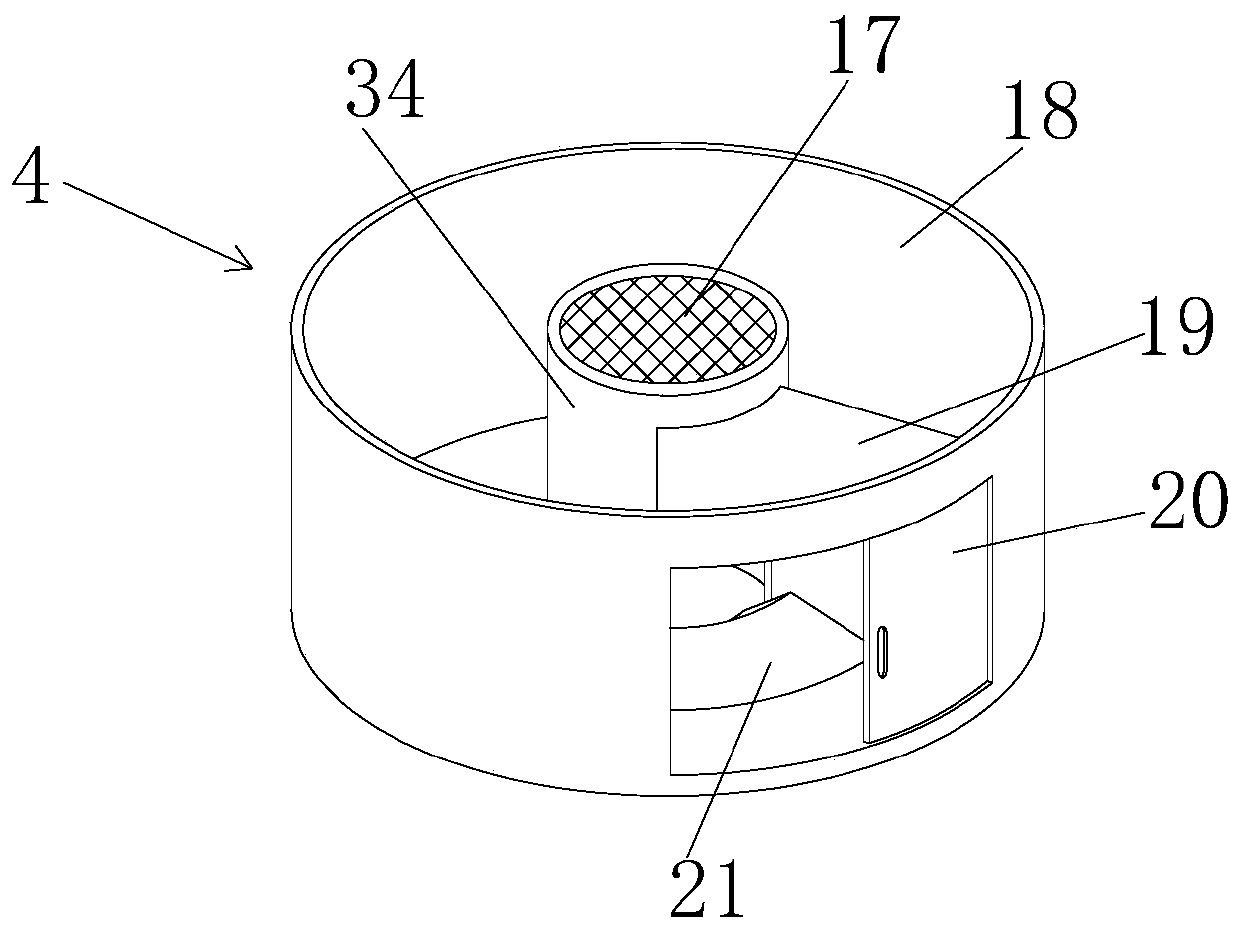

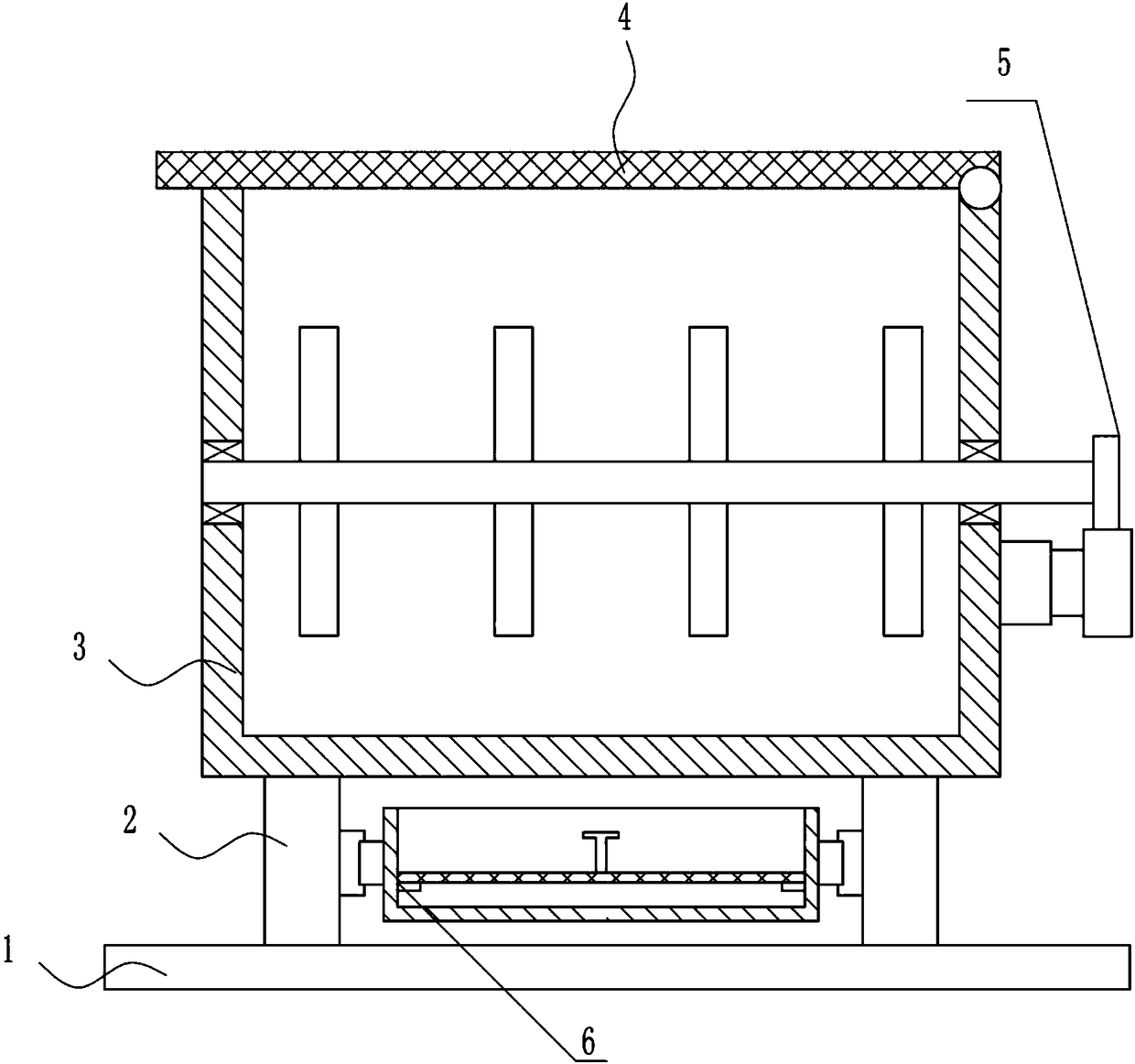

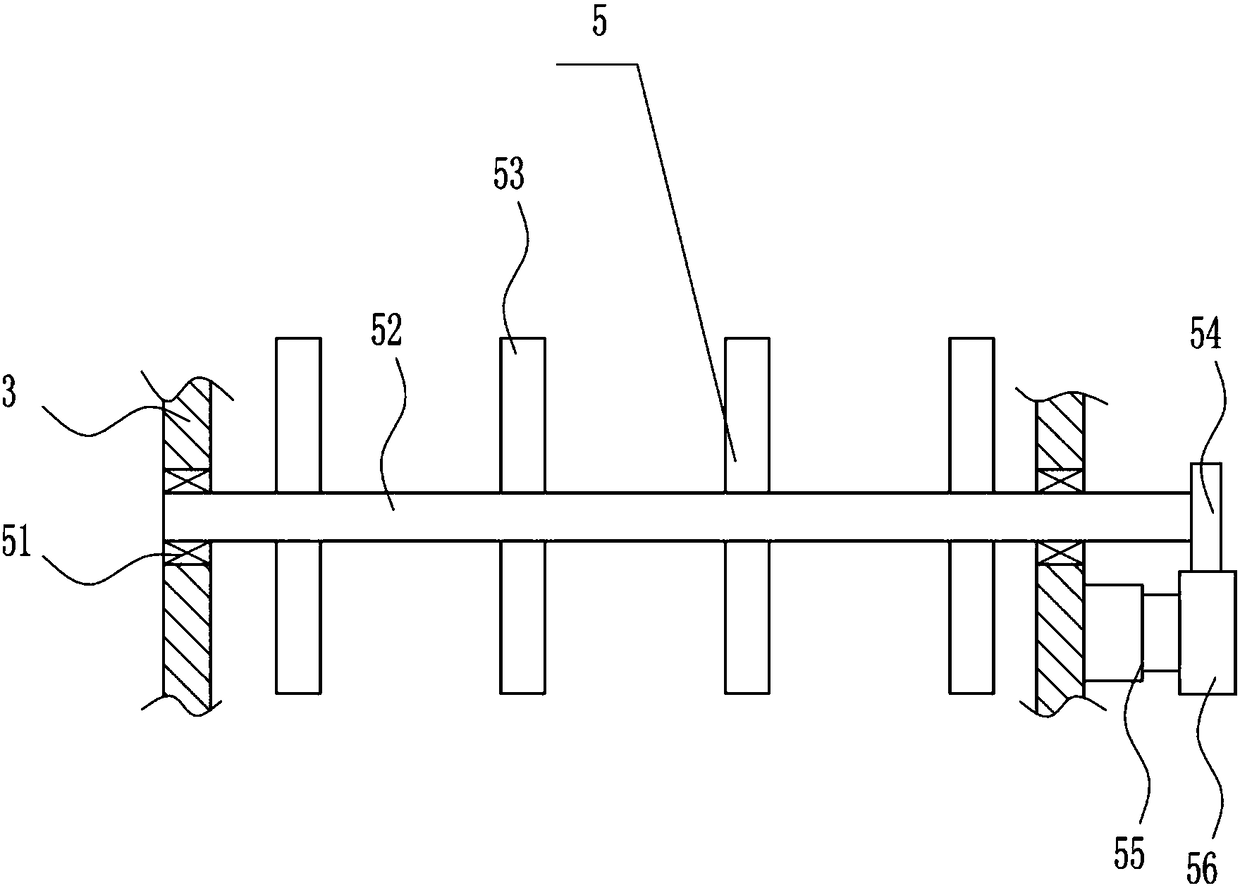

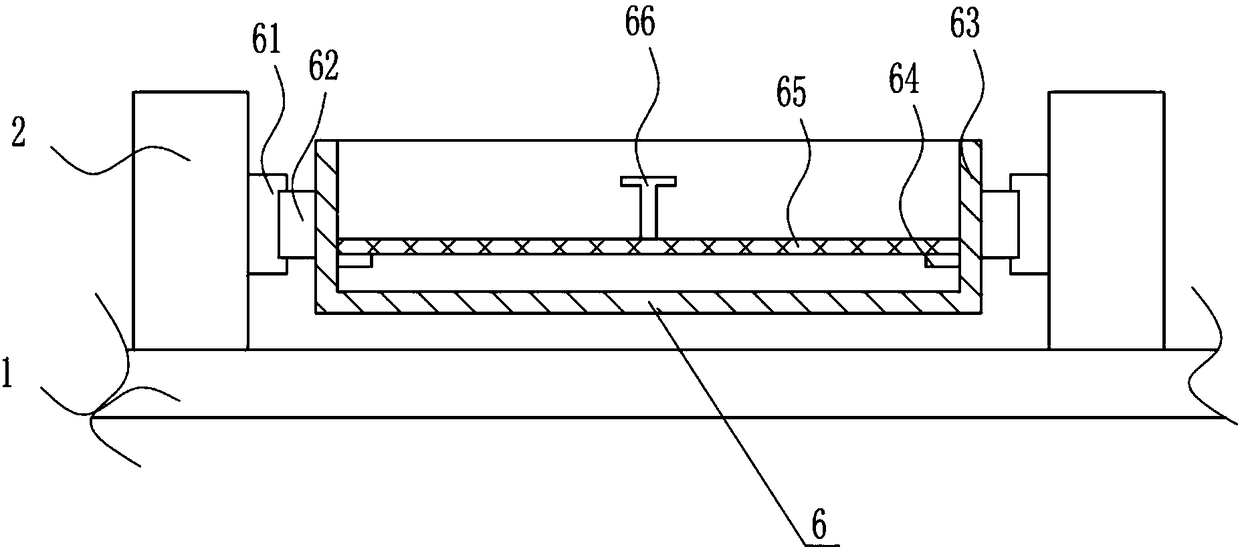

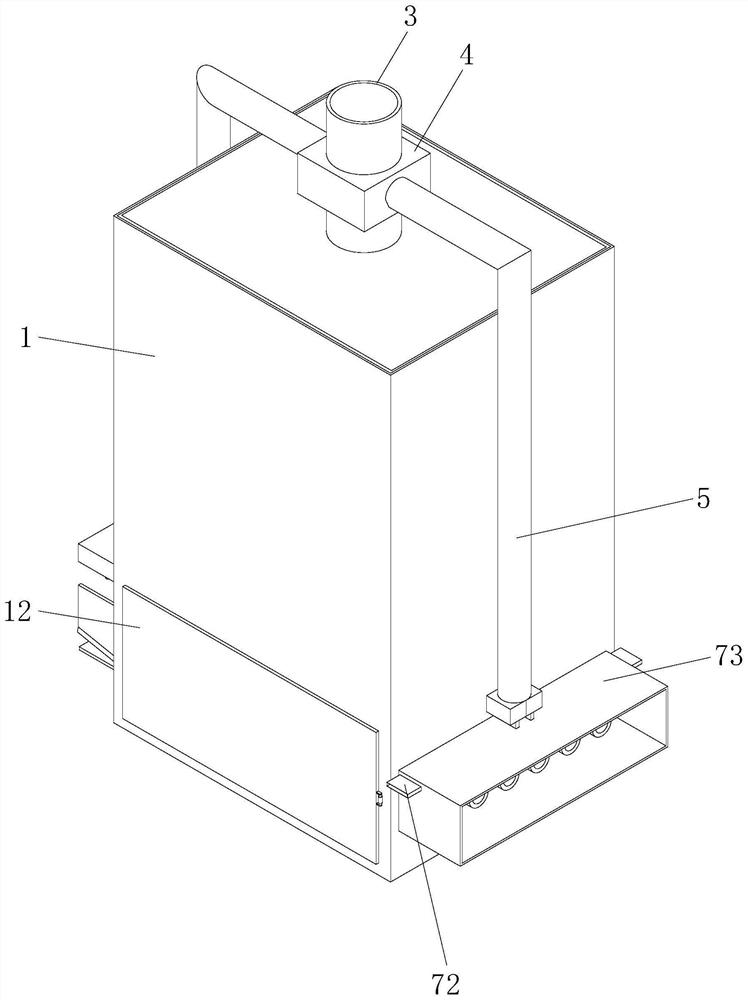

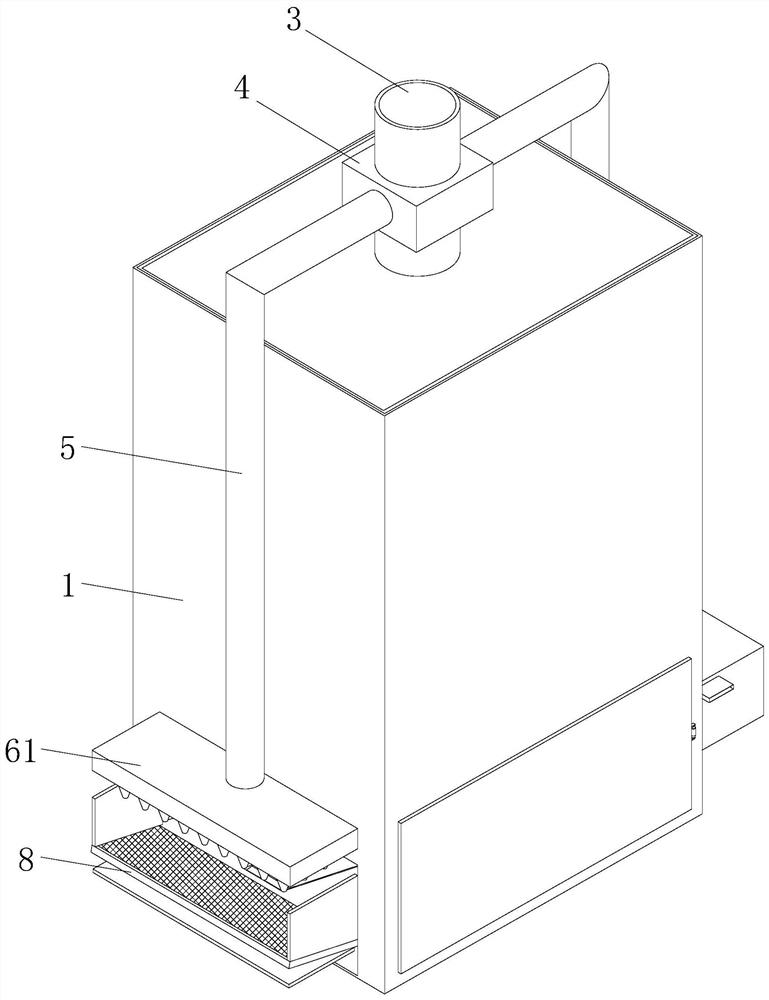

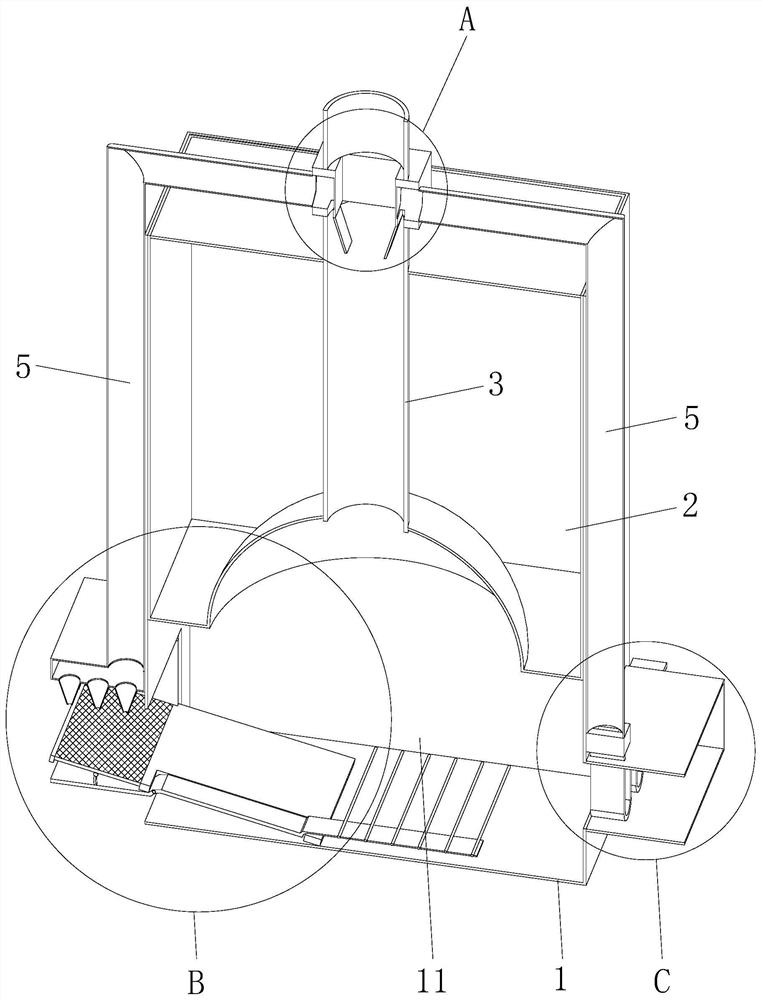

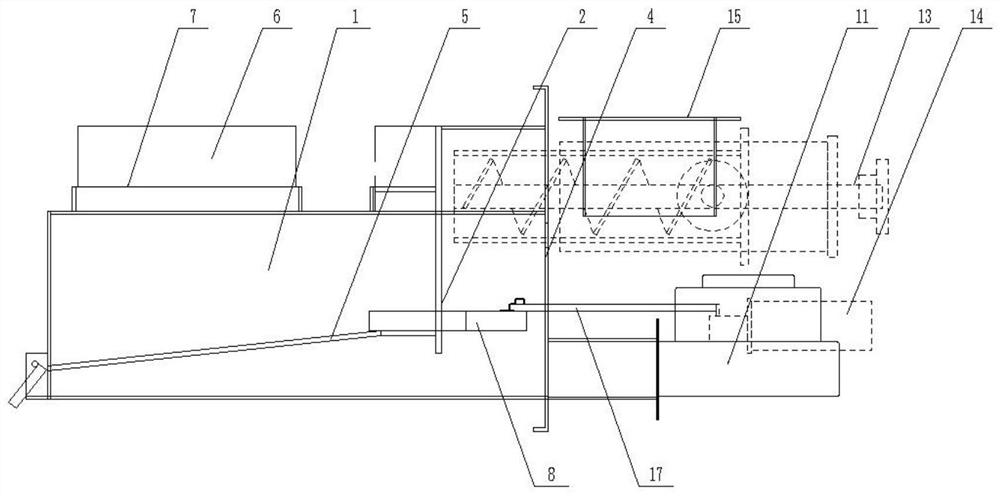

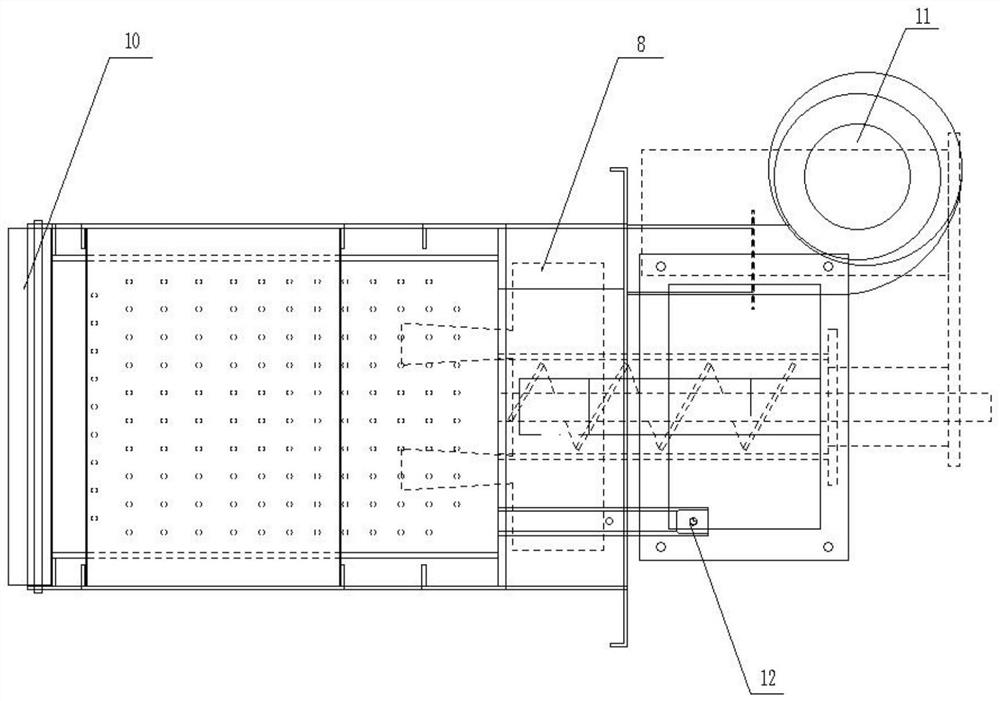

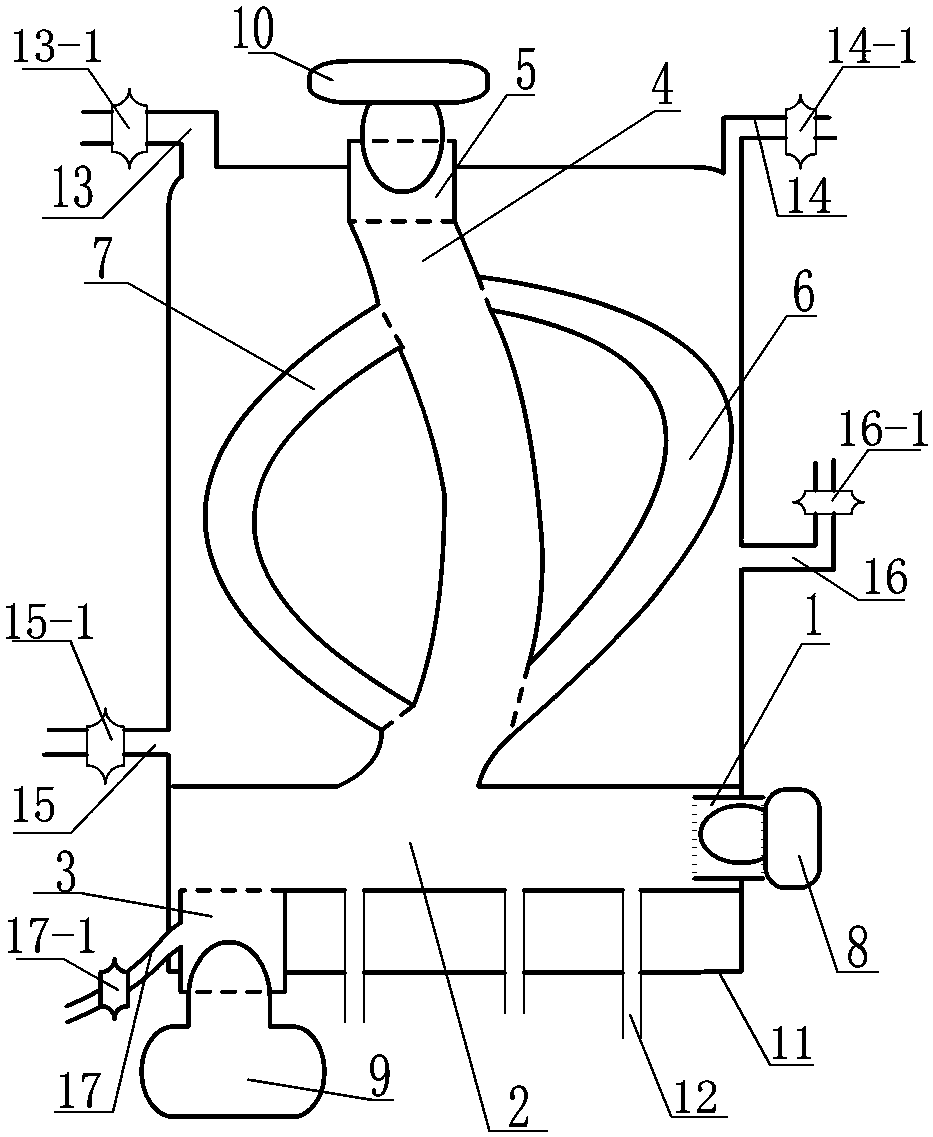

Municipal sludge drying device

InactiveCN107473556AImprove the heating effectStrong burningSludge treatment by de-watering/drying/thickeningDispersed particle filtrationSludgeProduct gas

The invention relates to a treating device and especially relates to a municipal sludge drying device. The technical problem to be solved by the invention is to provide the municipal sludge drying device which is time-saving and labor-saving, is capable of caking sludge for bringing convenience in treatment to people, is capable of filtering and then exhausting the gas generated in the treatment process and is difficult to cause the treatment person feel uncomfortable. In order to solve the technical problem, the municipal sludge drying device provided by the invention comprises an n-shaped frame, wherein supporting legs are symmetrically arranged on left and right sides of the bottom in the n-shaped frame; a placement device is arranged between the inner side walls of the supporting legs on left and right sides; a circular frame is arranged between the top ends of the supporting legs on left and right sides; and the circular frame is located right above the placement device. According to the invention, a filtering device is arranged for filtering and then exhausting the gas generated in the sludge treatment process, an airing device is capable of promoting the coal flaming and the sludge heating effect is better.

Owner:魏亦南

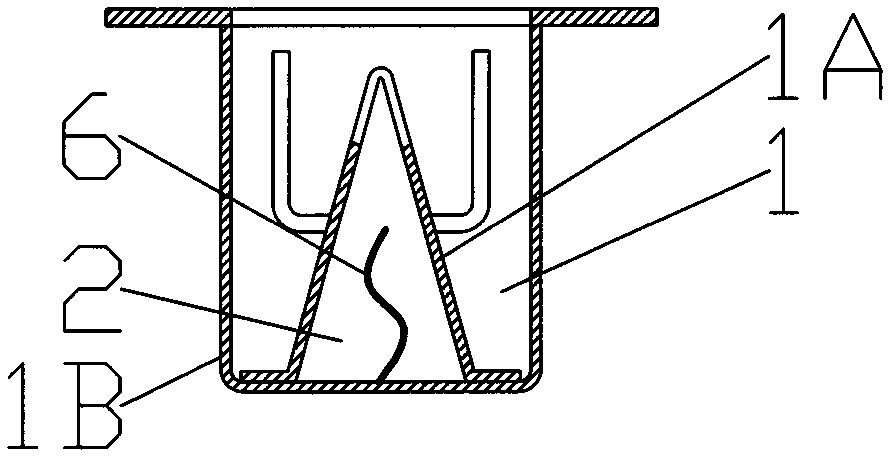

Garbage incinerator

The invention discloses a garbage incinerator which comprises an incinerator body, a grate arranged in the incinerator body, and a blocking piece used for preventing garbage from dropping on the grate, wherein penetrable holes are formed in the blocking piece, and the blocking piece is arranged in the incinerator body, and located above the grate. The garbage fed newly can be laid on the blocking piece due to the arrangement of the blocking piece, so that the garbage can not drop on the grate directly to put out flame on the grate; the garbage can be dried and combusted on the blocking piece, and then drops on the grate for after-combustion through the penetrable holes in the blocking piece; and the combustion is sufficient.

Owner:福建省泷澄建设集团有限公司

Garbage incinerator

The invention discloses a garbage incinerator which comprises an incinerator body, a grate arranged in the incinerator body, and a blocking piece used for preventing garbage from dropping on the grate, wherein penetrable holes are formed in the blocking piece, and the blocking piece is arranged in the incinerator body, and located above the grate. The garbage fed newly can be laid on the blocking piece due to the arrangement of the blocking piece, so that the garbage can not drop on the grate directly to put out flame on the grate; the garbage can be dried and combusted on the blocking piece, and then drops on the grate for after-combustion through the penetrable holes in the blocking piece; and the combustion is sufficient.

Owner:福建省泷澄建设集团有限公司

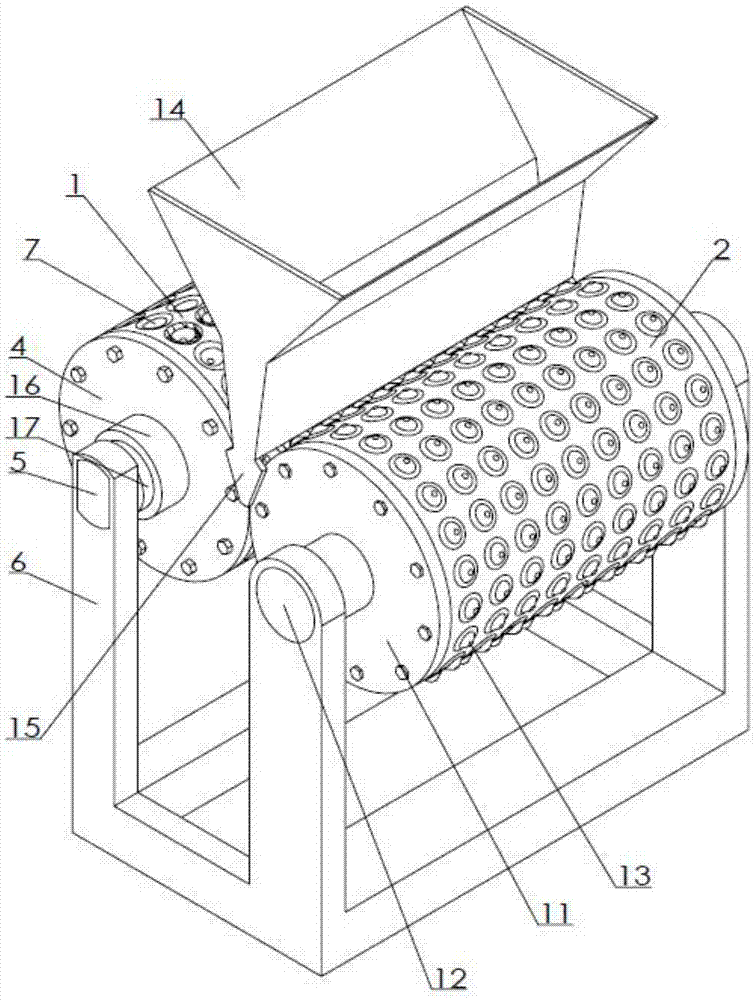

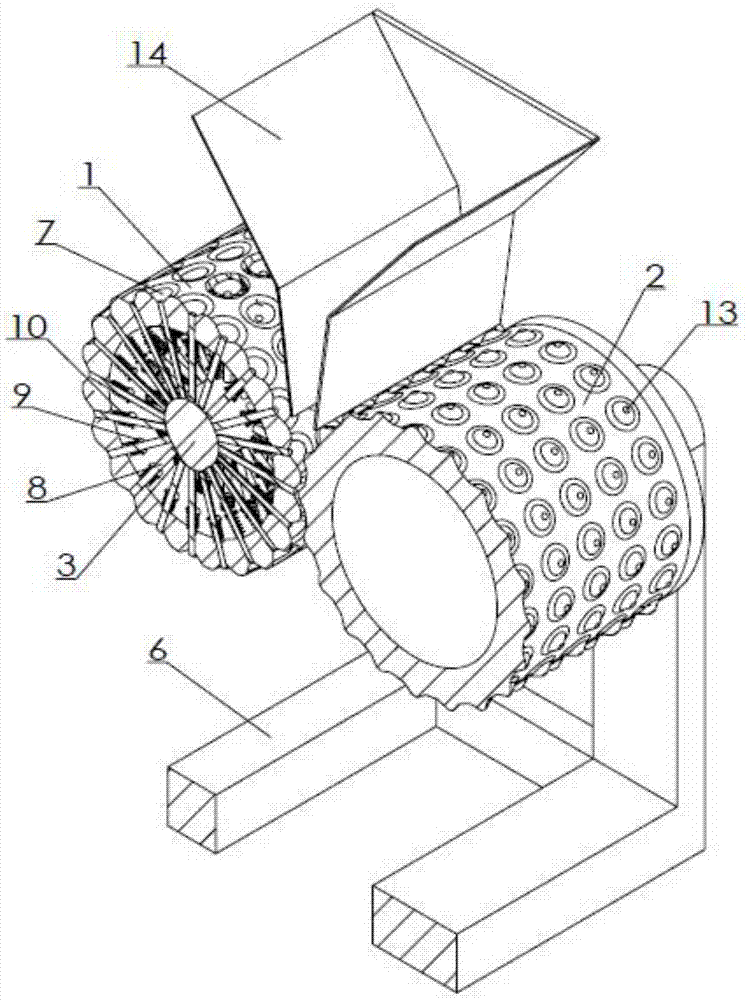

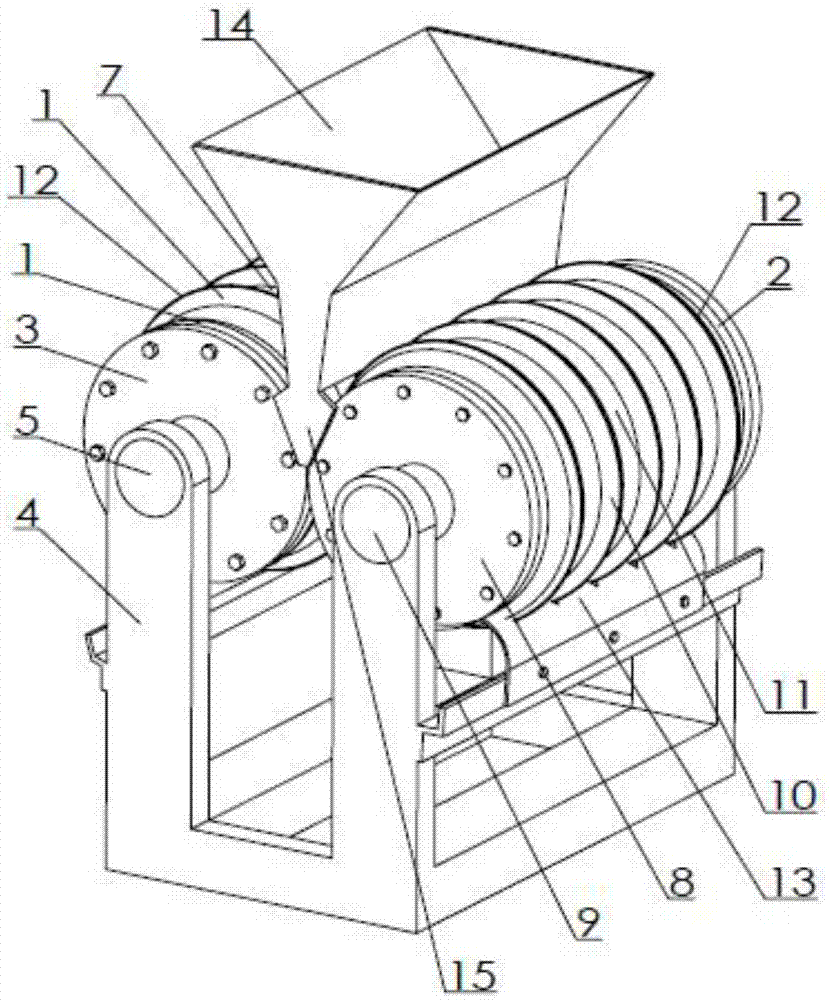

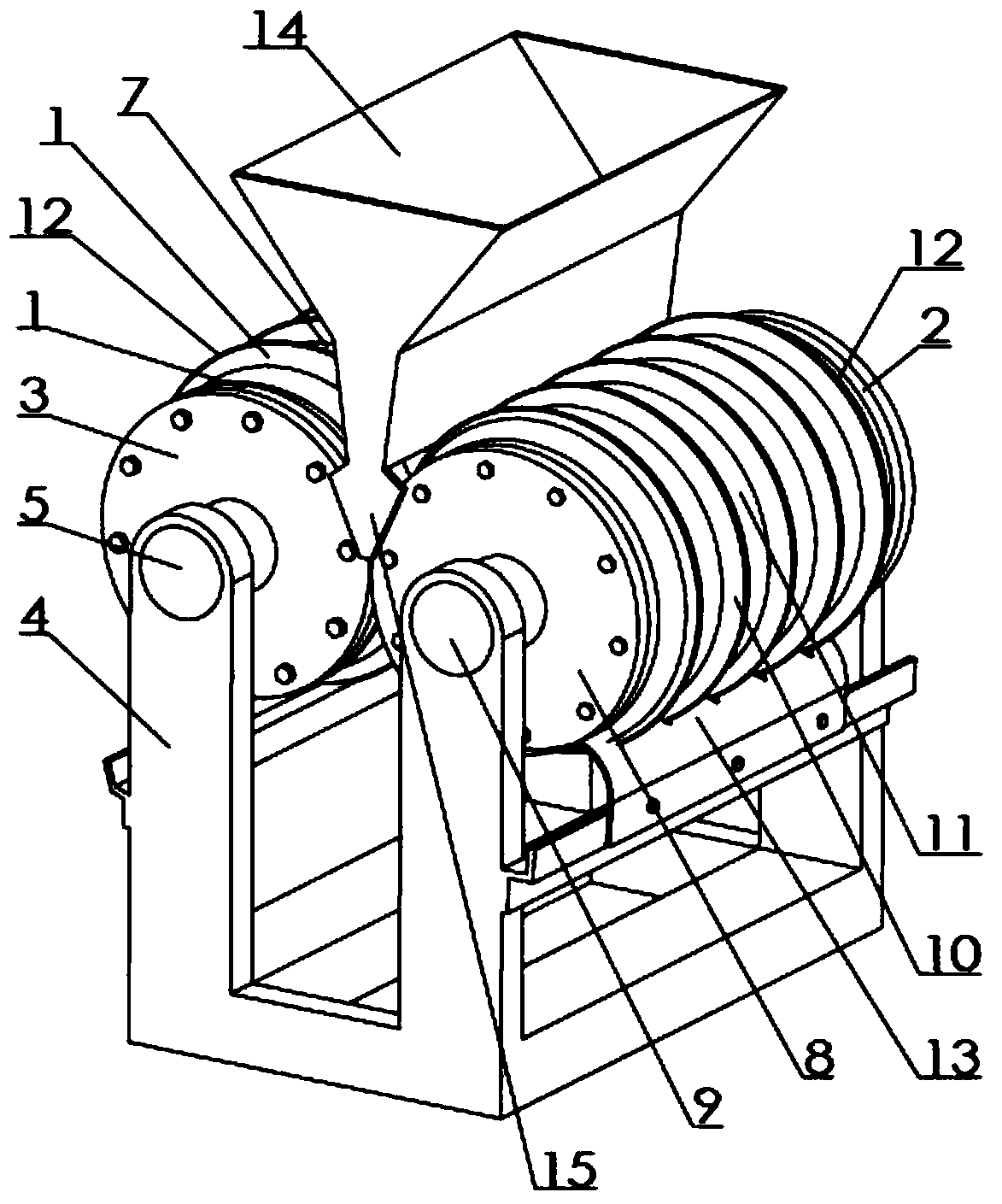

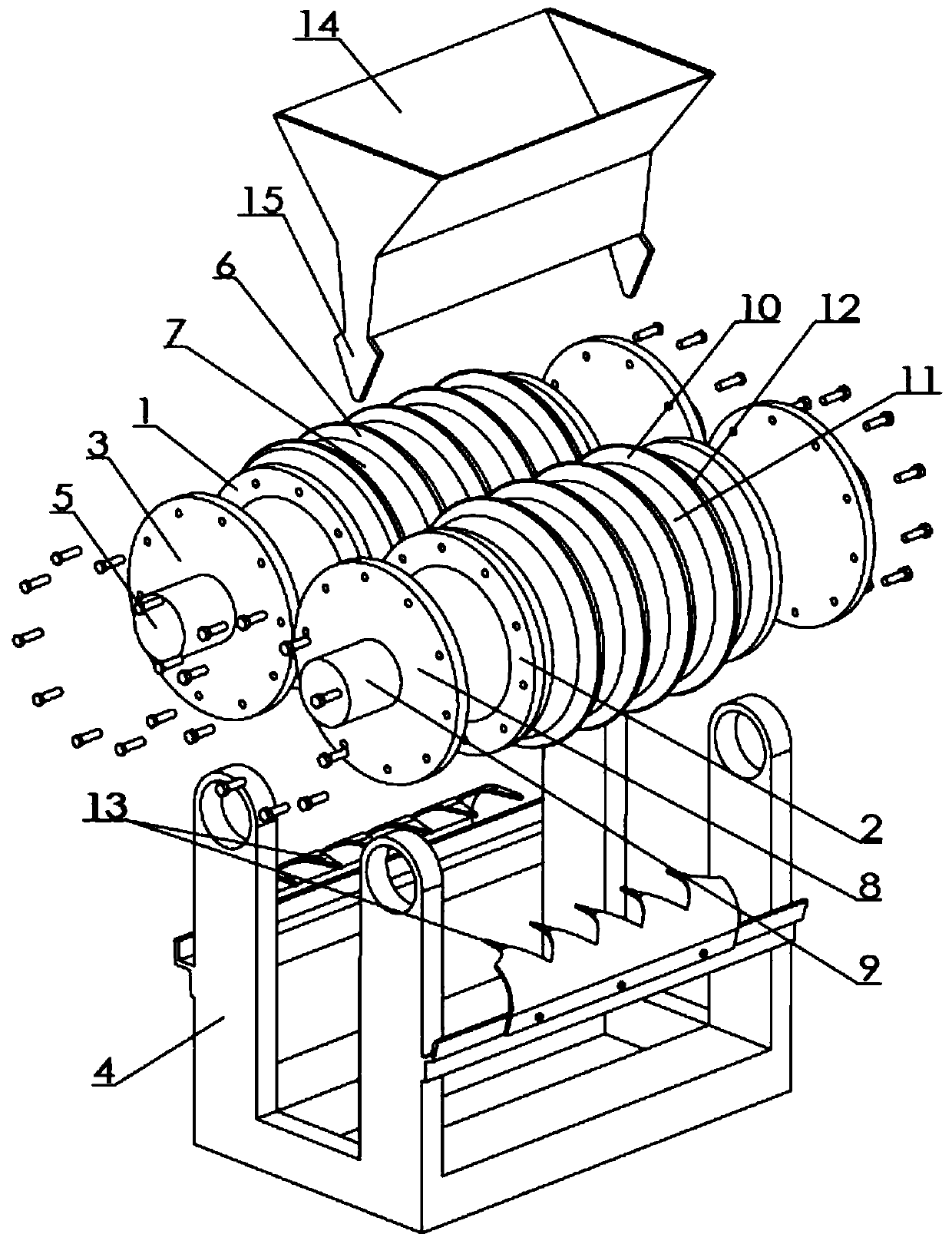

Roll compression device for bio-fuels

The invention discloses a roll compression device for bio-fuels. The roll compression device for the bio-fuels is characterized by comprising a main roll and a synchronous roll, wherein the main roll is barrel-shaped; a fixed shaft rod is arranged at an axis position; a cam shaft with a downwards-projecting part is arranged at a position aligned with the main roll, of the middle section of the shaft rod; polished shafts coaxial with the main roll are arranged at the two ends of the shaft rod; a shaft sleeve sleeves each polished shaft; each shaft sleeve is connected with a main end plate connected with the corresponding end surface of the main roll; the polished shafts at the two ends are connected with a location shaft respectively; each location shaft is fixedly connected with a support; peripherally-distributed recessions are arranged on the surface of the main roll; a hole penetrating through the sidewall of the main roll is arranged in the bottom of each recession; an ejection rod is fitted in each hole; and the inner end of each ejection rod is ejected onto the cam shaft. According to the invention, the pressed and broken particles have large gaps after being accumulated, a gas flow is smooth and combustion is vigorous after a boiler is filled with the particles, and moreover, the gaps can be furthest reserved through thoroughly combusting thin ash, thus promoting combustion.

Owner:CHONGQING HUAWANLUN BIOLOGICAL NEW ENERGY TECH CO LTD

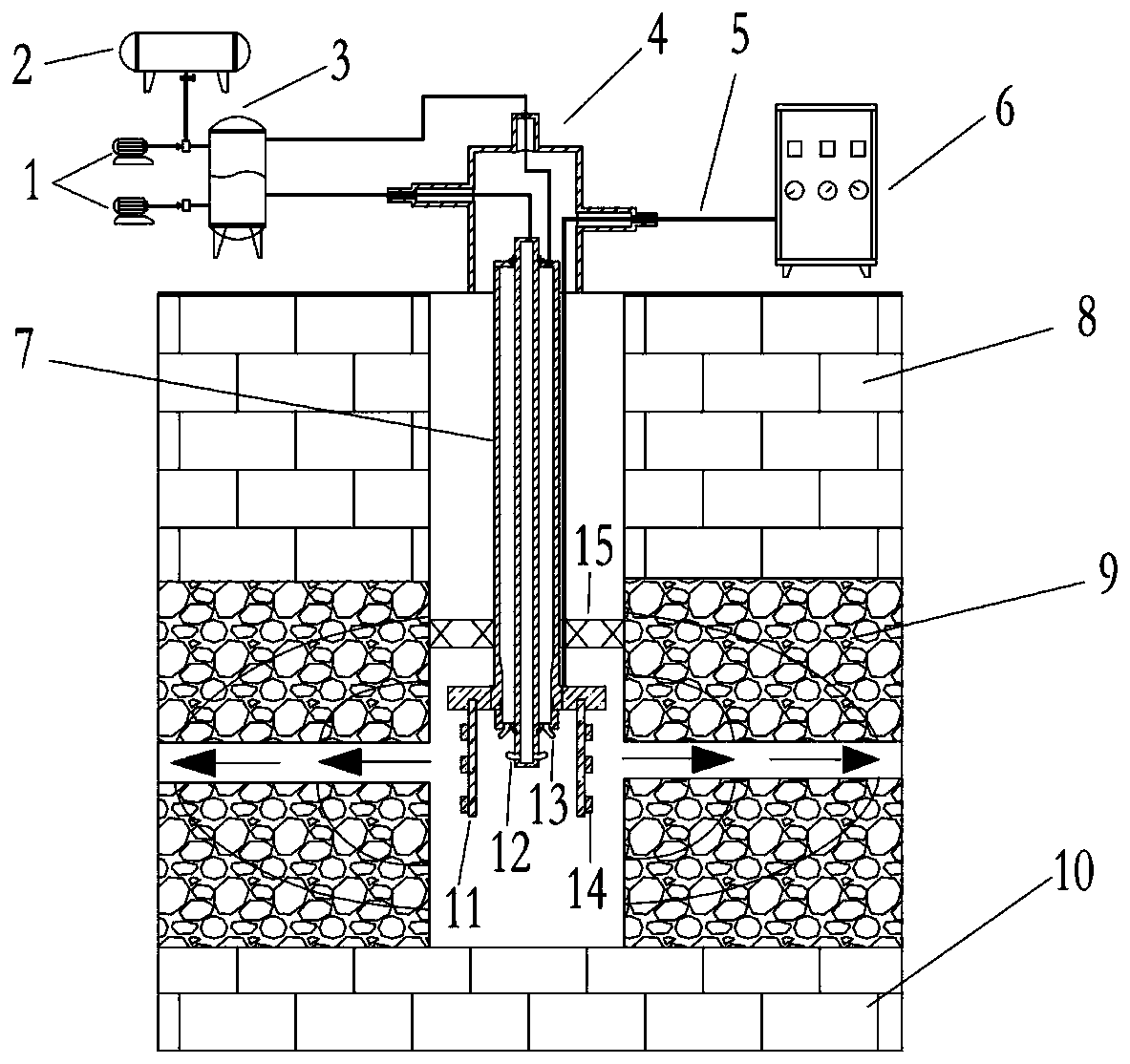

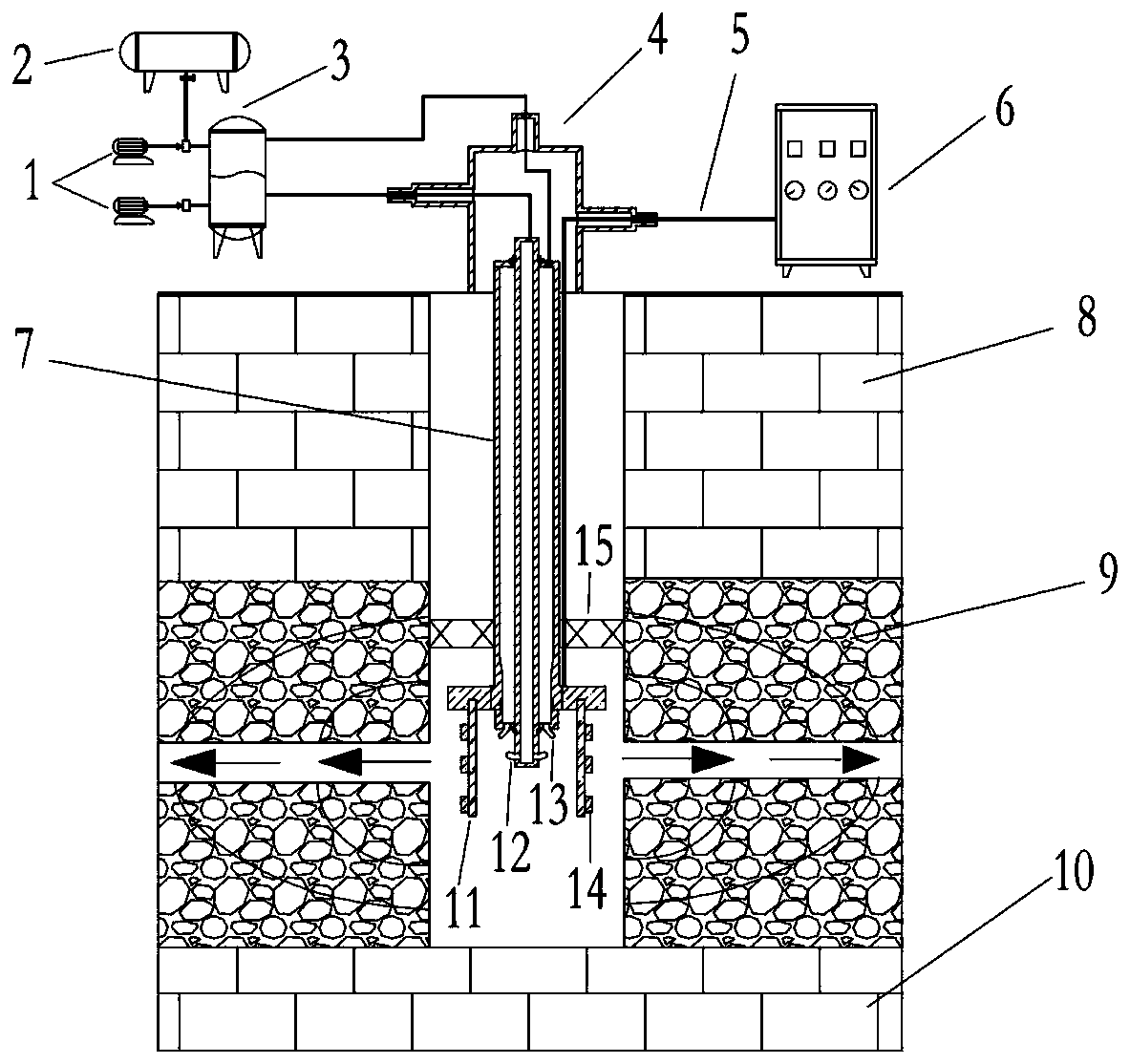

Oil shale in-situ exploitation downhole ignition and heating device and heating method

ActiveCN109707356AReduce transportation lossIncrease profitGeothermal energy generationFluid removalControl systemHeater Rod

The invention discloses an oil shale in-situ exploitation downhole ignition and heating device and a heating method. The ignition and heating device comprises a high-pressure oil gas injection system,an ignition and heating measurement and control system, a downhole pipe column cable system and a downhole igniting system. When the ignition and heating device operates, firstly, compressed air is injected in a well through a center channel of a dual-wall drill pipe, and high-speed air flow is generated through an air nozzle; and then fuel oil is transported in the well through an annular hollowchannel between the inner wall and the outer wall of the dual-wall drill pipe, the fuel oil is atomized through a swirl nozzle and fully mixed with the high-speed air flow, the fuel oil is ignited under the heating action of a heating rod, and the heat generated by burning is used for heating an oil shale layer. Flame detectors monitor the burning conditions of downhole, a downhole packer enablesthe peak surface of the burning to extend and expand towards the ground layer in the well for heating an oil shale ore deposit. According to the oil shale in-situ exploitation downhole ignition and heating device and the heating method, the loss caused by energy pipeline transportation is reduced, and the burning efficiency of the fuel oil and the utilization ratio of the energy are improved greatly.

Owner:JILIN UNIV

Garbage incinerator

The invention discloses a garbage incinerator, comprising an incinerator body, a fire grate and a support layer, wherein the fire grate is arranged inside the incinerator body; the support layer is used for supporting garbage which is thrown in the incinerator body and is arranged inside the incinerator body and above the fire grate; fire channel gaps are formed in the support layer; flame on the fire grate passes through the fire channel gaps and burns the garbage on the support layer; the size of the garbage on the support layer is reduced after combustion; the garbage falls from the fire channel gaps and is burned out on the fire grate. The garbage is supported on the support layer and cannot fall on the fire grate to extinguish flame on the fire grate, so that higher temperature can be kept in the incinerator body, a stable heat source is formed in the incinerator body; as a large amount of water exists in the garbage, the garbage is supported by the support layer, is dried firstly by the flame on the fire grate and the temperature in the incinerator body and then is burned, and combustion is sufficient.

Owner:郑维明

Small environment-friendly incinerator for garbage disposal

The invention provides a small environment-friendly incinerator for garbage disposal. The small environment-friendly incinerator comprises connecting pieces, connecting threads, inward shrinkage springs, a mounting piece, a threaded head and a hand-lifting piece. A rotating blocking piece is of a rectangular-plate-shaped structure, and the middle of the lateral side of the rotating blocking pieceis connected with a rotating shaft in a welded mode. A drawing panel is of a rectangular-plate-shaped structure, the inner side edge of the drawing panel is connected with a drawing inner piece in a welded mode, the outer side edge of the drawing panel is connected with a pull handle in a welded mode, and the drawing panel is mounted at the bottom of the lateral side of a main body. A rotating baffle is rotated manually firstly, then the pull handle is pulled manually to pull out the drawing panel and the drawing inner piece, ignited materials are placed inside the drawing inner piece, the drawing panel and the drawing inner piece are pushed into the main body, the rotating baffle is rotated to block the drawing panel, and a power supply of a combustion booster is switched on, so that thematerials inside the drawing inner piece burn more vigorously.

Owner:杨耙

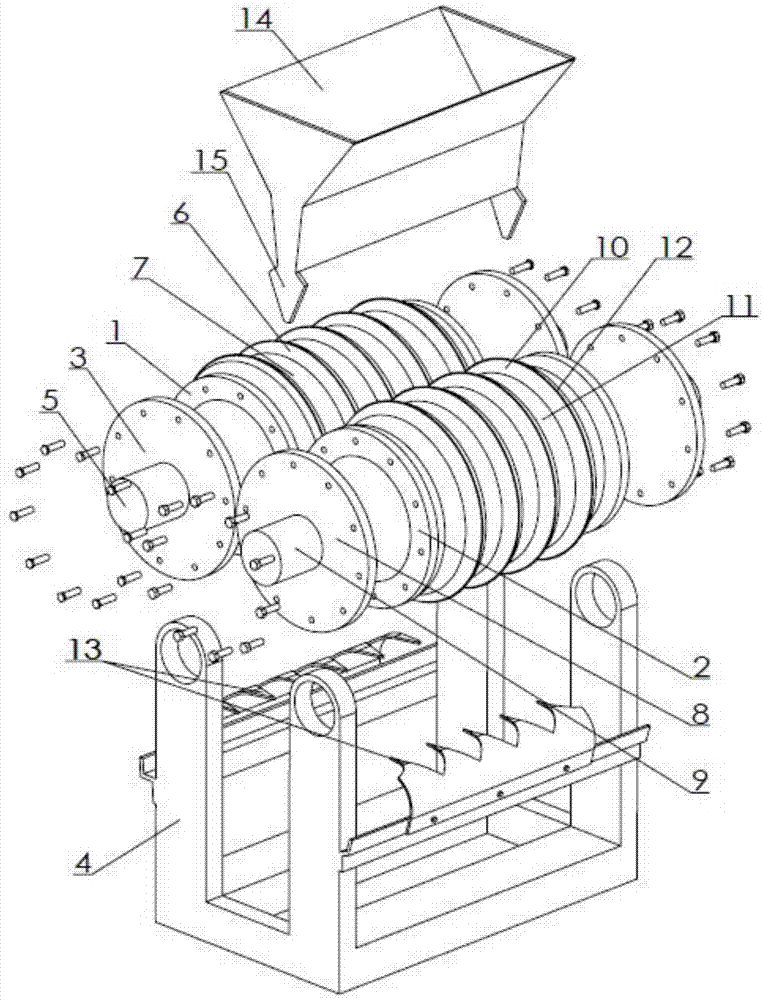

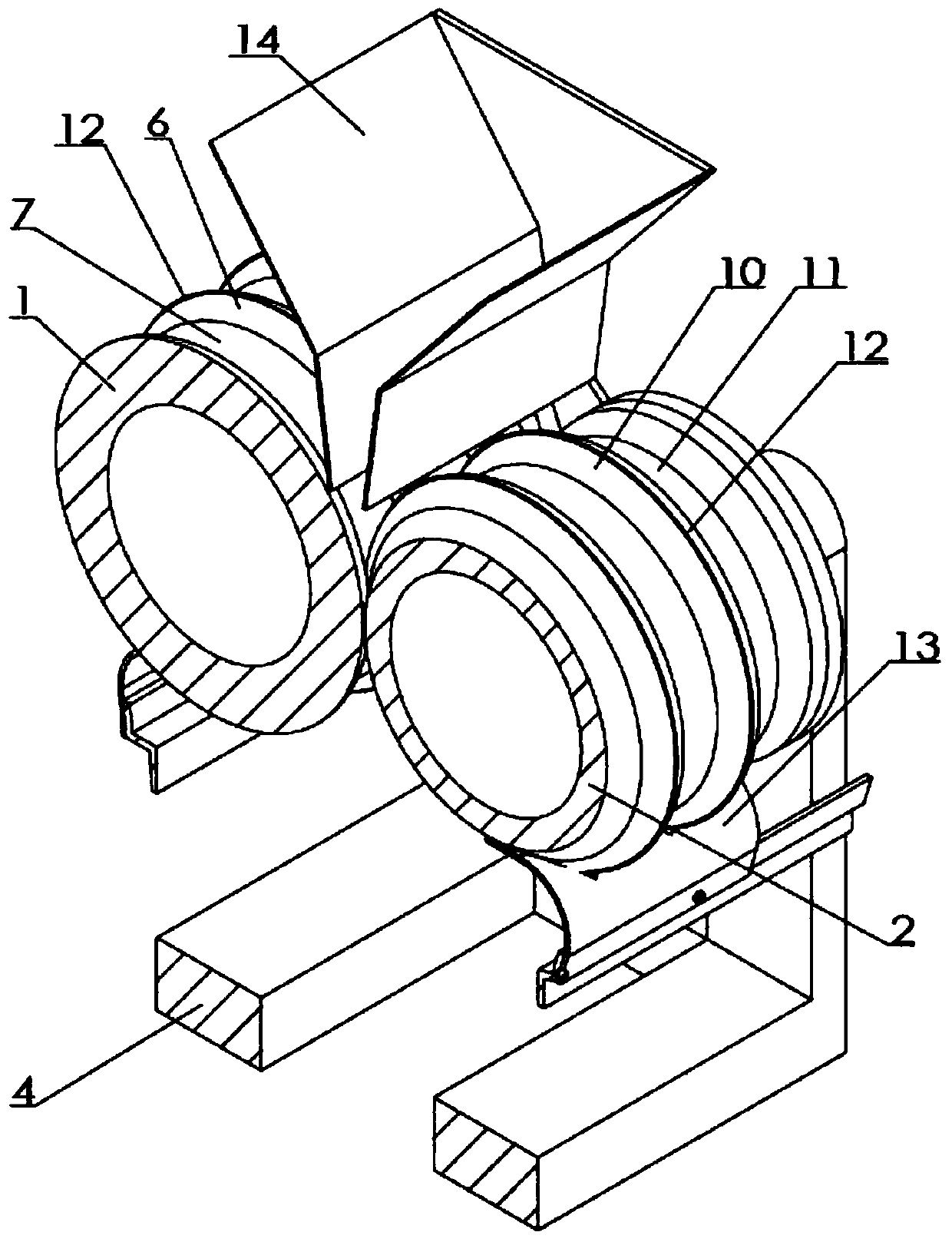

Biofuel curved piece type pressing device

The invention discloses a biofuel curved piece type pressing device. The biofuel curved piece type pressing device is characterized by comprising a main roller and a synchronous roller; the main roller is cylindrical; the two end surfaces of the main roller are fixedly connected with main end plates; the two main end plates are connected with main transmission rollers coaxially connected to a bracket with the main roller; peripheral main wave peaks and peripheral main wave troughs are axially spaced on the surface of the main roller; the synchronous roller is cylindrical, has the same length with the main roller, and is parallel to the axis of the main roller; the two ends of the synchronous roller are fixedly connected with synchronous end plates; the synchronous end plates are fixedly connected with synchronous transmission shafts coaxial with the synchronous roller; the synchronous transmission shafts and the main transmission rollers are connected through synchronous gears, and are opposite in rotating direction; and peripheral synchronous wave peaks and peripheral synchronous wave troughs are axially spaced on the surface of the synchronous roller. Particles obtained by pressing and smashing are accumulated to obtain big gaps, are filled in a boiler to realize smoothness of air currents, and are vigorously burnt; and burnt thin dust can retain the gaps to the greatest extent to accelerate combustion.

Owner:CHONGQING HUAWANLUN BIOLOGICAL NEW ENERGY TECH CO LTD

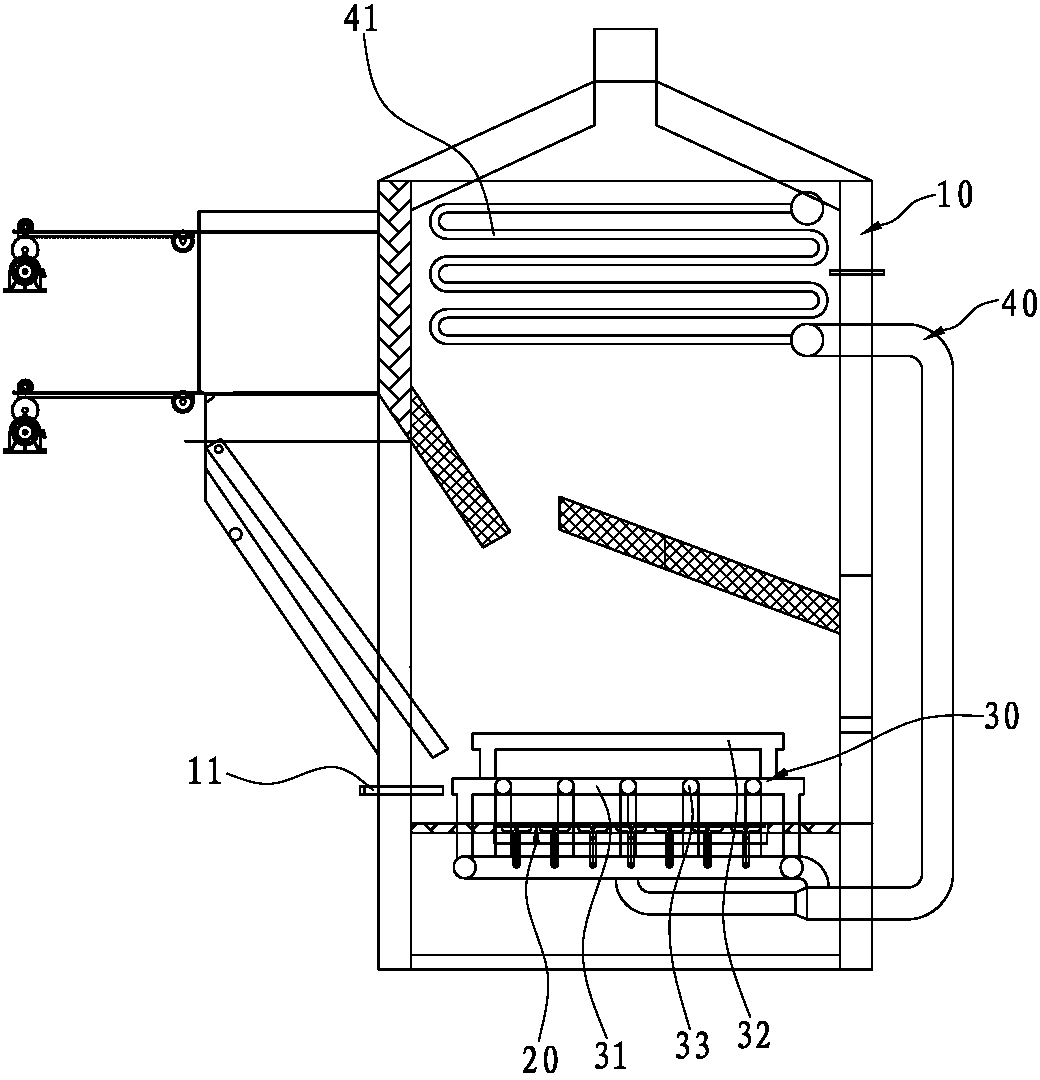

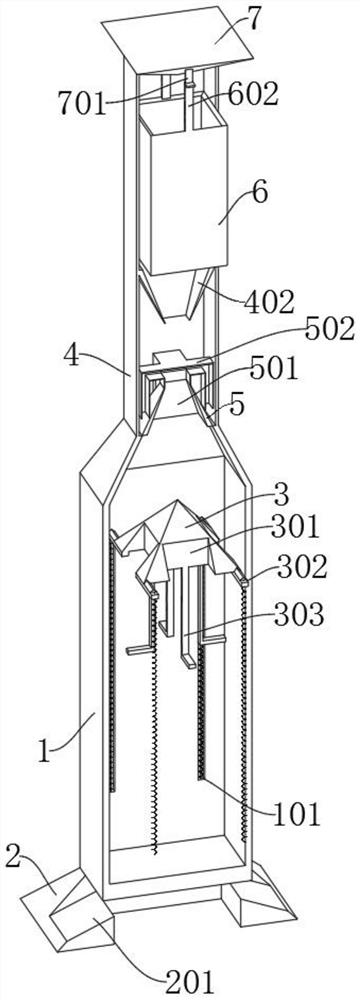

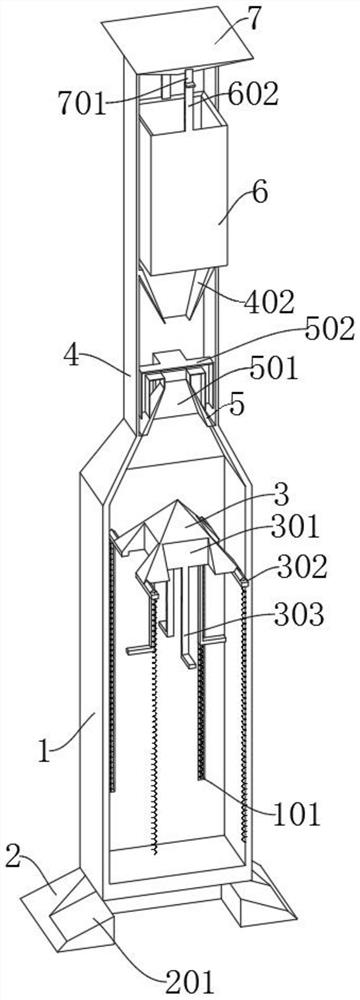

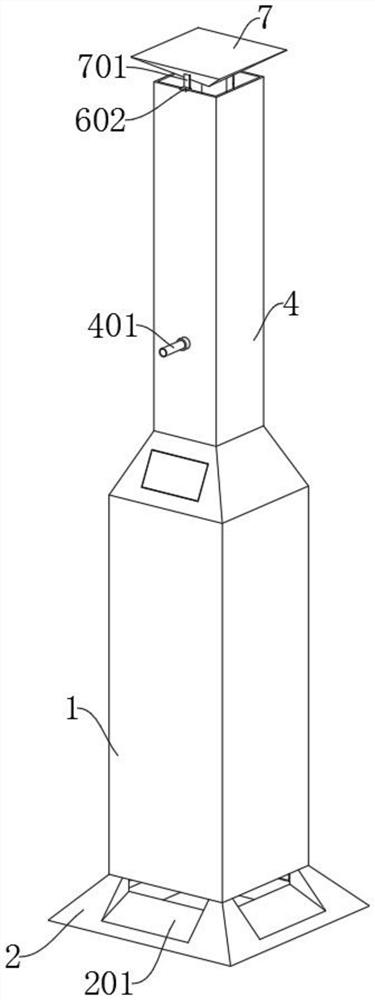

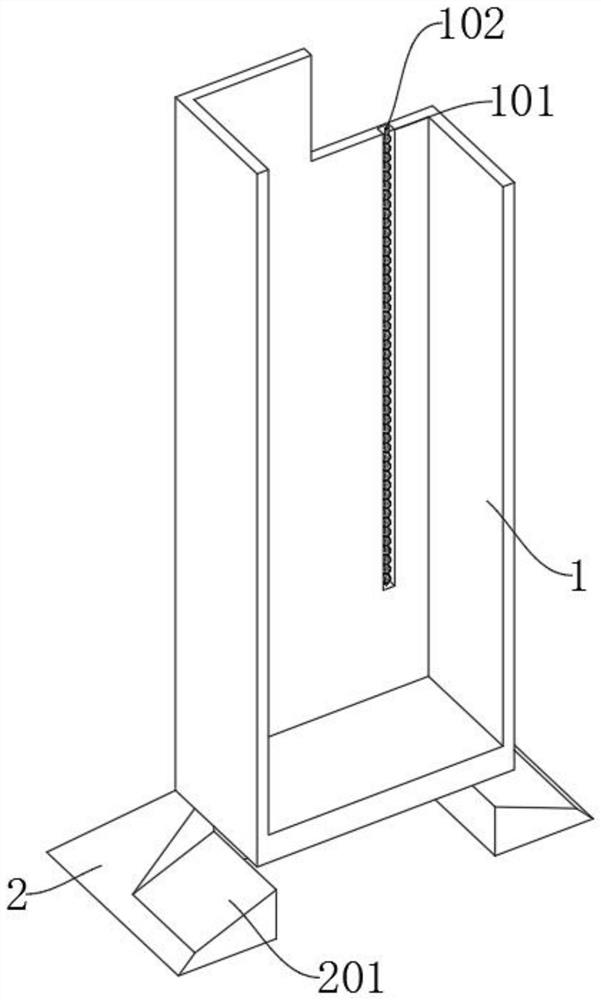

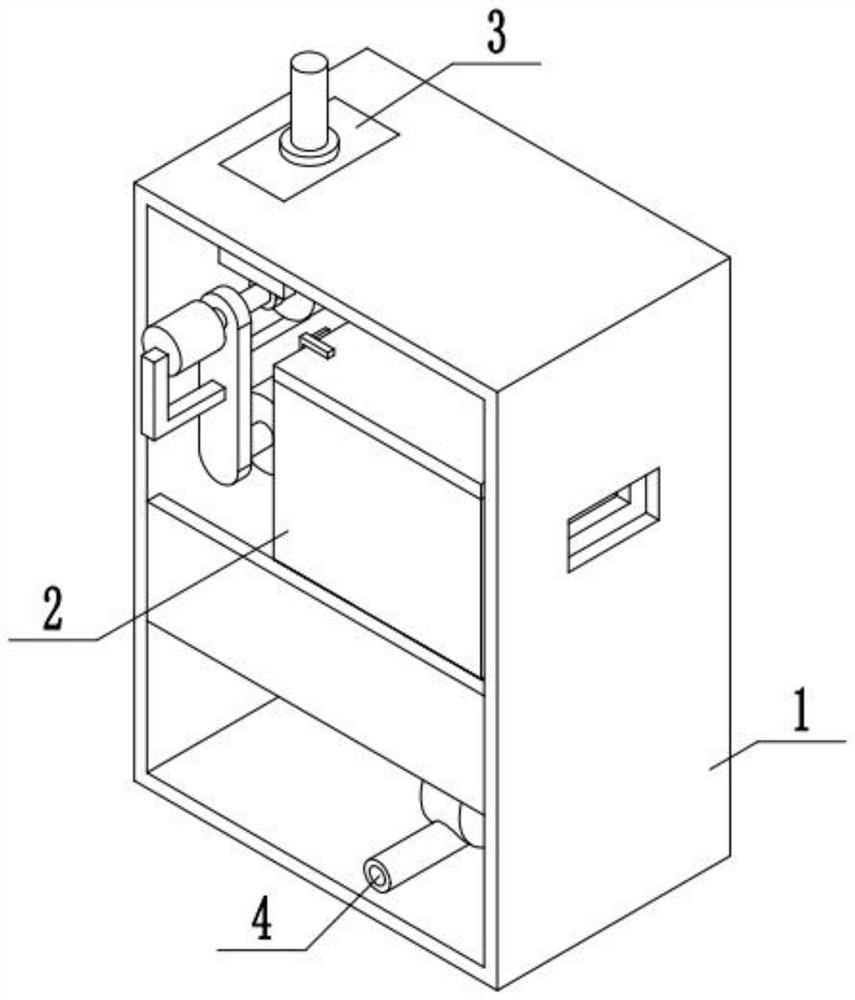

Garbage pyrolysis and incineration harmless disposal equipment

InactiveCN112344335AEffective incinerationBurn completelyIncinerator apparatusCombined combustion mitigationProcess engineeringIncineration

The invention provides garbage pyrolysis and incineration harmless disposal equipment, and relates to the technical field of garbage incineration equipment. The garbage pyrolysis and incineration harmless disposal equipment aims to solve the problems that when a garbage pyrolysis and incineration harmless disposal device in the prior art is used, the phenomenon that garbage incineration is not thorough is prone to occurring, and the garbage pyrolysis and incineration harmless disposal device in the prior art cannot be automatically stressed to push garbage incineration and cannot automaticallypromote garbage incineration. The garbage pyrolysis and incineration harmless disposal equipment comprises a main body, a bottom piece and a moving piece; the main body is of a rectangular structure,and an incineration bin is arranged inside the main body; the top end of the bottom piece is connected with the bottom of the main body in a fixed connection mode; and the top end of a top piece is of a rectangular tubular structure. The moving piece is used for being installed inside the main body, so that the moving piece can receive power transmitted by a spring through a stress rod, and whengarbage is not added, the moving piece can be in a rising state, after the garbage is added, the garbage can press the moving piece to move downwards, the garbage can be in contact with a fire source,and therefore the garbage can be effectively incinerated.

Owner:莱西市盈德装备技术中心

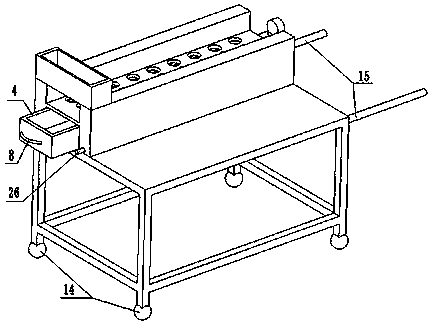

Safe energy-saving barbecue oven

Owner:郑勇

Energy-saving efficient environment-friendly air returning boiler

InactiveCN104879788AImprove combustion efficiencyFull of firepowerLighting and heating apparatusStove/ranges for heating waterEngineeringHearth

The invention discloses an energy-saving efficient environment-friendly air returning boiler which comprises a boiler body and a waste heat recycle and desulfuration device. The boiler body comprises a boiler shell and a smoke pipe, a boiler main body is arranged in the boiler shell, a hearth and a boiler ash chamber are arranged in the boiler main body, a filler opening is formed in the hearth, a boiler ash opening is arranged on the boiler ash chamber, a fire grate is arranged between the hearth and the boiler ash chamber, a cavity is formed between the boiler shell and the boiler main body, and a boiler cover is arranged on the top of the boiler shell and is higher than the boiler main body. The boiler is simple and reasonable in structure, integrates cooking, heating and baking, and is convenient to use. The cavity is formed between the boiler shell and the boiler main body, and a hot water pipe is arranged on the outer side of the boiler main body so that the hot water pipe can be heated through the hearth, and generated smoke flows upwards and flows out from the smoke pipe through the cavity. Meanwhile, the hot water pipe can be heated for the second time through the smoke. A spiral water pipe is further arranged on the hearth, so that heat and smoke waste heat of the hearth are effectively used, and the heat utilization rate is increased.

Owner:苏州福利恒电子科技有限公司

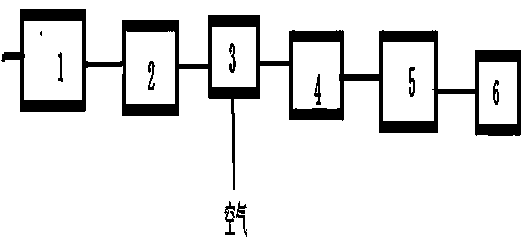

Alcohol-based fuel stove

PendingCN110388659AStable deliveryFierce firepowerDomestic stoves or rangesLiquid heating fuelAlcoholRare earth

The invention discloses an alcohol-based fuel stove. The alcohol-based fuel stove comprises a safety valve, a gasifier, a mixer, a filter, a control valve, a burner and pipelines, wherein the safety valve, the gasifier, the mixer, the filter, the control valve and the burner are sequentially connected, and the pipelines enable all the parts to be connected; the gasifier comprises an electric heating body, and the electric heating body comprises a metal base plate, a rare-earth thick film dielectric layer and a rare-earth thick film circuit, wherein the rare-earth thick film dielectric layer and the rare-earth thick film circuit are located on the metal base plate; and the filter is arranged upstream or downstream of the control valve. According to the fuel stove, an electric heating gasification device is arranged on a fuel output pipeline, in the cold ignition process of the stove, the electric heating body of the gasifier can quickly heat and gasify liquid fuel, so that the preheating time is greatly shortened and can be shortened to be within 10 seconds, and the stove can rapidly generate fiercely-burning flames even in the cold ignition process; and by virtue of the filter, thecarbon deposit generated in the burning process of the burner can be reduced, the adjustment of the thermal power can be met, and therefore the purposes of energy conservation can be achieved.

Owner:广州空港新能源科技有限公司

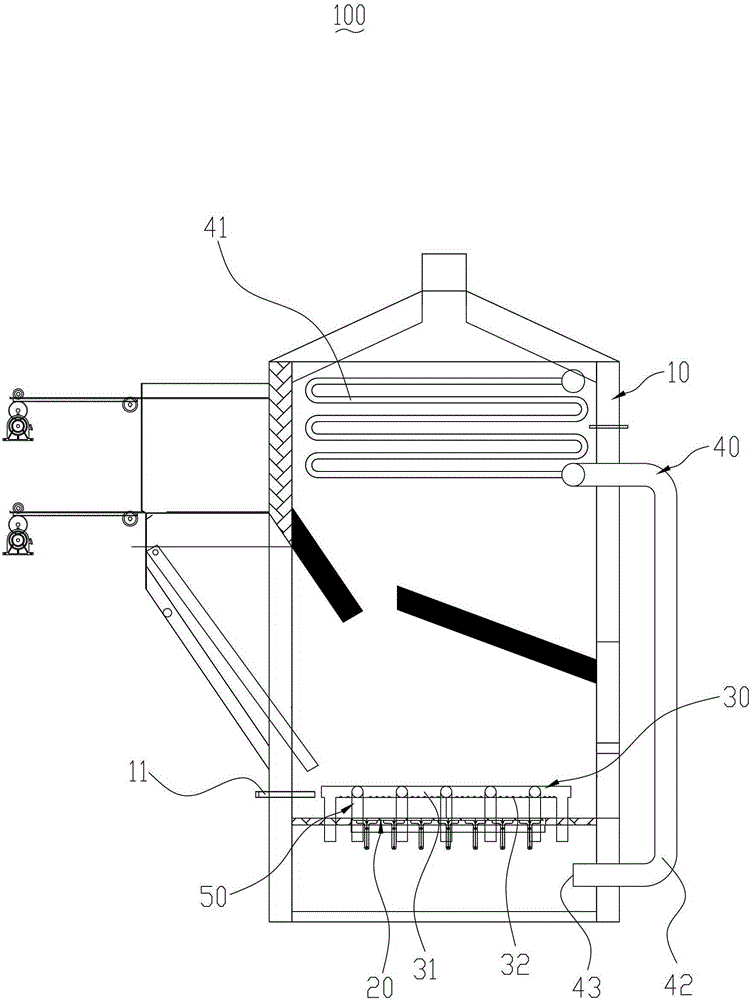

Environment-friendly industrial flue gas comprehensive treatment boiler and using method thereof

InactiveCN108680036ASimple structureEasy to operateIncreasing energy efficiencyWaste heat treatmentAutomatic controlCombustion

The invention provides an environment-friendly industrial flue gas comprehensive treatment boiler and a using method thereof. The environment-friendly industrial flue gas comprehensive treatment boiler comprises a slag removing box, a box door, a boiler and a motor base, the box door is installed on the slag removing box, the slag removing box is connected with the boiler, an air inlet pipe is installed on the boiler and connected with a fan, the fan is connected with a motor, the motor is connected with the motor base, a combustion mesh is arranged in the boiler, and a sealing cover rotatingbase is arranged on the boiler and connected with a sealing cover. The industrial flue gas treatment device is simple in structure, convenient to operate and complete in function and can achieve the functions of flue gas dust removal, desulfuration and the like; and in addition, the flue gas comprehensive treatment boiler is high in automation degree, automatic control and online monitoring can beconducted to complete water inlet and water pumping work, the labor intensity of workers is greatly reduced, pollution to the environment is reduced, and the national environmental protection requirements are met.

Owner:QUZHOU KECHUANG IND DESIGN SERVICES

Garbage pyrolysis and incineration harmless treatment method

InactiveCN112344336AEffective incinerationBurn completelyIncinerator apparatusCombined combustion mitigationProcess engineeringIncineration

The invention provides a garbage pyrolysis and incineration harmless treatment method, and relates to the technical field of garbage incineration equipment. The garbage pyrolysis and incineration harmless treatment method is completed by garbage pyrolysis and incineration harmless treatment equipment, and then garbage pyrolysis and incineration harmless treatment is realized. The garbage pyrolysisand incineration harmless treatment method solves the problems that when an existing garbage pyrolysis and incineration harmless treatment device is used, the phenomenon of incomplete garbage incineration is likely to occur, garbage incineration cannot be pushed by automatic stress, and garbage incineration cannot be automatically promoted.

Owner:莱西市盈德装备技术中心

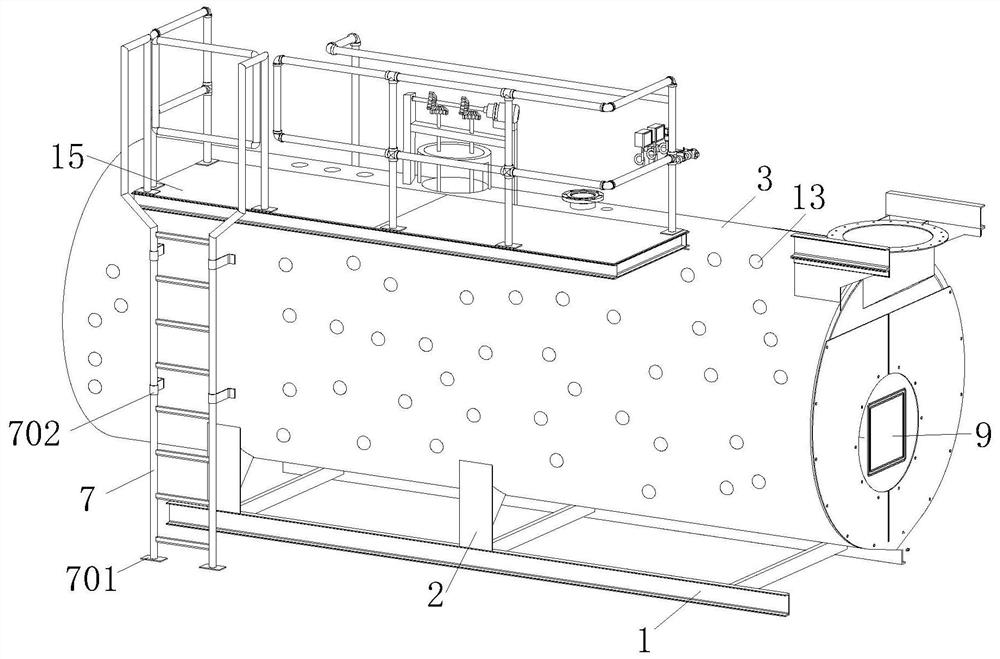

Industrial coal-fired boiler

InactiveCN112503503AEasy maintenanceEasy to cleanAir/fuel supply for combustionSteam boilersThermodynamicsCombustion

The invention relates to the technical field of boilers, in particular to an industrial coal-fired boiler. The industrial coal-fired boiler comprises a bottom frame, a boiler body, a crawling ladder and a sealing mechanism, a plurality of supporting rods are arranged at the top of the bottom frame, the boiler body is arranged at the top ends of the supporting rods, the boiler body is of a hollow structure, a pot cavity is formed in the boiler body, a furnace body is arranged in the pot cavity, and the crawling ladder is installed on one side of the boiler body. Convenience is brought to use ofthe industrial coal-fired boiler, a platform is installed at the top end of the boiler body, and people can stand on the upper edge to carry out operation on the top end of the industrial coal-firedboiler through the platform; and hot gas and smoke dust generated by combustion in a furnace cavity are discharged out of the industrial coal-fired boiler through a steel pipe, and when the hot gas and the smoke dust pass through the steel pipe, heat in the hot gas and the smoke dust can be transferred to the pot cavity through the steel pipe to heat water in the pot cavity, so that the heat of waste gas is reused, energy consumption is reduced, and the economic benefits are increased.

Owner:李昊

Efficient return air furnace

InactiveCN104848261AImprove combustion efficiencyFull of firepowerLighting and heating apparatusStove/ranges for heating waterAir preheaterFlue gas

The invention discloses an efficient return air furnace which comprises a furnace shell, a smoke pipe, a boiler tail smoke flue, a multi-stage air preheater arranged in the boil tail smoke flue, a discharge flue, a dust remover arranged on the discharge flue and a chimney arranged in the rear of the dust remover and is communicated with the discharge flue. A furnace body is arranged in the furnace shell, a hearth and an ash chamber are arranged in the furnace body, a packing port is arranged in the hearth, an ash hole is arranged in the ash chamber, and a grate is arranged between the hearth and the ash chamber. The efficient return air furnace is simple and reasonable in structure, cooking, heating and baking are integrated, convenience in use is achieved, a cavity is arranged between the furnace shell and the furnace body, a hot water pipe is arranged on the outer side of the furnace body, the water pipe can be heated by the hearth, generated flue gas flows upwardly to flow out through the smoke pipe via the cavity, the hot water pipe can be heated secondarily through the flue gas, a spiral water pipe is further arranged in the hearth, heat of the hearth and flue gas waste heat can be effectively utilized, and heat utilization rate is increased.

Owner:苏州福利恒电子科技有限公司

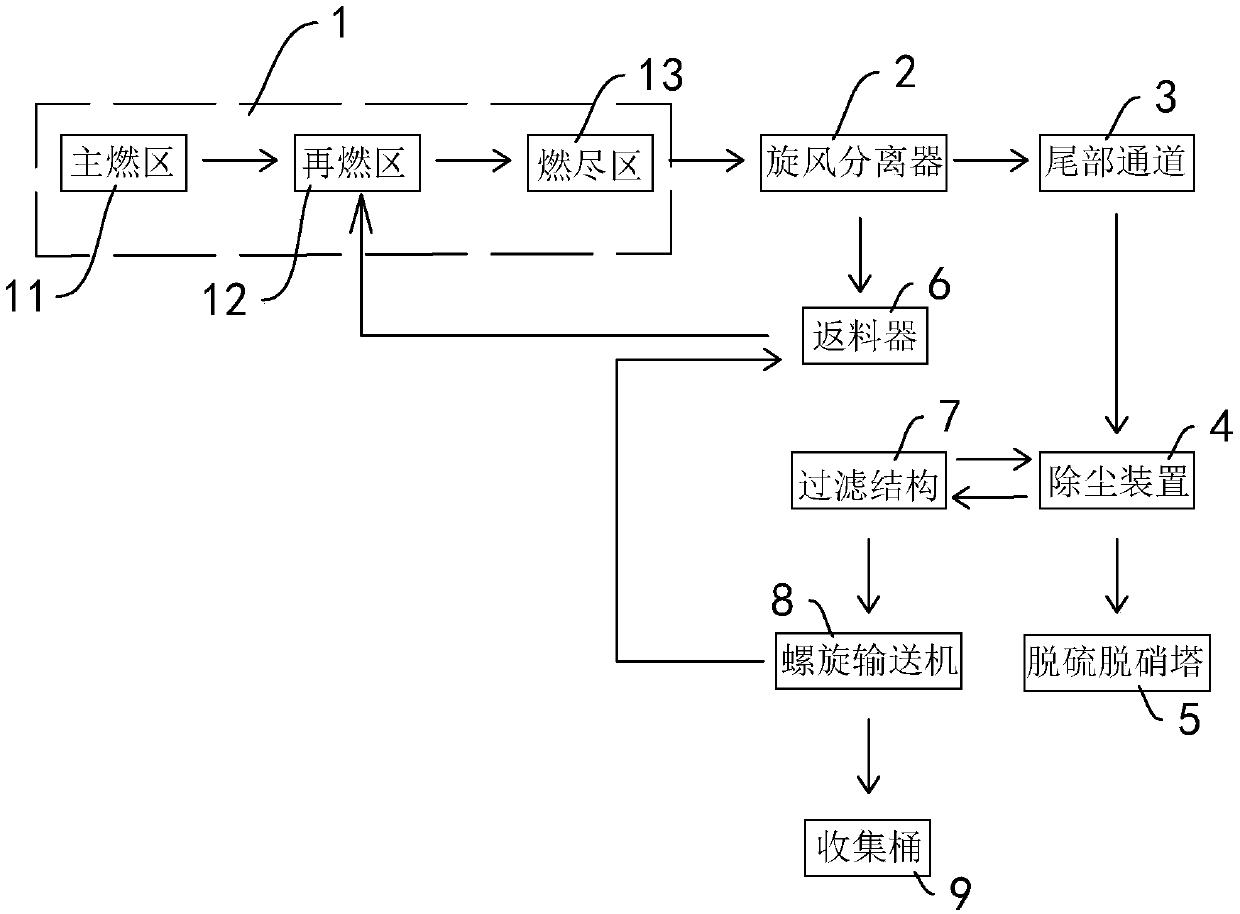

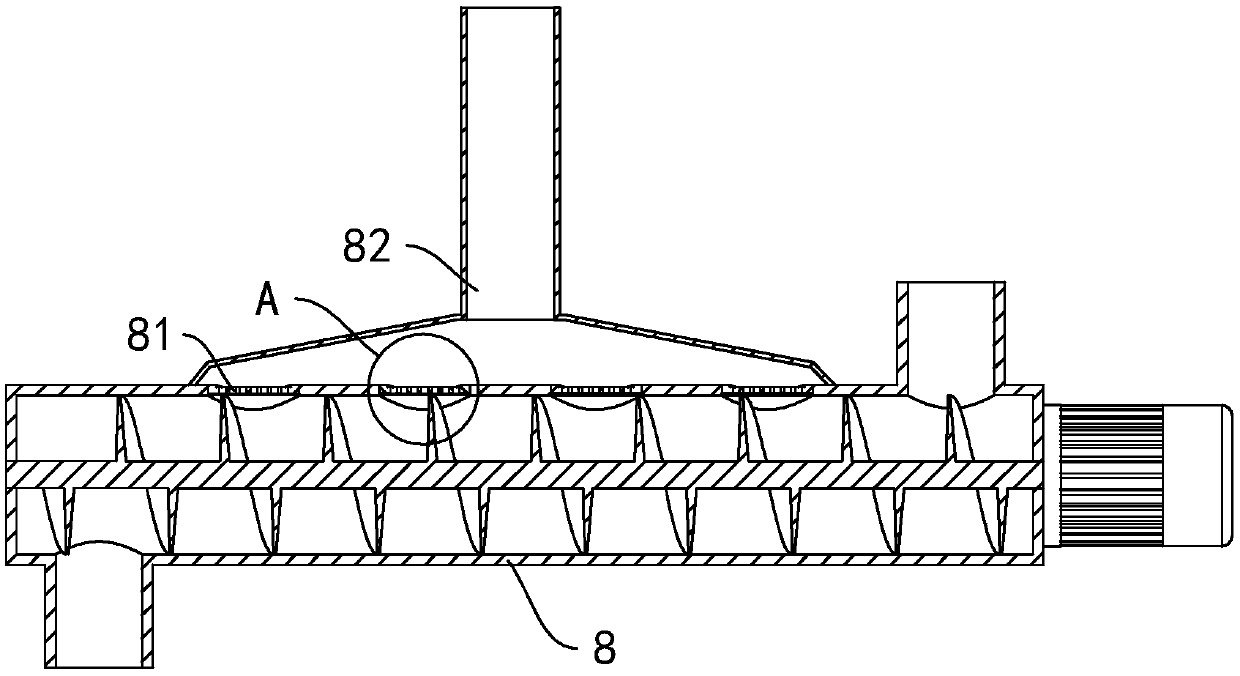

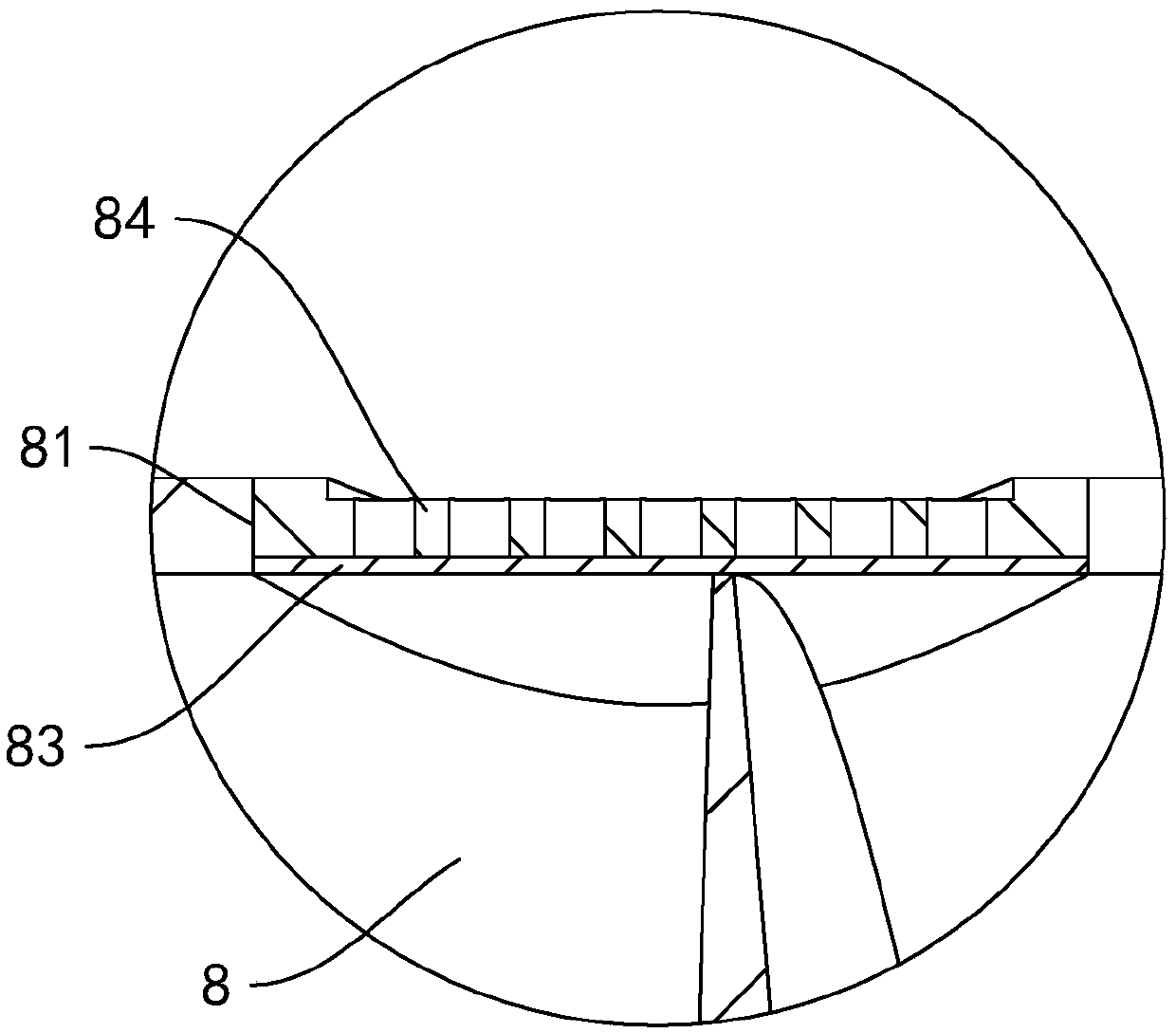

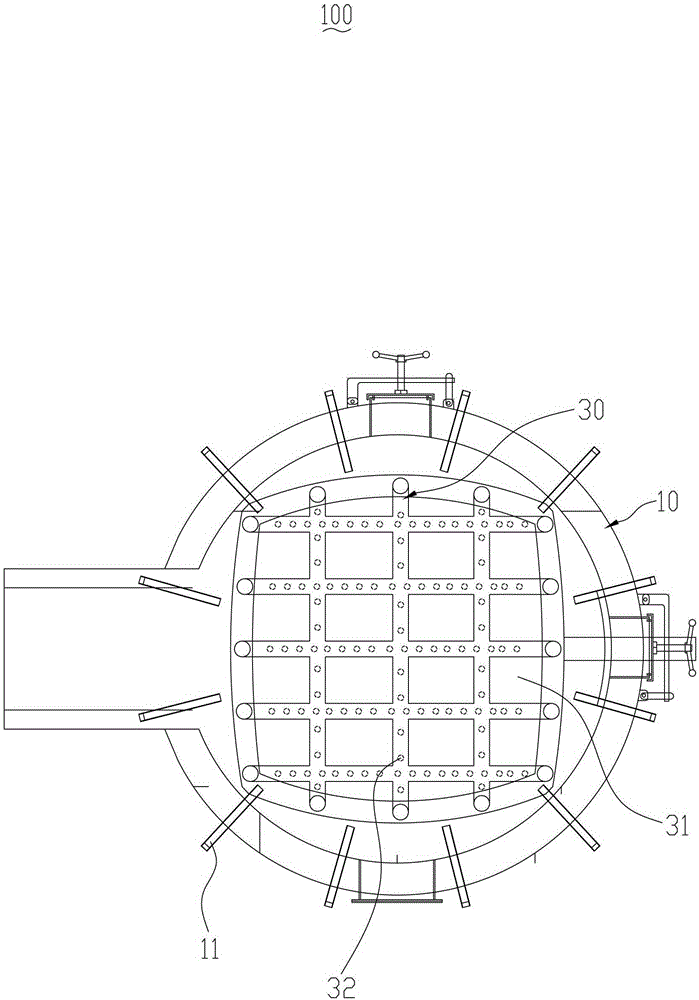

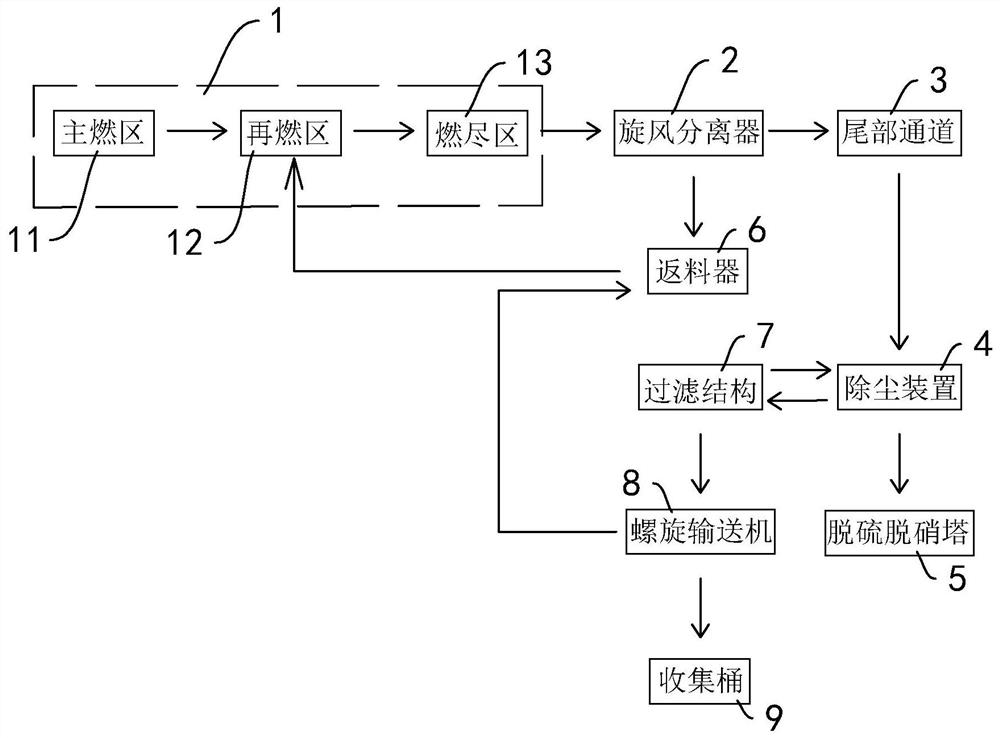

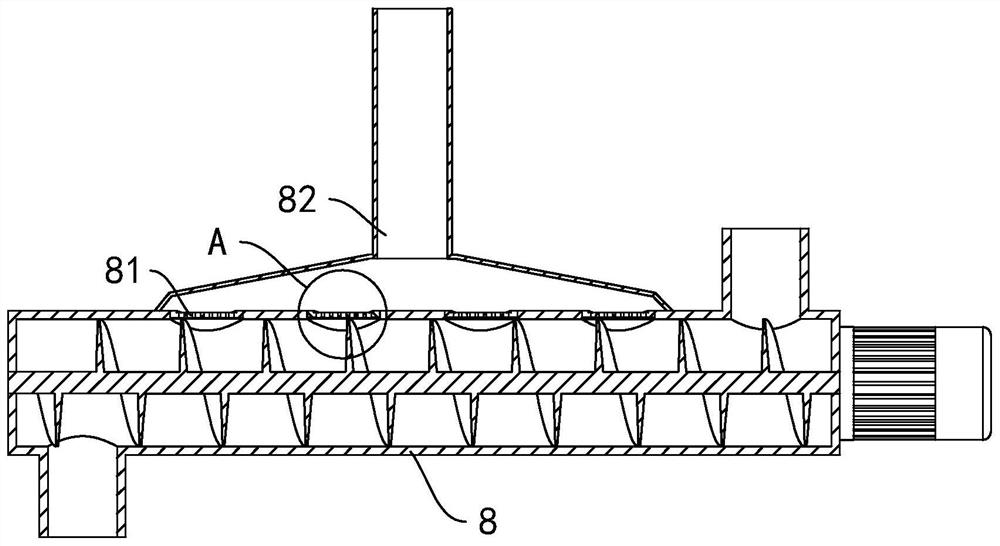

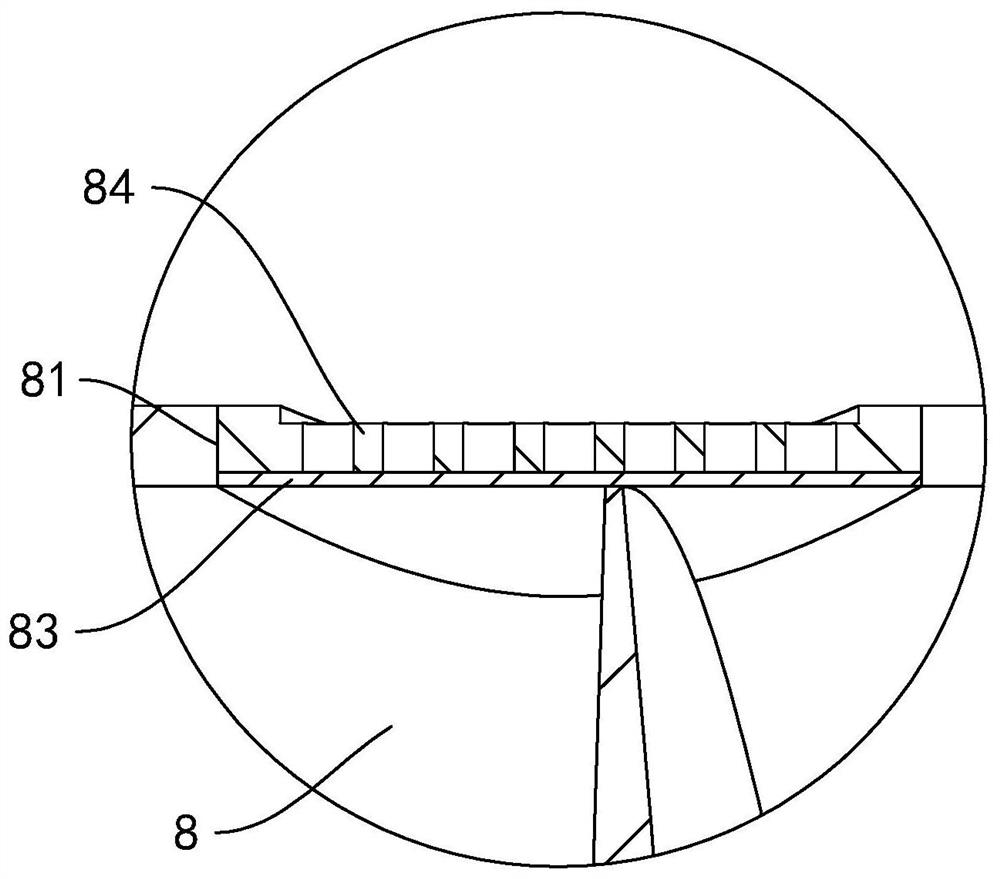

Efficient clean coal combustion technology

ActiveCN109579037AEfficient removalReduce pollutionHuman health protectionEmission preventionWater vaporAtmospheric air

The invention discloses an efficient clean coal combustion technology, and belongs to the field of thermoelectricity. According to key points of the technical scheme, the technology comprises the following steps that S1, combustion is conducted, a coal feeding machine is adopted to convey coal powder into a furnace hearth of a circulating fluidized bedboiler; S2, separating is conducted; S3, heatexchanging is conducted; S4, dedusting is conducted; S5, desulphurization and denitrification are conducted, smoke is conveyed to a desulphurization and denitrification tower; S6, coal powder ash is collected, in the S4, liquid containing the coal powder ash is filtered with a filter cloth to obtain coal powder ash mud and filtering water; S7, drying is conducted, the coal powder ash mud is conveyed to a collecting barrel by a spiral conveying machine, and the coal powder ash mud is dried when conveyed; and S8, steam is collected, the steam produced by coal powder ash mud drying in the S7 is conveyed to a back-feeder, so that the steam and coarse particles enter the furnace hearth together. The efficient clean coal combustion technology has the effect of reducing pollution to the atmosphere by fine coal ash.

Owner:SAINYEAR HLDG GRP HANGZHOU COGENERATION

Energy-saving and environment-friendly wood stove

ActiveCN109974034AReduce labor intensitySave electricityDomestic stoves or rangesLighting and heating apparatusAirflowDeflection angle

The invention discloses an energy-saving and environment-friendly wood stove. The energy-saving and environment-friendly wood stove comprises supporting legs, a bottom plate and a stove body; a feeding port is formed in the part, close to the bottom, of the outer wall of the stove body; the outer wall of the feeding port is rotationally connected with a stove door through a hinge; an ignition stove head is fixed to the part, located at the upper edge of the feeding port, of the inner wall of the stove body; and a plurality of grooves are formed in the bottom surface of the ignition stove headat equal angles. The deflection angle of an air inlet bin is adjusted according to the direction of air, so that an air flow outside is led into the stove body to the greatest extent so as to carry out combustion supporting on wood; the combustion-supporting is carried out on the wood through the ignition stove head, ashes combusted by the wood are prevented from blocking flaming nozzles through asmoke blocking ring, the structure is novel, and the problem that the wood stove is inconvenient in ignition is solved effectively; and first air inlets and second air inlets of an air inlet ring arealigned, and a cooking stove head is simply ignited so as to heat a pot body at the upper part of a pot frame, so that the situation that food can not be cooked due to that fact that the wood is insufficient is avoided.

Owner:灵璧县浩翔信息科技有限公司

a waste incinerator

The invention discloses a garbage incinerator, comprising an incinerator body, a fire grate and a support layer, wherein the fire grate is arranged inside the incinerator body; the support layer is used for supporting garbage which is thrown in the incinerator body and is arranged inside the incinerator body and above the fire grate; fire channel gaps are formed in the support layer; flame on the fire grate passes through the fire channel gaps and burns the garbage on the support layer; the size of the garbage on the support layer is reduced after combustion; the garbage falls from the fire channel gaps and is burned out on the fire grate. The garbage is supported on the support layer and cannot fall on the fire grate to extinguish flame on the fire grate, so that higher temperature can be kept in the incinerator body, a stable heat source is formed in the incinerator body; as a large amount of water exists in the garbage, the garbage is supported by the support layer, is dried firstly by the flame on the fire grate and the temperature in the incinerator body and then is burned, and combustion is sufficient.

Owner:郑维明

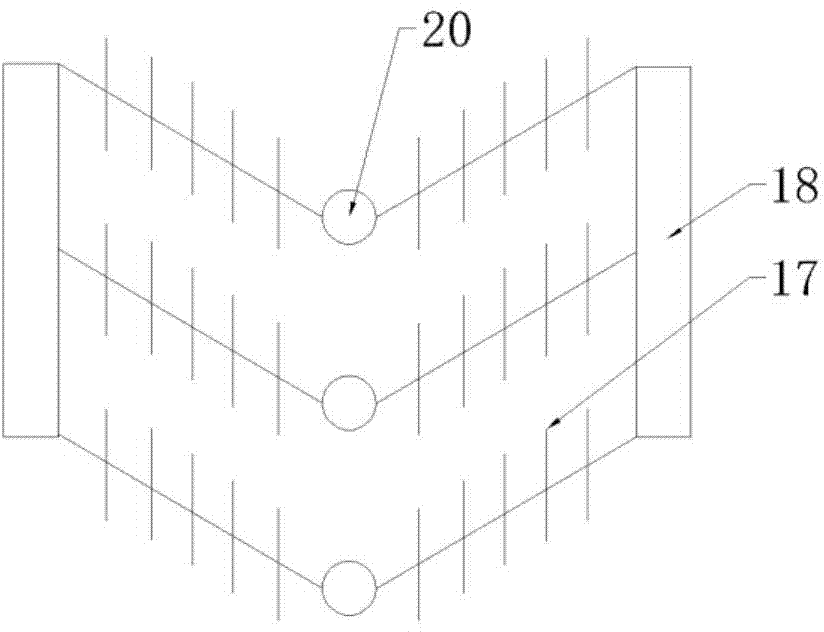

A Clean Coal Efficient Combustion Process

ActiveCN109579037BEfficient removalReduce pollutionHuman health protectionCombination devicesWater vaporDust control

The invention discloses an efficient clean coal combustion technology, and belongs to the field of thermoelectricity. According to key points of the technical scheme, the technology comprises the following steps that S1, combustion is conducted, a coal feeding machine is adopted to convey coal powder into a furnace hearth of a circulating fluidized bedboiler; S2, separating is conducted; S3, heatexchanging is conducted; S4, dedusting is conducted; S5, desulphurization and denitrification are conducted, smoke is conveyed to a desulphurization and denitrification tower; S6, coal powder ash is collected, in the S4, liquid containing the coal powder ash is filtered with a filter cloth to obtain coal powder ash mud and filtering water; S7, drying is conducted, the coal powder ash mud is conveyed to a collecting barrel by a spiral conveying machine, and the coal powder ash mud is dried when conveyed; and S8, steam is collected, the steam produced by coal powder ash mud drying in the S7 is conveyed to a back-feeder, so that the steam and coarse particles enter the furnace hearth together. The efficient clean coal combustion technology has the effect of reducing pollution to the atmosphere by fine coal ash.

Owner:SAINYEAR HLDG GRP HANGZHOU COGENERATION

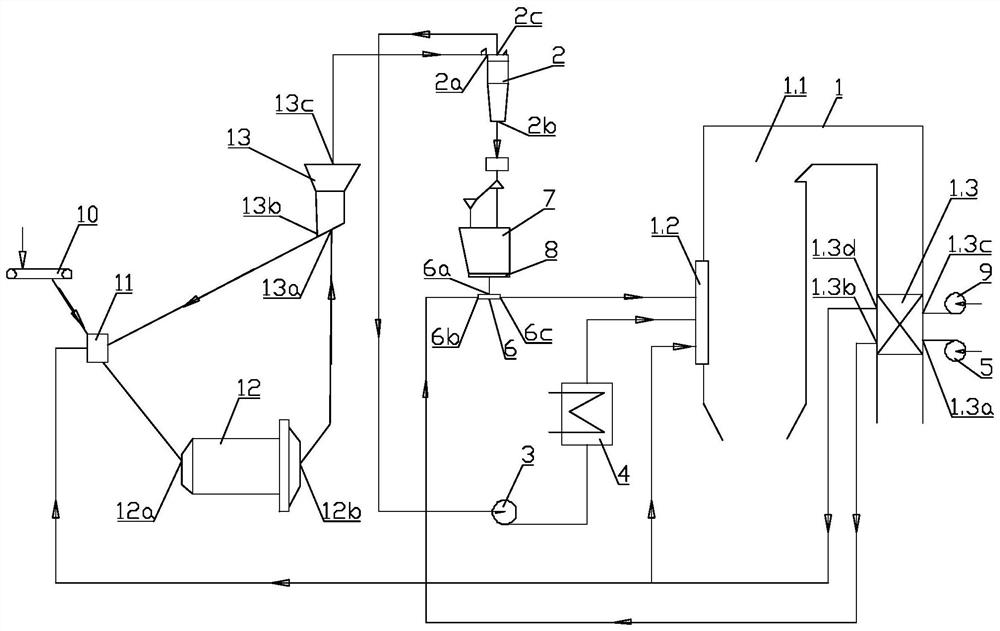

Storage bin type hot air powder feeding and pulverizing system adopting tertiary air heating

PendingCN112146120AConducive to high temperature combustion in the furnaceIncrease the proportion of secondary airIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyHot blastAir heater

The invention relates to the technical field of coal pulverizing, in particular to a storage bin type hot air powder feeding and pulverizing system adopting tertiary air for heating. The storage bin type hot air powder feeding and pulverizing system comprises a boiler, a fine powder separator for separating pulverized coal from tertiary air, a powder discharging fan for conveying the tertiary airand a tertiary air heater for heating the tertiary air, the boiler comprises a hearth and a combustor in communication with the front end of the hearth, and a tertiary air outlet of the fine powder separator is connected with the combustor through the powder discharging fan and the tertiary air heater in sequence. The tertiary air separated by the fine powder separator is heated and then sent to the combustor, so that the tertiary air can be used as secondary air of a main combustion area of the boiler, on one hand, the temperature of the tertiary air is increased, high-temperature combustionof the hearth is facilitated, and on the other hand, the secondary air proportion is increased, hearth air distribution is optimized, hearth organization combustion is facilitated, the pulverized coal, smoke and air are mixed more strongly, combustion in the hearth is stronger, and therefore the carbon content of fly ash is smaller, mechanical incomplete losses are smaller, and the combustion efficiency of the boiler is higher.

Owner:SHANGHAI POWER EQUIP RES INST +1

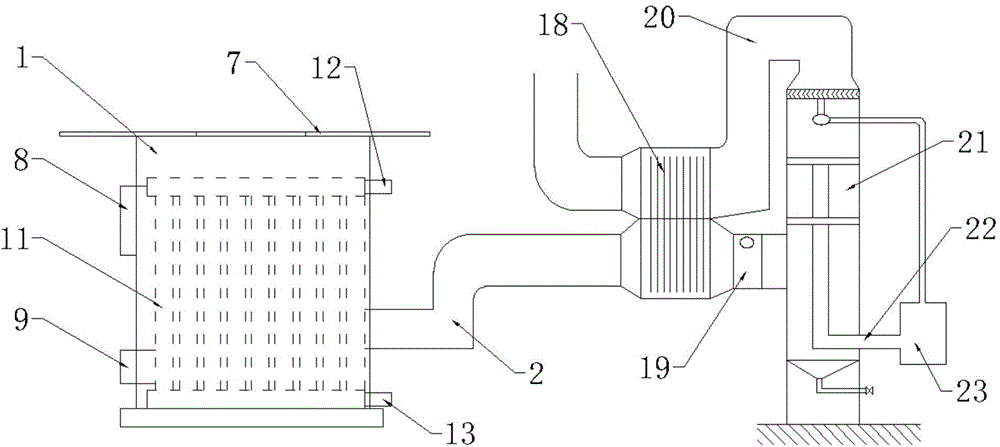

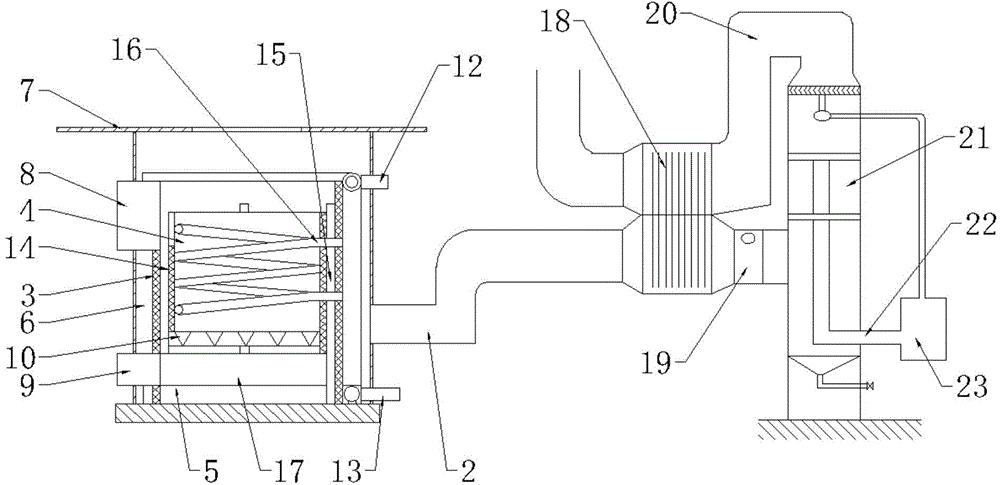

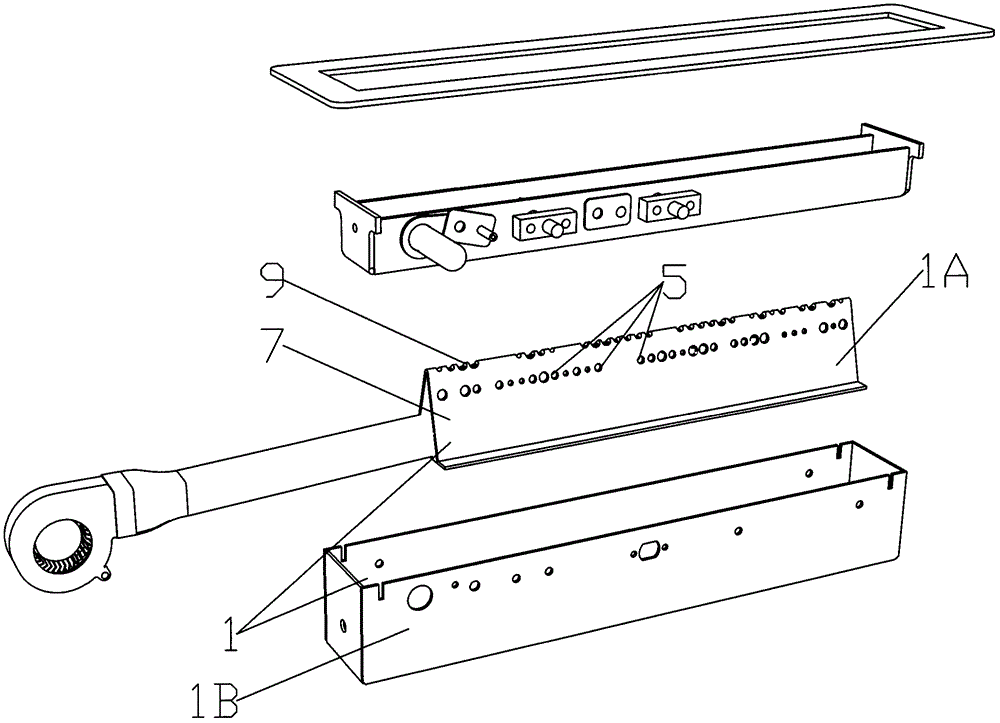

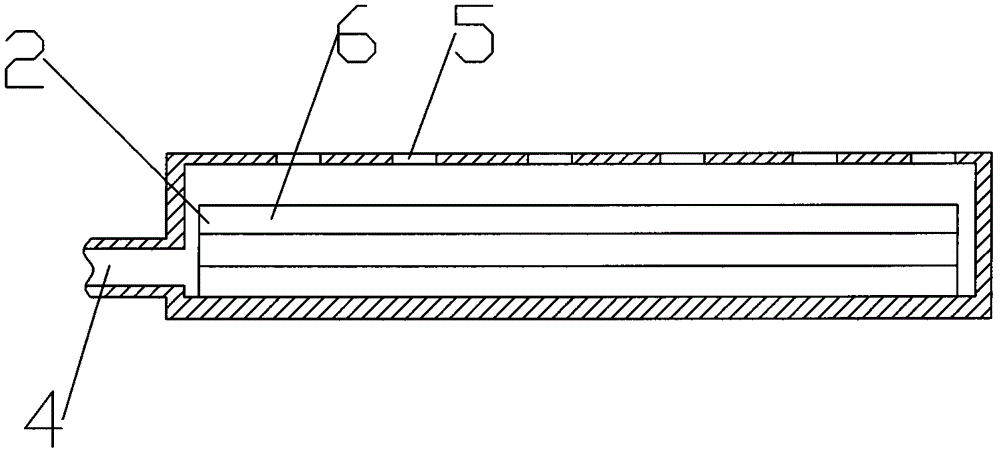

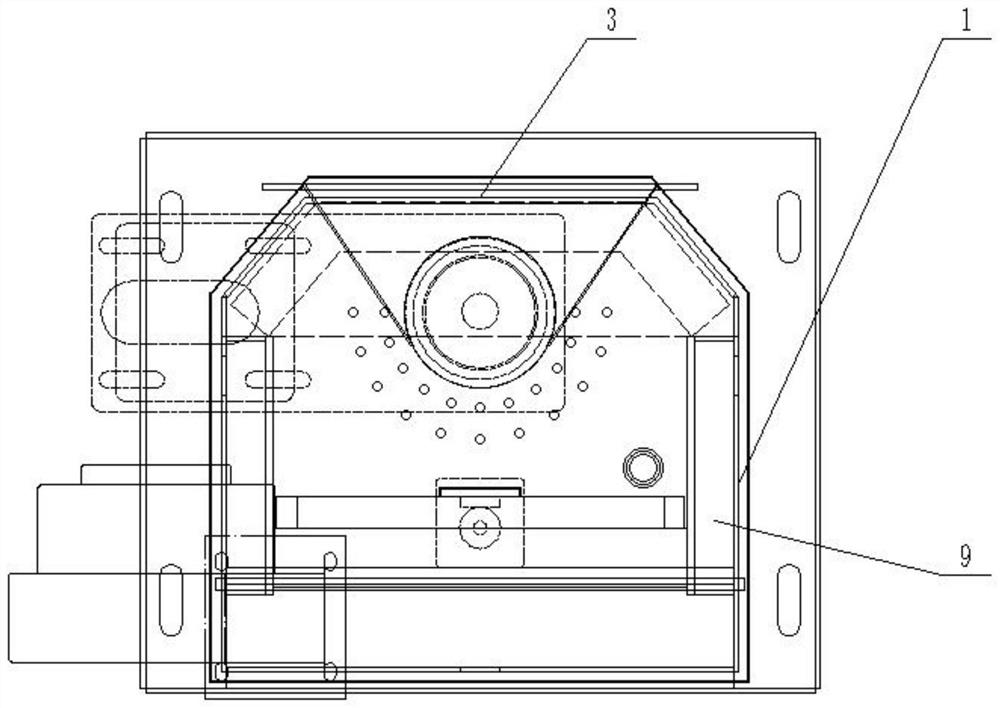

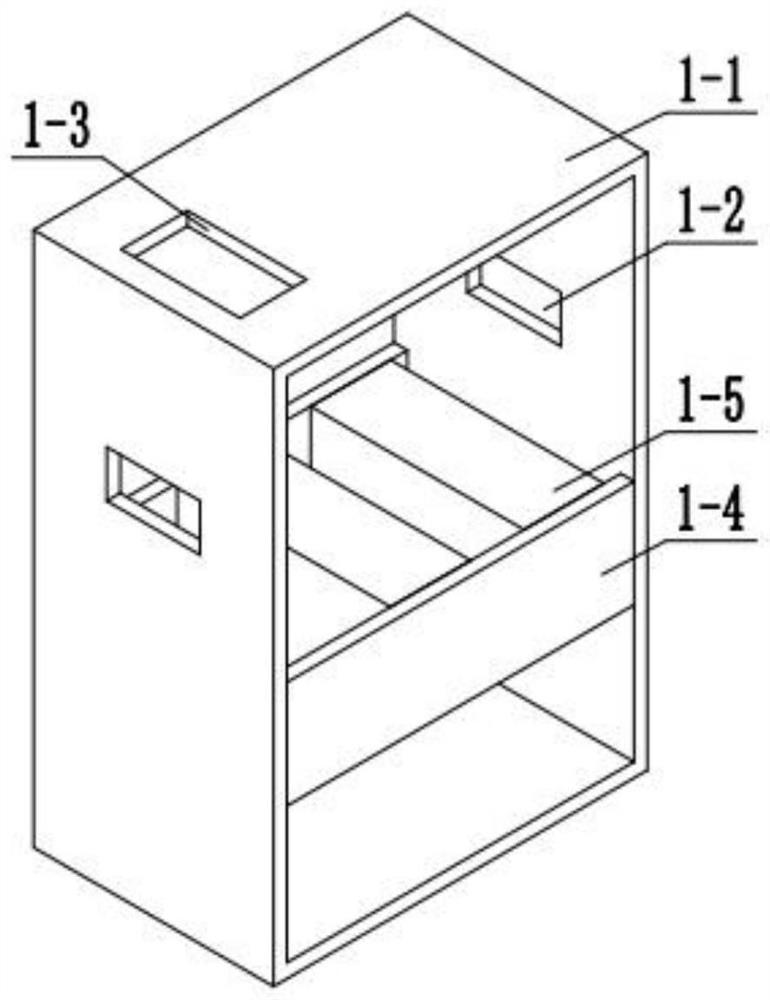

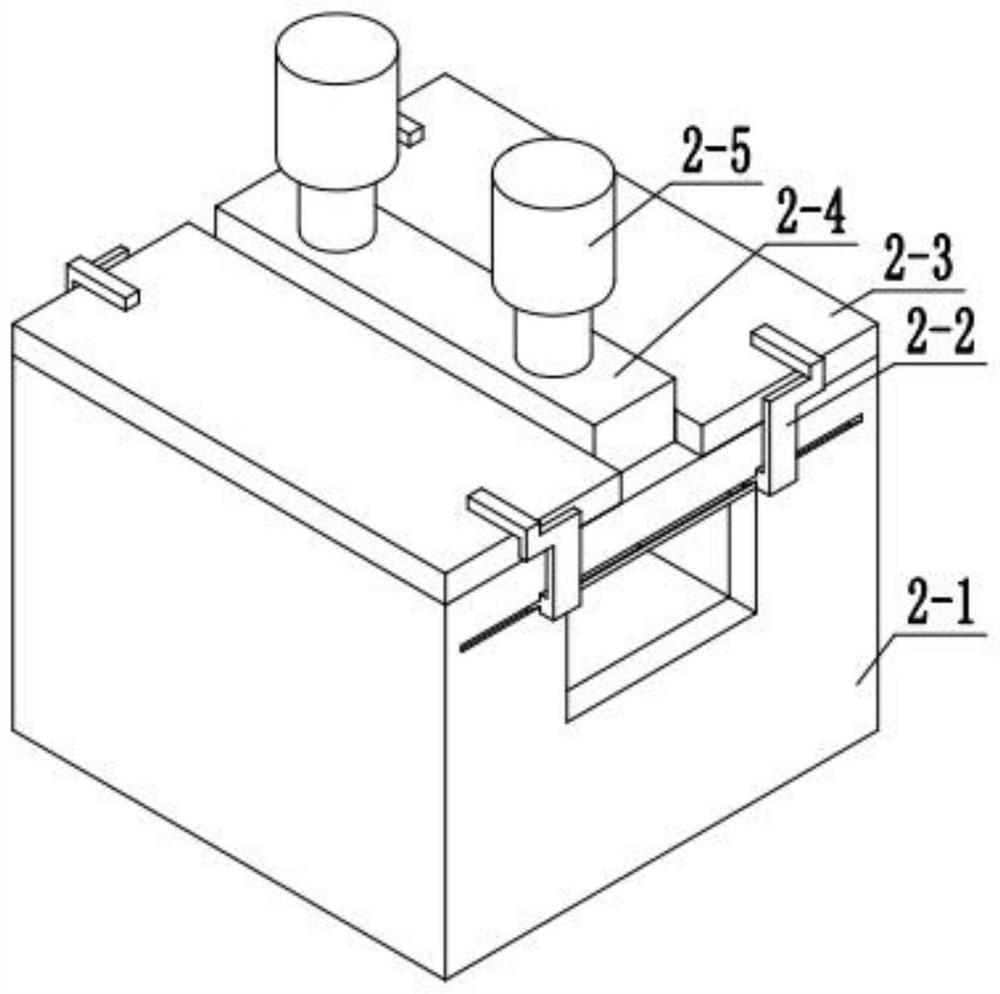

Collecting device for monitoring whether construction site dust reaches standards or not

InactiveCN108225994AAvoid cloggingStrong burningParticle suspension analysisPhysical well beingArchitectural engineering

The invention relates to a collecting device and particularly relates to a collecting device for monitoring whether construction site dust reaches the standards or not. The invention aims to provide the collecting device for monitoring whether the construction site dust reaches the standards or not, which has the advantages that the labor intensity is small, the detection effect is good, manual detection is not needed and dust can not be sucked so as to avoid the influence on body health. In order to solve the technical problem, the collecting device for monitoring whether the construction site dust reaches the standards or not, provided by the invention, comprises a bottom plate and the like, wherein support legs are symmetrically mounted at the left and right sides of the top of the bottom plate, a placing device is arranged between inner side surfaces of the support legs at the left and right sides, a first placing frame is mounted between the top ends of the support legs at the left and right sides, a stirring device is arranged at the middle part of the first placing frame, and a stirring part of the stirring device is positioned in the first placing frame. A vibrating deviceis used for enabling dust to completely fall into the first placing frame to prevent a screen plate from being blocked; and a blowing device can be used for enabling coal to be burnt more vigorously,and the detection efficiency is higher.

Owner:查宇

Biofuel sheet press

The invention discloses a biofuel curved piece type pressing device. The biofuel curved piece type pressing device is characterized by comprising a main roller and a synchronous roller; the main roller is cylindrical; the two end surfaces of the main roller are fixedly connected with main end plates; the two main end plates are connected with main transmission rollers coaxially connected to a bracket with the main roller; peripheral main wave peaks and peripheral main wave troughs are axially spaced on the surface of the main roller; the synchronous roller is cylindrical, has the same length with the main roller, and is parallel to the axis of the main roller; the two ends of the synchronous roller are fixedly connected with synchronous end plates; the synchronous end plates are fixedly connected with synchronous transmission shafts coaxial with the synchronous roller; the synchronous transmission shafts and the main transmission rollers are connected through synchronous gears, and are opposite in rotating direction; and peripheral synchronous wave peaks and peripheral synchronous wave troughs are axially spaced on the surface of the synchronous roller. Particles obtained by pressing and smashing are accumulated to obtain big gaps, are filled in a boiler to realize smoothness of air currents, and are vigorously burnt; and burnt thin dust can retain the gaps to the greatest extent to accelerate combustion.

Owner:CHONGQING HUAWANLUN BIOLOGICAL NEW ENERGY TECH CO LTD

fireplace burner

ActiveCN102434879BStrong burningImprove the combustion processLiquid fuel evaporation burnersBlast-producing apparatusCombustionEngineering

The invention discloses a fireplace combustion device, which comprises a combustion groove, wherein the combustion groove comprises a combustion strip and a strip groove; an air channel is formed in the combustion strip; the combustion strip is provided with an air hole for communicating the outside with the air channel; the air inlet of the air channel is provided with an air blower; and a turbulent flow device is arranged in the air channel. The air inlet of the air channel of the fireplace combustion device provided by the invention is provided with the air blower, so that the air amount can be increased, the flame burns more vigorously, the flame is stronger and better heating and atmosphere creating effects are achieved. Moreover, the turbulent flow device is arranged in the air channel, and can be used for refracting and shunting, so that air stream changes in more ways, and combustion flame has higher jumping property and stronger kinetic effect and is more attractive.

Owner:温州爱盟科技有限公司

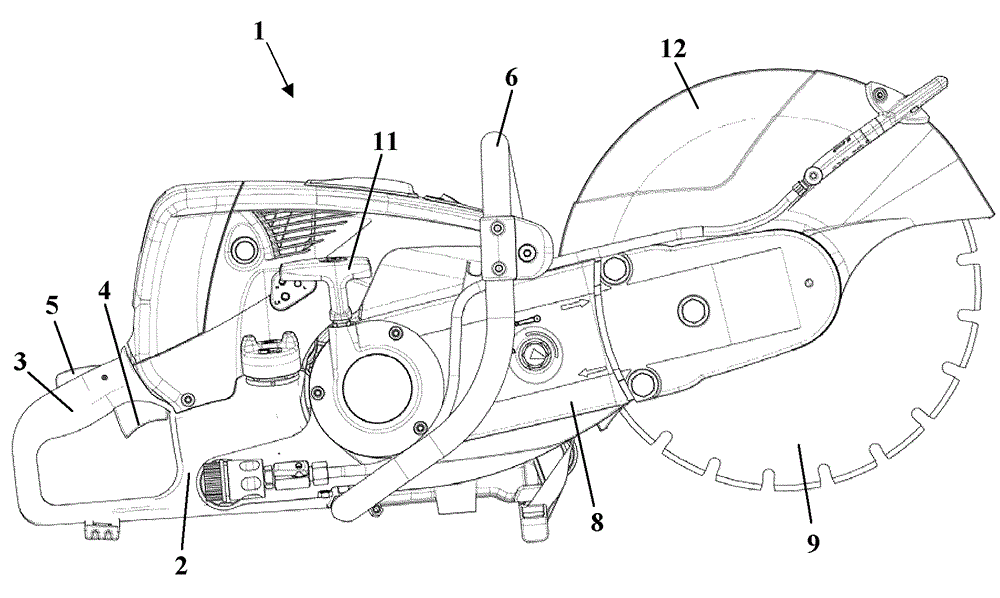

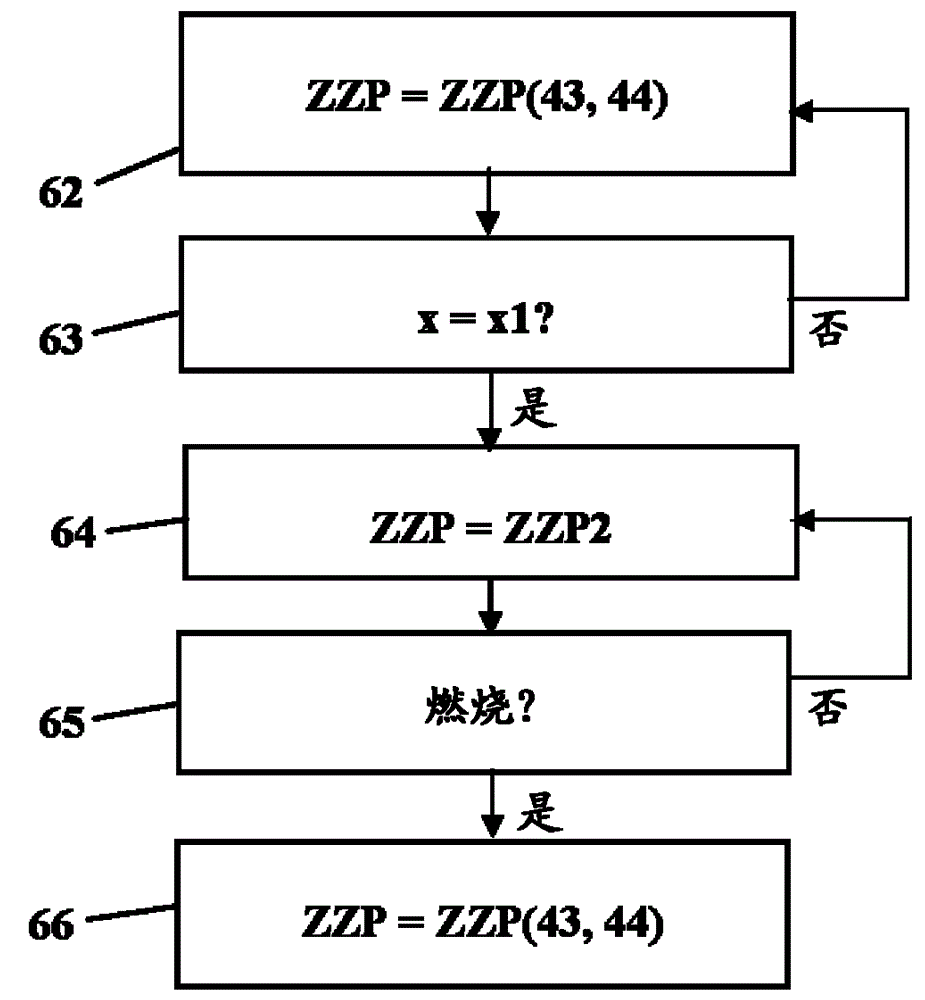

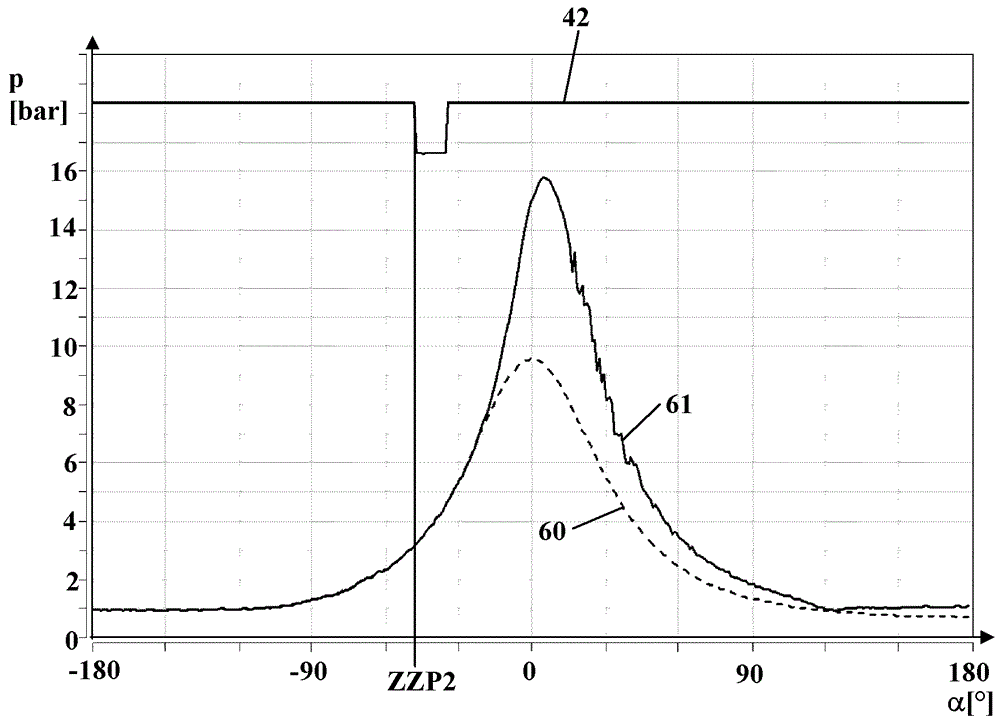

Method for operating internal combustion engine

InactiveCN104100388AClose reliableGuaranteed uptimeElectrical controlInternal combustion piston enginesExternal combustion engineReciprocating motion

Owner:ANDREAS STIHL AG & CO KG

Energy-saving boiler

PendingCN113405258AImprove the heating effectImprove heating efficiencySievingFluid heatersWater storageCombustion

The invention discloses an energy-saving boiler, and relates to the technical field of energy-saving boilers. A water storage device is fixed in a boiler body of the energy-saving boiler, a water inlet end and a water outlet end are arranged at the top and the bottom of the rear side of the water storage device correspondingly, the part, located at the bottom of the water storage device, in the boiler body is a combustion heating area, and an overhaul door plate is installed at the position, located at the combustion heating area, of the front side of the boiler body; and a fuel adding opening and an oxygen inlet are formed in the portions, located at the left side and the right side of the combustion heating area, of the furnace body correspondingly, and an inwards-concave hemispherical part is arranged at the bottom of the water storage device. According to the energy-saving boiler, the heating effect of coal on the water storage device in the combustion heating area can be improved by arranging the inwards-concave hemispherical part at the bottom of the water storage device, smoke generated by coal combustion can be exhausted by arranging a smoke exhaust cylinder, and meanwhile, the smoke exhaust cylinder penetrates through the water storage device, so that high-temperature flue gas in the smoke exhaust cylinder can heat water in the water storage device, and the water heating efficiency of the boiler is improved.

Owner:邓瑞

Burner with convex slag pushing plate

InactiveCN112254121AEfficient removalWell mixedSolid fuel combustionCasings/liningsThermodynamicsCombustor

The invention discloses a burner with a convex slag pushing plate. The burner comprises a burner body, wherein the burner body comprises a combustion chamber component and a preheating air distribution chamber component; the combustion chamber component comprises a combustion chamber; the combustion chamber is defined by an air chamber plate, an air chamber vertical plate, an air chamber upper supplementing plate and an air chamber blocking plate; a fixed fire grate is arranged in the combustion chamber; the fixed fire grate is provided with a fire grate ash leaking hole; the upper end of theright side of the fixed fire grate is provided with the convex slag pushing plate; the left side of the convex slag pushing plate is provided with a plurality of protruding plate parts; the middle ofthe right side of the convex slag pushing plate is connected to a slag pushing plate connecting plate; the right end of the slag pushing plate connecting plate is connected to a transmission device; the fixed fire grate divides the combustion chamber of the combustion chamber component into a combustion cavity and an ash removal cavity; the combustion cavity is arranged above the ash removal cavity;an ash removal opening is arranged in the left end of the ash removal cavity; and an ash removal door is arranged at the ash removal opening. The convex slag pushing plate is arranged, so that slagblocks adhered to the middle of the fixed fire grate can be more easily and effectively removed.

Owner:SHANDONG DUOLE NEW ENERGY TECH CO LTD

Rapid forging and pressing device for plate chain

PendingCN114472795AStrong burningRealize the function of forgingForging/hammering/pressing machinesForging press detailsAir blowerForge

The invention belongs to the related field of forging and pressing, and particularly relates to a plate chain rapid forging and pressing device which comprises a device outer shell and further comprises a forging and pressing mechanism, a feeding and taking-out mechanism and an air blowing mechanism. The forging and pressing mechanism is installed on the device outer shell, the feeding and taking-out mechanism is connected with the forging and pressing mechanism and installed on the device outer shell, and the air blowing mechanism is connected with the forging and pressing mechanism. In order to solve the problems that in the prior art, only the bottom of a forge piece is heated, the heating speed is low, heating is not uniform, the forging effect is seriously affected, in the forging process, the forge piece is very troublesome to move, manual feeding is needed, time and labor are wasted, certain dangerousness exists, and the forge piece is difficult to move. The invention provides a rapid forging and pressing device for a plate chain to solve the problem.

Owner:恒利达(福建)重工发展有限公司

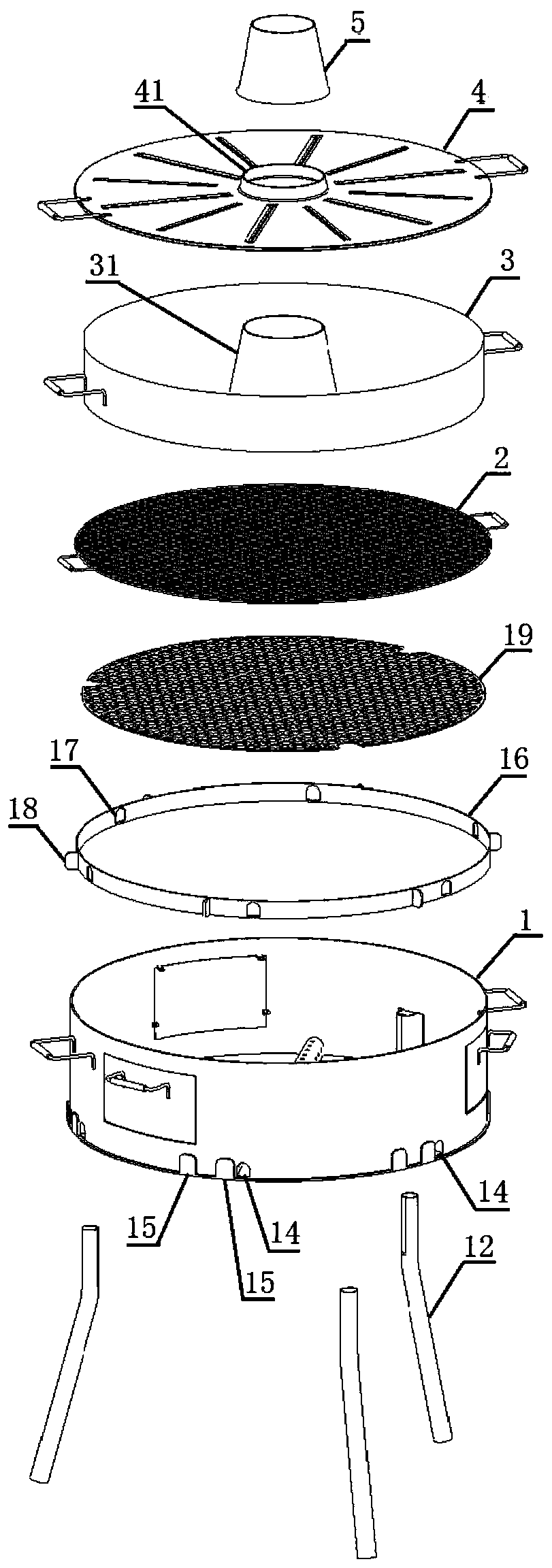

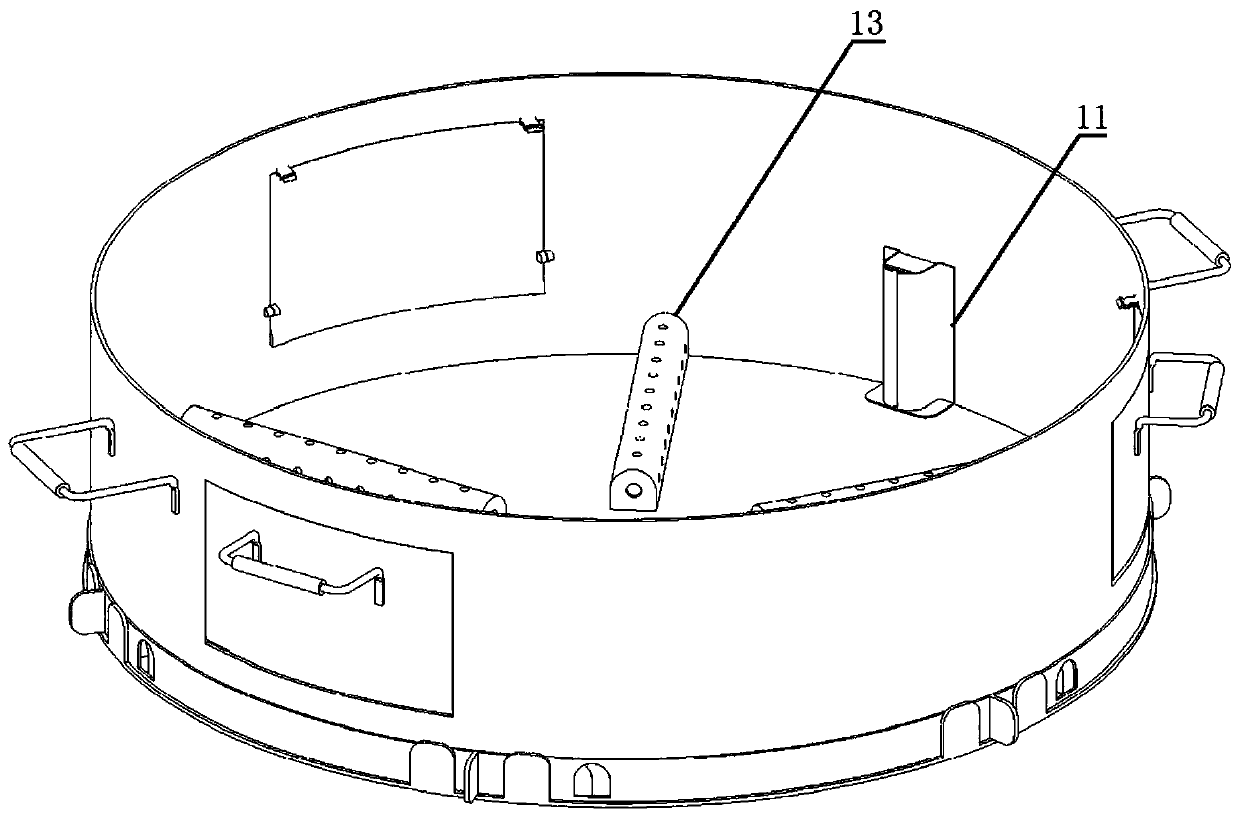

Multifunctional oven

InactiveCN111214100ASmoke avoidStrong burningDomestic stoves or rangesLighting and heating apparatusEngineeringFood material

A multifunctional oven comprises an oven body and a barbecue wire mesh, wherein an oven door is arranged on the oven body, and fuel is put into the oven body from the oven door or an opening in the top part of the oven body; and the barbecue wire mesh is placed on the opening in the top part of the oven body for use. The multifunctional oven further comprises a baking pan and a baking tray, wherein a baking pan smoke pipe protruding upwards is arranged in the middle of the baking pan, and a baking tray smoke column protruding upwards is arranged in the middle of the baking tray. The multifunctional oven truly achieves the effect that one oven serves several purposes, the barbecue wire mesh is arranged on one oven body and is used for roasting skinned food materials which are not afraid ofsmoking; the baking pan with the smoke exhaust pipe protruding upwards is arranged in the middle of the same oven body, the baking pan is covered with the baking tray after food materials are placed in the baking pan, smoke generated by charcoal combustion is exhausted upwards through the smoke exhaust pipe, and the baking pan can be used for making baked food or cooking soup and rice; and when the baking pan is not covered with the baking tray, hot pot soup bases and corresponding food materials are directly added into the baking pan, and the baking pan has the function of a hot pot and can be used for making the hot pot.

Owner:NANAN LIDI HOUSEHOLD ITEMS CO LTD

High-efficiency balanced heating type hot gas generating barrel container

InactiveCN109751588AAvoid unevennessImprove efficiencyBoiler flue tubes/fire tubesBoiler cleaning apparatusCombustion chamberEngineering

The invention discloses a high-efficiency balanced heating type hot gas generating barrel container. A combustion chamber is horizontally arranged on the lower portion in an inner container body, andthe outer wall of the combustion chamber and the inner wall of the inner container body are welded in a sealed manner; a first draught fan barrel penetrates through the inner container body to be horizontally arranged at the right end of the combustion chamber, and the first draught fan barrel communicates with the combustion chamber; a combustion barrel penetrates through the inner container bodyto be vertically arranged on the bottom face of the left portion of the combustion chamber, and the combustion barrel communicates with the combustion chamber; a main heating pipe is vertically arranged on the middle portion of the upper face of the combustion chamber, and the main heating pipe communicates with the combustion chamber; the main heating pipe is located on the middle portion in theinner container body; a second draught fan barrel penetrates through the inner container body to be vertically arranged on the middle portion of the upper end of the main heating pipe, and the seconddraught fan barrel communicates with the main heating pipe; a first arc-shaped pipe is arranged on the right side of the main heating pipe, and the first arc-shaped pipe communicates with the main heating pipe; and a second arc-shaped pipe is arranged on the left side of the main heating pipe, and the second arc-shaped pipe communicates with the main heating pipe.

Owner:周小辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com