Method for operating internal combustion engine

An internal combustion engine and combustion chamber technology, applied in the direction of internal combustion piston engine, combustion engine, engine starting, etc., can solve the problems of complex manufacturing of pressure reducing valves, and achieve the effect of preventing smooth operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

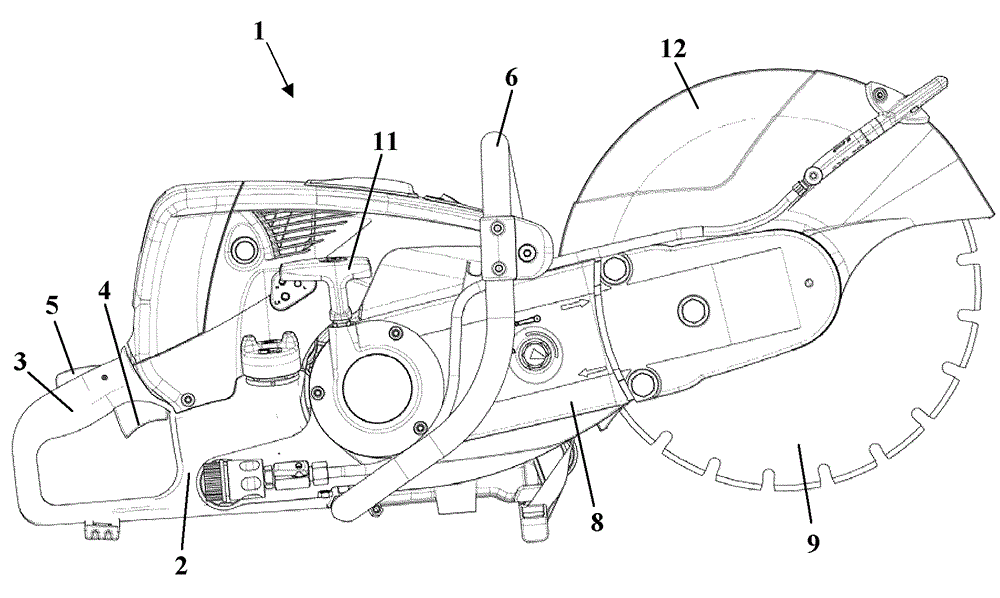

[0024] figure 1 A cutting machine 1 is shown as an example for a portable hand-held power tool. The method for operating an internal combustion engine, which will be explained in more detail below, can also be used in internal combustion engines for other fields of application, in particular in other work implements such as power saws, free cutters, blowers, jet implements, harvesting implements, mowers, etc. In internal combustion engines such as lawn mowers. The cutting machine 1 has a housing 2 to which two handles for guiding the cutting machine 1 during operation, namely a rear handle 3 and a handle 6 , are fastened. A throttle lever 4 and a throttle lever lock 5 are pivotably mounted on the rear handle 3 . On the side of the housing 2 facing away from the rear handle 3 a cantilever 8 projects forward, at its free end a cutting disc 9 is rotatably mounted. The cutting disk 9 is covered over a part of its circumference by a protective cover 12 . Arranged in the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com