Rapid forging and pressing device for plate chain

A forging and fast technology, applied in forging/pressing/hammer devices, driving devices of forging presses, forging presses, etc., can solve the problems of slow heating speed, time-consuming, laborious, dangerous, etc., and achieve the effect of stable transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment one, combining Figure 1-Figure 8 Be explained:

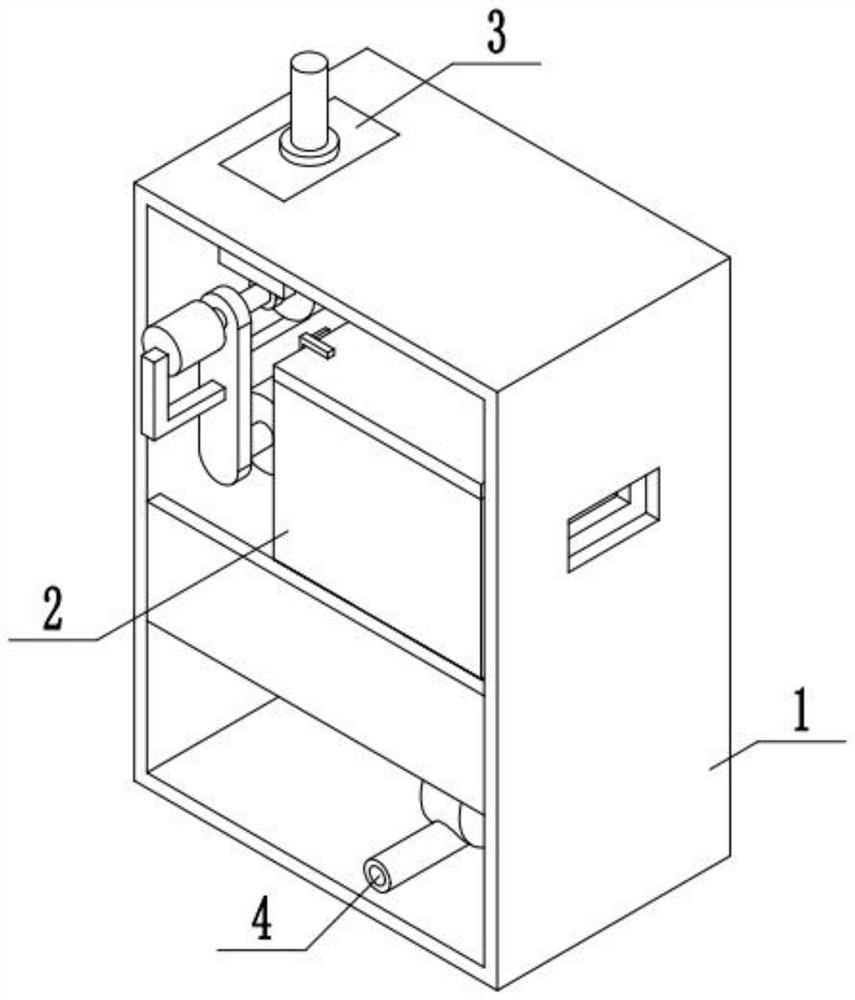

[0029] A plate chain rapid forging device, comprising: the device outer shell 1, also includes: a forging mechanism 2, a feeding and taking out mechanism 3 and a blowing mechanism 4, the forging mechanism 2 is installed on the device outer shell 1, the feeding and taking out mechanism 3 and the forging press Mechanisms 2 are connected, feed and take-out mechanism 3 is installed on device outer shell 1, blowing mechanism 4 is installed on forging mechanism 2, and blowing mechanism 4 is installed on device outer shell 1.

Embodiment 2

[0030] Embodiment two, combining Figure 1-Figure 8 Be explained:

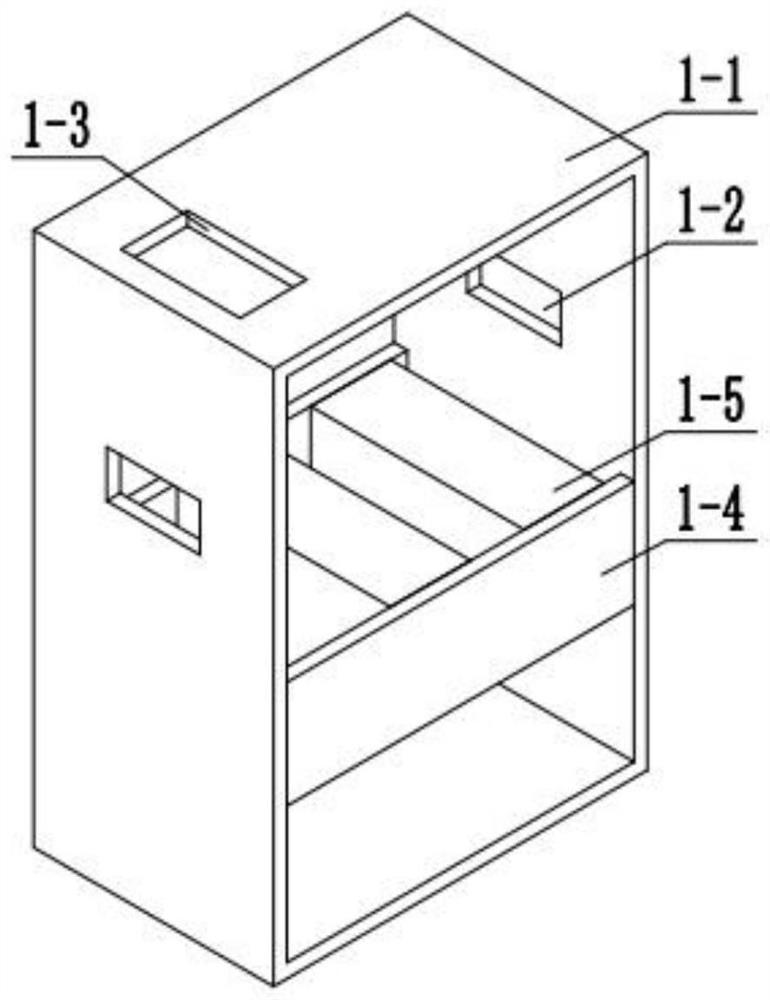

[0031] The device outer shell 1 comprises: an outer shell body 1-1, a feed port 1-2, a take-out mechanism installation groove 1-3, a baffle plate 1-4 and a beam 1-5, and the outer shell body 1-1 is provided with a The feed port 1-2 used in conjunction with the forging mechanism 2, the outer shell body 1-1 is provided with a take-out mechanism installation groove 1-3 for installing the feed and take-out mechanism 3, and the outer shell body 1-1 is equipped with a baffle plate 1 -4, there are two baffles 1-4, and the two ends of the beam 1-5 are fixedly installed on the baffle 1-4.

Embodiment 3

[0032] Embodiment three, combining Figure 1-Figure 8 Be explained:

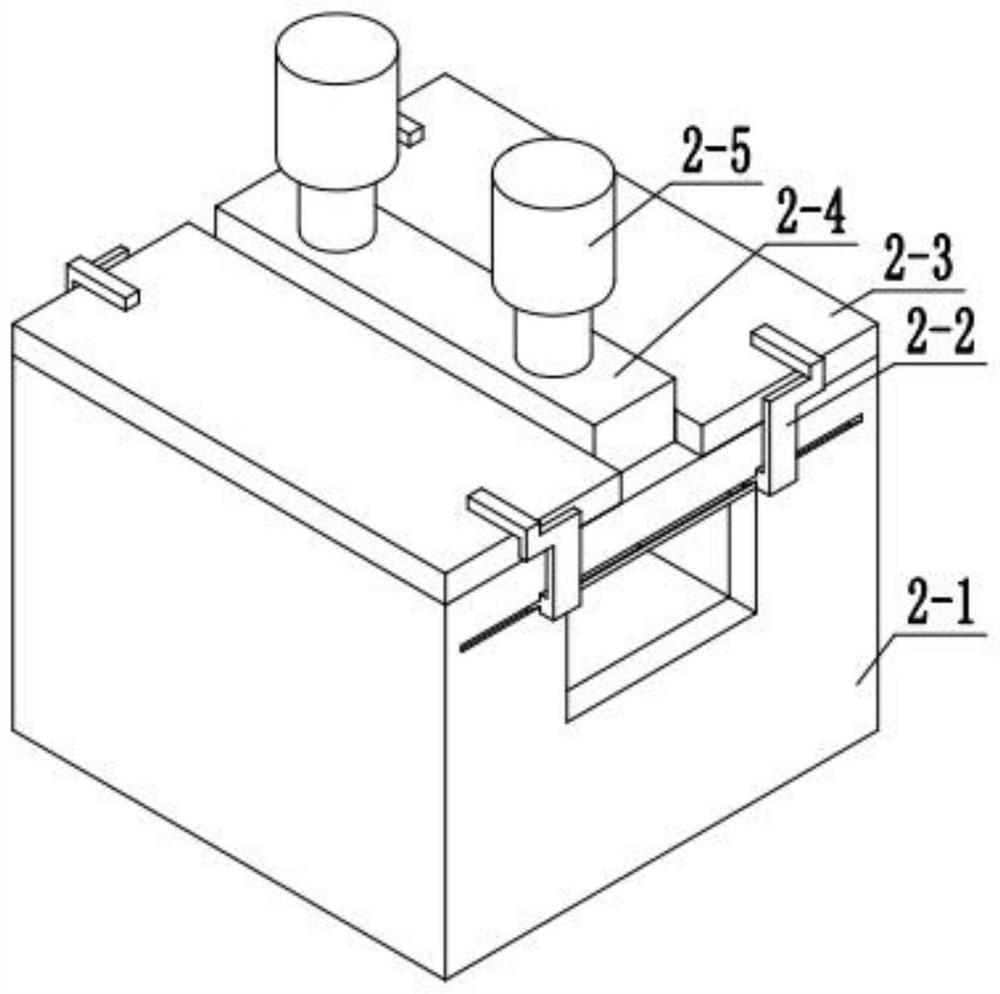

[0033] The forging mechanism 2 includes: a coal box body 2-1, a cover fixing buckle 2-2, a cover body 2-3, a forging head 2-4 and a hydraulic cylinder 2-5, and the coal box body 2-1 is installed on the beam 1-5 On the coal box body 2-1, a cover fixing buckle 2-2 for fixing the cover 2-3 is installed, the hydraulic cylinder 2-5 is installed on the outer shell body 1-1, and the hydraulic cylinder 2-5 is installed with The forging head 2-4, the forging head 2-4 is located in the coal box 2-1;

[0034]The coal box 2-1 includes: box body 2-1-1, trapezoidal chute 2-1-2, feed opening 2-1-3 and forging chamber 2-1-4, box body 2-1- 1 is provided with a trapezoidal chute 2-1-2 for installing the cover fixing buckle 2-2, the box body 2-1-1 is provided with a material feeding port 2-1-3, and the forging chamber 2-1- 4 Installed on the box body 2-1-1, pass the plate chain through the feed port 1-2 and the feed port 2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com