Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Simplify soldering steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Welding technology for steel plates

InactiveCN104588850AWelding safetyGuarantee welding qualityArc welding apparatusSheet steelEngineering

The invention discloses a welding technology for steel plates, and relates to the technical field of welding technologies. The welding technology includes the four steps of pre-welding preparing, temporary tack welding, welding and post-welding processing. By means of the welding technology for the steel plates, the welding steps are simplified, the welding mode is simple, standard specifications are selected for materials, and the steel tube welding quality can be guaranteed; a regular welding mode is provided for the steel plates which are 3 mm in thickness, and rapid and safe welding of the steel plates which are 3 mm in thickness is facilitated.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

Welding technology for steel plate

The invention discloses a welding technology for a steel plate and relates to the technical field of welding technologies. The welding technology includes four steps of preparing before welding, tack welding, welding and processing after welding. According to the welding technology for the steel plate, the welding steps are simplified, the welding mode is simple, material selection is accurate and standard, the welding quality of a steel pipe can be ensured, a standard welding mode is provided for the steel plate 1 millimeter in thickness, and the steel plate which is 1 mm in thickness can be easily, rapidly and safely welded.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

Aluminum plate welding process

InactiveCN104439641AWelding safetyChoose accurate specificationArc welding apparatusWelding/soldering/cutting articlesEngineeringSteel tube

The invention discloses an aluminum plate welding process, and relates to the technical field of welding processes. The aluminum plate welding process mainly includes the four steps of pre-weld preparation, tack weld, welding and post-weld treatment. By the adoption of the aluminum plate welding process, welding steps are simplified, the welding mode is simple, materials are accurately and standardly selected and used, the welding quality of steel pipes can be guaranteed, the standard welding mode is provided for aluminum plates with the thickness being 4 mm, and quick and safe welding of the aluminum plates with the thickness being 4 mm is facilitated.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

Tungsten electrode inert gas shielded welding process of aluminum plate

InactiveCN104526128AWelding safetyGuarantee welding qualityArc welding apparatusWelding/soldering/cutting articlesSpot weldingMaterials science

The invention discloses a tungsten electrode inert gas shielded welding process of an aluminum plate and relates to the welding process technical field. The tungsten electrode inert gas shielded welding process mainly comprises four steps of preparation before welding, temporary spot welding, welding and treatment after the welding. According to the tungsten electrode inert gas shielded welding process of the aluminum plate, the welding steps are simplified, the welding method is simple, the material selection is accurate and standard, the welding quality of the aluminum plate can be ensured, a standard welding way is provided for the aluminum plate, and the rapid and safe welding on the aluminum plate is facilitated.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

0Cr18Ni9 stainless steel plate welding process

InactiveCN104439616AWelding safetyGuarantee welding qualityArc welding apparatusMetallurgyMaterial selection

The invention discloses a 0Cr18Ni9 stainless steel plate welding process, and relates to the technical field of welding processes. The 0Cr18Ni9 stainless steel plate welding process mainly includes the steps of preparation before welding, tack weld, welding and treatment after welding. By means of the 0Cr18Ni9 stainless steel plate welding process, the welding steps are simplified, a welding mode is simple, material selection is precise and standard, the welding quality of 0Cr18Ni9 stainless steel plates can be guaranteed, the standard welding mode is provided for the 0Cr18Ni9 stainless steel plates, and quick and safe welding of the 0Cr18Ni9 stainless steel plates is facilitated.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

16 Mn steel plate argon arc welding process

InactiveCN104439643AWelding safetyGuarantee welding qualityArc welding apparatusWelding/soldering/cutting articlesEngineeringMaterial selection

The invention discloses a 16 Mn steel plate argon arc welding process, and relates to the technical field of welding processes. The 16 Mn steel plate argon arc welding process mainly includes the steps of preparation before welding, tack weld, welding and treatment after welding. By means of the 16 Mn steel plate argon arc welding process, the welding steps are simplified, a welding mode is simple, material selection is precise and standard, the welding quality of 16 Mn steel plates can be guaranteed, the standard welding mode is provided for the 16 Mn steel plates, and quick and safe welding of the 16 Mn steel plates is facilitated.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

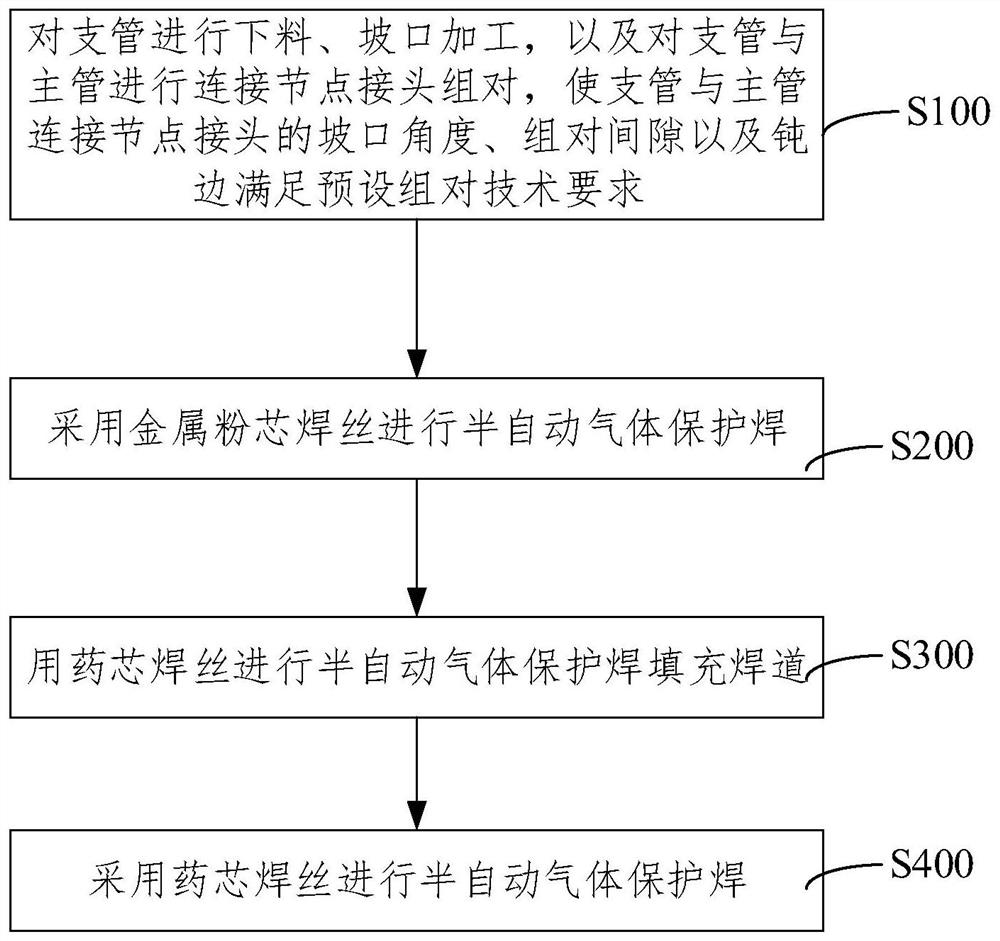

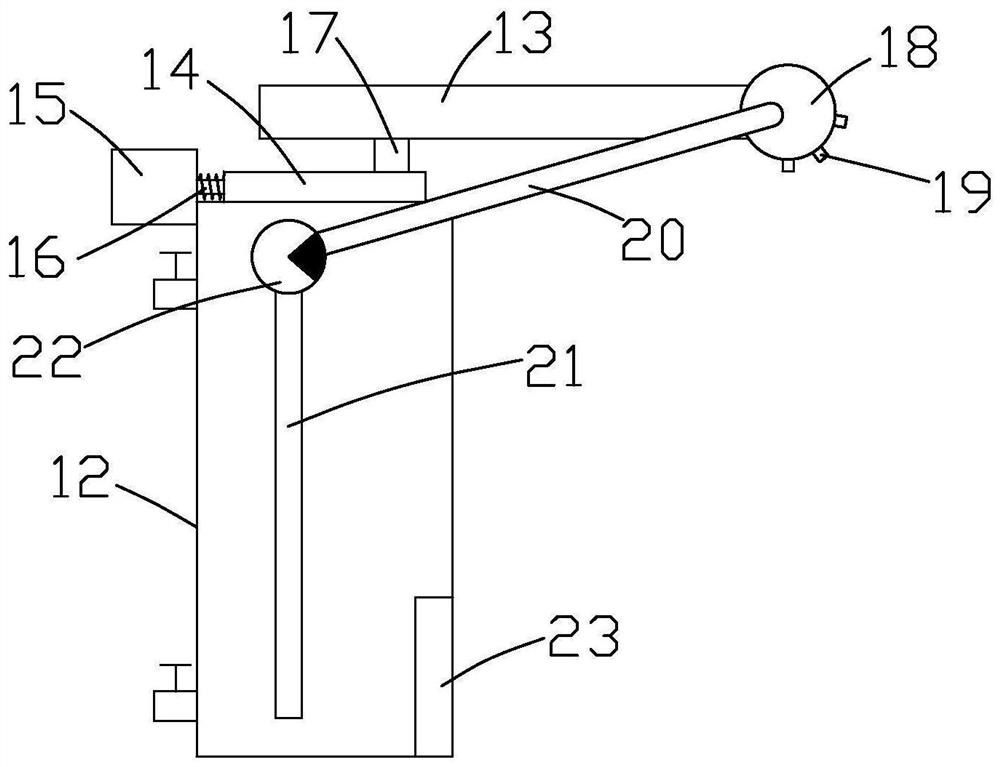

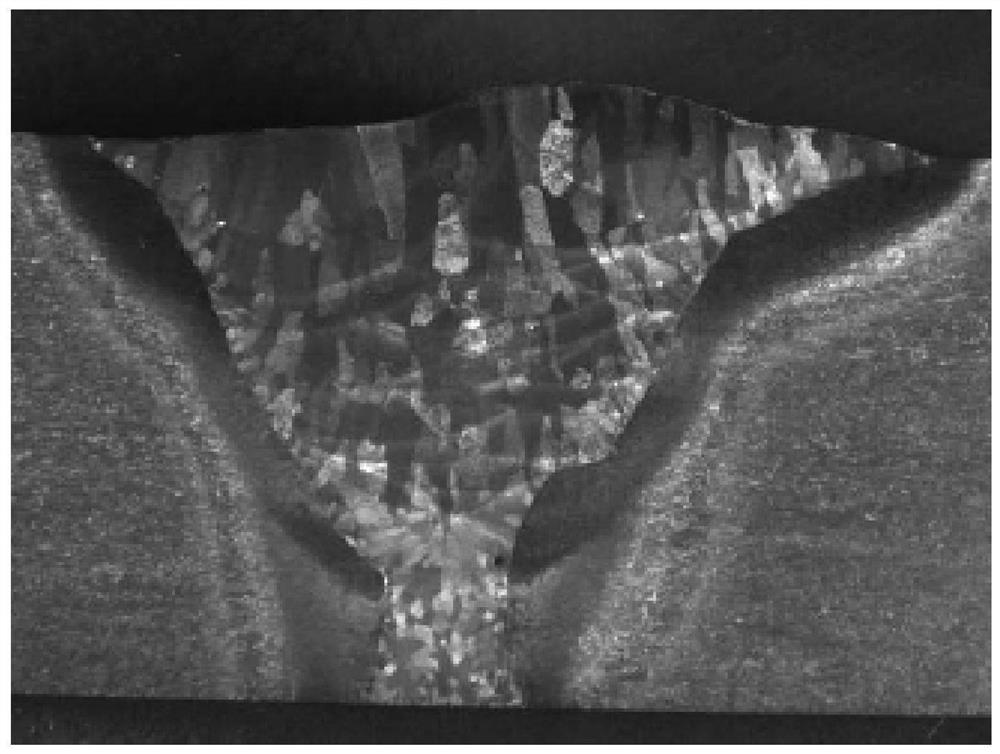

New welding process method for connecting joints between branch pipe and main pipe of steel structure in ocean engineering

InactiveCN111843122ASimplify soldering stepsReduce labor intensityElectrode supporting devicesWelding accessoriesMetal powderMachining

The invention discloses a new welding process method for connecting joints between a branch pipe and a main pipe of a steel structure in ocean engineering. The new welding process method includes thefollowing steps that blanking and assembling are conducted, blanking and groove machining are conducted on the branch pipe, connecting joint ends between the branch pipe and the main pipe are assembled, and the groove angle, the assembly gap and truncated edges of the connecting joint ends between the branch pipe and the main pipe meet preset assembly technical requirements; bottom sealing weldingis conducted, and metal powder cored wires are adopted for semi-automatic gas shielded welding; filling welding is conducted, and flux-cored wires are adopted for semi-automatic gas shielded welding;and covering welding is conducted, and the flux-cored wires are adopted for semi-automatic gas shielded welding. Semi-automatic gas shielded welding is adopted in the welding process, the welding wire only needs to be replaced once, the welding steps are greatly simplified, the problems of constantly changing welding equipment and welding rods are avoided, the labor intensity of welding is reduced, the welding efficiency is improved, and thus the welding cost of the steel structure joints is greatly reduced.

Owner:OFFSHORE OIL ENG QINGDAO +1

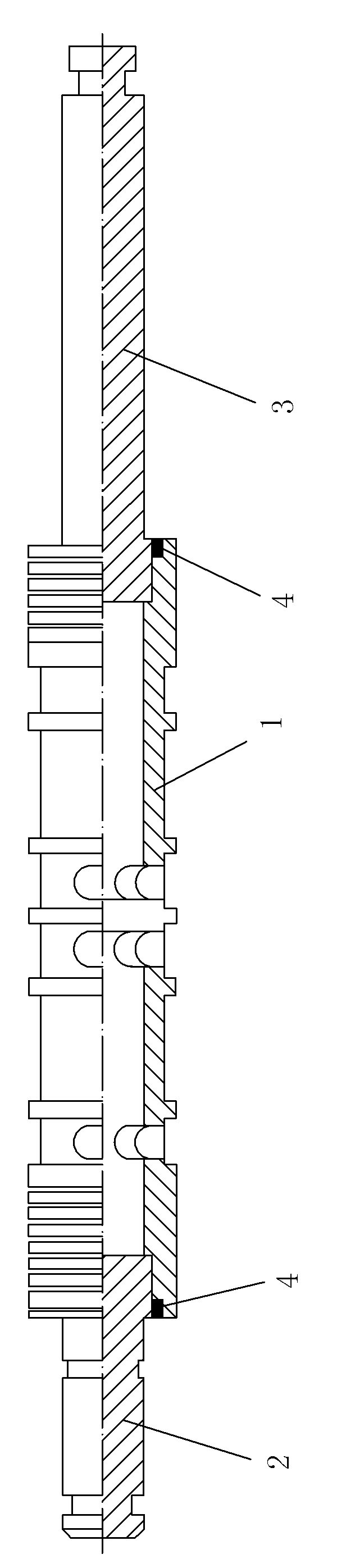

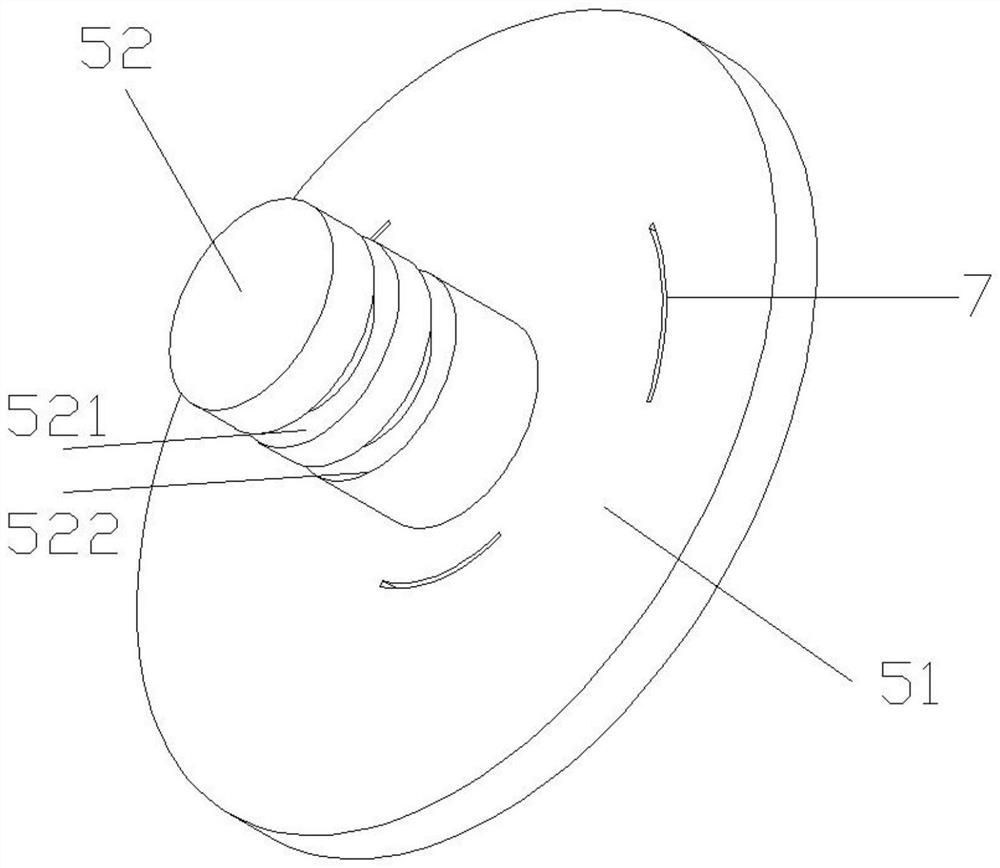

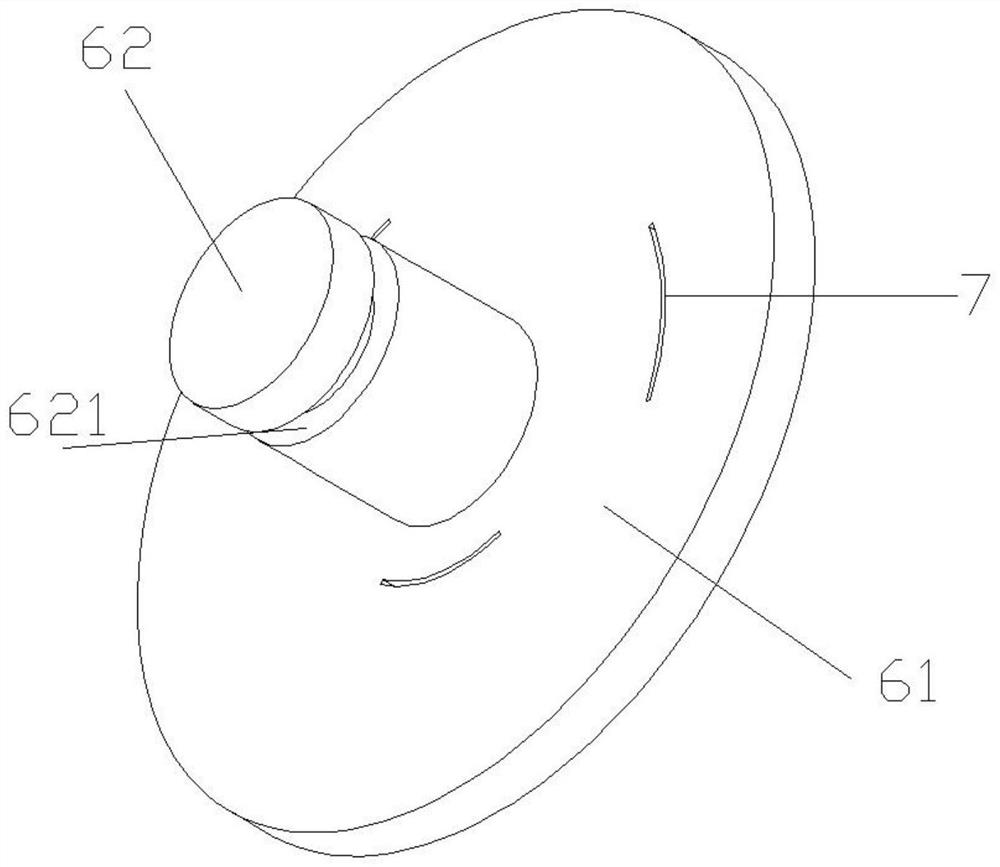

Valve plug of height adjustment reversing valve and girth welding process thereof for height adjustment system of coal mining machine

ActiveCN102168698ASimple structureReasonable designServomotor componentsDriving meansEngineeringSoldering

The invention discloses a valve plug of a height adjustment reversing valve and a girth welding process thereof for a height adjustment system of a coal mining machine. The valve plug comprises a valve plug body, a left plug head and a right plug head; the left plug head and the right plug head are respectively provided with a left annular boss and a right annular boss the outer diameter of whichare the same with the outer diameter of the valve plug body; and the left annular boss and the valve plug body as well as the right annular boss and the valve plug body are respectively fastened and connected through a circular ring-shaped soldering joint which is arranged along the valve plug body radially. The girth welding process comprises the following steps: 1. groove treatment; 2. preheating before welding; 3. girth welding; and 4. heat preservation after welding. The valve plug and the process provided by the invention have the advantages of reasonable design, simple welding steps, good welding quality and long service life of valve plug manufacturing, are convenient to operate, and multiple actual problems of small operation space, smaller effective welding cross section area, lower strength, poor welding quality and higher rejection rate, is inconvenient to operate, the welding quality of the valve plug is not easy to control and the like in welding for the existing valve plug can be solved effectively.

Owner:XIAN COAL MINING MACHINERY

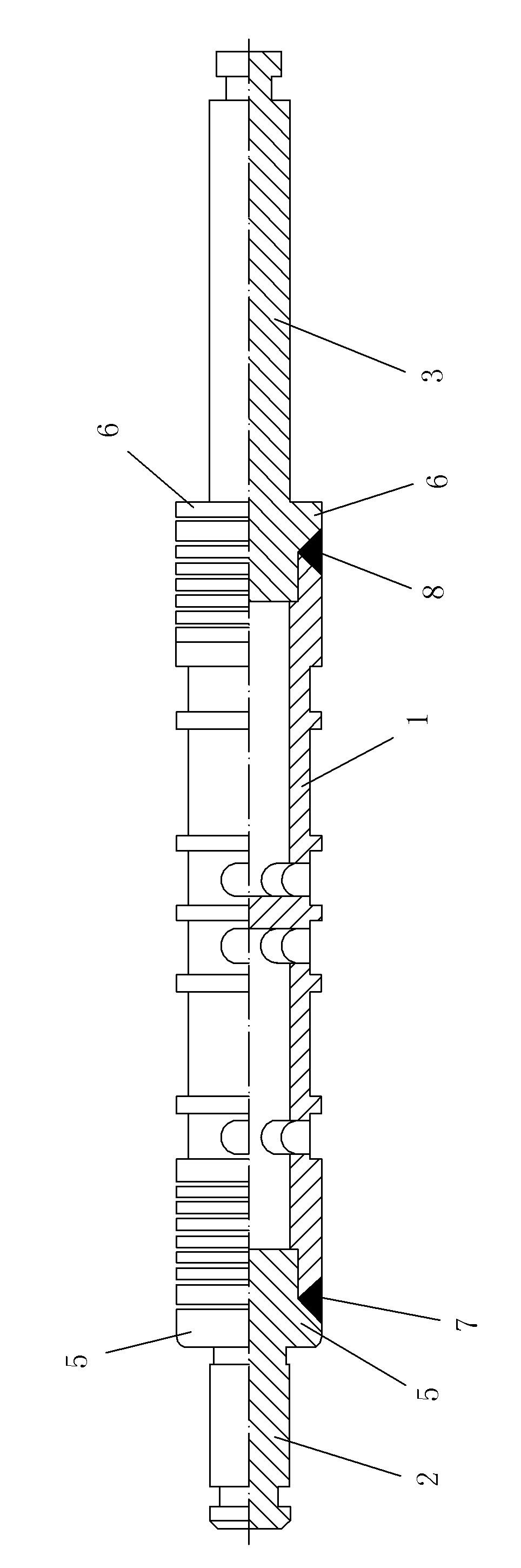

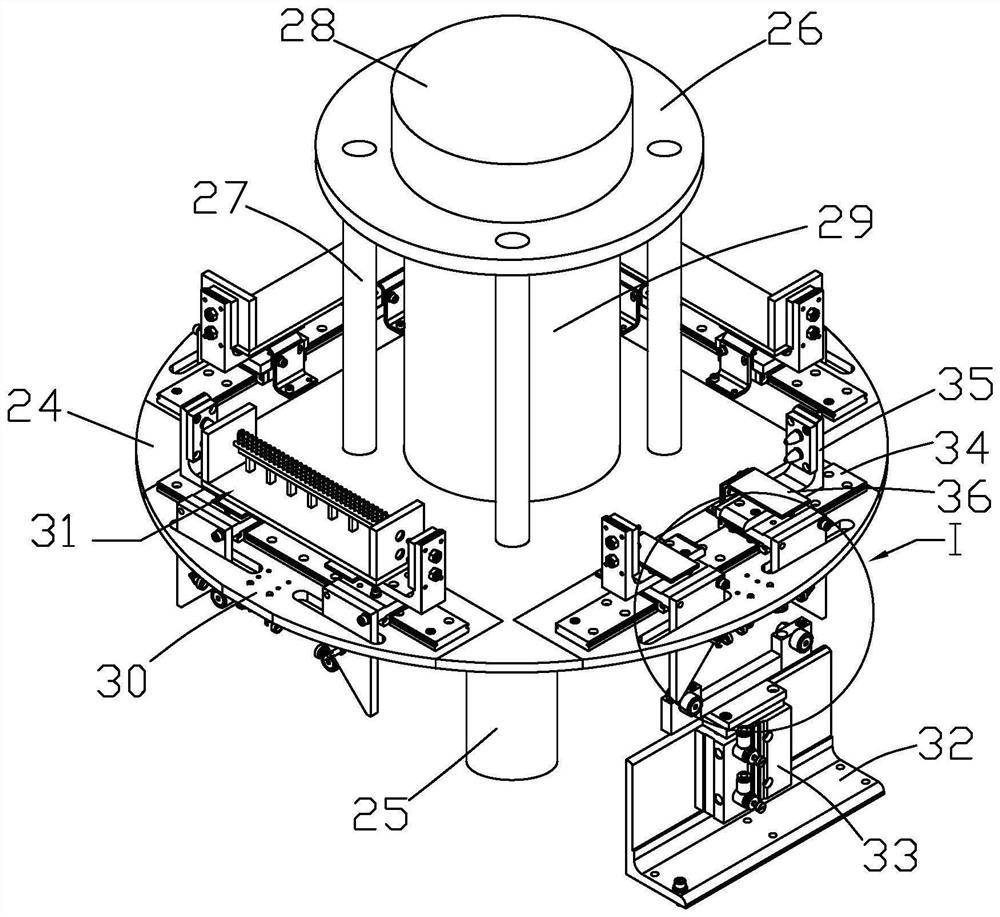

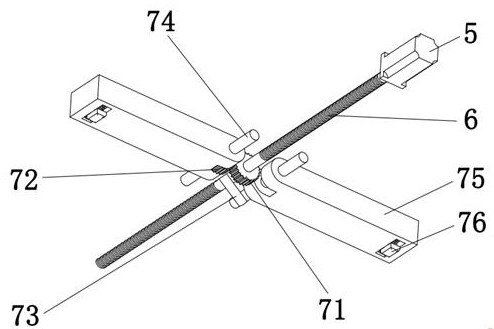

Flute-shaped pipe welding machine and welding method thereof

ActiveCN112809249AImprove welding efficiencyImprove welding precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a flute-shaped pipe welding machine and a welding method thereof. The flute-shaped pipe welding machine comprises a box body and a conveying belt; the conveying belt is arranged on one side of the box body; a rotating mechanism and a shielding mechanism are arranged in the box body; the rotating mechanism is rotatably connected to the center of the box body, and the shielding mechanism is arranged in the box body; the shielding mechanism divides the interior of the box body into a feeding and discharging bin, a welding bin, a cooling bin and a detection bin; an opening mechanism is arranged in the feeding and discharging bin; a welding mechanism is arranged in the welding bin; a cooling mechanism is arranged in the cooling bin; and a detection mechanism is arranged in the detection bin. The method comprises the steps of flute-shaped pipe clamping and feeding, welding box clamping, flute-shaped pipe welding, flute-shaped pipe cooling and flute-shaped pipe detection. According to the flute-shaped pipe welding machine and the welding method thereof provided by the invention, flute-shaped pipes can be welded at multiple stations at the same time, the welding efficiency of the flute-shaped pipes is improved, meanwhile, the process steps can be shortened, and the welding precision and welding quality of the flute-shaped pipes are improved.

Owner:XINCHANG KECHUANG AUTOMATION EQUIP

Processing process for bucket welding joint

InactiveCN104985336AChoose accurate specificationGuarantee welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMaterial selection

The invention discloses a processing process for a bucket welding joint. The processing process includes the first step of a welding joint mode and the second step of a processing method. According to the processing process for the bucket welding joint, the welding steps are simplified; the welding mode is simple; material selection is accurate and standard; the welding quality of a bucket can be ensured, and especially processing of the welding joint can be ensured.

Owner:LIUZHOU JINMAO MACHINERY

Iron plate welding process

InactiveCN104842047AChoose accurate specificationGuarantee welding qualityWelding accessoriesEngineeringMaterial selection

The invention discloses an iron plate welding process. The thickness of an iron plate is 3 mm. The iron plate welding process comprises the following steps of 1 preparation before welding, 2 tack weld, 3 welding and 4 processing after welding. The welding steps are simplified, a welding mode is simple, material selection is accurate and specified, and the welding quality of steel pipes can be ensured.

Owner:LIUZHOU JINMAO MACHINERY

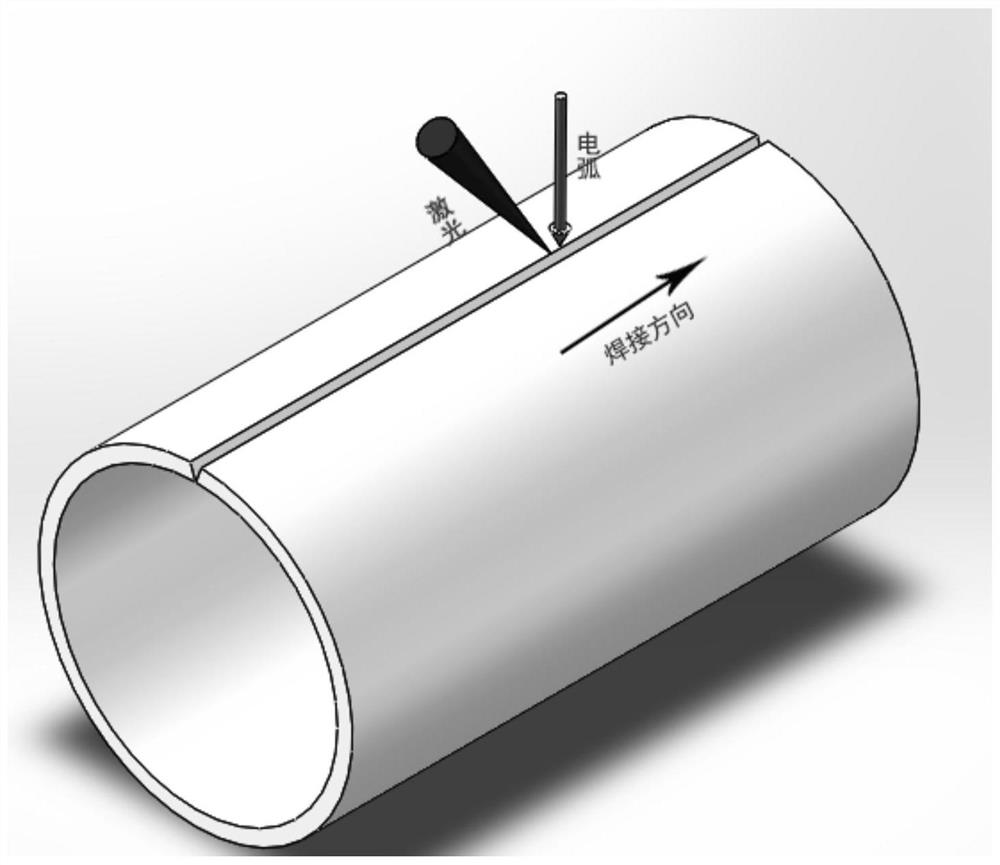

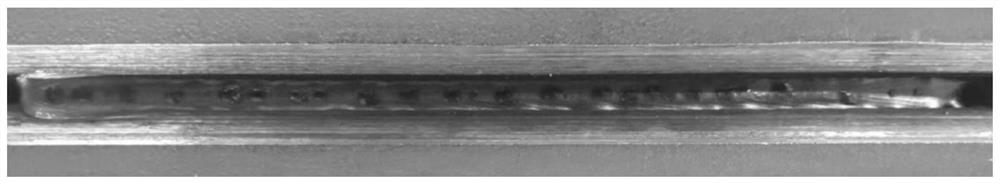

Efficient titanium alloy laser-electric arc composite heat source pipeline welding process

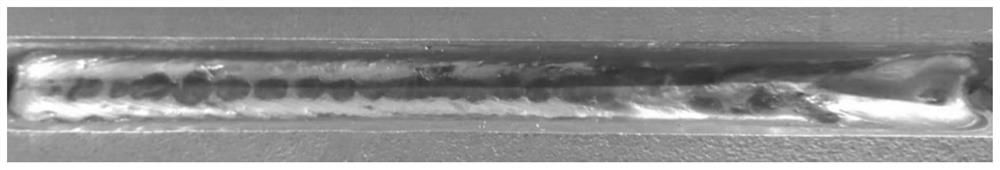

PendingCN113210869ASimplify soldering stepsSimple welding methodWelding/soldering/cutting articlesMetal working apparatusWeld seamThin slab

The invention provides an efficient titanium alloy laser-electric arc composite heat source pipeline welding process. The efficient titanium alloy laser-electric arc composite heat source pipeline welding process comprises the following steps that a groove is processed according to the plate thickness of a to-be-welded workpiece, greasy dirt at a welding part is cleaned, and the surface of the to-be-welded workpiece is kept dry; spot welding fixing is conducted on the to-be-welded workpiece before formal welding according to the size of the to-be-welded workpiece; a laser-TIG electric arc composite main mode is selected for welding; whether cold filling wire / cosmetic welding exists or not is determined according to the groove form of the to-be-welded workpiece, and if yes, a welding wire with the preset diameter is selected for filling according to the preset wire feeding speed; high-quality welding seam forming of longitudinal and circular seams of a pipeline is achieved through thin plate single-layer welding and thick plate multi-layer and multi-pass welding of the to-be-welded workpiece; and after welding, weld seams which do not meet the standard are polished, and splashes are removed. The welding steps are simplified, the welding mode is simple, material selection is accurate and standard, and the titanium pipe welding quality can be guaranteed.

Owner:JIANGSU TONGYU STEEL PIPE GRP +1

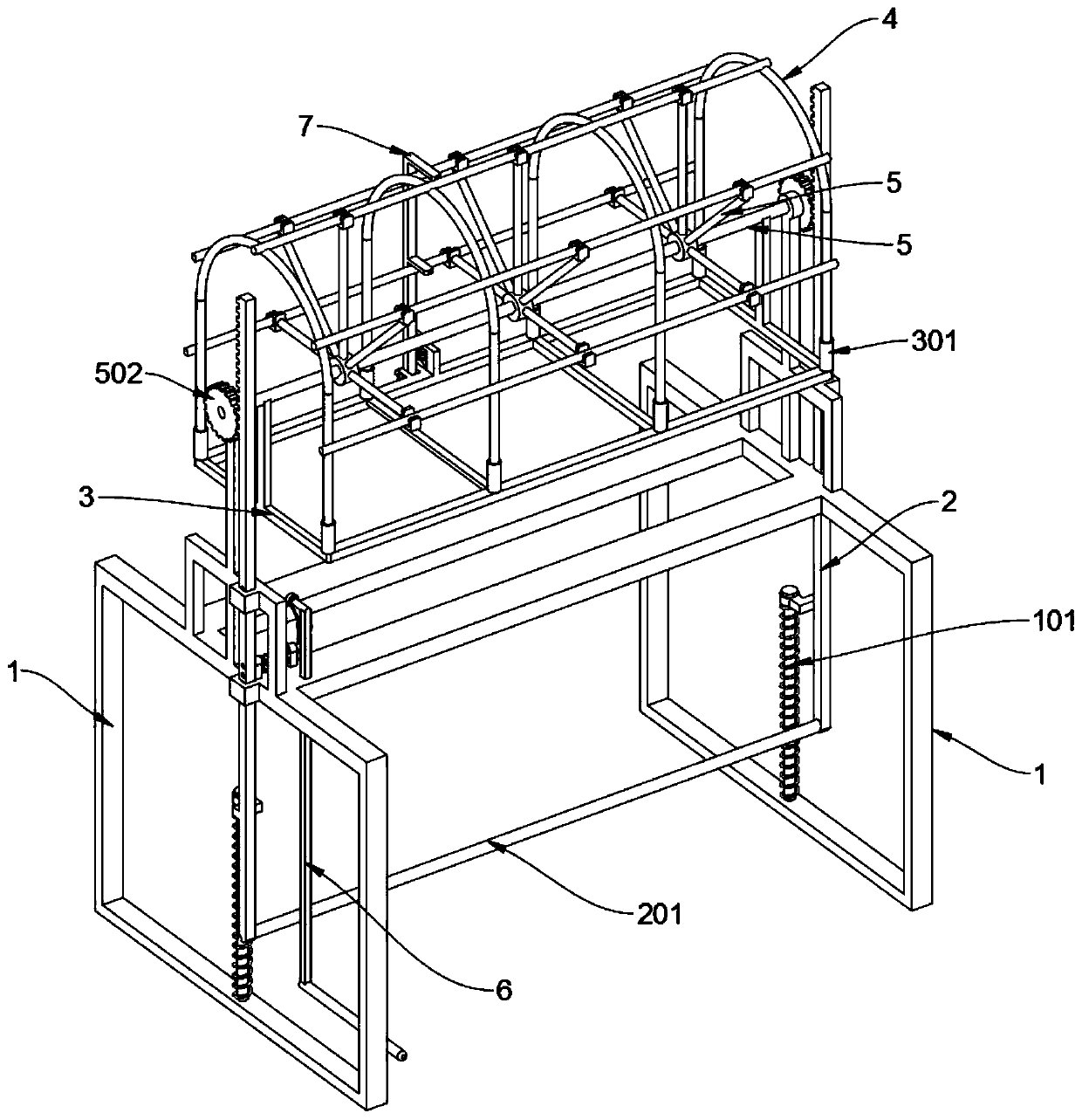

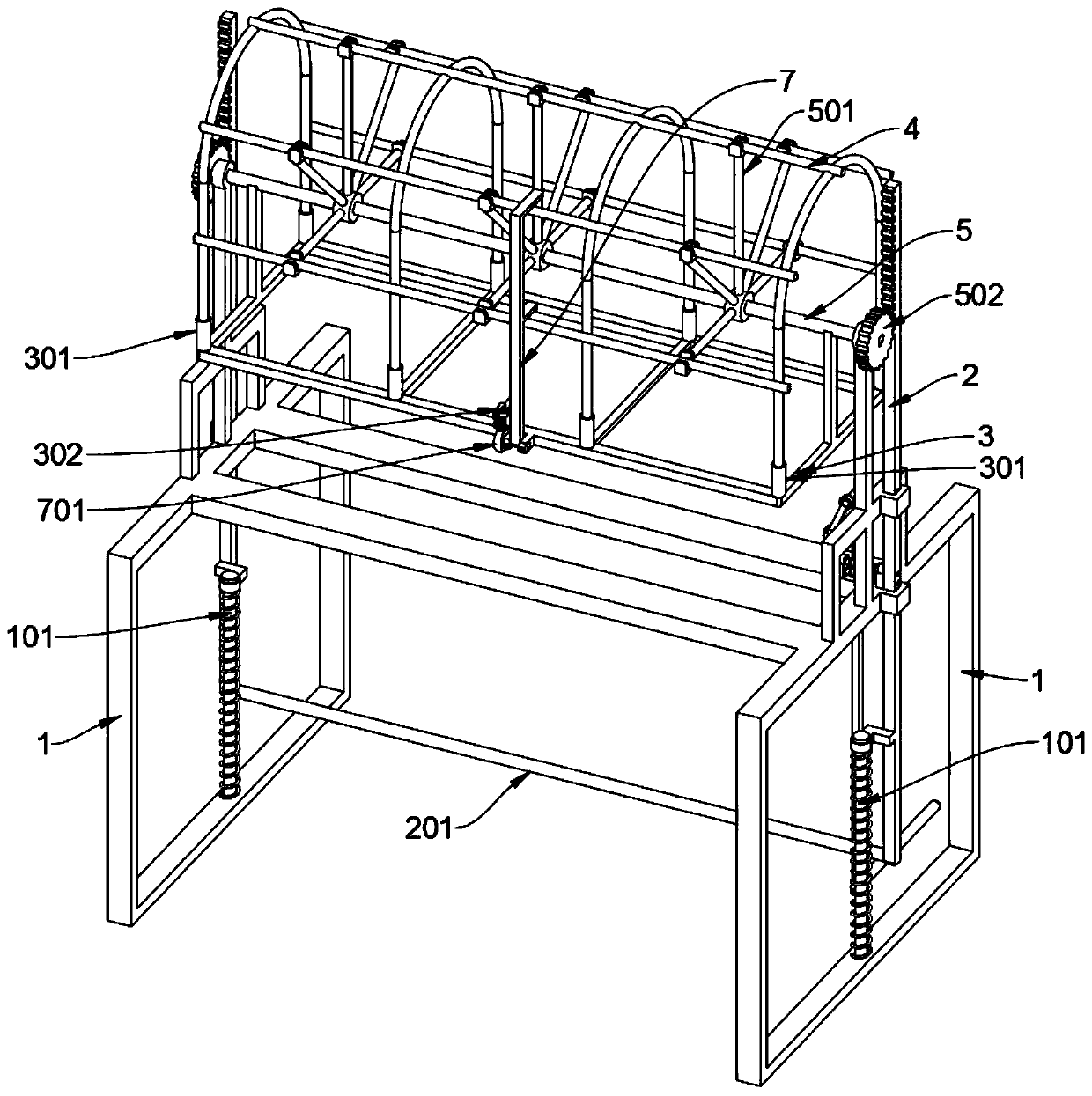

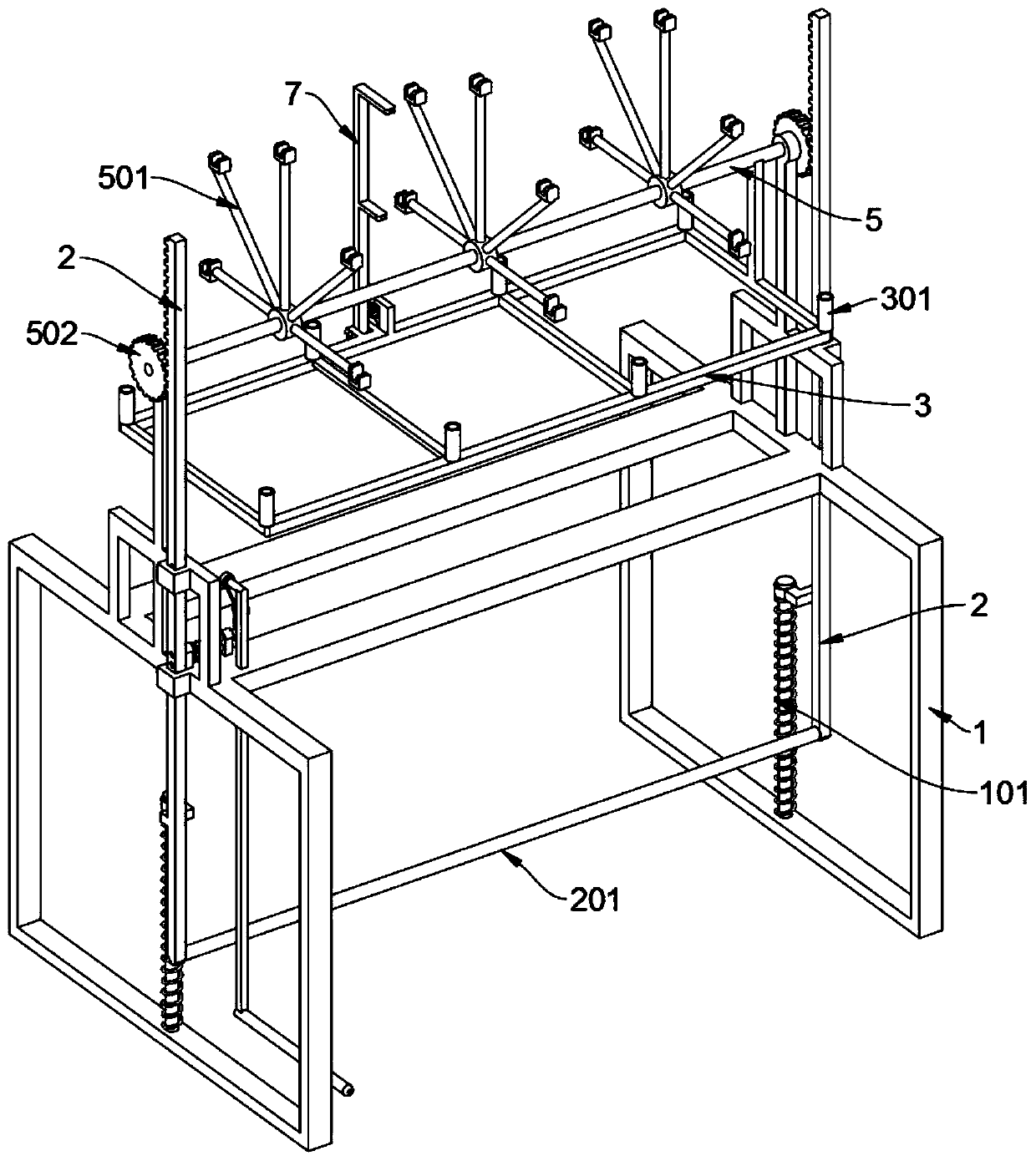

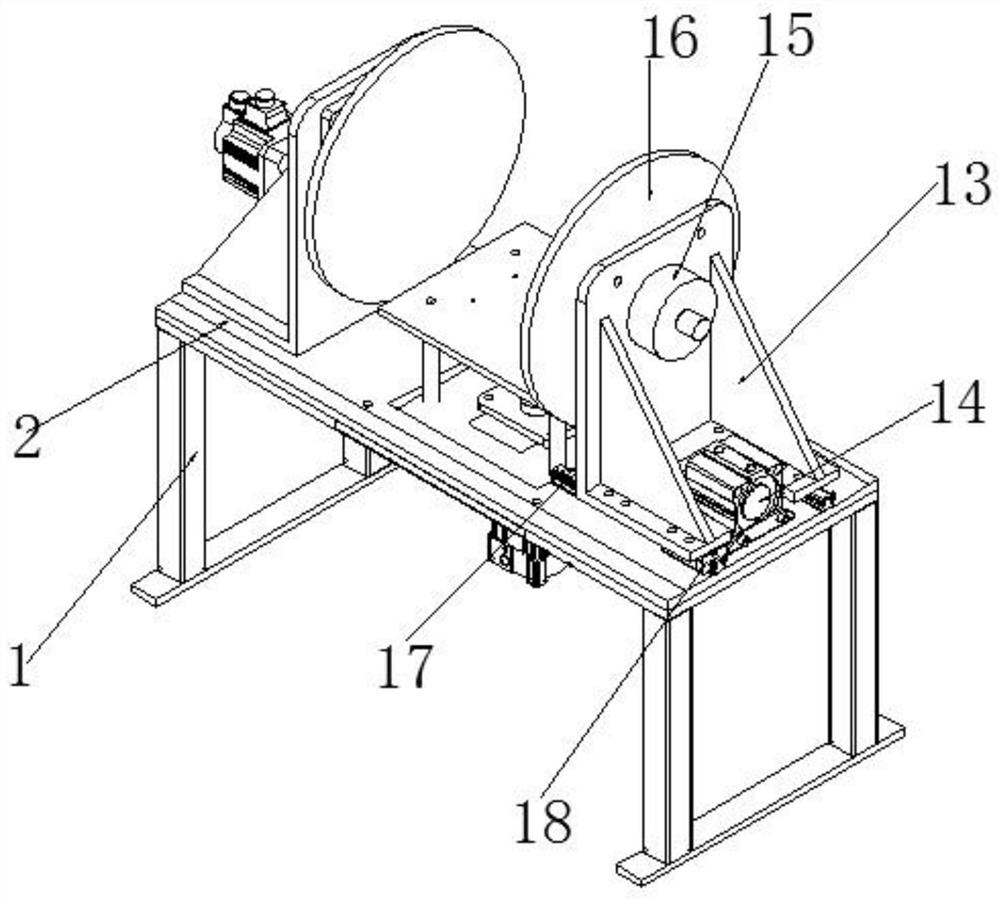

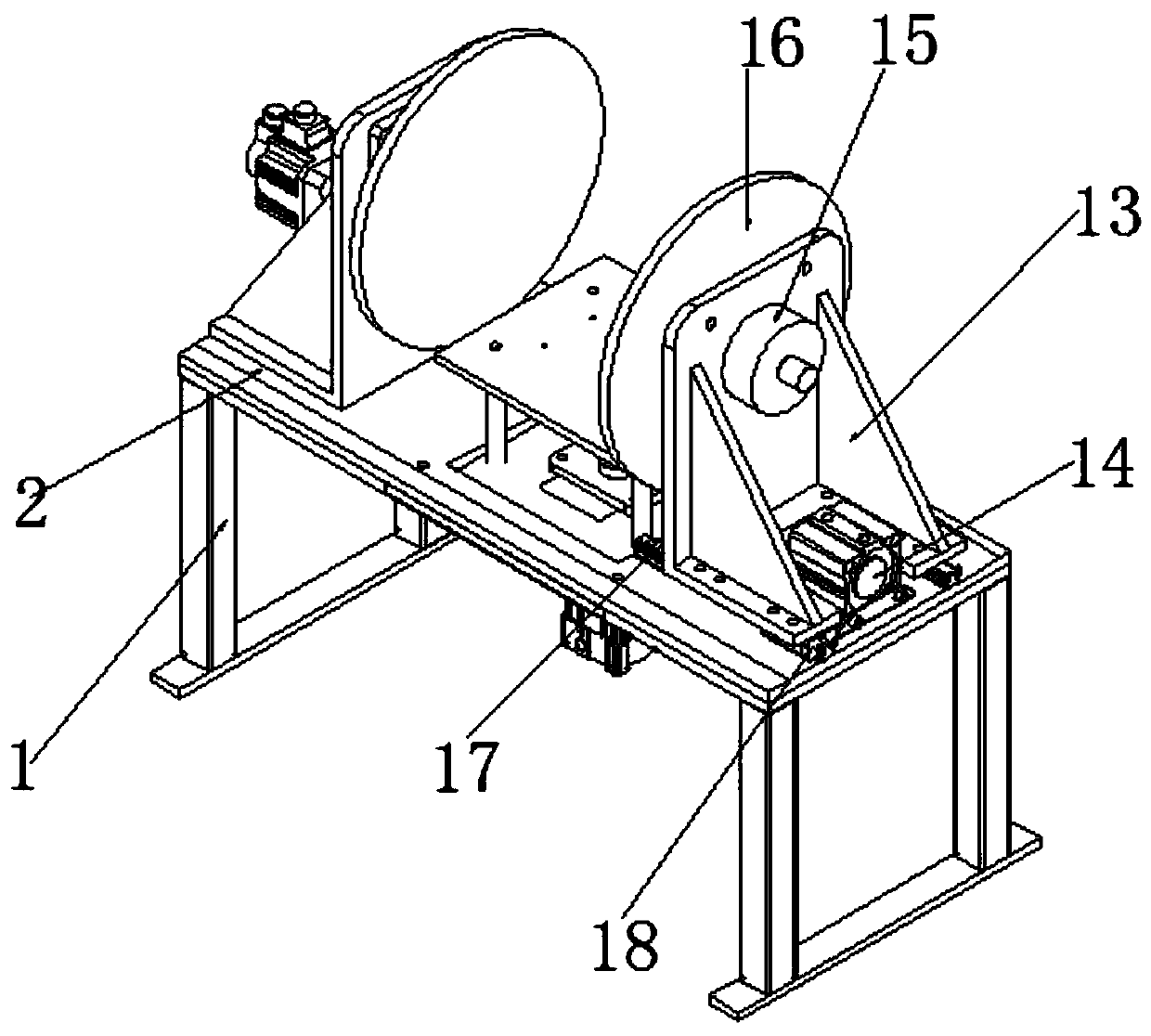

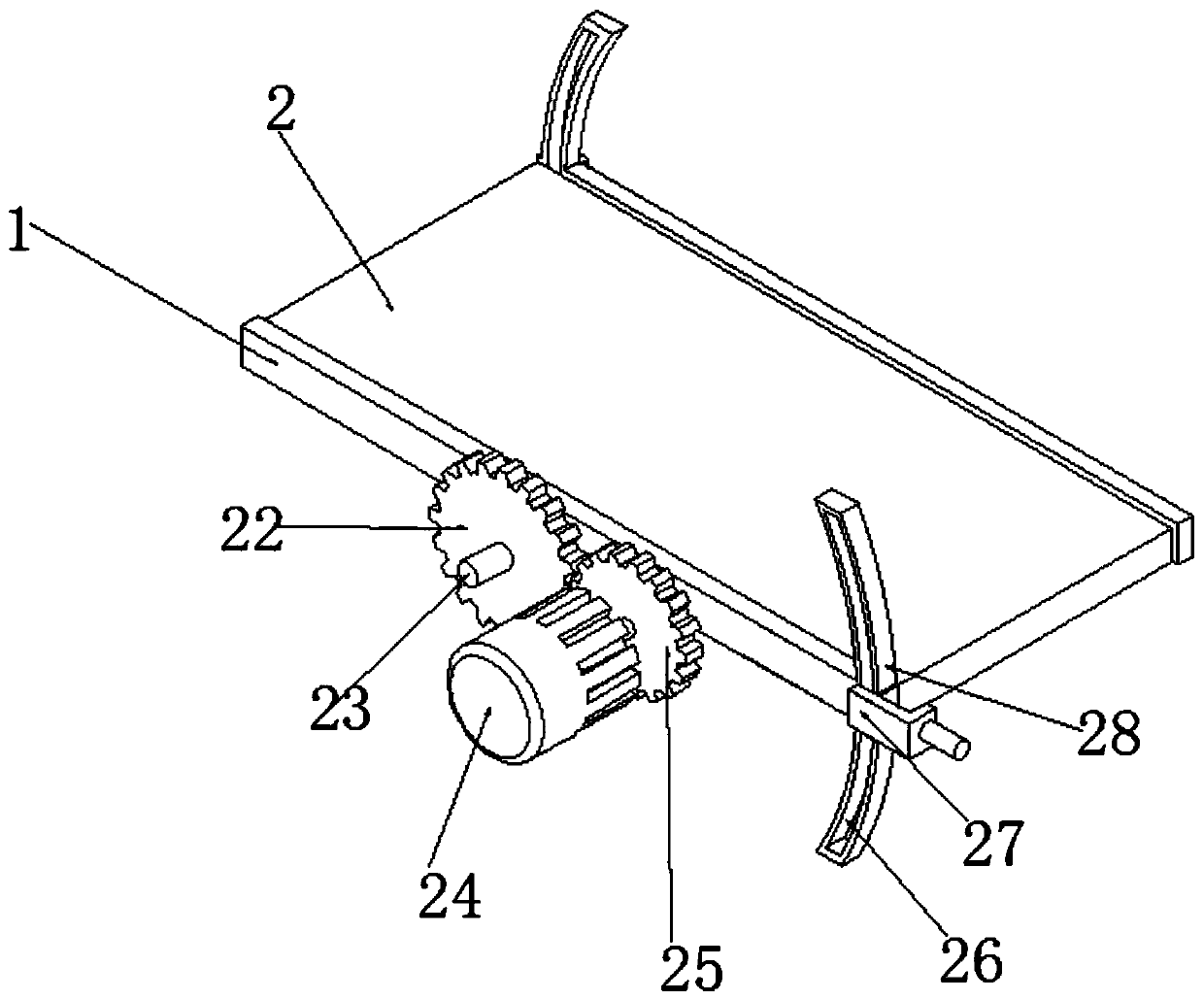

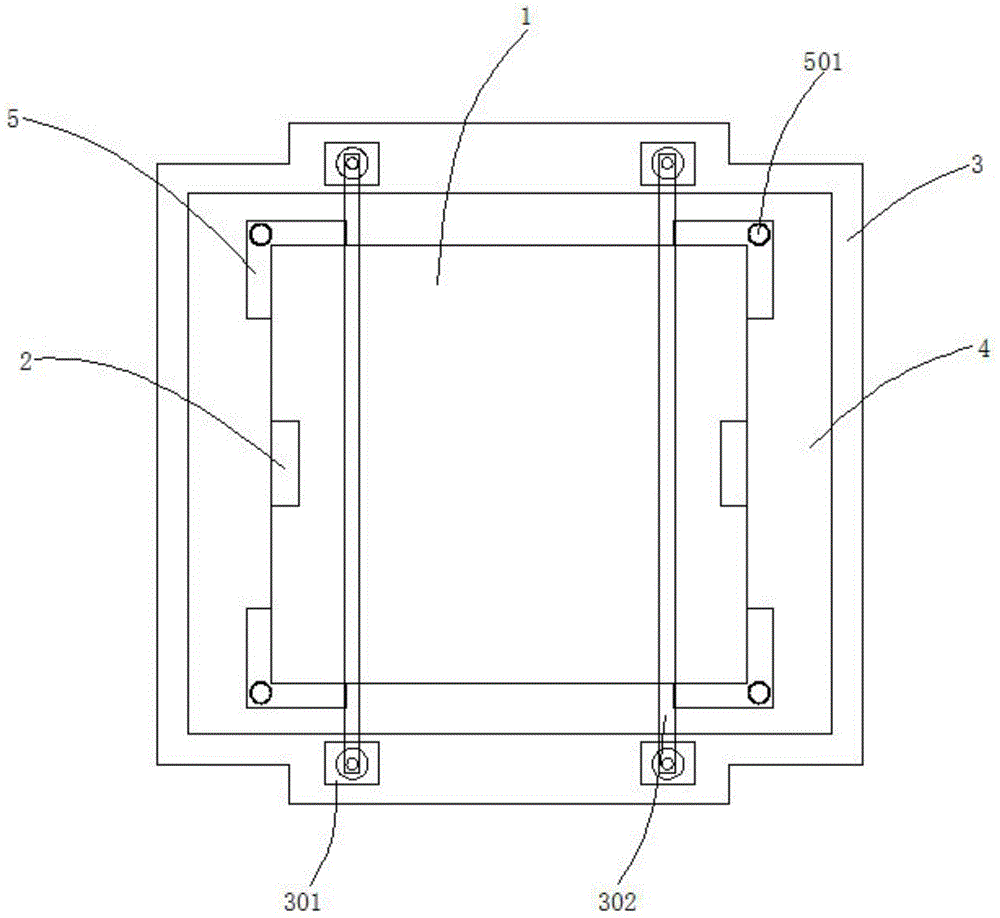

Welding tooling for production of main framework based on stainless steel metal cage

InactiveCN111589995AMeet a full range of welding needsSimplify soldering stepsWire networkStructural engineeringSS - Stainless steel

The invention discloses welding tooling for the production of a main framework based on a stainless steel metal cage, and relates to the technical field of metal cage welding tooling. The problems that in existing welding tooling, in order to meet the all-round welding requirements, a framework needs to be switched and turned manually, or workers are required to walk around to the back of the framework, resulting in a complicated welding process are solved. The welding tooling for the production of the main framework based on the stainless steel metal cage comprises supporting frames, a bottomframe and a rotating rack, the supporting frames comprise vertical support positioning shafts and positioning ear plates, the left and right supporting frames are both of rectangular structures, andthe two supporting frames are fixed together by two cross support connecting plates symmetrically weld to the top ends of the supporting frames to form the main framework of the tooling. According tothe welding tooling, through two claw plates on a guard board, two cross support connecting rods on the back of a cage body can be clamped and positioned, so as to avoid falling of the cross support connecting rods with overturning of the rotating rack.

Owner:于洋洋

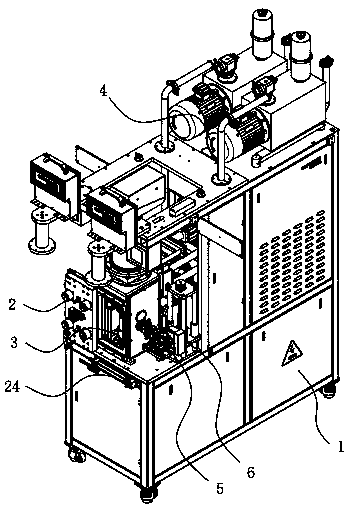

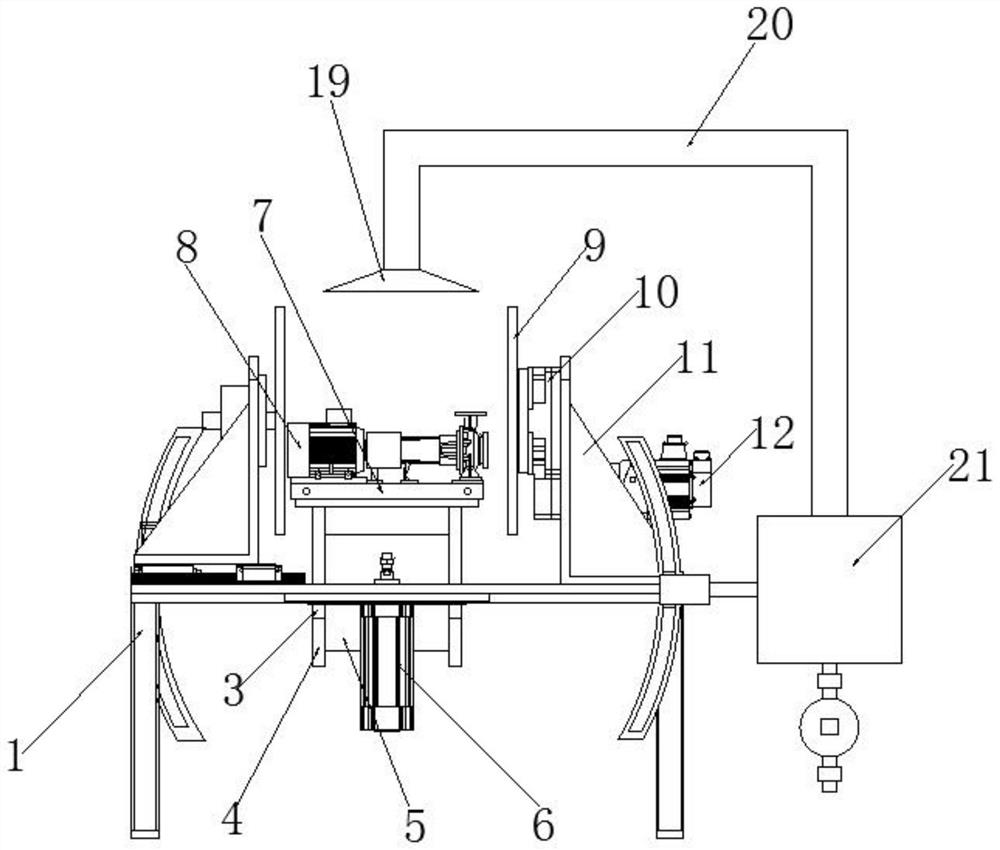

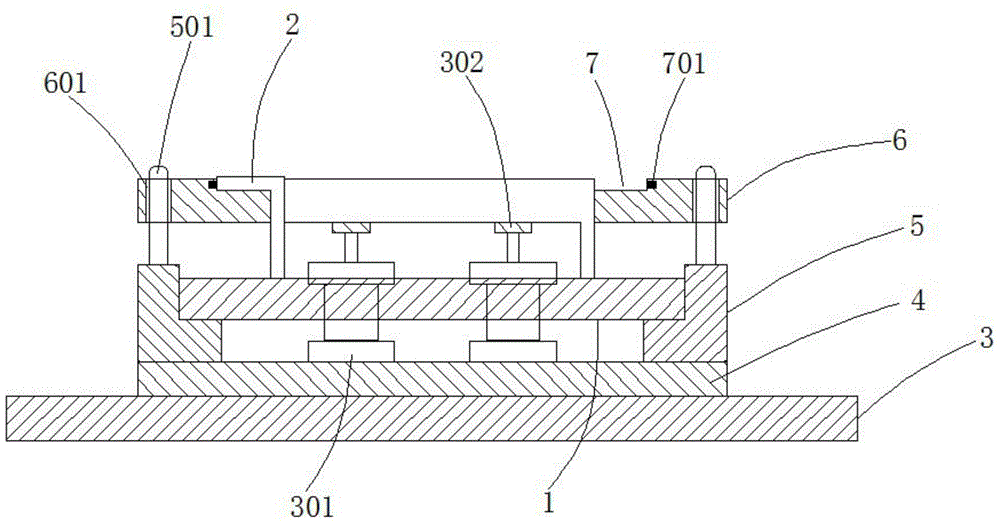

Vacuum pumping welding device and method for pressure vessel

PendingCN111531276ASimple structureSimplify the welding processLaser beam welding apparatusPhysicsLaser soldering

The invention discloses a vacuum pumping welding device and method for a pressure vessel. The vacuum pumping welding device for the pressure vessel comprises a frame, a placement chamber provided witha placement cavity and arranged on the frame, a pressure vessel clamp arranged in the placement cavity, a vacuum pumping mechanism communicating with the placement cavity, and a laser welding machinearranged on the frame and used for hermetically welding the pressure vessel, wherein the pressure vessel clamp comprises a lower jaw plate arranged in the placement cavity, a first drive motor for driving the lower jaw plate to rotate, and an upper jaw plate rotationally arranged in the placement cavity along its own axis and positioned on the upper side of the lower jaw plate, and a drive component used for driving the upper jaw plate to move close to or far from the lower jaw plate. The vacuum pumping welding device for the pressure vessel is simple in structure, simple in the vacuum pumping welding process of the pressure vessel, low in cost, and good in hermetically welding effect. The vacuum pumping welding method for the pressure vessel is simple in vacuum pumping welding step of the pressure vessel, and good in hermetically welding effect.

Owner:THERMOS JIANGSU HOUSEWARES

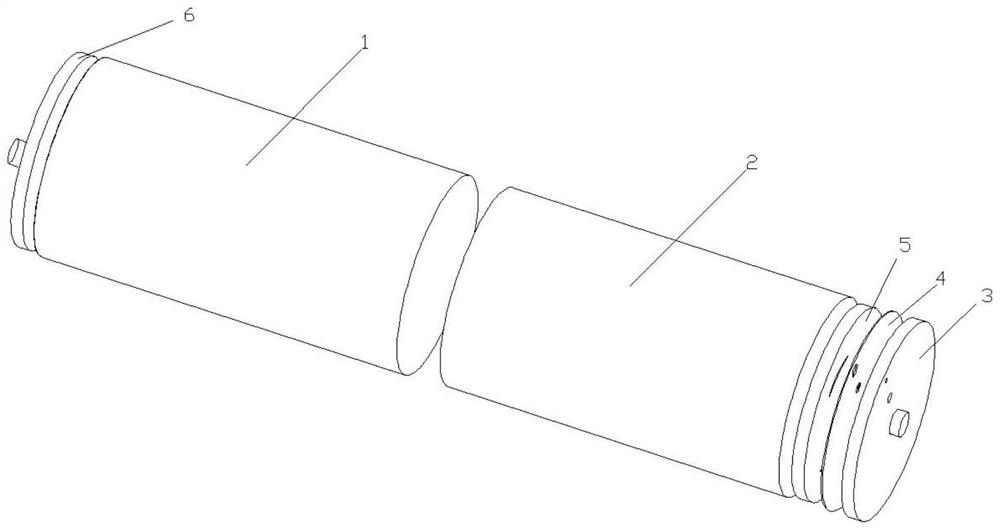

Lithium battery and assembly method

PendingCN114824435AFirmly connectedAccurate connectionAssembling battery machinesLi-accumulatorsInternal resistanceElectric current flow

The lithium battery comprises a shell, a battery cell, a positive electrode cover plate, a positive electrode insulating sheet, a positive electrode current collecting structure and a negative electrode current collecting structure, the shell is a hollow cylindrical tube, the positive electrode end is open, the negative electrode end is closed, an assembly through hole A is formed in the center of the surface of the negative electrode end, the positive electrode cover plate is installed on the positive electrode current collecting structure, and the positive electrode insulating sheet is installed on the battery cell. The positive electrode insulation sheet is installed on the positive electrode current collecting structure and located between the positive electrode cover plate and the positive electrode current collecting structure, the battery cell positive electrode face is welded to the positive electrode current collecting structure, the battery cell negative electrode face is welded to the negative electrode current collecting structure, and the negative electrode current collecting structure is connected with the shell negative electrode end through an assembly through hole A. The invention has the beneficial effects that the current collecting columns are arranged on the current collecting plates, so that the connection between the current collecting columns and the current collecting plates is enhanced, the internal resistance of the battery is further reduced, and the current is increased; and the insulating sheet and the cover plate are directly mounted on the current collecting column, so that the welding steps are reduced, and the technological process is simplified.

Owner:英能基(成都)科技有限公司

Efficient laser-electric arc composite heat source high-strength steel pipeline straight seam welding process

PendingCN113210870AChoose accuratelyChoose accurate specificationWelding/soldering/cutting articlesMetal working apparatusShielding gasWeld seam

The invention provides an efficient laser-electric arc composite heat source high-strength steel pipeline straight seam welding process which comprises the following steps that a groove is machined according to the plate thickness of a to-be-welded workpiece, greasy dirt at a welded part is removed, and the surface of the to-be-welded workpiece is kept dry; spot welding fixing is conducted on the to-be-welded workpiece before formal welding according to the size of the to-be-welded workpiece; a laser-MAG electric arc composite main mode is selected for welding, mixed gas of 82% of Ar and 18% of CO2 is selected as protective gas, and a high-strength steel welding wire with the diameter ranging from 1.0 mm to 1.6 mm is selected as a welding wire; the to-be-welded workpiece is subjected to multi-layer and multi-pass welding with different welding modes and parameter matching on each layer, and high-quality forming of a straight welding seam of a pipeline is achieved; and polishing and cleaning are conducted on the periphery of the welding seam after welding. According to the efficient laser-electric arc composite heat source high-strength steel pipeline straight seam welding process, the welding steps are simplified, the welding mode is simple, material selection is accurate and standard, and the titanium pipe welding quality can be guaranteed.

Owner:JIANGSU TONGYU STEEL PIPE GRP +1

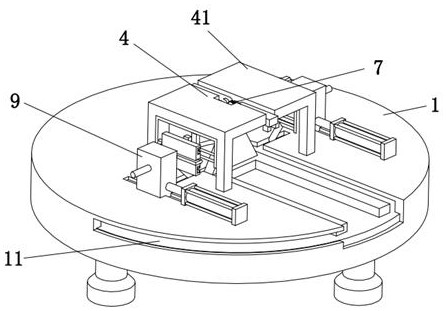

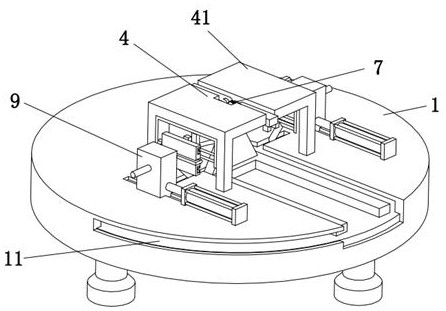

A kind of welding tool for pump valve installation and its welding method

ActiveCN110814586BAchieve regulationEnsure stabilityDispersed particle filtrationWelding/cutting auxillary devicesStructural engineeringPollution

The invention discloses a welding tool for pump valve mounting. The welding tool comprises a base, a rotating base, a box body, a first mounting base, a second mounting base, a dust collection box anda suction pressure tank. The rotating base is rotatably mounted in the top side of the base, a first hydraulic rod is mounted on the center of the bottom of the rotating base, sleeves are arranged atthe positions, on the periphery of the first hydraulic rod, in the rotating base, a mounting plate is arranged at the position, above the rotating base, of the telescopic end of the first hydraulic rod, guide rods are arranged on the periphery of the bottom of the mounting plate, the guide rods penetrate through the sleeves, one end of the rotating base is provided with a first mounting base, anda first servo motor is arranged on one side of the first mounting base. A pump valve is rapidly mounted and fixed, the pump valve can be conveniently subjected to multi-angle adjusting in the weldingprocess, the welding step is simplified, welding operation is facilitated, through stretching out and drawing back of a fourth hydraulic rod, dust treatment is finished, noise pollution is greatly reduced, and the whole treatment manner is environment-friendly, sanitary and free of pollution.

Owner:合肥华升泵阀股份有限公司

Argon arc welding process for iron plate

InactiveCN104985297AWelding safetyGuarantee welding qualityArc welding apparatusWelding/soldering/cutting articlesEngineeringSpot welding

The invention discloses an argon arc welding process for an iron plate. The argon arc welding process for the iron plate comprises the first step of processing of a welding part and selection of welding materials, the second step of temporary spot welding, the third step of welding, and the fourth step of postweld treatment. By means of the argon arc welding process for the iron plate, the welding steps are simplified, the welding mode is simple, material selection is accurate and standard, the welding quality of the iron plate can be guaranteed, the standard welding mode is provided for the iron plate, and rapid and safe welding of the iron plate is facilitated.

Owner:LIUZHOU JINMAO MACHINERY

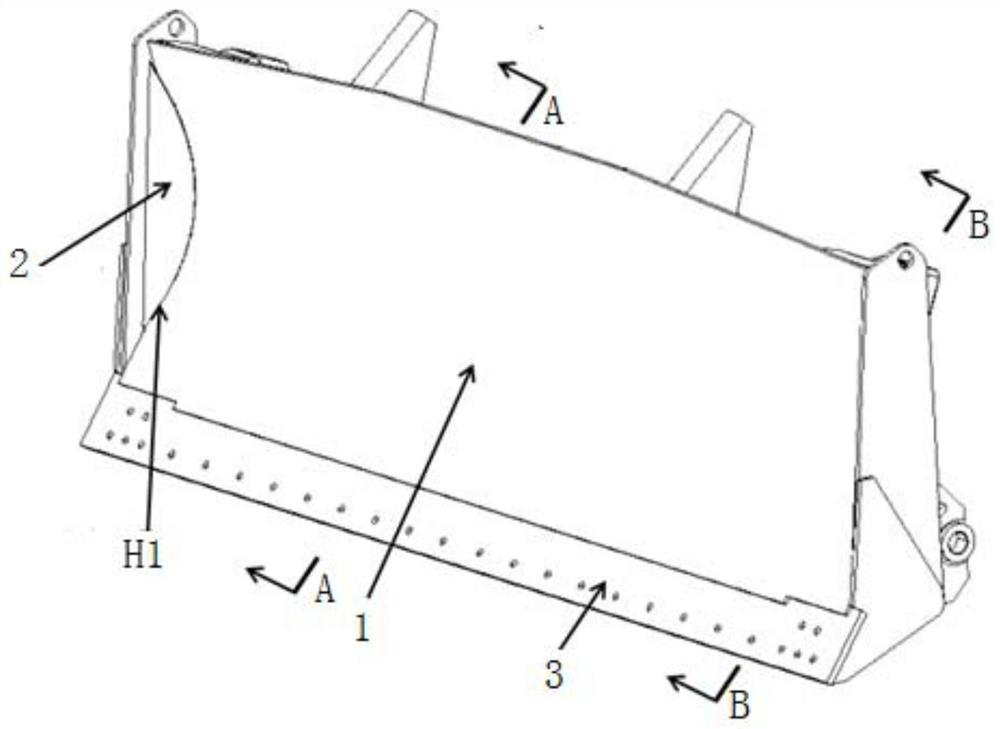

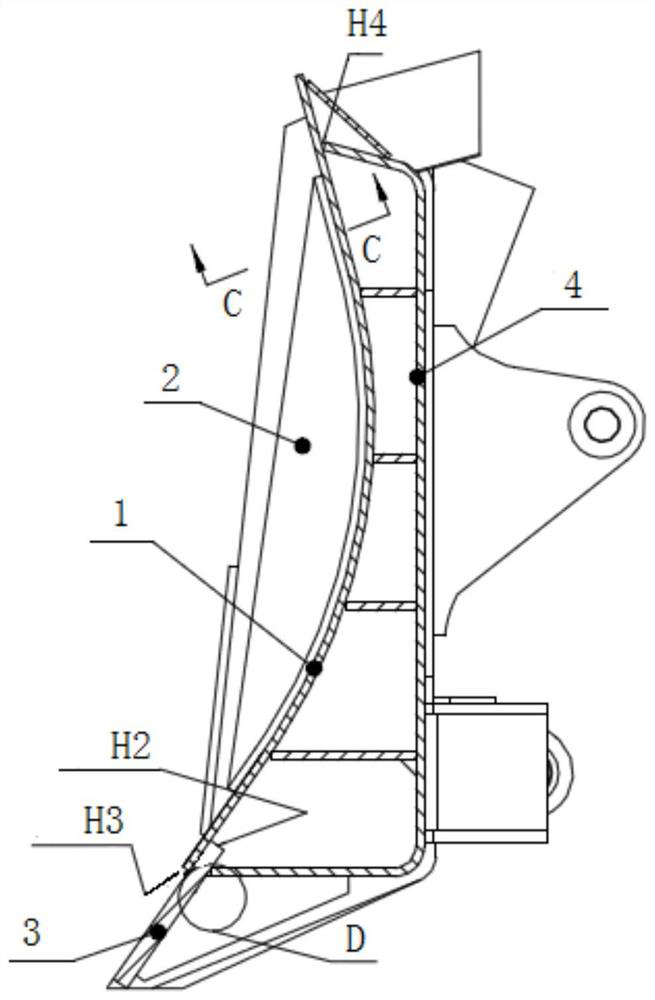

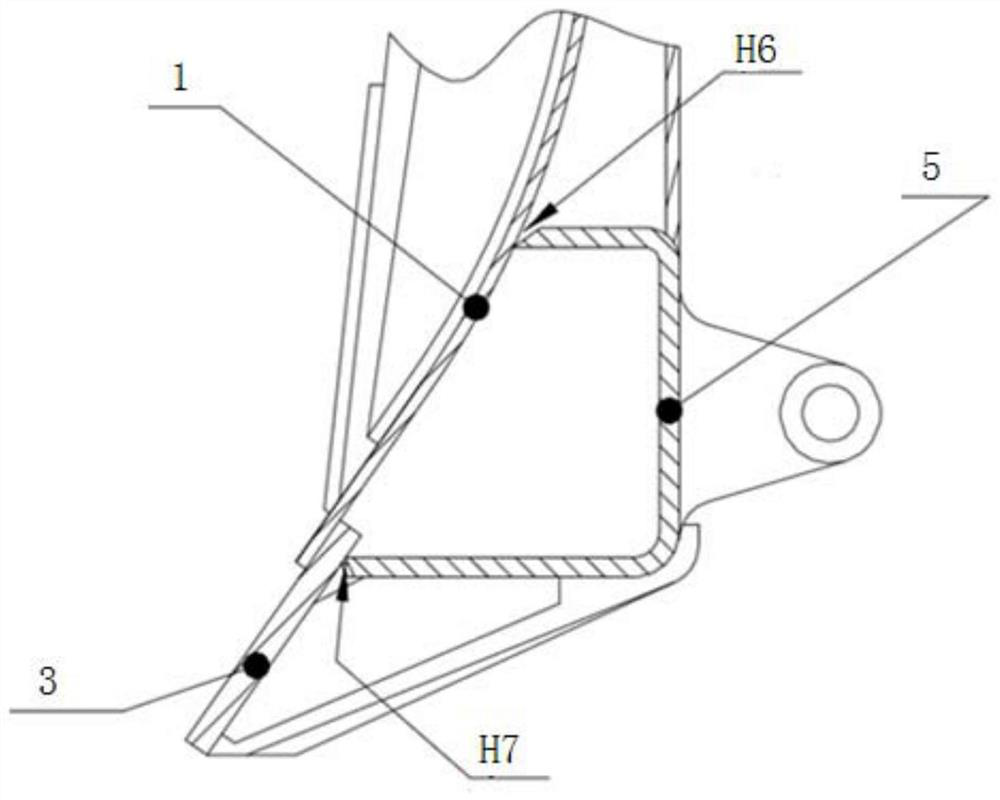

A welding process for bulldozer blade

ActiveCN108672899BImprove wear resistanceImprove mechanical propertiesArc welding apparatusButt weldingWear resistance

The invention relates to the technical field of bulldozers, and in particular to a welding process for a bulldozer blade. The bulldozer blade includes an arc-shaped plate, a crescent plate, a tool rest plate and a rear wall plate, wherein the arc-shaped plate and the crescent plate are both High-strength wear-resistant plate is used, and CO is used for welding 2 Gas shielded welding, first butt welding the crescent plate and the arc plate, then butt welding the tool holder plate and the arc plate, and finally welding the rear wall plate to the arc plate and the arc plate. The tool holder plate is butt welded. First, the arc plate and the crescent plate are made of high-strength wear-resistant plates, which significantly improves the wear resistance of the bulldozer; The optimal welding sequence between components, the mechanical properties of the blade after welding are excellent, and the impact performance is better.

Owner:SHANTUI CONSTR MASCH CO LTD

Technology of welding air cylinder cover aluminum sheet for automobile

The invention discloses a technology of welding an air cylinder cover aluminum sheet for an automobile. The technology comprises the following steps of: step a. removing oil stains, aluminum scraps and oxidation films on parts to be welded of the end face and edge of an aluminum alloy sheet to be welded in the range of 20mm by using acetone and a rotary file so as to show metallic luster; step b.sticking a protective film on the sheet, wherein no bubbles are allowed in the protective film, and no protective film is stuck in the range of 3-5 mm from a welding part to the interior; step c. checking whether the surface of a workpiece is wet, and if the surface of the workpiece is wet, welding after drying; step d. selecting 3-6cm as the length of spot welding according to the size of a welding structural component; step e. carrying out abutting joint of an I-shaped groove, and welding by selecting welding wires with the diameter of 1.2mm, the welding current of 130-150A and the welding voltage of 19-22V at the gas flow rate of 10-18L per minute and the welding speed of 350-500mm per minute; and step f. polishing unaesthetic welded joints, and clearing splashes. According to the technology, welding steps are simplified, a welding mode is simple, the material selection is accurate and standardized, and the welding quality of steel pipes can be ensured.

Owner:安徽省佳隆汽车配件有限公司

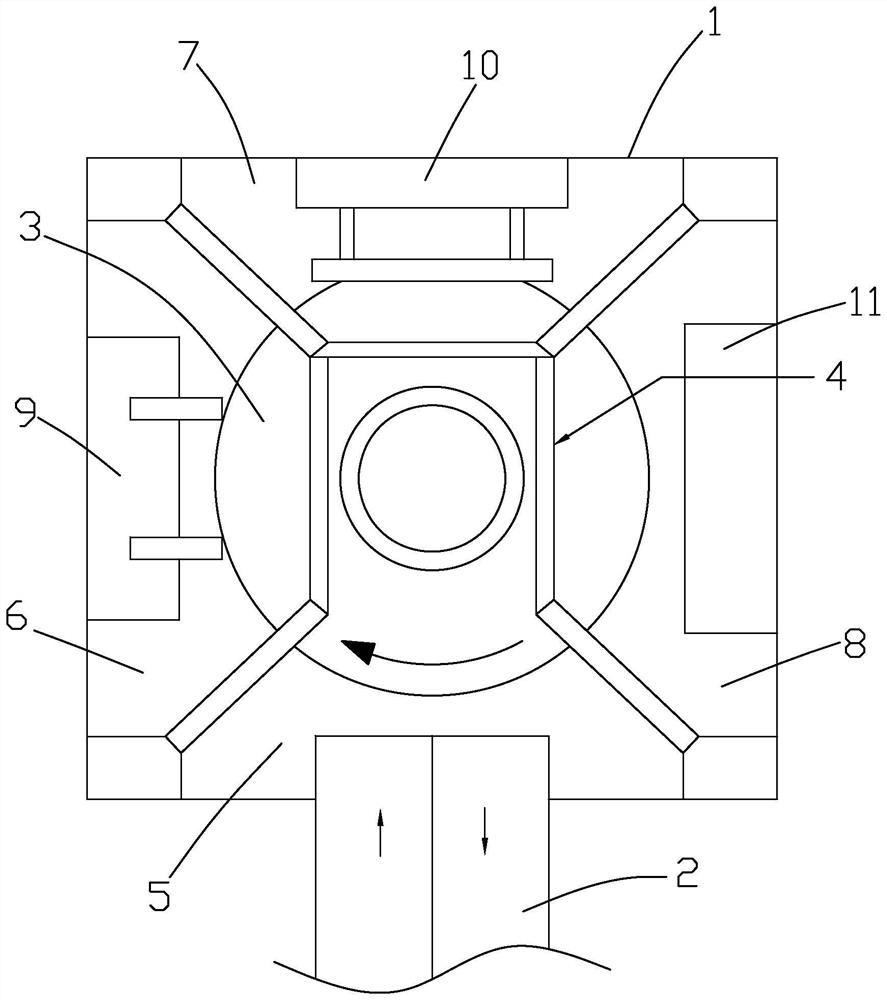

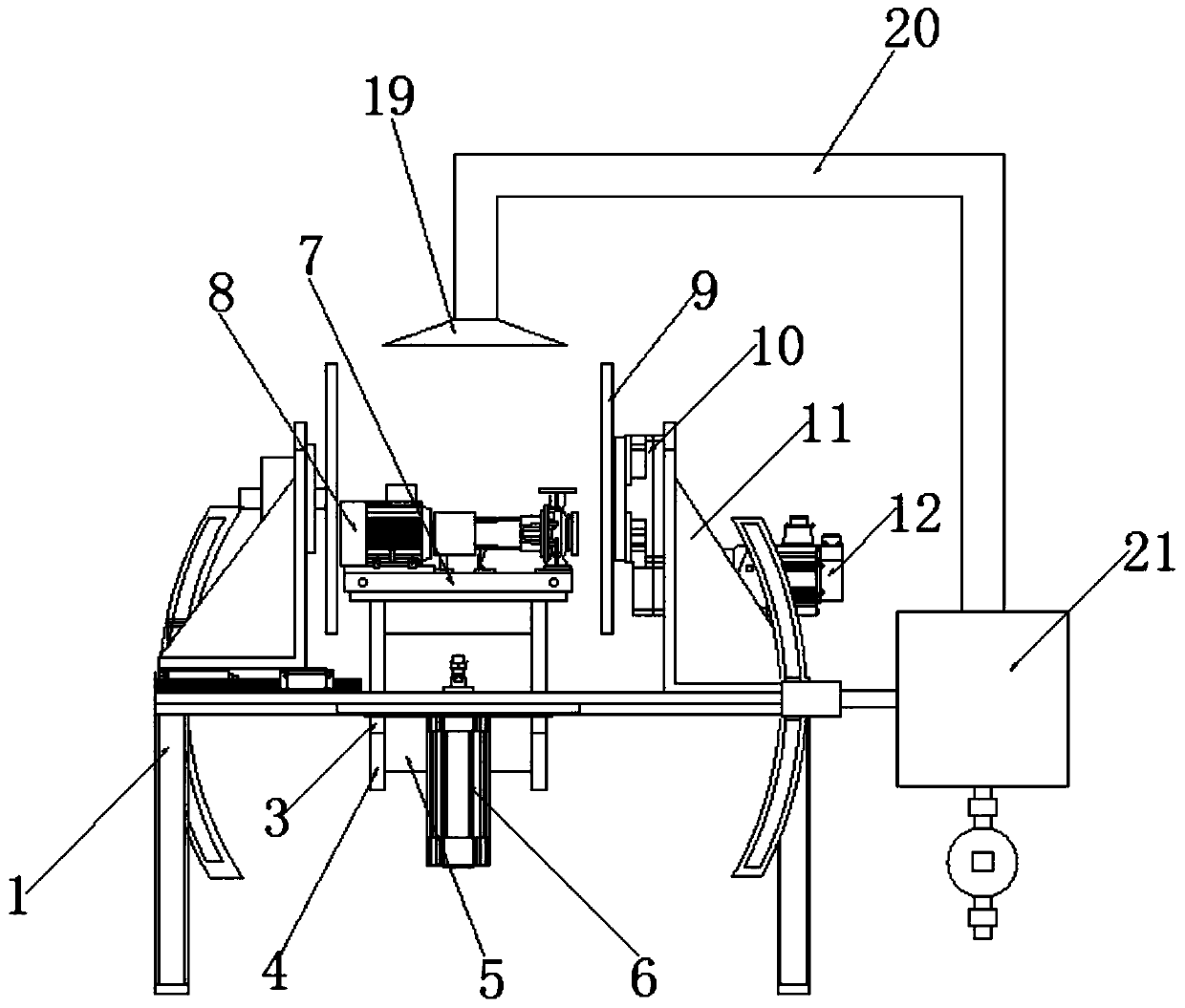

Welding tool for pump valve mounting and welding method thereof

ActiveCN110814586ASimplify soldering stepsEasy welding operationDispersed particle filtrationWelding/cutting auxillary devicesStructural engineeringManufacturing engineering

The invention discloses a welding tool for pump valve mounting. The welding tool comprises a base, a rotating base, a box body, a first mounting base, a second mounting base, a dust collection box anda suction pressure tank. The rotating base is rotatably mounted in the top side of the base, a first hydraulic rod is mounted on the center of the bottom of the rotating base, sleeves are arranged atthe positions, on the periphery of the first hydraulic rod, in the rotating base, a mounting plate is arranged at the position, above the rotating base, of the telescopic end of the first hydraulic rod, guide rods are arranged on the periphery of the bottom of the mounting plate, the guide rods penetrate through the sleeves, one end of the rotating base is provided with a first mounting base, anda first servo motor is arranged on one side of the first mounting base. A pump valve is rapidly mounted and fixed, the pump valve can be conveniently subjected to multi-angle adjusting in the weldingprocess, the welding step is simplified, welding operation is facilitated, through stretching out and drawing back of a fourth hydraulic rod, dust treatment is finished, noise pollution is greatly reduced, and the whole treatment manner is environment-friendly, sanitary and free of pollution.

Owner:合肥华升泵阀股份有限公司

Robot wire feeding welding process

InactiveCN105817777AChoose accurate specificationQuality assuranceLaser beam welding apparatusDrive wheelSpot welding

The invention discloses a wire-feeding welding process of a robot. The stainless steel case is connected with the stainless steel bottom plate, and the connected stainless steel case is subjected to pulse laser spot welding. Each side of the stainless steel case should be corresponding to the side of the stainless steel bottom plate. The welding points of the robot should be symmetrical, and the driving structure of the wire feeding should be placed on the axis of the robot, so that the distance between the driving wheel and the wire feeding nozzle is close to complete the wire feeding welding. Through the above method, the present invention can improve welding efficiency, simplify welding steps and work flow, and save equipment cost and labor cost.

Owner:SUZHOU TIANHONG LASER

Welding process for steel plate

InactiveCN107999926AGuarantee welding qualityAvoid it happening againArc welding apparatusWelding/soldering/cutting articlesSheet steelEngineering

The invention discloses a welding process for a steel plate. The welding process comprises the following steps that 1, pre-welding preparation is carried out, specifically, dirt on the surface of a to-be-welded part is removed; 2, spot welding is carried out, specifically, pre-positioning is carried out on the to-be-welded part; and 3, welding is carried out, specifically, welding technological parameters conforming to conditions are selected for welding the to-be-welded part. The welding process for the steel plate has the advantages that the welding steps are simplified, the welding processis simple, the welding quality of steel pipes can be guaranteed, the hardening structure is effectively prevented during welding, the welding stress is reduced, and the welding deformation is reduced.

Owner:ANHUI WALTER MACHINERY TRADE

T-type steel argon arc welding process

InactiveCN104972206AChoose accurate specificationGuarantee welding qualityArc welding apparatusWelding/soldering/cutting articlesEngineeringSpot welding

The invention discloses a T-type steel argon arc welding process, which comprises the steps: 1 treatment of welding parts and selection of welding materials; 2 temporary spot welding; 3 welding; and 4 post-weld treatments. The T-type steel argon arc welding process simplifies welding steps, simple in welding mode, accurate and regulate in material selection, can guarantee welding quality of T-type steels, supplies a regulated welding mode, and is beneficial for rapid and safe welding of the T-type steels.

Owner:LIUZHOU JINMAO MACHINERY

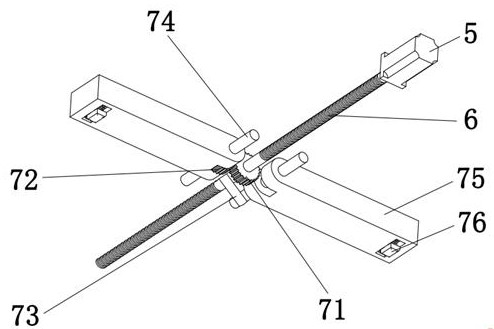

Manual pallet truck welding device

ActiveCN113427184BEasy to locateShorten positioning timeWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryStructural engineering

The invention discloses a manual pallet truck welding device and relates to the technical field of pallet truck welding. It includes a housing on which a first motor, a turntable and a center frame are arranged, the first motor is arranged at the bottom of the casing, the turntable is arranged in the middle of the casing and is rotatably connected with the casing, and the The output shaft of the first motor is fixedly connected to the bottom of the turntable, the center frame is arranged on the top of the housing, welding assemblies are arranged on both sides of the center frame, the second motor, two-way screw, a first positioning component and two second positioning components. The present invention can adaptively change the welding angle of the welding torch according to the angle of different trapezoidal blocks, so that the welding torch is always welded in the middle of the welding angle, which ensures the formation of the welding seam and improves the welding effect, and the angle adjustment of the welding torch is consistent with The lateral positioning of the trapezoidal block is carried out simultaneously, which simplifies the welding steps and improves the work efficiency during welding.

Owner:山东山宇重工机械有限公司

Manual pallet truck welding device

ActiveCN113427184AEasy to locateShorten positioning timeWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryPallet jack

The invention discloses a manual pallet truck welding device, and relates to the technical field of pallet truck welding. The device comprises a shell, a first motor, a rotating disc and a center frame are arranged on the shell, the first motor is arranged at the bottom of the shell, the rotating disc is arranged in the middle of the shell and rotationally connected with the shell, an output shaft of the first motor is fixedly connected with the bottom of the rotating disc, the center frame is arranged at the top of the shell, welding assemblies are arranged on the two sides of the center frame correspondingly, and a second motor, a two-way screw, a first positioning assembly and two second positioning assemblies are arranged in the center frame. A welding angle of a welding gun can be adaptively changed according to angles of different trapezoidal blocks, so that the welding gun is always located in the middle of the welding included angle for welding, welding seam forming is guaranteed, the welding effect is improved, angle adjustment of the welding gun and transverse positioning of the trapezoidal blocks are conducted at the same time, the welding steps are simplified, and the working efficiency during welding is improved.

Owner:山东山宇重工机械有限公司

Welding positioning device

InactiveCN104785984AImprove welding efficiencyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a welding positioning device which comprises a backing plate, clamping plates, a working table, an installing plate, positioning blocks, a welding plate and positioning grooves. The installing plate is located at the top of the working table, the positioning blocks are located on the periphery of the installing plate and connected with the installing plate in a welding mode, the welding plate is located at the upper ends of the positioning blocks and connected with the positioning blocks in a sliding mode, and the positioning grooves are located on the edges of the top of the welding plate and are in a rectangular shape. According to the welding positioning device, the backing plate is firstly arranged on the upper portion of the installing plate, the fine positioning function can be achieved through the positioning blocks on the periphery, then the welding plate is arranged, the clamping plates are lastly arranged in the positioning grooves in the welding plate to achieve quick positioning, and then welding can be directly conducted. The welding steps are simplified, and the welding efficiency and quality of the clamping plates can be greatly improved.

Owner:池州信安电子科技有限公司

Carbon steel and high speed steel hybrid welding process

InactiveCN106346134AOvercoming Difficult-to-Solder FeaturesFast welding speedWelding/soldering/cutting articlesLaser beam welding apparatusSlagCarbon steel

The invention provides a carbon steel and high speed steel hybrid welding process. The carbon steel and high speed steel hybrid welding process comprises the steps of 1, pre-welding treatment; 2, welding: using the clamp to combine the carbon steel and the high speed steel processed in step 1, with the protection of inert gases using continuous laser welding to finish the welding work, in the welding process using vacuum cleaner to vacuum the welding slag, using welding gas cleaner to clean the gases; 3, post-welding treatment, which is the completion of the hybrid welding process of carbon and high speed steel. The present invention has the advantages that the use of continuous laser welding successfully overcomes the welding difficulty of high speed steel and accelerates the welding speed, shortens the welding procedure and simplifies the welding operation. At the same time the use of clamp helps to combine the carbon steel and the high speed steel together, thus avoids the low precision due to long term friction and improves the welding quality.

Owner:SUZHOU TIANHONG LASER

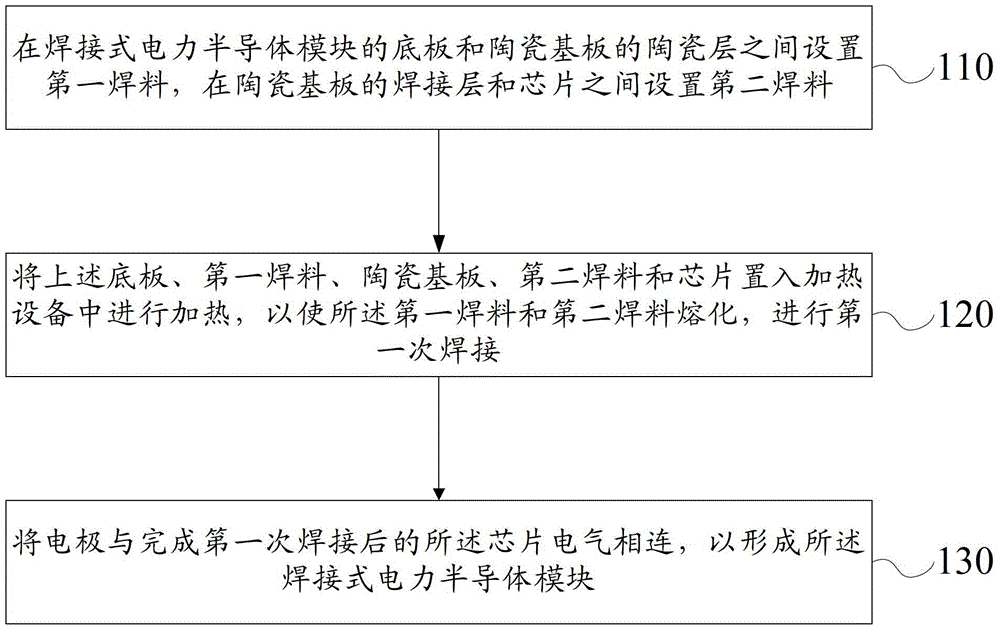

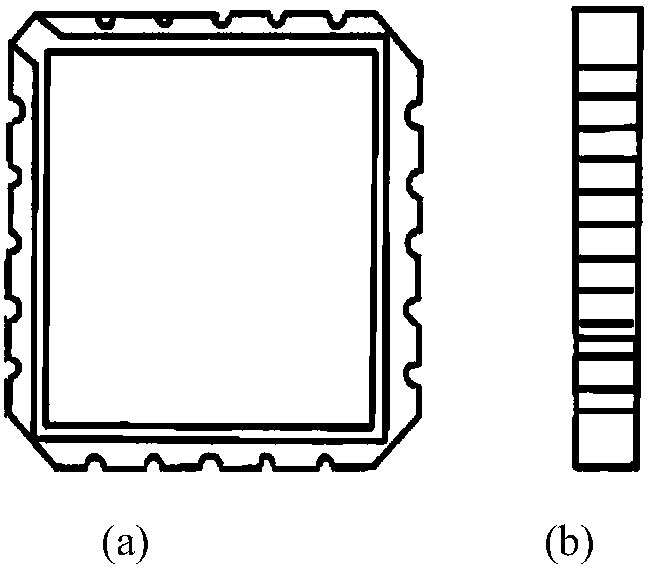

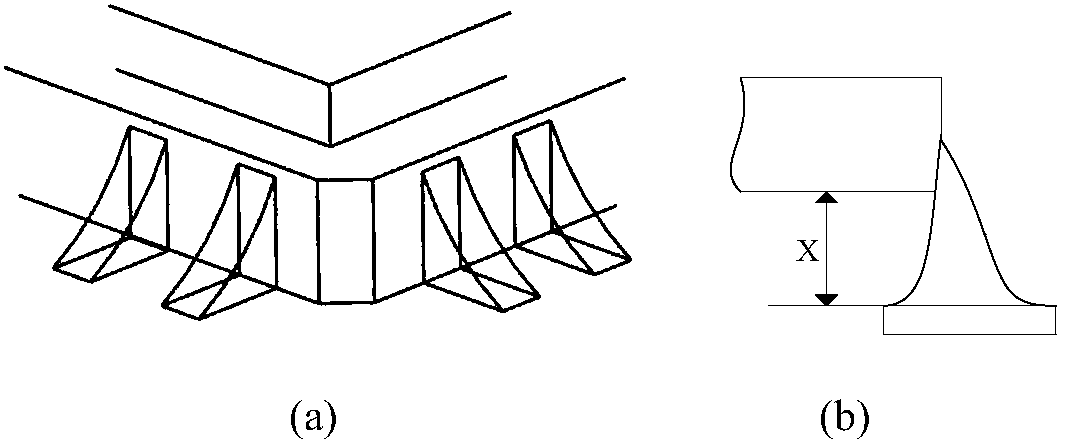

Welding method for welding power semiconductor modules

InactiveCN103579023BSimplify soldering stepsImprove welding efficiencySemiconductor/solid-state device manufacturingPower semiconductor deviceElectric power

The invention provides a soldering method for a soldered power semiconductor module, which includes: setting a first solder between the bottom plate of the soldered power semiconductor module and the ceramic layer of the ceramic substrate, and setting a second solder between the soldering layer of the ceramic substrate and the chip. Solder; the above-mentioned base plate, first solder, ceramic substrate, second solder and chip are placed in heating equipment and heated, so that the first solder and the second solder are melted, and the first soldering is carried out; the electrode and the second solder are completed The chips after one soldering are electrically connected to form the soldered power semiconductor module. The invention can simplify welding steps and improve welding efficiency.

Owner:XIAN YONGDIAN ELECTRIC

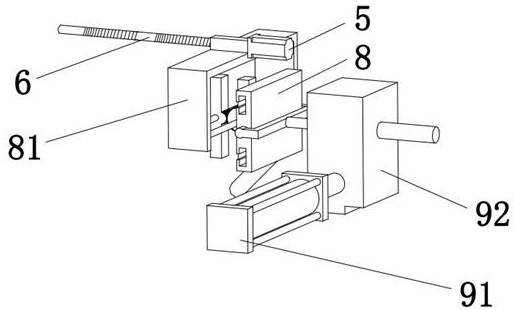

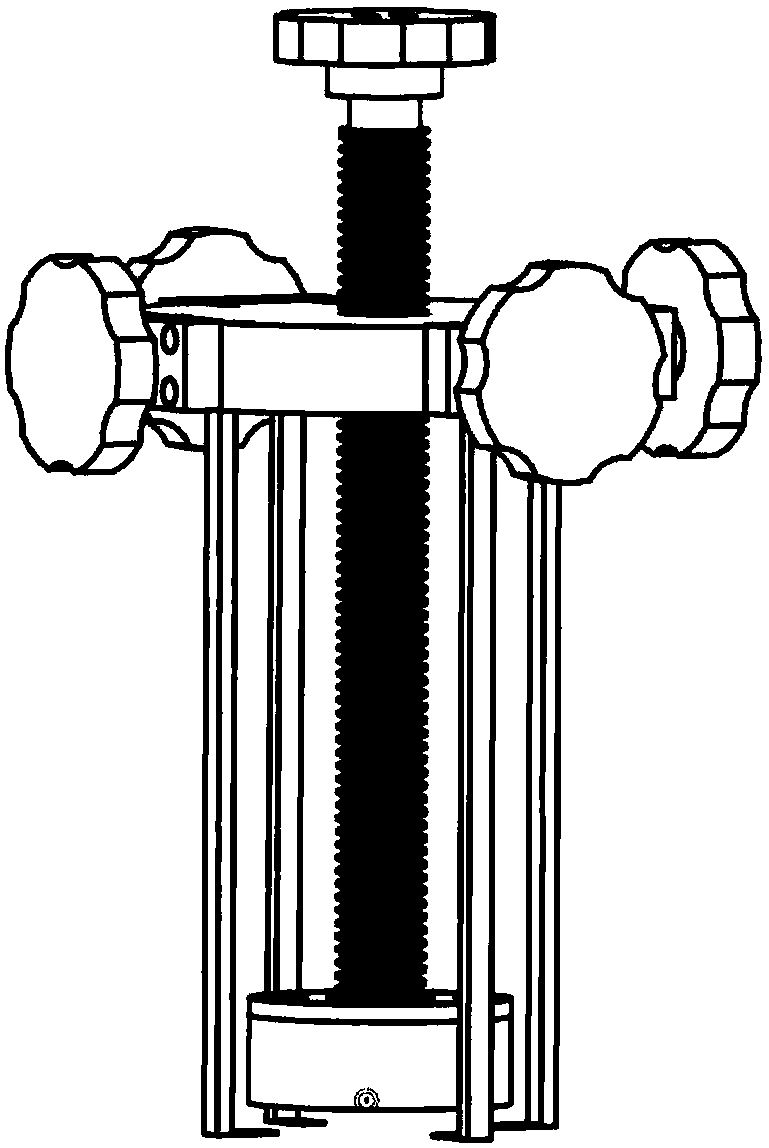

Auxiliary device for manually welding components

ActiveCN108213644AControl tin intakeSimplify the alignment processWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention provides an auxiliary device for manually welding components. The auxiliary device is composed of a pressing assembly and a clamping assembly; the pressing component comprises a height adjusting hand wheel, a pressing screw, a bearing, a bearing outer ring fixing pressing plate and a pressing base; and the clamping assembly comprises a supporting plate, metal supports, clamping adjusting hand wheels, clamping screws and screw fixing blocks. The auxiliary device has the advantages that the pressing assembly can press the components, no displacement or rotation of the pressed components can be caused, and therefore relative isolation can be realized; and the clamping assembly support the components through L-shaped structures at the lower ends of the metal supports, the positions of the metal supports can be adjusted, expansion and retraction can be realized, and therefore the effect of clamping the components can be achieved.

Owner:西安应用光学研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com