Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Simple compensation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fiber Optic Temperature and Pressure Sensor and System Incorporating Same

InactiveUS20080212917A1Simple and effective compensationSimple compensation processCladded optical fibreFluid pressure measurement by electric/magnetic elementsSpectral envelopePolarizer

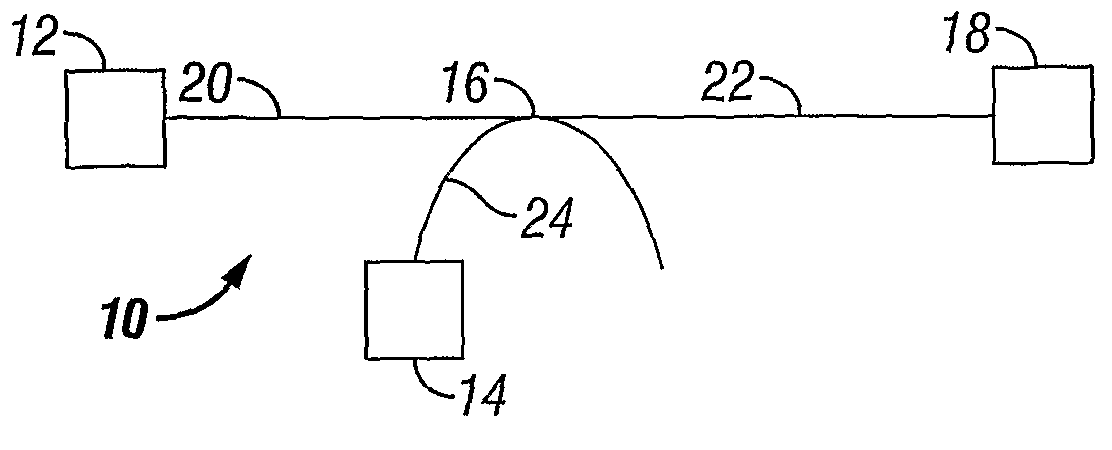

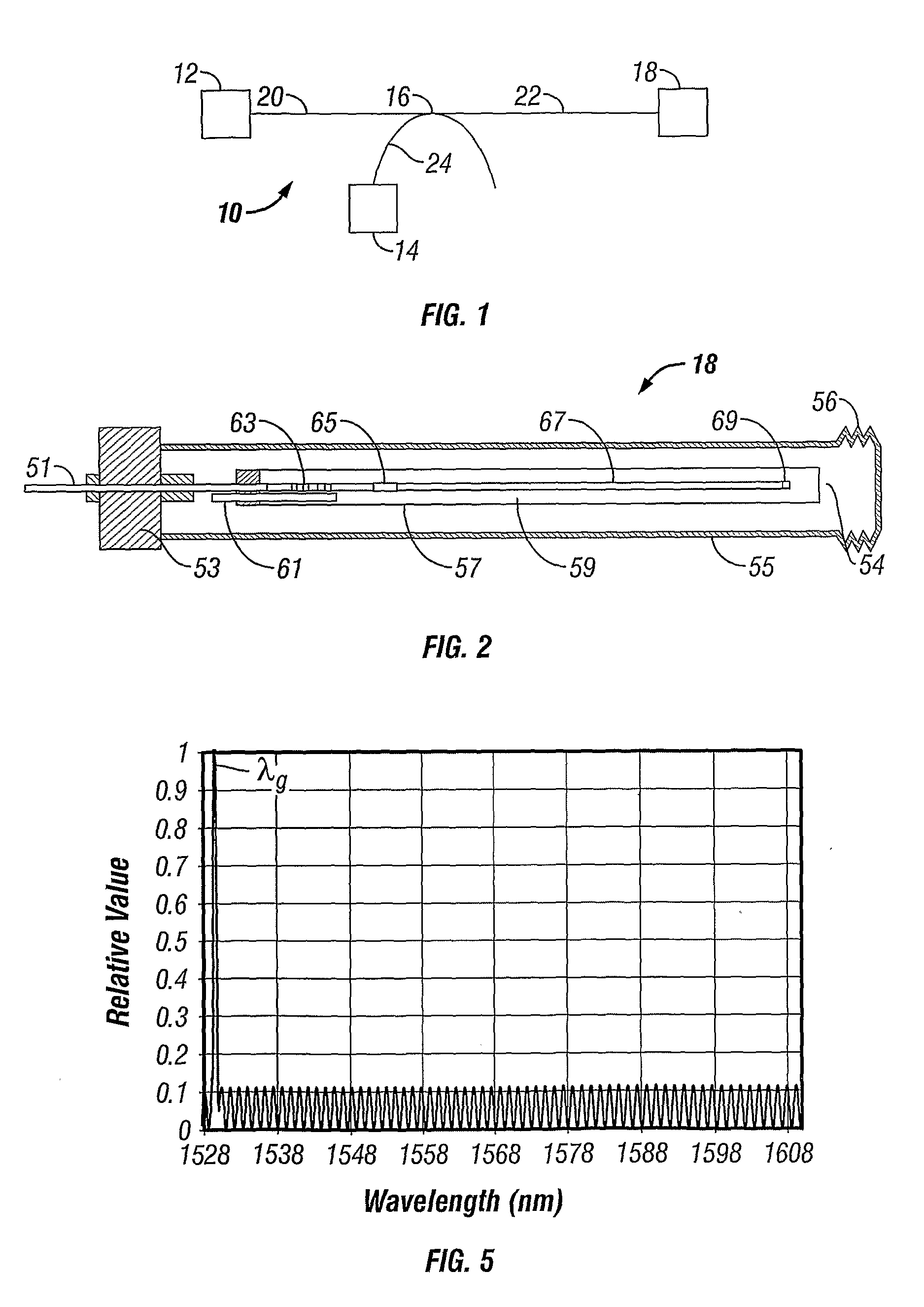

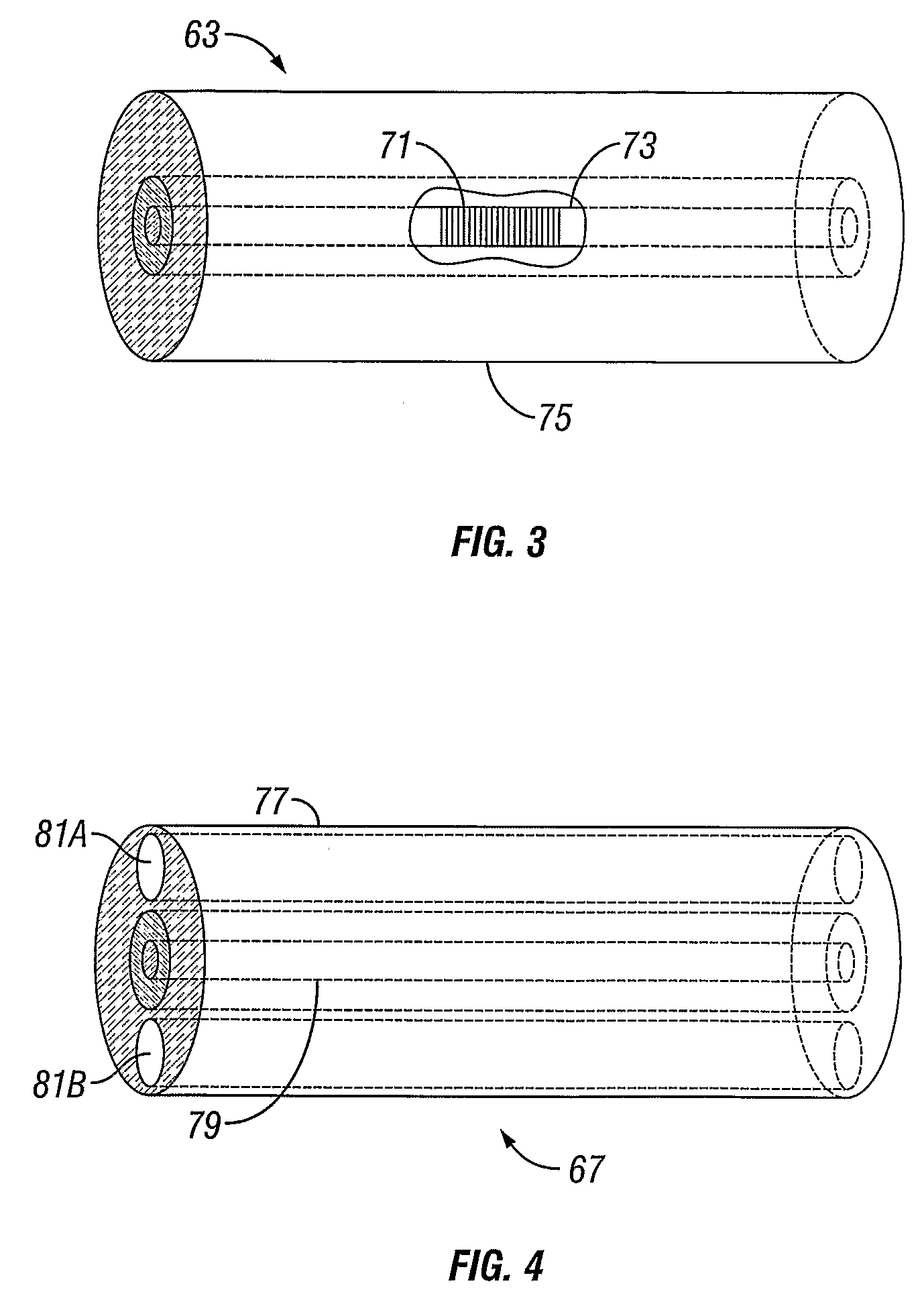

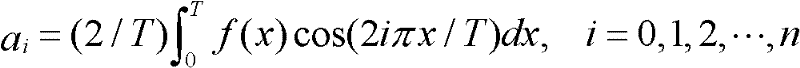

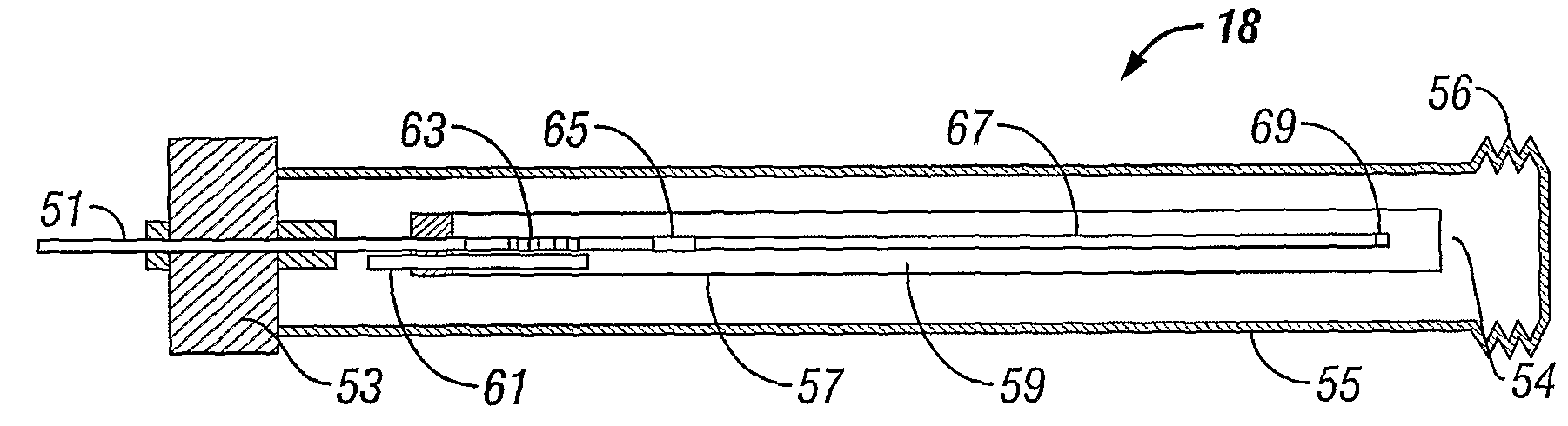

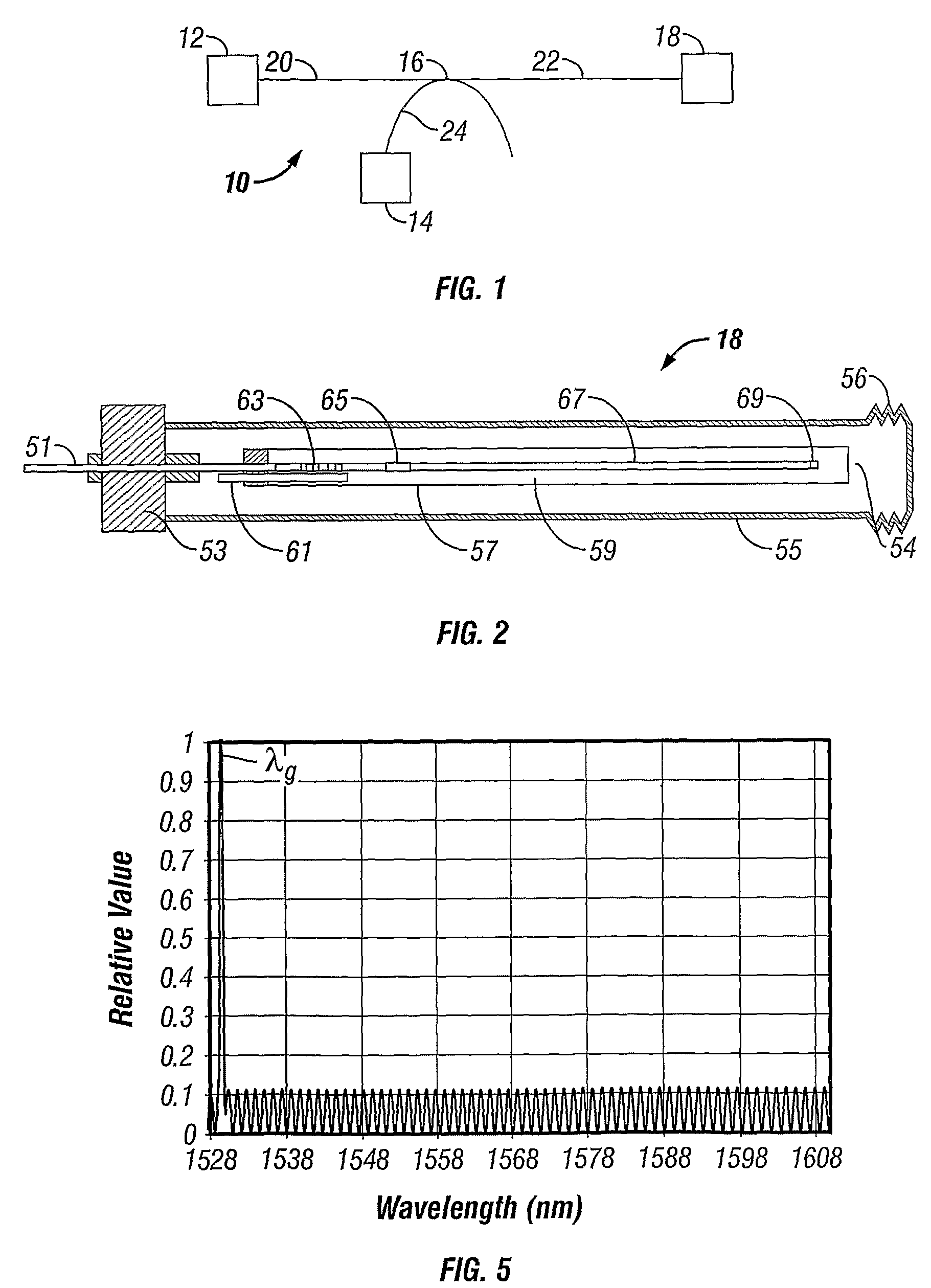

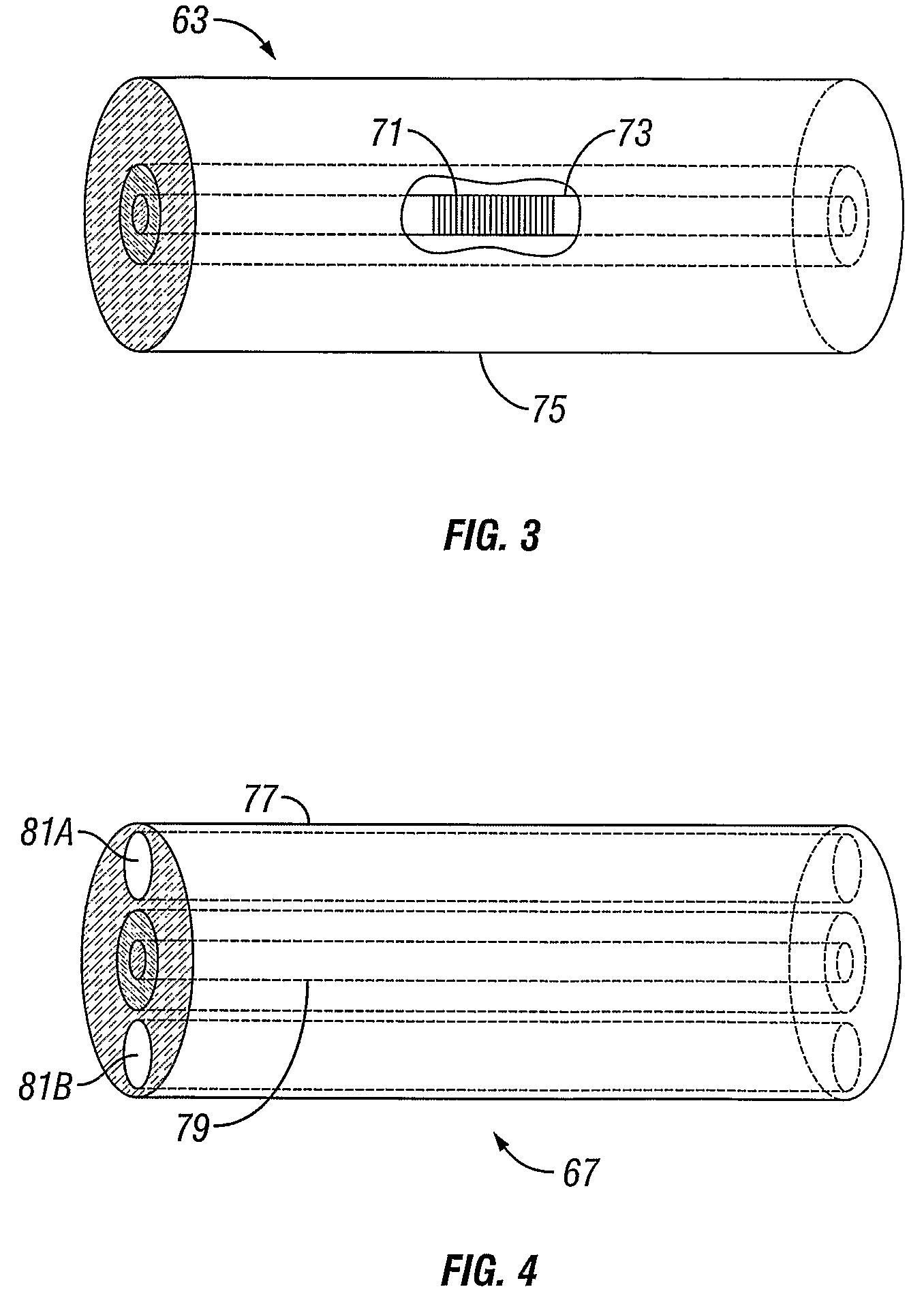

A sensing system including a sensor having an enclosure that defines a chamber, a fiber optic segment extending from outside the enclosure into the chamber, and a sequence of optical processing elements within the chamber. The elements include a fiber Bragg grating, a polarizer, a side hole fiber, and a mirror. A light source is arranged to direct light to the sensor(s). A spectral analyzer is arranged to detect light reflected back from the sensor(s). The fiber Bragg grating substantially reflects a first spectral envelope while transmitting the remainder of the optical spectrum to the polarizer and side hole fiber. The polarizer, side hole fiber, and mirror cooperate to return an optical signal within a second spectra! envelope. The characteristic wavelength of a peak in the first spectral envelope is highly sensitive to temperature and relatively weakly sensitive to pressure. The period of the optical signal within the second spectral envelope is highly sensitive to pressure and relatively weakly sensitive to temperature. The spectral analyzer measures these spectral components to simultaneously derive a measure of temperature and pressure that effectively compensates for temperature-pressure cross-sensitivity of the sensor(s).

Owner:SCHLUMBERGER TECH CORP

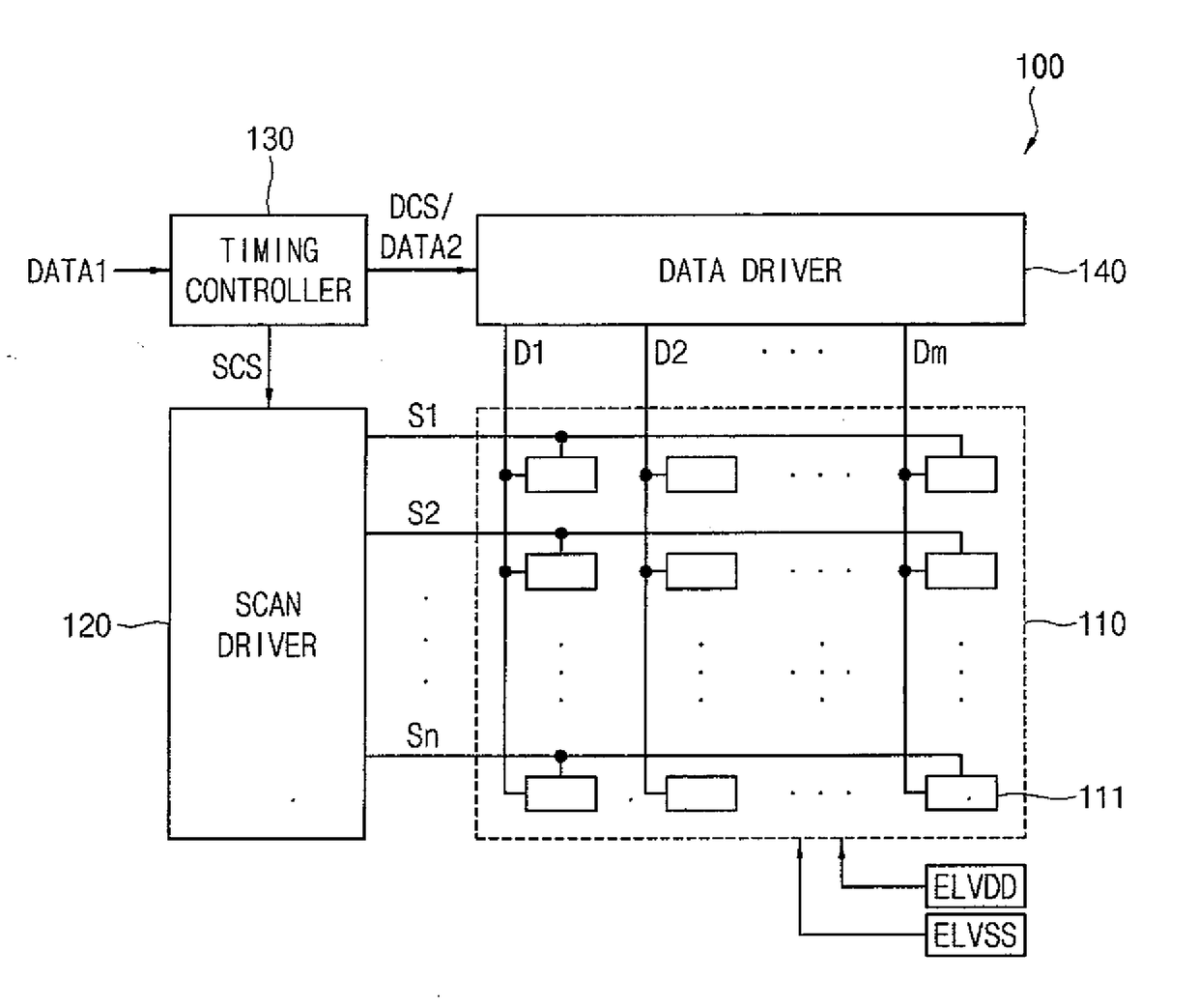

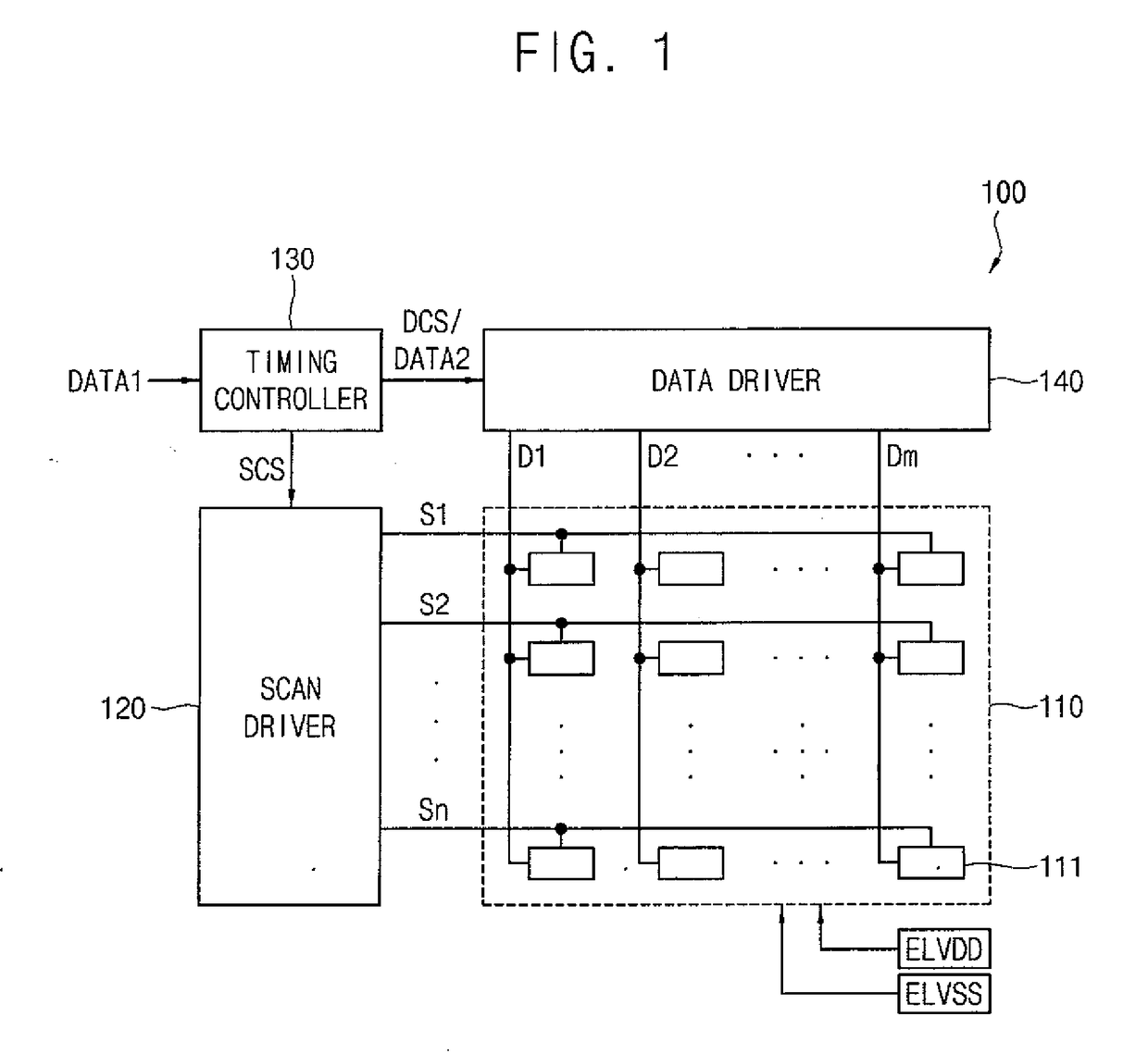

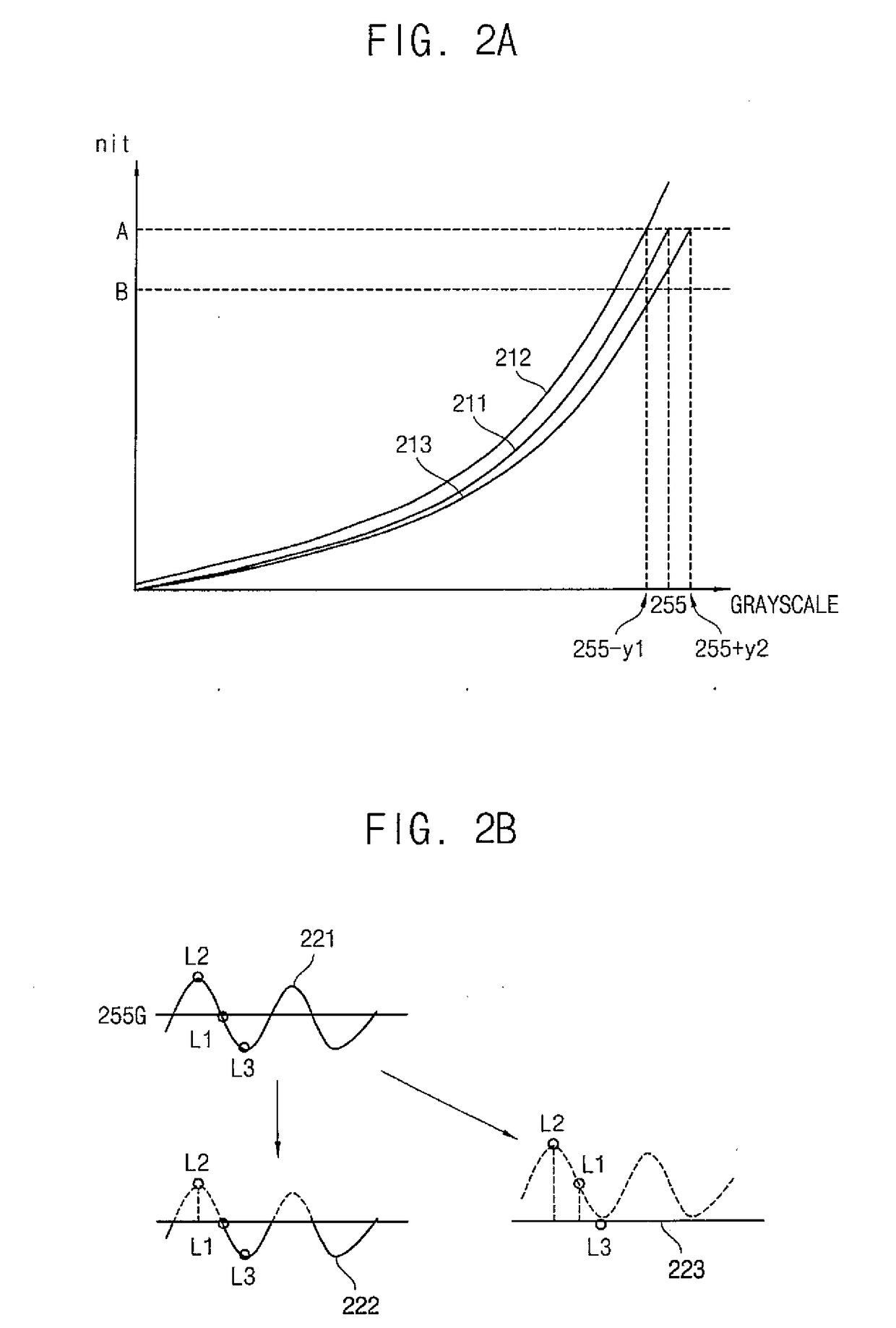

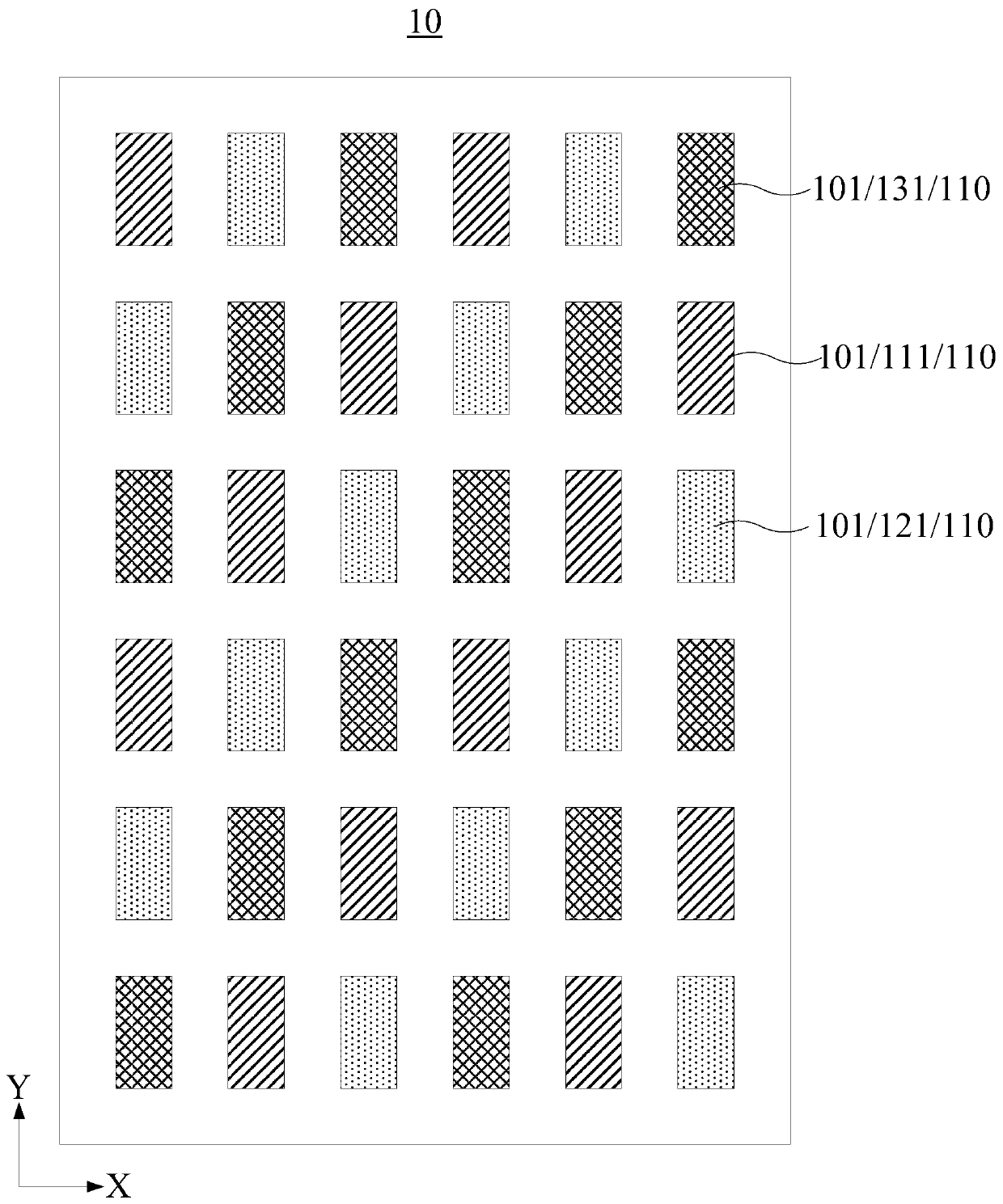

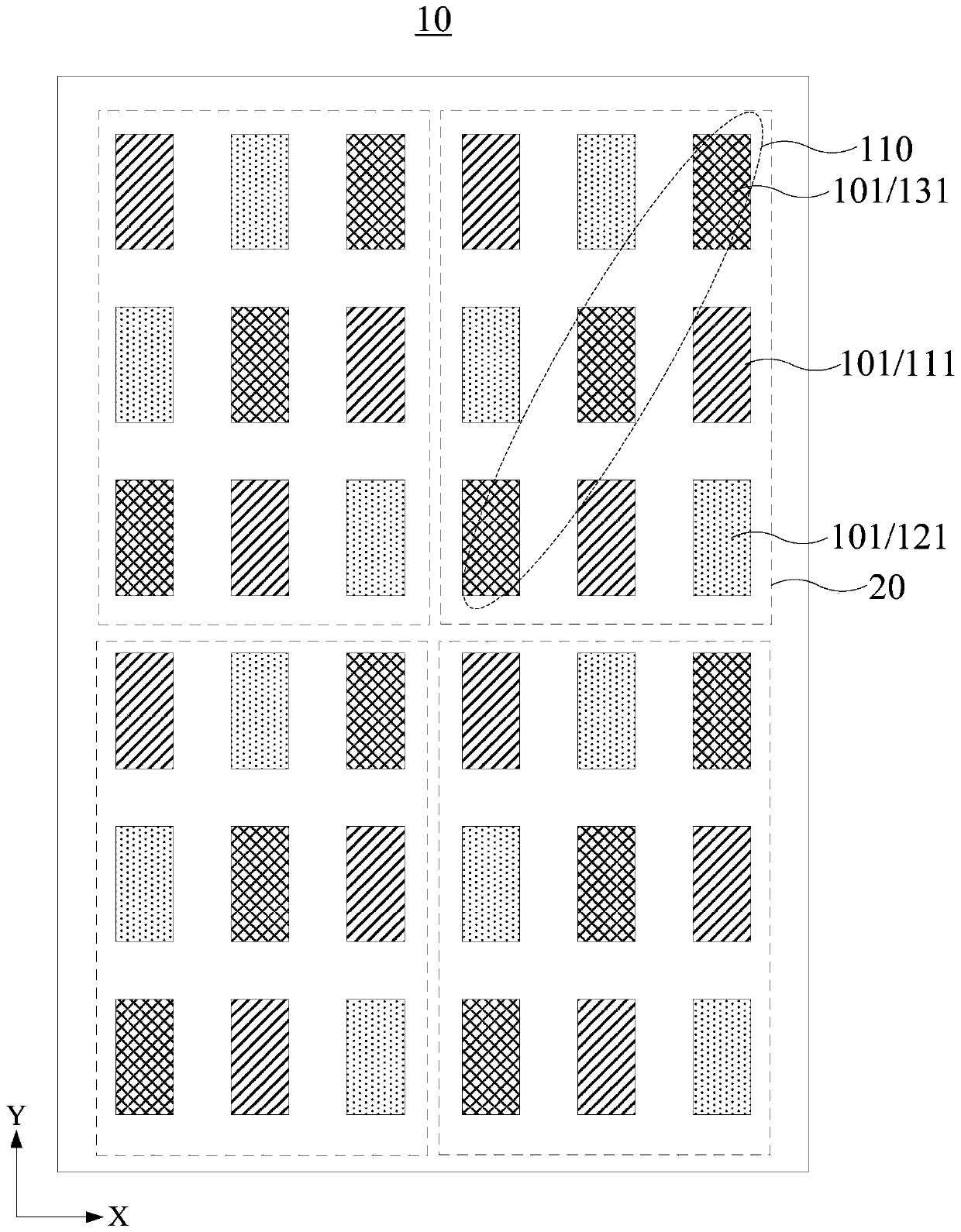

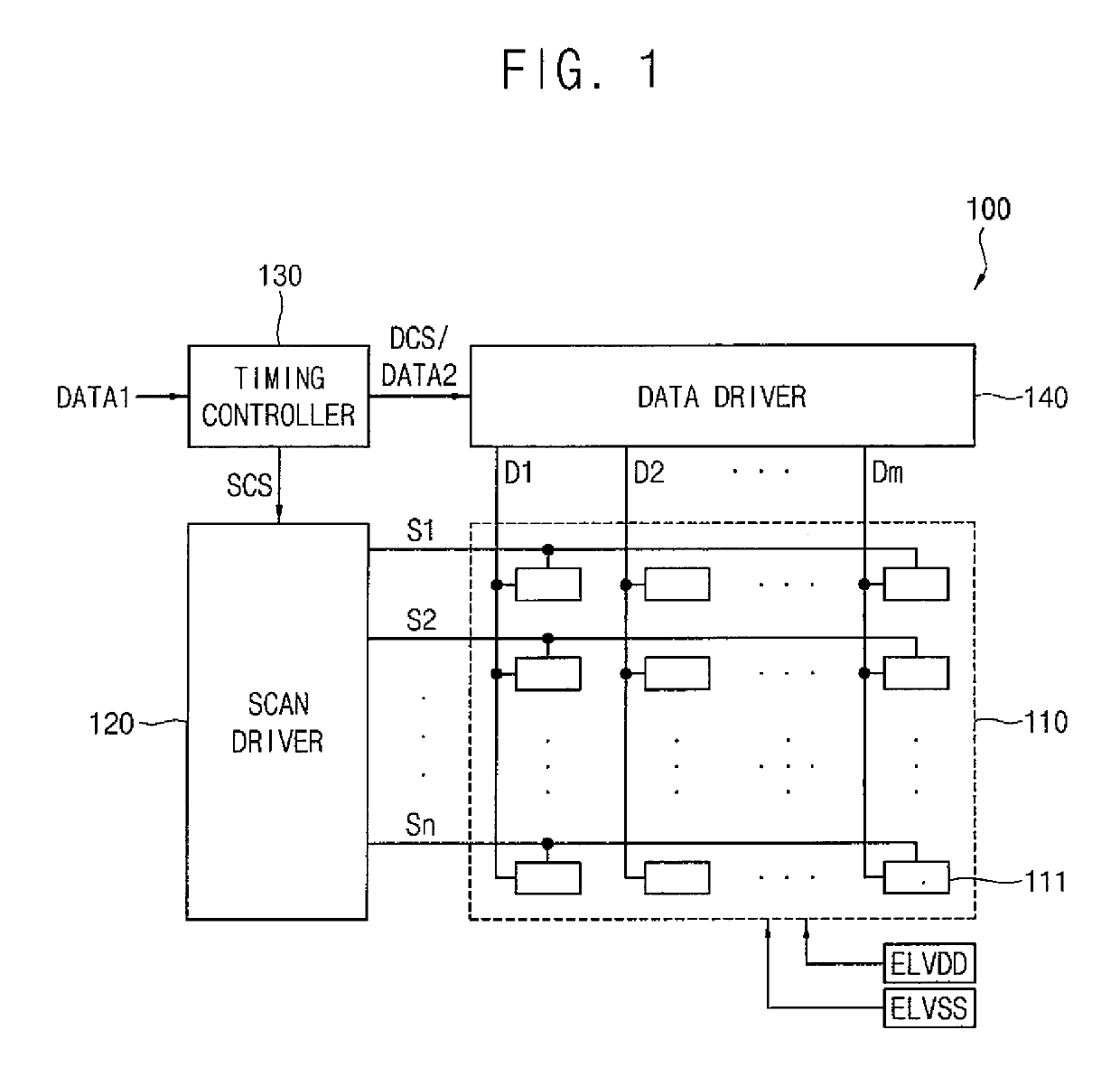

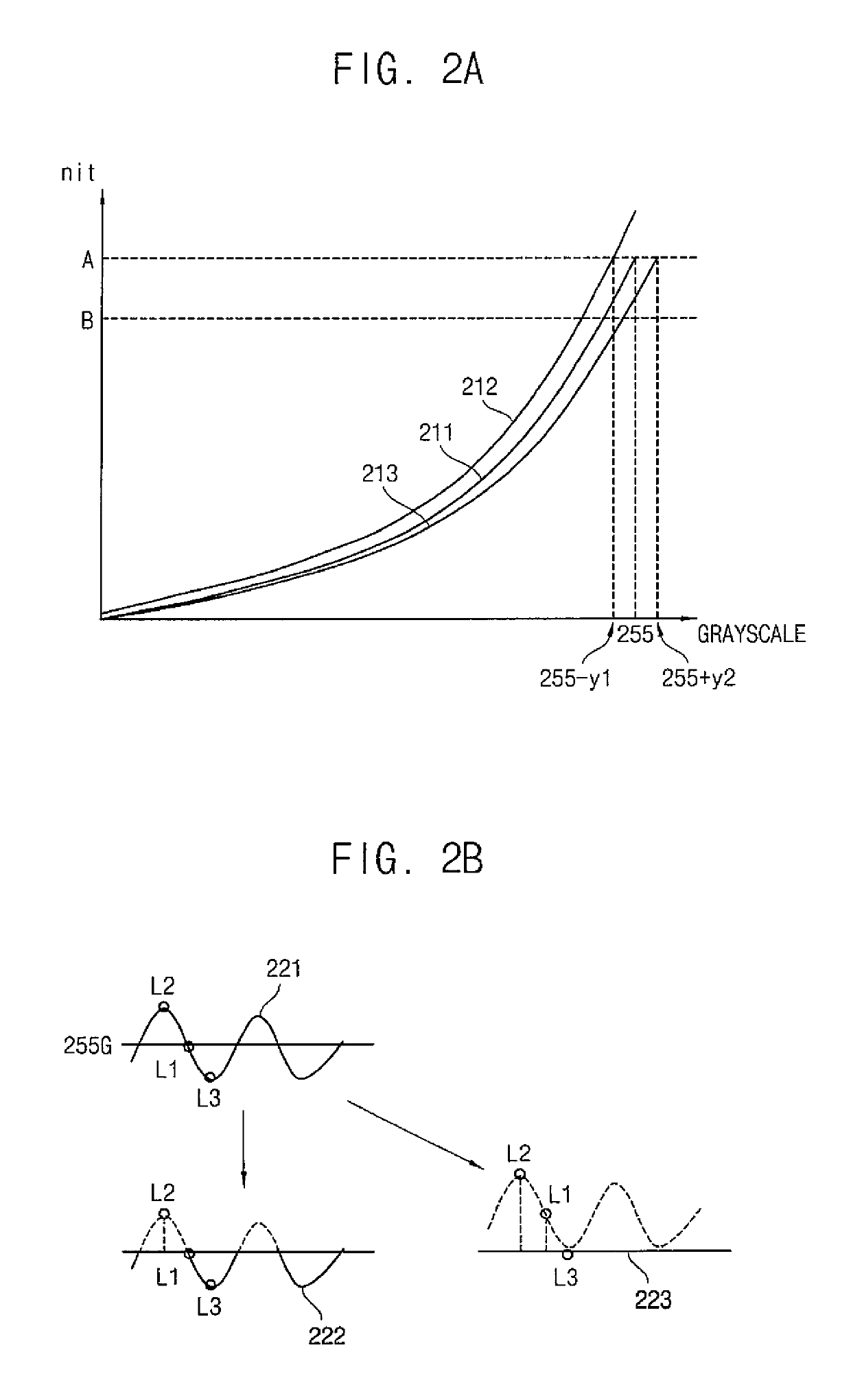

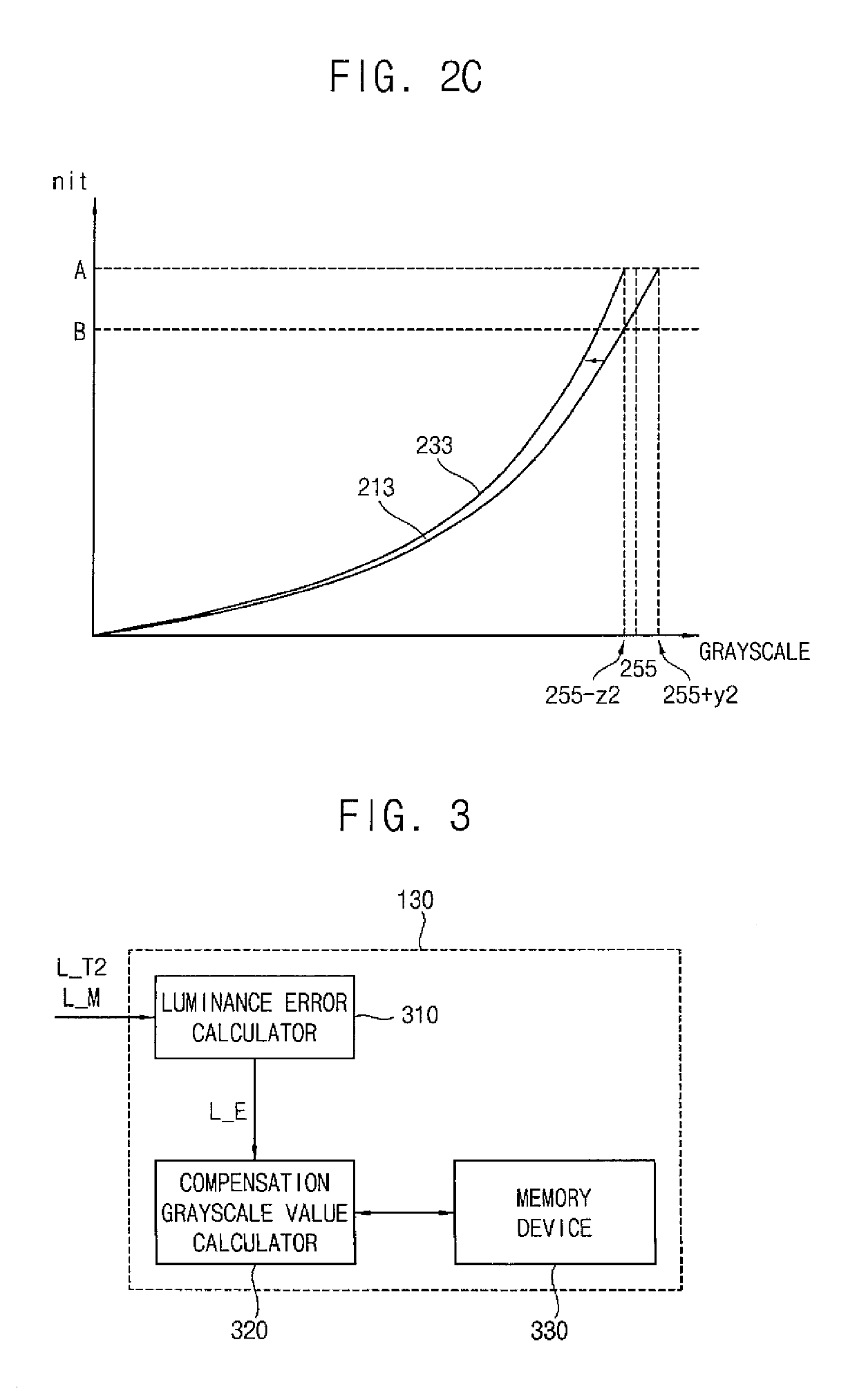

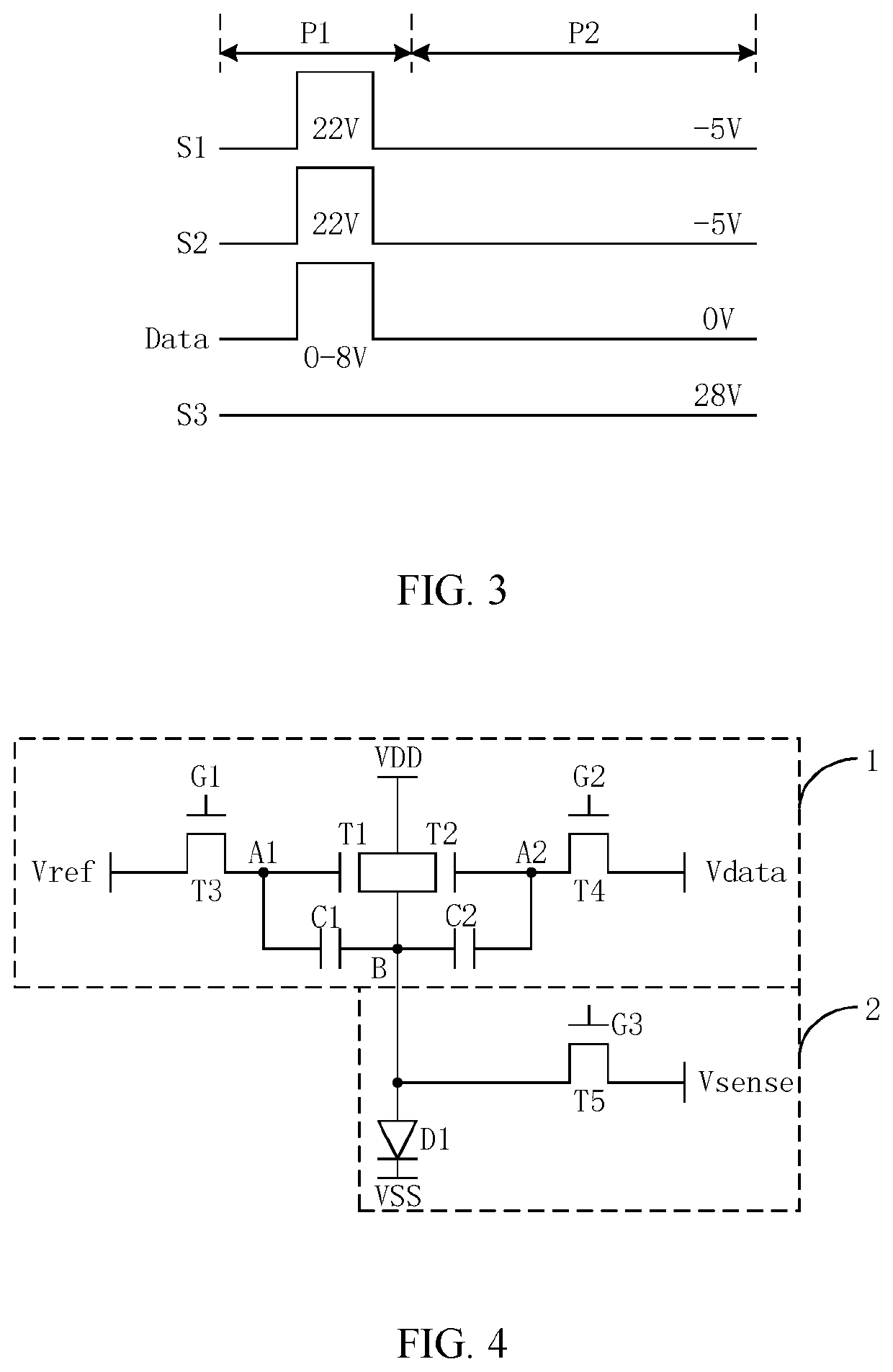

Display device and optical compensation method of a display device

ActiveUS20170206825A1Simple processImprove display qualityStatic indicating devicesDisplay devicePixel brightness

An optical compensation method for a display device including a pixel is provided. The method includes: providing test data having a first grayscale value to the display device; measuring a luminance of the pixel which emits light based on the test data; and calculating a compensation grayscale value based on a second target luminance and the measured luminance of the pixel. The second target luminance is lower than a first target luminance which is set based on the first grayscale value.

Owner:SAMSUNG DISPLAY CO LTD

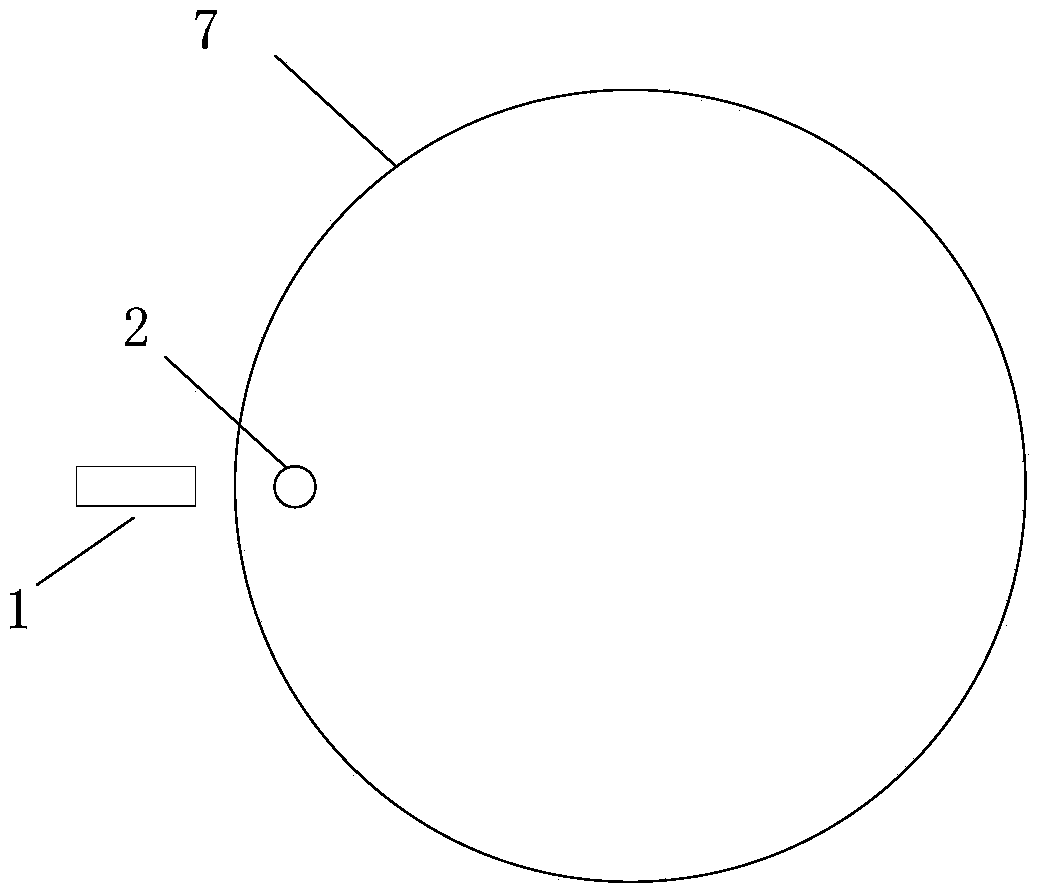

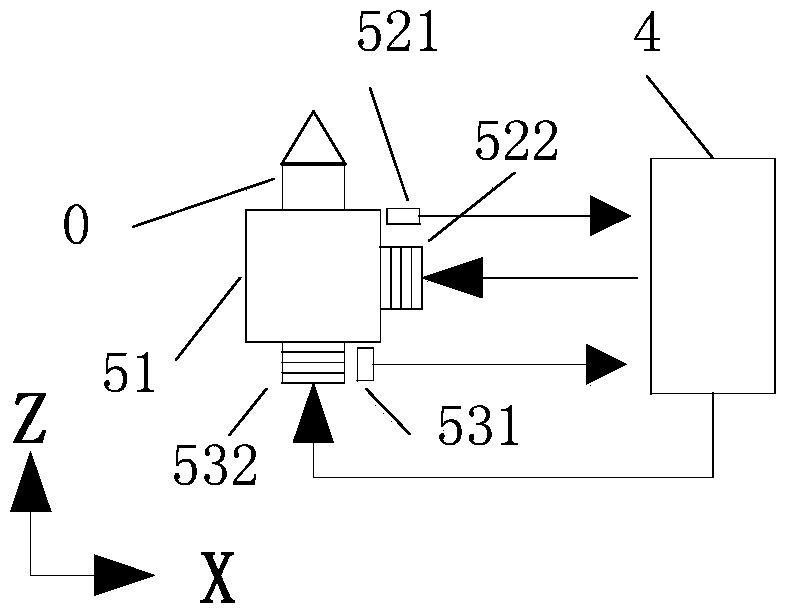

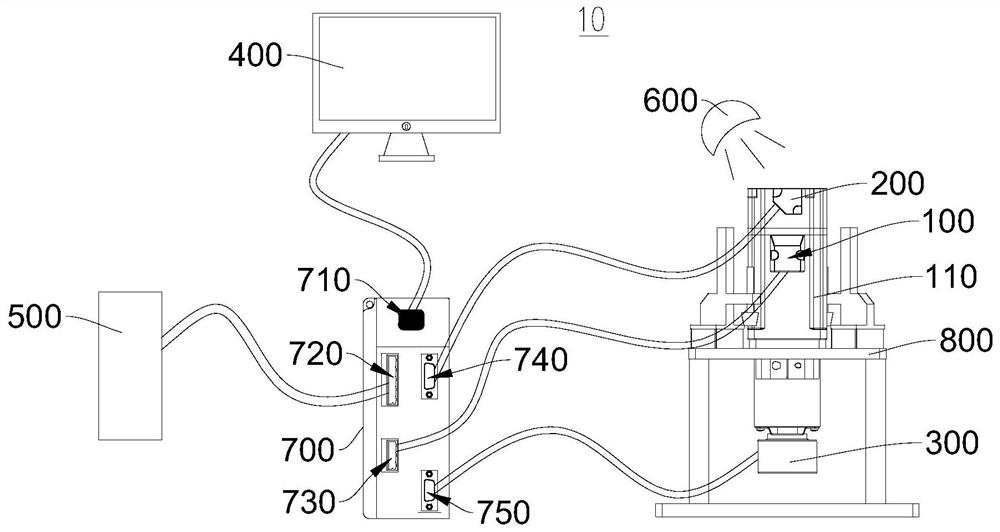

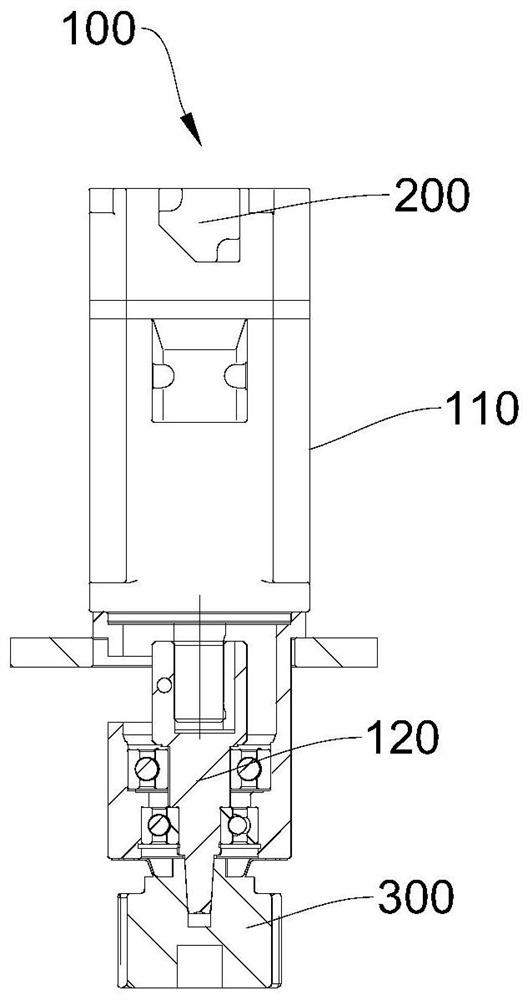

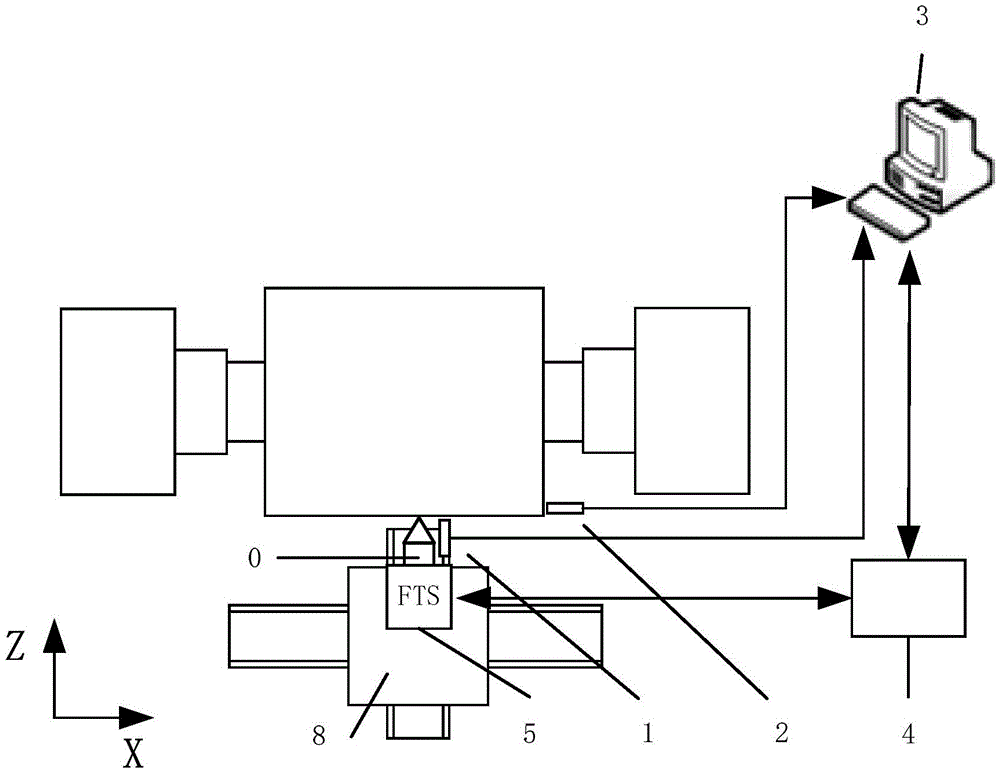

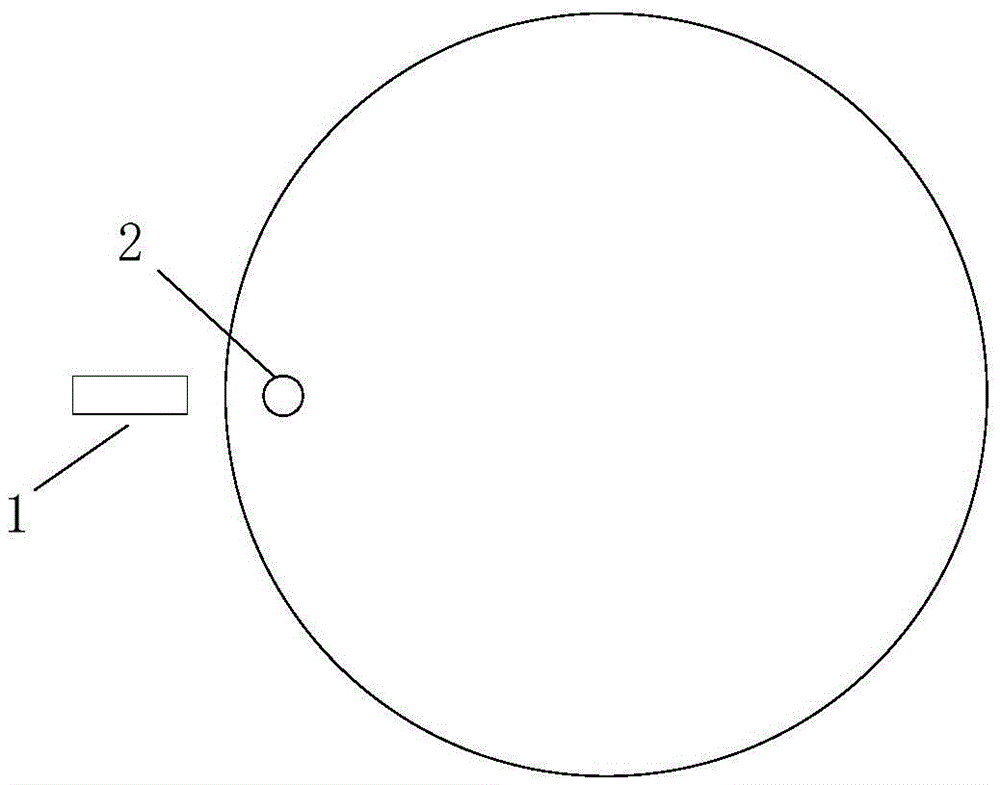

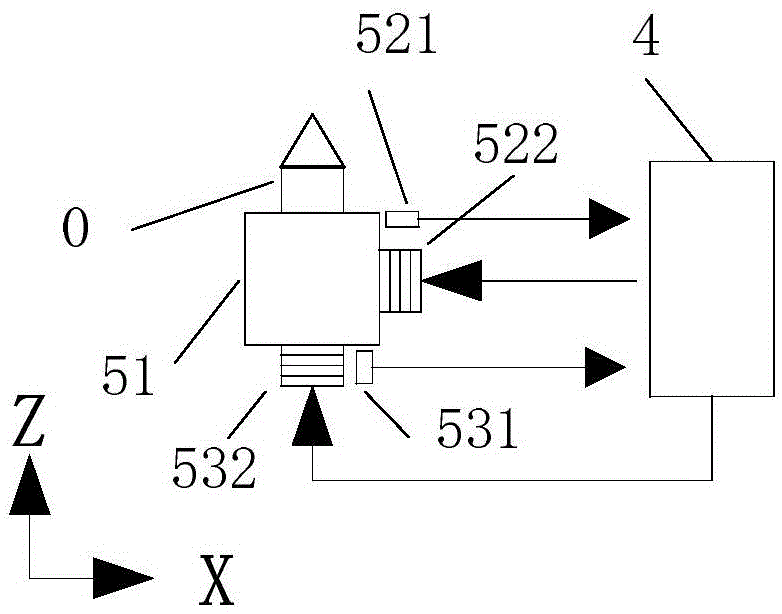

Device and method for compensating composition error of main shaft in real time

InactiveCN104070406AFast measurement and compensationImproving Error Compensation AccuracyMeasurement/indication equipmentsOther manufacturing equipments/toolsTwo degrees of freedomMachine tool

The invention discloses a device and a method for compensating a composition error of a main shaft in real time. The device comprises a radial capacitance displacement sensor, an axial capacitance displacement sensor, a control computer, a two-degree of freedom sharp knife servo controller and a two-degree of freedom sharp knife servo unit, wherein the output end of the radial capacitance displacement sensor is connected with the first input end of the control computer; the output end of the axial capacitance displacement sensor is connected with the second input end of the control computer; the two-degree of freedom sharp knife servo controller is respectively connected with the control computer and the two-degree of freedom sharp knife servo unit; the two-degree of freedom sharp knife servo unit is connected with a processing cuter; the radial capacitance displacement sensor is arranged at one side of the processing cutter, and the axial line thereof is vertically intersected with the axial line of a work-piece; the axial capacitance displacement sensor is arranged on one end face of the work-piece, and the axial line thereof is vertical to the end face of the work-piece. The device and the method for compensating the composition error of the main shaft in real time can perform on-line and real-time measurement and compensation on the composition error simply, rapidly and comprehensively, and can be widely applied to the field of precision machine tool machining.

Owner:GUANGDONG UNIV OF TECH

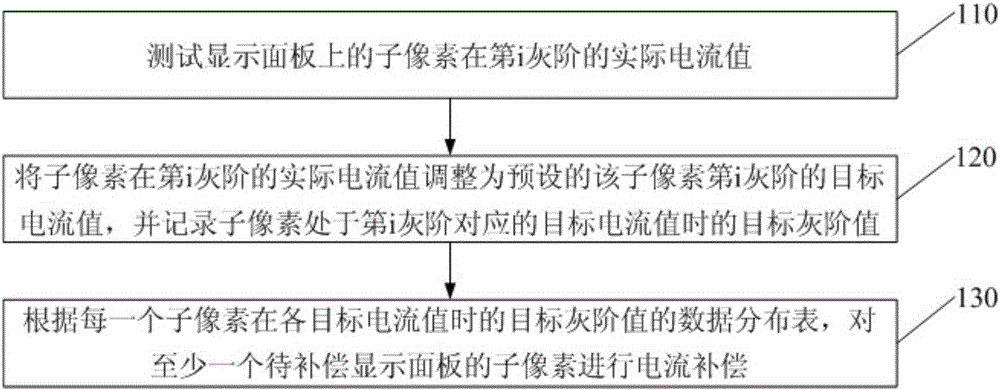

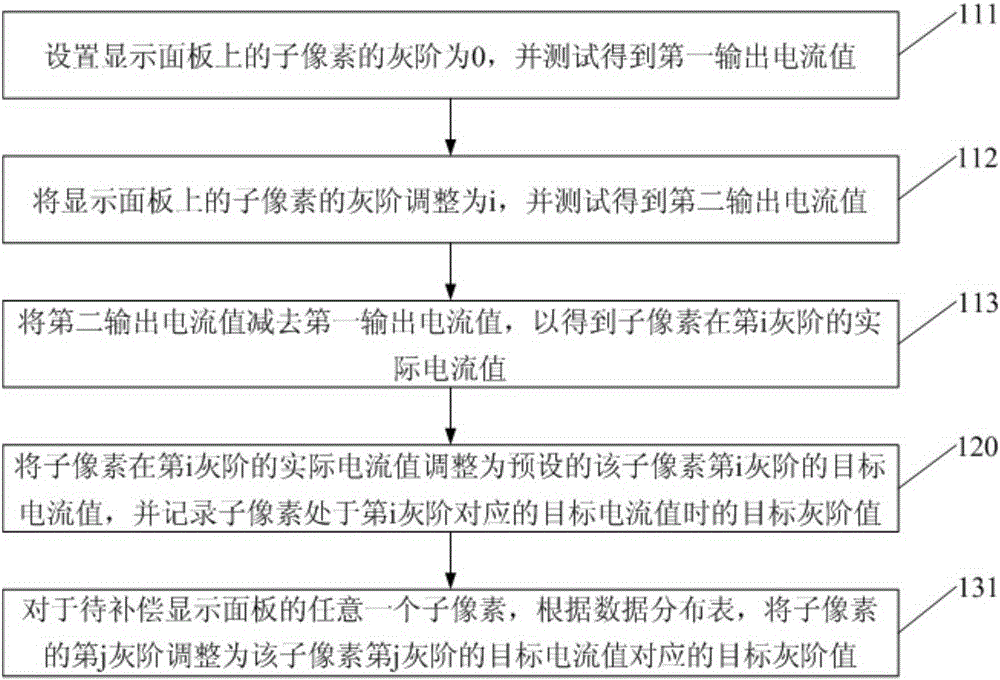

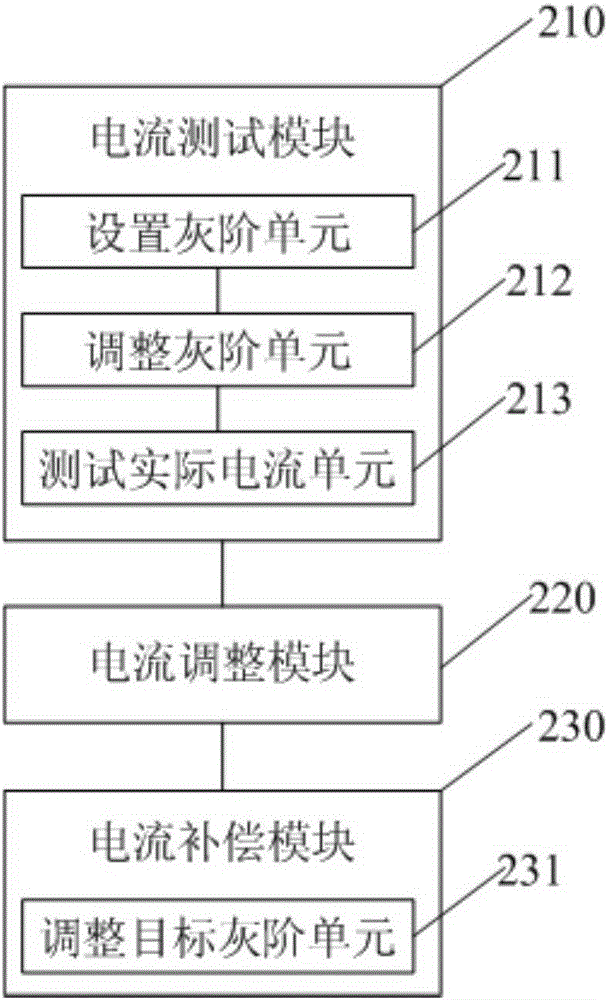

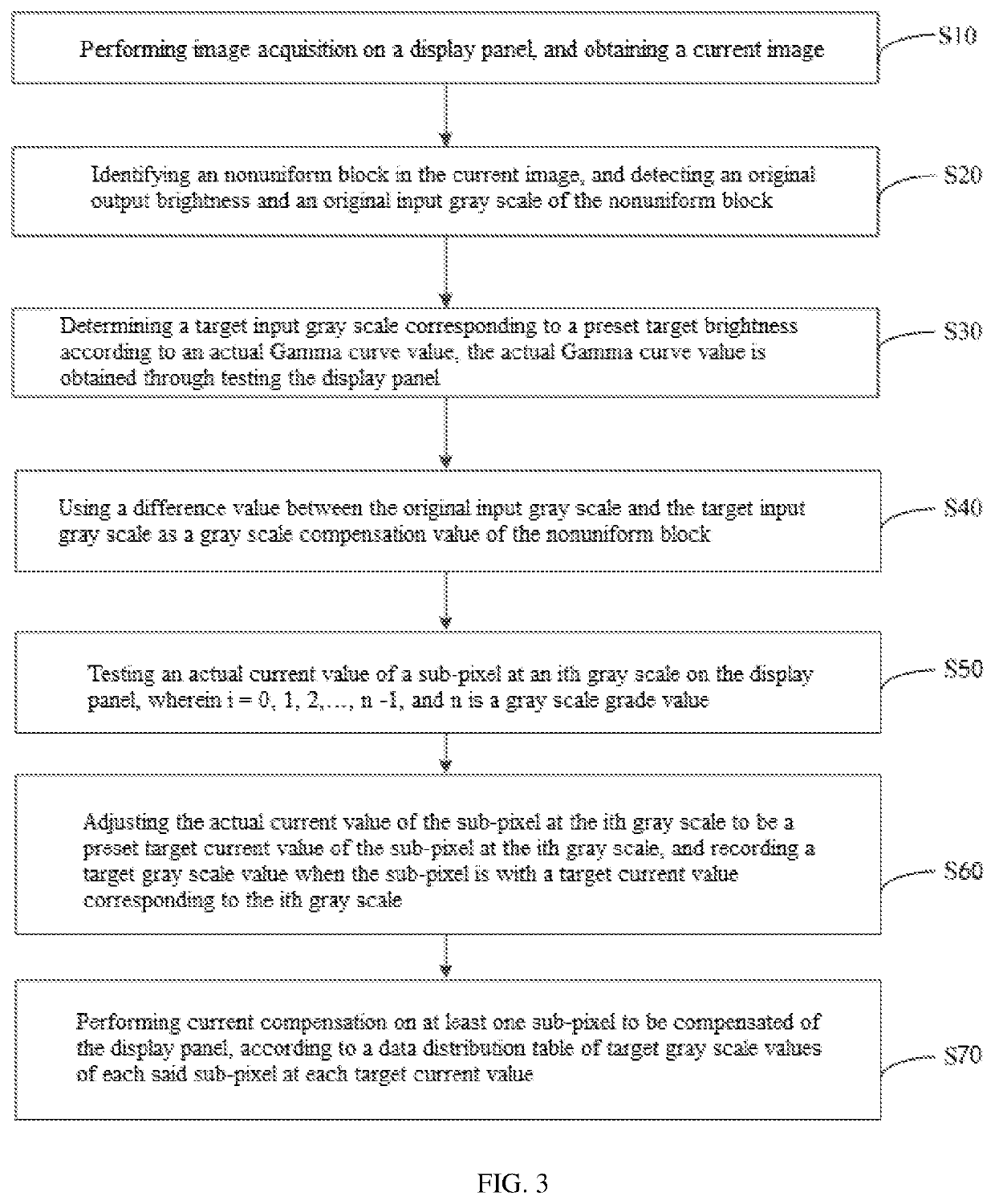

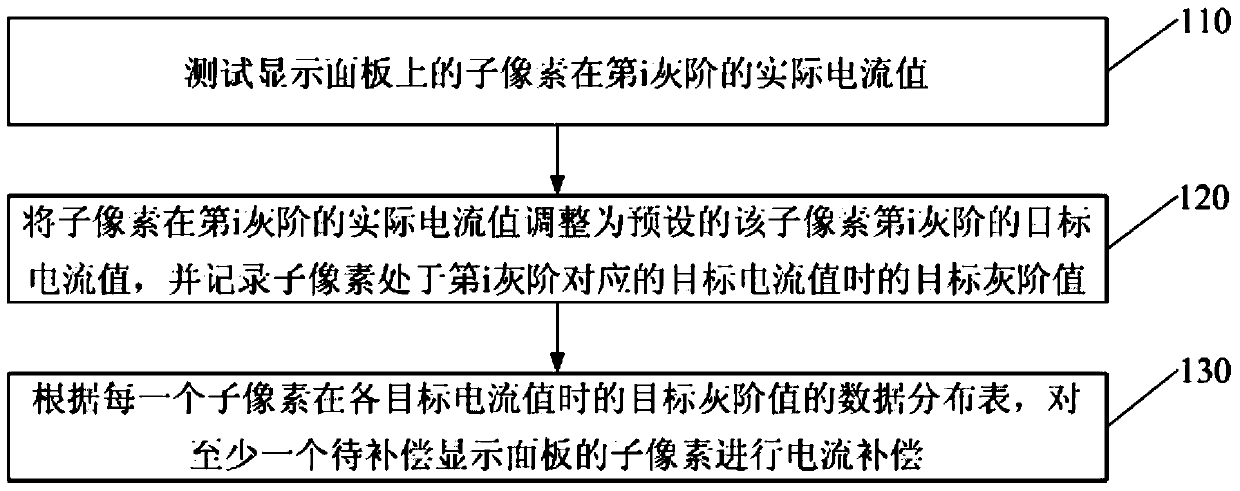

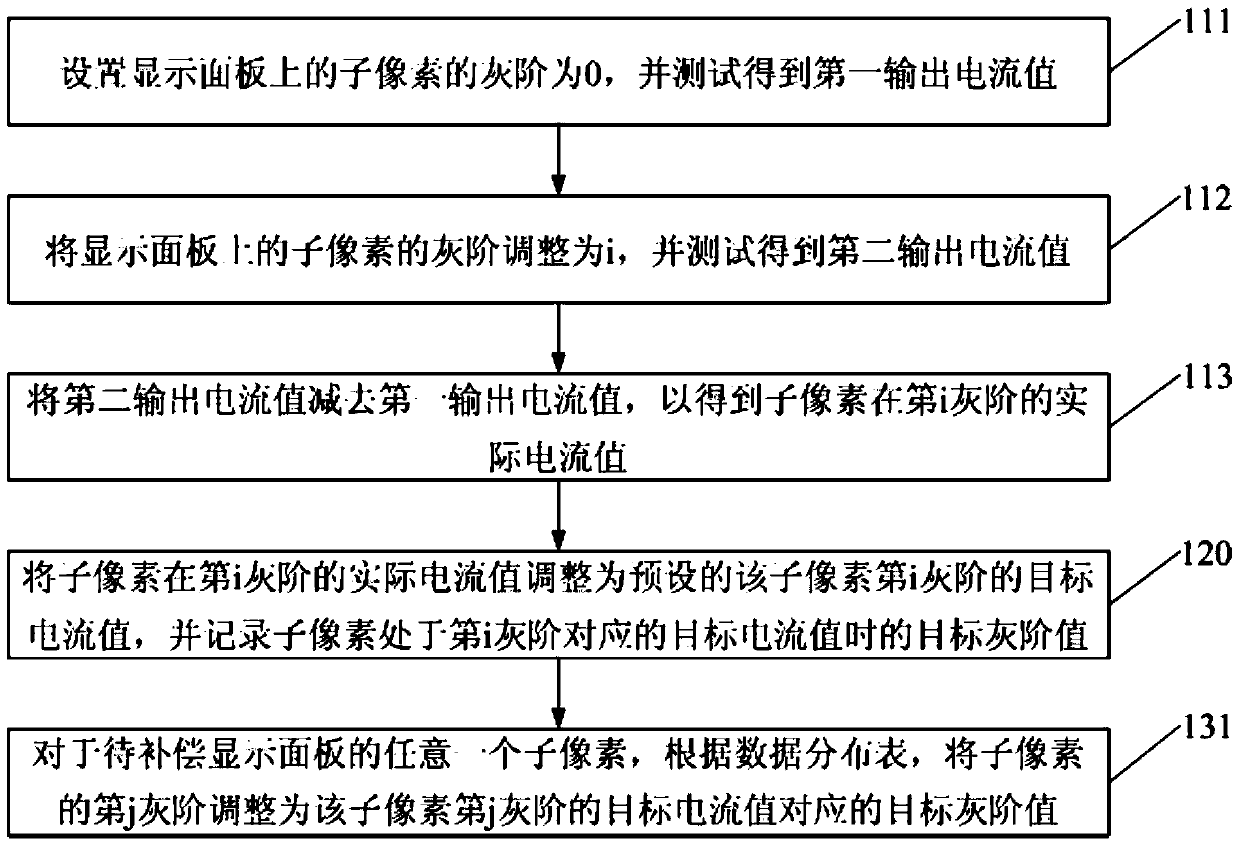

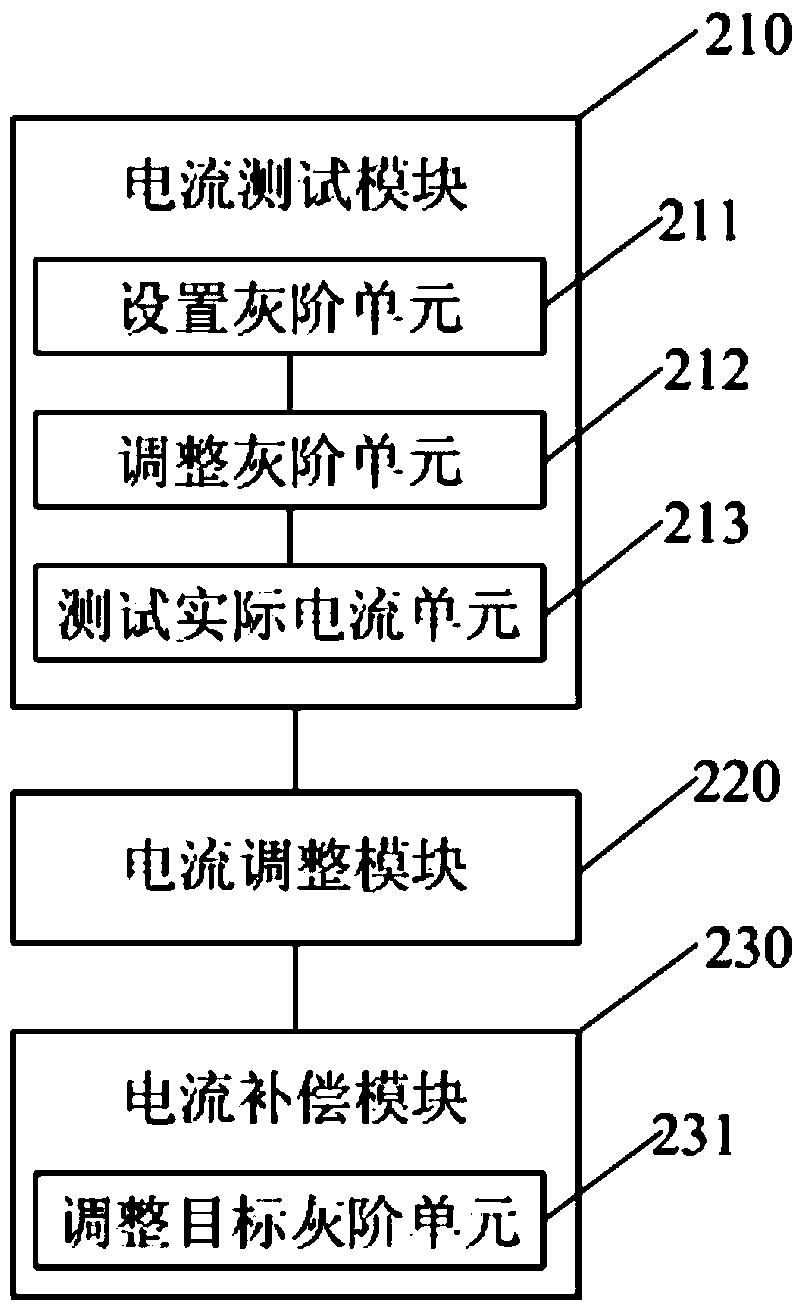

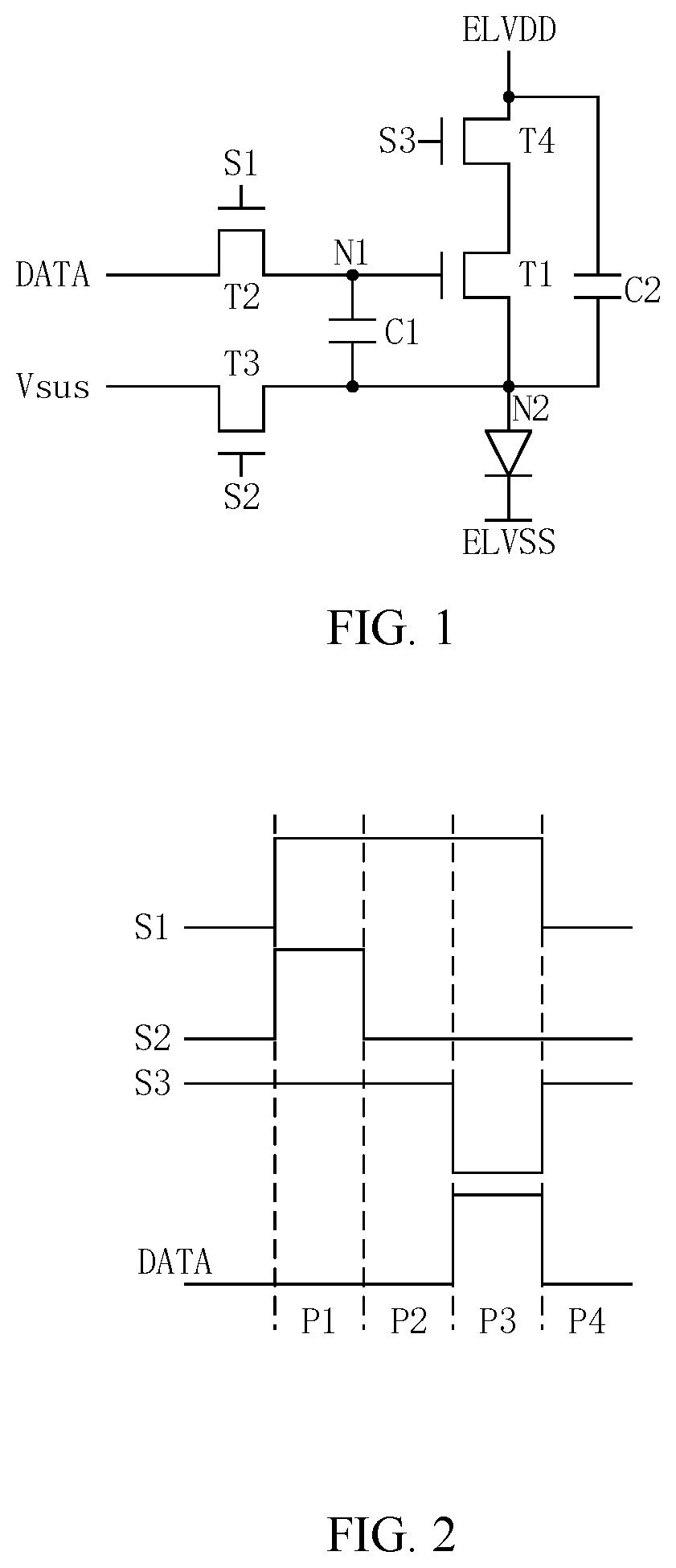

Display panel pixel current compensation method and system

ActiveCN105304024AGood compensationSimple compensation processStatic indicating devicesCompensation effectCurrent distribution

Embodiments of the invention disclose a display panel pixel current compensation method and system. The compensation method comprises steps of testing the practical current value of a subpixel on a display panel at an i-th gray scale; adjusting the practical current value of the subpixel at the i-th gray scale to a preset target current value of the subpixel at the i-th gray scale, and recording a target gray scale value of the target current value when the subpixel is at the i-th gray scale; and based on a data distribution list of target gray scale values of each subpixel at each target current value, performing current compensation of at least one subpixel of a to-be-compensated display panel. Based on the obtained data distribution list, any subpixel of display panels of the same type in mass production can be compensated, so that current of an overall display panel is uniformly distributed. Compared with the prior art, the invention is characterized in that no special compensation circuit is additionally required, the compensation effect is good, the compensation process is simple, and a phenomenon that nonuniform display due to nonuniform current distribution in long-time operation is prevented.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

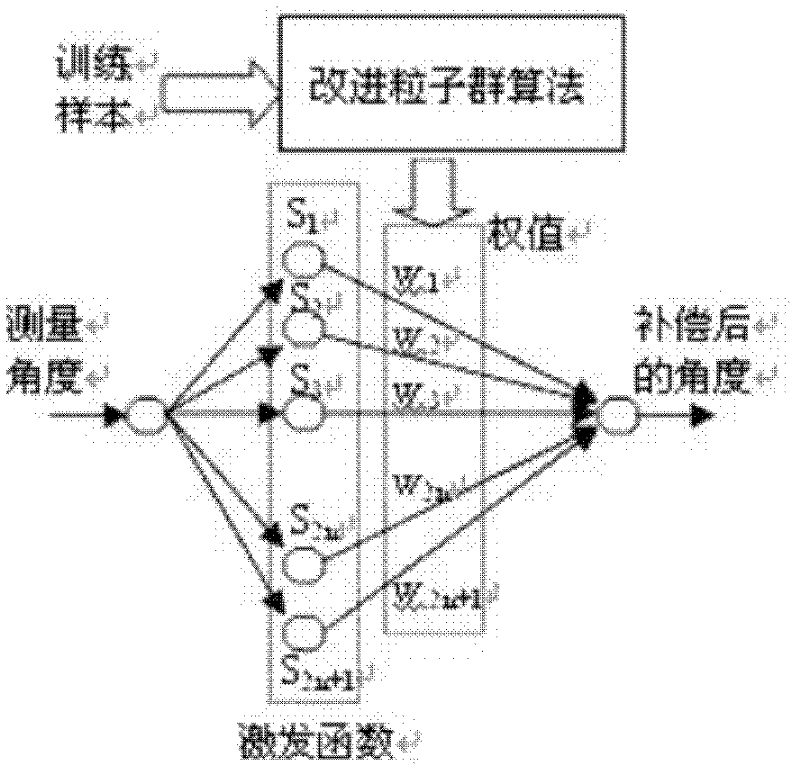

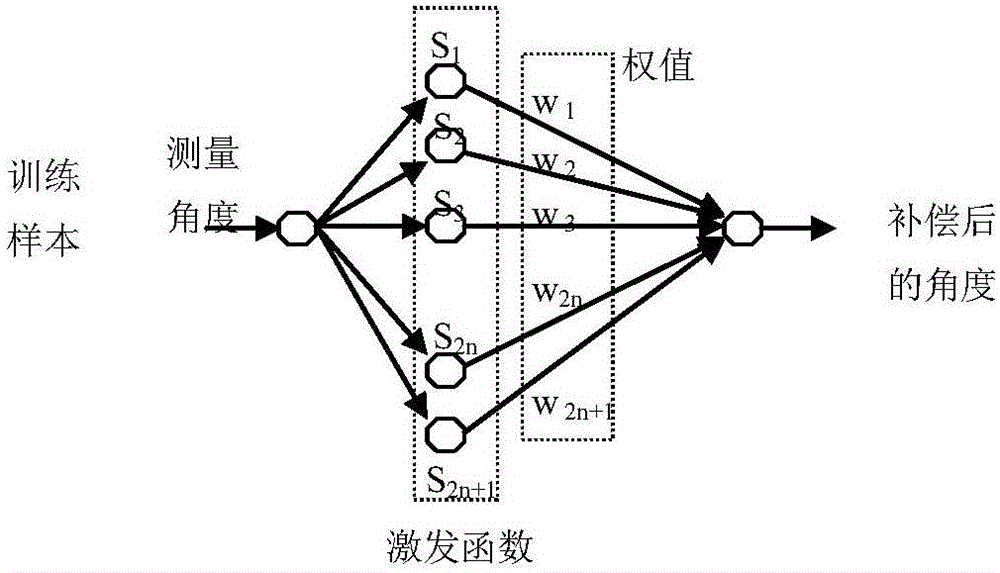

Error compensation method for photoelectric encoder

ActiveCN102506914ALower requirementSimple compensation processBiological neural network modelsConverting sensor output opticallyObservational errorNonlinear approximation

The invention discloses an error compensation method for a photoelectric encoder. Based on improved particle swarm optimization and a Fourier neural network principle, the method is used for improving the measurement accuracy of the photoelectric encoder, and is particularly suitable for an angle measuring system requiring low cost and high accuracy. According to the method, a compass error is modeled by a Fourier neural network, and the weight of the neural network is optimized by the improved particle swarm optimization, so that an accurate error model is obtained to compensate a measured value of the photoelectric encoder. The error model established by the method can realize accurate mapping of a sample space and has high nonlinear approximation capability; and by the method, local minimum is avoided, a defect that the neural network has ultralow convergence rate, oscillates and the like is overcome, measurement errors of the photoelectric encoder are effectively reduced, and the measurement accuracy of the photoelectric encoder is greatly improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Fiber optic temperature and pressure sensor and system incorporating same

InactiveUS7684656B2Simple compensation processRugged and inexpensiveCladded optical fibreFluid pressure measurement by electric/magnetic elementsCross sensitivityGrating

A sensing system including a sensor having an enclosure that defines a chamber, a fiber optic segment extending from outside the enclosure into the chamber, and a sequence of optical processing elements within the chamber. The elements include a fiber Bragg grating, a polarizer, a side hole fiber, and a mirror. A light source is arranged to direct light to the sensor(s). A spectral analyzer is arranged to detect light reflected back from the sensor(s). The fiber Bragg grating substantially reflects a first spectral envelope while transmitting the remainder of the optical spectrum to the polarizer and side hole fiber. The polarizer, side hole fiber, and mirror cooperate to return an optical signal within a second spectra! envelope. The characteristic wavelength of a peak in the first spectral envelope is highly sensitive to temperature and relatively weakly sensitive to pressure. The period of the optical signal within the second spectral envelope is highly sensitive to pressure and relatively weakly sensitive to temperature. The spectral analyzer measures these spectral components to simultaneously derive a measure of temperature and pressure that effectively compensates for temperature-pressure cross-sensitivity of the sensor(s).

Owner:SCHLUMBERGER TECH CORP

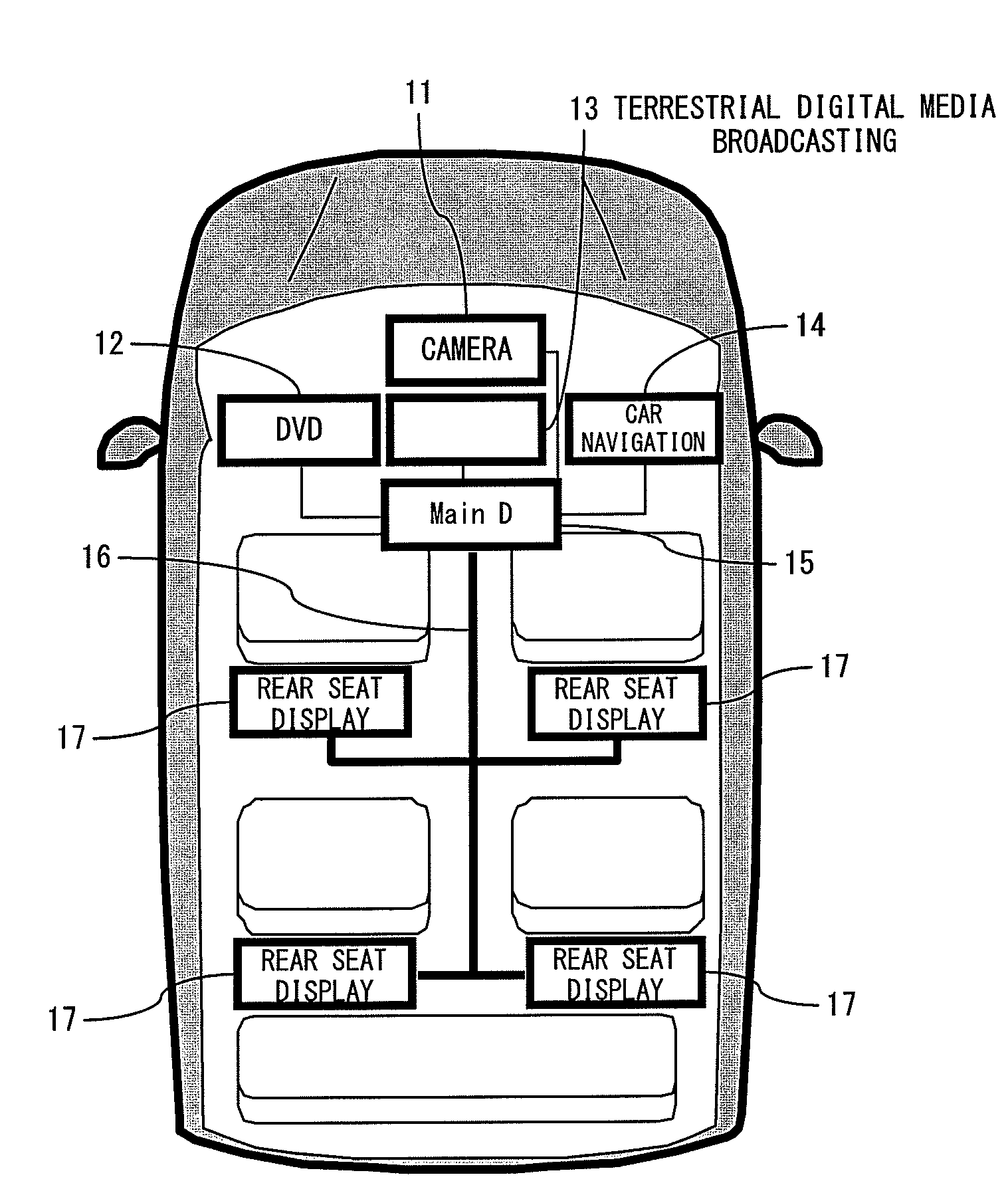

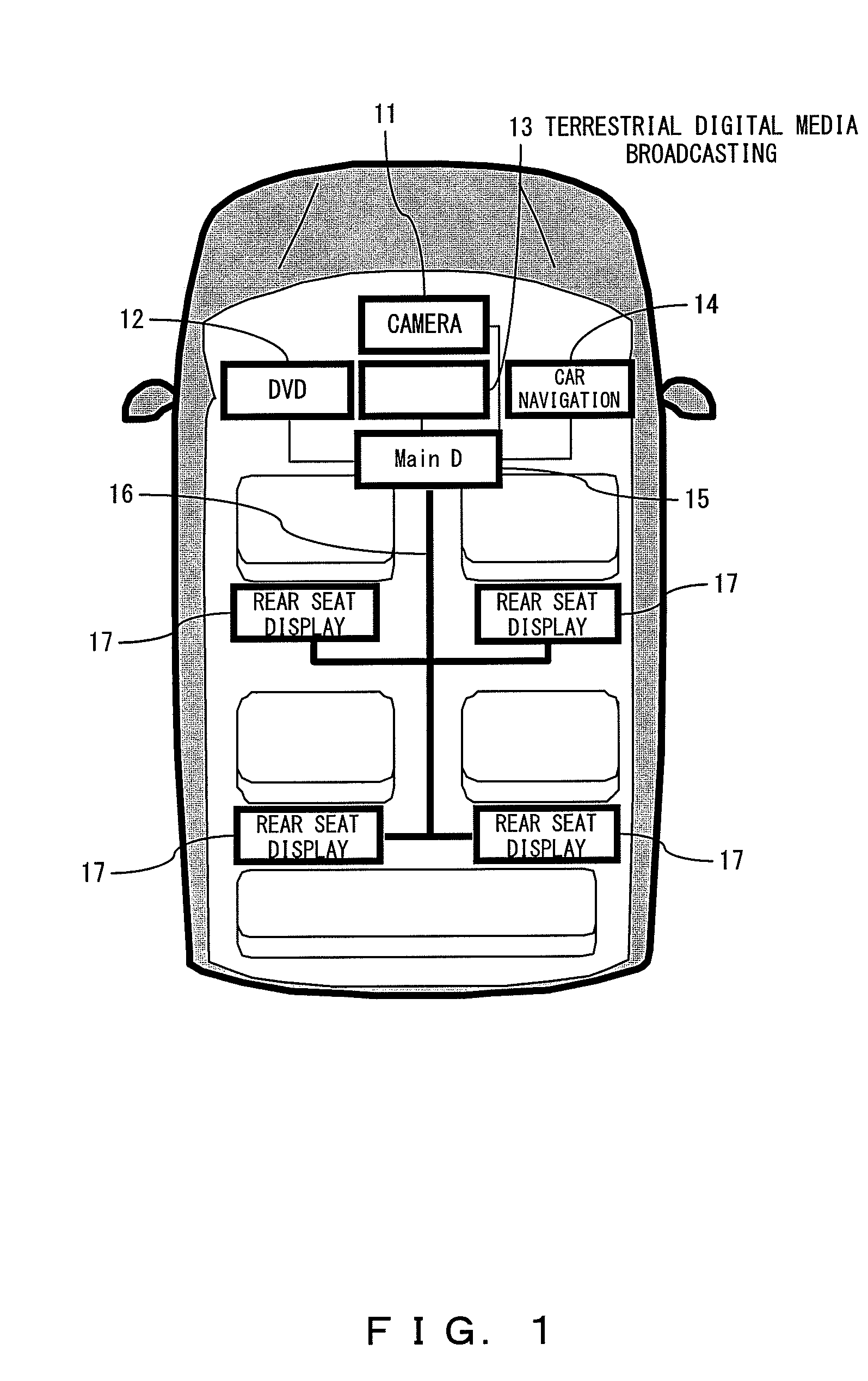

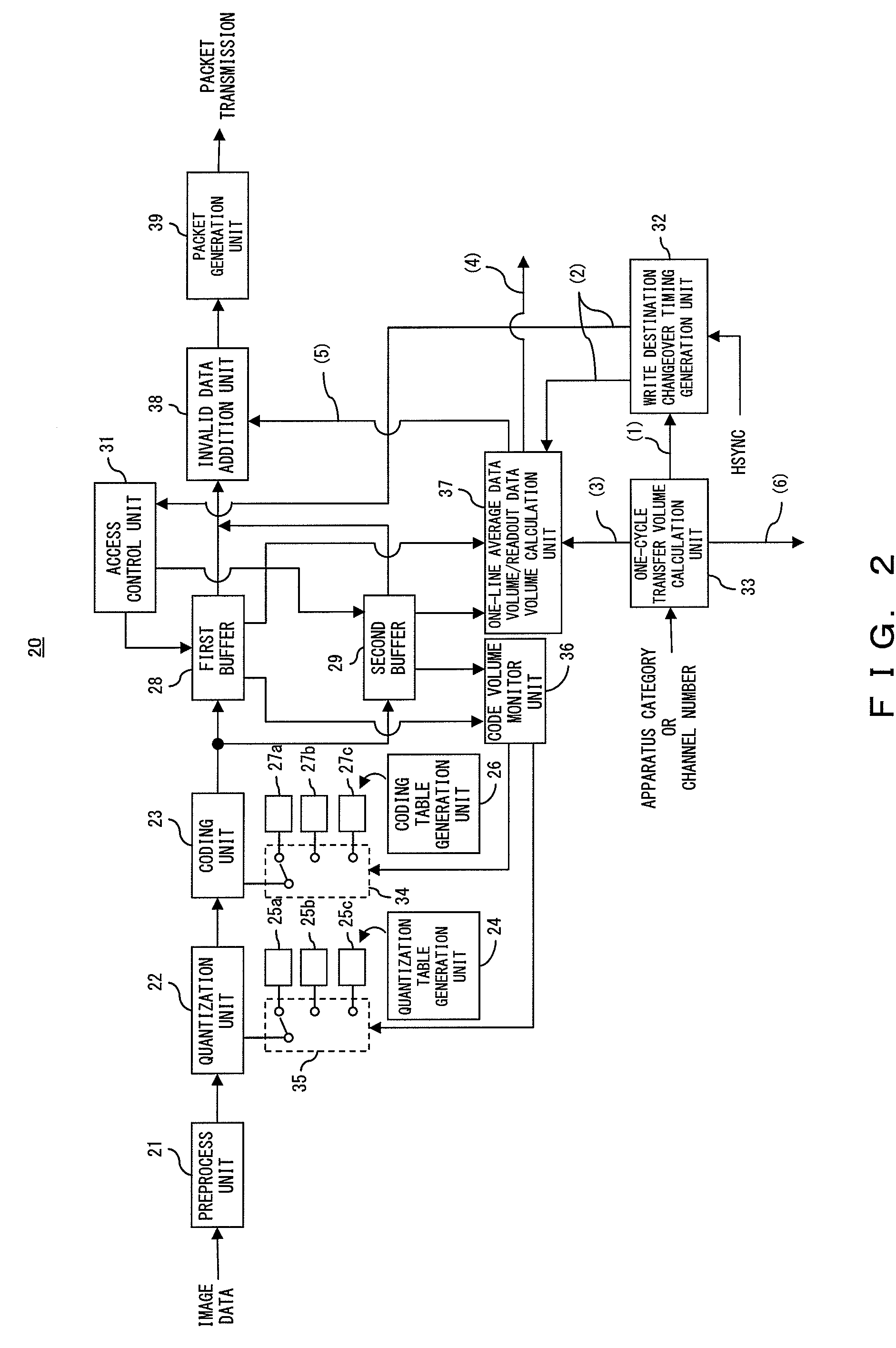

Data transfer device and data transfer method

InactiveUS20090010342A1Low costSimple compensation processPicture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningNetwork packetInvalid Data

The present invention aims at providing an image data transfer device capable of transferring image data in real time with a simple comprisal. The device according to the present invention calculates both the number of lines of the image data to be transferred in one cycle and the volume of data corresponding to the aforementioned number of lines on the basis of the category of the image data, stores data in an amount that is equivalent to the aforementioned number of lines of the image data processed by a variable length coding, calculates the difference between the calculated data volume corresponding to the number of lines and the volume of data stored, adds invalid data to the data stored in an amount that is equivalent to the calculated difference and generates, transmits a packet on the basis of the data to which the invalid data has been added.

Owner:FUJITSU LTD

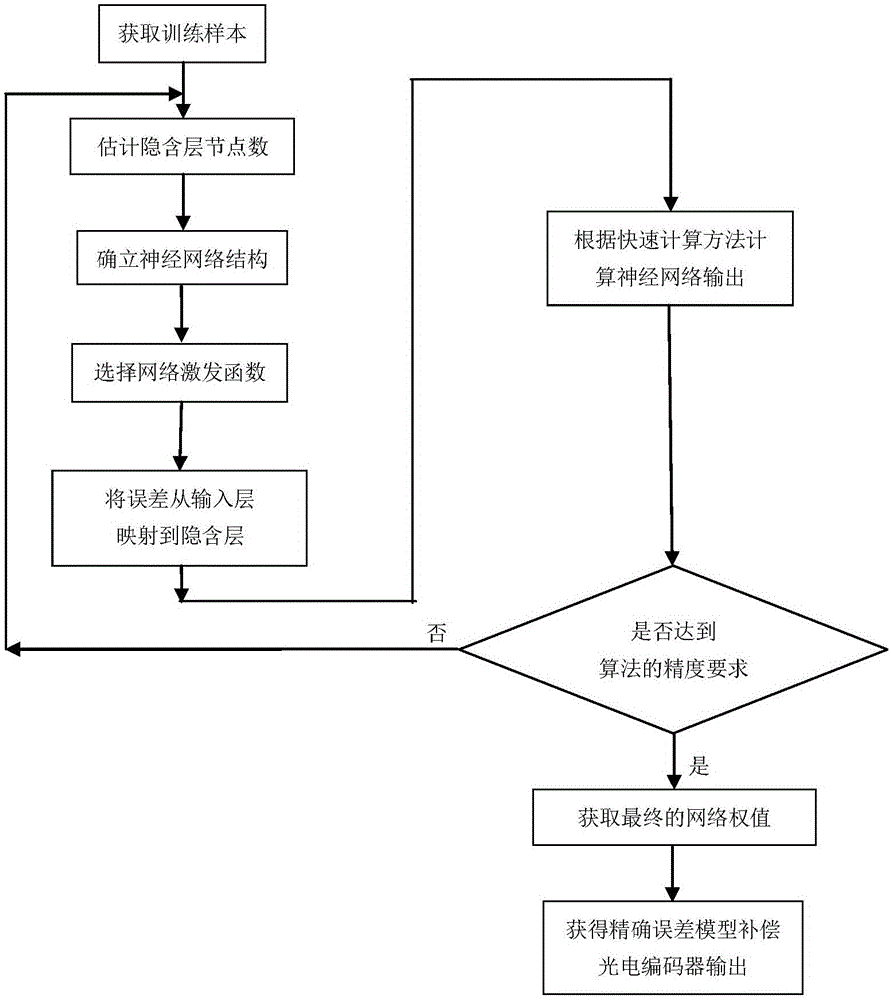

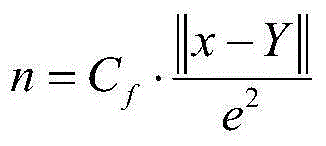

Neural-network-based rapid compensation method for photoelectric encoder

The invention discloses a neural-network-based rapid compensation method for photoelectric encoder. The method can increase compensation precision and compensation speed, and can simplify compensation procedures and reduce requirements to a needed instrument. The method includes: first, randomly rotating the photoelectric encoder in a circle, and acquiring a training sample; then adopting a single input and single output three-layer feed-forward Fourier neural network to establish a photoelectric encoder error compensation model, and estimating the number of nodes in hidden layers based on the characteristics of an object function; at last based on the actual result, correcting the number of the nodes so as to prevent the inefficiency due to repeated and varied attempts in a trial-and-error method. According to the invention, directed to the problem of slow convergence of the iteration training method, the method, through mapping the errors to nodes in the hidden layers of orthogonal triangle function basis, rapidly solves a minimum norm solution from the hidden layers to a weight of an output layer, which substantially reduces the time required by solving the weight of the neural network and greatly reduces time complexity and space complexity in calculation.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

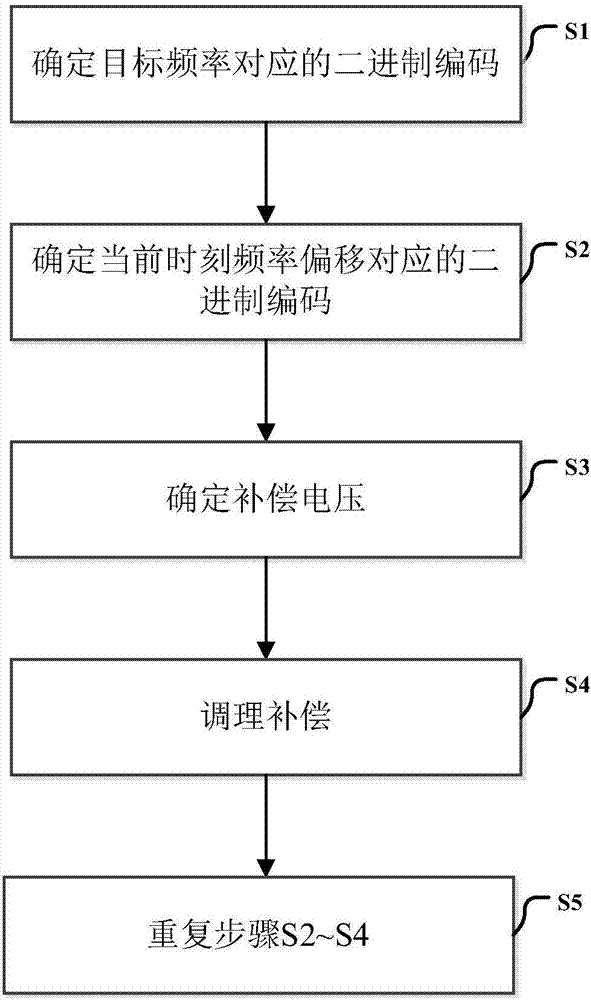

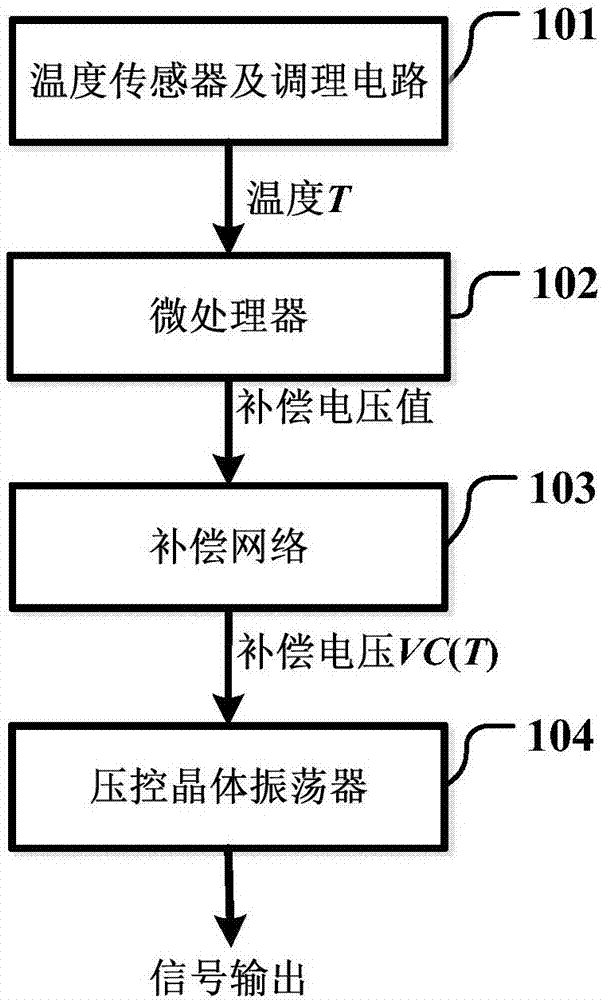

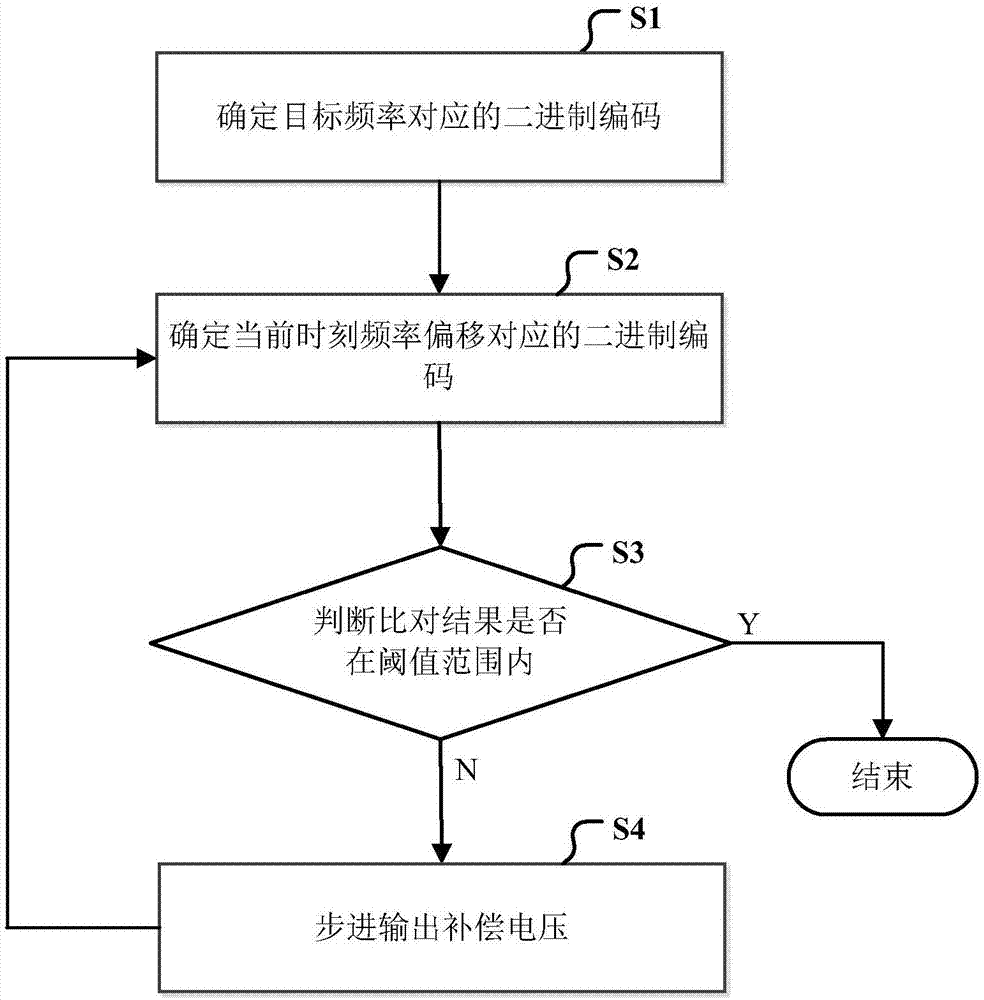

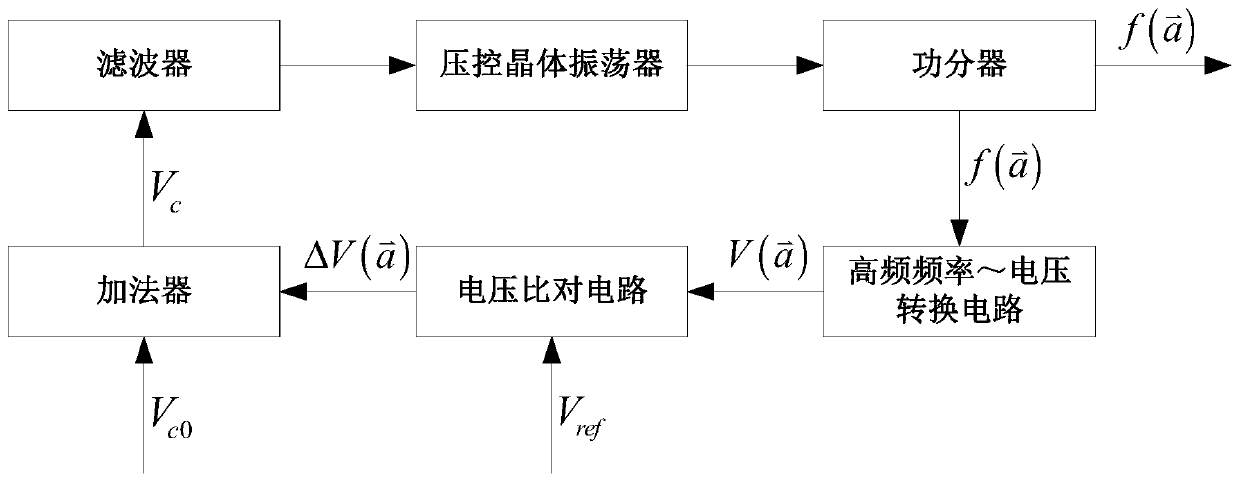

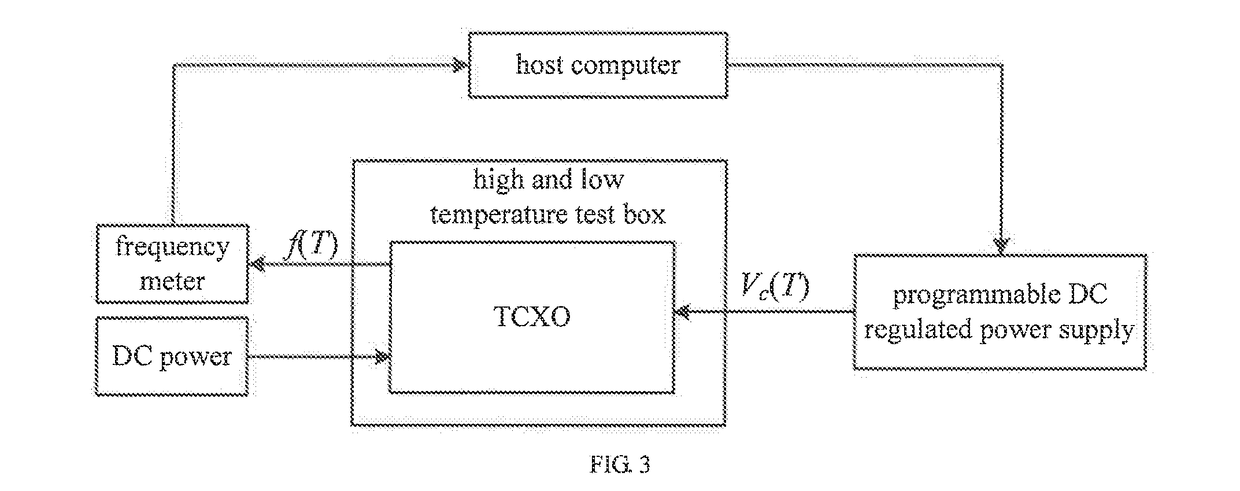

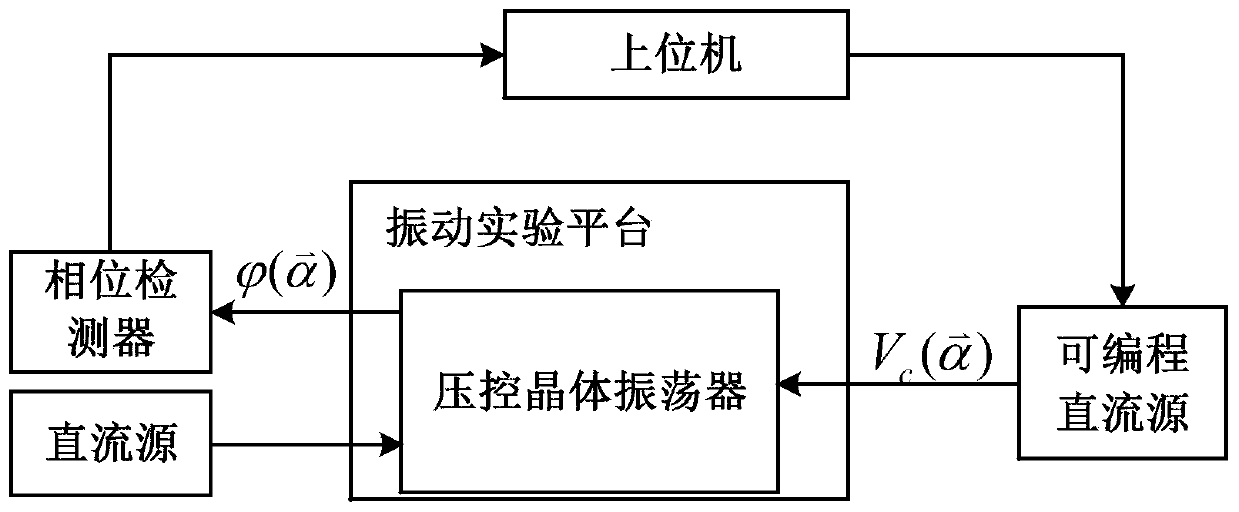

Digital temperature compensation method of crystal oscillator

ActiveCN107257240AOvercoming temperature hysteresisEasy real-time high-precision compensationGenerator stabilizationHysteresisClosed loop feedback

The invention discloses a digital temperature compensation method of a crystal oscillator, wherein a closed-loop feedback compensation framework is adopted. According to the method, a binary coding B0i corresponding to a target frequency f0 is determined and stored in a microprocessor. When the temperature changes, the microprocessor conducts real-time measurement on the output frequency of a VCXO to generate a binary code B1i. Meanwhile, the microprocessor compares with the above binary code B1i with a binary code corresponding to the target frequency to obtain a binary code of the needed compensation information. Finally, the binary code of the needed compensation information is converted into a compensation voltage through a digital-to-analog converter to be input to a voltage-controlled adjusting end of the VCXO. Therefore, the target frequency is output, and the temperature compensation is achieved. Compared with a digital temperature compensation method of an existing crystal oscillator, the above digital temperature compensation method does not need any temperature sensor. Meanwhile, the frequency deviation related to the temperature in real time is directly converted into a binary code which is in one-to-one correspondence with the temperature. Moreover, the binary code is converted into a corresponding compensation voltage for temperature compensation. Therefore, the temperature hysteresis problem caused by the fact that the temperature change of a temperature sensor and the temperature change of a crystal resonator are not synchronous in an existing temperature compensation crystal oscillator (TCX0) is overcome.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

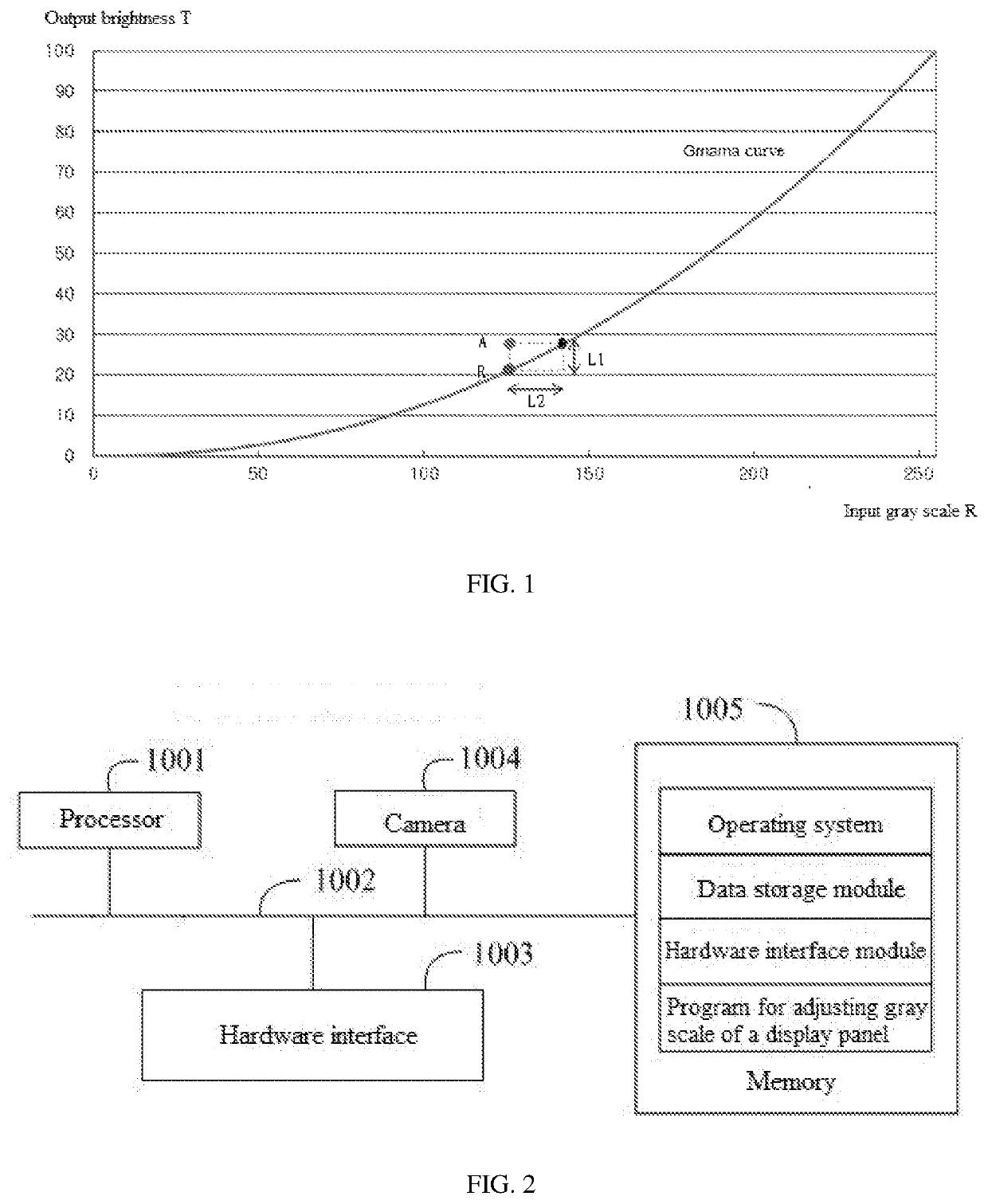

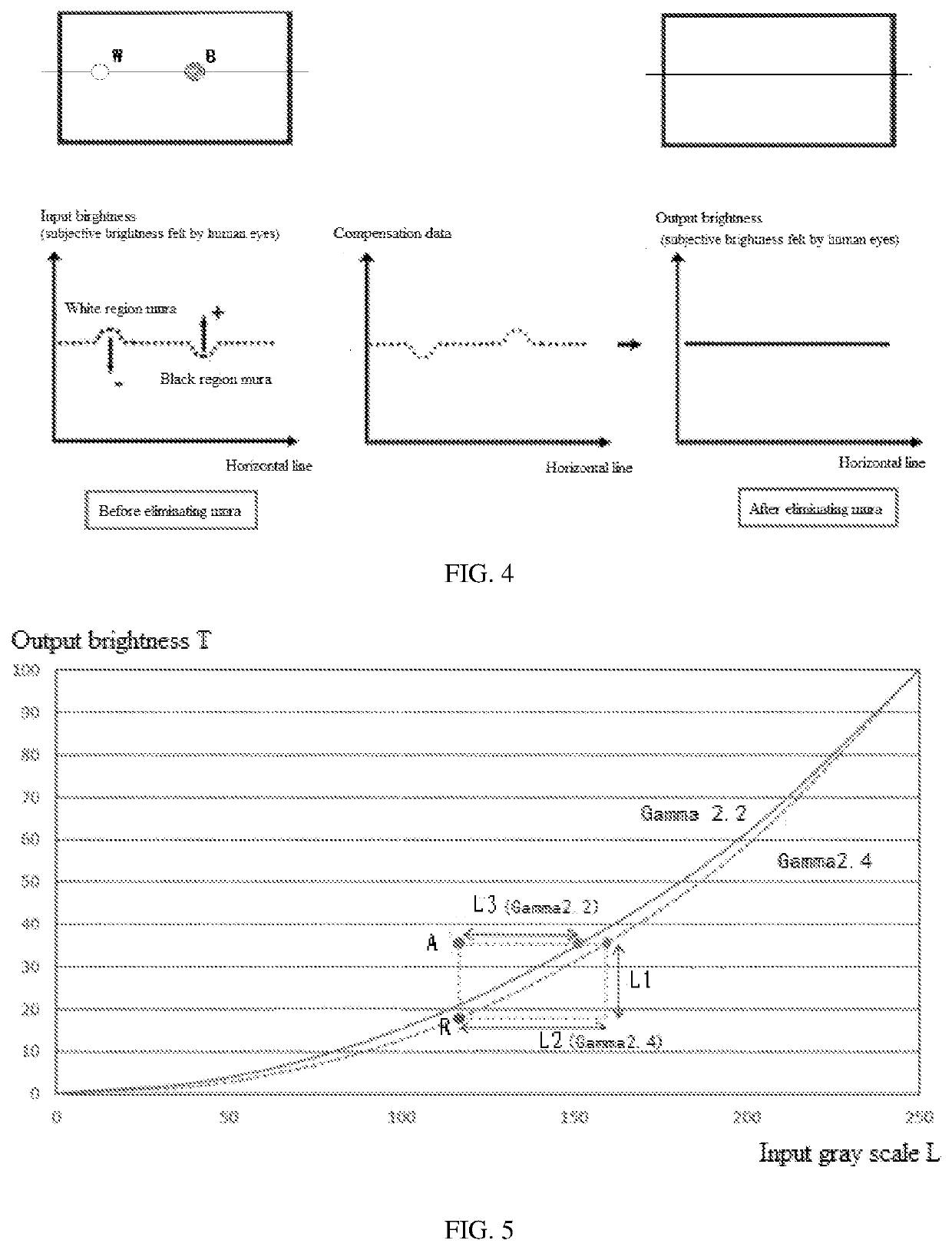

Method and device for adjusting gray scale of display panel

ActiveUS20200184912A1The effect is accurateAccurately and effectively eliminatedCathode-ray tube indicatorsPictoral communicationComputer graphics (images)Algorithm

The present disclosure discloses a method and a device for adjusting gray scale of a display panel, the method comprises: performing image acquisition on a display panel, and obtaining a current image; identifying an nonuniform block in the current image, and detecting an original output brightness and an original input gray scale of the nonuniform block; determining a target input gray scale corresponding to a preset target brightness according to an actual Gamma curve value, the actual Gamma curve value is obtained through testing the display panel; using a difference value between the original input gray scale and the target input gray scale as a gray scale compensation value of the nonuniform block.

Owner:HKC CORP LTD +1

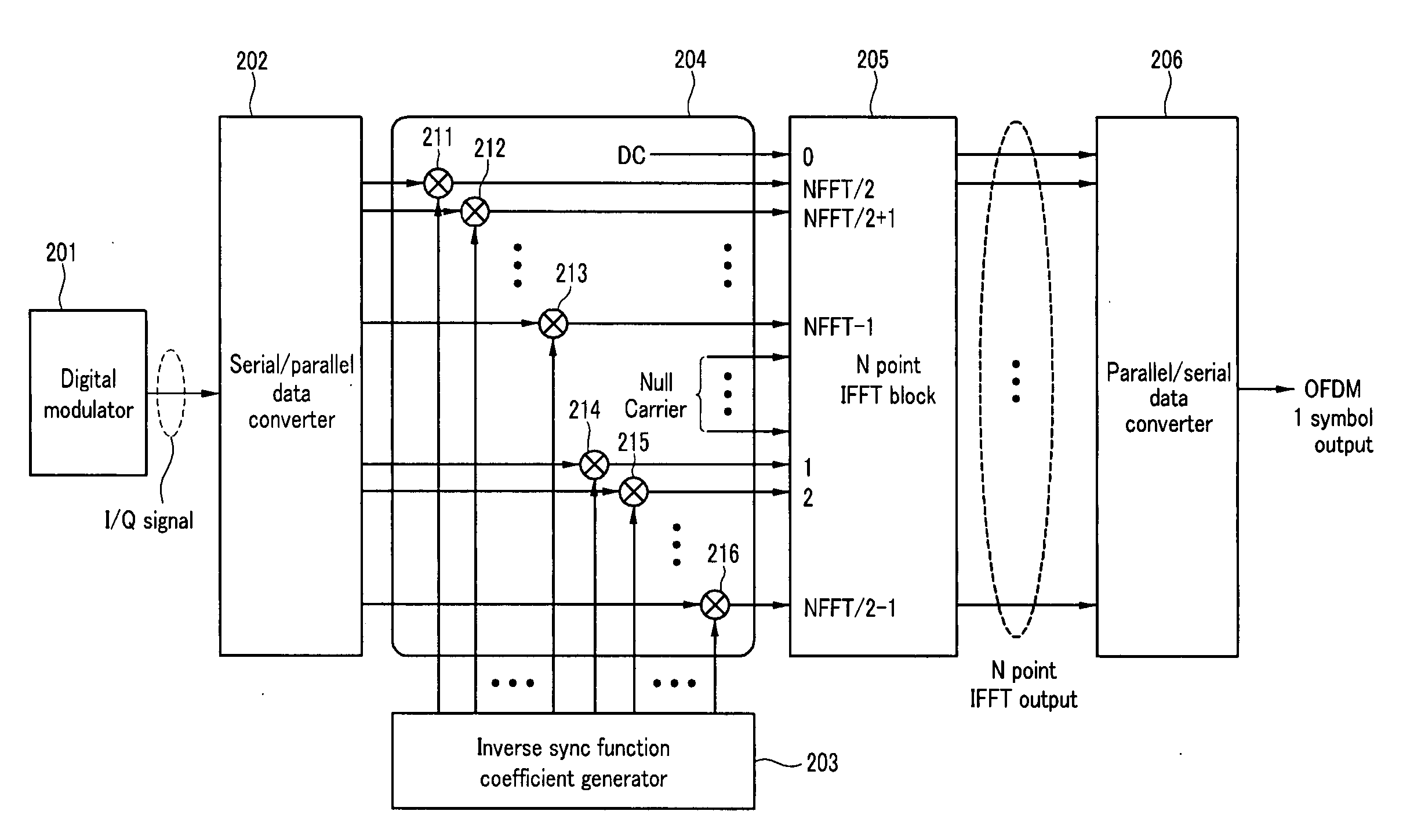

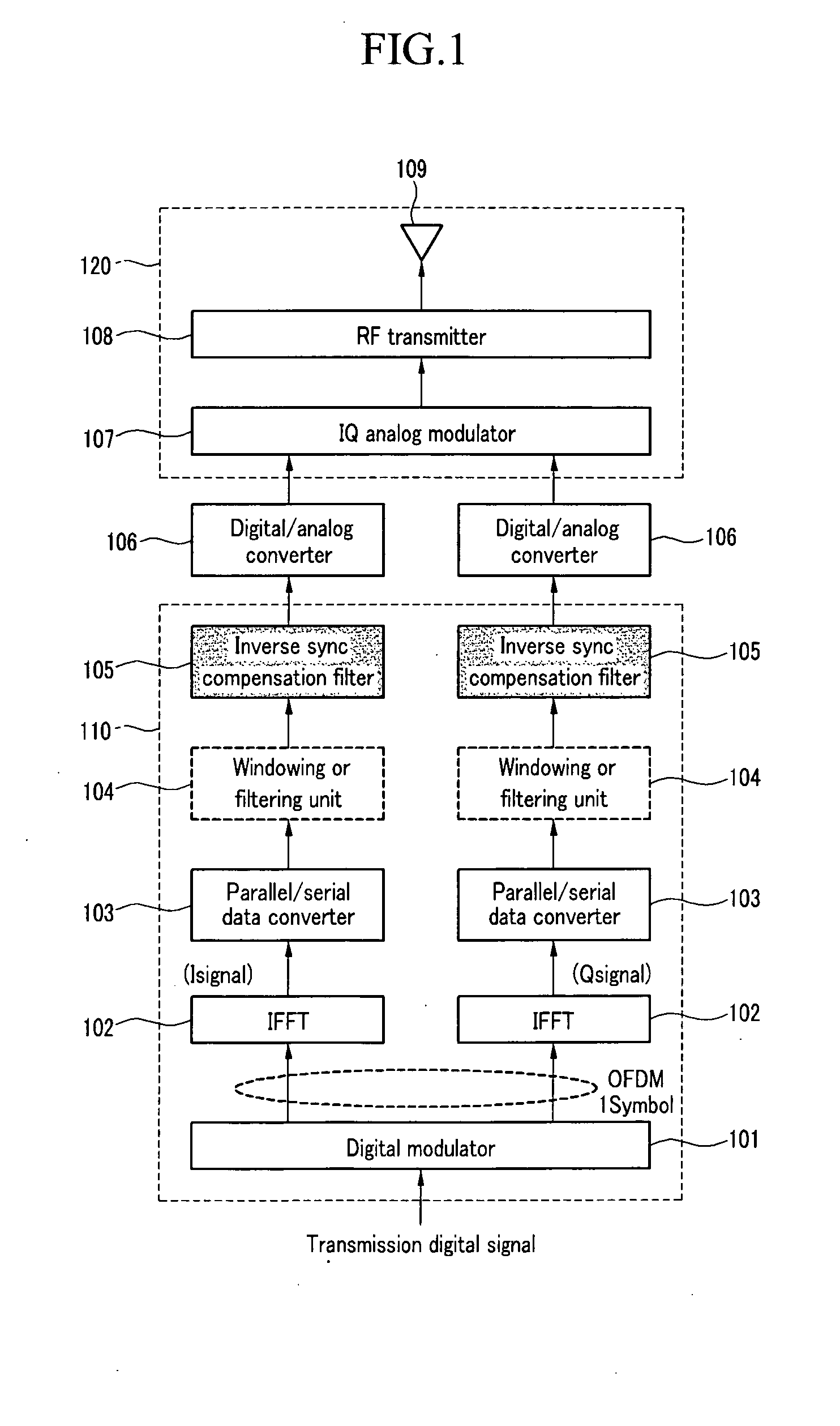

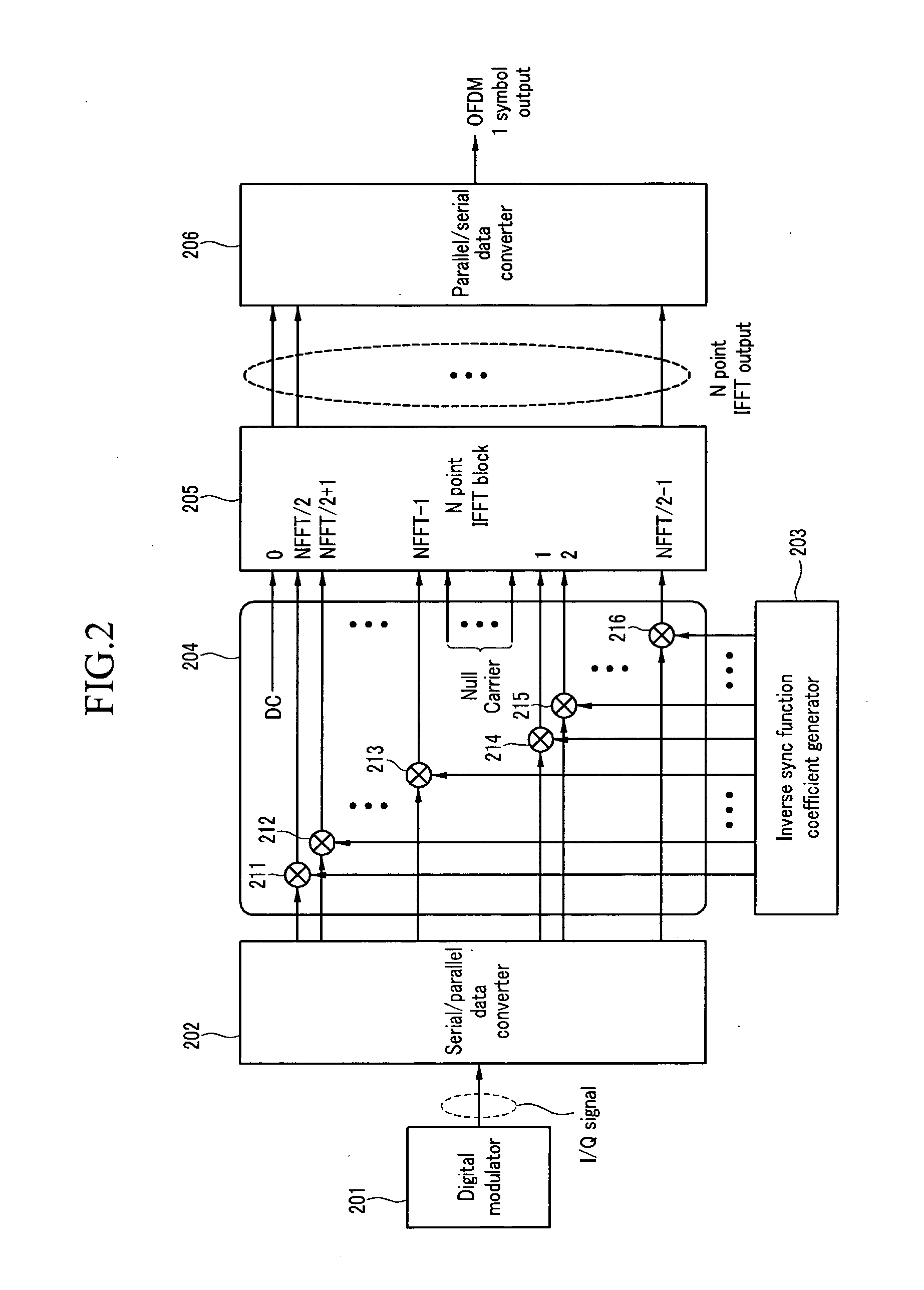

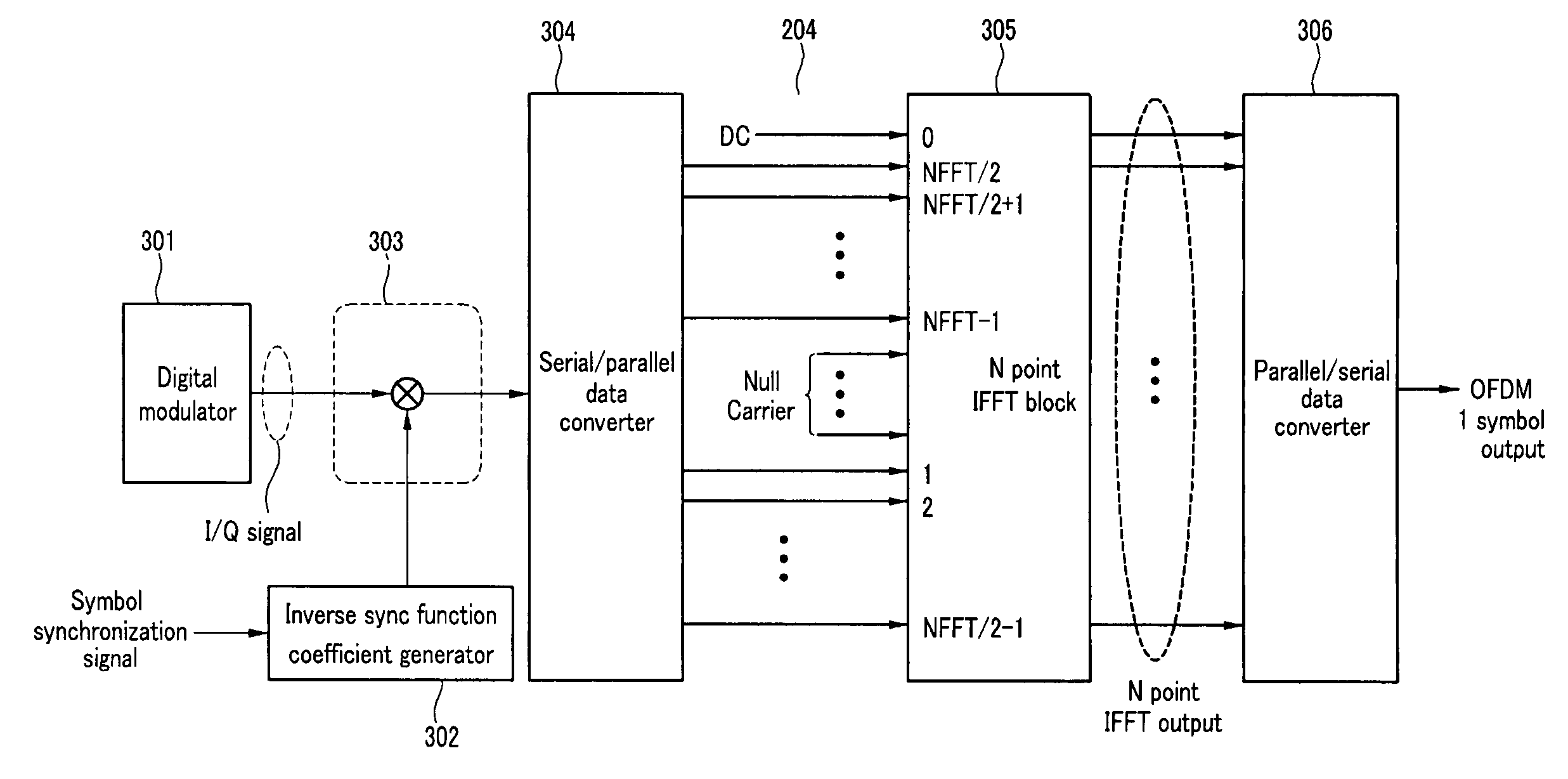

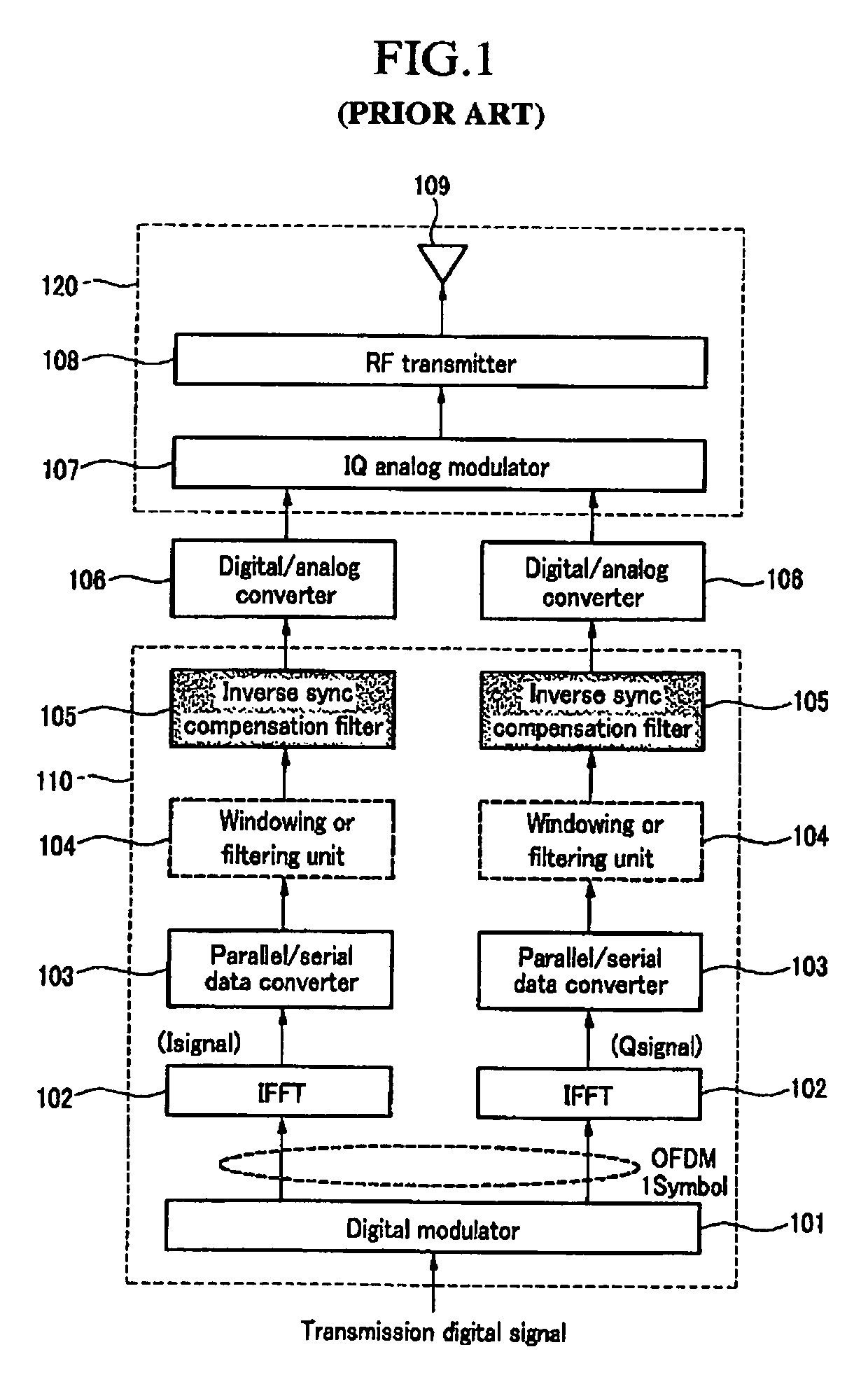

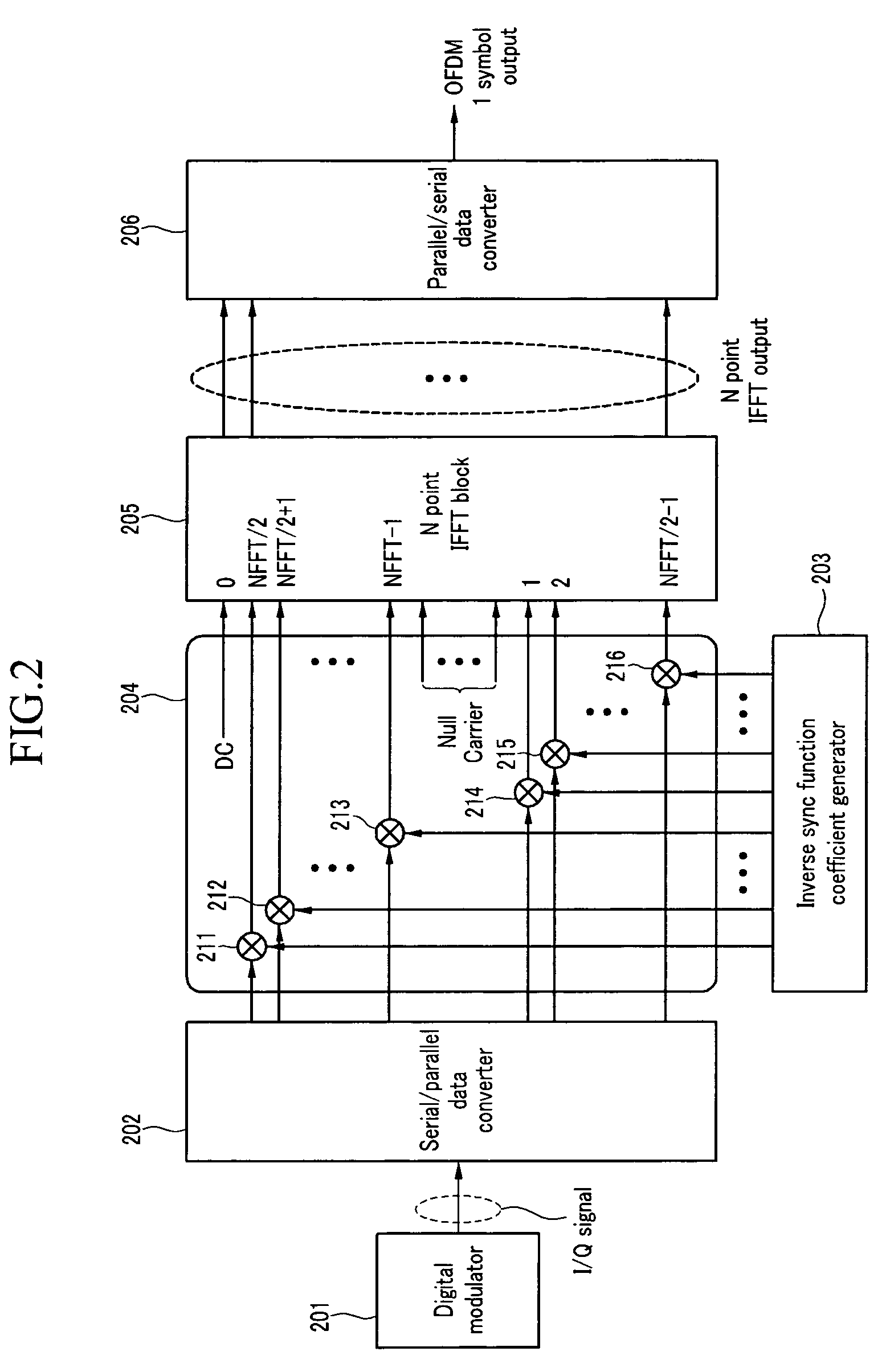

Device for compensating radio frequency distortion in orthogonal frequency division multiplexing transmission system and method thereof

ActiveUS20070133698A1Compensation DistortionSimple compensation processCarrier regulationSecret communicationUltrasound attenuationLookup table

The present invention relates to a device for compensating a radio frequency distortion caused by a sample / hold operation of a digital / analog converter in an orthogonal frequency division multiplexing (OFDM) transmission system, and a method thereof. In a digital transmission system, an edge frequency signal of a transmission signal band is distorted by a sample / hold operation of a digital / analog converter such that a signal attenuation is generated at a frequency domain by a sync function having a zero point at a sample frequency of a transmission signal. In the present invention, the signal distortion may be compensated by multiplying a coefficient of an inverse sync function by a signal weight value at the frequency domain, and it may be compensated by using a single multiplier and a lookup table storing the coefficient of the inverse sync function.

Owner:ELECTRONICS & TELECOMM RES INST

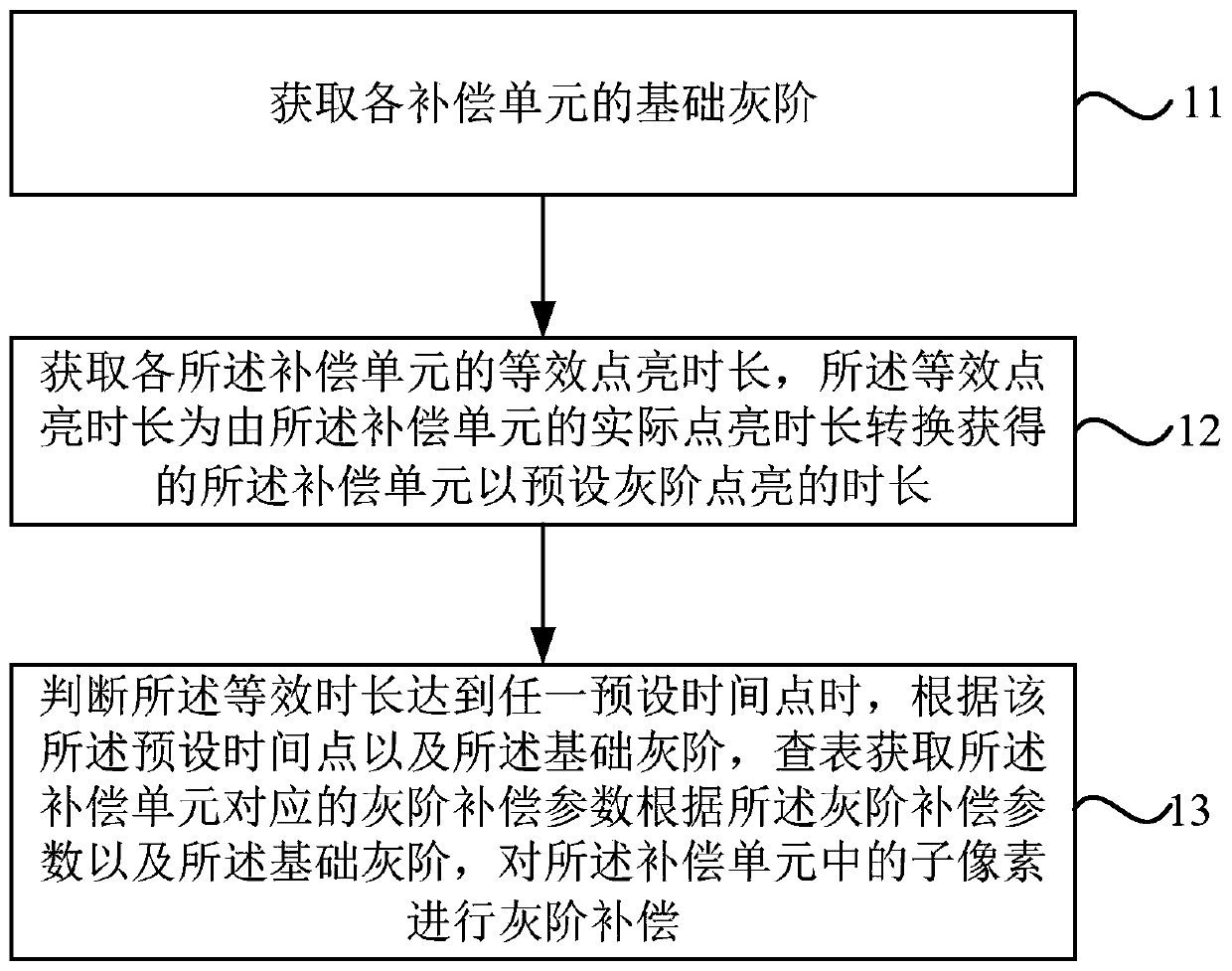

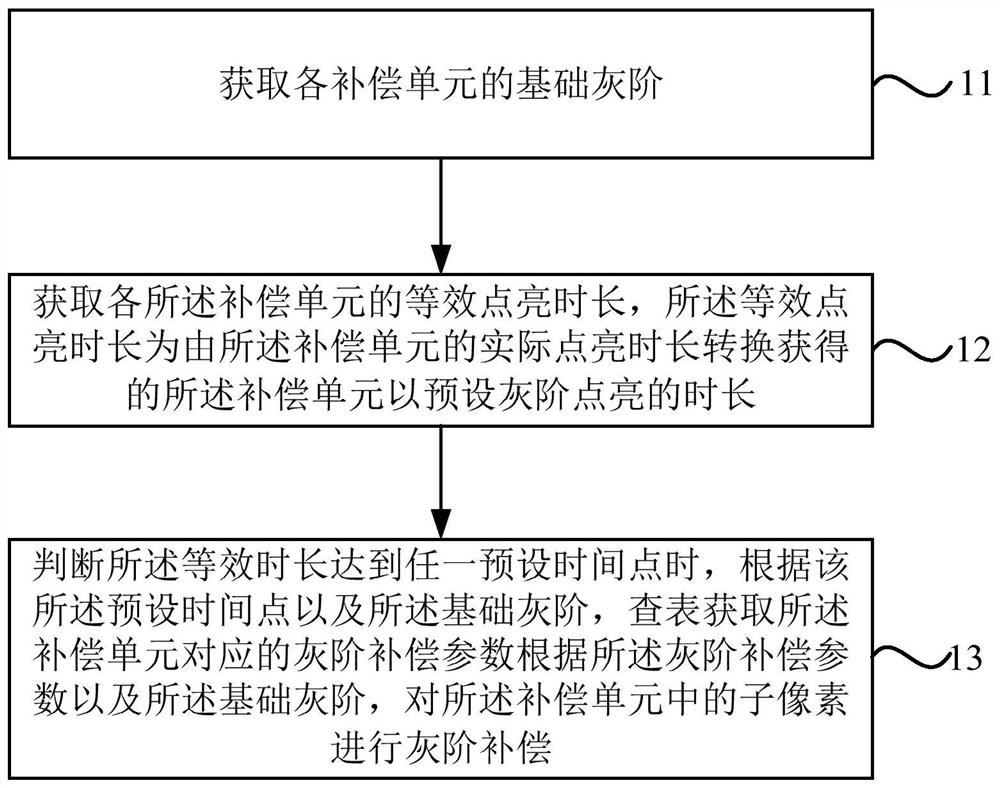

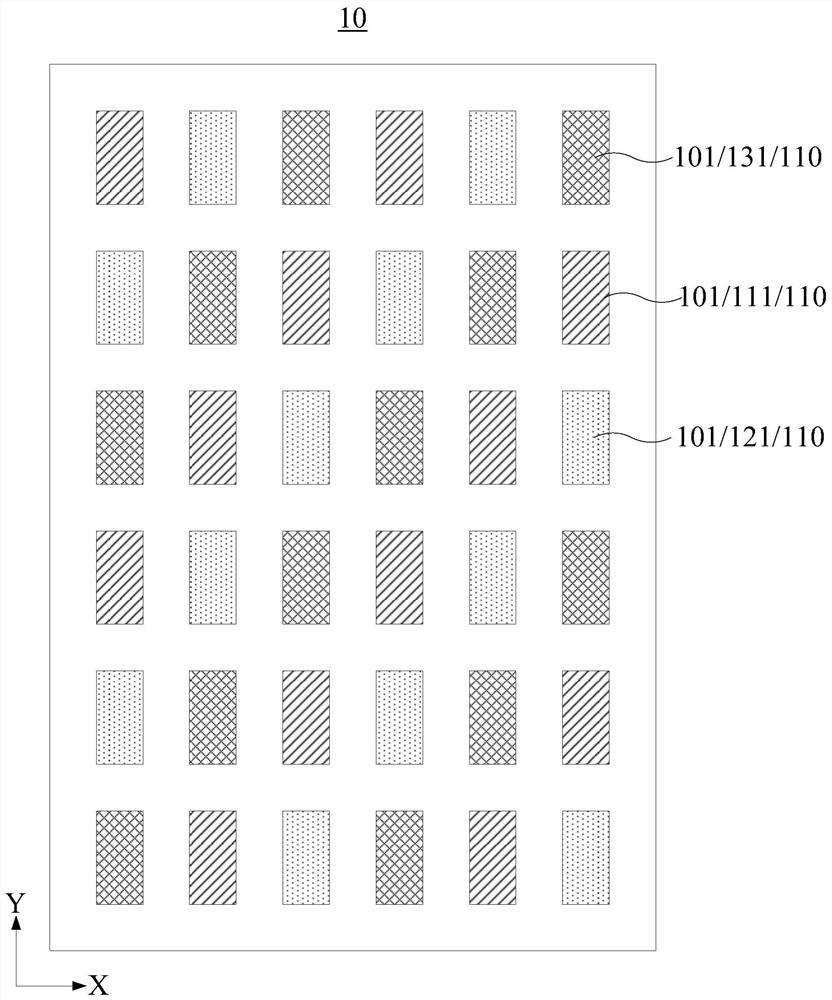

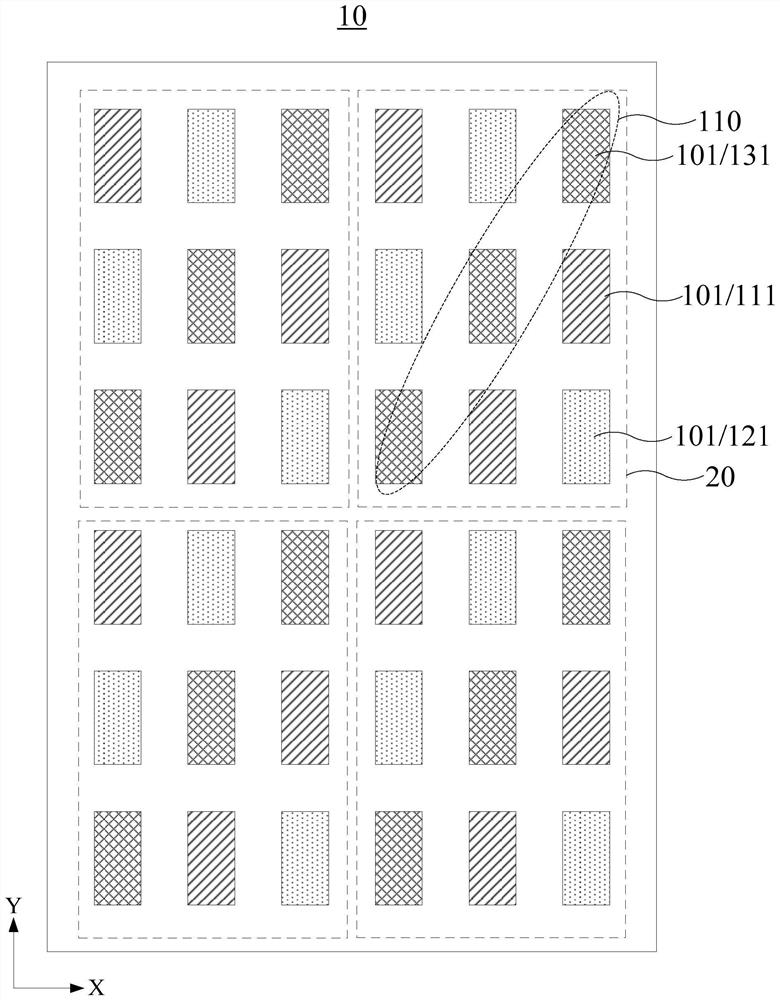

Gray scale compensation method and device and display equipment

ActiveCN111161677ATo achieve targeted compensationSimple compensation processStatic indicating devicesAlgorithmGrey level

Owner:XIAMEN TIANMA MICRO ELECTRONICS

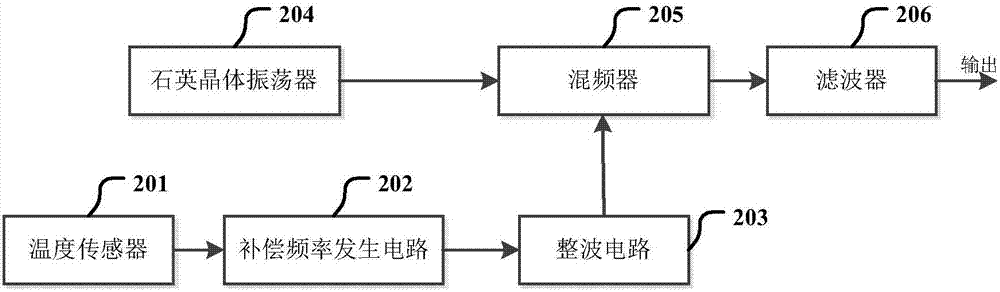

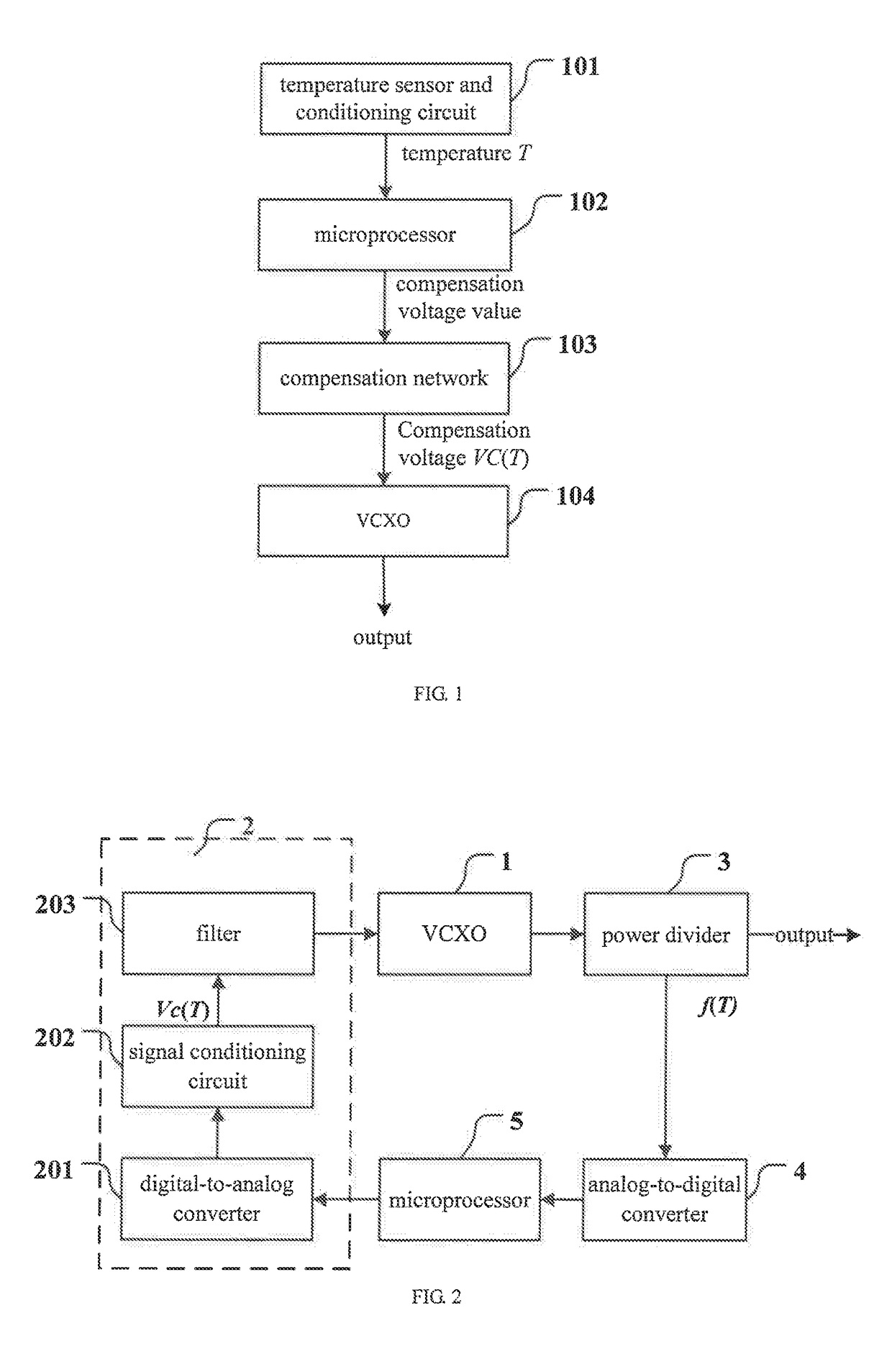

Stepping temperature compensation method of crystal oscillator

ActiveCN107276581AOvercoming temperature hysteresisEasy real-time high-precision compensationGenerator stabilizationMicrocontrollerHysteresis

The invention discloses a stepping temperature compensation method of a crystal oscillator. The method adopts the closed-loop feedback compensation architecture, and comprises the following steps: firstly determining the binary coding B0i corresponding to a target frequency f0, and storing in a single chip microcomputer; when the temperature change is existent, sending a signal with a mode frequency of f(T) to an A / D converter to convert into the corresponding binary coding B1i, and inputting to the single chip microcomputer to compare with the binary coding B0i of the target frequency f0, setting the threshold range deltaB in the single chip microcomputer, comparing the B0i with the B1i, judging whether a comparison result B0i-B1i is in the threshold range; if the B0i-B1i is not in the threshold range, compensating by using the stepping binary coding B2i, and then sending into the single chip microcomputer to compare with the B0i after the compensation, cyclically compensating in this way until the comparison result B0i-B1i is in the threshold range, thereby finally realizing the temperature compensation. Compared with the existing temperature compensate crystal oscillator, the method disclosed by the invention is free from using a temperature sensor, a temperature hysteresis problem caused by asynchronous wafer temperature change of the temperature sensor and the crystal resonator in the existing TCXO is overcome.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

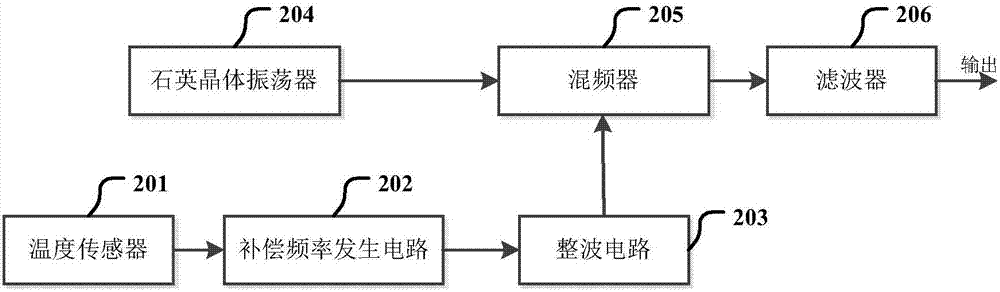

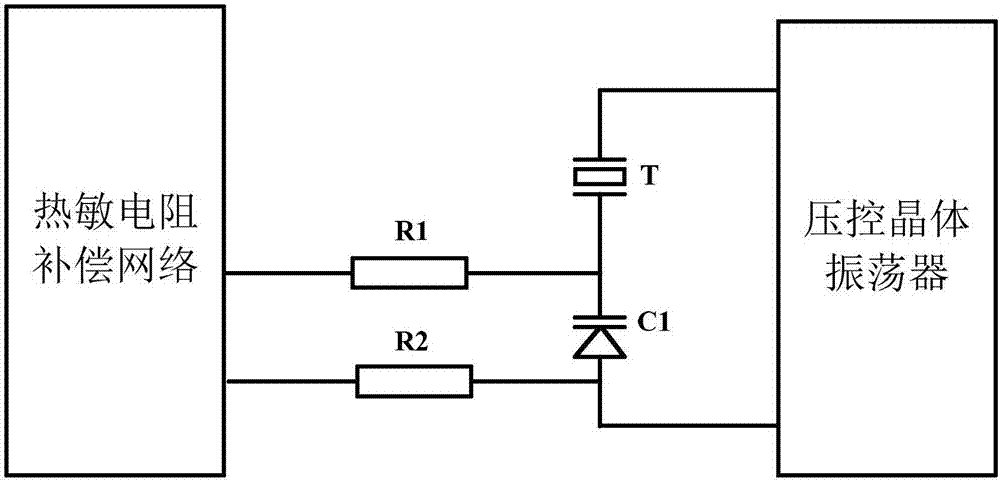

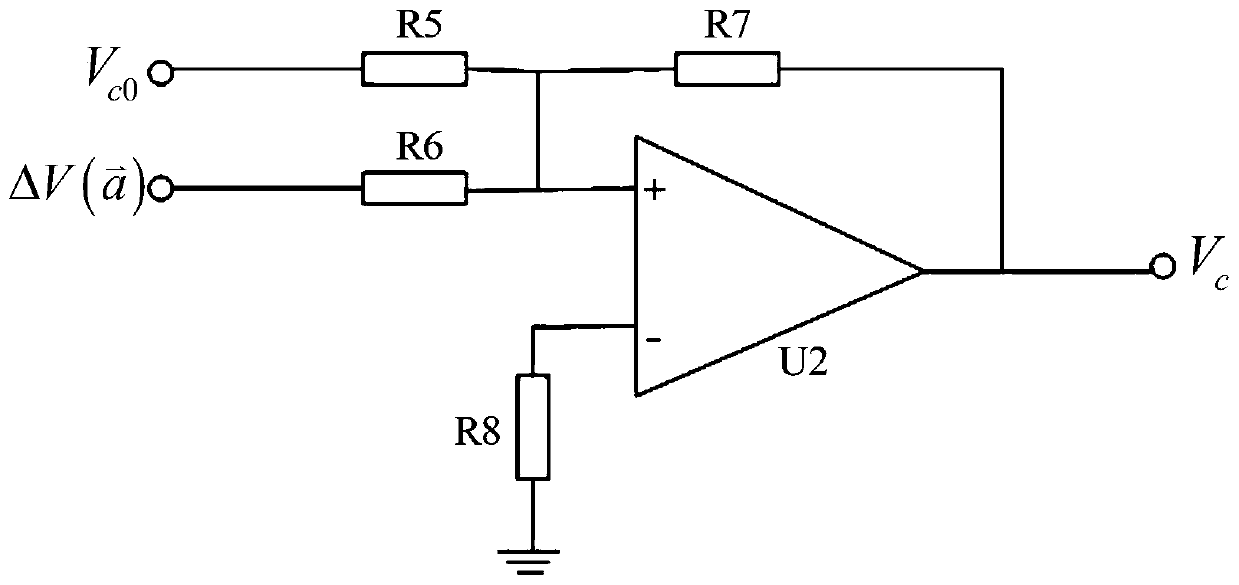

Temperature compensate crystal oscillator based on analog circuit

ActiveCN107276582AOvercoming temperature hysteresisEasy real-time high-precision compensationPulse automatic controlGenerator stabilizationHysteresisClosed loop feedback

The invention discloses a temperature compensate crystal oscillator based on an analog circuit. The temperature compensate crystal oscillator adopts the closed-loop feedback compensation architecture, an output signal is divided into two paths, wherein one path is input into a frequency-voltage conversion circuit; a voltage signal corresponding to the current temperature point is obtained according to the output frequency of a voltage-controlled crystal oscillator, the voltage signal is subtracted from the reference voltage through the voltage comparison circuit, and then amplified to obtain a compensate voltage signal; the compensate voltage signal is filtered through a filter, and then is fed back to a voltage-controlled voltage control end of the voltage-controlled crystal oscillator to perform the compensation, so that the voltage-controlled crystal oscillator outputs the signal with an expected frequency, wherein the expected frequency is the target frequency f0. The temperature compensate crystal oscillator directly converts the frequency related to the temperature in real time into the compensate voltage signal, which is in one-to-one corresponding mapping relation with the temperature related frequency to perform the temperature compensation without needing a temperature sensor. The method can overcome the temperature hysteresis problem caused by asynchronous wafer temperature change of the temperature sensor and the crystal resonator in the existing TCXO (temperature compensate crystal oscillator).

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

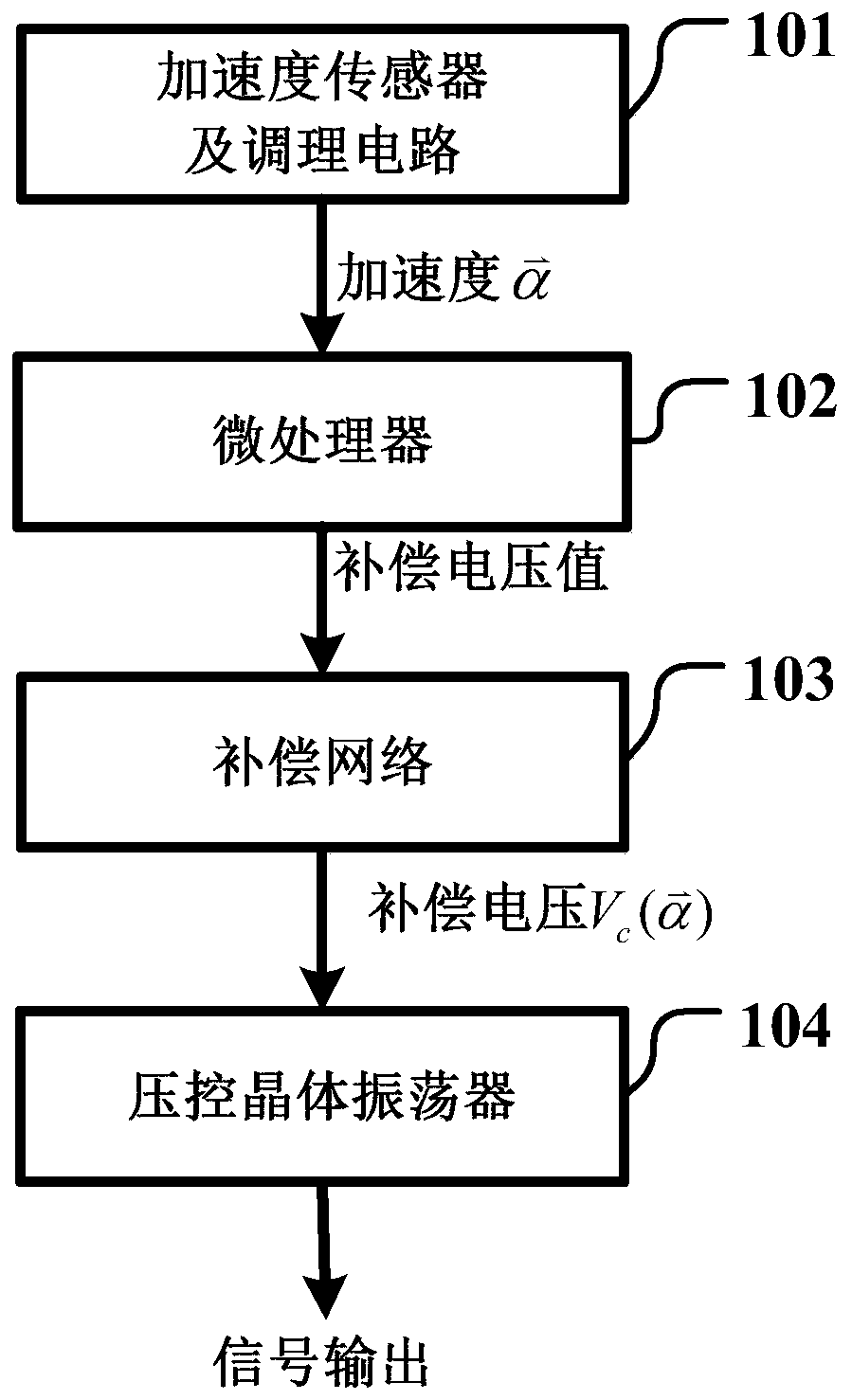

Analog anti-vibration crystal oscillator compensation device and method

PendingCN110798148AEasy real-time high-precision compensationSimple compensation processOscillations generatorsPhysicsResonator

The invention discloses an analog anti-vibration crystal oscillator compensation device and method. A voltage-controlled crystal oscillator, a power divider, a high-frequency frequency-voltage conversion circuit, a voltage comparison circuit, an adder and a filter are connected in sequence to form a closed-loop compensation framework, frequency is directly associated with compensation voltage through the high-frequency frequency-voltage conversion circuit, and real-time high-precision compensation is easier to achieve. An acceleration sensor is not needed, the frequency related to vibration inreal time is directly converted into the compensation voltage in one-to-one correspondence with the frequency for compensation, and the hysteresis problem caused by asynchronous acceleration when anacceleration sensor and a crystal resonator wafer are used in an existing anti-vibration crystal oscillator can be solved. The compensation process and the compensation structure are simple, integration and batch production are easy. The invention can be well suitable for crystal oscillators of various frequencies, and especially for high-frequency crystal oscillators poor in compensation effect..

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Encoder calibration system and control method thereof

PendingCN111854824ASimple compensation processHigh compensation accuracyAutomatic recalibrationElectric machineControl engineering

Owner:湖北立锐机电有限公司

Display device and optical compensation method of a display device

ActiveUS10249231B2Easy to controlSimple compensation processStatic indicating devicesDisplay devicePixel brightness

Owner:SAMSUNG DISPLAY CO LTD

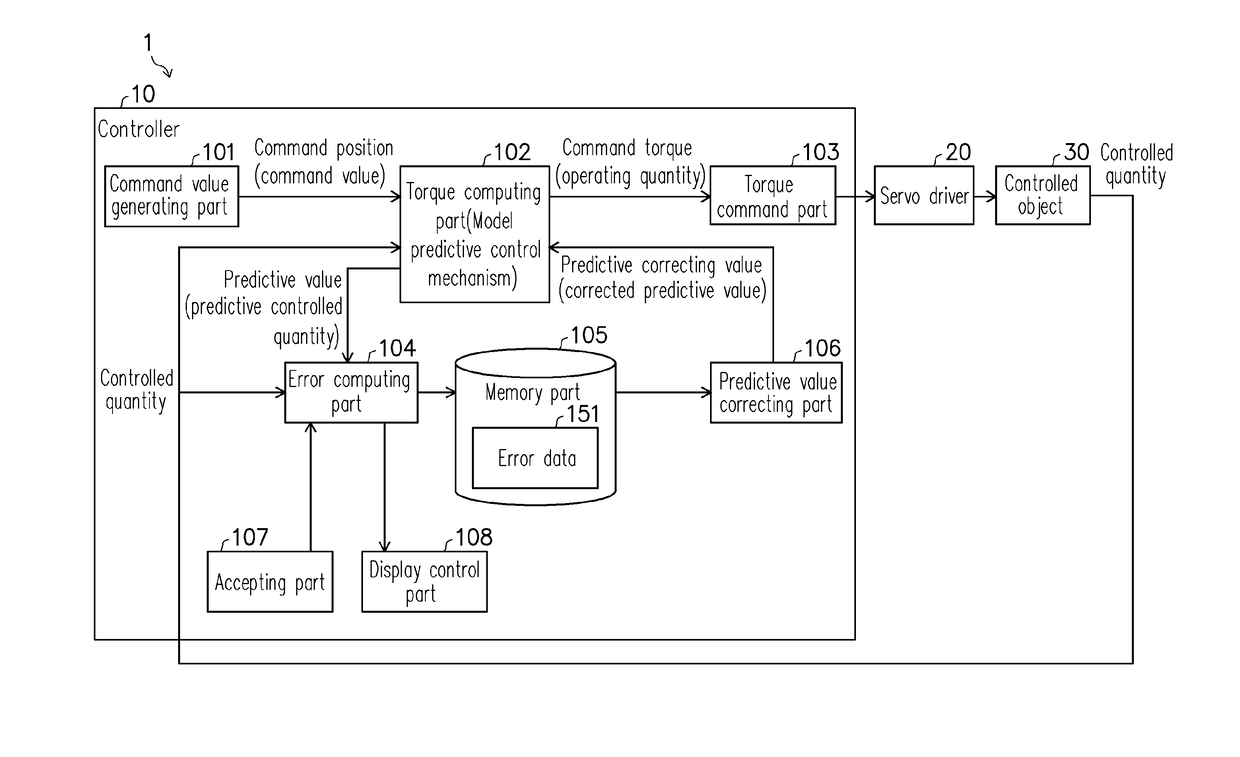

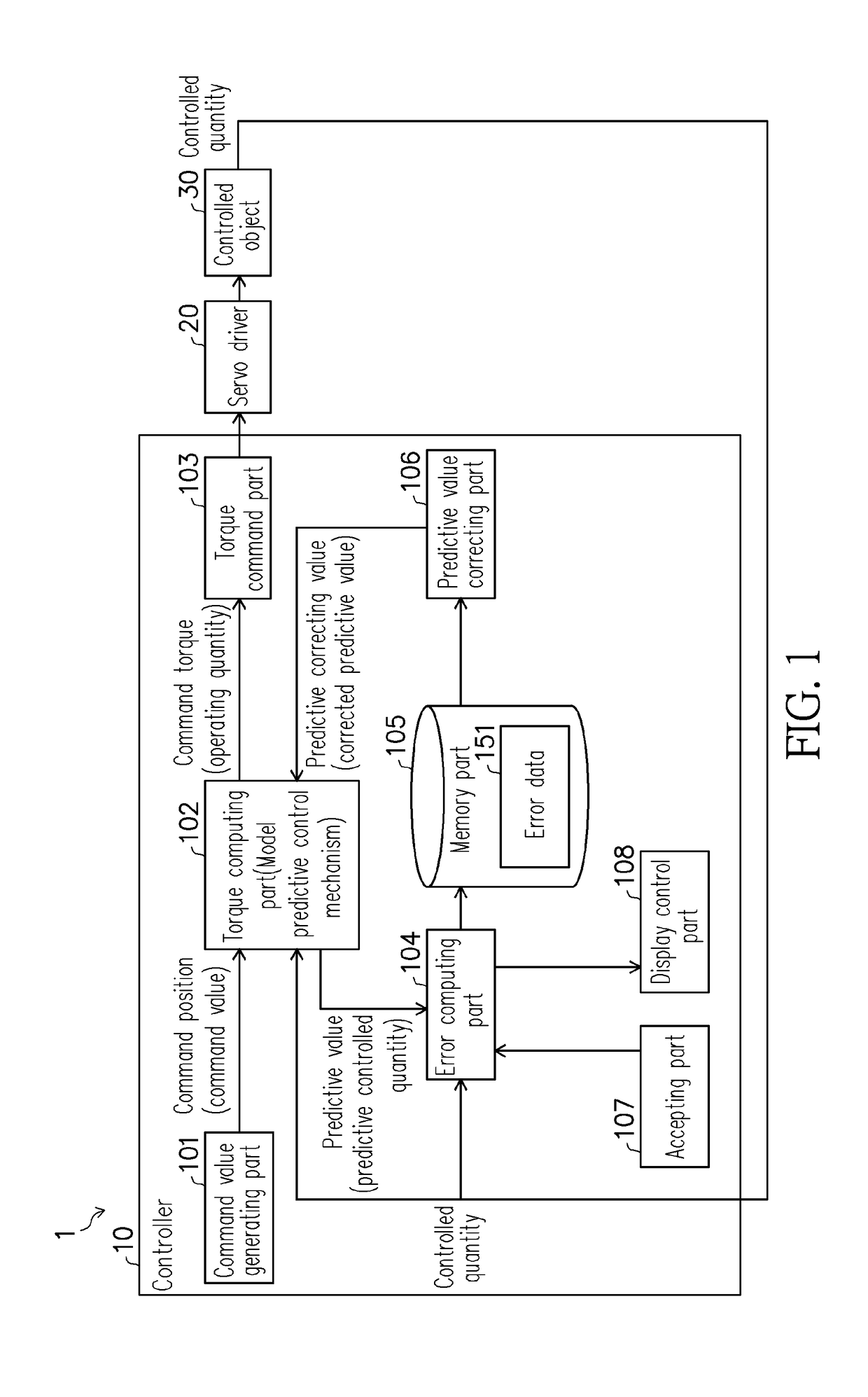

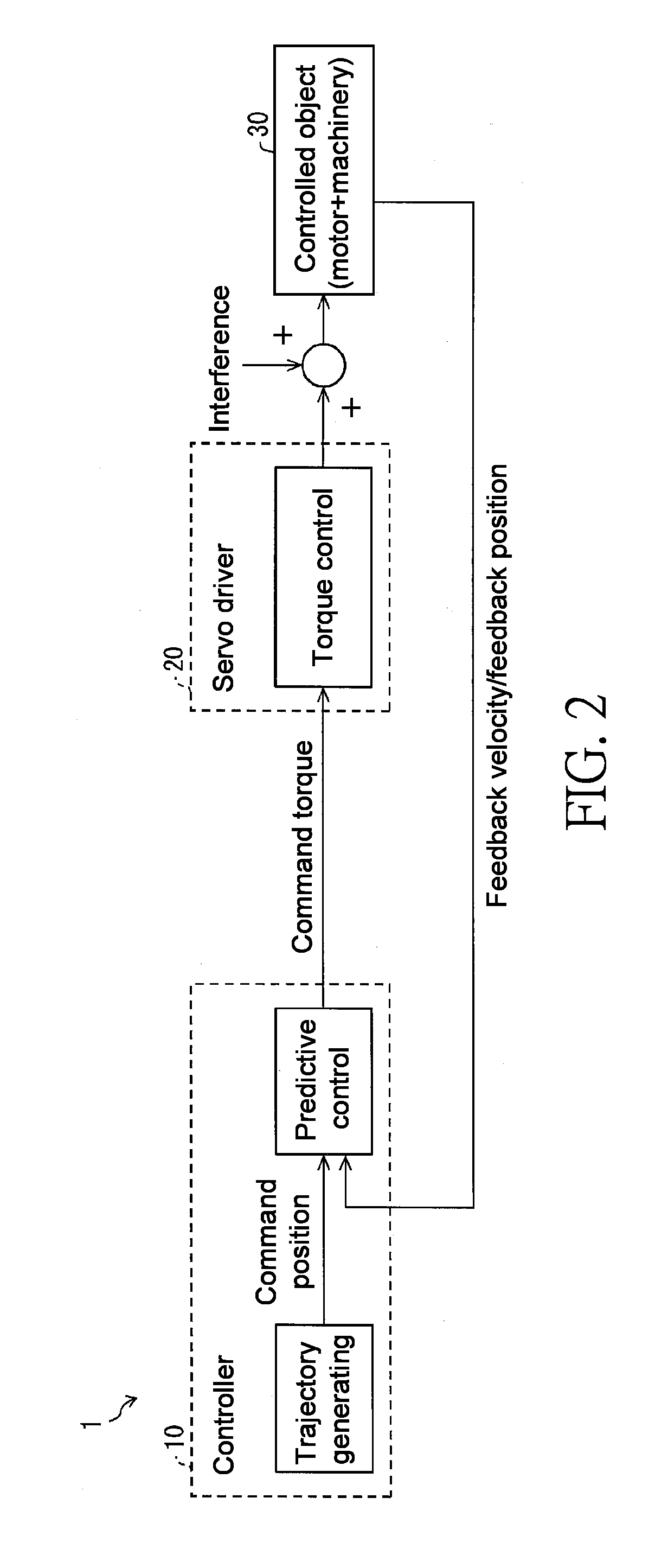

Model predictive control device, control method of model predictive control device, information processing program and recording medium

ActiveUS20180067460A1Raise the possibilitySimple compensation processAdaptive controlInformation processingMotor control

The present invention simplifies the processing for compensating an influence for a controlled quantity generated from shaping interference in motion control. A controller (10) as a model predictive control device computes an error between an actually measured value of a controlled quantity in a certain action cycle when shaping interfering is applied and a predictive value of the controlled quantity in the certain action cycle, i.e., the model predictive error, and corrects the predictive value in the action cycle after the certain action cycle by using the computed model predictive error.

Owner:ORMON CORP

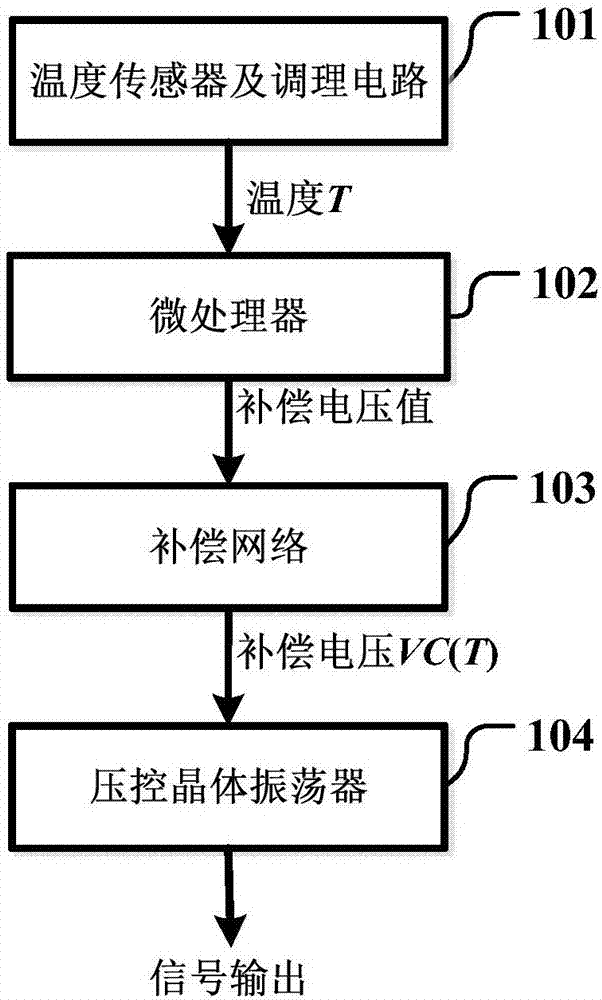

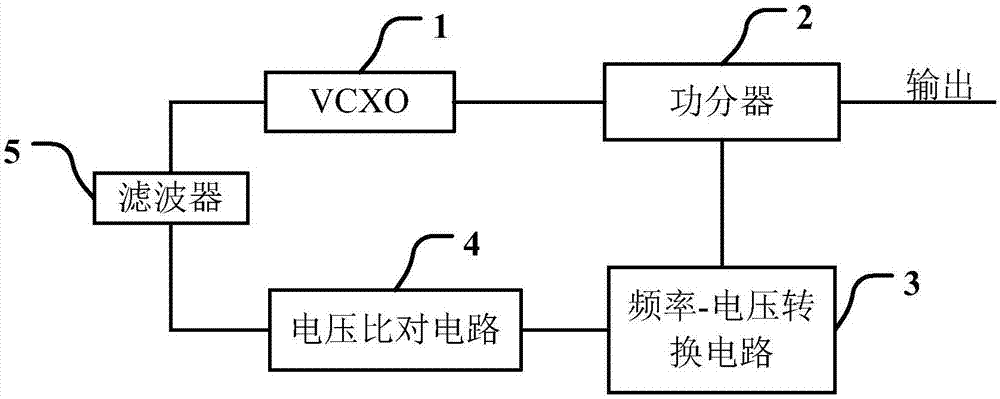

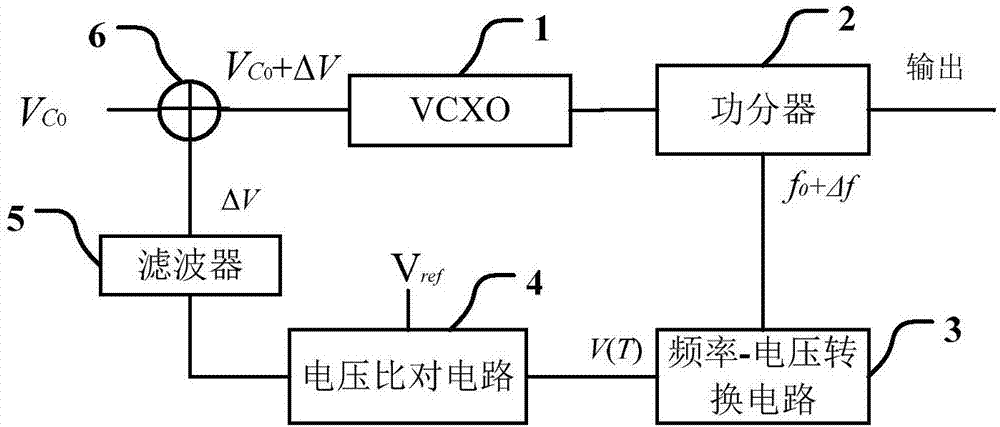

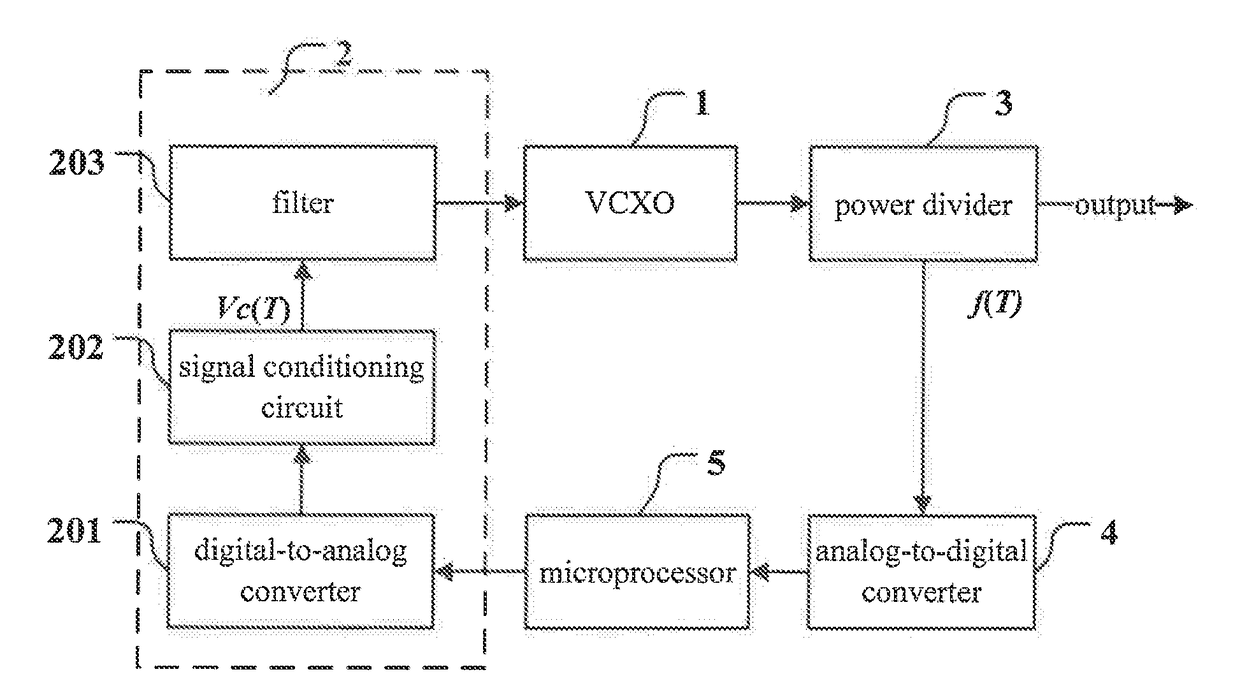

Temperature-compensated crystal oscillator based on digital circuit

ActiveUS20170373638A1Easily realizedSimple compensation processImpedence networksGenerator stabilizationHysteresisClosed loop

The present invention provides a temperature-compensated crystal oscillator based on digital circuit, a closed-loop compensation architecture is employed to realize the high precision compensation of the crystal oscillator. The output frequency f(T) of the TCXO to be compensated is directly connected with the compensation voltage Vc(T) in real time, and the compensation voltage is fed back to the voltage control terminal of the VCXO to be compensated to compensate, so that the output frequency after compensation is equal to the target frequency signal, thus avoiding the frequency shift of output signal caused by temperature hysteresis, i.e. the discrepancy between the temperature acquired by a temperature senor and the real temperature of the resonant wafer in the prior art.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Device for compensating radio frequency distortion in orthogonal frequency division multiplexing transmission system and method thereof

ActiveUS7929639B2Simple compensation processCarrier regulationSecret communicationUltrasound attenuationEngineering

The present invention relates to a device for compensating a radio frequency distortion caused by a sample / hold operation of a digital / analog converter in an orthogonal frequency division multiplexing (OFDM) transmission system, and a method thereof. In a digital transmission system, an edge frequency signal of a transmission signal band is distorted by a sample / hold operation of a digital / analog converter such that a signal attenuation is generated at a frequency domain by a sync function having a zero point at a sample frequency of a transmission signal. In the present invention, the signal distortion may be compensated by multiplying a coefficient of an inverse sync function by a signal weight value at the frequency domain, and it may be compensated by using a single multiplier and a lookup table storing the coefficient of the inverse sync function.

Owner:ELECTRONICS & TELECOMM RES INST

A real-time compensation device and method for comprehensive error of spindle

InactiveCN104070406BCompensation errorSimple compensation processMeasurement/indication equipmentsOther manufacturing equipments/toolsEngineeringMachine tool

Owner:GUANGDONG UNIV OF TECH

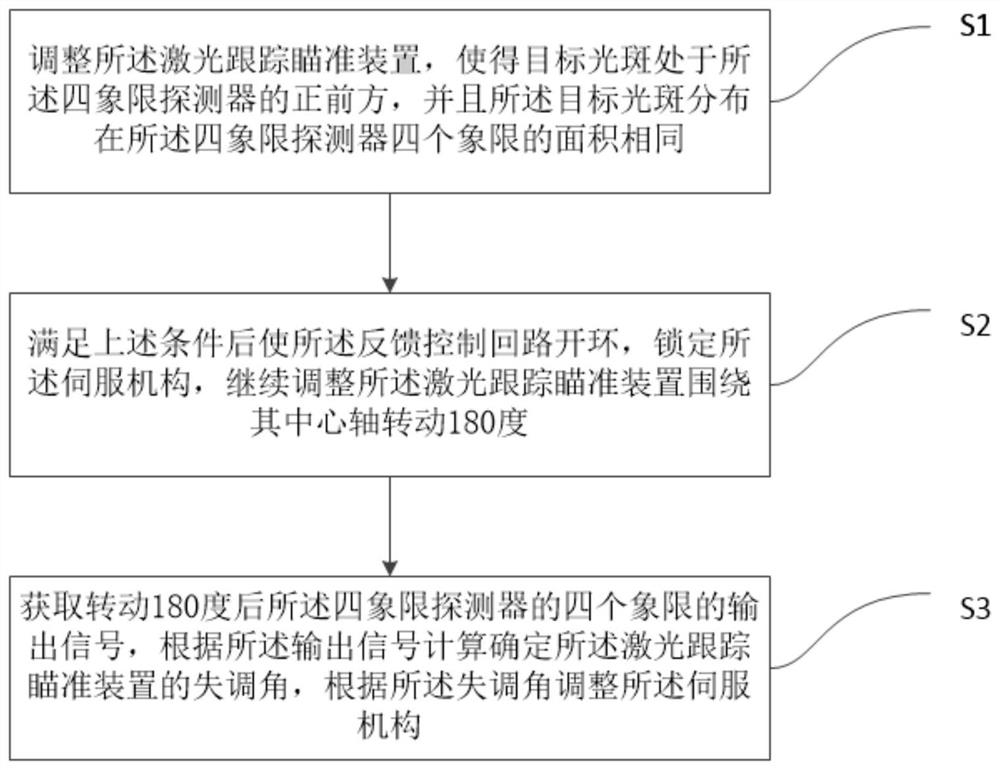

Optical zero compensation method and system for laser tracking and aiming device

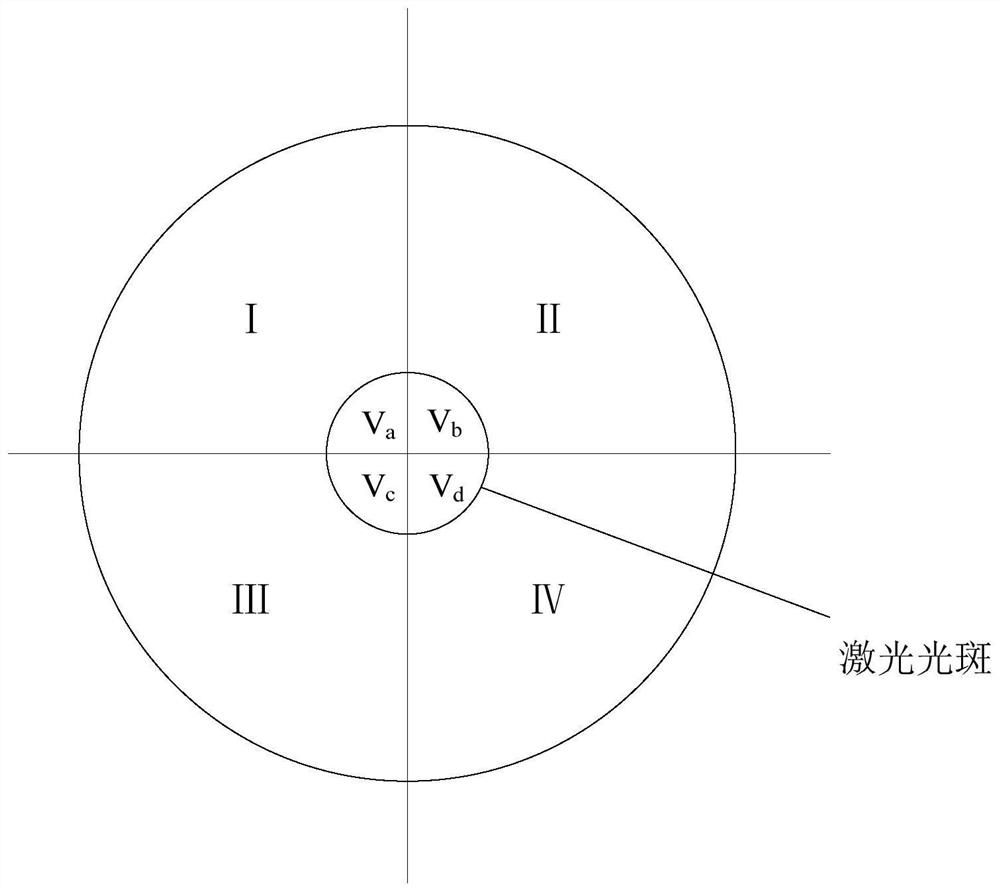

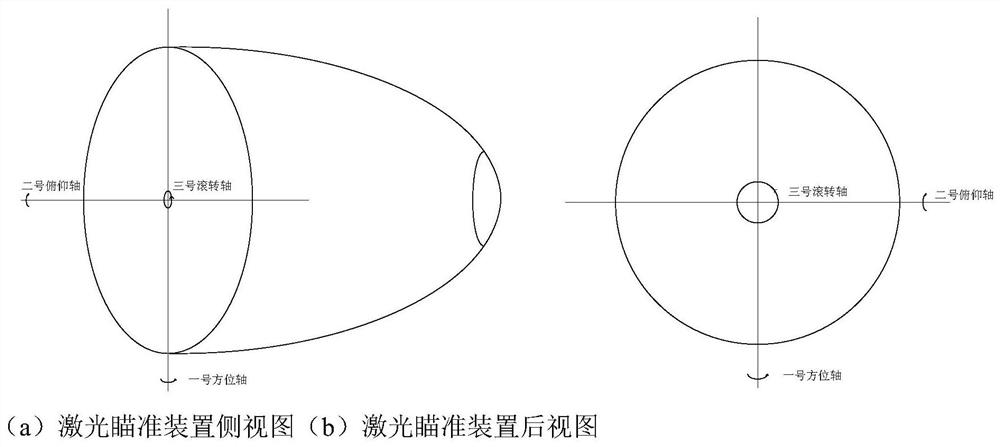

PendingCN113791399ASimple compensationAvoid repeated disassemblyElectromagnetic wave reradiationEngineeringServomechanism

The invention discloses an optical zero compensation method and system for a laser tracking and aiming device. The method comprises the steps that: the laser tracking and aiming device is adjusted, so that target light spots are located right in front of a four-quadrant detector, and the areas of the target light spots distributed in four quadrants of the four-quadrant detector are the same; after the conditions are met, a feedback control loop is opened, a servo mechanism is locked, and the laser tracking and aiming device is continuously adjusted to rotate around the center axis by 180 degrees; output signals of the four quadrants of the four-quadrant detector after 180-degree rotation are obtained, the misalignment angle of the laser tracking and aiming device is calculated and determined according to the output signals, and the servo mechanism is adjusted according to the misalignment angle. According to the method and system of the invention, the error of the laser tracking and aiming device can be compensated simply and quickly, repeated disassembly and assembly can be avoided, and manpower is saved.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

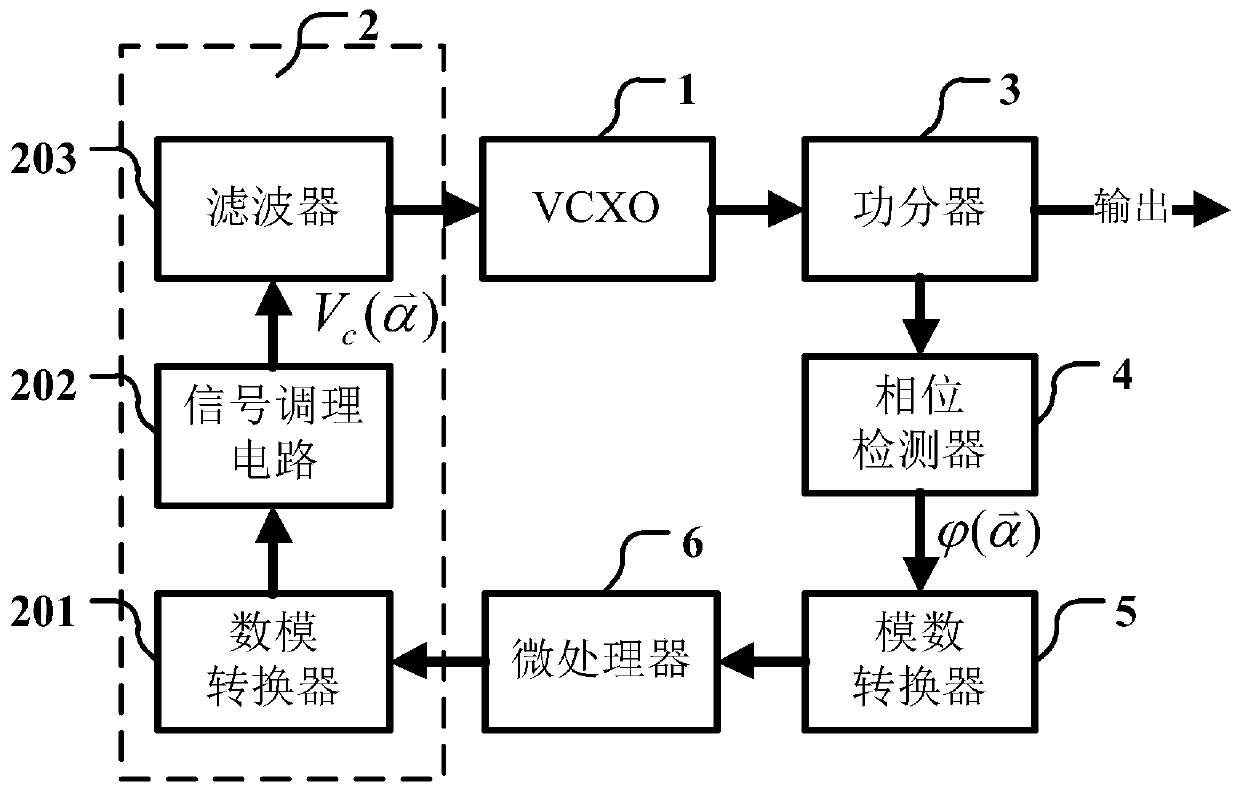

Anti-vibration crystal oscillator

ActiveCN111010089AAchieve high precision phase compensationAchieving Phase CompensationOscillations generatorsSoftware engineeringDigital converter

The invention discloses an anti-vibration crystal oscillator, and the crystal oscillator adopts a closed-loop compensation framework based on a digital circuit to realize high-precision compensation of the crystal oscillator. Firstly, an output signal of an acceleration compensation crystal oscillator is divided into two paths by a power divider: one path is outputted, and the other path is sent to a phase detector to extract a phase signal, is converted into a phase value in a binary coding form by an analog-to-digital converter, and then is transmitted into a microprocessor; a pre-stored phase value-compensation voltage value binary coding table is used for looking up a table to obtain a binary code of a required compensation voltage value, and then the binary code of the compensation voltage value is converted into a required compensation voltage by a digital-to-analog converter, and the required compensation voltage is inputted to the voltage control end of the voltage-controlled crystal oscillator, so the oscillator outputs a signal with a stable phase and finally acceleration compensation is realized, and the problem of phase error caused by inconsistency and asynchronism ofacceleration acquired by a sensor and real-time acceleration of a resonance wafer in the conventional acceleration compensation crystal oscillator is solved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

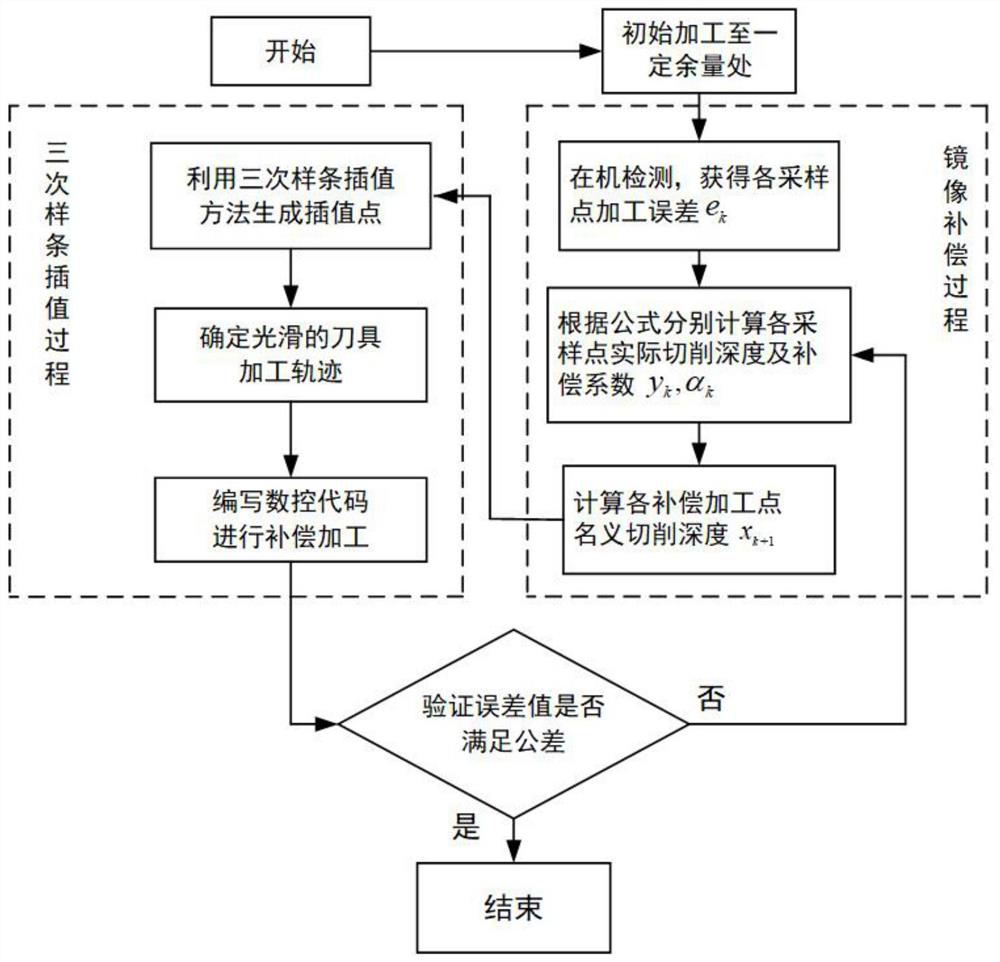

Machining Error Compensation Method of Thin-walled Parts Based on Mirror Image Method and Cubic Spline Interpolation

ActiveCN109765843BSimple compensation processHigh precisionProgramme controlComputer controlMethod of image chargesAlgorithm

The invention discloses a method for compensating processing errors of thin-walled parts based on mirror image method and cubic spline interpolation. The method sequentially processes initial blanks to a position with a certain margin and uses an on-machine detection system to obtain corresponding sampling points. Machining error e at k and the actual depth of cut value y k , Calculate the compensation coefficient α k Then get the nominal depth of cut x in the next compensation machining k+1 , Finally, use the cubic spline interpolation method to generate a limited number of interpolation points according to the size of the interpolation interval to obtain the optimal tool machining path; this method is based on the on-machine detection data, and establishes an optimized mirror image error compensation model by introducing compensation coefficients, combined with The cubic spline interpolation method generates enough interpolation points to obtain the optimal tool machining path, thereby simplifying the machining error compensation model of thin-walled parts, improving compensation efficiency and ensuring machining accuracy.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

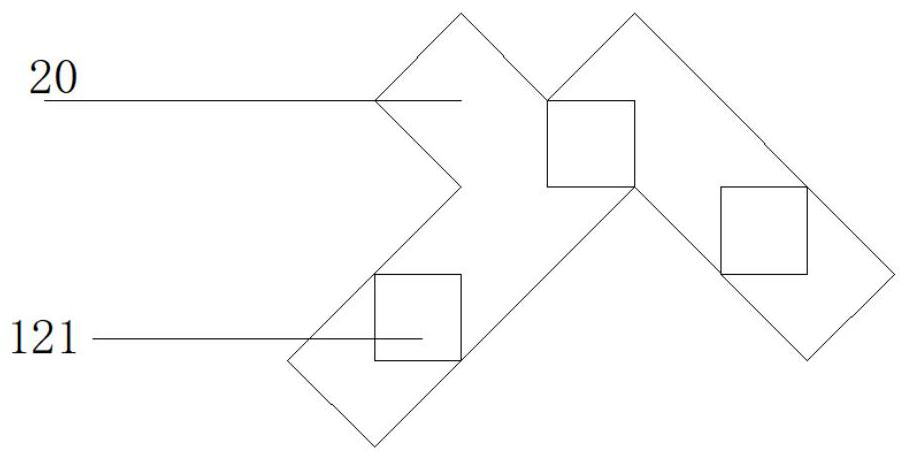

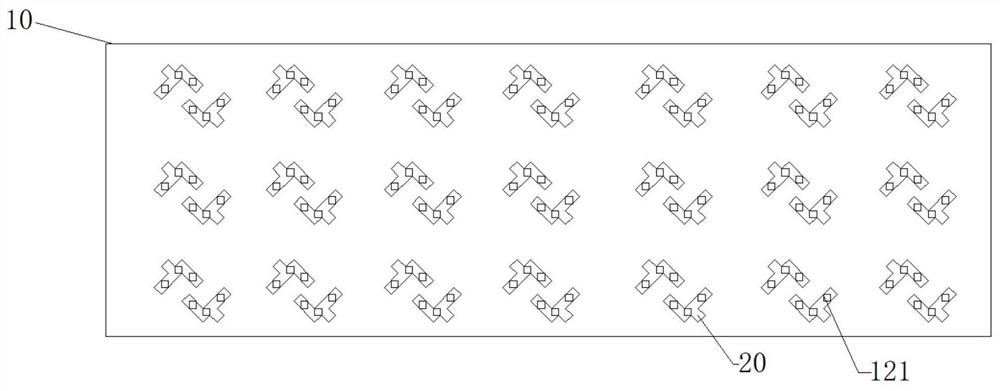

A substrate electroplating method and substrate prepared therefrom

ActiveCN111405775BImprove etching yieldReduce consumptionPrinted circuit manufacturePhysical chemistryWindow opening

The invention provides a substrate electroplating method, the substrate includes a plurality of circuit board units, the method includes the following steps: providing a substrate, the substrate includes an insulating layer and a metal layer; forming a barrier layer on the metal layer, The barrier layer has a first opening and a second opening, the first opening corresponds to the area to be electroplated of the circuit board unit, the second opening corresponds to the compensation plating area; the second opening The window is arranged in the waste area of the substrate; electroplating is performed on the substrate; wherein, the area distribution of the compensation electroplating area is adjusted according to the distribution of the current density of the substrate before compensation. The method of the invention has a simple compensation process, improves the uniformity of the electroplated metal in the area to be electroplated, the etching yield of the circuit board, and the controllability of manufacturing, and at the same time reduces energy consumption and saves costs.

Owner:MFLEX YANCHENG CO LTD

A pixel current compensation method and system for a display panel

ActiveCN105304024BGood compensationSimple compensation processStatic indicating devicesCompensation effectGray level

Embodiments of the present invention disclose a pixel current compensation method and system for a display panel. The compensation method includes: testing the actual current value of a sub-pixel on the display panel at the i-th gray level; The current value is adjusted to the preset target current value of the ith grayscale of the subpixel, and the target grayscale value when the subpixel is at the target current value corresponding to the ith grayscale is recorded; The data distribution table of the target grayscale value at the current time is used to perform current compensation on at least one sub-pixel of the display panel to be compensated. In the present invention, any sub-pixel of the same type of mass-produced display panel can be compensated according to the obtained data distribution table, so that the current of the entire display panel is evenly distributed. Compared with the prior art, no dedicated compensation circuit needs to be added, and The compensation effect is good, the compensation process is simple, and it will not cause new uneven display due to uneven current distribution when working for a long time.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

Model predictive control device, control method of model predictive control device, information processing program and recording medium

ActiveUS10353354B2Simple compensation processAdaptive controlInformation processingModel predictive control

Owner:ORMON CORP

A grayscale compensation method and device, display device

ActiveCN111161677BTo achieve targeted compensationSimple compensation processStatic indicating devicesComputer graphics (images)Display device

The invention discloses a grayscale compensation method and device, and a display device. The gray scale compensation method includes obtaining the basic gray scale of each compensation unit; obtaining the equivalent lighting time of each compensation unit, the equivalent lighting time being the compensation unit obtained by converting the actual lighting time of the compensation unit to the preset gray When the equivalent duration reaches any preset time point, according to the preset time point and the basic gray scale, look up the table to obtain the gray scale compensation parameters corresponding to the compensation unit. According to the gray scale compensation parameters and the basic gray scale , performing gray scale compensation on the sub-pixels in the compensation unit. The technical solution provided by the embodiment of the present invention has high compensation accuracy and no overcompensation phenomenon, and thus does not need to solve the overcompensation problem after the grayscale compensation operation, which is beneficial to simplify the grayscale compensation process.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

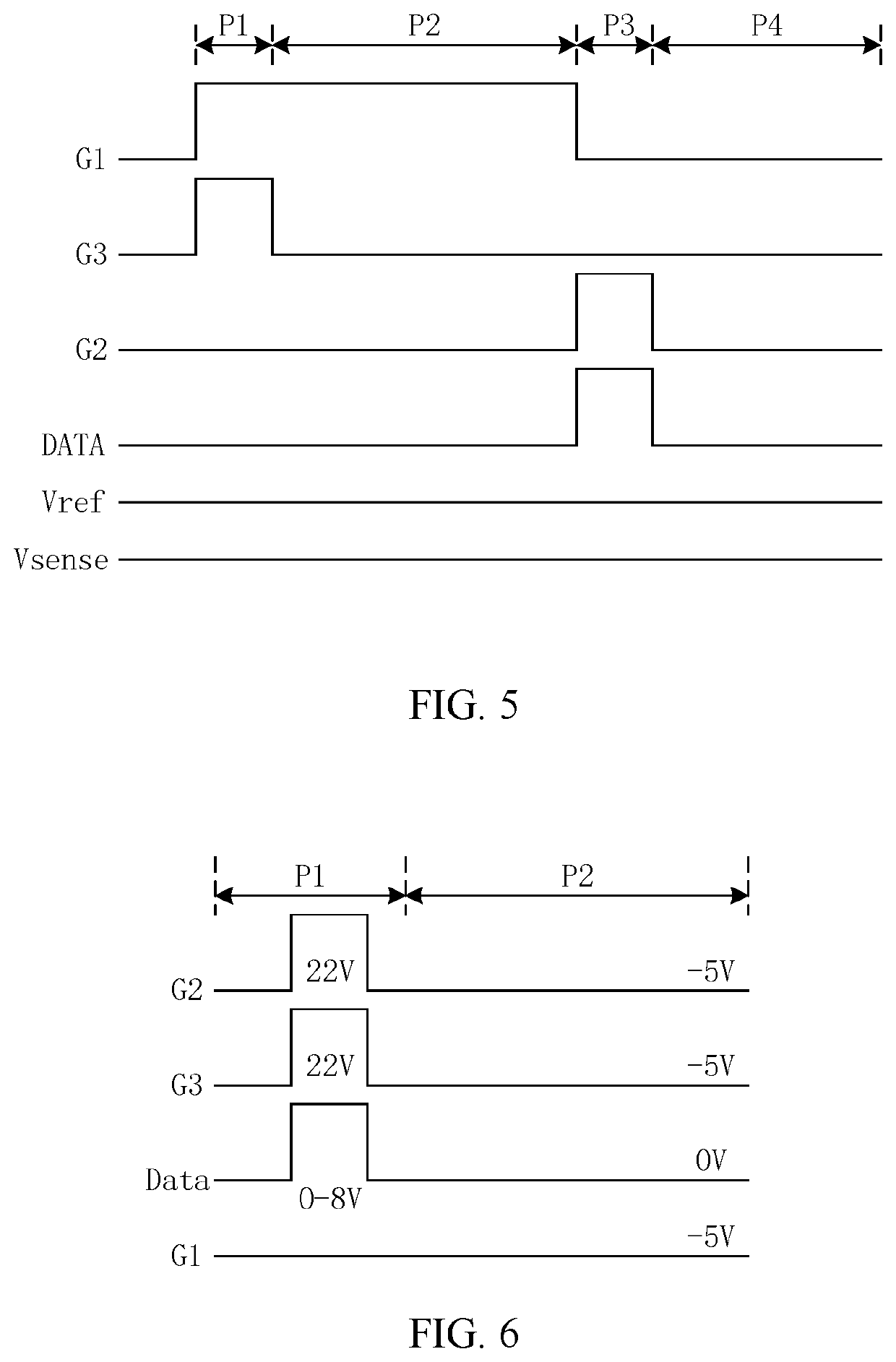

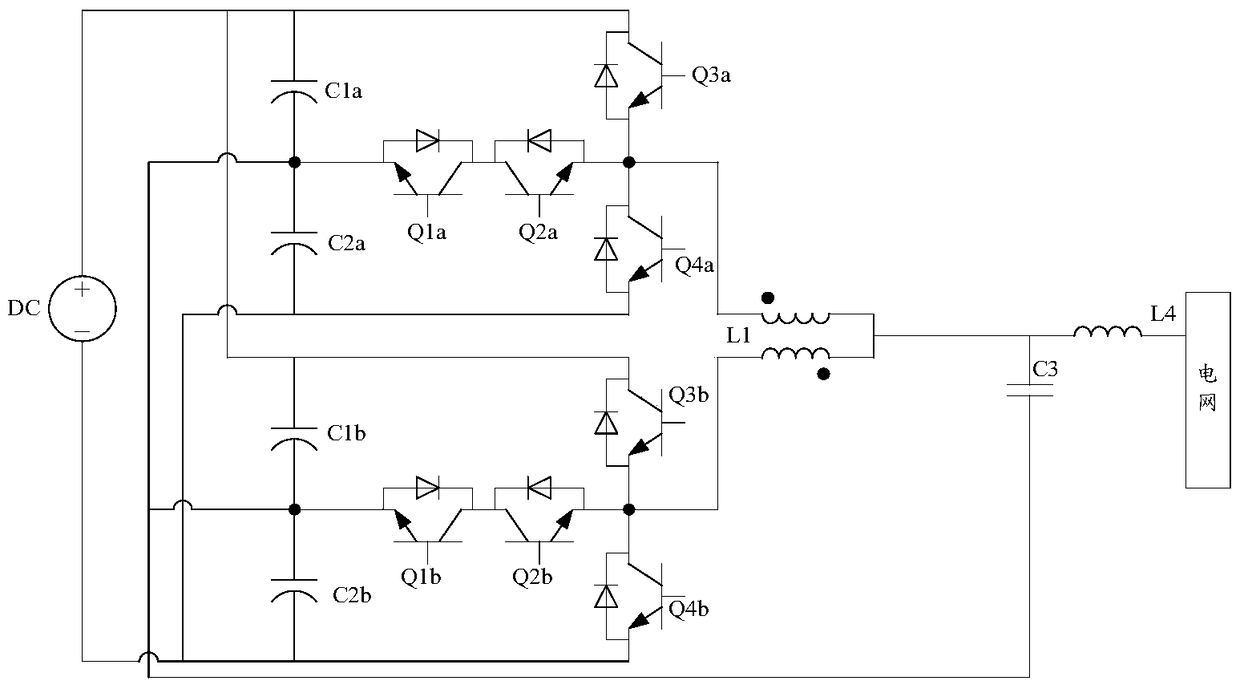

Mixed compensation circuit, control method thereof, and display device

ActiveUS20210407404A1Improve circuit stabilityHigh compensation accuracyStatic indicating devicesDisplay deviceHemt circuits

The present disclosure provides a mixed compensation pixel circuit, control method, and display device, the mixed compensation pixel circuit includes an internal compensation circuit and an external compensation circuit. The internal compensation circuit includes a first thin film transistor, a second thin film transistor, a third thin transistor, and a fourth thin transistor, the external compensation circuit includes a fifth thin transistor. By optimizing the pixel circuit architecture, the present disclosure does not have an NTFT with a positive long-term relative voltage, improves the stability of the circuit, simplifies the compensation process, and improves the accuracy of compensation.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

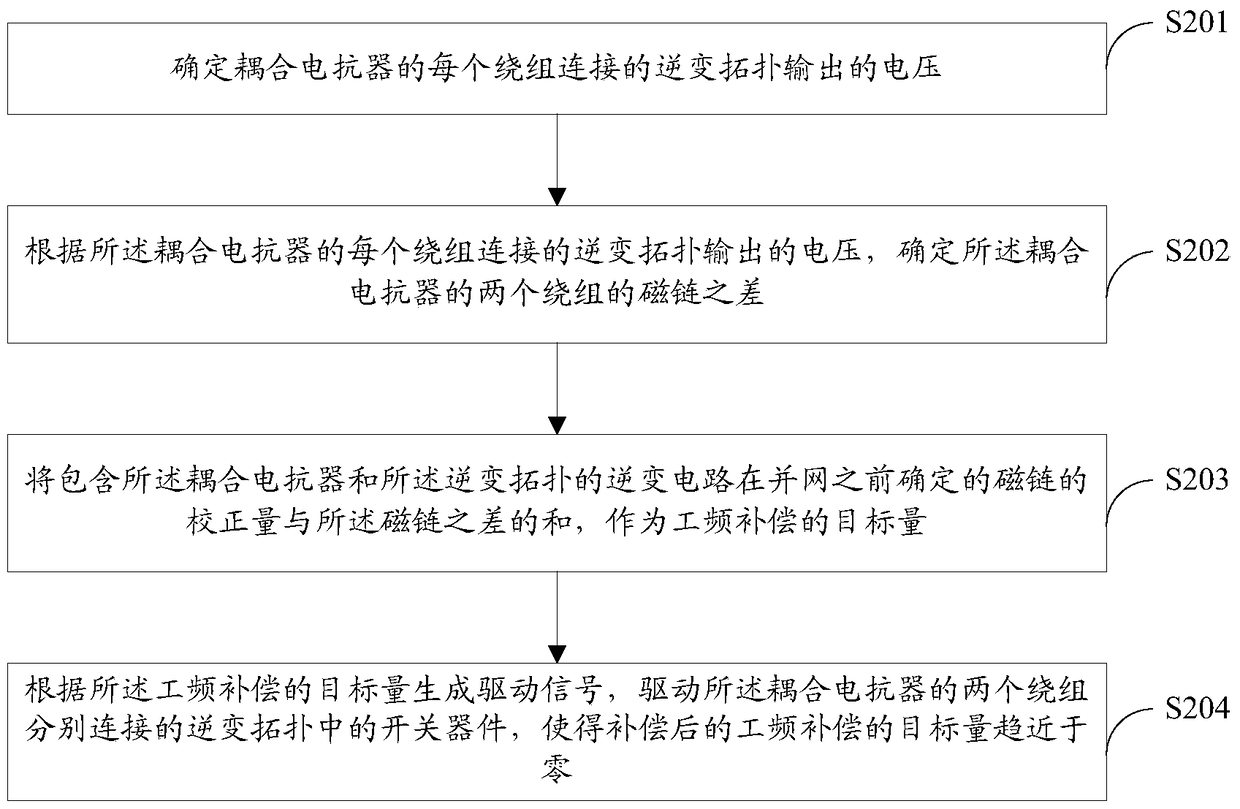

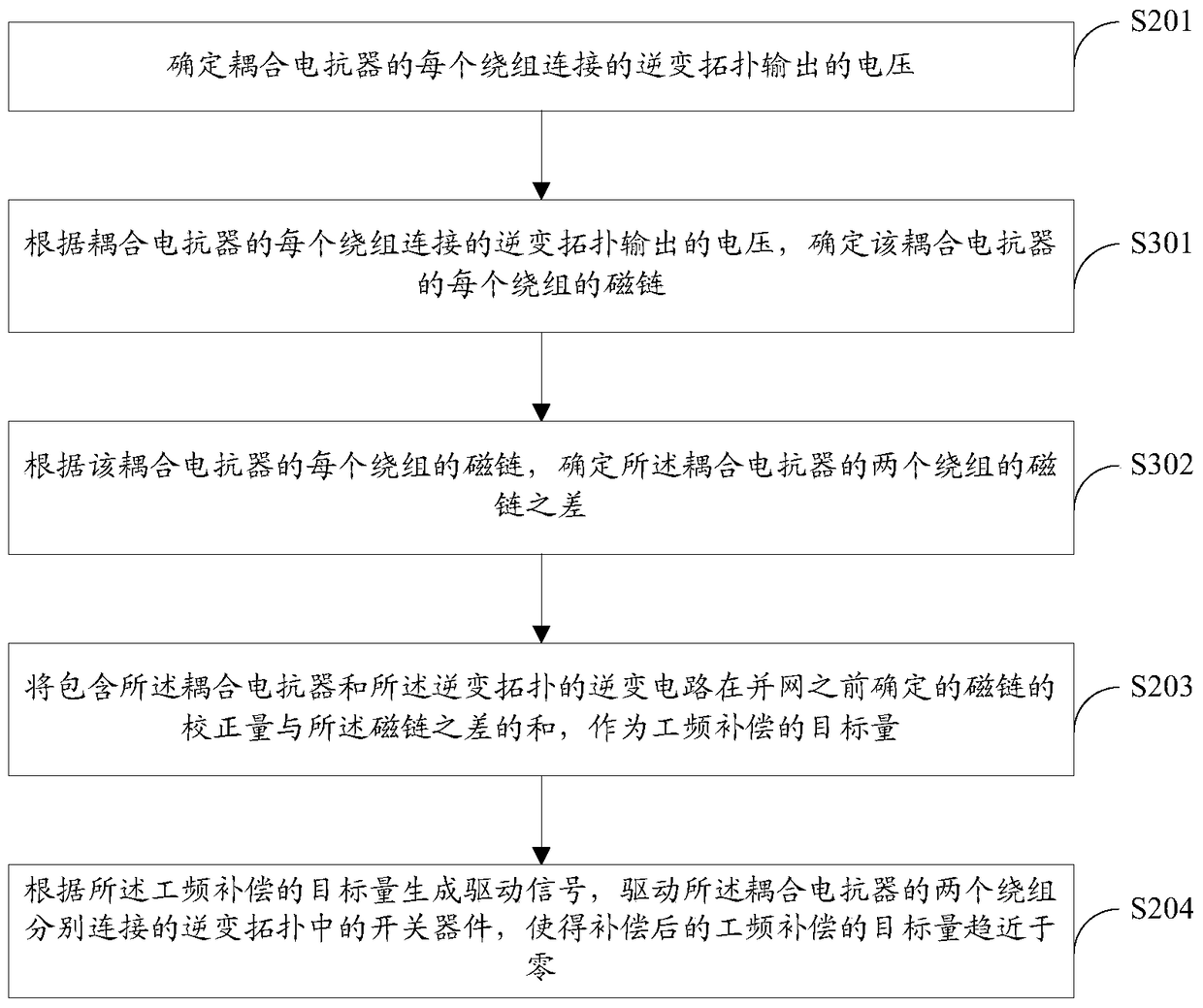

A control method and device for preventing magnetic saturation of coupling reactor

Owner:EMERSON NETWORK POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com