Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Shorten the settlement distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

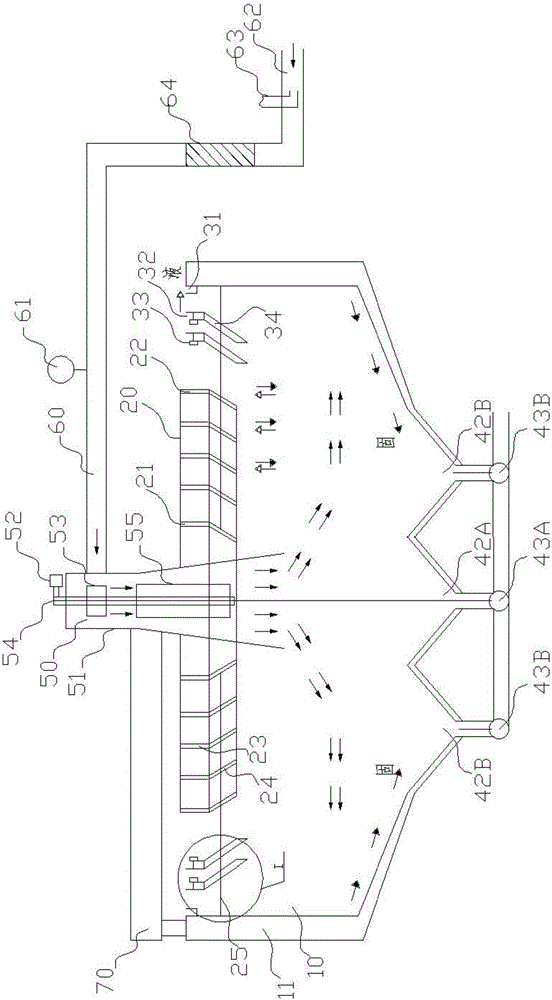

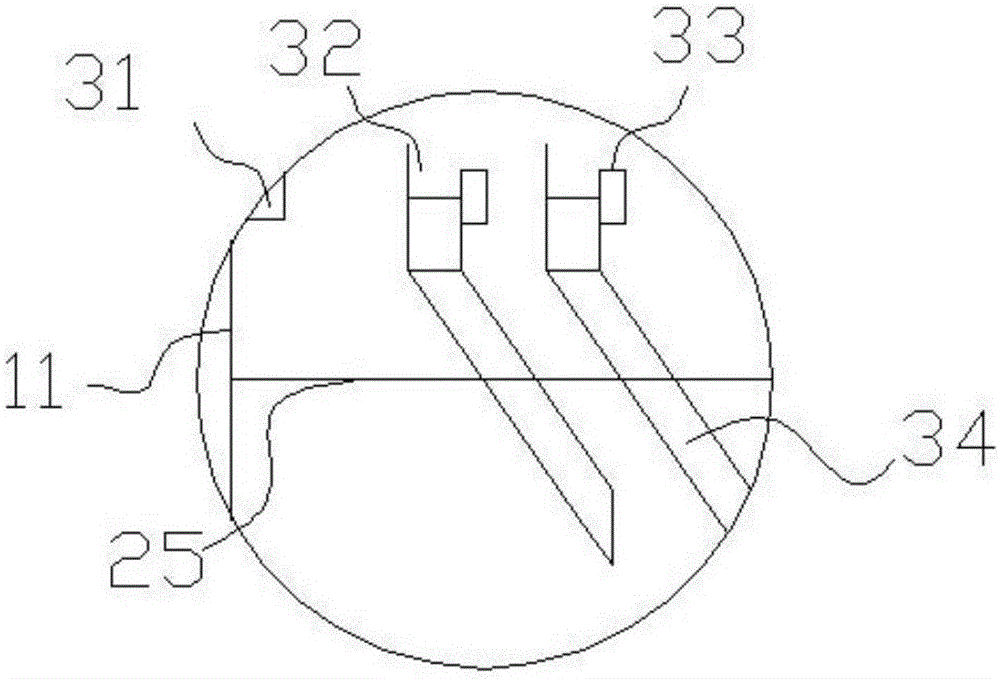

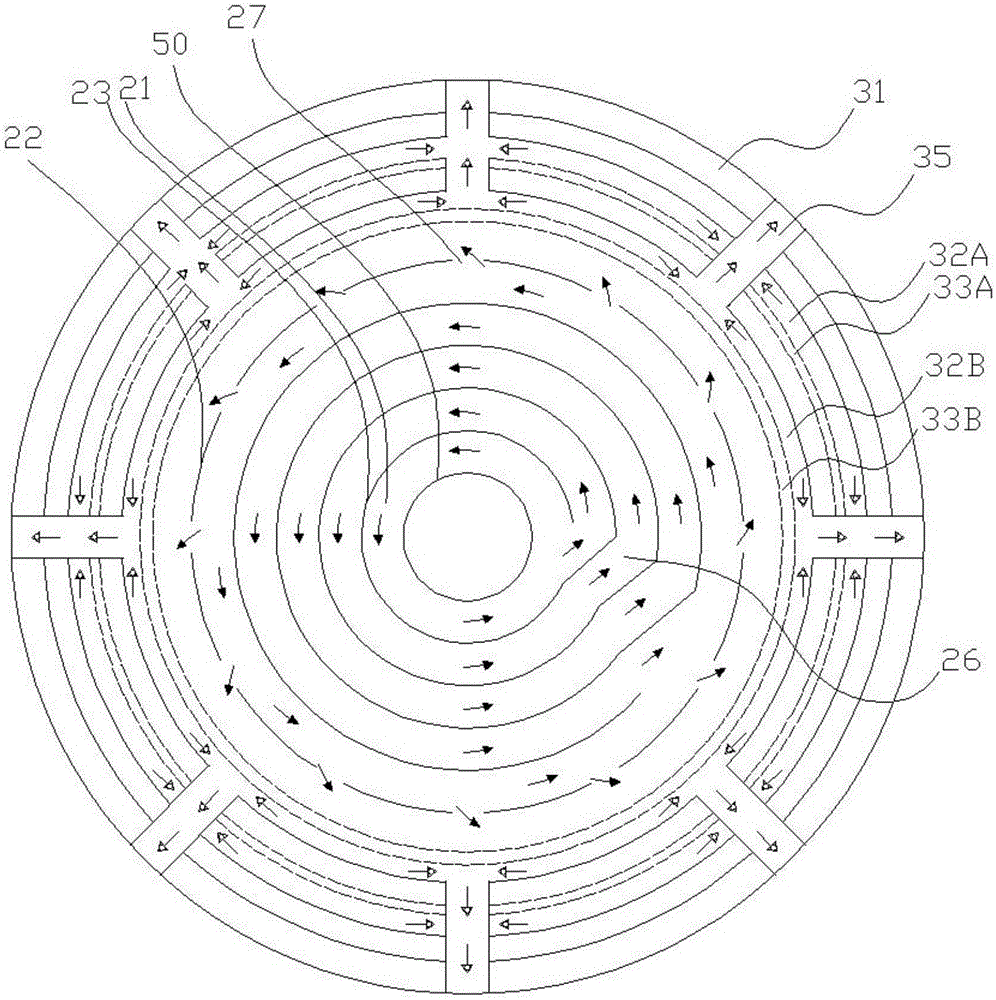

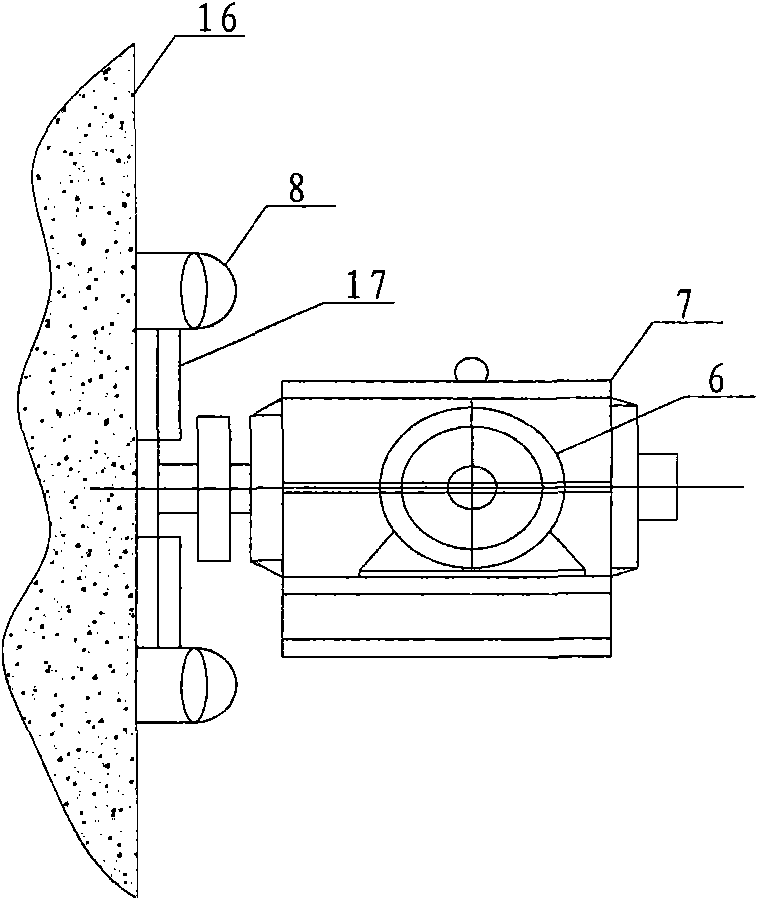

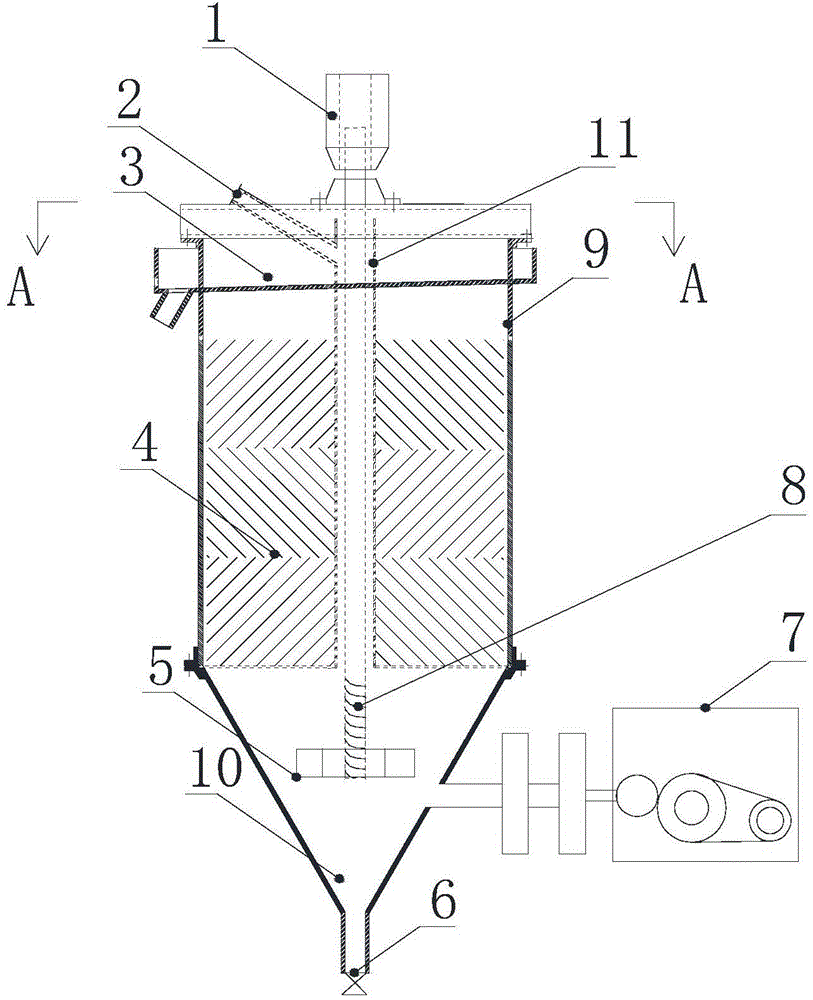

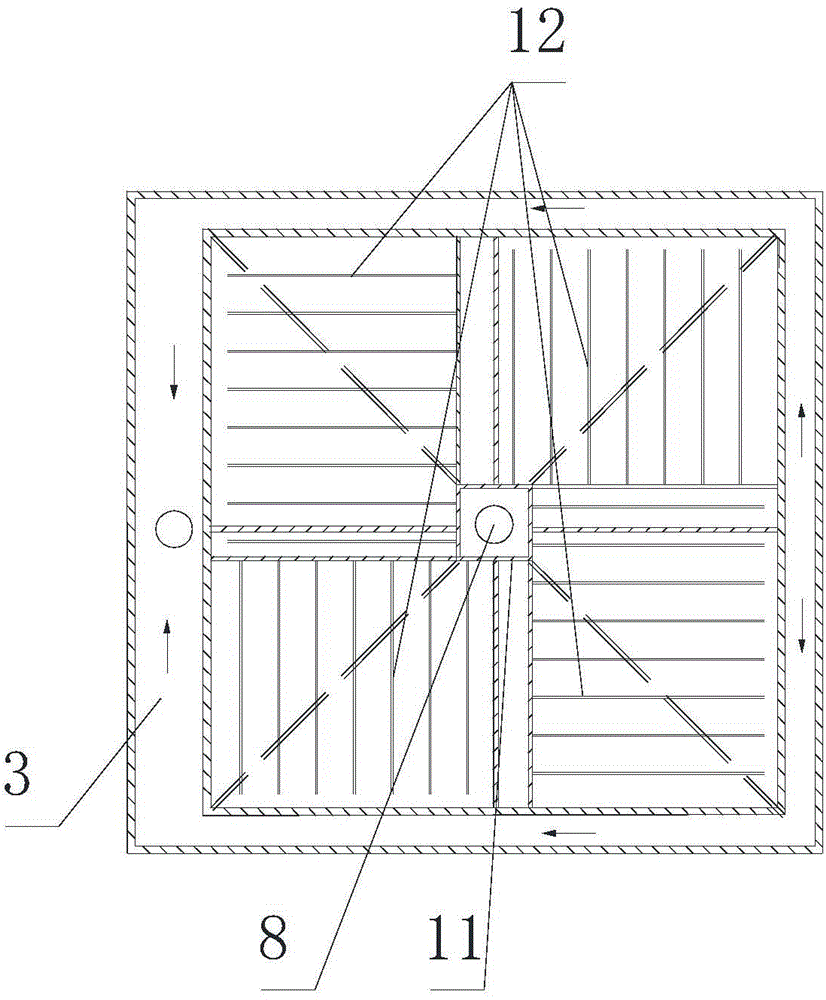

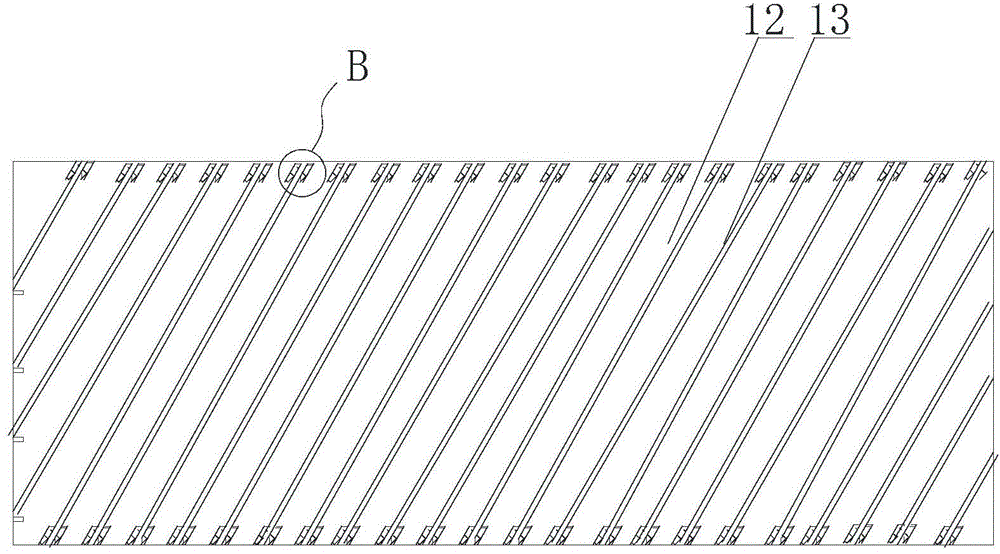

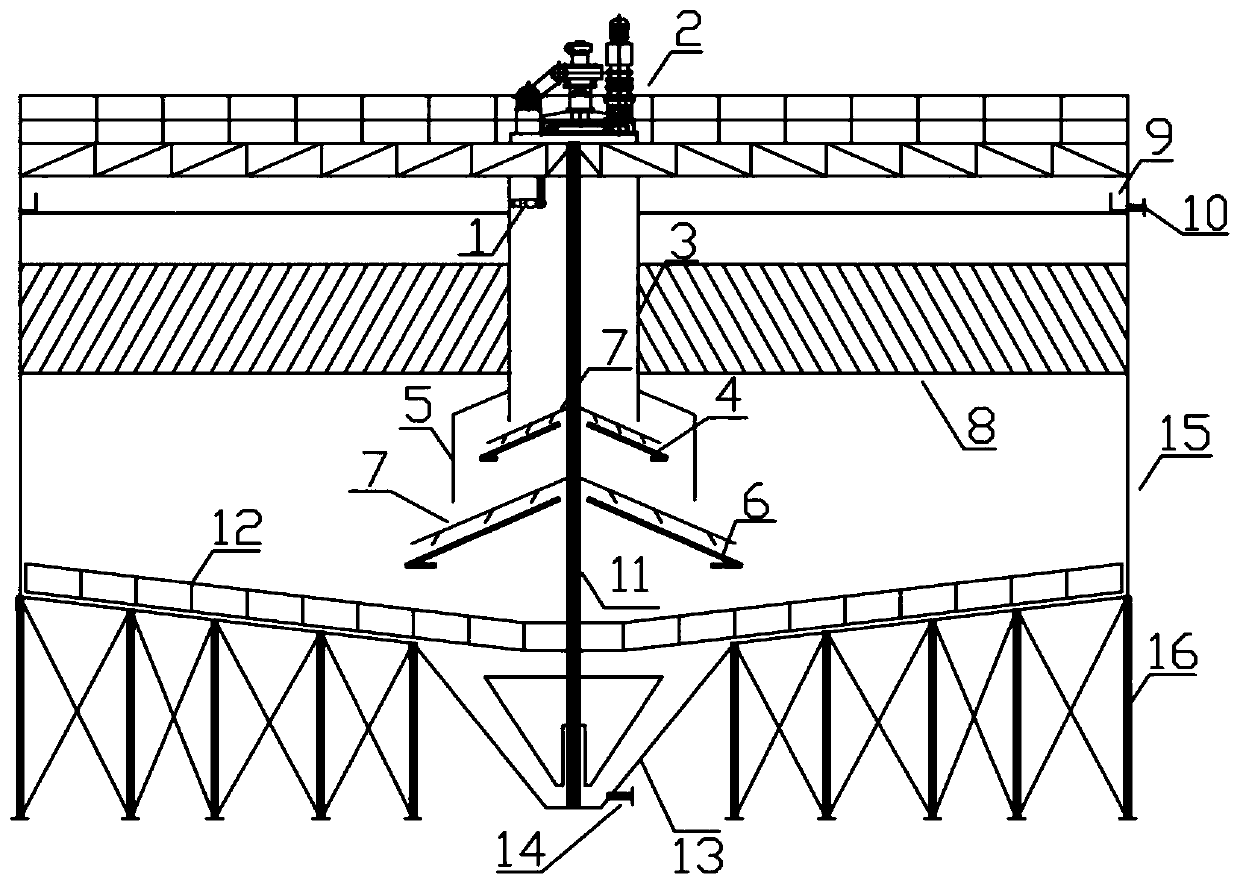

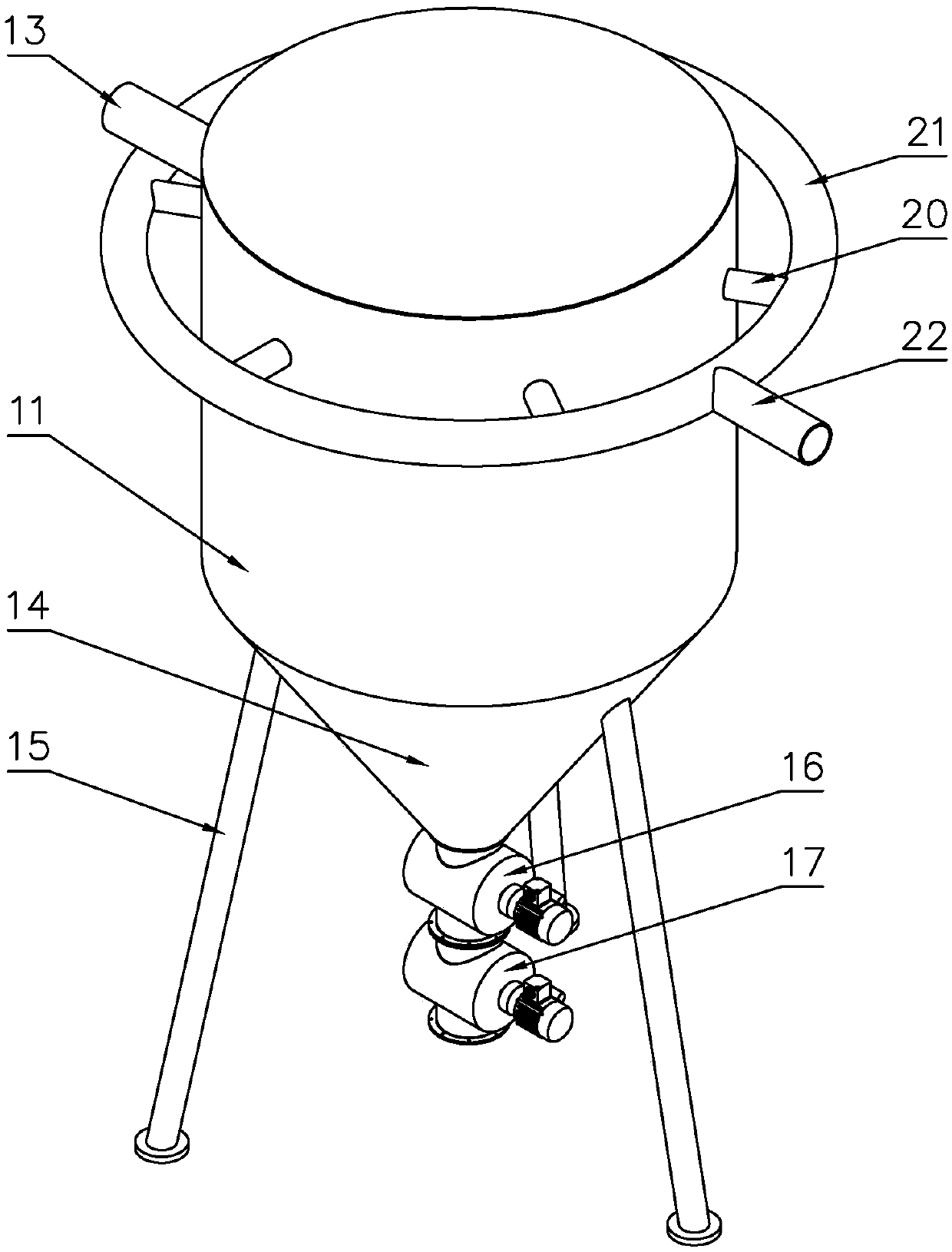

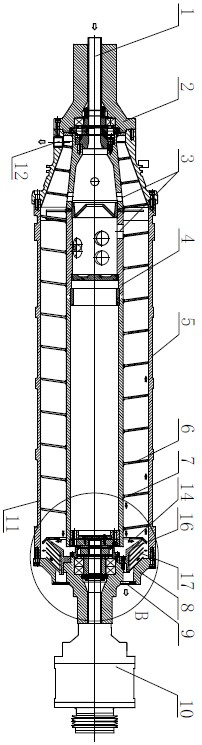

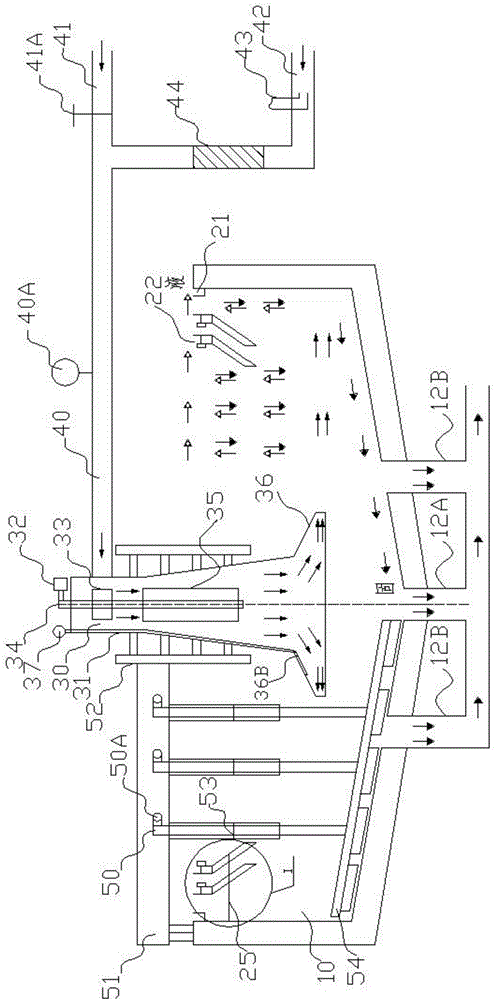

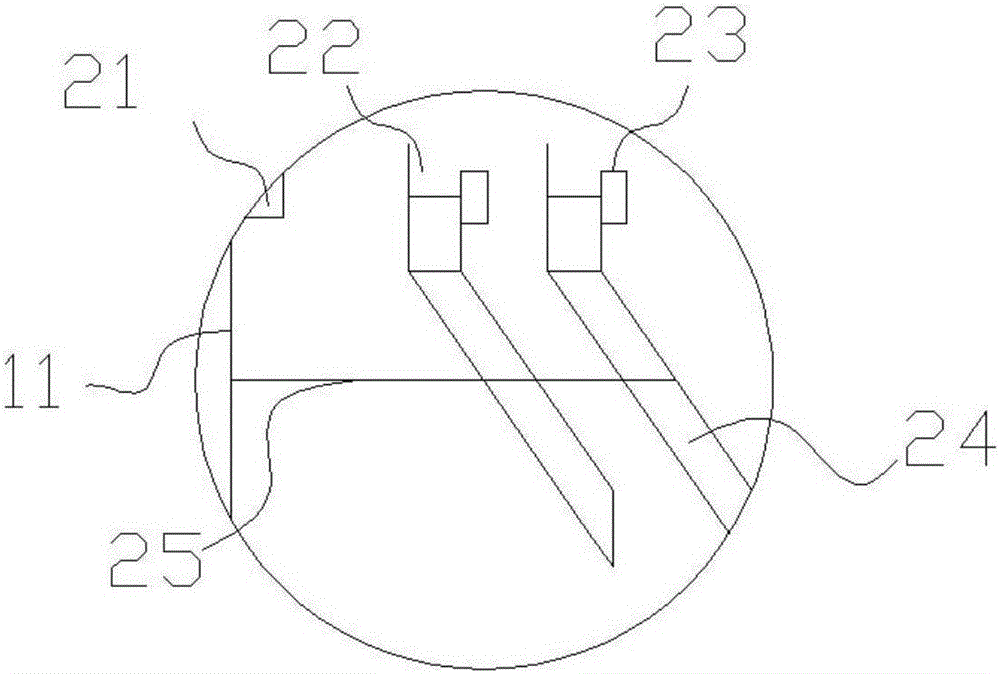

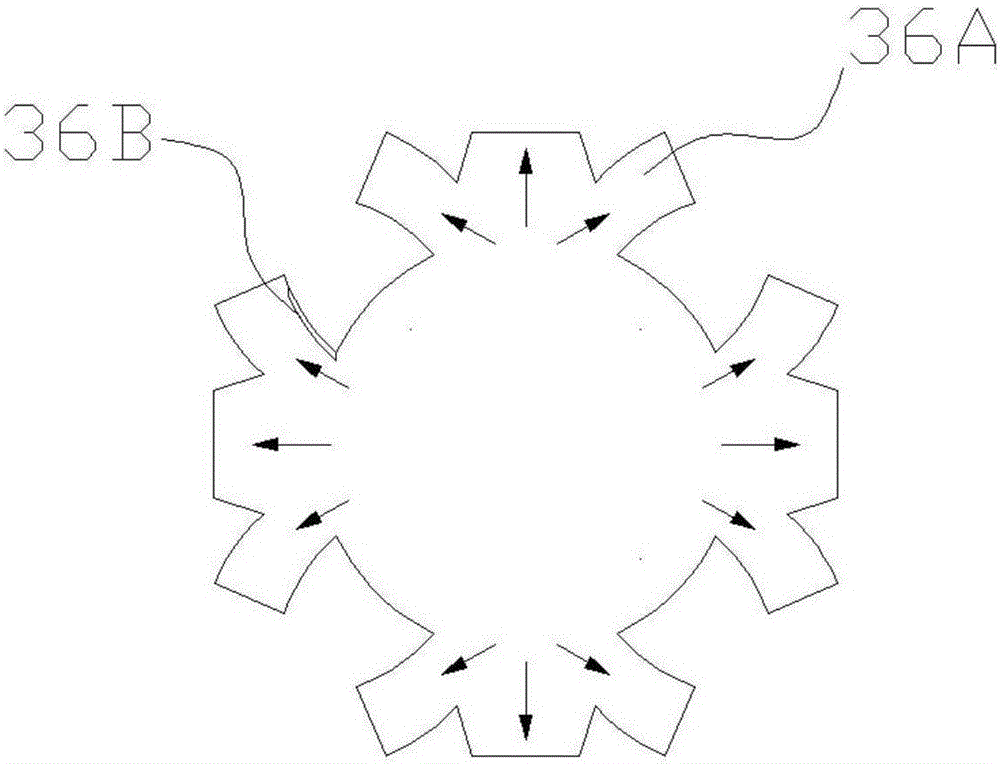

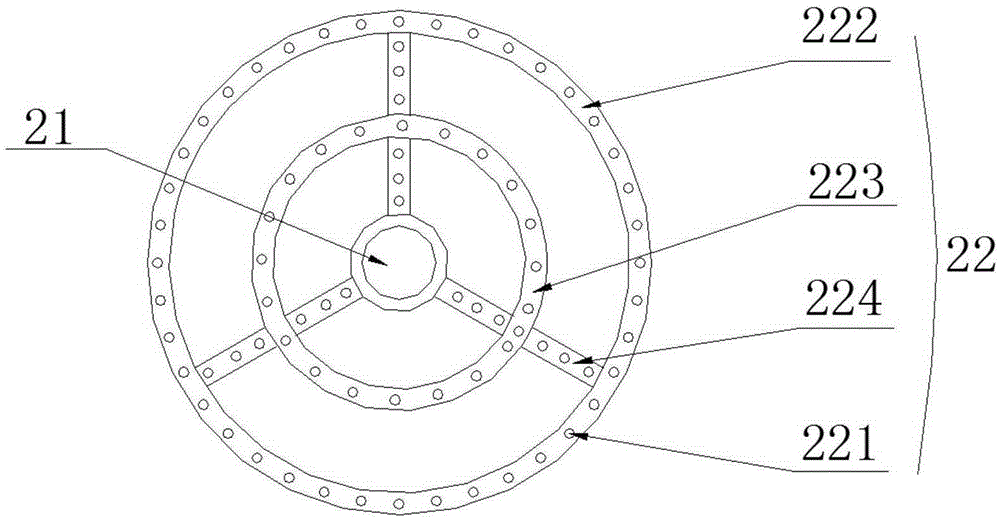

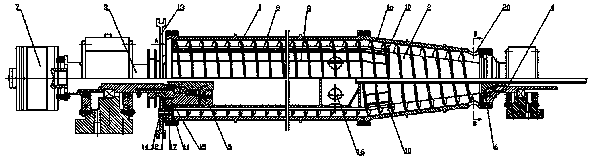

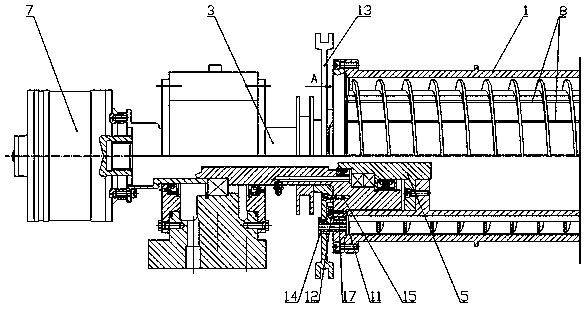

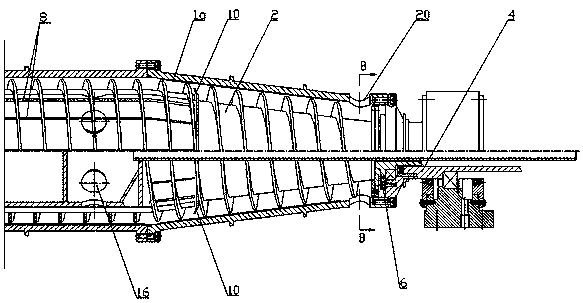

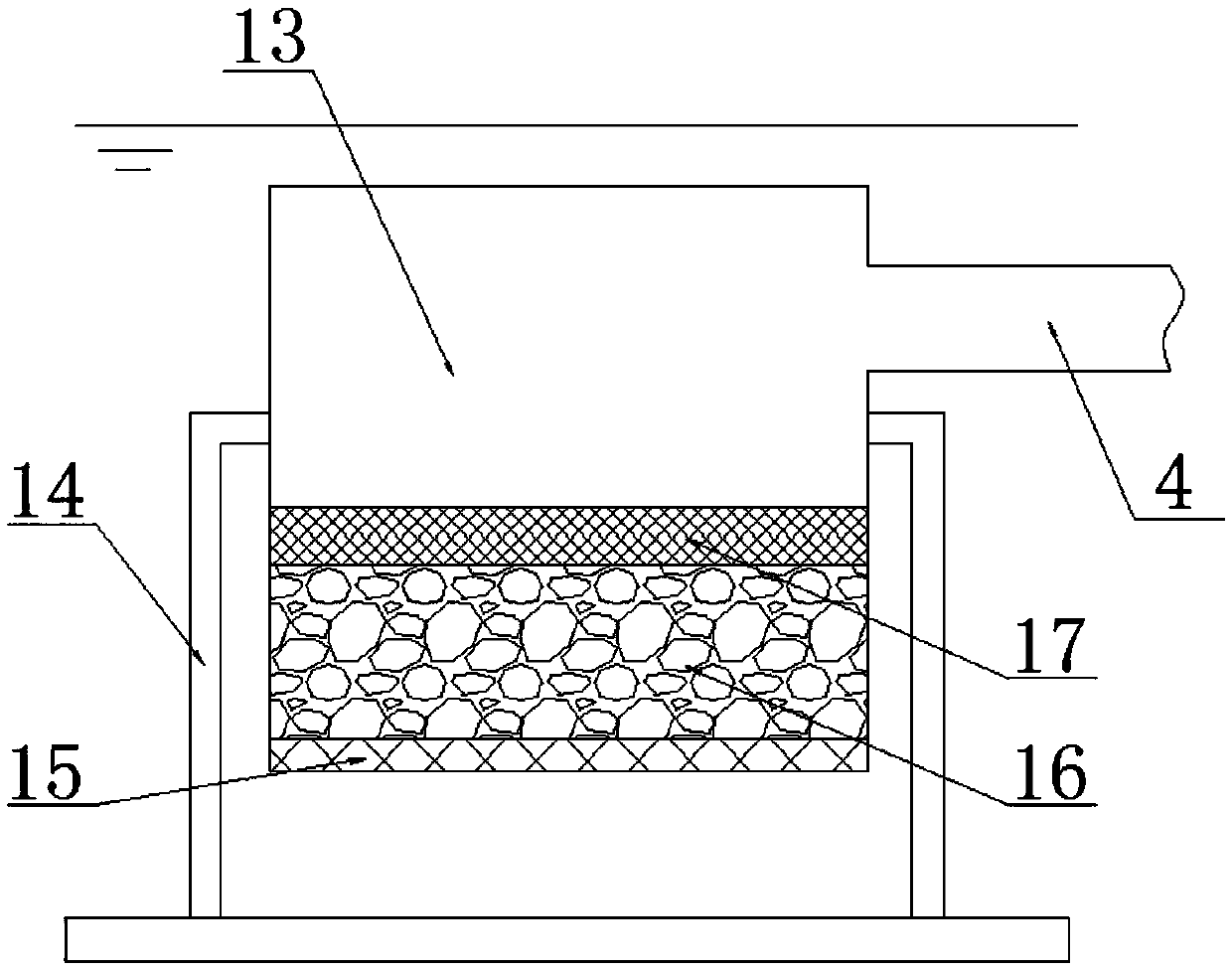

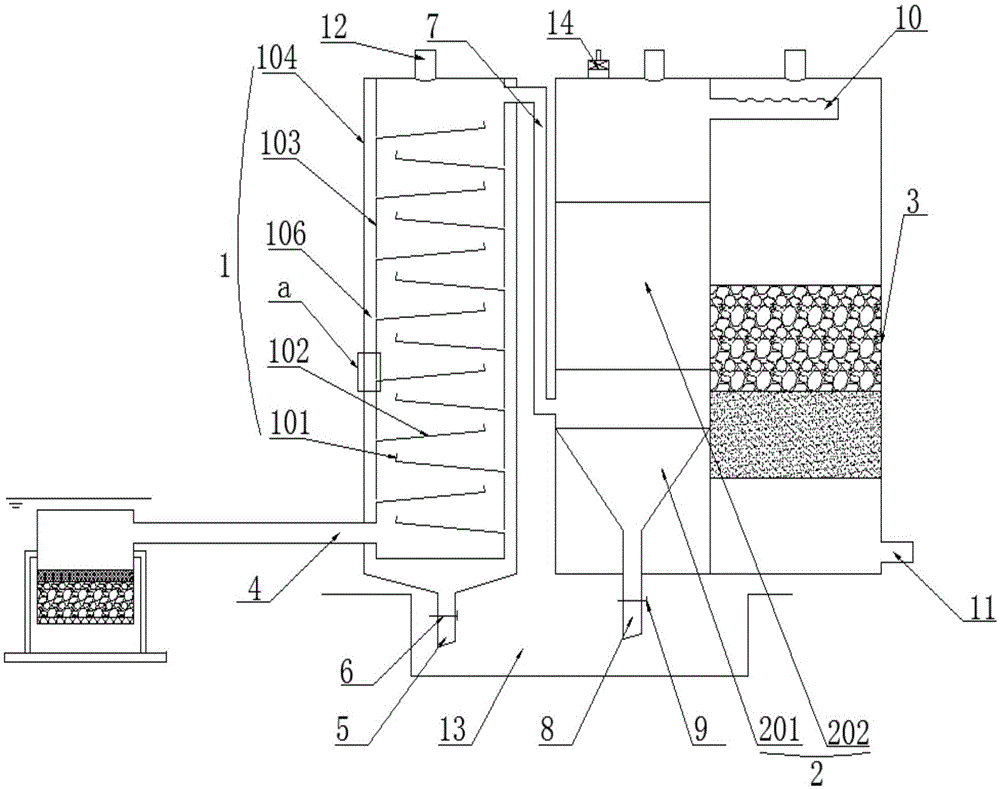

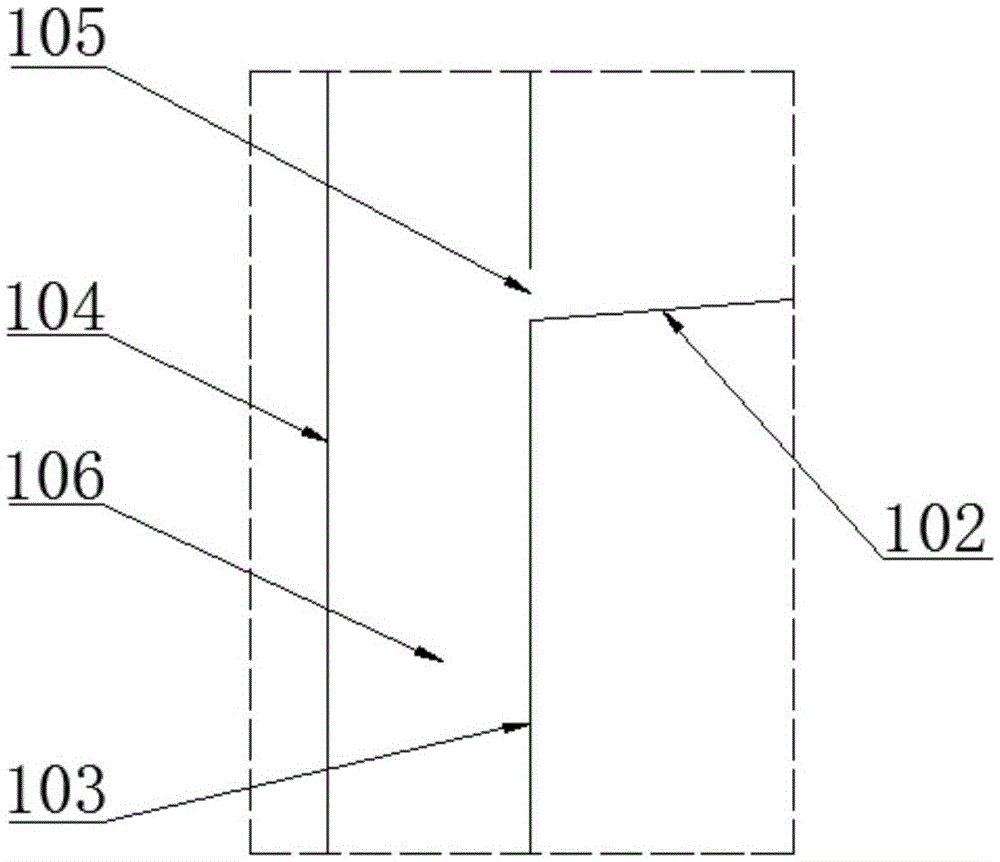

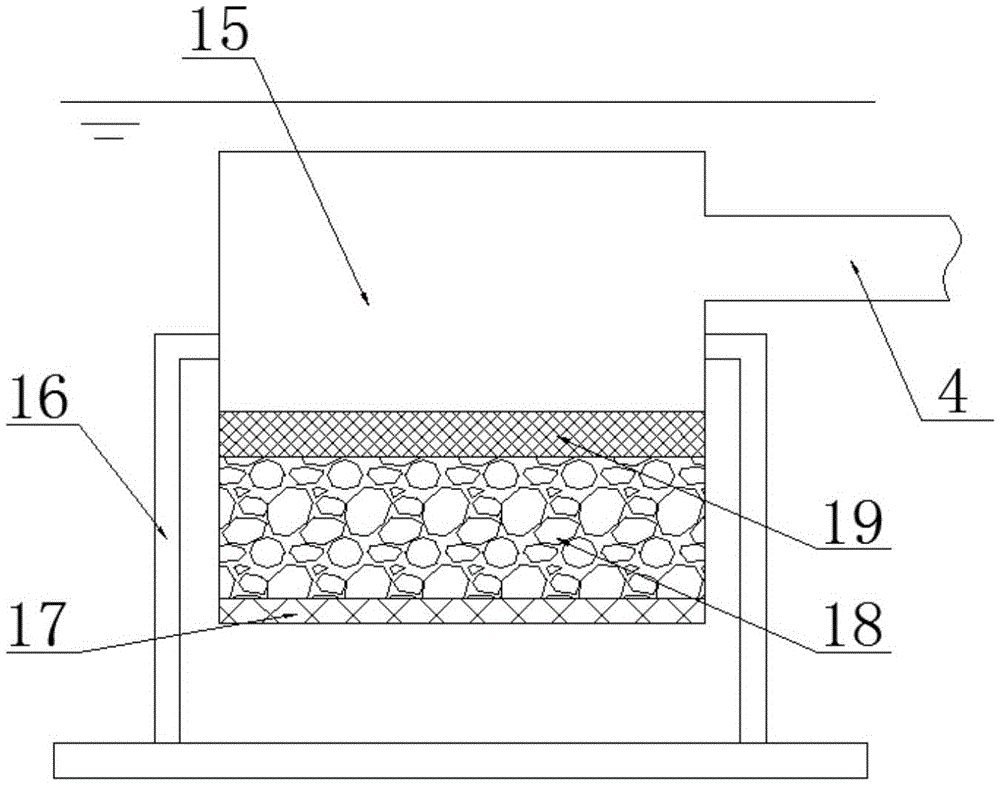

Rake-free thickener with rotary annular channels

ActiveCN105944407AEnsure stabilityImprove settlement performanceSedimentation regulating devicesSettling tanks feed/dischargeWater concentrationEngineering

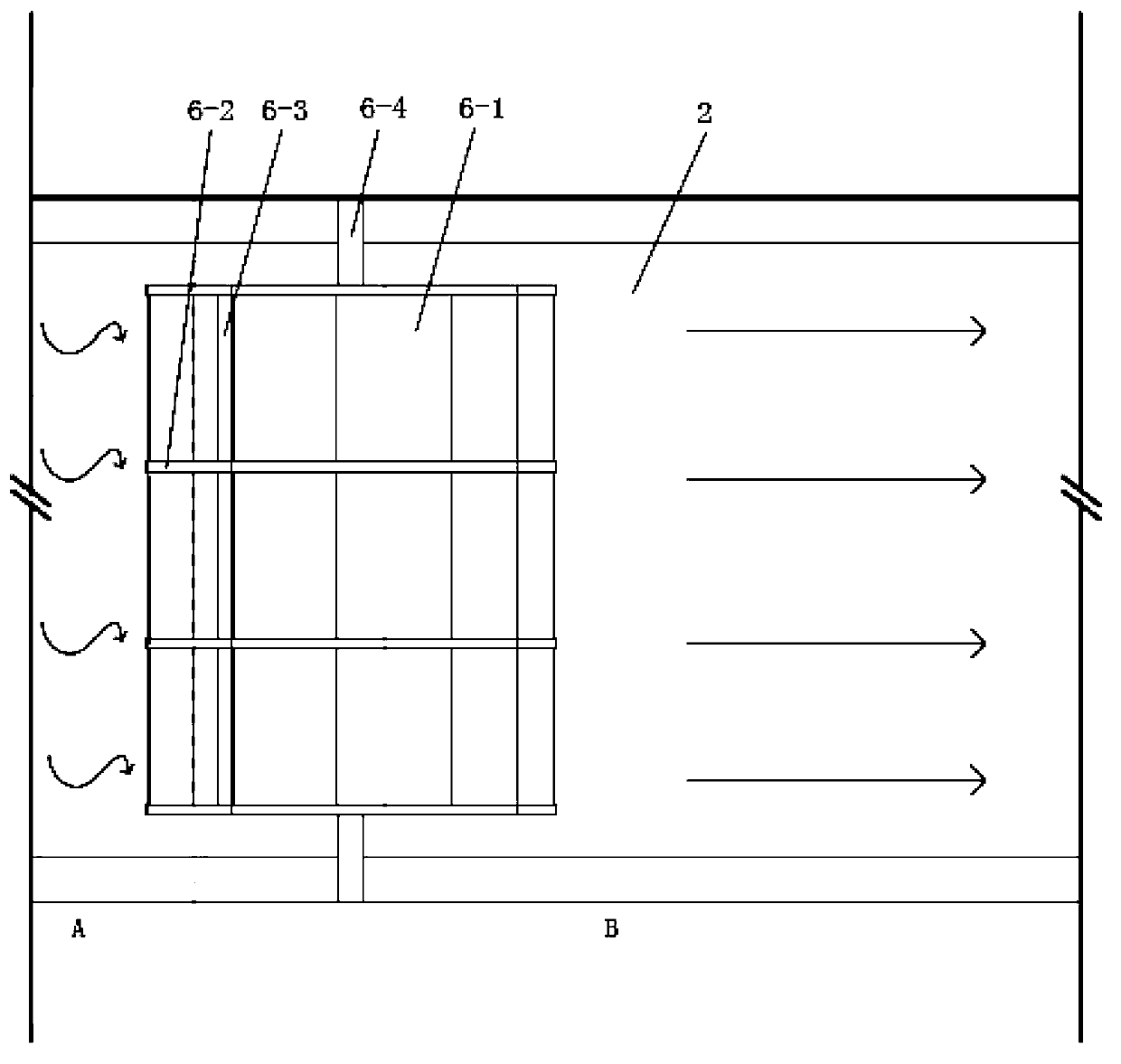

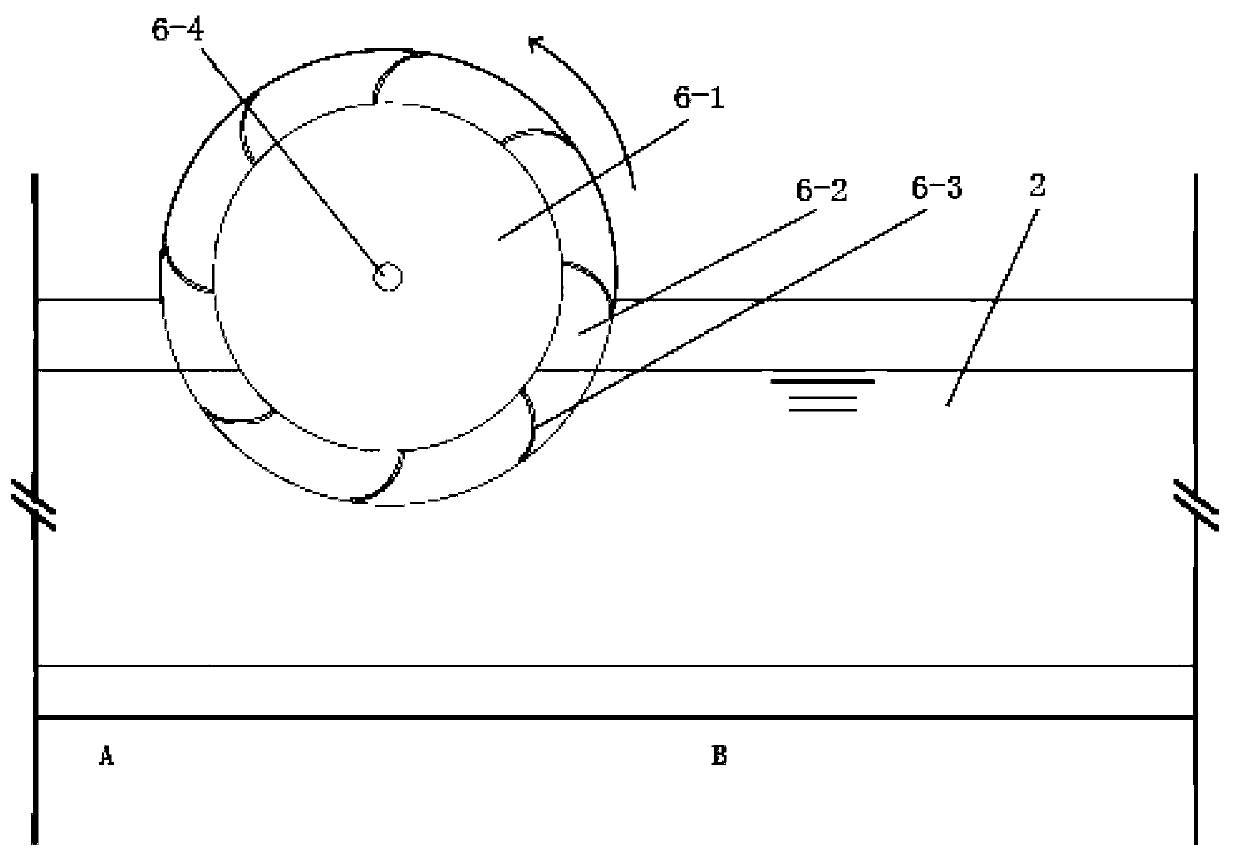

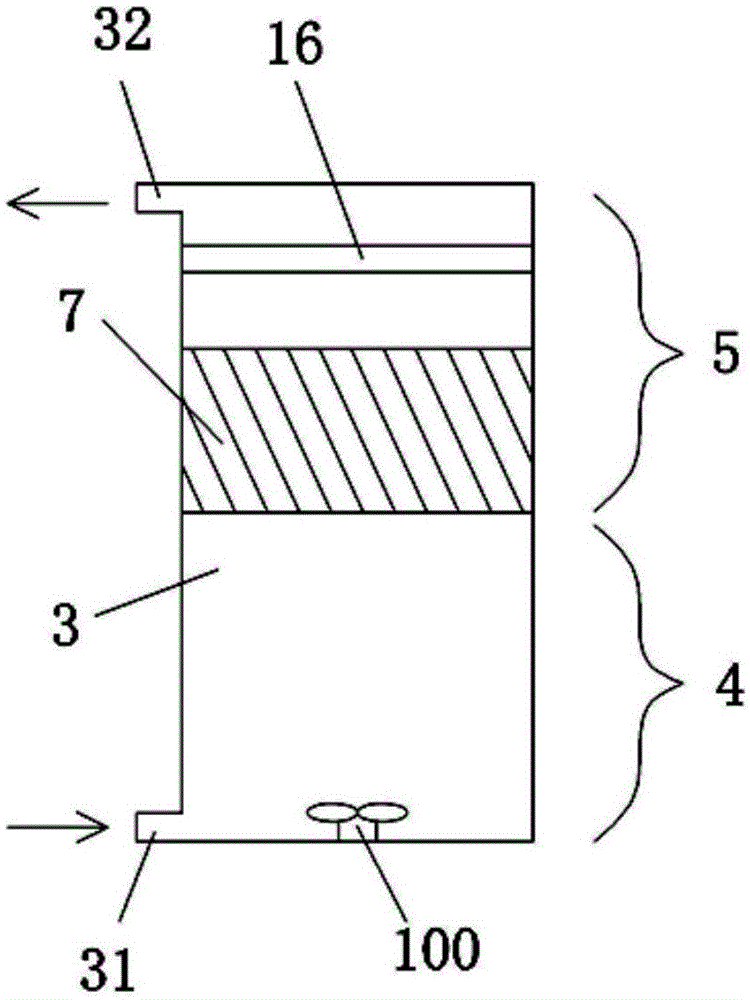

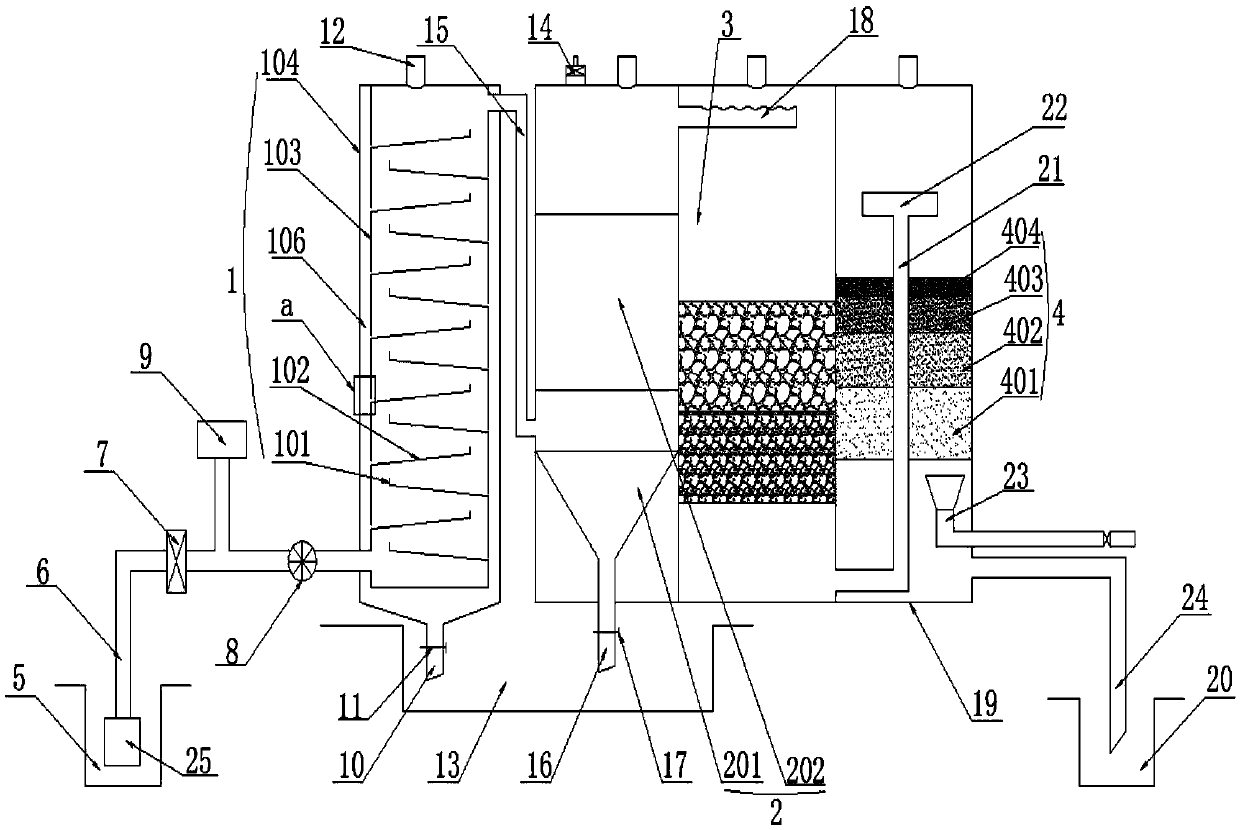

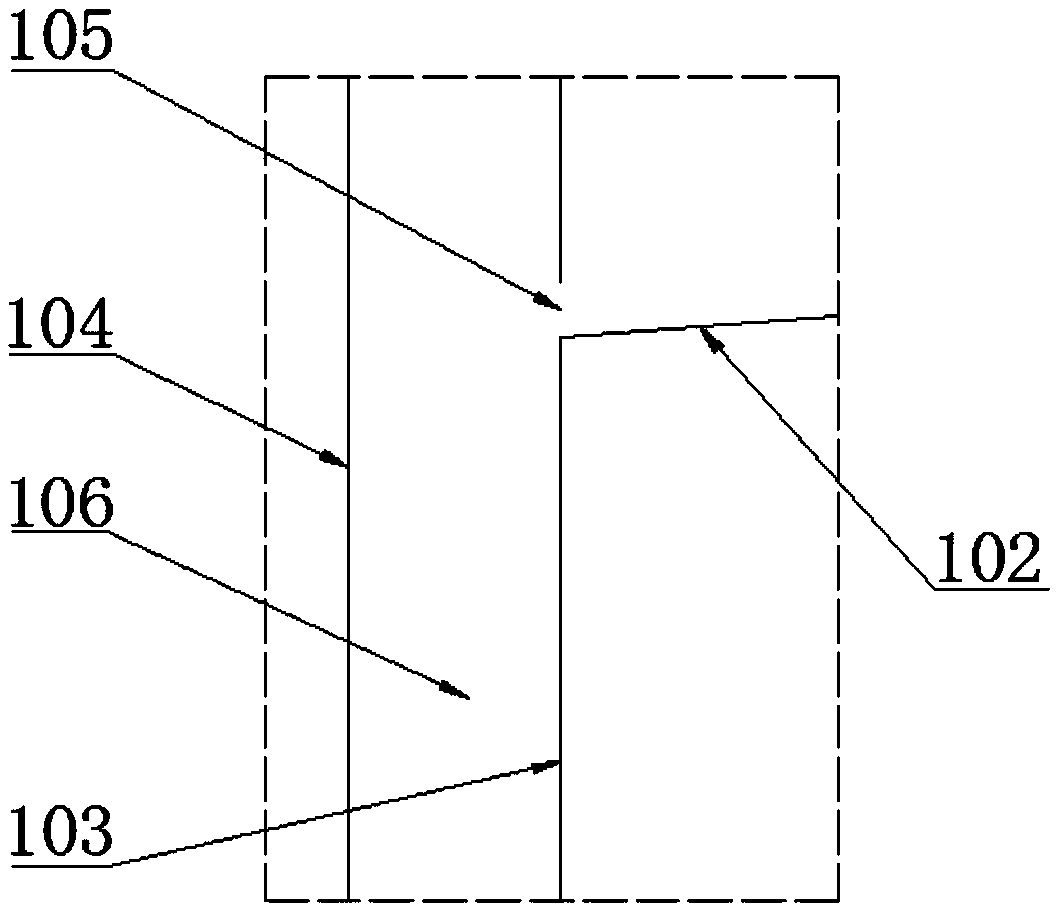

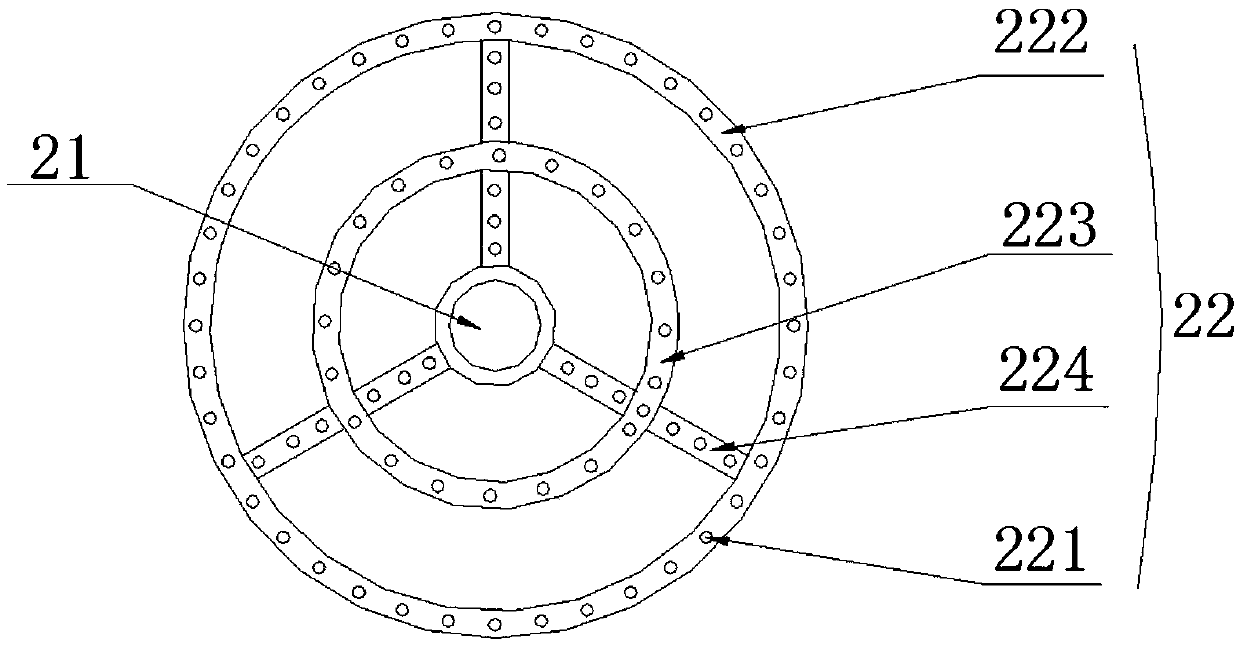

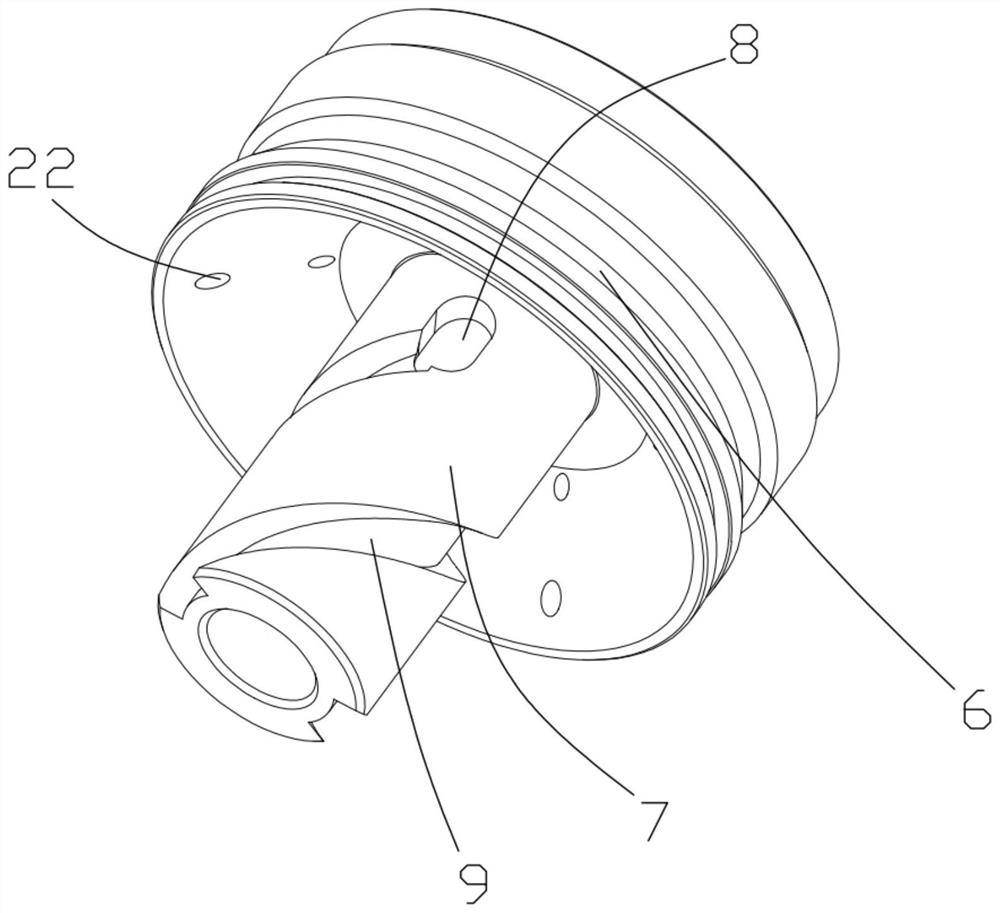

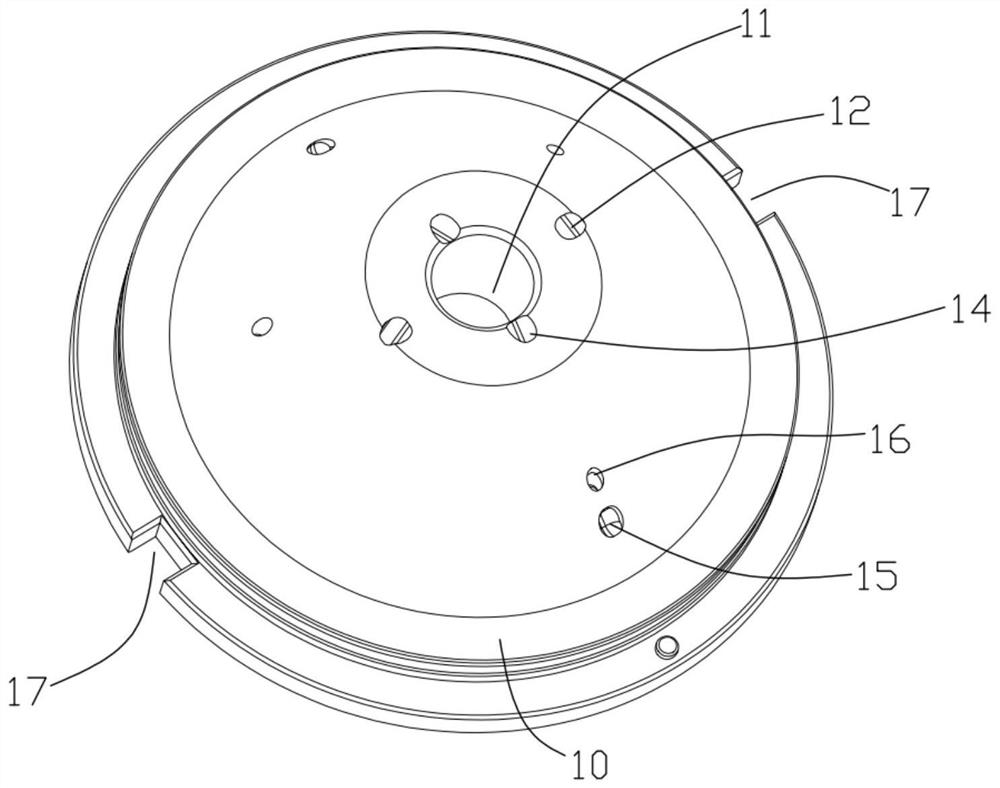

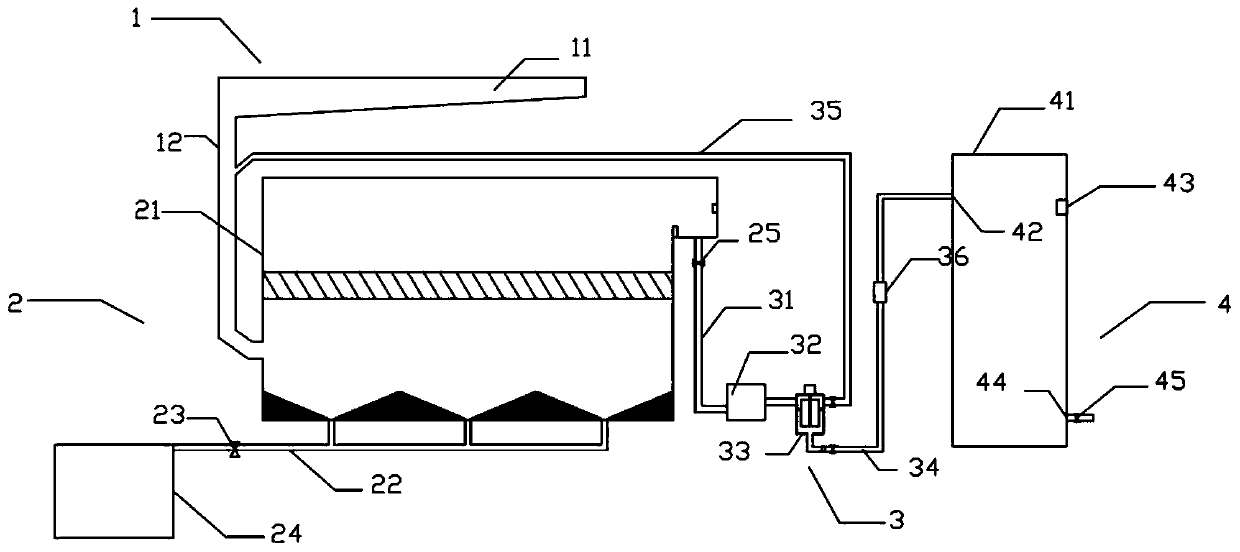

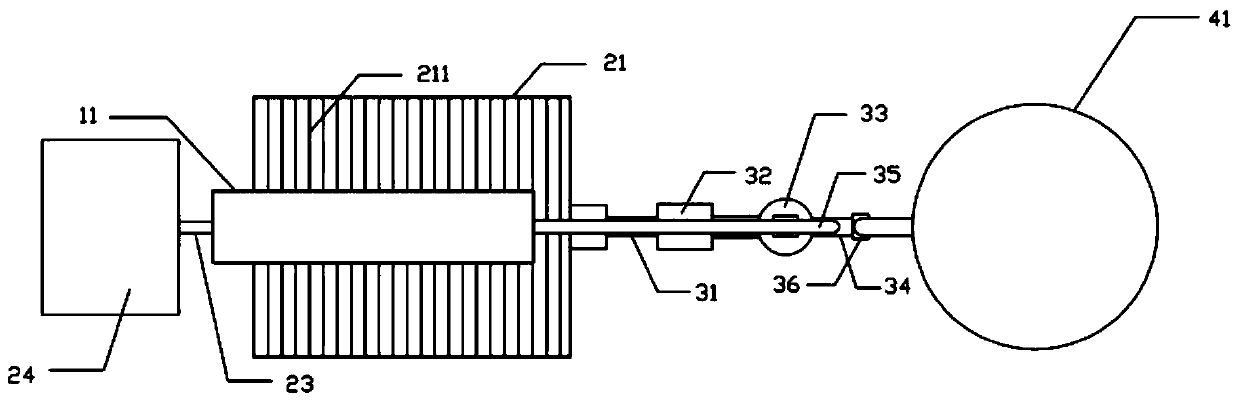

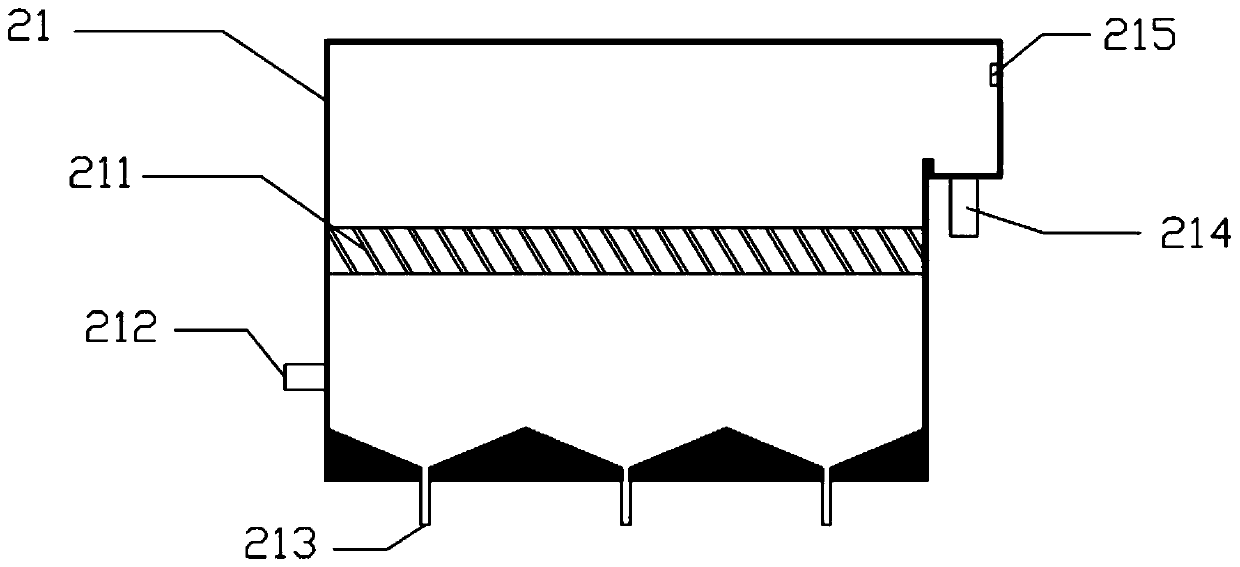

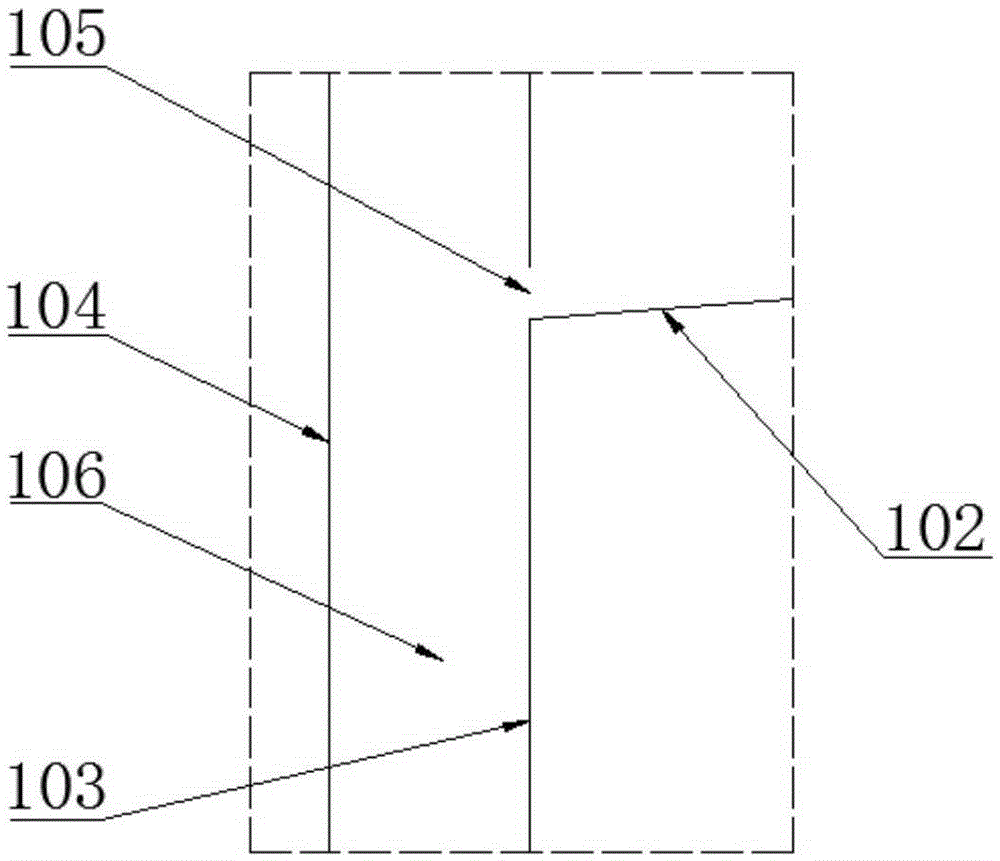

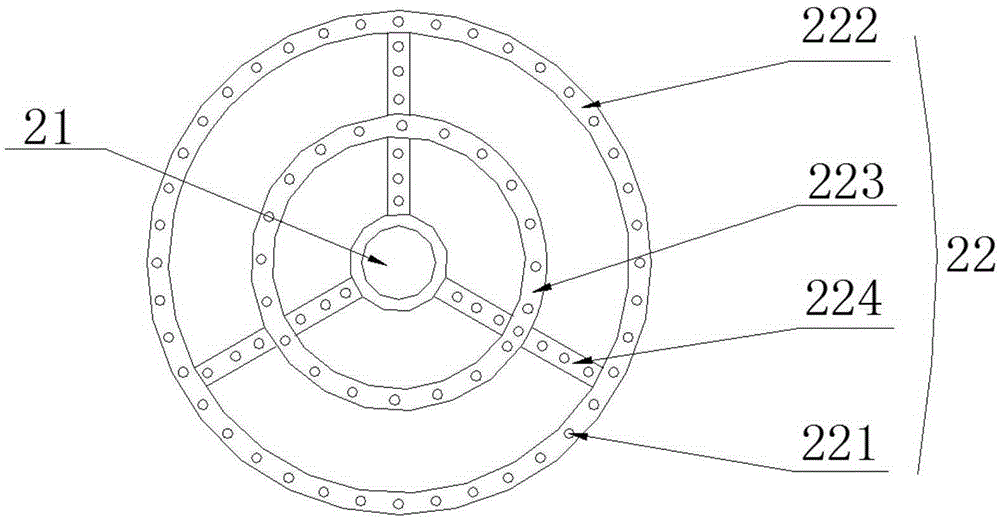

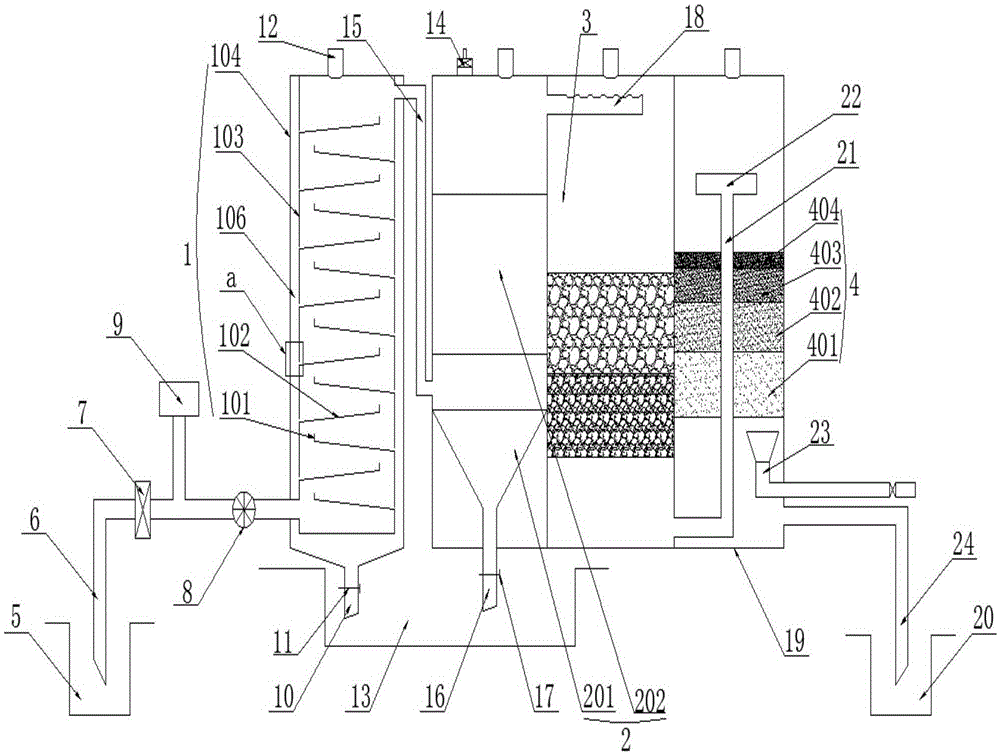

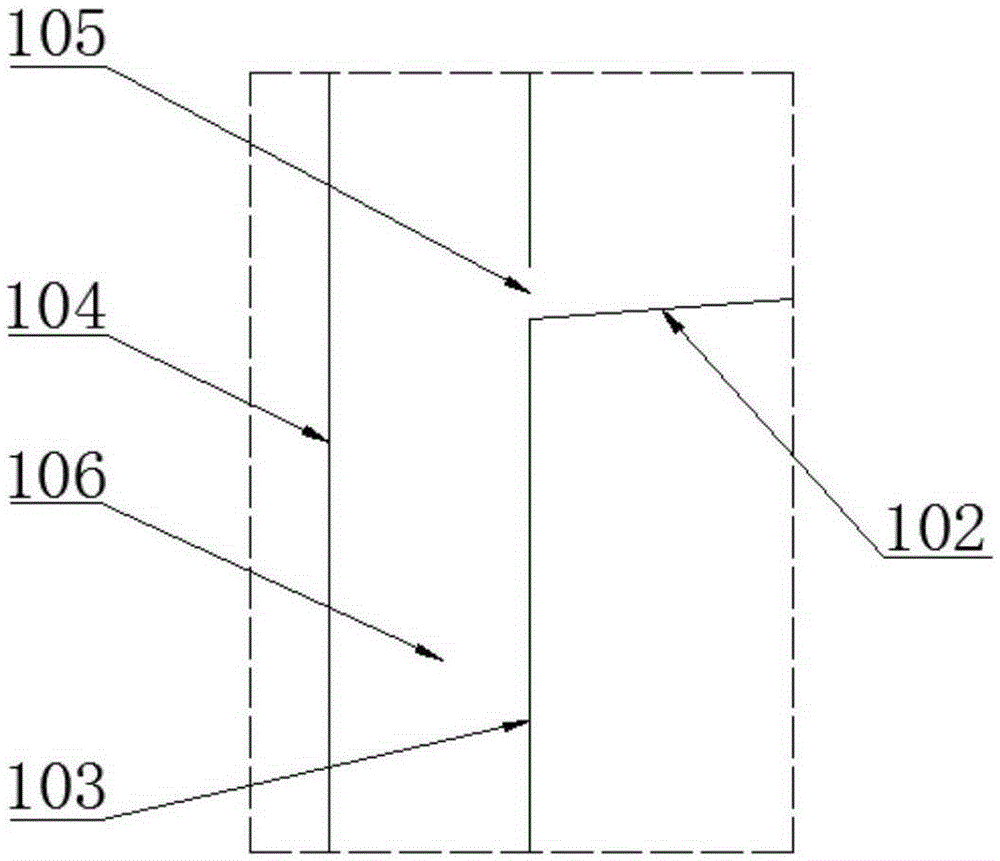

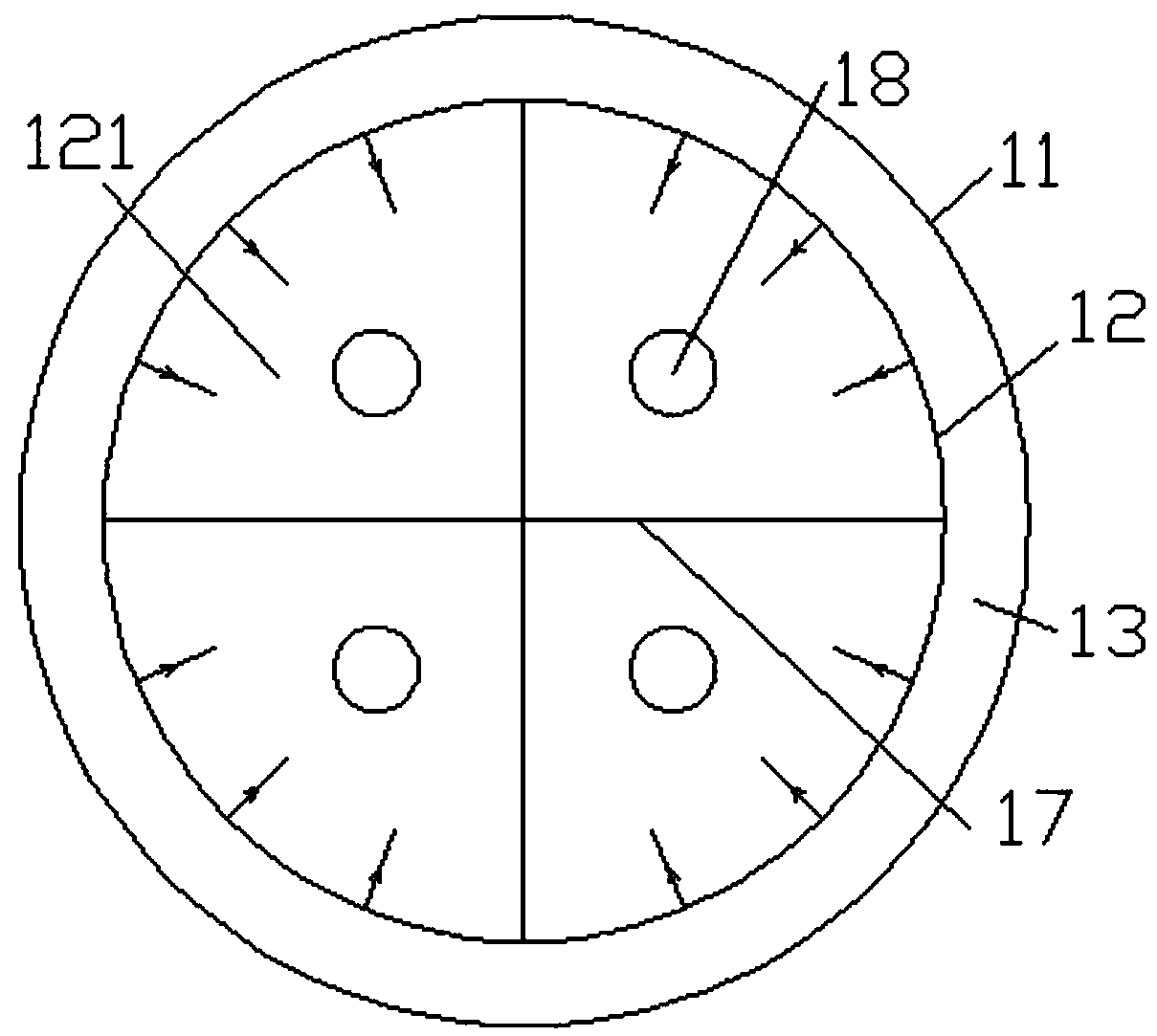

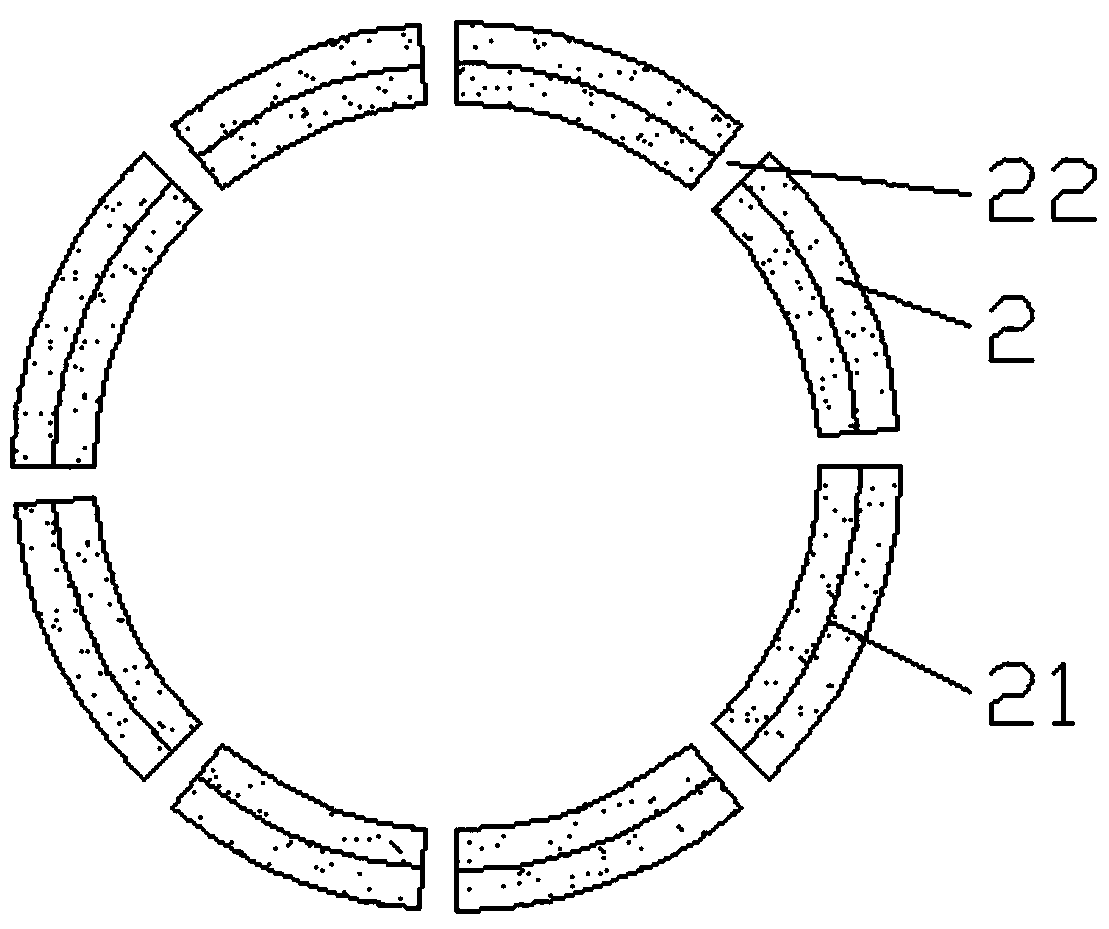

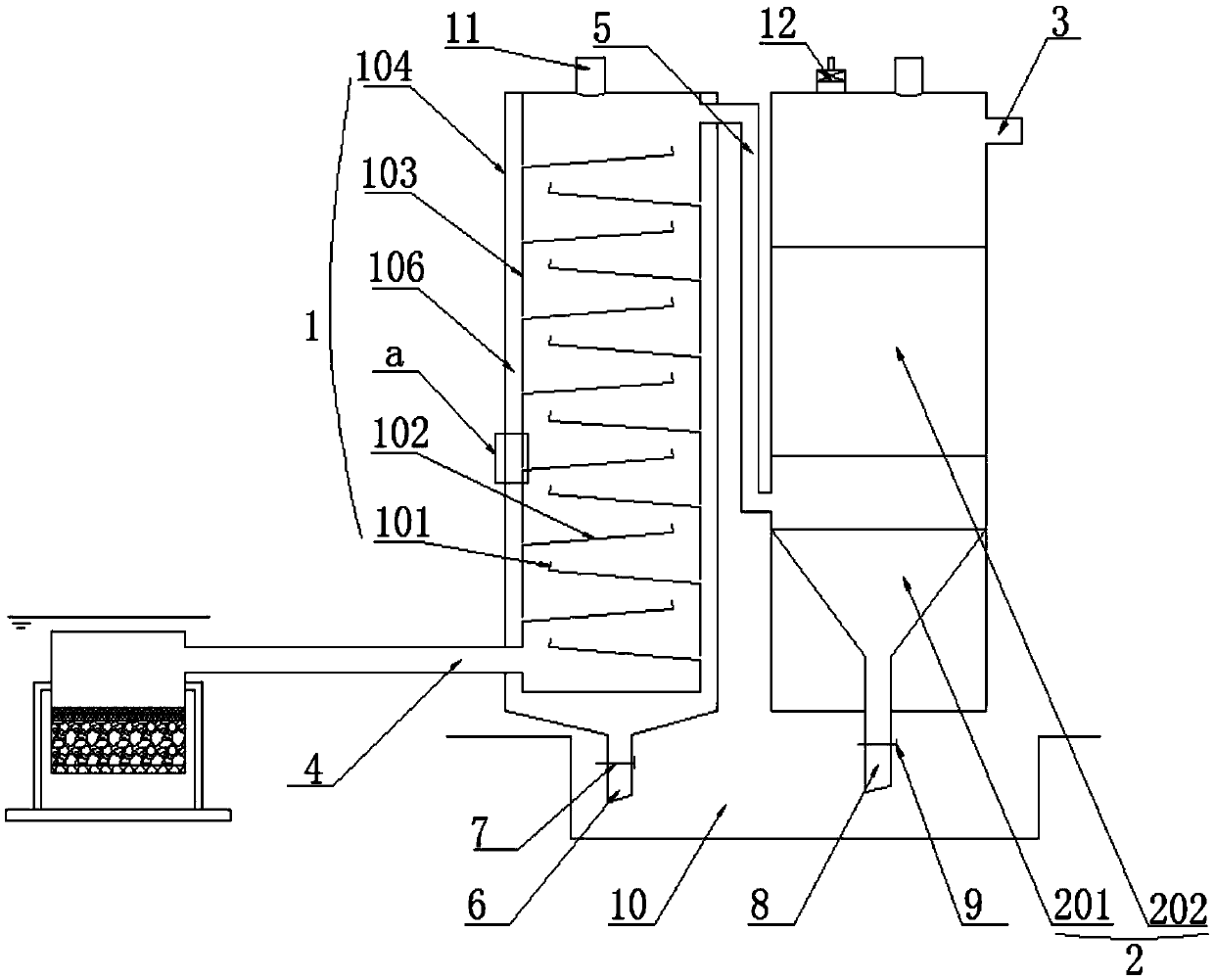

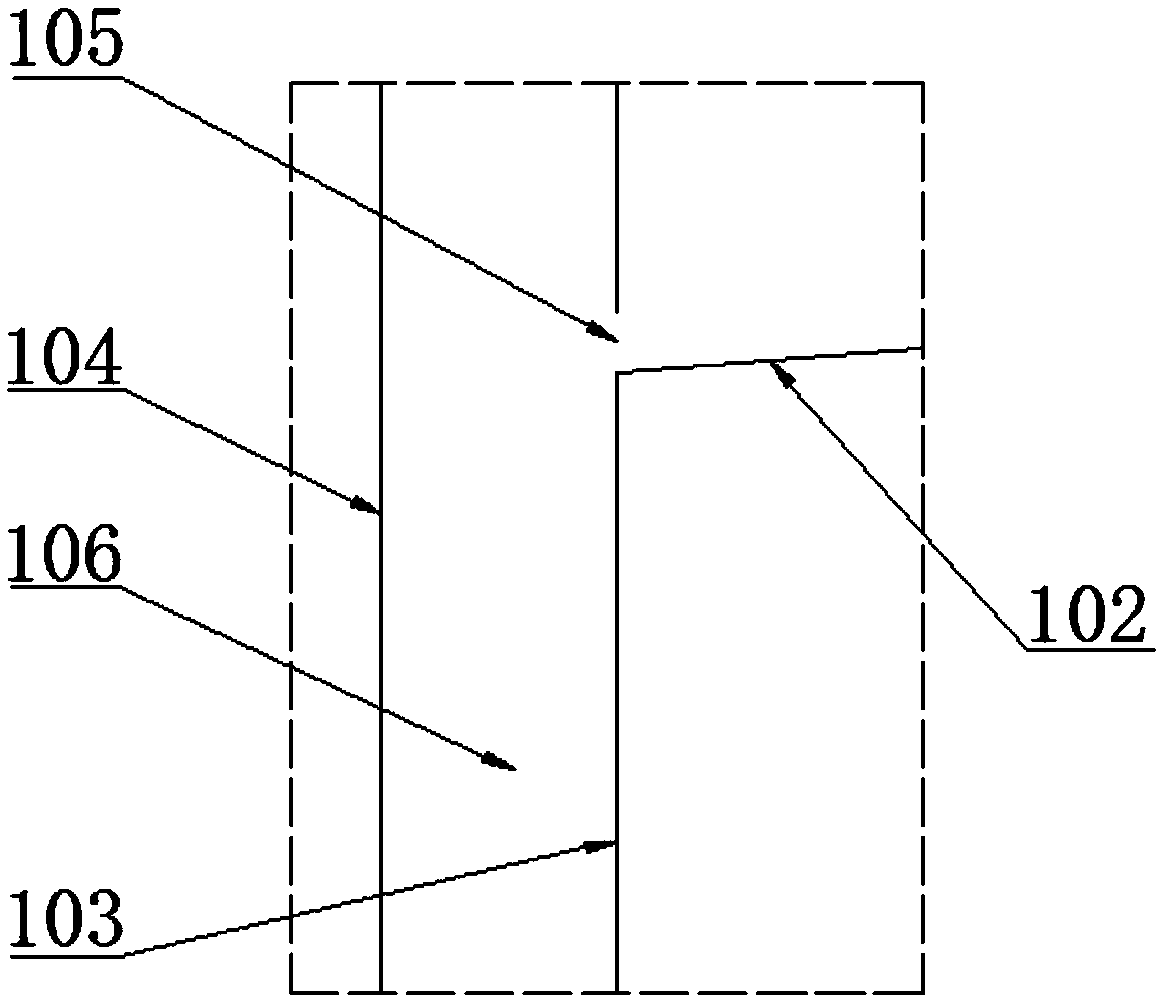

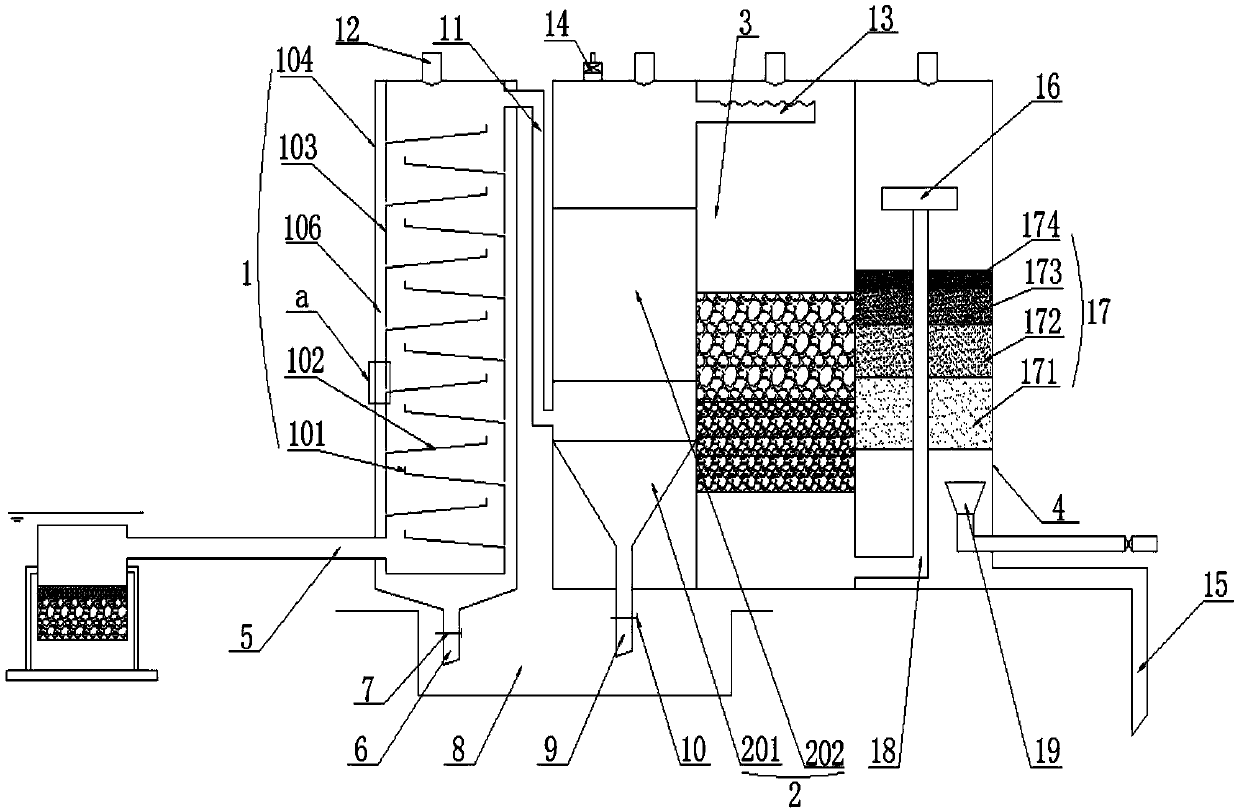

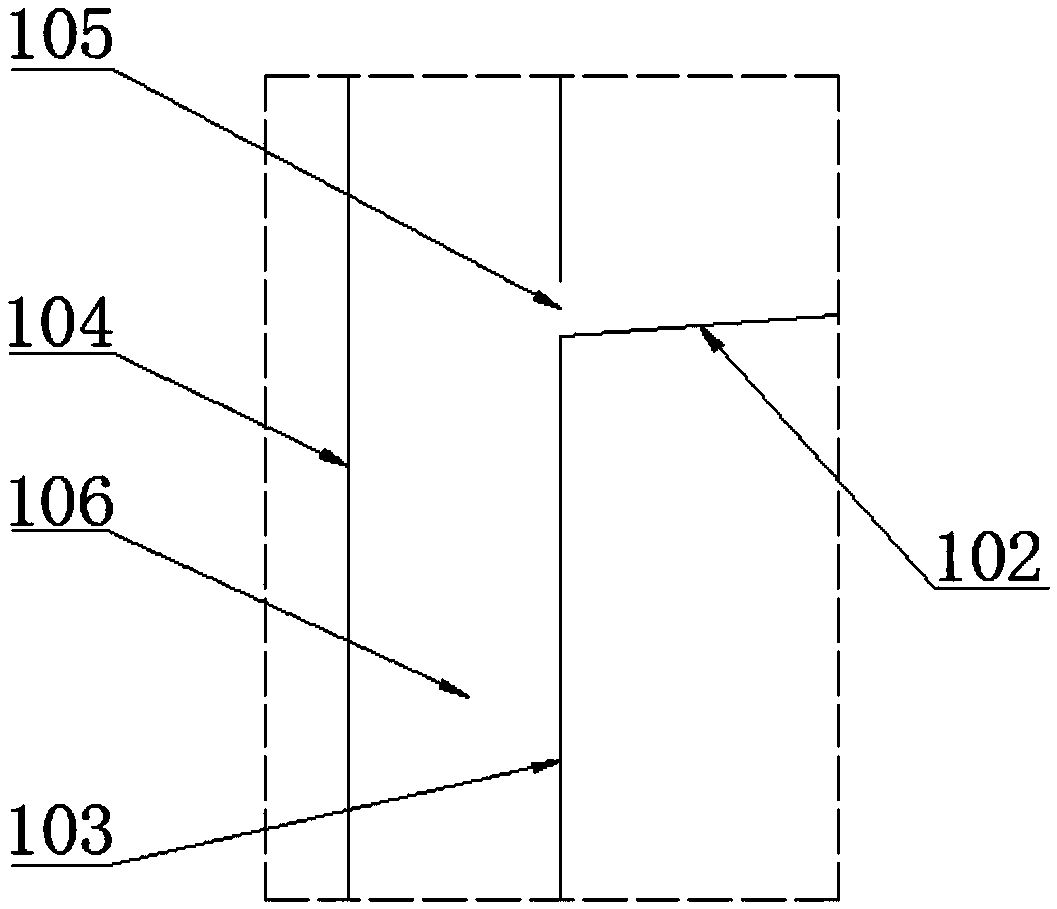

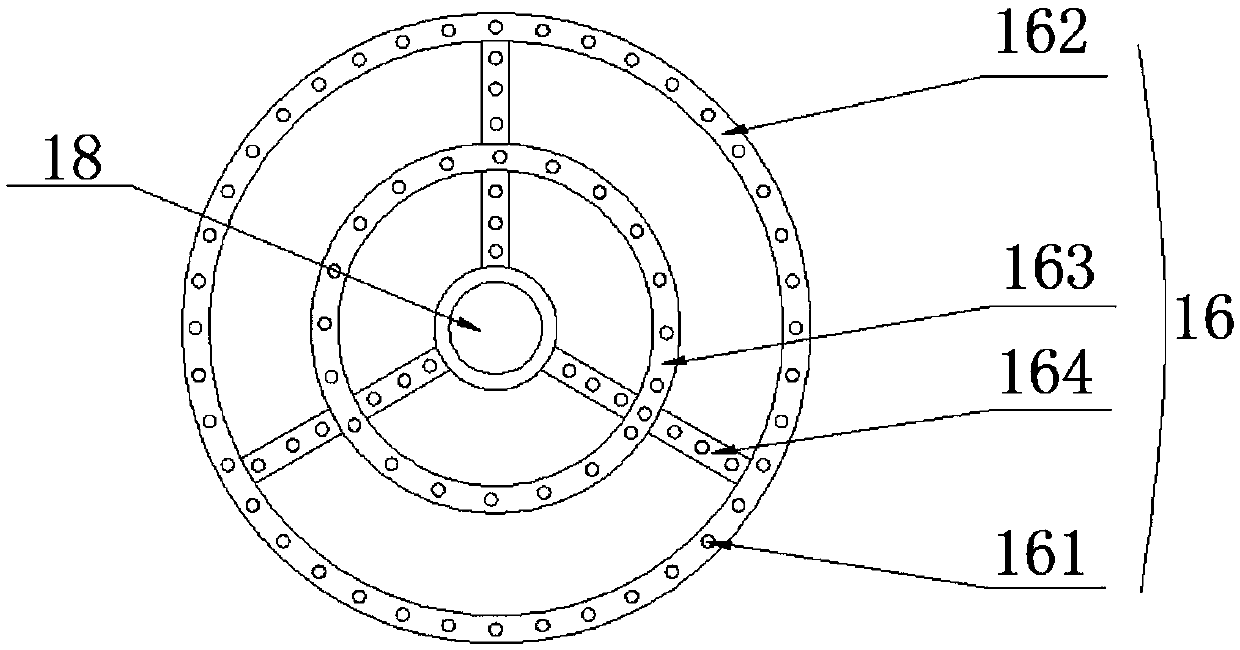

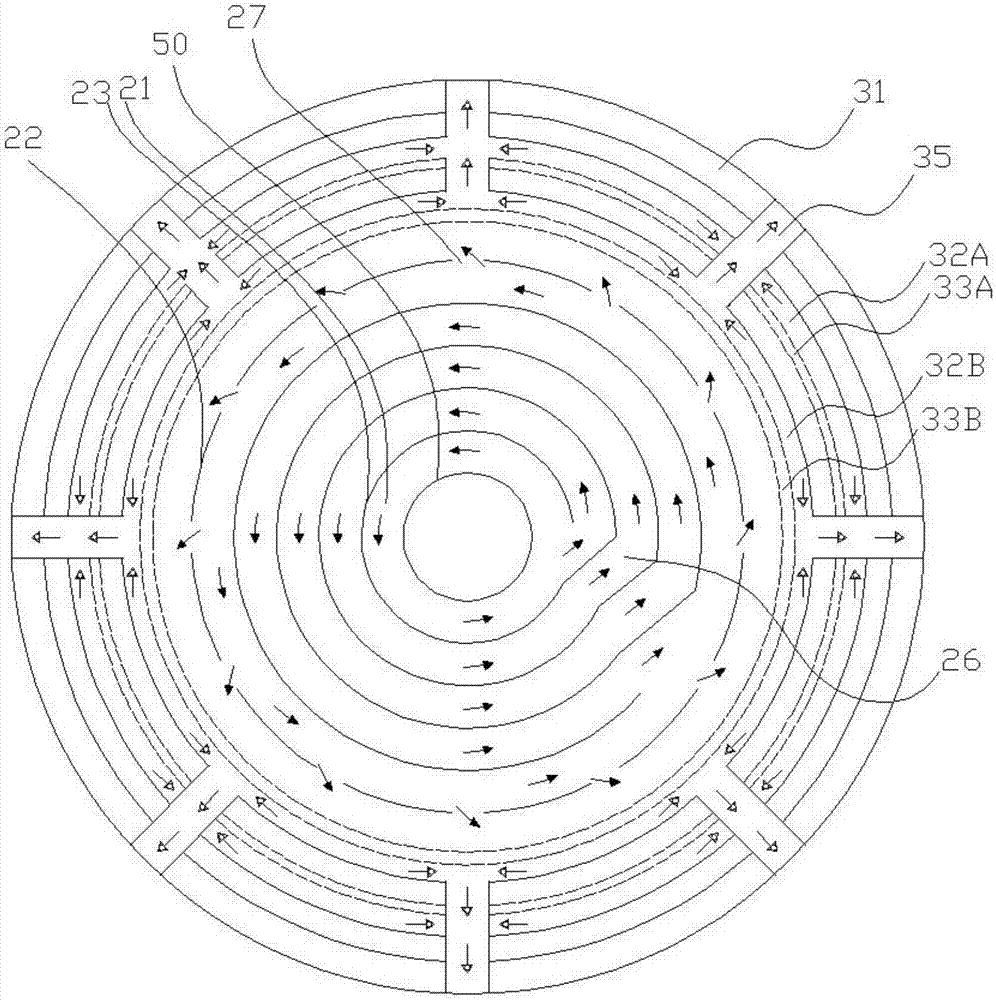

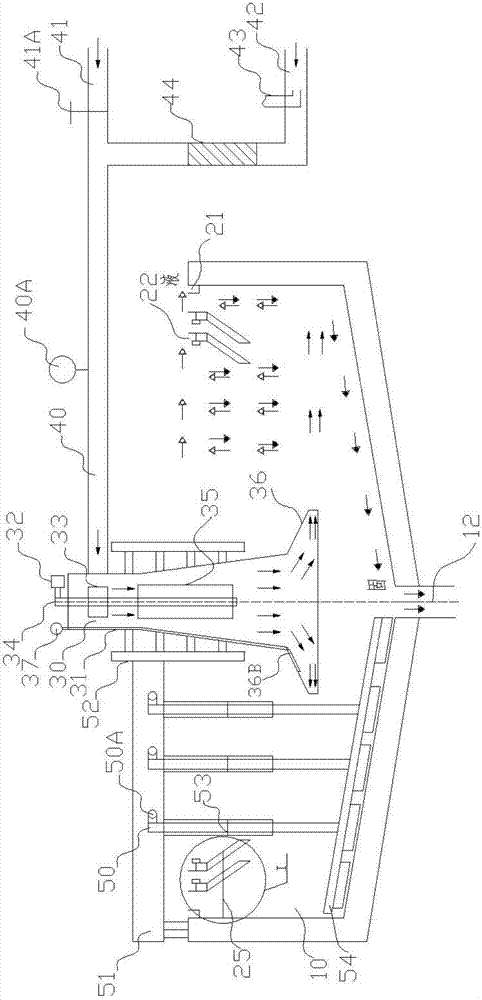

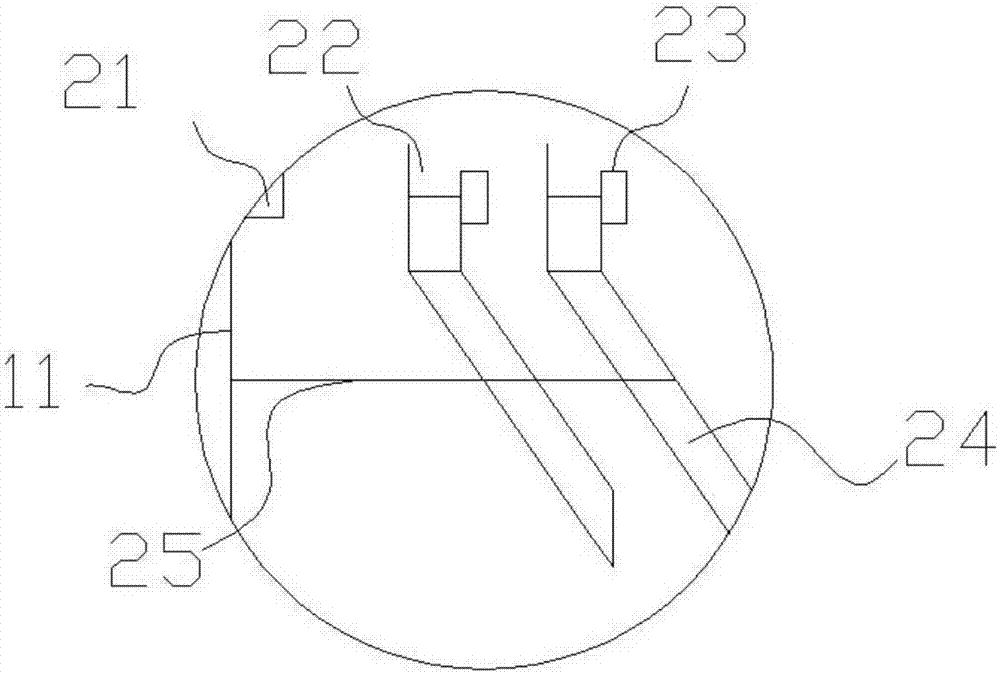

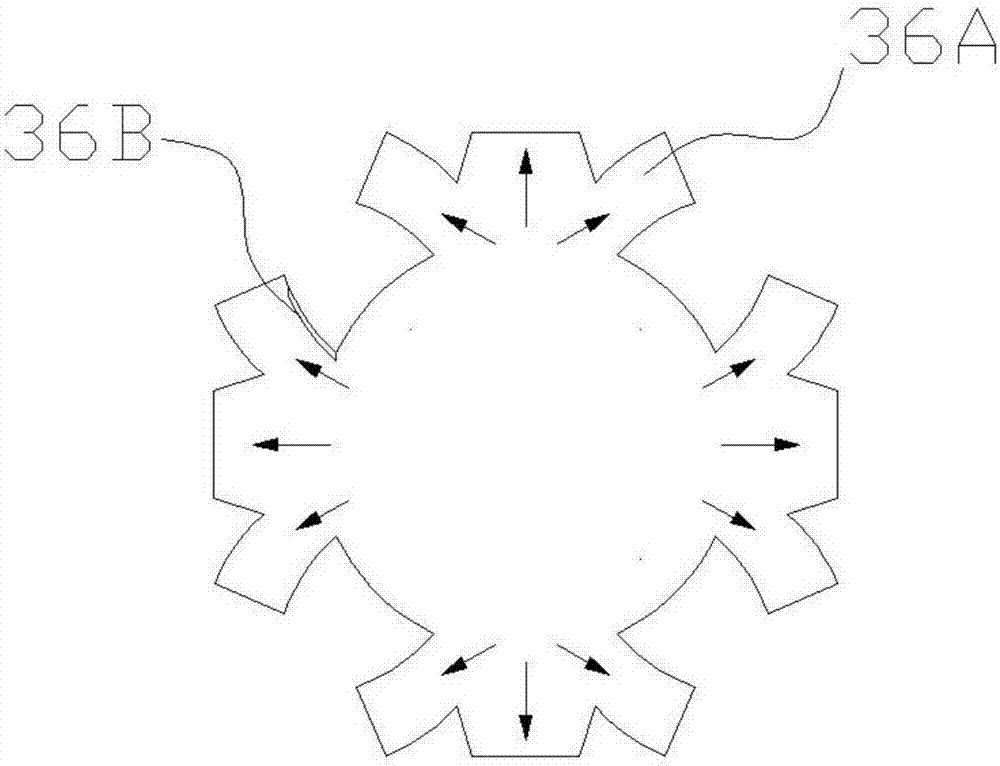

The invention relates to the field of slime water concentration and clarification, in particular to a rake-free thickener with rotary annular channels. The rake-free thickener at least comprises a thickener body, and further comprises rotary annular channels, wherein the rotary annular channels are used for constraining upper-layer ore pulp inside the thickener to do reciprocatory motion; the rotary annular channels consist of a plurality groups of annular channels of which the diameters are increased gradually; adjacent annular channels are mutually communicated through connecting channels; each group of the annular channels comprises an upper annular partitioning plate and a lower inclined settlement plate; overflowing ore pulp is discharged out from overflow weirs; the overflow weirs comprise annular overflow weirs and composite overflow weirs; settled granules are fed into a bottom flow discharge system; the bottom flow discharge system consist of bottom flow collecting cabins, bottom flow holes and corresponding bottom flow pumps; the rake-free thickener further comprises a feeding pipeline and a driving stirring mechanism; a stirring machine is driven by residual power of the feeding pipeline conveying the ore pulp to rotate so as to uniformly mix the ore pulp with medicines. The rake-free thickener has the characteristics of being low in energy consumption, low in repairing workload, low in medicine consumption and free of rake.

Owner:ANHUI UNIV OF SCI & TECH

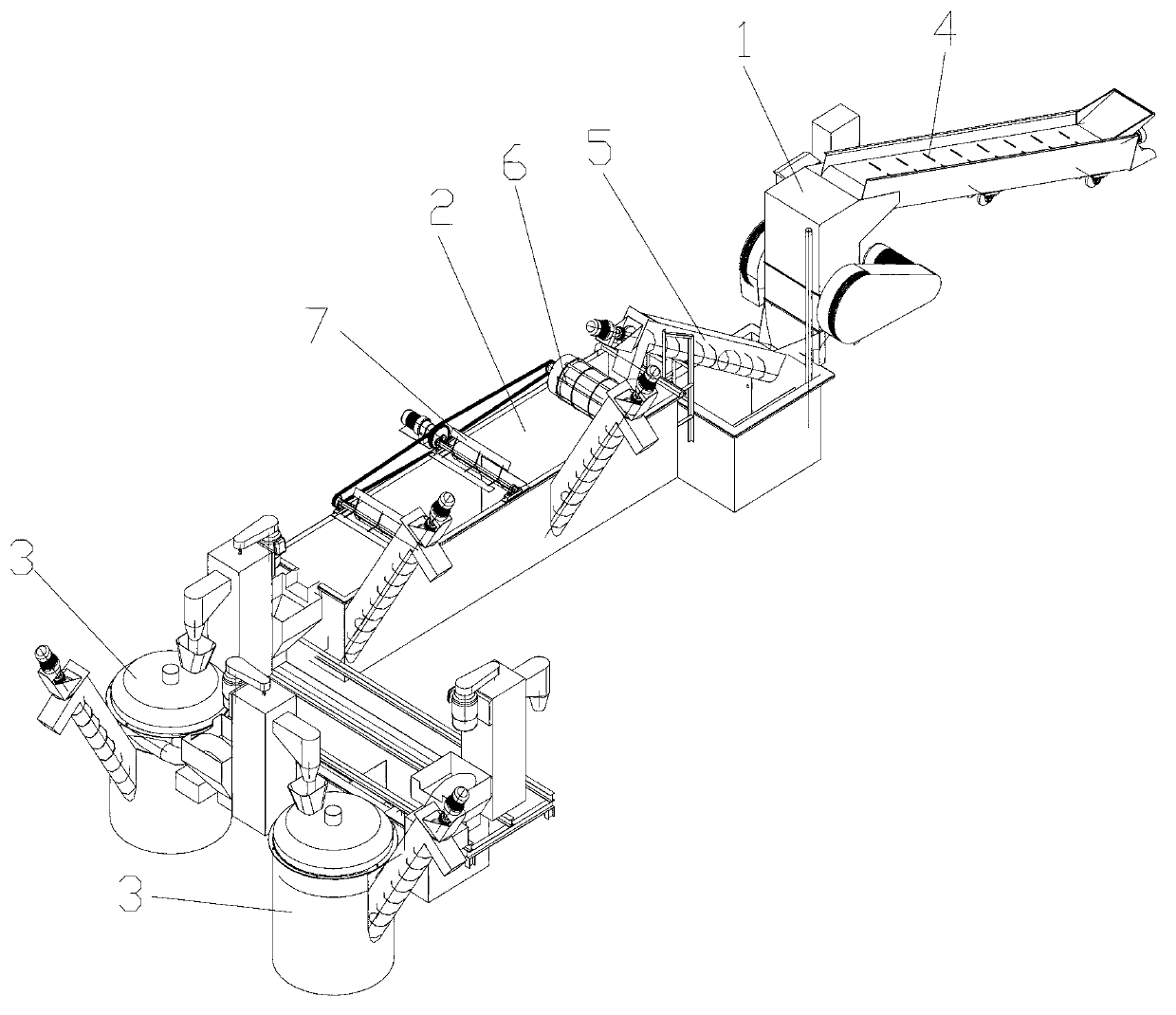

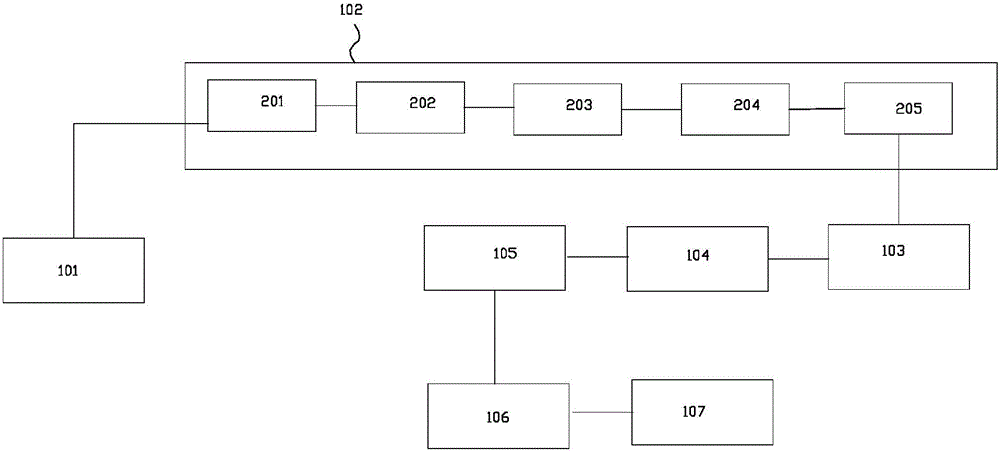

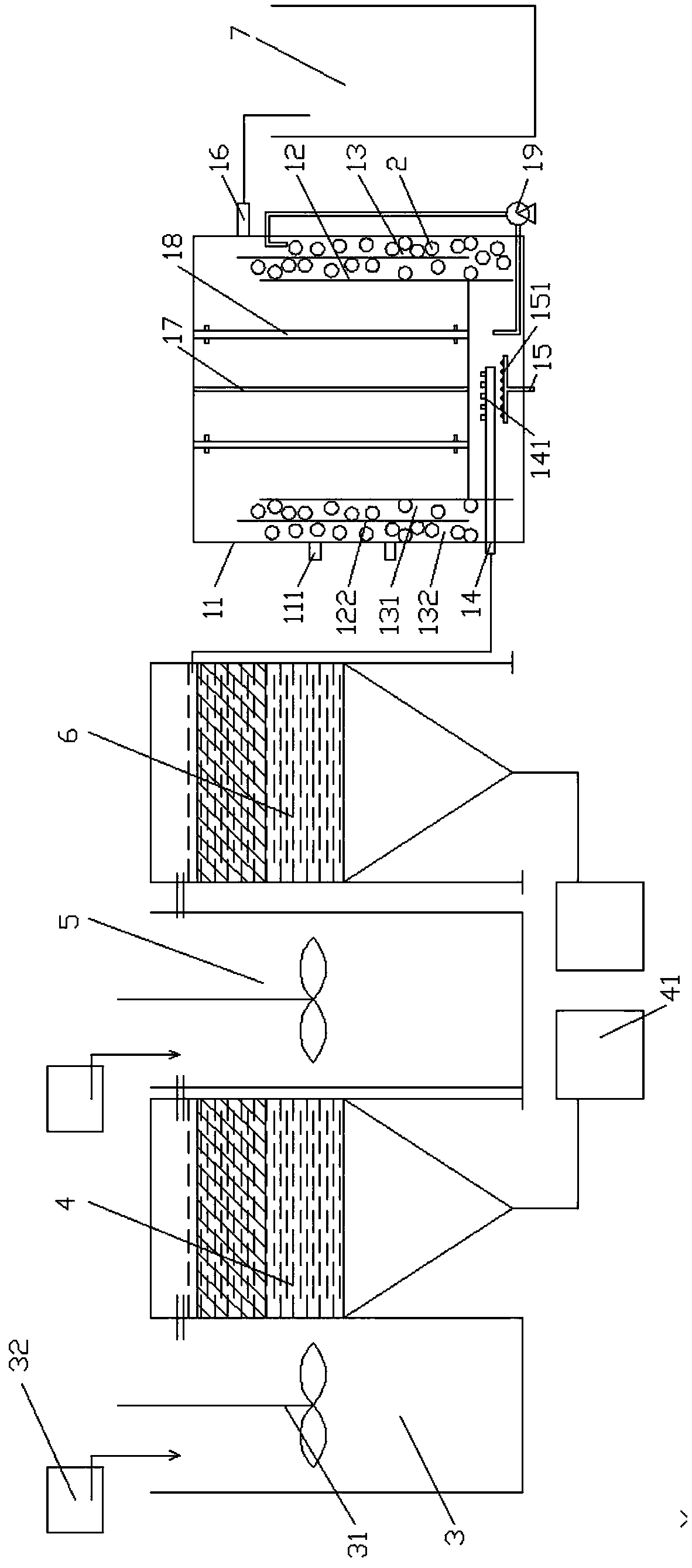

Cyclone-type waste plastic crushing, sorting, and washing method and system

ActiveCN103213214AEasy to sortEasy to cleanPlastic recyclingMechanical material recoveryCycloneTreatment effect

The invention relates to a cyclone-type waste plastic crushing, sorting, and washing system. Along a material delivery direction, the system comprises the following components arranged sequentially: a crusher used for crushing waste plastic, a flotation tank used for sorting waste plastic pieces according to density differences of flotation medium and the waste plastic pieces; and one or more than two serially connected cyclone sorting and washing devices used for carrying out cyclone sorting and waste plastic piece washing through a fluid medium. The invention also relates to a cyclone-type waste plastic crushing, sorting, and washing method. According to the system and the method, the structure is simple, waste plastic treatment process continuity and automation are realized, treatment efficiency and treatment effect are effectively improved, and waste plastic automatic sorting and washing are realized. The system and the method belong to the technical field of waste plastic recovery.

Owner:冯愚斌

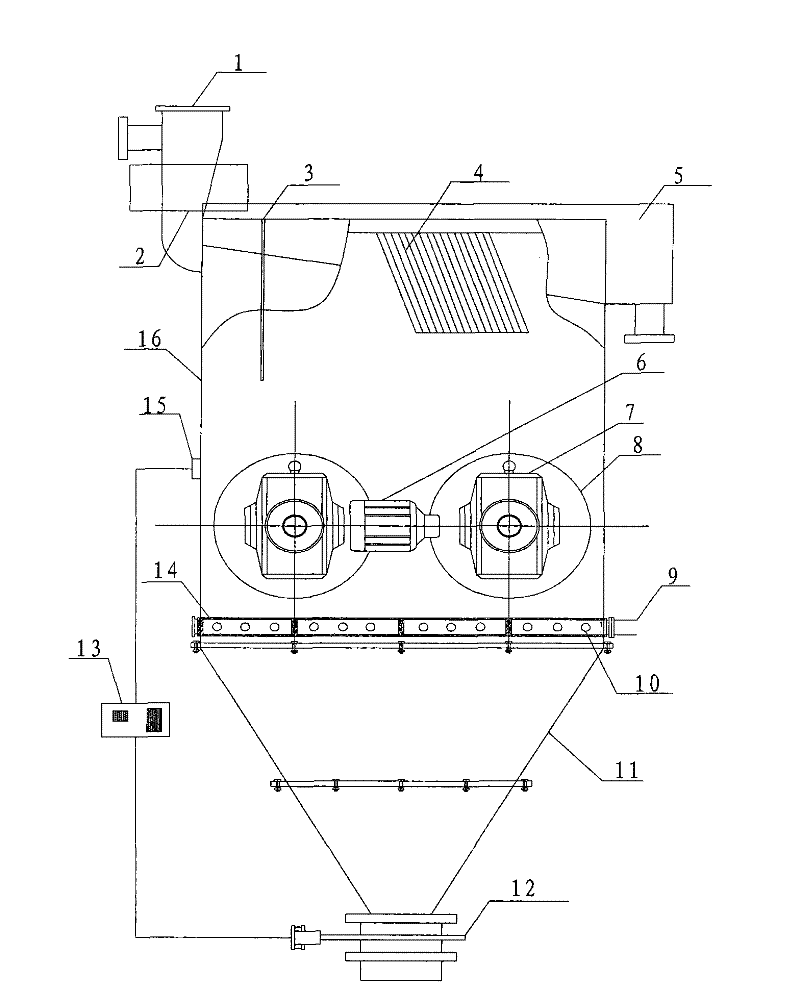

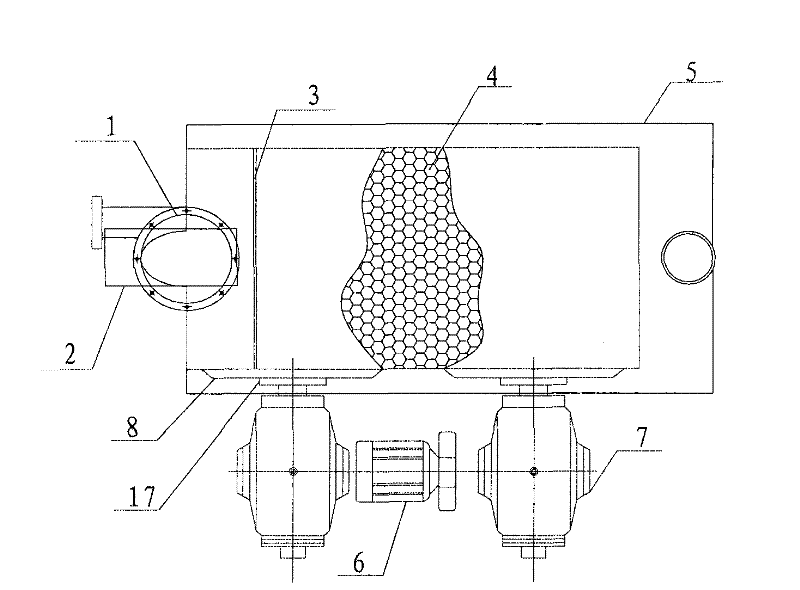

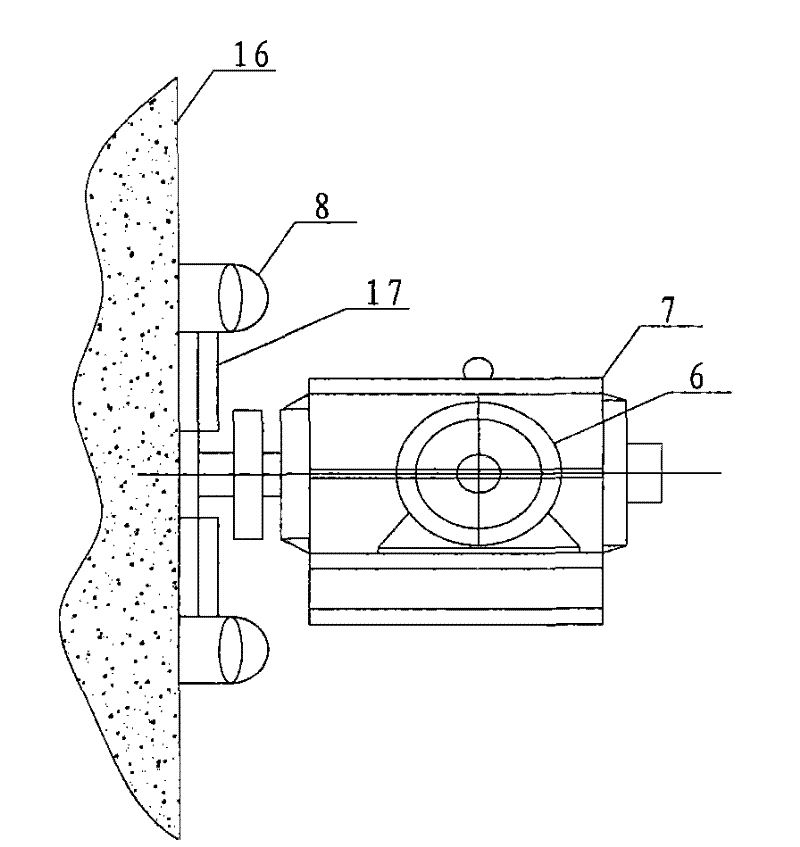

Hindered bed separator

InactiveCN101628256AImprove sorting effectImprove processing powerWet separationUltrasonic generatorEngineering

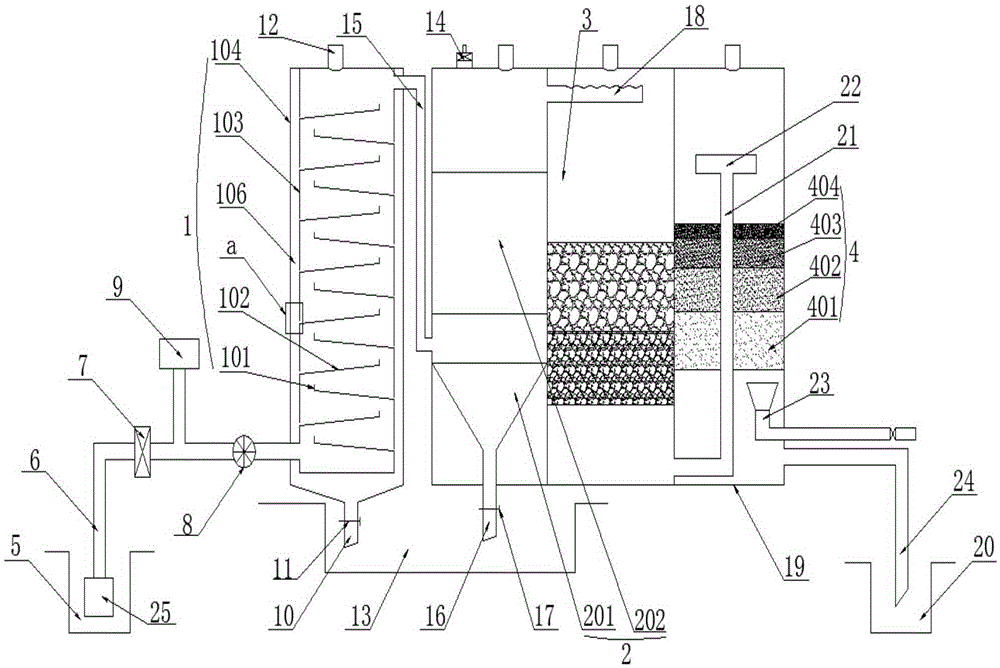

The invention relates to a hindered bed separator. The separator comprises a separator bed body (16), a feeding well (1) arranged at one side of the upper part of the separator bed body, an underflow collecting cone (11) at the bottom of the separator lathe bed, a clean coal overflow collecting tank (5) arranged at the upper part of the separator bed body and a control system, and is characterized in that a supersonic generator (2) is arranged below a feeding port of the feeding well (1); a plurality of inclined pipes (4) are arranged at the upper part of an inner cavity of the separator bed body in the equispaced manner, the lower pipe orifices of the inclined pipes are communicated with the inner cavity of the separator bed body, and the upper pipe orifices are communicated with the clean coal overflow collecting tank (5); a pipenet current distributor is paved in the cavity of the joint part of the separator bed body (16) and the underflow collecting cone (11); and a pulsating device is arranged on one side wall of the separator bed body for generating pulsating current.

Owner:HENAN POLYTECHNIC UNIV

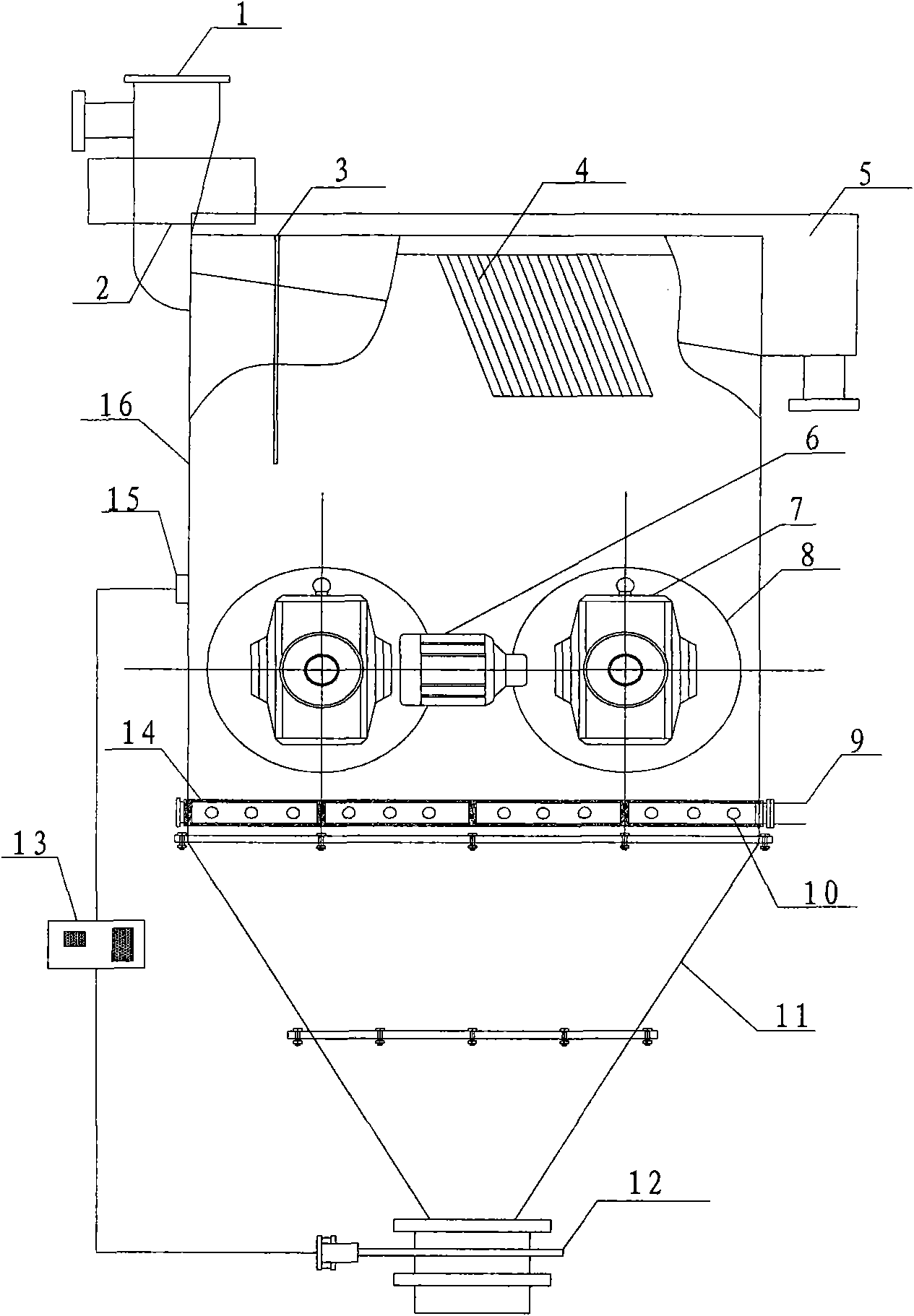

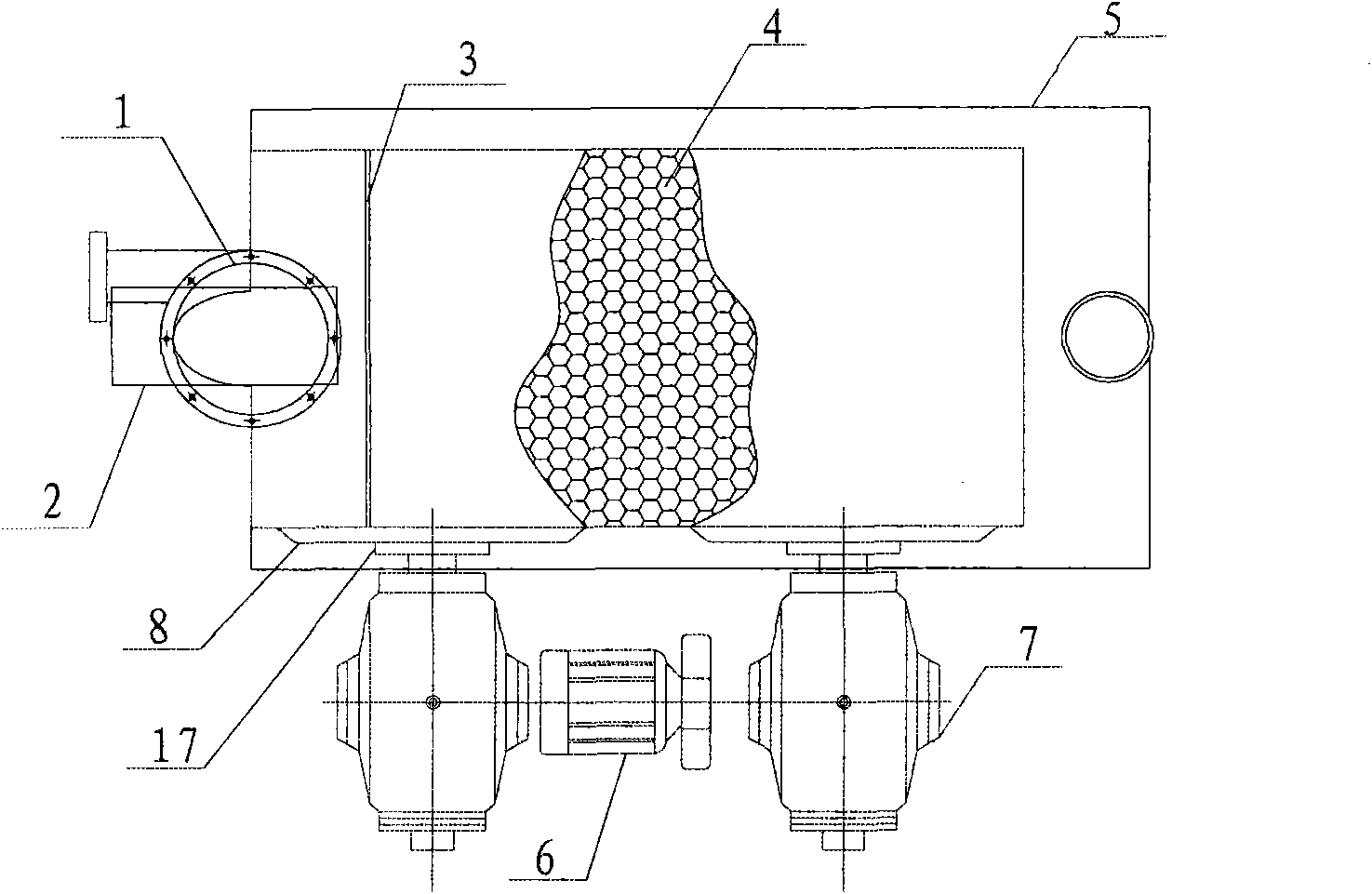

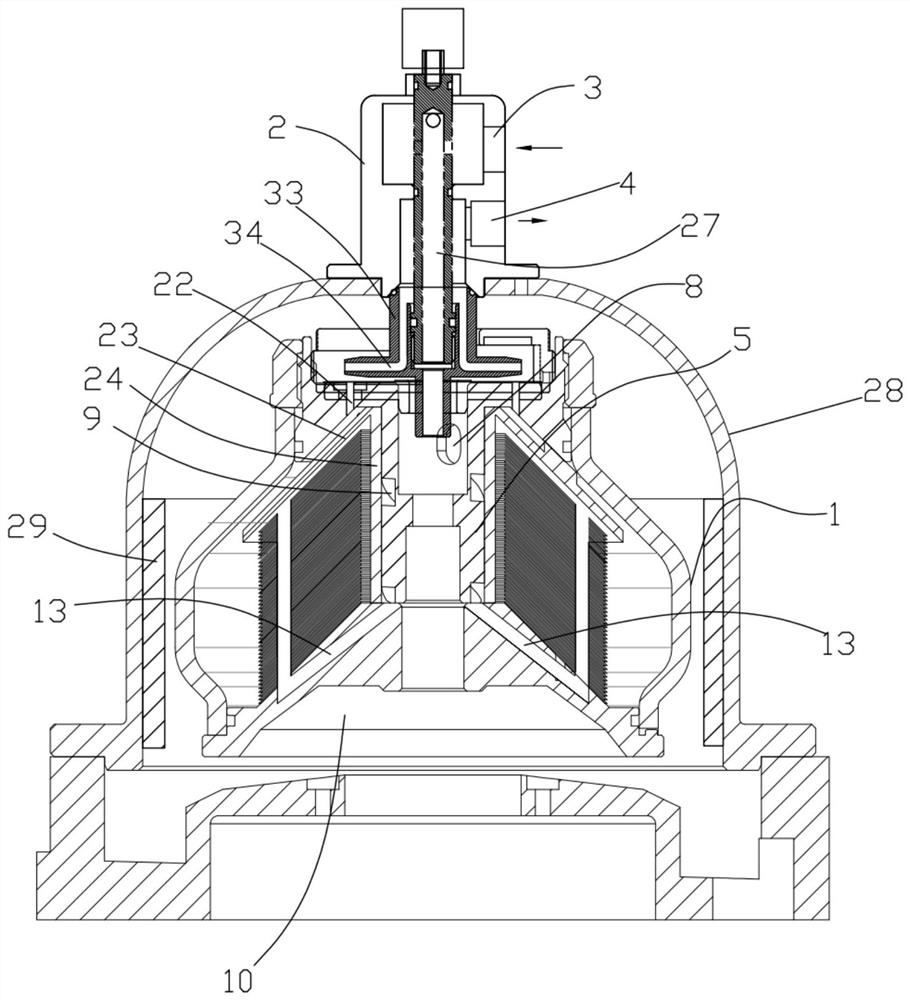

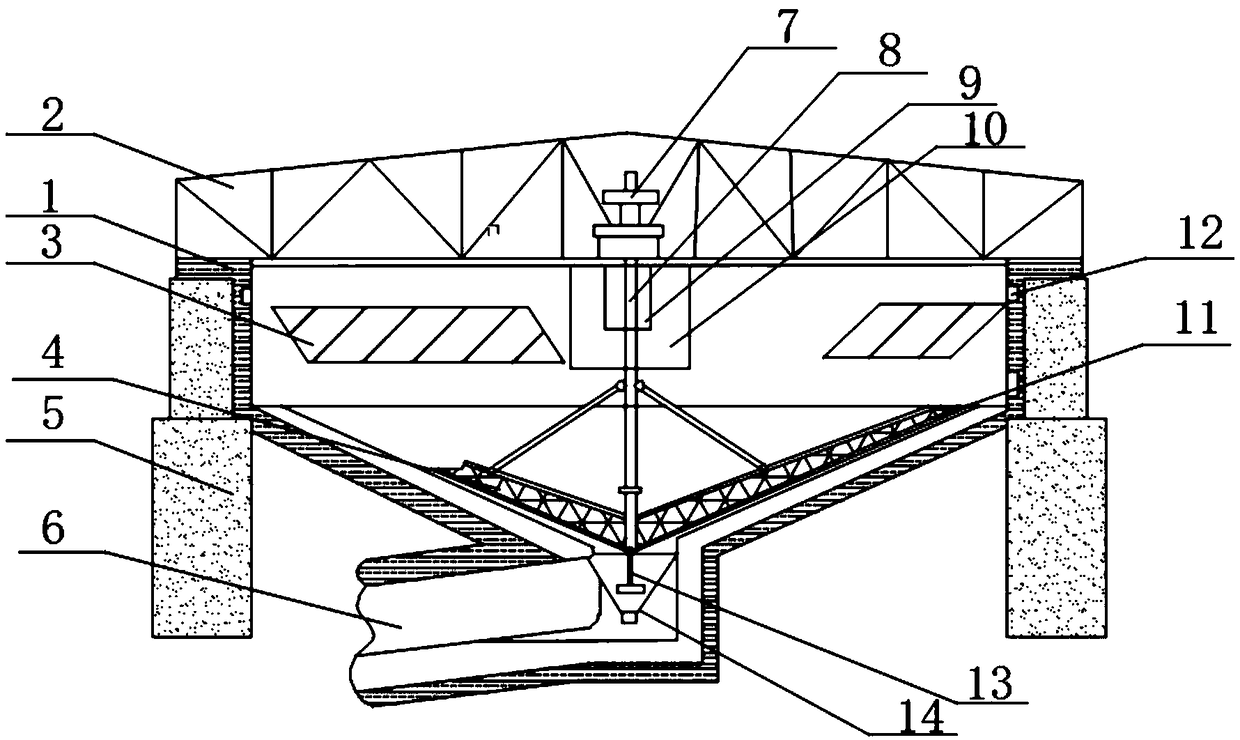

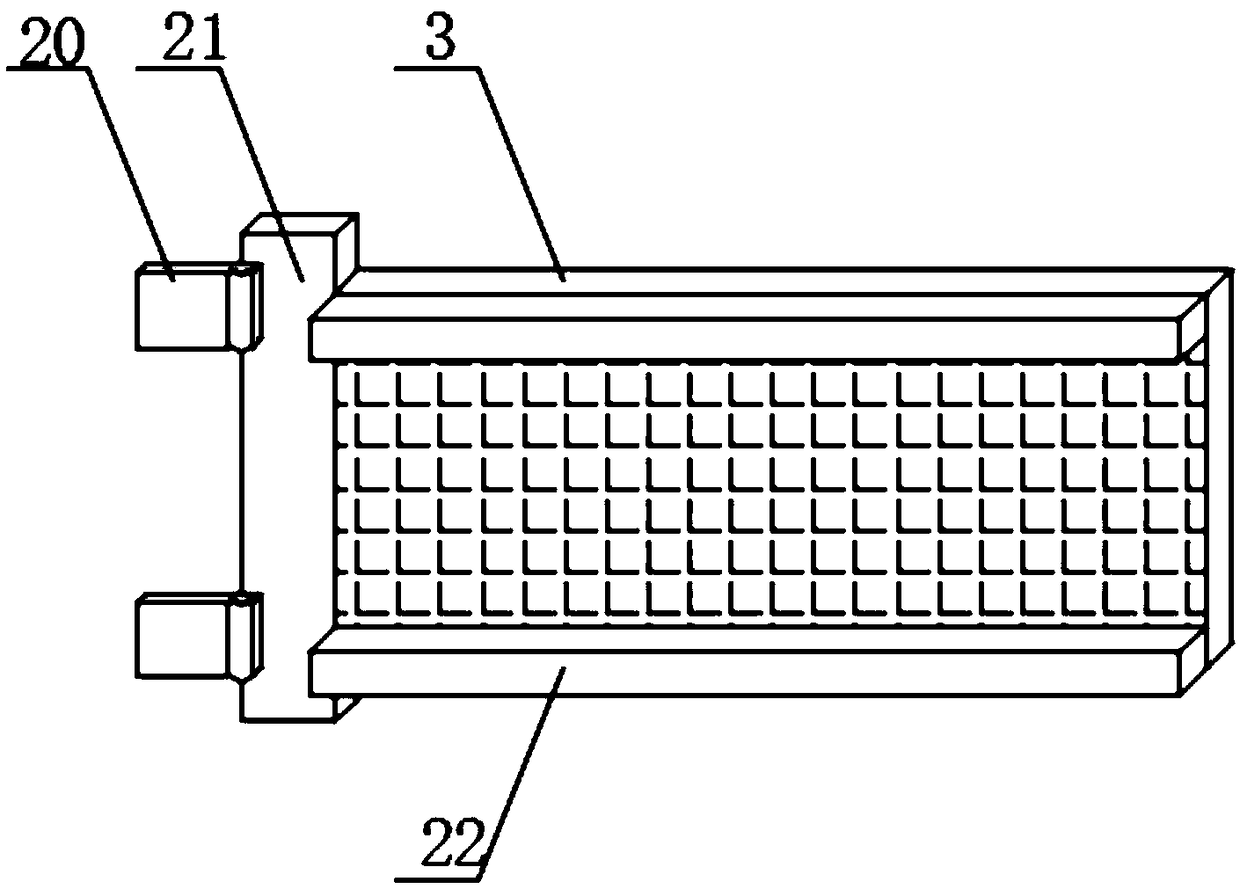

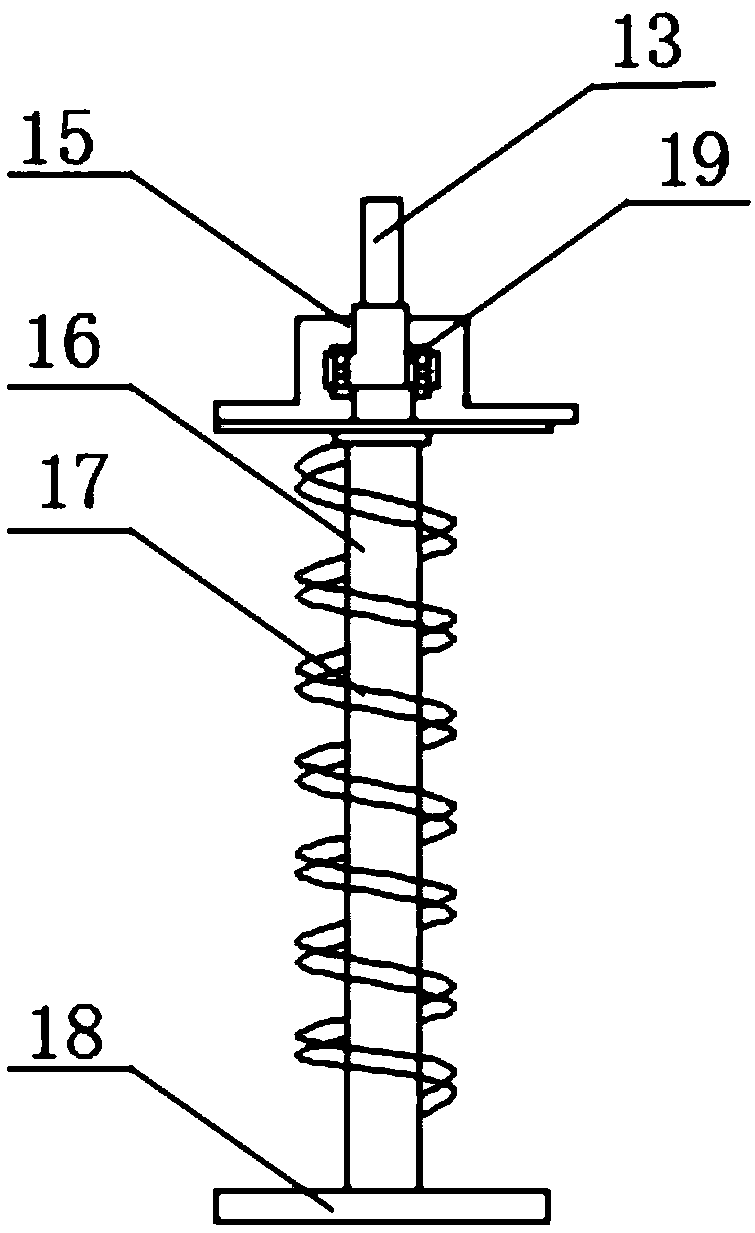

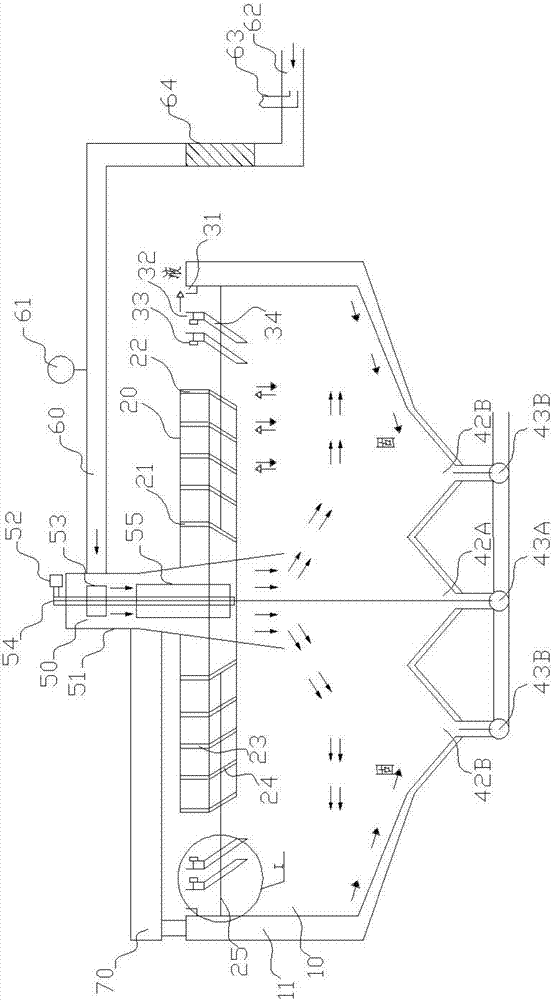

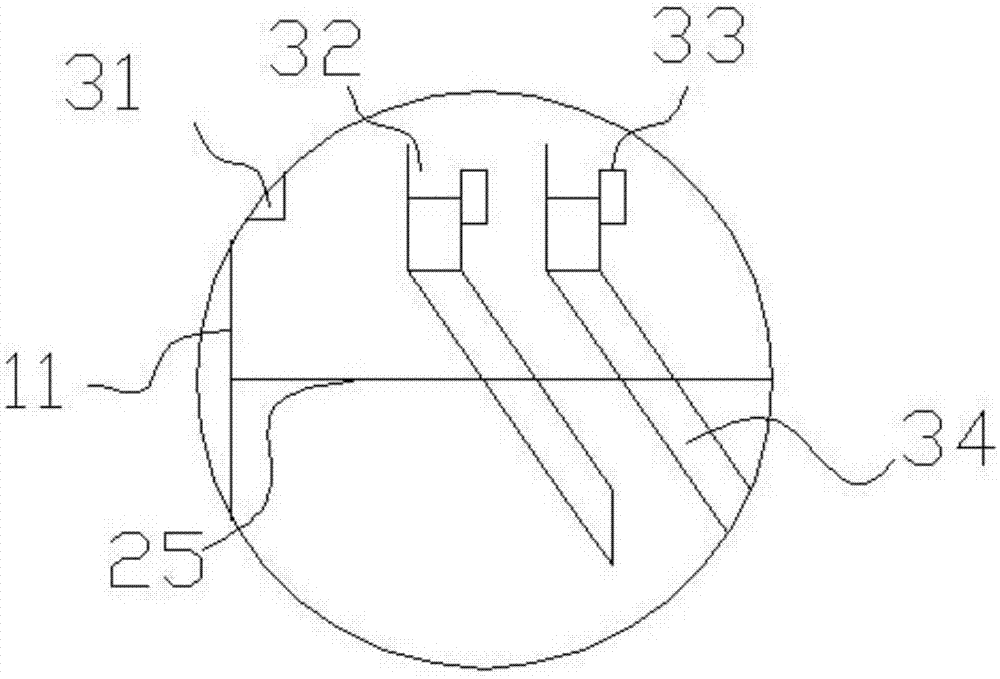

Comprehensive force field multithread gravity concentrator

The invention discloses a comprehensive force field multithread gravity concentrator. The gravity concentrator comprises a gravity concentrator main body, a comprehensive force field precipitation separation area, a driving device, a rotation device and a pulsation device, wherein the rotation device and the dithering device are arranged at the lower part of the gravity concentrator main body, and enable the lower part of the gravity concentrator main body to form the comprehensive force field precipitation separation area under the combined action of a turbulence fluid field and a pulsation force field; the rotation of the rotation device is driven by the driving device; a feeding opening is formed in the central area at the top of the gravity concentrator; the feeding opening is communicated with the comprehensive force field precipitation separation area at the lower part through a central feeding pipe; an underflow opening is formed in the bottom of the comprehensive force field precipitation separation area; the upper part of the comprehensive force field precipitation separation area is communicated to the overflow dam part at the top of the gravity concentrator main body through an upstream passage encircling the central feeding pipe; baffle board components are uniformly arranged in the upstream passage to form an inclined board settling area. The gravity concentrator has the advantages that the gravity concentrator is high in sorting accuracy, stable and reliable in work, low in energy consumption, and environment-friendly.

Owner:CENT SOUTH UNIV

Glassware processing wastewater treatment technology

InactiveCN103739110AEasy to handleIncrease the sedimentation areaWaste water treatment from ceramic industriesMultistage water/sewage treatmentSludge cakeCalcium hydroxide

The invention discloses a glassware processing wastewater treatment technology. The technology comprises the following steps: 1, processing wastewater is discharged to an oil separation pool, and water discharged from the oil separation pool flows to an adjustment pool; 2, wastewater discharged from the adjustment pool is pumped to a coagulation reaction pool, calcium hydroxide is added to wastewater to adjust the pH value to 7.5-8.5, a coagulant PAC and a flocculating agent PAM are added to carry out a coagulation reaction, the obtained wastewater automatically flows to an inclined tube sedimentation pool through a water distribution tank in order to realize solid-liquid separation, and sludge in a bucket is discharged to a sludge pool; 3, water discharged from the sedimentation pool automatically flows to a sand filter for sand filtration, and water discharged from the sand filter flows to a clear water pool; and 4, sludge in the inclined tube sedimentation pool is pumped to a sludge concentration pool through a sludge pump and is concentrated, the obtained sludge concentrate is press-dried to form sludge cakes, the sludge cakes are artificially cleaned and bagged, and a filtrate flows to a wastewater adjustment pool. The technology has the advantages of simplicity, increase of the processing capability of the sedimentation pool by utilizing a laminar flow principle, shortening the sedimentation time by shortening particle settlement distances, and increase of the processing efficiency by increasing the sedimentation area of the sedimentation pool.

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

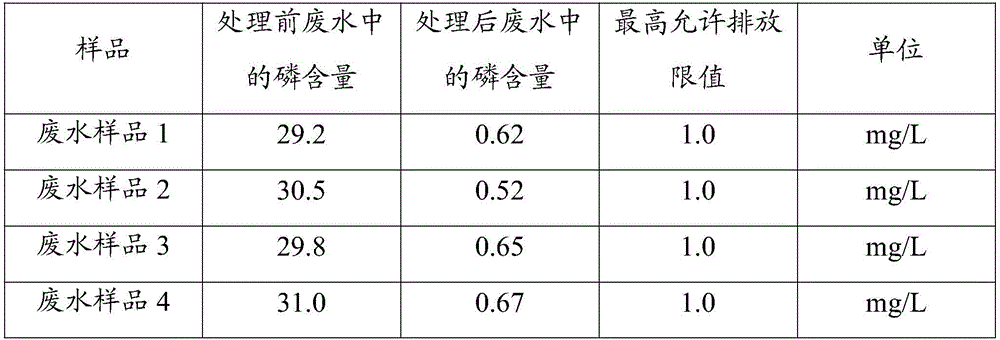

Method for dephosphorization of electroplating wastewater

ActiveCN105906143AImprove biodegradabilityFacilitated releaseWaste water treatment from metallurgical processTreatment with aerobic and anaerobic processesPhosphateHydrolysis

The invention relates to a method for dephosphorization of electroplating wastewater. The method includes the following steps: enabling the electroplating wastewater to sequentially pass a hydrolysis acidification tank, an activated sludge system, an inclined tube sedimentation tank, an ozone sedimentation tank, an aerated biological tank, a Fenton coagulating basin and a chemical precipitation tank, and discharging the electroplating wastewater up to the standard. The 'biochemical treatment-advanced oxidation-coagulating sedimentation' processes are integrated for deep treatment of non-positive phosphate in electroplating industry wastewater electroplating plots. By the method, the problem that it is not easy for the phosphorus index of the electroplating plots to reach the standard stably for a long time can be solved, wastewater treatment efficiency and social and economic benefits are improved, and clean production, energy conservation and emission reduction are realized.

Owner:惠州金茂源环保科技有限公司

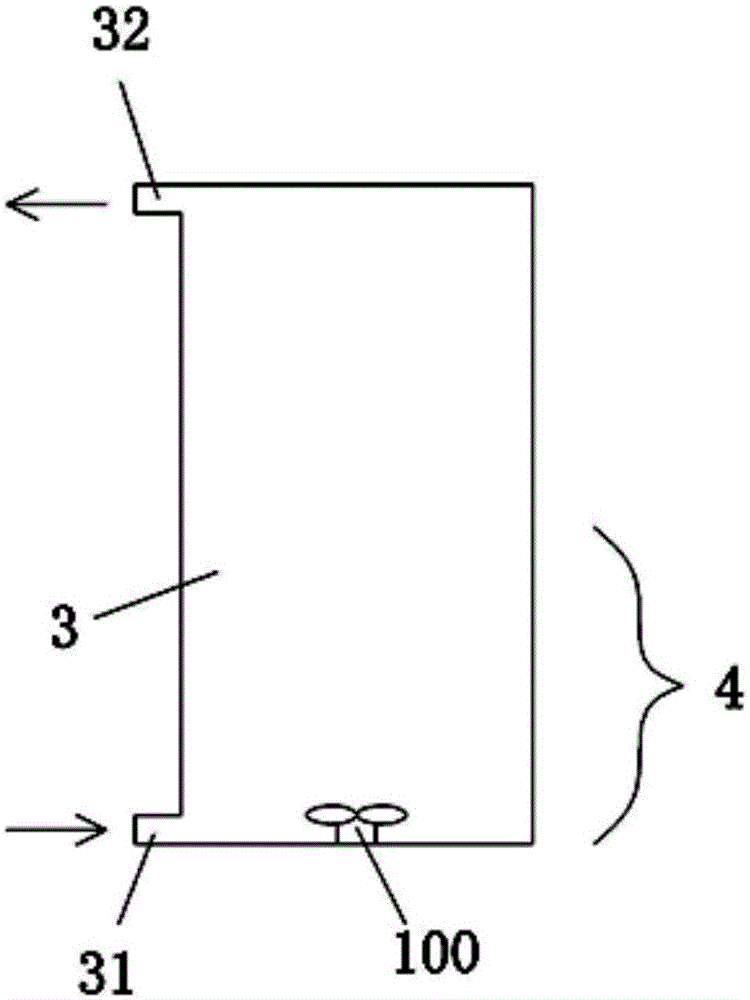

Method and reactor for million kilowatt nuclear power station to process radioactive wastewater

ActiveCN105161156AFast preprocessingPromote full accessRadioactive decontaminationSorbentNuclear power

The invention discloses a method and reactor for a million kilowatt nuclear power station to process radioactive wastewater. According to the method, adsorbents with the specific gravity larger than that of the radioactive wastewater is scattered in the radioactive wastewater through stirring, and the adsorbents are used for nuclide ions in the radioactive wastewater. The lower portion of an inner cavity of the reactor is an adsorbing reaction area, and a separating area is arranged on the upper portion of the inner cavity of the reactor. A radioactive wastewater inlet and a stirring device are arranged in the adsorbing reaction area. An intercepting device for keeping the adsorbents stay in the reactor is arranged in the separating area. A water outlet for processed wastewater is formed in the upper portion of the intercepting device. According to the reactor, existing adsorption of a fixed bed is changed into adsorption of a flowing bed, powder or small particle adsorbents can be selected so that the specific surface area can be increased, the adsorbents and the radioactive wastewater can make full contact by stirring the powder or the small particle adsorbents in the radioactive wastewater, and a large amount of radioactive wastewater can be fast preprocessed.

Owner:LINGDONG NUCLEAR POWER +5

Water treatment equipment

InactiveCN105502729AEfficient removalImprove filtering effectTreatment involving filtrationMultistage water/sewage treatmentGratingFiltration

The invention discloses water treatment equipment, which comprises a raw water tank, a primary sedimentation tower, an inclined tubing sedimentation room, a filtration room and an adsorption room. A water taking and filtering device is arranged inside the raw water tank. The device comprises a water taking tank and a fixed support. The bottom of the water taking tank is open and provided with grating, and the inside of the water taking tank is provided with a material filter layer. A water inlet pipeline is provided with an on-line flow detector, a coagulation-dosing device and a high pressure pump. The primary sedimentation tower comprises inner and outer towers and a sludge discharge channel arranged between the outer tower and the inner tower. Baffle plates which are tilted upwards are arranged in a relatively-crossed manner inside the inner tower. A sludge collecting device and an inclined tubing sedimentation device are disposed inside the inclined tubing sedimentation room. The middle part of the filtration room is provided with a filter layer. Multiple adsorption layers are arranged inside the adsorption room. Raw water at a water taking end can be preliminarily filtered, and turbidity of raw water is further reduced by the utilization of the primary sedimentation tower. Then, the raw water further flows through treatment rooms such as the inclined tubing sedimentation room, the filtration room and the like to reach the drinking water standard. The whole system has a compact layout and occupies a small area.

Owner:重庆奕冉环保设备有限公司

High-efficiency solid-liquid clarification and separation device

PendingCN111450581AReduce processing sizeReduce effluxSettling tanks feed/dischargeWater/sewage treatment by flocculation/precipitationSludgeEngineering

The invention discloses a high-efficiency solid-liquid clarification and separation device. The device comprises a bottom bracket, a cylinder body, a flow guide device, an inclined plate, a mud scraping mechanism and a speed reducer, wherein the cylinder body is mounted on the bottom bracket, the speed reducer is arranged on the cylinder body, the flow guide device comprises a flow guide barrel and a reflecting plate, the reflecting plate is arranged below the flow guide barrel, the top of a first-stage flow guide barrel is communicated with a sewage / grey water inlet, the top of a second-stageflow guide barrel is connected to the outer side of a lower end opening of a first-stage flow guide barrel, and auxiliary scraping arms are arranged on the upper surface of a first-stage reflecting plate and the upper surface of a second-stage reflecting plate respectively, a slag / sludge concentration hopper is arranged at the bottom of the cylinder body, a scraping arm is arranged on a bottom plate of the cylinder body, and the scraping arm and auxiliary scraping arms jointly form the sludge scraping mechanism. According to the invention, the specific surface area is increased, the treatmentload is increased, the diffusion flow is enhanced by the flow guide reflection device, the water distribution is more uniform, the flow velocity is more stable, the liquid medicine is more fully mixed, and the clarification and separation efficiency is greatly improved.

Owner:宜兴市荣盛达环保有限公司

Multistage precipitating device for industrial sewage treatment

InactiveCN107737488AImprove precipitation effectImprove sedimentation efficiencyFiltration circuitsShort loopSewage

The invention discloses a multistage precipitating device for industrial sewage treatment. The device comprises an outer barrel, an inner barrel, a water inlet pipe, a sand collecting hopper, a plurality of supporting legs, a discharge valve I, a plurality of short joints, an annular pipe and a water outlet pipe, wherein the water inlet pipe is arranged on one side of the upper portion of the inner barrel and the water inlet pipe is tangentially connected to the inner barrel; the outer barrel is arranged on one side out of the inner barrel; the short joints which are uniformly distributed arearranged on one side of the upper portion of the outer barrel and are connected to the outer barrel in a through manner; and the short joints are connected to the annular pipe, the water outlet pipe is arranged on one side of the short joints, the sand collecting hopper which is funnel-shaped is arranged on one side of the lower portion of the outer barrel, the supporting legs are arranged on oneside of the outer side of the sand collecting hopper, and the discharge valve I is arranged on one side of the lower portion of the sand collecting hopper. The water inlet pipe is tangentially connected to the inner barrel, sand is removed by rotational flow in the inner barrel to remove most precipitates, and precipitation is performed in the outer barrel, so that the sewage precipitating effectis enhanced, and the sewage precipitating efficiency is improved.

Owner:张士伟

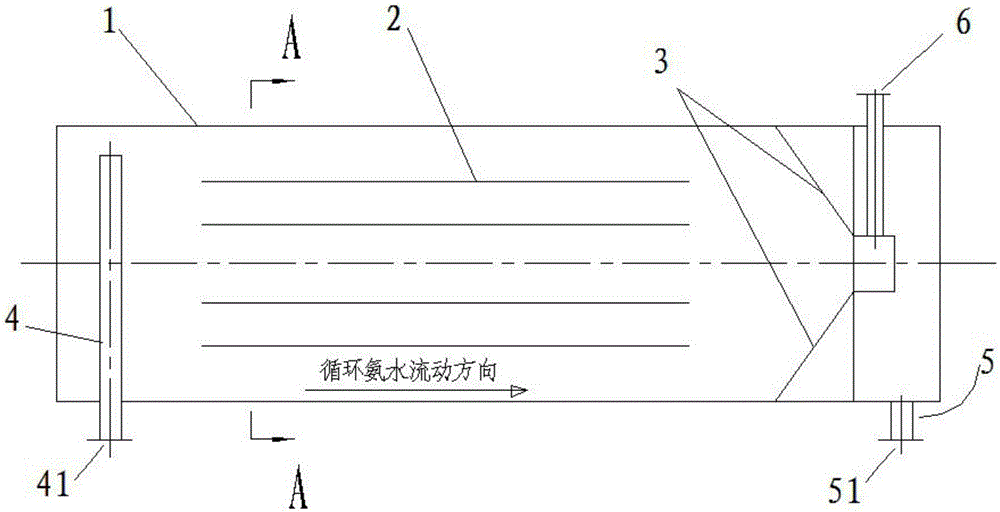

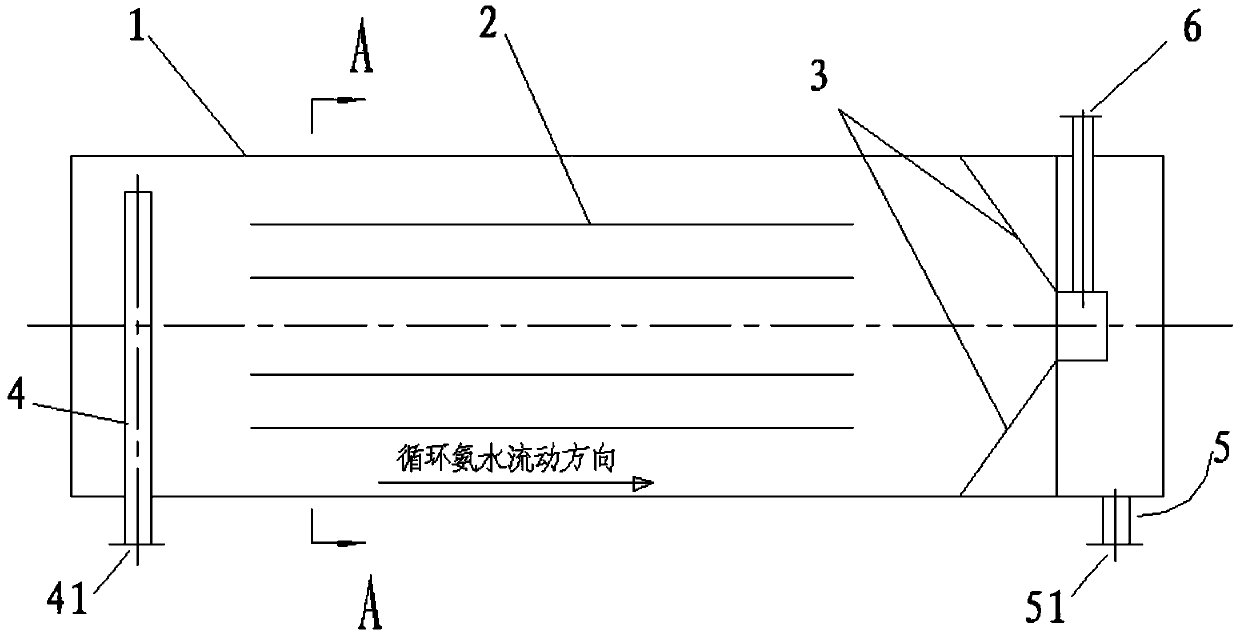

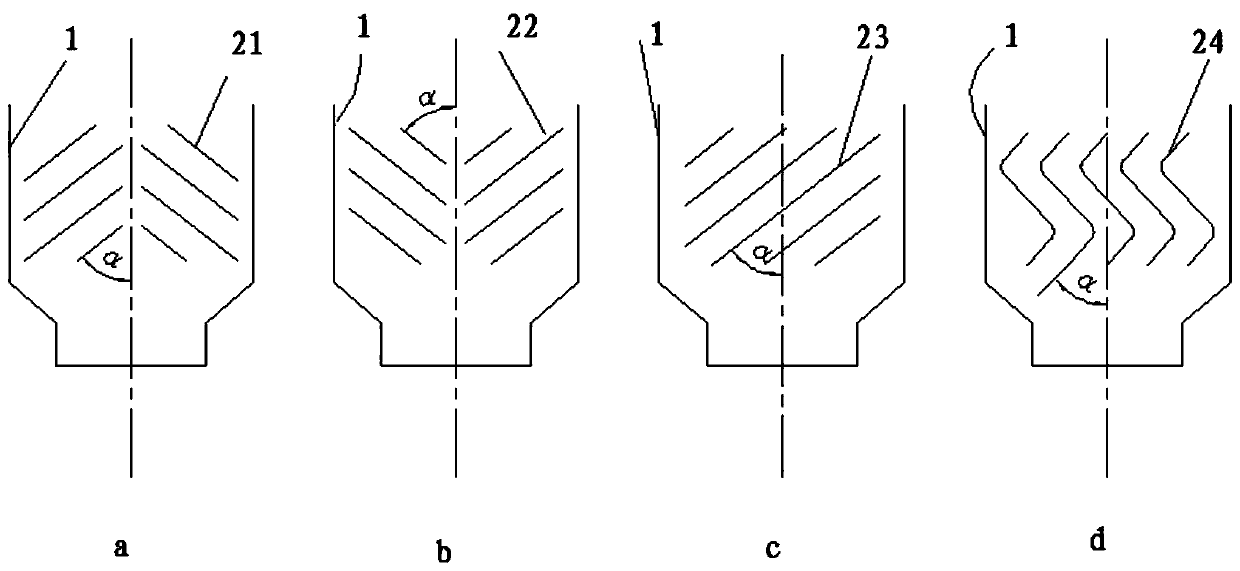

Ammonia water clarifying tank

ActiveCN105413257AEasy to separateAchieve separationLiquid separationSedimentation settling tanksSettling basinAmmonia

The invention discloses an ammonia water clarifying tank. The ammonia water clarifying tank comprises a rectangular sedimentation pond tank body, wherein a circulating ammonia water inlet pipeline is arranged at one end of the tank body and a circulating ammonia water outlet pipeline is arranged at the other end of the tank body; an inlet of the circulating ammonia water inlet pipeline and an outlet of the circulating ammonia water outlet pipeline are formed in the lower part of the tank body; a sedimentation plate group is arranged in the rectangular sedimentation pond tank body; sedimentation plates are arranged along the flowing direction of circulating ammonia water; the large sedimentation pond tank body is divided into a plurality of layers by the sedimentation plates; a top light oil collection device is arranged at the upper part of the circulating ammonia water outlet pipeline; the top light oil collection device is connected with a light oil outlet pipeline; and pre-set distances are reserved among the two ends of the sedimentation plates, and an inlet side and an outlet side of the circulating ammonia water respectively. The ammonia water clarifying tank is internally and additionally provided with the sedimentation plates and the large sedimentation pond tank body is divided into the plurality of layers by the sedimentation plates, so that the sedimentation distance is reduced by times, shallow tank separation is realized, and the separation effect of oil, water and residues is improved; and the separation of the ammonia water and light oil is further realized through the light oil collection device.

Owner:JINAN METALLURGICAL CHEM EQUIP CO LTD +1

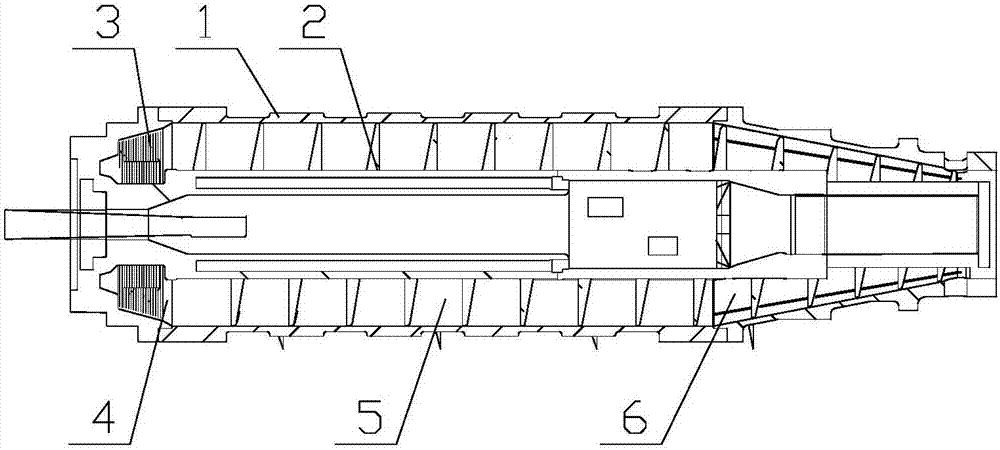

Horizontal spiral automatic discharge type sedimentation centrifuge with thorough separation effect

InactiveCN106964497AShorten the settlement distanceInhibitionRotary centrifugesEngineeringCentrifuge

The invention discloses a completely separated horizontal spiral automatic unloading sedimentation centrifuge. The drum is provided with a liquid inlet and a liquid outlet. Arranged in the same direction, the screw pusher mechanism is provided with discs arranged perpendicular to the axial direction near the liquid outlet, and multiple discs are arranged in layers. The horizontal spiral automatic unloading decanter centrifuge with thorough separation through the above optimization design has a reasonable structural design. By setting a multi-layer disc structure at the liquid outlet, the separated liquid phase hits the disc, shortening the solid The sedimentation distance of phase particles increases the sedimentation area, realizes the secondary solid-liquid separation, and at the same time suppresses the gas bubbles generated by high-speed rotation, so that the separated liquid phase is clearer and the separation effect is greatly improved.

Owner:ANHUI PUYUAN SEPARATION MACHINERY MFG CO LTD

Ammonia clarifier

ActiveCN105413257BEasy to separateAchieve separationLiquid separationSedimentation settling tanksEngineeringSettling basin

The invention discloses an ammonia water clarifying tank. The ammonia water clarifying tank comprises a rectangular sedimentation pond tank body, wherein a circulating ammonia water inlet pipeline is arranged at one end of the tank body and a circulating ammonia water outlet pipeline is arranged at the other end of the tank body; an inlet of the circulating ammonia water inlet pipeline and an outlet of the circulating ammonia water outlet pipeline are formed in the lower part of the tank body; a sedimentation plate group is arranged in the rectangular sedimentation pond tank body; sedimentation plates are arranged along the flowing direction of circulating ammonia water; the large sedimentation pond tank body is divided into a plurality of layers by the sedimentation plates; a top light oil collection device is arranged at the upper part of the circulating ammonia water outlet pipeline; the top light oil collection device is connected with a light oil outlet pipeline; and pre-set distances are reserved among the two ends of the sedimentation plates, and an inlet side and an outlet side of the circulating ammonia water respectively. The ammonia water clarifying tank is internally and additionally provided with the sedimentation plates and the large sedimentation pond tank body is divided into the plurality of layers by the sedimentation plates, so that the sedimentation distance is reduced by times, shallow tank separation is realized, and the separation effect of oil, water and residues is improved; and the separation of the ammonia water and light oil is further realized through the light oil collection device.

Owner:JINAN METALLURGICAL CHEM EQUIP CO LTD +1

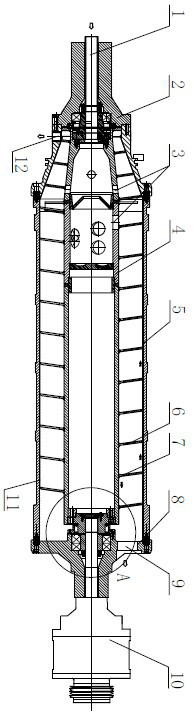

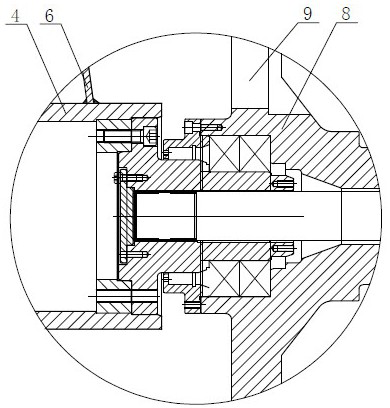

Disc stack centrifuge provided with single centripetal pump with spiral acceleration function and centrifugal equipment

PendingCN113245072AExtended separation timeImprove separation efficiencyRotary centrifugesEngineeringScrew thread

The invention provides a disc stack centrifuge provided with a single centripetal pump with a spiral acceleration function and disc stack centrifugal equipment provided with the single centripetal pump. The disc stack centrifuge is characterized in that a liquid inlet and outlet cover body is used for introducing mixed liquid and discharging light liquid; a spiral guide mechanism is arranged at the lower part of the liquid inlet and outlet cover body; the spiral guide mechanism comprises a fixing cover, a hollow column is arranged in the center of the fixing cover, a mixed liquid inlet pipe is inserted into the hollow column, at least two sets of openings are formed in the side wall of the end of the hollow column, and threaded grooves are formed in the positions, corresponding to the openings, of the outer wall of the hollow column; and the bottom of the hollow column is communicated with a guide disc. In the internal flow channel structure of the disc stack centrifuge, after entering the liquid inlet channel, mixed liquid is immediately accelerated by a screw pump in the hollow column to be pushed into a bottom liquid inlet channel and is immediately accelerated to the same rotating speed of the centrifuge, the separation effect is accelerated, and the defect that liquid entering a rotary drum cannot be completely accelerated to the rotating speed of the centrifuge through a traditional centrifuge with a single centripetal pump is overcome.

Owner:昆山金牛动力机械有限公司

Horizontal screw centrifuge

PendingCN112387427ARotate synchronouslyPrevent flow rejectionRotary centrifugesSpiral bladeEngineering

The invention discloses a horizontal screw centrifuge. A spiral conveyor is located in a rotary drum shell, a feeding pipe is in communication with an inner pipe of the spiral conveyor, a dischargingport is formed in the inner pipe, spiral blades are fixed to the periphery of the inner pipe, a light phase outlet is located in an end cover on one side of the rotary drum shell, an isolation disc ofa disc system is arranged between the spiral blade at the tail end of the spiral conveyor and the light phase outlet, the isolation disc is fixed to the spiral conveyor, a flow channel is formed in the side, close to the inner pipe, of the isolation disc, and a solid phase channel is formed between the isolation disc and the inner wall of the rotary drum; and the disc system is positioned betweenthe isolation disc and the light phase outlet, and is fixed with the rotary drum. The disc system is additionally arranged between the rotary drum shell close to the light phase outlet and the innerpipe, tiny solid particles are rapidly separated from a liquid phase, the content of the tiny solid particles in a liquid is greatly reduced, and therefore final clear liquid with higher purity can beobtained, filtering treatment of the tiny solid particles does not need to be carried out in the later procedure, and the centrifuge capability of the centrifuge is increased.

Owner:JIANGSU JUNENG MASCH CO LTD

Efficient concentrator with self-cleaning and rake pressing prevention functions

ActiveCN105797444AGuaranteed effective working volumeShorten the flow fieldSettling tanks feed/dischargeSedimentation settling tanksWater concentrationEngineering

The invention relates to the field of coal slime water concentration and clarification, in particular to an efficient concentrator with self-cleaning and rake pressing prevention functions.The efficient concentrator at least comprises a concentrator body, a diffuser, a high-pressure dredging pipeline, base flow openings and hydraulic rake lifting devices.The diffuser and the high-pressure dredging pipeline are used for cleaning material layers in the concentrator, the base flow openings are used for draining base flow in the concentrator, and the hydraulic rake lifting devices are used for lifting up a rake frame; the base flow openings include a central base flow opening and side edge base flow openings, the central base flow opening is formed in the center of a circular ring at the bottom of the concentrator, and the side edge base flow openings are formed in a circular ring of the central base flow opening in the perpendicular direction and the horizontal direction.The efficient concentrator has the advantages that materials can be discharged by the aid of the hydraulic rake lifting devices, the high-pressure dredging pipeline and the multiple base flow openings, accordingly, stable concentration of the material layers in the concentrator can be guaranteed, the rake frame can work smoothly, and 'rake pressing' phenomena can be completely eradicated; the efficient concentrator further comprises a driving stirring mechanism and composite overflow weirs, accordingly, ore pulp and chemicals can be uniformly mixed with one another, upper-layer clarified liquid can be timely drained, and the efficient concentrator is low in energy consumption, maintenance and chemical consumption.

Owner:ANHUI UNIV OF SCI & TECH

Acid liquid collection device for polar plate production and operation method of acid liquid collection device

InactiveCN110548338AEfficient removalHigh degree of automationLead-acid accumulator electrodesFiltration circuitsMagnetic valveLiquid storage tank

The invention discloses an acid liquid collection device for polar plate production. The acid liquid collection device comprises an acid liquid collection mechanism, a preliminary sedimentation mechanism, a filter mechanism and an acid liquid storage mechanism, the acid liquid collection mechanism comprises a collection tank and a guide pipe, the preliminary sedimentation mechanism comprises a sedimentation pond, a mud discharge pipe, a mud discharge valve, a collection box and a first magnetic valve, the filter mechanism comprises a liquid inlet pipe, an acid pumping pump, a filter valve, anacid conveying pipe, a mud discharge pipe and a flowmeter, and the acid liquid storage mechanism comprises an acid liquid storage tank, a third liquid inlet, a second liquid level sensor, an acid outlet and a liquid drain valve. The invention further discloses an operation method of the device. The acid liquid sediments large-particle lead plaster through the sedimentation pond, the sedimented acid liquid is pumped into the filter valve by using the acid pumping pump, small-particle lead plaster is filtered by acid liquid through the filter valve, and is collected in the acid liquid storage tank along the acid conveying pipe, the secondliquid level sensor is arranged in the acid liquid storage tank, and the effect of monitoring the acid liquid reserve can be played. The whole device has high automation degree and high acid liquid collection efficiency.

Owner:JIESHOU HUAYU POWER SUPPLY

Tap water plant water treatment equipment with water getting and filtering device

InactiveCN105347562AEfficient removalImprove filtering effectMultistage water/sewage treatmentSludgeFiltration

The invention discloses tap water plant water treatment equipment with a water getting and filtering device. The equipment comprises a raw water pond, a primary settling tower, an inclined-tube settling chamber, a filtration chamber and an adsorption chamber, wherein the raw water pond, the primary settling tower, the inclined-tube settling chamber, the filtration chamber and the adsorption chamber are connected in sequence; the water getting and filtering device is arranged in the raw water pond and comprises the filtration chamber and a water storage chamber connected with the filtration chamber; a filter screen is arranged in the filtration chamber; an on-line flow detector, a coagulation dosing device and a high pressure pump are arranged on a water inlet pipeline; the primary settling tower comprises an inner tower body, an outer tower body and a sludge discharge channel between the inner tower body and the outer tower body, and baffle plates which incline upwards are arranged oppositely in a crossed mode in the inner tower body; an inclined-tube settling device is arranged in the inclined-tube settling chamber; a filter layer is arranged in the middle of the filtration chamber; multiple adsorption layers are arranged in the adsorption chamber. The tap water plant water treatment equipment can perform primary filtration on raw water at the water getting end and further lower the turbidity of the raw water through the primary settling tower; the raw water flows through the inclined-tube settling device, the filtration chamber and other treatment chambers and then can basically reach drinking water standards; the whole system is compact in layout and occupies a small area.

Owner:重庆米步环保科技有限公司

Water-plant integrated water purifying device

InactiveCN105347570AAccelerated settlementShorten the settlement distanceMultistage water/sewage treatmentSludgeTurbidity

The invention discloses a water-plant integrated water purifying device. The water-plant integrated water purifying device comprises a raw water pool, a primary sedimentation tower, a slant tube precipitating chamber, a filtering chamber and an adsorption chamber, wherein the raw water pool, the primary sedimentation tower, the slant tube precipitating chamber, the filtering chamber and the adsorption chamber are sequentially connected. The primary sedimentation tower comprises an inner tower body and an outer tower body, baffle plates slant upwards are oppositely and crossways arranged in the inner tower body, a sludge collecting device and a slant tube precipitating device are arranged in the slant tube precipitating chamber, and the lower portion of the slant tube precipitating chamber is connected with the top of the primary sedimentation tower through a tube; a water distributing tube connected with the upper portion of the slant tube precipitating chamber is arranged at the upper portion of the filtering chamber, a filtering layer is arranged in the middle of the filtering chamber, and a water outlet is formed in the bottom of the filtering chamber; a plurality of adsorption layers and a vertical water distributing tube are arranged in the adsorption chamber, the upper end of the vertical water distributing tube penetrates through the adsorption layers and is connected with a water distributing device, and the lower end of the vertical water distributing tube extends out the adsorption chamber and is connected with the water outlet of the filtering chamber. By means of the water-plant integrated water purifying device, the turbidity of raw water is greatly reduced through the primary sedimentation tower; after further flowing through the processing chambers such as the slant tube precipitating chamber and the filtering chamber, the raw water can basically meet the drinking water standard, and the whole system is compact in layout and small in occupied area.

Owner:重庆米步环保科技有限公司

Three-phase horizontal spiral centrifuge for oil-water sand separation

PendingCN108067358AEasy to separateShorten the settlement distanceRotary centrifugesOil phaseThree-phase

The invention relates to a three-phase horizontal spiral centrifuge for oil-water sand separation, belonging to the field of oil exploration and development. 12 vertical plates are circularly welded on the wall of a spiral conveyor of the horizontal spiral centrifuge, and the blades of the spiral conveyor are welded on the vertical plates. By the addition of the 12 vertical plates, the sedimentation distance of oil drops in a liquid pool is reduced, the sedimentation time is prolonged, and the separation of oil phase and a water phase and a water phase is facilitated. A cylindrical-conical oilbaffle plate is welded on the wall of the center-right end of the cylindrical-conical junction of the spiral conveyor and can block the oil phase to move towards the direction of a sand outlet, and thereof the oil content of sand production is reduced. An annular guide plate is arranged at the position, close to the large end, of a revolving drum and is more beneficial to the separation of the oil phase and the water phase, and therefore the oil removal efficiency is improved. An overflow oil baffle plate is arranged on the outer end face of a large-end flange and is used for controlling thesize of an overflow oil outlet, therefore the depth of the liquid pool is adjusted, and the optical oil-water separation effect is achieved. Practice shows that the three-phase horizontal spiral centrifuge has an obvious separation effect on oil-water sand.

Owner:DALIAN UNIV OF TECH

Efficient flocculation thickener

InactiveCN108635917AGuarantee the unimpeded dischargeAvoid cloggingSettling tanks feed/dischargeSedimentation settling tanksEngineeringPrecipitation

The invention discloses an efficient flocculation thickener. The efficient flocculation thickener comprises a shell body and bridge piers, wherein the shell body is arranged on two adjacent groups ofthe bridge piers; a bridge frame is arranged at the upper end of the shell body; a main shaft is arranged at the middle position in the shell body; a driving device is arranged at the upper end of themain shaft; a flow stabilization barrel is arranged at a part, close to the top end, of the outer surface of the main shaft; a supporting barrel is arranged on the outer surface of the flow stabilization barrel; the flow stabilization barrel and the supporting barrel are coaxially arranged through the main shaft; overflowing holes are formed in positions above two sides of the shell body; a shortrake is arranged at a part, close to the bottom end, of one side of the main shaft; a long rake is arranged at the bottom end of the other side, corresponding to the short rake, of the main shaft. The efficient flocculation thickener disclosed by the invention is provided with a material push plate and an inclined flow plate, so that the discharging smoothness of slurry in the device is ensured,a precipitation distance of ore grains is shortened, the precipitation area is enlarged and a better application prospect is brought.

Owner:石城县华辉选矿设备制造有限公司

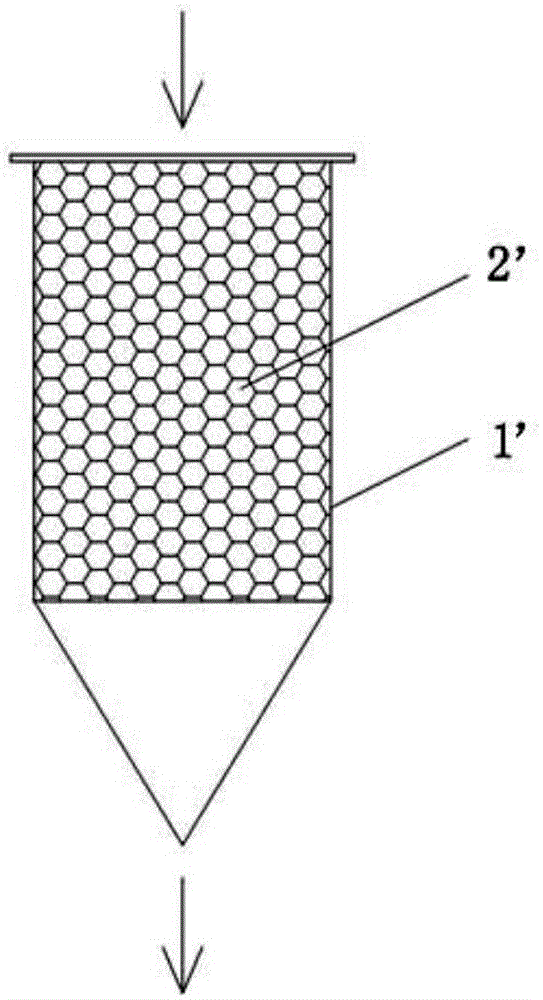

Emulsion low-pressure treatment device

PendingCN108689536AIncrease the sedimentation areaShorten the settlement distanceWater treatment compoundsMultistage water/sewage treatmentWater dischargeEmulsion

The invention discloses an emulsion low-pressure treatment device which comprises a demulsification tank, a primary sedimentation tank, a reaction tank, an advanced oxidizer, a secondary sedimentationtank and a clear water tank in sequential serial connection. Wastewater is primarily treated biochemically in the demulsification tank and the reaction tank, the advanced oxidizer comprises a reactorbarrel, a reflective diversion barrel is arranged in the reaction barrel, a filler area is formed between the reflective diversion barrel and the reactor barrel, a water incoming pipe and an air incoming pipe penetrate the filler area on the lower portion of the reactor barrel, a water distributor and an aerator are arranged at an opening of the bottom of the reflective diversion barrel, and a water discharging pipe is arranged on the upper portion of the reactor barrel; titanium dioxide catalysis plates divide the reflective diversion barrel into a plurality of longitudinal oxidation areas,ultraviolet lamp poles are arranged at the centers of the oxidation areas, the advanced oxidizer sectionally irradiates, the catalysis plates are completely within an optimal catalysis distance of theultraviolet lamp poles, and reflective diversion barrel can reflect ultraviolet emitted from the ultraviolet lamp poles, enhance illumination and improve photocatalysis efficiency.

Owner:SUZHOU FANGZHOU ENVIRONMENTAL PROTECTION TECH CO LTD

Settling apparatus with intake water filtering unit for waterworks

The invention discloses a settling apparatus with an intake water filtering unit for a waterworks. The settling apparatus comprises the intake water filtering unit, a primary settling tower and an inclined tube deposition chamber; the intake water filtering unit comprises an intake water tank and a fixing support, wherein the intake water tank is fixed on the fixing support, a bottom opening of the intake water tank is provided with a grating, and a filter material layer is arranged in the intake water tank; the primary settling tower comprises an inner tower and an outer tower, wherein the bottom of the inner tower is provided with a water inlet pipe connected with the upper part of the intake water tank, the wall of the inner tower is provided with upwardly-inclined baffle plates arranged in a relatively intersecting manner; and an inclined tube deposition unit is arranged in the inclined tube deposition chamber, the lower part of the inclined tube deposition chamber is communicated with the top of the inner tower, and the top of the inclined tube deposition chamber is provided with a water outlet pipe. According to the invention, since the intake water filtering unit is arranged at the water intake end of the settling apparatus, the settling apparatus is capable of effectively removing floating objects in water; meanwhile, the baffle plates are utilized to shorten the settling distance of impurities and accelerate the sedimentation rate of impurities; and after secondary deposition by the inclined tube deposition chamber, most impurities in water are removed.

Owner:巴东县全欣水务有限公司

Clean water treatment device with taken water filtering device

InactiveCN105417776AReduce distanceAccelerated settlementSpecific water treatment objectivesTreatment involving filtrationPipingRaw water

The invention discloses a clean water treatment device with a taken water filtering device. The clean water treatment device comprises the taken water filtering device, a primary sedimentation tower, an inclined pipe settling chamber and a filtering chamber; the taken water filtering device comprises a fixing support and a taken water tank fixed on the fixing support, the bottom surface of the taken water tank is open and is provided with a grille, and the interior of the taken water tank is provided with a material filtering layer; the primary sedimentation tower comprises an inner tower body and an outer tower body, the tower bottom of the inner tower body is provided with a water inlet pipe connected with the upper portion of the taken water tank, and the tower wall of the inner tower body is provided with upwards-inclined baffle plates in a relative intersecting mode; an inclined pipe settling device is arranged in the inclined pipe settling chamber, and the lower portion of the inclined pipe settling device is communicated with the top of the inner tower body through a pipeline; the top of the filtering chamber is provided with a water distribution pipe communicated with the top of the inclined pipe settling chamber, the bottom of the filtering chamber is connected with a water outlet pipe, and the middle of the filtering chamber is provided with a filtering layer. According to the clean water treatment device, the water taking end is provided with the taken water filtering device, the impurity sedimentation distance is shortened through the baffle plates, the impurity sedimentation speed is increased, and raw water basically can reach the drinking water standard after being settled and filtered through the inclined pipe settling chamber and the filtering chamber.

Owner:重庆奕冉环保设备有限公司

Treatment method for comprehensive sewage of smelting

InactiveCN110981041ALarge specific surface areaIncrease reaction rateSludge treatmentWater contaminantsSocial benefitsSludge

The invention discloses a treatment method for comprehensive sewage of smelting. The method comprises the following steps: introducing the comprehensive sewage of smelting into a wastewater regulatingtank to regulate a pH value of the sewage; then lifting the comprehensive sewage to a reduction reaction tank, adding a reducing agent, and carrying out a reduction reaction; after the reaction, introducing the comprehensive sewage into a coagulation reaction tank, adjusting the pH value of the comprehensive sewage to 7, then adding a heavy metal remover, and carrying out treatment; introducing the treated sewage into an inclined-tube sedimentation tank for flocculating settling, enabling the obtained supernatant to enter a clean water tank, and treating the obtained sludge for refining of heavy metals or other treatment; introducing the obtained supernatant into an LEC electro-catalytic oxidation device for degradation of organic pollutants, and discharging the sewage after the sewage reaches the standard. When the method is used for treating the comprehensive sewage, high efficiency and low cost are achieved, environmental protection is facilitated, and certain social benefits and economic benefits are achieved.

Owner:河南菲迪泰环境科技有限公司

Waterwork water purification treatment equipment with water taking and filtering device

InactiveCN105502714AEfficient removalAccelerated settlementSpecific water treatment objectivesTreatment involving filtrationGratingFiltration

The invention discloses waterwork water purification treatment equipment with a water taking and filtering device. The equipment of the invention comprises a water taking and filtering device, a primary sedimentation tower, an inclined tubing sedimentation room, a filtration room and an adsorption room, which are successively connected. The water taking and filtering device comprises a water taking tank fixed on a fixed support. The bottom of the water taking tank is open and is provided with grating, and a material filtering layer is arranged inside the water taking tank. The primary sedimentation tower comprises inner and outer towers. Baffle plates which are tilted upwards are arranged in a relatively-crossed manner inside the inner tower. An inclined tubing sedimentation device is arranged inside the inclined tubing sedimentation room. A filtering layer is arranged in the middle part of the filtration room. Multiple adsorption layers are mounted inside the adsorption room. Impurities at a water taking end can be preliminarily filtered out; turbidity of raw water is further reduced by the utilization of the primary sedimentation tower; and raw water passes through the inclined tubing sedimentation room, the filtration room and the adsorption room to further remove residual impurities in water. The whole system has a compact layout and occupies a small area.

Owner:QIJIANG COUNTY SHIZIQIAO WATER SUPPLY CO LTD

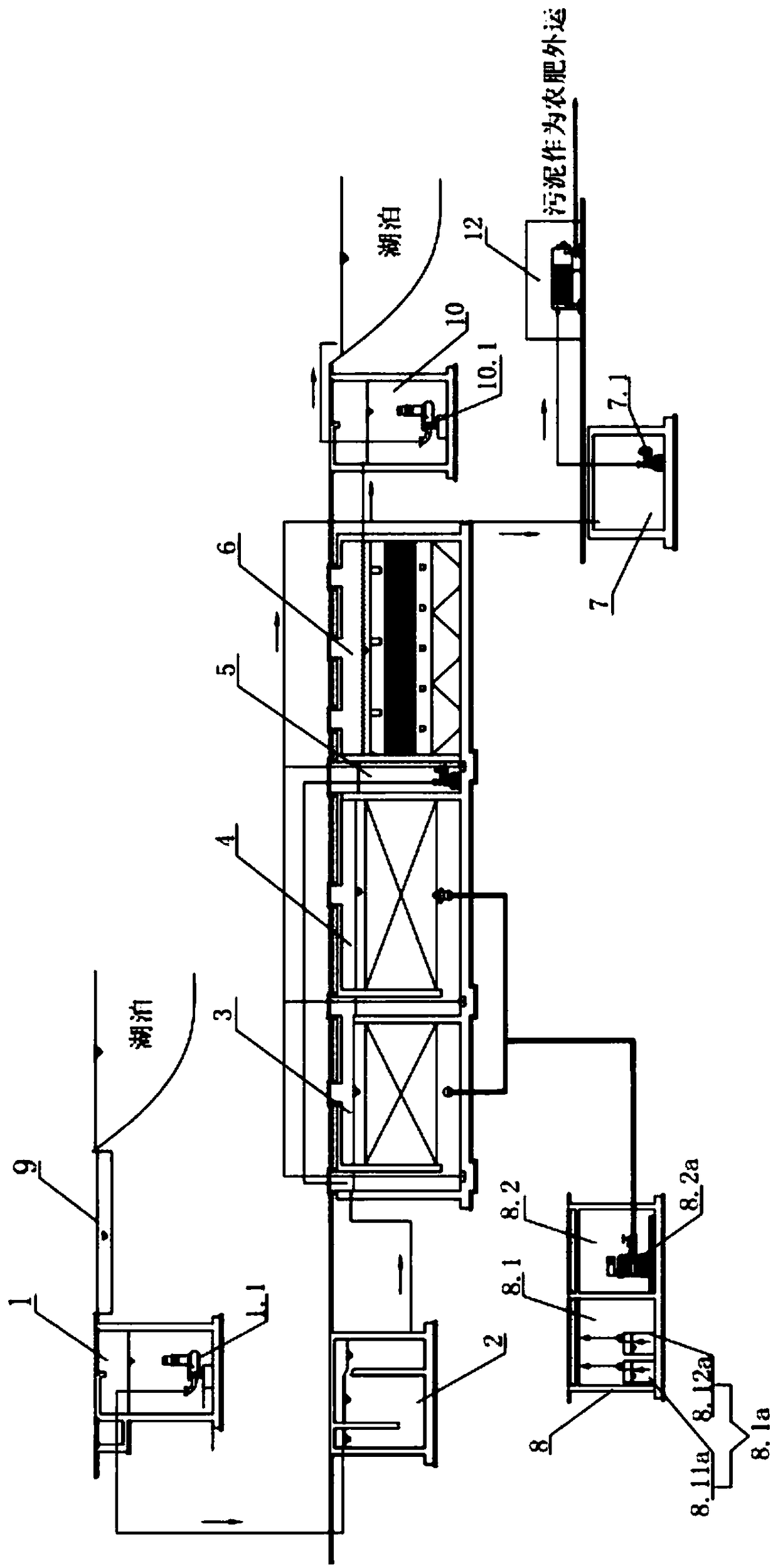

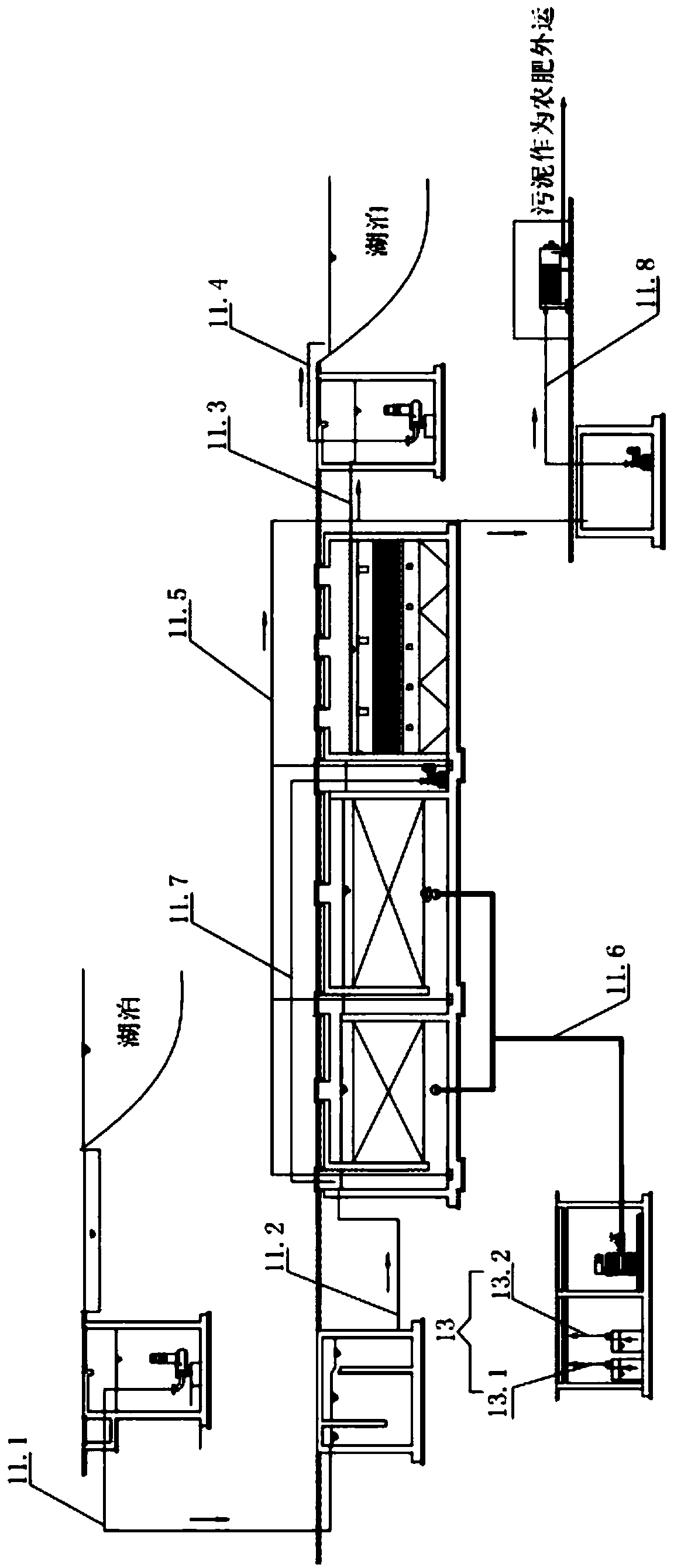

Lake water purifying treatment system for improving lake water quality

PendingCN109399875AIncrease the sedimentation areaShorten the settlement distanceTreatment using aerobic processesTreatment with anaerobic digestion processesFertilizerSewage treatment

The invention discloses a lake water purifying treatment system for improving lake water quality. The lake water purifying treatment system comprises a water inlet pump station, a water distribution well, a purifying tank, a water outlet pump station, a sludge tank and a device room. A first lifting pump is arranged in the water inlet pump station and is connected with the water distribution wellthrough a first pipeline, the water distribution well is connected with the purifying tank through a second pipeline, the purifying tank is connected with the water outlet pump station through a thirdpipeline, and a second lifting pump is arranged in the water outlet pump station and discharges purified and treated lake water into a lake through a fourth pipeline. The sludge tank is connected with the purifying tank through a fifth pipeline. The device room comprises a dosing chamber and a fan chamber, wherein a dosing system is arranged in the dosing chamber and is connected with a sedimentation basin through a dosing pipeline, and an air blower is arranged in the fan chamber and is connected with an anoxic pond and an aerobic tank through a sixth pipeline. The lake water purifying treatment system is high in sewage treatment efficiency and good in sewage purifying effect, and meanwhile treated sludge can serve as a fertilizer for reuse.

Owner:武汉一念元环境科技有限公司

A rakeless thickener with a rotary annular channel

ActiveCN105944407BEnsure stabilityImprove settlement performanceSedimentation regulating devicesSettling tanks feed/dischargeWater concentrationEngineering

The invention relates to the field of slime water concentration and clarification, in particular to a rake-free thickener with rotary annular channels. The rake-free thickener at least comprises a thickener body, and further comprises rotary annular channels, wherein the rotary annular channels are used for constraining upper-layer ore pulp inside the thickener to do reciprocatory motion; the rotary annular channels consist of a plurality groups of annular channels of which the diameters are increased gradually; adjacent annular channels are mutually communicated through connecting channels; each group of the annular channels comprises an upper annular partitioning plate and a lower inclined settlement plate; overflowing ore pulp is discharged out from overflow weirs; the overflow weirs comprise annular overflow weirs and composite overflow weirs; settled granules are fed into a bottom flow discharge system; the bottom flow discharge system consist of bottom flow collecting cabins, bottom flow holes and corresponding bottom flow pumps; the rake-free thickener further comprises a feeding pipeline and a driving stirring mechanism; a stirring machine is driven by residual power of the feeding pipeline conveying the ore pulp to rotate so as to uniformly mix the ore pulp with medicines. The rake-free thickener has the characteristics of being low in energy consumption, low in repairing workload, low in medicine consumption and free of rake.

Owner:ANHUI UNIV OF SCI & TECH

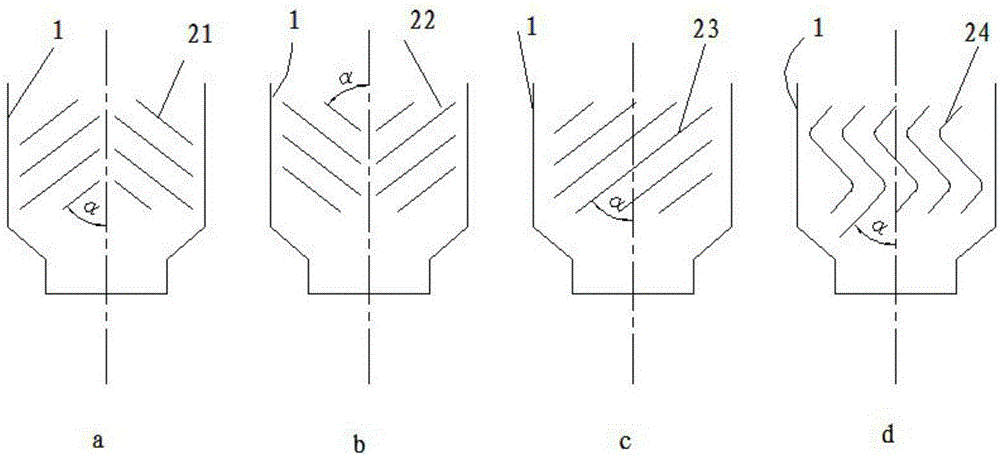

A Low Chemical Consumption Concentrator with Composite Overflow Weir

ActiveCN105797443BHigh clarityEnsure claritySettling tanks feed/dischargeSedimentation settling tanksFeed driveWater concentration

The invention relates to the field of coal slime water concentration and clarification, in particular to a concentrator with low chemical consumption and composite overflow weirs.The concentrator at least comprises a concentrator body.An overflow weir comprises annular overflow weirs and the composite overflow weirs, the annular overflow weirs are arranged on the periphery of the overflow weir, the composite overflow weirs are annularly arranged along the inside of the overflow weir, an inflation adjusting lifting and floating barrier is arranged on a side of each composite overflow weir and is used for adjusting overflow discharge rates, oblique settlement plates are arranged on the lower portions of the composite overflow weirs in fixed connection modes, and final clarification settlement treatment on rising overflow water can be carried out.The concentrator has the advantages that the movement speeds of horizontal flow in the concentrator body can be effectively reduced by the composite overflow weirs, accordingly, favorable settlement conditions can be provided for particles in ore pulp, the peripheral annular overflow weirs and the composite overflow weirs are jointly operated, and effects of obviously improving the processing efficiency of the concentrator and the clarity of the overflow water can be realized; the concentrator further comprises a driving stirring mechanism, the driving stirring mechanism can be driven by ore pulp feeding driving force to rotate, accordingly, the ore pulp and chemicals can be uniformly mixed with one another, and the concentrator is low in energy consumption, maintenance and chemical consumption.

Owner:ANHUI UNIV OF SCI & TECH

Hindered bed separator

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com