Hindered bed separator

A sorting machine and interference bed technology, applied in the field of coal preparation, can solve the problems of poor adaptability of coal quality, poor sorting effect, single flow pattern, etc., and achieve the effects of reducing pollution, improving sorting accuracy and increasing processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

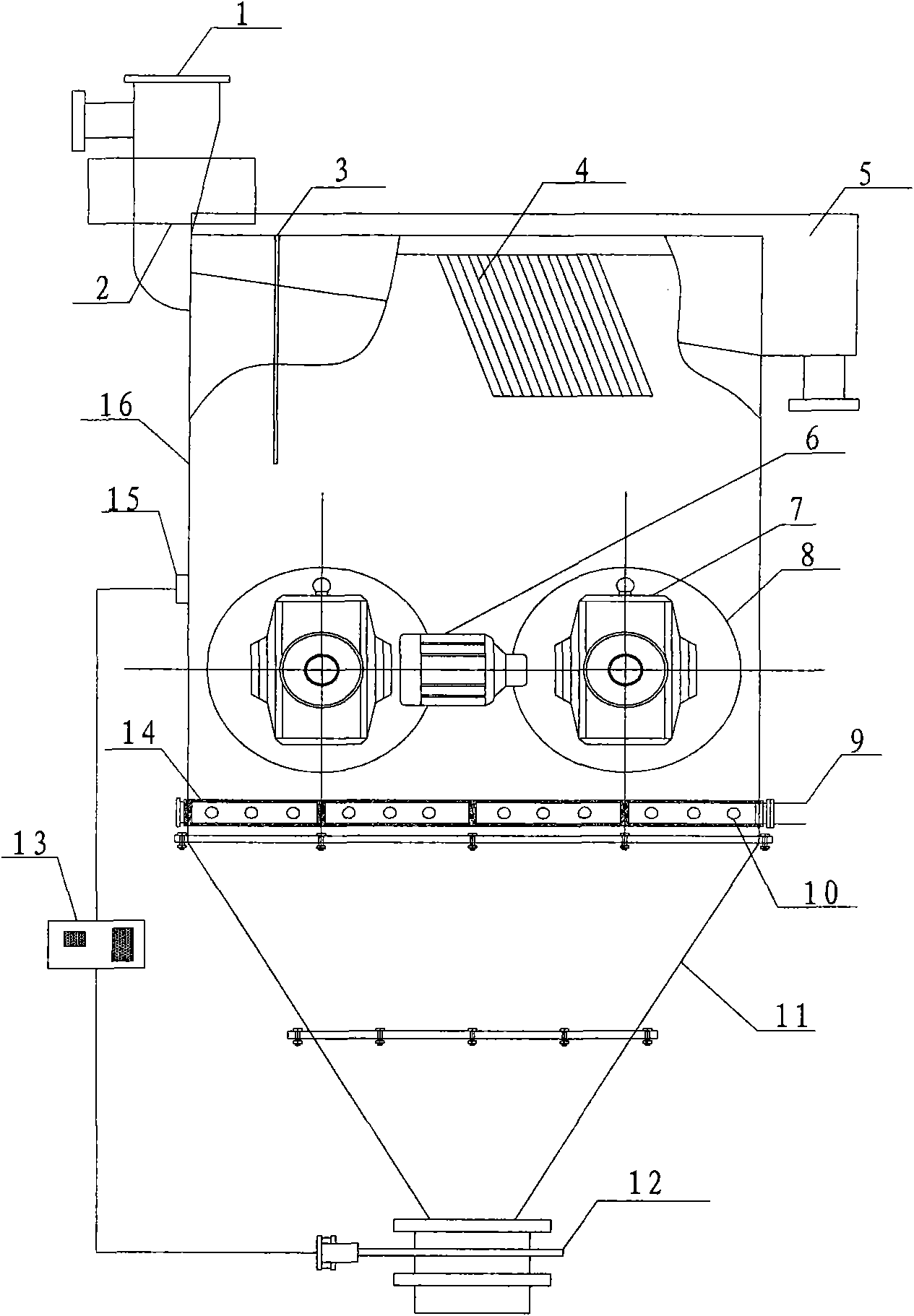

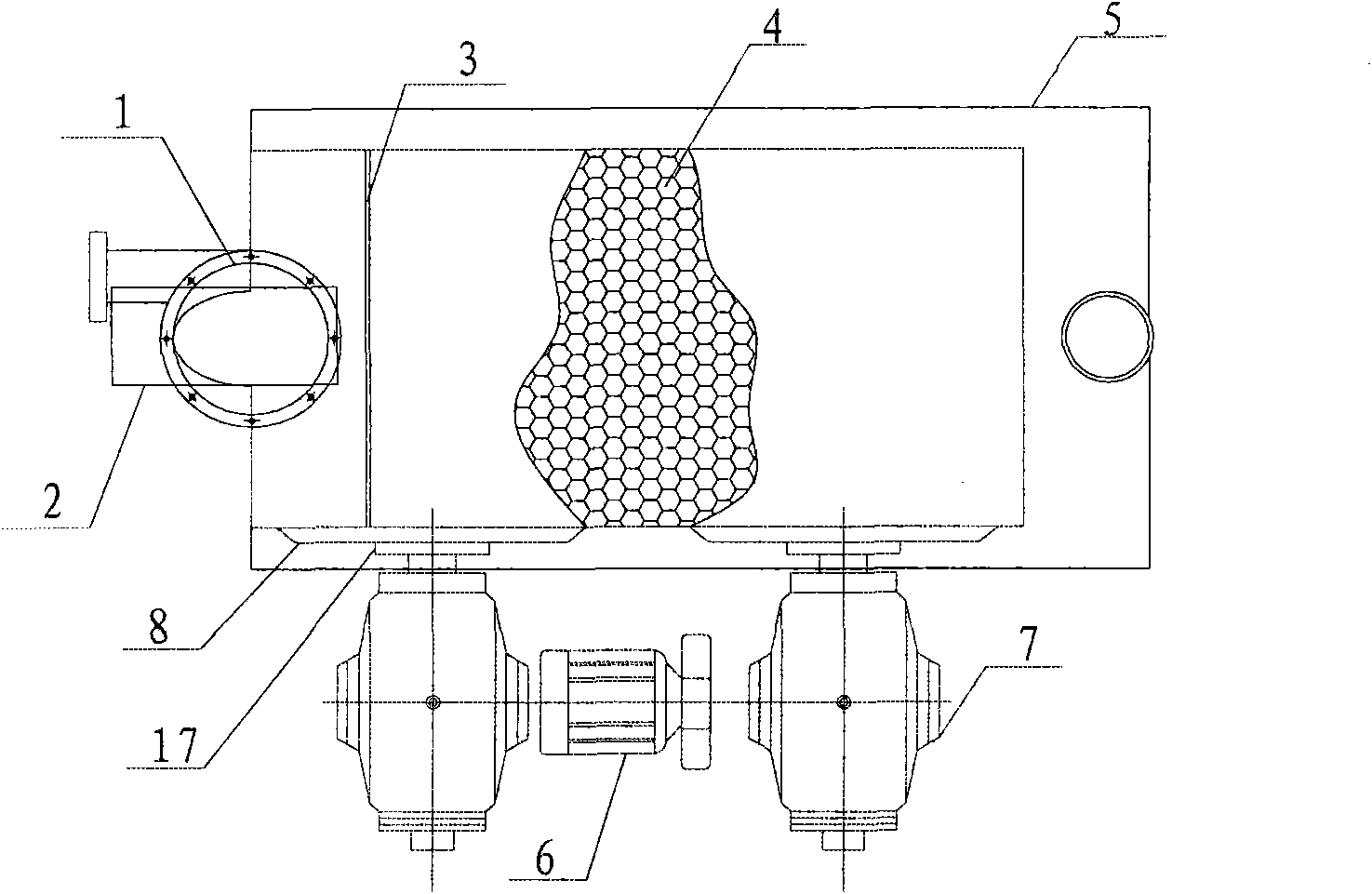

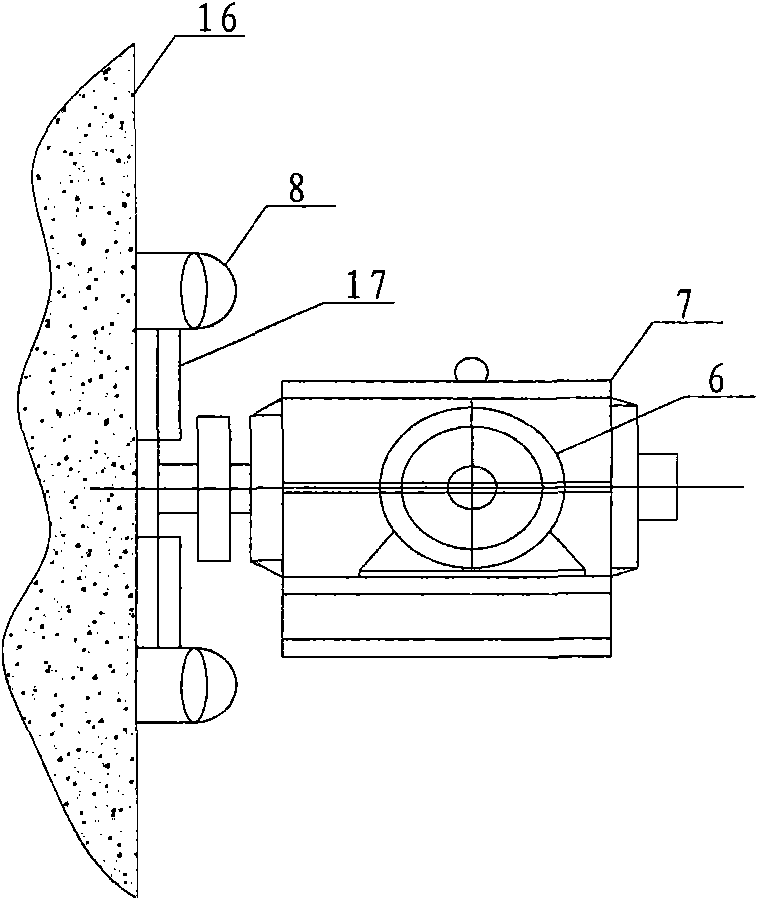

[0023] Such as figure 1 As shown, the disturbing bed sorter of the present invention includes a sorting machine body 16, a feeding well 1 installed on one side of the upper part of the sorting machine body, an underflow collecting cone 11 located at the bottom of the sorting machine body, and a bottom flow collecting cone 11 arranged on the sorting machine body The clean coal overflow collection tank 5 and the control system on the upper part of the body; the ultrasonic generator 2 is arranged below the feed port of the feed well 1; the sorting machine body below the feed well 1 discharge port The inner cavity is provided with a feeding baffle 3 for dispersing the materials to the middle of the inner cavity. The feeding baffle 3 is consistent with the width of the sorting machine body, and is fixed on the feeding side of the sorting bed by a card slot, and Ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com