Multistage precipitating device for industrial sewage treatment

A technology for industrial sewage and graded precipitation, applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of long time required to complete precipitation, large floor space, low efficiency, etc., to shorten the sedimentation distance, The effect of improving processing power and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

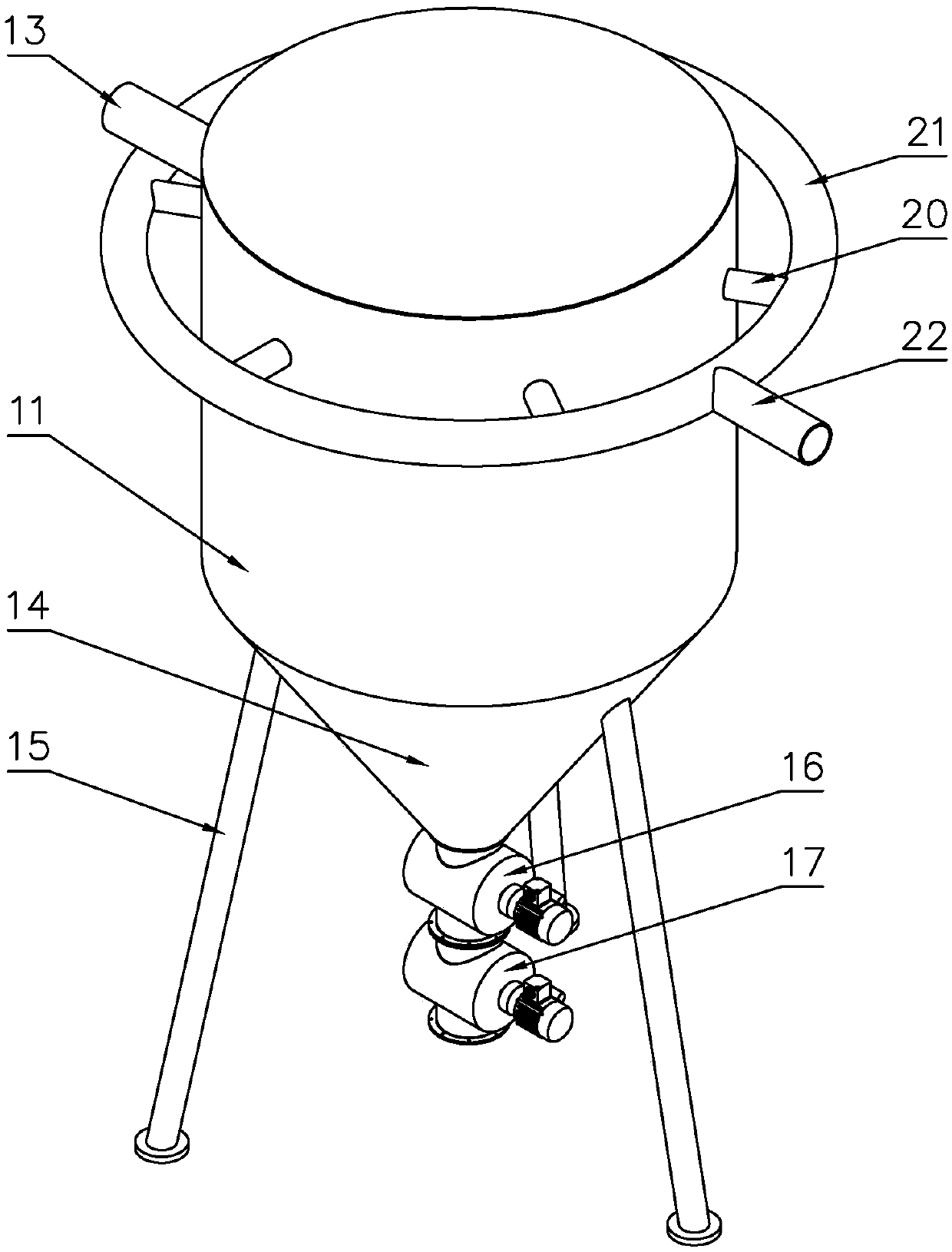

[0020] To facilitate the understanding of those skilled in the art, the following is attached Figure 1-3 , The technical scheme of the present invention is further explained in detail.

[0021] A multi-stage sedimentation device for industrial sewage treatment, including an outer cylinder 11, an inner cylinder 12, an inlet pipe 13, a sand collecting bucket 14, an outrigger 15, a discharge valve I 16, a short connection 20, a loop pipe 21, and an outlet pipe 22, The upper side of the inner cylinder 12 is provided with a water inlet pipe 13, which is tangentially connected to the inner cylinder 12. The sewage enters the inner cylinder 12 through the water inlet pipe 13 tangentially. Part of the dust particles in the sewage are caused by gravity and centrifugal force. It is captured by the inner wall of the inner cylinder 12 under the action of the inner cylinder; the outer cylinder 11 is provided on the outer side of the inner cylinder 12, and the dust particles in the sewage sett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com