Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Shorten packing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

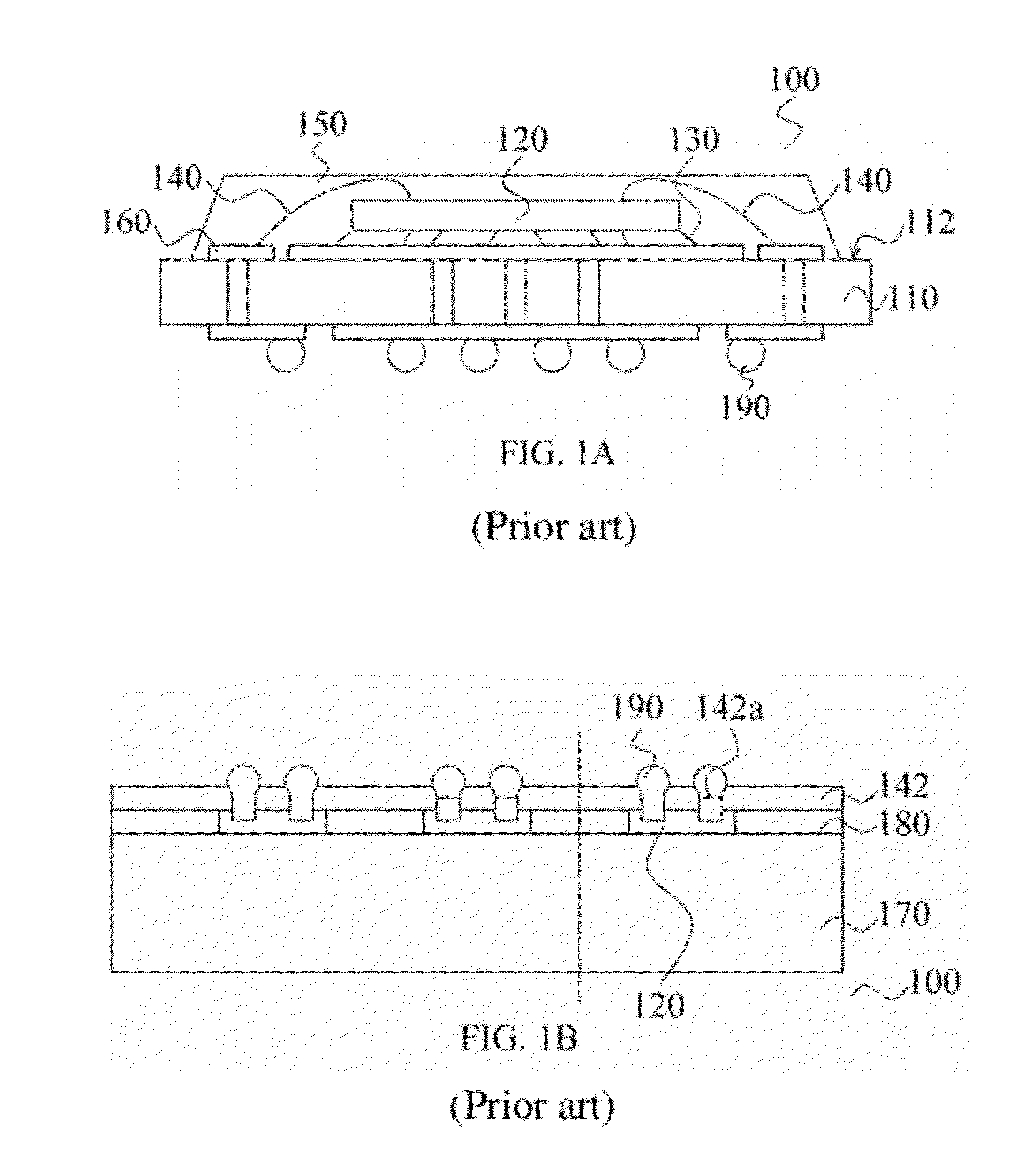

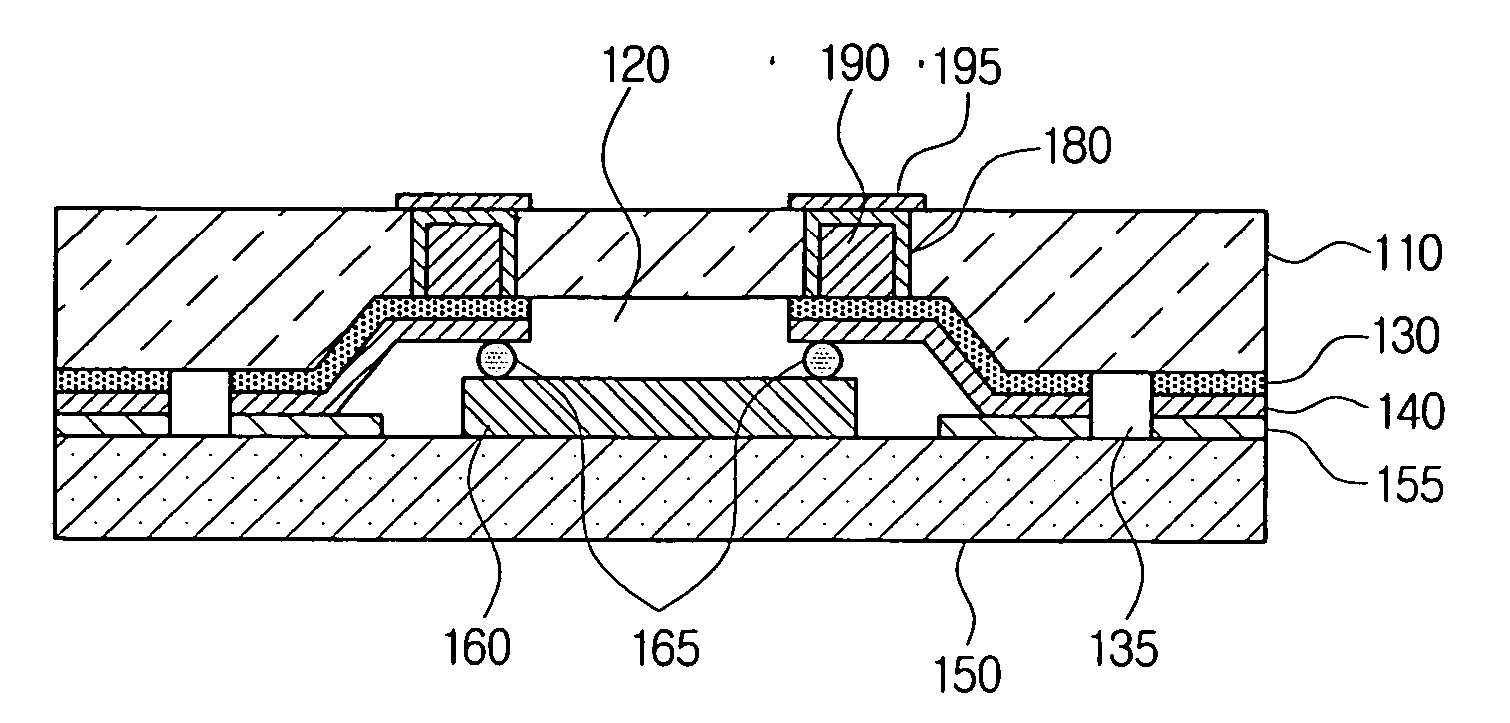

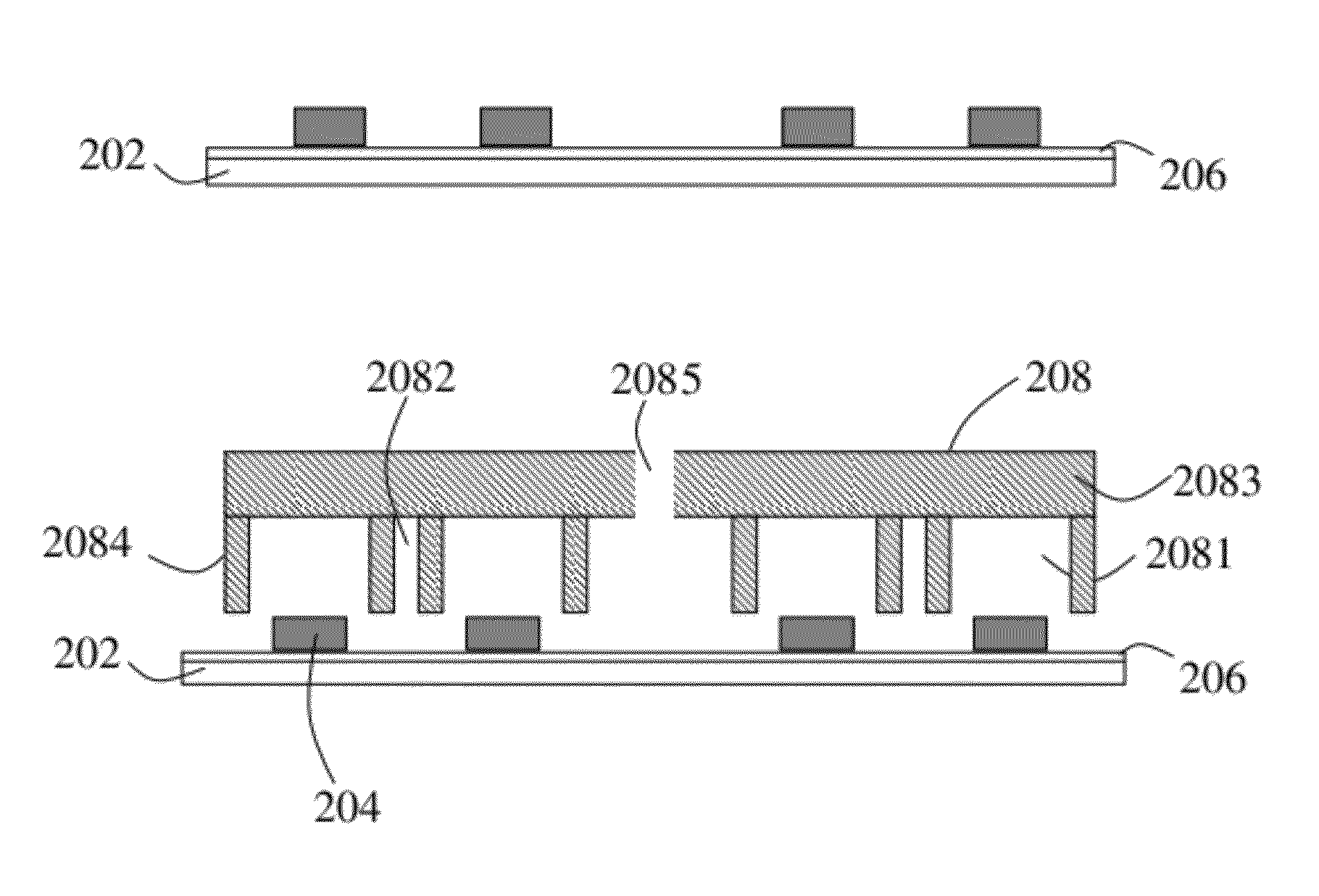

Light emitting diode (LED) with longitudinal package structure

InactiveUS20090045418A1Improve lighting efficiencyReduce coverageStatic indicating devicesSolid-state devicesConductive materialsEngineering

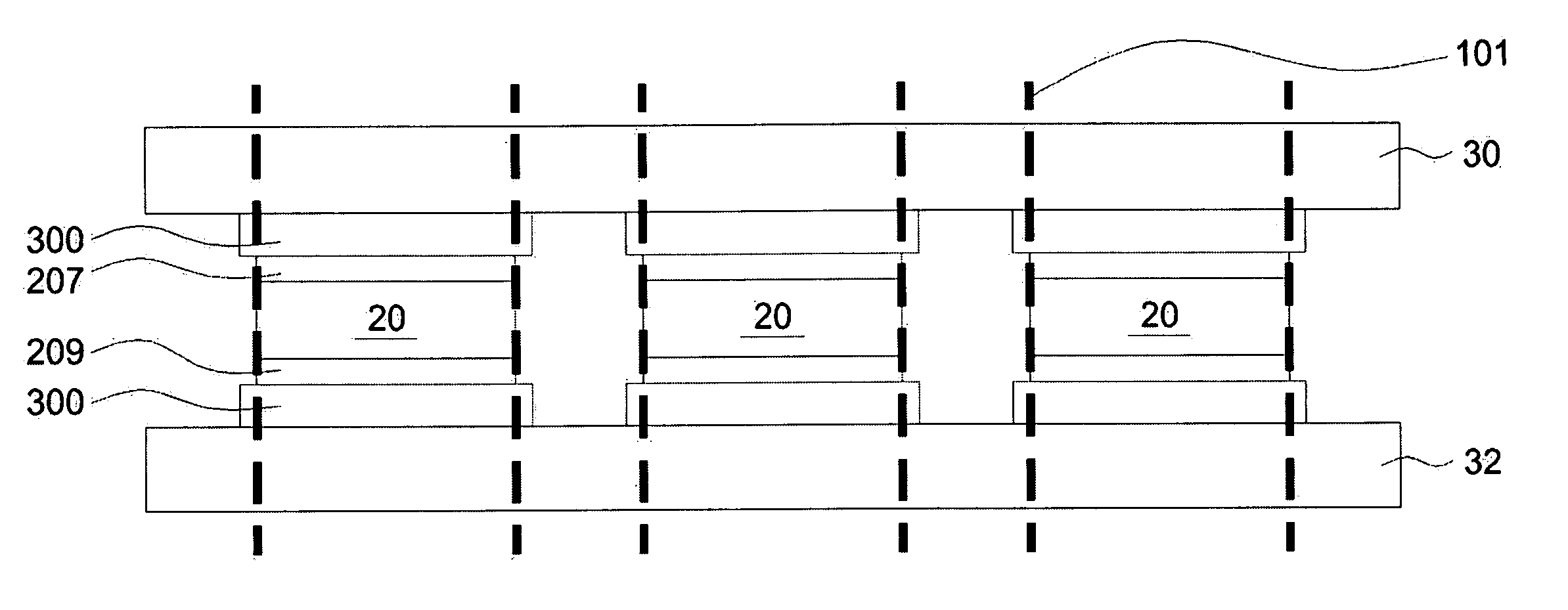

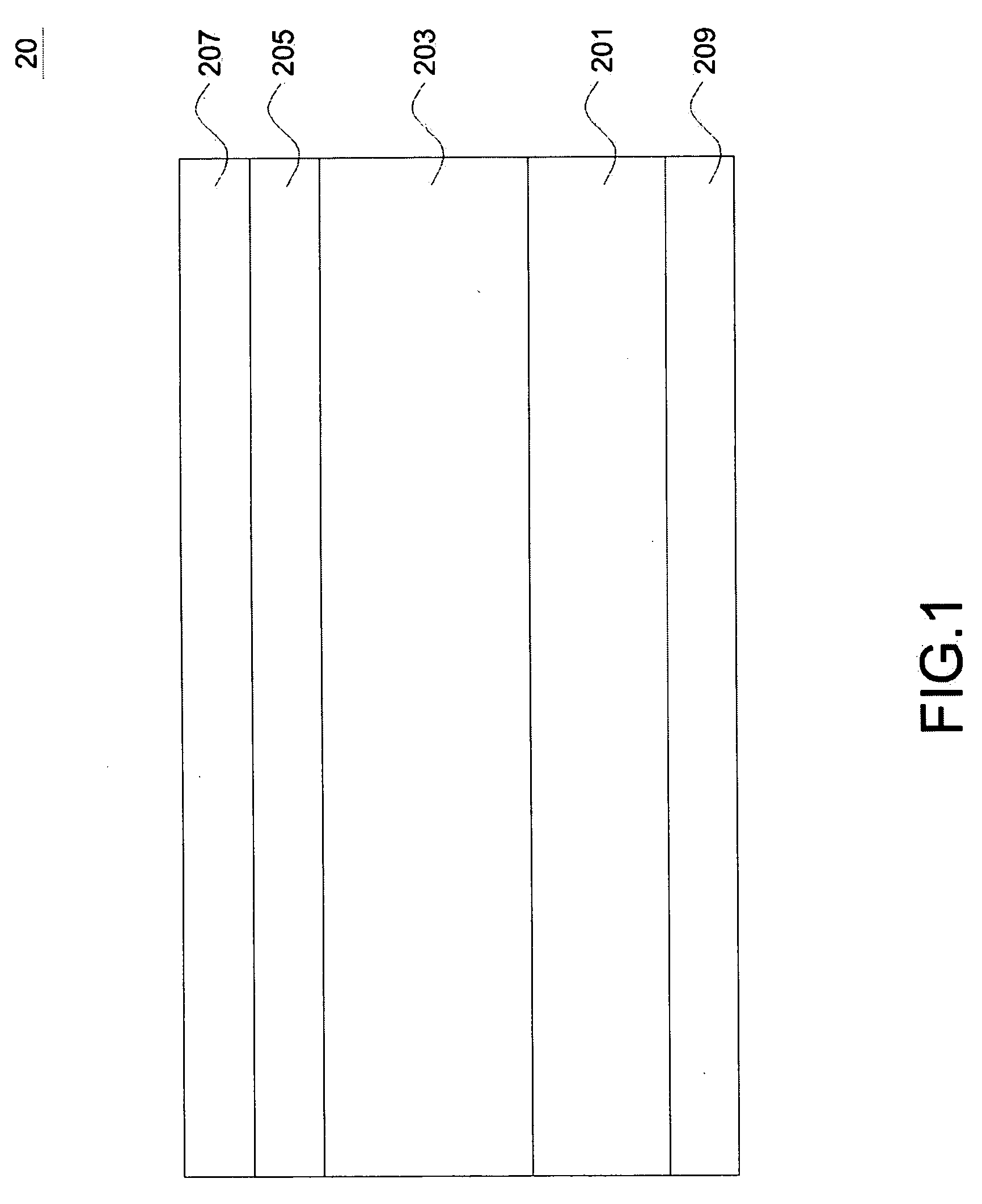

The present invention provides erected LED package structure, which includes: a carrier substrate having a first surface, a second surface and a plurality of through holes passed through the first surface and the second surface of the carrier substrate, and the conductive material filled with each of the through holes; a LED having a semiconductor layer capable of the light emitting and an N electrode and a P electrode formed on the two sides of the semiconductor layer thereon; a first transparent carrier substrate having a metal layer thereon, in which the metal layer electrically connected to the N electrode of the LED and to the conductive material which is formed on the first surface of the carrier substrate; a second transparent carrier substrate having another metal layer thereon, in which another metal layer electrically connected to the P electrode of the LED and to another conductive material which is formed on the first surface of the carrier substrate; and a plurality of connecting elements electrically connected to the plurality of conductive material which is formed on the second surface of the carrier substrate.

Owner:YEH HSIN HUI

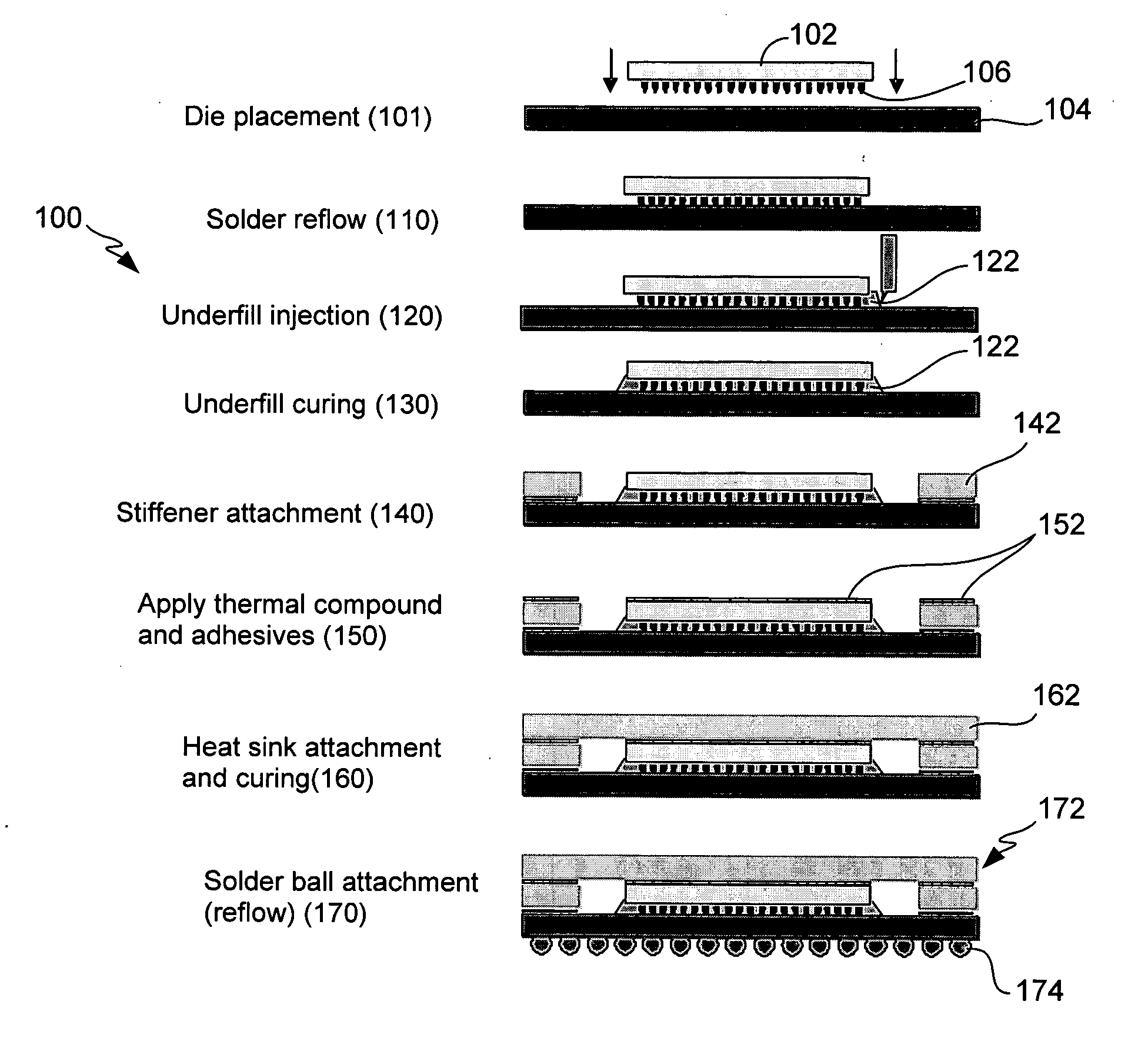

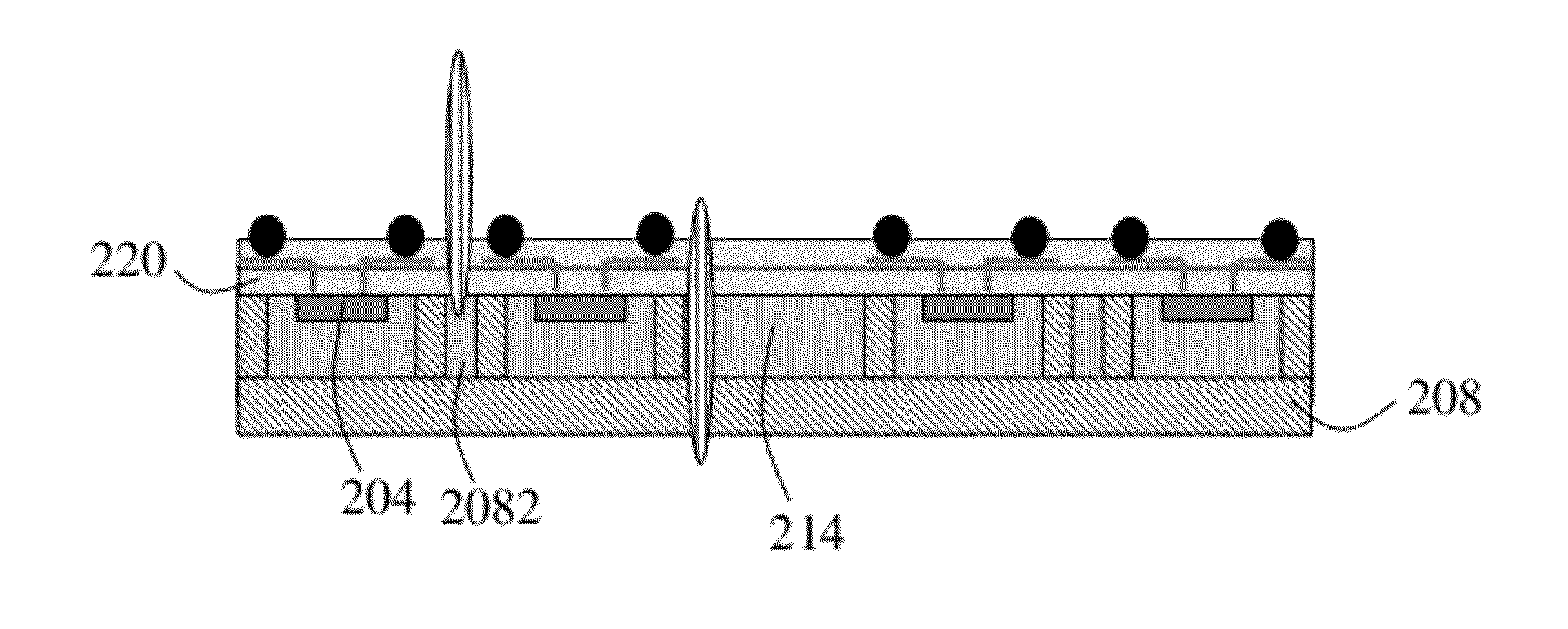

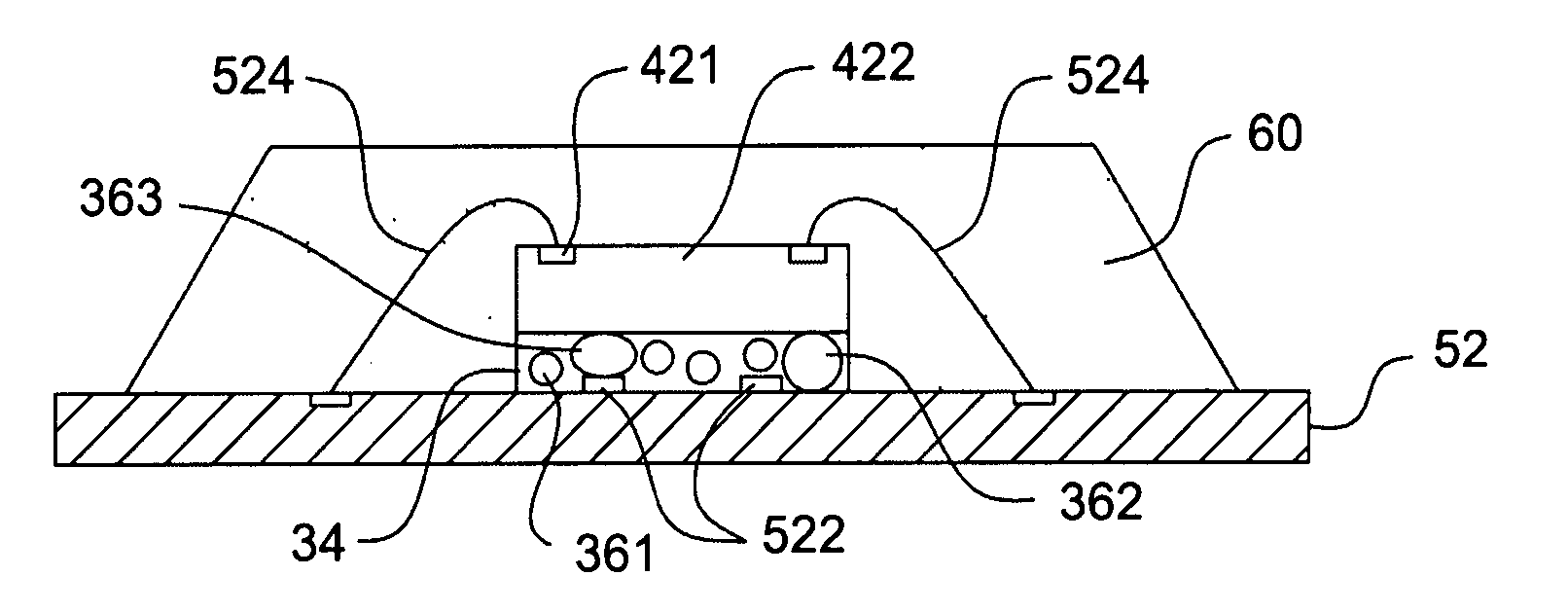

Consolidated flip chip BGA assembly process and apparatus

InactiveUS7262079B2Shorten packing timeSimple equipmentSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageSingle application

A flip chip packaging technique and associated apparatus that consolidates many or all of the steps in a conventional flip chip packaging process results in substantially decreased packaging time, e.g., only one to two hours, complexity, e.g., requiring fewer pieces and much simpler equipment, and cost, arising from reduced equipment operation and maintenance time and decreased labor. An assembly fixture useful for implementing the consolidated assembly technique engages and holds in place a semiconductor flip chip die with a plurality semiconductor package components in a desired package configuration so that they can be assembled into a semiconductor package with a single application of heat and pressure.

Owner:ALTERA CORP

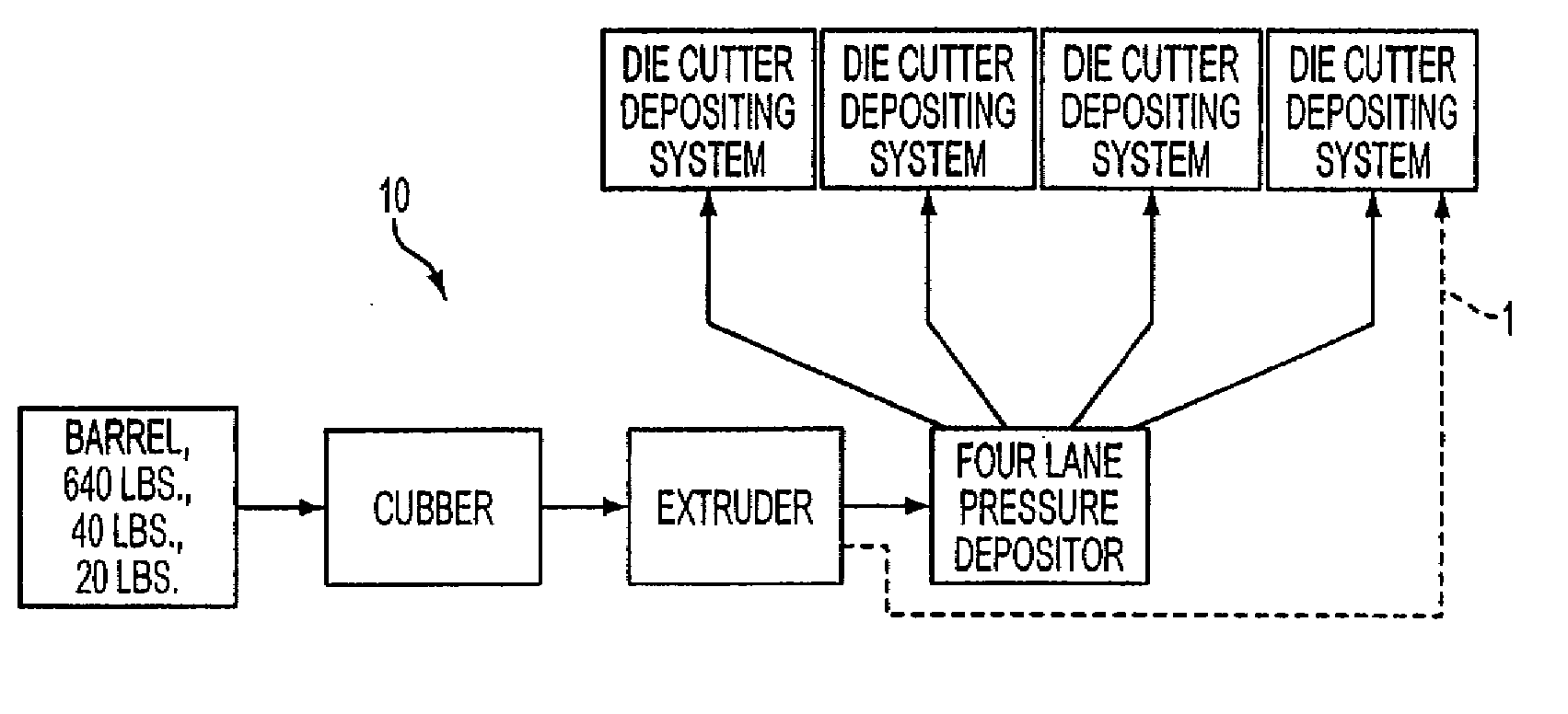

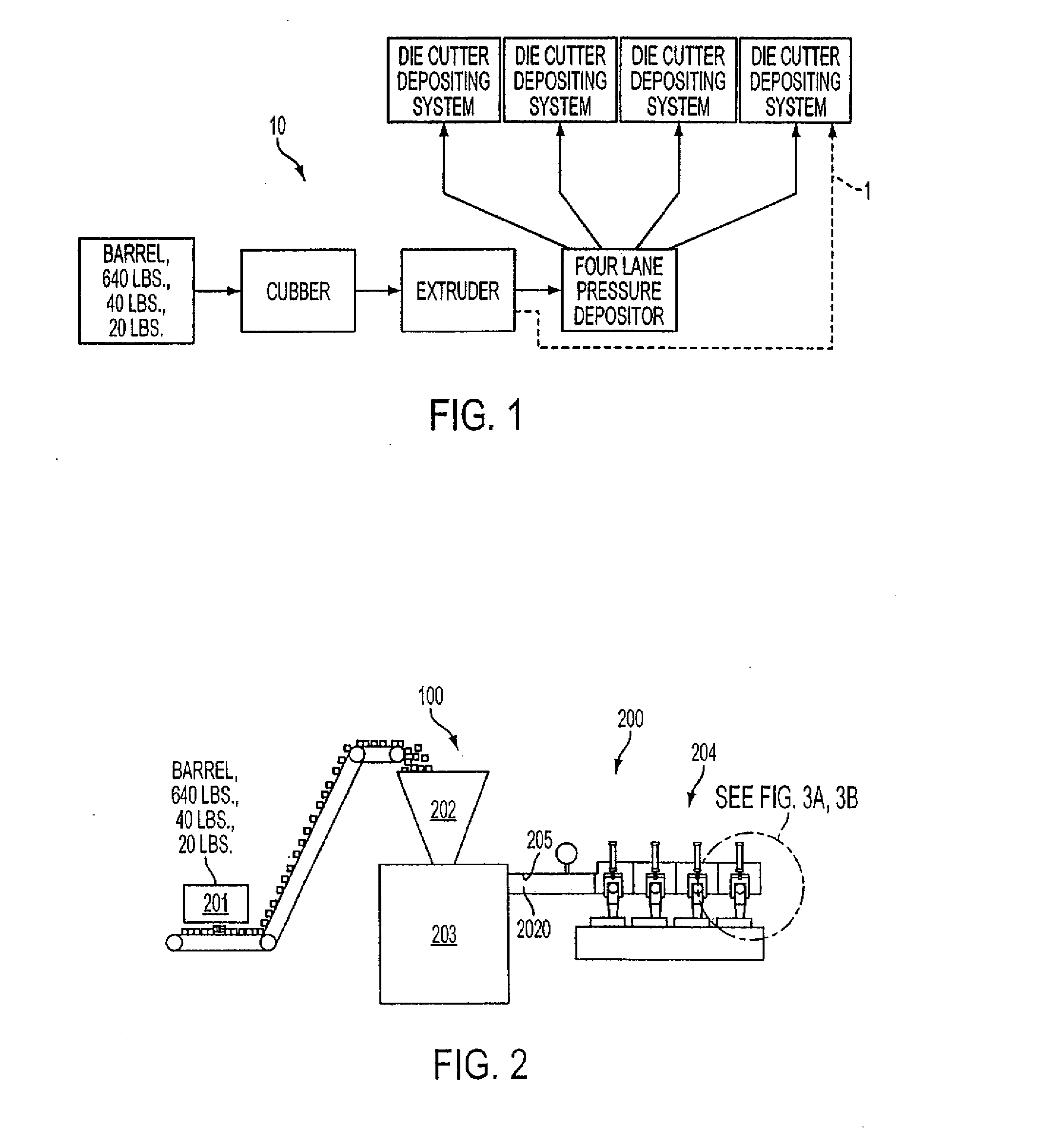

Method and system for making extruded portions of cheese

InactiveUS20070166448A1Minimize handlingShorten packing timeCheese manufactureFood shapingEngineeringHeat treated

A method and system are provided for portioning a cheese mass to be sliced and shredded directly from a quantity of bulk cheese, without the need to thermally process the cheese. The cheese extrudate strands and sheets are cut to provide discrete cheese shreds and slices, and can be automatically portioned and deposited in packages.

Owner:KRAFT FOODS GRP BRANDS LLC

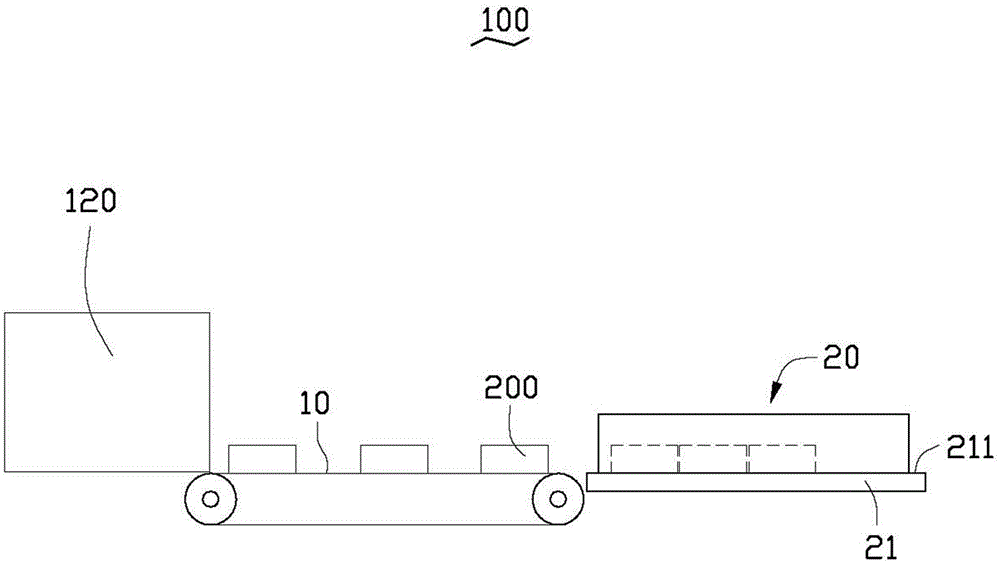

Conveying device

ActiveCN102874432AAvoid customer complaintsShorten packing timePackaging protectionBristleConveyor belt

The invention relates to a conveying device which comprises a conveyor belt and a speed-reduced cleaning unit, wherein the speed-reduced cleaning unit comprises a bearing plate, a first hairbrush plate and a second hairbrush plate, wherein the first hairbrush plate and the second hairbrush plate are arranged on the opposite sides of the bearing plate, the bearing plate is provided with a bearing surface for bearing products to be encased with certain kinetic energy and conveyed by the conveyor belt, the first hairbrush plate is provided with a first bristle surface, and bristles are formed on the surface of the first bristle surface, the second hairbrush plate is provided with a second bristle surface, and bristles are formed on the surface of the second bristle surface, the first bristle surface and the second bristle surface are arranged opposite to each other, and a channel for products to be encased is defined by the first bristle surface, the second bristle surface and the bearing surface so as to enable products to be encased to pass through, and the first bristle surface and the second bristle surface are used for carrying out frictional speed reduction and cleaning on products to be encased when the products to be encased pass through the channel. Compared with the prior art, the conveying device not only can avoid that an encasing workshop section has an accumulation phenomenon because the conveying speed of products to be encased is overquick, and can carry out dust cleaning on products to be encased.

Owner:GOLD HONG YE PAPER

Semiconductor package and method of fabricating same

InactiveUS6921715B2Shorten packing timeStable structureSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

Owner:SHEN YU NUNG

Adaptive packing method, device, apparatus and storage medium based on genetic algorithm

InactiveCN109447311AImprove space utilizationReduce waste of resourcesForecastingLogisticsGenetic algorithmComputer science

The present invention discloses a method adopting a genetic algorithm, which, according to the packing sequence parameters of the articles to be packed, the placement mode parameters and the recommended container parameters, combines into a packing scheme, namely the chromosome of the genetic algorithm, the evolution and variation of chromosomes are iterated, an approximate optimal packing schemeis generated, so that that time when simultaneous bin is required is solved. According to the problem of dynamically adapting containers for the objects to be packed, when a single container is low onspace, supporting the use of multiple containers to complete the boxing process at one time, that is to say, a fixed quantity of articles is loaded by combining the least packing containers, therefore, when a single container cannot be filled with all the articles to be packed, the invention screens out the best container combination packing scheme with the least containers and the highest spaceutilization ratio by combining the number of containers and the space utilization ratio through the genetic algorithm when the articles to be packed are packed according to the customer's fixed quantity, thereby completing the article packing and reducing the waste of resources.

Owner:深圳市递四方信息科技有限公司

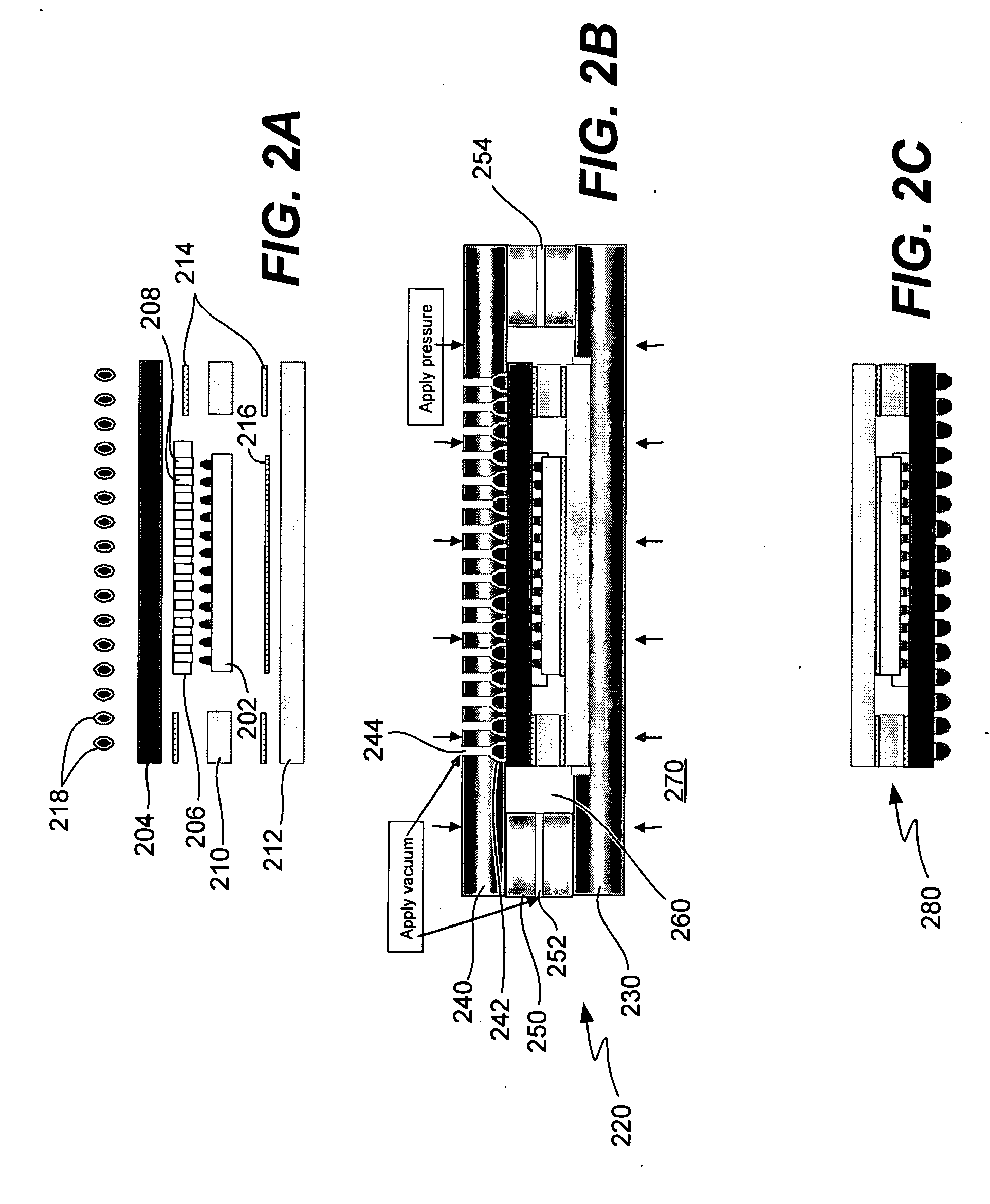

Consolidated flip chip BGA assembly process and apparatus

InactiveUS20060175710A1Decrease packaging timeDecrease laborSemiconductor/solid-state device detailsSolid-state devicesEngineeringSingle application

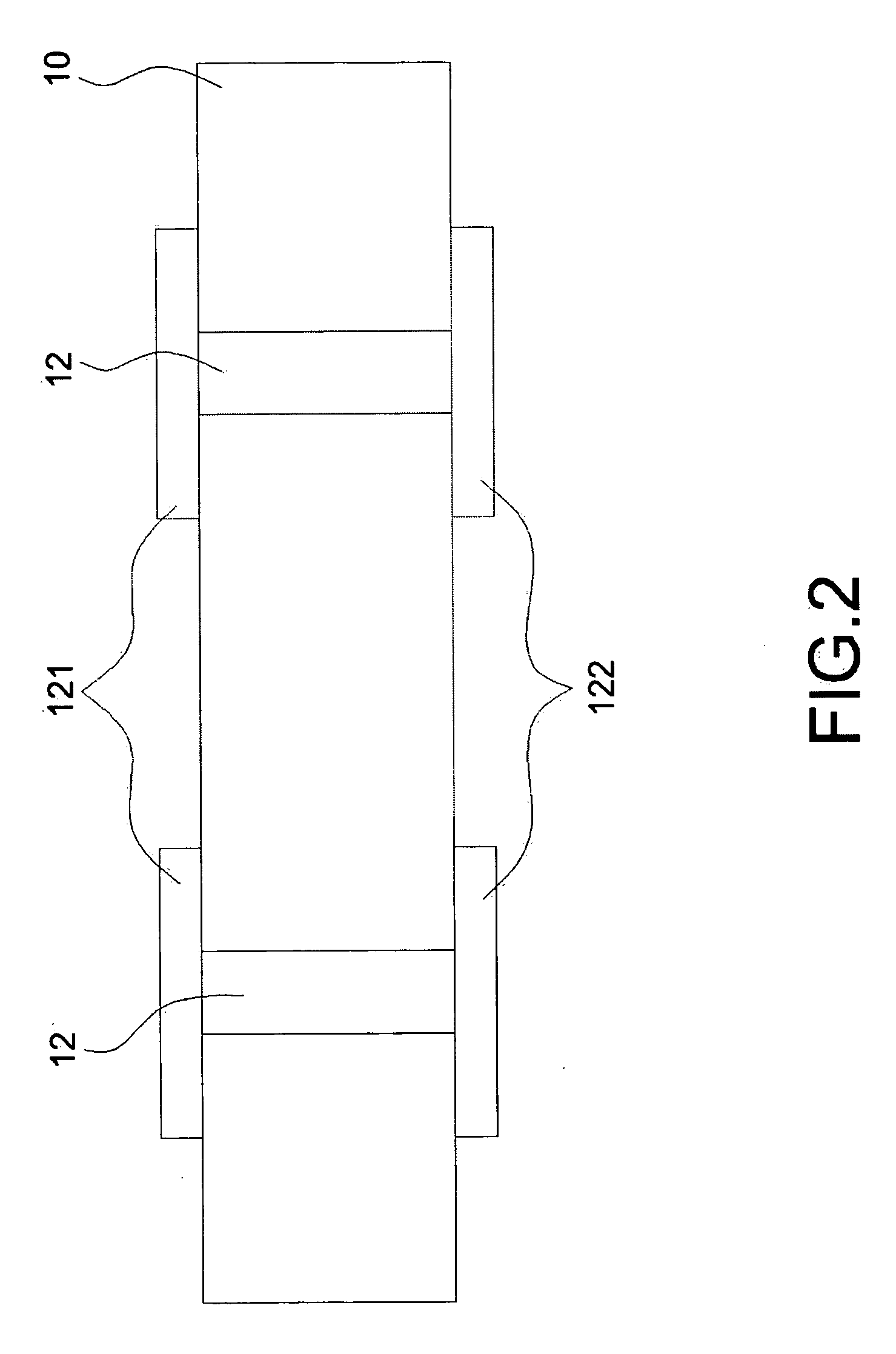

A flip chip packaging technique and associated apparatus that consolidates many or all of the steps in a conventional flip chip packaging process results in substantially decreased packaging time, e.g., only one to two hours, complexity, e.g., requiring fewer pieces and much simpler equipment, and cost, arising from reduced equipment operation and maintenance time and decreased labor. An assembly fixture useful for implementing the consolidated assembly technique engages and holds in place a semiconductor flip chip die with a plurality semiconductor package components in a desired package configuration so that they can be assembled into a semiconductor package with a single application of heat and pressure.

Owner:ALTERA CORP

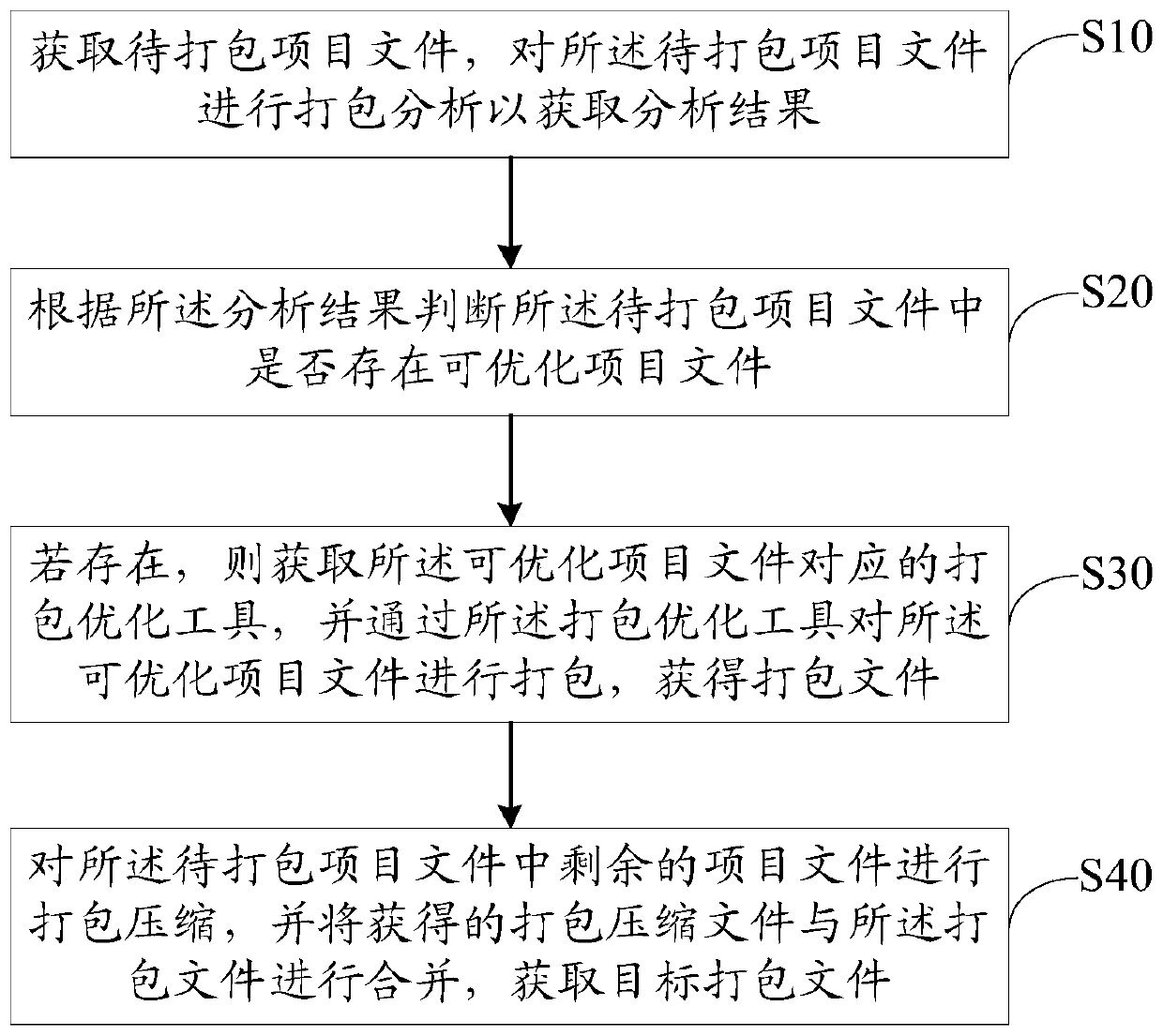

File packaging method and device, equipment and storage medium

PendingCN110286917AShorten packing timeImprove packaging efficiencySoftware deploymentComputer scienceSoftware technology

The invention relates to the software technology, and discloses a file packaging method and device, equipment and a storage medium, and the method comprises the steps: carrying out the packaging analysis of a to-be-packaged project file, and judging whether an optimization project file exists in the to-be-packaged project file or not; if yes, obtaining a corresponding packaging optimization tool, and packaging the optimizable project file according to the packaging optimization tool to obtain a packaged file; packaging and compressing the remaining project files; combining the obtained packaged compressed file with the packaged file to obtain a target package file. Packaging and analyzing is carried out firstly, whether an optimizable project file exists or not is determined according to an analysis result; the optimized project file is optimally packaged according to the packaging optimization tool if so, so that the optimized project file can be packaged in a targeted manner, and the packaging compression of other files is not influenced even if a single optimized project file fails to be packaged, thereby shortening the file packaging time and improving the packaging efficiency.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

Injection molding system and method of chip package

ActiveUS20120187582A1Low costShorten production timeSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsShell moldingFilling materials

The injection molding system comprises a substrate, an inner cover, a molding tool, and a bottom plate. The substrate is used to locate at least one semiconductor device under molding and the inner cover with at least one first injection via, cavity and runner placed over the substrate. In addition, the molding tool includes at least one second injecting via aligned with the runner and the bottom plate is placed under the substrate. Furthermore, a filling material is filled into the cavity and runner of the inner cover during molding. In order to avoid overflowing the filling material, the system further comprises an O-ring placed between the molding tool and the inner cover. The inner radius of the O-ring corresponds with the inner radius of the injection via and is aligned with it.

Owner:ADL ENG

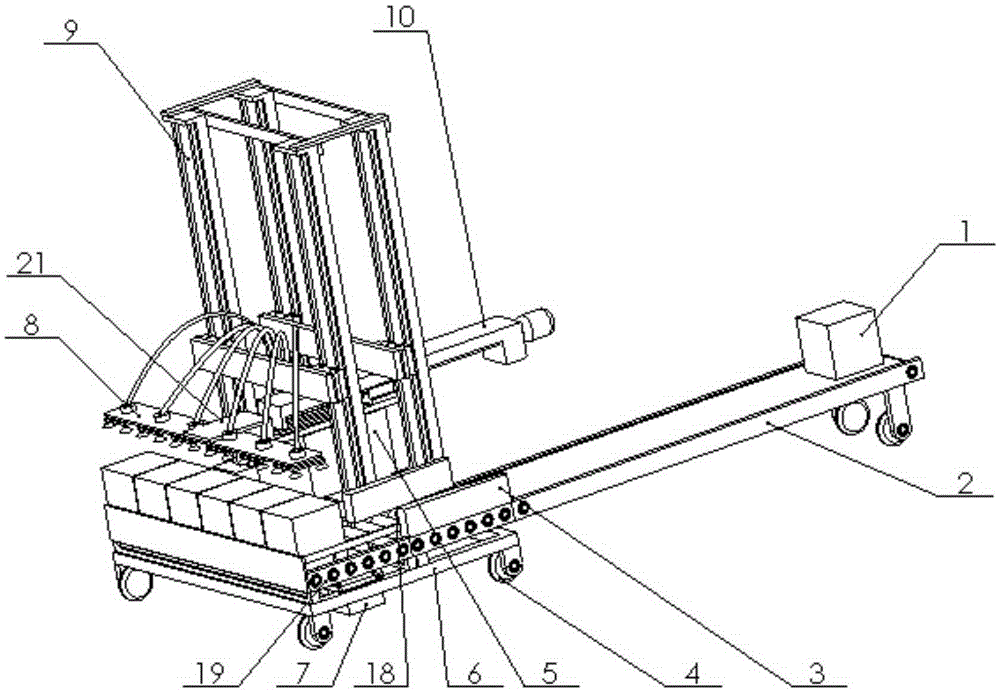

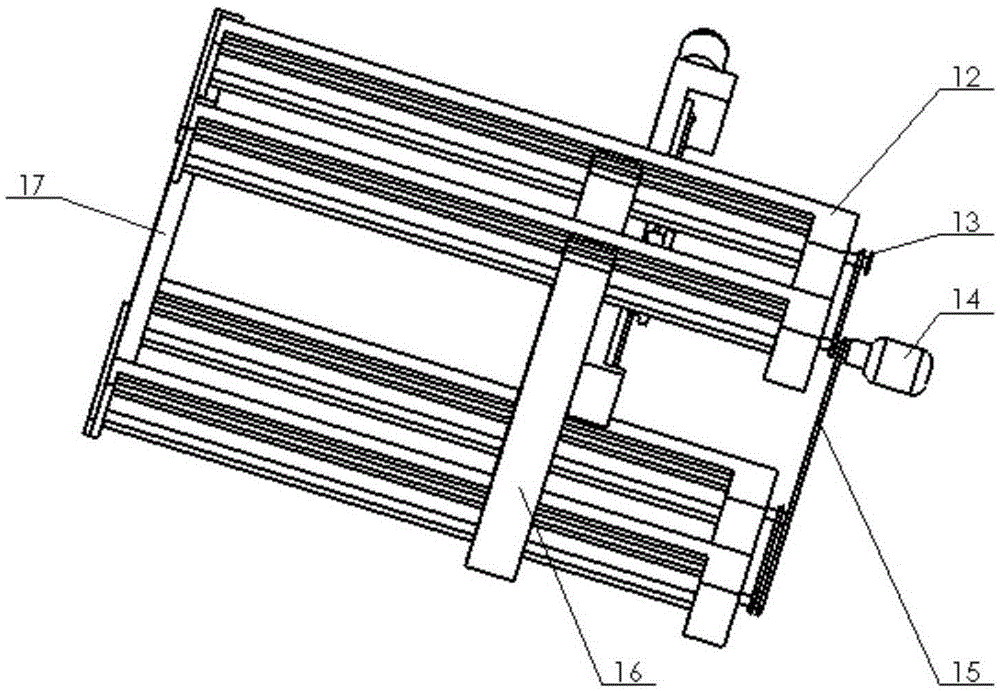

Pneumatic quick stacker crane for container

InactiveCN105347054AImprove delivery efficiencyFast palletizingStacking articlesDe-stacking articlesSlide plateConveyor belt

The invention discloses a pneumatic quick stacker crane for a container. An existing stacker crane is complex in structure and low in stacking efficiency. A roller platform is arranged at a front portion of a frame of the pneumatic quick stacker crane; a transverse box pushing mechanism transversely pushes packaging boxes conveyed by a conveyor belt mechanism on the roller platform; a longitudinal pushing mechanism comprises a lead rod guide rail sliding table, a longitudinal push plate, and two equal-height sliding plates arranged with a distance therebetween; the two ends of each sliding plate are fixed with sliding tables of two lead screw guide rail sliding tables of an elevator mechanism; a guide rail of the lead rod guide rail sliding table of the longitudinal pushing mechanism is fixed with the two sliding plates; the longitudinal push plate is fixed with a sliding table of the lead rod guide rail sliding table of the longitudinal pushing mechanism and a sucker mechanism; a lead screw of the lead rod guide rail sliding table of the longitudinal pushing mechanism is driven by a servo motor. The conveyor belt mechanism and the transverse box pushing mechanism of the pneumatic quick stacker crane for the container are capable of continuously conveying the packaging boxes to the roller platform, thereby improving the box conveying efficiency; after the packaging boxes are gathered into a row, all the packaging boxes are sucked up by the sucker mechanism and once conveyed into the container by the longitudinal pushing mechanism, and therefore, a stacking speed is increased.

Owner:河南小大机器人股份公司

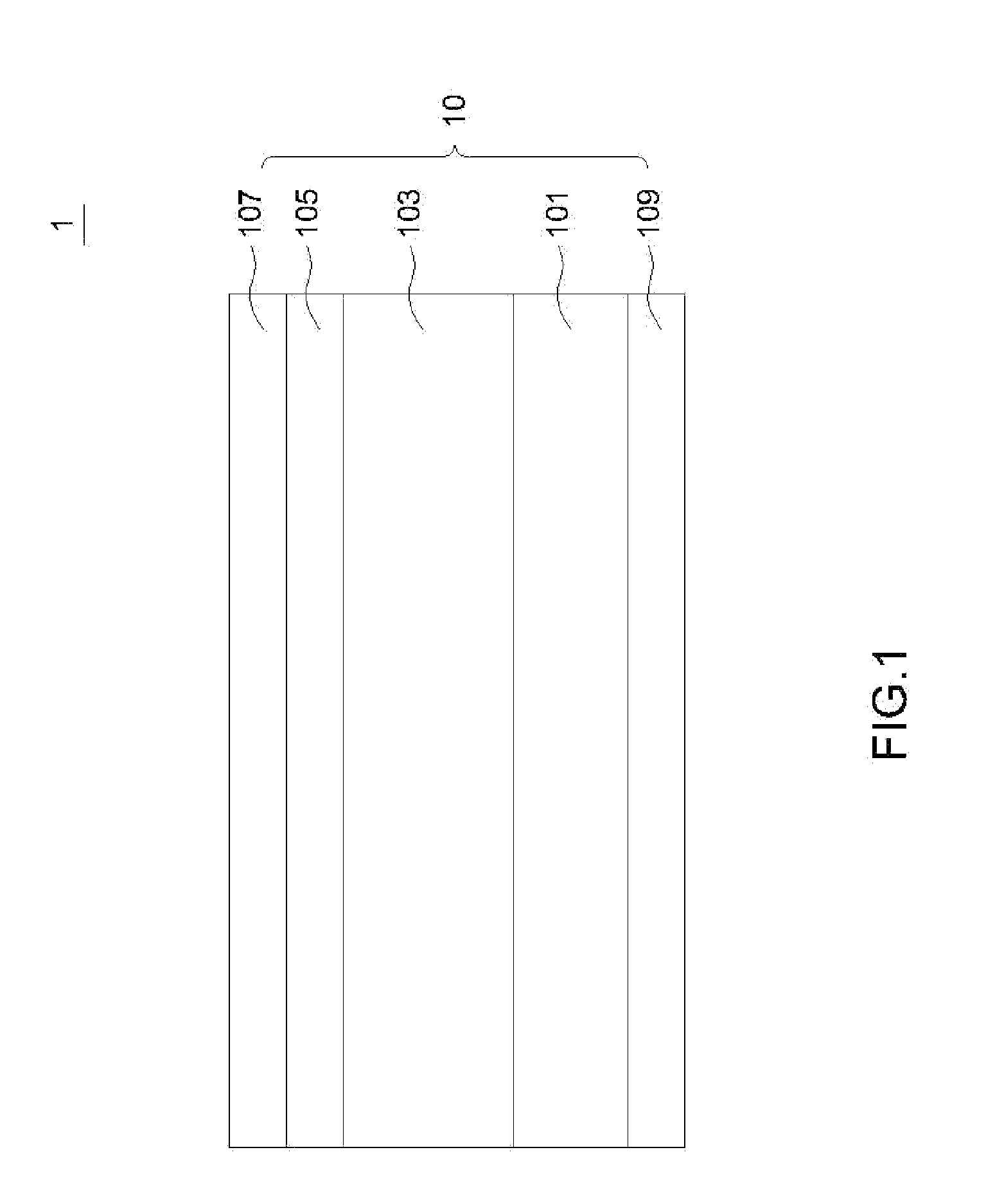

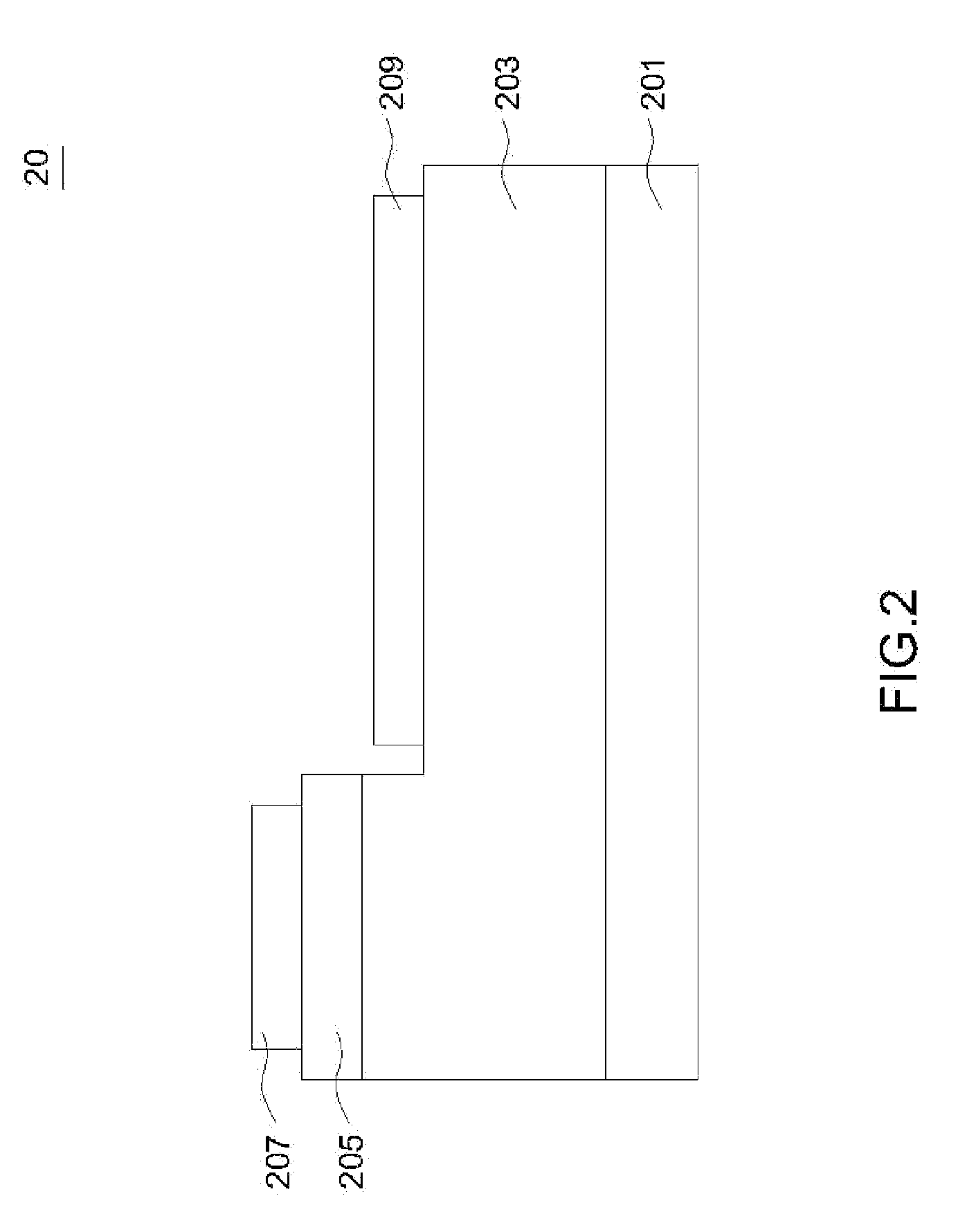

Packaging chip and packaging method thereof

InactiveUS20060273444A1Fast plating speedShorten packing timeSemiconductor/solid-state device detailsSolid-state devicesEngineeringAdemetionine

A packaging chip in which a circuit module is packaged and a method of packaging a circuit module are provided. The packaging chip includes a base wafer; a circuit module on the base wafer; a packaging wafer having a cavity and combined with the base wafer so that the circuit module fits inside the cavity; a connecting electrode connecting upper and lower surfaces of the cavity; and a seed layer between the connecting electrode and the packaging wafer. The method includes etching a lower surface of the packaging wafer to form a cavity, stacking a metal layer in an area of the lower surface, combining the base wafer with the packaging wafer, polishing the packaging wafer, forming a viahole through the packaging wafer, stacking a seed layer on the packaging wafer, plating the inside of the viahole, removing the seed layer and forming an electrode.

Owner:SAMSUNG ELECTRONICS CO LTD +1

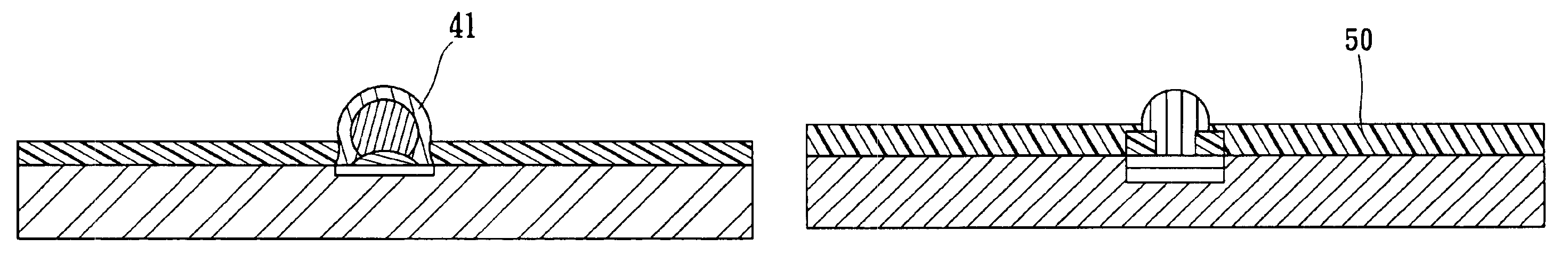

Film and chip packaging process using the same

InactiveUS20080113472A1Relieve stressEliminate cracksSemiconductor/solid-state device detailsSolid-state devicesElastomerMolten state

A film includes a removable base material, a resin layer and a plurality of arc elastomers. The resin layer is a partially-cured resin which is in a half-melting state with viscosity at a temperature higher than a first temperature and in a solid state without viscosity at a temperature lower than a second temperature, and the resin layer in a solid state is adhered on the base material. The arc elastomers are disposed inside the resin layer. The present invention further provides a chip packaging process using the film.

Owner:ORIENT SEMICON ELECTRONICS

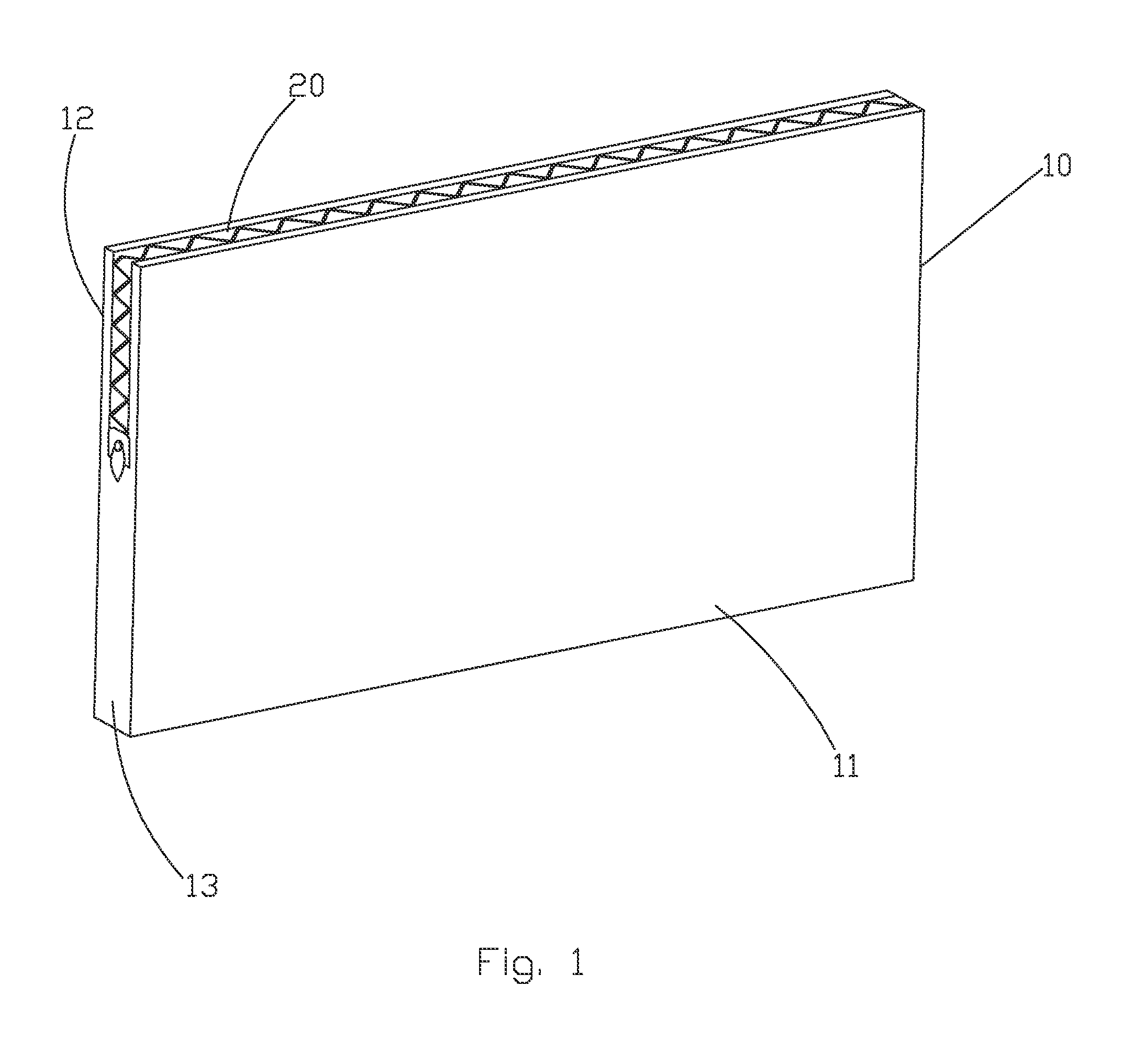

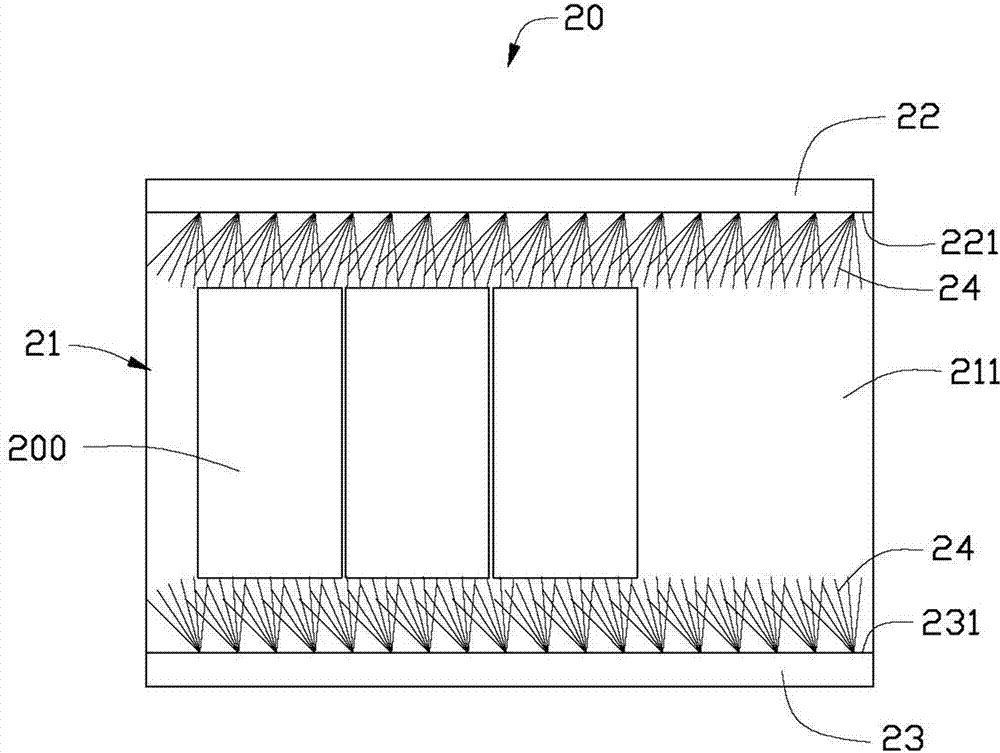

Zipper Type Liquid Crystal Module Packaging Bag and Method for Packaging Liquid Crystal Module with Same

InactiveUS20130292295A1Easy to packEasy accessConnecting packagesFlexible container closureEngineeringAntistatic Materials

The present invention provides a zipper type liquid crystal module packaging bag and a method for packaging a liquid crystal module with the packaging bag. The packaging bag includes a bag body and a zipper mounted to the bag body. The bag body forms an opening for receiving entry of a liquid crystal module into the bag body. The zipper is mounted to the opening. Through zipping up and down the zipper, the opening is opened or closed. The bag body has inside surfaces and outside surfaces that are respectively opposite to each other. The inside surfaces are made of a soft antistatic material. The arrangement of zipper allows packaging and deposition / removal of the liquid crystal module to be done conveniently. The inside surfaces of soft antistatic material provide excellent resistance against static electricity and good protection of the surface of the liquid crystal module.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

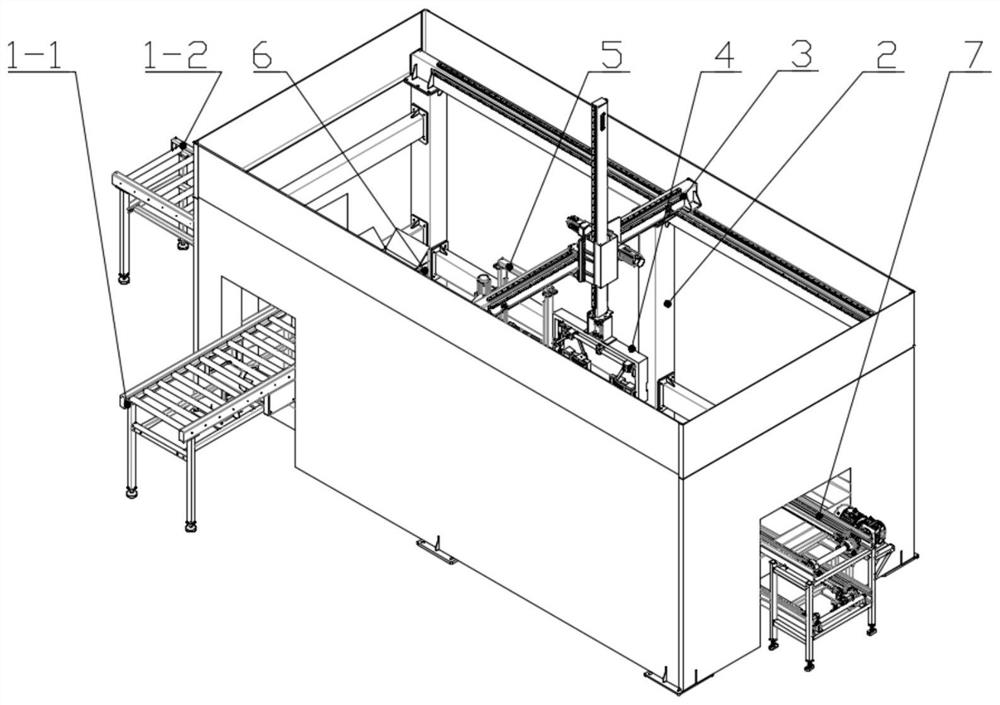

Automatic boxing machine for articles on production line

ActiveCN111776270AImprove packaging efficiencyReduce manufacturing costConveyorsCharge manipulationManufacturing lineIndustrial engineering

The invention discloses an automatic boxing machine for articles on a production line. The automatic boxing machine comprises a packaging box input roller line I, a product output roller line II, a three-degree-of-freedom mounting rack, a boxing manipulator, a tray reversing device, a packaging box positioning and steering device and a circulating speed chain; the packaging box input roller line Iis used for inputting packaging boxes into the packaging box positioning and steering device; the product output roller line II is used for outputting the boxed articles; the equipment frame is usedfor fixing the three-degree-of-freedom mounting rack; the three-degree-of-freedom mounting frame is used for driving a boxing manipulator installed on the three-degree-of-freedom mounting frame to dolinear motion in six directions; the boxing manipulator is used for grabbing the to-be-boxed articles on the circulating speed chain and placing the to-be-boxed articles into the packaging box; the tray reversing device is used for conveying empty trays conveyed from the upper layer of the circulating speed chain to the lower layer of the circulating speed chain; the packaging box positioning andsteering device is used for receiving the packaging box input by the packaging box input roller line I and conveying the boxed articles to the product output roller line II; and the circulating speedchain is used for conveying to-be-boxed articles and recycling the empty trays. According to the automatic boxing machine for the articles on the production line, by means of the mechanical control mode, boxing of articles is achieved, and recycling of the empty trays is further achieved while boxing is conducted.

Owner:KUNMING UNIV OF SCI & TECH

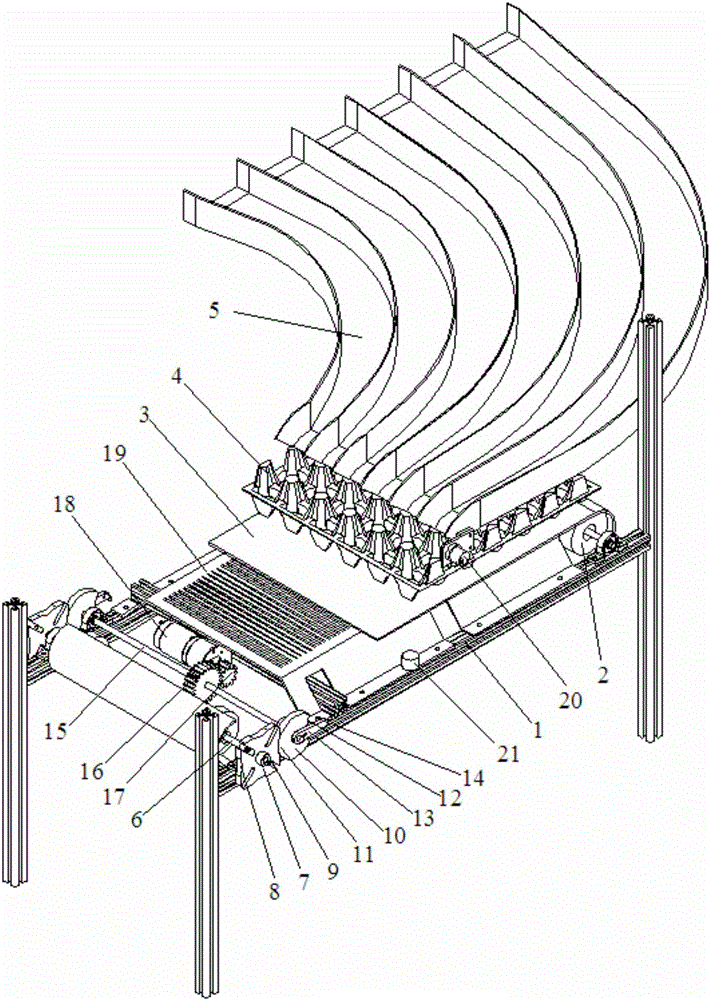

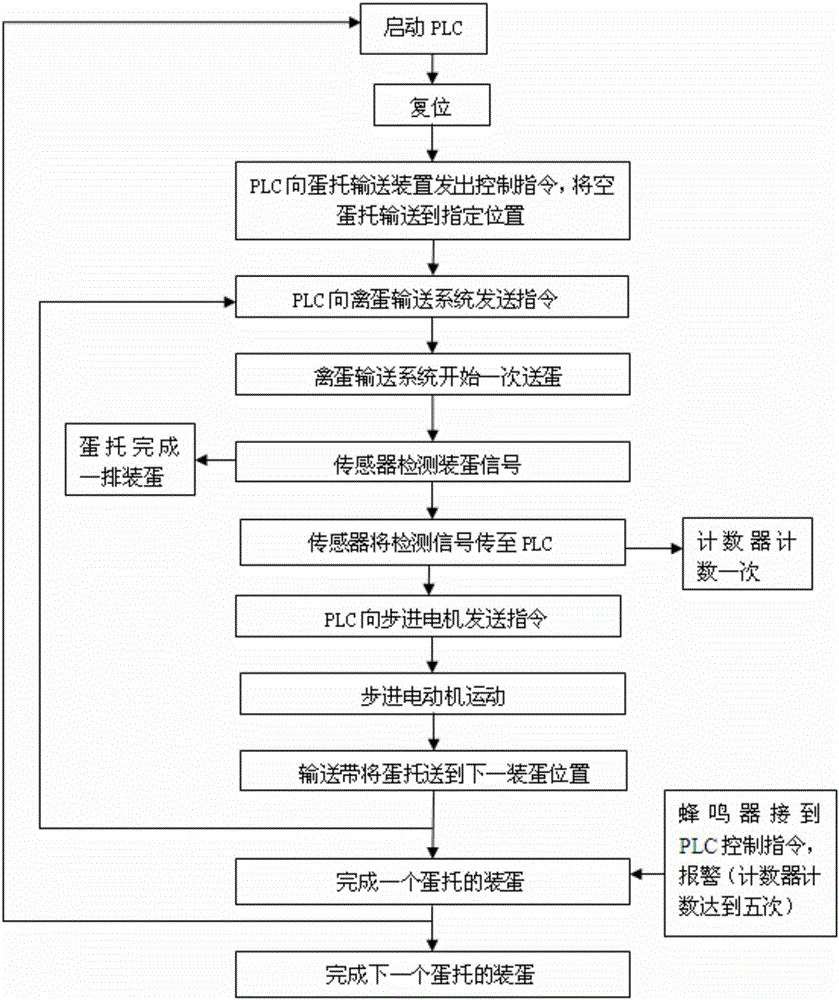

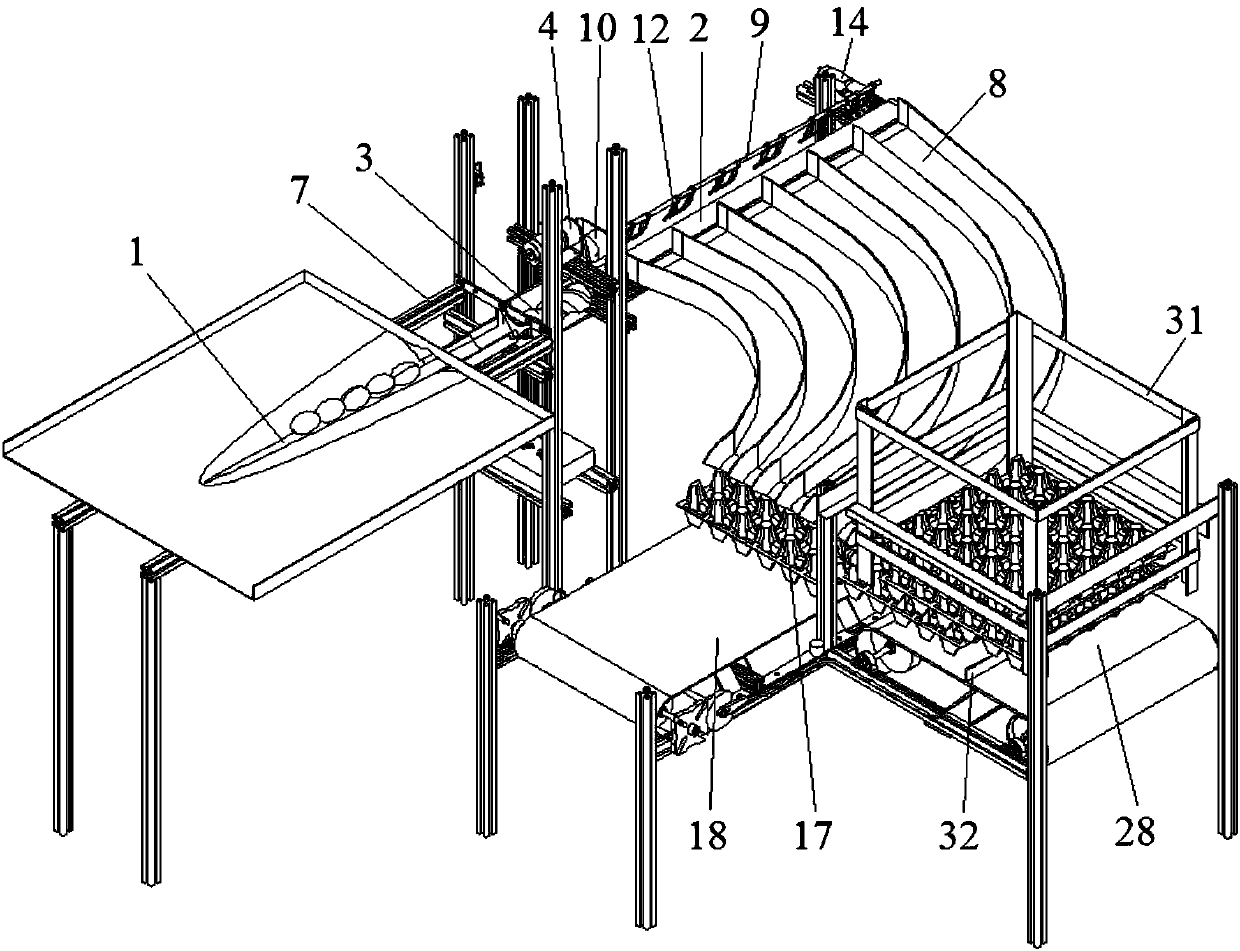

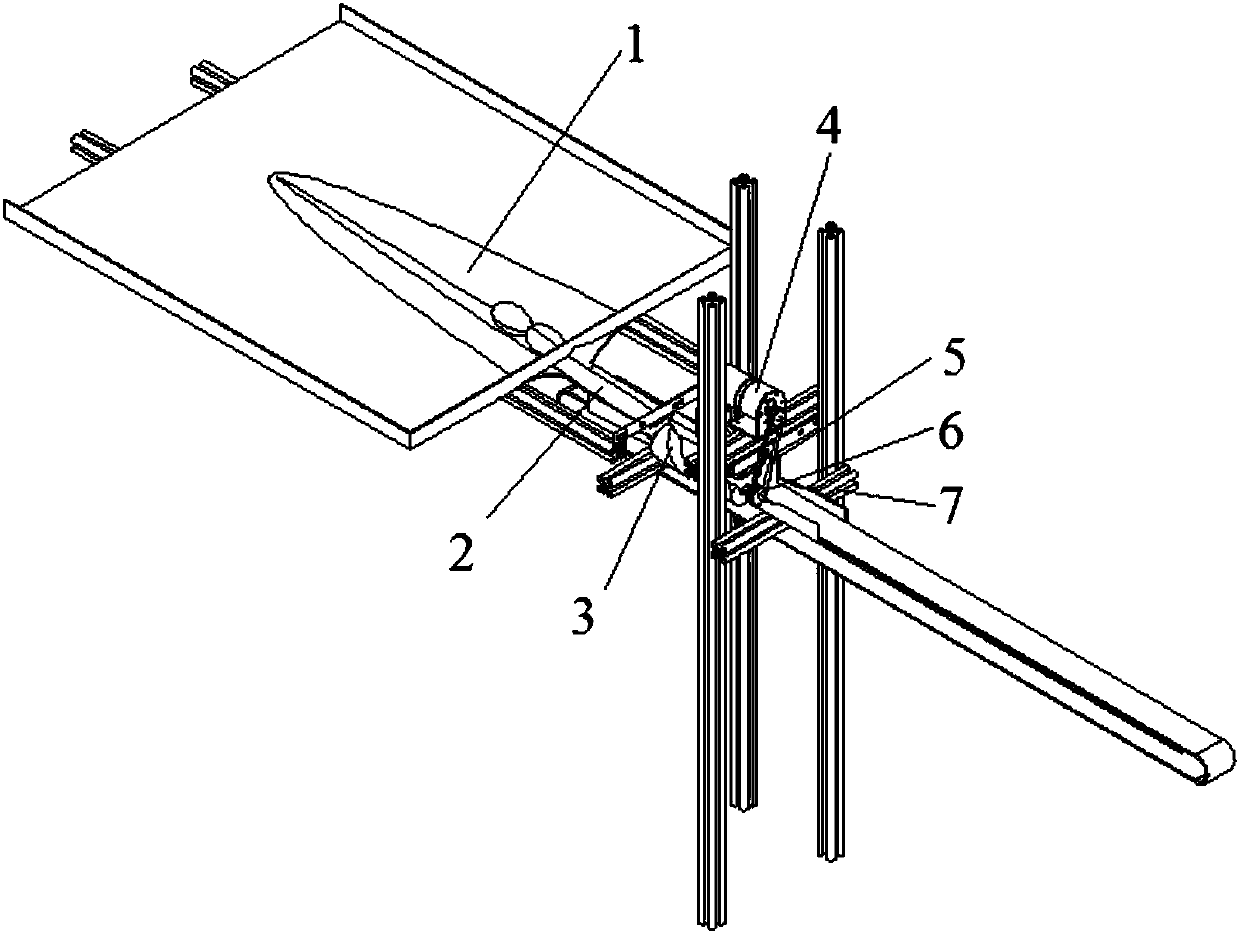

Stepping egg packing device and control method thereof

InactiveCN106043788AShorten packing timeReduce labor intensityPackaging eggsPackaging automatic controlProduction lineControl system

Provided are a stepping egg packing device and a control method of the stepping egg packing device. The stepping egg packing device comprises a mechanical system and a control system. The mechanical system and the control system are matched with each other. Egg delivery signals are detected through a sensor and transmitted to a PLC module, and then a stepping motor is controlled to move to drive an egg carton to move. In this way, the stepping egg packing device can automatically put eggs on multiple rows and lines of egg sites on the egg carton, achieve automatic egg packing, shorten the egg packing time and improve the egg packing efficiency; and workers just need to take away the egg carton filled with the eggs, and therefore the labor intensity of the workers is lowered. Because of the adopted PLC module, the stepping egg packing device is suitable for production lines of different production efficiency and different specifications. Because electric drive is adopted, the stepping egg packing device is high in accuracy, capable of saving energy, environmentally friendly, low in noise, capable of achieving precise control and easy to expand.

Owner:LIAONING TECHNICAL UNIVERSITY

Anti-gouges intelligent transport case for fresh products

InactiveCN113602650APrevent spoilageAvoid lostLiving organism packagingShock-sensitive articlesElectric machineryTransportation technology

The invention belongs to the technical field of fresh product transportation, and particularly relates to an anti-gouge intelligent transport case for fresh products. The anti-gouge intelligent transport case for the fresh products comprises a shell, a conveying belt, a rotating roller, a motor, baffles and a refrigeration component. According to the anti-gouge intelligent transport case for the fresh products provided by the invention, the space in the transport case is divided into multiple independent spaces through the conveying belt and the baffles, and the fresh products are independently placed in the separated independent spaces in the fresh product transportation process, so that the fresh products are prevented from being squeezed and rubbed mutually in the transportation process; meanwhile, the conveying belt and the baffles can move, so that when the fresh products are placed, the face, with the large area, of each baffle faces the side of a placing opening; in the placing process, the fresh products cannot touch the small-area side walls of the baffles, so that the surfaces of the fresh products cannot be scratched; and compared with a traditional fixed separation mode, the side wall of a separation plate is not prone to being impacted during feeding, so that damage to the skins of the fresh products in the boxing process is reduced, corrosion is reduced, and economic losses are avoided.

Owner:韩金磊

Automatic stacking output mechanism

Owner:SHANDONG SONGYUAN AUTOMATION EQUIP

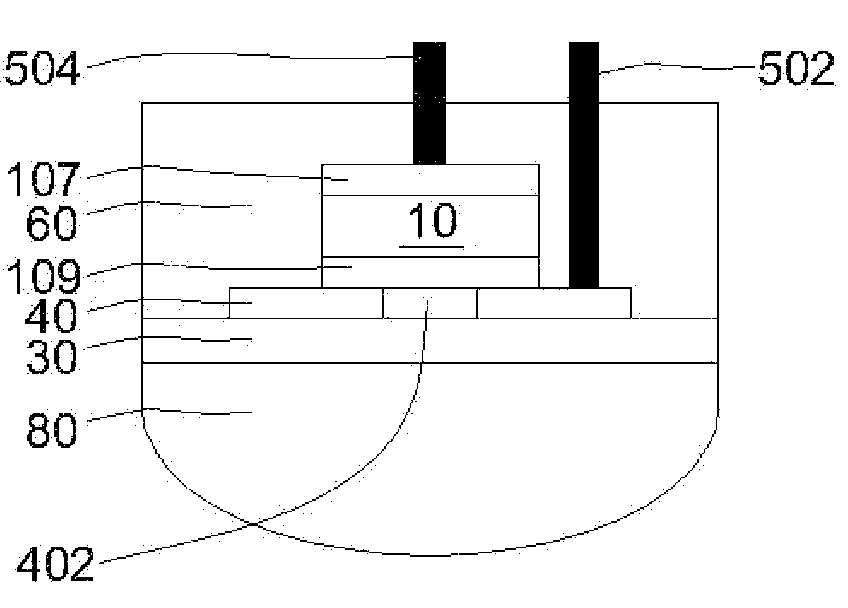

Injection molding system and method of chip package

ActiveUS8293572B2Low costShorten the timeSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsShell moldingFilling materials

The injection molding system comprises a substrate, an inner cover, a molding tool, and a bottom plate. The substrate is used to locate at least one semiconductor device under molding and the inner cover with at least one first injection via, cavity and runner placed over the substrate. In addition, the molding tool includes at least one second injecting via aligned with the runner and the bottom plate is placed under the substrate. Furthermore, a filling material is filled into the cavity and runner of the inner cover during molding. In order to avoid overflowing the filling material, the system further comprises an O-ring placed between the molding tool and the inner cover. The inner radius of the O-ring corresponds with the inner radius of the injection via and is aligned with it.

Owner:ADL ENERGY CORP

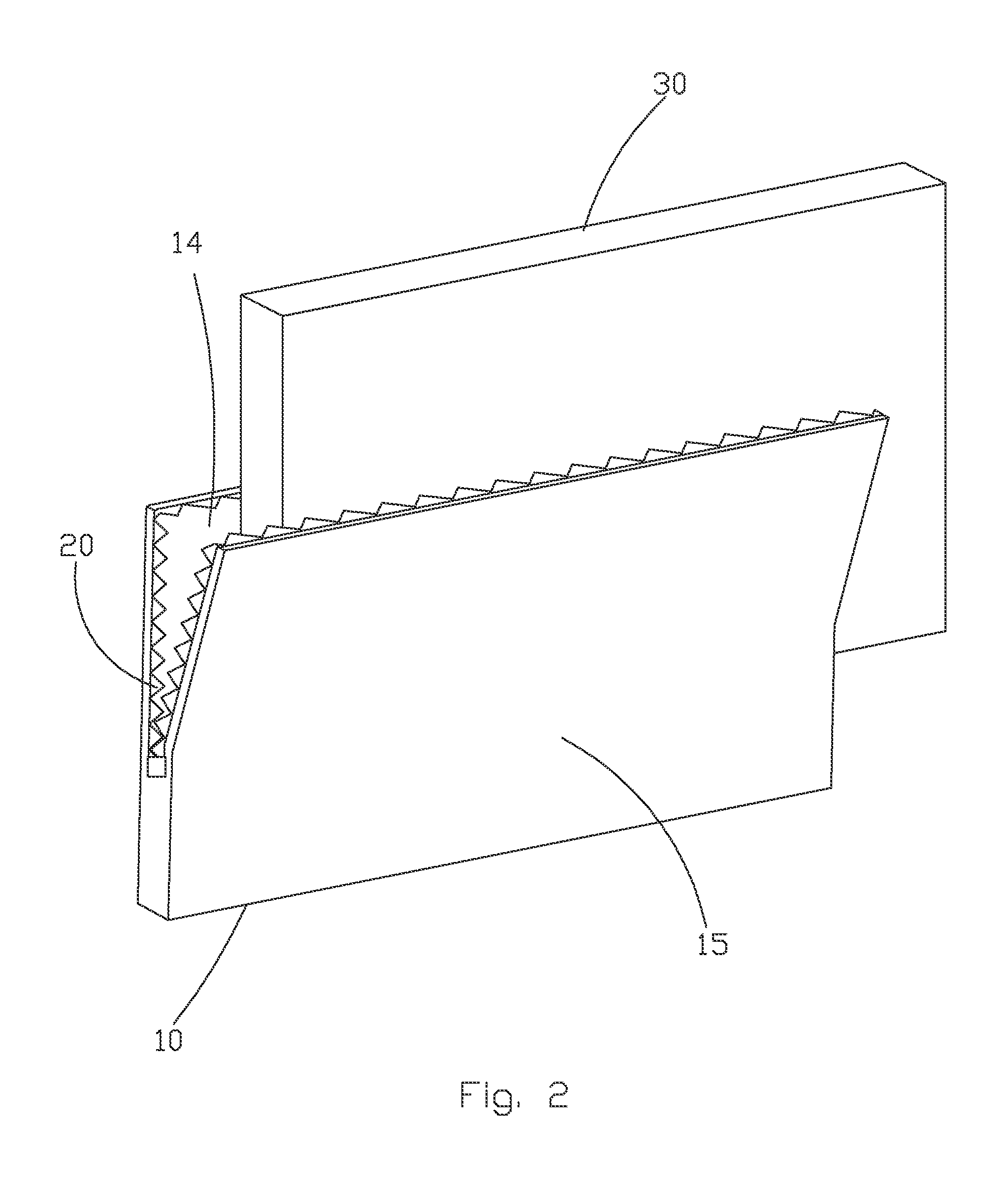

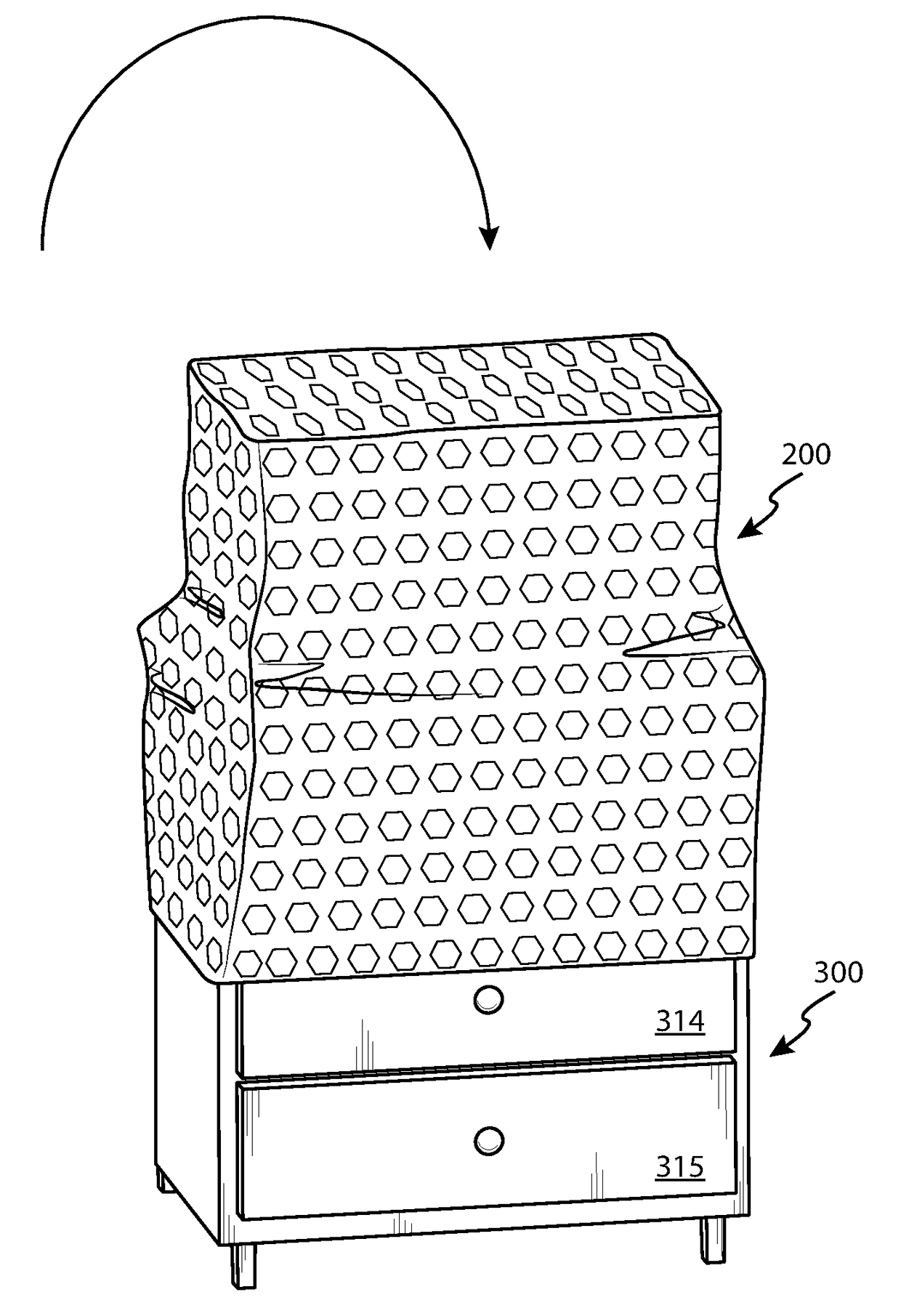

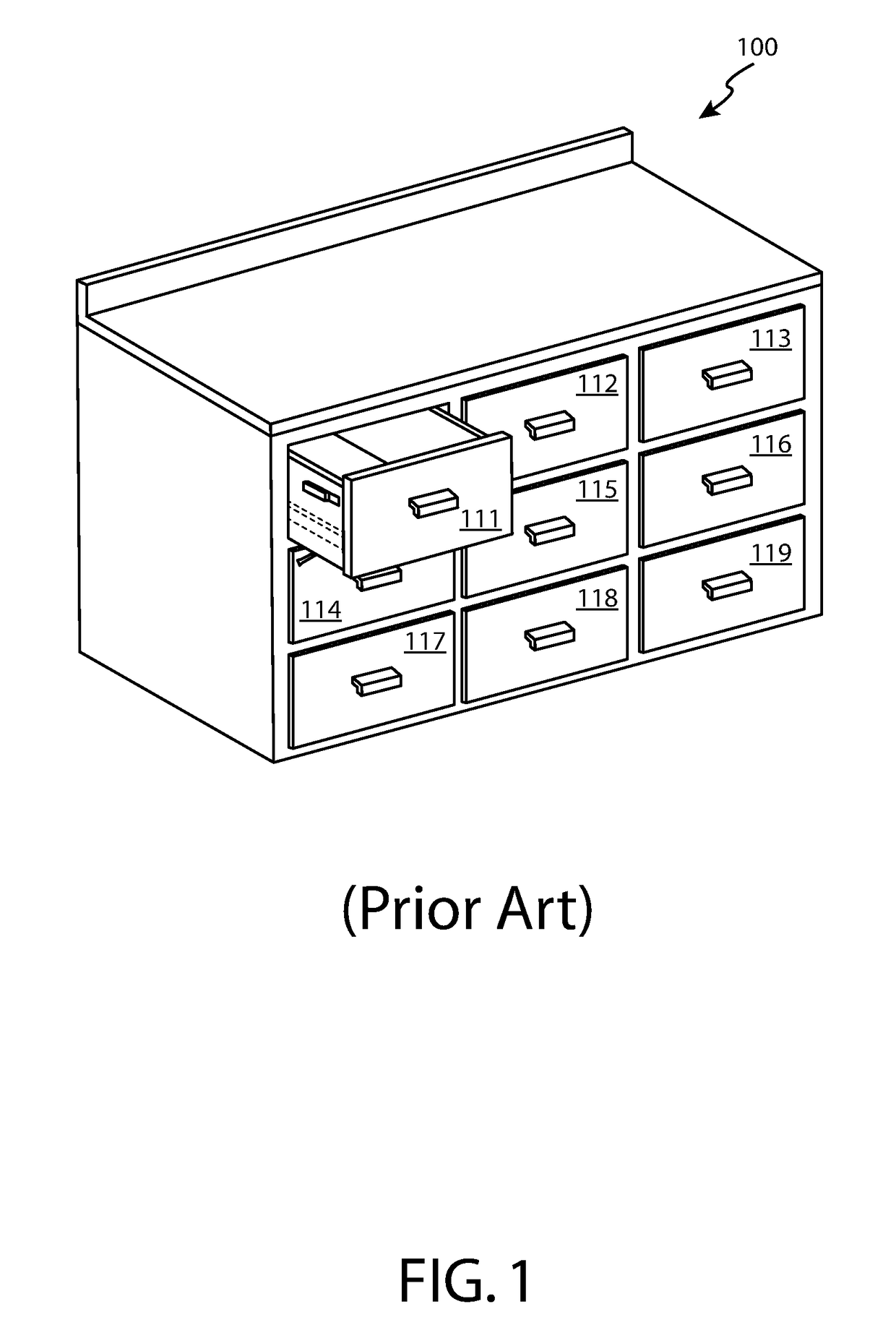

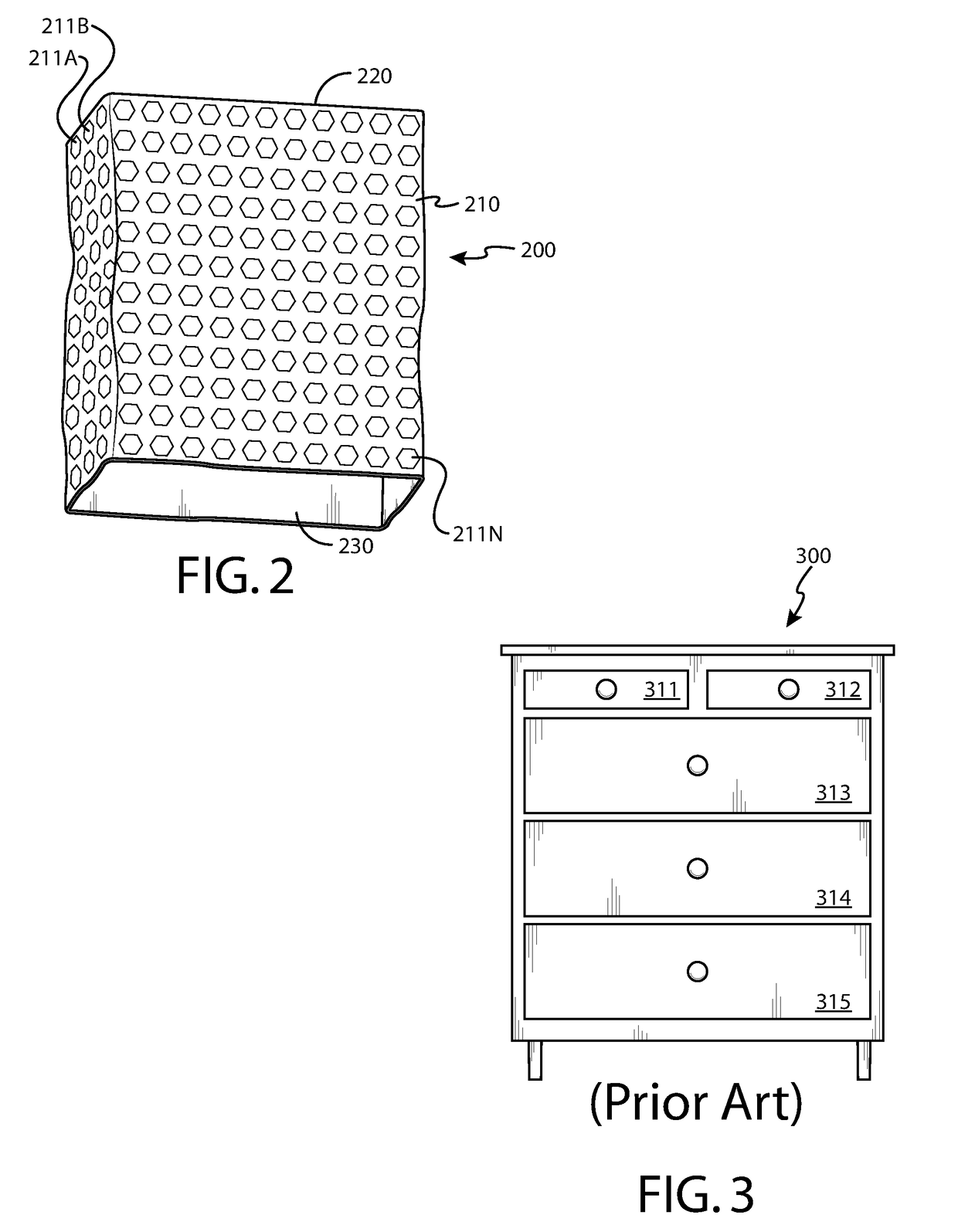

Protective Cover for Moving Items

InactiveUS20170305631A1Shorten packing timeEasily slipped over moving itemWardrobesFlexible coversEngineeringMoving parts

The present invention provides a resilient and tough, but flexible protective cover that hugs and squeezes various types of moving items without the need for any external securing means such as tape, rope, straps, large rubber bands, plastic, etc. The protective cover prevents damage to items that might occur during the course of moving. It eliminates, among other types of damage, scuffs, scrapes, dents, and scratches that could happen when items are being moved. While the protective cover is “hugging” the items, it also keeps items with moving components such as desks, dressers, cabinets, and appliances, in place by preventing shifting or movement of the moving components.

Owner:LEWIS MICHAEL RAY

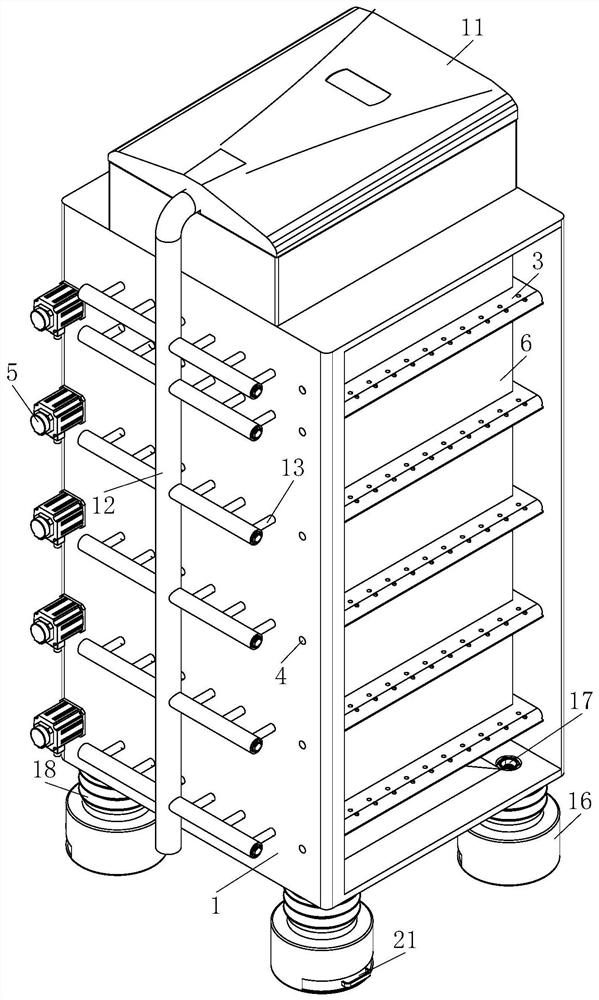

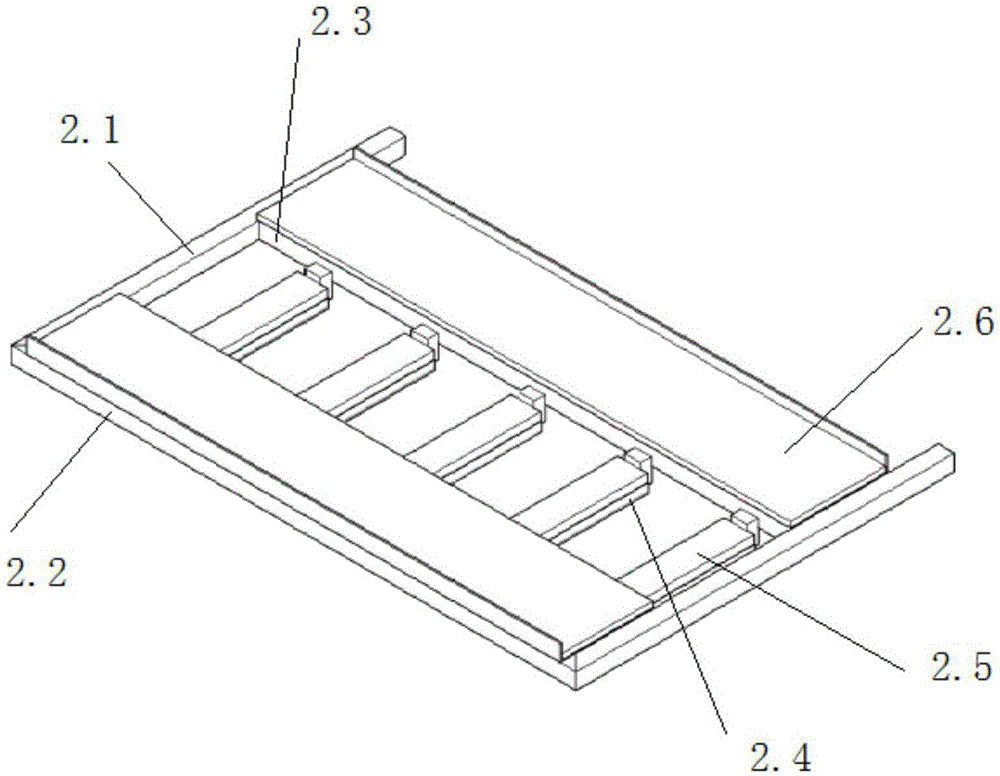

Front floor reinforcer assembly packing container

InactiveCN105923241AAvoid scratchesAvoid elasticPackaging vehiclesContainers for machinesStructural engineeringMechanical engineering

The invention discloses a front floor reinforcer assembly packing container of an automobile. The front floor reinforcer assembly packing container comprises directional wheels, universal wheels, a front tractor and a back tractor and further comprises an outer frame and trays. The trays are installed in the outer frame. The front tractor and the back tractor are installed on the front portion and the back portion of the outer frame correspondingly. The universal wheels are installed at the front end of the bottom of the outer frame. The directional wheels are installed at the back end of the bottom of the outer frame. A forklift position is further arranged at the bottom of the outer frame. Each tray is formed by combining longitudinal square pipes, transverse square pipes and tray supports and is of a U structure. Grooves are formed in the middle of each tray and provided with foam. Plastic plates are arranged on the planes at the two ends of each tray. According to the front floor reinforcer assembly packing container of the automobile, the phenomena that parts are scratched and bounced out of the container in the transportation process can be effectively avoided; the encasing time is saved; over-shipment, short-shipment and the count trouble are avoided; the effect of being clear at a glance is achieved; and the parts are stable, clean and free of dust.

Owner:WUHAN HUIHENG IND

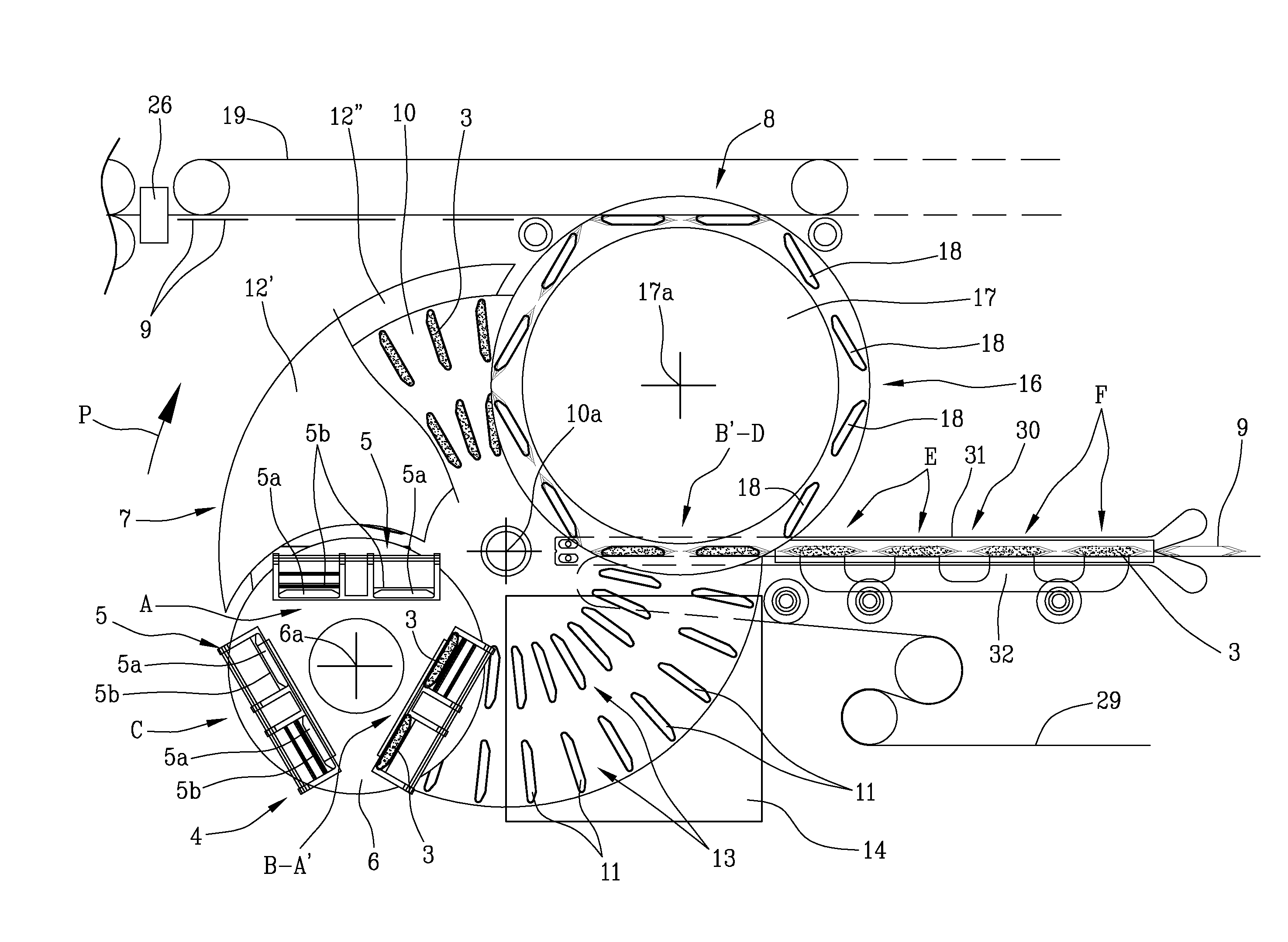

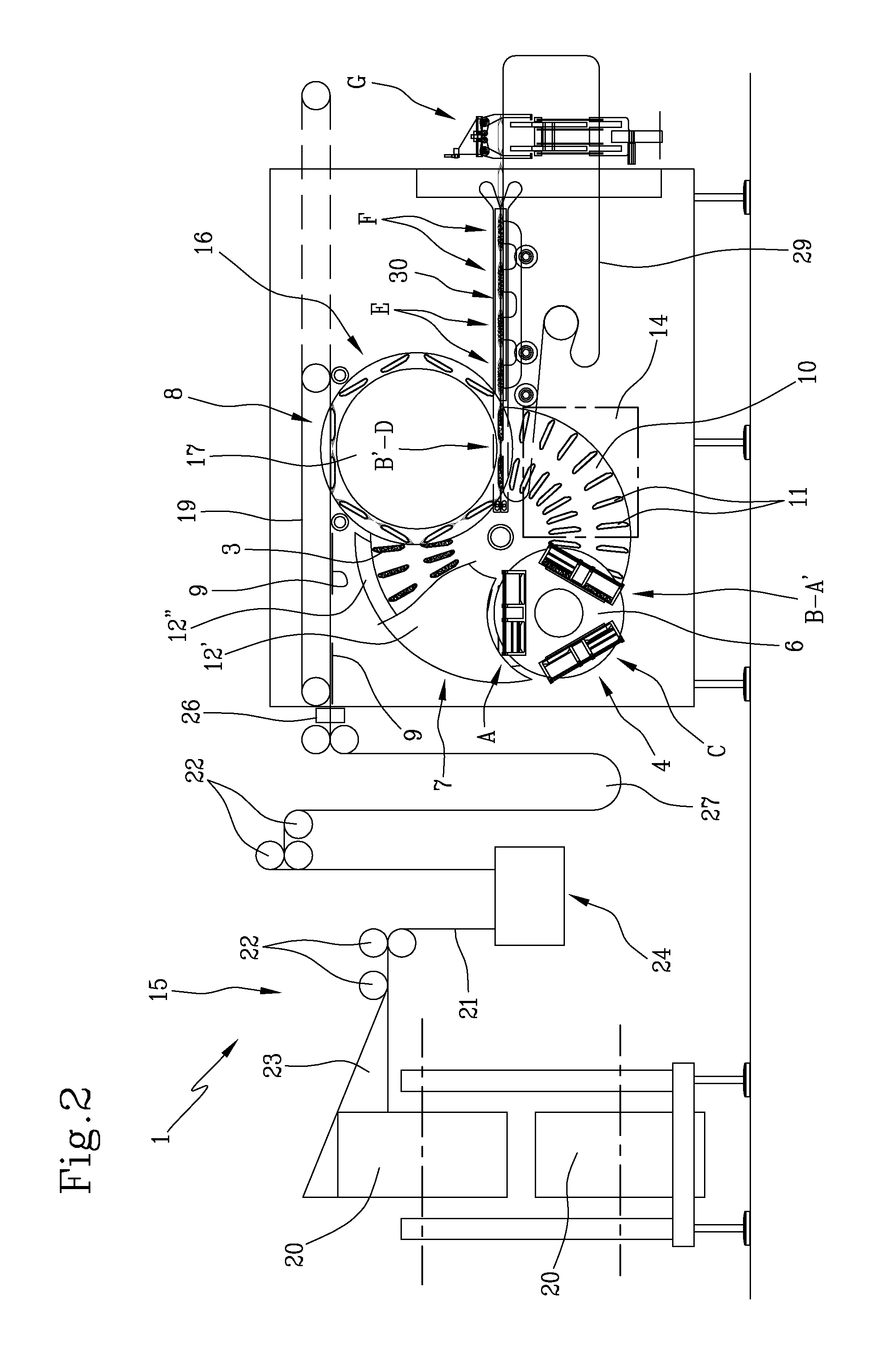

Machine and method for packaging fiber material

ActiveUS8938937B2Improve the level ofExtended shelf lifePackaging cigaretteSolid materialFiberEngineering

A machine for packaging fiber material comprises feed means (2) supplying predetermined portions of fiber material (3) in an ordered succession, compacting means (4) by which the portions of fiber material (3) are compacted initially, a feed station (8) to which packs (9) are supplied for filling with the fiber material (3), a filling station (D) at which the fiber material (3) is inserted into the packs (9), and a closure station (E) located downstream of the filling station (D), at which the filled packs (9) are sealed. The machine further comprises fiber material (3) compressing and forming means (7) by which each of the portions of fiber material (3) is maintained in a state of compression downstream of the compacting means (4) for a prescribed interval of time, in such a way that the selfsame portion of fiber material (3) is caused to assume a compact geometry of tablet-like form prior to its insertion into the respective pack (9).

Owner:AZIONARIA CONSTR MASCH AUTOMATICHE A C M A SPA

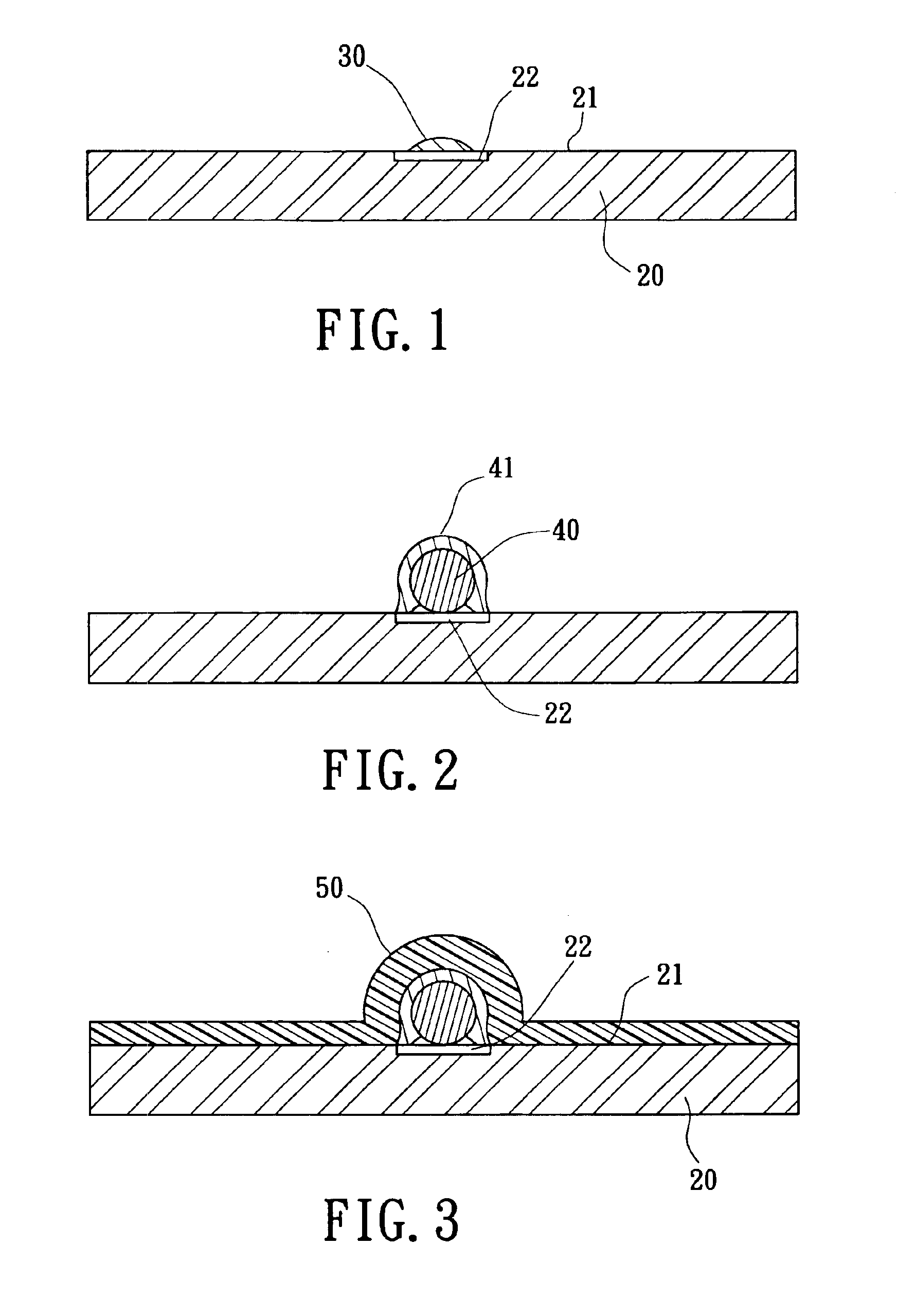

Light emitting diode package structure

InactiveUS20090078953A1Cut costPeriod be reduceSolid-state devicesSemiconductor devicesSemiconductorMetal

The present invention provides a light emitting diode (LED) package, which includes a carrier substrate having a first surface and a second surface; a metal layer formed in the first surface of the carrier substrate, and a through hole formed in the central area of the metal layer to expose the portion of the first surface of the carrier substrate; a LED having a semiconductor layer capable of light emitting, and an N electrode and a P electrode on the two sides of the semiconductor layer, in which P electrode is electrically connected to the first surface of the metal layer; a first connecting element is electrically connected to the metal layer; a second connecting element is electrically connected to the N electrode; and an encapsulated material is formed to cover the LED, the metal layer, the exposed first connecting element and the second connecting element.

Owner:YEH HSIN HUI

Storage and boxing combination method

The invention provides a storage and boxing combination method. The method is characterized by comprising the following steps: 1) making boxing orders according to a delivery requirement of a customer; 2) dividing a garment warehouse into a plurality of corresponding small regions according to the number of boxing orders, wherein the number of garments stored in each region is the same as the number of boxed garments; 3) when produced garments are put in storage, conveying garments of different sizes into the corresponding regions for storage according to the sizes required in the boxing orders; and 4) taking out the garments from the storage regions corresponding to the boxing orders during boxing, and directly performing boxing. The method has the beneficial effects that the process of sorting the stored garment sizes during boxing for delivery is reduced, the boxing time is shortened, the labor for boxing is reduced, and the boxing efficiency is improved.

Owner:TIANJIN JINCHENG CLOTHING APPL CO LTD

A poultry egg automatic packing machine

InactiveCN106043787BShorten packing timeImprove sorting efficiencyPackaging eggsMotor driveEngineering

An automatic packing machine for poultry eggs, including a first conveyor belt, one end of the first conveyor belt is used for feeding poultry eggs, and a spiral drum is arranged in the middle, and the spiral drum is driven to rotate by the first motor, and a plurality of poultry eggs are separated at equal intervals Arranged on the first conveyor belt, one side of the first conveyor belt is provided with multiple egg delivery tracks, and the end of the egg delivery track away from the first conveyor belt is facing multiple egg loading positions in the same row of egg trays. , egg feeding track and poultry eggs correspond one by one, a rotating shaft is erected on the top of the first conveyor belt, and a plurality of toggle brushes are evenly arranged on the rotating shaft, and the rotating shaft is driven by the first stepping motor, which drives the toggle brushes to rotate, so as to Push the poultry eggs into the egg feeding track and enter the egg loading position correspondingly. The egg tray is placed on the second conveyor belt. When the egg loading position on the same row on the egg tray is full of eggs, the second stepping motor drives the second conveyor The belt moves a certain distance for the next row of egg loading positions to load eggs. The above-mentioned automatic box packing machine can improve the efficiency of sorting and packing poultry eggs, and reduces the labor intensity of workers.

Owner:LIAONING TECHNICAL UNIVERSITY

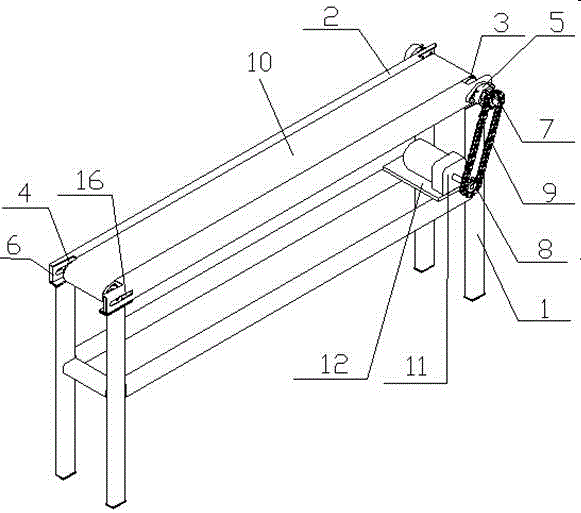

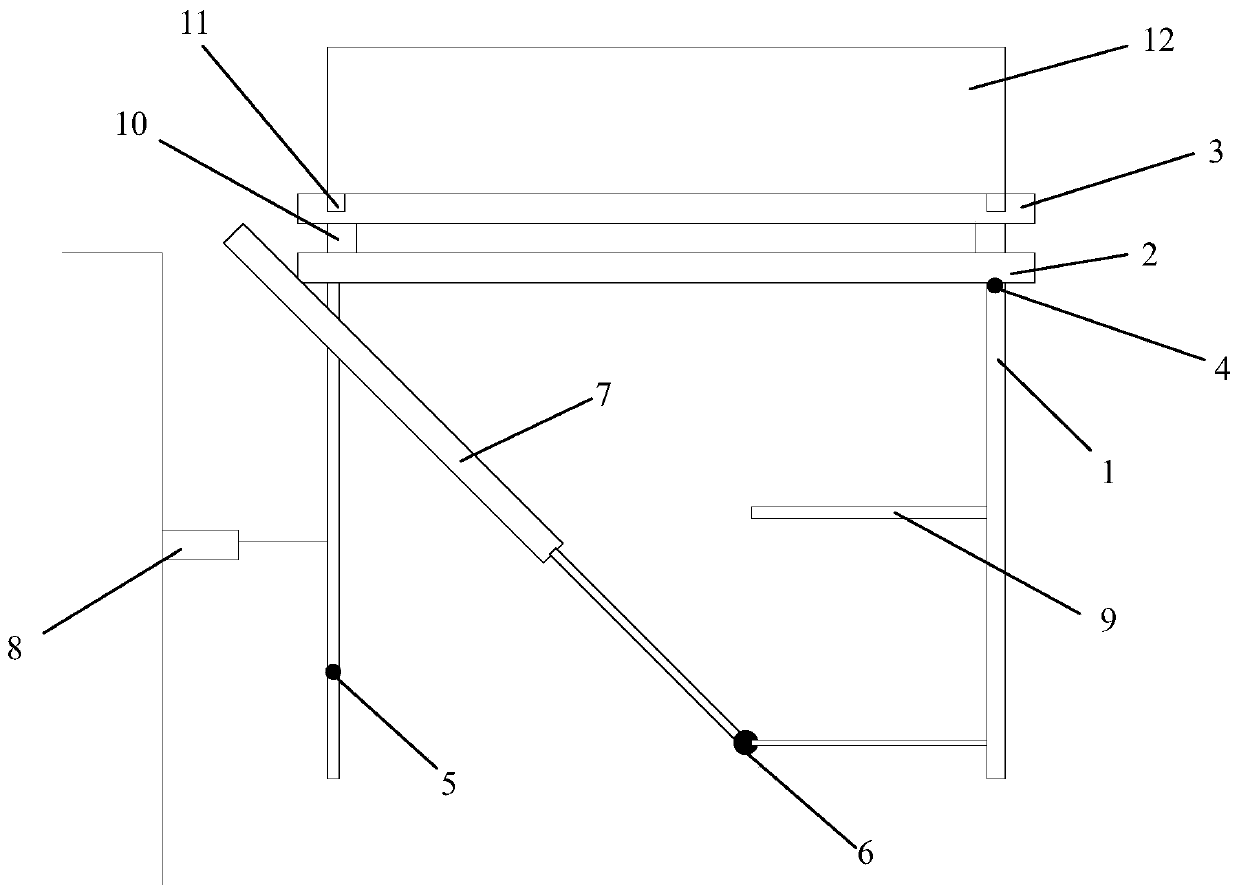

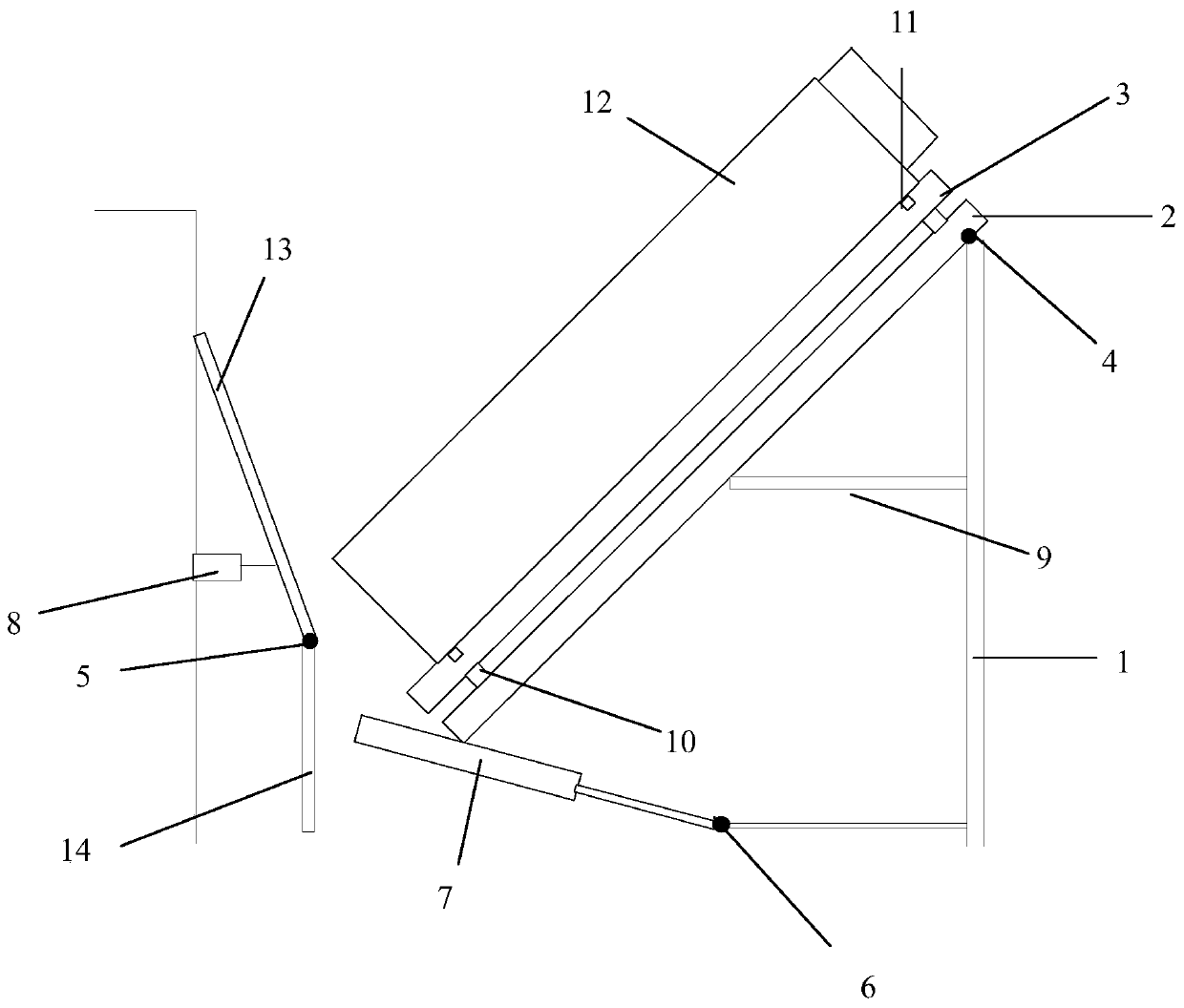

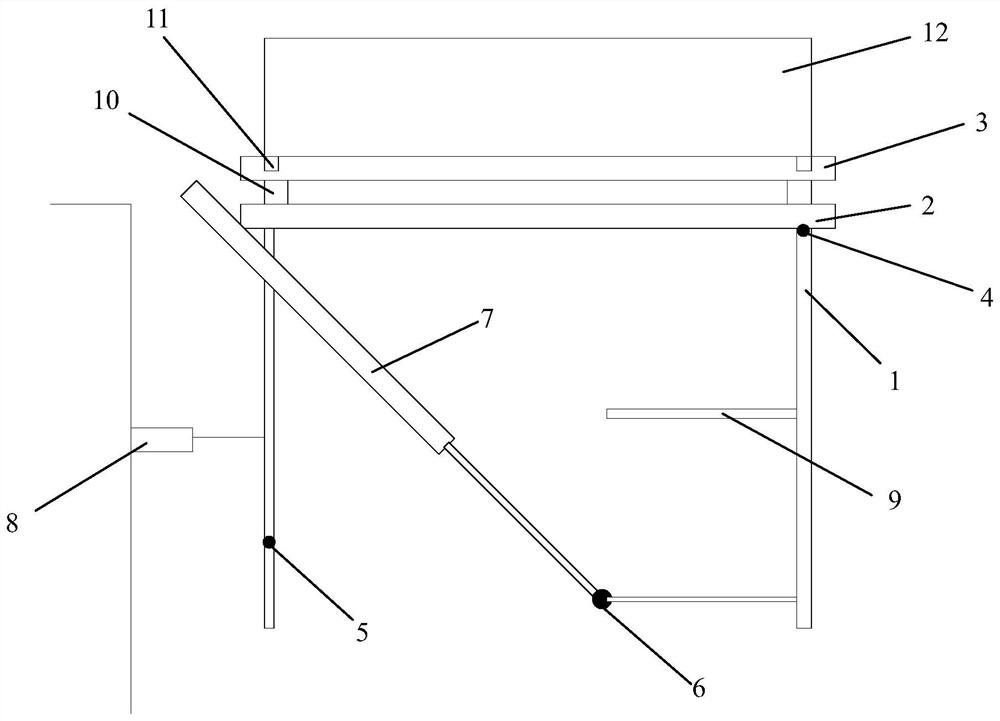

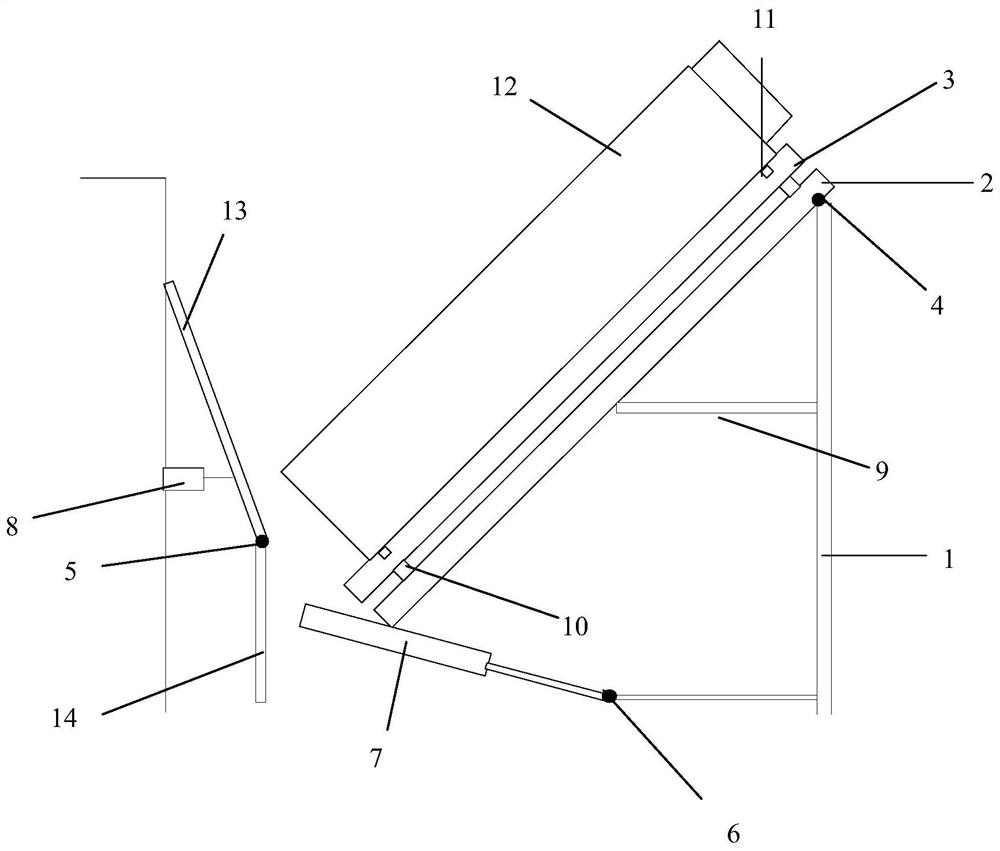

Sunken container-tumbling platform

ActiveCN110436213AShorten packing timeReduce material lossLoading/unloadingFixed positionEngineering

The invention provides a sunken container-tumbling platform. The sunken container-tumbling platform comprises a support, a turnover plate, two first supporting legs, two second supporting legs, a first hydraulic cylinder, a second hydraulic cylinder, a bearing table and a control device. A first rotary base is arranged on one side of the support; one end of the turnover plate is movably connectedwith the first rotary base through a first rotary shaft, and clamping grooves are formed in the two sides of the other end of the turnover plate; one ends of the two first supporting legs are clampedwith the clamping grooves; one ends of the second supporting leg are hinged to the other ends of the first supporting legs; a cylinder body of the first hydraulic cylinder is fixedly arranged on the support, and a piston rod of the first hydraulic cylinder is connected with a cross beam between the first supporting legs; a cylinder body of the second hydraulic cylinder is fixedly arranged at the other end of the turnover plate, and a piston rod of the second hydraulic cylinder is movably connected with a second rotating base of the fixed position through a second rotating shaft; the bearing table is fixedly arranged on the turning plate, and rotary locks are arranged at four corners of the bearing table; and the control device is connected with the first hydraulic cylinder, the second hydraulic cylinder and a rotating air cylinder. The sunken container-tumbling platform is simple in structure, convenient to maintain, low in manufacturing cost, simple to operate, capable of being operated by a single person and free of professional training.

Owner:KAIYUAN KAIFENG MACHINERY CO LTD

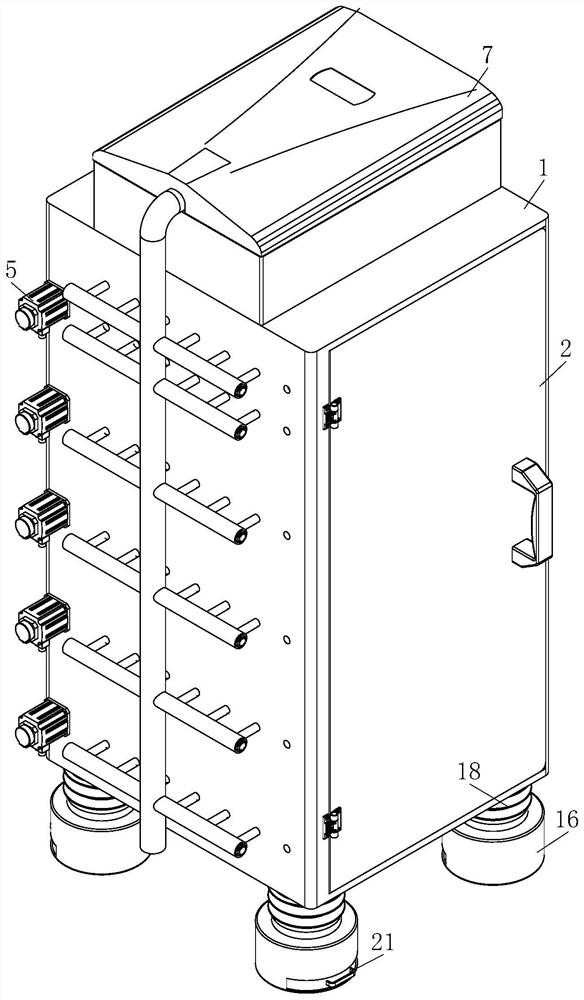

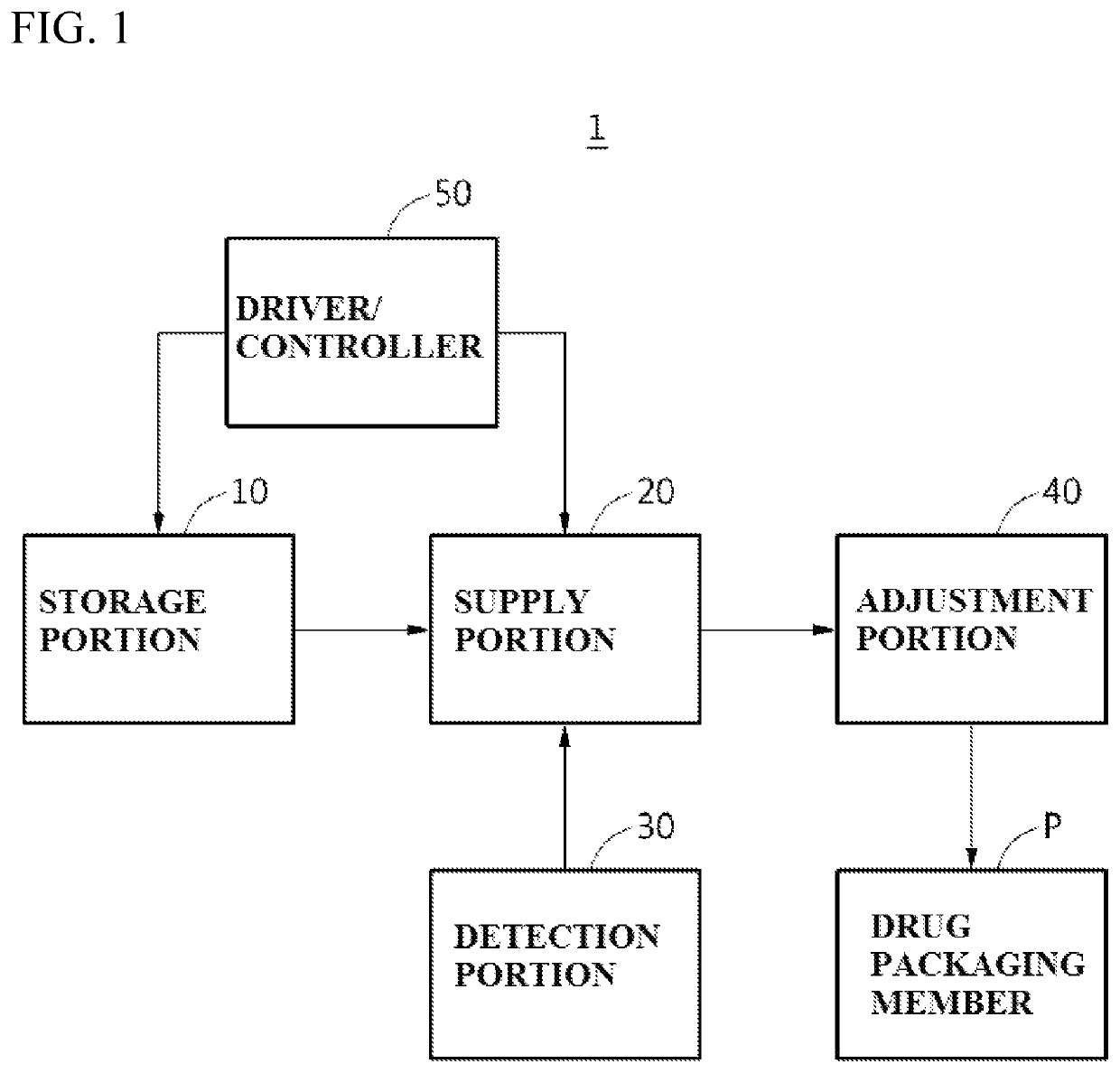

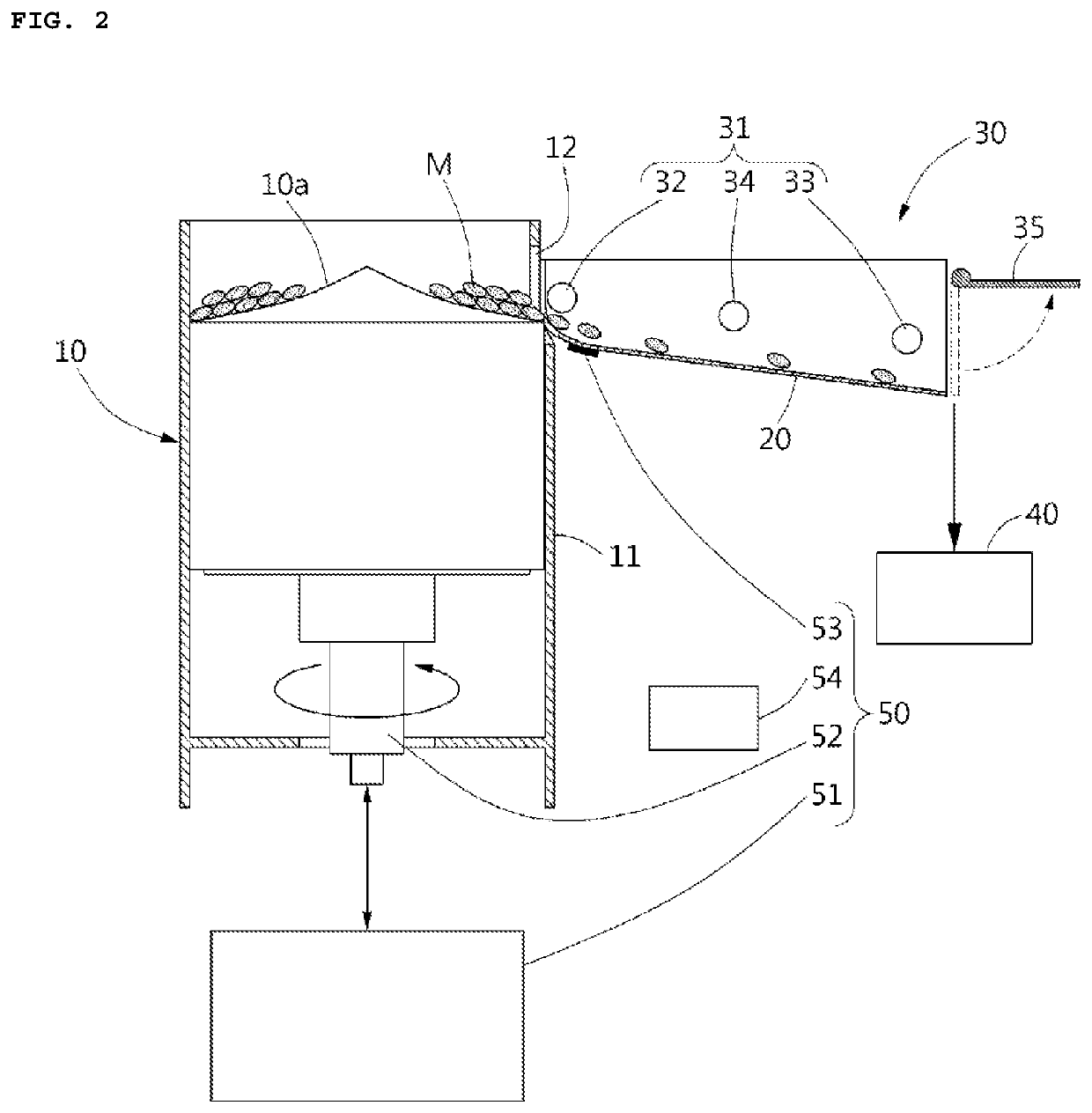

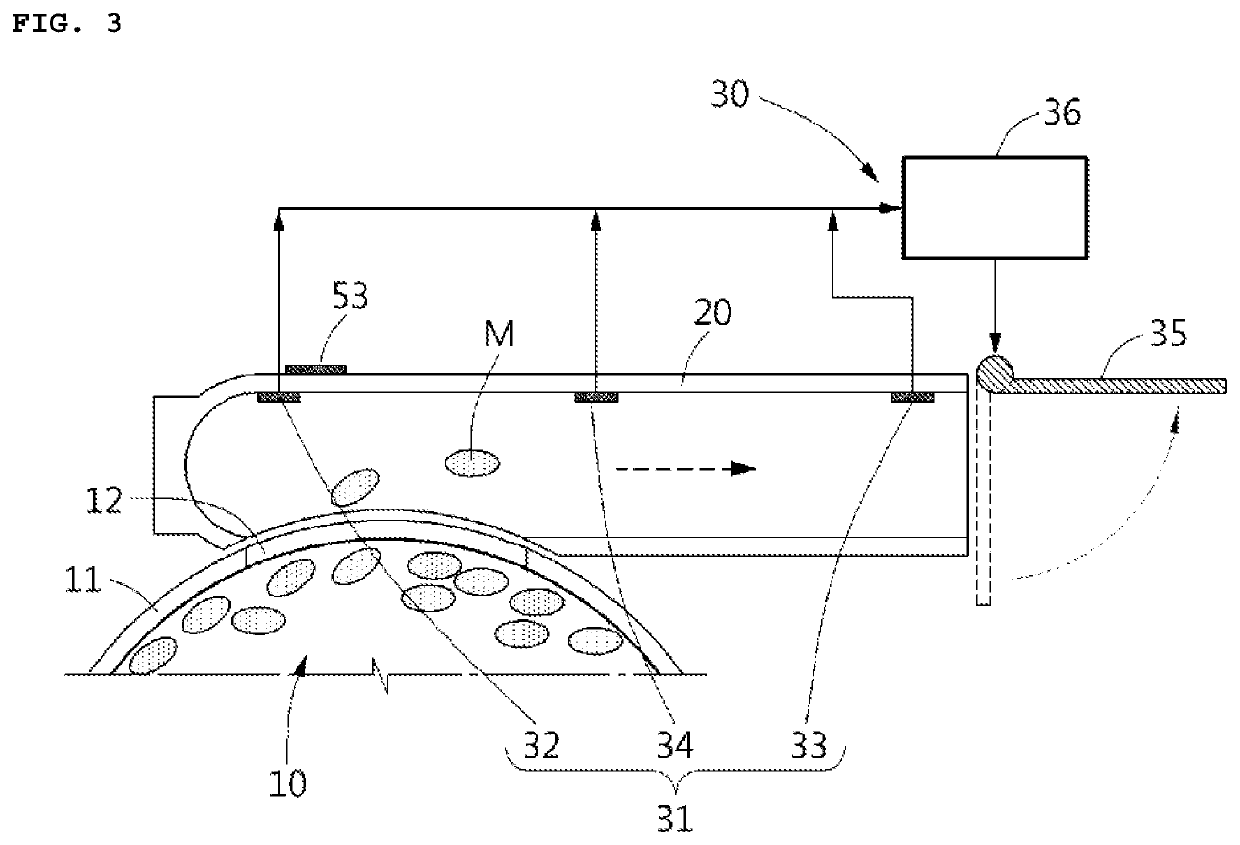

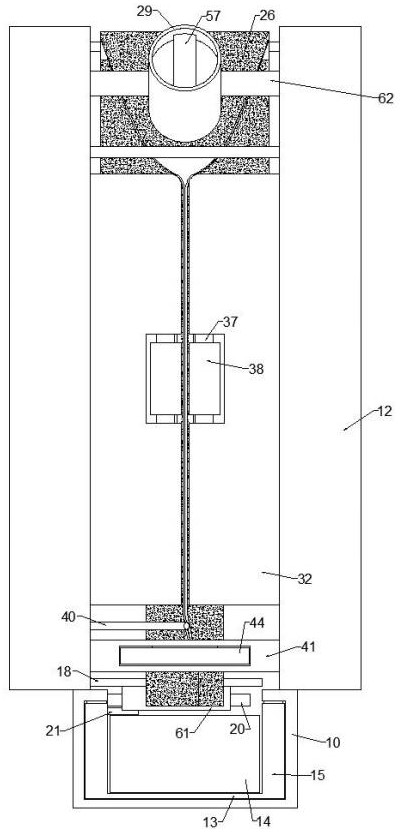

Drug packaging unit and drug transfer method for same

ActiveUS10843823B2Shorten delivery timeShorten packing timePackaging automatic controlSolid materialControlled drugsEmergency medicine

A drug packaging unit is disclosed. The drug packaging unit includes a storage portion separately discharging a plurality of units of a drug, a supply portion supplying the drug to a drug packaging member, a detection portion detecting a drug supply error by detecting the drug passing through the supply portion, an adjustment portion adjusting the number of units of drug discharged out of the supply portion, and a driver / controller individually driving the storage portion and the supply portion, thereby putting the drug on standby to be discharged. With this structure, it is possible to reduce a drug packaging time and it is easy to control drug supply.

Owner:CRETEM

Food packaging bag sealing equipment with sorting function

InactiveCN114476253AAvoid damageThe same numberWrapper twisting/gatheringPackaging automatic controlStructural engineeringFood packaging

The food packaging bag sealing equipment with the sorting function comprises a platform, a smooth cavity is formed in the platform, a loading plate is arranged on the bottom wall of the smooth cavity in a sliding mode, two sliding plates which are symmetrical front and back are fixedly arranged on the top face of the loading plate, and a sorting box is fixedly arranged between the two sliding plates; three separation shafts are fixedly arranged on the front side face of the sliding plate on the rear side from left to right, separation plates are fixedly arranged on the bottom faces of the three separation shafts, two supporting plates which are symmetrical front and back are fixedly arranged on the top face of the platform, a fixing plate and a limiting cylinder are fixedly arranged between the two supporting plates, and the right side face of the fixing plate is fixed to the left side face of the limiting cylinder. According to the packaging bag arranging and boxing device, packaged food packaging bags can be automatically arranged and boxed, the boxing efficiency of the packaging bags is improved, the counter is installed, it is ensured that the number of food in each packaging bag is consistent, and the packaging bag arranging and boxing device is convenient to use. And the phenomenon of empty packaging bags in the production process is prevented.

Owner:JIANGSU OUK PACKAGING TECH

Conveying device

ActiveCN102874432BAvoid customer complaintsShorten packing timePackaging protectionBristleEngineering

The invention relates to a conveying device which comprises a conveyor belt and a speed-reduced cleaning unit, wherein the speed-reduced cleaning unit comprises a bearing plate, a first hairbrush plate and a second hairbrush plate, wherein the first hairbrush plate and the second hairbrush plate are arranged on the opposite sides of the bearing plate, the bearing plate is provided with a bearing surface for bearing products to be encased with certain kinetic energy and conveyed by the conveyor belt, the first hairbrush plate is provided with a first bristle surface, and bristles are formed on the surface of the first bristle surface, the second hairbrush plate is provided with a second bristle surface, and bristles are formed on the surface of the second bristle surface, the first bristle surface and the second bristle surface are arranged opposite to each other, and a channel for products to be encased is defined by the first bristle surface, the second bristle surface and the bearing surface so as to enable products to be encased to pass through, and the first bristle surface and the second bristle surface are used for carrying out frictional speed reduction and cleaning on products to be encased when the products to be encased pass through the channel. Compared with the prior art, the conveying device not only can avoid that an encasing workshop section has an accumulation phenomenon because the conveying speed of products to be encased is overquick, and can carry out dust cleaning on products to be encased.

Owner:GOLD HONG YE PAPER

A kind of sunken box-turning platform

ActiveCN110436213BReduce lossesShorten packing timeLoading/unloadingHydraulic cylinderRotational axis

Owner:KAIYUAN KAIFENG MACHINERY CO LTD

Ganoderma lucidum antler cultivation bagged material preparation method

InactiveCN107686413AReduce manufacturing costMeeting nutritional needsBioloigcal waste fertilisersFertilizer mixturesMaterials preparationAnimal science

The invention discloses a ganoderma lucidum antler cultivation bagged material preparation method, which comprises the following preparation steps of pre-wetting: sieving saw dust, then adding water to prewet the saw dust for 3 to 4 days; mixing materials: pouring 92% of the saw dust, 3% of rice bran and 5% of wheat bran into a material barrel according to weight percentage; adding water; bagging:charging a cultivation material into a polypropylene culture bag to be prepared into a cultivation bagged material; sterilizing: putting the cultivation bag into a sterilizing cabinet after being prepared and performing high-temperature sterilization instantly. According to the ganoderma lucidum antler cultivation bagged material preparation method disclosed by the invention, production cost is reduced by a certain proportion of raw materials and a simple technology; ganoderma lucidum antler bagged arrangement time is shortened to 20 to 25 days, the yield of ganoderma lucidum antler is increased, production work procedures are simplified, and scale production of the ganoderma lucidum antler is achieved.

Owner:福建绿宝食品集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com