Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Shortcuts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SIM card slot, SIM card push-pull processing method and terminal thereof

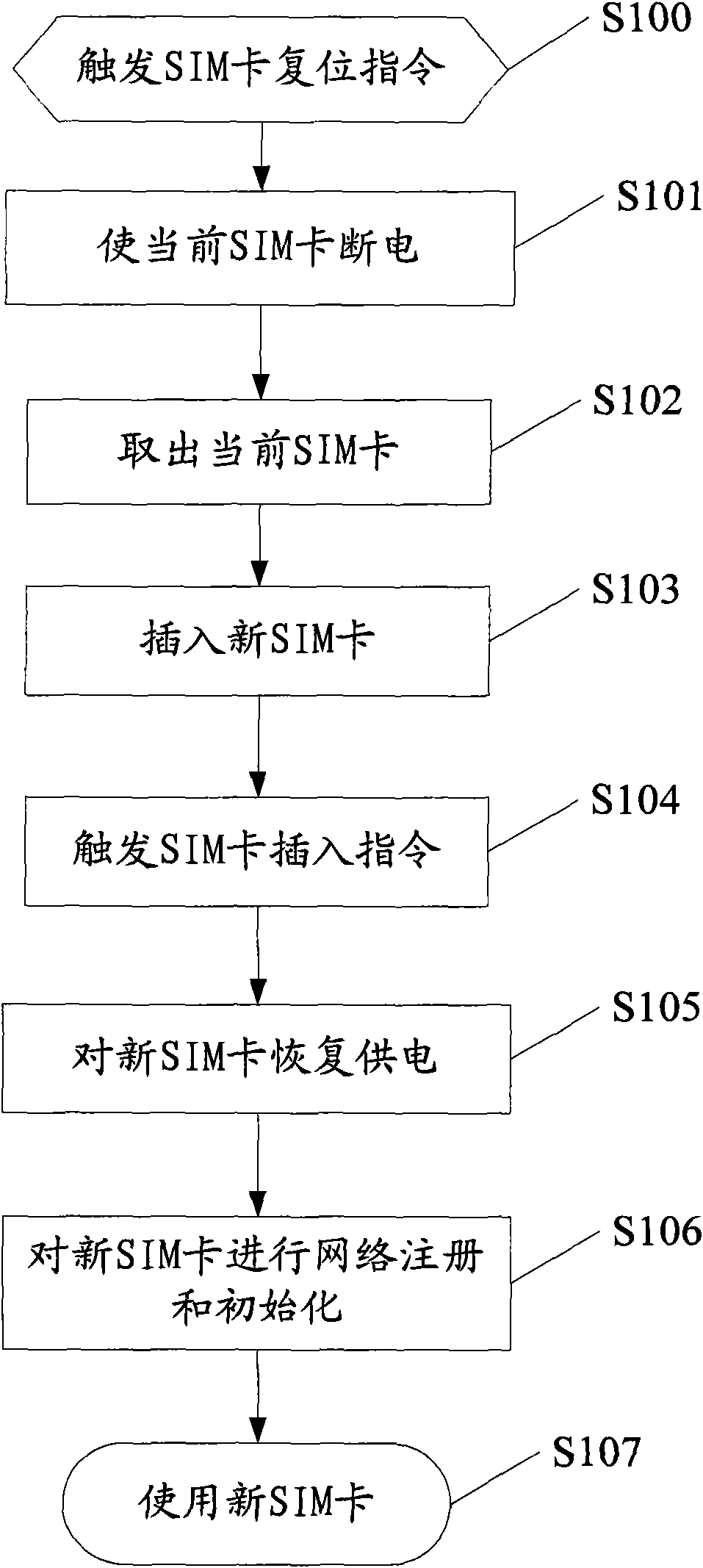

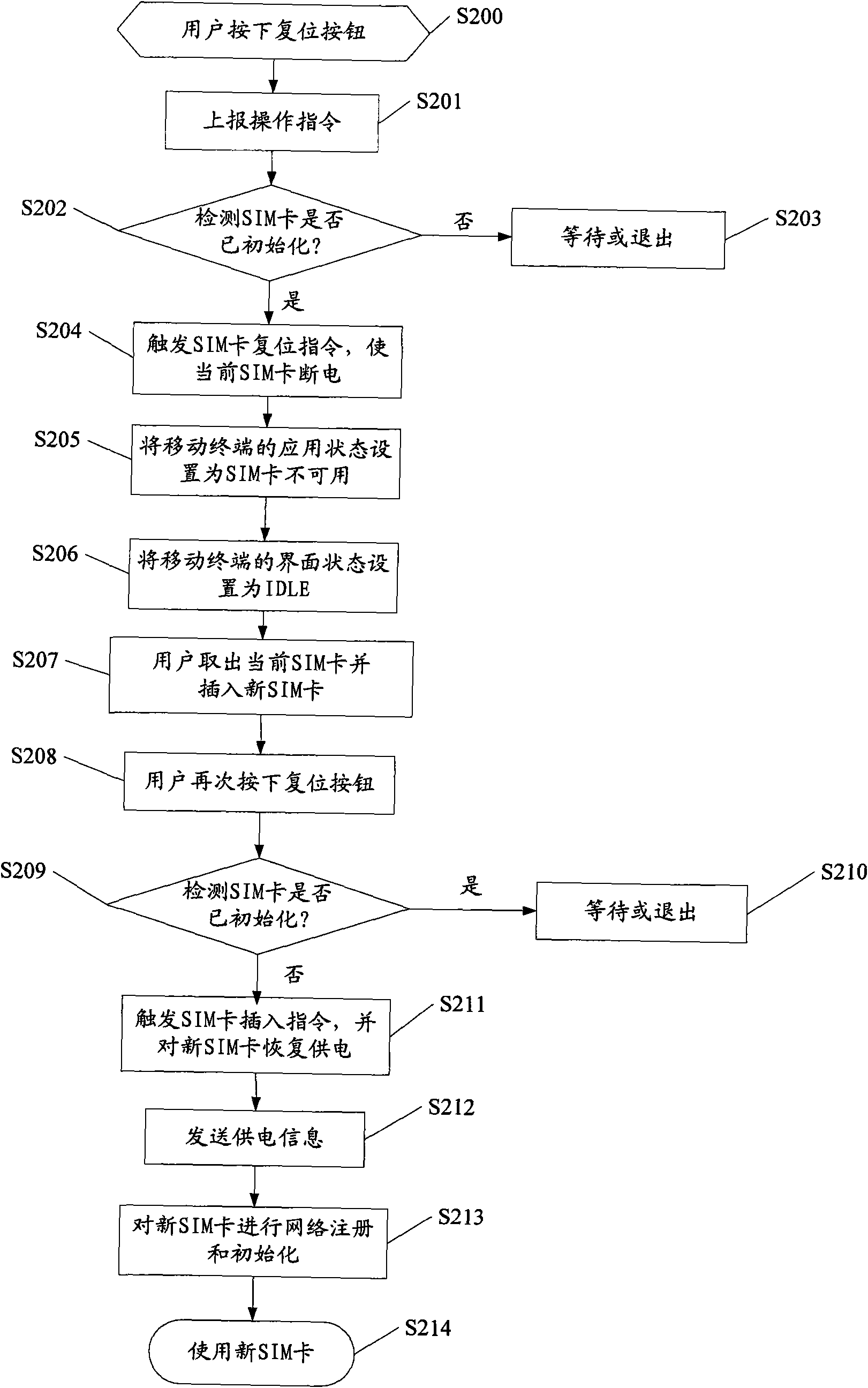

The invention discloses an SIM card push-pull processing terminal which comprises a push-pull control module, a power supply control module, a register module and an SIM card slot, wherein the push-pull control module is used for triggering an SIM card reset instruction, reporting the SIM card reset instruction to the power supply control module and triggering an SIM card push instruction after taking out a current SIM card from the SIM card slot and pushing a new SIM card in the SIM card slot under the condition of maintaining the power connection state of a power supply of a mobile terminal; the power supply control module is used for powering down the current SIM card according to the SIM card push instruction, restoring power supply to the new SIM card according to the SIM card push instruction and sending power supply information to the register module; and the register module is used for carrying out a network register and initialization on the new SIM card according to the power supply information. The invention realizes the hot push-pull on the mobile terminal, has safety and reliability and can provide more flexible and humanized services for users.

Owner:ZTE CORP

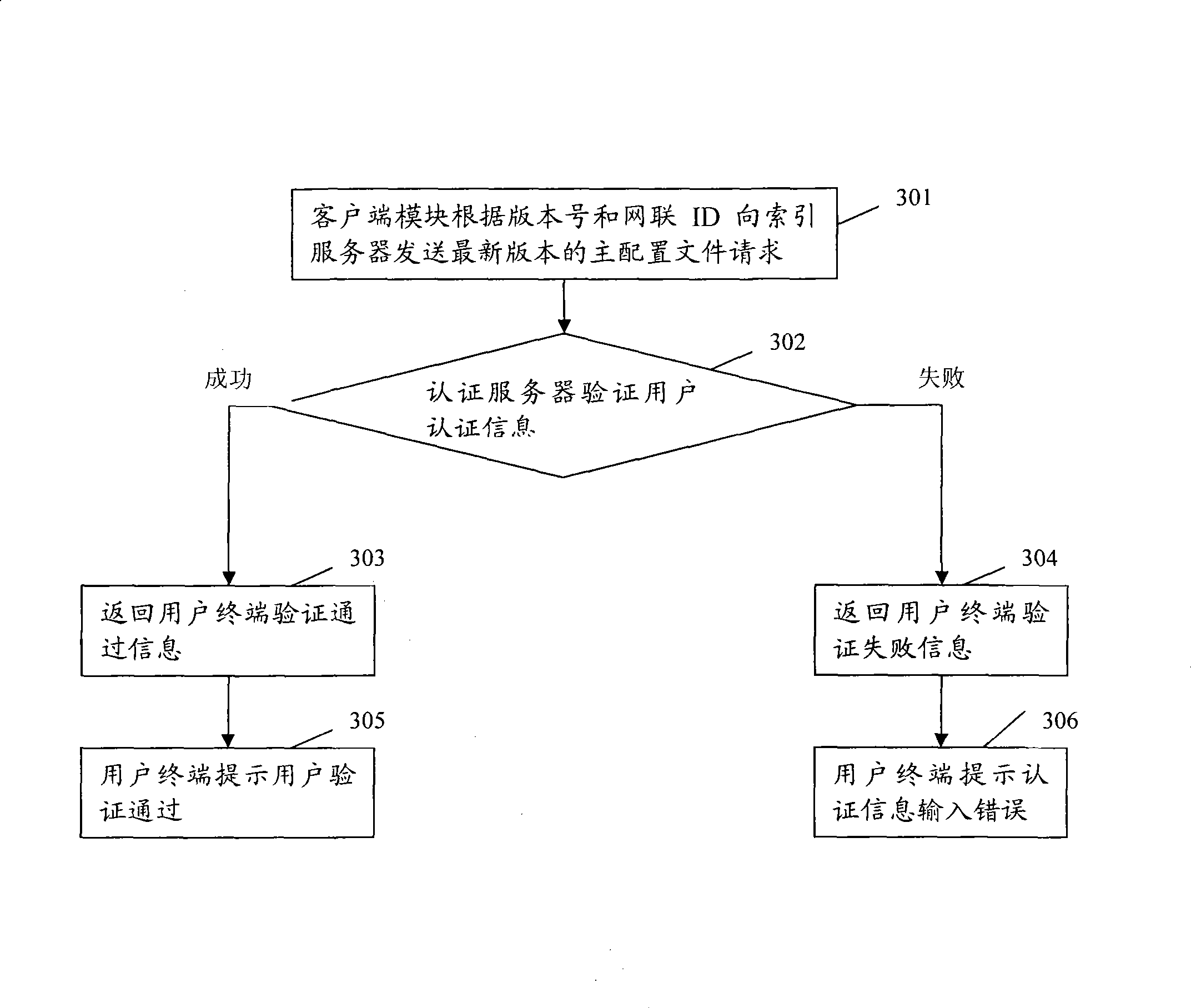

System and method for displaying network information by computer background screen

InactiveCN101383842AEasy to browseTake advantage ofUser identity/authority verificationSpecial data processing applicationsOperational systemApplication server

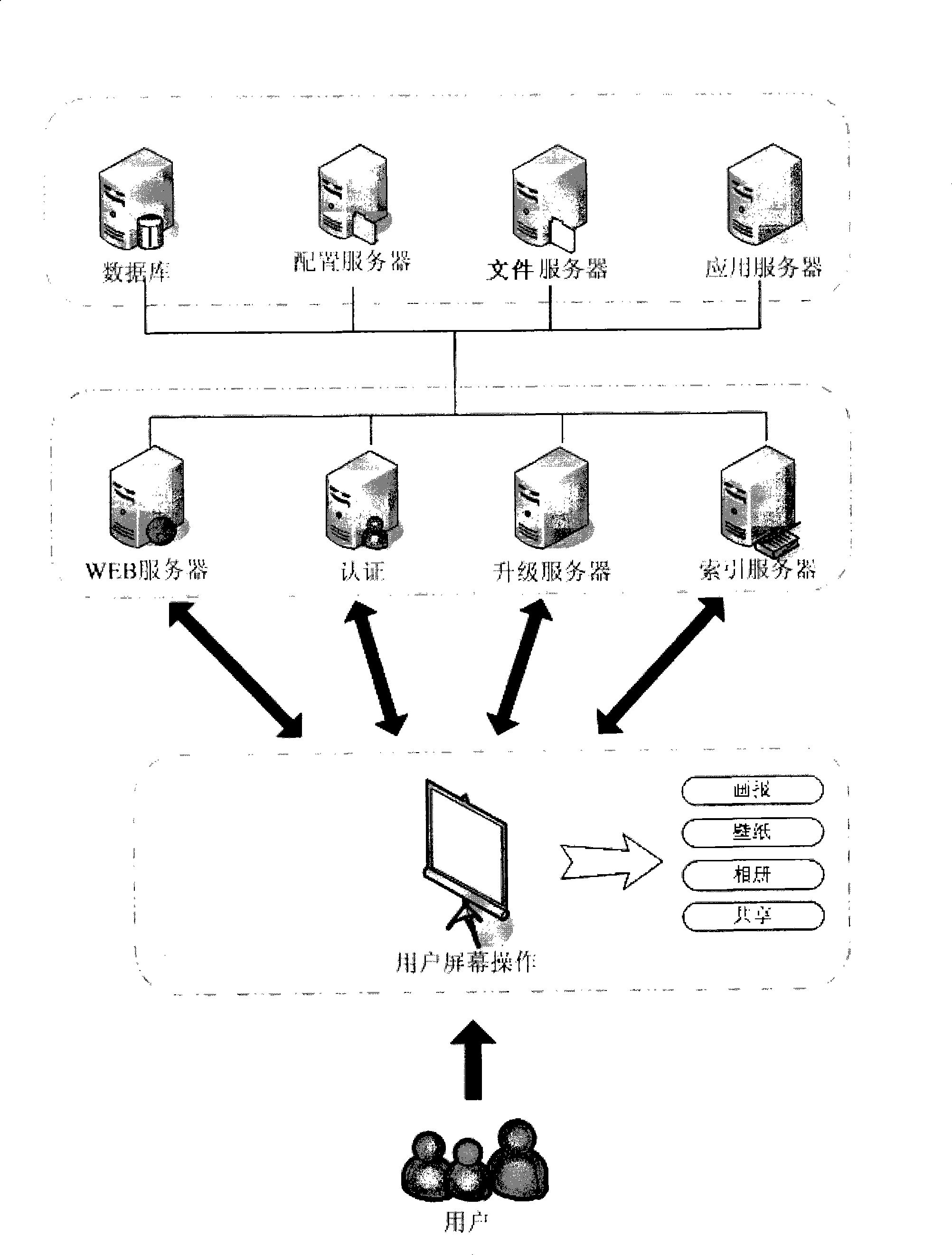

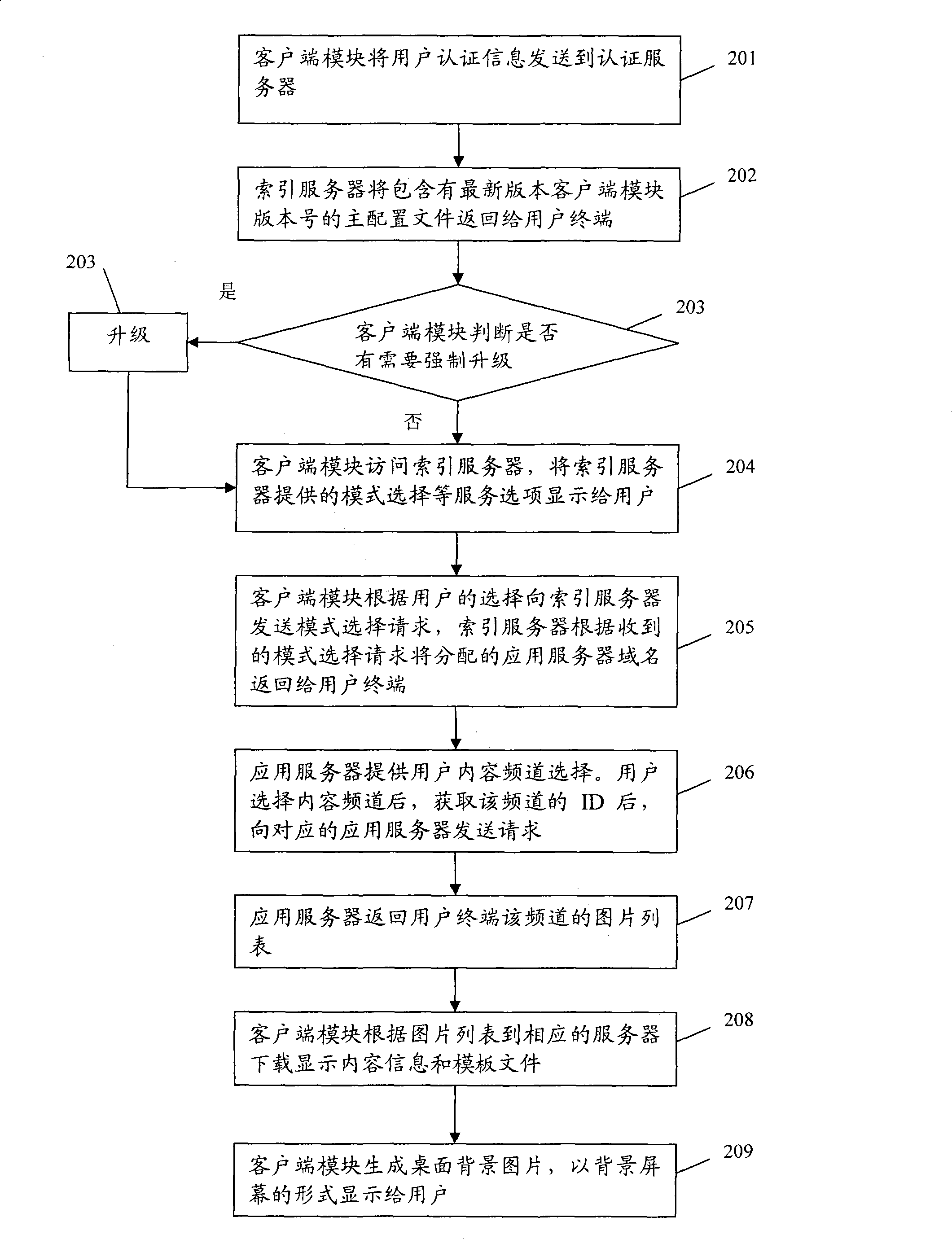

The invention discloses a system and a method which utilize a background screen of a computer to display network information. The method comprises the following steps: a display content information server is arranged at a server side and is used for preserving display content information of the background screen; a config server is used for providing a template file of the background screen; an application server is used for treating a request for a background screen display mode of a user terminal and returning the display content information and address information of the template file to the user terminal; after a user selects the background screen display mode, the user terminal sends the request of the background screen display mode to the server side; the server side returns the display content information of the display mode and the template file to the user terminal; and the user terminal causes a display content to be produced to a desktop background picture according to the template file, and a desktop interface of an operation system is called to be displayed to the user in a form of the background screen.

Owner:BEIJING CAPITAL ONLINE NETWORK TECH

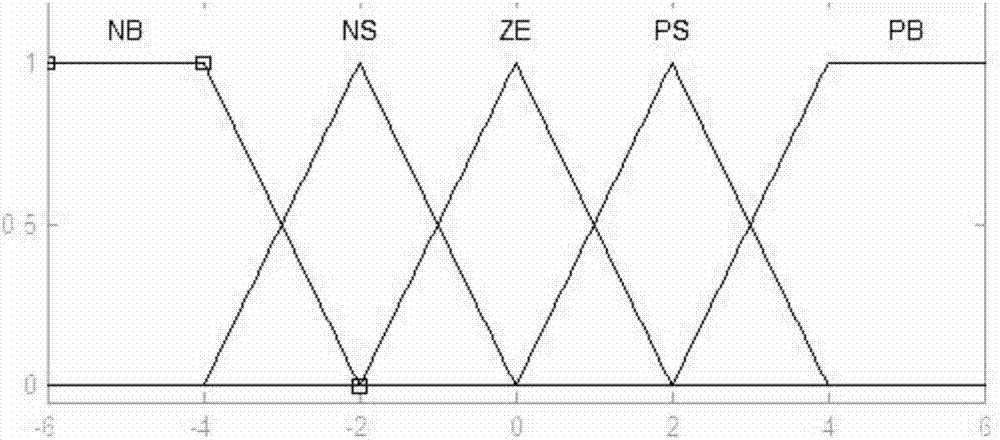

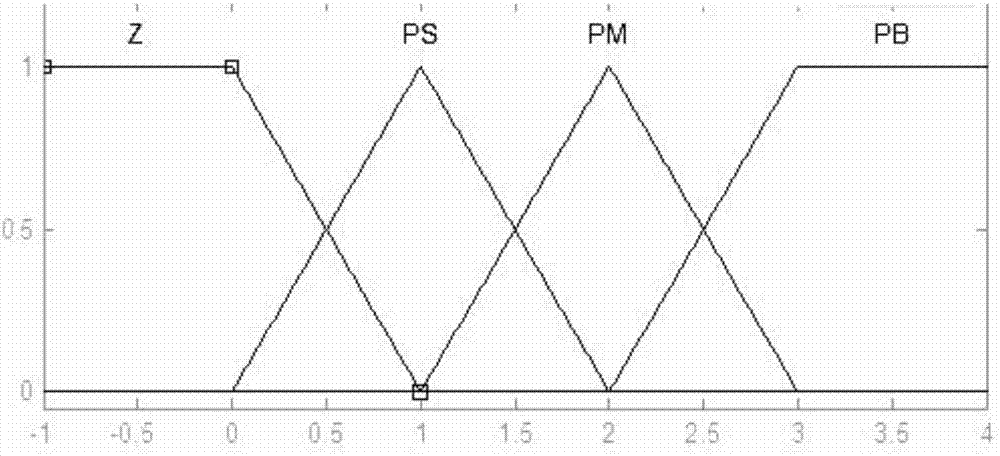

Intelligent wheelchair man-machine interaction control system and method based on eye movement recognition

ActiveCN107260420AControl Method AdvantagesSolve control problemsInput/output for user-computer interactionWheelchairs/patient conveyanceOlder peopleWheelchair

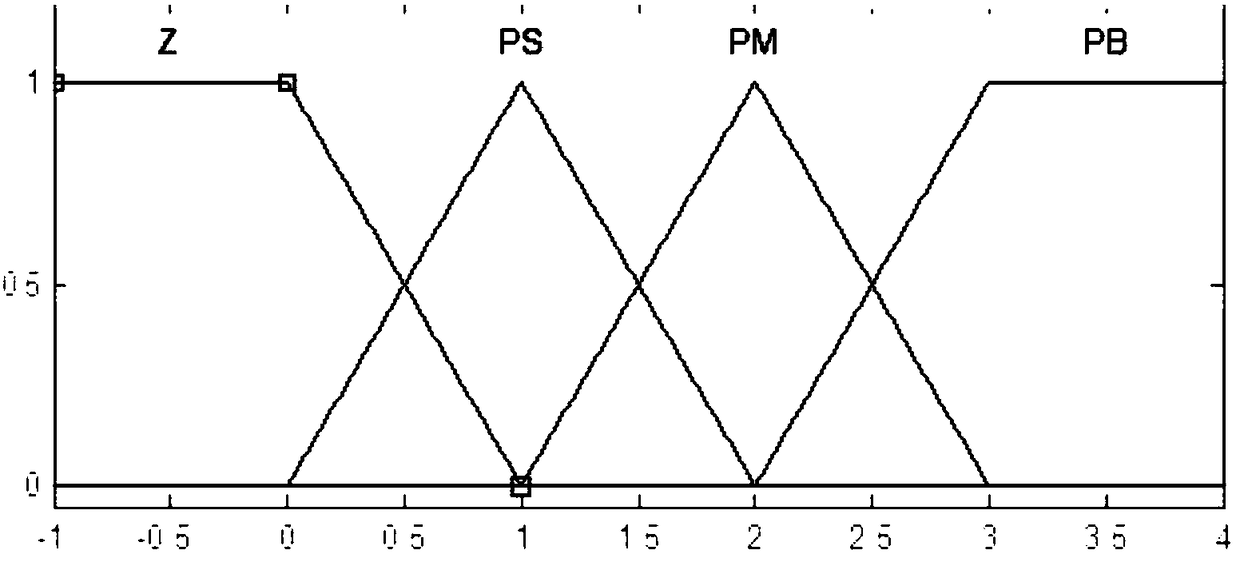

The invention discloses an intelligent wheelchair man-machine interaction control system and an intelligent wheelchair man-machine interaction control method based on eye movement recognition. According to the system and the method, an electromyographic signal acquisition module is used for collecting electromyographic signals of the eyes, characteristic selection is carried out on the electromyographic signals, eye movement recognition is carried out according to the electromyographic characteristic change difference during blink, thus the accurate judgment on the conscious blinking is realized, further, the accurate control over the direction of a wheelchair is realized by combining a plurality of conscious blinking modes, a fuzzy controller part takes a signal electromyographic integral value and signal slope as input and the running speed of the intelligent wheelchair as output, then a two-dimensional structure fuzzy controller with two inputs and single output is built, and thus the accurate control over the running speed of the wheelchair is realized. According to the system and the method, the scheme is diversified, the operation mode is simple, convenient and rapid, the learning is easy, the special requirements of old people and disabled people in the control mode are fully considered, the control problem of the intelligent wheelchair system caused by the fact that a traditional control mode is not flexible in operation and a user responds slowly is avoided, and the practical requirements of the old people and the disabled people are well adapted.

Owner:NANJING UNIV OF POSTS & TELECOMM

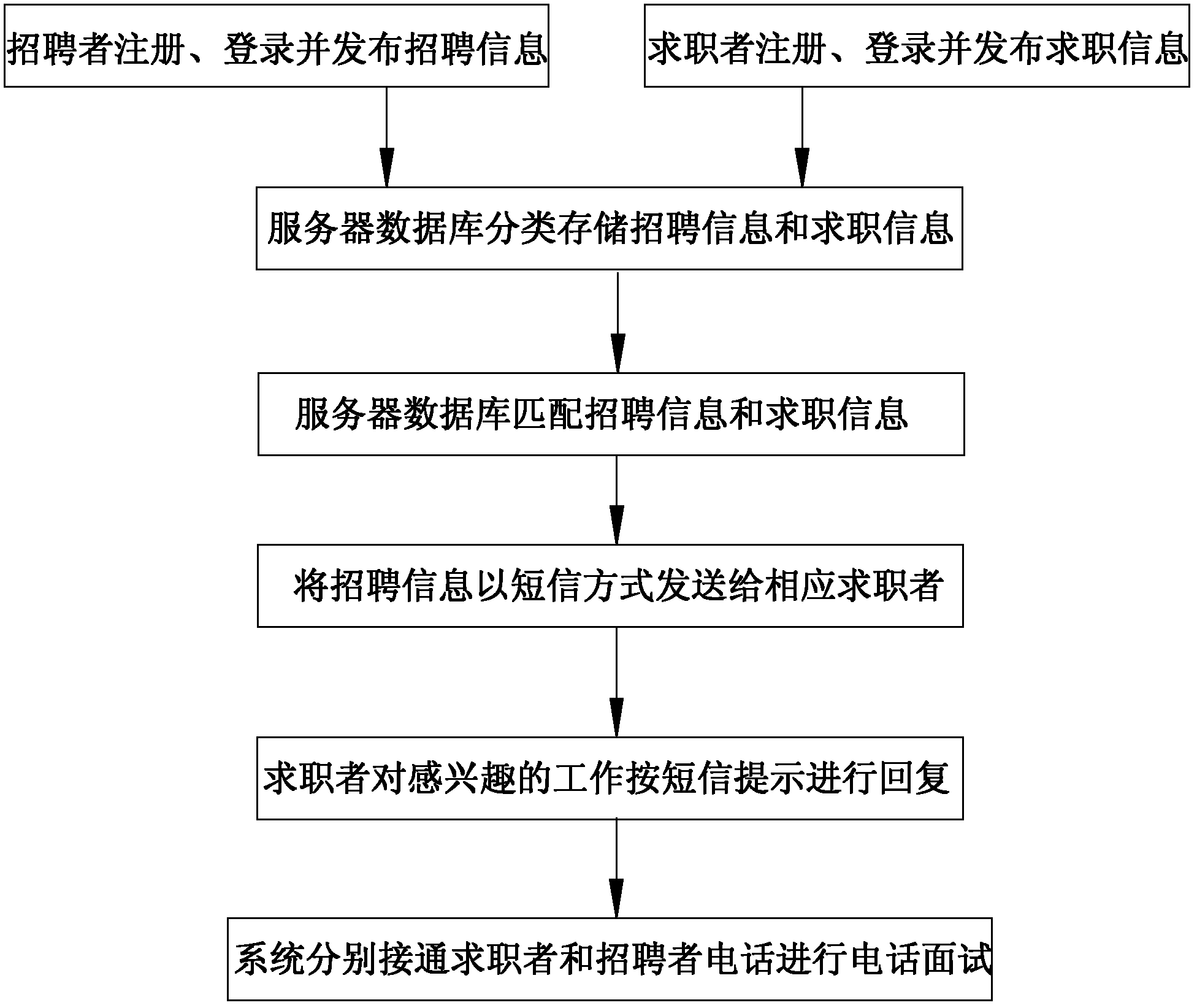

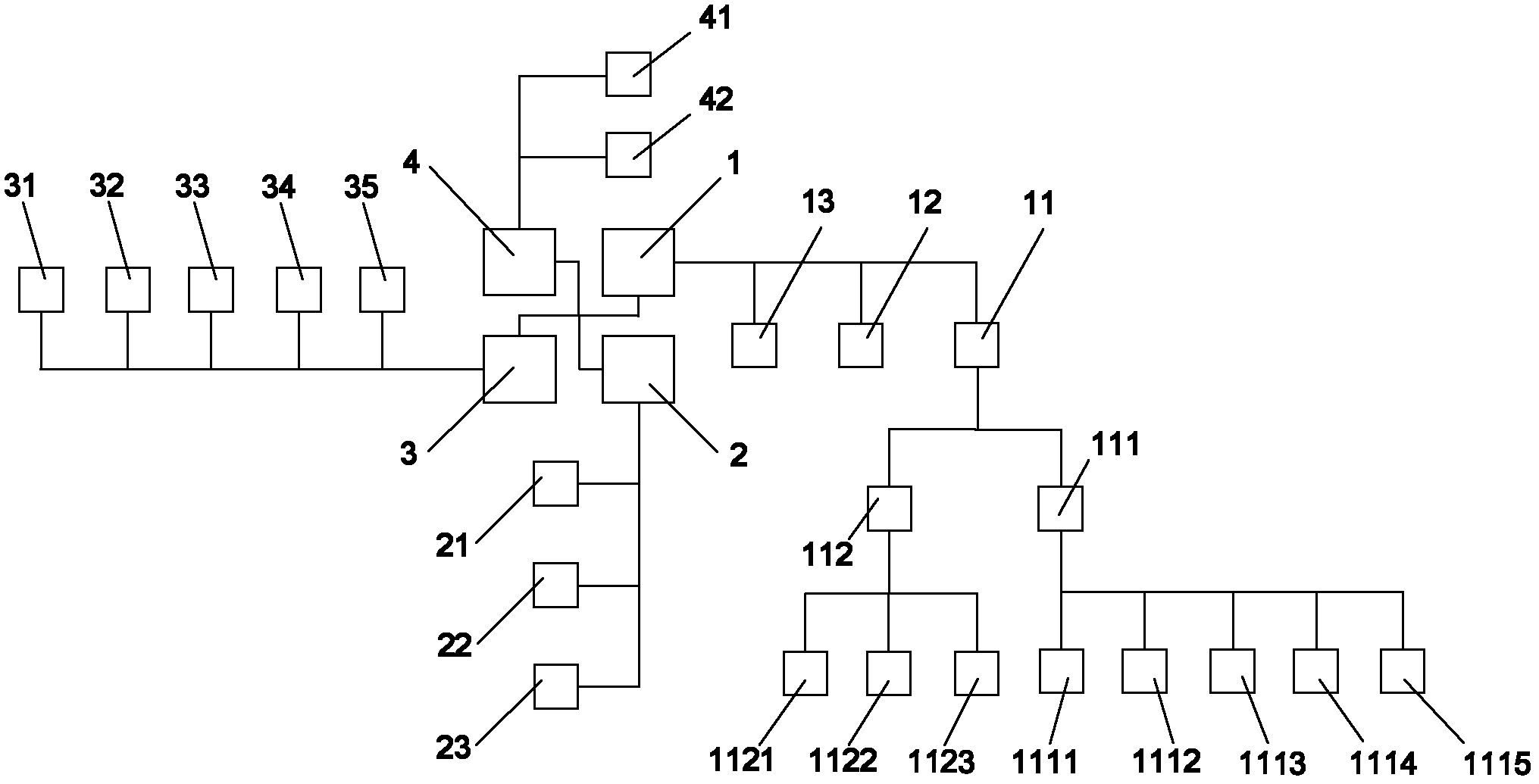

Method and system for introducing job movably by using short message and multi-party voice conversation

InactiveCN102542348AEasy to operateShortcutsData processing applicationsBroadcast service distributionDecision systemControl system

The invention relates to a method and a system for introducing a job movably by using a short message and a multi-party voice conversation. The method comprises the following steps that: 1, a job hunter and a recruiter register, login and respectively fill in job-search information and recruitment information by using an internet or a mobile phone; 2, database stores the job-search information and the recruitment information in a classified mode; 3, the system matches the job-search information with the recruitment information and sends the matched recruitment information to the mobile phone of the job hunter through the short message; 4, the job hunter replies to the job in which the job hunter is interested according to prompts of the short message; and 5, the system dials the mobile phones of the job hunter and the recruiter automatically to ensure that a telephone interview is performed through the multi-party voice conversation. The system comprises an interactive system, a core decision making system, a core control system and an executive system. The method and the system for introducing the job movably by using the short message and the multi-party voice conversation have the advantages that: an operation mode is simple and convenient, job search and recruitment can be positioned more accurately, time and energy which are invested on the job search and the recruitment are reduced, and more chances are provided for job hunters and recruiters.

Owner:CHONGQING GUANGDIAN NETWORK INFORMATION TECH

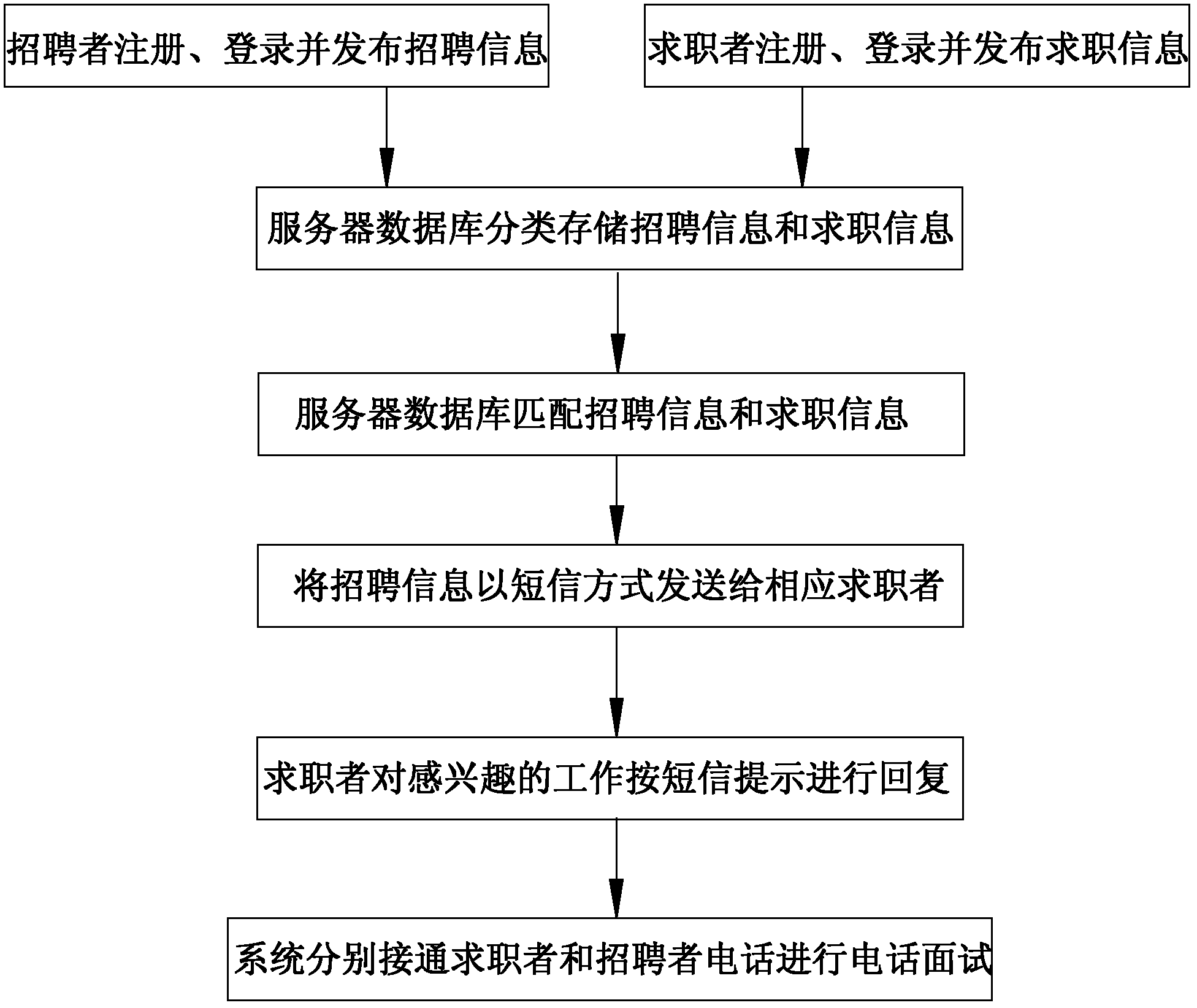

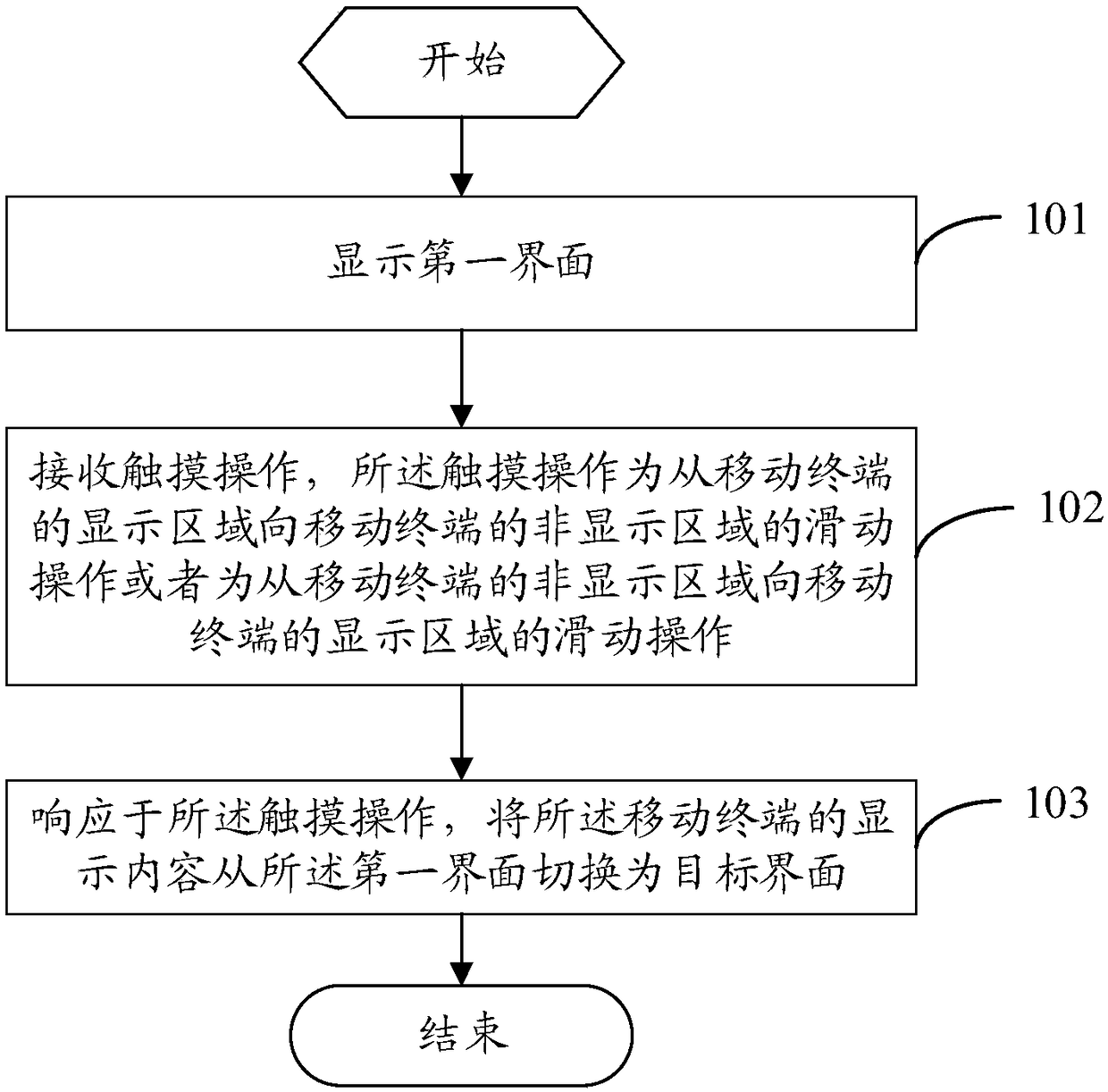

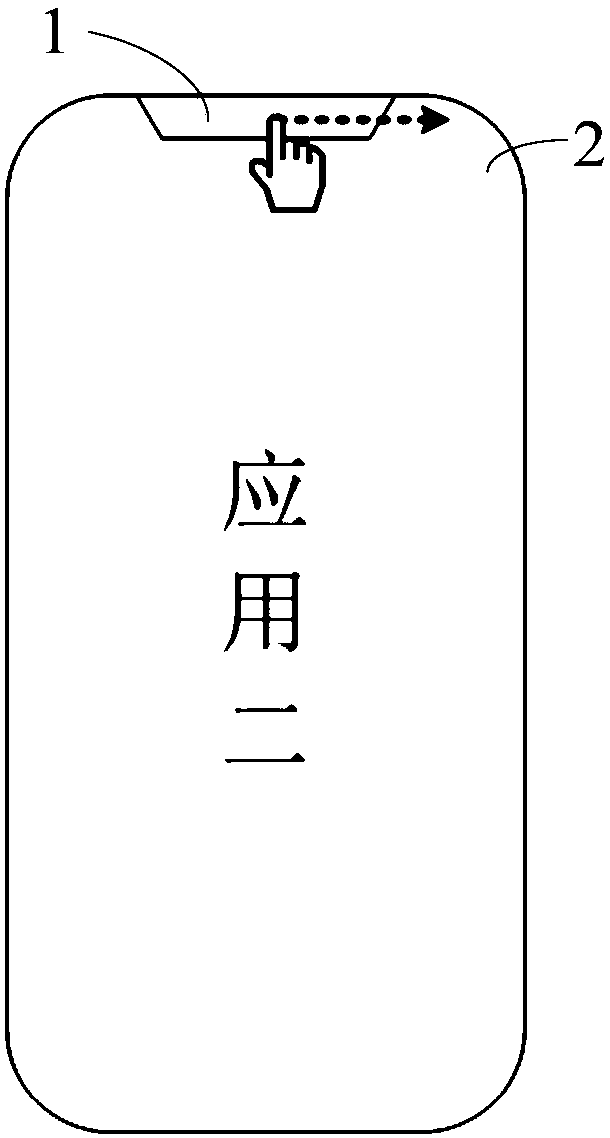

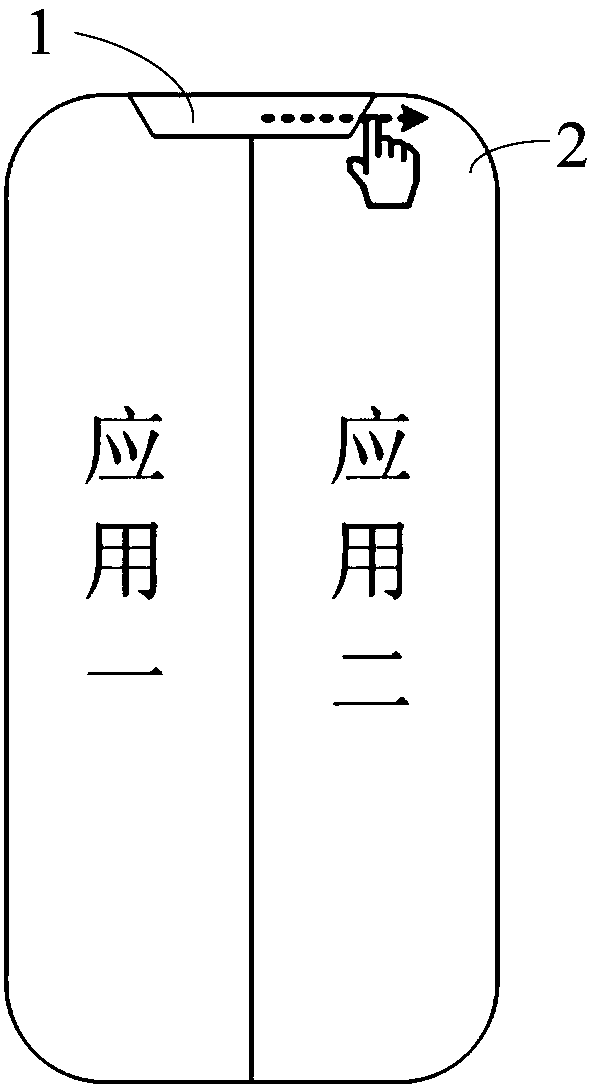

Interface switching method and mobile terminal

InactiveCN108446068ARealize switchingShortcutsInput/output processes for data processingOperation modeComputer engineering

The present invention relates to the technical field of communications, and provides an interface switching method and a mobile terminal. The method comprises: displaying a first interface; receivinga touch operation, wherein the touch operation is a sliding operation from a display area of the mobile terminal to a non-display area of the mobile terminal or a sliding operation from a non-displayarea of the mobile terminal to a display area of the mobile terminal; and switching display content of the mobile terminal from the first interface to a target interface in response to the touch operation. Thus, the user can quickly switch the interfaces by performing a sliding operation on the display area and the non-display area of the mobile terminal, so that by using the interface switching method of embodiments of the present invention, when the interface being displayed needs to be switched, the operation mode is fast.

Owner:VIVO MOBILE COMM CO LTD

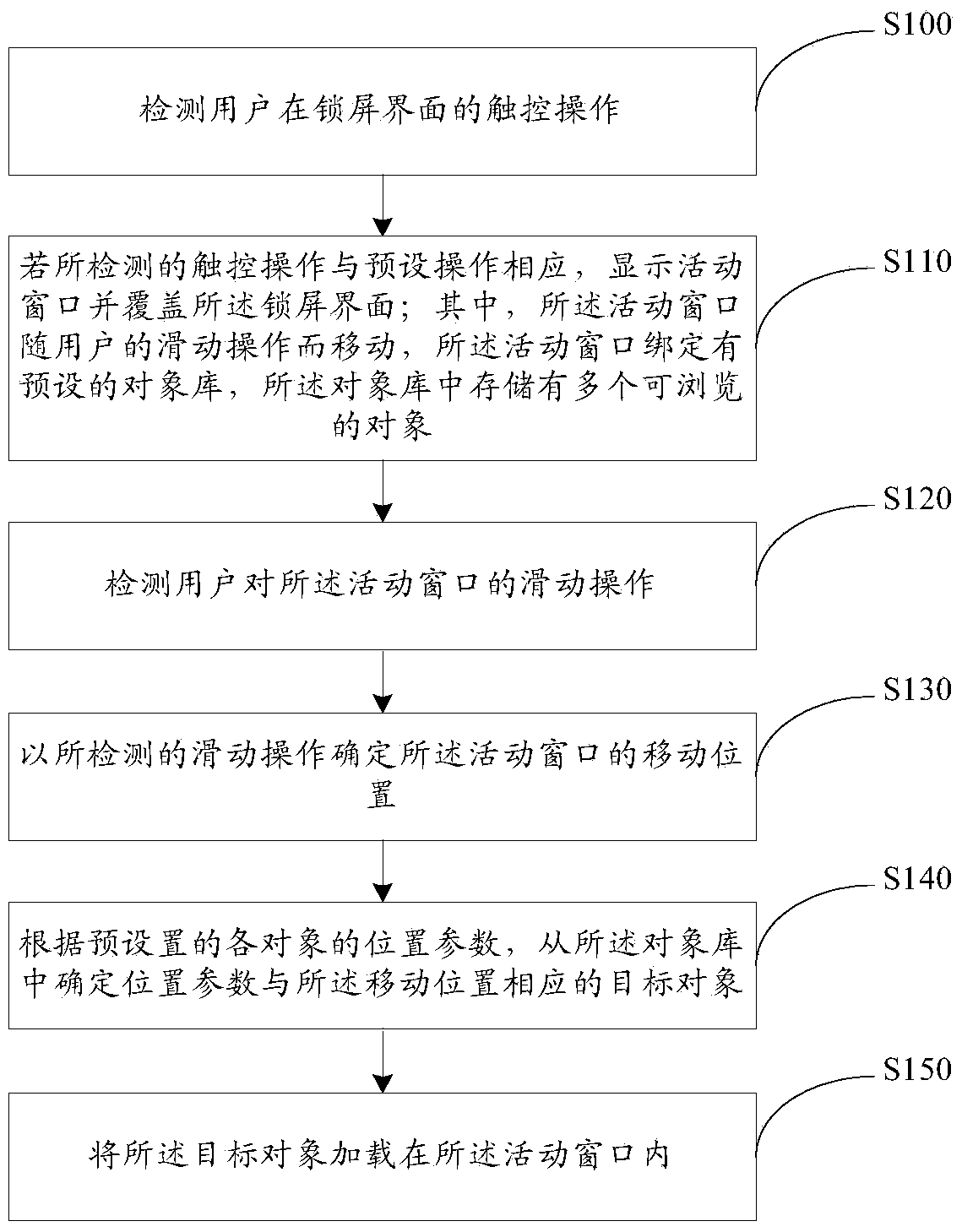

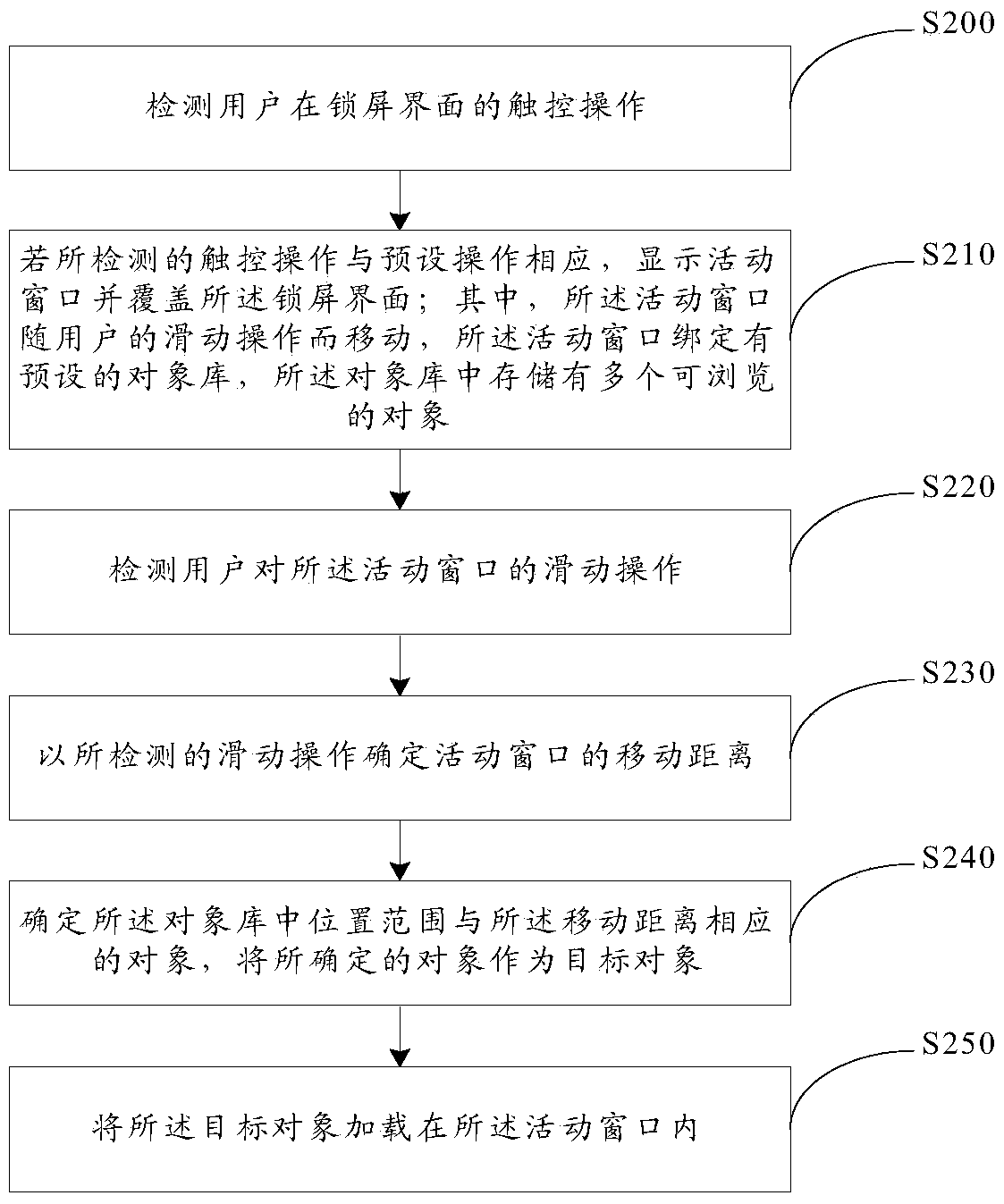

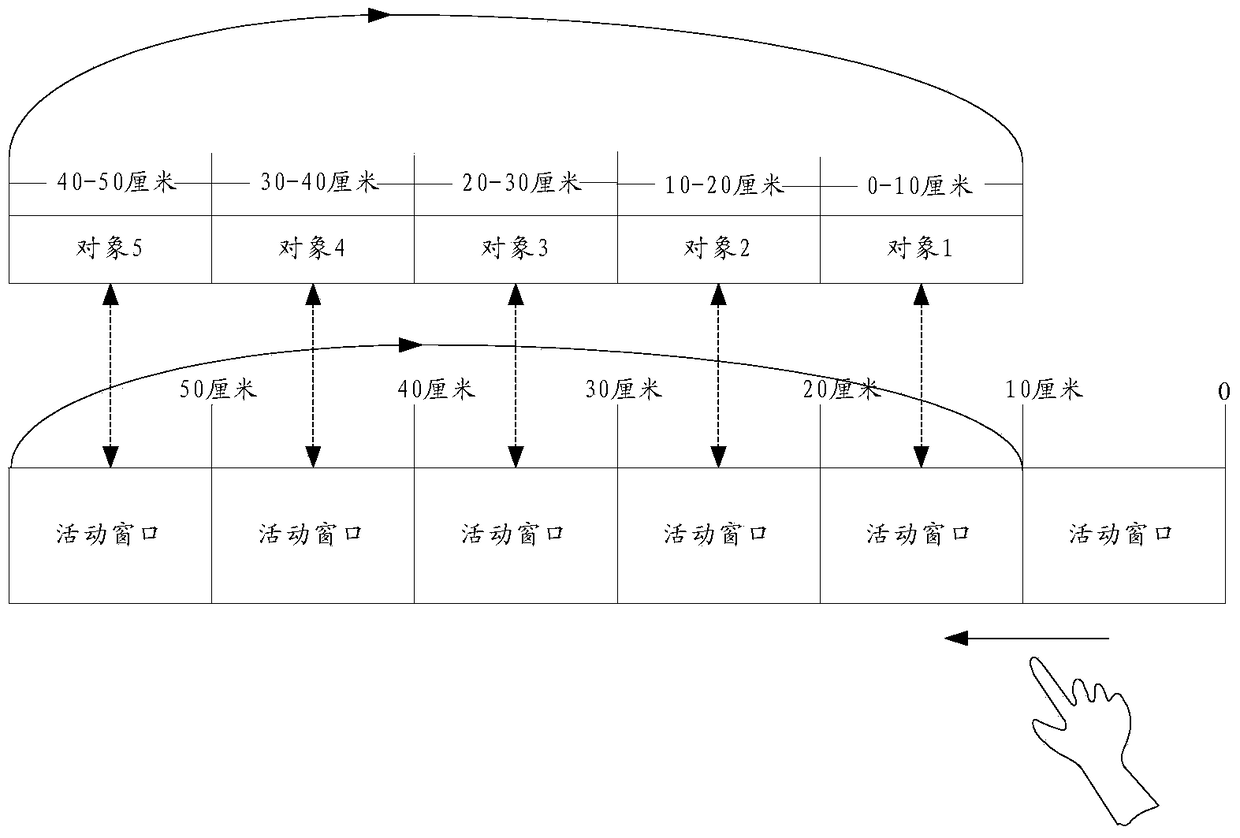

Object browsing method based on lock screen interface and terminal equipment

ActiveCN105094679AShortcutsInput/output processes for data processingTerminal equipmentComputer terminal

The embodiment of the invention provides an object browsing method based on a lock screen interface and terminal equipment. The method comprises the steps of detecting a touch operation of a user on the lock screen interface; if the detected touch operation corresponds to a preset operation, displaying an active window and covering the lock screen interface, wherein the active window moves along with the sliding operation of the user, the active window is bound with a preset object library, and a plurality of browsable objects are stored in the object library; detecting the sliding operation of the user for the active window; determining the moving position of the active window according to the detected sliding operation; according to preset position parameters of objects, determining target objects corresponding to the position parameters and the moving position; loading the target objects in the active window. According to the object browsing method, the purpose of browsing the objects on the lock screen interface in a rapid-operation mode is achieved.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

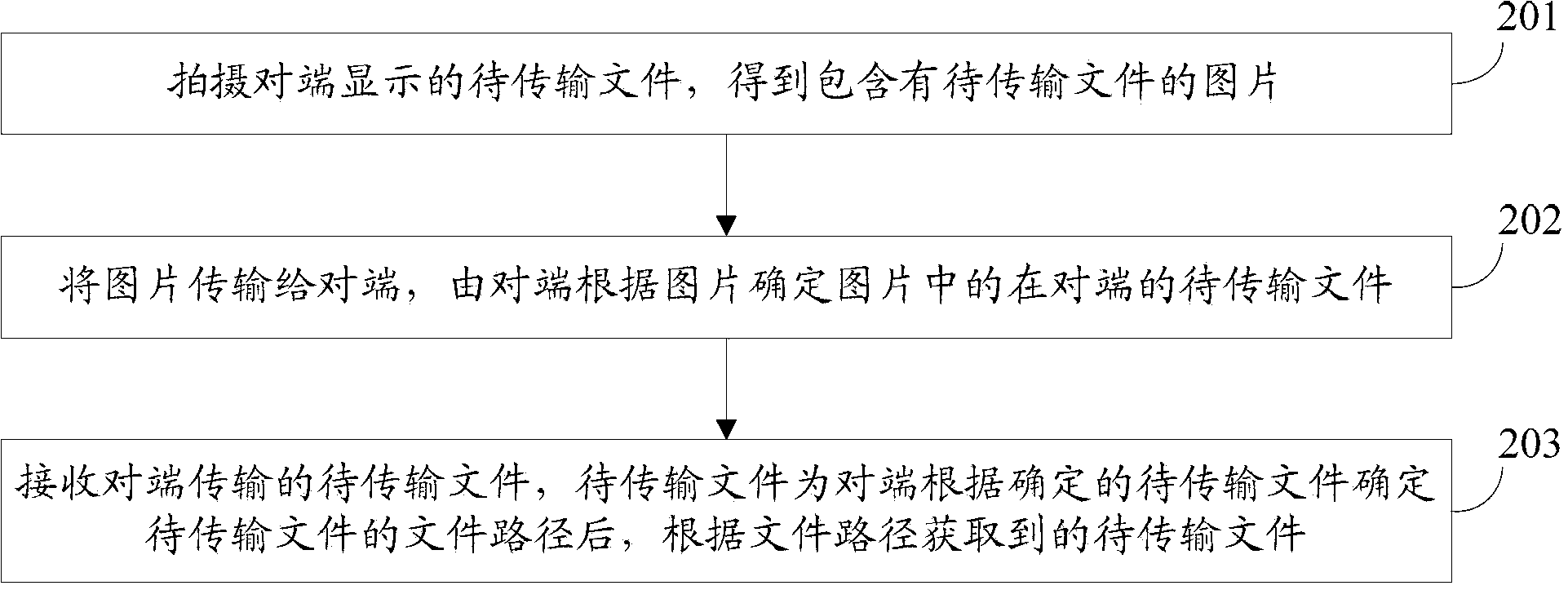

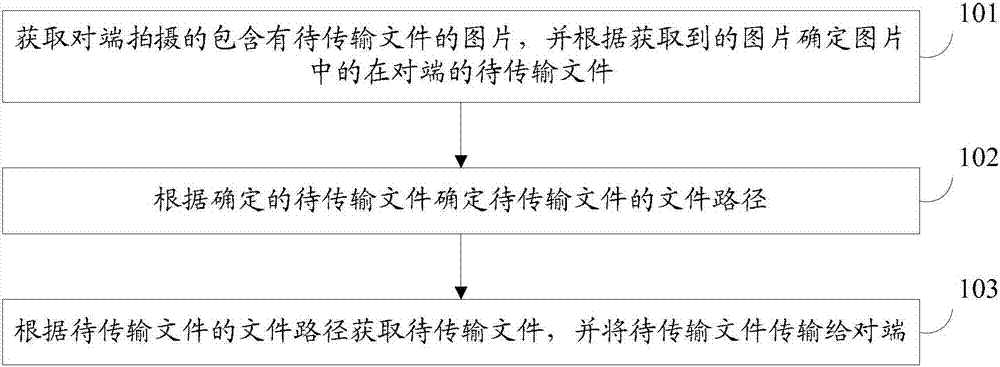

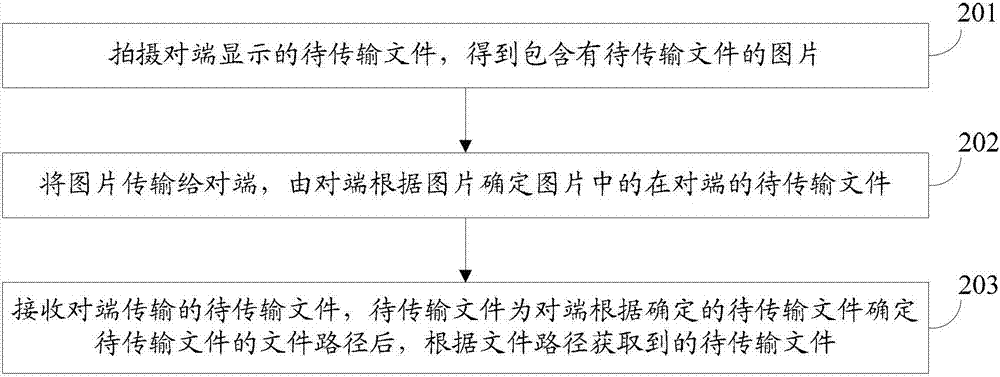

Method, terminal and system for transmitting files

ActiveCN103840859AGood choiceEasy transferNetwork topologiesDatabase distribution/replicationOperating system

The invention discloses a method, terminal and system for transmitting files, and belongs to the field of communication. The method comprises the steps that pictures which are shot by an opposite terminal and contain the files to be transmitted are acquired, and the files to be transmitted in a local terminal are determined according to the pictures; the file paths of the files to be transmitted are determined according to the files to be transmitted; the files to be transmitted are acquired according to the file paths of the files to be transmitted, and the files to be transmitted are transmitted to the opposite terminal. After the pictures which are shot by the opposite terminal and contain the files to be transmitted are acquired through the terminal for transmitting the files, the files to be transmitted in the pictures at the local terminal are determined according to the pictures, the file paths are determined according to the determined files to be transmitted, the to-be-transmitted files acquired according to the file paths are transmitted to the opposite terminal, therefore, the files to be transmitted do not need to be selected through manual dragging with a mouse or finger clicking and other modes, the files to be transmitted can be selected and transmitted in terminals with small screens conveniently, and therefore the operation method of transmitting the files is simpler, more convenient and faster.

Owner:SHENZHEN TENCENT COMP SYST CO LTD

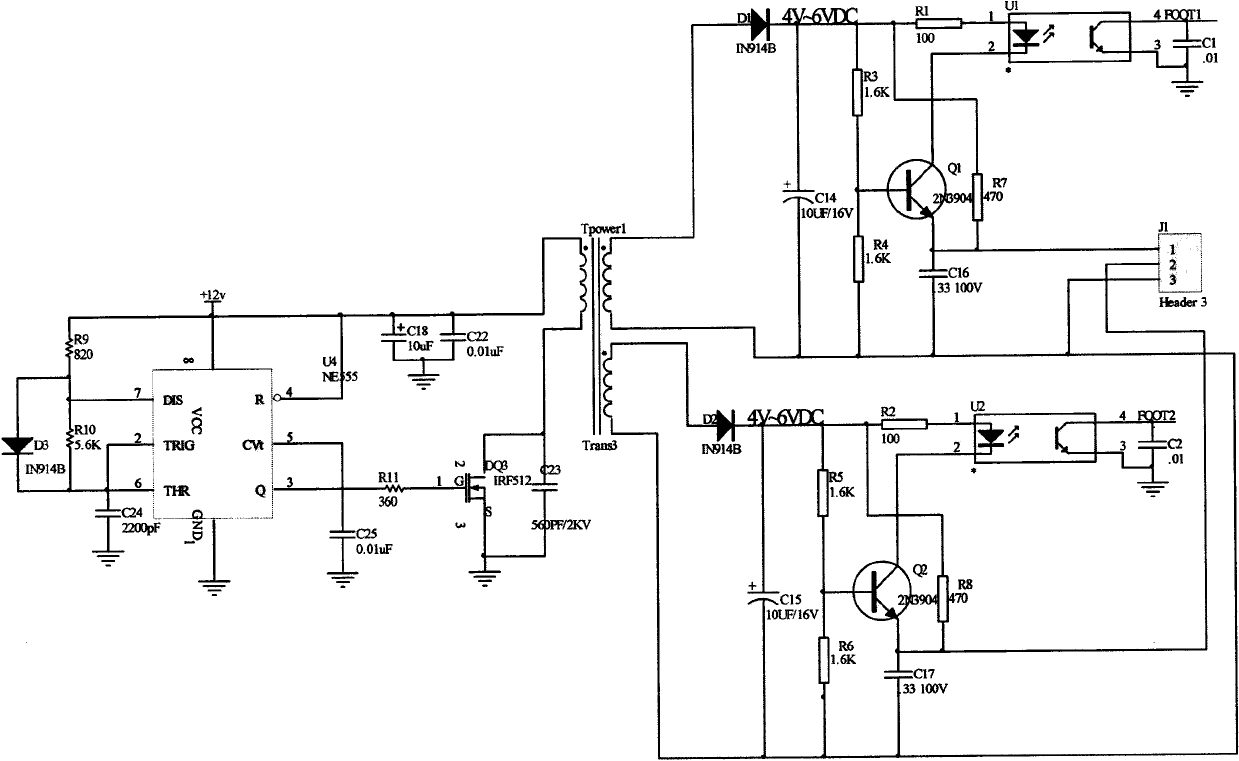

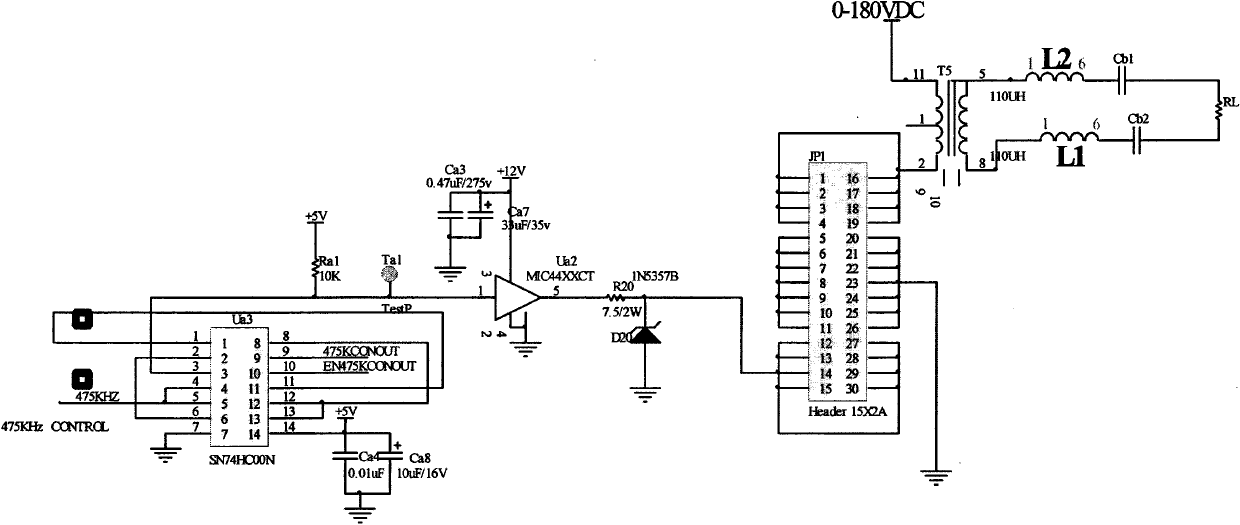

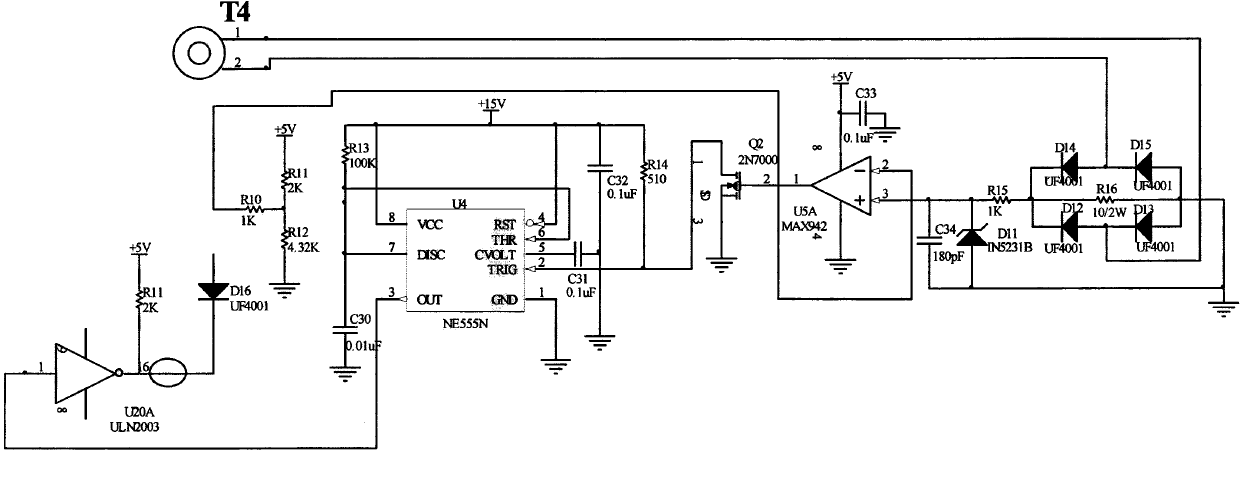

High-frequency electrosurgical station

InactiveCN103784194ASolve the urgent needs of the marketGood effectSurgical instruments for heatingSurgical operationHuman body

A high-frequency electrosurgical station applicable to surgeries and worthy of popularization is a special high-power high frequency generator. The high-frequency electrosurgical station generates high frequency current of specific frequency, waveform and load power curves; the high frequency current directly acts on the surface of biological tissues and centrally heats the tissues to volatilize tissue elements, and accordingly physical effects such as cutting and hemostasis are achieved. Through high-frequency power output by a main unit of the high-frequency electrosurgical station and jaw pressure of vessel forceps, collagen and fibrous protein in human tissues fuse and degenerate, walls of blood vessels fuse into a transparent tape, and permanent luminal closure is achieved. In open surgery or endoscopic surgery, a vessel closure cutting system can be given to full play for any vein, artery or tissue-bundle, smaller than 7mm in diameter, and closing or cutting is safer, faster or more convenient. The above advantages are hardly found in ultracision harmonic scalpels and bipolar coagulation. The high-frequency electrosurgical station has the functions of unipolar incision, unipolar coagulation, bipolar coagulation, bipolar incision, large vessel close-cutting and the like and is a necessity for operating rooms in future.

Owner:ANGEL MEDICAL TECH NANJING

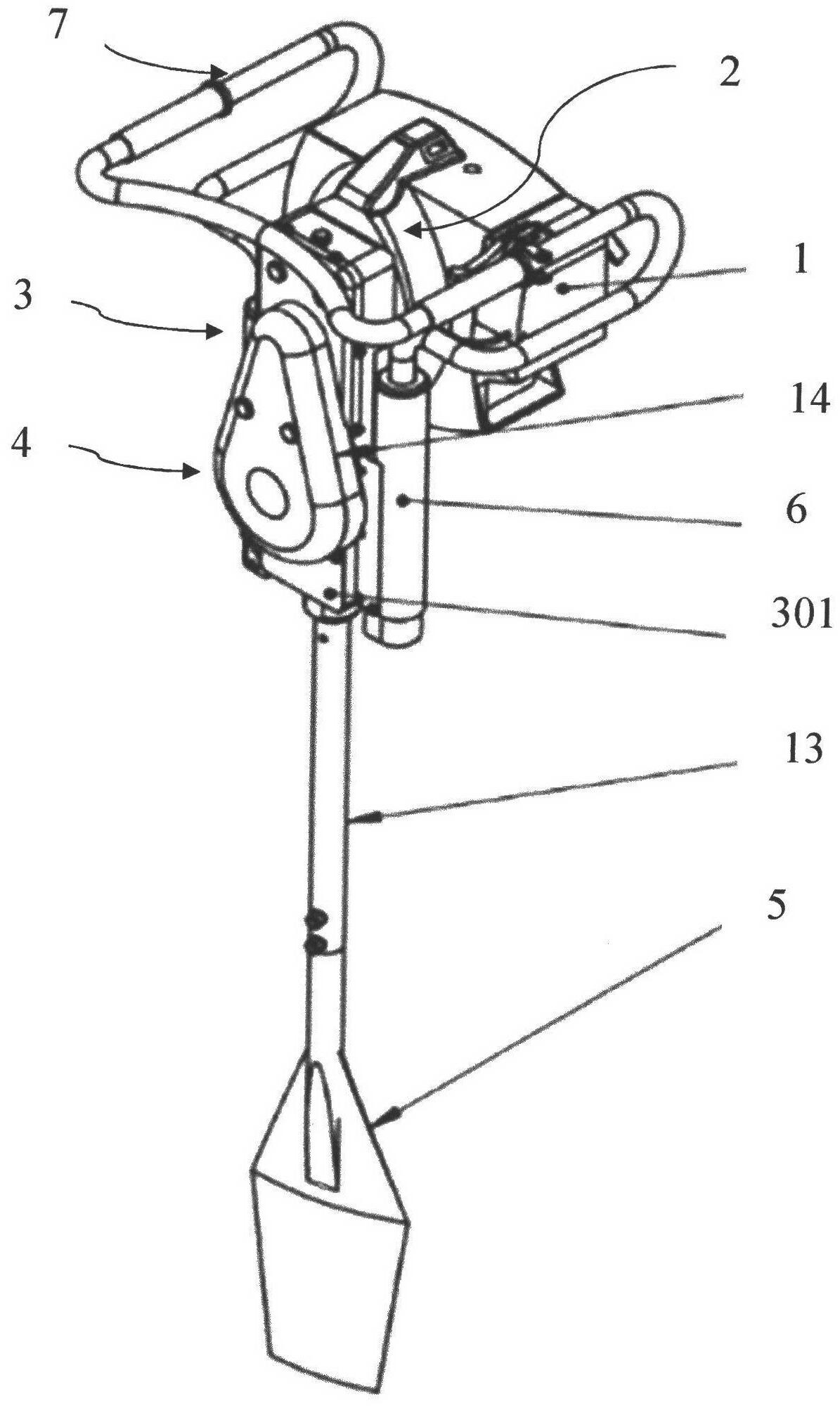

Portable tree digging machine

The invention discloses a portable tree digging machine, which comprises an engine, a machine seat device, a motive power connection device, a box frame connected component, a work head, a shock-absorbing device and an operation rod, wherein the machine seat device is arranged on the engine, the motive power connection device is arranged on the machine seat device, the box frame connected component is arranged at one end of the motive power connection device, the work head is arranged at the end part of the box frame connected component, the shock-absorbing device is arranged at the side surface of the box frame connected component, and the operation rod is connected with the shock-absorbing device. The portable tree digging machine solves the problems of low work efficiency, time waste, labor waste and the like of the traditional spade and has the characteristics that the practicality is high, the use is convenient, the efficiency is high, safety and reliability are realized, and the like.

Owner:江苏巧力林业机械科技有限公司

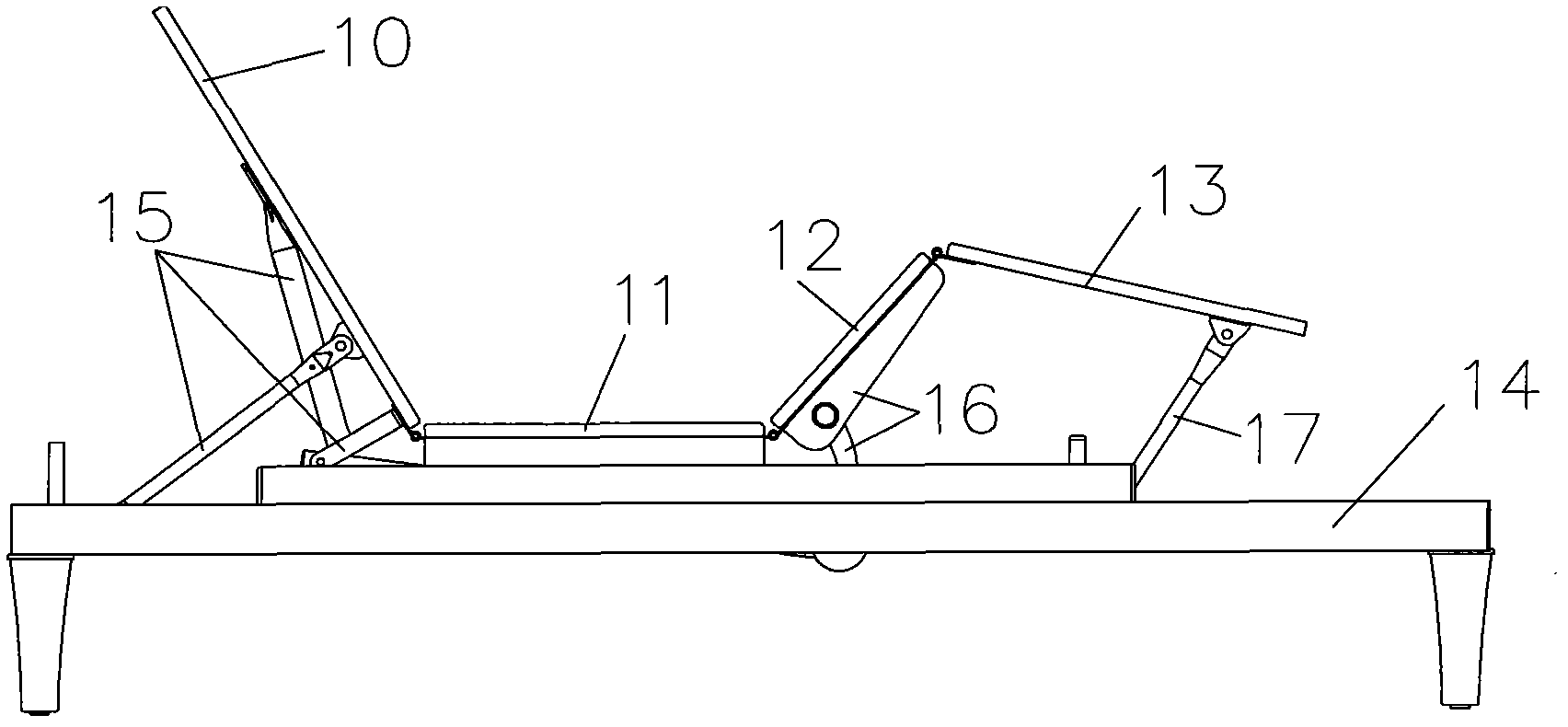

Synchronously operated electric beds with accurate identification

The invention discloses synchronously operated electric beds with accurate identification. Each bed comprises a bed body and a bed plate arranged at the upper portion of the bed body. The bed body is provided with a driving motor connected with the bed plate through a linkage rod. The driving motor is further connected with an electric control system comprising a fixed controller arranged on the bed body and connected with the driving motor and remote controls in mutual connection through wireless signals. At least two electric beds are abreast arranged, and the controllers arranged on the bed bodies of the two electric beds are connected through a synchronous connecting line. The two synchronously operated electric beds mainly accurately identify the operation direction and positions of the motors through a Haul sensor, achieve independent control of adjusting any angle, and ensure bed frames are in an independently and statically fixed state during adjustment. During adjustment, if arms and the like are suppressed, expand aple poly ephylene (EPE) surrounding edge sponge can have a safe protection function, and the whole body is simple in structure and safe.

Owner:KEESON TECH CORP LTD

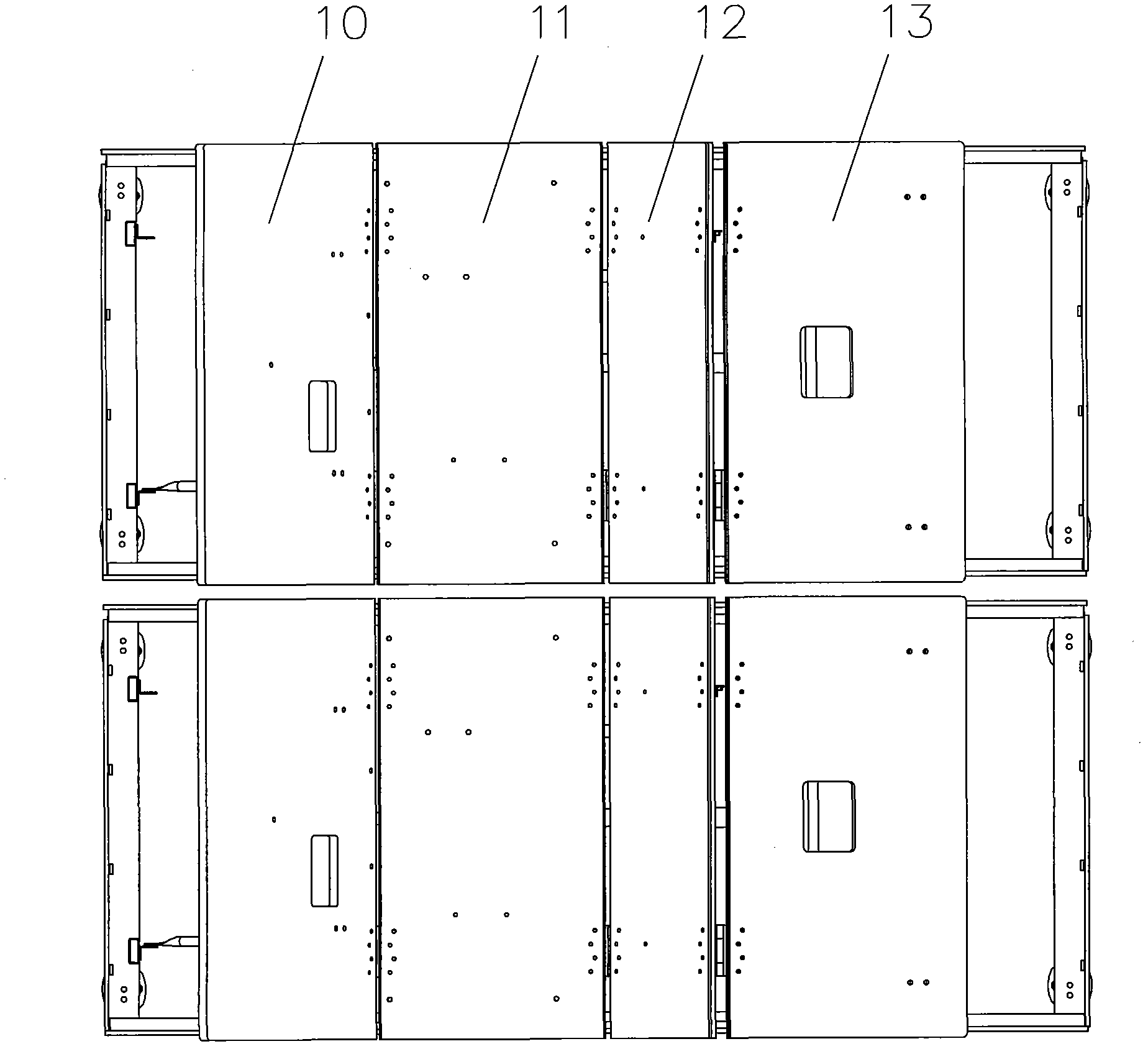

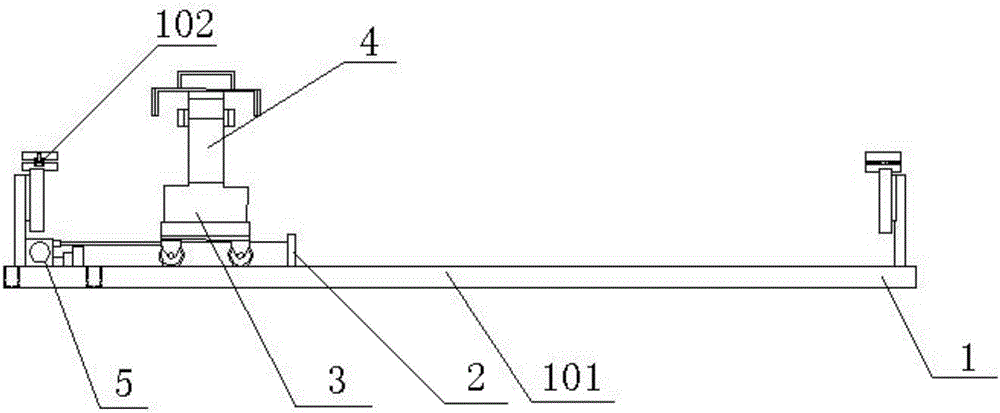

Intelligent pressure welding platform suitable to high voltage power transmission lines

ActiveCN106099607AGuarantees a straight crimpSolve the situation that the crimping size is out of toleranceLine/current collector detailsRail pressureHydraulic pump

The invention discloses an intelligent pressure welding platform suitable to high voltage power transmission lines and belongs to the field of power delivery line construction devices. The platform includes a guide rail pressure welding carriage, a horizontal moving oil cylinder, a pressing jaw trolley, a pressing jaw, a displacement sensor, a gasoline engine hydraulic pump and a programmable controller. The guide rail pressure welding carriage includes a pedestal and a line clamp. The horizontal moving oil cylinder is arranged on the guide rail pressure welding carriage. The horizontal moving oil cylinder is connected to the gasoline engine hydraulic pump through a hydraulic pipe. The pressing jaw trolley is fixed on the horizontal moving oil cylinder. The pressing jaw is installed on the pressing jaw trolley and is connected to the gasoline engine hydraulic pump. The displacement sensor is disposed on the guide rail pressure welding carriage and is in separate connection to the pressing jaw trolley and the programmable controller. The programmable controller is connected to the gasoline hydraulic pump. Compared with prior art, the platform can use the programmable controller to realize digital control in the process of pressure welding, and a pressure sensor acquires pressure signals to achieve accurate control in the process of pressure welding. The platform increases construction efficiency, safety and reliability.

Owner:吉林省送变电工程有限公司 +1

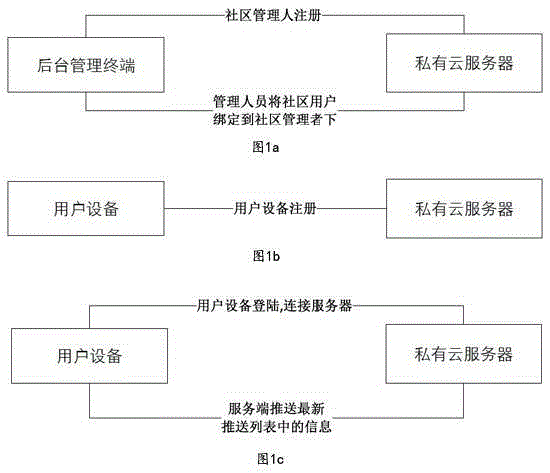

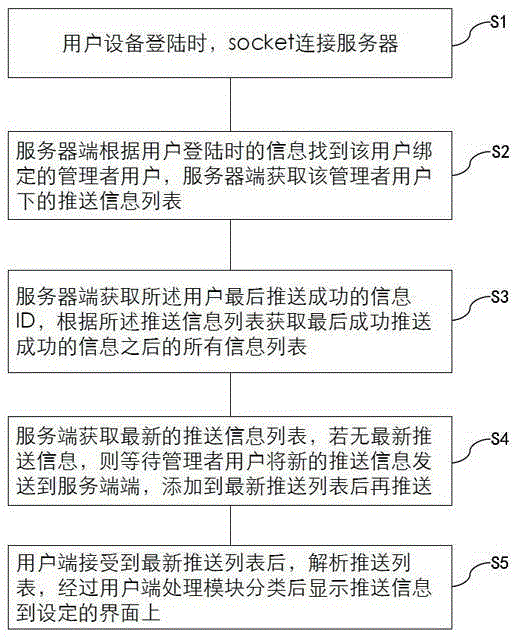

Community service system based on set top box

InactiveCN105554055ASave manpower and material resourcesEasy to operateData processing applicationsTransmissionCommunity settingEngineering

The invention provides a community service system based on a set top box. The community service system comprises a user side, a background management side and a server side. The system also comprises a user side registration module which registers and saves registration information to the server side; and a background management side registration module which binds account information of each user in a community with community manager registration information and saves the registration information in the server side and acquires the push information list of the users on the server side. The background management side transmits push information to the user side according to the push information list acquired on the server side. The user side receives the latest push information and then analyzes the push information, and the push information is displayed on a set interface through classification of a processing module. The beneficial effects of the community service system based on the set top box are that cost of community management services is saved and working efficiency of the community services is greatly enhanced.

Owner:MEIBEIKE TECH CO LTD

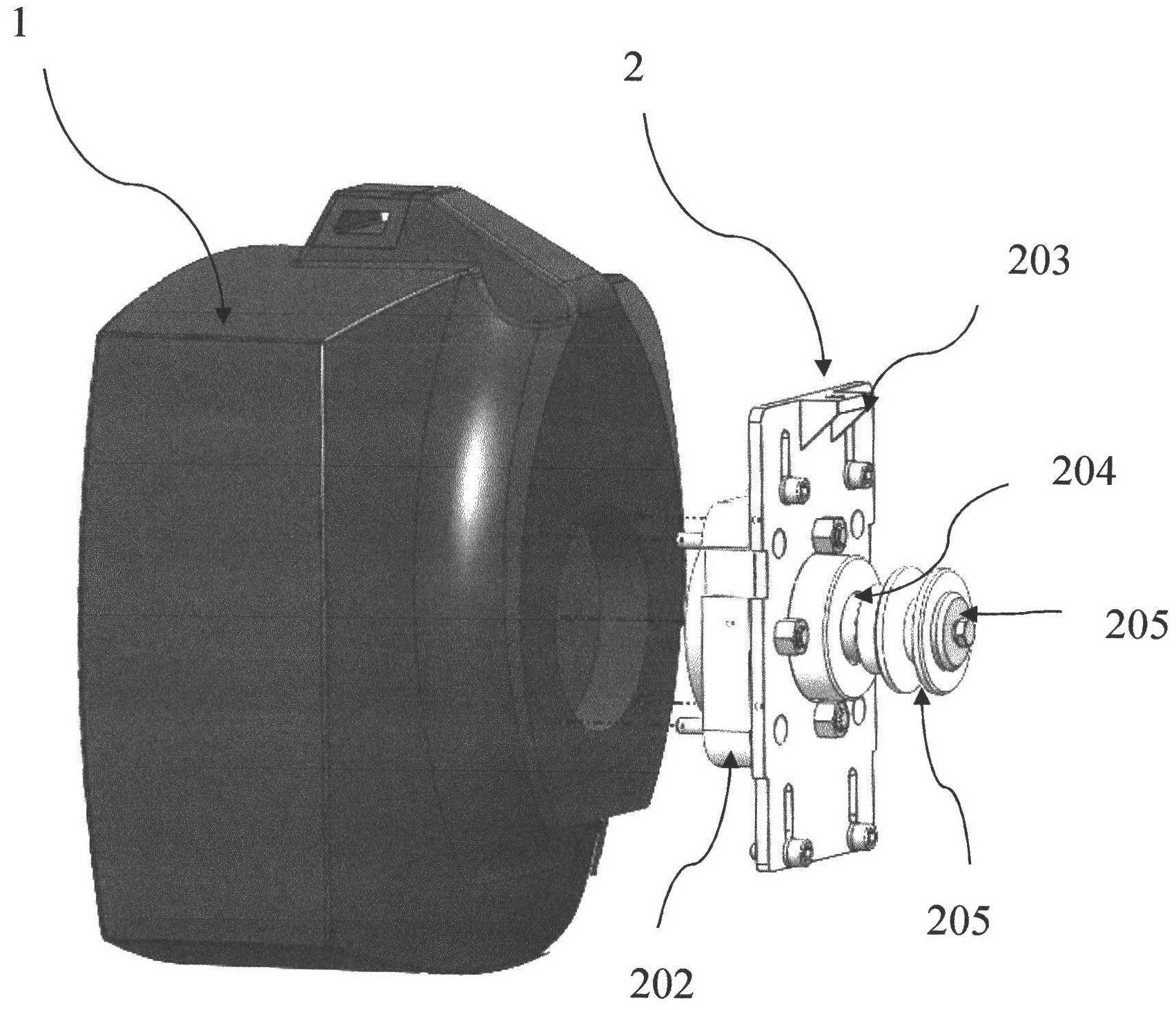

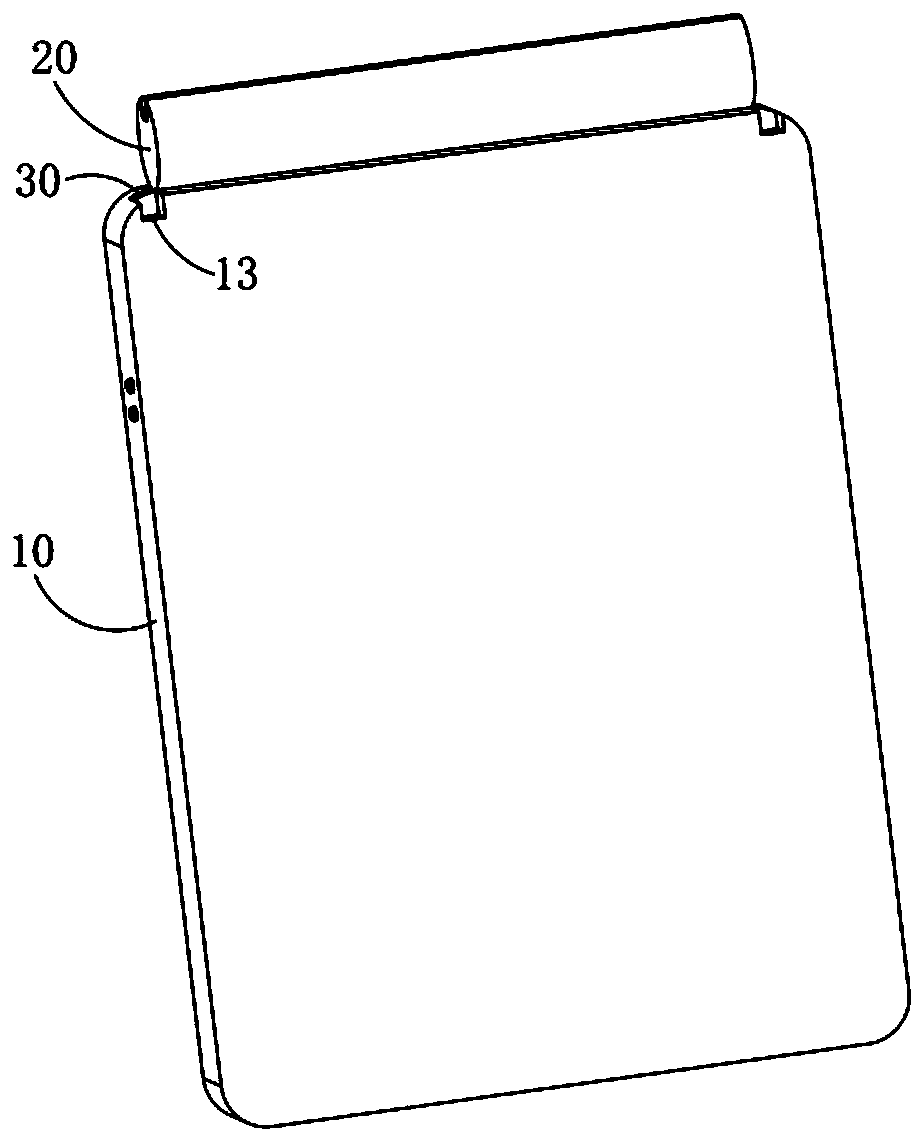

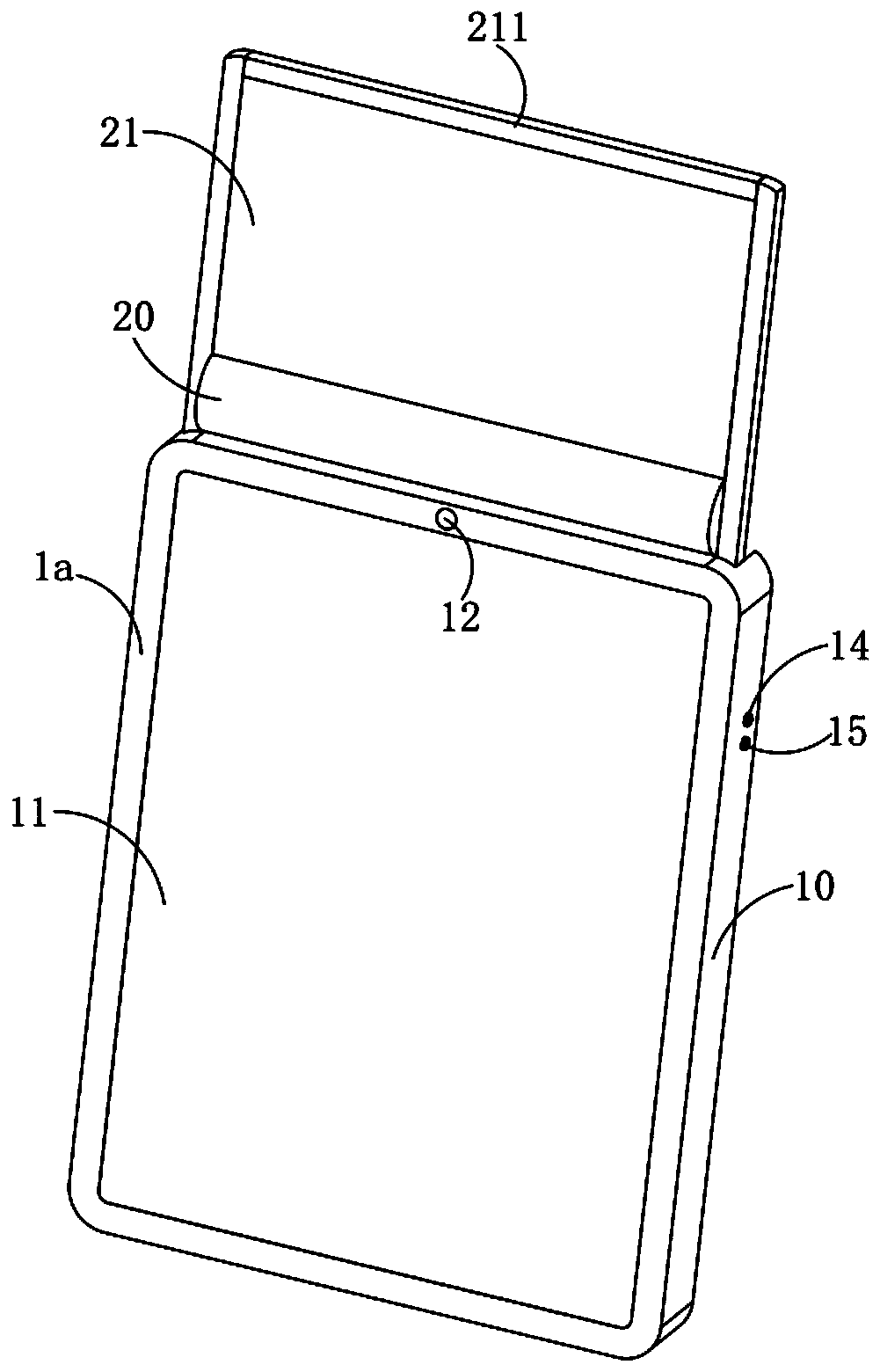

Eye protection tablet computer with flexible display screen

PendingCN111091759AImprove experienceReduce volumeDigital data processing detailsIdentification meansComputer hardwareTablet computer

The invention relates to the technical field of intelligent terminal equipment. The invention discloses an eye protection tablet computer with a flexible display screen. The eye protection tablet computer comprises a tablet computer body, a reel shell and a pull rod; a first display screen is arranged on the front surface of the tablet computer body; the reel shell is arranged at the top of the tablet computer body; the reel shell is rotatably provided with a second display screen; the second display screen is a flexible screen, the second display screen can rotate relative to the reel shell so as to be switched between a first state and a second state, and a pull rod is arranged on the tablet computer body in a sliding mode and used for driving the second display screen to be switched from the first state to the second state. The eye protection tablet computer is small in size, convenient to carry and good in user experience.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

Special pesticide preparation device for agricultural planting

PendingCN112755885AEasy to transportQuick fixTransportation and packagingRotary stirring mixersAgricultural engineeringMedicine bottles

The invention discloses a special pesticide preparation device for agricultural planting, which comprises a base and a preparation box mounted on the base, a bidirectional high-speed stirring and uniform mixing device is arranged on one side of the lower part in the preparation box, and a rotary adjusting type pesticide liquid conveying and mixing device is arranged below the center in the preparation box. An air pressure adjusting type liquid medicine conveying driving device is arranged at the upper part in the preparation box. According to the device, liquid medicine in the multiple liquid medicine bottles is conveyed according to the corresponding conveying speed through air pressure in different constant ranges in the multiple adjusting sleeves, the multiple kinds of liquid medicine are evenly mixed through the even mixing disc, the liquid medicine is sprayed into the conveying water pipe after being evenly mixed, the liquid medicine is prepared in real time according to the optimal proportion, and the efficiency is improved. Various pesticides are prepared, diluted and used at the same time, the requirement for preparation of various pesticides in conventional agricultural planting can be met, and workers can conveniently use the pesticide preparation device.

Owner:张广才

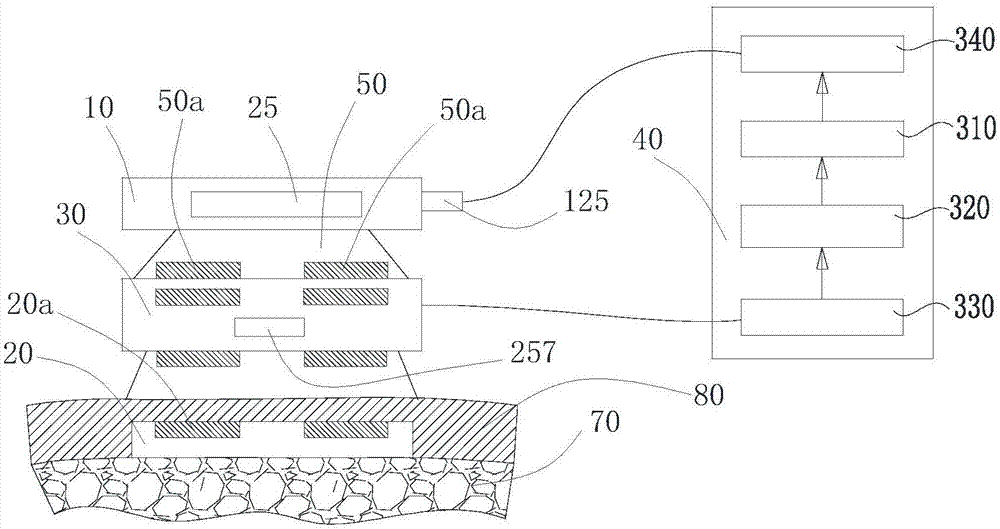

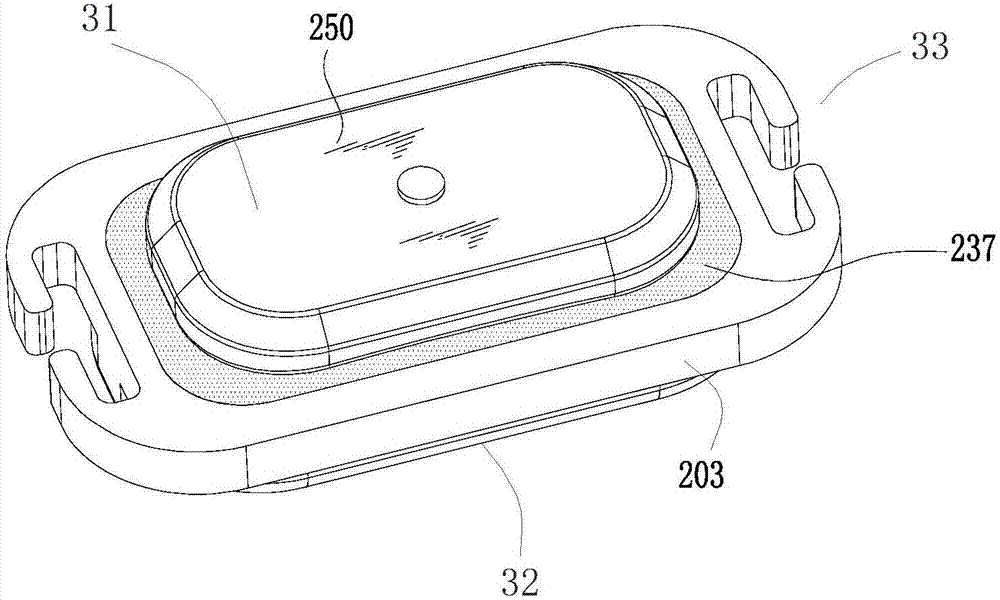

Sound acquisition and analysis system for hearing aid

PendingCN106921925AHigh acquisition sensitivityAvoid damageSets with pocket amplifiersElectronic input selection/mixingElectricityEngineering

The invention relates to a sound acquisition and analysis system for a hearing aid. The sound acquisition and analysis system for the hearing aid comprises a hearing aid, a magnetic implant, sound acquisition equipment and a processing and analysis system; the magnetic implant is implanted in the skin outside a human skull; the hearing aid is connected with the magnetic implant through the sound acquisition equipment; an electromagnetic bone conduction oscillator is arranged in the hearing aid; a magnetic gasket is arranged at the lower side of the hearing aid; the electromagnetic bone conduction oscillator is connected with the magnetic gasket outside the hearing aid through a conduction metal sheet; the sound acquisition equipment comprises a shell; a sound sensor is built in the shell; the sound sensor is in communication connection with the processing and analysis system; an upper magnetic end magnetically connected with the magnetic gasket is arranged at the upper end of the shell; and a lower magnetic end magnetically connected with the magnetic gasket is arranged at the lower end of the shell. By means of the sound acquisition and analysis system for the hearing aid disclosed by the invention, the sound acquisition equipment acquires sound transmitted through the magnetic gasket from the hearing aid, and converts the sound into electric signals; therefore, the output condition of the bone conduction hearing aid is measured in real time; the signals are output into the processing and analysis system, so that real-time processing and analysis are carried out; and thus, sound signals transmitting into the skull of a patient are evaluated.

Owner:ZHEJIANG NUROTRON BIOTECH

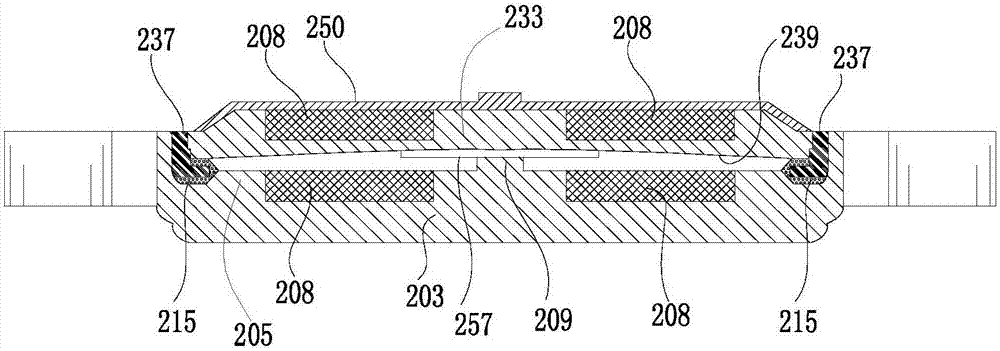

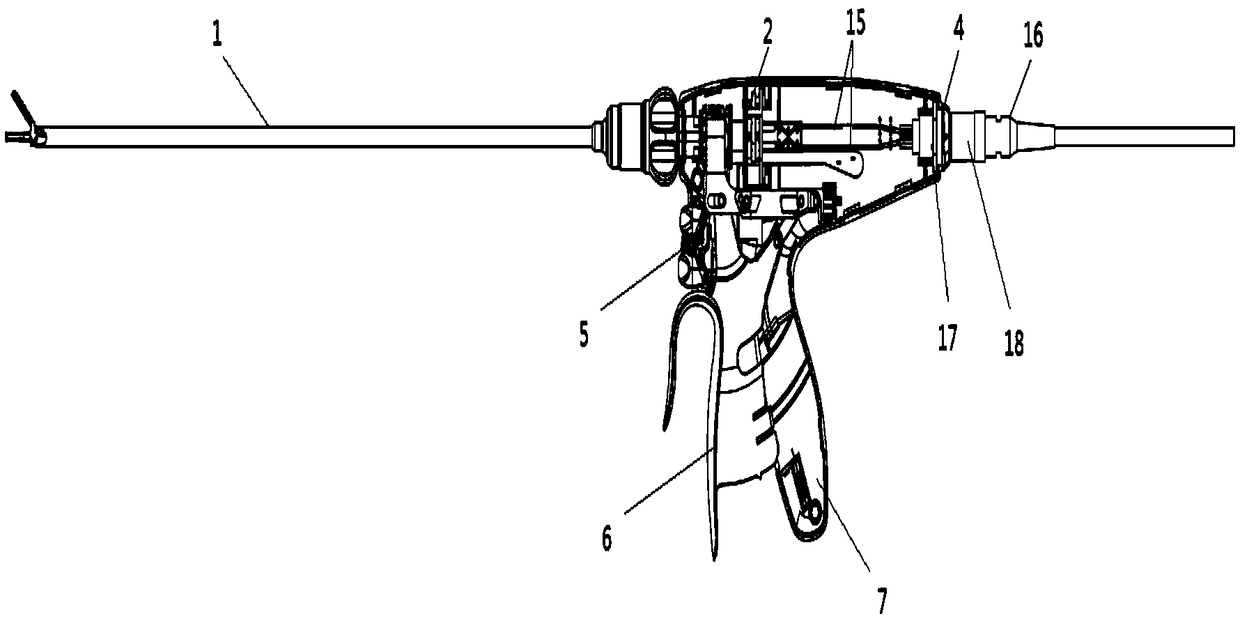

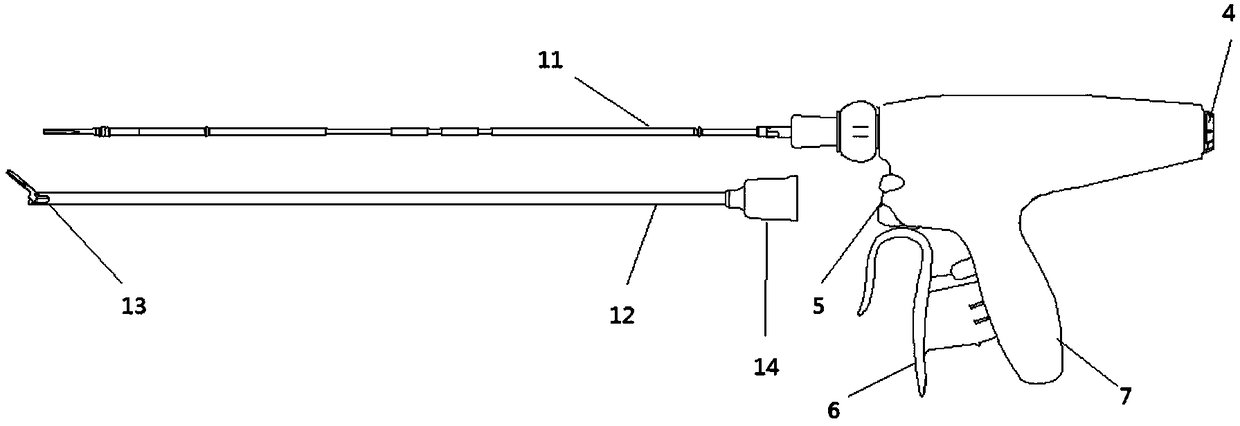

Ultrasonic surgical integrated knife

The invention relates to the technical field of a medical instrument, and particularly to an ultrasonic surgical integrated knife. The ultrasonic surgical integrated knife comprises the components ofa handle which internally provided with an energy transducer; and a cutter assembly which comprises a cutter bar and a cutter head that are sleeved with each other, wherein the cutter bar is detachably connected with the cutter head, and the cutter bar is fixedly connected with the energy transducer. According to the ultrasonic surgical integrated knife, the energy transducer is arranged in the handle; the cutter bar is fixedly connected with the energy transducer; and therefore the produced handle of the integrated knife can be used by multiple times; because the cutter head which is disposable in the cutter assembly can be changed, a cross infection risk of the surgery can be prevented. Furthermore the integrated knife does not require assembling before the surgery, thereby supplying high convenience through a quick use mode, and preventing mistakes because of a tedious assembly structure in an assembling process.

Owner:BEIJING ANHEJIALIER TECH CO LTD

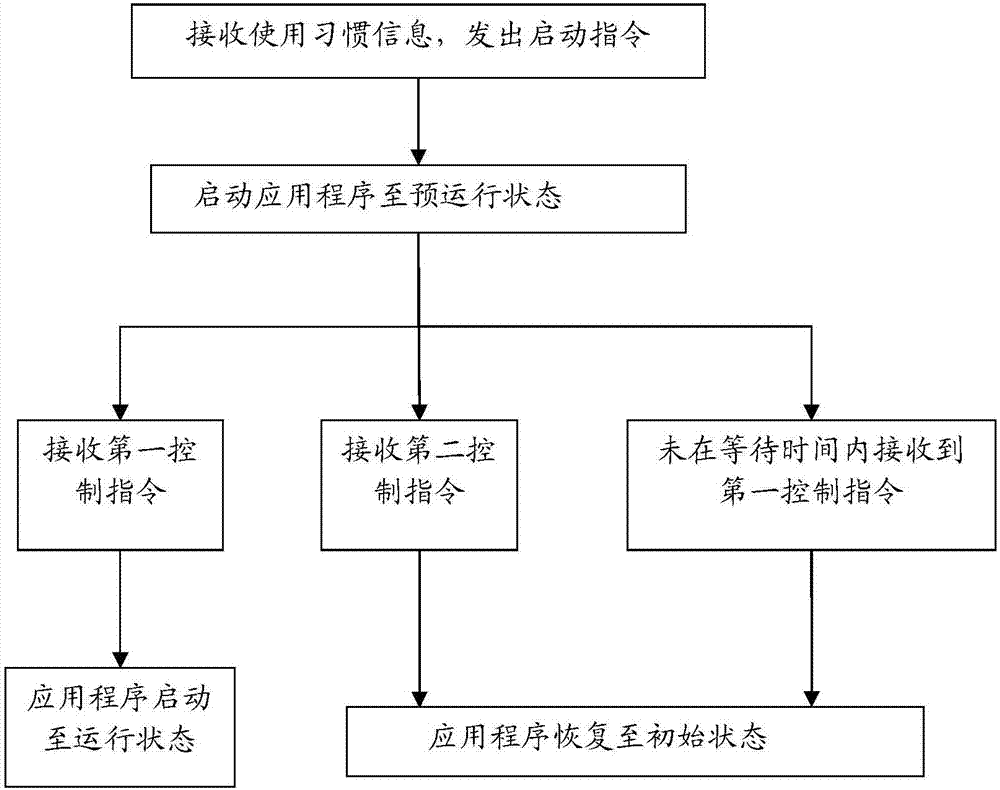

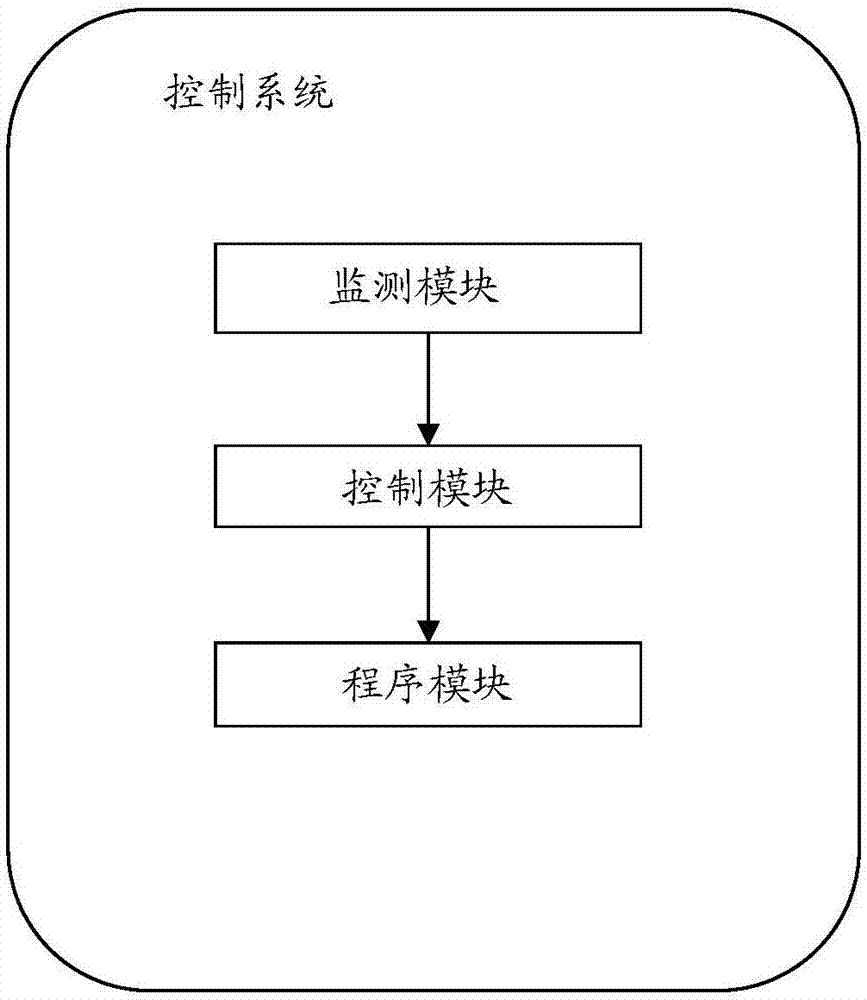

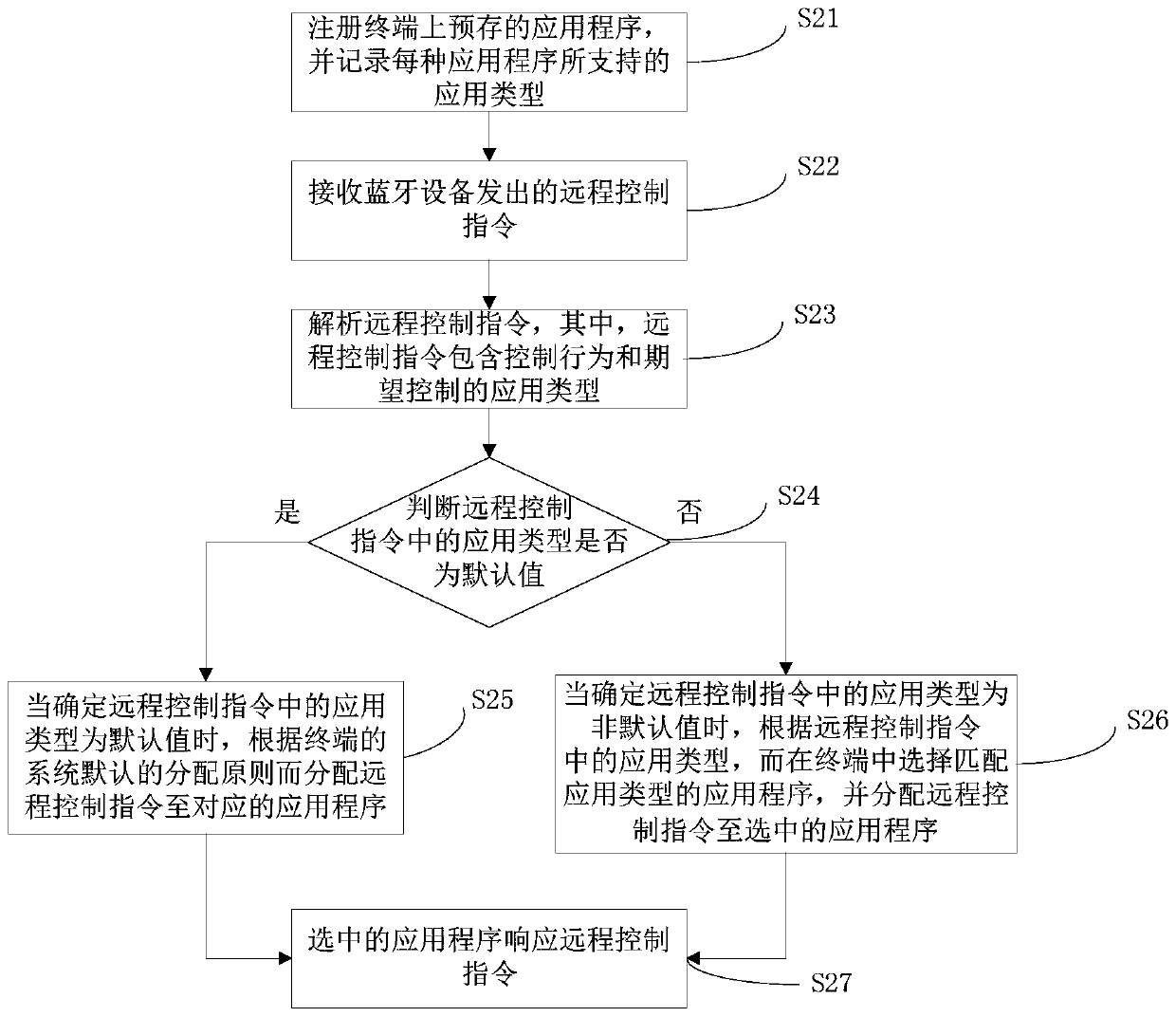

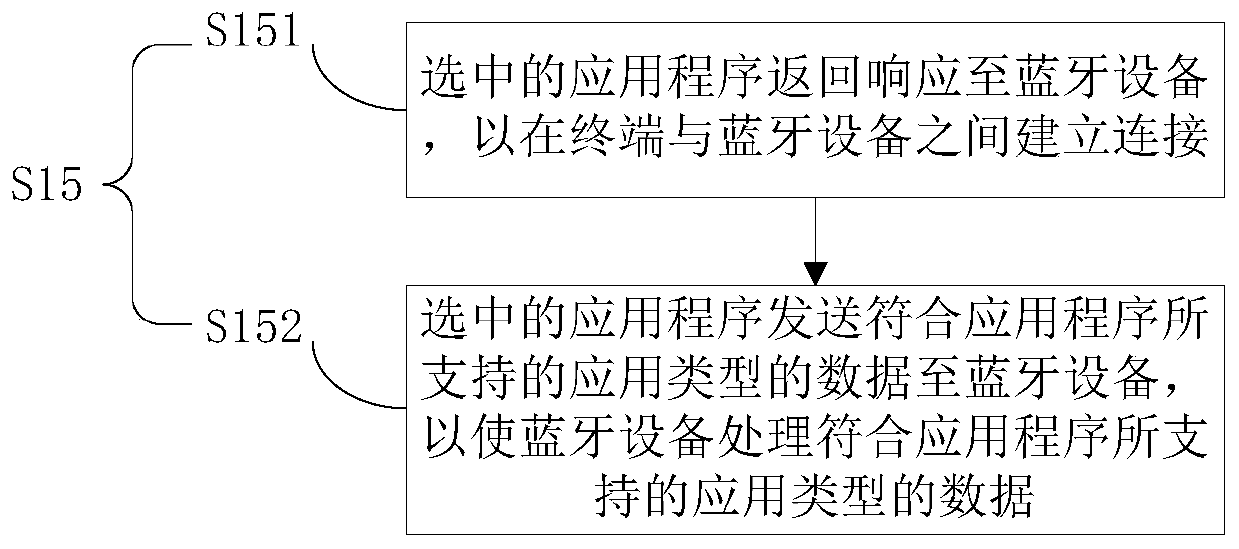

Control method and system of application program based on intelligent terminal

PendingCN107391200AFast startupQuick responseProgram loading/initiatingControl systemApplication software

The invention provides a control method and system of an application program based on an intelligent terminal. The control method comprises the following steps of receiving using habit information, and generating a starting instruction for starting at least one application program according to the using habit information; starting the application program from an initial state to a pre-running state according to the starting instruction; switching the application program to a running state from the pre-running state when the intelligent terminal receives a first control instruction matched with the using habit information, and starting the application program; returning the application program to the initial state from the pre-running state when the intelligent terminal receives a second control instruction not matched with the using habit information or does not receive the first control instruction within a waiting time. The control system comprises a measuring module, a control module and a program module. By means of the control method and system of the application program based on the intelligent terminal, the speed of the intelligent terminal of starting the application program can be increased.

Owner:SHANGHAI TRANSSION CO LTD

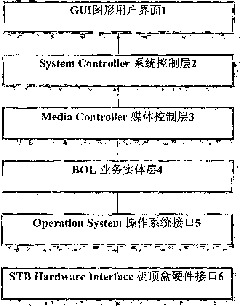

Set top box-based multimedia electronic library system and method

InactiveCN101827249AShortcutsRealize e-readingTelevision system detailsColor television detailsGraphical user interfaceSet top box

The invention discloses a set top box-based multimedia electronic library system and a set top box-based multimedia electronic library method. The system is designed according to a layered framework and comprises a graphical user interface layer, a system control layer, a media control layer, a service entity layer, an operation system interface and a set top box (STB) hardware interface, wherein the graphical user interface layer is used for displaying various application services based on a display browse function of a set top box browser; the system control layer serves as a service resolver initiated by the graphical user interface layer; the media control layer is used for realizing processing operation of electronic book data; the service entity layer is used for realizing two service elements, namely reading based on a local electronic book and borrowing from an electronic library based on a cable television network; the operation system interface serves as an interface which is used for connecting an operation system platform used for realizing the system; and the set top box hardware interface layer is used for connecting with a set top box through a USB interface. Due to the adoption of the set top box-based multimedia electronic library system and the set top box-based multimedia electronic library method, a convenient and quick method for massive reading is provided for users.

Owner:SUN YAT SEN UNIV

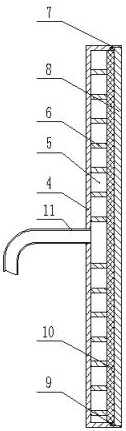

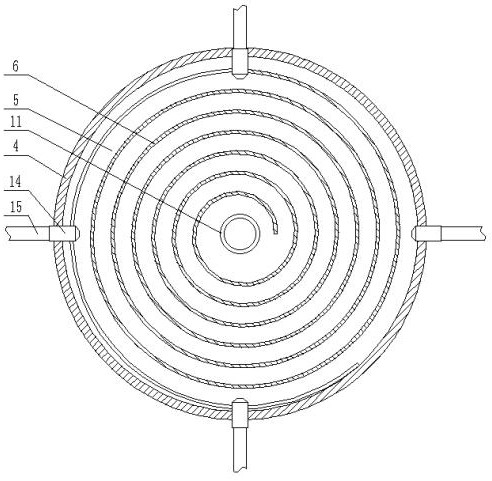

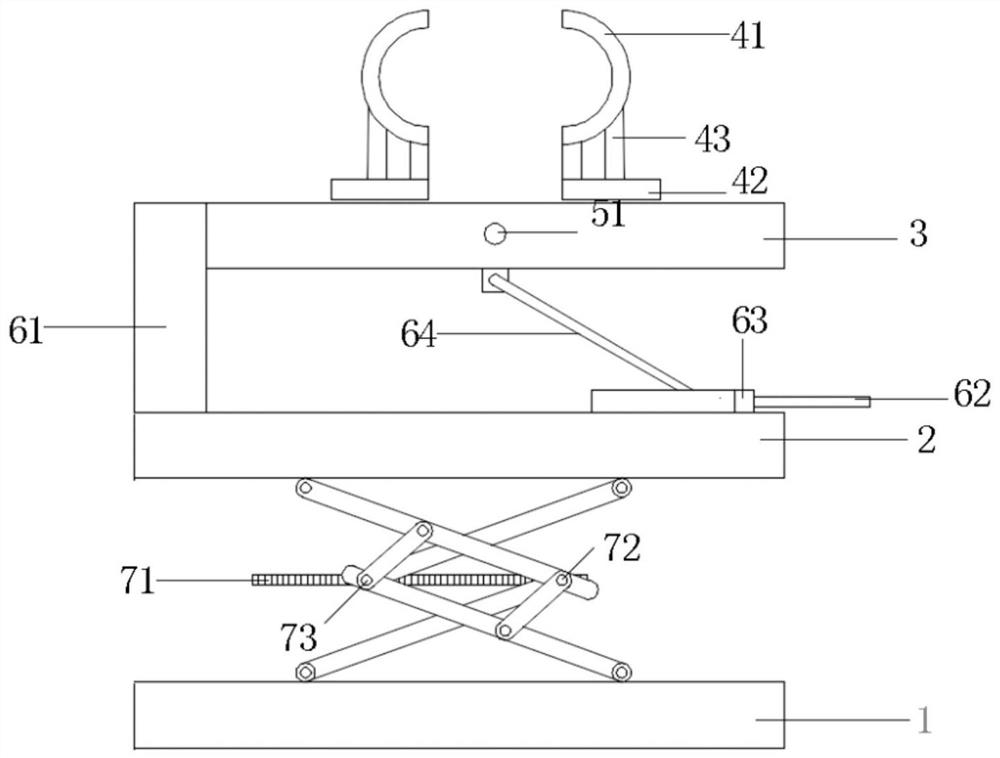

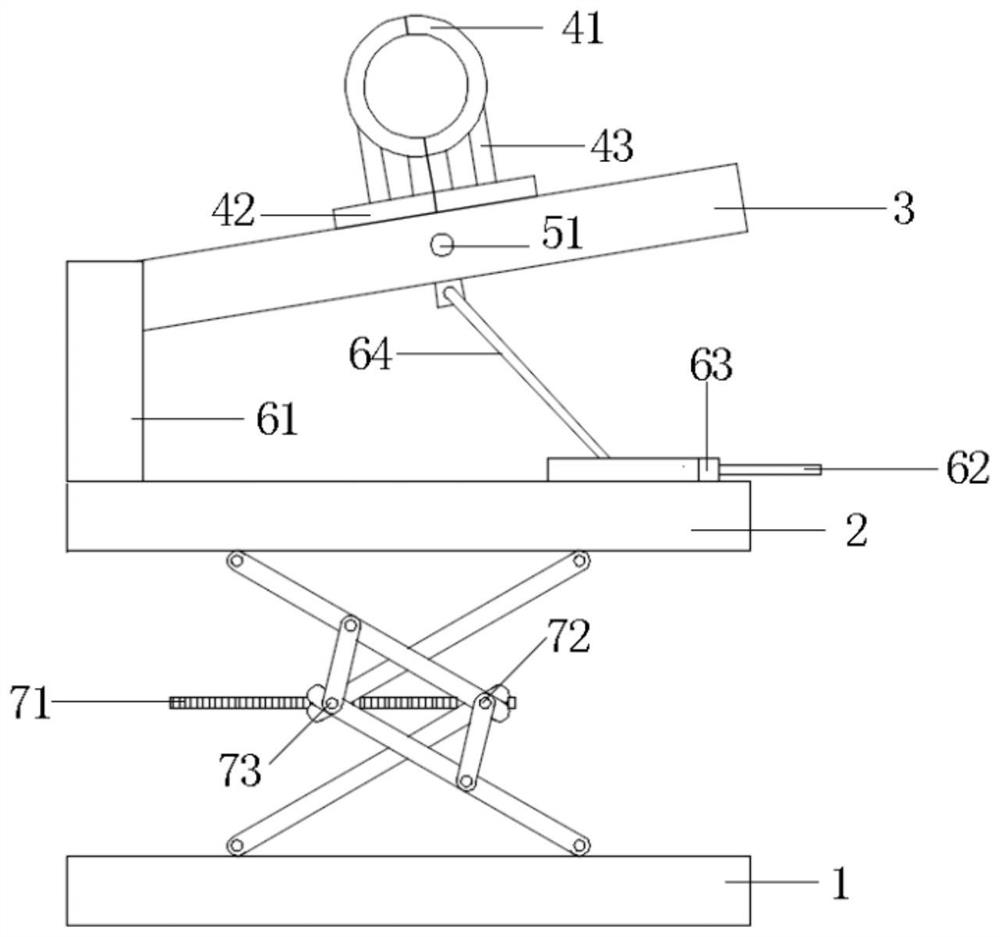

Heating device connected to outside of oil pipeline

ActiveCN113175580AAvoid damageReach heightPipe supportsPipe heating/coolingEngineeringMechanical engineering

The invention discloses a heating device connected to the outside of an oil pipeline. The angle and height can be adjusted according to the environment so that heating assemblies can be attached to the surface of the oil pipeline. The heating device comprises a first platform, a second platform, a third platform, the heating assemblies, a horizontal driving assembly, an angle adjusting assembly and a height adjusting assembly. The second platform is located between the first platform and the third platform; the second platform is parallel to the first platform; the height adjusting assembly is connected between the first platform and the second platform; the angle adjusting assembly is connected between the second platform and the third platform; and the horizontal driving assembly is installed on the third platform. The two heating assemblies both comprise an arc-shaped heating plate, a control element and a base, wherein the arc-shaped heating plates are installed on the bases; the control elements are installed in the bases; and the bases of the two heating assemblies are connected to the horizontal driving assembly and arranged oppositely. The heating device has the characteristics of being convenient to operate and high in adaptability.

Owner:CHENGDU ZHENGSHENG ENERGY TECH DEV CO LTD

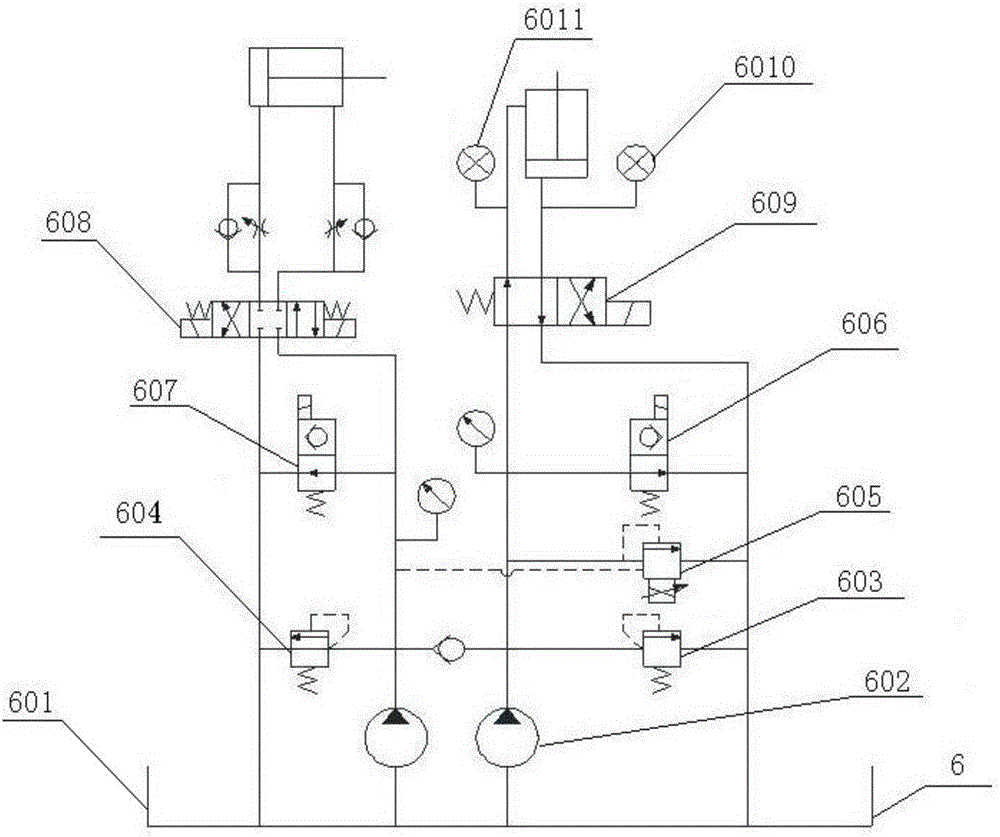

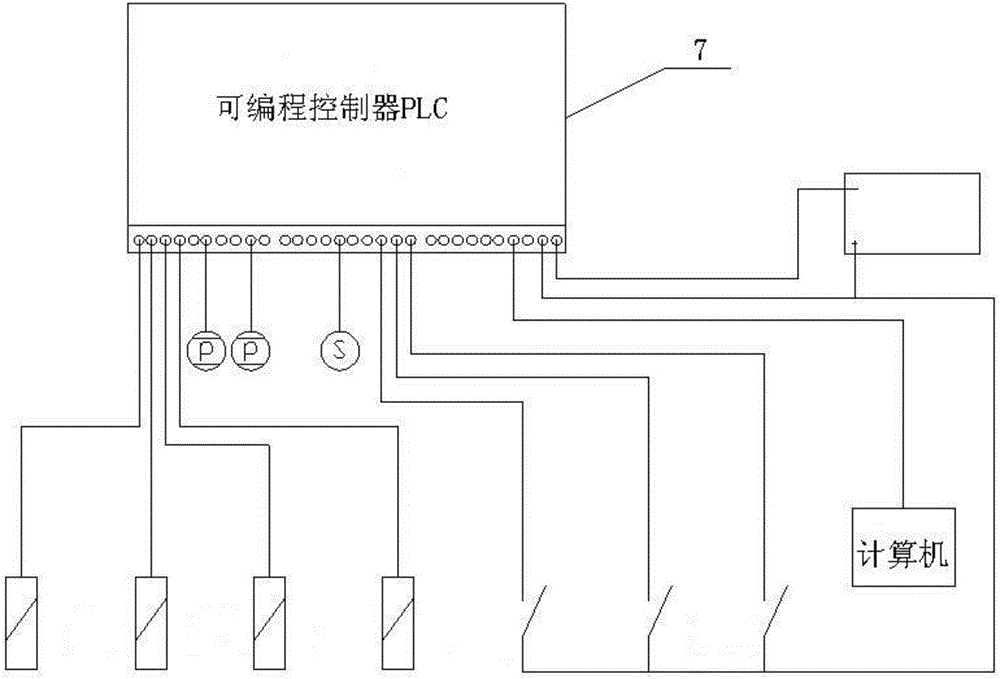

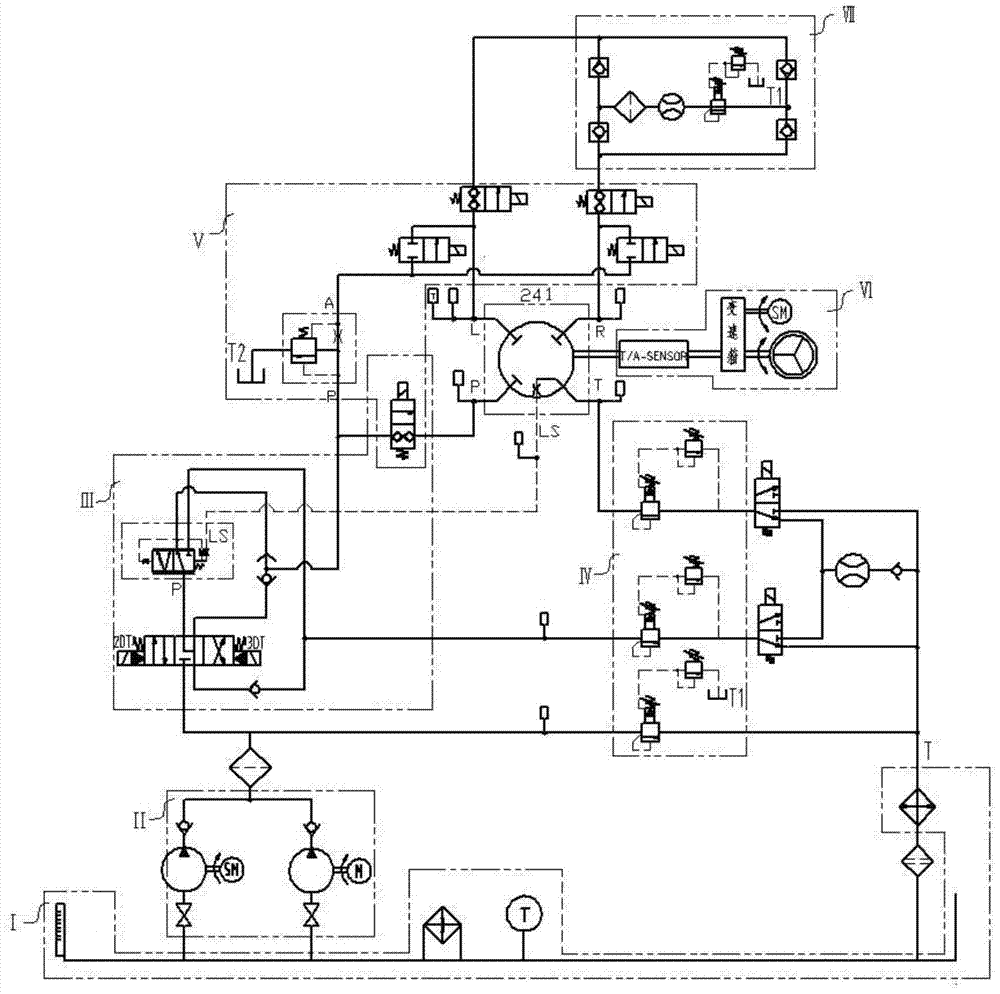

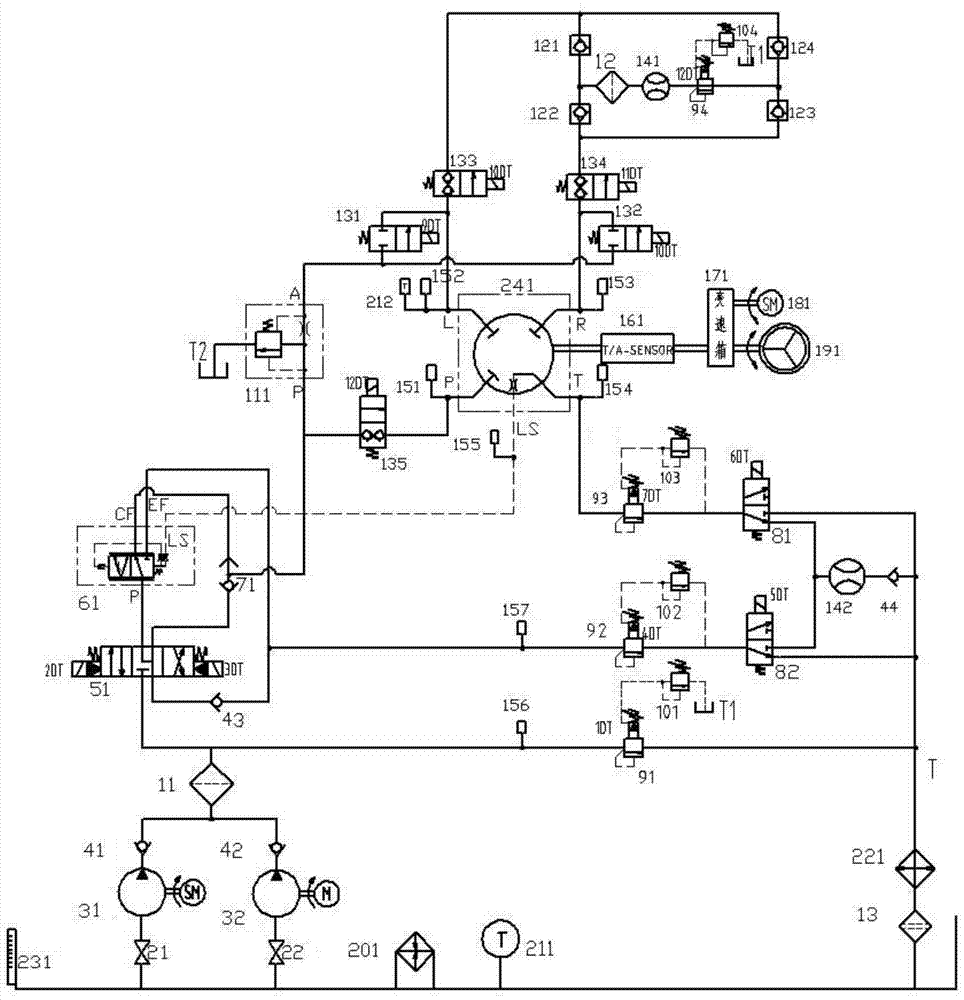

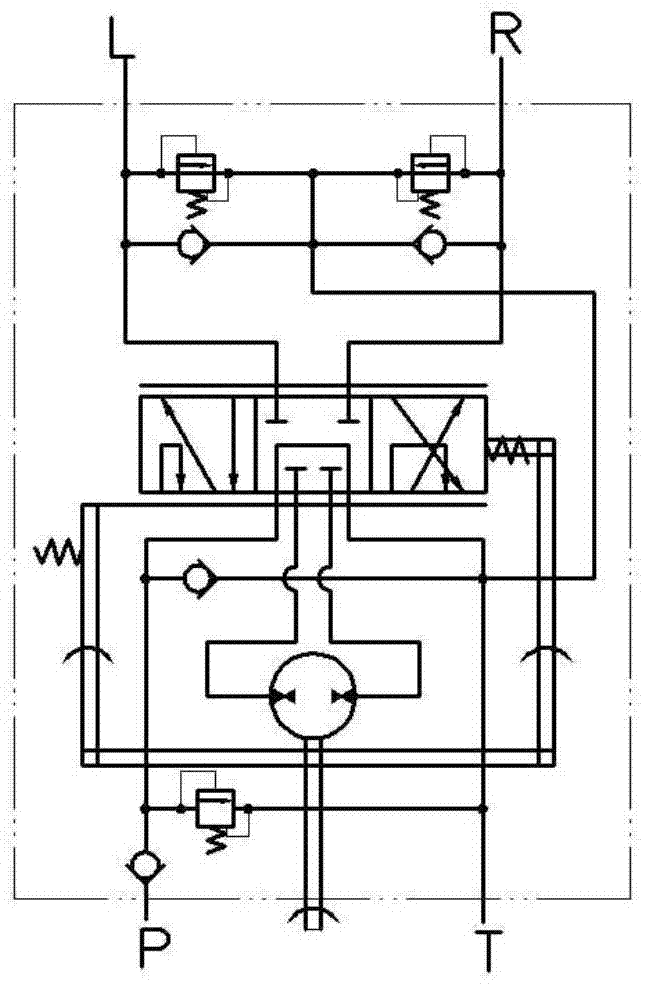

Multifunctional test system for full hydraulic steering gear

InactiveCN105134692BMeet remote switchingRealize remote switchingFluid-pressure actuator testingTest performanceLoad sensing

The invention discloses a multifunctional testing system of a full hydraulic steering gear. The system comprises a fuel tank module (I) having a temperature control system, a motor pump set module (II) having a flow regulating system, a system fuel way switching module (III), a remote pressure loading module (IV), an overload valve performance testing module (V), an operation control mechanism (VI), a bridge circuit analog loading module (VIII), a sensor data acquisition module, an electric control system and a computer data processing center. According to the testing system, testing systems for load sensing type steering gears and other functional steering gears (such as open-core nonreactive type steering gears, open-core reactive type steering gears, closed-core nonreactive type steering gears and the like) can be switched through the system fuel way switching module. Data acquisition and processing are performed on pressure, flow, torque and rotating speed parameters in test performance by the aid of various sensors, PLCs (programmable logic controllers) and the like, and product performance is accurately distinguished.

Owner:WUHU ZHONGYI HYDRAULIC TECH

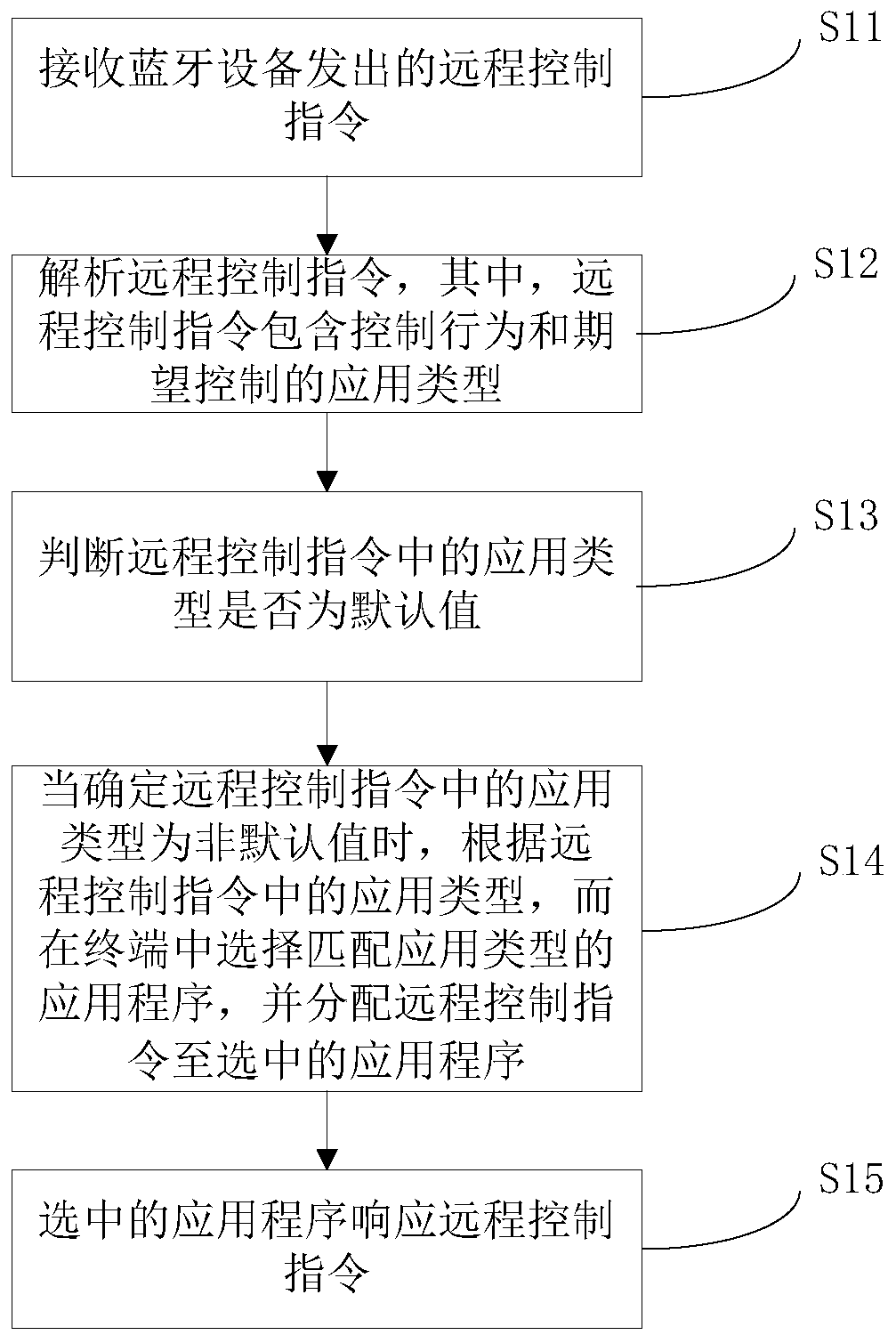

A method and system for remote bluetooth control terminal application

ActiveCN106604204BAccurate method of operationShortcutsSubstation equipmentShort range communication serviceComputer hardwareRemote control

Owner:合肥市贵谦信息科技有限公司

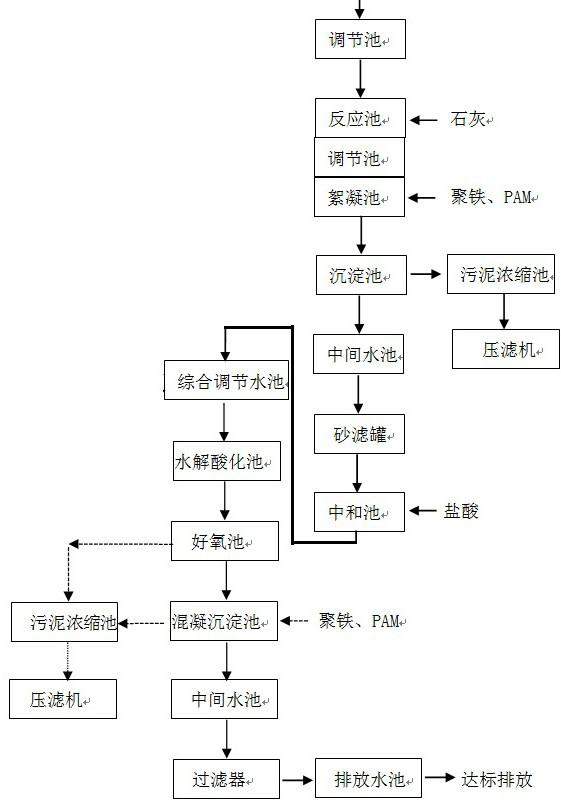

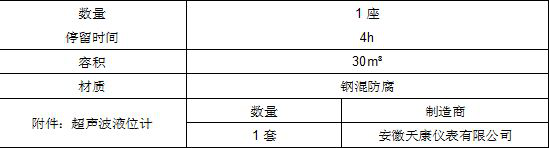

Phosphating wastewater treatment system and method

PendingCN111943437AImprove reaction efficiencyEasy to handleWater contaminantsTreatment involving filtrationFlocculationFluid phase

The invention provides a phosphating wastewater treatment system and method. The phosphating wastewater treatment system comprises a phosphating wastewater adjusting pool, which is connected with a reaction pool, wherein the reaction pool is connected with a central adjusting pool, the central adjusting pool is connected with a flocculation pool, the flocculation pool is connected with a sedimentation pool, the solid phase outlet of the sedimentation pool is connected with a sludge concentration pool, the sludge concentration pool is connected with a filter press, the liquid phase outlet of the sedimentation pool is connected with an intermediate water pool, the intermediate water pool is connected with a sand filter tank, the sand filter tank is connected with a neutralization pool, the neutralization pool is connected with a biochemical treatment system, the reaction pool, the central adjusting pool and the flocculation pool adopt a triple box type structure, a stirrer is arranged inthe central adjusting pool, and a lime supply box is connected in the reaction pool, and the flocculation pool is connected with a flocculant adding box. According to the invention, environmental pollution caused by phosphatization wastewater is avoided, and up-to-standard discharge of wastewater is realized.

Owner:JIANGSU HUAHUI ENVIRONMENTAL PROTECTION TECH

Intelligent wheelchair human-computer interaction control system and method based on eye movement recognition

ActiveCN107260420BControl Method AdvantagesSolve control problemsInput/output for user-computer interactionWheelchairs/patient conveyanceControl mannerSimulation

The invention discloses an intelligent wheelchair man-machine interaction control system and an intelligent wheelchair man-machine interaction control method based on eye movement recognition. According to the system and the method, an electromyographic signal acquisition module is used for collecting electromyographic signals of the eyes, characteristic selection is carried out on the electromyographic signals, eye movement recognition is carried out according to the electromyographic characteristic change difference during blink, thus the accurate judgment on the conscious blinking is realized, further, the accurate control over the direction of a wheelchair is realized by combining a plurality of conscious blinking modes, a fuzzy controller part takes a signal electromyographic integral value and signal slope as input and the running speed of the intelligent wheelchair as output, then a two-dimensional structure fuzzy controller with two inputs and single output is built, and thus the accurate control over the running speed of the wheelchair is realized. According to the system and the method, the scheme is diversified, the operation mode is simple, convenient and rapid, the learning is easy, the special requirements of old people and disabled people in the control mode are fully considered, the control problem of the intelligent wheelchair system caused by the fact that a traditional control mode is not flexible in operation and a user responds slowly is avoided, and the practical requirements of the old people and the disabled people are well adapted.

Owner:NANJING UNIV OF POSTS & TELECOMM

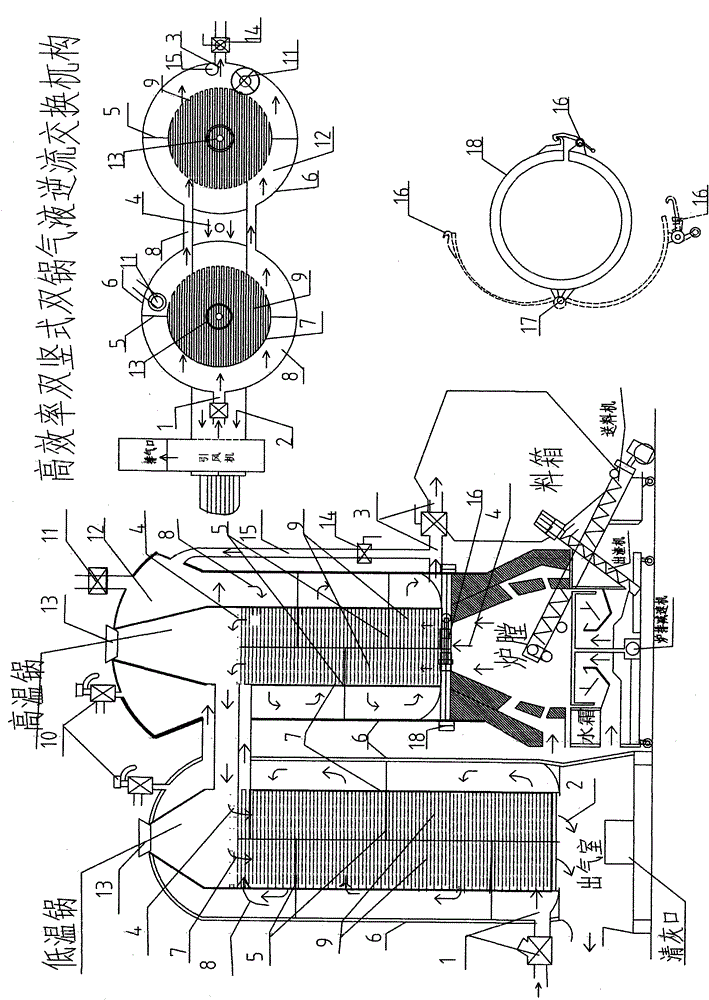

High-efficiency double-vertical-pot gas-liquid reverse-flow exchange mechanism

The invention discloses a high-efficiency double-vertical-pot gas-liquid reverse-flow exchange mechanism, and relates to technical structures that according to the relation separation between pots and a furnace, the pots are managed independently, the furnace is managed independently, the pots and the furnace fulfill duties respectively, and the optimal efficiency is achieved. The mechanism comprises a high-temperature pot and a low-temperature pot which are separated in order to improve efficiency of the pots. The lower portion of the high-temperature pot is movably connected with a flame releasing opening of a furnace, the lower portion of the low-temperature pot is connected with a gas-dust chamber, the gas-dust chamber is connected with a discharge pipe, the upper portion of the high-temperature pot is fixedly connected with the upper portion of the low-temperature pot in a gas-communication and liquid-communication mode, an inlet for cold liquid is limited to be a smoke outlet, and a high-temperature flame gas inlet is limited to be a hot water or steam outlet. For combination of the pots and the furnace, an assembly latch and an eccentric wheel pull buckle are combined, in this way, rapid connection and rapid separation can be achieved, boiler failures can be rapidly removed, and recovering of normal operation is rapid. The defects that for all kinds of present fuel combustion boilers, due to failures, the boilers stop working and quench, and then time is delayed, and dirt at dead corners inside the boilers is difficult to clear away are overcome, more importantly, liquid-gas reverse-flow exchange is adopted so that the highest exchange efficiency can be achieved, the discharging temperature of smoke is higher than the injection temperature of the liquid by about 20 DEG C, and the technology achieves the lowest discharging temperature of boiler smoke at the present.

Owner:WENZHOU WEISHENG TECH ENVIRONMENTAL PROTECTION EQUIP

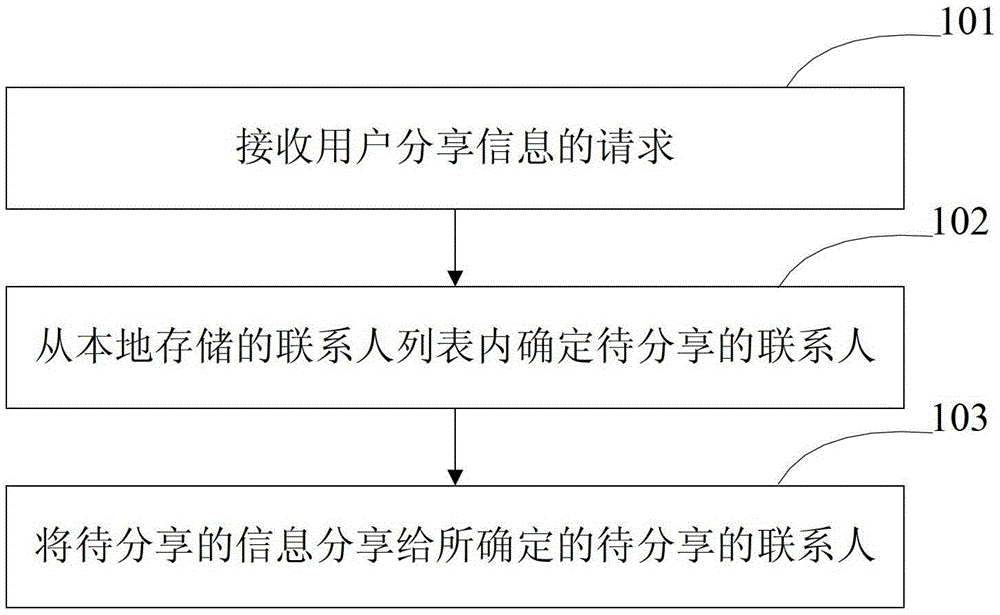

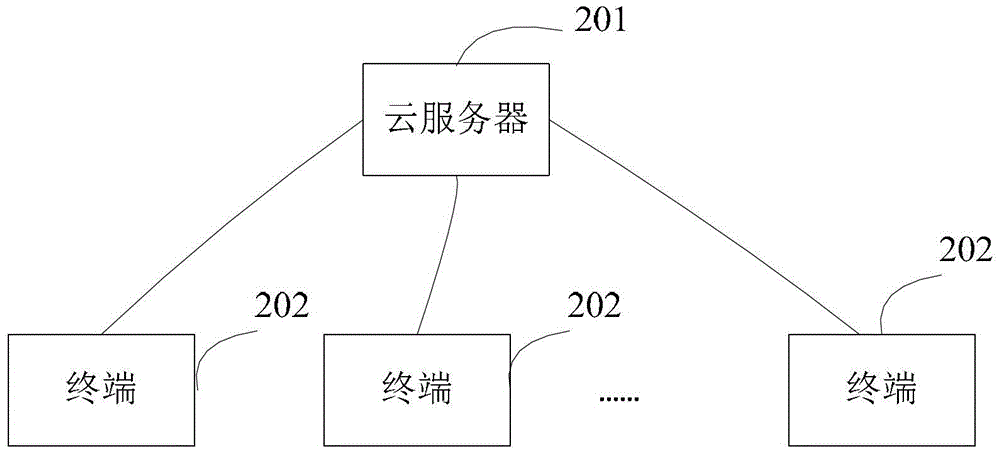

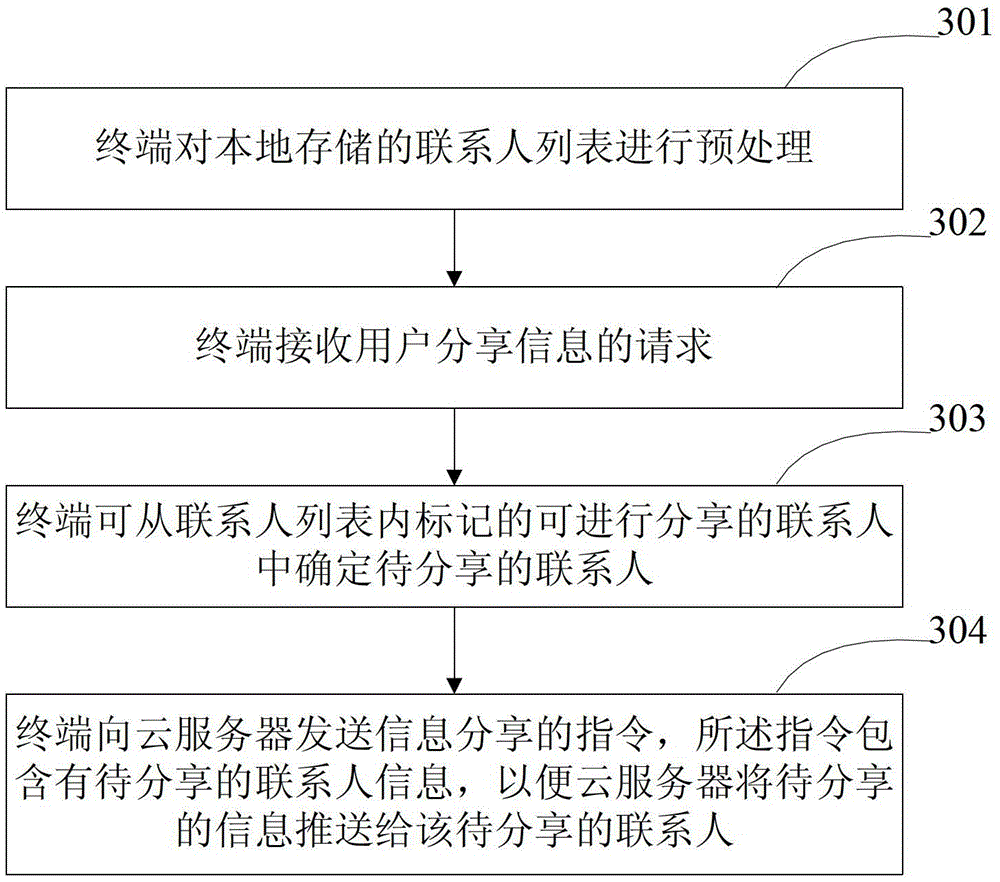

A method, device and terminal for information sharing

ActiveCN103200224BEasy to operateShortcutsServices signallingSubstation equipmentInformation sharingEngineering

The invention discloses an information sharing method, device and terminal, which belong to the field of communication technology. After receiving a request from a user to share information, the contact person to be shared is determined from a locally stored contact list, and then the contact person to be shared is determined. The information is shared with the determined contacts to be shared, and the information sharing can be realized through the contact list stored in the terminal, and the operation mode is convenient and fast.

Owner:XIAOMI INC

Method, terminal and system for transferring files

ActiveCN103840859BGood choiceEasy transferDatabase distribution/replicationNear-field systems using receiversTerminal systemFile transfer

The invention discloses a method, a terminal and a system for transmitting files, belonging to the communication field. The method includes: obtaining a picture taken by the opposite end that contains the file to be transmitted, and determining the file to be transmitted at the local end according to the picture; determining the file path of the file to be transmitted according to the determined file to be transmitted; obtaining the file path of the file to be transmitted according to the file path Files to be transferred, and transfer the files to be transferred to the peer. In the present invention, after obtaining the picture containing the file to be transmitted taken by the opposite end through the terminal of the file transmission, the file to be transmitted at the local end in the picture is determined according to the picture, and the file path is determined according to the determined file to be transmitted, and the file path is obtained according to the file path. The file to be transferred can be transferred to the peer end, so that there is no need to manually select the file to be transferred by dragging the mouse or clicking with the finger, and it is realized that the file to be transferred can be conveniently selected and transferred even in some terminals with small screens, so that the The operation method of transferring files is simpler and faster.

Owner:SHENZHEN TENCENT COMP SYST CO LTD

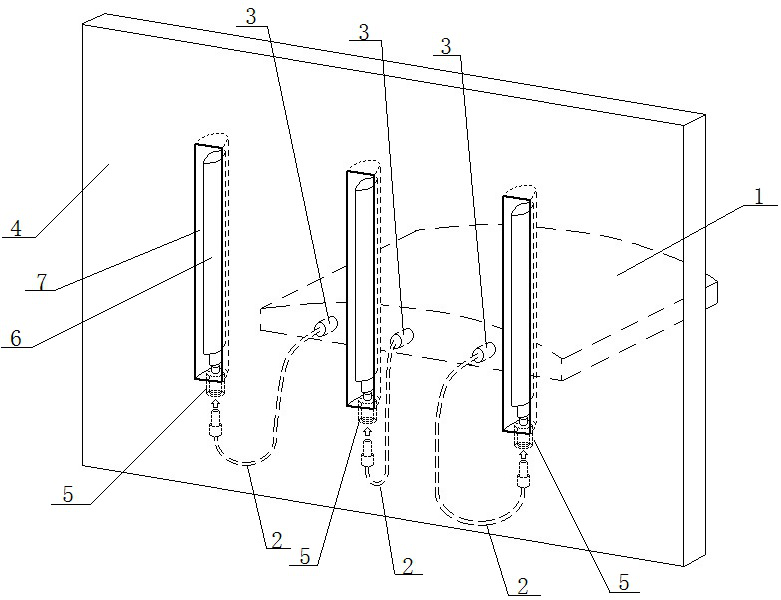

Hidden type external antenna gateway device

ActiveCN108712326AAchieve free rotationGuaranteed appearanceNetwork connectionsSelection arrangementsFree rotationEngineering

The invention relates to a hidden type external antenna gateway device. The device is designed based on a structure in which a gateway device body (1) and antenna rods (6) are separated from each other; strip-shaped slots (7) corresponding to the antenna rods (6) are disposed on the outer surface of a box cover (4) of a network equipment box; free rotation of the antenna rods (6) inside the corresponding strip-shaped slots (7); and simultaneously for a gateway device body (1) built in a box body, communication lines (2) are used for achieving connection communication between wireless network ports (3) on the gateway device body (1) and the antenna rods (6), so that the antenna rods are placed in an external space in the form of a groove while storage is achieved for the gateway device body(1), and therefore, the quality of wireless signal receiving and sending is effectively ensured, original appearance of the outer surface of the box cover (4) is maintained in a maximum manner, and perfect combination of the gateway device and the network equipment box is achieved.

Owner:苏州诺登德智能科技有限公司

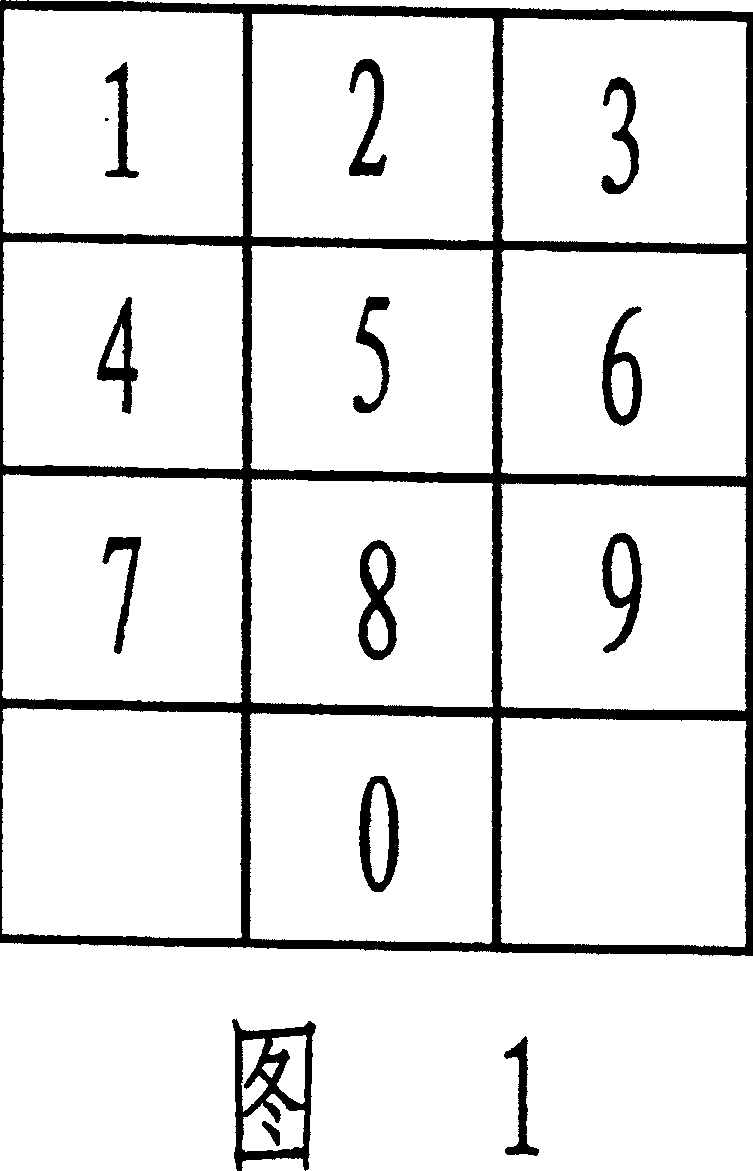

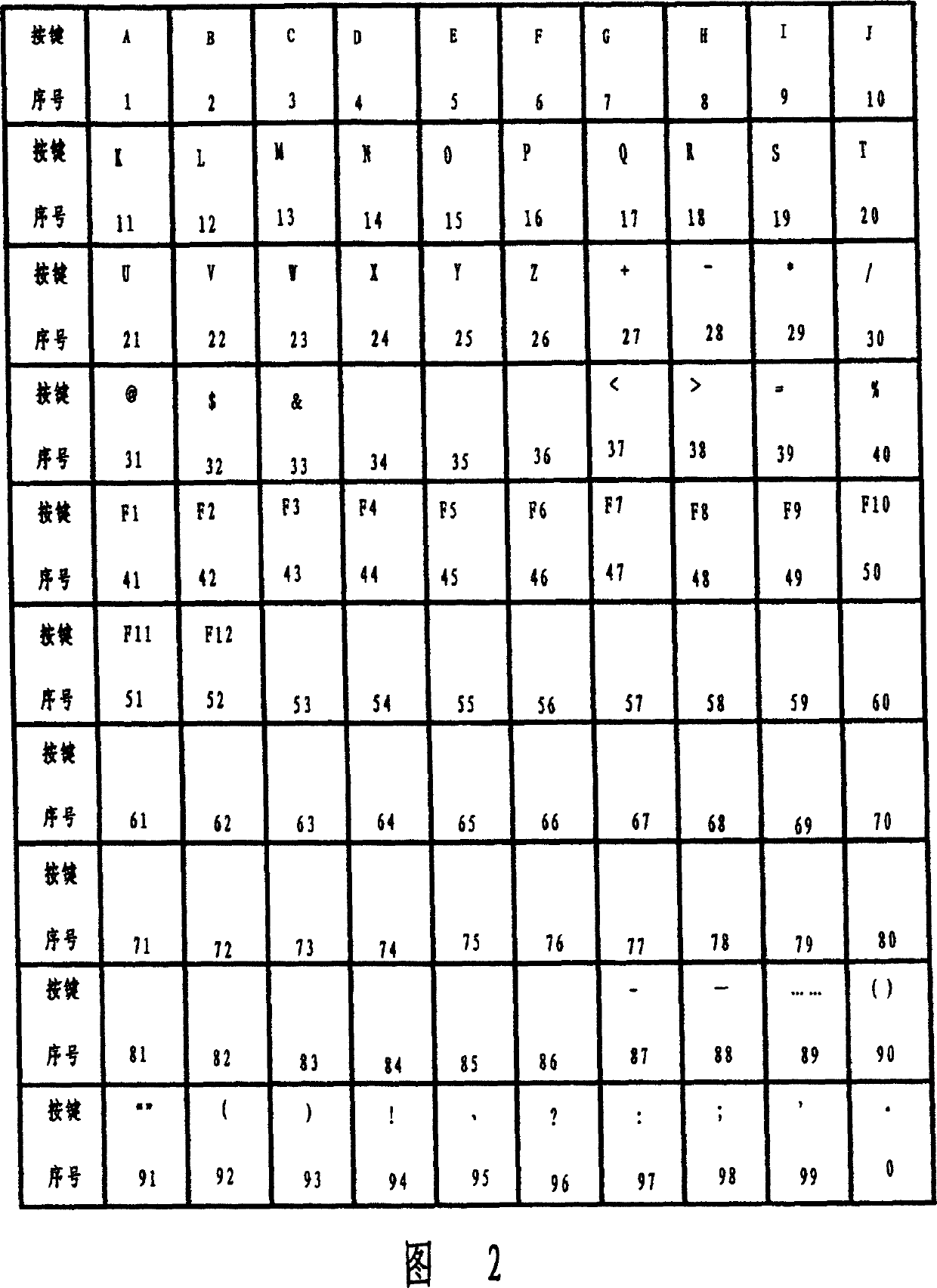

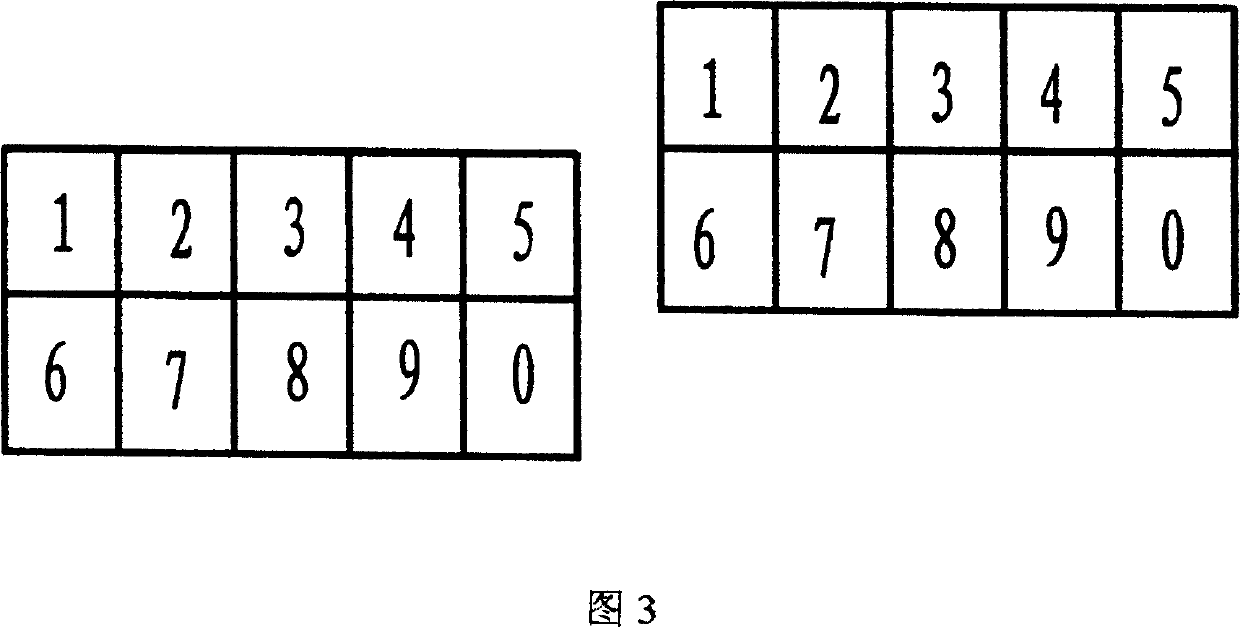

Method for inputting English letters and Chinese characters with numeral keypad

InactiveCN1252571CEasy to operateShortcutsInput/output processes for data processingMicrocomputerArabic numerals

The invention relates to a method for inputting characters into computer, particularly a method for inputting English and Chinese characters by using numeral key buttons only. The main technical scheme is as follows: (1) 10 keys marked with 0-9 are placed on keypad, (2) four Curners coding method familiar to people is adopted to constitute Chinese character coding scheme, (3) 1-26 Arabic numbers is corresponding to 26 English letter A-Z, (4) 27-30 Arabic numbert is corresponding to four signs: pulse, minus, multiply and division, (5) the Arabic numbers 21-23, 27-30 is corresponding to '@', '$', '&', '<', '>', '=', '%', (6) the Arabic numbers 41-57 is corresponding to F1-F12, (7) the Arabic numbers 87-99 and 0 is corresponding to 145 punctuation. The method makes operation easier.

Owner:唐金龙

A hidden external antenna gateway device

ActiveCN108712326BAchieve free rotationGuaranteed appearanceNetwork connectionsSelection arrangementsTelecommunicationsEngineering

The invention relates to a hidden type external antenna gateway device. The device is designed based on a structure in which a gateway device body (1) and antenna rods (6) are separated from each other; strip-shaped slots (7) corresponding to the antenna rods (6) are disposed on the outer surface of a box cover (4) of a network equipment box; free rotation of the antenna rods (6) inside the corresponding strip-shaped slots (7); and simultaneously for a gateway device body (1) built in a box body, communication lines (2) are used for achieving connection communication between wireless network ports (3) on the gateway device body (1) and the antenna rods (6), so that the antenna rods are placed in an external space in the form of a groove while storage is achieved for the gateway device body(1), and therefore, the quality of wireless signal receiving and sending is effectively ensured, original appearance of the outer surface of the box cover (4) is maintained in a maximum manner, and perfect combination of the gateway device and the network equipment box is achieved.

Owner:苏州诺登德智能科技有限公司

Object browsing method and terminal device based on lock screen interface

ActiveCN105094679BShortcutsInput/output processes for data processingTerminal equipmentOperation mode

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com