Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Rubbing effect is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rattan bamboo plus material and preparation method thereof

InactiveCN101264679AWide range of usesImprove breathabilityLamination ancillary operationsCane mechanical workingUltravioletBiomedical engineering

The invention provides a cany bamboo fabric and preparation method, which comprises a cany skin layer or a bamboo skin layer (1) and a lapping cloth layer (2); wherein, the cany skin layer or the bamboo skin layer (1) are produced through the scraping and silking or drawing out and planishing treatments; the cany skin layer or the bamboo skin layer (1) are compounded with the lapping cloth layer (2) together. The cany bamboo fabric is characterized in that (a) the processes of degreasing, purifying, stewing, acid treatment and bleaching treatment are added between the process of silking or drawing out and the process of planishing, (b) the cany skin or the bamboo skin are weaved into the cany skin layer or the bamboo skin layer (1), and (c) the processes of softening finishing and hot compression and fixation are processed as the cany skin layer or the bamboo skin layer (1) are compounded with the lapping cloth layer (2) together. The cany bamboo fabric has the advantages of beautiful appearance, good performance of ultraviolet resistance, soft texture, uneasy to fold, free of yellowing, easy to clean, being applicable to the production of clothing, bedding articles, high grade car pad set, slipcover, window curtain, carpet, and shoes and hats, and versatility.

Owner:周觉民

External use medicine for quickly treating herpes zoster

InactiveCN1836715ASignificant effectUnique curative effectAntiviralsPlant ingredientsDiseaseCurative effect

The herpes zoster treating external applied medicine is prepared with 22 kinds of Chinese medicinal materials, including gentian root, corktree bark, skullcap root, red peony root, gromwell, etc. in certain weight proportion and through soaking in medical alcohol. It has the functions of clearing away heat, drying damp, cooling blood, promoting blood circulation, dissipating blood stasis, etc. It is used mainly in treating herpes zoster and has fast acting, high healing rate and less recurrence. It may be also used in treating common skin diseases to result in high healing effect.

Owner:李有凤

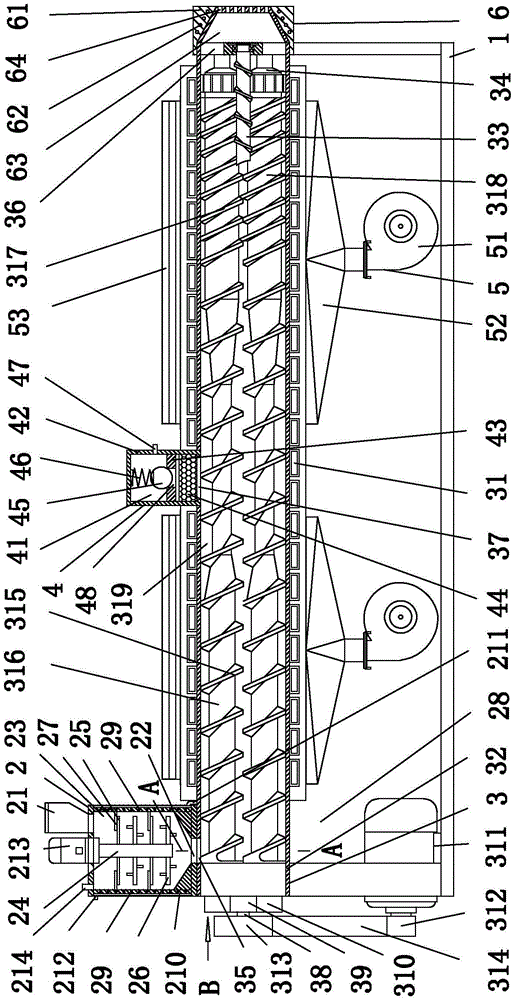

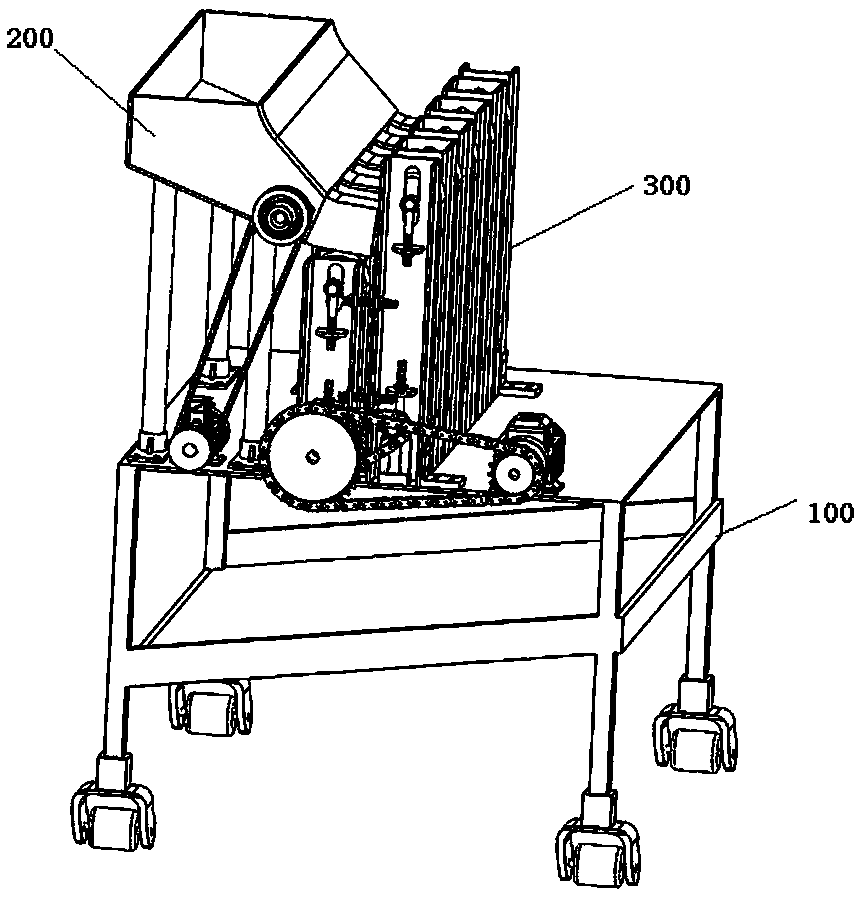

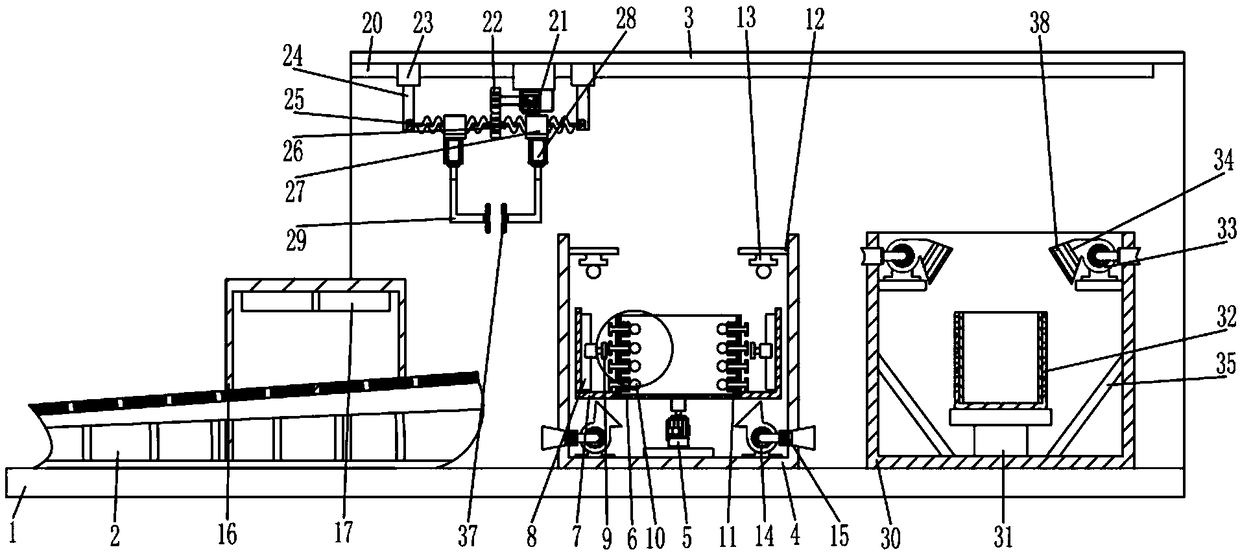

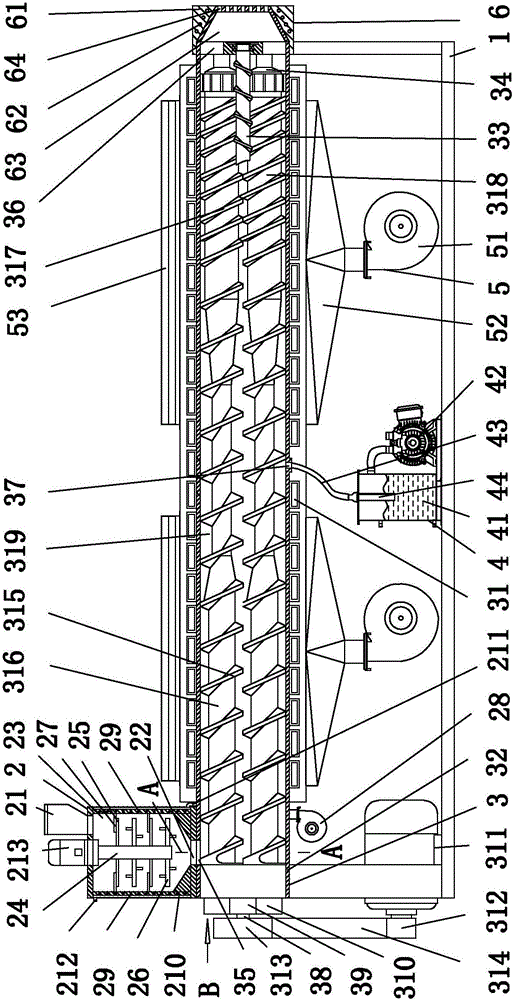

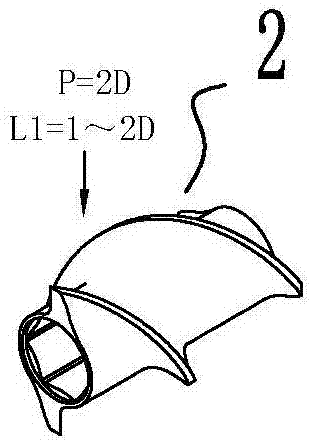

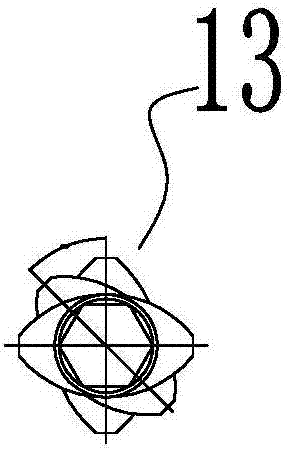

Film crushing plasticator

ActiveCN105710985AImprove the mixing effectImprove toughnessPlastic recyclingMechanical material recoveryAir filterEngineering

The invention relates to the field of recycling of waste plastics and provides a film crushing plasticator. The film crushing plasticator comprises a machine frame and further comprises a crushing, stirring and preplasticizing device, a plasticizing and toughening device and an exhaust air filter device, wherein the crushing, stirring and preplasticizing device is provided with a feeding hopper and a discharging outlet; the plasticizing and toughening device comprises a barrel provided with a barrel heating device and connected with the machine frame, a middle spiral push rod connected with the barrel in a pivoted mode, a plurality of outer spiral push rods distributed in the circumferential direction of the middle spiral push rod and connected with the barrel in a pivoted mode, and a spiral push rod drive device; and the barrel is provided with a plasticizing inlet located at the rear portion of the side body of the barrel and communicating with the discharging outlet, a plasticizing outlet located in the front end of the barrel, and an exhaust hole communicating with an inlet of the exhaust air filter device. The film crushing plasticator is good in effect of mixing, extruding and rubbing of plasticized raw materials in the plasticizing process, gas is exhausted easily, and prepared plastic renewable raw materials are good in toughness.

Owner:NINGBO LVHUA RUBBER & PLASTIC MACHINERY IND & TRADE

Coin sorting device

InactiveCN105931365AImprove finishing efficiencySimple structureCoin/currency accepting devicesSingle foldEngineering

The invention discloses a coin sorting device. The coin sorting device comprises a rubbing mechanism which is used for rubbing and folding folded banknotes, and a feeding mechanism which is used for feeding single folded banknotes into the rubbing mechanism. The feeding mechanism comprises a banknote feeding bin which is used for temporarily storing the banknotes, and a negative pressure sucker which is used for sucking the single banknotes. A banknote separating device is arranged on one side, which is away from the rubbing mechanism, of the banknote feeding bin. The banknote separating device comprises a vertical feeding bucket and a blowing device. An air inlet which is arranged along the tangential direction is arranged on the side wall, which is close to the lower end, of the feeding bucket. The air outlet of the blowing device is connected with the air inlet through a pipeline. A discharge hole is arranged in the side wall, which is close to the upper end, of the feeding bucket. The feeding end of the banknote feeding bin joins in the discharge hole of the feeding bucket. The coin sorting device provided by the invention has the advantages of simple structure, wide application range, high feeding efficiency, great rubbing effect, high coin sorting efficiency and the like.

Owner:CHONGQING UNIV OF TECH

Manufacturing method of multicolored leather

InactiveCN103252970ATo achieve the effect of multi-color combinationRaise the gradeLamination ancillary operationsLaminationWaxPaperboard

The invention discloses a manufacturing method of multicolored leather. The manufacturing method comprises the following steps of: selecting a PU (Poly Urethane) material; spraying one layer of printing ink on the PU material; manufacturing a cutting die; coloring the cutting die by using paint; then cutting the PU material; manufacturing a copper die according to a needed pattern and determining a pressing and printing position on a pressing and printing machine by using a paperboard; placing the copper die and adjusting pressing and printing intensity; heating the copper die; then loosening the pressing and printing machine and taking the PU material out; polishing the PU material by using a polishing machine; after the polishing machine is started, coating a layer of brushing-off wax on wiping cloth so that the wiping cloth is matched with the brushing-off wax to remove the printing ink on the PU material to expose a bottom color of the PU material; and after the polishing is finished, the colors of the PU material are different, so as to have the effect of restoring ancient ways. The manufacturing method of the multicolored leather disclosed by the invention is good in brushing-off effect and can improve the grade of the leather.

Owner:严祥成

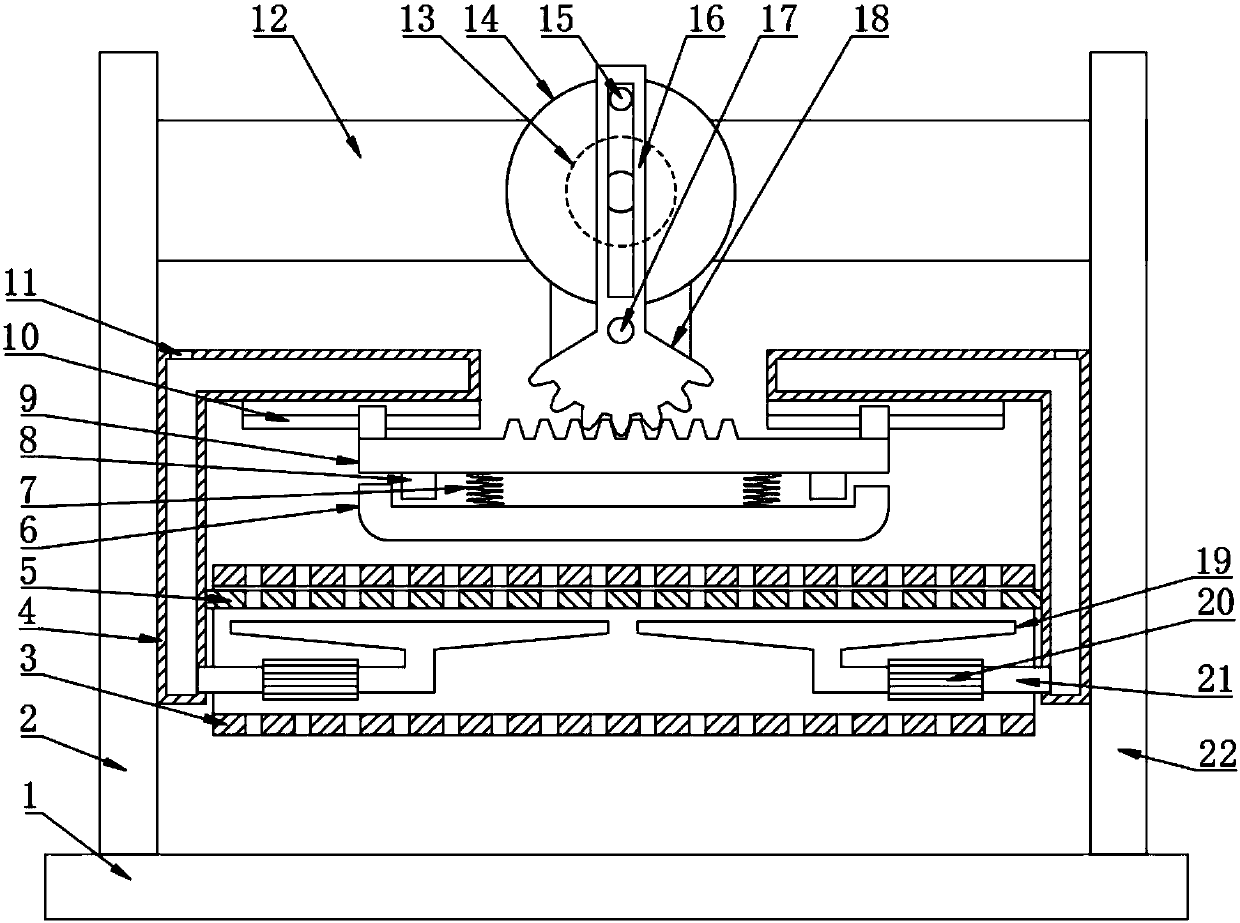

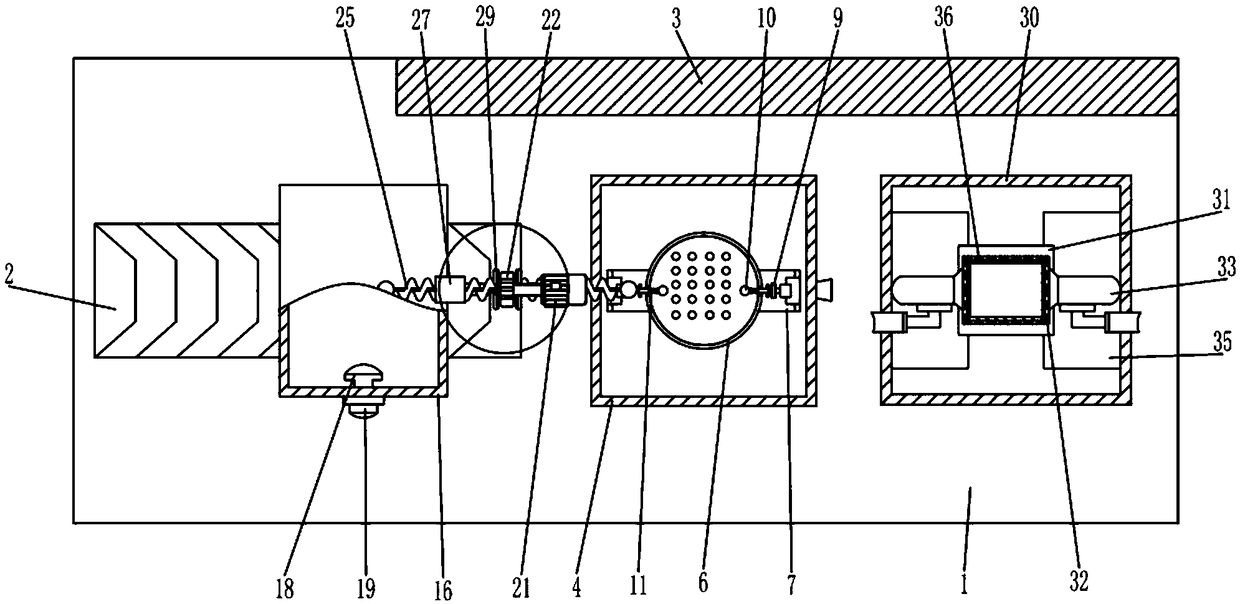

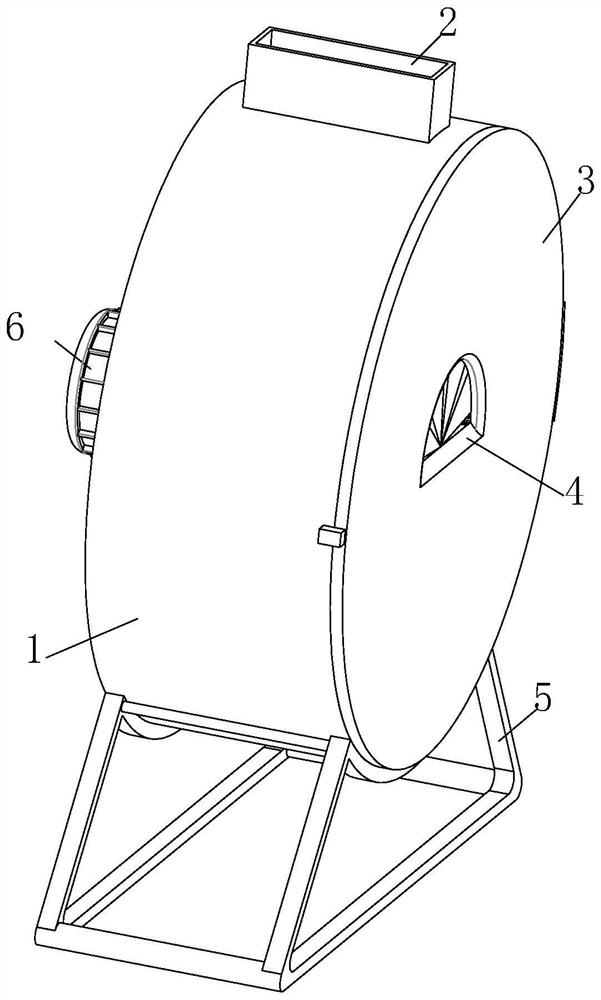

Rubbing and drying device for radix codonopsis

InactiveCN107669729AImprove processing efficiencyIncrease profitDrying gas arrangementsDrying chambers/containersCodonopsisEngineering

The invention discloses a rubbing and drying device for radix codonopsis. The rubbing and drying device comprises a base, wherein a left supporting plate and a right supporting plate are separately arranged on the left side and the right side of the top of the base; heat collecting plates are fixedly connected to the left supporting plate and the right heat collecting plate; sliding rails are respectively arranged on the bottom walls of the tops of the left and right heat collecting plates; a rack is in sliding connection with the lower parts of the sliding rails; a rubbing plate is connectedto the bottom of the rack through springs; a fixed plate is fixedly connected between the left supporting plate and the right supporting plate; a speed reducer is arranged on the fixed plate; a rotarytable is connected with a motor shaft of the speed reducer; a first pin shaft is arranged on the front end face of the rotary table; a sector gear meshed with the rack is rotationally connected to the bottom of the front end face of the fixed plate by a second pin shaft; a swing rod is fixedly connected to the top of the sector gear; a first pin shaft is positioned in a rectangular opening of theswing rod. According to the rubbing and drying device disclosed by the invention, the radix codonopsis is rubbed by left-right movement of the rubbing plate and is repeatedly performed, and the rubbing effect is good; by arranging compression springs, the rubbing plate can adapt to the radix codonopsis with different thicknesses, and the rubbing strength is more uniform.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

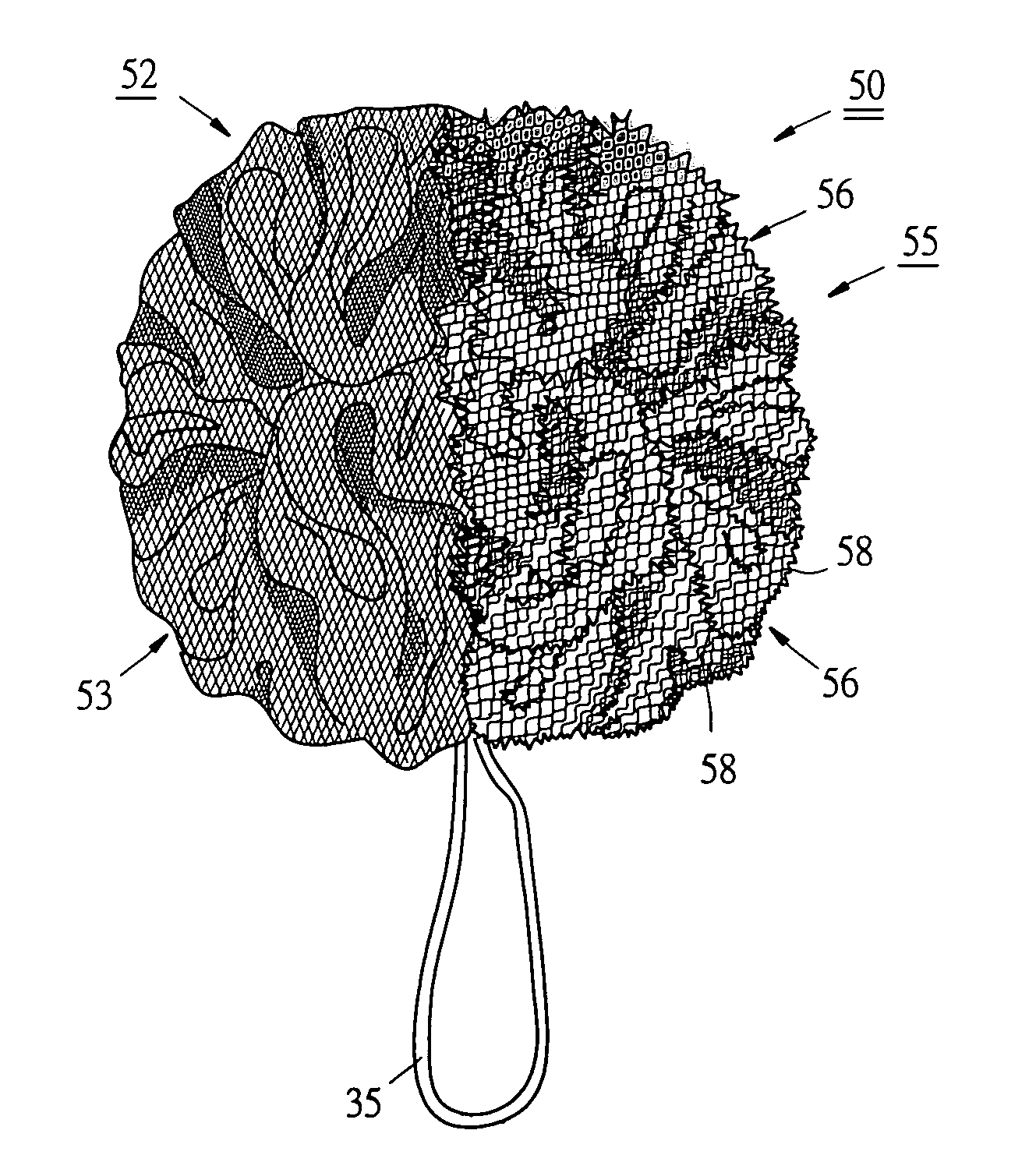

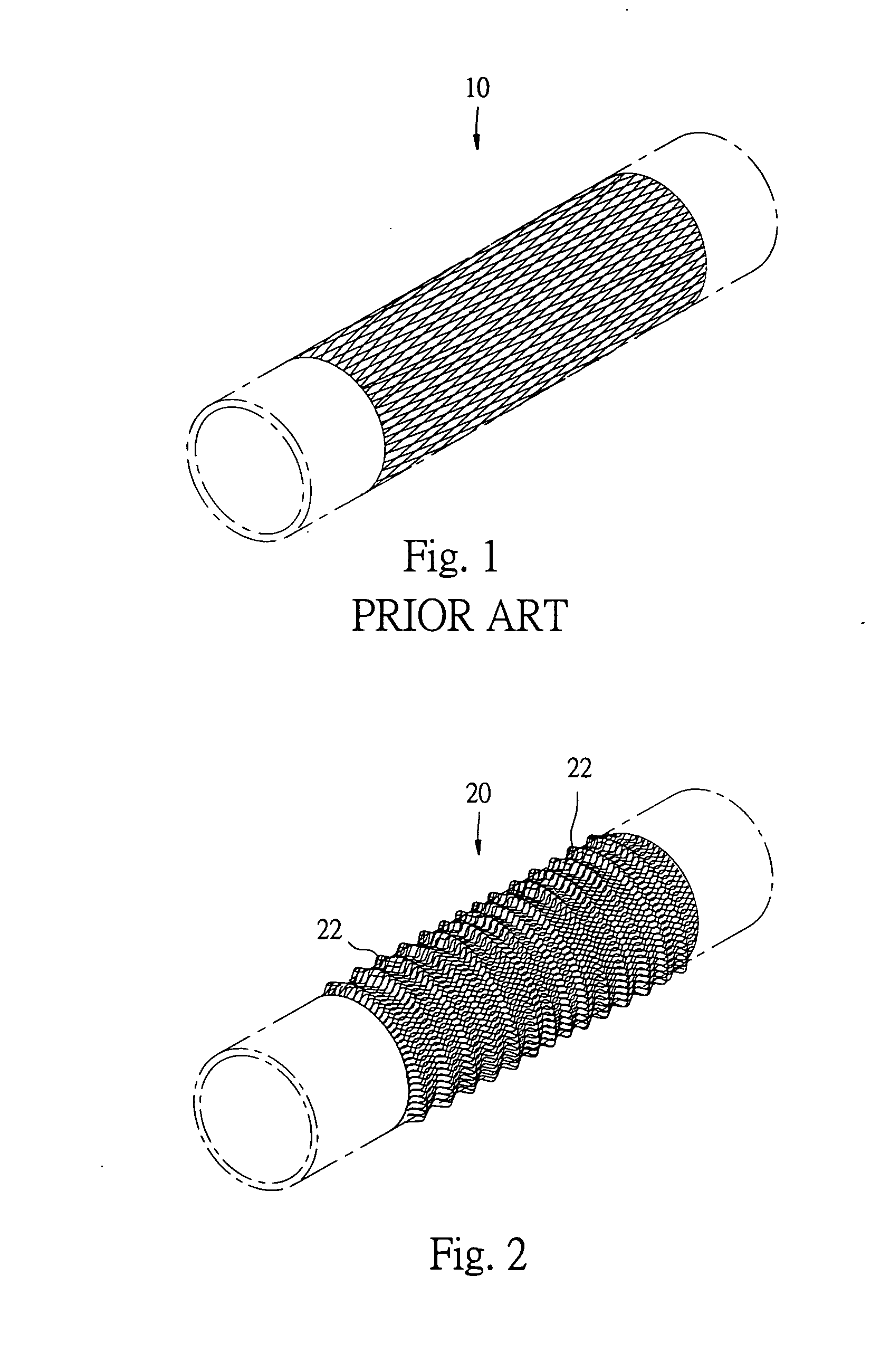

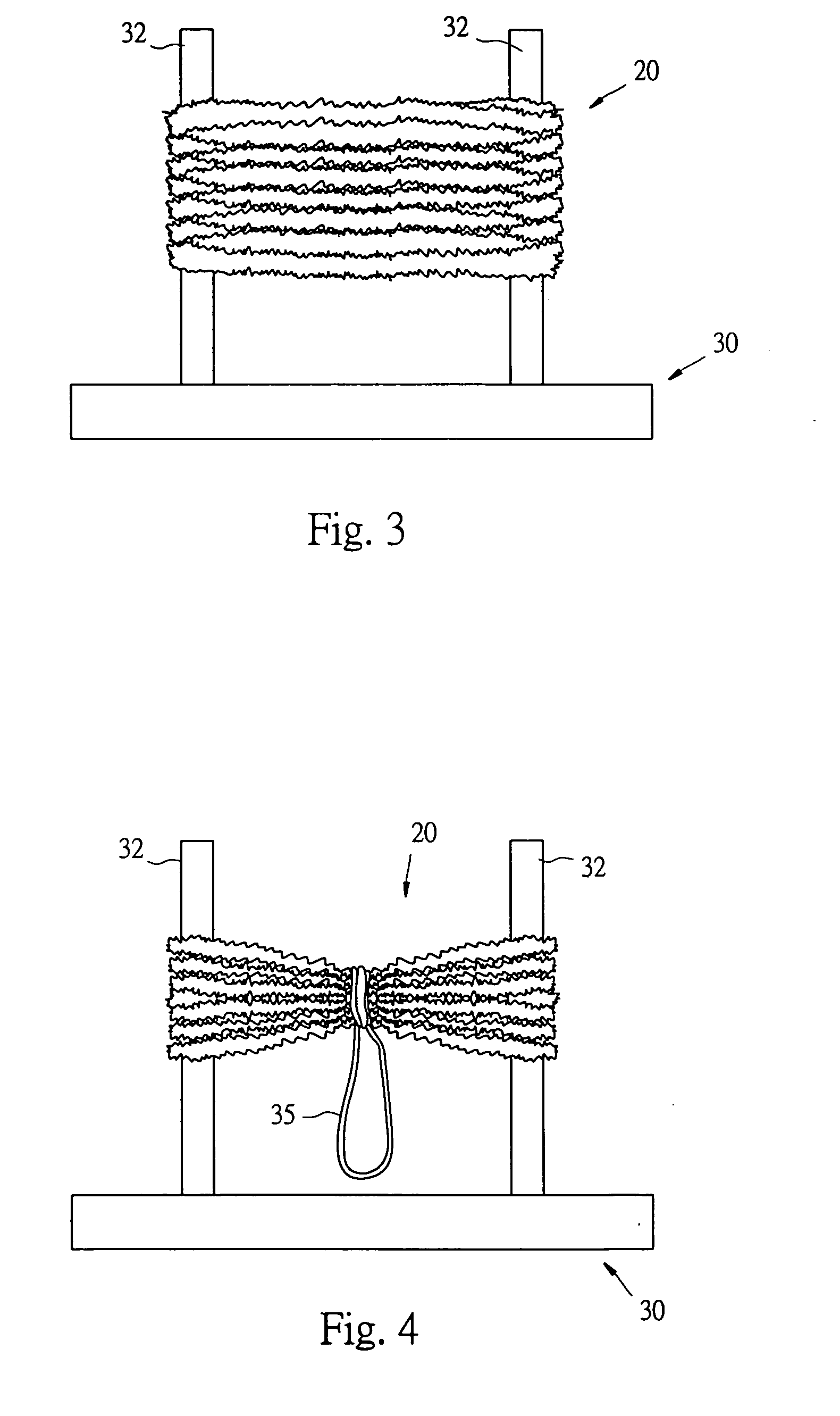

Bath utility

InactiveUS20070209132A1High densityImprove rigidityBoard cleaning devicesCarpet cleanersHigh densityMechanical engineering

A bath utility made from a plastic mesh tube. The bath utility is a spongy body having multiple stacked folds. The folds of the bath utility partially or totally have continuous fine wave or saw tooth configurations. Accordingly, the bath utility has a rougher surface for providing better rubbing effect for a user's skin. In addition, the bath utility has higher density and better rigidity.

Owner:CHEN CHING

Automatic sewage and waste impurity treatment equipment

ActiveCN109482268APromote recoveryEfficient recyclingSolid waste disposalMagnetic separationSurface layerSewage

The invention provides automatic sewage and waste impurity treatment equipment. The automatic sewage and waste impurity treatment equipment comprises a transferring and conveying mechanism, a smashingmechanism and a magnetic attraction mechanism. The transferring and conveying mechanism comprises a first conveying assembly and a second conveying assembly, the first conveying assembly and the second conveying assembly are arranged in a vertically staggered mode, the smashing mechanism is arranged at the input end of the of the first conveying assembly, and the magnetic attraction mechanism isarranged right above the middle part of the first conveying assembly. According to the automatic sewage and waste impurity treatment equipment, a principle of which a permanent magnet has magnetism and can attract a permeability magnetic material is adopted, a protruding part is arranged on a first conveying belt, pressing plates are arranged on the end parts of magnetic rods, when the magnetic rods are in contact with the protruding part in an abutting mode, the magnetic rods retract, the pressing plates rub with the protruding part, and impurities conveyed on the first conveying belt can beextruded by the pressing plates, the sewage and waste impurities which cover the surface of the permeability magnetic material are peeled off, the technical problem of rapidly peeling off the sewage and waste impurities on the surface layer of the permeability magnetic material is solved, and the technical effect of rapidly and efficiently recycling the permeability magnetic material is achieved.

Owner:威海晒尔自动化设备有限公司

Construction method of asphalt surface course under overcast, rainy, wet and cold conditions

InactiveCN102839582ASolve the problem that the construction of asphalt pavement cannot be carried outExtended construction seasonIn situ pavingsClimate change adaptationRoad surfaceAsphalt pavement

The invention discloses a construction method of an asphalt surface course in a low temperature and wet environment, and the construction method comprises the steps of designing a warm mixed asphalt mixture and preparing a raw material; adopting a coarse dense-graded asphalt mixture and forming a level S-shaped grading curve, mixing and producing the warm mixed asphalt mixture in a mixing cylinder, transporting the warm mixed asphalt mixture to a construction site, drying and heating a pavement, keeping a working plane dry, paving the warm mixed asphalt mixture continuously and uniformly, and conducting initial rolling, rerolling and final rolling on the pavement. The invention provides a general and feasible drying method of the wet, icy and snowy working plane. A heater used for reclamation construction of the asphalt pavement is adopted to heat and dry the pavement, so that the problem that the asphalt surface course cannot be constructed in the low temperature and wet environment in winter is solved.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

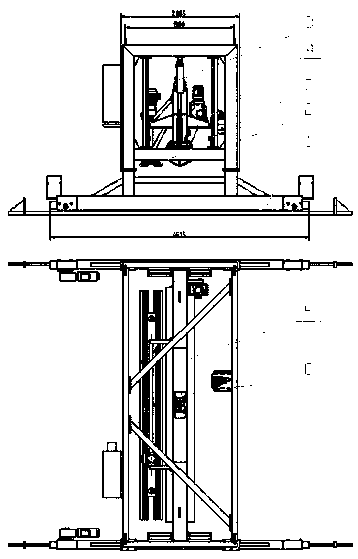

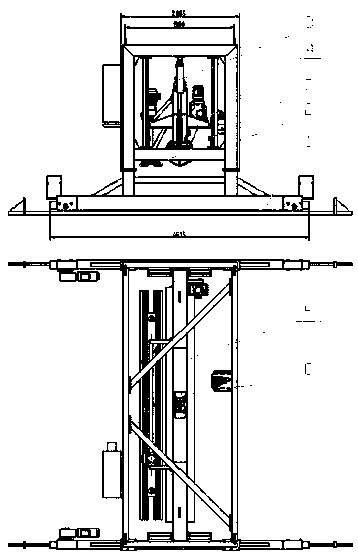

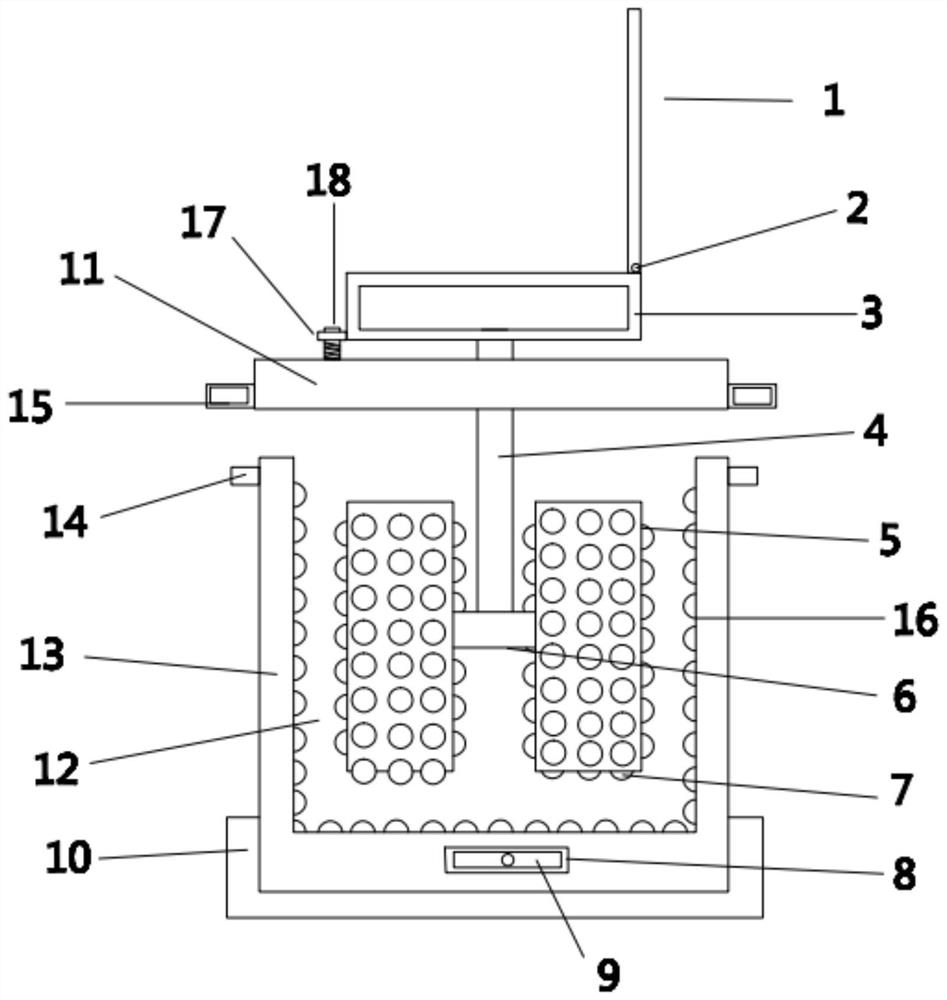

Equipment for imitating manually vibrating and leveling concrete members

The invention relates to the technical field of building material equipment, and discloses equipment for imitating manually vibrating and leveling concrete members. The equipment comprises a walking beam, wherein a U-shaped main bracket is welded to the top of the walking beam; a lifting oil cylinder is mounted on the inner wall of the top of the main bracket; a lifting frame I is fixedly connected to the bottom of the lifting oil cylinder; a leveling mechanism and a press roller are separately mounted on the upper side and the lower side of the lifting frame I; and a vibrating motor is also mounted on the outer wall of the lifting frame. According to the equipment disclosed by the invention, the press roller is used for performing pre-leveling on the front end; during rolling, the press roller also vibrates along with the bracket; the leveling device at the rear part adopts high-frequency reciprocating leveling motion of a narrow-leveling slab, and also vibrates along with the bracket; the concrete members are integrally compacted and leveled; the leveling effect is better, the solidity of the concrete is better, and the quality of the manufactured goods is guaranteed.

Owner:上海电气研砼(徐州)重工科技有限公司

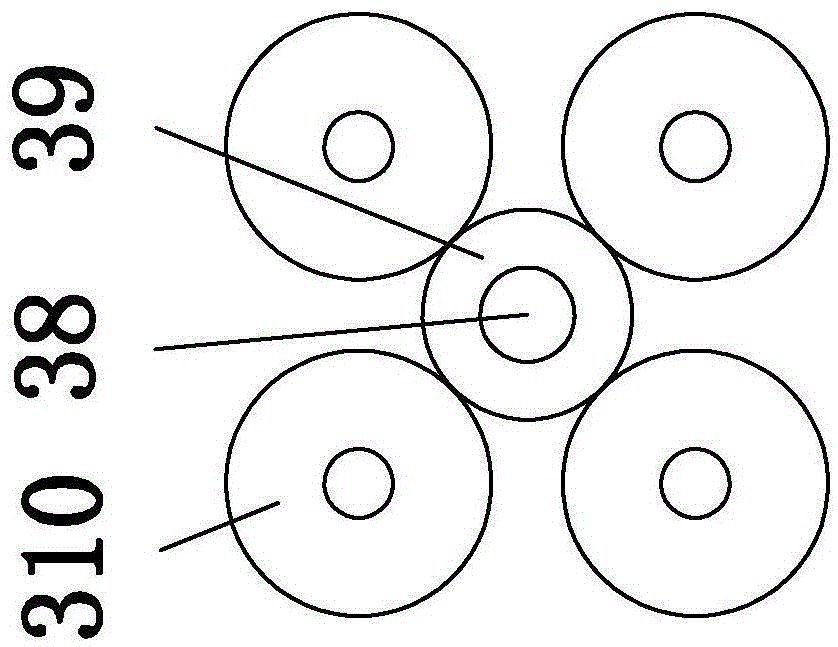

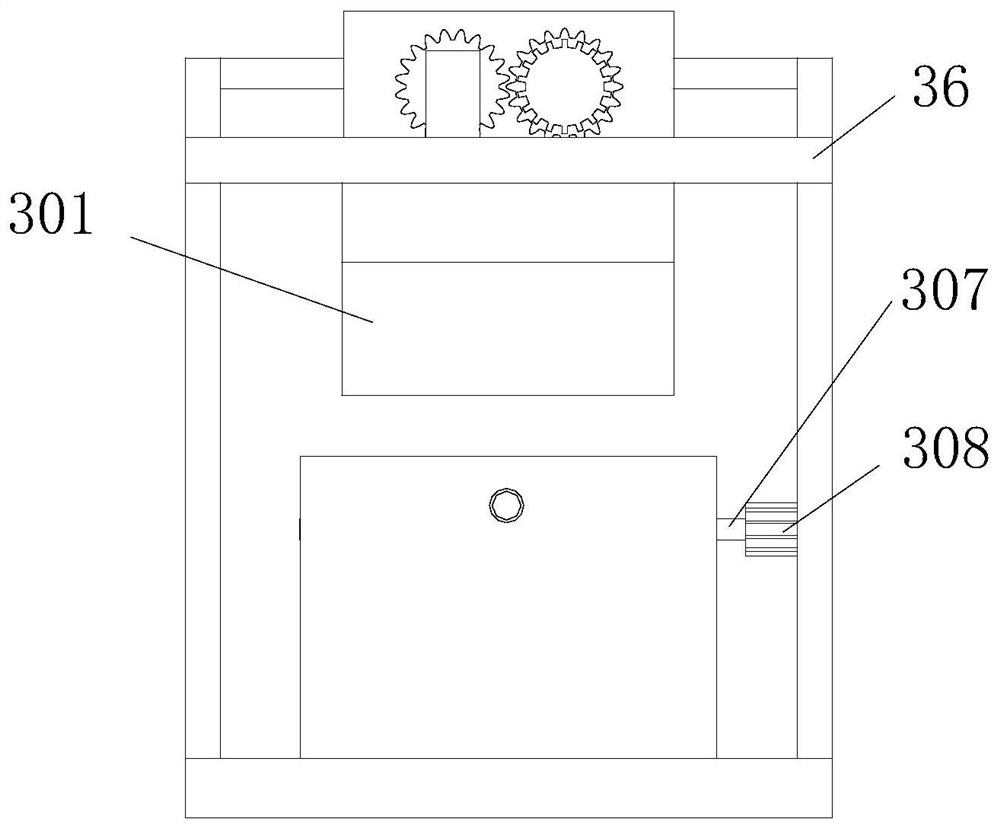

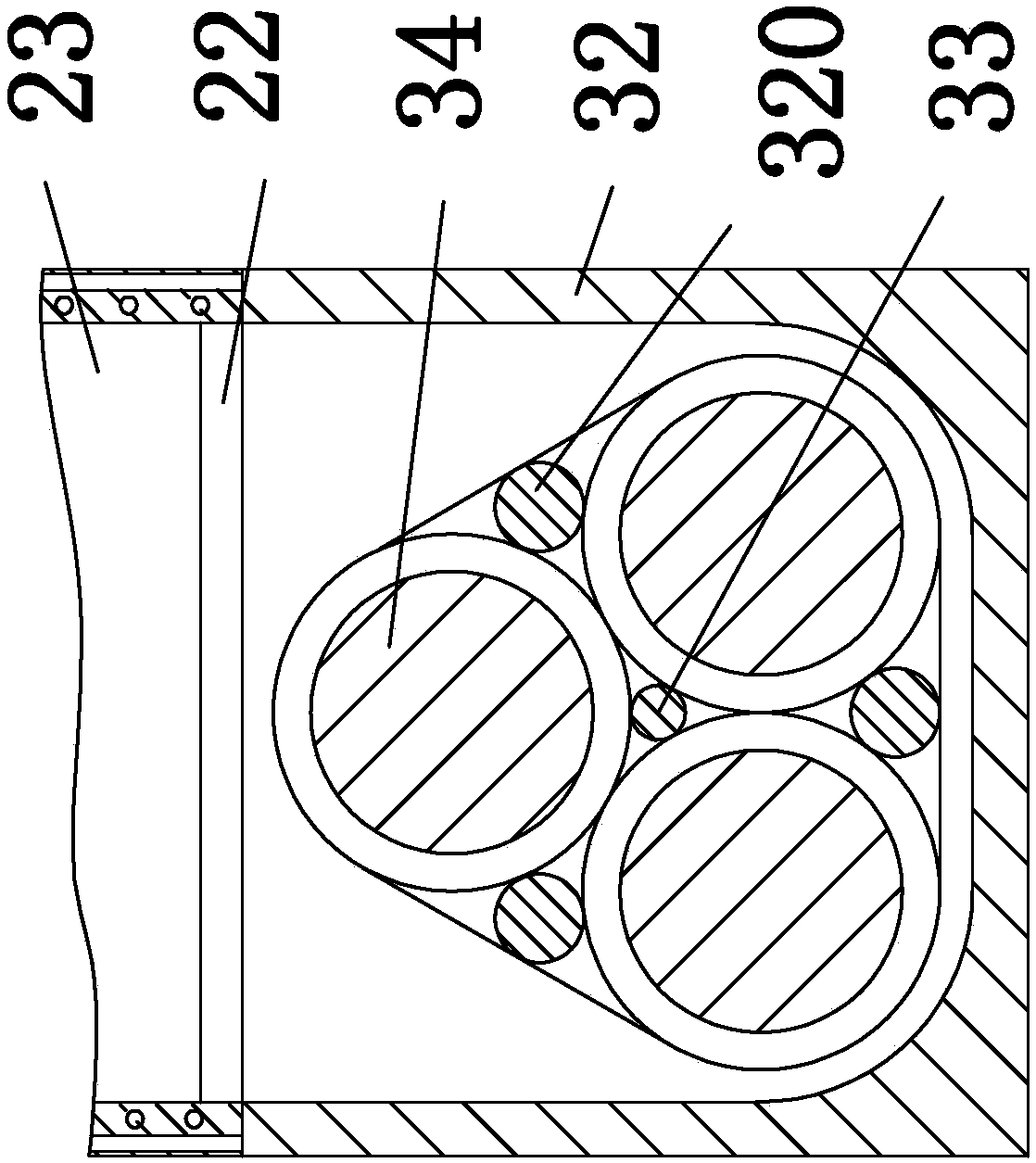

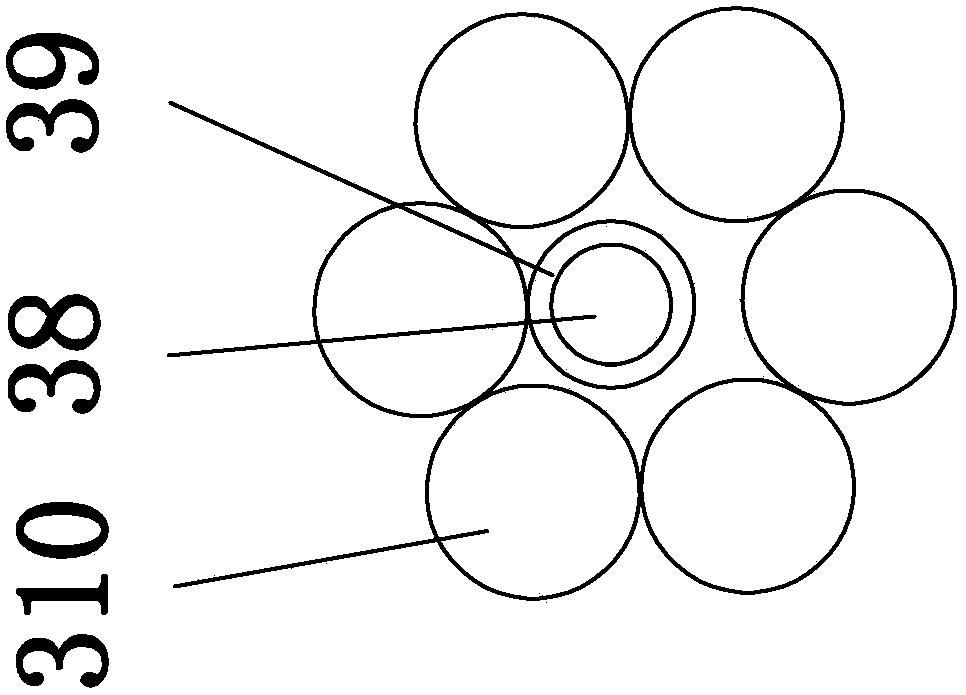

Broken plastic regeneration plasticizer

ActiveCN105711055AReduce gapEasy dischargePlastic recyclingMechanical material recoveryVacuum pumpingPlasticizer

The invention relates to the field of waste plastic recycle, and aims at providing a broken plastic regeneration plasticizer. The broken plastic regeneration plasticizer comprises a machine base, a cutting-mixing pre-plasticizing device, a main plasticizing device and a vacuum suction filter device, wherein the cutting-mixing pre-plasticizing device is provided with a feeding hopper and a discharging port; the main plasticizing device comprises a cylinder which is provided with a cylinder heating device and connected with the machine base, a middle rod, two ends of which are connected with the cylinder, a plurality of main spiral push rods, two ends of which are pivoted with the cylinder, and a push rod driving device; an auxiliary spiral push rod is arranged in the interspace outside every two adjacent main spiral push rods; two ends of the auxiliary spiral push rods are pivoted with the cylinder; and the cylinder is provided with a plasticizing inlet which is arranged at the rear part of the side of the cylinder and communicated with the discharging port, a plasticizing outlet which is located at the front end of the cylinder, and an exhaust vent which is communicated with the inlet of the vacuum suction filter device.

Owner:NINGBO LVHUA RUBBER & PLASTIC MACHINERY IND & TRADE

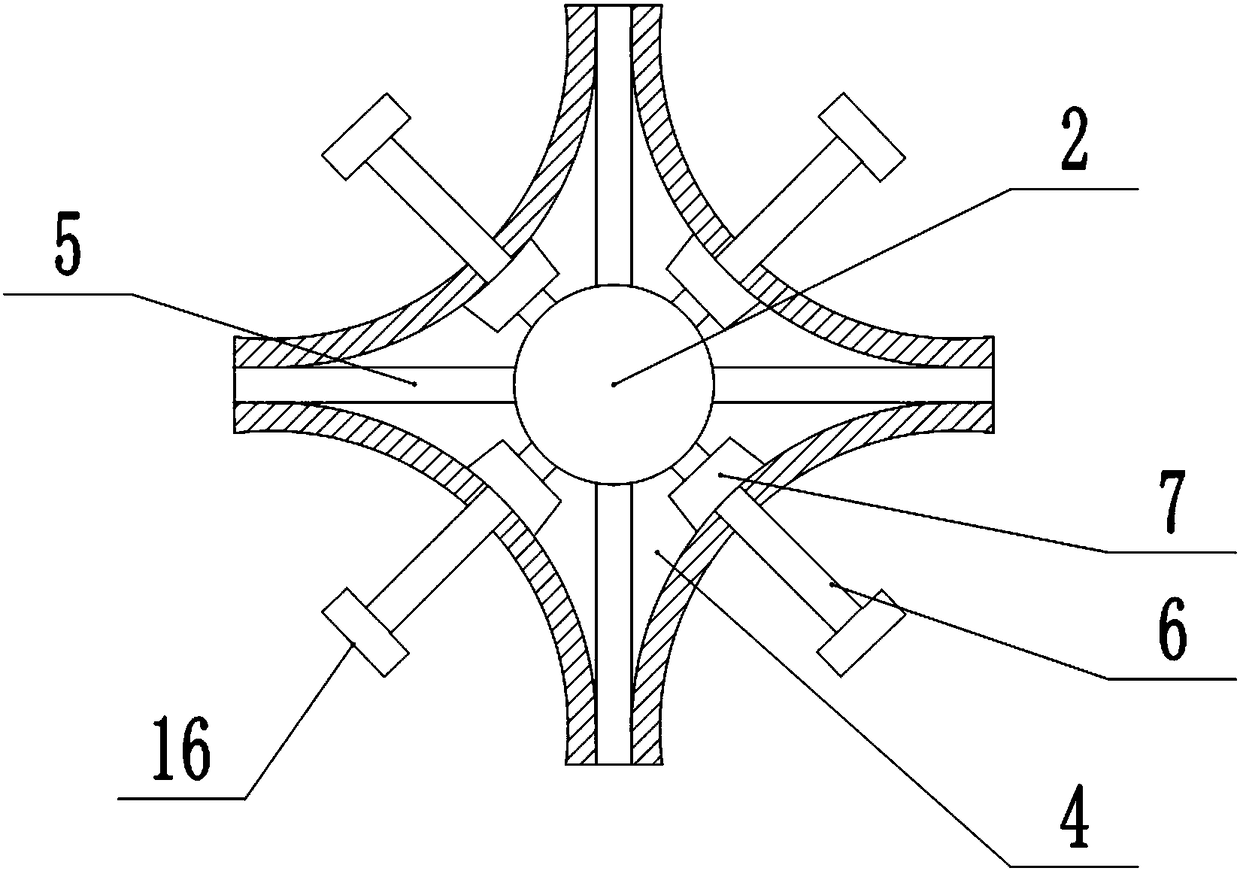

Self-adapting-based walnut kneading type shell breaker

The invention discloses a self-adapting-based walnut kneading type shell breaker, and relates to the technical field of walnut shell breaking. The self-adapting-based walnut kneading type shell breaker comprises a shell breaking device, wherein the shell breaking device comprises a shell breaking mechanism; the shell breaking mechanism comprises a first belt, a second belt and an adjusting device;the first belt is inclined to the second belt; a wedge-shaped shell breaking channel is formed between the first belt and the second belt; the speed of the first belt is different from that of the second belt; and the adjusting device is used for adjusting the distance and the inclination angle between the first belt and the second belt. The invention aims to overcome the defects in the prior art, and provides the self-adapting-based walnut kneading type shell breaker. Shearing force and extrusion force which are periodic are provided to walnuts between the two belts through the two belts atdifferent speeds so as to break shells of the walnuts, the distance and inclination angle between the two belts are adjustable to adapt to the walnuts in different sizes and different types, and the requirements of high shell breaking rate and low kernel breaking rate are met simultaneously.

Owner:SHIHEZI UNIVERSITY

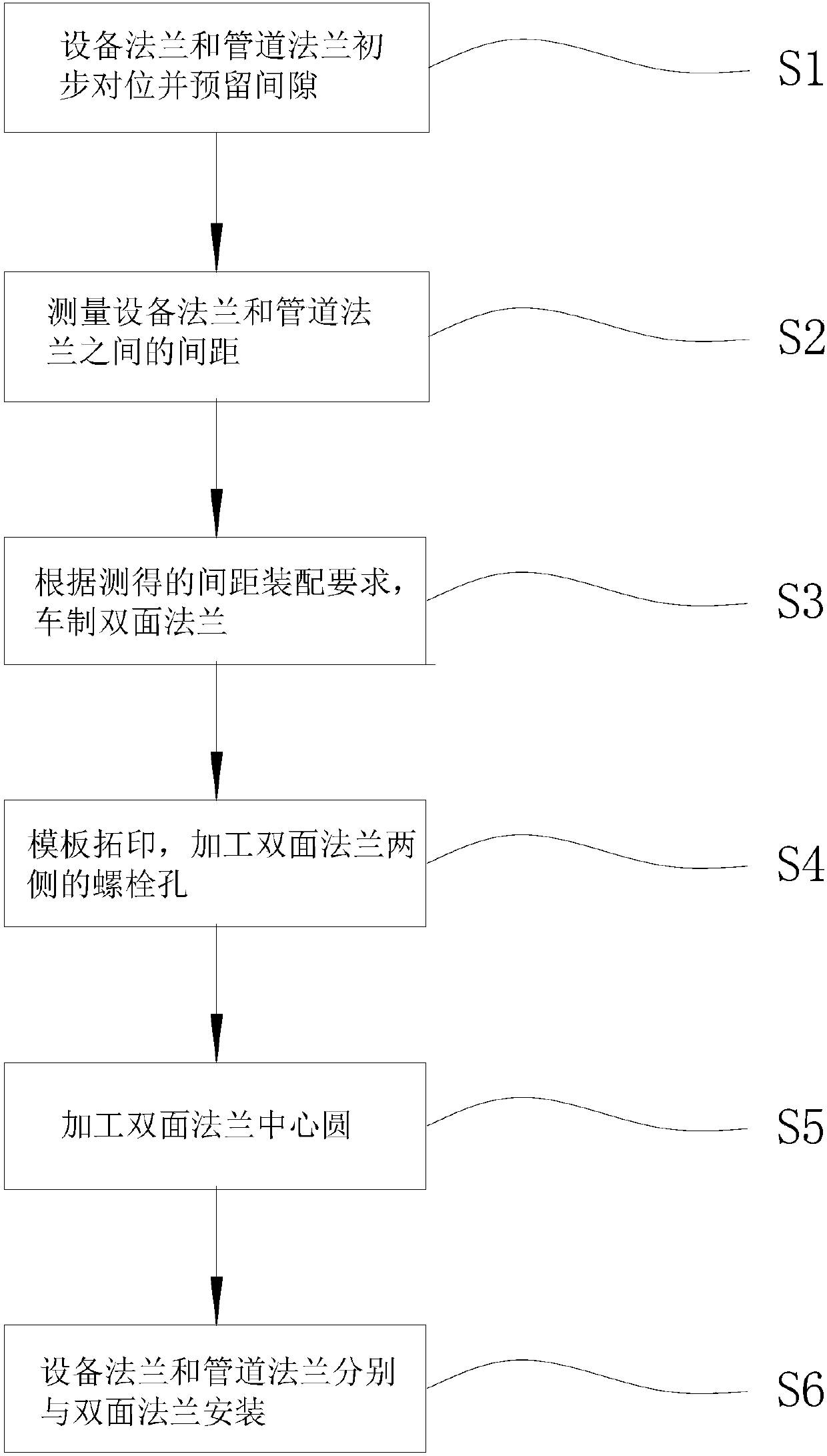

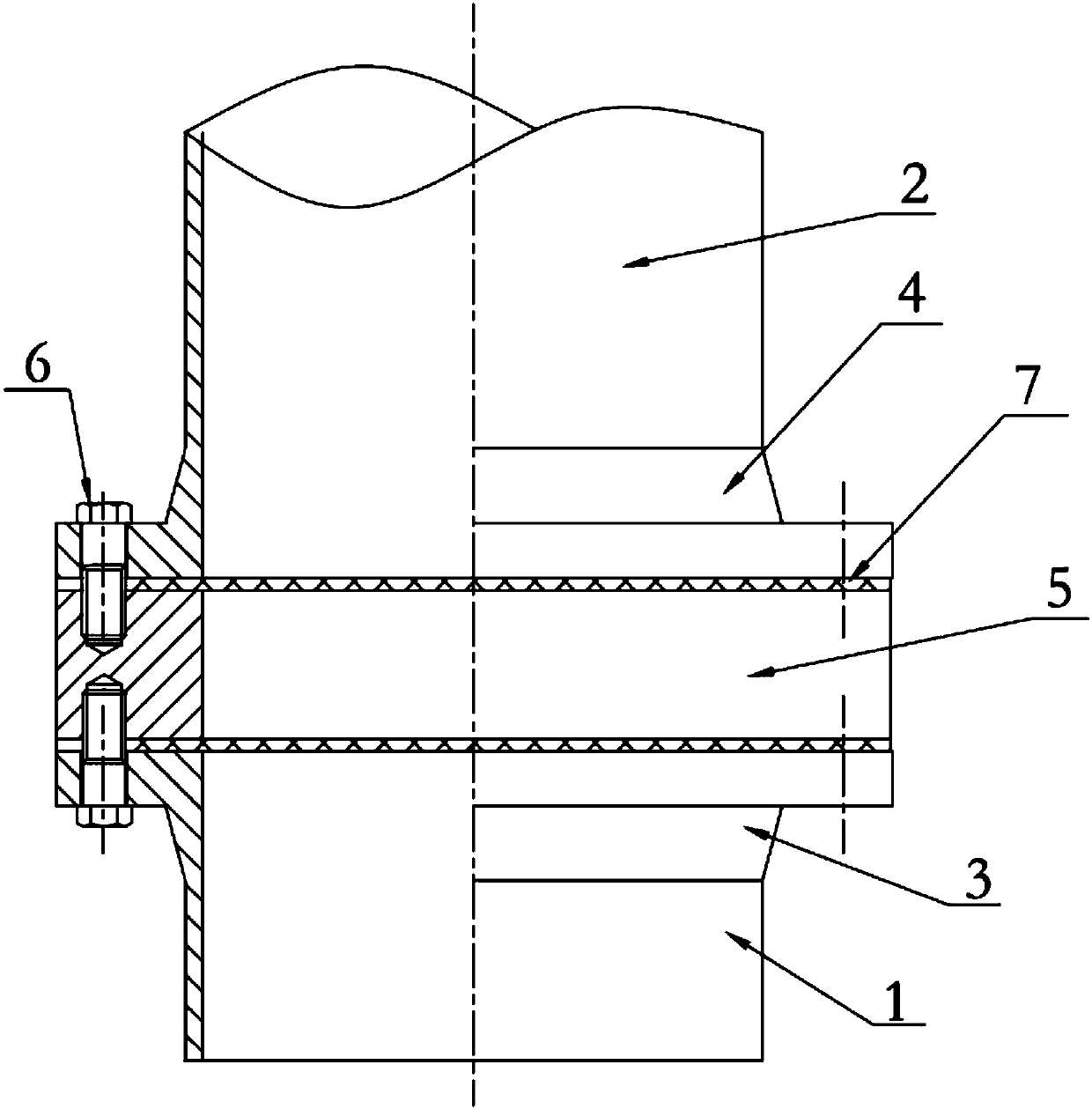

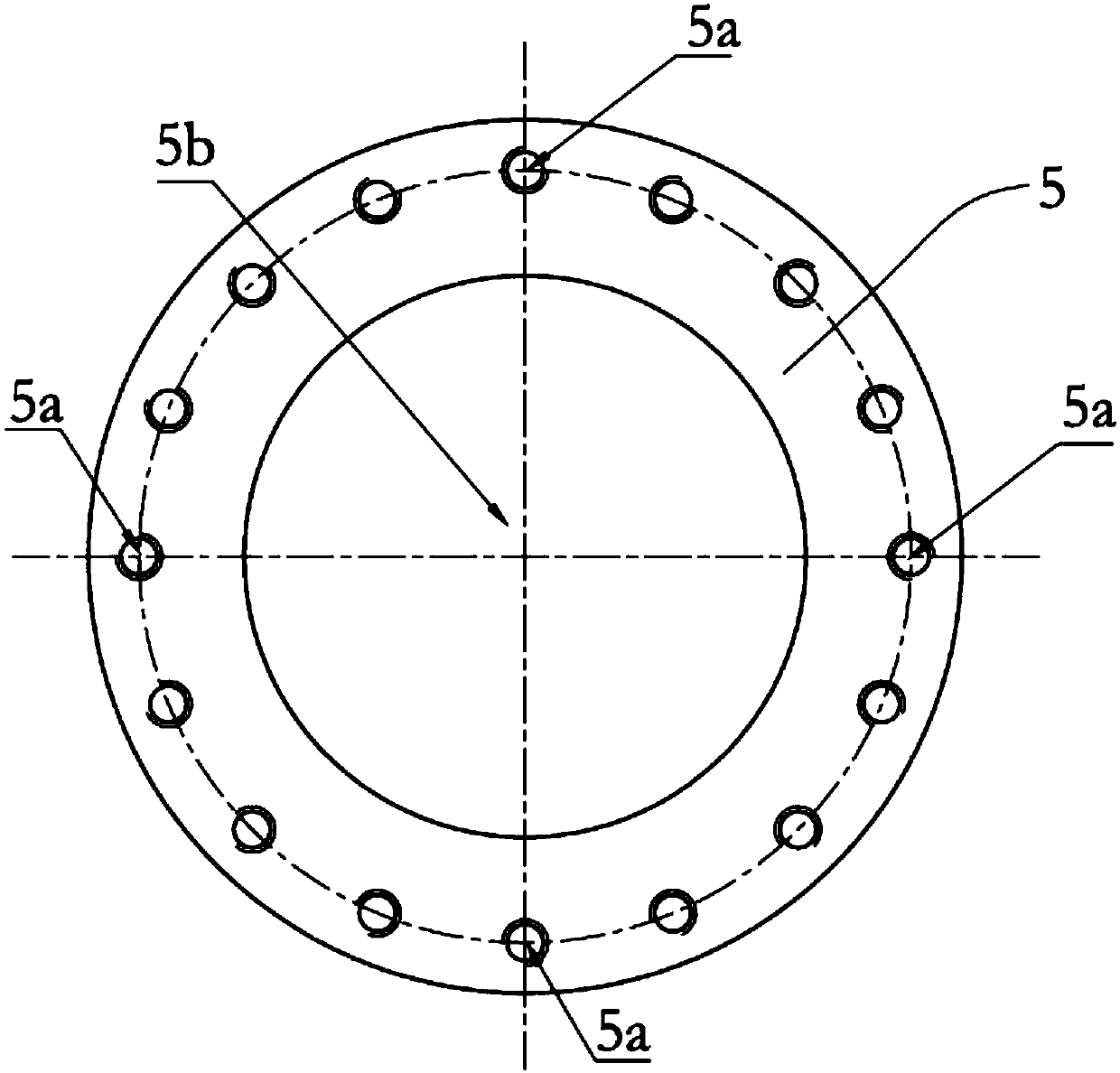

Double-face flange pipeline connection method

ActiveCN108050322AImprove sealingWide connection applicabilityFlanged jointsButt jointUltimate tensile strength

The invention provides a double-face flange pipeline connection method. The double-face flange pipeline connection method comprises the following steps that an equipment flange is connected to an equipment pipe opening; a pipeline flange is connected onto a pipeline pipe opening; equipment and a pipeline are primarily butt jointed, and a clearance is preserved between the equipment and the pipeline; distances between multiple corresponding quadrantal points of the equipment flange and the pipeline flange are measured; a double-face flange is turned according to the measured distances and assembly requirement of the equipment flange and the pipeline flange; templates are used for rubbing, and bolt holes of the double-face flange are machined according to the templates; a central circle of the double-face flange is machined according to the inner diameter of the equipment and the inner diameter of the pipeline; the double-face flange is placed between the pipeline flange and the equipment flange and are aligned; and bolts on two sides of the double-face flange are arranged. By adopting the double-face flange pipeline connection method with the technical scheme, the double-face flangepipeline connection method is simple in construction; labor intensity of workers can be lowered; construction cost is low; connection between the equipment and the pipeline is stable; and pipeline aligning precision is high.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

Microfiber leather processing machine with automatic feeding, drying and tanning functions

The invention discloses a microfiber leather processing machine with the automatic feeding, drying and tanning functions. The microfiber leather processing machine comprises a bearing plate, a conveying belt and a mounting frame; the conveying belt is arranged on the upper wall surface of the bearing plate; the mounting frame is arranged on the upper wall surface of the bearing plate and is located above the conveying belt; a drying unit is arranged at the position, located on one side of the conveying belt, of the upper wall surface of the bearing plate; a tanning unit is arranged at the position, located on one side of the drying unit, of the upper wall surface of the bearing plate; and a cooling unit is arranged at the position, located on one side of the tanning unit, of the upper wallsurface of the bearing plate. The microfiber leather processing machine has the beneficial effects that tanning is carried out on microfiber leather through an executing mechanism, and the microfiberleather is heated through a heating structure in the tanning process of the microfiber leather, so that the tanning process of the microfiber leather is rapider and good in effect.

Owner:烟台蓝海博隆超纤新材料有限公司

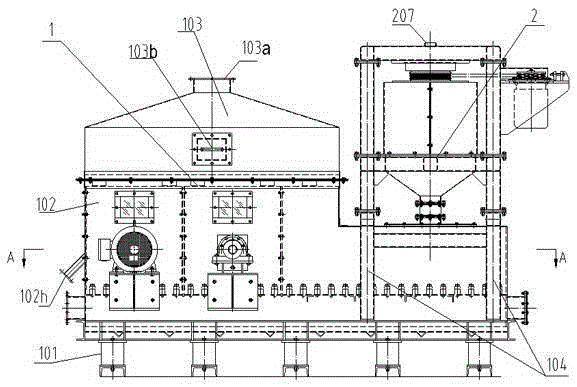

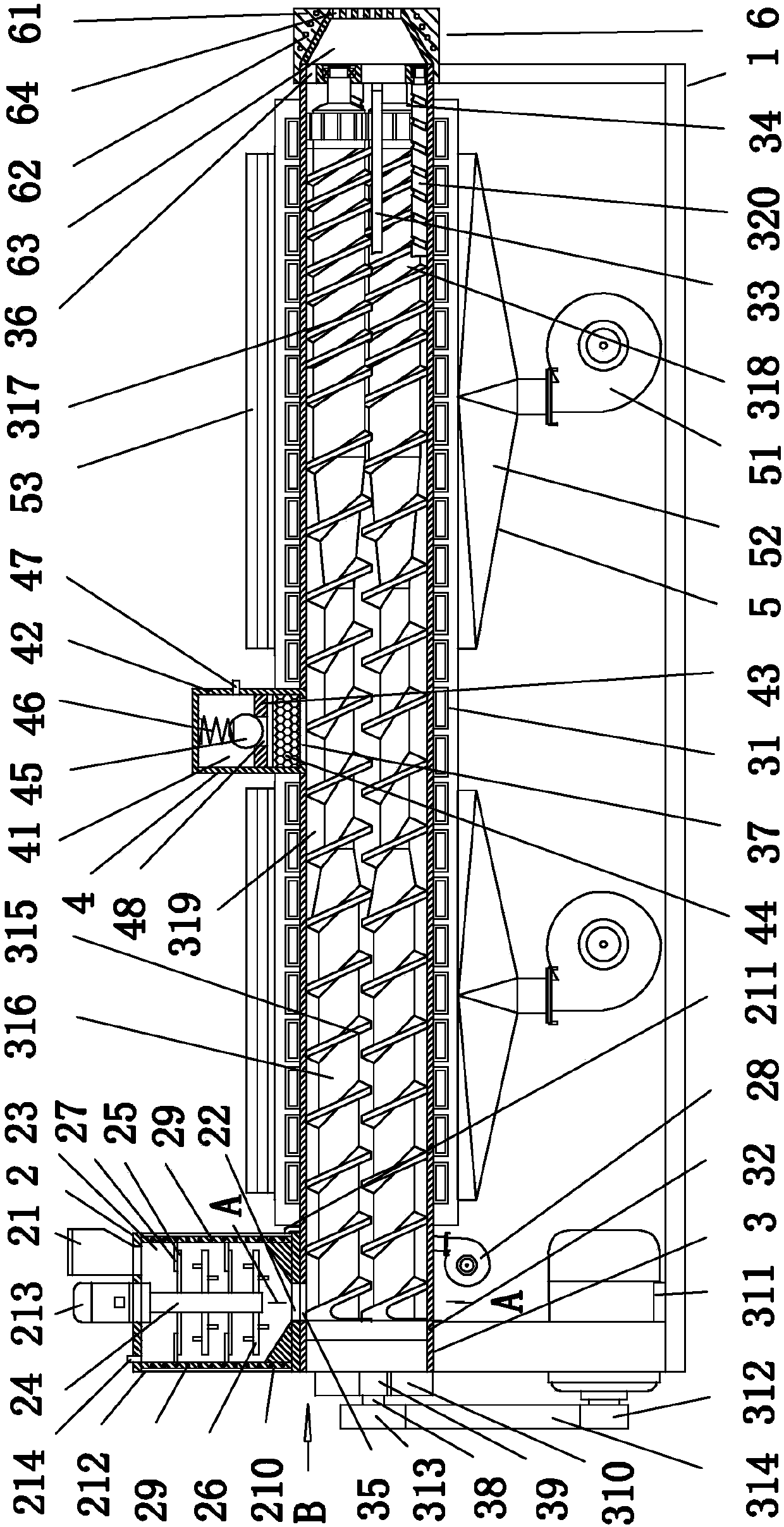

Composite used sand regenerator

ActiveCN105363998ATo achieve the purpose of removing dustAvoid throwing outMould handling/dressing devicesEngineeringInjection air

A composite used sand regenerator comprises a powerful ash removing machine and a rubbing type regenerator, wherein the powerful ash removing machine is provided with a rack; a sand box is arranged on the rack; the inside of the sand box is divided into a left cavity, a middle cavity and a right cavity by a first partition and a second partition; two rotating shafts are respectively arranged in the left cavity and the middle cavity; two ends of each rotating shaft are rotatably arranged on the rack or the outer wall of the sand box; a sand polishing wheel is arranged on each rotating shaft; the two rotating shafts are driven to rotate by respective driving devices I; a plurality of air injection holes are formed in the bottom of the sand box; a nozzle is arranged at each air injection hole; the nozzles are connected to an air supply system; an air box is arranged at the top of the sand box; an air outlet is formed in the top of the air box; the rubbing type regenerator is arranged above the right cavity through four supporting legs; a discharging opening of the rubbing type regenerator is communicated with the right cavity; used sand passing openings are respectively formed in the first partition and the second partition; and a regenerated sand outlet is formed in a side wall of the left cavity. The composite used sand regenerator is high in used sand regeneration efficiency and good in regeneration effect.

Owner:AUTOMOTIVE ENG CORP +1

Carrot seed prickly hair removing device

The invention belongs to the field of processing, and particularly relates to a carrot seed prickly hair removing device. A hollow rotating shaft is rotationally connected into a box, an air bag communicated with an inner cavity of the rotating shaft is arranged at the lower end of the rotating shaft, multiple blades are arranged at the lower end of the rotating shaft in the circumferential direction, support rods are connected among the blades, limiting blocks are arranged at the ends, away from the rotating shaft, of the support rods, sliding blocks are slidably connected to the support rods, the sliding blocks are fixed to the inner wall of the air bag, first through holes allowing the support rods to pass through are formed in the side wall of the air bag, and a friction pad is arranged on the lower portion of the air bag; a piston is slidably connected into the rotating shaft, a piston rod is fixedly connected to the upper side of the piston, an end face cam is fixedly connected to the top of a rack, and the upper end of the piston rod is slidably connected with the lower end of the end face cam; a second through hole is formed in the portion, located on the upper side of thepiston, of the rotating shaft, a blocking plate used for blocking a second through hole is fixedly connected to the piston, and a fiber adsorption layer used for adsorbing prickly hair is arranged onthe inner wall of the rotating shaft. According to the device, the requirement of mechanically removing the prickly hair on the surface of carrot seeds is met.

Owner:重庆田益种子有限公司

Crushed film regeneration plasticator

ActiveCN105729649AImprove the mixing effectImprove toughnessPlastic recyclingMechanical material recoveryEngineeringPlastic recycling

The invention relates to the field of waste plastic recycling, and aims at providing a crushed film regeneration plasticator. The crushed film regeneration plasticator comprises a rack and further comprises a cutting and stirring pre-plasticizing device, a plasticizing toughening device and a vacuum air pumping and filtering device, and the cutting and stirring pre-plasticizing device is provided with a feeding hopper and a discharging port. The plasticizing toughening device comprises a cylinder, a middle spiral push rod, a plurality of outer spiral push rods and a spiral push rod drive device, wherein the cylinder is provided with a cylinder heating device and connected with the rack, the middle spiral push rod is in pivot joint with the cylinder, and the multiple outer spiral push rods are distributed along the circumference of the middle spiral push rod and are in pivot joint with the cylinder. The cylinder is provided with a plasticizing inlet located in the rear portion of the side body of the cylinder and communicating with the discharging port, a plasticizing outlet located in the front end of the cylinder, and an air pumping hole communicating with an inlet of the vacuum air pumping and filtering device. The crushed film regeneration plasticator has good mixing, extruding and kneading effects on plasticizing raw materials in the plasticizing process, air is easily exhausted, and manufactured plastic regeneration raw materials are good in tenacity.

Owner:NINGBO LVHUA RUBBER & PLASTIC MACHINERY IND & TRADE

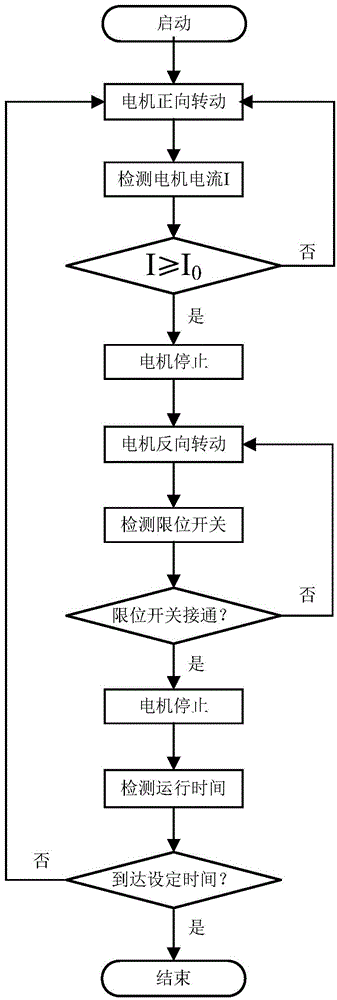

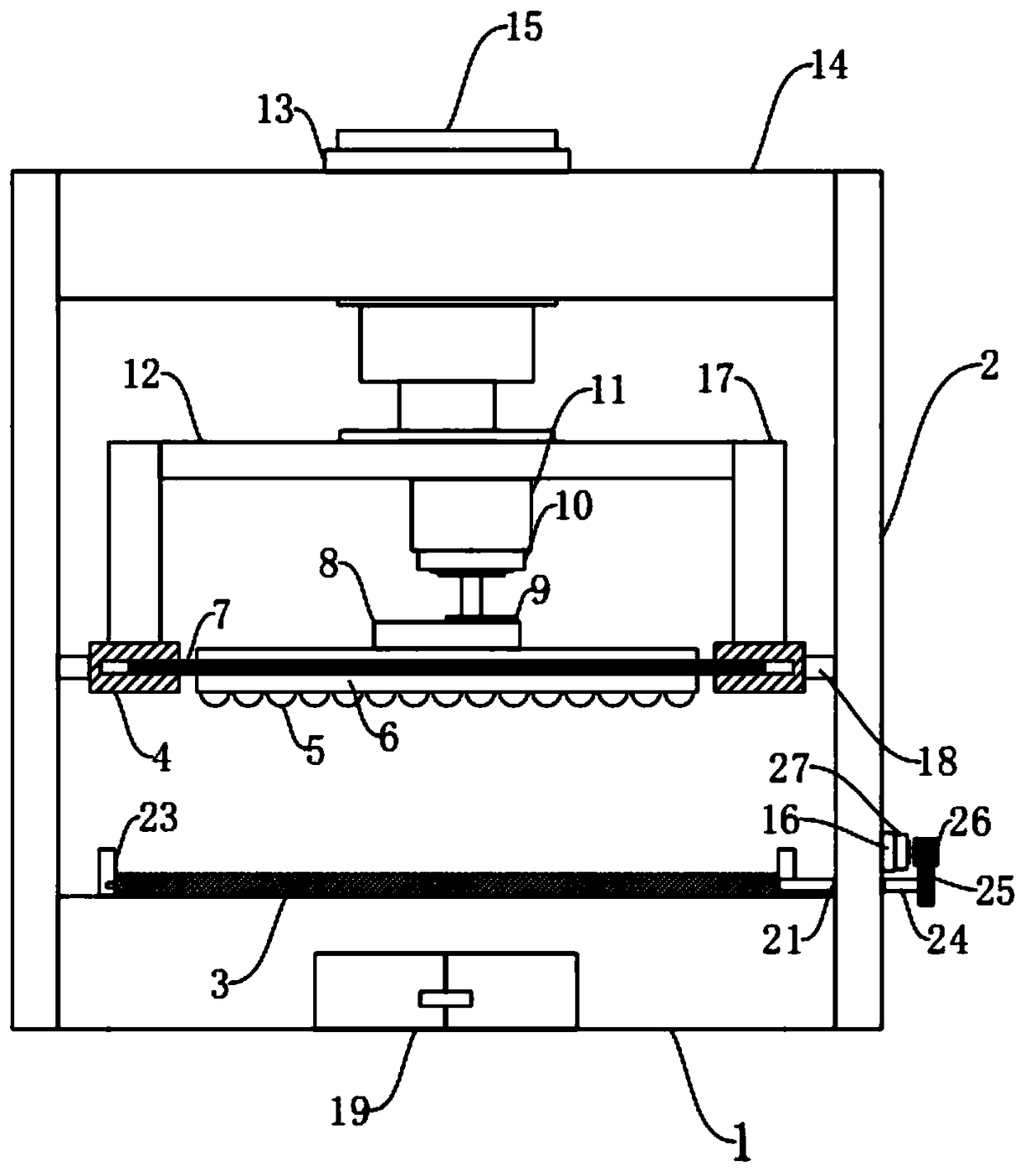

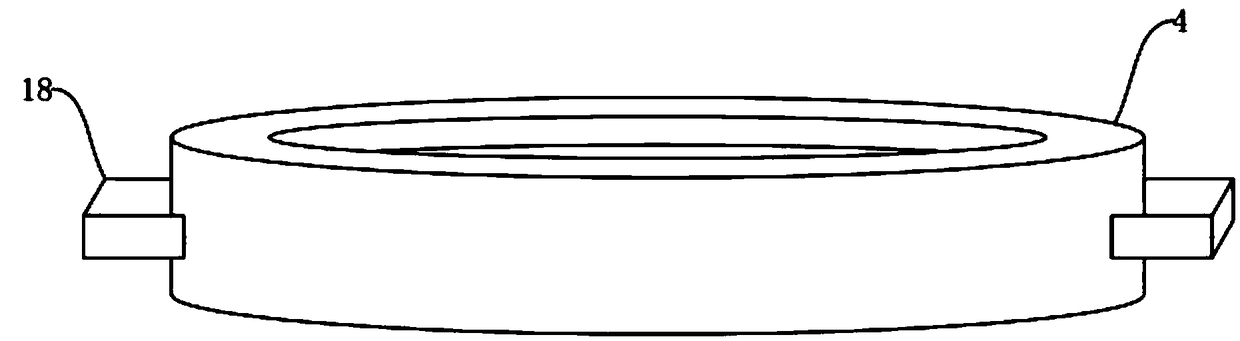

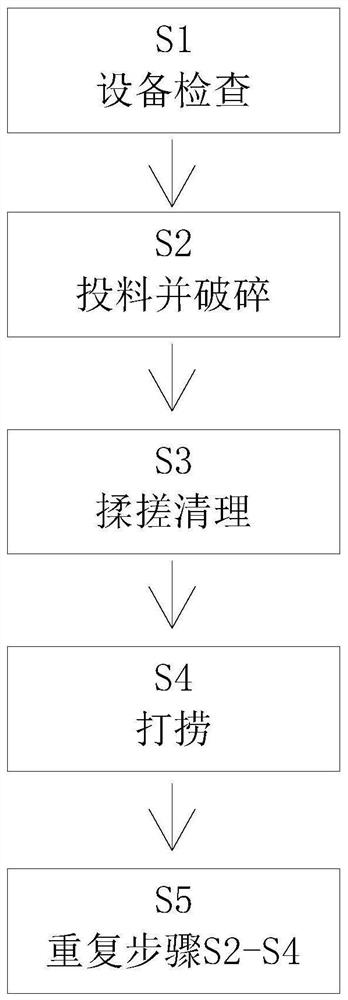

Control method for reciprocating piston type washing machine and washing machine

InactiveCN104975461ASolve technical problems that cannot be well controlledRubbing effect is goodOther washing machinesControl devices for washing apparatusEngineeringExtreme position

The invention provides a control method for a reciprocating piston type washing machine. The control method for the reciprocating piston type washing machine comprises the following steps that step a, a motor rotates to drive a piston to run; step b, in the running process of the piston, a detecting unit detects whether the piston reaches an extreme position of a running stroke or not; step c, when the detecting unit detects that the piston reaches the extreme position of the running stroke, a control unit controls the motor to stop rotating and change the rotating direction, the steps a-c are repeated, and when the detecting unit detects that the piston does not reach the extreme position of the running stroke, the motor continues an original moving state, the steps b-c are repeated. By means of the control method for the reciprocating piston type washing machine and the washing machine, the technical problem that the piston stroke of a piston type washing machine can not be well controlled is solved, it is guaranteed that the strength of the extrusion force exerted on clothes during washing every time is accordant, the machine is prevented from being damaged, the wear of the clothes is relieved, the better kneading effect is achieved, and the washing effect is effectively improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Banana plant fabric and preparation method thereof

ActiveCN101974818AWeakStrong toughnessHeating/cooling textile fabricsBleaching apparatusYarnBanana Plant

The invention relates to a banana plant fabric prepared by weaving yarns made by reeling off or scraping, degreasing and hydraulically processing raw banana plant materials. The banana plant fabric is characterized in that each round banana filament has the diameter of 0.3-1.0 mm after the raw banana plant materials are reeled off, or each flat banana filament has the width of 0.5-0.65 mm and the thickness of 0.1-0.4 mm after the raw banana plant materials are scrapped, and the raw banana plant materials are degreased with a caustic soda solution with the concentration of 10-20 g / l at a room temperature for 40-55 h. During the preparation of the fabric of the invention, the special requirements for the diameters or the widths and the thicknesses of the banana filaments after reeling off or scraping are matched with the factors, such as degreasing liquid concentration, time, and the like adopted in the degreasing treatment so that the prepared fabric has good flexibility, strong toughness and firm dyeing; and the requirements for being used as wallpaper, carpet, tablecloth or even clothes fabrics are satisfied.

Owner:郭建南 +1

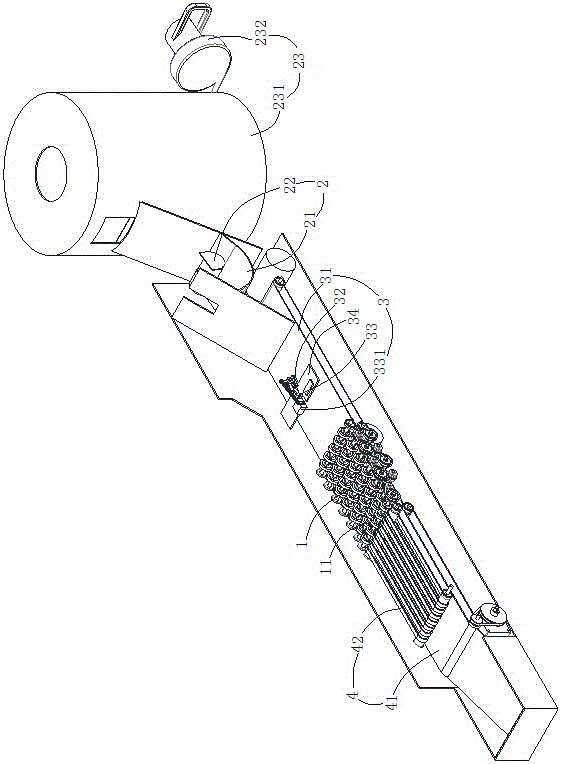

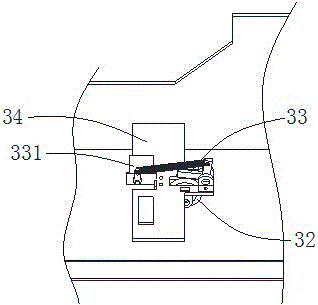

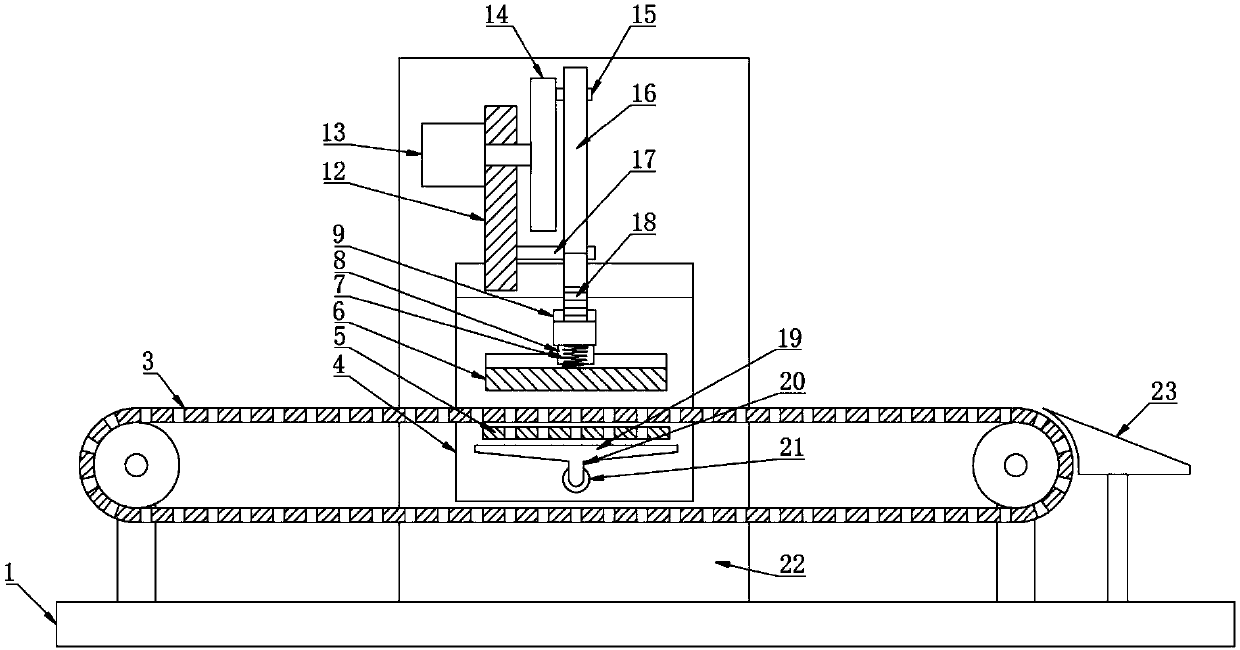

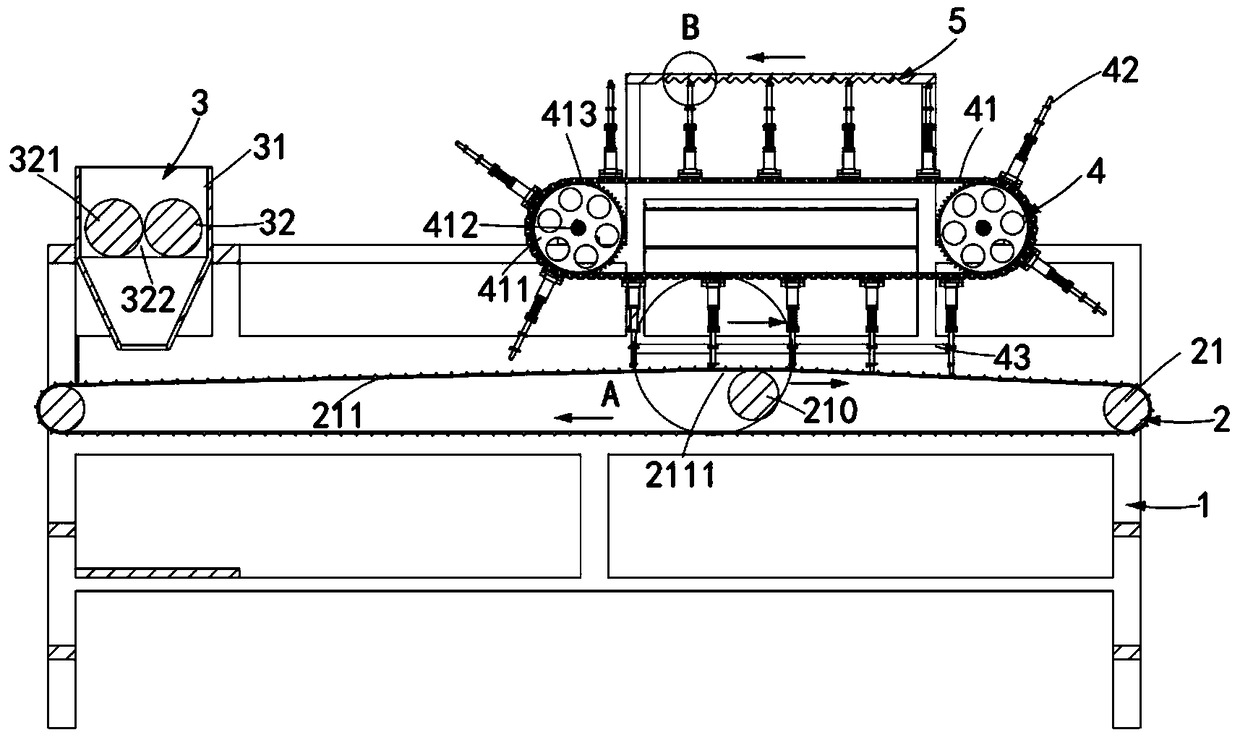

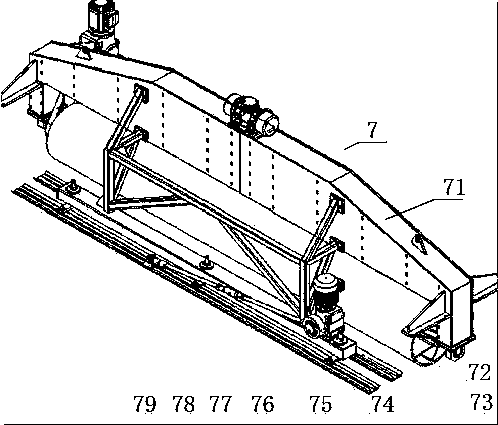

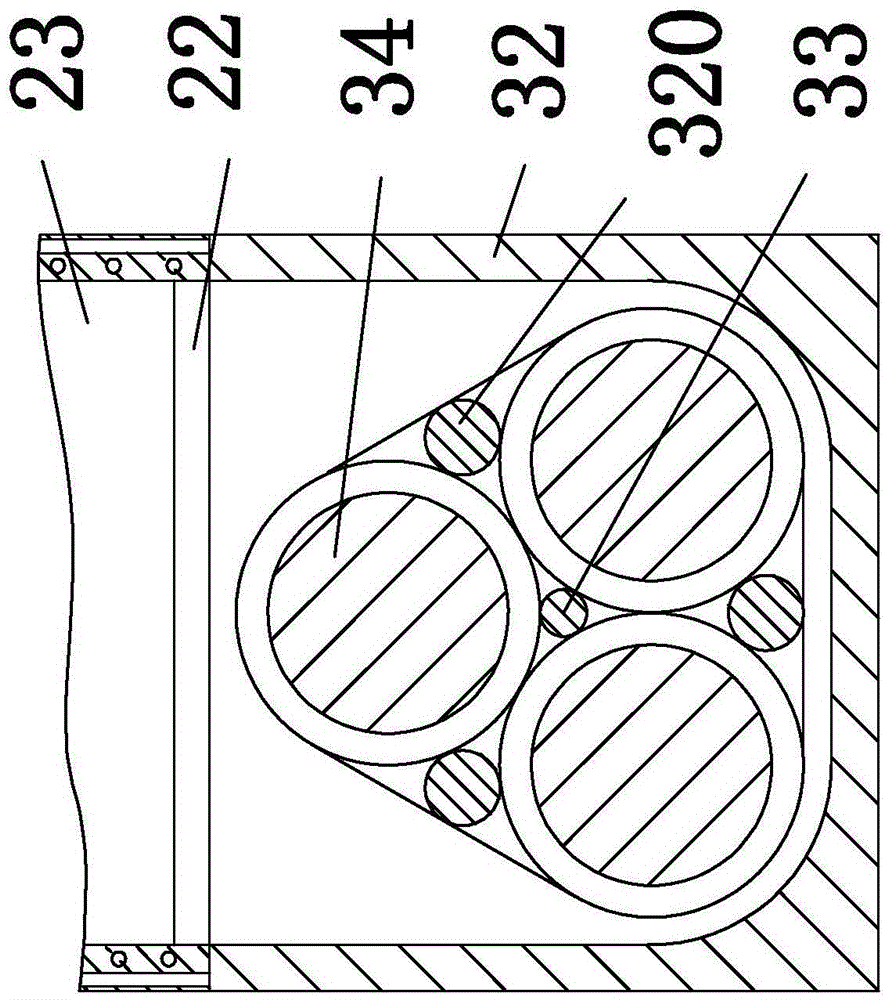

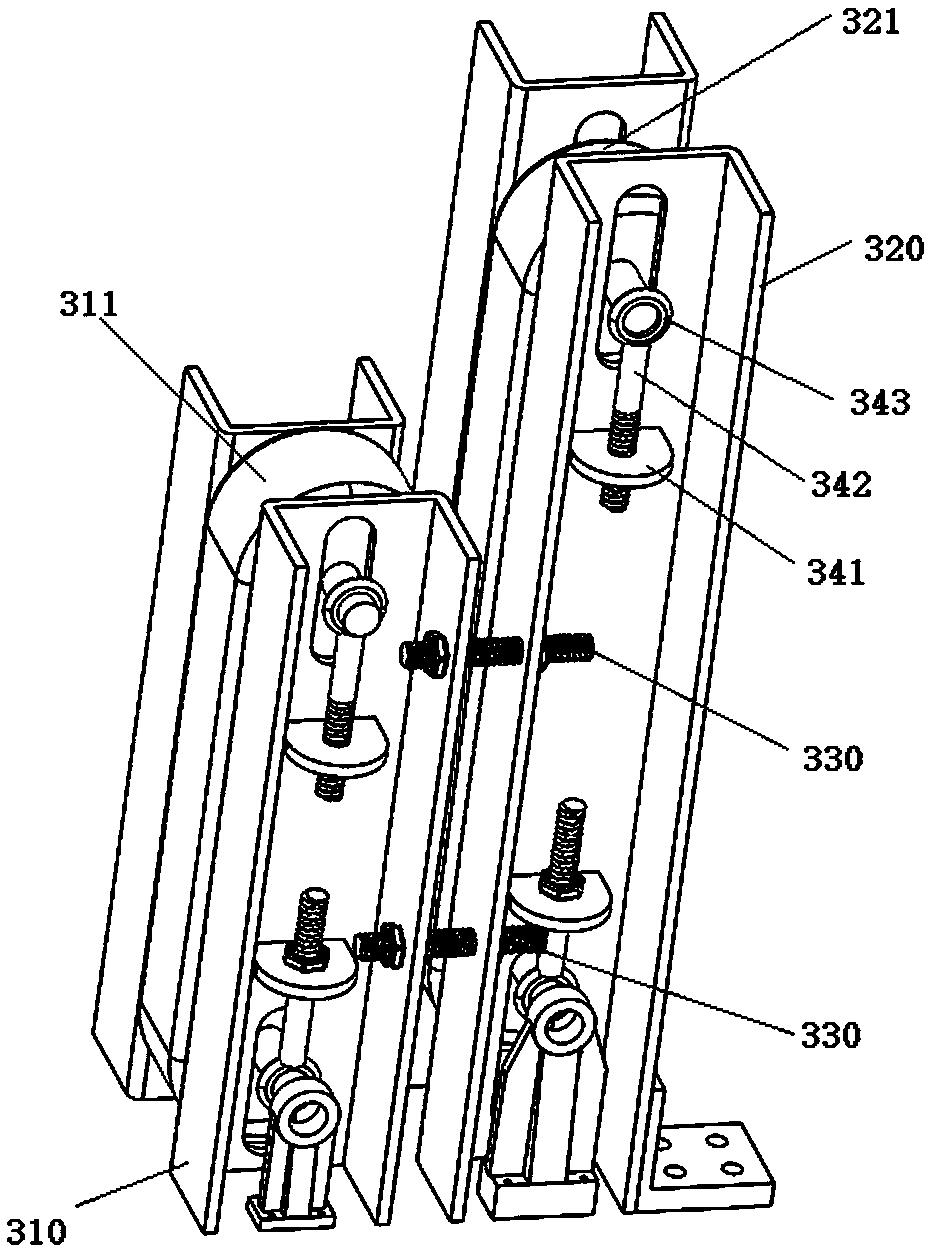

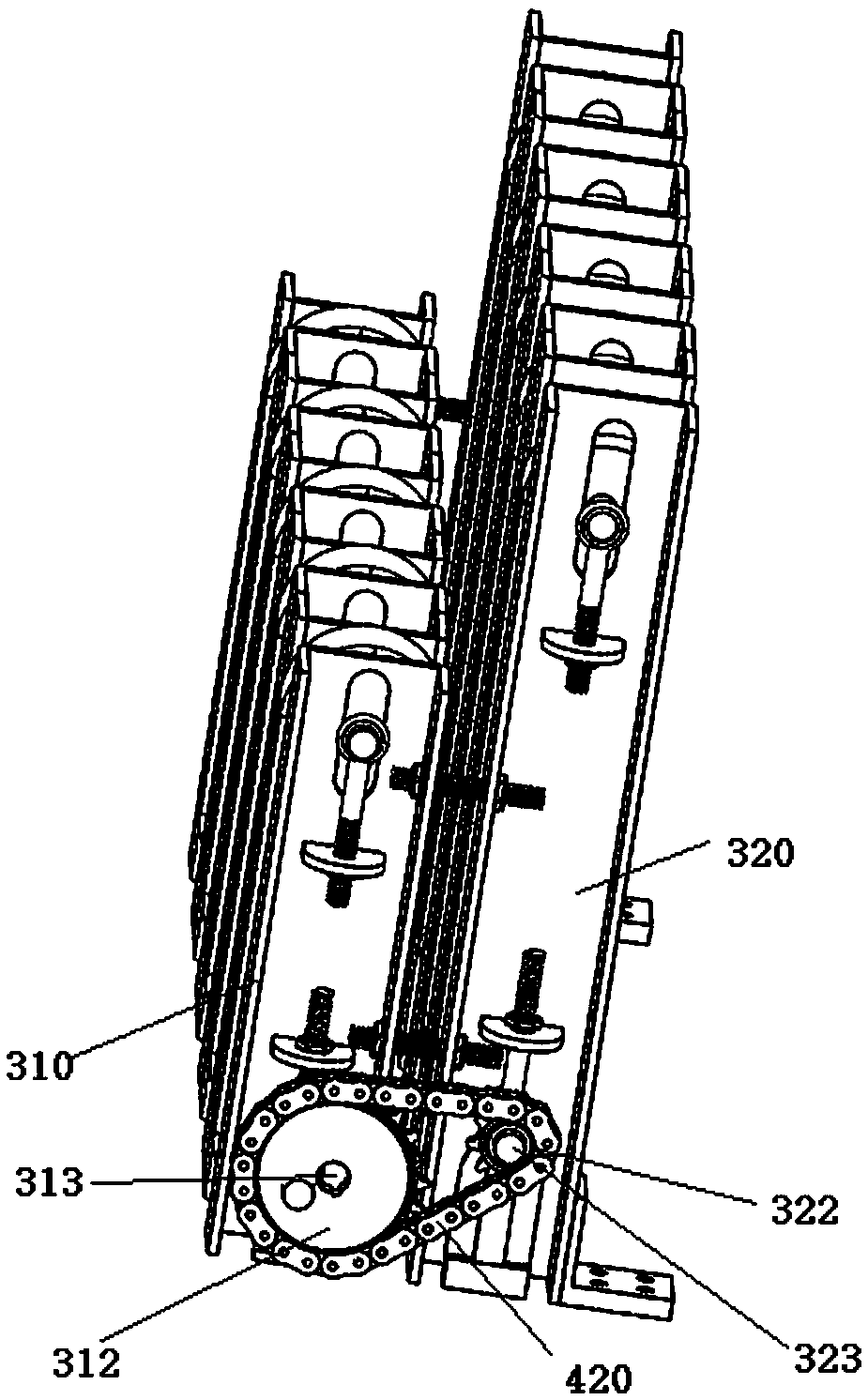

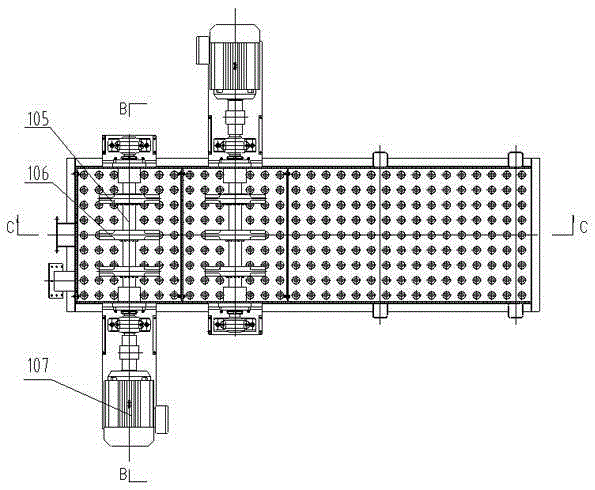

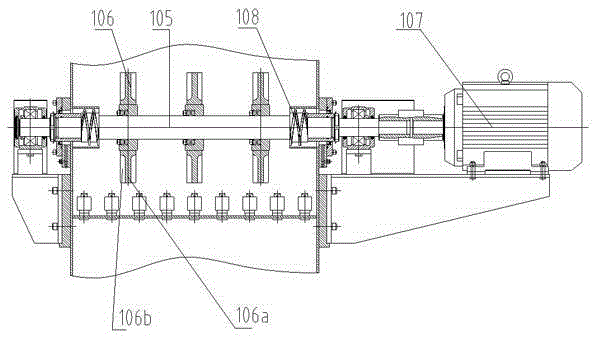

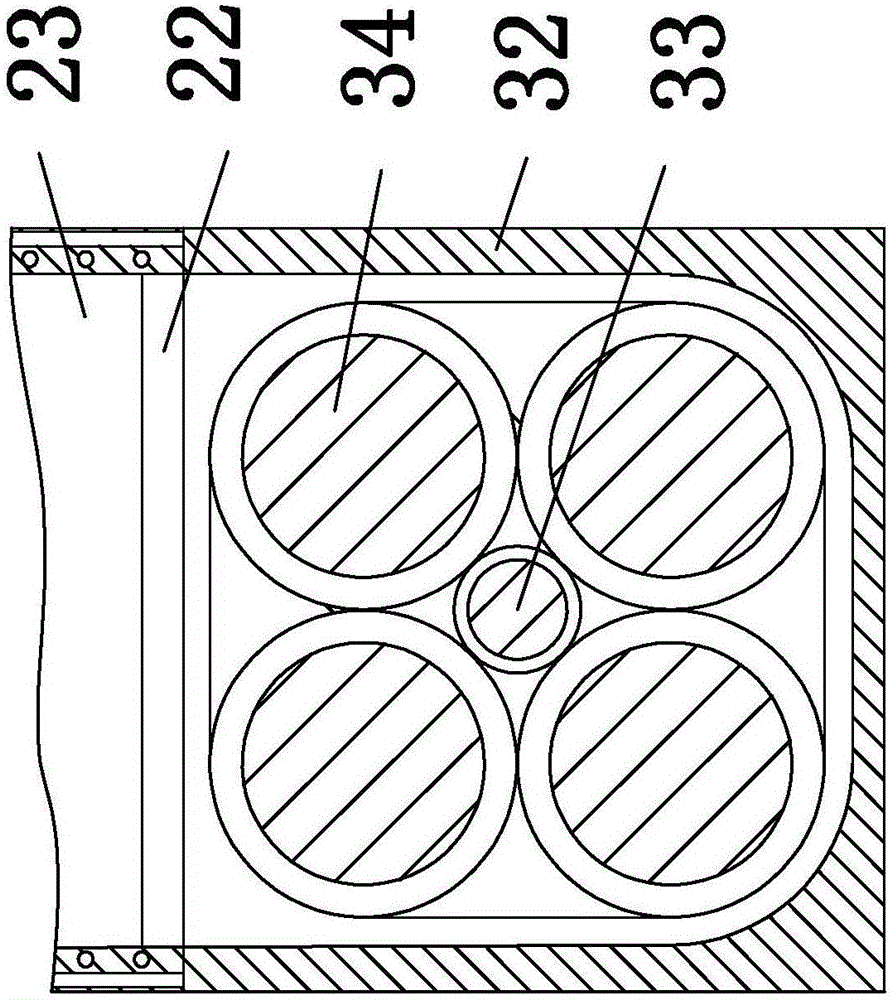

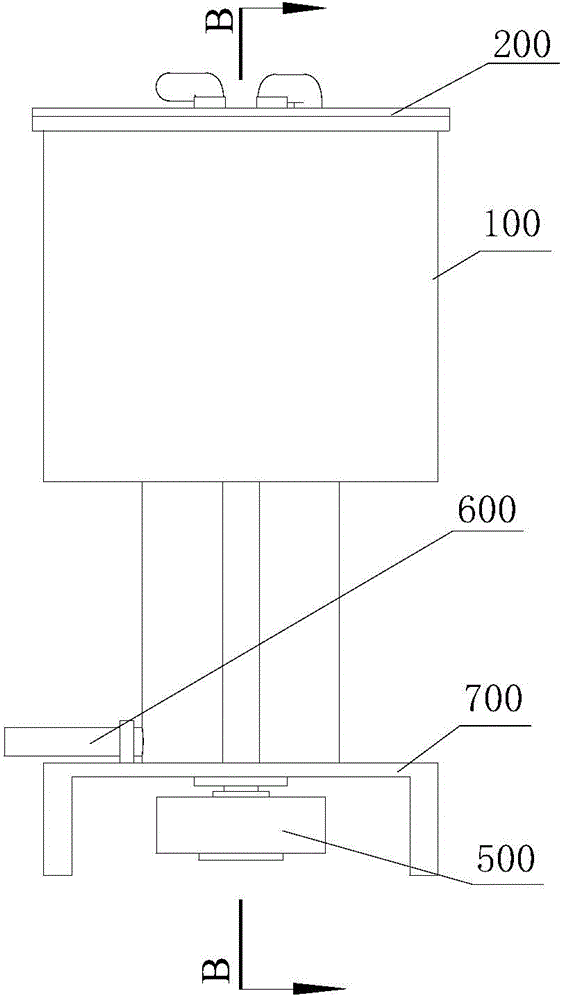

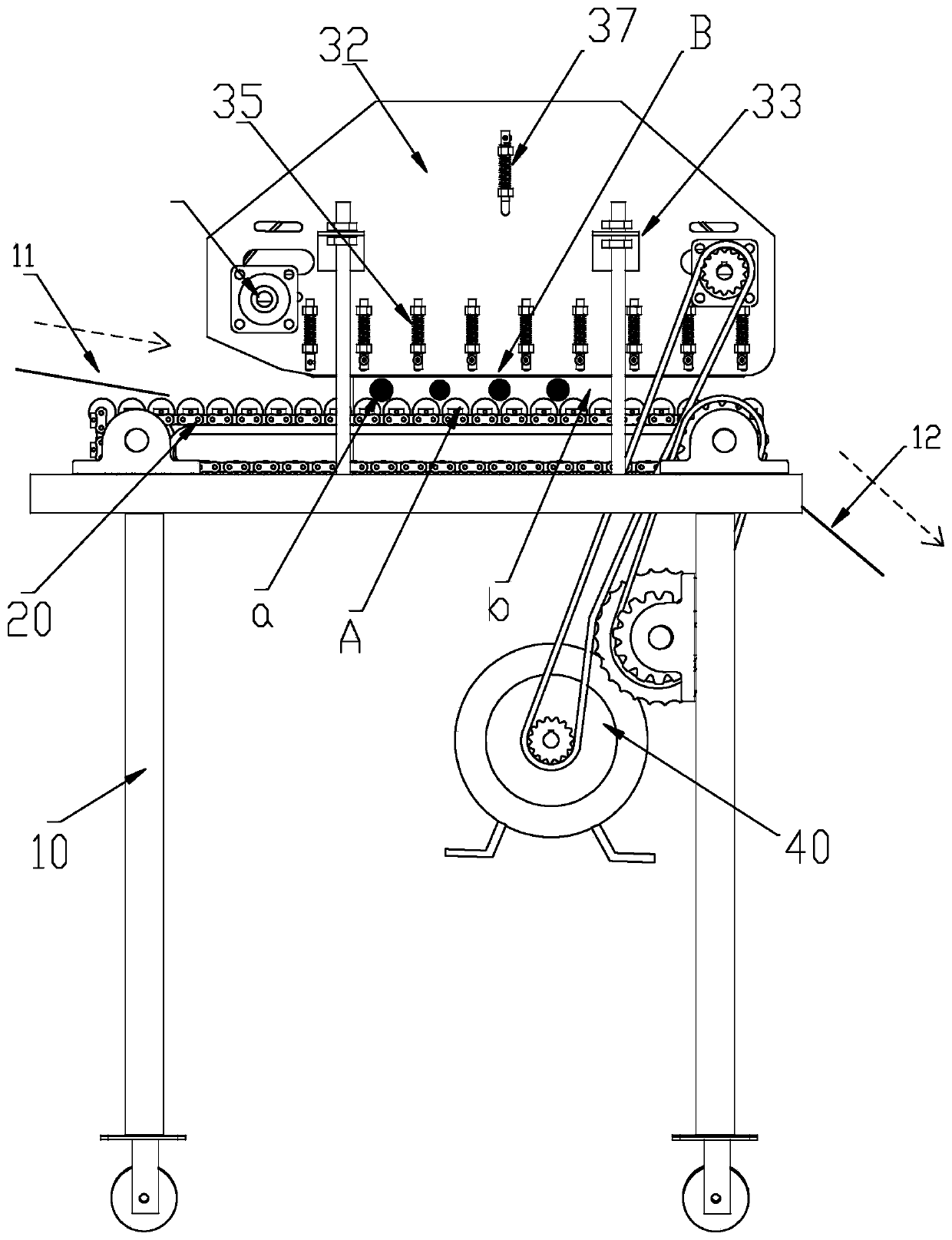

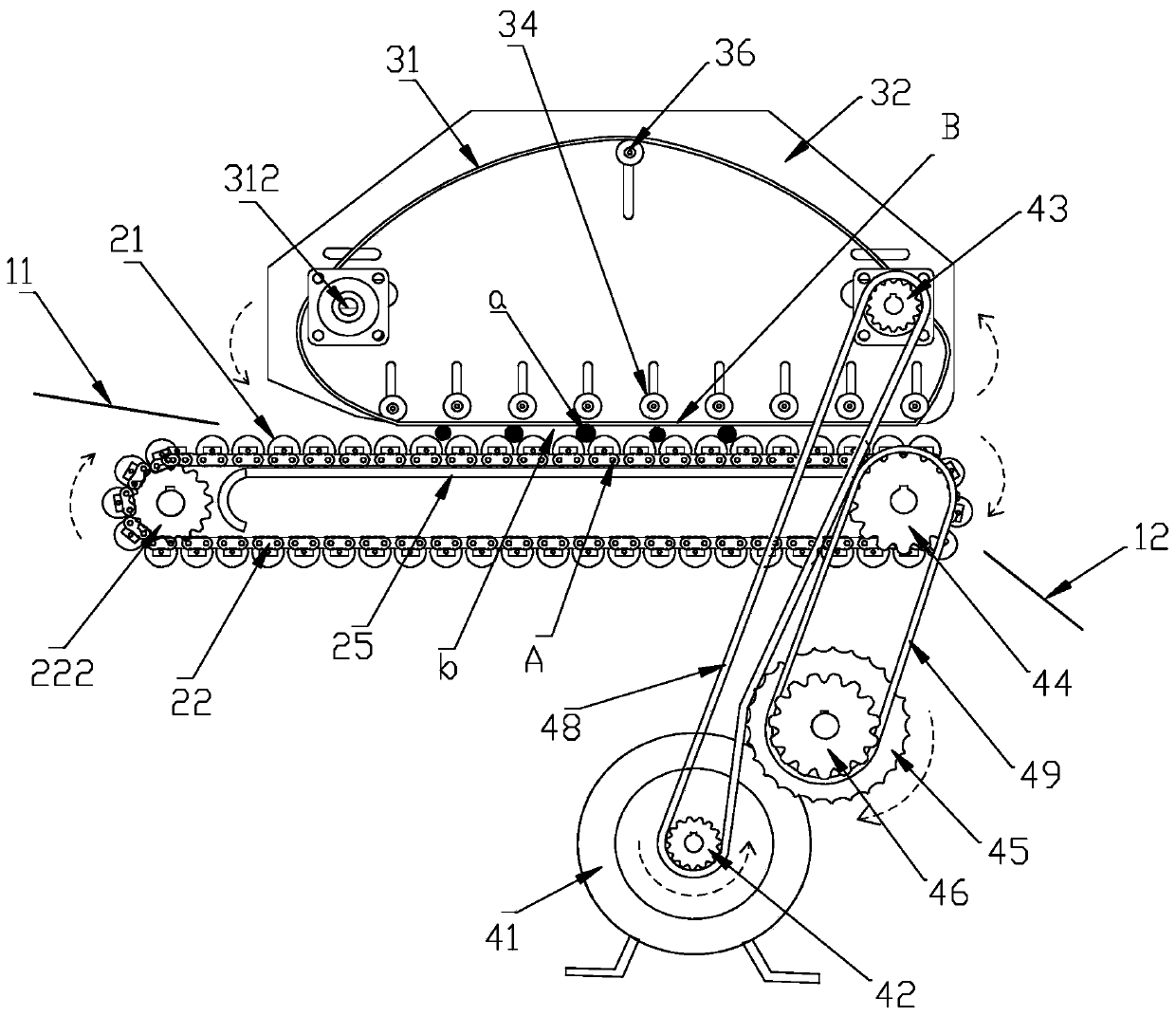

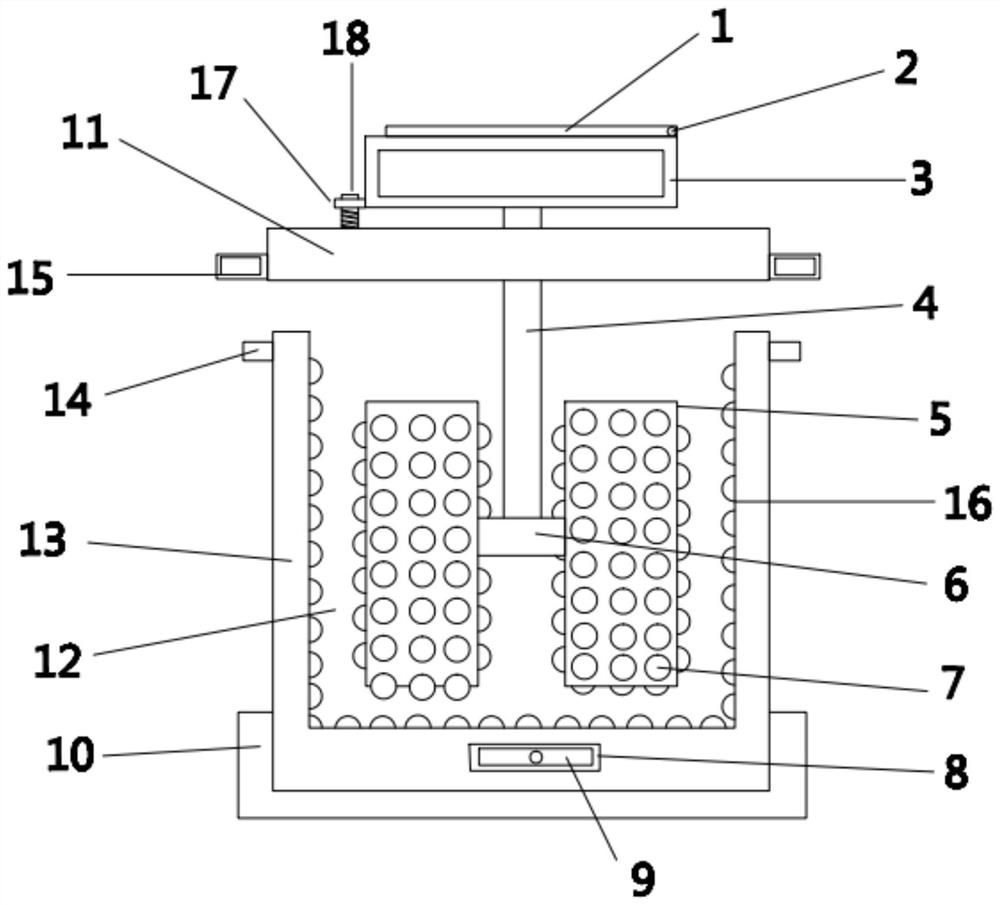

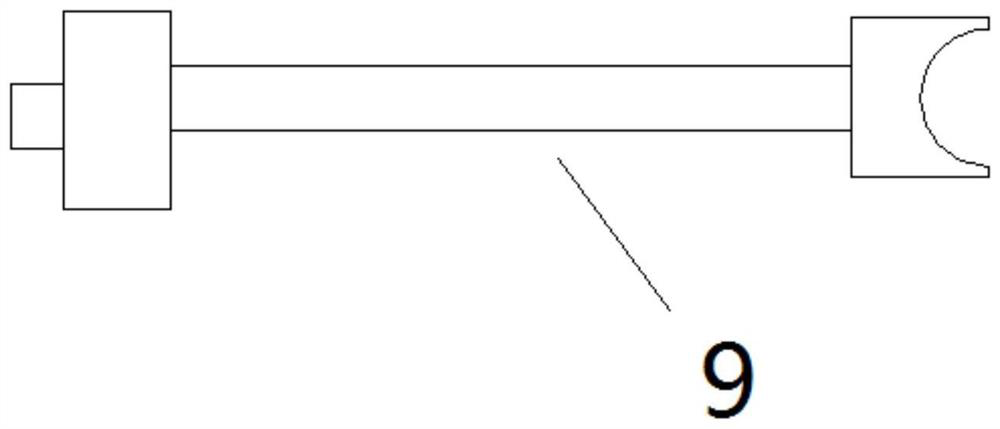

Automatic radix astragali kneading device

PendingCN109850477ARealize automatic kneading processingRubbing effect is goodConveyorsCleaning using toolsEngineeringFriction force

The invention relates to the technical field of Chinese herbal medicine processing, in particular to an automatic radix astragali kneading device which comprises a rack, a main transmission mechanism,an extrusion transmission mechanism and a drive control mechanism; the main transmission mechanism is provided with a horizontal conveying section; the extrusion transmission mechanism is provided with a horizontal extruding section; the horizontal conveying section and the horizontal extruding section are identical in a running direction and different in a running speed; the horizontal conveyingsection comprises multiple conveying drums; and the horizontal extruding section and each conveying drum form an opposite roller state between radix astragali and each conveying drum in the process of clamping the radix astragali. For the automatic radix astragali kneading device, by utilizing a speed difference of the main transmission mechanism and the extrusion transmission mechanism in the running directions, a speed difference is formed between the horizontal conveying section and the horizontal extruding section and enables the horizontal extruding section and the radix astragali on theconveying drums to generate friction, and the opposite roller state is formed between the radix astragali and the conveying drums by utilizing the friction force between the horizontal extruding section and the radix astragali, so that the radix astragali can be repeatedly kneaded by utilizing the conveying drums, and automatic kneading processing of the radix astragali is realized.

Owner:内蒙古索利得设备有限公司

Peanut hull smashing device

The invention discloses a peanut hull smashing device. The device comprises a collection box, a containing disc is rotatably installed at the inner side of an annular baffle, and a rotation shaft is fixedly installed at the right side of the containing disc; a first gear is fixedly installed at the right end of the rotation shaft and is in transmission connection with a second gear, the second gear is rotatably connected with a first motor, and a mounting plate is fixedly installed above the collection box through a supporting plate; an air cylinder is fixedly installed in the middle of the mounting plate, a piston rod of the air cylinder is fixedly connected with a movable plate, and an annular guide rail is fixedly installed at the lower end of the movable plate through a support; an annular limit plate is slidingly installed in the middle of the annular guide rail and fixedly installed at the outer side of a press plate, a fixing sleeve is fixedly installed at the upper end of the press plate, and an eccentric wheel is arranged at the inner side of the fixing sleeve and rotatably connected with the second motor. The peanut hull smashing device can knead and smash peanut hulls through annular motion, and the hull smashing efficiency is high.

Owner:李丽芬

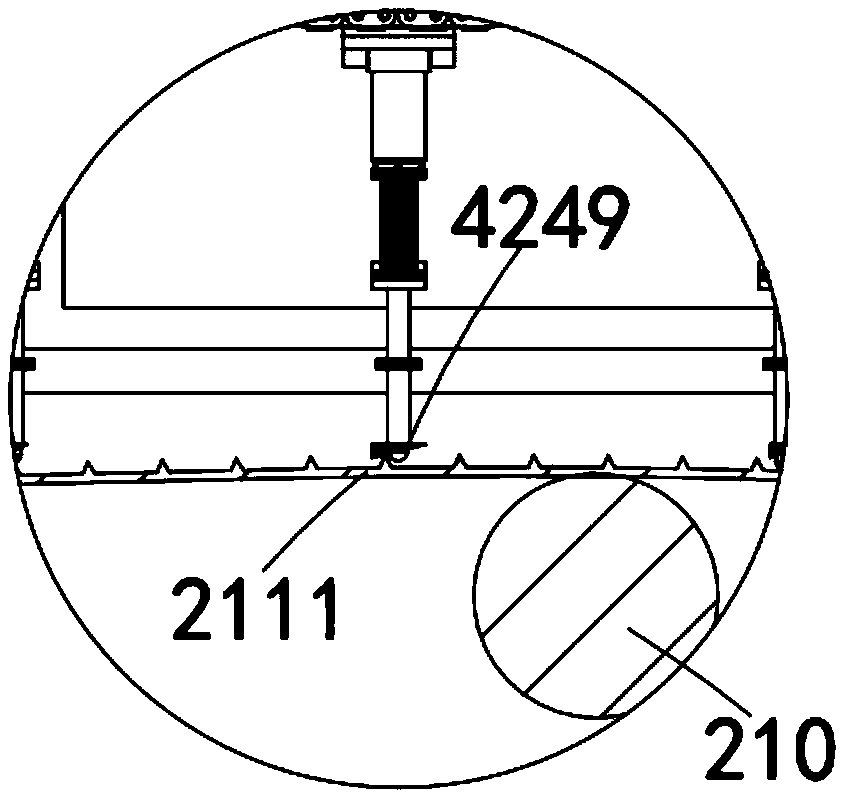

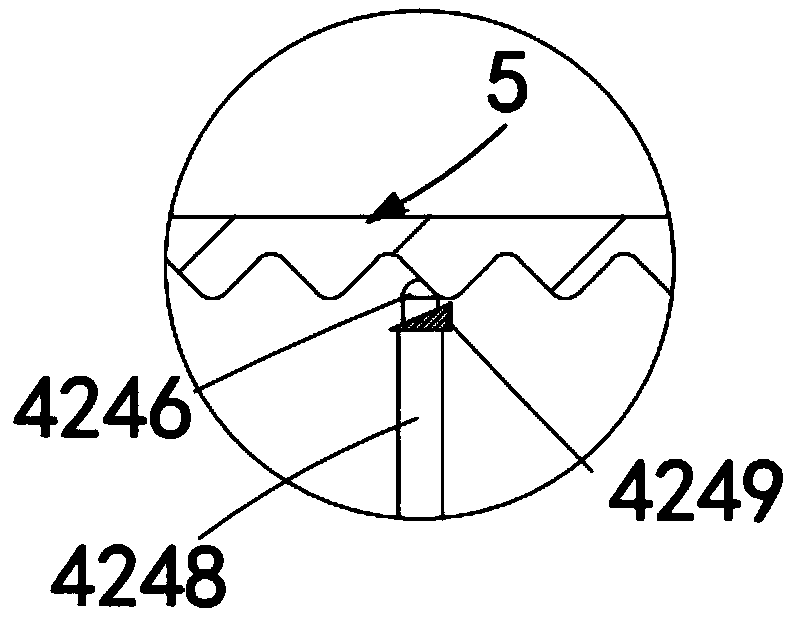

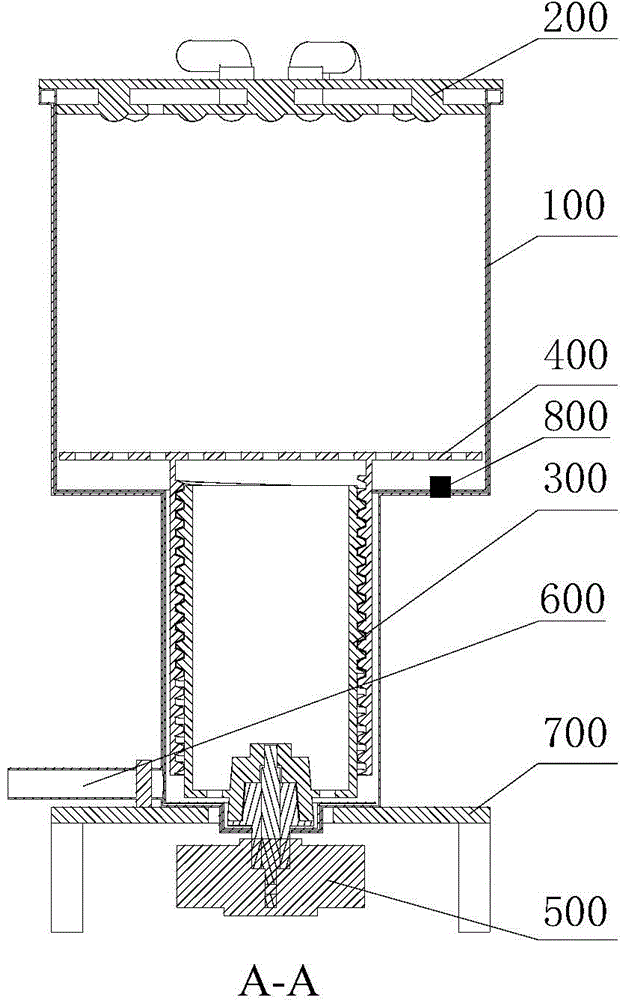

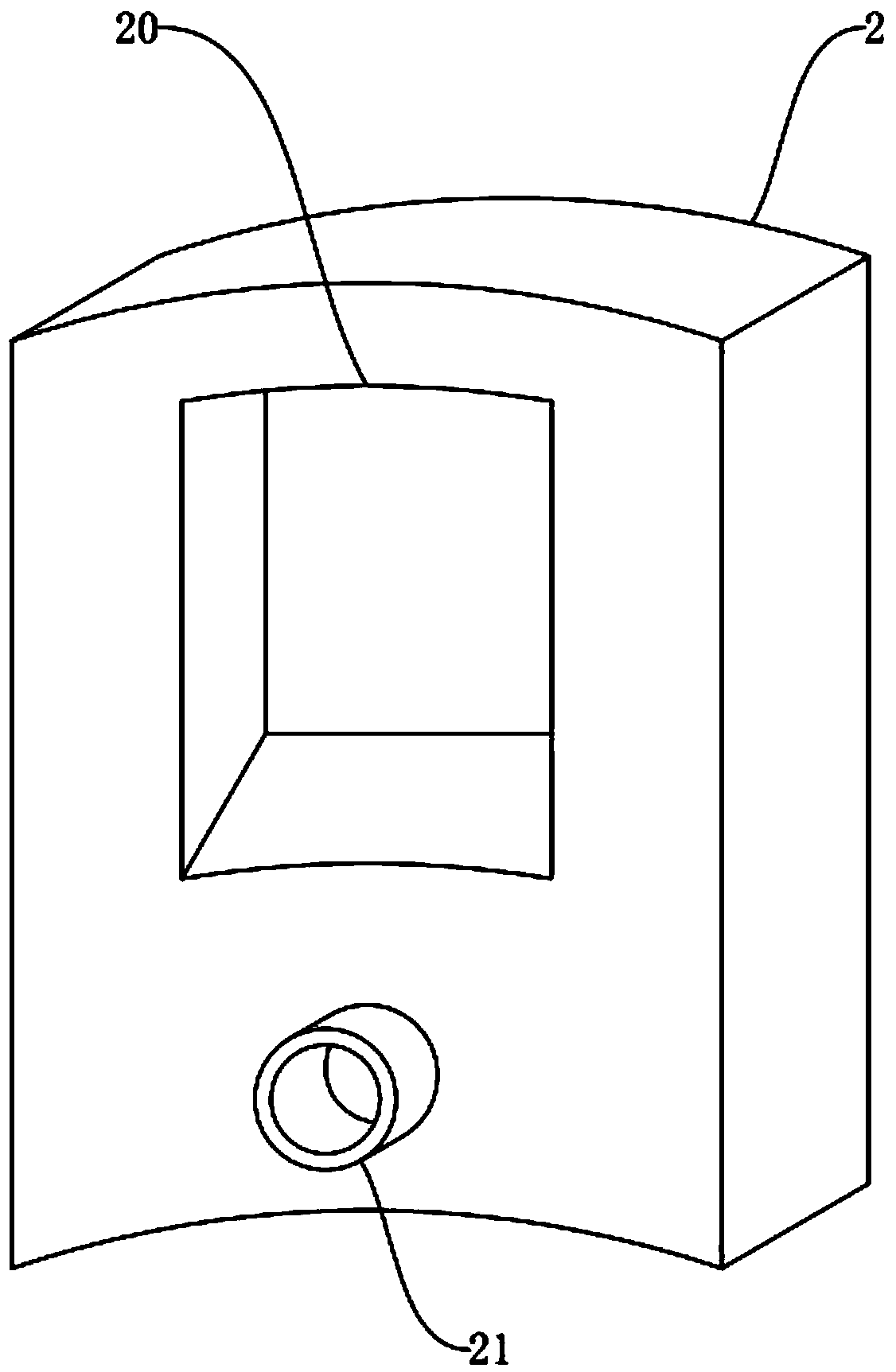

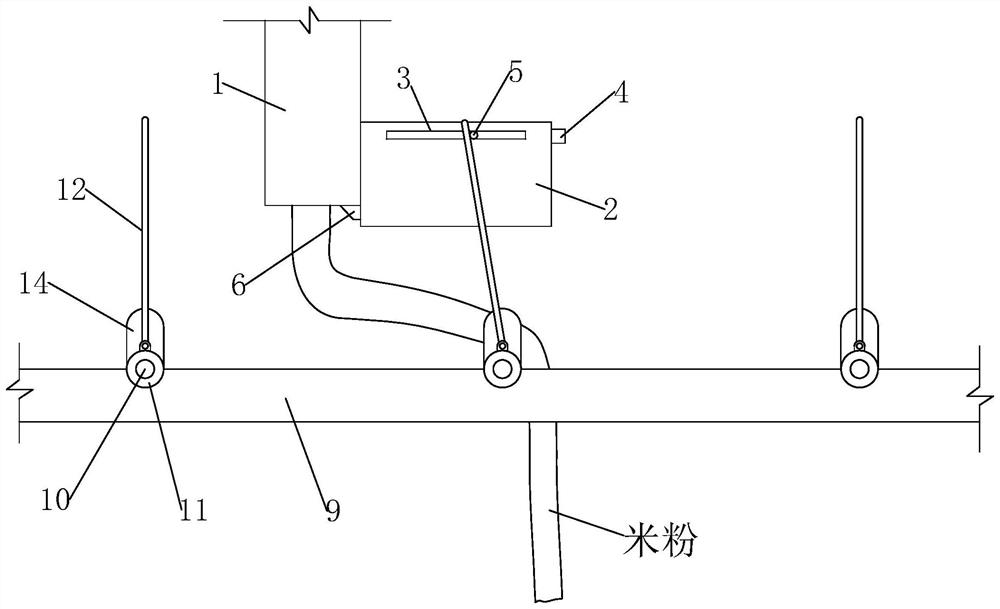

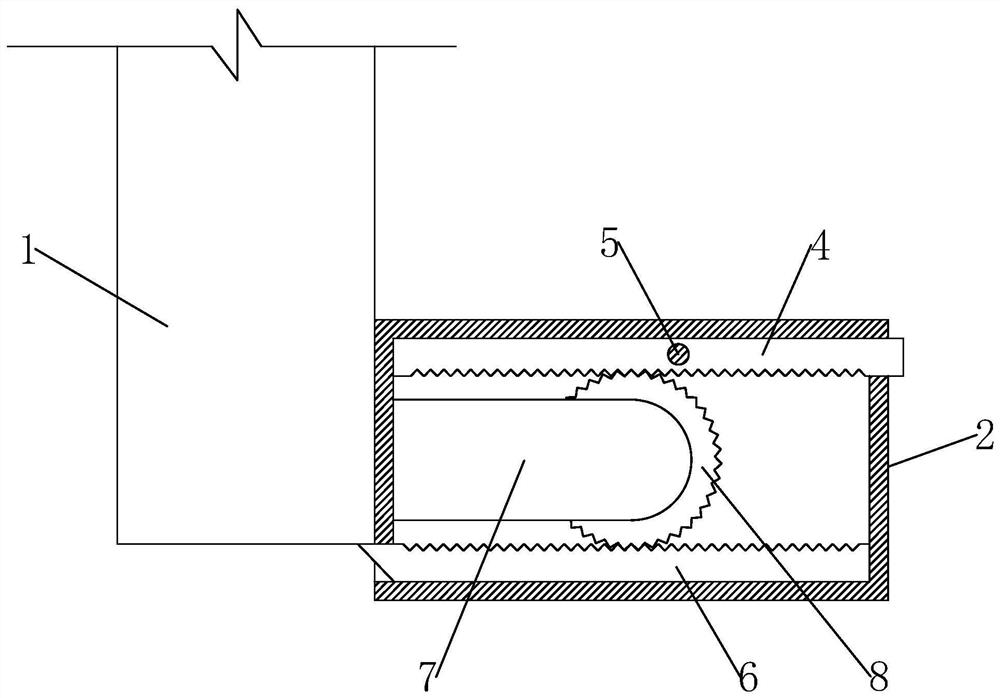

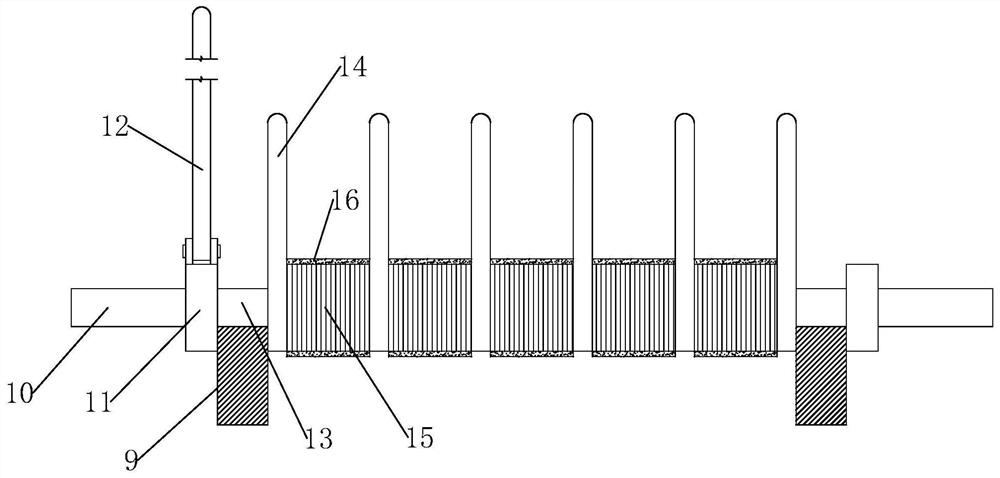

Rice noodle racking mechanism

InactiveCN113040320AAutomate operationNo labor requiredFood shapingAgricultural engineeringMechanical engineering

The invention discloses a rice noodle racking mechanism, which belongs to the technical field of rice noodle production, and has the technical scheme that the rice noodle racking mechanism comprises a rice noodle machine for producing rice noodles, and is characterized in that an automatic cutting mechanism is used for automatically cutting the rice noodles produced from the rice noodle machine and can cut the rice noodles into small sections with equal length, the automatic cutting mechanism comprises a box body, the box body is fixedly installed on one side of a rice noodle outlet of the rice noodle machine, an upper toothed plate is movably arranged in the box body and tightly attached to the upper wall of the box body, the end, away from the rice noodle machine, of the upper toothed plate can movably penetrate from the interior of the box body to the exterior, a protruding column is vertically and fixedly installed on the front side of the upper toothed plate, a penetrating opening is formed in the front side wall of the box body, and the protruding column penetrates from the interior of the box body to the exterior through the penetrating opening and moves along with the upper toothed plate. The rice noodle racking mechanism can automatically cut off rice noodles and automatically rack the rice noodles, a matched rice noodle placing frame can assist in rubbing and scattering the rice noodles, the rubbing and scattering effect on the rice noodles is good, and the operation is simple.

Owner:乐安县恒源食品有限公司

Peanut cleaning machine for food processing

InactiveCN113575988ATo achieve the effect of scrapingEasy to cleanFood treatmentAgricultural scienceAgricultural engineering

The invention relates to the technical field of food processing, and discloses a peanut cleaning machine for food processing. The peanut cleaning machine comprises a cleaning roller, a falling opening, a front cover and a support, the falling opening is fixedly installed at the upper end of the cleaning roller, a driving motor is fixedly installed at the rear end of the cleaning roller, the front cover is hinged to the front end of the cleaning roller, and the support is fixedly installed at the lower end of the cleaning roller. A falling outlet is formed in the front face of the front cover, the support is fixedly installed at the lower end of the cleaning roller, a connecting cylinder is arranged in the cleaning roller, a rubber sleeve is fixedly connected to the outer wall of the connecting cylinder, and a rubber grinding layer is fixedly connected to the inner wall of the cleaning roller. According to the peanut cleaning machine for food processing, soil on the surfaces of peanuts can be more conveniently removed through vibration and twisting force, the peanuts are scraped towards the two sides by driving springs to achieve offset bending, the surfaces of the peanuts are cleaned more cleanly, the surfaces of the peanuts are further cleaned through scraping of metal sleeves arranged in a wrinkled mode. The better cleaning effect is achieved.

Owner:嘉兴凡星科技有限公司

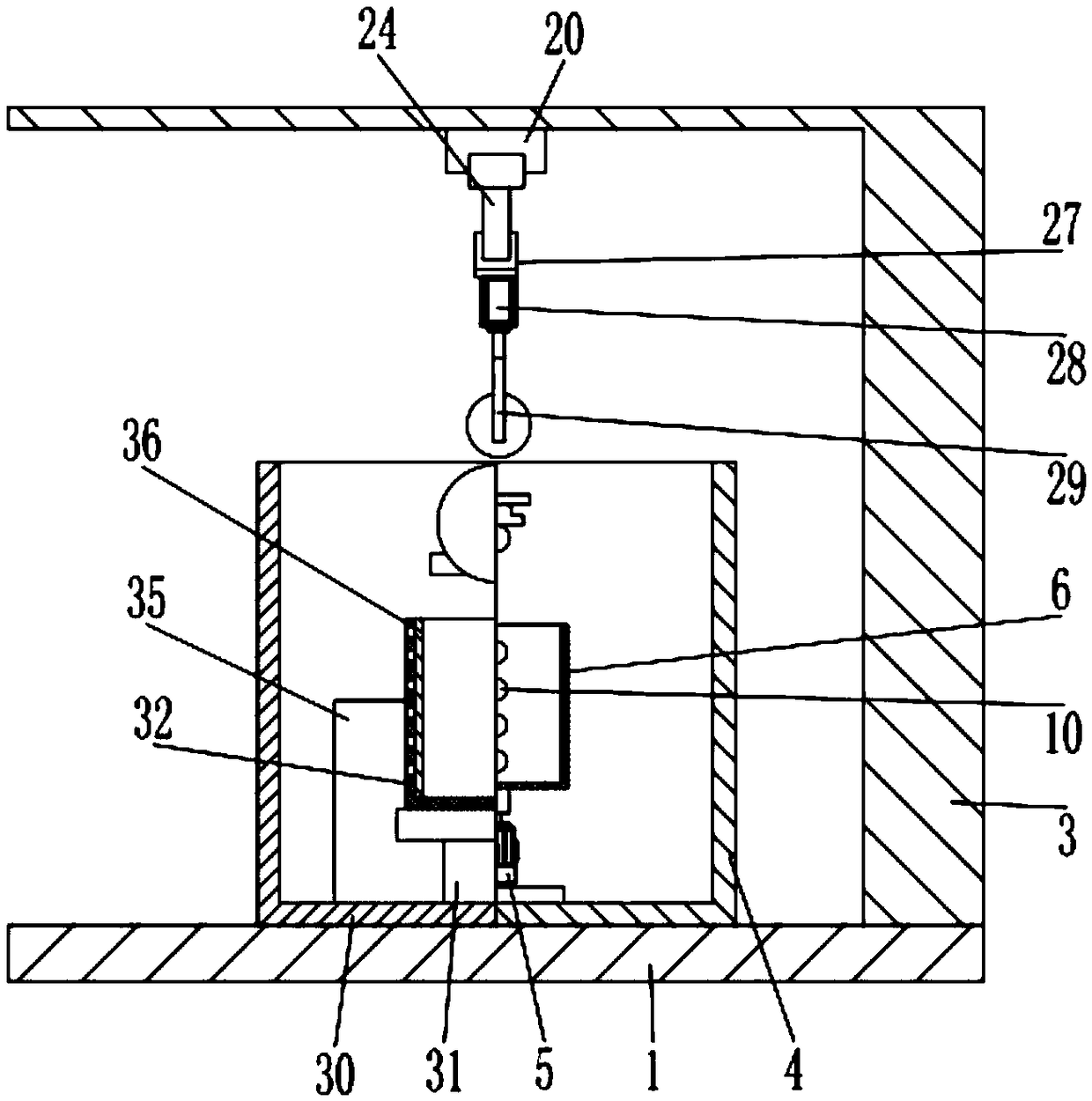

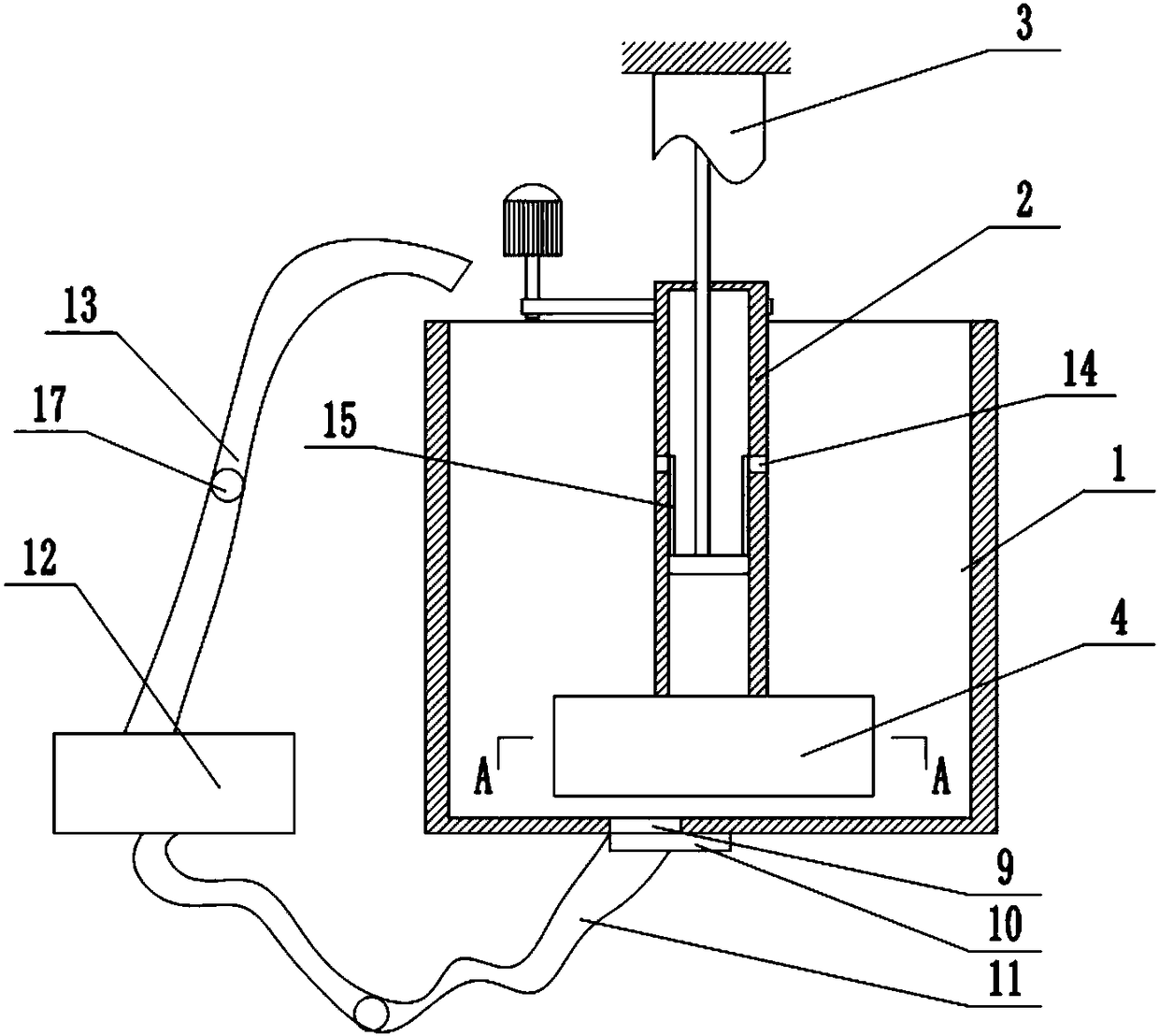

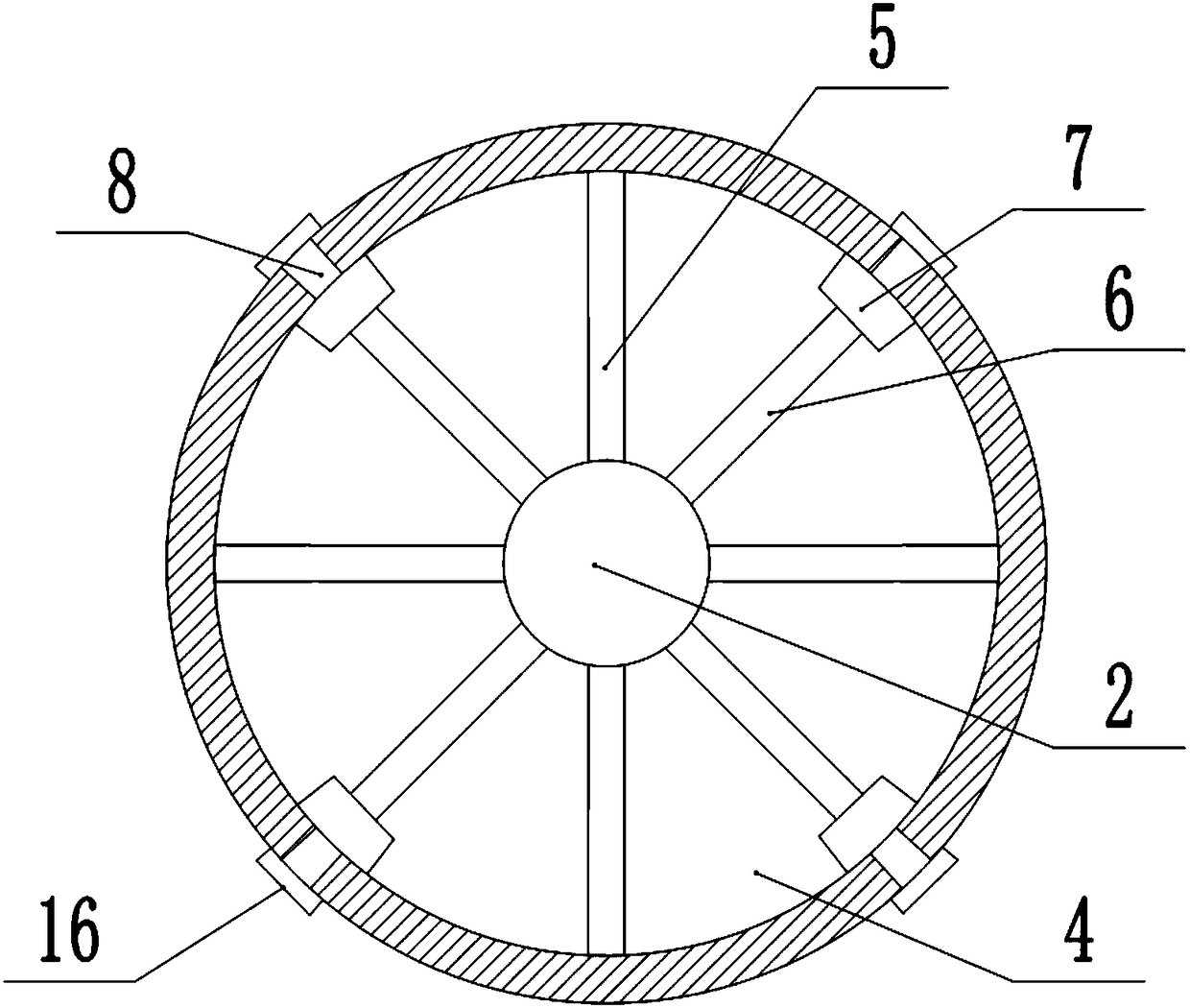

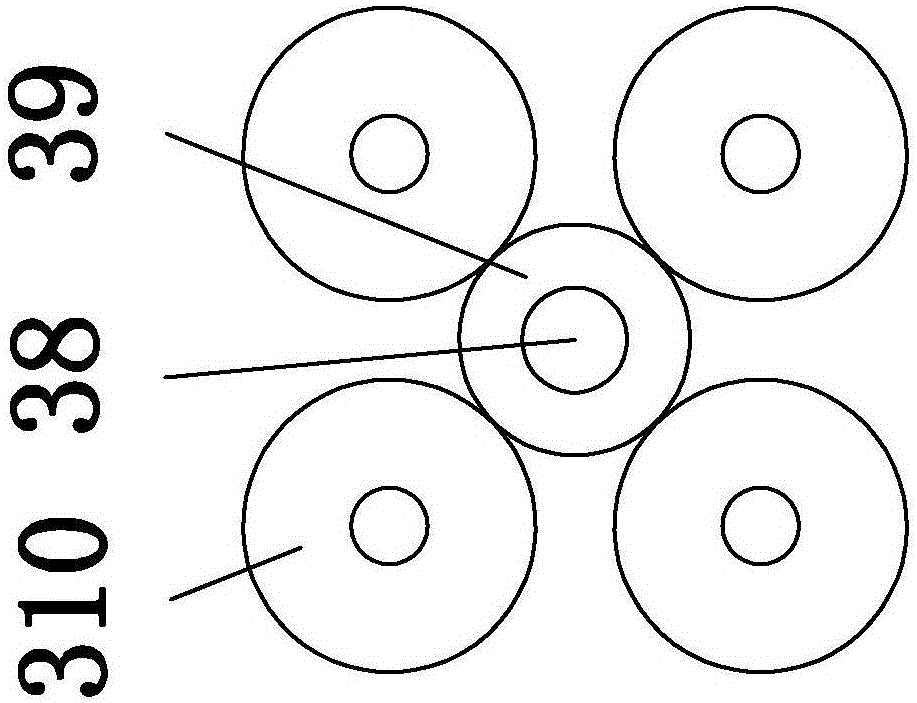

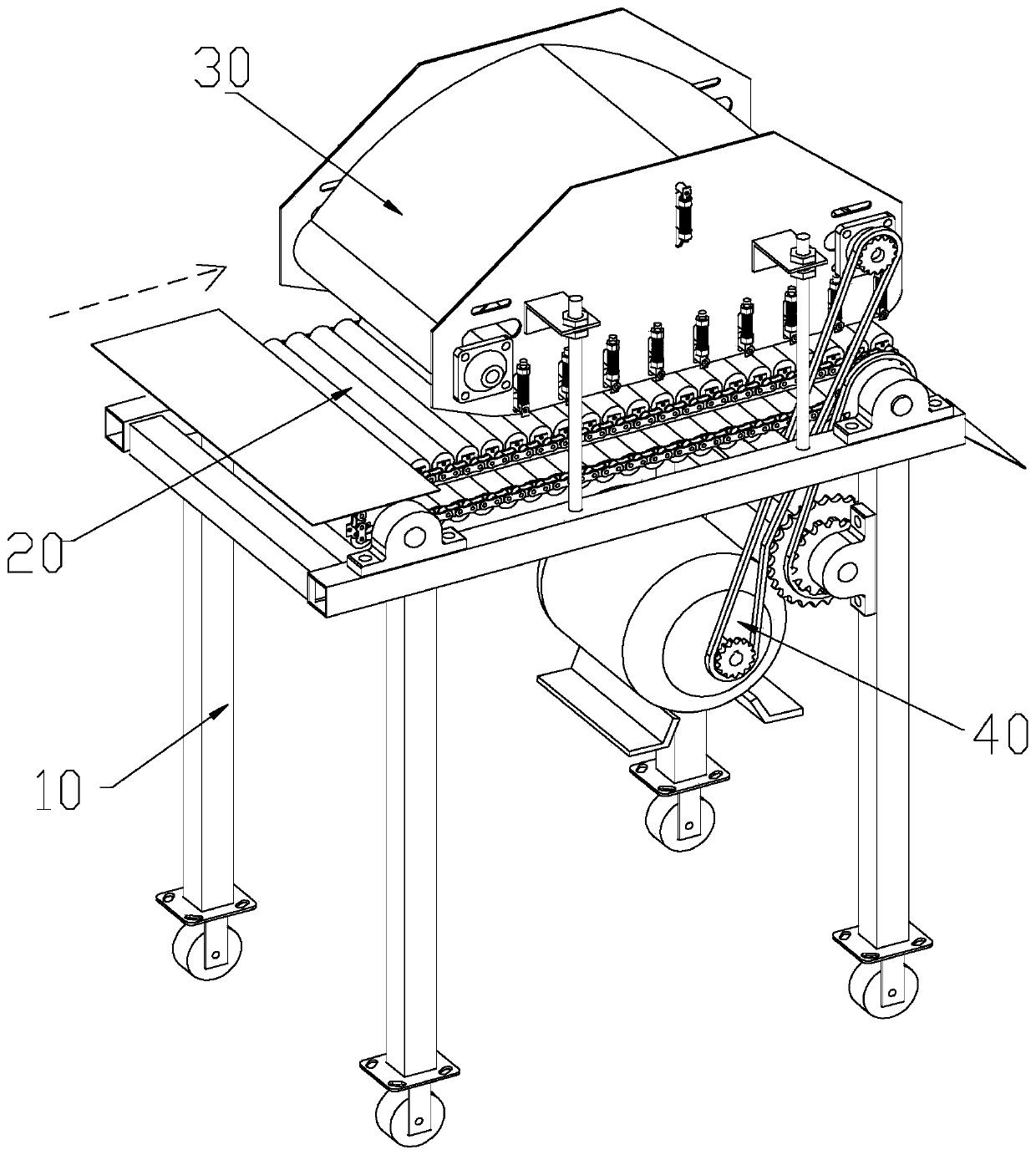

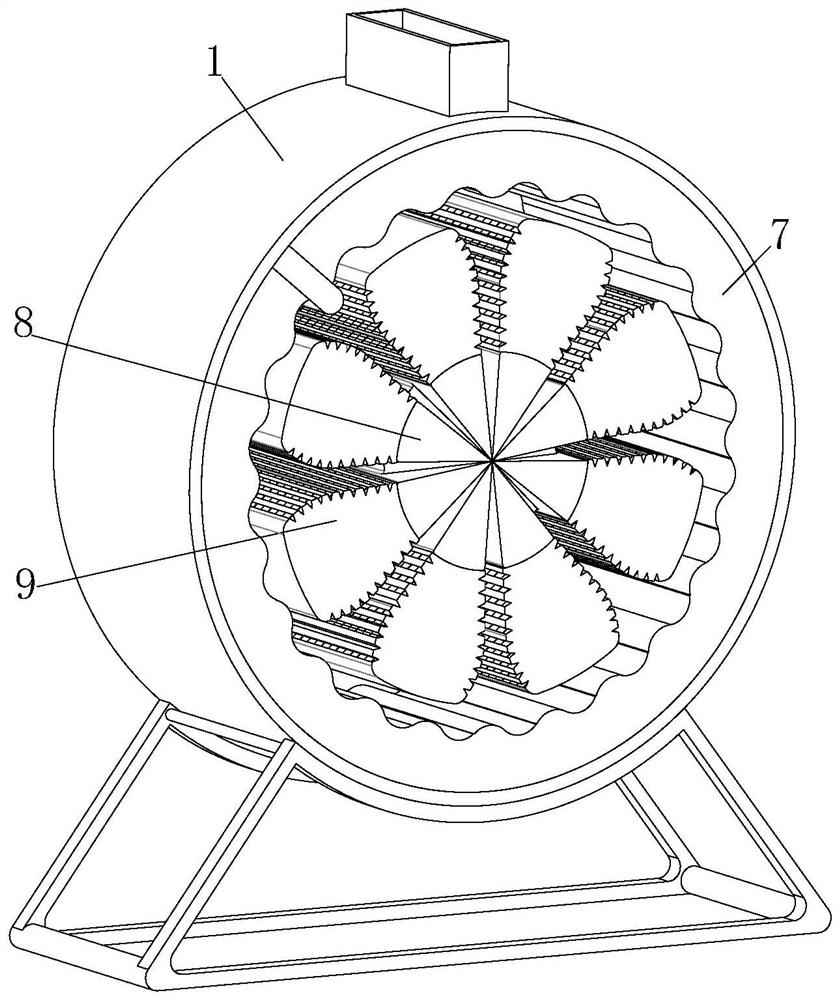

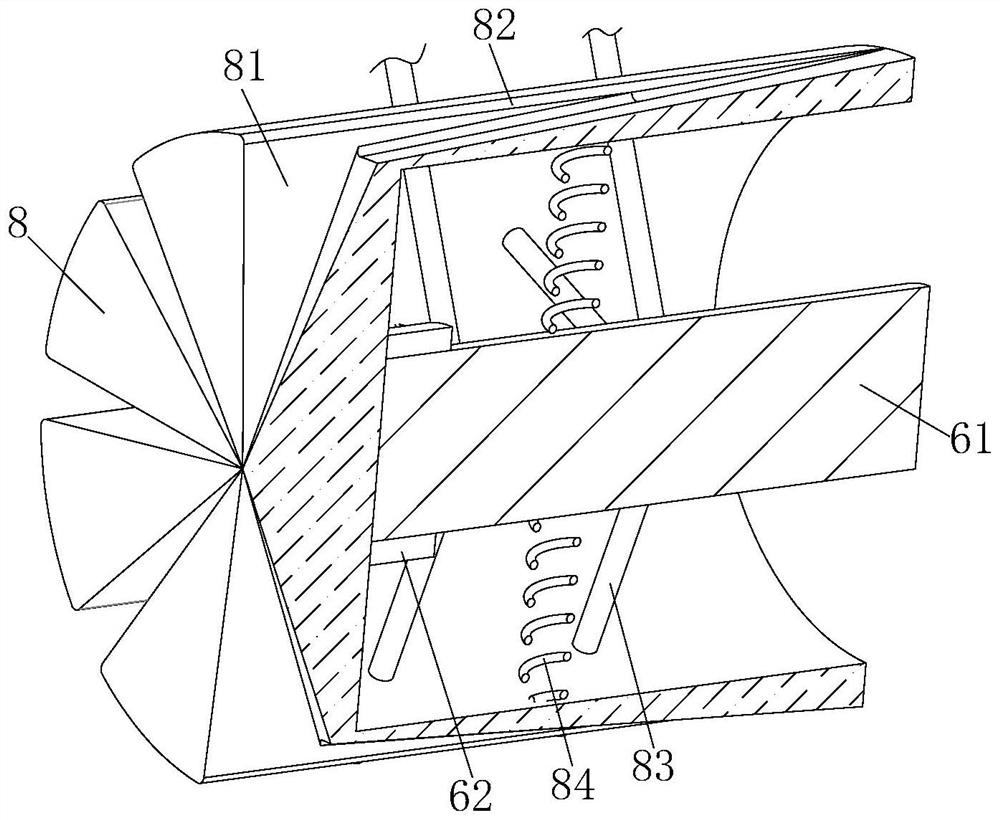

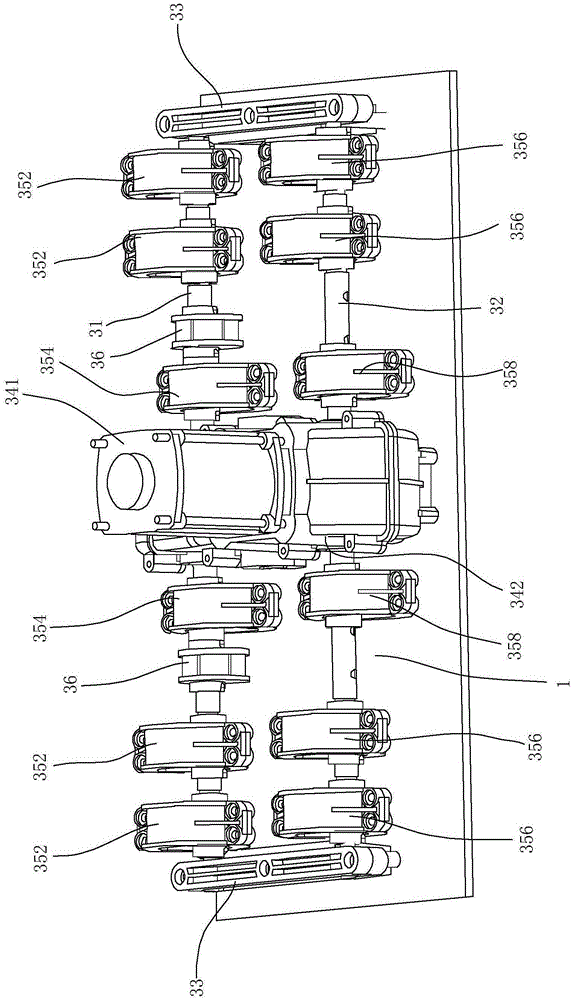

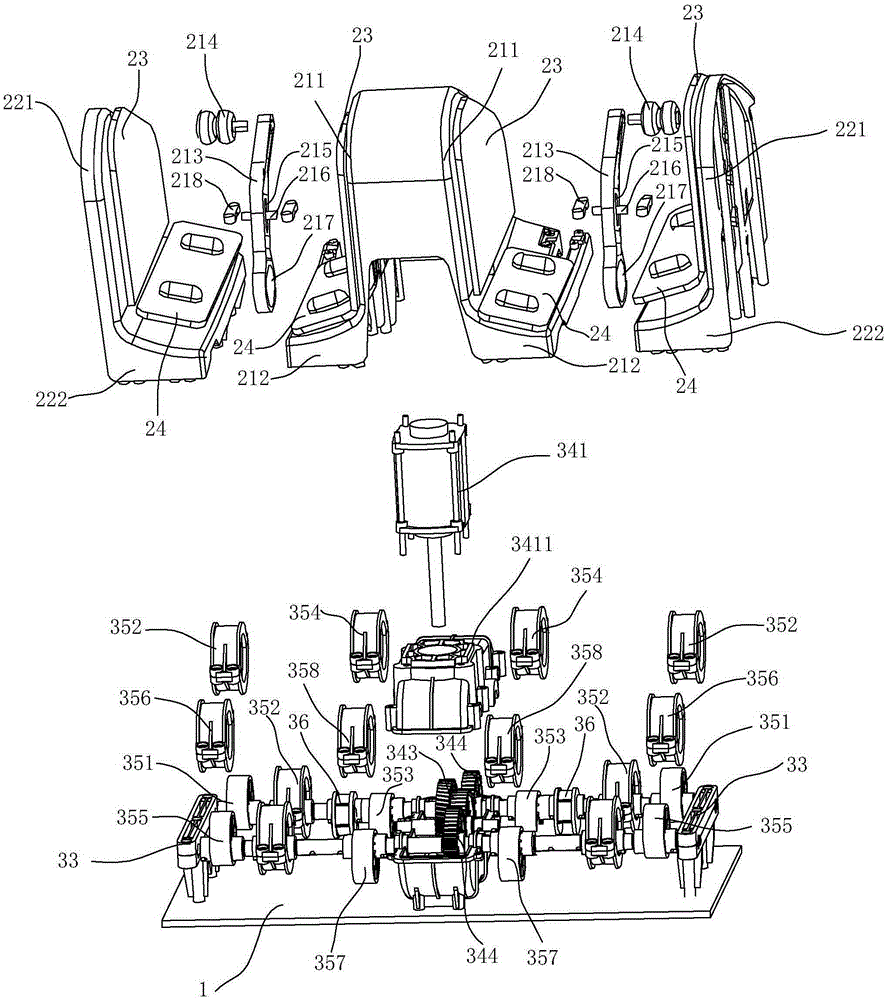

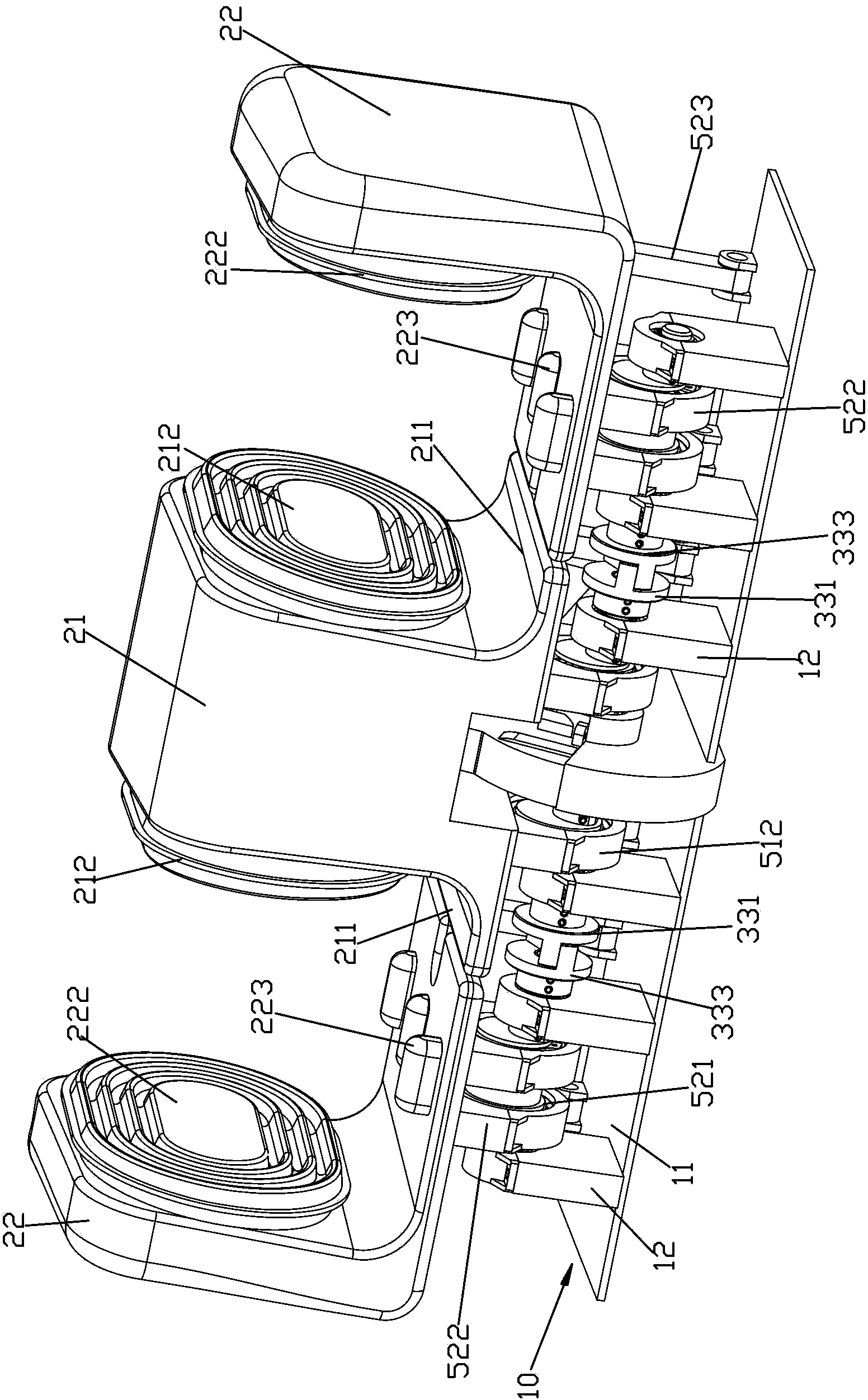

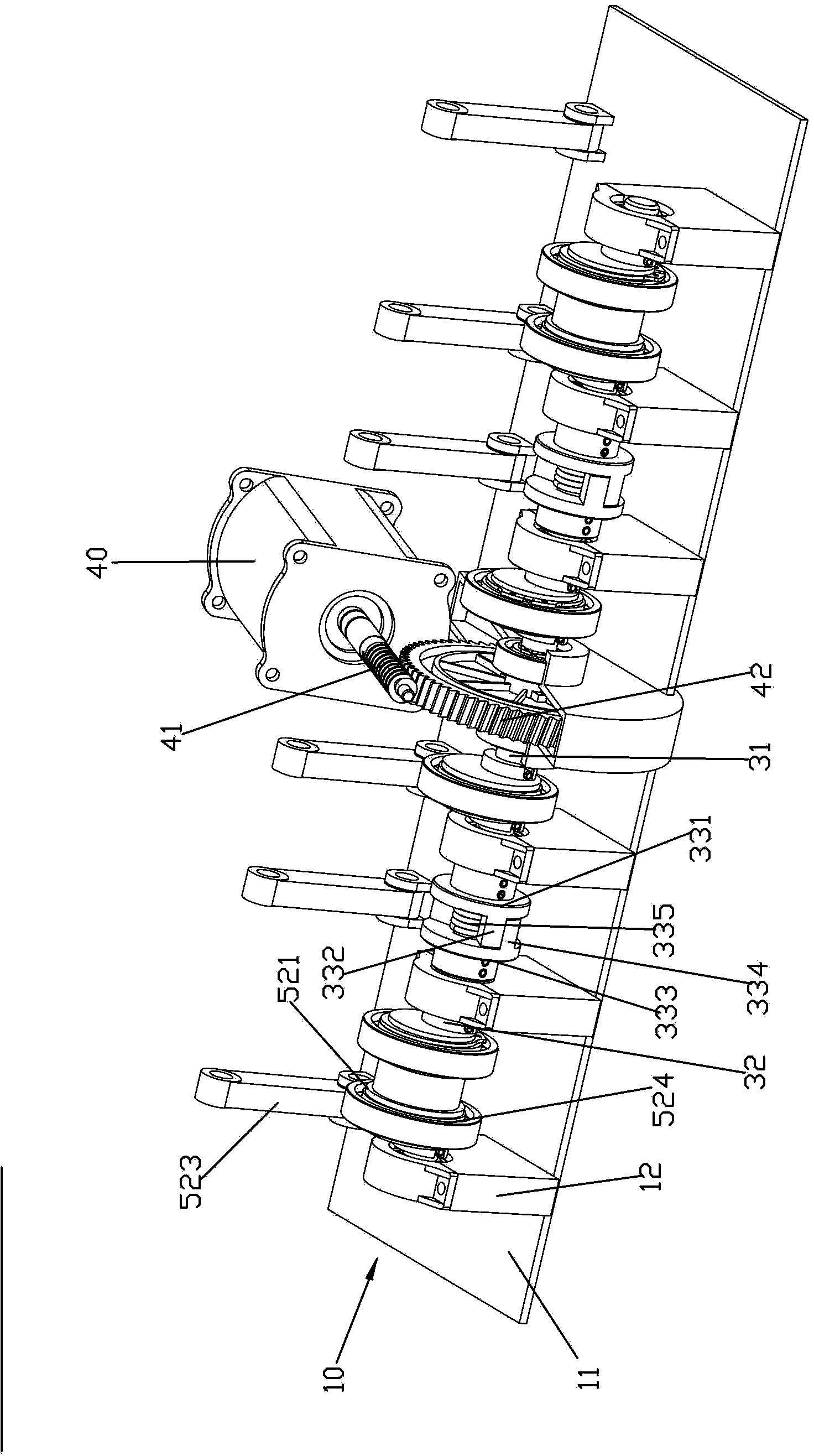

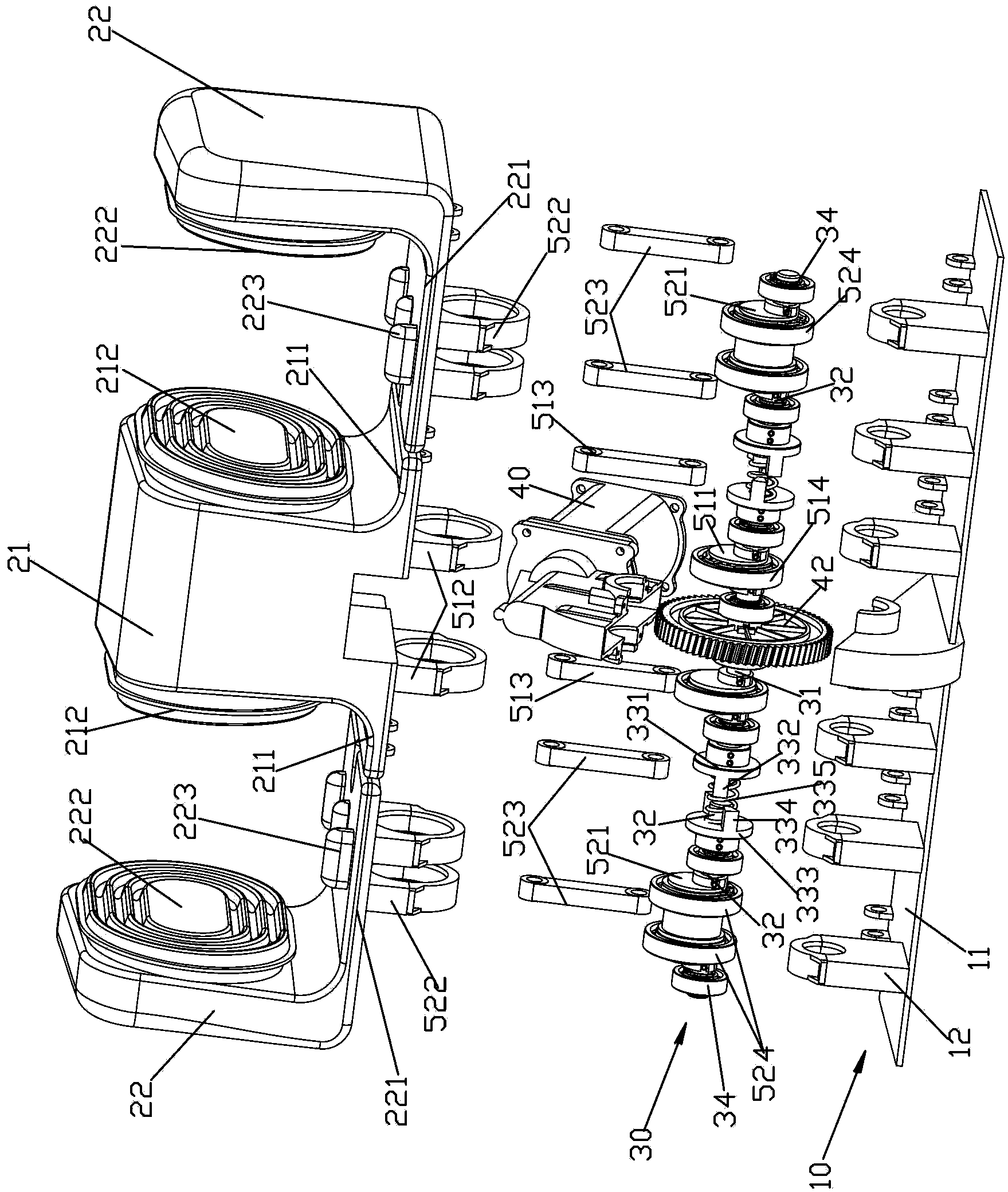

rubbing massager

ActiveCN104107136BBig-amplitudeRubbing effect is goodDevices for pressing relfex pointsRoller massageMedicineDrive shaft

The invention discloses a rubbing massage device. The rubbing massage device comprises a base, a rubbing massage mechanism and a driving mechanism used for driving the rubbing massage mechanism. The rubbing massage mechanism comprises at least one pair of side bases. Each pair of side bases comprises the first side base and the second side base. The rubbing massage device is characterized in that the driving mechanism comprises a driving motor, a first driving shaft and a second driving shaft, the first driving shaft and the second driving shaft are driven by the drive motor, and the first driving shaft and the second driving shaft are arranged on the base in parallel at intervals. First eccentric rotation wheels are arranged at the positions, corresponding to the positions of the second side bases, of the first drive shaft and drive one end of each second side base to swing, and second eccentric rotation wheels are arranged at the positions, corresponding to the positions of the second side bases, of the second drive shaft and drive the other end of each second side base to swing in the same direction. Third eccentric rotation wheels are arranged at the positions, corresponding to the positions of the first side bases, of the first drive shaft and drive one end of each first side base to swing, and fourth eccentric rotation wheels are arranged at the positions, corresponding to the positions of the first side bases, of the second drive shaft and drive the other end of each first side base to swing in the same direction.

Owner:NINGBO BINGHANG ELECTRONICS SCI & TECH CO LTD

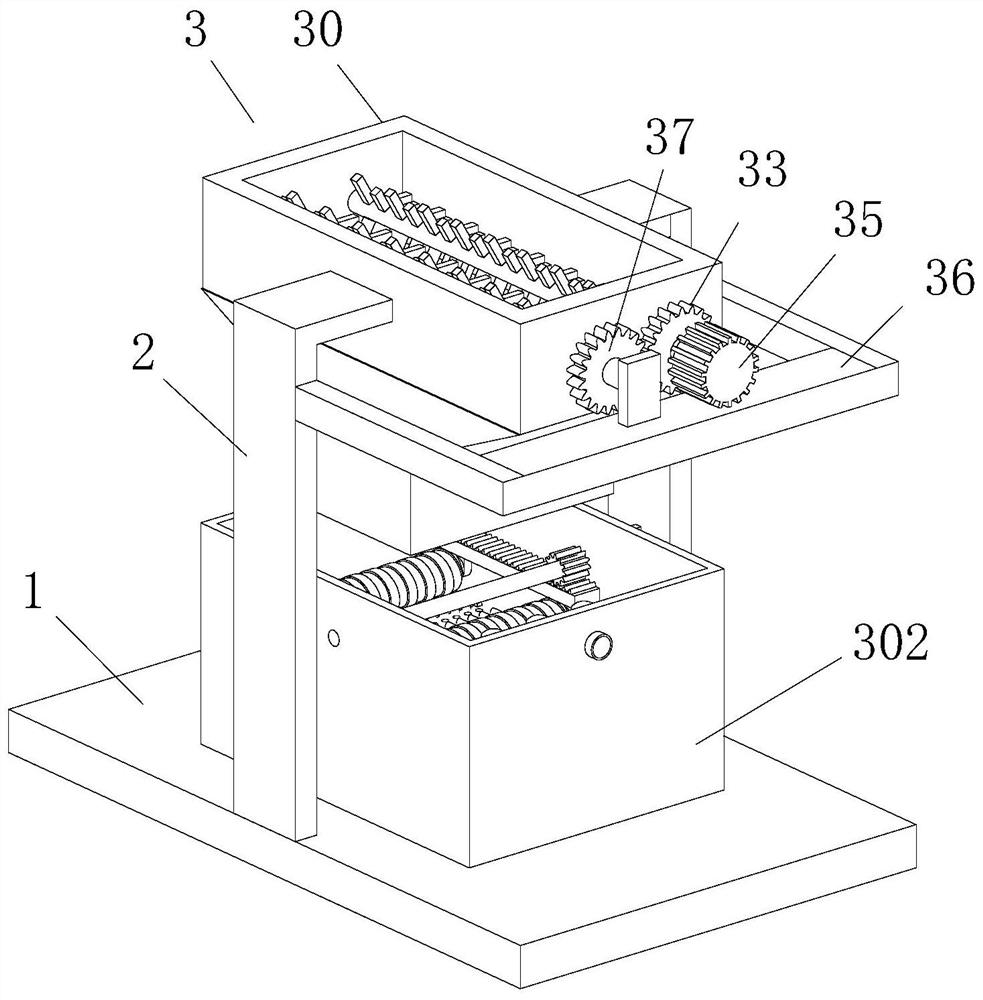

Degradable plastic film recycling method

InactiveCN112497575AIncrease cleaning rateRealize the function of reciprocating kneadingPlastic recyclingGrain treatmentsPlastic filmMaterials science

The invention provides a degradable plastic film recycling method. The degradable plastic film recycling method adopts the following equipment for recycling treatment, wherein the equipment comprisesa base, L-shaped frames and a crushing device, the lower end of the base is connected with the existing ground, the L-shaped frames are mounted at the upper end of the base in a front-and-back symmetry manner, and the crushing device is installed between the upper ends of the front and back L-shaped frames that are opposite to each other. According to the degradable plastic film recycling method,through mutual cooperation of a first motor, a rotating shaft, a first gear and a second gear, two mounting shafts can synchronously rotate towards the inner sides, so that crushing cutters on the twomounting shafts extrude and cut plastic films, and the function of crushing the plastic films is achieved, and the subsequent cleaning rate of the plastic films is further improved.

Owner:王晓春

crushing plastic plasticizing machine

ActiveCN105710984BImprove the mixing effectImprove toughnessPlastic recyclingMechanical material recoveryEngineeringToughness

The invention relates to the field of waste plastic recycling, and aims at providing a broken plastic plasticator. The broken plastic plasticator comprises a machine base, a cutting-up and stirring preplasticizing device, a main plasticizing device and an air exhausting filtering device, wherein the cutting-up and stirring preplasticizing device is provided with a feeding hopper and a discharging opening; the main plasticizing device comprises a barrel which is provided with a barrel heating device and connected with the machine base, a middle rod with the two ends connected with the barrel, a plurality of main spiral push rods in pivot joint with the barrel and a push rod driving device; an auxiliary spiral push rod is arranged in a gap of the outer sides of every two adjacent main spiral push rods; the two ends of each auxiliary spiral push rod are in pivot joint with the barrel; the barrel is provided with a plasticizing inlet which is formed in the rear portion of the side body of the barrel and is communicated with the discharging opening, a plasticizing outlet formed in the front end of the barrel and an air exhausting opening communicated with an inlet of the air exhausting filtering device. In the plasticizing process of the broken plastic plasticator, the mixing, extruding and rubbing effect on plasticizing raw materials is good, gas can be easily exhausted out, and toughness of prepared plastic regeneration raw materials is good.

Owner:NINGBO LVHUA RUBBER & PLASTIC MACHINERY IND & TRADE

Stepped twin-screw extrusion device and bulking machine

The invention discloses a stepped twin-screw extrusion device and a bulking machine which comprises twin screws arranged in parallel, wherein screw configuration of the twin screws adopts a stepped variable pitch double-threaded screw structure; and the twin screws comprise a 2-time screw diameter coarse pitch double-threaded screw structure, a three-forward kneading block, a 1.5-time twin-screw structure, a primary three-forward three-backward kneading block, a one-time twin-screw structure, a secondary three-forward three-backward kneading block, a primary one-time slotted twin-screw structure, a double-threaded inverted screw structure, a secondary one-time slotted twin-screw structure and a discharging conical screw structure which are connected in sequence from a feeding hole in the front end of the screw to a discharging hole. According to the stepped twin-screw extrusion device and the bulking machine, retention time of materials in a chamber of the bulking machine is long, thekneading effect is excellent, the pressure in the chamber is uniform, the product stability is high, discharging uniformity is realized, the product is uniform in material form and excellent in kneading effect, the material curing degree is excellent, and the machine is suitable for producing high-oil low-starch (with starch content of 10% or less) high-grade floating and sinking feed.

Owner:嘉兴润阳机械有限公司

Chinese herbal medicine processing and rubbing device

InactiveCN112932963AEasy to take outRubbing effect is goodPharmaceutical product form changeMedicinal herbsMechanical engineering

The invention relates to a Chinese herbal medicine processing and rubbing device, which comprises a box body and a box cover arranged at an upper end opening of the box body, a rubbing cavity used for containing Chinese herbal medicine is formed in the box body, and a rubbing part used for rubbing the Chinese herbal medicine in the rubbing cavity is arranged at the lower end of the box cover; the rubbing part comprises a rotating rod, a rubbing head in direct contact with medicinal materials is arranged at the lower end of the rotating rod, the rubbing head is composed of at least two rubbing hammers distributed in an array mode, the multiple rubbing hammers are connected through a connecting shaft, and the upper end of the rotating rod penetrates through a penetrating hole formed in the box cover. The upper end of the rotating rod is connected with a lifting handle arranged above the box cover, and a rocker is arranged at the upper end of the lifting handle. The Chinese herbal medicine processing and rubbing device facilitates Chinese herbal medicine rubbing, and is simple in structure and convenient to use.

Owner:XIAN SHIQING MEDICINE TECH CO LTD

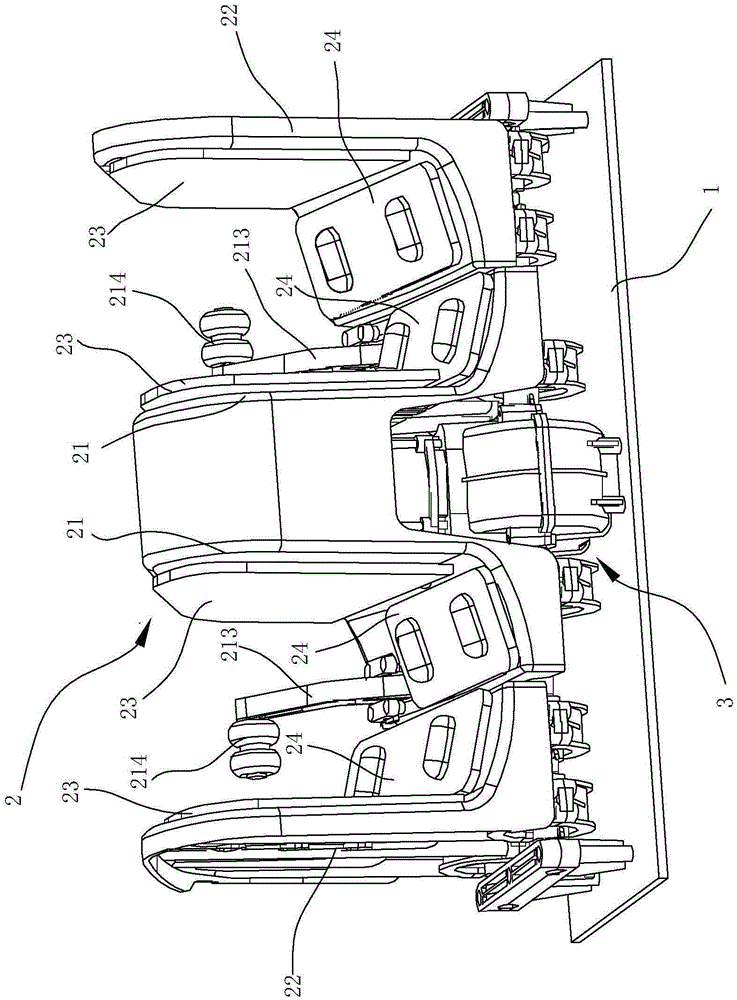

Kneading massager

ActiveCN102940566BShorten the lengthGuaranteed coaxialitySuction-kneading massageDrive shaftCoupling

The invention discloses a kneading massager which comprises a base, a kneading massaging mechanism, a rotary shaft assembly and a power system. The kneading massaging mechanism comprises at least a pair of side bases. The rotary shaft assembly comprises a driving shaft, a driven shaft and a coupler. The driving shaft and the driven shaft are fixedly provided with eccentric parts which are in transmission connection with the side bases to drive the side bases to move in a manner relative to the base. The coupler comprises a main coupling base fixedly connected with the driving shaft and a driven coupling base fixedly connected with the driven shaft. A matching structure is arranged between the main coupling base and the driven coupling base. The matching structure comprises two driving faces opposite to the main coupling base and two driven faces facing the driven coupling base. The two driving faces are located between the two driven faces. The central angles of the two driving faces are smaller than the central angles of the two driven faces. The power system is in transmission connection with the driving shaft, and when the driving shaft rotates forwards and reversely, the first and second eccentric parts are not equal in included angle, so that relative movement between the first and second side bases can be controlled by forward and reverse rotation.

Owner:XIAMEN COMFORT SCIENCE & TECHNOLOGY GROUP CO LTD +1

Preparation method of gloss oil finishing emulsion

InactiveCN113265020AHigh solid contentImprove wear resistanceAntifouling/underwater paintsPaints with biocidesPolymer science(Hydroxyethyl)methacrylate

The invention discloses a preparation method of gloss oil finishing emulsion, and belongs to the technical field of finishing emulsion preparation. The preparation method comprises the following steps: S1, pre-emulsifying, adding the deionized water, a K12 emulsifier and a PCA-039 emulsifier into a pre-emulsification cylinder, stirring and mixing for 15 minutes, sequentially adding styrene, butyl acrylate, hydroxyethyl methylacrylate, acrylic acid, acrylamide and DBP plasticizer, emulsifying and stirring for 30 minutes to obtain a pre-emulsion for later use. The gloss oil finishing emulsion provided in the invention is relatively high in solid content, compared with the prior art, the gloss oil finishing emulsion has the advantages of higher wear resistance, better set-off prevention effect, clear appearance of a wet film for a long time, no yellowing in long-time use, favorable water resistance, favorable scrubbing resistance and favorable market prospects.

Owner:广东金万联防水材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com