Microfiber leather processing machine with automatic feeding, drying and tanning functions

A technology of automatic feeding and microfiber leather, which is applied in the direction of textiles and papermaking, can solve the problems of personal hazards, affecting processing quality, and low processing efficiency, and achieve good and fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

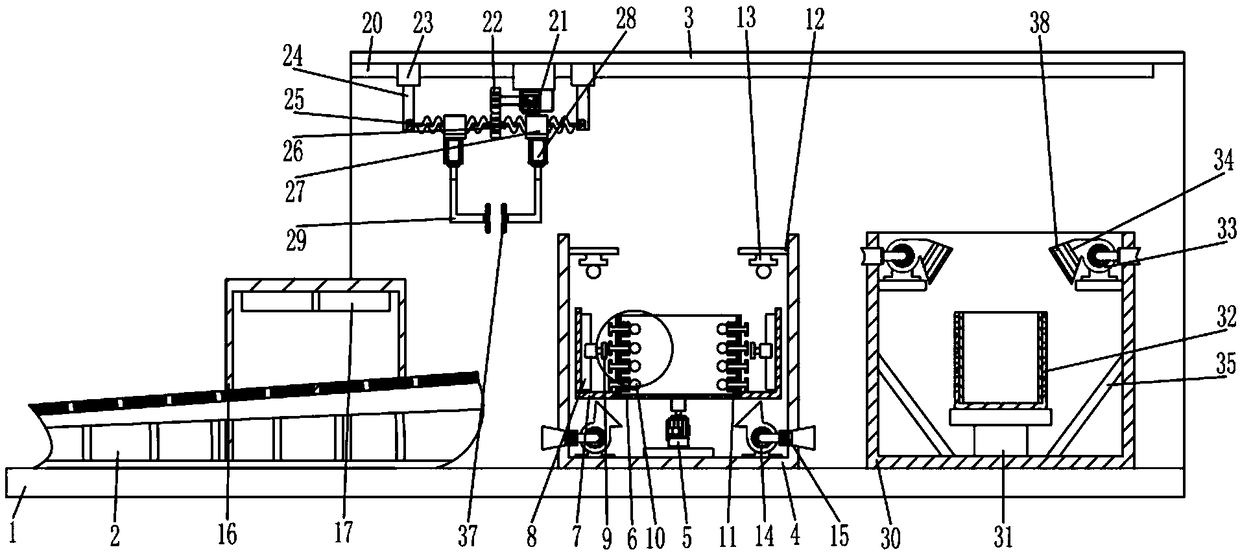

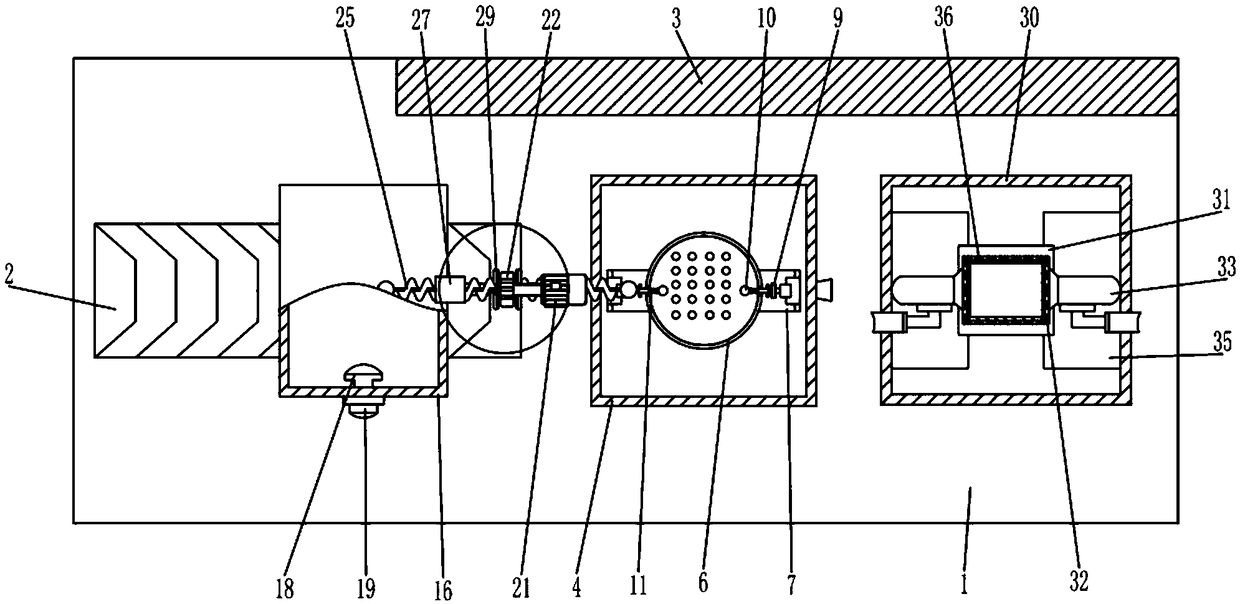

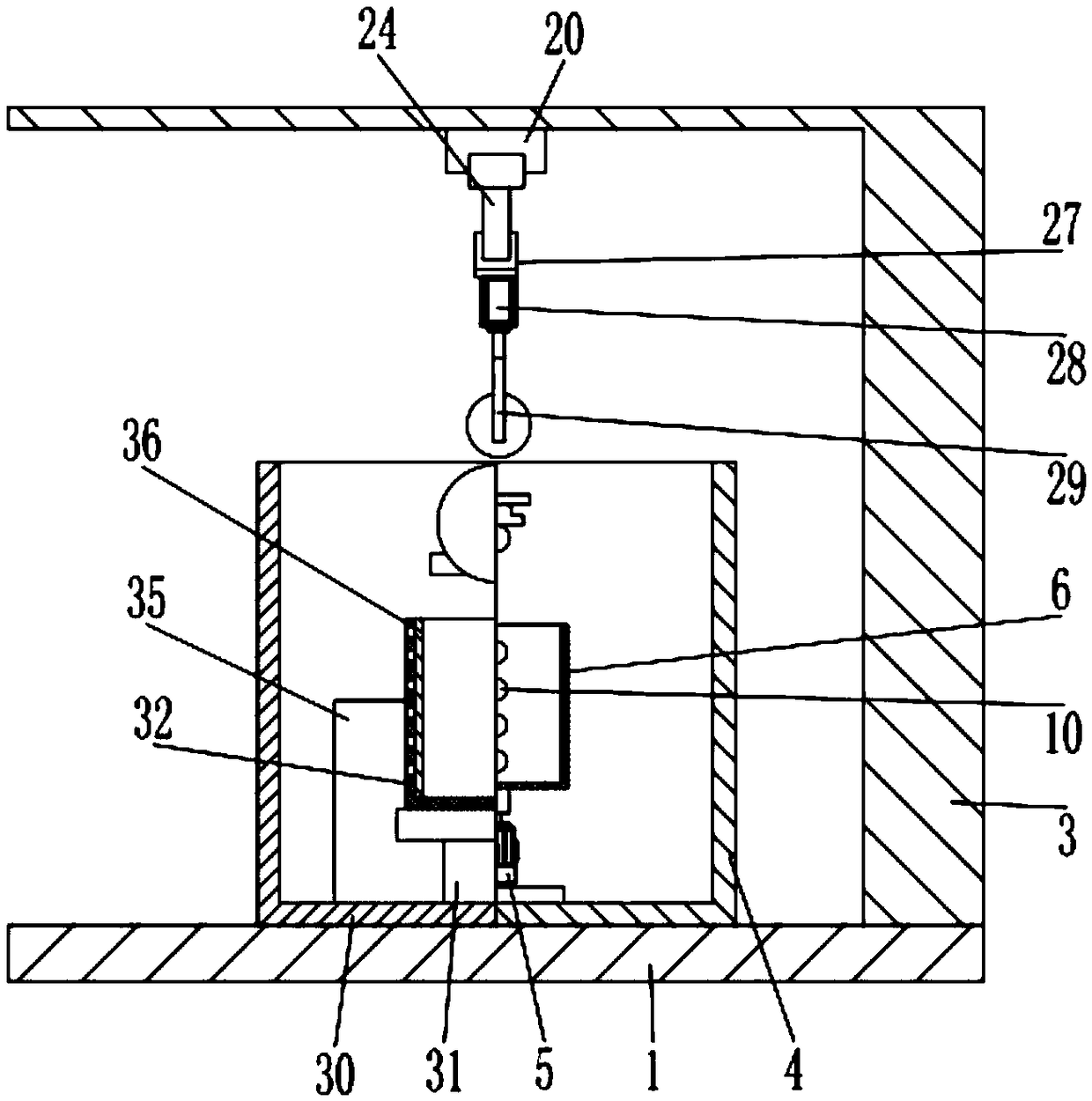

[0031] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5As shown, a microfiber leather processing machine with automatic feeding, drying and kneading function includes a loading plate 1, a conveyor belt 2 and a mounting frame 3, the conveyor belt 2 is placed on the upper wall of the loading plate 1, and the mounting frame 3 is placed On the upper wall surface of the bearing plate 1 and above the conveyor belt 2, a drying unit is installed on the upper wall surface of the bearing plate 1 and located on one side of the conveyor belt 2, and a kneading unit is installed on the upper wall surface of the bearing plate 1 and located on one side of the drying unit, A cooling unit is installed on the upper wall of the bearing plate 1 and is located at one side of the kneading unit; the kneading unit includes: an actuator and a heating mechanism; the actuator includes: a kneading chamber 4, a first servo Motor 5, kneading cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com