Control method for reciprocating piston type washing machine and washing machine

The technology of a reciprocating piston and a control method is applied to the control device of a washing machine, other washing machines, washing devices, etc., which can solve the problems that the reciprocating piston washing machine cannot well realize the stroke control of the piston, and achieve good washing effect, less damage, and Good squeezing and kneading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

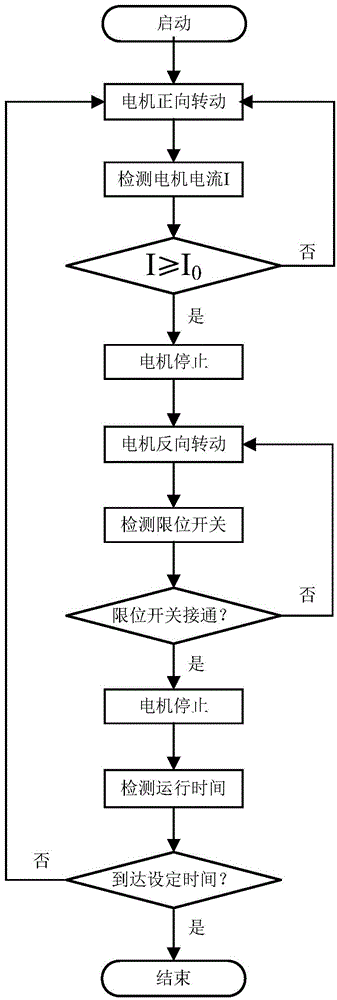

[0078] Such as figure 1 As shown, in the control method of a reciprocating piston washing machine of the present invention, the detection unit includes a current detection unit for detecting the motor current and a limit switch for detecting whether it has reached the lower limit position. Specifically, it includes the following steps: (1) Start the washing machine;

[0079] (2) The motor rotates forward;

[0080] (3) The detection unit detects the motor current I;

[0081] (4) Judging whether the detected motor current I satisfies: I≥I 0 ; If satisfied, the motor stops; if not satisfied, repeat steps (2) to (3);

[0082] (5) The motor rotates in reverse;

[0083] (6) Detection limit switch;

[0084](7) Determine whether the limit switch is on: if it is on, the motor will stop; if it is not on, repeat steps (5) to (6);

[0085] (8) Detect running time;

[0086] (9) Determine whether the running time reaches the set time; if it reaches the set time, end the washing progra...

Embodiment 2

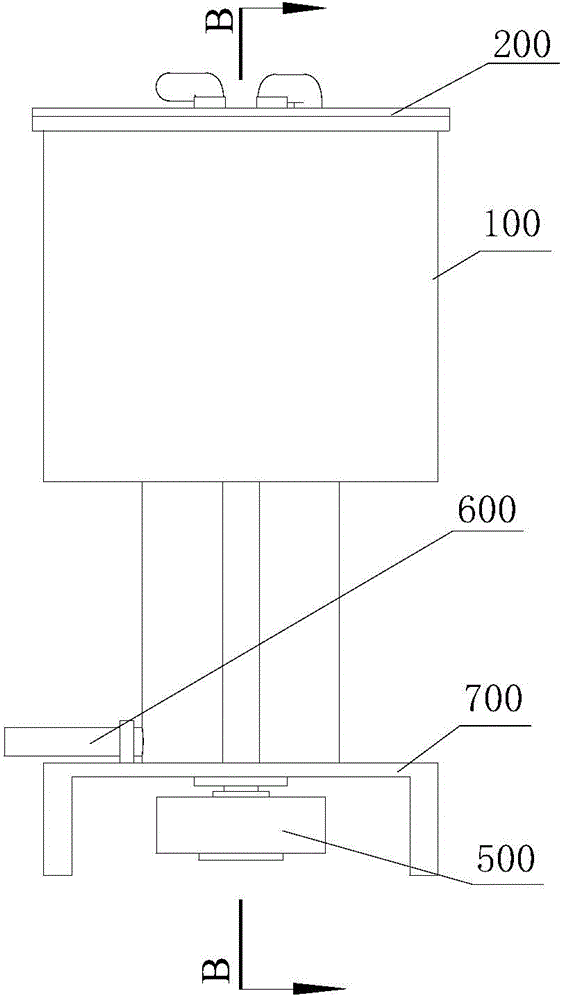

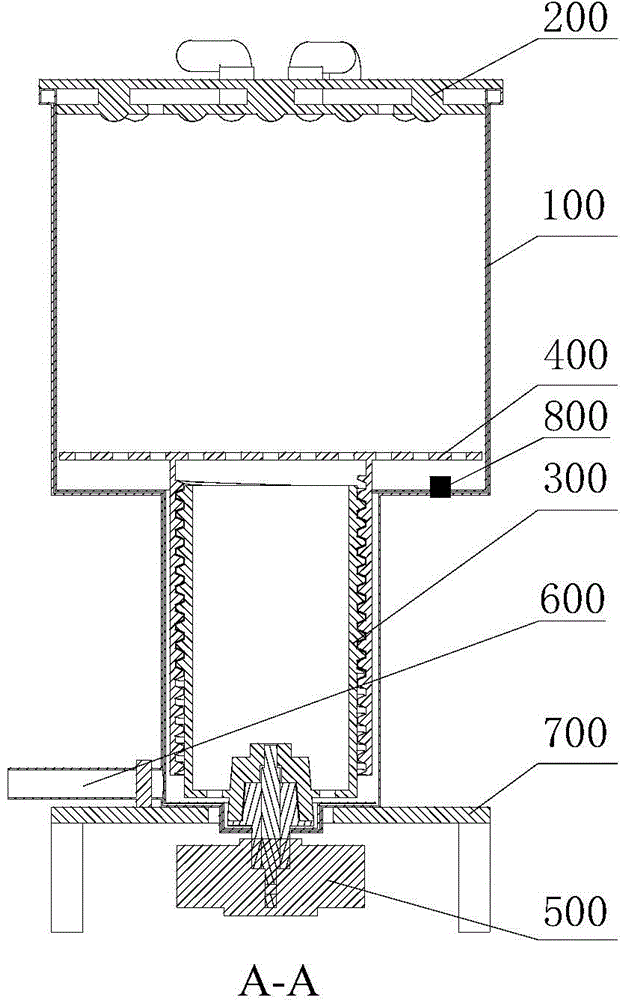

[0088] Such as figure 2 and image 3 As shown, a reciprocating piston washing machine using the method of the present invention includes a washing tub 100, an upper cover 200, a transmission mechanism 300, a piston 400 and a driving device 500, and the upper cover 200 can be opened / closed and connected to the washing tub On the opening of 100, the transmission mechanism 300 and the piston (400) are arranged inside the washing tub 100; the washing tub 100 includes upper and lower parts, and the upper part of the washing tub 100 is used for holding / washing clothes, and the washing tub The lower part of 100 is provided with a transmission mechanism 300, the input end of the transmission mechanism 300 is connected to the driving device 500, the transmission mechanism 300 and the piston 400 are screw driven, and the driving device 500 drives the piston 400 to reciprocate up and down in the washing tub 100 through the transmission mechanism 300 .

[0089] The washing machine of t...

Embodiment 3

[0091] Such as Figure 4 and Figure 5 As shown, a reciprocating piston washing machine using the method of the present invention includes a washing tub 100, an upper cover 200, a transmission mechanism 300, a piston 400 and a driving device 500, and the upper cover 200 can be opened / closed and connected to the washing tub On the opening of 100, the transmission mechanism 300 and the piston 400 are arranged inside the washing tub 100; the washing tub 100 includes upper and lower parts, the upper part of the washing tub 100 is used for holding / washing clothes, and the washing tub 100 The transmission mechanism 300 is arranged in the lower part, the input end of the transmission mechanism 300 is connected with the driving device 500, the transmission mechanism 300 and the piston 400 are driven by a rack and pinion, and the driving device 500 drives the piston 400 to reciprocate up and down in the washing tub 100 through the transmission mechanism 300 .

[0092] The washing mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com