Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Reduced tipping moment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

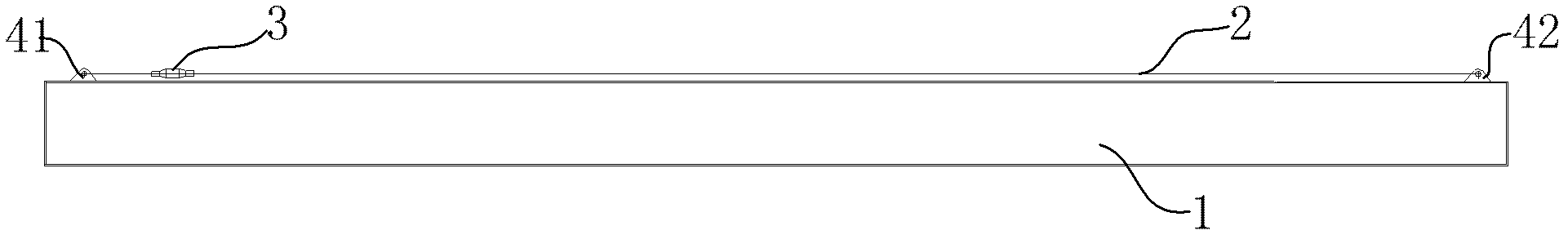

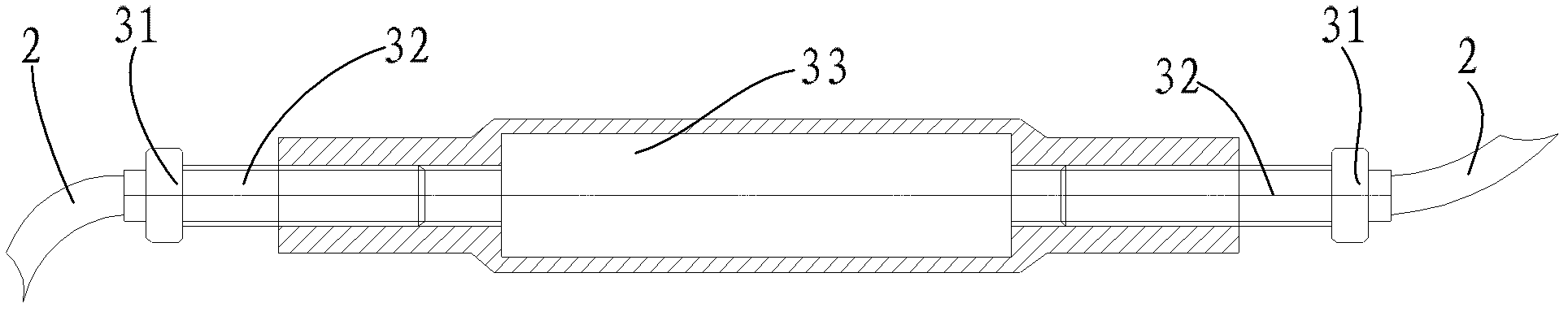

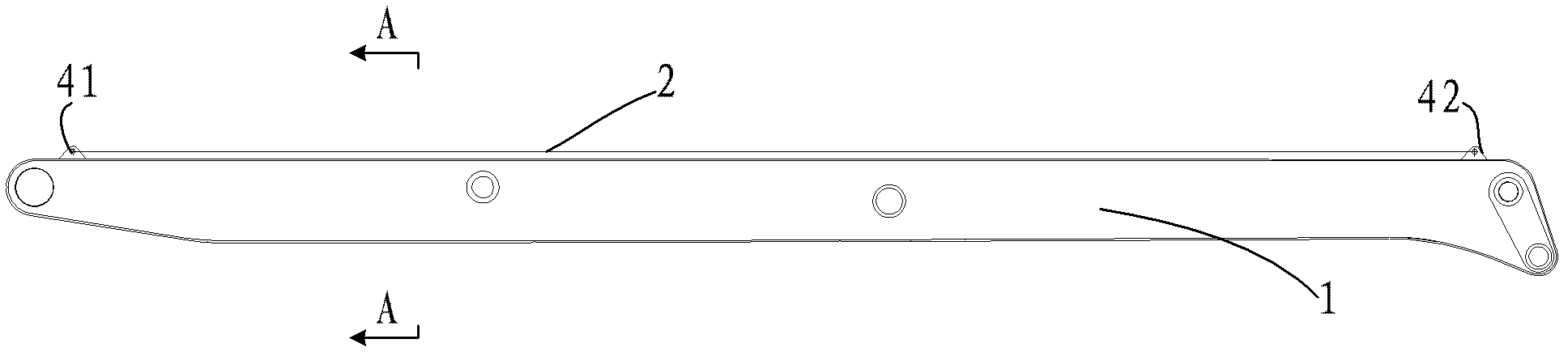

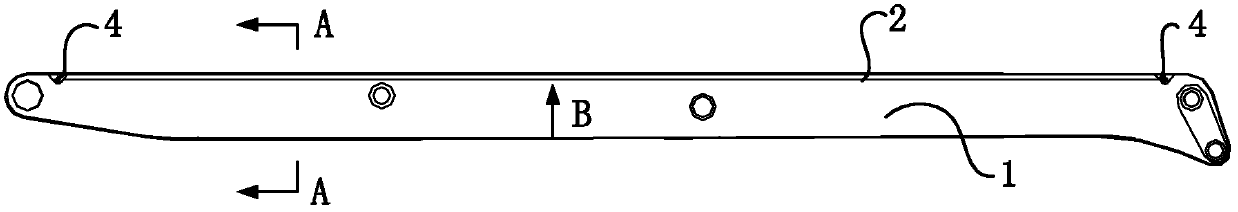

Tensile beam, arm support and pump truck

The invention provides a tensile beam comprising a beam body and at least one stay cable arranged on the beam body, wherein the stay cable is arranged on the tensioned surface of the beam body along the axial direction of the beam body and is provided with a pre-tightening force. The invention also provides an arm support and a pump truck comprising the arm support, wherein the arm support comprises at least one arm segment manufactured by adopting the tensile beam. Through the technical scheme of the invention, the tension born by the beam body can be increased; on the premise that the length and the loading capacity of the arm support can be guaranteed, the thickness of plates of the arm support can be decreased; therefore, the flexibility of motions of the arm support is improved, the manufacturing material is decreased, and the manufacturing difficulty is reduced.

Owner:SANY HEAVY IND CO LTD (CN)

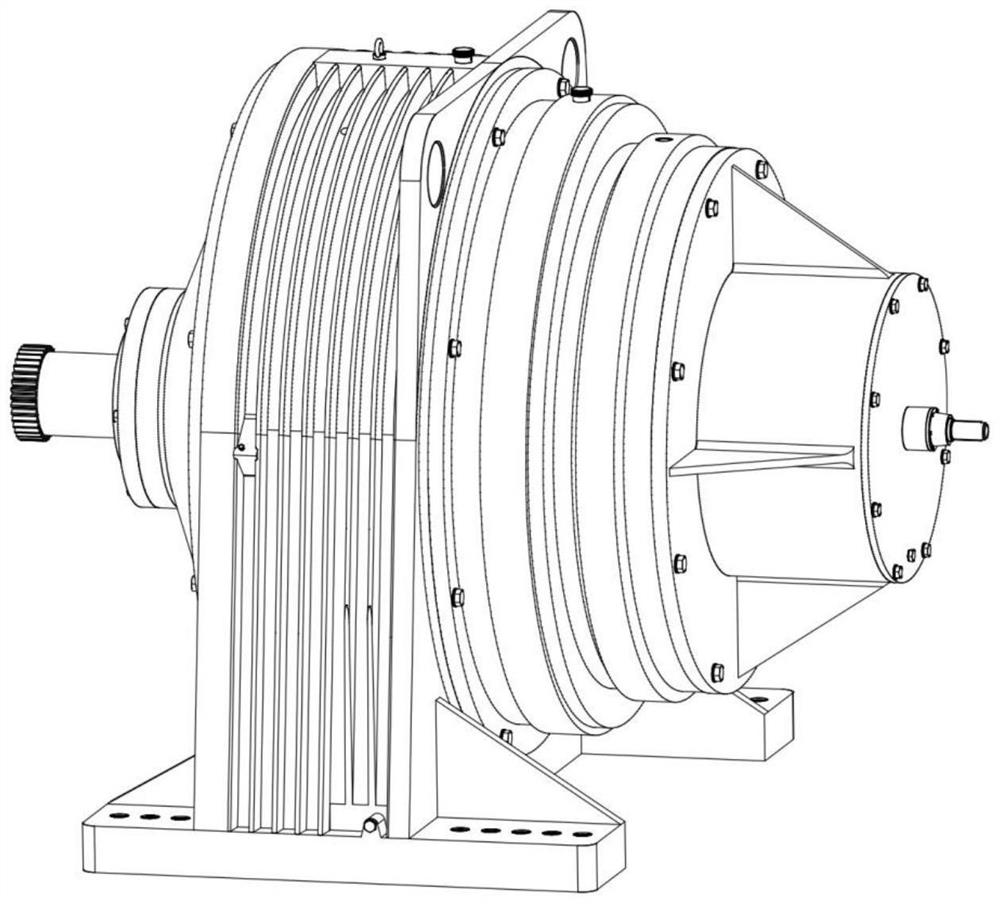

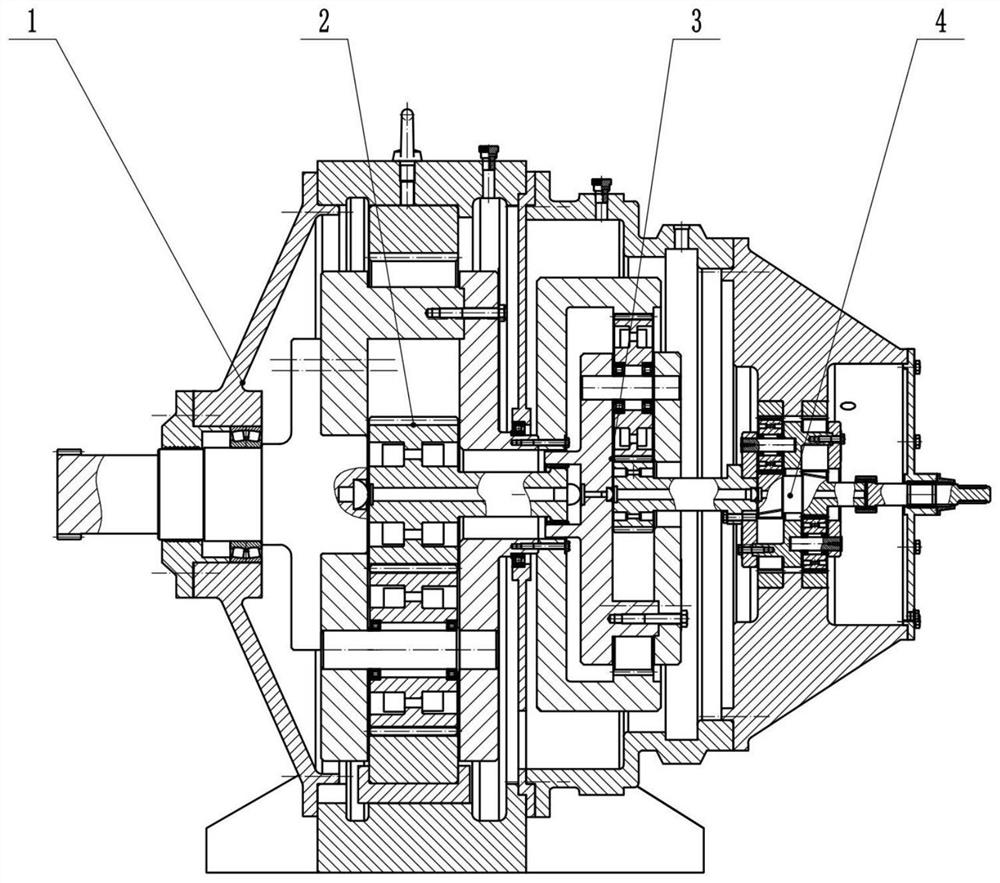

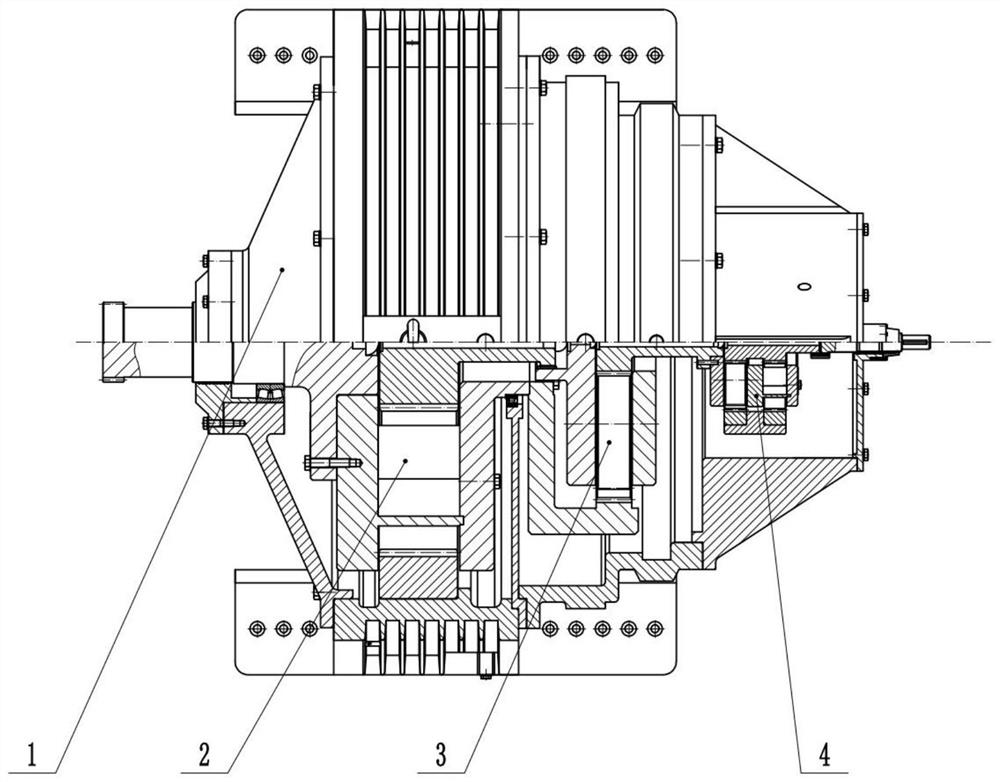

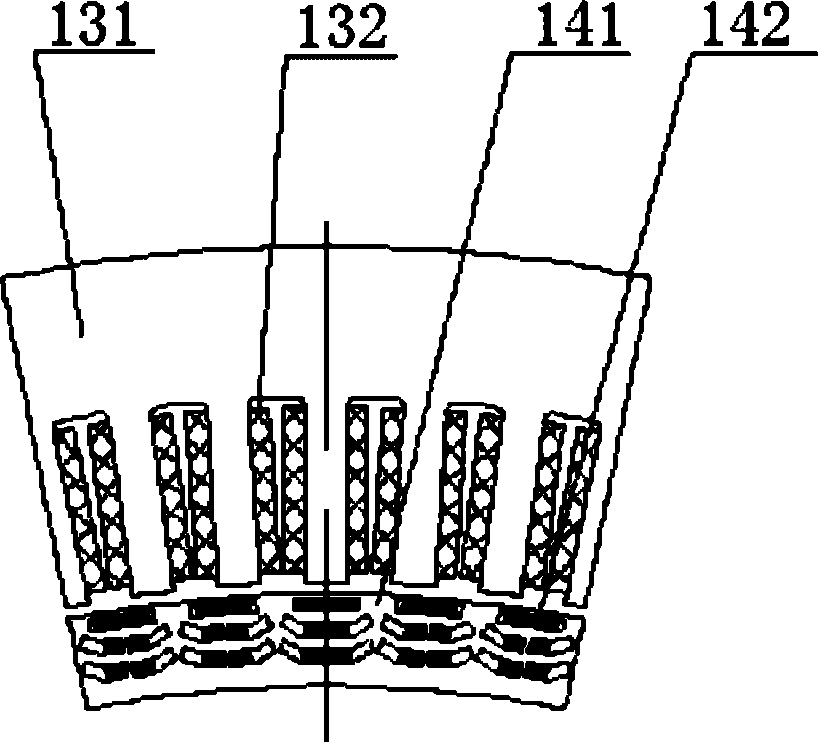

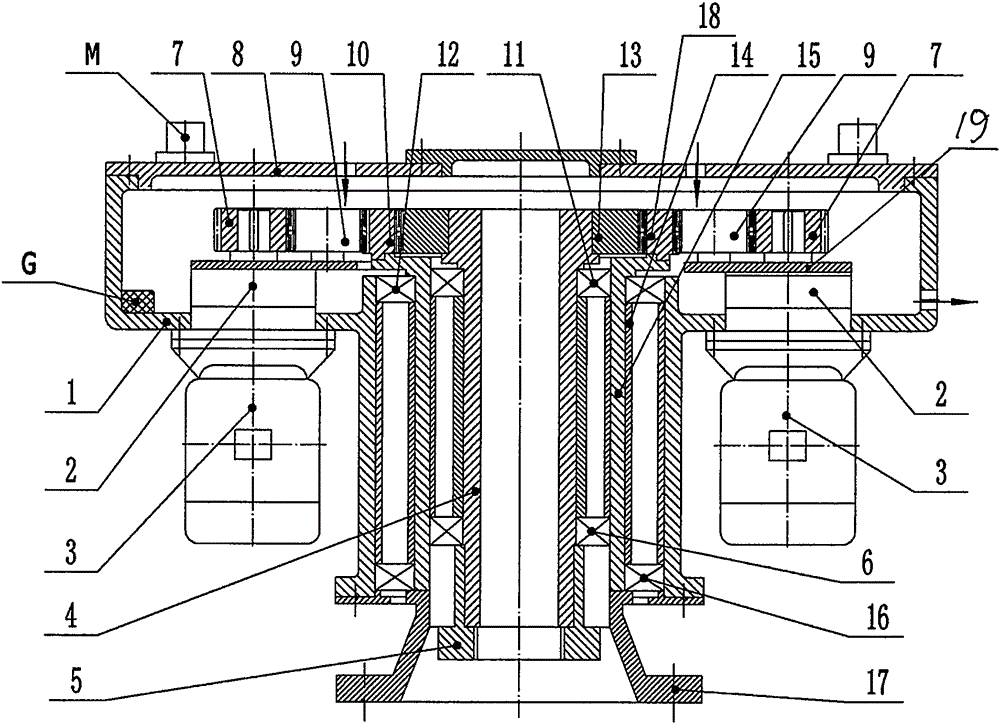

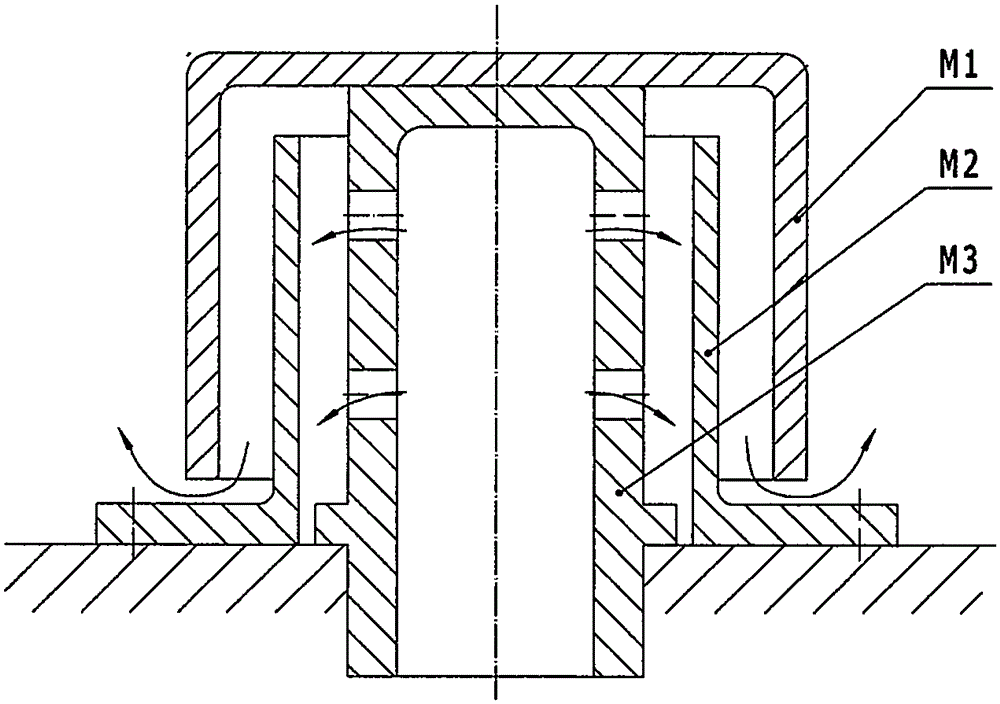

Double-air-gap hybrid excitation direct drive switched reluctance wind power generator and unit system thereof

InactiveCN103023243AReduce vibrationReduce noiseMagnetic circuit rotating partsWind motor combinationsControl systemPower factor

The invention relates to a double-air-gap hybrid excitation direct drive switched reluctance wind power generator and a unit system thereof. The power generator comprises a main bearing, an inner stator, an outer stator and a rotor, wherein the inner stator uses a centering bearing for centering. The unit system comprises a vane hub, a power converter, a direct current battery, an inverter and load, a control system, an auxiliary power supply and the wind power generator. The vane hub is connected with the main bearing of the double-air-gap hybrid excitation switched reluctance wind power generator, a rotary disc of the rotor and the rotor, the double-air-gap hybrid excitation switched reluctance wind power generator is connected with the power converter, the direct current battery is connected among the power converter, the inverter and the load in parallel, and the direct current battery, the power converter and the auxiliary power supply are connected with the control system respectively. Motor power density is improved greatly, effective material utilization rata and motor power factors are improved greatly, and weight, cost, vibration and noise of the motor are reduced greatly.

Owner:GUODIAN UNITED POWER TECH

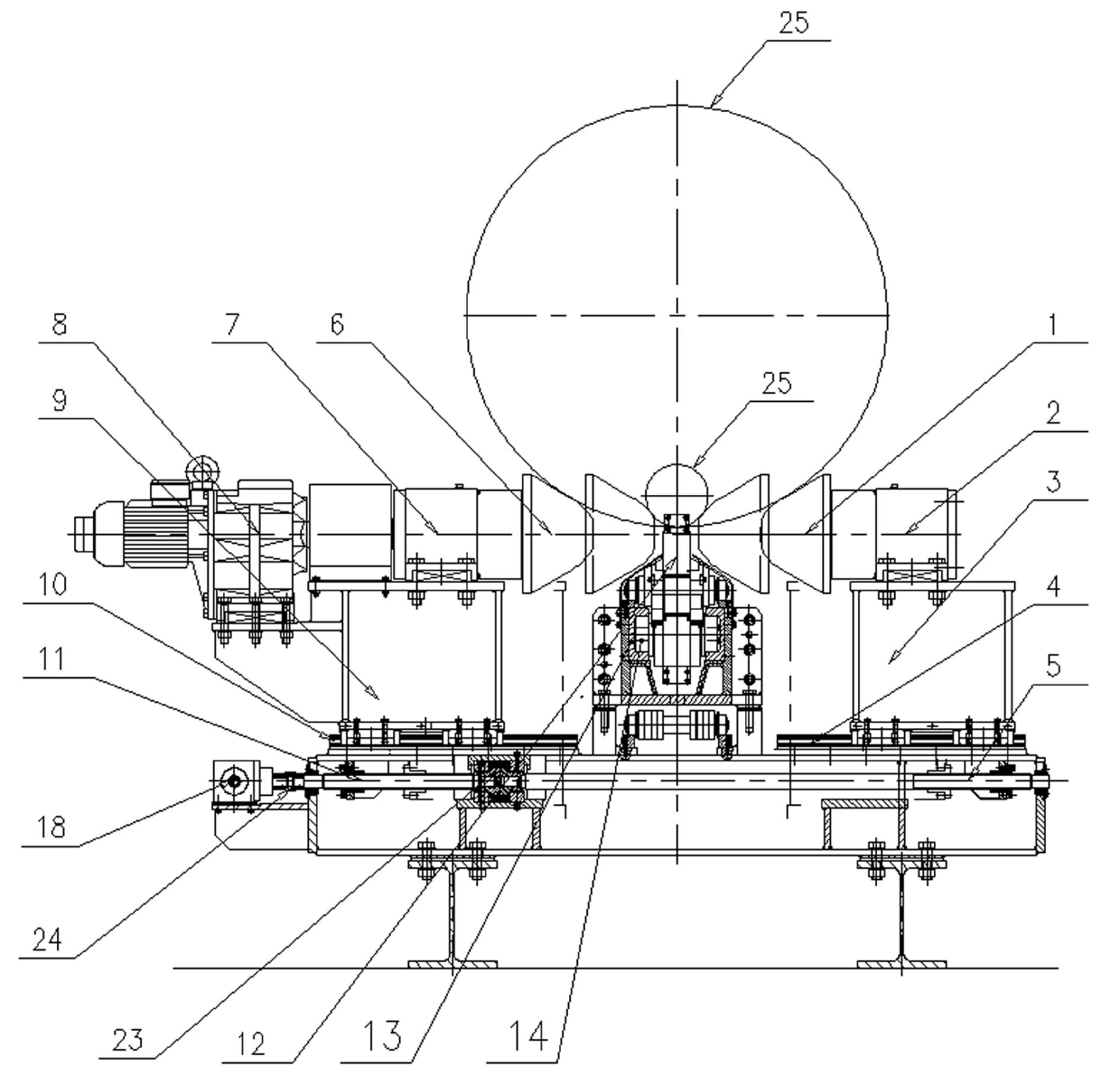

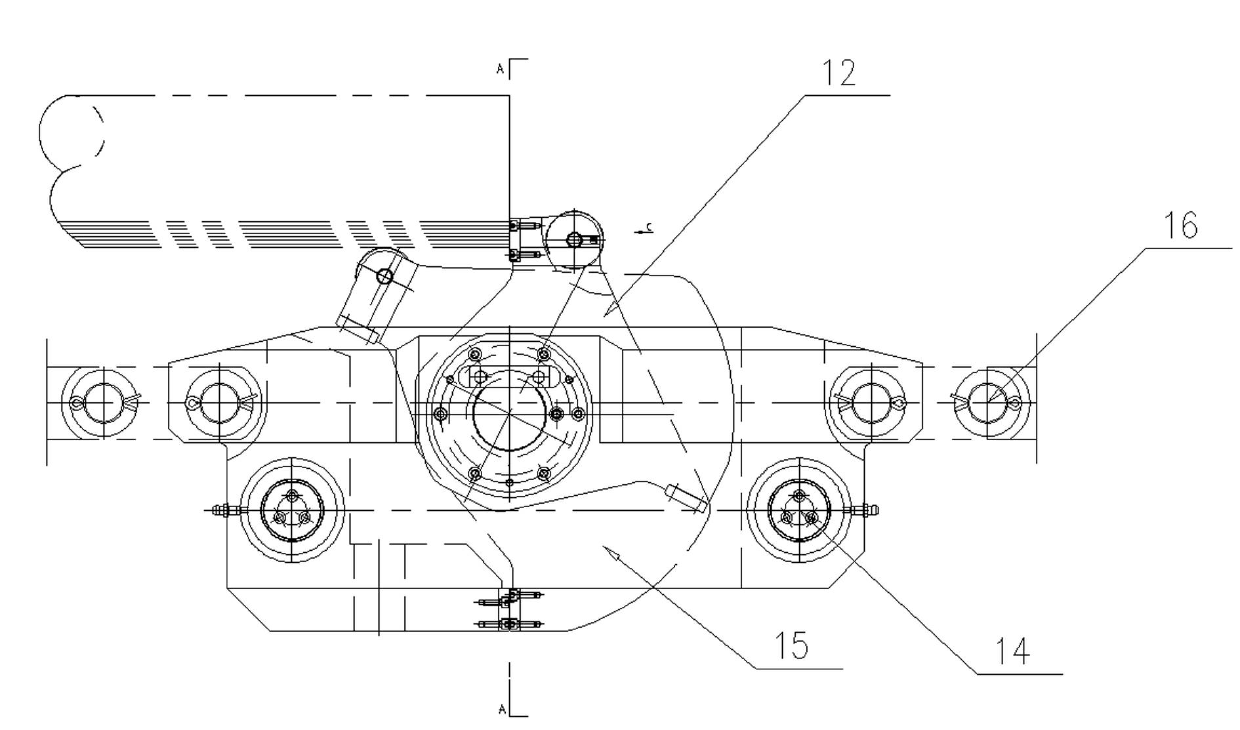

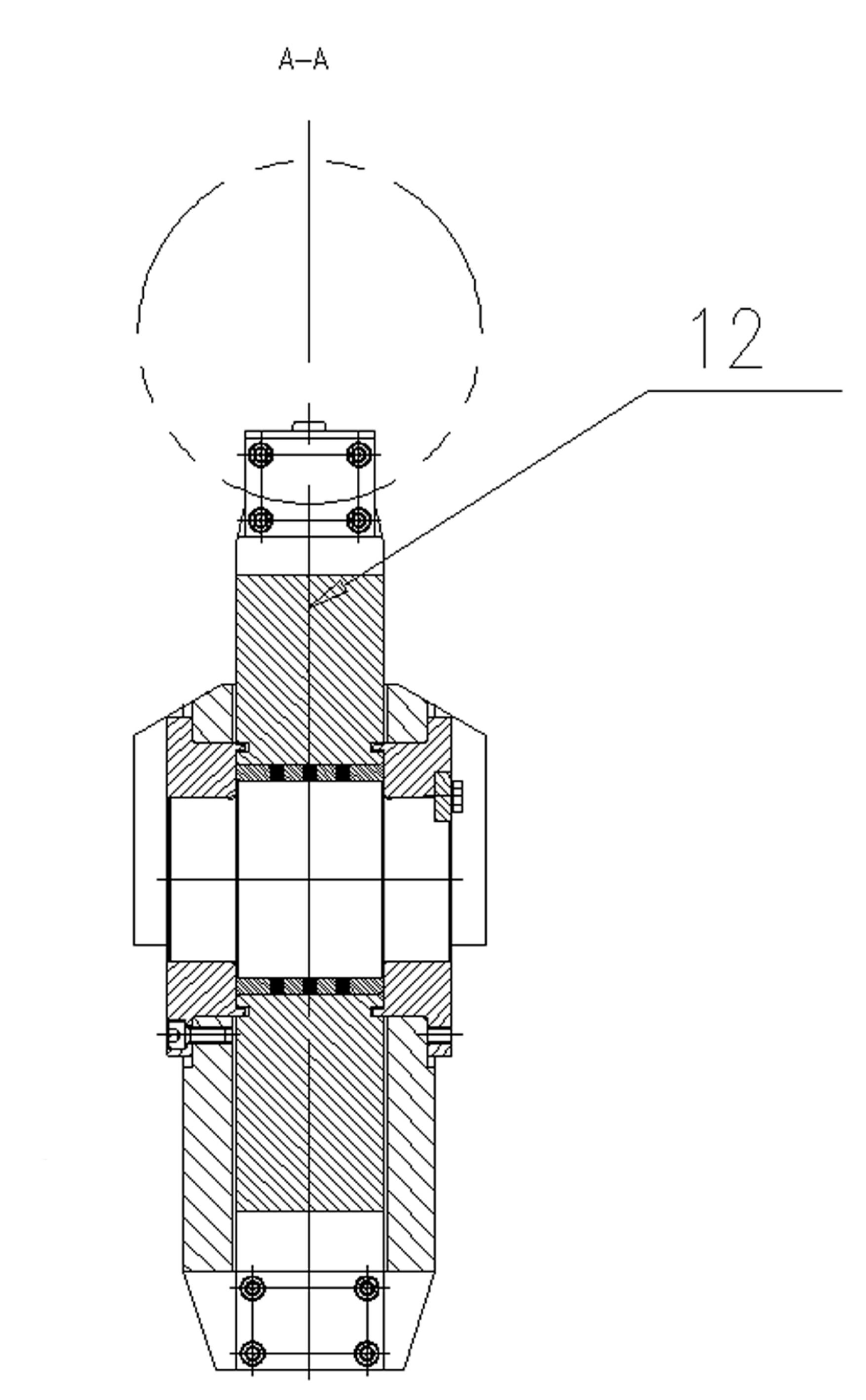

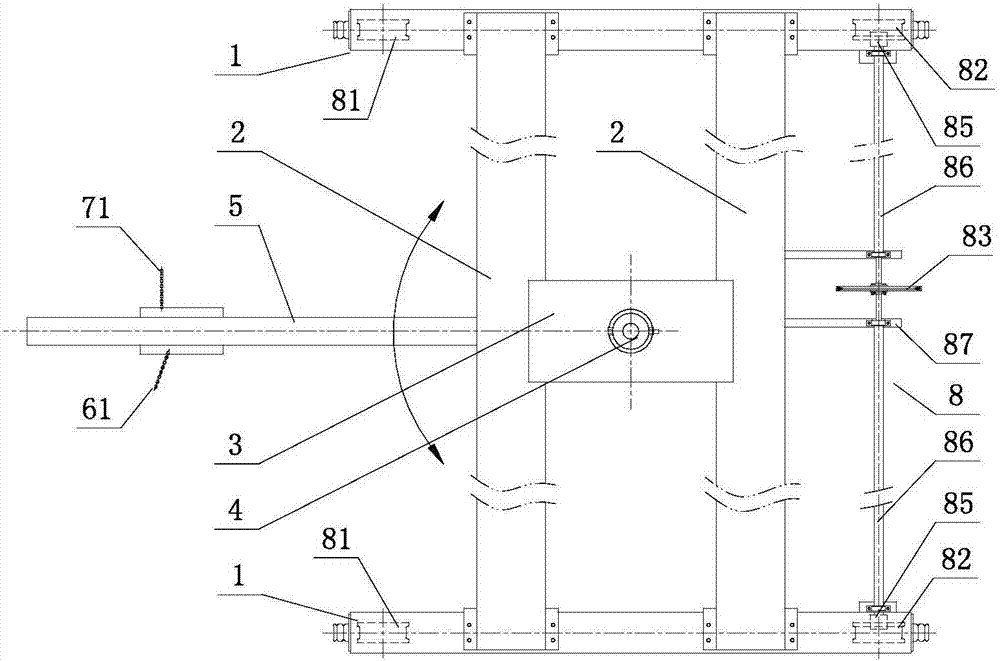

Heavy rail scaling apparatus and method

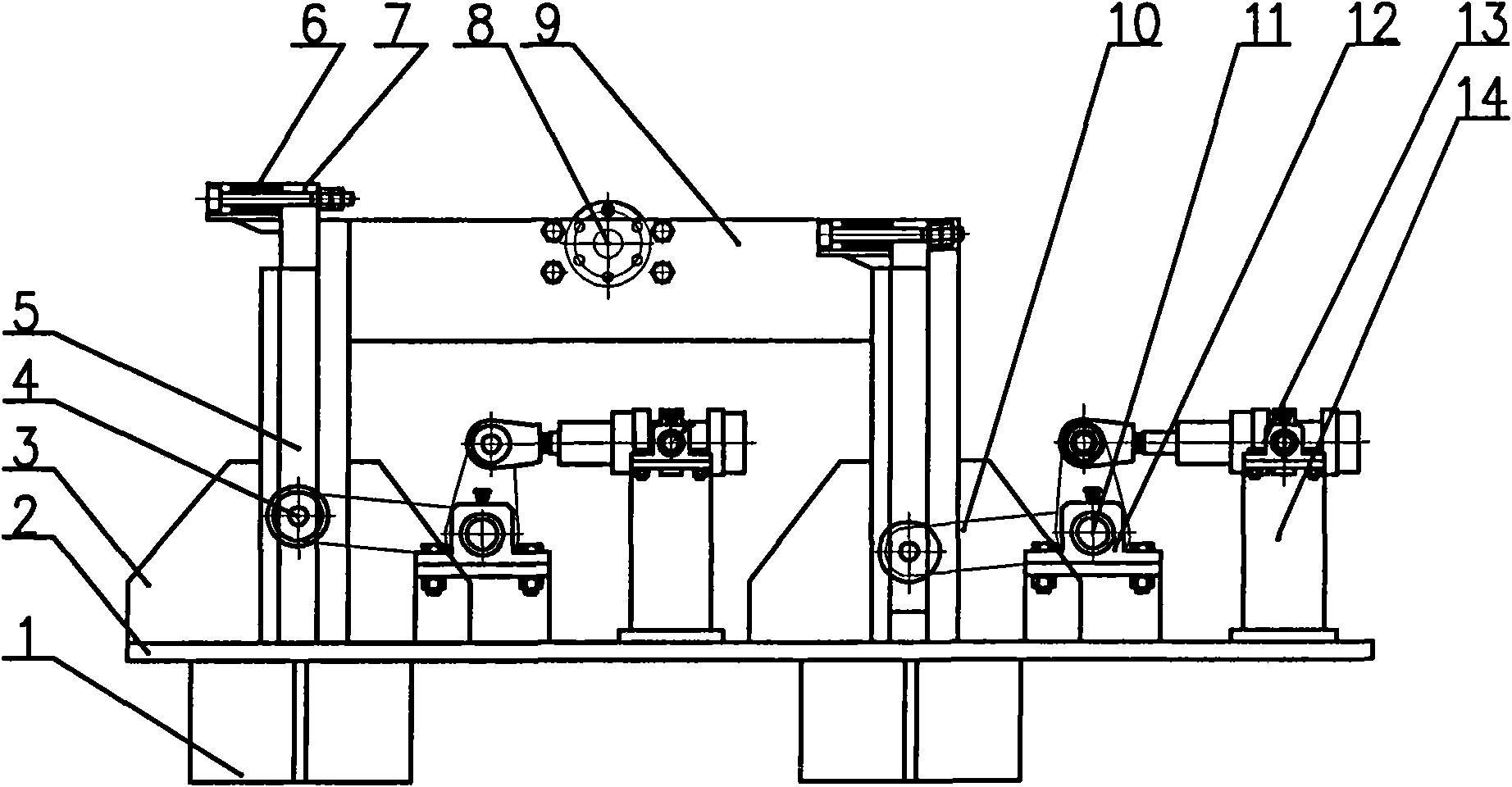

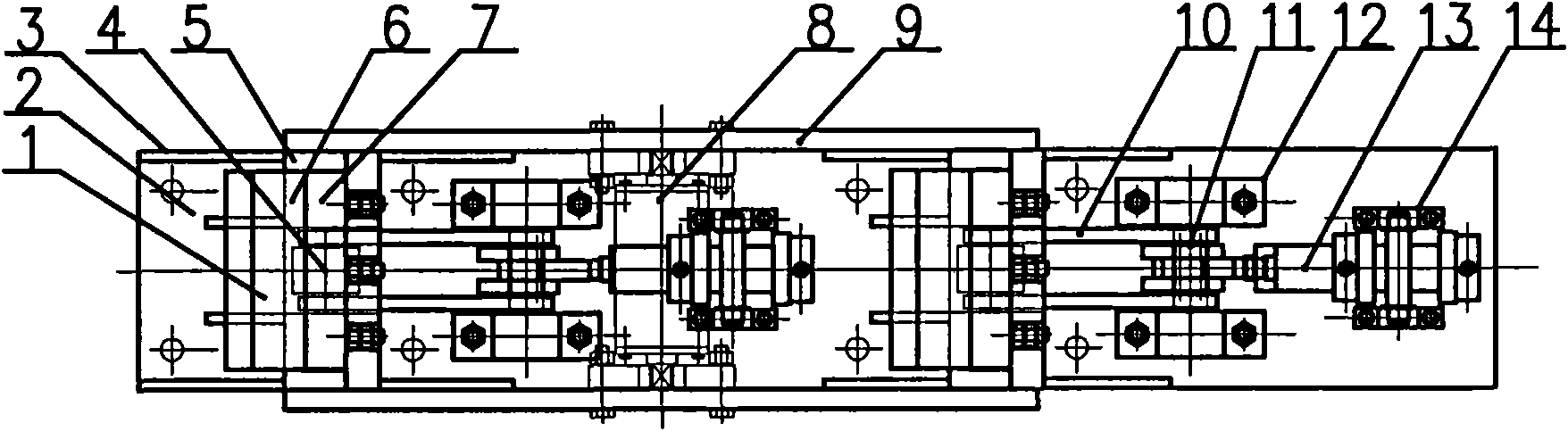

ActiveCN102039537AExtended service lifeAvoid damageMetal working apparatusPositioning apparatusEngineeringTransmission system

The present invention provides a heavy rail scaling apparatus and a method therefor. The apparatus is a single-set or double-set mechanical scaling apparatus comprising a striking head elevating system, a transmission system, a frame and a detection switch. According to the invention, an electrohydraulic push rod is taken as power source to drive a swing rod to swing, a top wheel arranged at the front of the swing rod is employed to control the rise and fall of a lifter plate to allow the striking head arranged at the top end of the lifter plate to be located at either a working position or as top position and cooperate with a scaling saw to realize accurate scaling of the heavy rail. By employing a front detection switch and a damping and thickness-adjusting striking head having a polyurethane bumper pad and an adjusting gasket unit, impact to the striking head can be reduced while the speed of a frequency-changing roller-way is controlled, the service life of the scaling apparatus can be prolonged, the precision of heavy rail scaling can be improved, and the tolerance of the length of the heavy rail is kept between +4mm and -4mm. The apparatus has a simple structure and is easy to operate and convenient to maintain. The method is reasonable, and enables stable system running process, high operation rate, and low accident rate. In addition, the apparatus can increase the yield of heavy rail. The present invention is particularly suitable to be used for the scaling of 95, 96, 99,100 meter heavy rails.

Owner:ANGANG STEEL CO LTD

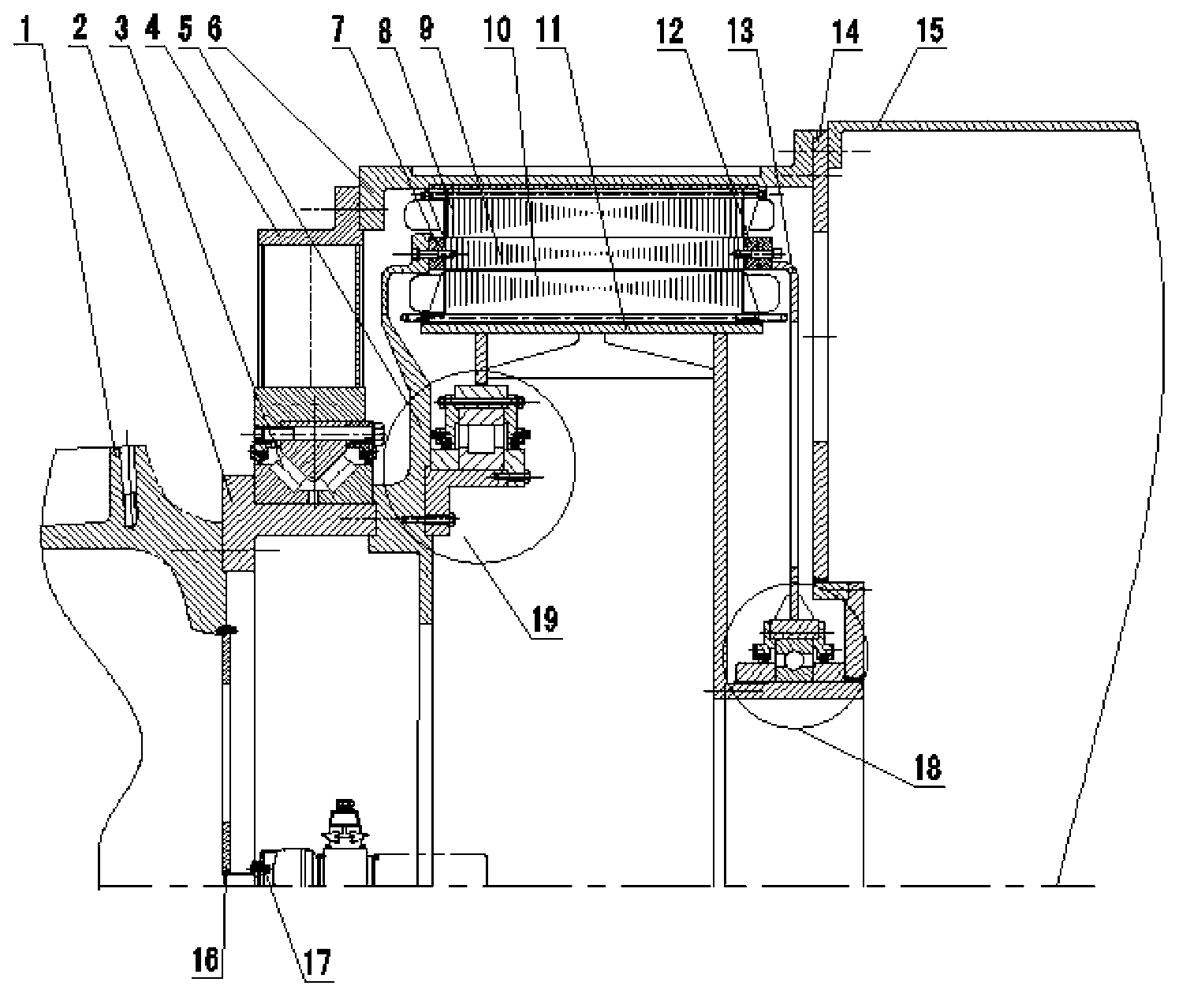

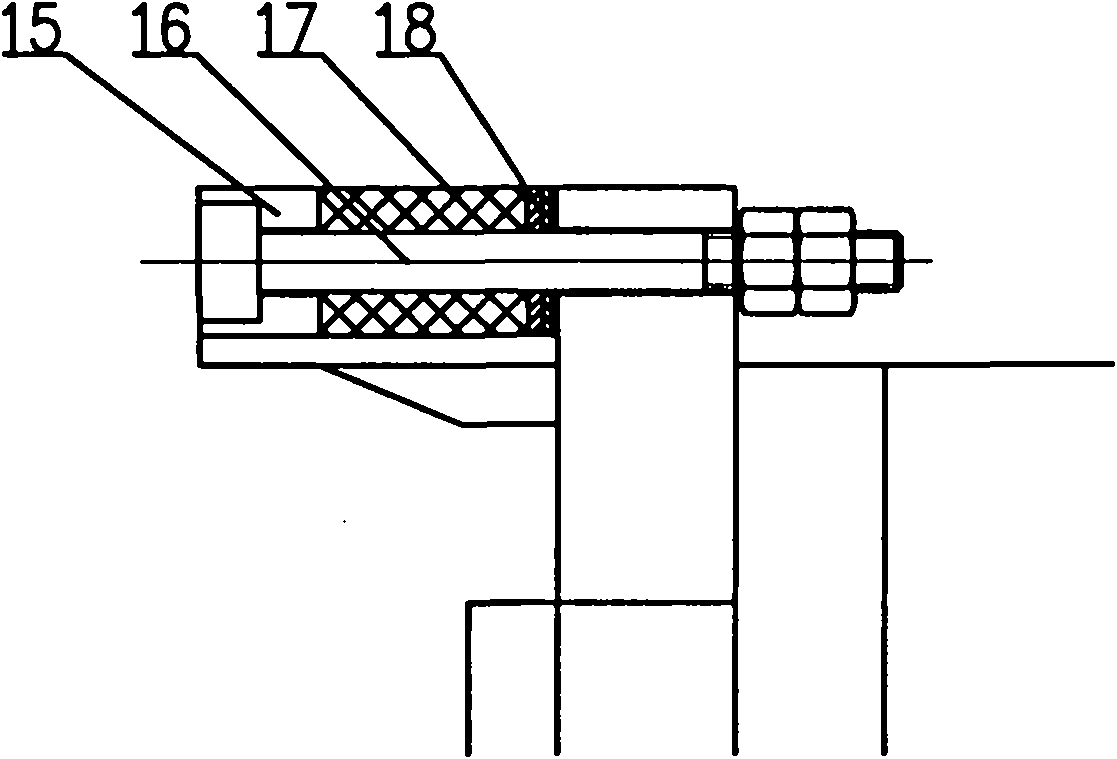

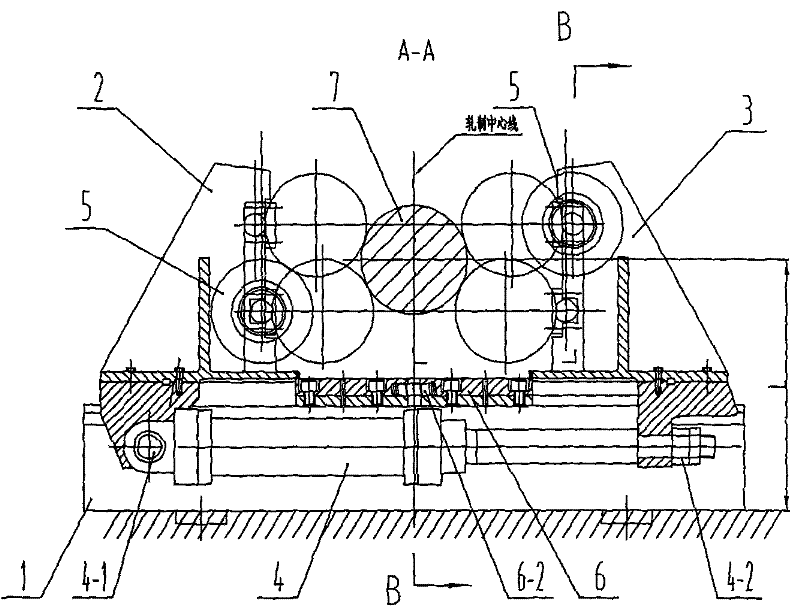

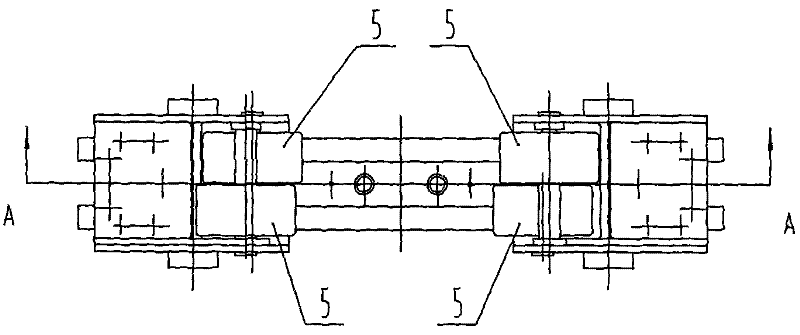

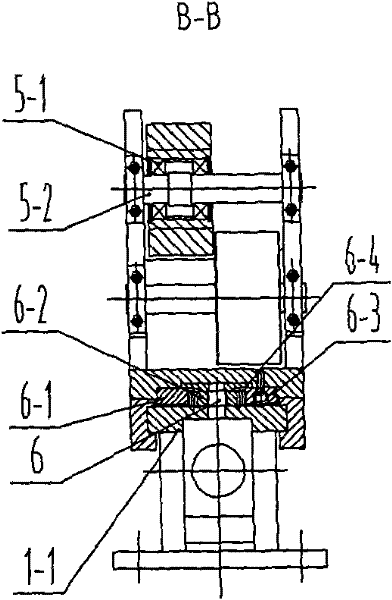

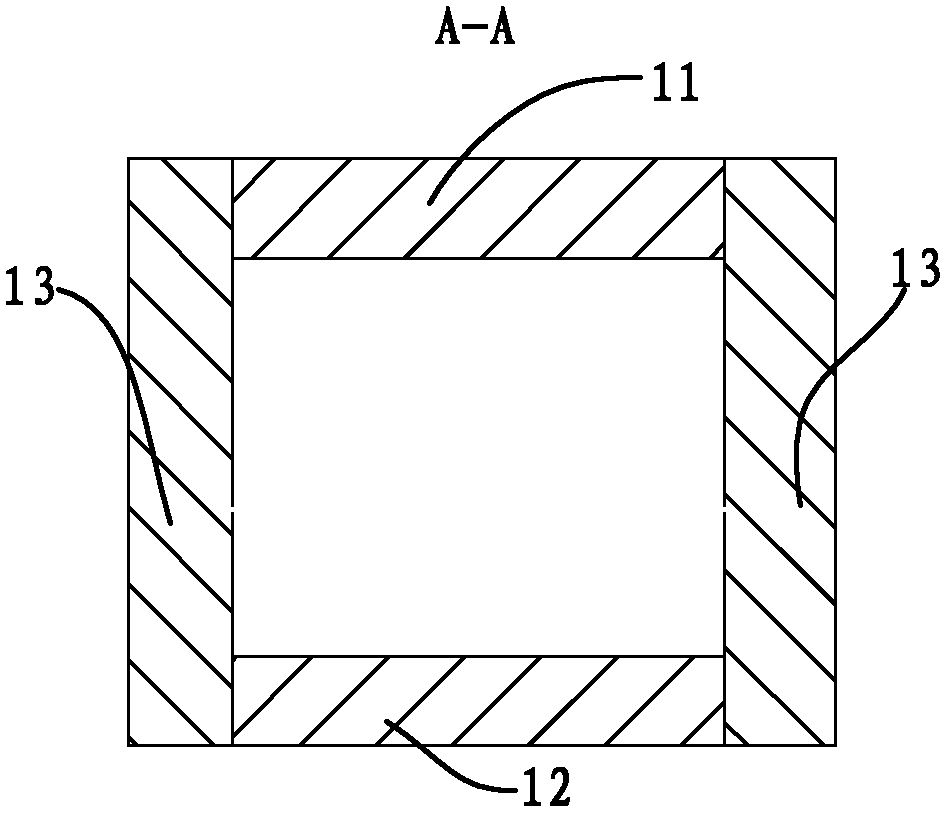

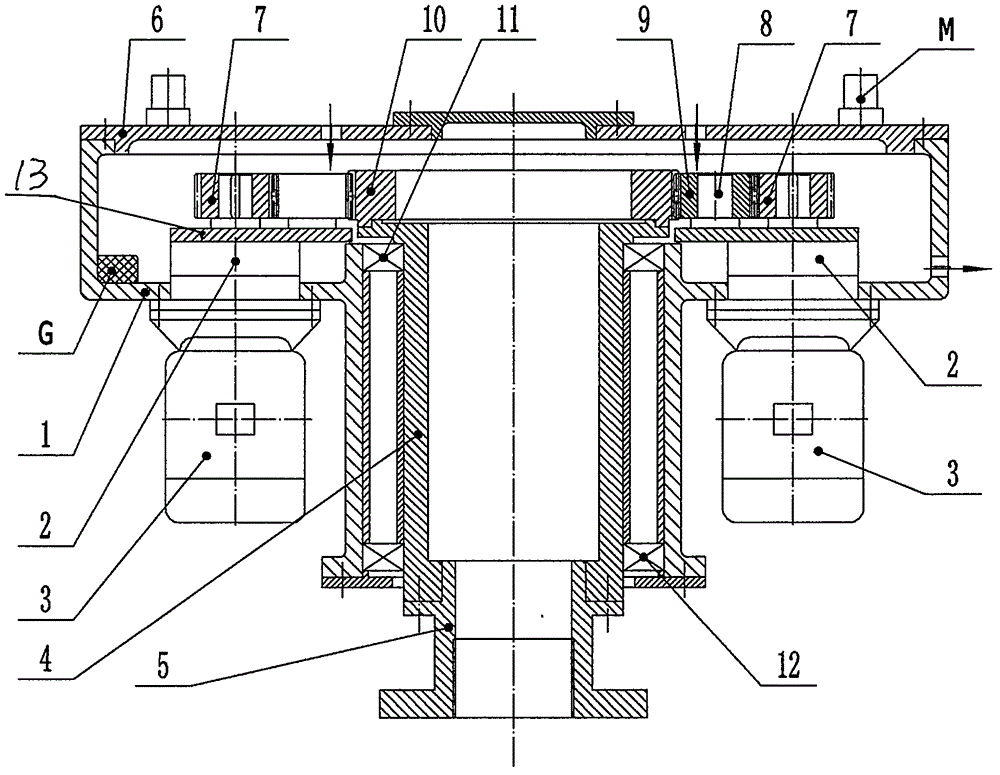

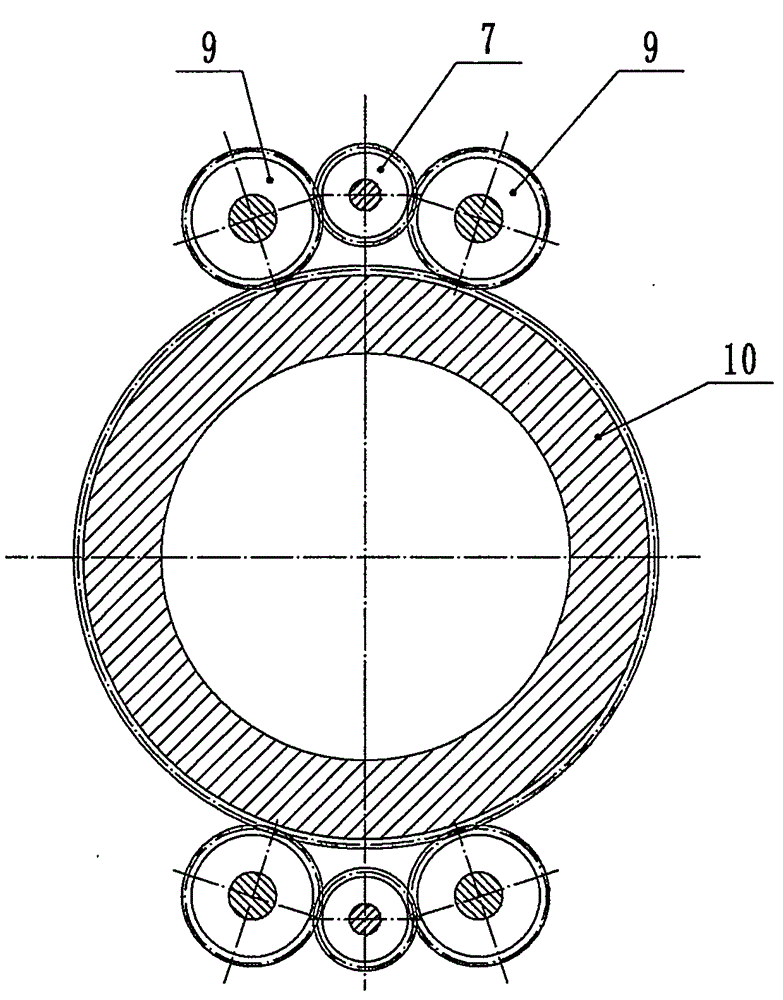

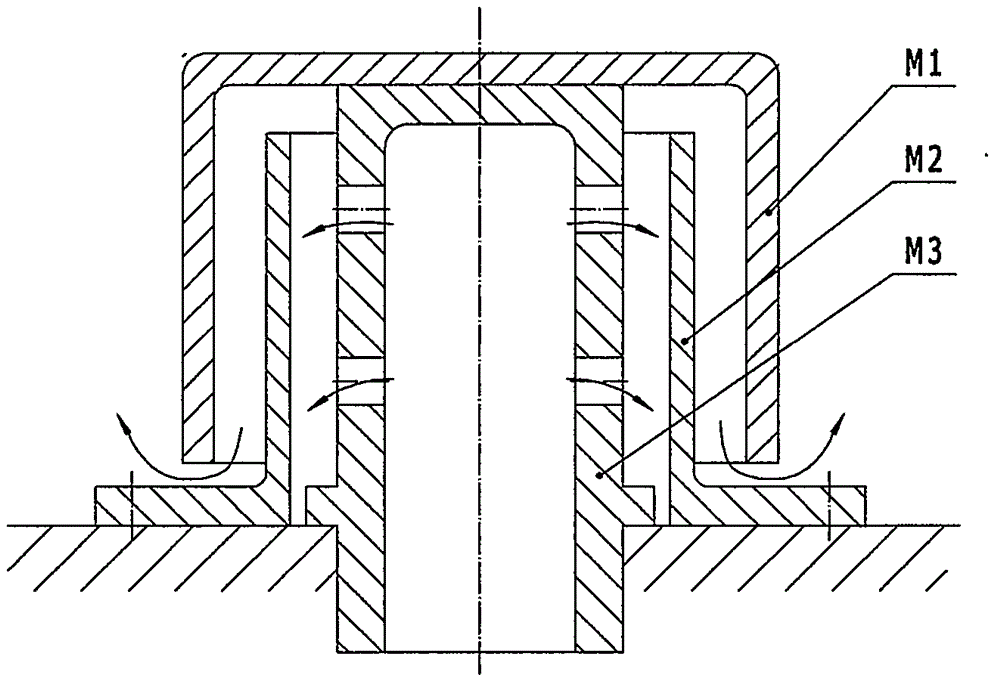

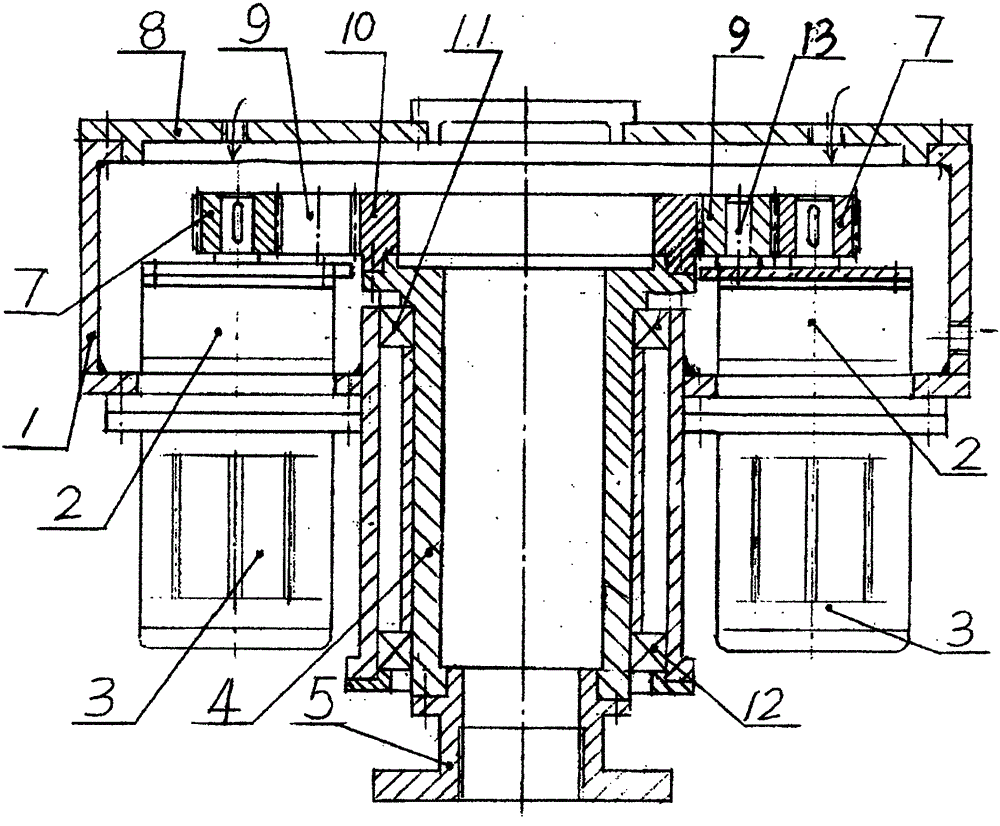

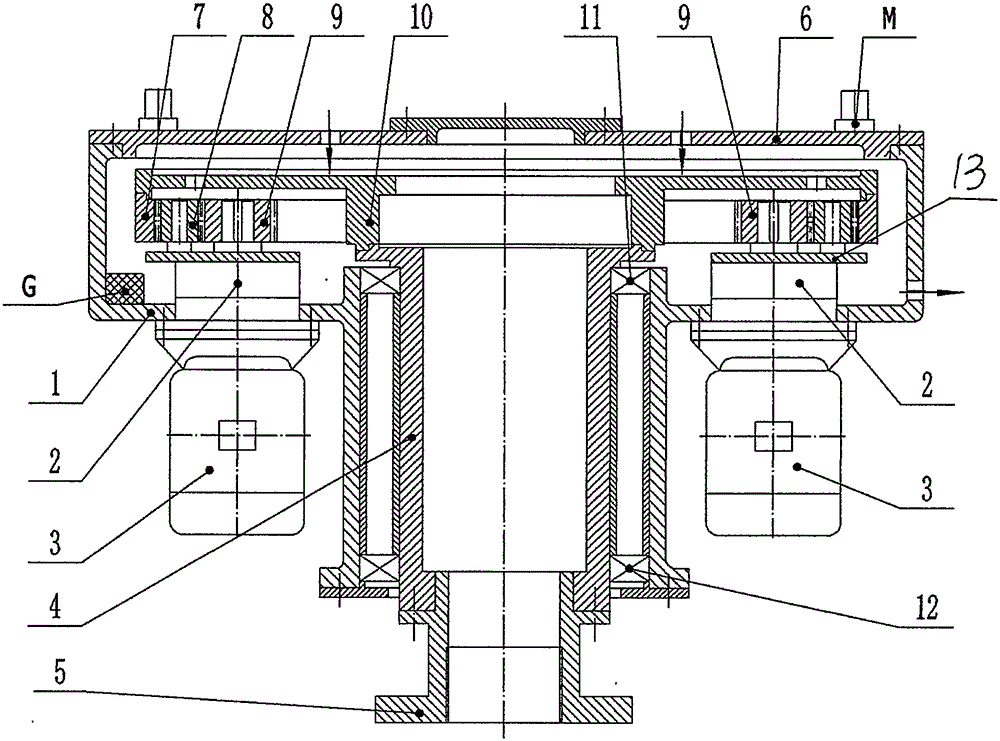

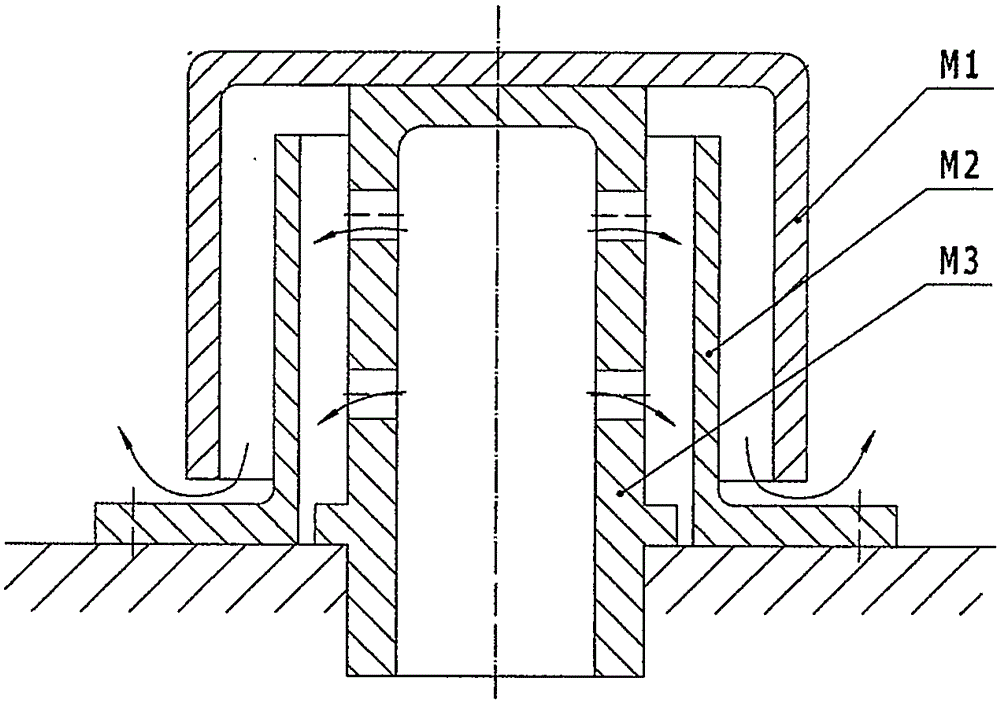

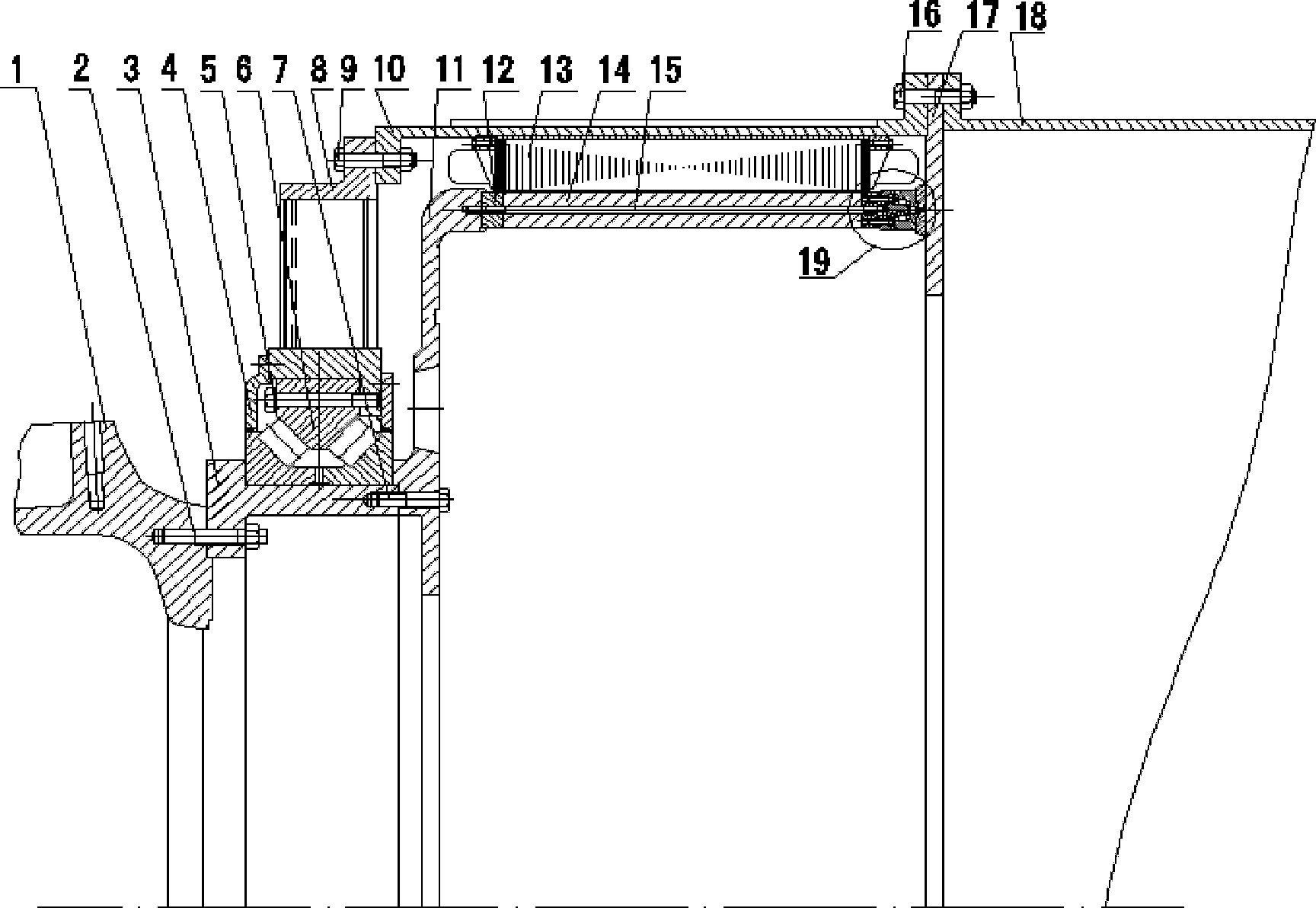

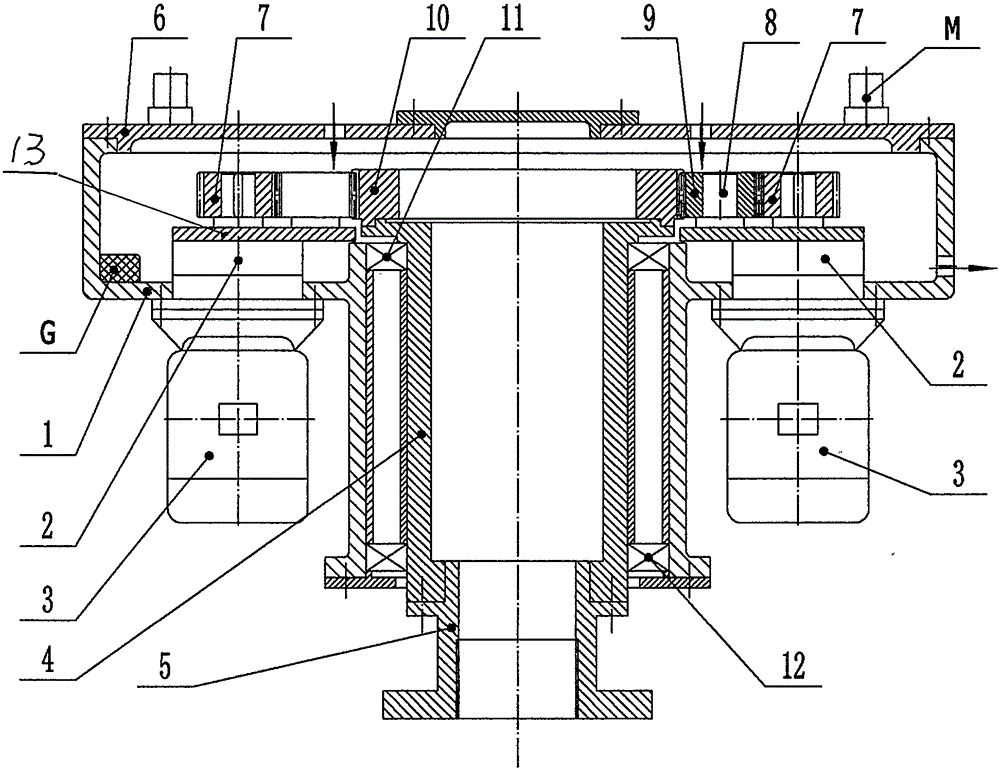

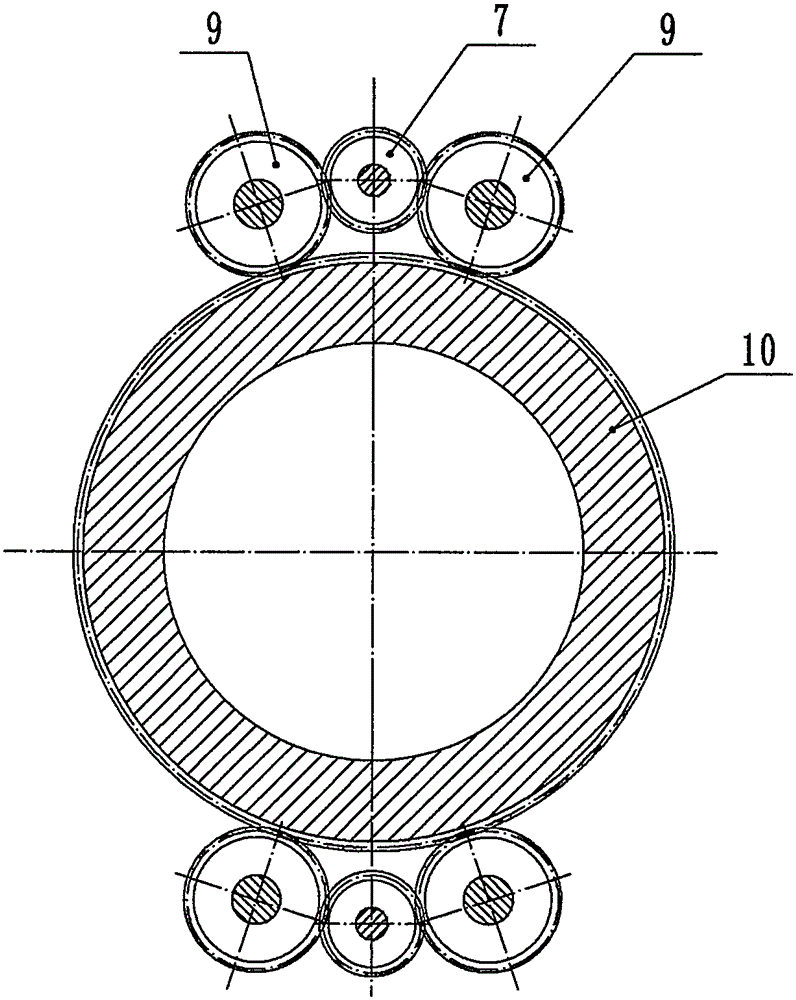

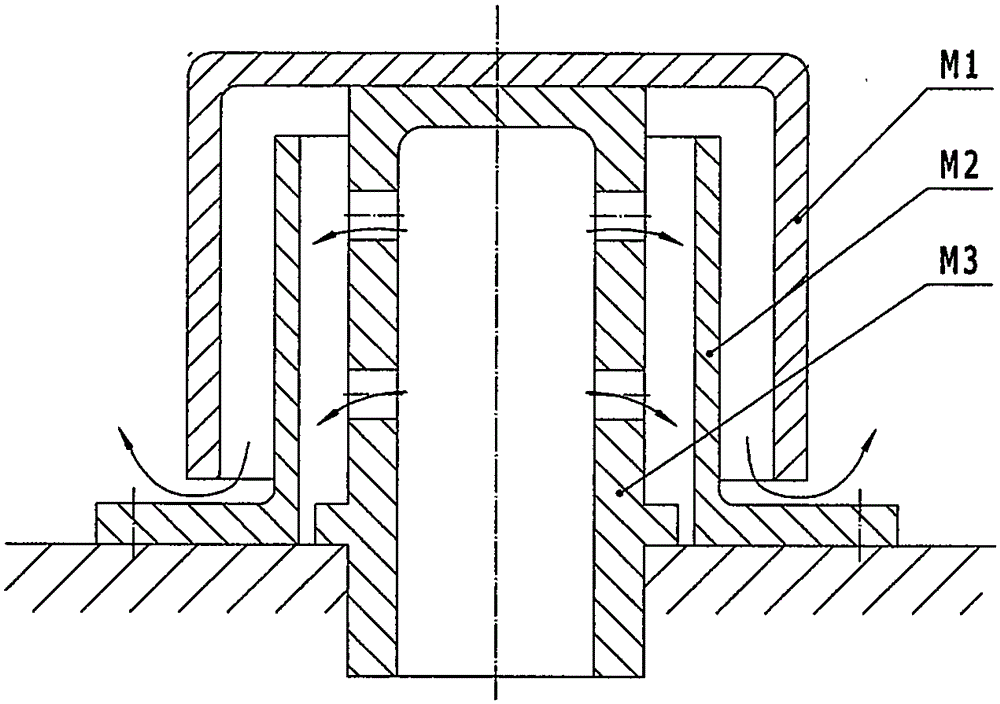

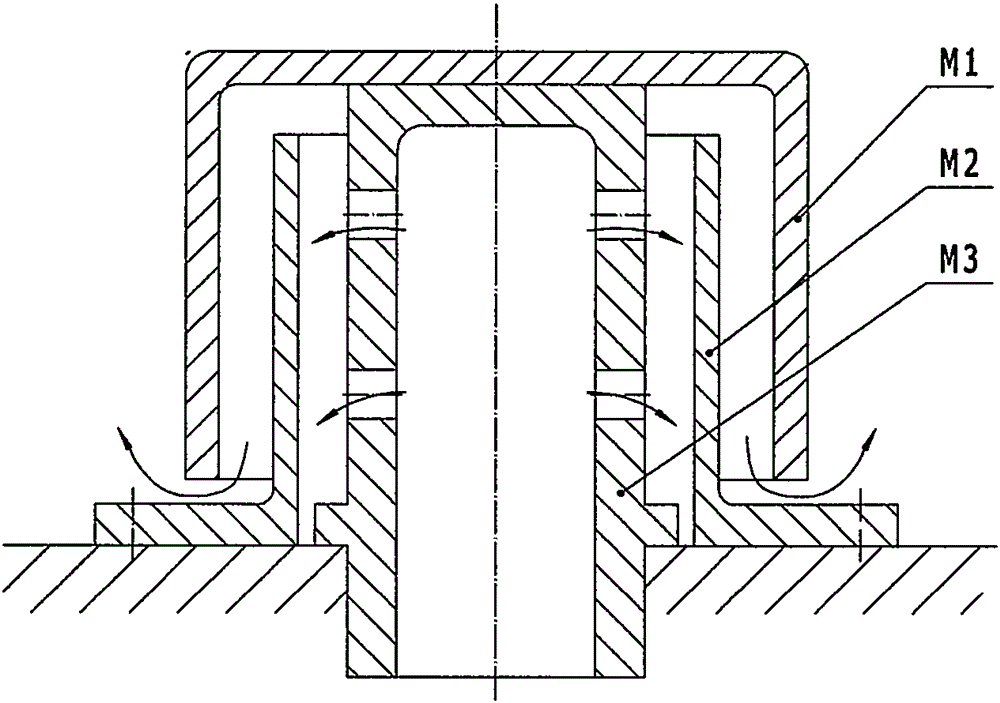

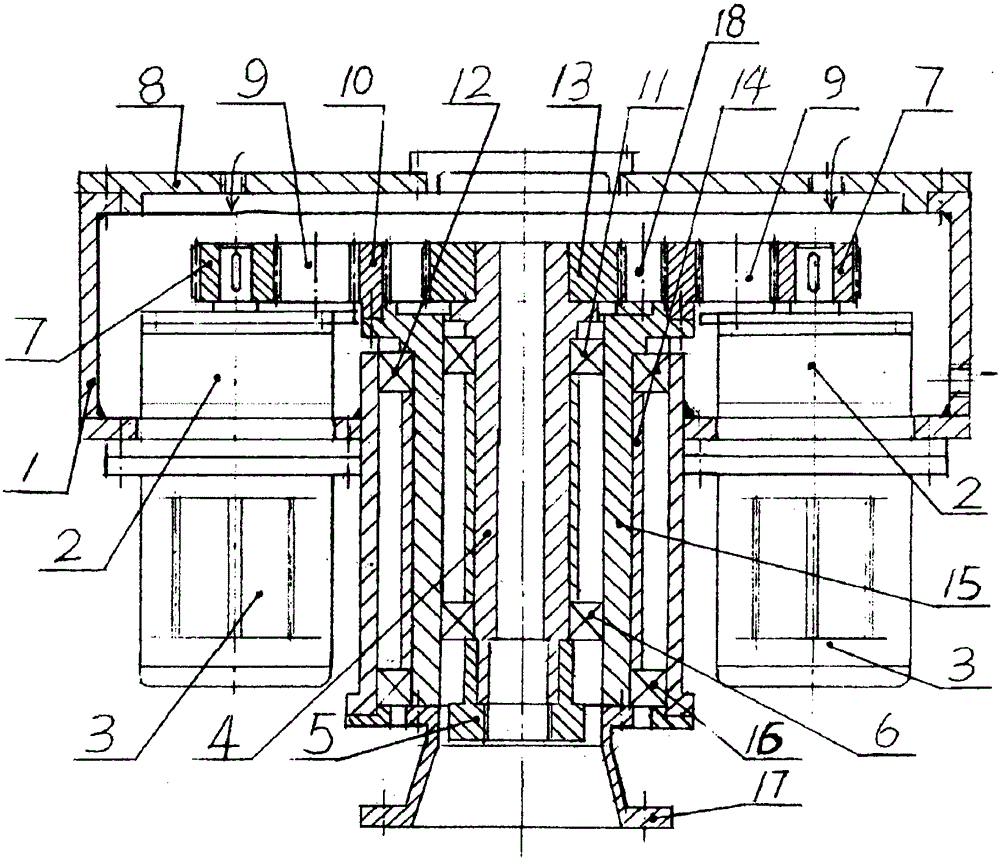

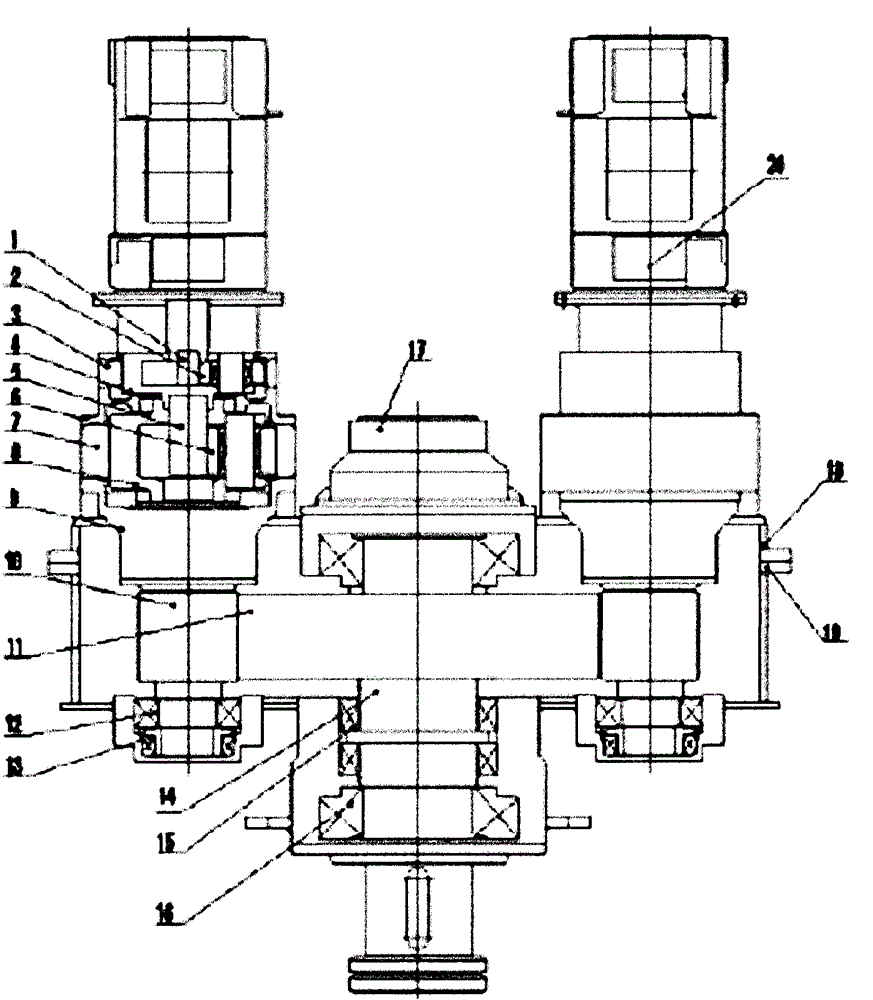

Mandrel-holding device for tube mills

InactiveCN101758074BLimit swingGuaranteed stabilityMandrelsMetal rolling arrangementsEngineeringMechanical engineering

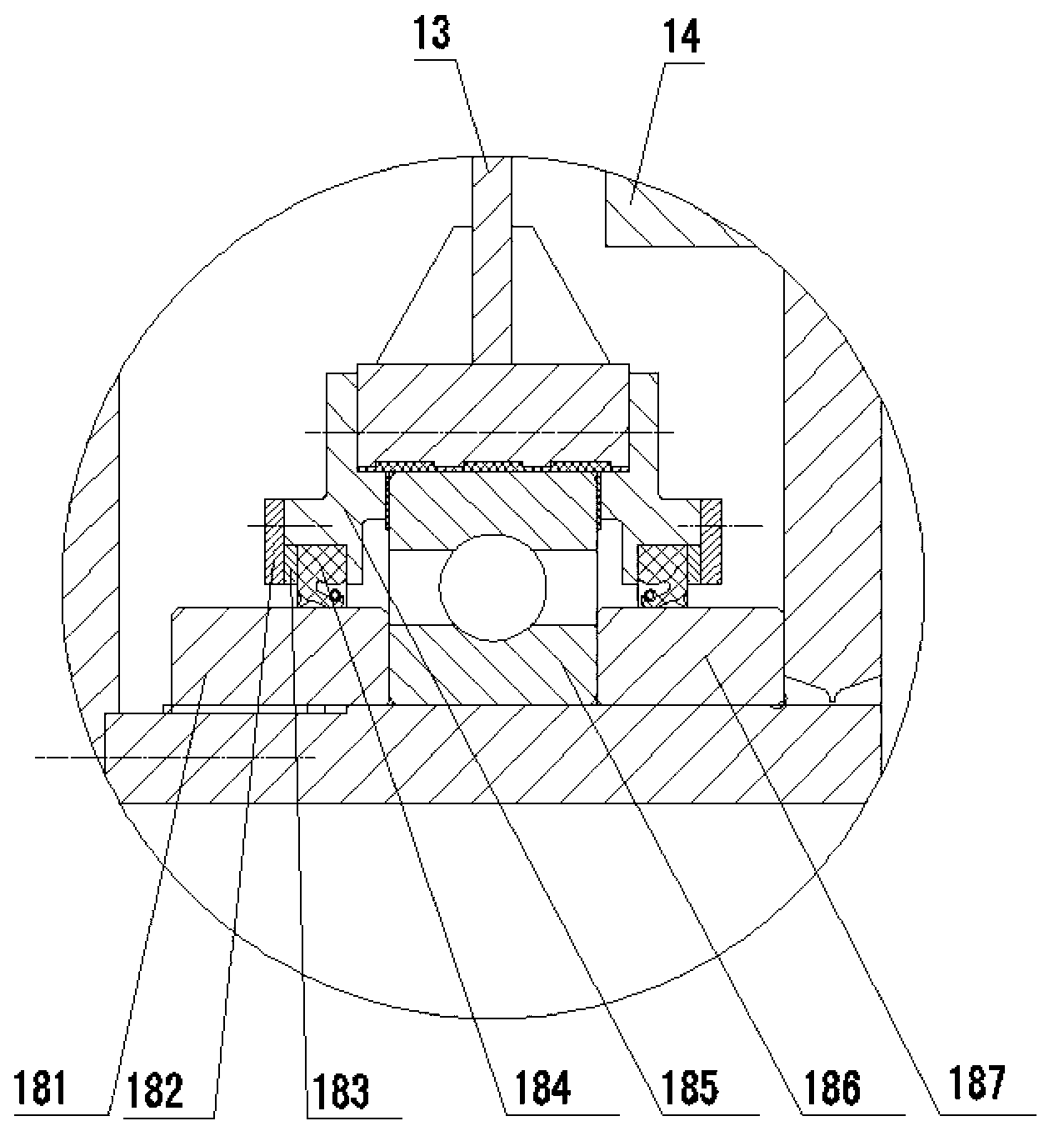

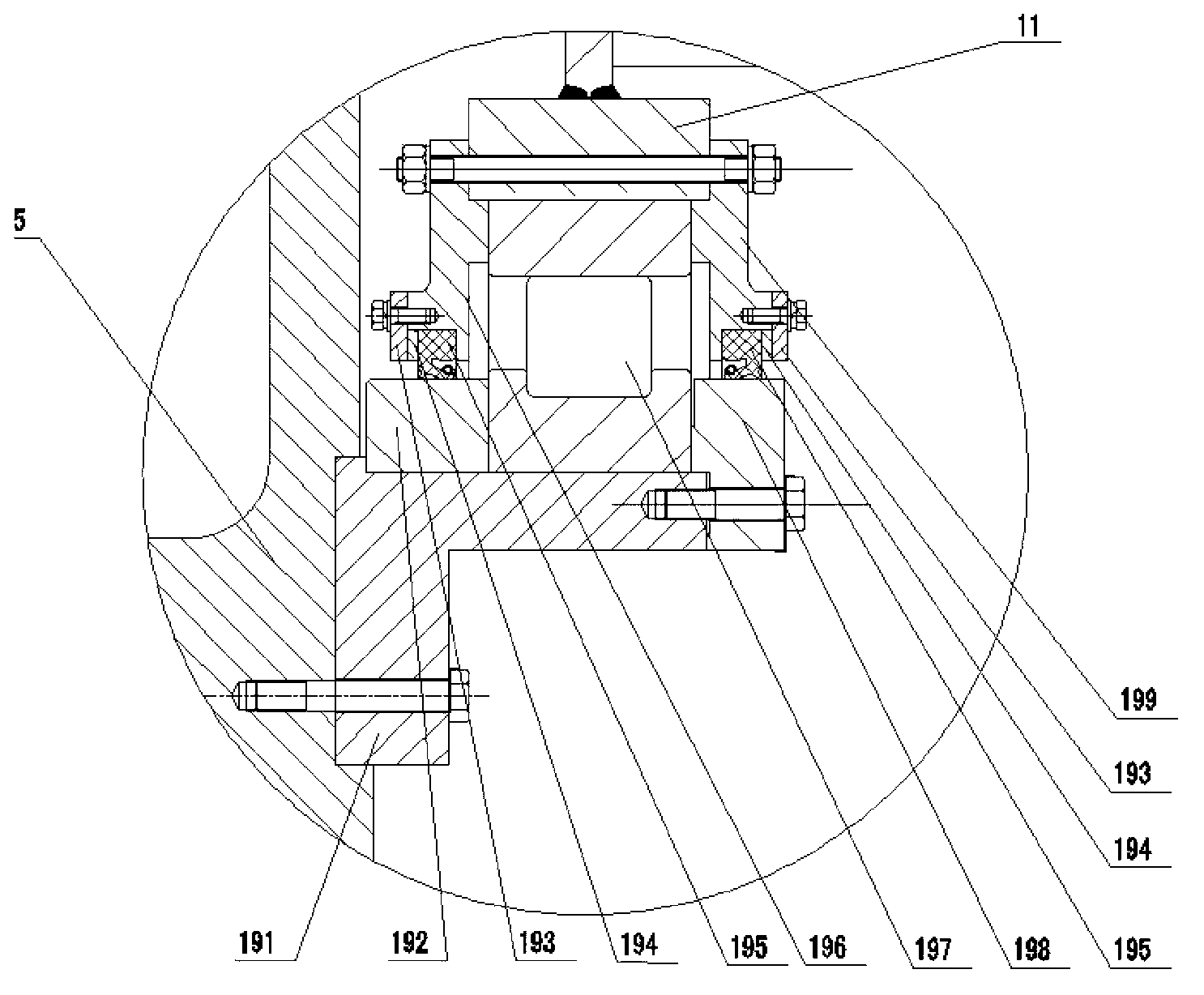

The invention discloses a mandrel-holding device for tube mills, which relates to a tube mill. The invention solves the problem that since the prior holding device cannot effectively limit the waggle of a mandrel, equipment can be damaged. A moving mechanism comprises a slide way, a left slide carriage and a right slide carriage, the slide way is mounted on a base, and is respectively connected with the bottom slide grooves of the left and the right slide carriages, the left slide carriage is connected with the bottom ear ring of a transversely arranged oil cylinder through a pin shaft, and the threaded piston rod of the oil cylinder is connected with the bottom of the right slide carriage through a nut; holding parts are four rollers, two of the holding parts are assembled on the left slide carriage, the other two holding parts are assembled on the right slide carriage, and the rollers are assembled on the carriage in a way that the rollers are transversely staggered from each other and that parts of the longitudinal excircles are superposed; a left rack is mounted on the left slide carriage, a right rack is mounted on the right slide carriage, and the left and the right racks are engaged with a gear fixed on the central line, so that a synchronous centering unit is formed.

Owner:TAIYUAN HEAVY IND

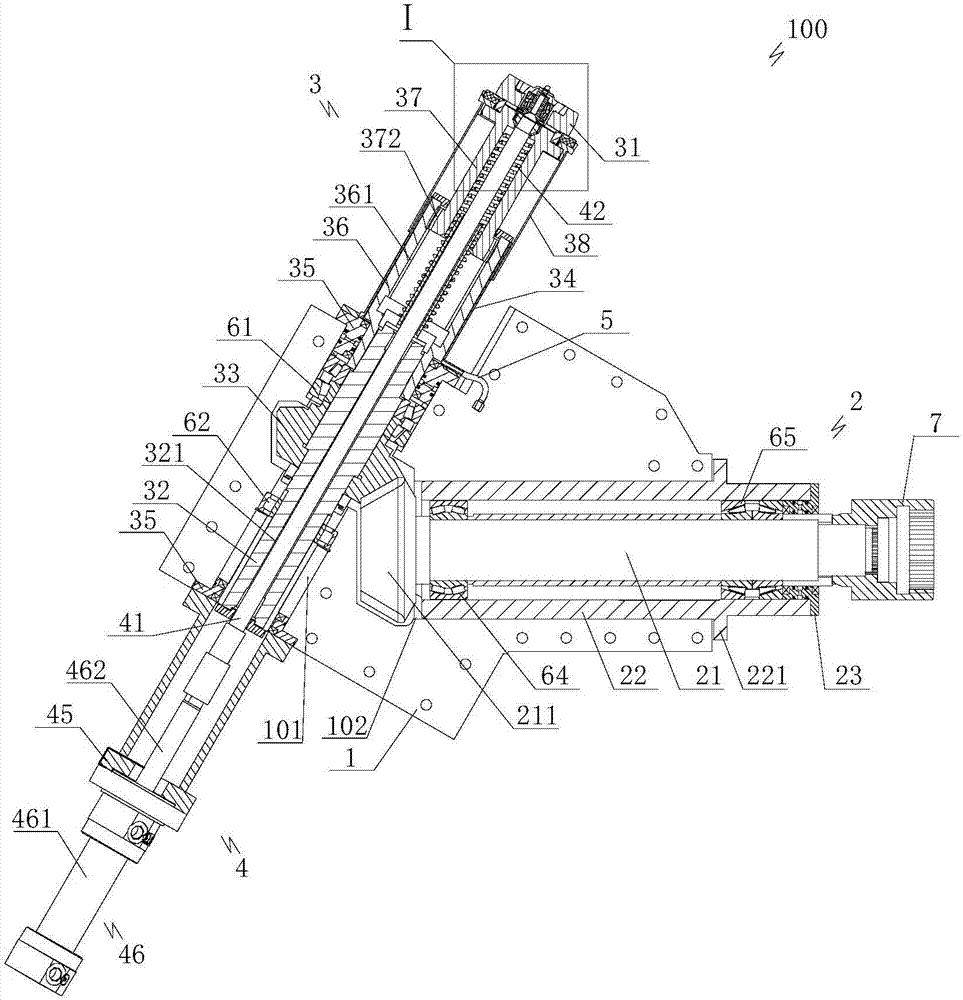

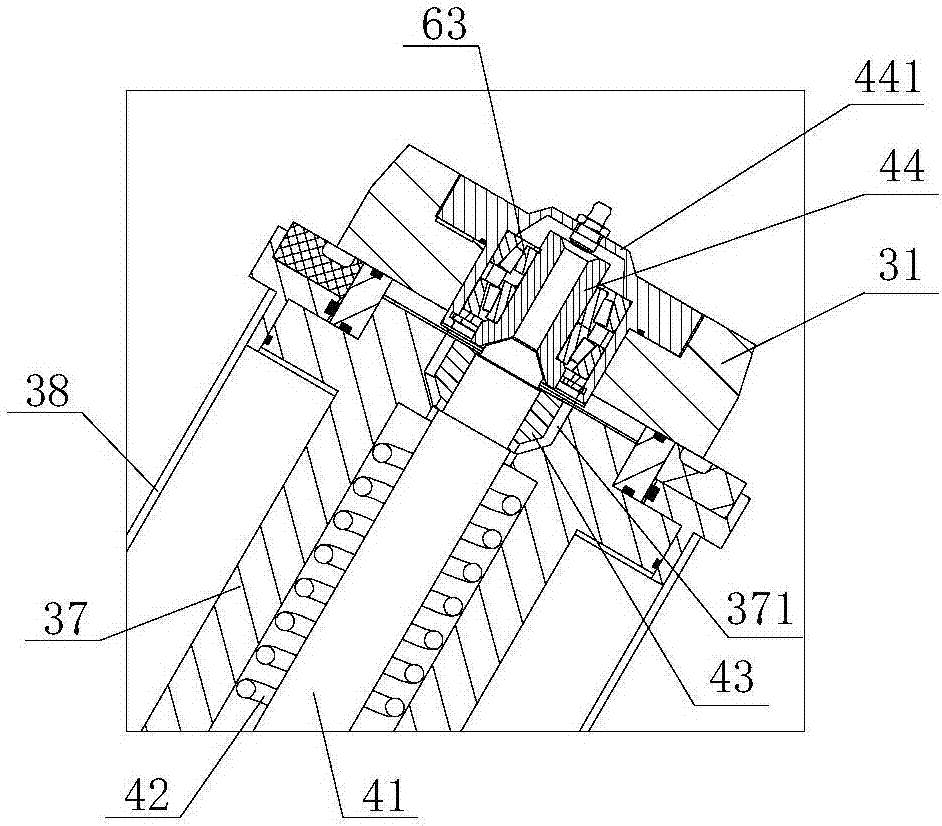

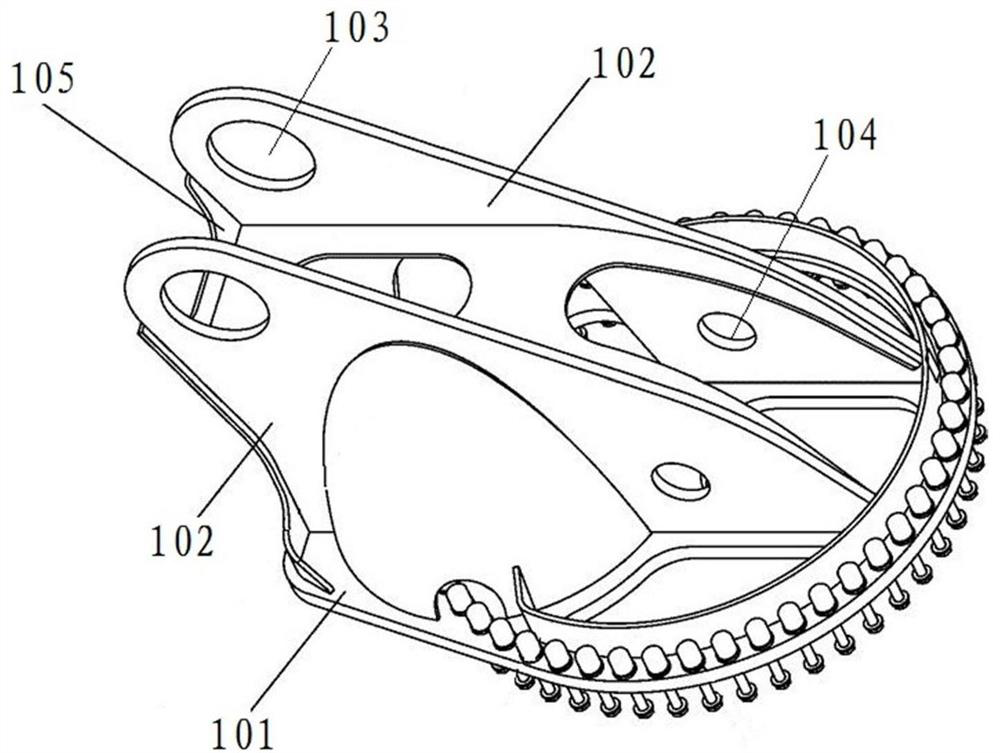

Prestress reinforced boom, prestress reinforced support leg and pump truck

InactiveCN102605957AImprove stress conditionImprove carrying capacityVehicle fittings for liftingBuilding material handlingEngineeringTruck

The invention provides a prestress reinforced boom and a prestress reinforced support leg. Each of boom segments of the boom and leg beams of the support leg comprises one or a plurality of cables disposed on a boom segment body or leg beam body. Each cable is disposed on a tensioned area or severely stressed area of the boom segment body or leg beam body lengthwise along the boom segment body or leg beam body. The cables are prestressed. The invention further provides a pump truck, which comprises the prestress reinforced boom and / or the prestress reinforced support leg. According to the technical scheme, the carrying capacity of the boom and the support leg can be improved, the thickness of plates can be reduced while the length and the carrying capacity of the boom and the support leg are guaranteed, and accordingly, the action flexibility of the boom and the support leg is improved, mechanical properties of various new materials can be given to full play, manufacturing cost can be reduced, and manufacturing difficulty can be reduced.

Owner:SANY HEAVY IND CO LTD (CN)

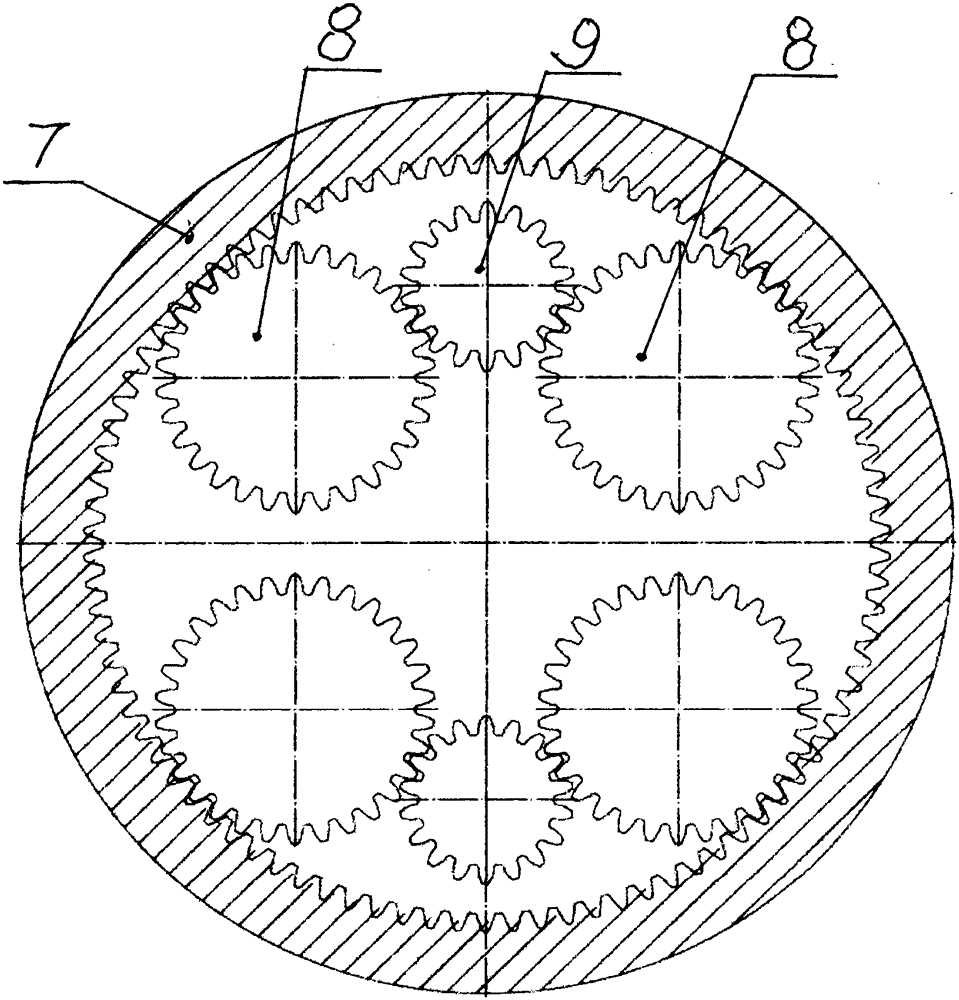

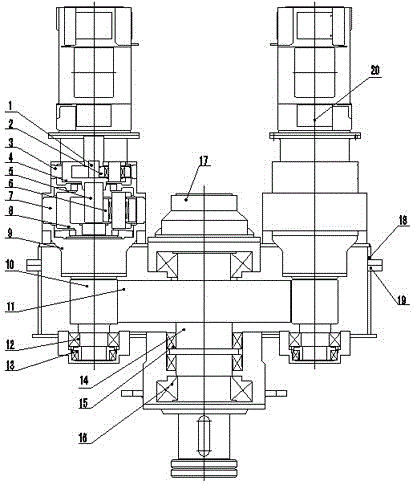

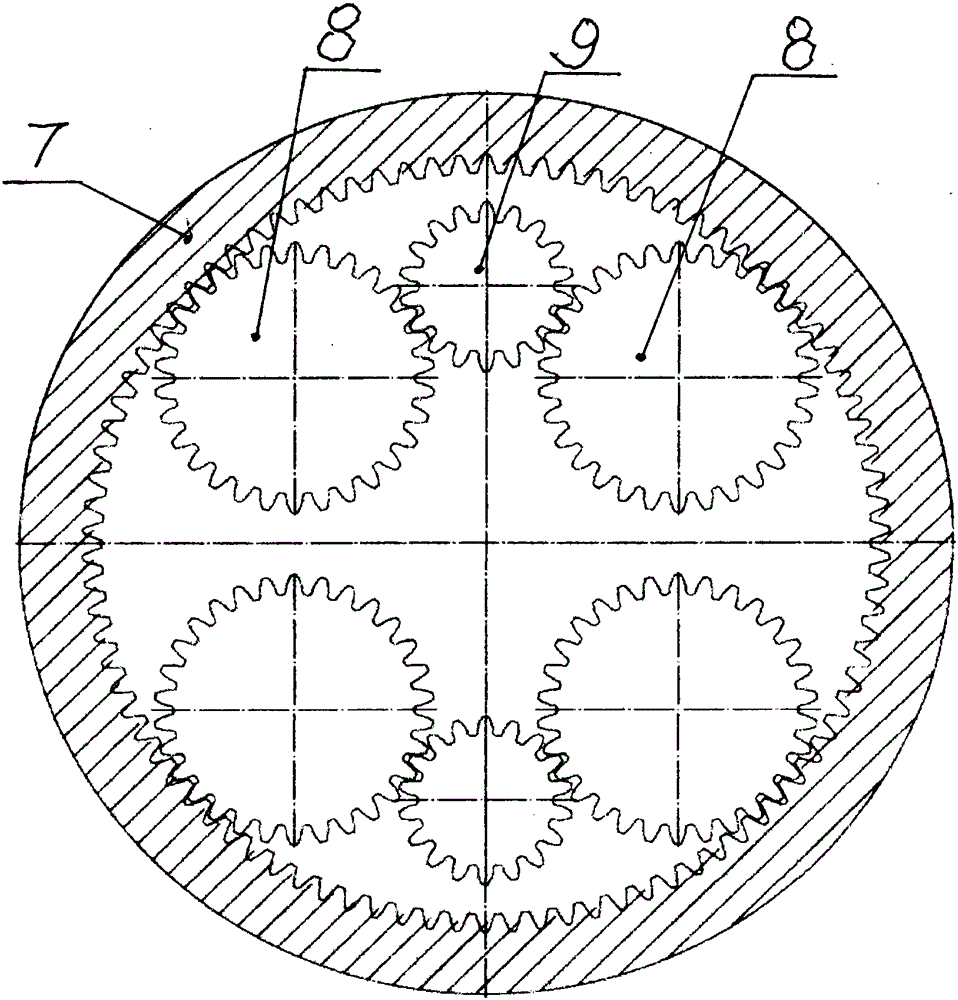

Oil temperature alarming star wheel external gearing four-division speed reducer of pile machine

InactiveCN105221672AKeep abreast of running dynamicsEffective dustproofConstructionsToothed gearingsDrive wheelElectric machine

The invention relates to the technical field of pile machine speed reduction, in particular to an oil temperature alarming star wheel external gearing four-division speed reducer of a pile machine. The speed reducer comprises a box, motors, a cover plate and a transmission piece, and is characterized in that an oil temperature sensor is arranged in the box; a labyrinth vent hood is arranged on the cover plate; the two motors are inversely connected to the lower portion of the box, and the shaft extension ends of the motors are connected with star wheel speed reducers; the transmission piece comprises driving wheels, division gears and a center gear ring; the driving wheels are arranged on output shafts of the star wheel speed reducers; the division gears are symmetrically arranged on the two sides, division gear shafts are fixed to supporting plates, and the supporting plates are connected to the end faces of star wheel speed reducer shells; the center gear ring is connected with a flange of a main cylinder; the main cylinder is supported in the box through bearings; and the main cylinder is connected with a drill rod flange connected with a drill rod. The speed reducer has the beneficial effects that the dynamic conditions of the speed reducer can be mastered according to oil temperature changes; pressure of air in the box and pressure of air outside the box are balanced through the labyrinth vent hood; the tilting moment of the pile machine is reduced through the inverted motors, and the titling accident probability is lowered; and four-division bearing capacity is high, and inner gear ring hardening and tempering are easier and lower in cost than carburization.

Owner:陈卫

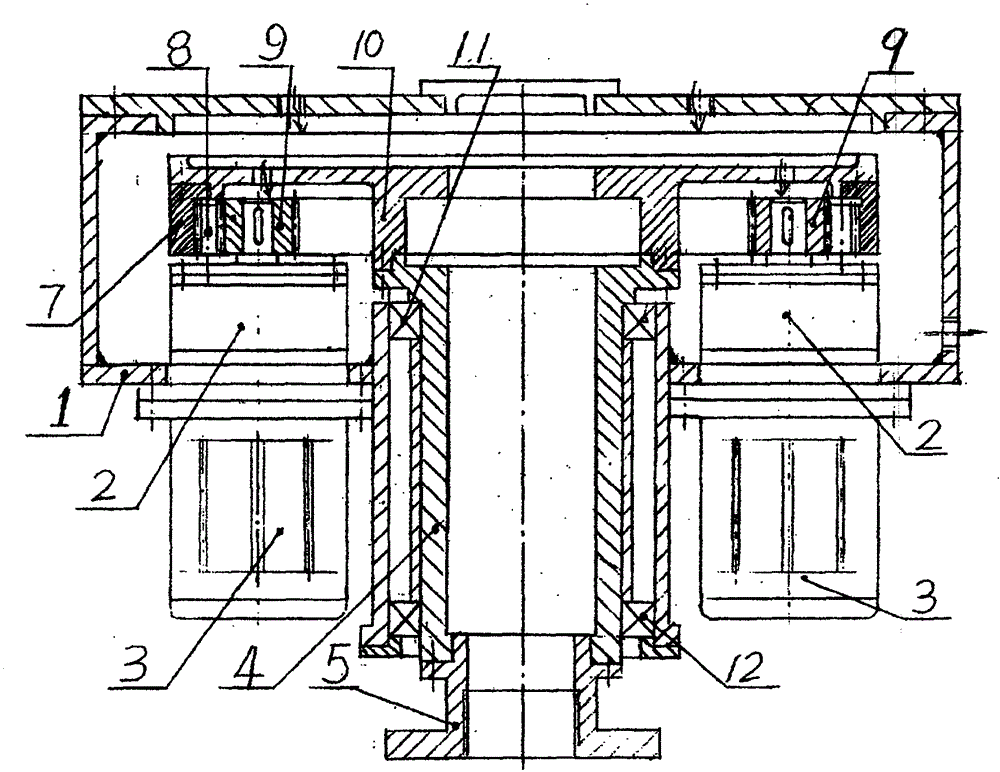

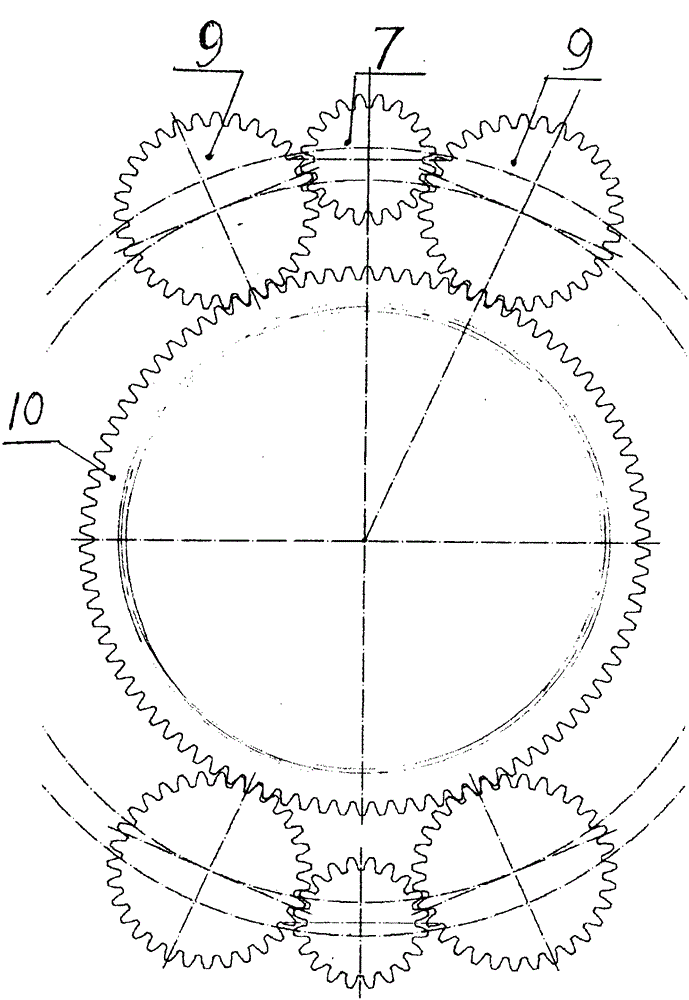

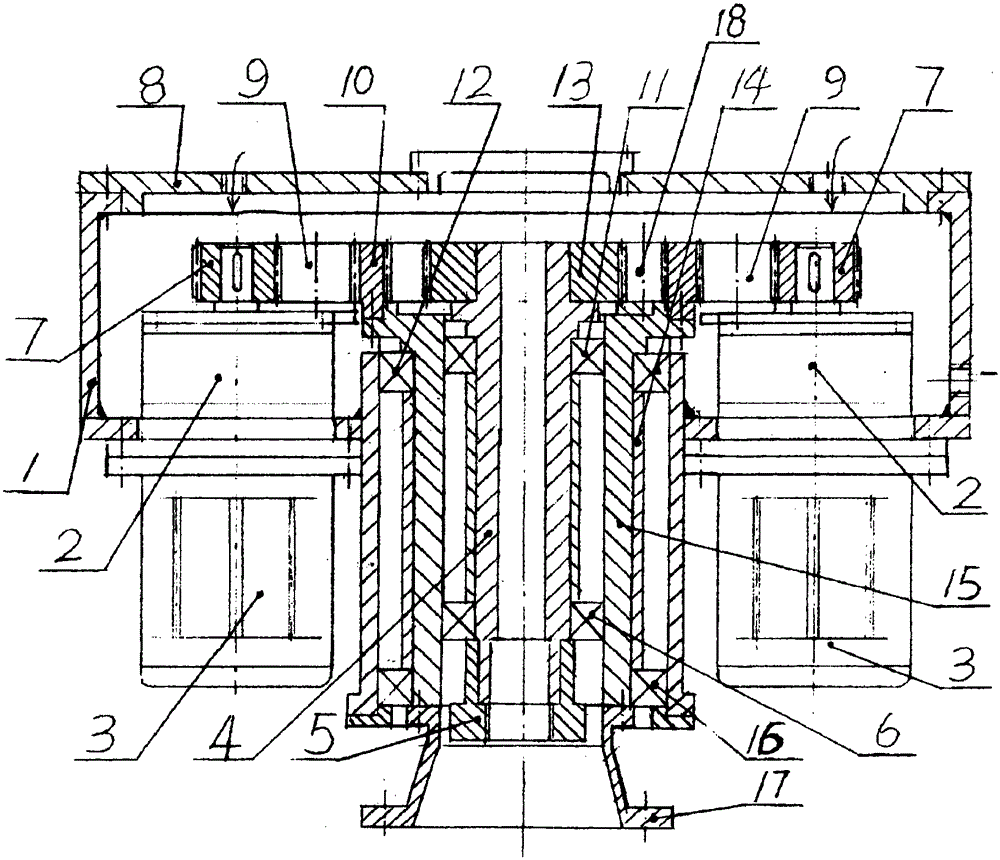

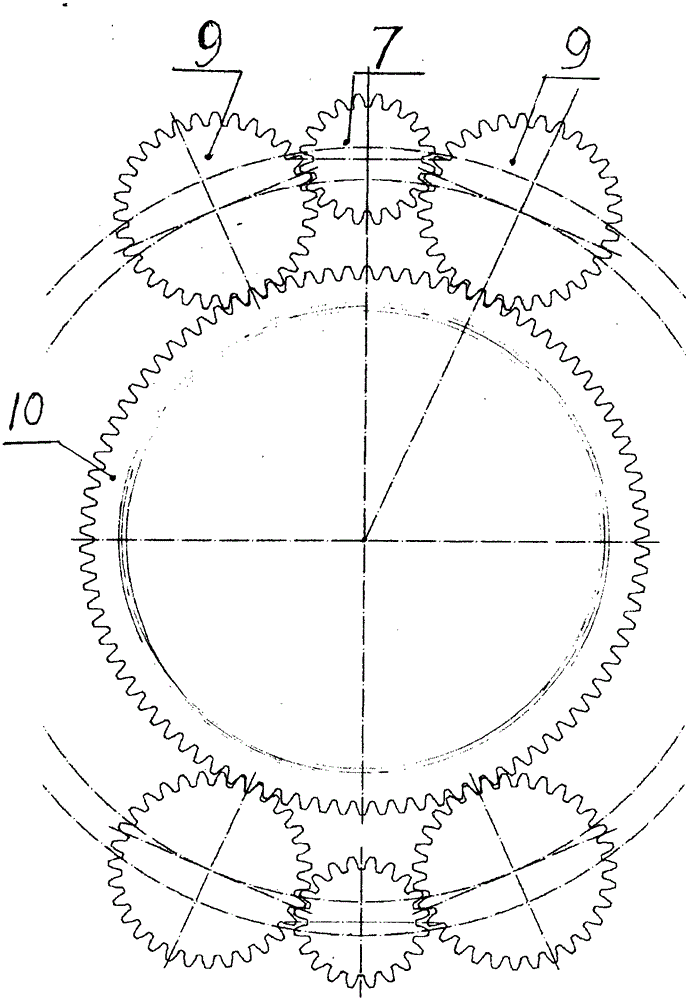

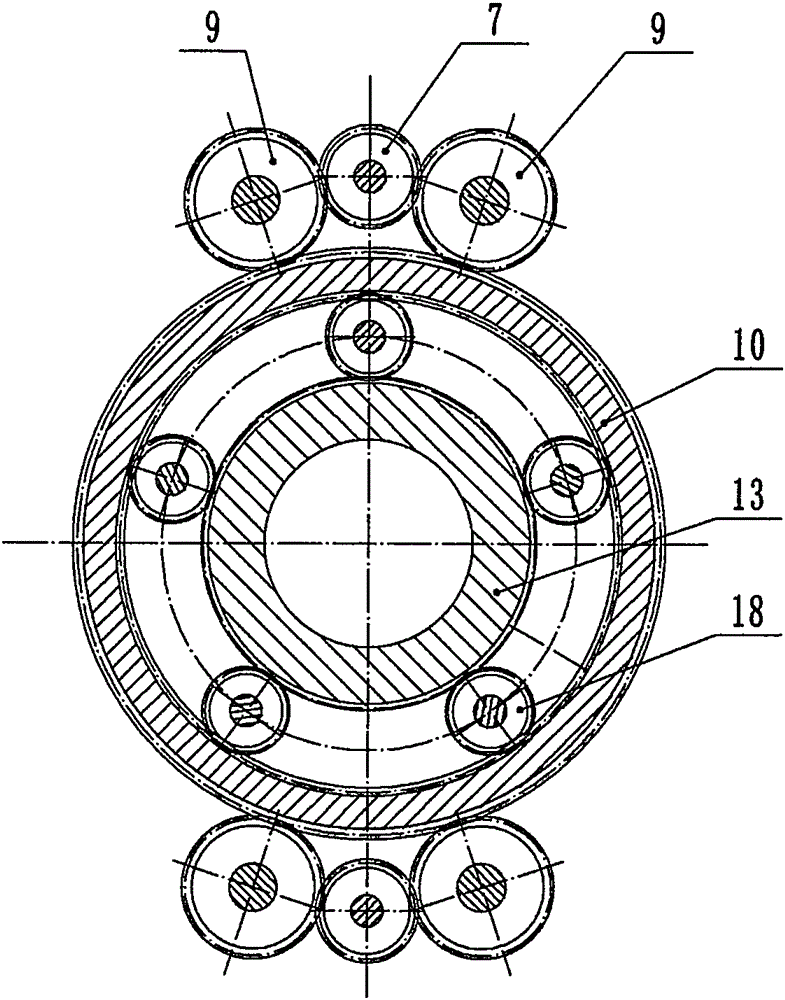

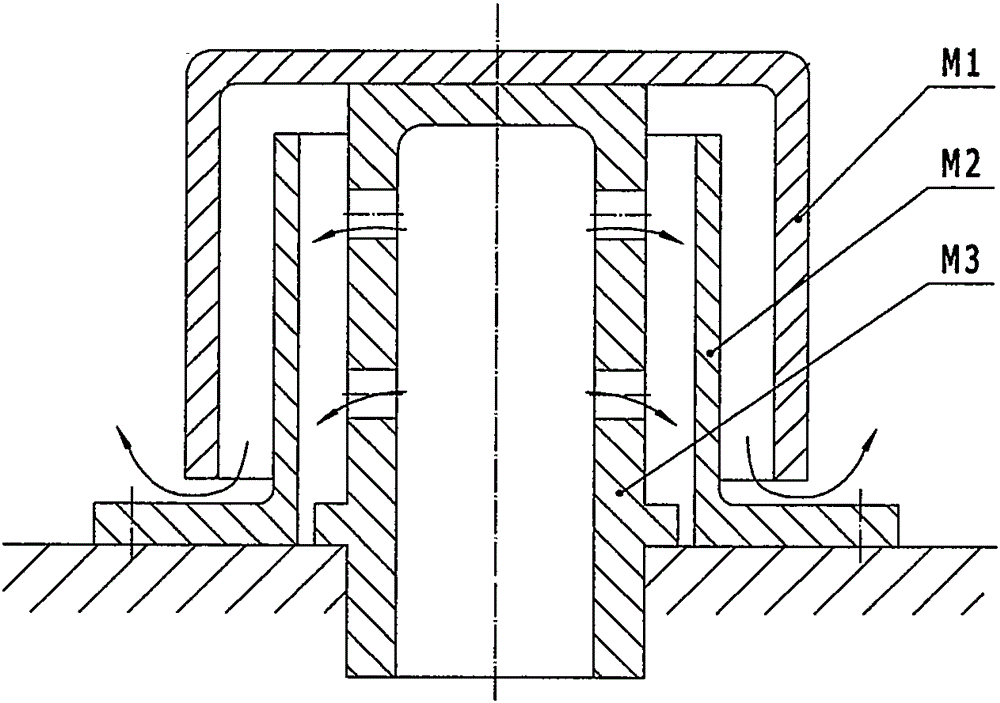

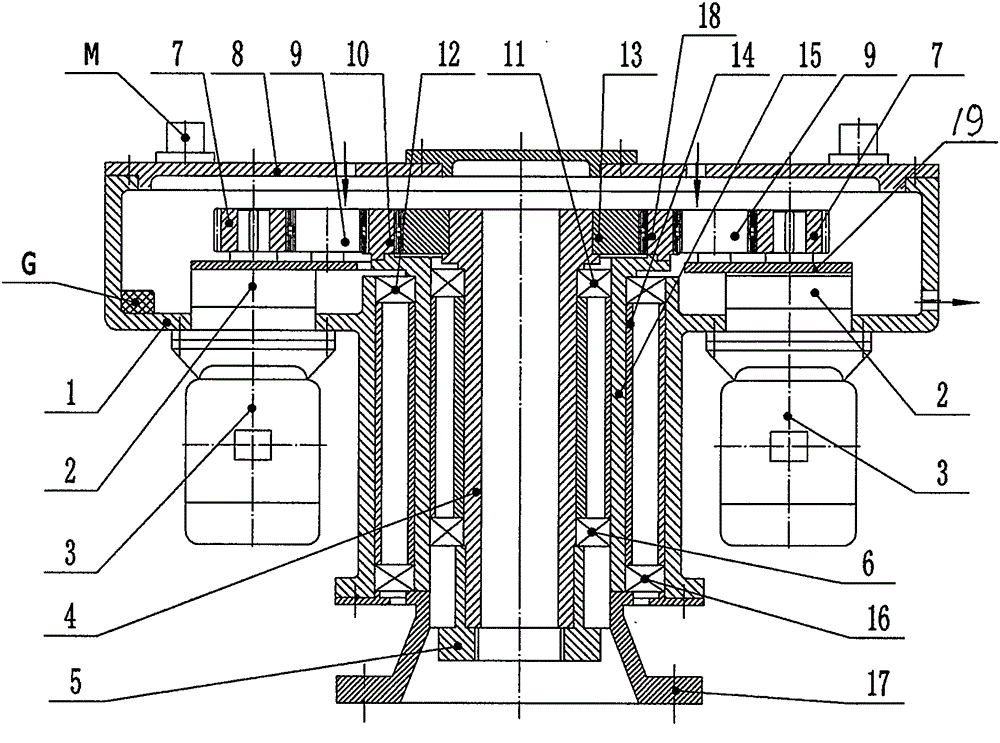

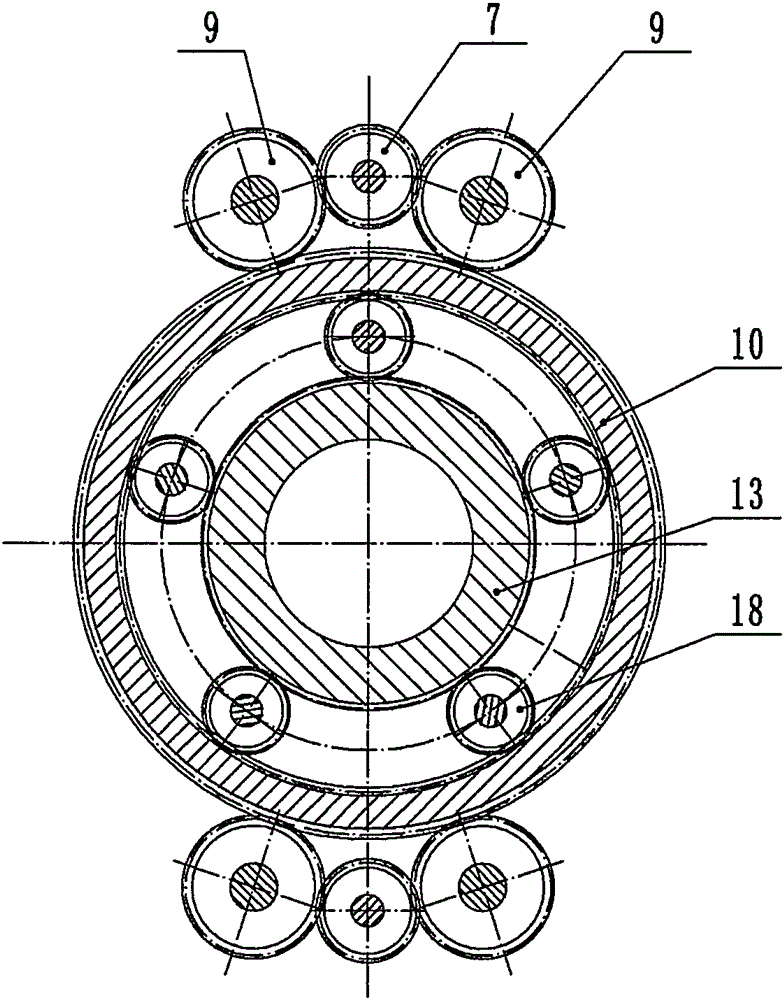

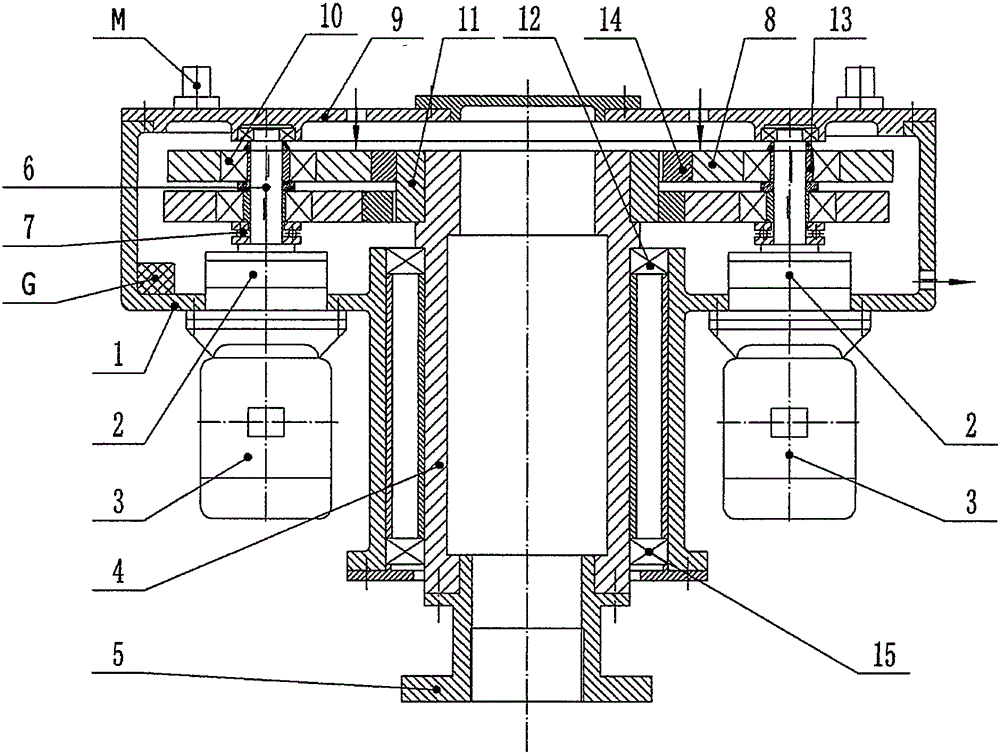

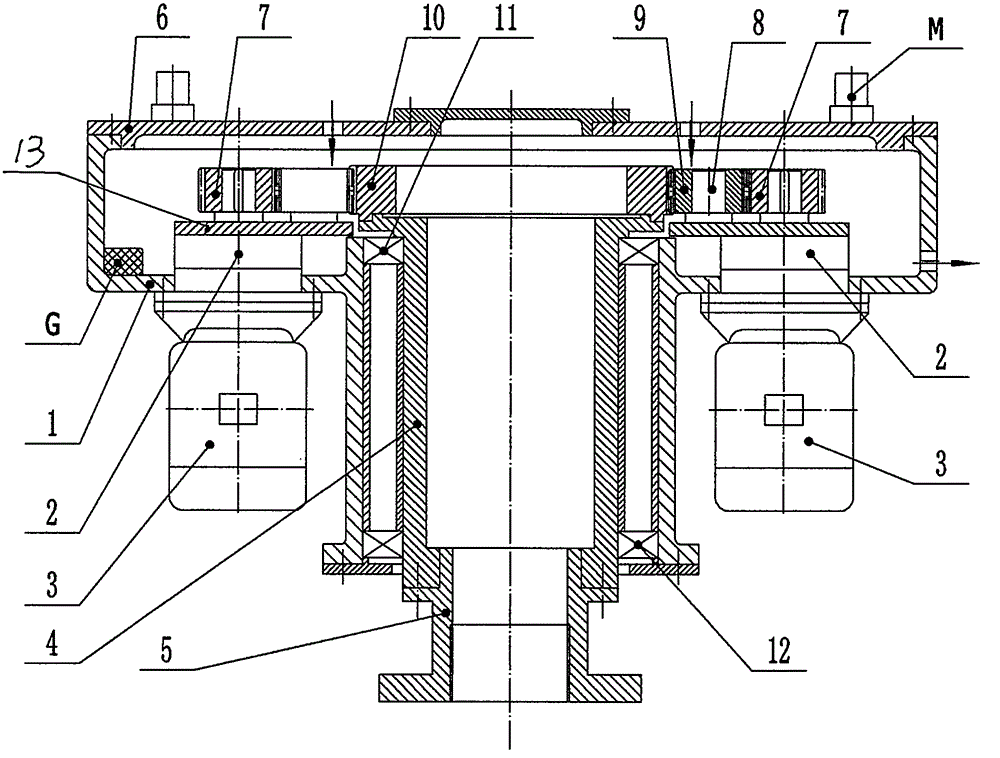

Motor-inversed inner engaging four-shunting piling machine decelerator

InactiveCN105006910AEasy maintenanceReduced tipping momentConstructionsToothed gearingsDrive wheelGear wheel

The invention relates to the technical field of piling machine deceleration. A motor-inversed inner engaging four-shunting piling machine decelerator comprises a housing, motors, a cover plate and an inner engaging four-shunting transmission member. The motor-inversed inner engaging four-shunting piling machine decelerator is characterized in that the shaft extension end of each motor is connected with an involute small-tooth-difference decelerator; the motors are connected with the lower portion of the housing in a reversed manner; the involute small-tooth-difference decelerator is arranged in the housing; the inner engaging four-shunting transmission member comprises a driving wheel, shunting gears which are symmetrical at two sides, and a central tooth ring; the mandrels of the shunting gears are fixed on a supporting plate; the supporting plate is connected with the cover plate of the housing of the involute small-tooth-difference decelerator; the central tooth ring is connected with a disc; the disc is connected with a main cylinder; the main cylinder is supported in the inner hole of the housing by means of two bearings; and the main cylinder is connected with a drilling rod flange. The motor-inversed inner engaging four-shunting piling machine decelerator is advantageous in that reverse mounting of the two motors realizes easy detachment between the motors and the decelerator, convenient mending and convenient maintenance; possibility of an overturning accident is reduced; and waterproof and dustproof performances of the motors are facilitated; the carrying capability of the inner engaging four-shunting manner is higher than that of two-shunting manner; the difficulty of an inner tooth ring technique is lower than that of a grinding tooth carburizing technique; and furthermore low cost and no easy cracking are realized.

Owner:吴小杰

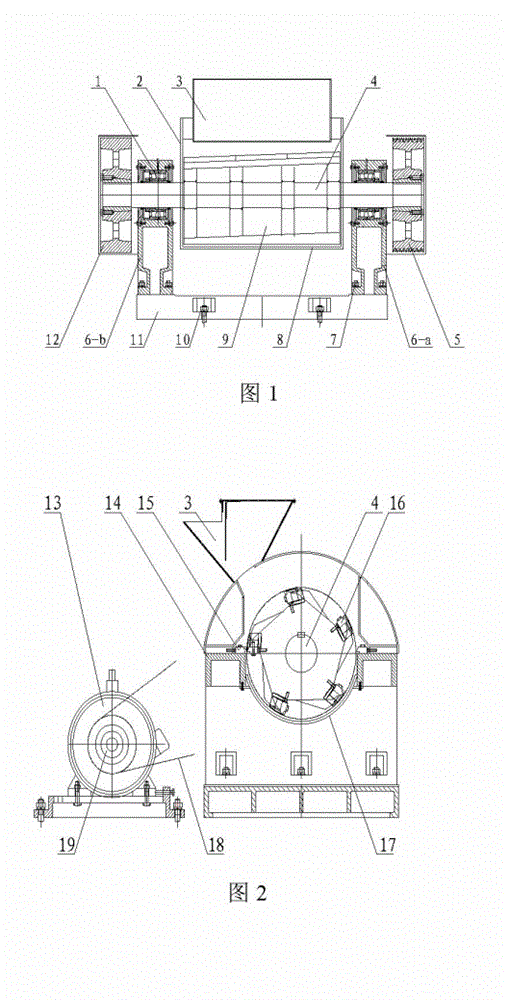

Block rubber breaking machine

InactiveCN102744806AIncrease productivitySave electricityPlastic recyclingMechanical material recoverySmall footprintMechanical engineering

The invention discloses a block rubber breaking machine which solves problems of existing breaking plants. The block rubber breaking machine mainly and structurally comprises a base (11), a support (6), a cutter device (9), a breaking chamber (8), a feed hopper (3) and a transmission system. The base (11) is fixed to the ground by eight foundation bolts (10), the support (6) is fixed onto the base (11) by six double-end studs (7) and provided with a self-aligning roller bearing (1) a cutter head (14), the cutter device (9) is mounted on the cutter head (14) and consists of a spindle cutter head (4), a fixed cutter (15) and a movable cutter (16), the transmission system drives the cutter device (9) to rotate, the cutter device (9) is completely sealed by a cover (2) of the breaking chamber (8), screen cloth (17) is disposed below the cutter device (9), and the feed hopper (3) is arranged on the cover (2). The block rubber breaking machine has the advantages that the block rubber breaking machine is small in occupied area, balance in stress and high in efficiency, is safe and pollution-free, overturning moment is reduced, the service life of a cutting edge of the cutter is long, the cutting edge can be reused after being repaired and ground, and is convenient to replaced, energy is saved, and consumption is reduced.

Owner:贾先义

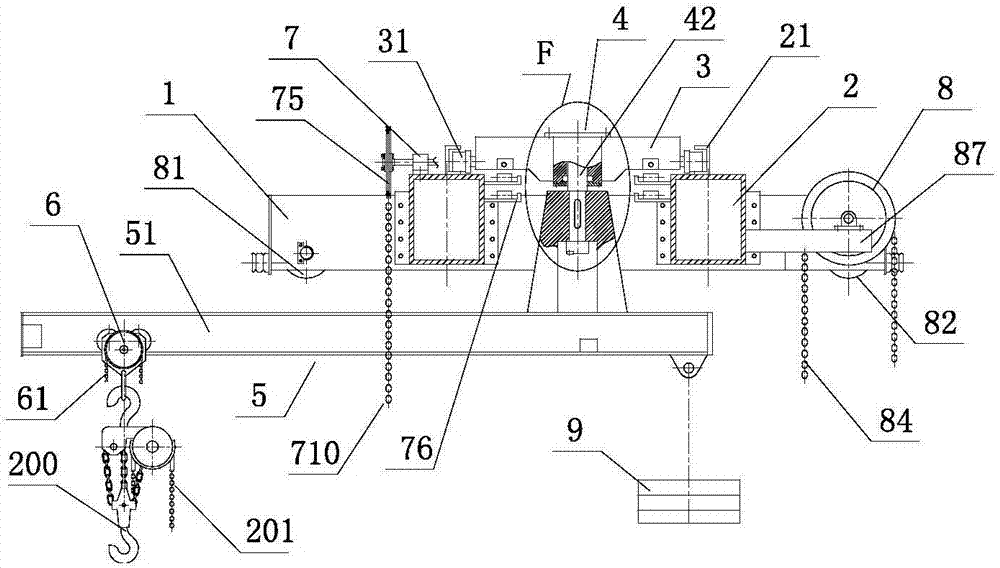

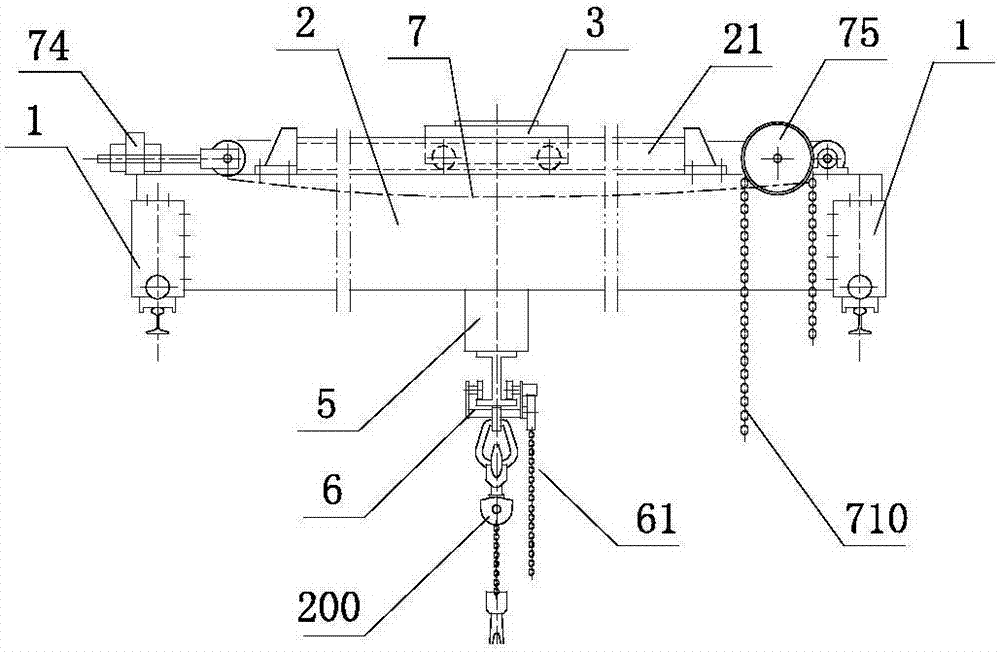

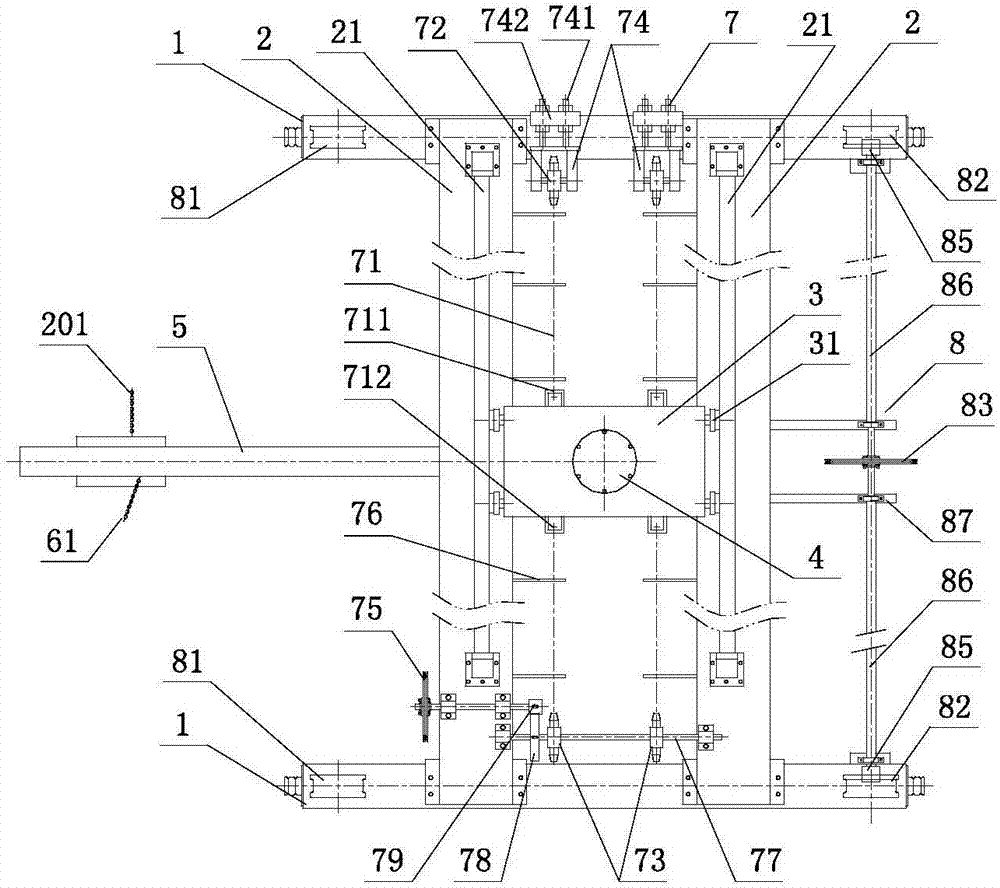

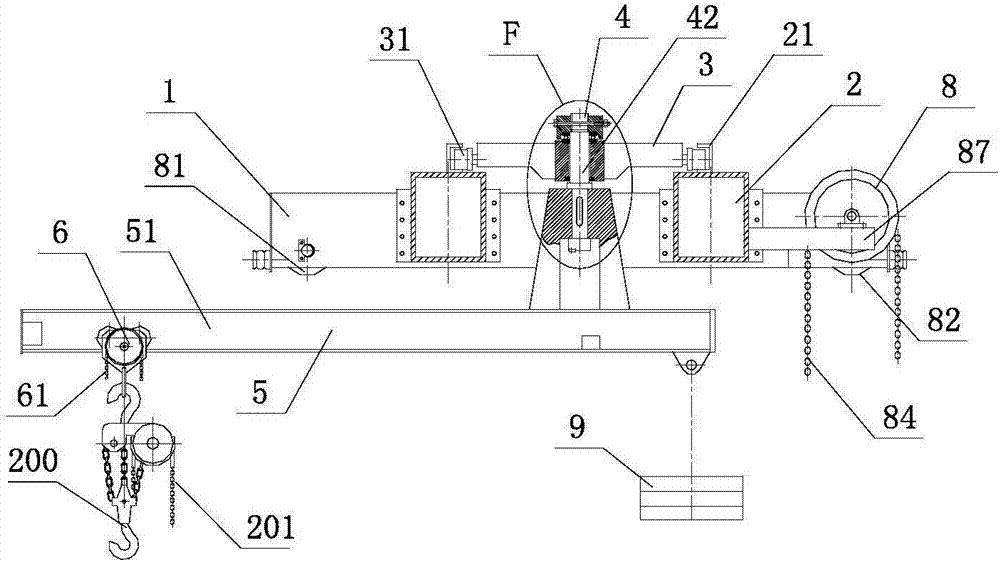

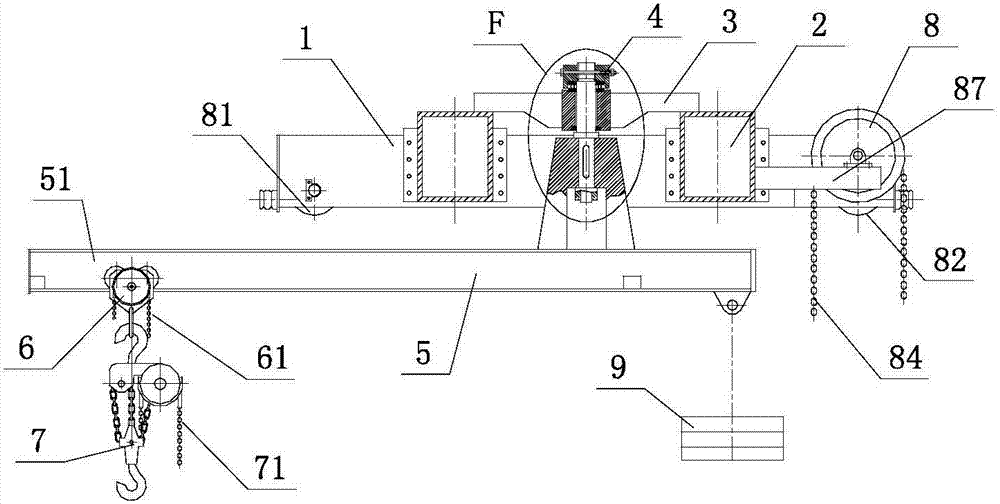

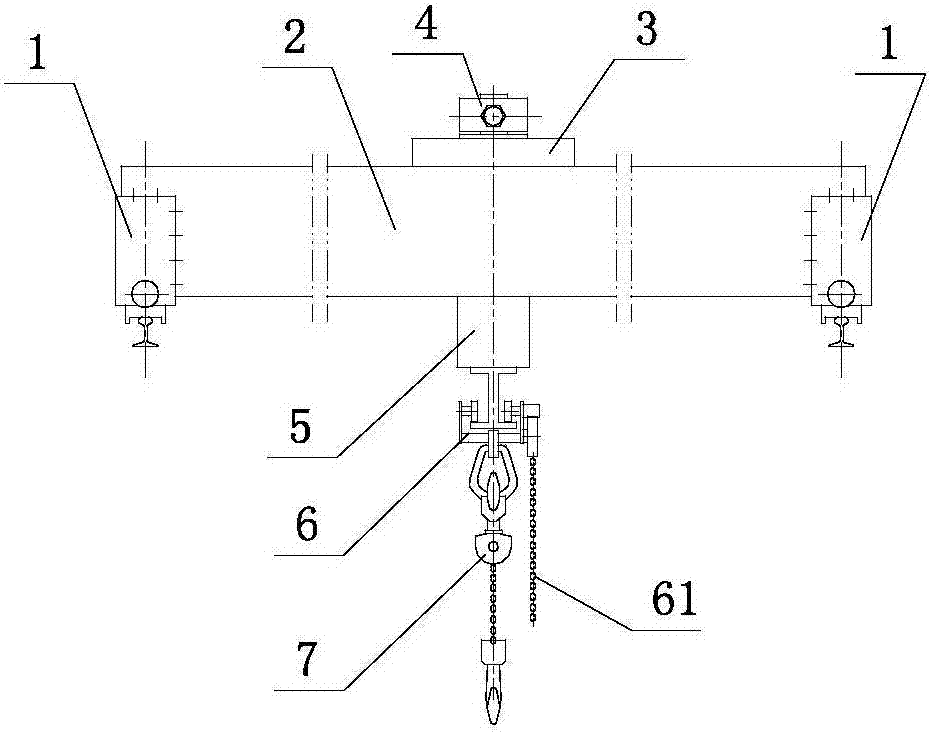

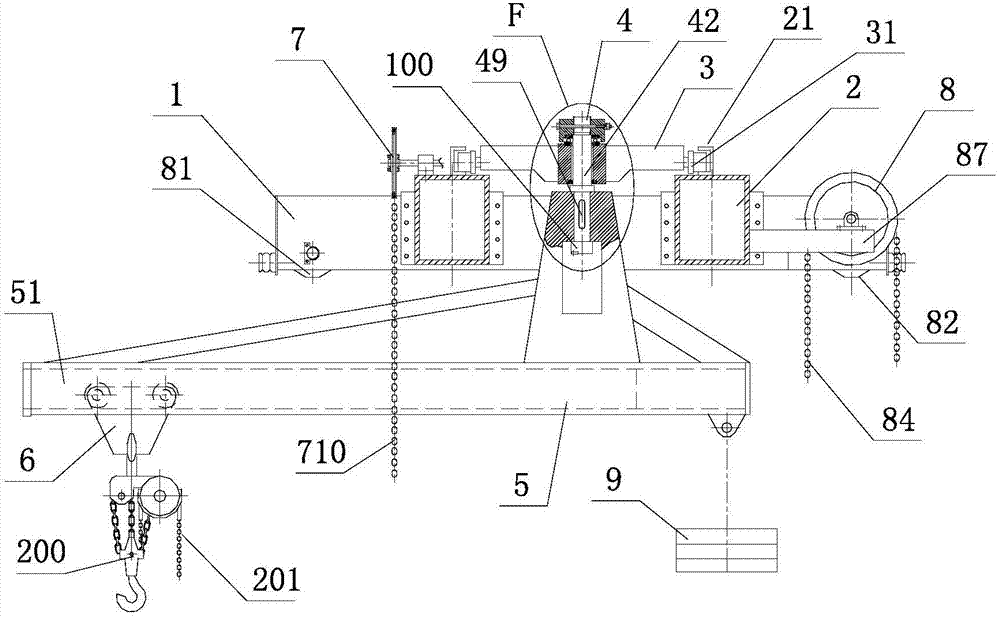

Dolly chain driven bridge cantilever crane with balancing counterweight

The invention discloses a dolly chain driven bridge cantilever crane with a balancing counterweight. The bridge cantilever crane comprises two end beams and two main beams which form a two-beam cranespan structure, wherein a hand-pulled trolley running device is arranged between the two end beams; inverted U-shaped tracks are arranged on the two main beams; a running dolly is arranged between andconnected with the two tracks; the running dolly is provided with a chain drive unit; the central part of the running dolly is provided with a rotating mechanism; a thrust bearing is connected with the interior of the rotating mechanism; the lower end of a suspender shaft in the rotating mechanism is connected with a cantilever member; one end of a cantilever beam on the cantilever member is connected with a hand-pulled trolley, and the balancing counterweight is hung on the other side of the cantilever beam; the hand-pulled trolley can horizontally move to and fro along the cantilever beam;a hand-pulled chain hoist is hung below the hand-pulled running trolley and capable of hoisting cargos; and the cantilever beam is located below the two main beams and capable of carrying out rotation, and can stretch out of a workshop for operation.

Owner:林霞

Novel wind power gear box

PendingCN114718994AReduce volumeReduce hysteresis problemGear lubrication/coolingToothed gearingsGear wheelCoupling

A novel wind power gear box belongs to the technical field of mechanical gear boxes and comprises a box body for supporting, and an input end, an intermediate stage and an output end are mounted in the box body and sequentially connected. Therefore, the structure can effectively reduce the return difference problem of the planetary gear train caused by manufacturing and mounting errors, so that the processing and mounting requirements on high-speed components can be properly reduced by utilizing the structure; the reliability of a design object is improved, so that the design object can be suitable for a power generation occasion with MW-level power; by means of the structure, axial force can be counteracted, the axial force on the shaft is reduced, the joint of the shaft can be fixed through the elastic check ring and connected with the gear coupling, meanwhile, the most beneficial floating uniform load mode is achieved, and the adverse effect of unbalance loading on reliability is reduced.

Owner:NORTHEASTERN UNIV

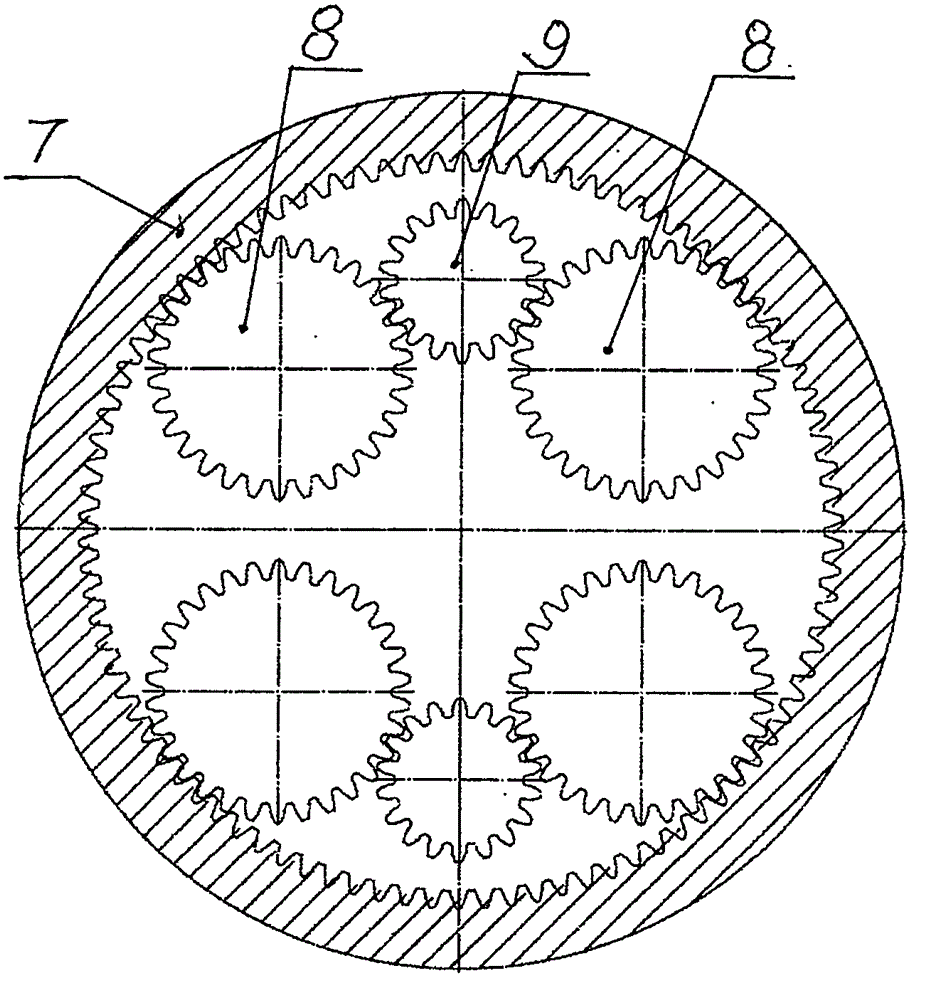

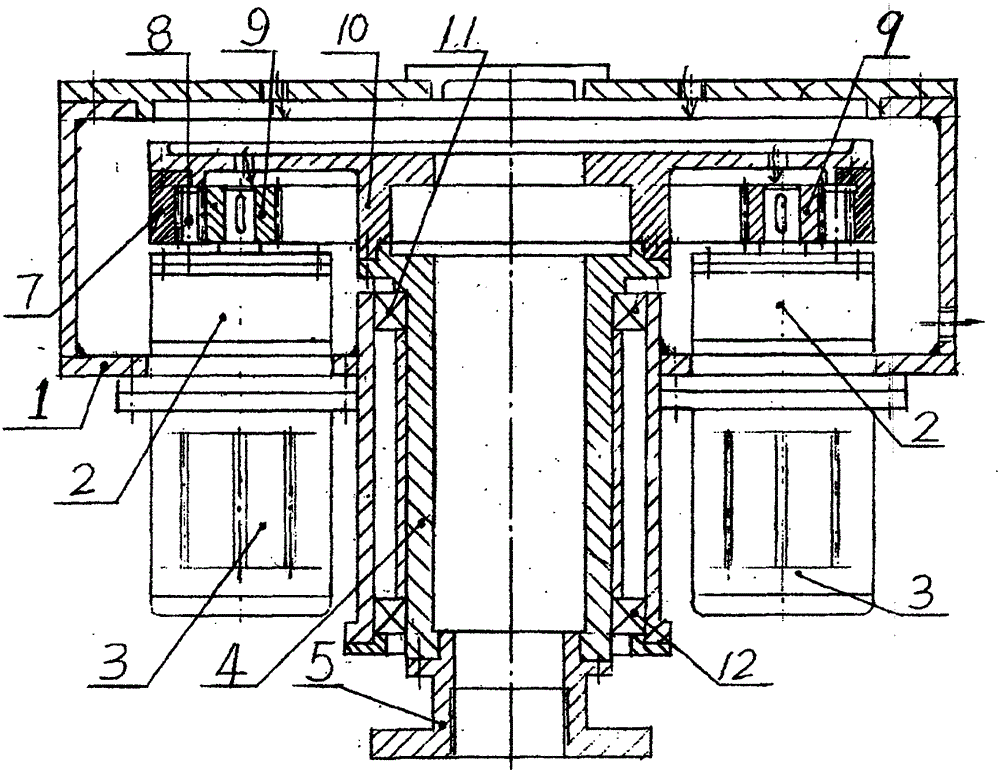

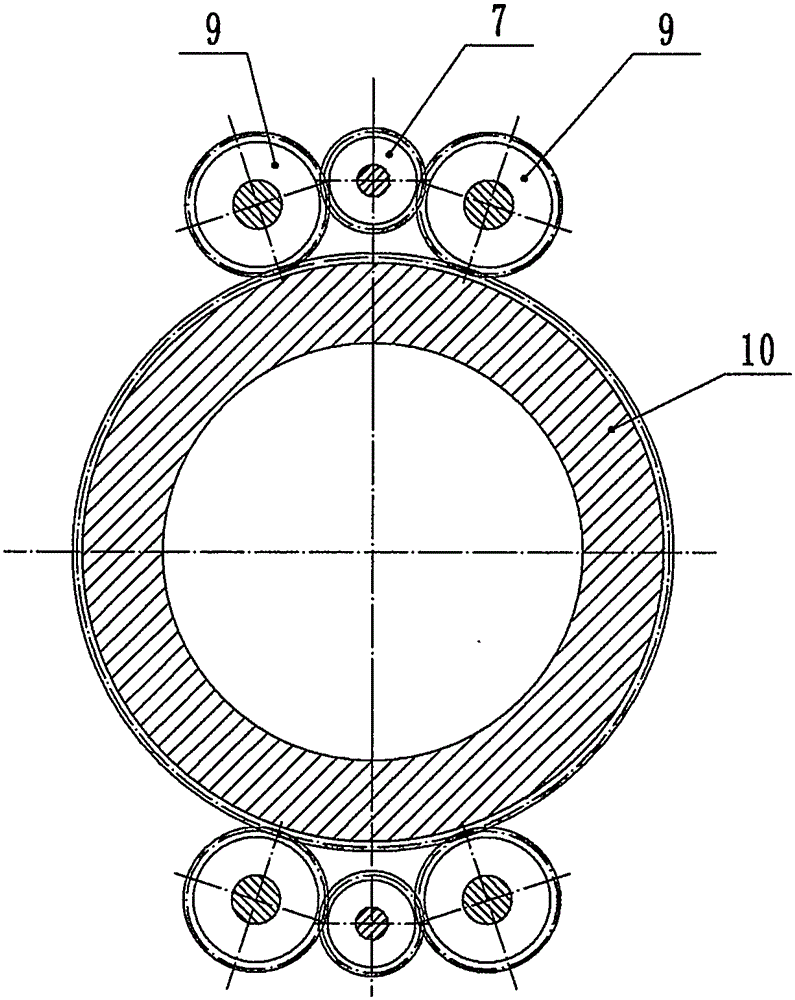

External gearing four-splitting pile machine speed reduction device with motors placed upside down

InactiveCN105065640AEasy maintenanceReduced tipping momentGearboxesToothed gearingsDrive wheelSpeed reduction

The invention relates to the technical field of pile machine speed reduction, in particular to an external gearing four-splitting pile machine speed reduction device with motors placed upside down. The device comprises a box body, the motors, a cover plate and a transmission component and is characterized in that the shaft extension ends of the motors are connected with a planetary reducer, the motors are connected to the lower side of the box body upside down, and the planetary reducer is arranged in the box body; the external gearing four-splitting transmission component comprises a driving wheel, splitting gears symmetrically arranged on the two sides, and a center gear ring, a mandrel of each splitting gear is fixed to a supporting plate connected to a cover plate of a planetary reducer shell, and the center gear ring is connected with a disc; the disc is connected with a main cylinder, the main cylinder is supported by inner holes of the box body through two bearings, and the main cylinder is connected with a drill rod flange. The device has the beneficial effects that due to the fact that the two motors are placed upside down, the motors and the speed reducer can be dismantled easily, and maintenance is convenient; the probability of tipping accidents is reduced; water resistance and dust resistance of the motors are improved; bearing capacity is higher under the external gearing four-splitting condition compared with the two-splitting condition, the difficulty of the inner gear ring technology is lower than that of the carburize-grinding technology, cost is low, and cracking does not happen easily.

Owner:吴小杰

Planetary internal-meshing four-shunt pile machine reducer with oil temperature alarm function

InactiveCN105179663AKeep abreast of running dynamicsEffective dustproofGear lubrication/coolingTransmission elementsDrive wheelReducer

The invention relates to the technical field of speed reduction of a pile machine and provides a planetary internal-meshing four-shunt pile machine reducer with an oil temperature alarm function. The planetary internal-meshing four-shunt pile machine reducer comprises a box body, motors, a cover plate and an internal-meshing four-shunt transmission part and is characterized in that an oil temperature sensor is arranged in the box body; one or two labyrinth vent hoods are arranged on the cover plate; each labyrinth vent hood comprises an outer housing, a labyrinth housing and an exhaust pipe; the two motors are invertedly connected with the lower part of the box body; the shaft-extension ends of the motors are connected with planetary reducers; the internal-meshing four-shunt transmission part comprises driving wheels, shunt gears in bilateral symmetry and central gear rings; the spindles of the shunt gears are fixed on support plates; the support plates are connected onto cover plates of housings of the planetary reducers; the central gear rings are connected with discs; the discs are connected with a main cylinder; the main cylinder is supported at a circular inner hole in the center of the box body through bearings; the main cylinder is connected with a drill rod flange. The planetary internal-meshing four-shunt pile machine reducer has the benefits as follows: the dynamic state of the reducer can be mastered, the air pressure inside the box body and the air pressure outside the box body are balanced, and since the motors are arranged invertedly, the overturning moment of the pile machine is reduced, and the overturning accident probability is reduced; the internal-meshing four-shunt bearing capacity is high, the quenching and tempering difficulty and carburization difficulty of the inner gear rings are low and the cost is low.

Owner:陈卫

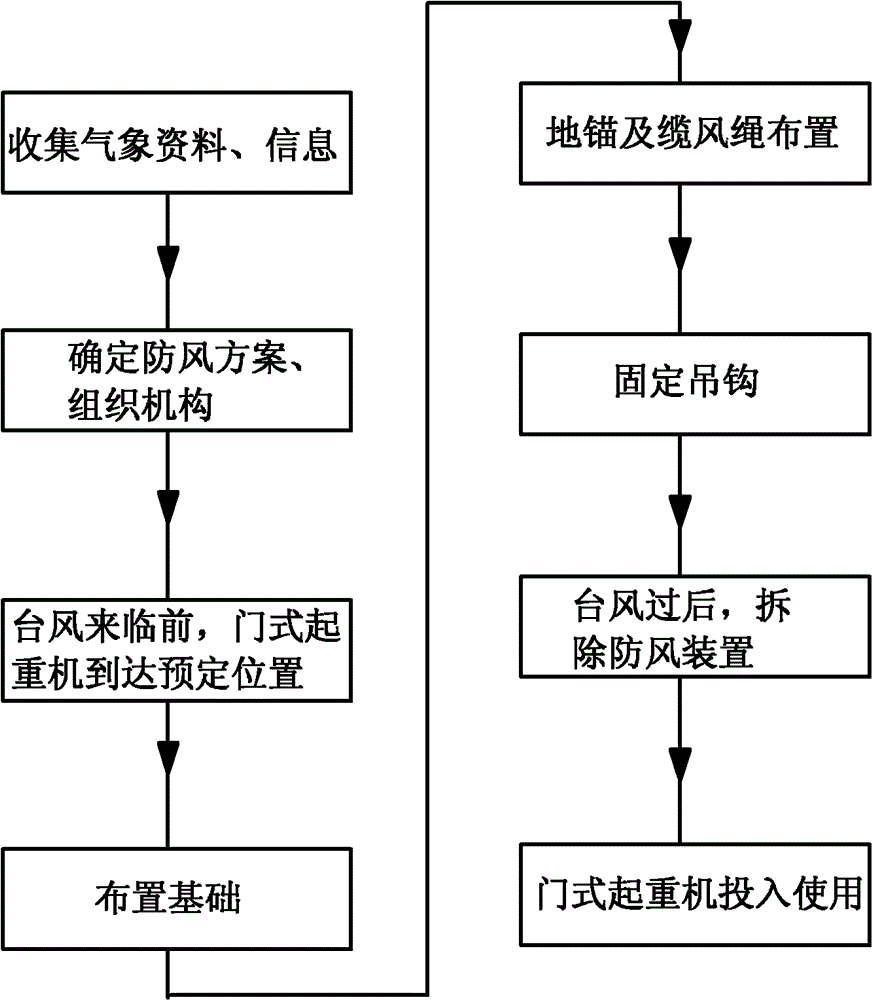

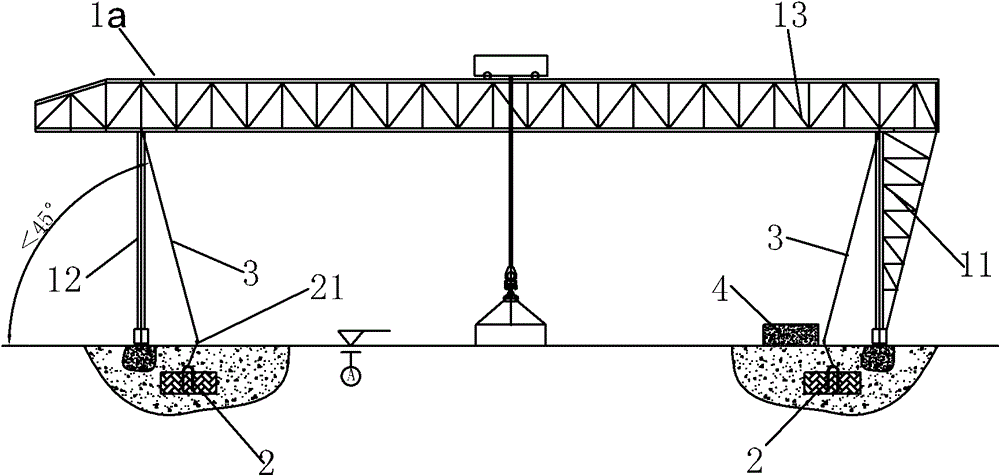

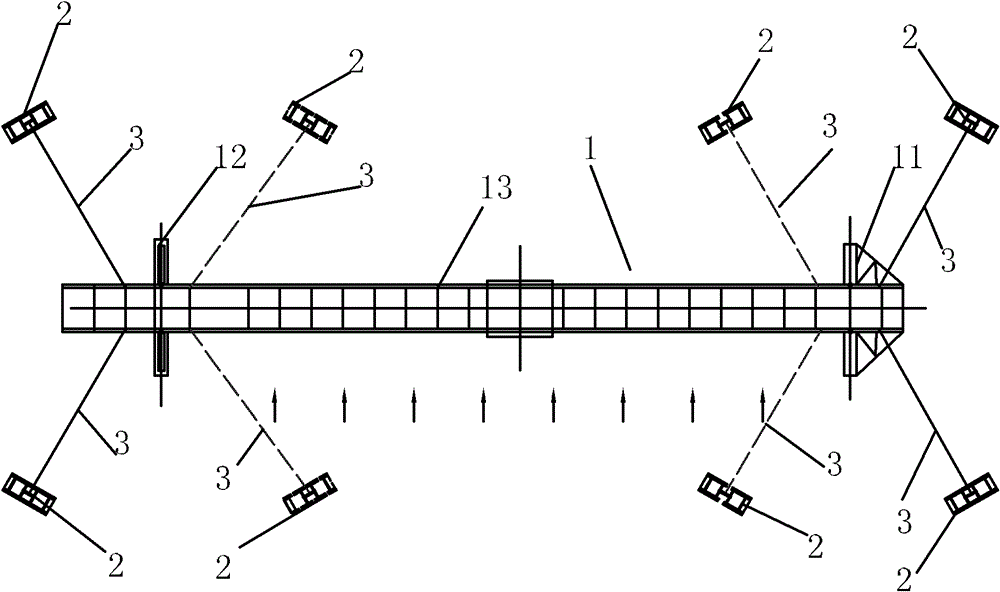

Anti-typhoon method for portal crane and special equipment thereof

InactiveCN102530721BAvoid damageMeet the requirements for resisting typhoon invasion of wind force level 11 or aboveTravelling gearSafety gearGantry craneWind force

The invention mainly relates to an anti-typhoon method for a portal crane and a special equipment thereof. The method is characterized by comprising: 1) collecting local typhoon data and forecast information and making a specific solution; 2) running the stopped portal crane to a preset position before a typhoon comes; 3) laying ground anchors and cable wind ropes; and 4) fixing a hook. According to the special device, ground anchors are arranged in rigid leg foundation pits of the rigid legs and flexible leg foundation pigs of the flexible legs of the portal crane, each ground anchor has a cable wind interface reserved on the ground; symmetric cable wind ropes are arranged on the front and back sides of the rigid legs and the front and back sides of the flexible legs of the portal crane; and an iron boots and ejecting wheels are placed under the big running wheels of the portal crane. According to the analysis on loads on different portal cranes under different wind scales, specific protective measures are adopted, the overturning moment of the portal crane is reduced, related protective main points are defined, and the equipment can resist grade 11 or above typhoons.

Owner:GUANGDONG ELEVATOR ENG MACHINERY +1

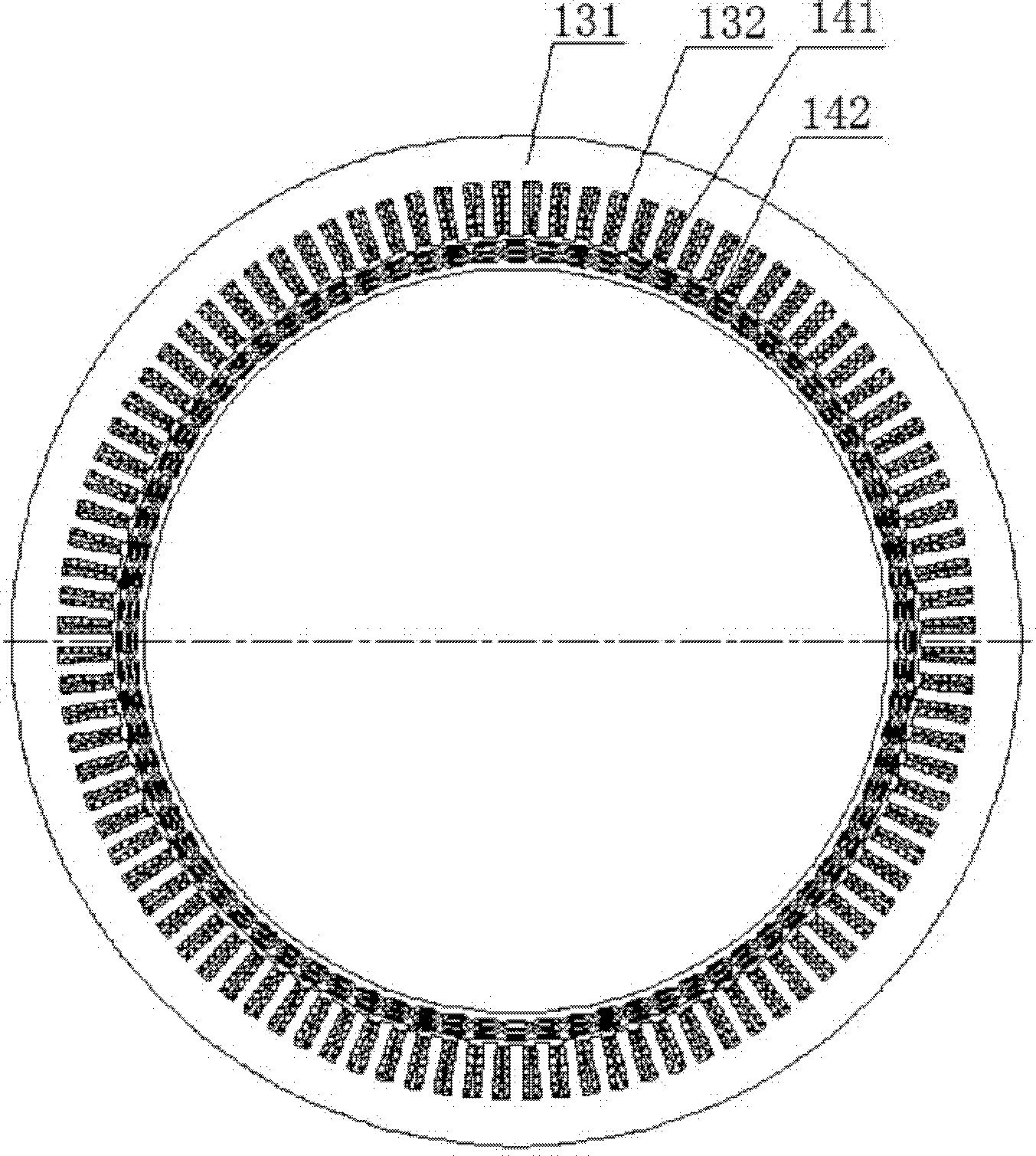

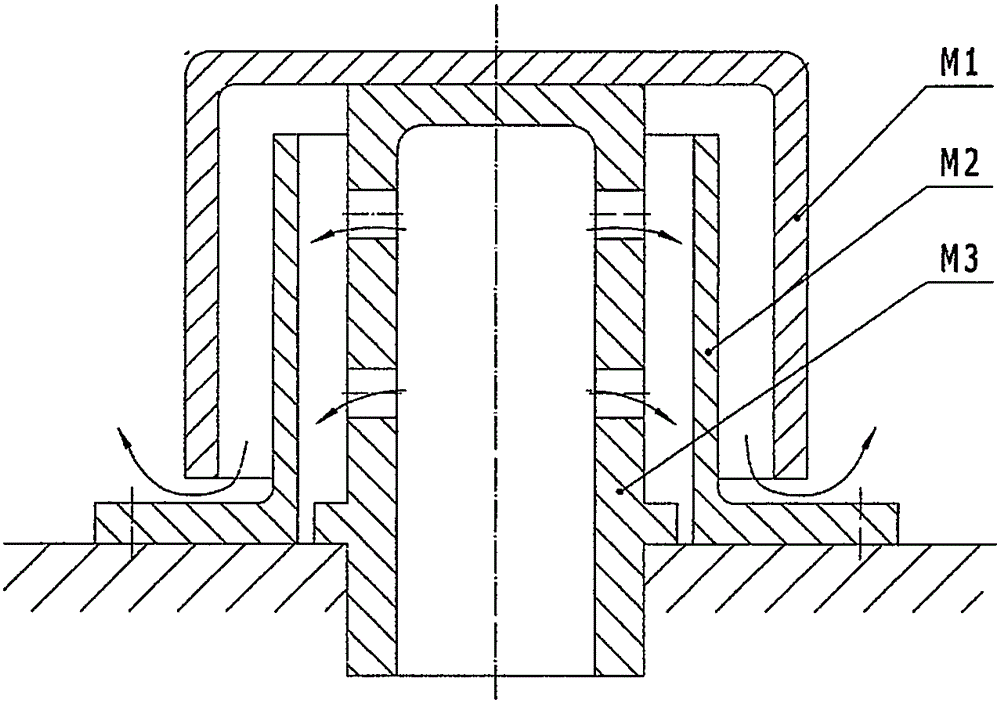

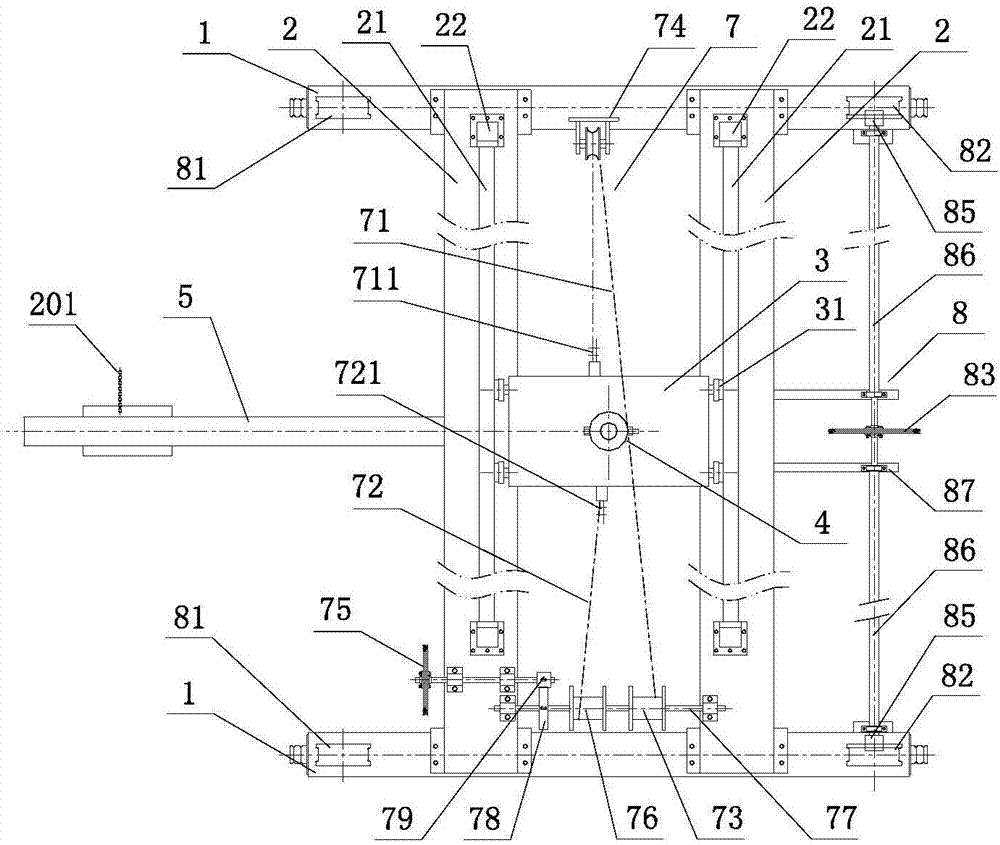

New steel tube positioning method used in steel tube conveying of tack welder and realization device

InactiveCN102430884AReduced tipping momentSmall heightWelding/cutting auxillary devicesAuxillary welding devicesRotation controlMaterials science

The invention relates to a method for steel tube lower generatrix-based constant-height positioning during steel tube conveying of a tack welder and a realization device. The realization device comprises a steel tube seam closer, wherein a steel tube propulsion device is arranged at the center line of the steel tube seam closer, left and right half conveying roller ways of the steel tube are arranged at the lateral sides of the center line of the steel tube seam closer, left and right half conveying rollers are installed on bearing seats of the left and the right half conveying rollers, the bearing seats of the left and the right half conveying rollers are installed on left and right sliding tables, the left and the right sliding tables are installed on left and right sliding table guide rail pairs, the left and the right sliding table guide rail pairs are installed on a common base, left and right screwing lead screws for driving the sliding tables to move are connected together at the end heads by a connector, and the left and the right screwing lead screws are used for controlling the synchronous opening and closing of the left and the right half conveying rollers by a rotation control mechanism. By means of the positioning method and realization device provided by the invention, the damage to a tube propulsion device body due to the increase of tilting moment of a propulsor during large-caliber steel tube seam closing is avoided, the caliber minimization of the steel tube undergoing seam closing is simultaneously realized, and the minimal conveying caliber is reduced to Phi 210 from original Phi 508.

Owner:TIANSHUI METALFORMING MACHINE TOOL GROUP

Diirect-driven generating set

ActiveCN102510142BSimplify the drivetrainSimple structureMagnetic circuit rotating partsDynamo-electric gearsMagnetic reluctanceMotor design

The invention discloses a direct-driven generator and a direct-driven generating set formed thereby. The direct-driven generator comprises a stator and a rotor, wherein the stator further comprises a stator core and a stator winding; the rotor further comprises a rotor core and permanent magnets placed in no less than one air slot of the rotor core; and the electromagnetic torque of the direct-driven generator comprises a permanent-magnet torque and a reluctance torque. The direct-driven generator synthesizes the characteristics of both a synchronous reluctance generator and a synchronous permanent-magnet generator, reflects a brand-new motor design and running concept, has the remarkable advantages of high power density, wide operation speed range, high efficiency, small size, light weight and the like, and greatly improves the competitive advantage of a direct-driven wind turbine when applied to the large-scale direct-driven wind turbine.

Owner:GUODIAN UNITED POWER TECH

Cycloid external meshed four-shunt pile machine speed reducer capable of realizing oil temperature alarming

InactiveCN105202166AKeep abreast of running dynamicsEffective dustproofGear lubrication/coolingDrive wheelElectric machine

The invention relates to the technical field of pile machine speed reduction, and discloses a cycloid external meshed four-shunt pile machine speed reducer capable of realizing oil temperature alarming. The pile machine speed reducer comprises a box body, motors, a cover plate and a transmission part, and is characterized in that an oil temperature sensor is arranged inside the box body; a labyrinth type vent hood is arranged on the cover plate; the two motors are inversely connected to the lower part of the box body; the shaft extension end of each motor is connected with a cycloid speed reducer; the transmission component comprises driving wheels, shunt gears and a center gear ring; each driving wheel is arranged on the output shaft of the corresponding cycloid speed reducer; the shunt gears are arranged symmetrically on the two sides; shafts of the shunt gears are fixed on support plates; each support plate is connected onto the end face of a housing of each cycloid speed reducer; the center gear ring is in flanged connection with a main cylinder; the main cylinder is supported in the box body by using bearings, and is connected with a drill rod flange; the drill rod flange is connected with a drill rod. The pile machine speed reducer has the benefits as follows: the speed reducer dynamic state can be mastered according to the oil temperature variation; the inside and outside of the box body reach air pressure balance by virtue of the labyrinth type vent hood; through the adoption of the inverse motors, the overturning moment of a pile machine is reduced, the incidence of overturning accidents is reduced, and the bearing force is high by virtue of the four-shunt manner; compared with carburization manner, the quenching and tempering manner for internal gear ring has the advantages that the difficulty is low and the cost is low.

Owner:陈卫

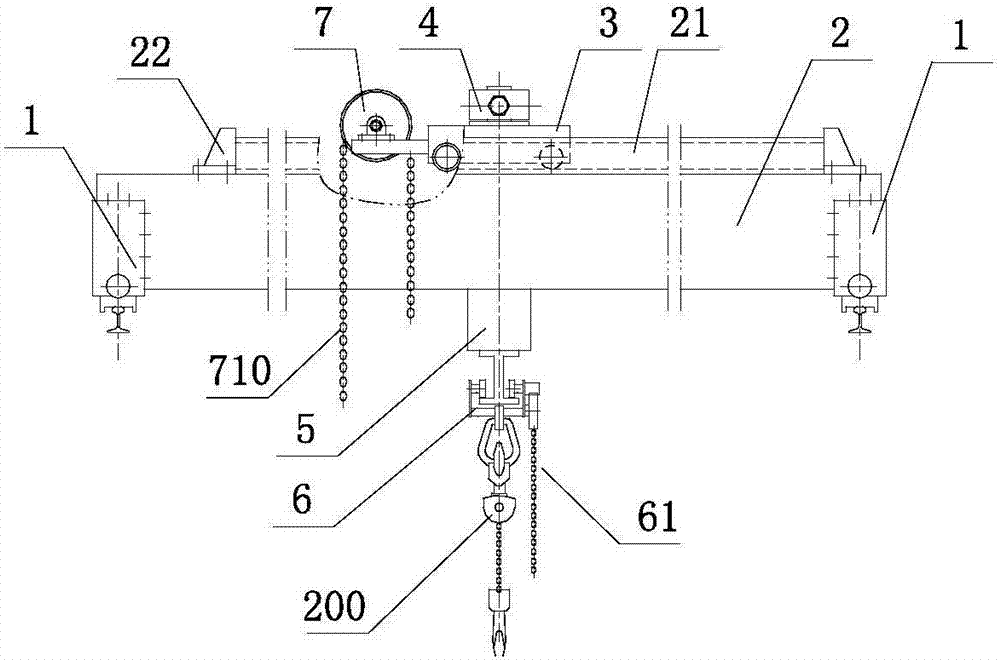

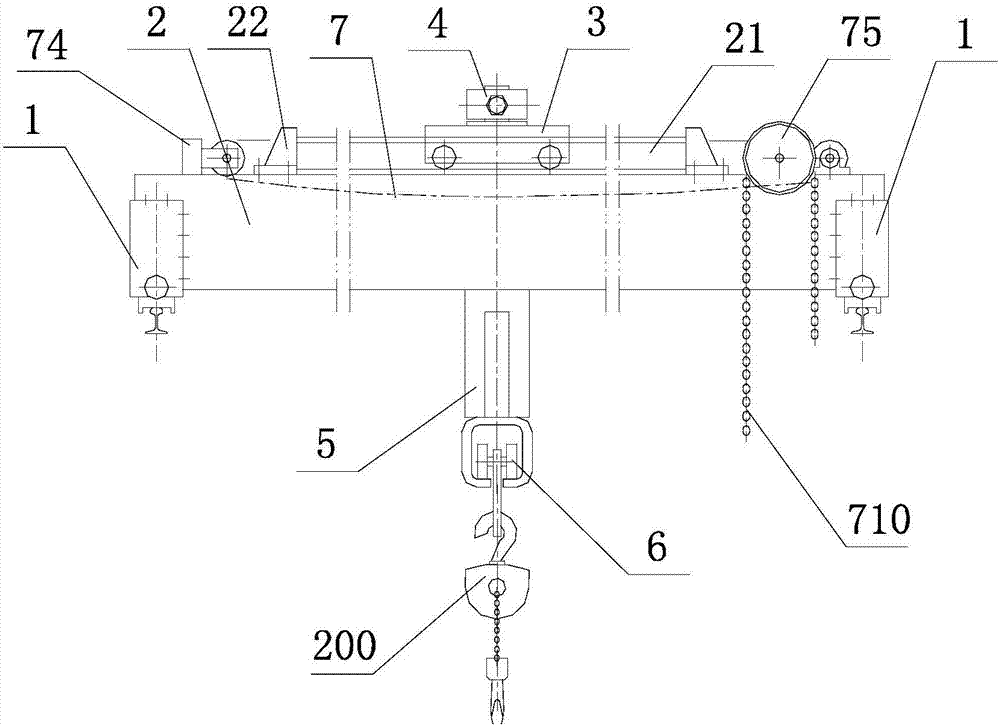

Dolly gear driven cantilever crane with balancing counterweight

InactiveCN107572389ATurn easilyEasy to operateTravelling cranesTravelling gearCantilevered beamGear drive

The invention discloses a dolly gear driven cantilever crane with a balancing counterweight. The cantilever crane comprises two end beams and two main beams which form a two-beam crane span structure,wherein a hand-pulled trolley running device is arranged between the two end beams; inverted U-shaped tracks are arranged on the two main beams; a running dolly is arranged between and connected withthe two tracks; the running dolly is provided with a gear drive unit and a rotating mechanism; a thrust bearing on the rotating mechanism is arranged above and connected with a bearing pedestal and fastened via locknuts; the lower end of a suspender shaft in the rotating mechanism is connected with a cantilever member; one end of a cantilever beam on the cantilever member is connected with a hand-pulled trolley and the balancing counterweight is hung on the other side of the cantilever beam for prevention of tilting; a hand-pulled chain hoist is hung below the hand-pulled trolley and capableof hoisting cargos; and the cantilever beam is located below the two main beams and capable of carrying out rotation, and can stretch out of a workshop for operation.

Owner:林霞

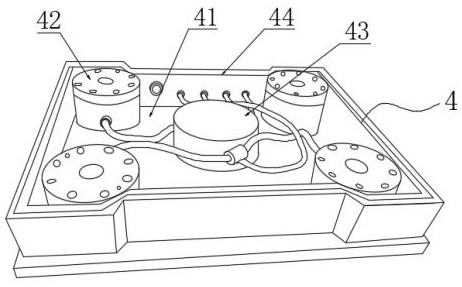

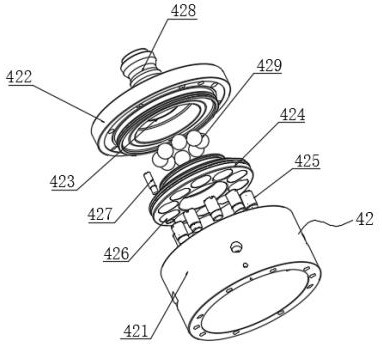

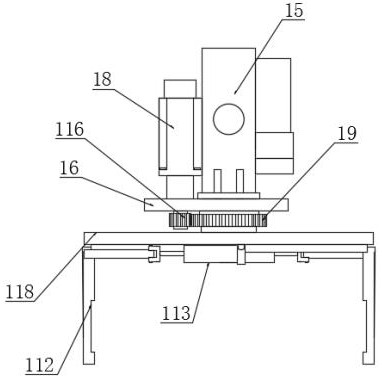

An intelligent production line for component manufacturing and its working method

ActiveCN112108929BFully automatedLarge locking forceMeasurement/indication equipmentsMetal working apparatusProduction lineRobot hand

The invention discloses an intelligent production line for parts manufacturing and a working method thereof, comprising a loading and unloading mechanism, a conveying mechanism, a production mechanism and a pallet mechanism, the conveying mechanism includes a fixing frame and a truss track fixed above the fixing frame, the A manipulator assembly is slidably connected to the surface of the truss track, and a lifting mechanical arm is slidably connected to the inner cavity of the manipulator assembly. The invention relates to the technical field of component processing. The intelligent production line and its working method for parts manufacturing enable different parts to be processed on the same equipment without changing the clamping method and cutting tool. The zero point positioning module is used to fix the processed workpiece on the clamping pallet. The truss robot grabs and clamps the pallet and puts it on the fixed clamping base of the CNC machine to realize the automation of loading and unloading of the CNC machine. The operator clamps the workpiece on the loading table without occupying the machine tool, realizing a truss The robot can be responsible for loading and unloading multiple CNC machines.

Owner:AVIC POWER SCI & TECH ENG

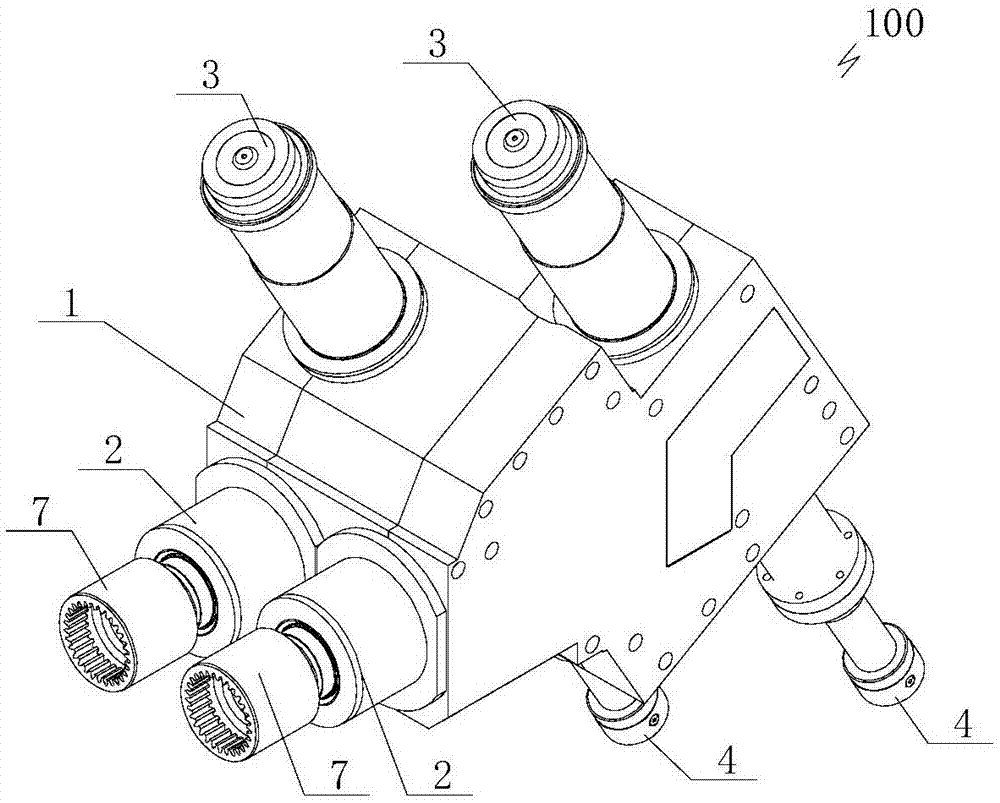

Corner gearbox for single-rack driving steel pipe stretch reducing mill

PendingCN107321798AAvoid damageInhibit sheddingRolling mill drivesMetal rolling arrangementsControl theoryPower transmission

The invention relates to a corner gearbox for a single-rack driving steel pipe stretch reducing mill. The corner gearbox comprises a box body, wherein two groups of power transmission systems of which the rotating directions are different penetrate through the box body in a sealing mode, the power transmission systems respectively comprise power input shaft systems and power output shaft systems, the output ends of the power output shaft systems respectively comprise external drum-type gears which can be connected with a milling rack, telescopic control parts respectively communicate with the other ends of the power output shaft systems, output shaft hole channels through which the power output shaft systems penetrate are formed in the box body, the power output shaft systems comprise hollow power output shafts, output shaft system bevel gears fixedly sleeve the power output shafts respectively, and the power output shafts are rotatably supported in the output shaft hole channels by virtue of output shaft bearing structures which sleeve both sides of the output shaft system bevel gears. According to the corner gearbox, the problem of unstable output shafts in the prior art is solved, and the stress optimization of the power output shaft systems is realized, so that the whole structure is stable.

Owner:BEIJING JINGCHENG RUIXINCHANGCAI ENG TECH +1

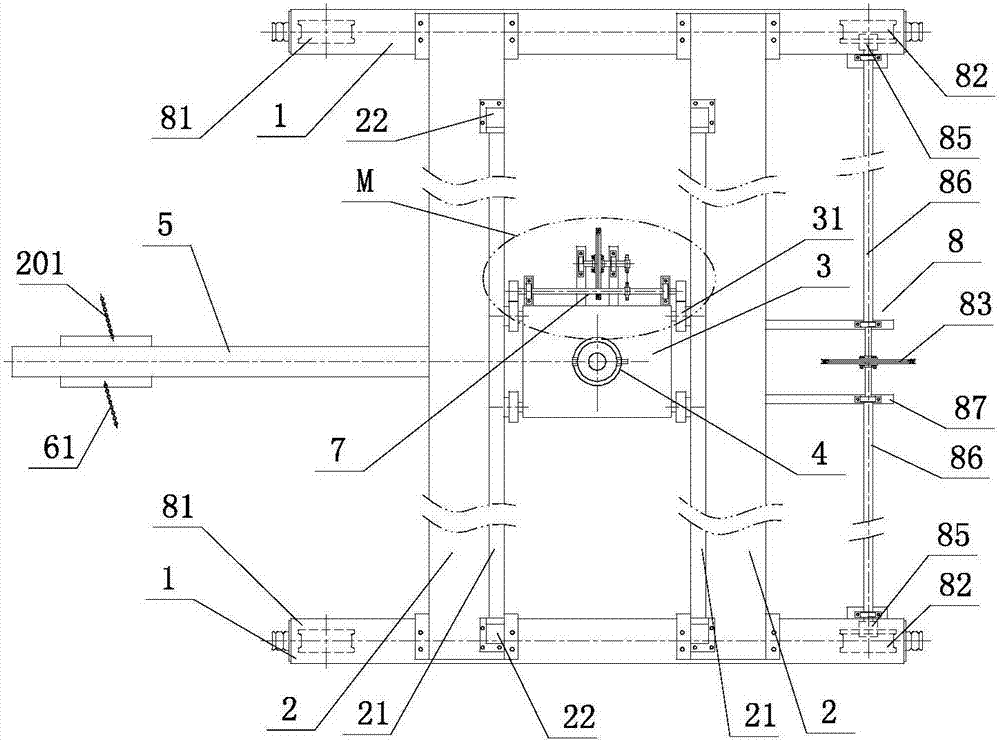

Hand-pulling driven cantilever crane with balancing counterweight

The invention discloses a hand-pulling driven cantilever crane with a balancing counterweight. The cantilever crane comprises two end beams and two main beams which form a two-beam crane span structure, wherein a hand-pulled trolley running device is arranged between the two end beams; a beam bench is arranged above and fixedly connected with the two main beams; the beam bench is provided with a rotating mechanism; a thrust bearing on the rotating mechanism is arranged above and connected with a bearing pedestal and fastened via locknuts; the lower end of a suspender shaft in the rotating mechanism is connected with a cantilever member; one end of a cantilever beam on the cantilever member is connected with a hand-pulled running trolley and the balancing counterweight is hung on the otherside of the cantilever beam for prevention of tilting; the hand-pulled running trolley can horizontally move to and fro along the cantilever beam; a hand-pulled chain hoist is hung below the hand-pulled trolley and capable of hoisting cargos; and the cantilever beam is located below the two main beams and capable of carrying out rotation, and can stretch out of a workshop for operation.

Owner:林霞

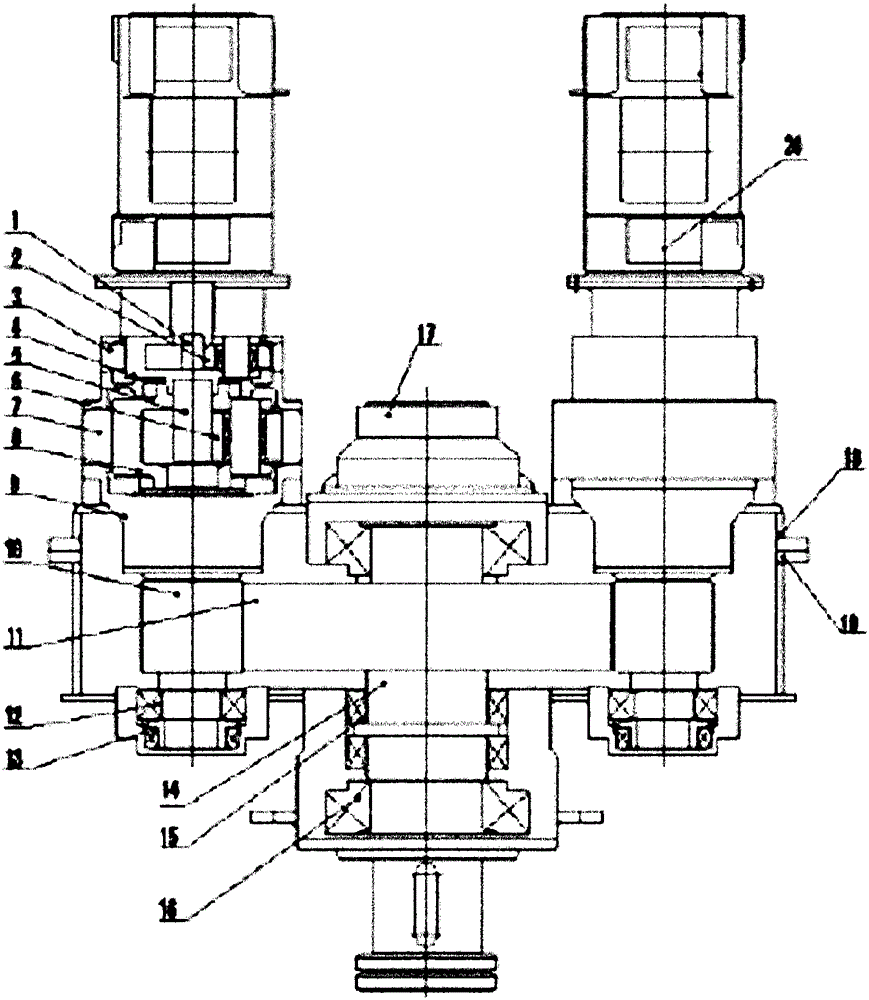

Speed reducer of motor reversely-arranged bidirectional output piling machine

InactiveCN105090379AReduced tipping momentReduce the chance of tipping accidentsToothed gearingsMechanical energy handlingDrive wheelReduction drive

The invention relates to the technical field of piling machine speed reducing, and discloses a speed reducer of a motor reversely-arranged bidirectional output piling machine. The speed reducer comprises a box body, two motors, a cover plate and a gear transmission part. The speed reducer is characterized in that the two motors are connected with double-cycloid speed reducer parts, and are connected with the lower part of the box body in a reversely arranged manner; the double-cycloid speed reducer parts are arranged in the box body; the gear transmission part comprises an outer gearing speed reducing part and an inner gearing quasi-planet speed increasing part; the outer gearing speed reducing part comprises driving wheels, diversion gears and an outer gear of a center tooth ring; the inner gearing quasi-planet speed increasing part comprises an inner tooth ring part of the center tooth ring, a quasi-planet wheel and a center gear; the diversion gears and a mandrel of the quasi-planet wheel are fixed in the cover plate; the center tooth ring is connected with an outer sleeve; the outer sleeve is supported in the cover plate by a first bearing and a second bearing; the center gear is connected with an inner cylinder; and the inner cylinder is supported in an inner hole of the outer sleeve by a third bearing and a fourth bearing. The speed reducer has the benefits that the lumpish motors and the speed reducer part are easy to dismount, so that the service and maintenance are convenient; a tilting moment of the piling machine is reduced, so that the probability of tipping accidents is reduced; and water prevention and dust prevention of the motors are facilitated.

Owner:吴小杰

Hypocycloid bidirectional output pile-driver speed reducer with oil temperature alarming function

InactiveCN105240509AKeep abreast of running dynamicsEffective dustproofConstructionsGear lubrication/coolingDrive wheelReduction drive

The invention relates to the technical field of speed reduction of pile drivers, in particular to a hypocycloid bidirectional output pile-driver speed reducer with an oil temperature alarming function. The hypocycloid bidirectional output pile-driver speed reducer comprises a box, motors, a cover plate and gear transmission parts and is characterized in that an oil temperature sensor is arranged in the box, and labyrinth vent hoods are arranged on the cover plate and each comprise an outer hood shell, a labyrinth shell and an exhaust pipe; the two motors are inversely connected with the lower side of the box, and shaft extension ends of the motors are connected with hypocycloid speed reducer bodies; the gear transmission parts comprise an outer meshing pair and an inner meshing pair; the outer meshing pair comprises a driving wheel, a distributing gear and outer teeth of a central circular ring; the inner meshing pair comprises inner teeth of the central circular ring, five quasi planet wheels and a central wheel; the central circular ring is connected with an outer sleeve, and the outer sleeve is supported in a central hole of the box through bearings; the outer sleeve is connected with a base plate, and a flange of the base plate is connected with a large sleeve of a pile driver; the central wheel is connected with an inner barrel, the inner barrel is supported in the outer sleeve through bearings, and the inner barrel is connected with a drill rod bushing. The hypocycloid bidirectional output pile-driver speed reducer has the beneficial effects that the dynamic state of the speed reducer can be mastered, the air pressure in the box and the air pressure outside the box are balanced, the motors are inversed to reduce the overturning moment of the pile driver, and thus the overturning accident probability is reduced.

Owner:陈卫

Oil-temperature warning star-wheel two-way outputting pile machine speed reducer

InactiveCN105202168AKeep abreast of running dynamicsEffective dustproofConstructionsToothed gearingsDrive wheelReducer

The invention relates to the technical field of pile machine speed reduction, and provides an oil-temperature warning star-wheel two-way outputting pile machine speed reducer. The oil-temperature warning star-wheel two-way outputting pile machine speed reducer comprises a case body, motors, a cover plate and a gear transmission part. The oil-temperature warning star-wheel two-way outputting pile machine speed reducer is characterized in that an oil temperature sensor is arranged in the case body, labyrinth type vent hoods are arranged on the cover plate, each labyrinth type vent hood comprises an outer shell, a labyrinth shell and an exhaust pipe, the motors are connected to the lower portion of the case body in an inverted mode, the drive ends of the motors are connected with star-wheel speed reducers, the gear transmission part comprises an external meshing pair and an internal meshing pair, the external meshing pair comprises driving wheels, diffluence gears and outer teeth of a center circle, the internal meshing pair comprises inner teeth of the center circle, five quasi planetary wheels and a center wheel, the center circle is connected with an outer sleeve which is supported in a center hole of the case body through bearings, the outer sleeve is connected with a base plate, and a base plate flange is used for being connected with a pile machine big casing; the center wheal is connected with an inner barrel which is supported in the outer sleeve through bearings, and the inner barrel is connected with a drill pipe sleeve. The oil-temperature warning star-wheel two-way outputting pile machine speed reducer has the advantages that the dynamic state of the speed reducer can be mastered, the air pressure inside and outside the case body is balanced, the tilting moment of the pile machine is reduced through the inverted motors, and the probability of tilting accidents is reduced.

Owner:陈卫

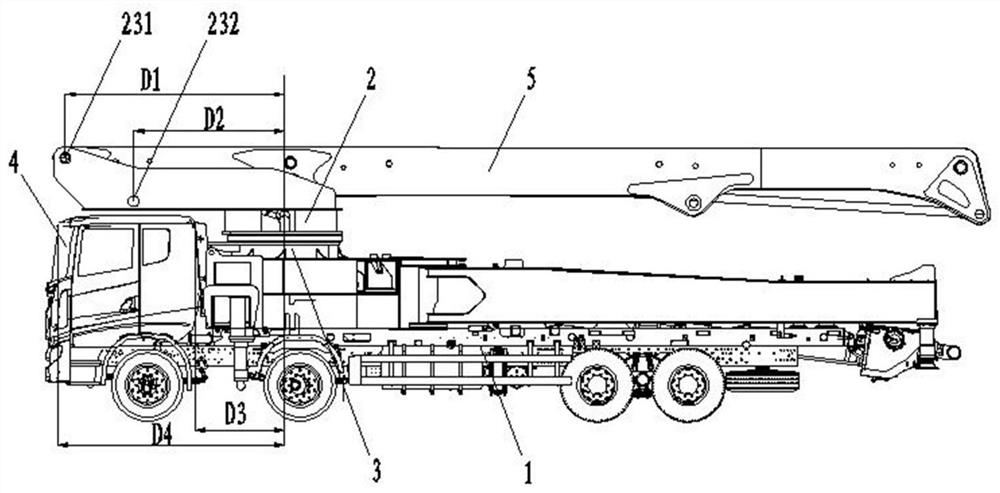

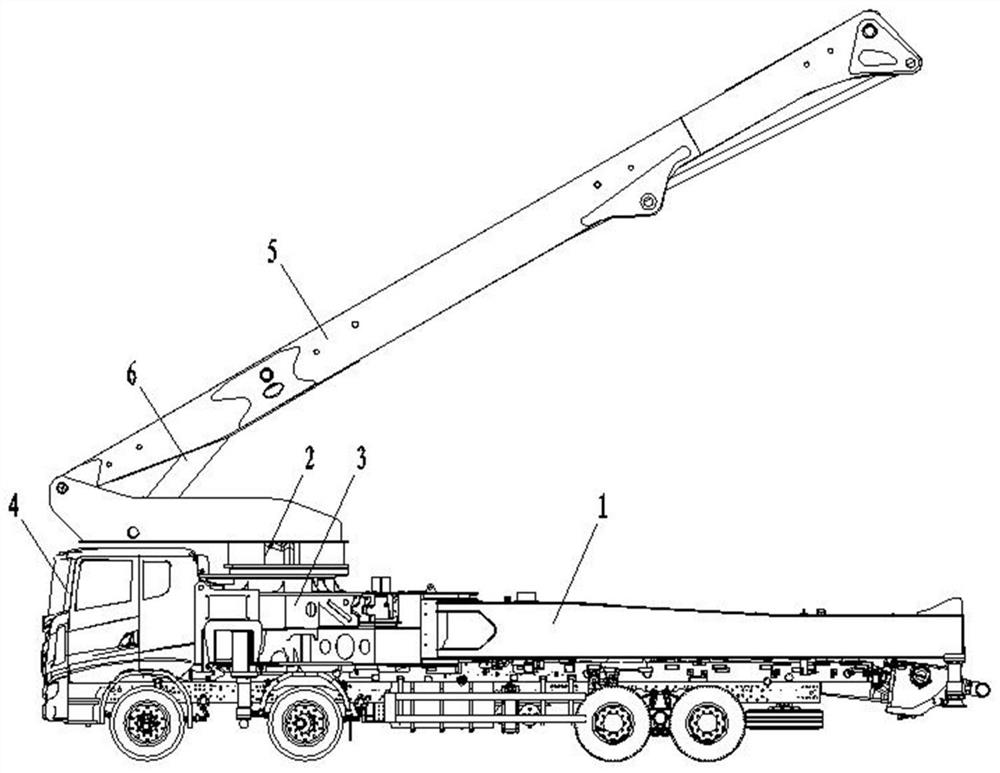

Work machine

ActiveCN114517582AIncrease layout lengthReduced tipping momentFire rescueBuilding material handlingControl engineeringStructural engineering

The invention provides an operation machine. The operation machine comprises a vehicle body, a rotary table, an arm frame and a luffing mechanism. A rotary assembly positioned behind the cab is mounted on the vehicle body; the rotary table is installed on the rotary assembly and comprises a hinge arm, the hinge arm can rotate to the position above the cab, and a first hinge structure and a second hinge structure are arranged on the hinge arm. The eccentric distance of at least one of the first hinge structure and the second hinge structure relative to the rotation axis of the rotary table is larger than the distance between the rear end of the cab and the rotation axis. The first hinge structure is hinged to the end of the arm support, the second hinge structure is hinged to one end of the luffing mechanism, and the other end of the luffing mechanism is hinged to the middle of the arm support. Based on eccentric arrangement of the rotary table, the arm support can rotate to the position above the cab along with the hinged arm, effective utilization of the spare space above the cab is achieved, the arrangement length of the arm support is greatly increased, the tipping moment of the arm support can be effectively reduced, and the operation capacity of the arm support is enhanced.

Owner:SANY AUTOMOBILE MFG CO LTD

Two-way output pile machine speed reducer with reverse motors

InactiveCN105090374AReduced tipping momentReduce the chance of tipping accidentsToothed gearingsTransmission elementsDrive wheelGear wheel

The invention relates to the technical field of pile machine speed reduction. A two-way output pile machine speed reducer with reverse motors comprises a box body, the motors, a cover plate and a gear transmission piece, and is characterized in that the two motors are connected with NBD planet speed reducers and connected to the lower portion of the box body in a reverse manner; the NBD speed reducers are arranged in the box body; the gear transmission piece comprises an outer meshing speed reduction piece and an inner meshing quasi-planet speed increase piece; the outer meshing piece comprises a driving wheel, a diversion gear and an outer gear of a central gear ring; the inner meshing piece comprises an inner gear ring of the central gear ring, a quasi-planet gear and a central gear; mandrels of the diversion gear and the quasi-planet gear are fixed into the cover plate; the central gear ring is connected with an outer sleeve; the outer sleeve is supported in the cover plate through a first bearing and a second bearing; and the central gear is connected with an inner cylinder which is supported in an inner hole of the outer sleeve through a third bearing and a fourth bearing. The two-way output pile machine speed reducer has the beneficial effects that the heavy motors and the speed reducers are easy to detach, and therefore repairing and maintenance are convenient; the overturning moment of a pile machine is reduced, and therefore the probability of turnover accidents is decreased; and water prevention and dust prevention of the motors are facilitated.

Owner:吴小杰

Planetary-hypocycloid double-annular-plate pile machine reducer with oil temperature alarm function

InactiveCN105179665AKeep abreast of running dynamicsEffective dustproofToothed gearingsGear lubrication/coolingRolling-element bearingReduction drive

The invention relates to the technical field of speed reduction of a pile machine and provides a planetary-hypocycloid double-annular-plate pile machine reducer with an oil temperature alarm function. The planetary-hypocycloid double-annular-plate pile machine reducer comprises a box body, motors, a cover plate and a transmission part, wherein the transmission part comprises eccentric bearings, annular plates, hypocycloid gear rings and cycloidal gears; the four eccentric bearings are respectively arranged on the output shafts of two NGWs; the eccentric bearing comprises rolling bearings and eccentric sleeves; the phase difference of two eccentric sleeves is 180 degrees; the hypocycloid gear rings are matched with the middles of the annular plates; the planetary-hypocycloid double-annular-plate pile machine reducer is characterized in that an oil temperature sensor is arranged in the box body; one or two labyrinth vent hoods are arranged on the cover plate; the motors are invertedly arranged below the box body; the shafts of the motors are connected with the NGWs; the bottommost eccentric sleeve is supported on a thrust bearing; the cycloidal gears are connected with a main cylinder; the main cylinder is supported in the box body through bearings; the main cylinder is connected with a flange and the flange is connected with a drill rod. The planetary-hypocycloid double-annular-plate pile machine reducer has the benefits as follows: the dynamic state of the reducer can be mastered according to oil temperature changes, the air pressure inside the box body and the air pressure outside the box body are balanced through the vent hoods, and since the motors are arranged invertedly, the overturning moment of the pile machine is reduced and the accident probability is reduced; since quadrupole motors can replace original sextupole motors for speed reduction of the NGWs, so that the cost and the weight are reduced.

Owner:陈卫

Inner gearing four-split pile driver reducer with inverted motors

InactiveCN105099070AEasy maintenanceReduced tipping momentMechanical energy handlingGear grindingDrive wheel

The invention relates to the technical field of pile driver reduction, and discloses an inner gearing four-split pile driver reducer with inverted motors. The inner gearing four-split pile driver reducer comprises a box body, motors, cover boards and inner gearing four-split transmission parts; the inner gearing four-split pile driver reducer is characterized in that extension ends of the motors are connected with double-cycloid reducers; the motors are connected with the lower part of the box body in an inverted manner; the double-cycloid reducers are arranged in the box body; each inner gearing four-split transmission part comprises driving wheels, bisymmetric splitting gears and a center gear ring; mandrels of the splitting gears are fixed on a support plate; each support plate is connected with each cover board of a double-cycloid reducer casing; each center gear ring is connected with a disk; each disk is connected with a main cylinder; each main cylinder is supported in an inner hole of the box body by virtue of two bearings; each main cylinder is connected with a drill pipe flange. The inner gearing four-split pile driver reducer with the inverted motors has the beneficial effects that the double motors are inverted, so that the motors and the reducer are easy to dismantle and convenient to repair and maintain; the overthrow accident probability is reduced; waterproofing and dustproofing of the motors are facilitated; the carrying capacity of the inner gearing four-split mode is higher than that of a two-split mode; the inner gear ring process is small in carburizing difficulty and gear grinding difficulty and low in cost; and the inner gearing four-split pile driver reducer is not easy to crack.

Owner:吴小杰

Roller mill

A roller mill (1) for grinding granular materials such as cement raw materials, cement clinker and similar materials is described, said roller mill (1) comprising: a housing (3) surrounding a grinding table (7) , the grinding table (7) is rotatable about a vertical axis (5), said grinding table is supported by the machine bed (11) via a support (9); at least one roller (13), which is rotatable about a substantially fixed axis (12 ) rotates, said roller configured to interact with the grinding table (7); and a motor (15) comprising a rotor (16) firmly connected to the grinding table (7), and a stator (17). The roller mill is characterized in that the stator (17) constitutes an integral part of the support (9) of the grinding table (7), so that at least some of the load exerted by said at least one roller (13) on the grinding table (7) It is transmitted to the machine base (11) via the stator (17).

Owner:F L SMIDTH & CO AS

NBD planet external meshing four-shunt pile driver speed reducer with oil temperature alarm function

InactiveCN105156642AKeep abreast of running dynamicsEffective dustproofGear lubrication/coolingDrive wheelGear wheel

The invention relates to the technical field of pile driver speed reduction, in particular to an NBD planet external meshing four-shunt pile driver speed reducer with an oil temperature alarm function. The NBD planet external meshing four-shunt pile driver speed reducer comprises a box, motors, a cover plate and a transmission part and is characterized in that an oil temperature sensor is arranged in the box; labyrinth type ventilating covers are arranged on the cover plate; the two motors are connected under the box in an inverted mode, and the extending ends of motor shafts are connected with NBD planet speed reducer bodies; the transmission part comprises driving wheels, shunt gears and a center gear ring, the driving wheels are arranged on output shafts of the NBD planet speed reducer bodies, the shunt gears are symmetrically arranged at the two sides, shafts of the shunt gears are fixed to supporting plates, the supporting plates are connected to end faces of housings of the NBD planet speed reducer bodies, the center gear ring is connected with a flange of a main cylinder, the main cylinder is supported in the box through bearings and connected with the flange, and the flange is connected with a drill rod. The NBD planet external meshing four-shunt pile driver speed reducer has the advantages that the dynamic condition of the speed reducer can be mastered according to changes of oil temperature; air pressure inside and outside the box is balanced through the labyrinth type ventilating covers; as the motors are arranged in the inverted mode, the overturning moment of a pile driver is reduced, the probability of overturning accidents is reduced, four-shunt bearing capacity is high, and hardening and tempering cost of the inner gear ring is low.

Owner:陈卫

Dolly steel rope driven crane with C-slot cantilever beam and balance weight

InactiveCN107572421AEasy to operateLess investmentTravelling cranesSafety gearCantilevered beamSteel rope

The invention discloses a dolly steel rope driven crane with a C-slot cantilever beam and a balance weight. The crane comprises two end beams and two main beams. Two end beams and two main beams forma dual beam crane span structure. A hand-pulled cart operation device is arranged between two end beams. An inverted U shape track is arranged above each main beam. A running dolly is arranged betweentwo tracks. The running dolly is provided with a steel rope driving device and a rotation mechanism. In the rotation mechanism, the lower end of a suspender shaft of the rotation mechanism is connected to a cantilever member. The cantilever beam of the cantilever member is formed by C shape steel channels, and the grooves are downward. A slide cart is arranged in the groove of one end of the cantilever beam, and a balance weight is hung on the other end of the cantilever beam so as to prevent tipping. The slide cart can horizontally reciprocate in the groove of the cantilever beam. A hand-pulled chain hoist is hung under the slide cart and can lift goods. The cantilever beam is arranged under two main beams, can stretch out of a workshop to operate, and is capable of rotating.

Owner:林霞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com