Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Reduced likelihood of wrinkling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

5182-O state aluminum alloy plate for automobile inner plate and production method for 5182-O state aluminum alloy plate

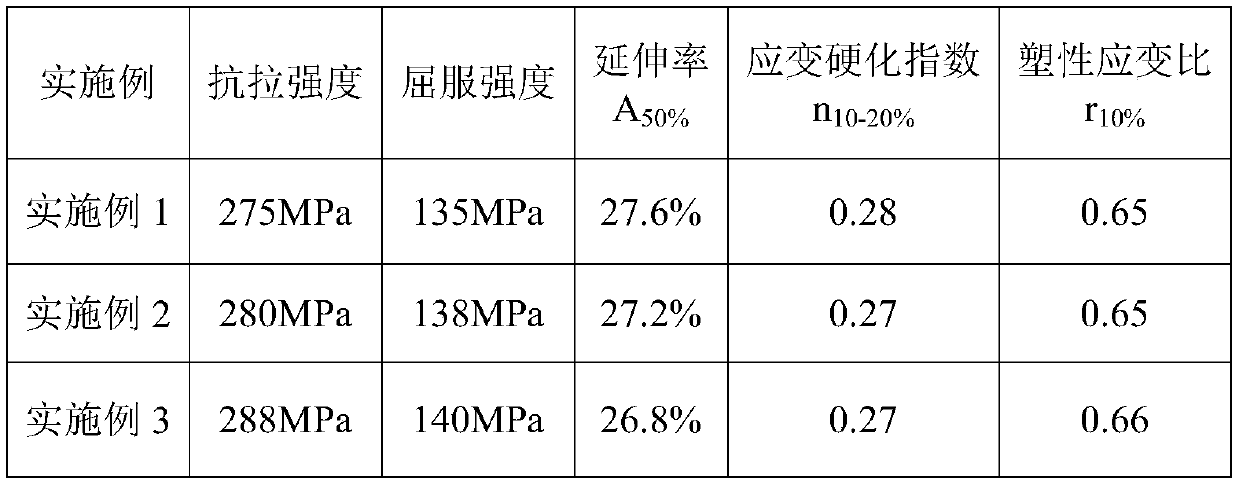

The invention relates to a 5182-O state aluminum alloy plate for an automobile inner plate. The 5182-O state aluminum alloy plate comprises the following raw materials in weight percentage: 0.1-0.15%of Si, 0.15-0.3% of Fe, no more than 0. 03% of Cu, 0.2-0.4% of Mn, 4.5-4.9% of Mg, 0.03-0.07% of Cr, no more than 0.1% of Zn, 0.015-0.04% of Ti and the balance Al. The production method comprises thesteps of batching; smelting and casting; ingot homogenizing heat treatment and milling surface machining; hot rolling; cold rolling; continuous and complete annealing of the finished product, wherein,the annealing furnace temperature is 420-480 DEG C, and the speed of the aluminum alloy strip in the furnace is 10-20 m / min; tension leveling line washing and withdrawing-straightening plate shape; and flying shear slicing. According to the 5182-O state aluminum alloy plate, the properties are stable, the internal texture is uniform, the machining plasticity is high, the orange peel line after stamping does not exist, and the strength is high.

Owner:河南明晟新材料科技有限公司

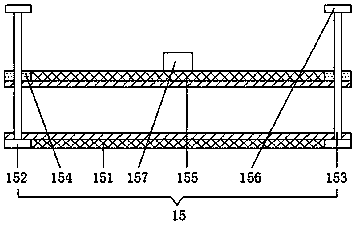

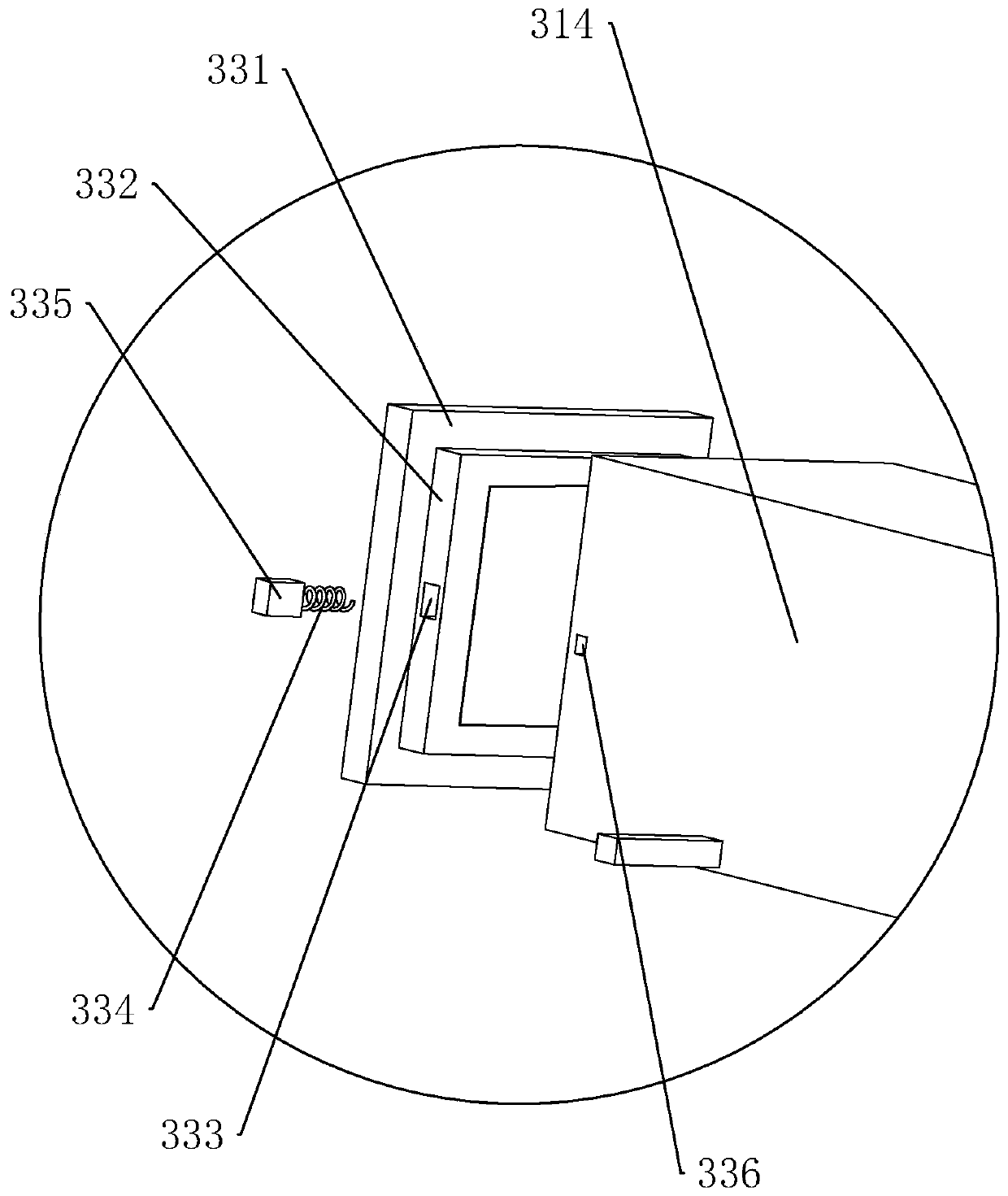

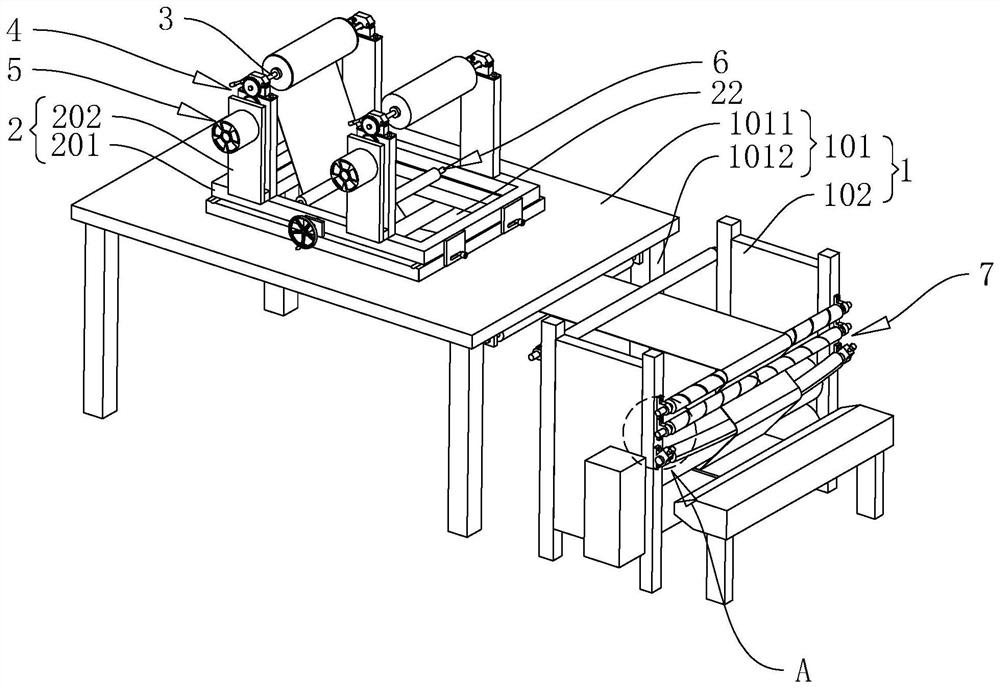

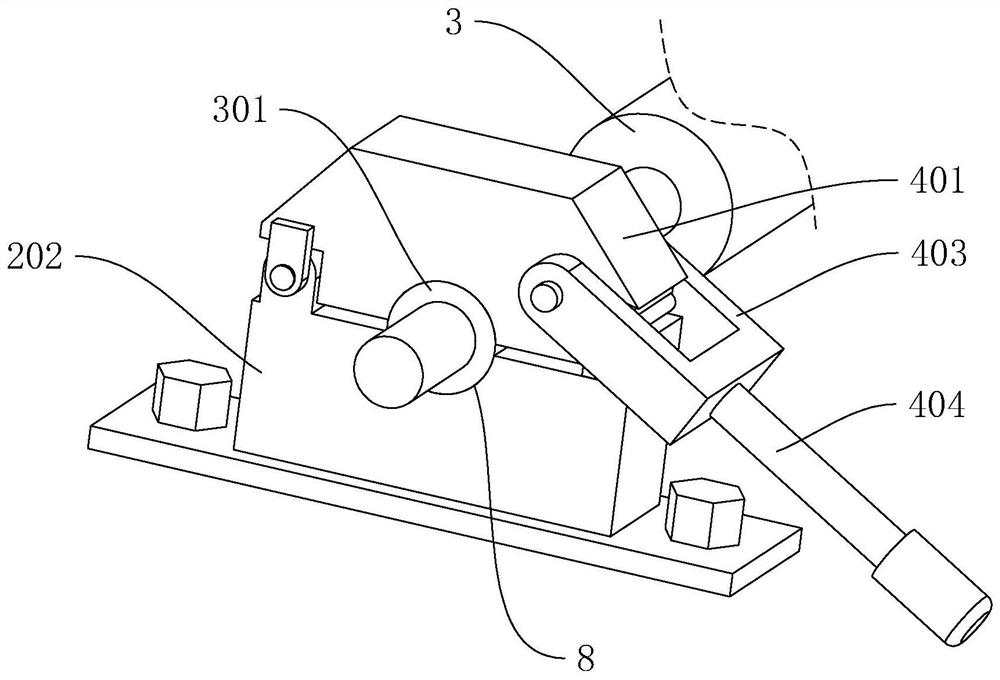

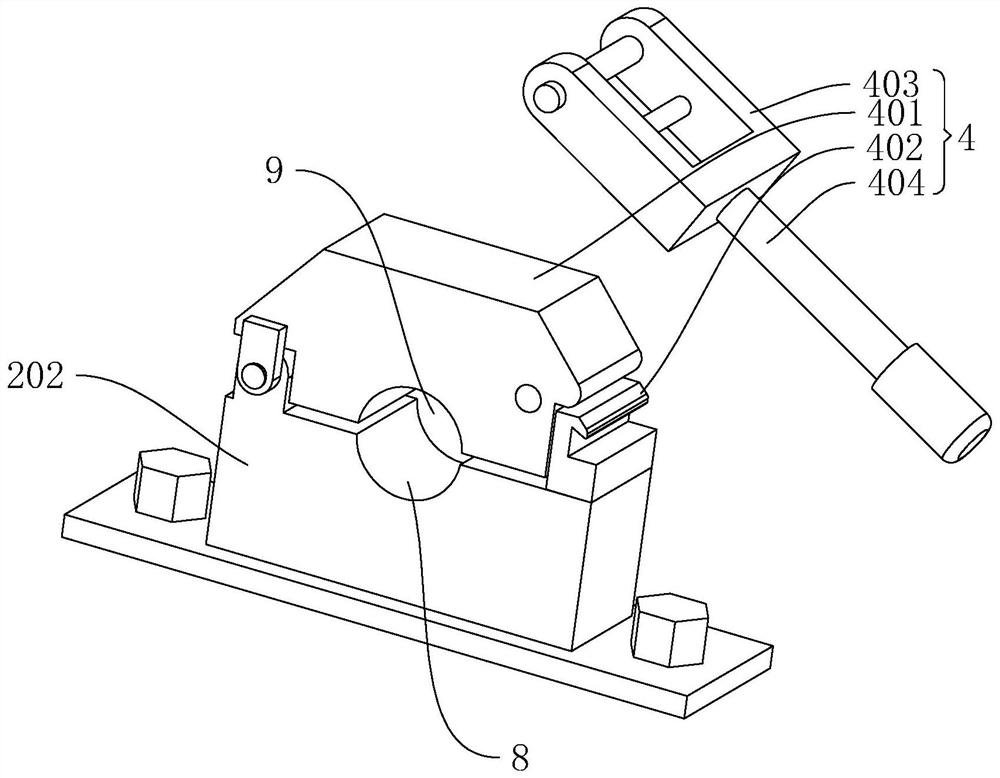

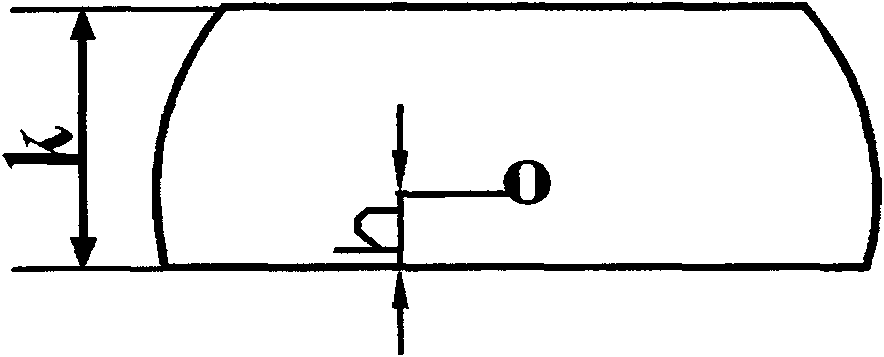

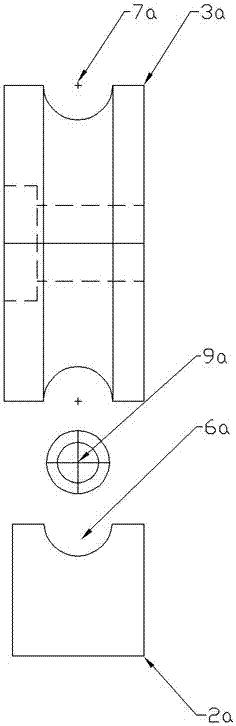

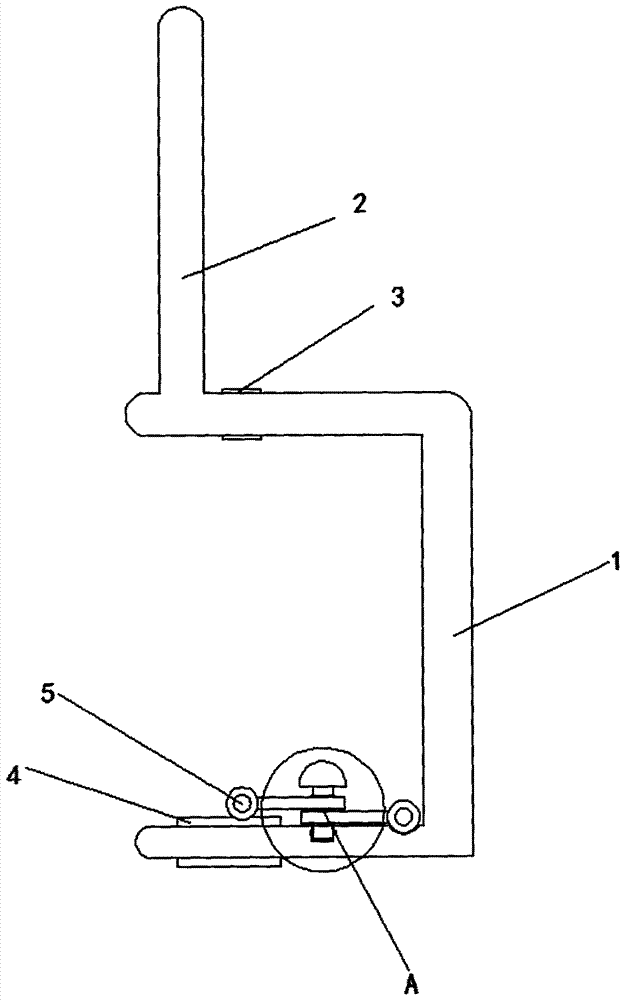

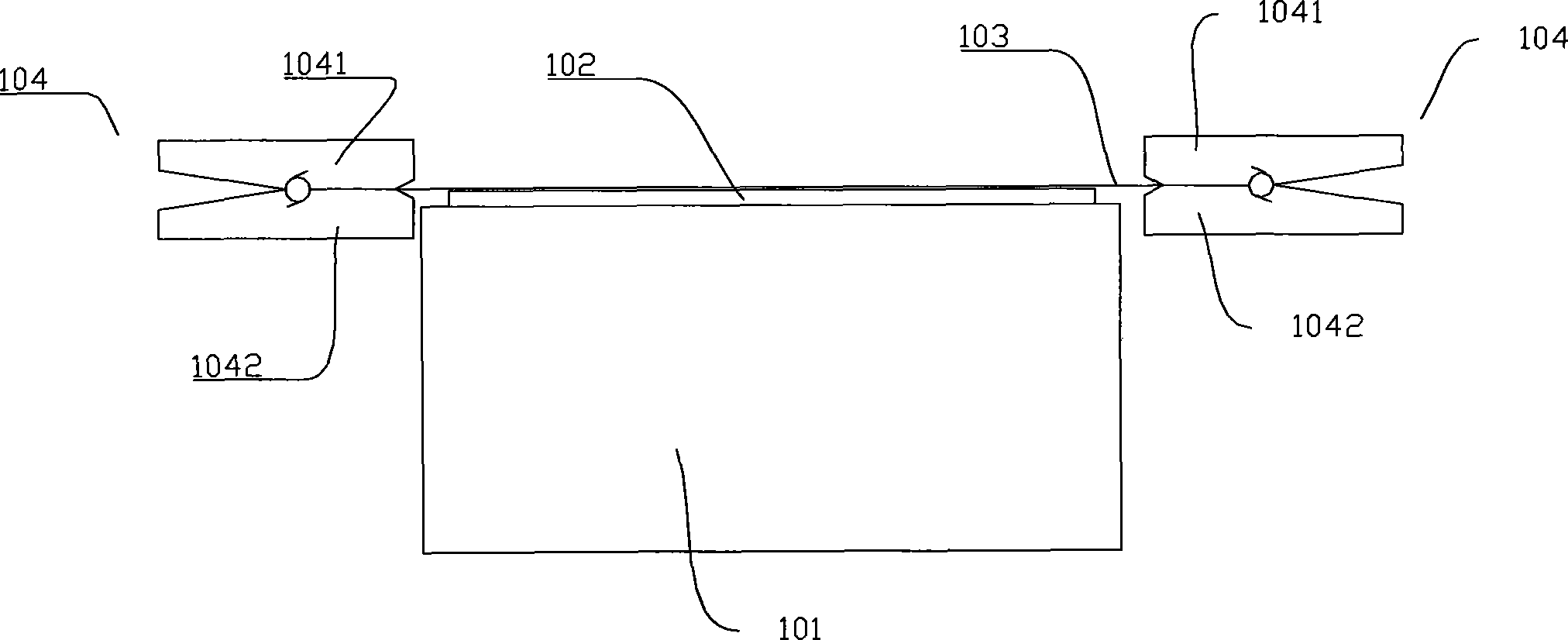

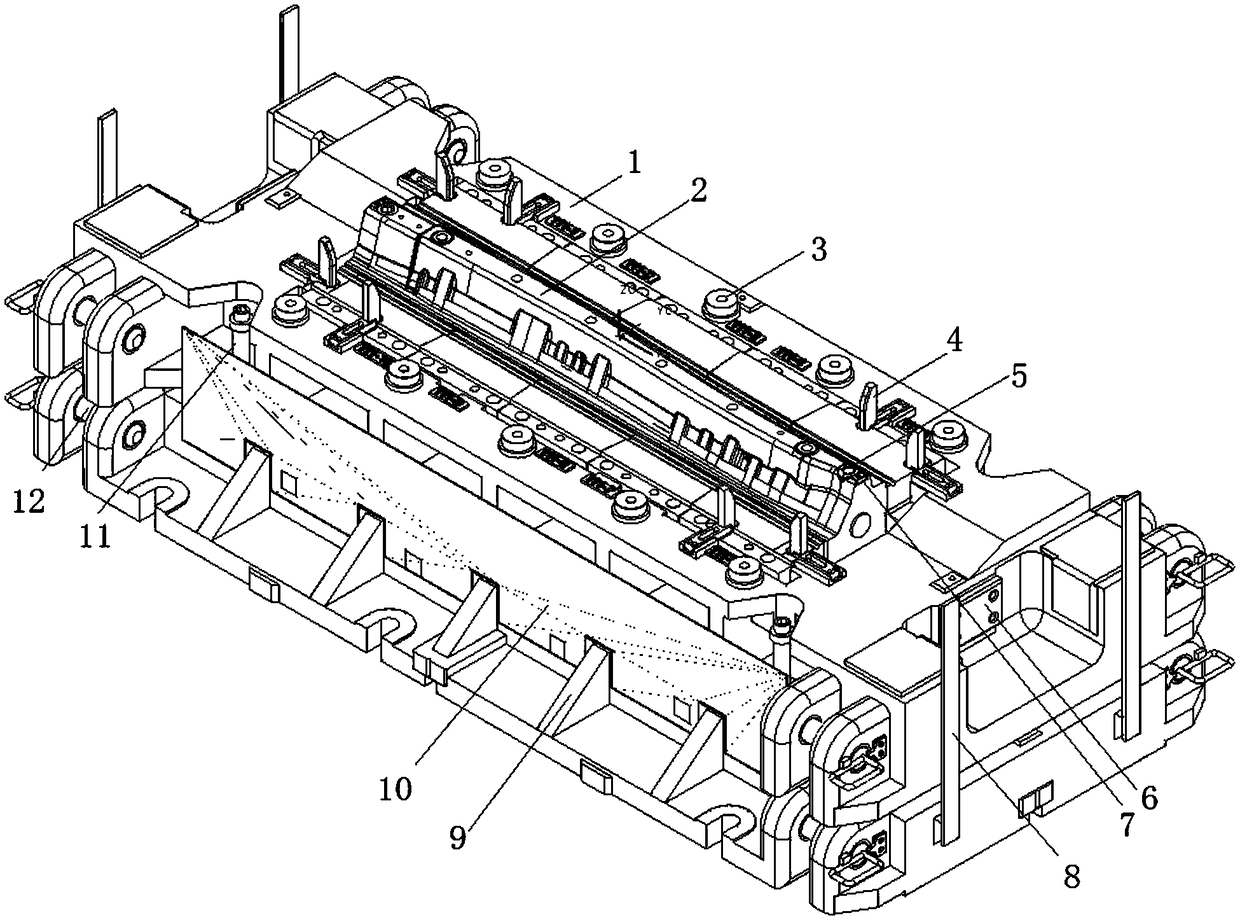

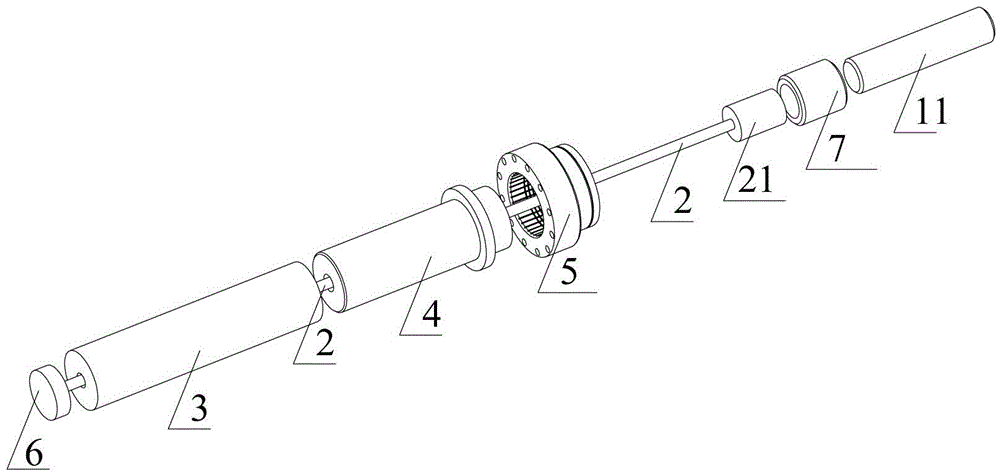

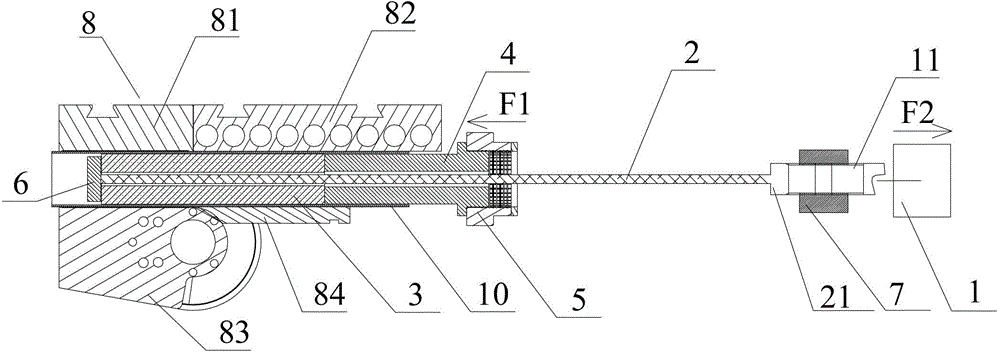

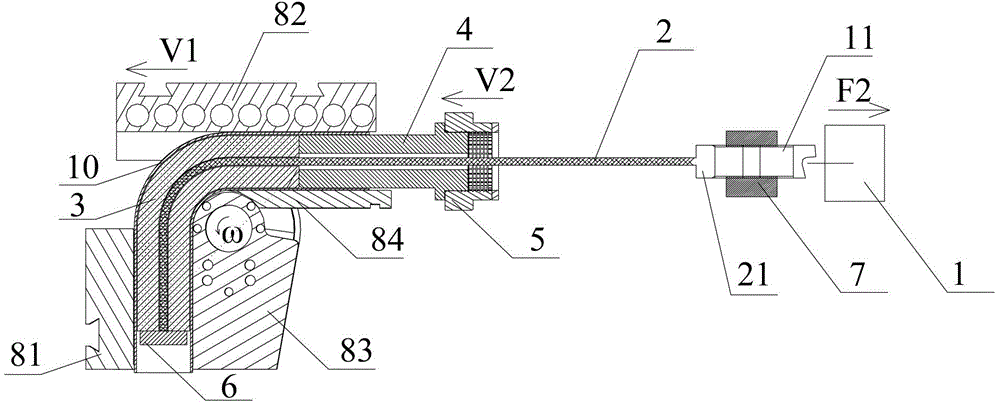

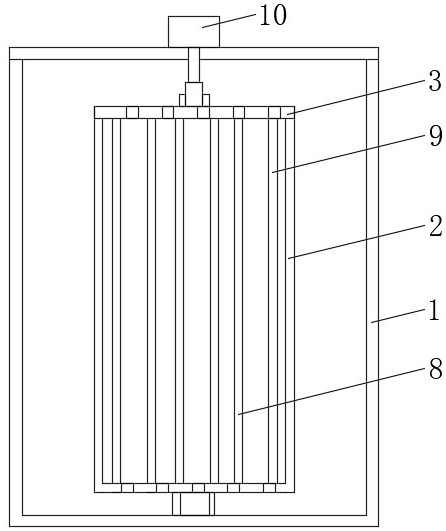

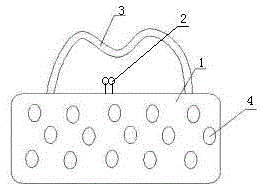

Numeric control bending core mould of thin-wall tube with large diameter

InactiveCN101758126AReduce excessive interferenceReduced likelihood of wrinklingEngineeringBend radius

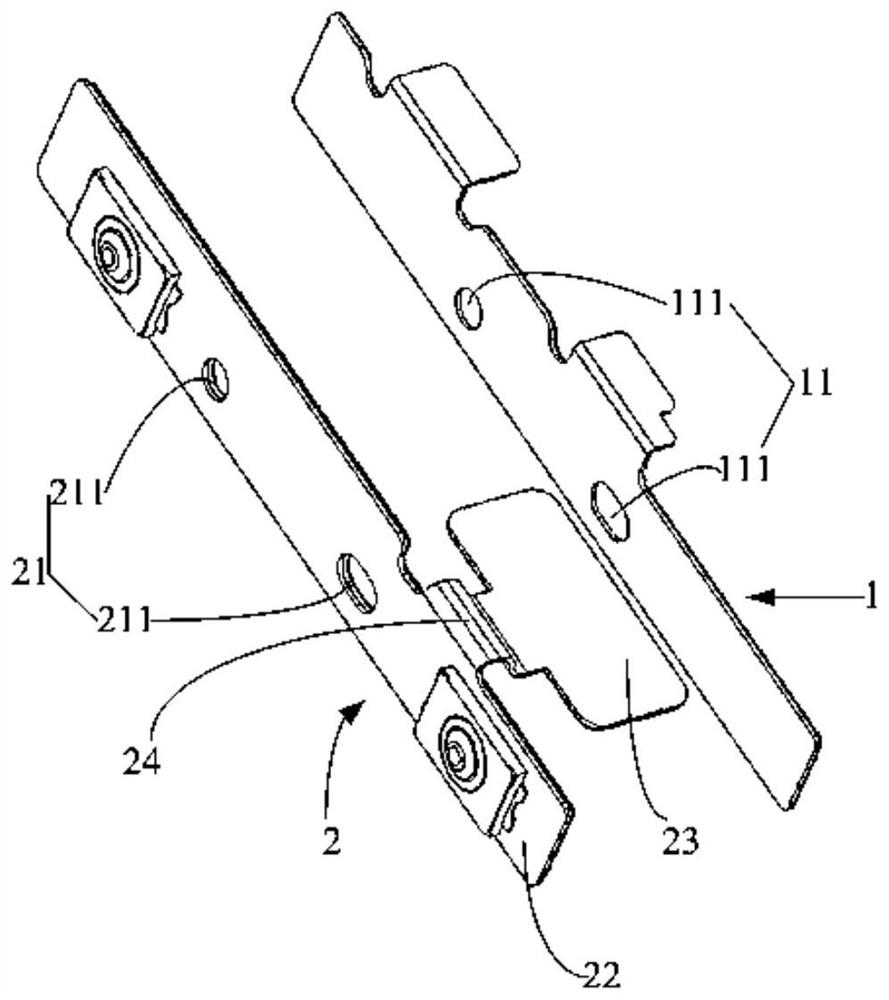

The invention discloses a numeric control bending core mould of a thin-wall tube with the large diameter, which comprises a core mould core rod (1), eccentric core heads (2), an intra-core head connecting member (3) and a spring (4). The numeric control bending core mould of the thin walled tube with the large diameter is characterized in that the core mould core rod (1) is connected with the eccentric core heads (2) and the eccentric core heads (2) by using a ball-and-socket structure, and the spring (4) clamps the intra-core head connecting member (3) on the eccentric core heads (2), and ball centers of the eccentric core heads (2) are in the position of the core head body instead of a geometric centre of the core head. By using the core mould, the numeric control bending core mould is adapted to bending deformation of tubing in various bending radiuses, has a significance for high-quality stable formation of the thin walled tube with the large diameter in the small bending radius, and can reduce the crinkling probability and the thin reduction degree of the tubing and improve bending quality of a conduit under a condition of no increasing flattened degree.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

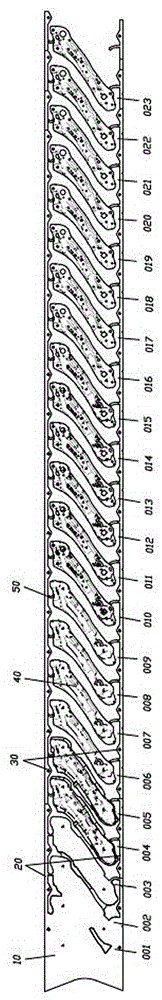

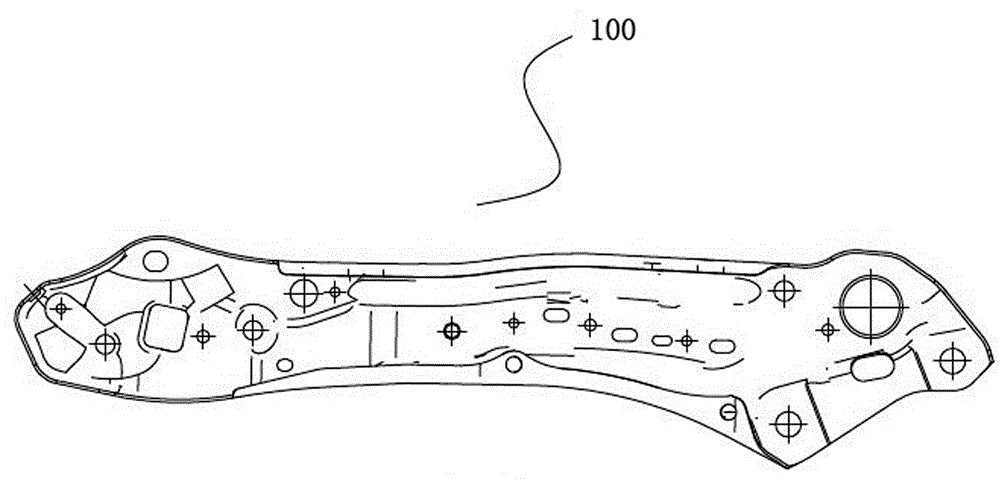

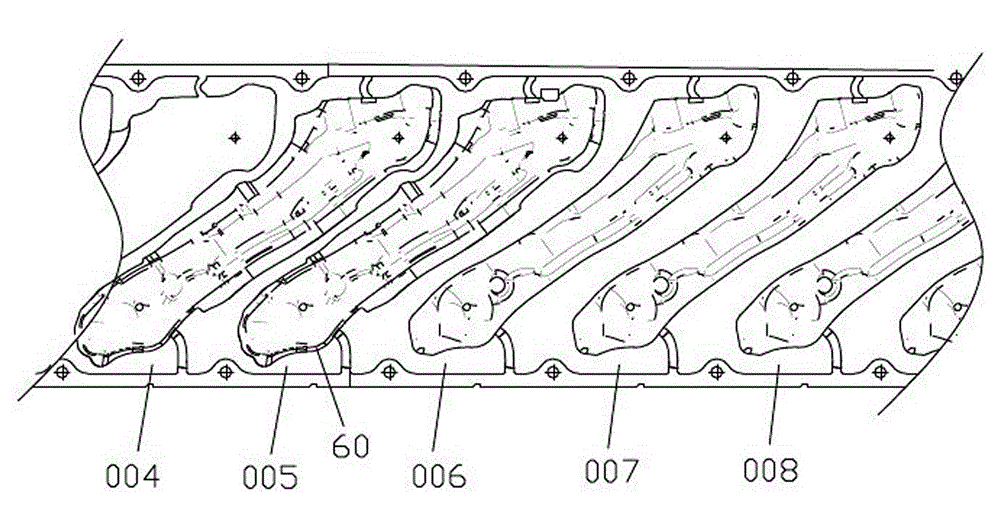

Process for forming side boards of backrests of automobile seats

The invention discloses a process for forming side boards of backrests of automobile seats, and relates to technologies for forming hardware. The process includes a downward flanging procedure. The downward flanging procedure includes steps of firstly, building a mathematical model of drawing rounded corners of drawing rounded corner parts of sheets and wrinkling regions on sheets in a downward flanging procedure; secondly, determining drawing rounded corner magnitude ranges and optimal drawing rounded corner magnitude values by the aid of the mathematical model; thirdly, drawing rounded corners according to the optimal drawing rounded corner magnitude values determined in the second step; fourthly, downwardly flanging the sheets along the drawing rounded corner parts. The magnitude of each drawing rounded corner is used as an independent variable in the mathematical model, the area of each wrinkling region is used as a dependent variable in the mathematical model, and the area of each wrinkling region is the sum of the areas of a plurality of wrinkling sub-regions; the mathematical model is built by the aid of data acquired in field tests. The areas of the wrinkling regions are minimized under the effect of the determined drawing rounded corner magnitude ranges and the determined optimal drawing rounded corner magnitude values. The method has the advantages that the mathematical model of the drawing rounded corners and the wrinkling regions is built via the tests, the drawing rounded corner magnitude ranges and the optimal drawing rounded corner magnitude values are determined, and the areas of the wrinkling regions are minimized under the effect of the determined drawing rounded corner magnitude ranges and the determined optimal drawing rounded corner magnitude values, accordingly, the problem of wrinkling of products can be solved, and the quality of the products can be greatly improved.

Owner:RAINBOW METAL TECH

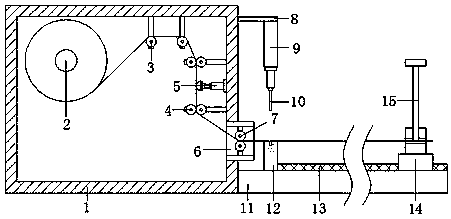

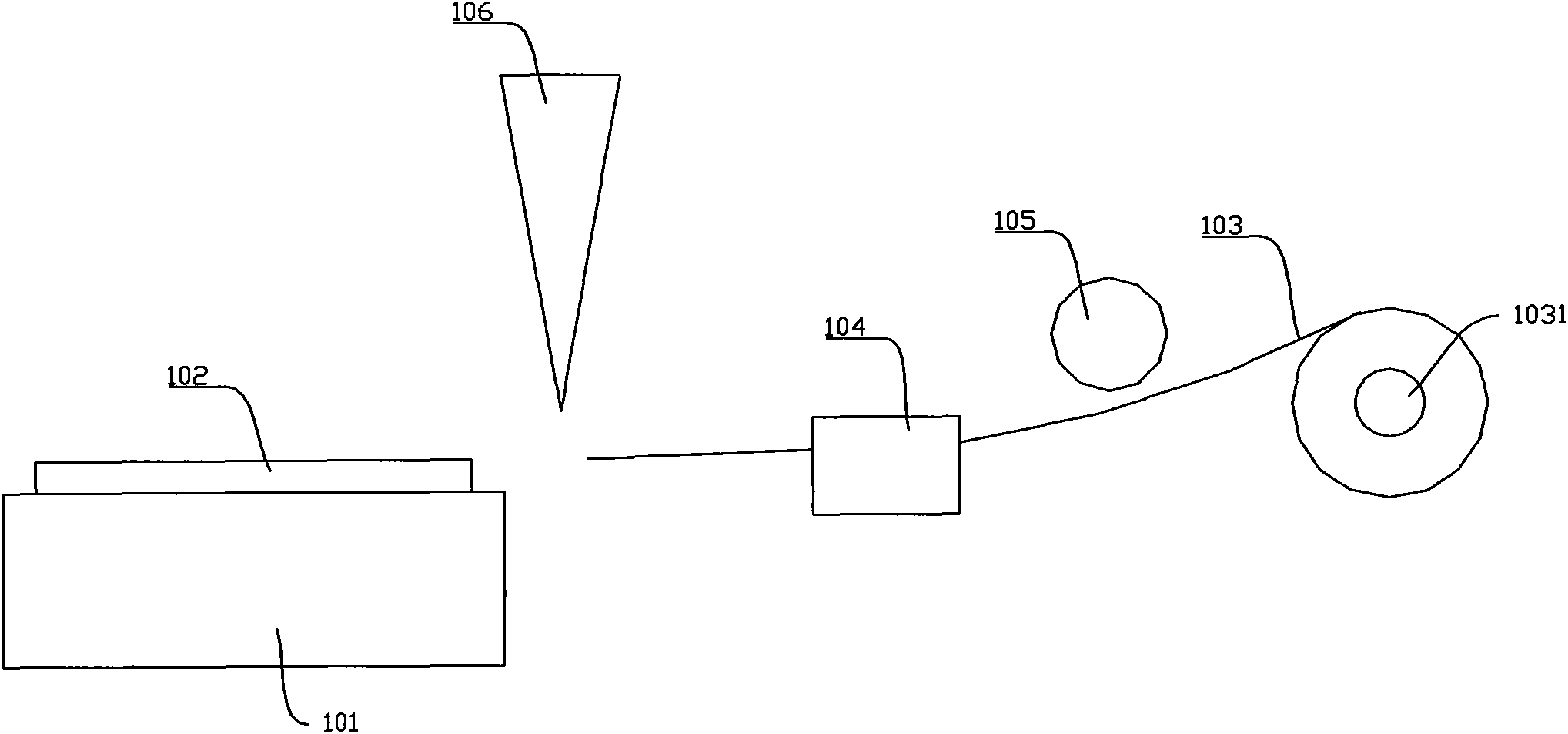

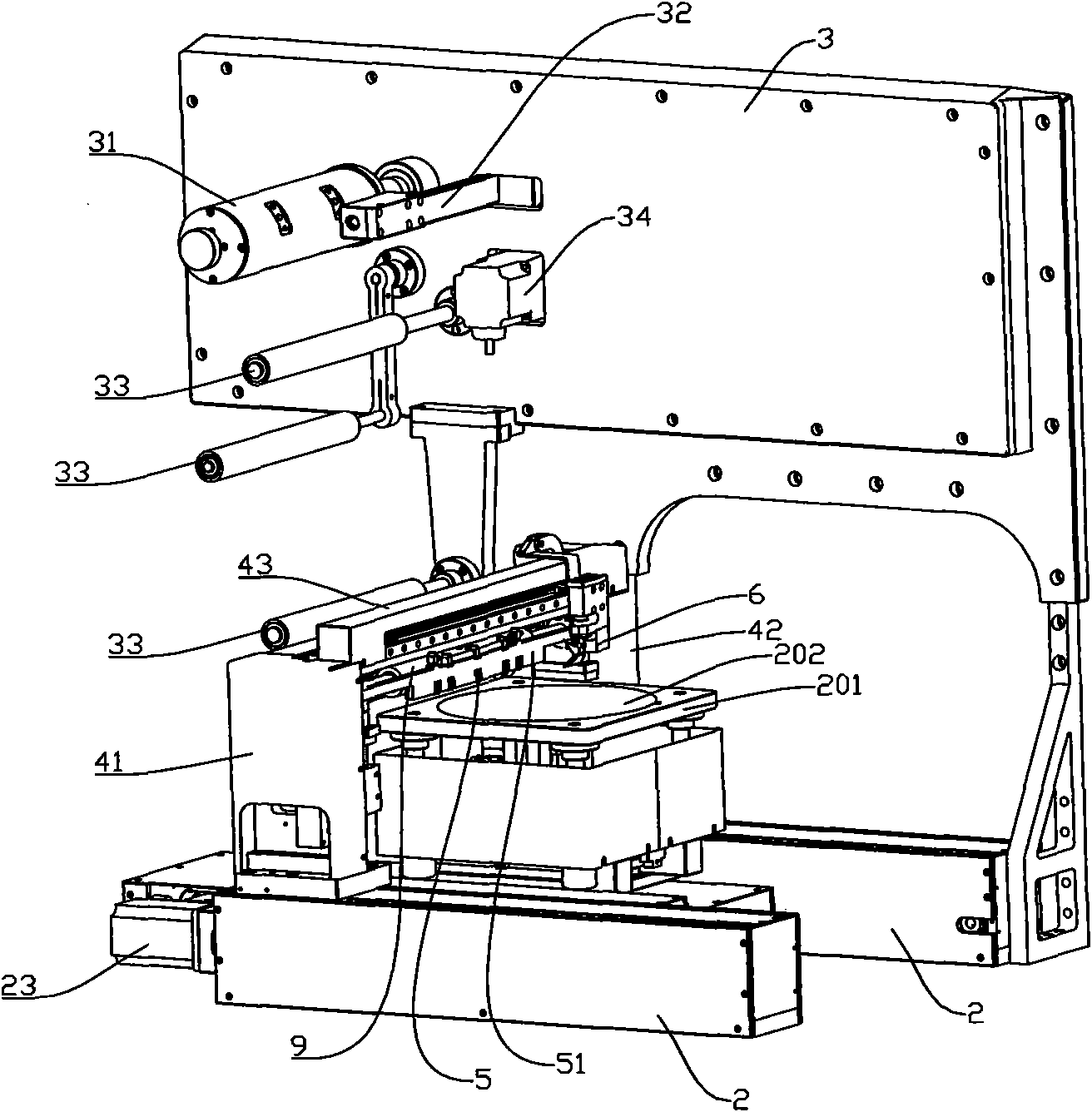

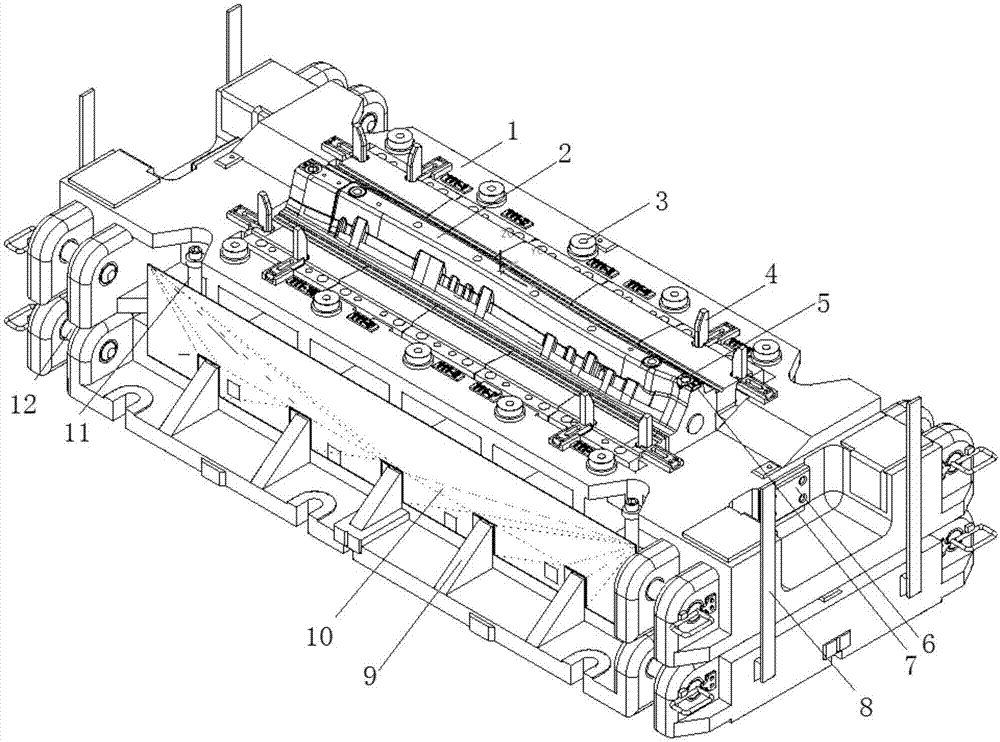

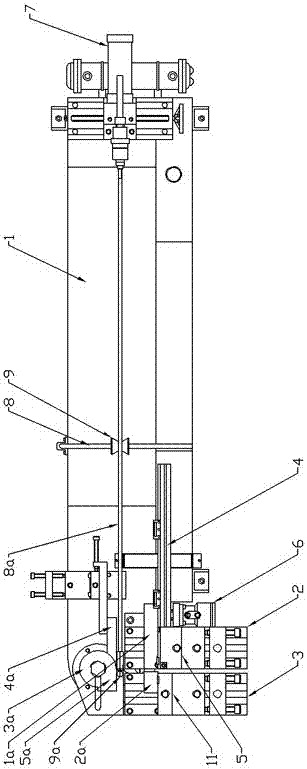

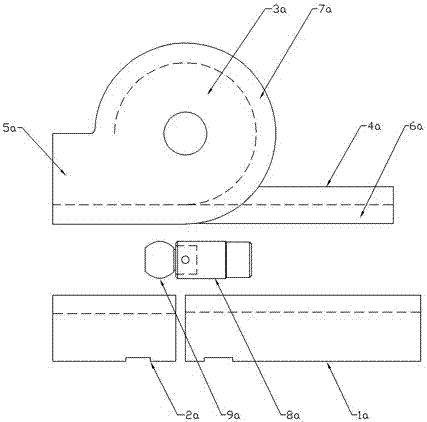

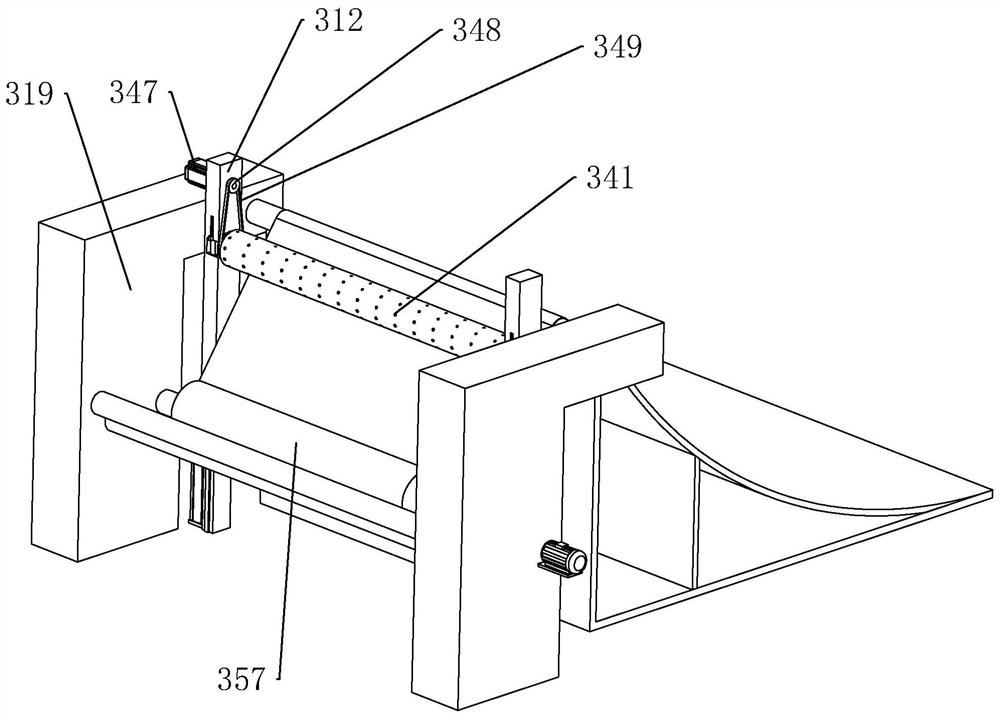

Short pitch film cutting machine

InactiveCN109019094AReduce pollutionReduced Possibility of ContaminationArticle deliveryWebs handlingEngineeringMechanical engineering

The invention discloses a short pitch film cutting machine. The short pitch film cutting machine comprises a material conveying box; a material conveying roll is arranged on the left side of an innercavity of the material conveying box; material guide rolls are symmetrically arranged on the left side and the right side of the top of the inner cavity of the material conveying box; an adjustment and material guide pair roll is arranged at the right side wall of the inner cavity of the material conveying box; an electric telescopic rod is arranged at the right side wall of the inner cavity of the material conveying box; a discharge port is formed at the bottom of the right side wall of the material conveying box; a parallel material guide pair roll is arranged at an inner cavity of the discharge port; a supporting frame is arranged at the top of the right side wall of the material conveying box; a pneumatic telescopic rod is arranged at the bottom of the supporting frame; a cutting knifeis arranged at the bottom of the pneumatic telescopic rod; a supporting base is arranged at the bottom of the right side wall of the material conveying box; a cutting table and a sliding rail are arranged at the top of the supporting base; the top of the sliding rail is connected with an electric sliding block in a sliding manner; and a film fixing mechanism is arranged at the top of the electricsliding block. The short pitch film cutting machine is reasonable in structural design, the probability of folding during film cutting can be reduced, an error during cutting is lowered, and adjustments can be made according to the requirement on the cut length.

Owner:HONGCHENG SCI & TECH LTD

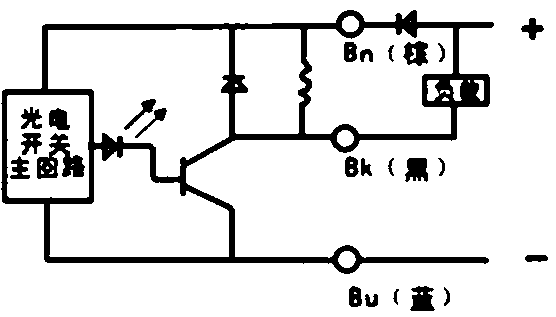

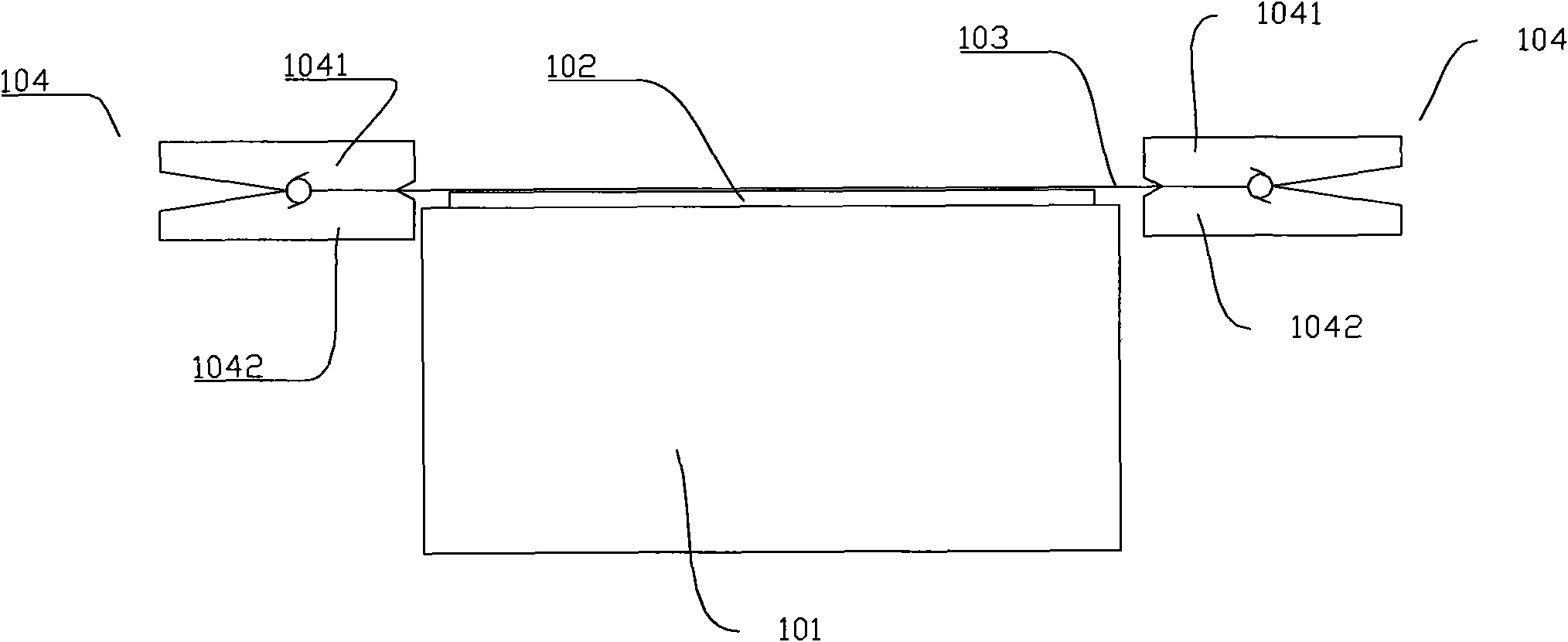

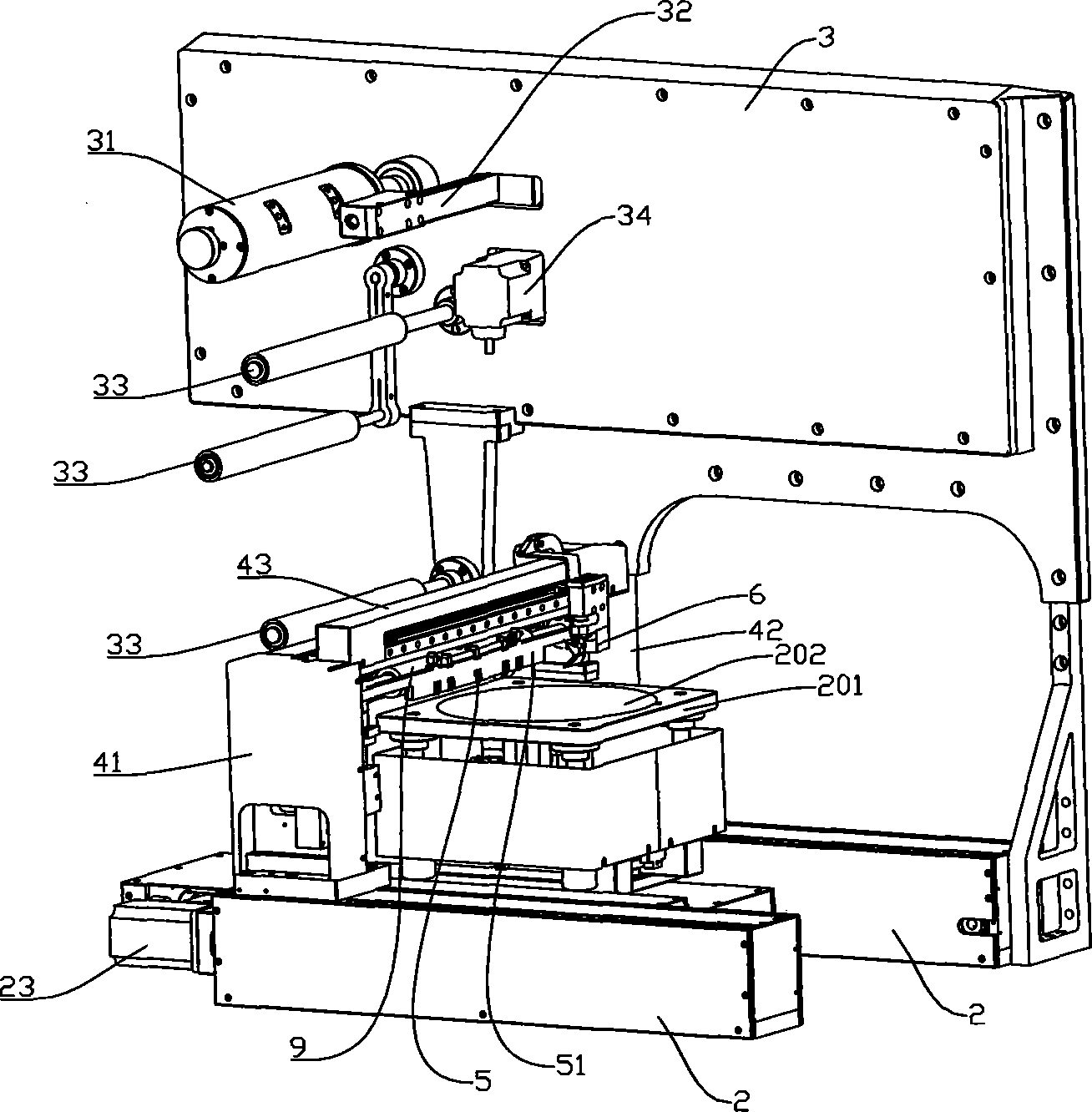

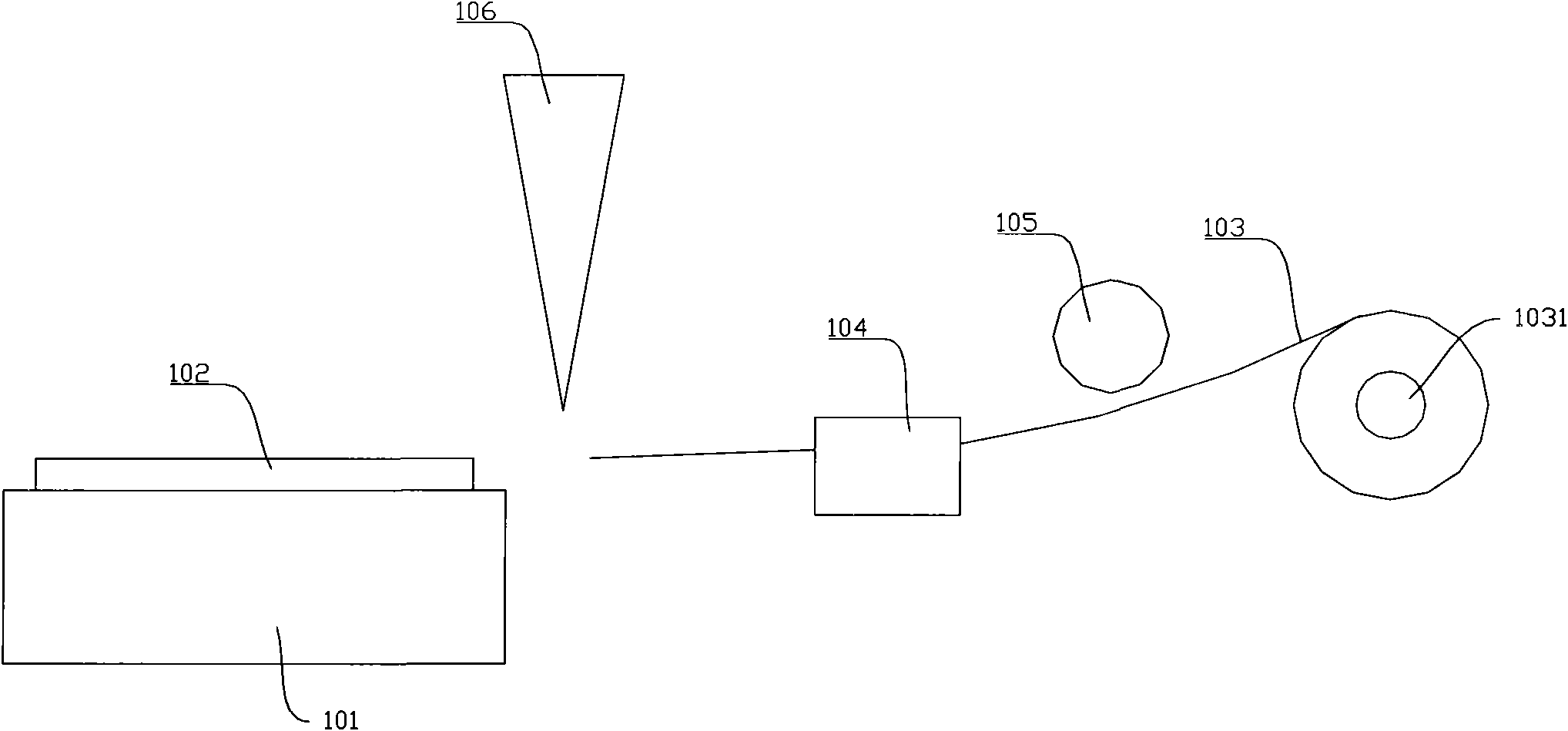

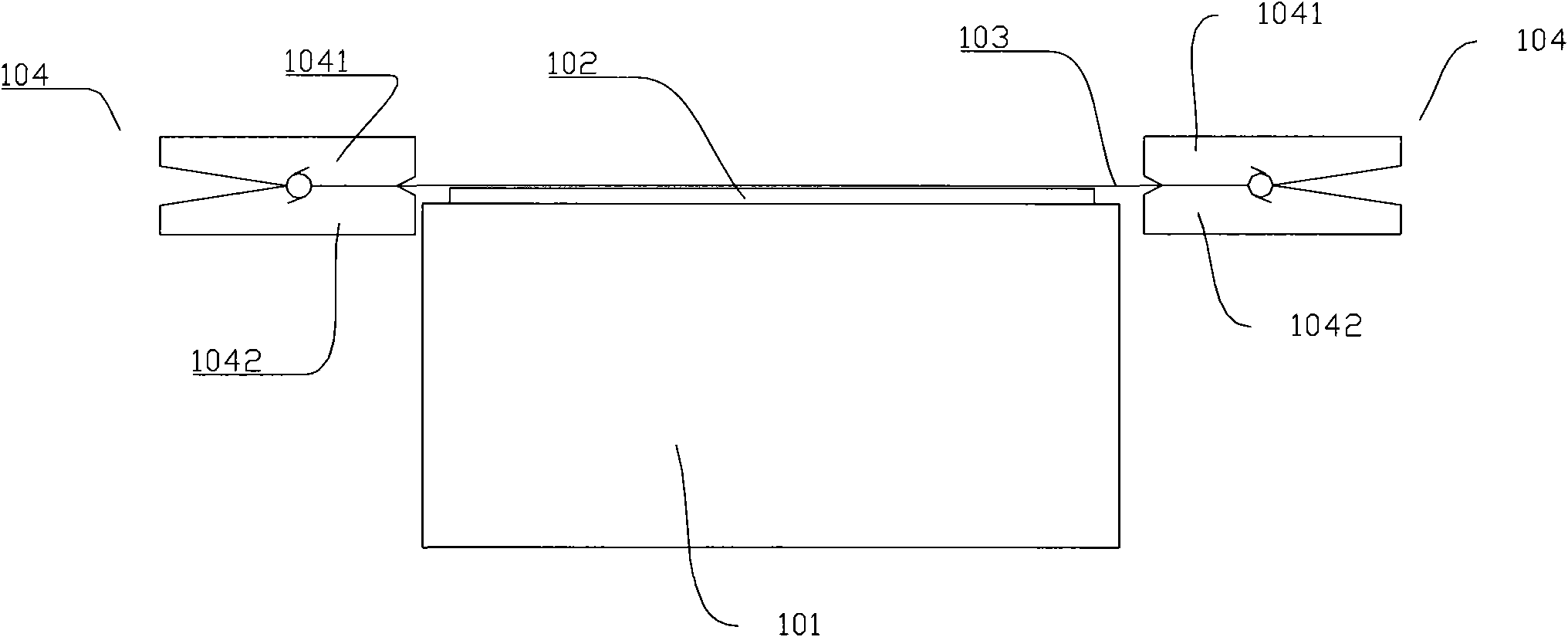

Film adhesion device for film active release

InactiveCN102148177ASolve wasteAvoid wrinklesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention discloses a film adhesion device for film active release. The device is characterized by comprising a supporting shaft and a driving device, wherein the supporting shaft is used for supporting an adhesive film roll; and the driving device drives the supporting shaft to rotate. The film adhesion device for the film active release changes the conventional mode of pulling an adhesive film by a film clamping device to drive the adhesive film roll to rotate so as to release the adhesive film into a mode of driving the adhesive film roll by the driving device to rotate so as to release the adhesive film actively. When the adhesive film is pulled by the film clamping device to cover a wafer, a pulling force applied to the adhesive film by the film clamping device can be quite small, so that the adhesive film cannot be deformed by stretching, and the quality of film adhesion is improved.

Owner:上海技美科技股份有限公司

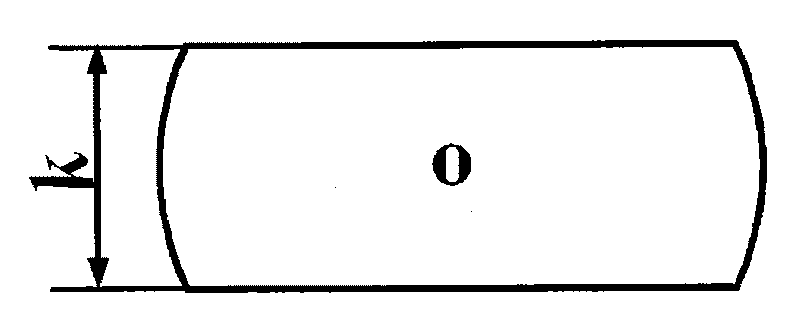

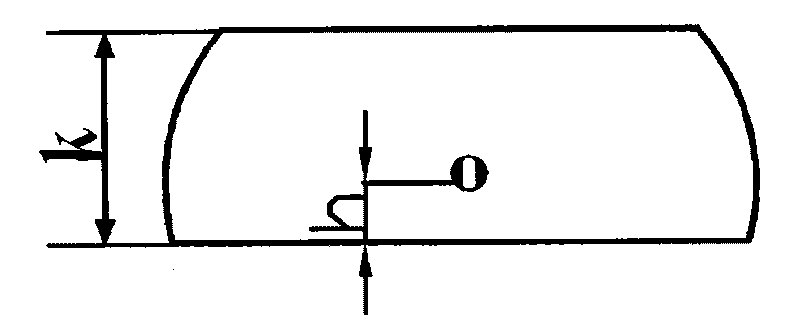

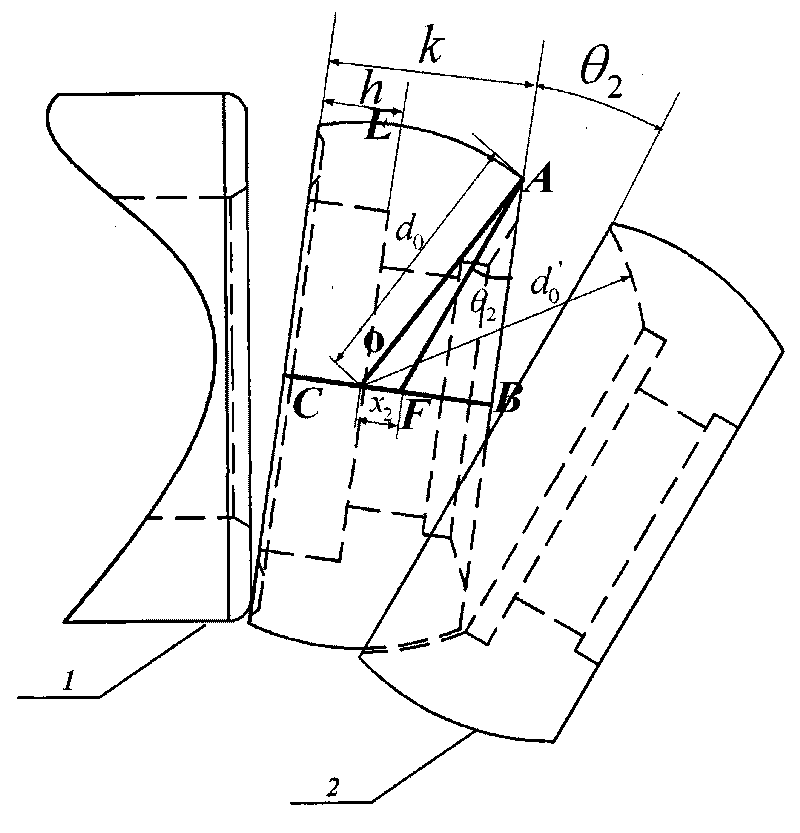

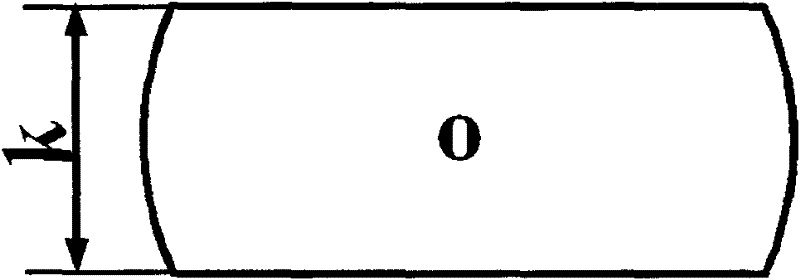

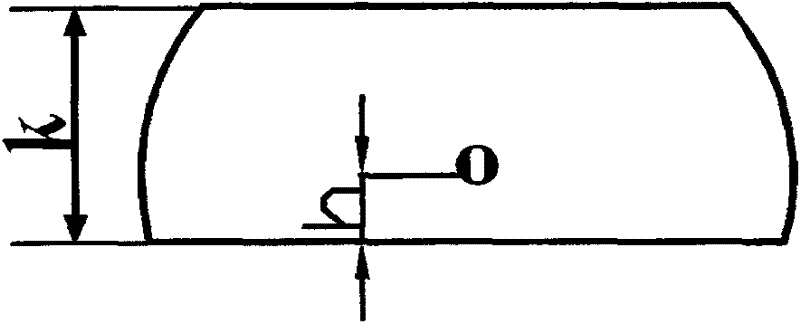

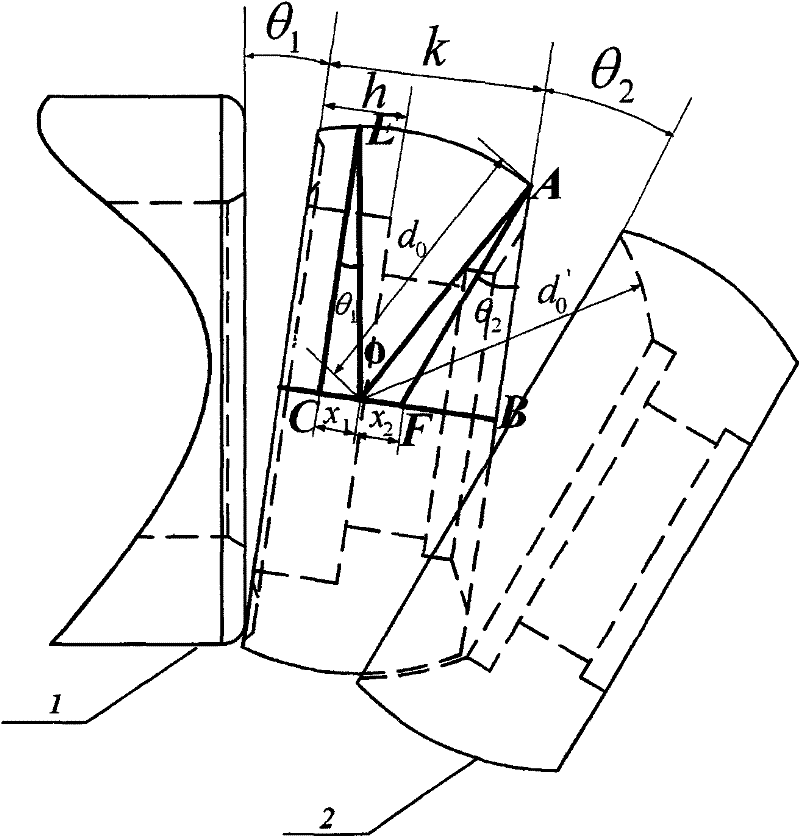

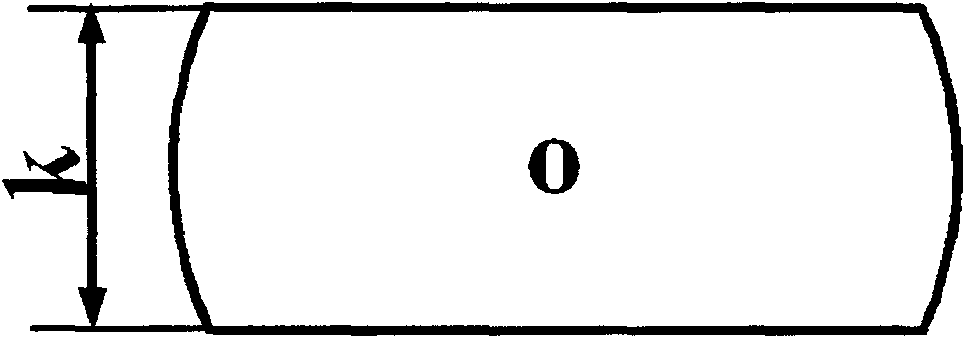

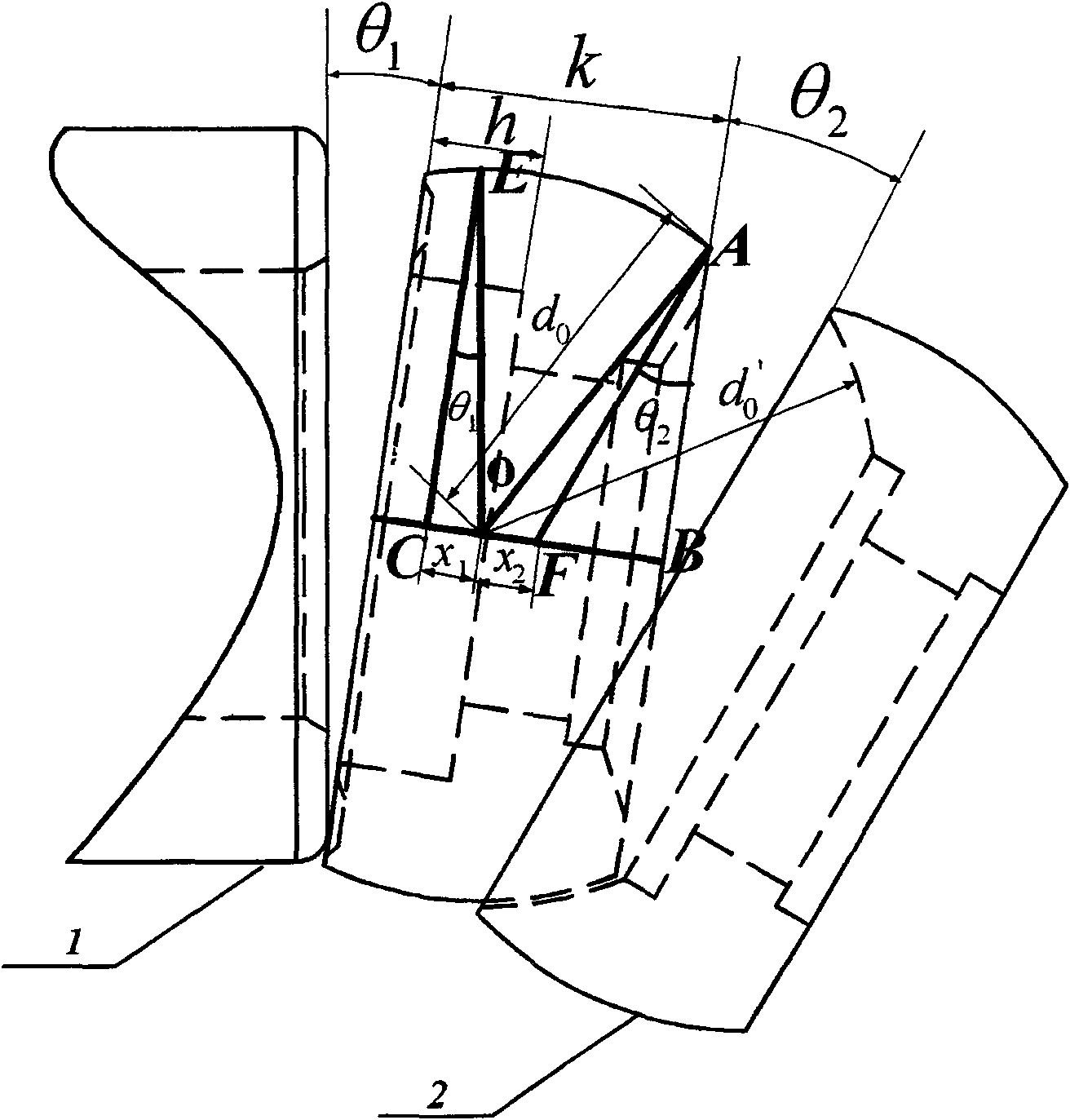

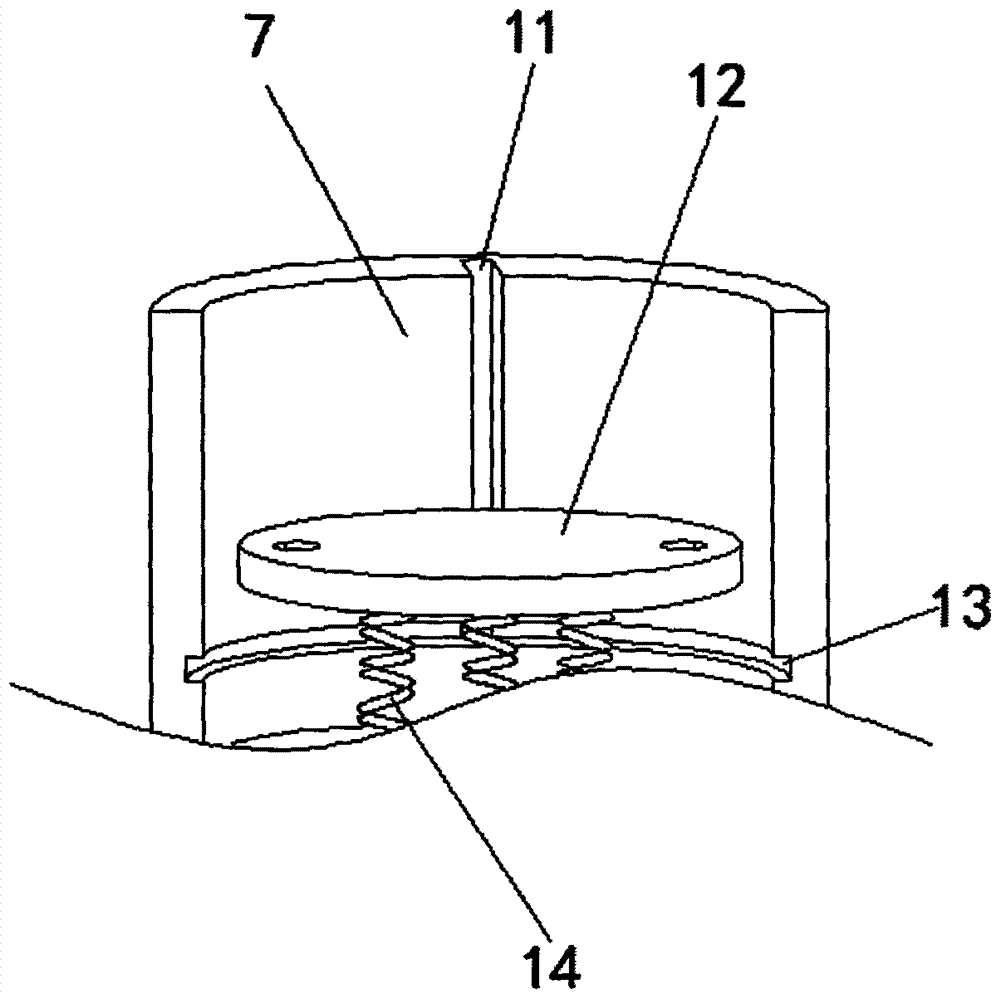

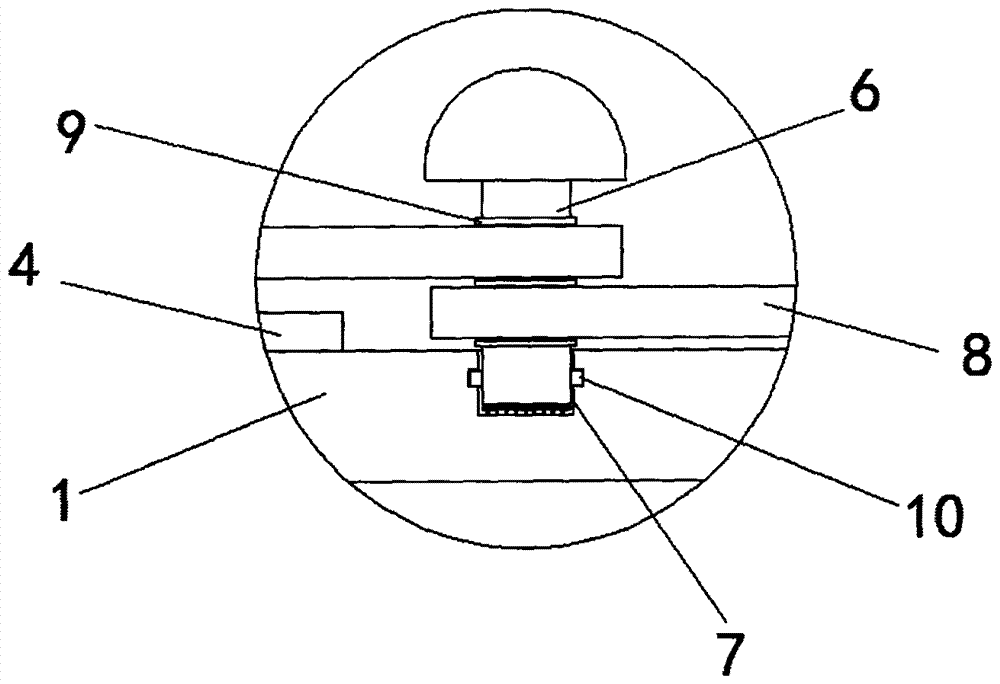

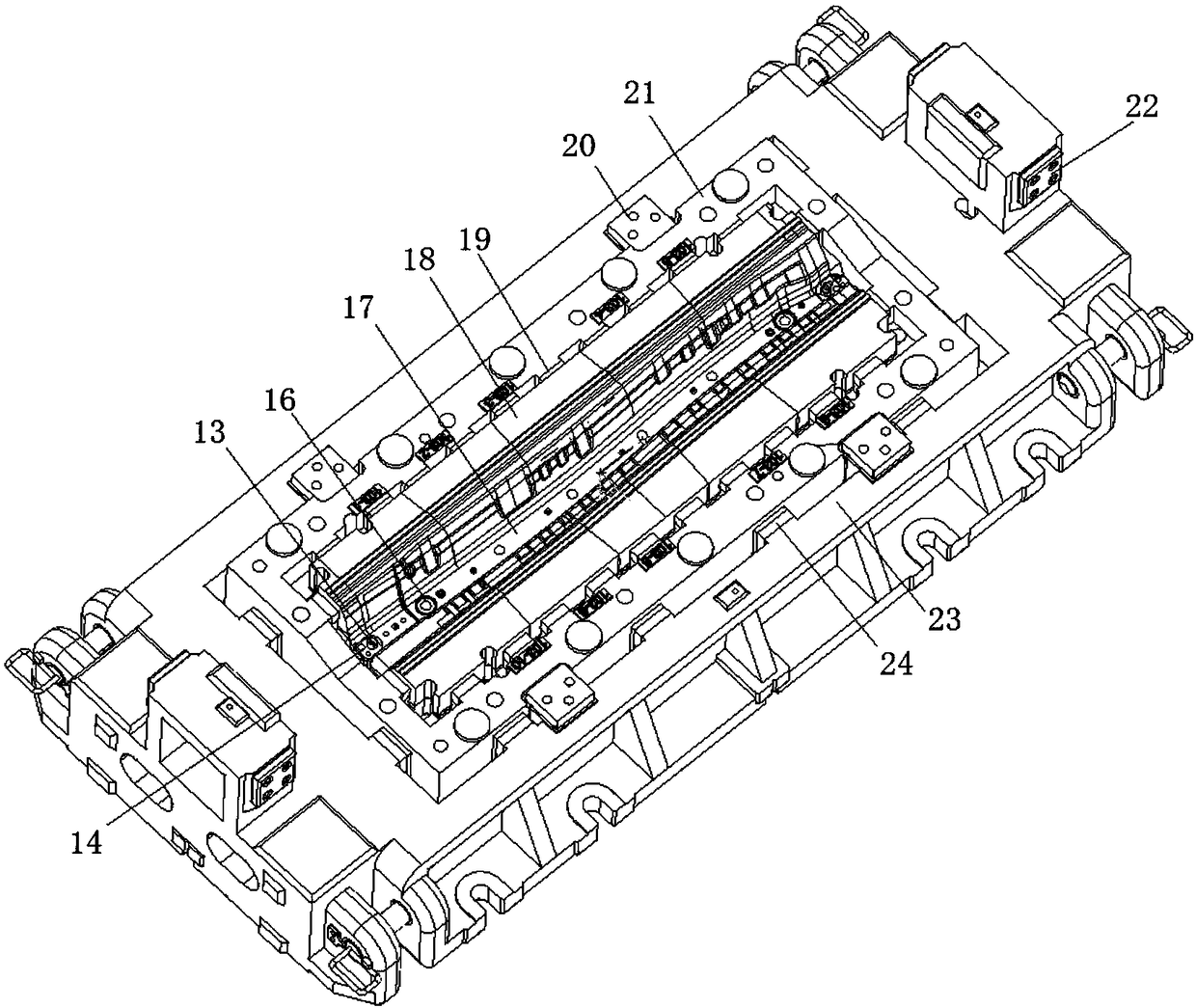

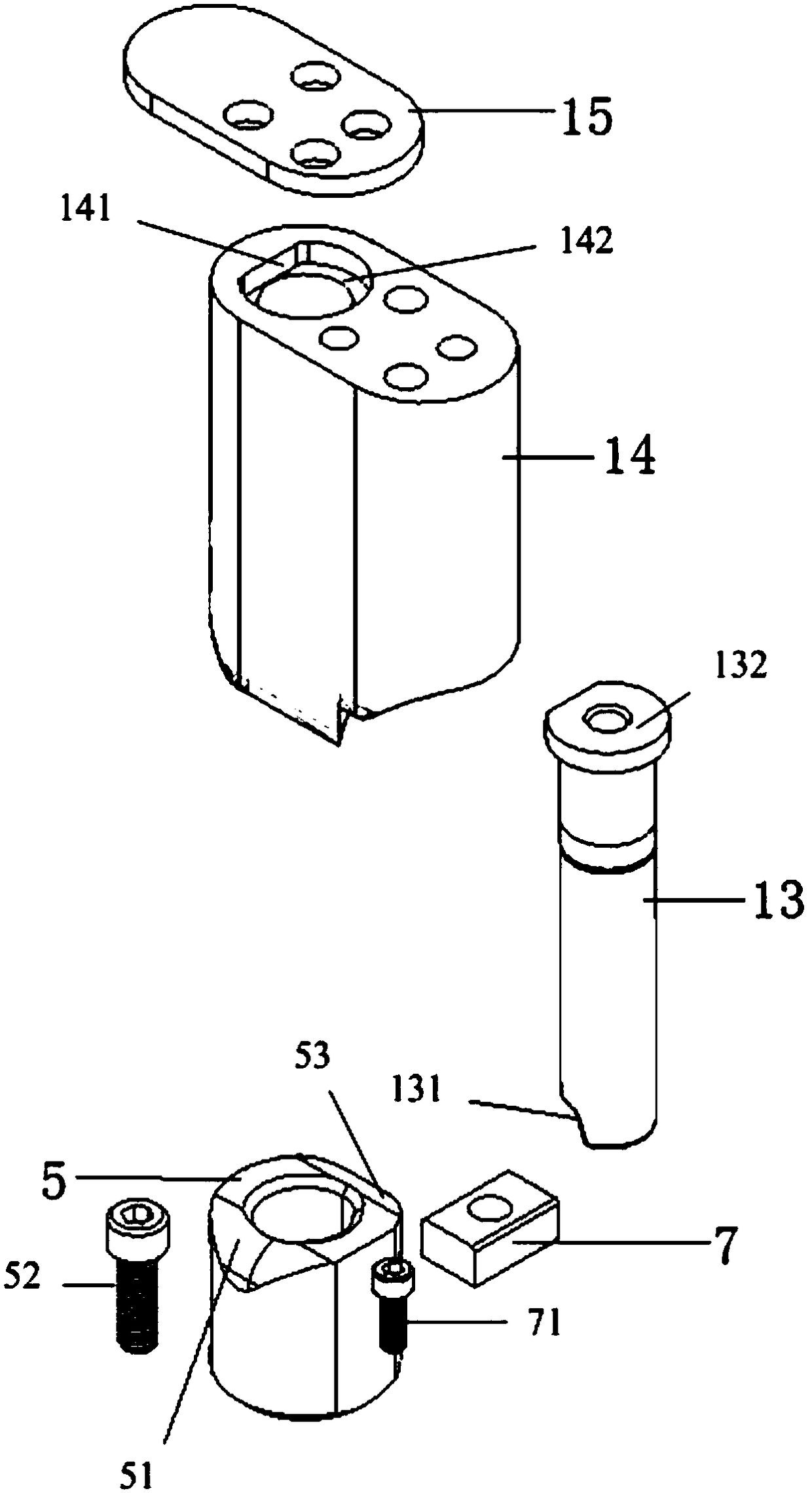

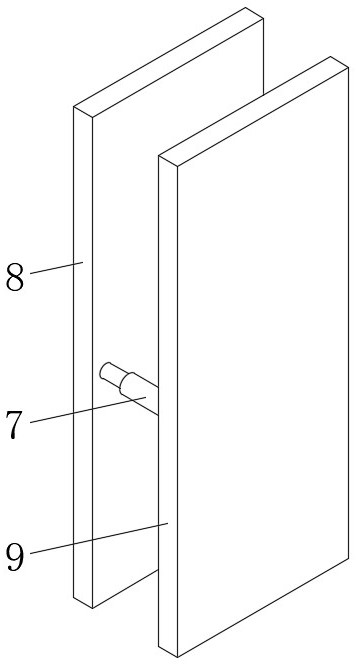

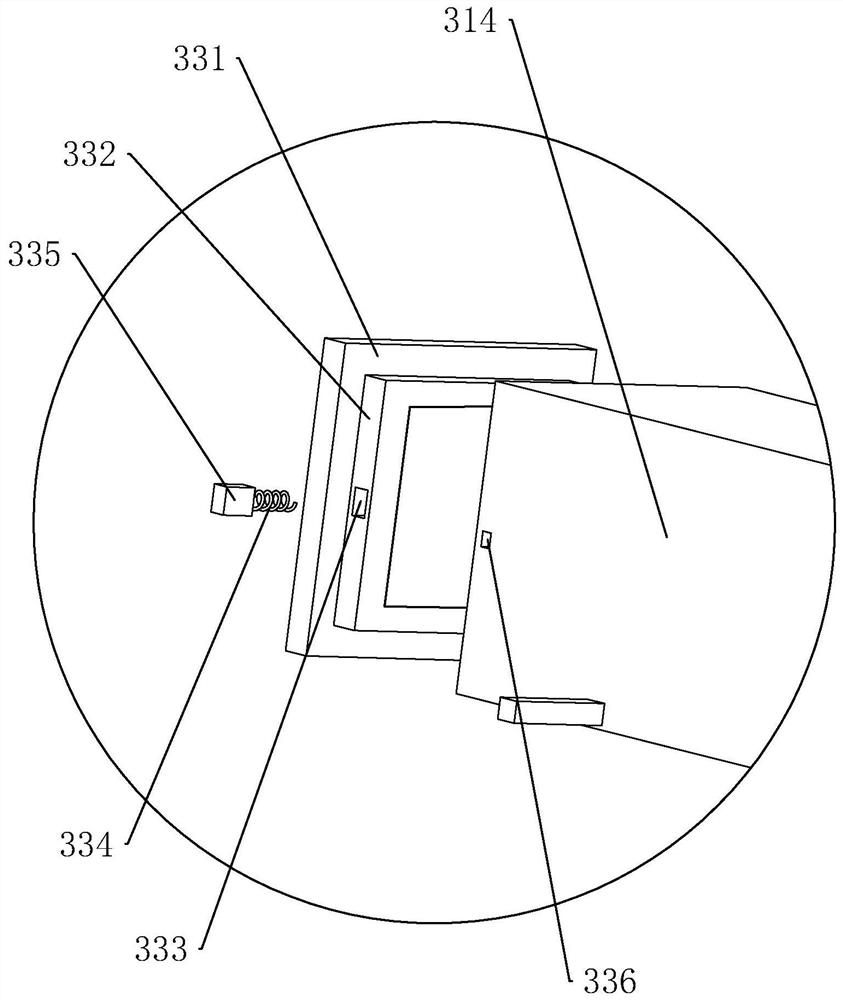

NC bending core head for thin walled tube of aluminum alloy with major diameter and design method thereof

InactiveCN102161059AReduce interference areaReduce excessive interferenceSpecial data processing applicationsElement modelingThinning

The invention relates to an NC bending core head for a thin walled tube of aluminum alloy with a major diameter and a design method thereof, wherein the core head comprises an core head(2), a mandrel core pin(1) and a connection member between the core heads(3). Further, the core heads are connected in a ball-and-socket structure manner. The eccentricity delta of the ball centre of the eccentric core (2) in the internal of the core head is delta=h / k, wherein h is the distance between the ball centre of core head and the large end of the core head, and k is the thickness of the core head. The inside radius d0' and the outer radius d0 of the core head, and x2 corresponding to the largest angle theta 2 of the core are determined, so that the relationship between the core distance h and the largest angle theta 2 of the eccentric core is established. Through finite element modeling, the scope of the largest angle theta 2 between the eccentric cores (2) is determined, and furthermore, the value range of h is determined. According to invention, an interference area between rotary core heads, and excess interference between the core heads and the tubing outside arc surfaces are reduced, so as to be suitable for bending and shaping of the tubing under various bending radii. Besides, the possibility of tubing wrinkling and the degree of thinning could be decreased, without increasing the flat degree of tubing.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

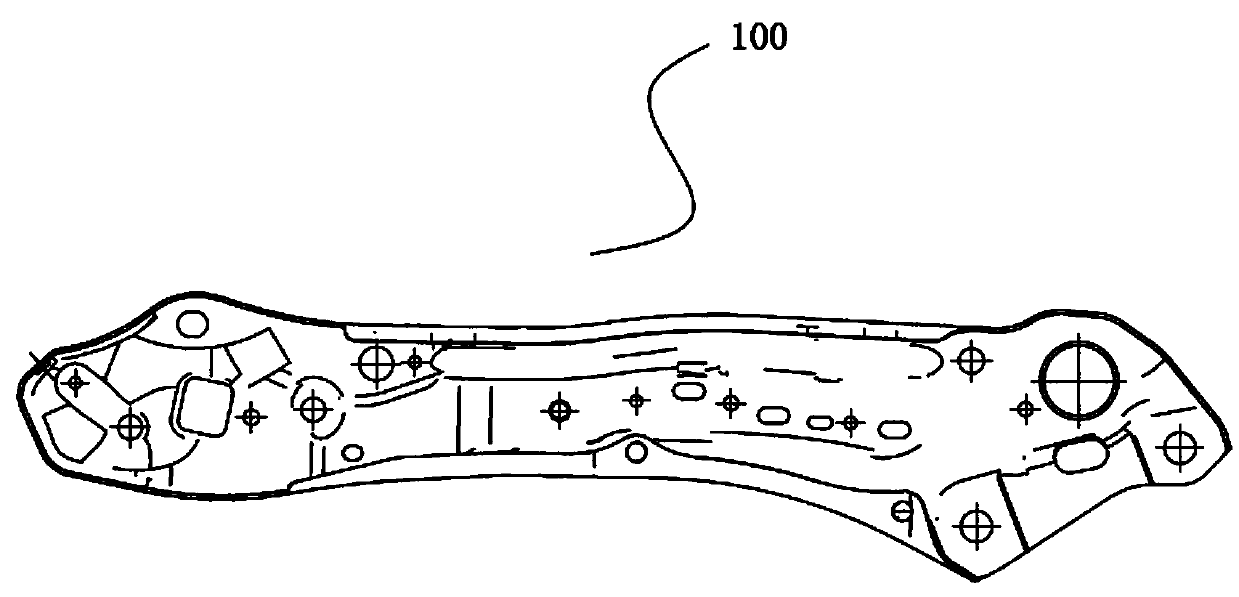

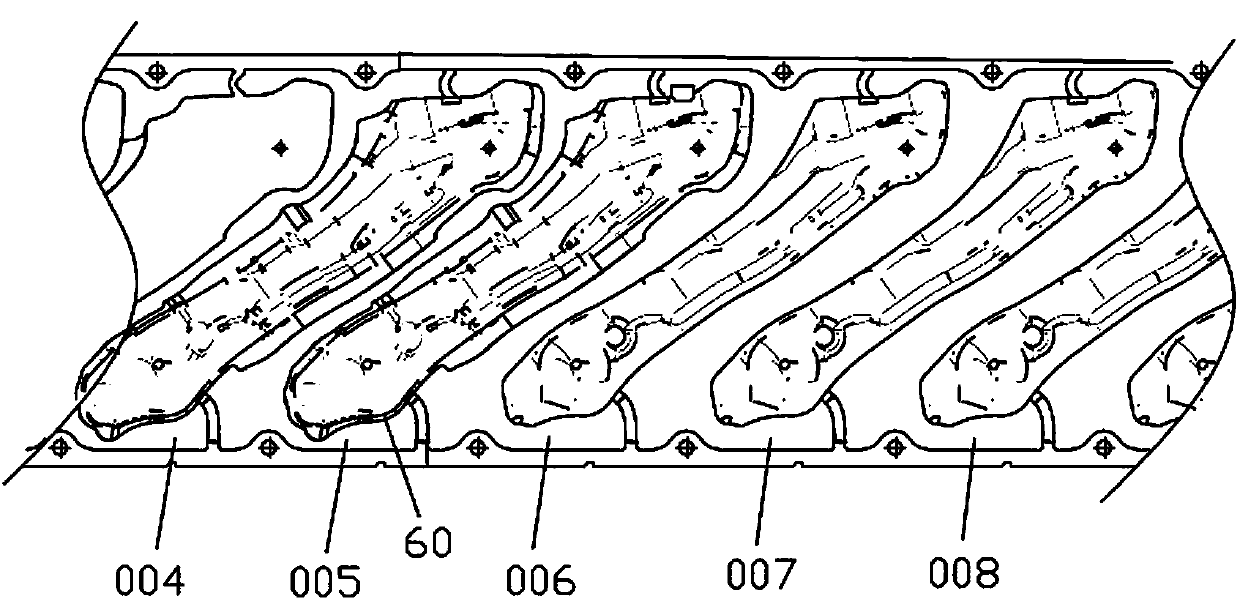

Beam part drawing mold

The invention provides a beam part drawing mold. The beam part drawing mold comprises an upper mold base, a lower mold base, a split concave mold arranged on the upper mold base, a split convex mold arranged on the lower mold base, two flanged convex molds and two flanged concave molds; two drawing ribs are oppositely arranged on two sides of the split concave mold; the extending direction of the drawing ribs is the same with the extending direction of the split concave mold; the two flanged convex molds are respectively arranged at two ends of the split concave mold; the two flanged concave molds are respectively arranged at two ends of the split convex mold; the two flanged concave molds are correspondingly matched with the two flanged convex molds one to one; flanged molding surfaces are arranged at one ends, far from the split concave mold, of the flanged convex molds; and matching surfaces matched with the flanged molding surfaces are arranged at one ends, far from the split convex mold, of the flanged concave molds. The beam part drawing mold can greatly reduce the corrugation possibility of two ends, is better in subsequent positioning effect, and meanwhile, can improve the material utilization rate and the forming effect.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

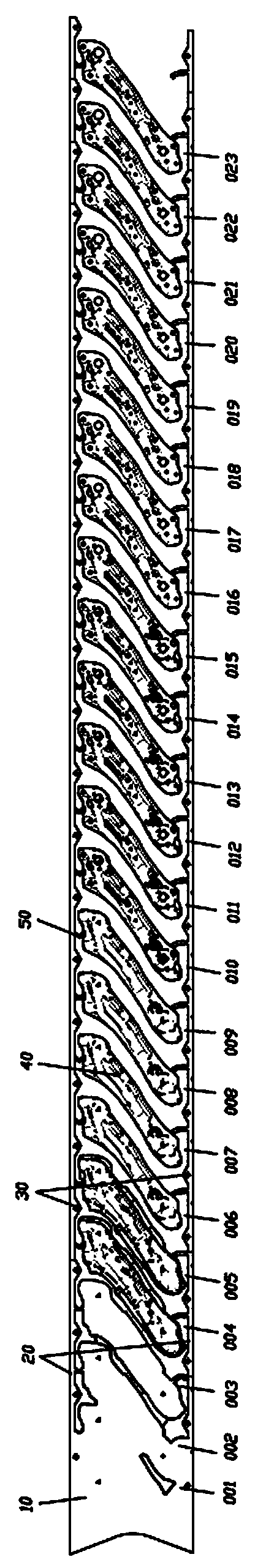

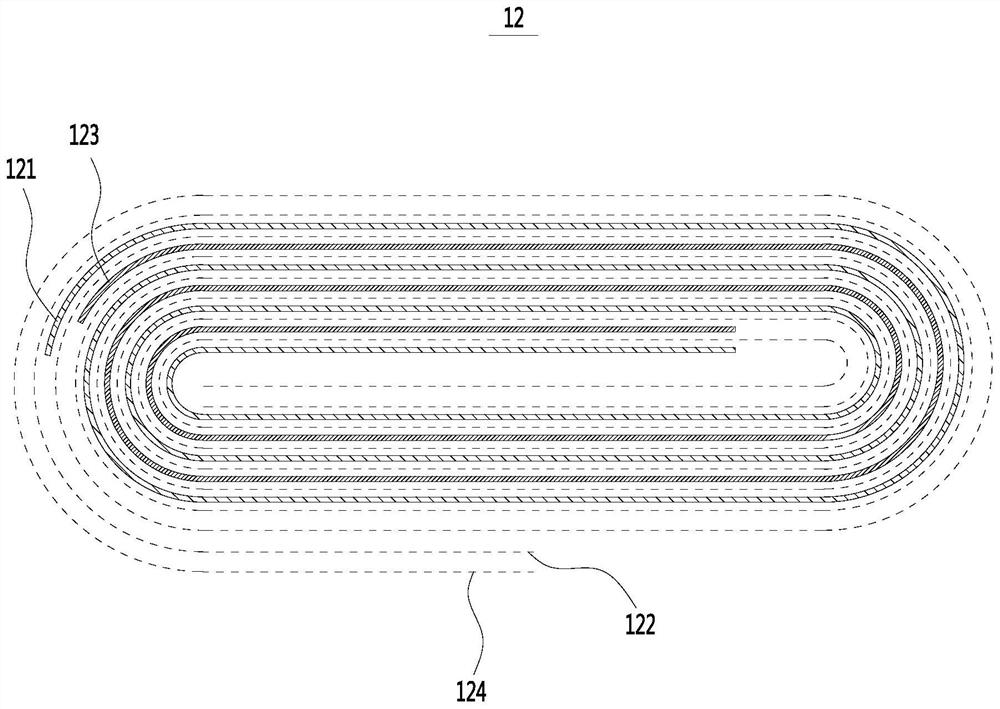

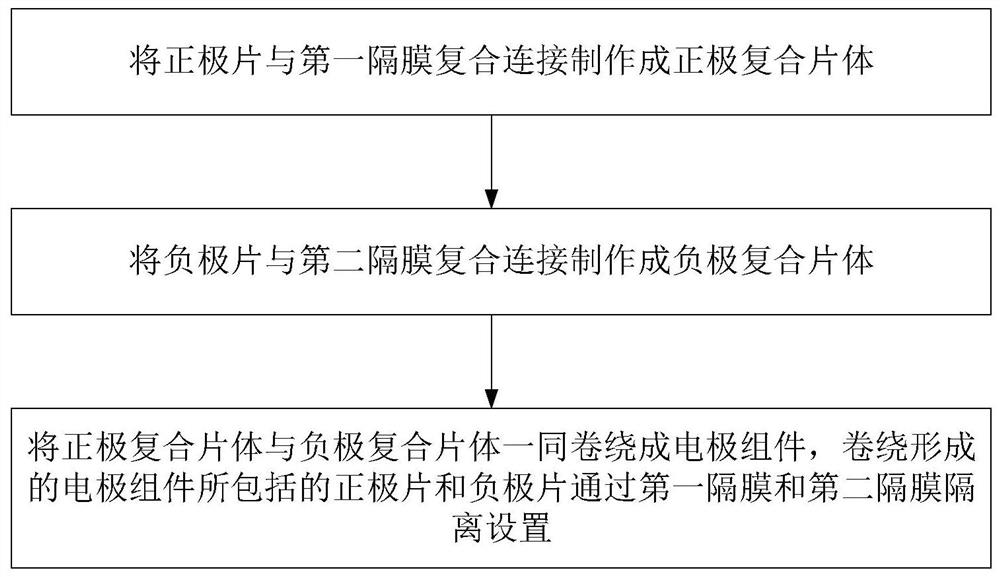

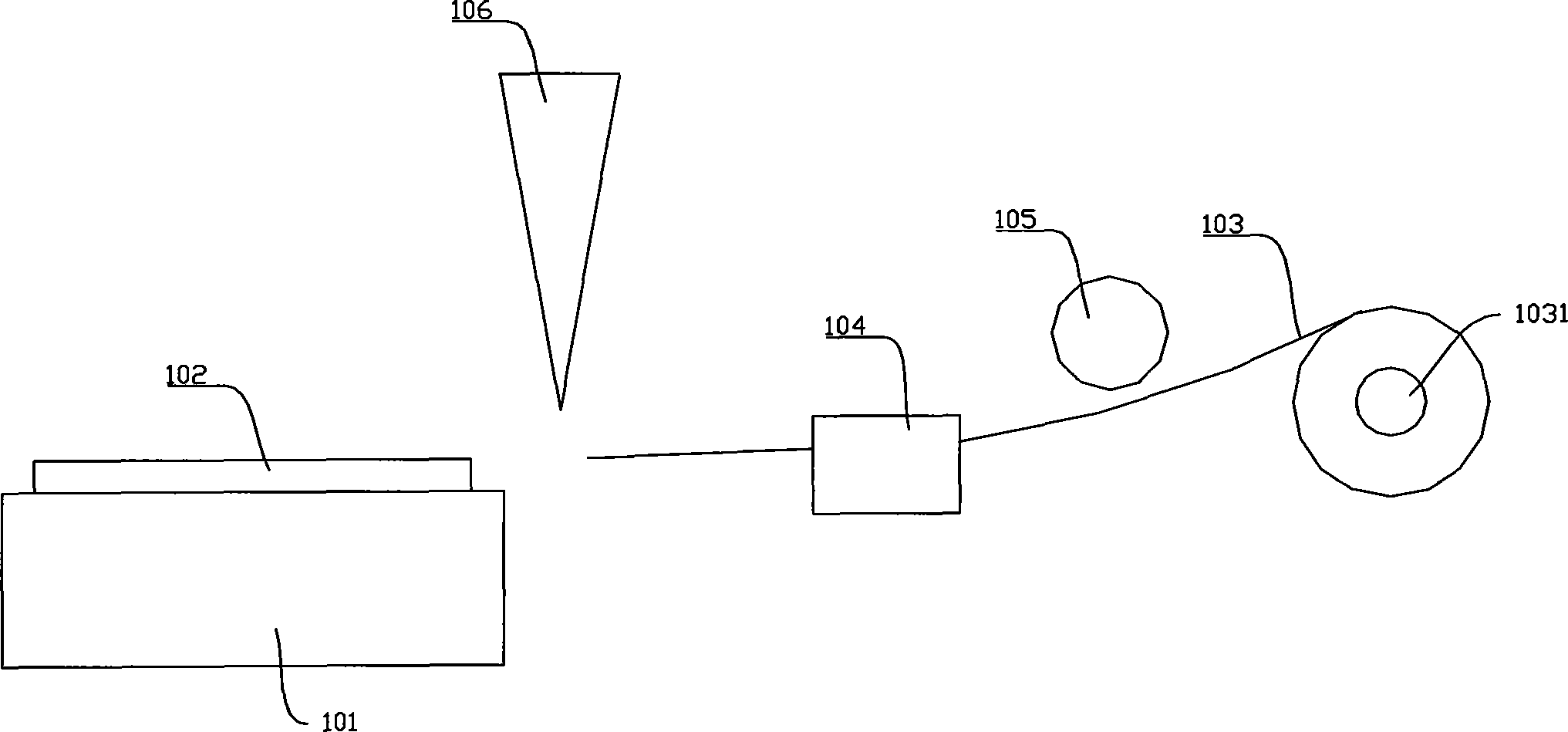

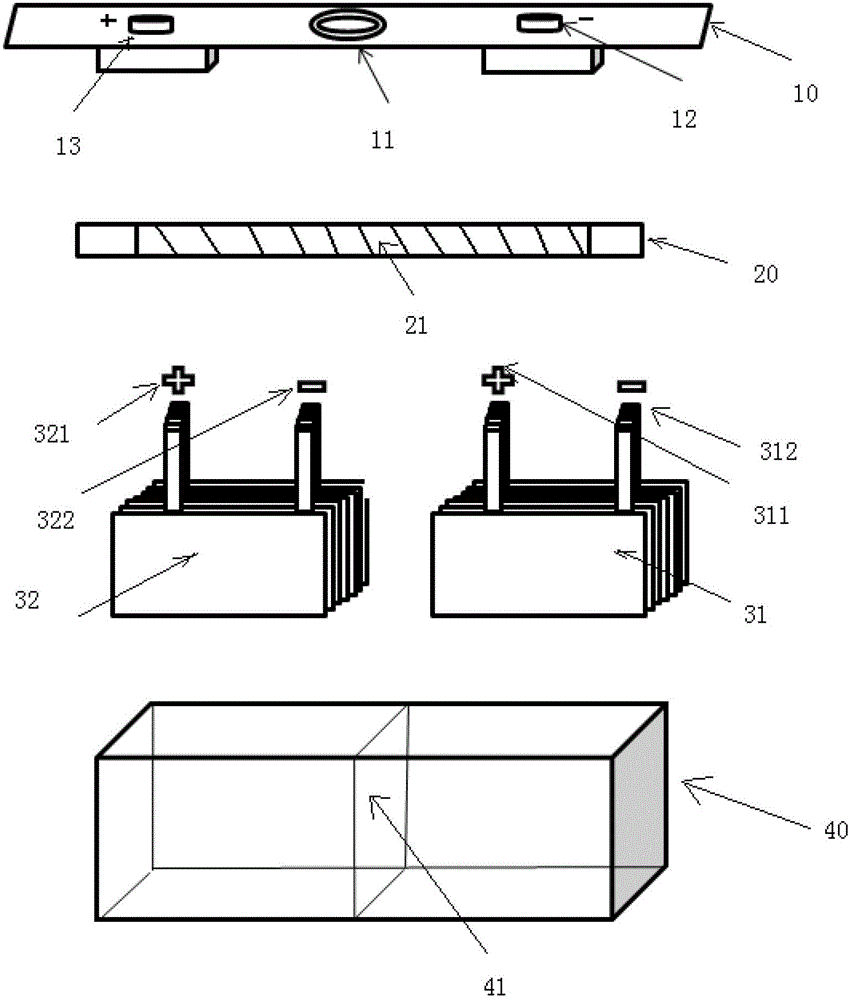

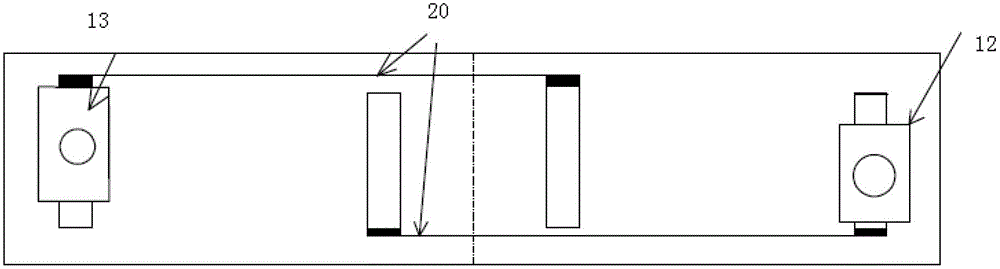

Method and apparatus for manufacturing electrode assembly of secondary battery

PendingCN112310461AReduce the possibility of misalignmentReduces chance of misalignmentAssembling battery machinesFinal product manufactureElectrical batteryEngineering

The present invention relates to a method and apparatus for manufacturing an electrode assembly of a secondary battery. The embodiment of the invention provides a method for manufacturing an electrodeassembly of a secondary battery. The method comprises the following steps that: a positive plate and a first diaphragm are compositely connected to manufacture a positive composite plate body; a negative plate and a second diaphragm are compositely connected to manufacture a negative composite plate body; the positive electrode composite plate body and the negative electrode composite plate bodyare wound together to form an electrode assembly, the positive plate and the negative plate are isolated through the first diaphragm and the second diaphragm. According to the method for manufacturingthe electrode assembly of the secondary battery, the yield of the electrode assembly can be improved, the structure of winding equipment is simplified, and the winding working efficiency is improved.

Owner:CONTEMPORARY AMPEREX TECH CO

Polyester fabric dyeing process

ActiveCN110205762AReduce the temperatureReduce yellowingHeating/cooling textile fabricsLiquid/gas/vapor removalYarnPolyester

The invention discloses a polyester fabric dyeing process which includes the steps: S1 gray fabric desizing; S2 gray fabric pre-shrinking; S3 leveling a post-set fabric by a leveler; S4 presetting theleveled fabric, guiding the fabric into a setter by a fabric feeder in the presetting process and performing presetting treatment; S5 minimizing alkali of the preset fabric; S6 performing medium setting treatment on warp yarns of the alkali minimized fabric; S7 dyeing the medium set fabric; S8 performing post-setting treatment on the dyed fabric through setting liquid by the setter to obtain a finished fabric. The setting liquid for setting comprises, by weight, 20-30 parts of softening agents, 30-40 parts of disodium hydrogen phosphate, 70-80 parts of plasticizers, 10-20 parts of glyceryl tristearate and 30-34 parts of polytetrafluoroethylene particles. The polyester fabric dyeing process has the advantage that polyester fabric setting effects are improved.

Owner:浙江创宇印染有限公司

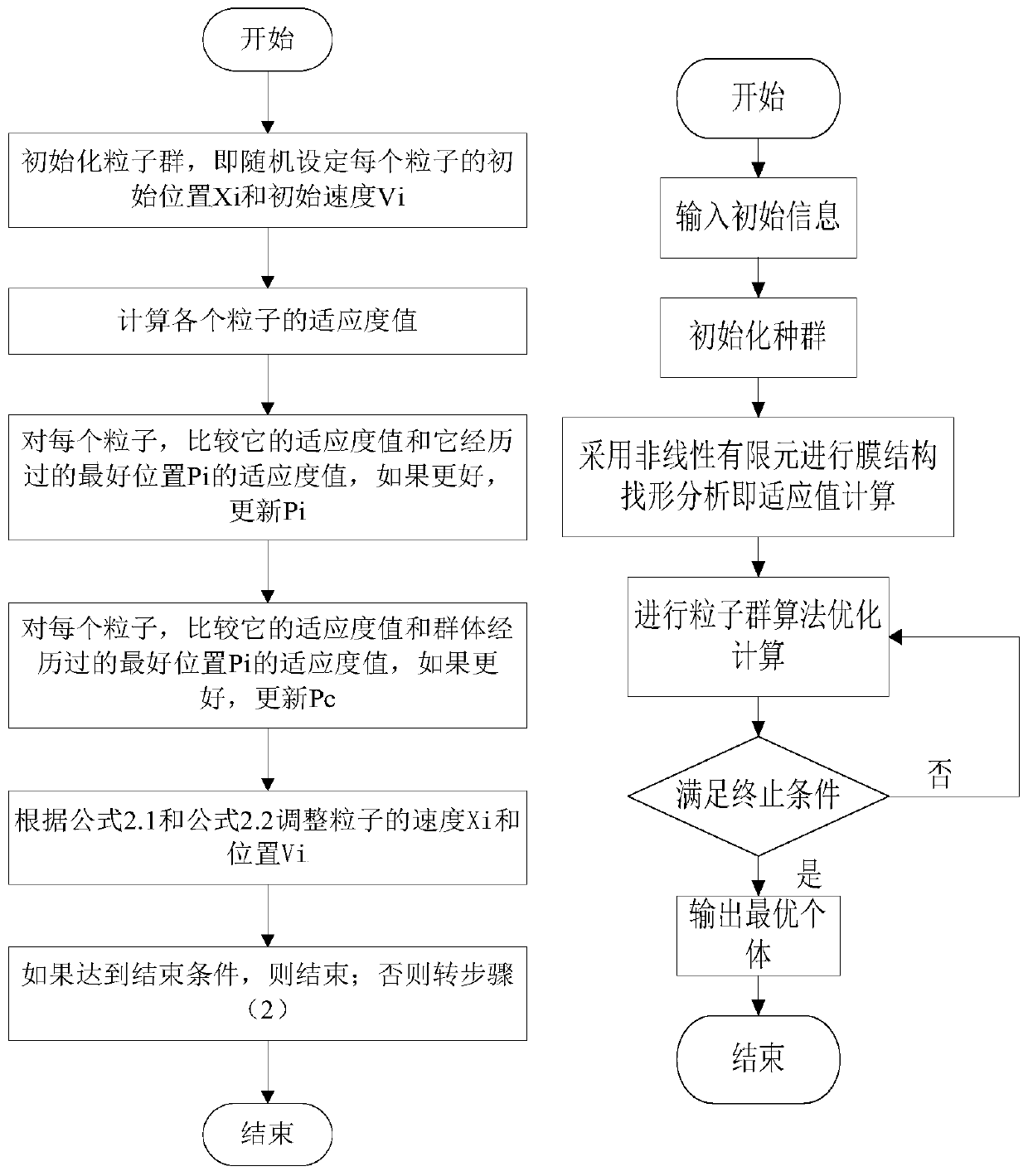

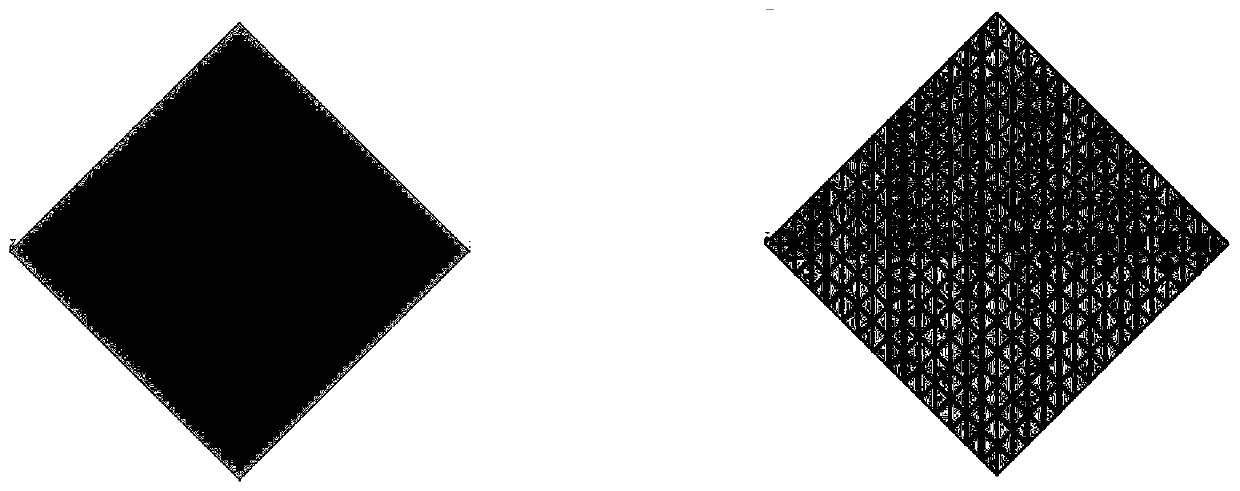

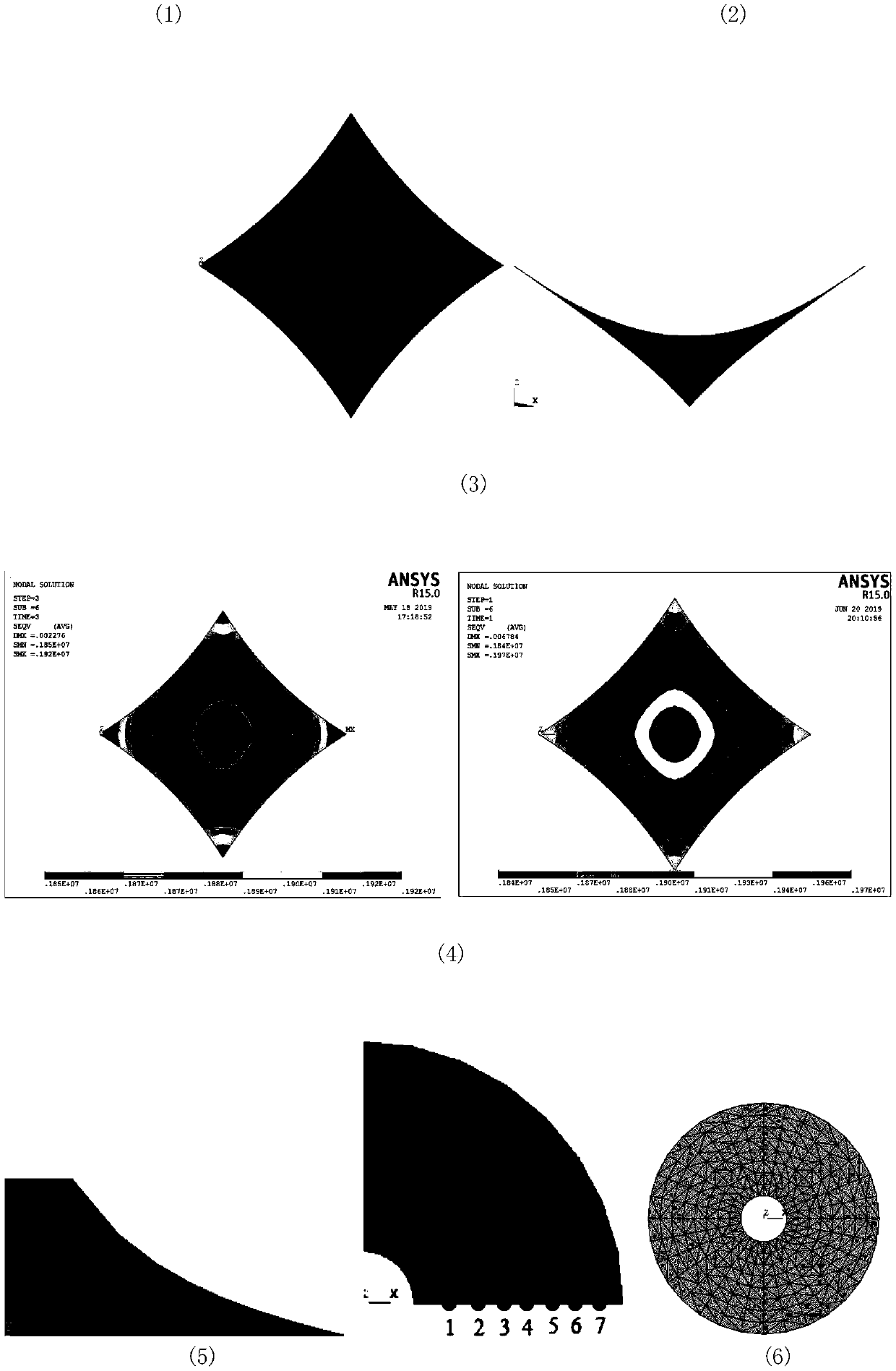

Cable membrane structure shape finding design method based on particle swarm optimization algorithm

ActiveCN111062072AReduced likelihood of wrinklingGeometric CADArtificial lifeMembrane surfaceEngineering

The invention discloses a cable membrane structure shape finding design method based on a particle swarm optimization algorithm, and the method comprises the following steps: selecting the particle swarm optimization algorithm as a basic method for the shape finding of a cable membrane structure through employing a numerical simulation method, determining the optimization steps and flow, and building a cable membrane structure optimization model. Three surfaces with different projection shapes, namely a rotary catenary surface, a saddle surface and a rhombic hyperboloid, are selected as examples, and a shape-finding analysis model of the cable membrane structure is established by a self-programming method; a shape finding form diagram and a membrane surface stress distribution diagram areobtained through shape finding optimization analysis, and a calculation result and an analysis value determined by the particle swarm algorithm for structure shape finding are further obtained, and thus further confirming a membrane initial prestress value with an optimal membrane surface shape finding result and obtaining an optimal cable membrane structure initial shape. And load analysis is performed on the cable membrane structure, and a judgment criterion of the cable membrane structure wrinkling is researched. Through wrinkle analysis on a typical cable membrane structure, the processingmethod for avoiding wrinkles is obtained. Therefore, the optimal shape finding of the cable membrane structure is achieved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Film laminating device and film laminating process for plastic sheet machine

InactiveCN112677441AVersatileImprove product qualityLamination ancillary operationsLaminationThin membraneEngineering

The invention relates to a film laminating device and a film laminating process for a plastic sheet machine, and relates to the field of sheet compounding equipment. The film laminating device comprises a rack, a support, an unwinding shaft, a limiting assembly, a driving assembly, a guiding assembly and a flattening assembly. The limiting assembly is used for positioning the unwinding shaft, the driving assembly is used for driving the unwinding shaft to rotate, the guiding assembly is used for guiding a thin film, and the flattening assembly is used for flattening the thin film. The support comprises a bottom frame and two vertical plates. One ends of the vertical plates are connected with the bottom frame, the two vertical plates are parallel and arranged in a spaced mode, lower grooves for containing the unwinding shaft are formed in the top ends of the vertical plates, the unwinding shaft is placed in the lower grooves, and each limiting assembly comprises a limiting block, a spring bolt, a locking ring and a handle. One ends of the limiting blocks are hinged to the top ends of the vertical plates, and the other ends of the limiting blocks are hinged to the corresponding locking rings. The lock rings are connected with the handles, upper grooves are formed in the sides, close to the lower grooves, of the limiting blocks, and the spring bolts are connected to one sides of the vertical plates and further matched with the locking rings. The film laminating device and the film laminating process for the plastic sheet machine have the effect of enriching the functions of the plastic sheet machine.

Owner:黄冈双健包装有限公司

NC bending core head for thin walled tube of aluminum alloy with major diameter and design method thereof

InactiveCN102161059BReduce interference areaReduce excessive interferenceSpecial data processing applicationsEngineeringElement modeling

The invention relates to an NC bending core head for a thin walled tube of aluminum alloy with a major diameter and a design method thereof, wherein the core head comprises an core head(2), a mandrel core pin(1) and a connection member between the core heads(3). Further, the core heads are connected in a ball-and-socket structure manner. The eccentricity delta of the ball centre of the eccentric core (2) in the internal of the core head is delta=h / k, wherein h is the distance between the ball centre of core head and the large end of the core head, and k is the thickness of the core head. The inside radius d0' and the outer radius d0 of the core head, and x2 corresponding to the largest angle theta 2 of the core are determined, so that the relationship between the core distance h and the largest angle theta 2 of the eccentric core is established. Through finite element modeling, the scope of the largest angle theta 2 between the eccentric cores (2) is determined, and furthermore, the value range of h is determined. According to invention, an interference area between rotary core heads, and excess interference between the core heads and the tubing outside arc surfaces are reduced, so as to be suitable for bending and shaping of the tubing under various bending radii. Besides, the possibility of tubing wrinkling and the degree of thinning could be decreased, without increasing the flat degree of tubing.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Rapid cold stretch bending technology for thin-walled small-radius pipes

The invention discloses a rapid cold stretch bending technology for thin-walled small-radius pipes and aims to provide a rapid cold stretch bending technology which is high in pipe bending efficiency, capable of preventing the pipes from wrinkling during bending and realizing smoothness of the bending surface and used for the thin-walled small-radius pipes. A thin-walled small-radius pipe bending machine is adopted to perform rapid cold stretch bending on the thin-walled small-radius pipes and comprises processing steps as follows: a, core feeding; b, clamping; c, bending; d, core retreating; e, clamping release; f, guide mold release. The rapid cold stretch bending technology is applied to the technical field of bending of the thin-walled small-radius pipes.

Owner:珠海市骏力弯管设备有限公司

Expandable embroidering machine presser foot

The invention discloses an expandable embroidering machine presser foot. The expandable embroidering machine presser foot comprises a U-shaped rod, wherein a connecting rod is arranged at the upper end of one side, close to a U-shaped opening, of the U-shaped rod; a first inserting opening is formed in the upper end of one side, close to the connecting rod, of the U-shaped rod; a second inserting opening, which corresponds to the first inserting opening, is formed in the lower end of the U-shaped rod; a groove is formed in the U-shaped rod located on the same side of the second inserting opening; a bottom plate is arranged at the bottom of the groove; the bottom plate and a bottom wall of the groove are connected through a plurality of springs; a vertical sliding groove is formed in a side wall of the groove; a fixed rod is arranged at the upper side of the bottom plate; a side wall of the fixed rod is provided with a sliding block matched with the vertical sliding groove; and an annular groove communicated with the vertical sliding groove is formed in the side wall of the groove. The expandable embroidering machine presser foot disclosed by the invention has a simple structure; the expandable embroidering machine presser foot can be used for carrying out embroidering work very well, and the fixed rod and parts matched with the fixed rod are arranged, so that the possibility that a product to be embroidered has folds can be reduced, and the efficiency of production is increased.

Owner:杨芝燕

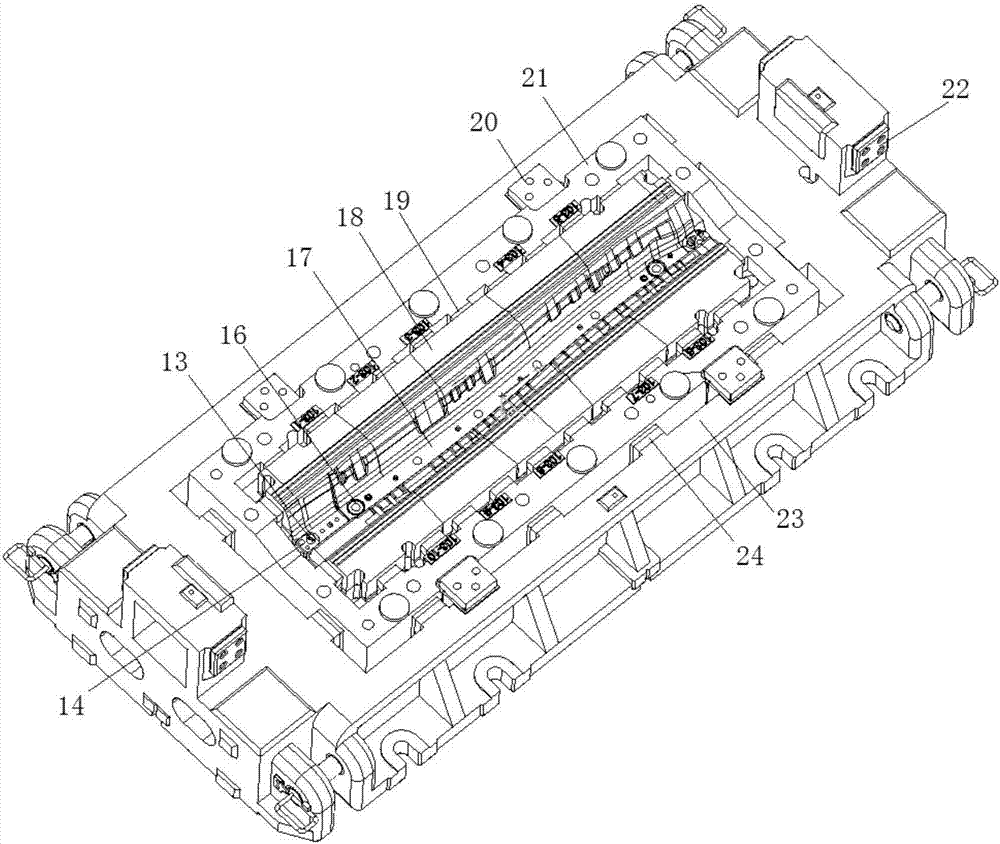

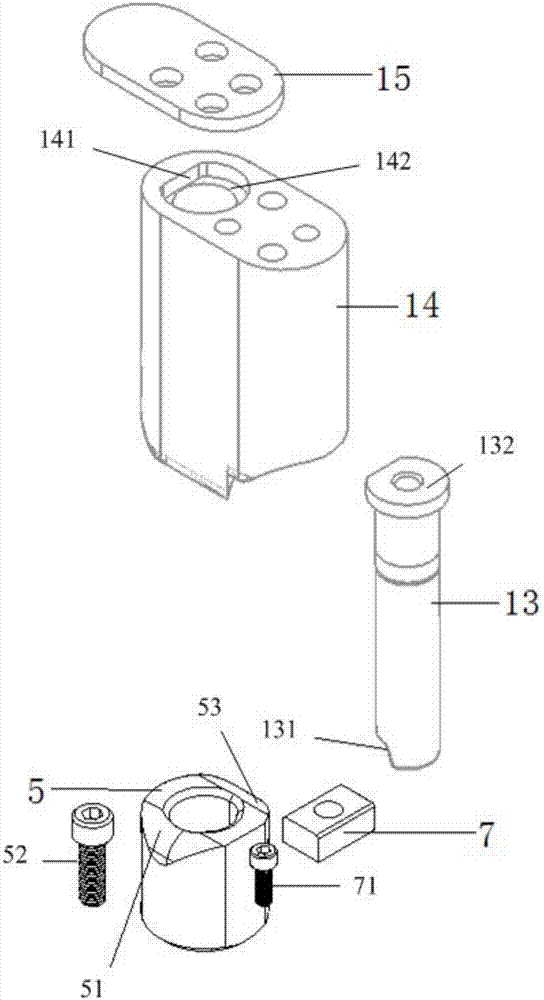

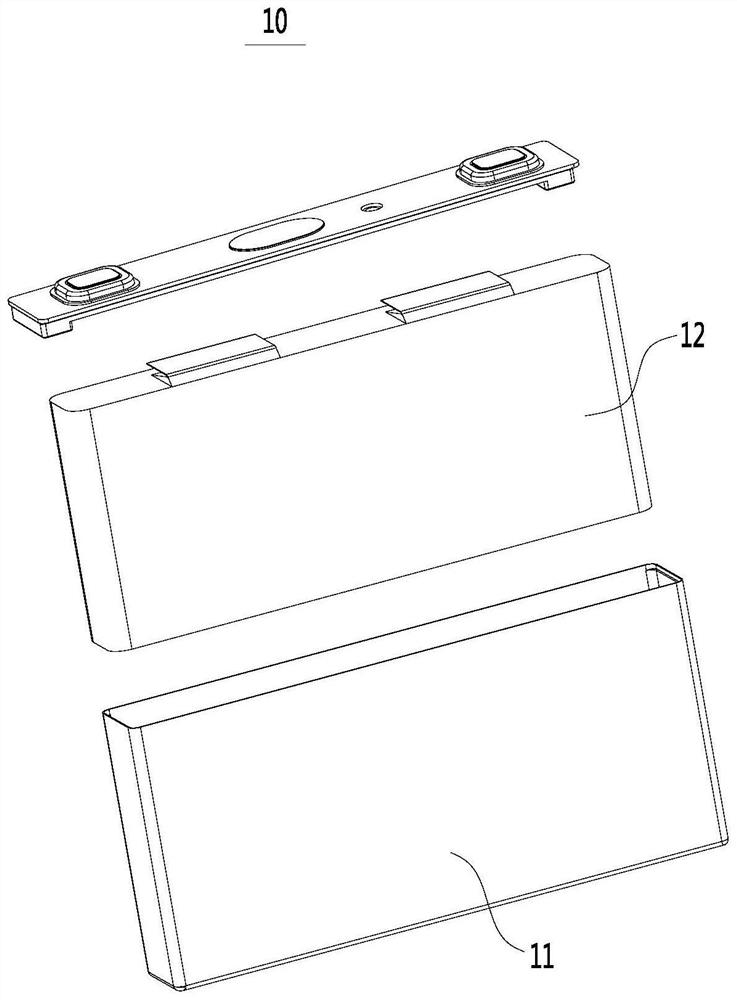

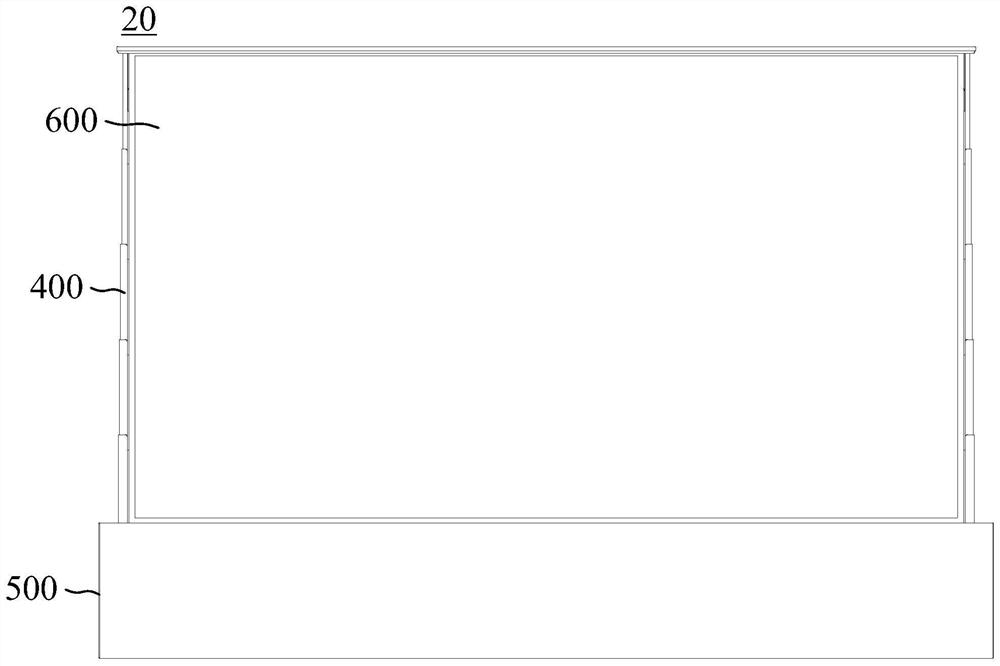

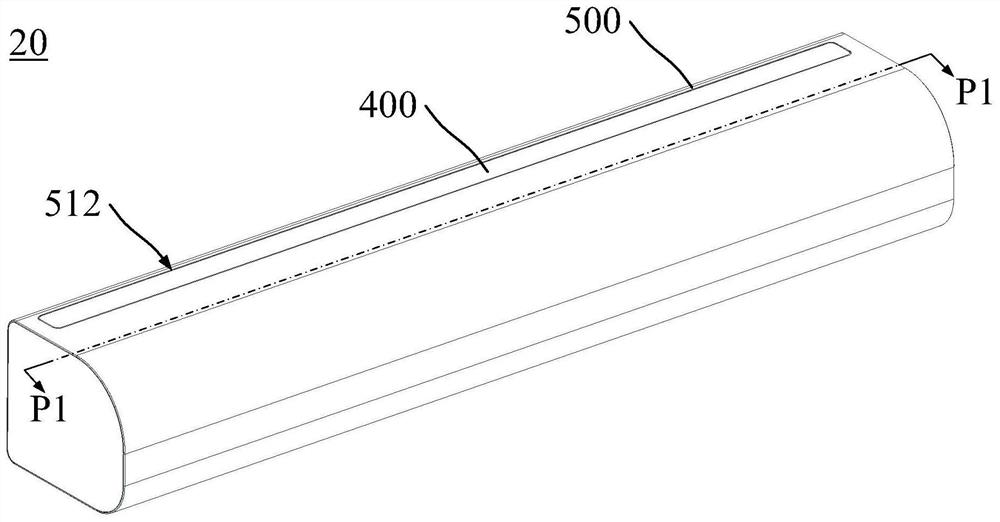

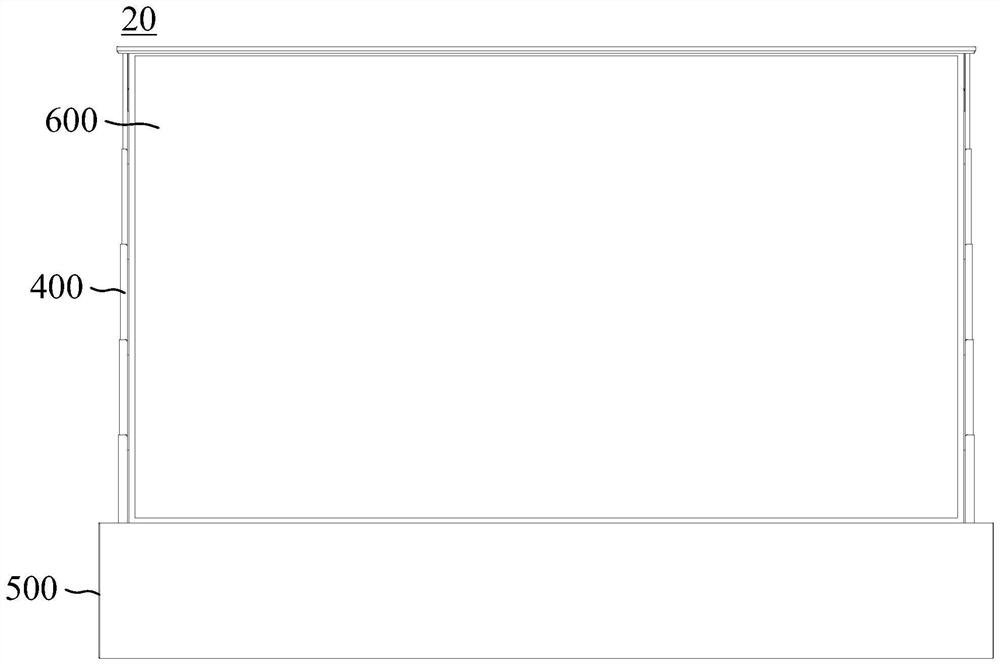

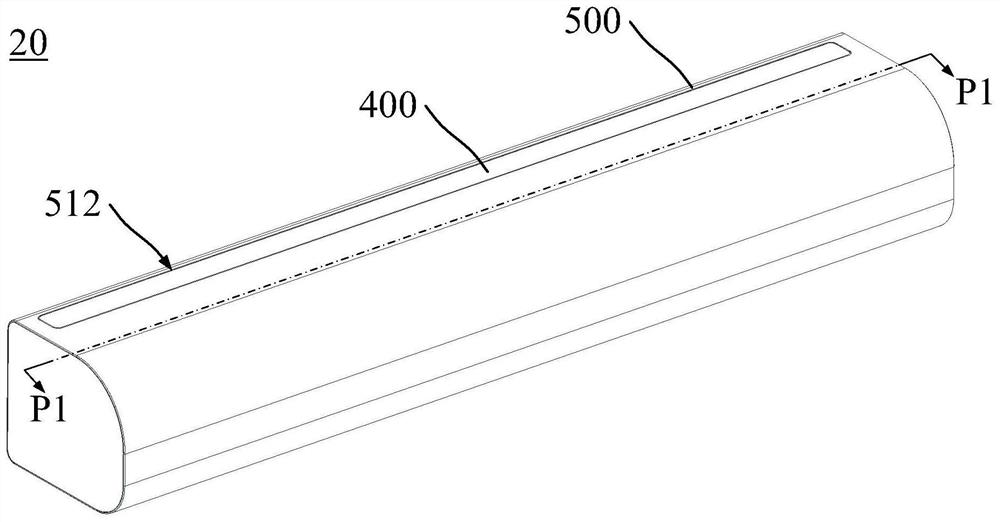

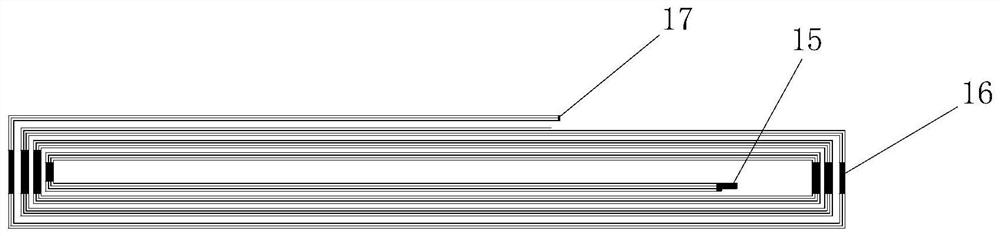

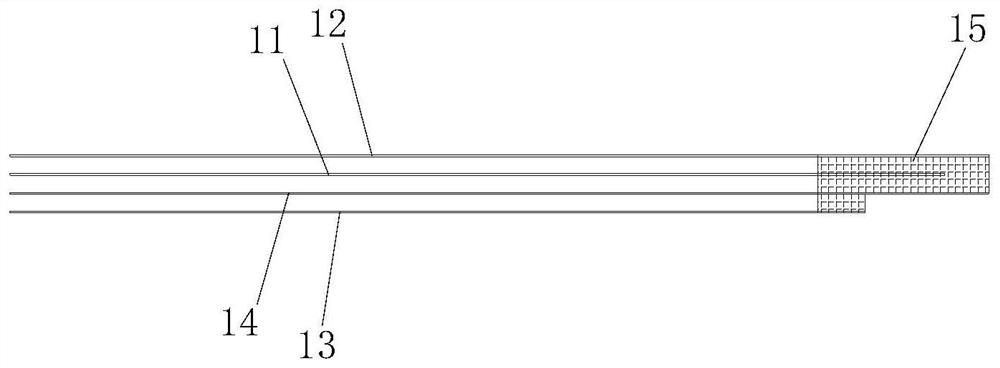

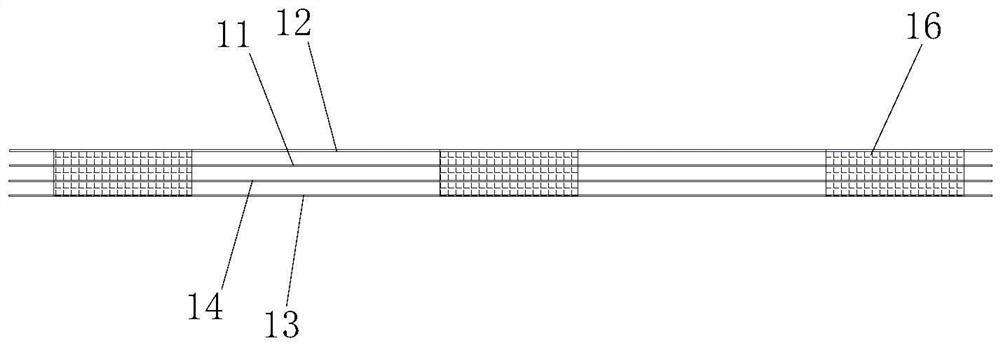

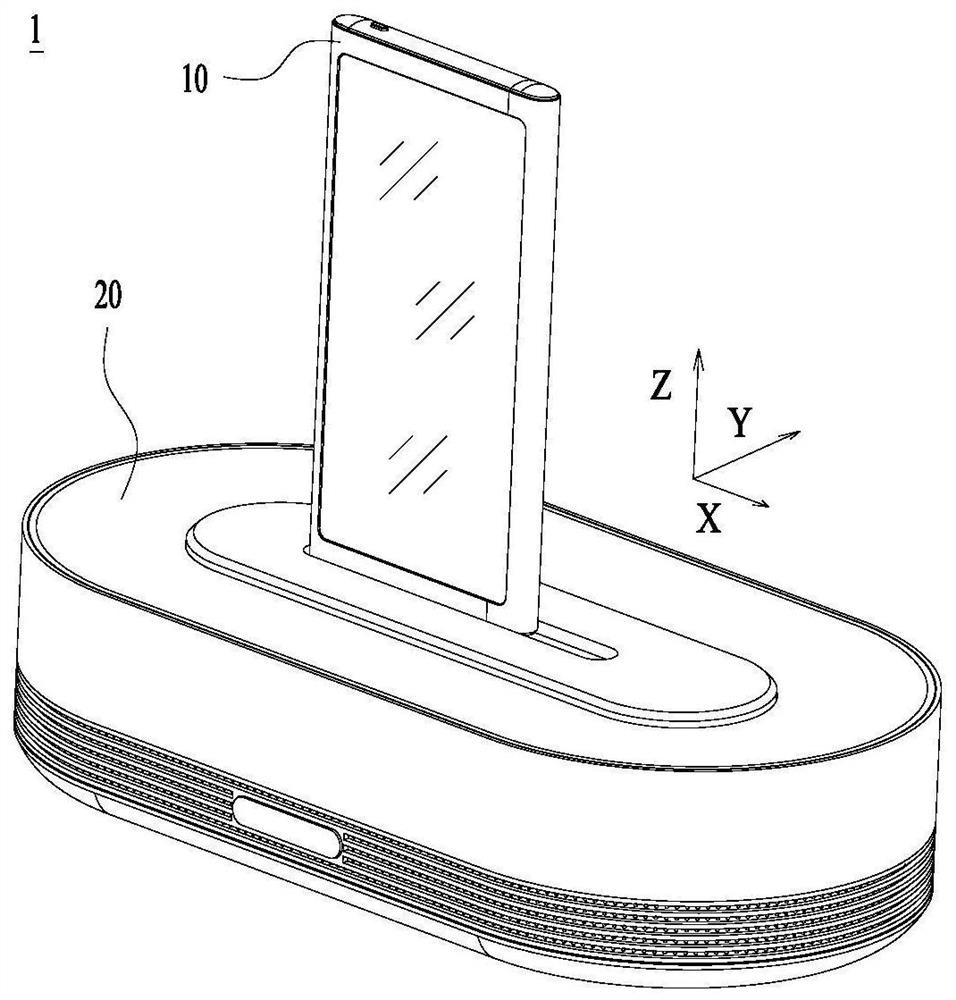

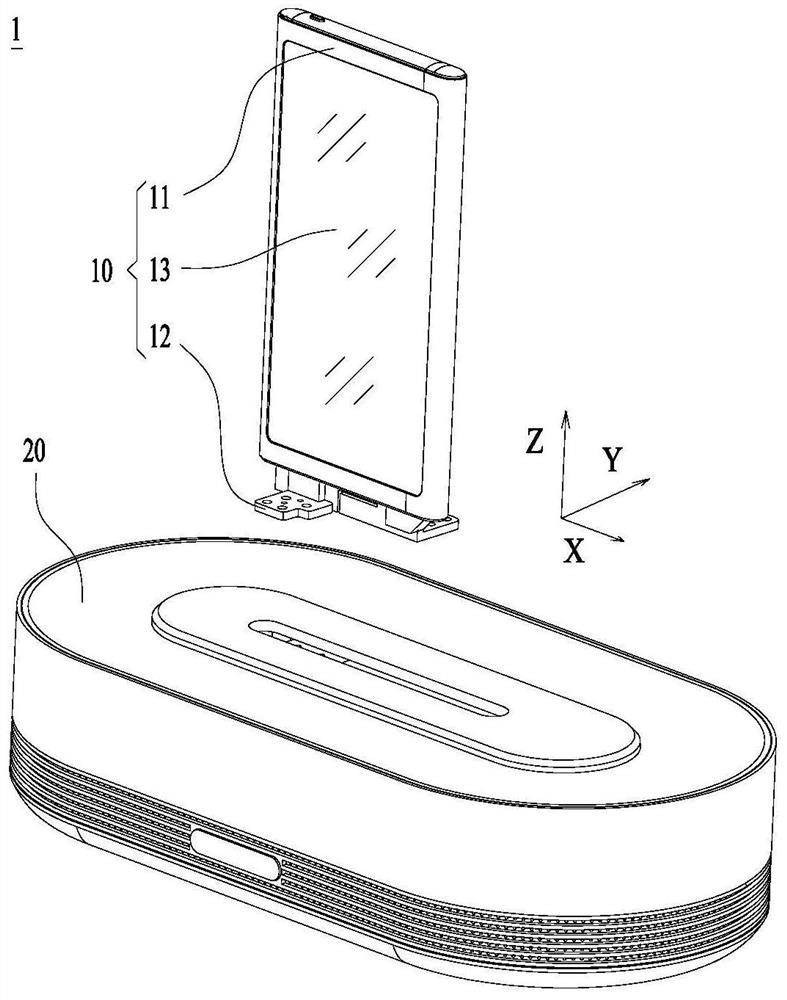

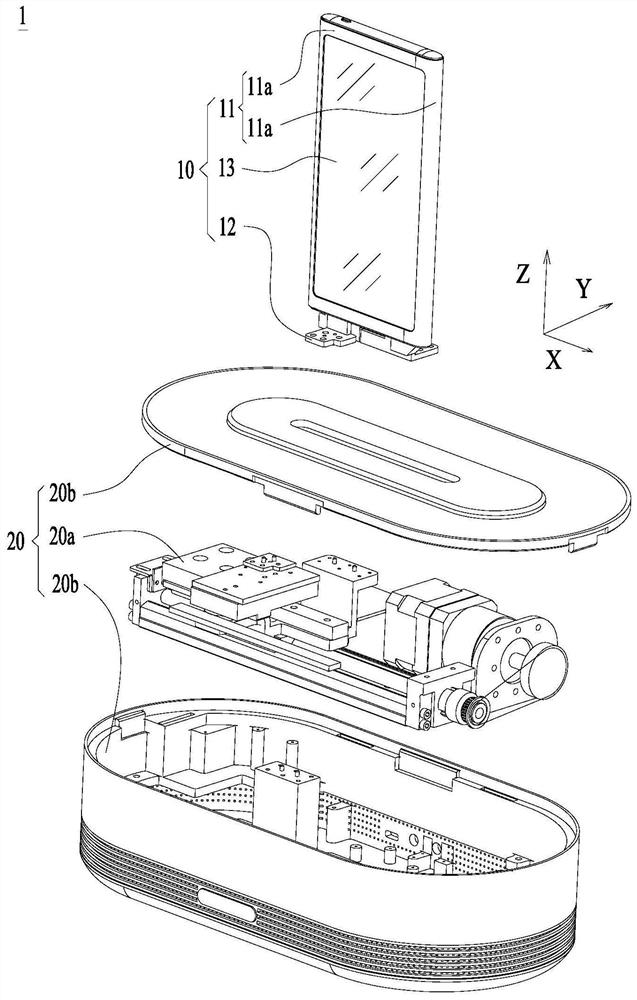

Display device

ActiveCN112383650APlay a supporting roleReduced likelihood of wrinklingTelephone set constructionsIdentification meansDisplay deviceEngineering

The embodiment of the invention provides a display device. The display device comprises a main body which is columnar and is provided with at least one end part, wherein the end part is used for bearing the display device so as to enable the display device to be in a standing state; a flexible screen assembly, wherein one end of the flexible screen assembly is arranged in the main body, and the flexible screen assembly can be stored in the main body or extend out of the main body from the main body; a supporting assembly, wherein one end of the supporting assembly is arranged in the main body,the other end of the supporting assembly is fixedly connected with the other end of the flexible screen assembly, and the supporting assembly can be contained in the main body or extend out of the main body from the interior of the main body; and a driving assembly arranged in the main body, wherein the driving assembly is used for driving the supporting assembly and the flexible screen assemblyto move synchronously so as to extend out of the main body from the interior of the main body or be stored in the main body from the exterior of the main body. The embodiment of the invention can enrich the characteristics of the display device.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Film adhesion device for film active release

InactiveCN102148177BSolve wasteAvoid wastingSemiconductor/solid-state device manufacturingPull force

The invention discloses a film adhesion device for film active release. The device is characterized by comprising a supporting shaft and a driving device, wherein the supporting shaft is used for supporting an adhesive film roll; and the driving device drives the supporting shaft to rotate. The film adhesion device for the film active release changes the conventional mode of pulling an adhesive film by a film clamping device to drive the adhesive film roll to rotate so as to release the adhesive film into a mode of driving the adhesive film roll by the driving device to rotate so as to release the adhesive film actively. When the adhesive film is pulled by the film clamping device to cover a wafer, a pulling force applied to the adhesive film by the film clamping device can be quite small, so that the adhesive film cannot be deformed by stretching, and the quality of film adhesion is improved.

Owner:上海技美科技股份有限公司

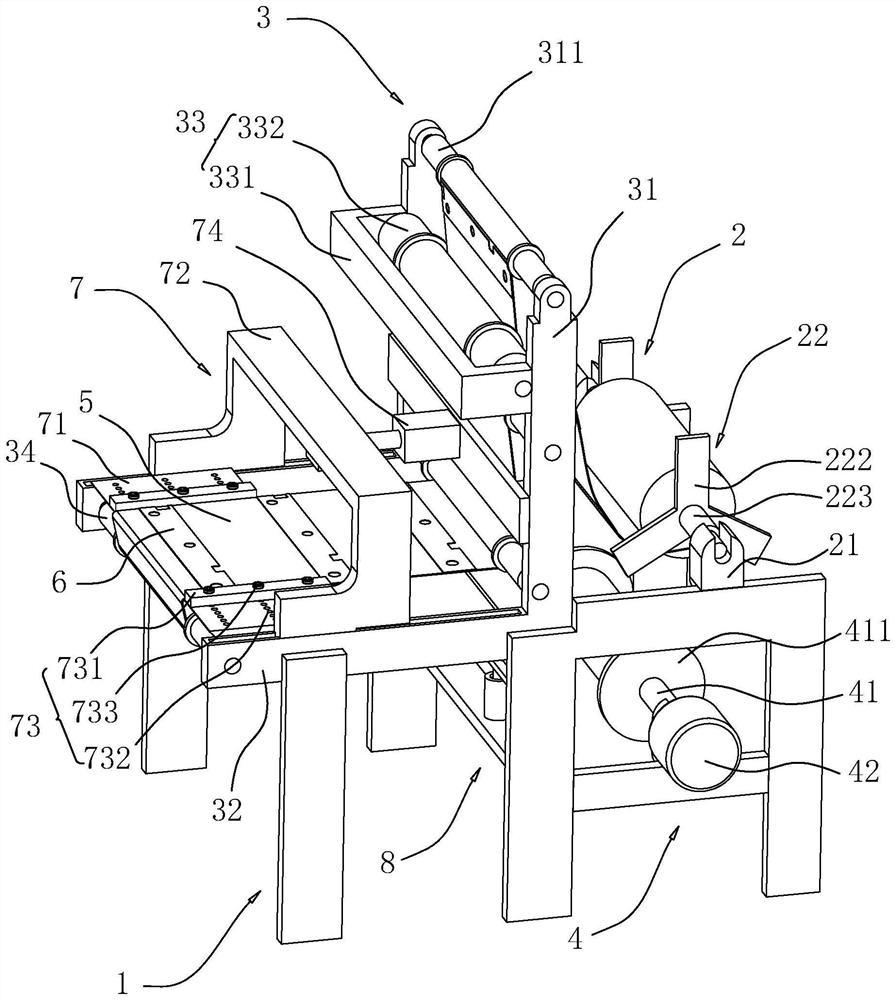

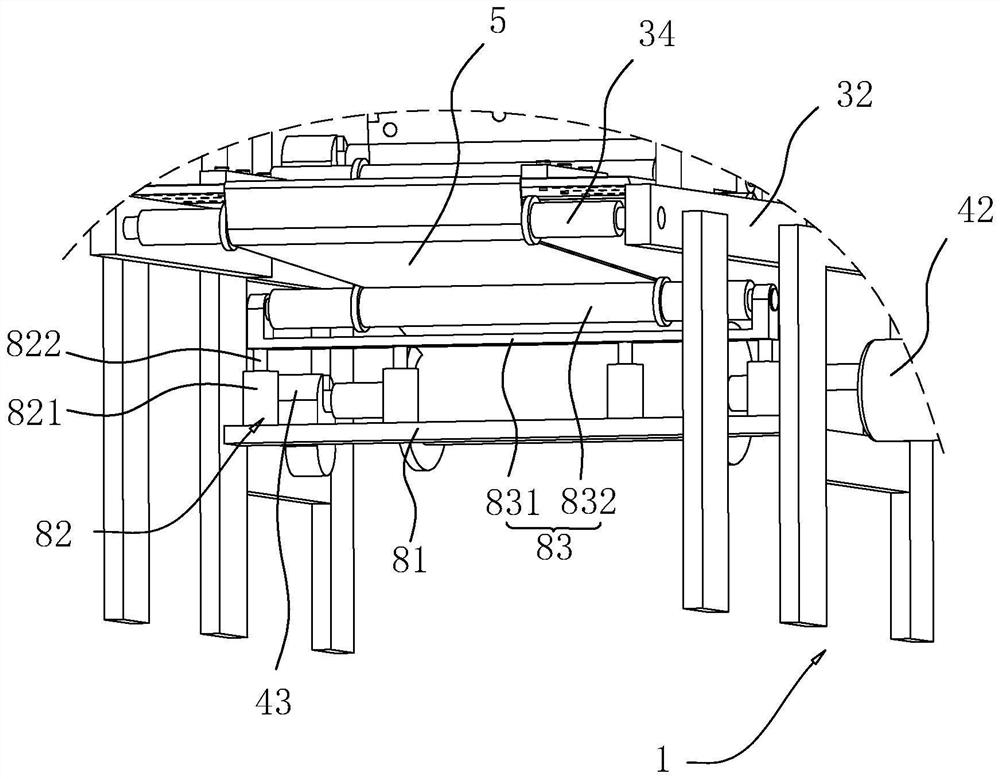

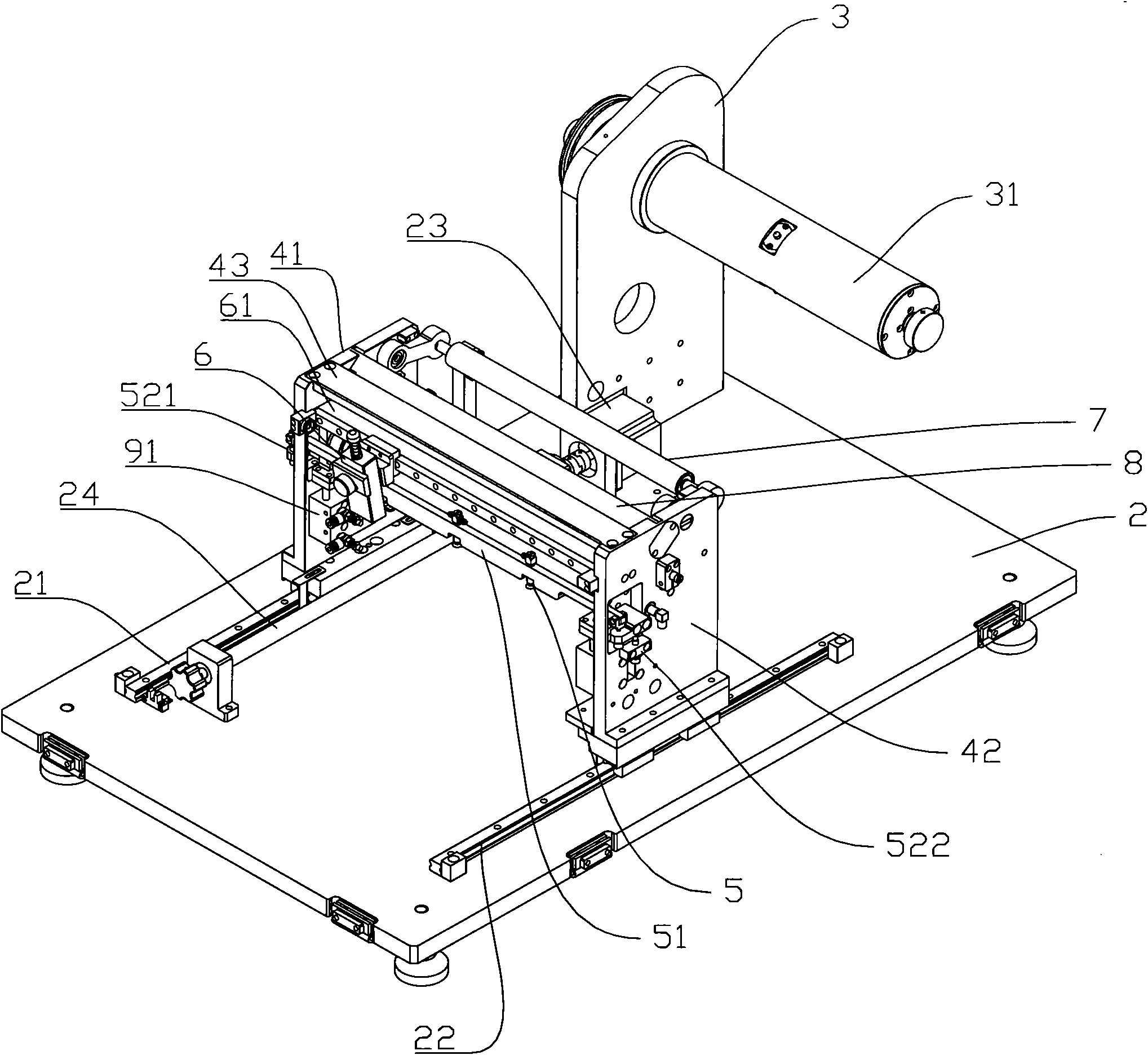

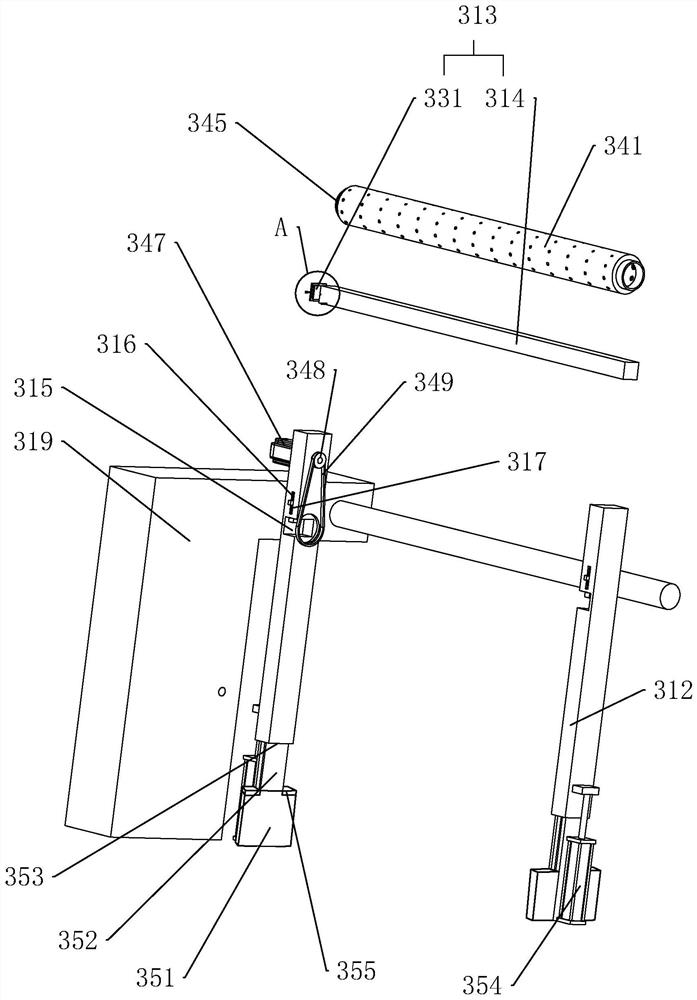

Label discharging system of automatic mylar pasting machine

ActiveCN114212340AReduced likelihood of wrinklingUncover smoothlyLabelling machinesWebs handlingMachineWaste material

The invention relates to the technical field of mylar pasting, in particular to a label discharging system of an automatic mylar pasting machine, which comprises a machine body, a feeding mechanism, a feeding frame group, a material pulling mechanism, a stripping mechanism and a tensioning mechanism, the feeding mechanism can feed the mylar film attached to the material belt. The feeding frame set can achieve the transition and transfer effects on the mylar film fed through the feeding mechanism. On one hand, the material pulling mechanism can pull the material belt and cooperate with the feeding mechanism and the feeding frame set to achieve continuous label discharging, and on the other hand, the material pulling mechanism can also collect the waste material belt after Mylar film uncovering while continuous label discharging is conducted; on one hand, the stripping mechanism can bear and transfer the material belt transferred by the feeding frame set, and on the other hand, the stripping mechanism can move in the direction close to or away from the feeding mechanism. The tensioning mechanism can elastically support and transfer the material belt running between the stripping mechanism and the material pulling mechanism. The Mylar film uncovering device has the advantage that the Mylar film uncovering effect is improved.

Owner:扬胜(天津)金属制品有限公司

A beam drawing die

The invention provides a beam part drawing mold. The beam part drawing mold comprises an upper mold base, a lower mold base, a split concave mold arranged on the upper mold base, a split convex mold arranged on the lower mold base, two flanged convex molds and two flanged concave molds; two drawing ribs are oppositely arranged on two sides of the split concave mold; the extending direction of the drawing ribs is the same with the extending direction of the split concave mold; the two flanged convex molds are respectively arranged at two ends of the split concave mold; the two flanged concave molds are respectively arranged at two ends of the split convex mold; the two flanged concave molds are correspondingly matched with the two flanged convex molds one to one; flanged molding surfaces are arranged at one ends, far from the split concave mold, of the flanged convex molds; and matching surfaces matched with the flanged molding surfaces are arranged at one ends, far from the split convex mold, of the flanged concave molds. The beam part drawing mold can greatly reduce the corrugation possibility of two ends, is better in subsequent positioning effect, and meanwhile, can improve the material utilization rate and the forming effect.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Tube bending inner supporting device and tube bending method

The invention discloses a tube bending inner supporting device and a tube bending method. The tube bending inner supporting device comprises a load mechanism, a steel wire rope, an elastic core die, a pushing die and a pushing part. The load mechanism is provided with a stretchy rod which contracts to one side. One end of the steel wire rope is connected with a stretchy end of the stretchy rod and the other end of the steel wire rope is connected with a top disc. The elastic core die, the pushing die and the pushing part sequentially and movably penetrate through the steel wire rope. One end of the elastic core die is connected with the top disc in an abutted mode. The pushing part is detachably connected with the pushing die and retracts through the stretchy rod of the load mechanism. The top disc is matched with the steel wire rope to pull the elastic core die and the pushing die tight, so that the elastic core die expands in an inner cavity of a tube in a radial mode and is fully contacted with the inner wall of the tube. According to the tube bending inner supporting device and the tube bending method, the core die is matched with the inner wall of the tube in a self-adapting mode, crinkling is avoided and manufacturing and use cost can be greatly reduced.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

display device

ActiveCN112383650BPlay a supporting roleReduced likelihood of wrinklingTelephone set constructionsIdentification meansComputer hardwareDisplay device

Embodiments of the present application provide a display device. The display device includes: a main body, which is cylindrical and has at least one end part, the end part is used to carry the display device so that the display device is in a standing state; a flexible screen assembly, one end is arranged in the main body, the The flexible screen assembly can be accommodated in the main body or protruded from the main body to the outside of the main body; a support assembly, one end of which is arranged in the main body, and the other end of the support assembly and the other end of the flexible screen assembly a fixed connection, the support assembly can be received in the main body or protruded from the main body to the outside of the main body; and a drive assembly disposed in the main body, the drive assembly is used for driving the support assembly The flexible screen assembly moves synchronously to extend from the inside of the main body to the outside of the main body or to be received in the main body from the outside of the main body. The embodiments of the present application can enrich the characteristics of the display device.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

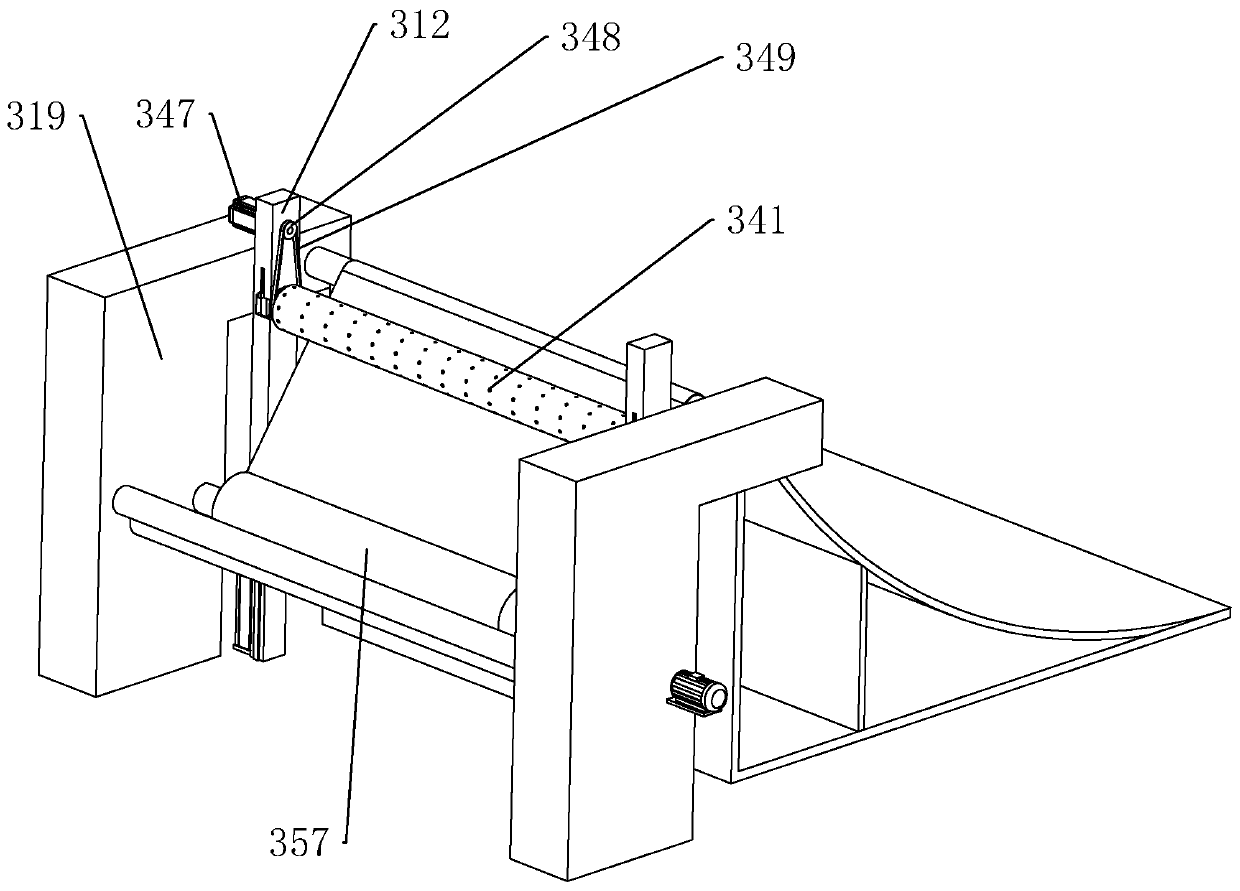

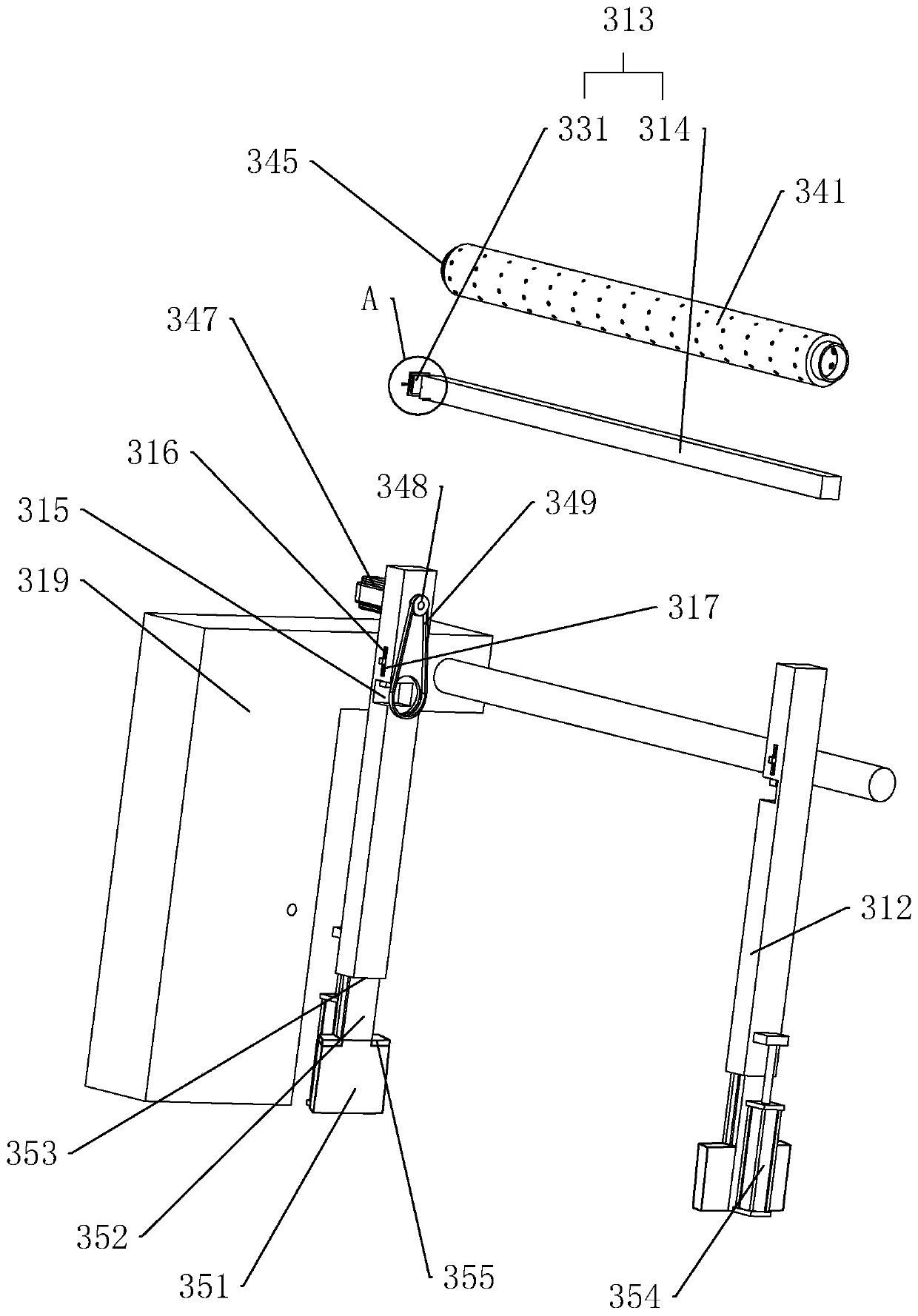

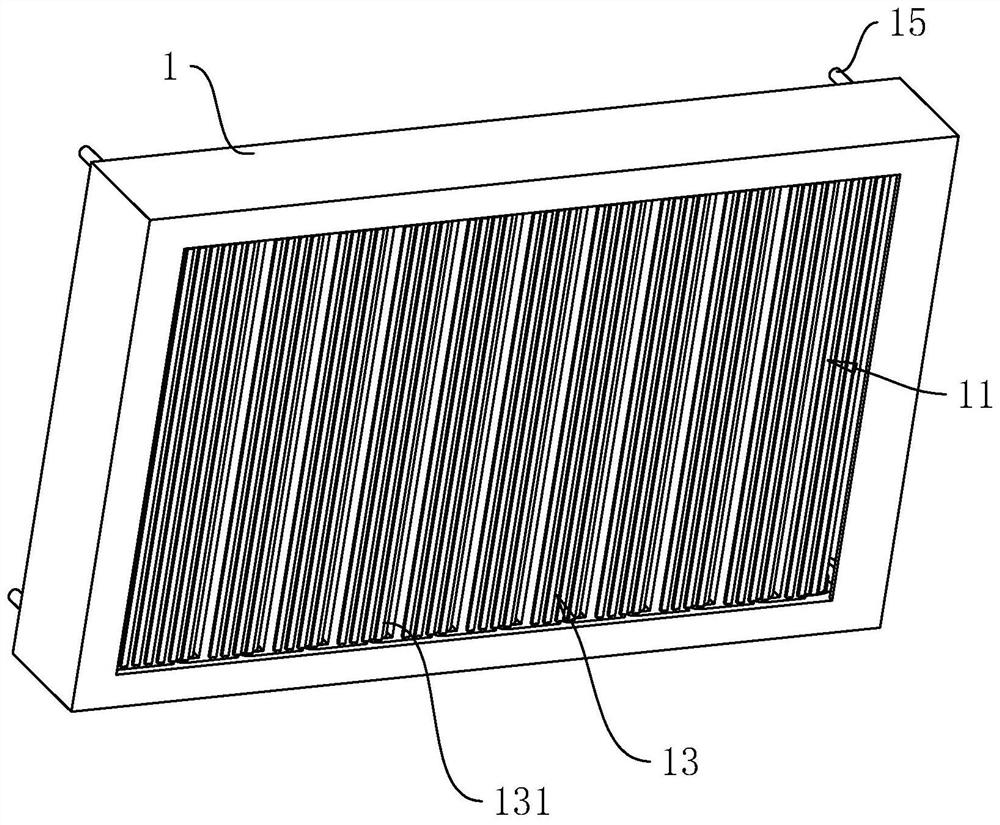

Composite battery winding equipment

PendingCN114883625AReduced Alignment DifficultyReduce in quantityAssembling battery machinesFinal product manufactureEngineeringPole piece

The invention discloses composite battery winding equipment which consists of a positive electrode composite unit, a negative electrode composite unit and a positive and negative composite unit for connecting the positive electrode composite unit and the negative electrode composite unit, the positive pole composite unit is used for heating and compounding a positive pole piece and a first diaphragm to form a positive pole composite piece body; the negative pole composite unit is used for heating and compounding a negative pole piece and a second diaphragm to form a negative pole composite piece body; and the positive and negative composite unit forms a battery cell by compositely winding the positive composite sheet body and the negative composite sheet body. On one hand, the total number of sheets entering a winding process can be reduced, so that the alignment difficulty of positive and negative pole sheets and a diaphragm is reduced, the possibility that the positive and negative pole sheets are not aligned with each other is reduced, the winding alignment precision is improved, winding dust is reduced, tension control is easier, low-tension control can be realized, and the production efficiency is improved; and on the other hand, the possibility of folding or wrinkling when the positive and negative pole pieces enter the winding process can be reduced, and the yield of the battery cell can be improved.

Owner:DONGGUAN ARECONN PRECISION MACHINERY

Film attaching method and device

InactiveCN102120380BSolve wasteAvoid wastingLaminationSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention discloses a film attaching method, which is characterized in that: a film is moved by a vacuum adsorption device, so that the film covers a wafer; and the film is pressed by a pressing device, so that the film is attached to the surface of the wafer. By the method, adhesive films can be saved, procedures are saved, the film attaching efficiency is improved, and the film attaching quality can be improved.

Owner:上海技美科技股份有限公司

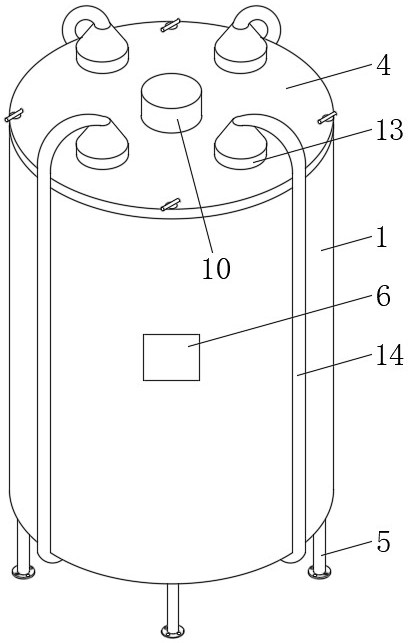

Production method for preparing high-end wood products through dewatering process

PendingCN113048760AImprove uniformityImprove dehydration effectDrying solid materials without heatDrying gas arrangementsProcess engineeringStructural engineering

The invention discloses a production method for preparing wood products through a dewatering process. A dewatering device is used for dewatering and drying, the dewatering device comprises a dewatering barrel, a fixing box and fixing mechanisms, the fixing box is arranged in an inner cavity of the dewatering barrel, the inner wall of the fixing box is connected with the multiple sets of of fixing mechanisms used for limiting wood products, and the fixing box is rotationally connected with the dewatering barrel through a bearing seat. The top end of the fixing box is rotationally connected with a box cover through a hinge, the top end of the dewatering barrel is connected with a barrel cover through multiple sets of vertical threaded rods, the top end of the barrel cover is connected with a power mechanism connected with the box cover, multiple sets of circulation mechanisms arranged in an annular array communicate between the dewatering barrel and the barrel cover, multiple sets of ventilation channels are formed in the periphery of the fixing box and the top end of the box cover, and multiple sets of supporting legs are connected to the bottom end of the dewatering barrel. By means of the method, the heating dewatering effect can be guaranteed, and the possibility that the surfaces of wood products are wrinkled due to dewatering can be reduced.

Owner:江西红锦发木业有限公司

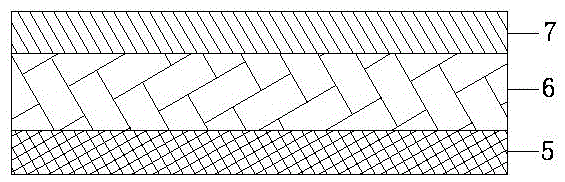

Wear-proof, antifouling and crease-resistant pearl bag made from leather

The invention relates to a wear-proof, antifouling and crease-resistant pearl bag made from leather. The wear-proof, antifouling and crease-resistant pearl bag made from leather is characterized by comprising a bag body (1), wherein the top of the bag body (1) is provided with a bag button (2); the upper side of the bag body (1) is provided with a bag belt (3); two ends of the bag belt (3) are respectively connected with two ends of the top of the bag body (1), so that the female can take the bag conveniently; multiple rows of sequins (4) arranged closely are embroidered at the surface of the bag body (1); the sequins (4) comprise PET film layers; the upper surfaces of the PET film layers are provided with color alternation layers, and the lower surfaces of the PET film layers are provided with light reflecting layers; the light reflecting layers are composed of microprism resin pyramids; the bottom surfaces of the light reflecting layers are plated with metal protective layers; the metal protective layers are aluminum-electroplated protective layers; a fabric used for the bag body (1) sequentially consists of a textile layer (5), a spongy layer (6) and a waterproof fabric layer (7) from inside to outside. The wear-proof, antifouling and crease-resistant pearl bag made from leather is flashing and beautiful, good in gas permeability, difficult to contaminate and difficult to wrinkle.

Owner:JIANGYIN JIAYI GIFT

Side key FPC assembly and assembling method thereof

InactiveCN113347781AInsert smoothlyImprove the problem of improper assemblyCircuit bendability/stretchabilityPrinted circuit manufactureEngineeringMechanical engineering

The invention relates to the technical field of mobile terminals and discloses a side key FPC assembly and an assembling method thereof. The side key FPC assembly comprises a side key, a first component and a second component, wherein one of the first component and the second component is a conductive reinforcing piece, the other one is an FPC, and the assembling method of the side key FPC assembly comprises steps of the first component being positioned in a jig; arranging a conductive adhesive layer on the surface of the first component or the surface, facing the first component, of the second component; and pre-positioning the second component in the jig and then pasting the second component on the first component. According to the side key FPC assembly and the assembling method thereof, a problem that in the prior art, in the process that a side key FPC is installed into a side key groove in a shell, assembling is not in place easily is solved.

Owner:NANCHANG HUAQIN ELECTRONIC TECH CO LTD

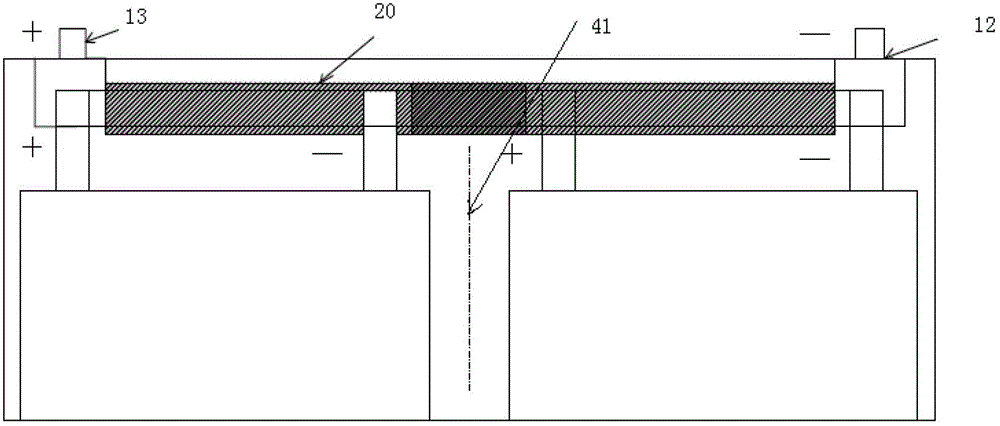

Multi-pole-set battery and manufacture method thereof

InactiveCN102945929BIncrease profitGuarantee the same capacityFinal product manufactureCell component detailsEngineeringElectrical and Electronics engineering

Owner:天津中聚电池技术有限公司 +1

A kind of dyeing process of polyester fabric

ActiveCN110205762BReduce the temperatureReduce yellowingHeating/cooling textile fabricsLiquid/gas/vapor removalPolyesterPolymer science

The invention discloses a polyester cloth dyeing process, comprising the following steps: S1: gray cloth desizing. S2: Gray fabric pre-shrinking; S3: Use a leveling machine to level the finished fabric; S4: Pre-set the leveled fabric, and use a cloth loading machine to import the fabric into the setting machine during the pre-setting process. Pre-setting treatment, the used sizing liquid during setting includes the following parts by weight: 20-30 parts of softening agent; 30-40 parts of disodium hydrogen phosphate; 70-80 parts of plasticizer; 10-30 parts of glyceryl tristearate 20 parts; 30-34 parts of polytetrafluoroethylene particles; S5: carry out alkali reduction treatment on the pre-shaped cloth; S6: carry out the finalizing treatment on the cloth after the alkali reduction is completed; The cloth is dyed; S8: use a setting machine to perform a post-setting treatment on the dyed cloth with a setting liquid; obtain the finished cloth through the above eight steps. The invention has the advantage of improving the setting effect of the polyester cloth.

Owner:浙江创宇印染有限公司

Molding process of car seat back side panel

The invention discloses a process for forming side boards of backrests of automobile seats, and relates to technologies for forming hardware. The process includes a downward flanging procedure. The downward flanging procedure includes steps of firstly, building a mathematical model of drawing rounded corners of drawing rounded corner parts of sheets and wrinkling regions on sheets in a downward flanging procedure; secondly, determining drawing rounded corner magnitude ranges and optimal drawing rounded corner magnitude values by the aid of the mathematical model; thirdly, drawing rounded corners according to the optimal drawing rounded corner magnitude values determined in the second step; fourthly, downwardly flanging the sheets along the drawing rounded corner parts. The magnitude of each drawing rounded corner is used as an independent variable in the mathematical model, the area of each wrinkling region is used as a dependent variable in the mathematical model, and the area of each wrinkling region is the sum of the areas of a plurality of wrinkling sub-regions; the mathematical model is built by the aid of data acquired in field tests. The areas of the wrinkling regions are minimized under the effect of the determined drawing rounded corner magnitude ranges and the determined optimal drawing rounded corner magnitude values. The method has the advantages that the mathematical model of the drawing rounded corners and the wrinkling regions is built via the tests, the drawing rounded corner magnitude ranges and the optimal drawing rounded corner magnitude values are determined, and the areas of the wrinkling regions are minimized under the effect of the determined drawing rounded corner magnitude ranges and the determined optimal drawing rounded corner magnitude values, accordingly, the problem of wrinkling of products can be solved, and the quality of the products can be greatly improved.

Owner:RAINBOW METAL TECH

Background wall for indoor decoration, and construction technology thereof

ActiveCN113777871AReduced likelihood of wrinklingNot prone to curlingWallsProjectorsStructural engineeringMechanical engineering

The invention belongs to the technical field of indoor background walls, and relates to a background wall for indoor decoration, and a construction technology thereof. The background wall comprises a background wall frame, a projection plate and a movable plate, the background wall frame is provided with a projection groove for projection of a projector, the movable plate is arranged at an opening of the projection groove, and the projection plate is arranged between the bottom wall of the projection groove and the movable plate; a containing groove used for containing the movable plate is formed in the background wall frame; a penetrating opening is formed in the inner wall of one side of the projection groove, the containing groove communicates with the penetrating opening, and a driving mechanism for driving the movable plate to move to the containing groove is connected between the movable plate and the background wall frame; and the movable plate comprises a plurality of splice plates, and the splice plates are arranged in the moving direction of the movable plate. According to the invention, the background wall is convenient to use, and the indoor aesthetic degree is improved at the same time.

Owner:东莞市景润装饰有限公司

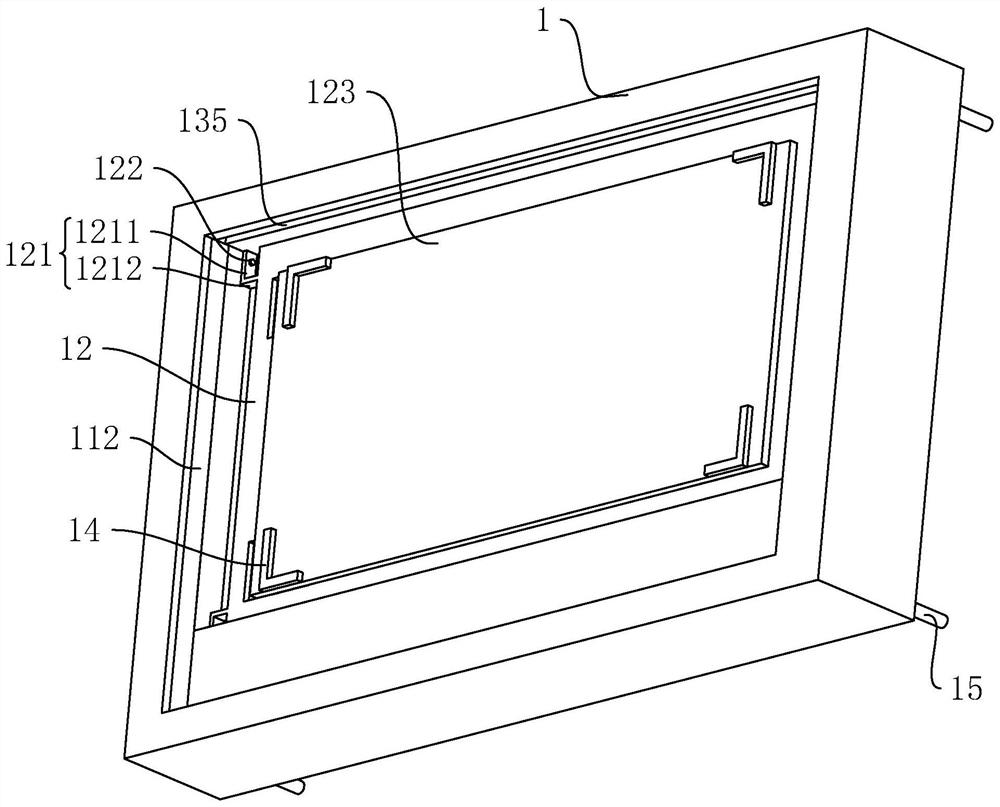

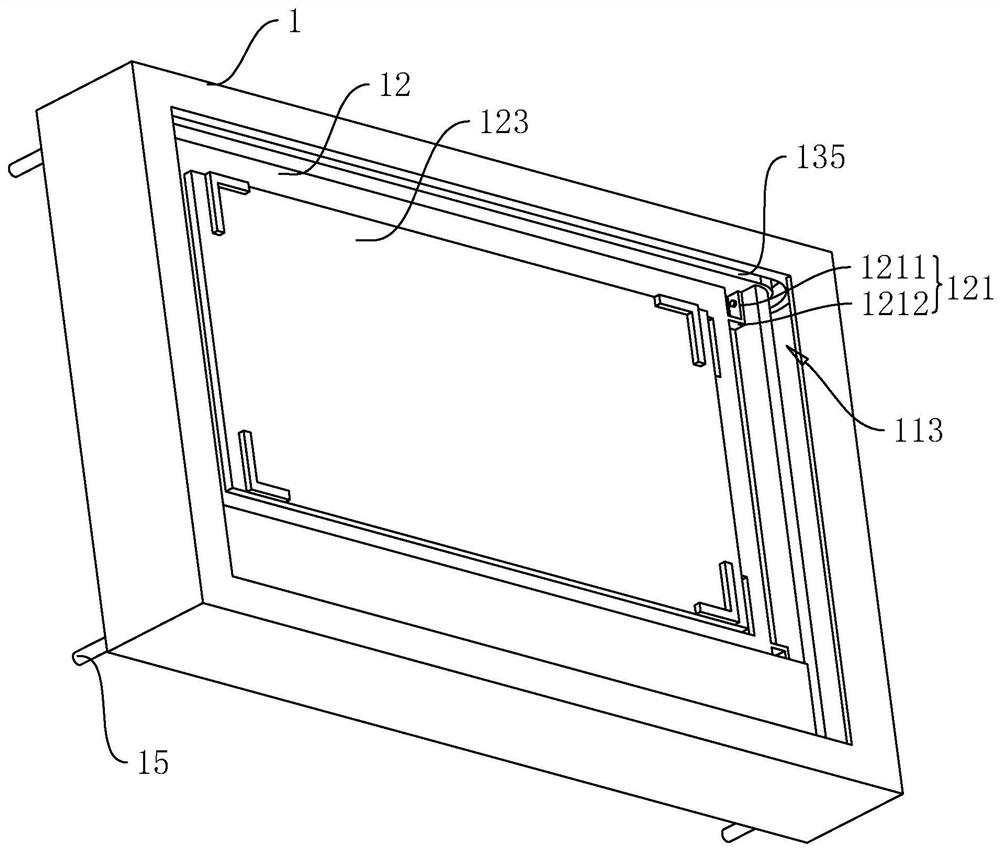

Supporting structural member and display device

ActiveCN113048346AReduced likelihood of wrinklingImprove experienceStands/trestlesComputer hardwareDisplay device

The invention relates to a supporting structural member and a display device. The supporting structural member comprises a supporting frame and a driving device, the supporting frame is provided with a screen body supporting face, the supporting frame comprises two supporting bodies and a screen body adapter, the two supporting bodies are connected with each other, one of the two supporting bodies can move relative to the other supporting body in the first direction, and the screen body adapter and the movable supporting body can move relative to each other in the first direction. The driving device comprises a driving assembly, the driving assembly drives one of the two supporting bodies to move relative to the other supporting body, and the driving assembly drives the screen body adapter and the moving supporting body to move in the same direction in the first direction. Wherein the driving assembly drives one of the two supporting bodies to move at a first speed V1 relative to the other supporting body, the driving assembly drives the screen body adapter to move at a second speed V2 relative to the other supporting body, and V2 is larger than V1. The supporting structural member can be used for changing the size of the display area, and daily requirements of people are met.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com