Polyester fabric dyeing process

A fabric and process technology, applied in the field of polyester fabric dyeing process, can solve the problems that the fabric setting effect cannot meet the requirements, brittleness, yellowing of the fabric, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

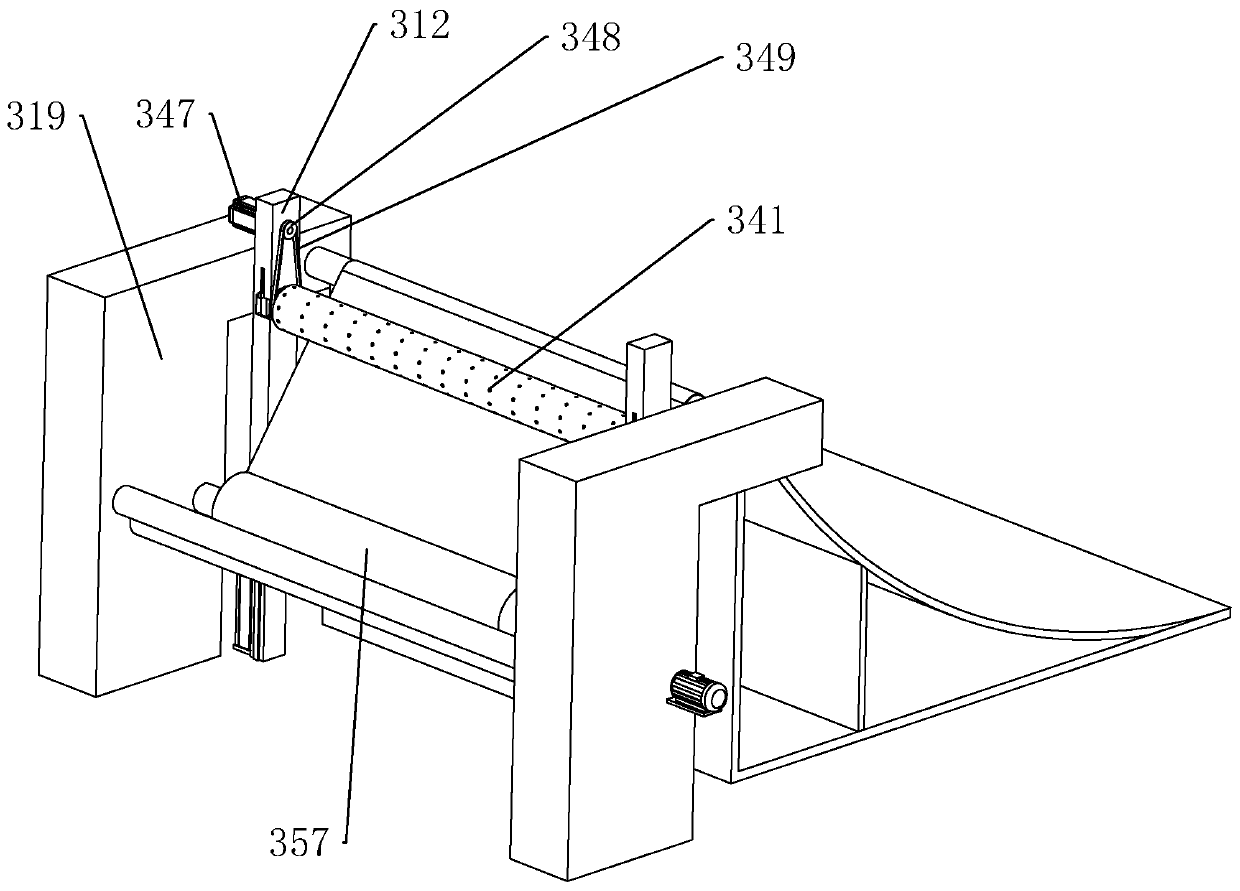

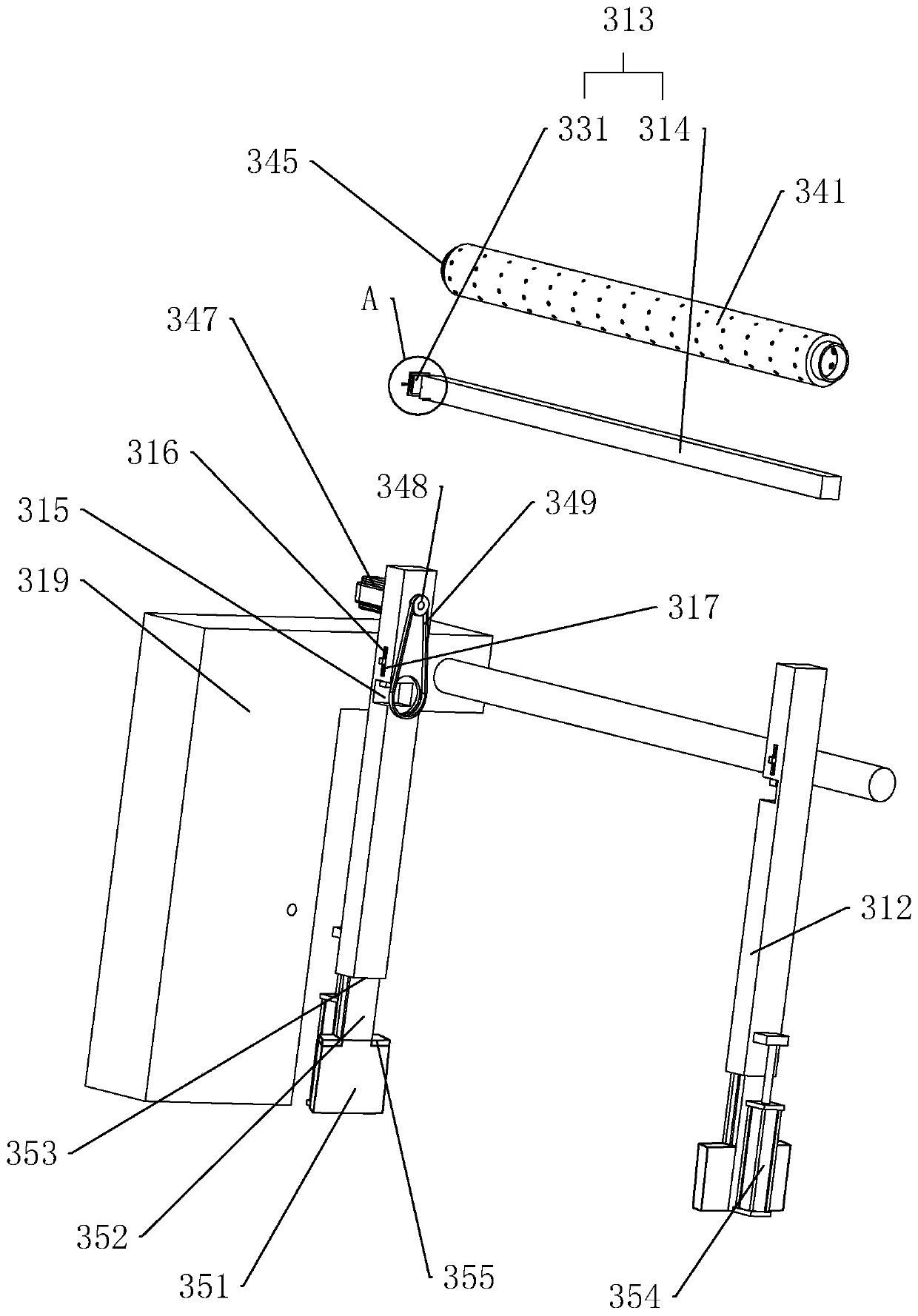

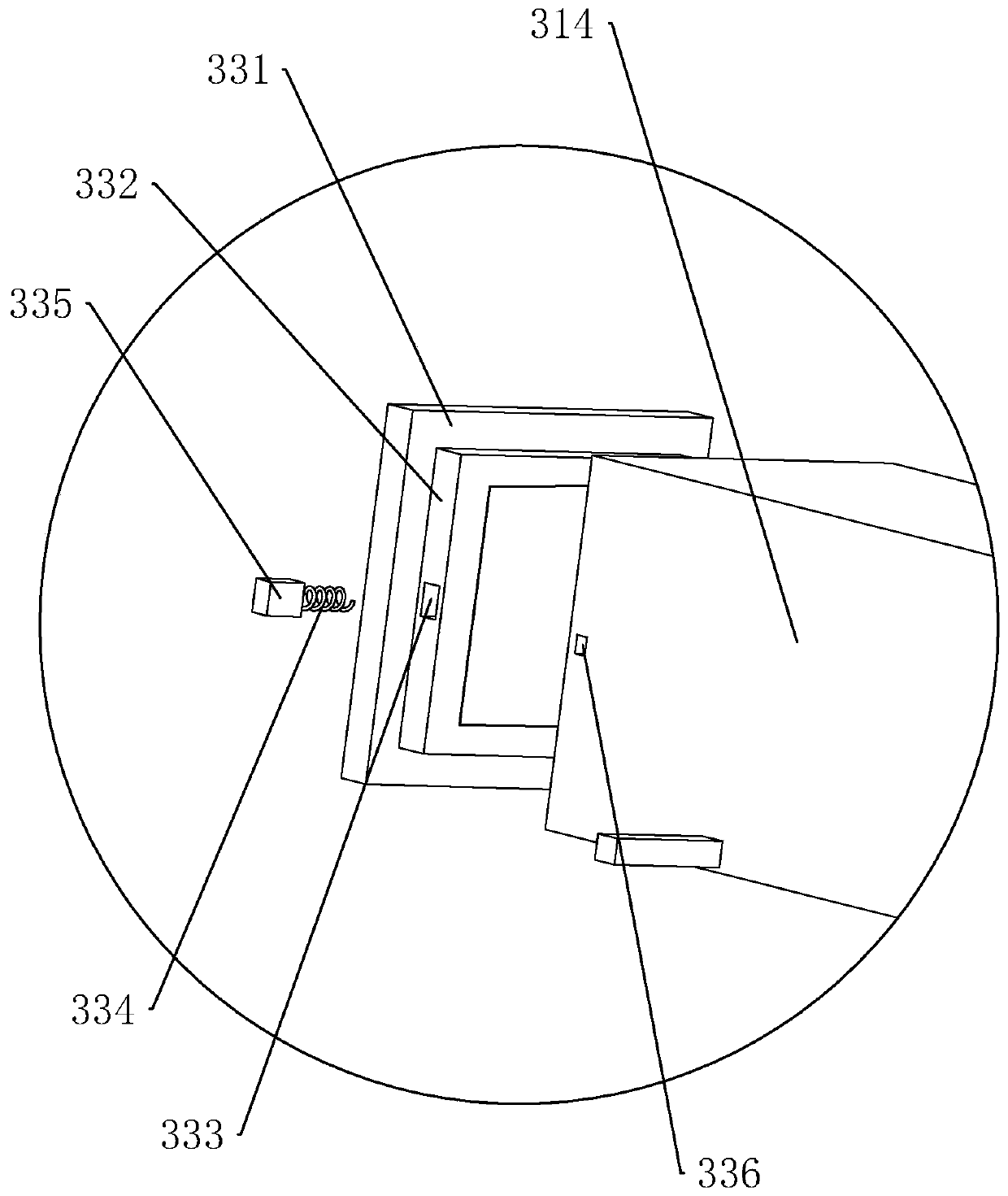

[0054] refer to figure 1 , the dyeing process of a kind of polyester cloth disclosed by the invention, comprises the following steps:

[0055]S1: Gray cloth desizing; S2: Gray cloth pre-shrinking, soaking the gray cloth in clean water, and drying at 120-130°C; S3: Smoothing the finished cloth with a skin pass machine. Titanium dioxide hydrosol is added during the leveling process; S4: Pre-setting the flattened fabric. During the pre-setting process, the fabric is imported into the setting machine equipment for pre-setting treatment using a cloth loading machine. The pre-setting temperature is set at 185°C-190°C , the setting time is 45-60s; the first auxiliary agent is added in the process of putting on the cloth, and the first auxiliary agent includes the following components in parts by weight: 20 parts of sodium dodecylbenzenesulfonate; 3 parts of ammonium salt; 15 parts of sodium bicarbonate; 80 parts of water. S5: carry out alkali reduction treatment on the pre-set clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com