NC bending core head for thin walled tube of aluminum alloy with major diameter and design method thereof

A technology for large-diameter, thin-walled tubes, applied in the field of eccentric core heads of CNC bending mandrels for large-diameter, thin-walled aluminum tubes. issues such as large scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

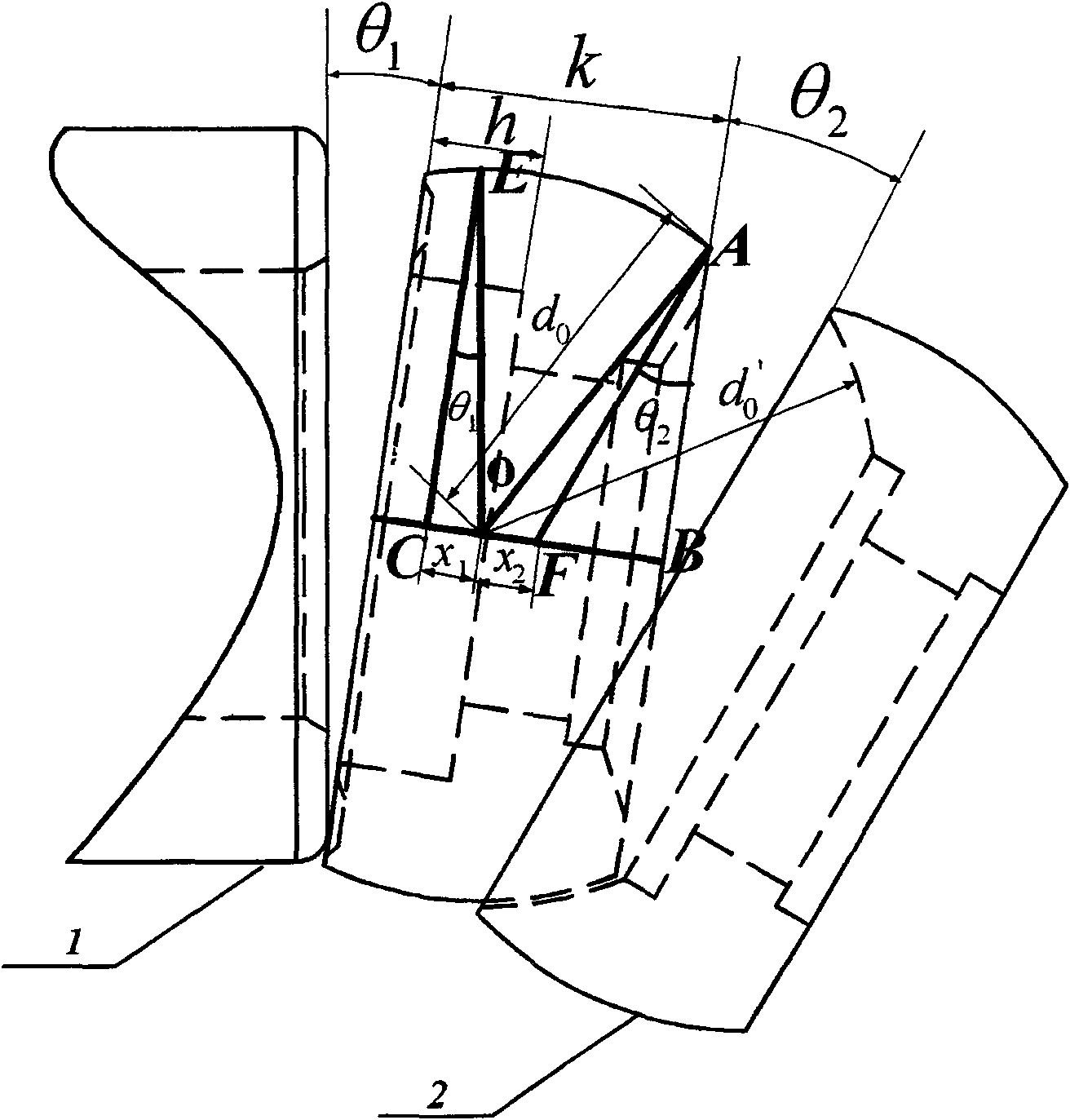

[0035] In this example, for a wall thickness of 1 mm, the bending factor R 0 The / D is 1.5, and the diameters D are 50mm, 70mm, 80mm and 100mm aluminum alloy pipes respectively. The eccentric core head 2 is used, that is, the position of the sphere center of the eccentric core head in the core head body is not at the geometric center of the core head. The degree of eccentricity δ of the core 2 is δ=h / k, where h is the distance from the center of the eccentric core to the large end of the core, and k is the thickness of the core. Under the condition of the same core thickness, the smaller h is, the greater the eccentricity of the core ( figure 2 ).

[0036] like Figure 5-Figure 7 As shown, the structure of the eccentric mandrel in this embodiment includes a mandrel mandrel 1, an eccentric mandrel 2, and a connector 3 between the mandrels, and the mandrels are connected by a ball-and-socket structure. The eccentricity of the eccentric core head 2 is respectively 0.28~0.33(D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com