Film laminating device and film laminating process for plastic sheet machine

A technology of laminating device and sheet machine, which is applied in the directions of lamination auxiliary operation, lamination, and layered products, etc., can solve the problem of single function of the molding machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

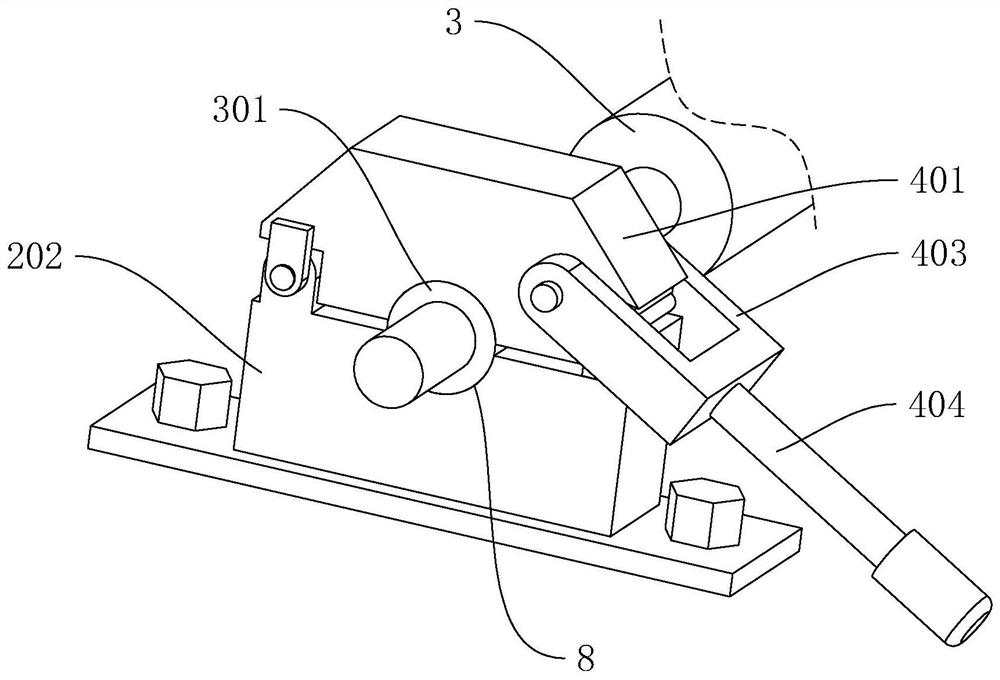

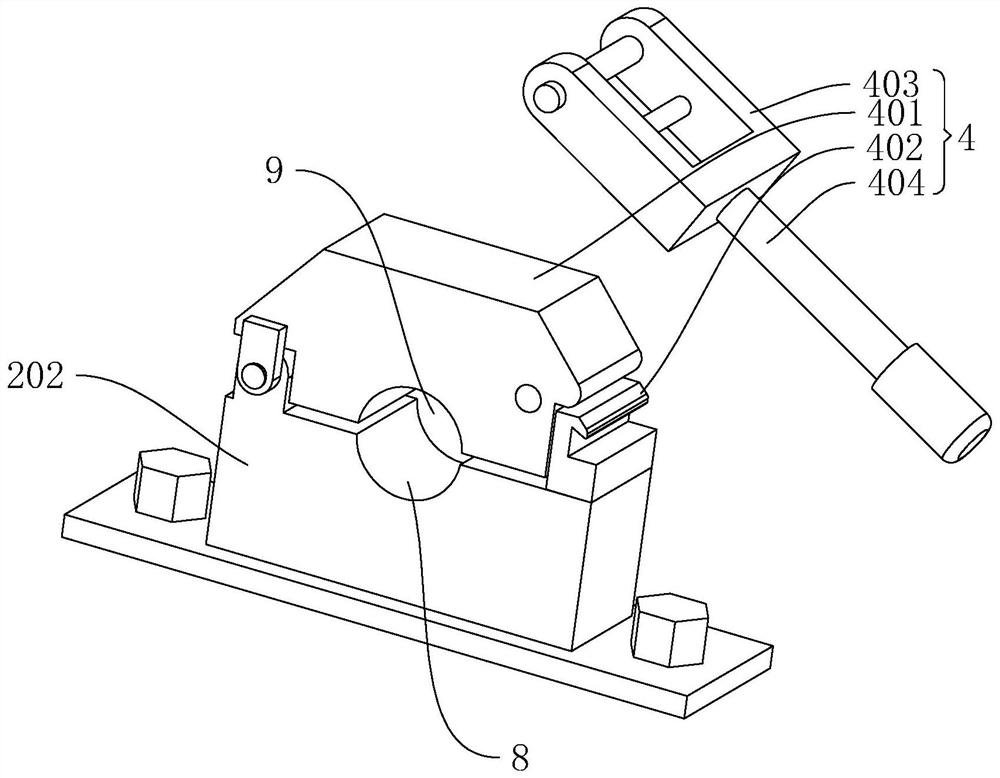

[0041] The following is attached Figure 1-9 The application is described in further detail.

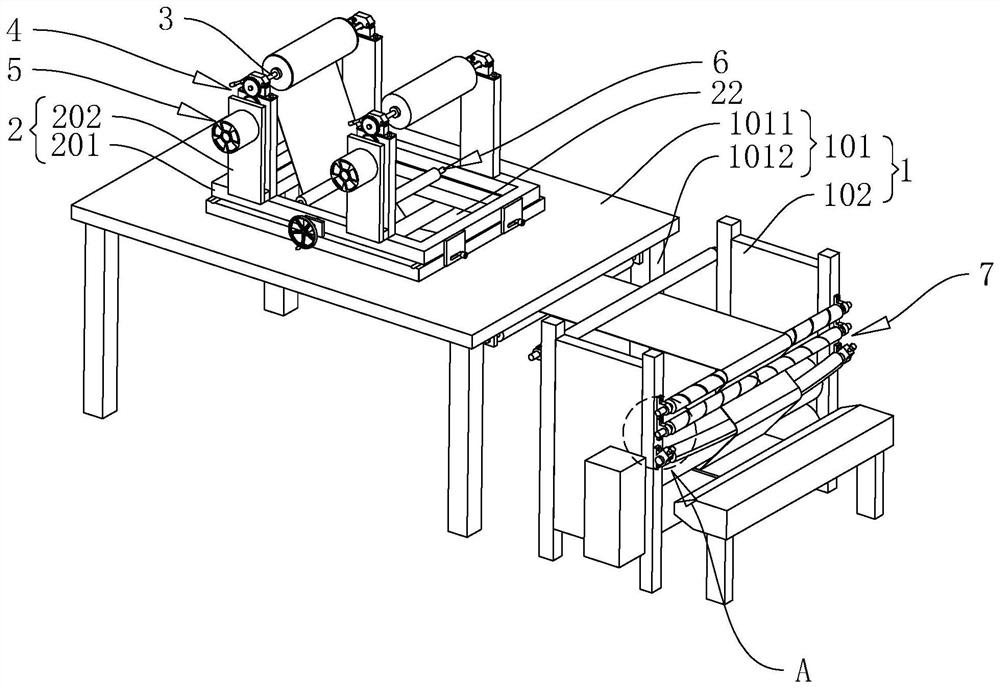

[0042] The embodiment of the present application discloses a laminating device for a plastic sheet machine. refer to figure 1 , the laminating device for a plastic sheet machine includes a frame 1 , a bracket 2 , an unwinding shaft 3 , a limit assembly 4 , a drive assembly 5 , a guide assembly 6 and a flatten assembly 7 . The frame 1 includes a left frame 101 and a right frame 102. The left frame 101 includes a support plate 1011 arranged horizontally and four support rods 1012 arranged vertically. The middle part of the support plate 1011 is provided with a rectangular through hole 22 and four support rods 1012. Located at the four corners of the support rod 1012, the top of the support rod 1012 is welded to the lower surface of the support rod 1012, and the right frame 102 includes two vertical and parallel vertical plates.

[0043] refer to figure 1 with figure 2 , the brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com