Label discharging system of automatic mylar pasting machine

A Mylar Machine, Automatic Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

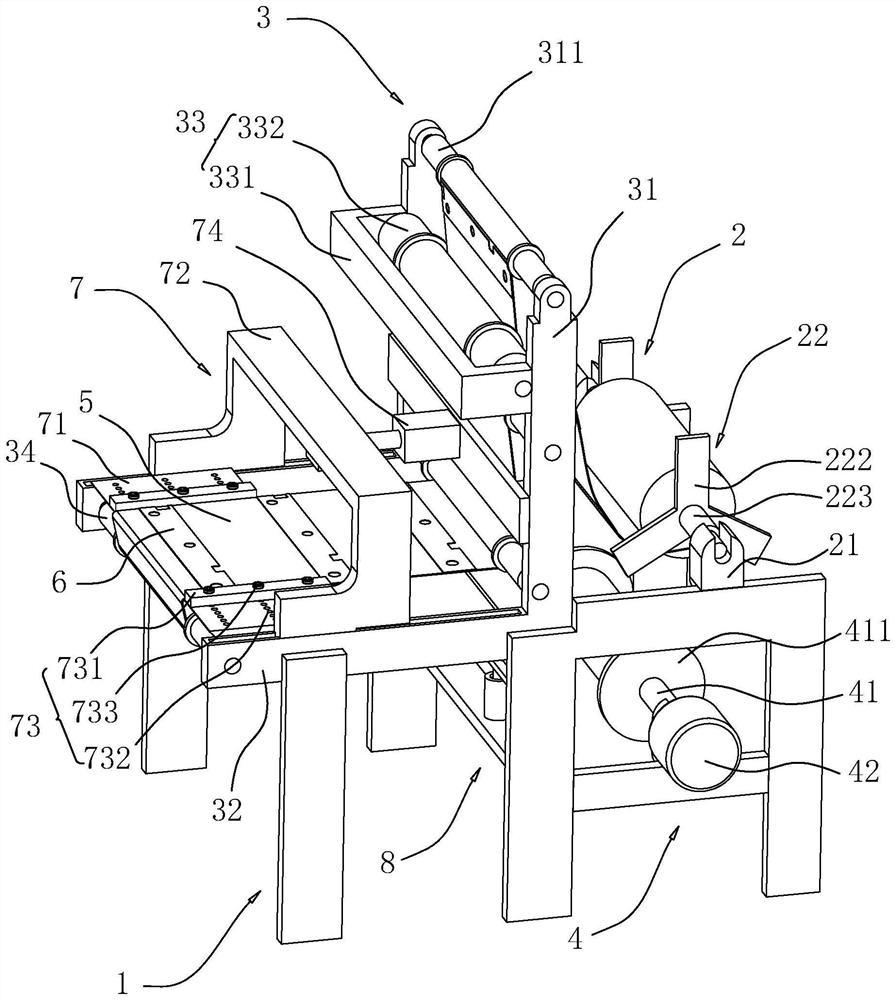

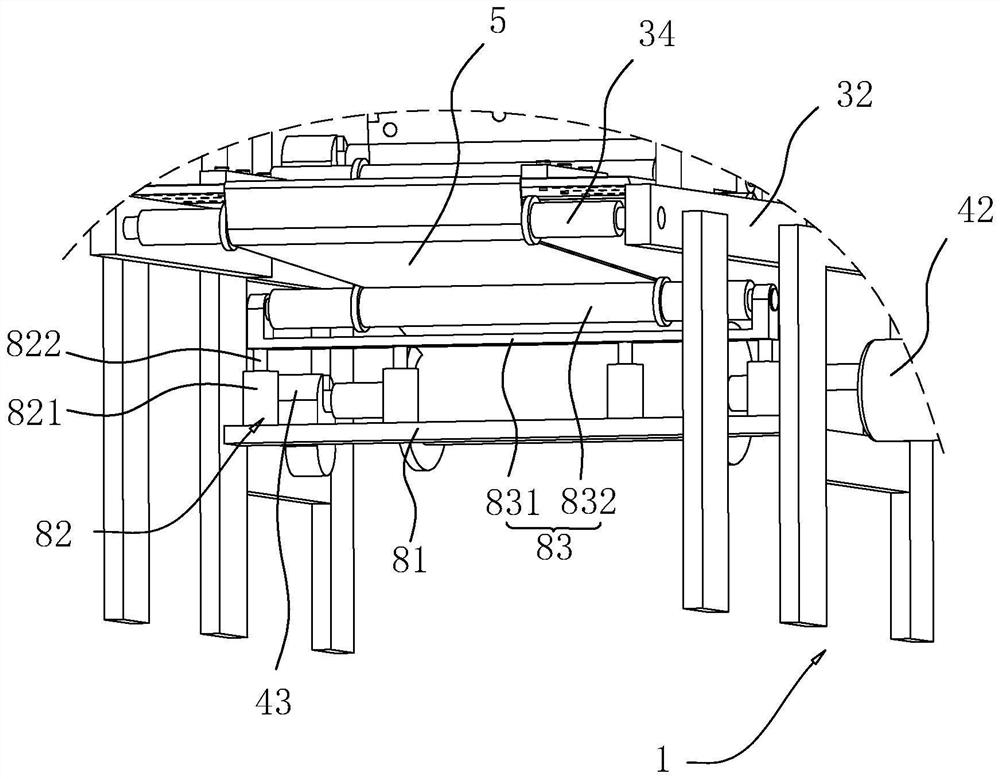

[0039] The following is attached Figure 1-2 The application is described in further detail.

[0040] The embodiment of the present application discloses a bidding system for an automatic Mylar labeling machine. refer to figure 1 , the labeling system is applied to the automatic Mylar labeling machine. The labeling system includes the body 1, the feeding mechanism 2, the feeding rack group 3 and the pulling mechanism 4. The feeding mechanism 2 is set on the body 1. The feeding mechanism 2 can The Mylar film 6 attached to the material belt 5 is temporarily stored, and the Mylar film 6 attached to the material belt 5 can also be loaded; the loading rack group 3 is arranged on the body 1 and is located at On the feeding side of the feeding mechanism 2, the feeding rack group 3 can play a transition and transfer role for the Mylar film 6 attached to the material belt 5 fed by the feeding mechanism 2; the pulling mechanism 4 is arranged on the upper Below the material mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com