Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Reduce the number of pressing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

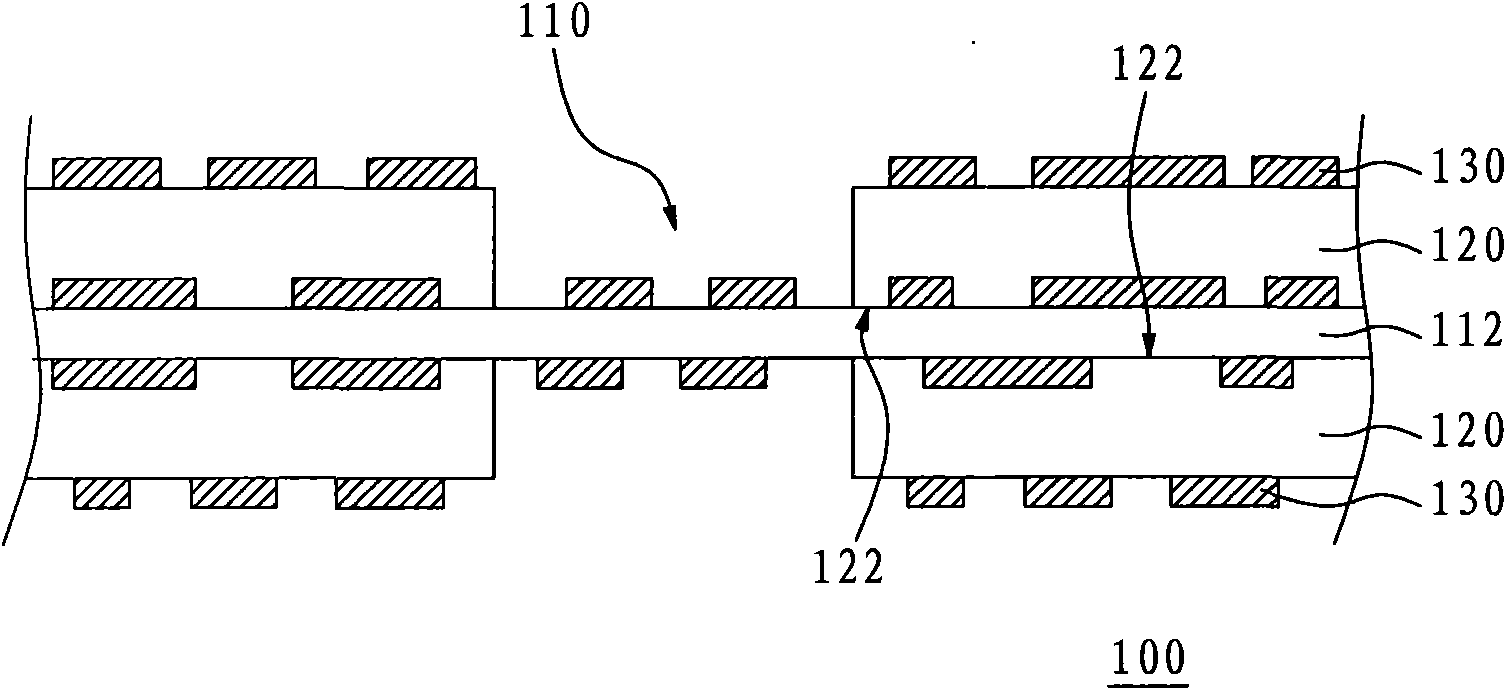

Soft-hard circuit board and process thereof

ActiveCN101990355AReduce manufacturing costShorten the lengthPrinted circuit assemblingPrinted circuits structural associationsManufacturing cost reductionPrinted circuit board

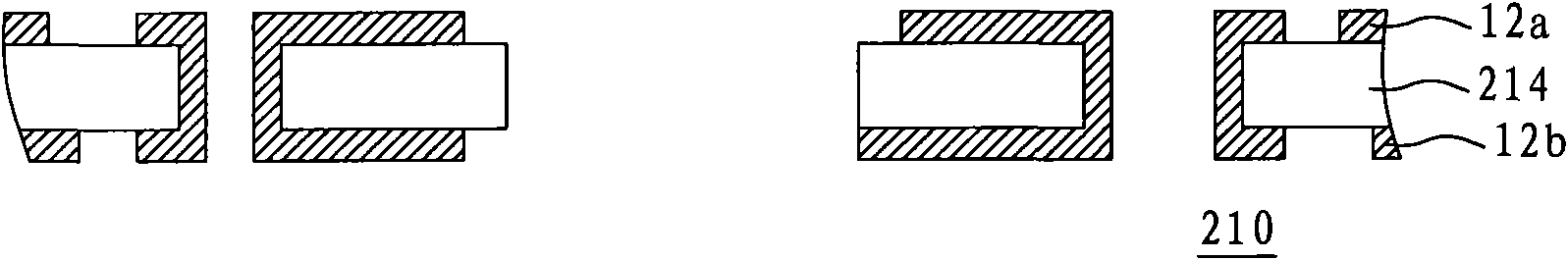

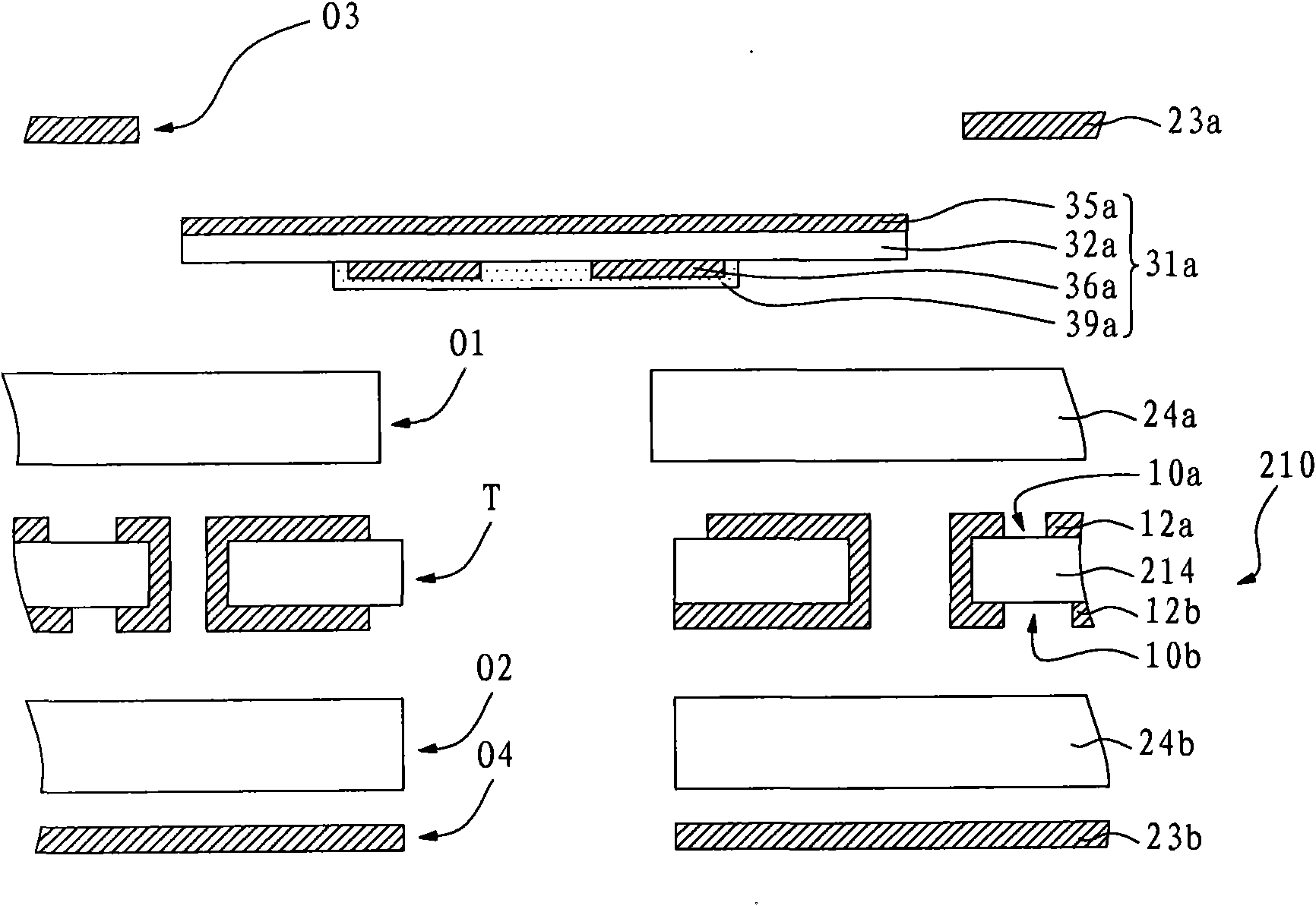

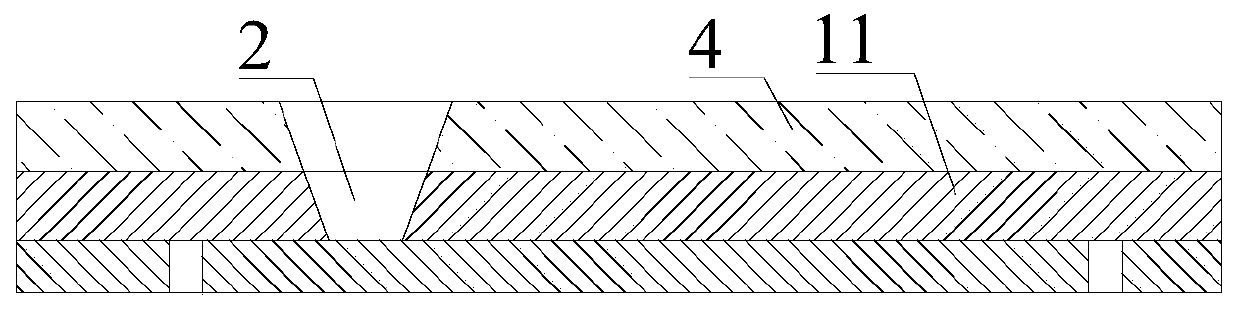

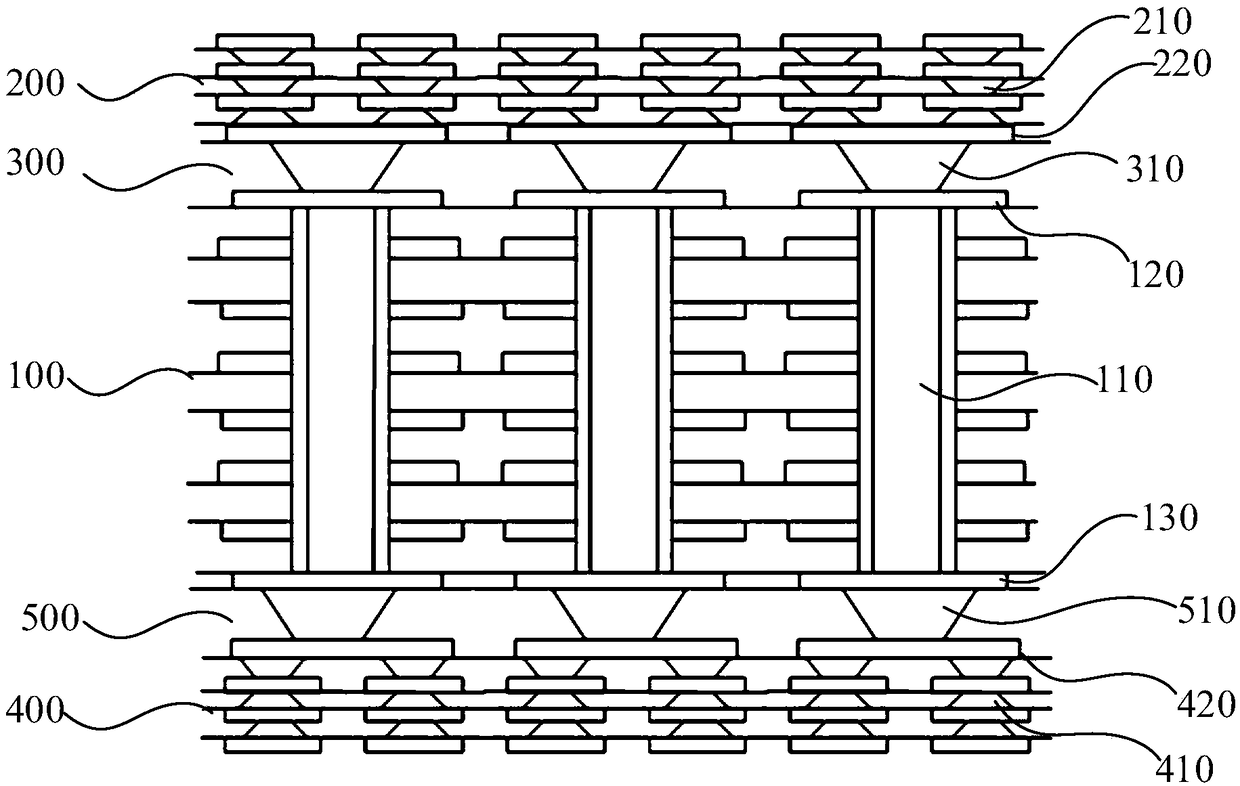

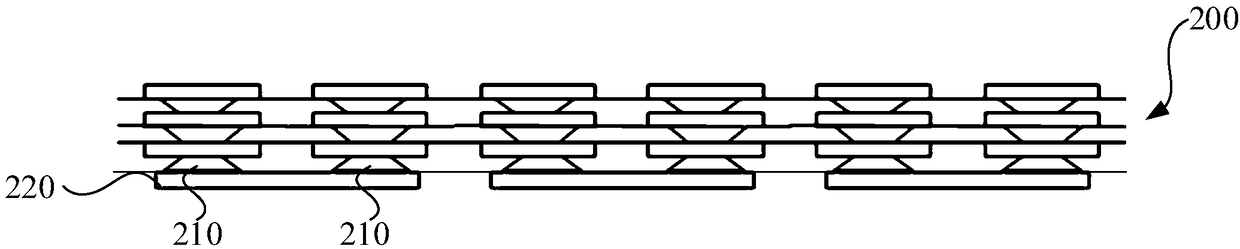

The invention relates to a soft-hard circuit board and a process thereof. The soft-hard circuit board comprises a hard circuit board, a first soft circuit board, a first outer composite layer and a plurality of first conductive connecting structures. The hard circuit board is provided with an upper surface, a lower surface opposite to the upper surface and a groove. The first outer composite layer is provided with a first opening communicated with the groove, and comprises a first outer circuit layer and a first insulating layer. The first insulating layer is arranged between the first outer circuit layer and the upper surface. The first soft circuit board is arranged on the first insulating layer and covers the groove. The first insulating layer is locally covered on the first soft circuit board. The first conductive connecting structures are arranged in the first insulating layer and electrically connected between the hard circuit board and the first soft circuit board. The soft-hard circuit board can reduce the demand of flexible substrates and greatly reduce the manufacturing cost, and also has the advantages of saving the assembly space and reducing the soft board length and the soft board pressing times.

Owner:UNIMICRON TECH CORP

Plastic woven bag edgefold shaping machine and method

InactiveCN110497653AReduces accidental creasingImprove hemming effectBag making operationsPaper-makingEngineeringPortal frame

The invention relates to a plastic woven bag edgefold shaping machine and a method. The machine comprises a clamping base, a working electric sliding block, a displacement frame, a synchronizing device, two positioning clamps, a portal frame, a driving cylinder, a pressing device and a mark ironing device. The working electric sliding block is mounted on the clamping base. The displacement frame is arranged on the working electric sliding block. The synchronizing device is mounted in the middle of the displacement frame. The two positioning clamps are mounted at the left and right ends of thesynchronizing device. The mark ironing device is mounted in the middle of the displacement frame. The portal frame is mounted on the displacement frame. The upper end of the portal frame is connectedwith the pressing device through the driving cylinder. By means of the plastic woven bag edgefold shaping machine and the method, the problems that an existing edgefold machine commonly adopts rigid pressing for woven fabric, two pressing dies are adopted for pressing the woven fabric repeatedly, clear folding marks can only be obtained through repeated pressing since the woven fabric is flexiblefabric, and the edgefold shaping effect is poor can be solved.

Owner:台州市伟鸿家居用品有限公司

Manufacturing method for embedding metal matrix into printed board

ActiveCN105430922AReduce moldingNo need to control depthPrinted circuit aspectsPrinted circuit manufacturePunchingEngineering

The invention relates to a manufacturing method for embedding a metal matrix into a printed board. The manufacturing method comprises the steps of (1) finishing circuit manufacturing on a line layer needing to be laminated; (2) obtaining an outline of the metal matrix needing to be embedded in a milling or punching manner; (3) forming a corresponding embedded groove in the printed board according to the outline and the size of the metal matrix in a milling or punching manner; (4) embedding the metal matrix into the embedded groove of the printed board; and (5) laminating the circuit layer and the printed board embedded with the metal matrix together by using prepreg. The manufacturing method reduces the lamination times and reduces the moulding of the prepreg without controlling the milling groove depth; and in addition, simple product manufacturing, higher efficiency and better quality are realized.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

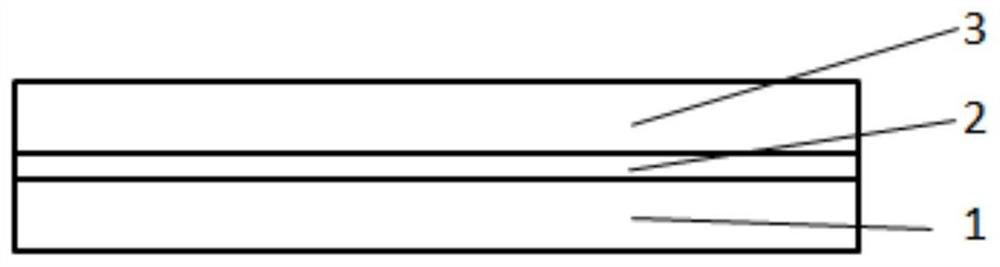

Multi-layer circuit board machining method

InactiveCN110072350AReduce manufacturing costHigh dimensional accuracyMultilayer circuit manufactureEngineeringMachining

The invention discloses a multi-layer circuit board machining method; the multi-layer circuit board machining method comprises the following steps of S1, carrying out preset circuit manufacturing on each board separately; S2, stacking the boards in a preset sequence so as to obtain a board pile; and S3, pressing the board pile at a time to obtain a multilayer circuit board. In the manufacturing process of the multi-layer circuit board, only one-time lamination is needed, so that the laminating frequency is greatly reduced, the production efficiency is favorably improved, the manufacturing costof the multi-layer circuit board is reduced; and the size precision of the multi-layer circuit board formed by one-time lamination is higher.

Owner:SHENZHEN SUNWAY COMM

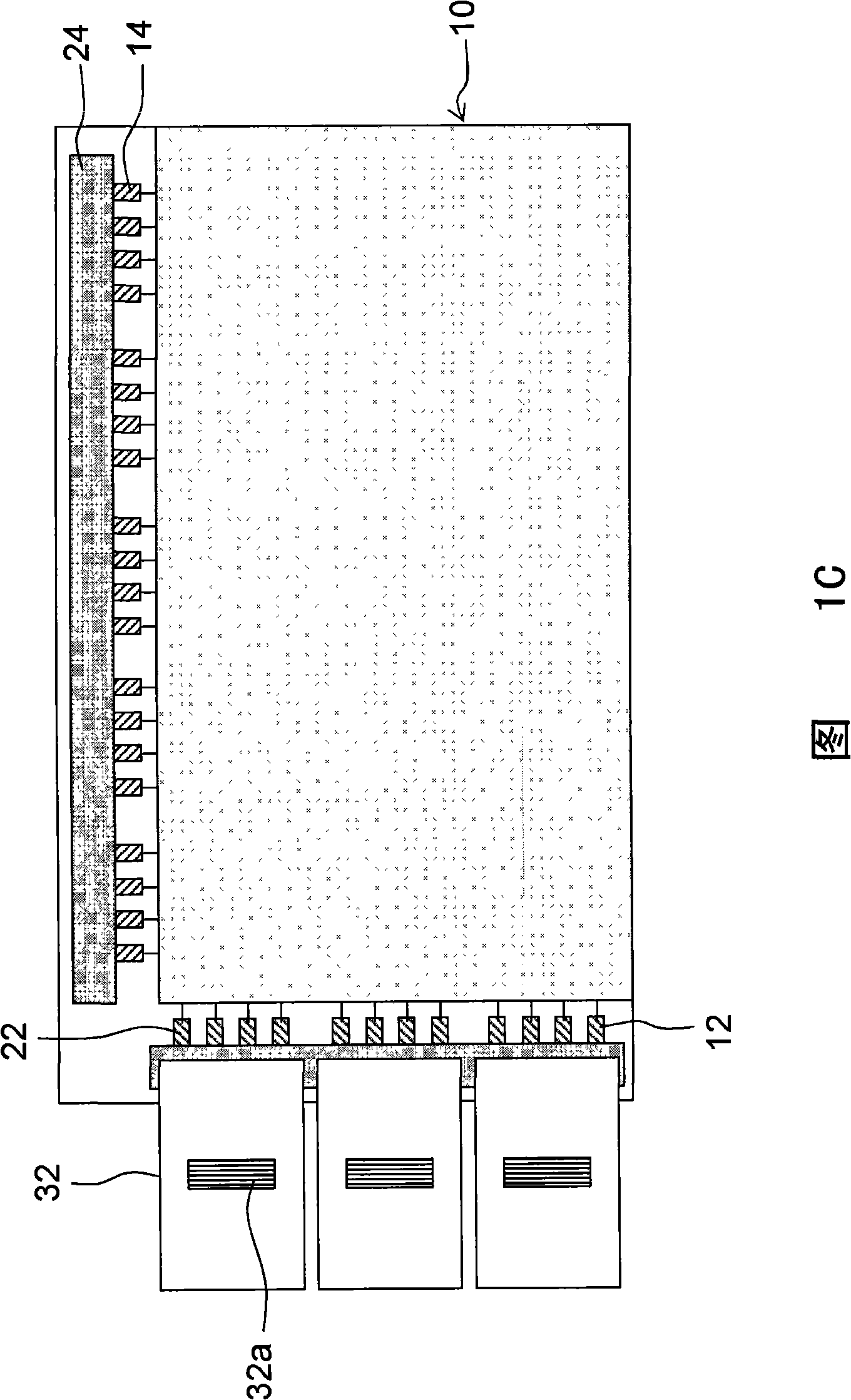

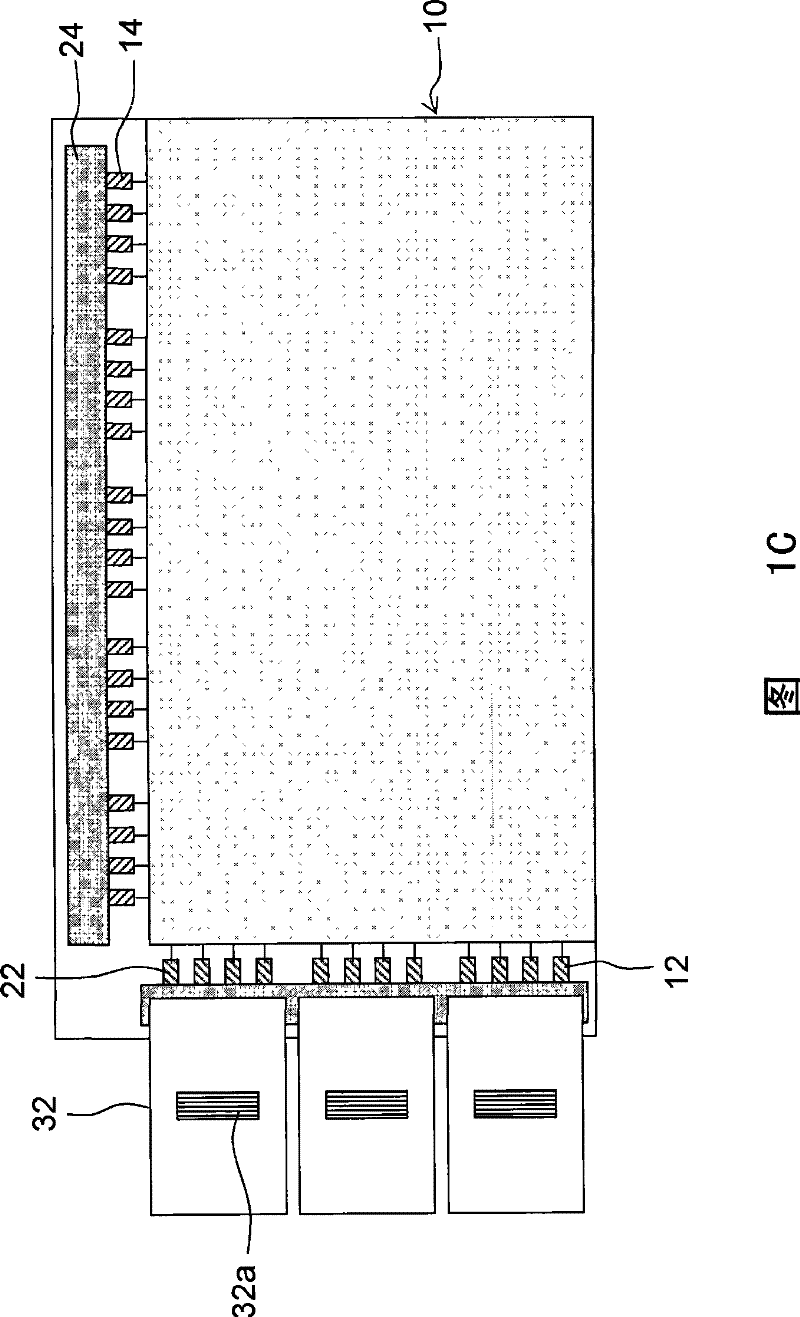

Joining method, display apparatus and display

InactiveCN101285972ASmall sizeReduce manufacturing costStatic indicating devicesNon-linear opticsAnisotropic conductive adhesiveDisplay device

The invention discloses a joint method suitable for jointing a display panel and a plurality of chips. A plurality of first join pads are arranged in a first peripheral circuit territory of the display panel, and a plurality of second joint pads are arranged in a second periphery circuit territory of the display panel. The joint method comprises the following steps: first, a first anisotropic conductive adhesive is attached to the first joint pad; a plurality of first chips are arranged on the first anisotropic adhesive; the first pressing manufacture process is carried out so that the first chips are electrically connected with the first joint pads; a second anisotropic conductive adhesive is attached to the second joint pads; and a plurality of second chips and at least one flexible circuit board are arranged on the second anisotropic conductive adhesive; then the second pressing manufacture process is carried out, so that the second chips and one end of the flexible circuit board are electrically connected with the second joint pads through the second anisotropic conductive adhesive. The joint method provided by the invention makes use of few steps to joint the plurality of chips and the display panel, thereby reducing manufacturing cost of a display device.

Owner:INNOLUX CORP

High-level, thick cop thin-core board laminating type method and PCB board

InactiveCN109219275AGuaranteed fixed effectImprove alignment accuracyMultilayer circuit manufactureConductive pattern layout detailsEngineeringCopper

A high-level, thick copper thin-core plate laminating type method and PCB board are disclosed. A laminating type is formed on the upper and lower surfaces of a laminated plate to be laminated before being laminated. The laminating type material is stacked first, and then the laminated plate to be laminated is placed on the laminating type material, and then the laminating type material is placed on the laminated plate to be laminated. The invention ensures the fixity between different layers of the pressing plate, avoids the deviation of the skateboard layer, improves the alignment precision between the layers, improves the yield, reduces the pressing times, shortens the production cycle and the production cost, and has the advantages of wide material selection, low cost and simple manufacture.

Owner:珠海杰赛科技有限公司 +1

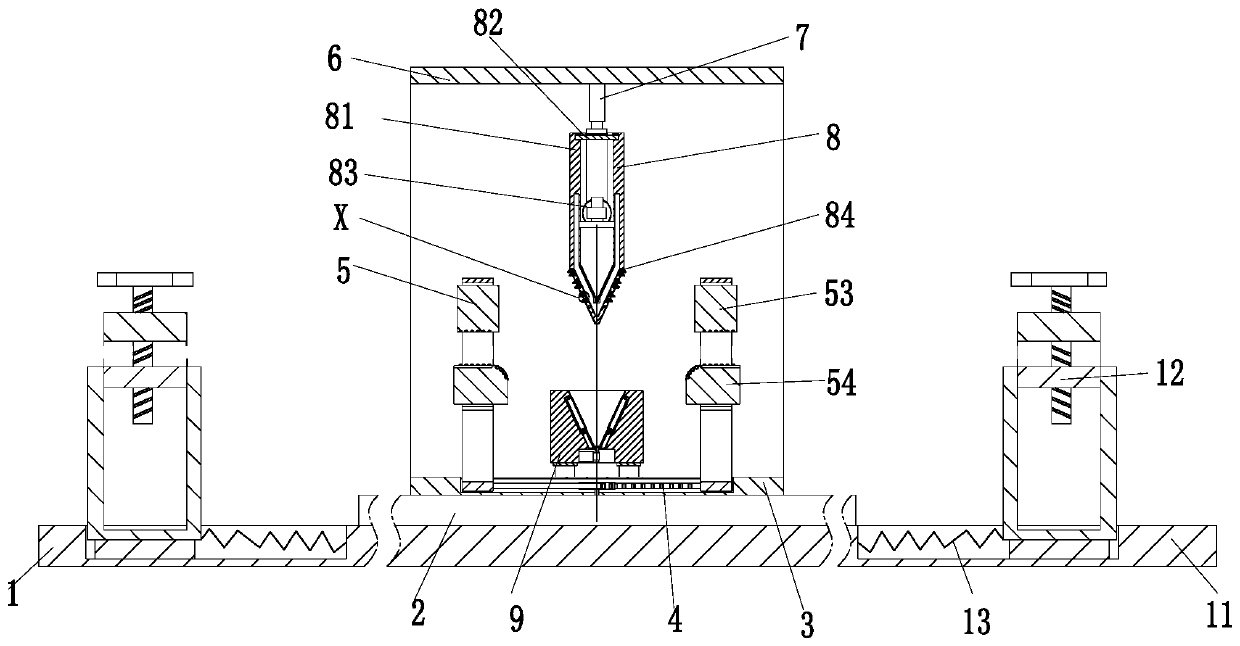

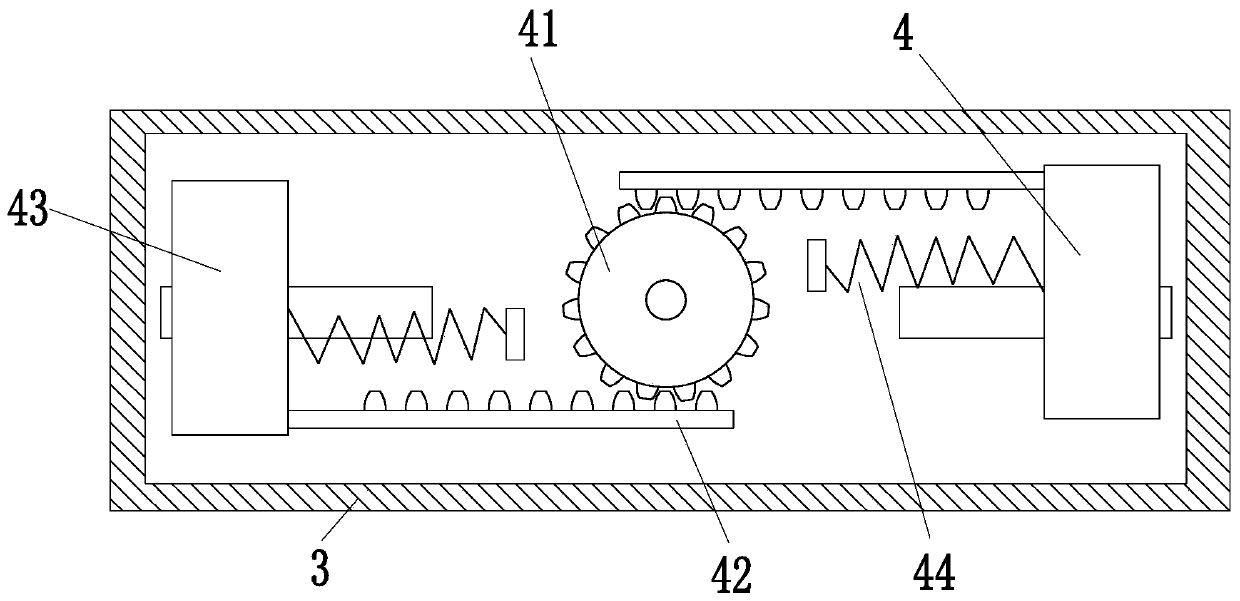

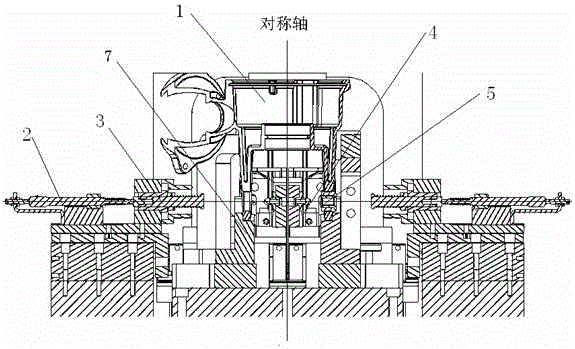

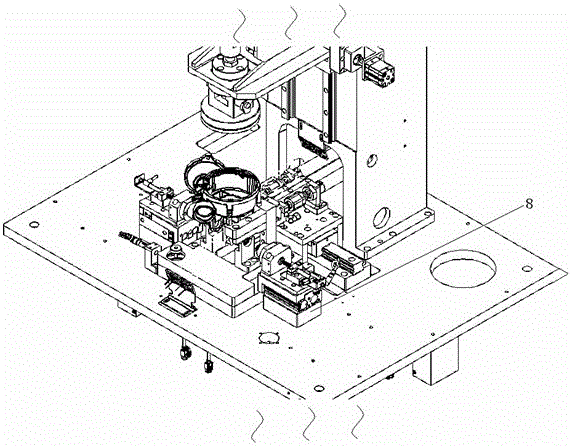

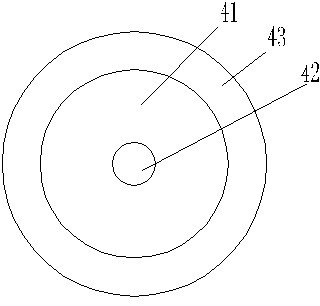

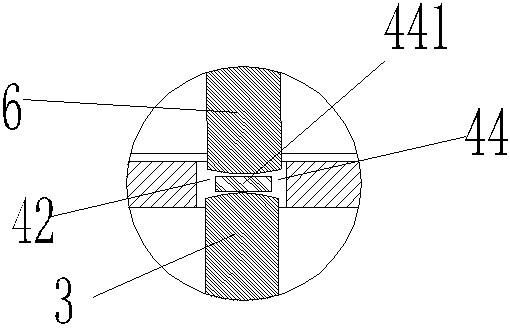

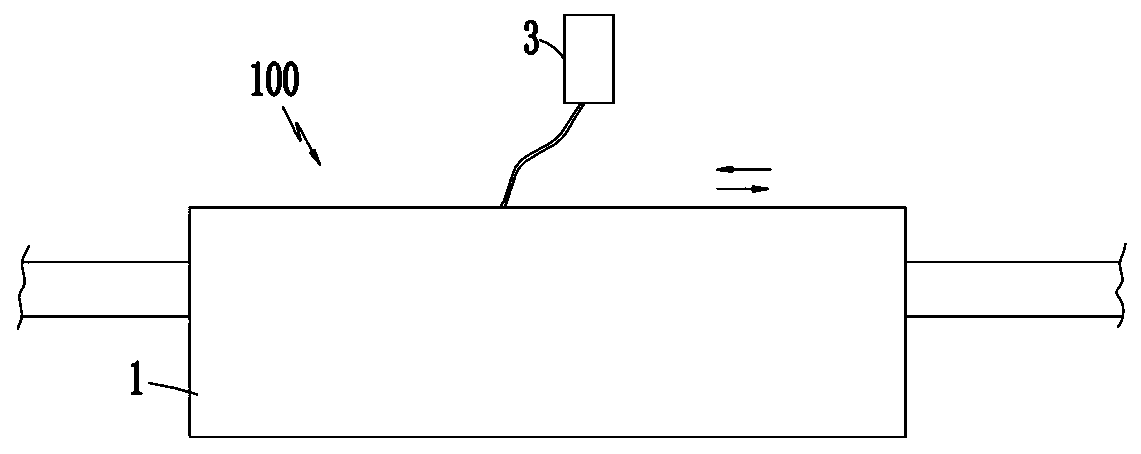

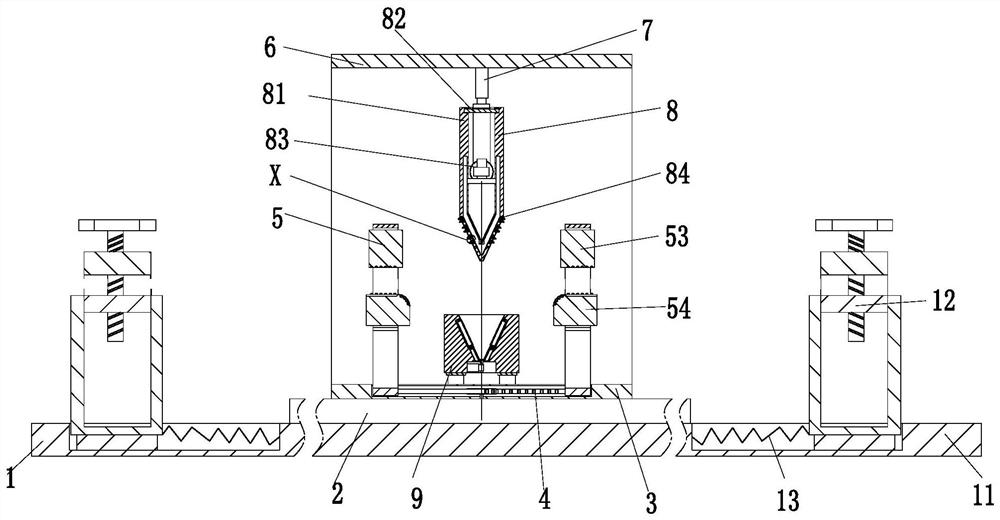

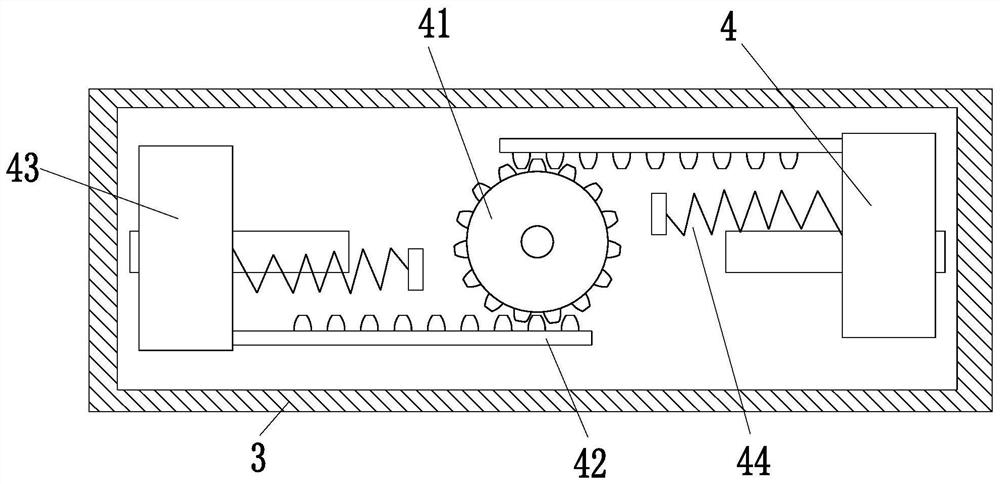

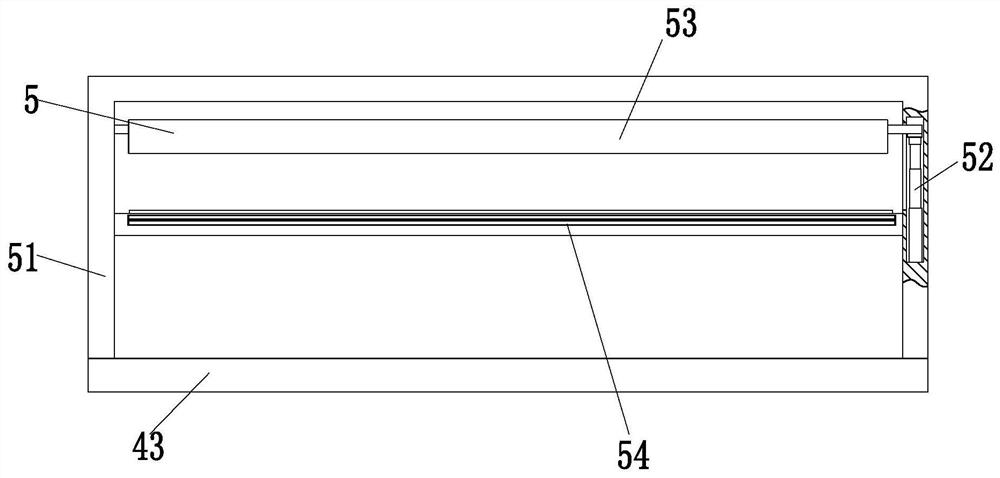

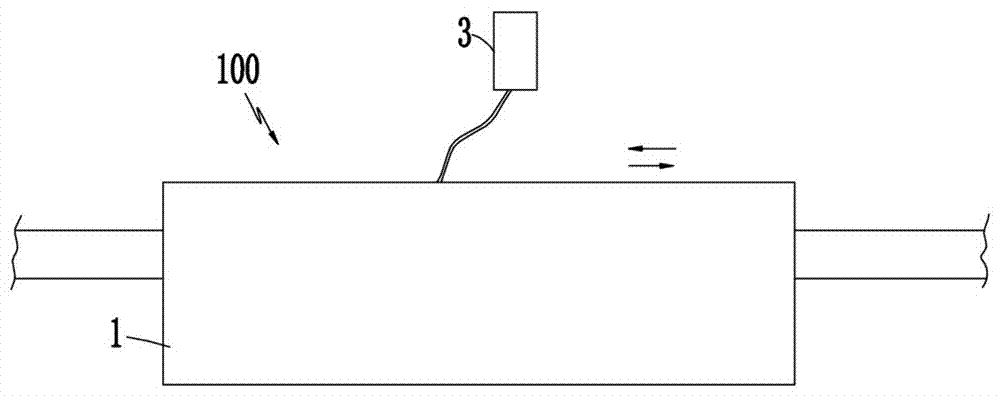

Rubber bushing automatic oil coating pressing and closed-loop pressing compensation system and method

ActiveCN106002176AReduce the number of pressingSave the beatMetal working apparatusClosed loopPosition sensor

The invention discloses a rubber bushing automatic oil coating pressing and closed-loop pressing compensation system. The system comprises a shell, a position sensor for detecting a pressing depth and a position, a floating spring mechanism, a rubber bushing pressing head and a rubber bushing; the rubber bushing is positioned on the rubber bushing pressing head; the position sensor is connected with the floating spring mechanism; the rubber bushing pressing head and the rubber bushing are in control connection; and the shell is positioned at the tops of the rubber bushing pressing head and the rubber bushing. Through the mode, the rubber bushing automatic oil coating pressing and closed-loop pressing compensation system, provided by the invention, realizes an automatic procedural learning function, and can reduce the pressing times to save the equipment beat.

Owner:NEXTEER AUTOMOTIVE SYST SUZHOU

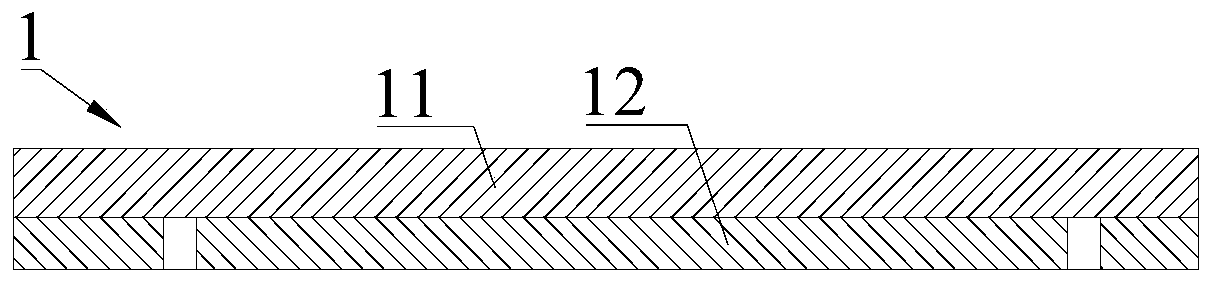

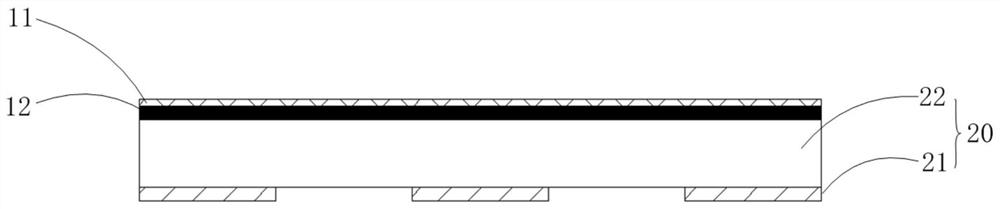

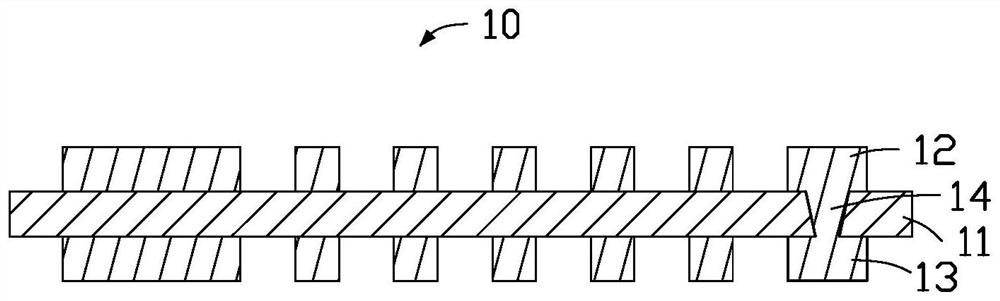

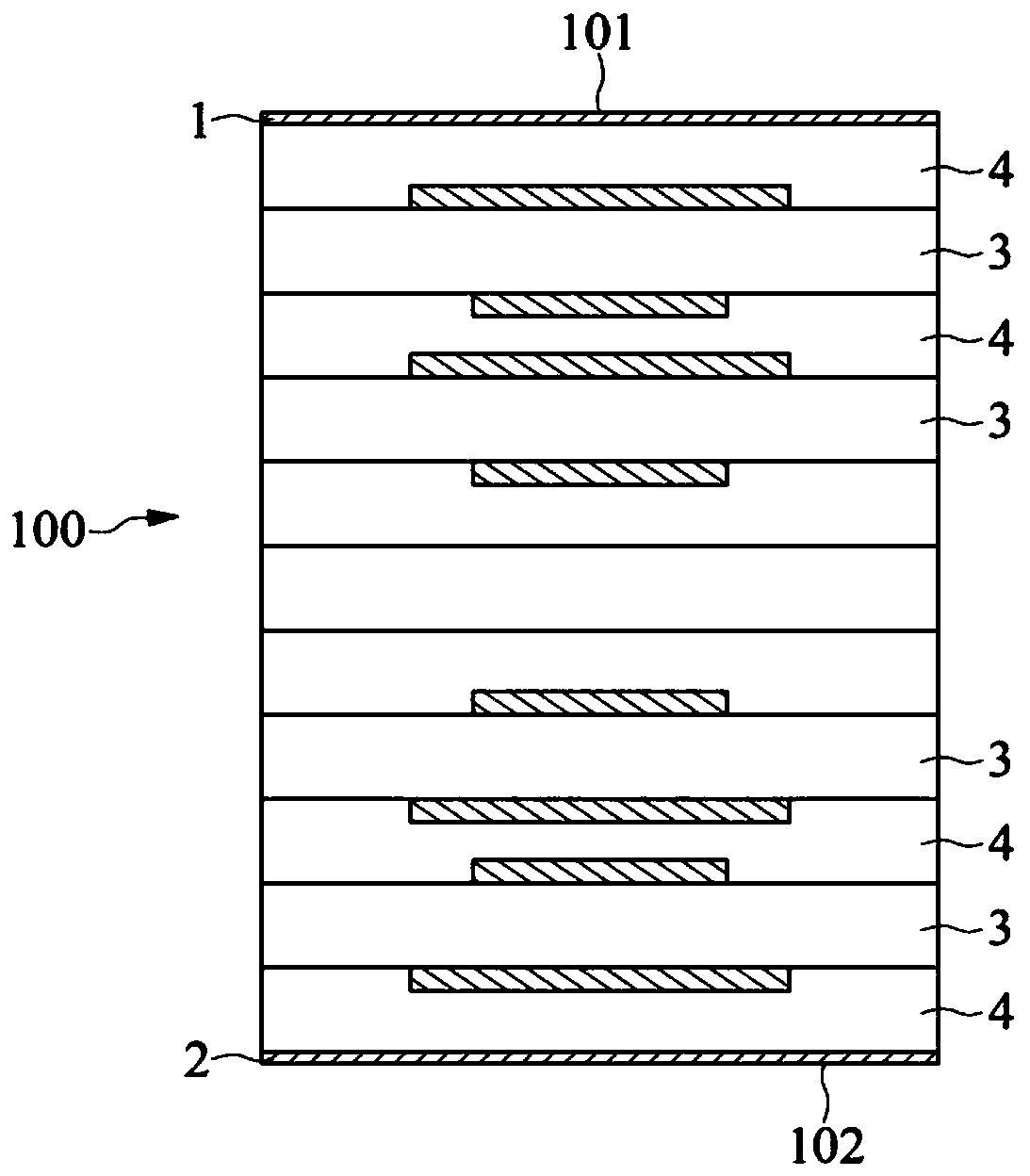

Primary lamination capacitor-embedding technology based on support substrate

ActiveCN108966516AAvoid breakingSolve productivityConductive material chemical/electrolytical removalMultilayer circuit manufactureEtchingCopper foil

The present invention discloses a primary lamination capacitor-embedding technology based on a support substrate. The technology comprises the following steps that: copper layers of two surfaces of acore plate are subjected to film pasting, an inner-layer circuit is formed at the upper surface of the core plate through processes of exposure, development and etching, and film removing is performed; the two surfaces of the core plate are subjected to film pasting, and the exposure of the inner-layer circuit is completed at the lower surface of the core plate through an exposure process; a support substrate is pasted at the outer side of the film of the upper surface of the core plate; the graph of the inner-layer circuit is formed at the lower surface of the core plate through a developmentprocess; the inner-layer circuit is formed at the lower surface of the core plate through an etching process, and film removing is performed; the support substrate at the upper surface of the core plate is removed and is pasted on the lower surface of the core plate, and the film and the support substrate on the core plate are removed; and the core plate is laminated with an outer layer of copperfoil through a prepreg to form a production plate. The primary lamination capacitor-embedding technology employs the support force of the support substrate and the film to prevent a dielectric layerfrom being damaged and reduces the number of the lamination times to once so as to reduce the cost and improve the production efficiency.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

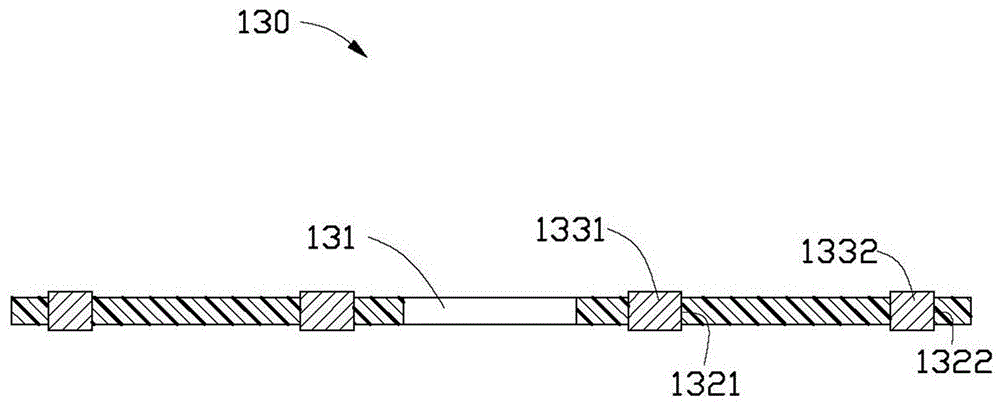

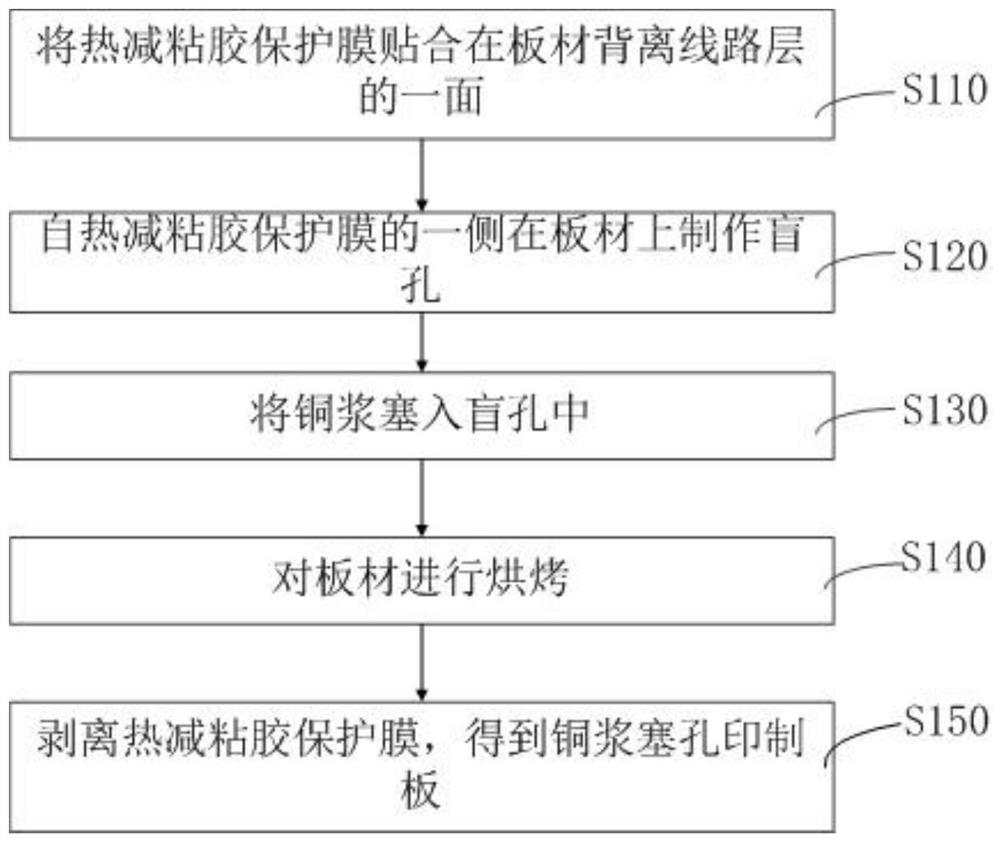

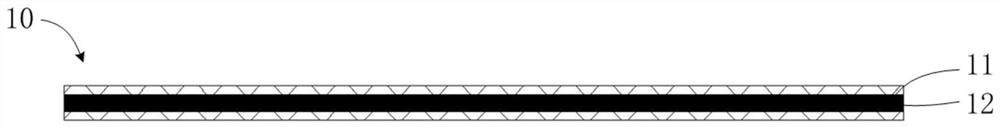

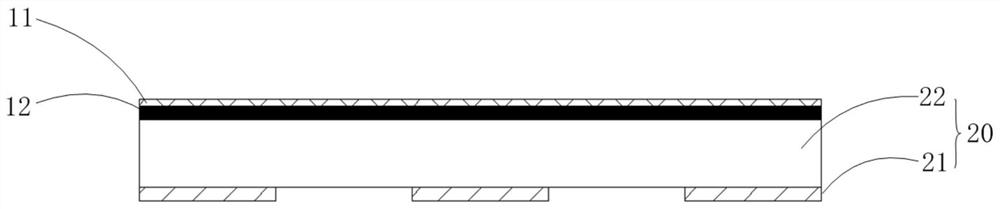

Manufacturing method of copper paste plug hole printed board and manufacturing method of FPC board

ActiveCN112601377AIncrease productivityLow viscosityNon-metallic protective coating applicationPrinted element electric connection formationFlexible circuitsProcess engineering

The invention is applicable to the technical field of flexible circuit boards, and provides a manufacturing method of a copper paste plug hole printed board. The manufacturing method comprises the following steps: attaching a heat-reducing adhesive protective film to one surface, deviating from a circuit layer, of a board, wherein the stripping force of the heat-reducing adhesive protective film after attachment is greater than 500 g / cm<2>; manufacturing a blind hole in the board from one side of the heat-reducing adhesive protective film; plugging copper paste into the blind hole; baking theboard, wherein the peeling force of the heat-reducing adhesive protective film after baking is less than 15 g / cm<2>; and stripping the heat-reducing adhesive protective film to obtain the copper pasteplug hole printed board. According to the manufacturing method of the copper paste plug hole printed board, the board surface can be prevented from being polluted by copper paste, meanwhile, board surface tearing deformation caused by mucilage glue is avoided, and the production efficiency and the product yield are improved. The invention further provides a manufacturing method of the FPC board.

Owner:KINWONG ELECTRONIC TECH (ZHUHAI) CO LTD

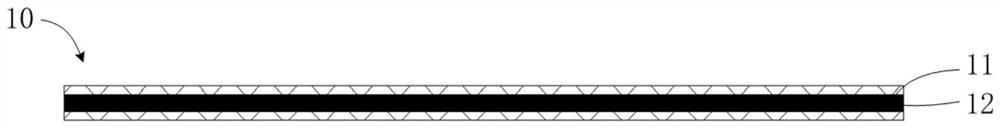

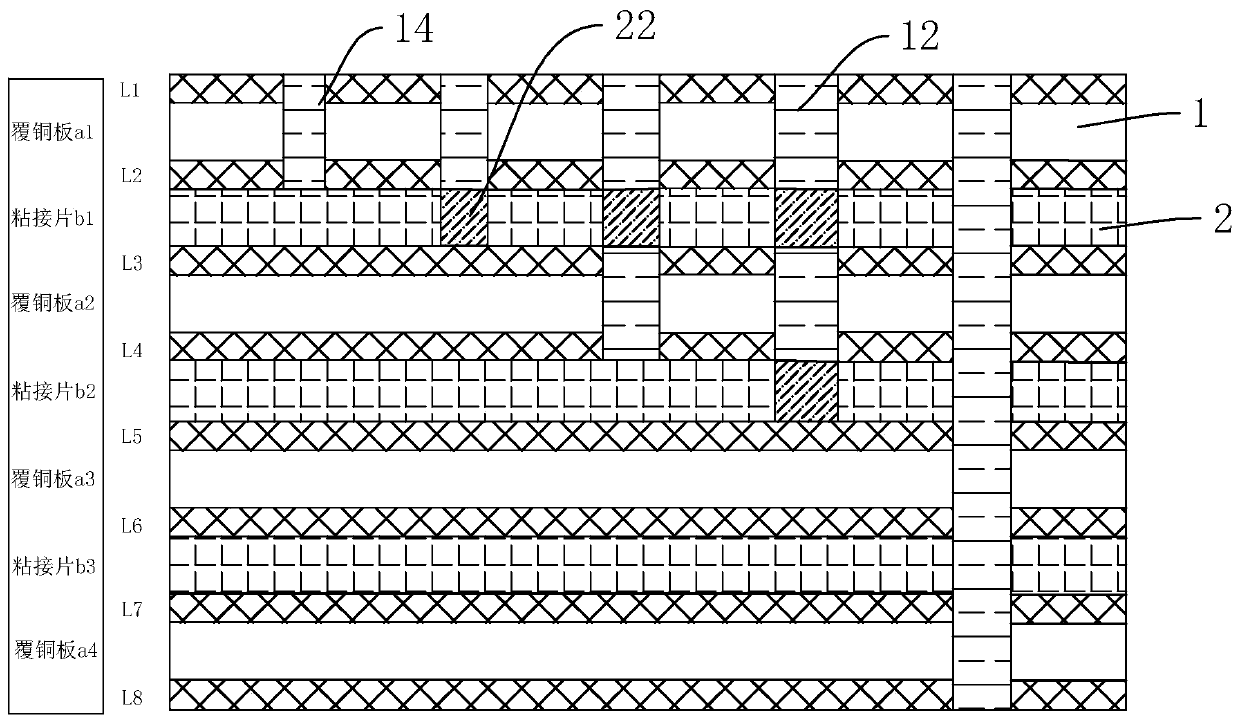

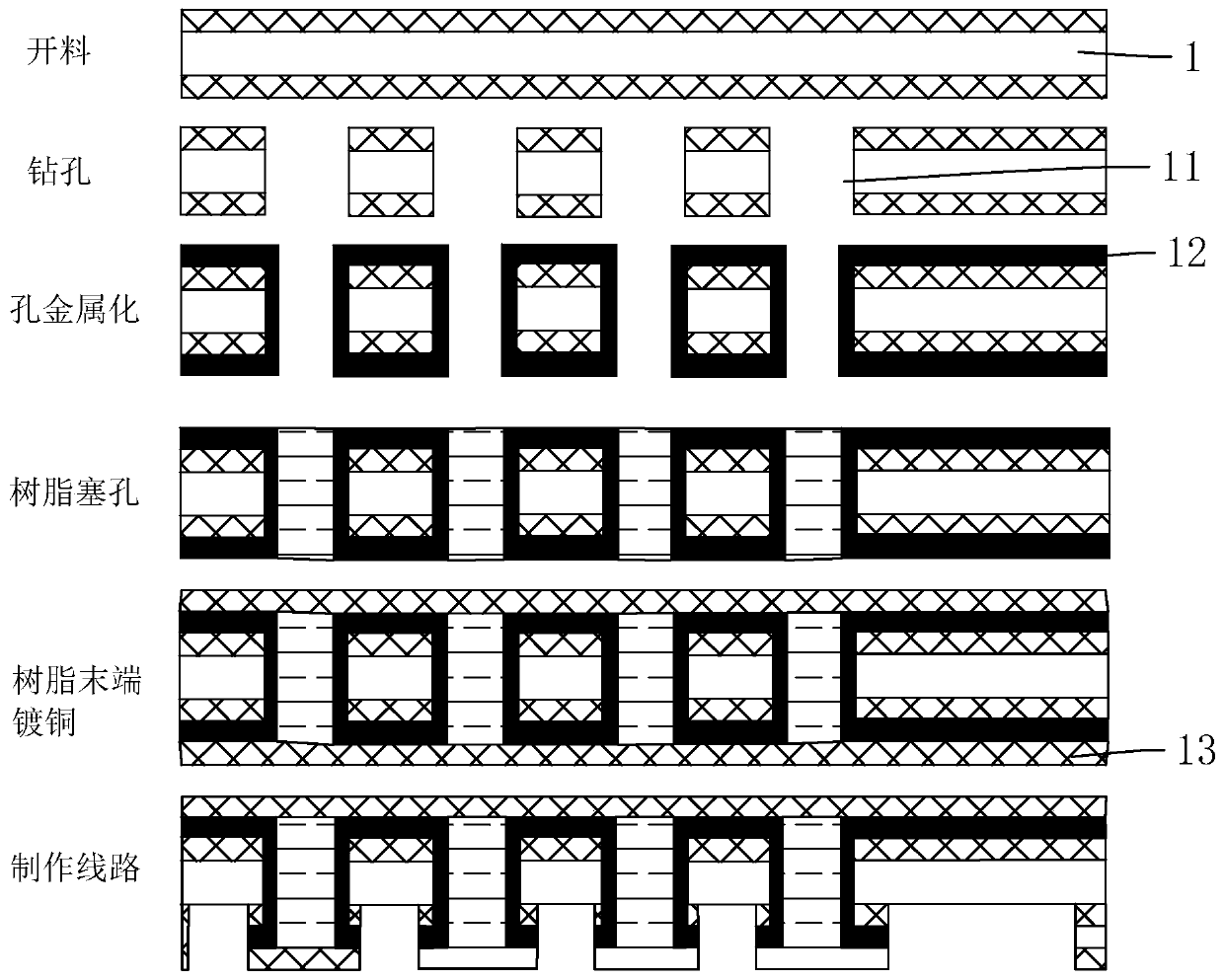

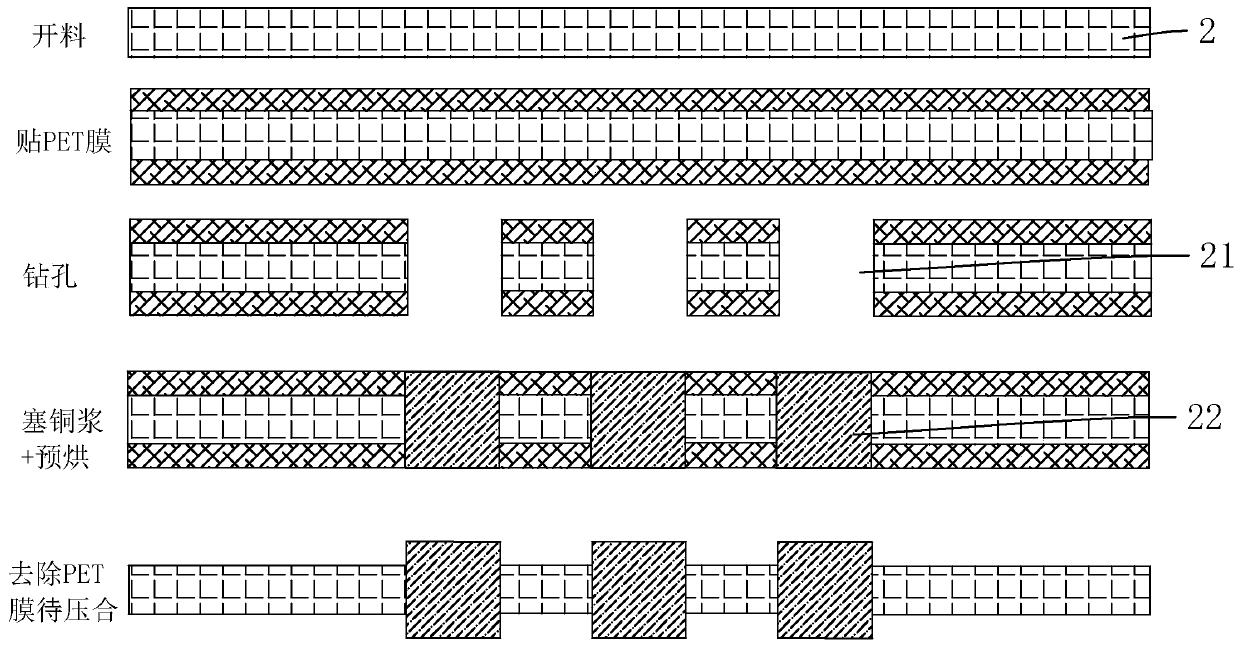

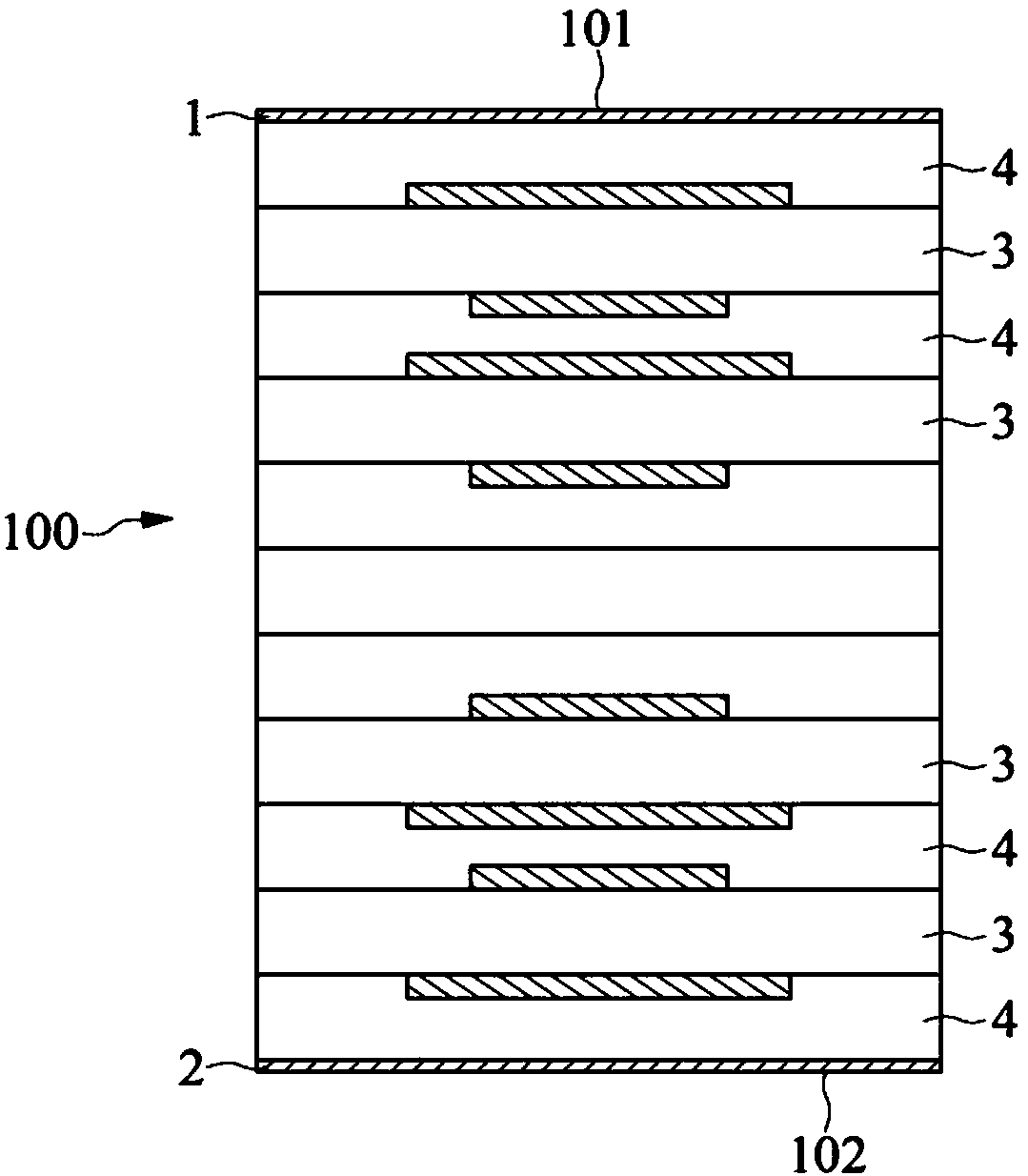

Blind buried hole printed circuit board and manufacturing method thereof

PendingCN110519915AAvoid pollutionRealize interlayer interconnectionPrinted circuit aspectsElectrical connection printed elementsCopper platingInterconnection

The invention discloses a blind buried hole printed circuit board, and the circuit board comprises multiple layers of copper-clad plates, and bonding sheets arranged between two adjacent layers of copper-clad plates; resin columns are disposed in the copper-clad plates, and second metal layers are disposed at the tail ends of the resin columns, wherein a first metal layer is connected with the second metal layers; copper paste is disposed in the bonding sheets, wherein the copper paste is connected with the second metal layers. The invention further comprises a manufacturing method of the blind buried hole printed circuit board. Holes are formed in the positions, corresponding to the blind buried holes, of the bonding sheets, and the copper paste is plugged into the holes; the copper pasteand a metal film are sintered together in the pressing process of the bonding sheets and the copper-clad plates, thereby achieving the interlayer interconnection; a PET film is attached to the bonding sheets before the bonding sheets are plugged into the holes through the copper paste for protection. According to the technical scheme, the lamination frequency can be reduced, the production efficiency can be improved, a printed circuit board with a blind buried hole structure can be realized for many times, the outermost layer copper plating frequency can be reduced, the outer layer copper thickness can be reduced, a smaller line width / spacing can be manufactured, and the circuit density of the circuit board can be improved.

Owner:珠海杰赛科技有限公司 +1

Circuit board and manufacturing method thereof

ActiveCN109803494AReduce the number of pressingShorten the production cycleElectrical connection printed elementsPrinted element electric connection formationEngineeringMaterial Perforation

The invention discloses a circuit board and a manufacturing method thereof. The manufacturing method of the circuit board includes the following steps: providing a multilayer board, wherein the multilayer board has a top surface and a bottom surface; implementing a first hole drilling step to form a first through hole running through the top surface and the bottom surface of the multilayer board;implementing a through hole plating step to plate a first conductive layer on the hole wall of the first through hole; implementing a first hole plugging step to fill the first through hole with resin; and implementing a second hole drilling step: carrying out hole drilling towards the first conductive layer of the multilayer board to form two first perforations which run through the top surface and the bottom surface of the multilayer board and are distributed at intervals, wherein each first perforation partially overlaps the first through hole, and part of the first conductive layer is removed so that the first conductive layer forms two first sub conductive layers separated from each other.

Owner:TRIPOD WUXI ELECTRONICS

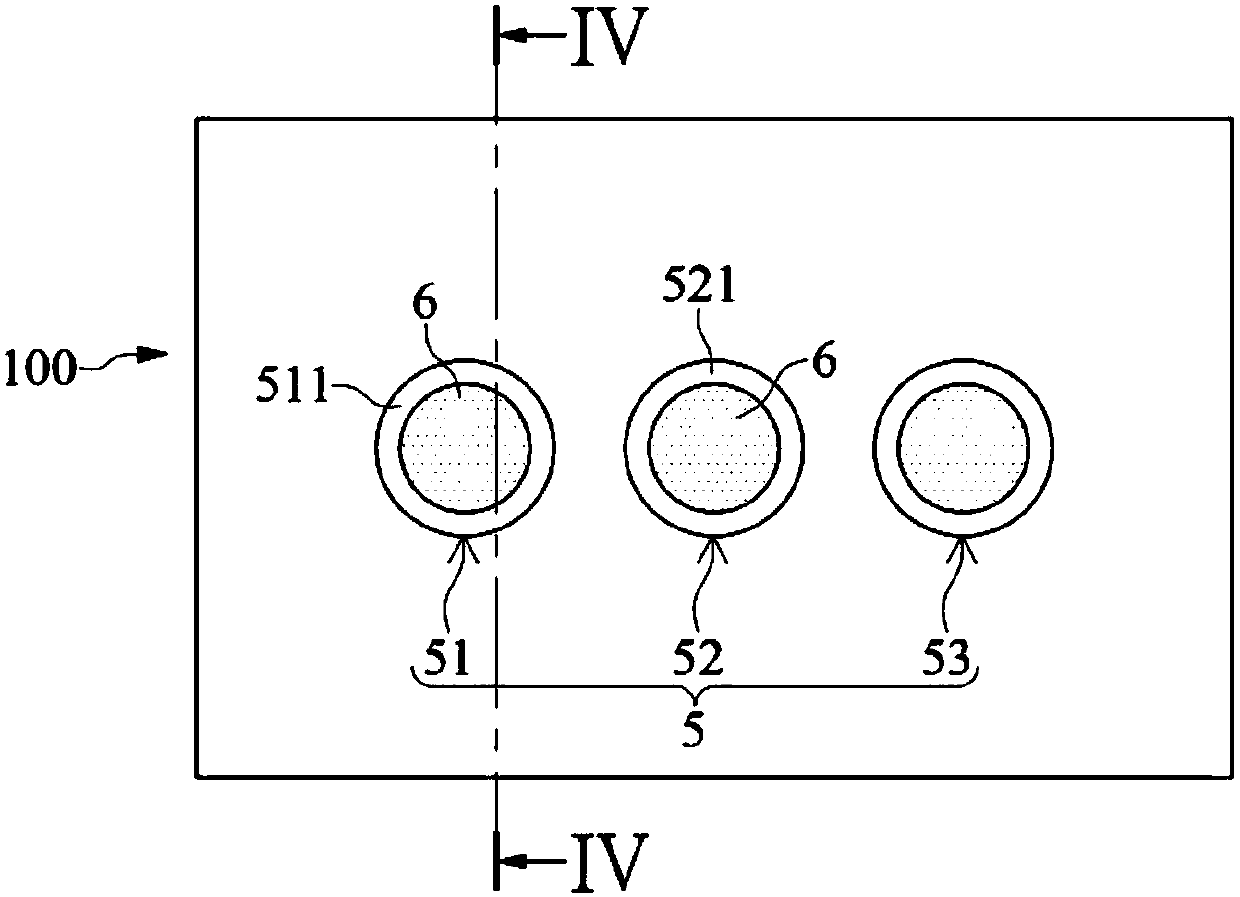

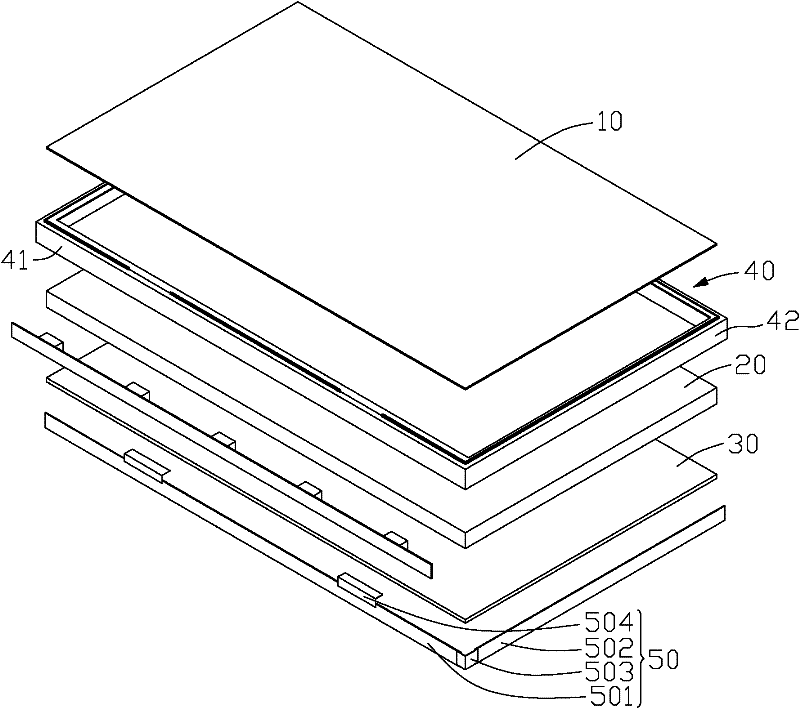

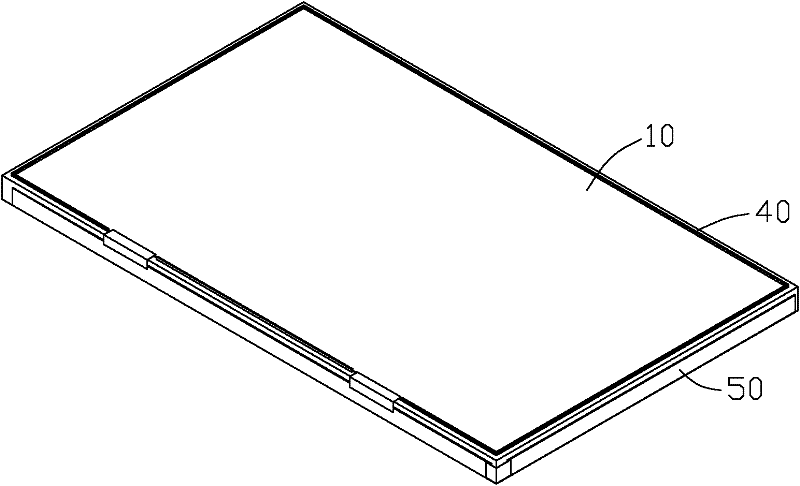

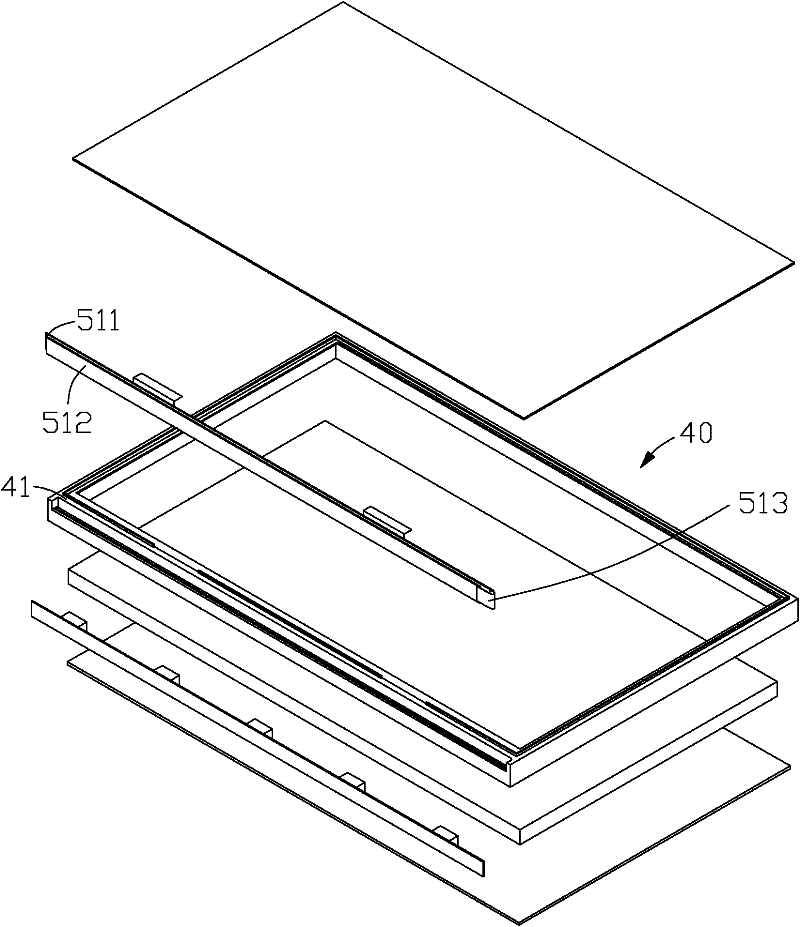

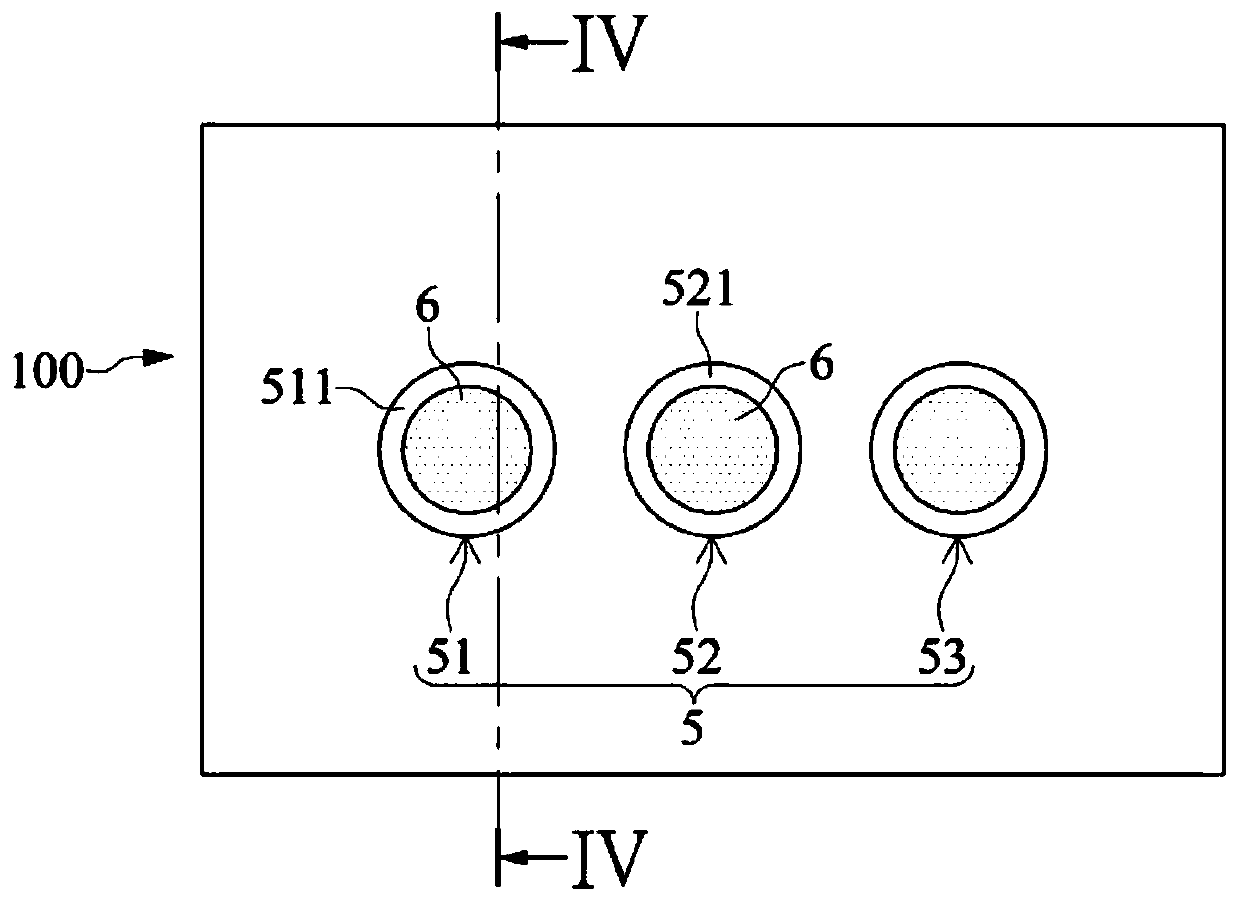

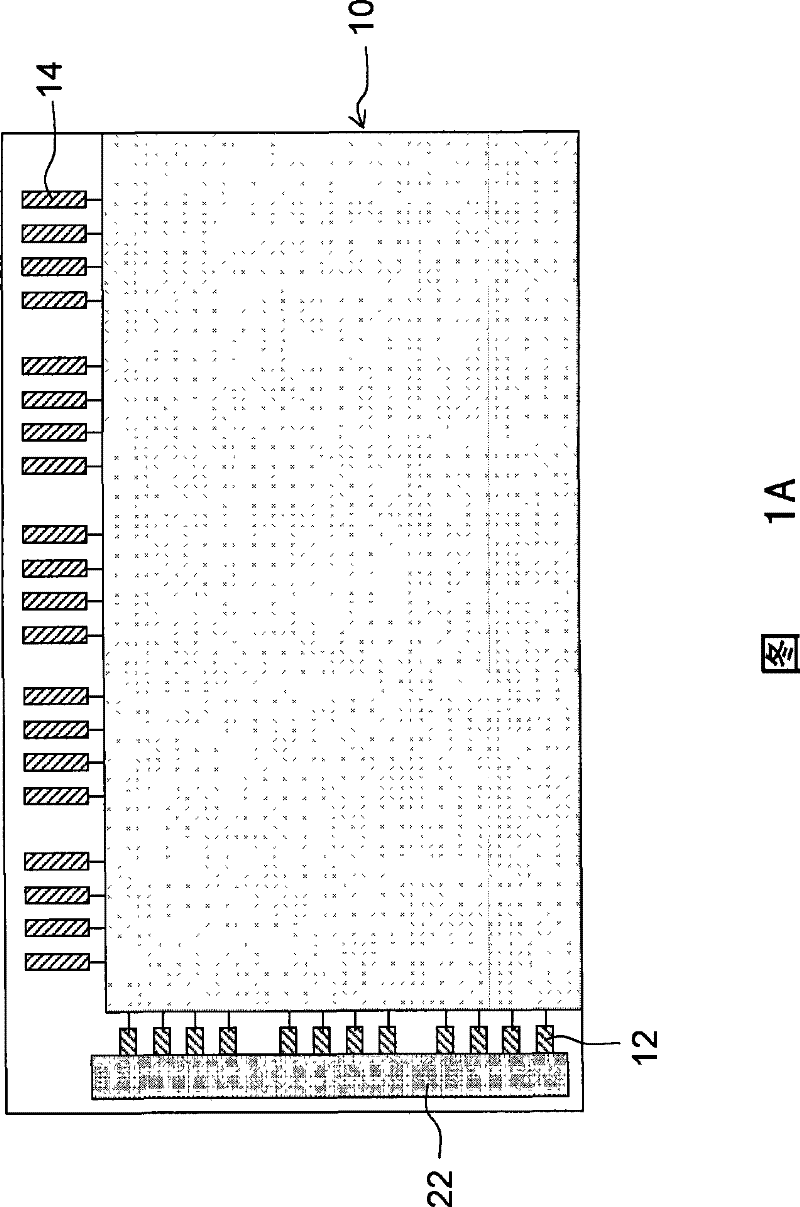

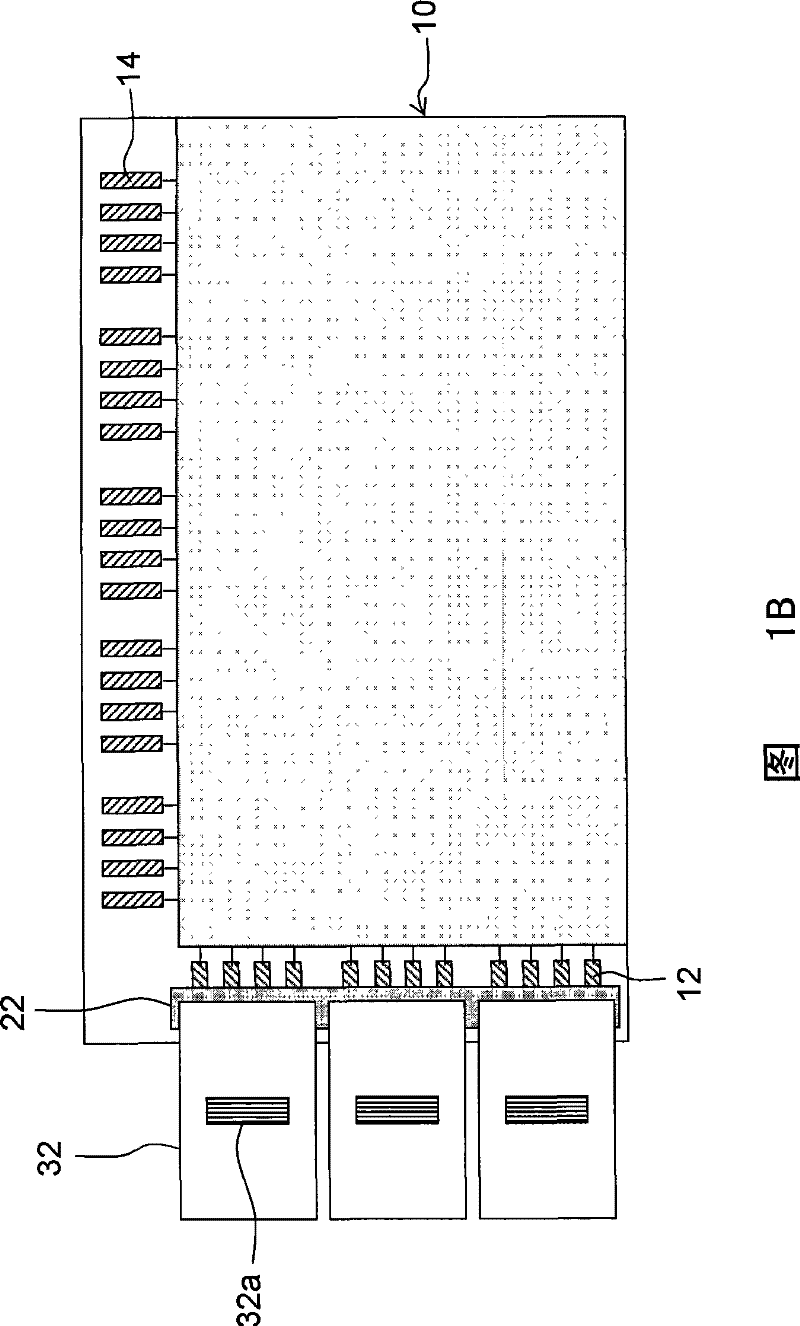

display module

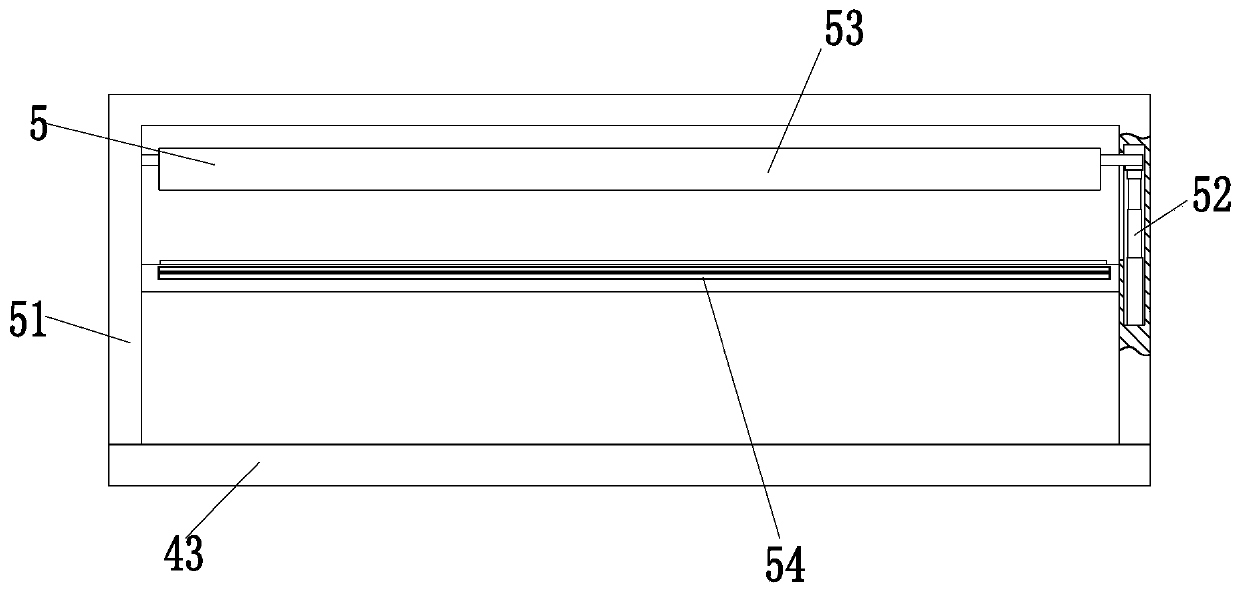

InactiveCN102262841AReduce the number of pressingAvoid thickeningIdentification meansBackplaneOptical membrane

The invention provides a display module. The display module comprises a display panel, an optical membrane group, a backboard, a glue frame and a rigid-flexible combination circuit board. The optical membrane group is arranged between the display panel and the backboard and the glue frame is used for fixing the optical membrane group. The rigid-flexible combination circuit board comprises a first rigid area, a second rigid area, a flexible area which is electrically connected between the first rigid area and the second rigid area, and a flexible connection part; the first rigid area is electrically connected with the display panel through the flexible connection part to establish an electric connection between the rigid-flexible combination circuit board and the display panel; and the first rigid area and the second rigid area are respectively distributed at different sides of the glue frame or are overlapped at the same side of the glue frame. The display module provided by the invention supplies flexible and various circuit board placing ways through utilizing the rigid-flexible combination circuit board so that the advantages of reducing assembling flow and reducing assembly difficulty and / or reducing the thickness of the display module and conveniently laminating can be realized.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

Soft-hard circuit board and process thereof

ActiveCN101990355BReduce manufacturing costShorten the lengthPrinted circuit assemblingPrinted circuits structural associationsManufacturing cost reductionEngineering

The invention relates to a soft-hard circuit board and a process thereof. The soft-hard circuit board comprises a hard circuit board, a first soft circuit board, a first outer composite layer and a plurality of first conductive connecting structures. The hard circuit board is provided with an upper surface, a lower surface opposite to the upper surface and a groove. The first outer composite layer is provided with a first opening communicated with the groove, and comprises a first outer circuit layer and a first insulating layer. The first insulating layer is arranged between the first outer circuit layer and the upper surface. The first soft circuit board is arranged on the first insulating layer and covers the groove. The first insulating layer is locally covered on the first soft circuit board. The first conductive connecting structures are arranged in the first insulating layer and electrically connected between the hard circuit board and the first soft circuit board. The soft-hard circuit board can reduce the demand of flexible substrates and greatly reduce the manufacturing cost, and also has the advantages of saving the assembly space and reducing the soft board length and the soft board pressing times.

Owner:UNIMICRON TECH CORP

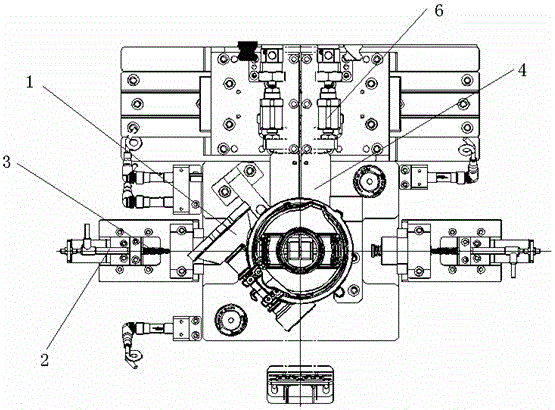

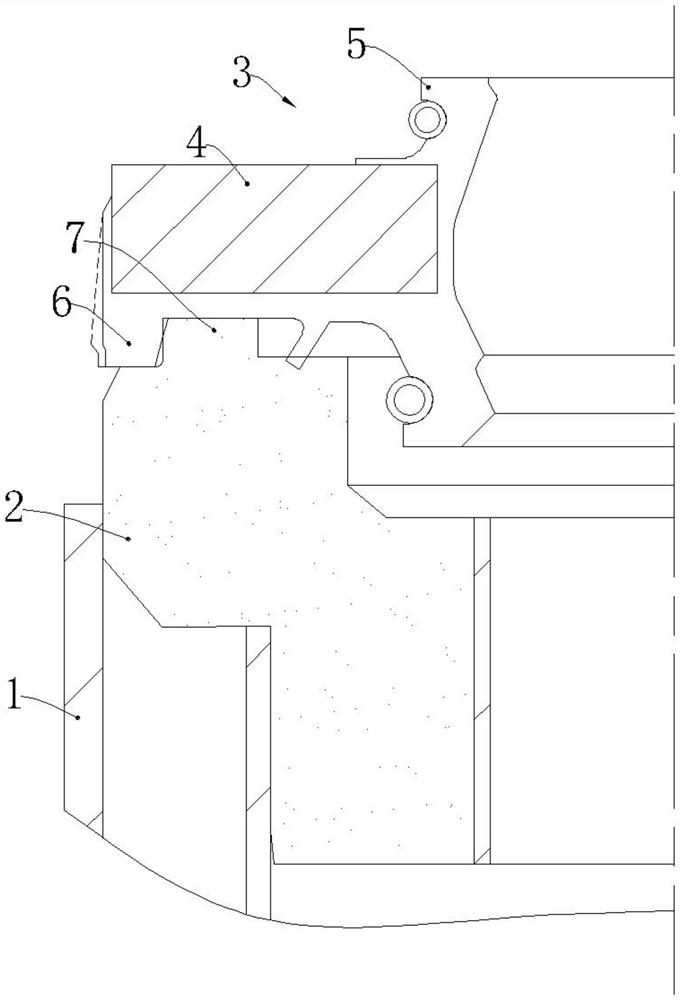

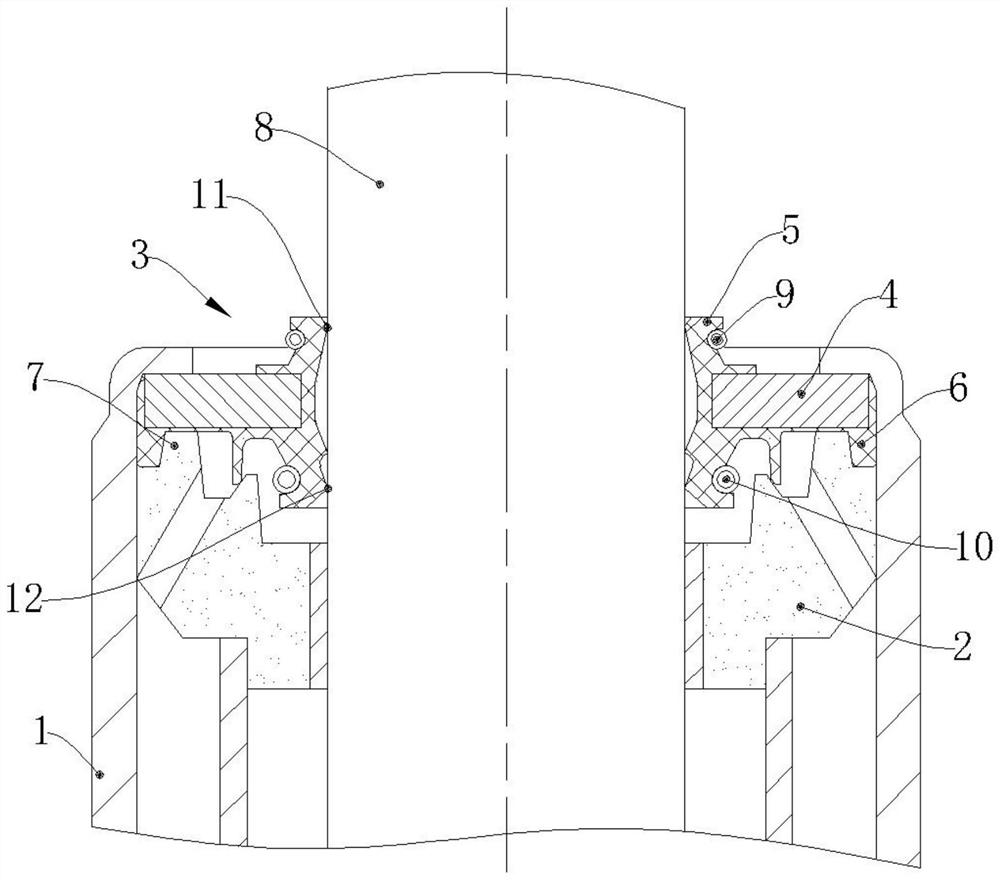

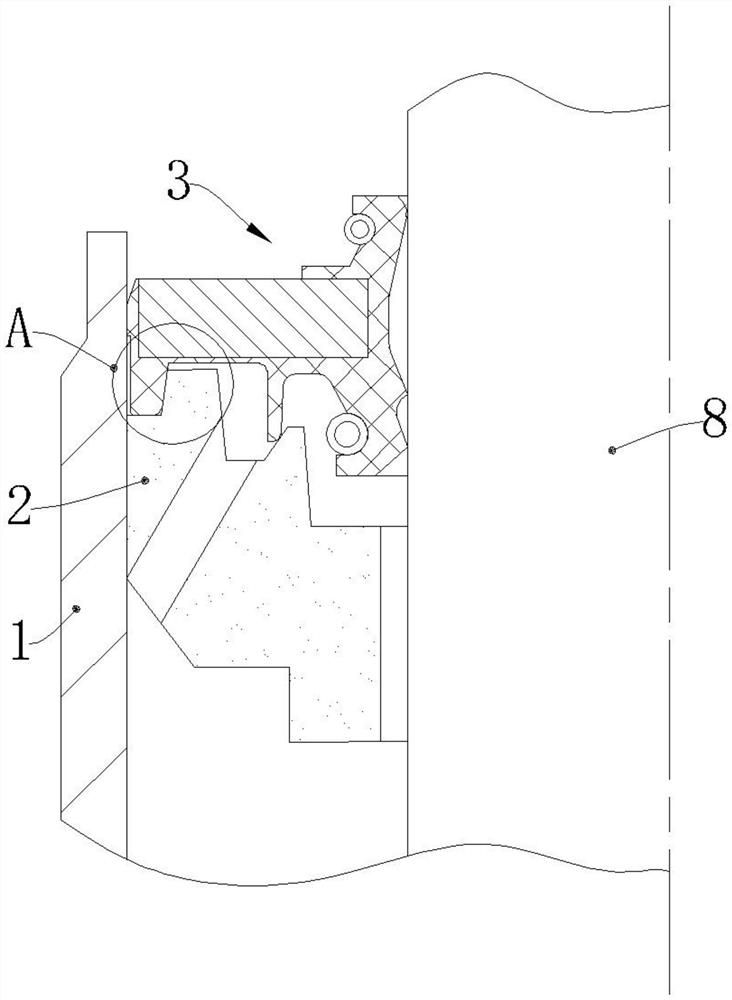

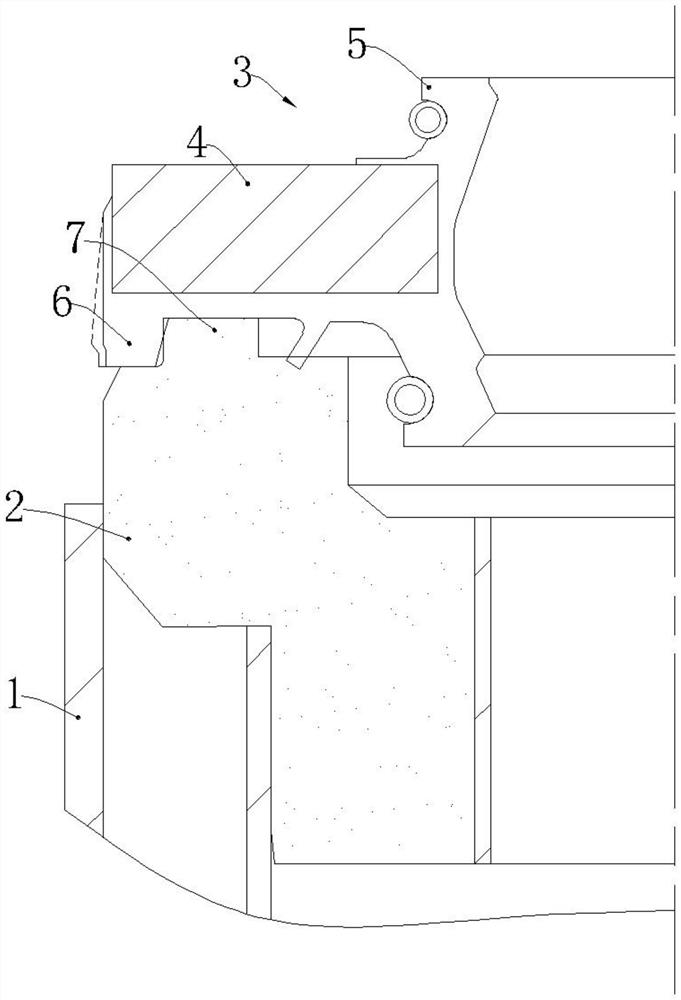

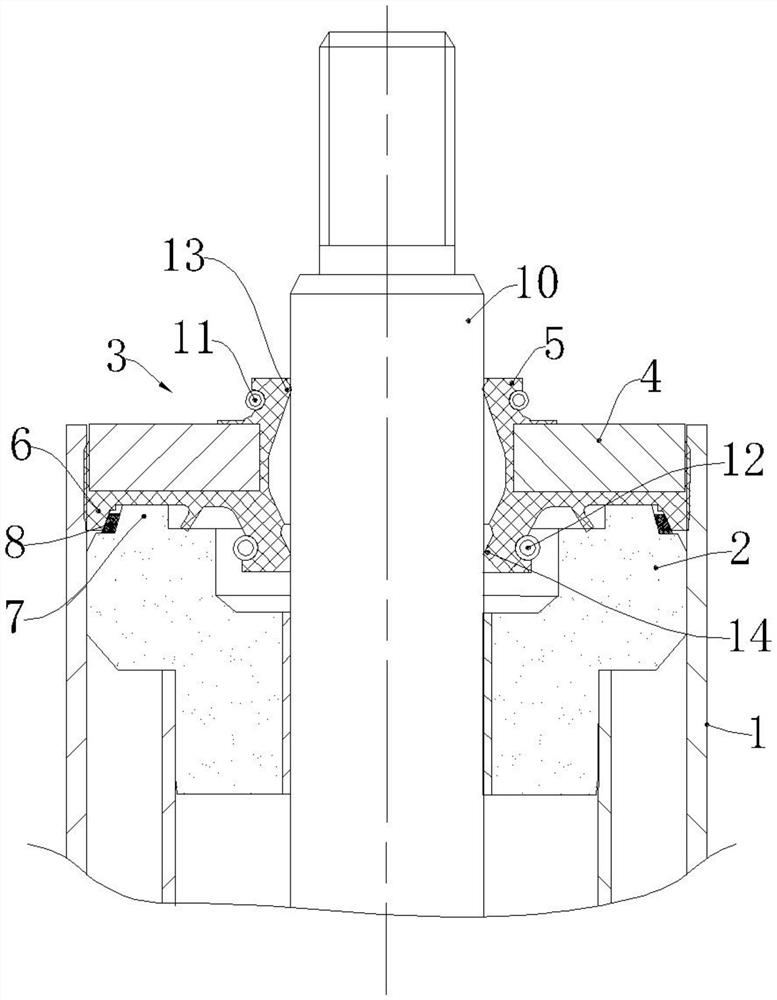

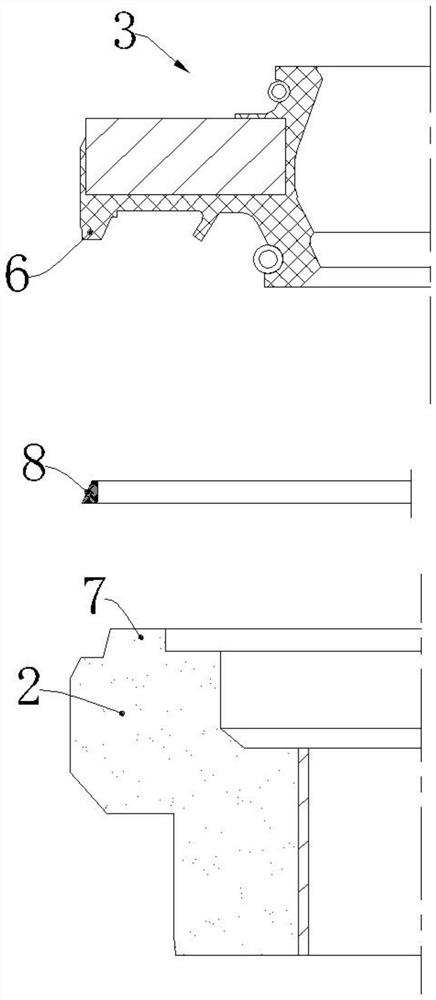

Assembly method of oil seal guider assembly

PendingCN114198452AReduce the number of pressingImprove assembly efficiencyEngine sealsSpringsInterference fitShock absorber

The invention relates to a shock absorber assembling technology, in particular to an assembling method of an oil seal guider assembly, which comprises the following steps of: A, sleeving an annular boss with an annular sealing body; b, an oil seal and a guider are pressed into the outer cylinder together; and C, after the guider is positioned, pressure is continuously applied to the oil seal, so that the annular sealing body is expanded to be in interference fit with the outer cylinder and the annular boss. According to the oil seal guider assembly, the characteristic that the annular sealing body made of rubber is deformed before and after being compressed is utilized, the press-fitting frequency in the assembling process of the oil seal guider assembly is reduced, and the assembling efficiency of a shock absorber is improved.

Owner:QINGDAO REGENCY OIL SEAL CO LTD

A Modification Technology of Small Pressure Mold

The invention relates to the field of molds, in particular to a low-pressure mold transformation technology. The technology comprises the steps of 1) cutter processing; 2) processing for a lower spherical part; 4) processing for an upper spherical part; 5) mold installation. According to the transformation technology, the surfaces of upper and lower molds are transformed into a micro-spherical cambered surface shape, and patterns and characters are carved into a micro cambered surface through a projection carving mode. The technology has the advantages that a workblank precious metal materialwith the thickness below 1.5 millimeters is better formed, and the product presses more full patterns and clear handwriting; the pressure tonnage required by product pressing is lowered, the service life of the molds is effectively prolonged, the dangerous factors such as mold cracking are reduced, and safety production is guaranteed; the pressing frequency is lowered, and the production efficiency of a pressing link is improved.

Owner:中国黄金集团三门峡中原金银制品有限公司

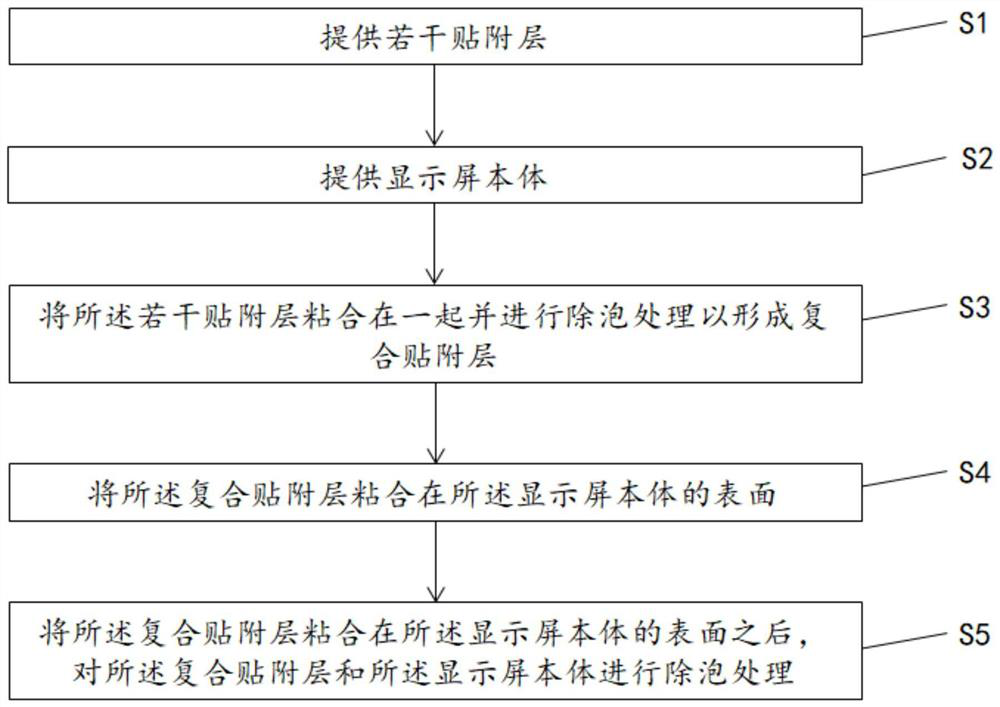

Preparation method of display screen

PendingCN114290787AReduce the number of pressingSo as not to damageLamination ancillary operationsLaminationMechanical engineeringChemistry

The invention provides a preparation method of a display screen. The preparation method comprises the following steps: providing a plurality of attaching layers; providing a display screen body; bonding the plurality of attachment layers together and carrying out defoaming treatment to form a composite attachment layer; bonding the composite attaching layer on the surface of the display screen body; and after the composite attaching layer is bonded to the surface of the display screen body, defoaming treatment is conducted on the composite attaching layer and the display screen body. According to the preparation method of the display screen, fitting bubbles are effectively reduced, and the display screen is prevented from being broken.

Owner:青岛维信诺电子有限公司

How to make a multilayer circuit board

ActiveCN110545635BImprove reliabilityReduce interface reliability issuesMultilayer circuit manufactureHemt circuitsEngineering

A method for manufacturing a multilayer circuit board, comprising the following steps: providing an inner circuit substrate, the inner circuit substrate at least including a base material layer and a first conductive circuit layer formed on a surface of the base material layer; The first conductive circuit layer includes a plurality of first conductive circuits; a first cover film is formed on the first conductive circuit layer, and the first cover film includes a first opening, and a part of the first conductive circuit from the first exposed in the opening; an outer line seed layer is formed on the first cover film, and an inner line protection layer is formed on the first conductive line exposed from the first opening, and the inner line protection layer The layer is non-copper metal or resist; forming a third conductive circuit layer on the outer circuit seed layer; and removing the outer circuit seed layer and the inner circuit protection layer. The manufacturing method of the multi-layer circuit board provided by the invention can reduce work flow and improve circuit reliability.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

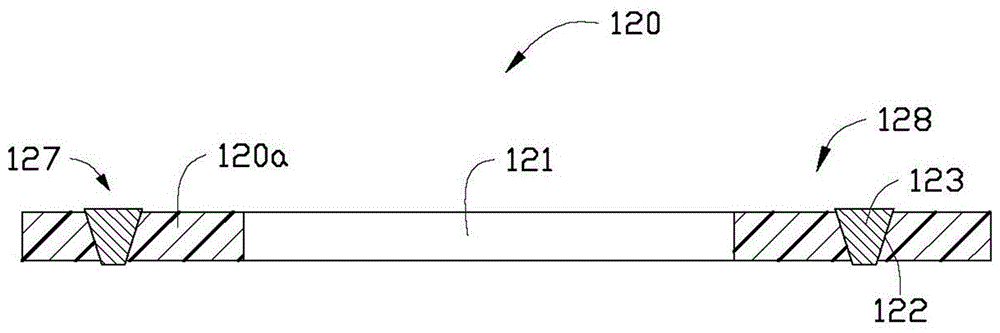

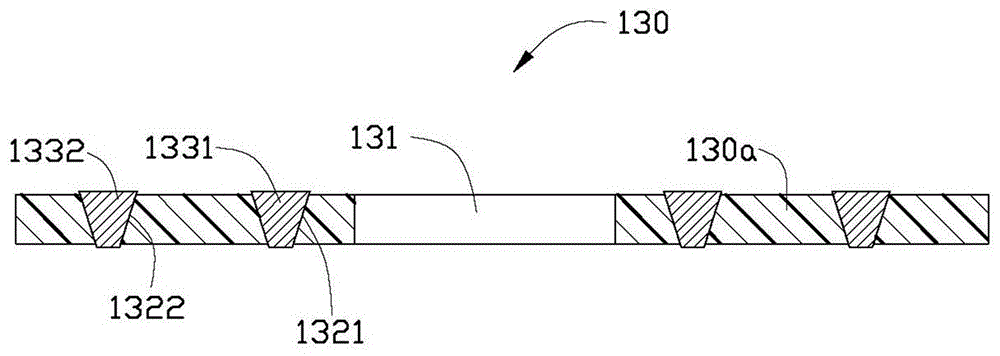

Manufacturing method for printed circuit board, and printed circuit board

InactiveCN108617112AReduce swellingEasy alignmentMultilayer circuit manufacturePrinted circuit board

The invention relates to a manufacturing method for a printed circuit board, and the printed circuit board. The method comprises the steps: drilling a first prefabricated plate to obtain a first sub-board with a first connecting hole, and drilling a second prefabricated plate to obtain a second sub-board with a second connecting hole; pre-pressing a first bonding sheet on the first sub-board; forming a first via hole corresponding to the first connecting hole on the first bonding sheet; and performing the stitching of the first sub-board and the second sub-board through the first bonding sheet. The printed circuit board is fabricated through the above-described manufacturing method. According to the printed circuit board as described above, the connection holes in the printed circuit boardare divided according to the apertures and the center distances of the holes in the printed circuit board, sand the first and second sub-board which are different are separated out, and then the first sub-board and the second sub-board are connected by through the first bonding sheet including the first via hole.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

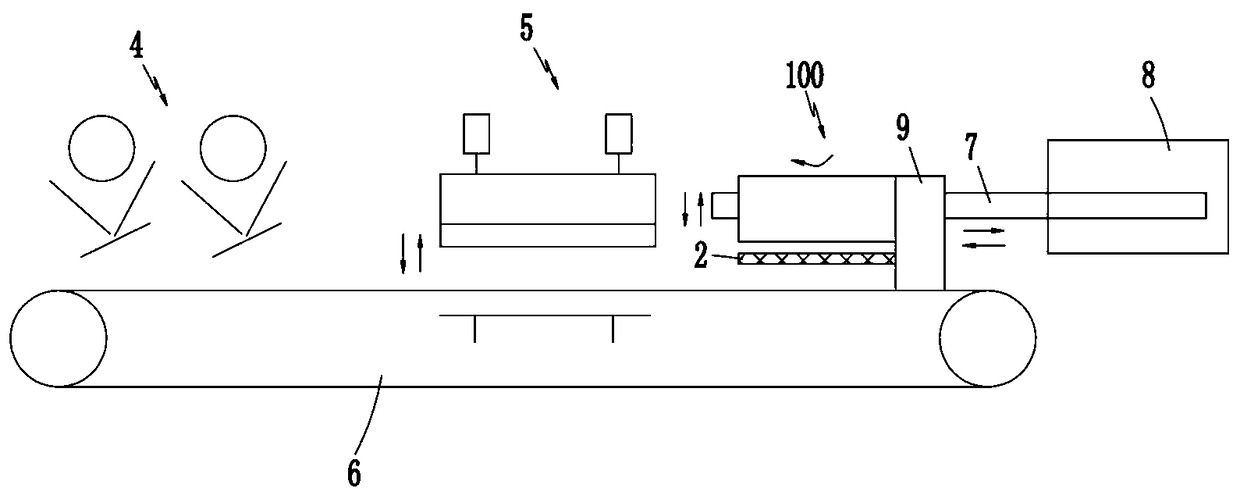

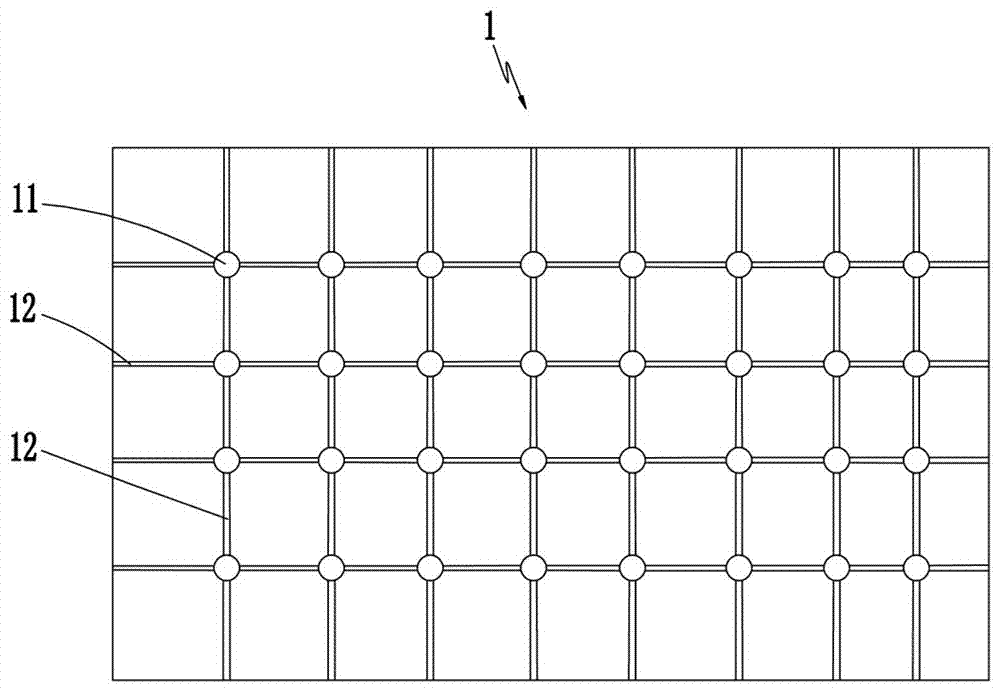

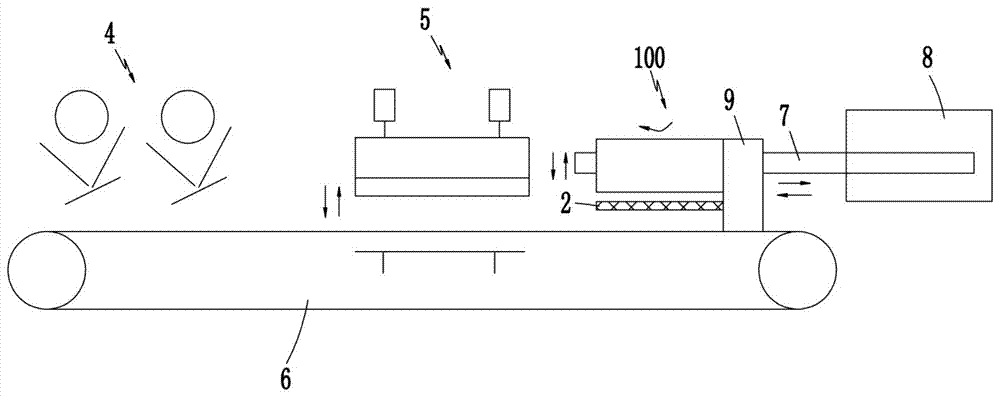

A vacuum suction blank structure and a feeding mechanism comprising the vacuum suction blank structure

The invention provides a vacuum blank adsorption structure which is simple in structure, low in cost, stable in work and capable of effectively ensuring stripes and patterns of a ceramic tile blank. The vacuum blank adsorption structure comprises a vacuum adsorption die used for adsorbing the ceramic tile blank, a lifting drive cylinder used for driving the vacuum adsorption die to rise and fall and a vacuum generation device used for enabling the vacuum adsorption die to generate a vacuum gas source. The bottom end face of the vacuum adsorption die is provided with a plurality of longitudinally and transversely formed air suction and exhaust grooves in an intersected mode. The intersection of each pair of intersected air suction and exhaust grooves is provided with an air hole communicating with the vacuum generation device. Compared with the prior art, according to the scheme, by adoption of the structural form, the traditional mode that a ceramic tile blank is conveyed into a press through a fidelity grating is changed, and the vacuum blank adsorption structural form in the scheme is utilized, and by adsorbing the ceramic tile blank through vacuum, it can be ensured that the blank is not prone to shaking in the transferring process, and the whole conveying process is stable.

Owner:GUANGDONG TIANBI CERAMICS

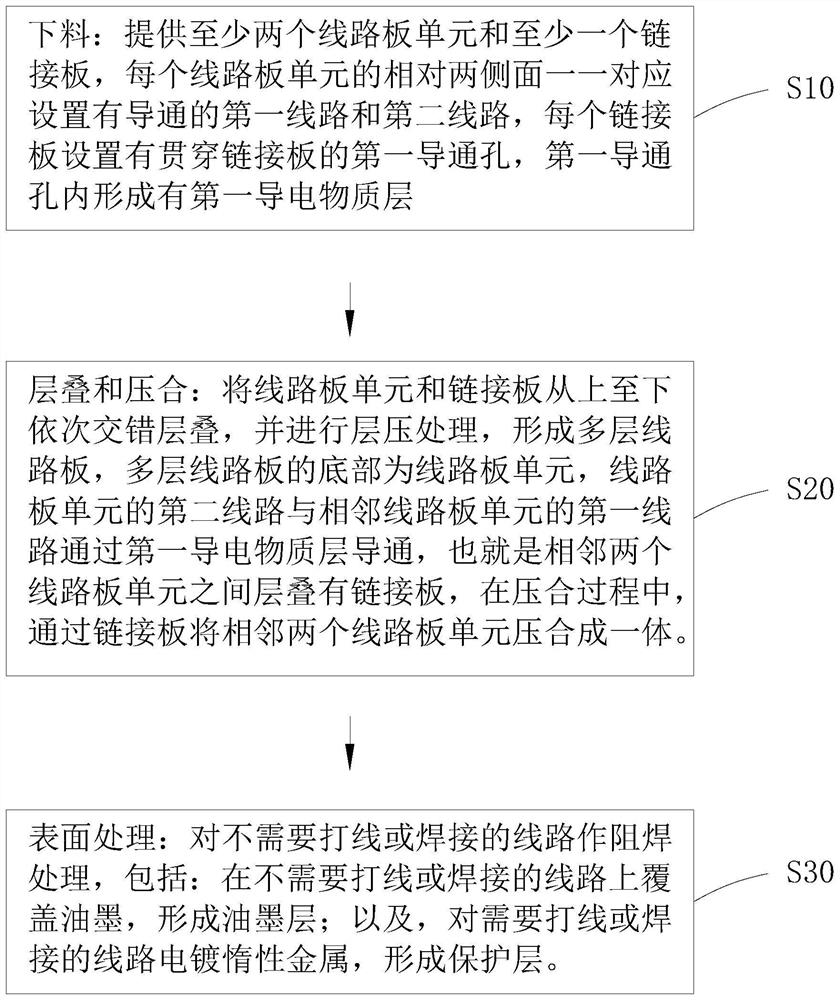

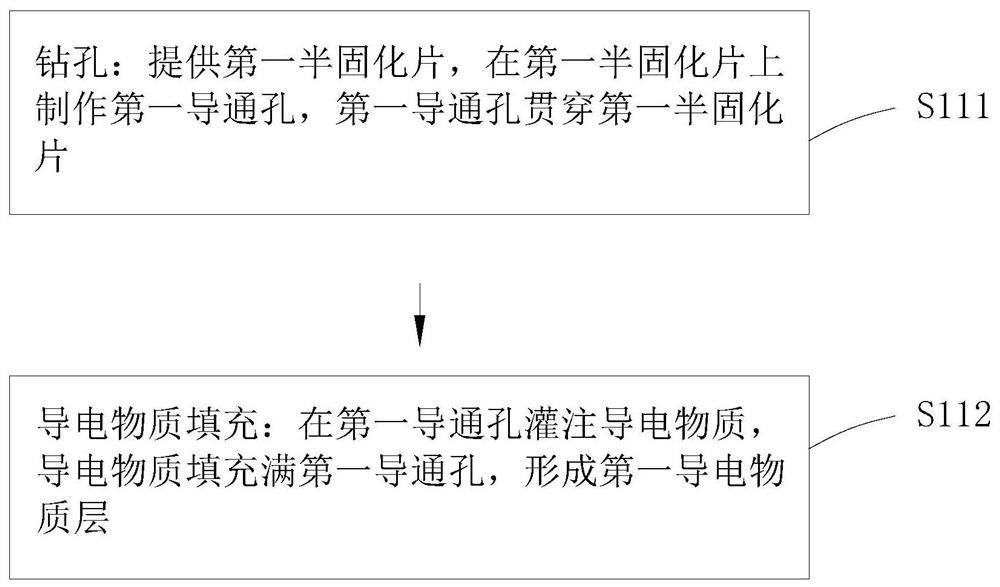

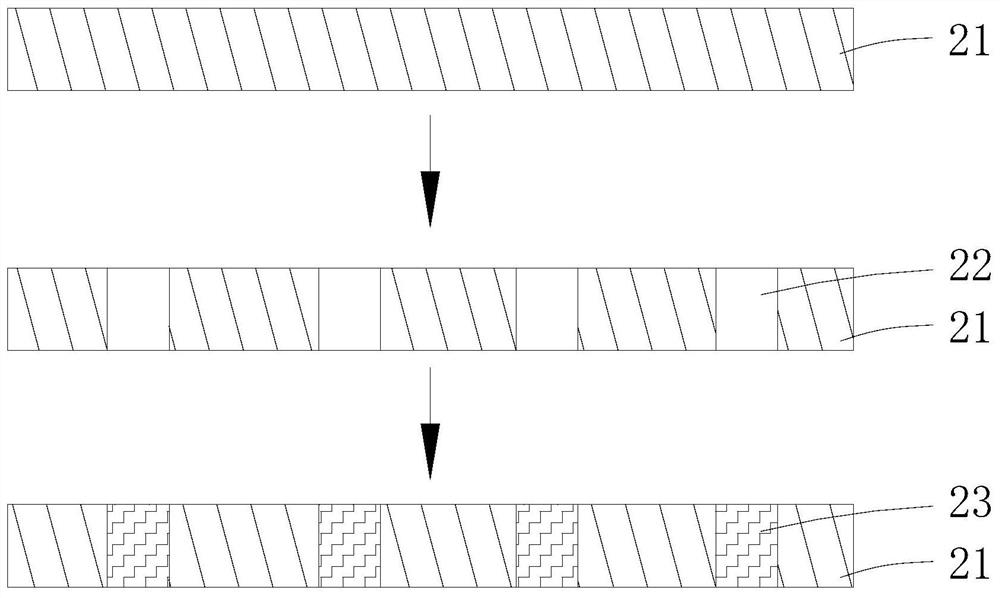

Multilayer circuit board preparation method and multilayer circuit board

PendingCN112087888AReduce manufacturing costImprove production yieldElectrical connection printed elementsMultilayer circuit manufactureStructural engineeringConductive materials

The invention discloses a multilayer circuit board preparation method and a multilayer circuit board, and the method comprises the steps: blanking: providing at least two circuit board units and at least one link plate, and enabling two opposite side surfaces of each circuit board unit to be provided with a first circuit and a second circuit in a one-to-one correspondence manner, wherein each linkplate is provided with a first via hole penetrating through the link plate, and a first conductive material layer is formed in the first via hole; and stacking and lamination: stacking the circuit board units and the link plates sequentially in a staggered mode from top to bottom, performing lamination processing, forming a multilayer circuit board, and connecting second circuits of the circuit board units with first circuits of the adjacent circuit board units through first conductive material layers; According to the preparation method, the circuit board units are prepared in advance, thenthe circuit board units are stacked according to a preset sequence, the link plates are stacked between every two adjacent circuit board units, every two adjacent circuit board units are integrated into a whole through the link plates, and it is guaranteed that the multilayer circuit board can still keep good conduction performance under the condition of external force.

Owner:SHENZHEN ZHIJIN ELECTRONICS

Circuit board and manufacturing method thereof

ActiveCN109803494BReduce the number of pressingShorten the production cycleElectrical connection printed elementsPrinted element electric connection formationEngineeringMechanical engineering

The invention discloses a circuit board and a manufacturing method thereof. The manufacturing method of the circuit board includes: providing a multilayer board; wherein the multilayer board has a top surface and a bottom surface; performing a first drilling step to form a first through hole penetrating the top surface and the bottom surface of the multilayer board; performing plating The through-hole step is to plate a first conductive layer on the hole wall of the first through-hole; the first plug-hole step is performed to fill the first through-hole with resin; and the second drilling step is performed, including: toward The first conductive layer of the multilayer board is drilled to form two first through holes in the multilayer board that penetrate the top surface and the bottom surface and are distributed at intervals; wherein each first through hole partially overlaps the first through hole. through holes, and remove part of the first conductive layer, so that the first conductive layer is formed into two first sub-conductive layers separated from each other.

Owner:TRIPOD WUXI ELECTRONICS

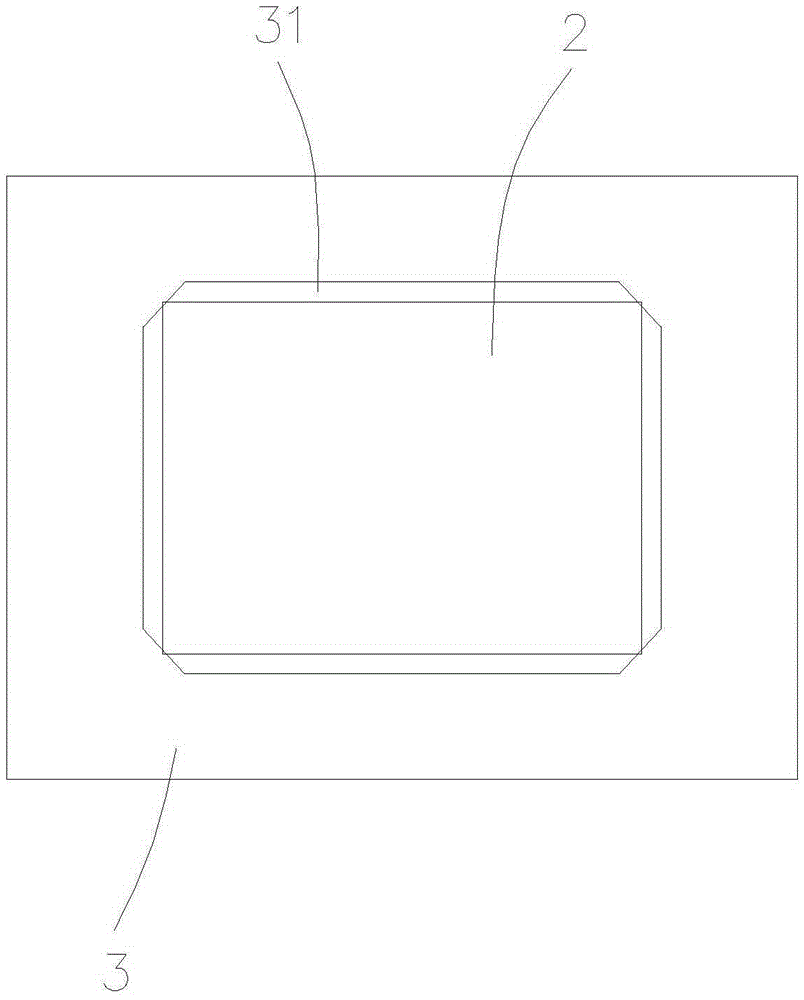

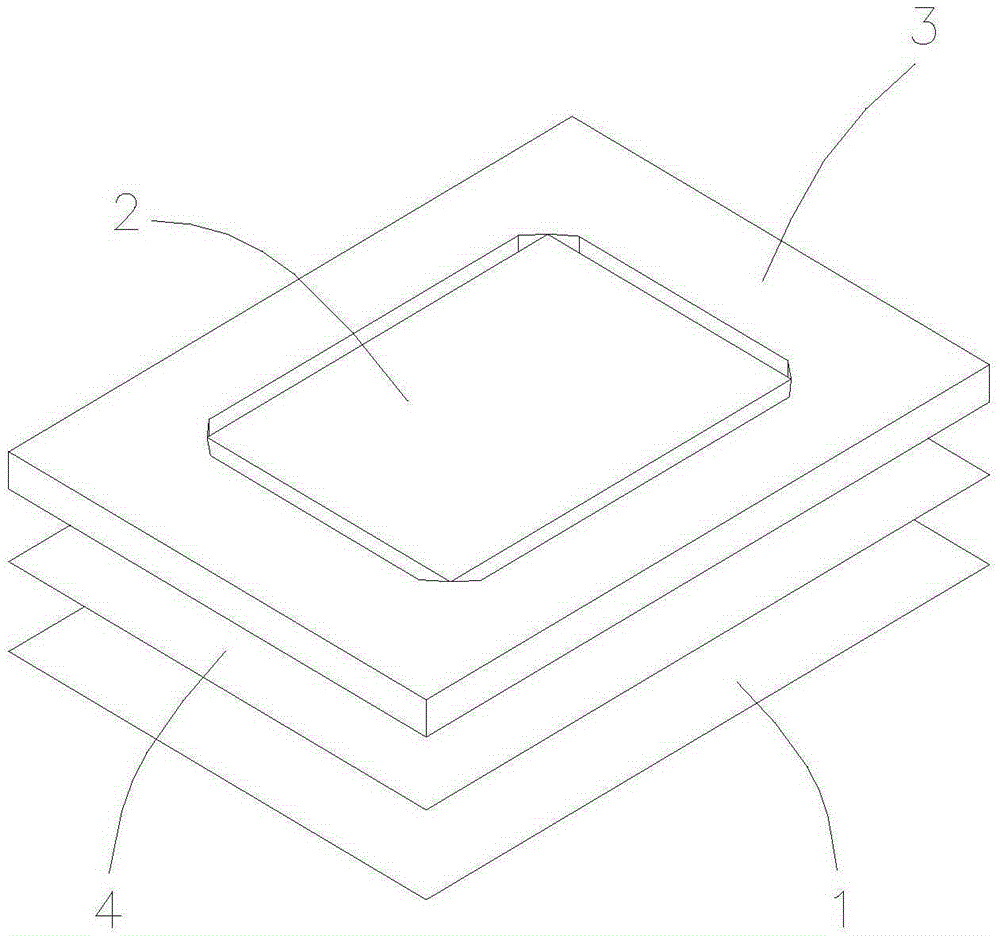

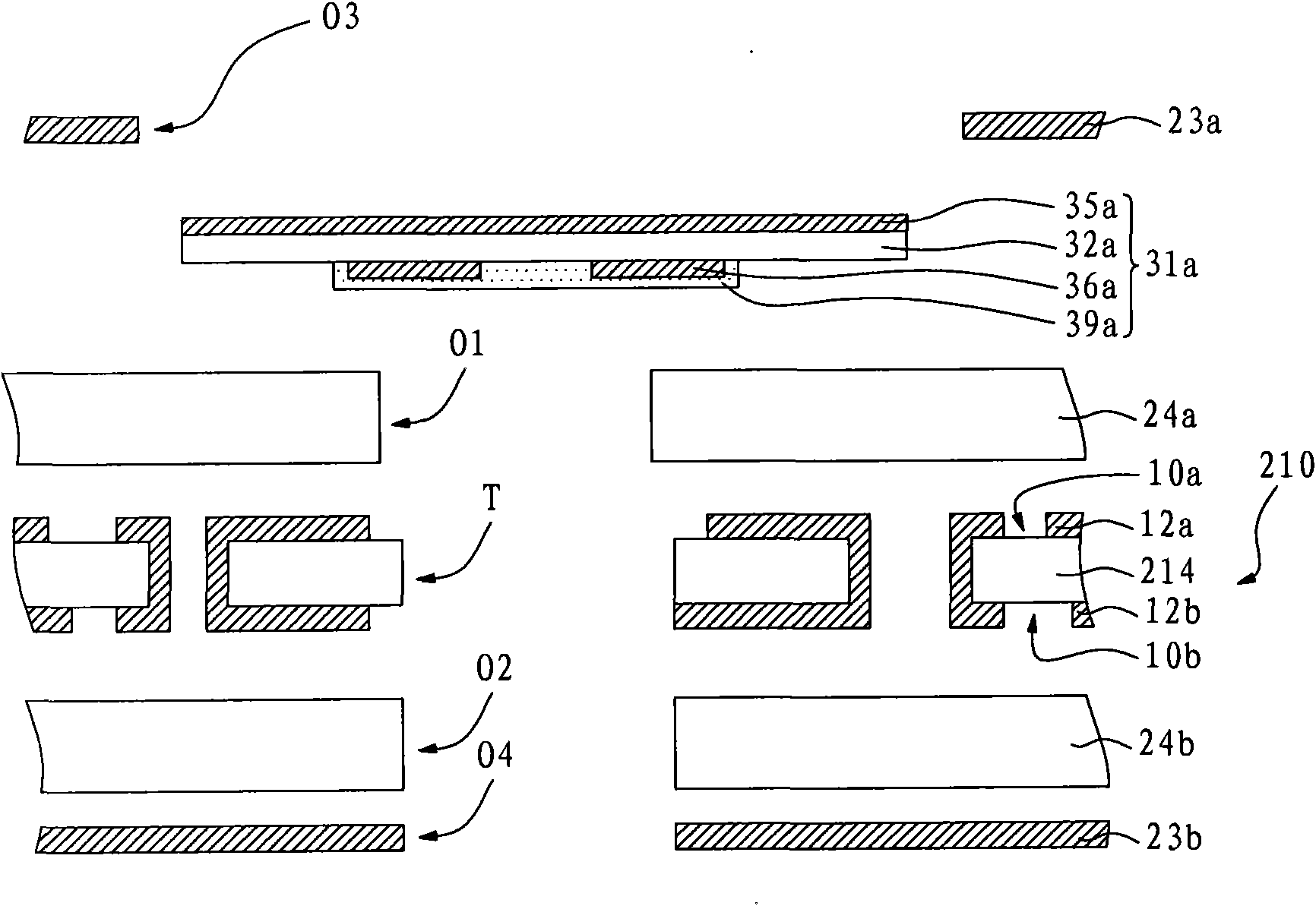

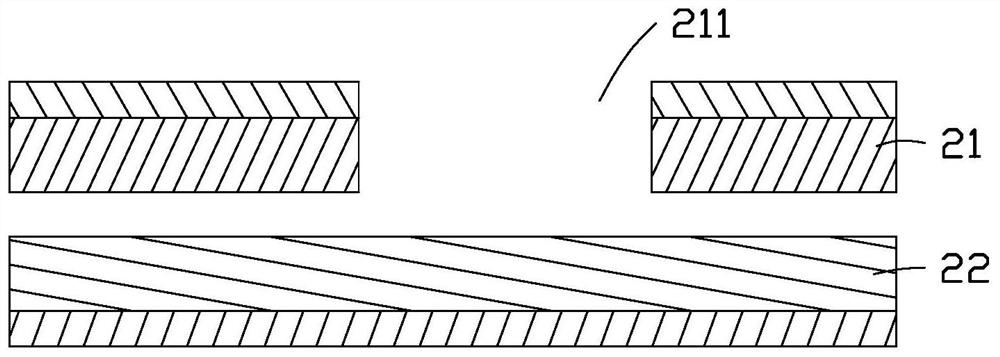

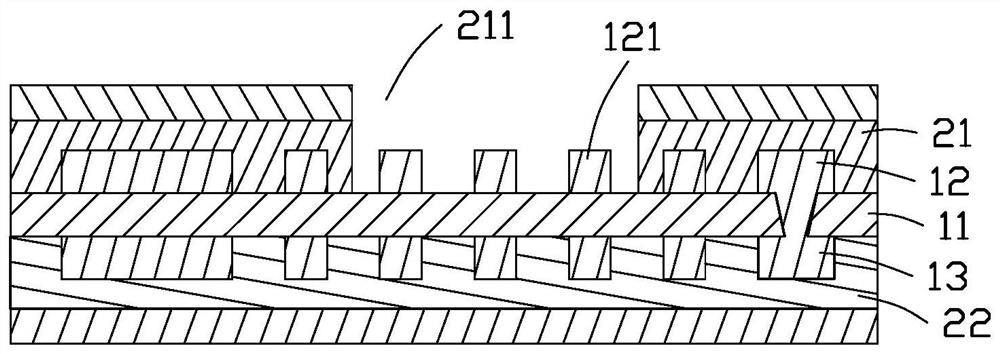

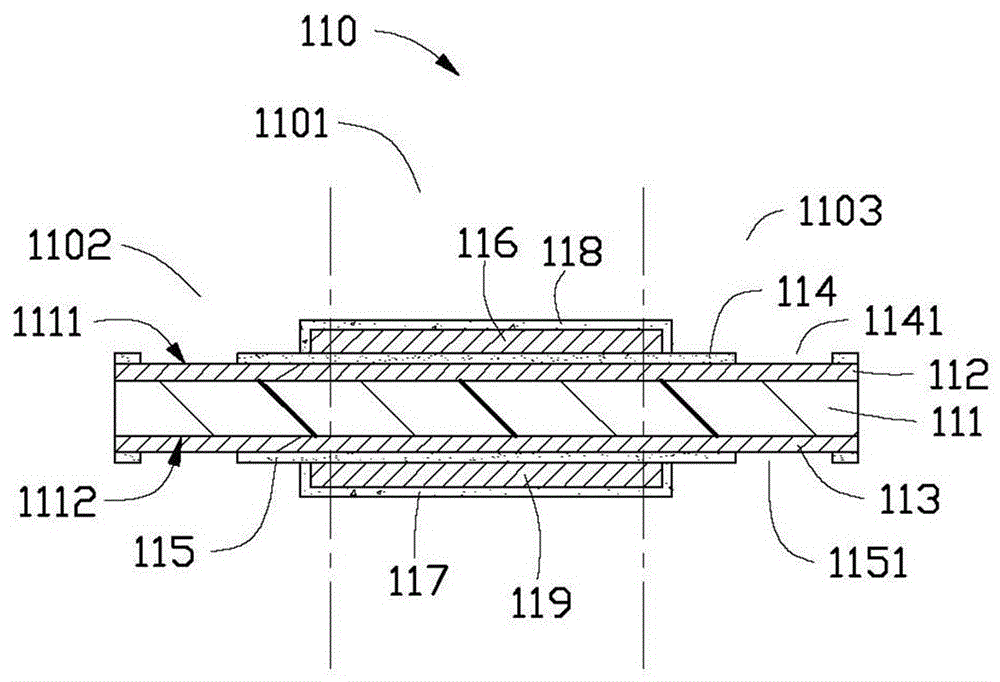

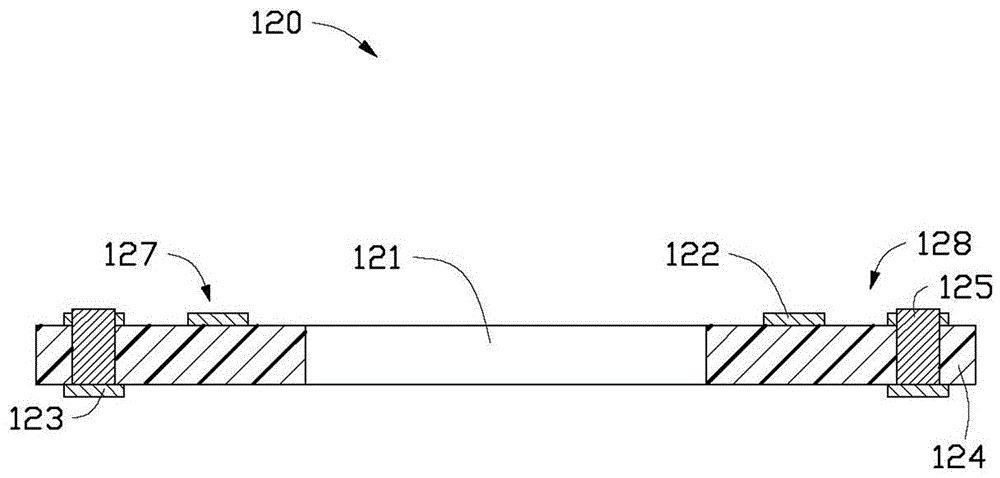

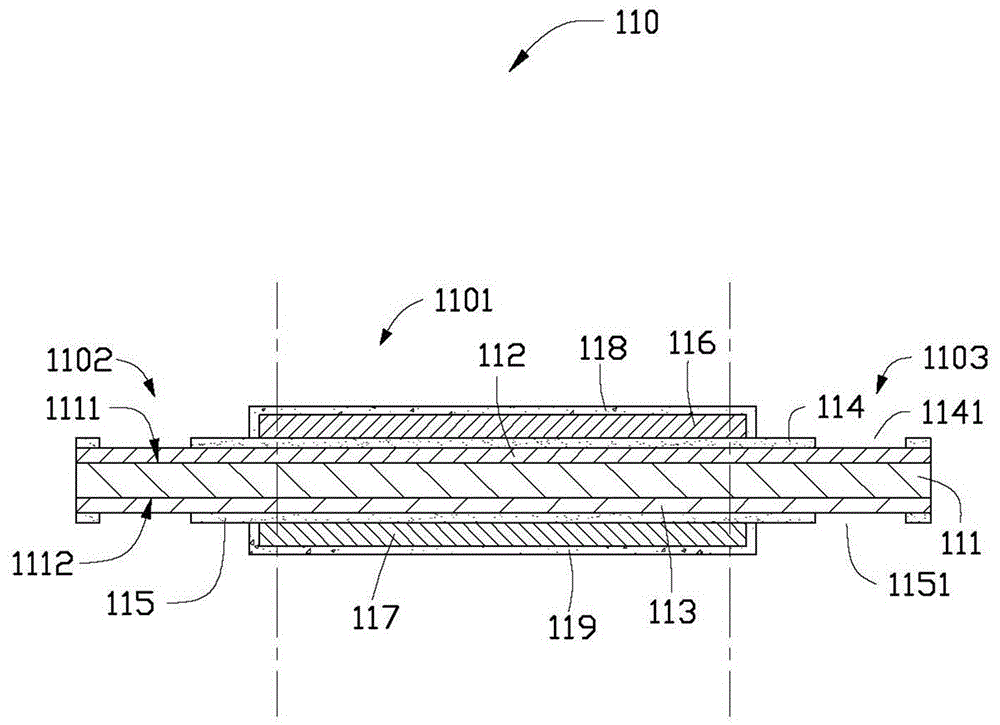

Rigid-flex circuit substrate, rigid-flex circuit board and manufacturing method

ActiveCN103635007BImprove reliabilityReduce manufacturing costPrinted circuit assemblingPrinted circuit detailsFlexible circuitsSheet film

A rigid-flex circuit substrate, comprising: a flexible circuit board, a core substrate, a first lamination film, a second lamination film, a third conductive circuit layer and a fourth conductive circuit layer, the flexible circuit board It includes an exposed area and a pressing area connected to the exposed area. The core substrate is connected to the pressing area. The first lamination film and the second lamination film are formed on both sides of the lamination area of the core substrate and the flexible circuit board. An electrical connector is formed in the core substrate, the first and the second laminated film, and the conductive circuit layer of the flexible circuit board is electrically connected with the third conductive circuit layer and the fourth conductive circuit layer through the electrical connector. The present invention also provides a manufacturing method of the rigid-flex circuit board, a rigid-flex circuit board and a manufacturing method thereof.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Manufacturing method of copper paste plug hole printed board and manufacturing method of fpc board

ActiveCN112601377BIncrease productivityLow viscosityNon-metallic protective coating applicationPrinted element electric connection formationFlexible circuitsAdhesive

This application is applicable to the technical field of flexible circuit boards, and proposes a method for manufacturing copper paste plugged printed boards, including: attaching a heat-relieving adhesive protective film to the side of the board away from the circuit layer; The peeling force of the adhesive protective film after bonding is greater than 500g / cm 2 ; Make a blind hole on the plate from one side of the heat-reducing adhesive protective film; insert copper paste into the blind hole; bake the plate, and the heat-reducing adhesive protective film is The peel force after baking is less than 15g / cm 2 ; Peel off the heat-reducing adhesive protective film to obtain a copper paste plugged printed board. The above-mentioned manufacturing method of the copper paste plugged printed board can prevent the copper paste from polluting the board surface, and at the same time prevent the board surface from being torn and deformed by glue, thereby improving production efficiency and product yield. The present application also proposes a method for manufacturing an FPC board.

Owner:KINWONG ELECTRONIC TECH (ZHUHAI) CO LTD

A method of manufacturing a printed board inlaid with a metal base

ActiveCN105430922BReduce moldingNo need to control depthPrinted circuit aspectsPrinted circuit manufacturePunchingEngineering

The invention relates to a manufacturing method for embedding a metal matrix into a printed board. The manufacturing method comprises the steps of (1) finishing circuit manufacturing on a line layer needing to be laminated; (2) obtaining an outline of the metal matrix needing to be embedded in a milling or punching manner; (3) forming a corresponding embedded groove in the printed board according to the outline and the size of the metal matrix in a milling or punching manner; (4) embedding the metal matrix into the embedded groove of the printed board; and (5) laminating the circuit layer and the printed board embedded with the metal matrix together by using prepreg. The manufacturing method reduces the lamination times and reduces the moulding of the prepreg without controlling the milling groove depth; and in addition, simple product manufacturing, higher efficiency and better quality are realized.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

A plastic woven bag folding and shaping machine and method

InactiveCN110497653BReduces accidental creasingImprove hemming effectBag making operationsPaper-makingPortal frameIndustrial engineering

Owner:台州市伟鸿家居用品有限公司

A system and method for automatic oil coating and press fitting and closed-loop press fitting compensation for rubber bushings

ActiveCN106002176BReduce the number of pressingSave the beatMetal working apparatusClosed loopPosition sensor

The invention discloses a rubber bushing automatic oil coating pressing and closed-loop pressing compensation system. The system comprises a shell, a position sensor for detecting a pressing depth and a position, a floating spring mechanism, a rubber bushing pressing head and a rubber bushing; the rubber bushing is positioned on the rubber bushing pressing head; the position sensor is connected with the floating spring mechanism; the rubber bushing pressing head and the rubber bushing are in control connection; and the shell is positioned at the tops of the rubber bushing pressing head and the rubber bushing. Through the mode, the rubber bushing automatic oil coating pressing and closed-loop pressing compensation system, provided by the invention, realizes an automatic procedural learning function, and can reduce the pressing times to save the equipment beat.

Owner:NEXTEER AUTOMOTIVE SYST SUZHOU

Assembling method of guiding device and oil seal of damper

ActiveCN113266663AImprove assembly efficiencyReduce the number of pressingSpringsShock absorbersPhysicsEngineering

The invention relates to the technology of assembly of dampers, in particular to an assembling method of a guiding device and an oil seal of a damper. The assembling method comprises the following steps: A, mounting an auxiliary mounting ring on the outer part of an annular boss; B, pre-locating the oil seal and the guiding device, that is, a part of a annular sealing body is sleeved on the outer part of the auxiliary mounting ring and an axial gap is reserved between the annular sealing body and the guiding device; C, pressing the oil seal and the guiding device into an outer tube together, continuously applying pressure to the oil seal after the guiding device is located until the axial gap is eliminated, and ensuring that the annular sealing body is interference fit with the inner wall of the outer tube. According to the assembling method disclosed by the invention, through arrangement of the rubber-made auxiliary mounting ring and pre-location of the auxiliary guiding device and the oil seal, the press-fit times of the guiding device and the oil seal in an assembling process can be reduced, and the assembling efficiency of the damper is improved.

Owner:青岛睿智森油封有限公司

Vacuum blank adsorption structure and feed mechanism including same

ActiveCN106926351ANot easy to shakeReduce the number of pressingShaping conveyorsGratingMechanical engineering

The invention provides a vacuum blank adsorption structure which is simple in structure, low in cost, stable in work and capable of effectively ensuring stripes and patterns of a ceramic tile blank. The vacuum blank adsorption structure comprises a vacuum adsorption die used for adsorbing the ceramic tile blank, a lifting drive cylinder used for driving the vacuum adsorption die to rise and fall and a vacuum generation device used for enabling the vacuum adsorption die to generate a vacuum gas source. The bottom end face of the vacuum adsorption die is provided with a plurality of longitudinally and transversely formed air suction and exhaust grooves in an intersected mode. The intersection of each pair of intersected air suction and exhaust grooves is provided with an air hole communicating with the vacuum generation device. Compared with the prior art, according to the scheme, by adoption of the structural form, the traditional mode that a ceramic tile blank is conveyed into a press through a fidelity grating is changed, and the vacuum blank adsorption structural form in the scheme is utilized, and by adsorbing the ceramic tile blank through vacuum, it can be ensured that the blank is not prone to shaking in the transferring process, and the whole conveying process is stable.

Owner:GUANGDONG TIANBI CERAMICS

Joining method, display apparatus and display

InactiveCN101285972BSmall sizeReduce manufacturing costStatic indicating devicesNon-linear opticsFlexible circuitsAnisotropic conductive adhesive

Owner:INNOLUX CORP

Rigid-flex circuit substrate, rigid-flex circuit board and manufacturing method

ActiveCN103635005BImprove reliabilityReduce manufacturing costPrinted circuit assemblingPrinted circuit detailsFlexible circuits

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com