Assembly method of oil seal guider assembly

An assembly method and a technology of a guide, which are applied to shock absorbers, shock absorbers, and engine seals, can solve problems such as ring seal damage, unrealizable assembly methods, and impact on shock absorber assembly efficiency, etc., to improve assembly Efficiency, the effect of reducing the number of press fittings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

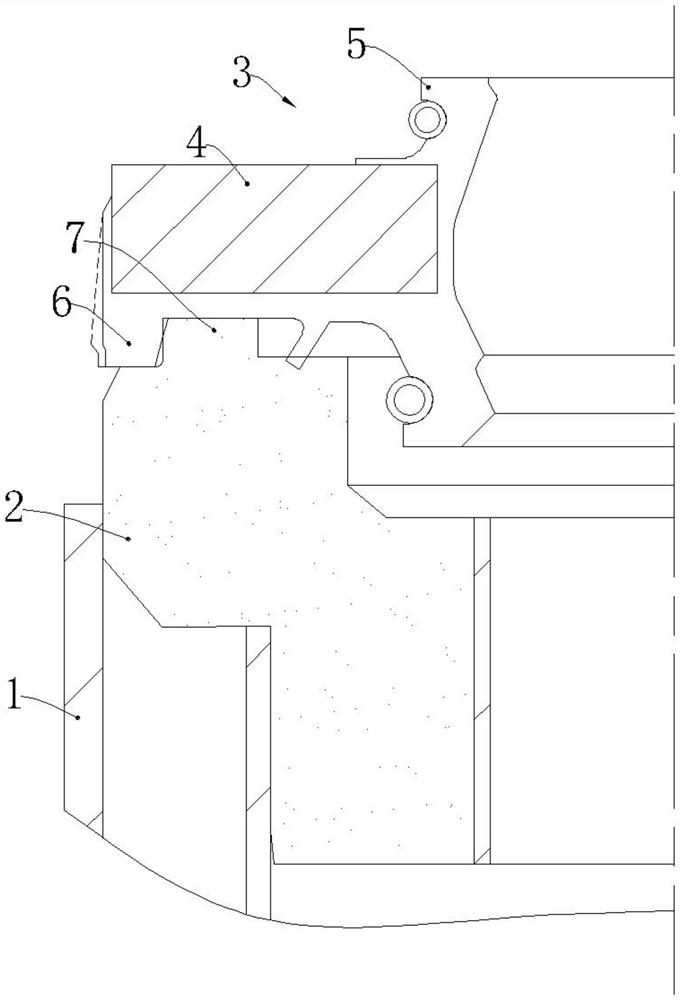

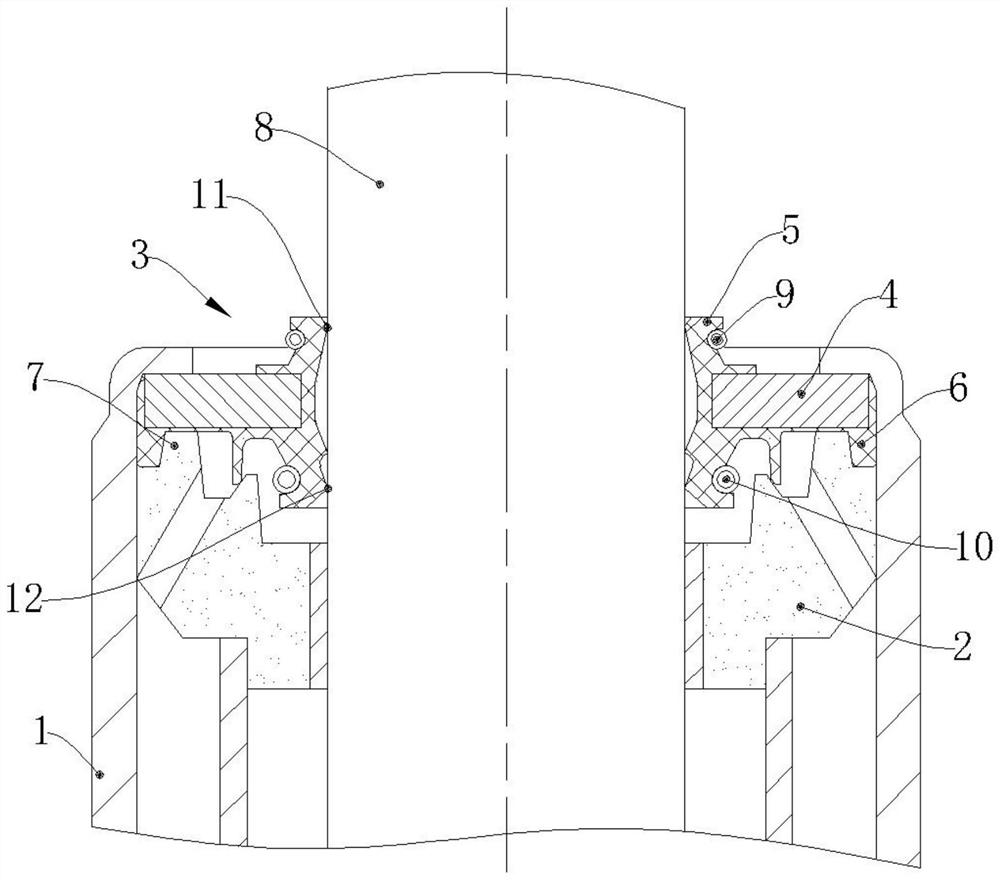

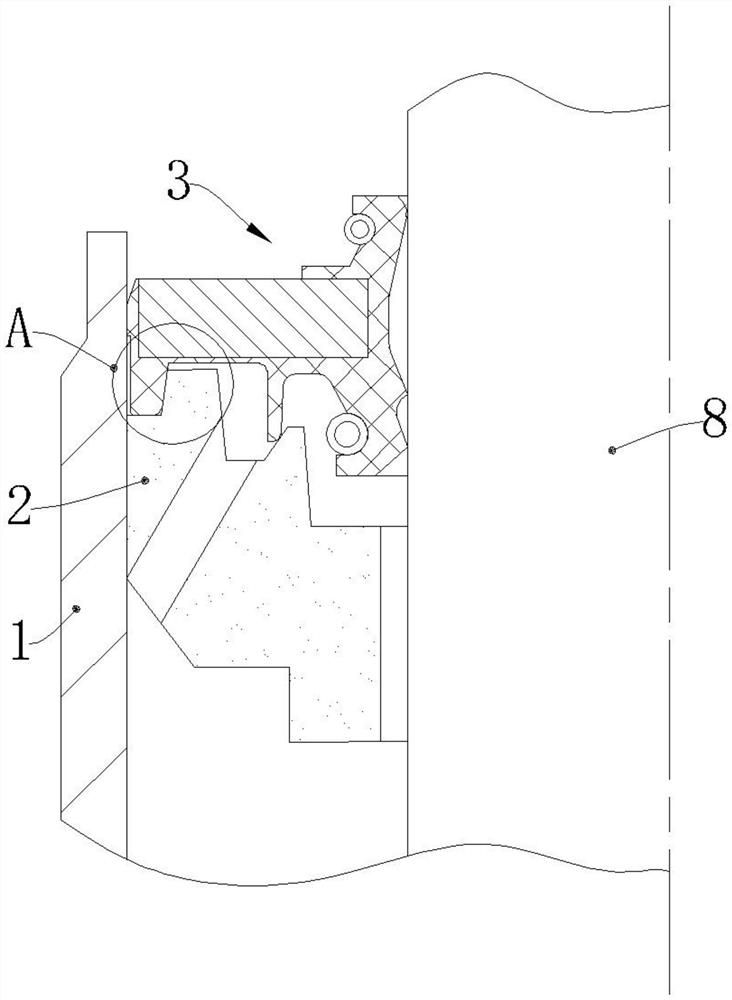

[0020] Figure 2-Figure 4 Embodiment 1 of the present invention is shown.

[0021] Such as figure 2 As shown, an oil seal guide assembly includes an outer cylinder 1, a guide 2, an oil seal 3, and a piston rod 8.

[0022] The oil seal 3 includes a vulcanized metal skeleton 4 and a rubber body 5, the lower end of the rubber body 5 is provided with an annular sealing body 6, the upper end of the guide 2 is provided with an annular boss 7, and the annular sealing body 6 is sleeved on the outside of the annular boss 7, and the guide 2 and the oil seal 3 are installed inside the outer cylinder 1.

[0023] When the annular sealing body 6 is not subjected to axial pressure, the annular sealing body 6 is in clearance fit with the outer cylinder 1 and the annular boss 7 respectively, and the height of the annular sealing body 6 is greater than that of the annular boss 7; When the annular sealing body 6 is compressed to the same height as the annular boss 7 , the annular sealing bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com