Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Reduce the number of bends" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

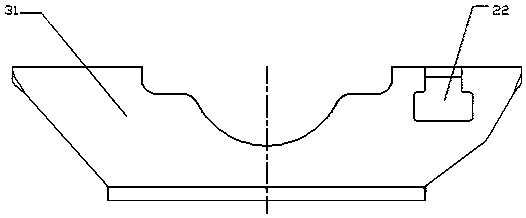

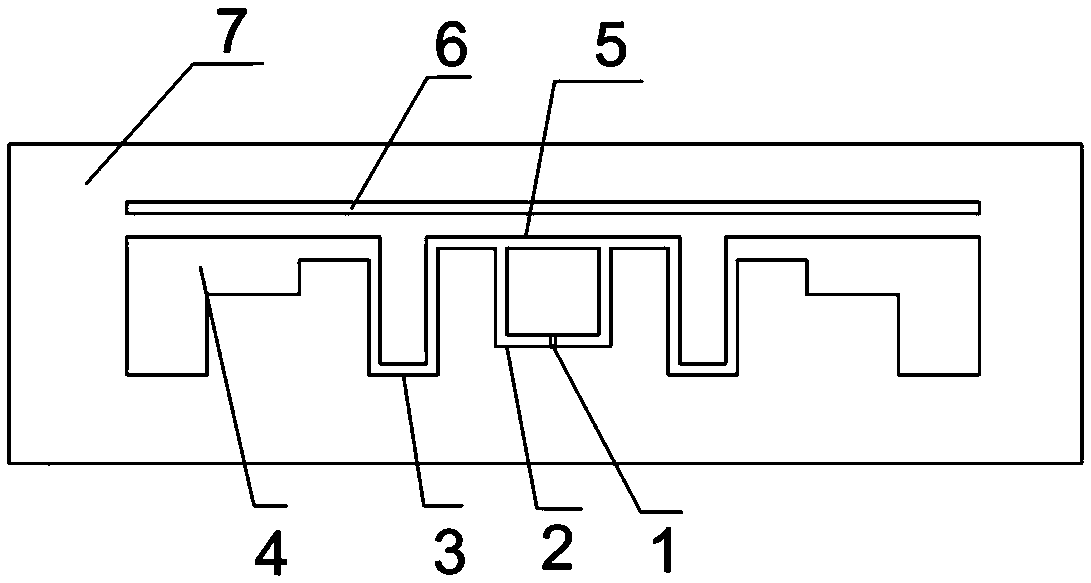

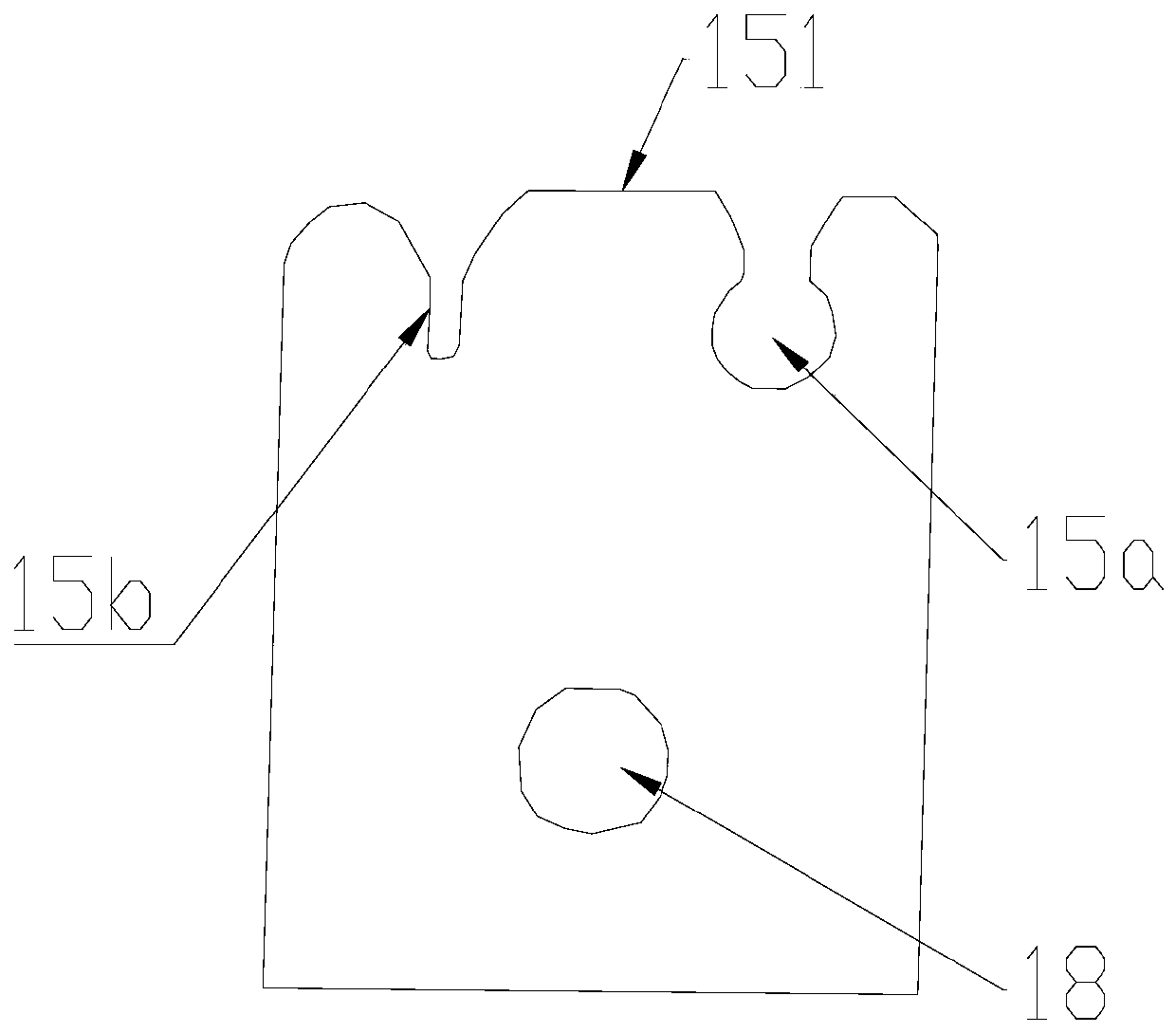

Anode ear for polymer or liquid flexible packing lithium ion electric core, and producing method thereof

ActiveCN101414673AReduce the number of bendsAvoid breakingCell component detailsPhysical chemistryMechanical engineering

The invention discloses an anode tab used in a polymer or liquid soft package lithium ion cell. The anode tab comprises an aluminum tab body on which a tab PP film is arranged. The anode tab is characterized in that a nickel coating is arranged on an end of the tab body; the nickel coating can be plated on the end of the tab body in a wrapped plating manner; the nickel coating can also be respectively plated on the front side of the tab body and the back side of the tab body; and the depth of the nickel coating at one side of the tab body can be 0.5-3.0 microns. The invention also discloses a production method of the tab used in the polymer lithium ion cell. The anode tab can be directly soldered with a protective circuit, which reduces the bending frequency of the tab, causes the tab not to be broken off easily, does not result in the problem of sealingoff (i.e., soldered joints fall off), effectively improves the product quality, prolongs the service life of the product and reduces a working procedure of changing the aluminum tabs into the nickel tabs for manufacturers of cells, and shortens the production period.

Owner:连云港海创电子科技有限公司

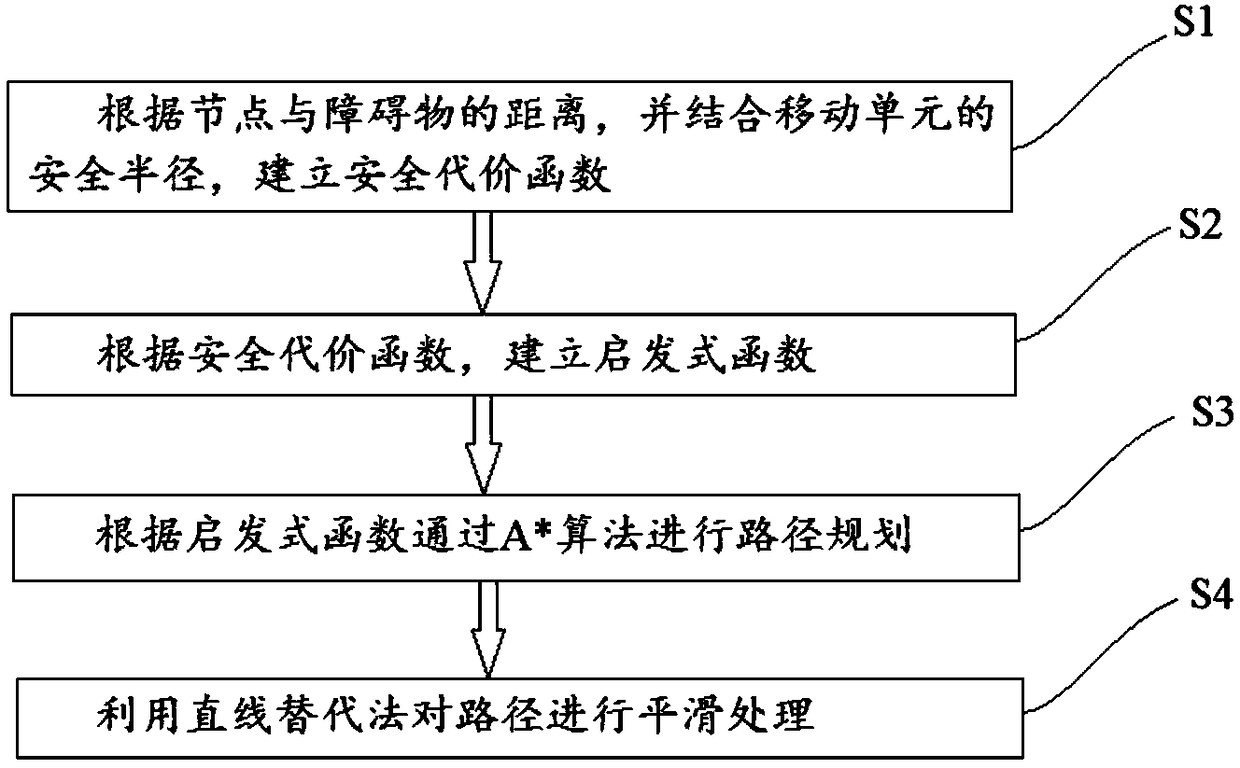

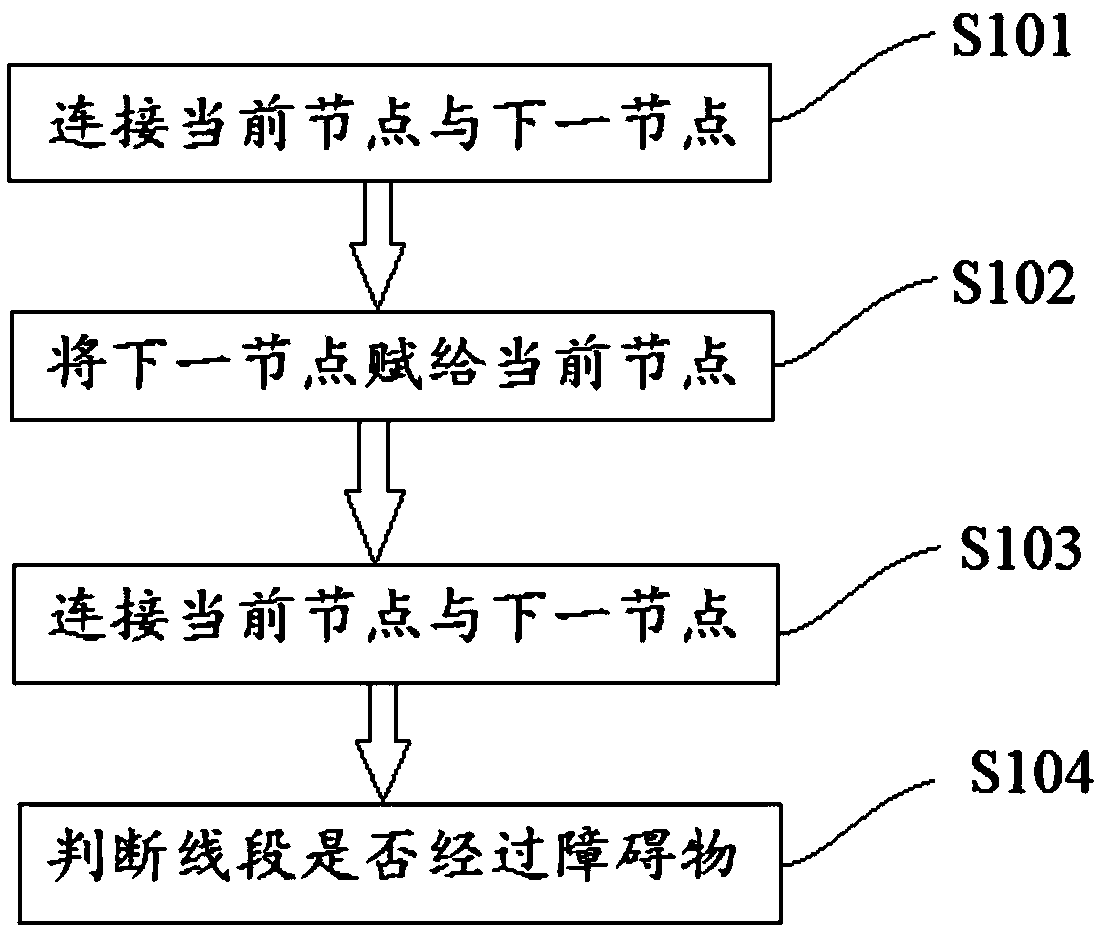

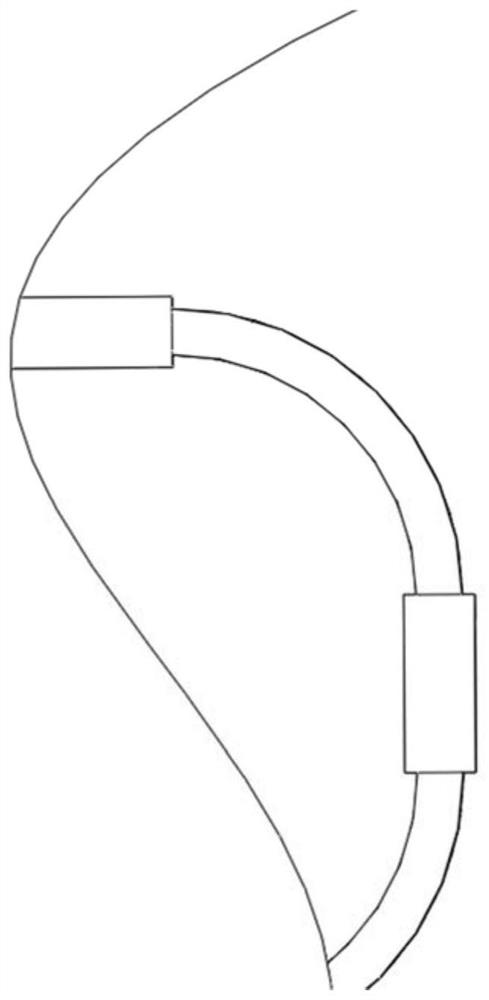

A*algorithm-based path planning method

PendingCN109443364AReduce the number of bendsEnsure safetyNavigational calculation instrumentsHeuristic functionPath plan

The invention relates to the field of intelligent robots, in particular to an A*algorithm-based path planning method. The method comprises the following steps of: S1, establishing a safety cost function according to a distance between a node and an obstacle and a safety radius of a mobile unit; S2, establishing a heuristic function according to the safety cost function; and S3, carrying out path planning through an A* algorithm according to the heuristic function. By using the method, the following effects can be achieved: through improving the heuristic function of the A* algorithm, safety cost estimation is added, so that the planned path is far away from the obstacle, and the safety of a robot during driving is ensured; and a linear replacement method is utilized to smoothen the path, so that the path is continuous and smooth, and the bend number of the path is decreased.

Owner:STATE GRID ZHEJIANG NINGBO YINZHOU POWER SUPPLY LTD CO +1

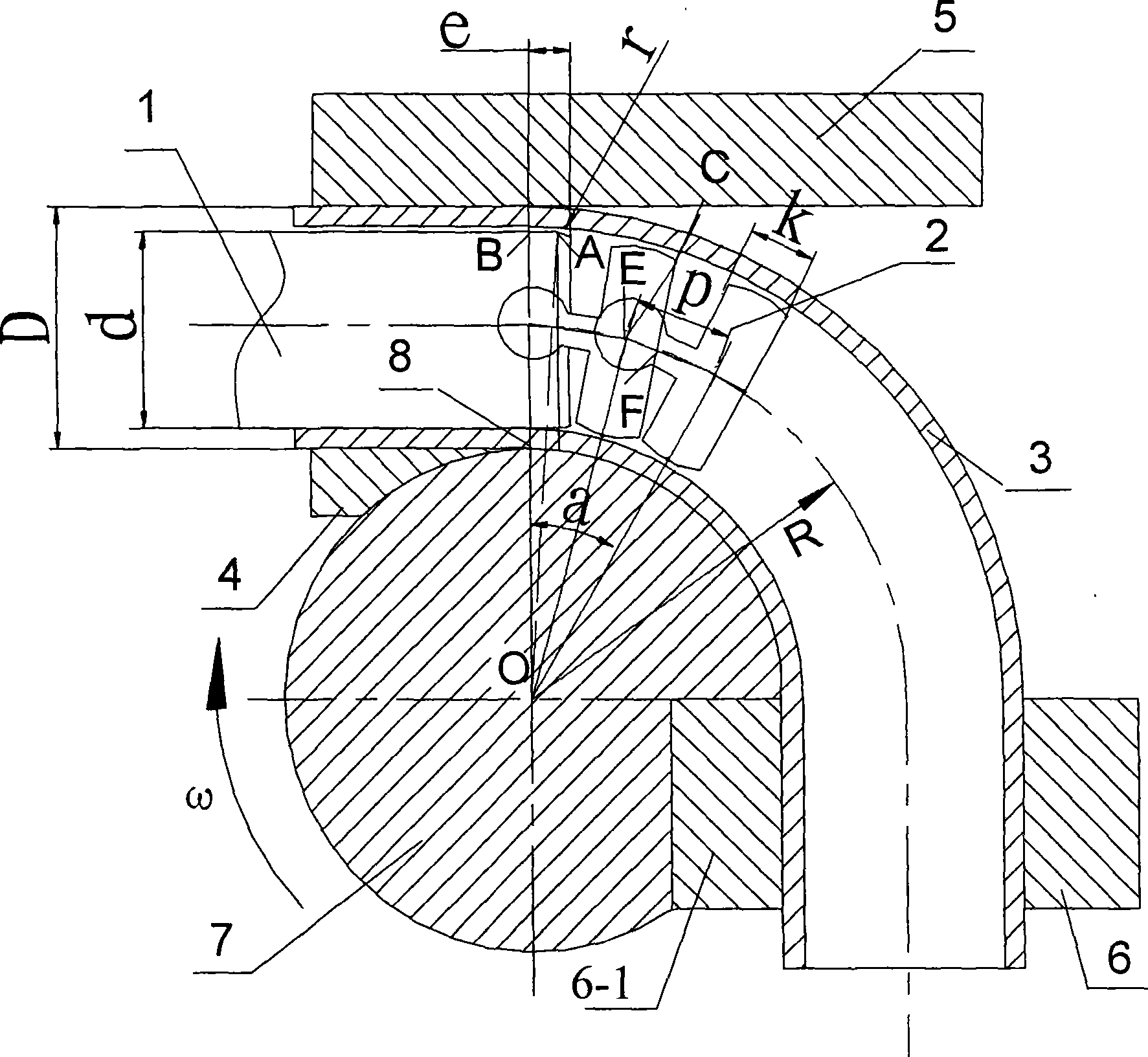

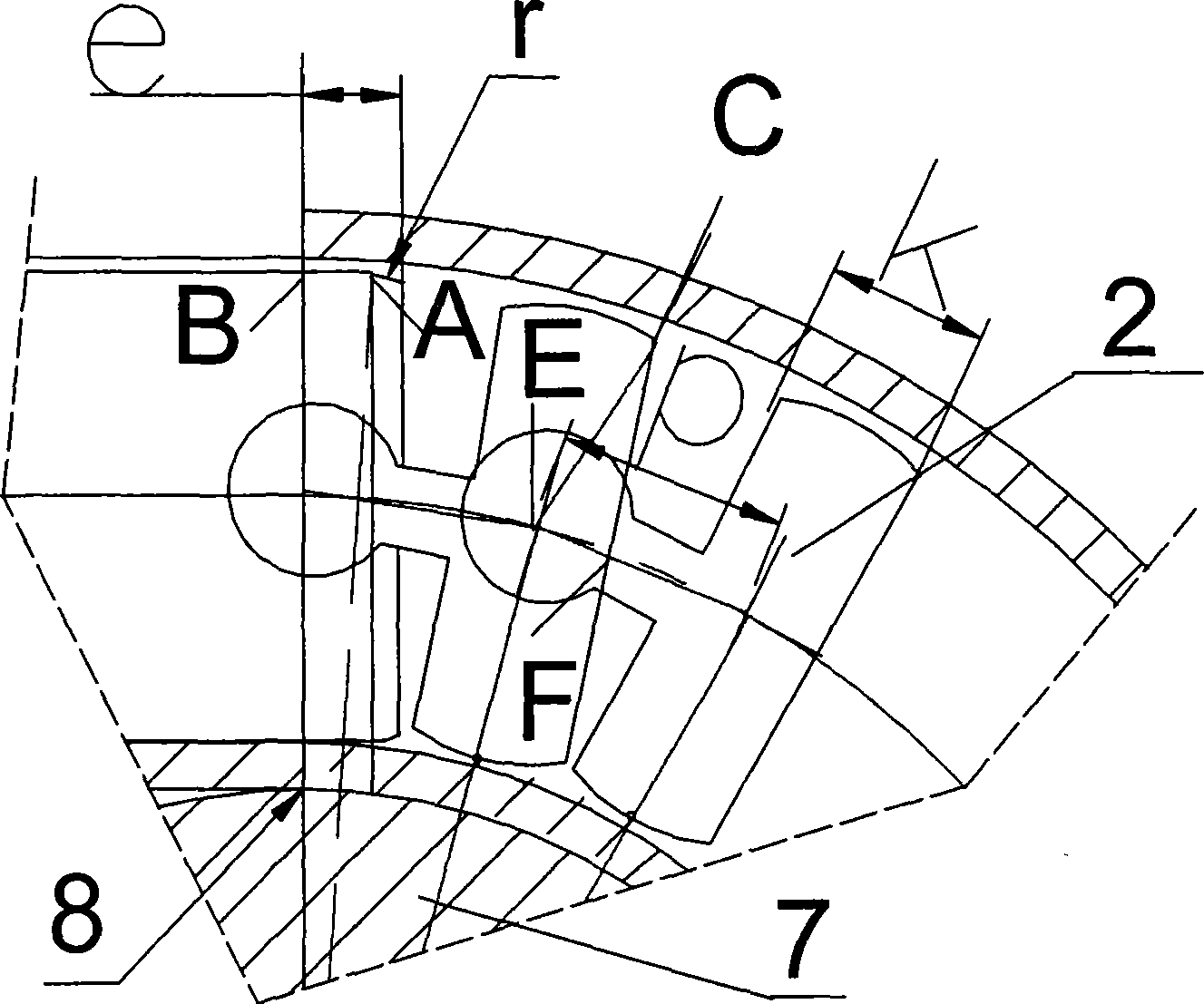

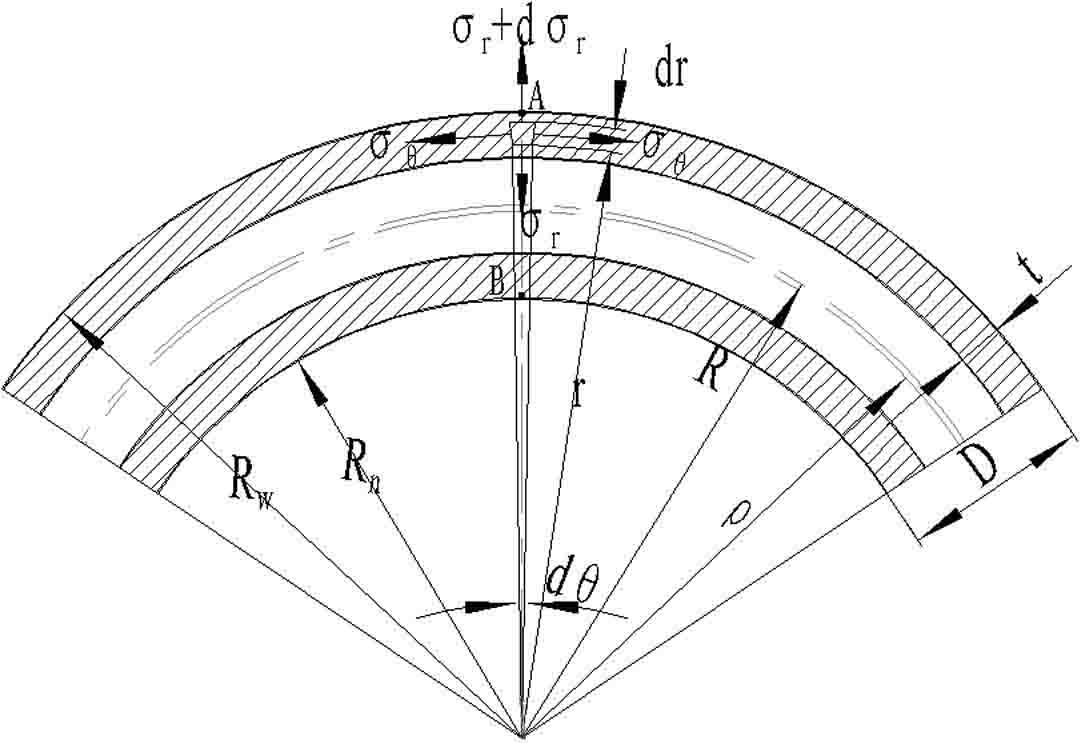

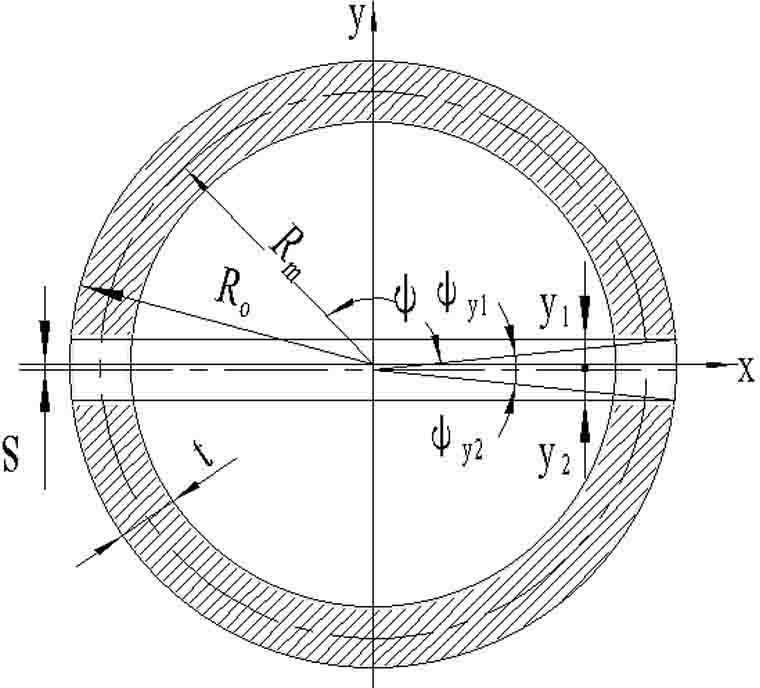

Method for designing thin walled pipe numerical control snake core mould parameter

InactiveCN101425097AReduce the number of bendsCore mold parameter optimizationShaping toolsSpecial data processing applicationsThin walledEngineering

The invention discloses a design method for a core die parameter in the thin-wall pipe digital control bending and forming process, which is characterized in that: firstly, modeling simplification is carried out on a core die complex connection structure through characteristic equivalence to obtain key parameters of a ball socket type structure core die (comprising a core rod and a flexible core head) which comprise a geometric structure of the core die and a function position in a bending pipe, and then, a reference formula of the corresponding core die parameter is deduced according to the plastic deformation character of the thin-wall bending pipe starting from geometric matching of the core die and a pipe. The design method for a bending pipe core die is simple and effective and can be used for fast selecting the core die parameter in the thin-wall bending pipe process under different bending conditions to compensate for the defects of an empirical formula in the actual production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Bending mechanism

Owner:CWB AUTOMOTIVE ELECTRONICS

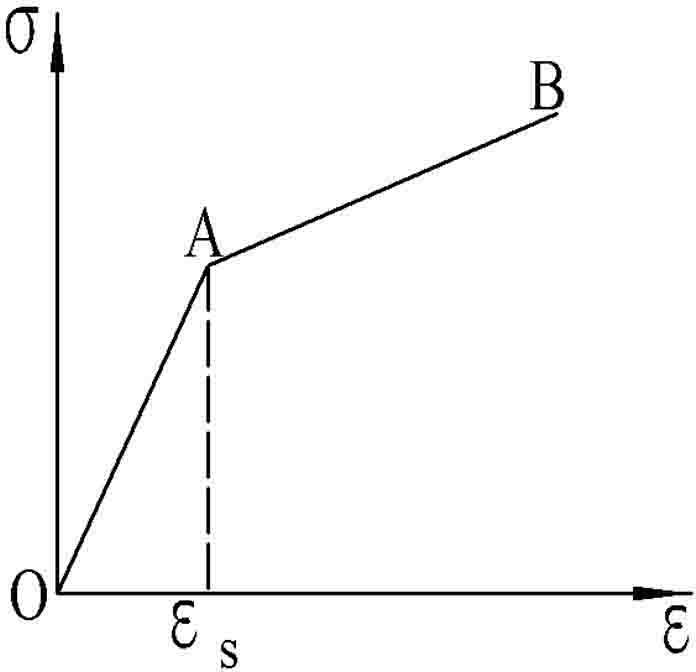

Bending pipe numerically-controlled instruction-generating method considering springback compensation

InactiveCN102527789AImprove forming qualityIncrease profitProgramme controlComputer controlPipe fittingEngineering

The invention relates to a bending pipe numerically-controlled instruction-generating method considering springback compensation, which comprises the following steps of: 1. calculation of the springback amount of a bending pipe; and 2. generation of a numerically-controlled instruction. The method can be used for guiding the springback compensation in practical bending pipe forming, and the effects of decreasing the frequency of trial bending and improving the forming quality of pipe fittings are achieved.

Owner:SHENYANG AIRCRAFT CORP

Flexible display screen and manufacturing method thereof

InactiveCN108205973APrevent looseningReduce bend radiusIdentification meansFlexible circuitsEngineering

The invention relates to the technical field of flexible display, and particularly relates to a flexible display screen and a manufacturing method thereof. The manufacturing method uses a bending fixture to fix an outer lead weld zone and a flexible circuit board of the flexible display screen, and then bends the bending fixture, so that the outer lead weld zone is bent as the bending fixture is bent; in addition, plastic supporting film having a certain stiffness is bonded between the flexible circuit board and the back surface of the flexible display screen, and the bent flexible circuit board is bonded to the back surface of the display screen through the supporting film; on the one hand, the supporting film can fix the flexible circuit board to avoid looseness of the flexible circuit board bound in a binding area in the bending and reduce the number of times of unnecessary bending of metal wires on the outer lead weld zone; on the other hand, the bending radius of the outer lead weld zone is adjusted through adjustment of the gap generated by the thickness of the supporting film, so that a metal wire film layer on the outer lead weld zone can be effectively prevented from beingbroken.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

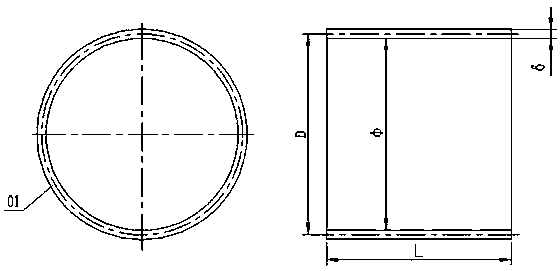

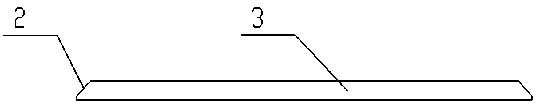

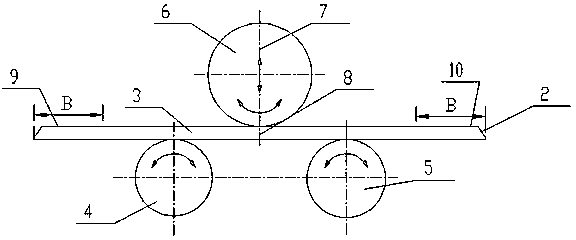

Multi-curvature forming method for stainless steel cylinder

The invention discloses a multi-curvature forming method for a stainless steel cylinder. The method is characterized by comprising the following steps: performing scribing and blanking according to the developed length of the medium diameter of a cylinder to be wound; machining peripheral welding grooves of a plate; rolling-forming a first-curvature circular arc, namely reserving a straight section, not to be wound for the formation of a circular arc, with a width B of 200 to 600 mm at each of the two ends of the cylindrical plate, and bending and winding the middle part of the cylindrical plate into a large circular arc with a curvature radius R of more than or equal to 0.5 Phi to form the first-curvature circular arc of the cylinder; rolling-forming second-curvature circular arcs, namely rolling the parts between the roots of the straight sections with the widths B of 200 to 600 mm and the large circular arc into circular arcs with curvature radiuses r of 0.2 to 0.5 Phi to form second-curvature circular arcs; rolling transition parts between the second-curvature circular arcs and the first-curvature circular arc into smooth transition; performing rolling until the grooves 2 in the two ends of the straight sections get close to each other; performing longitudinal seam assembly and welding on the cylinder, placing the cylindrical body at a horizontal position, and welding longitudinal seams; performing roundness correction on the cylinder after welding.

Owner:SHANGHAI TONGHUA STAINLESS STEEL PRESSURE VESSEL ENG

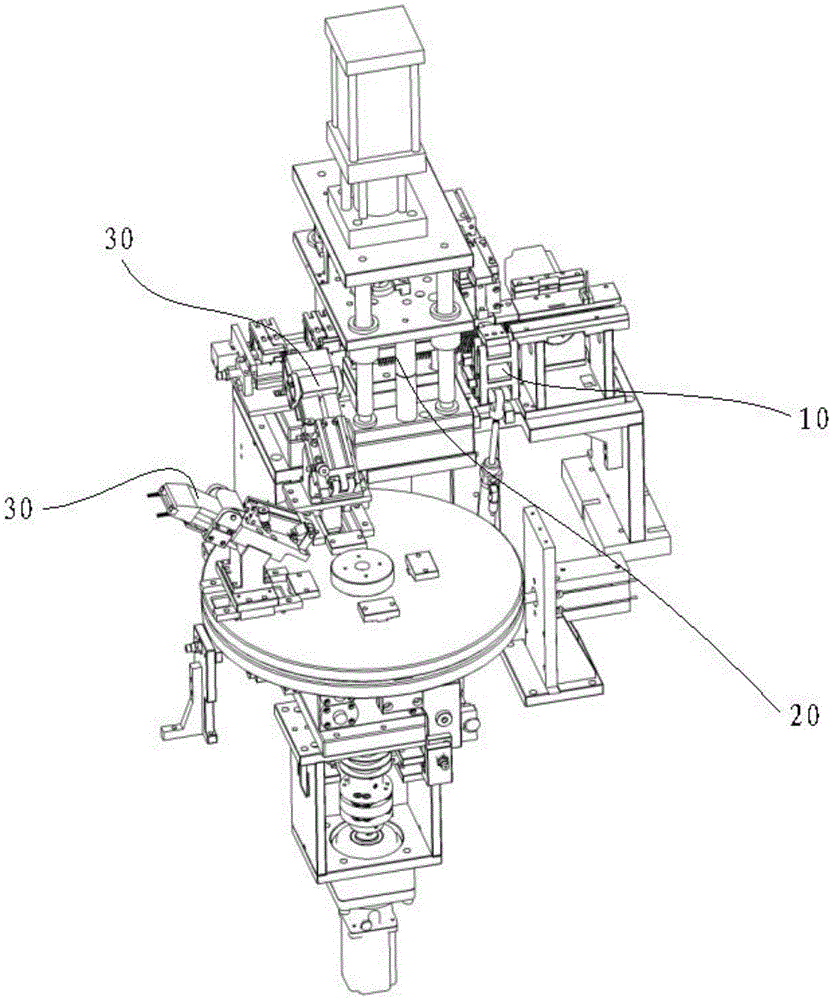

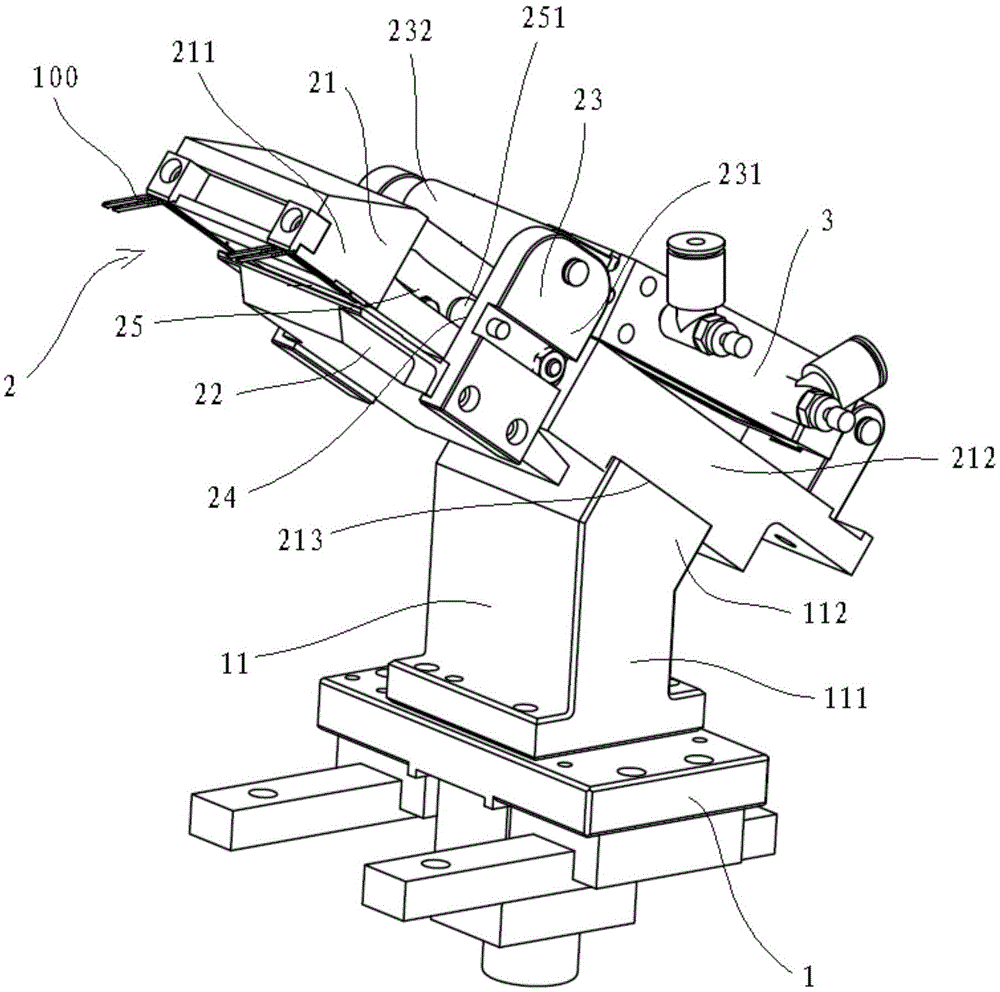

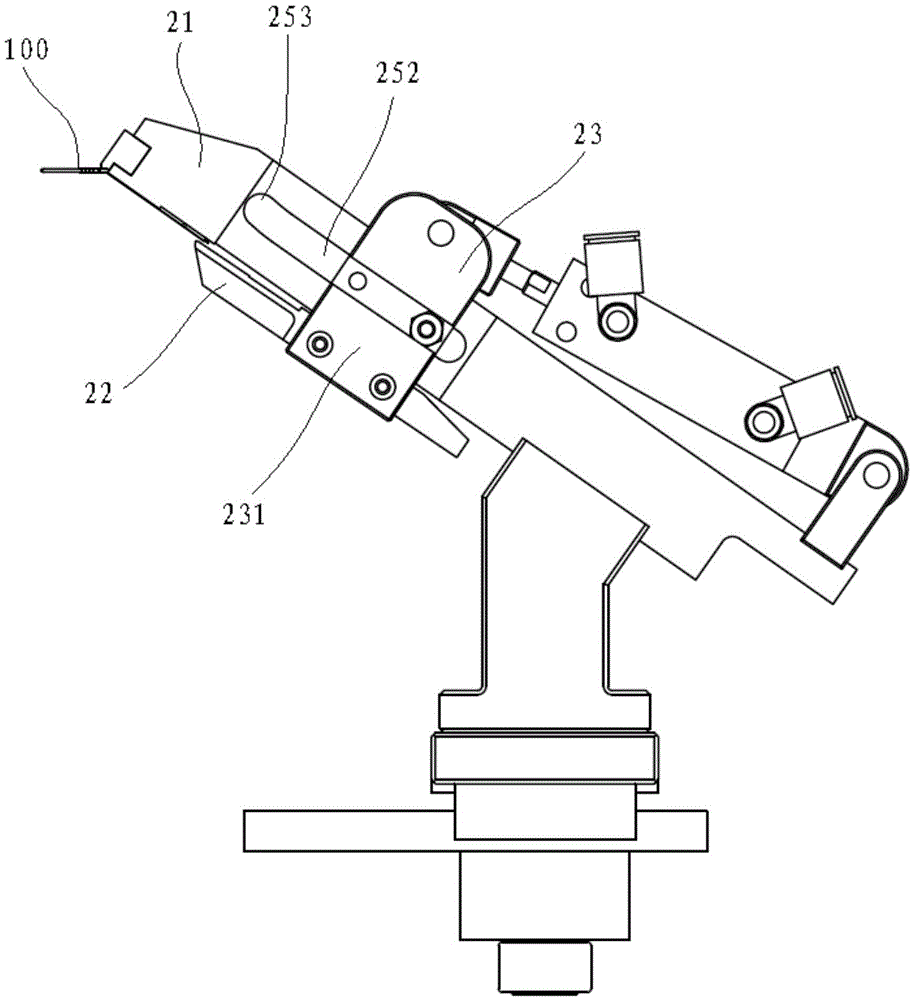

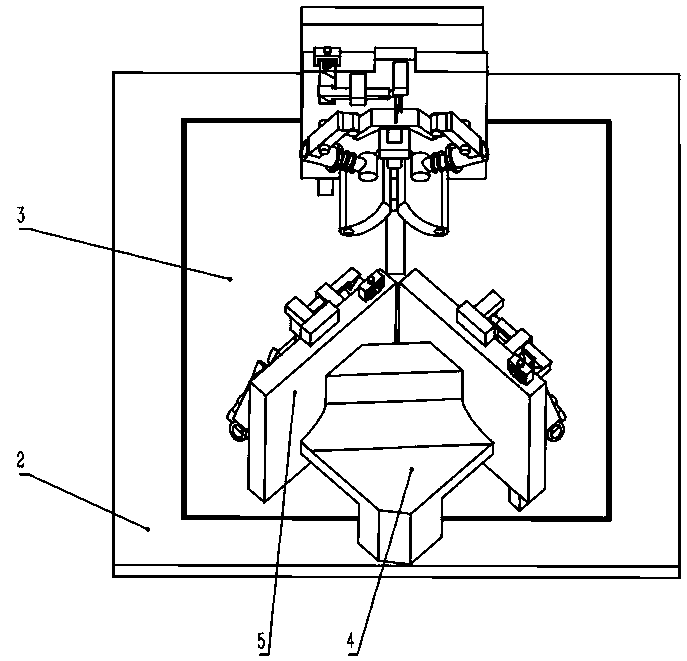

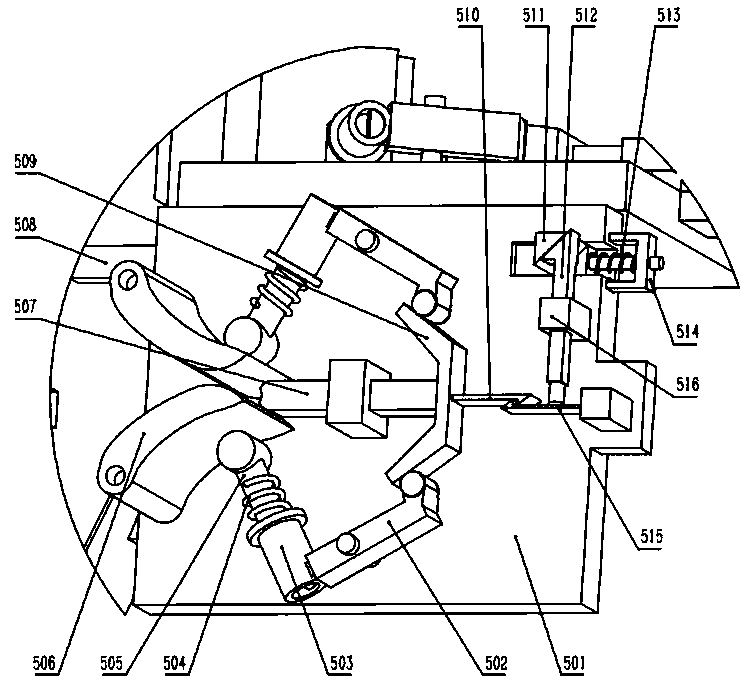

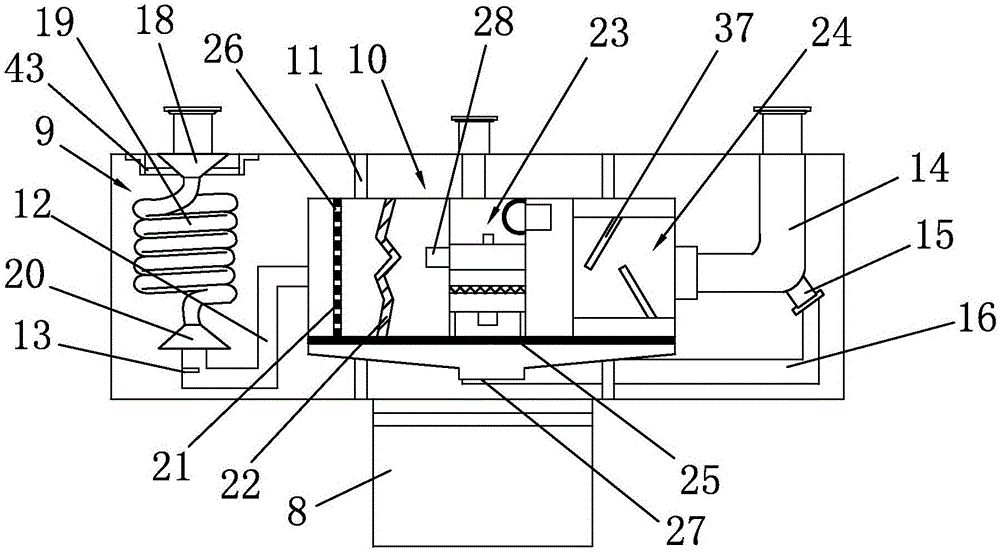

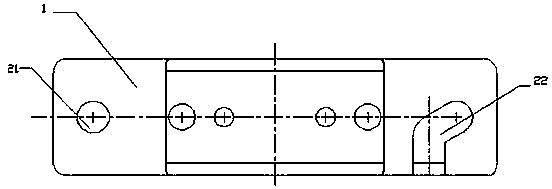

PIN bent plugging and taking device

ActiveCN105576477AReduce production processIncrease productivityContact member manufacturingContact member assembly/disassemblyBiomedical engineering

The invention provides a PIN bent plugging and taking device comprising a bending mechanism which bends a PIN, a cutting mechanism which cuts a PIN material strap into single bent PINs, and a clamping jaw mechanism which clamps the bent PIN from the cutting mechanism and plugs the PIN in a PIN bearer. The clamping jaw mechanism comprises a base which is provided with a supporting structure, a clamping jaw structure and a clamping jaw driving device. The clamping jaw structure comprises a fixed clamping jaw which is obliquely installed on the supporting structure, a flexible clamping jaw and a connecting structure. The clamping surface of the flexible clamping jaw is arranged to be opposite to the clamping surface of the fixed clamping jaw, and the distance between the clamping surface of the flexible clamping jaw and the clamping surface of the fixed clamping jaw is reduced when the clamping surface of the flexible clamping jaw slides towards a first direction along the clamping surface of the fixed clamping jaw; and the distance between the clamping surface of the flexible clamping jaw and the clamping surface of the fixed clamping jaw is increased when the clamping surface of the flexible clamping jaw slides towards a second direction opposite to the first direction along the clamping surface of the fixed clamping jaw. Production process is reduced, production efficiency is enhanced and cost is reduced by the PIN bent plugging and taking device.

Owner:CWB AUTOMOTIVE ELECTRONICS

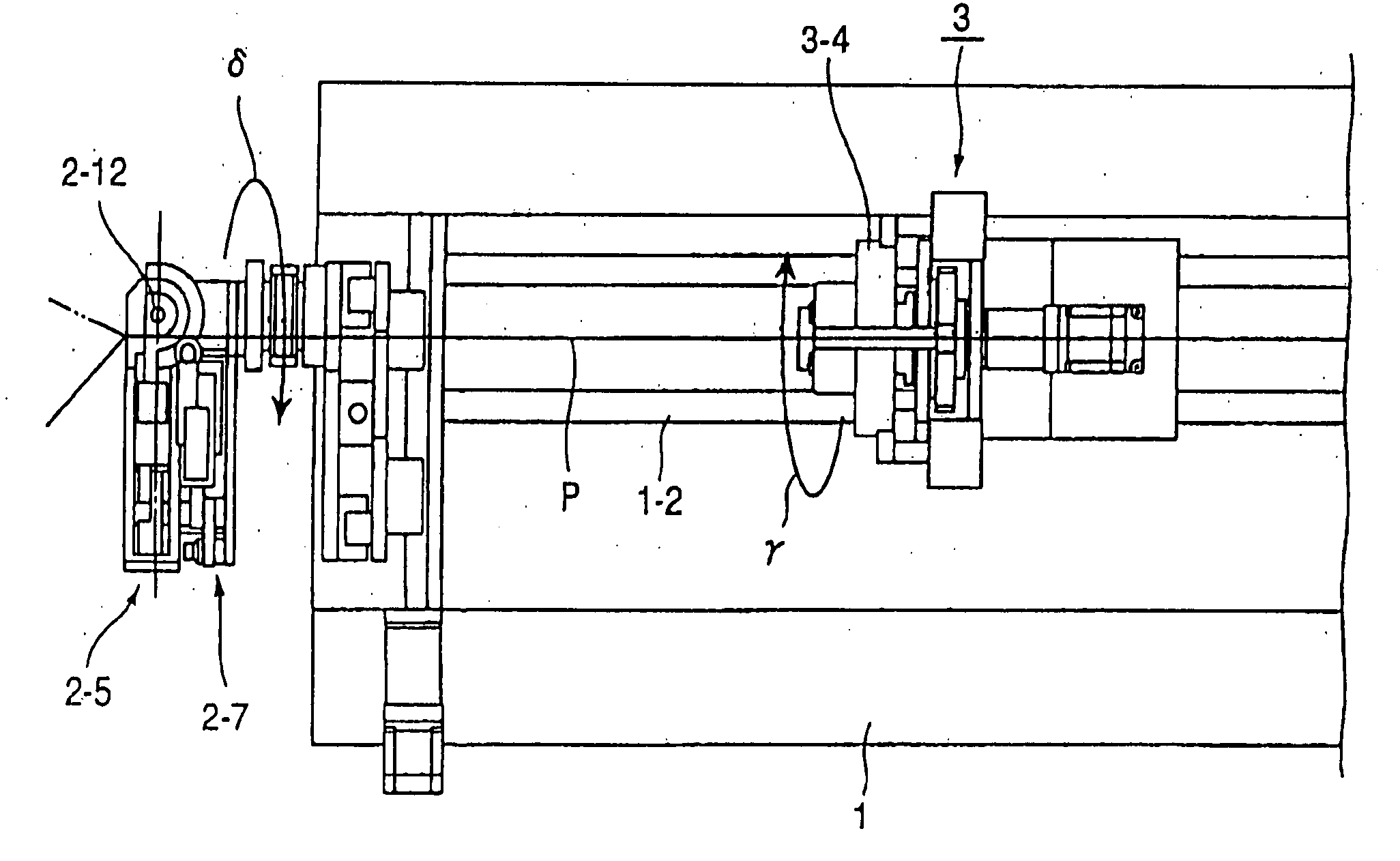

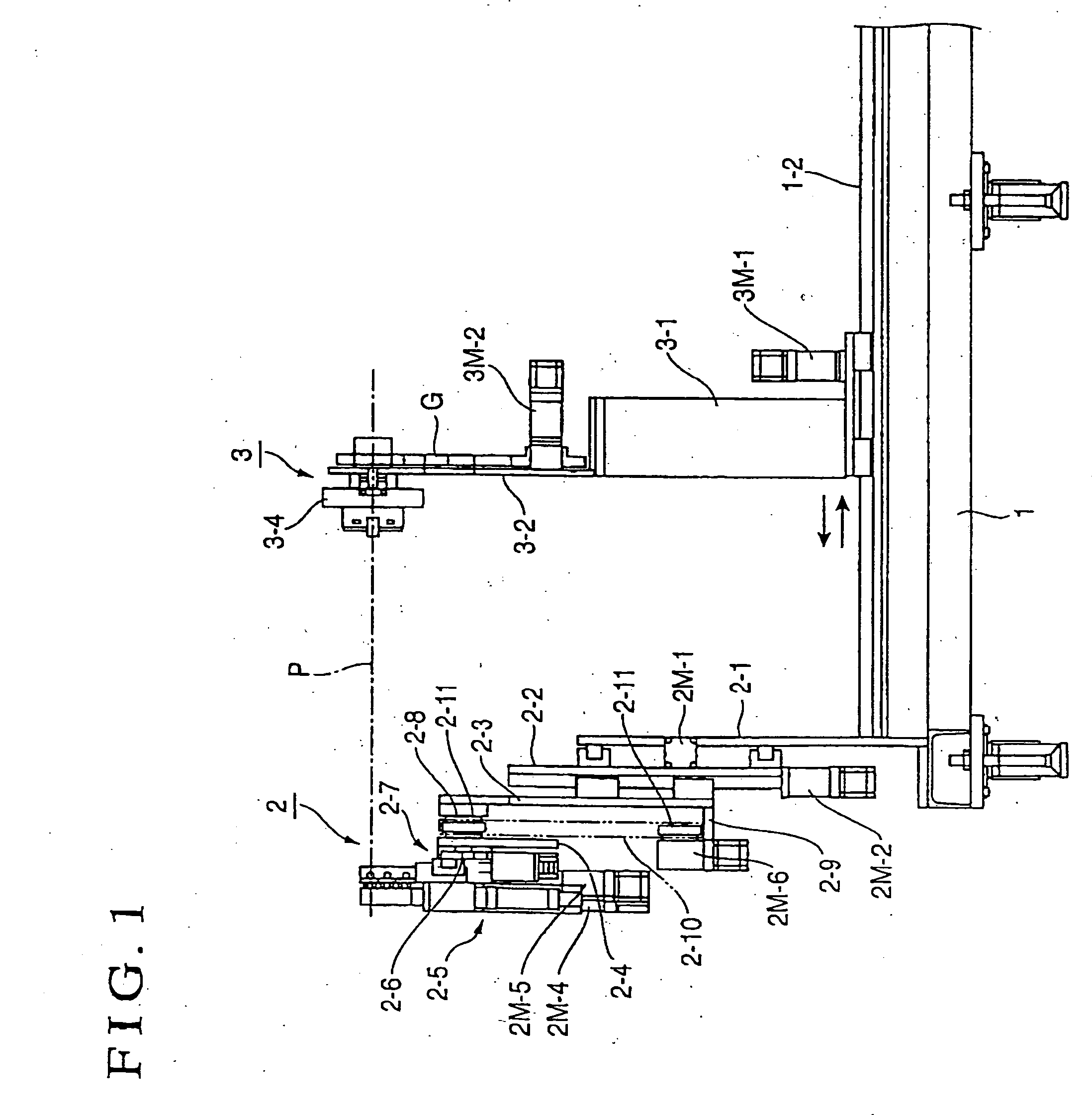

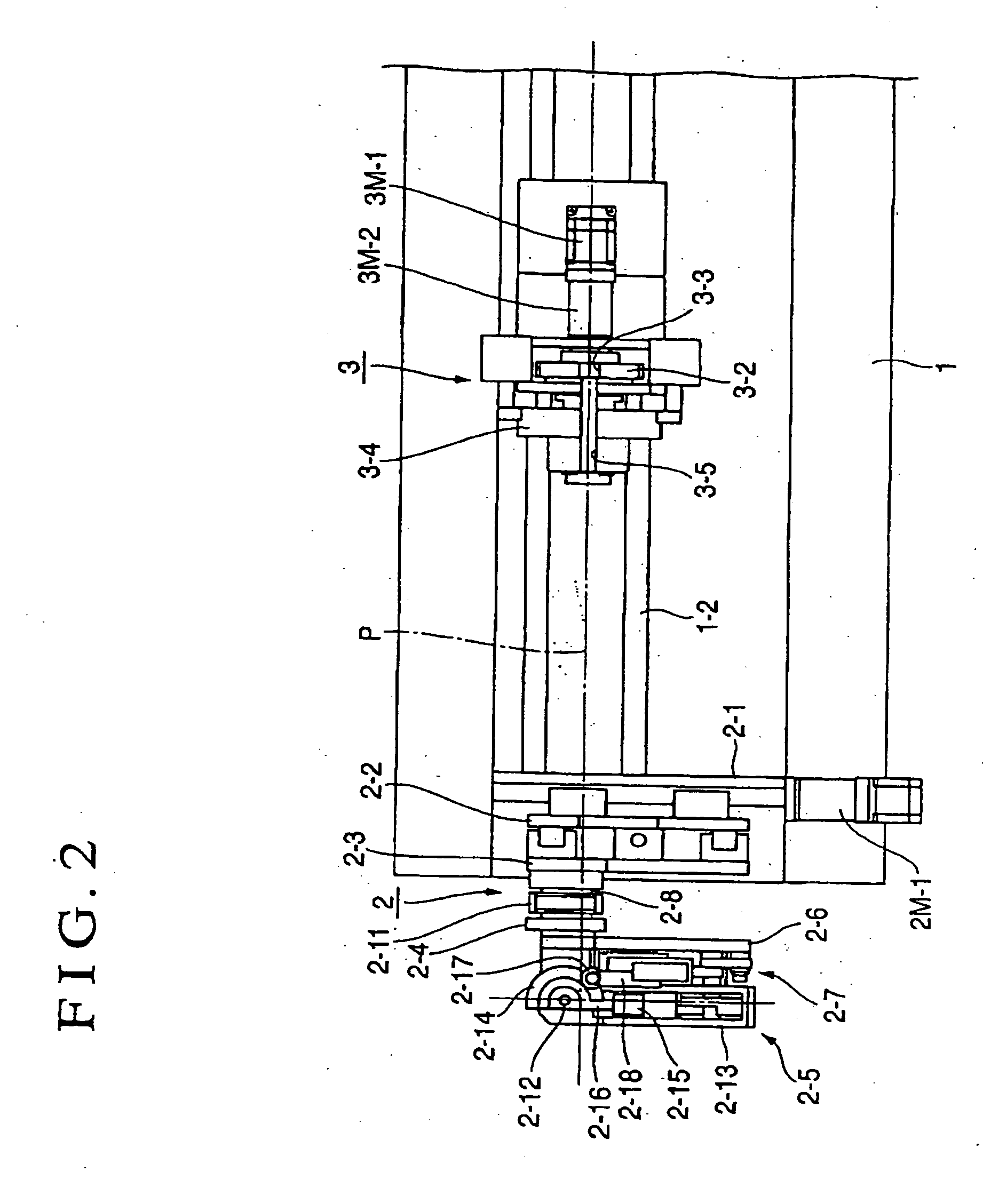

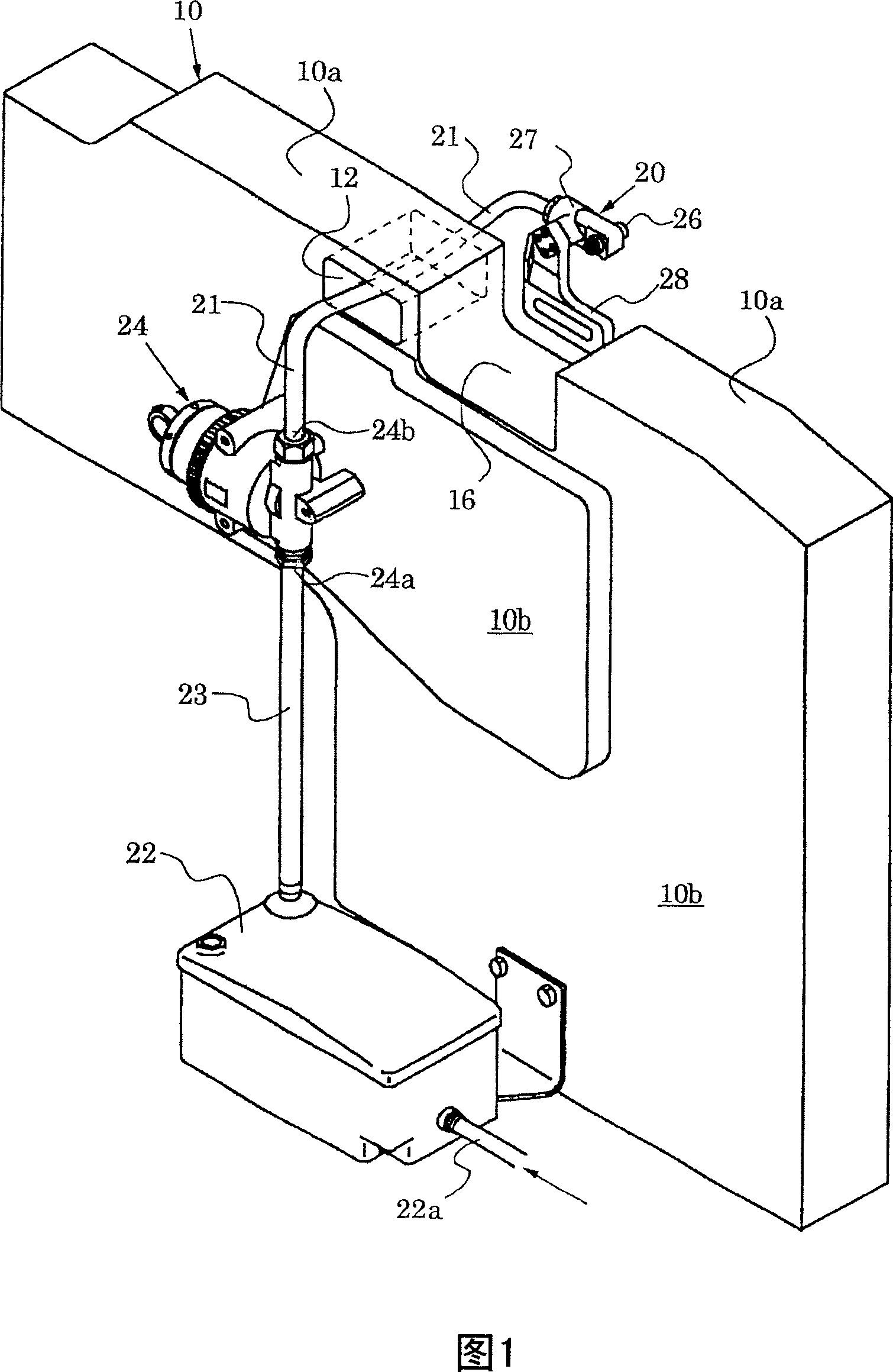

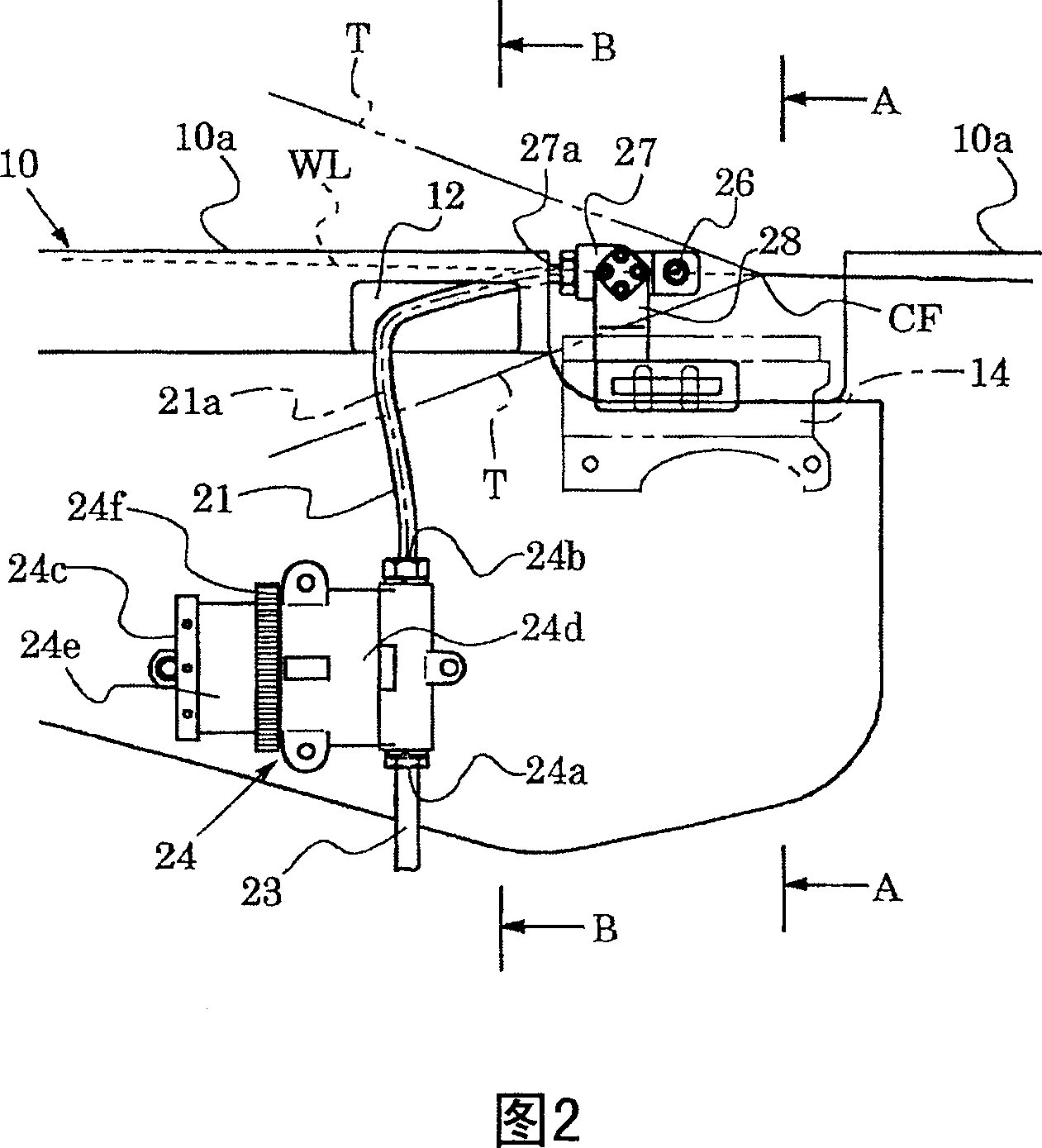

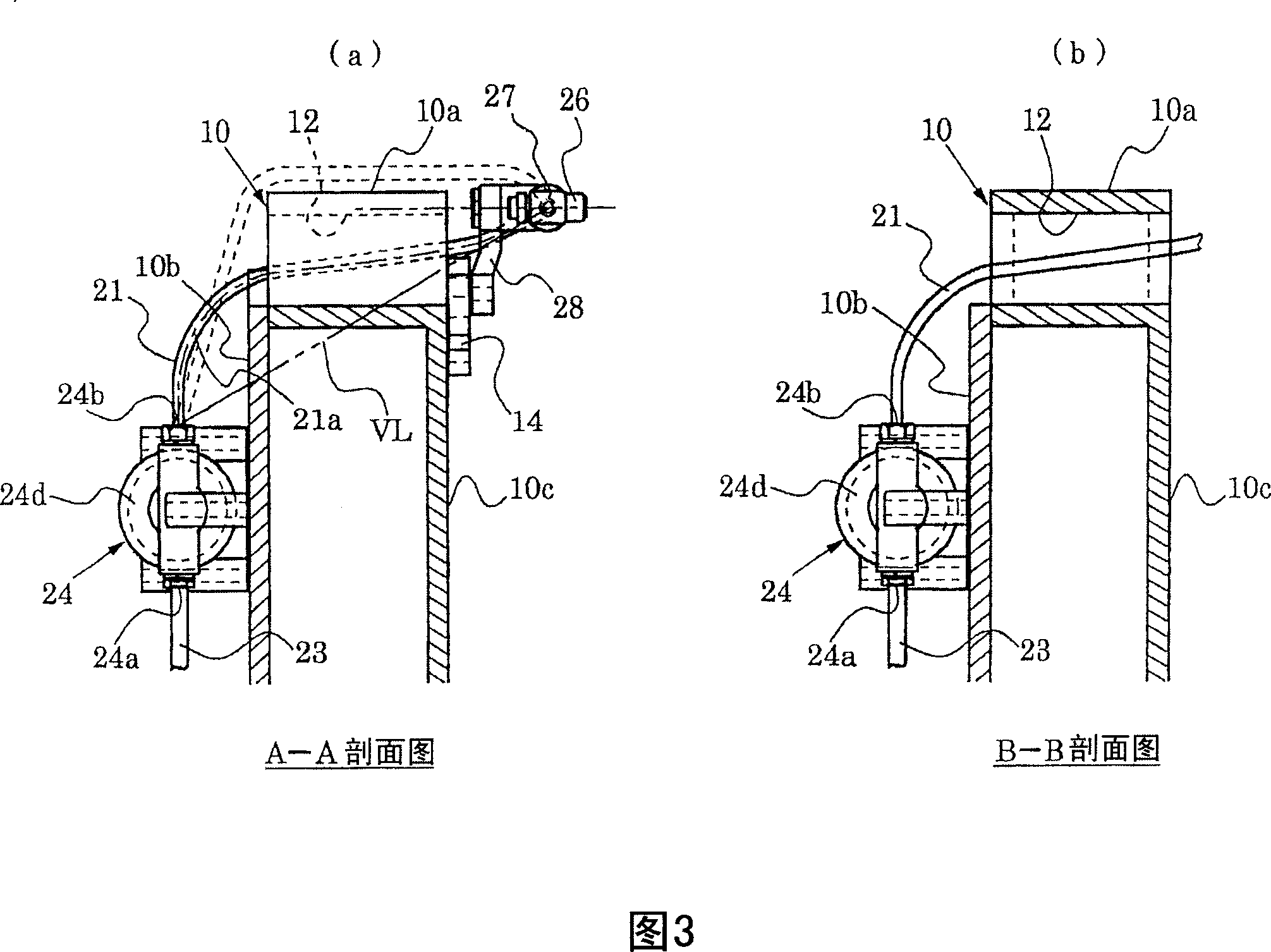

Bending device for tube

A tube bending device having draw-bending and compression-bending functions and capable of bending in all processes in a unit of device is provided. The device performing bending by rotating the tube at a predetermined angle with the tube pressured against a circumferential surface of a bending die, the device including a movable type of tube bending unit movable in a longitudinal direction of a tube to be processed or a fixed type of tube bending unit and a tube twisting unit for rotating the tube freely at a predetermined angle with a center of the tube being an axis core is characterized in that the tube bending unit has one or both of draw-bending and compression-bending functions and is provided rotatably in a vertical plane about an axis parallel to the axis core of the tube so that the displacement amount in a tube twisting operation can be reduced.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

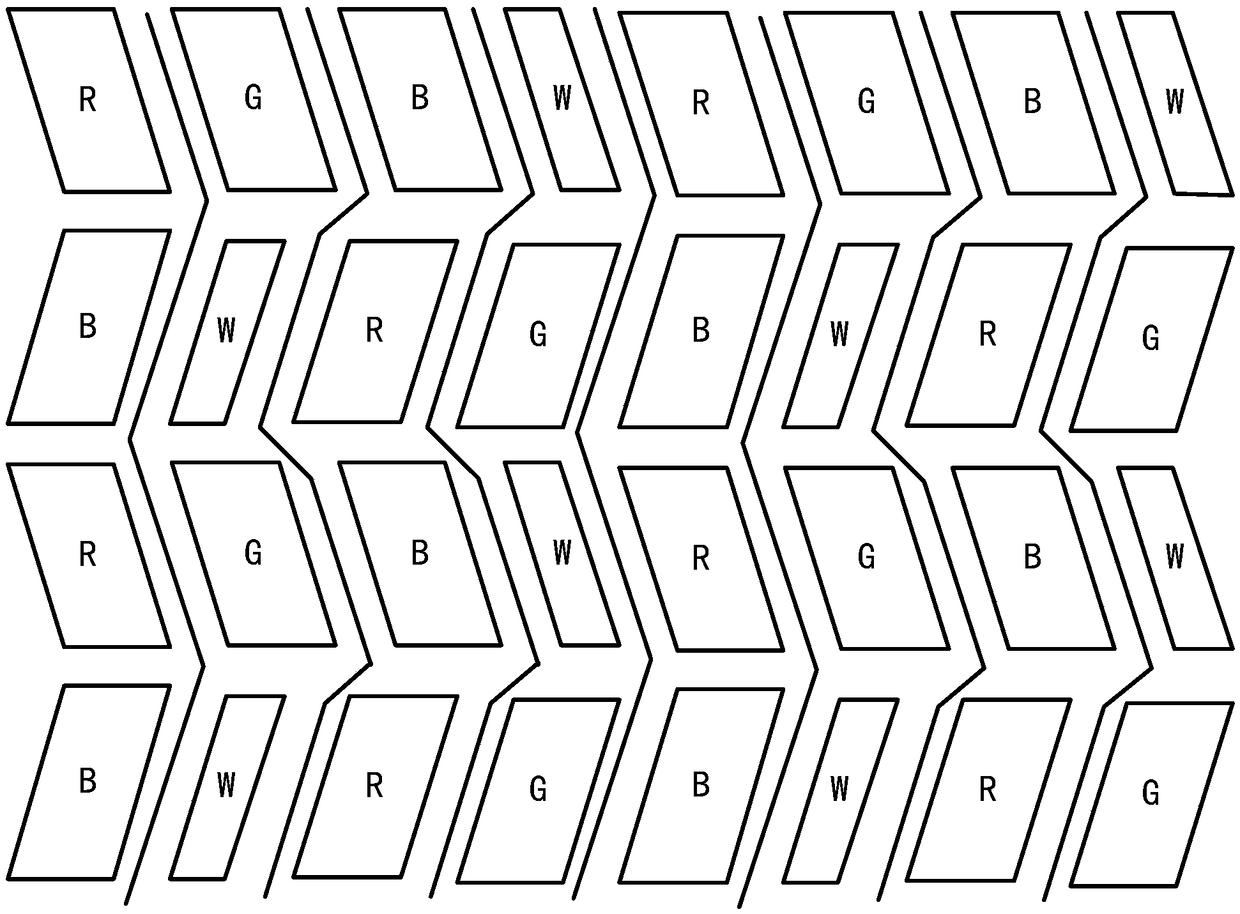

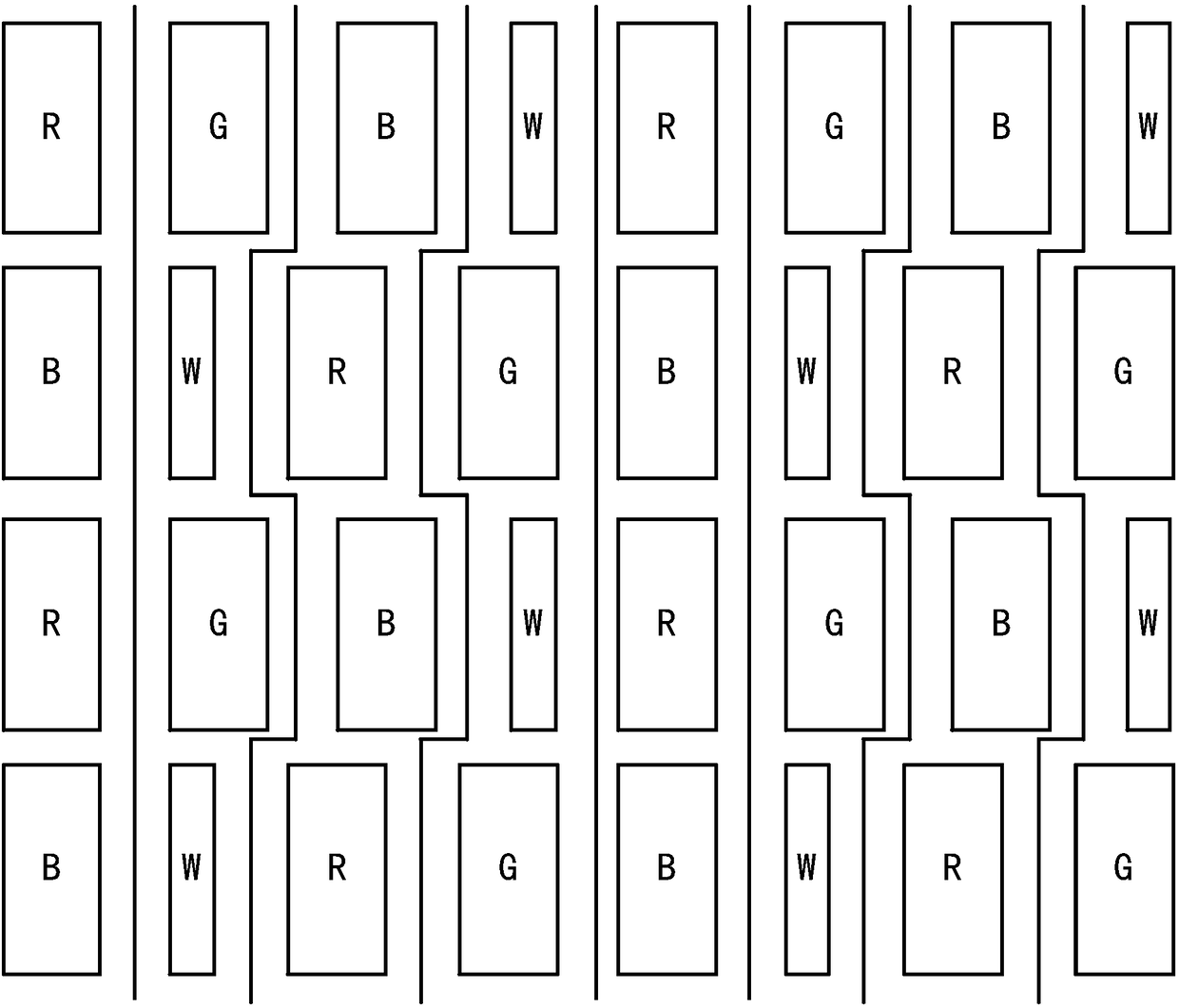

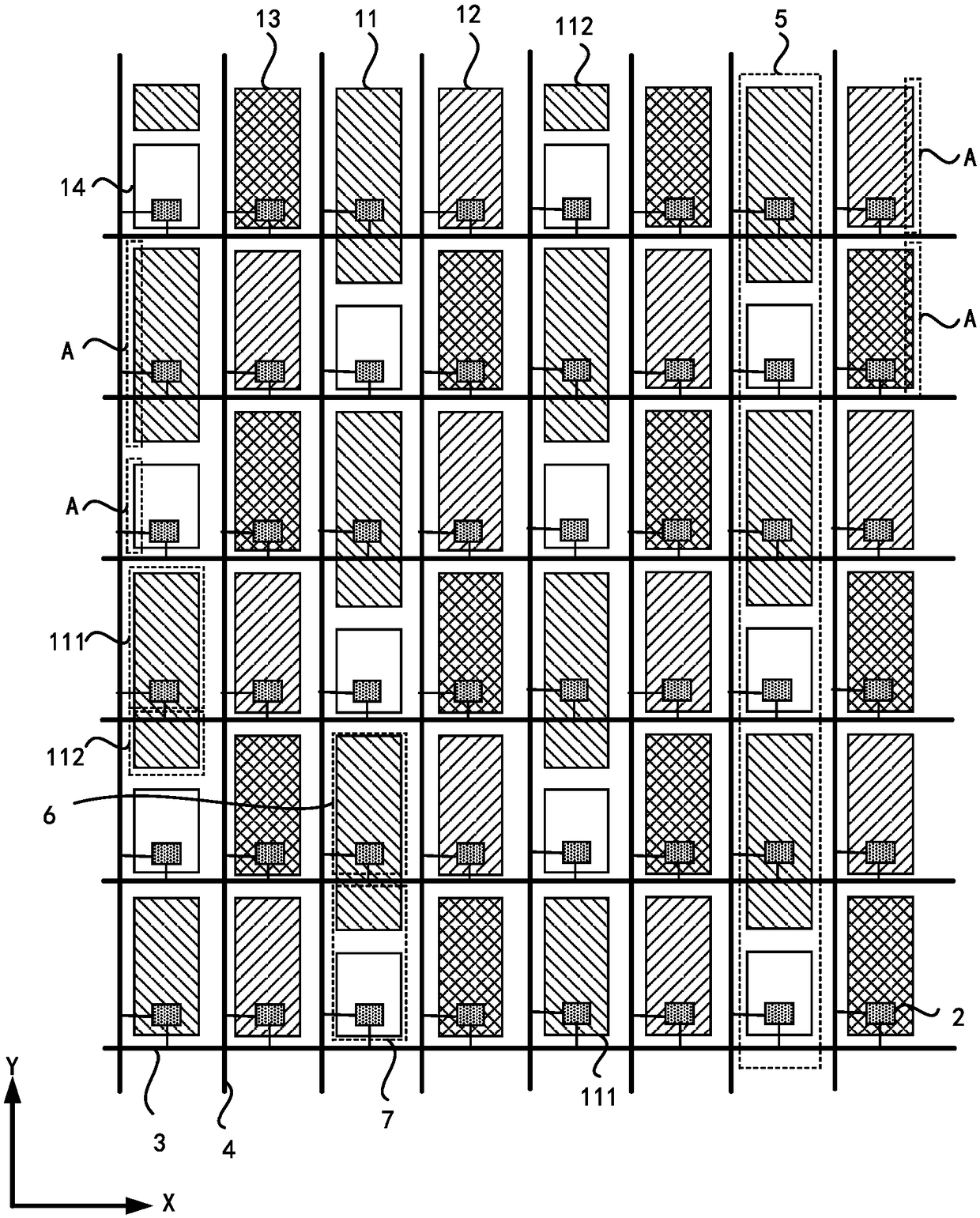

Display panel and display device

ActiveCN108227267ASimple arrangementReduce disconnection rateNon-linear opticsBreakage probabilityDisplay device

An embodiment of the invention provides a display panel and a display device. The display panel comprises white sub-pixel units, first sub-pixel units, second sub-pixel units and third sub-pixel units. Thin film transistors which correspond to the white sub-pixel units, the first sub-pixel units, the second sub-pixel units and the third sub-pixel units among each row of sub-pixel units are positioned on the same straight line; the widths of the white sub-pixel units are equal to those of the first sub-pixel units in row directions, the white sub-pixel units and the first sub-pixel units are alternately arranged in column directions, and the opening areas of the first sub-pixel units are larger than those of the white sub-pixel units. Compared with the prior art, the display panel and the display device in the embodiment of the invention have the advantage that the display panel and the display device in the designs are favorable for reducing the bending frequencies of partial data cables and accordingly are favorable for reducing the breakage probability of data cables in manufacturing procedures.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

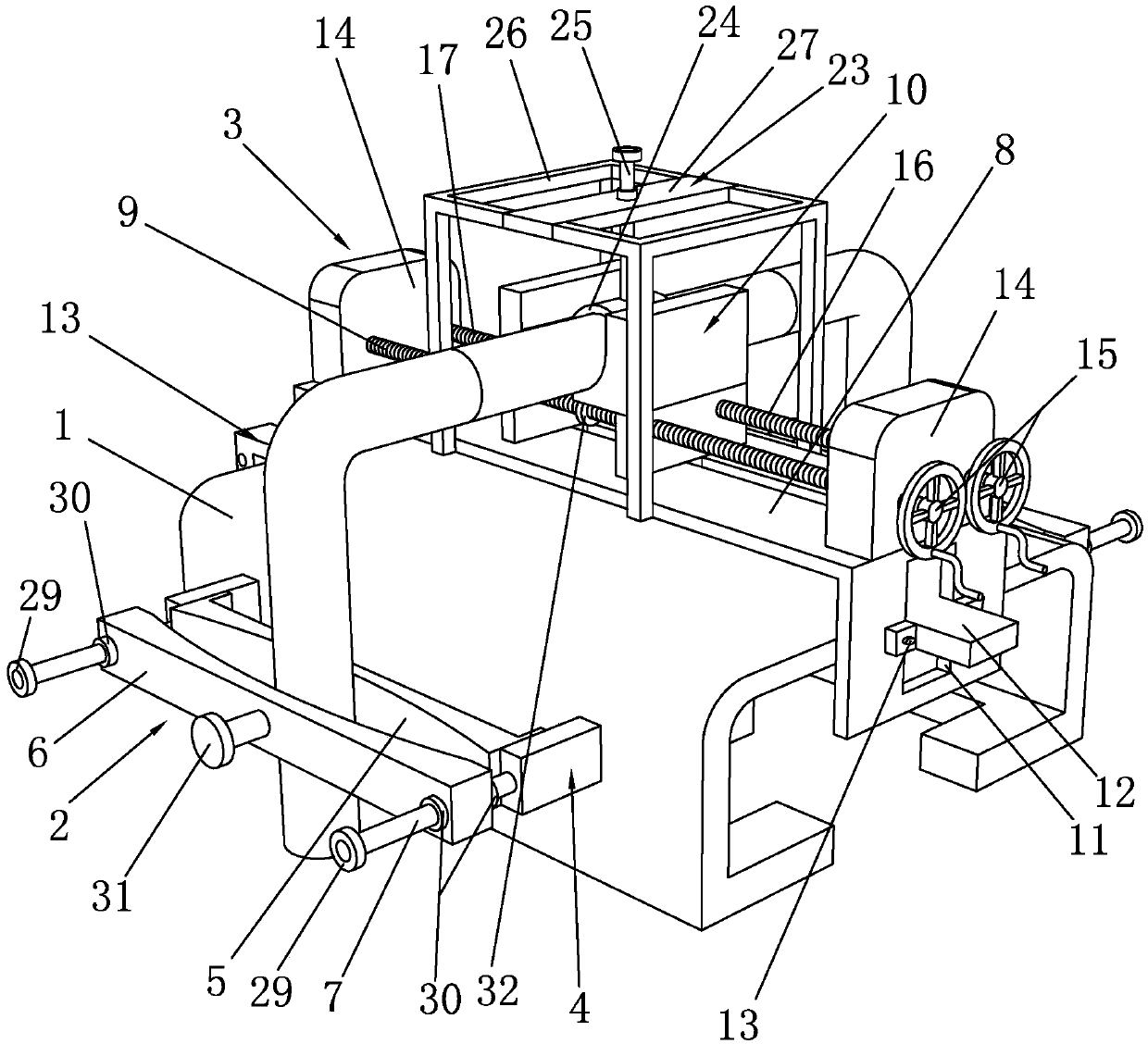

External pipeline paving device of large-scale air purifying equipment

The invention discloses an external pipeline paving device of large-scale air purifying equipment. The device comprises a fixing cover, horizontal positioning frames and a vertical positioning frame;the vertical positioning frame comprises a U-shaped bottom plate, transverse sliding rods and supporting brackets, the front end and the rear end of the transverse sliding rods are provided with firstthreaded sections and second threaded sections, and the thread directions of the first thread sections and the second thread sections are opposite, and the first threaded sections and the second threaded sections are provided with supporting brackets. According to the device, the external pipeline is integrally supported and fixed through the paving device, so that the overall stability of the pipeline is ensured, then the paving device and the equipment are connected and fixed, the operation difficulty of directly paving the pipeline on the surface of the equipment is reduced, and the pipeline and the inner pipeline in the equipment can be conveniently connected and fixed, and the tight performance after the pipeline is in butt joint is improved, and the multiple parts of the pipeline can be simultaneously supported and positioned through the paving device, the structure stability of the external pipeline is effectively ensured, and the effects of damping and noise reducing are achieved.

Owner:嘉兴市良友制衣有限公司

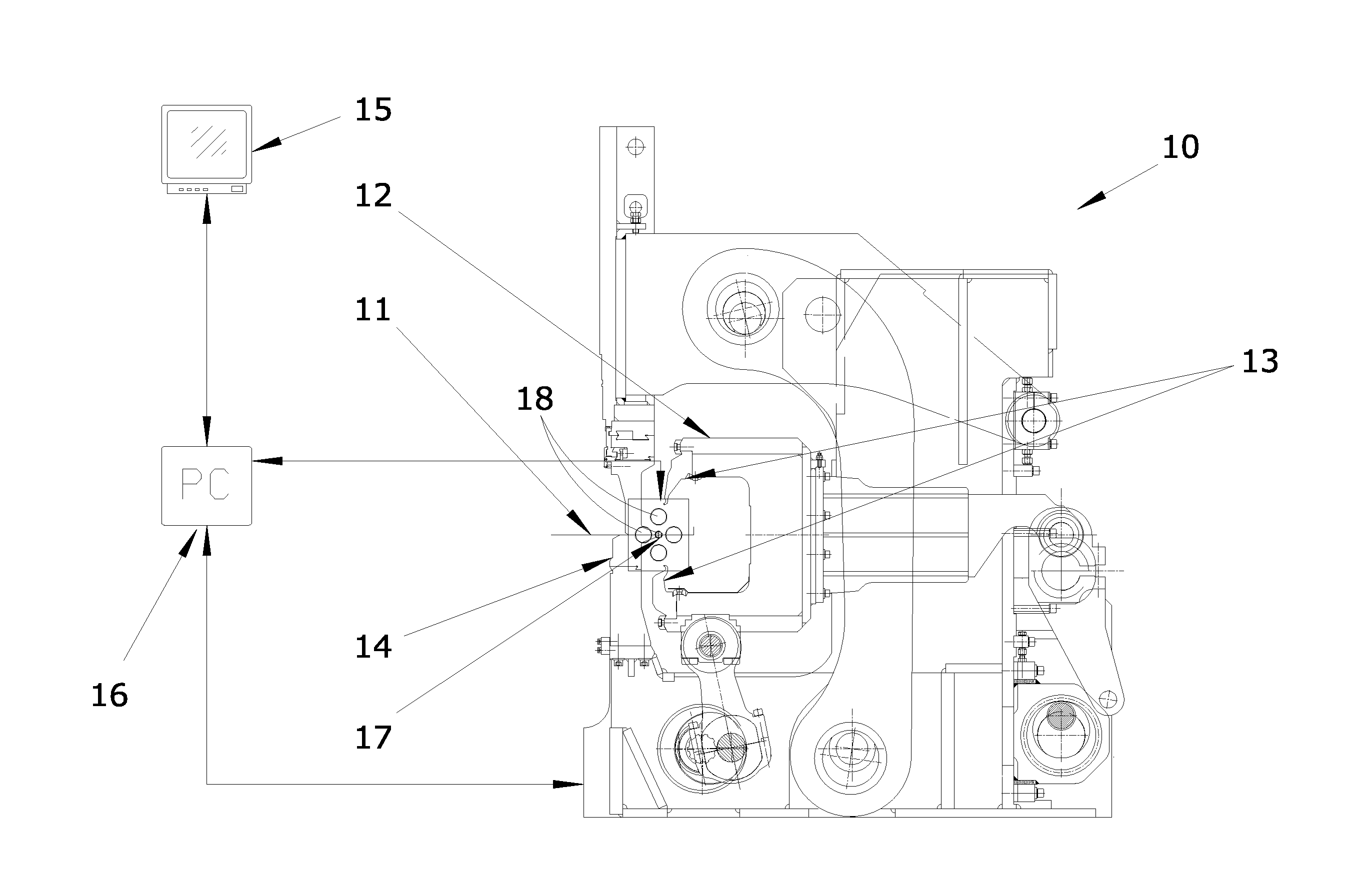

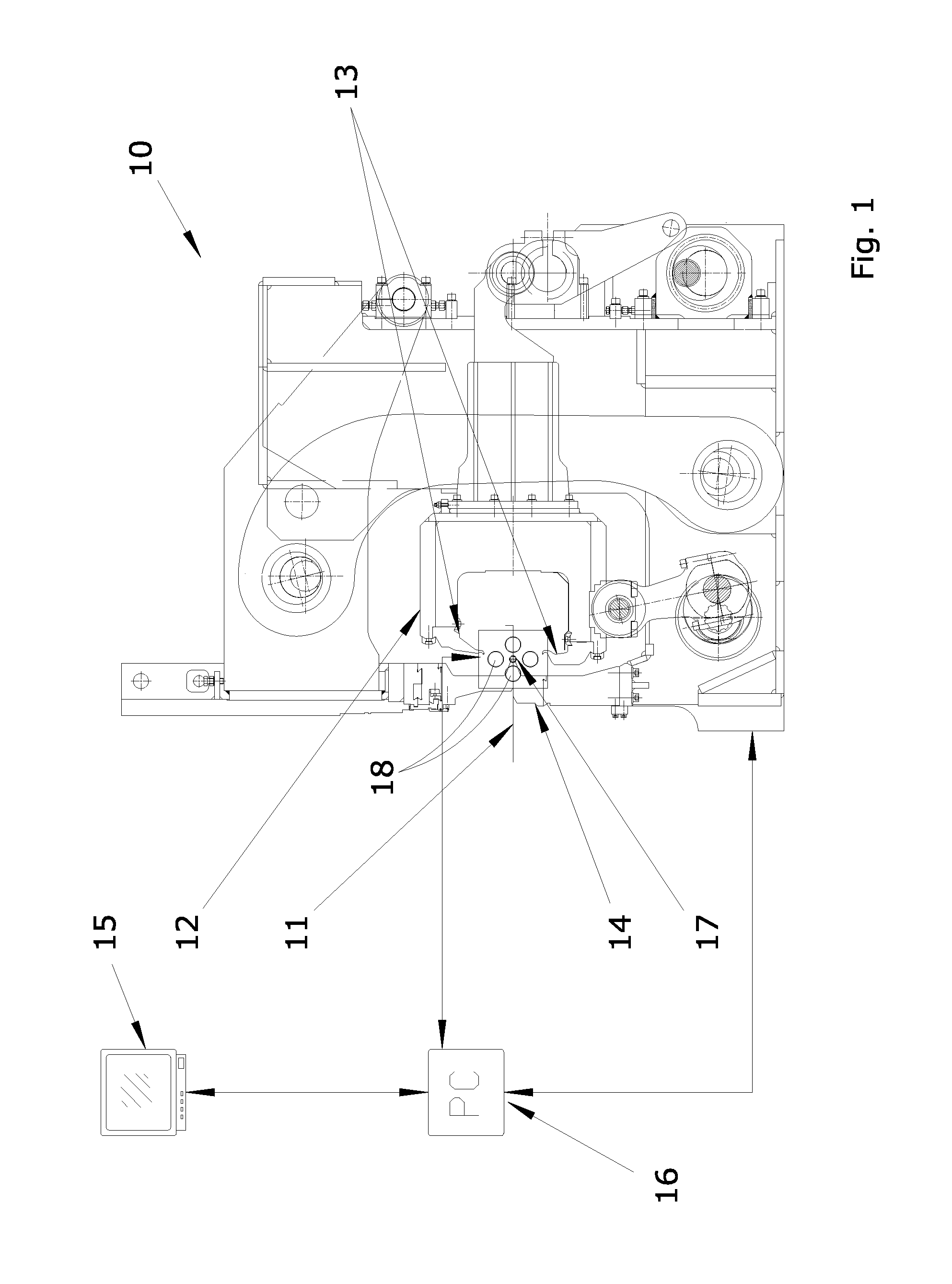

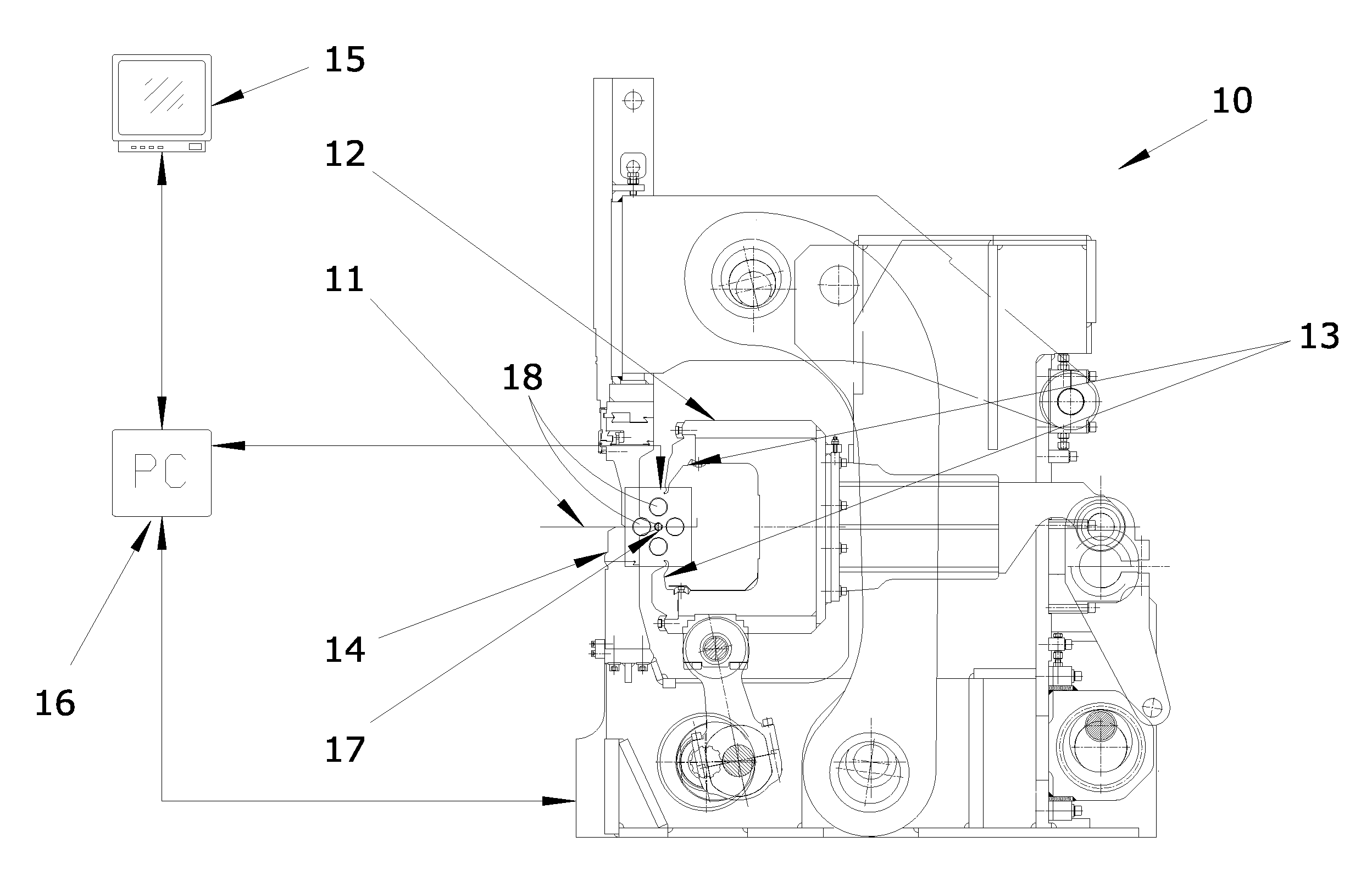

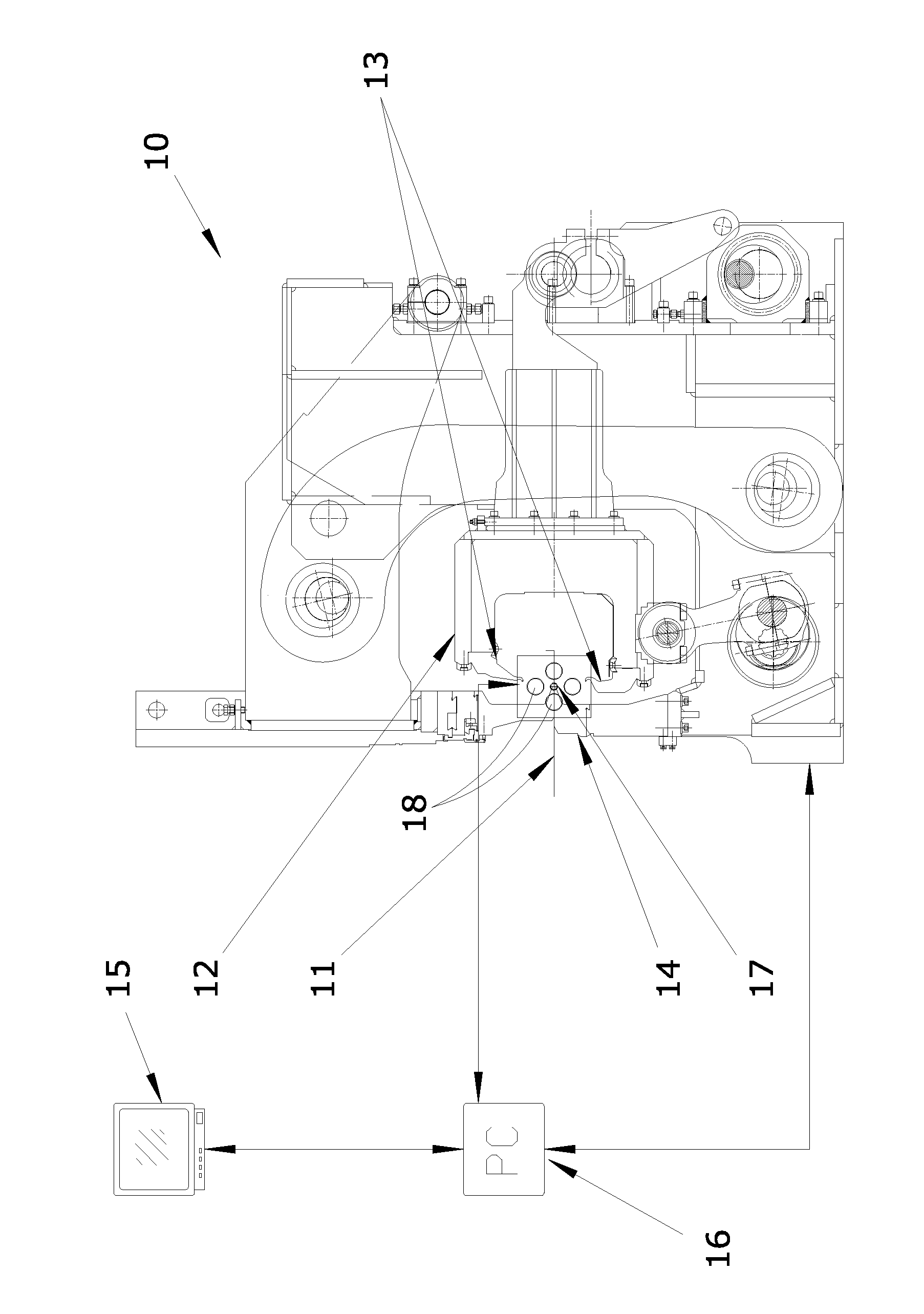

Procedure for the dynamic correction of the bending angle of sheet metal on a panel bender machine

ActiveUS20130340494A1Improve accuracyReduce the number of bendsShaping safety devicesMetal working apparatusMachine controlMetal sheet

Described is a procedure for bending a sheet of sheet metal on a panel bender machine wherein upon bending the sheet of metal sheet a first software (BE) for machine control transmits to a second software (VS) for management of a TV camera (17), positioned in alignment with the bending line, the data relating to the nominal bending angle, the bending length, the distance of the bent edge from the centre line of the panel bender and the thickness of the metal sheet. The second software (VS) acquires an image of the bent metal sheet, identifies the spatial position of the straight line corresponding to the bent edge of the sheet of sheet metal and then calculates its geometric coordinates in accordance with a preset referencing system, and supplies to the first software (BE) the value of the angle of the bend performed. The machine control is returned to the first software (BE), which calculates the difference between the angle of the bend actually performed and the angle of the nominal bend and then orders the start of a new bend corresponding to the angular difference, thereby obtaining a bend corresponding to the nominal bend.

Owner:PRIMA IND

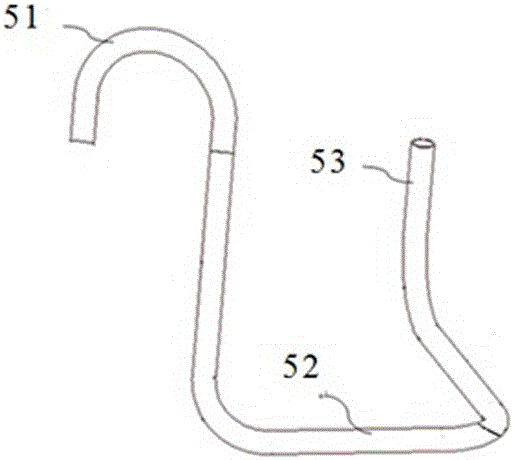

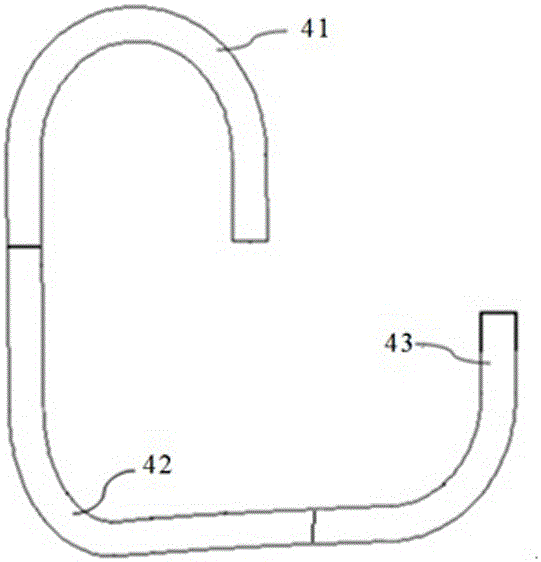

Air conditioner outdoor unit piping, method for forming damping material on piping and air conditioner outdoor unit

InactiveCN105757828AImprove loss factorGood damping performanceLighting and heating apparatusNoise suppressionPipingMechanics

The invention discloses an air conditioner outdoor unit piping, a method for forming a damping material on the piping and an air conditioner outdoor unit.The air conditioner outdoor unit piping comprises an air suction pipe section and an exhaust pipe section, and the damping material which has the damping and denoising properties is formed on the outer surfaces of the air suction pipe section and the exhaust pipe section.According to the air conditioner outdoor unit piping, the method for forming the damping material on the piping and the air conditioner outdoor unit, due to the fact that the damping material which has the damping and denoising properties is sprayed on the outer surfaces of the air suction pipe section and the exhaust pipe section of the air conditioner outdoor unit, vibration of the air suction pipe section and the exhaust pipe section can be weakened, and noise caused by vibration is reduced; the piping design on the air suction pipe section and the exhaust pipe section is simple; meanwhile, airflow noise caused by refrigerant circulating in the air suction pipe section and the exhaust pipe section can be reduced, vibration and noise of the air conditioner outdoor unit can be reduced, and the refrigerating efficiency of the air conditioner outdoor unit is improved.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

Organic light-emitting diode, display and application thereof

ActiveCN102082239AReduce widthReduce volumeSolid-state devicesSemiconductor/solid-state device manufacturingRight triangleDisplay device

The invention discloses an organic light-emitting diode (OLED), a display and application thereof. Each lead of the organic light-emitting diode respectively corresponds to a line of negative electrodes; each of leads corresponding to a first line of negative electrodes and a second line of negative electrodes comprises an overlap part, a connection part and an extension part; an upper side of each of the extension parts and a lower side of each of the overlap parts are connected; each of the extension parts has a shape of a right angled triangle, and one right-angle side of the right angled triangle is connected with each of the overlap parts and the other right-angle side of the right angled triangle is connected with one of the connection parts; and the width of the first line of leads is reduced, so that the width of a screen body and the size of the OLED are reduced. The width of two side leads is saved on the two sides of the whole screen body, and other lines of leads can move inward by the width of one lead, so that the size of the manufactured screen body can be reduced. Each of the connection parts is directly connected with an integrated circuit (IC) area without bending by forming the extension parts.

Owner:KUNSHAN VISIONOX DISPLAY TECH +2

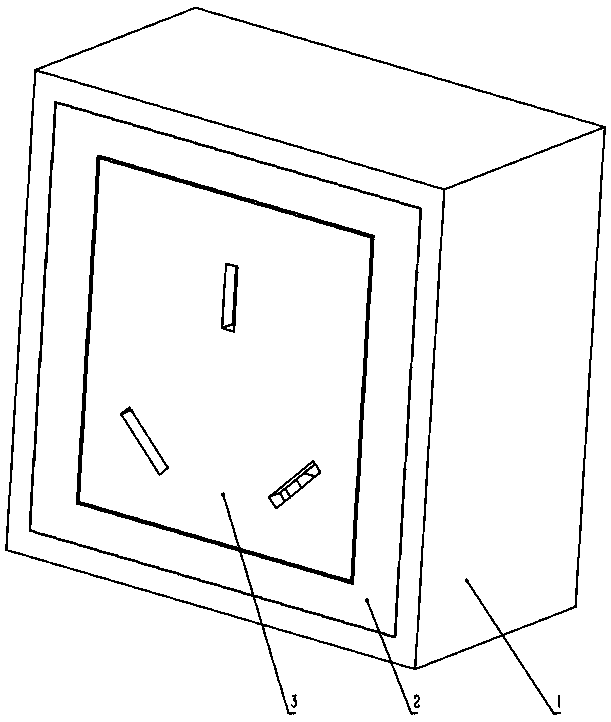

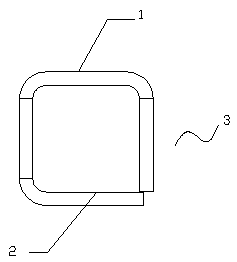

Automatic clamping safety socket

ActiveCN108736209AExtended service lifeReduce the number of bendsCoupling contact membersFatigue IntensityContact pressure

The invention provides an automatic clamping safety socket, which comprises a casing, a concentric-square-shaped frame, a panel, a bracket and a contact unit. The automatic clamping safety socket is characterized in that the panel is arranged in a rectangular hole in the middle of the concentric-square-shaped frame; the casing is arranged outside the concentric-square-shaped frame; the concentric-square-shaped frame and the casing are connected through screws; a jack is arranged on the panel; the back of the concentric-square-shaped frame is provided with the bracket for mounting the contact unit, and one contact unit is arranged on the rear part of each jack; a swing rod, a trapezoid frame and a top rod are arranged so that the metal piece of the jack is increased along with the increaseof the insertion depth, thereby increasing the contact pressure, and enhancing the conductive capability; the two contact copper pieces are hinged so that the bending number of times of the copper piece can be reduced, thereby reducing the fatigue intensity and increasing the service life of the socket.

Owner:SHENZHEN CUCO SMART TECH CO LTD

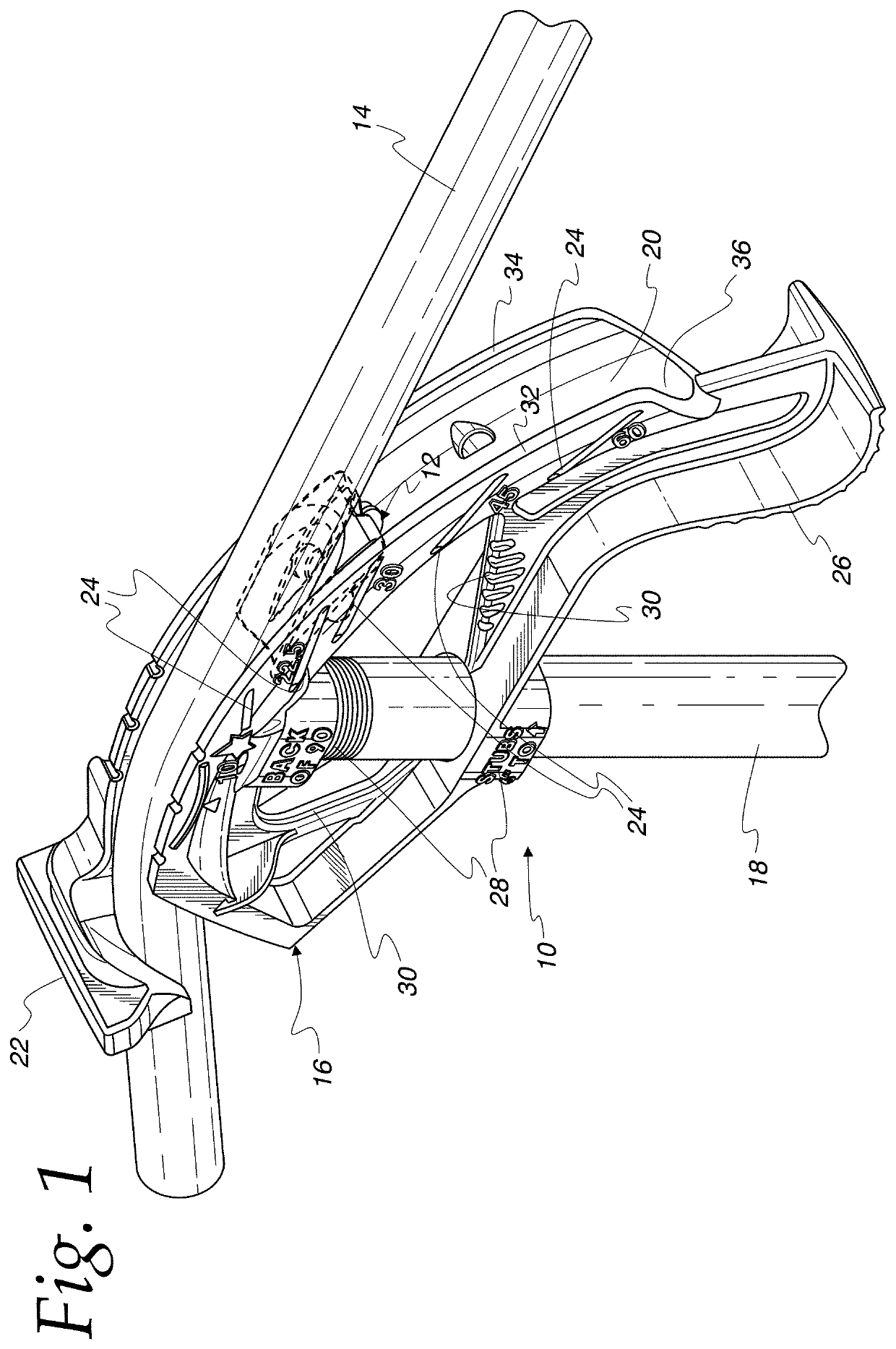

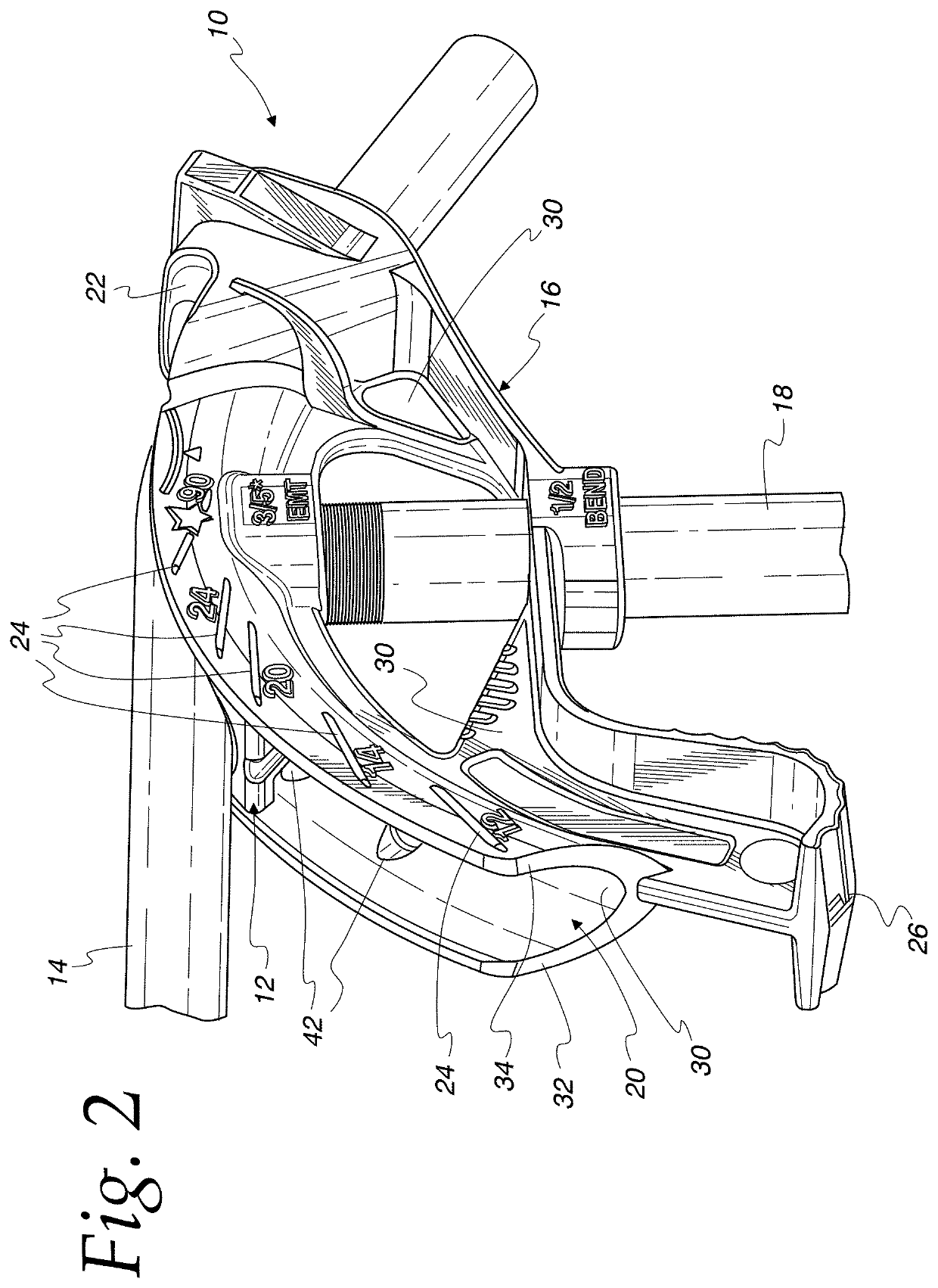

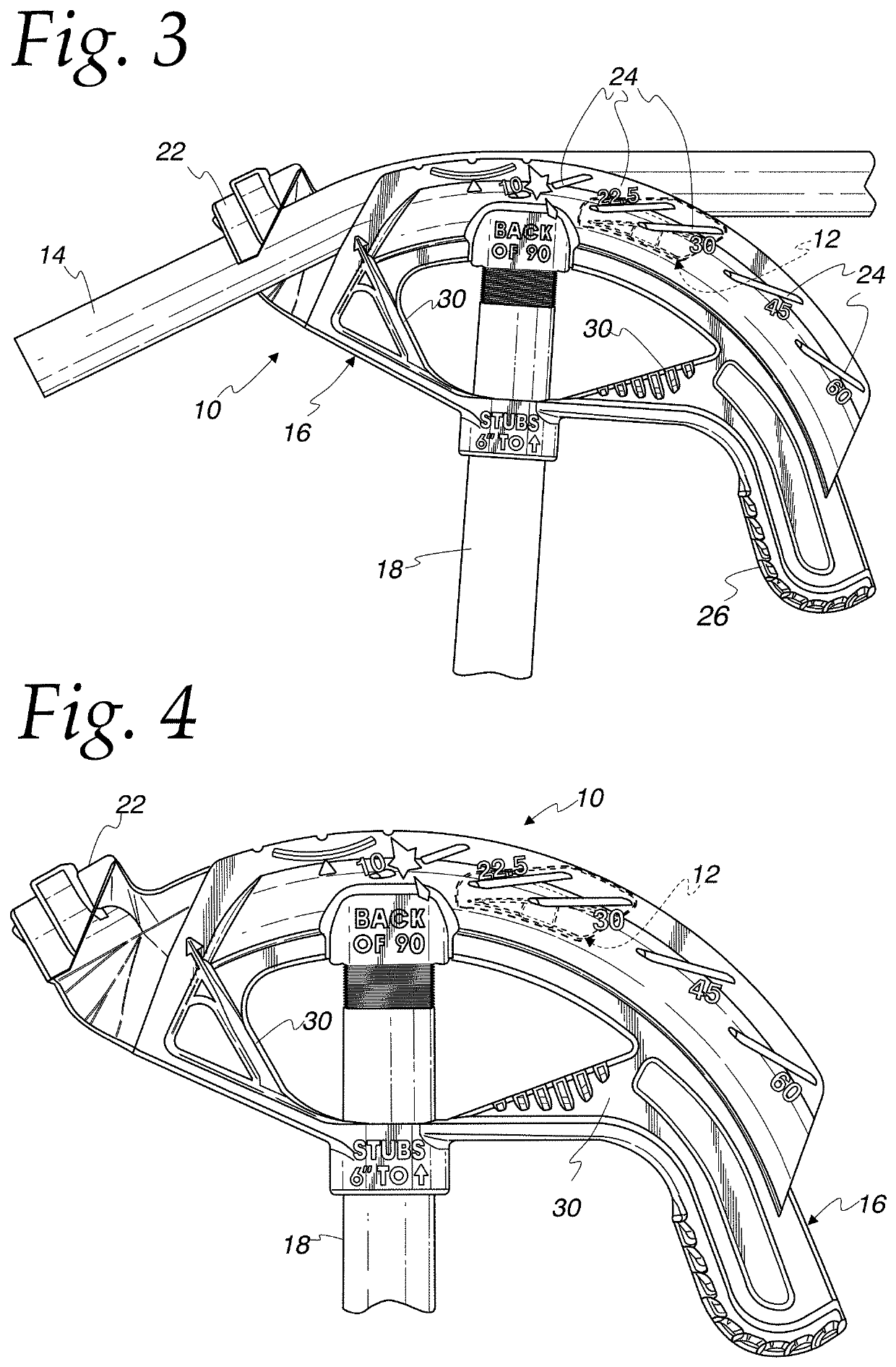

Manual conduit bender with angle setter

A manual conduit bender includes an angle setter that can be selectively engaged with a bender head to allow users to precisely set common bend angles.

Owner:KLEIN TOOLS INC

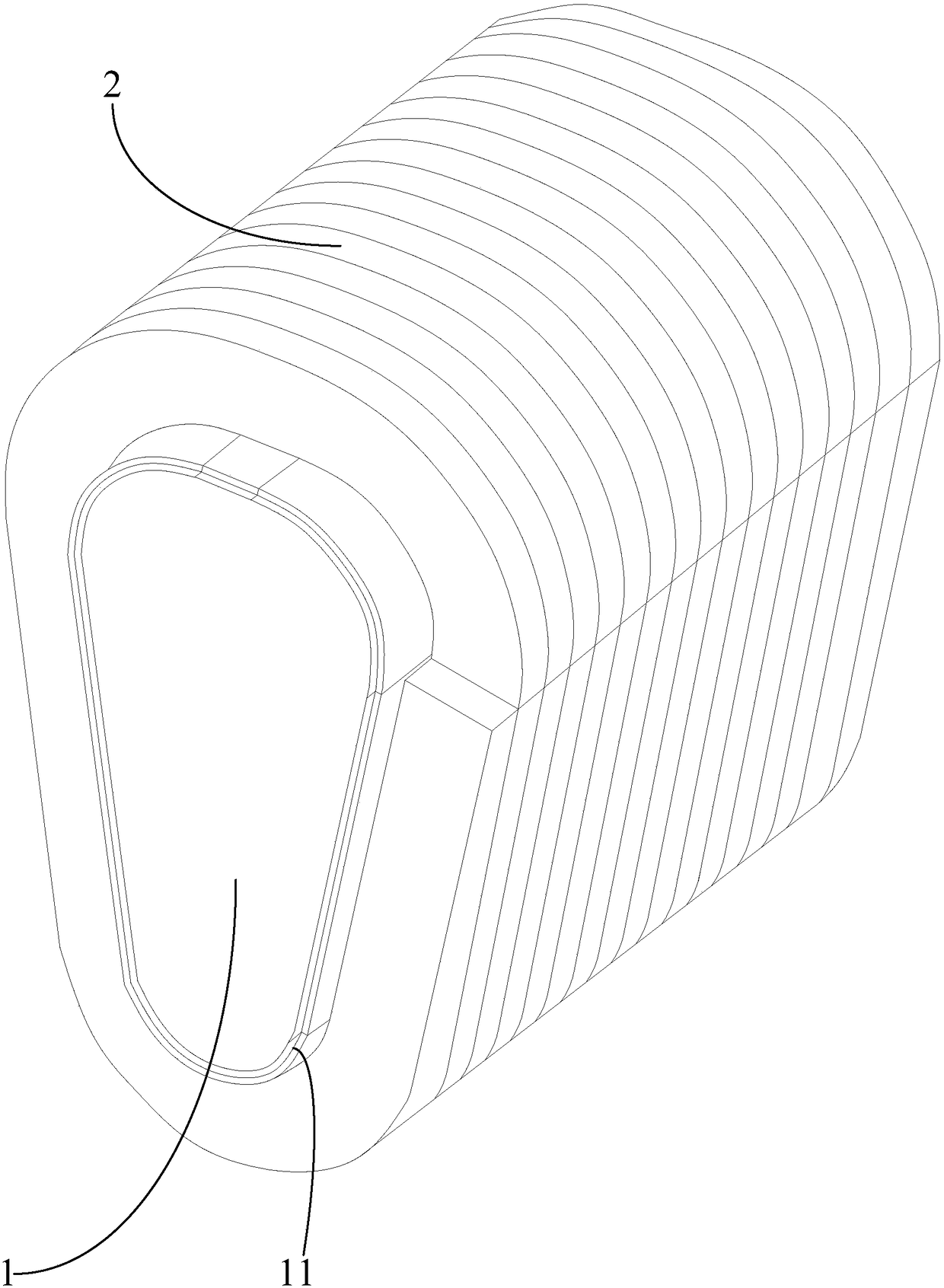

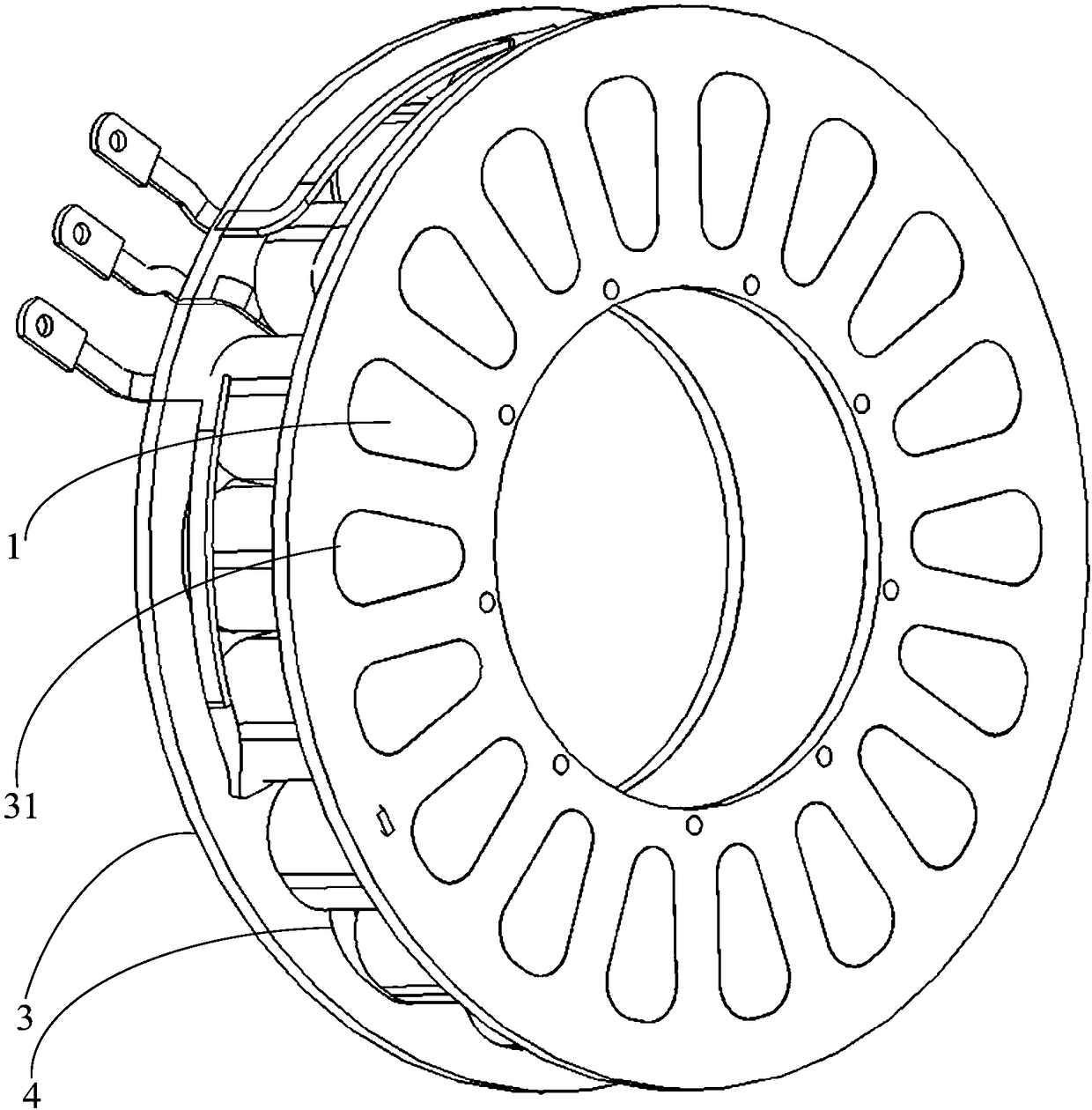

Stator iron core winding unit, stator assembly of disc type motor and disc type motor

InactiveCN108075589AReduce stressNumber of times to avoid bendingMagnetic circuit stationary partsWindings conductor shape/form/constructionMultiple layerTriangular prism

The invention provides stator iron core winding units, a stator assembly of a disc type motor and the disc type motor. The stator iron core winding units all comprise stator iron cores which are in ridge arc transition and are in a triangular prism shape, integrated windings and fixing glue, the integrated windings comprise multiple-layer wire winding coils spirally wound on the outer side faces of the stator iron cores in the length direction of the stator iron cores, the multiple-layer wire winding coils are bendingly wound by flat wires in the length direction of the cross section of the flat wires, and the radius of ridge transition arcs of the stator iron cores is not smaller than the length of the cross section of the flat wires. The bending portions of the flat wires can be prevented from fracturing.

Owner:仪坤动力科技(上海)有限公司

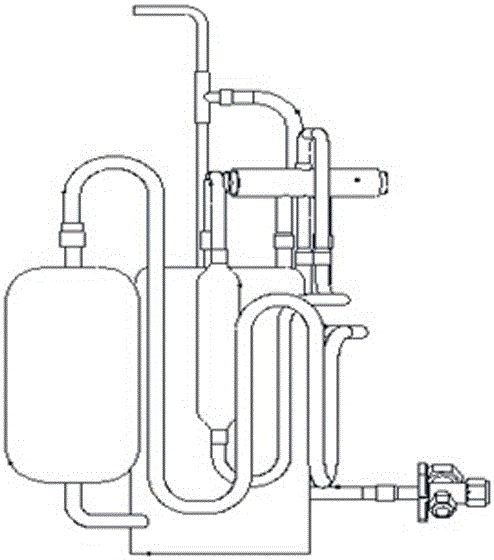

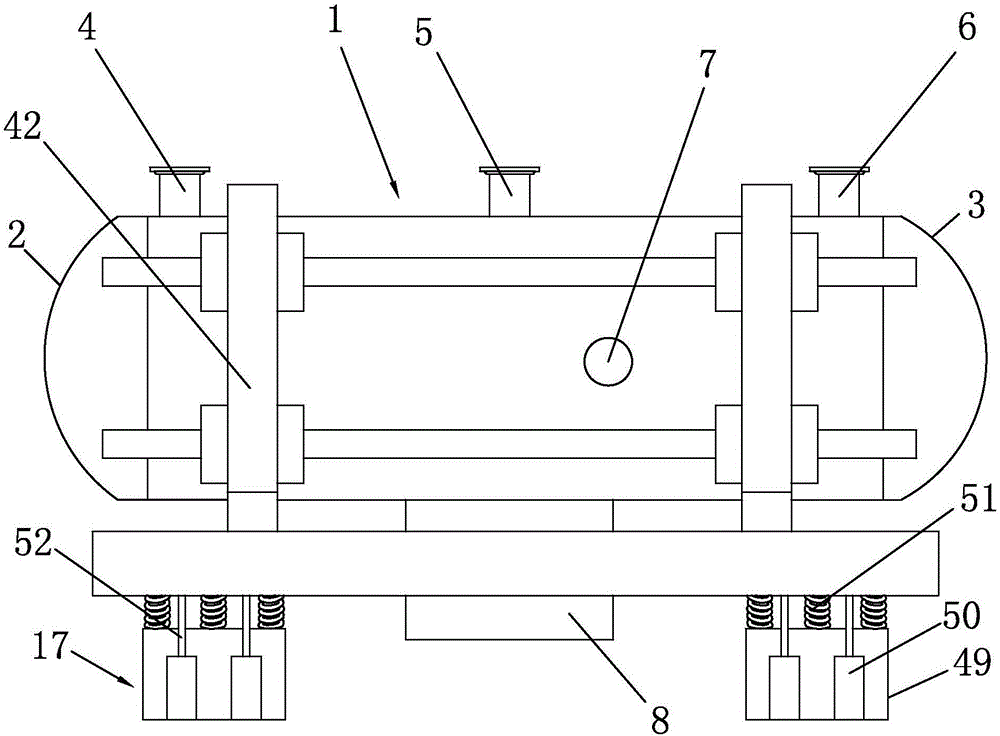

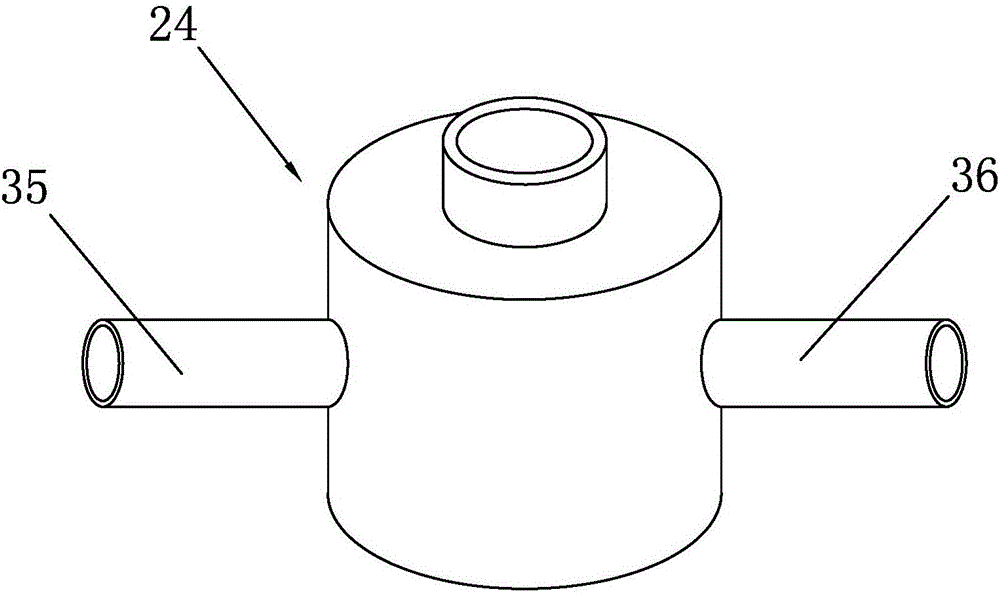

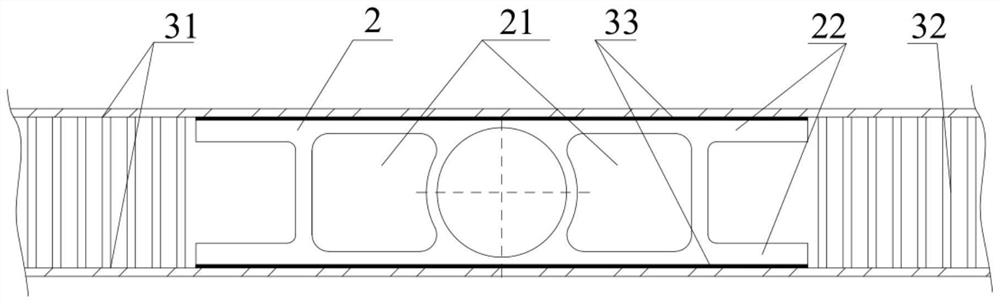

Horizontal type liquid storage device and installation method thereof

The invention discloses a horizontal type liquid storage device and an installation method thereof. The horizontal type liquid storage device comprises a liquid storage device barrel and an installation fixing rack, wherein an air inlet, an oil return hole and an air outlet are formed above the liquid storage device barrel; the liquid storage device barrel is internally provided with a buffer tube and a treating barrel, and the treating barrel is connected with the buffer tube by an air inlet pipe; an outlet of the treating barrel is connected with the air outlet by an air outlet pipe; the installation method comprises the following steps: (1) preparatory work; (2) installation of parts in the liquid storage device barrel; (3) installation between the liquid storage device barrel and a left seal cover as well as a right seal cover; (4) installation between the liquid storage device barrel and the installation fixing rack; (5) connection and fixation between the liquid storage device and a compressor. The horizontal type liquid storage device is simple in structure and high in practicality; by improving an internal structure of the horizontal type liquid storage device, the work stability of a whole refrigerating system is improved; furthermore, by the design of the installation fixing rack, the horizontal type liquid storage device is more conveniently installed and fixed, and the structural design of the horizontal type liquid storage device is more reasonable.

Owner:新昌县行峰制冷配件厂

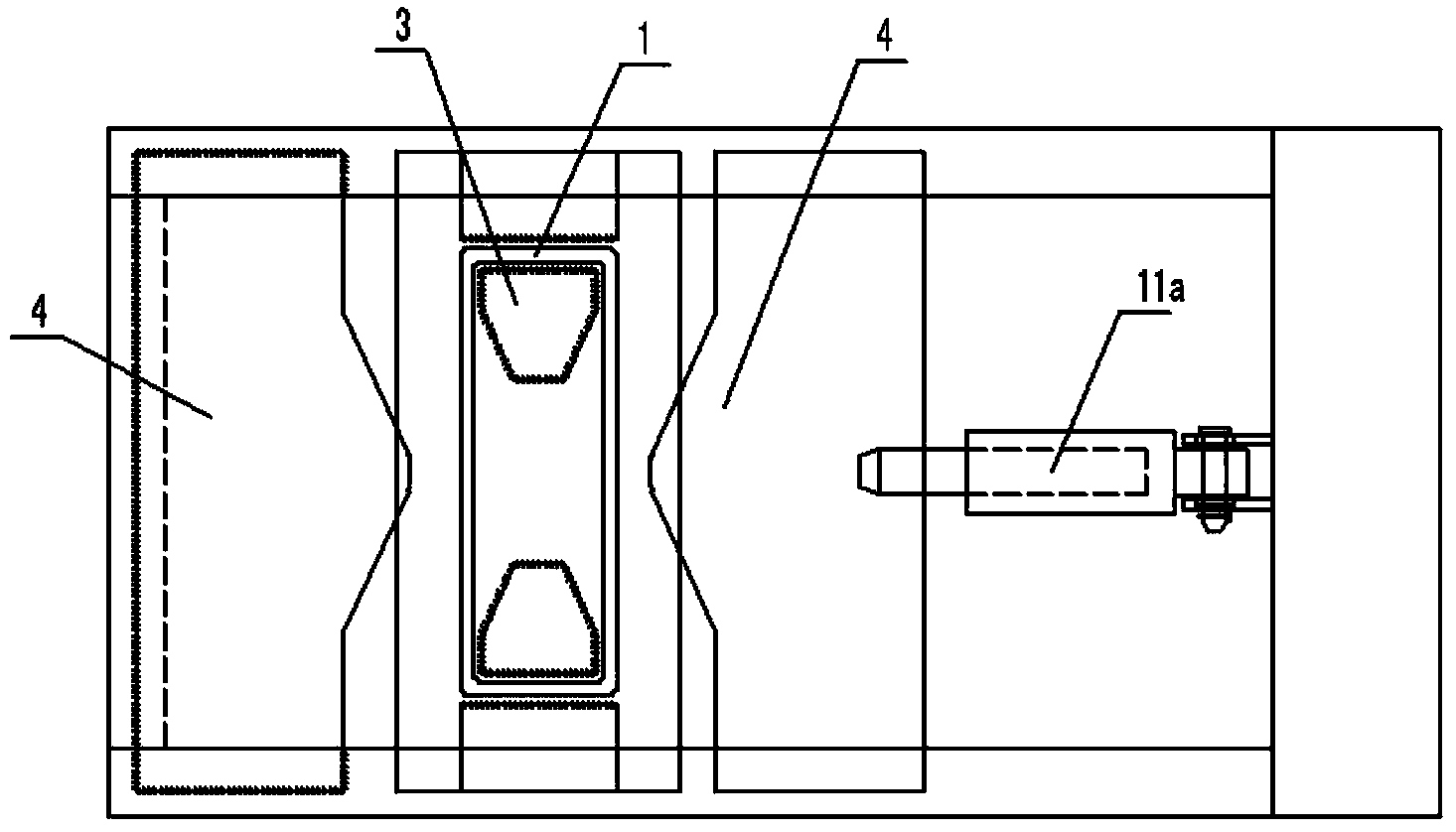

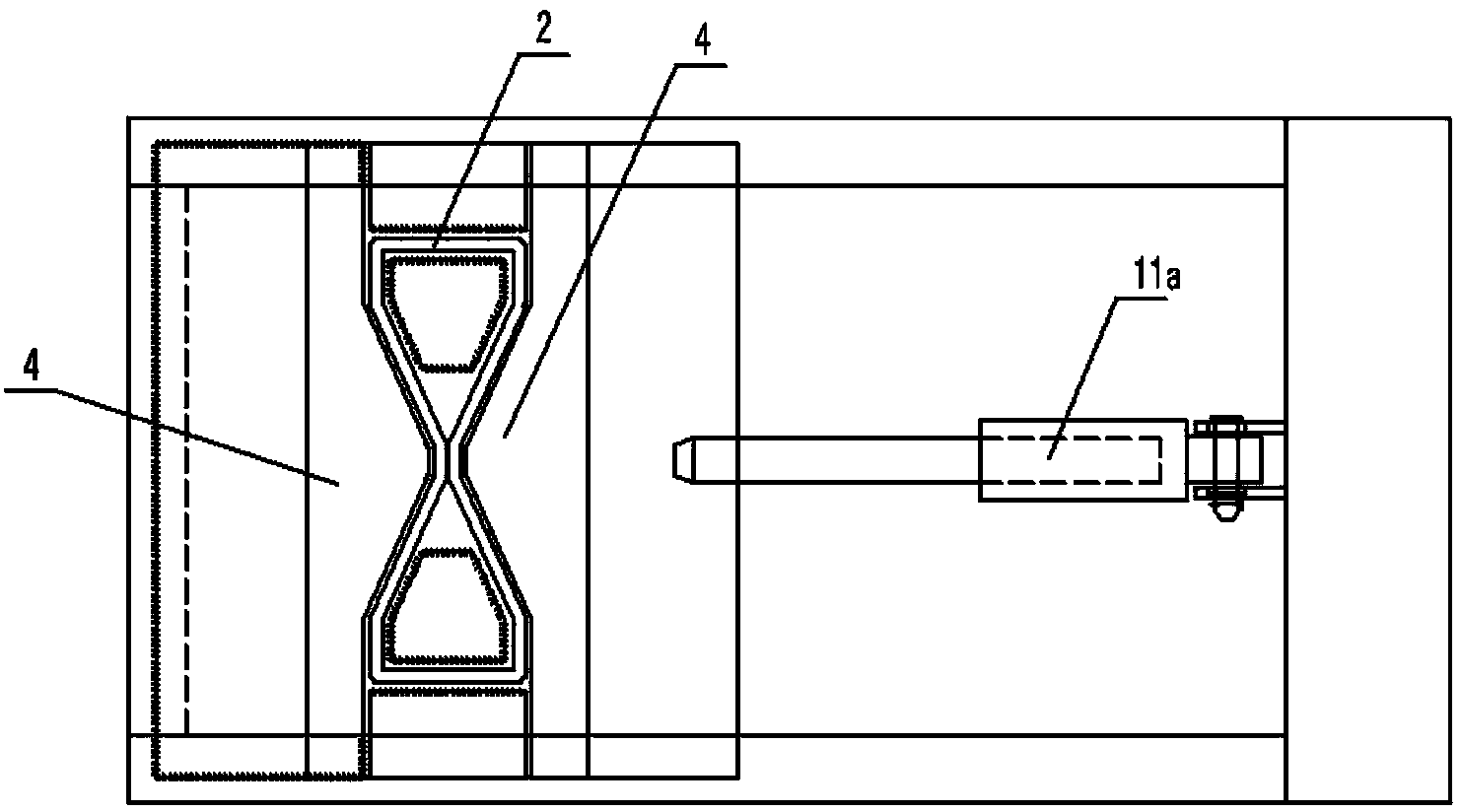

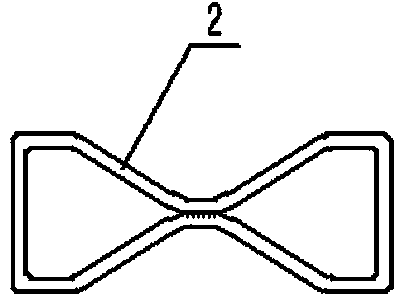

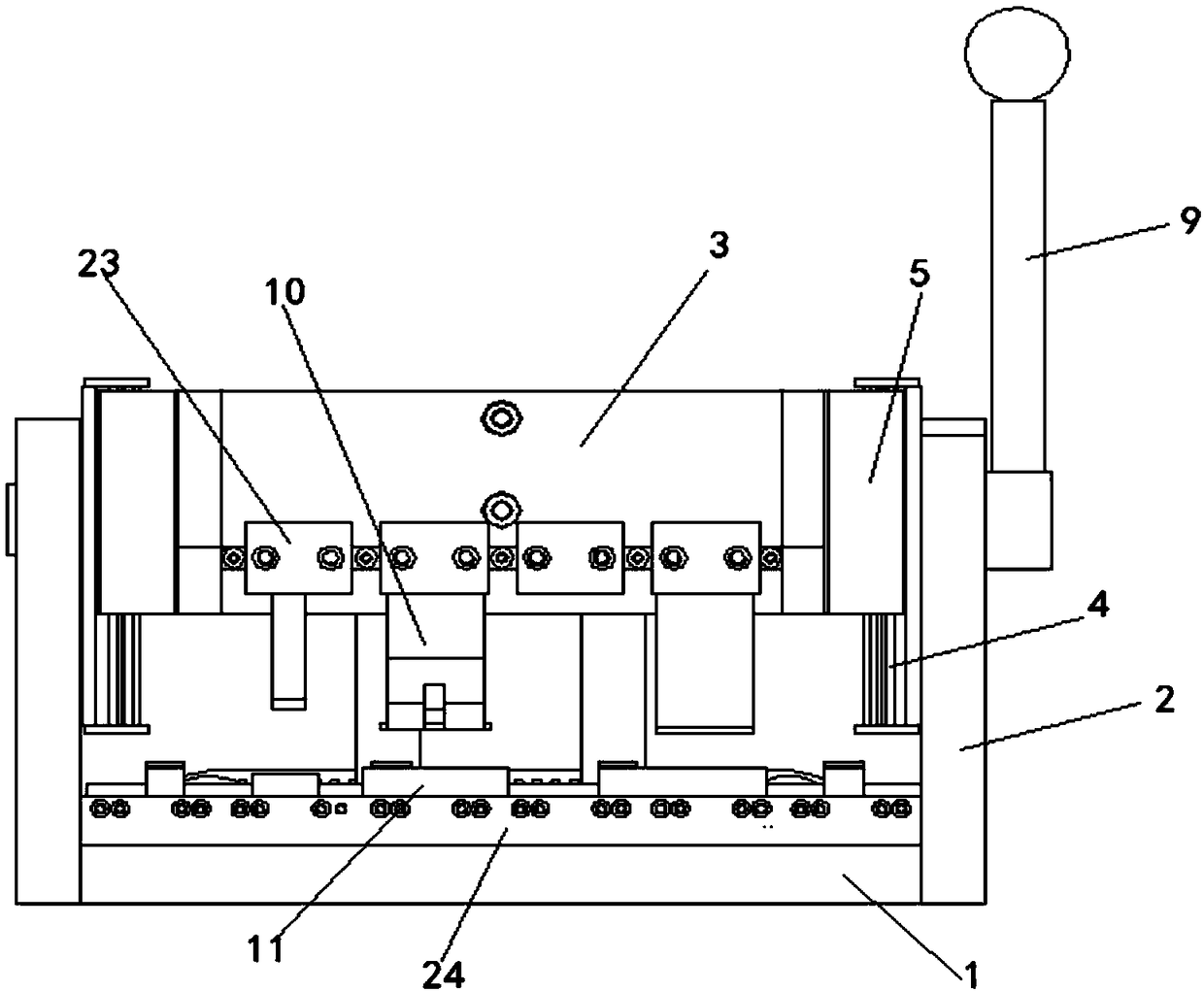

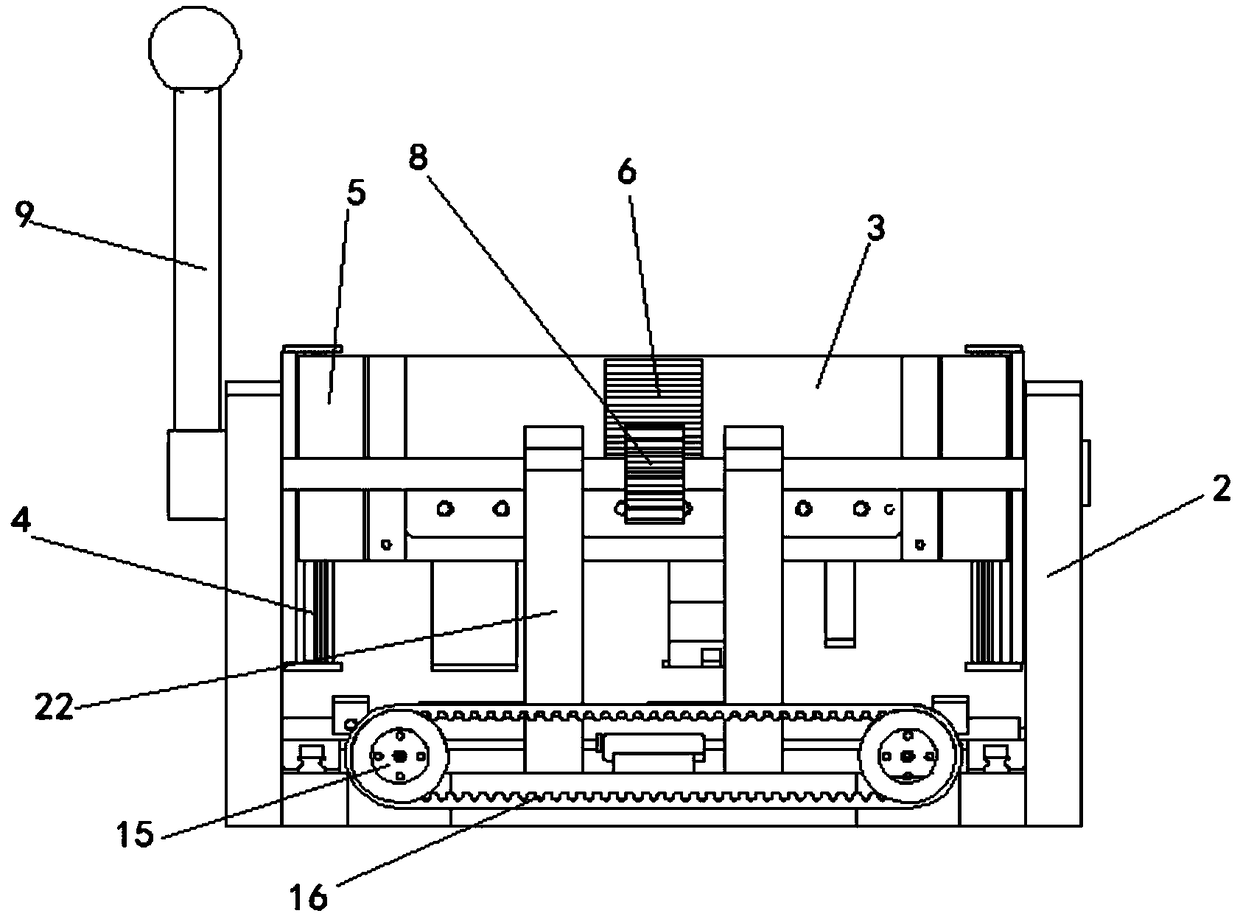

8-shaped rib processing machine

The invention discloses an 8-shaped rib processing machine which is characterized by comprising a horizontal processing unit and a vertical processing unit, wherein the horizontal processing unit is used for extruding a horizontally-placed rectangular steel bar frame between a left side frame and a right side frame in opposite directions until the left side frame and the right side frame are folded in the middle and welding the left side frame and the right side frame at the middle folded position to form a horizontal 8-shaped frame; the vertical processing unit is used for extruding the horizontal 8-shaped frame downwards at the middle folded position until the horizontal 8-shaped frame is in preset bending on a vertical face. The 8-shaped rib processing machine is reasonable in structural design, high in processing precision, low in construction cost and high in production efficiency.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

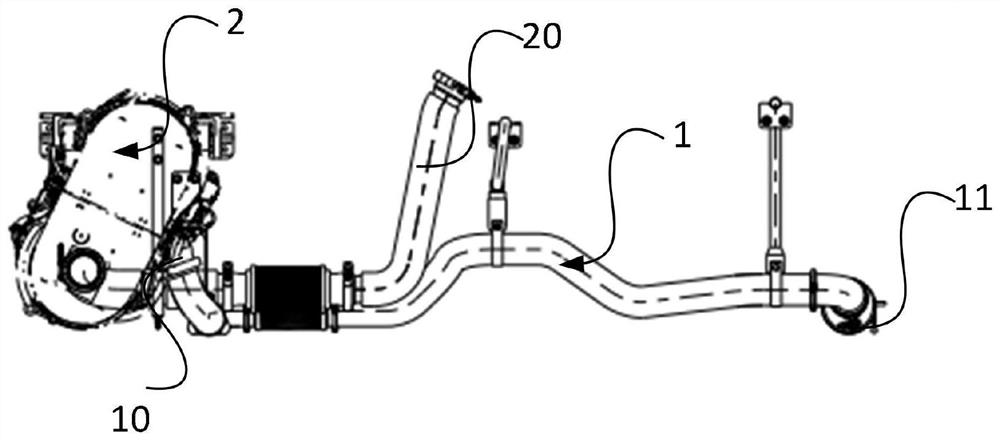

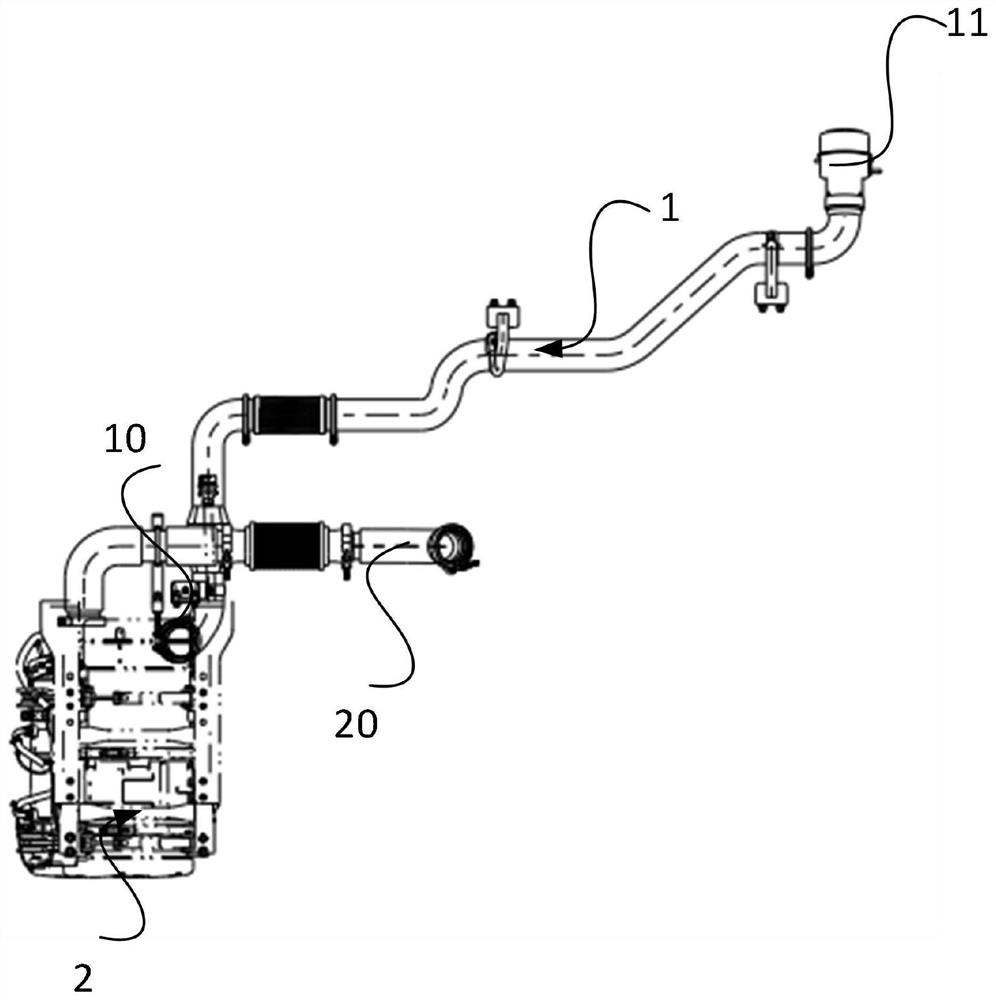

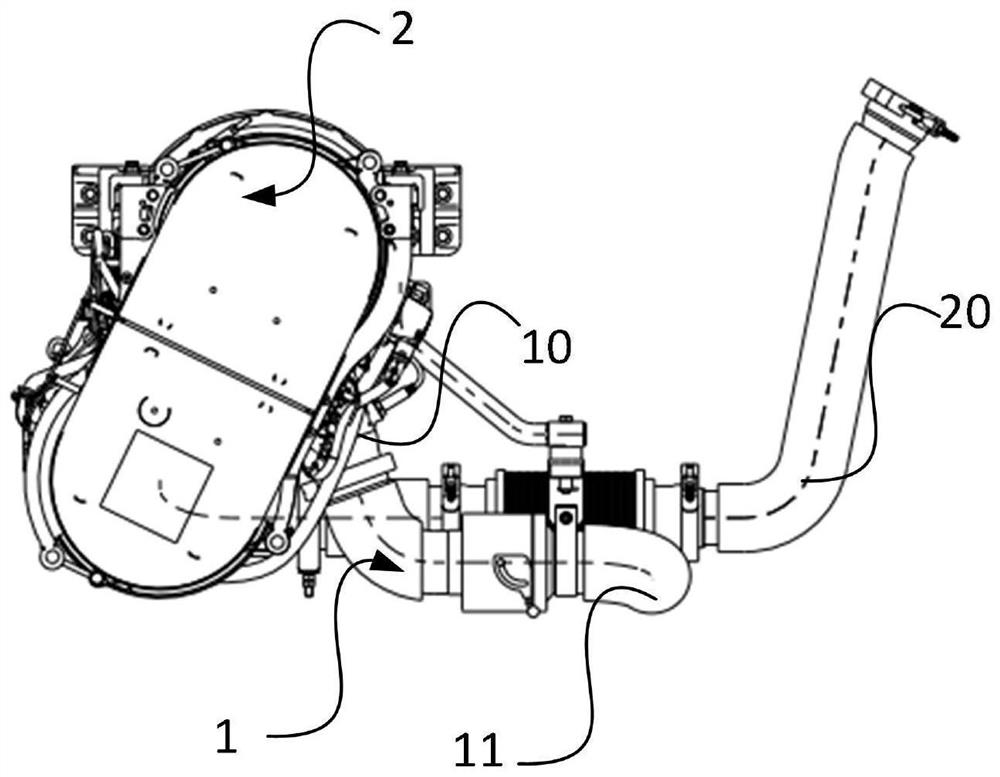

Exhaust tail pipe of hazardous chemical vehicle

ActiveCN112031906AShorten the lengthReduce the number of bendsExhaust apparatusSilencing apparatusPhysicsExhaust gas

The invention relates to the technical field of engine exhaust systems, in particular to an exhaust tail pipe of a hazardous chemical vehicle. The exhaust tail pipe comprises a tail pipe body and a guide face, the tail pipe body comprises a gas inlet and an exhaust port, and the gas inlet is used for being connected with a postprocessor; and the guide face is connected to the exhaust port. The exhaust tail pipe has a using state, when the exhaust tail pipe is in the using state, the gas inlet is connected with the postprocessor, the guide face inclines towards the ground so that the exhaust path of tail gas exhausted through the exhaust port can incline towards the ground, and a gas inlet pipe of the postprocessor is located outside the exhaust path. The problems that the exhaust tail pipeis very long, consequently, the manufacturing cost of a whole vehicle is greatly increased; and in addition, in order to avoid interference with other structures at a front wall of a cab, the exhausttail pipe needs to be bent at multiple positions, and the exhaust efficiency of the exhaust tail pipe is affected are solved.

Owner:DONGFENG COMML VEHICLE CO LTD

Tube clamping rack and shaping method thereof

The invention relates to a tube clamping rack. The tube clamping rack is characterized in that the tube clamping rack comprises a tube clamping rack body; the tube clamping rack body is provided witha bottom area, a top surface area and a side area. The shaping method of the tube clamping rack is characterized by including the following steps of: material unloading; punching; first bending; and second bending. The tube clamping rack of the invention is integrally shaped; punching at a plurality of positions of the tube clamping rack body can be completed at one time through the punching stepin a technique process, and at the same time, the precision of the punching can be ensured, and production procedures can be reduced; and in a bending process, bending is performed twice, so the number of the times of bending can be decreased, and therefore, the accuracy of products after the bending is performed can be improved, and the production efficiency of the products can be improved.

Owner:江苏亚信电子科技有限公司

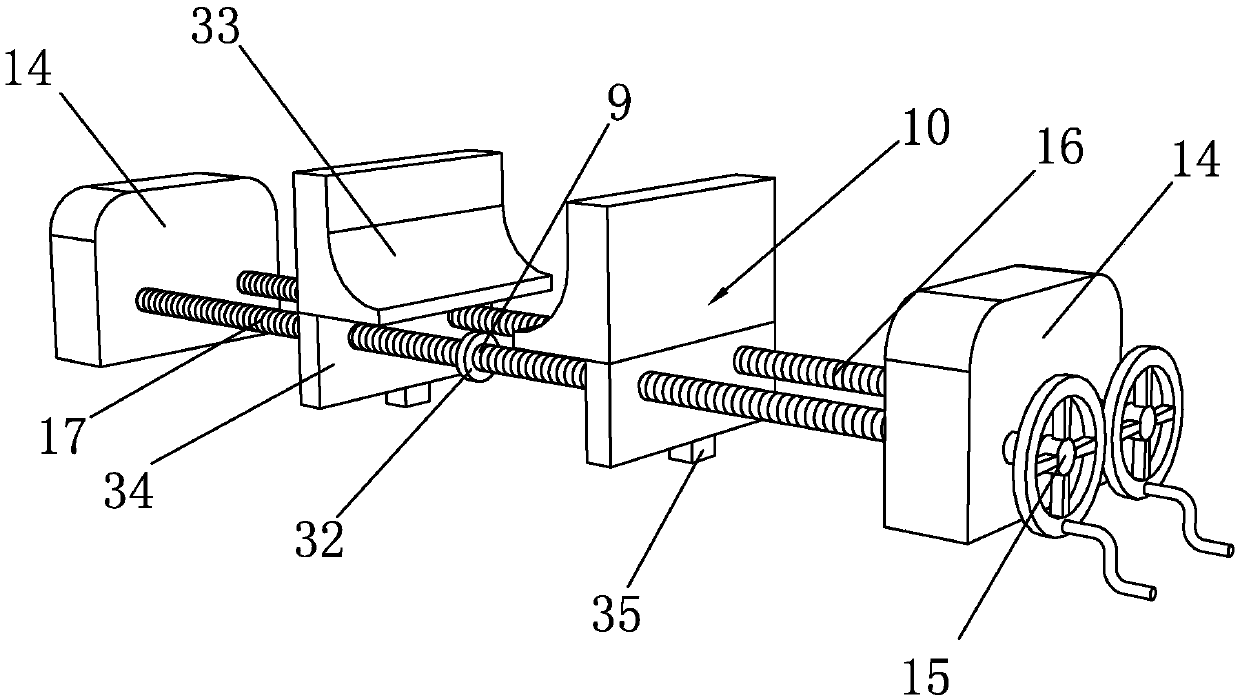

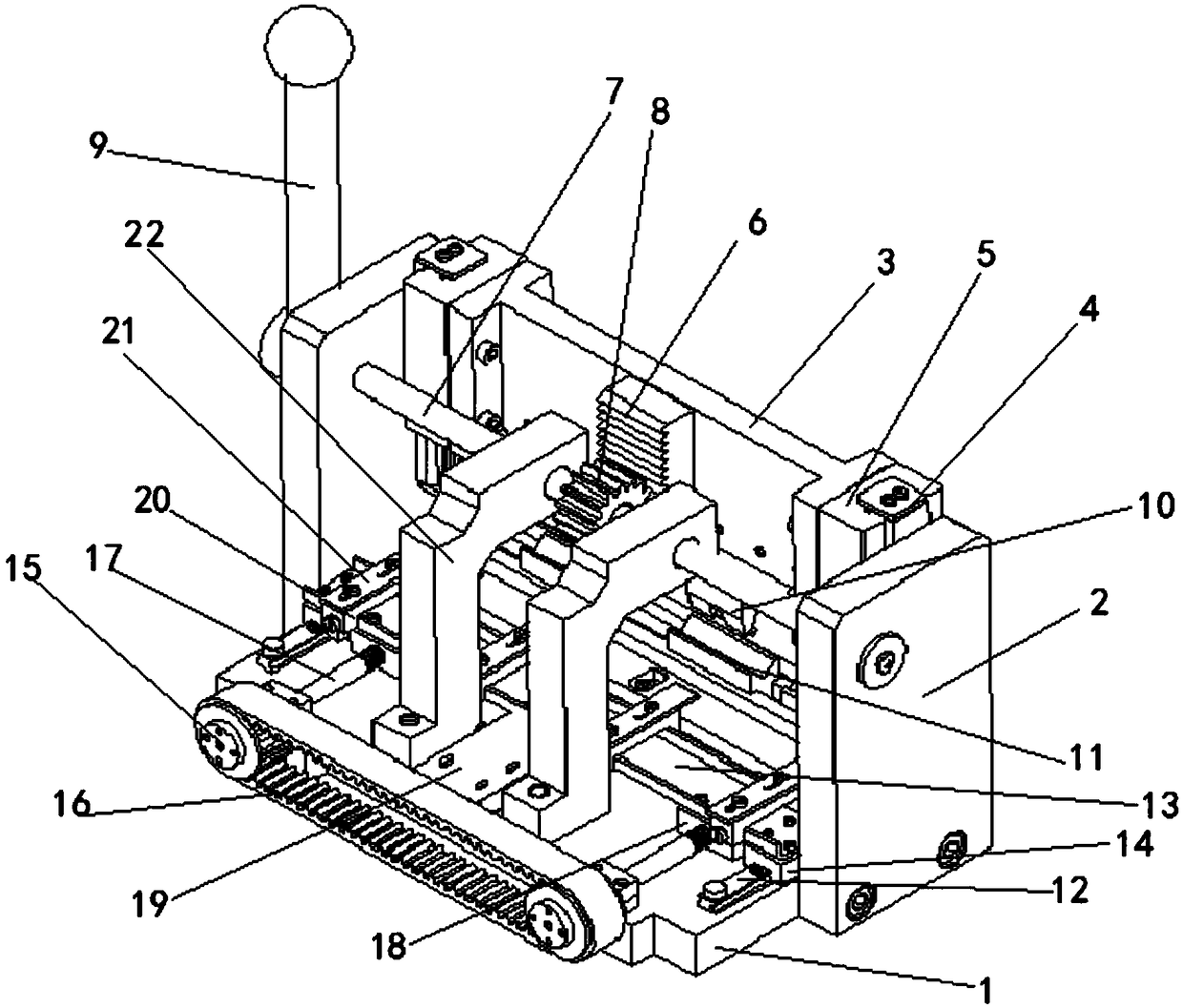

Miniature bending machine for machining small thin-wall part

ActiveCN108704957ASimple and easy to control the intensityReduce the number of bendsMetal-working feeding devicesPositioning devicesThin walledEngineering

The invention discloses a miniature bending machine for machining a small thin-wall part, and belongs to the technical field of bending devices. The miniature bending machine comprises a bottom plate,side plates, guide rails, guide rail plates and a transverse plate; the side plates are distributed on the two sides of the bottom plate and are perpendicular to the bottom plate, the guide rails areinstalled on the side plates on the two sides, the guide rail plates which are distributed outside the guide rails and enable the guide rails to be inlaid and can slide relative to the guide rails, and the transverse plate is installed between the two guide rail plates; an upper profiling mould is arranged on the transverse plate, and a transmission rack is arranged on the inner side face of thetransverse plate; the miniature bending machine further comprises a shaft and a force arm rod, wherein the shaft is inlaid in the two side plates and can rotate relative to the side plates, the forcearm rod is connected to the shaft and can drive the shaft to rotate, and a gear corresponding to the transmission rack is arranged on the shaft; and a concave mould corresponding to the upper profiling mould is arranged on the bottom plate. According to the miniature bending machine, the bending machine is manually driven by the force arm, the longitudinal manual feeding control is realized only by the gear-rack meshing transmission, and the force degree is simple and easy to control; and the bending machine is used for various special-shaped and small sheet metal parts, only the universal upper profiling mould and the universal concave mould need to be manufactured to be directly processed, and the cost is low.

Owner:SICHUAN JIUZHOU ELECTRIC GROUP

Procedure for the dynamic correction of the bending angle of sheet metal on a panel bender machine

ActiveUS9259773B2Improve accuracyReduce the number of bendsShaping safety devicesMetal working apparatusMachine controlMetal sheet

Owner:PRIMA IND

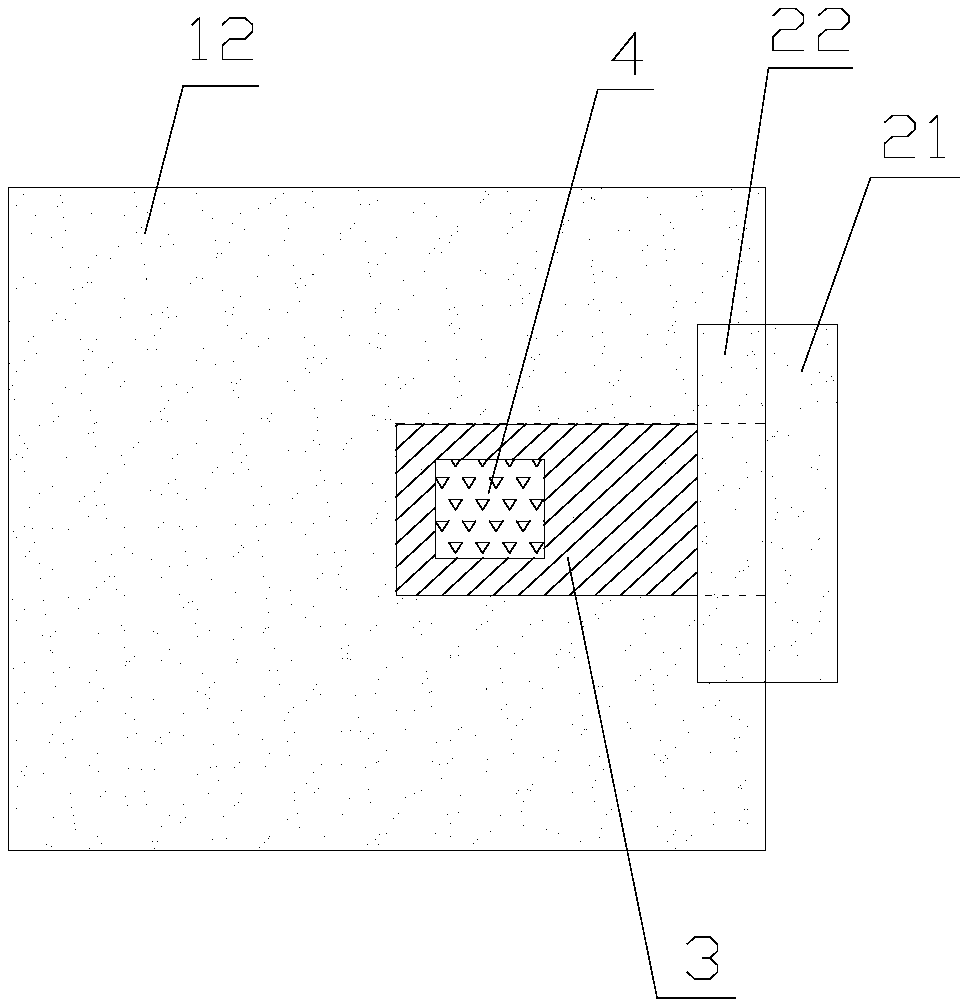

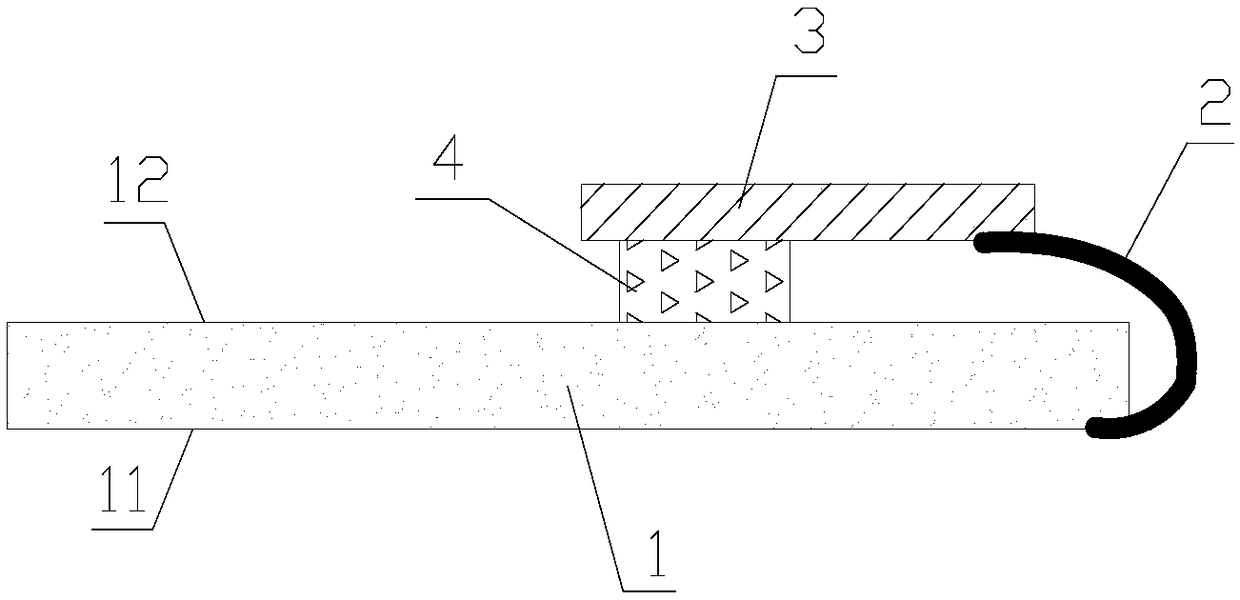

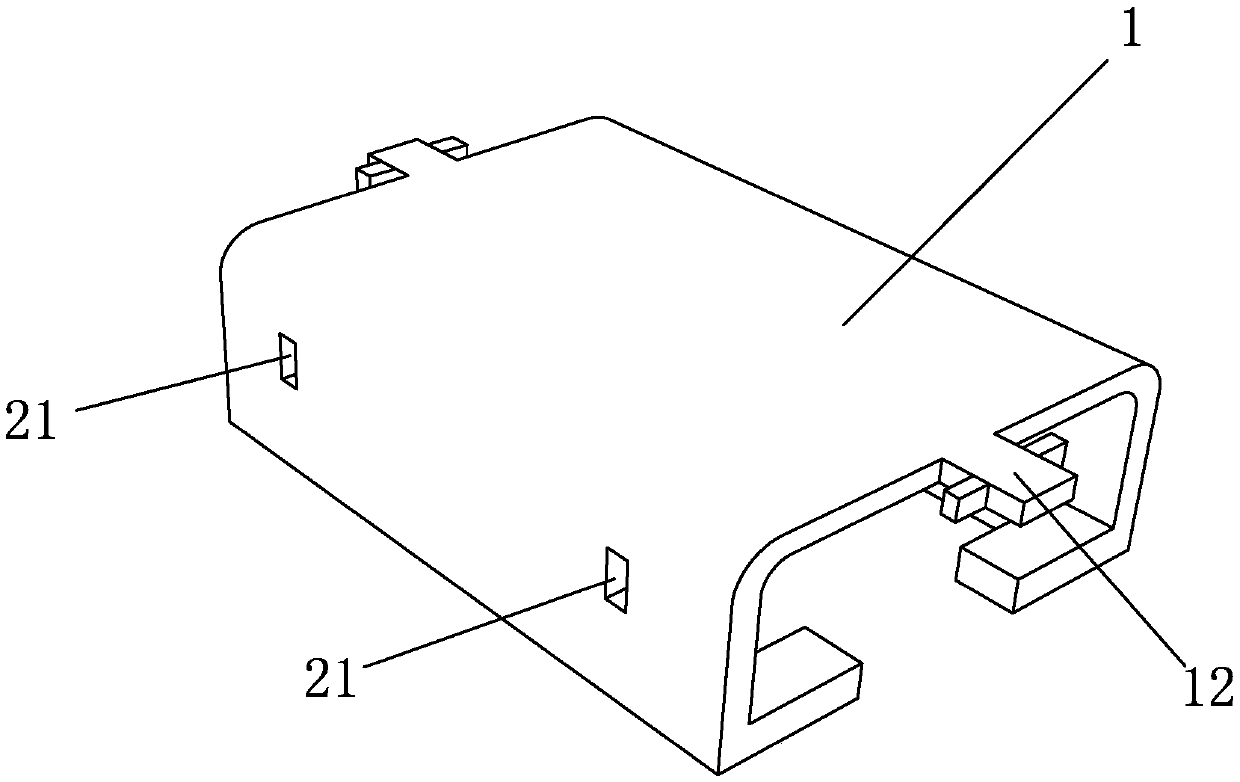

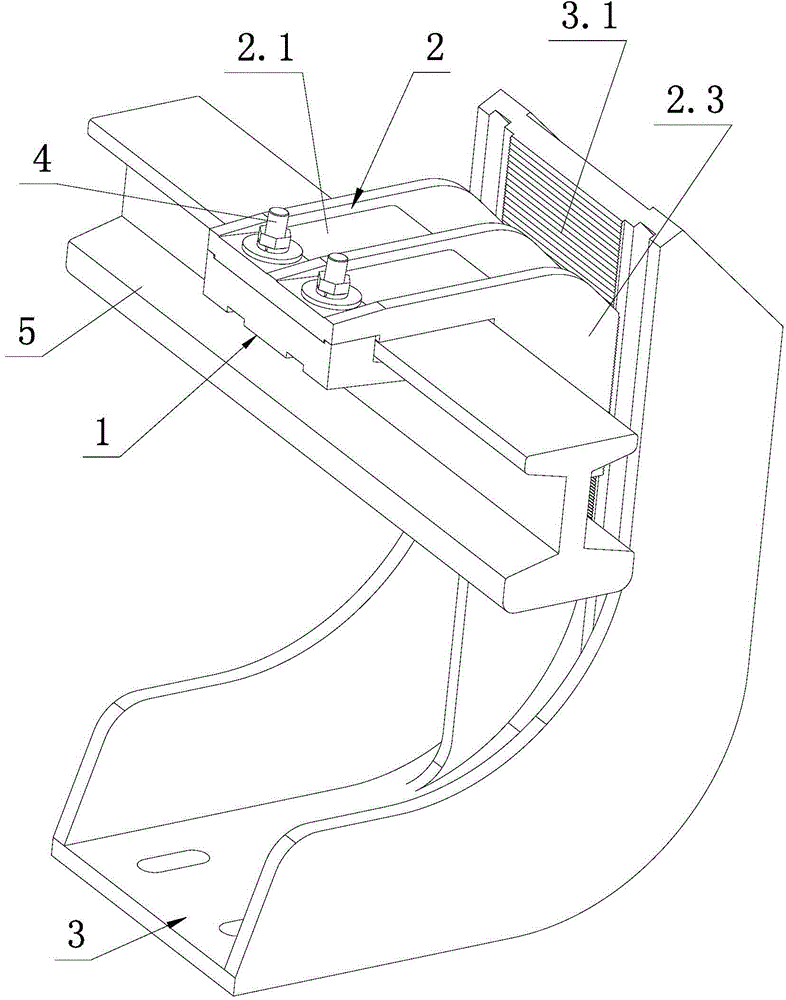

Subway third-rail insulating bracket

The invention discloses a subway third-rail insulating bracket. The subway third-rail insulating bracket comprises an insulating fastener (1), an insulating carrier frame (2) and a base (3), wherein the insulating bracket (2) comprises a top beam (2.1), a lower supporting plate (2.2) and an inclined arm (2.3); the rear end of the top beam (2.1) and the rear end of the lower supporting plate (2.2) are fixed on the front end surface of the inclined arm (2.3); the insulating fastener (1) is composed of a vertical plate (1.1) and an inclined supporting plate (1.2); the upper end surface of the vertical plate (1.1) is a lower inclined surface (1.3); the front end of the bottom surface of the top beam (2.1) is an upper inclined surface (2.4); the insulating fastener (1) is in threaded connection with the top beam (2.1) through a bolt (4) perpendicular to the upper inclined surface (2.4); and the lower supporting plate (2.2), the inclined arm (2.3), the top beam (2.1) and the insulating fastener (1) form a chamber for accommodating the upper part of a third rail (5). The bracket is good in stability and firmness, and can avoid potential safety hazards.

Owner:NINGBO HUAYUAN FRP ELECTRICAL APPLIANCE MFR

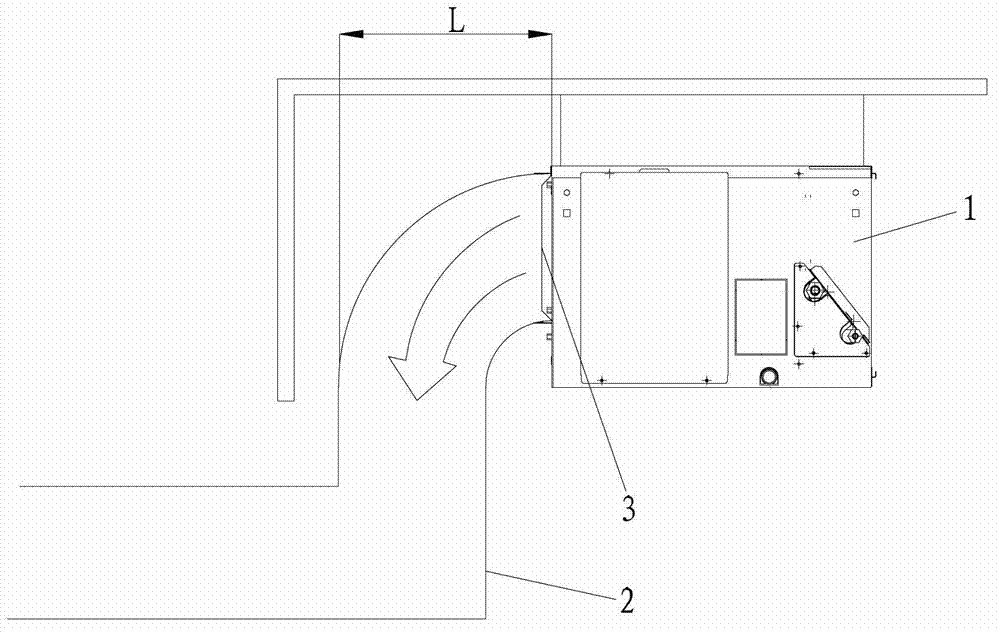

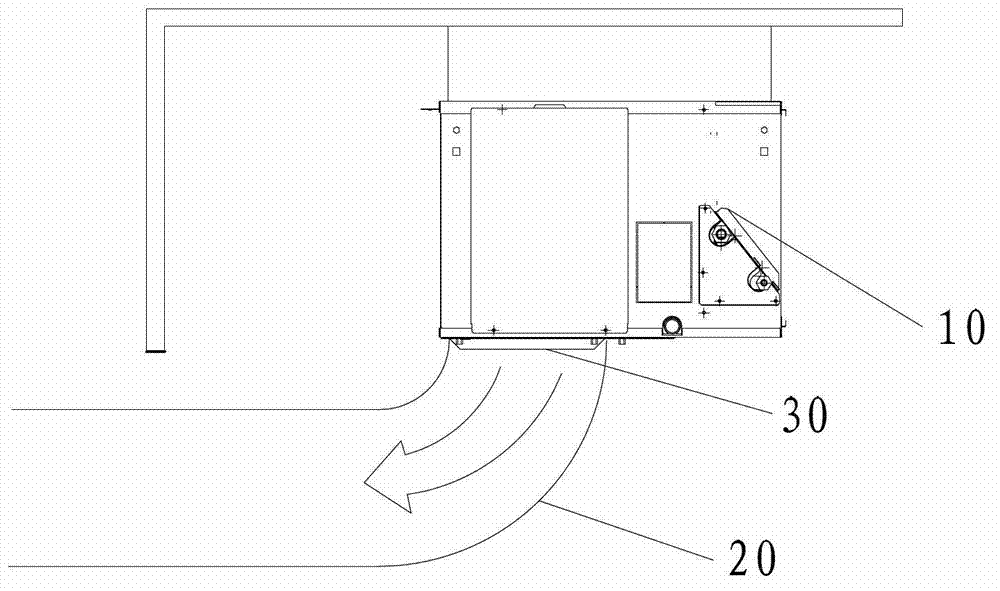

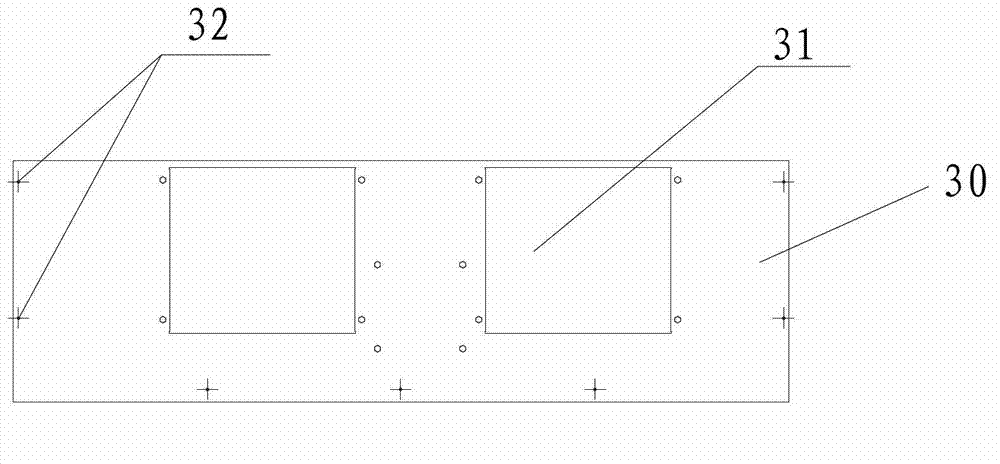

Installing structure of air supplying pipe in air pipe machine and air pipe machine

ActiveCN102778013AReduce the number of bendsReduce material costsDucting arrangementsLighting and heating apparatusEngineeringTuyere

The invention discloses an installing structure of an air supplying pipe in an air pipe machine. The installing structure comprises an air supplying plate, an air pipe machine body and a closing plate, wherein the bottom surface of the air pipe machine body is provided with a first connecting hole for connecting with the air supplying plate, and the side surface of the air pipe machine body is provided with a second connecting hole; the second connecting hole and the first connecting hole have installation interchangeability; the air supplying plate is provided with an air supplying port and first installing holes; the first installing holes are matched with the first connecting hole and the second connecting hole and are used for installing the air supplying plate on the bottom surface and the side surface; the air supplying plate is also provided with a wind wheel and a motor for driving the wind wheel to rotate; the closing plate is provided with second installing holes which are matched with the first connecting hole and the second connecting hole and are used for connecting the closing plate with the bottom surface and the side surface. The invention also provides an air pipe machine with the installing structure of the air supplying pipe in the air pipe machine. The installing structure has the advantages that the installation difficulty of the air supplying pipe can be reduced, the installation convenience is improved and the static pressure loss is reduced.

Owner:MIDEA GRP CO LTD

Radio frequency identification tag antenna applied to dense environment

ActiveCN111478018ASimple structureReduce the number of bendsAntenna supports/mountingsRadiating elements structural formsAxis of symmetryTag antenna

The invention relates to a radio frequency identification tag antenna applied to a dense environment, which belongs to the technical field of wireless antennas. The antenna comprises a tag chip, a loading strip, a radiation patch and a dielectric substrate; the radiation patch comprises a pair of stepped radiation arms, a pair of U-shaped connecting arms, a pair of L-shaped connecting arms and linear connecting arms; the linear connecting arms are symmetrical relative to the symmetry axis of the tag antenna; the pair of stepped radiation arms, the pair of U-shaped connecting arms and the pairof L-shaped connecting arms are all located on the inner side of the linear connecting arms, and the loading strip is located on the outer side of the linear connecting arms; the loading strip is in alinear strip shape and is parallel to the linear connecting arms; when the distance between the loading strip and the radiation patch is 2 mm, the maximum power transmission coefficient of the radiofrequency identification tag antenna is greater than 0.7. When the tag antenna is located in an environment with a large distance between tags, the tag antenna also has a wide frequency band and stable performance. The radio frequency identification tag antenna is simple in structure and good in production manufacturability.

Owner:HEFEI UNIV OF TECH

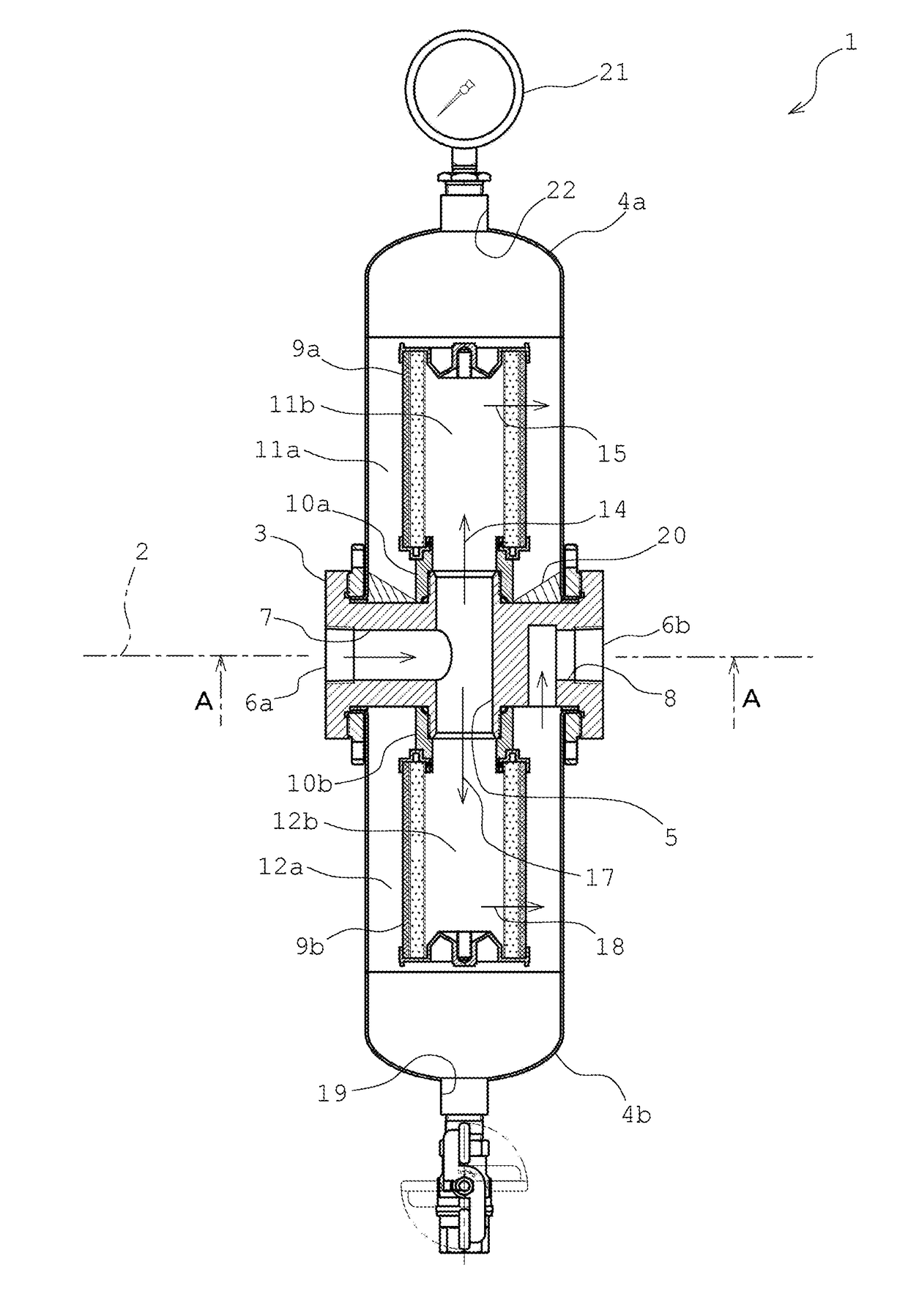

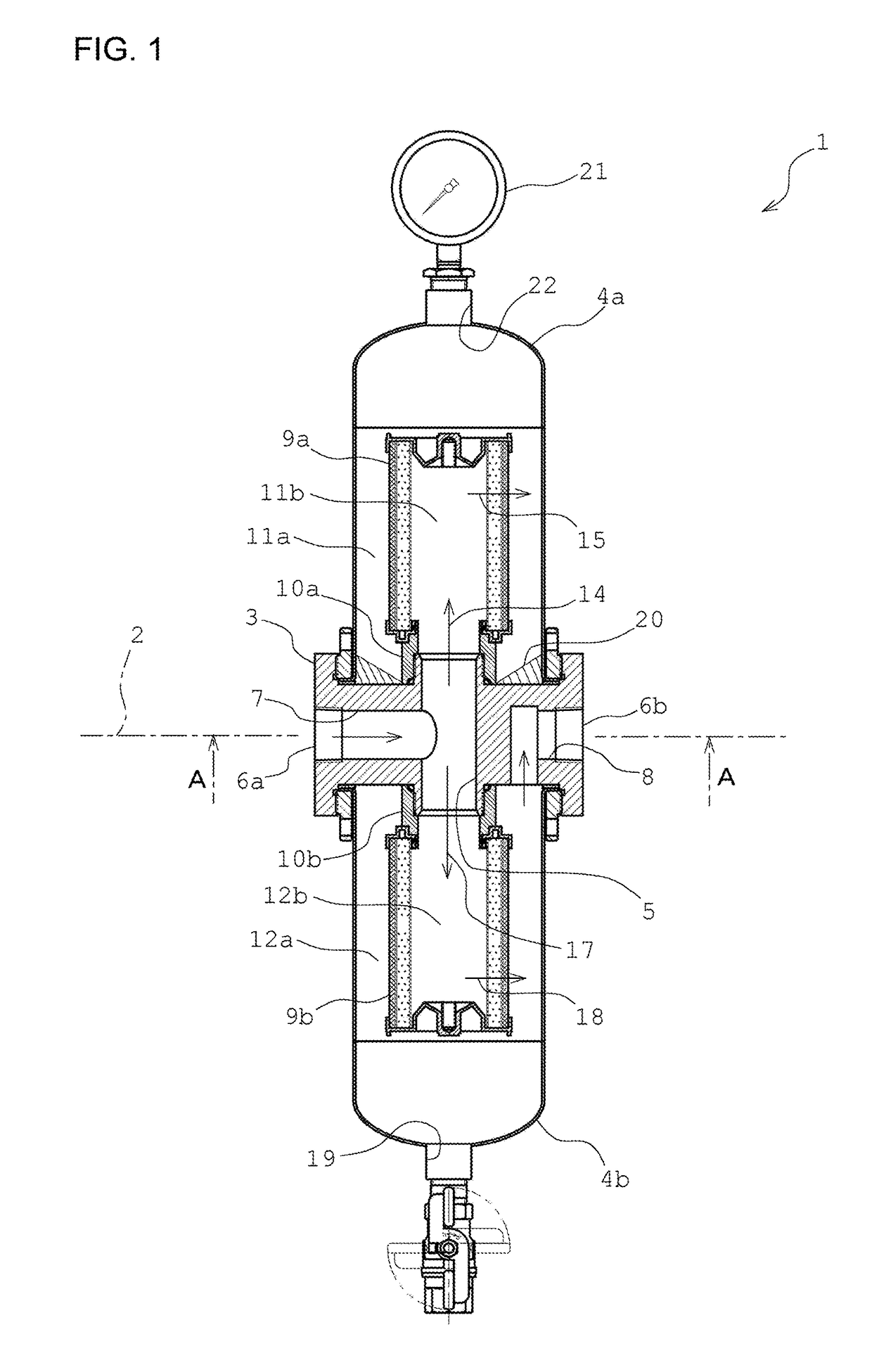

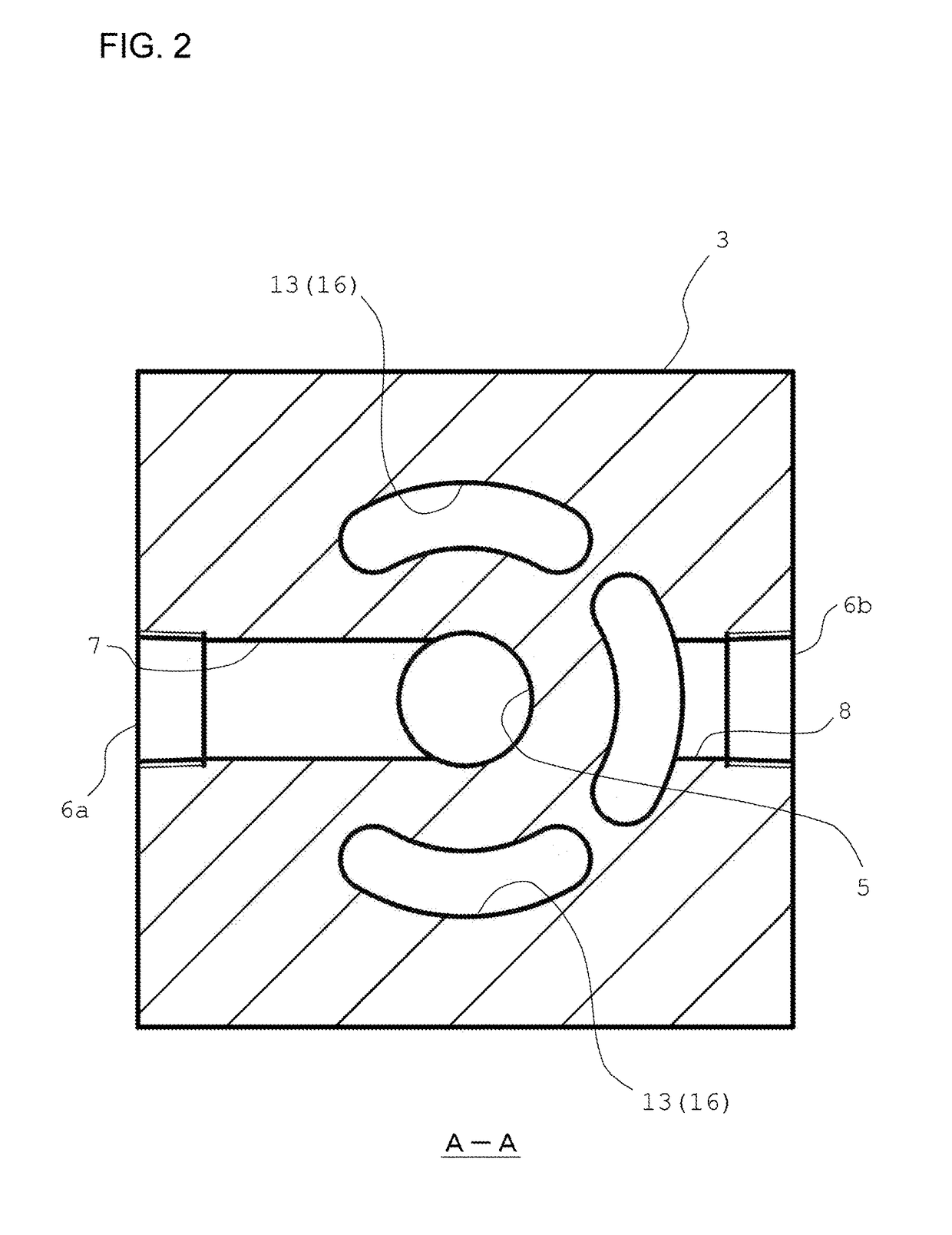

Filter apparatus for compressed air

ActiveUS20170232375A1High trafficReduce the number of timesGas treatmentDispersed particle filtrationEngineeringOuter space

A compressed air filter apparatus includes a main flow path as a flow path in which compressed air should circulate, formed in a body to extend from a first opening into a penetration hole, an upper inner flow path extending from the penetration hole to an upper inner space, an upper inner and outer flow path extending from the upper inner space to an upper outer space to pass through an upper filer element, a communication flow path extending from the upper outer space to a lower outer space to pass through a communication hole, a secondary flow path extending from the lower outer space to a second opening, a lower inner flow path extending from the penetration hole to a lower inner space, and a lower inner and outer flow path extending from the lower inner space to the lower outer space to pass through a lower filter element.

Owner:FUKUHARA KK

Spraying type weaving machine

The present invention provides a water jet type loom, which is equipped with: a weft insertion pump for feeding the water used for the weft insertion and arranged at the side surface of outside of a loom frame of its yarn feeding side and a nozzle unit including a weft insertion nozzle arranged at almost the same height with a warp line at more warp yarn row side than the loom frame. The water-supplying tubes are arranged so that: among water supplying tubes connected to the nozzle unit from the weft insertion pump, the center of the tubular passage positioned within the presenting range of the loom frame associated at least with the width direction of the loom is positioned at the lower part of the height position of the upper surface of the loom frame. The object of the present invention is to provide a water jet type loom capable of performing weft insertion stably.

Owner:TSUDAKOMA KOGYO KK

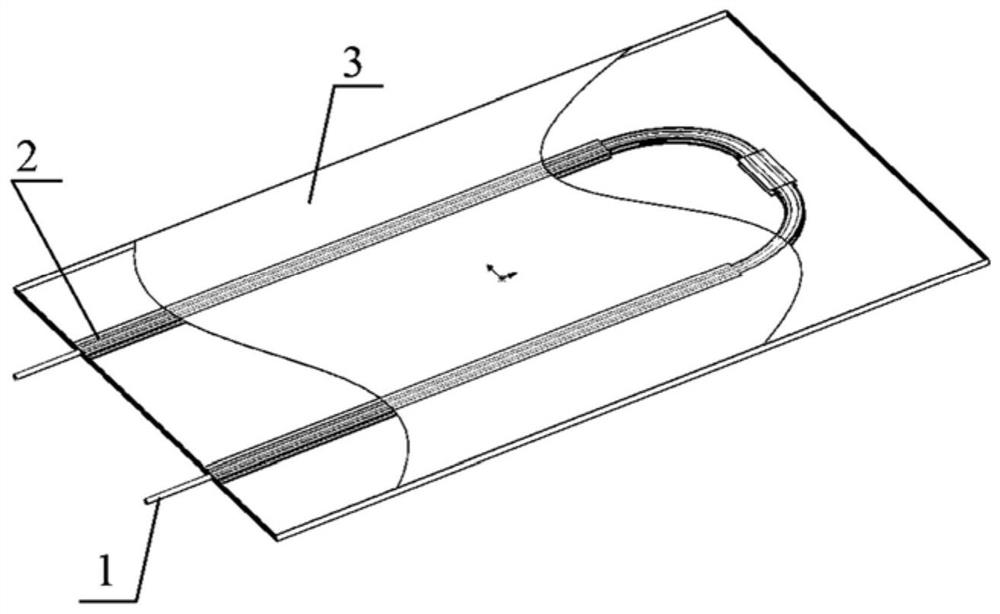

Phase change type radiator

InactiveCN111806730AReasonable structureEasy to useCosmonautic environmental control arrangementCosmonautic vehiclesHoneycombEngineering

The invention provides a phase change type radiator. The phase change type radiator comprises an inlet and outlet pipeline (1), a fluid pipeline (2) and a honeycomb plate (3). The fluid pipeline (2) is provided with a phase change structure; the fluid pipeline (2) is bent into a U-shaped structure; the inlet and outlet pipeline (1) is connected with the fluid pipeline (2); and the fluid pipeline (2) is buried in the honeycomb plate (3). The invention provides the phase change type radiator which is composed of the fluid pipeline with a phase change structure, a honeycomb plate, and the inlet and outlet pipeline, the inlet and outlet pipeline is located at the two ends of the fluid pipeline with the phase change structure, and the upper surface and the lower surface of the fluid pipeline with the phase change structure are connected with an inner surface skin of the honeycomb plate.

Owner:SHANGHAI LIZHENG SATELLITE APPL TECH CO LTD

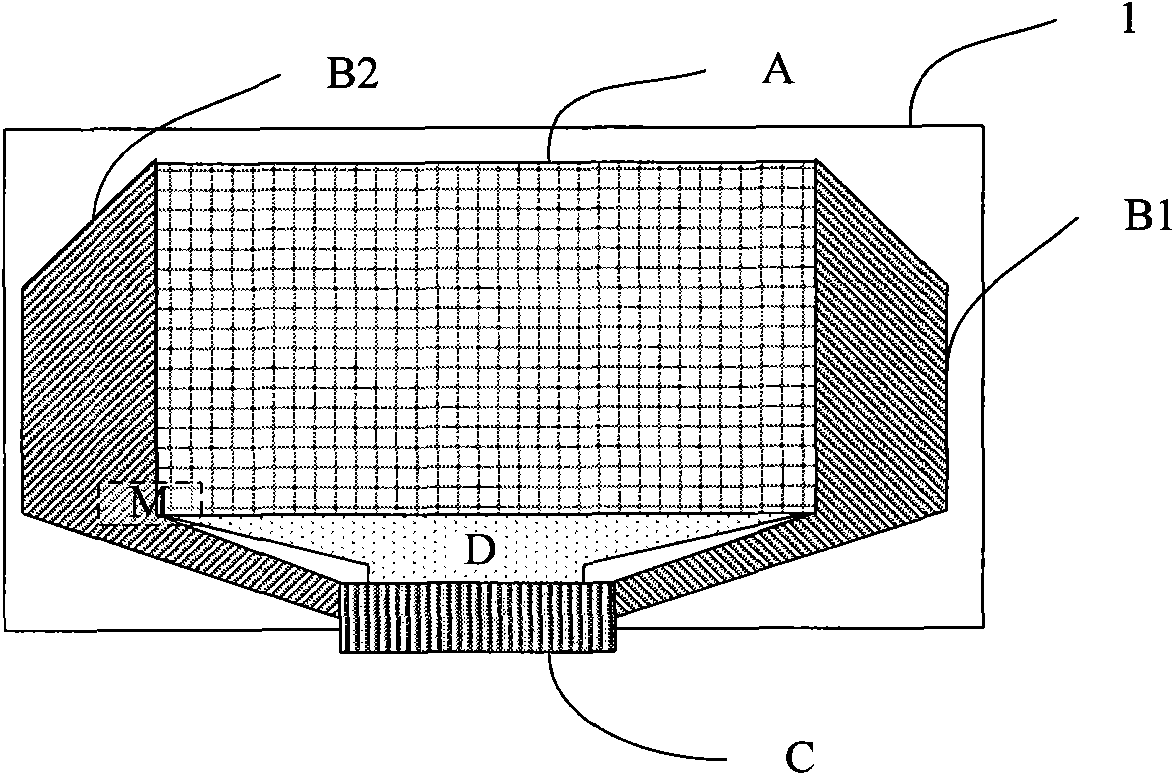

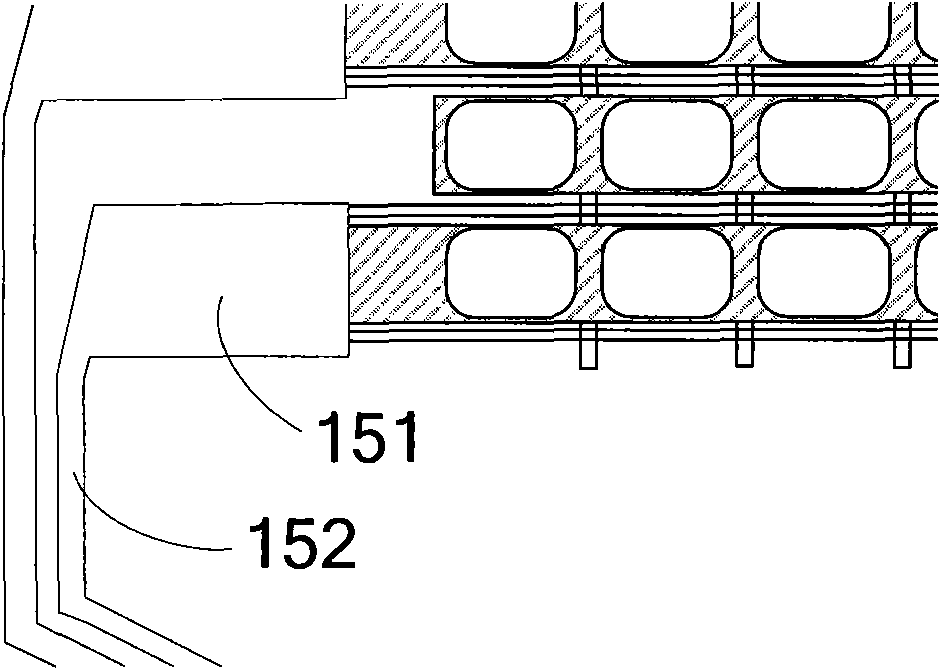

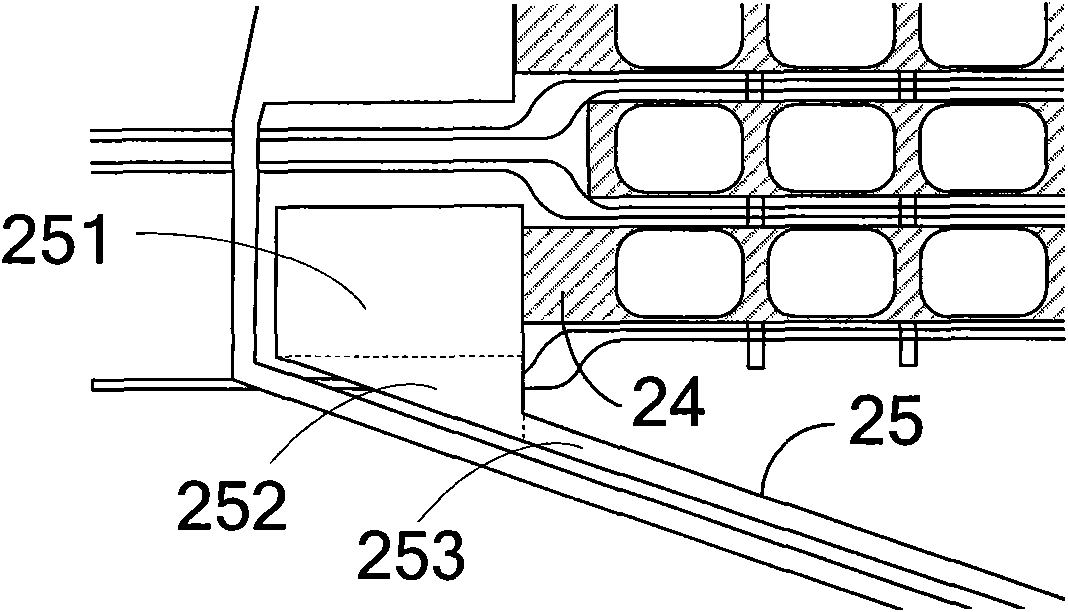

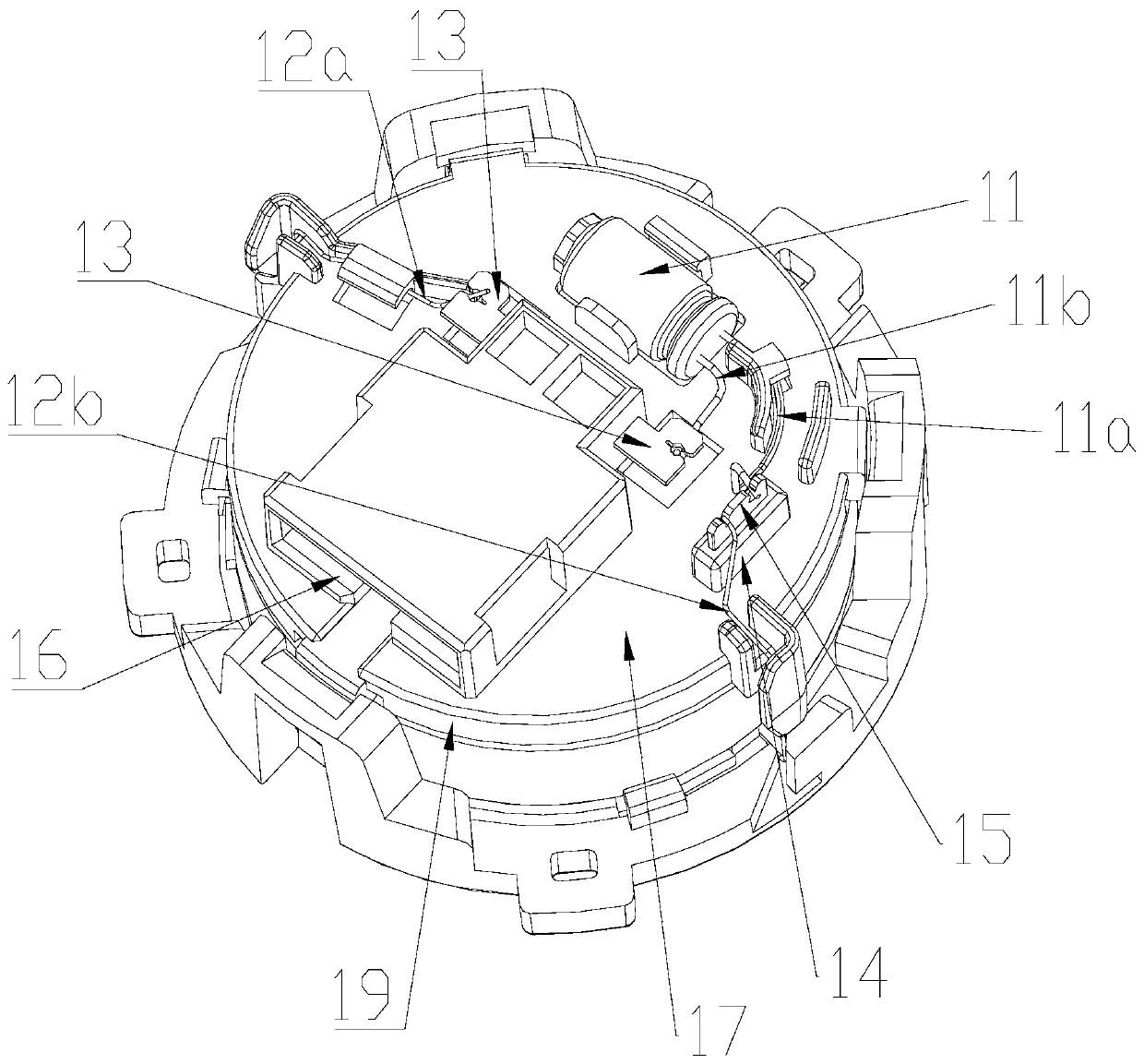

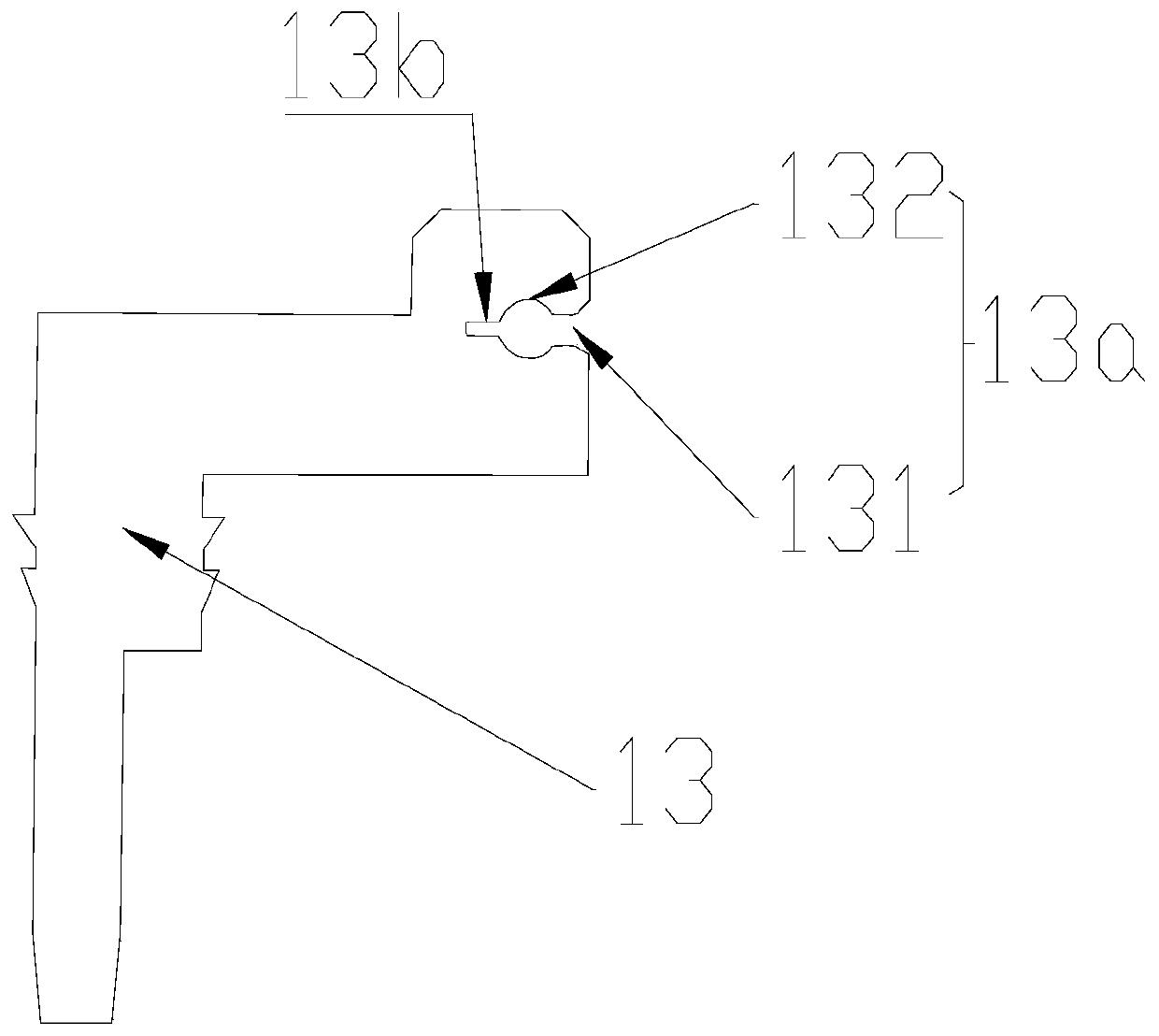

Socket device of sounding device and sounding device

ActiveCN110545510AReduce the number of conductor bendsSimple structureElectrical transducersLoudspeakersEngineeringElectrical conductor

The invention discloses a socket device of a sounding device and the sounding device. The socket device comprises a cylindrical side wall part and a bottom part arranged at one end of the cylindricalside wall part in a sealing manner; a plurality of wiring terminals are arranged on the outer surface of the bottom part; the plurality of wiring terminals comprise a first terminal; the first terminal is provided with a first side edge opposite to the outer surface, the first side edge is recessed inwards to form a first clamping groove and a second clamping groove, the first clamping groove is configured to be used for being connected with a conductor of a first component, and the second clamping groove is configured to be used for being connected with a conductor of a second component. Thesocket device provided by the invention is very easy to operate during assembly and is suitable for industrial production.

Owner:潍坊歌尔丹拿电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com