Spraying type weaving machine

A loom, water jet technology, applied in looms, textiles, textiles and paper making, etc., can solve the problems of reducing the convergence of jet water, unable to perform stable weft insertion, and detrimental to the stability of weft insertion. The above problems, the effect of preventing increase in resistance, and preventing early breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

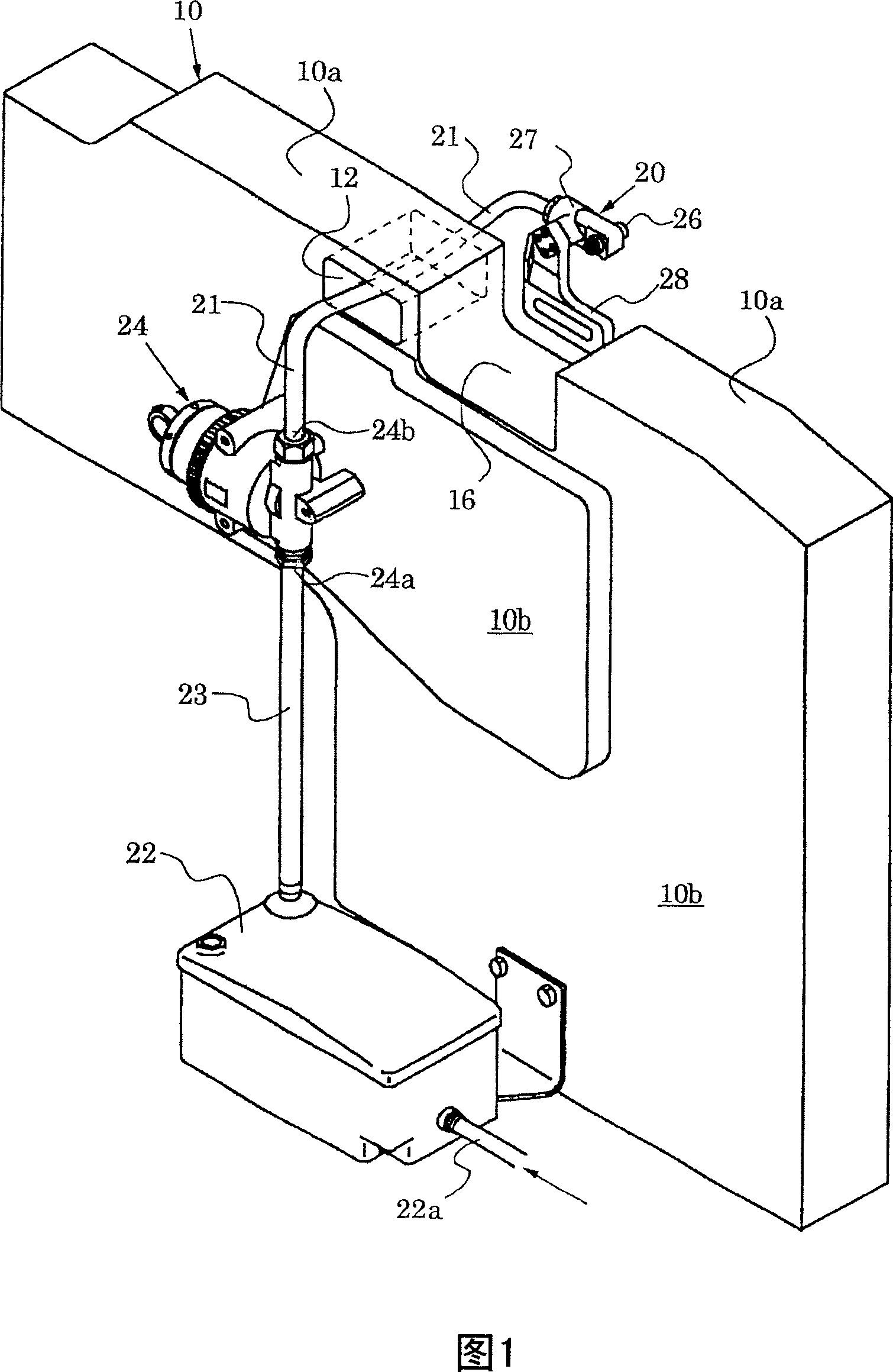

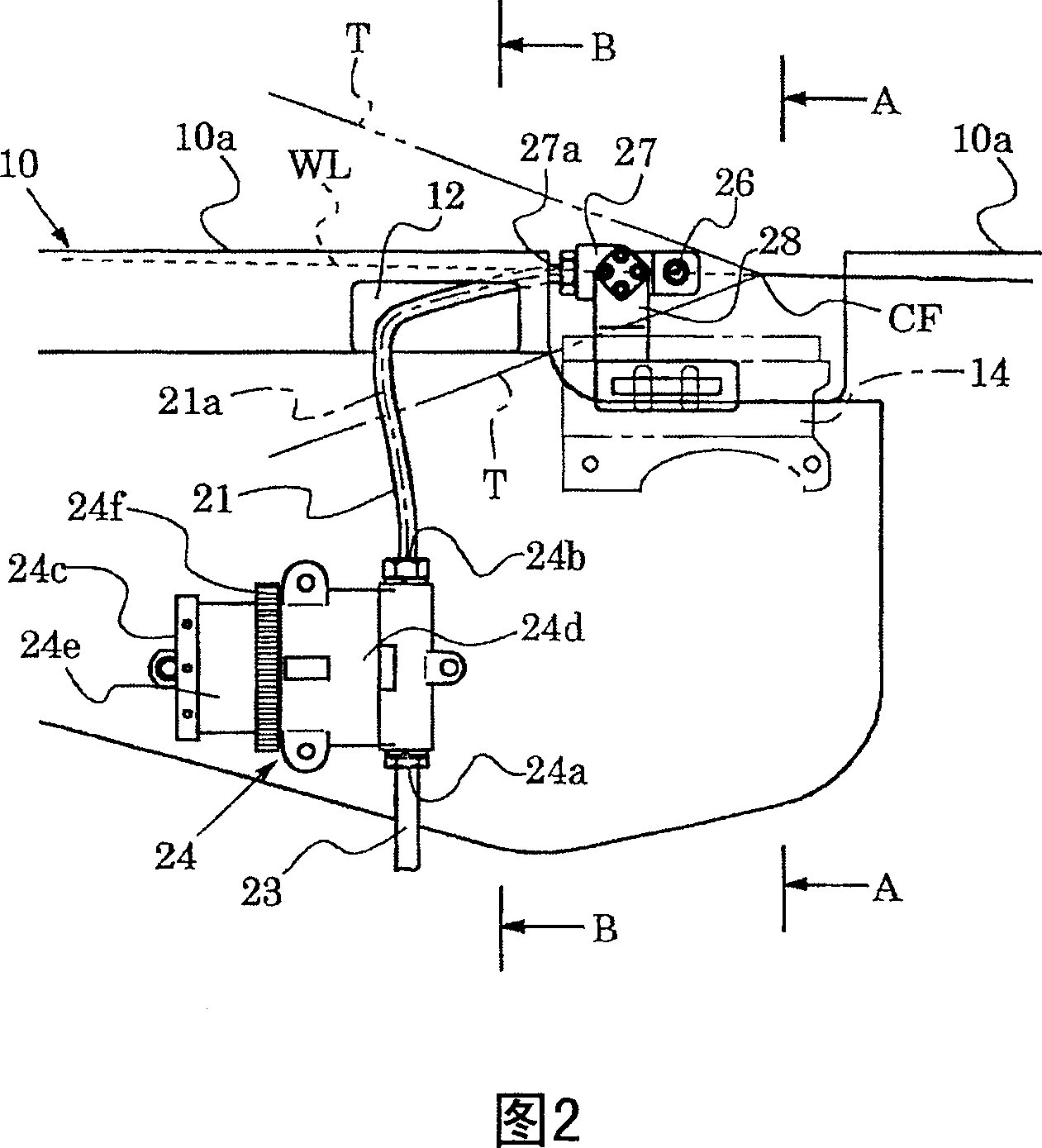

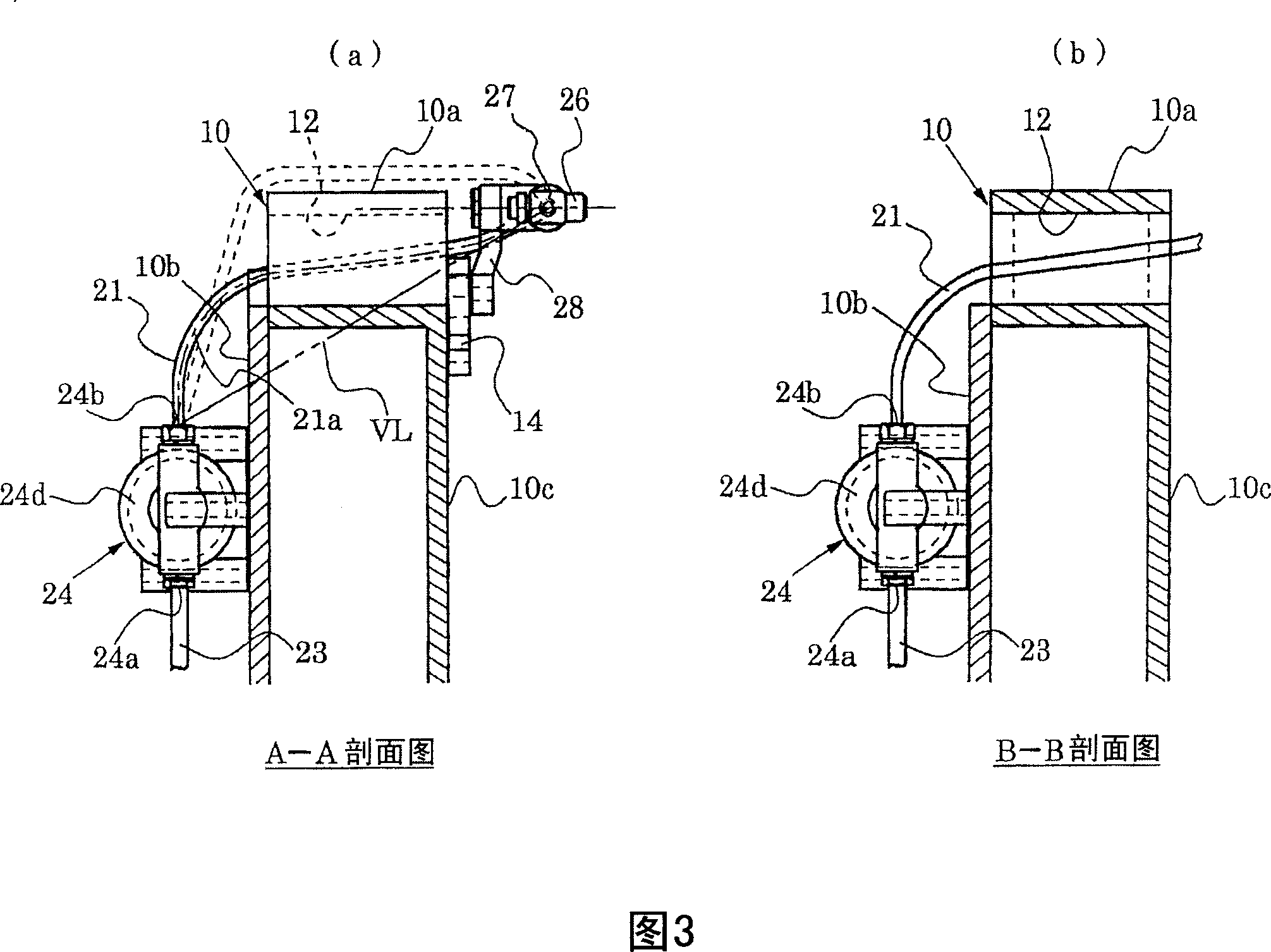

[0027] Shown in Fig. 1~4 is an embodiment of the present invention, have shown the frame 10 that is suitable for the yarn supply side of the water-jet loom of the present invention and the weft insertion that is attached to the frame 10 in Fig. 1 A sketch of the device.

[0028] The weft insertion device includes a constant water level water tank 22 supplied with water from a water supply source not shown, a weft insertion water pump 24 and a nozzle unit 20 . The constant water level water tank 22 is disposed on the ground near the outer side (the side opposite to the warp row (opposite to the fabric) side) 10b of the frame 10, and is connected to a water supply source with a water supply pipe 22a.

[0029] The water pump 24 itself for weft insertion is a well-known pump, and generally consists of a main body portion 24d that stores water when sucked in, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com