Method for designing thin walled pipe numerical control snake core mould parameter

A technology of parameter design and bending core, applied in the direction of electric digital data processing, calculation, metal processing equipment, etc., can solve problems such as unreasonable parameter design or installation of core mold, non-universal, production problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

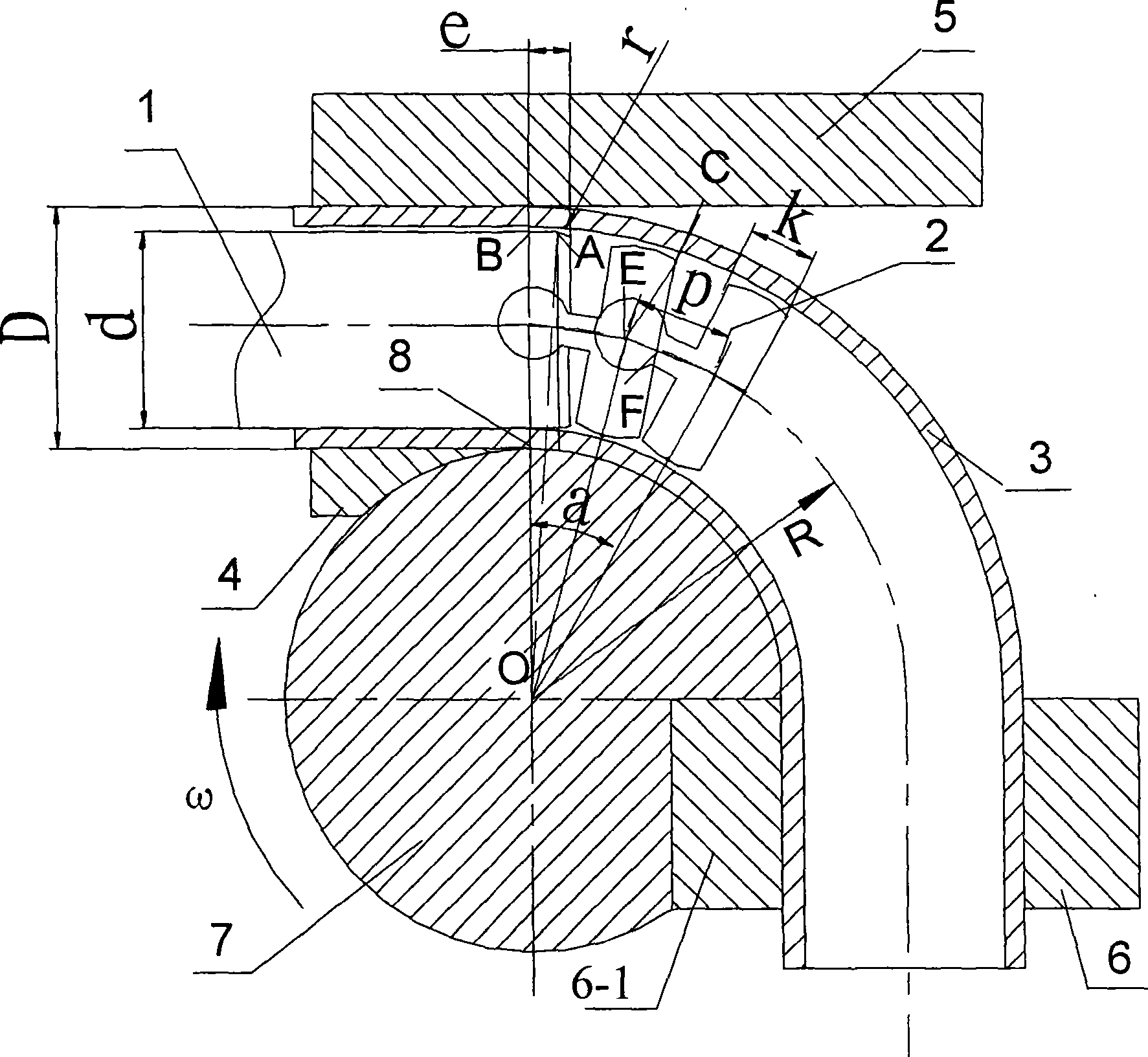

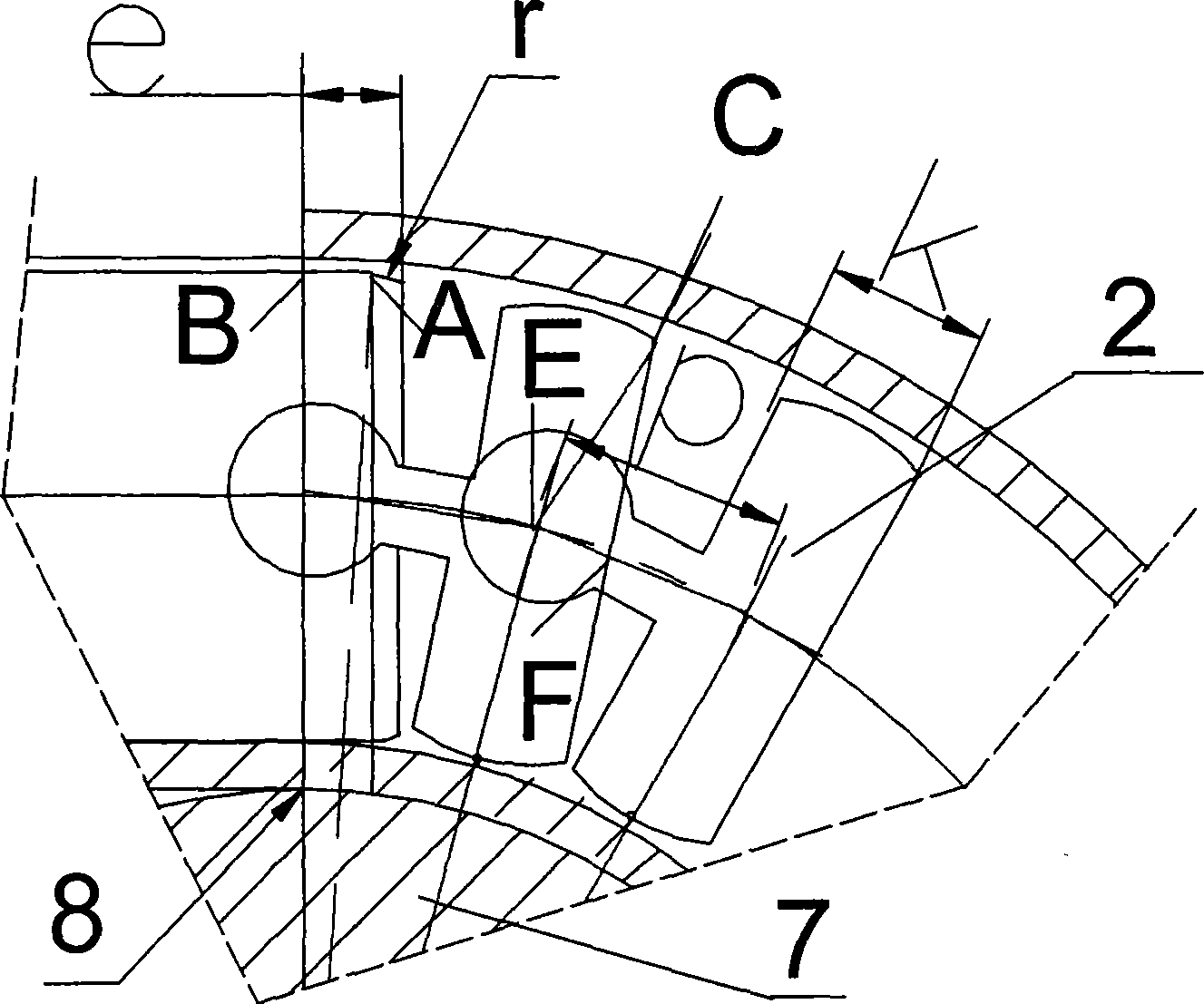

[0040] According to the above reference formula, the parameters of the mandrel of the NC pipe bending are pre-designed, and the reference values of the mandrel parameters corresponding to the 5 different pipe bend specifications are obtained by solving, so as to guide the finite element modeling and facilitate the design and experiment of the actual production mold Quick selection of reasonable parameters during mold adjustment.

[0041] The pipe bending specifications are 38×1×42 (pipe outer diameter×wall thickness×central line bending radius), 38×1×57, 50×1×75 and 50×1×100. The derivation process is as follows:

[0042] (1) Due to the pipe / mandrel gap C max When it does not exceed 20% of the wall thickness, it can ensure that no instability and wrinkling will occur, so the pipe / mandrel gap c max The value is 0.2mm, and the minimum mandrel diameter corresponding to the bending process of different bending specifications can be obtained according to formula (1). Furthermo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com