Bending pipe numerically-controlled instruction-generating method considering springback compensation

A technology of springback compensation and command generation, which is applied in the direction of program control, computer control, general control system, etc., can solve the problems of low forming quality of parts, many factors affecting springback, and difficult springback prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] A method for generating numerical control commands for bending pipes considering springback compensation, the method comprising the following steps:

[0052] Step 1. Calculate the springback of the elbow

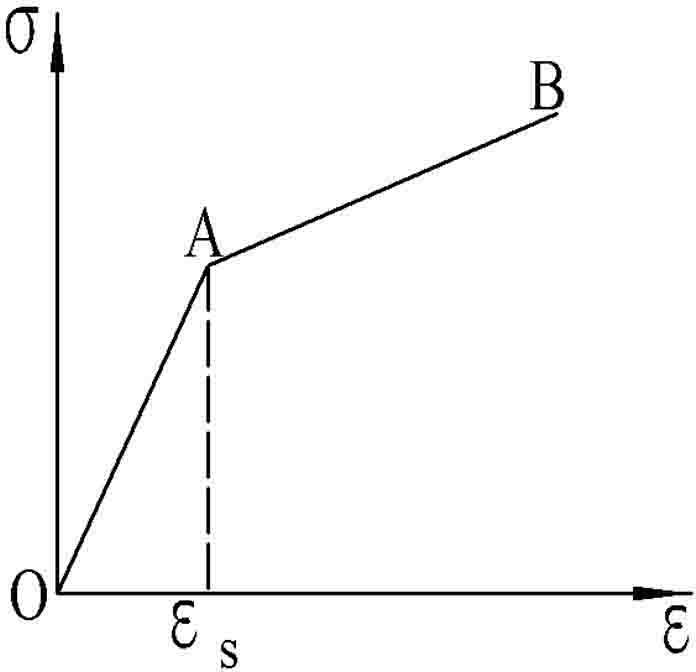

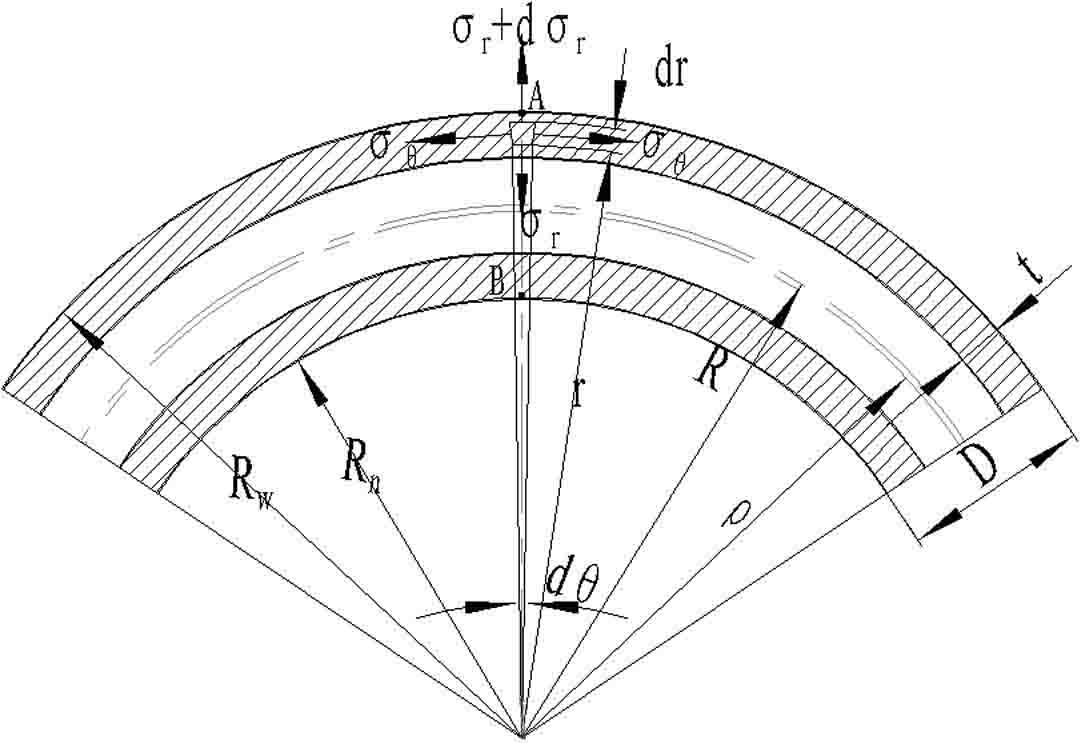

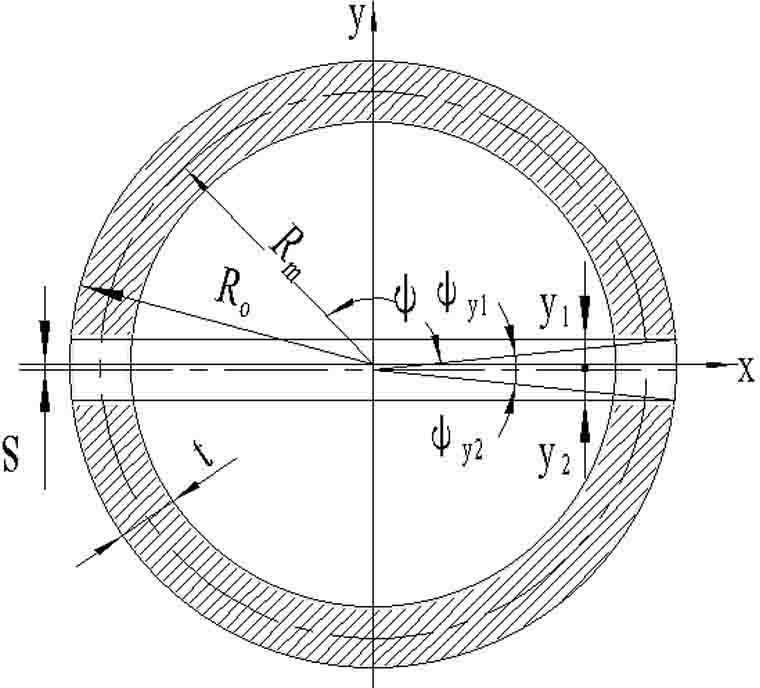

[0053] In step 1, the springback calculation adopts a bilinear strengthening model, see figure 1 , , E and E 1 are the slopes of line segments OA and AB, respectively. This approximate mechanical model is accurate enough for some materials, and if the slope of AB is small enough, it can be considered as an ideal elastoplastic body. Because the plastic forming of pipes is a complex process, in order to analyze the springback of pipes, the following assumptions are adopted: 1) The material volume is constant; 2) The material is homogeneous and isotropic; 3) Assuming a flat section, the section is still vertical after bending 4) Stress-neutral layer and strain-neutral layer overlap, but neutral layer shift occurs; 5) Distortion of pipe section, wall thickness chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com