Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Reduce manual configuration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

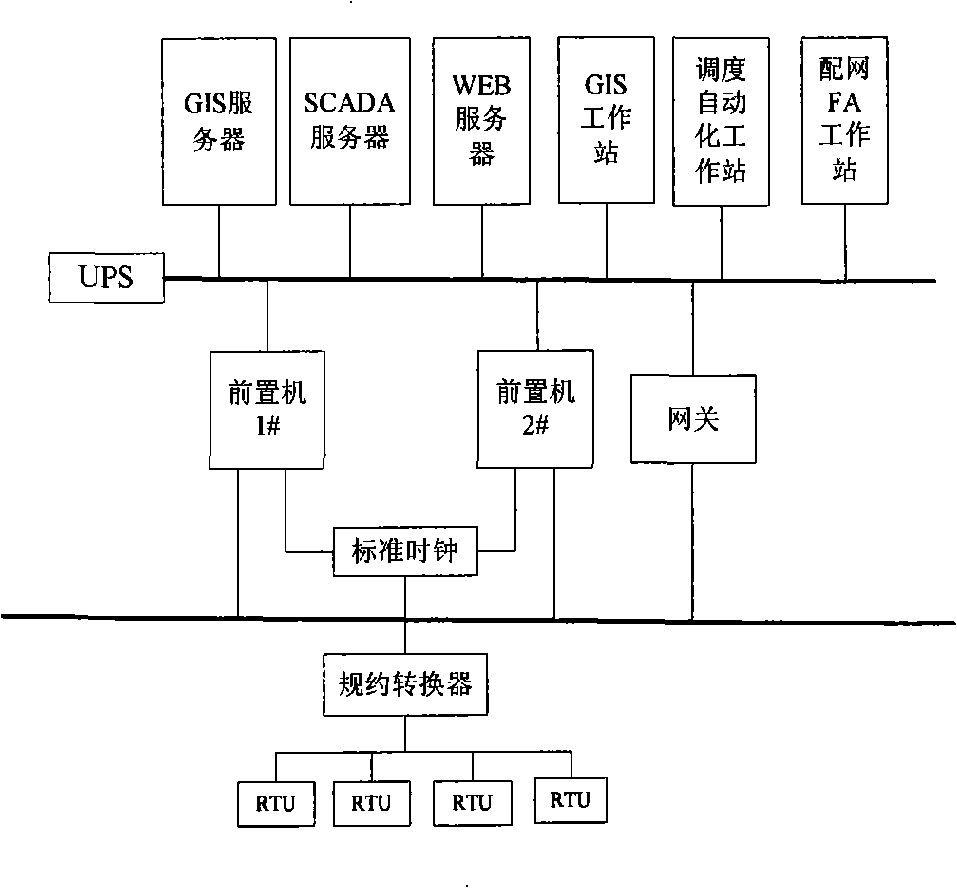

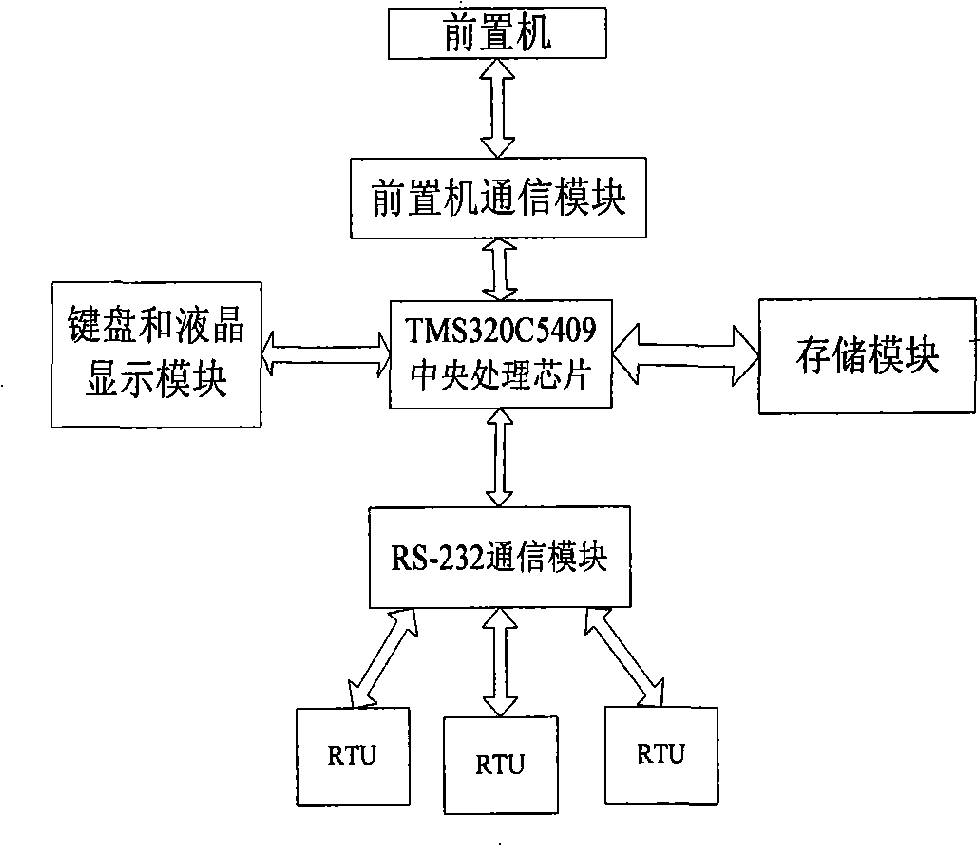

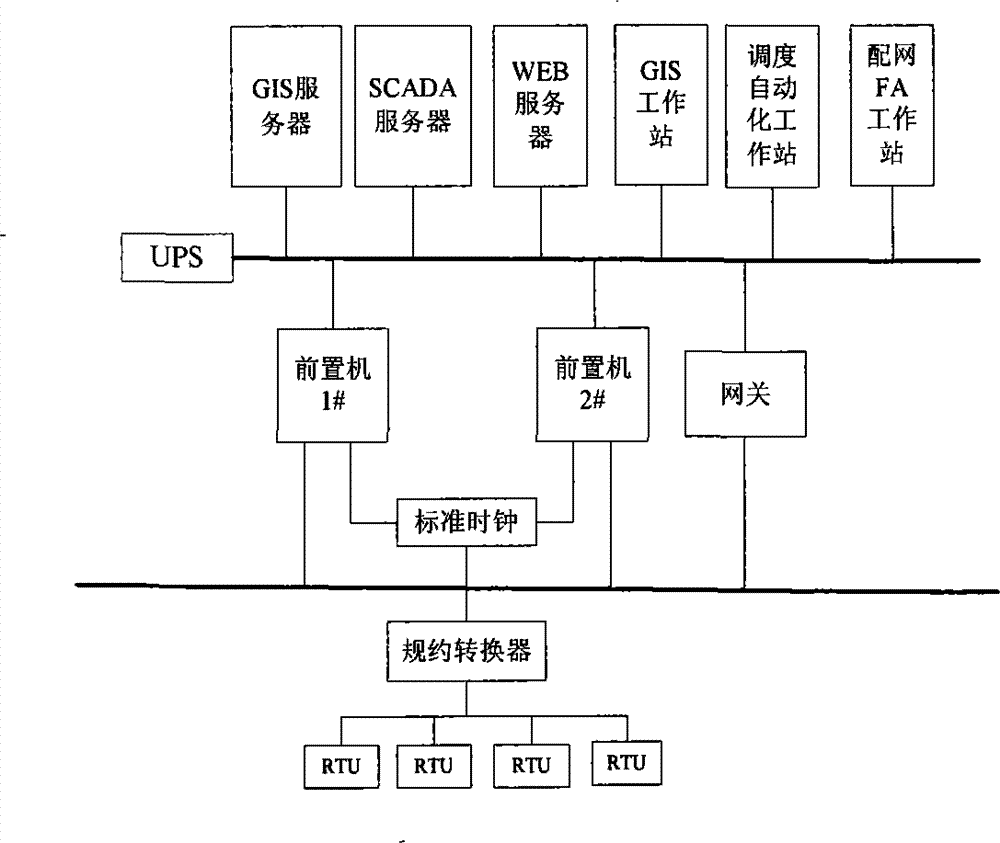

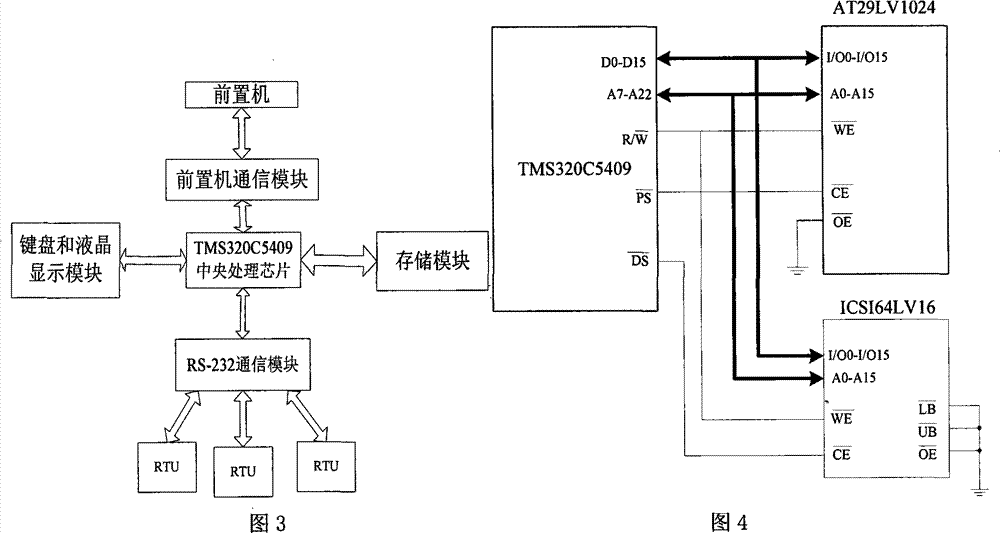

An intelligent protocol conversion device and method based on embedded QNX operating system

InactiveCN101267448AReduce manual configurationImplement automatic conversionElectric signal transmission systemsTransmissionCommunications systemOperational system

The invention provides a device and a method for intelligent terms conversion. The device comprises a DSP central processing chip, a memory module, a display and keyboard operation module and an uplink-downlink communication module, wherein the memory module, the display and keyboard operation module and the uplink-downlink communication module are connected with the DSP central processing modulerespectively, a front-end computer communication module is connected with a front-end computer through a RS-232 bus, a RS-232 communication module is connected with a plurality of sub-stations RTU bya serial expansion circuit, a term converter is arranged between the RTU and the front-end compute of a power communication system, the uploaded communication protocol of the sub-stations RTU are intelligently recognized by a fuzzy expert system, the format of the recognized terms are converted into a unified terms format, uploaded to the front-end computer, and uploaded to each level of workstation by the front-end computer. The invention has the advantages that operators can realize automatic recognition and conversion of terms of interconnected two parties by the device without knowing theterms types of the interconnected two parties, thus avoiding the error possibly brought by manual operation.

Owner:NORTHEASTERN UNIV +2

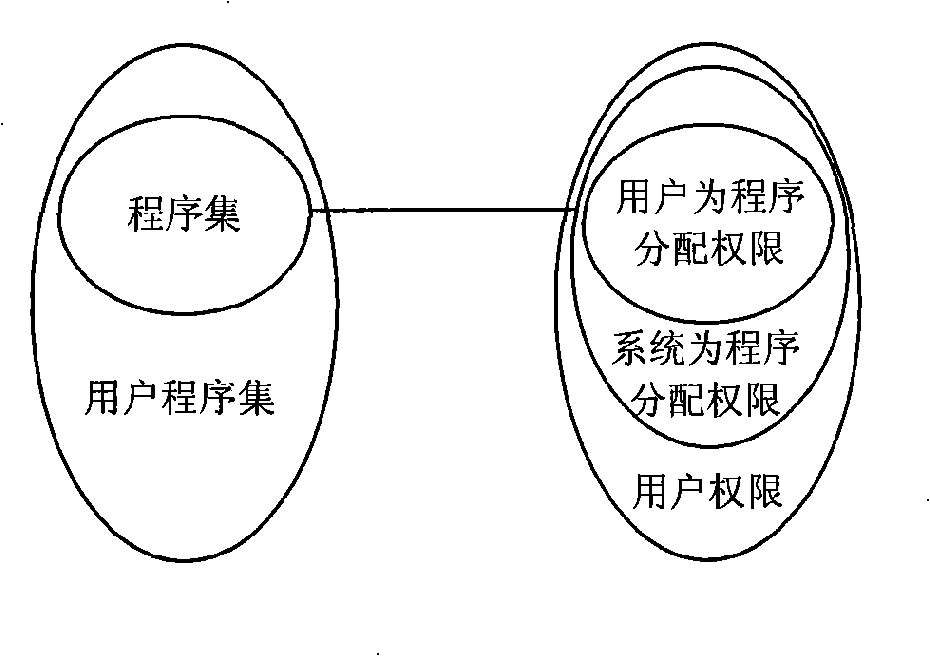

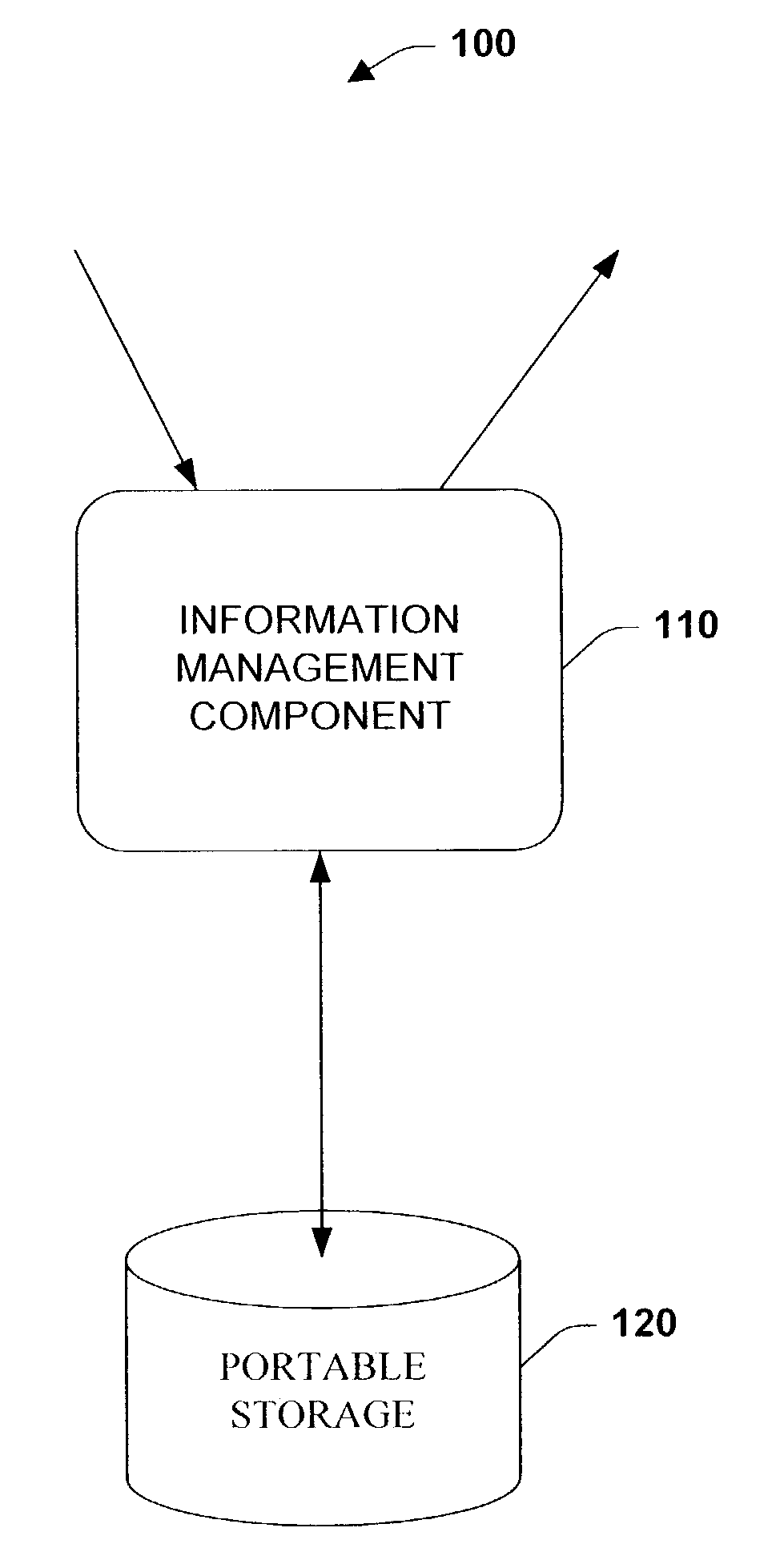

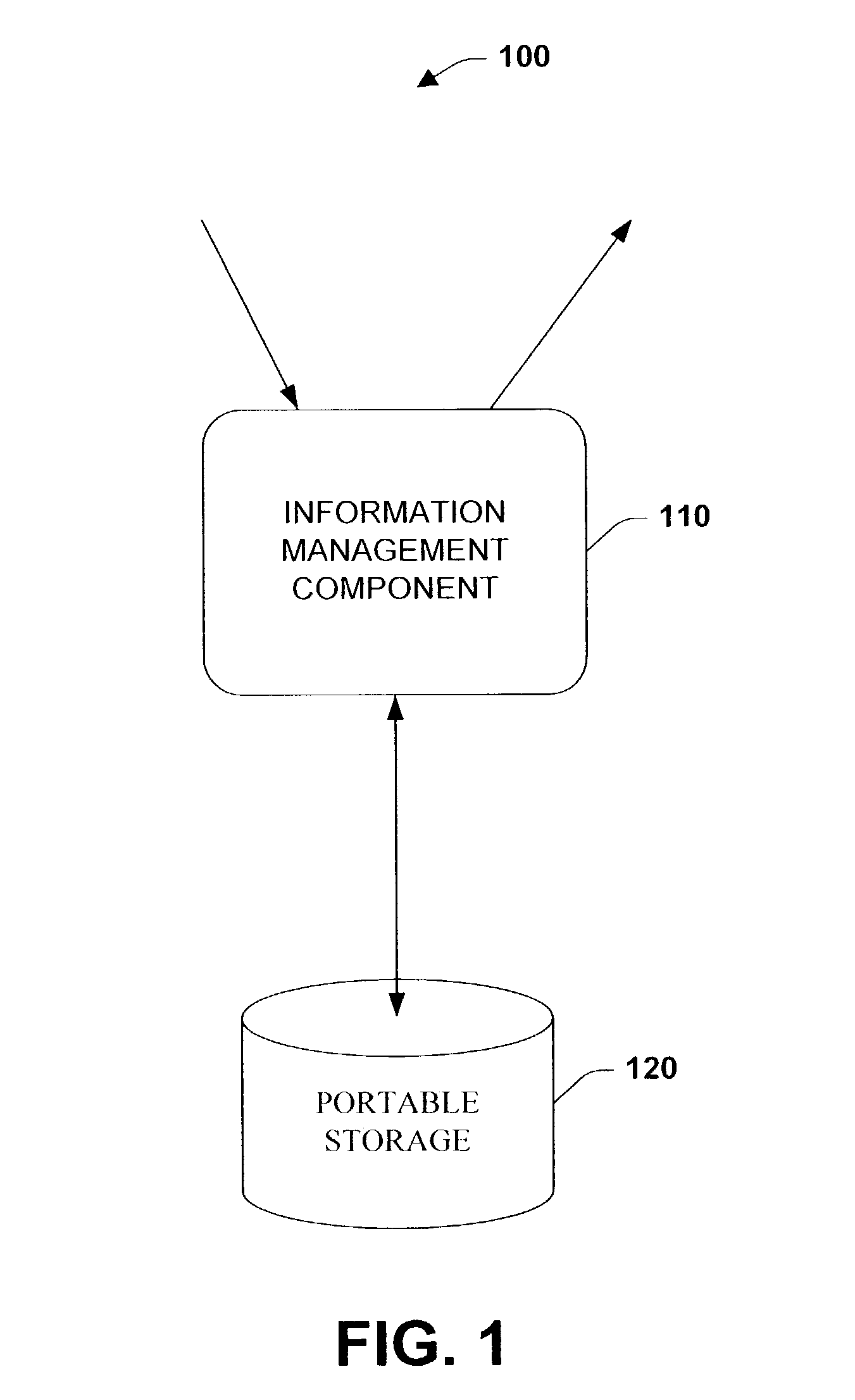

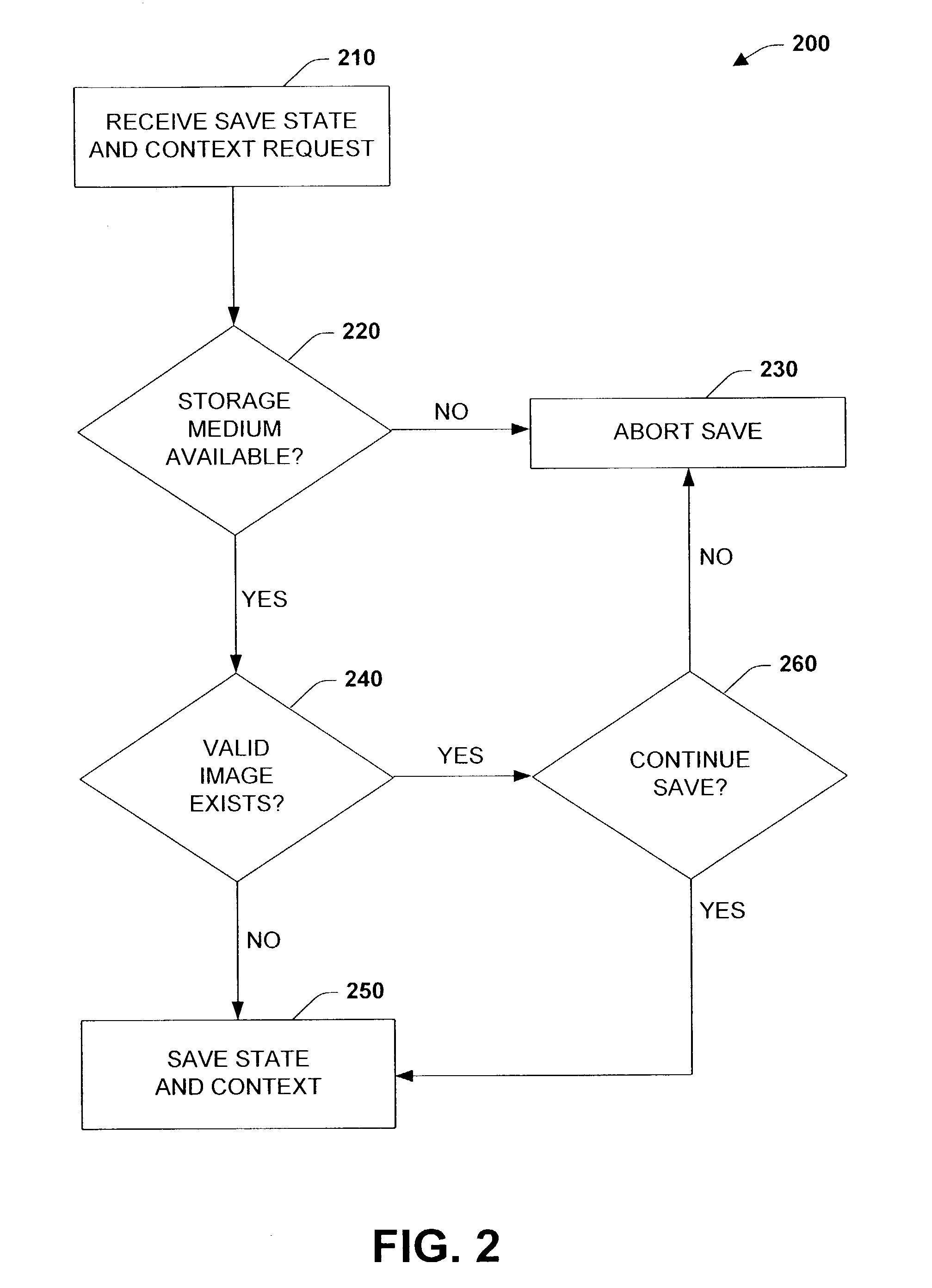

Systems and methods to port controller state and context in an open operating system

InactiveUS7050859B1Reduce manual configurationShorten the timeNumerical controlMicroprogram loadingOperational systemCombined use

The present invention relates to systems and methods to port controller state and context via non-volatile portable memory to controllers employing an open operating system. The present invention provides for saving a controller's state and context, for example after the controller has been suitably configured. The saved image can then be employed for subsequent controller startups to resume a particular state and context, utilized during maintenance to return a controller to a previously saved state and context, and employed to efficiently configure similar controllers via porting and / or loading the saved image to the similar controllers, which mitigates manual controller configuration. The present invention can be employed in connection with various industrial controller designs, memory configurations, and data transfer techniques. In addition, the present invention provides for serial and / or concurrent state and context transfers between controllers and memory devices.

Owner:ROCKWELL AUTOMATION TECH

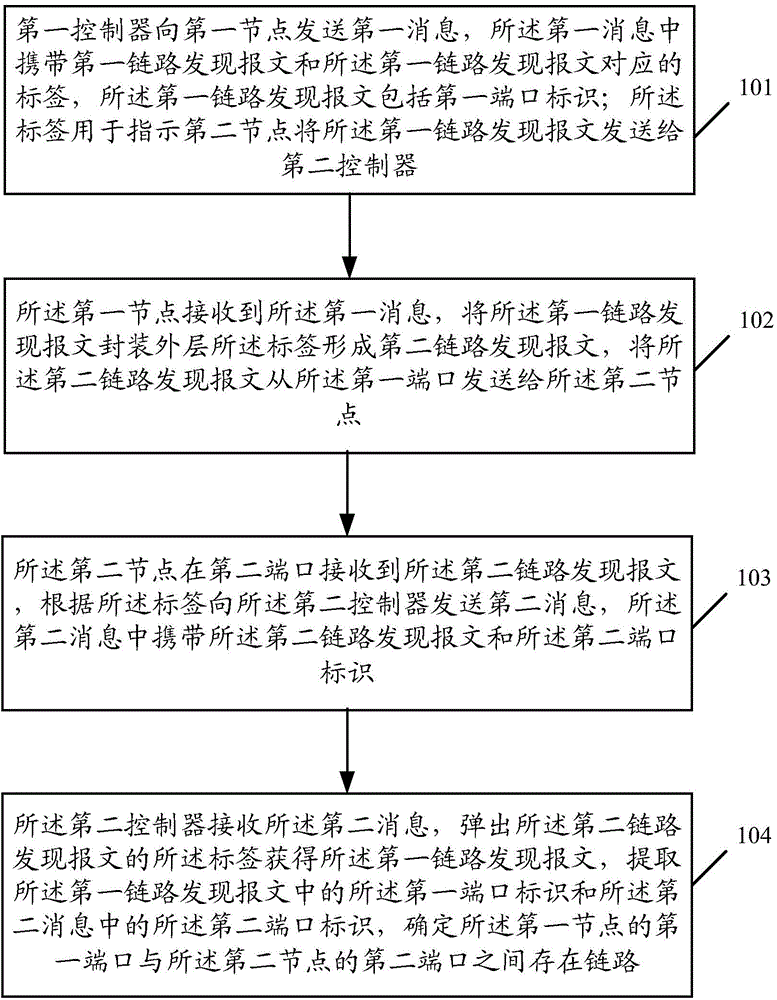

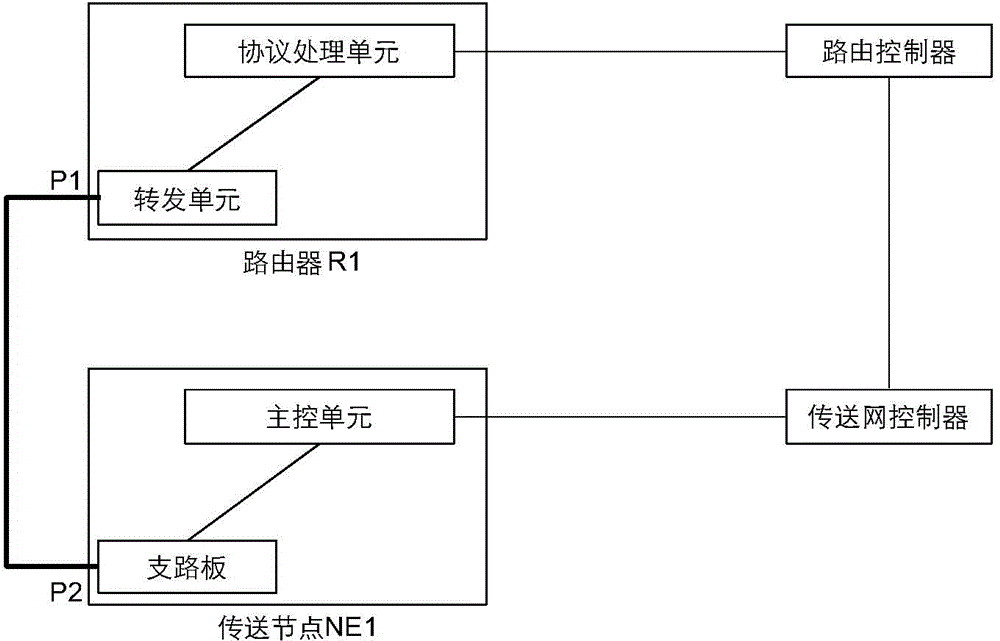

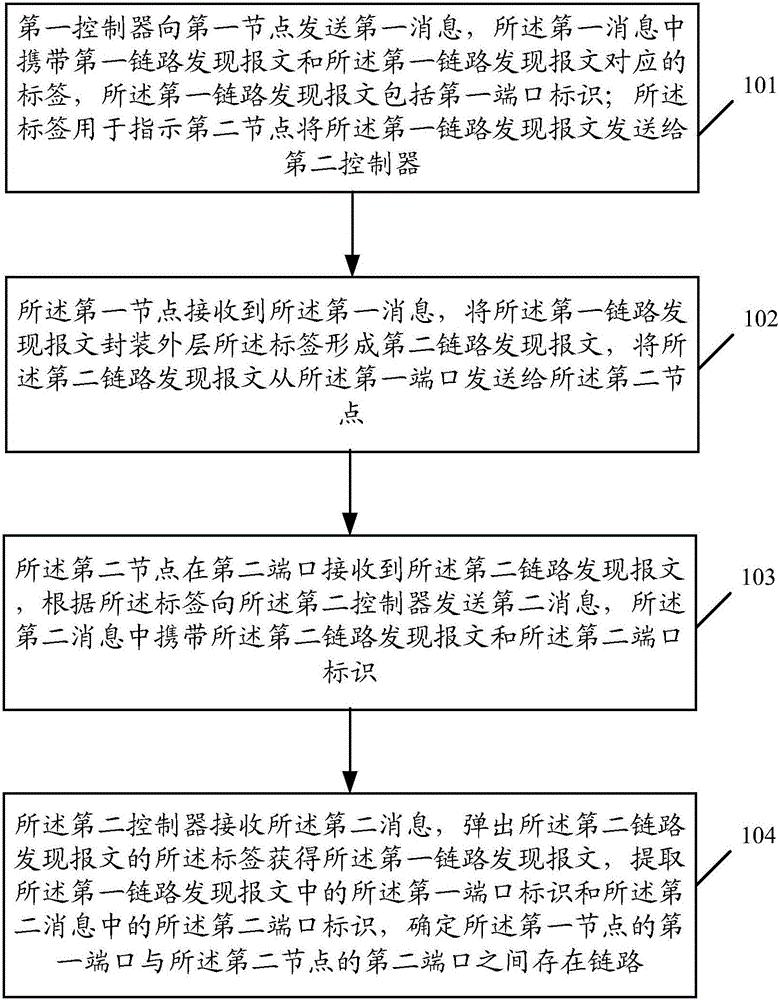

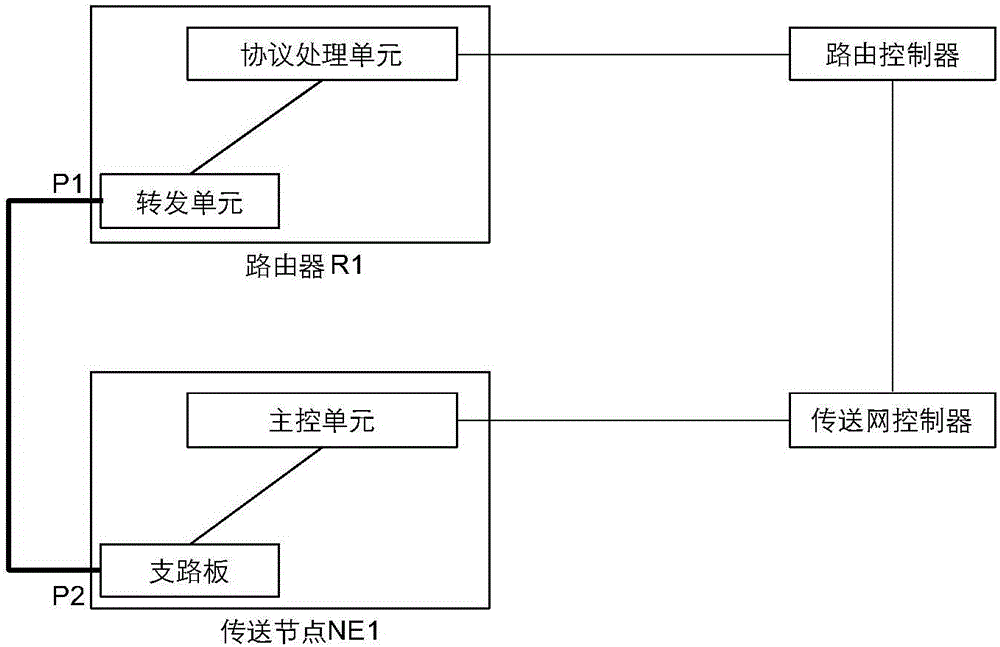

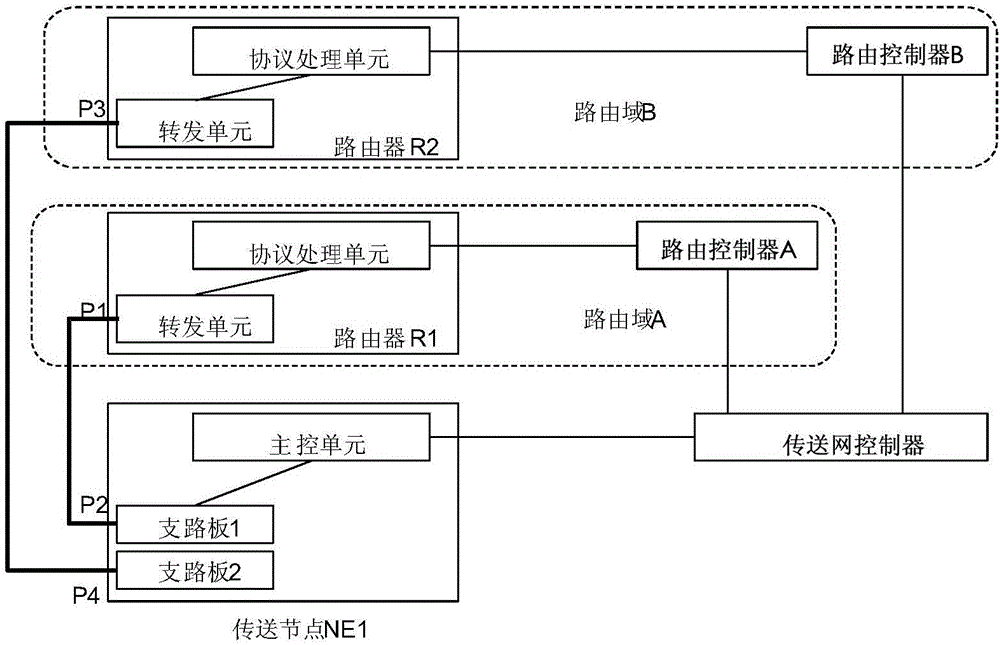

Method, system and equipment for finding link

ActiveCN103828310AReduce manual configurationImprove reliabilityData switching networksCross layerTransmission network

The invention provides a method for finding a link. According to the method, a first controller sends a first information to a first node, the first node receives the first information, and a message found by a second link is sent to a second node by a first port; the second node receives the message found by the second link at a second port and sends a second information to a second controller according to a tag, and the second information carries the message found by the second link and a second port identity; the second controller receives the second information, extracts a first port identity of the message found by a first link and the second port identity of the second information, and determines that a link exists between a first port of the first node and the second port of the second node so that automatic finding of the information of a cross-layer link can be realized via a routing controller and a transmission network controller, manual configuration is reduced, the realization is simple, and the reliability is high.

Owner:HUAWEI TECH CO LTD

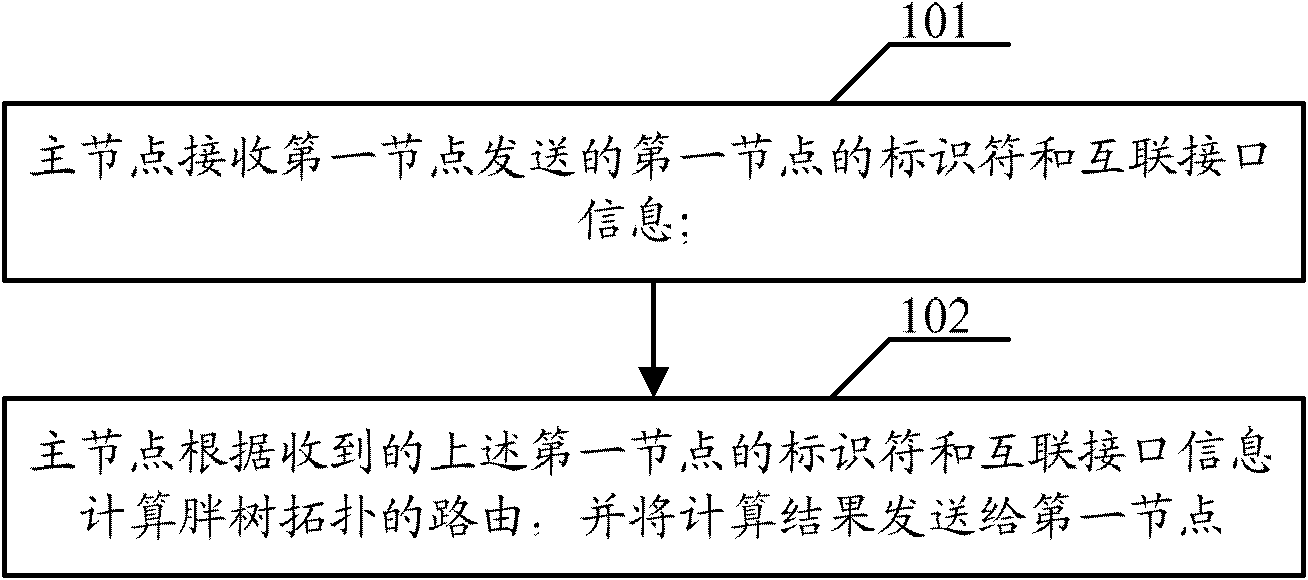

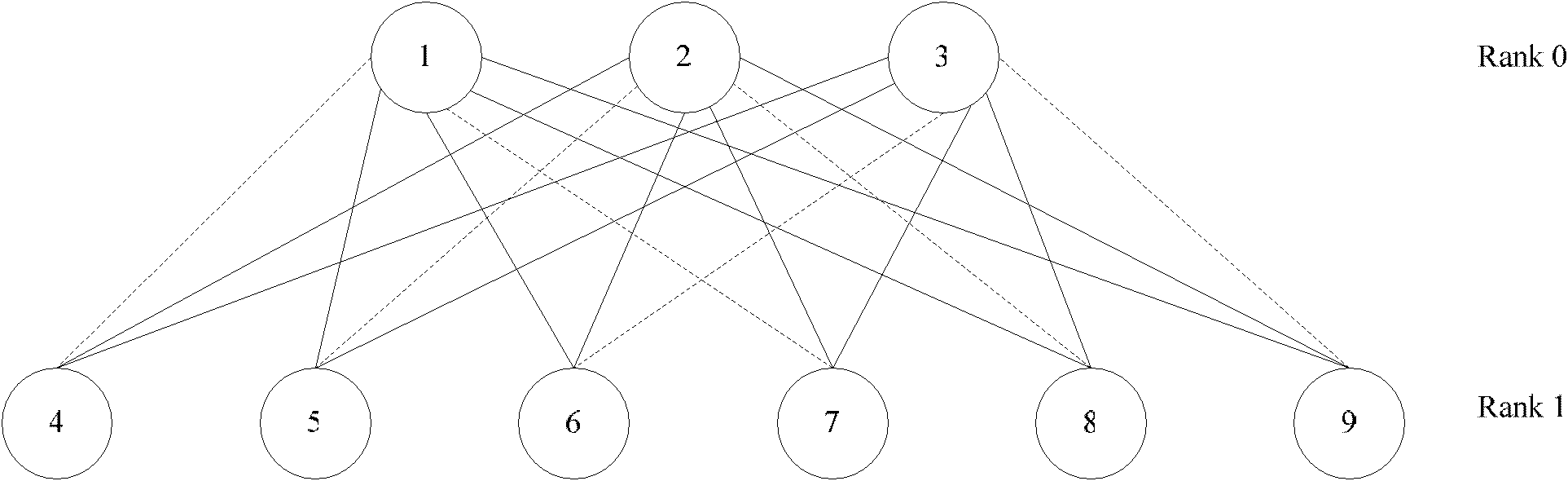

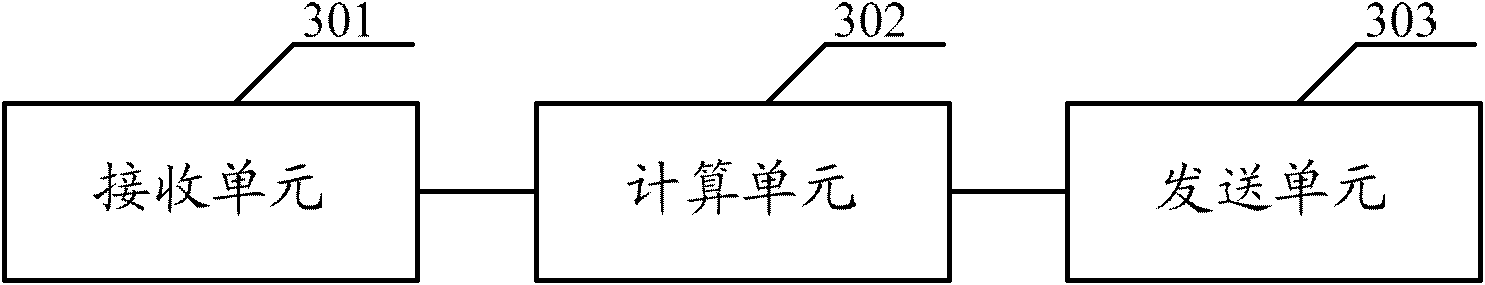

Routing computation method of fat-tree topology, node equipment and communication system

InactiveCN102164081ACut down on the manual configuration processReduce configuration errorsData switching networksInterconnectionCommunications system

The embodiment of the invention discloses a routing computation method of fat-tree topology, node equipment and a communication system. The method comprises the following steps: a main node receives the identifier and interconnection interface information of a first node which are sent by a first node,; the first node can be other nodes except the main node in the fat tree; the main node and the first node belong to the same fat tree, and the order of the main node in the fat tree is 0; according to the received identifier and interconnection interface information of the first node, the route of the fat tree topology is calculated; and a calculation result is sent to the first node. Through the identifier and interconnection interface information of the first node which are sent by the first node according to the identifier and interconnection interface information of the main node, the main node knows the topology of the fat tree; and then, a rough is calculated according to the topology and the calculated route is sent to the first node; therefore, lots of maual configuration can be reduced configuration errors are decreased and configuration speed is improved.

Owner:HUAWEI TECH CO LTD

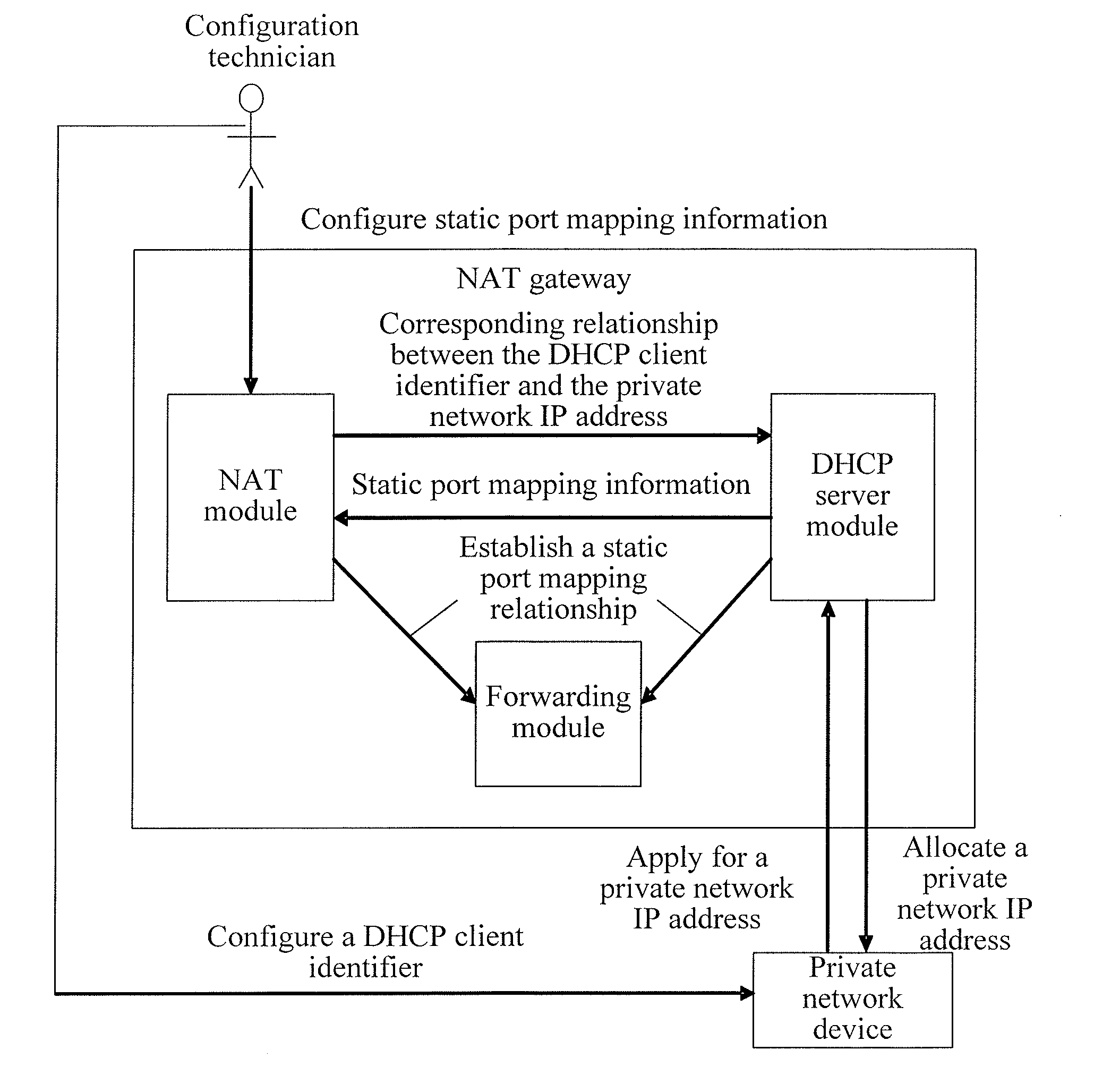

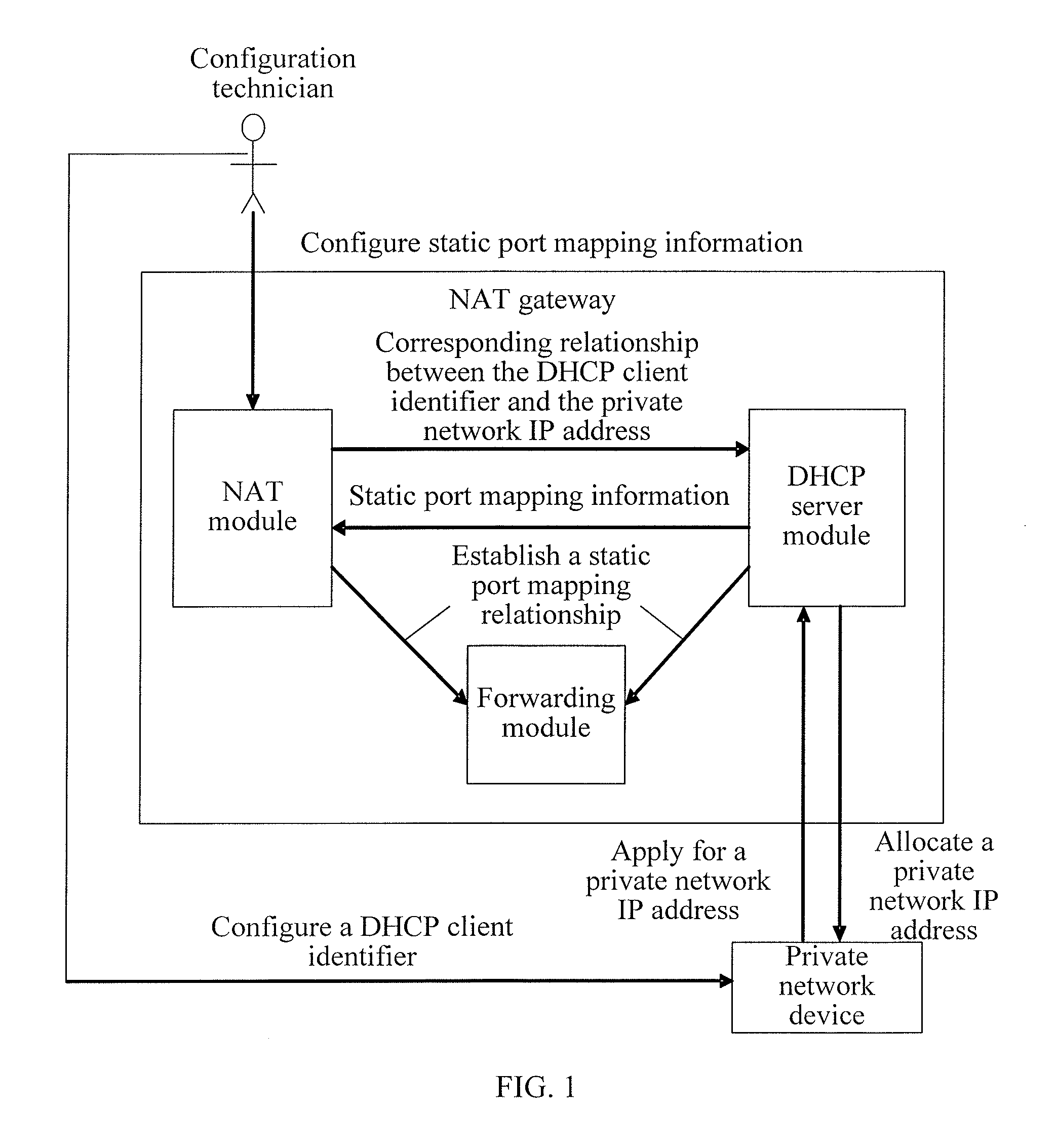

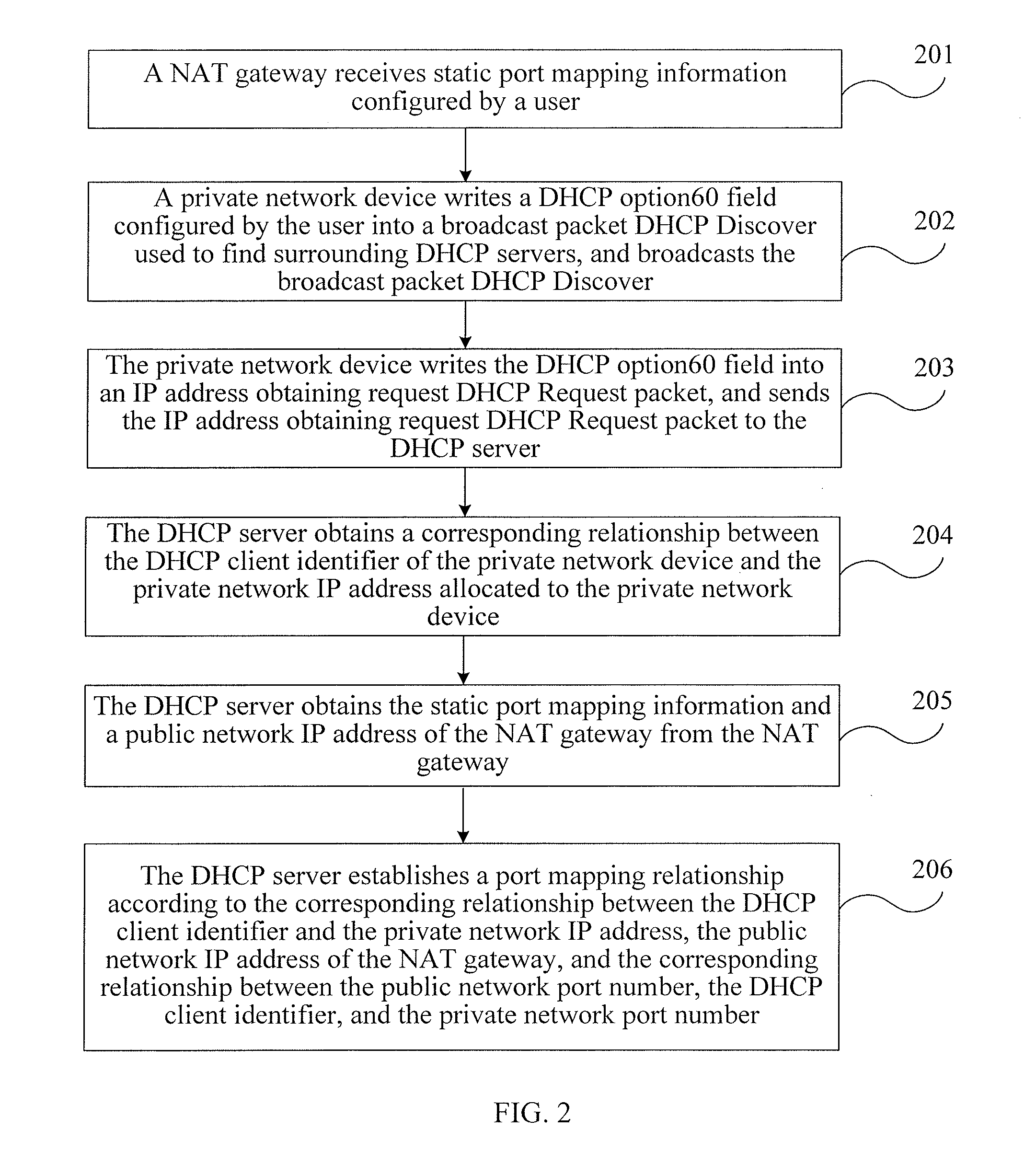

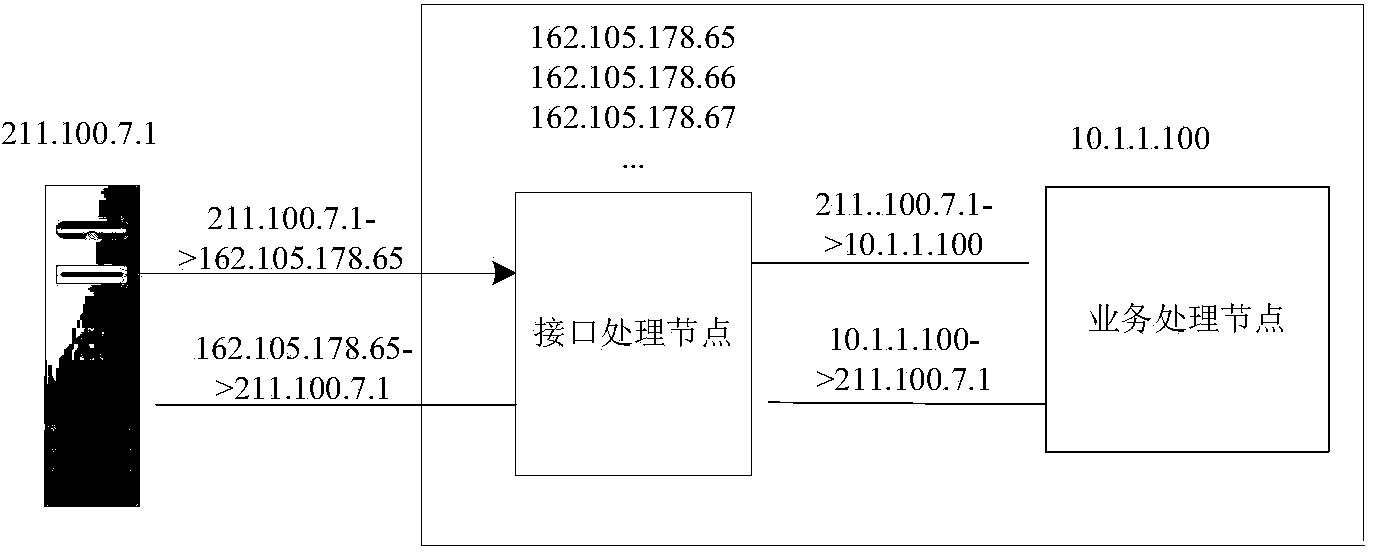

Port mapping method and apparatus, and communication system

InactiveUS20130058256A1Reduce configurationReduce probabilityData switching by path configurationNetwork connectionsCommunications systemPrivate network

Embodiments described herein disclose a port mapping method and apparatus, and a communication system. A method includes: obtaining static port mapping information that includes a corresponding relationship between a public network port number, a DHCP client identifier, and a private network port number; obtaining a corresponding relationship between the DHCP client identifier and a private network IP address, and a public network IP address of a NAT gateway; and establishing a port mapping relationship according to the obtained public network IP address of the NAT gateway, the corresponding relationship between the DHCP client identifier and the private network IP address, and the static port mapping information.

Owner:HUAWEI TECH CO LTD

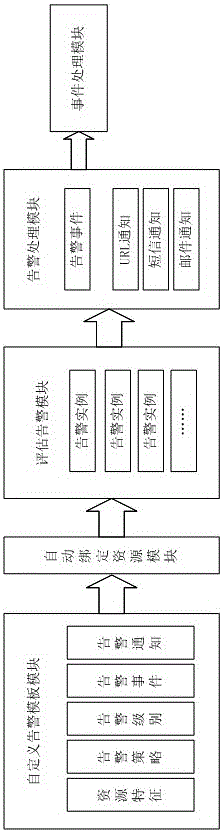

Alarming system for private cloud platform and realization method thereof

InactiveCN106301919AFlexible responseMonitor alarm statusData switching networksAlarm stateDependability

The invention discloses an alarming system for a private cloud platform and a realization method thereof, which belong to the technical field of cloud platform monitoring and alarming so as to solve technical problems of how to flexibly monitor alarming states of various resources, reducing an artificial cultivation process and enhancing service reliability. According to the adopted technical scheme, the alarming system comprises a self-defined alarming module template, an automatic binding resource module, an evaluation alarming module, an alarming processing module and an event processing module, wherein contents of the self-defined alarming module template comprise resource characteristics, an alarming strategy, an alarming level, an alarming event and an alarming notification; the self-defined alarming module template is used for providing a basis for the automatic binding resource module in the case of resource building; the automatic binding resource module is used for building alarming instances for resources meeting the resource characteristics in the case of resource building according to the resource characteristics in the self-defined alarming module template; and the evaluation alarming module is used for evaluating an alarming level and processing the alarming event according to the alarming level.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

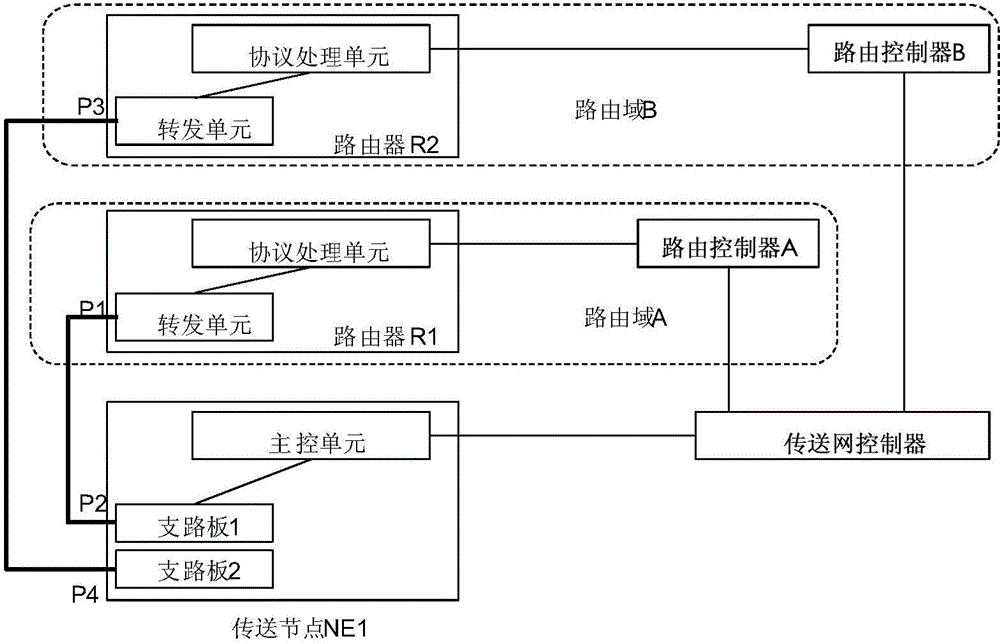

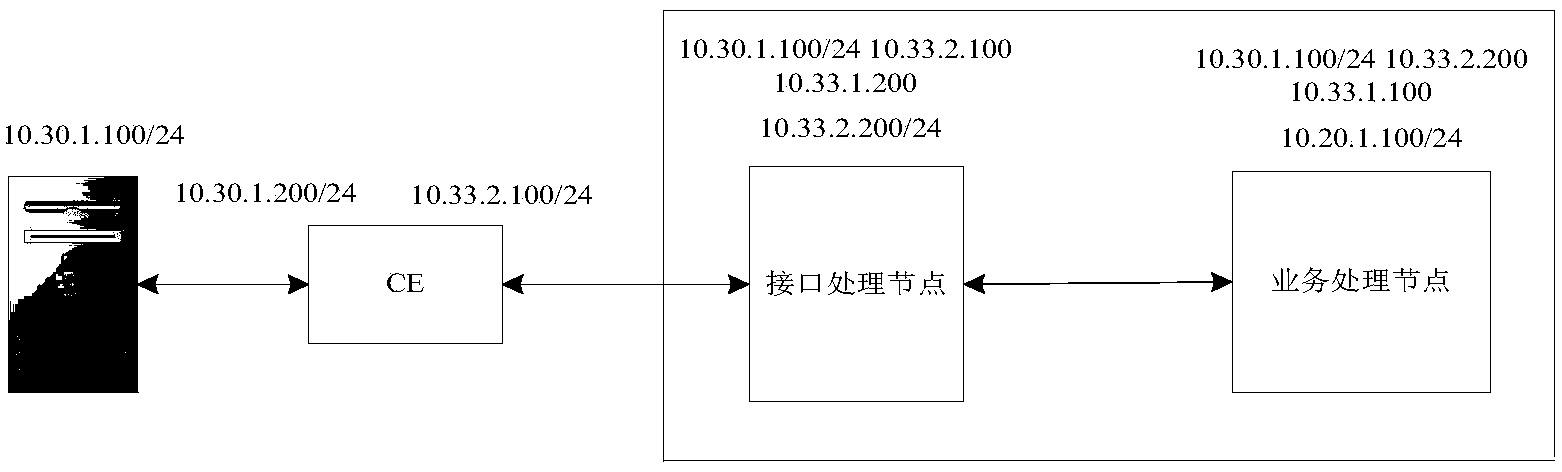

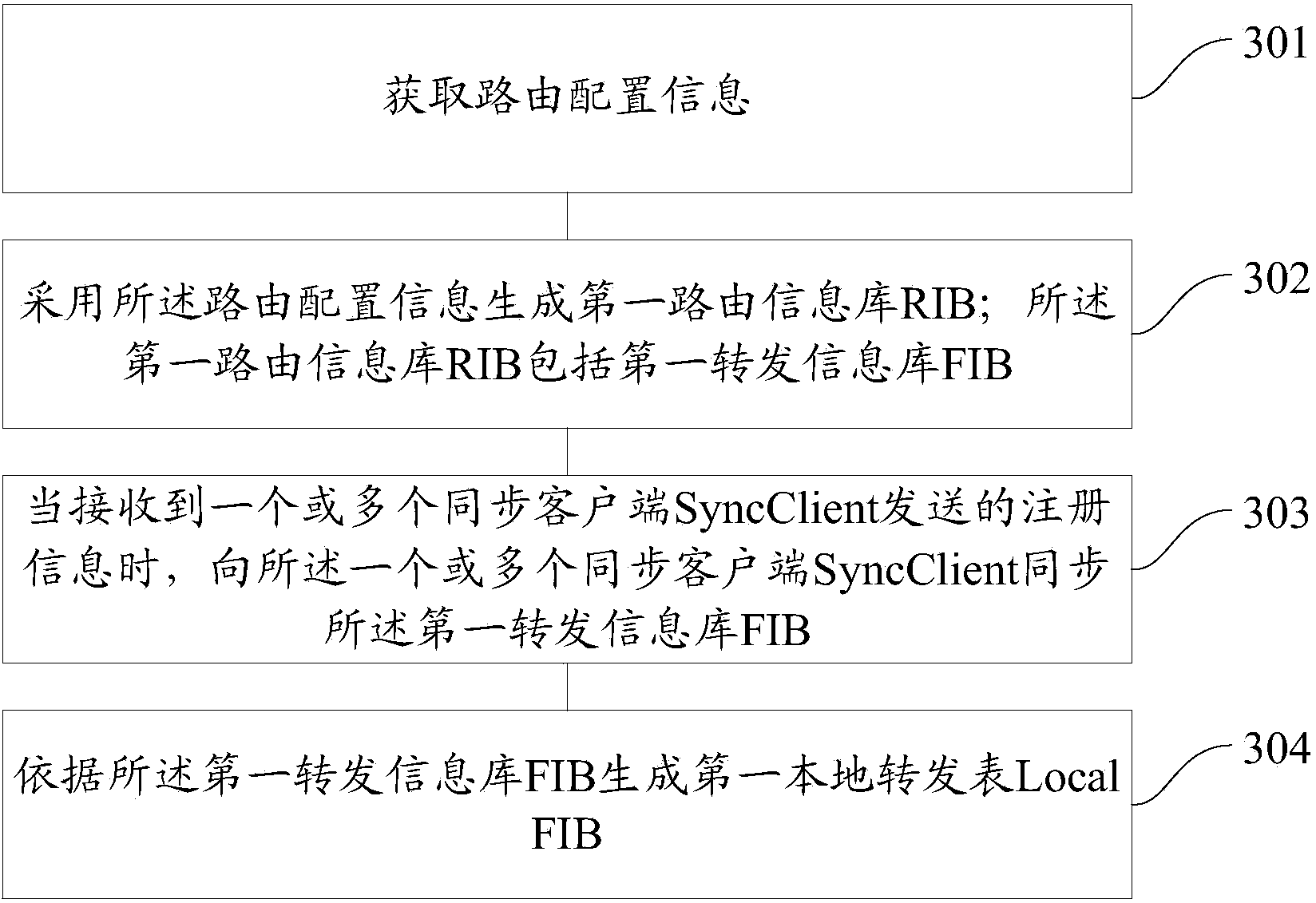

Routing method based on distributed architecture and routing system based on distributed architecture

ActiveCN104253748AAvoid conversionReduce complexityData switching networksInformation repositoryDistributed computing

The embodiment of the invention provides a routing method based on a distributed architecture and a routing system based on the distributed architecture. The distributed architecture comprises one or more synchronization client(s). The method comprises the steps of acquiring route configuration information; generating a first routing information base (RIB) by the route configuration information, wherein the first RIB comprises a first forwarding information base (FIB); when the registration information sent by the one or more synchronization client(s) is received, enabling the first FIB to be synchronized with the one or more synchronization client(s); according to the first FIB, generating a first local forwarding table (Local FIB). After the method and the system are adopted, the forwarding efficiency is increased, the complexity of configuration is reduced, and the manual configuration is reduced.

Owner:DATANG MOBILE COMM EQUIP CO LTD

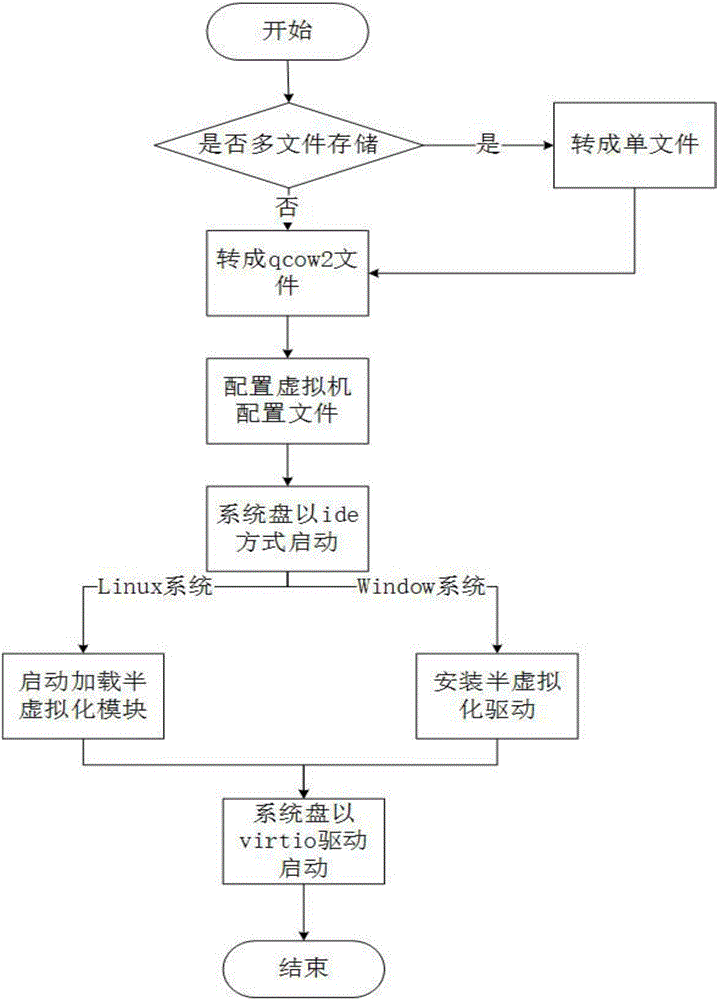

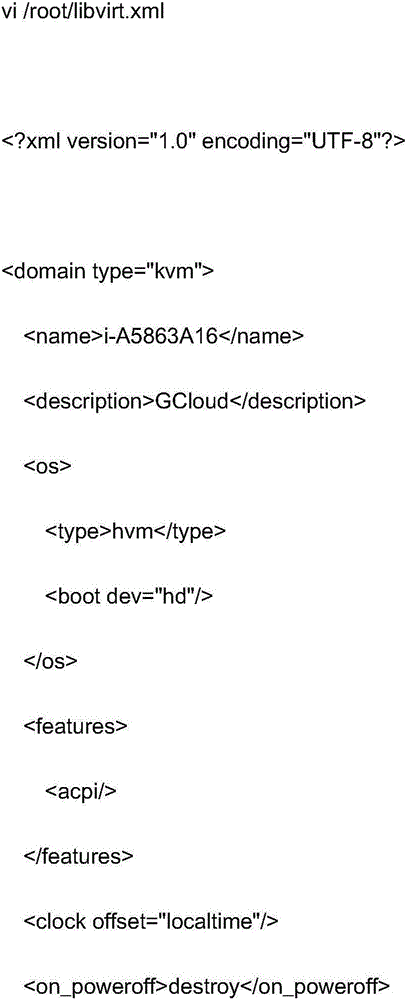

Method for converting vmware virtual machine into kvm virtual machine

InactiveCN106201653AImprove migration speedReduce complexitySoftware simulation/interpretation/emulationVirtualizationComputer science

The invention relates to the technical field of cloud computing and virtualization, and especially relates to a method for converting a vmware virtual machine into a kvm virtual machine. The method comprises the following steps of firstly, if a magnetic disk file of the vmware virtual machine is multifile storage, then merging the magnetic disk file of the vmware virtual machine into one magnetic disk file; secondly, according to the type of the magnetic disk file, converting the magnetic disk file into a qcow2 file; thirdly, configuring a libvirt file and adding corresponding equipment; and finally, opening a virtual machine, if the virtual machine is a windows virtual machine, then installing a corresponding para-virtualization driver, and if the virtual machine is a linux virtual machine, then loading a corresponding para-virtualization module. The method for converting the vmware virtual machine into the kvm virtual machine provided by the invention solves the problems that the migration of a vmware virtual machine application on the kvm virtual machine is complex, time-consuming and low in fault tolerant rate; and the method can be applied to the conversion and use of virtual machines.

Owner:G CLOUD TECH

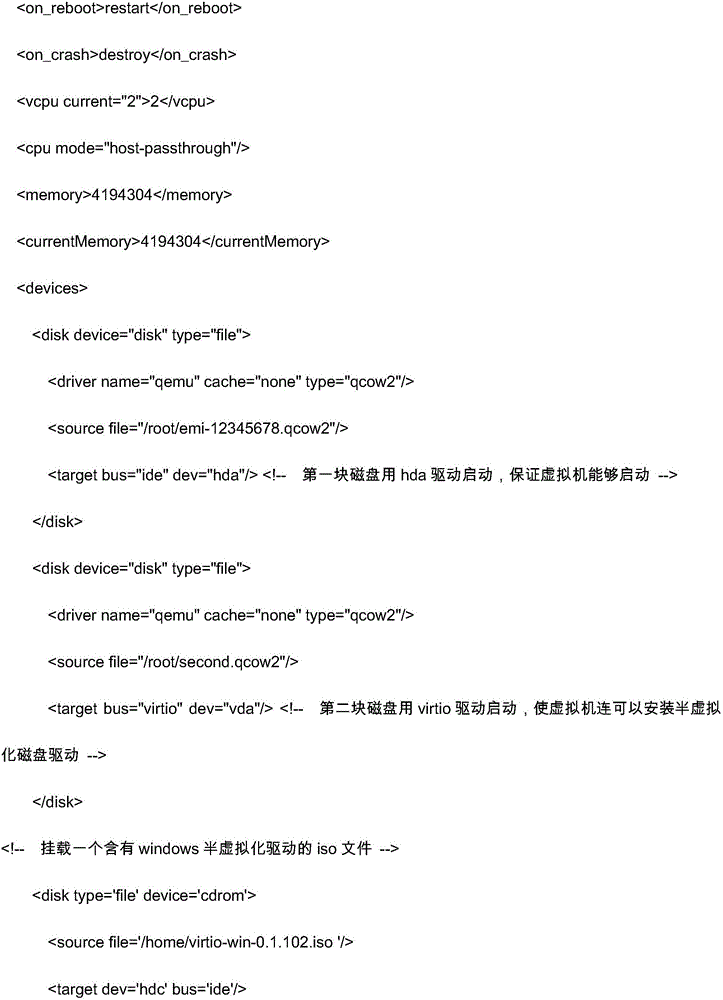

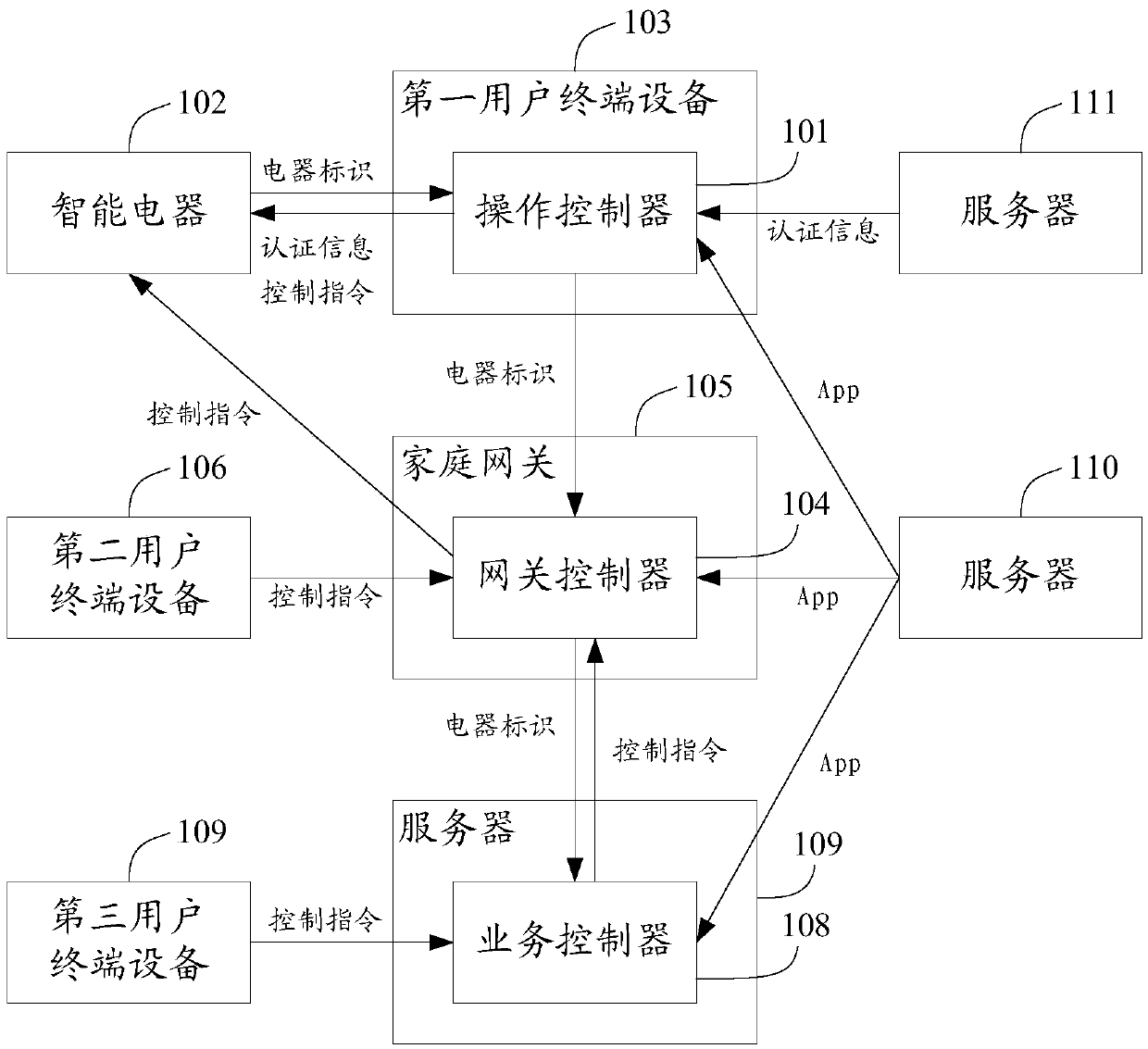

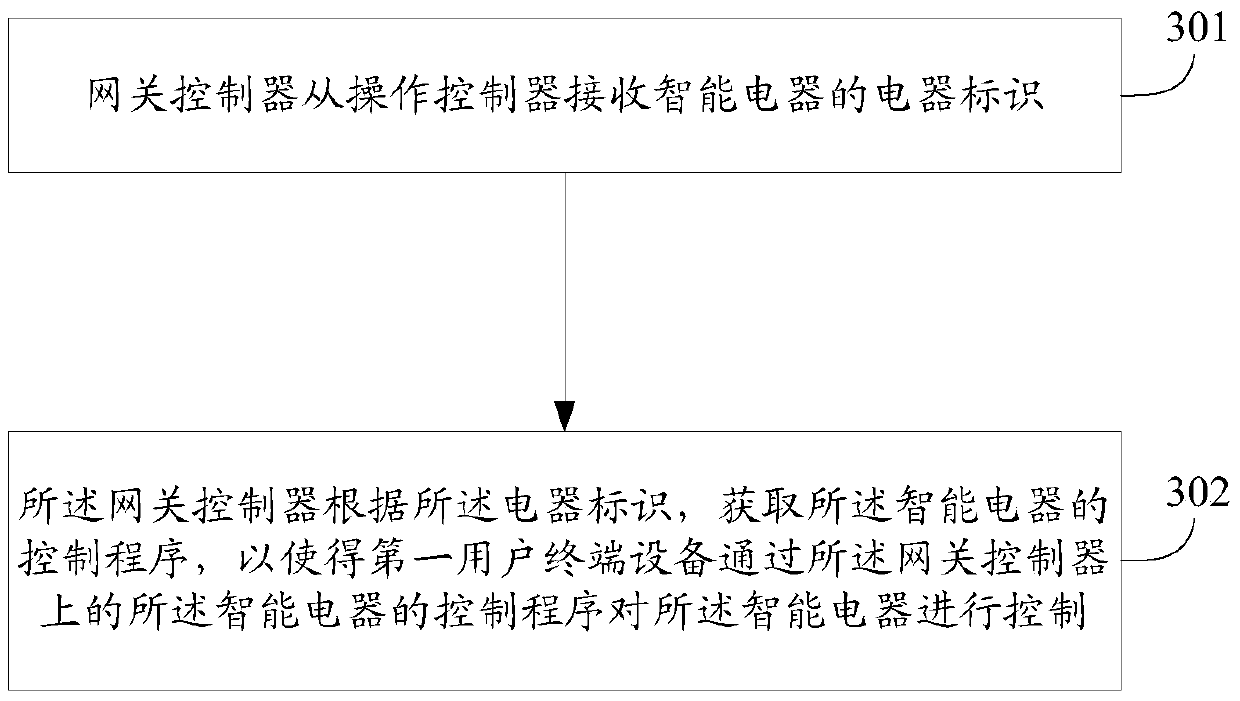

Method and device for controlling intelligent electric appliance

ActiveCN105511275AReduce manual configurationEasy to controlComputer controlProgramme total factory controlTerminal equipmentEmbedded system

The embodiment of the invention discloses a method and a device for controlling an intelligent electric appliance. The method comprises the steps of receiving an electric appliance identifier sent from the intelligent electric appliance by an operation controller, wherein the electric appliance identifier is used for uniquely identifying the intelligent electric appliance; acquiring the control program of the intelligent electric appliance by the operation controller based on the electric appliance identifier; and controlling the intelligent electric appliance by the operation controller through the control program. According to the embodiments of the present invention, users can control the intelligent electric appliance more simply by means of user terminal equipment.

Owner:HUAWEI TECH CO LTD

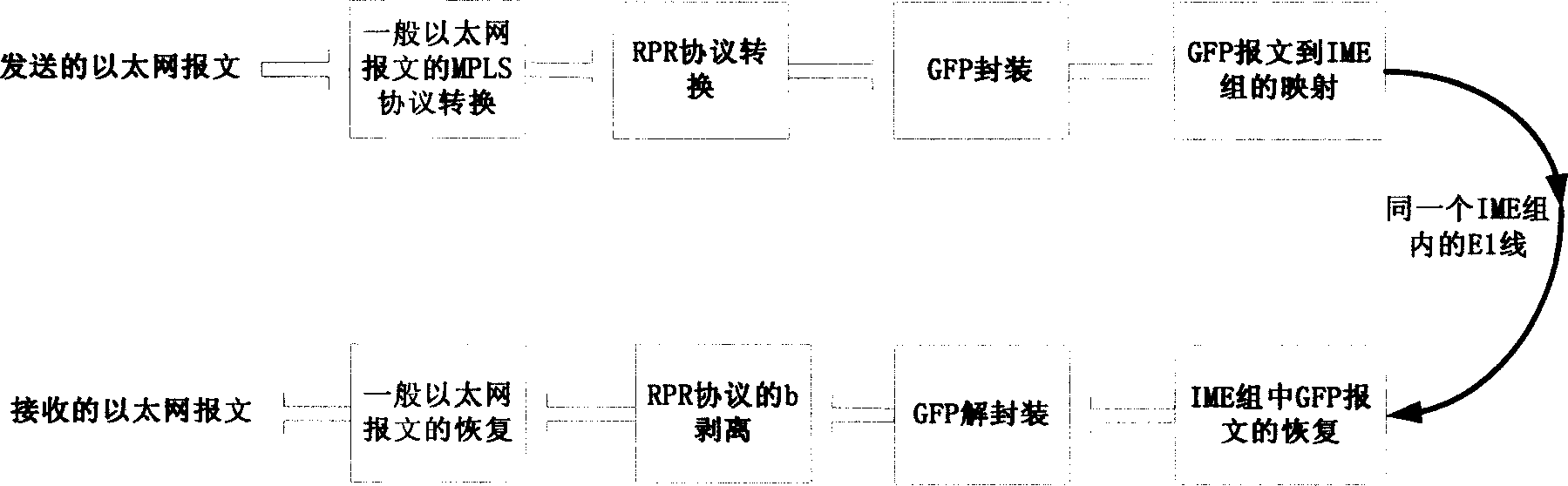

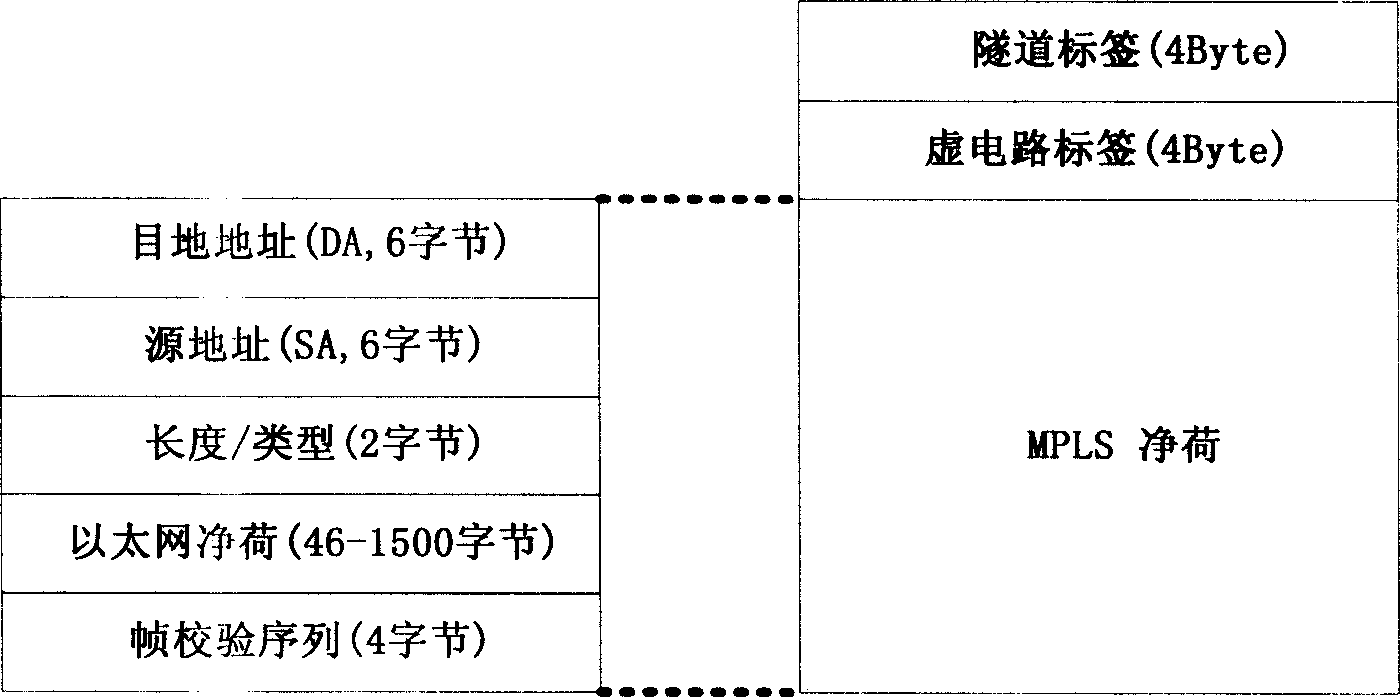

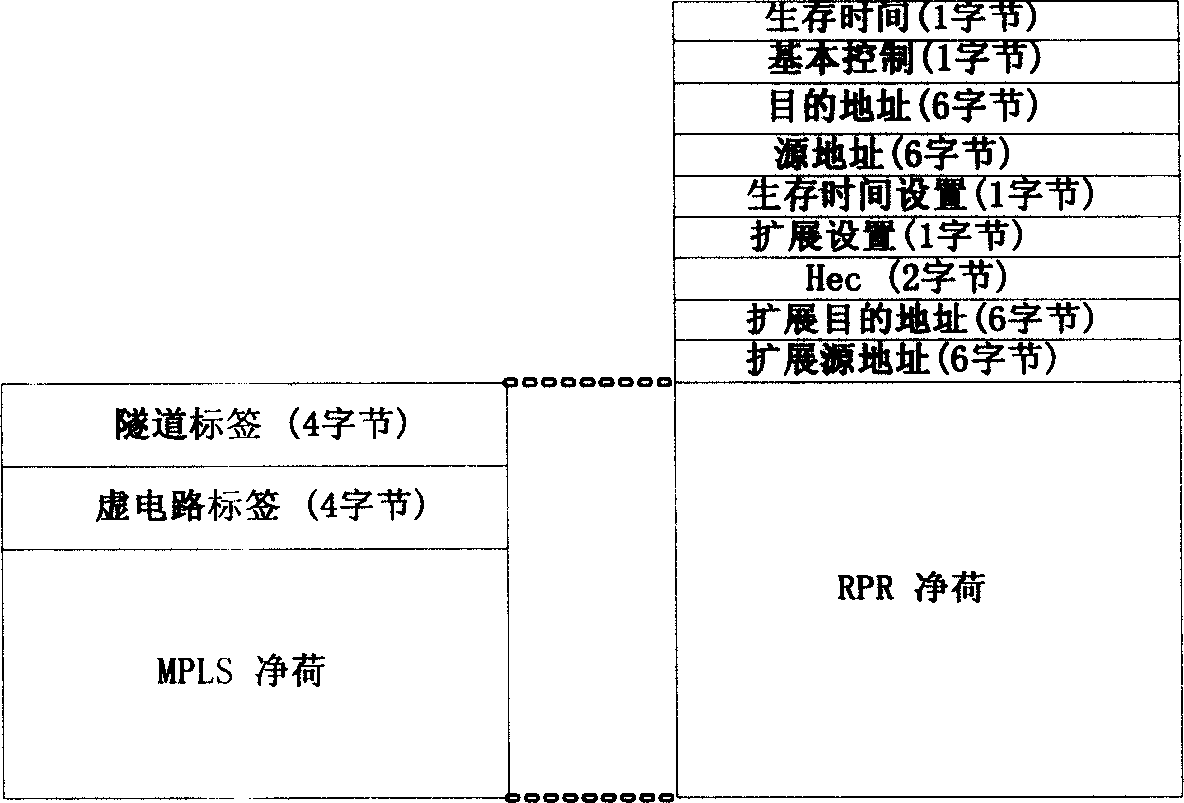

A method of Ethernet transmission in a plurality of E1 channels

InactiveCN1722699AMeet service requirementsReduce in quantityLoop networksNetworks interconnectionEthernetComputer science

This invention relates to a method of the Ethernet transferring in several E1 channels, characterized in that it uses carrying platform to transfer Ethernet, wherein the carrying platform uses several E1 as the physics layer of the RPR; it applies MPLS agreement and RPR agreement to enclose the Ethernet message; for the group with RPR format, using backward multiply usage method to transfer in several E1, adjusting the belt width through increasing or decreasing the number of E1 channel; it also can build loop based on E1, making several technical index of MPLS and RPS transferring in E1 channel.

Owner:BEIJING HUAWEI DIGITAL TECH

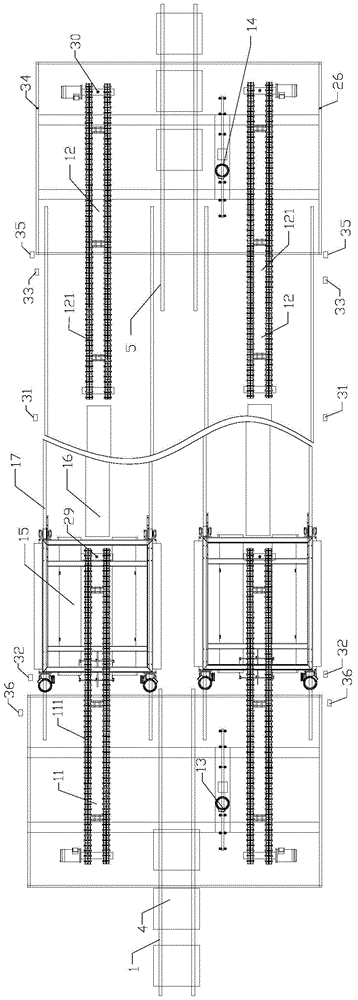

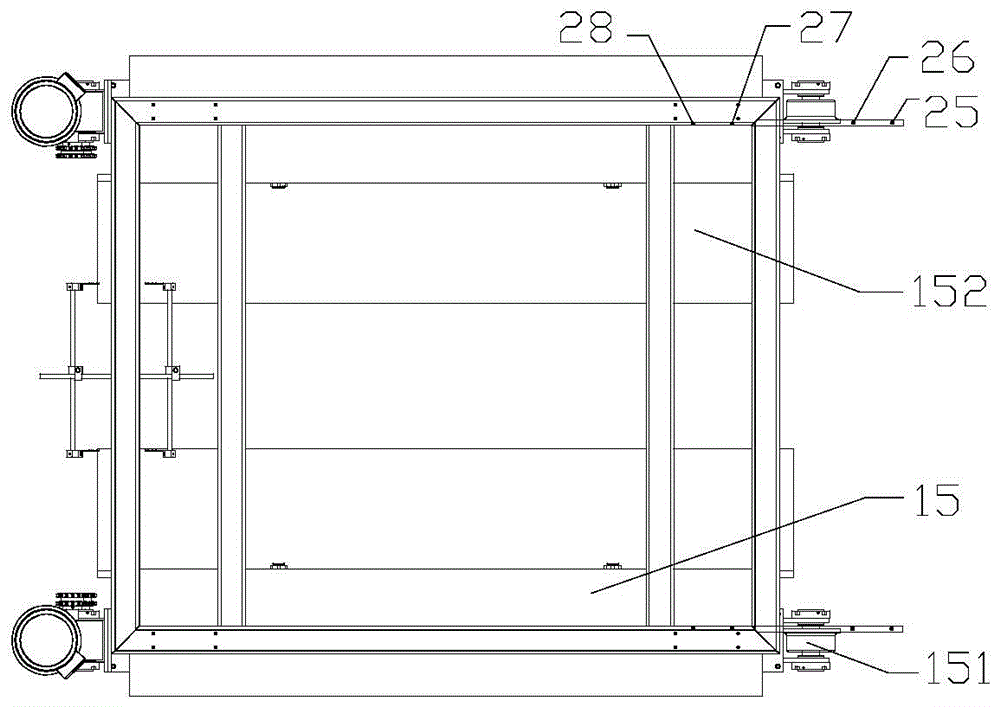

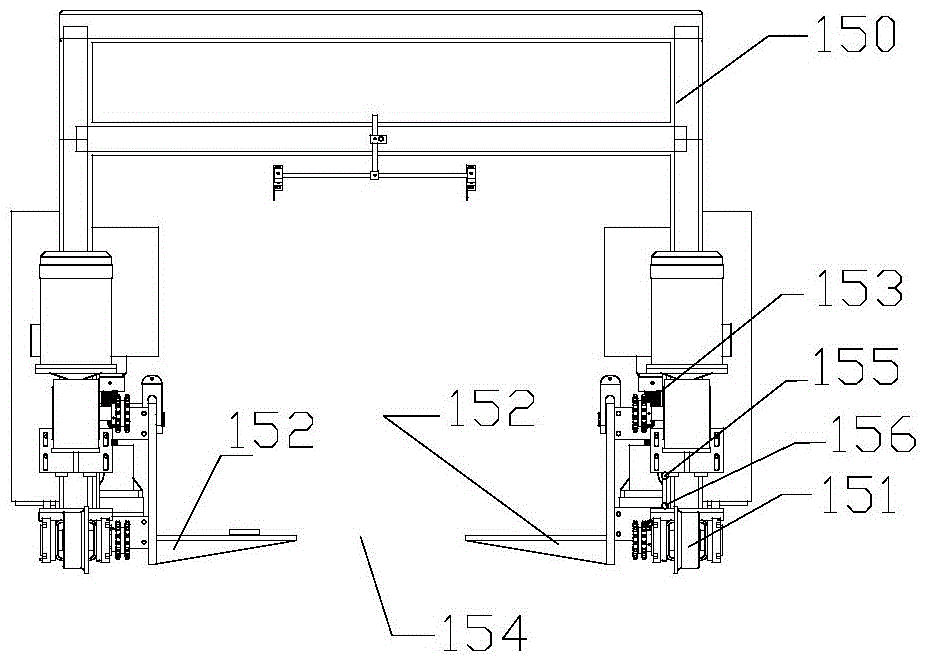

BIM-based assembling supporting piece design method and system

InactiveCN108427801AShorten production timeReduce manual configurationGeometric CADConfiguration CADManufacturing engineeringDesign methods

The invention discloses a BIM-based assembling supporting piece design method and system applied to the field of fabricated buildings. The method comprises the steps that property information of to-be-supported components is acquired, a supporting piece model base based on BIM design and preset supporting piece arrangement rules are utilized to allocate supporting pieces to the to-be-supported components, and a supporting design file is generated, wherein the supporting pieces corresponding to all the to-be-supported components are saved in the supporting piece model base, and supporting methods of the supporting pieces corresponding to all the to-be-supported components are saved in the supporting piece arrangement rules. According to the BIM-based assembling supporting piece design method and system, through the established supporting piece model base based on BIM design and the preset supporting piece arrangement rules, the corresponding supporting pieces are automatically allocatedto the to-be-supported components, the supporting design file is generated, the connection relation between the supporting pieces and the to-be-supported components is saved, the corresponding supporting pieces are automatically configured by use of the property information of the to-be-supported components, manual configuration is omitted, production time of the supporting design file is saved,and working efficiency is improved.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

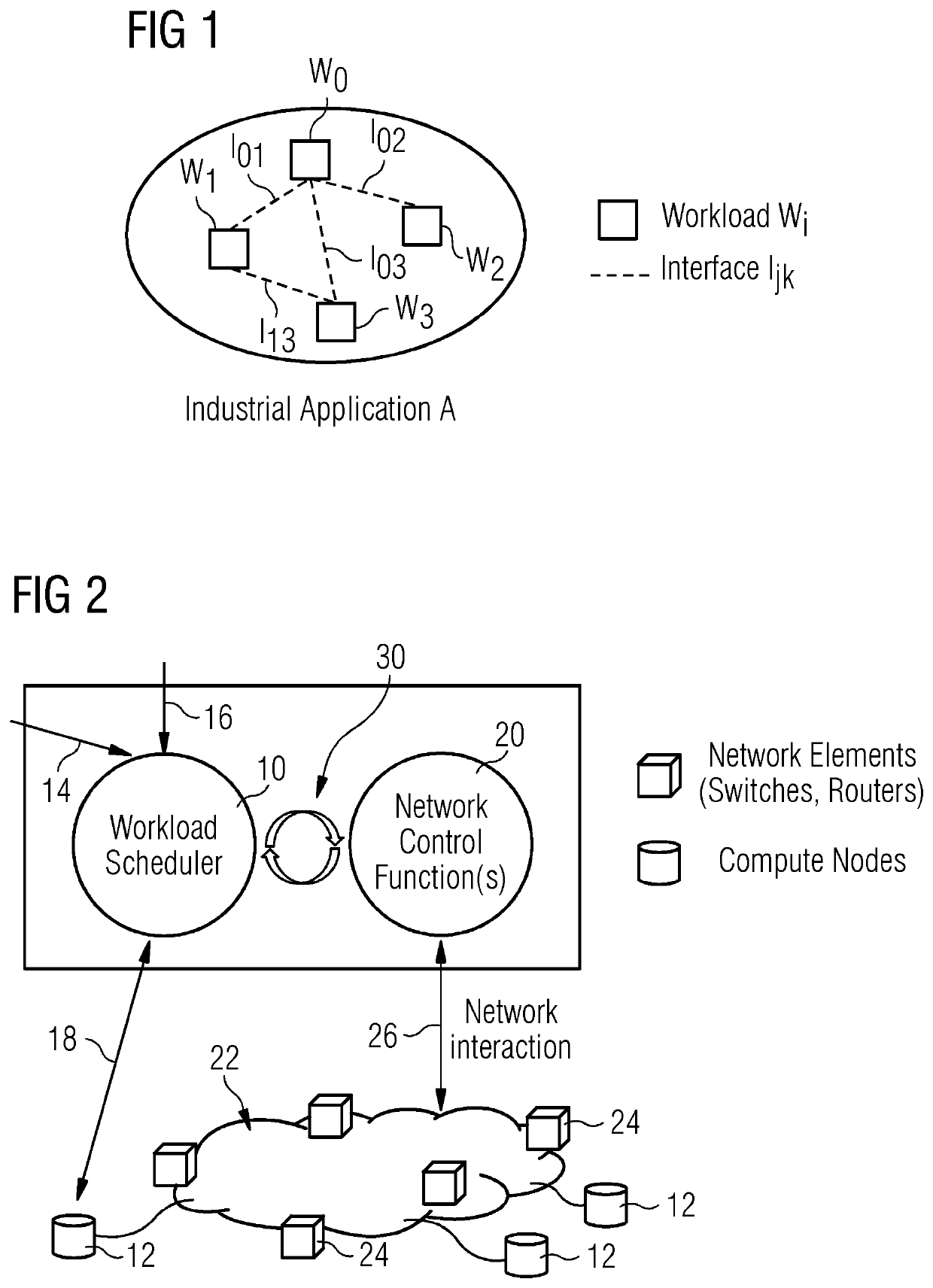

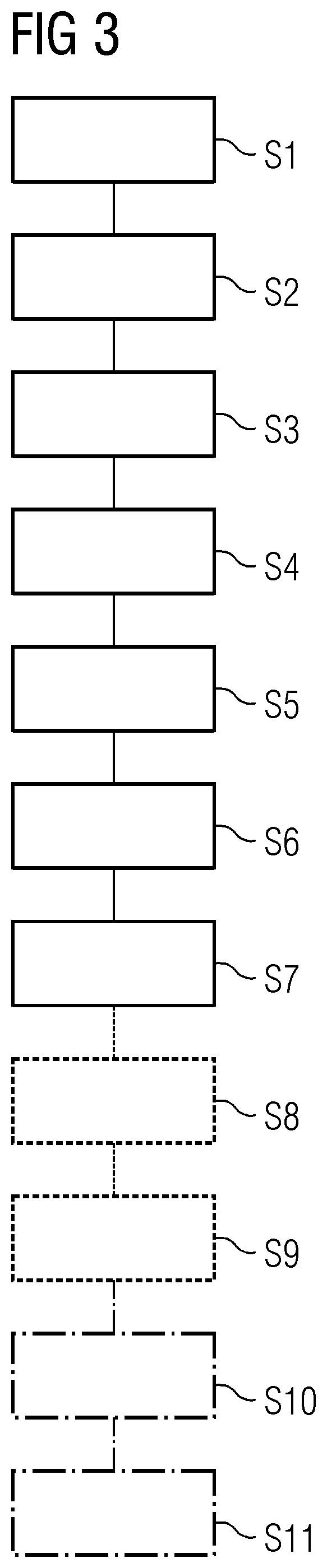

Method for operating a network-aware container orchestration system

InactiveUS20200314204A1Improve certaintyScheduling decision becomes more complexData switching networksScheduling functionControl communications

A method for operating a container orchestration system is disclosed, including a scheduling function means, being designed and configured to map industrial applications A decomposed into application components on an infrastructure represented by a plurality of compute nodes connected by a communication network including a plurality of network elements, a network control function means being designed and configured to control a plurality of communication services provided with the communication network, and an interface means being designed and configured to manage interactions between the scheduling function means and the network control function means. The method takes into consideration the properties of the network connecting compute nodes when scheduling distributed applications on them. Characteristics of the coupled network like bandwidth, latency, real-time behavior, availability, or the like are considered explicitly.

Owner:SIEMENS AG

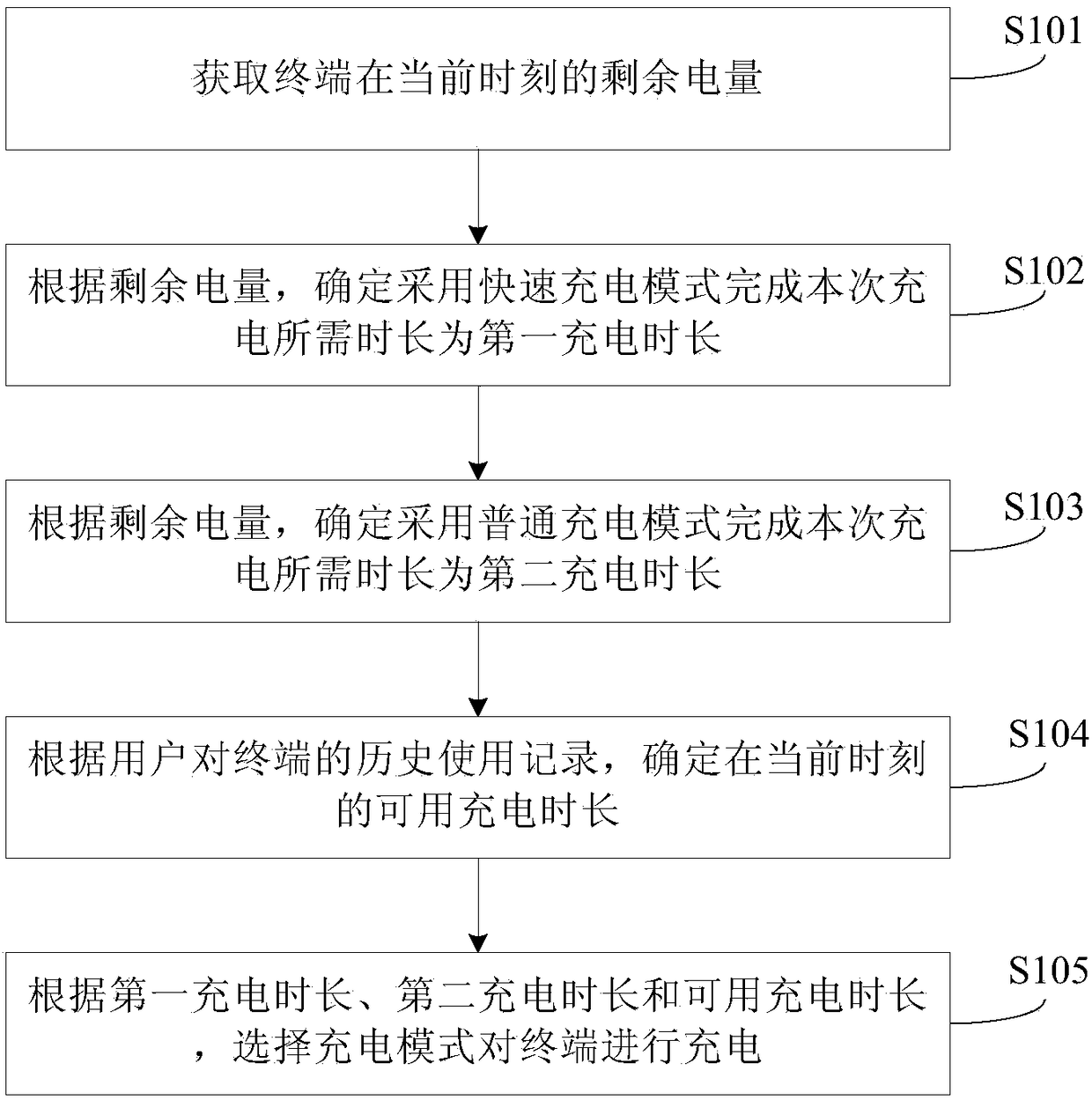

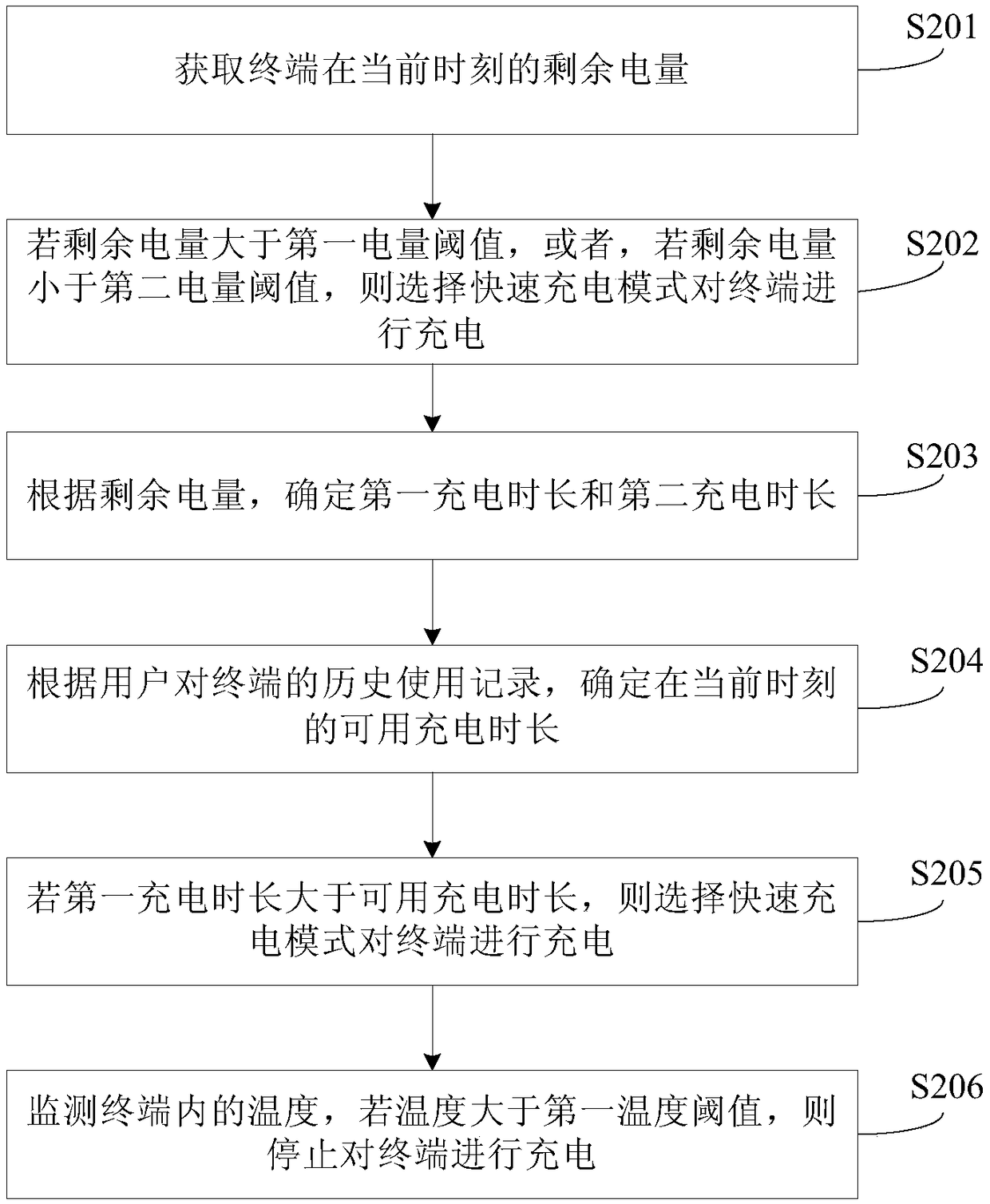

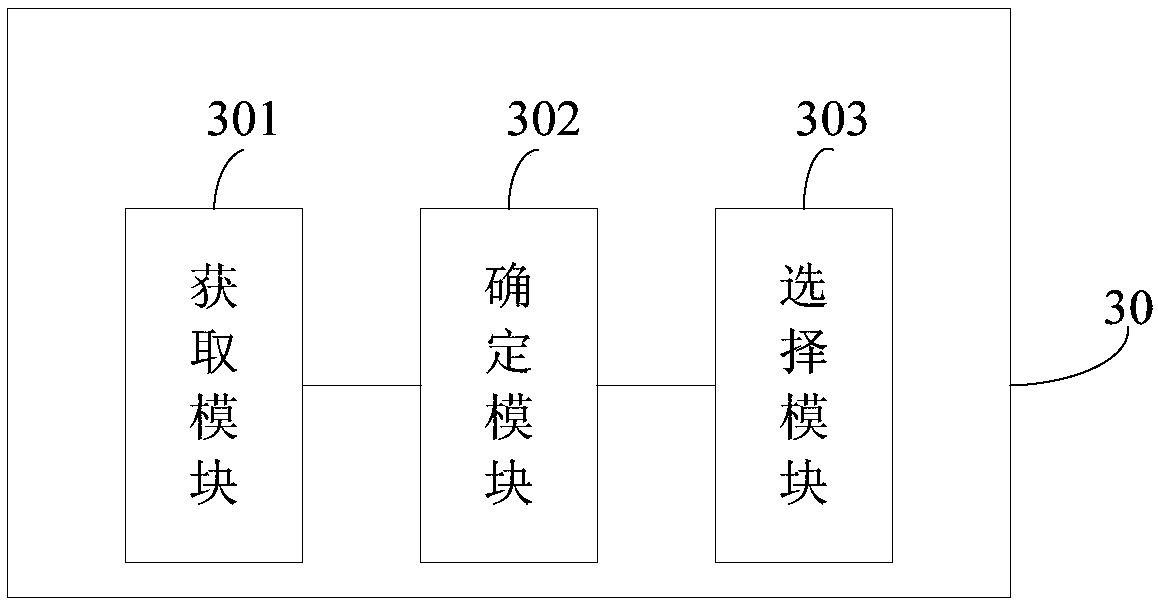

Charging management method, device and terminal

InactiveCN108777330AImprove experienceHigh selectivityBatteries circuit arrangementsSecondary cells charging/dischargingComputer terminalElectrical and Electronics engineering

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

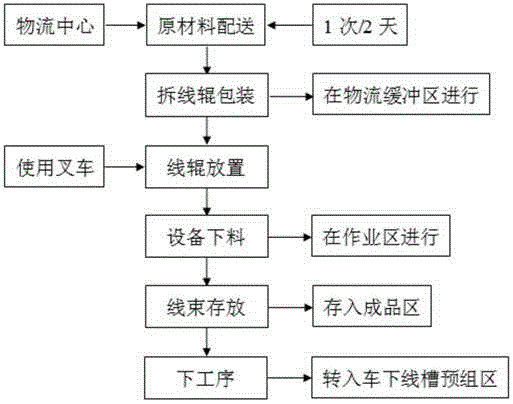

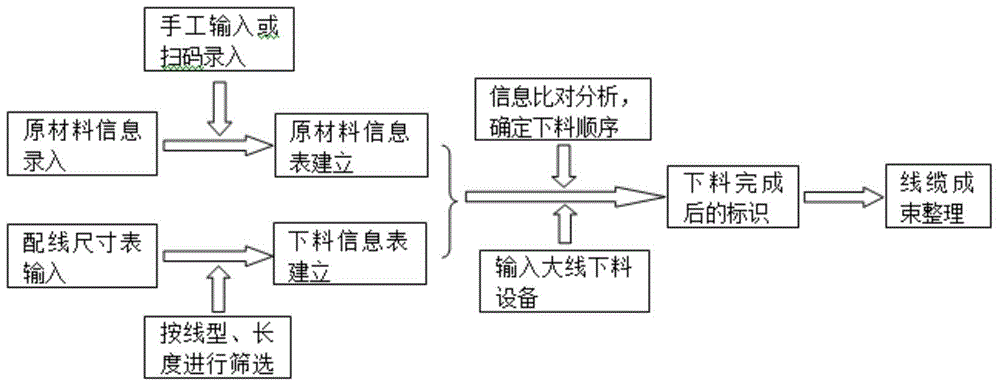

Rail vehicle large wire manufacturing system design and production method

ActiveCN105005277AReasonable useConducive to nesting designTotal factory controlProgramme total factory controlSystems designVariable length

The present invention mainly aims to solve the problem and insufficiency at the aspects of design and manufacturing method of a conventional rail vehicle electrical wire harness, provides a design and production method of forming a rail vehicle large wire automatic manufacturing system which can fully combine the characteristics of the rail vehicle cable work, such as many wire types, thick wire diameter, variable length, etc., considers the influence of the production factors simultaneously, such as the production demands, the material mating, etc., and optimizes the type selection and configuration.

Owner:CRRC QINGDAO SIFANG CO LTD

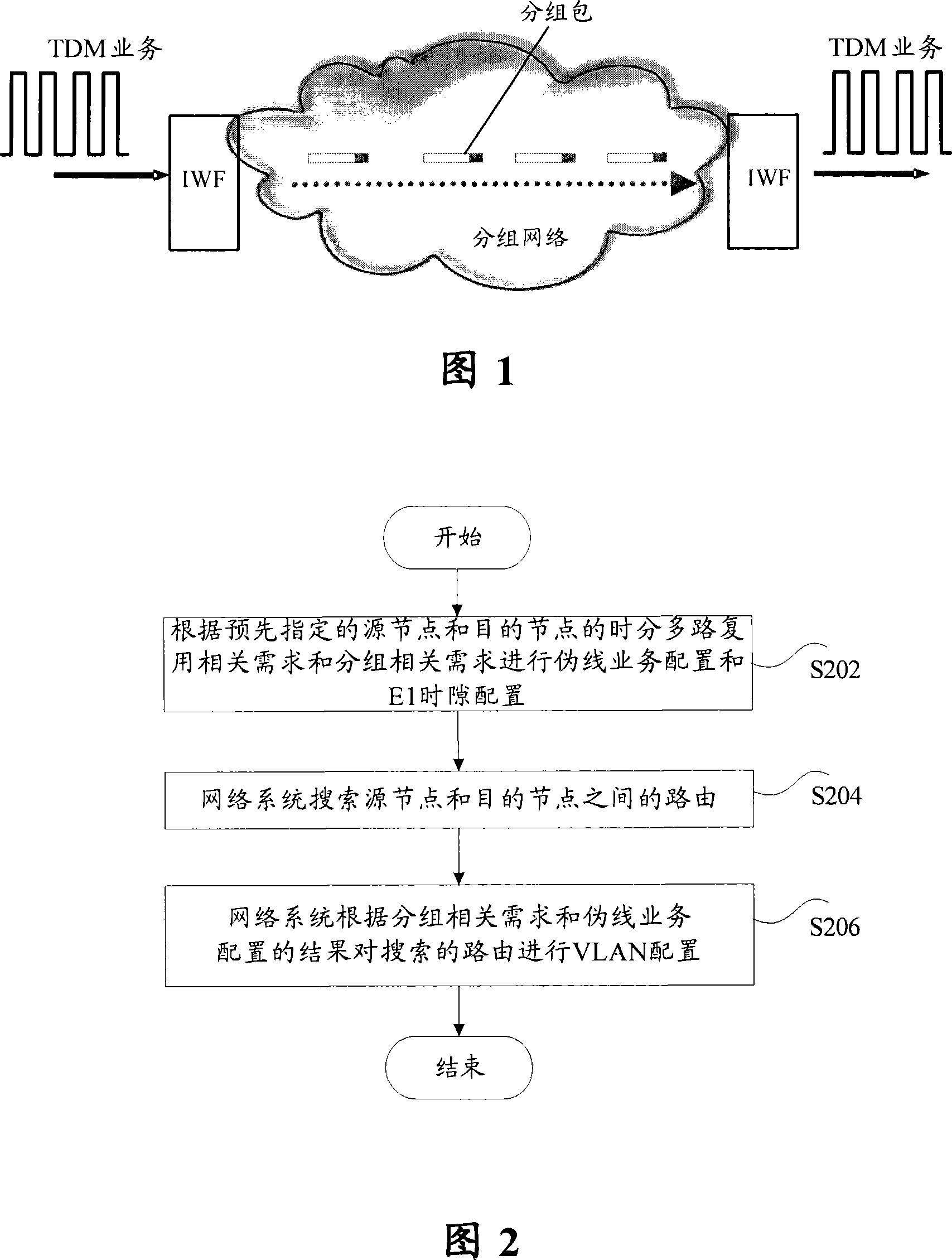

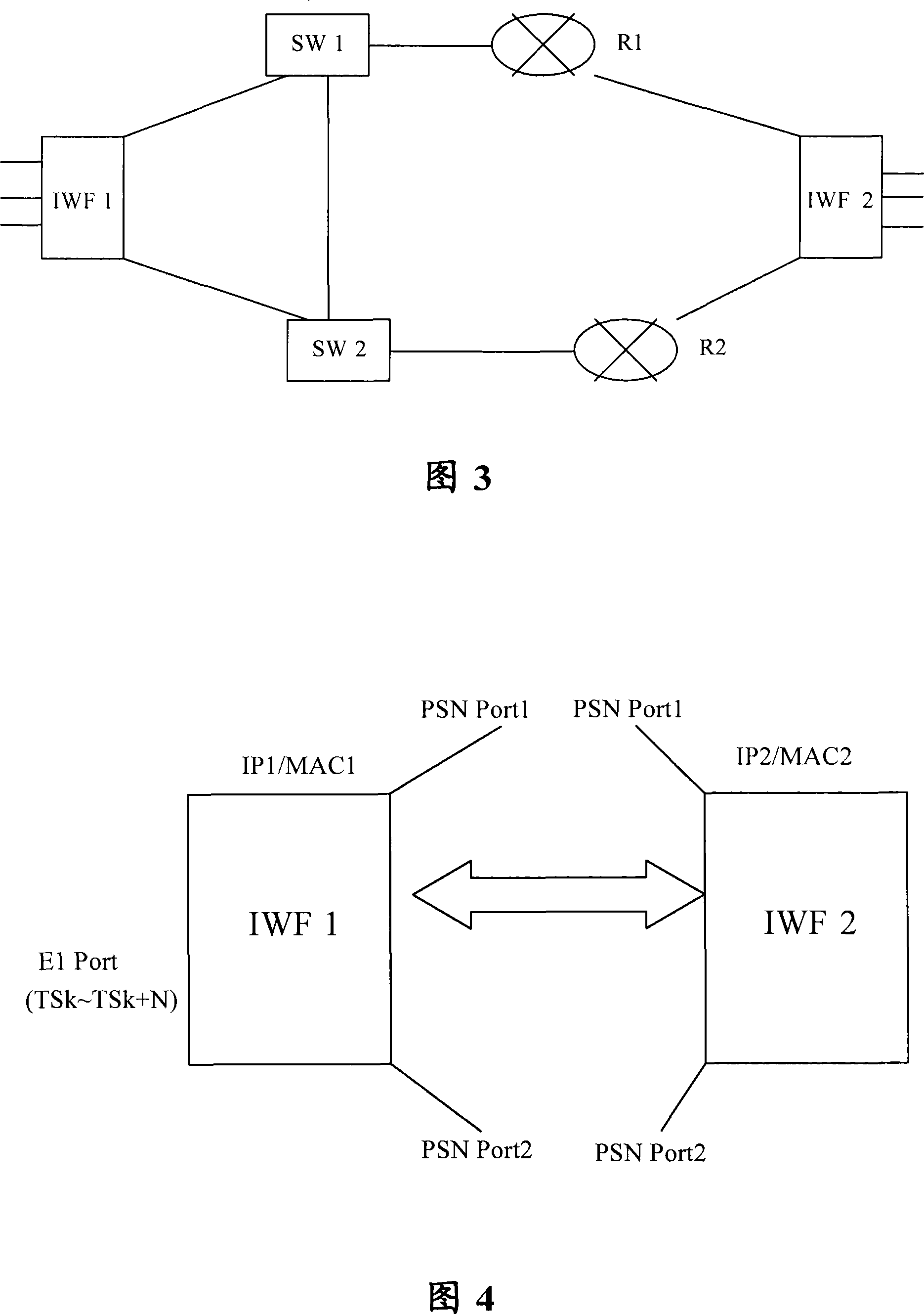

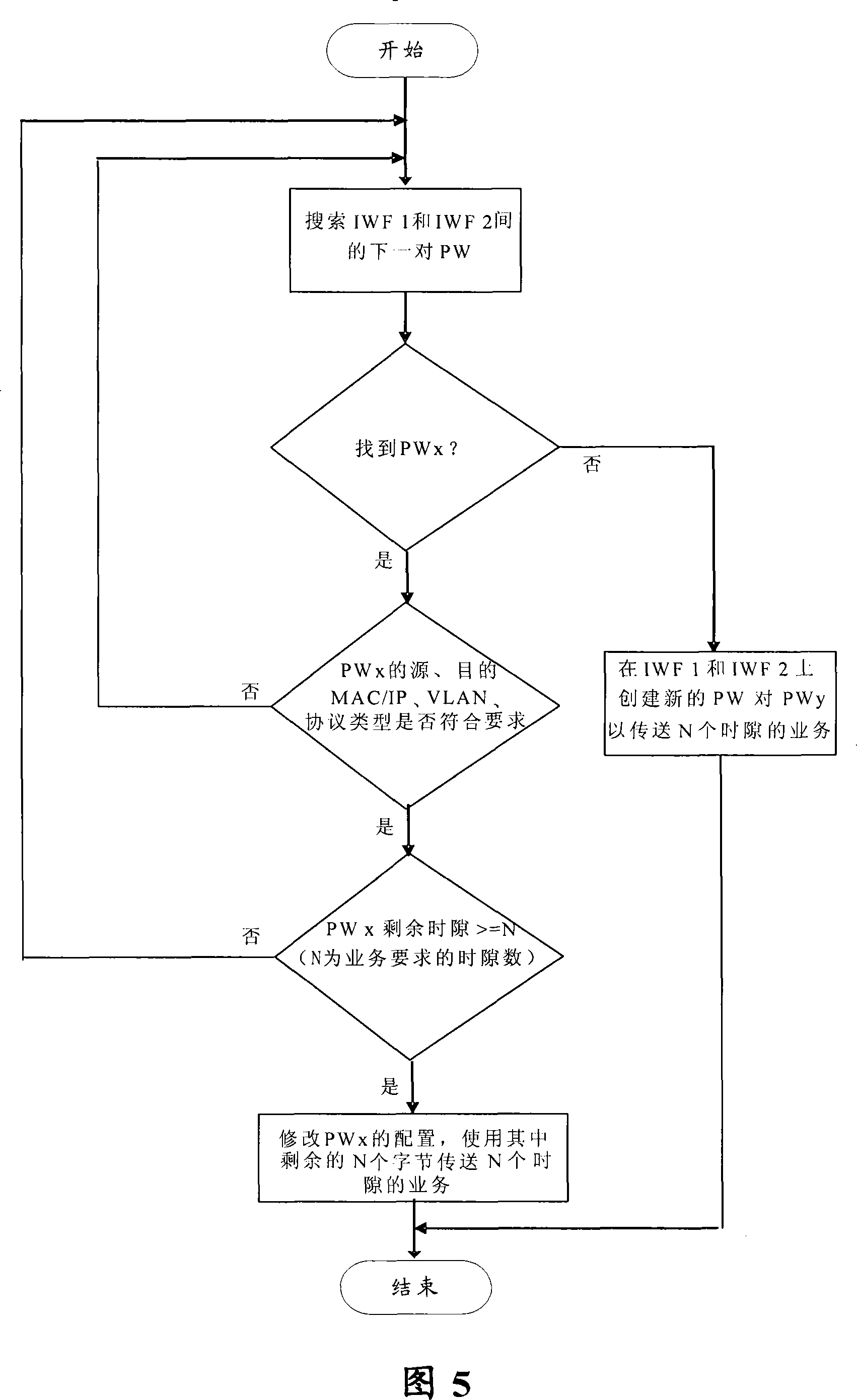

Method for collocating circuit simulation end to end business

InactiveCN101227337AImprove activation efficiencyReduce manual configurationNetworks interconnectionNetworked systemPseudo-wire

The invention discloses a method for arranging end-to-end services of circuit simulation, which comprises step S202, arranging pseudo-wire services and E1 time slots according to time division multiplexing relevant requirements and grouping relevant requirements of a source node and an objective node, step S204, searching a route between the source node and the objective node by a network system, and step 206, arranging VLAN for the route which is searched according to the grouping relevant requirements and a result for arranging the pseudo-wire services by the network system. The invention can greatly reduce an artificial arrangement process, lower the occurrence rate of errors, and increase the efficiency for recanalizing services.

Owner:ZTE CORP

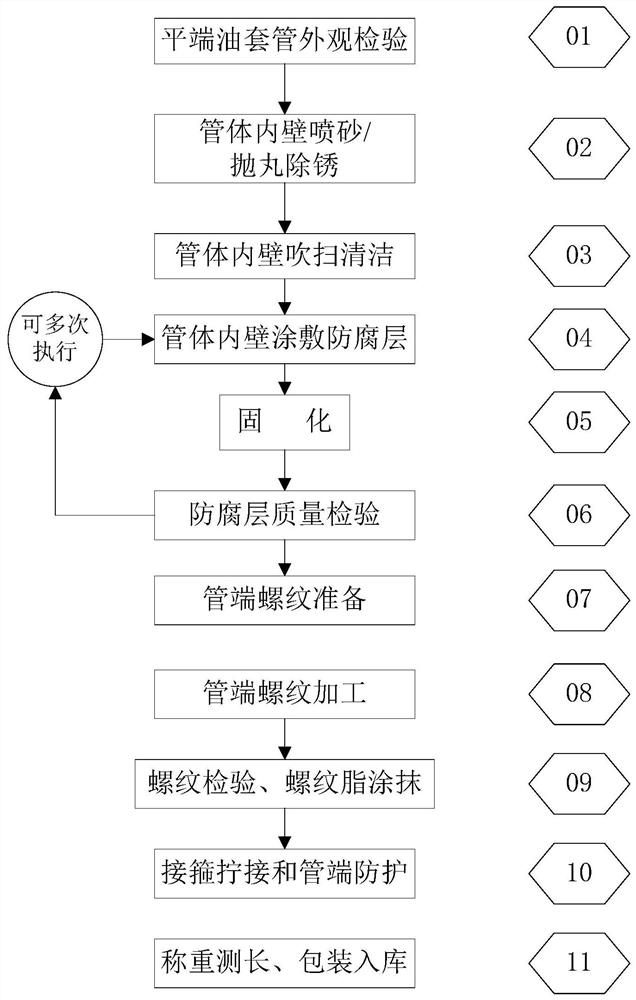

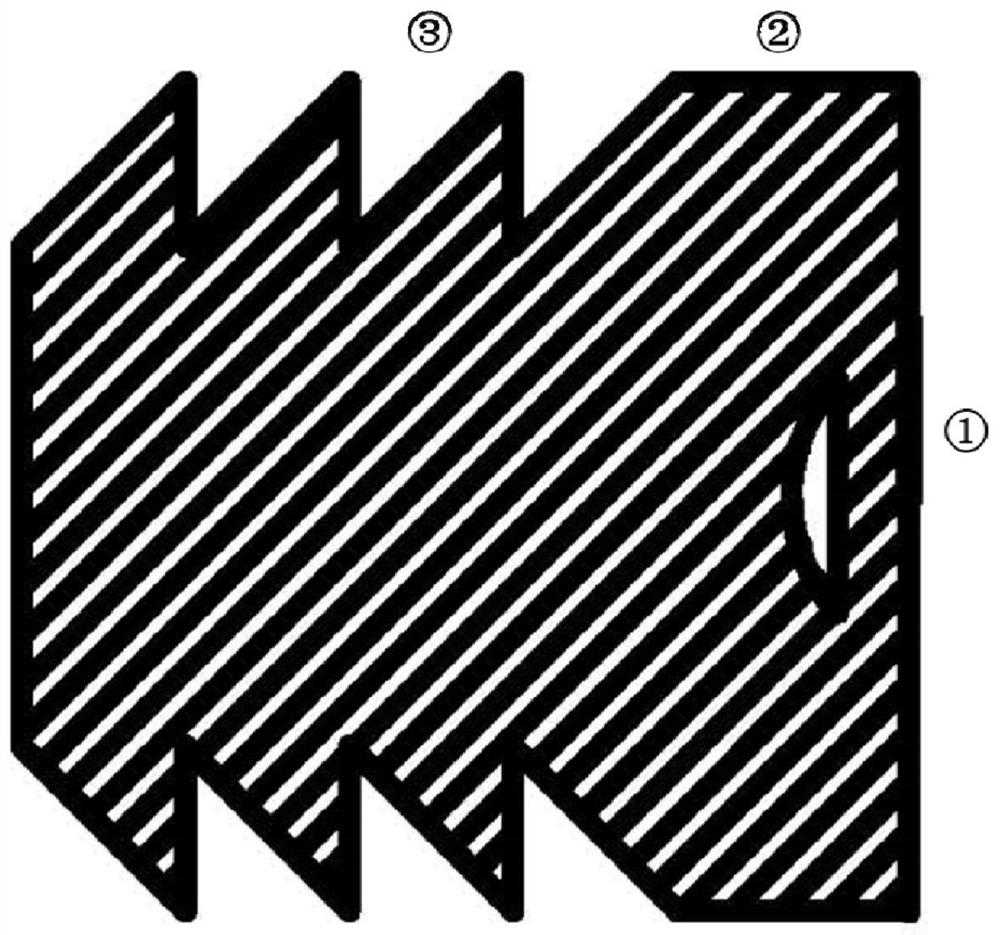

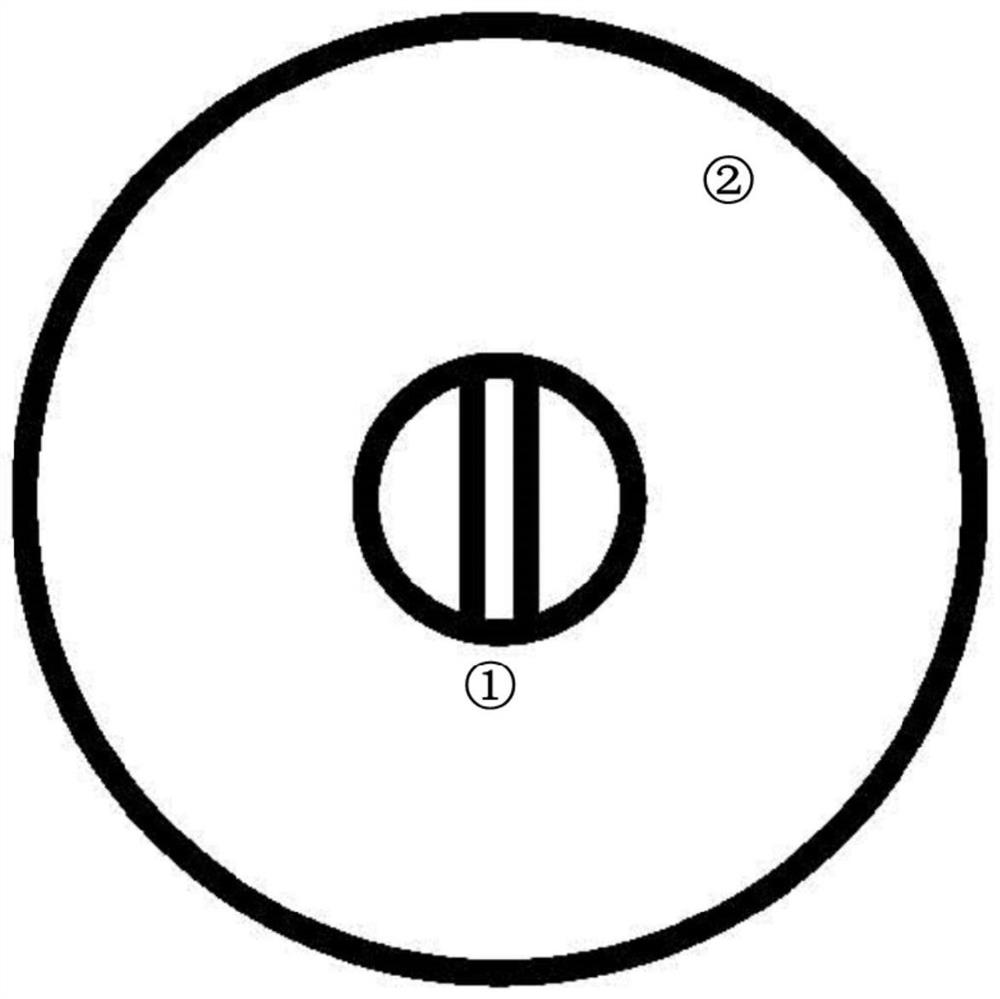

Anti-corrosion coating process in oil casing pipe

ActiveCN112439678AReduce excessive frictionGuaranteed friction strengthThread cutting machinesHollow article cleaningMachine partsMachining process

The invention provides an anti-corrosion coating process in an oil casing pipe. The process comprises the following steps that firstly, the inner wall of the flat-end oil casing is cleaned; secondly,anti-corrosion layer coating treatment and curing treatment are conducted on the inner wall of a flat-end oil casing pipe body; thirdly, threads at the pipe end of the oil casing pipe are machined; inthe thread machining process, the highest temperature of the inner wall of the thread machining part does not exceed 90% of the upper limit value of the temperature resistance of an anti-corrosion layer of the pipe body in terms of the celsius degree; cutting fluid used for thread machining does not damage the anti-corrosion layer coated on the inner wall of the oil casing pipe; and fourthly, theoil casing pipe is subjected to coupling tightening and pipe end protection, and the whole anti-corrosion coating process in the oil casing pipe is completed. The technological process is simple, thedefective product generation probability is low, and the anti-corrosion coating process can be well suitable for coating in the oil casing pipe of high-temperature-resistant anti-corrosion paint, andcoating in the low-end and conventional paint oil casing pipe for temporary storage and transportation is achieved at a low price.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method, system and device for link discovery

ActiveCN103828310BReduce manual configurationImprove reliabilityData switching networksTransport networkCross layer

The present invention provides a method for link discovery. In the method, a first controller sends a first message to a first node. After receiving the first message, the first node reports the second link discovery A message is sent from the first port to the second node; the second node receives the second link discovery message at the second port, and sends the second link discovery message to the second controller according to the label. message, the second message carries the second link discovery message and the second port identifier; the second controller receives the second message, and extracts the first link discovery message The first port identifier in the second message and the second port identifier in the second message determine that there is a link between the first port of the first node and the second port of the second node, thereby implementing The routing controller and transport network controller can automatically discover the information of cross-layer links, reduce manual configuration, and achieve simple and high reliability.

Owner:HUAWEI TECH CO LTD

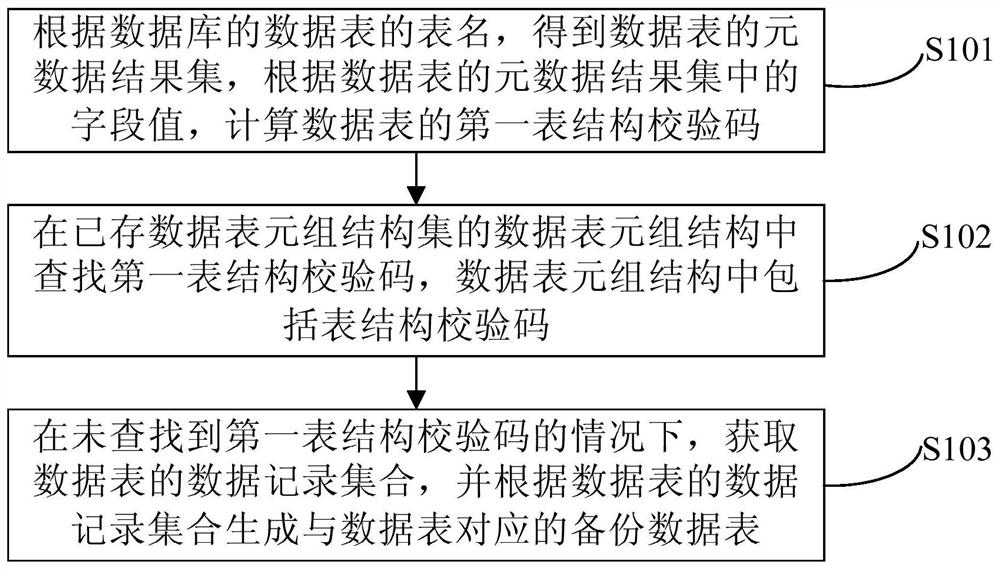

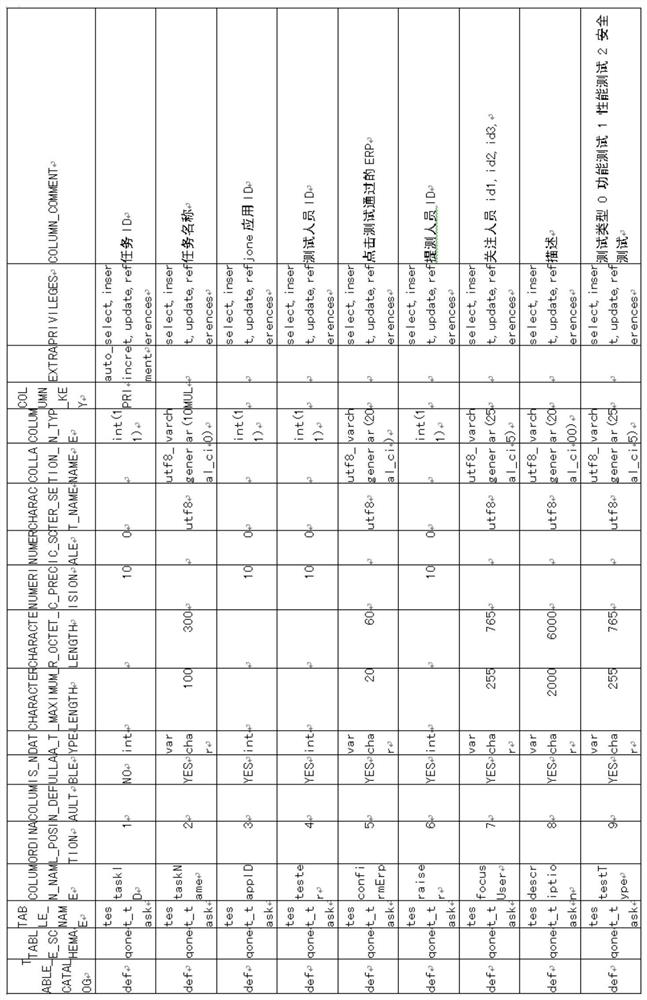

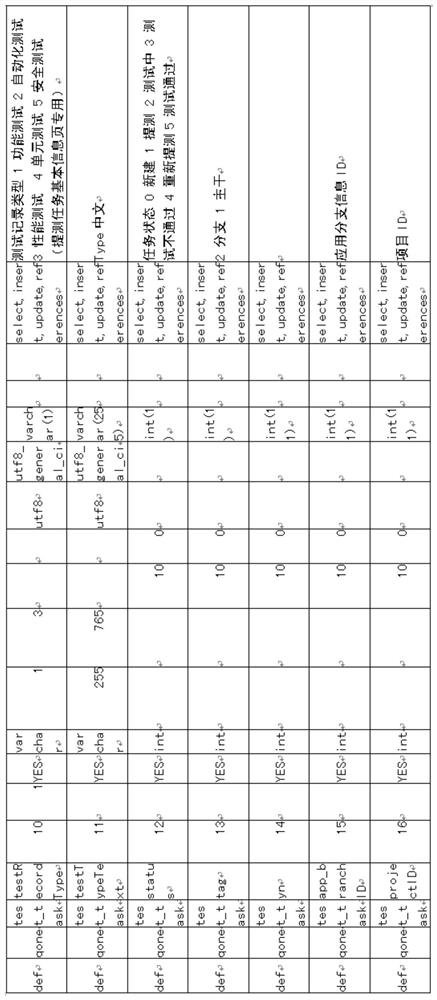

Database backup method, database restoration method and related devices

ActiveCN113760600ANo version restrictionsReduce occupancyDatabase updatingDatabase distribution/replicationTable (database)Datasheet

The invention discloses a database backup method, a database restoration method and related devices and relates to the technical field of computers. A specific embodiment of the method comprises steps of calculating a first table structure check code of a data table of a database, and generating a backup data table of the data table under the condition that the first table structure check code is not found in a data table tuple structure of a stored data table tuple structure set. According to the method, automatic identification of database increment and modification, rapid data export, shortening of backup time, reduction of backup disk space occupation and reduction of artificial configuration of incremental backup can be achieved, database version limitation is avoided, universality is good, checking can be directly conducted in an SQL mode, backup data can still be accessed under the condition that a database server is damaged, and data modification can be customized.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

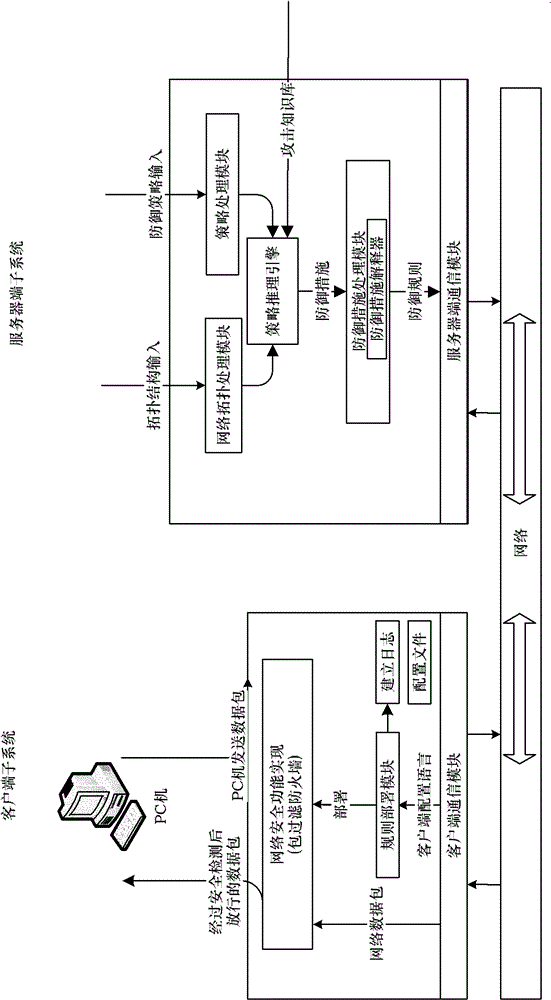

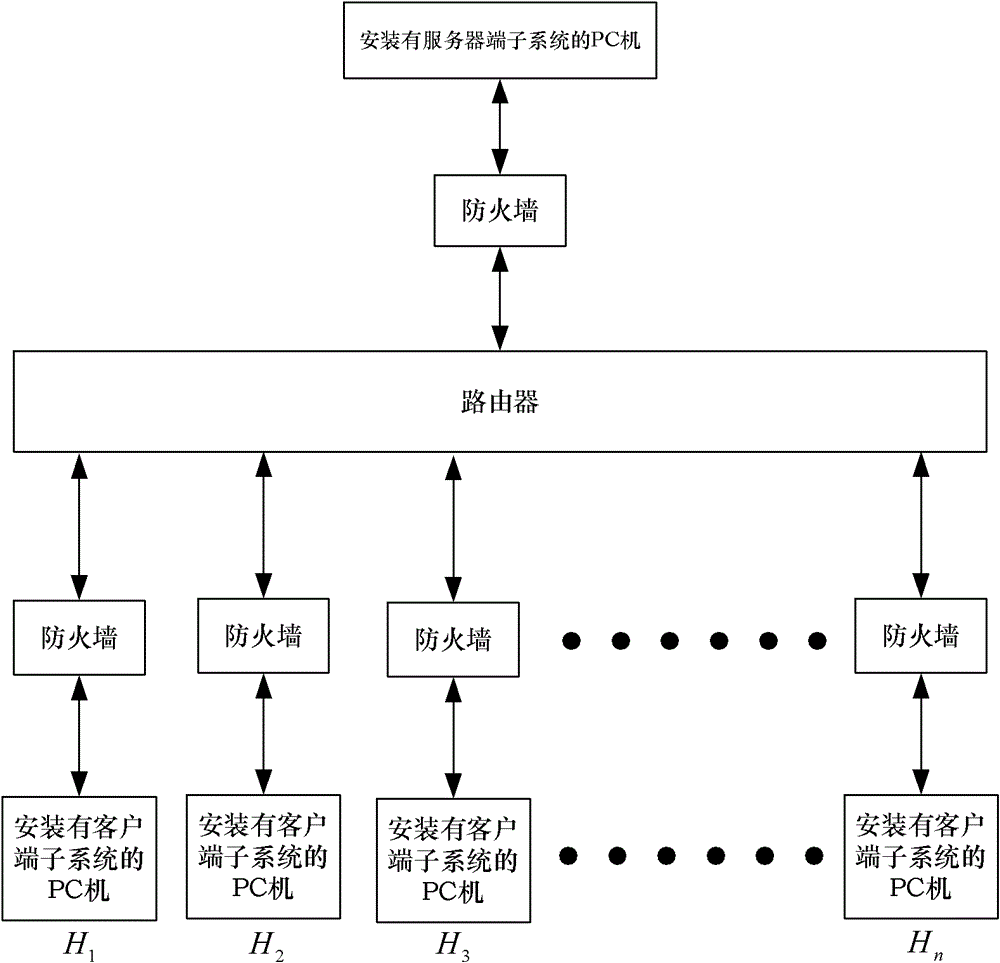

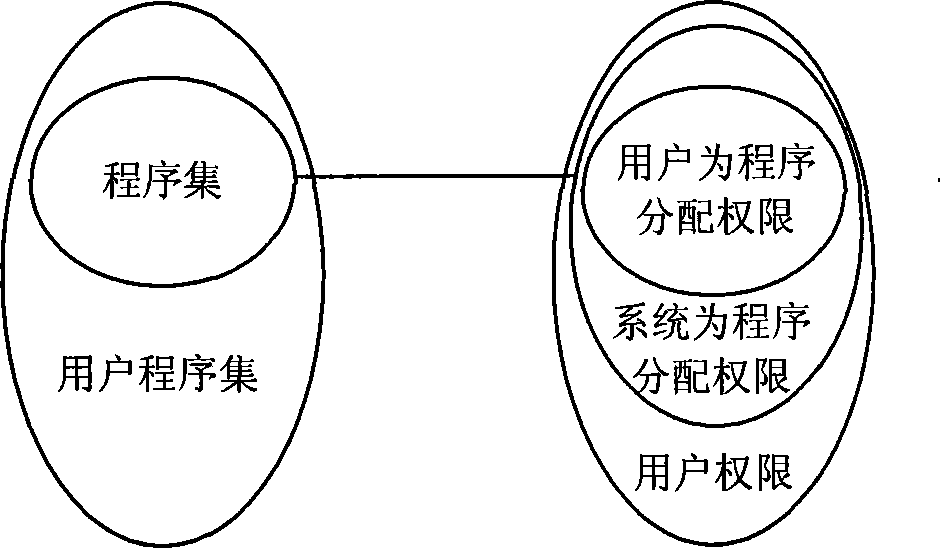

Distributed network firewall system of Linux based on defense strategy

The invention discloses a distributed network firewall system of Linux based on a defense strategy, which provides network security protection for a computer with a Linux operating system in a local area network. The system has a distributed structure which consists of a server terminal subsystem and a client subsystem. In the network firewall system, a network topologic structure for the local area network is firstly constructed in the server terminal for the local area network to be protected and then services to be protected and possibly attacked manners are selected and a defense rule document is generated. The defense rule document is timely updated in the client system and deployed to achieve the purpose of protection. A plurality of defense rules aiming at different computers and services in the network are generated by means of strategy reasoning and explanation of the client system to protect all computers with the client subsystem and firewall correspondingly. One defense strategy is set for a single network node to safely protect the plurality of network nodes simultaneously.

Owner:BEIHANG UNIV

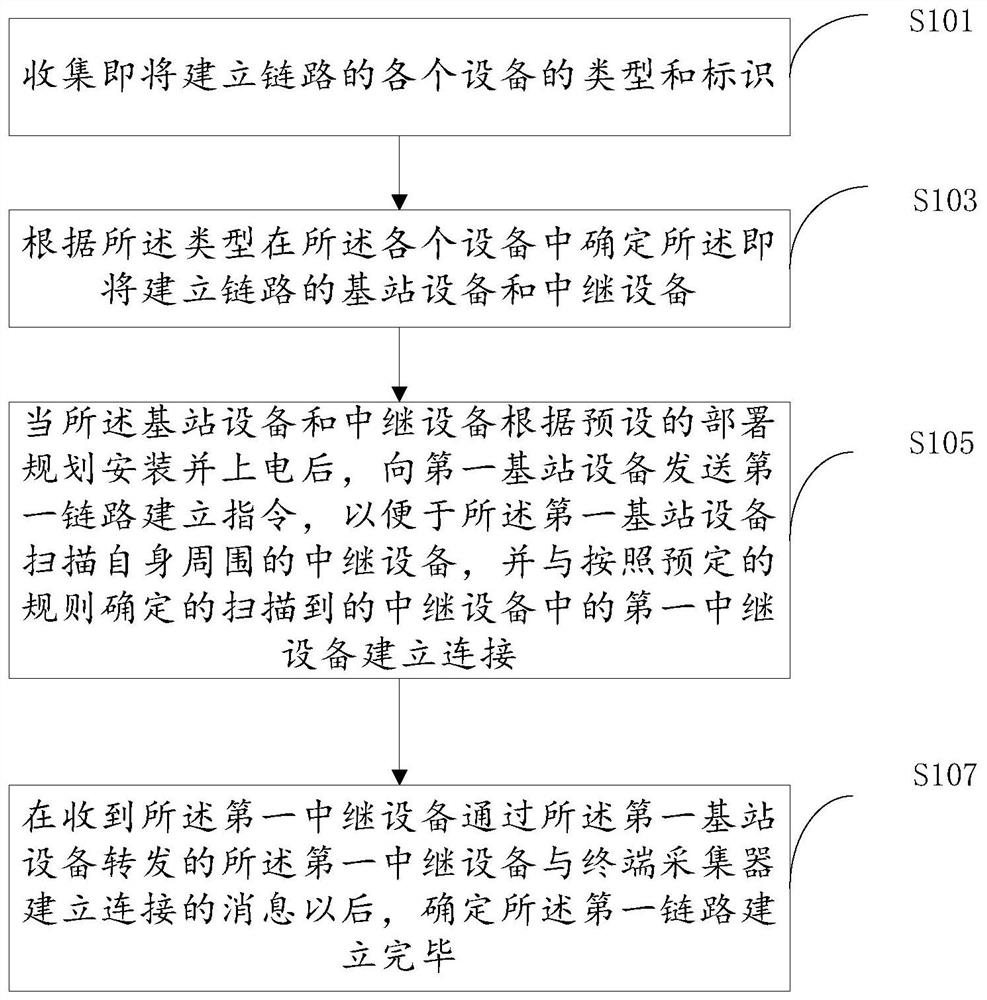

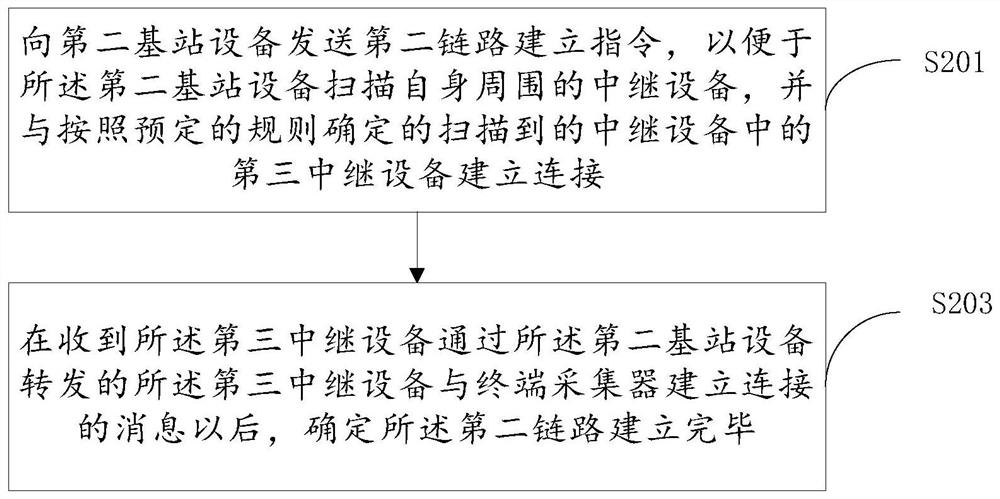

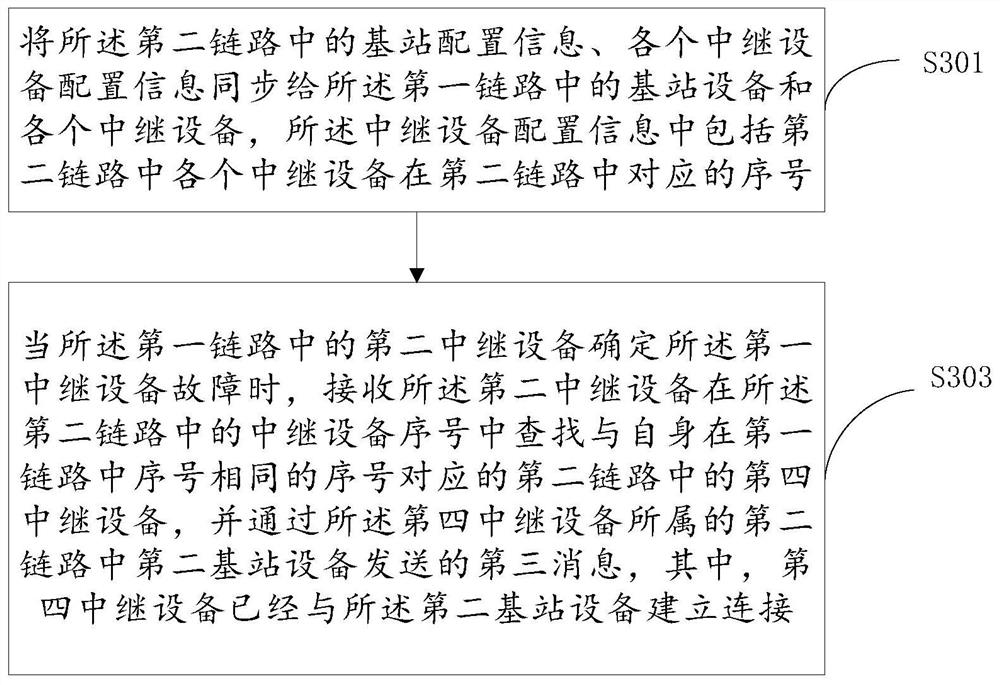

Method for establishing lora long-distance transmission link and server

ActiveCN112533299AImprove construction efficiencyIncrease the number ofSynchronisation arrangementConnection managementTrunkingEngineering

The invention provides a method and a server for establishing a lora long-distance transmission link. The method comprises the following steps of: collecting the type and identification of each pieceof equipment of which the link is about to be established; determining base station equipment and relay equipment of which the link is about to be established in the equipment according to the type; after the base station equipment and the relay equipment are installed and powered on according to a preset deployment plan, sending a first link establishment instruction to first base station equipment, so that the first base station equipment scans the relay equipment around the first base station equipment and establishes connection with the first relay equipment in the scanned relay equipmentdetermined according to a preset rule; and determining that the first link is completely established after receiving a message of establishing connection between the first relay equipment and a terminal collector forwarded by the first relay equipment through the first base station equipment. The installation cost is saved, and the reliability is improved.

Owner:RUIJIE NETWORKS CO LTD

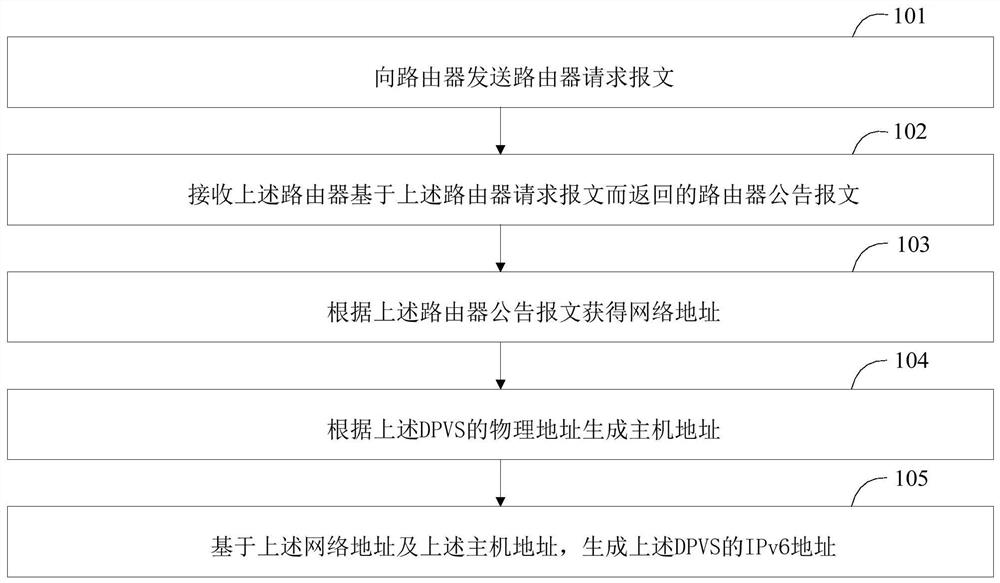

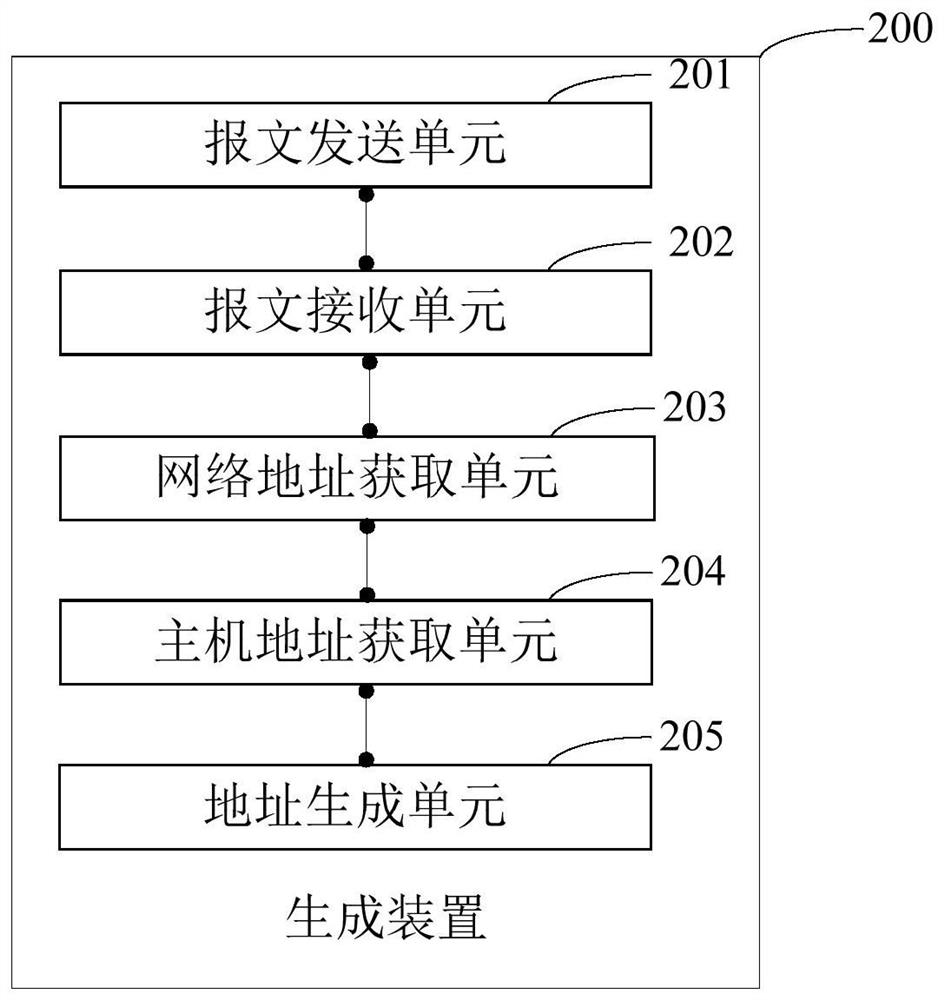

IPv6 address generation method, IPv6 address generation device and load balancer

ActiveCN112671947AImprove the efficiency of address managementRapid deploymentData switching networksNetwork addressingPhysical address

The invention discloses an IPv6 address generation method, an IPv6 address generation device, a load balancer and a computer readable storage medium. The method is applied to a high-performance layer 4 load balancer DPVS, and comprises the following steps: sending a router request message to a router; receiving a router announcement message returned by the router based on the router request message; obtaining a network address according to the router announcement message; generating a host address according to the physical address of the DPVS; and generating an IPv6 address of the DPVS based on the network address and the host address. According to the scheme of the invention, the method can achieve the quick generation of the IPv6 address after the DPVS is initialized, improves the address management efficiency of the DPVS, and achieves the quick deployment of the DPVS.

Owner:THE CHINESE UNIV OF HONG KONG SHENZHEN +1

Brick storage system for semi-finished bricks and brick storage method

Owner:JIANGXI HEMEI CERAMICS +1

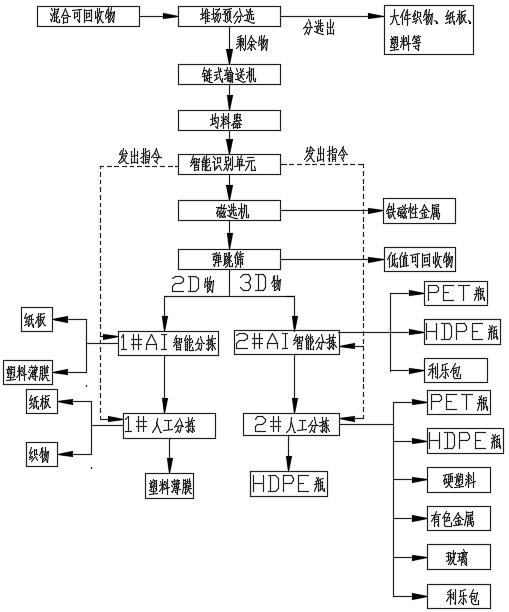

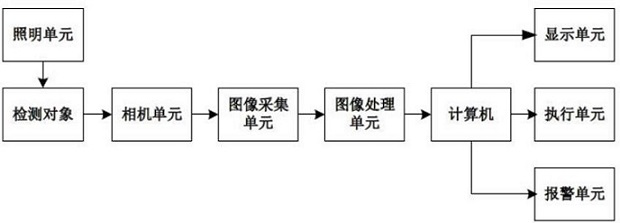

Recyclable material classification intelligent dispatching system and dispatching method thereof

The invention provides a recyclable material classification intelligent dispatching system and a dispatching method thereof. The dispatching system comprises a storage yard pre-sorting unit, a feeding unit, an intelligent recognition unit and an execution unit which are sequentially connected. The storage yard pre-sorting unit is used for sorting out large fabrics, paperboards and plastics in mixed recyclable materials; the feeding unit is used for transferring residues pre-sorted in a storage yard to a sorting production line; the intelligent recognition unit is used for recognizing various material components in the pre-sorted mixed recyclable materials for intelligent recognition and data statistics and calculation, and the rear-end ratio is optimized; and the execution unit is used for executing an instruction issued by the intelligent recognition unit for material sorting. The intelligent recognition unit comprises a camera, a lighting unit and a computer, the camera is electrically connected with the computer, the camera is located over a conveying belt, a lens is vertically downward, an image processing module is carried in the computer, and the image processing module receives images collected by the camera and conducts classification and quantity statistics on the recyclable materials.

Owner:TAICANG GOLDENMA METAL STRUCTURE

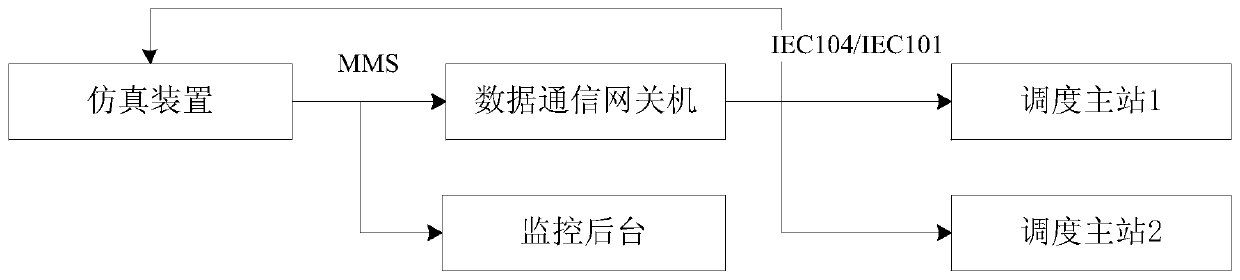

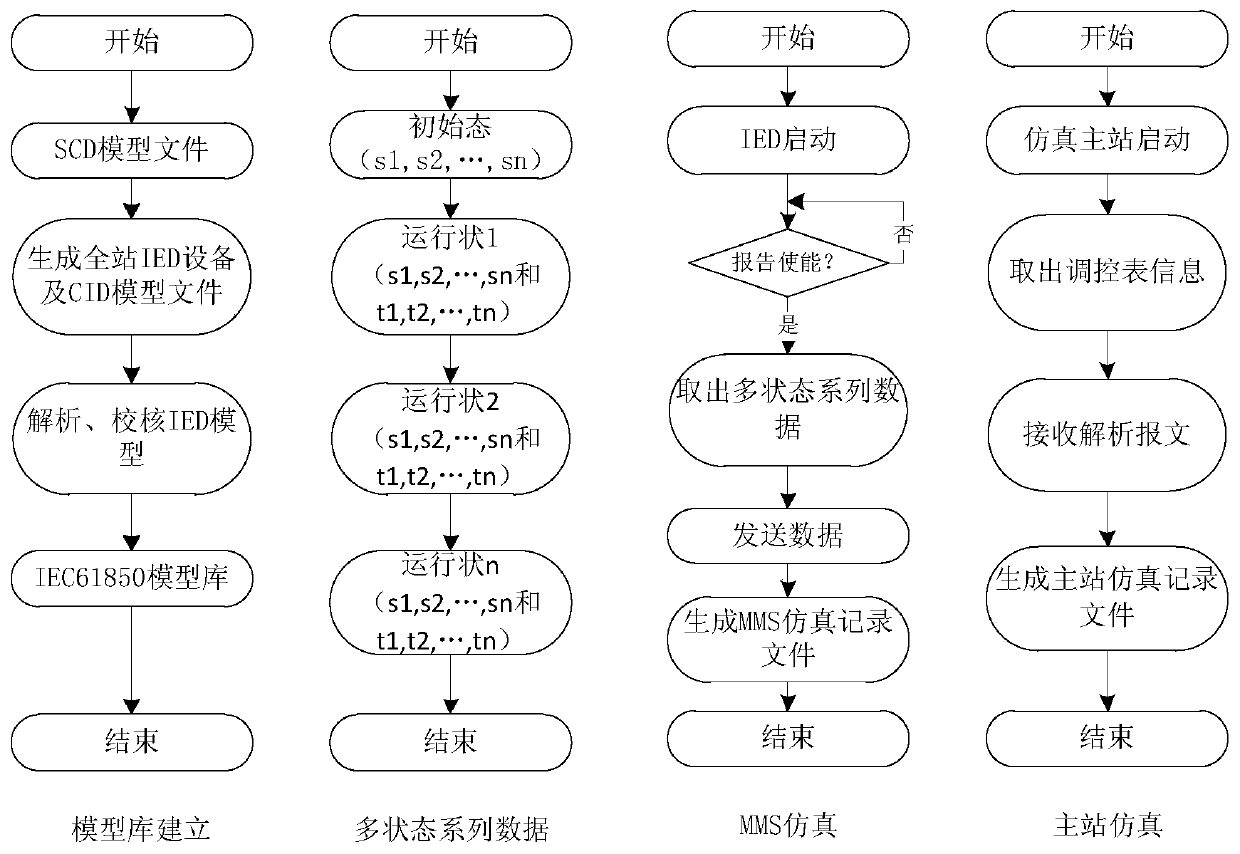

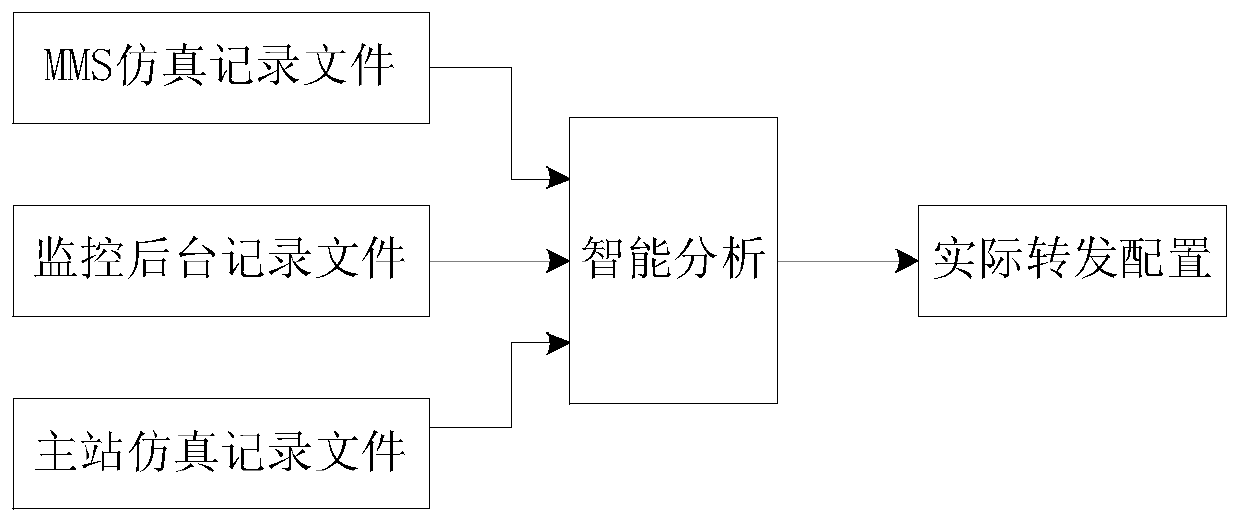

A portable power grid dispatching automation simulation verification system

InactiveCN110212532BReduce manual configurationAvoid Sending Fault MessagesAc network circuit arrangementsReliability engineeringData model

The invention relates to a portable power grid scheduling automation simulation verification system, which belongs to the technical field of power system automation. The system includes simulation device and intelligent analysis and point-to-point system; simulation device includes: data model generation module, MMS simulation module, simulation data generation module, master station simulation module and monitoring control module; intelligent analysis and point-to-point system includes: remote signaling An analysis unit, a telemetry analysis unit, a remote control unit, a remote signaling automatic point-setting unit and a telemetry automatic point-setting unit. The invention not only realizes the automatic acceptance of the master and sub-stations, but also reduces the test time and manual configuration.

Owner:STATE GRID CORP OF CHINA +1

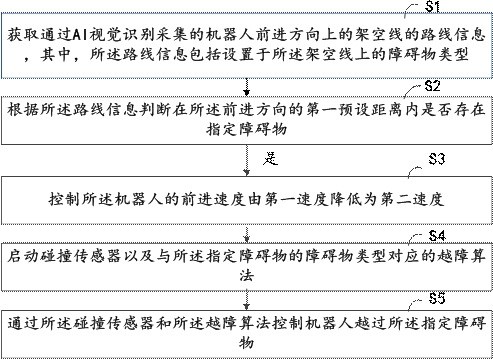

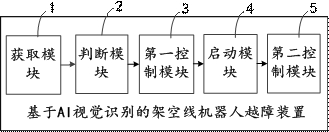

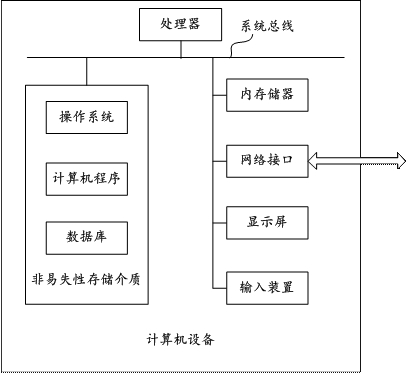

Overhead line robot obstacle crossing method, device and equipment based on AI visual identification

ActiveCN112684804AReduce the chance of failureImprove efficiencyPosition/course control in two dimensionsVision basedVisual recognition

The invention relates to the field of robots, and discloses an overhead line robot obstacle crossing method based on AI visual recognition, and the method comprises the steps: obtaining the route information, collected through vision, of an overhead line in the advancing direction of a robot, wherein the route information comprises the type of an obstacle disposed on the overhead line; according to the route information, judging whether a specified obstacle exists within a first preset distance in the advancing direction or not; if yes, controlling the forward speed of the robot to be reduced from the first speed to a second speed; starting a collision sensor and an obstacle crossing algorithm corresponding to the obstacle type of the specified obstacle; controlling the robot to cross a specified obstacle through a collision sensor and an obstacle crossing algorithm. The speed change of the robot in the inspection process is controlled through the AI visual recognition analysis and acquisition device for matching and recognizing the obstacle type and the obstacle distance, the failure probability of high-speed collision of the collision sensor is reduced, obstacle crossing can still be conducted smoothly when the collision sensor fails, the line inspection efficiency of the overhead line robot is improved, and the service life of the overhead line robot is prolonged.

Owner:中科开创(广州)智能科技发展有限公司

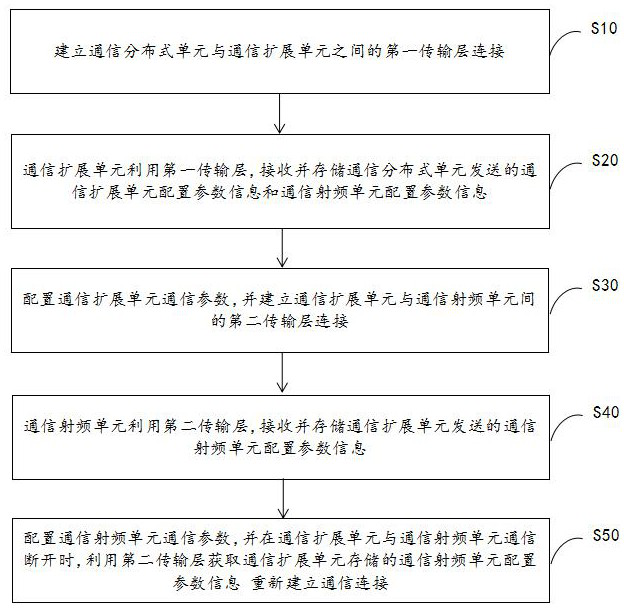

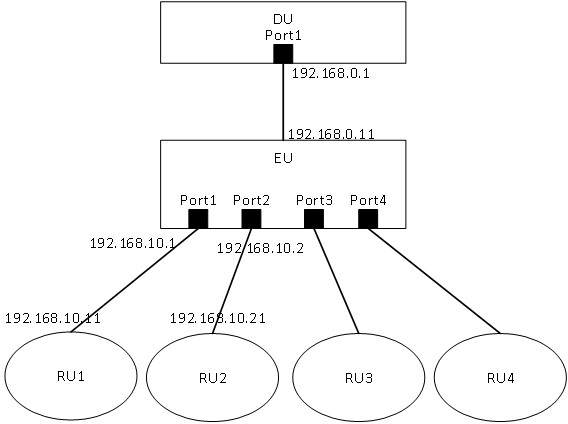

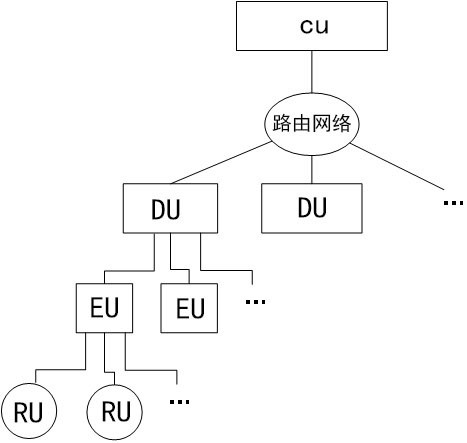

Communication radio frequency unit automatic configuration recovery method and device, equipment and storage medium

ActiveCN112702753ASolve the failure to automatically configureTroubleshoot technical issues with AutoRecoverConnection managementAuto-configurationRadio frequency

The invention discloses an automatic configuration recovery method, device and equipment for a communication radio frequency unit, and a storage medium. According to the method, the configuration information needed by a communication distributed unit, a communication expansion unit and the communication radio frequency unit is stored in a storage of the communication distributed unit, and the manual configuration is reduced through an automatic configuration method, so the communication radio frequency unit can be inserted. Meanwhile, the configuration information of the communication radio frequency unit which is available before link breakage is stored, so that the communication radio frequency unit can be directly used after being reconnected. According to the communication expansion unit device, configuration data of the lower hanging communication radio frequency units can be automatically generated, the number of the lower hanging communication radio frequency units does not need to be planned in advance, and the networking mode of the device can be flexibly adjusted. The technical problem that in the prior art, communication equipment in a 5G mobile communication network cannot be automatically configured and recovered is solved.

Owner:四川创智联恒科技有限公司

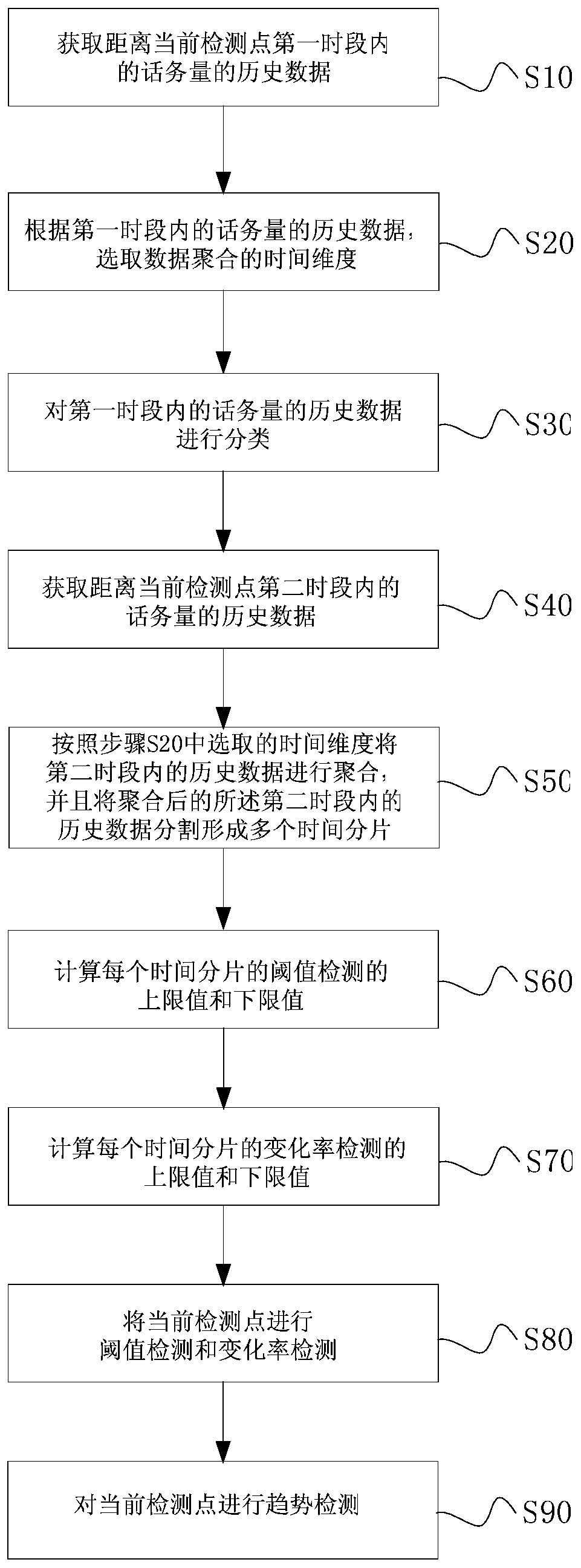

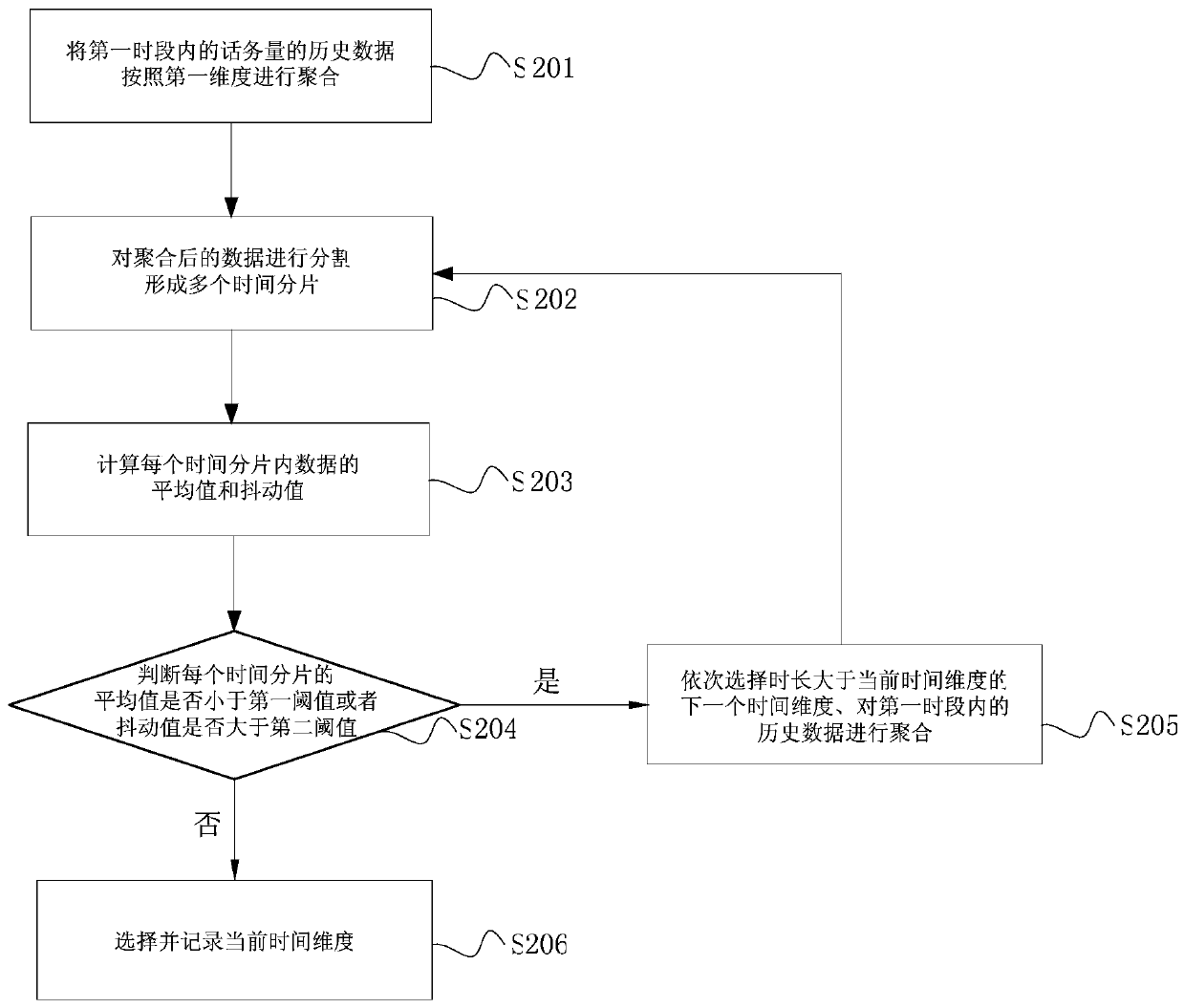

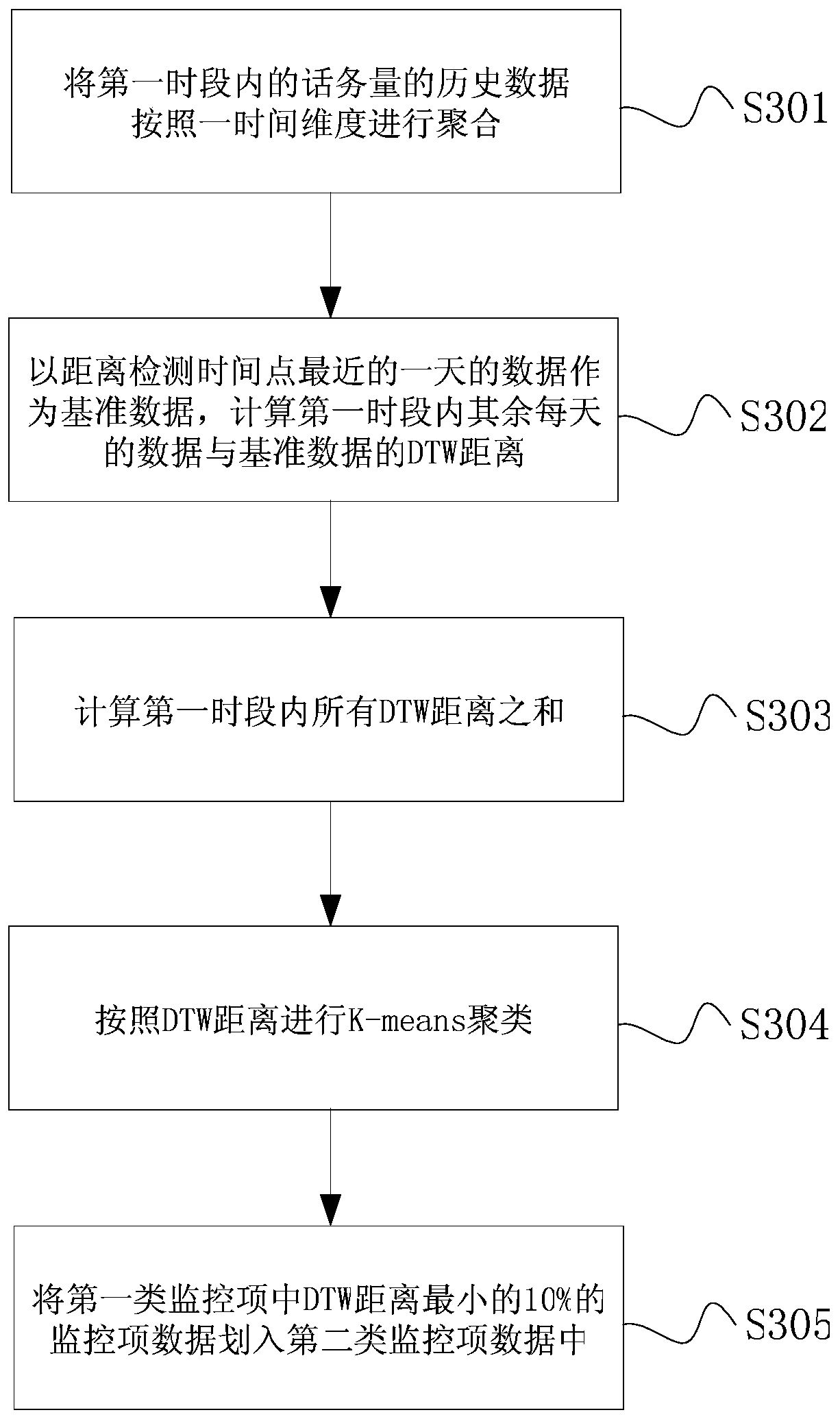

Automatic detection method and system for traffic abnormalities, storage medium, and electronic equipment

ActiveCN107766533BImprove accuracyReduce false alarm rateRelational databasesHardware monitoringLower limitData aggregator

Owner:CTRIP TRAVEL NETWORK TECH SHANGHAI0

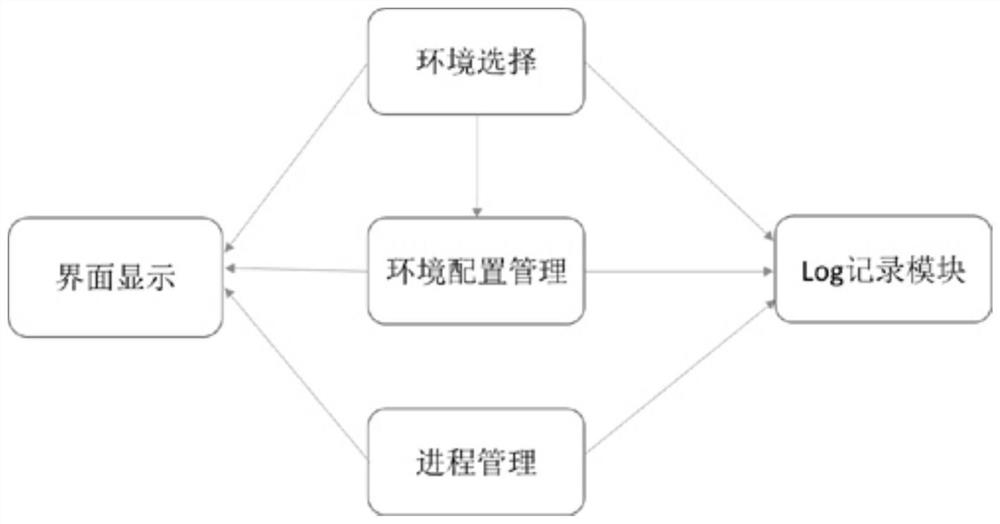

An automatic configuration tool on Linux financial self-service terminal

ActiveCN110795145BFast and stable deploymentReduce manual configurationVersion controlConfiguration Management (ITSM)Development environment

The invention discloses an automatic configuration tool on a Linux financial self-service terminal, comprising an environment selection module, an environment configuration management module, a process management module, an interface display module and a Log recording module; the environment configuration management module includes dependency installation, customization File deployment location, setting file access rights, svn configuration, system environment variable configuration and hardware access rights configuration; the operating status of the environment configuration management module includes developer mode, development environment mode and deployment operating environment mode; the process management module automatically finds it according to the process name The PID of the process; the interface display module provides the display function; the Log recording module records the changes of the configuration according to the time point. Through the above-mentioned manner, the present invention can improve the efficiency and quality of environment deployment of domestic linux financial equipment, so that the environment deployment of financial equipment can meet the needs of rapidly developing business.

Owner:INSPUR FINANCIAL INFORMATION TECH CO LTD

An intelligent protocol conversion device and method based on embedded QNX operating system

InactiveCN101267448BReduce manual configurationImplement automatic conversionElectric signal transmission systemsTransmissionCommunications systemComputer module

The invention provides a device and a method for intelligent terms conversion. The device comprises a DSP central processing chip, a memory module, a display and keyboard operation module and an uplink-downlink communication module, wherein the memory module, the display and keyboard operation module and the uplink-downlink communication module are connected with the DSP central processing modulerespectively, a front-end computer communication module is connected with a front-end computer through a RS-232 bus, a RS-232 communication module is connected with a plurality of sub-stations RTU bya serial expansion circuit, a term converter is arranged between the RTU and the front-end compute of a power communication system, the uploaded communication protocol of the sub-stations RTU are intelligently recognized by a fuzzy expert system, the format of the recognized terms are converted into a unified terms format, uploaded to the front-end computer, and uploaded to each level of workstation by the front-end computer. The invention has the advantages that operators can realize automatic recognition and conversion of terms of interconnected two parties by the device without knowing theterms types of the interconnected two parties, thus avoiding the error possibly brought by manual operation.

Owner:NORTHEASTERN UNIV LIAONING +2

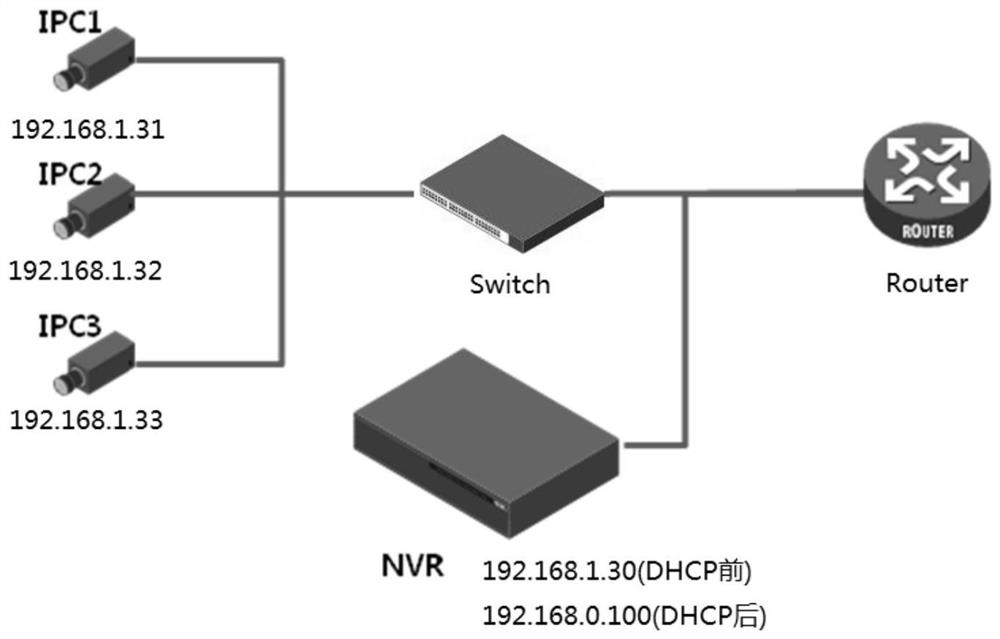

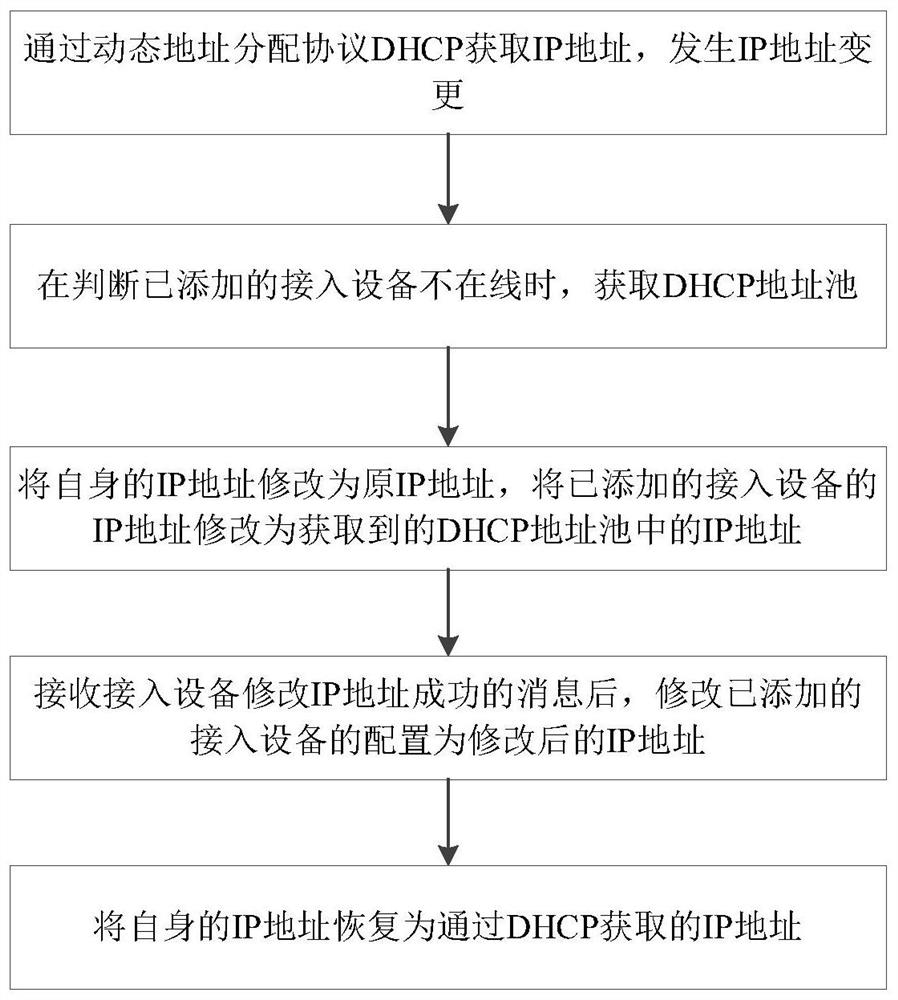

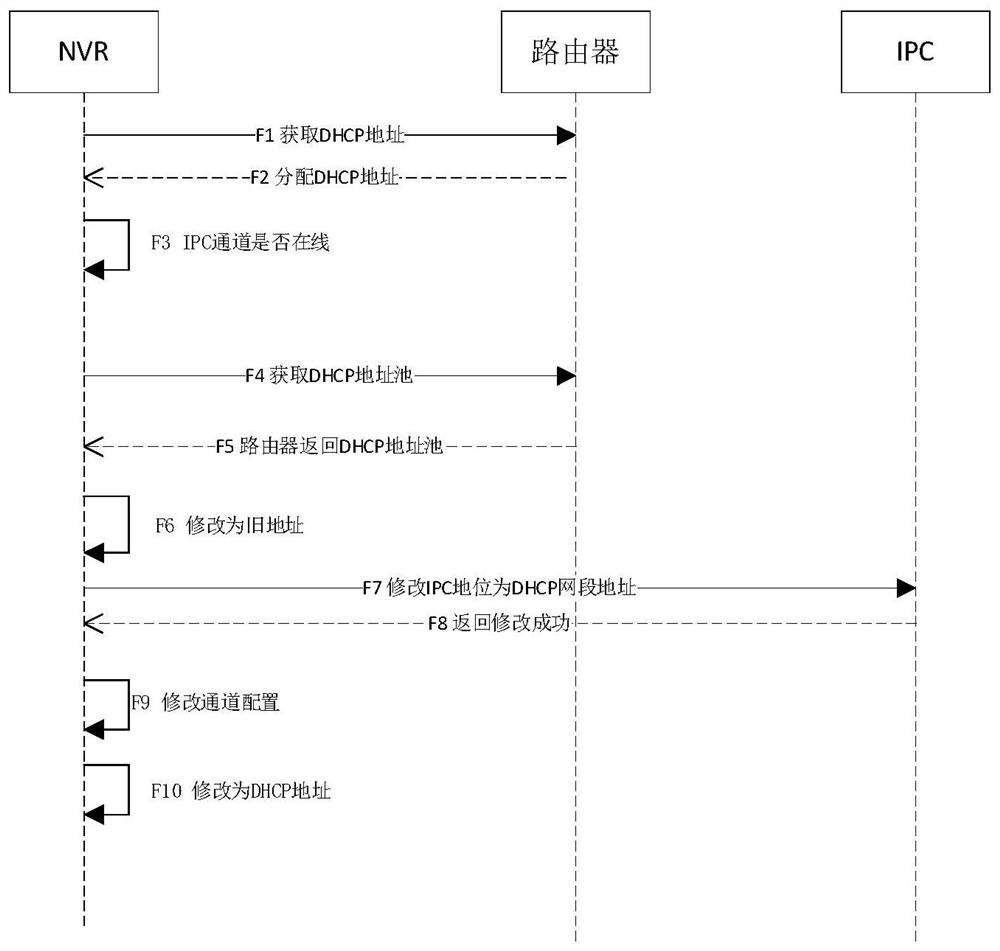

A method and device for keeping an access device online

The invention discloses a method and a device for keeping an access device online. An access management device obtains an IP address through a dynamic address allocation protocol DHCP, and when an IP address change occurs, it obtains the DHCP address when judging that the added access device is not online. After the address pool is allocated by DHCP, modify the original address to communicate with the network of the original access device, and modify the access device to the address of the DHCP network segment. After the modification is successful, modify the access management device back to the DHCP address. To ensure that the access device is always online on the access management device. The invention not only reduces the operation of the access equipment, but also reduces the manual configuration on the access management equipment, and significantly improves the user experience and reduces the configuration cost.

Owner:ZHEJIANG UNIVIEW TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com