Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Reduce evaporation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

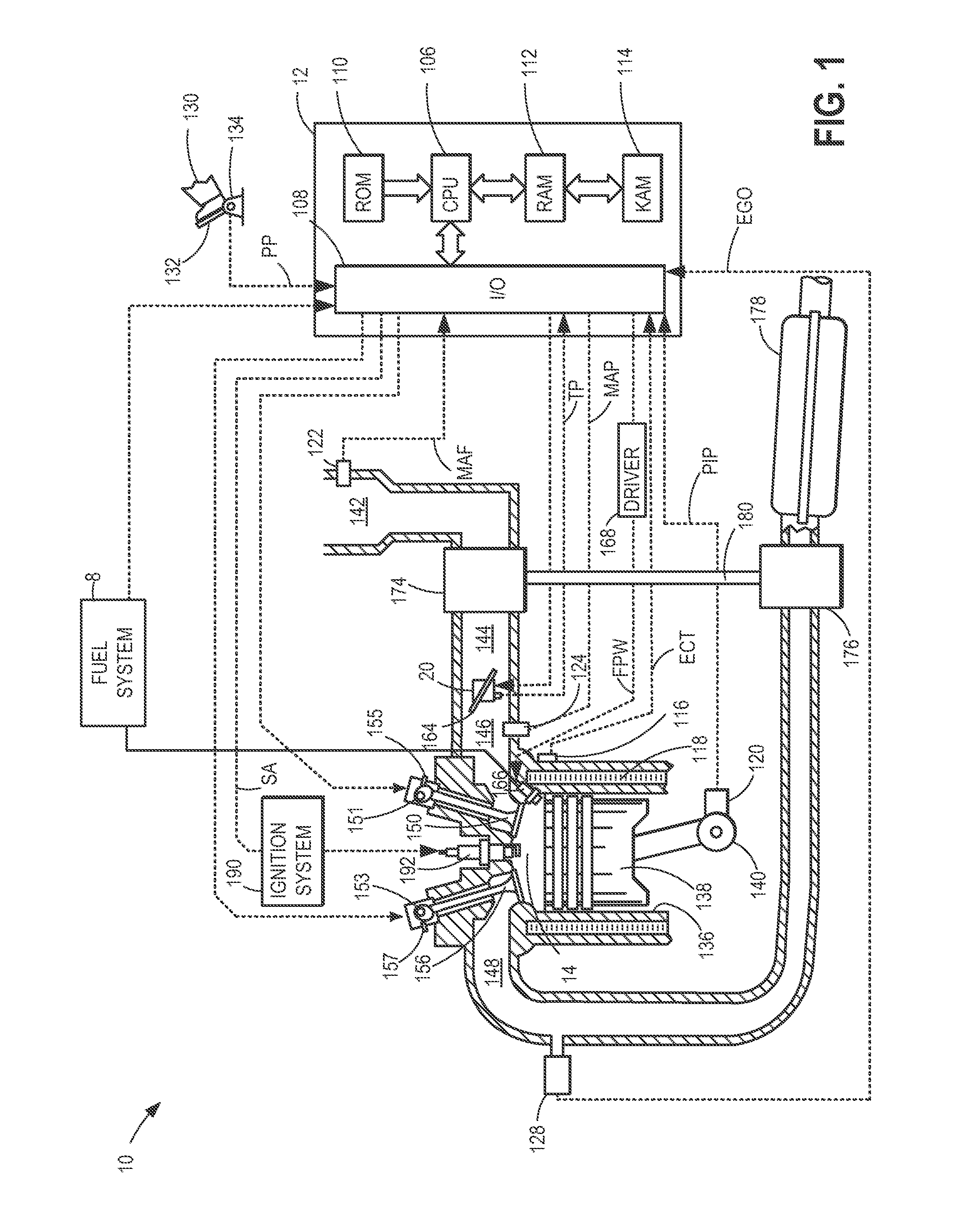

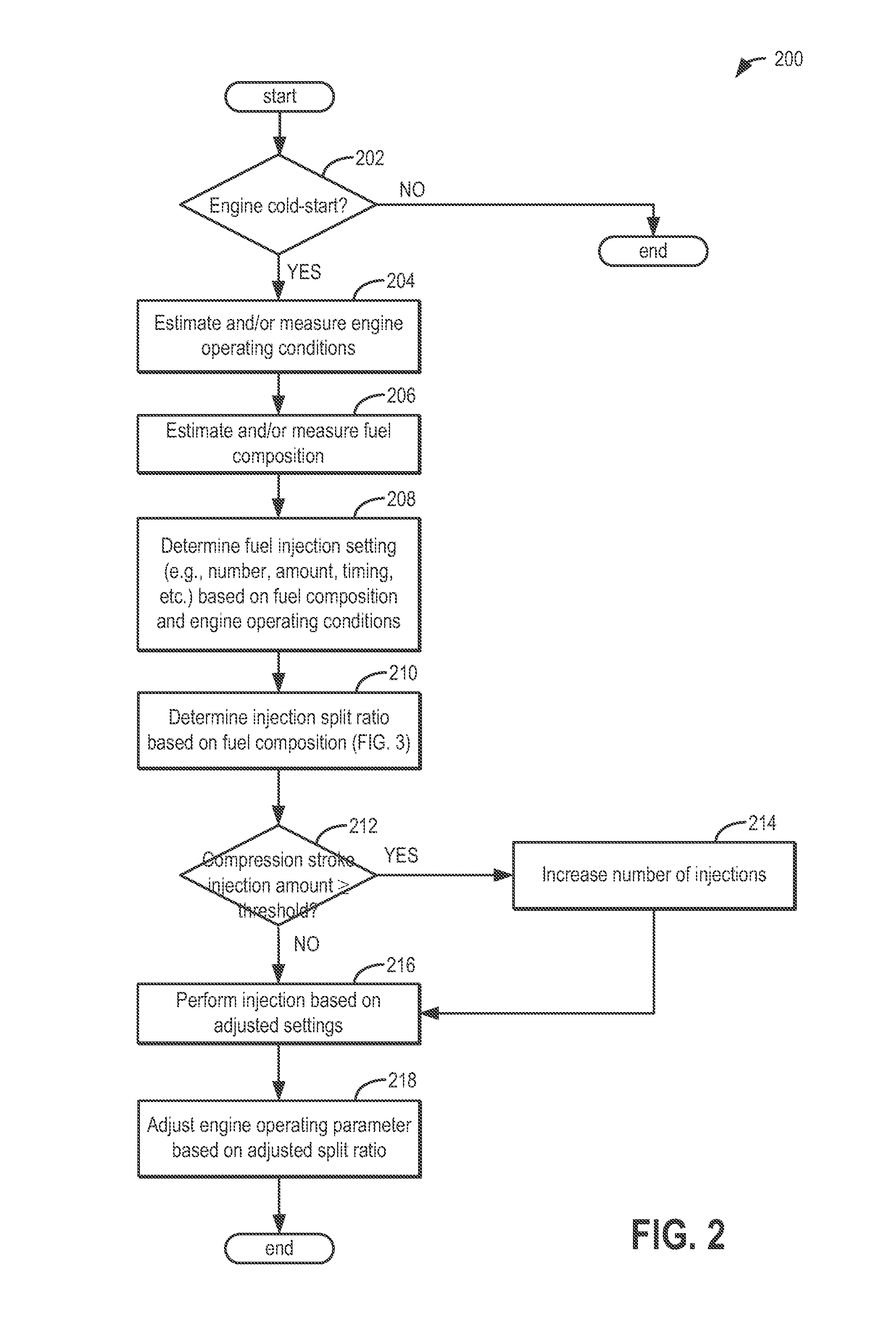

Fuel-based injection control

ActiveUS20110184629A1High latent heatImprove peak torque output of engineElectrical controlInternal combustion piston enginesAlcohol contentControl system

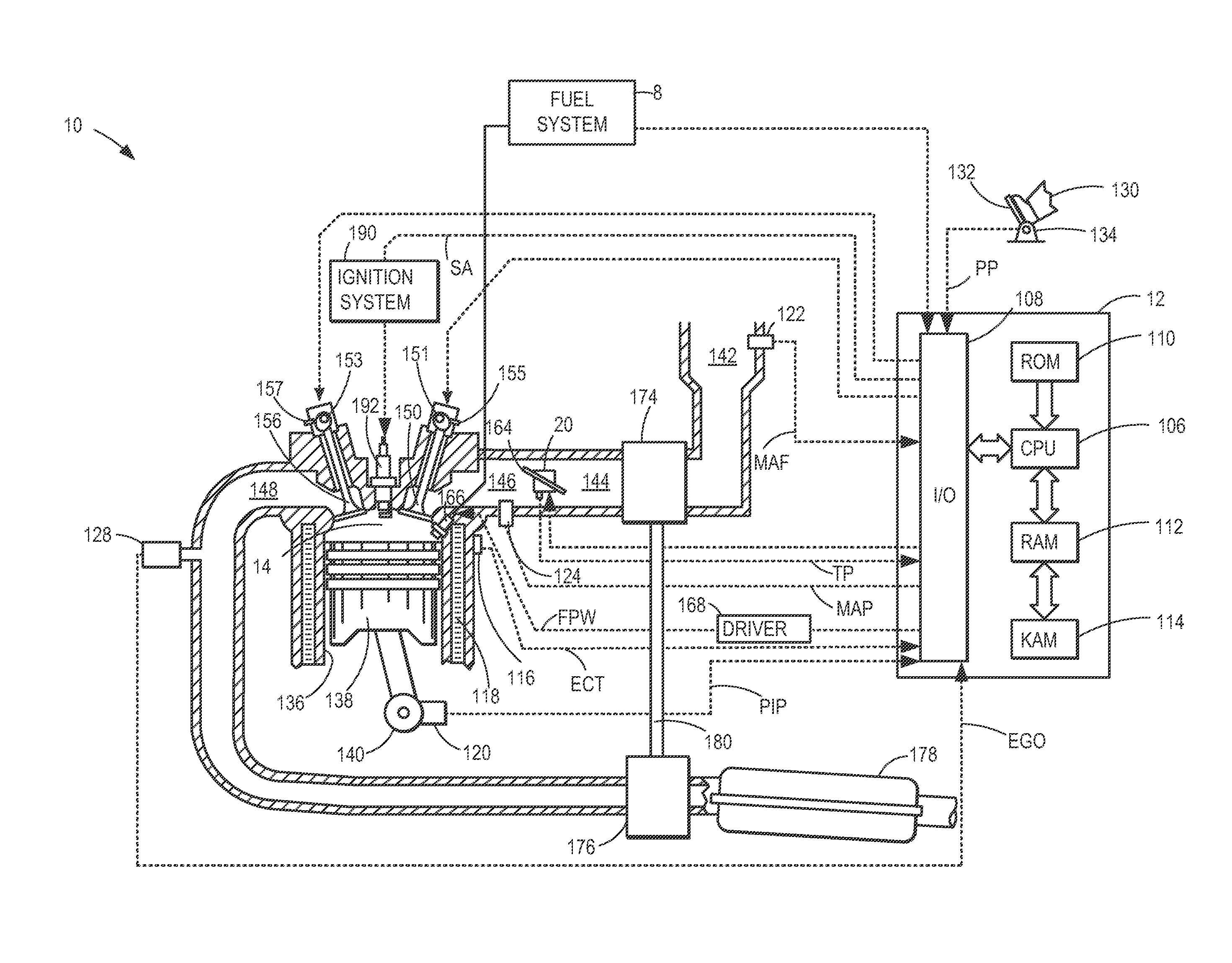

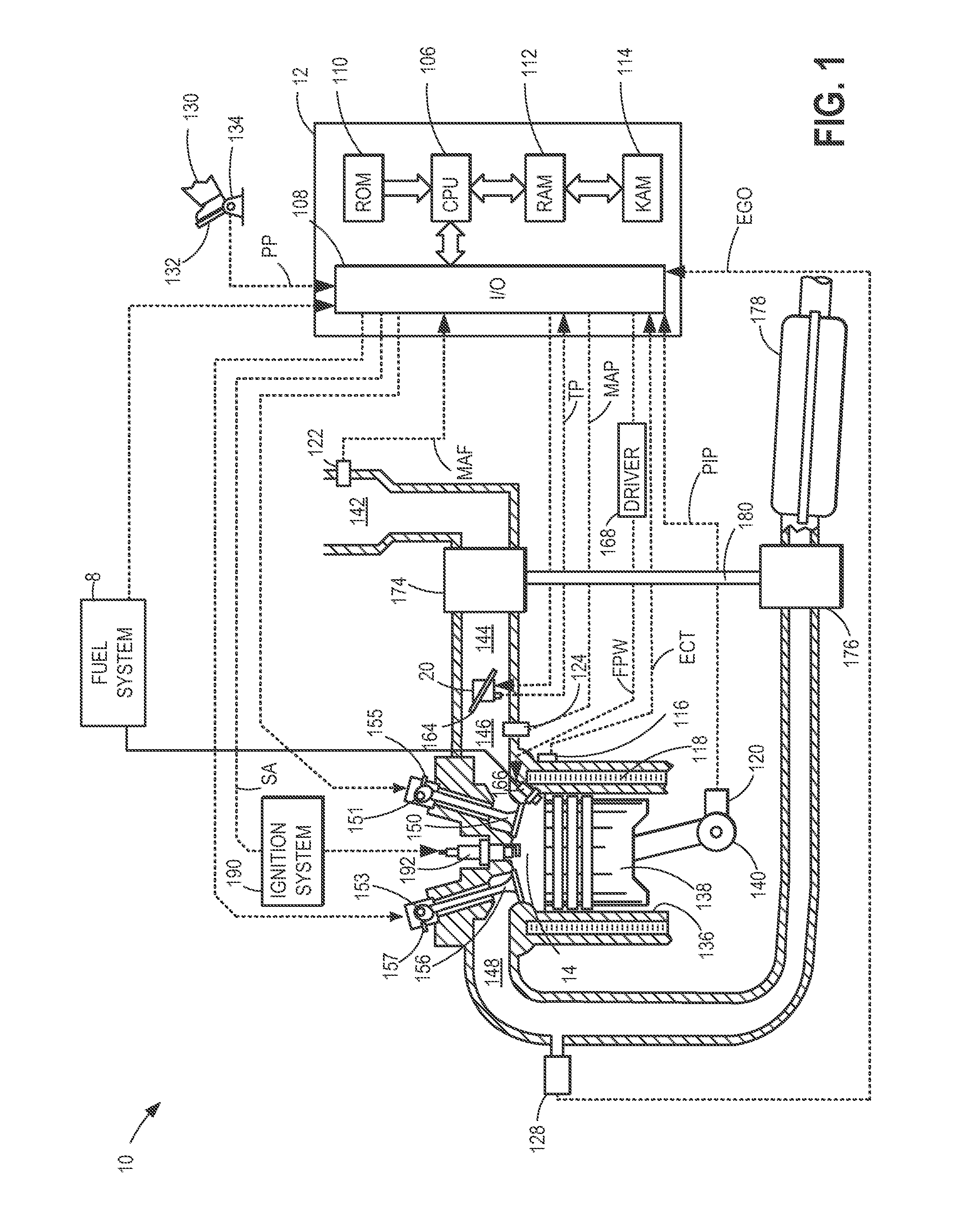

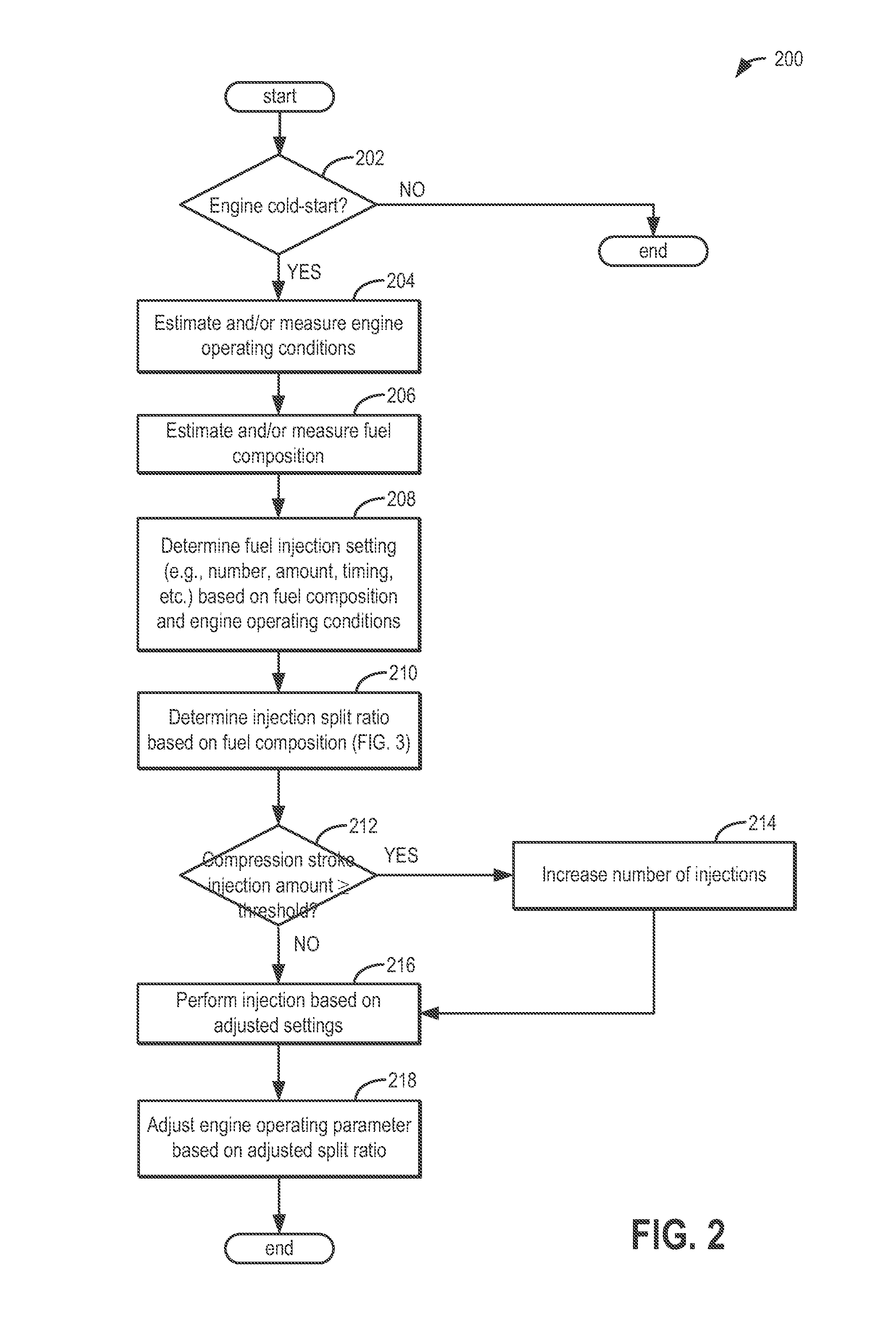

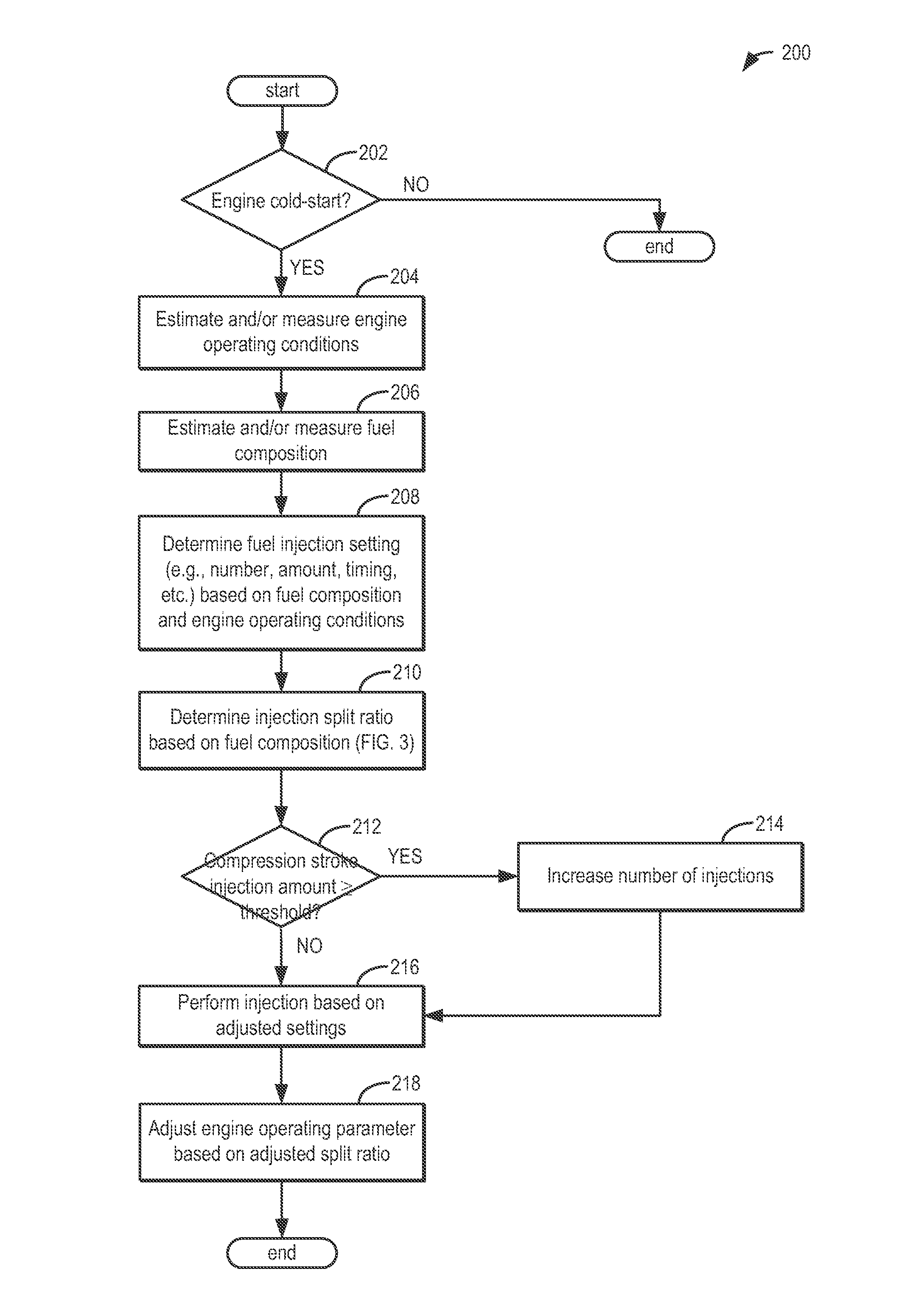

Systems and methods of operating an engine with a varying fuel composition. In one example, a split injection is performed during engine cranking with at least some fuel injected in the intake stroke and some fuel injected in the compression stroke. Further, a split ratio of the injection is adjusted based on the alcohol content of the injected fuel.

Owner:FORD GLOBAL TECH LLC

Fuel-based injection control

ActiveUS8447496B2High latent heatImprove peak torque output of engineElectrical controlInternal combustion piston enginesAlcohol contentControl system

Systems and methods of operating an engine with a varying fuel composition. In one example, a split injection is performed during engine cranking with at least some fuel injected in the intake stroke and some fuel injected in the compression stroke. Further, a split ratio of the injection is adjusted based on the alcohol content of the injected fuel.

Owner:FORD GLOBAL TECH LLC

Method for extracting maca bioactive components based on ultrasonic wave

ActiveCN104688796AIncreased alkaloid yieldReduce manufacturing costPlant ingredientsHigh concentrationHigh pressure

The invention discloses a method for extracting maca bioactive components based on ultrasonic wave. The product containing high-concentration maca bioactive components is finally obtained by means of using a high-pressure wall-cracking technology and an ultrasonic wave extracting technology to process the maca root tuber. Compared with the current extracting technology, the method has the advantages that the bioactive components such as maca alkaloid, the macaenes and the macamides in the maca root tuber are effectively extracted, the raw material utilization rate is increased and the production cost is reduced. Furthermore, the product prepared according to the method has high bioactivity and much better healthcare effect than that of the prior art.

Owner:广东长兴生物科技股份有限公司

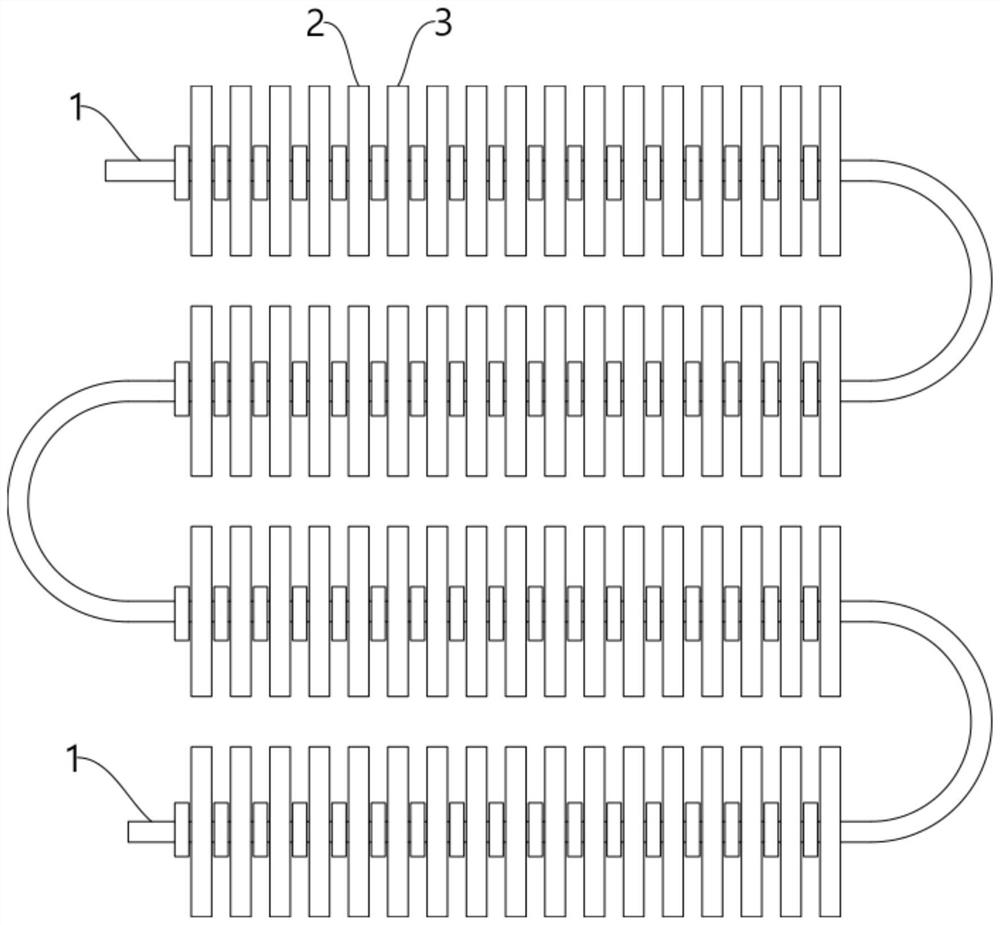

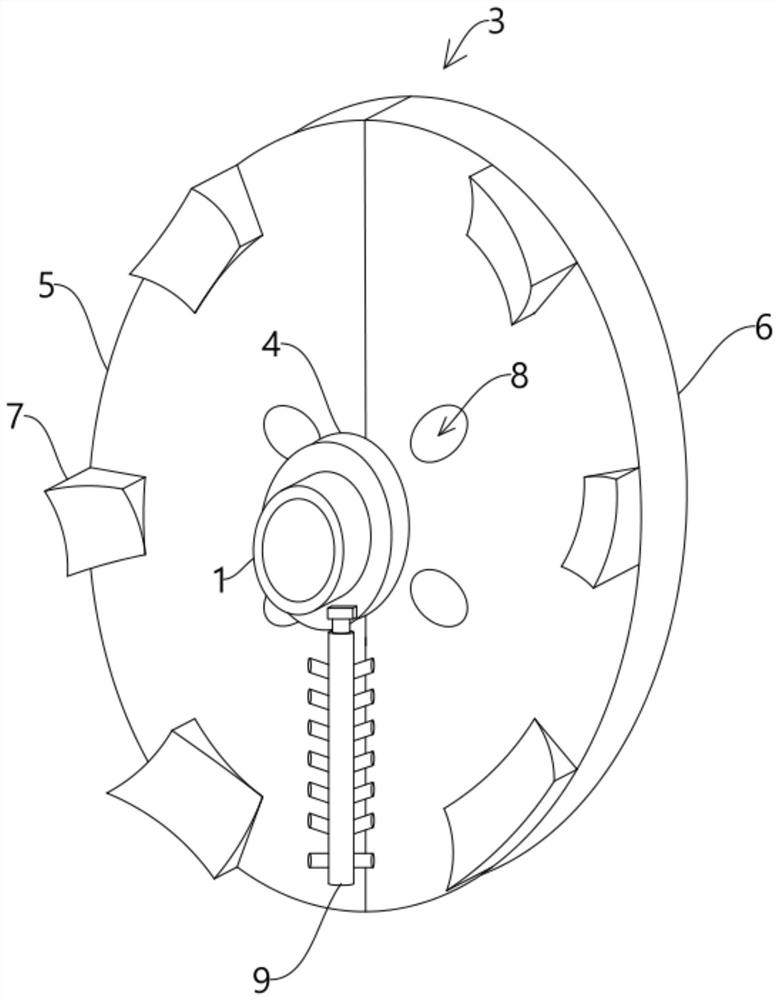

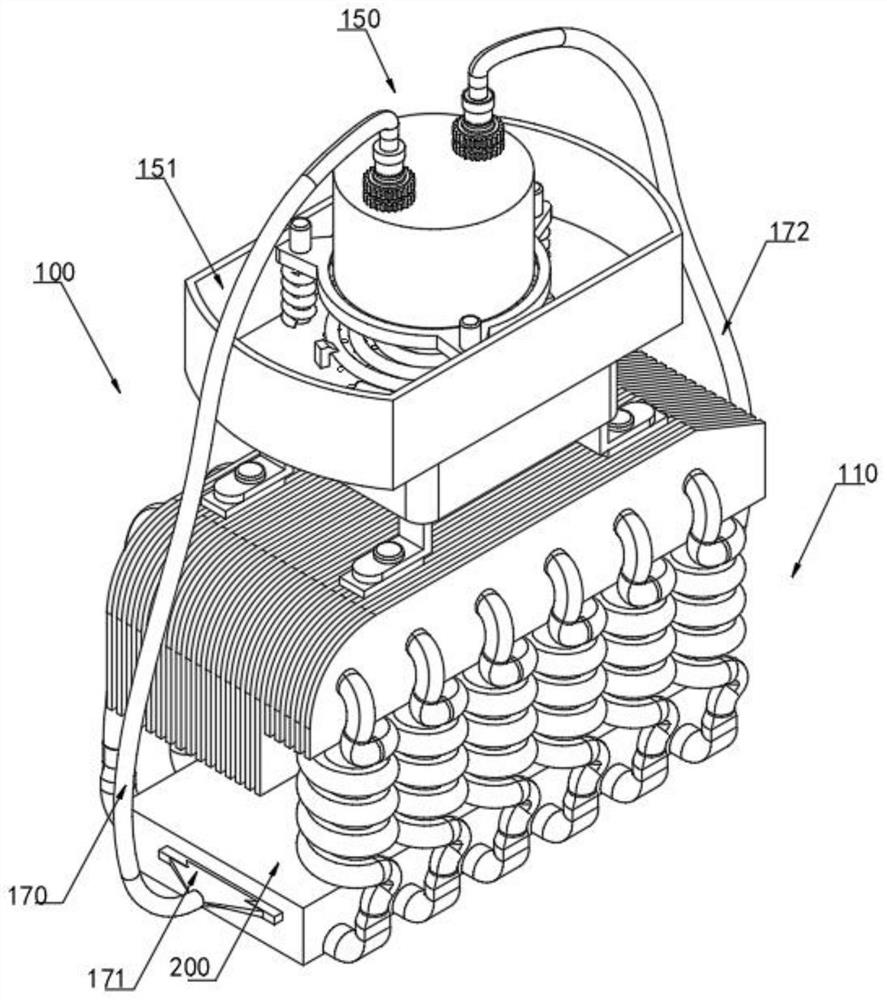

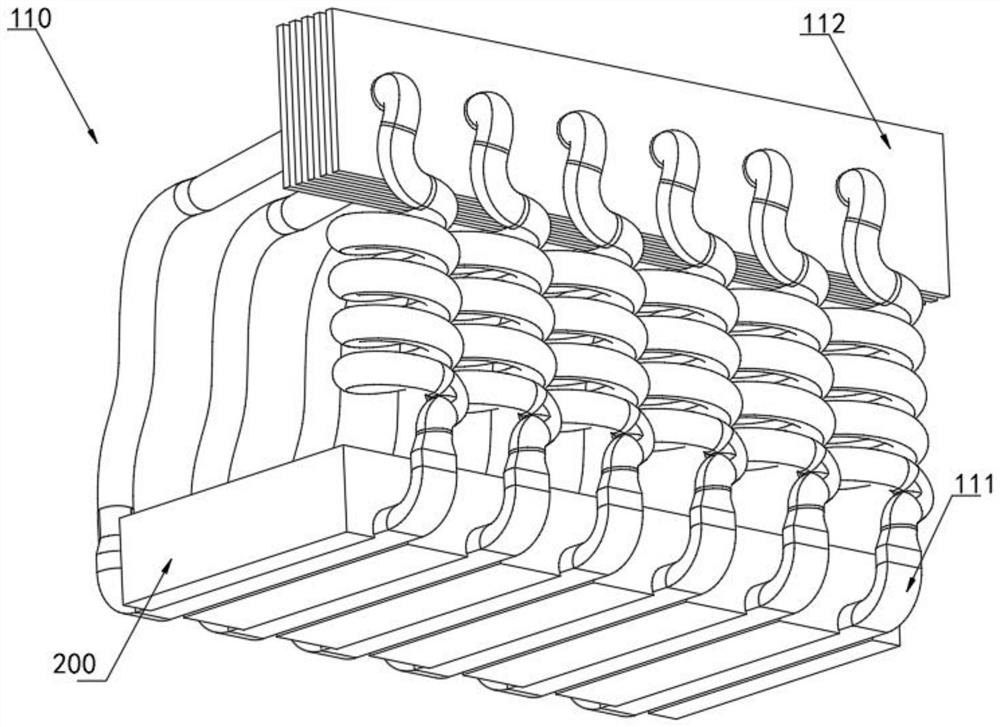

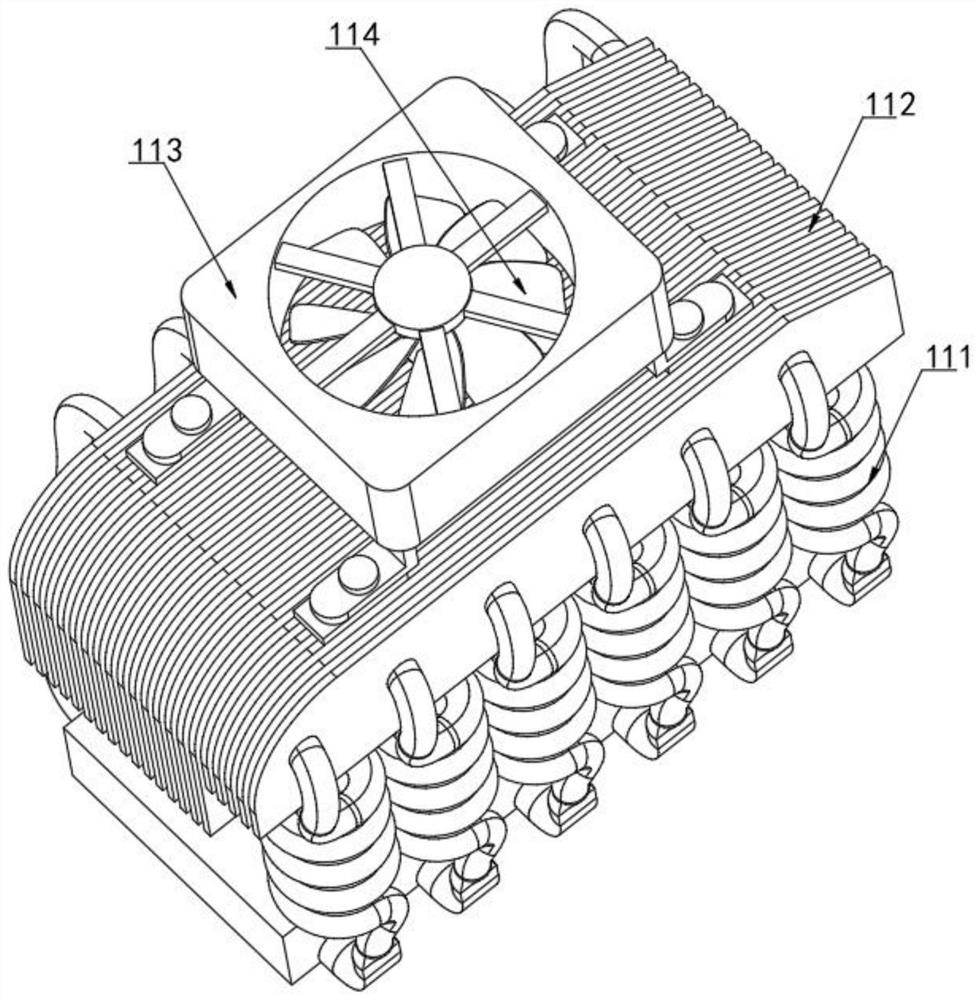

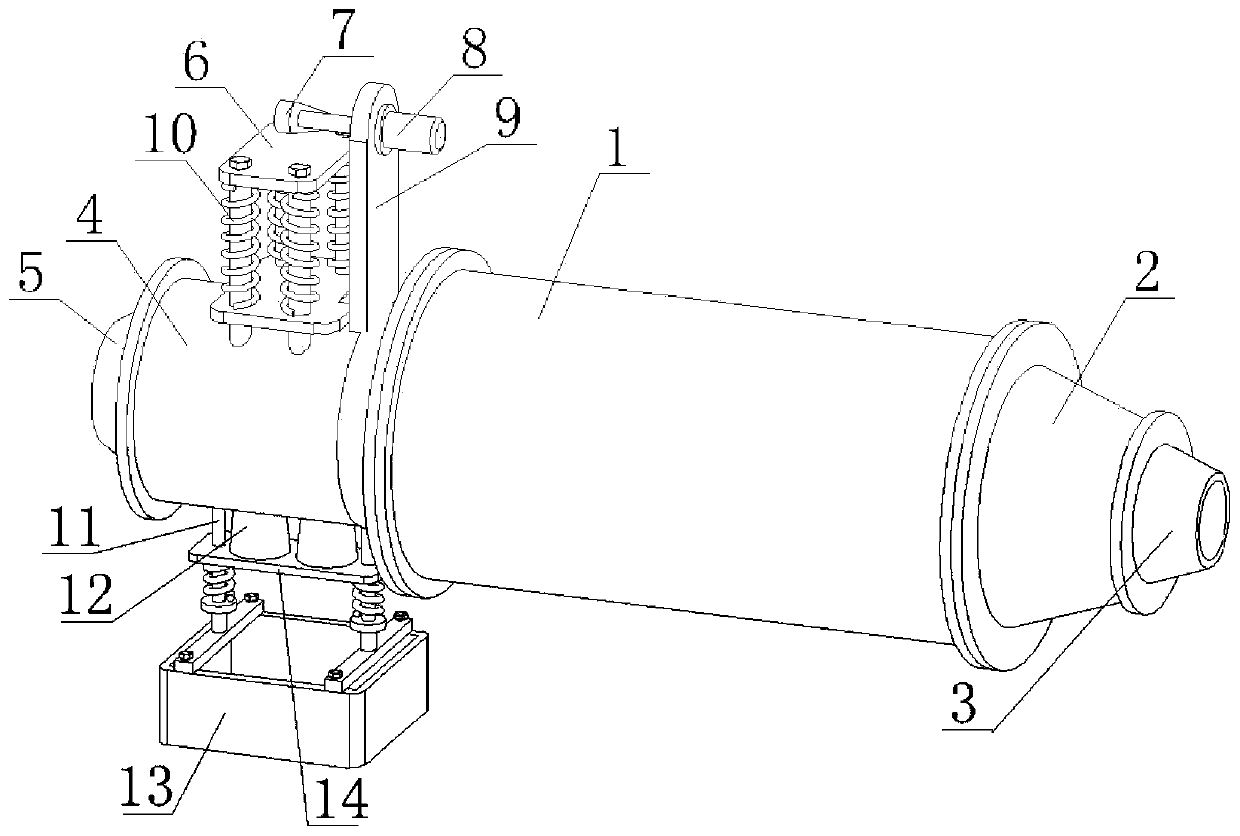

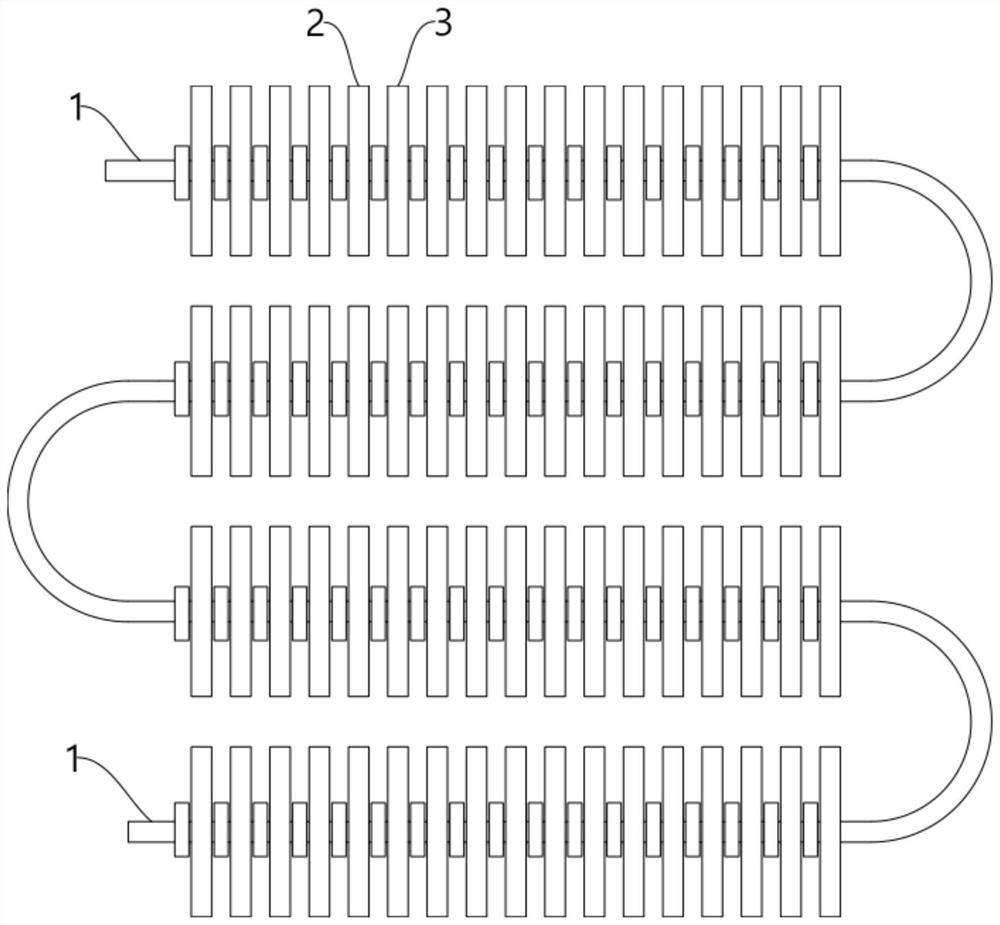

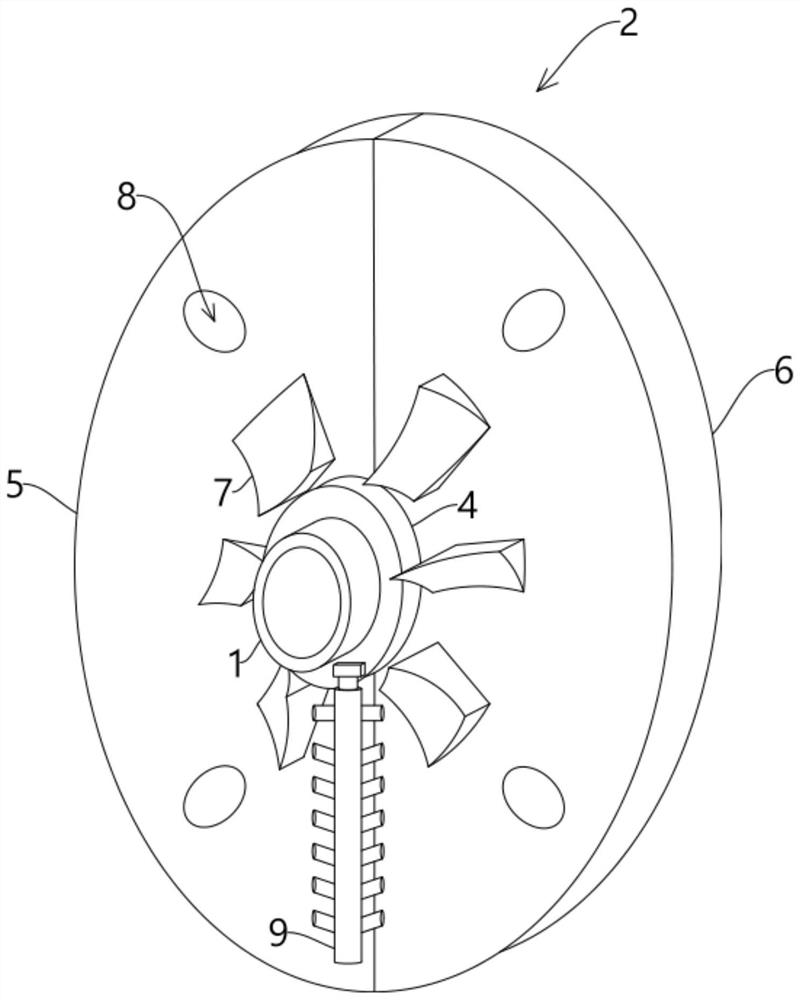

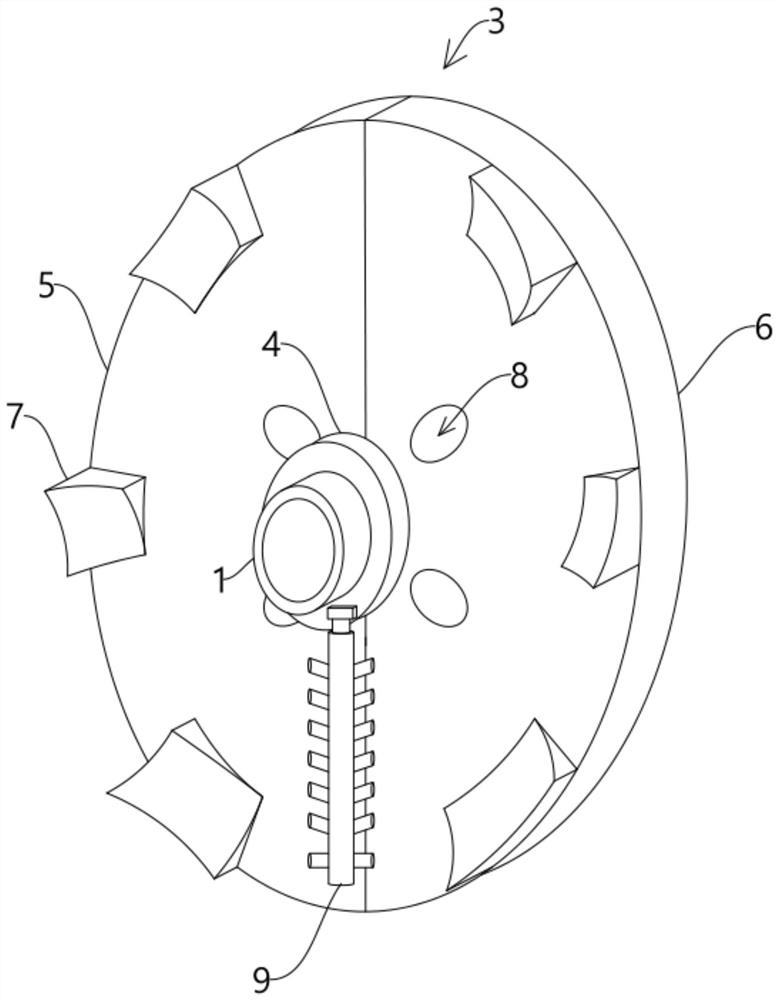

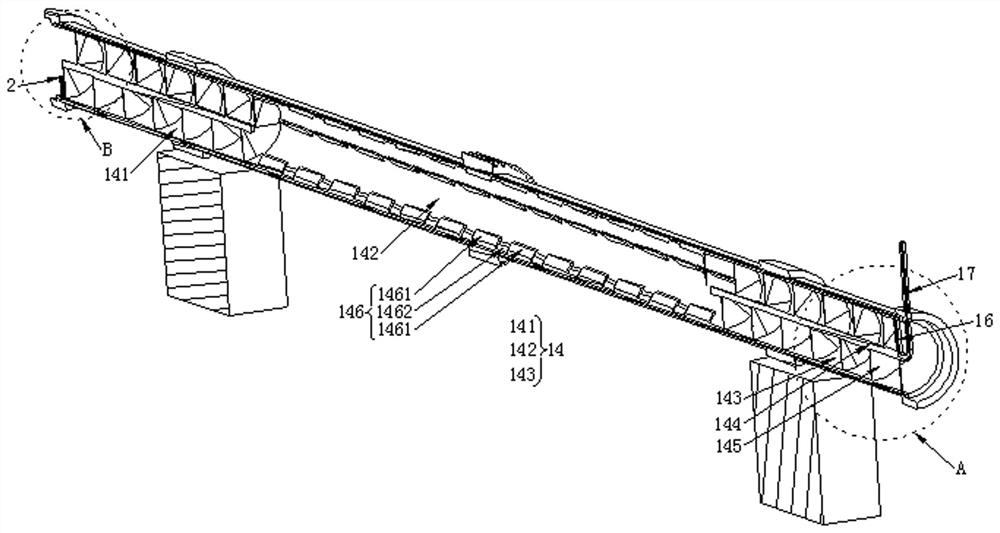

Pipeline fin evaporator

ActiveCN113587496AImprove heat transfer efficiencyEnsure normal flowEvaporators/condensersTubular elementsWater storageEngineering

The invention discloses a pipeline fin evaporator. Multiple first fins and second fins are movably arranged on an evaporation pipe in a crossing and sleeving manner, the gradual change trends of the thicknesses of air inducing blocks of the first fins and the second fins in the circumferential direction of annular distribution are opposite, the gradual change trends of the thicknesses of any air inducing blocks of the first fins and any air inducing blocks of the second fins in the direction away from the circle centers of the first fins and the second fins are opposite, elastic cleaning brushes are fixedly connected to the outer sides of elastic cleaning cylinders, the elastic cleaning cylinders are fixedly connected with elastic extrusion columns cooperating with the air inducing blocks to achieve extrusion, and second magnetic blocks cooperating with first magnetic blocks to achieve water pressing are arranged in water storage troughs in a sliding manner. In the using process, the fluid state of air is disturbed through rotation of the first fins and the second fins, through cooperative arrangement of vent holes and the air inducing blocks, air circulation is guided, meanwhile, the contact area of the air and the fins is increased, the contact time of the air and the fins is prolonged, and through cooperative arrangement of the elastic cleaning brushes, the elastic extrusion columns and the like, the surfaces of the fins are cleaned.

Owner:合肥美菱有色金属制品有限公司

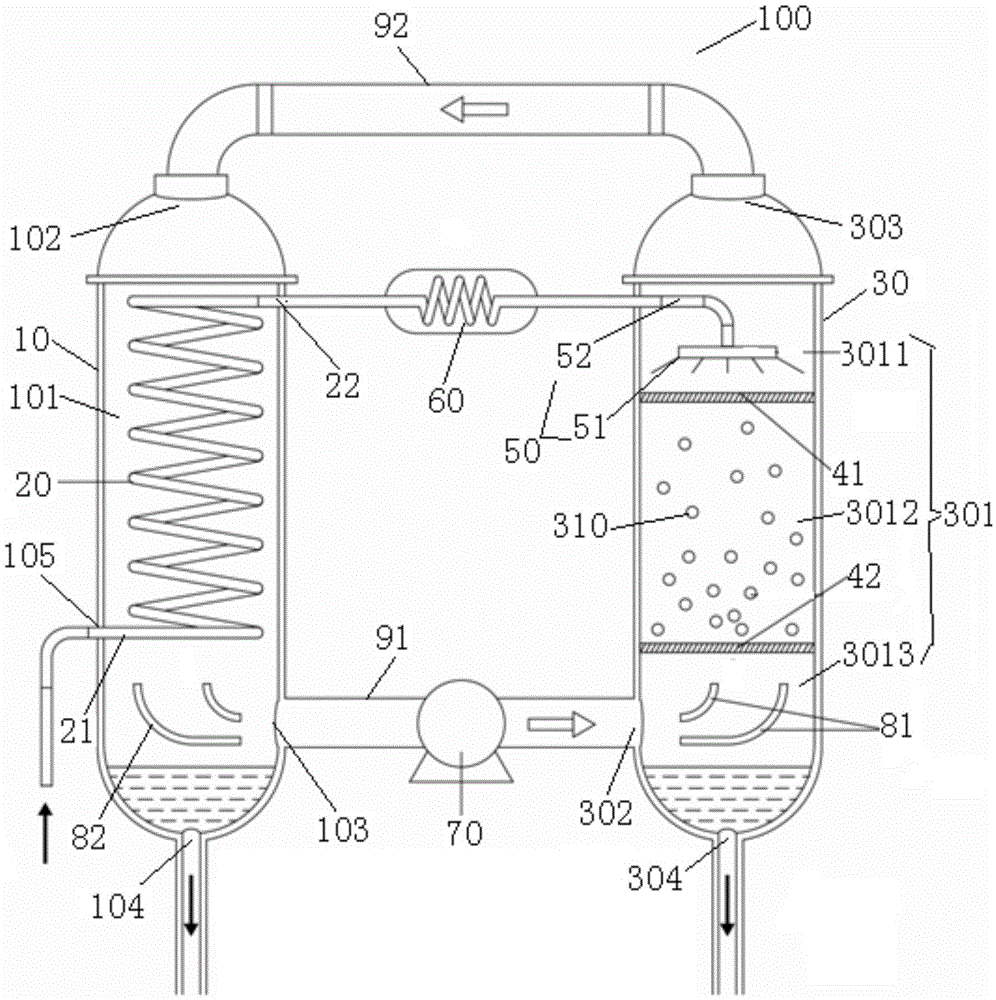

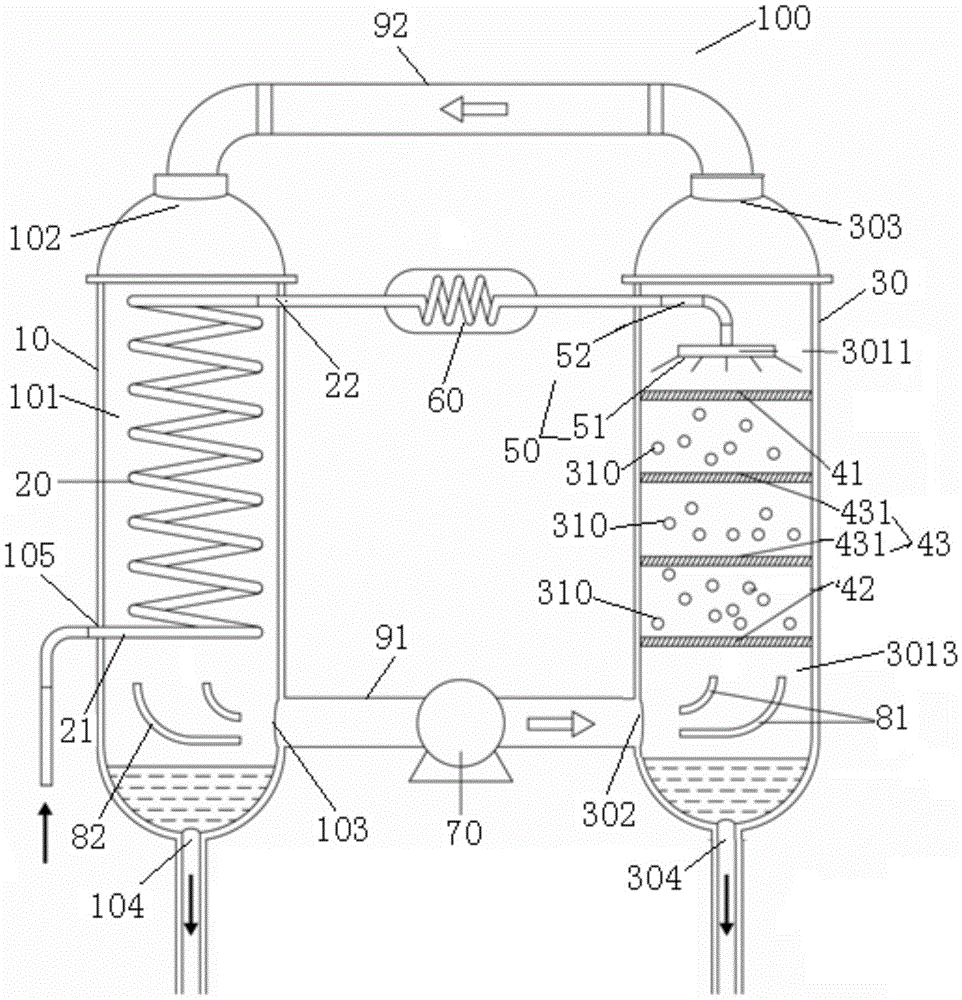

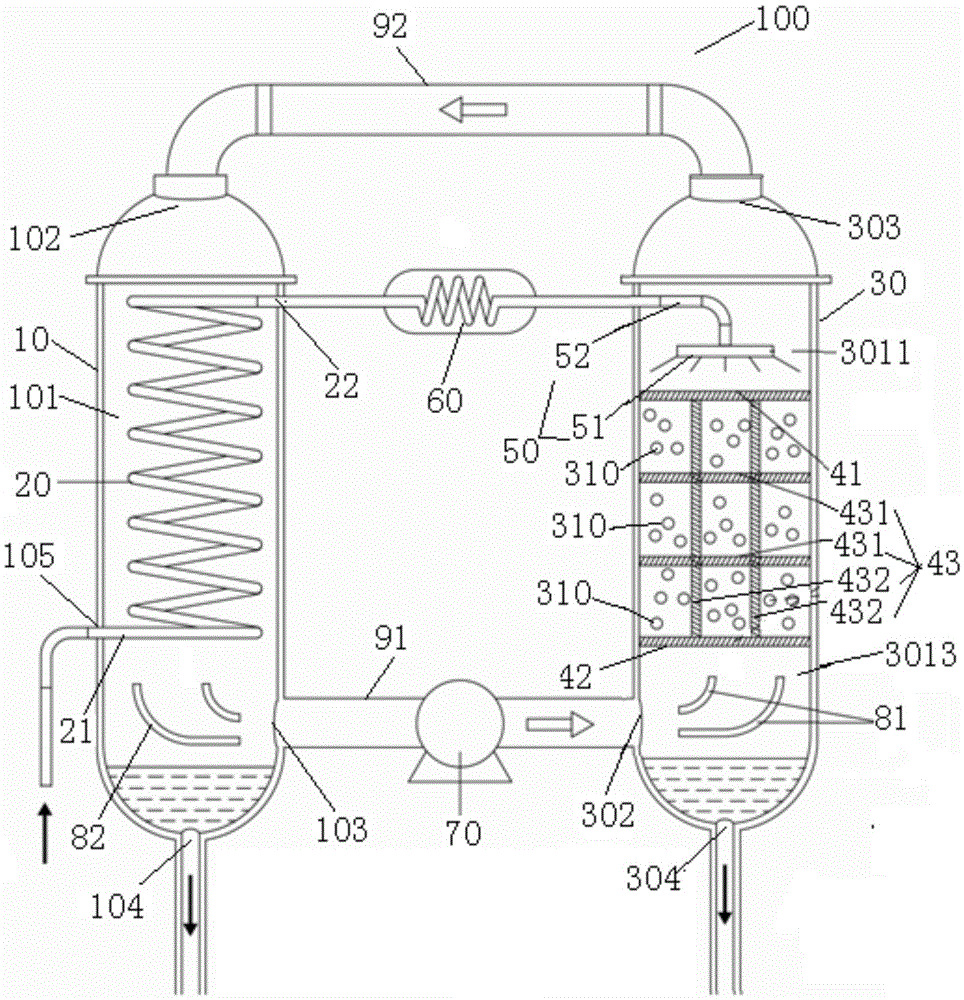

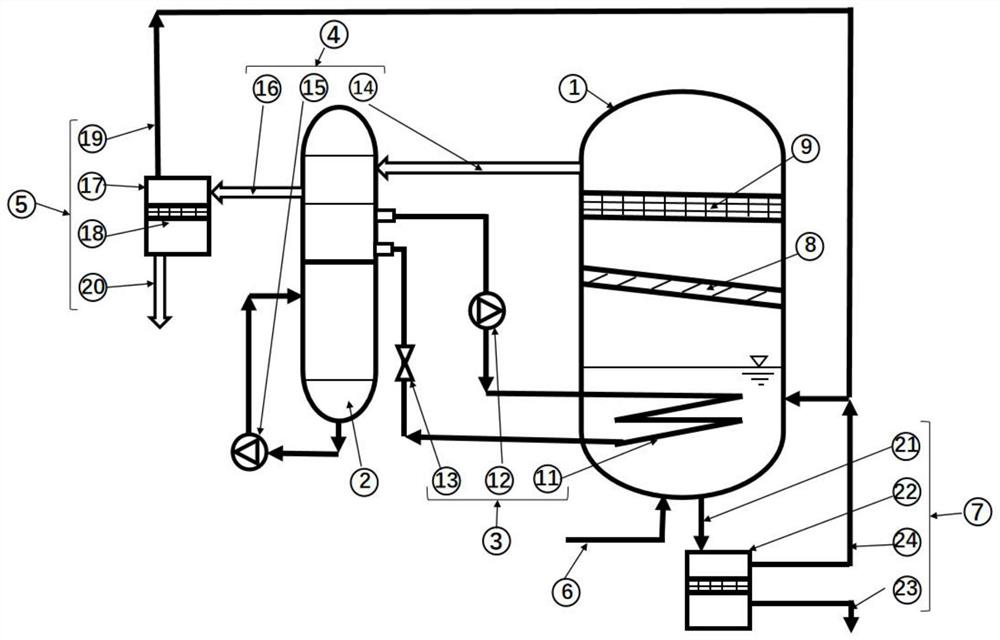

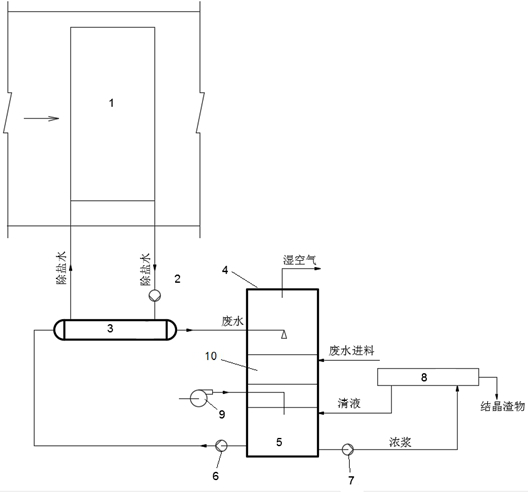

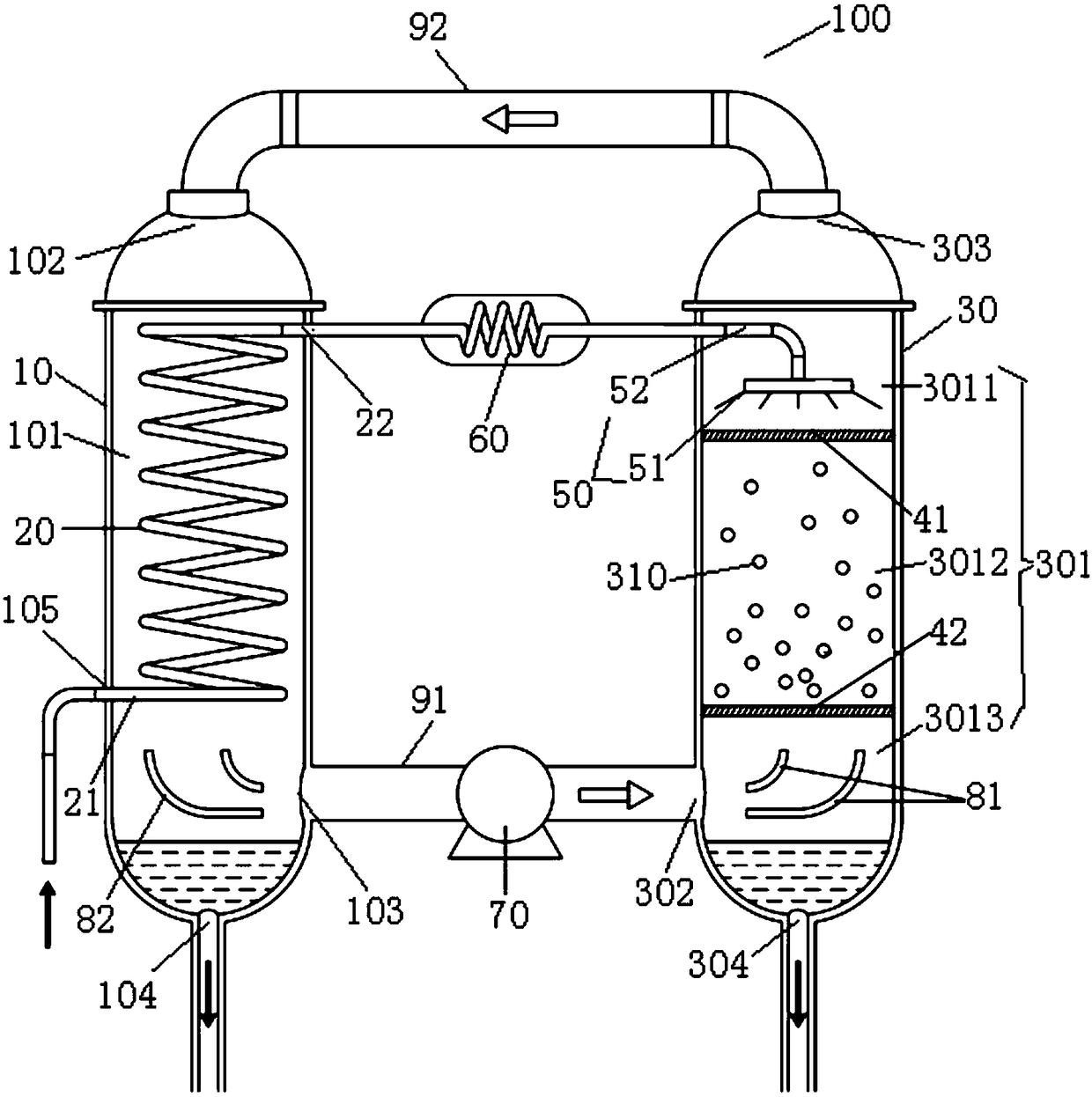

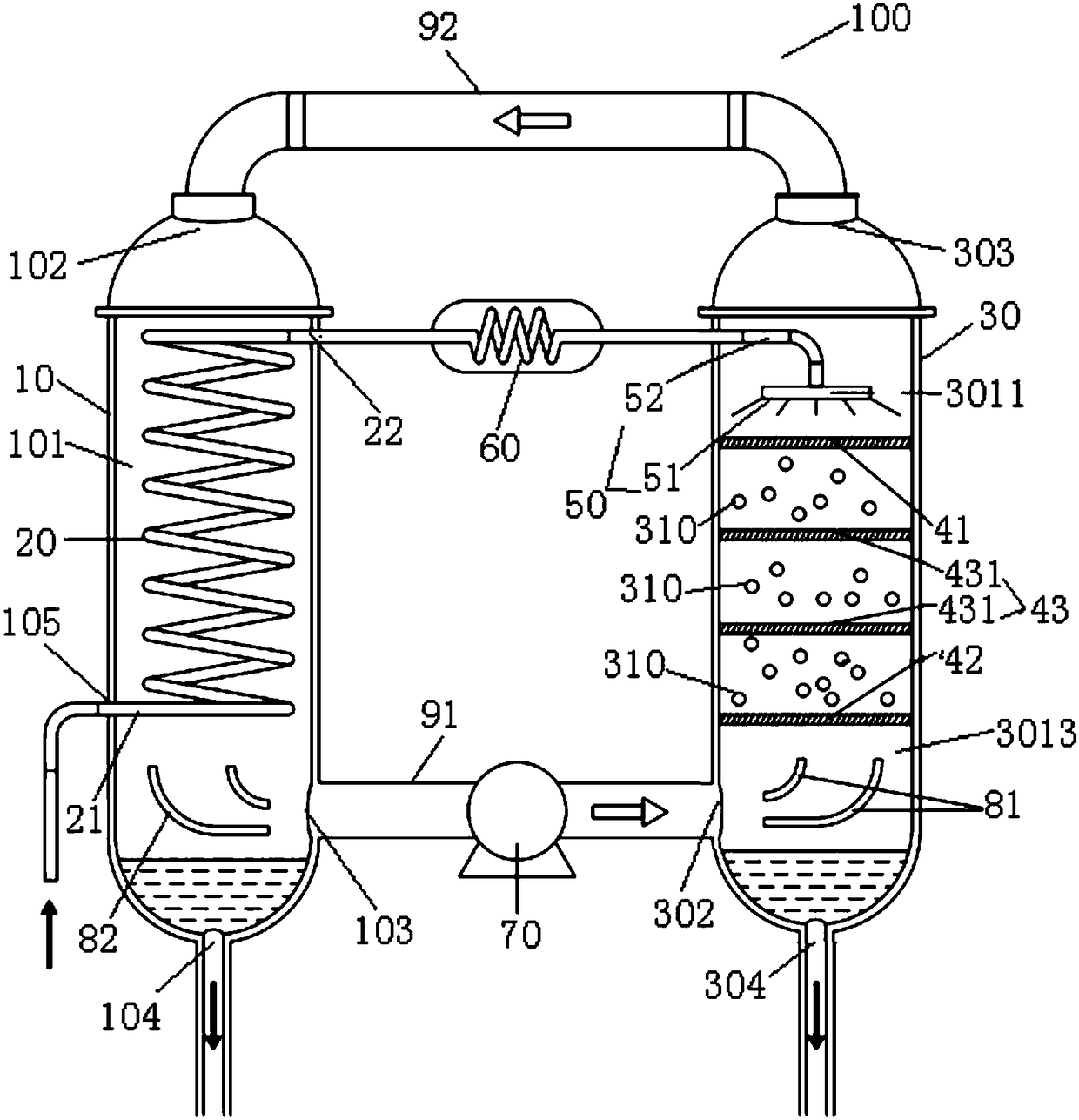

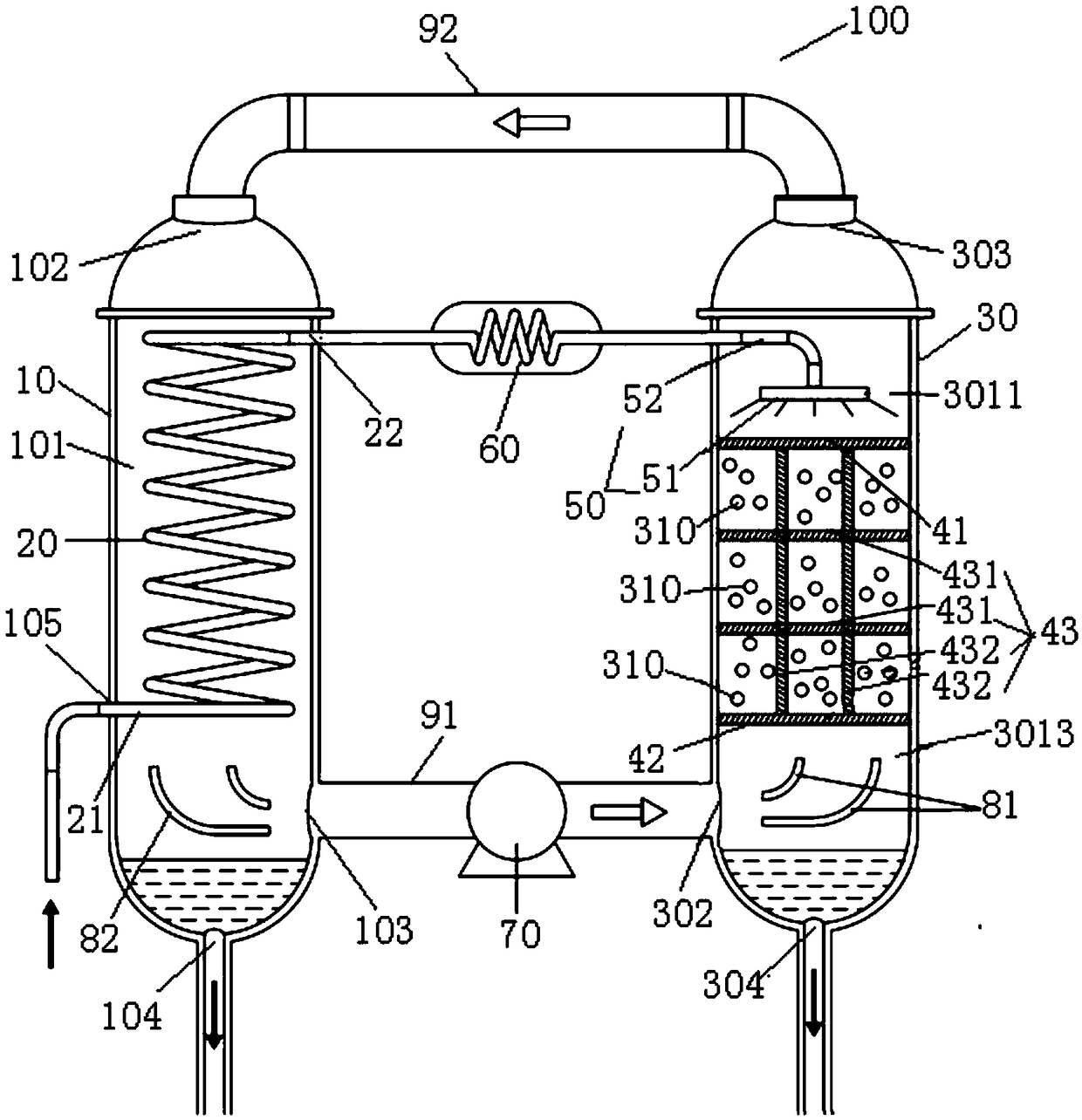

Humidification and dehumidification type water purification device for evaporation enhancement of fluidized bed

ActiveCN105621509AImprove purification efficiencyHigh heat and mass transfer coefficientSeawater treatmentEnergy based wastewater treatmentFluidized bedSewage

The invention discloses a humidification and dehumidification type water purification device for evaporation enhancement of a fluidized bed. The humidification and dehumidification type water purification device comprises a condensation chamber, a condenser, an evaporation chamber, an upper partition board, a lower partition board, a spraying device, a heating device and a drive device, wherein an evaporation cavity is limited in the evaporation chamber, a second gas inlet, a second gas outlet and a sewage outlet are formed in the evaporation chamber, and the second gas outlet is communicated with a first gas inlet; the upper partition board and the lower partition board are arranged in the evaporation cavity in a spaced mode so as to divide the evaporation cavity into an upper cavity, a middle cavity and a lower cavity, suspended solid particles are arranged in the middle cavity, the second gas inlet is communicated with the lower cavity, and the second gas outlet is communicated with the upper cavity. The spraying device is provided with a spraying nozzle in the upper cavity. The heating device is connected between the spraying device and a water outlet pipe. The drive device is connected between a first gas outlet and the second gas inlet. By means of the humidification and dehumidification type water purification device, water purification efficiency can be improved, the structure is simple, and cost is low.

Owner:TSINGHUA UNIV

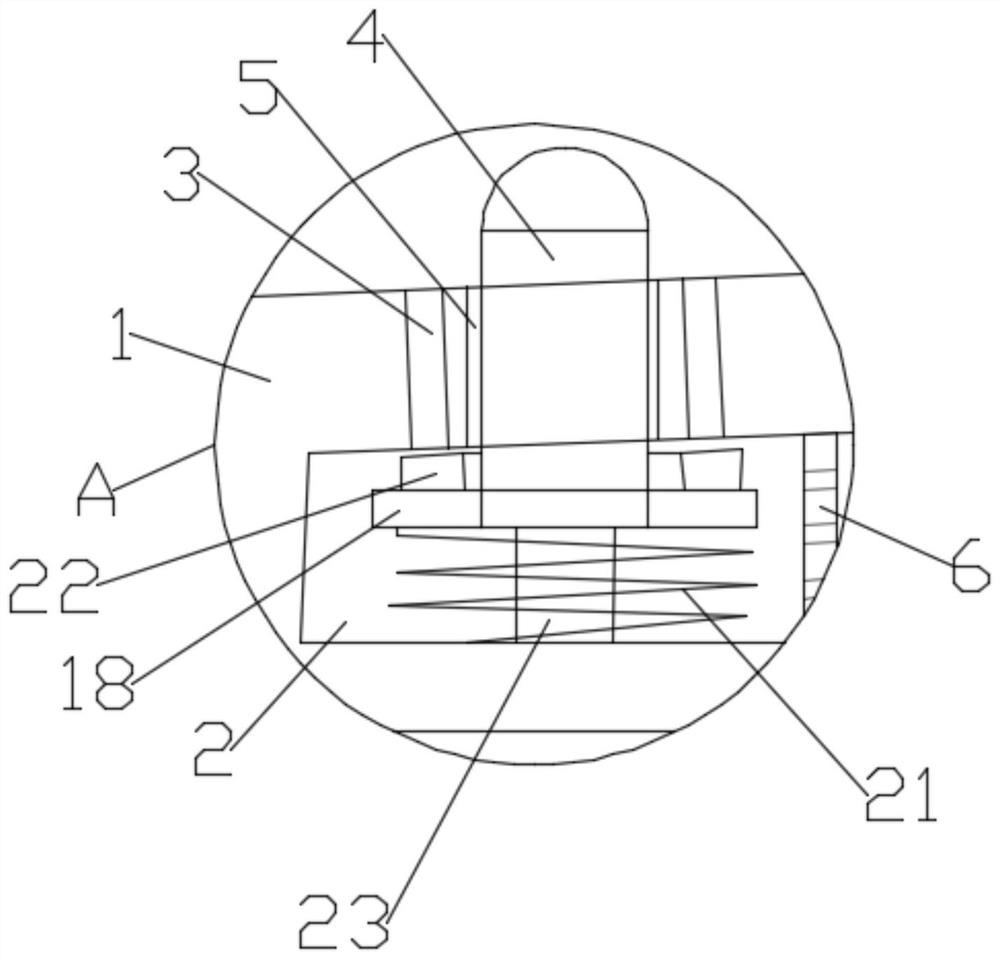

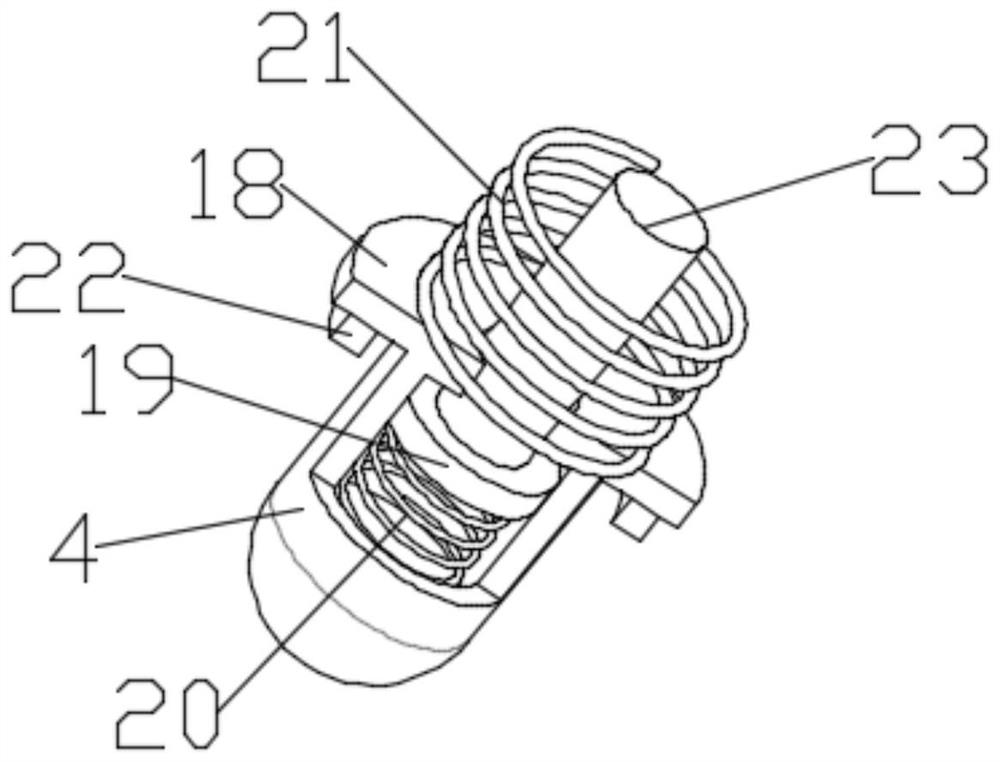

Self-balancing liquid supplementing and exhausting device for temperature control equipment

PendingCN111980910ARealize closed loopMake sure to inflatePositive displacement pump componentsLiquid fuel engine componentsTemperature controlProcess engineering

The invention discloses a self-balancing liquid supplementing and exhausting device for temperature control equipment. The self-balancing liquid supplementing and exhausting device comprises a liquidpump, a liquid outlet pipeline, a working pipeline and a liquid return pipeline, and further comprises a heater barrel and a liquid inlet pipeline, and further comprises a liquid supplementing water tank, a liquid supplementing pipe and an exhausting pipe. The self-balancing liquid supplementing and exhausting device can solve the problem that when a liquid pumping pump is used for pumping liquid,air in the pump and pipelines of the pump must be manually exhausted into the pump every time the pump is started.

Owner:合肥亦威科技有限公司

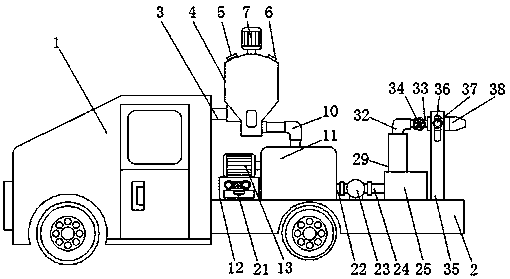

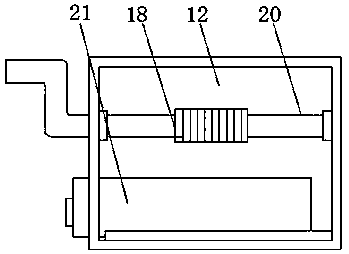

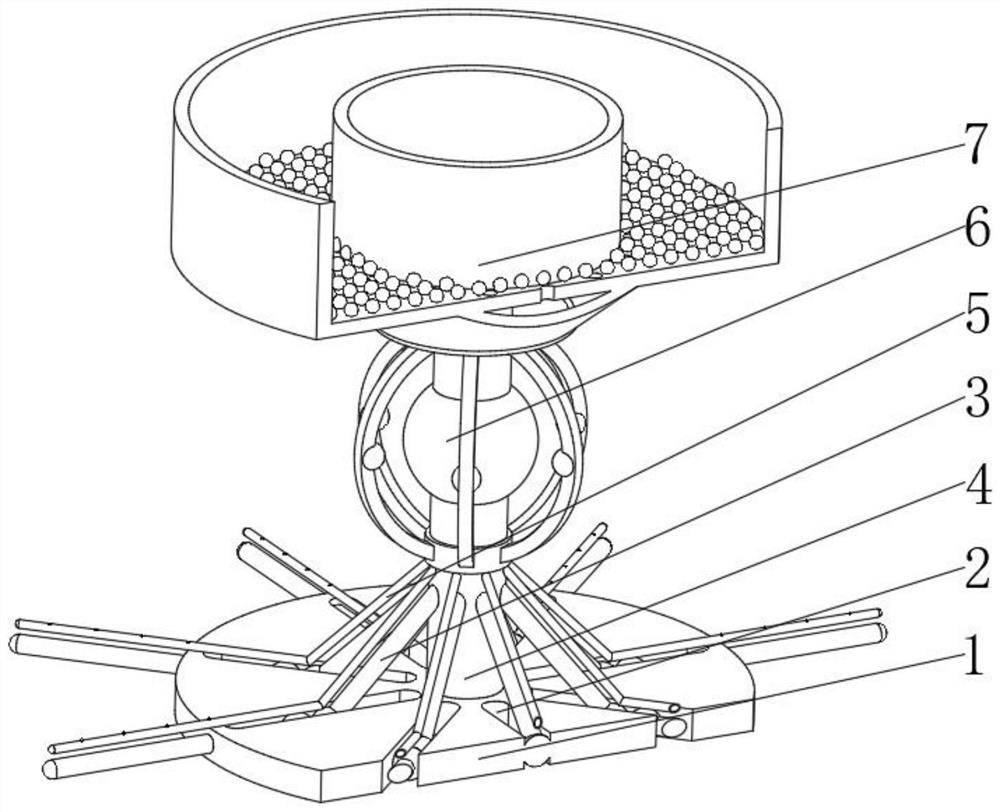

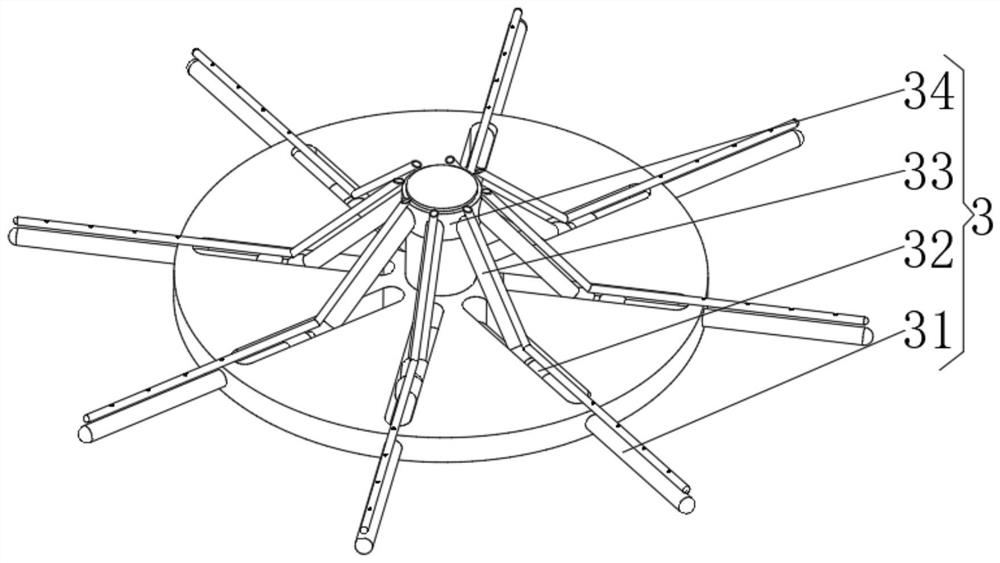

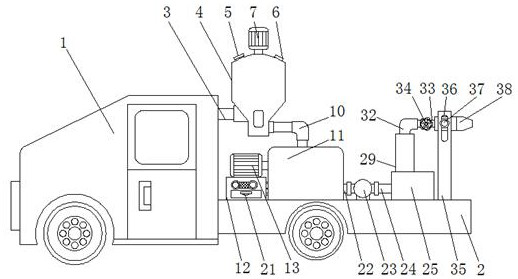

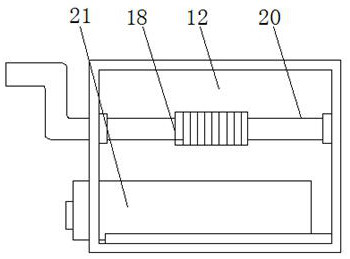

Liquid pesticide spraying vehicle with environment protection performance

ActiveCN108541678AEnvironmental performanceReduce exposureTransportation and packagingRotary stirring mixersEngineeringVolumetric Mass Density

The invention relates to the technical field of environment protection devices and discloses a liquid pesticide spraying vehicle with environment protection performance. The liquid pesticide sprayingvehicle comprises a driving vehicle head; the right side of the driving vehicle head is fixedly provided with a fixing rod and a supporting vehicle board in sequence from top to bottom; the other endof the fixing rod is fixedly provided with a mixing box; a mud inlet and a water inlet are separately formed in the left and right ends of the top of the mixing box; and the middle of the top of the mixing box is fixedly provided with a stirring motor. According to the liquid pesticide spraying vehicle with the environment protection performance, specified amounts of liquid pesticide and mud are added into the mixing box through the mud inlet and the water inlet, then, a stirring rod drives stirring blades to stir, and finally, a mixed liquid of a pesticide and the mud is sprayed on vegetativeby a spray head, so that the density of the pesticide is increased, the volatilization efficiency of the pesticide is reduced, the problems that it is very difficult to effectively ensure that the pesticide is absorbed by the vegetative, and meanwhile, it is very easy to damage the environment and affect the health of operating staff if the pesticide is directly sprayed are solved, and the practicability of the device is greatly improved.

Owner:阜阳市金睿环保科技有限公司

Wood single-plate microwave drying device and drying method

ActiveCN105276926AIndustrial Application BreakthroughSuitable for dryDrying solid materials with heatHearth type furnacesElectricityMicrowave

The invention provides a wood single-plate microwave drying device and drying method. The wood single-plate microwave drying device comprises a microwave heating device, a ventilation device controlling the ventilation quantity of the microwave heating device and a metering device metering the electricity consumption of the microwave heating device and is characterized in that the ventilation device is arranged on one side of the microwave heating device, and air in the microwave drying device enters the ventilation device through a ventilation opening in one side of the microwave heating device and is then discharged. In a work state, the metering device records the electricity consumption E of the microwave heating device when the wood water evaporation quantity is G so as to obtain a wood single-plate microwave drying water extracting rate eta. The numerical value of the wood single-plate microwave drying water extracting rate can be measured and calculated. Technical difficulties limiting the microwave wood drying technology for many years can be digitized, and a substantial breakthrough is made in the industrial application of the microwave wood drying technology.

Owner:山东千森木业集团有限公司

Energy storage battery cabin temperature control method, energy storage discharge control method and energy storage application system

PendingCN114122544AAvoid damageReduce heat exposureCell temperature controlSecondary cells charging/dischargingAutomotive engineeringElectrical battery

The invention relates to the technical field of control, in particular to an energy storage battery cabin temperature control method, an energy storage discharge control method and an energy storage application system.The energy storage battery cabin temperature control method comprises the steps of temperature detection, temperature control over the surface of a battery, battery work and discharge control; the detection result is fed back to the integrated chip in the battery compartment, the integrated chip sends an electric signal to the power supply in the battery compartment, and when the environment temperature in the battery compartment is higher than the working temperature of the battery, namely the surface temperature of the battery is too high, the heat dissipation assembly works to dissipate heat of the battery; according to the invention, the temperature of the battery is reduced and increased by using the heat pipe and the water vapor, and the battery and external electric elements are protected by adopting the hole-type semiconductor and the electronic semiconductor, so that the problem that the battery is easily damaged due to'hot work 'and'cold work' of the battery and the battery works at an abnormal temperature is solved.

Owner:深圳千锂马新能源科技有限公司

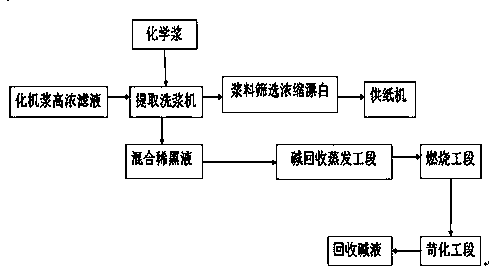

Chemi-mechanical pulping high-concentration filtrate treatment method

PendingCN110878482AImprove liquidityMake sure to removePulp liquors combustionWashing/displacing pulp-treating liquorsFiberBlack liquor

The invention relates to a chemi-mechanical pulping high-concentration filtrate treatment method. The method comprises the following steps: 1, feeding high-concentration filtrate generated by a chemi-mechanical pulping production line into a chemical pulp hot water tank, adding washing water, and performing mixing; 2, pumping out a mixed solution of the high-concentration filtrate and the washingwater in the chemical pulping hot water tank, feeding the mixed solution into a drum-type vacuum pulp washer, and filtering the obtained pulp layer; 3, feeding a mixed solution of the high-concentration filtrate obtained by filtering the pulp layer in the drum-type vacuum pulp washer and the washing water into a black liquor tank for temporary storage; 4, pumping out the solution in the black liquor tank, mechanically filtering the solution, feeding the filtered solution into the evaporation section of an alkali recovery workshop, and carrying out evaporation concentrating through a multi-effect evaporator; and 5, feeding the evaporated and concentrated solution meeting process requirements into an alkali recovery boiler, combusting the solution, feeding the obtained melt into a green liquor tank, and performing causticization treatment to recover the alkali liquor. Most fine fibers can be removed, the scaling phenomenon of an alkali recovery evaporator is effectively reduced, the evaporation efficiency is improved, and energy consumption is reduced.

Owner:MCC PAPER YINHE

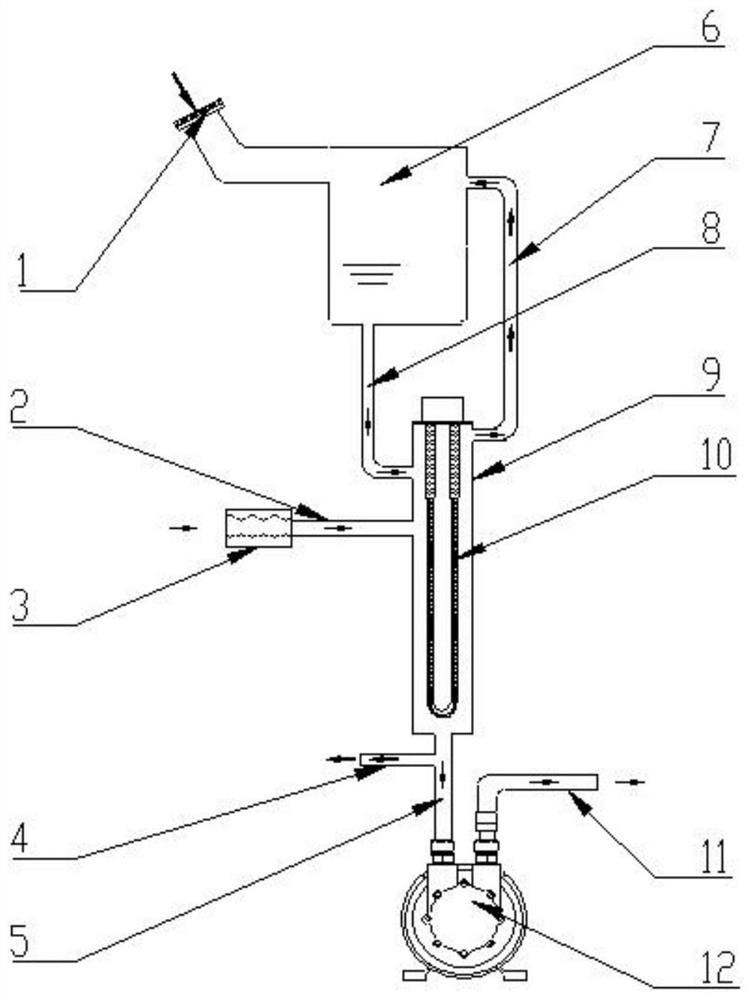

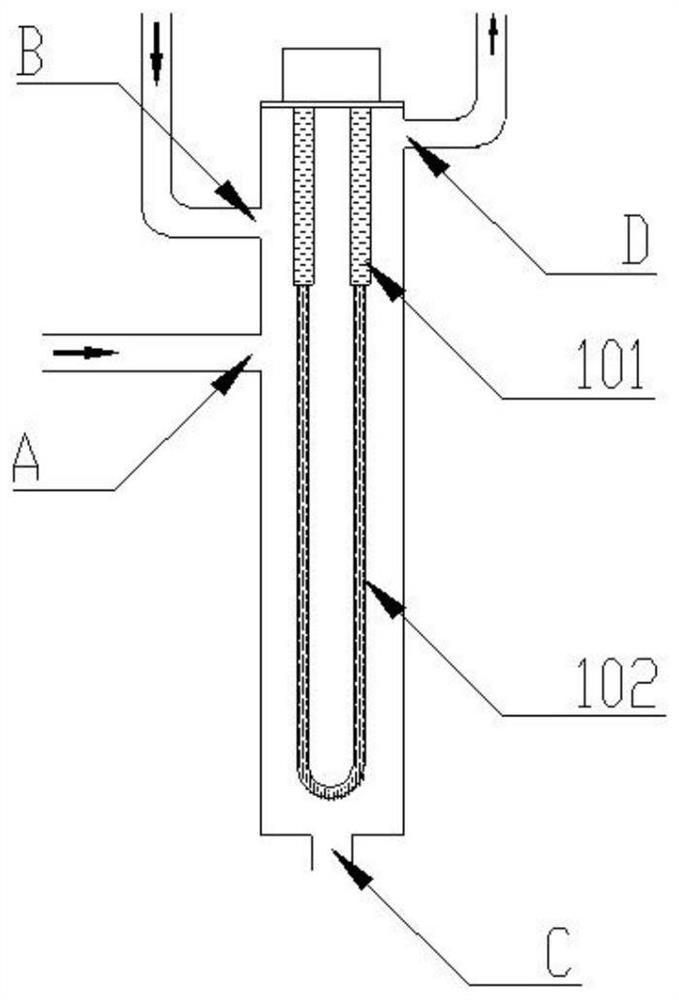

Energy-saving and environment-friendly thermal deaerator

InactiveCN108826270AImprove the efficiency of heating and oxygen removalAchieve recyclingLiquid degasificationFeed-water heatersWater storage tankLiquid water

The invention discloses an energy-saving and environment-friendly thermal deaerator. The energy-saving and environment-friendly thermal deaerator comprises a deaerator body. A deoxygenation head is mounted at the top end of the deaerator body. A recovery pipe is mounted at the top end of the deoxygenation head. A water storage tank is mounted on one side of the deaerator body. A second separator is mounted at the top end of the water storage tank. The energy-saving and environment-friendly thermal deaerator is provided with the recovery pipe, a preheater, a condensate water return pipe, a condensing agent circulating pipe, a condenser and a condensing agent discharge pipe. Primary waste steam and secondary waste steam discharged from the interior of the deaerator body are recovered throughthe recover pipe. The recovered waste steam firstly passes through the recover pipe to go into the condenser and is subjected to heat exchange through a condenser pipe in the condenser. After heat exchange, water vapor in the waste steam is condensed into liquid water. Heat in the waste steam is transferred to a condensing agent in the condenser pipe. The condensed liquid water passes through a pressure valve and the condensate water return pipe to be discharged into the water storage tank, and the cyclic utilization of water is realized.

Owner:冯萍

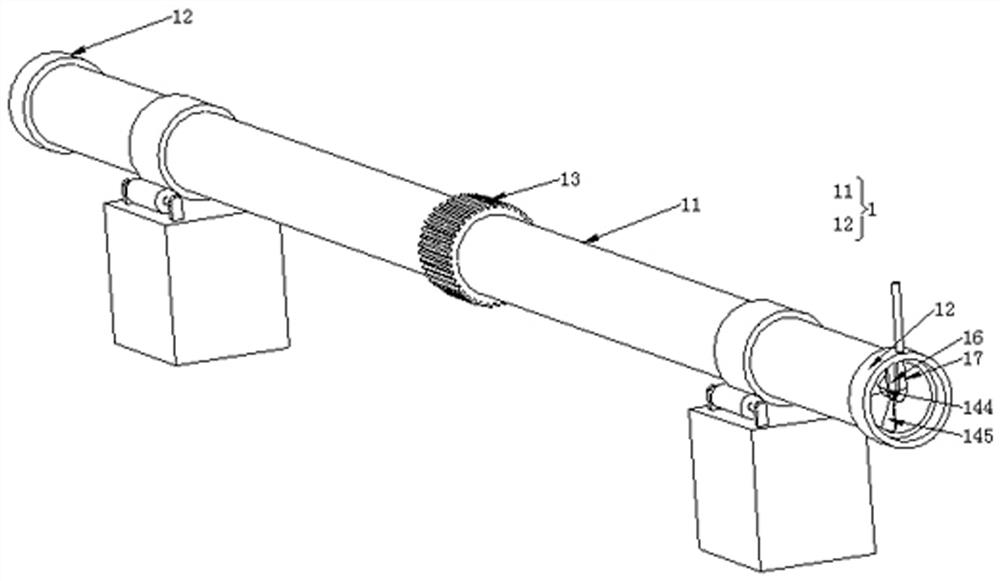

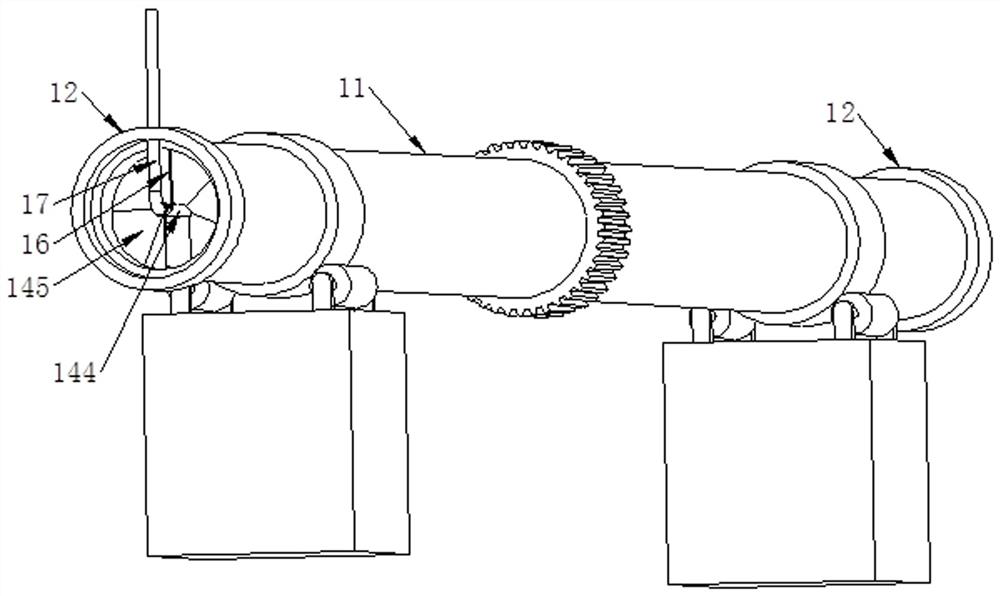

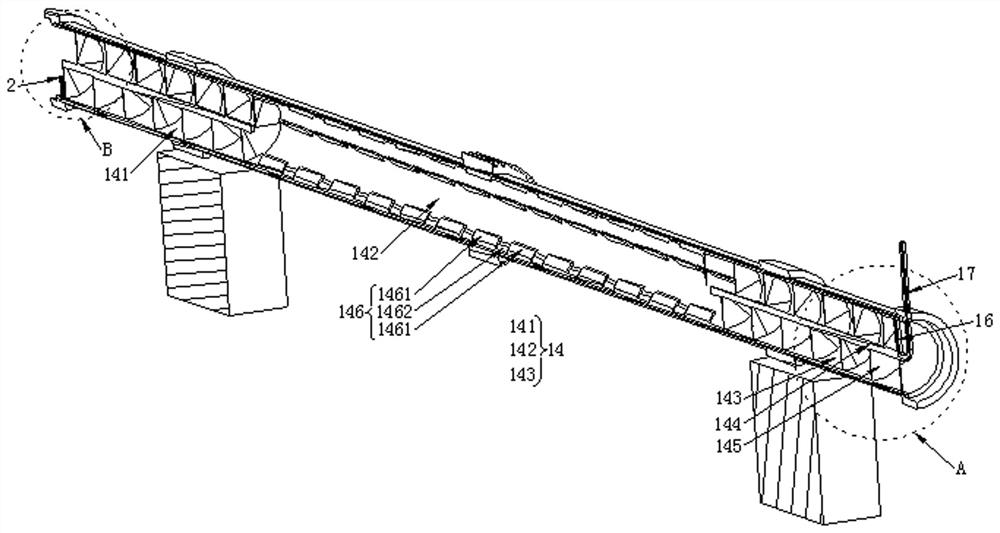

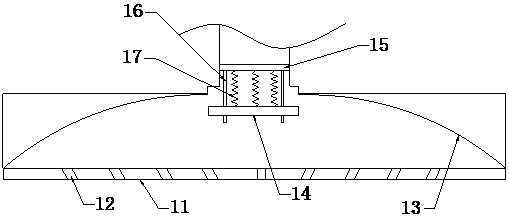

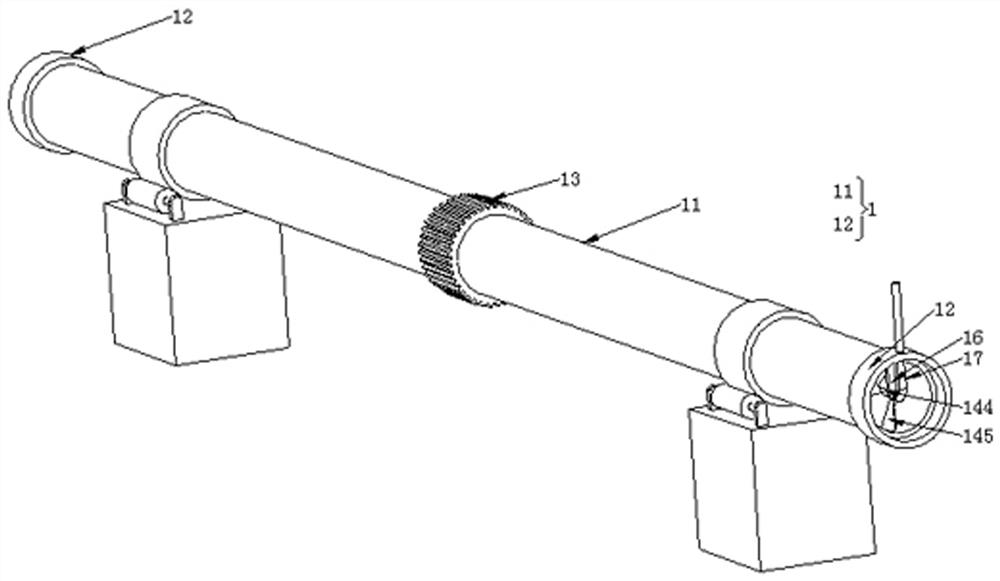

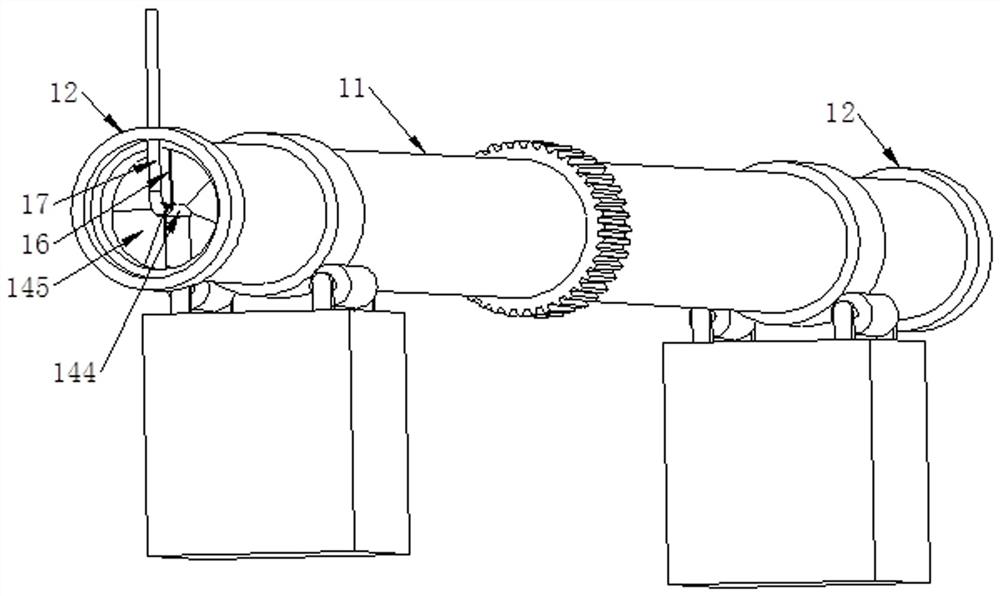

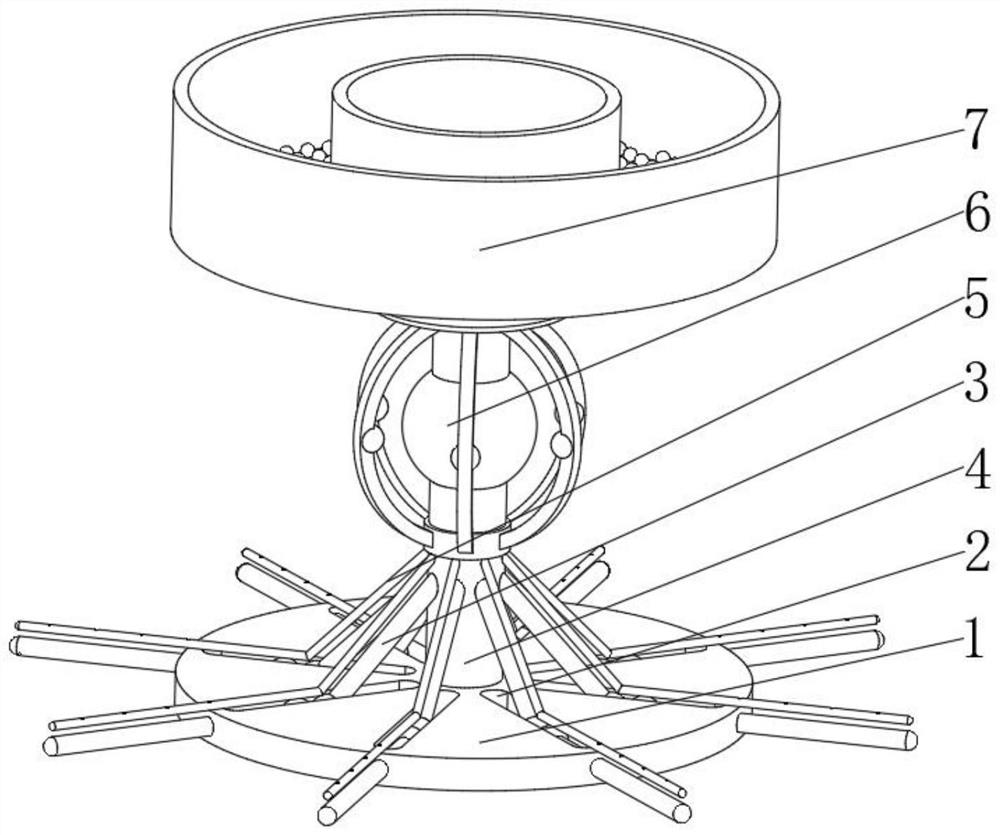

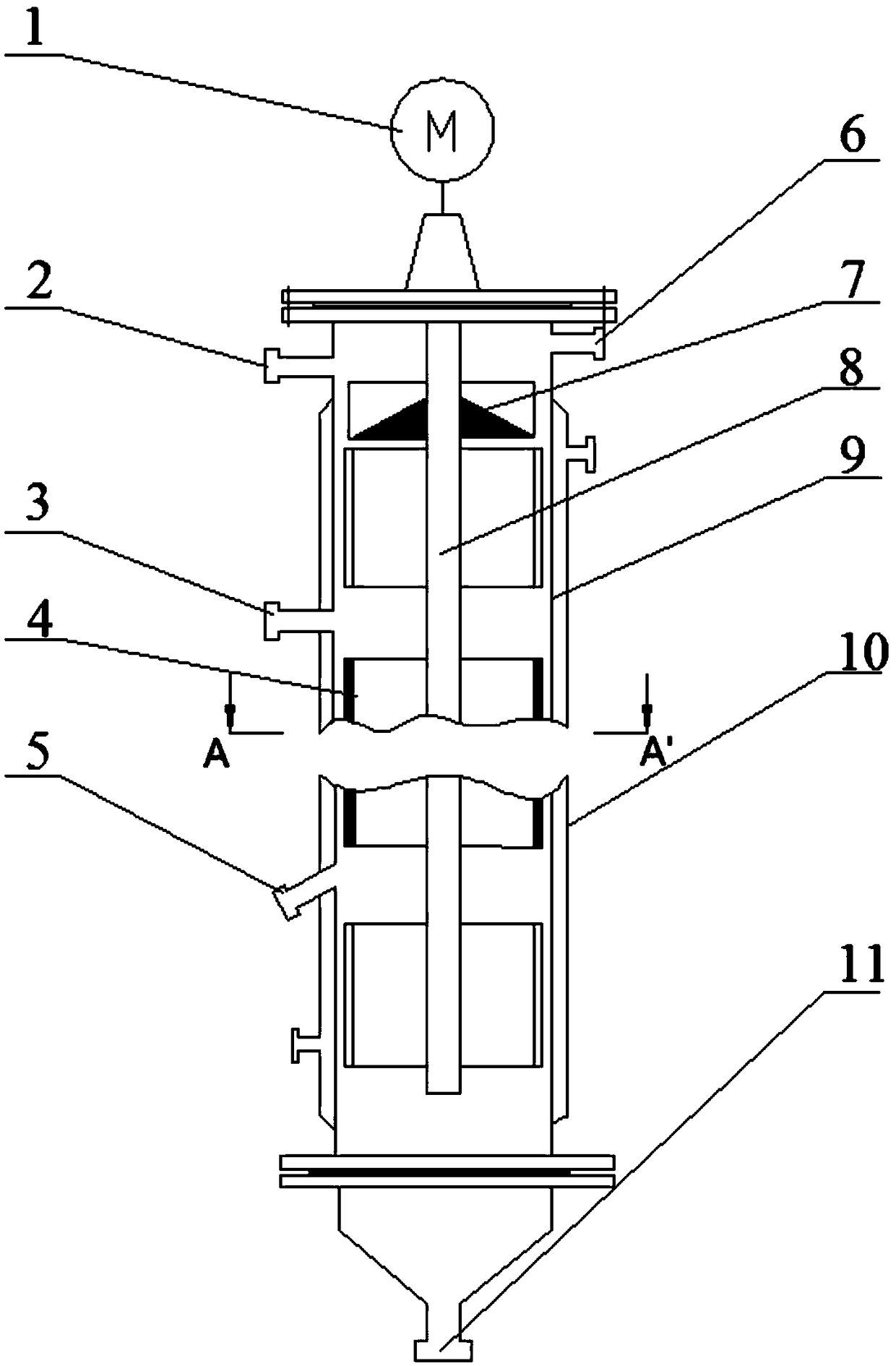

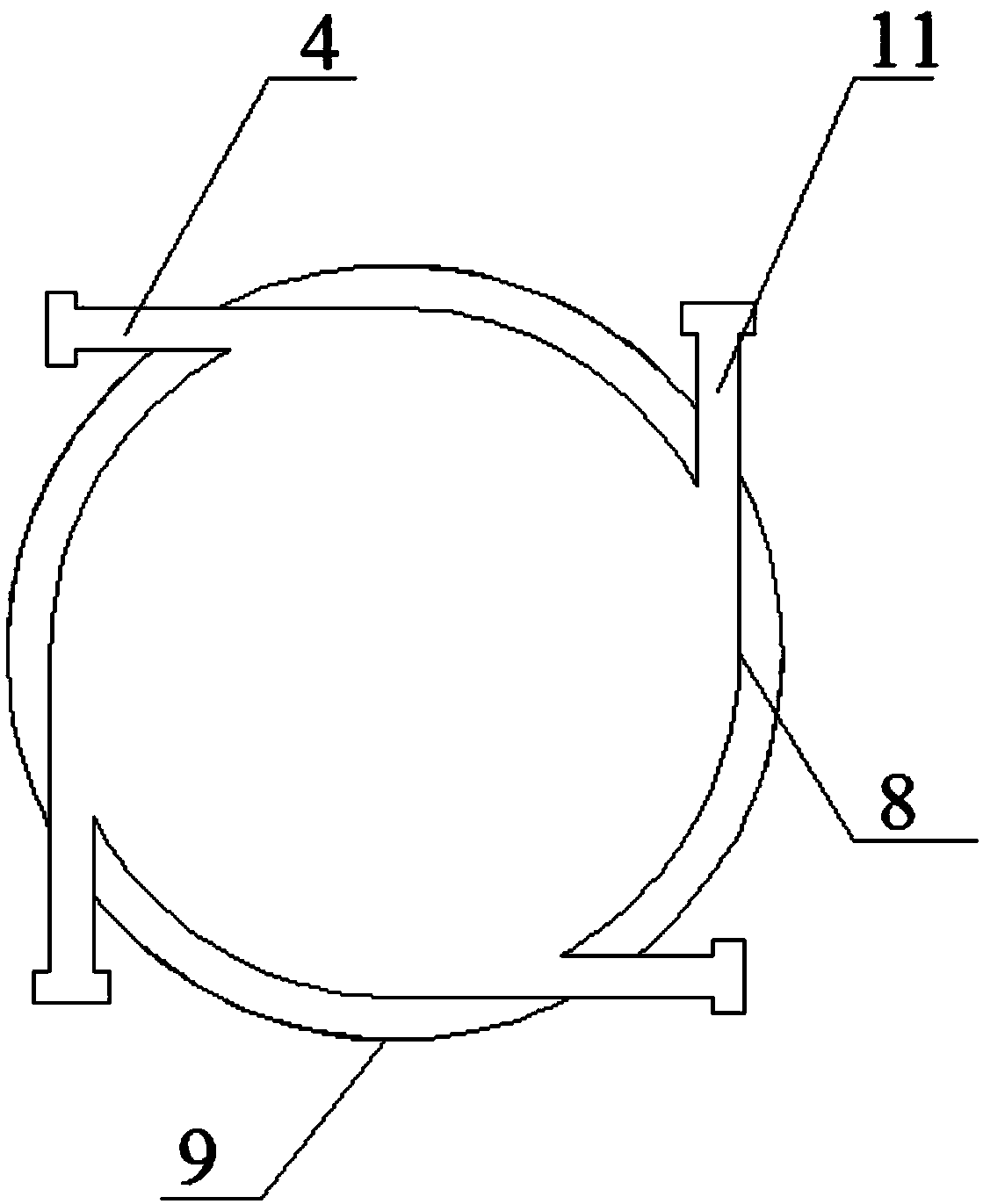

Rotary kiln with functions of reducing waste heat volatilization efficiency and recycling waste heat

ActiveCN113739566AReduce evaporation efficiencyReduce energy consumptionRotary drum furnacesIncreasing energy efficiencyThermodynamicsProcess engineering

The invention discloses a rotary kiln with functions of reducing waste heat volatilization efficiency and recycling waste heat. The rotary kiln is used for firing lithium battery raw materials. The rotary kiln comprises a rotary drum body, the rotary drum body comprises a drum body and two supporting annular sleeves, and the two ends of the drum body are movably connected with the supporting annular sleeves in a sleeved mode respectively and supported by the supporting annular sleeves so that the drum body can rotate relative to the supporting annular sleeves. A driven gear is fixed to the outer wall of the drum body, and the driven gear is used for being connected with an external driving gear to drive the drum body. A raw material firing cavity and a gas heat insulation cavity which are mutually independent are arranged in the rotary drum body. The raw material firing cavity extends in the axial direction of the rotary drum body. The gas heat insulation cavity is of an annular structure and surrounds the periphery of the raw material firing cavity, and the gas heat insulation cavity also extends in the axial direction of the drum body. The gas heat insulation cavity is provided with a gas inlet which communicates with a gas source, and the gas heat insulation cavity communicates with the raw material firing cavity through a gas outlet of the gas heat insulation cavity. The volatilization efficiency of waste heat can be reduced; and the waste heat can be fully recycled and utilized, so that the energy consumption is reduced.

Owner:FOSHAN TIANLU INTELLIGENT EQUIP TECH CO LTD

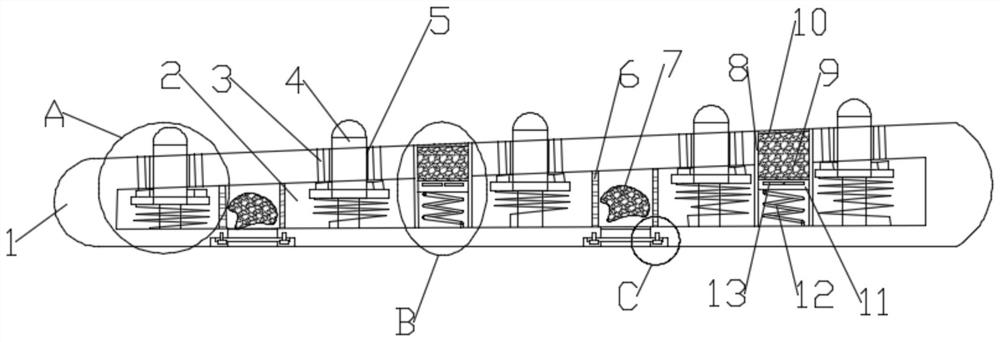

Power plant wastewater evaporation crystallizer

PendingCN111389122AReduce adhesionAvoid cloggingDispersed particle filtrationTransportation and packagingReciprocating motionElectric machinery

The invention discloses a power plant wastewater evaporation crystallizer which comprises an evaporation pipe inlet, a horizontal section, an evaporation pipe main body, an outlet chamber and an evaporation pipe outlet which are sequentially communicated. The evaporation pipe inlet is hermetically connected with the horizontal section through a flange, the horizontal section is connected with theevaporation pipe main body, and the gas outlet end of the evaporation pipe main body is connected with the outlet chamber. The power plant wastewater evaporation crystallizer is simple in structure, adriving motor, a cam, a first spring, a sliding rod, a top plate, a second spring, a guide column and other structures are matched, the steel wire brush can do longitudinal reciprocating motion on the filter screen, the conical column can do longitudinal reciprocating motion, smoke dust can be effectively prevented from adhering to the inner wall of the evaporation pipe main body and the outer wall of the wastewater spray head, the atomizing effect of the nozzle is prevented from being reduced, the possibility that the outlet of the evaporator is blocked is reduced, dust on the filter screencan be removed without disassembling and cooling the equipment, a large amount of manpower and time are saved, the utilization rate of the equipment is increased and the equipment is convenient to use.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD +1

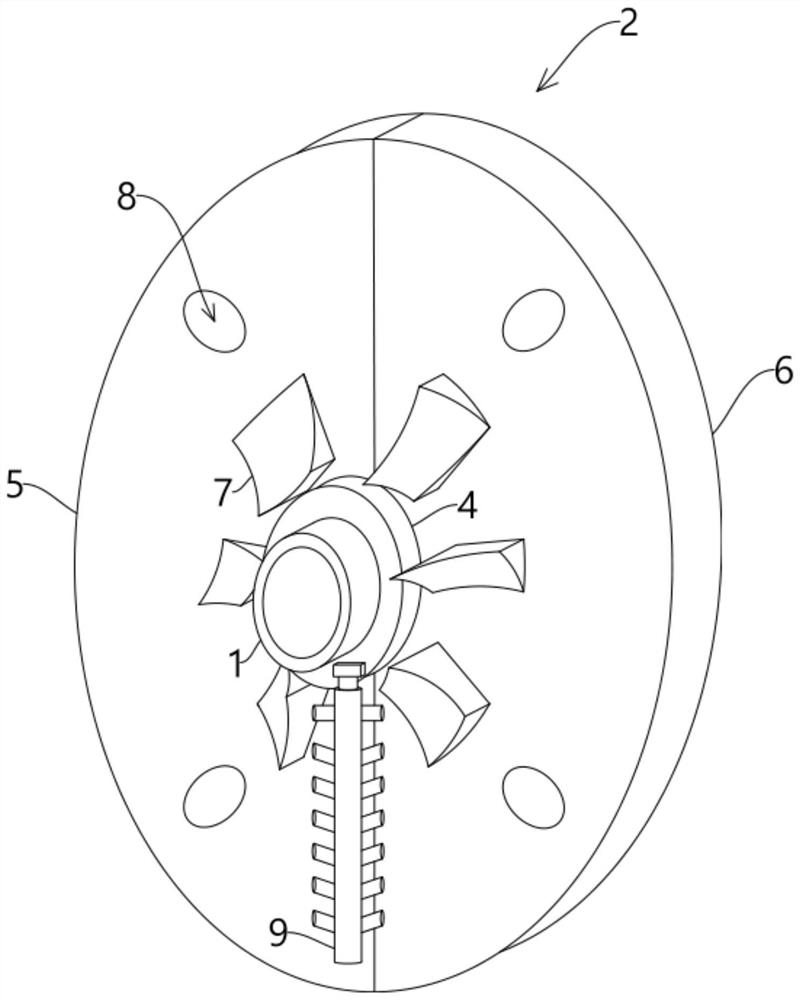

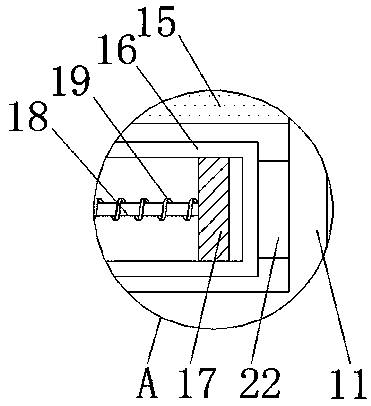

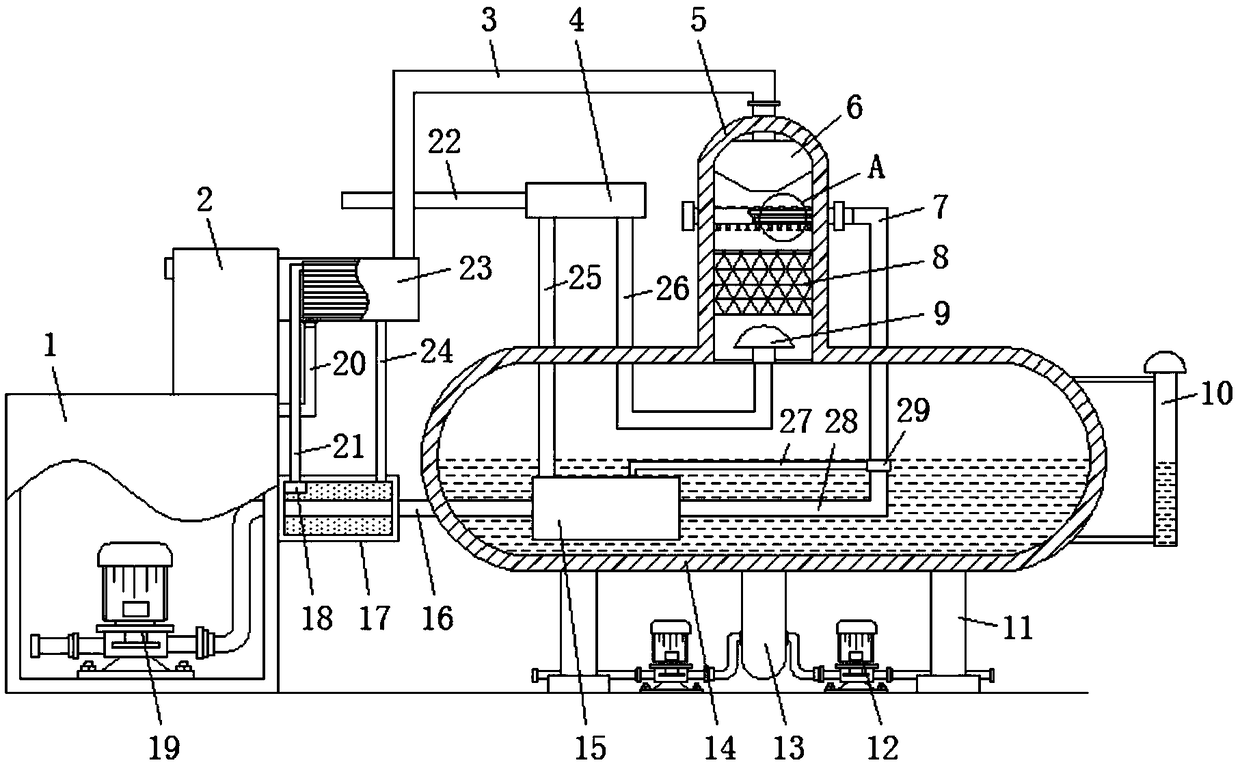

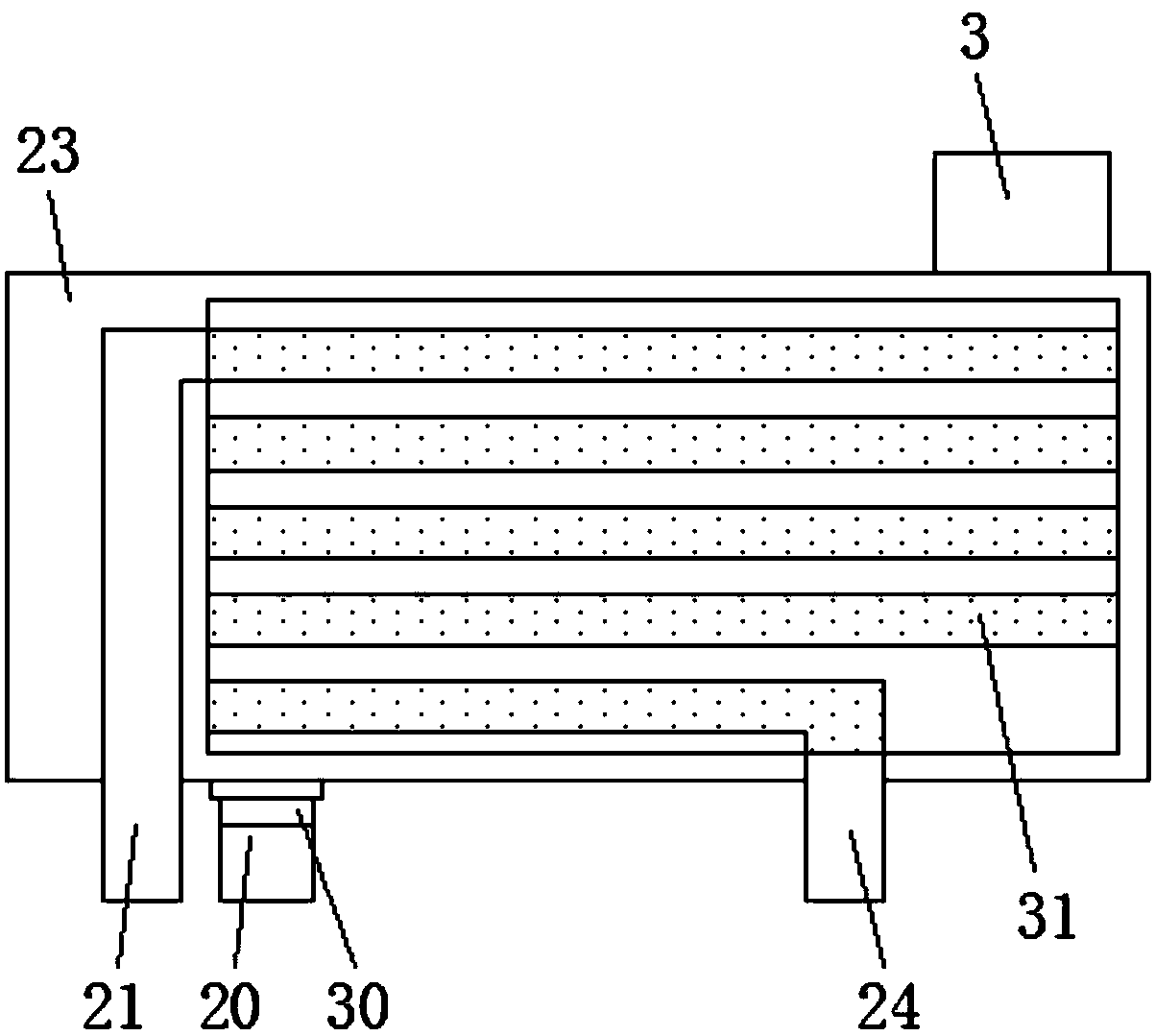

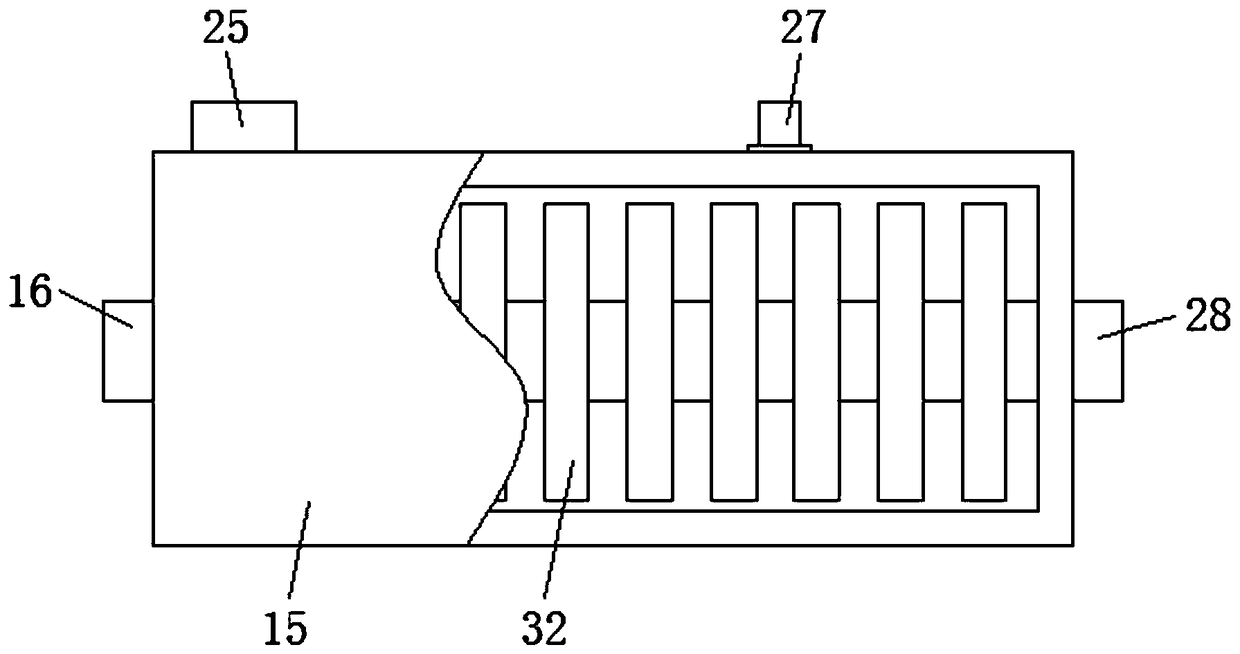

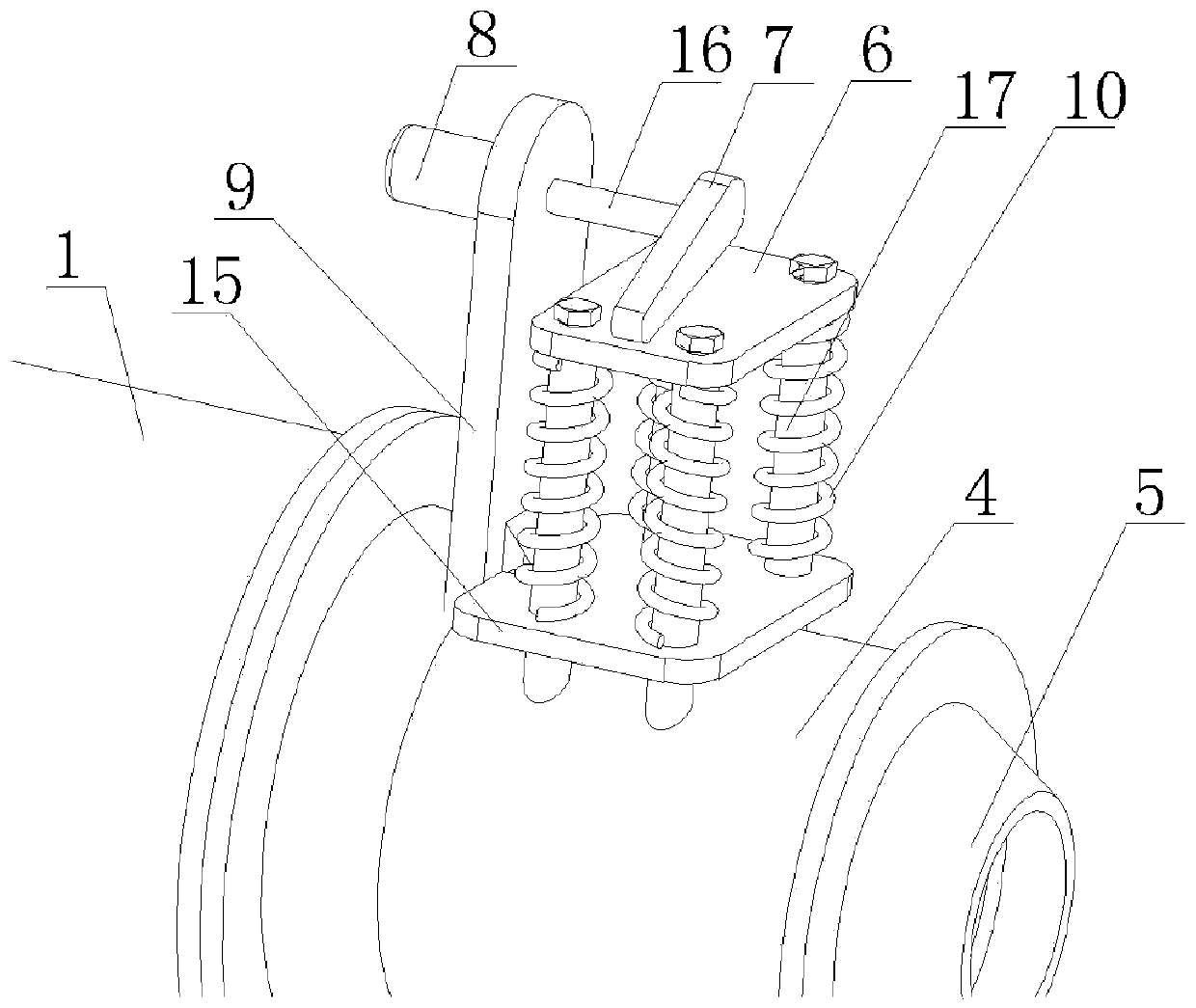

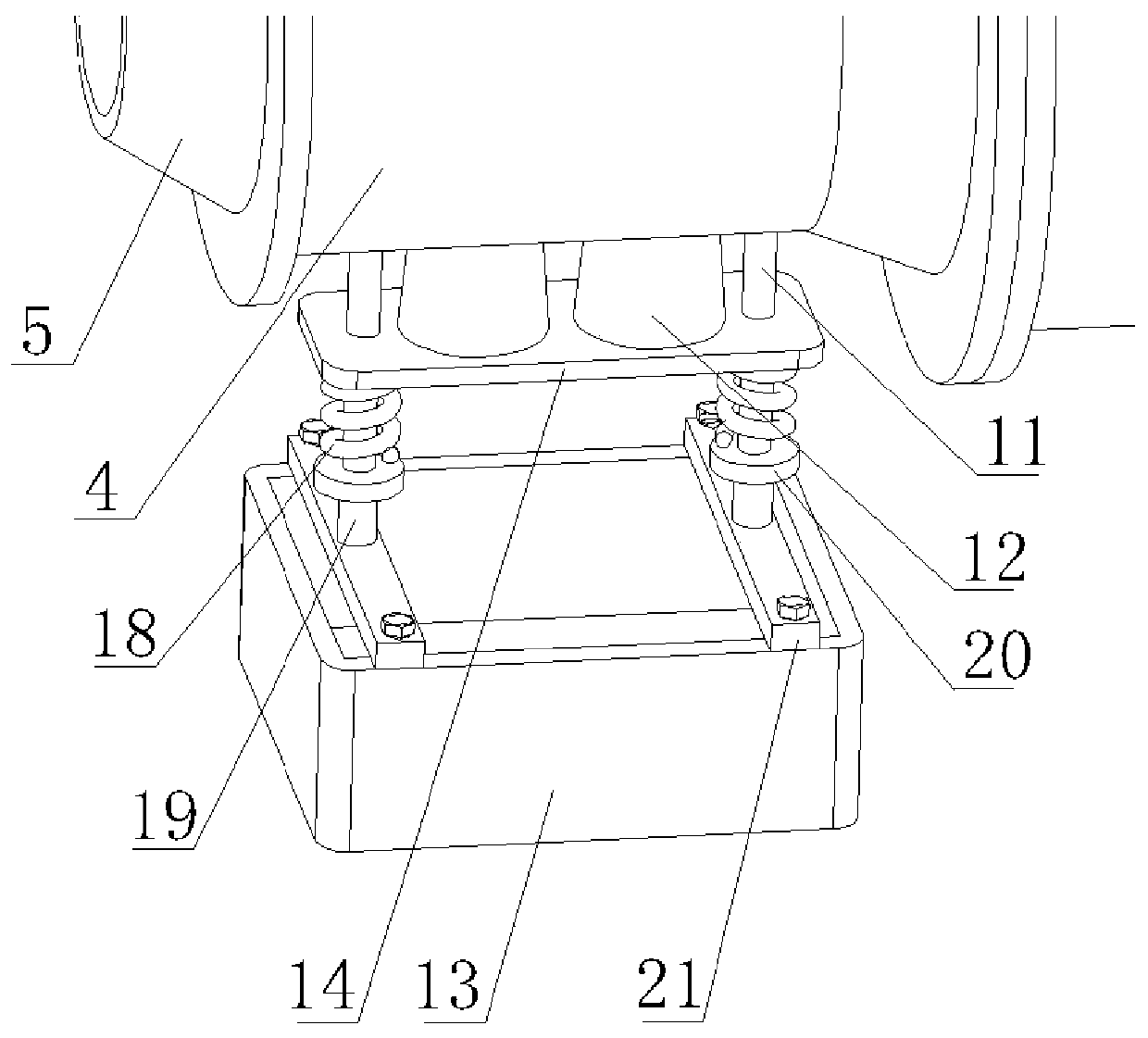

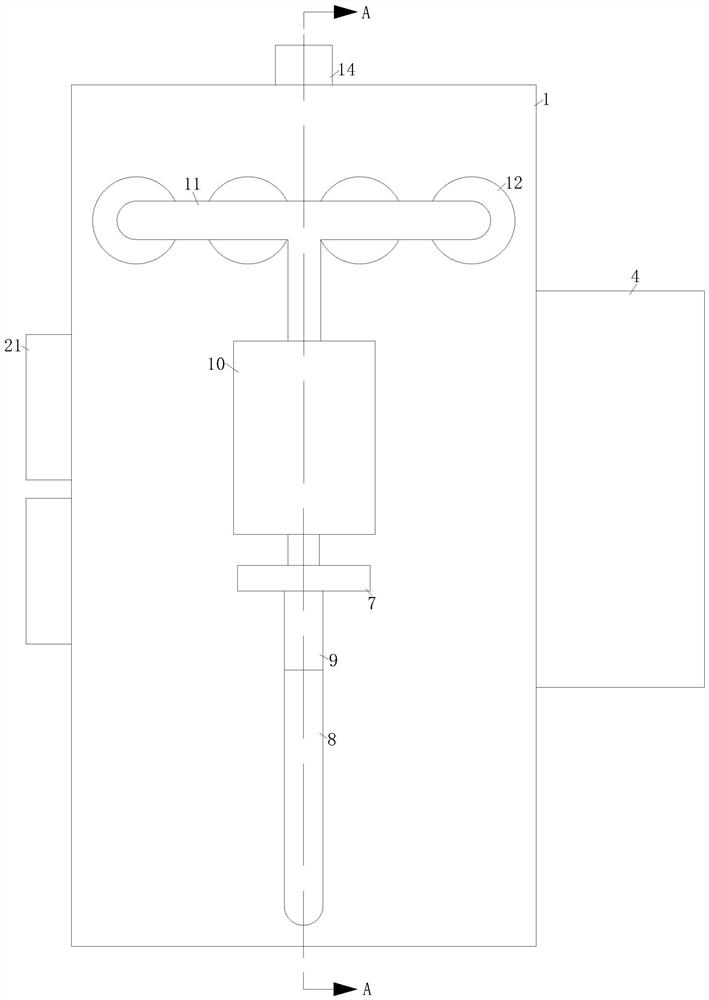

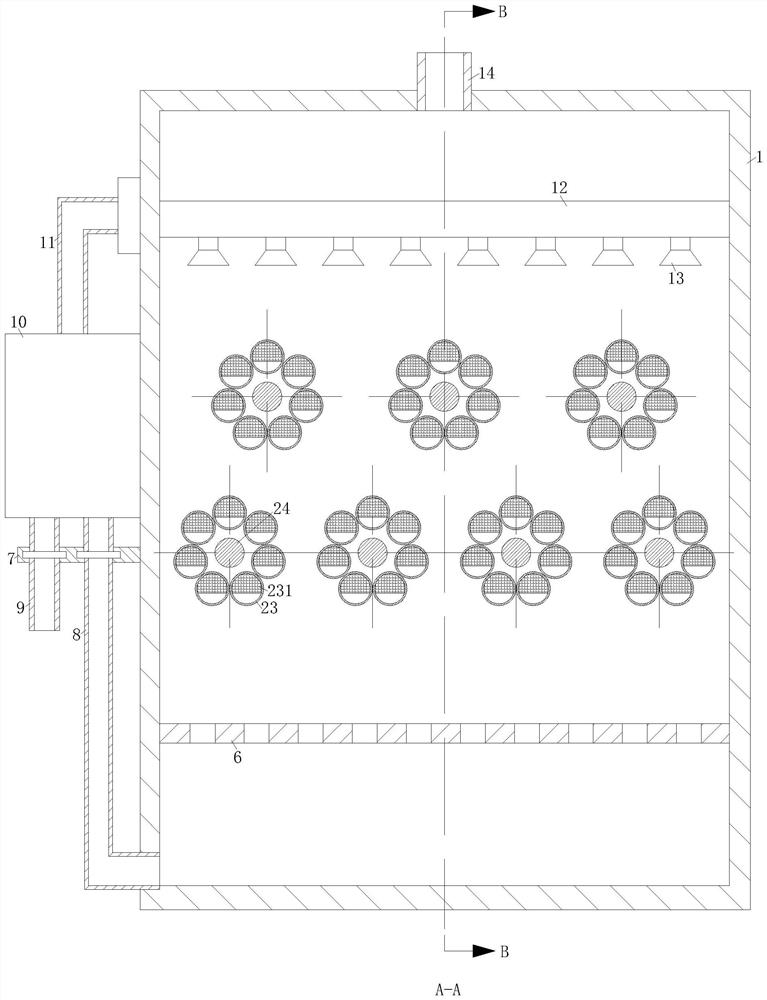

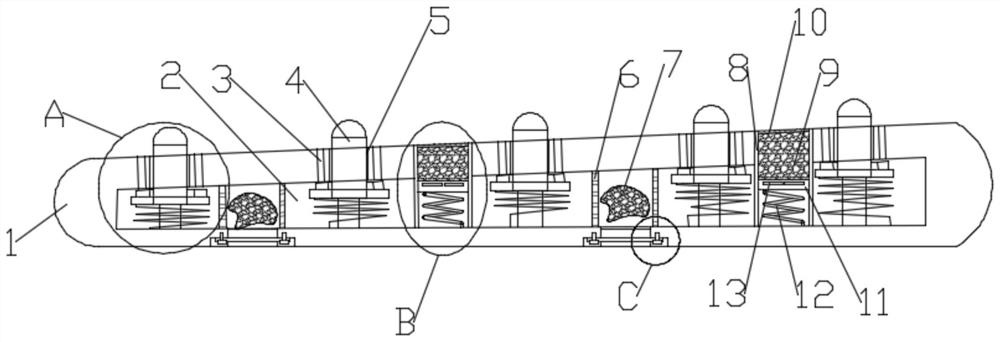

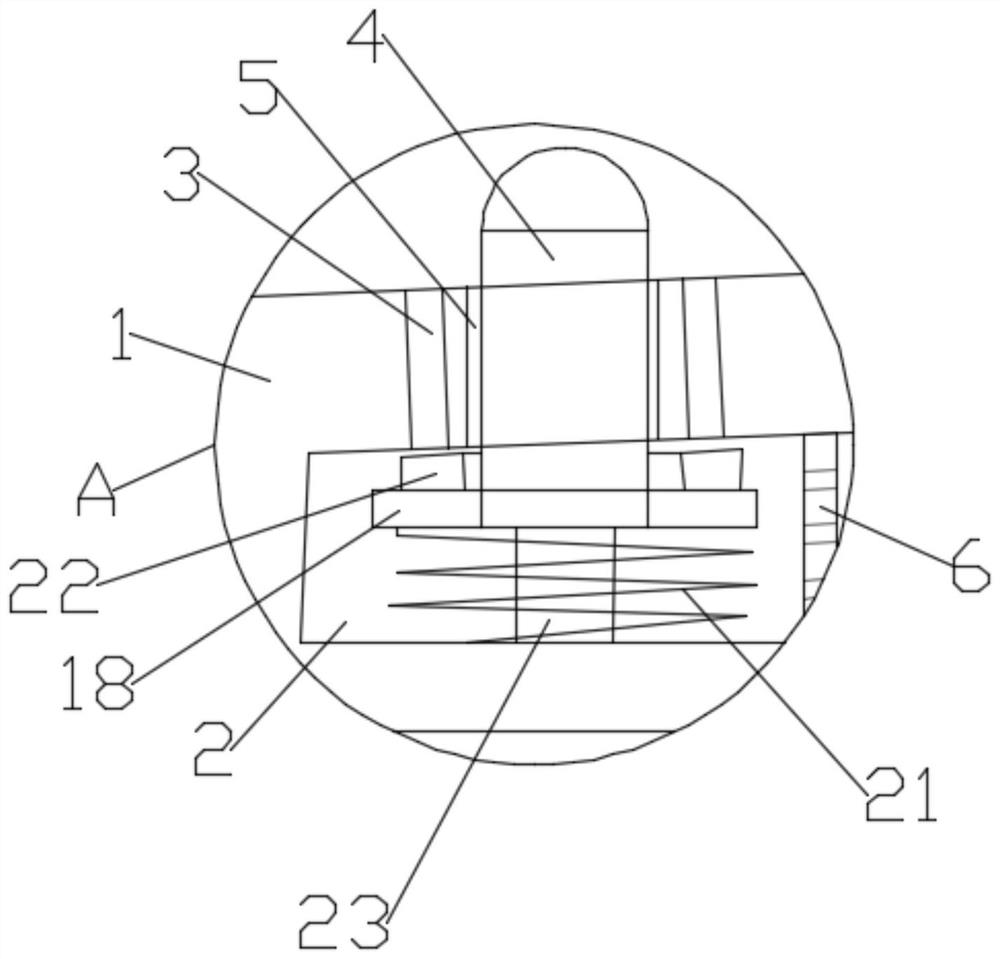

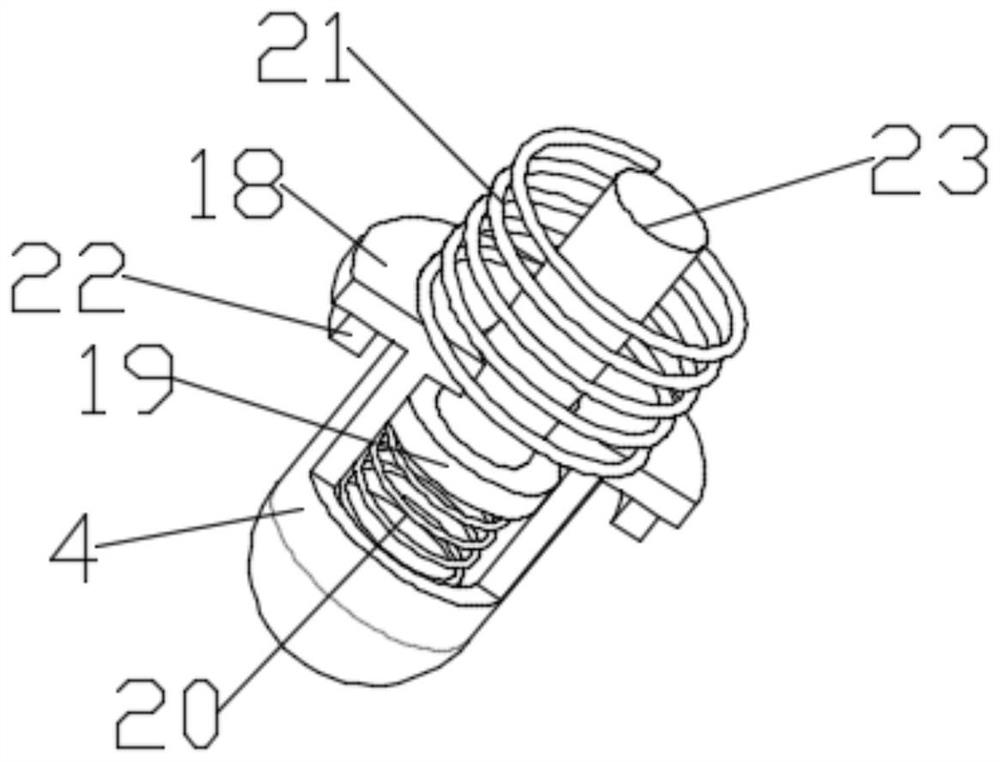

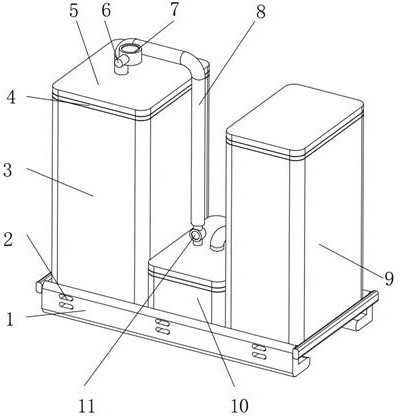

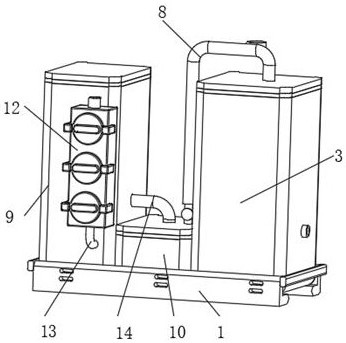

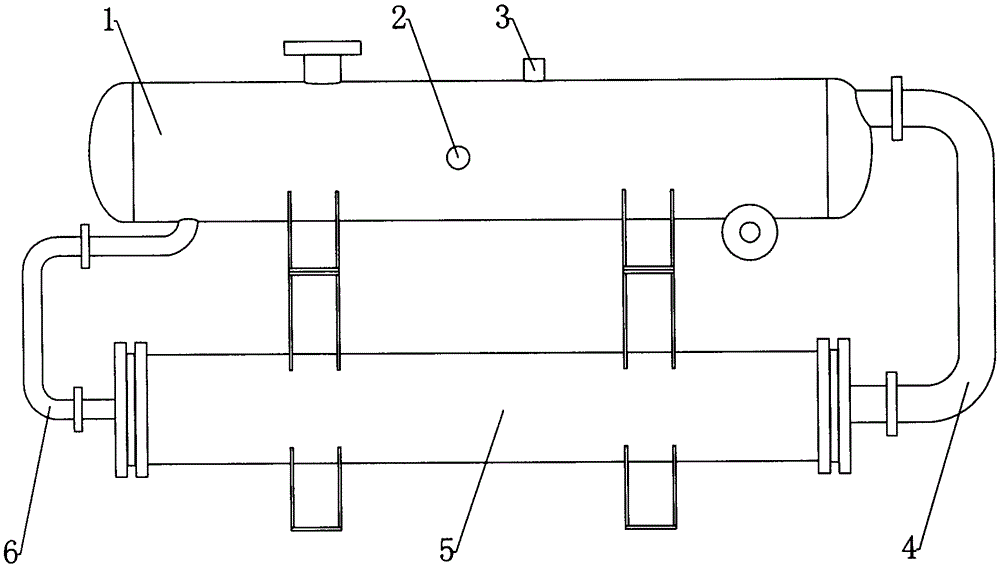

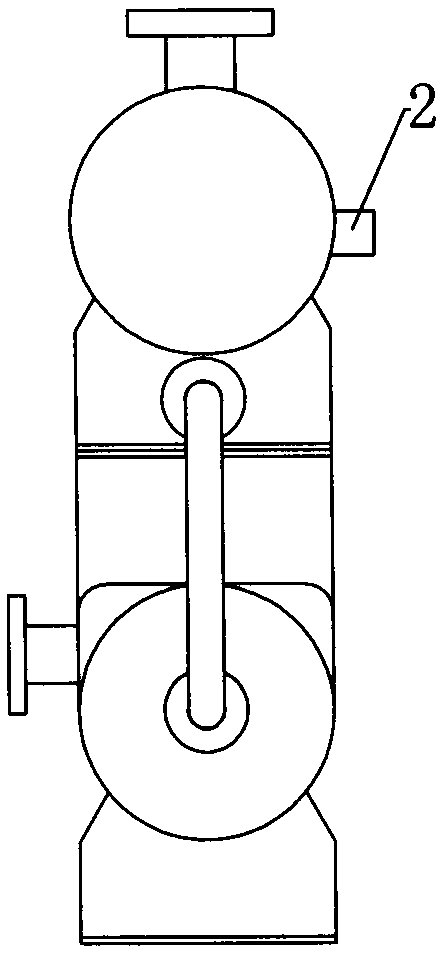

A compound methanol evaporator

ActiveCN113521773BReduce evaporation efficiencyGuaranteed buffer timeEvaporator accessoriesChemical industryLiquid stateElectric machinery

The present invention involves the field of evaporator technology. Specifically, a composite methanol evapator, including the box, the inner wall of the box is set with a filter, a two -layer evaporation mechanism is set up above the filter.Uniformly distributed, the inner wall of the box is set with multiple groups of round tubes, and the two ends of the multiple groups of round tubes are fixed with the sides of the inner wall of the box. There are multiple sets of atomized nozzles below the round tube.The end wall of the input liquid is connected to the inner wall of the round tube. The left side of the round tube runs through the inner wall of the box and extends to the outer fixing connection of the T -shaped tube.Users can use the liquid pump to spray liquid methanol through the atomized noble spray head on the evaporation mechanism. The motor will drive the evaporation mechanism to rotate the temperature in the process of using the use process, so as to avoid the spray of liquid methanol in the evaporation mechanism.Temperature cannot recover in time and reduce the evaporation efficiency of methanol.

Owner:浙江嘉诚动能科技股份有限公司

A duct fin evaporator

ActiveCN113587496BImprove heat transfer efficiencyEnsure normal flowEvaporators/condensersTubular elementsThermodynamicsWater storage tank

The invention discloses a pipe-finned evaporator, wherein a plurality of first fins and second fins are crossed and sleeved on the evaporation tube, and the thickness of the air-inducing blocks of the first fins and the second fins is along the The gradual trend of the circumferential direction of the annular distribution is opposite, and the thickness of any air-inducing block of the first fin and the second fin is opposite to the gradual trend in the direction away from the center of the circle, and an elastic cleaning brush is fixedly connected to the outside of the elastic cleaning cylinder, so The elastic cleaning cylinder is fixedly connected with an elastic extrusion column that cooperates with the air-inducing block, and the water storage tank is slidably provided with a second magnetic block that magnetically cooperates with the first magnetic block to press water. The rotation of the first fin and the second fin disturbs the fluid state of the air, and through the cooperation of the ventilation hole and the air-inducing block, the contact area and duration of the air and the fin are increased while guiding the air circulation, and the elastic cleaning is also carried out. The matching arrangement of brushes and elastic extrusion columns, etc., cleans the surface of the fins.

Owner:合肥美菱有色金属制品有限公司

Low-temperature evaporator and control system thereof

ActiveCN113289358AGuaranteed stabilityNot easy to scaleEvaporator accessoriesEnergy based wastewater treatmentEvaporatorSteam condensation

The invention discloses a low-temperature evaporator and a control system thereof. The low-temperature evaporator comprises an evaporator and a condenser, a waste liquid part, a defoaming part and a steam part are sequentially arranged in the evaporator from bottom to top, the condenser is divided into a pipe layer and a shell layer, and a heat supply circulation loop assembly is arranged between the waste liquid part of the evaporator and the shell layer of the condenser. A steam condensation assembly is arranged between a steam part of the evaporator and a pipe layer of the condenser, the output end of the steam condensation assembly is connected with a distilled water deep purification assembly, and a waste liquid inlet pipeline and an oil-water separation assembly are further arranged at the bottom of the evaporator. A control system of a low-temperature evaporator comprises a power-on monitoring module, a power-off monitoring module and a fault diagnosis module. The low-temperature evaporator and the control system thereof are high in automation degree, excellent in defoaming performance and high in effluent quality.

Owner:常州思特恩节能科技有限公司

A drug massage insole

ActiveCN111904099BReduce evaporation efficiencyImprove evaporation efficiencyInsolesDevices for pressing relfex pointsPhysical medicine and rehabilitationMassage

The embodiment of the present invention relates to the technical field of insole, and specifically discloses a medicinal massage insole, comprising an insole body, a cavity is opened in the insole body, and a plurality of groups of massage components are arranged on the top of the cavity, and the cavity is There are multiple sets of support mesh plates fixedly arranged, each set of support mesh plates is provided with a medicine bag, and the bottom plate of the cavity is detachably installed with a plurality of sets of support mesh plates corresponding to the support mesh plates one-to-one. A cover plate is installed; the top of the cavity is also provided with a plurality of sets of fixed cylinders alternately arranged with the massage assembly, and a protective mesh plate is provided at the top of the fixed cylinder. In the embodiment of the present invention, the first support spring and the second support spring are arranged to improve the effect of massaging the feet by the massage protrusions; in addition, under the heating action of the heating rod, the volatilization of the drug particles in the fixed cylinder can be improved Efficiency, to ensure the effect of drug particles on the feet.

Owner:HENAN BANGNI BIOLOGICAL ENG CO LTD

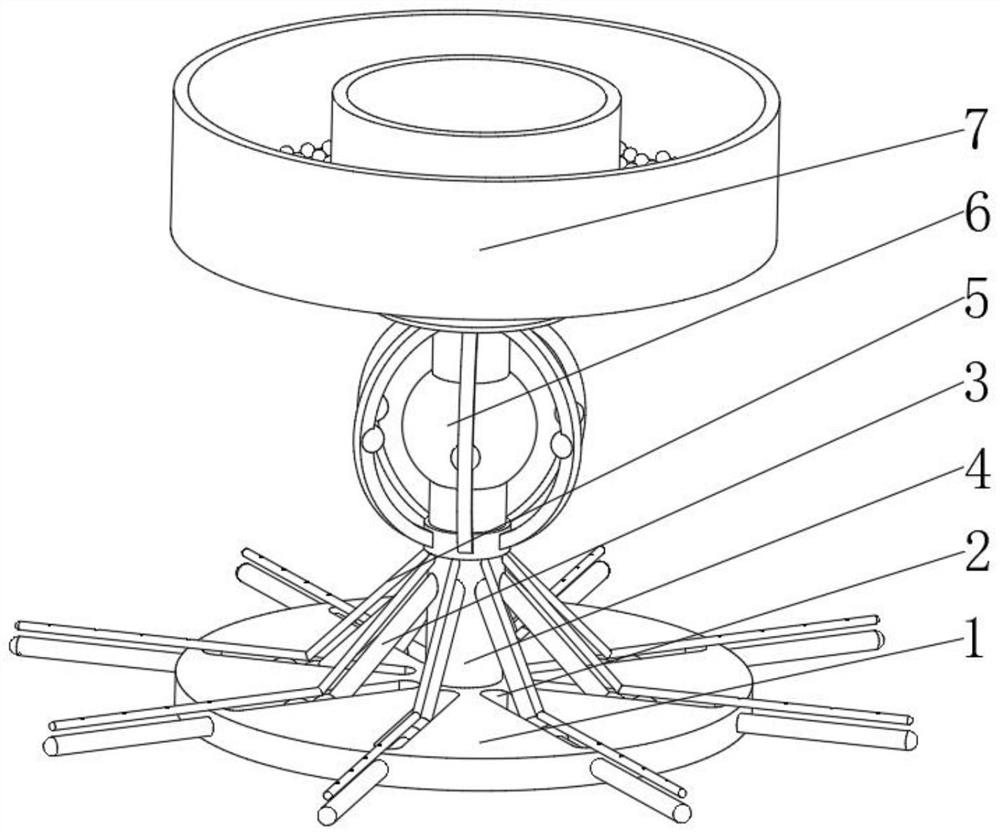

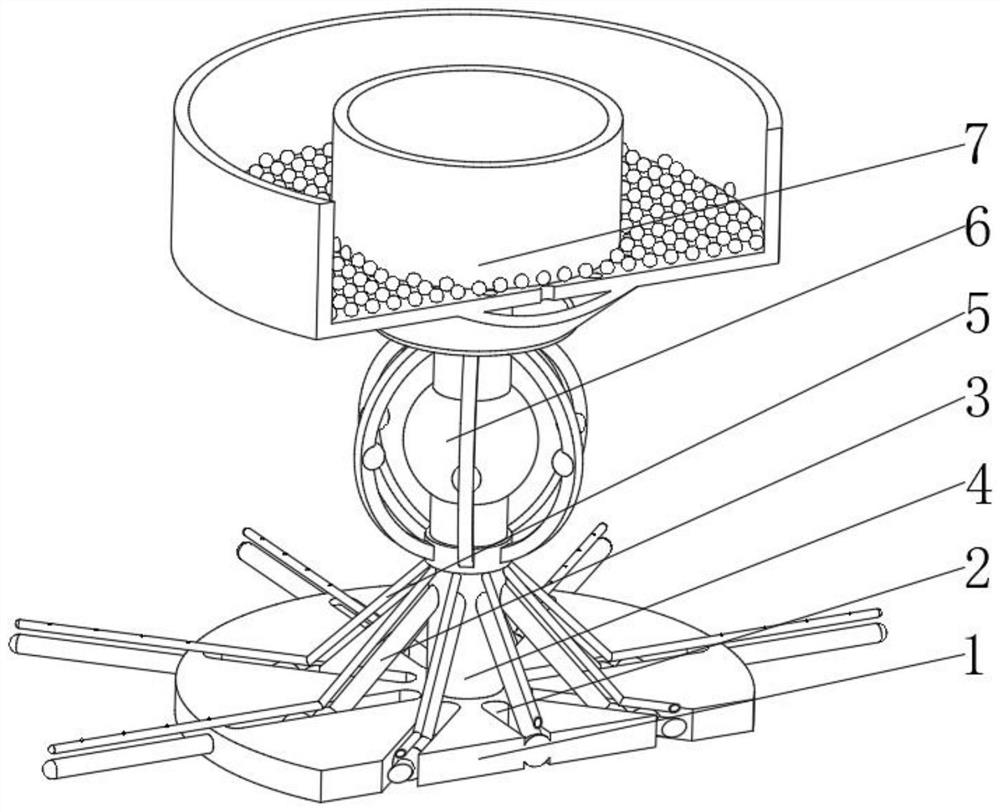

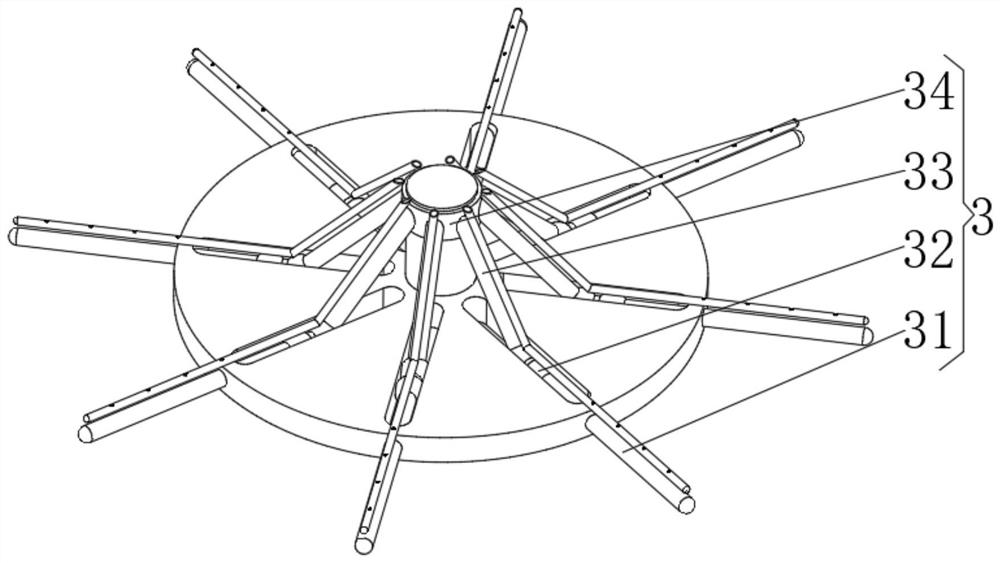

A forest protection equipment for ecological protection

ActiveCN113577599BAvoid damageReduce weightWatering devicesFire rescueProtection forestEnvironmental resource management

The invention discloses an ecological protection forest protection equipment, which specifically includes: a fixed seat plate, the fixed seat plate has a circular plate body, and is characterized in that: and a through protective groove opened on the top of the circular plate body, and installed The thermal measurement device that runs through the inner cavity of the protective groove, the support column installed on the top of the circular plate body, and the infusion tube installed on the support column above the thermal measurement device, and installed on the A control device on the top of a support column, and a carrying device installed on the top of the control device, the invention relates to the technical field of ecological protection. The internal thermal measuring device is protected through the opening of the protective groove to prevent the components from being damaged by the creatures in the forest during use. At the same time, the cooperation with the fixed seat plate is beneficial to reduce the weight of the equipment itself and facilitate installation Handling and placement.

Owner:青岛枫和市政园林建设有限公司

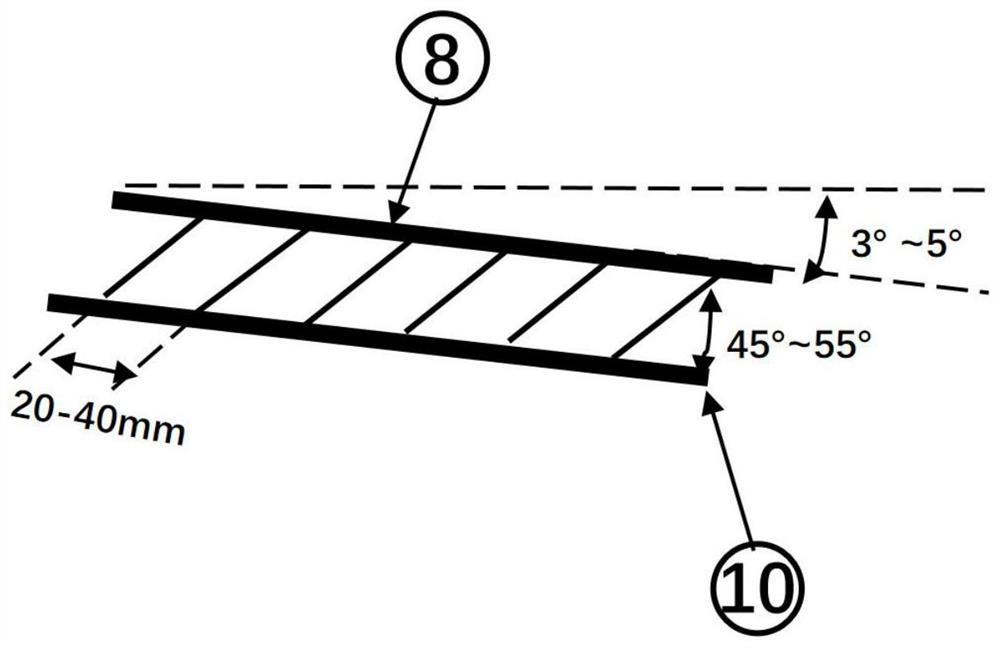

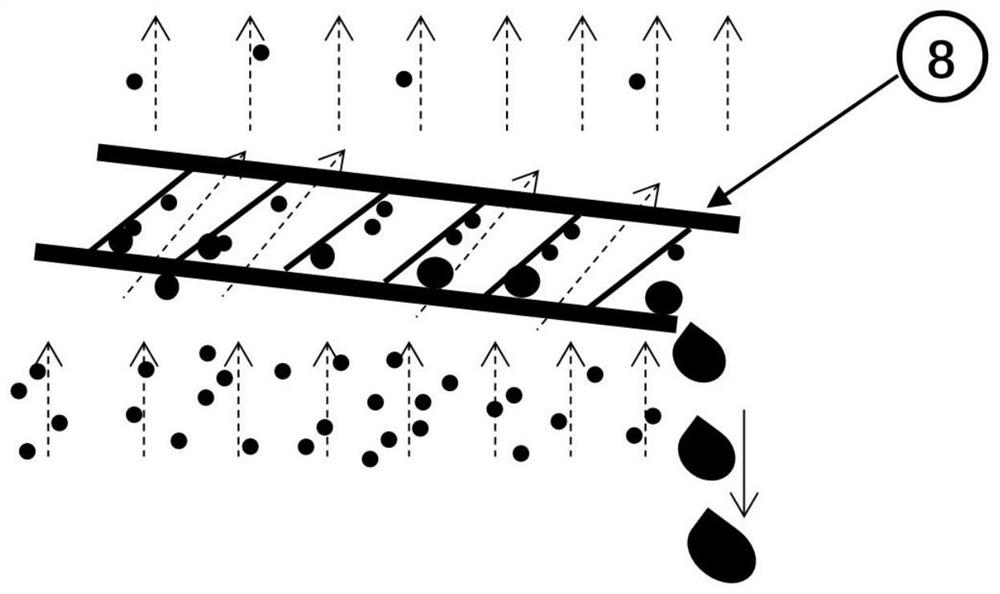

System and process for realizing zero discharge of wastewater by contacting dry and cold carrier gas with hot wastewater

ActiveCN114105239ACutting costsLow running costWater treatment parameter controlGeneral water supply conservationWastewaterWater resource management

The invention discloses a system and a process for realizing zero discharge of wastewater by contacting dry and cold carrier gas with hot wastewater, comprising: a heat exchange device for heating wastewater, a wastewater outlet of which is connected with a spray layer at the top of an evaporation device; the bubbling device is arranged in the evaporation device, and a nozzle of the bubbling device is inserted into wastewater; an inlet of the fan is communicated with a gas source, an outlet of the fan is connected with a gas inlet of the bubbling device, and the fan is used for providing dry and cold carrier gas for the bubbling device; the straight-through flow guide device comprises a plurality of liquid distribution elements which are vertically arranged in parallel, and the straight-through flow guide device is arranged in the evaporation device and located above the preset liquid level of the wastewater. The dry and cold carrier gas is subjected to shallow bubbling below the wastewater liquid level of the evaporation device through the bubbling device to generate a main concentration process. The temperature and the humidity of the carrier gas after the main concentration process are increased, the evaporation efficiency of the waste water is reduced, at the moment, secondary heat exchange and mass transfer are carried out on the carrier gas and the sprayed waste water in the straight-through flow guide device, and the straight-through flow guide device can be effectively prevented from being scaled and blocked.

Owner:SHANDONG GUOSHUN CONSTR GRP

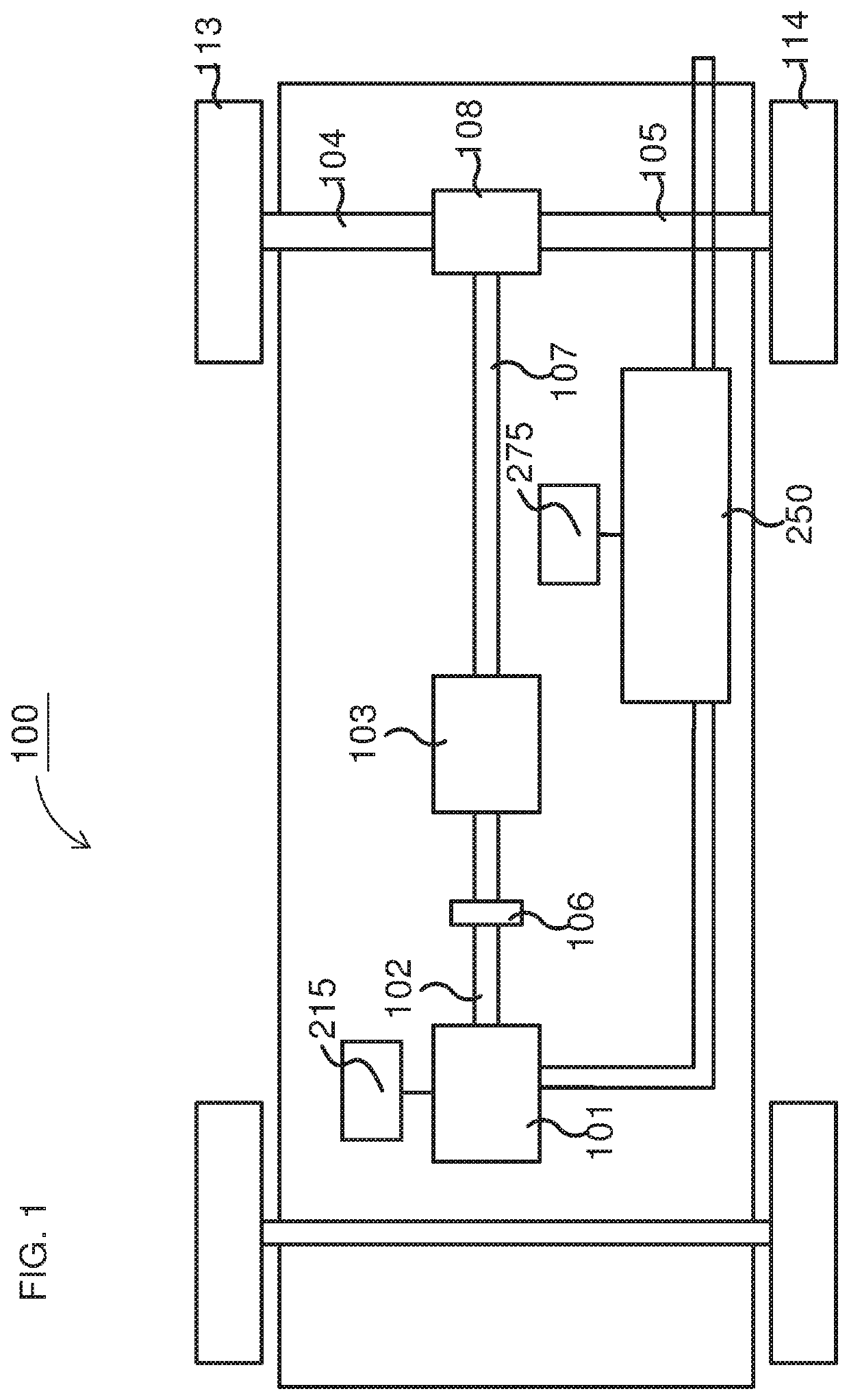

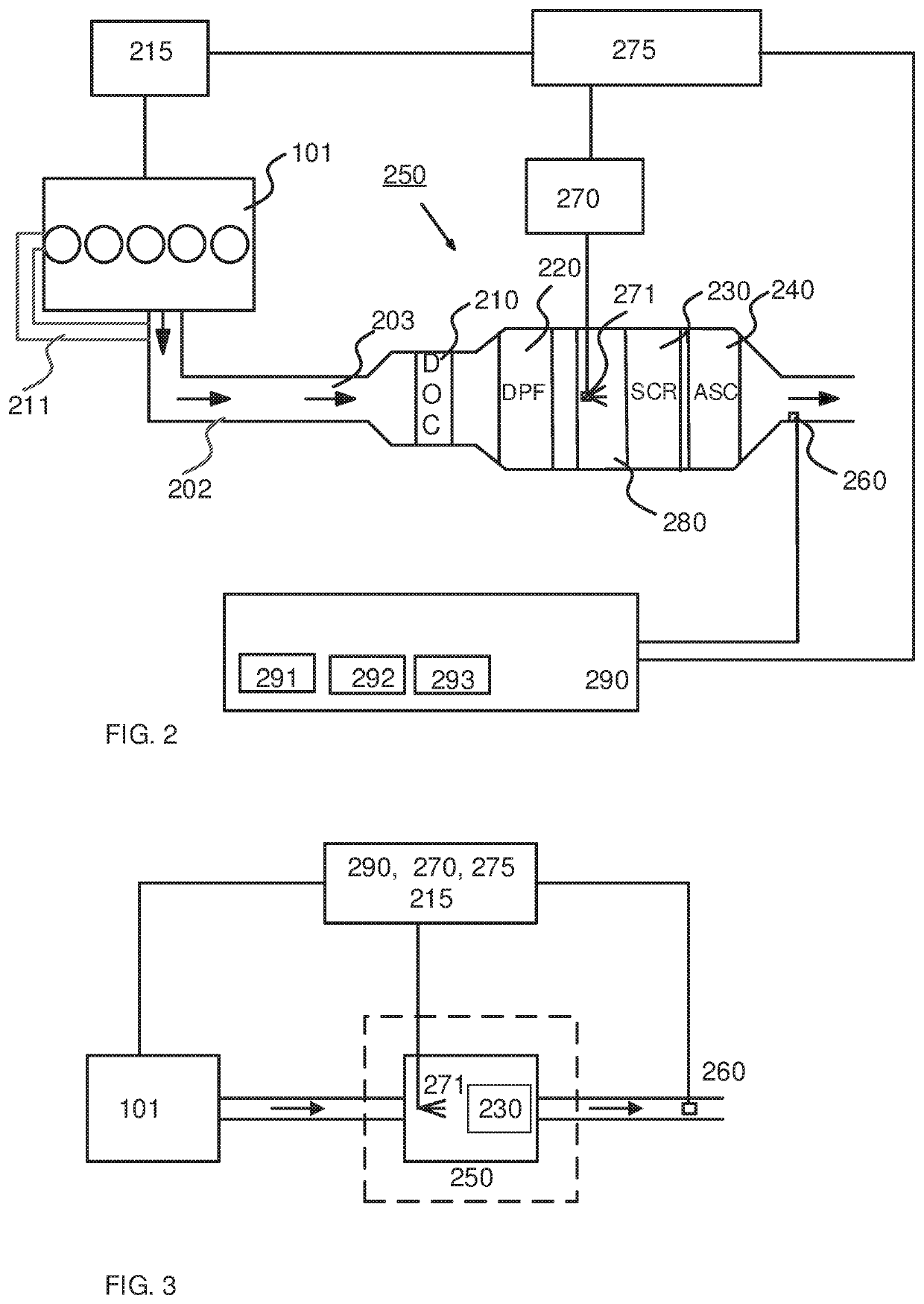

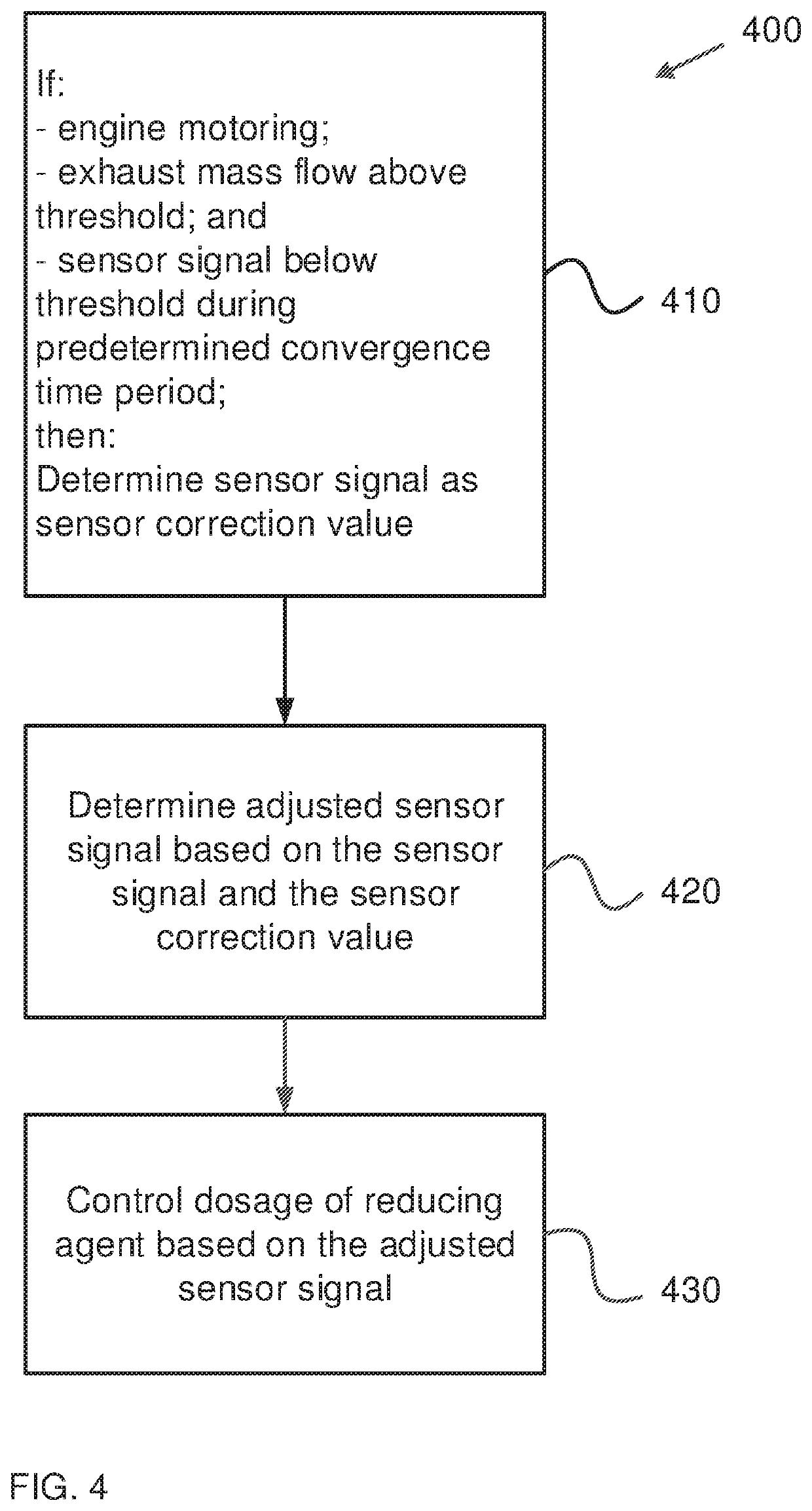

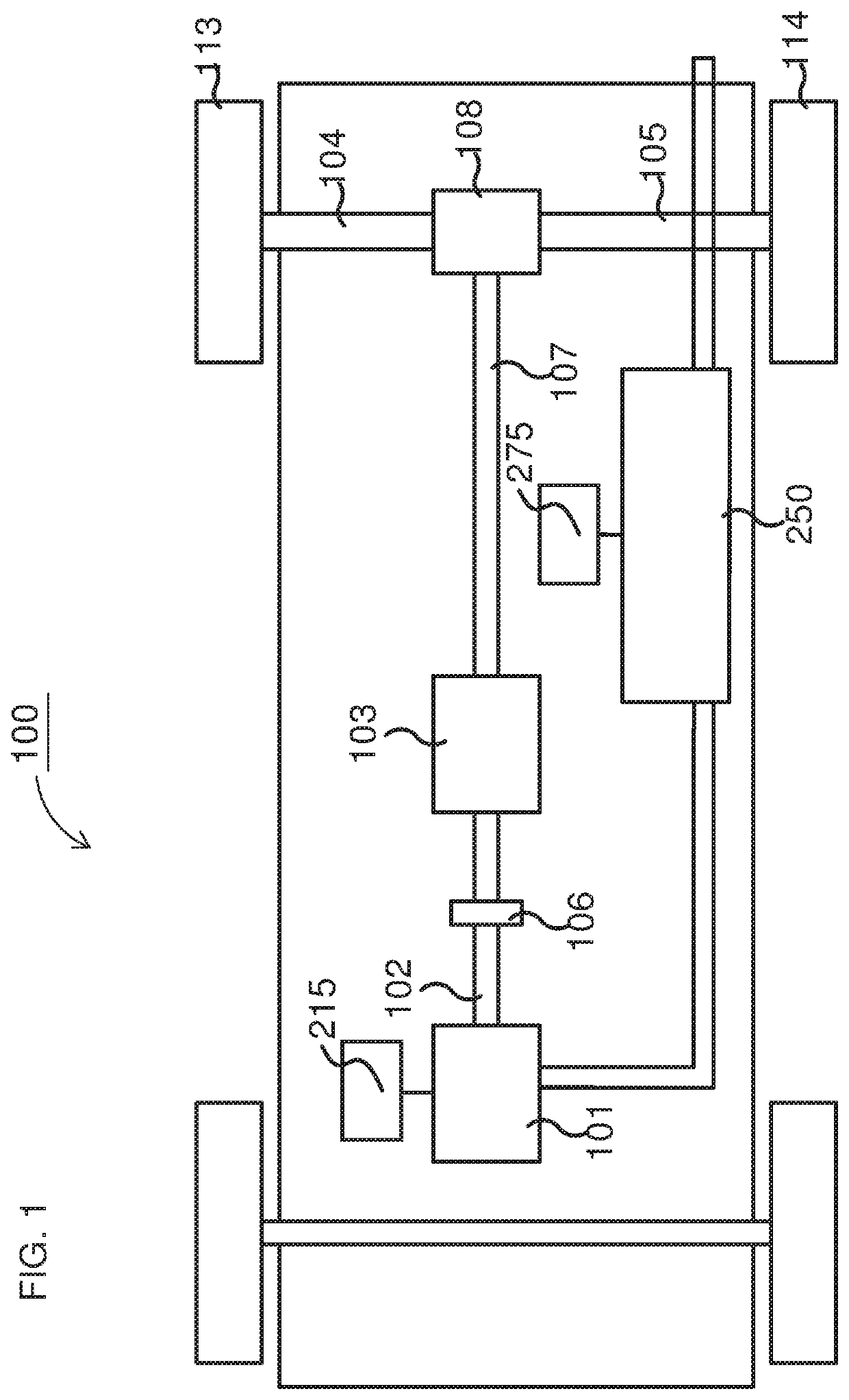

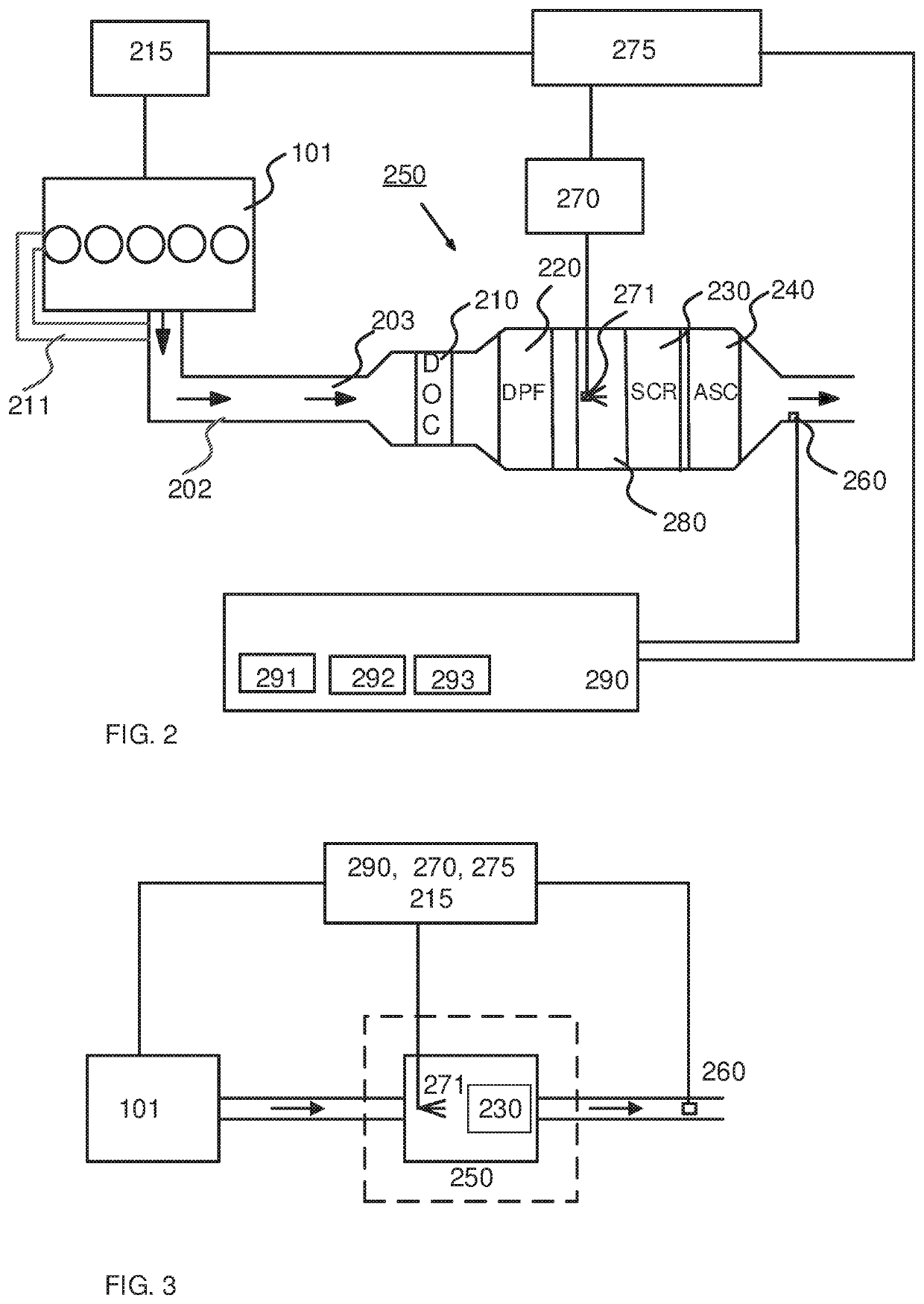

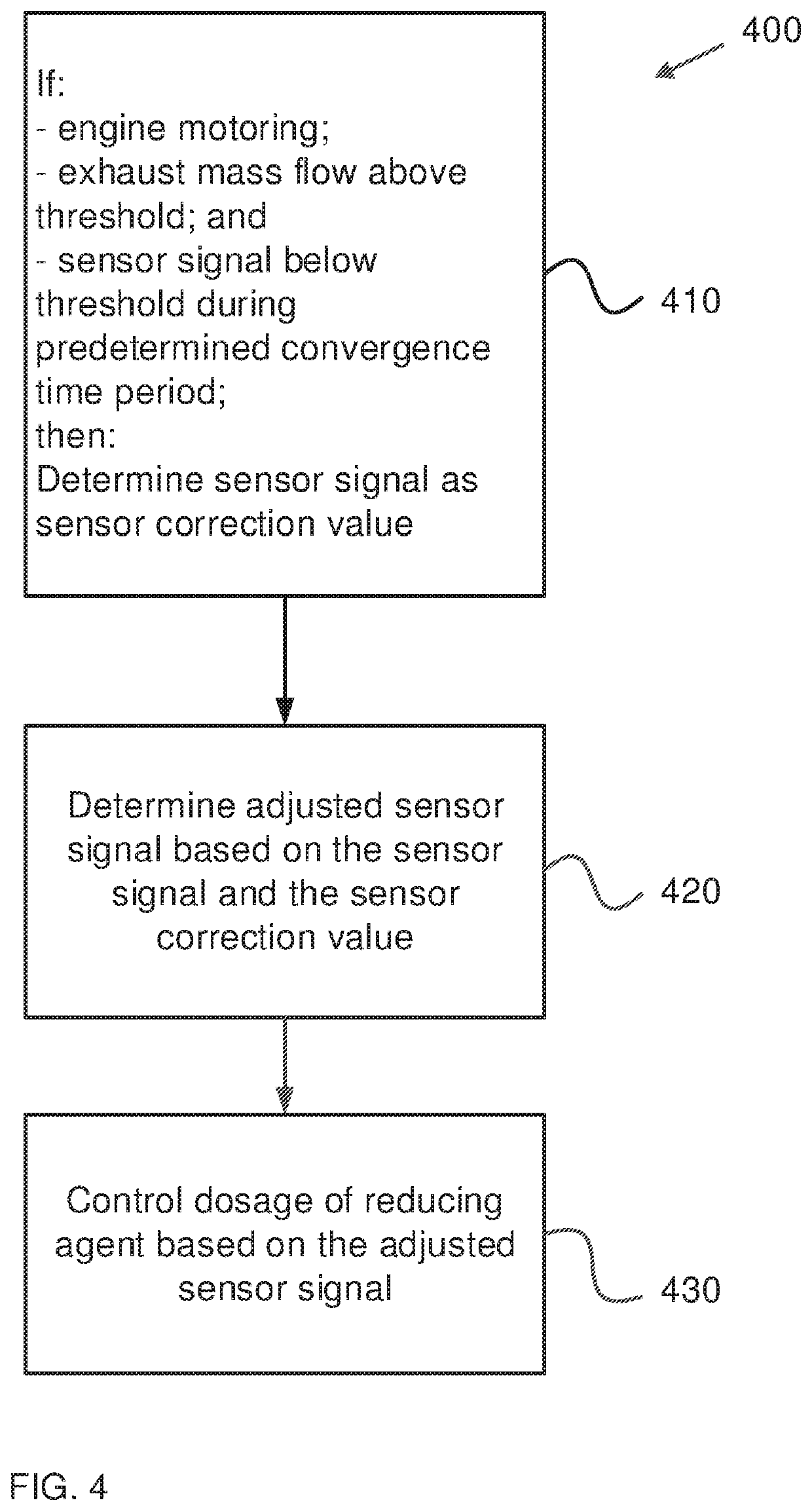

Method and control system for control of dosage of a reducing agent

ActiveUS20210148265A1Robustness of controlAccurate and robust determinationInternal combustion piston enginesExhaust apparatusNitrogen oxidesPtru catalyst

Disclosed is a method for control of dosage of a reducing agent into an exhaust stream, which includes: determining at least one sensor signal SNOx from at least one nitrogen oxides NOx sensor arranged downstream of at least one of the one or more reduction catalysts as at least one sensor correction value SNOx_corr, respectively, if: 1) the engine rotates without fuel supply; 2) an exhaust mass flow M′exh is greater than an exhaust mass flow threshold M′exh_th; M′exh>M′exh_th; and 3) the sensor signal SNOx has had a value smaller than a sensor signal threshold SNOx_th; SNOx<SNOx_th; during at least a predetermined time period Tcon; determining at least one adjusted sensor signal SNOx_adj based on the at least one sensor signal SNOx and the at least one sensor correction value SNOx_corr, respectively; and controlling the dosage of the reducing agent based on the at least one adjusted sensor signal SNOx_adj.

Owner:SCANIA CV AB

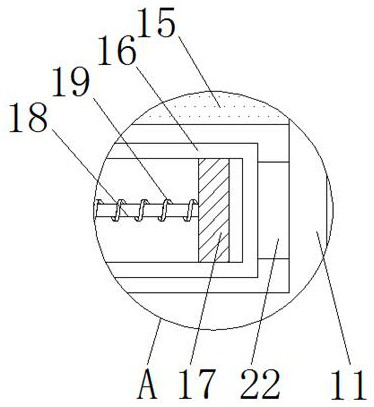

A rotary kiln with the functions of reducing waste heat volatilization efficiency and recovering waste heat

ActiveCN113739566BReduce evaporation efficiencyReduce energy consumptionRotary drum furnacesIncreasing energy efficiencyThermodynamicsGear wheel

The invention discloses a rotary kiln with functions of reducing waste heat volatilization efficiency and recovering waste heat, which is used for firing lithium battery raw materials. It includes a rotary cylinder, the rotary cylinder includes a cylinder body and two support ring sleeves, and the two ends of the cylinder body are respectively movably socketed on one of the support ring sleeves, and are supported by the support ring sleeves, so that the cylinder body can be rotated relative to the support ring sleeves. Make a turn. A driven gear is fixed on the outer wall of the cylinder, and the driven gear is used to connect with an external driving gear to drive the cylinder. The rotary cylinder is provided with independent raw material firing chamber and gas heat insulation chamber. The raw material firing chamber extends along the axial direction of the rotary cylinder. The gas heat-insulation chamber is in the form of a ring structure and is arranged around the periphery of the raw material firing chamber, and the gas heat-insulation chamber also extends along the axial direction of the cylinder body. The gas heat insulation chamber has an air inlet connected with the gas source, and the gas heat insulation chamber communicates with the raw material firing chamber through its own gas outlet. It can reduce the volatilization efficiency of waste heat; and can fully recover and utilize waste heat, thereby reducing energy consumption.

Owner:FOSHAN TIANLU INTELLIGENT EQUIP TECH CO LTD

Method and control system for control of dosage of a reducing agent

ActiveUS11125132B2Increase back pressureIncrease fuel consumptionInternal combustion piston enginesExhaust apparatusNitrogen oxidesPtru catalyst

Owner:SCANIA CV AB

Ecological protection forest protection equipment

ActiveCN113577599AAvoid damageReduce weightWatering devicesFire rescueProtection forestEnvironmental engineering

The invention discloses ecological protection forest protection equipment which specifically comprises a fixed seat plate which is provided with a circular plate body. The ecological protection forest protection equipment is characterized by comprising a through protection groove formed in the top of the circular plate body, a heat measurement device installed in an inner cavity of the through protection groove, a supporting column installed at the top of the circular plate body, an irrigation pipe mounted on the support column and positioned above the heat measurement device, a control device mounted at the top of the support column and a bearing device mounted at the top of the control device. The invention relates to the technical field of ecological protection. Through the arrangement of the through protection groove, the internal heat measurement device is protected, the situation that components are damaged due to the fact that the components are touched by organisms in a forest in the using process is avoided; and meanwhile, through cooperation with the fixed seat plate, the weight of the equipment can be reduced, and carrying and arrangement are facilitated.

Owner:青岛枫和市政园林建设有限公司

A chemical spray vehicle with environmental performance

ActiveCN108541678BEnvironmental performanceReduce exposureRotary stirring mixersTransportation and packagingSprayerElectric machinery

The invention relates to the technical field of environmental protection devices, and discloses a liquid medicine spraying vehicle with environmental protection performance, which includes a driving head, and the right side of the driving head is fixedly installed with a fixed rod and a supporting vehicle plate in sequence from top to bottom. The other end of the rod is fixedly equipped with a mixing box, the left end of the top surface of the mixing box is provided with a mud inlet, the right end of the top surface of the mixing box is provided with a water inlet, and the middle part of the top surface of the mixing box is fixedly installed with a stirring motor . The potion spraying vehicle with environmental protection performance puts the specified potion and soil into the mixing box through the mud inlet and water inlet, and then drives the stirring blade to stir through the stirring rod, and finally sprays the mixture of pesticide and soil to the vegetation through the nozzle. Liquid, which increases the density of pesticides, reduces the volatilization efficiency of pesticides, and solves the problem that it is difficult to effectively ensure the absorption of pesticides by vegetation when spraying pesticides directly, and at the same time it is easy to endanger the environment and affect the health of workers. the practicability of the device.

Owner:阜阳市金睿环保科技有限公司

Method for extracting maca bioactive components based on ultrasound

ActiveCN104688796BIncreased alkaloid yieldReduce manufacturing costPlant ingredientsHigh concentrationBULK ACTIVE INGREDIENT

The invention discloses a method for extracting maca bioactive components based on ultrasonic waves. The maca root is processed by high-pressure wall breaking technology and ultrasonic extraction technology, and finally a product containing high-concentration maca bioactive components is obtained. Compared with the existing extraction technology, the extraction method of the present invention can effectively extract maca alkaloids, macaenes, macamides and other bioactive components in the maca tuber, improve the utilization rate of raw materials and reduce production costs. Simultaneously, the product prepared according to the method of the invention has higher biological activity, and the health care effect is obviously better than that of the prior art.

Owner:广东长兴生物科技股份有限公司

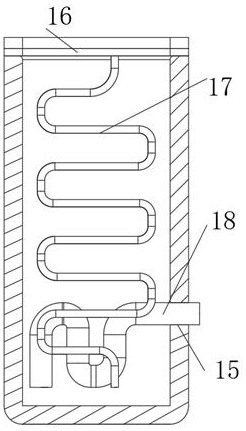

Vertical scraped film evaporator with multi-stage swirling feed

PendingCN109499082ARestricted flow patternUniform thicknessEvaporator accessoriesDrive shaftEvaporation

The invention relates to a vertical scraped film evaporator with multi-stage swirling feed, which comprises an evaporation barrel with a liquid phase discharge port at a lower end, a transmission device arranged on the evaporation barrel and a heating jacket provided outside the evaporation barrel. The transmission device drives a transmission shaft penetrating through the interior of the evaporation barrel, and a first feed port and a plurality of second feed port are sequentially formed from the top to the bottom on the outer wall of the evaporation barrel along the axial direction, a liquiddistributor for feeding the first feed port is fixed on the transmission shaft, and rotary scrapers are arranged below the liquid distributor, the transmission shaft is provided with a plurality of rotary scrapers corresponding to each of the second feed ports, and the outer wall, on which each of the second feed ports is located, of the evaporation barrel is uniformly provided with a plurality of third feed ports along the outer circumferential direction thereof. The evaporator of the invention can improve the liquid film flow pattern distribution inside the rotary scraper evaporator effectively and adjust the concentration gradient of the concentrated material by setting a plurality of feed ports for segmented liquid distribution, avoid the phenomenon of channeling and material stickingwall, and improve the actual evaporation efficiency of the rotary scraper evaporator.

Owner:江苏拓驰工程技术开发有限公司

Medicine massage insole

ActiveCN111904099AImprove evaporation efficiencyGuaranteed function and effectInsolesDevices for pressing relfex pointsEngineeringBiomedical engineering

The embodiment of the invention relates to the technical field of insoles, and particularly discloses a medicine massage insole which comprises an insole body, a cavity is formed in the insole body, multiple sets of massage assemblies are arranged at the top of the cavity, multiple sets of supporting net plates are fixedly arranged in the cavity, and a medicine bag is arranged in each set of supporting net plates. A plurality of groups of mounting cover plates in one-to-one correspondence with the supporting net plates are detachably mounted on a bottom plate of the cavity through mounting assemblies; a plurality of groups of fixing cylinders which are alternately arranged with the massage assemblies are further arranged at the top of the cavity, and protective net plates are arranged at the top ends of the fixing cylinders. According to the embodiment of the invention, through the arrangement of the first supporting spring and the second supporting spring, the effect of massaging thefeet by the massaging bulges is improved; besides, under the heating action of the heating rod, the volatilization efficiency of the medicine particles in the fixing cylinder can be improved, and theaction effect of the medicine particles on the feet is guaranteed.

Owner:HENAN BANGNI BIOLOGICAL ENG CO LTD

Humidification and dehumidification water purification device with fluidized bed enhanced evaporation

ActiveCN105621509BImprove energy utilizationHigh maintenance costSeawater treatmentEnergy based wastewater treatmentFluidized bedSolid particle

Owner:TSINGHUA UNIV

Water tank for oxyhydrogen machine

PendingCN111762944ALow costReduce energy consumptionSpecific water treatment objectivesTreatment involving filtrationProcess engineeringWater storage tank

The invention discloses a water tank for an oxyhydrogen machine, and relates to the technical field of household oxyhydrogen machines. The problem that household pure water is high in cost is solved.The water tank specifically comprises a support, a mounting hole is formed in the inner wall of the support, a condensation tank, a water storage tank and an evaporation tank are fixed to the outer wall of the support, a filtering mechanism is fixedly mounted on the outer wall of one side of the water storage tank, the inner space of the water storage tank communicates with the filtering mechanismthrough a connecting pipe, and a condensation cover is fixed to the outer wall of the top of the condensation tank through bolts. Tap water is primarily filtered by using the filtering mechanism, water is heated and evaporated through the heating mechanism, then the water is purified after steam is condensed, and then the purified water is input into ionization equipment and is ionized, so that the household oxyhydrogen machine provided with the water tank can directly use tap water to obtain pure hydrogen and oxygen, and the water use cost of the household oxyhydrogen machine is reduced.

Owner:安徽明天氢能科技股份有限公司

High efficiency heat exchanger for freon low temperature unit

ActiveCN103851833BImprove operational efficiencyImprove reliabilityEvaporators/condensersPotential differenceEvaporation

The invention discloses a high-efficiency heat exchanger for a freon low-temperature unit. The freon low-temperature unit comprises a compressor. The high-efficiency heat exchanger for the freon low-temperature unit comprises a gas-liquid separation device, an evaporator, a gas pipe and a liquid pipe, wherein the gas-liquid separation device is arranged above the evaporator, and on one side of the gas-liquid separation device, the upper end of the liquid pipe is communicated with the gas-liquid separation device and the lower end of the liquid pipe is communicated with an inlet of the evaporator; on the other side of the gas-liquid separation device, the upper end of the gas pipe is communicated with the gas-liquid separation device and the lower end of the gas pipe is communicated with an outlet of the evaporator. After optimization, potential difference determined by the height difference between the gas-liquid separation device and the evaporator is bigger than the flowing resistance of a refrigerant evaporation loop; the gas-liquid separation device comprises a liquid level meter and an oil return device; one end of the oil return device stretches to a position below the liquid level of the gas-liquid separation device and the other end of the oil return device is connected with the compressor. The high-efficiency heat exchanger for the freon low-temperature unit has the advantages that the consumption is lower, the heat exchange efficiency is high and the refrigerating capacity can be improved.

Owner:昆山台佳机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com