Power plant wastewater evaporation crystallizer

A technology for evaporating crystallizer and power plant wastewater, which is applied in gaseous effluent wastewater treatment, chemical instruments and methods, heating water/sewage treatment, etc. path and other issues to prevent blockages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

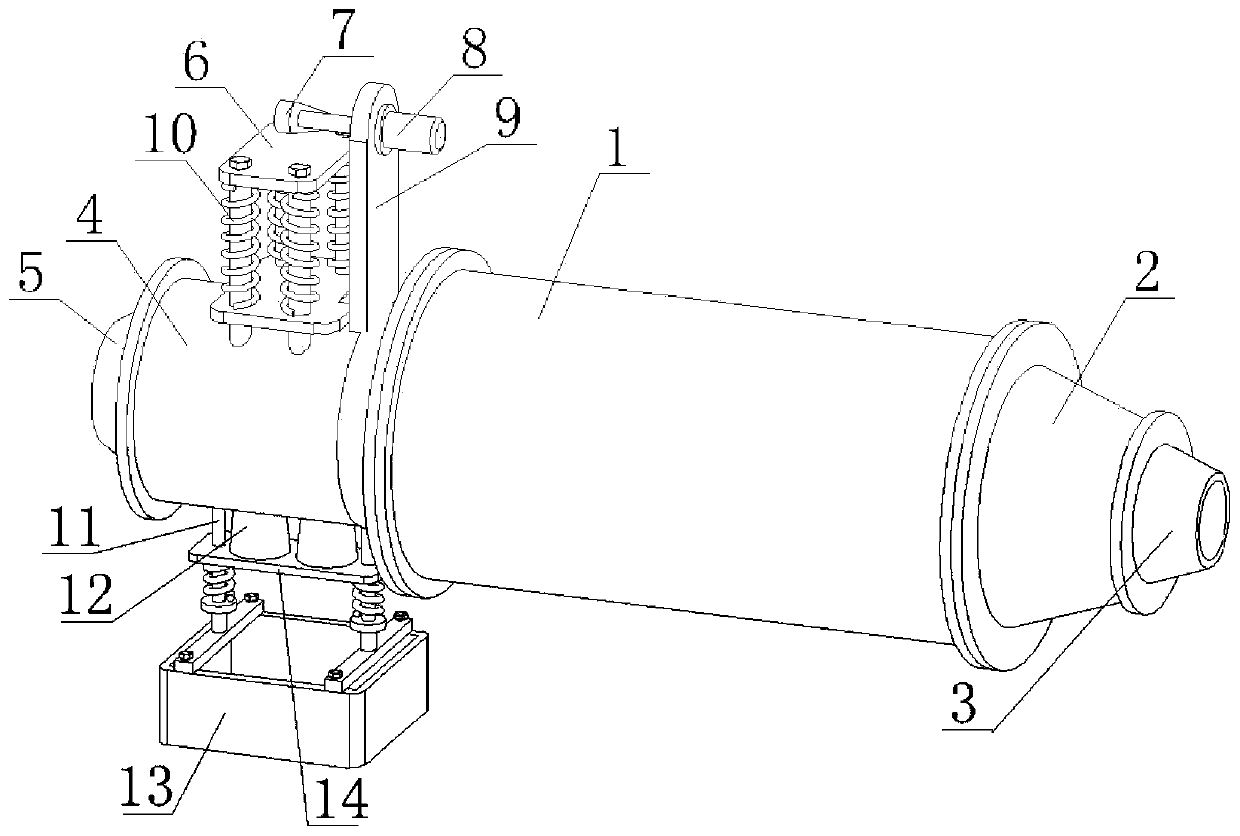

[0034] Such as figure 1 As shown, a power plant wastewater evaporation crystallizer in this embodiment includes an evaporation tube inlet 5, a horizontal section 4, an evaporation tube main body 1, an outlet chamber 2, and an evaporation tube outlet 3 connected in sequence, and the evaporation tube inlet 5 and the horizontal section 4 Through the flange sealing connection, the horizontal section 4 is connected to the evaporation tube main body 1, the gas outlet end of the evaporation tube main body 1 is connected to the outlet chamber 2, the outlet chamber 2 is connected to the evaporation tube outlet 3 through a flange sealing connection, and the inner wall of the horizontal section 4 is fixed A filter screen 25 is installed, and the top and the bottom are respectively provided with a first through hole and a second through hole. In this embodiment, there are four first through holes and two second through holes.

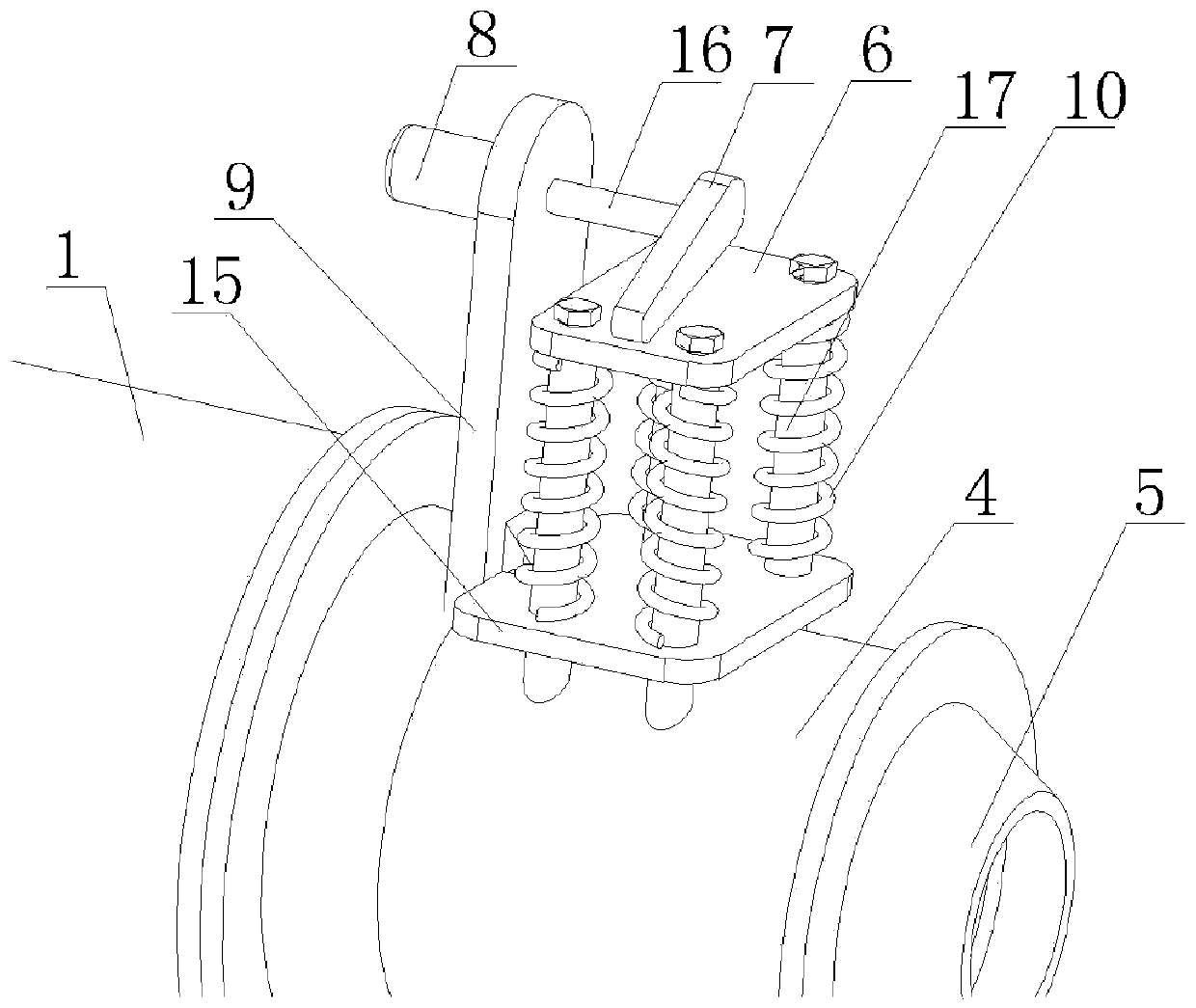

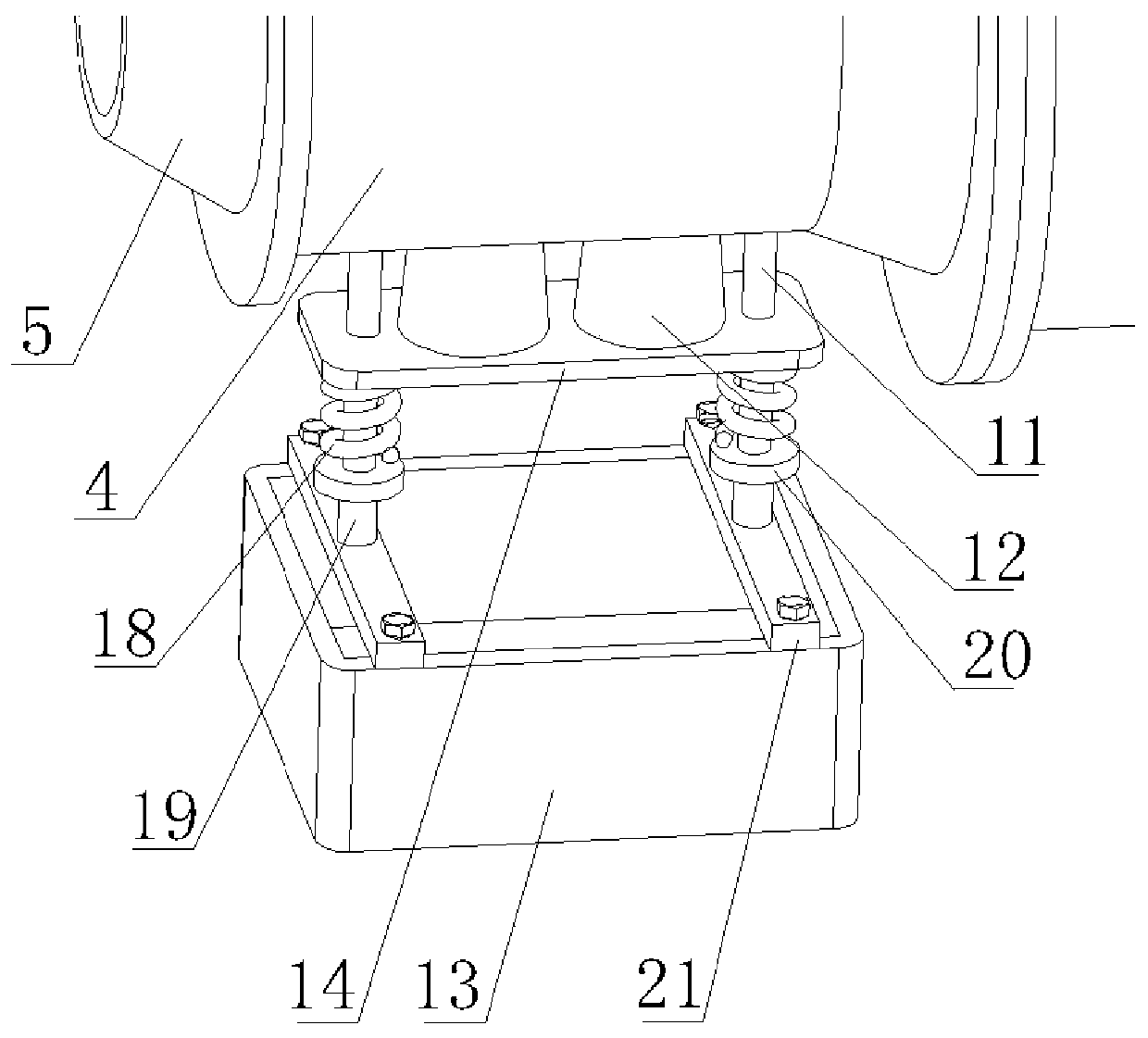

[0035] combine figure 2 As shown, the top of the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com