Low-temperature evaporator and control system thereof

A low-temperature evaporator and control system technology, applied in the direction of evaporator adjustment/control, evaporator accessories, evaporation, etc., can solve the problems of water quality decline, risk and economic cost increase, and initial cost, etc., to reduce waste liquid treatment Quantity, improve water quality, ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

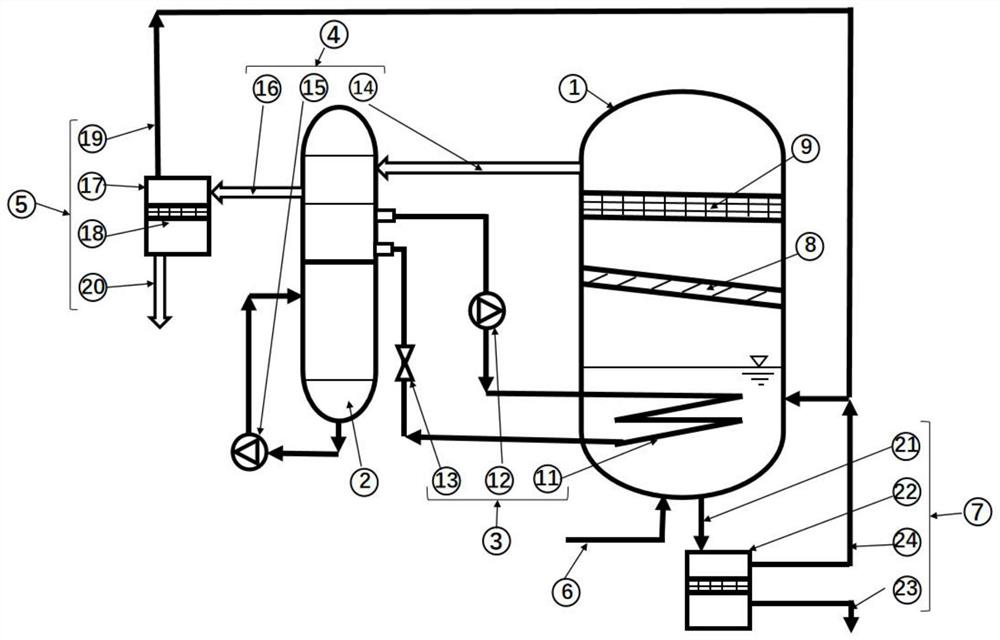

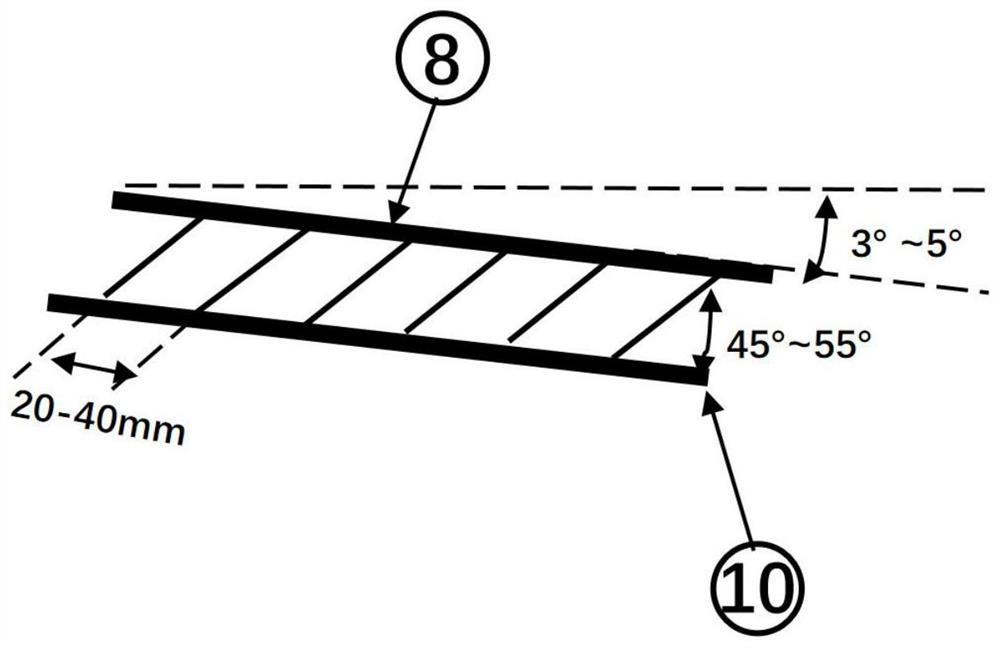

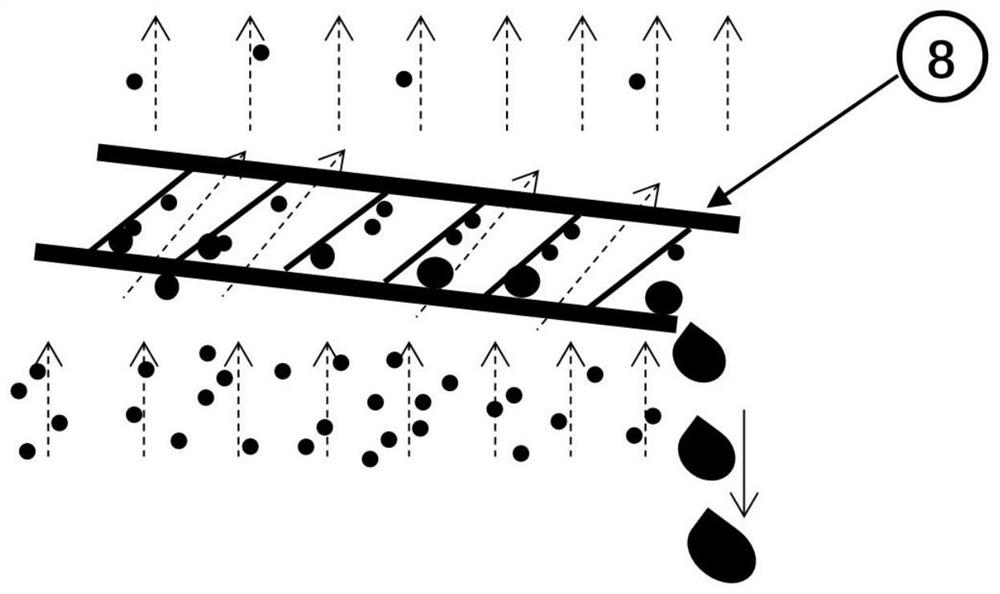

[0036] Embodiment: the present invention provides technical scheme, as figure 1 , a low-temperature evaporator, including an evaporator 1 and a condenser 2, the evaporator 1 is sequentially composed of a waste liquid part, a defoaming part, and a steam part from bottom to top, and the waste liquid part holds waste liquid to be concentrated, and the defoaming part The part is used to capture and gather the small droplets carried in the water vapor, and after forming large droplets, it flows back to the waste liquid part by its own weight. The steam part is the water vapor after removing the small droplets. The condenser 2 is divided into tube layer and Shell layer, between the waste liquid part of the evaporator 1 and the shell layer of the condenser 2, a heat supply cycle circuit assembly 3 is arranged, and the heat supply cycle circuit assembly 3 is used to provide heat energy to the waste liquid part to make the waste liquid Boiling and evaporating in the range of 36-38°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com