Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

160results about How to "Reduce broken rice rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method allowing lower broken rice rate

The invention relates to a processing method allowing lower broken rice rate and belongs to the technical field of rice processing. The processing method includes the steps of rice screening, stone removal, magnetic separation, moisture measurement and drying or atomizing, hulling, husked rice separation, thickness classification, moisture measurement and drying or atomizing, rolling, white rice classification, cooling, polishing, color sorting, water content detection, and sterilizing and packaging. The rice processed by the processing method is low in broken rice rate, long in shelf life and good in glossiness, and flavor of the rice is rarely lost.

Owner:GUIZHOU FENGGANG COUNTY SHENNONG RICE IND

Rice machining process

InactiveCN103691508AQuality improvementReduce broken rice rateGrain treatmentsHorticultureRice grain

The invention provides a rice machining process which is finished by adopting thirteen processes of unhulled rice sieving, drying, stone removing, magnetic separation, rice hulling, husked rice separation, thickness grading, rice milling, white rice grading, color sorting, polishing, white rice grading and finished product packing. Impurities are removed by sieving, rice yield can be increased in the subsequent machining by drying, the rice quality is improved by grading for multiple times, the machining process has no pollution, a low-temperature light-rubbing rice milling mode is adopted, the rice crushing ratio is reduced and the economical benefits are improved.

Owner:聂俊

Refined rice processing method

InactiveCN104815714AGuaranteed purityHigh purityGrain huskingGrain polishingBroken riceMoisture measurement

The invention discloses a refined rice processing method. The refined rice processing method comprises the following steps of rice screening, stone removal, magnetic separation and rice shelling, rice-bran separating, secondary shelling, thickness grading, moisture measurement and drying or atomizing, rice milling and white rice grading, rice cooling, polishing, color sorting, secondary white rice grading and moisture content detection, and packaging. The refined rice processing method comprises a plurality of impurity removal steps, and consequently, the purity of rice is guaranteed, the produced rice is high in purity, and the safety and the processing efficiency in the processing process are guaranteed. In the rice shelling and rice milling steps of the refined rice processing method, the material temperature is strictly controlled so that the material can be always kept in a relative low temperature appropriate environment, and the crack ratio and the broken rice rate can be reduced and the complete particle rate can be increased; the original faint scent of rice is maintained. The refined rice processing method is used for solving the problems of surface damage and uneven polishing in the rice polishing process by controlling the polishing water temperature and the dampening amount; as a result, the surfaces of all the rice grains polished can be kept smooth and clean, and the quality guarantee period of the rice can be prolonged.

Owner:ANHUI YOUYUAN FOOD

Method for milling rice in embryos retaining manner

The invention discloses a method for milling rice in an embryos retaining manner. A domestic machine for milling rice in an embryos retaining manner is used for milling the rice and comprises a grain hopper, a power transmission system, a polishing system, a machine shell and a system for screening milled rice with embryos, wherein the grain hopper, the power transmission system, the polishing system and the system for screening the milled rice with the embryos are mounted in the machine shell; a feeding opening of the grain hopper is formed in the machine shell; an outlet of the grain hopper is connected with the polishing system; the polishing system is connected with the system for screening the milled rice with the embryos; and the power transmission system provides required power for the polishing system. Finished rice is bright and clean, embryo retaining rate is high, rice husks, rice polishings, the milled rice with embryos and broken rice can be screened automatically, so that the milled rice with embryos do not contain the rice husks, the rice polishings or the broken rice, moreover, in a rice milling process, the temperature is stable, and the energy consumption is small.

Owner:HUNAN AGRICULTURAL UNIV +1

Rice fine processing technology

InactiveCN106391168AImprove drying efficiencyThe processing procedure is simpleGrain huskingGrain polishingBroken riceWhite rice

The invention discloses a rice fine processing technology which comprises the following steps of unhusked rice screening, stone removal, magnetic separation, soaking in a dietary alkali solution, washing, drying and moisture removal, rice husking, husked rice separation, thickness classification, rice milling, soaking in a soaking solution, drying and moisture removal, white rice classification, rice cooling, polishing, color sorting, secondary white rice classification, sterilization and packaging. According to the method, processing technological procedures are simple, the milled rice rate is high, the production cost of rice processing enterprises can be reduced, and the rice produced through the method is clean, good in degree of finish and low in broken rice rate.

Owner:金健粮食(益阳)有限公司

Rice deep processing technology and characteristic

InactiveCN107282166AQuality improvementNo pollution in the processGrain treatmentsGrazingEconomic benefits

The invention discloses a process and characteristics of deep processing of rice, comprising the following steps: rice screening, drying, stone removal, magnetic separation, rice hulling, paddy separation, thickness grading, moisture measurement, rice milling and white rice grading, cold rice , Polishing, color sorting, secondary white rice grading, moisture content testing, packaging fifteen processes. The technology and characteristics of the deep processing of rice in the present invention can improve the quality of finished rice through multiple classifications. The processing process of the present invention is environmentally friendly and pollution-free, adopts a low-temperature light rubbing rice milling mode, reduces the broken rice rate, and improves economic benefits.

Owner:安徽联邦农业科技有限公司

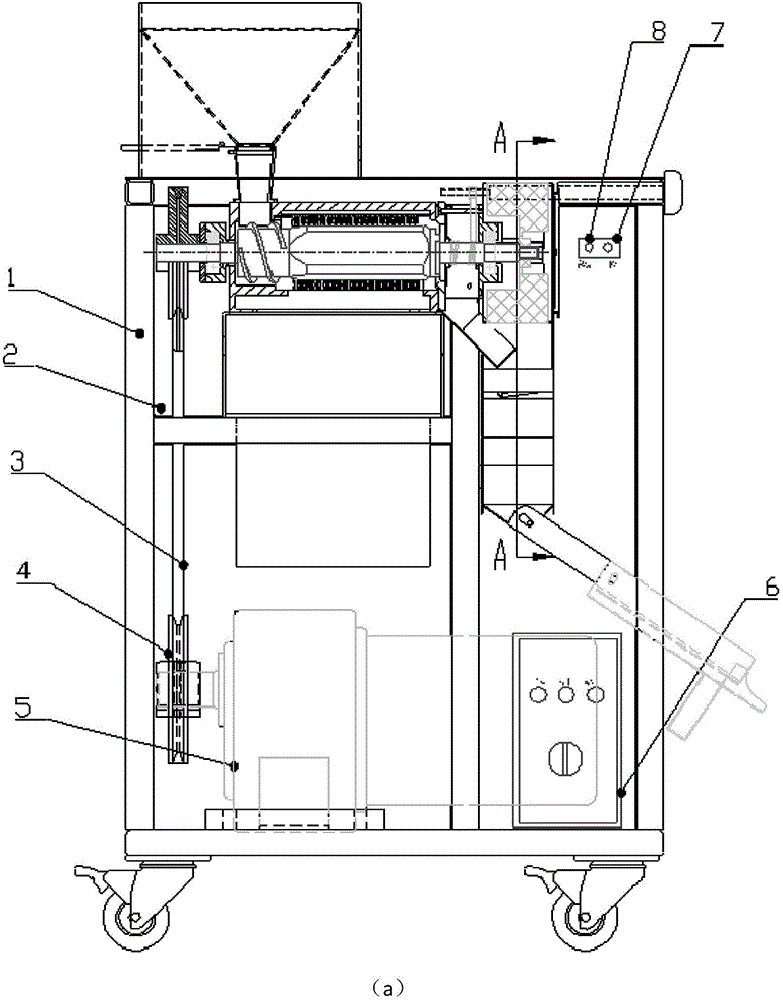

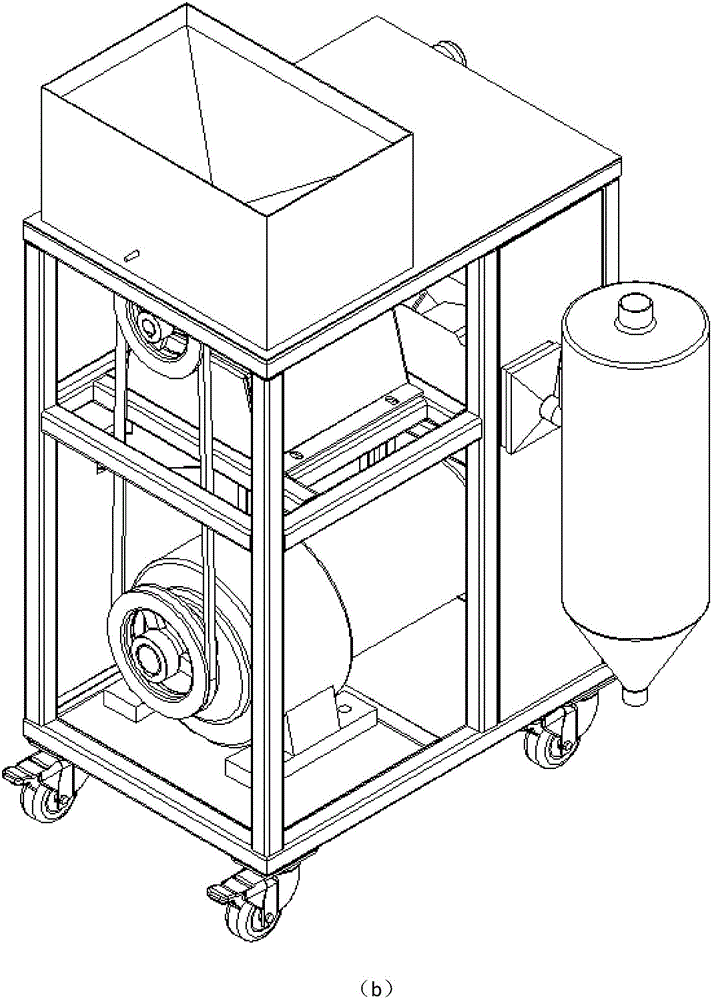

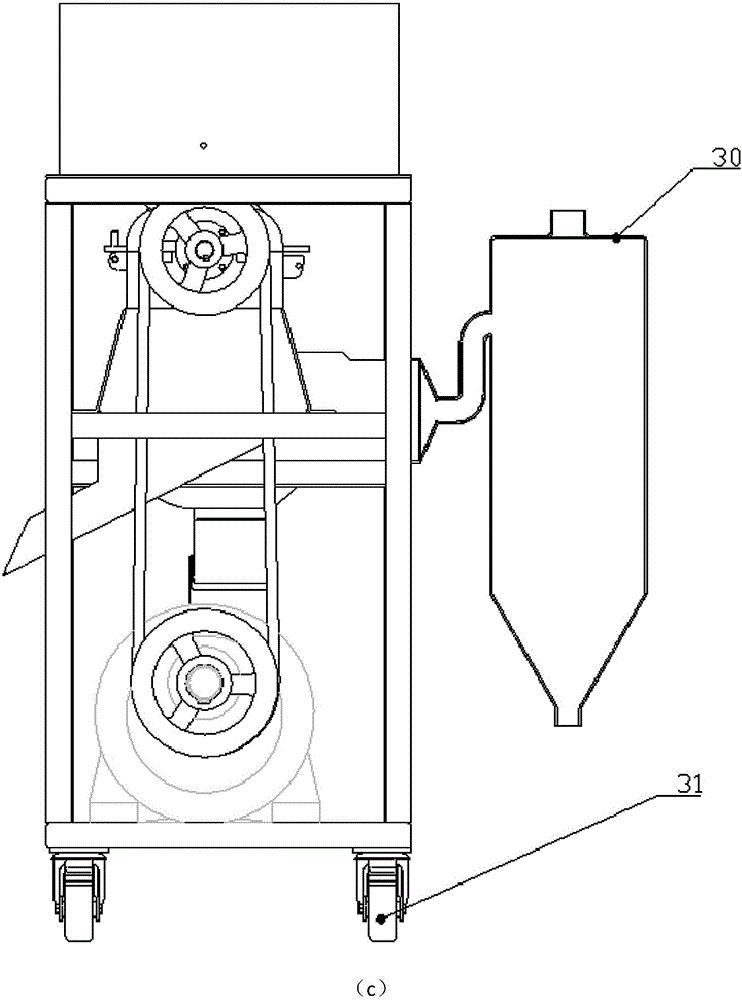

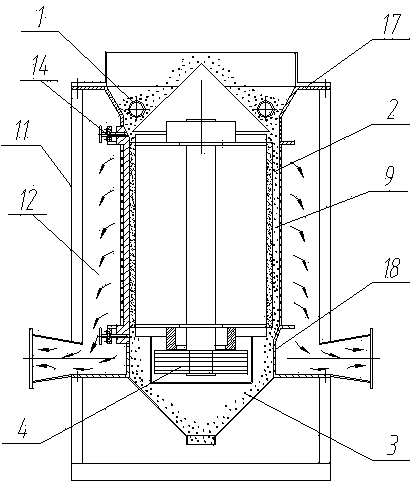

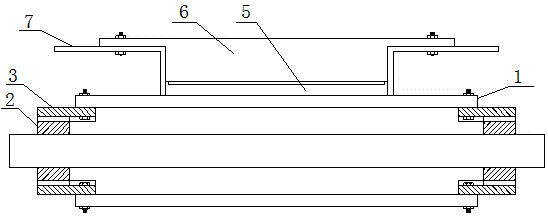

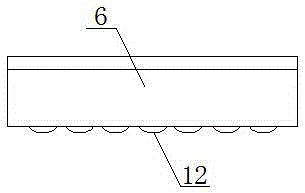

Belt type lattice flow rice husking machine and rice husking method

ActiveCN104338574AReduce power consumptionReduce broken rice rateGrain huskingGrain polishingAgricultural engineeringBroken rice

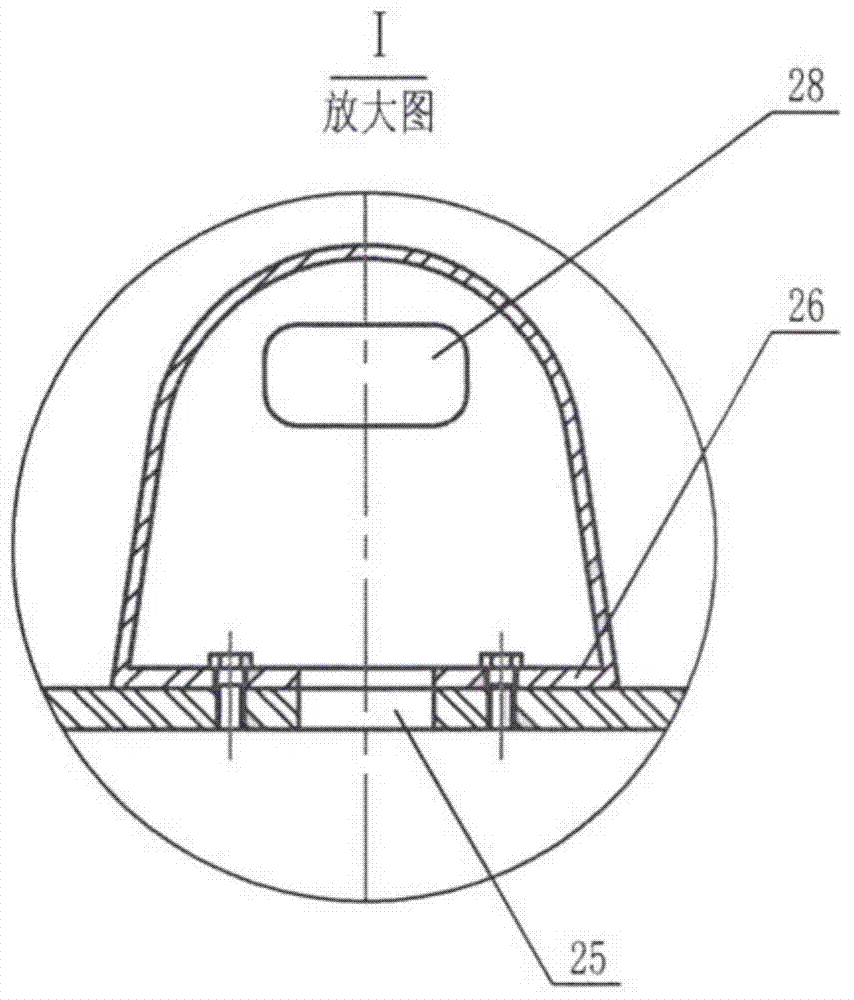

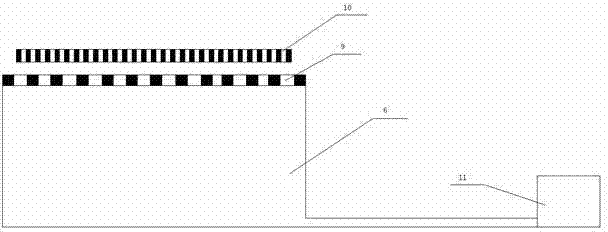

The invention provides a belt type lattice flow rice husking machine and a rice husking method. The traditional whitening manner has the main problems of large energy consumption and much broken rice. The reason is that for the traditional technology, coarse rice rotates along with a husking roller in a spiral way in the process of husking and peeling, a gap is formed between a rice blade of the rice husking machine and the husking roller, the rice can penetrate through the gap, the structure causes the relative friction function required by the husking and the peeling to be greatly reduced, and a lot of power can be consumed without any reasons. The rice husking machine comprises a feeding device (1), a whitening chamber (2), a discharging device (3), a transmission device (4) and a machine frame (5), wherein the whitening chamber comprises two groups (rows) of rice husking rooms (9) which are arranged oppositely and are defined by milling belts (6), flow separation bodies (7) and rice sieves (8), and the milling belts wind around rollers (10) at both ends of the machine frame to form annular belts; the distance between the flow separation bodies and the milling belts is below 2mm; the rice sieves are mounted on the outer sides of the flow separation bodies, a negative pressure space (12) is formed between the outer sides of the rice sieves and a casing (11), and the negative pressure space is connected with an air suction fan. The rice husking machine is used for husking the rice.

Owner:HARBIN BEICANG GRAIN STORAGE PROJECT & EQUIP

Minitype rice husking machine

The invention discloses a minitype rice husking machine, which comprises a rice husking shell, a rice husking hopper, a motor, a rice discharging hopper and a sieving body, wherein the motor is located in the rice husking shell, is installed through a motor installing rack, and is directly fixed with a rice husking revolving shaft. A motor butt-joint hole is formed in the rice husking revolving shaft and the revolving shaft is directly butt jointed and fixed with the motor; a groove is arranged on the rice husking revolving shaft; a main body part of the rice husking revolving shaft is provided with a material propelling screw and a reverse screw reversed to the propelling screw; butt joint and fixation between the motor and the rice husking revolving shaft can be realized through bolts; a spring is arranged between the motor and the rice husking revolving shaft; and the two ends of the spring are directly clamped at the two bolts. The problem that the traditional rice husking equipment slips when adopting a belt to transmit is solved, and in addition, the rice husking revolving shaft is directly driven through the motor, so that the energy loss in a transmission process is reduced.

Owner:彭攀桦

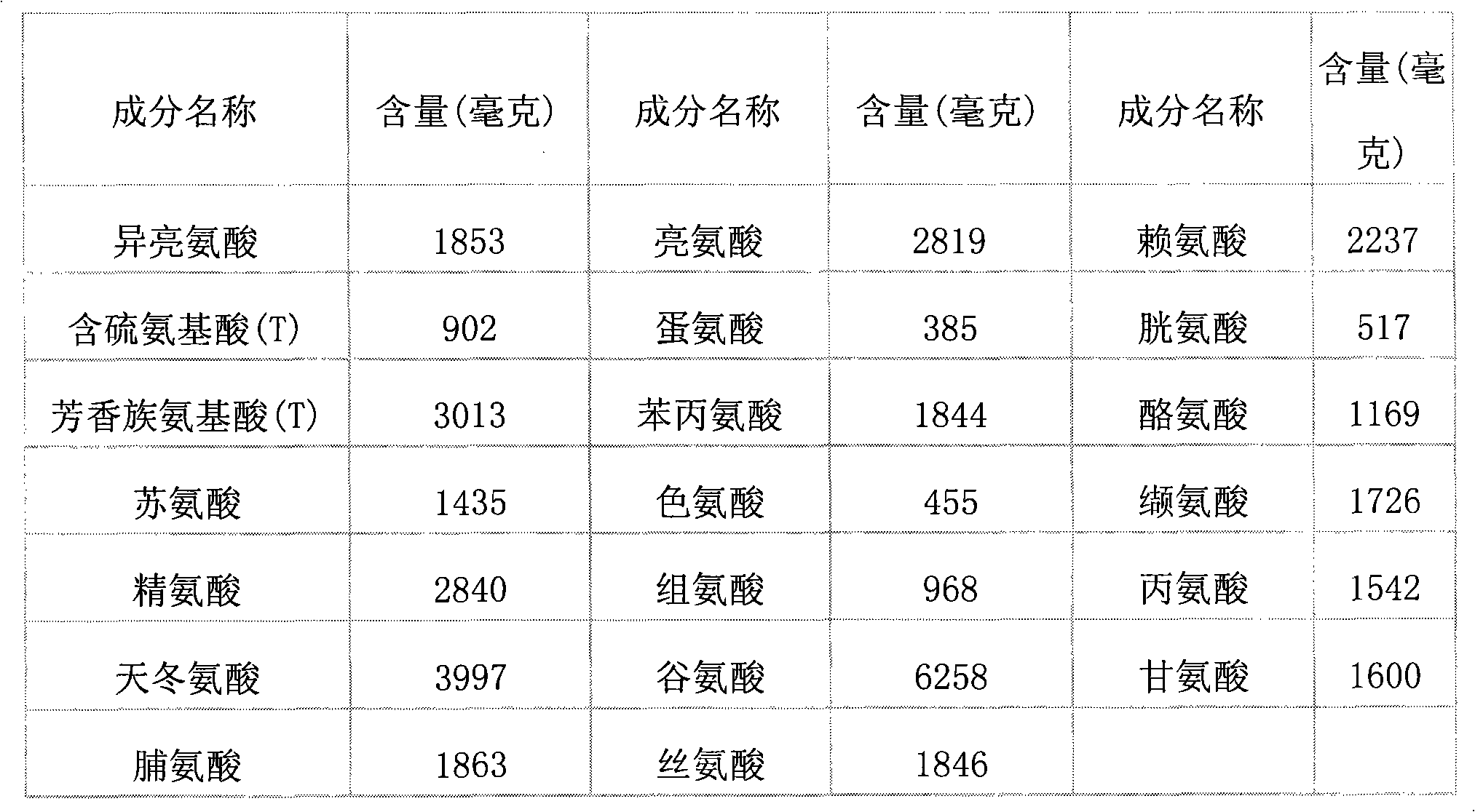

High-plumule millet nutritious rice flour and processing method thereof

InactiveCN101904464ABalanced nutritionImprove immunityDough treatmentFood preparationFiberDietary fiber

The invention discloses high-plumule millet nutritious rice flour, which comprise the components of plumule-containing millet outer flour, soybean flour, all-millet flour and wheat flour in a weight mixing ratio of 20-30:1-5:3-5:60-80. The processing method of the nutritious rice flour comprises: removing large-size impurities by using a primary cleaning screen; removing small-size impurities in a vibrating screen; removing light impurities; removing stones by a stone removing machine; dressing by magnetic separation; primarily striking grains for husking 40 to 50 percent of grains; secondarily striking grains for husking over 90 percent of grains; dressing by magnetic separation; forcefully coarsening by a roller 1 and coarsely rolling; finely rolling by a roller 4; taking the plumule-containing outer flour by a flour sucker; grading by a grader; dressing by magnetic separation; mixing by a mixer; and packing. The high-plumule millet nutritious rice flour is advantageous over rice flour in terms of vitamin content, mineral content, trace element content and the like, can be used to make various foods and has a balance nutrition structure due to the combination of coarse and fine rice flour. The high-plumule millet nutritious rice flour can improve body immunity and has a remarkable health-care effect. The high-plumule millet nutritious rice flour contains rich dietary fibers and therefore is favorable for promoting gastrointestinal motility and digestion of people. A problem of coarse mouthfeel of millet is solved. The high-plumule millet nutritious rice flour has a strong and agreeable fragrance and is suitable for people of all ages.

Owner:辽宁兴诺米业有限责任公司

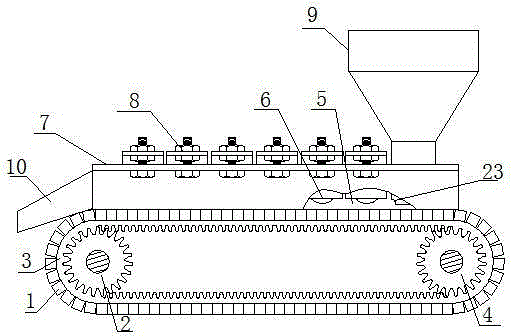

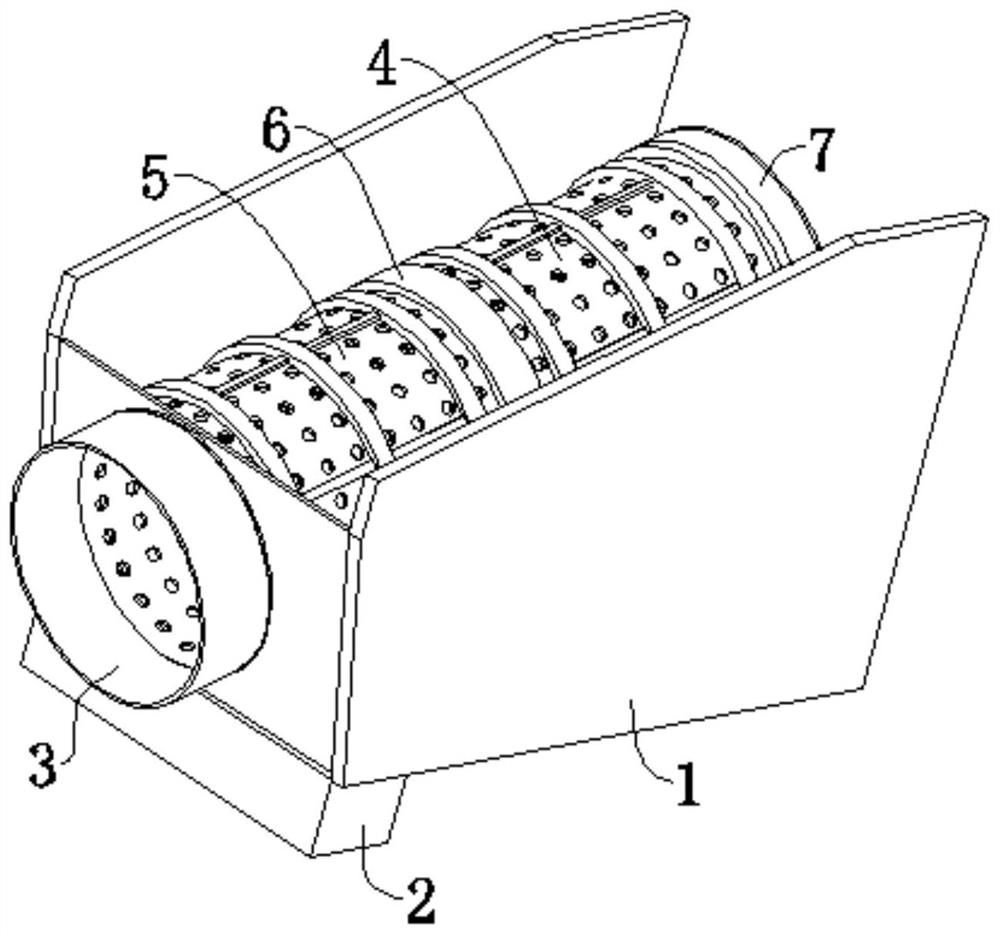

Crawler type rice mill

ActiveCN105251567AReduce impactReduce broken rice rateGrain treatmentsAgricultural engineeringEngineering

The invention discloses a crawler type rice mill. The crawler type rice mill comprises a hopper, a discharging barrel, a rack and a conveying mechanism, wherein rice knives are mounted on the rack, the conveying mechanism comprises a driving wheel, a driven wheel and a conveyor belt matched with the driving wheel and the driven wheel, the hopper is communicated with one end of a rice milling channel through a feeding opening, the discharging barrel is communicated with the other end of the rice milling channel, a plurality of milling strips are mounted on the conveyor belt, the milling strips are transversely and densely arranged on the conveyor belt, the rice milling channel is formed between the milling strips and the rice knives, the sides, opposite to the rice knives, of the milling strips are milling surfaces, and clearances allowing rice grains to rotate are arranged between the adjacent rice knives. The crawler type rice mill is high in milling efficiency, low in electricity consumption, high in rate of remained germs and low in rice crushing rate, and is durable.

Owner:彭才贵

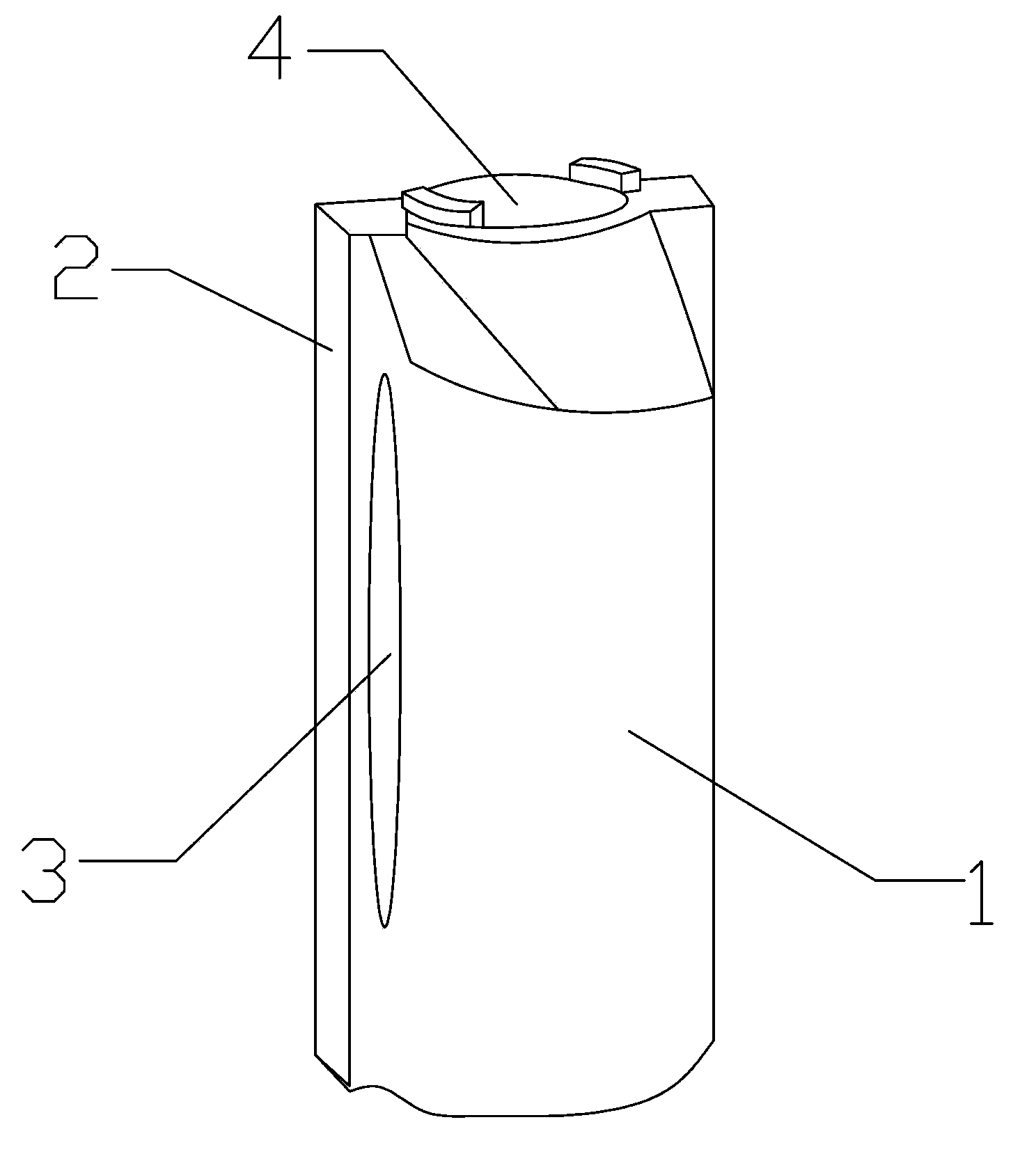

Vertical rice machine

InactiveCN105983463AIntegrity guaranteedHigh speedGrain huskingGrain polishingAgricultural engineeringEngineering

The invention discloses a rice milling machine, in particular to a vertical rice milling machine, comprising a main body of a rice milling machine and an inner compartment, the main body of the rice milling machine is provided with an inner compartment, and is characterized in that the rice milling machine One side of the top of the main body is fixedly connected with a feed port, the center of the top of the main body of the rice milling machine is fixedly connected with a motor, and the center of the bottom end of the motor is movably connected with a motor shaft, and passes through the top of the main body of the rice milling machine to enter the inner warehouse. The bottom end of the motor shaft is fixedly connected with a roller, the bottom end of the inner bin is fixedly connected with a disc, the bottom end of the main body of the rice mill is fixedly connected with a channel, and one end of the channel is fixedly connected with a blower. The present invention is a vertical rice thresher, which adopts a new structure, uses a vertical method, and adopts a large area of rubbing to peel the rice, so as to ensure the integrity of the rice produced after the rice is peeled, and The rice milling speed is fast, which greatly reduces the broken rice rate of rice and improves the work efficiency of rice milling.

Owner:吴晓明

Rice dust removing equipment

ActiveCN107214147AReduce broken rice rateImprove dust removal effectCleaning using gasesEngineeringFood processing

The invention belongs to the field of food processing and particularly discloses rice dust removing equipment. The rice dust removing equipment comprises a dust removing mechanism, a communicating pipe, a rice purification mechanism and a rice collection tank which are connected in sequence. The rice purification mechanism comprises a rice purification cavity. The rice purification cavity is provided with a dust blowing port and a dust outlet port. The rice dust removing equipment is characterized in that the dust removing mechanism comprises a shell; a dust removing unit used for removing dust is arranged on the shell; a screening unit used for separating rice from dust and enabling the dust to fly is mounted in the shell; and a stirring unit which is used for loosening rice through stirring and is capable of avoiding collision with the rice is rotationally connected into the screening unit. Through the scheme, friction of the rice with the equipment in the dust removing process can be reduced, the rice breakage rate in the dust removing process is lowered, centralized dust removing of the rice can be achieved by flying the dust, and the rice is subjected to two times of dust removing, so that the dust removing effect is greatly improved.

Owner:GUIZHOU QIANBEI GRANARY METERS

Technology for reserving nutrient source of germ-remaining rice

ActiveCN108579853ARetain nutrientsReduce broken rice rateGrain huskingGrain polishingAdditive ingredientAleuron

The invention relates to a technology for reserving a nutrient source of germ-remaining rice. The problem that the large number of natural nutrition ingredients of the rice are prone to running away by adopting a traditional technology is mainly solved. The technology is characterized by comprising the following steps that (1), impurities of the rice are cleared away firstly; (2), glumes are further taken off from the rice, the impurities and immature green grains are cleared; (3), the rice treated through the step (2) is lifted to a first-time slight-milling bran-stripping layer, a second-time slight-milling bran-stripping layer, a third-time slight-milling bran-stripping layer, a fourth-time slight-milling germ-remaining layer and an aleuron layer of an intelligent germ-remaining and rice-milling machine; and (4), through treatment, the germ-remaining rice is uniform in size and length, complete in condition and unified in grade. According to the technology for reserving the nutrientsource of the germ-remaining rice, the natural nutrition ingredients of germs and the aleuron layer of the nutrient source can be reserved, and the milled rice rate is high.

Owner:黑龙江省稻无疆农业科技有限责任公司

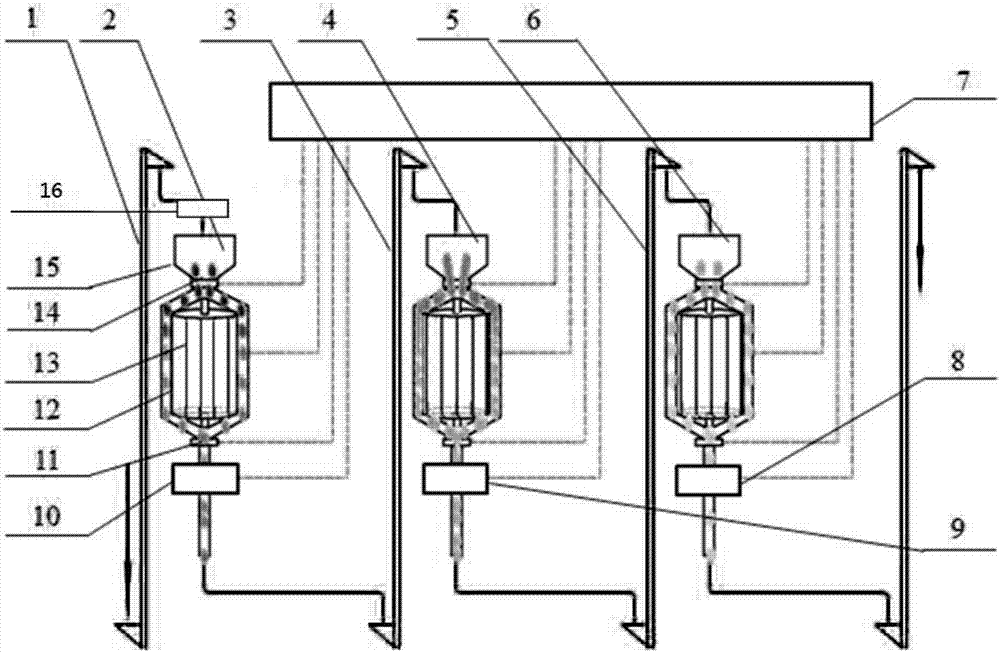

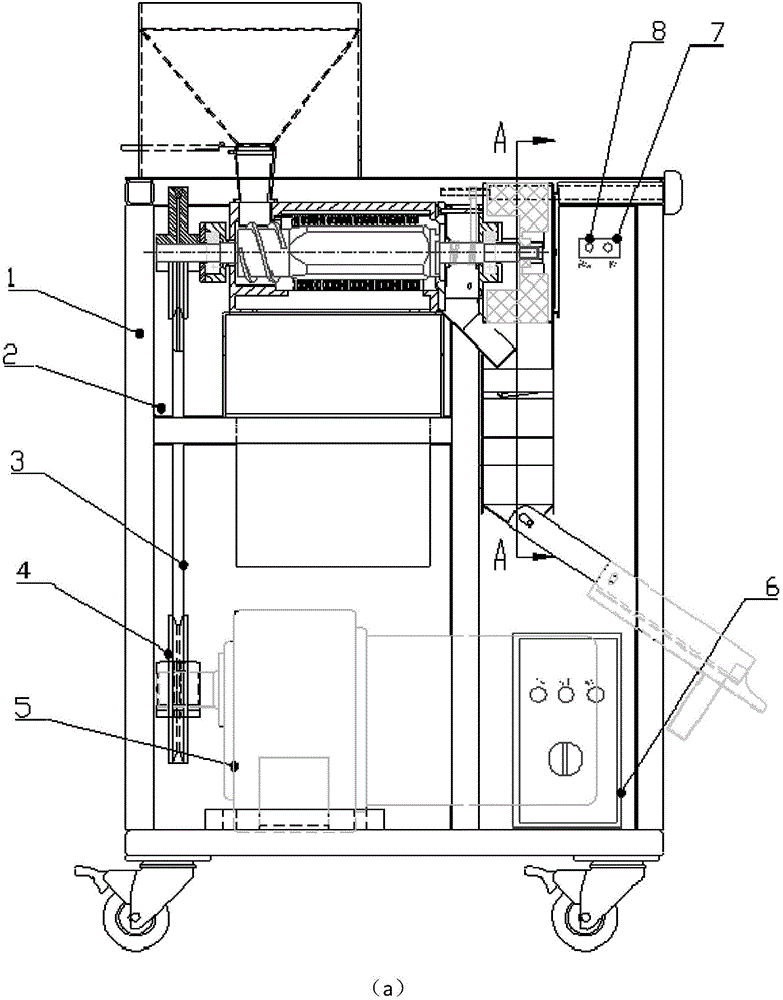

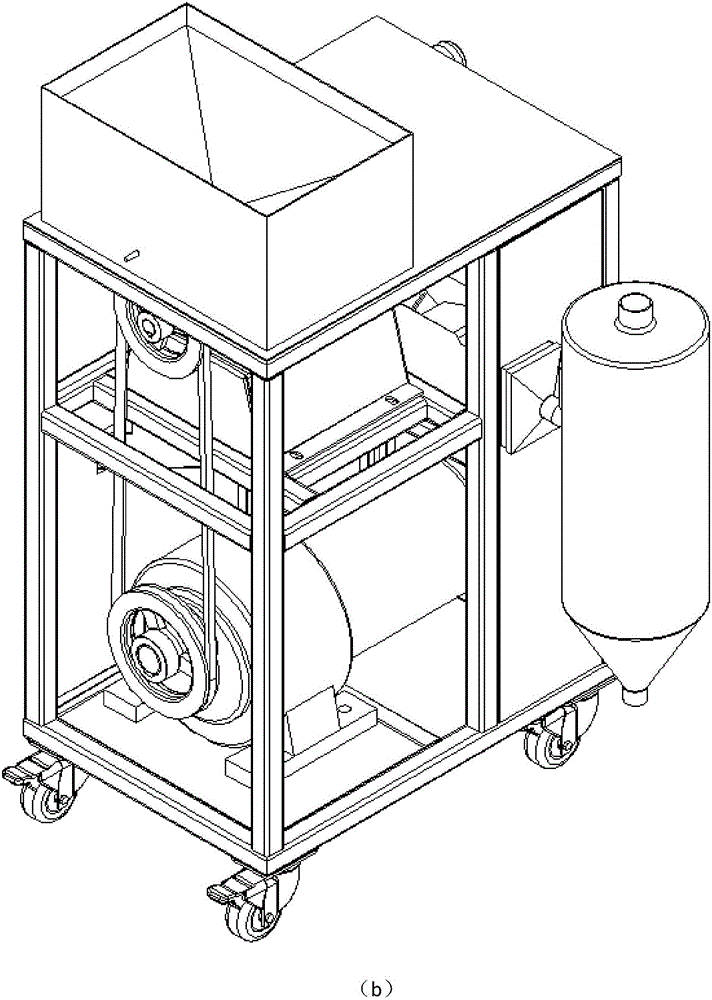

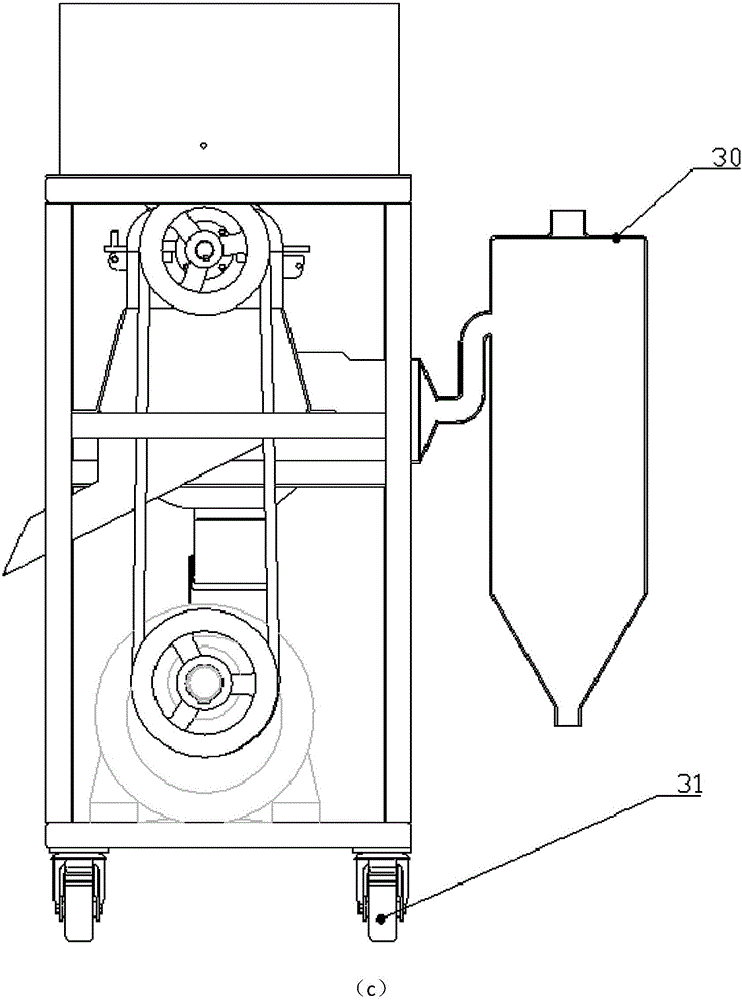

Automatic rice milling unit and control method

ActiveCN106902910ARetain nutrientsAvoid consumptionGrain huskingGrain polishingAgricultural engineeringObject detection

The invention discloses an automatic rice milling unit and a control method. The automatic rice milling unit comprises a control device and three sequentially connected rice milling machines. Each rice milling machine comprises a feed door, a rice milling chamber, a roller and a discharge door, wherein the feed door is arranged at the top of the rice milling chamber, the discharge door is arranged at the bottom of the rice milling chamber, both the opening degrees of the feed door and the discharge door can be adjusted, the roller is arranged in the rice milling chamber, and the rotation speed of the roller can be adjusted; the discharge door of the first rice milling machine is connected with the feed door of the second rice milling machine; the discharge door of the second rice milling machine is connected with the feed door of the third rice milling machine; and the rice milling unit further comprises four detection devices; the control device is used for adjusting the opening degrees of the feed doors and the discharge doors of all the rice milling machines, and the rotation speed of the roller according to milled objects detection data obtained by the first detection device, the second detection device, the third detection device and the fourth detection device. Through the automatic rice milling unit and the control method, labor cost can be reduced, and rice quality is improved.

Owner:国粮武汉科学研究设计院有限公司

Household type embryo-protection rice husking machine for rice

The invention discloses a household type embryo-protection rice husking machine for rice. The household type embryo-protection rice husking machine for the rice comprises a grain hopper, a power transmission system, a fine smashing system, a rice husking machine shell and an embryo rice screening system; the grain hopper, the power transmission system, the fine smashing system and the embryo rice screening system are all installed in the rice husking machine shell; the rice husking machine shell is provided with a feeding opening of the grain hopper; an outlet of the grain hopper is connected with the fine smashing system, and the fine smashing system is connected with the embryo rice screening system; and the power transmission system provides needed power for the fine smashing system. According to the household type embryo-protection rice husking machine for rice, rice finished products are bright and pure white, the embryo retaining rate is high, chaffs, rice skin bran, embryo rice and smashed rice can be automatically screened, and no chaffs, rice bran and smashed rice exists in the embryo rice; and in the rice husking process, the temperature is stable, and less energy is consumed.

Owner:HUNAN AGRICULTURAL UNIV +1

Fine processing technology of rice

InactiveCN110102361AEasy to processAvoid it happening againGrain huskingGrain polishingBroken riceRice grain

The invention belongs to the field of rice processing, and particularly relates to a fine processing technology of rice. The technology solves the problems that an existing rice processing technologyhas a poor rice processing effect, and processed rice has a high broken rice rate. The technology comprises the following steps of removing impurities in the rice, and then putting the rice in a placewith sufficient sunlight for airing; husking the rice through a rice husker; putting the preliminarily-husked rice into a husked rice separator for husked rice separation, then sifting out unhusked rice, and re-sending the unhusked rice into the rice husker for husking; milling the husked rice to be white through a rice mill; removing brown rice, yellow rice and other mixed-color rice grains in the rice through a color sorter; polishing the rice through a polisher; sterilizing the rice through ultraviolet light; conducting quantitative vacuum nitrogen filling packaging on the sterilized rice,and storing the packaged rice into a rice barn. According to the fine processing technology, a traditional technology is improved, so that the broken rice rate of the processed rice is lowered, and the fine processing effect of the rice is improved.

Owner:湖南省天天来米业有限公司

Rice processing technology

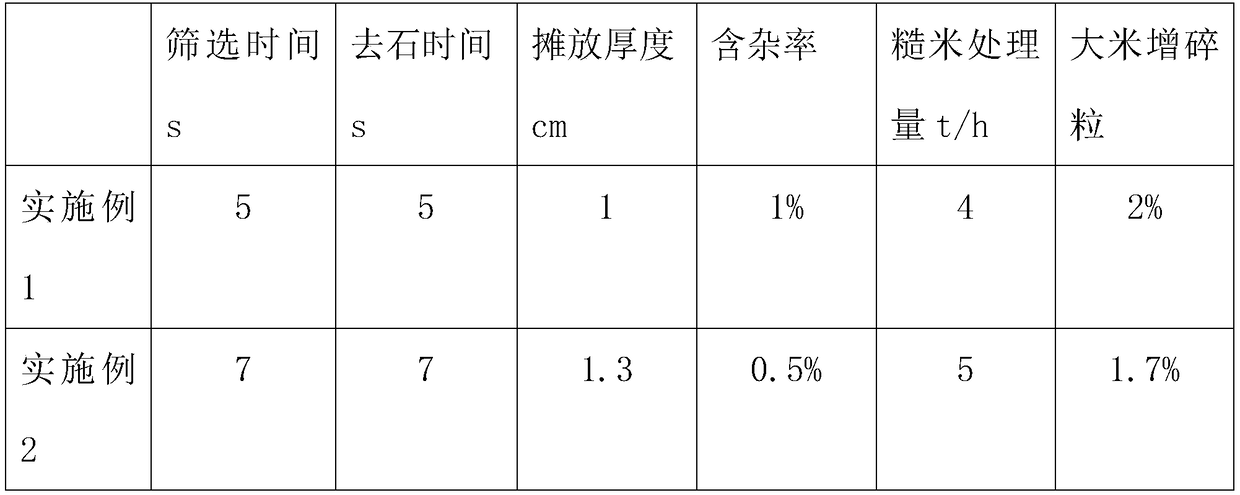

The invention discloses a rice processing technology. The rice processing technology comprises the following specific steps of screening, specifically, harvested rice is put into a roller precleaner for removing straw and other impurities, and the time is 5 to 10 seconds; stone removing, specifically, the rice screened in the above step is put into a stone remover to remove soil, sandstone blocksand other foreign matters mixed in the rice, and the time is 5 to 10 seconds; magnetic separating, specifically, the rice with the stone removed in the above step is put into a magnetic separator to remove iron chips and other impurities, and the impurity rate is not more than 1%; and dehumidifying. According to the rice processing technology, through screening layer by layer, stone removal and magnetic separation, various impurities in the rice are effectively filtered out, so that the rice processing is cleaner; the cleanliness of the rice is increased, meanwhile the damage of the impuritiesto the processing machine is reduced, and the service life is prolonged; the white rice is graded twice, the broken rice rate of the rice is reduced, the qualified rate of the rice processing is ensured, the rice quality is increased, and better use prospects are brought.

Owner:安徽鑫泉米业股份有限公司

Rice processing system having reduced rate of broken rice

ActiveCN104437716AReduce breakage ratePenetrate fastGrain huskingGrain polishingBroken riceEngineering

A rice processing system having reduced rate of broken rice comprises a rice conveying and wetting device, a husking device, a rice mill and a polisher. The rice conveying and wetting device is used for wetting cleaned rice and allowing water attaching to the surface of rice to quickly permeate into husks and husked rice. The husking device is used for husking the wetted rice provided by the rice conveying and wetting device so as to husk the wetted rice and separate the husks from the husked rice. The rice mill is used for milling the husked rice conveyed by the husking device so as to obtain white rice. The polisher is used for polishing the white rice conveyed by the rice mill so as to obtain polished rice which is crystal clear and smooth.

Owner:NINGXIA HAOWANG RICE IND GRP

Production method of germinated rice

InactiveCN102599435ASimple production processEasy to implementFood preparationOzone generatorPesticide residue

The invention relates to the technical field of food processing, one of grain deep processing, in particular to a production method of germinated rice. The production method has the following advantages: more particularly, germination of unhusked rice is directly accelerated to prepare germinated unhusked rice and then the germinated unhusked rice is processed into the finished product, namely germinated rice; in the implementation process, the unhusked rice is soaked and sterilized in ozone water solution prepared by an ozone generator and a gas-liquid mixing pump, so that the pesticides on the surface of the unhusked rice can be effectively oxidized, the pesticide residues can be reduced and the quality of the germinated rice product can be guaranteed; after being soaked in cold water and warm water alternately, the unhusked rice is put in the environment with temperature being 30-33 DEG C and relative humidity being 85-90% to undergo germination acceleration to prepare the germinated unhusked rice; the germinated unhusked rice is processed into the germinated rice after being dried in the low temperature state; the comprehensive nutritive indexes of the germinated rice product produced by the method greatly exceed the comprehensive nutritive indexes of the common rice; the germinated rice product has magical effect on improving sub-health of modern people; and the product has low production cost, good effects and good prospect.

Owner:何寒

Parboiled rice production and graded soaking method

InactiveCN105725057AImprove permeabilityIncrease contentYeast food ingredientsFood dryingYeastFiltration

The invention discloses a parboiled rice production and graded soaking method.The method is technically characterized in that cleaned unhulled rice is subjected to graded soaking two times.The cleaned unhulled rice is soaked in a solution of citric acid with the concentration being 1% and cellulose enzyme (enzyme activity is 5000 u / g and concentration is 0.010-0.015%) for the first time, soaking temperature is 45-55 DEG C, soaking pressure is 300-400 kpa, and soaking time is 1-2 h.The unhulled rice soaked for the first time is subjected to filtration so that soaking liquid can be filtered out, second time of normal pressure soaking is performed, and soaking is performed for 2-3 h in a selenium solution with the concentration being 60 micron mol / L at the temperature of 30-45 DEG C.After the unhulled rice is processed, water content is controlled to be 40-42%, the unhulled rice is conveyed into a cooking vessel through a conveying device, the cooking vessel is closed, 120 DEG C saturated steam is introduced, and starch of unhulled rice endosperms is fast gelatinized.The cooked unhulled rice is gradually dried till the water content is 14%, the temperature of the unhulled rice is gradually lowered through a tempering technology after each drying procedure, and it is guaranteed that temperature and water of various portions of the unhulled rice are uniform; the dried unhulled rice is hulled, ground and packaged, and parboiled rice finished products are made.

Owner:国粮武汉科学研究设计院有限公司

Flexible rice mill with abrasive balls and grain milling method

ActiveCN104492522AIncrease the direct grinding areaGood for grinding and sheddingGrain huskingGrain polishingBroken riceEngineering

The invention discloses a flexible rice mill with abrasive balls and a grain milling method. The flexible rice mill is technically characterized in that a frame unit 8 comprises a housing composed of a cylinder base 21, an outer cylinder 3 and a cover 2; a carborundum inner cylinder 4 is disposed inside the outer cylinder 3 inside the upper portion of the cylinder base 22; a hollow shaft 5 mounted through a bearing set 20, a top sealing set 22, a bottom sealing set 17 and a bearing cap 19 is disposed inside the housing; a thrower disc 23 is disposed at the top end of the hollow shaft 5; a plurality of paddles are symmetrically and evenly distributed on the outer surface of the hollow shaft. The grain milling method includes proportional compounding of grain and the abrasive balls, feeding of mixture, flexible milling by the abrasive balls, lifting of the mixture, secondary milling by the abrasive balls, grading of grain and abrasive ball mixture, finishing of finished products, recycling of the abrasive balls and the like. The flexible rice mill and the grain milling method have the advantages that the flexible rice mill is simple in structure, milling contact area is great, interior milling pressure is low, speed is low, rate of broken rice is low, and rice yield is high.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Coix seed huller

InactiveCN107737622ASimple structureImprove shelling efficiencyGrain huskingGrain polishingEngineeringProduct processing

The barley shelling machine of the present invention relates to the field of agricultural product processing equipment, in particular to a barley shelling machine, comprising a feeding hopper and a fixed grinding disc, characterized in that the feeding hopper is connected to an upper casing through a base, and the fixed grinding disc is There is a feeding channel in the center, which communicates with the feeding hopper; a main shaft is connected to the upper casing through a bearing seat, and the bearing seat is fixedly connected with the upper casing. One end of the main shaft is fixedly connected with a rotating grinding disc, and the other end is There is a belt pulley connected to it, the central axes of the rotating grinding disc and the fixed grinding disc are on the same straight line, and the rotating grinding disc and the fixed grinding disc are arranged parallel to each other; the invention has the advantages of simple structure, high husking efficiency, low broken rice rate, and low energy consumption. The relative speed between the fixed grinding disc and the rotating grinding disc is used to rub the coix seed grain, and the mutual rubbing and friction between the barley grain and the sand grains of the mill disc makes the cortex of the barley grain be torn under different forces, so as to achieve the purpose of shelling.

Owner:SHAANXI YIPINDA PETROCHEM CO LTD

Pumpkin nutritional rice and preparation method thereof

The present invention discloses a pumpkin nutritional rice and a preparation method thereof. The pumpkin nutritional rice includes the following raw materials in parts by weight: 10-30 parts of pumpkin powder and 60-90 parts of rice flour. The rice flour is a composition of yellow rice flour, millet flour and rice flour. The pumpkin nutritional rice uses five cereals and coarse cereals as raw materials, and according to people's nutritional and dietary requirements, some pure natural and green nutrients of the coarse cereals are uniformly concocted in proportion. By using the "controllable pasting extrusion granulation", firstly the pulverized rice flour, rice germ and five cereals and coarse cereals are uniformly mixed and concocted in accordance with a certain proportion, then remodeled to be a nutritional rice which has consistent size, appearance, specific gravity and cooking performance with the natural rice by recombining the starch molecules using a specialized extrusion equipment, thus significant loss of nutrients during the deep processing of the rice is avoided, and the presences of various nutrients in substances are ensured.

Owner:武威金谷香营养米业有限公司

Refining method for rice processing

InactiveCN109954535AReduce moisture contentReduce extrusion pressureGrain treatmentsEconomic benefitsMagnetic separator

The invention discloses a refining method for rice processing, and belongs to the field of rice processing. The method comprises the steps that unhusked rice is tedded, specifically, the unhusked riceis tedded in a cement floor in a clear weather with sufficient sunlight; impurities in the unhusked rice are removed, specifically, the unhusked rice is conveyed to a vibrating screen and a magneticseparator in sequence; husked rice is wetted and dried, specifically, the unhusked rice is conveyed into an atomizing device through a conveyor belt, is wetted and then is heated by adopting an automatic constant-temperature heating device; husking is carried out, specifically, the unhulled rice is conveyed into a rice huller for husking treatment; paddy separation is carried out, specifically, the husked rice is conveyed to a specific gravity paddy separator through a conveyor belt for paddy separation; the husked rice is wetted and dried, specifically, the husked rice is conveyed into the atomizing device through the conveyor belt and is wetted; rice milling is carried out, specifically, a rice mill is adopted, it is guaranteed that the stone content of cleaned grains is smaller than 1 grain / kg; milled rice is wetted; the milled rice is polished; color sorting is carried out; sterilizing is carried out; and packaging is carried out. The method has the advantages that the broken ricerate is lower, the appearance quality of the rice is good, the edible quality is high, and the economic benefits of rice processing enterprises are increased.

Owner:安徽宏虎粮油股份有限公司

Unpolished rice tempering and enzyme deactivation equipment

The invention relates to unpolished rice tempering and enzyme deactivation equipment, comprising a tempering box, a blanking opening and a discharging opening on the tempering box, conveying belts placed inside the tempering box, hot air square pipes and cold air square pipes below the conveying belts. Unpolished rice falls down to the conveying belts from the blanking opening and is conveyed to the discharging opening to be conveyed out; the tempering box is internally provided with five layers of conveying belts; all the layers of conveying belts are arrayed in a staggered manner; the hot air square pipes and the cold air square pipes are arrayed below each layer of conveying belt; the hot air square pipes are connected with a saturated steam generator through a pipeline and the cold air square pipes are connected with an air cooler through a pipeline; air blowing openings are distributed on the hot air square pipes and the cold air square pipes; the conveying belts are provided with small holes for an air flow to pass through; and the quantities and the lengths of the hot air square pipes and the cold air square pipes on each conveying layer are different. The unpolished rice tempering and enzyme deactivation equipment has good tempering effect and can be used for killing worms, mildews and bacteria hidden in the unpolished rice in a tempering process and passivating lipolytic enzymes such as lipoxidase and lipase.

Owner:NANCHANG UNIV

Processing method of flavor rice rich in nutrition

InactiveCN110180617AHigh nutritional valueImprove digestion and absorption rateGrain huskingGrain polishingNutritionBroken rice

The invention discloses a processing method of flavor rice rich in nutrition. The processing method comprises the following steps that 1, rice is conveyed into an iron sieve impurity removal device toremove impurities, and drying and dehumidifying are carried out; 2, the rice is soaked in a first solution, drained and subjected to vacuum treatment; 3, fumigating treatment is carried out; 4, the fumigated rice is subjected to husk separation, grain separation, rice milling and grading to obtain rice; 5, a compound is sprayed to the surface of the rice, and the rice is polished; 6, the rice isput into a freeze drier for drying; 7, the rice is subjected to color sorting, grading and finished product packaging. According to the processing method of the rice rich in nutrition, the rice is soaked in the first solution and subjected to fumigating treatment, so that the nutrition value and digestive absorption rate of the rice are increased, and the appetite is promoted; the compound is sprayed to the surface of the rice before polishing, the broken rice rate of the rice is low, rice grains are uniform, the surface is smooth and full, and the rice is glittering and translucent.

Owner:江苏草地泥生态农业发展有限公司

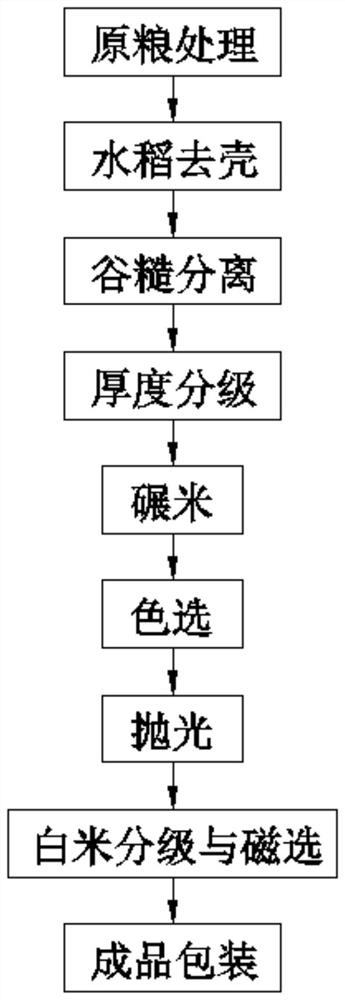

Rice processing method and equipment

ActiveCN111992482AReduce broken rice rateReduce wasteSievingScreeningAgricultural engineeringBroken rice

The invention discloses a rice processing method and equipment, and belongs to the technical field of rice processing. The processing method comprises the steps of raw grain processing, rice hulling,husked rice separation, thickness grading, rice milling, color sorting, polishing, rice grading and magnetic separation, and finished product packaging. A rice grading and magnetic separation integrated machine comprises a shell, a driving mechanism, a first filter cylinder, a second filter cylinder and a lantern ring. The first filter cylinder, the lantern ring and the second filter cylinder arein butt joint in sequence to form a roller for screening rice. The roller is obliquely arranged, an inlet pipe is arranged at the high end of the roller, and an extension pipe is arranged at the low end of the roller. The bottom of the shell is provided with a broken rice outlet, the driving mechanism is used for driving the first filter cylinder and the second filter cylinder to rotate around thecentral axes of the first and second filter cylinders respectively, and magnet pieces are arranged in the first filter cylinder. The process is simple, the equipment cost is low, the processing costis reduced, and after scrap iron in the rice is removed, the rice quality can be effectively improved.

Owner:芷江凯丰米业有限公司

Rice processing method

The invention relates to the technical field of cereal processing, in particular to a rice processing method. The rice processing method specially comprises the following steps that after being washed, unhulled rice is soaked in a sodium carbonate water solution with the concentration being 5% and then is subjected to vacuum freezing and centrifugal treatment, and the unhulled rice is put into water and hulled; brown rice is put into a 2% calcium glycerophosphate water solution to be soaked, the brown rice is put into water after being subjected to vacuum freezing and instant high-temperature treatment, and hulling is carried out; and after rice is dried at a lower temperature, a layer of cow milk protein peptide is sprayed onto the surface of the rice in a mist manner, then, the rice is introduced into a polishing machine to be polished, the rice is dried in an instant high-low-temperature drying manner till the water content is lower than 2%. The finally obtained rice grains are uniform, smooth in surface, satiate and crystal clear.

Owner:颍上县锡安山米业有限公司

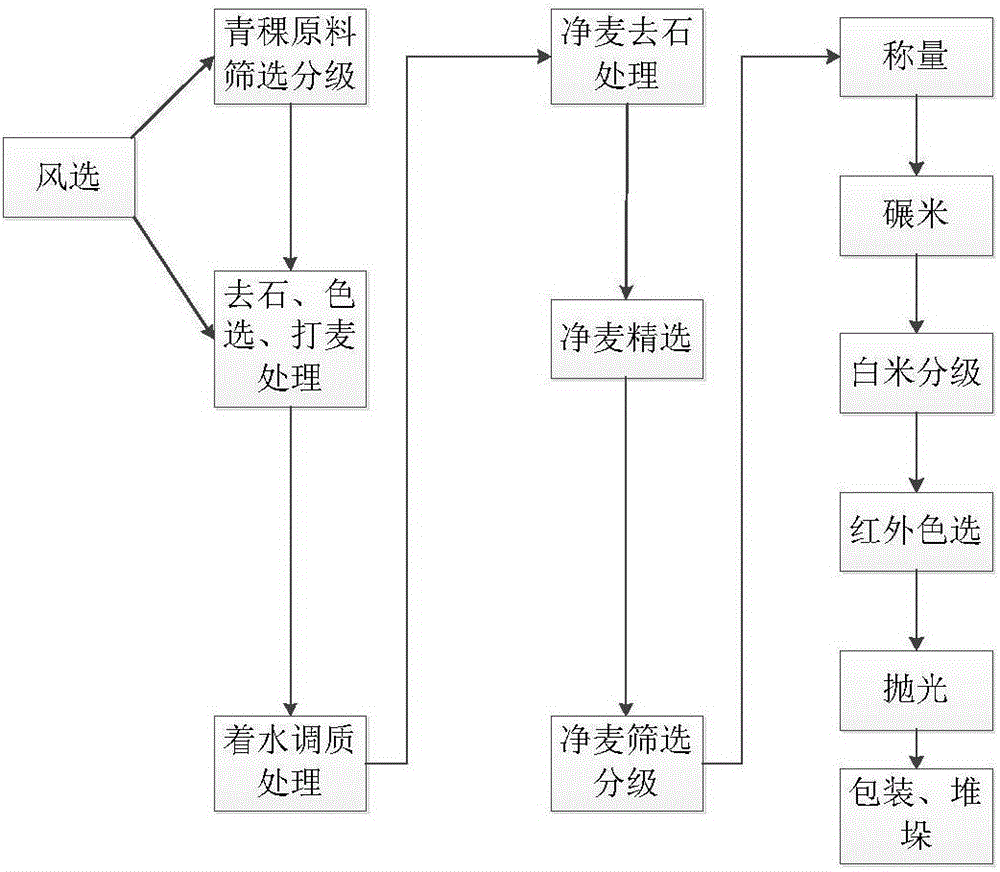

Highland barley processing technology

ActiveCN106000515AGuaranteed machining accuracyReduce broken rice rateGrain huskingGrain polishingBroken riceHygiene

The invention provides a highland barley processing technology which comprises a highland barley milling section. The technology is characterized by further comprising color sorting carried out on milled highland barley. A fine sorting function is added in the moisten highland barley cleaning process, and therefore foreign grains, incomplete grains, round beans and buckwheat can be separated out; in the highland barley milling section, four to seven emery rolls and one to two iron rolls are combined to work, the whole rice percentage can reach 80% and is improved by more than 10%, processing precision is ensured, the broken rice rate is reduced, and fine processing is achieved; before fine highland barley is packaged, color sorting for fine highland barely is increased, it is ensured that the product contains no impurity or incomplete grains such as immature grains, grains damaged by insects, spotted grains, mildew grains and brown rice grains, and food safety and dietetic hygiene are ensured; the finished product is automatically stacked after being packaged, the number of workers of enterprises is greatly reduced, the labor intensity is reduced, and mechanical work is achieved. All the working procedures can be completed through machines, and fine, large-scale and automatic production of highland barley can be achieved.

Owner:WUXI DADONG GRAIN ENG TECH CO LTD

Novel rice milling emery roll

InactiveCN103566995AReduce volumeReduce weightGrain huskingGrain polishingPulp and paper industryEnergy consumption

The invention provides a novel rice milling emery roll which comprises an emery roll body and a metal core sleeve which is embedded in an inner hole of the emery roll body. The novel rice milling emery roll is characterized in that the emery roll body is a special-shaped body composed of a square part and an arc-shaped part, the horizontal plane of the arc-shaped part is connected to the square part, the out-protruding surface of the arc-shaped part points outwards, and long-strip-shaped air spraying holes are respectively formed in two sides of the protruding arc-shaped part. The novel rice milling emery roll is simple in structure, low in manufacturing cost and good in machining quality, can reduce energy consumption and can be widely used in the rice milling industry.

Owner:湖北省鄂州市天元砂辊有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com