Crawler type rice mill

A rice milling machine and crawler type technology, applied in grain processing and other directions, can solve the problems of high broken rice rate, high rice germ loss rate and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

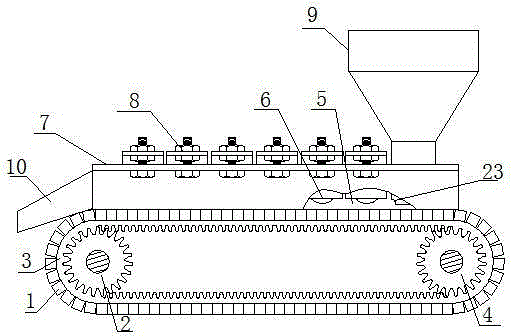

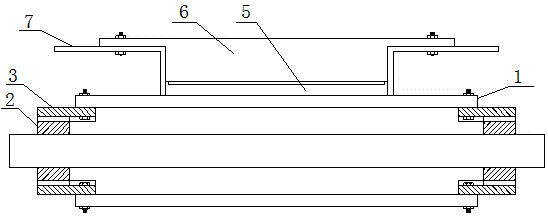

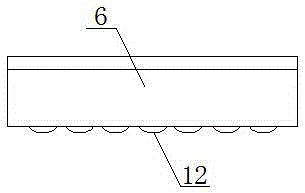

[0027] see Figure 1 to Figure 12 As shown, the crawler-type rice mill is a horizontal structure, including a hopper 9, a discharge barrel 10, a frame 7 and a transmission mechanism, the frame 7 is equipped with a rice knife 6, and the transmission mechanism includes a driving wheel 4 and a driven wheel 2 And the conveyor belt 3 that cooperates with driving wheel 4 and driven wheel 2, transmission mechanism adopts synchronous belt transmission mechanism (also can use sprocket chain transmission mechanism) in the present embodiment. A plurality of rolling strips 1 are installed on the conveyor belt, and the rolling strips 1 are bar-shaped oilstones 17, preferably diamond fiber oilstones, and the rolling strips 1 can also be metal strips 19 made of high-strength metal materials. The rolling surface of the metal strip 19 needs to be provided with tooth patterns. When rolling bar 1 is oil stone, oil stone 17 is installed in the frame 18, is connected with conveyor belt 3 bolts by...

Embodiment 2

[0029] Referring to Embodiment 1, the crawler-type rice milling machine is designed as a vertical vertical structure, which is basically similar to the horizontal structure in Embodiment 1. The difference is that the frame 6 is arranged vertically to form a vertical rice milling machine. Passage 5, rice cutter and abrasive belt transmission mechanism are arranged on the left and right sides of this rice milling passage 5 accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com